Page 1

'99 · TD-S · 001

MITSUBISHI

TRANSPORT REFRIGERATION UNIT

TDJ300D

TDJ430D

SERVICE MANUAL

Page 2

Introduction

This service manual describes the outline and maintenance procedures, etc., of the refrigeration unit, and is

intended to be used by the service personnel of the unit. Read this manual thoroughly before using to ensure

quick and waste-less servicing and to maintain the performance of the refrigeration unit.

• How to read the type

TDJ430D - 2 L 2

Indication of power voltage

[ 2: DC24V

Indication of temperature range

L: For refrigeration

[Inside temperature range: -30 to 25°C]

Indication of compressor operation

1: Vehicle driving engine operation

[

2: Vehicle driving engine operation and motor operation

Model name

[Example]

TDJ300D - 1 L 2

Type 1 (Type 2)

In this manual, these are shown by abbreviating

as type 1 and type 2.

Page 3

Safety Precautions

● Read the "Safety Precautions" thoroughly before using inspections and maintenance.

● The precautions described here are classified as " WARNINGS" and " CAUTIONS". Items that could lead to

fatalities or serious injuries during inspection and maintenance are listed as " WARNINGS". Note that even the items

listed as " CAUTIONS" could lead to series results depending on the situation. In any case, important information

related to safety is described, and must be observed.

● The meaning of the symbols used in this manual are as follows.

Never carry out. Always follow the instructions and carry out.

WARNINGS

(1) Never touch the high temperature sections such as the movable sections, exhaust pipe,

and high pressure side piping while the refrigeration unit is operating.

Failure to observe this could lead to burns.

(2)

If the refrigerant gas leaks during work, always ventilate the area.

Toxic gas could be generated if the refrigerant gas contacts fire.

(3)

According to this manual, securely install the product unit. If it is poorly installed, it will

cause refrigerant leakage, electric shock or fire.

(4)

For installation, apply the method which must be sufficiently durable for the weight of

the product unit.

If the strength is insufficient or the installation is poor, the product unit will drop

to cause an accident or wound.

(5)

Don't change any setting value of the protector or safety device. If any setting value is

changed, the product unit will be punctured or fired.

(6)

Don't mix any other refrigerant, air or similar except the specified refrigerant into the

refrigeration cycle.

If it is mixed, the pressure will become abnormally high in the refrigerant cycle, resulting in puncture

or wound.

(7)

Do not make modifications.

Making modifications could lead to injuries, electric shocks or f ires due to abnormal operation.

CAUTIONS

Before starting the refrigeration unit operation, confirm that the doors and screws for

the outer plates, etc., are completely tightened. Contacting the rotary parts could lead

to injuries.

Page 4

1. Characteristics ··········································· 1

2. Specification················································ 2

3. General information ································· 4

3.1 Controller ··············································· 4

3.2 Drive system··········································· 4

3.3 Operation control···································· 4

3.4 Defroster ················································· 4

3.5 Protective device····································· 4

4. Name of each component······················ 5

5. Adjustment of test operation················ 6

5.1 Pre-operation inspection ·························· 6

5.2 Inspection during operation····················· 6

6. Daily operation ············································ 6

6.1 Description of operation for the

controller ·················································· 6

6.2 Other operations ······································· 7

6.3 Operation of special service switches ······ 7

6.4 Operation sequence ·································· 7

6.5 Operation of display switches ·················· 8

6.6 Defrosting operation and manual

defrosting ················································· 8

7. Loading ··························································· 9

7.1 Inspection before loading ························ 9

7.2 Loading procedure ··································· 9

7.3 Unloading ················································ 10

7.4 Caution to be taken for the usage ············ 10

8. Refrigerant piping system ····················· 11

8.1

Refrigerant piping system diagram

·········· 11

8.2 Freezing cycle ········································· 11

9. Control system ············································ 12

10. Description of main parts······················· 13

10.1 Compressor ·············································· 13

10.2 Magnet clutch ·········································· 13

10.3 Heat accumulator ····································· 14

10.4 Accumulator ············································ 14

10.5 Electromagnetic valve ····························· 15

10.6 Check valve ············································· 15

10.7 Receiver ··················································· 15

10.8 Sight glass ················································ 16

10.9 Dryer ························································ 16

10.10 Condenser fan motor ······························· 16

10.11 Evaporator fan motor ······························· 17

10.12 Multi-function valve ································ 17

10.13 Expansion valve ······································· 17

10.14 Defrost thermostat (DTS) ························ 18

10.15 Dual pressure switch (DPS) ····················· 18

10.16 Storage temperature sensor (TH) ············ 18

10.17 Td sensor (Td) ········································· 19

10.18 Controller ················································· 19

10.19 Drain hose heater (option) ······················· 20

11. Electric wiring diagram ··························· 21

11.1 Sequence diagram ···································· 21

11.2 Wiring layout drawing ····························· 24

11.3 Explanation of operation ························· 28

12. Periodic inspection ··································· 34

12.1 Inspection at the time of installation

and test run ·············································· 34

12.2 Daily inspection ······································· 34

12.3 Monthly inspection ·································· 35

12.4 Six-mouth inspection ······························· 35

12.5 Bolt tightening table for each section ······ 35

12.6 Caution to be taken at the time of

daily inspection ········································ 36

12.7 Caution to be taken at the time of

periodic inspection ·································· 38

12.8 Check sheet (Installation, test run and

periodic inspection) ································· 40

12.9 Pressure table for standard operation ······ 41

13. Defect and its cause ································· 42

13.1 Diagnosis of defects on refrigerant

system······················································ 42

13.2

Charging the refrigerant <R404A>

·········· 46

13.3 Diagnosis of defects on electric parts······ 47

14. Method to select a model with

jumper cable ················································· 64

15. Refrigerant saturated pressure

table (R404A) ················································ 65

16. Installation procedure ····························· 66

16.1 Cautionary points during installation ······ 66

16.2 Cautionary and requested points

during installation ···································· 67

16.3 Reference drawing of installation ············ 71

Contents

Page 5

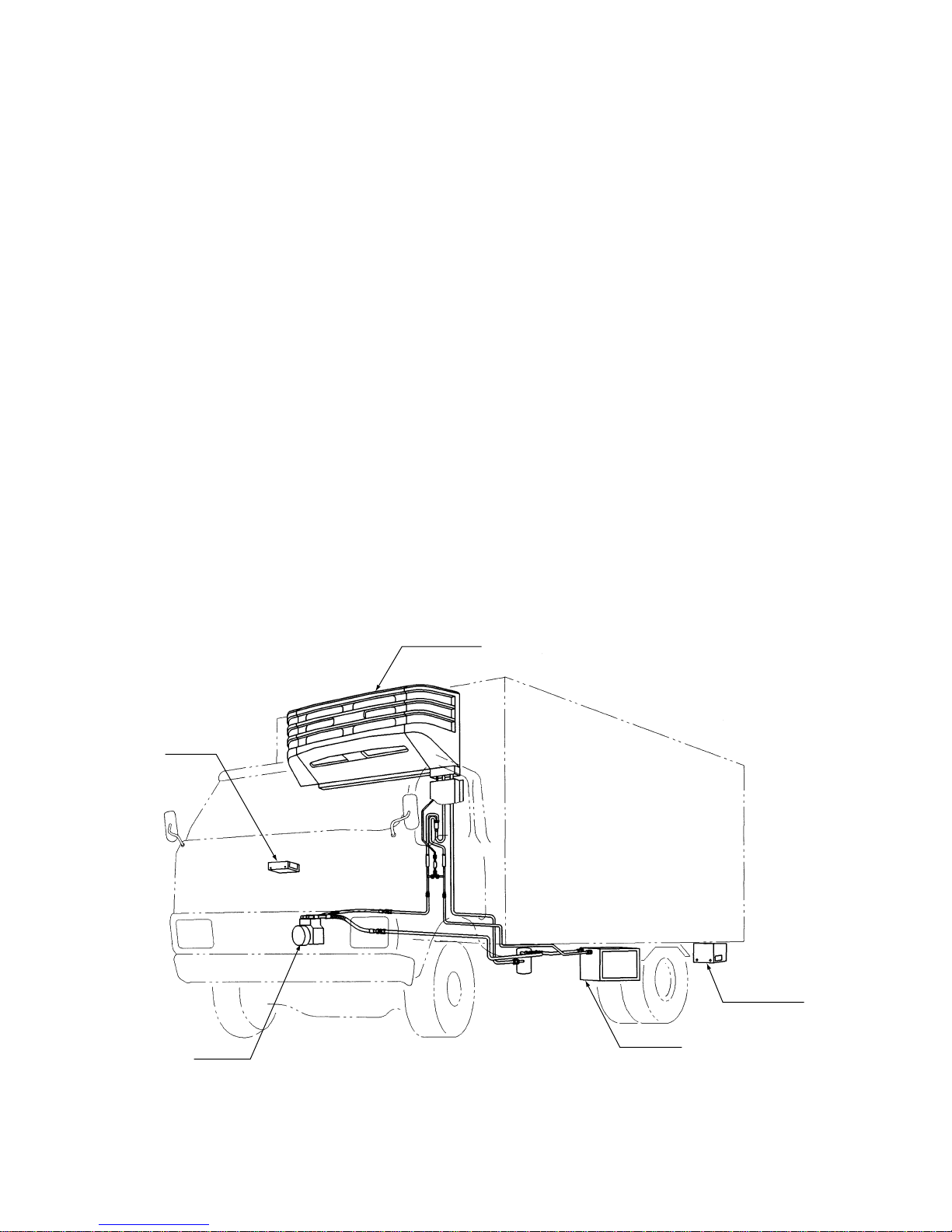

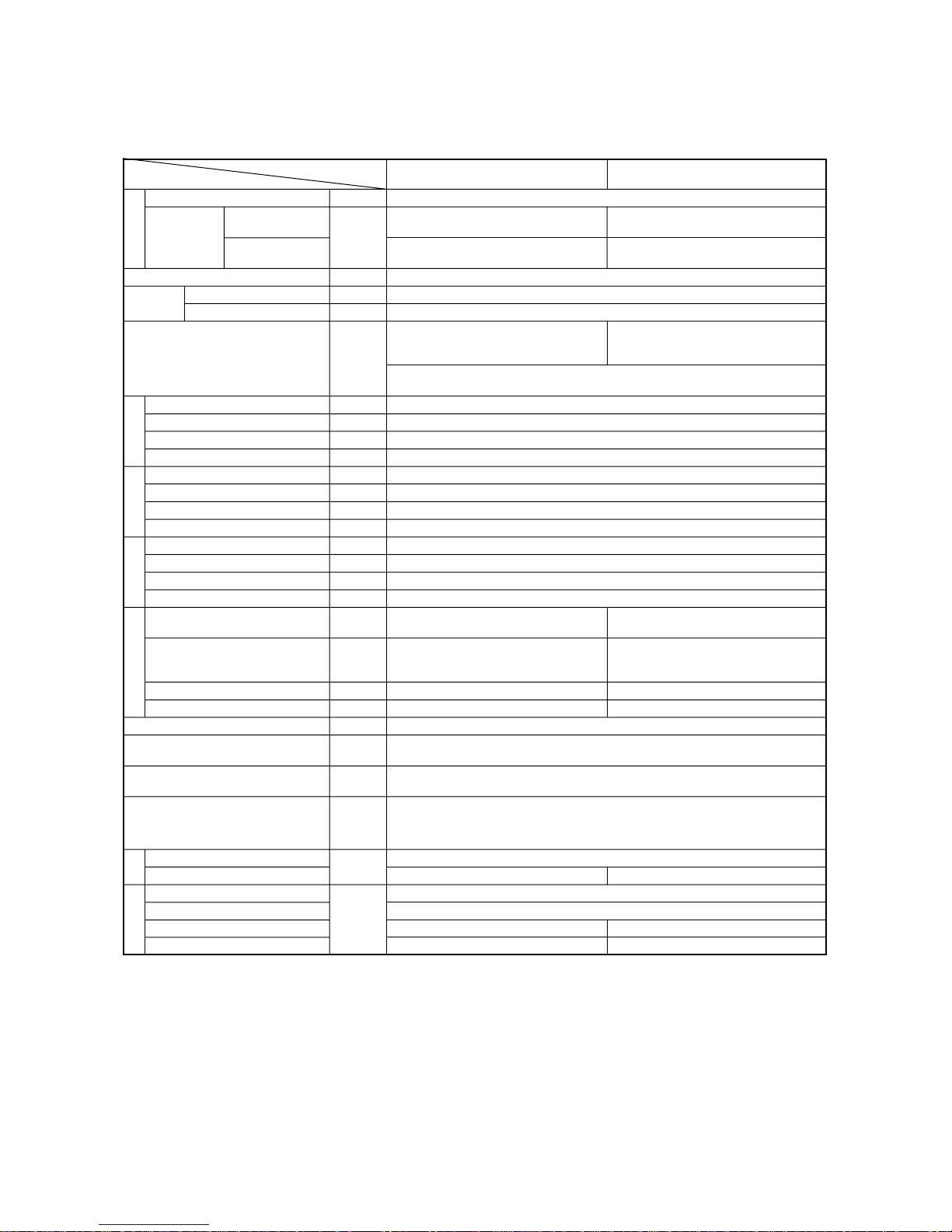

1. Characteristics

We have developed this refrigeration unit based on our long years of accumulation of refrigeration technique.

(1) The refrigeration unit is a compactly arranged and unitized type which can be easily installed and removed because

of a nose-mounted type.

(2) The refrigeration unit can operate in the range of the outside temperature of -5°C ~ 40°C to keep the inside

temperature in the rage of -30°C ~ 25°C. However, it is impossible to keep the inside temperature higher than the

outside temperature.

(3) The unit is easy to operate and capable of making automatic operation by switch.

(4) The refrigeration unit, which has adopted a new controller with a letter display function, can accurately establish a

desired storage air temperature digitally. And also the pre-operation inspection for the unit can be easily made by a

simple button operation, and easy diagnosis of defects will set you at ease in using the unit.

(5) The compressor is operated by the engine of a truck with a belt, and it starts and stops with magnet clutch “ON” and

“OFF”. The magnet clutch becomes “ON” and “OFF” by thermostat.

(6) The evaporator fan with DC motor installed respectively to them perform directly connected operation.

(7) Timer and manual defroster remove frost and always bring refrigeration effect into full play.

(8) New refrigerant R404A which are tender for the environments are employed.

(9) The new multi-function valve is employed. This prevents the refrigerant from returning to the high-pressure control

or compressor, and has a function for excellent start under the different pressure balance. This considerably

improves the capacity in the high temperature range, and makes the pull-down early.

– 1 –

Refrigeration unit

Controller

Compressor

Power source box

(Type 2 only)

Motor pack

(Type 2 only)

Page 6

2. Specification

(1) TDJ300D

– 2 –

Ambient temperature

0°C

-18°C

Function

Inside air temperature

Outside air temperature

Drive method

Model

Discharge

Revolution

Refrigeration oil

Type

Fan

Revolution of fan

Fan motor

Type

Fan

Revolution of fan

Fan motor

Type

Power source

Revolution

Rated output

Enclosed refrigerant volume

Storage air temperature

adjustment

Defroster

Safety device

Refrigeration unit

Motor pack

Refrigeration unit

Compressor

Motor pack

Accessories

Type

Item

°C

W

(kcal/h)

°C

°C

cm

3

/rev

min

-1

cm

3

min

-1

W

min

-1

W

min

-1

kW

kg

°C

W×H×D

mm

kg

35

3490 (3000) 3490 (3000) * [2790 (2400)]

2150 (1850) 2150 (1850) * [1740 (1500)]

Cooling

-30 ~ 25

-5 ~ 40

CR2211L-A

110

600 ~ 3600 * (1420)

Diamond Freeze MA32, 350

Aluminum tube, Corrugate fin

Propeller fan, Directly connected to fan motor

2100

75 × 2

Copper pipe, Aluminum fin

Centrifugal fan, Directly connected to fan motor

2000

70 × 2

—

Totally enclosed fan-cooled 3-phase motor

3-phase AC220V 60Hz,

—

380V 50/60Hz, 415V 50Hz

—

1500/1800 (50/60Hz)

—

2.2

R404A : 1.7

-30 ~ 25 (Microcomputer controller)

Automatic defrosting (Timer system)

Dual-pressure switch

[High pressure side] CUT OUT 2.94MPa (30kgf/cm2), CUT IN 2.35MPa (24kgf/cm2)

[Low pressure side] CUT OUT 0.20MPa (2.0kgf/cm2), CUT IN 0.23MPa (2.3kgf/cm2)

Over current relay 11A (Type 2 only), Fusible plug 95°C, Discharging temperature sensor 135°C

1596 × 666 × 499

—

492 × 300 × 385

67

7.3 (Include magnet clutch)

—

54

11 45

Return air

temperature

Range of

usage

Performance

Compressor

Condenser

EvaporatorMotor

Unit size

Weight

Compressor: Belt-driven from a vehicle

engine

Condenser fan

Evaporator fan

}

Direct drive by direct current motor

Compressor: Belt-driven from a vehicle

engine and belt-driven by

motor

Note: (1) The capacity of refrigeration (performance) shown in the above parenthesis represents case of 60Hz motor drive.

