Mitsubishi SUZ-KA50, SUZ-KA35, SUZ-KA60, SUZ-KA71VA2, SUZ-KA35VAH Installation Instructions Manual

...Page 1

Air-Conditioners

SUZ-KA25, KA35, KA50, KA60, KA71VA2

SUZ-KA25, KA35VAH

INSTALLATION MANUAL

For safe and correct use, read this manual and the indoor unit installation manual thoroughly before installing

the air-conditioner unit.

INSTALLATIONSHANDBUCH

Aus Sicherheitsgründen und zur richtigen Verwendung vor der Installation die vorliegende Bedienungsanleitung

und die Installationsanleitung der Innenanlage gründlich durchlesen die Klimaanlage.

MANUEL D’INSTALLATION

Avant d’installer le climatiseur, lire attentivement ce manuel, ainsi que le manuel d’installation de l’appareil

intérieur pour une utilisation sûre et correcte.

INSTALLATIEHANDLEIDING

Lees deze handleiding en de installatiehandleiding van het binnenapparaat zorgvuldig door voordat u met het

installeren van de airconditioner begint.

MANUAL DE INSTALACIÓN

Para un uso correcto y seguro, lea detalladamente este manual y el manual de instalación de la unidad interior

antes de instalar la unidad de aire acondicionado.

MANUALE DI INSTALLAZIONE

Per un uso sicuro e corretto, leggere attentamente il presente manuale ed il manuale d’installazione dell’unità

interna prima di installare il condizionatore d’aria.

EΓΧEIPIΔIO OΔHΓIΩN EΓKATAΣTAΣHΣ

Για σωστή και ασφαλή χρήση, διαβάστε προσεκτικά αυτό το εγχειρίδιο καθώς και το εγχειρίδιο εγκατάστασης

της εσωτερικής μονάδας, προτού εγκαταστήσετε τη μονάδα του κλιματιστικού.

MANUAL DE INSTALAÇÃO

Para uma utilização segura e correcta, leia atentamente este manual e o manual de instalação da unidade

interior antes de instalar o aparelho de ar condicionado.

INSTALLATIONSMANUAL

Læs af sikkerhedshensyn denne manual samt manualen til installation af indendørsenheden grundigt, før du

installerer klimaanlægget.

INSTALLATIONSMANUAL

Läs bruksanvisningen och inomhusenhetens installationshandbok noga innan luftkonditioneringen installeras

så att den används på ett säkert och korrekt sätt.

MONTAJ ELKİTABI

Emniyetli ve doğru kullanım için, klima cihazını monte etmeden önce bu kılavuzu ve iç ünite montaj kılavuzunu

tamamıyla okuyun.

РУКОВОДСТВО ПО УСТАНОВКЕ

Для обеспечения безопасной и надлежащей эксплуатации внимательно прочтите данное руководство

и руководство по установке внутреннего прибора перед установкой кондиционера.

FOR INSTALLER

FÜR INSTALLATEURE

POUR L’INSTALLATEUR

VOOR DE INSTALLATEUR

PARA EL INSTALADOR

PER L’INSTALLATORE

ΓΙΑ ΑΥΤΟΝ ΠΟΥ ΚΑΝΕΙ ΤΗΝ ΕΓΚΑΤΑΣΤΑΣΗ

PARA O INSTALADOR

TIL INSTALLATØREN

FÖR INSTALLATÖREN

MONTÖR İÇİN

ДЛЯ УСТАНОВИТЕЛЯ

English

Deutsch

Français

Nederlands

Español

Italiano

Eλληνικά

Português

Dansk

Svenska

Türkçe

Русский

Page 2

Contents

1. The following should always be observed for safety . . . . . . . . . . . . . . . . . . . . 2

2. Selecting the installation location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3. Installation diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4. Drain piping for outdoor unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

5. Refrigerant piping work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

6. Electrical work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

7. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1. The following should always be observed for safety

• Please provide an exclusive circuit for the air conditioner and do not connect other electrical appliances to it.

• Be sure to read “The following should always be observed for safety” before installing the air conditioner.

• Be sure to observe the cautions specifi ed here as they include important

items related to safety.

The indications and meanings are as follows.

•

Warning:

Could lead to death, serious injury, etc.

