Page 1

Page 2

Page 3

Introduction

Thank you for purchasing this THERMAL DIGIPLATER TDP-324 made by MITSUBISHI PAPER MILLS,

LTD.

Read this manual carefully before using the Thermal Digiplater and become familiar with the installation

and operation procedures.

Keep this user’s manual at hand so that it can be referred to at any time during operation of the Thermal

Digiplater.

This manual has been carefully prepared, however, if you find any mistakes, or have any questions,

please let us know.

If this manual is lost or damaged, promptly place an order for a new one from a distributor near you.

If this Thermal Digiplater is transferred to another party, please attach this manual to the Thermal

Digiplater.

After receiving this product, check that:

○ It is the product that you ordered.

○ It has not been damaged during shipping.

○ All accessories are present.

* If a damaged or abnormal part is found, contact the distributor immediately.

Copyright © 2010: Mitsubishi Paper Mills Limited

The copyright for this entire manual belongs to Mitsubishi Paper Mills Limited.

Copying, reprinting, reproduction of this manual in whole or in part in any medium

without our express consent infringes upon the copyright and the rights of the publisher.

The specifications in this document are subject to change without prior notice for product improvement.

All brand and product names referenced in this document are trademarks or registered trademarks of

their respective companies.

Page 4

Page 5

Table of Contents

TDP-324

Table of Contents - 1

Table of Contents

Chapter 1 Safety Precautions...............................................................1

1.1 Cautions for working environment and installation ................................................. 2

1.2 Handling the Thermal Digiplater................................................................................ 3

1.3 Kind of warning labels and its attachment part ........................................................5

1.4 Handling plate before and after platemaking............................................................ 6

Chapter 2 Installation and Setup..........................................................7

2.1 Unpacking and setup procedure................................................................................ 7

2.2 Unpacking ...................................................................................................................8

2.3 Checking the accessories.......................................................................................... 9

2.4 Names and functions of parts.................................................................................. 10

2.4.1 Names of parts ...................................................................................................................... 10

2.4.2 Functions of parts.................................................................................................................. 12

2.5 Connecting the power cable .................................................................................... 13

2.6 Connecting the USB cable ....................................................................................... 14

2.7 Installing the plate tray............................................................................................. 15

2.8 Setting the plate........................................................................................................ 16

2.9 Change Method of Flange Position ......................................................................... 21

Chapter 3 Use of Operation Panel......................................................23

3.1 Power switch............................................................................................................. 23

3.2 Operation panel......................................................................................................... 23

3.2.1 LED indications ..................................................................................................................... 24

3.2.2 Operation button.................................................................................................................... 24

3.2.3 LCD indications ..................................................................................................................... 25

3.3 Explanation of the user mode.................................................................................. 26

3.3.1 Selecting a plate size channel............................................................................................... 27

3.3.2 Setting the plate size ............................................................................................................. 28

3.3.3 Adjusting the print density ..................................................................................................... 30

3.3.4 Checking the firmware versions ............................................................................................ 31

3.3.5 Setting the Head Cleaning Mode and Execution of Head Cleaning ..................................... 32

3.3.6 Display of Plate Remains, and Reset of Plate Remains Counter......................................... 38

3.3.7 Display of Print Counter, and Reset of Print Counter............................................................ 39

3.3.8 Setup of Plate Remains SW(on/off) ...................................................................................... 40

3.3.9 Execution of Platen Cleaning ................................................................................................ 41

3.3.10 Setting the Pinch Cleaning Mode and Execution of Pinch Cleaning .................................... 42

3.3.11 Display of accumulated print distance................................................................................... 46

3.3.12 Set up a print Interval ............................................................................................................ 47

Chapter 4 Daily Maintenance..............................................................49

Page 6

Table of Contents

TDP-324

Table of Contents - 2

4.1 Cleaning the parts inside the Thermal Digiplater ...................................................49

4.1.1 Cleaning the thermal head .................................................................................................... 50

4.1.2 Cleaning the main pinch roller ............................................................................................... 52

4.1.3 Cleaning the platen roller ...................................................................................................... 54

4.1.4 Cleaning the feeding pinch roller ........................................................................................... 56

4.1.5 Cleaning the cleaning rollers ................................................................................................. 58

4.1.6 Cleaning the image sensor.................................................................................................... 60

4.1.7 Cleaning the head position plate ........................................................................................... 62

4.2 Cleaning the cover of the Thermal Digiplater ......................................................... 64

4.3 Cleaning the filters.................................................................................................... 64

4.4 Consumable parts.....................................................................................................65

Chapter 5 Trouble shooting............................................................... 67

5.1 When an error message is displayed ...................................................................... 67

5.2 Plate jam.................................................................................................................... 68

5.3 When parts of image area are missing from the printed plate...............................71

5.4 Plate is not correctly detected ................................................................................. 72

5.5 When power is off during printing........................................................................... 74

Chapter 6 After-sales service ............................................................ 75

Chapter 7 Specification...................................................................... 77

7.1 Basic specification ................................................................................................... 77

7.2 Outline figure ............................................................................................................ 77

Page 7

Chapter 1 Safety Precautions

TDP-324

-1-

Chapter 1 Safety Precautions

The purpose of this manual is to use this product safely.

Carefully read this manual and leaflets attached to the Thermal Digiplater and become familiar with the

installation and operation procedures for safe use.

This manual contains precautionary statements to prevent hazardous operations.

The statements are categorized as follows so that you can better understand all safety precautions

for this Thermal Digiplater.

It is impossible for us to anticipate all hazards that may occur when the Thermal Digiplater is installed

and used under various environmental conditions. Therefore, all possible warnings and cautions are

not included in the user’s manual, other leaflets or labels on the Thermal Digiplater.

Should the Thermal Digiplater be operated or inspected in any way other than as indicated in the

user’s manual, you shall be responsible for the safety.

The precautionary notes on how to use and inspect the Thermal Digiplater indicated in the user’s

manual and other leaflets are intended only for when the Thermal Digiplater is used for its originally

specified purpose.

Should the Thermal Digiplater be used for any purposes other than as intended in the user’s manual,

you shall be solely responsible for the safety.

Never perform operations that are prohibited in the user’s manual and other leaflets.

I

ndicates a hazardous situation that could result in death or serious injury if the

Thermal Digiplater is handled incorrectly.

Indicates a

hazardous situation that could result in mi

nor in

jury or property damage

if the Thermal Digiplater is handled incorrectly.

Indicates causes of problem or conditions of working environment.

Page 8

Chapter 1 Safety Precautions

TDP-324

-2-

1.1 Cautions for working environment and installation

Pay attention to the following to use the Thermal Digiplater safely:

D

o not install th

e Thermal Digiplater in an area with an extremely low or high

temperature. Do not install it, for example, in

an area of a ski site or skating rink with

a low ambient temperature or in an outdoor area where it will be exposed to direct

sunl

ight and heat.

Do not put a v

essel containing water, such as a vase, plant pot, cup, or any metallic

article on this Thermal Digiplater. If water is spilt or a metallic piece enters the

Thermal Digiplater, a fire or electric shock c

an occur.

Do not cover the vent holes

of the Thermal Digiplater. Doing so will not allow the

heat to escape from the Thermal Digiplater, thereby causing a fire.

Do not insert or drop a metallic or flammable article i

nside through any vent hole.

Doing so can cause a fire or electric shock.

Provide an electric oulet at an accessible place near this product.

Do not use the

Thermal Digiplater in a

n environment with volatile substances, such

as alcohol and thinner, or cumbustible gases.

Make sure that children

do not tou

ch the Thermal Digiplater and cables. Failure to

do so can result in injury or electric shock.

Do not

install the Thermal Digiplater in damp, dusty or sandy places, such as a

bathing place, a bathroom, near a hot spring, on a road or by the side of a pool.

Doing so can cause a fire, electric shock or failure.

Do not install th

e Thermal Digiplater on a shaky

stand, inclined floor or any other

unstable place. If so, it can fall or turn over and cause personal injury.

Page 9

Chapter 1 Safety Precautions

TDP-324

-3-

1.2 Handling the Thermal Digiplater

Pay attention to the following warnings and caution when handling the Thermal Digiplater:

Take the

Thermal Digiplater

out of the package and place it on a horizontal and stable

table or desk.

As it weighs approximately 55 kg(121 lbs), it is dangerous for a single person to try to

hold or carry the

Thermal Digiplater

.

When taking it out of the package, take care not to

injure your fingers or hands.

The

Thermal Digiplater

’s center of gravity is at the front. Take care not to lose balance

when carrying it. At least 2 persons are required to carry and install it

.

Use extreamly caution when carrying it on a slippery floor.

If it is dropped and damaged, turn off the power switch on the main body, disconnect the

power cable from the electric oulet and contact the distributor. If it is used without

servicing, it can cause a fire or electric shock.

Plug the power cable all the way into the

electric oulet

.

The thermal head is heated w

hile the Therm

al Digiplater is

operating. This is not an

abnormal phenomenon. It is heated to a high temperature. Never touch it.

If

an abnormality occurs, take only the measures for the abnormalities described in this

users manual. If normal operation cannot be recovered, contact the distributor from

whom you bought it.

Page 10

Chapter 1 Safety Precautions

TDP-324

-4-

Use only the power cable supplied with the Thermal Digiplater. Be sure to connect

the power cable to the electric oulet to be grounded according to all relevant local

regulations(resistance:less than 100 ohm). If a short circuit occurs while the

Thermal Digiplater is operating without being grounded, a fire or electric shock can

occur. In addition, radio and television reception can be affected. If the Thermal

Digiplater cannot be grounded, consult the distributor.

If you touch the surface of the thermal head directly with your hand, the head can be

damaged. If hard particles, such as sand, enter the head, it can be damaged. Take

care when handling the head.

Use the USB cable supplied with

the Thermal Digiplater to connect i

t to your

computer when installing the Thermal Digiplater.

Do not disconnect the power cable while data is bein

g printed or transferred. Doing

so can cause the Thermal Digiplater to break down.

Page 11

Chapter 1 Safety Precautions

TDP-324

-5-

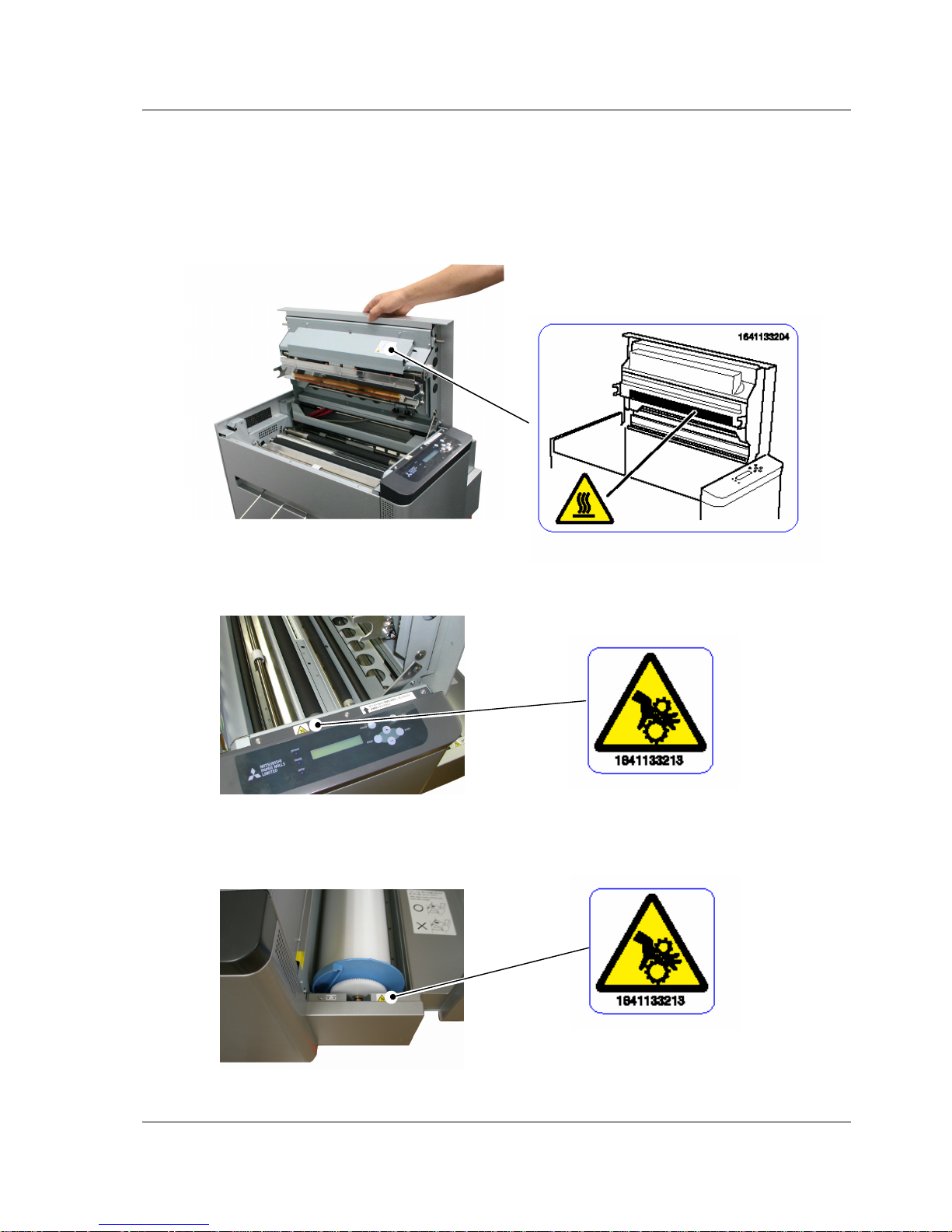

1.3 Kind of warning labels and its attachment part

The following warning labels are attached inside the Thermal Digiplater to prevent the accident and

avoid the danger. If the label come off or can’t be seen, contact the distributor from whom you bought it

immediately.

