Page 1

A

A

A

A

A

A

A

A

Mitsubishi Electric Air Conditioning Network System

Integrated centralized control software TG-2000A

Operation Manual (Site adjustment)

Contents

Please read this manual before using the unit.

Please keep this manual for future use.

WT03901X14

1. Safety Precautions............................................. 1

2. System Requirements ....................................... 3

3. System Configuration ........................................ 11

4. Flow of Site Adjustment..................................... 12

5. Installation.......................................................... 16

6. Part Names and Functions ................................ 37

7. Initial Startup and Shutdown .............................. 46

8. System Setting Procedure................................. 48

8.1 System Setting Screen ............................. 48

8.2 System Setting Procedure........................ 49

8.3 User Set-up............................................... 50

8.4 Site Name Set-up ..................................... 61

8.5 Password Set-up .......................................61

8.6 AG-150A/G-50A Connection Set-up......... 62

8.7 System Configuration Set-up .................... 63

8.8 Set-up DIDO, AI and PI controller.................. 71

8.9 PLC for general equipment set-up ............ 75

8.10 IC I/O Signal Set-up.................................. 80

8.11 Monitoring Screen Set-up ......................... 83

8.12 Watt Hour Meter Set-Up (For RS-485) ..... 92

8.13 Measurement Meter Set-up (For PLC) ..... 93

8.14 Energy Monitoring Set-up......................... 96

8.15 Charge Set-up (For RS-485)....................103

8.16 Charge Set-up (For PLC, PI controller

and without WHM connection)................. 105

8.17 Energy Saving/peak Cut Set-up............... 112

8.18 Night Mode Set-up...................................120

8.19 Auto Change Over Set-up .......................121

8.20 Time Set-up .............................................124

8.21 Monitoring and Changing the Meter

9. Charge Data Correction and Remedy................127

10. Error Code List...................................................153

11. Setting Check List ............................................ 158

Present Value .......................................... 126

9.1 Result of Air-conditioning Charge

Calculation................................................127

9.2 Maintenance of Charge Data ....................129

9.3 Operation Amount Data Monitoring ..........134

9.4 Charge Parameter Output ........................136

9.5 Charging Remedy..................................... 137

9.6 Remedial Apportioning of Charges ........... 148

9.7 Maintenance of Charge Comparison Data

When G-50A and WHM/Measurement

Meter Fail or Are Replaced.......................151

ppendix 1 : Checking the Windows Service Pack

Version and Memory Size…………...194

ppendix 2 : Auto Log-in Confirmation Method......202

ppendix 3 : Correcting the Power Apportioning

Bill When AG-150A/G-50A Fails

or Is Replaced................................... 204

ppendix 4 : Shortening the Charging Test Run....206

ppendix 5 : Backing Up the System Setting Data 209

ppendix 6 : Upgrading the Functions ................... 211

ppendix 7 : Expanding the System ......................214

ppendix 8 : Charging Setting for A and K Control

and LOSSNAY Units......................... 217

2008 - Oct. (Ver. 5.1*/5.5*)

