Mitsubishi SUH-1VR.TH, SUH-1.6VR, SUH-1.6VR.TH, SUH-1.6VR2, SUH-1.6VR2.TH Service Manual

...Page 1

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

SPLIT-TYPE, AIR CONDITIONERS

TECHNICAL & SERVICE MANUAL

Outdoor unit

[Model names] [Service Ref.]

SUH-1VR SUH-1VR.TH

SUH-1.6VR SUH-1.6VR.TH

SUH-1.6VR2 SUH-1.6VR2.TH

No. OC282

REVISED EDITION-A

SUH-2VR SUH-2VR.TH SUH-2VR

SUH-2.5VR SUH-2.5VR.TH

SU-1.6NR SU-1.6NR.TH

SU-2NR SU-2NR.TH

SU-2.5NR SU-2.5NR.TH

SU-1VR SU-1VR.TH

SU-1.6VR SU-1.6VR.TH SU-1.6VR.TH-T

SU-1.6VR2 SU-1.6VR2.TH

SU-2VR SU-2VR.TH SU-2VR

SU-2.5VR SU-2.5VR.TH SU-2.5VR.TH-T

1

.TH SUH-2VR

1

.TH SU-2VR.TH-T

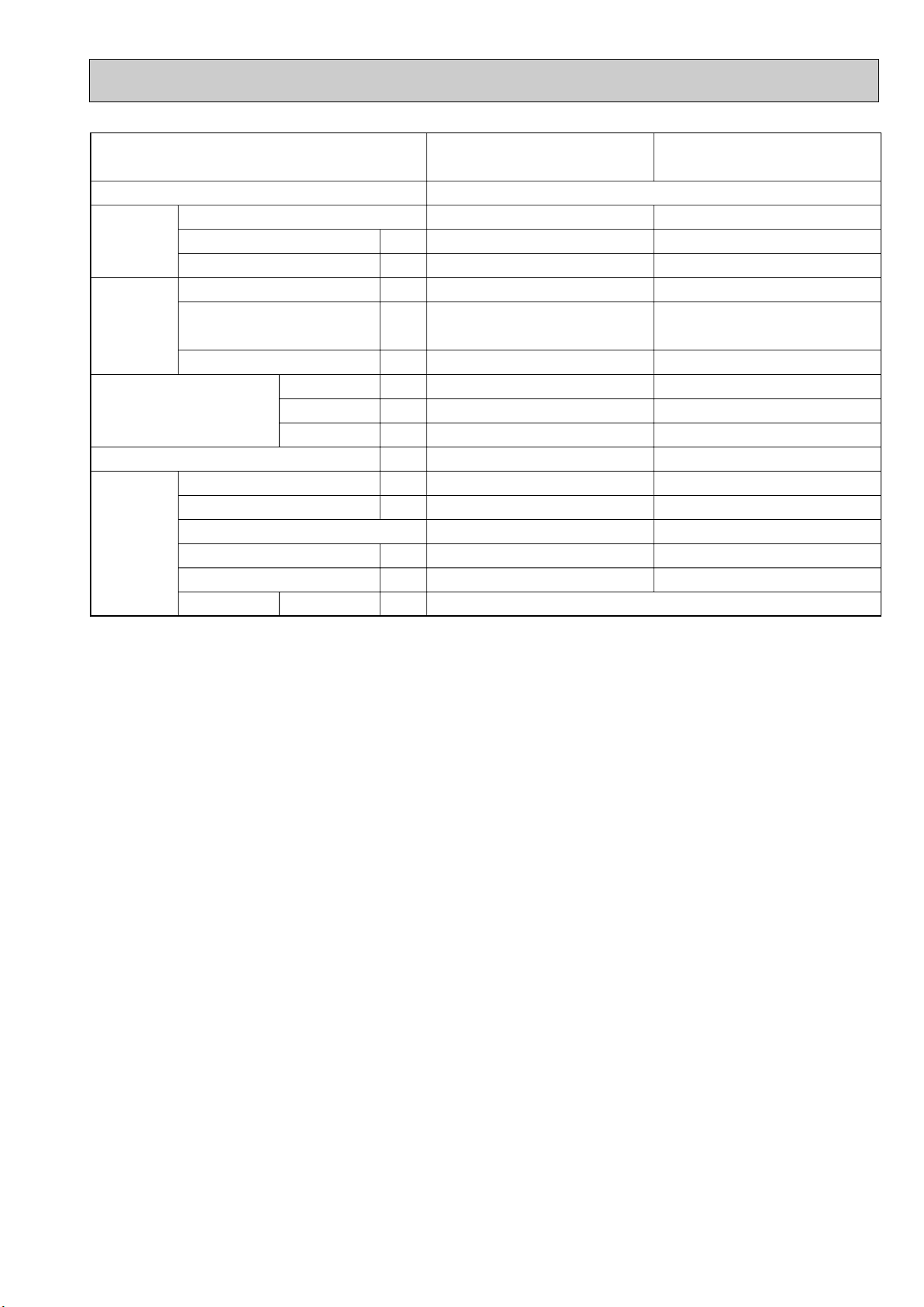

CONTENTS

1. TECHNICAL CHANGES···········································2

2. COMBINATION OF INDOOR OUTDOOR UNITS·····2

3. PART NAMES AND FUNCTIONS·····························2

4. SPECIFICATIONS·····················································3

5. DATA··········································································6

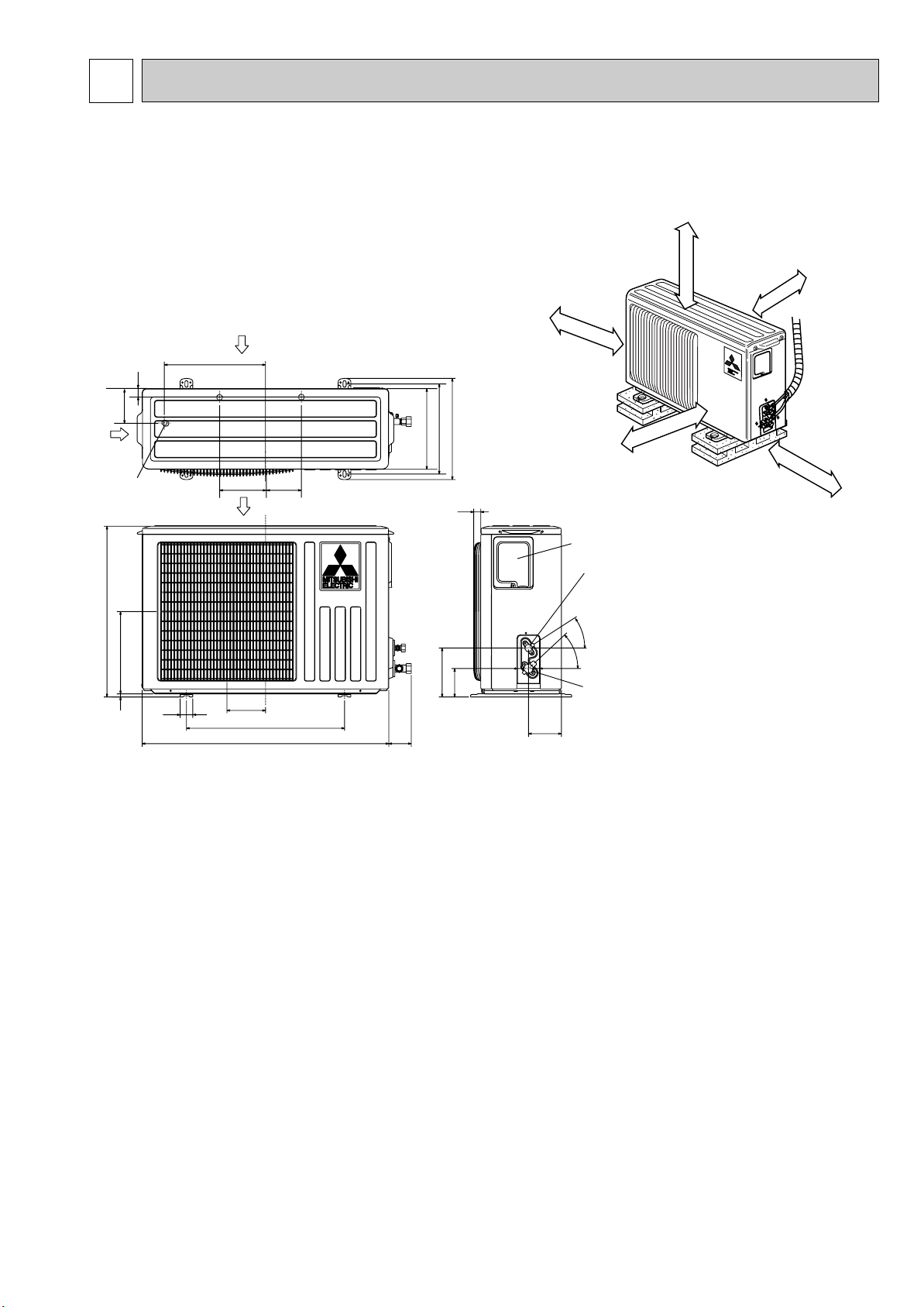

6. OUTLINES AND DIMENSIONS································9

7. WIRING DIAGRAM ·················································12

8.

REFRIGERANT SYSTEM DIAGRAM

OUTDOOR UNIT

9. TROUBLESHOOTING ············································26

10. DISASSEMBLY PROCEDURE ·······························28

11. PARTS LIST ····························································44

2

.TH

···························18

• SUH-2VR2.TH is added to REVISED EDITION-A .

• Please void OC282.

Page 2

1

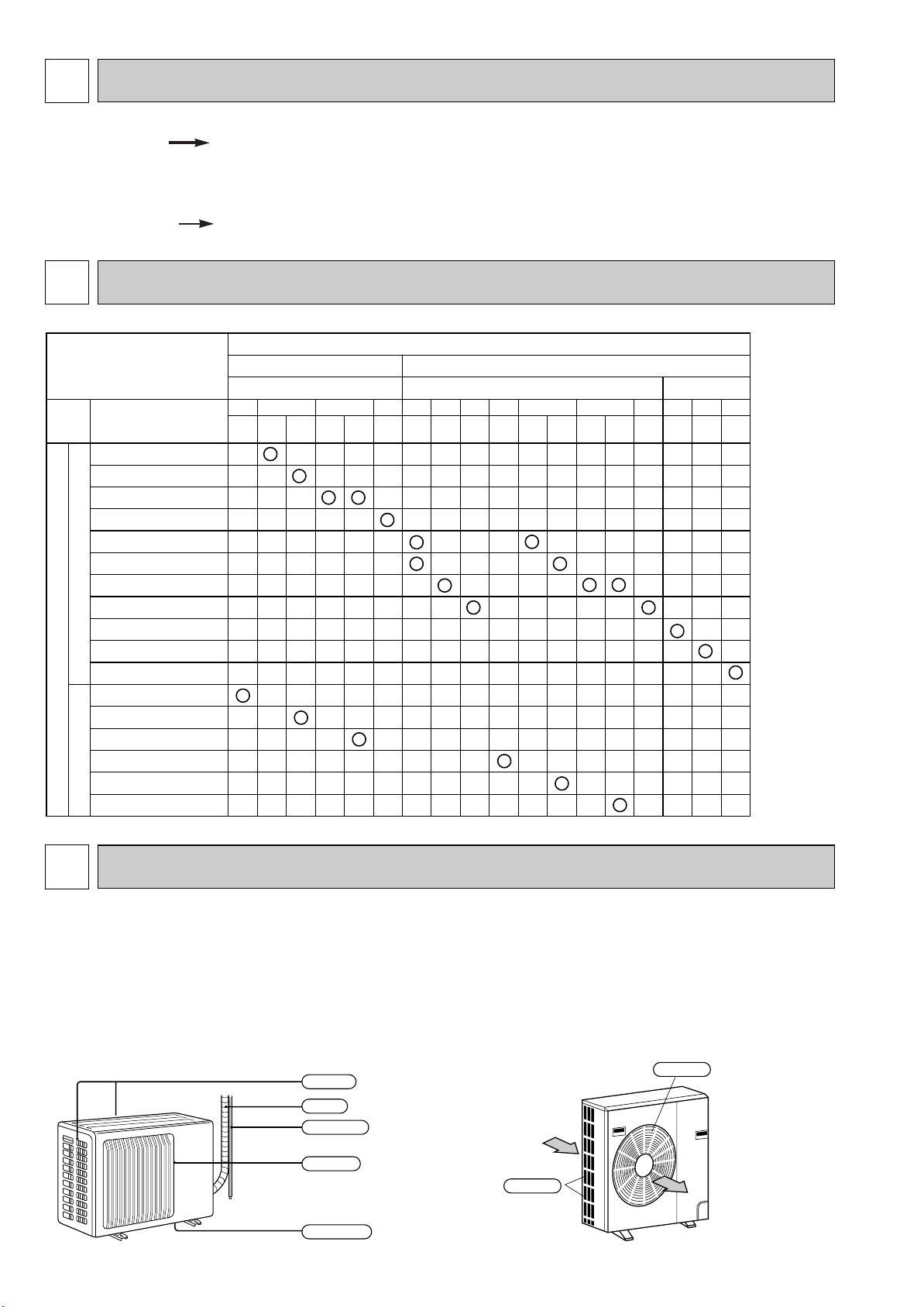

Air intake

Air outlet

Drain outlet

Piping

Drain hose

SEH-1.6AR.TH

SEH-1.6AR1.TH

SEH-2AR.TH

SEH-2.5AR.TH

SE-1.6AR.TH

SE-1.6AR1.TH

SE-2AR.TH

SE-2.5AR.TH

SE-1.6AR.TH-T

SE-2AR.TH-T

SE-2.5AR.TH-T

SLH-1AR.TH

SLH-1.6AR.TH

SLH-2AR.TH

SL-1AR.TH

SL-1.6AR.TH

SL-2AR.TH

VR

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

VR2

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

VR

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

NR

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

NR

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

NR

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

VR

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

VR

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

VR

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

VR2

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

VR

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

VR

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

1.6

Service Manual No.

OC281OC280

Service Ref.

2 2.5 2.5

1

1.6 2 2.5

1

VR

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

2 2.5

1.6

1.6 2

VR

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

VR1

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

VR

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

VR

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

Indoor unit

SUH- • .TH

Heat pump type

Outdoor unit

Cooling only type

SU- • .TH SU- • .TH-T

VR1

VR2

Air inlet

Air outlet

TECHNICAL CHANGES

SUH-2VR1.TH SUH-2VR2.TH

● OUTDOOR HEAT EXCHANGER has changed.

● RESTRICTOR VALVE has changed.

● CAPILLARY TUBE has changed.