Page 12

Chapter 1 Safety Precautions

TDP-324

-6-

1.4 Handling plate before and after platemaking

When handling plate, observe the following instructions:

When handling

plate before platemaking:

Use plate specified by Mitsubishi Paper Mills, Ltd.

Wrap the plate with the black polybag and avoid high temperature and high

humidity, and store it in the cool and dark place.

(at a temperature of 30℃℃℃℃(86 ゚゚゚゚ F) or lower and a humidity of 60% RH or less)

Do not touch the plate surface with your hand.

Finger prints can deteriorate the printing quality.

When handlin

g plate after platemaking:

Store plates avoiding direct sunlight.

Store plates away from organic solvents such as benzine, thinner and alcohol. In

addition, avoid direct contact with hands.

If the printed images come into contact with hands or any of these substances,

discoloration can occur to the plates.

Page 13

Chapter 2 Installation and Setup

TDP-324

-7-

Chapter 2 Installation and Setup

2.1 Unpacking and setup procedure

This chapter explains procedures from unpacking to setting up the Thermal Digiplater.

Be sure to read Chapter 1 Safety Precautions before proceeding to this chapter.

Perform the following to unpack and install:

1.

Open the box and take out the Thermal Digiplater and accessories.

2.

Check the names and functions of the Thermal Digiplater’s parts.

3.

Take out the protective inserts.

4.

Connect the power cable.

5.

Connect the USB cable.

6.

Install the plate tray.

7.

Turn on the power switch.

8.

Set the spools to the plate and place the plate into the Thermal Digiplater.

Page 14

Chapter 2 Installation and Setup

TDP-324

-8-

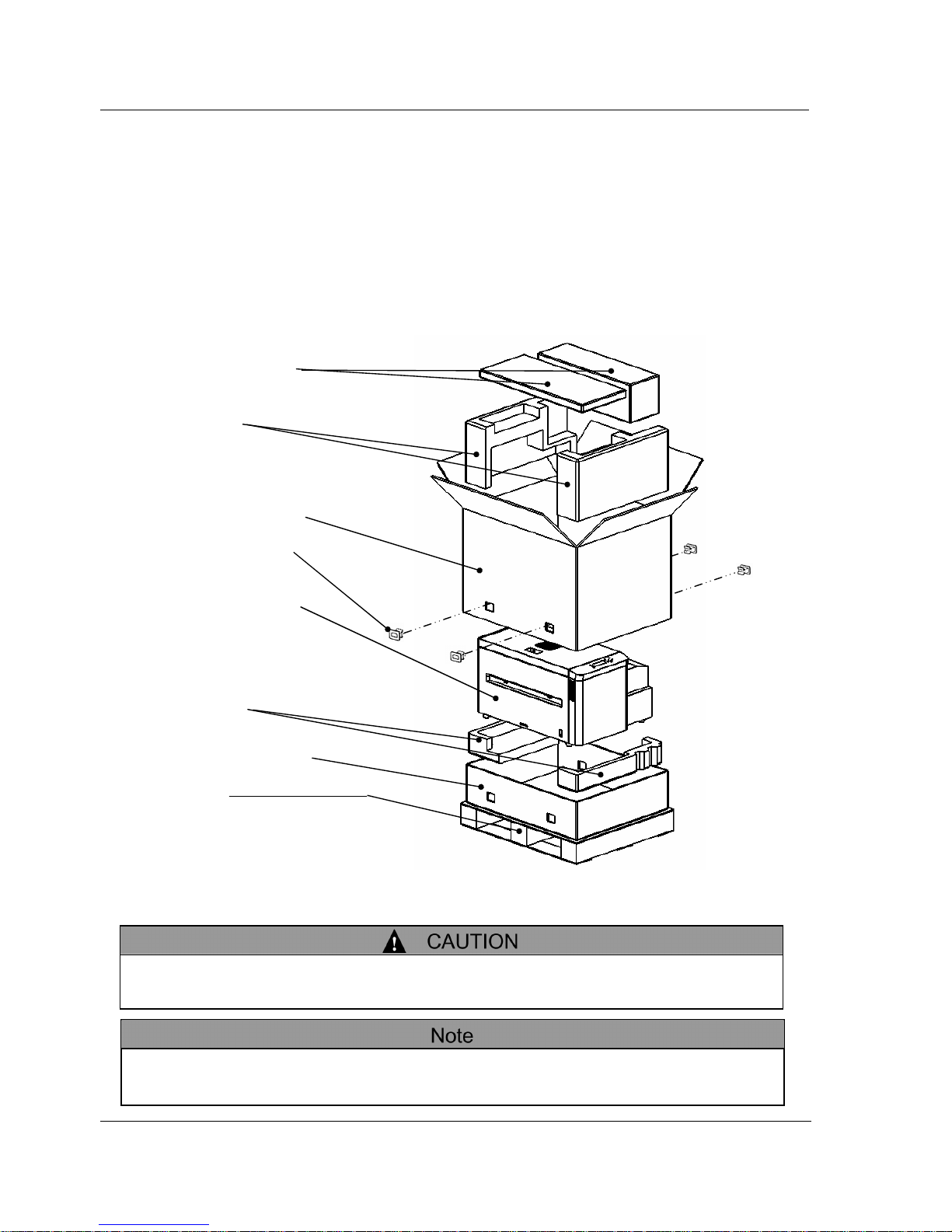

2.2 Unpacking

First, unpack and check the contents.

The box contains the Thermal Digiplater, accessories and protective inserts.

The accessories are: Spool, Flange, power cable, USB cable, plate tray, user’s manual, the

TDPController CD-ROM with the user’s manual, Technical Guide, and Project warranty.

Do not discard the packaging materials. The box and protective inserts will be

required to transfer or transport the Thermal Digiplater. Keep them in a safe place.

T

his Thermal Digiplater weighs approx. 55 kg(121 lbs). Take care when handling it.

When taking out and carrying, securely hold it by its bottom.

Accessories box

Cushion

Carton box(upper)

Joint (four places)

Thermal Digiplater

Cushion

Carton box (lower)

Pallet

(made from corrugated paper)

Page 15

Chapter 2 Installation and Setup

TDP-324

-9-

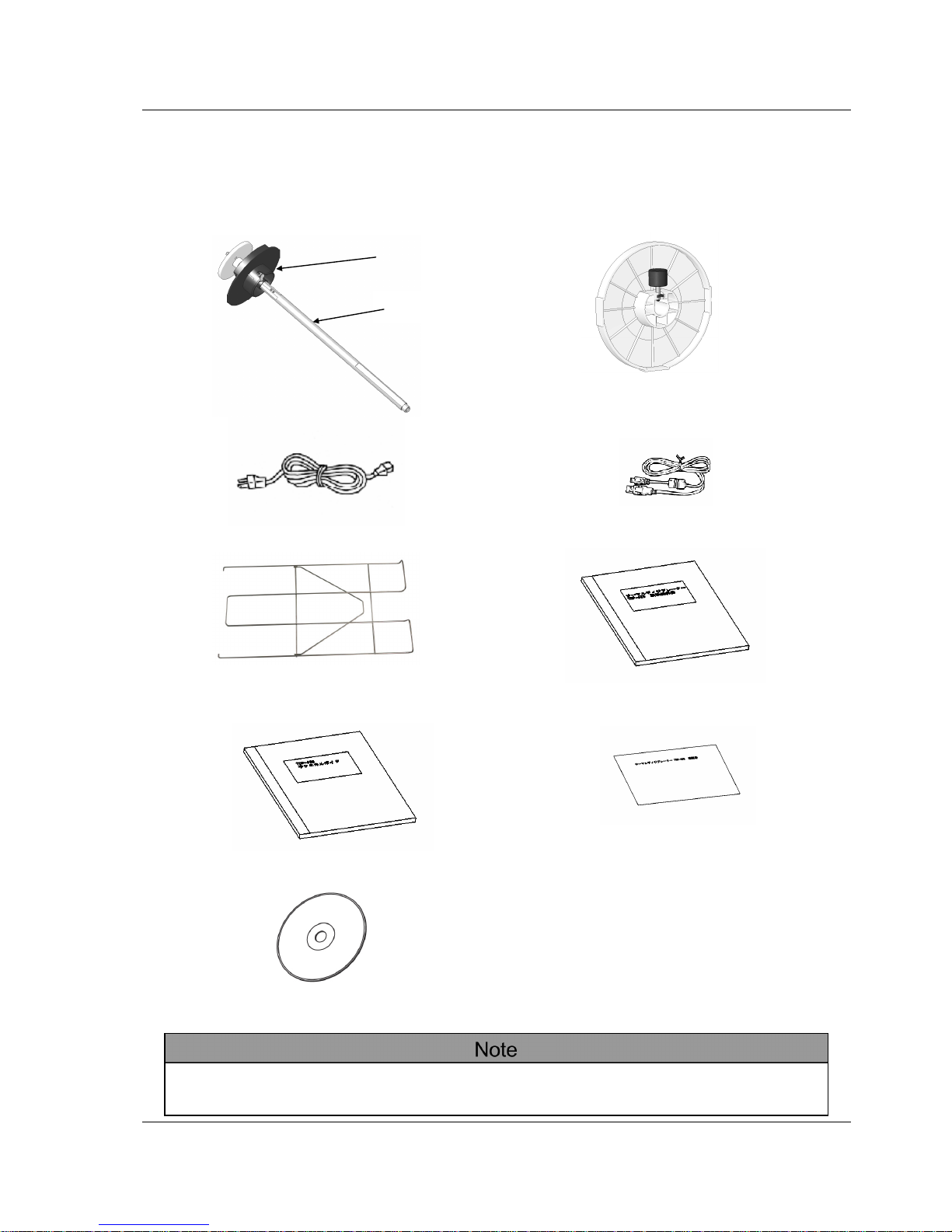

2.3 Checking the accessories

Take out the accessories from the box and from inside of the Thermal Digiplater. Check that the following

items, as illustrated below, are present.

Spool Flange(anti-gear side)

Power cable USB cable

Plate tray User’s manual

Technical guide

TDPController CD-ROM

Product warranty

If an accessory is missing, contact the distributor immediately.