Page 2

Contents

1. Safety Precautions.............................................................. 1

2. System Requirements ........................................................3

2.1 Requirements (system recommendations) ................ 3

2.2 Compatible Units ....................................................... 4

2.3 Restrictions................................................................ 5

2.4 Other Devices.......................................................... 10

3. System Configuration .......................................................11

3.1 System Configuration Example................................ 11

3.2 Hardware Connection Diagram................................ 11

4. Flow of Site Adjustment.................................................... 12

4.1 Flow of Site Adjustment........................................... 12

4.2 Tools for Site Adjustment......................................... 13

4.3 Step 1: Test operation from central controller

AG-150A/G-50A....................................................... 13

4.4 Step 2: Connecting and installing the PLC............... 13

4.5 Step 3: Initial setting of integrated centralized

control software TG-2000A...................................... 14

4.6 Step 4: Test operation from integrated centralized

control software TG-2000A...................................... 15

5. Installation.........................................................................16

5.1 Pre-installation Steps ............................................... 16

5.1.1 Checking the AG-150A version and

the G-50A version.......................................... 16

5.1.2 Preparing for TG-2000A setup.......................18

5.2 TG-2000A Setup(TG-2000A Ver.5.5* or later) ......... 19

5.2.1 Setup ............................................................. 21

5.2.2 Running TG-2000A Setup (New setup)......... 22

5.2.3 Upgrading the TG-2000A version.................. 24

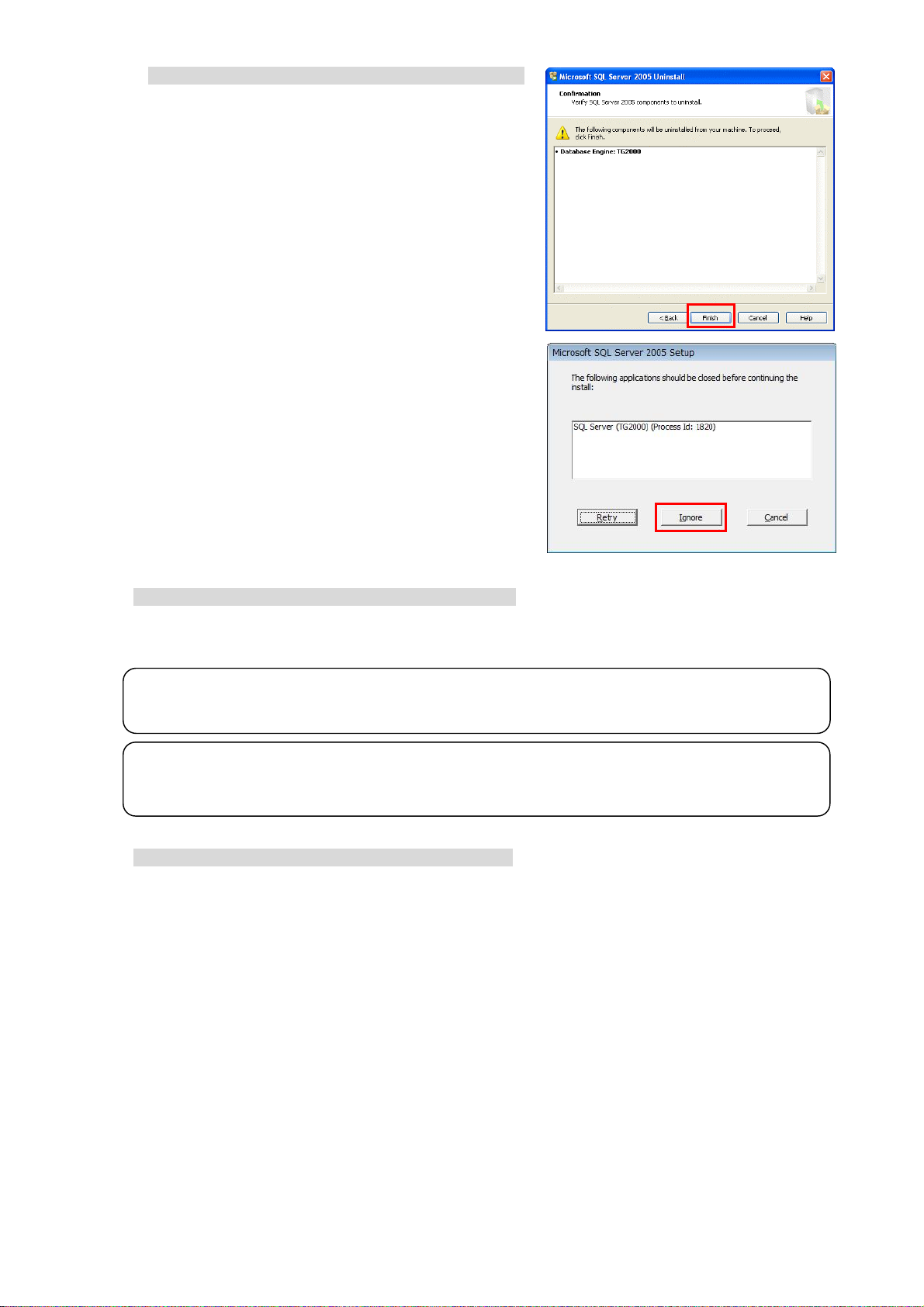

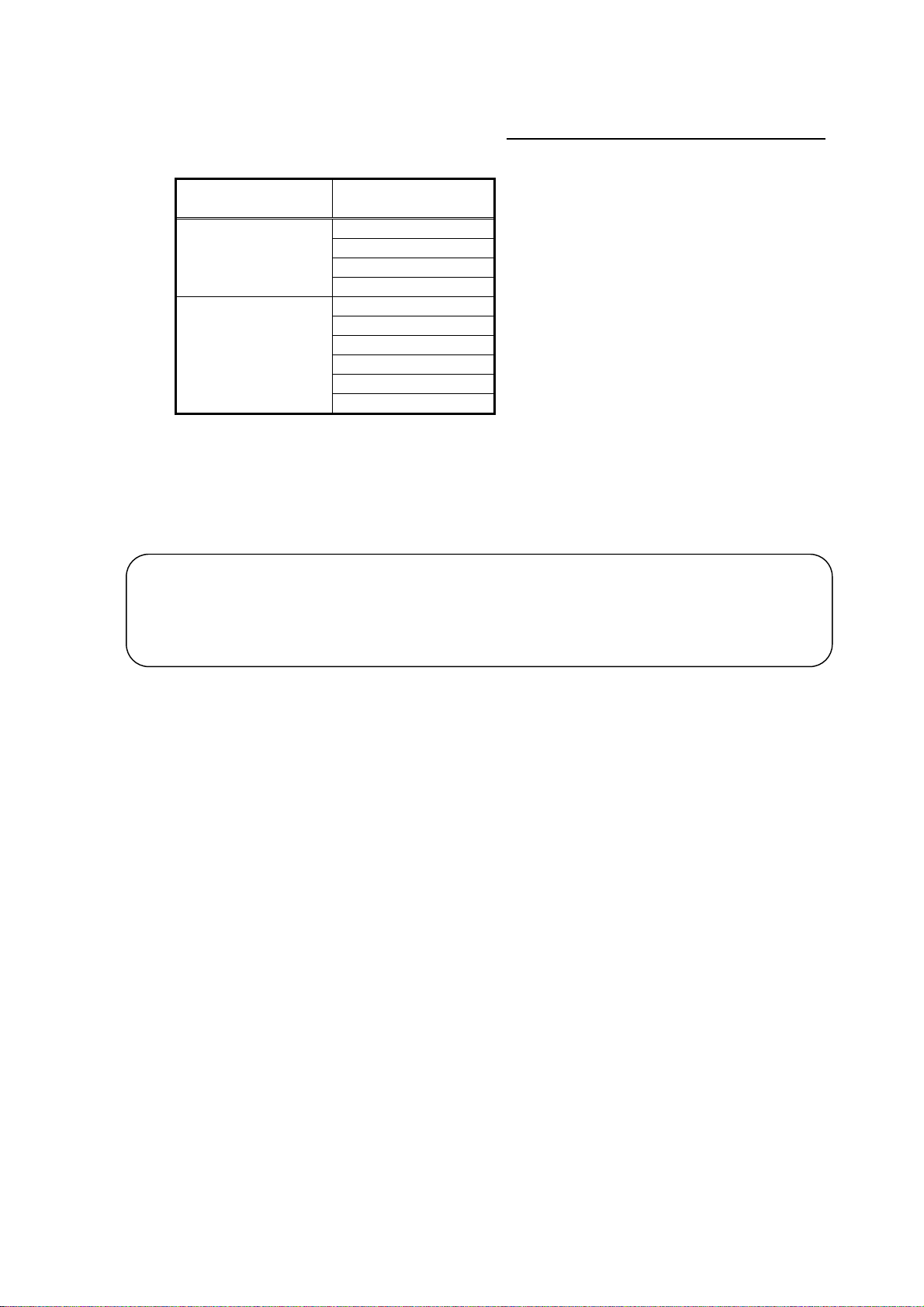

5.2.4 TG-2000A Uninstall ........................................26

5.2.5 Adding files to the ignore list on the

anti-virus software ........................................... 28

5.3 TG-2000A Setup(TG-2000A Ver.5.1*) ..................... 29

5.3.1 Setup ............................................................. 29

5.3.2 Running TG-2000A Setup (New setup)......... 30

5.3.3 Upgrading the TG-2000A version.................. 33

5.3.4 TG-2000A Uninstall ........................................35

5.3.5 Adding files to the ignore list on the

anti-virus software ........................................... 36

6. Part Names and Functions ............................................... 37

6.1 Window Elements.................................................... 37

6.2 Basic Mouse Operation ........................................... 38

6.3 Accessing Functions and Moving between

Windows .................................................................. 38

7. Initial Startup and Shutdown ............................................. 46

7.1 Before startup .......................................................... 46

7.2 Startup ..................................................................... 46

7.3 Shutdown................................................................. 47

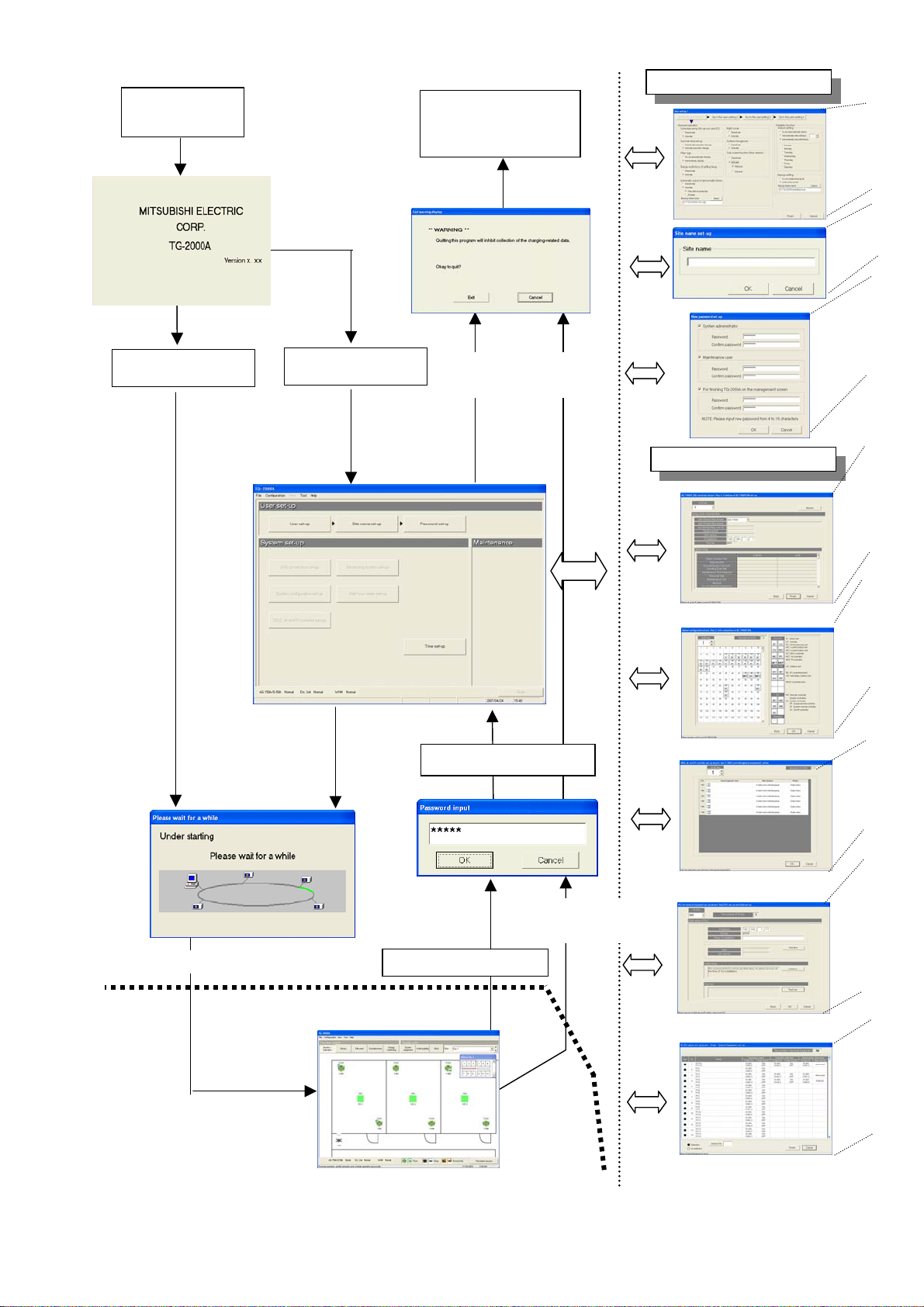

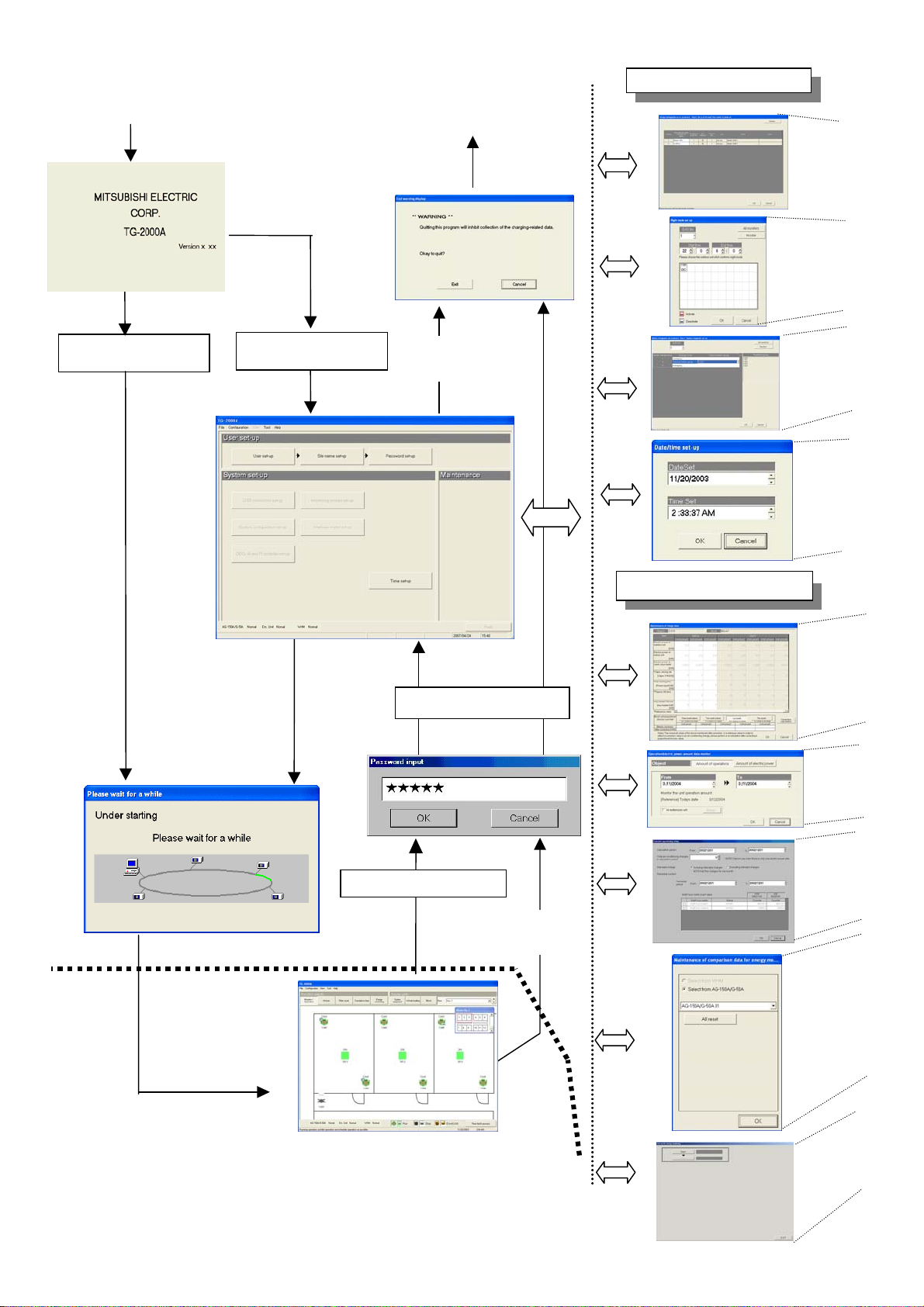

8. System Setting Procedure................................................ 48

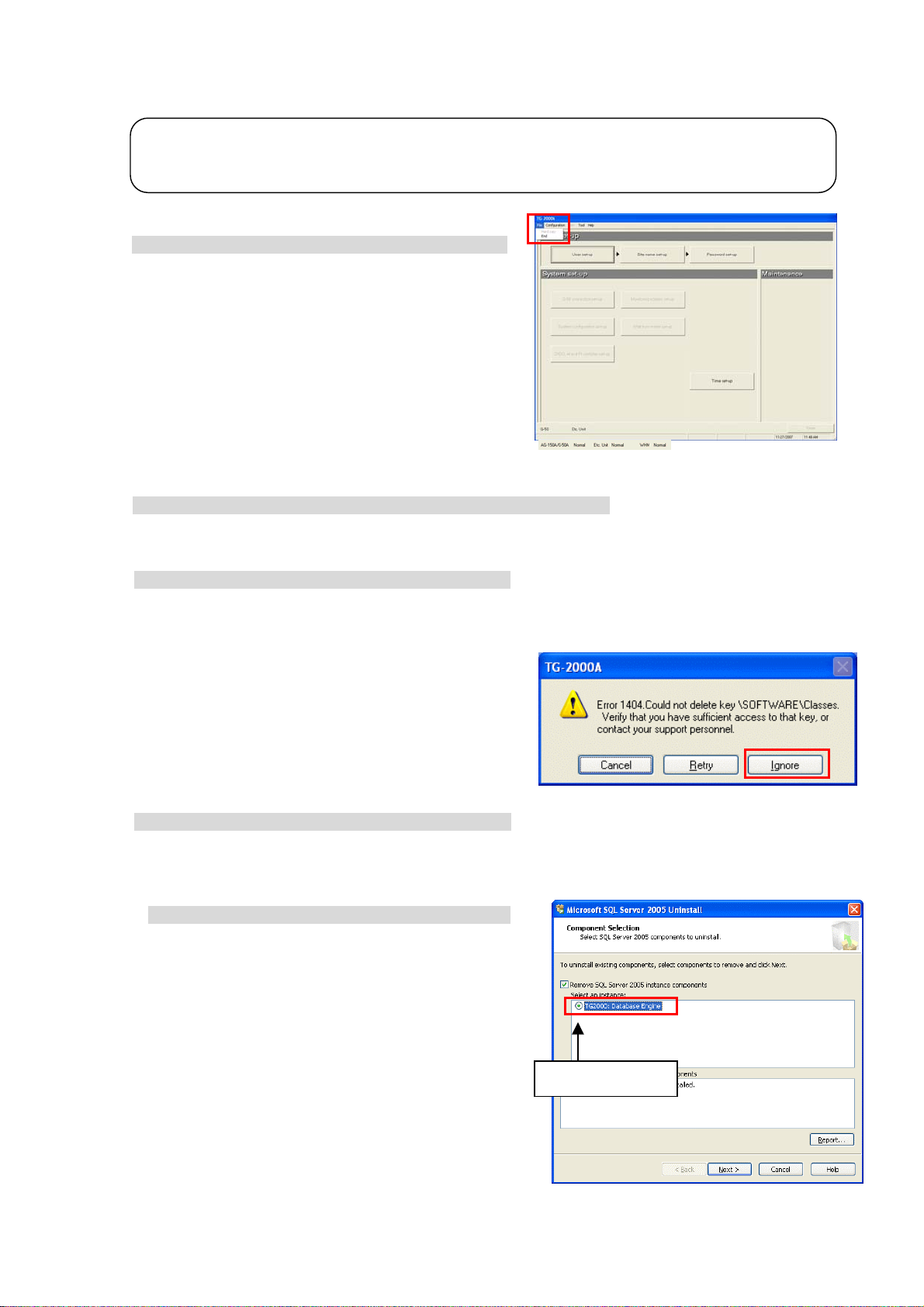

8.1 System Setting Screen ............................................ 48

8.2 System Setting Procedure....................................... 49

8.3 User Set-up.............................................................. 50

8.3.1 General Operation......................................... 51

8.3.2 Reliability Function ........................................52

8.3.3 Connection Setting ........................................ 53

8.3.4 Energy Saving/Peak Cut and IC I/O

Signal/Interlocked Control Setting ................. 54

8.3.5 Energy Monitoring Related............................ 54

8.3.6 Transmission of Automatic Output File

by email .......................................................... 57

8.3.7 Setting the Warning Sound............................. 58

8.3. 8 Trend Setting .............................................................. 59