TDJ300D - 1L2 TDJ300D - 2L2

Page 7

(2) TDJ430D

– 3 –

Ambient temperature

0°C

-18°C

Function

Inside air temperature

Outside air temperature

Drive method

Model

Discharge

Revolution

Refrigeration oil

Type

Fan

Revolution of fan

Fan motor

Type

Fan

Revolution of fan

Fan motor

Type

Power source

Revolution

Rated output

Enclosed refrigerant volume

Storage air temperature

adjustment

Defroster

Safety device

Refrigeration unit

Motor pack

Refrigeration unit

Compressor

Motor pack

Accessories

Type

Item

°C

W

(kcal/h)

°C

°C

cm

3

/rev

min

-1

cm

3

min

-1

W

min

-1

W

min

-1

kW

kg

°C

W×H×D

mm

kg

35

5000 (4300) 5000 (4300) * [4070 (3500)]

2790 (2400) 2790 (2400) * [2210 (1900)]

Cooling

-30 ~ 25

-5 ~ 40

CR2318LWR

181.2

600 ~ 3600 * (1420)

Diamond Freeze MA32, 800

Aluminum tube, Corrugate fin

Propeller fan, Directly connected to fan motor

2100

75 × 2

Copper pipe, Aluminum fin

Centrifugal fan, Directly connected to fan motor

2000

70 × 3

—

Totally enclosed fan-cooled 3-phase motor

3-phase AC220V 60Hz,

—

380V 50/60Hz, 415V 50Hz

—

1500/1800 (50/60Hz)

—

3.7

R404A : 2.1

-30 ~ 25 (Microcomputer controller)

Automatic defrosting (Timer system)

Dual-pressure switch

[High pressure side] CUT OUT 2.94MPa (30kgf/cm2), CUT IN 2.35MPa (24kgf/cm2)

[Low pressure side] CUT OUT 0.20MPa (2.0kgf/cm2), CUT IN 0.23MPa (2.3kgf/cm2)

Over current relay 15A (Type 2 only), Fusible plug 95°C, Discharging temperature sensor 135°C

1596 × 666 × 499

—

570 × 340 × 398

72

7.3 (Include magnet clutch)

—

85

11 47

Return air

temperature

Range of

usage

Performance

Compressor

Condenser

EvaporatorMotor

Unit size

Weight

Compressor: Belt-driven from a vehicle

engine

Condenser fan

Evaporator fan

}

Direct drive by direct current motor

Compressor: Belt-driven from a vehicle

engine and belt-driven by

motor

Note: (1) The capacity of refrigeration (performance) shown in the above parenthesis represents case of 60Hz motor drive.

TDJ430D - 1L2 TDJ430D - 2L2

Page 8

3. General information

3.1 Controller

The refrigeration unit employs a new microcomputerized

controller which has a character display function, and

the desired inside temperature can be accurately and

digitally set with the soft touch type switch. Moreover,

a trouble can be easily diagnosed.

3.2 Drive system

(1) In case of engine drive from a running vehicle

The refrigeration unit is operated in which the

engine of a running vehicle drives the compressor

by belt and condenser fan and evaporator fan are

driven by a direct current motor respectively.

After having the ignition switch of its vehicle

turned on and the vehicle started, the refrigeration

unit can be operated with the controller operation

switch "ON".

(2) In case or motor drive (Type 2)

The refrigeration unit is equipped with a motor

drive besides engine drive from a running vehicle

and can be operated by the power supply (standard

specification, 3-phase AC 220V 60Hz, 380V

50/60Hz, 415V 50Hz) at a garage, truck terminal,

ferry boat, etc.

It can be operated with the controller operation

switch "ON" after connecting three-phase power

source to an outlet of the power source box.

3.3 Operation control

When a storage air temperature is higher than the

temperature established by the thermostat, it starts

cooling operation with the magnet clutch of the

compressor connected, and when the storage air

temperature has been lowered to the temperature

established by the thermostat, the magnet clutch will be

disconnected and the fan stops together with the

compressor, which in turn stops cooling operation. The

evaporator does not stop but continues to operate.

3.4 Defroster

In order to prevent the evaporator from being covered

with frost and reducing its cooling effect, the defrost

timer (it will be established within three hours before

being shipped out from our factory) operates

defrosting.

When defrosting has been completed and temperature

of the evaporator has risen, changes to cooling

operation by the defrost thermostat. Also the evaporator

fan stops during the defrosting operation, keeping

warm air from going into the inside.

Further when the storage is loaded with watery goods

or cooling in the storage is slow, defrosting can be

made by manual operation.

3.5 Protective device

The refrigeration unit is protected both by a protective

device (dual pressure switch) which stops the unit when

discharging pressure of the compressor becomes

unusually high and the dissolving plug which

discharges refrigerant when the pressure becomes

higher due to fire, etc.

Also these devices will stop the refrigeration units

when discharging temperature of the compressor

becomes unusually high due to leakage of refrigerant,

etc. When the unit has been abnormally stopped by the

protective device (except fusible plug), an abnormal

indication lamp will display its abnormality.

– 4 –

Page 9

4. Name of each component

(1) Refrigeration unit

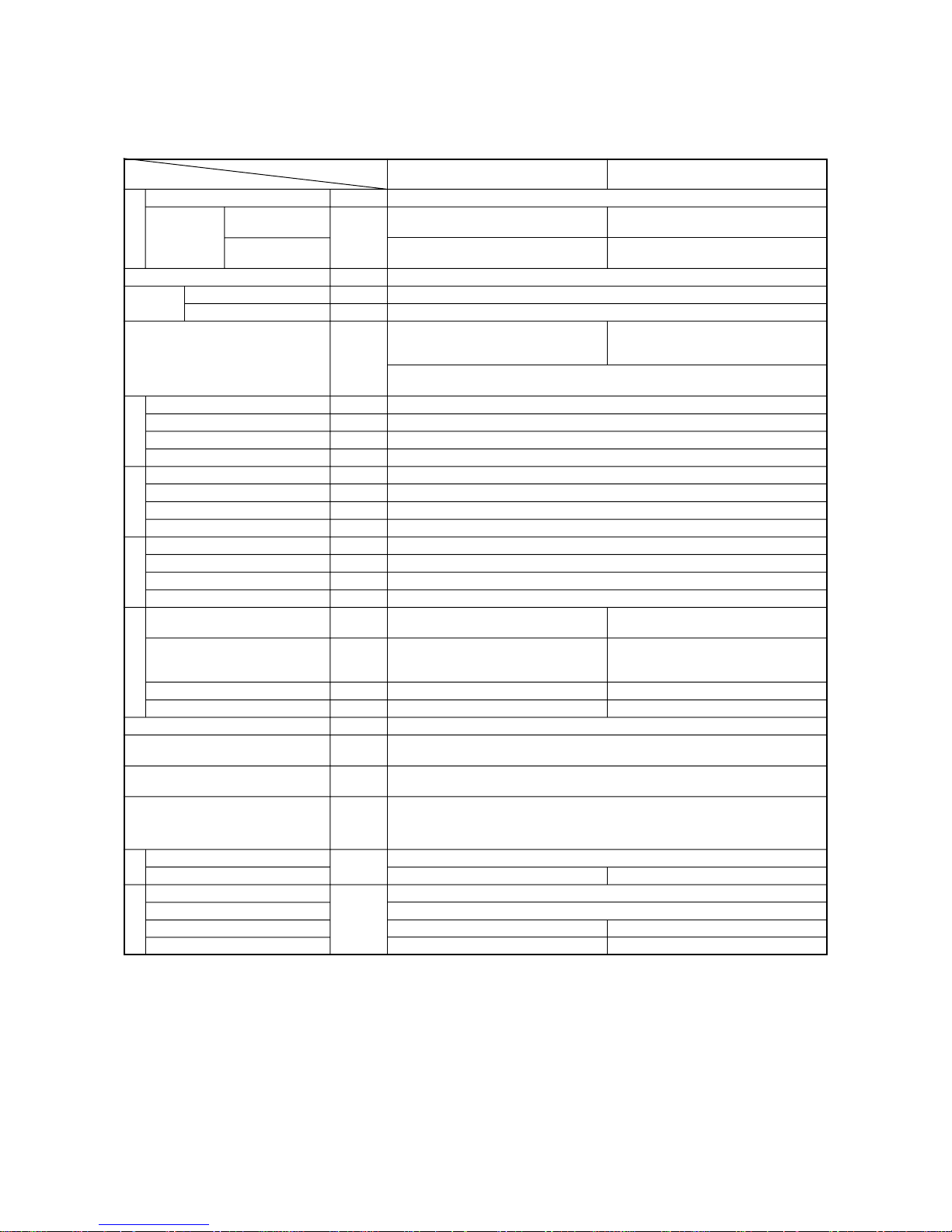

(2) Controller

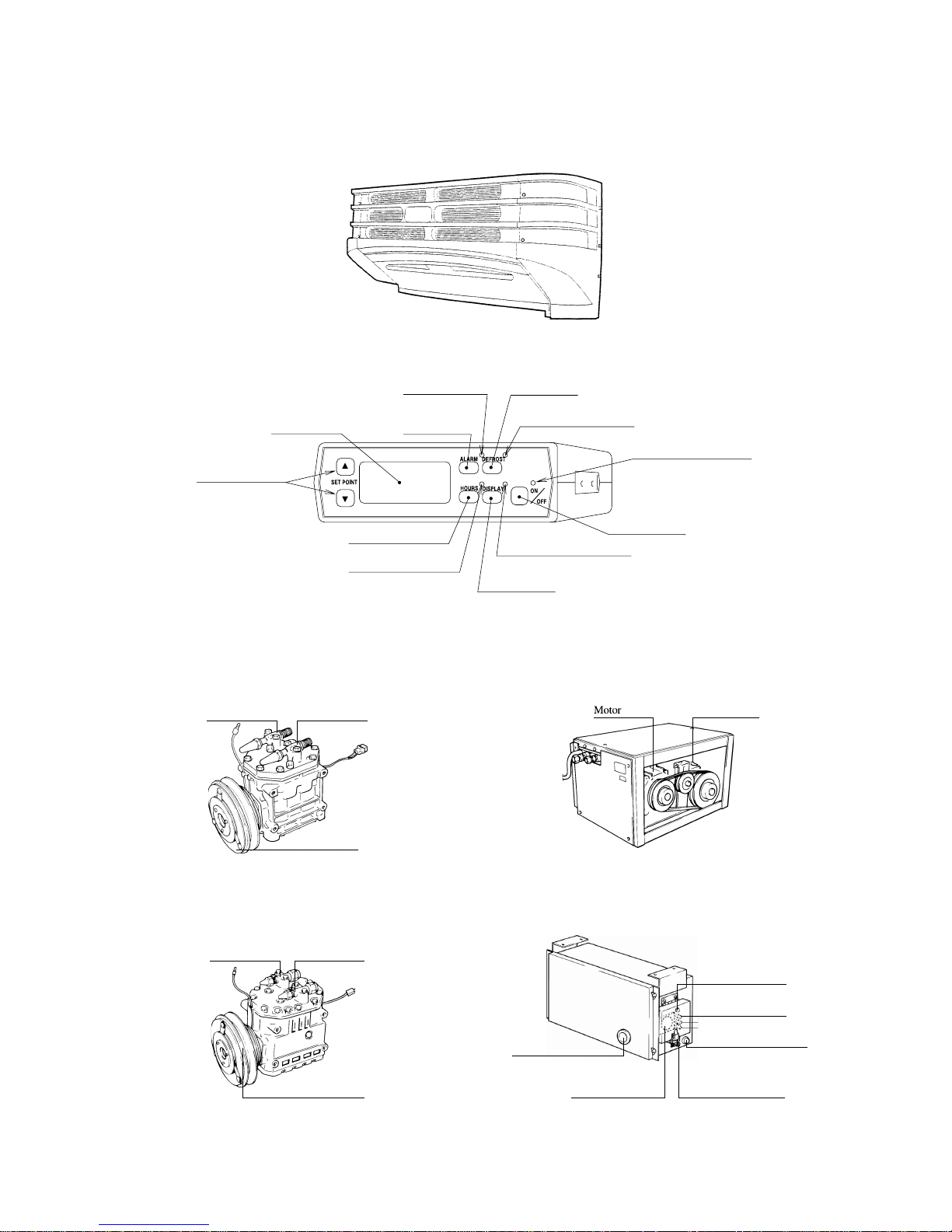

(3) Compressor

(a) TDJ300D

(b) TDJ430D

(4) Motor pack (only for type 2)

(5) Power source box (only for type 2)

– 5 –

Discharge

service valve

Suction

service valve

Magnet clutch

Discharge

service valve

Magnet clutch

Suction

service valve

Limit switch

Power source outlet

Power source

indication lamp

Alarm indication lamp

(Motor overcurrent relay

active indicator)

Fuses

Manual reset button

(For motor overcurrent relay)

Compresso

r

Alarm lamp

(red)

Defrost switch

Defrost indication lamp

(orange)

Operation indication lamp

(green)

Display indication lamp

(green)

Operation switch

Display switch

Alarm switch

Digital display

Hours switch

Hours indication lamp

(green)

Temperature setting

switches

Page 10

5. Adjustment of test operation

5.1 Pre-operation inspection

(1) Check the seal going through the board of

refrigeration unit.

(2) Check if the clamp of the tubing is adequate.

(3) Check if the drain hose is connected properly and

the clamp is proper.

(4) Check the belt for looseness, degree of parallel

(Coming out of the interline) and flaw.

(5) Check if components such as compressor, pully,

belt, tubing and wiring are touching each other.

(6) More tightening of fixing bolts for the following

units.

•

Refrigeration unit

•

Compressor and bracket

•

Magnet clutch

•

Tension pulley and bracket

•

Fan motor and fan

(7) Check the electric wiring for mis-wiring and the

clamp for properness.

(8) Check the wiring terminal for looseness and the

covering of wiring for flaw.

(9) Check the refrigerant system for gas leakage (oil

leakage).

(10) Check electric wiring for grounding and defective

insulation. (Type 2 only)

5.2 Inspection during operation

(1) Check the compressor, magnet clutch, motor, fan

and tubing for abnormal sound and vibration.

(2) Check the refrigerant sight glass for color and

degree of flashing.

(3) Check the compressor and magnet clutch for start

and stop due to the thermostat.

(4) Check refrigeration (indication by temperature

display and high and low pressure).

(5) Check the defroster for operation.

(6) Check the dual pressure switch for operation.

(7) Check the motor for drive (Type 2 only) and

buzzer with ignition switch "ON".