({4.0X{2.4XL660) ({3.0X{2.0XL250)

2

COMBINATION OF INDOOR OUTDOOR UNITS

3

PART NAMES AND FUNCTIONS

SUH-1VR.TH SUH-1.6VR.TH SUH-2VR.TH SUH-2.5VR.TH

SU-1VR.TH SU-1.6VR.TH SU-2VR.TH SU-2.5VR.TH

SUH-1.6VR2.TH SUH-2VR1.TH

SU-1.6NR.TH SU-2NR.TH SU-2.5NR.TH

SU-1.6VR2.TH SU-2VR1.TH

SU-1.6VR.TH-T SU-2VR.TH-T SU-2.5VR.TH-T

SUH-2VR2.TH

2

Page 3

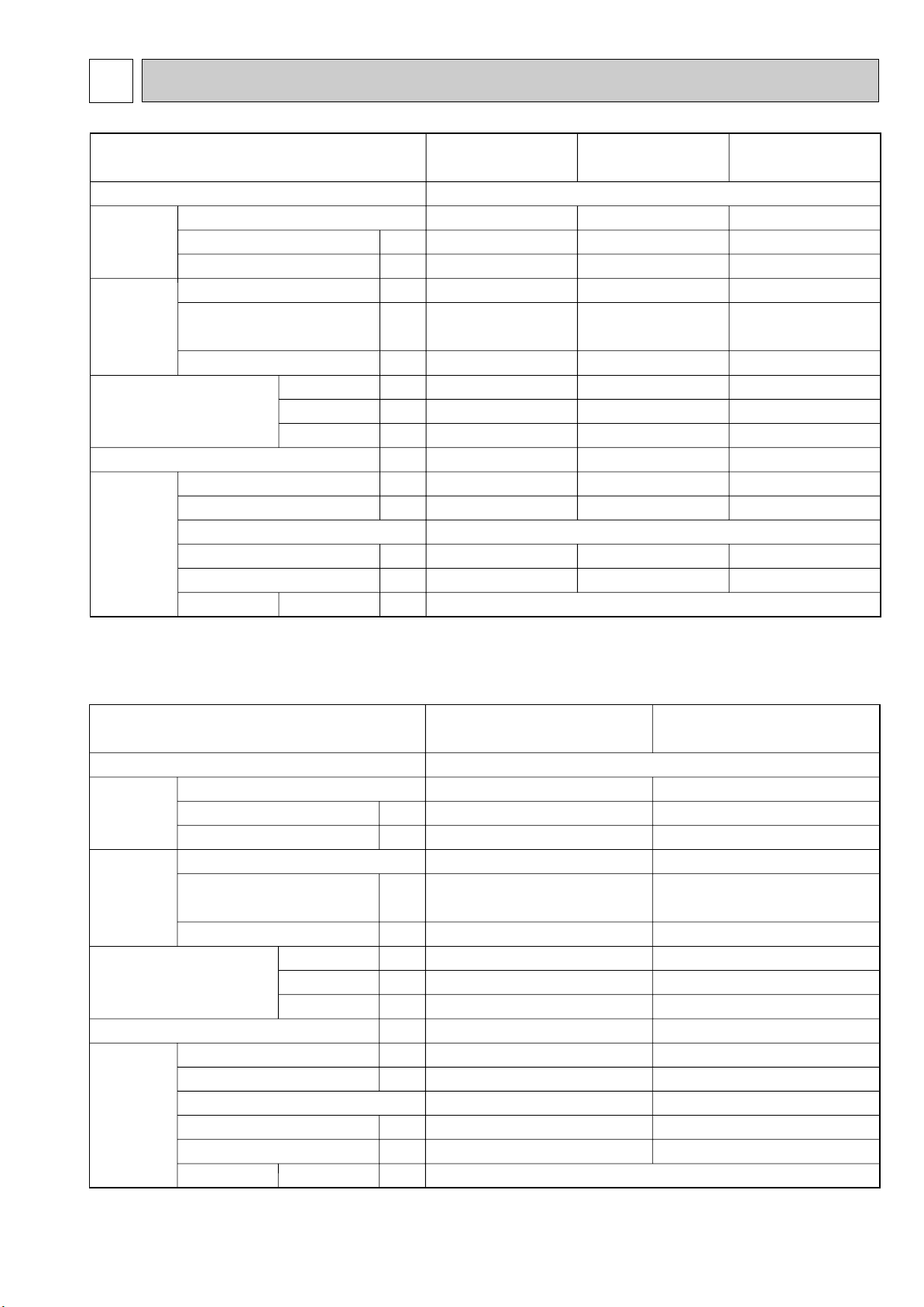

4

SUH-2VR.TH

SUH-2VR1.TH

SUH-2VR2.TH

Single phase, 220-240V, 50Hz

33.18

NH-38VMDT

1700

C-R: 1.07 C-S: 2.26

RA6V50-OF

WHT-BLK : 116

BLK-RED : 111

28(990)

850

605

290

59

52

810-845

1.8

MS-32(N-1) O 1.2

SUH-2.5VR.TH

NH-47VMDT

2200

C-R: 0.96 C-S: 2.70

RA6V85-AA

45(1590)

870

850

295

72

53

720-750

2

2.4

MS-32(N-1) O 1.2

WHT-BLK : 62.7

BLK-YLW : 30.2

YLW-RED : 62.9

1

Power supply

Service Ref.

W

"

"

m3/min(CFM)

mm

mm

mm

kg

dB

rpm

kg

R

k"

Compressor

Outdoor

fan motor

Dimensions

Width

Height

Depth

RT61(at 0:)

Weight

Special

remarks

Model

Output

Winding resistance (at 20:)

Model

Winding resistance (at 20:)

Airflow

Sound level (Hi)

Fan speed (Hi)

Fan speed regulator

Refrigerant filling capacity (R-22)

Refrigerant oil

Thermistor

Power supply

Service Ref.

W

"

"

m3/min(CFM)

mm

mm

mm

kg

dB

rpm

kg

R

k"

Compressor

Outdoor

fan motor

Dimensions

Width

Height

Depth

RT61(at 0:)

Weight

Special

remarks

Model

Output

Winding resistance (at 20:)

Model

Winding resistance (at 20:)

Airflow

Sound level (Hi)

Fan speed (Hi)

Fan speed regulator

Refrigerant filling capacity (R-22)

Refrigerant oil

Thermistor

SUH-1VR.TH

Single phase, 220-240V, 50Hz

SUH-1.6VR.TH

RH-174VGHT

800

C-R: 3.30 C-S: 5.80

PN6V23-UA

WHT-BLK : 353

BLK-RED : 321

28(990)

780

540

255

33

47

710-760

0.8

MS-56 O 0.30

RH-247VHAT

1200

C-R: 2.13 C-S: 3.91

RA6V40-EE

WHT-BLK : 130

BLK-RED : 135

36(1270)

850

605

290

43

50

780-820

1

1.65

MS-56 O 0.52

33.18

SUH-1.6VR2.TH

RH-277VHAT

1300

C-R: 1.80 C-S: 3.00

RA6V40-EE

WHT-BLK : 130

BLK-RED : 135

36(1270)

850

605

290

43

50

780-820

1.4

MS-56 O 0.52

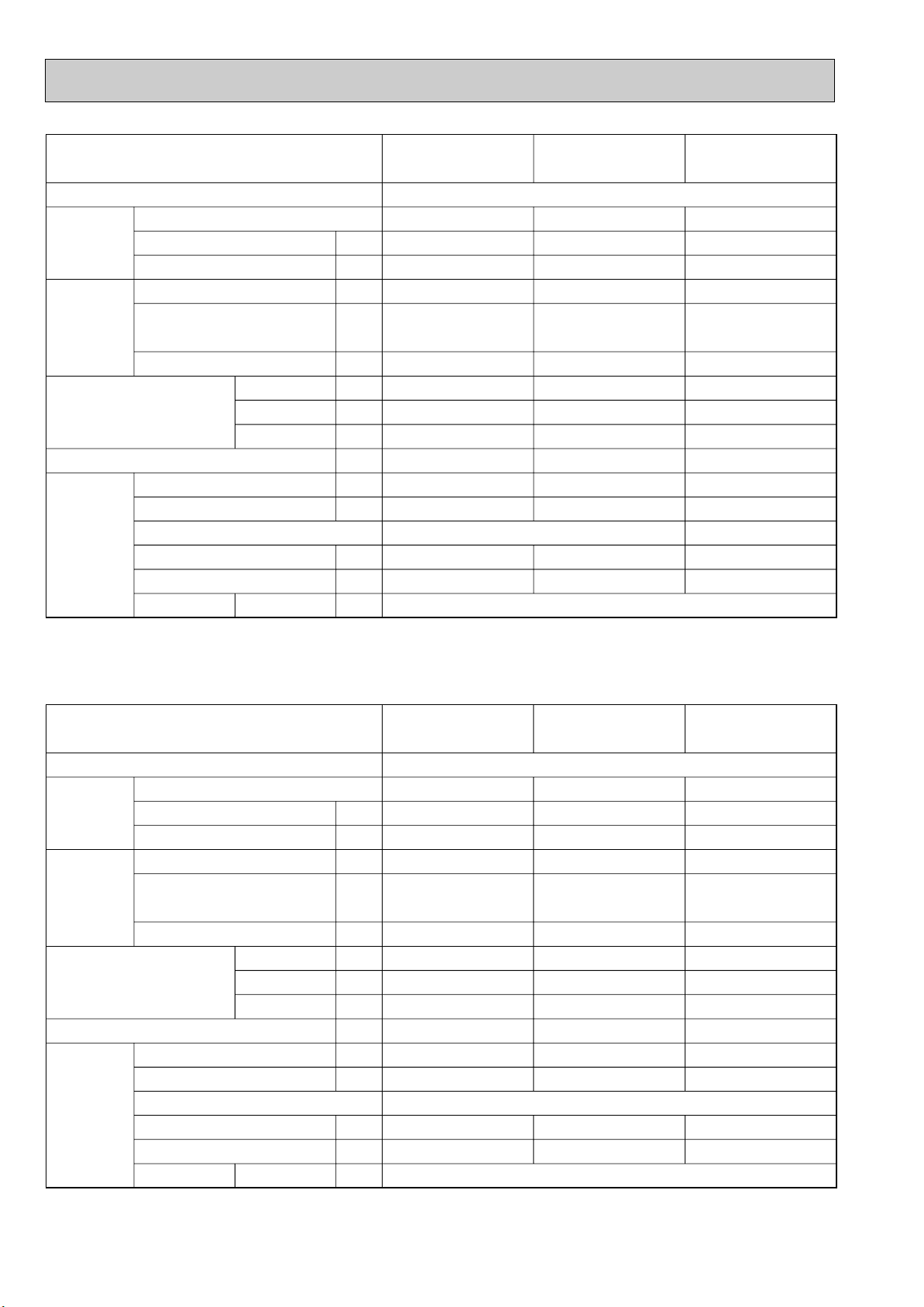

SPECIFICATIONS

3

Page 4

SU-1.6NR.TH SU-2NR.TH

Single phase, 220V, 60Hz

RH-207NHDT

1000

C-R: 1.68 C-S: 2.78

RA6V40-EE

WHT-BLK : 130

BLK-RED : 135

38(1340)

850

605

290

38

51

820

0.9

MS-56 O 0.52

NH-33NCDT

1500

C-R: 0.92 C-S: 1.93

RA6V50-OF

WHT-BLK : 116

BLK-RED : 111

39(1380)

850

605

290

55

52

860

1.65

MS-32(N-1) O 0.85

33.18

SU-2.5NR.TH

NH-38NBDT

1700

C-R: 0.83 C-S: 1.83

RA6V60-AB

41(1450)

850

605

290

61

54

930

2

2.15

MS-32(N-1) O 1.2

WHT-BLK : 81

BLK-YLW : 92

YLW-RED : 102

1

Power supply

Service Ref.

W

"

"

m3/min(CFM)

mm

mm

mm

kg

dB

rpm

kg

R

k"

Compressor

Outdoor

fan motor

Dimensions

Width

Height

Depth

RT61(at 0:)

Weight

Special

remarks

Model

Output

Winding resistance (at 20:)

Model

Winding resistance (at 20:)

Airflow

Sound level (Hi)

Fan speed (Hi)

Fan speed regulator

Refrigerant filling capacity (R-22)

Refrigerant oil

Thermistor

SU-1VR.TH

Single phase, 220-240V, 50Hz

SU-1.6VR.TH

SU-1.6VR.TH-T

RH-174VGHT

800

C-R: 3.30 C-S: 5.80

RA6V23-HC

WHT-BLK : 353

BLK-RED : 321

28(990)

780

540

255

32

45

710-760

0.8

MS-56 O 0.30

RH-247VHAT

1200

C-R: 2.13 C-S: 3.91

RA6V40-EE

WHT-BLK : 130

BLK-RED : 135

37(1310)

850

605

290

38

50

780-820

1

0.9

MS-56 O 0.52

33.18

SU-1.6VR2.TH

RH-277VHAT

1300

C-R: 1.80 C-S: 3.00

RA6V40-EE

WHT-BLK : 130

BLK-RED : 135

37(1310)

850

605

290

38

50

780-820

0.9

MS-56 O 0.52

Power supply

Service Ref.

W

"

"

m3/min(CFM)

mm

mm

mm

kg

dB

rpm

kg

R

k"

Compressor

Outdoor

fan motor

Dimensions

Width

Height

Depth

RT61(at 0:)

Weight

Special

remarks

Model

Output

Winding resistance (at 20:)

Model

Winding resistance (at 20:)

Airflow

Sound level (Hi)

Fan speed (Hi)

Fan speed regulator

Refrigerant filling capacity (R-22)

Refrigerant oil

Thermistor

4

Page 5

Compressor

Outdoor

fan motor

Dimensions

Weight

Special

remarks

Service Ref.

Power supply

Model

Output

Winding resistance (at 20:)

Model

Winding resistance (at 20:)

Airflow

Width

Height

Depth

Sound level (Hi)

Fan speed (Hi)

Fan speed regulator

Refrigerant filling capacity (R-22)

Refrigerant oil

Thermistor

RT61(at 0:)

W

"

"

m3/min(CFM)

mm

mm

mm

kg

dB

rpm

kg

R

k"

SU-2VR.TH SU-2VR1.TH

SU-2VR.TH-T

Single phase, 220-240V, 50Hz

NH38VMDT

1700

C-R: 1.07 C-S: 2.26

RA6V50-OF

WHT-BLK : 116

BLK-RED : 111

28(990)

850

605

290

55

52

810-845

1

1.6

MS-32(N-1) O 1.2

SU-2.5VR.TH

SU-2.5VR.TH-T

NH47VMDT

2200

C-R: 0.96 C-S: 2.70

RA6V60-AB

WHT-BLK : 81

BLK-YLW : 92.2

YLW-RED : 102

39(1380)