8.4 Site Name Set-up ....................................................61

8.5 Password Set-up ..................................................... 61

8.6 AG-150A/G-50A Connection Set-up ........................ 62

8.6.1 Setting Procedure and Restrictions ...............62

8.6.2 Number of AG-150A/G-50A

set-up (Step 1)...............................................62

8.6.3 IP address of AG-150A/G-50A

set-up (Step 2)...............................................62

8.7 System Configuration Set-up....................................63

8.7. 1 Setting Procedure and Restrictions......................63

8.7.2 AG-150A/G-50A data collection (Step 1).........63

8.7.3 Unit composition set-up (Step 2).....................64

8.7.4 Set-up of refrigerant system (Step 3)...............68

8.7.5 Set-up of group (Step 4) ................................ 69

8.7.6 Interlocked setting (Step 5) .........................................71

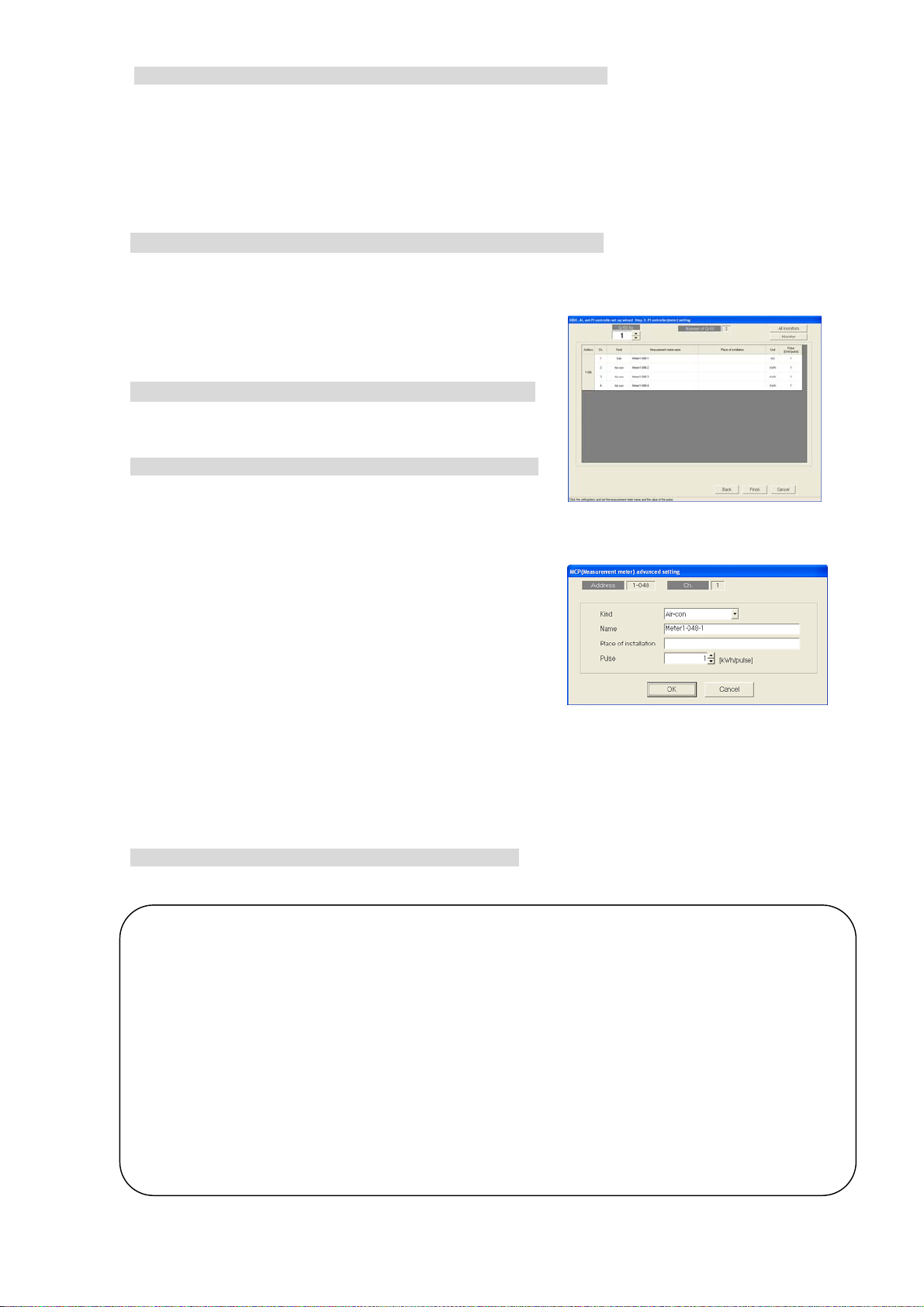

8.8 Set-up DIDO, AI and PI controller.................................72

8.8.1 Setting Procedure and Restrictions ...............72

8.8.2 DIDO controller (general equipment)

set-up (Step 1)...............................................72

8.8.3 AI controller Set-up(Step 2) ...........................73

8.8.4 PI controller (Meter) Set-up(Step 3) ............... 74

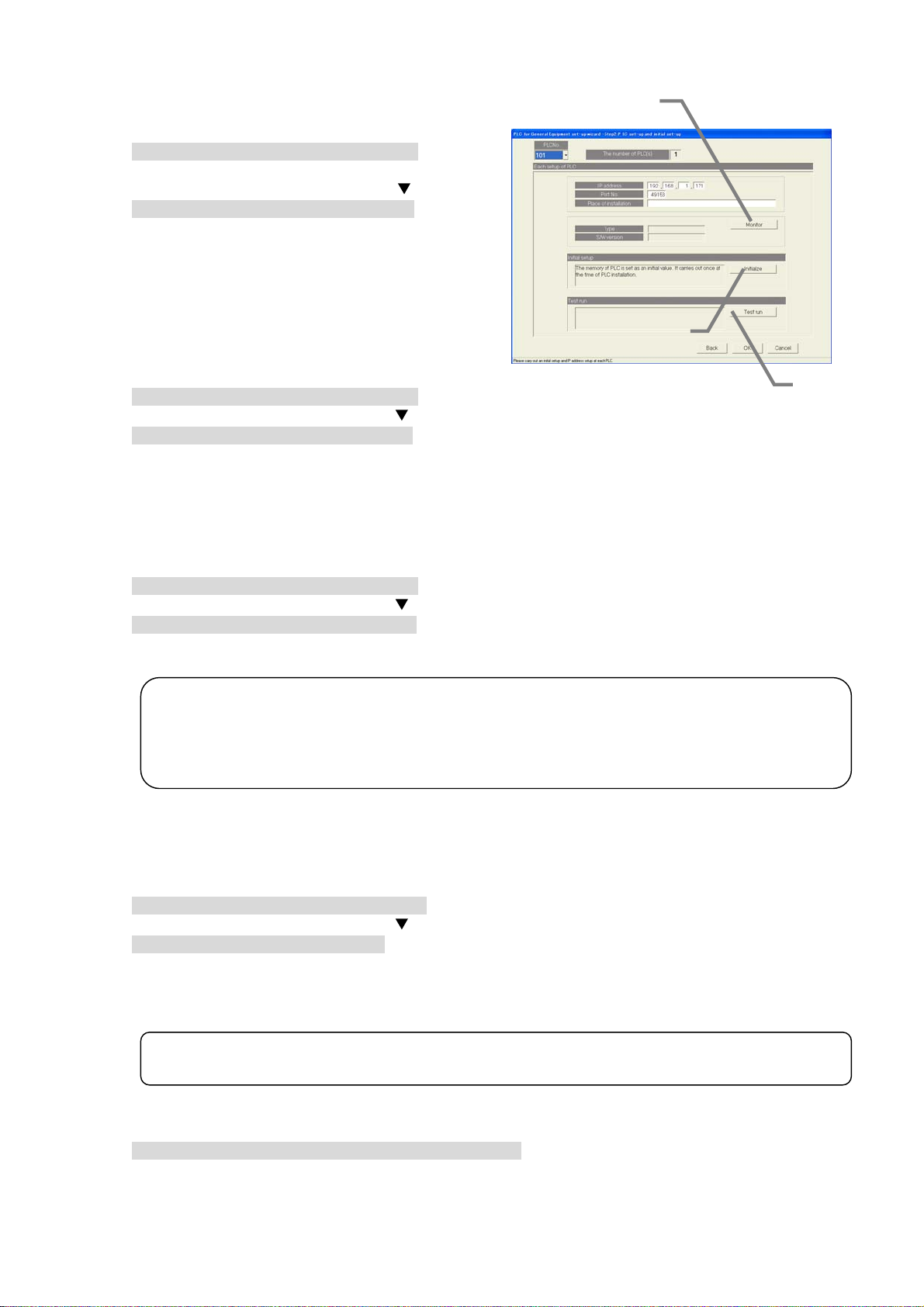

8.9 PLC for general equipment set-up ...........................75

8.9.1 Setting Procedure and Restrictions ...............75

8.9.2 Number of PLC unit set-up (Step 1)...............75

8.9.3 PLC set-up and initial setting (Step 2)............76

8.9.4 Function setting (Step 3)................................77

8.9.5 Advanced setting (air conditioner status

monitor setting) (Step 4) ................................ 77

8.9.6 Advanced setting (Peak cut function

setting) (Step 5) .............................................77

8.9.7 General equipment setting (Step 6)............... 78

8.10 IC I/O Signal Set-up ................................................. 80

8.10.1 Setting Procedure and Restrictions ...............80

8.10.2 General Equipment Set-up (Step 1)...............81

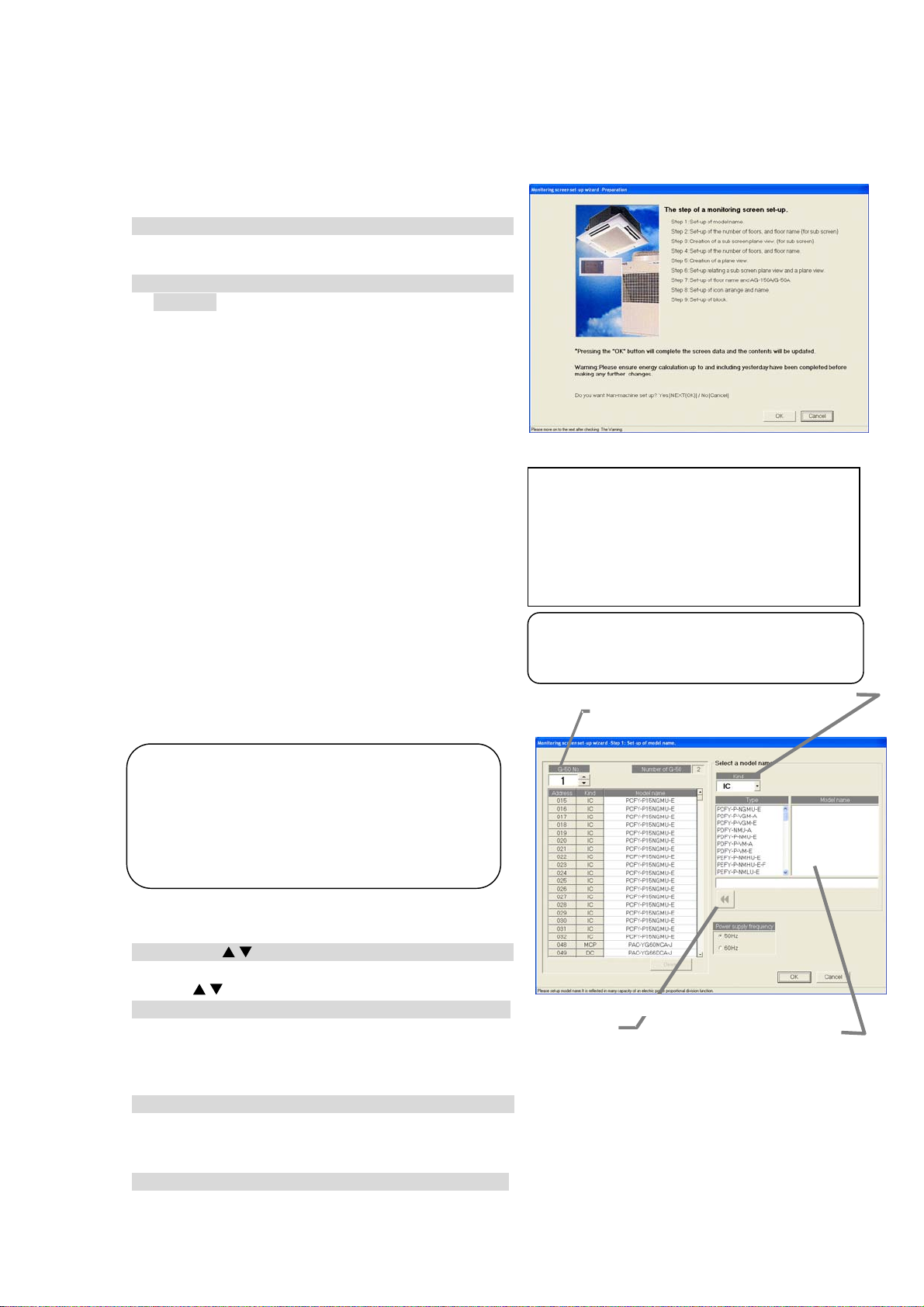

8.11 Monitoring Screen Set-up ........................................83

8.11.1 Configuration Procedure and Restrictions ..... 83

8.11.2 Set-up of model name (Step 1)......................83

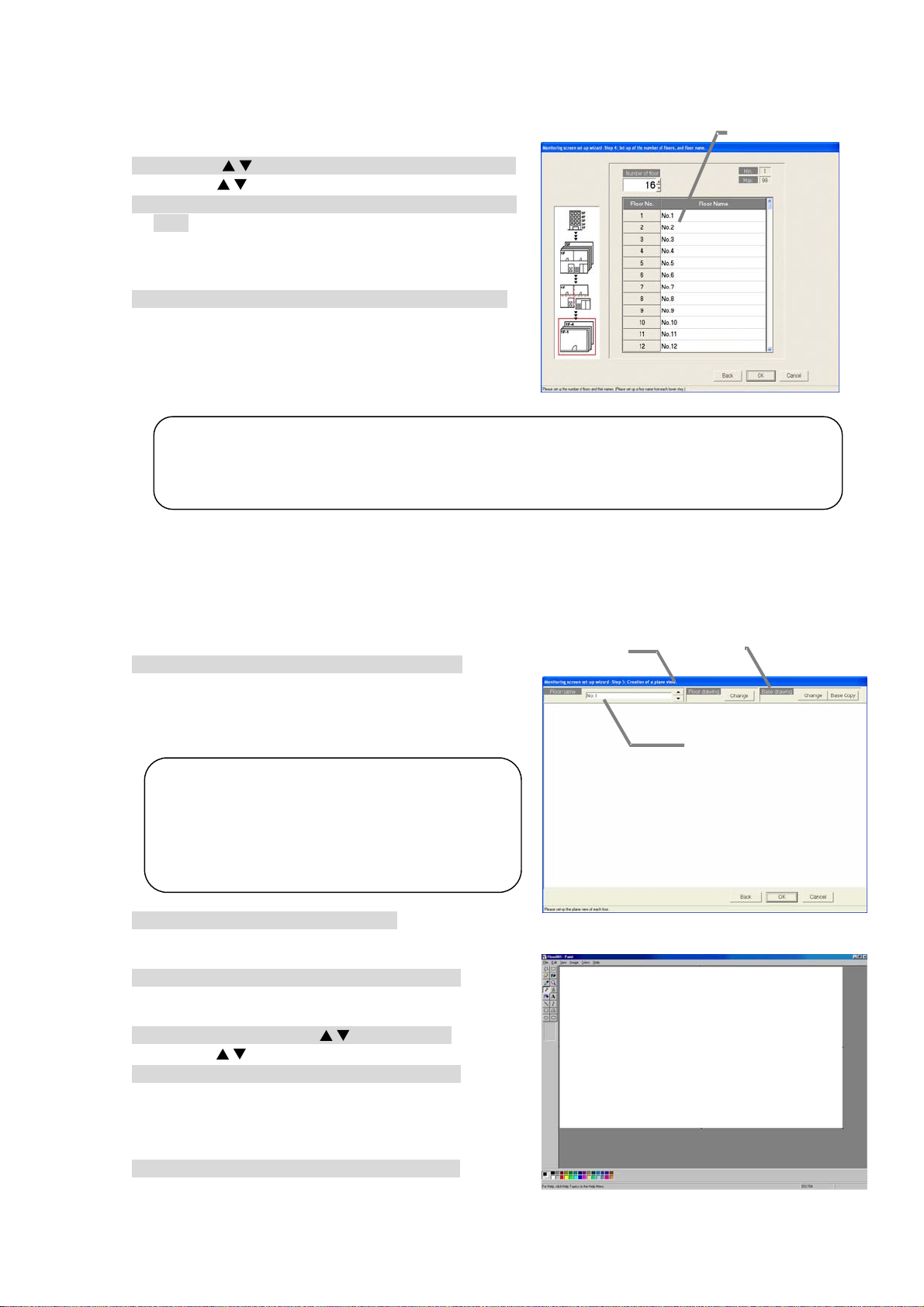

8.11.3 Set-up of the number of floors, and

floor name (for sub screen) (Step 2).............. 84

8.11.4 Creation of a sub screen plane view

(Step 3)..........................................................85

8.11.5 Set-up of the number of floors, and

floor name (Step 4)........................................86

8.11.6 Creation of a plan view (Step 5).....................86

8.11.7 Set-up relating a sub screen plan view

and a plan view (Step 6) ................................ 87

8.11.8 Set-up of floor name

and AG-150A/G-50A (Step 7)........................ 87

8.11.9 Set-up of icon arrange and name (Step 8)..... 88

8.11.10 Set-up of block (Step 9) .................................90

8.12 Watt Hour Meter Set-up (ForRS-485) ...................... 92

8.12.1 Setting Procedure and Restrictions ...............92

8.12.2 Watt Hour Meter Setting (Step1)....................92

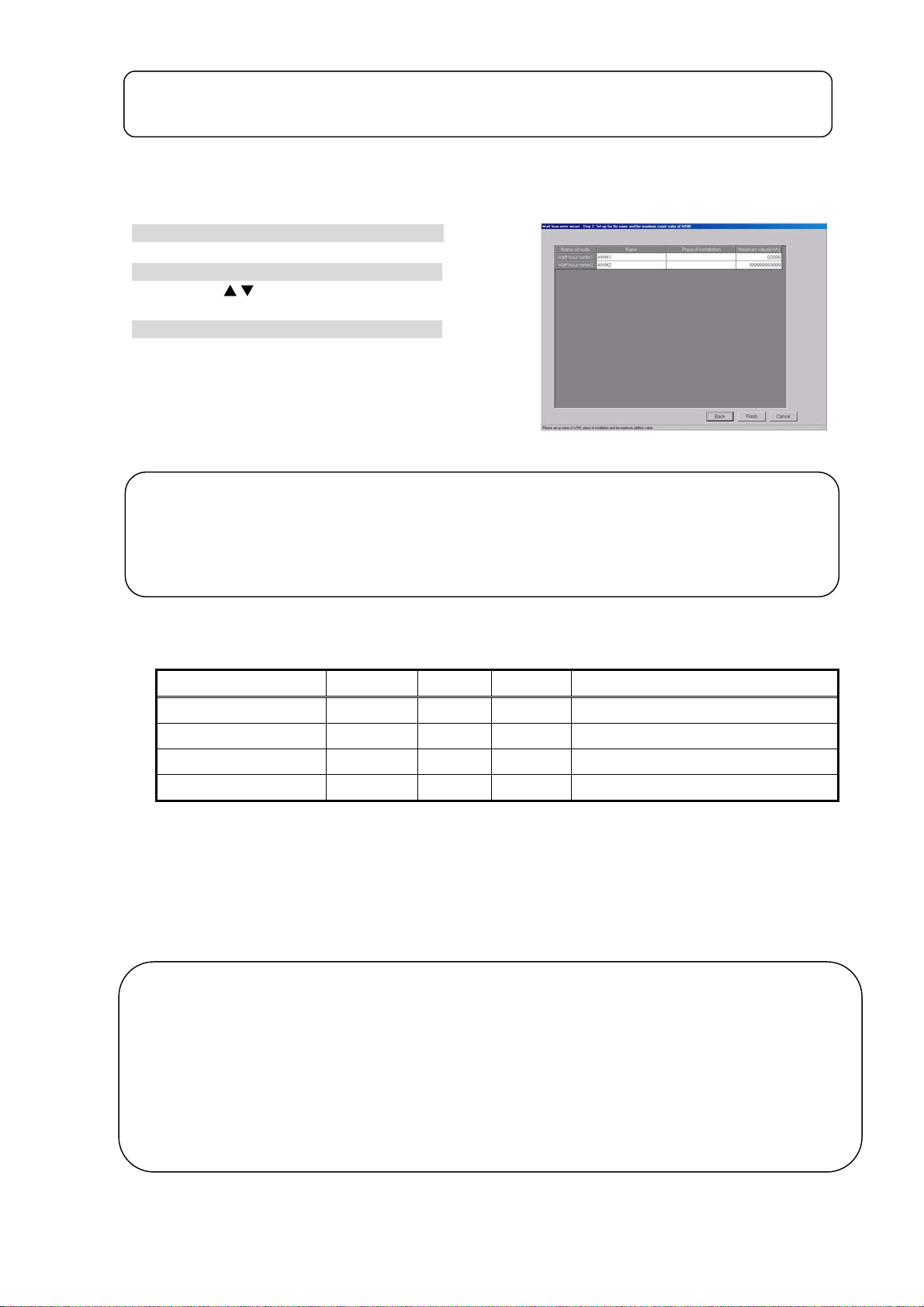

8.12 .3 Set-up for the Name and the Maximum

Integrated Value of WHM (Step 2).............................93

8.13 Measurement Meter Set-up (For PLC) ................... 93

8.13.1 Setting Procedure and Restrictions ...............94

8.13.2 The number of PLC(s) (Step 1)...................... 94

8.13.3 PLC set-up and initial set-up (Step 2)............94

8.13.4 Measurement meter set-up (Step 3).............. 95

8.14 Energy Monitoring Set-up ........................................ 96

8.14.1 Setting Procedure and Restrictions ...............96

8.14.2 Division mode (Step 1)...................................97

8.14.3 Relation between outdoor Unit

and watt hour Meter (Step 2).........................98

8.14.4 Electrical specification of outdoor units

(Step 3)..........................................................99

8.14.5 Relation between indoor units

and watt hour meters (Step 4) ..................... 100

8.14.6 Electrical specification of indoor units

(Step 5)........................................................101

8.14.7 Charge Blocks (Step 6)................................101

Page 3

8.15 Charge Set-up (For RS-485) ................................................103

8.15.1 Currency unit set ......................................... 103

8.15.2 Charge set ................................................... 103

8.15.3 Standard charge set ....................................104

8.16 Charge Set-up (For PLC, PI controller

and without WHM connection)............................... 105

8.16.1 Setting Procedure and Restrictions............. 105

8.16.2 Currency unit set (Step 1)............................ 105

8.16.3 Basic charge setting (Step 2).......................106

8.16.4 Season period setting (Step 3) .................... 106

8.16.5 Weekly charge setting ................................. 106

8.16.6 Annual charge setting.................................. 108

8.16.7 Setting the meter unit price.......................... 111

8.17 Energy Saving/Peak Cut Set-up ............................112

8.17.1 Energy saving setting .................................. 112

8.17.1.1 Setting Procedures and Restrictions....... 112

8.17.1.2 Energy saving setting (Step 1) ................ 112

8.17.2 Peak Cut Setting ........................................ 115

8.17.2.1 Setting Procedures and Restrictions....... 117

8.17.2.2 Peak cut WHM setting (Step 1)...............117

8.17.2.3 Peak cut setting (Step 2)......................... 118

8.18 Night Mode Set-up................................................. 120

8.18.1 Setting Procedure and Restrictions............. 120

8.18.2 Night Mode Set-up ..................................... 120

8.19 Auto Change Over Set-up .....................................121

8.19.1 Setting Procedure and Restrictions............. 121

8.19.2 Auto change over set-up (Step 1) ................ 122

8.20 Time Set-up ........................................................... 124

8.21 Monitoring and Changing

the Meter Present Value........................................ 126

9. Charge Data Correction and Remedy............................. 127

9.1 Result of Air-conditioning Charge Calculation........ 127

9.2 Maintenance of Charge Data................................. 129

9.2.1 Preparing for Charging Data Maintenance ..129

9.2.2 Maintenance Methods and Restrictions....... 129

9.2.3 Unit Data Maintenance................................ 130

9.2.4 Watt Hour Meter Data Maintenance ............ 133

9.2.5 Verify Test Operation of Watt Hour Meter.... 134

9.3 Operation Amount Data Monitoring .......................134

9.4 Charge Parameter Output ..................................... 136

9.5 Charging Remedy.................................................. 137

9.5.1 Remedial apportioning setting screen

(RS-485)...................................................... 137

9.5.2 Remedy when computer HDD fails

(no backup).................................................. 140

9.5.3 Remedy when computer HDD fails

(backup)....................................................... 142

9.5.4 Apportioning method when computer

crashes........................................................ 143

9.5.5 Remedy when watt hour meter fails

(monitoring impossible) ...............................145

9.5.6 Remedy for system information

setting error .................................................147

9.6 Remedial Apportioning of Charges ........................ 148

9.6.1 Preparing for remedial apportionment of

charges........................................................ 148

9.6.2 Remedial Apportionment Set-up window

(PLC) ........................................................... 149

9.7 Maintenance of Charge Comparison Data When

