Mitsubishi S SERIES Brochure

S-SERIES

OUTDOOR UNITS

1. SPECIFICATIONS ........................................................................................................................................................S-2

2. EXTERNAL DIMENSIONS ...........................................................................................................................................S-3

3. CENTER OF GRAVITY ................................................................................................................................................ S-4

4. ELECTRICAL WIRING DIAGRAMS .............................................................................................................................S-5

5. REFRIGERANT CIRCUIT DIAGRAMS AND THERMAL SENSORS ...........................................................................S-7

6. SOUND PRESSURE LEVELS ..................................................................................................................................... S-8

7. CAPACITY TABLES .....................................................................................................................................................S-9

7-1. Correction by T emperature ............................................................................................................................S-9

7-2. Correction by Total Indoor ............................................................................................................................S-10

7-3. Correction by Refrigerant Piping Length ......................................................................................................S-12

7-4. Correction at Frost and Defrost ...................................................................................................................S-13

7-5. Operation Temperature Range .................................................................................................................... S-13

8. OPTIONAL PARTS .....................................................................................................................................................S-14

8-1. Branch Joint .................................................................................................................................................S-14

8-2. Header ......................................................................................................................................................... S-15

S-SERIES

S-SERIES (Sept. 2010)

S-1

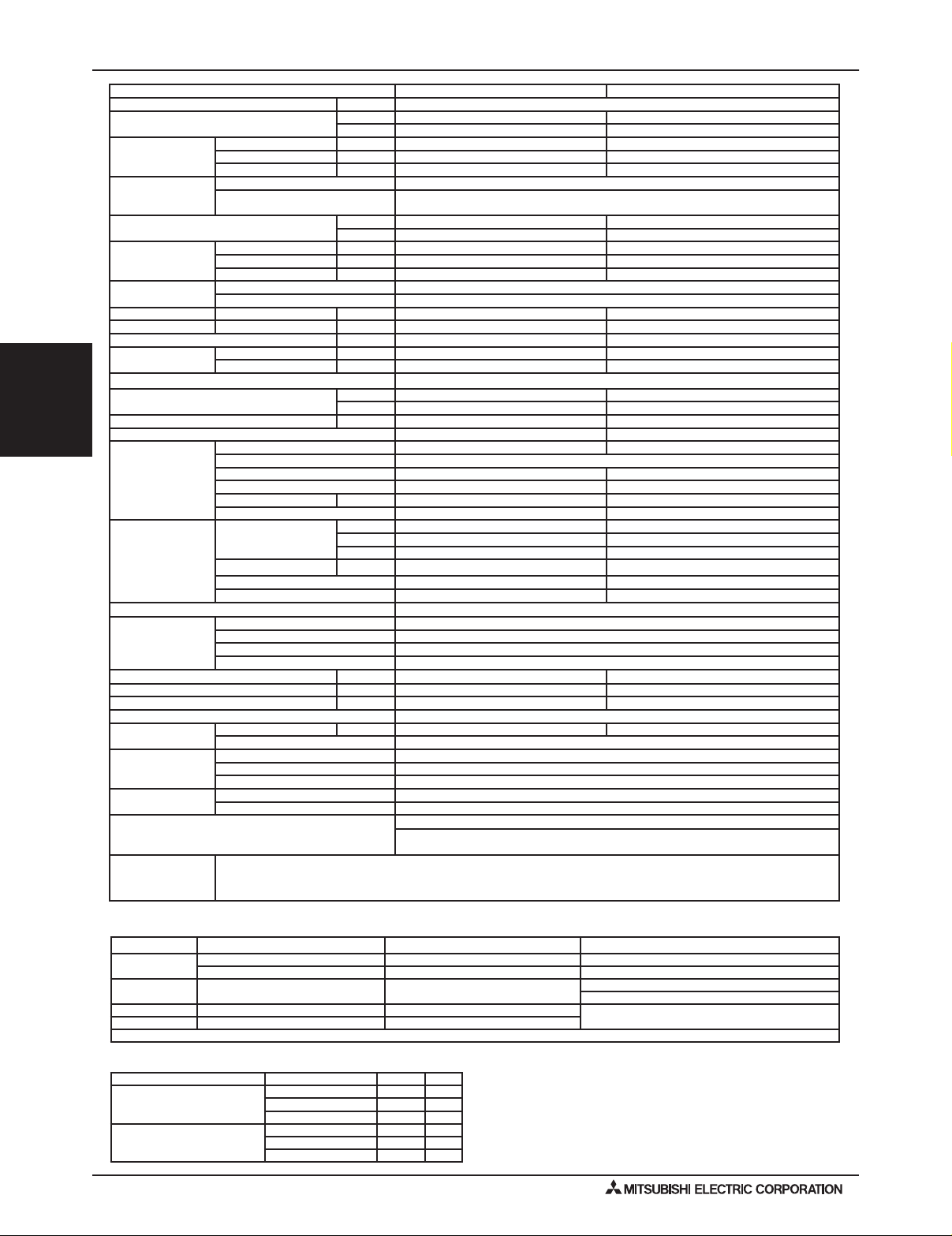

1. SPECIFICATIONS

Model PUMY-P36NHMU(-BS) PUMY-P48NHMU(-BS)

Power source 1-phase 208 / 230 V 60Hz

Cooling capacity (Nominal) *1

Power input kW 3.22 *3 4.97 *3

Current input (208 / 230) A 14.23 / 15.74 *3 24.0 / 21.7 *3

COP (kW / kW) 3.29 2.83

Temp. range of

cooling

Heating capacity (Nominal) *2

Temp. range of

heating

Indoor unit Total capacity 50-130% of outdoor unit capacity 50-130% of outdoor unit capacity

connectable Model / Quantity P06-P36 / 1-6 P06-P54 / 1-8

Sound pressure level (measured in anechoic room) dB <A> 49 / 51 50 / 52

Diameter of

refrigerant pipe (O.D.)

External nish Galvanized sheets (+powder coating for -BS type) *4 <MUNSELL 3Y 7.8/1.1>

External dimension H x W x D

Net weight lbs(kg) 287 (130) 287 (130)

S-SERIES

Heat exchanger Salt-resistant cross n & copper tube Salt-resistant cross n & copper tube

Compressor

FAN

HIC circuit (HIC: Heat Inter-Changer) -

Protection

Minimum Circuit Ampacity A 26 26

Recommended Fuse/Breaker Size A 30 30

Maximum Fuse Size A 40 40

Defrost method Auto-defrost mode (Reversed refrigerant circle)

Refrigerant

Drawing

Standard

attachment

Optional parts

Remark

Indoor 59 to 75 degFW.B. (15 to 24 degCW.B.)

Outdoor

Power input kW 2.93 *3 4.88 *3

Current input (208 / 230) A 12.88 / 14.24 *3 23.6 / 21.3 *3

COP (kW / kW) 3.99 3.23

Indoor 59 to 81 degFD.B. (15 to 27 degCD.B.)

Outdoor 0 to 60 degFW.B. (-18 to 15.5 degCW.B.)

Liquid (High pressure) in. (mm) 3/8 (9.52) Flare (total length>=393ft. [120m]) 3/8 (9.52) Flare (total length>=393ft. [120m])

Gas (Low pressure) in. (mm) 5/8 (15.88) Flare 5/8 (15.88) Flare

Type Inverter scroll hermetic comp. Inverter scroll hermetic comp.