Caution:

Could lead to serious injury in particular environments when operated incorrectly.

Warning:

• Do not install it by yourself (customer).

Incomplete installation could cause injury due to fi re, electric shock, the

unit falling or leakage of water. Consult the dealer from whom you purchased the unit or special installer.

• Install the unit securely in a place which can bear the weight of the unit.

When installed in an insuffi cient strong place, the unit could fall causing

injured.

• Use the specifi ed wires to connect the indoor and outdoor units securely

and attach the wires fi rmly to the terminal board connecting sections so

the stress of the wires is not applied to the sections.

Incomplete connecting and fi xing could cause fi re.

• Do not use intermediate connection of the power cord or the extension

cord and do not connect many devices to one AC outlet.

It could cause a fi re or an electric shock due to defective contact, defective

insulation, exceeding the permissible current, etc.

Check that the refrigerant gas does not leak after installation has completed.

•

• Perform the installation securely referring to the installation manual.

Incomplete installation could cause a personal injury due to fi re, electric

shock, the unit falling or leakage of water.

• After reading this manual, be sure to keep it together with the instruction

manual in a handy place on the customer’s site.

: Indicates a part which must be grounded.

Warning:

Carefully read the labels affi xed to the main unit.

• Perform electrical work according to the installation manual and be sure to

use an exclusive circuit.

If the capacity of the power circuit is insufficient or there is incomplete

electrical work, it could result in a fi re or an electric shock.

• Attach the electrical part cover to the indoor unit and the service panel to

the outdoor unit securely.

If the electrical part cover in the indoor unit and/or the service panel in the

outdoor unit are not attached securely, it could result in a fi re or an electric

shock due to dust, water, etc.

• Be sure to use the part provided or specified parts for the installation

work.

The use of defective parts could cause an injury or leakage of water due to

a fi re, an electric shock, the unit falling, etc.

• Ventilate the room if refrigerant leaks during operation.

If the refrigerant comes in contact with a fl ame, poisonous gases will be

released.

When pumping down the refrigerant, stop the compressor before discon-

•

necting the refrigerant pipes. The compressor may burst if air etc. get into it.

Caution:

• Perform grounding.

Do not connect the ground wire to a gas pipe, water pipe arrester or telephone ground wire. Defective grounding could cause an electric shock.

• Do not install the unit in a place where an infl ammable gas leaks.

If gas leaks and accumulates in the area surrounding the unit, it could

cause an explosion.

• Install a ground leakage breaker depending on the installation place (where

it is humid).

If a ground leakage breaker is not installed, it could cause an electric

shock.

2. Selecting the installation location

2.1. Outdoor unit

• Where it is not exposed to strong wind.

• Where airfl ow is good and dustless.

• Where it is not exposed to rain and direct sunshine.

• Where neighbours are not annoyed by operation sound or hot air.

• Where rigid wall or support is available to prevent the increase of operation

sound or vibration.

• Where there is no risk of combustible gas leakage.

• When installing the unit at a high level, be sure to fi x the unit legs.

• Where it is at least 3 m away from the antenna of TV set or radio. (Otherwise,

images would be disturbed or noise would be generated.)

• Please install it in an area not affected by snowfall or blowing snow. In areas

with heavy snow, please install a canopy, a pedestal and/or some baffl e boards.

• Install the unit horizontally.

• Perform the drainage/piping work securely according to the installation

manual.

If there is a defect in the drainage/piping work, water could drop from the

unit and household goods could be wet and damaged.

• Fasten a fl are nut with a torque wrench as specifi ed in this manual.

When fastened too tight, a fl are nut may broken after a long period and

cause a leakage of refrigerant.

Caution:

Avoid the following places for installation where air conditioner trouble is liable to occur.

• Where there is too much machine oil.

• Salty environment as seaside areas.

• Hot-spring areas.

• Where sulfi de gas exists.

• Other special atmospheric areas.

The outdoor unit produces condensate during the heating operation. Select the installation place to ensure to prevent the outdoor unit and/or the

grounds from being wet by drain water or damaged by frozen drain water.