AG-150A/G-50A and WHM/Measurement

Meter Fail or Are Replaced.................................... 151

9.8 Maintaining the charge data by deleting the

carry over amount for the unused unit prices ....... 152

10. Error Code List................................................................ 153

11. Setting Check List .........................................................158

11.1 Setting Check List ................................................ 158

11.2 Test Run Check ................................................... 159

11.3 Charging Test Run Check ....................................162

11.3.1 Charging (No WHM connection)

Test Run Check........................................... 162

11.3.2 Proportionally Divided Power Charge

(RS-485 WHM connection) Test Run

Check...........................................................168

11.3.3 Test run check of power apportionment

billing (Electric amount pulse count) ............ 174

11.3.4 Charging test run operation methods...........182

11.4 Energy saving and peak cut checks ...................... 183

11.5 System information CSV Output..................................186

11.5.1

Air Conditioning Unit Start/Stop Information

CSV Output ................................................186

11.5.2 Test Run for the Charge Function Information

CSV Output .................................................. 187

11.5.3 Create a Test Run Check sheet..................... 188

Air Conditioning unit start/stop test check sheet ...190

Test run for the charge function check sheet......... 193

Appendix 1 : Checking the Windows Service

Pack Version and Memory Size ..................... 194

Appendix 2 : Auto Log-in Confirmation Method.................. 202

Appendix 3 : Correcting the Power Apportioning Bill When

AG-150A/G-50A Fails or Is Replaced ........... 204

Appendix 4 : Shortening the Charging Test Run................ 206

Appendix 5 : Backing Up the System Setting Data ............ 209

Appendix 6 : Upgrading the Functions............................... 211

Appendix 7 : Expanding the System.................................. 214

Appendix 8 : Charging Setting for A and K Control and

LOSSNAY Units............................................ 217

Page 4

In this manual, Microsoft® Windows Vista® Business is called Windows Vista, Microsoft® Windows® XP

Professional is called Windows XP and Microsoft® Windows® 2000 Professional is called Windows 2000. In

this manual, Microsoft® Excel 2007/2003/XP/2000 is called Excel.

Trademarks

MS, Microsoft, Microsoft logo, and Windows are registered trademarks and trade names of Microsoft

Corporation. Adobe logo, Acrobat, Adobe PDF logo, Reader are registered trademarks and trade names

of Adobe Systems Incorporated.

Each company may use as registered trademarks and trade names the product names used in this

manual.

-About this manual-

The operation manual consists of three volumes, “Site adjustment”, ”Management”, and ”Wide area”.

This manual is “Site adjustment”. These manuals are accessible from the Help menu on TG-2000A.

Acrobat® Reader is required to read these manuals. (Ver. 5.0E or later recommended)

– Term description –

• “Man-machine” : Indicates a computer with integrated centralized control software TG-2000A.

(Man-machine interface abbreviation)

• “AG-150A” and ”G-50A”:

Refer to centralized controllers AG-150A and G-50A.

On the screen of integrated centralized control software TG-2000A, AG-150A and

G-50A may appear as AG-150A/G-50A, AG-150/G-50, or G-50.

TG-2000A Ver.5.50 or earlier does not support AG-150A connection. Unless otherwise

specified, read AG-150A/G-50A as G-50A in this manual.

•

"PLC" : Abbreviation for Programmable Logic Controller.

The TG-2000A system uses two PLCs; the electric amount count software and PLC for

general equipment software.

The electric amount count software measures the electric amount with the PLC, the

general control operates and monitors the general equipment, etc.

• "Power apportioning billing"

Billing support function that apportions the electric amount used by the air

conditioner. The following three methods are available:

Manual electric amount input

... A watt hour meter (WHM) is not connected, and instead the charge percentage is

calculated according to the percentage of power used. The service power is

measured with the separately installed WHM, and the service charges are

obtained from the charge percentage.

Electric amount pulse count

... The electric amount is measured by the PLC, and the service electric amount is

monitored by via the LAN to automatically apportion and calculate the electricity

charges.

The designated PLC and optional software are used.

Direct read in of power value into computer

... The RS-485 output watt hour meter is directly connected to the computer

containing the integrated software (via an RS-232-C/RS-485 converter), and the

service power is input.

The service power rate is automatically apportioned and calculated.

• "WHM" : Abbreviation for Watt Hour Meter.

• "Service power rate":

The service power rate indicates the power rate (apportioned rate) apportioned

based on the service state of the air conditioner, etc.

• "Always connected to AG-150A/G-50A system - Activate": <Recommended mode>

Refers to charging method that is operated by connecting this integrated centralized

control software TG-2000A constantly to the AG-150A/G-50A and PLC via a LAN.

Leave the computer power ON to keep the TG-2000A running.

PI controller instead of the PLC can be connected.

Page 5

• "Always connected to AG-150A/G-50A system - Deactivate":

Refers to charging method that connects this integrated centralized control software

TG-2000A to the AG-150A/G-50A and PLC once a month via the LAN. The charges for

the last month are calculated and output at once. The charging function can be used

efficiently by starting the computer and integrated centralized control software

TG-2000A on the day after the set settlement date.

PI controller instead of the PLC can be connected.

"IC I/O signal" : Refers to a contact mounted on the air conditioner's indoor unit. A general equipment can

•

be connected to the IC I/O signal using this contact and a PLC for general equipment to

operate and monitor the system.

"DIDO controller": Refers to the controller (PAC-YG66DCA) that can monitor or control general

•

(DC) equipment.

•

"AI controller" : Refers to the controller (PAC-YG63MCA) that has a function to measure temperature

(MCT) and humidity.

•

"PI controller" : Refers to the controller (PAC-YG60MCA) that has a function to calculate cumulative

(MCP) pulses from such metering devices as watt-hour meter.

- About screen -

• This instruction manual may use the development version screen in some case.

- Simple operation manual -

• A simple operation manual is available in addition to this instruction manual (Site adjustment, Management).

The simple operation manual is stored as a pdf file in the "Manual" folder on the TG-2000A Setup CD.

Acrobat Reader (Version 5.0E or later recommended) is required to view this pdf file.

Page 6

Page 7

r

pany

p

t

1. Safety Precautions

• Please read the Safety Precautions section very carefully before using the unit.

• The safety cautions provided here are very important for your safety. Please observe them at all times.

• The degree of danger involved with incorrect operation of the unit are indicated in this manual using

the following symbols.

WARNING Incorrect operation could result in death or severe injury.

CAUTION Incorrect operation could result in injury or damage to property.

• After reading this information, please keep this manual together with the operation manual (Management)

in a location where the operator can see it. Also, when changing operators give both of these manuals to

the new operator.

Note : Please observe the safety precautions de tailed in the installation manua ls an d ope rat ion

manuals of the other machines such as computers, peripherals, and air conditioners.

WARNING

The customer must not do any wiring or

electrical work.