6. Daily operation

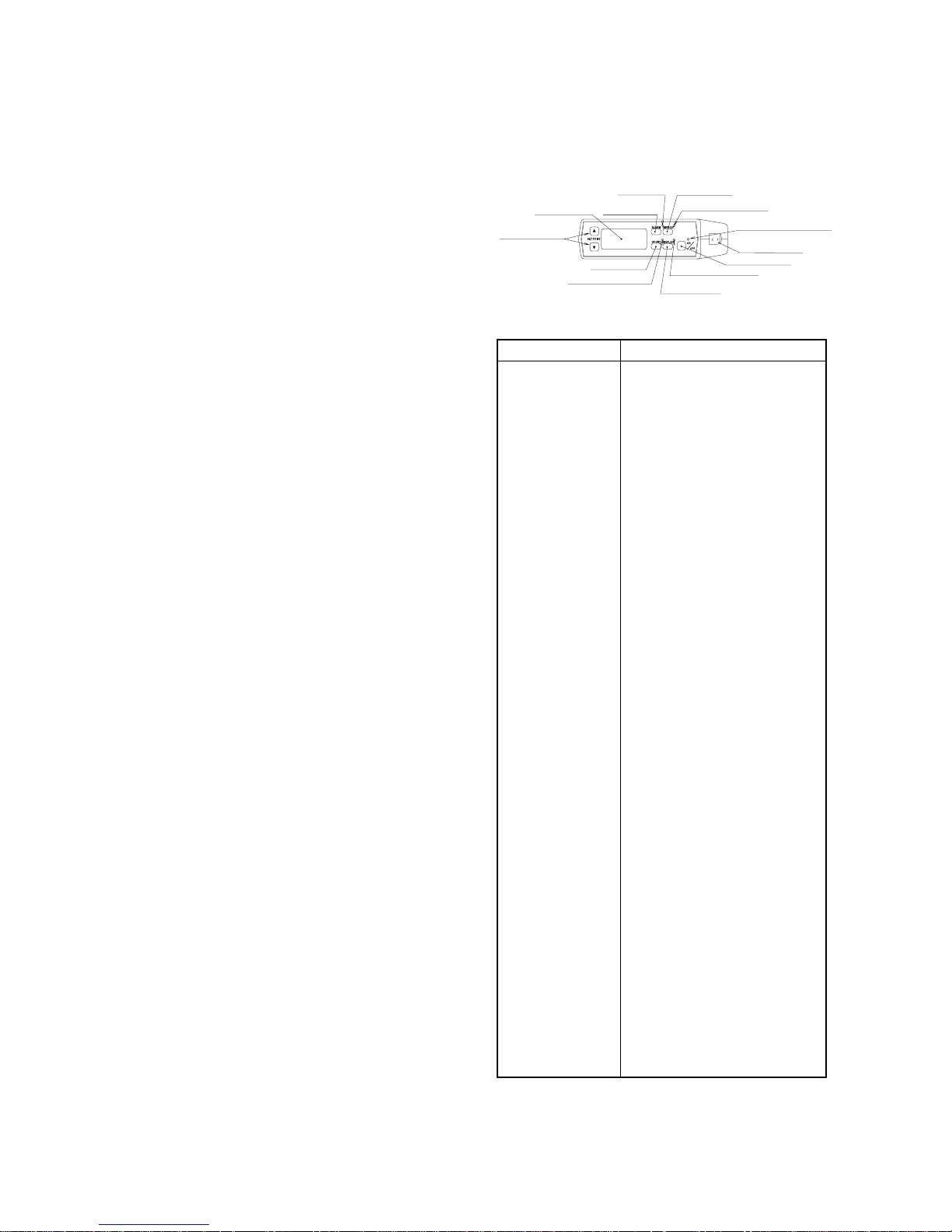

6.1 Description of operation for the controller

Description of operation for the controller

Name Operation

The switch starts or stops the

refrigeration unit.

The lamp (green) is lit when the

operation switch is on.

The switch turns on the forcible

defrosting operation.

The lamp (orange) is lit when

defrosting is in operation.

When the alarm lamp lights or blinks,

press the switch, and all faults which

occur will be indicated as the code on

the digital display unit.

When a fault occurs, the alarm lamp

(red) lights and blinks.

The in-container temperature,

incontainer preset temperature, fault

display code and integrated operation

time are displayed according to the

switches.

The switch changes the incontainer

preset temperature.

The switch makes the working time

(operation hours) of the evaporator

fan displayed.

Press the hours switch, and the lamp

(green) will come on.

When the refrigeration unit stops,

press this switch, and the incontainer

temperature will be displayed on the

digital display unit for 5 seconds.

Moreover, when the refrigeration unit

runs, press this switch, and the

incontainer temperature will be

displayed if the preset temperature,

fault code or integrated operation

time is displayed in the display unit.

Press the display switch, and the

lamp (green) will come on.

Buzzer prevents improper start.

Keeping the power code for motor

drive connected, turn the vehicle

ignition key to "ON", and the buzzer

integrated in the controller will sound

to stop the refrigeration unit.(Even if

the refrigeration unit stops, the buzzer

will sound.

– 6 –

3 Alarm lamp

(red)

2 Defrost switch

2 Defrost indication lamp

(orange)

1 Operation indication lamp

(green)

7 Display indication lamp

(green)

1 Operation switch

C Buzzer (built-in)

7 Display switch

3 Alarm switch

4 Digital display

6 Hours switch

6 Hours indication lamp

(green)

5 Temperature setting

switches

1 Operation switch

(ON/OFF)

2 Operation

indication lamp

3 Defrosting switch

4 Defrosting

indication lamp

5 Alarm switch

6 Alarm lamp

7 Digital display

8 Temperature

setting switches

9 Hours switch

0 Hours indication

lamp

A Display switch

B Display

indication lamp

C Buzzer

(Type 2 only)

Page 11

6.2 Other operations

When the refrigeration unit stops (power is supplied),

the following operations are ready.

(1) Change of inside-container preset temperature

DISPLAY ··· To higher temperature

e

··· To lower temperature

After pressing "display switch", press the switch

or , and the inside-container preset

temperature will be displayed on the digital

display unit in the blinking mode to select the

inside-container temperature setting mode.

Continuously press the switch, and the preset

temperature will vary.

··· T o higher

temperature

··· T o lo wer

temperature

(Continuously press the switch or , and the

temperature will continue varying.)

5 seconds after the finger is released from the

switch, the inside-container temperature will be

displayed.

Then, the digital display unit will go out after

other 5 seconds. Thus, it will be completely set.

(2) Integrated operation time

DISPLAY e HOURS

After pressing "display switch", press "hours

switch", and the integrated operation time will be

displayed on the digital display unit.

5 seconds after the finger is released, the inside

container temperature will be displayed. Then, the

digital display unit will go out after other 5

seconds.

Thus, it will be completed.

6.3 Operation of special service switches

When the operation switch is "off", the following

operation is ready.

(1) How to clear the evaporator operation time

1 Press the display switch.

2 Press the hours switch and temperature setting

switch together for 4 seconds, and it will be

cleared.

(2) How to display the fault history

1 Press the display switch and alarm switch together

for 4 seconds, and max. 5 faults which have

occurred will be displayed with the codes in

sequence from the newest one.

2 When the fault history is displayed, press the

alarm switch and temperature setting switch

together for other 4 seconds, and the fault history

will be cleared.

(3) How to change the defrost timer setting

1 Press the display switch and defrost switch

together for 4 seconds, and the preset temperature

will be displayed.

2 Press the defrosting switch together with the

temperature setting switch or , and the

defrosting time will be changed in the range of 1

to 6 hours.

6.4 Operation sequence

(1) In case of engine drive from a running vehicle

1 Start the engine which drives the car.

2 Turn the operation switch to "ON".

(When the operation switch comes "ON", the

operation lamp (green) will come on.)

3 Setting of inside-container temperature

Press either temperature setting switch or ,

and the inside-container setting temperature on the

digital display unit will blink to indicate the

inside-container temperature setting mode.

Keep the switch pressed as it is, and the setting

temperature will vary.

··· T o higher

temperature

··· T o lo wer

temperature

(Continuously press the switch or , and the

temperature will continue varying.)

Keep the temperature setting switch pressed, and

release the finger from the switch when the

temperature indicated on the digital display unit

reaches the inside container pressure temperature

(transportation temperature).

After 5 seconds, the digital display unit will return

to display the inside-container temperature. Thus,

the inside-container temperature setting mode will

be completed.

▼▲

Every push of the switch

changes the temperature

by 1°C.

▼

▲

▼▲

▼▲

▼

▼

▼▲

Every push of the switch

changes the temperature

by 1°C.

▼

▲

▼▲

▼

▲

– 7 –

Page 12

Since the controller is provided with the function

(memory function) which memorizes the

temperatures preset in the refrigeration unit up to

now, check the preset temperature by pressing

either temperature setting switch or one

time for the assurance's sake.

4 Stopping

• To turn it "OFF", press the operation switch

again and the refrigeration operation will be

stopped.

• Turn the operation switch to "OFF", and the

operation indication lamp and digital display

unit will go out.

Note: Before turning the ignition switch of the car to

"OFF", be sure to turn the operation switch of the

refrigeration unit to "OFF".

(2) Motor driven type (Type 2 alone)

1 Turn the ignition switch of the vehicle to "OFF",

and connect the receptacle of the motor drive

power supply to supply electric power.

Note: Before connecting the power supply, make sure

that the operation switch is "OFF".

2 Press the operation switch to "ON".

When the operation switch becomes "ON", the

operation indication lamp will come on. (Green)

3 Inside temperature setting

Press either setting switch or , and the inside

set temperature on the digital display unit will be

displayed in the blinking mode with the inside

temperature setting mode selected.

Keep the switch pressed as it is, and the setting

temperature will vary.

··· T o higher

temperature

··· T o lo wer

temperature

(Continuously press the switch or , and the

temperature will continue varying.)

When the temperature indicated on the digital

display unit is brought to a desired inside

temperature (transportation temperature) by

pressing the temperature setting switch, release the

finger from the switch.

After 5 seconds, the digital display will return to

the inside temperature with the temperature setting

mode ended.

Since the controller has the function to

memorize the temperature which was set during

last operation of the refrigeration unit, press

either temperature setting switch or once

to check the memorized temperature for

caution's sake.

4 Stopping

• Press the operation switch again to turn it to

"OFF", and cooling operation will be stopped.

• Turn the operation switch to "OFF", and the

operation indication lamp and digital display

will go out.

Note: 1) Before disconnecting the receptacle of the

motor drive power supply, be sure to turn the

operation switch of the refrigeration switch to

"OFF".

2) Don't start or stop the unit by using the power

supply breaker or connecting/disconnecting

the power supply plug. Otherwise, it will

cause an electric circuit trouble or electric

shock.

3) Prevent rain and water from splashing over

the receptacle area of the power box, or it will

cause an electric shock when the motor is

driven.

6.5 Operation of display switches

(1) When the refrigeration unit is operating

When the preset temperature, fault code or

integrated operation time is displayed on the

digital display unit, it can be returned to the insidecontainer temperature.

(2) When the refrigeration unit is stopped

Press the display switch, and the inside-container

temperature will be displayed on the digital

display unit. At this time, press the following

switch, and the selected content will be displayed.

• Single push of or ····Preset temperature

• ALARM······························Fault code

• HOURS·······························Operation time

• DEFROST···························Defrost interval time

6.6 Defrosting operation and manual defrosting

Defrosting operation is applied to prevent the cooling

effect from dropping since the evaporator is frosted.

▼▲

▼▲

▼▲

Every push of the switch

changes the temperature

by 1°C.

▼

▲

▼▲

▼▲

– 8 –

Page 13

The defrost timer (factory-set at every 3 hours at

shipment) will automatically work for automatic

defrosting.

When the delay timer of 1 minute runs out after

defrosting is completed, it will be automatically

switched into the cooling operation.

At this time, the evaporator fan is stopped to prevent

the warm wind from entering the room.

(1) Method to change the timer setting of defrosting.

Though the defrost timer was factory-set at every 3

hours at shipment, it is adjustable in the range of 1

to 6 hours.

1 Turn the operation switch to "OFF".

2 Press both display switch and defrost switch

together for 4 seconds, the preset time will be

displayed.

3 The preset time can be changed by pressing the

temperature setting switch or with the

defrost switch pressed.

(2) Manual defrosting method

If inside cooling becomes poor since frost sticks to

the evaporator, manual defrosting is possible.

Press the defrost switch during cooling operation.

• The defrost indication lamp (orange) is lit

during defrosting operation.

• The operation indication lamp is lit during

defrosting operation. (Green)

It will automatically return to the cooling

operation when defrosting is complete. (It can not

be manually returned to OFF.)

After 60 minutes, it will be automatically

returned to the cooling operation with the

defrost forced ending timer (integrated).

7. Loading

7.1 Inspection before loading

(1) Clean inside of the storage.

(2) Inspect the car side and the refrigeration unit.

(3) Establish a storage air temperature.

(4) Before loading, make sure to perform

cooling operation, and refrigerate the

storage up to an established temperature

in advance.

First of all, it is necessary to refrigerate a storage

in order to transport and deliver goods properly.

Under the blazing sun in midsummer, inside of a

storage may become as hot as 60°C. And so if

freight is put in it without cooling the storage in

advance, a defect due to improper transportation

temperature will happen.

• Operate the refrigeration unit under the shade.

• In case of engine drive, operate it with engine

running more than 800min

-1

.

• On Type 2, make pre-cooling operation done by

the motor drive.

(5) Check the sight glass during operation

and confirm that there is no bubbling and

that the checking color is green.

7.2 Loading procedure

(1) Load a refrigerator freight truck with the

goods which have been cooled to an

established air temperature in advance by

some other cooling device.

(Never load anything hot and warm in the truck

because it will only cause overloading operation to

the refrigeration unit.)

(2) Perform loading b y stopping the refrigeration

unit and in a short time, if possible.

▼▲

– 9 –

How to make an effective cooling

operation in advance.

Page 14

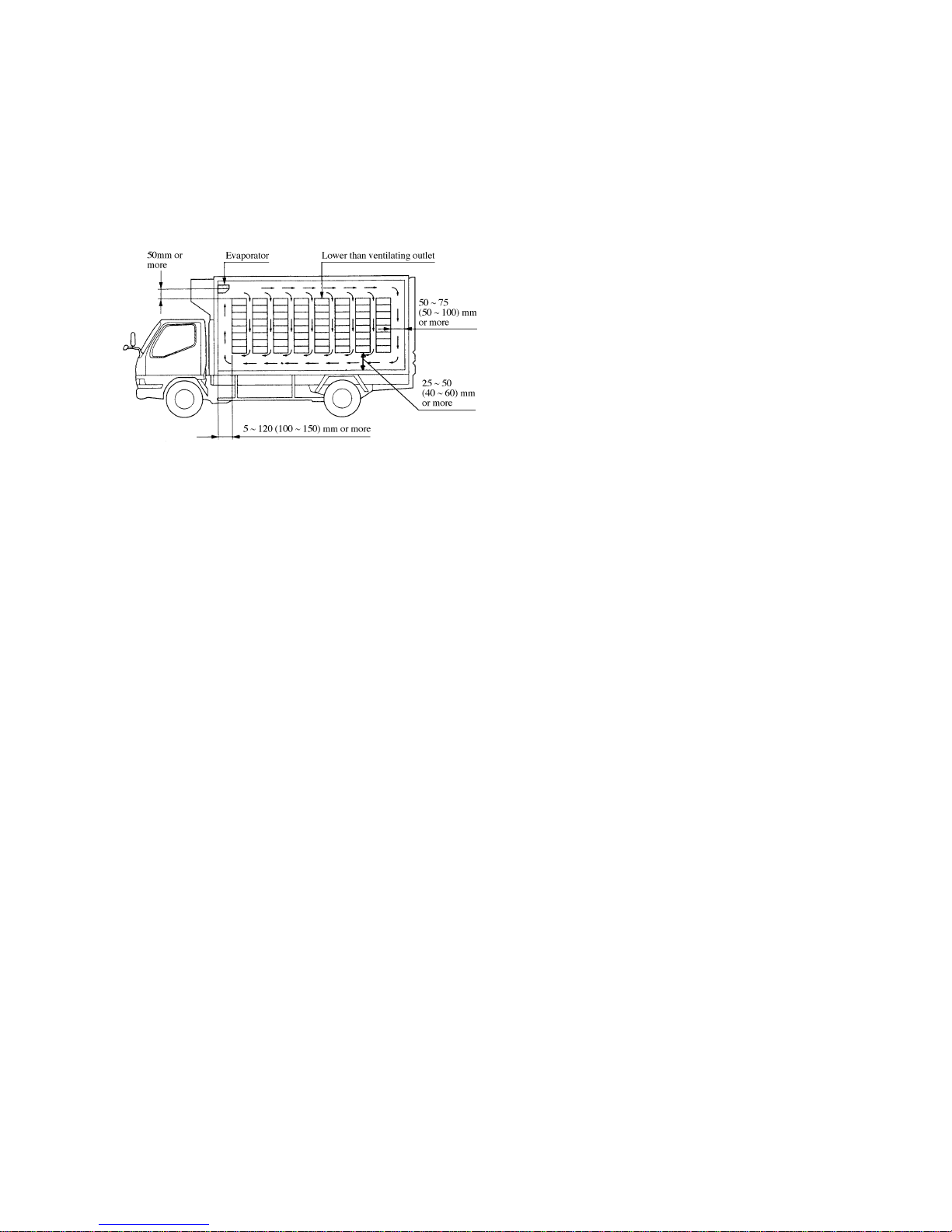

(3) Load so as to allow cool air circulating every

corner of the storage.