Manufacturer SHIZUOKA Works,MITSUBISHI ELECTRIC CORPORATION

Operating Range 33-100% 25-100%

Starting method Inverter Inverter

Case heater kW - Lubricant FV50S FV50S

Airow rate

External static press. in.WG(Pa) 0 (0) 0 (0)

Type x Quantity Propeller fan x 2 Propeller fan x 2

Control, Driving mechanism DC-control, Direct-driven DC-control, Direct-driven

High pressure protection High pressure sensor, High pressure switch 601 psi (4.15 MPa)

Inverter circuit (COMP., FAN) Over-current protection,Over-heat protection

Compressor Discharge thermo protection,Over-current protection

Fan motor Over-heat protection,Voltage protection

Type x Original charge lbs + oz (kg) R410A x (18 lbs + 12 oz) (8.5kg) R410A x (18 lbs + 12 oz) (8.5kg)

Control Indoor LEV

External BK01B409

Wiring RG79V166

Refrigerant cycle Document Installation Manual

Accessory Grounded lead wire x 2 , Conduit plate

Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be referred to the

Installation Manual.

3. For details on the electrical data needed for installing these units, see the S-Series System Design section.

4. For information on standard anti-corrosion protection and -BS treatment, see the S-Series System Design section.

BTU / h 36,000 48,000

kW 10.6 14.1

BTU / h 40,000 54,000

kW 11.7 15.8

in. 53-5/32 x 37-13/32 x 13 53-5/32 x 37-13/32 x 13

mm 1,350 x 950 x 330 1,350 x 950 x 330

cfm 3,530 3,530

m3 / min 100 100

L / s 1,667 1,667

50 to 115 degFD.B.(10 to 46 degCD.B.): in case of connecting PKFY-P06/P08 type indoor unit.

Air Outlet Guide (One piece, requires two pieces): PAC-SG59SG-E; Wind Bafe (One piece,

requires two pieces: WB-PA2); Drain Pan: PAC-SG64DP-E; Drain Socket: PAC-SG61DS-E

23 to 115 degFD.B. (-5 to 46 degCD.B.)

Joint: CMY-Y62-G-E, Header: CMY-Y64/68-G-E

Note: *1 Nominal cooling conditions *2 Nominal heating conditions Unit converter

Indoor:

Outdoor: 95degF D.B. (35degC D.B.)

Pipe length: 25ft.(7.6m) 25ft.(7.6m)

Level difference: 0ft.(0m) 0ft.(0m)

* Due to continuing improvement, above specications may be subject to change without notice.

80degF D.B./ 67degF W.B. 70degF D.B. kcal =kW x 860

(26.7degC D.B./ 19.4degC W.B.) (21.1degC D.B.) BTU/h =kW x 3,412

47degF D.B./ 43degF W.B.

(8.3degC D.B./ 6.1degC W.B.)

3

cfm =m

lb =kg / 0.4536

* Above specication data is subject to rounding variation.

Energy Efciencies

Model Indoor Unit Type SEER HSPF

PUMY-P36NHMU (-BS)

PUMY-P48NHMU (-BS)

S-2

Non-ducted 14.3 8.2

Ducted and Non-ducted 14.3 8.2

Ducted 14.3 8.2

Non-ducted 15.5 8.7

Ducted and Non-ducted 15 8.7

Ducted 14.5 8.7

S-SERIES (Sept. 2010)