(Flange(gear side))

(Spool shaft)

Page 16

Chapter 2 Installation and Setup

TDP-324

-10-

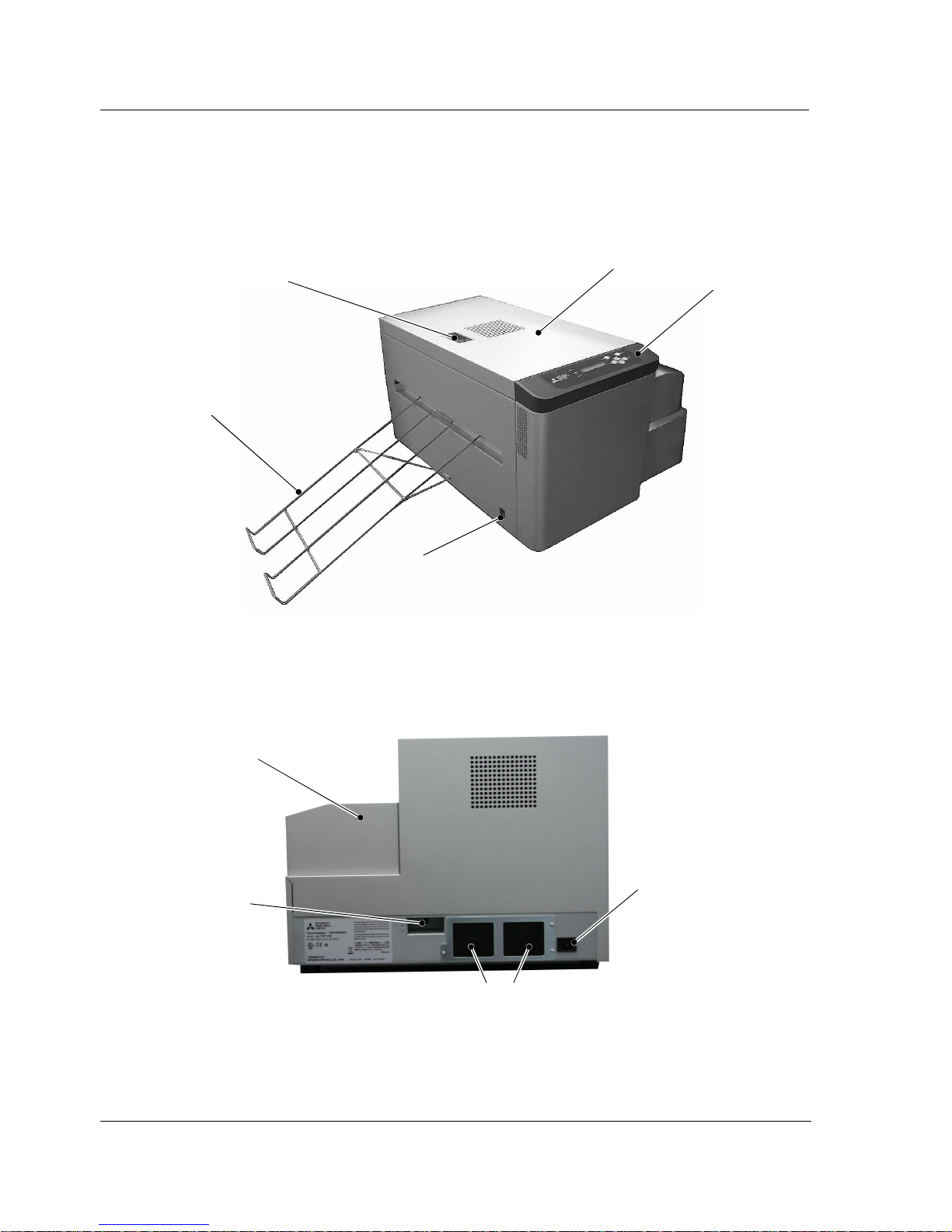

2.4 Names and functions of parts

2.4.1 Names of parts

Front

Rear

Operation panel

Opening lever A

Upper cover

Plate tray

Power switch

Power input

terminal

USB terminal

Plate cover

Filters

Page 17

Chapter 2 Installation and Setup

TDP-324

-11-

Inside the Thermal Digiplater

Thermal head

Cleaning roller (discharge side)

Cleaning roller (entrance side)

Platen roller

Main pinch roller

Feeding pinch roller

Page 18

Chapter 2 Installation and Setup

TDP-324

-12-

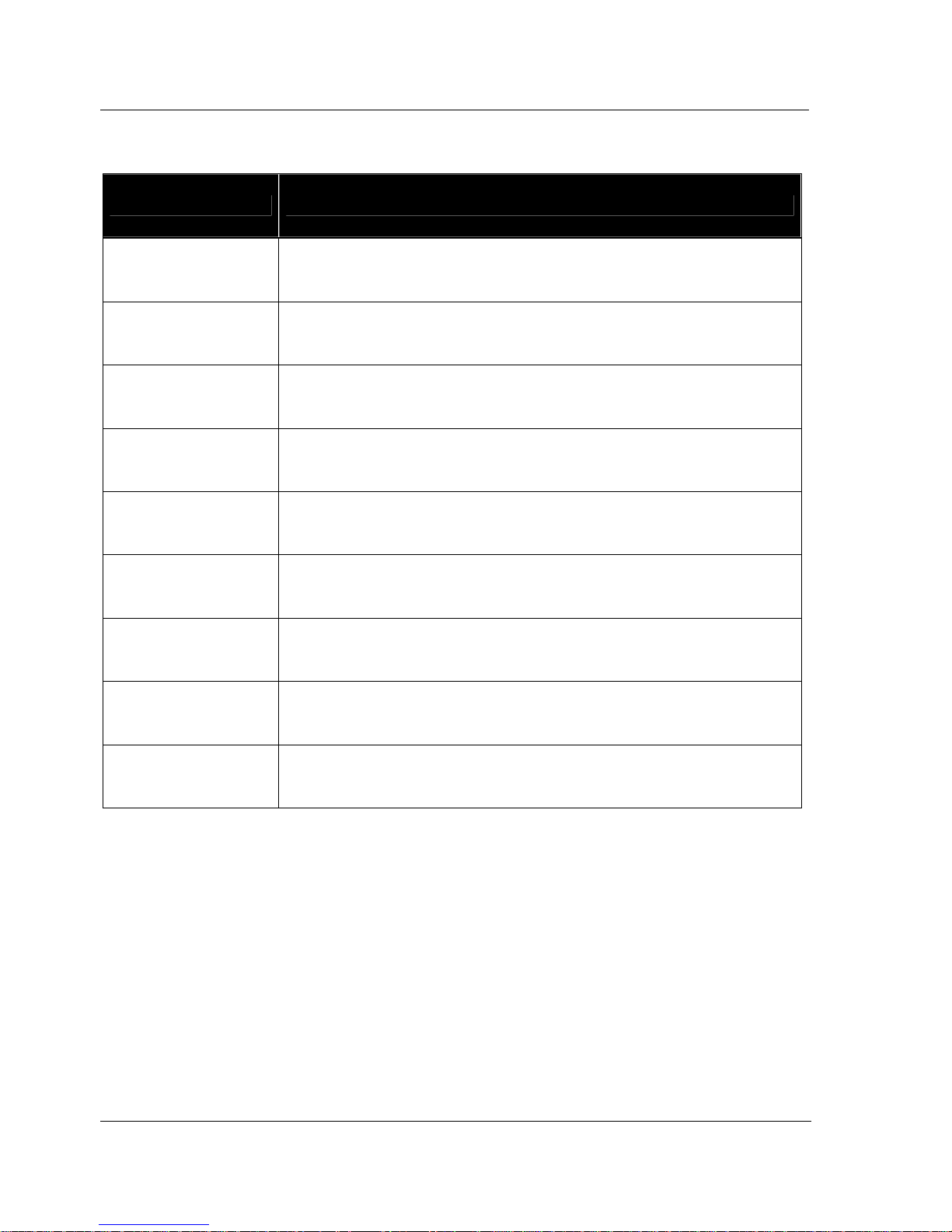

2.4.2 Functions of parts

Name Function/Description

Upper cover

Open this cover when inspecting and cleaning the thermal head and the rollers such as

the main pinch roller, the platen roller and so on, and when removing a jamming plate

portion.

Operation panel

The operation buttons, LCD display (referred to as the LCD below) and status lamps are

located here.

Power switch

Switch to turn the power to the Thermal Digiplater on or off.

Pressing “|” turns on the power while pressing “O” turns off the power.

<Caution> After turning off the power, turn on the power after a lapse of 3

seconds or more.

Power input terminal Connect the power cable.

USB terminal Connect the USB cable.

Thermal head

Add the heat to the plate and print.

<Caution> The head is heated to a high temperature while the Thermal Digiplater

is operating. Do not touch. Touching it directly with your hand can cause failure.

Platen roller Rubber roller to feed with plate.

Cleaning roller

(Entrance and discharge

sides)

Rubber rollers to remove dust and foreign matters from the plate surface.

One installed at the entrance side and the other at the discharge side.

Filter Prevent dust and foreign substances in air from entering inside the Thermal Digiplater.

Page 19

Chapter 2 Installation and Setup

TDP-324

-13-

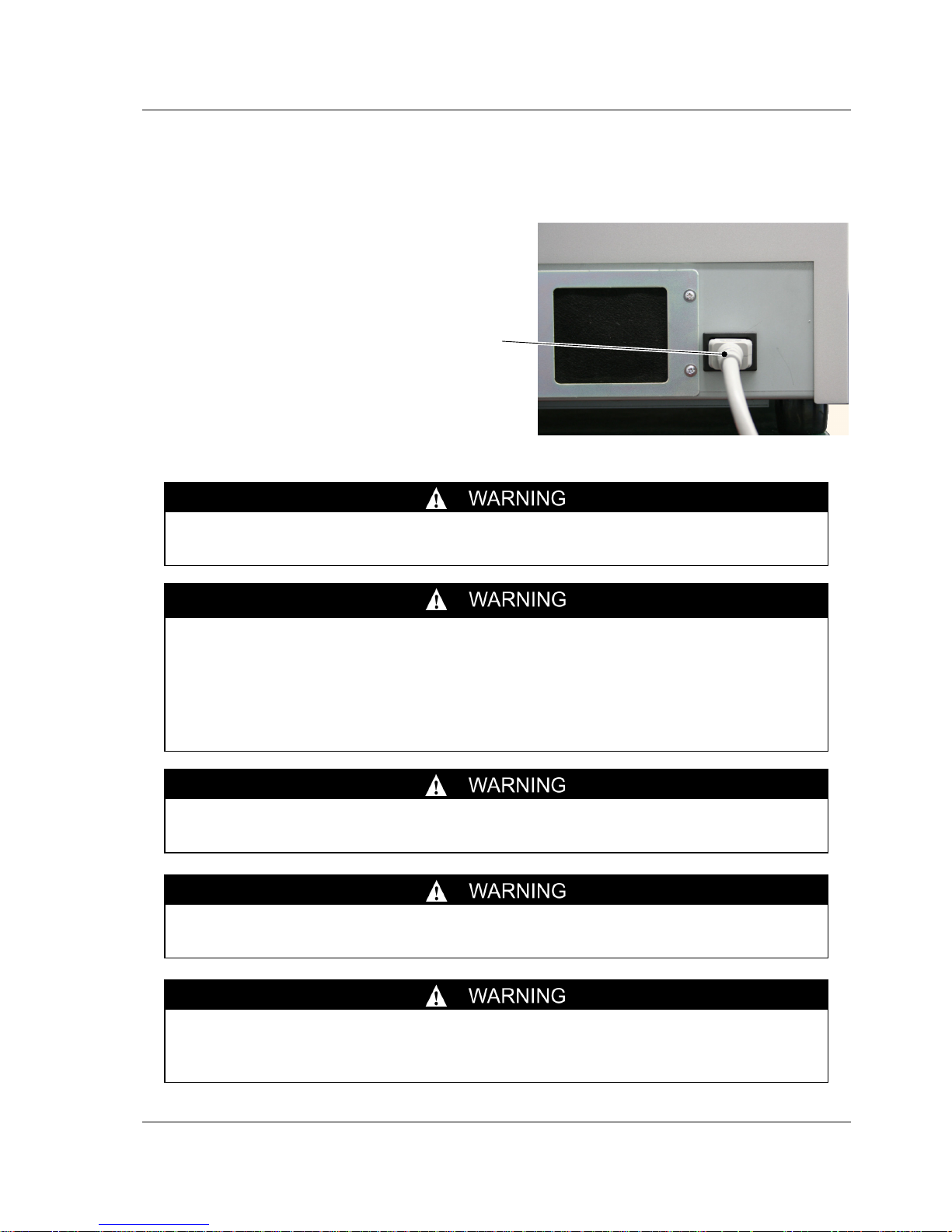

2.5 Connecting the power cable

Connect the power cable by observing the following instructions:

1.

Insert the power cable supplied into the

power input terminal at the back of the

Thermal Digiplater.

Before connecting the power cable, make sure that the power switch is off.

Use only the power cable supplied with the product or a specified one.

Be sure to connect the power cable to the electric outlet to be grounded according

to all relevant local regulations(resistance:less than 100 ohm). If a short circuit

occurs while the Thermal Digiplater is operating without being grounded, a fire or

electric shock can occur. If the Thermal Digiplater cannot be grounded, consult the

distributor.

Plug the power cable all the way into

the

electric outlet.

Failure to do so can cause a fire or failure.

Do not connect or disconnect the power cable with wet hands.

Doing so can cause an electric shock.

Do not scratch, damage or rework the power

cable.

Do not put a heavy article on the cable. Do not pull or forcibly bend it.

Doing so can damage the power cable and cause a fire or electric shock.