To circulate cold wind, the clearance between the

cargo and room wall must be 30mm or more on

both sides and the following values on the rear

side, front side and floor except the blow-out area

from the ceiling evaporator.

The values in ( ) are applicable for TDJ430D.

(4) Make the upper side of the load as flat as can be.

(5) After loading, operate the refrigeration unit.

7.3 Unloading

(1) Perform unloading after stopping the

refrigeration unit.

(2) Opening the door of the storage once will make

the inside temperature going up momentarily, so

open and close the door quickly so as to not let the

cool air out.

(3) When loading and unloading, make sure to use a

curtain in order to keep outside air from coming in

and cool air going out.

7.4 Caution to be taken for the usage

(1) In case of using a refrigerator freight truck as a

refrigerator for a long time consecutively, make

the entire indoor temperature as high as a plus

degree and melt the ice completely.

(2) Operate the refrigeration unit more than 15

minutes once in 3 or 4 days even if the unit is not

used for a long period of time.

(3) Avoid using only either the engine of a truck or the

motor of a unit for long. If one of them is not

going to be used for long, make sure to operate

either of them more than 15 minutes once in every

3 or 4 days.

Remarks: Operation procedure operate the unit for about

15 minutes, After switching "ON" and "OFF"

repeat at intervals of several seconds.

In case of driving engine operation type operate by

idling condition.

(4) The display indication of the controller may flicker

due to wireless (wireless of both our manufactured

vehicles and other makes). If a wireless in installed

in our vehicle, disconnect it.

(5) Regarding the power source and voltage of motor

drive:

• In case of standard specification, set up the

power volume which allows a rush voltage on

the refrigeration unit side to be able to secure

more than 180V when the motor is started.

• Motor specification

Standard specification 3-phases AC 220V 60Hz,

380V 50/60Hz, 415V 50Hz

• In case of using commercial power source, a

measure to cope with electric leakage for power

supply circuit is required.

(6) Washing

• When washing a vehicle, be careful not to splash

water directly to the electric equipments inside

the refrigeration unit.

• When cleaning the condenser and evaporator

coil, never make a high pressure washing by a

high pressure washing machine as it crushes the

fin. Also never make a steam washing as it

increases pressure inside of the units unusually

and is dangerous.

– 10 –

Page 15

8. Refrigerant piping system

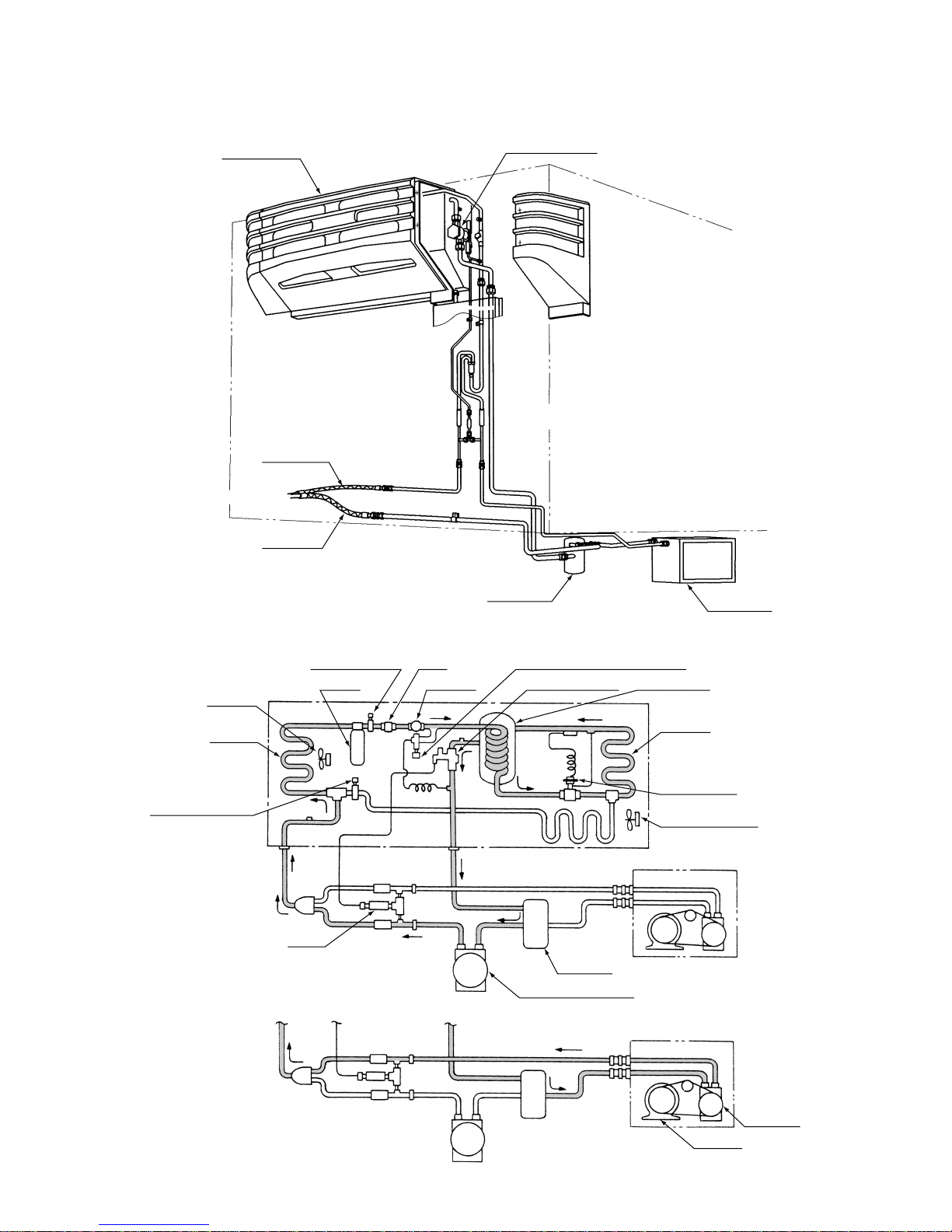

8.1 Refrigerant piping system diagram

8.2 Freezing cycle

(1) Refrigeration cycle

– 11 –

Multi-function valve

Motor pack

(Type 2 only)

Accumlator

(Type 2 only)

Refrigeration unit

Discharge hose

Suction hose

To vehicle’s compressor

Condenser

fan motor

Condenser

Dual pressure switch

Defrost electromagnetic

valve (closed)

Strainer

Motor pack

Refrigeration unit

Receiver Sight glass Multi-function valve Heat accumlator

Evaporator

Expansion valve

Evaporator fan motor

Accumlator

Compressor

AC motor

Conpressor (Engine side)

Dryer Liquid injection electromagnetic valve

(Discharge)

(Discharge)

(Suction)

(Suction)

Engine drive type

Motor drive type

Remarks:

The figure shows an example of Type 2.

Type 1 is not equipped with motor pack

and accumulator.

Page 16

(2) Defrost cycle

9. Control system

– 12 –

Defrost

electromagnetic

valve (open)

Motor pack

Refrigeration unit

Engine drive type

Motor dirve type

Refrigeration unit

Power source

box

Td2 sensor

Motor pack

To battery (+) terminal

Fusible link

On the 1 type, connect it to the battery as it is.

In case of type2

Ground

Ground

Control box

Controller

Compressor

To ignition

switch

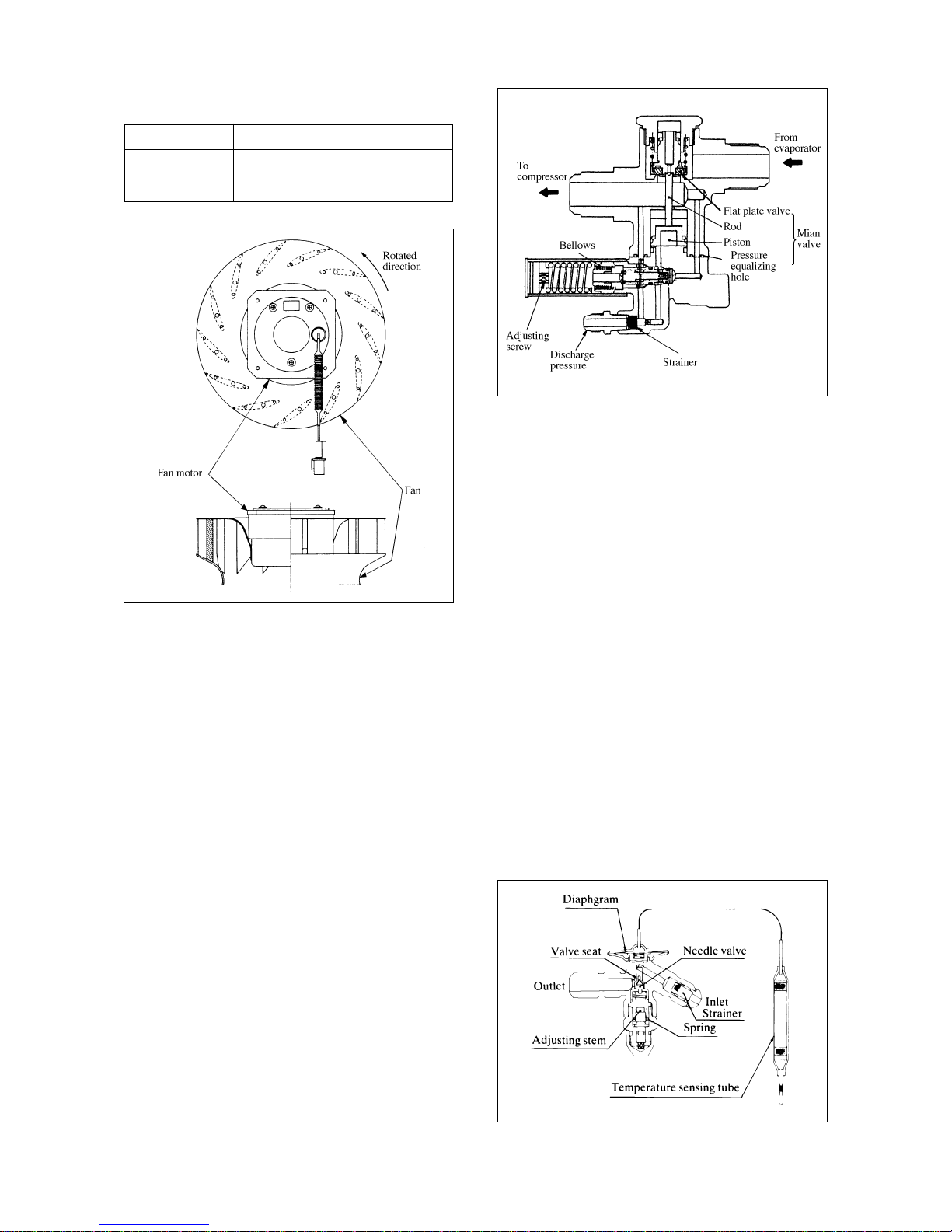

Td1 sensor

Remarks:

The figure shows an example of Type 2.

Type 1 is not equipped with motor pack

and accumulator.

Page 17

10. Description of main parts

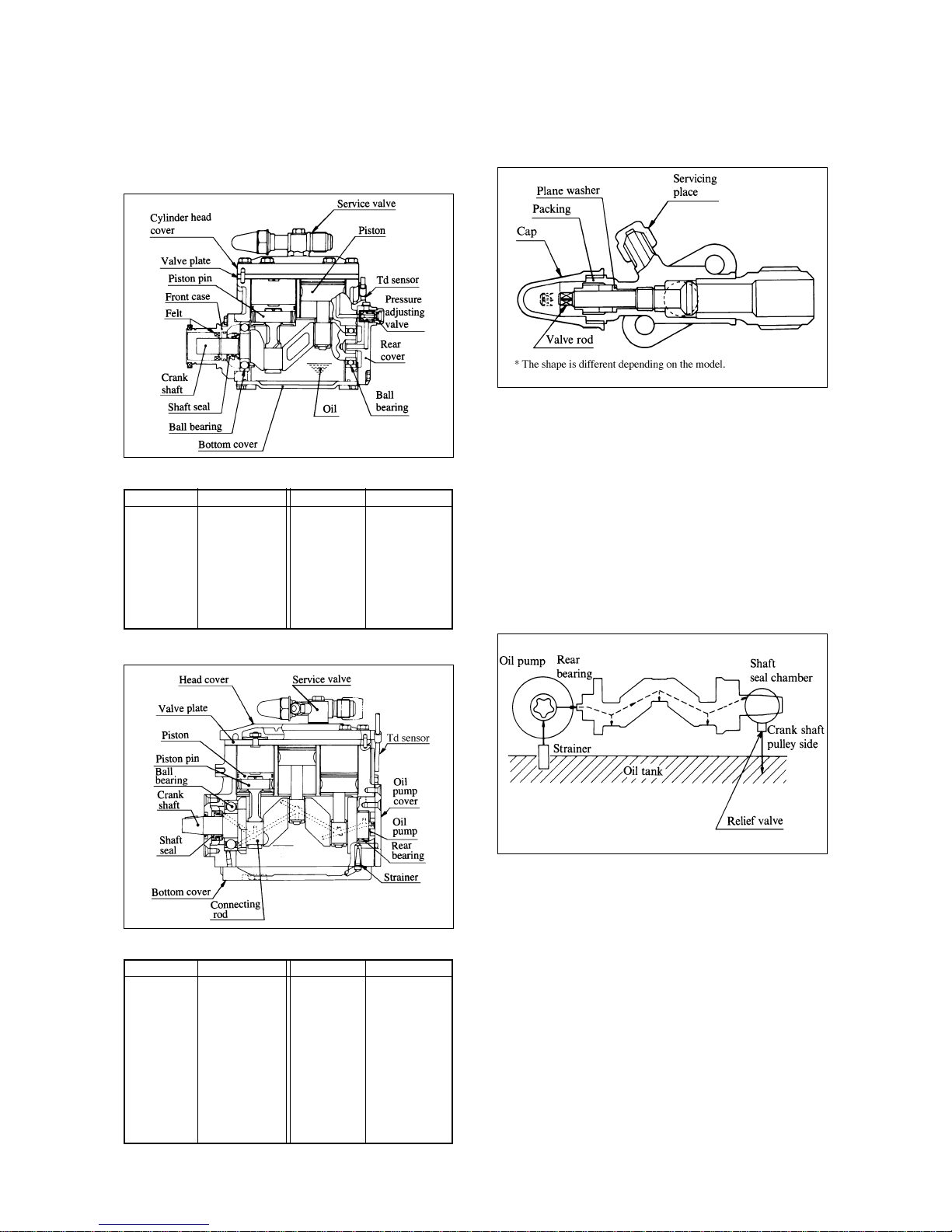

10.1 Compressor

(1) TDJ300D

(2) TDJ430D

(3) Service valve

The compressor are equipped with a suction

service valve and discharge service valve.

Note: When working the pipe for service, finally

connect the suction and discharge pipes of the

compressor since the refrigerator oil is highly

liable to absorb water.