2

Page 3

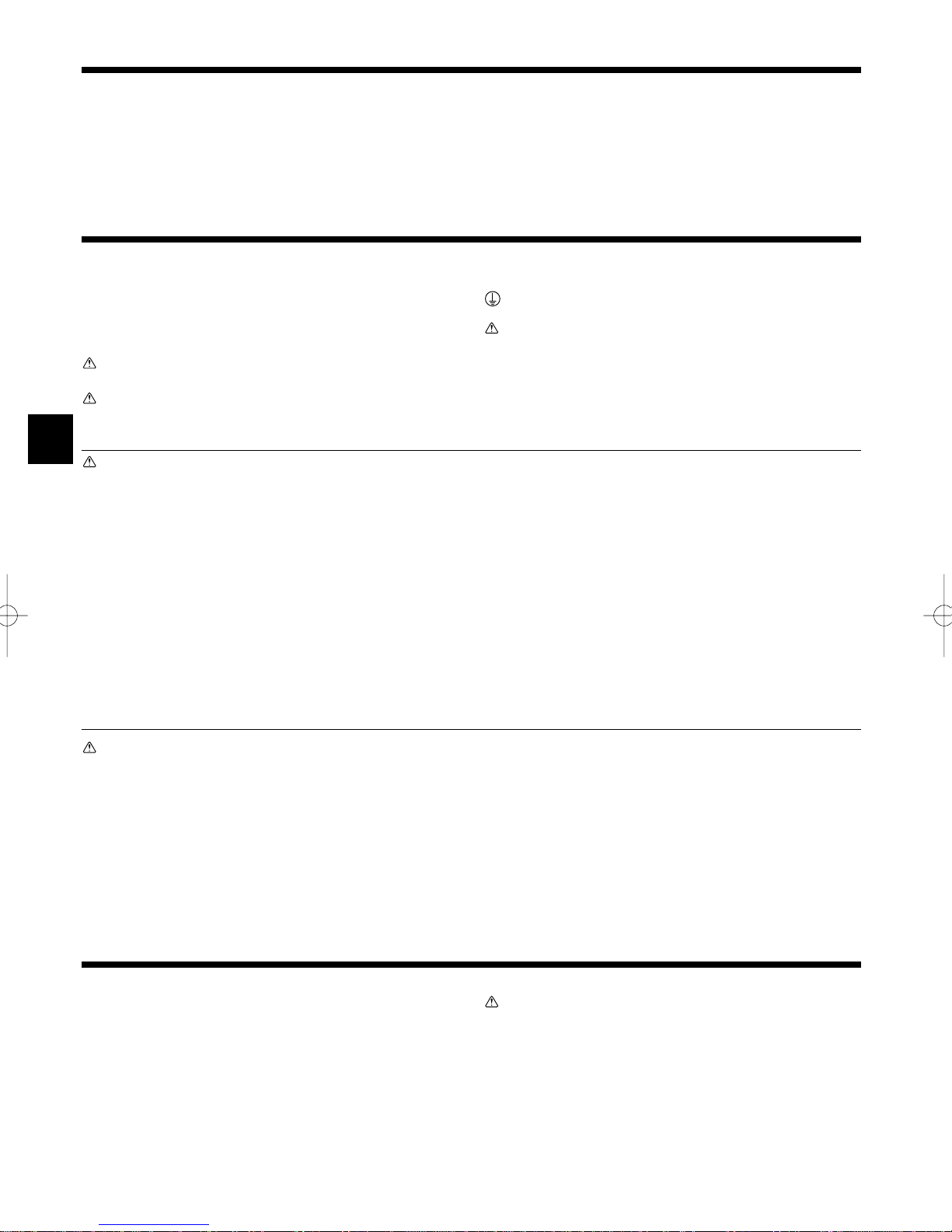

3. Installation diagram

SUZ-KA25/KA35VA2

SUZ-KA25/KA35VAH

344.5

2-10 mm × 21 mm slot

SUZ-KA50/KA60VA2

285

3.1. Outdoor unit (Fig. 3-1)

Drainage hole (W42)

(In case of Heater models W33)

800

400

Air inlet

500

Air outlet

150

44

69

304 - 325

40

(mm)

Ventilation and service space

■ SUZ-KA25/KA35VA2

SUZ-KA25/KA35VAH

100 mm or more

A

B 350 mm or more

C Basically open 100 mm or more without any obstruction in front and on both

sides of the unit.

