Mitsubishi Electric SUZ-KA09, SUZ-KA12, SUZ-KA15, SUZ-KA18NA, SUZ-KA09NA Installation Manual

...Page 1

POUR L’INSTALLATEUR

PARA EL INSTALADOR

FOR INSTALLER

Air-Conditioners

SUZ-KA09, KA12, KA15, KA18NA

INSTALLATION MANUAL

For safe and correct use, read this manual and the indoor unit installation manual thoroughly before installing

the air-conditioner unit.

MANUEL D’INSTALLATION

Avant d’installer le climatiseur, lire attentivement ce manuel, ainsi que le manuel d’installation de l’appareil

intérieur pour une utilisation sûre et correcte.

MANUAL DE INSTALACIÓN

Para un uso correcto y seguro, lea detalladamente este manual y el manual de instalación de la unidad interior

antes de instalar la unidad de aire acondicionado.

Français

Español

English

Page 2

2

Contents

1. The following should always be observed for safety . . . . . . . . . . . . . . . . . . . . 2

2. Selecting the installation location

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3. Installation diagram

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4. Refrigerant piping work

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

5. Electrical work

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

6. Maintenance

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1. The following should always be observed for safety

Caution:

Could lead to serious injury when operated incorrectly.

• After reading this manual, be sure to keep it together with the instruction

manual in a handy place on the customer’s site.

: Indicates a part which must be grounded.

Warning:

Carefully read the labels afxed to the main unit.

Warning:

■ Do not install the unit by yourself (user).

Improper or incomplete installation could cause re, electric shock, injury due to

the unit falling, or water leakage. Consult a qualied installer or the dealer from

whom you purchased the unit.

■ Follow the instructions detailed in the installation manual.

Incomplete installation could cause re or electric shock, injury due to the unit

falling, or leakage of water.

■ Install the unit securely in a place that can bear the weight of the unit.

If the installation location cannot bear the weight of the unit, the unit could fall

causing injury.

■ Perform electrical work according to the installation manual and be sure to

use an exclusive circuit. Do not connect other electrical appliances to the

circuit.

If the capacity of the power circuit is insufcient or there is incomplete electrical

work, it could result in a re or an electric shock.

■ Ground the unit correctly.

Do not connect the ground wire to a gas pipe, water pipe, lightning rod or telephone ground. Defective grounding could cause electric shock.

■ Do not damage the wires.

Damaged wires could cause re.

■ Be sure to shut off the main power when setting up the indoor P.C. board

or wiring.

Failure to do so could cause electric shock.

■ Use the specied wires to securely connect the indoor and outdoor units.

Attach the wires rmly to avoid applying stress to the terminal block.

Improper connection could cause re.

■ Do not install the unit in a place where ammable gas may leak.

If gas leaks and accumulates around the unit, it could cause an explosion.

■ Do not use intermediate connection of the power cord or the extension

cord. Do not connect many devices to one AC outlet.

It could cause a re or an electric shock.

■ Use the parts provided or specied parts for the installation work.

The use of defective parts could cause an injury or leakage of water due to a

re, an electric shock, the unit falling, etc.

■ Securely attach the electrical cover to the indoor unit and the service panel

to the outdoor unit.

If the electrical cover of the indoor unit and/or the service panel of the outdoor

unit are not attached securely, dust, water, etc. could collect in the unit and could

cause a re or an electric shock.

■ When installing or relocating the unit, make sure that no substance other

than the specied refrigerant (R410A) enters the refrigerant circuit.

Any foreign substances in the refrigerant circuit can cause abnormal pressure

rise or an explosion.

■ Do not discharge the refrigerant into the atmosphere. Check that the refrig-

erant gas does not leak after installation has been completed. If refrigerant

leaks during installation, ventilate the room.

If refrigerant comes in contact with a re, harmful gas could be generated.

If refrigerant gas leaks indoors, and comes into contact with the ame of a fan

heater, space heater, stove, etc., harmful gases will be generated.

■ Use appropriate tools and piping materials for installation.

The pressure of R410A is 1.6 times higher than R22. Not using the appropriate

tools and materials, or improper installation could cause the pipes to burst caus-

ing an injury.

■ When pumping down the refrigerant, stop the compressor before discon-

necting the refrigerant pipes.

If the refrigerant pipes are disconnected while the compressor is running and the

stop valve is open, air could be drawn in and the pressure in the refrigeration

cycle could become abnormally high, causing the pipes to burst.

■ When installing the unit, securely connect the refrigerant pipes before

starting the compressor.

If the compressor is started before the refrigerant pipes are connected and the

stop valve is open, air could be drawn in and the pressure in the refrigeration

cycle could become abnormally high, causing the pipes to burst.

■ Fasten a are nut with a torque wrench as specied in this manual.

If fastened too tight, a are nut could break and cause refrigerant leakage.

■ Install the unit according to national wiring regulations.

Caution:

■ Depending on the installation area, install a Ground Fault Interrupt (GFI)

circuit breaker.

If the Ground Fault Interrupt (GFI) circuit breaker is not installed, an electric

shock could occur.

■ Perform the drainage/piping work securely according to the installation

manual.

If there is defect in the drainage/piping work, water could drip from the unit, and

damage household items.

• Please provide an exclusive circuit for the air conditioner and do not connect other electrical appliances to it.

• Be sure to read “The following should always be observed for safety” be

-

fore installing the air conditioner.

• Be sure to observe the cautions specied here as they include important

items related to safety.

• The indications and meanings are as follows.

Warning:

Could lead to death or serious injury.

■ Do not touch the air inlet or the aluminum ns of the outdoor unit.

This could cause injury.

■ Do not install the outdoor unit where small animals may live.

If small animals enter the unit and damage its electrical parts, it could cause a

malfunction, smoke emission, or re. Keep the area around the unit clean.

Page 3

3

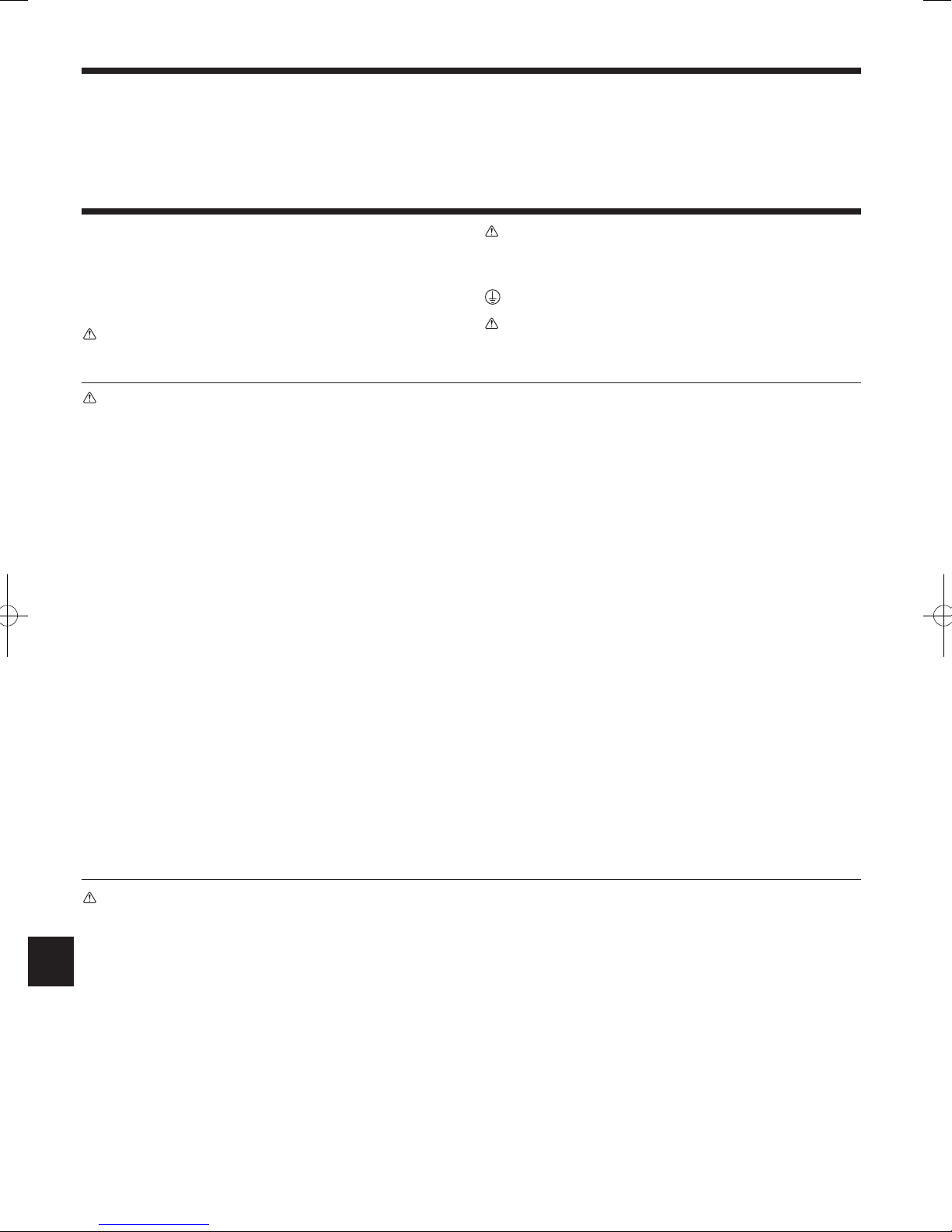

3. Installation diagram

2.1. Outdoor unit

• Where it is not overly exposed to strong winds.

• Where airow is good and dustless.

• Where neighbors are not annoyed by operation sound or hot air.

• Where rigid wall or support is available to prevent the increase of operation sound

or vibration.

• Where there is no risk of combustible gas leakage.

• If installing the unit in a location high above the ground, be sure to secure the unit

legs.

• Where it is at least 10 ft. (3 m) away from the antenna of TV set or radio. Opera

-

tion of the air conditioner may interfere with radio or TV reception in areas where

reception is weak. An amplier may be required for the affected device.

• Install the unit horizontally.

• Please install it in an area not affected by snowfall or blowing snow. In areas with

heavy snow, please install a canopy, a pedestal and/or bafe boards.

Note:

• It is advisable to make a piping loop near outdoor unit so as to reduce vibration.

• For increased efciency, install the outdoor unit in a location where continuous

direct sunlight or excessive water can be avoided as much as possible.

Caution:

When operating the air conditioner in low outside temperature, be sure to follow the

instructions described below.

• Never install the outdoor unit in a place where its air inlet/outlet side may be ex

-

posed directly to wind.

• To prevent exposure to wind, install the outdoor unit with its air inlet side facing

the wall and a bafe board on the air outlet side.

Avoid the following places for installation where air conditioner trouble is liable to

occur.

• Where ammable gas could leak

• Where there is an excessive amount of machine oil in the air.

• Salty places such as the seaside.

• Where sulde gas is generated such as a hot spring.

• Where there is high-frequency or wireless equipment.

The outdoor unit produces condensate during the heating operation. Select the installation place to ensure to prevent the outdoor unit and/or the grounds from being

wet by drain water or damaged by frozen drain water.

2. Selecting the installation location

Open 2 sides of left,

right, or rear side.

4

in.

(100

mm)

or

more

14

in.

(350

mm)

or

more

8

in.

(200

mm)

or

more

Basically open 4 in.

(100 mm) or more

without any obstruction

in front and on both

sides of the unit.

4 in.