/min x 35.31

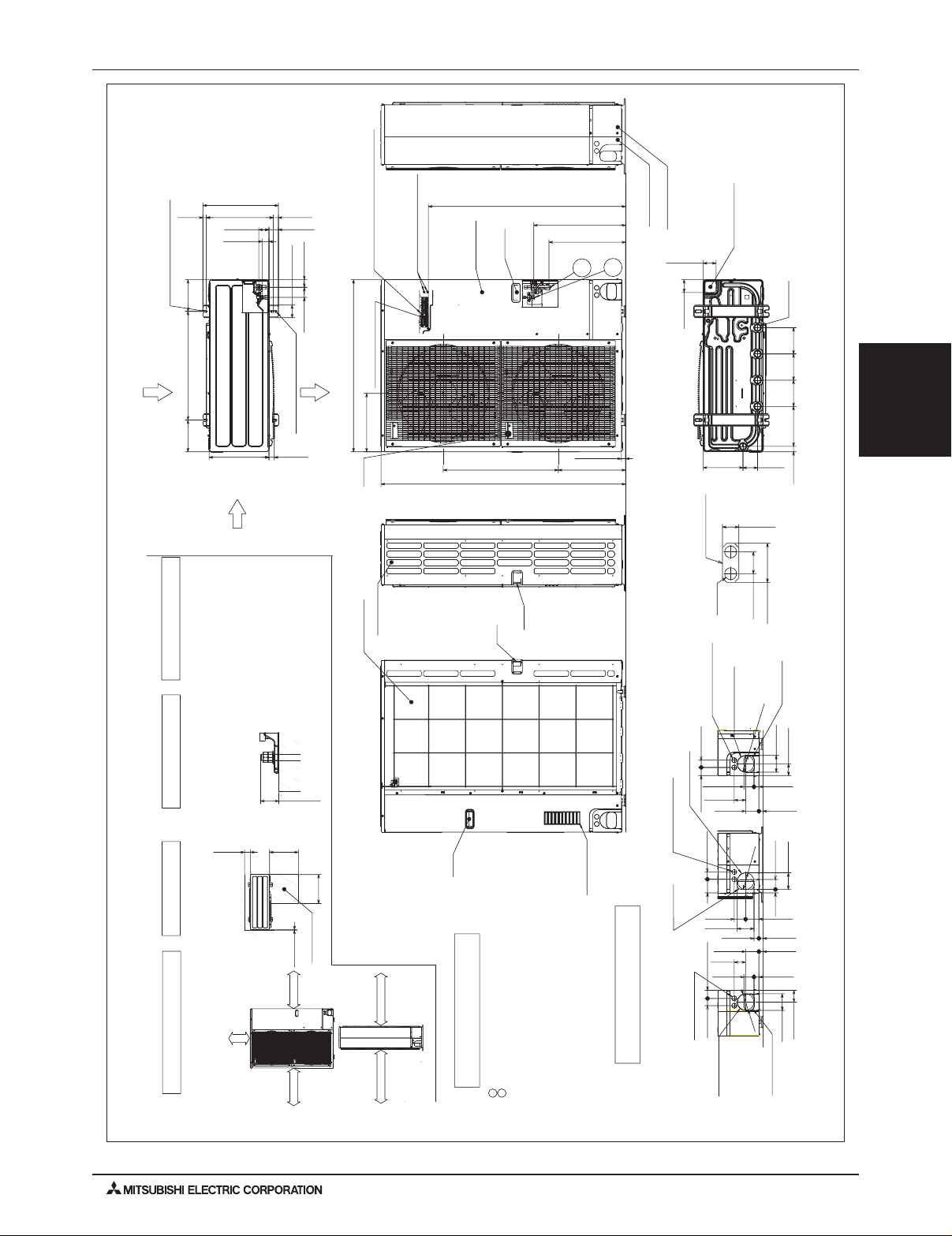

2. EXTERNAL DIMENSIONS

PUMY-P36,48NHMU(-BS)

19<3/4>

2-U Shaped notched hole

(Foundation Bolt M10<W3/8>)

175

<6-7/8>

Rear Air Intake

600<23-5/8>

175

<6-7/8>

4 PIPING-WIRING DIRECTIONS

Piping and wiring connections

can be made from 4 directions:

front,right,rear and below.