Power cable

Page 20

Chapter 2 Installation and Setup

TDP-324

-14-

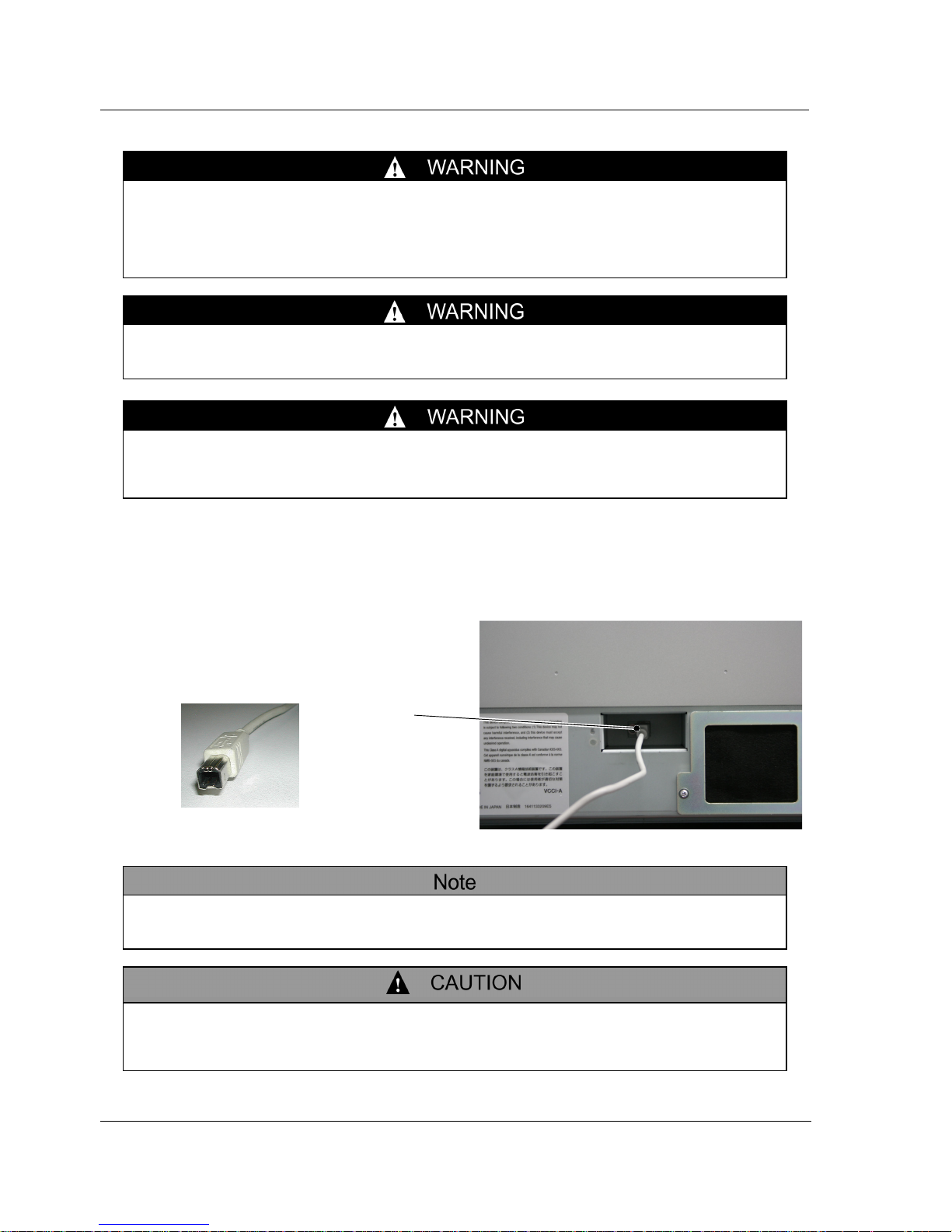

2.6 Connecting the USB cable

1.

Connect the USB cable connected to your

PC to the USB terminal at the back of the

Thermal Digiplater

When mo

ving the Thermal Digiplater, disconnect the power cable

from the

electric

outlet and make sure that all external connecting lines have been disconnected.

If a cord is kept connected, it can be scratched, and a fire or electric shock can

occur, or you can trip and be injured.

If the

Thermal Digiplater is not used for a long time, disconnect the power cable

from the electric outlet for safety.

Do not conn

ect the power cable to an electric outlet to which other cords are

connected. Requires a dedicated electric outlet.

Doing so can cause a fire or electric shock.

USB cable

[Product compatible with USB

2.0 standard]

Use only the USB cable supplied with the product or a specified one. If a cable other

than the supplied cable is used, incorrect printing can result.

Be

fore dis connecti ng the USB cable, m ake sure that the

Thermal Digiplater

is in th e standby state. If disconnecte d during data trans fer, the Thermal

Digiplater can be damaged.

Thermal Digiplater side is a type B connector(square)

Page 21

Chapter 2 Installation and Setup

TDP-324

-15-

2.7 Installing the plate tray

1.

Insert one of the claws of the plate tray into

the corresponding mounting hole for the

plate tray.

2.

While slightly widening the plate tray,

insert the other claw into the other

mounting hole.

3.

Secure the tray by inserting the bottom of

the stopper into the stopper slit.

A plate c

utter is installed inside the plate discharge port. Do not put fingers. Doing

so can cause injure.

Plate tray

Stopper

Plate exit

Stacking quantity is up to 5 plates on the

plate tray.

Do not stack more than 5 plates on it.

Page 22

Chapter 2 Installation and Setup

TDP-324

-16-

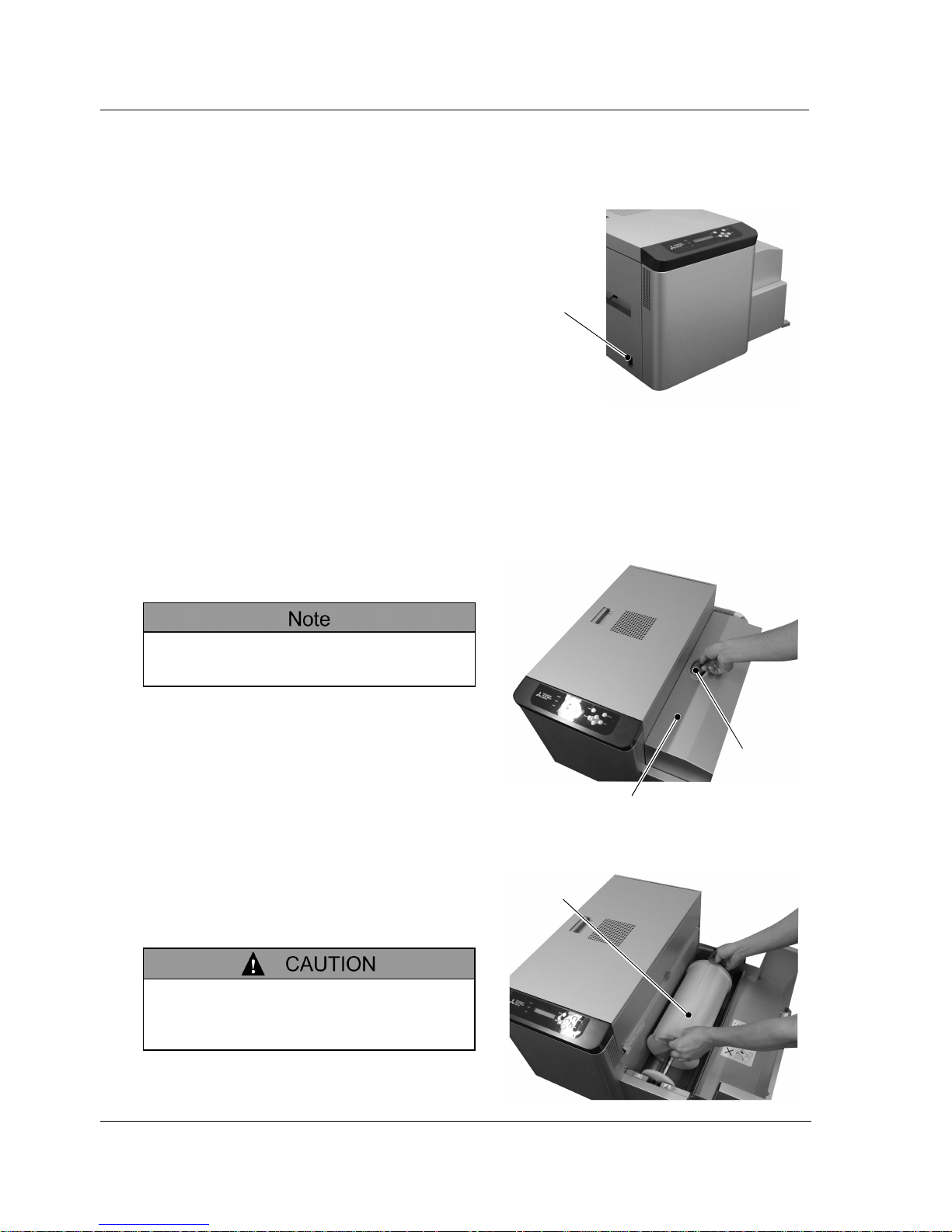

2.8 Setting the plate

1.

Turn on the power to the Thermal

Digiplater.

2.

Set the size of the plate to be installed on the operation panel.

See 3.3.1 Selecting a plate size.

3.

By holding the opening lever B, open the

plate cover.

4.

When there is any used plate, pull out the

lead edge of the plate and lift up the plate

with the spool, and take it out.

Do not open the plate cover extremely

quickly or forcibly 90 degrees or more.

Power switch

Plate roll

The plate weighs approx. 10 kg(22 lbs).

Handle it carefully so as not to drop it.

Dropping it is dangerous.

Plate cover

Opening lever B

Page 23

Chapter 2 Installation and Setup

TDP-324

-17-

The direction

which inserts

a shaft

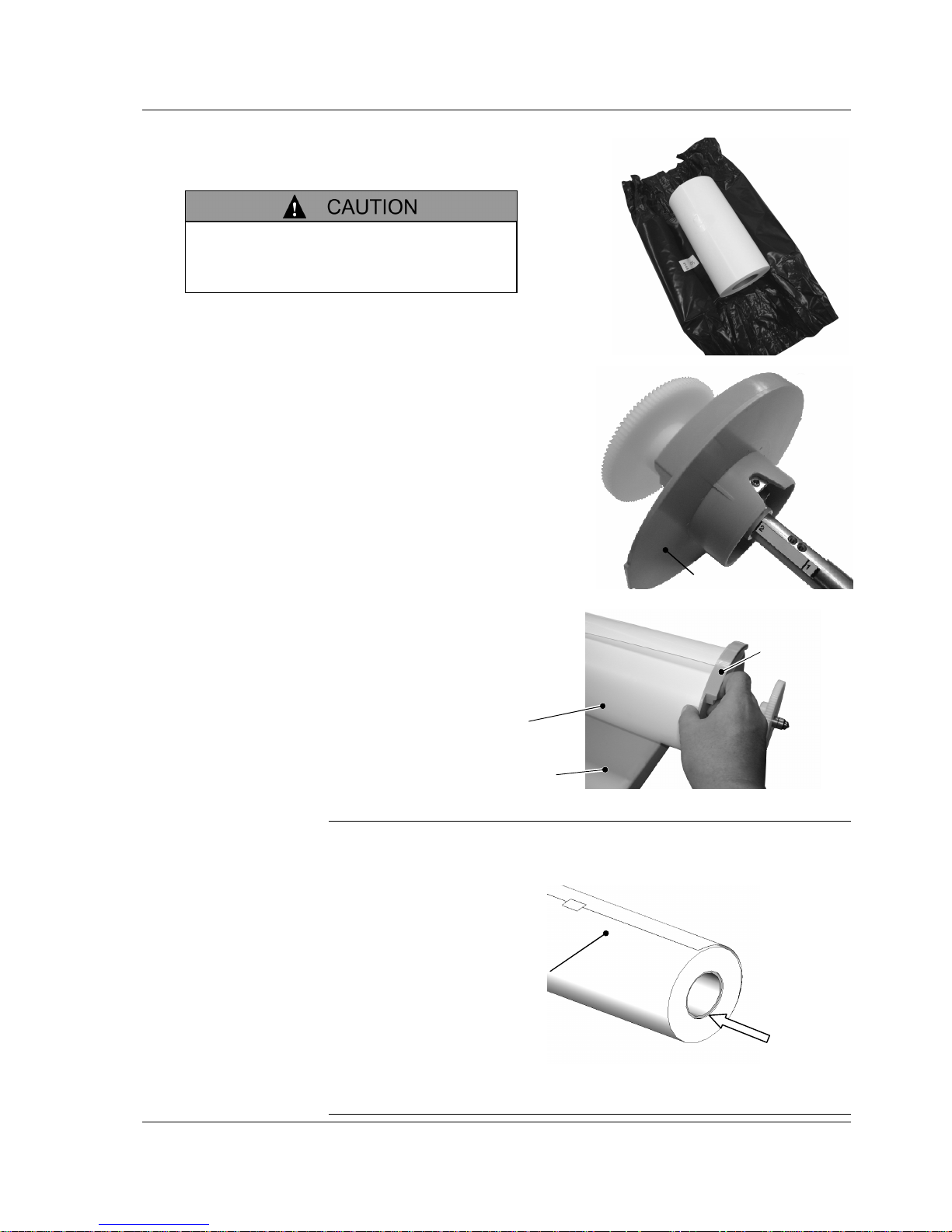

5.