(100 mm)

or more

mm:tinUhcni:tinU

31-1/2

19-11/16

Air inlet

Air outlet

13-9/16

11-1/4

2-3/8×13/16 slot

12-12-3/4

1-9/16

800

500

Air inlet

Air outlet

2-10×21 slot

344.5

285

150

40

304-325

515/16

mm:tinUhcni:tinU

33-1/16

14-3/16

19-11/16

Air inlet

6-5/8

15-7/16

13

Air outlet

4-3/8 x 13/16 slot

1-9/16

40

840

169

500

Air

inlet

392

330

360

Air outlet

4-10 x 21 slot

20 in. (500 mm)

or more

4

in.

(100

mm)

or

more

4

in.

(100

mm)

or

more

14

in.

(350

mm)

or

more

20

in.

(500

mm)

or

more

SUZ-KA09, KA12, KA15NA SUZ-KA18NA

When the piping is to be attached to a wall containing metals (tin plated) or metal netting, use a chemically treated wooden piece 25/32 in. (20 mm) or thicker between the

wall and the piping or wrap 7 to 8 turns of insulation vinyl tape around the piping.

Units should be installed by licensed contractor accordingly to local code requirement.

Note:

When operating the air conditioner in low outside temperature, be sure to follow the instructions described below.

• Never install the outdoor unit in a place where its air inlet/outlet side may be exposed directly to wind.

• To prevent exposure to wind, install the outdoor unit with its air inlet side facing the wall.

• To prevent exposure to wind, it is recommended to install a bafe board on the air outlet side of the outdoor unit.

Drain piping for outdoor unit

Install the unit horizontally.

Do not use drain socket in cold regions. Drain may freeze and make the fan stop.

The outdoor unit produces condensate during the heating operation. Select the installation place to ensure to prevent the outdoor unit and/or the grounds from being

wet by drain water or damaged by frozen drain water.

Page 4

4

4. Refrigerant piping work

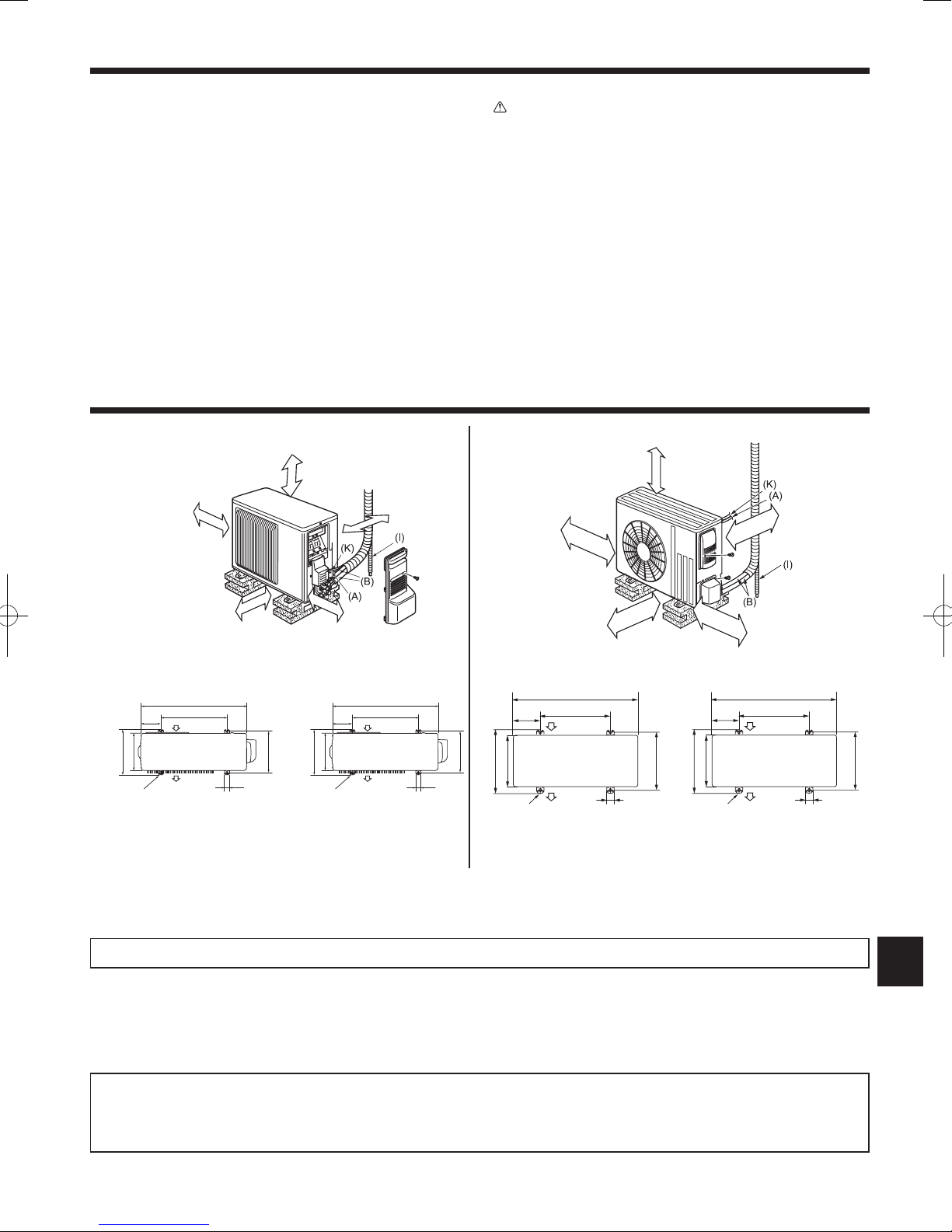

4.1. Refrigerant pipe (Fig. 4-1, Fig. 4-2)

► Check that the difference between the heights of the indoor and outdoor

units, the length of refrigerant pipe, and the number of bends in the pipe

are within the limits shown below.

Models

A Pipe length

(one way)

B Height

difference

C Number of

bends (one way)

SUZ-KA09, KA12,

KA15

Max. 65 ft (20 m) Max. 40 ft (12 m)

Max. 10

SUZ-KA18 Max. 100 ft (30 m) Max. 50 ft (15 m) Max. 10

• Height difference limitations are binding regardless of which unit, indoor or out

-

door, is positioned higher.

• Refrigerant adjustment ... If pipe length exceeds 25 ft. (7.5 m), additional refrig

erant (R410A) charge is required.

(The outdoor unit is charged with refrigerant for pipe length up to 25 ft. (7.5 m).)

Pipe length

Up to 25 ft (7.5 m)

No additional charge is required.

Exceeding 25 ft (7.5 m)

Additional charge is required.

(Refer to the table below.)

Refrigerant to

be added

SUZ-KA09, KA12, KA15 1.62 oz each 5 ft. (30 g/m)

SUZ-KA18 1.08 oz each 5 ft. (20 g/m)

• Table below shows the specications of pipes commercially available.

Model Pipe

Outside

diameter

Min. wall

thickness

Insulation

thickness

Insulation

material

inch (mm) inch (mm) inch (mm)

SUZ-KA09

For liquid 1/4 (6.35) 0.0315 (0.8) 5/16 (8)

Heat resisting

foam plastic

0.045 specic

gravity

For gas 3/8 (9.52) 0.0315 (0.8) 5/16 (8)

SUZ-KA12

For liquid 1/4 (6.35) 0.0315 (0.8) 5/16 (8)

For gas 3/8 (9.52) 0.0315 (0.8) 5/16 (8)

SUZ-KA15

For liquid 1/4 (6.35) 0.0315 (0.8) 5/16 (8)

For gas 1/2 (12.7) 0.0315 (0.8) 5/16 (8)

SUZ-KA18

For liquid 1/4 (6.35) 0.0315 (0.8) 5/16 (8)

For gas 1/2 (12.7) 0.0315 (0.8) 5/16 (8)

• To prevent condensation, insulate the 2 refrigerant pipes.

• Refrigerant pipe bending radius must be 4 in. (100 mm) or more

Caution:

Be sure to use the insulation of specied thickness (table on the above). Excessive

insulation may cause incorrect installation of the indoor unit, and too little insulation

may cause condensate to form.

• The unit has ared connections on both indoor and outdoor sides.

• Remove the valve cover from the outdoor unit, then connect the pipe.

• Refrigerant pipes are used to connect the indoor and outdoor units.

• Be careful not to crush or over bend the pipe in pipe bending.

ø1/4 (6.35)

ø3/8 (9.52)

ø3/8 (9.52)

ø1/2 (12.7)

Fig. 4-1

Fig. 4-2

D Indoor unit

E Outdoor unit

A Indoor unit

B Outdoor unit

4.2. Flaring work (Fig. 4-3)

1) Cut the cooper pipe as straight as possible with a pipe cutter.

2) Remove all burrs from the cut section of pipe, ensuring that precautions are

taken to avoid getting metal shavings into the piping.

3) Remove are nuts attached to indoor and outdoor units, then put them on pipe.

4) Flaring work. Firmly hold copper pipe in the dimension shown in the table. Select

A inch (mm) from the table according to the tool you use.

5) Check

• Compare the ared work.

•

If are is defective, cut off the section and repeat procedure.

Pipe diameter

inch (mm)

Nut

inch (mm)

A inch (mm) Tightening torque

Clutch

type tool

for R410A

Clutch

type tool

for R22

Wing nut

type tool

for R22

N·m

ft·lb

(kgf·cm)

1/4 (6.35) 1/4 (17)

0 to 0.02

(0 to 0.5)

0.04 to

0.06

(1.0 to 1.5)

0.06 to

0.08

(1.5 to 2.0)

13.7 to 17.7

10 to 13

(140 to 180)

3/8 (9.52) 3/8 (22)

34.3 to 41.2

25 to 30

(350 to 420)

1/2 (12.7) 1/2 (26)

0.08 to

0.10

(2.0 to 2.5)

49.0 to 56.4

36 to 42

(500 to 575)

5/8 (15.88) 5/8 (29)

73.5 to 78.4

54 to 58

(750 to 800)

Copper

pipe

Good

90°

Tilted

No good

Burr

Copper pipe

Spare reamer

Pipe cutter

Smooth all around

Even length

all around

Inside is shin

-

ing

without any

scratches.