850

605

290

61

53

860-890

2

2.15

MS-32(N-1) O 1.2

33.18

5

Page 6

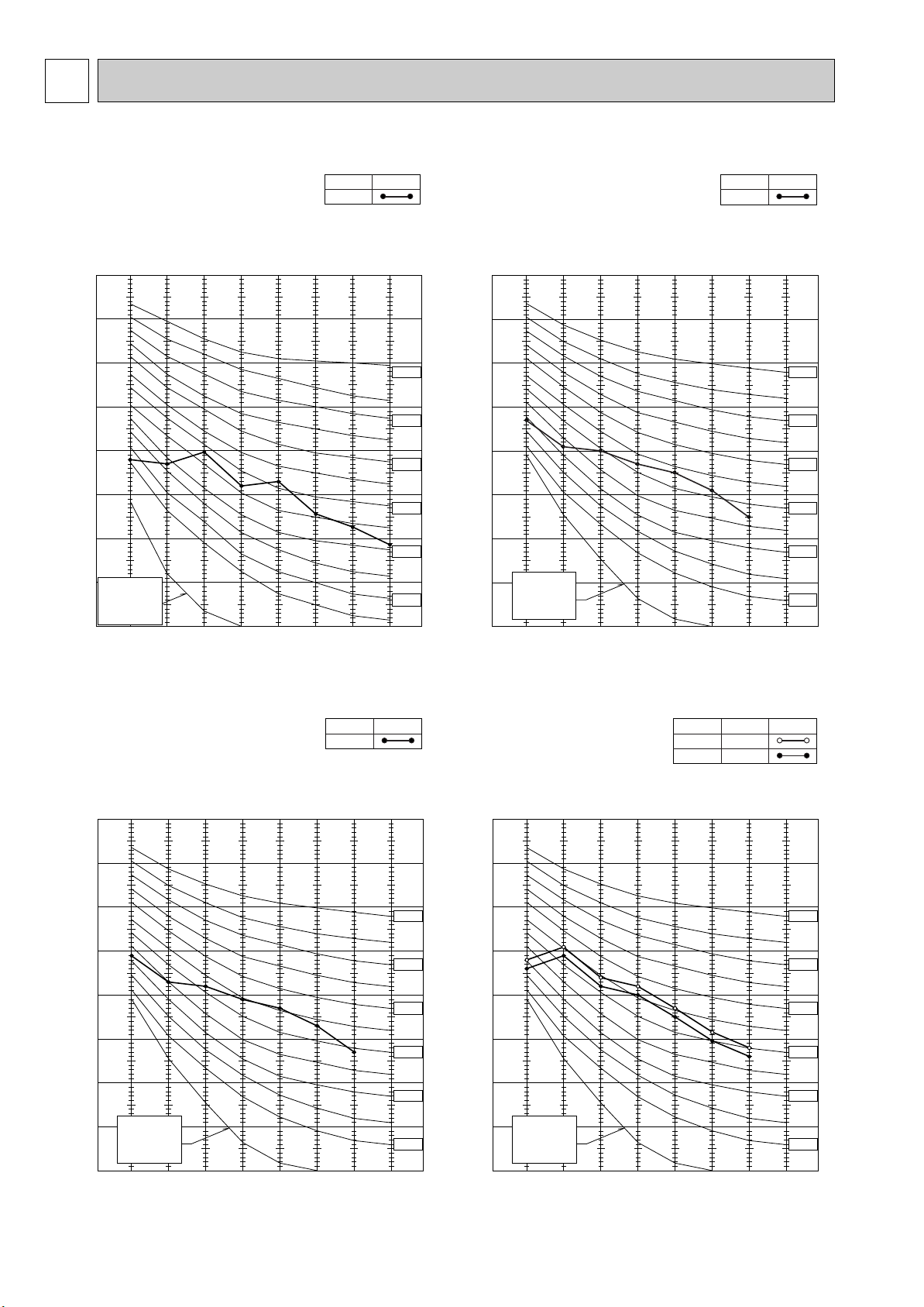

5 DATA

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

NC-60

NC-50

NC-40

NC-30

NC-70

NC-20

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

SUH-1VR.TH

47

SPL(dB) LINE

<50Hz>

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

NC-60

NC-50

NC-40

NC-30

NC-70

NC-20

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

SUH-1.6VR.TH

SUH-1.6VR2.TH

50

SPL(dB) LINE

<50Hz>

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

NC-60

NC-50

NC-40

NC-30

NC-70

NC-20

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

SUH-2VR.TH

SUH-2VR

1.TH

SUH-2VR

2.TH

52

SPL(dB) LINE

<50Hz>

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

NC-60

NC-50

NC-40

NC-30

NC-70

NC-20

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

SUH-2.5VR.TH

Hi

Lo

NOTCH

53

51

SPL(dB) LINE

<50Hz>

NOISE CRITERION CURVES

6

Page 7

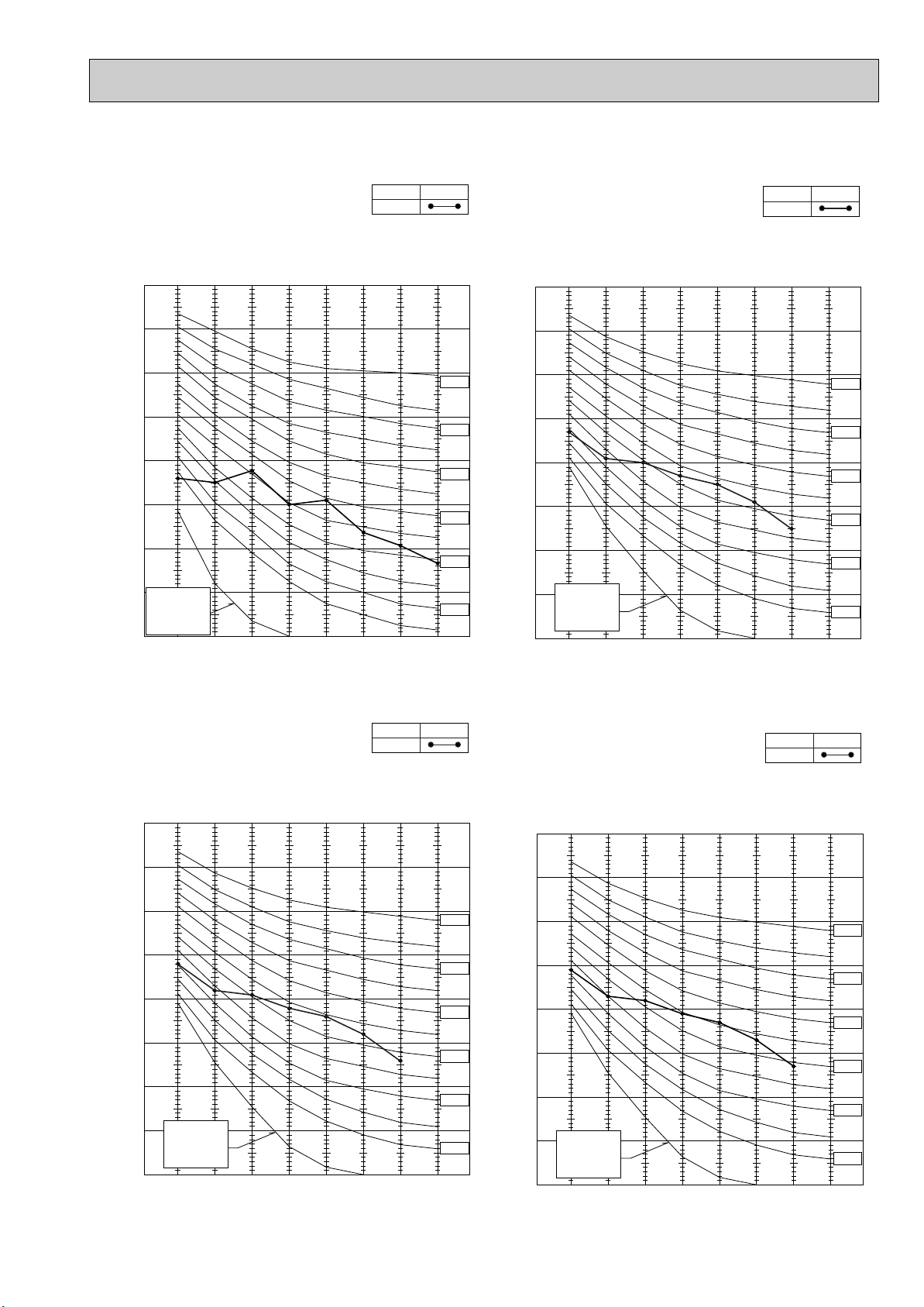

SU-1VR.TH

<50Hz>

SPL(dB) LINE

45

SU-1.6VR.TH

SU-1.6VR2.TH

SU-1.6VR.TH-T

<50Hz>

SPL(dB) LINE

50

90

80

70

60

50

40

30

20

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

10

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

SU-1.6NR.TH

SPL(dB) LINE

51

90

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

<60Hz>

90

80

70

60

50

40

30

APPROXIMATE

20

THRESHOLD OF

HEARING FOR

CONTINUOUS

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

NOISE

10

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

SU-2VR.TH

SU-2VR1.TH

SPL(dB) LINE

52

SU-2NR.TH

SU-2VR.TH-T

90

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

<50/60Hz>

80

70

60

50

40

30

APPROXIMATE

20

THRESHOLD OF

HEARING FOR

CONTINUOUS

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

NOISE

10

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

80

70

NC-70

60

NC-60

50

NC-50

40

NC-40

30

NC-30

APPROXIMATE

20

THRESHOLD OF

HEARING FOR

CONTINUOUS

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

NOISE

10

63 125 250 500 1000 2000 4000 8000

NC-20

BAND CENTER FREQUENCIES, Hz

7

Page 8

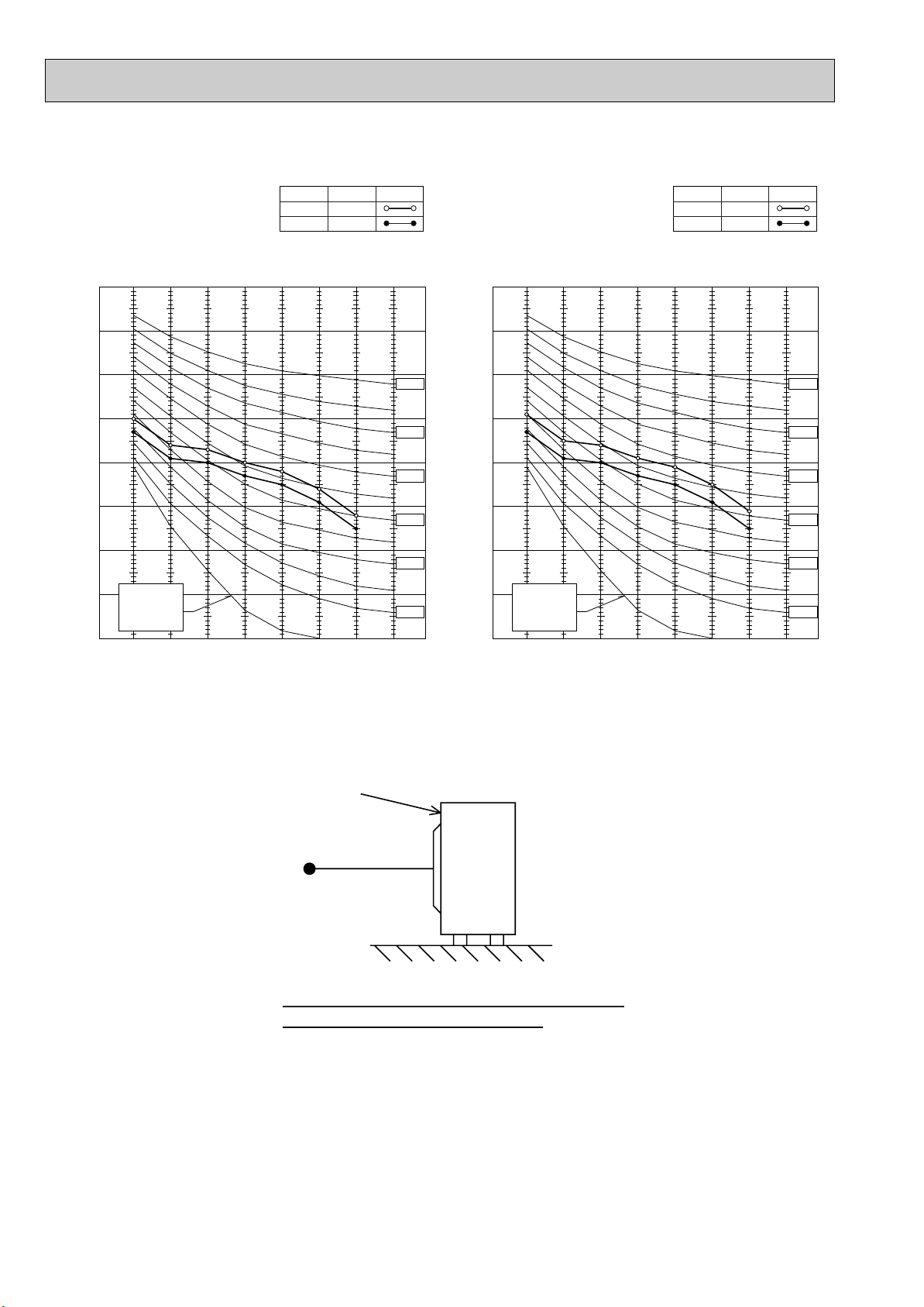

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

NC-60

NC-50

NC-40

NC-30

NC-70

NC-20

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

SU-2.5NR.TH

Hi

Lo

NOTCH

54

50

SPL(dB) LINE

<60Hz>

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

NC-60

NC-50

NC-40

NC-30

NC-70

NC-20

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

SU-2.5VR.TH

SU-2.5VR.TH-T

Hi

Lo

NOTCH

53

50

SPL(dB) LINE

<50Hz>

1m

UNIT

MICROPHONE

Ambient temperature 35°C (Cooling) / 7°C (Heating)

Test conditions are based on JIS Z8731

8

Page 9

6

320

25

43-

35-

155

90

104

74

260

10

780

500

122

40

540

320

285

255

Service panel

Gas refrigerant

pipe joint

Refrigerant pipe

(flared) [9.52

Liquid refrigerant

pipe joint

Refrigerant pipe

(flared) [6.35

Air out

Air in

Air in

109

32

110

147

Drainage

3holes [33

If clearance

behind the outdoor

units only 40B or 50B

side A must be

fully open.

10cm or more

10cm or more

10cm or more

Outdoor

unit

35cm or more

REQUIRED SPACE

A

40cm or more

OUTLINES AND DIMENSIONS

SUH-1VR.TH

SU-1VR.TH

Unit: mm

9

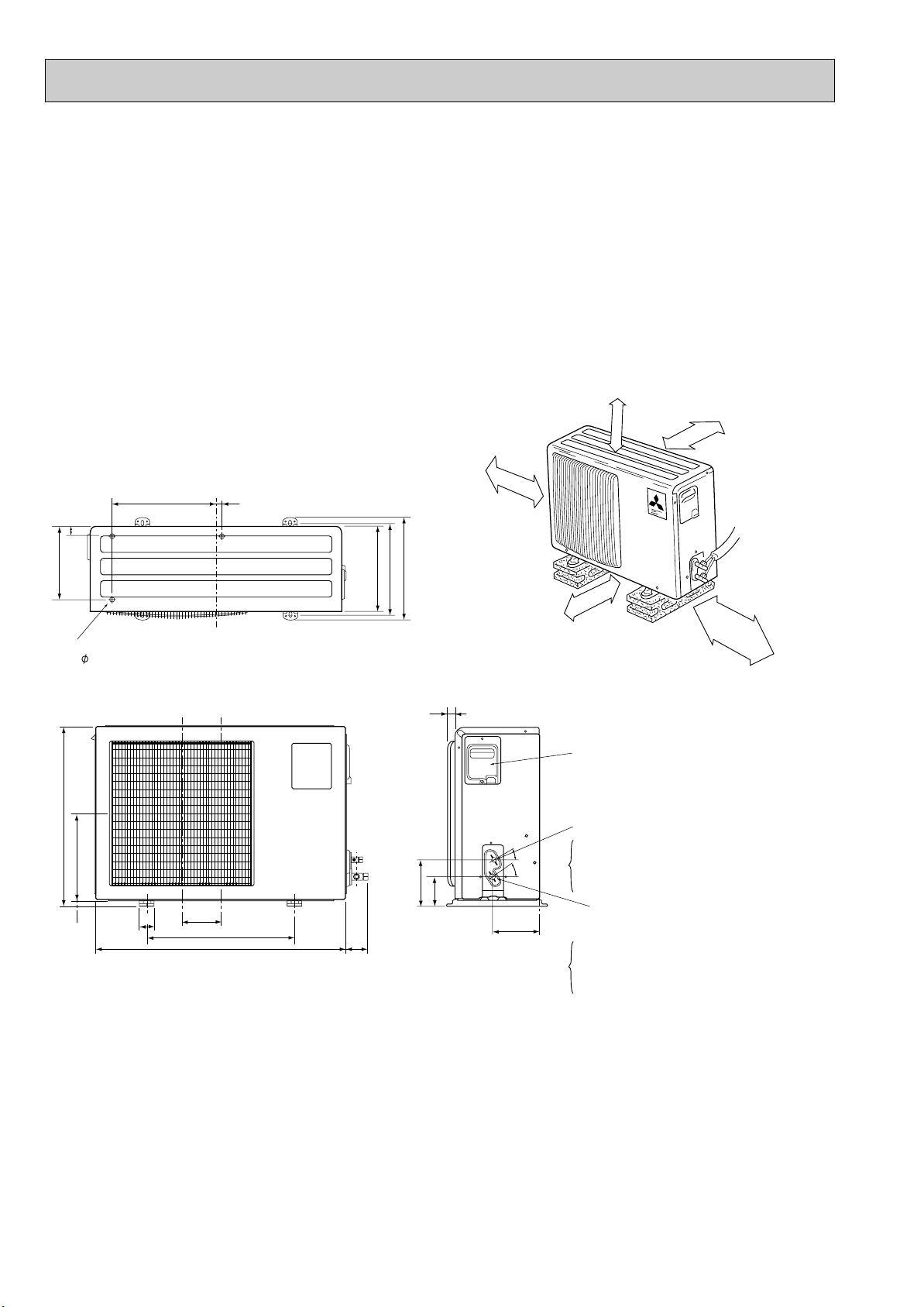

Page 10

350

Drainage

3holes 16.2

35

248

20

290

310

345

10cm or more

10cm or more

10cm or more

50cm or more

35cm or more

If the right/left sides or

back side is vacant,the

front has only to be 50cm

unobstructed.

If the front or right/left sides

are vacant, the top has only

to be 10cm unobstructed.