D 200 mm or more (Open two sides of left, right, or rear side.)

■ SUZ-KA50/KA60/KA71VA2

100 mm or more

A

B 350 mm or more

C 500 mm or more

When the piping is to be attached to a wall containing metals (tin plated) or metal

netting, use a chemically treated wooden piece 20 mm or thicker between the wall

and the piping or wrap 7 to 8 turns of insulation vinyl tape around the piping.

Units should be installed by licensed contractor accordingly to local code requirement.

Note:

When operating the air conditioner in low outside temperature, be sure to follow the instructions described below.

• Never install the outdoor unit in a place where its air inlet/outlet side may be exposed directly to wind.

• To prevent exposure to wind, install the outdoor unit with its air inlet side facing

the wall.

• To prevent exposure to wind, it is recommended to install a baffl e board on the

air outlet side of the outdoor unit.

SUZ-KA71VA2

840

34

Air inlet

500

Drainage 3 holes

(ø33)

51

Air inlet

330

515

299

66

Air outlet

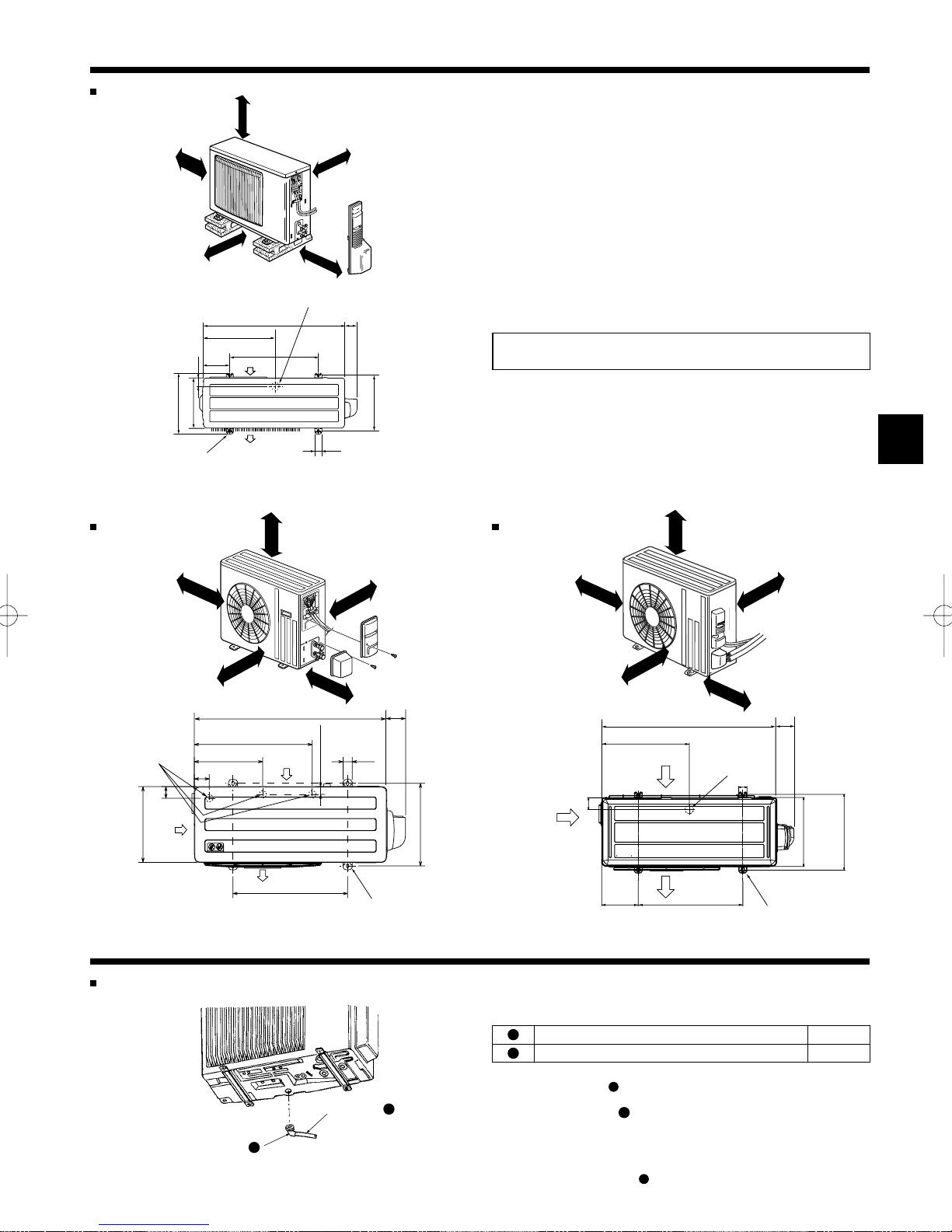

4. Drain piping for outdoor unit (Fig. 4-1)

SUZ-KA25/35VA2

Drain socket

(For VA2 type only)

1

Fig. 4-1

40

Drain hose

81

360

4-10 mm × 21 mm slot

3

(mm)

Fig. 3-1

81

40

2-10 mm × 21 mm slot

330

(mm)

360

Air inlet

840

417.5

Air inlet

50

Air outlet

500175

Drainage hole

(W42)

4.1. Accessories

Check the following parts before installation.

<Outdoor unit>

1

Drain socket (for VA2 type only) 1

Drain cap ø33 (for SUZ-KA50/KA60 only) 2

2

• Provide drain piping before indoor and outdoor piping connection. (It will be hard

to install drain socket

prior to drain piping as outdoor unit becomes immovable.)

• Connect the drain hose

shown in the fi

• Make sure to provide drain piping with a downhill grade for easy drain fl ow.

Note:

Do not use the drain socket

makes the fan stop.

1