(4) Lubrication system (TDJ430D)

Lubrication oil is supplied forcibly to respective

bearings, pistons, tank shaft pins and shaft seals by

the oil pump.

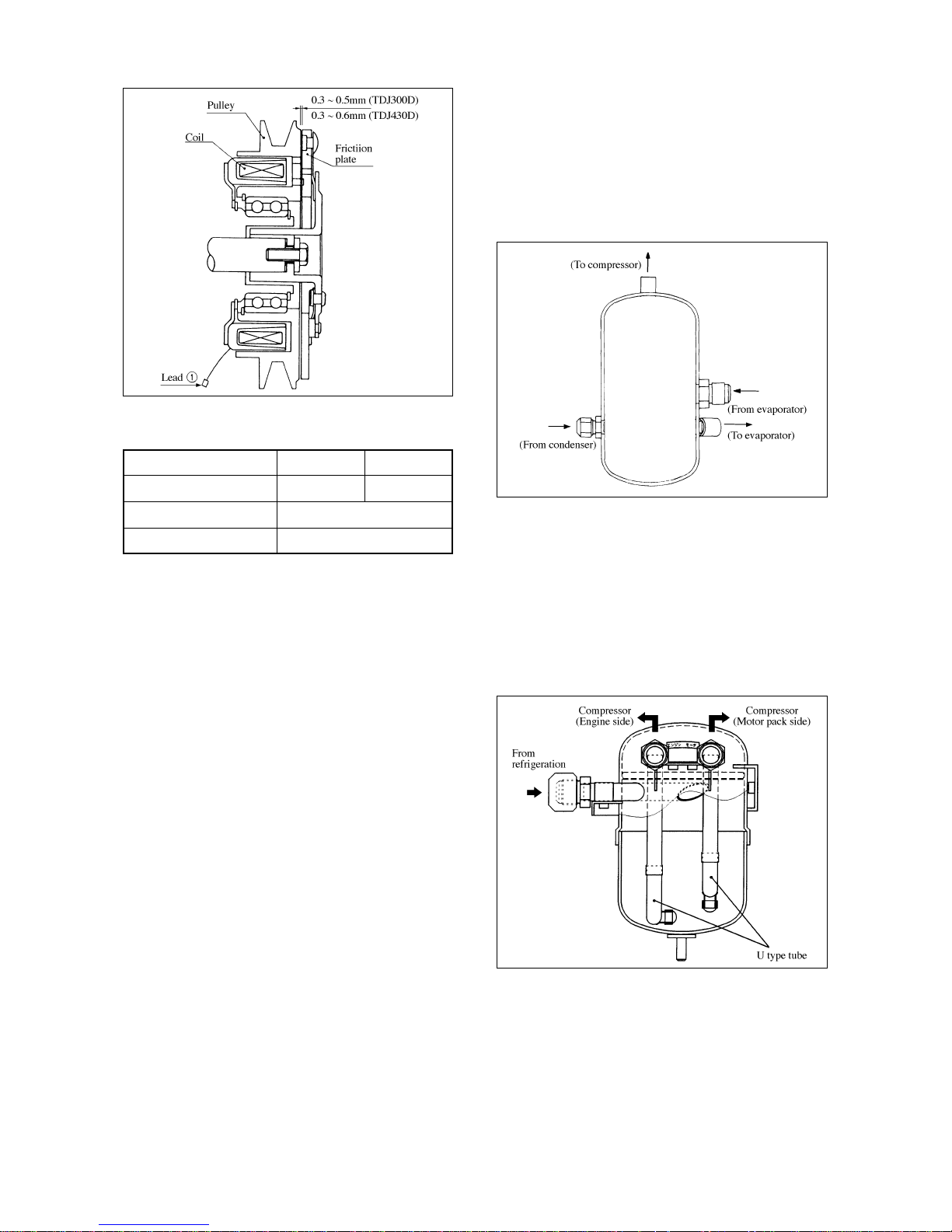

10.2 Magnet clutch

The magnet clutch is installed in the crank shaft of the

compressor, and turns on and off the compressor by

indication of the thermostat. When cooling is required

it is "ON" and when not required it is "OFF".

– 13 –

CR2211L-A

Name

Model

Volume of

discharge

Revolution

Specification

CR2211L-A

110cm

3

/rev

600 ~ 3600min

-1

(motor 1420min-1)

Name

Weight

Lubricating

oil

Amount of

oil

Specification

7.3kg

(include magnet

clutch)

Diamond Freeze

MA32

350cm

3

CR2318LWR

Name

Model

Lubricating

method

Volume of

discharge

Revolution

Specification

CR2318LWR

Compulsory

lubrication

181.2cm

3

/rev

600 ~ 3600min

-1

(motor 1400min-1)

Name

Weight

Lubricating

oil

Amount of

oil

Specification

13.5kg

(include magnet

clutch)

Diamond Freeze

MA32

800cm

3

Service valve

Schematic diagram of lubrication system

Page 18

– 14 –

Specification

How to determine defective or not defective.

When the battery voltage is applied between the lead

1 and the ground wire of the main body, the

compressor will turn if the pulley and the friction plate

stick together (it clinks).

If it will not turn even when voltage is applied, it is

defective. Measure by a tester the continuity between

the lead 1 and a ground of the main body, and it is

normal if there is continuity and defective if no

continuity due to disconnection of the coil. When

sound is heard, it is defective due to wear of the

bearing. If the magnet clutch is defective, replace its

assembly.

Measuring of air-gap

TDJ300D: 0.3 ~ 0.5mm

TDJ430D: 0.3 ~ 0.6mm

10.3 Heat accumulator

While separating liquid refrigerant from gas refrigerant

so as not to let the compressor sucks the liquid

refrigerant, increase capacity of refrigeration by

making a heat-exchange of high temperature liquid

refrigerant and low temperature gas refrigerant.

10.4 Accumulator (type 2 only)

Separate liquid refrigerant from gas refrigerant so as

not to let the compressor sucks the liquid refrigerant.

Here, the refrigerant is designed to flow from U type

tube only to the engine side or motor pack side where

the compressor is in operation.

Volume

Direction of revolving

Belt used

TDJ300D TDJ430D

53W 31W

Right

Type B × one each

Heat accumulator

Accumulator

Magnet clutch

Page 19

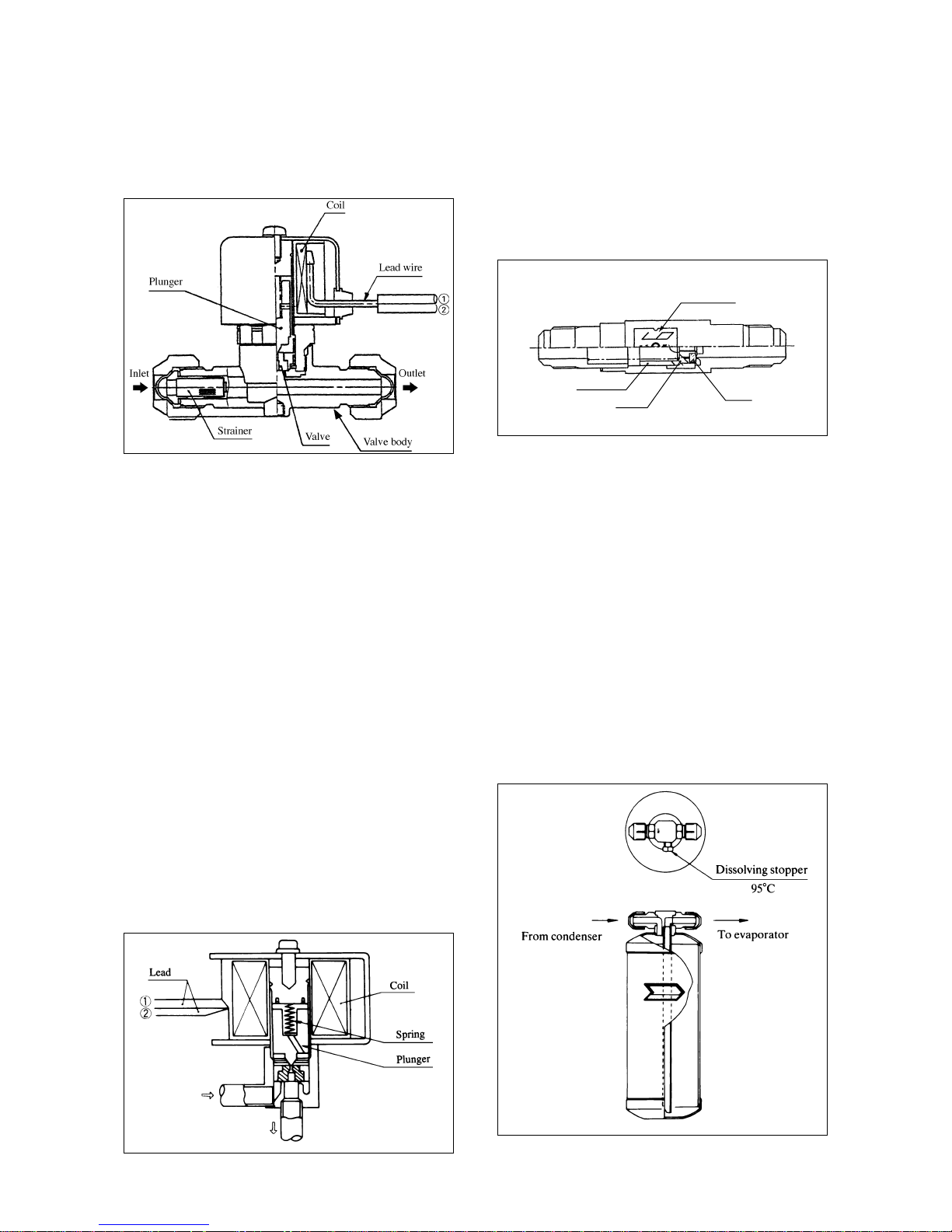

10.5 Electromagnetic valve

(1) Defrost electromagnetic valve

It is installed in order to flow hot gas into the

evaporator side when defrosting.

How to determine defective or not defective:

When continuity of the lead between 1 and 2 is

measured, the coil is normal if there is continuity

and if not, it is defective.

Before the coil is electrified, the temperature at the

inlet and outlet of refrigerant differs. So if the

temperature becomes the same after the coil is

electrified, the plunger is operating normally.

If the temperature differs the plunger is stuck.

Easy way to find out the problem:

When you electrify the coil with your hand

touching the electromagnetic valve, it is normal if

your hand feels a shock as the plunger goes up

with a click sound.

(2) Liquid injection electromagnetic valve

It opens when delivery temperature (at the sensor)

of the compressor becomes more than 125°C,

keeping the delivery temperature from becoming

high.

How to determine defective or not defective:

Same as defrost electromagnetic valve.

Refer to "defrost electromagnetic valve".

10.6 Check valve

It is installed to prevent the refrigerant from flowing

back ward.

How to determine defective or not defective:

Make a judgment by the difference of temperature at

the inlet and outlet of the check valve and replace it if it

is leaking.

10.7 Receiver

It reserves the refrigerant which has been liquefied by

the condenser.

The receiver has a dissolving stopper which will melt

and discharge the refrigerant in order to prevent a

danger due to unusual high temperature.

When the stopper has been melted, replace it with a

new one.

– 15 –

Defrost electromagnetic valve

Liquid injection electromagnetic valve

Arrow mark

Disk

Main valve

Spring

Check valve

Receiver

Page 20

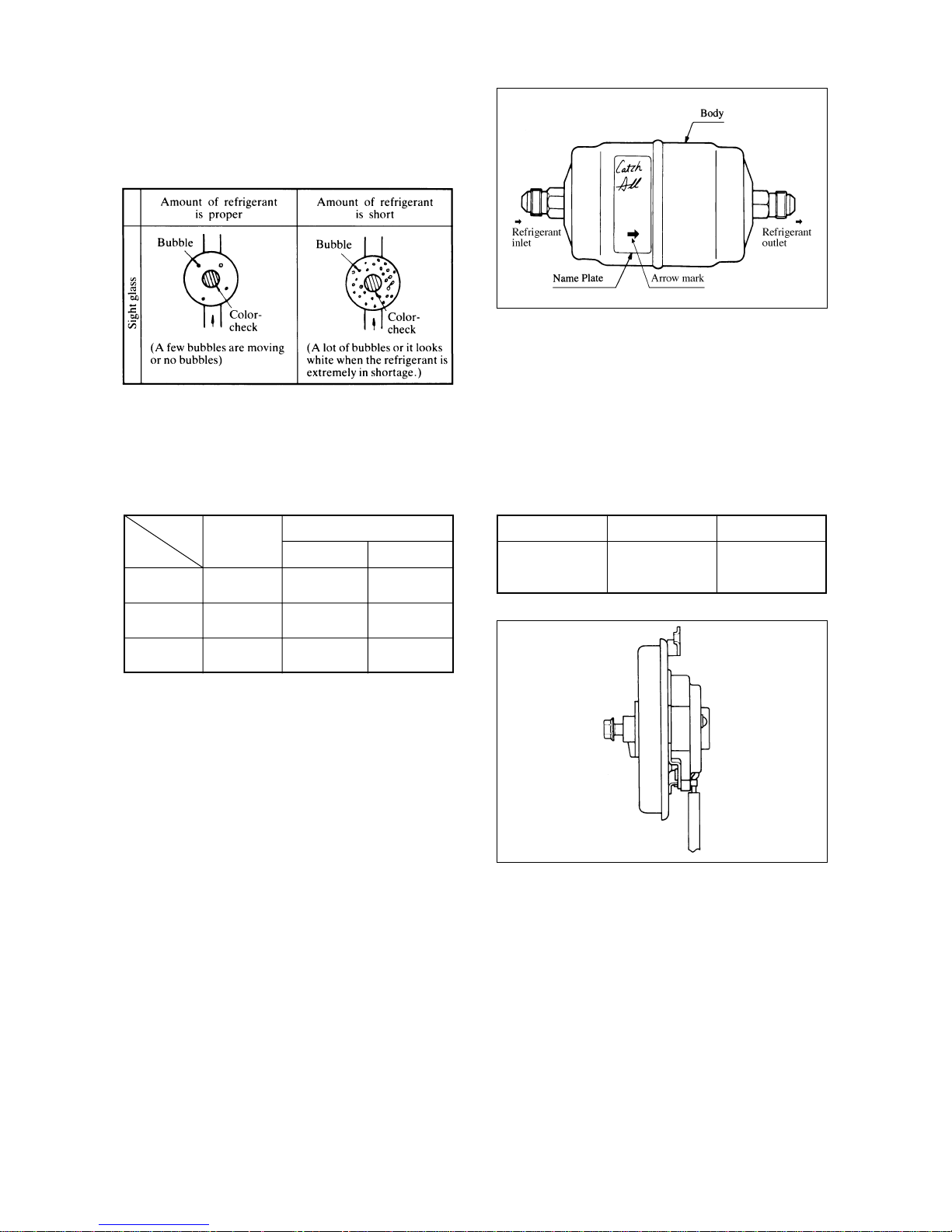

10.8 Sight glass

It can judge the circulating amount of refrigerant and

existence of water in the refrigerant.

If the refrigerant is short, repair the leaking place and

then charge gas.

How to determine existence of water:

Color of a color-check

In case of yellow color, it in necessary to vacuum and

replace the dryer.

10.9 Dryer

Moisture and foreign materials are eliminated from the

refrigerant. If the desiccant (molecular sieve) in the

dryer can not remove moisture (the check color of the

sight glass becomes yellow), replace the dryer

assembly. Also if inside of the dryer is clogged during

operation, there will be a difference in temperature

between the inlet and the outlet, and the outlet side

becomes cool.

When the dryer is replaced, replace it quickly. Here,

when installing the dryer, pay heed to its direction and

install it on the unit with the arrow mark aligned to the

flow of the refrigerant.