417<16-13/32>

56<2-7/32>

37<1-15/32>

330<13>

Side Air Intake

70<2-3/4>

2-12 x 36 Oval hole

(Foundation Bolt M10<W3/8>)

28<1-3/32> 370<14-9/16>

53<2-3/32>

56<2-7/32> 42<1-21/32>

Air Discharge

30<1-3/16>

Left ........ For the power supply

Center ... For the transmission line

Right ...... For concentration control

Terminal block

( )

Ground for the transmission line

Ground for concentration control

Ground for the power supply

("GR"marking position)

950<37-13/32>

322<12-11/16>

Handle

Side Air Intake

Rear Air Intake

Handle

Service panel

635<25>371<14-19/32>

1350<53-5/32>

Handle

Handle

1088<42-27/32>

*1 507<19-31/32>

1

Ref. : PUMY_NHMU_EXD_USDB_P36-48

Unit : mm(in)

Front piping cover

Rear piping cover

*1 423<16-21/32>

2

23<29/32>

Bottom piping hole

(Knockout)

71<2-13/16>

71<2-13/16>

1/2 Conduit attachment

When installing the conduit.

Set the attachment to the

inner side of each panel.

2-ø22<7/8>

Conduit hole

(2-ø27<1-1/16>Knockout)

Rear trunking hole

(Knockout)

ø92

40<1-9/16>

74<2-19/32>

<3-5/8>

Drain hole

5-n33<1-5/16>

145

<5-23/32>

145

<5-23/32>

145

<5-23/32>

220

<8-21/32>

81<3-3/16> 219<8-5/8>

30<1-3/16>

31<1-7/32>

Rear piping hole

(Knockout)

S-SERIES

mm<inch>

FOUNDATION

Please secure the unit firmly

with 4 foundation (M10<W3/8>)

2 SERVICE SPACE 3 FOUNDATION BOLTS

Dimensions of space needed

for service access are

1 FREE SPACE (Around the unit)

The diagram below shows a

basic example.

<Foundation bolt height>

bolts.(Bolts and washers must

be purchased locally.)

<5-29/32>

Min.150mm

shown in the below diagram.

FREE

Explantion of particular details is

given in the installation manuals etc.

<19-11/16>

Min.500mm

Min.500mm

Service space

Min.10mm<3/8>

Min.10mm<3/8>

Min.10mm<3/8>

30mm<1-3/16>

Max.

<19-11/16>

Min.150mm<5-29/32>

Min.1000mm<39-3/8>

Handle

ø9.52 (3/8 inch)

Example of Notes

1 ......Refrigerant GAS pipe connction (FLARE) ø15.88 (5/8 inch)

*1......Indication of STOP VALVE connection location.

2 ......Refrigerant LIQUID pipe connection (FLARE)

S-SERIES (Sept. 2010)

Right trunking hole

(Knockout)

45<1-25/32> 40<1-9/16>

Conduit hole

(2-ø27<1-1/16>Knockout)

40<1-9/16>

Air intake

75

<2-31/32>

Right piping hole

(Knockout)

45<1-25/32>40<1-9/16>

Conduit hole

(2-ø27<1-1/16>Knockout)

Piping Knockout Hole Details

Front trunking hole

(Knockout)

63<2-1/2>

73<2-7/8>

ø92

92<3-5/8>

73<2-7/8>

<2-1/2>

63

55<2-3/16>

ø92

<3-5/8>

<3-5/8>

Front piping hole

92<3-5/8>

19<3/4> 55<2-3/16>

92<3-5/8>

(Knockout)