605

29220

50

183

500

161

850

74

30

100

157

35

30

Service panel

Liquid refrigerant

pipe joint

Refrigerant pipe

(flare)

Gas refrigerant

pipe joint

Refrigerant pipe

(flare)

[12.7 (SUH-1.6VR(2).TH) (SU-1.6NR.TH)

(SU-1.6VR(2).TH,SU-1.6VR.TH-T)

[15.88 (SUH-2VR.TH) (SU-2/2.5NR.TH)

(SU-2/2.5VR.TH,SU-2/2.5VR.TH-T)

[6.35 (SUH-1.6/2VR(2).TH) (SU-1.6/2NR.TH)

(SU-1.6/2VR(2).TH,SU-1.6/2VR.TH-T)

[9.52 (SU-2.5NR.TH)

(SU-2.5VR.TH,SU-2.5VR.TH-T)

SUH-1.6VR.TH SUH-2VR.TH

SUH-1.6VR2.TH SUH-2VR1.TH

SUH-2VR2.TH

SU-1.6NR.TH SU-2NR.TH SU-2.5NR.TH

SU-1.6VR.TH SU-2VR.TH SU-2.5VR.TH

SU-1.6VR2.TH SU-2VR1.TH

SU-1.6VR.TH-T SU-2VR.TH-T SU-2.5VR.TH-T

Unit: mm

10

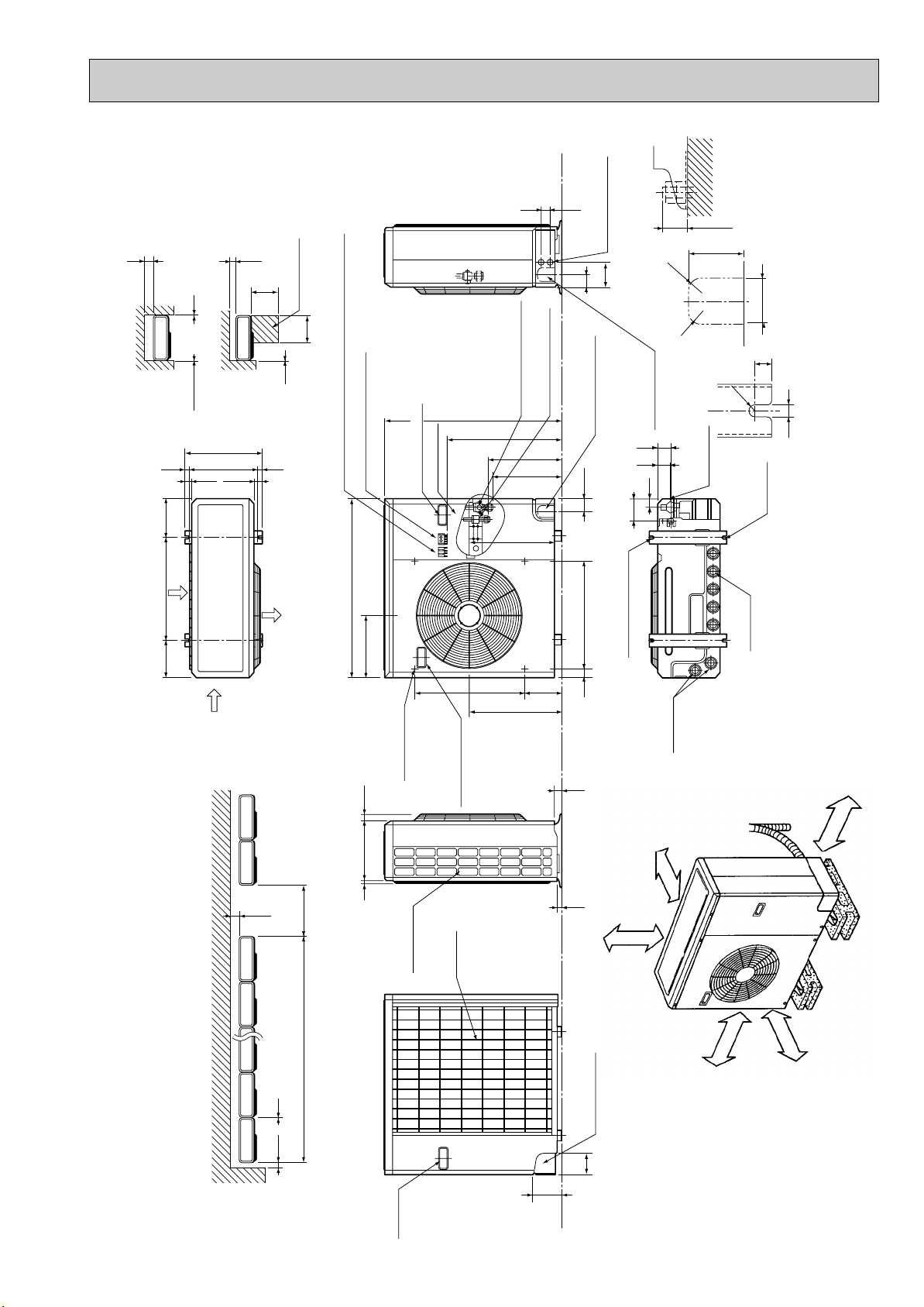

Page 11

SUH-2.5VR.TH

Unit : mm

200

Note:Allow adequate

upper clearance

10

150

500

Service space

4553

Knock out holes for

power line 2-[27

120

60

R20

25 max.

Standard bolt length

80

65

500

Front opening

10

10

Outdoor Unit-Necessary surrounding clearance

362

1715

Air intake

500

185 185

330

39.5 27.5

Air intake

Air outlet

Refrigerant-pipe flared

connection [15.88 5/8F

Refrigerant-pipe flared

553

connection [9.52 3/8F

Knock out hole

352

337

403

179 524

441

850

Terminal block for power line

Terminal block for indoor and outdoor unit connection

870

302

Service panel

Handle for moving

Outlet guide

installation hole

Handle for moving

for front piping

40 60524

33

Knock out hole

(refrigerant,drainage

and wiring)

104

2-12o23 Oval holes

(standard bolt M10)

R20

for right piping

(refrigerant,drainage

and wiring)

45

42

Bottom

33

piping hole

Drain hole

Front right piping holes-

detail figures

17

R6

12

2-U-shaped

notched

holes

Drain hole

More than 350 mm

724295

200

1000For 10 units or less

The upper side must be open.

Outdoor Unit-Necessary surrounding clearance

(Concentrated installation)

100 10

Handle

for moving

Side air intake

Rear fresh

air intake

11

23

95

138

More than 100 mm

Open as a rule

More than 500 mm if the

front and both sides are open.

Rear piping hole

More than 200 mm if three

area obstacles to both sides.

More than 10 mm

Open as a rule

More than 500 mm if the

back both sides and top

are open.

Page 12

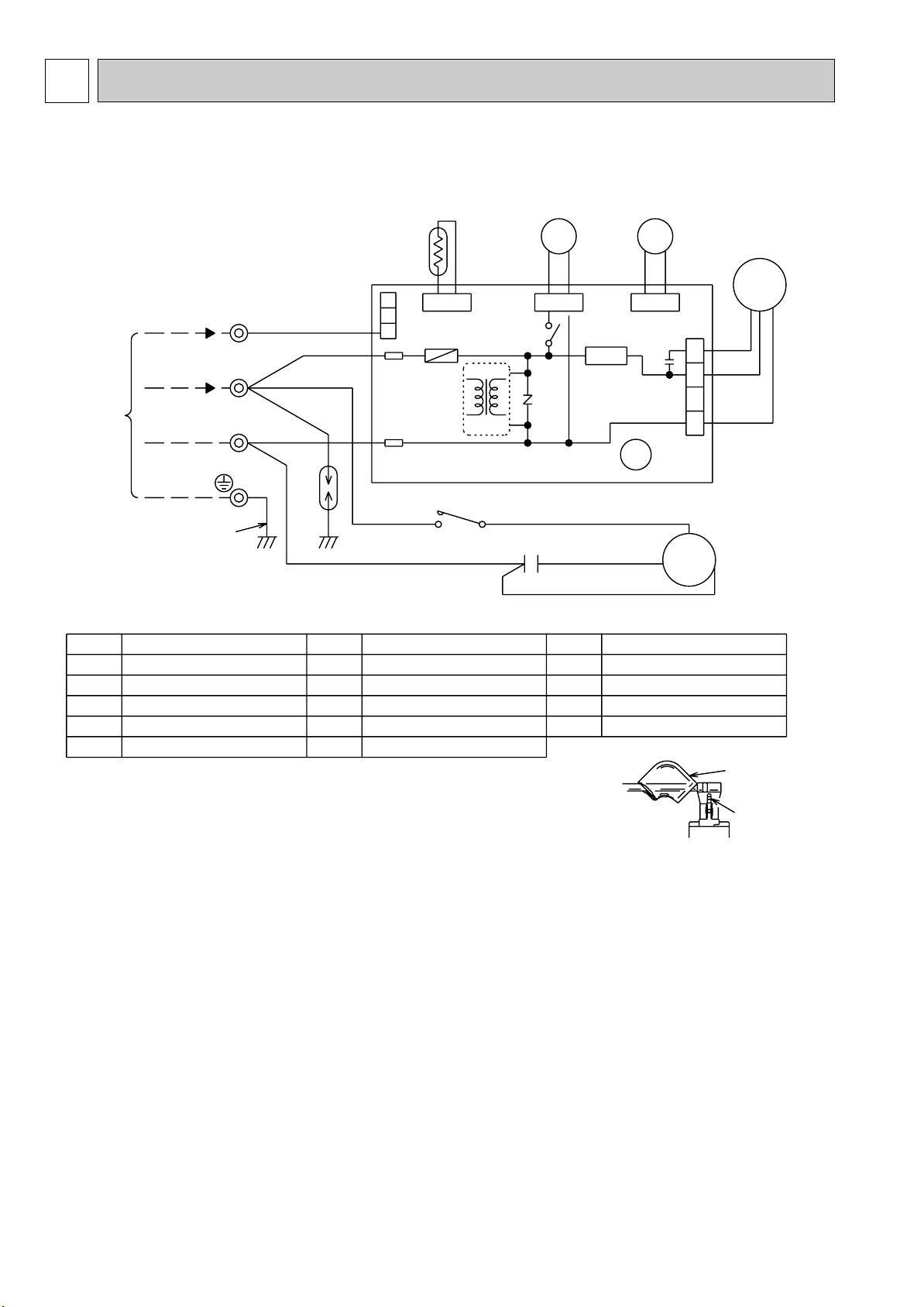

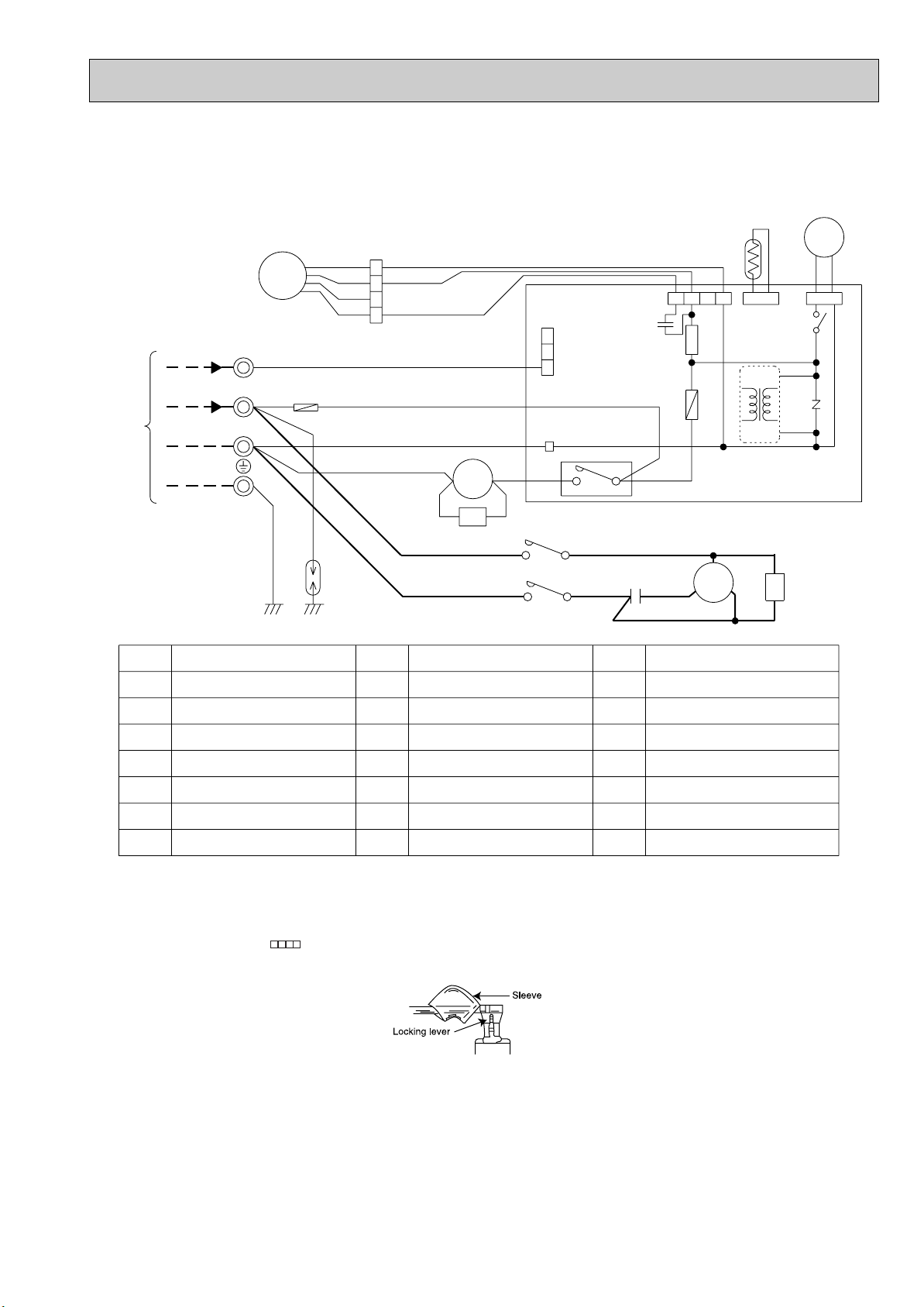

7

CN720

52C

X62

21S4

CN721

MF

SR61

CN611

MC

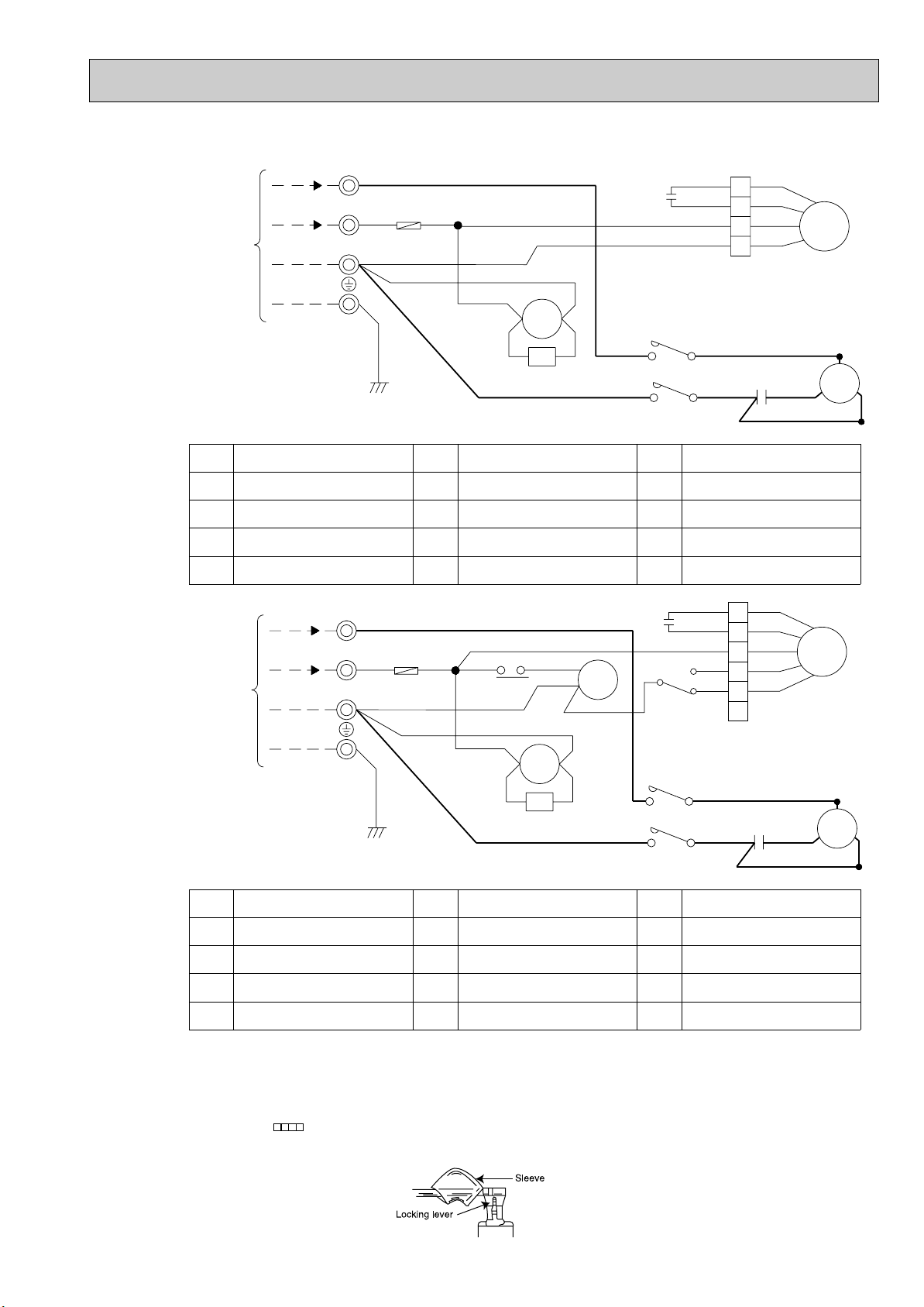

3

2

1

locking lever

1 Slide the sleeve.

2 Pull the wire while

pushing the locking lever.

sleeve

WHT

WHT

VLT

VLT

NO

COM

52C

w

TAB21

WHT

RED

RED

WHT

w

BLU

RED

BLK

CN730

C65

DEICER P.C. BOARD

RT61

F61

IC881

X62

CN711

BLK

NR61

TRANS

TAB20

RS

C

C1

TO

INDOOR UNIT

CONNECTING

3 w

NAME

SYMBOL

NAME

SYMBOL

NAME

SYMBOL

C1

C65

DSAR

F61

IC881

COMPRESSOR CAPACITOR

FAN MOTOR CAPACITOR

SURGE ABSORBER

FASE (2A)

DC/DC CONVERTER

NOTE :1. Use copper conductors only (For field wiring).