A

Flare nut

Die

C

opper pipe

Clutch type

Flaring tool

Wing nut type

Uneven Burred

Fig. 4-3

Page 5

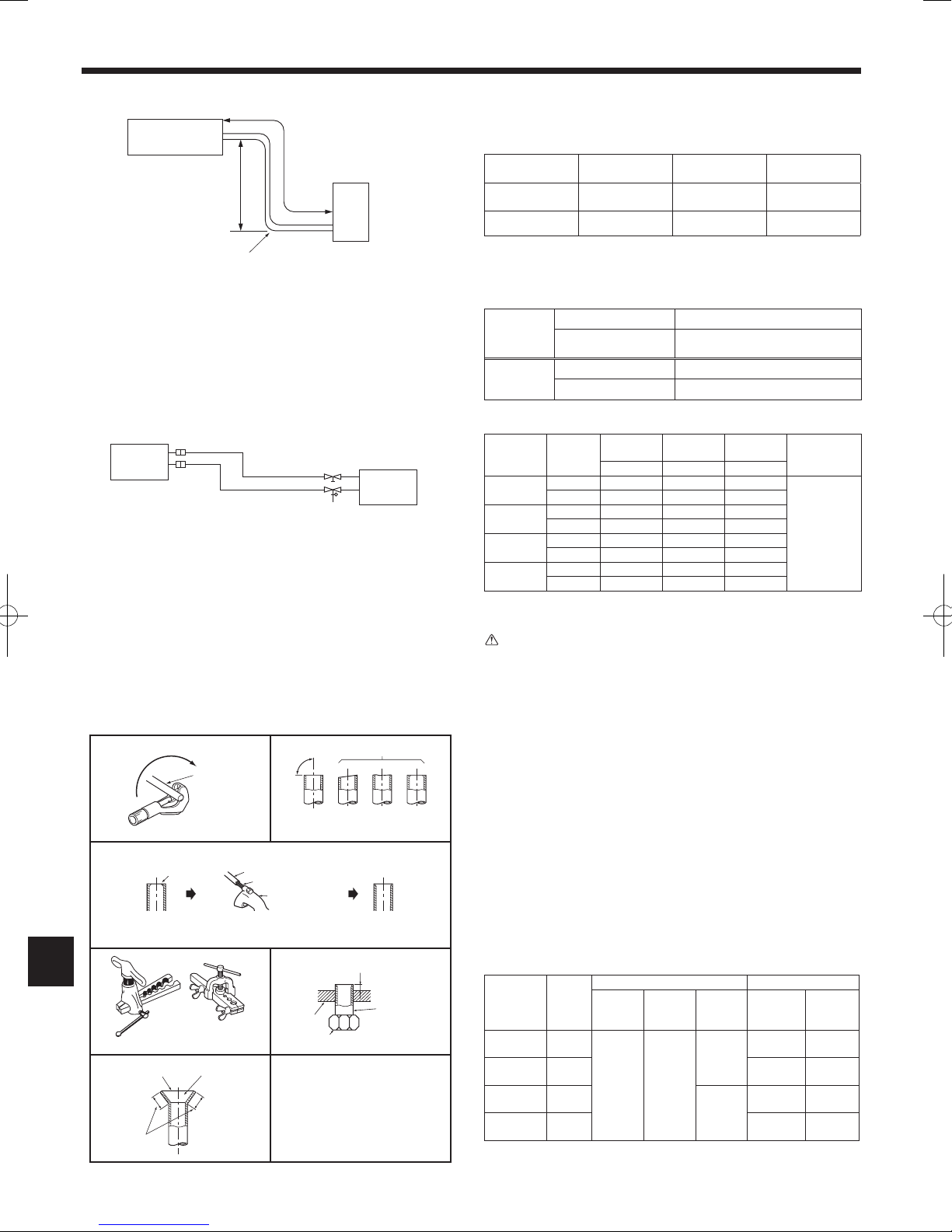

Flare cutting dimensions

45˚± 2˚

90˚± 0.5˚

Flare nut tightening torque

ø

A

R1/64 to R1/32

(inch)

A Liquid pipe

B Gas pipe

C Insulation

D Taping

Fig. 4-5

5

4. Refrigerant piping work

4.3. Connecting pipes (Fig. 4-4, Fig. 4-5)

• Fasten are nut with a torque wrench as specied in the table (refer to 4.2.).

• When fastened too tight, are nut may eventually break and cause refrigerant

leakage.

[Fig. 4-5]

• Apply thin layer of refrigerant oil to pipe and joint seating surface before tightening

are nut. A

• Use 2 wrenches to tighten piping connections.

B

• Use leak detector or soapy water to check for gas leaks after connections are

completed.

• Apply refrigerant oil over the entire are seat surface.

C

• Use the are nuts for the following pipe size. D

KA09, KA12 KA15, KA18

Gas side Pipe size inch (mm) 3/8 (9.52) 1/2 (12.7)

Liquid side Pipe size inch (mm) 1/4 (6.35) 1/4 (6.35)

*1: The are nut is attached to its pipe.

*2: The are nut is in the outdoor unit accessory.

Do not use the are nuts other than the attachment. If it is used, a gas leakage

or even a pipe extraction may occur.

• Refrigerant pipe bending radius must be 4 in. (100 mm) or more.

• Make sure the pipes do not contact the compressor. Abnormal noise or vibration

may result.

1 Pipes must be connected starting from the indoor unit.

Flare nuts must be tightened with a torque wrench.

2 Flare the liquid pipes and gas pipes and apply a thin layer of refrigerant oil

(Applied on site).

Warning:

Be careful of ying are nut. (Internally pressurized)

Remove the are nuts as follows:

1. Loosen the nut until you hear a hissing noise.

2. Do not remove the nut until the gas has been completely released (i.e.,

hissing noise stops)

3.

Check that the gas has been completely released, and then remove the nut.

A (Fig. 4-5)

Pipe diameter

Flare dimensions

øA dimensions

inch (mm) inch (mm)

1/4” (6.35) 11/32 - 23/64 (8.7 - 9.1)

3/8” (9.52) 1/2 - 33/64 (12.8 - 13.2)

1/2” (12.7) 41/64 - 21/32 (16.2 - 16.6)

5/8” (15.88) 49/64 - 25/32 (19.3 - 19.7)

Fig. 4-4

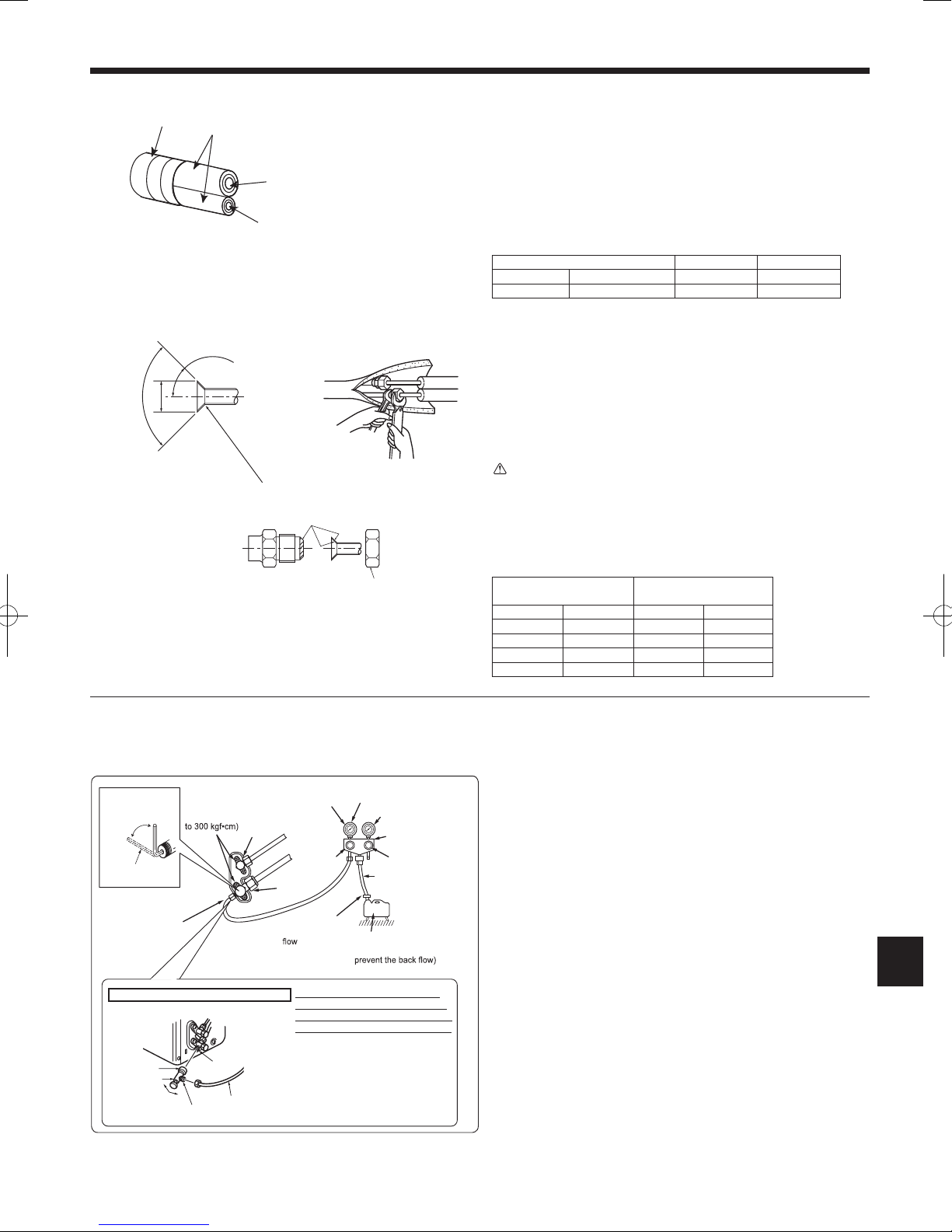

4.4. Purging procedures and leak test

1) Remove service port cap of stop valve on the side of the outdoor unit gas pipe.

2) Connect gauge manifold valve and vacuum pump to service port of stop valve

on the gas pipe side of the outdoor unit.

3) Run the vacuum pump 15 minutes or more.

4) Check the vacuum with the gauge manifold valve, then close it and shut off the

vacuum pump.

5) Leave as it is for one or two minutes. Make sure pointer gauge manifold valve

remains in the same position. Conrm that pressure gauge shows -0.101 MPa

[Gauge] (-30 in.Hg [-760 mmHg]).

6) Quickly remove gauge manifold valve from service port of stop valve.

7) After refrigerant pipes are connected and evacuated, fully open all stop valves

on both sides of gas pipe and liquid pipe. Operating the unit without fully opening

the valves lowers the performance and causes problems.

8) Refer to 4.1. Refrigerant pipe, and charge the prescribed amount of refrigerant if

needed. Be sure to charge slowly with liquid refrigerant. Otherwise, composition

of the refrigerant in the system may be changed and affect performance of the

air conditioner.

9) Tighten cap of service port.

10) Conduct a leak test

Stop valve for

GAS

Stop

valve cap

(Torque 19.6 to

29.4 N•m, 200

Vacuum pump (or the vacuum

pump with the function to

Gauge manifold valve

(for R410A)

Compound pressure gauge

(for R410A)

–0.101 MPa

(–30

in.Hg

[–760 mmHg])

Handle

Low

Handle

High

Adapter for preventing

the back

Charge

hose

(for R410A)

*Close

*Open

Hexagonal

wrench

Precautions when using the control valve

When attaching the control valve

to the service port, valve core may

deform or loosen if excess pressure

is applied. This may cause gas leak.

Service port

Charge hose

Body

Close

Open

Control valve

A

When attaching the control valve to

the service port, make sure that the

valve core is in closed position, and

then tighten part A. Do not tighten

part A or turn the body when valve

core is in open position.