65<2-9/16>

27<1-1/16> 55<2-3/16>

23<29/32>

92<3-5/8>

73<2-7/8> 63<2-1/2>

23<29/32> 27<1-1/16>

23<29/32>

27<1-1/16>

65<2-9/16>

S-3

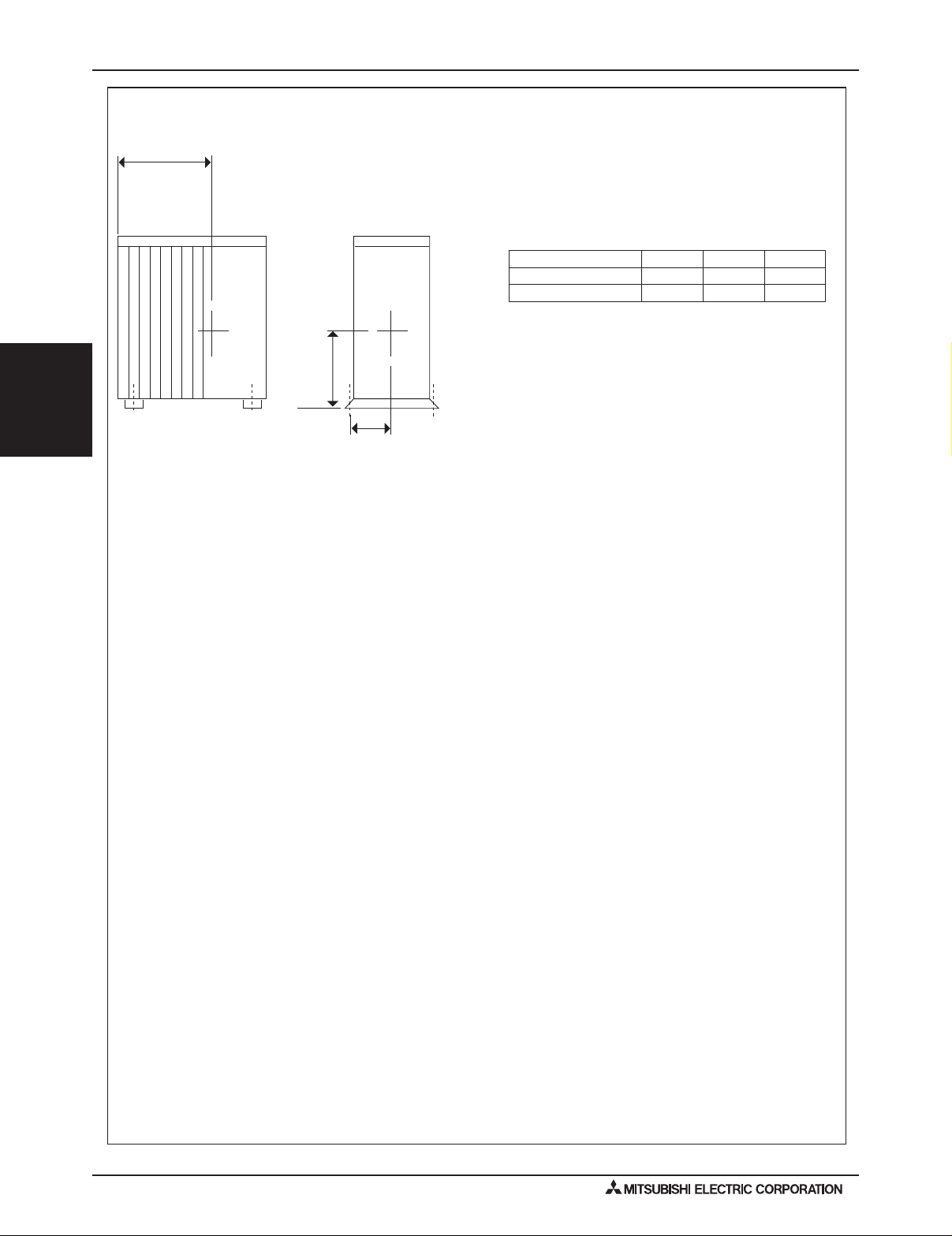

3. CENTER OF GRAVITY

PUMY-P36,48NHMU

X

S-SERIES

Unit : mm[in.]