if indoor and outdoor piping connection is conducted

3

gure for drainage.

(obtainable at a store, inside diameter: 15 mm) as

1

in the cold region. Drain may freeze and it

3

Page 4

5. Refrigerant piping work

(B)

(C)

Fig. 5-1

ø9.52

ø12.7

ø15.88

ø6.35

ø9.52

Fig. 5-2

(A)

A Indoor unit

B Outdoor unit

A Indoor unit

B Outdoor unit

5.1. Refrigerant pipe (Fig. 5-1)

► Check that the difference between the heights of the indoor and outdoor

units, the length of refrigerant pipe, and the number of bends in the pipe

are within the limits shown below.

Models

SUZ-KA25/KA35 Max. 20 m Max. 12 m Max. of 10

SUZ-KA50/KA60/KA71 Max. 20 m Max. 30 m *(15 m) Max. of 10

*( ): MFZ

• Height difference limitations are binding regardless of which unit, indoor or outdoor, is positioned higher.

• Refrigerant adjustment ... If pipe length exceeds 7 m, additional refrigerant

(R410A) charge is required.

(The outdoor unit is charged with refrigerant for pipe length up to 7 m.)

Pipe length

Refrigerant

to be added

Piping preparation

• Refrigerant pipes of 3, 5, 7, 10 and 15 m are available as optional items.

(1) Table below shows the specifi cations of pipes commercially available.

Model Pipe

SUZ-KA25

SUZ-KA35

SUZ-KA50

SUZ-KA60

SUZ-KA71

(2) Ensure that the 2 refrigerant pipes are well insulated to prevent condensation.

(3) Refrigerant pipe bending radius must be 100 mm or more.

SUZ-KA25/KA35 type 30 g × (refrigerant piping length (m) -5)

SUZ-KA50/KA60 type 20 g × (refrigerant piping length (m) -7)

For liquid 6.35 1/4 0.8 mm 8 mm

For gas 9.52 3/8 0.8 mm 8 mm

For liquid 6.35 1/4 0.8 mm 8 mm

For gas 9.52 3/8 0.8 mm 8 mm

For liquid 6.35 1/4 0.8 mm 8 mm

For gas 12.7 1/2 0.8 mm 8 mm

For liquid 6.35 1/4 0.8 mm 8 mm

For gas 15.88 5/8 0.8 mm 8 mm

For liquid 9.52 3/8 0.8 mm 8 mm

For gas 15.88 5/8 1.0 mm 8 mm

(A) Pipe length

(one way)

Up to 7 m No additional charge is required.