Take out the new plate from the black

polybag.

6.

Change the flange(gear side) position of

the spool according to the size of the plate

to be used.

Please refer to "2.9 The change method of flange position."

7.

Insert the shaft of the spool into the core of

the plate and gently force the flange(gear

side) of the spool on the side of the plate.

[Useful tip]

When inserting the shaft of the spool into the core of the plate, place the

plate so that the lead edge of the winding plate is upward. Then, insert the

shaft of the spool from the right-hand side.

As the outer diameter of the flange is larger than the outer diameter of the

plate, it is recommended that this work is performed with the right-hand side

of the plate protruding from the work table.

Spool

(Flange(gear side))

Plate

Work table

Th

e plate weighs approx. 10 kg(22 lbs).

Handle it carefully so as not to drop it.

Dropping it is dangerous.

Flange(gear side)

Lead edge of the winding plate

Page 24

Chapter 2 Installation and Setup

TDP-324

-18-

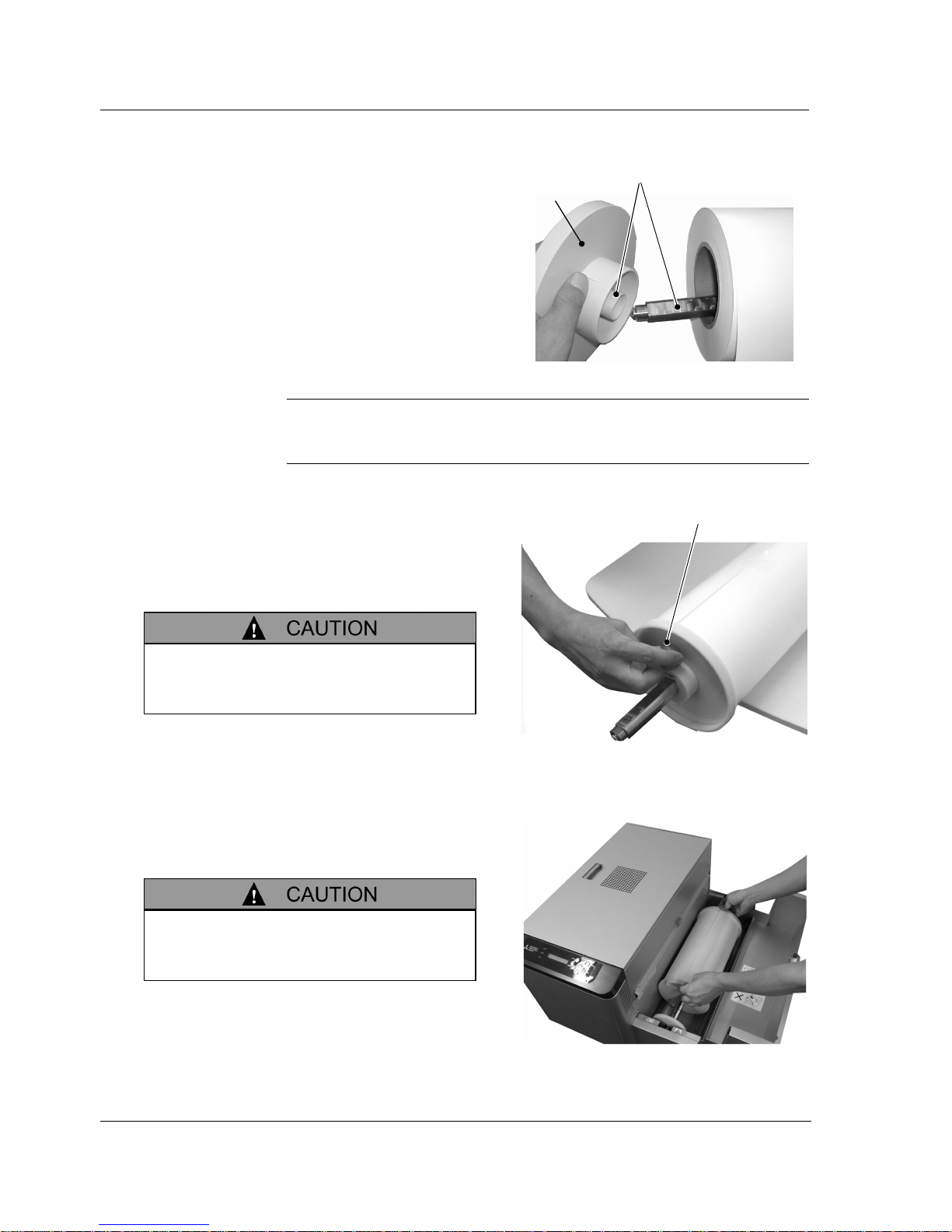

Flange (anti-gear side)

Stopper

8.

Install and fit the flange(anti-gear side) to

the end of the shaft on the opposite side of

the plate.

[Useful tip]

The flange (anti-gear side) has a stopper notch and the shaft has stopper

notches to prevent empty rotation. Check the directions of the spool stopper

notch and notches on the shaft to fit the spool correctly.

9.

Tighten the screw to fix, forcing the flange

(anti-gear side) on the side of the plate,

and fix the flange (anti-gear side).

10.

Install the plate by placing the spool into the

plate box.

Screw to fix

The plate weighs approx. 10 kg(22 l

bs).

Handle it carefully so as not to drop it.

Dropping it is dangerous.

Do not tighten the screw too much. It

may damage flange.

Page 25

Chapter 2 Installation and Setup

TDP-324

-19-

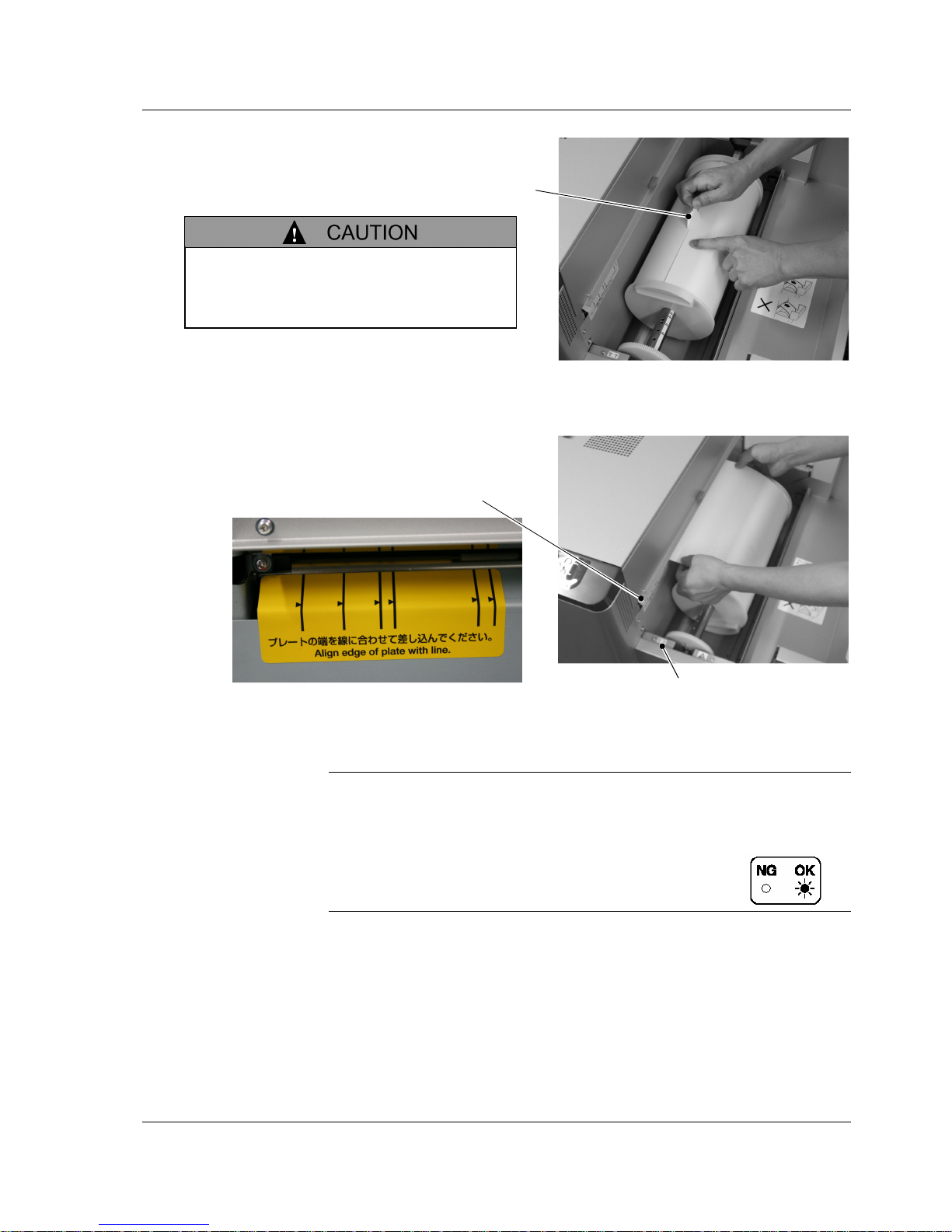

11.

Remove the seal fixing the end of the

plate.

12.

Feed in the plate by hand, aligning the side

edge of the plate with the line on the plate

guiding seal.

[Useful tip]

When the end of the plate is inserted into the plate feeding port, the motor

starts to operate to assist the feeding of the plate. The motor will stop when

the plate setting is completed.

When the plate setting is completed, the ”NG” LED lamp goes off and “OK”

LED lamp turns on.

Fixing seal

Plate guiding seal

LED

Tear off and remove the seal completely.

Entry of fragments of the seal into the feed

path can cause trouble in feeding and/or

printing.

Page 26

Chapter 2 Installation and Setup

TDP-324

-20-

13.

Slowly close the plate cover.

14.

Press the loading button on the operation

panel.

[Useful tip]

If the size of the plate placed in this machine does not match the plate size set,

the loading will not be completed correctly. If an error occurs, check the size of

the actual plate and the plate size set on this machine. Then, install and set the

correct plate.

15.

Plate moves back and forth, and set the

skew right. Then cut 2 plates with about

310mm(12.2inches) and discharge them

forcibly.

・ When loading button is pressed for more than 2 seconds, the plate is not cut off.

Please refer to “3.2.2 Operation button”.

Plate cover

ready to road

Be careful not

to catch fingers when

closing the plate cover.

Page 27

Chapter 2 Installation and Setup

TDP-324

-21-

2.9 Change Method of Flange Position

Please change the flange position of a spool according to the size of the plate to be used.

1.

Loosen the screw which secures the flange.

Turns in the direction of the illustration arrow,

applying a finger to the knob part of the fixed screw.

2.

Flange is set at the position corresponding

to plate size.

・Please confirm the relation between plate size

and a flange position using table on the right.

・Please unite the field of a flange inner side

with the line described at the spool shaft.

The field of a flange inner side meets with a line.

Example:

When setting to flange position

"2” The line on

the left-hand side of number

"2" and the field

of a flange inner side should line up.

Flange

Spool shaft

Flange position Plate width(inch)

1

324(12.75)

318(12.50)

no number

310(12.19)

305(12.00)

A

292(11.5)

286(11.25)

279(11.00)

•

On spool shaft, there are

indications of 2 to 5 and B,

however these are not used in

this product (TDP-324)

Page 28

Chapter 2 Installation and Setup

TDP-324

-22-

3.

Tighten the screw and fix flange.

・Turns in the direction of the illustration arrow,

applying a finger to the knob part of a fixed screw.

・Please fasten securely, turning until the screw stops.

(Flange set position and the relation of the range which can be printed)

Relation between flange set position and print area is shown on diagram below.

Please confirm the print area before generating print data.

Example: The relation of the plate

and the range which can be

printed in th

e case of setting a

flange to "1

" and using a plate with

a width of 324mm.