Have the dealer or a specialist do any wiring or

electrical work. Do not do it yourself. Doing the

work yourself may result in improper installation

which may cause electric

Do not make any improvements or repairs

for any reason.

Making improper improvements or repairs may

cause electric shock or fire. For repairs, consult

the com

Stop operation immediately if an error

message appears on the computer and the

unit stops or is no t ope r ati n g pro p erly.

Failing to do so may result in fire or damage to

the unit. Immediately contact the company from

which the uni

Do not use the product for any other

purpose.

This product is for use with the Mitsubishi

Electric Building Air Conditioning Control

System. Do not use it with any other air conditioning control system or for any other application. Doing so may cause the unit to malfunction.

Do not use with other applications.

Use the PC that uses this product with this

product only. Using it with other applications

may cause faulty operation.

Warning to all users (User Agreement)

This document is a contract between the customer and Mitsubishi Electric Corporation. By using this

application, you agree to the following conditions and are considered a user.

• Mitsubishi Electric and associated suppliers are not responsible for any collateral, secondary, o

special damages, even if notified by the distributor of the possibility of a certain type of damage.

Mitsubishi Electric is not responsible for any rights claimed by a third party.

from which the unit was purchased.

was purchased.

CAUTION

Do not relocate the unit yourself.

Relocating the unit yourself may result in

incorrect installation which may cause electric

shock or fire. To relocate the unit, consult the

company from which the unit was purchased.

Read the installation manuals and operation manuals for the computer, peripherals

and other machines.

Improper operation could result in fire or damage

to the com

Read the installation manual and operation

manual for the air conditioner controller.

Improper operation could result in fire or damage

to the air conditioner controller.

Keep children away from the unit.

Inspections and maintenance can be

dangerous. Do not let children near the unit

during these times.

uter or peripherals.

1

Page 8

Safety Guidelines for the Computer Running the with the TG-2000A.

a

s

A

e

e

a

e

r

y

t

A

a

g

s

o

e

A

e

(1) Precautions for selecting a computer

Select a desktop computer.

• Depending on the function, it is recommended to use

desktop as opposed to a laptop computer as there i

a tendency for heat to build up in a laptop.

• Some laptop computers cannot be run for long

hours.

Use a computer/operating environment with specifications capable of running the TG-2000A function.

• Run the function using the specified OS. There is a possibility that the function cannot be used when running an

OS other than specified.

• Use a busine ss model computer . There are cases when it is not possible to install or run the application with

other applications on a computer or laptop intended for personal use.

Computer based UPS recommended.

• It is recommended to use a UPS to protect data from

momentary power outages or power cuts.

It is particularly recommended to employ a UPS when

using power apportioning billing.

(2) Precautions for General usage

Do not place the computer in any of the following

locations.

•

following environments.

A place where there is: a lot of dust, a likelihood of

shock or vibration, instability, a heater or speaker

nearby, direct exposure to sunlight, a likelihood of

dropping, a possibility that the computer may be

exposed to moisture or high temperature, or where it

may be exposed to sudden temperature fluctuations or

heat.

Do not close the lid when using a laptop.

• There is a possibility of an internal temperature build-up,

fire or burning. Use in an area with sufficient ventilation.

• The system may start Stand By or Hibernate function

and stop functions of TG-2000A by closing the lid.

Do not touch the computer air vent.

• The air emitted by the ventilator is hot and may result in

burning if exposed to the skin.

Do not tamper with the computer fan .

• Tampering with the computer fan may result in

temperature build-up, fire, or accident.

n error or accident may occur when using in th

Ensure to read the computer/peripheral

instruction manual.

• A fire or accident may occur due to improper use of th

equipment.

void covering the computer or AC adapter with

a cloth or blanket, or locating them on or near

heater.

• There is a possibility of internal temperature build-up,

fire or burnin

under the above situations.

Cut the poweror disconnect the power cabl

immediately if smoke, or an abnormal smell o

noise emanates from the computer .

• Using the computer in the above circumstances ma

result in fire, burning, or electric shock. Please consul

the maker of the equipment/computer.

Use the hard disk, floppy disk, or CD media a

indicated.

• Do not expose the hard disk, floppy disk, or CD t

shock or vibration during use.

• Do not cut the power or reboot the computer while th

hard disk, floppy disk, or CD is in use.

•

lways turn OFF the power when moving th

computer.

Note: Refer to chapter 2 and 5.

(3) Other precautions

Precautions relating to the computer and peripheral equipment

• Please consult the maker regarding damage to the computer or peripheral equipment. We will not be held

responsible for damage occurring at the user’s site.

Safety Guideline for LAN connection of AG-150A/G-50A

Connect AG-150A/G-50A to a private network.

• AG-150A/G-50A are designed to be used with TG-2000A on a private network.

• Use a security device such as a VPN (Virtual Private Network) router when connecting to the Internet.

2

Page 9

2. System Requirements

2.1 Requirements (system recommendations)

TG-2000A version System Requirements

AG-150A and G-50A compatible

TG-2000A

To use the functions supported by

older versions of G-50A compatible

TG-2000A

*1 Upgrade TG-2000A V er . 5.20 to V er.5.5* or later.

TG-2000A Ver.5.5* or later

TG-2000A Ver.5.1* OS: Windows XP/2000

We recommend the following software and hardware when using this application (TG-2000A).

Item Requirement Recommended

PC PC/AT interchangeable machine

(Recommended: IBM, HP,DELL)

CPU

HDD

Storage

device

Resolution 1024 × 768 or higher, 65536 colors or more

Serial port 1 port or more Required when using RS-485 communication WHM

LAN 1 port (10BASE-T/100BASE-TX) *1

Modem 56K modem or TA Required when using a modem in wide area

USB 2 port or more It uses it for the data backup.

OS

Other Computer must be dedicated for this use

CoreTM 2 Duo 1.66GHz or faster

(Windows Vista for Core 2 Duo)

Pentium® M 1.7GHz or faster Pentium® M 2.0GHz or faster

Pentium

In Windows Vista : 1GB or more 2GB or more Memory

In Windows XP / 2000 : 512MB or more 1GB or more

Standard 6 GB or more (2GB or more of C

Wide area 20GB or more (Free space) Standard : max. 200MB/site

FDD, CD-ROM drive Devices other than those shown at the left may

Windows Vista® Business

Windows® XP Professional

Windows

*Use TG-2000A Ver.5.1* for Windows® 2000

Professional.

(TG-2000A).

® 4 2.4GHz or faster Pentium® 4 2.8GHz or faster

drive free space necessary)

Service Pack 1 *2

Service Pack 3 *2

® 2000 Professional

Service Pack 4 *2

Operation check completed, using IBM, HP and

DELL (Business model is recommended)

Core

40GB or more of C drive free space necessary

When using the trend function, the drive used for

automatic output must have the following free

space according to the number of groups.

200 groups = 2GB, 500 groups = 5GB, 1000

groups = 10GB, 2000 groups = 20GB

also be installed.

(Not necessary when using PLC)

mode.

English version only

*Computer must support each OS.

English version only

*Computer must support each OS.

English version only

*Computer must support each OS.

Must be used for 24-h o ur constant operation

(Only some functions. Refer to sectio n 2.3 for

details)

*1 Purchase the option, or use the equipment recommended for the computer when purchasing the

computer.

*2 It is necessary to correspond to each Service Pack. TG-2000A is not normally set up at the

uncorrespondence. Please apply Service Pack of the correspondence.

OS: Windows Vista/XP

*1

(Not compatible with Windows 2000)

Refer to the table below for details.

(Not compatible with Windows Vista)

Refer to the table below for details.

TM

2 Duo 2.4GHz or faster

3

Page 10

2.2 Compatible Units

The TG-2000A has two main functions: air conditioner controller and cost accounting. However, not all

functions are available with all air conditioners.

Table: Compatible units and function list (: supported, ∆: Certain restrictions apply, ×: Not supported)

Function

Model

Y series *1

Super Y series *1

R2 series *1

WR2 series *1

WY series *1

Multi S series *1 *5

Free plan Indoor unit *2

Free plan LOSSNAY *3 △*6

OA processing unit *1 △*7

“A” control type *4

“K” control type *4

Room Air Conditioner

Air To Water Booster

unit

Air To Water HEX unit × × × ×

*1: Can be calculated for each charging block. May not be available with some older models.

*2: Indoor unit models before Free Plan models do not support a charge apportioning billing method based on the

“capacity save.” The existence of even a single unit of those types in the system requires that the method of

charge apportioning billing be set to either “Thermo on time” or “Fan operation time.”

Certain restrictions apply to large-capacity indoor units when malfunctions occur.

*3: LOSSNAY groups to which the remote controller is connected support the charging system.

*4: Not all of the A-control and K-control units support these functions. (e.g., The calculation of the charge for the

auxiliary heater may not be handled by these units.)

*5: Outdoor unit capacity control function is not available.

*6: Only the function to stop the units is available.

*7: When the attribute is IC (indoor unit): Same type of energy-save control unit as with the Freeplan Indoor unit is

When the attribute is FU (LOSSNAY with a heater/humidifier): no direct energy-save control is possible.

*8: Inverter models support the outdoor unit capacity save control function.

*9: Outdoor unit Thermo-OFF control function is not supported. Only the fan control function is available.

*10: Only the temperature control function or the function to stop the units is available.

Control/

Maintenance

(Adapter required)

(Converter required)

(Adapter required)

× × × ×

Charging (Billing)

without WHM

possible.

Charging (Billing) with WHM

*1 △*8

*1 △*9

× △ (Requires separate watt

hour meters. Bills calculated

based on the reading of each

watt hour meter)

Energy

Saving/

Peak Cut

△*10

4

Page 11

2.3 Restrictions

The following restrictions apply to the TG-2000A application.

(1) System configuration limits

Use TG-2000A with the vers ions described in this manual with AG-150 Ver. 1.0* or later or with

G-50A Ver. 3.22 or later.

Number of units Notes

AG-150A/G-50A Max. 40 units

Indoor unit Max. 2000 units (including all IC,

KIC, AIC, LC, FU, MCT, MCP

and DC *12)

General equipment

(PLC)

General equipment

(IC I/O signal)

PI controller (MCT)

*14

Meter *14 Up to 160 units (5 PLC units for

[Symbol] IC: Indoor unit, LC: LOSSNAY, FU: OA processing unit, AIC: “A” controller,

KIC: “K” controller, MCP:PI controller, MCT:AI controller, DC:DIDO controller

*1: The version can be confirmed with the method explained in section 8.6.3.

*2: Use G-50A Ver. 2.31 or later to use the power apportioning billing function.

*3: Use G-50A Ver. 2.50 or later to use the energy saving/peak cut function.

*4: Only 32 units each can be connected for the PLC for general equipment. These are the general equipment No.

1**-1 to 32 listed in Section 8.9.4. 33 to 100 cannot be used due to restrictions for the PLC for general

equipment.

*5: When G-50A is more than Ver.2.50, TG-2000A of Ver.2.00 does not operate.

*6: Use G-50A Ver. 2.60 or later when using the night mode or auto change over function.

*7: Up to 350 general equipment units can be connected to the IC I/O signal with each G-50A. However, the

integrated software TG-2000A can control only up to 2000 general equipment units connected to the IC I/O

signal. Use G-50A Ver.2.70 or later when using the IC I/O signal function.

*8: The combination use of TG-2000A Ver4.70 and G-50A Ver2.71 expands the set temperature range limit

function (such as the upper limit of the set temperature for the Cool (Dry) mode, the lower limit for the Heat

mode and the upper and the lower limit for the Auto mode).

*9 The combination of TG-2000A Ver.4.80 and G-50A Ver.2.51 support a charge apportioning billing method of

A-control and K-control units.

*10 When using G-50A initial setting Web, the combination of G-50A Ver.2.80 or later and TG-2000A Ver.4.80 or

later must be used.

*11 When using the 1ºF temperature setting function, use the combination of G-50A Ver.3.00 or later and

TG-2000A Ver.5.00 or later. The indoor unit supporting the 1ºF temperature setting function is also required.

*12 1 contact point for DIDO Controller is converted to 1 unit. Up to 50 units are connectable to each AG-150A/G-50A.

*13 DIDO Controller, AI Controller and PI Controller are supported by G-50A Ver.3.20 and TG-2000A Ver.5.10 or later.

*14 Only either PLC or PI Controller can be connected for meter connection. Bo th ca nnot b e conn ected at the same time.

(2) Group setting restrictions

Item Restrictions Note

Remote controls 2 per group * Other remote controls besides M-NET type will not work *1

Number of indoor units

connected to a group

Number of SC and RC

connected to a group

Groups per floor

*1 The ME remote controller and MA remote controller cannot be used together for the same group.

*2 Set the same function unit for the group.

*3 Set units with different models or functions in another group.

[Symbol] SC: System controller, RC: Remote controller, DC: DIDO controller

Up to 640 units (including 20

PLCs for general equipment)

Up to 2000 units *7 Max. 350 units/(AG-150/G-50A)

UP to 40 units *13

(Up to 160 meters)

power rate pulse count)

1 to 16

4 per group * The number of AG-150A/G-50A is not included

Max. 50 groups

per floor

AG-150A Ver.1.0*

G-50A Ver. 2.10 or later *1,2,3,4,5,6,8,9,10,11

Max. 50 units/

(AG-150/G-50A) *12,13

Max. 32 units/PLC

Max. 5 units/(AG-150/G-50A)

Max. 40 units/TG-2000A

Max. 32 units/PLC

* IC, AIC, KIC, LC and DC cannot be used within the same

group. It is not possible for group settings to span

AG-150A/G-50A *2,3

Up to 50 groups can be displayed on one floor of the whole

building window.

5

Page 12

(3) Block setting

• The block comes in two types, operation block and charge block.

• The operation block is an aggregate of groups, and it is possible to set a different model group

for the same operation block.

• The charge block consists of an aggregate of operation blocks.

* The blocks controlled with the AG-150A/G-50A browser are the same as the operation blocks.

Operation blocks extending over AG-150A/G-50A can be set only with the integrated software TG-2000A.

• The operation block should be set individually for the K-control model, A-control model, DIDO

controller, LOSSNAY and free plan indoor unit.

(4) Notes on using K-control models

When using a K transmission converter (model name: PAC-SC25KA, PAC-SC25KAA(-E)) to

manage K-control models, take note of the following. See the documentation provided with the K

transmission converter for more detail.

• The address of the K transmission converter will be the smallest address of the K-control model

+ 200.