Service port cap

(Torque 13.7 to

17.7 N•m, 140 to

180 kgf•cm)

*4

to 5 turns

Stop valve

for LIQUID

Pressure gauge

(for R410A)

Page 6

6

5. Electrical work

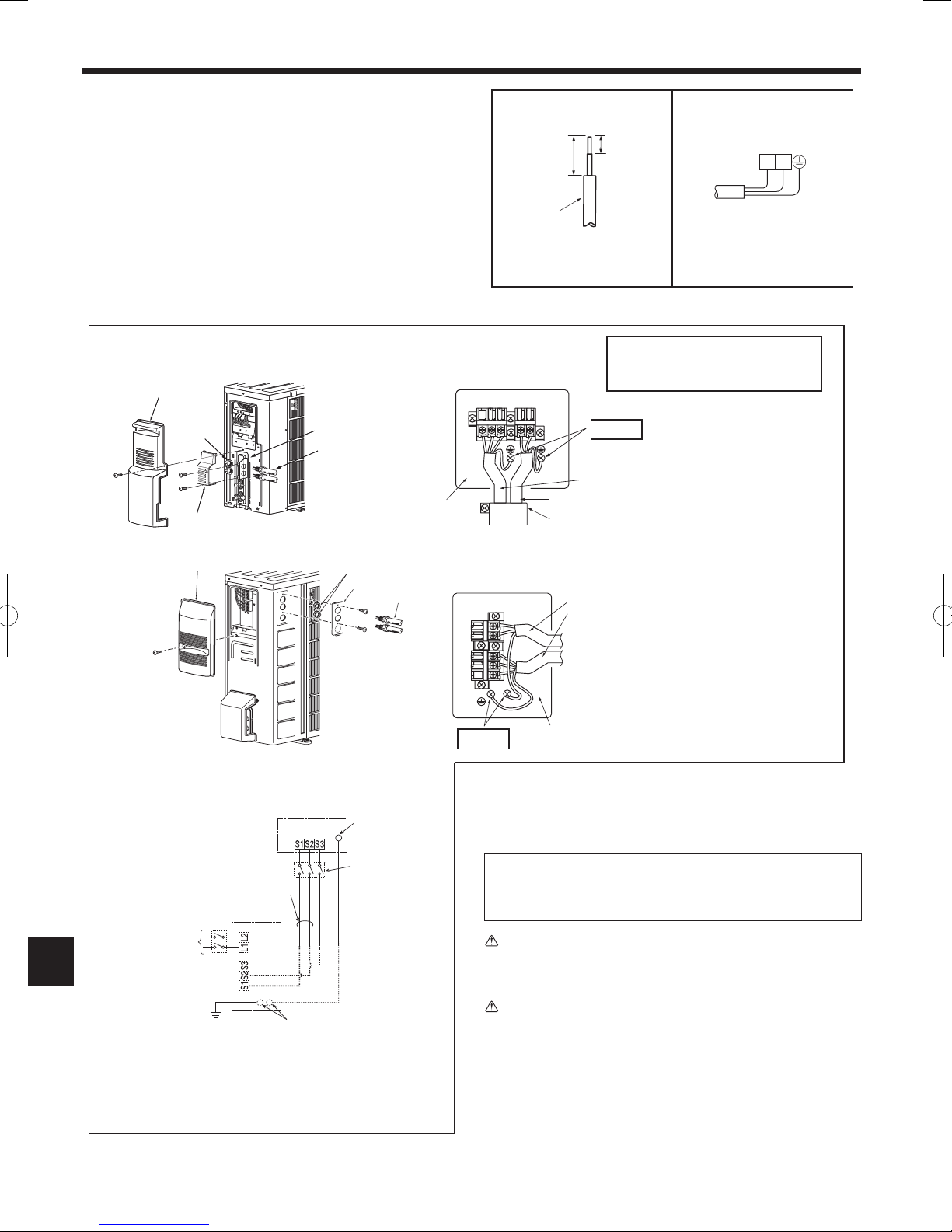

5.1. Connecting wires for outdoor unit

1) Remove the service panel.

2) Remove the conduit cover.

3) Attach the conduit connector to conduit plate with lock nut then secure it against

unit with screws.

4) Connect ground wires of indoor/outdoor unit connecting wire (A) and power sup

-

ply cord (K) to the TB support.

5) Loosen the terminal screw, and attach indoor/outdoor unit connecting wire (A)

from the indoor unit correctly on the terminal block. Attach the wire to the terminal block securely so that its core cannot be seen, and no external force affects

the connecting section of the terminal block.

6) Firmly tighten the terminal screws. After tightening, verify that the wires are

tightly fastened.

7) Connect power supply cord (K).

8) Install the conduit cover.

9) Install the service panel securely.

Lead wire

Power supply cord (K)

L1

L2

1-3/8 in.

(35 mm)

19/32 in.

(15

mm)

Terminal block

Conduit cover

Power supply cord (K)

Indoor/outdoor unit

connecting wire (A)

• Make earth wire a little longer than others.

(More than 2-3/8 in. [60 mm])

• For future servicing, leave some slack in

the connecting wires.

Service panel

Lock nut

Conduit cover

Conduit plate

Connector

Grounding

terminal

TB support

Terminal block

to conduit cover

Power supply cord (K)

Indoor/outdoor unit

connecting wire (A)

Service panel

Lock nut

Conduit cover

Connector

TB support

Grounding

terminal

INDOOR UNIT

Terminal block

208/230 V AC

1phase, 60 Hz

Grounding

terminal**

Disconnect

switch*

OUTDOOR UNIT

Grounding

terminal**

Ground

Power supply

208/230 V AC,

1phase 2wires.

60 Hz

Terminal

block 1

Remark:

* A disconnect switch is

required.

Check the local code.

** Use a ring tongue termi

nal in order to connect a

ground wire to terminal.

Terminal block 2

SUZ-KA09, KA12, KA15NA

SUZ-KA18NA

• Connect the cable from the indoor unit correctly on the terminal-block.

• Use the same terminal block and polarity as is used with the indoor unit.

• For aftercare maintenance, give extra length to connecting cable.

• Both ends of connecting cable (extension wire) are peeled off. When too long,

or connected by cutting off the middle, peel off power supply cable to the size

given in the gure.

• Be careful not to contact connecting cable with piping.

Caution:

• Use care not to make miswiring.

• Firmly tighten the terminal screws to prevent them from loosening.

• After tightening, pull the wires lightly to conrm that they do not move.

Warning:

• Be sure to attach the service panel of the indoor unit securely. If it is not

attached correctly, it could result in a re or an electric shock due to dust,

water, etc.

• Tighten terminal screws securely.

• Wiring should be done so that the power lines are not subject to tension.

Otherwise, heat may be generated or re may occur.

Page 7

S1

S2

S3

S1

S2

S3

208/230V

Single phase

Isolator

3 poles isolator

A-Control

Outdoor Unit

A-Control

Indoor Unit

7

5. Electrical work

Warning:

In case of A-control wiring, there is high voltage potential on the S3 terminal caused by electrical circuit design that has no electrical insulation between power

line and communication signal line. Therefore, please turn off the main power supply when servicing. And do not touch the S1, S2, S3 terminals when the power

is energized. If isolator should be used between indoor unit and outdoor unit, please use 3-pole type.

6. Maintenance

5.2. Field electrical wiring

Outdoor unit model SUZ-KA09, KA12, KA15NA SUZ-KA18NA

Power supply ~/N (single), 60 Hz 208/230 V ~/N (single), 60 Hz 208/230 V

Max. Fuse size (time delay) *1 15 A 15 A

Min. Circuit Ampacity 12 A 14 A

Wiring

Wire No. ×

size

Outdoor unit power supply 2 × Min. AWG 14 2 × Min. AWG 14

Outdoor unit power supply earth 1 × Min. AWG 14 1 × Min. AWG 14

Indoor unit-Outdoor unit 3 × AWG 14 (Polar) 3 × AWG 14 (Polar)

Indoor unit-Outdoor unit ground 1 × Min. AWG 16 1 × Min. AWG 16

Circuit

rating

Outdoor unit L1-L2 *2 AC 208/230 V AC 208/230 V

Indoor unit-Outdoor unit S1-S2 *2 AC 208/230 V AC 208/230 V

Indoor unit-Outdoor unit S2-S3 *2 DC 12 V - 24 V (Polar) DC 12 V - 24 V (Polar)

*1. Use ground leakage breaker (NV).

*2. The gures are NOT always against the ground.

S3 terminal has DC24 V against S2 terminal. However between S3 and S1, these terminals are NOT electrically insulated by the transformer or other device.

Notes: 1. Wiring size must comply with the applicable local and national code.

2.

Use copper supply wires.

3. Use wires rated 600V or more for the power supply cables and the indoor/outdoor unit connecting cables.

4. Install an earth longer than other cables.

6.1. Gas charge (Fig. 6-1)

1. Connect gas cylinder to the service port of stop valve (3-way).

2. Execute air purge of the pipe (or hose) coming from refrigerant gas cylinder.

3. Replenish specied amount of refrigerant, while running the air conditioner for

cooling.

Note:

In case of adding refrigerant, comply with the quantity specied for the refrigerating cycle.

Caution:

• Do not discharge the refrigerant into the atmosphere.

Take care not to discharge refrigerant into the atmosphere during installation, reinstallation, or repairs to the refrigerant circuit.

• For additional charging, charge the refrigerant from liquid phase of the gas

cylinder.

If the refrigerant is charged from the gas phase, composition change may

occur in the refrigerant inside the cylinder and the outdoor unit. In this

case, ability of the refrigerating cycle decreases or normal operation can

be impossible. However, charging the liquid refrigerant all at once may

cause the compressor to be locked. Thus, charge the refrigerant slowly.

To maintain the high pressure of the gas cylinder, warm the gas cylinder with warm

water (under 104 °F, 40 °C) during cold season. But never use naked re or steam.

A Indoor unit

B Union

C Liquid pipe

D Gas pipe

E Stop valve

F Outdoor unit

G Refrigerant gas cylinder

operating valve

H Refrigerant gas cylinder for R410A with siphon

I Refrigerant (liquid)

J Electronic scale for refrigerant charging

K Charge hose (for R410A)

L Gauge manifold valve (for R410A)

M Service port

Fig. 6-1

Page 8

8

Index

1. Les mesures de sécurité suivantes doivent toujours être observées

Attention:

Pouvant entraîner des blessures graves si l’unité n’est pas utilisée correctement.

•

Lorsque vous aurez lu le manuel en entier, veuillez le garder dans un endroit

pratique, chez le client, avec le manuel d’utilisation.

:Indique un élément qui doit être mis à la terre.

Avertissement:

Prendre soin de lire les étiquettes se trouvant sur l’appareil principal.

Avertissement:

■ N’installez pas l’unité vous-même (utilisateur).

Une installation incorrecte ou incomplète peut être à l’origine d’un incendie, d’un

choc électrique ou de blessures à la suite de la chute de l’unité ou de fuites d’eau.

Contactez un technicien qualié ou le revendeur à qui vous avez acheté l’unité.

■ Suivez les instructions détaillées dans le manuel d’installation.

Une installation incomplète peut être à l’origine d’un incendie, d’un choc électrique ou de blessures à la suite de la chute de l’unité ou de fuites d’eau.

■

Installez solidement l’unité dans un endroit capable de supporter son poids.

Si l’emplacement d’installation ne peut pas supporter le poids de l’unité, celle-ci

risque de tomber et de provoquer des blessures.

■ Exécutez les travaux électriques selon le manuel d’installation et veillez à

utiliser un circuit unique. Ne branchez pas d’autres appareils électriques

au circuit.

Un circuit électrique d’une capacité insufsante ou des travaux électriques incomplets peuvent être à l’origine d’un incendie ou d’un choc électrique.

■ Raccordez correctement l’unité à la terre.

Ne branchez pas le l de terre à un tuyau de gaz ou d’eau, à un paratonnerre ou

à la ligne de terre téléphonique. Une mise à la terre défectueuse peut entraîner

un choc électrique.

■ Veillez à ne pas endommager les câbles.

Des câbles endommagés peuvent provoquer un incendie.

■ Veillez àtoujourscouper l’alimentation principale lorsdela conguration

de la carte à circuits imprimés interne ou du câblage.

Le non-respect de cette recommandation peut entraîner un choc électrique.

■ Utilisezles câblesspéciéspourraccorderen toutesécuritélesunitésin-

terne et externe. Fixez les câbles solidement pour éviter toute pression sur

le bloc de raccordement.

Un raccordement incorrect peut provoquer un incendie.