2. “w” shows the terminals with a lock mechanism, so they cannot be

removed when you pull the lead wire.

Be sure to pull the lead wire by pushing the locking lever (projected part)

of the terminal with a finger.

MC

MF

NR61

RT61

SR61

COMPRESSOR (INNER THERMOSTAT)

FAN MOTOR (INNER THERMOSTAT)

VARISTOR

DEFROST THERMISTOR

SOLID STATE RELAY

TB

X62

21S4

52C

TERMINAL BLOCK

4-WAY VALVE RELAY

4-WAY VALVE SOLENOID COIL

COMPRESSOR CONTACTOR

w

TB

12VDC

220-240V~

2

WHT

DSAR

w

BLU

GRN/YLW

N

4

3

2

1

BLK

BLK

WIRING DIAGRAM

SUH-1VR.TH

12

Page 13

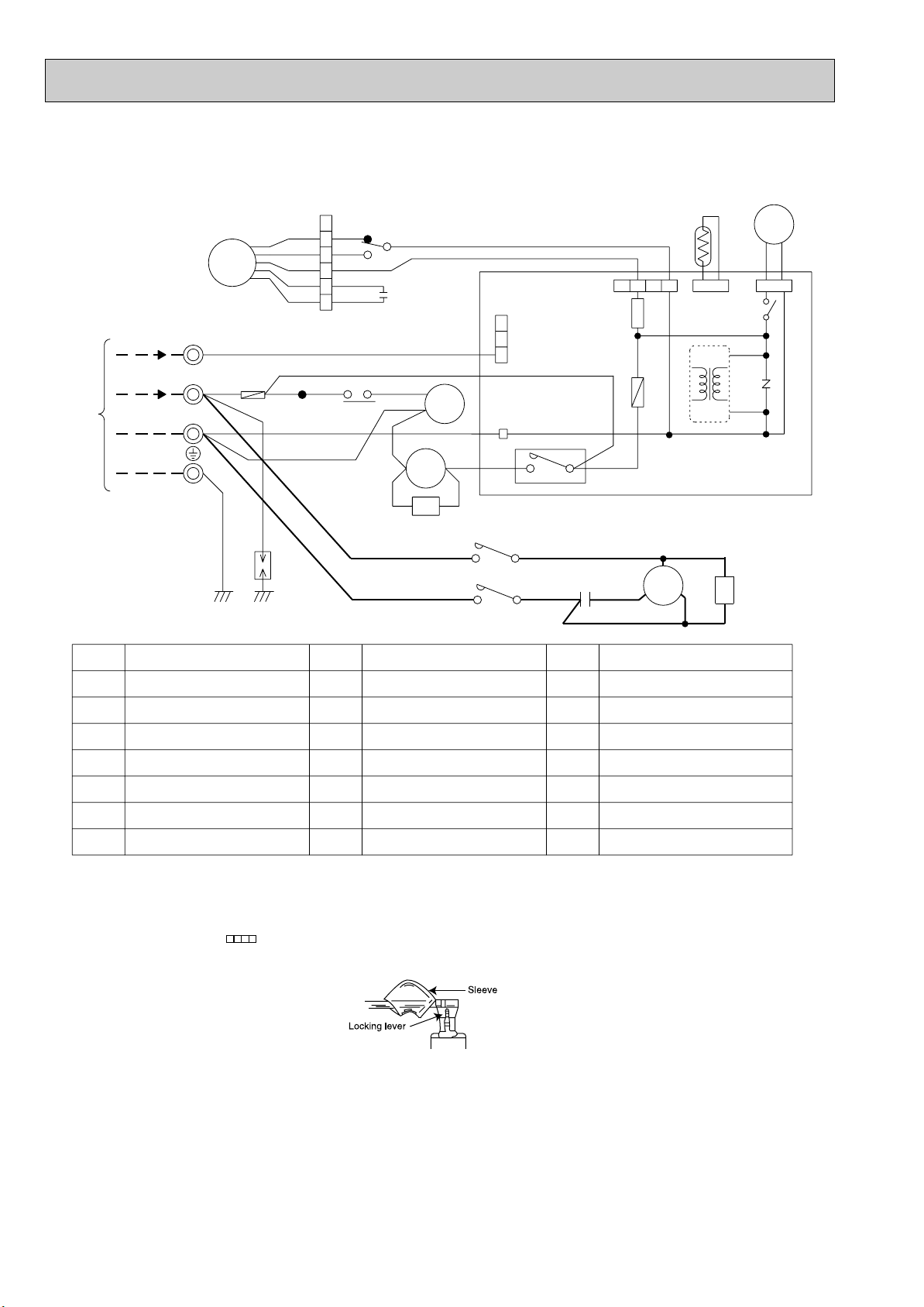

SUH-1.6VR.TH SUH-2VR.TH

220-240V

12VDC

RED

BLK

BLU

F

WHT

WHT

WHT

DSAR

TB

GRN/YLW

RED

W

W

WW

W

W

W

W

W

3

2

N

TO INDOOR

UNIT

CONNECTING

WHT

BLU

BLK

WHT

ORN

RED

MF

BLU

WHT

A1

A2

VLT YLW

CR

52C1

BLU

CZ

WHTWHT

T3/6L3/5

L1/1 T1/2

52C1

WHT

C1

RED

BLK

S

C

R

MC

4

TAB20

52C

3

YLW

CN730

2

1

3

C65

SR61

X62

NR61

TRANS

IC881

BLK

CN721

BLK

21S4

DEICER

P.C. BOARD

CN711

CN661

123

RT61

4

F61

2

1

3

4

TB

CZ SURGE ABSORBER 3

CR SURGE ABSORBER 2

IC881 DC/DC CONVERTER

F61 FUSE (2A)

CONTACTOR

4-WAY VALVE SOLENOID COIL

21S4

X62

MF

FAN MOTOR

<INNER THERMOSTAT>

MC

COMPRESSOR

<INNER THERMOSTAT>

SR61

RT61

NR61 V ARIST OR

F

C65

SYMBOL

NAME NAME

C1

DSAR

SYMBOL

COMPRESSOR CAPACITOR

SURGE ABSORBER 1FAN MOTOR CAPACITOR

FUSE (2A)

TERMINAL BLOCK

52C1

52C

COMPRESSOR CONTACTOR

4-WAY

VALVE RELAY

SOLID STATE RELAY

DEFROST THERMISTOR

NAME

SYMBOL

SUH-1.6VR2.TH SUH-2VR1.TH

SUH-2VR2.TH

NOTE :1. Use copper conductors only. (For field wiring)

2. Since the indoor and outdoor unit connecting wires have polarity, connect them according to the numbers

(N,2,3 and ;).

3. Symbols below indicate.

/:Terminal block, : Connector

4. ”w” shows the terminals with a lock mechanism,so they cannot be removed when you pull the lead wire.

Be sure to pull the wire by pushing the locking lever (projected part) of the terminal with a finger.

1Slide the sleeve.

2Pull the wire while pushing the locking lever.

13

Page 14

SUH-2.5VR.TH

RED

ORN

WHT

BLK

YLW

12VDC

TB

YLW

2

1

BLK

WHT

ORN

RED

3

4

5

6

MF

X1

BRN

SR61

X62

BLK

CN721

CN730

2

1

3

BLK

21S4

1

5

3

C2

CN711

CN661

123

RT61

4

A2

A1

ORN

WHT

YLWVLT

TB2

CR

WHT

4

52C1

F61

NR61

TRANS

IC881

220-240V~

DSAR

GRN/YLW

RED

W

W

W

W

WW

3

2

N

TO INDOOR

UNIT

CONNECTING

WHT

RED

7

RED

VLT

BLU

26F1

X1

WHT

TAB20

52C

3

YLW

DEICER

P.C. BOARD

BLU

WHTWHT

CZ

T3/6L3/5

BLU

L1/1 T1/2

52C1

WHT

C1

RED

BLK

S

C

R

MC

BLU

8

F

CZ SURGE ABSORBER 3

CR SURGE ABSORBER 2

IC881 DC/DC CONVERTERF61 FUSE (2A)

CONTACTOR

4-WAY VALVE SOLENOID COIL

21S4

X62

MF

FAN MOTOR

<INNER THERMOSTAT>

MC

COMPRESSOR

<INNER THERMOSTAT>

TB,TB2

SR61

RT61

NR61 V ARIST OR

F

C2

SYMBOL

NAME NAME

C1

DSAR

SYMBOL

COMPRESSOR CAPACITOR

SURGE ABSORBER 1

FAN MOTOR CAPACITOR

FUSE (2A)

TERMINAL BLOCK

52C1

THERMAL REED SWITCH

26F1

X1 FAN MOTOR RELAY

52C

COMPRESSOR CONTACTOR

4-WAY VALVE RELAY

SOLID STATE RELAY

DEFROST THERMISTOR

NAME

SYMBOL

NOTE :1. Use copper conductors only. (For field wiring)

2. Since the indoor and outdoor unit connecting wires have polarity, connect them according to the numbers

(N,2,3 and ;).

3. Symbols below indicate.

/:Terminal block, : Connector

4. ”w” shows the terminals with a lock mechanism,so they cannot be removed when you pull the lead wire.

Be sure to pull the wire by pushing the locking lever (projected part) of the terminal with a finger.

1Slide the sleeve.

2Pull the wire while pushing the locking lever.

14

Page 15

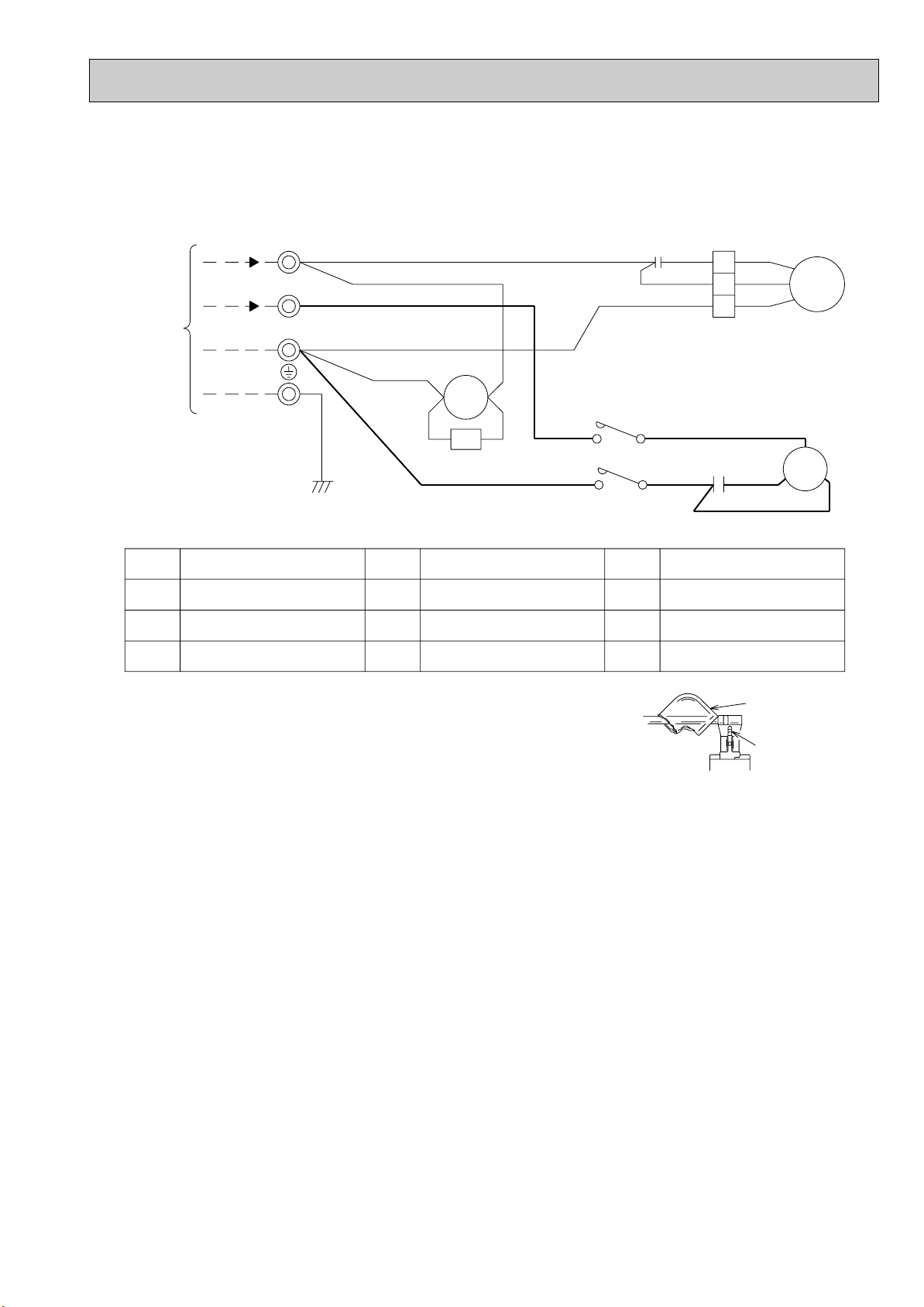

SU-1VR.TH

RED

WHT

RED

BLU

locking lever

sleeve

COMPRESSOR CONTACTOR

52C

VLT

YLW

BLU

WHT

RED

52C

52C

2

1

3

C2

WHT

BLK

RED

WHT

MF

MC

CR

A2

A1

BLU

L1/1

L3/5

R

C

S

BLK

RED

C1

T1/2

T3/6

BLU

GRN/YLW

3

2

N

TB

TO

INDOOR UNIT

CONNECTING

220-240V~

220-240V~

w

w

w

1 Slide the sleeve.

2 Pull the wire while

pushing the locking lever.

NAME

SYMBOL

NAME

SYMBOL

NAME

SYMBOL

CR

C1

C2

SURGE ABSORBER

COMPRESSOR CAPACITOR

FAN MOTOR CAPACITOR

NOTE :1. Use copper conductors only (For field wiring).

2. “w” shows the terminals with a lock mechanism, so they cannot be

removed when you pull the lead wire.

Be sure to pull the lead wire by pushing the locking lever (projected part)

of the terminal with a finger.