10.10 Condenser fan motor

Remarks: The brush can not be replaced

– 16 –

Dryer

Revolution

2100min

-1

Electric current

3.2A

Input

70W

Condenser fan motor

Sight glass

Green

Light green

Yellow

Judgment

Normal

Rather

abnormal

Abnormal

Moisture amount

Refrigerant

temperature 24°C

Refrigerant

temperature 38°C

15 ppm or less

15 ~90 ppm

90 ppm or more

30 ppm or less

30 ~140 ppm

140 ppm or more

Page 21

10.11 Evaporator fan motor

Note: The fan motor is press-fit to the fan.

Replace it as the assembly of the fan.

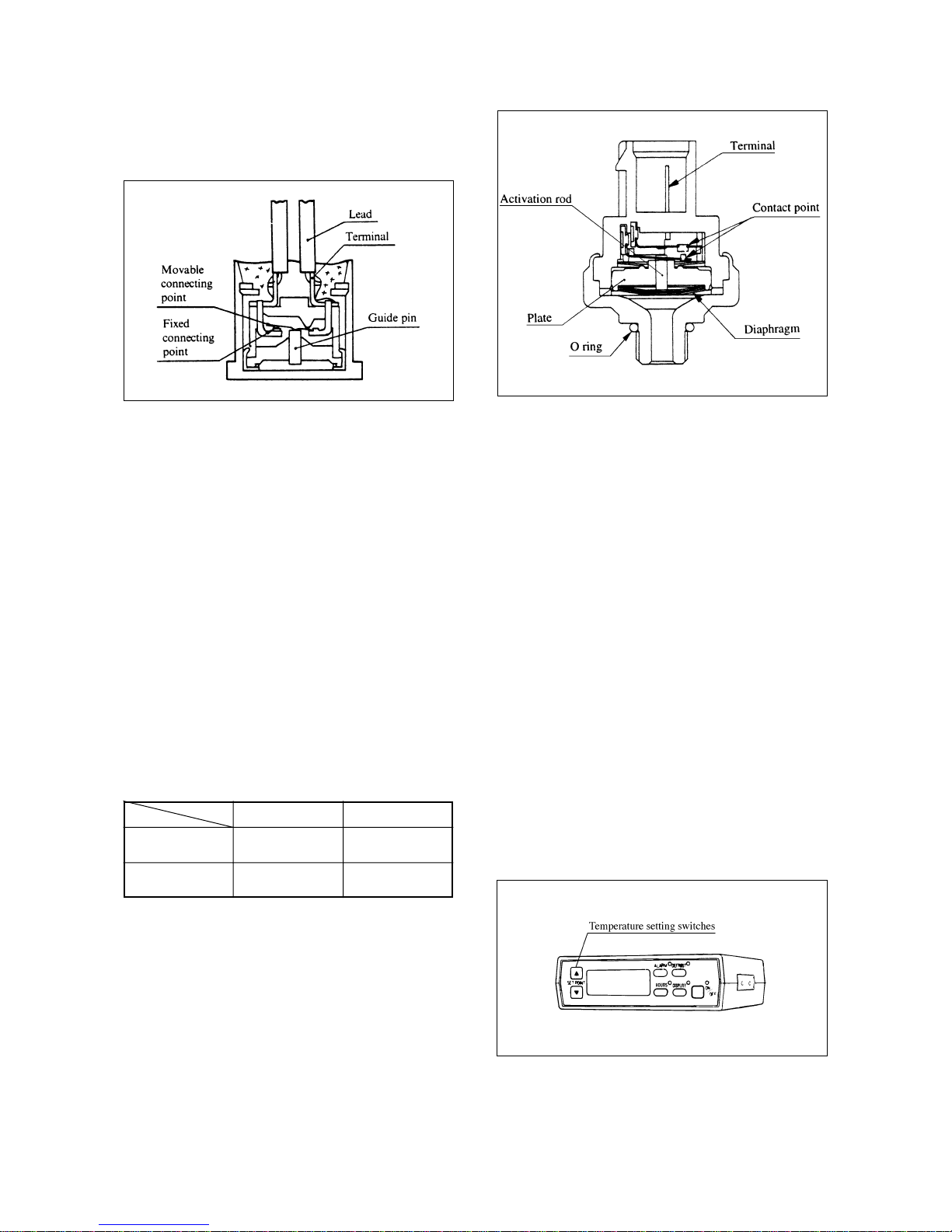

10.12 Multi-function valve

The multi-function valve features the following.

(1) At the abnormally high pressure, the suction

pressure is controlled to allow the unit to operate

without any abnormal stop (high-pressure cutting).

(2) Since the main valve of the multi-function valve is

closed when the unit is stopped, the liquid does not

return. This eliminates a danger of liquid

compression to improve the reliability of the

compressor.

(3) The pressure equalizing hole of the multi-function

valve makes the pressure difference early balanced

soon after the unit is stopped. This will reduce the

starting torque.

Note: (1) Since the multi-function valve was factory-

set at shipment, don't adjust it at the site.

If the adjusting screw is turned, the setting will

become disturbed to cause a poor operation.

(2) When installing the multi-function valve

and connecting the pipe, don't apply any

shock to the multi-function valve.

Otherwise, it will cause gas leakage or

improper operation.

10.13 Expansion valve

The valve detects overheat at the outlet of the

evaporator so that proper amount of refrigerant can

flow into the evaporator, and make an automatic

adjustment.

When adjusting, turn the adjusting screw at a revolution

of 1/4 and then 1/2 little by little, and see how much

heated it is.

– 17 –

Revolution

2000min

-1

Electric current

2.92A or less

Input

70W

Multi-function valve

Evaporator fan motor (Fan assembly)

Expansion valve

Page 22

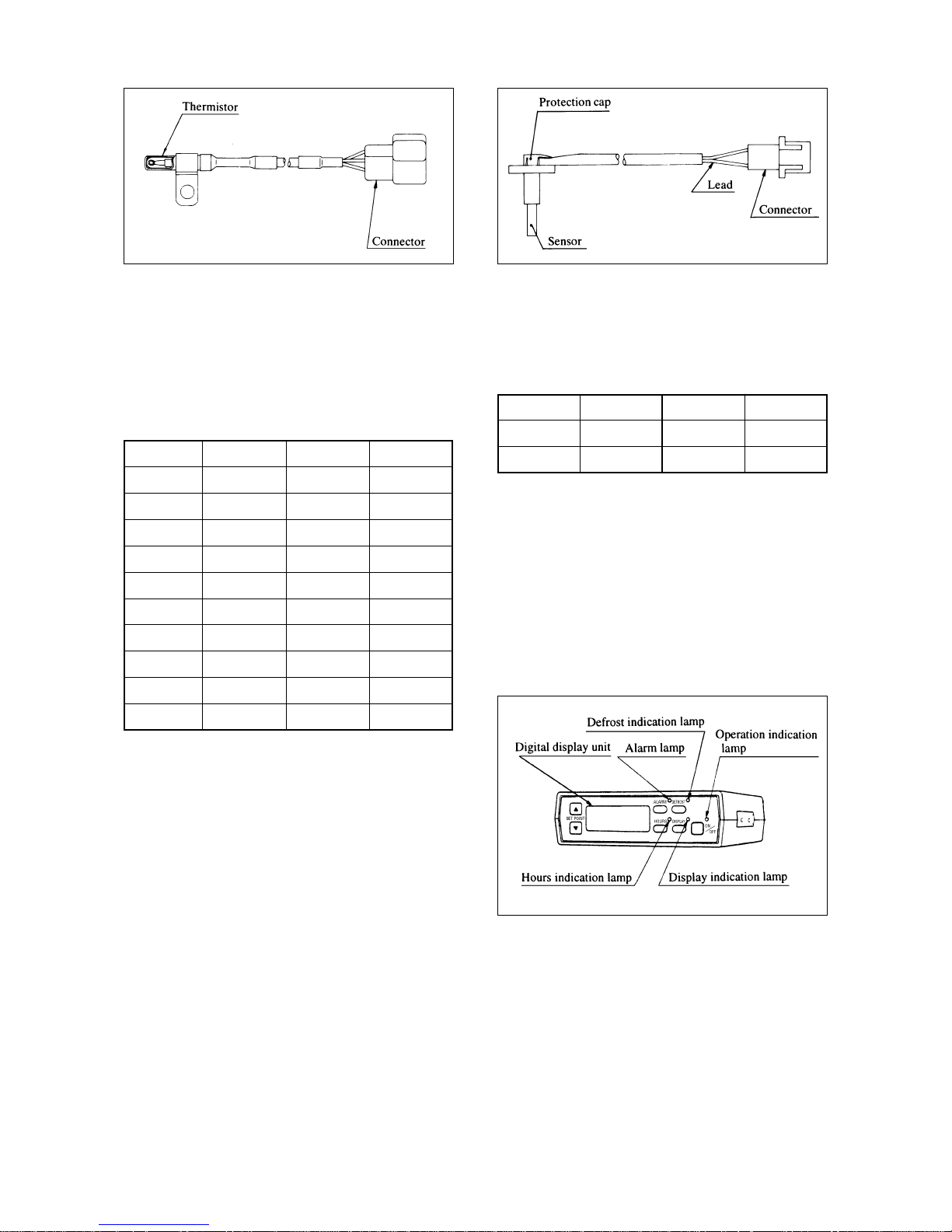

10.14 Defrost thermostat (DTS)

It detects temperature of the evaporator coil and

indicates an end of defrosting.

CUT IN 0 ± 3°C

CUT OUT 8 ± 3°C

Not adjustable

How to determine defective or not defective

Put the defrost thermostat into a household electric

refrigerator and check as you look at a thermometer. It

is normal if there is continuity under 0°C and no

continuity above 8°C.

10.15 Dual pressure switch (DPS)

When the delivery pressure becomes excessively high

or low, it is dangerous. So, the dual pressure switch

(normally close type) is activated to stop the

compressor.

Setting valve MPa (kgf/cm

2

)

CUT OUT CUT IN

2.94 ± 0.2 2.35 ± 0.2

High pressure side

(30 ± 2) (24 ± 2)

0.20 ± 0.02 0.23 ± 0.02

Low pressure side

(2.0 ± 0.2) (2.3 ± 0.2)

Adjustment is impossible.

Judgment whether is proper or not

[High pressure side]

If there is any continuity when the pressure is

2.94MPa (30kgf/cm

2

) or lower during stop and

operation, and there is not when the pressure is

2.94MPa (30kgf/cm

2

) or higher, it is proper.

[Low pressure side]

If there is any continuity when the pressure is

0.20MPa (2.0kgf/cm

2

) or less during stop and

operation, and there is not when the pressure is

0.20MPa (2.0kgf/cm

2

), it is proper.

10.16 Storage temperature sensor (TH)

The sensor detects a storage temperature in order to

keep its temperature to an established temperature,

keeping the magnet clutch or the relay "ON" and

"OFF".

Setting of storage temperature is made by the

temperature setting switches of the controller.

– 18 –

Defrost thermostat

Dual pressure switch

Controller

Page 23

How to determine defective or not defective

(a) Measure continuity by removing the connector at

the edge of temperature detection.

(b) Resistance value at the edge of temperature

detection in normal condition.

(Unit kΩ)

°C Rmin. Rnom. Rmax.

-30 25.293 26.316 27.376

-20 15.125 15.572 16.031

-10 9.342 9.524 9.709

0 5.940 6.000 6.060

10 3.810 3.882 3.995

20 2.505 2.573 2.644

25 2.049 2.113 2.179

30 1.687 1.746 1.808

40 1.163 1.213 1.265

50 0.819 0.860 0.903

(c) If the resistance value is widely out of order,

remove it at the edge of the temperature detection

(with lead) and replace it.

(d) If the above resistance value is normal, check the

controller.

10.17 Td sensor (Td)

It detects delivery temperature of the compressor and

stops the refrigeration unit or opens the liquid injection

electromagnetic valve.

• If the delivery temperature becomes more than 125°C,

opens the liquid injection electromagnetic valve in

order to lower delivery temperature.

• If the delivery temperature becomes more than 135°C,

stops the refrigeration unit.

How to determine defective or not defective:

Measure the resistance value by removing the

connector.

Resistance value in normal condition

200°C 0.430kΩ 100°C 5.228kΩ

175°C 0.738kΩ 25°C 80.470kΩ

115°C 3.352kΩ

10.18 Controller

A new controller with a character display function has

been adopted, which enables to set digitally a desired

storage temperature accurately. In addition to it, preoperation inspection for the refrigeration unit can be

made by a simple button operation and a diagnosis at

the time of the unit being defective can also be made

easily.

Display function

• Operation indication lamp

• Defrost indication lamp

• Alarm lamp

• Hours indication lamp

• Display indication lamp

– 19 –

Storage temperature sensor Td sensor

Controller

Page 24

• Inside-container temperature

• Fault display

• Inside-container preset temperature

• Operation times

• Defrost timer

Remarks: As to abnormal indication, refer to page 47.

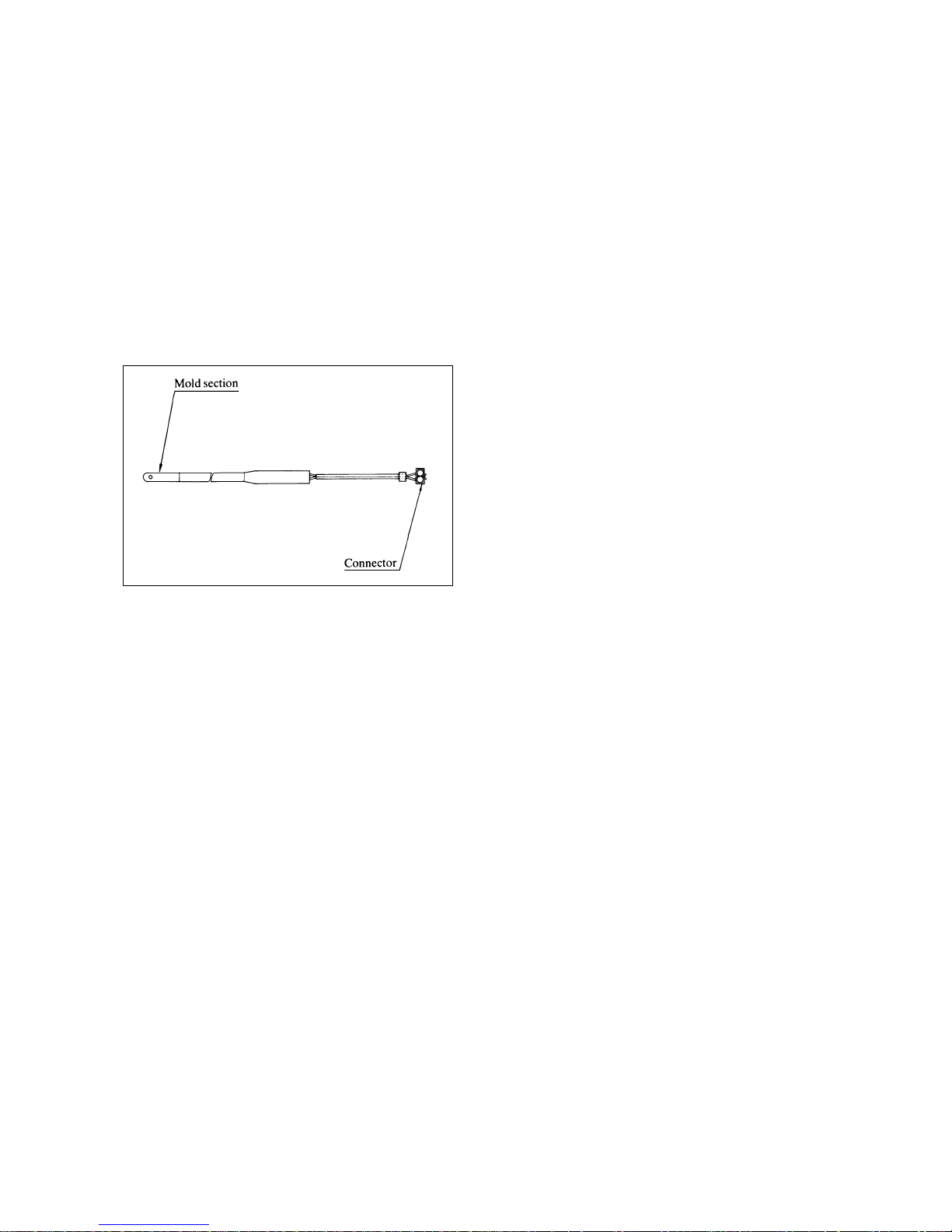

10.19 Drain hose heater (option)

It is electrified when the defrost thermostat is "ON" and

prevent the drain hose from being frozen.