■

N’installezpasl’unitédansunendroitexposéàdesfuitesdegazinammable.

La fuite ou l’accumulation de gaz autour de l’unité peut entraîner une explosion.

■

N’utilisez pas de raccord intermédiaire ou de rallonge pour brancher le cordon d’alimentation. Ne branchez pas plusieurs appareils à une prise secteur.

Cela peut provoquer un incendie ou un choc électrique.

■ Utilisez les pièces fournies ou spécifiées lors des travaux d’installation.

L’utilisation de pièces défectueuses peut être à l’origine de blessures ou de fuites d’eau dues à un incendie, un choc électrique, la chute de l’unité, etc.

■ Fixez correctement le couvercle du boîtier électrique de l’unité interne et le

panneau de service de l’unité externe.

Si le couvercle du boîtier électrique de l’unité interne et/ou le panneau de service

de l’unité externe sont mal xés, ils risquent de provoquer un incendie ou un choc

électrique en raison de la poussière, de l’eau, etc. présentes dans le circuit.

■ Lors de l’installation ou du déplacement de l’unité, veillez à ce qu’aucune

autresubstancequeleréfrigérant spécié(R410A) nepénètre dansle cir

-

cuit de réfrigération.

La présence d’une substance étrangère dans le circuit de réfrigération peut pro-

voquer une augmentation anormale de la pression, voire une explosion.

■ Nelibérezpasleréfrigérantdansl’atmosphère.Vériezl’absencedefuites

de gaz réfrigérant une fois l’installation terminée. En cas de fuite de réfrigérant pendant l’installation, aérez la pièce.

Si le réfrigérant entre en contact avec un feu, des substances toxiques peuvent

se dégager. Si le réfrigérant entre en contact avec la flamme d’un appareil de

chauffage à ventilation, chauffage d’appoint, poêle, etc., des substances toxiques peuvent se dégager.

■ Utilisez les outils et l’équipement de tuyauterie adaptés à l’installation.

La pression du réfrigérant R410A est 1,6 fois supérieure à celle du R22. L’utilisation d’outils et d’équipements non adaptés ou une installation incomplète peut

provoquer l’éclatement des tuyaux et blesser quelqu’un.

■ Pendant l’opération d’aspiration du réfrigérant, arrêtez le compresseur

avant de débrancher les tuyaux de réfrigérant.

Si les tuyaux de réfrigérant sont débranchés alors que le compresseur fonctionne et si le robinet d’arrêt est ouvert, de l’air pourrait être aspiré et la pression

du cycle de réfrigération pourrait augmenter de façon anormale, entraînant l’

explosion des tuyaux.

■ Pendant l’installation de l’unité, branchez correctement les tuyaux de réfri-

gérant avant de lancer le compresseur.

Si le compresseur démarre avant le branchement des tuyaux de réfrigérant et si le

robinet d’arrêt est ouvert, de l’air pourrait être aspiré et la pression du cycle de réfrigération pourrait augmenter de façon anormale, entraînant l’explosion des tuyaux.

■ Fixezunécrou évaséavec uneclédynamométrique commespécié dans

ce manuel.

S’il est trop serré, il risque de se rompre et de provoquer une fuite de réfrigérant.

■ Installez l’unité conformément aux normes électriques nationales.

Attention:

■ Installez un disjoncteur de fuites à la terre selon l’endroit d’installation.

Si le disjoncteur de fuites à la terre n’est pas installé, un choc électrique peut se

produire.

■ Réalisez les travaux de vidange/tuyauterie conformément au manuel d’ins-

tallation.

Si les travaux de vidange/tuyauterie ne sont pas réalisés correctement, de l’eau

pourrait s’écouler de l’unité et endommager le mobilier.

• Veuillez prévoir un circuit réservé au climatiseur et ne pas brancher d’

autres appareils électriques sur ce circuit.

• Veuillez lire en entier “Les mesures de sécurité suivantes doivent toujours

être respectées” avant d’installer le climatiseur.

• Comme ces mesures sont très importantes pour votre sécurité, veuillez les

respecter.

• Lessymbolessignient:

Avertissement:

Pouvant entraîner des blessures graves, voire la mort.

■ Ne touchez ni l’entrée d’air ni les ailettes en aluminium de l’unité externe.

Cela peut provoquer des blessures.

■ N’installez pas l’unité externe à proximité de l’habitat de petits animaux.

Si des petits animaux entrent dans l’unité et endommagent ses composants

électriques, ils peuvent provoquer un dysfonctionnement, des émissions de fumée ou un incendie. Nettoyez régulièrement la périphérie de l’unité.

1. Les mesures de sécurité suivantes doivent toujours être observées . . . . . . . 8

2. Choisir l’emplacement de l’installation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3. Schéma d’installation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4. Mise en place des tuyaux de réfrigérant

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5. Installations électriques

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6. Entretien

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Page 9

9

3. Schéma d’installation

2.1. Appareil extérieur

• Emplacement à l’abri de vents violents.

• Emplacement favorisant une bonne circulation d’air sans poussière.

• Emplacement ne générant pas de nuisance pour les voisins (bruit de fonctionne

-

ment ou air chaud).

• Emplacement sur un mur ou un support rigide pour éviter l’augmentation du bruit

de fonctionnement ou des vibrations.

• Emplacement qui ne risque pas d’être exposé à des fuites de gaz combustible.

• Lorsque l’unité est placée en hauteur, les pieds doivent être xés.

• Emplacement à une distance de 10 ft. (3 m) minimum de l’antenne TV ou radio.

Le fonctionnement du climatiseur peut interférer avec la réception TV ou radio

dans des zones où la réception est faible. Il peut s’avérer nécessaire de brancher

un amplicateur sur l’appareil concerné.

• Installez l’unité horizontalement.

• Installez l’unité dans un endroit à l’abri du vent et de la neige. Dans les zones

soumises à de fortes chutes de neige, installez un abri, un socle et/ou des écrans

de protection.

Remarque:

• Il est conseillé de faire une boucle avec le tuyau à proximité de l’unité externe

pour réduire les vibrations.

• Pour une meilleure efcacité, installez l’unité externe dans un endroit à l’abri des

rayons directs du soleil et des chutes excessives d’eau.

Attention:

Si vous utilisez le climatiseur alors que la température extérieure est basse, veillez

à observer les instructions ci-dessous.

• N’installez jamais l’unité externe dans un endroit où le côté présentant l’entrée/la

sortie d’air risque d’être directement exposé au vent.

• Pour protéger l’unité externe du vent, installez-la de façon à ce que l’entrée d’air

soit face au mur et placez un écran de protection du côté de la sortie.

Pour éviter tout dysfonctionnement, ne placez pas le climatiseur dans les endroits

suivants.

• En présence de fuites de gaz inammable.

• En présence d’une quantité excessive d’huile de machine dans l’air.

• En présence d’air salé (bord de mer).

• En présence de gaz sulfurique (source thermale).

• En présence d’équipements haute fréquence ou sans l.

L’unité extérieure produit de la condensation lors du mode de chauffage. Choisir l’

endroit où le climatiseur sera monté de façon à éviter à l’unité extérieure et/ou aux

sols d’être mouillés par les condensats ou endommagés par le gel des condensats.

2. Choisir l’emplacement de l’installation

4

pouce

(100

mm)

minimum

14

pouce

(350

mm)

minimum

8

pouce

(200

mm)

minimum

4 pouce

(100 mm)

minimum

mm:UnitéUnité: pouce

31-1/2

19-11/16

Entrée d’air

13-9/16

11-1/4

2-3/8×13/16

12-12-3/4

1-9/16

800

500

2-10×21

344,5

285

150

40

304-325

515/16

mm:Unité

33-1/16

14-3/16

19-11/16

6-5/8

15-7/16

13

Sortie d’air

4-3/8 x 13/16

1-9/16

40

840

169

500

392

330

360

4-10 x 21

20 pouce (500 mm)

minimum

4 pouce (100mm)

minimum

4 pouce (100mm)

minimum

14 pouce (350mm)

minimum

20 pouce (500mm)

minimum

Unité: pouce

Fente de

Fente de

Fente de

Fente de

Sortie d’air

Sortie d’air

Sortie d’air

Entrée d’air

Entrée d’air Entrée d’air

SUZ-KA09,KA12,KA15NA SUZ-KA18NA

Lorsque les tuyaux seront attachés à un mur contenant des métaux (fer-blanc) ou du grillage en métal, utiliser un morceau de bois traiter chimiquement de 25/32 pouce

(20 mm) ou plus entre le mur et les tuyaux ou envelopper les tuyaux de 7 ou 8 couches d’isolant en vinyle.

Les appareils doivent être installés par un technicien qualié suivant les réglementations locales en vigueur.

Remarque:

Si vous utilisez le climatiseur alors que la température extérieure est basse, veillez à observer les instructions décrites ci-dessous.

• N’installez jamais l’appareil extérieur dans un endroit où le côté présentant l’entrée/sortie d’air risque d’être directement exposé au vent.

• Pour protéger l’appareil extérieur du vent, installez-le de façon à ce que l’entrée d’air soit face au mur.

• Pour éviter toute exposition au vent, il est recommandé d’installer un écran de protection du côté de la sortie d’air de l’appareil extérieur.

Tuyau de vidange pour unité externe

Installez l’unité horizontalement.

N’utilisez pas de prise de vidange dans des régions froides. Sinon, l’eau de vidange pourrait geler et provoquer l’arrêt du ventilateur.

L’unité externe produit de la condensation lors de la phase de chauffage. Choisissez l’emplacement d’installation de façon à veiller à ce que l’unité externe et/ou le sol

ne deviennent pas humides en raison de condensats ou qu’ils ne soient pas endommagés par du condensat gelé.

Réa lis ez une ouver tur e

de 4 pouce (100 mm) mi-

nimum sans obstruction à

l’avant et des deux côtés

de l’unité.

Réalisez deux ouvertures

du côté gauche, droit ou

à l’arrière.

Page 10

10

4.Miseenplacedestuyauxderéfrigérant

4.1.Tuyauxderéfrigérant(Fig.4-1,Fig.4-2)

►Vérierqueladifférence de hauteur entreles appareils intérieur et exté-

rieur, la longueur du tuyau de réfrigérant et le nombre de coudes permis

dans le tuyau se situent au sein des limites reprises dans le tableau cidessous.

Modèles

A Longueur du

tuyau (un sens)

B Différence de

hauteur

C Nombre de

coudes (un sens)

SUZ-KA09, KA12,

KA15

max. 65 ft (20 m) max. 40 ft (12 m) max. of 10

SUZ-KA18

max. 100 ft (30 m) max. 50 ft (15 m) max. of 10

• Les spécifications concernant la différence d’élévation s’appliquent à toutes

dispositions des appareils intérieurs et extérieurs, sans tenir compte de celui qui

est le plus élevé.

• Équilibrage au réfrigérant ... Si la longueur de la tuyauterie dépasse 25 ft (7,5 m),

un supplément de réfrigérant (R410A) doit être rajouté.

(L’appareil extérieur est chargé d’une quantité de réfrigérant sufsante pour une

tuyauterie allant jusqu’à 25 ft (7,5 m).)

Longueur de

tuyauterie

Jusqu’à 25 ft (7,5 m)

Aucun supplément de réfrigérant n’est exigé.

Dépasse 25 ft (7,5 m)

Un supplément de réfrigérant à rajouter.

(Consulter le tableau ci-dessous.)