MC

MF

TB

COMPRESSOR (INNER THERMOSTAT)

FAN MOTOR (INNER THERMOSTAT)

TERMINAL BLOCK

15

Page 16

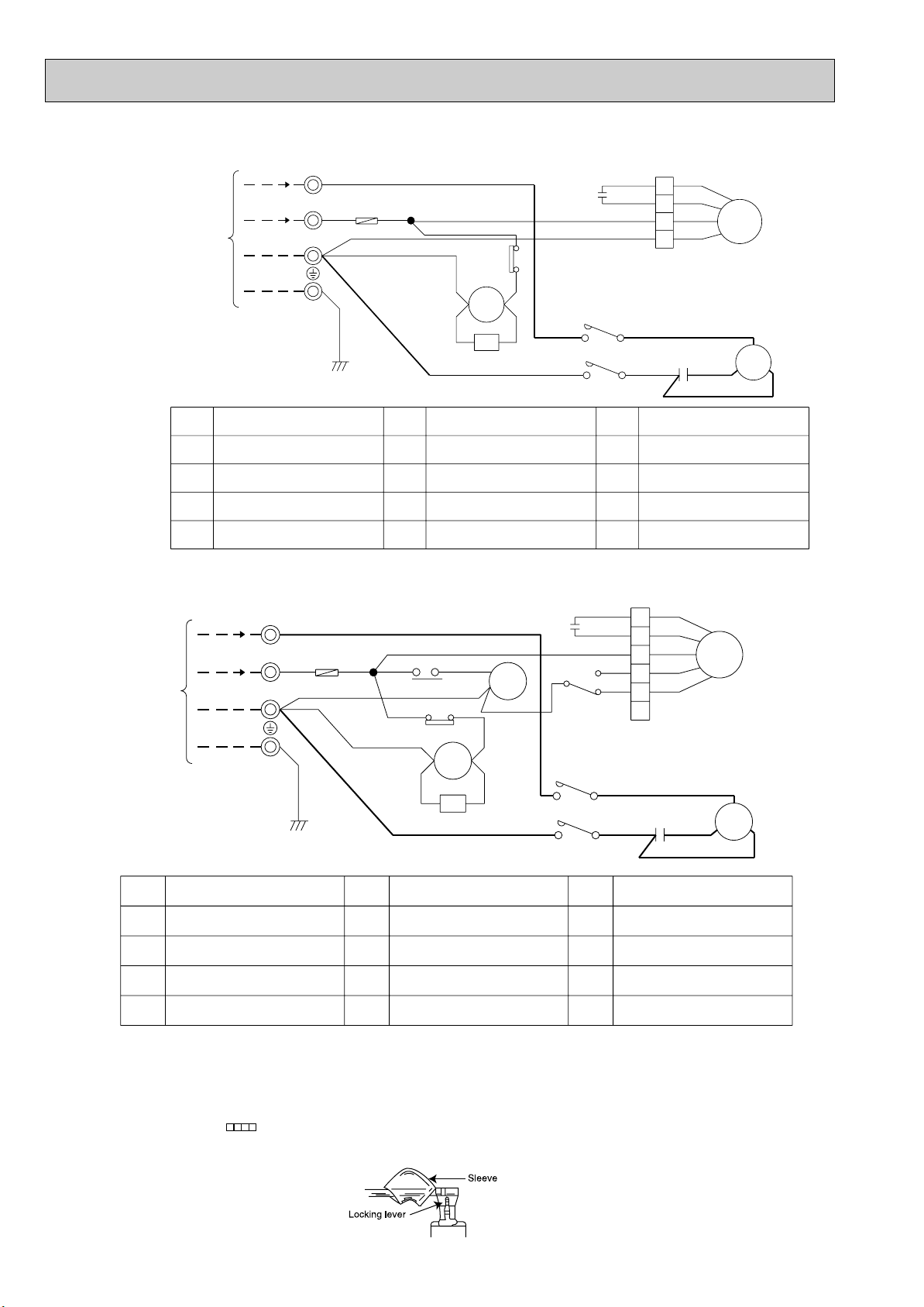

SU-1.6NR.TH

BLK

BLK

YLW

VLT

26C

BLU

WHT

RED

RED

BLU

WHT

ORN

RED

52C

52C

4

3

2

1

C2

WHT

BLK

ORN

RED

WHT

MF

MC

CR

A2

A1

BLU

F

TB2

L1/1

L3/5

R

C

S

BLK

RED

C1

T1/2

T3/6

BLU

GRN/YLW

2

3

TO INDOOR

UNIT

CONNECTING

W

W

W

TB

220V, 60Hz

220V, 60Hz

THERMAL SWITCH26C

TB2 TERMINAL BLOCKF FUSE(2A)

CR SURGE ABSORBER

TERMINAL BLOCK

COMPRESSOR CONTACTOR52C

TB

FAN MOTOR

(INNER THERMOSTAT)

(INNER THERMOSTAT)

COMPRESSOR

MC

FAN MOTOR CAPACITOR

COMPRESSOR CAPACITOR

C2

C1

NAME

SYMBOL

NAME

SYMBOL

NAME

SYMBOL

MF

N

YLW

VLT

BLK

CR

A2

A1

26C

BLK

BLU

ORN

BLU

X1

26F1

F

RED

8

7

BLU

RED

WHT

52C

TB2

RED

C2

GRN/YLW

2

3

RED

N

W

W

W

TB

220V, 60Hz

220V, 60Hz

L1/1

L3/5

MC

R

C

S

BLK

RED

C1

WHT

52C

T1/2

T3/6

BLU

TO INDOOR

UNIT

CONNECTING

1

3

5

X1

6

5

4

3

2

1

YLW

MF

YLW

BLK BLK

WHT

RED

ORN

WHT

ORN

RED

THERMAL SWITCH26CTB2 TERMINAL BLOCKF FUSE(2A)

CR SURGE ABSORBER

THERMAL LEAD SWITCH26F1

FAN MOTOR RELAYX1

TERMINAL BLOCK COMPRESSOR CONTACTOR52CTB

FAN MOTOR

(INNER THERMOSTAT)

(INNER THERMOSTAT)

COMPRESSOR

MF

MC

FAN MOTOR CAPACITOR

COMPRESSOR CAPACITOR

C2

C1

NAME

SYMBOL

NAME

SYMBOL

NAME

SYMBOL

SU-2NR.TH

SU-2.5NR.TH

NOTE :1. Use copper conductors only. (For field wiring)

2. Since the indoor and outdoor unit connecting wires have polarity, connect them according to the numbers

(N,2,3 and ;).

3. Symbols below indicate.

/:Terminal block, : Connector

4. ”w” shows the terminals with a lock mechanism,so they cannot be removed when you pull the lead wire.

Be sure to pull the wire by pushing the locking lever (projected part) of the terminal with a finger.

16

1Slide the sleeve.

2Pull the wire while pushing the locking lever.

Page 17

SU-1.6VR.TH

VLT

YLW

BLU

WHT

WHT

RED

RED

BLU

WHT

ORN

RED

52C

52C

4

3

2

1

C2

WHT

BLK

ORN

RED

WHT

MF

MC

CR

A1

A2

BLU

F

TB2

L1/1

L3/5

R

C

S

BLK

RED

C1

T1/2

T3/6

BLU

GRN/YLW

2

3

TO INDOOR

UNIT

CONNECTING

N

TB

220-240V,50Hz

220-240V,50Hz

W

W

W

W

W

W

YLW

VLT

BLU

ORN

1

3

5

X1

BLU

X1

26F1

F

RED

8

7

BLU

RED

WHT

52C

CR

TB2

WHT

RED

A1

A2

6

5

4

3

2

1

YLW

C2

MF

YLW

BLK BLK

WHT

RED

ORN

WHT

ORN

RED

L1/1

L3/5

MC

R

C

S

BLK

RED

C1

WHT

52C

T1/2

T3/6

BLU

GRN/YLW

2

3

RED

TO INDOOR

UNIT

CONNECTING

N

TB

220-240V,50Hz

220-240V,50Hz

W

W

W

TB2 TERMINAL BLOCKF FUSE(2A)

CR SURGE ABSORBER

TERMINAL BLOCK

COMPRESSOR CONTACTOR52C

TB

FAN MOTOR

(INNER THERMOSTAT)

(INNER THERMOSTAT)

COMPRESSOR

MF

MC

FAN MOTOR CAPACITOR

COMPRESSOR CAPACITOR

C2

C1

NAME

SYMBOL

NAME

SYMBOL

NAME

SYMBOL

TB2 TERMINAL BLOCKF FUSE(2A)

CR SURGE ABSORBER

THERMAL LEAD SWITCH26F1

FAN MOTOR RELAYX1

TERMINAL BLOCK COMPRESSOR CONTACTOR52CTB

FAN MOTOR

(INNER THERMOSTAT)

(INNER THERMOSTAT)

COMPRESSOR

MF

MC

FAN MOTOR CAPACITOR

COMPRESSOR CAPACITOR

C2

C1

NAME

SYMBOL

NAME

SYMBOL

NAME

SYMBOL

SU-1.6VR2.TH

SU-2VR.TH

SU-2VR1.TH

SU-1.6VR.TH-T

SU-2VR.TH-T

SU-2.5VR.TH

SU-2.5VR.TH-T

NOTE :1. Use copper conductors only. (For field wiring)

2. Since the indoor and outdoor unit connecting wires have polarity, connect them according to the numbers

(N,2,3 and ;).

3. Symbols below indicate.

/:Terminal block, : Connector

4. ”w” shows the terminals with a lock mechanism,so they cannot be removed when you pull the lead wire.

Be sure to pull the wire by pushing the locking lever (projected part) of the terminal with a finger.

17

1Slide the sleeve.

2Pull the wire while pushing the locking lever.

Page 18

8

Outdoor

heat

exchanger

Flared connection

Defrost

thermistor

RT61

Flared connection

Stop valve

Stop valve

(with service port)

Strainer

Capillary tube

({3.0x{1.8xL330)w1

({3.0x{1.6xL420)w2

w1 SUH-1.6VR.TH

w2 SUH-1.6VR2.TH

Capillary

tube

({3.0x{1.6xL550)w1

({3.0x{1.8xL550)w2

Restrictor valve

Refrigerant flow in cooling

Compressor

Accumulator

Strainer 1

valve

Muffler

Refrigerant flow in heating

Refrigerant pipe [12.7

(Option)

(with heat insulator)

Refrigerant pipe

(Option) [6.35

(with heat insulator)

Discharge

Pressure

Regulator

Reversing

Outdoor

heat

exchanger

Flared connection

Flared connection

Stop valve

Stop valve

(with service port)

Strainer 2

Capillary tube

({3.0x{1.4xL580)

Capillary tube

({3.0x{1.6xL400)

Restrictor valve

Refrigerant flow in cooling

Compressor

Accumulator

Strainer 1

valve

Muffler

Refrigerant flow in heating

Refrigerant pipe [9.52

(Option)

(with heat insulator)

Refrigerant pipe

(Option) [6.35

(with heat insulator)

Discharge

Pressure

Regulator

Reversing

Defrost

thermistor

RT61

Capillary

tube

({3.0X{1.4XL800)X2

REFRIGERANT SYSTEM DIAGRAM

SUH-1VR.TH

SUH-1.6VR.TH

SUH-1.6VR2.TH

18

Page 19

SUH-2VR.TH

SUH-2VR1.TH

SUH-2VR2.TH

Refrigerant pipe [15.88

(Option)

(with heat insulator)

Stop valve

(with service port)

Flared connection

Flared connection

Refrigerant pipe

(Option) [6.35

(with heat insulator)

Muffler

Accumulator

Stop valve

Strainer

Reversing

valve

Strainer 1

Compressor

Capillary tube

({4.0X{2.4XL660)···2VR

({3.0X{2.0XL250)···2VR2.TH

Restrictor valve

Refrigerant flow in cooling

Refrigerant flow in heating

Discharge

Pressure

Regulator

Defrost

thermistor

RT61

Outdoor

heat

exchanger

Capillary

tube

({3.0X{1.6XL860)X2

(1).TH

SUH-2.5VR.TH

Refrigerant pipe [15.88

(Option)

(with heat insulator)

Ball valve

Flared connection

Flared connection

Refrigerant pipe

(Option) [9.52

(with heat insulator)

Muffler

Accumulator

Strainer 3

Ball valve

(with service port)

Reversing

valve

Compressor

Strainer 2

Discharge

Pressure

Regulator

Distributor

Capillary tube

({4.0x{2.0xL410)

Refrigerant flow in cooling

Refrigerant flow in heating

Outdoor

heat

exchanger

Defrost

thermistor

RT61

19

Page 20

SU-1.6NR.TH

Outdoor

heat

exchanger

Flared connection

Flared connection

Stop valve

Stop valve

(with service port)

Strainer

Capillary tube

(

[3.0x[2.0xL100

)

Capillary tube

(

[3.0x[2.0xL700

)

Refrigerant flow

Compressor

Refrigerant pipe [15.88

(Option)

(with heat insulator)

Refrigerant pipe

(Option) [6.35

(with heat insulator)

Accumulator

Dis pressure

regulator

Dis pressure

regulator

Outdoor

heat

exchanger

Flared connection

Flared connection

Stop valve

Stop valve

(with service port)

Strainer

Capillary tube

(

[3.0x[2.0xL100

)

Capillary tube

(

[3.0x[2.0xL600

)

Refrigerant flow

Accumulator

Compressor

Refrigerant pipe [15.88

(Option)

(with heat insulator)

Refrigerant pipe

(Option) [9.52

(with heat insulator)

Outdoor

heat

exchanger

Flared connection

Flared connection

Stop valve

Stop valve

(with service port)

Strainer

Capillary tube

(

[3.0x[1.8xL100

)

Capillary tube

(

[3.0x[1.8xL550

)

Refrigerant flow

Compressor

Refrigerant pipe [12.7

(Option)

(with heat insulator)

Refrigerant pipe

(Option) [6.35

(with heat insulator)

Dis pressure

regulator

SU-2NR.TH

SU-2.5NR.TH

20

Page 21

SU-1VR.TH

SU-1.6VR.TH

SU-1.6VR2.TH

SU-1.6VR.TH-T

Refrigerant pipe [9.52

(Option)

(with heat insulator)

Flared connection

Flared connection

Refrigerant pipe

(Option) [6.35

(with heat insulator)

Refrigerant pipe [12.7

(Option)

(with heat insulator)

Flared connection

Stop valve

(with service port)

Stop valve

Refrigerant flow

Stop valve

(with service port)

Compressor

Capillary tube

(

[3.0x[1.4xL600

)

Strainer

Outdoor

heat

exchanger

Outdoor

heat

exchanger

SU-2VR.TH

SU-2VR

1.TH

SU-2VR.TH-T

Flared connection

Refrigerant pipe

(Option) [6.35

(with heat insulator)

Refrigerant pipe [15.88

(Option)

(with heat insulator)

Flared connection

Flared connection

Refrigerant pipe

(Option) [6.35

(with heat insulator)

Stop valve

Refrigerant flow

Stop valve

(with service port)

Accumulator

Stop valve

Refrigerant flow

Compressor

Capillary tube

(

[3.0x[1.8xL800

(

[3.0x[1.8xL500

Compressor

Capillary tube

(

[3.0x[2.0xL570

Strainer

)···SU-1.6VR.TH(-T)

)···SU-1.6VR2.TH

Outdoor

heat

exchanger

Strainer

)

21

Page 22

Dis pressure

regulator

Outdoor

heat

exchanger

Flared connection

Flared connection

Stop valve

Stop valve

(with service port)

Strainer

Capillary tube

(

[3.0x[2.0xL100

)

Capillary tube

(

[3.0x[2.0xL700

)

Refrigerant flow

Accumulator

Compressor

Refrigerant pipe [15.88

(Option)

(with heat insulator)

Refrigerant pipe

(Option) [9.52

(with heat insulator)

SU-2.5VR.TH

SU-2.5VR.TH-T

22

Page 23

MAX. REFRIGERANT PIPING LENGTH & MAX. HEIGHT DIFFERENCE

Indoor unit

SEH-1.6AR.TH SEH-1.6AR

1.TH

SE-1.6AR.TH SE-1.6AR

1.TH

SE-1.6AR.TH-T

SEH-2AR.TH

SE-2AR.TH

SE-2AR.TH-T

SEH-2.5AR.TH

SE-2.5AR.TH

SE-2.5AR.TH-T

SUH-1.6VR.TH SUH-1.6VR2.TH

SU-1.6NR.TH SU-1.6VR.TH SU-1.6VR2.TH

SU-1.6VR.TH-T

SUH-2VR.TH SUH-2VR

1.TH SUH-2VR2.TH

SU-2NR.TH SU-2VR.TH SU-2VR

1.TH

SU-2VR.TH-T

SUH-2.5VR.TH

SU-2.5NR.TH SU-2.5VR.TH

SU-2.5VR.TH-T

15(49)

{12.7(1/2)

{15.88(5/8)

{6.35(1/4)

{9.52(3/8)

Outdoor unit

Piping size O.D. : mm (in.)

Gas Liquid

Length : m(ft)

A

Service Ref.