Capacity 6W

– 20 –

Displayed on

the digital

display unit.

Drain hose heater

Page 25

11. Electric wiring diagram

11.1 Sequence diagram

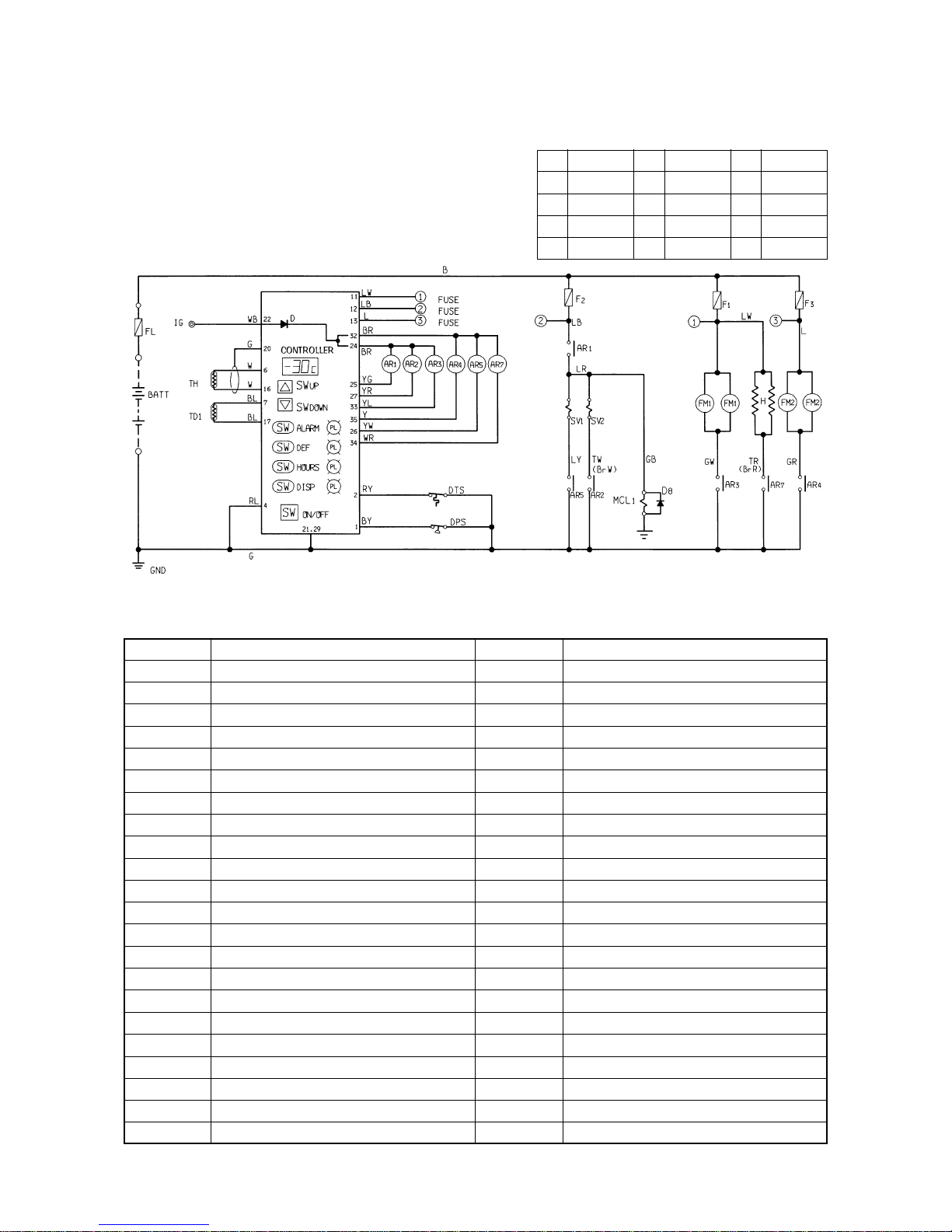

(1) TDJ300D-1L2, TDJ430D-1L2

Remarks: Three FM

1

(evaporator fan motor) are provided on TDJ430D.

– 21 –

Explanation of mark

SYMBOL

SW

UP

SW

DOWN

SW

ALARM

SW

DEF

SW

HOURS

SW

ON/OFF

SW

DISP

PL

ALARM

PL

DEF

PL

HOURS

PL

DISP

TH

DPS

TD

1

DTS

FL

BA TT

IG

NAME

Temperature setting switch (up)

Temperature setting switch (down)

Alarm switch

Defrost switch

Hours switch

Operation switch

Display switch

Alarm lamp

Defrost indication lamp

Hours indication lamp

Display indication lamp

Storage temperature sensor

Dual pressure switch

Td sensor (engine side)

Defrost thermostat

Fusible link

Battery

Ignition terminal

SYMBOL

AR

1

AR

2

AR

3

AR

4

AR

5

AR

7

F

1

F

2

F

3

FM

1

FM

2

H

MCL

1

SV

1

SV

2

NAME

Thermostat relay

Liquid injection electromagnetic relay

Evaporator fan motor relay

Condenser fan motor relay

Defrost electromagnetic valve relay

Drain hose heater relay

Fuse (*1: 15A, *2: 25A)

Fuse (10A)

Fuse (15A)

Evaporator fan motor

Condenser fan motor

Drain hose heater (option)

Magnet clutch (engine side)

Defrost electromagnetic valve

Liquid injection electromagnetic valve

*1: TDJ300D

*2: TDJ430D

Code Wire color Code Wire color Code Wire color

B Black Y Yellow P Pink

W White L Blue V Violet

R Red Br Brown Gy Gray

G Green O Orange Lg Light green

Wire color codes

wire colors are identified by the following color codes.

Page 26

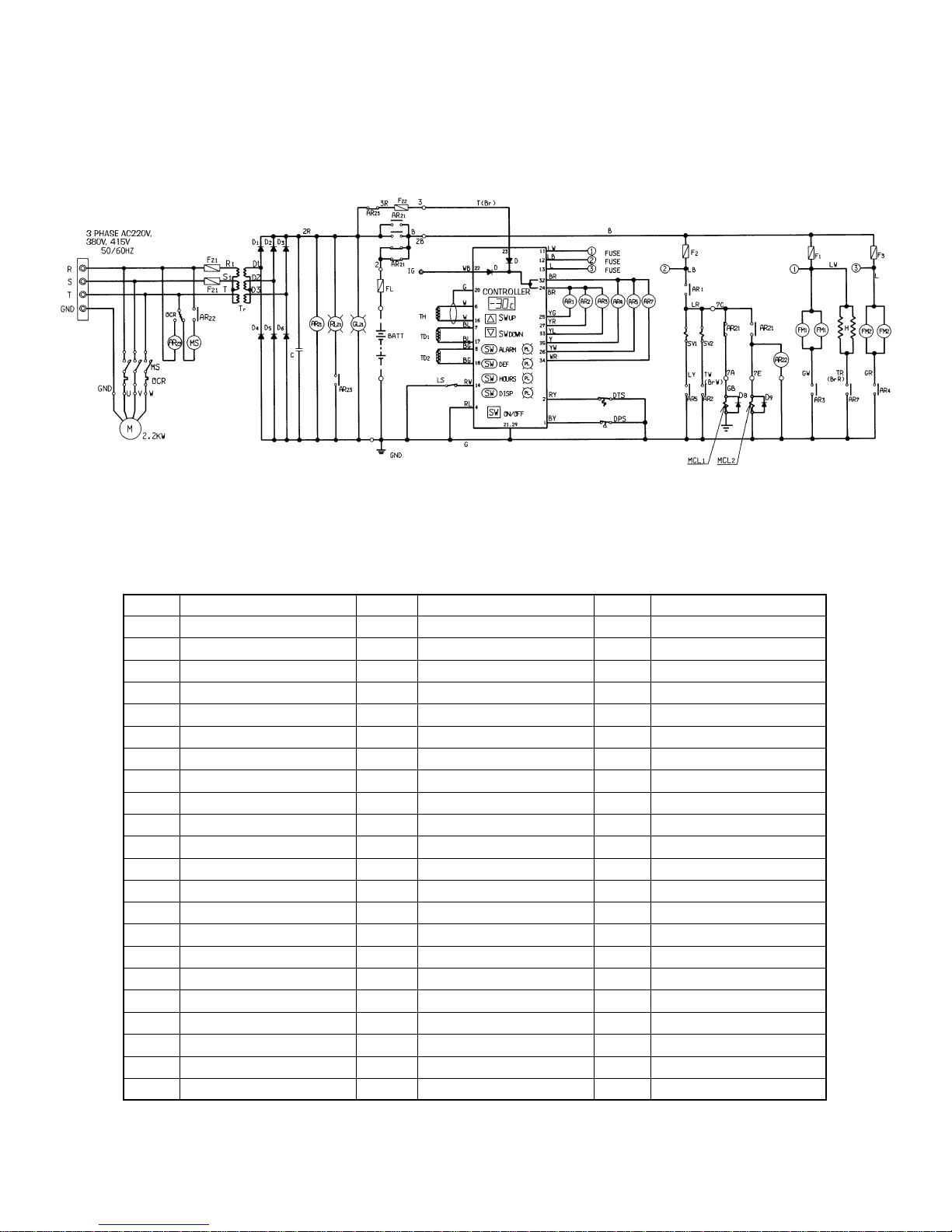

(2) TDJ300D-2L2

– 22 –

Explanation of mark

SYMBOL

SW

UP

SW

DOWN

SW

ALARM

SW

DEF

SW

HOURS

SW

ON/OFF

SW

DISP

PL

ALARM

PL

DEF

PL

HOURS

PL

DISP

TH

DPS

TD

1

TD

2

FL

BA TT

IG

SYMBOL

GL

21

RL

21

F

21

F

22

AR

21

AR

22

AR

23

LS

MS

T

r

D

1, 2, 3

D

4, 5, 6

D

8, 9

C

M

NAME

Temperature setting switch (up)

Temperature setting switch (down)

Alarm switch

Defrost switch

Hours switch

Operation switch

Display switch

Alarm lamp

Defrost indication lamp

Hours indication lamp

Display indication lamp

Storage temperature sensor

Dual pressure switch

Td sensor (engine side)

Td sensor (motor side)

Fusible link

Battery

Ignition terminal

NAME

AC power indication lamp

OCR operation indication lamp

Fuse (3A)

Fuse (5A)

AC-DC transfer relay

Actuator relay

OCR relay

Limit switch (plug cap)

Electromagnetic switch (with OCR)

Transformer

Diode

Diode

Diode

Condenser

Motor

SYMBOL

AR

1

AR

2

AR

3

AR

4

AR

5

AR

7

F

1

F

2

F

3

FM

1

FM

2

H

MCL

1

MCL

2

SV

1

SV

2

NAME

Thermostat relay

Liquid injection electromagnetic relay

Evaporator fan motor relay

Condenser fan motor relay

Defrost electromagnetic valve relay

Drain hose heater relay

Fuse (15A)

Fuse (10A)

Fuse (15A)

Evaporator fan motor

Condenser fan motor

Drain hose heater (option)

Magnet clutch (engine side)

Magnet clutch (motor side)

Defrost electromagnetic valve

Liquid injection electromagnetic valve

Page 27

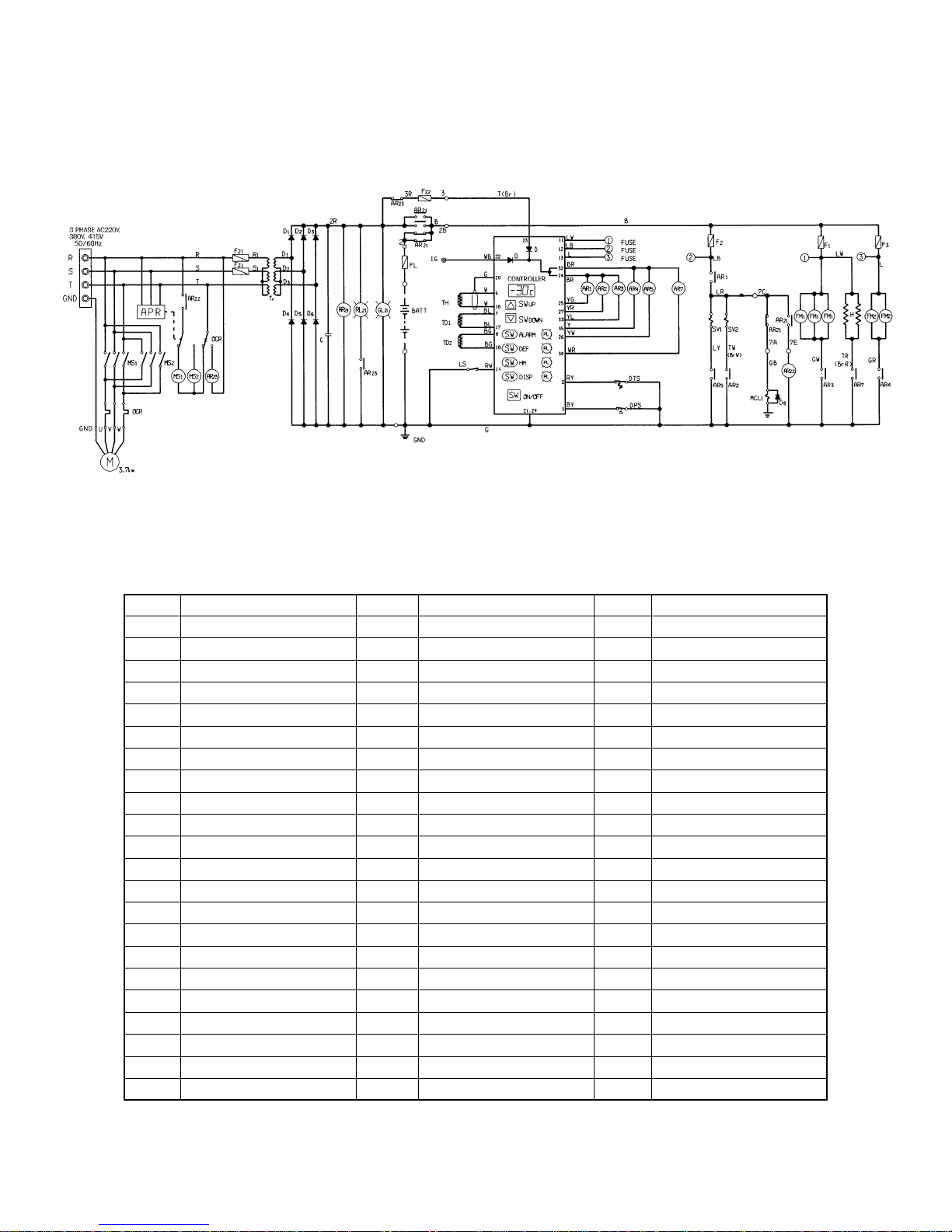

(3) TDJ430D-2L2

– 23 –

Explanation of mark

SYMBOL

SW

UP

SW

DOWN

SW

ALARM

SW

DEF

SW

HOURS

SW

ON/OFF

SW

DISP

PL

ALARM

PL

DEF

PL

HOURS

PL

DISP

TH

DPS

TD

1

TD

2

DTS

FL

BA TT

IG

SYMBOL

GL

21

RL

21

F

21

F

22

AR

21

AR

22

AR

23

LS

MS

T

r

D

1, 2, 3

D

4, 5, 6

D

8

C

APR

M

NAME

Temperature setting switch (up)

Temperature setting switch (down)

Alarm switch

Defrost switch

Hours switch

Operation switch

Display switch

Alarm lamp

Defrost indication lamp

Hours indication lamp

Display indication lamp

Storage temperature sensor

Dual pressure switch

Td sensor (engine side)

Td sensor (motor side)

Defrost thermostat

Fusible link

Battery

Ignition terminal

NAME

AC power indication lamp

OCR operation indiction lamp

Fuse (3A)

Fuse (5A)

AC-DC transfer relay

Actuator relay

OCR relay

Limit switch (plug cap)

Electromagnetic switch (with OCR)

Transformer

Diode

Diode

Diode

Condenser

Antiphase detection relay

Motor

SYMBOL

AR

1

AR

2

AR

3

AR

4

AR

5

AR

7

F

1

F

2

F

3

FM

1

FM

2

H

MCL

1

SV

1

SV

2

NAME

Thermostat relay

Liquid injection electromagnetic relay

Evaporator fan motor relay

Condenser fan motor relay

Defrost electromagnetic valve relay

Drain hose heater relay

Fuse (25A)

Fuse (10A)

Fuse (15A)

Evaporator fan motor

Condenser fan motor

Drain hose heater (option)

Magnet clutch (engine side)

Defrost electromagnetic valve

Liquid injection electromagnetic valve

Page 28

11.3 Explanation of operation (Explanation is made for TDJ300D-2L2)

(1) In case of engine drive

1. Start the engine of a vehicle to be run.

2. Turn the operation switch to "ON".

• Operation indication lamp will light. (green)

• AR

3

(Evaporator fan motor relay) is energized, and FM1(evaporator fan motor) is electrified and then the

evaporator fan turns.