Model

PUMY-P36NHMU

PUMY-P48NHMU

G

Z

G

Y

XYZ

590(23-1/4) 185(7-5/16) 500(19-11/16)

590(23-1/4) 185(7-5/16) 500(19-11/16)

S-4

Ref. : PUMY_ NHMU_COG_USDB_P36-48

S-SERIES (Sept. 2010)

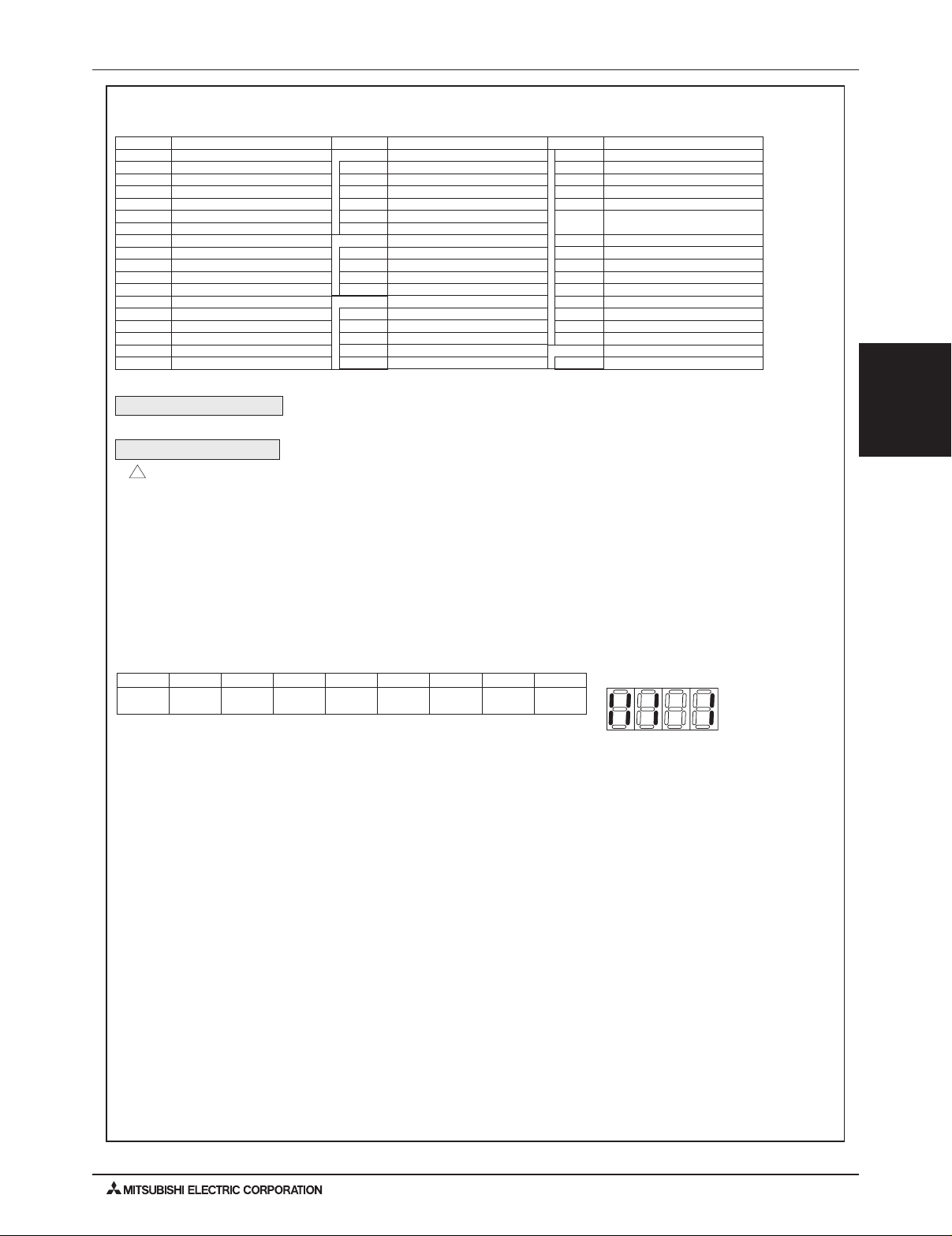

4. ELECTRICAL WIRING DIAGRAMS

PUMY-P36,48NHMU(-BS)