Exceeding 7 m

SUZ-KA71 type 55 g × (refrigerant piping length (m) -7)

Outside diameter

mm inch

Additional charge is required.

(Refer to the table below.)

(B) Height

difference

Min. wall

thickness

Insulation

thickness

(C) Number of

bends (one way)

Insulation

material

Heat resisting

foam plastic

0.045 specifi c

gravity

Caution:

Using careful insulation of specifi ed thickness. Excessive thickness prevents

storage behind the indoor unit and smaller thickness causes dew drippage.

a Copper tubes

b Good

/

90°

21034

c No good

d Tilted

e Uneven

f Burred

Fig. 5-3

5.2. Flaring work

• Main cause of gas leakage is defect in fl aring work.

Carry out correct fl aring work in the following procedure.

5.2.1. Pipe cutting (Fig. 5-3)

• Using a pipe cutter cut the copper tube correctly.

5.2.2. Burrs removal (Fig. 5-4))

/

0

1

2

a Burr

b Copper tube/pipe

c Spare reamer

d Pipe cutter

Fig. 5-4

/

a Flare nut

0

b Copper tube

Fig. 5-5

/

0

1

A

3

2

1

0

a Flaring tool

b Die

c Copper tube

d Flare nut

e Yoke

• Completely remove all burrs from the cut cross section of pipe/tube.

• Put the end of the copper tube/pipe to downward direction as you remove burrs

in order to avoid burrs drop in the tubing.

5.2.3. Putting nut on (Fig. 5-5)

• Remove fl are nuts attached to indoor and outdoor unit, then put them on pipe/

tube having completed burr removal.

(not possible to put them on after fl aring work)

5.2.4. Flaring work (Fig. 5-6)

• Carry out fl aring work using fl aring tool as shown at the right.

Pipe diameter

(mm)

6.35 0 - 0.5 9.1

9.52 0 - 0.5 13.2

12.7 0 - 0.5 16.6

15.88 0 - 0.5 19.7

Firmly hold copper tube in a die in the dimension shown in the table at above.

When the tool for R410A is used

A (mm)

Clutch type

Dimension

B

+0

-0.4

(mm)

Fig. 5-6

4

Page 5

5. Refrigerant piping work

B

0

/

23456

1

Fig. 5-7

5.2.5. Check (Fig. 5-7)

• Compare the fl ared work with a fi gure in right side hand.

If fl are is noted to be defective, cut off the fl ared section and do fl aring work again.

•

a Smooth all around f Scratch on fl ared plane

b Inside is shining without any scratches g Cracked

c Even length all around h Uneven

7

d Too much i Bad examples

e Tilted

• Apply a thin coat of refrigeration oil on the seat surface of pipe. (Fig. 5-8)

For connection fi rst align the center, then tighten the fi rst 3 to 4 turns of fl are nut.

•

• Use tightening torque table below as a guideline for indoor unit side union joint

section, and tighten using two wrenches. Excessive tightening damages the fl are

section.

Fig. 5-8

5.5. Purging procedures leak test

PURGING PROCEDURES

Connect the refrigerant pipes (both the liquid and gas pipes) between the indoor

and the outdoor units.

Remove theserviceport cap of the stop valve onthe side of the outdoor unit gaspipe.

(The stop valve will not work in its initial state fresh out of the factory (totally closed

with cap on).)

Connect the gage manifold valve and the vacuum pump to the service port of the

stop valve on the gas pipe side of the outdoor unit.

Copper pipe O.D.

(mm)

Flare nut O.D.

(mm)

Tightening torque

(N·m)

ø6.35 17 14 - 18

ø9.52 22 34 - 42

ø12.7 26 49 - 61

ø15.88 29 68 - 82

Warning:

When installing the unit, securely connect the refrigerant pipes before starting the compressor.

Warning:

Be careful of fl ying fl are nut! (Internally pressurized)

Remove the fl are nut as follows:

1. Loosen the nut until you hear a hissing noise.

2. Do not remove the nut until the gas has been completely released (i.e.,

hissing noise stops).

Check that the gas has been completely released, and then remove the nut.

3.

Remove the gage manifold valve quickly from the service port of the stop valve.