Print start side

Range which can be printed

When it sets to B

When it sets to A

When it sets to no-number

When you set the flange to 1

Page 29

Chapter 3 Use of Operation Panel

TDP-324

-23-

Chapter 3 Use of Operation Panel

3.1 Power switch

The power switch is located on the left side surface of this machine. Pressing the upper side (“l”) turns on

the power while pressing the lower side (“O”) turns off the power.

3.2 Operation panel

The buttons, LED lamps and LCD on the operation panel are explained below.

Power switch

LCD display screen

power LED

ready LED

error LED

menu button

loading button

+ button

clear button enter button

- button

Before d isconnectin g t he USB c able, ma ke sure tha t t he

Thermal Digiplater

is in th e standby state. If disconnecte d during data trans fer, incorrect

printing can result.

Page 30

Chapter 3 Use of Operation Panel

TDP-324

-24-

3.2.1 LED indications

LED indications are shown in the following table.

Name

Indicated

color

Description

power LED Orange This lamp is on when the power is on.

ready LED Green This lamp is on when the Thermal Digiplater is ready for printing.

error LED Red

This lamp is on when an abnormality occurs in the Thermal Digiplater.

Also, this is on druing “Initializing” and “booting up”.

3.2.2 Operation button

The functions of the operation buttons are shown in the following table.

Name Function

loading button

Use this button to set a plate.

1. When this button is pressed at Ready state, the plate is fed for a certain length

of plate and cut off, then it is set at the set position.

2. When this button is pressed for more than 2 seconds at Ready state, the plate

is fed for a certain length of plate, and set at the set position.

menu button Use this button to select from the menu.

enter button Use this button to save an operation or a setting to be executed in the user mode.

clear button Use this button to exit the currently selected menu item in the user mode.

+ button Use this button to select an item from the menu in the user mode.

- button Use this button to select an item from the menu in the user mode.

Page 31

Chapter 3 Use of Operation Panel

TDP-324

-25-

3.2.3 LCD indications

The LCD shows the Thermal Digiplater status as shown in the following table.

*: The following chart is the list of display in Millimeter Mode (factory setting). In case of Inch Mode (factory

setting), some display may differ. Please refer to the next page for details.

Data shown on the LCD

English Japanese

Description

Initializing

ショキカチュウ

The Thermal Digiplater is being initialized.

Booting up

キドウチュウ

The firmware is being started.

In the case of the plate remaining swittch on

□□□ □□□×□□□ □□m

*1

*2 *3

□□□ □□□×□□□ □□m

*1

*2 *3

The Thermal Digiplater is ready for printing.

*1.Selected plate size channel number is displayed.

eg. Custom channel: C01

Free mode channel: F01

*2.Set plate name (size) is displayed.

*3.The remaining length(m) of the plate set in the Thermal

Digiplater is displayed.

In the case of the plate remaining swittch off

□□□ □□□×□□□

*1

*2

□□□ □□□×□□□

*1

*2

The Thermal Digiplater is ready for printing.

*1.Selected plate size channel number is displayed.

eg. Custom channel: C01

Free mode channel: F01

*2.Set plate name (size) is displayed.

Ready to load

ローディングシテクダサイ

The Thermal Digiplater is ready for plate loading as the plate

has been set.

Receiving

データ ジュシンチュウ

Data is being received.

Printing

プリント チュウ

The Thermal Digiplater is in printing operation.

Cooling Down

ヘッド レイキャクチュウ

The thermal head is being cooled. Printing is temporarily

suspended until the thermal head has cooled down.

Warming Up

ヘッド カオンチュウ

The thermal head is being preheated. Printing is temporarily

suspended until the thermal head has warmed up.

Plate Loading

プレート ロードチュウ

Plate is being loaded.

Plate Reloading

プレート サイロードチュウ

The end of the plate is being fed to the standby position.

Data Creating

データ テンカイチュウ

Test print data is being generated.

*: In case of Inch Mode (factory setting), print status is shown as follows.

Data shown on the LCD

English Japanese

Description

In the case of the plate remaining swittch on

□□□ □□.□×□□.□ □□□

*1

*2 *3

□□□ □□.□×□□.□ □□□

*1

*2

*3

The Thermal Digiplater is ready for printing.

*1.Selected plate size channel number is displayed.

eg. Custom channel: C01

Free mode channel: F01

*2.Set plate name (size) is displayed.

*3.The remaining length of the plate set in the Thermal

Digiplater is displayed in feet. (unit is omitted)

In the case of the plate remaining swittch off

□□□ □□.□×□□.□

*1

*2

□□□ □□.□×□□.□

*1

*2

The Thermal Digiplater is ready for printing.

*1.Selected plate size channel number is displayed.

eg. Custom channel: C01

Free mode channel: F01

*4.Set plate name (size) is displayed.

Page 32

Chapter 3 Use of Operation Panel

TDP-324

-26-

3.3 Explanation of the user mode

In the user mode, the following are possible:

Items available in the user mode

LCD indications

English Japanese

Description

Plate Size プレート サイズ Select a plate size channel.

Size Set サイズ セッテイ Set a plate size.

Density Density Adjust the density of print.(-20% to +40% in increments of 1%)

Firmware Version Firmware Version The firmware version can be checked.

Head Cleaning ヘッド クリーニング

Execute thermal head cleaning.

Set thermal cleaning mode.

Plate プレート Display plate remains, and resets plate remains counter.

Counter カウンタ Display print count, and resets print counter.

Remains Sw ザンリョウ スイッチ Set on or off for display of plate remains.

Platen Cleaning プラテン クリーニング Execute platen cleaning.

Pinch Cleaning ピンチ クリーニング

Execute pinch cleaning and sets cleaning mode.

Manage Count

マネージカウント

Display accumulated print distance.

This message is displayed only when Manage Count Sw is set at ON

(factory setting).

Interval Set

インターバル セッテイ

Set a plate number that you want to stop printing (Thermal head

maintenance purpose)

1.

To switch to the user mode, press the menu button in the ready state.

2.

Pressing the + or - button repeatedly changes the menu item available.

The message shown on the LCD will change as show in below.

LCD message cycle when + button is pressed repeatedly

LCD message cycle when - button is pressed repeatedly

[

Firmware Version

][

Plate Size

] [

Density][Size Set

]

[

Remains Sw

] [

Platen Cleaning

]

[

Pinch Cleaning

][

Counter

]

[

Plate

]

[

Interval Set

]

[

Head Cleaning

]

Manage Count

]

Page 33

Chapter 3 Use of Operation Panel

TDP-324

-27-

3.3.1 Selecting a plate size channel

1.

In the ready state, press the menu button

and display “Plate Size” on the LCD.

2.

Press the enter button to select the

operation for changing the plate size

channel.

3.

Press the + or - button to display a

different plate size channel.

・・・・

In case of Inch Mode, it will be shown in inches,

as shown below.

[Size01:12.7×19.3]

4.

Press the enter button to select the

desired plate size channel.

5.

Press the clear button repeatedly until the

ready state is displayed.

Plate Size

Plate Size

Size01: 324×492

Size01: 324×492

Page 34

Chapter 3 Use of Operation Panel

TDP-324

-28-

3.3.2 Setting the plate size

1.

In the ready state, press the menu button

once, press the + button once, and display

“Size Set” on the LCD.

2.

Press the enter button to select the operation

for selecting a plate size channel.

3.

Press the + or - button to display a different

plate size channnel.

4.

Press the enter button to select the desired

plate size.

CSize xx: Custom size channels (10)

FSize xx: Free-mode channlel (5)

5.

Press the enter button to select the plate

width.

• In case of Millimeter Mode, it can be

selected from 8 types as shown below.

254*,279,286,292,305,310,318,324(mm)

• In case of Inch Mode, it can be selected from

8 types as shown below.

10.00*,11.00,11.25,11.5,12.00,12.19,12.50,

12.75(inch)

Width: 324mm

Size Set

CSize01: 310x150

CSize05: 310x150

CSize05: 310x150

The size, 254mm(10.00 inch), isn’t available

on TDP-324 though you choose it.

The size, 254mm(10.00) is only available at

the specific model,

TDP-324B

.

Page 35

Chapter 3 Use of Operation Panel

TDP-324

-29-

6.

If you set a plate size for a free-mode

channnel, this set up is finished. Press the

clear button repeatedly until the ready

state is displayed.

If you set a plate size for a custom

mode channel, please move to “step 7”.

7.

Press the enter button to confirm the width

setting. Then, set a plate length.

・In case of Millimeter Mode

It can be set from 150mm to 530mm in

increments of 1mm.

・In case of Inch Mode

It can be set from 5.91 inches to 20.87 inches,

In increments of 1/100 inch.

[Useful tip]

To change values, use the following buttons:

In case of Millimeter Mode

menu button: Increment the number by 10

+ button: Increment the number by 1

loading button: Decrement the number by 10

- button: Decrement the number by 1

In case of Inch Mode

menu button: 2-digit integral part is incremented by 10.

loading button:2-digit integral part is decremented by 10.

+ button:2-digit decimal number area is incremented by 1.

- button: 2-digit decimal part decremented by 1

.

8.

Press the enter button to confirm the

length setting.

9.

Press the clear button repeatedly until the

ready state is displayed.

Length: 492mm

FSize01:310x***

Page 36

Chapter 3 Use of Operation Panel

TDP-324

-30-

3.3.3 Adjusting the print density

1.

In the ready state, press the menu button

once, press the + button until “Density”

displays on the LCD.

2.

Press the enter button to select the

operation for adjusting the print density.

3.

Change the print density by pressing the +

or - button.

[Useful tip]

The density can be adjusted within -20% to +40%, in increments of 1%.

4.

Press the enter button to confirm the

changed density.

5.

Press the clear button repeatedly until the

ready state is displayed.

Density

Density

***

%

Density 101%

Density 101%

Page 37

Chapter 3 Use of Operation Panel

TDP-324

-31-

3.3.4 Checking the firmware versions

1.

In the ready state, press the menu button

once, press the + button until “Firmware

Version” displays on the LCD.

2.

Press the enter button to select the

operation for checking firmware versions.

3.

Press the + or - button to display another

firmware version.

4.

Press the clear button repeatedly until the

ready state is displayed.

Firmware Version

MAIN Ver. **.**

TABLE Ver. **.

**

Page 38

Chapter 3 Use of Operation Panel

TDP-324

-32-

3.3.5 Setting the Head Cleaning Mode and Execution of Head Cleaning

Setup of the automatic cleaning mode(ON/OFF)

The automatic cleaning mode(ON/OFF) is set as follows.

When it is set at ON, the automatic head cleaning is executed every time before printing.

1.

In the ready state, press the menu button

once, press the + button until display ”Head

Cleaning” on the LCD.

2.

Press the enter button to select the operation

for setting the Cleaning mode.

3.

Press the enter button, and display the

setting state (on/off) of head cleaning mode.

4.

Press the + or - button to change the setting

(on/off) of head cleaning mode.

5.

Press the enter button to confirm the setting

(normal/Special) of head cleaning mode.

6.

Press the clear button repeatedly until the

ready state is displayed.

Head Cleaning

Cleaning Sw

Cleaning Sw:off

Cleaning Sw:on

Cleaning Sw:on

Page 39

Chapter 3 Use of Operation Panel

TDP-324

-33-

Setup of the head cleaning mode (Normal/Special)

Select a head cleaning mode (normal mode / special mode)

• Normal Mode: Black bar with setup length is printed.

• Special Mode: Black bar is printed in the blank area at the top of the printed plate.

1.

In the ready state, press the menu button

once, press the + button until ”Head Cleaning”

displays on the LCD.

2.

Press the enter button once, press the +

button until ”Cleaning mode” displays on the

LCD.

3.

Press the enter button, and display the setting

state (Normal/Special) of head cleaning mode.

4.

Press the + or - button to change the setting

(Normal/Special) of head cleaning mode.

5.

Press the enter button to select the operation

for setting the state (Normal/Special) of head

cleaning mode.

6.

Press the clear button repeatedly until the

ready state is displayed.

Special

Head Cleaning

Cleaning mode

Normal

Special

Page 40

Chapter 3 Use of Operation Panel

TDP-324

-34-

Setup of the cleaning length (Normal mode)

The length of the black bar printed at the time of head cleaning(Normal mode) execution is changed

as follows.

1.

In the ready state, press the menu button

once, press the + button until ”Head Cleaning”

displays on the LCD.

2.

Press the enter button once, press the +

button once, and display ”Cleaning Length” on

the LCD.

3.

Press the enter button, and display the setting

state of cleaning length.

4.