Quantité de

réfrigérant à

rajouter

SUZ-KA09, KA12, KA15 1,62 oz par 5 ft. (30 g/m)

SUZ-KA18

1,08 oz par 5 ft. (20 g/m)

•

Le tableau ci-dessous montre les spécications des tuyaux disponibles en commerce.

Modèle Tuyau

Diamètre

extérieur

Epaisseur

min. du mur

Epaisseur

de l’isolant

Matériau

d’isolation

pouce (mm) pouce (mm) pouce (mm)

SUZ-KA09

à liquide 1/4 (6,35) 0,0315 (0,8) 5/16 (8)

Plastique ex-

pansé résistant

à la chaleur

d’une densité

spécique de

0,045

à gaz 3/8 (9,52) 0,0315 (0,8) 5/16 (8)

SUZ-KA12

à liquide 1/4 (6,35) 0,0315 (0,8) 5/16 (8)

à gaz 3/8 (9,52) 0,0315 (0,8) 5/16 (8)

SUZ-KA15

à liquide 1/4 (6,35)

0,0315 (0,8) 5/16 (8)

à gaz 1/2 (12,7) 0,0315 (0,8) 5/16 (8)

SUZ-KA18

à liquide 1/4 (6,35) 0,0315 (0,8) 5/16 (8)

à gaz 1/2 (12,7) 0,0315 (0,8) 5/16 (8)

•

Pour éviter la formation de condensation, isolez les deux conduites de réfrigérant.

• Le rayon de pliage de la conduite de réfrigérant doit être de 4 pouce (100 mm)

minimum.

Attention:

Utilisez toujours un matériau d’isolation de l’épaisseur spéciée (tableau à droite).

Une isolation trop épaisse peut être à l’origine d’une installation incorrecte de l’

unité interne ; une isolation trop ne peut provoquer la formation de condensation.

•

L’unité comporte des raccordements évasés sur les faces intérieure et extérieure.

• Retirez le couvercle de vanne de l’unité externe et raccordez le tuyau.

• Les conduites de réfrigérant servent à raccorder les unités interne et externe.

• Veillez à ne pas écraser ni plier de manière excessive le tuyau lors de sa mise

en forme.

ø1/4 (6,35)

ø3/8 (9,52)

ø3/8 (9,52)

ø1/2 (12,7)

Fig.4-1

Fig.4-2

D Appareil intérieur

E Appareil extérieur

4.2.Evasement(Fig.4-3)

1) Coupez correctement le tuyau de cuivre avec un coupe-tuyaux.

2) Ébarbez parfaitement la partie tronçonnée du tuyau en évitant d’introduire des

éclats de métal dans la tuyauterie.

3)

Retirez les écrous évasés xés sur les unités interne, puis posez-les sur le tuyau.

4) Travaux d’évasement. Tenez fermement le tuyau de cuivre à la dimension indiquée dans le tableau. Sélectionnez A en pouce (mm) dans le tableau suivant l’

outil que vous utilisez.

5) Contrôle

• Comparez les travaux d’évasement.

•

Si l’évasement n’est pas conforme, coupez la section et recommencez la procédure.

Diamètre

du tuyau en

pouce

(mm)

Écrou

en pouce

(mm)

A en pouce (mm) Couple de serrage

Outil à ma-

nivelle pour

le modèle

R410A

Outil à ma-

nivelle pour

le modèle

R22

Ecrou à

oreilles

pour le mo-

dèle R22

N·m

ft·lb

(kgf·cm)

1/4 (6,35) 1/4 (17)

0 à 0,02

(0 à 0,5)

0,04 à

0,06

(1,0 à 1,5)

0,06 à

0,08

(1,5 à 2,0)

13,7 à 17,7

10 à 13

(140 à 180)

3/8 (9,52) 3/8 (22)

34,3 à 41,2

25 à 30

(350 à 420)

1/2 (12,7) 1/2 (26)

0,08 à

0,10

(2,0 à 2,5)

49,0 à 56,4

36 à 42

(500 à 575)

5/8 (15,88) 5/8 (29)

73,5 à 78,4

54 à 58

(750 à 800)

90°

A

C

Fig.4-3

A Appareil intérieur

B Appareil extérieur

Tuyau en cuivre

Conforme

Non conforme

Incliné

Irrégulier

Ébarbé

Ébarber

Tuyau en cuivre

Alésoir supplémentaire

Coupe-tuyaux

Outil

d’évasement

Modèle à

manivelle

Modèle avec

écrous à ailette

Filière

Tuyau en cuivre

Écrou évasé

Poncez le pourtour

du tuyau

Intérieur brillant

et sans rayures.

Égalisez la longueur

tout autour du tuyau

Page 11

Robinet

d’arrêt

pour GAZ

Bouchon du

robinet d’arrêt

(couple 19,6 à

29,4 N•m, 200

à 300 kgf•cm)

Pompe à vide

(ou pompe à vide équipée d’

une fonction anti-reflux)

Vanne du collecteur à

jauge (pour le modèle

R410A)

Manomètre combiné

(pour le modèle R410A)

–0,101 MPa

(–30

pouce Hg

[–760 mmHg])

Poignée

basse

Poignée haute

Adaptateur

anti-reflux

Tuyau de charge

(pour le modèle R410A)

*Fermer

*Ouvrir

Clé hexagonale

Précautions à prendre lors de l’utilisation

de la vanne de commande

Ouverture de

service

Tuyau de charge

Corps

Fermer

Ouvrir

Vanne de

commande

A

Bouchon de l’ouverture

de service

(couple 13,7 à 17,7 N•m,

140 à 180 kgf•cm)

*4

à 5 tours

Robinet d’arrêt

pour LIQUIDE

Manomètre

(pour le modèle R410A)

Flare cutting dimensions

45˚± 2˚

90˚± 0,5˚

Flare nut tightening torque

ø

A

R1/64 à R1/32

(pouce)

A Conduit de liquide

B Conduit de gaz

C Isolation thermique

D Rubanage

Fig.4-5

A Dimension de l’évasement

B Couple de serrage du raccord conique

11

4.Miseenplacedestuyauxderéfrigérant

4.3.Connexiondestuyaux(Fig.4-4,Fig.4-5)

• Serrez l’écrou évasé avec une clé dynamométrique comme spécié dans le tableau (se reporter à la section 4-2).

• S’il est trop serré, il risque de se rompre et de provoquer une fuite de réfrigérant.

[Fig. 4-5]

• Appliquer un lm mince d’huile réfrigérante sur la surface du tuyau et du support

du joint avant de serrer l’écrou évasé. A

• Utiliser deux clés pour serrer les connexions des tuyaux.

B

•

Lorsque le raccord des tuyaux est terminé, utiliser un détecteur de fuite de gaz ou

une solution savonneuse à base d’eau pour s’assurer qu’il n’y ait pas de fuite de gaz.

• Appliquer de l’huile réfrigérante sur toute la surface évasée du fond. C

• Utiliser les écrous évasés correspondant aux tailles de tuyaux suivantes. D

KA09, KA12 KA15, KA18

Côté gaz Diamètre du tuyau pouce (mm) 3/8 (9,52) 1/2 (12,7)

Côté liquide Diamètre du tuyau pouce (mm) 1/4 (6,35) 1/4 (6,35)

*1: Le raccord conique est xé à son tuyau.

*2: Le raccord conique se trouve dans l’accessoire pour appareil extérieur.

Ne pas utiliser les écrous évasés autres que la pièce jointe: cela pourrait provoquer une fuite de gaz, voire l’extraction du tuyau.

•

Le rayon de pliage de la conduite de réfrigérant doit être de 4 pouce (100 mm) minimum.

• Vérier que les tuyaux ne touchent pas le compresseur. Des vibrations ou des

bruits anormaux pourraient se produire.

1 Raccorder les tuyaux en commençant par l’appareil intérieur.

Serrer les écrous évasés à l’aide d’une clé dynamométrique.

2 Evaser les conduits de liquide et de gaz, puis appliquer un lm mince d’huile

réfrigérante (application sur site).

Avertissement:

Attention aux écrous évasés volants. (pressurisation interne)

Retirer l’écrou évasé en procédant comme suit:

1.Desserrerl’écroujusqu’àcequ’unsifementsefasseentendre.

2.

Ne jamais retirer l’écrou tant que tout le gaz ne s’est pas échappé (c’est-

àdirelorsquelesifements’arrête).

3.

Vériersitoutlegazs’estéchappéavantderetirerl’écrou.

A (Fig. 4-5)

Diam. ext. Tuyau en cuivre

Dimensions évasement

Dimensions øA

pouce (mm) pouce (mm)

1/4” (6,35) 11/32 - 23/64 (8,7 - 9,1)

3/8” (9,52) 1/2 - 33/64 (12,8 - 13,2)

1/2” (12,7) 41/64 - 21/32 (16,2 - 16,6)

5/8” (15,88) 49/64 - 25/32 (19,3 - 19,7)

Fig.4-4

4.4.Procéduresdepurgeettestdecontrôledesfuites

1) Retirez le bouchon de l’ouverture de service du robinet d’arrêt du côté du tuyau

de gaz de l’unité externe.

2) Raccordez la vanne du collecteur à jauge et la pompe à vide à l’ouverture de

service du robinet d’arrêt du côté du tuyau de gaz de l’unité externe.

3) Faites fonctionner la pompe à vide pendant 15 minutes minimum.

4) Contrôlez la dépression ainsi obtenue avec la vanne du collecteur à jauge, puis

fermez la vanne et arrêtez la pompe à vide.

5) Patientez pendant une minute ou deux. Assurez-vous que l’aiguille de la vanne

du collecteur à jauge reste dans la même position. Vériez que le manomètre

indique une pression de –0,101 MPa [Jauge] (–30 pouce Hg [–760 mm Hg]).

6) Retirez rapidement la vanne du collecteur à jauge de l’ouverture de service du

robinet d’arrêt.

7) Lorsque les conduites de réfrigérant sont raccordées et purgées, ouvrez com

-

plètement les robinets d’arrêt aux deux extrémités des tuyaux de liquide et de

gaz. La mise en service sans ouvrir complètement les robinets d’arrêt diminue le

rendement de l’unité et peut entraîner des problèmes.

8) Reportez-vous à la section 4.1. Tuyaux de réfrigérant et chargez la quantité de

réfrigérant recommandée si nécessaire. Veillez à verser lentement le liquide

réfrigérant. Sinon, la composition du réfrigérant dans le système peut changer et

affecter les performances du climatiseur.

9) Serrez le bouchon de l’ouverture de service.

10) Effectuez un test de contrôle des fuites

Lorsque vous xez la vanne commande

à l’ouverture de service, le noyau de

vanne peut se déformer ou se relâcher

en cas de pression excessive. Cela peut

entraîner une fuite de gaz.

Lorsque vous xez la vanne de commande à l’ouverture de service, veillez

à ce que le noyau de vanne soit en

position fermée, puis serrez la partie A.

Ne serrez pas la partie A ou ne tournez

pas le corps lorsque le noyau de vanne

est en position ouverte.

Page 12

12

5.Installationsélectriques

5.1.Raccordementdescâblesdel’unitéexterne

1) Retirez le panneau de service.

2) Déposez le cache de conduit.

3) Attachez le connecteur de conduit à l’aide d’un contre-écrou et xez-la contre l’

unité avec des vis.

4) Raccordez les câbles de terre du câble de connexion de l’unité interne/externe (A)

et le cordon d’alimentation (K) au support TB.

5)

Desserrez la vis de raccordement et branchez le câble de connexion de l’unité interne/externe (A) depuis l’unité interne au bloc de raccordement. Fixez fermement le

câble au bloc de raccordement pour ne pas faire apparaître son noyau et n’appliquez

aucune force extérieure à la section de branchement du bloc de raccordement.