Indoor unit

SEH-1.6AR.TH

SEH-1.6AR

1.TH

SEH-2AR.TH

SEH-2.5AR.TH

SE-1.6AR.TH SE-1.6AR1.TH

SE-1.6AR.TH-T

SE-2AR.TH

SE-2AR.TH

SE-2AR.TH-T

SE-2.5AR.TH

SE-2.5AR.TH-T

SUH-1.6VR.TH

SUH-1.6VR2.TH

SUH-2VR.TH SUH-2VR

1.TH SUH-2VR2.TH

SUH-2.5VR.TH

SU-1.6NR.TH SU-1.6VR.TH SU-1.6VR2.TH

SU-1.6VR.TH-T

SU-2NR.TH

SU-2VR.TH SU-2VR

1.TH

SU-2VR.TH-T

SU-2.5VR.TH SU-2.5NR.TH

SU-2.5VR.TH-T

1650

1400

1800

2400

900

1650

1600

2150

0

0

50

65

15

100

130

30

150

195

45

200

260

60

250

325

75

300

390

90

350

455

105

400

520

120

Outdoor unit

Refrigerant piping length (one way)

7m 8m 9m 10m11m12m13m14m15m

Outdoor unit :

precharged

(up to 7m)

Service Ref.

Calculation : (SEH-2.5AR)og=65g/mo(Refrigerant piping length minus 7m)

(SEH-1.6/2AR)og=50g/mo(Refrigerant piping length minus 7m)

(SE-)og=15g/mo(Refrigerant piping length minus 7m)

ADDITIONAL REFRIGERANT CHARGE (R-22 : g)

If pipe length exceeds 7m, additional refrigerant (Freon 22) charge is required

23

A : Refrigerant piping

Max.length

15m(49ft)

7m(23ft)

Max. Height difference *

(g)

Page 24

A: Refrigerant piping

Max.length

20m(66ft)

Max. Height difference *

8m(26ft)

MAX. REFRIGERANT PIPING LENGTH & MAX. HEIGHT DIFFERENCE

Indoor unit

SLH-1AR.TH

SL-1AR.TH

SLH-1.6AR.TH

SL-1.6AR.TH

SLH-2AR.TH

SL-2AR.TH

SUH-1VR.TH

SU-1VR.TH

SUH-1.6VR2.TH

SU-1.6VR2.TH

SUH-2VR1.TH SUH-2VR2.TH

SU-2VR1.TH

20(66)

{9.52(3/8)

{12.7(1/2)

{15.88(5/8)

{6.35(1/4)

Outdoor unit

Piping size O.D. : mm (in.)

Gas Liquid

Length : m(ft)

A

Models

wIt does not matter which unit is higher.

Indoor unit

SLH-1AR.TH

SLH-1.6AR.TH

SLH-2AR.TH

SL-1AR.TH

SL-1.6AR.TH

SL-2AR.TH

SUH-1VR.TH

SUH-1.6VR2.TH

SUH-2VR1.TH SUH-2VR2.TH

SU-1VR.TH

SU-1.6VR2.TH

SU-2VR

1.TH

800

1,400

1,800

800

900

1,600

0

0

0

25

50

15

50

100

30

75

150

45

100

200

60

125

250

75

150

300

90

175

350

105

200

400

120

225

450

135

250

500

150

275

550

165

300

600

180

325

650

195

Outdoor unit

Refrigerant piping length (one way)

7m 8m 9m 10m 11m 12m 13m 14m 15m 16m 17m 18m 19m 20m

Outdoor unit :

precharged

(up to 7m)

Models

Calculation : (SLH-1AR)og=25g/mo(Refrigerant piping length minus 7m)

(SLH-1.6/2AR)og=50g/mo(Refrigerant piping length minus 7m)

(SL-1/1.6/2AR)og=15g/mo(Refrigerant piping length minus 7m)

ADDITIONAL REFRIGERANT CHARGE (R-22 : g)

If pipe length exceeds 7m, additional refrigerant (Freon 22) charge is required

24

(g)

Page 25

Ball valve

(liquid side)

Service port

Valve knob Lo

Valve knob Hi

Charge hose

Vacuum

pump

Manifold

valve

Compound gauge Pressure gauge

-1.01✕10 Pa

(-760mmHg)

Stop valve

Stop valve

Stop valve

Close

Caps

Gauge manifold valve

Gas pipe

Connection

pipe

Open

Vacuum pump

Service port

Hexagonal

wrench

Liquid pipe

Hexagonal

wrench

EVACUATION PROCEDURES

Connect the refrigerant pipes (both the liquid and gas

pipes) between the indoor and the outdoor units.

Remove the service port cap of the stop/ball valve.

(The stop/ball valve will not work in its initial state fresh out of the factory (totally closed with cap on).)

Connect the gauge manifold valve and the vacuum pump to the service port of the stop/ball valve .

Run the vacuum pump. (Vacuumize for more than 15 minutes.)

Check the vacuum with the gauge manifold valve, then close the gauge manifold valve, and stop the

vacuum pump.

Leave as it is for one or two minutes. Make sure the pointer of the gauge manifold valve remains in the

same position. Confirm that the pressure gauge show-0.1MPa(-79cmHg)

<SUH-1, 1.6, 2>

<SUH-2.5>

<SU-1, 1.6, 2, 2.5>

Remove the gauge manifold valve quickly from the service port of the stop/ball valve.

After refrigerant pipes are connected and evacuated, fully open all stop/ball

valves on gas and liquid pipe sides.

Operating without fully opening lowers the performance and causes trouble.

Pipe length :

7m maximum

No gas charge is

needed.

Pipe length

exceeding 7m

Charge the prescribed

amount of gas.

Tighten the cap to the service port to obtain the initial status.

Retighten the cap.

Leak test

25

Page 26

9

9-1. Test point of P.C. board

•Deicer P.C. board

TROUBLESHOOTING

Outdoor fan motor

220-240V AC

}

Solenoid coil

220-240V AC

}

R601

5~10V DC

}

+

DEICER P.C. BOARD

INPUT

220-240V AC

}

Defrost thermistor(RT61)

}

Fuse 2A/250V

Defrost interval

time short pin

+

J9

}

J8

5V DC

}

12V DC

+

+

}

52C

12V DC

Defrost interval

Defrost termination

temperature change

Jumper wire JPC and JPE

26

Page 27

9-2. Trouble criterion of main parts

Defrost

thermistor

(Outdoor)

Compressor

Measure the resistance with a tester.

(Part temperature 10°C ~ 40°C)

Measure the resistance between the terminal with a tester.

(Coil wiring temperature 10°C ~ 40°C)

Measure the resistance between the terminals with a tester.

(Coil wiring temperature -10°C ~ 40°C)

1VR

1.6, 2NR

1.6, 2VR

1.6VR2, 2VR1, 2VR

2

SU-2.5NR

SU-2.5VR

SUH-2.5VR

Outdoor fan

motor

Check method and criterion

Part name

Normal

1VR

Normal

SUH-

WHT-BLK

BLK-RED

BLK-YLW

YLW-RED

311~381Ω

283~347Ω

—

—

1.6VR, 1.6VR2

115~141Ω

118~146Ω

—

—

2VR, 2VR1, 2VR2

102~126Ω

98~120Ω

—

—

2.5VR

55~68Ω

—

27~33Ω

55~68Ω

5kΩ~60kΩ

Abnormal

Abnormal

Opened or

short-circuited

1

VR

Normal

SU-

WHT-BLK

BLK-RED

BLK-YLW

311~381Ω

283~347Ω

—

1.6

NR, VR, VR2

115~141Ω

118~146Ω

—

2

NR, VR, VR

1

102~126Ω

98~120Ω

—

2.5

NR, VR

72~88Ω

90~110Ω

81~99Ω

Abnormal

Opened or

short-circuited

1VR

Normal

SUH-

C-R

C-S

2.9~3.6Ω

5.1~6.3Ω

1.9~2.3Ω

2.4~4.2Ω

1.6~2.0Ω

2.6~3.2Ω

0.9~1.2Ω

2.0~2.4Ω

0.8~1.0Ω

1.8~2.2Ω

1.6VR 1.6VR2 2.5VR

2VR, 2VR1, 2VR2

Abnormal

Opened or

short-circuited

VR

1 1.6 2 2.5

Normal

SU-

C-R

C-S

2.9~

3.6Ω

5.1~

6.3Ω

1.5~

1.9Ω

2.4~

3.0Ω

1.9~

2.3Ω

3.4~

4.2Ω

1.6~

2.0Ω

2.6~

3.2Ω

0.8~

1.0Ω

1.7~

2.1Ω

0.9~

1.2Ω

2.0~

2.4Ω

0.7~

0.9Ω

1.6~

2.0Ω

0.8~

1.0Ω

1.8~

2.2Ω

NR NR NRVR VRVR2

VR, VR

1

Abnormal

Opened or

short-circuited

Opened or short-circuited

Figure

C

S

R

BLK

RED

WHT

BLK

RED

WHT

MAIN

AUX

FUSE

BLK

RED ORN

WHT

MAIN

AUX

P

BLK YLW

RED ORN

WHT

MAIN

AUX.2

AUX.1

P

BLKYLW

RED ORN

WHT

MAIN

AUX.2

AUX.1

P

SUH-1VR.TH SUH-1.6VR.TH SUH-2VR.TH SUH-2.5VR.TH

SUH-1.6VR2.TH SUH-2VR

SUH-2VR

1.TH

2.TH

SU-1.6NR.TH SU-2NR.TH SU-2.5NR.TH

SU-1VR.TH SU-1.6VR.TH SU-2VR.TH SU-2.5VR.TH

SU-1.6VR2.TH SU-2VR

1.TH

SU-1.6VR.TH-T SU-2VR.TH-T SU-2.5VR.TH-T

27

p

: Inner protector

Page 28

10 DISASSEMBLY PROCEDURE

SUH-1VR.TH

OPERATING PROCEDURE PHOTOS

1. Removing the cabinet

(1) Remove the screws for the top panel.

(2) Remove the screw for the service panel.

(3) Remove the screws for the cabinet.

(4) Remove the screws for the front panel and motor support.

(5) Remove the service panel, and remove the screw from

the insides.

(6) Remove the top panel.

(7) Remove the cabinet.

Photo 3

Screw for

service panel

Screw for

top panel

Service

panel

Photo 1

Screws for front panel and motor support

Screws

for

cabinet

Screws for cabinet

Photo 2

Screw for

top panel

2. Removing the deicer P.C. board

(1) Remove the service panel and the cabinet.

(2) Disconnect all the connectors and the terminals on the

deicer P.C. board.

(3) Remove the deicer P.C. board.

Photo 4

Deicer

P.C. board

Screws for

cabinet

Screws

28

Screw

Relay panel

Terminal

block

Page 29

OPERATING PROCEDURE PHOTOS

3. Removing the propeller fan and the outdoor fan

motor

(1) Remove the cabinet. (Refer to 1.)

(2) Remove the propeller fan nut.

(3) Remove the propeller fan.

NOTE : Loose the propeller fan in the rotating direction for

removal.

When attaching the propeller fan, align the mark on the

propeller fan and the motor shaft cut section.

Set the propeller fan in position by using the cut on the

shaft and the mark on the propeller fan.

(4) Remove lead clamps and disconnect the outdoor fan motor

connector.

(5) Remove screws fixing the fan motor.

(6) Remove the outdoor fan motor.

Photo 5

Set screws for

outdoor fan motor

Propeller fan

Lead clamps

Outdoor

fan motor

connector

4. Removing the compressor

(1) Remove the cabinet. (Refer to 1)

(2) Remove the relay panel.

(3) Remove the soundproof felt.

(4) Remove the terminal cover on the compressor.

(5) Disconnect lead wires from the glass terminal of the com-

pressor.

(6) Recover gas from the refrigerant circuit.

(7) Disconnect the welded part of the discharge pipe.

(8) Disconnect the welded part of the suction pipe.

(9) Remove nuts fixing the compressor.

)

(

Remove the compressor.

10

NOTE

● Before using a burner, reclaim gas from the pipes until the

pressure gauge shows 0 kg/cm

● Use the burner under the condition that gas can be recovered

even when the inner pressure rises by heat.

2

(0 MPa).

Propeller fan nut

Photo 6

Discharge pipe

Glass

terminal

Compressor

Outdoor

fan motor

Suction pipe

29

Compressor

set nuts

Terminal cover

Page 30

SUH-1.6VR2.TH

OPERATING PROCEDURE PHOTOS

1. Removing the front panel

(1) Remove the screws of the front panel.

(2) Hold the bottom of the front panel on the both side to

remove the cabinet.

Photo 1

Photo 2

Screws

2. Removing the deicer P.C. board

(1) Remove the service panel and the front panel.

(2) Disconnect all the connectors and the terminals on the

deicer P.C. board.

(3) Remove the deicer P.C. board.

Screws

Service

panel

Photo 3

Deicer

P.C. board

Compressor contactor

30

Terminal

block

Page 31

OPERATING PROCEDURE

PHOTOS

3. Removing the outdoor fan motor

(1) Remove the front panel. (Refer to 1)

(2) Unconnect the connector remove the clamp of fan motor

lead wire.

(3) Remove the propeller nut and remove the propeller fan.

(4) Remove screws fixing the fan motor.

4. Removing the compressor

(1) Remove the cabinet. (Refer to 1)

(2) Remove the relay panel.

(3) Remove the soundproof felt.

(4) Remove the terminal cover on the compressor.

(5) Disconnect lead wires from the glass terminal of the com-

pressor.

(6) Recover gas from the refrigerant circuit.

(7) Disconnect the welded part of the discharge pipe.

(8) Disconnect the welded part of the suction pipe.

(9) Remove nuts fixing the compressor.

)

(

Remove the compressor.

10

Photo 4

propeller fan

Propeller

fan nut

Photo 5

Discharge pipe

Set screws for

outdoor fan motor

Outdoor

fan motor

Terminal cover

NOTE

● Before using a burner, reclaim gas from the pipes until the

pressure gauge shows 0 kg/cm

● Use the burner under the condition that gas can be recovered

even when the inner pressure rises by heat.

2

(0 MPa).

Suction

pipe

Compressor

Compressor nuts

31

Page 32

SUH-2VR1.TH SUH-2VR2.TH

OPERATING PROCEDURE PHOTOS

1. Removing the front panel

(1) Remove the screws of the front panel.

(2) Hold the bottom of the front panel on the both side to

remove the cabinet.

Photo 1

Photo 2

Screws

2. Removing the deicer P.C. board

(1) Remove the service panel and the front panel.

(2) Disconnect all the connectors and the terminals on the

deicer P.C. board.

(3) Remove the deicer P.C. board.

Screws

Service

panel

Photo 3

Deicer

P.C. board

Compressor contactor

32

Terminal

block

Page 33

OPERATING PROCEDURE

PHOTOS

3. Removing the outdoor fan motor

(1) Remove the front panel. (Refer to 1)

(2) Unconnect the connector remove the clamp of fan motor

lead wire.

(3) Remove the propeller nut and remove the propeller fan.

(4) Remove screws fixing the fan motor.

4. Removing the compressor

(1) Remove the cabinet. (Refer to 1)

(2) Remove the relay panel.

(3) Remove the soundproof felt.

(4) Remove the terminal cover on the compressor.

(5) Disconnect lead wires from the glass terminal of the com-

pressor.

(6) Recover gas from the refrigerant circuit.

(7) Disconnect the welded part of the discharge pipe.

(8) Disconnect the welded part of the suction pipe.

(9) Remove nuts fixing the compressor.

)

(

Remove the compressor.

10

Photo 4

propeller fan

Propeller

fan nut

Photo 5

Terminal cover

Glass

terminal

Set screws for

outdoor fan motor

Outdoor

fan motor

Discharge pipe

Suction pipe

NOTE

● Before using a burner, reclaim gas from the pipes until the

pressure gauge shows 0 kg/cm

● Use the burner under the condition that gas can be recovered

even when the inner pressure rises by heat.

2

(0 MPa).

Compressor

Compressor

set nuts

33

Page 34

SUH-2.5VR.TH

OPERATING PROCEDURE PHOTOS

1. Removing the electrical parts

(1)

Remove the 5 screws and the top panel. (3 screws in

front and 2 screws in rear

(2)

Remove the screw of the cover panel. To remove the

cover panel, pull it toward you and unhook the catches from the side panel.

(3)

Remove the screw of the service panel. To remove the

service panel, pull it down toward you and unhook the

catches on the both sides.

)

Photo 1

Screws

Top panel

Service panel

Panel cover

Front panel

Photo 2

Capacitor

Contactor

2. Removing the fan motor

(1)

Remove the 3 screws of the front panel. Open the

front panel to a 45-degree angle. Then lift it and

unhook the 3 catches to remove.