After refrigerant pipes are connected and evacuated, fully open all stop valves on

gas and liquid pipe sides.

Operating without fully opening lowers the performance and causes trouble.

Pipe length :

7 m maximum

No gas charge is needed.

Pipe length exceeding 7 m

Charge the prescribed

amount of gas.

Run the vacuum pump. (Vacuumize for more than 15 minutes.)

Checkthevacuum with thegage manifold valve, thenclose the gagemanifoldvalve,

and stop the vacuum pump.

Leave it as is for one or two minutes. Make sure the pointer of the gage manifold

valve remains in the same position. Confirm that the pressure gage show -0.101

MPa (-760 mmHg)

-0.101 MPa

Stop valve

*Close

*Open

Hexagonal wrench

*4 to 5 turns

Stop valve

Service port

(-760 mmHg)

Handle

Low

Stop

valve

Charge hose

(for R410A)

Window

Compound pressure

gauge (for R410A)

Pressure gauge

(for R410A)

Gauge manifold

valve (forR410A)

Handle High

Charge hose

(for R410A)

Vacuum

pump

Adapter for

preventing

the back flow

(or the vacuum

pump with the

function to

prevent theback

flow)

Tighten the cap to the service port to obtain the initial status.

Retighten the cap.

Leak test

5

Page 6

6. Electrical work

LN

1S2S

6.1. Outdoor unit (Fig. 6-1, Fig. 6-2, Fig. 6-3, Fig. 6-4)

1 Remove the service panel.

S1

S2

S3

S3

21

A Indoor unit

B Outdoor unit

C Wired main switch/fuse

D Grounding

2 Wire the cables referring to the Fig. 6-1, Fig. 6-2, Fig. 6-3 and the Fig. 6-4.

For Power supply

Power supply cord SUZ-KA25/KA35: 1.5 mm² or more

Be sure to fi x the

indoor/outdoor unit

connecting wire using this cord clamp.

Fig. 6-1

Indoor terminal block

Earth wire (green/yellow)

Indoor/outdoor unit connecting wire

3-core 1.5 mm² or more

L

Outdoor terminal block

SUZ-KA50/KA60/KA71: 2.5 mm² or more

N

Fig. 6-2

Fig. 6-3

A Loosen terminal screw

B Terminal block

C Lead wire

Fig. 6-4

Service panel

Remove fi xing

screw to open the

service panel.

•

Perform wiring as shown in the diagram to the lower left. (Procure the cable locally)

(Fig. 6-2)

Make sure to use cables of the correct polarity only.

A Connecting cable

B Indoor terminal block

C Outdoor terminal block

D Always install an earth wire longer than other cables.

E Power supply cord

Caution:

• Use care not to make miswiring.

• Firmly tighten the terminal screws to prevent then from loosening.

• After tightening, pull the wires lightly to confi rm that they do not move.

• Connect cable from the indoor unit correctly on the terminal-block.

Use the same terminal block and polarity as is used with the indoor unit.

•

• For aftercare maintenance, give extra length to connecting cable.

• Both end of connecting cable (extension wire) are peeled off. When too

long, or connected by cutting off the middle, peel off power supply cable to

the size given in the fi gure.

Be careful not to contact connecting cable with piping.

•

Caution:

• Use care not to make miswiring. (Fig. 6-4)

• Firmly tighten the terminal screws to prevent them from loosening.

• After tightening, pull the wires lightly to confi rm that they do not move.

Warning:

• Be sure to attach the service panel of the outdoor unit securely. If it is not

attached correctly, it could result in a fi re or an electric shock due to dust,

water, etc.

• Tighten terminal screws securely.

• Wiring should be done so that the power lines are not subject to tension.

Otherwise, heat may be generated or fi re may occur.