6) Serrez fermement les vis de xation. Après l’opération de serrage, vérifiez que

les câbles sont bien fixés.

7) Branchez le cordon d’alimentation (K).

8) Installez le cache de conduit.

9) Reposez correctement le panneau de service.

L1

L2

1-3/8 pouce

(35 mm)

19/32 pouce

(15

mm)

SUZ-KA09,KA12,KA15NA

SUZ-KA18NA

• Connecter le câble de l’appareil intérieur à la boîte de sorties.

• Utiliser le même bloc de sorties et la même polarité que pour l’unité intérieure.

• Pour pouvoir effectuer des révisions dans le futur, laisser un peu de jeu dans le

câble de connexion.

• Les deux extrémités du câble de connexion (rallonge) doivent être dénudées.

Lorsque le câble est trop long ou lorsqu’il est relié à partir du milieu, dénuder le

câble d’alimentation en respectant les dimensions indiquées à droite.

•

Faire attention que le câble de connexion n’entre pas en contact avec les tuyaux.

Attention:

• Faitesattentiondebrancherleslscorrectement.

• Serrer fermement les vis des bornes pour les empêcher de se desserrer.

• Puistirerlégèrementsurleslspourvousassurerqu’ilsnebougentpas.

Avertissement:

• Veiller à visser correctement le panneau de service à l’appareil extérieur.

Si le panneau de service n’est pas bien installé, de l’eau, des poussières,

etc. pourraient pénétrer à l’intérieur de l’appareil, entraînant un risque d’

incendie ou de décharge électrique.

• Resserrer convenablement les vis des terminaux.

• Le câblage doit s’effectuer sans que les lignes d’alimentation électrique

soient soumises à une tension. Sinon, il pourrait y avoir surchauffe, voire

un risque d’incendie.

Fil conducteur

Cordon d’alimentation (K)

Panneau de service

Contre-écrou

Cache de conduit

Plaque de conduit

Connecteur

Support TB

Câble de connexion de l’

unité interne/externe (A)

Cordon d’alimentation (K)

Cache de conduit

Borne de

mise à la terre

Bloc de raccordement

Bloc de raccordement

vers le cache de conduit

Borne de

mise à la terre

Support TB

Câble de connexion de l’

unité interne/externe (A)

Cordon d’alimentation (K)

Panneau de service

Contre-écrou

Plaque de conduit

Connecteur

Borne de mise à

la terre**

Sectionneur*

Borne de mise à la terre**Mise à la terre

Alimentation électrique monophasée

208/230 V c.a., 2

câbles, 60 Hz

UNITE INTERNE

UNITE EXTERNE

208/230Vc.a.

monophasé,60Hz

Bloc de

raccordement

Bloc de

raccordement 2

Bloc de

raccordement 1

Remarque :

* Un sectionneur est nécessaire.

Vériez la réglementation locale.

** Utilisez une borne à languette

circulaire pour raccorder le câble

de terre.

• Veillez à ce que le câble de terre soit un peu plus

long que les autres. (2-3/8 pouce [60 mm] minimum)

• Laissez du jeu dans les câbles de connexion Pan

-

neau de service en vue d’entretiens ultérieurs.

Page 13

S1

S2

S3

S1

S2

S3

208/230V

Single phase

Isolator

3 poles isolator

A-Control

Outdoor Unit

A-Control

Indoor Unit

13

5.Installationsélectriques

Avertissement:

S’il s’agit d’un câblage de commande A, un risque de haute tension existe sur la borne S3 en raison d’une conception de circuit électrique dépourvue d’un

isolant électrique entre la ligne de commande et la ligne de signal de communication. Par conséquent, mettre l’alimentation principale hors tension lors de l’

entretien. Veiller également à ne pas toucher les bornes S1, S2 et S3 lorsque l’alimentation est sous tension. S’il faut placer un sectionneur entre les appareils

extérieur et intérieur, en utiliser un de type tripolaire.

6. Entretien

5.2.Raccordezlescâblesélectriques

Modèle de l’appareil extérieur SUZ-KA09, KA12, KA15NA SUZ-KA18NA

Alimentation ~/N (monophasé), 60 Hz 208/230 V ~/N (monophasé), 60 Hz 208/230 V

Taille max. des fusibles (temporisé) *1 15 A 15 A

Intensité min. du circuit 12 A 14 A

Raccorde-

ment du

câble N° taille

× (mm²)

Alimentation de l’appareil extérieur 2 × Min. AWG 14 2 × Min. AWG 14

Alimentation de l’appareil extérieur, mise à la terre 1 × Min. AWG 14 1 × Min. AWG 14

Appareil intérieur-Appareil extérieur 3 × AWG 14 (Polaire) 3 × AWG 14 (Polaire)

Appareil intérieur-Appareil extérieur, mise à la terre 1 × Min. AWG 16 1 × Min. AWG 16

Intensité

du

circuit

Appareil extérieur L1-L2 *2 CA 208/230 V CA 208/230 V

Appareil intérieur-Appareil extérieur S1-S2 *2 CA 208/230 V CA 208/230 V

Appareil intérieur-Appareil extérieur S2-S3 *2 CC 12 V - CC 24 V (Polaire) CC 12 V - CC 24 V (Polaire)

*1. Utilisez un disjoncteur de fuites à la terre (NV).

*2. Les chiffres NE sont PAS toujours en rapport avec la terre.

La borne S3 présente CC 24 V par rapport à la borne S2. Cependant entre les bornes S3 et S1, l’isolation électrique n’est PAS assurée par un transformateur ou tout autre dispositif.

Remarques:1.Latailledeslsdoitêtreconformeauxréglementationsnationalesetlocalespertinentes.

2.Utiliserdeslsd’alimentationencuivre.

3.Utiliserdeslsd’uneintensiténominalede600Voupluspourlescâblesd’alimentationetlescâblesderaccordementdel’appareilintérieur/

l’appareil extérieur.

4.Installeruncâbledeterrepluslongquelesautrescâbles.

6.1. Charge de Gaz (Fig. 6-1)

1. Raccorder le tuyau de gaz au port de service de la vanne d’arrêt (à 3 voies).

2. Purger l’air du tuyau raccordé au tuyau de gaz réfrigérant.

3. Ajouter la quantité spéciée de réfrigérant, pendant que le climatiseur fonctionne

en mode rafraîchissement.

Remarque:

En cas d’ajout de réfrigérant, respecter la quantité précisée pour le cycle de

réfrigération.

Attention:

• Ne pas décharger le réfrigérant dans l’atmosphère.

Faire attention de ne pas décharger le réfrigérant dans l’atmosphère durant l’

installation, une nouvelle installation ou la réparation du circuit réfrigérant.

• En cas de supplément de charge, charger le réfrigérant sous sa forme liquide à partir d’un cylindre de gaz.

Si le réfrigérant est chargé sous sa forme gazeuse, sa composition risque

desemodieràl’intérieurducylindreetdansl’appareilextérieur.Dansce

cas, la capacité de refroidissement du réfrigérant diminue ou le fonctionnement normal peut même s’avérer impossible. Attention: une charge trop

rapide de tout le réfrigérant liquide risque de bloquer le compresseur; dès

lors, nous conseillons de charger le réfrigérant lentement.

Pour maintenir une pression élevée dans le cylindre de gaz, le réchauffer avec de l’

eau chaude (d’une température inférieure à 104°F, 40°C) pendant la saison froide.

Ne jamais utiliser une amme vive ou de la vapeur pour effectuer cette opération.

A Appareil intérieur

B Raccord

C Conduite de liquide

D Conduit de gaz réfrigérant

E Robinet d’arrêt

F Appareil extérieur

G Vanne de fonctionnement

du cylindre de réfrigérant

H

Cylindre de gaz réfrigérant pour R410A, avec siphon

I Réfrigérant (liquide)

J Echelle électronique pour la charge de réfrigérant

K Conduite exible de chargement (pour le R410A)

L Jauge collectrice (pour le R410A)

M Prise de service

Fig. 6-1

208/230 V

monophasé

Sectionneur

Appareil

extérieur de

“commande A”

Appareil

intérieur de

“commande A”

Sectionneur tripolaire

Page 14

14

Contenido

1. Por razones de seguridad, deberá observarse siempre lo siguiente . . . . . . . 14

2. Selección del lugar de instalación

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3. Diagrama de instalación

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4. Colocación de los tubos de refrigerante

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5. Trabajo eléctrico

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6. Mantenimiento

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1. Por razones de seguridad, deberá observarse siempre lo siguiente

Cuidado:

Podría causar lesiones graves si se manipula incorrectamente.

• Tras la lectura de este manual, asegúrese de guardarlo junto al manual de

instrucciones en un lugar accesible de las instalaciones del cliente.

: Indica una pieza que debe estar conectada a tierra.

Atención:

Lea atentamente las etiquetas adheridas a la unidad principal.

Atención:

■ El usuario no debe instalar la unidad.

Una instalación incorrecta o defectuosa podría causar incendios, descargas

eléctricas o lesiones debidos a una caída de la unidad o escapes de agua.

Consulte a un instalador cualicado o al concesionario en el que adquirió esta

unidad.

■ Siga las instrucciones incluidas en el manual de instalación.

Una instrucción defectuosa podría causar incendios, descargas eléctricas, lesio

-

nes debidas a una caída de la unidad o escapes de agua.

■

Asegúrese de que el lugar de instalación puede soportar el peso de la unidad.

Si el lugar de instalación no puede aguantar el peso de la unidad, ésta podría

caerse y causar daños.

■ Realice la instalación eléctrica siguiendo las instrucciones del manual de

instalación y asegurándose de emplear un circuito exclusivo. No conecte

otros dispositivos eléctricos al circuito.

Si el circuito de alimentación no tiene suciente capacidad o la instalación eléctrica se insuciente, podría producirse un incendio o una descarga eléctrica.

■ Conecte correctamente la unidad a tierra.

No conecte el cable de tierra a una tubería de gas, de agua, pararrayos o la

cable de tierra de un teléfono. Una conexión a tierra defectuosa podría provocar

una descarga eléctrica.

■ Evite dañar los cables.

Unos cables dañados podrían provocar incendios.

■ Asegúrese de desconectar el conmutador de alimentación general al insta-

lar la placa de circuito impreso o el cableado.

De no hacerlo, podría provocar una descarga eléctrica.

■ Utilice los cables indicados para conectar de forma segura las unidades

interiores y exteriores. Conecte bien los cables de modo que no queden

tensos en el panel de terminales.

Una conexión incorrecta podría provocar un incendio.

■ No instale la unidad en un lugar donde puede pueda haber fugas de gas

inamable.

Si hay fugas de gas y se acumula alrededor de la unidad, podría producirse una

explosión.

■ No emplee conexiones intermedias del cable de alimentación ni tampoco

un cable de extensión. Evite también conectar demasiados aparatos a una

sola toma de CA.

Esto podría provocar un incendio o una descarga eléctrica.

■ Utilice las piezas suministradas o indicadas para efectuar la instalación.

El empleo de piezas defectuosas podría provocar lesiones o escapes de agua a

causa de un incendio, una descarga eléctrica, la caída de la unidad, etc.

■ Fijermemente lacubierta delainstalacióneléctricaa launidadinteriory

el panel de servicio, a la unidad exterior.

Si no se jan con rmeza la cubierta de instalación eléctrica de la unidad interior

y el panel de servicio de la unidad exterior, podría acumularse polvo, agua, etc.

en la unidad y producirse un incendio o una descarga eléctrica.