• Set the K control model addresses so that they are larger than the M transmission model addresses.

• When setting a group containing K-control models, make the group number the same as the smallest

unit address in the group.

• K-control LOSSNAY models are not applicable.

Group

Block for operation

Block for charging

(5) Notes on using A control mode

• Use the A/M-NET Adapter (model name: PAC-SF48MA(-E)). Set the group to “Group with only

A-control”.

(6) Countermeasure when an error occurs

• Note that each control or function may not operate properly when rebooting (*1) or when a fault

occurs in the central controller AG-150A/G-50A or other controllers and so on. Since each error

is displayed when it occurs, it is recommended to solve the faults quickly.

*1 Indicates that the system is restarting.

(7) Notes on charge system

• This charge system does not actually calculate the power consumption by each air

conditioning unit. Rather, it helps calculate the capacity output of each air condit ioning

unit, using the unique apportioning method developed by Mitsubishi.

Mitsubishi shall not be held responsib le for any problem or damage resulting from the

use of TG-2000A, including but not limited to the cases as described in section (8) below.

• If there is a group that is not set in the charge block, the electric power amount for that group will

not be included in the air-conditioning charge. If there are groups which require charging to be

divided, set those groups as operation blocks or charge blocks to accomplish this.

• Some older M-NET control indoor units are not compatible with the charge function.

• When the system is changed or the air conditioner is extended, which may require address

changes, the charge calculation may be affected in some cases.

Executing such changes or extensions are recommended after gaining approval from the

building owner(s).

• Irregular processes, such as repeated apportioning of power or non-apportioning of power (*1),

may occur due to communication errors with the central controller AG-150A/G-50A , PLC or PI

controller , etc. If the rates are not apportioned, a recovery process must be executed with the

charge maintenance function, etc.

*1 For power apportioning billing function's (Direct read in of power value into computer) function

• The power rate accuracy relies on the watt hour meter. The measurements for the gas, etc.,

also rely on the meters, so an error could occur in the accuracy during operation.

6

Page 13

• When using the power apportion billing in the always connected to AG-150A/G-50A system

state, the integrated centralized control software TG-2000A must be run at all times (24-hours).

The air conditioning rate results will appear in red if the software stops. When using the direct

read in of power value into computer function (RS-485 WHM), power apportion billing in the

always connected to AG-150A/G-50A system state is used.

• Only one of PLC (PAC-YG11CDA), PI controller (MCP), and RS-485 can be connected with

watt hour meter. The system cannot accept the mixed connection. Also, in the case of using

RS-485, some functions are restricted.

• Perform the “Charging Test Run Check” as described in section 11.3 before using the

apportioned electricity charge function.

(8) Charging (Billing) restrictions

The air conditioning cost calculation method use by this integrated centralized control software

TG-2000A is the Mitsubishi proprietary general electric power apportioning method.

Depending on each country's laws and regulations, etc., there may be cases these measured

charges cannot be used for certificate of transaction.

Before starting use, the building owner and building tenant should bind an agreement or

contract indicating that the air conditioning charges are part of the usage fees with an

independent contract indicating "The air conditioning charges are collected with an apportioning

method that considers the air conditioner's operation state instead of charges according to the

measured power rate (including during emergency operation when a failure occurs)".

(1) A watt hour meter is not installed on each air conditioner's power supply section to calculate

the rate.

(2) This system cannot be used for applications requiring calculations made by installing a watt

hour meter on each air conditioner.

(3) This system estimates the air conditioner apportioned power rate, and cannot be used as a

certificate of transaction.

(4) Even if the air conditioner is run for the same length of time, the air conditioning charges

may differ according to the air conditioner's operation load state.

(5) Even if one or several air conditioners are connected to one watt hour meter, the watt hour

meter apportions with the total power rate. Thus, an error could occur. Multiple air conditioners

are considered as one air conditioner when apportioning and calculating.

(6) The air conditioner is energized even when stop, so the air conditioning charges are

calculated even if the air conditioner is not used.

(7) If a fault occurs in the computer, AG-150A/G-50A, PLC or PI controller, remedial measures

will be taken with the past average apportioned rate, etc.

(8) Mitsubishi will not be held liable in any case as the watt hour meter and gas meter, etc.,

rates are retrieved as pulses, and the performance and accuracy rely on the meters.

* The gas meter, etc., also counts with a pulse converter and thus cannot be used as a certificate

of transaction.

Note that the counted value includes remedial measures taken when a fault occurs.

(9) Energy saving and peak cut functions

• Note that when using the peak cut function, Mitsubishi will not be held liable even if faults occur

when the service power rate exceeds the contracted power rate value due to the control

operation settings or a fault in the AG-150A/G-50A, PLC or PI controller.

• The energy saving and peak cut control units are the operation block and outdoor unit in the

AG-150A/G-50A unit.

• During peak cut control (for PLC(PAC-YG11CDA)), the AG-150A/G-50A monitors only one watt

hour meter. This can be set for each AG-150A/G-50A. This cannot be used with a system for

which two or more watt hour meters are connected to the air conditioner controlled by one

AG-150A/G-50A. Use the power rate count software Version 1.01 or later.

• During peak cut control for watt hour meter connected with PI controller, only one watt hour

meter monitored by the AG-150A/G-50A can be selected. When using other AG-150A/G-50As

for peak cut control (*1), up to three AG-150A/G-50As can be connected with the

AG-150A/G-50A.

*1:AG-150A/G-50A, connected with watt hour meter, monitors peak cut control lever every one minute. When the

control level changes, the change reflect AG-150A/G-50As with one minute delay. Control level should be set with

some float to avoid over peak cut electric power.

• During peak cut control (for Demand control equipment), up to 10 AG-150/G-50As can be monitored

with PLC for demand input software. When using more than 10 AG-150A/G-50A s, install multiple

number of PLCs. PLC for demand input software (PAC-YG41CDA) should be used for PLC.

7

Page 14

(10) Set temperature range limit function

• On ME remote control system, the target for the temperature range limit setting is only ME remote

controller and individual browser.

• On MA remote control system, the target for the temperature range limit setting is only MA remote

controller and individual browser. This function cannot be used depending on the indoor unit model.

(On MA remote control system, TG-2000A is supported by Ver.5.10 or later, and G-50A is supported by

Ver. 3.20 or later.)

Valid remote controller Set temperature range

limit

PAR-F27MEA-E Partly possible *1 ME remote controller

PAR-F27MEA-F Possible

PAC-SE51CRA-E Impossible ME simple remote

controller

PAC-SE51CRA-F Possible

MA remote controller PAR-21MAA Possible *2

PAC-YT51CRA Impossible Simple MA controller

PAC-YT51CRB Possible *2

*This chart is for TG-2000A Ver4.70 and G-50A Ver2.71systems.

*1 Only the lower limit of the set temperature for the Cool (Dry) mode and the upper limit for the Heat mode can be set

with the ME remote controller, PAR-F27MEA-E.

For ME remote controller, model name is written on the packing label or on the notice sticker on the backside of the

remote controller lid.

For ME simple remote controller, model name is written on the packing label or on the rated nameplate of the remote

controller.

*2 This function cannot be used depending on the indoor unit models. This chart is for TG-2000A Ver5.10 (or later) and

G-50A Ver3.20 (or later) systems.

(11) Initial settings

• Even if the operation settings are unclear, set all of the initial setting items selected for use.

Some functions may not work if any setting is omitted.

• In addition to installing (setting up) the PLC software, the PLC must be initialized from the

TG-2000A.

• Make sure the clock is synchronized with the clocks on AG-150A/G-50A and PLC.

Resynchronize the clock as necessary.

(12) Operation of the integrated centralized control software TG-2000A

• Either "Activate" or "Deactivate" can be selected for "always connected to AG-150A/G50A

system" of the TG-2000A. *Recommended setting: “Activate”

• When "Activate" is selected, the following functions are carried out automatically. When

"Deactivate" is selected, these are carried out semi-automatically.

• Power apportion billing data collection

• Apportioning, settlement calculation process

• Automatic output of settlement results

• The functions that run in the "always connected to AG-150A/G50A system" state can be used in

"Activate" state, but cannot be used in the "Deactivate" state. These functions will not operate

when the system is stopped.

• Trend functions (temperature, on/off, mode, power amount, humidity)

• Peak cut functions (only peak cut operation history functions)

• Set the TG-2000A to the "Deactivate" state when using the following functions.

• Summer time ----- From the day prior to and after shifting to and from summer time

• Season period --- From the day prior to and after shifting between normal and seasonal

power apportion billing.

• The G-50A, PLC or PI controller errors cannot be detected while the TG-2000A is stopped.

If the G-50A, PLC or PI controller is faulty, stopped or the power is OFF, the data required for charging

will not be collected, and schedule operation of the air conditioner or general equipment will not be

possible. Periodically confirm that the operation is correctly, and that no abnormalities are occurring.

• When "Activate" is selected, leave the computer power ON so that the integrated software

TG-2000A program runs 24 hours. (to prevent the program from stopping, do not use the

"System standby" or "System halt state" power supply optional functions.)

• The integrated software TG-2000A program runs for 24 hours, so always leave the computer's

power ON.

• Do not put any access restrictions such as “Read Only” on the folders on WINDOWS, TG2000,

MSSQL7, or on the ones that are specified in the user settings window of TG-2000A.

(13) Computer name

• Never change the computer name when setting up the integrated centralized control software

TG-2000A. The software will not operate if the computer name and the server name are

different.

8

Page 15

(14) Expanding billing target devices

• Always stop the air conditioner, fan and power rate count PLC or PI controller,

before expanding the devices.

• The billing function and power count function will not work correctly while the devices are being

expanded.

• Always change and check the system settings with the TG-2000A after finishing the expansion work.

Always test the operation after changing and checking the system settings.

(15) Using general equipment

• There may be cases when the general equipment cannot be monitored or operated due to a

disconnection in the wiring with the general equipment or a fault in the PLC (or DIDO controller).

Mitsubishi will not be held liable in the event of any damage. A circuit should be provided for

remedial operations when a fault occurs.

• The license number does not need to be registered in the AG-150A/G-50A when using the PLC

for general equipment software Version 1 Series.

(16) Function description

• The function/specifications may partially change and improvements may be made without any

notice.

(17) TG-2000A License

* Refer to the end of "Safety Precautions" in Chapter 1.

9

Page 16

2.4 Other Devices

Other devices specified or recommended for use with the TG-2000A are listed below.

Name Manufacturer Model Notes

HUB (None specified) (None specified) 10BASE-T must be usable.

Printer (None specified) (None specified) Supports a page printer only

(Must run under the OS used

(Windows Vista/XP/2000).)

Watt hour meter

(RS-485)

RS-232C/

RS-485

converter

PLC

* For electric

amount pulse

count

* For PLC for

general

equipment

software

(Ver. 1 Series)

1 Northern Design

(Electronics) Ltd.

2 Elcomponent

Limited

3 CIRCUTOR

4 Elcontrol energy

1 POWER RAIL 323 +

OPTION Module

2 AEM31D/485

3 CVM-BC-ITF-RS485-

C2

4 ED39din 485

Only supports RS-485 output of

the specified model and

manufacturer

(None specified) (None specified) Necessary when measuring the

electric power.

Ex) B&B Electronics Model

485DRJ

Black Box Model IC520A-F or

IC108A

* Regarding watt hour meter 2,

the converter from the manufacturer may also emit light.

Mitsubishi Electric CPU module : Q02CPU

Base module : Q33B

Power supply module:

Q61P-A1

or Q61P-A2

Input module : QX40

Output module:

QY40P

Ethernet module:

QJ71E71-100

These are used for the power

apportion billing (electric amount

pulse count) or general equipment

operation/monitor function.

Dedicated PLC software (PACYG11CDA, etc.) is required for

each function.

* The output unit is not required

for the electric amount pulse

count PLC.

PLC

* For PLC for

general

equipment

software

(Ver. 2 Series)

* For PLC for

demand input

software

(Ver.2 Series)

Watt hour meter

(for PLC or

PI controller)

UPS

(Uninterruptible

power supply)

Mitsubishi Electric CPU module : Q02HCPU

Base module : Q33B

(Q35B, Q38B, Q312B)

Power supply module:

Q61P-A1/A2

Input module : QX40

Output module: QY40P

Ethernet module:

QJ71E71-100

Use for the general equipment's

operation/monitor function,

schedule or operation/monitor

function of general equipment

connected to IC I/O signal,

interlocking control of

air-conditioners and general

equipment.

Dedicated PLC software (PACYG21CDA) is required. *1

Also used with peak cut function

connecting the demand controller.

Dedicated PLC for demand input

software (PAC- YG41CDA) is

required. *1

(None specified) (None specified) WHM corresponding to 0.1 sec.

or longer pulse output

(semiconductor relay)

* 1kWh/pulse or less is required.

(10/1/0.1 kWh/pulse)

(None specified) (None specified) Install when using the power

apportion billing function. (Any

type suitable for use with

computers)

*1 This version is not compatible with the demand controller compatible peak cut function.

10

Page 17

e

r

y

t

e

-

A

-

A

y

t

T

A

A

A

A

3. System Configuration

3.1 System Configuration Example

[Image drawing]

HUB

Integrated centralized

control softwar

TG-2000A

Power

LAN

*1

suppl

G-150

50

G

uni

Outdoor unit

Indoor unit

or G-50A

Power

suppl

uni

50

G

G-150

or G-50A

*2

DIDO controller

PI controller

Pulse

Pump

Measurement Meter

(Electric, Gas, Water,

Amount of Heat)

*2

Watt Hour Meter Pulse Count PLC

Pulse

Monitor status

Measurement Meter

(Electric, Gas, Water,

Amount of Heat)

General Purpose Control PLC

Chiller Pump

*1: Connect AG-150A/G-50A to a private network. (Only use on the private network.)

Use a security device such as a VPN (Virtual Private Network) router when connecting to the Internet.

*2: Either PLC or PI Controller can be connected to the Measurement meter.

3.2 Hardware Connection Diagram

(1) LAN connection

Connect the LAN cable to the computer. For the location of the LAN connector for the computer,

refer to the Instruction Manual of the computer.

TG-2000A

LAN

Note:

• Use a HUB with a repeater or a switch.

• When using a HUB with a repeater, execute the LAN cascade connection as shown

below.

For 10BASE-T, the cascade connection is executable up to a maximum of 4 stages.

For 100BASE-TX, the cascade connection is executable up to a maximum of 2 stages.