Press the + or - button to change the setting of

the cleaning length.

【【【【Useful tip】】】】

It can be set from 10mm to 50mm, in increments of 1mm.

When the setting value is enlarged, the effect of head cleaning becomes large,

but cleaning time becomes long.

5.

Press the enter button to confirm the setting of

the special length.

6.

Press the clear button repeatedly until the

ready state is displayed.

Head Cleaning

Cleaning Len 10

Cleaning Len 50

Cleaning Length

Cleaning Len 50

Page 41

Chapter 3 Use of Operation Panel

TDP-324

-35-

Setup of the cleaning length (Special mode)

The length of the black bar printed at the time of head cleaning(Special mode) execution is changed

as follows.

1.

In the ready state, press the menu button

once, press the + button until ”Head

Cleaning” displays on the LCD.

2.

Press the enter button once, press the +

button until ”Special Length” displays on the

LCD.

3.

Press the enter button, and display the setting

state of special length.

4.

Press the + or - button to change the setting of

the special length.

【【【【Useful tip】】】】

It can be set from 5mm to 10mm, it increments of 1mm.

When the setting value is enlarged, the effect of head cleaning becomes large,

but cleaning time becomes long.

5.

Press the enter button to confirm the setting of

the special length.

6.

Press the clear button repeatedly until the

ready state is displayed.

ヘッドクリーニング

Head Cleaning

Special Length

Special Length 5

Special Length10

Special Length10

Page 42

Chapter 3 Use of Operation Panel

TDP-324

-36-

Setup of head cleaning interval

Set the interval for head cleaning.

1.

In the ready state, press the menu button

once, press the + button until ”Head Cleaning”

displays on the LCD.

2.

Press the enter button once, press the +

button until ”Cleaning Num” displays on the

LCD.

3.

Press the enter button, and display the

setting state of cleaning interval.

4.

Press the + or - button to change the setting of

cleaning interval.

[Useful tip]

It can be set from 1 to 100 in increments of 1.

When “1” is selected, the head cleaning is executed every time. When “100” is

selected, the head cleaning is executed every 100 prints.

5.

Press the enter button to confirm the setting of

cleaning interval.

6.

Press the clear button repeatedly until the

ready state is displayed.

ヘッドクリーニング

ヘッドクリーニング

Head Cleaning

Cleaning Num

Cleaning Num 1

Cleaning Num100

Cleaning Num100

Page 43

Chapter 3 Use of Operation Panel

TDP-324

-37-

Execution of head cleaning

Head cleaning is executed. (Black bar with setup length is printed and discharged) as follows.

* Cleaning length at Normal Mode is applied.

1.

In the ready state, press the menu button

once, press the + button until ”Head Cleaning”

displays on the LCD.

2.

Press the enter button once, press the +

button until ”Cleaning” displays on the LCD.

3.

Press the enter button to execute head

cleaning.

4.

Press the clear button repeatedly until the

ready state is displayed.

Head Cleaning

Cleaning

Cleaning

Page 44

Chapter 3 Use of Operation Panel

TDP-324

-38-

3.3.6 Display of Plate Remains, and Reset of Plate Remains Counter

Display of plate remains and reset of plate remains counter are executed as follows.

When reset is executed, plate remains counter is 75m or 246ft at the time of brand-new plate,

and printed length is subtracted in increments of 1m or 1ft until reset is executed next time.

1.

In the ready state, press the menu button

once, press the + button until ”Plate” displays

on the LCD.

2.

Press the enter button, and display the

remains of the plate.

3.

Press the enter button to come to the state

which can reset the remains of the plate.

4.

Press the enter button to reset the remains of

the plate.

※.Press the clear button when not resetting.

・・・・

In case of Feet Mode, it will be shown in feets,

as shown,

[Plate 246 ft]

5.

Press the clear button repeatedly until the

ready state is displayed.

Plate

Plate □□m

Reset?

Plate 75m

Page 45

Chapter 3 Use of Operation Panel

TDP-324

-39-

3.3.7 Display of Print Counter, and Reset of Print Counter

Display of print counter and reset of print counter are executed as follows.

Where reset is executed, print counter is「0」, and the number of the printed plates is added

until reset is executed next time.

1.

In the ready state, press the menu button

once, press the + button until ”Counter”

displays on the LCD.

2.

Press the enter button, and display the print

counter.

3.

Press the enter button to come to the state

which can reset print counter.

4.

Press the enter button to reset print counter.

* Press the clear button when not resetting.

5.

Press the clear button repeatedly until the

ready state is displayed.

Counter

Reset?

Counter 0

Counter □□□□

Page 46

Chapter 3 Use of Operation Panel

TDP-324

-40-

3.3.8 Setup of Plate Remains SW(on/off)

1.

In the ready state, press the menu button

once, press the + button until ”Remains Sw”

displays on the LCD.

2.

Press the enter button, and display the setting

state (on/off) of “Remains SW” .

3.

Press the + or - button to change the state

(on/off) of “Remains SW”.

4.

Press the enter button to confirm the setting of

“Remains SW.

5.

Press the clear button repeatedly until the

ready state is displayed.

Remains Sw

Remains

off

Remains

on

Remains

on

Page 47

Chapter 3 Use of Operation Panel

TDP-324

-41-

3.3.9 Execution of Platen Cleaning

Please use this mode when you clean-up a platen roller.

Please refer to Chapter 4 about the cleaning method of the platen roller.

1.

In the ready state, press the menu button

once, press the + botton until “Platen

cleaning” displays on the LCD.

2.

Press the enter button to select the

operation for platen cleaning mode.

3.

After closing Upper cover, press the enter

button once, and a platen roller rotates 60

degrees.

If you want to clean up a entire roller,

please repeat this 6 times.

4.

Press the clear button repeatedly until the

ready state is displayed.

Platen Cleaning

Ready to rotate

Now rotating

Page 48

Chapter 3 Use of Operation Panel

TDP-324

-42-

3.3.10 Setting the Pinch Cleaning Mode and Execution of Pinch Cleaning

This mode is used when pinch roller is cleaned.

After black bar with setup length is repeatedly printed at setup number of times, a plate

feed for cleaning is executed. At setup number of times, and printed plate with black bar

is cut and discharged.

Setting the print length of black bar

Set up the print length of black bar print for pinch cleaning.

1.

In the ready state, press the menu button

once, press the + button until ”Pinch Cleaning”

displays on the LCD.

2.

Press the enter button, and display ”Print

Length” on the LCD.

3.

Press the enter button, and display the

setting state of print length.

4.

Press the + or - button to change the setting of

the print length.

[Useful tip]

It can be set from 100mm to 500mm, in increments of 1mm.

When the setting value is enlarged, the effect of head cleaning becomes large,

but cleaning time becomes long.

Pinch Cleaning

Print Length 100

Print Length 500

Print Length

Page 49

Chapter 3 Use of Operation Panel

TDP-324

-43-

5.

Press the enter button to confirm the setting of

the print length.

6.

Press the clear button repeatedly until the

ready state is displayed.

Setting the number of times for black bar print

Set the number of times to print black bar for pinch cleaning.

1.

In the ready state, press the menu button

once, press the + button until ”Pinch Cleaning”

displays on the LCD.

2.

Press the enter button once, press the +

button once, and display ”Print Num” on the

LCD.

3.

Press the enter button, and display the setting

state of print number.

4.

Press the + or - button to change the setting of

the print number.

[Useful tip]

It can be set from 1 to 5, in increments of 1.

When the setting value is enlarged, the effect of head cleaning becomes large,

but cleaning time becomes long.

Pinch Cleaning

Print Length 500

Print Num

Print Num 1

Print Num 5

Page 50

Chapter 3 Use of Operation Panel

TDP-324

-44-

5.

Press the enter button to confirm the setting of

the print number.

6.

Press the clear button repeatedly until the

ready state is displayed.

Setting the number of times for cleaning

Set up the number of times for cleaning (plate feed).

1.

In the ready state, press the menu button

once, press the + button until ”Pinch Cleaning”

displays on the LCD.

2.

Press the enter button once, press the +

button until ”Cleaning Num” displays on the

LCD.

3.

Press the enter button, and display the

setting state of cleaning number.

4.

Press the + or - button to change the setting of

the cleaning number.

【【【【Useful tip】】】】

It can be set from 1 to 10, in increments of 1.

When the setting value is enlarged, the effect of head cleaning becomes large,

but cleaning time becomes long.

Print Num 5

Pinch Cleaning

Cleaning Nm

Cleaning Num 1

Cleaning Num10

Page 51

Chapter 3 Use of Operation Panel

TDP-324

-45-

5.

Press the enter button to confirm the setting of

the cleaning number.

6.

Press the clear button repeatedly until the

ready state is displayed.

Execution of Pinch cleaning

Pinch cleaning is executed.

1.

In the ready state, press the menu button

once, press the + button until ”Pinch Cleaning”

displays on the LCD.

2.

Press the enter button once, press the +

button until ”Cleaning” displays on the LCD.

3.

Press the enter button to execute head

cleaning.

4.

Press the clear button repeatedly until the

ready state is displayed.

Pinch Cleaning

Cleaning Num 10

Cleaning

Cleaning

Page 52

Chapter 3 Use of Operation Panel

TDP-324

-46-

3.3.11 Display of accumulated print distance

Displays accumulated print distance.

This message is displayed only when Manage Count Sw is set at ON (factory setting).

1.

In the ready state, press the menu button

once, press the + button until ”Manage Count”

displays on the LCD.

2.

Press the enter button to display “Manage

Count”(accumulated print distance).

・In case of Millimeter mode, accumulated print

distance is shown in meter.

・In case of Inch mode, accumulated print distance

is shown in feet. (unit is omitted)

3.

Press the clear button repeatedly until the

ready state is displayed.

Count □□□m

Manage Count

Page 53

Chapter 3 Use of Operation Panel

TDP-324

-47-

3.3.12 Set up a print Interval

Printing is interrupted at the number that you input in this mode for cleaning a thermal

head.

• The counter is reset automatically after you power down a machine even if print

jobs don’t reach the number that you input.

• When print jobs reach the number that you input, “Restart” is displayed on the LCD.

Then you need to press a enter button to reset the counter.

1.

In the ready state, press the menu button

once, press the + button until ”Interval Set”

displays on the LCD.

2.

Press the enter button to display a setting

state of “Interval Set”.

・default setting is 0 (disable this mode)

3.

Press the enter button after input Interval

setting.

[Useful tip]

It can be set from 10 times to 500 times in increments of 10 times.

To change values, use the following buttons:

menu button: Increment the number by 100, + button: Increment the number by 10

loading button: Decrement the number by 100, - button: Decrement the number by 10

4.

Press the clear button repeatedly until the

ready state is displayed.

Interval 0

Interval Set

Interval 50

Page 54

Chapter 3 Use of Operation Panel

TDP-324

-48-

(MEMO)

Page 55

Chapter 4 Daily Maintenance

TDP-324

-49-

Chapter 4 Daily Maintenance

4.1 Cleaning the parts inside the Thermal Digiplater

To keep the best print quality, clean the thermal head, image sensor, head-position plate, platen roller,

cleaning rollers, the main pinch roller and the feeding pinch roller by following the steps as instructed

below. Please clean them at the following frequency.

• Every day after finishing whole jobs

Thermal head

Image with many halftone does is apt to get it dirty, and there sometimes needs to

be cleaned several times a day.

• Once a week

Main pinch roller

Platen roller

Feeding roller

Cleaning rollers

• Once a month

Image sensor

Head-position plate

Page 56

Chapter 4 Daily Maintenance

TDP-324

-50-

4.1.1 Cleaning the thermal head

1.

By holding the opening lever A on the top

of the upper cover, open the upper cover.

[Useful tip]

A locking lever is provided to the upper cover to prevent the cover from closing

down. When opening the upper cover, be sure to open it to the position where

the locking lever locks effectively.

2.

Wipe the heating element (thin glassy

band) of the thermal head with a

recommended cleaning cloth soaked in

the adequate amount of recommended

cleaning fluid, applying it overall and

uniformly, and moving it from side to side.

.

Upper cover

Locking lever

Opening lever A

Do not open the

upper

cover extremely

quickly or forcibly 90 degrees or more.

The thermal head

is hot just after

printing. Do not touch it directly by

hand.

Fingerprints on the thermal head

heating element can cause the

thermal head to fail. Do not touch it

directly by hand.

Be careful not to be injured by

protrusions in the Thermal Digiplater.

Thermal head

Page 57

Chapter 4 Daily Maintenance

TDP-324

-51-

3.

Wipe the heating element of the thermal

head with a rub small pieces of wrapping

sheet (3M #4000), applying it overall and

uniformly, and moving it from side to side.