SYMBOL NAME SYMBOL NAME SYMBOL NAME

TB1 Terminal Block <Power Supply>

TB3 Terminal Block <Comunication Line>

TB7 Terminal Block <

MC Motor For Compressor

MF1,MF2 Fan Motor

21S4 Solenoid Valve<Four-Way Valve>

63H High Pressure Switch

63L Low Pressure Switch

63HS High Pressure Sensor

SV1 Solenoid Valve<Bypass valve>

TH3

TH4 Thermistor<Discharge>

TH6 Thermistor<Low Pressure Saturated>

TH7

TH8

DCL

ACTM

CE Main Smoothing Capacitor

Thermistor<Outdoor Pipe>

Thermistor<Outdoor>

Thermistor<Heatsink>

Reactor

Active Filter Module

Centralized Control Line>

P.B. Power Circuit Board

TABU/V/W

TABS/T

TABP1/P2/P

TABN1/N2/N

DS2,DS3

IPM

N.F. Noise Filter Circuit Board

LI/LO

NI/NO

EI,E2

52C

C.B.

SW1

SW2

SW3

SW4

SW5

Connection Terminal<U/V/W-Phase>

Connection Terminal<L/N-Phase>

Connection Terminal<DC Voltage>

Connection Terminal<DC Voltage>

Diode Bridge

Power Module

Connection Terminal<L-Phase>

Connection Terminal<N-Phase>

Connection Terminal<Ground>

52C Relay

Controller Circuit Board

Switch<Display Selection>

Switch<Function Selection>

Switch<Test Run>

Switch<Model Selection>

Switch<Function Selection>

M-NET P.B.

Ref. : PUMY-NHMU_EWD_USDB_P36-48_2

SW6

SW7

SW8

SWU1

SWU2

CNLVB

SS

CN3D

CN3S

CN3N

CN51

LED1,LED2

LED3

F1,F2

X501~505

TP1

Switch<Function Selection>

Switch<Function Selection>

Switch<Function Selection>

Switch<Unit Address Selection, 1st digit>

Switch<Unit Address Selection, 2nd digit>

Connector<To N.F. Board CN52C>

(Symbol of Board is CNLVB)

Connector<Connection For Option>

Connector<Connection For Option>

Connector<Connection For Option>

Connector<Connection For Option>

Connector<Connection For Option>

LED<Operation Inspection Display>

LED<Power Supply to Main Microcomputer>

Fuse<T6,3AL250V>

Relay

M-NET Power Circuit Board

ConnectionTerminal<Ground>

Caution for electrical work

Use copper supply wires.

Cautions when Servicing

• WARNING: When the main supply is turned off, the voltage [340 V] in the main capacitor will drop to 20 V in approx. 2

!

minutes (input voltage: 240 V). When servicing, make sure that LED1, LED2 on the outdoor circuit board goes out, and then

wait for at least 1 minute.

• Components other than the outdoor board may be faulty: Check and take corrective action, referring to the service manual.

Do not replace the outdoor board without checking.

NOTES:

1.Refer to the wiring diagrams of the indoor units for details on wiring of each indoor unit.

Self-diagnosis function

The indoor and outdoor units can be diagnosed automatically using the self-diagnosis switch

(SW1) and LED1, LED2 (LED indication) found on the multi-controller of the outdoor unit.

LED indication : Set all contacts of SW1 to OFF.

• During normal operation

• The LED indicates the drive state of the controller in the outdoor unit.

Bit

Indication

1

Compressor

operated

2

52C321S44SV15(SV2)

6

-

7

Always lit

-

• When fault requiring inspection has occurred

The LED alternately indicates the inspection code and the location of the unit in which

the fault has occurred.

[Example]

When the compressor and

SV1 are turned during cooling

operation.

8

12345678

S-SERIES

S-SERIES (Sept. 2010)

S-5

Loading...

Loading...