*Refer to the HUB Instructions Manual for the maximum connectable number of HUBs.

10BASE-

or

100BASE-TX

straight cable

HUB

To G-50A

To P LC

Remot

controlle

11

Page 18

p

r

A

A

A

)

4. Flow of Site Adjustment

4.1 Flow of Site Adjustment

When the task of site adjustment is subdivided into smaller tasks as shown in the figure below, the

tasks can be broadly grouped into four steps. The benefit of following these for steps when carrying

out the tasks of site adjustment is that if troubles do arise, it will be clear which step caused the

problem. This makes it easier to solve problems and this results in a more efficient execution of site

adjustment tasks.

(Step 2 can be skipped when not using the PLC.)

Carry out site adjustment, by following the step by step instructions shown below.

<System example>

Step 1 AG-150A/G-50A test run

Check that the air conditioners and controllers

are correctly configured and that the air conditioner works.

Step 2 PLC connections and installation

Connect the PLC and device hardware, and

install the PLC software into the PLC. *1

Step 3 PC connections and settings

Connect and set up the software and hardware on the PC with TG-2000A installed.

Check that it is ready for operation.

Check that the TG-2000A man-machine system can correctly operate air conditioner units of all

the managed systems by issuing TG-2000A commands.

Integrated centralized

control software

TG-2000A

Step 3

Step 4

Use PLC?

YES

HUB

Step 4 TG-2000A system test run

Power supply unit

LAN

G-150

or G-50

Step 1

Step 1

Step 2

* For the test operation method of the air conditioner,

DIDO controller, AI controller, PI controller

and central controller AG-150A/G-50A, refer to the

relevant installation manuals.

* Check that only the air conditioner test

operation has been completed before starting

Ste

1.

NO

12

* If PLC is not used, step 2 can be skipped.

*1. Refer to the instruction manual for the PLC,

electric amount count software or PLC fo

general equipment software.

* Refer to Chapter 4 in this booklet for details.

Meters

(electricity, gas,

water, calorific

value

PLC

Pulse

Status monitor

Chiller Pump

Page 19

4.2 Tools for Site Adjustment

r

A

A

You will need the following equipment and reference material in order to easily carry out site adjustment.

<Measurement instruments>

• Tester : to check the wiring and the voltage

<Reference material>

• All necessary drawings of the air conditioning control system

• TG-2000A Instruction Manual (Site Adjustment (this manual), Management)

• Instruction Manual and Installation Manual for each air conditioner unit and controller

• Instruction manual for PLC, electric amount count software or PLC for general equipment

software.

<Other material>

• License number : AG-150A/G-50A license number required to use functions

• Floppy disk : used when copying data

• CD-R/USB memory: used to store generated data and copy it to the site PC.

• TG-2000A CD : Integrated centralized control software TG-2000A setup disk

• Initial setting tool : Computer in which this tool is installed

• LAN cable : PAC-YG00FA: LAN cable for connection to the front of G-50A (as

necessary)

• PLC setting tool : GX Developer (Mitsubishi Electric) software

(including the dedicated RS-232-C cable)

*PLC…. Must be installed at site with system using PLC.

• Table setting tool : Table setting tool for PLC for general equipment software (required only

when an interlocking control is performed)

• Screwdriver kit

• Other usual maintenance tools

• Maintenance tool: needed when using interlock control function of DIDO controller and AI

controller.

4.3 Step 1: Test operation from central controller AG-150A/G-50A

Perform only the test operation of the air-conditioning system of the central controller AG-150A/G-50A.

(1) Preliminary check

Check that the test operation of the air conditioner has been completed.

Check that the central controller AG-150A/G-50A is set to Group and Interlock.

(The initial setting is executable using the initial setting Web or the AG-150A/G-50A.)

Integrated centralized

control software

TG - 2000A

HUB

Power

supply unit

G-150

or G-50A

Step1

(2) Test operation from central controller AG-150A/G-50A

After supplying power to the central controller AG-150A/G-50A and all air conditioners, perform the

test operation from the central controller AG-150A/G-50A and check the operation state of each

unit.

* For the test operation method, refer to the installation manual for the air conditioner or the

central controller AG-150A/G-50A.

4.4 Step 2 Connecting and installing the PLC

(1) Preliminary check

Check that the PLC has been installed and its power wired, and that the pulse wiring to the watt

hour meter to the wiring to the general equipment has been completed.

Note:

• Refer to the installation manual or instruction manual enclosed with the PLC for details on

setting and operating the PLC.

Maintenance Tip:

• Before wiring to the general device or confirming the connection, always notify the controller o

work supervisor of the destination device, and request that person to witness the work.

13

Page 20

(2) Installing the electric amount count software or PLC for general equipment software or PLC for

r

demand input

Format the PLC memory, and install the electric amount count software or PLC for general

equipment software or PLC for demand input software to count the power rate pulses with the PLC

or to use the general control or peak cut functions.

Note:

• Refer to the installation manuals enclosed with the electric amount count software or PLC fo

general equipment software or PLC for demand input software.

4.5 Step 3: Initial setting of integrated ce ntralized control software TG-20 00A

(1) Set-up of integrated centralized control software TG-2000A

Make preparations to allow the computer to be operative in order to install the integrated centralized

control software TG-2000A. After performing the set-up preparations, set up the integrated

centralized control software TG-2000A.

Note:

• For the set-up procedure, refer to Chapter 5.

• For safety, check the installation state/connection before turning the power ON.

(2) Check the AG-150A/G-50A IP address and computer (which uses the integrated centralized control

software)

Check the AG-150A/G-50A IP address. Check the IP address used for the integrated centralized

control software at the same time. Normally, set the sub-net to "255.255.255.0".

Set the integrated centralized control software's IP address, etc., using the Windows(OS)

network setti ng fu n c ti o n .

For a LAN dedicated to the AG-150A/G-50A system, it is recommended to set the IP address

within the following range.

Models IP address range

AG-150A/G-50A main unit [192.168.1.1] to [192.168.1.40]

Computer for browser [192.168.1.101] to [192.168.1.149]

Computer for integrated centralized control software [192.168.1.150]

PLC [192.168.1.151] to [192.168.1.200]

PLC for electric amount count software [192.168.1.151] to [192.168.1.155]

PLC for general equipment PLC software [192.168.1.171] to [192.168.1.190]

PLC for demand input PLC software [192.168.1.191] to [192.168.1.194]

Computer of initial setting tool [192.168.1.201]

* To connect to the existing LAN, set the IP address and sub-net mask set by the LAN manager.

(3) LAN connection confirmation

Check that the LAN cable is connected to the AG-150A/G-50A, computer (using integrated

software), and hub, and that power is supplied to the hub.

(4) Initial setting of integrated centralized control software

Start the integrated centralized control software TG-2000A to execute the initial setting.

Note:

• For the initial setting method of the integrated centralized control software TG-2000A, refer to

Chapters 6 to 8.

• In a system using a PLC, initialize the PLC with the integrated centralized control software

TG-2000A so that the PLC can be used.

14

Page 21

4.6 Step 4: Test operation from integrated centralized control software TG-2000A

Perform the test operation from the integrated centralized control software TG-2000A to check the

operation state and monitor display of the air conditioner.

For the operation procedure, refer to the Instruction Manual (Management).

Note:

• For confirmation in the test operation, use the checklist shown in Chapter 11.

• Perform the normal operation from the integrated centralized control software TG-2000A to

execute the test operation/confirmation. (The test operation function is not included in the

start/stop function.)

Maintenance Tip

• When carrying out test run with the general equipment, so not start and stop the site devices

without approval from the device's controller or work supervisor. Ask that person to witness

the test run.

15

Page 22

t

s

5. Installation

5.1 Pre-installation Steps

The preparation required for setting up the integrated centralized control software TG-2000A is

explained in this section.

5.1.1 Checking the AG-150A version and the G-50A version

1) Checking the AG-150A version

Check the AG-150A version with one of the following methods.

Method 1 : Using the initialization tool

The version can be monitored from the Basic Setting window.

Method 2 :Using the AG-150A main unit

The version can be found at the right bottom corner of the Login screen that appears

when is pressed.

2) Checking the G-50A version

Check the G-50A version with one of the following methods.

Method 1 : Using the initialization tool

The version can be monitored from the Basic Setting window.

Method 2 : Using the G-50A main unit

Press the [↑][↓] buttons for two seconds or longer to open the Initialization Mode

Menu window. Then, press the [ ] button to open the second menu window. The

version will appear at the lower right.

* If the integrated centralized control software TG-2000A has already been installed, the AG-150A version

and the G-50A version can be confirmed with section 8.6.3.

Note:

・ In using TG-2000A and AG-150A or G-50A in combination, it is recommended that the lates

versions of the software be used.

(Reference) As of Oct. 2008, th e comb ination of TG-200 0A Ver.5.50 and G- 50A Ver.3.22 i

recommended.

・ When using Energy saving and Peak cut function via G-50A Ver.3.20 or later, use TG-2000A Ver.

5.10 or later.

Check the central controller G-50A version. Update if it is not the applicable version.

Applicable G-50A version

Use Do not use

Power apportion billing

1

function

Energy saving/peak cut

function

2

Set temperature range

limit function

3 Auto change function

4 Night mode function

5 IC I/O signal function

Expansion of set

6

temperature range limit

function

Billing function of A/K

7

control units

Ver.2.51 or later

Ver.2.60

or later

Ver.2.70

or later

Ver.2.71

or later

Functions are available with Ver 2.80.

Functions are available with Ver 2.60.

Functions are available with Ver 2.70.

Functions are available with Ver 2.71.

Functions are available with Ver. 2.21.

Functions are available with Ver. 2.50.

Remarks

Ver.2.80

or later

Ver.2.90

or later

Ver.3.00

or later

Ver.3.20

or later

Functions are available with Ver 2.80.

Functions are available with Ver 2.90.

Functions are available with Ver 3.00.

Functions are available with Ver 3.20.

16

8 Initial setting Web

Energy save settings for

9

the A-control Inverter

Slim outdoor units

1ºF temperature

10

setting function

DIDO, AI and PI controller

11

function

Page 23

Updating the AG-150A

Monitor the system for the target AG-150A.

Step Item Details

1 Connect the LAN cable Connect the AG-150A and computer with the LAN.

Set the Update Program

2

CD for AG-150A

Insert the Update Program CD (for AG-150A) in the computer's

CD-ROM drive.

3 Start the Monitor tool Update screen will be displayed automatically.

Input the IP address, and

4

start the Monitor

5 Complete the Monitor

Input the IP address on the Monitor window, and then press the

[Start Monitor] button.

The Monitor is completed when the progress graph reaches

100%.

Updating the G-50A

Monitor the system for the target G-50A.

Step Item Details

1 Connect the LAN cable Connect the G-50A and computer with the LAN.

Set the Update Program

2

CD for G-50A

Insert the Update Program CD (for G-50A) in the computer's

CD-ROM drive.

3 Start the Monitor tool Update screen will be displayed automatically.

Input the IP address, and

4

start the Monitor

5 Complete the Monitor

Input the IP address on the Monitor window, and then press the

[Start Monitor] button.

The Monitor is completed when the progress graph reaches

100%.

Note:

• If a communication error occurs while updating the system, the AG-150A/G-50A will

standby in the Monitor mode for ten minutes. Click on the [Start Monitor] button again to

restart the Monitor.

The license for the “Web monitor” must be registered from the AG-150A unit.

• Take the following measures if update fails and the system does not startup properly.

[G-50A]

Turn the power to the G-50A back on with buttons [1] and [0] on the G-50A unit being

held down, and keep them held down for 10 more seconds. G-50A will start up in the

Update mode. Follow the instructions on the screen and try performing an update

again.

[GB-50A]

Turn SW 1-1 and 1-2 on the GB-50A unit, and then turn the power on. G-50A will start

up in the Update mode. Follow the instructions on the screen and try performing an

update again.

After the update, turn the service switch SW1 to OFF, and reboot the unit.

[Operation environment]

A computer containing the integrated centralized control software TG-2000A can be used, but

when updating the system with a different computer, make sure that the computer satisfies the

following operation environment.

Table AG-150A/G-50A Monitor computer operation environment

Item Details

OS Windows Vista/XP/2000

CPU Pentium® 133MHz or fas ter (The required CPU speed depends on Windows

(OS).)

Memory 64Mbyte or more (The required memory size depends on Windows (OS).)

Built-in LAN port or LAN card One

Others CD-ROM drive (required for installation), mouse or other pointing device

17

Page 24

5.1.2 Preparing for TG-2000A setup

Preparing for installation

Before installing the TG-2000A application, do the following checks and preparatory steps.

Note:

• The AG-150A- and G-50A-compatible TG-2000A must be used to Ver. 5.5* or later. These

versions of the TG-2000A run on Windows Vista or Windows XP.

• To use the functions supported by older versions of G-50A-compatible TG-2000A, use TG-2000A

Ver. 5.1* This version runs on Windows XP or Windows 2000.

Steps Action Details How to

1 Check the OS Check the OS Service Pack version.

2 Check the memory Check the requirement of the memory

3 Check the HDD free

space

4 Printer settings *1 Install the printer driver and check that

• Windows Vista

® Business:

Service Pack 1

• Windows

® XP Professional:

Service Pack 3

• Windows

® 2000 Professional:

Service Pack 4

*Only English version

*Use TG-2000A Ver.5.1* for Windows® 2000

Professional.

capacity for OS used.