4.

Wipe the heating element with a

recommended cleaning cloth soaked in

the adequate amount of recommended

cleaning fluid.

5.

Release the locking lever and close the

upper cover slowly.

The heating element

Upper cover

Locking lever

Page 58

Chapter 4 Daily Maintenance

TDP-324

-52-

4.1.2 Cleaning the main pinch roller

1.

By holding the opening lever A on the top

of the upper cover, open the upper cover.

[Useful tip]

A locking lever is provided to the upper cover to prevent the cover from closing

down. When opening the upper cover, be sure to open it to the position where

the locking lever locks effectively.

2.

When the plate is set, pull it out with your

hands.

3.

Wipe the main pinch roller with a

recommended cleaning cloth soaked in

the adequate amount of recommended

cleaning fluid.

Upper cover

Locking lever

Opening lever A

Do not open the

upper

cover extremely

quickly or forcibly 90 degrees or more.

Main pinch roller

Page 59

Chapter 4 Daily Maintenance

TDP-324

-53-

4.

Release the locking lever and close the

upper cover slowly.

5.

Reset the plate.

Upper cover

Locking lever

Page 60

Chapter 4 Daily Maintenance

TDP-324

-54-

4.1.3 Cleaning the platen roller

1.

By holding the opening lever A on the top

of the upper cover, open the upper cover.

[Useful tip]

A locking lever is provided to the upper cover to prevent the cover from closing

down. When opening the upper cover, be sure to open it to the position where

the locking lever locks effectively.

2.

When the plate is set, pull it out with your

hands.

3.

Wipe the rubber part of the platen roller

with a recommended cleaning cloth

soaked in the adequate amount of

recommended cleaning fluid.

• Please rotate the platen roller using the function

of "Platen cleaning mode" in the 3.3.9 section,

and clean the entire circumferences of the

rubber part.

• In order to clean the entire circumferences of the

rubber part, it is necessary to repeat operation

of "3." in the 3.3.9th section at least 6 times.

Upper cover

Locking lever

Opening lever A

Do not open the

upper

cover extremely

quickly or forcibly 90 degrees or more.

Platen roller

Page 61

Chapter 4 Daily Maintenance

TDP-324

-55-

4.

Release the locking lever and close the

upper cover slowly.

5.

Reset the plate.

Upper cover

Locking lever

Be careful not to scratch the rubber surface.

Dirt on the platen roller can affect the print size accuracy.

After cleaning, wait until recommended cleaning fluid has evaporated sufficiently before

starting printing. (It is recommended that the Thermal Digiplater be left for about 5 minutes

after cleaning

.)

Do not put your hand or cleaning cloth close to the inside of the Thermal Digiplater during

the platen roller rotation.

Page 62

Chapter 4 Daily Maintenance

TDP-324

-56-

4.1.4 Cleaning the feeding pinch roller

1.

By holding the opening lever A on the top

of the upper cover, open the upper cover.

[Useful tip]

A locking lever is provided to the upper cover to prevent the cover from closing

down. When opening the upper cover, be sure to open it to the position where

the locking lever locks effectively.

2.

When the plate is set, pull it out with your

hands.

3.

Remove the upper feeding roller, and wipe

the white roller part with a recommended

cleaning cloth soaked in the adequate

amount of recommended cleaning fluid.

Upper cover

Locking lever

Opening lever A

Do not open the

upper

cover extremely

quickly or forcibly 90 degrees or more.

feeding pinch roller

Page 63

Chapter 4 Daily Maintenance

TDP-324

-57-

4.

Wipe the rubber part of the bottom roller

with a recommended cleaning cloth

soaked in the adequate amount of

recommended cleaning fluid.

• It’s very difficult to rotate the bottom roller by

hands, please use the function of "Platen

cleaning mode" in the 3.3.9 section, and clean

the entire circumferences of the rubber part.

• In order to clean the entire circumferences of the

rubber part, it is necessary to repeat operation

of "3." in the 3.3.9th section at least 6 times.

5.

Release the locking lever and close the

upper cover slowly.

6.

Reset the plate.

Upper cover

Locking lever

Page 64

Chapter 4 Daily Maintenance

TDP-324

-58-

4.1.5 Cleaning the cleaning rollers

1.

By holding the opening lever A on the top

of the upper cover, open the upper cover.

[Useful tip]

A locking lever is provided to the upper cover to prevent the cover from closing

down. When opening the upper cover, be sure to open it to the position where

the locking lever locks effectively.

2.

When the plate is set, pull it out with your

hands.

3.

Wipe the cleaning rollers with a

recommended cleaning cloth soaked in

the adequate amount of recommended

cleaning fluid.

[Useful tip]

Cleaning rollers are provided on the entrance and discharge sides.

Upper cover

Locking lever

Opening lever A

Do not open the

upper

cover extremely

quickly or forcibly 90 degrees or more.

Cleaning rollers

Page 65

Chapter 4 Daily Maintenance

TDP-324

-59-

4.

Release the locking lever and close the

upper cover slowly.

5.

Reset the plate.

Upper cover

Locking lever

Page 66

Chapter 4 Daily Maintenance

TDP-324

-60-

4.1.6 Cleaning the image sensor

1.

By holding the opening lever A on the top

of the upper cover, open the upper cover.

[Useful tip]

A locking lever is provided to the upper cover to prevent the cover from closing

down. When opening the upper cover, be sure to open it to the position where

the locking lever locks effectively.

2.

Wipe the image sensor with a

recommended cleaning cloth soaked in

the adequate amount of recommended

cleaning fluid.

Upper cover

Locking lever

Opening lever A

Do not open the

upper

cover extremely

quickly or forcibly 90 degrees or more.

Image sensor

Page 67

Chapter 4 Daily Maintenance

TDP-324

-61-

3.

Release the locking lever and close the

upper cover slowly.

Upper cover

Locking lever

Page 68

Chapter 4 Daily Maintenance

TDP-324

-62-

Head-position plate

4.1.7 Cleaning the head position plate

1.

By holding the opening lever A on the top

of the upper cover, open the upper cover.

[Useful tip]

A locking lever is provided to the upper cover to prevent the cover from closing

down. When opening the upper cover, be sure to open it to the position where

the locking lever locks effectively.

2.

Wipe the head-position plate with a

recommended cleaning cloth soaked in

the adequate amount of recommended

cleaning fluid, applying it overall and

uniformly, and moving it from side to side.

.

Upper cover

Locking lever

Opening lever A

Do not open the

upper

cover extremely

quickly or forcibly 90 degrees or more.

Page 69

Chapter 4 Daily Maintenance

TDP-324

-63-

3.

Release the locking lever and close the

upper cover slowly.

Upper cover

Locking lever

Page 70

Chapter 4 Daily Maintenance

TDP-324

-64-

4.2 Cleaning the cover of the Thermal Digiplater

To remove dirt, wipe the cover of the Thermal Digiplater with a dry soft cloth.

If dirt cannot be removed by wiping with a dry cloth, lightly wipe the cover with a damped cloth which has

been soaked in water or a little diluted neutral detergent.

4.3 Cleaning the filters

If it gets dust on the vent holes and filters, clean them with a vacuum cleaner.

Should any foreign matter (metallic fragments, water or liquids) gets into the

Thermal Digiplater, turn off the power switch, disconnect the power cable from the

electric outlet, and contact the distributor.

Using the Thermal Digiplater

without removing the foreign matter can cause a fire or

electric shock.

Should th

e Thermal Digiplater be used in an abonormal state (generat

ing heat,

smoking or abnormal o

dors), it can cause a fire or electric shock. Turn off the power

switch immediately, disconnect the power cable from the electric outlet and contact

the distributor.

Vent holes

Filters

If the surfaces are wiped with a volatile liquid, such as benzine or thinner, or

sprayed with insecticide, they can become discolored or cracked.

Page 71

Chapter 4 Daily Maintenance

TDP-324

-65-

4.4 Consumable parts

Consumable parts for the Thermal Digiplater are shown on the following table.

No. Name

1 Thermal head(Assembly)

2 Cleaning roller

3 Cutter unit

4 Filter

*Available supply period for consumable parts is 5 years after it is discontinued.

*It will be informed separately about discontinuing the product.

Page 72

Chapter 4 Daily Maintenance

TDP-324

-66-

(MEMO)

Page 73

Chapter 5 Trouble shooting

TDP-324

-67-

Chapter 5 Trouble shooting

5.1 When an error message is displayed

When an error occurs, an error message will be shown on the LCD on the operation panel.

The error messages shown on the LCD and the measures to be taken are explained below.

Message on the LCD Condition Measures

Plate Empty

The plate has been used up or no

plate has been installed.

If the plate has been used up, supply with a

new plate.

No Plate The plate is not set. Please set the plate.

Unmatch Plate

The size of the plate placed in this

machine does not match the plate size

set.

Check the size of the actual plate and the

plate size set on this machine. Then install

and set the correct plate.

Plate Jam * Plate jam

Remove the jammed plate. If plate jams

occur frequently, consult Service department.

Mecha Error *

Problem in the mechanical system of

the Thermal Digiplater

Control Error *

Problem in the control board of the

Thermal Digiplater

Temp Sens Err *

A temperature sensor of the Thermal

Digiplater is defective.

Sensor Error *

Problem in the sensor system of the

Thermal Digiplater

Turn the power to the Thermal Digiplater off

and on. If the Thermal Digiplater cannot be

restored by turning the power off and on, it

may be necessary to repair the Thermal

Digiplater. Consult Service department.

* The messages on the LCD show a code number for service in the boxes ().

When consulting Service department, please quote a code number.

Page 74

Chapter 5 Trouble shooting

TDP-324

-68-

5.2 Plate jam

If a plate jam occurs, turn off the power and remove the jammed plate.

1.

Turn off the power switch.

2.

By holding the opening lever A on the top

of the upper cover, open the upper cover

to check the plate condition.

If there is no plate left,

go to When there is no plate left

(page 69).

If there is plate left,

go to When there is plate left

(page 70).

Power switch

Opening lever A

Upper cover

Do not open the plate cover extremely

quickly or forcibly 90 degrees or more.

The thermal head is hot just after

printing. Do not touch it directly by

hand.

Fingerprints on the thermal head

heating element can cause the

thermal head to fail. Do not touch it

directly by hand.

Be careful not to be injured by

protrusions in the Thermal Digiplater.

Page 75

Chapter 5 Trouble shooting

TDP-324

-69-

When there is no plate left

1.

Turn on the power switch.

2.

Reset the plate.

See 2.8 Setting the plate.

Power switch

Page 76

Chapter 5 Trouble shooting

TDP-324

-70-

When there is plate left

1.

Open the plate cover and pull the plate out

with your hands.

2.

If the plate cannot be pulled out, cut off the

jammed and folded sections with scissors,

and pull the plate out.

3.

Reset the plate.

See 2.8 Setting the plate.

Plate

Do not open the plate cover extremely

quickly or forcibly 90 degrees or more.

Page 77

Chapter 5 Trouble shooting

TDP-324

-71-

5.3 When parts of image area are missing from the

printed plate

Incorrect print with straight streaky missing parts in the direction of plate feed

This may have been caused by contamination on the thermal head. Clean it as instructed in Chapter

4 , 4.1 Cleaning the parts inside the Thermal Digiplater.

If this problem cannot be solved by cleaning, the head may be broken. Consult Service department.

Incorrect print with dotted missing parts

This may have been caused by contamination on the cleaning rollers. Clean them as instructed in

Chapter 4 , 4.1 Cleaning the parts inside the Thermal Digiplater.

Page 78

Chapter 5 Trouble shooting

TDP-324

-72-

5.4 Plate is not correctly detected

The error message “Plate Empty” is displayed when the plate has not been used up.

Contaminated plate sensors may not have correctly detected the plate. Clean the plate sensors by

following the steps as instructed below.

If this problem cannot be solved by cleaning, the sensors may be defective. Consult Service department.

1.

Turn off the power switch.

2.

By holding the opening lever A on the top

of the upper cover, open the upper cover.

[Useful tip]

A locking lever is provided to the upper cover to prevent the cover from closing

down. When opening the upper cover, be sure to open it to the position where

the locking lever locks effectively.

Power switch

Opening lever A

Upper cover

Do not open the

upper

cover extremely

quickly or forcibly 90 degrees or more.

The thermal head is hot just after

printing. Do not touch it directly by

hand.

Fingerprints on the thermal head

heating element can cause the

thermal head to fail. Do not touch it

directly by hand.

Be careful not to be injured by

protrusions in the Thermal Digiplater.

Page 79

Chapter 5 Trouble shooting

TDP-324

-73-

3.