■ Al instalar o reubicar la unidad, asegúrese de que no entra ninguna otra

sustancia excepto el refrigerante especificado (R410A) en el circuito de

refrigeración.

Cualquier sustancia extraña en el circuito de refrigeración puede provocar una

elevación anómala de la presión o una explosión.

■ No descargue el refrigerante en el ambiente. Una vez acabada la instala-

ción, compruebe que no haya fugas de gas refrigerante. Si se producen

fugas de refrigerante durante la instalación, ventile la habitación.

Si el refrigerante entra en contacto con una llama, podría generarse gas nocivo.

Si se produjeran pérdidas de gas refrigerante en un interior y entraran en con

tacto con la llama de un calefactor con ventilador, un calentador, una estufa, etc.

se generarían gases nocivos.

■ Utilice las herramientas apropiadas y los materiales de conducción ade-

cuados para la instalación.

La presión del refrigerante R410A es 1,6 veces mayor que la del R22. Si no se

utilizan herramientas o materiales apropiados, o si se realiza una instalación

defectuosa, las tuberías podrían estallar y provocar lesiones.

■ Al bombear el refrigerante, detenga el compresor antes de desconectar las

tuberías de refrigerante.

Si las tuberías de refrigerante se desconectan con el compresor en marcha y

las válvula de retención se abre, podría entrar aire y la presión del ciclo de re

frigeración aumentaría de forma anómala, lo que podría hacer que las tuberías

estallaran.

■ Alinstalarla unidad,conecte lastuberías derefrigerante deforma jaan-

tes de poner en marcha el compresor.

Si el compresor se pone en marcha antes de que las tuberías de refrigerante

estén conectadas y la válvula de retención se abre, podría entra aire y la presión

del ciclo de refrigeración aumentaría de forma anómala, lo que podría hacer que

las tuberías estallaran.

■ Apriete la tuerca abocardada mediante una llave dinamométrica tal como

seespecicaenelpresentemanual.

Si la aprieta demasiado, la tuerca abocardada podría romperse y causar pérdi

das de refrigerante.

■

Instale la unidad de acuerdo con la normativa para instalaciones eléctricas.

Cuidado:

■ Instale un disyuntor del interruptor de fallo de conexión a tierra (GFI) en

función de la zona de instalación.

Si no está instalado el disyuntor del interruptor de fallo de conexión a tierra (GFI),

podría producirse una descarga eléctrica.

■ Para efectuar un drenaje y una instalación de tuberías seguros, siga las

indicaciones del manual de instalación.

Un drenaje o una instalación de tuberías defectuosos podría causar un escape

de agua en la unidad y dañar los enseres del hogar.

• Proporcione un circuito exclusivo para el acondicionador de aire y no conecte otros dispositivos eléctricos a este circuito.

• Antes de instalar la unidad de aire acondicionado, asegúrese de leer “Por

razones de seguridad, deberá observarse siempre lo siguiente”.

• Asegúrese de observar las precauciones aquí especicadas, dado que in

-

cluyen elementos importantes en relación a la seguridad.

• Lasindicacionesysusignicadosonlossiguientes.

Atención:

Podría causar la muerte o lesiones graves.

■ No toque la entrada de aire ni las aletas de aluminio de la unidad exterior.

Esto podría causar lesiones.

■ No instale la unidad exterior donde puedan vivir animales pequeños.

Si los animales penetran en la unidad y dañan las piezas eléctricas podría pro

vocar fallos de funcionamiento, humos o incendios. Mantenga limpia el área

alrededor de la unidad.

Page 15

15

3. Diagrama de instalación

2.1. Unidad exterior

• Donde no esté expuesta a vientos fuertes.

• Donde haya un buen ujo de aire sin polvo.

• Donde el ruido o el aire caliente causados por el funcionamiento no moleste a los

vecinos.

• Donde haya una pared o un punto de apoyo rme para evitar un mayor ruido o

vibración durante el funcionamiento.

• Donde no exista riesgo de fugas de gas combustible.

• Si se instala la unidad en alto, asegúrese de jar las patas de la unidad.

• Donde esté a una distancia mínima de 10 pies (3 m) de cualquier antena de tele

visión o radio. El funcionamiento del acondicionador de aire puede interferir con

la capacidad de recepción del televisor o la radio. Puede ser necesario conectar

el receptor afectado a un amplicador.

• Instale la unidad en horizontal.

• Instálela en una área donde no sufra el efecto provocado por una nevada, viento

o nieve. En zonas de intensa nieve, la rogamos que instale un toldo, pedestal y/o

pantallas acústicas planas.

Nota:

• Se recomienda establecer el circuito cerrado de la tubería cerca de la unidad ex

-

terior para reducir la vibración.

• Para mayor ecacia, instale la unidad exterior en una ubicación donde se pueda

evitar, en la medida de lo posible, la luz solar directa continua o agua excesiva.

Cuidado:

Si utiliza el acondicionador de aire cuando la temperatura exterior sea baja, obser

-

ve las instrucciones siguientes.

• No instale nunca la unidad exterior en un lugar en el que el lado de entrada/sali

-

da de aire quede expuesto directamente al viento.

• Para evitar la exposición al viento, instale la unidad exterior con el lado de entra

-

da de aire hacia la pared y placa deectora en el lado de salida de aire.

Para instalar el aparto de aire acondicionado, evite los lugares siguientes donde es

más probable que ocurran problemas.

• Donde pueda haber una fuga de gas inamable.

• Donde haya demasiado aceite para maquinaria.

• En ambientes salobres, como las zonas costeras.

• Donde haya gas sulfúrico, como en zonas de baños termales.

• Donde haya algún equipo inalámbrico o de alta frecuencia.

La unidad exterior provoca condensación durante la función de calefacción. Selec

cione un lugar para la instalación en el que la unidad exterior y las tomas de tierra

no se humedezcan con agua de drenaje ni se dañen debido a la congelación de

este agua de drenaje.

2. Selección del lugar de instalación

4

pulg.

(100

mm)

o más

14

pulg.

(350

mm)

o más

8

pulg.

(200

mm)

o más

4 pulg.

(100 mm)

o más

pulganda:Unidad

31-1/2

19-11/16

Entrada de aire

13-9/16

11-1/4

Ranura de

2-3/8

×

13/16

12-12-3/4

1-9/16

800

500

Salida de aire

Ranura de

2-10

×

21

344,5

285

150

40

304-325

515/16

33-1/16

14-3/16

19-11/16

6-5/8

15-7/16

13

1-9/16

40

840

169

500

392

330

360

20 pulg. (500 mm)

o más

4 pulg. (100 mm)

o más

:Unidad

mm

Salida de aire

Entrada de aire

4 pulg. (100 mm)

o más

14 pulg. (350 mm)

o más

20 pulg. (500 mm)

o más

pulganda:Unidad

:Unidad

mm

Entrada de aire

Ranura de

4-3/8

×

13/16

Salida de aire

Ranura de

4-10

×

21

Salida de aire

Entrada de aire

SUZ-KA09, KA12, KA15NA SUZ-KA18NA

Cuando tenga que instalar la tubería en una pared que contenga metales (no metalizada) o una malla metálica, coloque una pieza de madera tratada químicamente de

25/32 pulg. (20 mm) o más de grosor entre la pared y la tubería o proteja a ésta última con 7 u 8 vueltas de cinta de vinilo aislante.

Las unidades deberán ser instaladas por una persona titulada, de acuerdo a las normas locales.

Nota:

Si utiliza el acondicionador de aire cuando la temperatura exterior es baja, observe las instrucciones siguientes.

• No instale nunca la unidad exterior en un lugar en el que el lado de la entrada/salida de aire quede expuesto directamente al viento.

• Para evitar la exposición al viento, instale la unidad exterior con el lado de la entrada de aire hacia la pared.

• Para evitar la exposición al viento, se recomienda instalar una placa deectora en el lado de salida de aire de la unidad exterior.

Tubería de drenaje para la unidad exterior

Instale la unidad horizontal.

No utilice tapa de desagüe en regiones frías. El desagüe se puede congelar y provocar la parada del ventilador.

La unidad exterior provoca condensación durante la función de calefacción. Seleccione un lugar para la instalación en el que la unidad exterior y los terminales de tierra

no se humedezcan con agua de drenaje ni se dañen debido a la congelación de este agua de drenaje.

Qu eda n bás ica men te 4

pulg. (100 mm) o más sin

obstrucci ones en la parte

delantera y a ambos lados

de la unidad.

Quede espacio a la izquierda,

a derecha o detrás.

Page 16

16

4. Colocación de los tubos de refrigerante

4.1. Tubería de refrigerante (Fig. 4-1, Fig. 4-2)

►Compruebe que la diferencia de altura entre las unidades interior y exte-

rior, la longitud del tubo de refrigerante y la cantidad de codos en la tubería se encuentren dentro de los límites que se indican a continuación.

Modelos

A

Longitud de las

tuberías (un sentido)

B

Diferencia de

altura

C

Número de codos

(un sentido)

SUZ-KA09, KA12,

KA15

Màx. 65 pies. (20 m) Màx. 40 pies. (12 m)

Màx. 10

SUZ-KA18

Màx. 100 pies. (30 m)

Màx. 50 pies. (15 m)

Màx. 10

• Las limitaciones de diferencia de altura son obligatorias sin importar qué unidad,

la interior o la exterior, está colocada más alta.

• Ajuste de refrigerante... Si la longitud de la tubería es superior a 25 pies. (7,5 m),

será necesario emplear más refrigerante (R410A)

(La carga de refrigerante de la unidad exterior está calculada para una longitud

máxima de tubería de 25 pies. (7,5 m)

.)

Longitud de

tubería

Hasta 25 pies (7,5 m)

No se necesita más carga.

Más de 25 pies. (7,5 m)

Se necesita más carga.

(Consulte la tabla de abajo.)

Cantidad de

refrigerante a

añadir

SUZ-KA09, KA12, KA15 1,62 oz cada 5 pies. (30 g/m)

SUZ-KA18 1,08 oz cada 5 pies. (20 g/m)

• La tabla siguiente muestra las especificaciones de los tubos comercialmente

disponibles.

Modelo

Tubo

Diámetro

exterior

Grosor mínimo

de la pared

Grosor de

aislamiento

Material

aislante

pulg. (mm) pulg. (mm) pulg. (mm)

SUZ-KA09

Para líquido

1/4 (6,35) 0,0315 (0,8) 5/16 (8)

Plástico de

espuma ter

-

morresistente

con un peso

especíco de

0,045

Para gas 3/8 (9,52) 0,0315 (0,8) 5/16 (8)

SUZ-KA12

Para líquido

1/4 (6,35) 0,0315 (0,8) 5/16 (8)

Para gas 3/8 (9,52) 0,0315 (0,8) 5/16 (8)

SUZ-KA15

Para líquido

1/4 (6,35) 0,0315 (0,8) 5/16 (8)

Para gas 1/2 (12,7) 0,0315 (0,8) 5/16 (8)

SUZ-KA18

Para líquido

1/4 (6,35) 0,0315 (0,8) 5/16 (8)

Para gas 1/2 (12,7) 0,0315 (0,8) 5/16 (8)

• Para evitar la condensación, aísle las 2 tuberías de refrigerante.

• El radio de curvatura de la tubería de refrigerante debe ser de 4 pulg. (100 mm)

o más.

Cuidado:

Asegúrese de utilizar un aislamiento de grosor especicado (tabla de la derecha). El