・Windows Vista : 1GB or more

・Windows XP/2000 : 512MB or more

Check that there is at least 2GB of free

space on the C drive. (OS already set

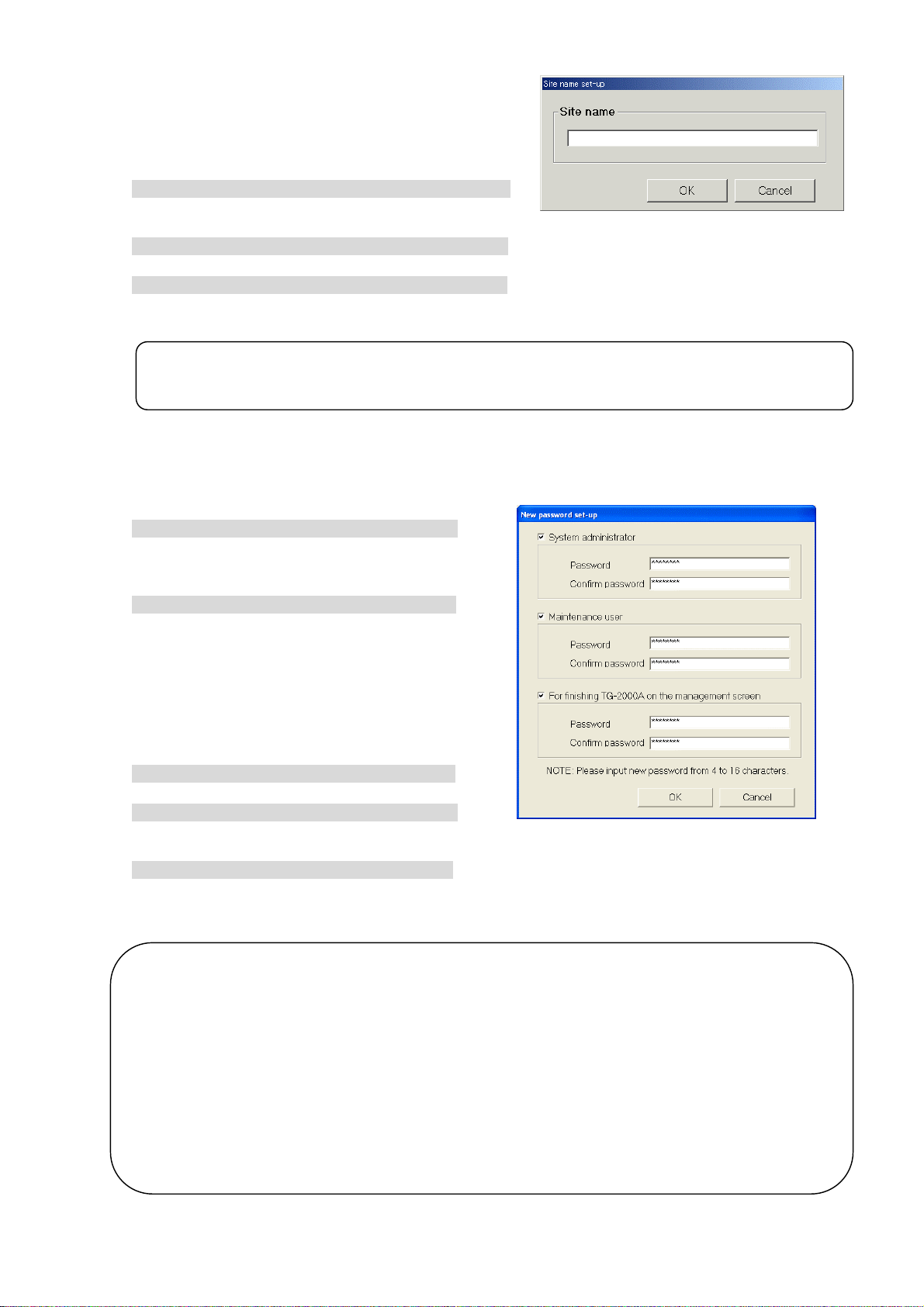

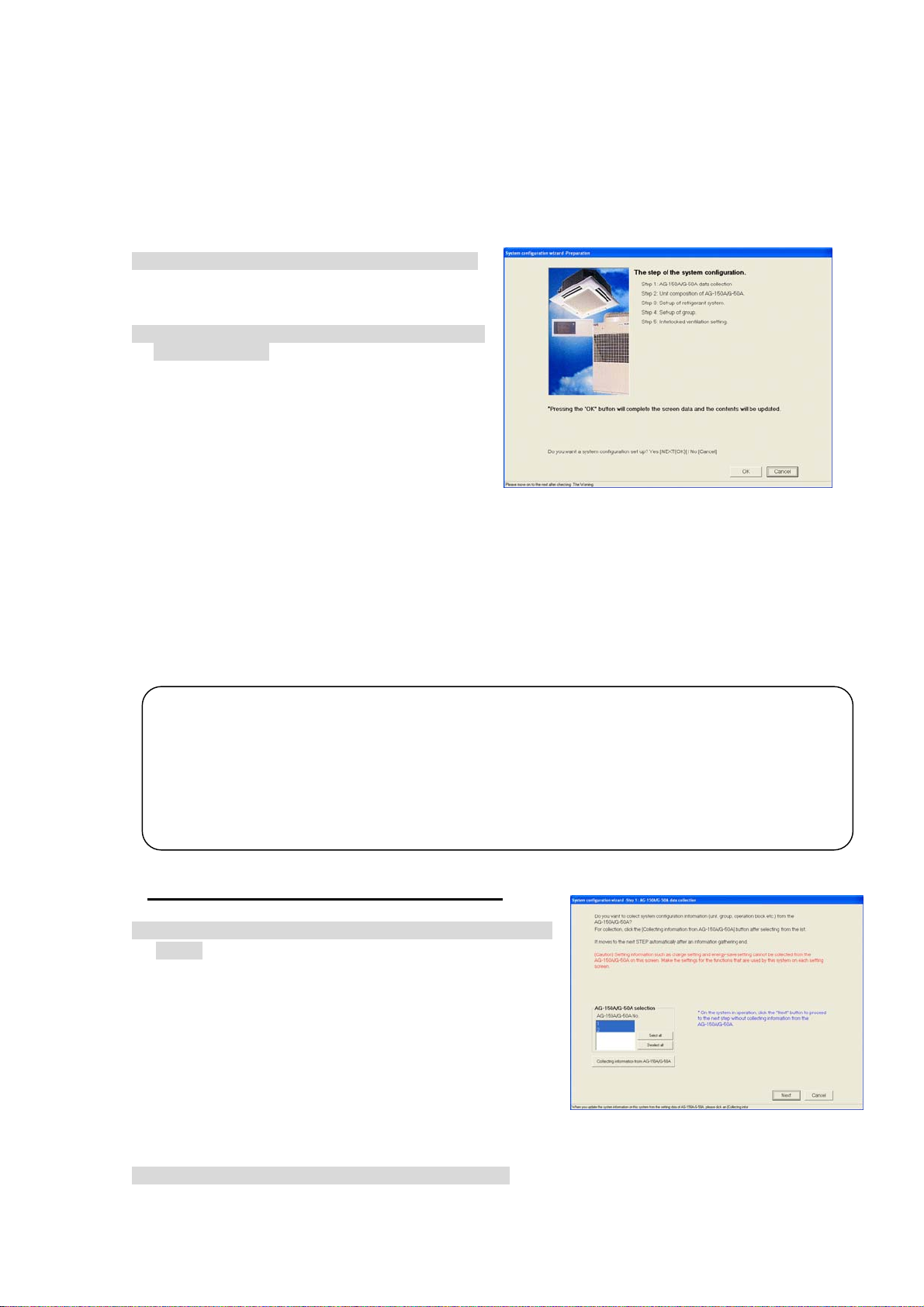

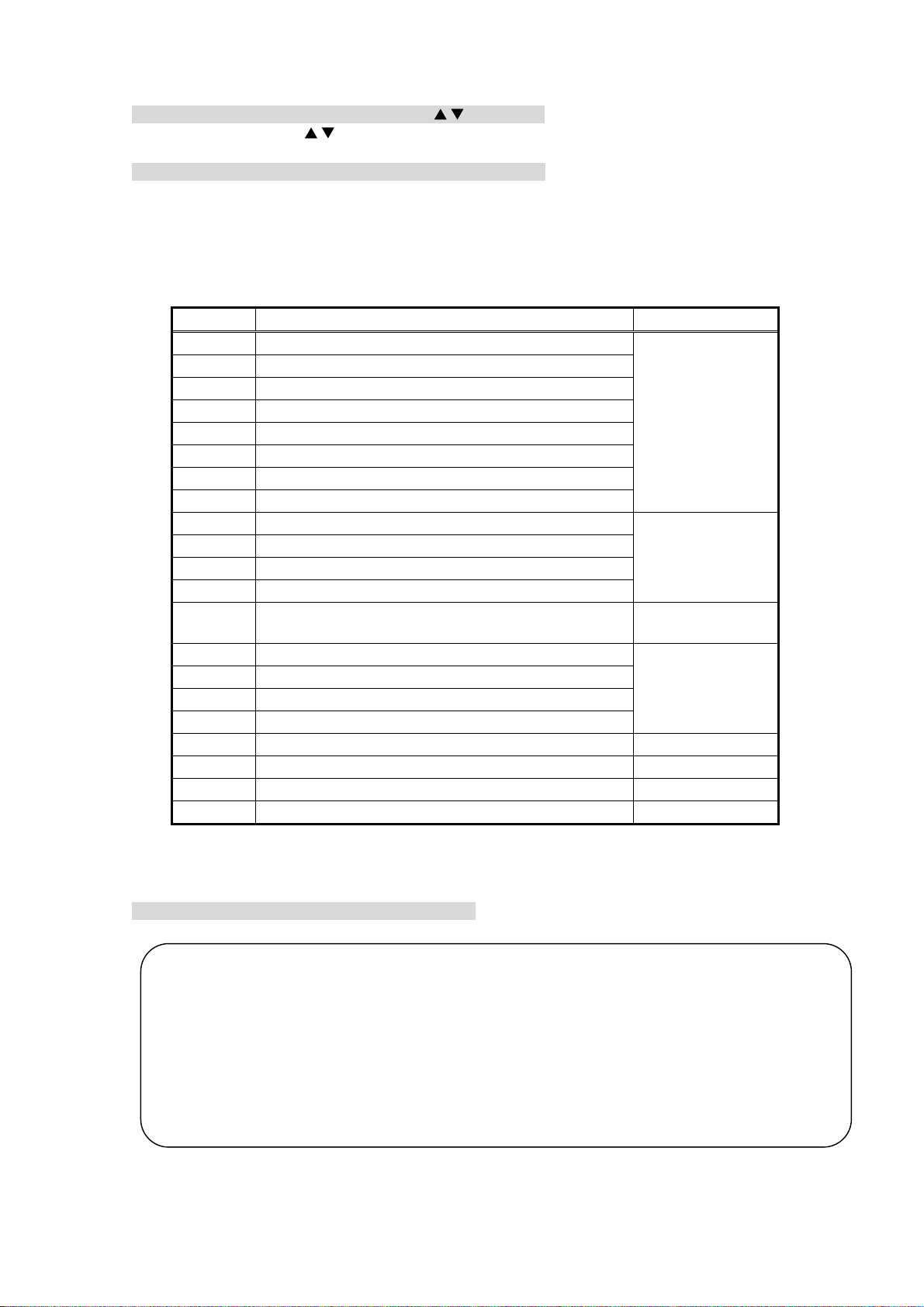

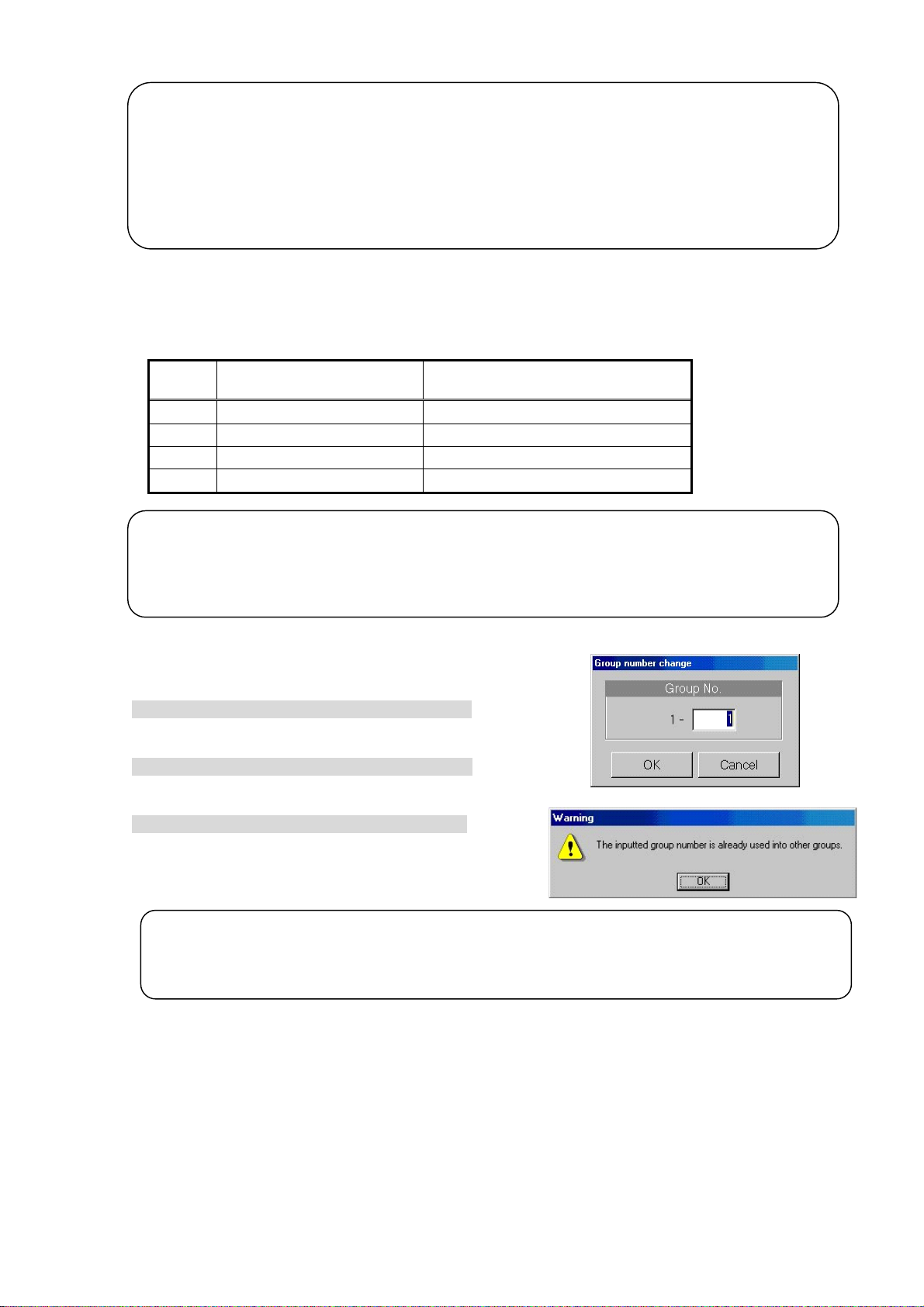

up)