3. When storage temperature is more than the established temperature (the thermostat is "ON").

• AR

1

(thermostat relay) is energized, and MCL1(magnet clutch on engine side) is electrified and then the

condenser fan turns.

• AR

4

(Condenser fan motor relay) is energized, and FM2(condenser fan motor) is electrified and then the

condenser fan turns.

4. When storage temperature is less than 0°C, DTS (defrost thermostat) is "ON".

• The defrost timer starts adding up time.

• AR

7

(drain hose heater relay) is energized and H (drain hose heater) (option) is electrified.

The above procedures make a cooling operation.

Remarks: If the delivery temperature becomes more than 125°C, AR

2

(Liquid injection relay) is energized and

SV

2

(Liquid injection electromagnetic valve) is electrified.

[Less than 120°C ······ non-energized]

– 28 –

A Cooling operation

Page 29

1. In case a storage temperature drops (thermostat "OFF") to an established temperature

• AR

1

(thermostat relay) is dropped out, and MCL1(magnet clutch) is disconnected and then the compressor stops.

• AR4(condenser fan motor relay) is dropped out, and FM2(condenser fan motor) is disconnected and then the

condenser fan stops.

Remarks: The followings are operating even when the unit has stopped with thermostat "OFF".

(1) The evaporator fan is rotating.

(2) In case the storage temperature is less than 0°C (DTS is "ON".):

• Drain hose heater is electrified.

• Defrost timer adds up time.

(3) Operation indication lamp (green) is on.

2. In case the storage temperature has become more than the established temperature (thermostat "ON")

• AR

1

(thermostat relay) is energized, and MCL1(magnet clutch) is electrified and then compressor turns.

• AR4(condenser fan motor relay) is energized, FM2(condenser fan motor) is electrified and then condenser fan

turns.

Storage temperature will be kept at a fixed temperature by repeating the abov e procedure.

– 29 –

B Operation of ON-OFF by thermostat during cooling operation.

Remarks: The following shows a diagram

being stopped by thermostat.

Page 30

1. When defrost switch has been turned on or defrost timer is operating (the timer is built into the controller and is set

in 3 hours for shipment from factory)

• Defrost indication lamp lights. (orange)

• AR

3

(evaporator fan motor relay) is dropped out, and FM1(evaporator fan motor) is disconnected and then

evaporator fan motor stops.

• AR

4

(condenser fan motor relay) is dropped out, FM2(condenser fan motor) is disconnected and then condenser

fan stops.

• AR

5

(defrost electromagnetic relay) is energized, and SV1(defrost electromagnetic valve) is electrified and open.

Defrost operation will start after going through the above procedure.

Remarks: Even if the unit is stopped by thermostat operation, defrost timer will operate or if defrost switch is turned

on, it performers defrost operation.

2. When frost is melted and evaporator coil temperature rises, DTS (defrost thermostat, "ON": 0°C "OFF": 8°C) turns off.

• Defrost indication lamp (orange) turns off.

• AR

3

(evaporator fan motor relay) is energized, and FM1(evaporator fan motor) is electrified and ev aporator f an turns.

• AR

4

(condenser fan motor relay) is energized, and FM2(condenser fan motor) is electrified and condenser fan turns.

• AR5(defrost electromagnetic relay) is dropped out, SV1(defrost electromagnetic valve) is disconnected and closed.

• AR

7

(drain hose heater relay) is dropped out and H (drain hose heater) is disconnected. (It will be electrified

when storage temperature drops and DTS becomes "ON".)

• Defrost timer becomes "OFF". (When storage temperature drops and DTS becomes "ON", it starts adding up time.)

Cooling operation will start after going through the above procedures.

– 30 –

C Defrost operation

Page 31

– 31 –

1. DPS (Dual pressure switch) operates ···· The unit

stops.

High pressure side

OFF : 2.94MPa (30.0kgf/cm

2

)

ON : 2.35MPa (24.0kgf/cm

2

)

Low pressure side

OFF : 0.20MPa (2.0kgf/cm

2

)

ON : 0.23MPa (2.3kgf/cm

2

)

• The alarm lamp lights (red).

• All relays are dropped out.

2. F

1

(fuse) is blown ···· The unit stops.

• The alarm lamp lights (red).

• All relays are dropped out.

3. F

2

(fuse) is blown ···· The unit stops.

• The alarm lamp lights (red).

• All relays are dropped out.

4. F

3

(fuse) is blown ···· The unit stops.

• The alarm lamp lights (red).

• All relays are dropped out.

5. FL (fusible link) is blown ···· The unit stops.

6. TD (Td sensor) operates ···· The unit stops.

("OFF" at compressor delivery temperature 135°C

and "ON" at 125°C)

• The alarm lamp lights (red).

• AR

1

(thermostat relay) is de-energized, MCL

1

(magnet clutch) is disconnected, and the

compressor stops.

• AR

4

(condenser fan motor relay) is de-

energized, FM

2

(condenser fan motor) is

disconnected, and the condenser fan motor

stops.

Remarks: (1) When alarm lamp lights, the defects

will be shown on the display when

alarm lamp is lit, press the alarm

switch, and the defects will be

shown on the display.

DPS operates ························

F

1

is blown ····························

F

2

is blown ····························

F

3

is blown ····························

TD operates ··························

Storage temperature sensor defect

·········································

(2) When pressure and temperature

drops, DPS and TD automatically

operate again.

(The light goes out if the operation

switch is turned "OFF".)

D Operation of protection device

Page 32

(2) In case of motor drive

Remarks: As the operation of the thermostat and defrost is the same with that of engine drive, refer to page 29 and 30.

1. Turn on the power.

• GL

21

(AC power indication lamp) lights.

• AR

21

(AC-DC transfer relay) is energized.

(automatic switch-over from engine drive to motor derive.)

2. Turn on the operation switch.

• Operation indication lamp lights (green).

• AR

3

(evaporator fan motor relay) is energized, and FM1(evaporator fan motor) is electrified and evaporator fan

turns.

3. When storage temperature is more than an established temperature (thermostat is "ON"):

• If AR

1

(thermostat relay) is energized:

When AR

22

(actuator relay) is energized, MS (electromagnetic switch) is energized, which electrifies M (motor)

and the motor turns.

• AR

4

(condenser fan motor relay) is energized, and FM2(condenser fan motor) is electrified and condenser fan

turns.

4. When storage temperature is less than 0°C, DTS (defrost thermostat) is "ON".

• Defrost timer starts adding up time.

• AR

7

(drain hose heater relay) is energized and H (drain hose heater) (option) is electrified.

Cooling operation will start after going through the above procedures.

Remarks: If the delivery temperature becomes more than 125°C, AR2(Liquid injection relay) is energized and SV

2

(Liquid injection electromagnetic valve) is electrified.

[Less than 120°C ······ non-energized]

– 32 –

A Cooling operation

Page 33

1. OCR (Overcurrent relay) operates ···· The unit stops.

• MS (electromagnetic switch) is dropped out, M (motor) is disconnected and the motor stops.

• AR

23

(OCR relay) is energized and RL21(OCR operation indication lamp) lights.

• All relays drop out because power source to the controller is OFF. For re-start, push OCR manual reset button.

Remarks: As for the procedures except for the above, refer to page 31 as they are the same with those of engine

drive.

– 33 –

B Operation of protection device

Page 34

12. Periodic inspection

Perform the periodic inspection for the items required

on the following period.

Write down necessary matters to the check sheet on

page 40.

1. Inspection at the time of installation and test run

2. Monthly inspection

3. Six-month inspection

12.1

Inspection at the time of installation and test run

(1) Check seals of refrigeration unit at the sections

passing through a van wall.

Check if the sealant is processed for sure and no

air goes in.

(2) Check the tubing clamp for adequacy.

Make sure tubing does not vibrate during driving.

(3) Check the drain hose for connection and drainage

and the clamp for adequacy.

(4) Check the belt for tension, degree of parallel

(stick-out of interline) and scratches.

Hold center of the belt and adjust its bending up to

about 7 ~ 10mm.

(5) Check if the belt is touching another parts such as

compressor, pulley, belt, tubing and wiring.

Especially check if abnormal sound is heard from

moving parts.

(6) Check if the mounting bolt is tightened more, if

the refrigeration unit, compressor, compressor

head, magnet clutch, tension pulley, bracket, fan

motor and fan are properly installed, if the unit is

deformed or if truck has scraches on the body.

(7) Check for wrong electrical wiring, clamp, loose

terminal.

(8) Check the service valve is opened of refrigerant

system.

(9) Check refrigerant system, oil and gas leakage,

connection part of tubing and installation of

functional parts.

(10) Abnormal sound and vibration

Check the compressor, magnet clutch, motor, fan

and tubing for abnormal sound and vibration.

(11) Inspection of sight glass

Color of the sight glass is to be green and the glass

has to have no excessive bubbles.

(12) Check starting and stopping of compressor,

magnet clutch and fan by thermostat.

(13) Cooling operation

Check display for temperature indication and

dropping of temperature.

(14) Check defrost for operation.

Check it by turning on manual defrost switch.

(15) Check DPS (Dual pressure switch) for operation.

CUT OUT (high): 2.94MPa (30kgf/cm

2

)

(low): 0.20MPa (2.0kgf/cm

2

)

(16) Check power source wiring (ground wire,

insulation resistance) (Type 2 only)

Note:

Insulation resistance measurement method (AC 3phase circuit only)

Short-circuit the power source terminal (R.S.T or

power source plug pin) and measure the insulation

resistance between the short-circuited section and

the grounded section by an insulation resistance

tester.

(17) Check the motor drive for operation. (Type 2 only)

(18) Check the buzzer for buzzing. (Type 2 only)

(19) Check the instruction manual.

12.2 Daily inspection

Refer to page 36 except the following items.

(1) Implement the checking items about the engine to

be run.

(2) Confirm that there are no abnormal sound and

vibration.

(3) Check if anything is touching the movable places.

(4) Check the compressor belt for tension, wear and

abnormal sound.

(5) Check if the condenser fan and evaporator fan are

turning.

(6) Check if the temperature indication of the display

is proper.

(7) Check commercial power driving equipment

(motor drive)

• Check the power source cord for damage.

Check if the power box cover is firmly fixed.

Check to see no water is in the plug receptacle.

• Check to see the motor is running and if

abnormal sound is heard during operation.

– 34 –

Page 35

(8) During transportation, look at the display from

time to time to see if it keeps and established

storage temperature.

12.3 Monthly inspection

(1) Check the belt for looseness, degree of parallel

(stick-out of interline) and scraches. (bending of

the belt is to be about 7mm ~ 10mm.)

(2) Check if anything is touching to another part.

(compressor, pulley, belt, tubing and wiring)

(3) Clean carefully the refrigeration unit and drain

pipe with soft brush.

The fins will be deformed or damaged if a hard

brush is used.

Note:

(a) Never make a high pressure washing with a

high pressure washing machine as it crushes

its fin.

(b) Never make a steam washing as it raises its

inside pressure unusually high and is

dangerous.

(4) Check the refrigerant sight glass for color and

degree of flash.

Green = Normal

Yellow = Abnormal (water in it)

Lots of bubbles = Insufficient refrigerant

(Replacement of dryer and refrigerant is needed if

water is in it)

(5) Check refrigeration. (Check temperature indication

on the display and high and low pressure power.)

As to high and low pressure power, refer to page

41.

(6) Implement the matters to be taken care of at the

time of periodic inspection as shown on page 38.

12.4 Six-mouth inspection

(1) Implement the checking items required at the time

of installation-test operation and monthly

checking. (excluding a check for mis-wiring)

(2) Check the relay for contact point.

Correct defective contact point due to short circuit.

(3) Carry out the warning items at the time of periodic

inspection listed on page 38.

12.5 Bolt tightening table for each section

(1) Standard tightening torques for flare nuts.

Tightening torque N·m(kgf·cm)

9.8 ~ 19.6 (100 ~ 200)

19.6 ~ 29.4 (200 ~ 300)

29.4 ~ 39.2 (300 ~ 400)

39.2 ~ 49.0 (400 ~ 500)

49.0 ~ 58.8 (500 ~ 600)

(2) Tightening torques of general N·m (kgf·cm)

SS41C S45C SUS304

No mark or 4 or 7 No mark

0.6 ~ 1.0 1.0 ~ 1.5 0.8 ~ 1.0

M3

(6 ~ 10) (10 ~ 15) (8 ~ 10)

1.0 ~ 1.5 2.0 ~ 3.0 2.0 ~ 2.5

M4

(10 ~ 15) (20 ~ 30) (20 ~ 25)

2.0 ~ 2.5 4.0 ~ 5.0 3.4 ~ 4.4

M5

(20 ~ 25) (40 ~ 50) (35 ~ 45)

3.5 ~ 4.4 6.9 ~ 8.3 6.4 ~ 7.8

M6

(36 ~ 45) (70 ~ 85) (65 ~ 80)

8.4 ~ 9.8 17.7 ~ 19.6 16.7 ~ 19.6

M8

(86 ~ 100) (180 ~ 200) (170 ~ 200)

17.0 ~ 19.6 35.3 ~ 40.2 33.3 ~ 38.2

M10

(173 ~ 200) (360 ~ 410) (340 ~ 390)

29.4 ~ 33.3 59.8 ~ 69.6 56.9 ~ 65.7

M12

(300 ~ 340) (610 ~ 710) (580 ~ 670)

47.1 ~ 53.0 96.1 ~ 107.9 91.2 ~ 104.9

M14

(480 ~ 540) (980 ~ 1100) (930 ~ 1070)

73.5 ~ 84.3 156.9 ~ 176.5 142.2 ~ 165.7

M16

(750 ~ 860) (1600 ~ 1800) (1450 ~ 1690)

– 35 –

Applicable

copper pipe

ø 6.35

ø 9.52

ø 12.7

ø 15.88

ø 19.05

Material

Head

mark

Thread

diameter

v

Page 36

12.6 Caution to be taken at the time daily inspection

Instruct users to comply with the following items.

– 36 –

No. Item Contents Care to be taken at the time of operation Anticipated defect Disposition (remarks)

1

2

3

4

5

6

Check for gas

leakage

Washing of

condenser coil

Painting of the

body

Caution to be

taken when not

using for long

Caution to be

taken when the

refrigeration

unit is not

used.

Caution to be

taken when a

refrigerator

truck is used

instead of a

refrigerator.

• Perform this as a daily

inspection as the amount

of refrigerant and water

in the refrigeration can

be checked by sight

glass.

• Prevention of dropping of

heat exchange due to

stain of coil

• Disposition for peeling of

paint on the metal section

of the units which have

been used for long and

for occurrence of rust.

• When not using for long,

decrease the refrigerant

staying in the compressor

and prevent the shaft seal

from running out of oil.

• Do not remove the

compressor belt.

• Preparatory refrigeration,

keeping load in

refrigeration, in case of

using an power-driven

equipment sold at a

market for long instead