(2)

Remove the propeller fan nut and the propeller fan.

(3)

Remove the 3 screws and the fan motor.

Disconnect the lead connectors.

Photo 3

Propeller

fan

Motor support

Propeller fan nut

Terminal blockScrews

Separator support plate

Lead

connectors

Valve bed

34

Page 35

OPERATING PROCEDURE PHOTOS

3. Removing the heat exchanger and the compressor

(1)

Remove the rear panel (2 screws in front, 1 screw on

the side, 3 screws in the rear). Remove the valve bed,

and open the rear panel to the rear to remove.

NOTE :

All panels are fixed by catches, and must be removed by

shifting up and down.

(2)

Remove the 4 screws of the right side panel and

remove it.

(3)

Remove the 3 screws of the rear guard and remove it.

(4)

Remove the 4 screws of the separator support plate

and remove it.

(5)

Remove the 2 screws of the motor support and

remove it.

(6)

Remove the 5 screws of the valve bed.

The valve bed is fixed by the catches on the right and

left sides.

Lift it to remove.

(7)

Remove the electrical parts box.

Disconnect the connectors from the high pressure

switch, crank case heater, shell thermo, and fan motor

lead.

(8)

Remove the 2 screws of the separator and remove it.

(9) Recover gas from the refrigerant circuit.

)

(

Remove the 2 screws of the heat exchanger and

10

remove it.

Detach the welded point of pipe.

(11)

Remove the 3 nuts of the compressor and remove it.

Detach the welded points of the compressor suction

pipe and discharge pipe.

Photo 4

Screws

Screws

Photo 5

Heat exchanger

Accumulator

NOTE

● Before using a burner, reclaim gas from the pipes until

the pressure gauge shows 0 kg/cm

● Use the burner under the condition that gas can be

recovered even when the inner pressure rises by heat.

2

(0 MPa).

Photo 6

Charge plug

Ball valve

Compressor

35

Page 36

SU-1VR.TH

OPERATING PROCEDURE PHOTOS

1. Removing the cabinet

(1) Remove the screws for the top panel.

(2) Remove the screw for the service panel.

(3) Remove the screws for the cabinet.

(4) Remove the screws for the front panel and motor support.

(5) Remove the service panel, and remove the screw from

the insides.

(6) Remove the top panel.

(7) Remove the cabinet.

Photo 3

Screw for

service panel

Screw for

top panel

Service

panel

Photo 1

Screws for front panel and motor support

Screws

for

cabinet

Screws for cabinet

Photo 2

Screw for

top panel

2. Removing the electrical parts

(1) Remove the cabinet.(Refer to 1)

(2) Remove the following parts.

•Compressor capacitor(C1)

•Outdoor fan capacitor(C2)

•Terminal block(TB)

•Compressor contactor(52C)

Photo 4

Outdoor

fan motor

connector

Screws for

cabinet

Compressor

contactor

36

Outdoor

fan

contactor

Terminal

block

Page 37

OPERATING PROCEDURE PHOTOS

3. Removing the propeller fan and the outdoor fan

motor

(1) Remove the cabinet. (Refer to 1.)

(2) Remove the propeller fan nut.

(3) Remove the propeller fan.

NOTE : Loose the propeller fan in the rotating direction for

removal.

When attaching the propeller fan, align the mark on the

propeller fan and the motor shaft cut section.

Set the propeller fan in position by using the cut on the

shaft and the mark on the propeller fan.

(4) Remove lead clamps and disconnect the outdoor fan motor

connector.

(5) Remove screws fixing the fan motor.

(6) Remove the outdoor fan motor.

Photo 5

Set screws for

outdoor fan motor

Propeller fan

Lead clamps

Outdoor

fan motor

connector

4. Removing the compressor

(1) Remove the cabinet. (Refer to 1)

(2) Remove the relay panel.

(3) Remove the soundproof felt.

(4) Remove the terminal cover on the compressor.

(5) Disconnect lead wires from the glass terminal of the

compressor.

(6) Recover gas from the refrigerant circuit.

(7) Disconnect the welded part of the discharge pipe.

(8) Disconnect the welded part of the suction pipe.

(9) Remove nuts fixing the compressor.

)

(

Remove the compressor.

10

NOTE

● Before using a burner, reclaim gas from the pipes until the

pressure gauge shows 0 kg/cm

● Use the burner under the condition that gas can be recovered

even when the inner pressure rises by heat.

2

(0 MPa).

Propeller fan nut

Photo 6

Discharge pipe

Glass

terminal

Compressor

Outdoor

fan motor

Suction pipe

37

Compressor

set nuts

Terminal cover

Page 38

SU-1.6VR2.TH

OPERATING PROCEDURE PHOTOS

1. Removing the cabinet

(1) Remove the screws of the cabinet.

(2) Hold the bottom of the cabinet on the both side to remove

the cabinet.

Photo 1

Photo 2

Screws

2. Removing the electrical parts

(1) Remove the cabinet.(Refer to 1)

(2) Remove the following parts.

•Compressor capacitor(C1)

•Outdoor fan capacitor(C2)

•Terminal block(TB)

•Compressor contactor(52C)

•Fuse(F)

Service

panel

Photo 3

Outdoor fan

capacitor

Outdoor

fan motor

connector

Screws

Fuse

38

Compressor

capacitor

Compressor

contactor

Terminal

block

Page 39

OPERATING PROCEDURE PHOTOS

3. Removing the propeller fan and the outdoor fan

motor

(1) Remove the cabinet. (Refer to 1.)

(2) Remove the propeller fan nut.

(3) Remove the propeller fan.

NOTE : Loose the propeller fan in the rotating direction for

removal.

When attaching the propeller fan, align the mark on the

propeller fan and the motor shaft cut section.

Set the propeller fan in position by using the cut on the

shaft and the mark on the propeller fan.

(4) Remove lead clamps and disconnect the outdoor fan motor

connector.

(5) Remove screws fixing the fan motor.

(6) Remove the outdoor fan motor.

Photo 5

Set screws for

outdoor fan motor

Propeller fan

Lead clamps

Outdoor

fan motor

connector

4. Removing the compressor

(1) Remove the cabinet. (Refer to 1)

(2) Remove the relay panel.

(3) Remove the soundproof felt.

(4) Remove the terminal cover on the compressor.

(5) Disconnect lead wires from the glass terminal of the

compressor.

(6) Recover gas from the refrigerant circuit.

(7) Disconnect the welded part of the discharge pipe.

(8) Disconnect the welded part of the suction pipe.

(9) Remove nuts fixing the compressor.

)

(

Remove the compressor.

10

NOTE

● Before using a burner, reclaim gas from the pipes until the

pressure gauge shows 0 kg/cm

● Use the burner under the condition that gas can be recovered

even when the inner pressure rises by heat.

2

(0 MPa).

Propeller fan nut

Photo 6

Discharge pipe

Glass

terminal

Compressor

Outdoor

fan motor

Suction pipe

39

Compressor

set nuts

Terminal cover

Page 40

SU-2VR1.TH

OPERATING PROCEDURE PHOTOS

1. Removing the cabinet

(1) Remove the screws of the cabinet.

(2) Hold the bottom of the cabinet on the both side to remove

the cabinet.

Photo 1

Photo 2

Screws

2. Removing the electrical parts

(1) Remove the cabinet.(Refer to 1)

(2) Remove the following parts.

•Compressor capacitor(C1)

•Outdoor fan capacitor(C2)

•Terminal block(TB)

•Compressor contactor(52C)

•Fuse(F)

Service

panel

Photo 3

Outdoor fan

capacitor

Outdoor

fan motor

connector

Screws

Fuse

40

Compressor

contactor

Terminal

block

Page 41

OPERATING PROCEDURE PHOTOS

3. Removing the propeller fan and the outdoor fan

motor

(1) Remove the cabinet. (Refer to 1.)

(2) Remove the propeller fan nut.

(3) Remove the propeller fan.

NOTE : Loose the propeller fan in the rotating direction for

removal.

When attaching the propeller fan, align the mark on the

propeller fan and the motor shaft cut section.

Set the propeller fan in position by using the cut on the

shaft and the mark on the propeller fan.

(4) Remove lead clamps and disconnect the outdoor fan motor

connector.

(5) Remove screws fixing the fan motor.

(6) Remove the outdoor fan motor.

Photo 5

Set screws for

outdoor fan motor

Propeller fan

Lead clamps

Outdoor

fan motor

connector

4. Removing the compressor

(1) Remove the cabinet. (Refer to 1)

(2) Remove the relay panel.

(3) Remove the soundproof felt.

(4) Remove the terminal cover on the compressor.

(5) Disconnect lead wires from the glass terminal of the

compressor.

(6) Recover gas from the refrigerant circuit.

(7) Disconnect the welded part of the discharge pipe.

(8) Disconnect the welded part of the suction pipe.

(9) Remove nuts fixing the compressor.

)

(

Remove the compressor.

10

NOTE

● Before using a burner, reclaim gas from the pipes until the

pressure gauge shows 0 kg/cm

● Use the burner under the condition that gas can be recovered

even when the inner pressure rises by heat.

2

(0 MPa).

Propeller fan nut

Photo 6

Terminal cover

Glass

terminal

Outdoor

fan motor

Discharge pipe

Suction pipe

41

Compressor

Compressor

set nuts

Page 42

SU-1.6NR.TH SU-2NR.TH SU-2.5NR.TH

SU-1.6VR.TH SU-2VR.TH SU-2.5VR.TH

SU-1.6VR.TH-T SU-2VR.TH-T SU-2.5VR.TH-T

OPERATING PROCEDURE PHOTOS

1. Removing the cabinet

(1) Remove the screws of the cabinet.

(2) Hold the bottom of the cabinet on the both side to remove

the cabinet.

Photo 1

Photo 2

Screws

2. Removing the electrical parts

(1) Remove the cabinet.(Refer to 1)

(2) Remove the following parts.

•Compressor capacitor(C1)

•Outdoor fan capacitor(C2)

•Terminal block(TB,TB2)

•Fan motor relay(X1)[For SU-2.5NR.TH, SU-2.5VR.TH and

SU-2.5VR.TH-T]

•Contactor(52C)

•Fuse(F)

Service

panel

Photo 3

Fuse

Screws

Terminal bed

42

Compressor

run capacitor

Compressor

Contactor

Page 43

OPERATING PROCEDURE

PHOTOS

3. Removing the outdoor fan motor

(1) Remove the cabinet. (Refer to 1)

(2) Unconnect the connector remove the clamp of fan motor

lead wire.

(3) Remove the propeller nut and remove the propeller.

(4) Remove screws fixing the fan motor.

4. Removing the compressor

(1) Remove the cabinet. (Refer to 1)

(2) Remove the relay panel.

(3) Remove the soundproof felt.

(4) Remove the terminal cover on the compressor.

(5) Disconnect lead wires from the glass terminal of the

compressor.

(6) Recover gas from the refrigerant circuit.

(7) Disconnect the welded part of the discharge pipe.

(8) Disconnect the welded part of the suction pipe.

(9) Remove nuts fixing the compressor.

)

(

Remove the compressor.

10

Photo 4

Propeller fan

Photo 5

Fan motor cable

Propeller fan nut

Terminal cover

Connector

Discharge

pipe

Suction

pipe

NOTE

● Before using a burner, reclaim gas from the pipes until the

pressure gauge shows 0 kg/cm

● Use the burner under the condition that gas can be recovered

even when the inner pressure rises by heat.

2

(0 MPa).

Glass

terminal

Compressor

Compressor nuts

43

Page 44

PARTS LIST11

OUTDOOR UNIT

STRUCTURAL PARTS

SUH-1VR.TH SU-1VR.TH

15

1

2

3

4

14

6

5

7

8

13

11

10

9

12

16

17

30

18

19

29

20

21

28

31

22

27

26

25

24

23

44

Page 45

No.

Parts No.

Parts name

Specification

Remarks

Unit

Amount

Wiring

Diagram

Symbol

Recommended

Q'ty

Q'ty/set

VR.TH

Price

(Drawing No.)

SU-1SUH-1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

RH-174VGHT

[9.52

[6.35

[6.35

25+ 440VAC

1.5+ 440VAC

VF12HU-302

S-N11EX

250V 2A

[3.0✕[1.4✕L800

[3.0✕[1.6✕L400

[3.0✕[1.4✕L580

[3.0✕[1.4✕L600

3RUBBERS/SET

2PCS/SET

MC

21S4

MF

MF

C1

C2

52C

52C

F61

DSAR

TB

TB

NR61

CR

RT61

E02 440 630

E02 336 630

E02 336 232

E02 336 521

E02 128 900

E02 336 506

E02 096 932

E02 339 290

E02 339 661

E02 339 662

E02 139 662

E02 440 490

E02 444 961

E02 336 245

E02 440 233

E02 339 233

E02 336 515

E02 336 297

E02 665 501

E07 112 301

E02 676 301

E02 694 353

E02 095 350

E02 282 340

E07 042 340

E02 095 382

E07 001 241

E07 112 451

E02 128 383

E02 198 374

E02 209 374

E02 085 385

E07 042 384

E02 289 310

E02 444 704

E02 440 705

E07 112 933

E02 205 933

E02 069 644

E02 154 642

E02 159 936

E02 134 937

E07 112 936

E02 339 936

1

1

1

1

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

2

1

1

1

1

1

1

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

OUTDOOR HEAT EXCHANGER

OUTDOOR HEAT EXCHANGER

CABINET

GRILLE (OUT)

COMPRESSOR

COMPRESSOR RUBBER MOUNT

ACCUMULATOR

BASE

STOP VALVE (GAS)

STOP VALVE (LIQUID)

STOP VALVE (LIQUID)

4-WAY VALVE SOLENOID COIL

4-WAY VALVE

SERVICE PANEL

BACK PANEL (OUT)

BACK PANEL (OUT)

MOTOR SUPPORT

TOP PANEL

PROPELLER FAN

OUTDOOR FAN MOTOR

OUTDOOR FAN MOTOR

COMPRESSOR CAPACITOR

OUTDOOR FAN CAPACITOR

COMPRESSOR CONTACTOR

COMPRESSOR CONTACTOR

FUSE (OUT)

FUSE HOLDER

DEICER P.C. BOARD

SURGE ABSORBER

TERMINAL BLOCK

TERMINAL BLOCK

VARISTOR

SURGE ABSORBER

DEFROST THERMISTOR

DRAIN SOCKET SET

DRAIN CAP

STRAINER

STRAINER

DIS PRESSURE REGULATOR

RESTRICTOR VALVE

CAPILLARY TUBE1

CAPILLARY TUBE2

CAPILLARY TUBE3

CAPILLARY TUBE3

Part numbers that are circled are not shown in the illustration.

45

Page 46

OUTDOOR UNIT

No.

1

2

3

4

5

6

7

8

9

RH-247VHAT

RH-277VHAT

3RUBBERS/SET

MF

MC

MC

Parts No.

Parts name

Specification

Remarks

Unit

Amount

Wiring

Diagram

Symbol

Recom-

mended

Q'ty

Q'ty/set

VR.TH

VR2.TH

VR.TH

VR.TH-T

VR2.TH

Price

(Drawing No.)

SU-1.6SUH-1.6

E02 141 521

E02 141 232

E07 042 630

E02 141 630

E02 141 501

E02 139 515

E02 140 515

E02 141 301

E02 075 506

E07 042 900

E07 111 900

E02 201 290

E07 113 290

E02 140 290

1

1

1

1

1

1

3

1

1

1

1

1

1

1

1

3

1

1

1

1

1

1

1

1

3

1

1

1

1

1

1

1

1

3

1

1

GRILLE (OUT)

CABINET

OUTDOOR HEAT EXCHANGER

OUTDOOR HEAT EXCHANGER

PROPELLER FAN

MOTOR SUPPORT

MOTOR SUPPORT

OUTDOOR FAN MOTOR

COMPRESSOR RUBBER MOUNT

COMPRESSOR

COMPRESSOR

BASE

BASE

BASE

STRUCTURAL PARTS

SUH-1.6VR.TH SU-1.6VR.TH SU-1.6VR.TH-T

SUH-1.6VR2.TH SU-1.6VR2.TH

30 29

28

27

25 241023

26

22

21

20

19

18

17

16

15

136312

141245 789 11

46

Page 47

Part numbers that are circled are not shown in the illustration.

No.

Parts No.

E02 134 932

10

E07 113 932

11

E02 140 661

12