6

Page 7

6. Electrical work

6.2. Field electrical wiring

S1

S2

*3

Indoor Unit

SUZ-KA50/KA60/KA71

Outdoor unit model SUZ-KA25/KA35 SUZ-KA35

Outdoor unit power supply ~/N (single), 50 Hz, 230 V ~/N (single), 50 Hz, 230 V ~/N (single), 50 Hz, 230 V

Outdoor unit input capacity Main switch (Breaker) *1 10 A 16 A 20 A

)

Outdoor unit power supply 2 × Min. 1.5 2 × Min. 2.0 2 × Min. 2.5

2

Outdoor unit power supply earth 1 × Min. 1.5 1 × Min. 2.0 1 × Min. 2.5

Indoor unit-Outdoor unit 3 × 1.5 (Polar) 3 × 1.5 (Polar) 3 × 1.5 (Polar)

Wiring

Wire No. ×

size (mm

Indoor unit-Outdoor unit earth 1 × Min. 1.5 1 × Min. 1.5 1 × Min. 1.5

Outdoor unit L-N *2 AC 230 V AC 230 V AC 230 V

Indoor unit-Outdoor unit S1-S2 *2 AC 230 V AC 230 V AC 230 V

rating

Circuit

Indoor unit-Outdoor unit S2-S3 *2 DC 12 V ~ DC 24 V DC 12 V ~ DC 24 V DC 12 V ~ DC 24 V

*1. A breaker with at least 3 mm contact separation in each poles shall be provided. Use earth leakage breaker (NV).

*2. The fi gures are NOT always against the ground.

S3 terminal has DC 24 V against S2 terminal. However between S3 and S1, these terminals are NOT electrically insulated by the transformer or other device.

*3. In case of PEAD-RP35JA series combination.

Notes: 1. Wiring size must comply with the applicable local and national code.

2. Power supply cords and Indoor/Outdoor unit connecting cords shall not be lighter than polychloroprene sheathed fl exible cord. (Design 60245 IEC 57)

3. Install an earth longer than other cables.

230 V

Single phase

Isolator

3 poles isolator

S1

Outdoor Unit

S2

S3

Warning:

There is high voltage potential on the S3 terminal caused by electrical circuit design that has no electrical insulation between power line and communication

signal line. Therefore, please turn off the main power supply when servicing. And do not touch the S1, S2, S3 terminals when the power is energized. If isolator

should be used between indoor unit and outdoor unit, please use 3-poles type.

S3

7. Maintenance

A Indoor unit H Refrigerant gas cylinder for R410A with siphon

B Union I Refrigerant (liquid)

C Liquid pipe J Electronic scale for refrigerant charging

D Gas pipe K Charge hose (for R410A)

E Stop valve L Gauge manifold valve (for R410A)

F Outdoor unit M Service port

G Refrigerant gas cylinder

operating valve

7.1. Gas charge (Fig. 7-1)

1. Connect gas cylinder to the service port of stop valve (3-way).

Execute air purge of the pipe (or hose) coming from refrigerant gas cylinder.

2.

3. Replenish specified amount of refrigerant, while running the air conditioner for cooling.

Note:

In case of adding refrigerant, comply with the quantity specifi ed for the refrig-

erating cycle.

Caution:

• Do not discharge the refrigerant into the atmosphere.

Take care not to discharge refrigerant into the atmosphere during installation, reinstallation, or repairs to the refrigerant circuit.

• For additional charging, charge the refrigerant from liquid phase of the gas

cylinder.

If the refrigerant is charged from the gas phase, composition change may

occur in the refrigerant inside the cylinder and the outdoor unit. In this

case, ability of the refrigerating cycle decreases or normal operation can

be impossible. However, charging the liquid refrigerant all at once may

cause the compressor to be locked. Thus, charge the refrigerant slowly.

To maintain the high pressure of the gas cylinder, warm the gas cylinder with warm

water (under 40°C) during cold season. But never use naked fi re or steam.

Fig. 7-1

7

Page 8

This product is designed and intended for use in the residential,

commercial and light-industrial environment.

The product at hand is

based on the following

EU regulations:

Please be sure to put the contact address/telephone number on

this manual before handing it to the customer.

• Low Voltage Directive 2006/95/EC

• Electromagnetic Compatibility Directive

2004/108/EC

HEAD OFFICE: TOKYO BLDG., 2-7-3, MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN

Authorized representative in EU: MITSUBISHI ELECTRIC EUROPE.B.V.

RG79D664H01 Printed in Thailand

HARMAN HOUSE, 1 GEROGE STREET, UXBRIDGE,

MIDDLESEX, UB8 1QQ, U.K.

Loading...

Loading...