Page 1

TECHNICAL MANUAL

Manual No.'10•SR-T-091D

INVERTER RESIDENTIAL AIR CONDITIONERS

(Split system, air to air heat pump type)

DRAFT

Wall mounted type

SRK50ZJ-S

SRK20ZJX-S

SRK25ZJX-S

SRK35ZJX-S

SRK50ZJX-S

SRK60ZJX-S

Floor standing type

SRF25ZJX-S

SRF35ZJX-S

SRF50ZJX-S

Ceiling concealed type

SRR25ZJ-S

SRR35ZJ-S

Ceiling cassette-4way compact type

FDTC25VD

FDTC35VD

Page 2

CONTENTS

1. SPECIFICATIONS ......................................................................................... 2

(1) Wall mounted type (SRK)

.........................................................................

2

(1) Indoor units

(1) Indoor units

............................................................................................. 15

(2) Floor standing type (SRF) ........................................................................ 8

(2) Outdoor units ............................................................................................20

(3) Remote controller .....................................................................................23

3. ELECTRICAL WIRING .................................................................................. 25

............................................................................................. 25

(2) Outdoor units ...........................................................................................30

(3) Ceiling concealed type (SRR) .................................................................. 11

(4) Ceiling cassette-4way compact type (FDTC) ...........................................13

2. EXTERIOR DIMENSIONS ............................................................................. 15

■How to read the model name

Example: SRK 20 Z

Series code

Inveter type

Product capacity

Model name SRK : Wall mounted type

SRC : Outdoor unit

SRF : Floor standing type

SRR : Ceiling concealed type

FDTC : Ceiling cassette-4way

compact type

JX-S

'10 • SR-T-091D

-

-

1

Page 3

-

2

-

'10 • SR-T-091D

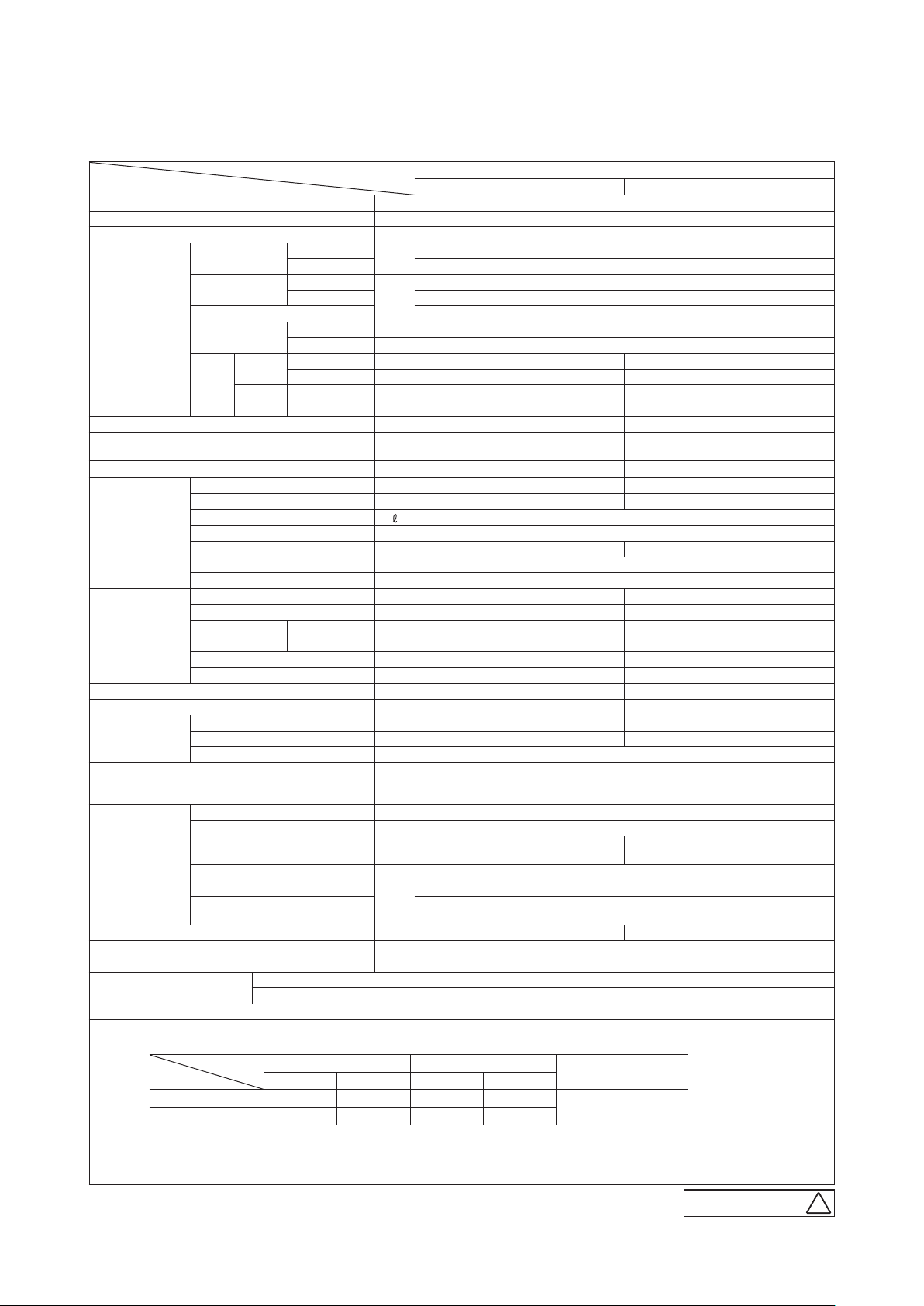

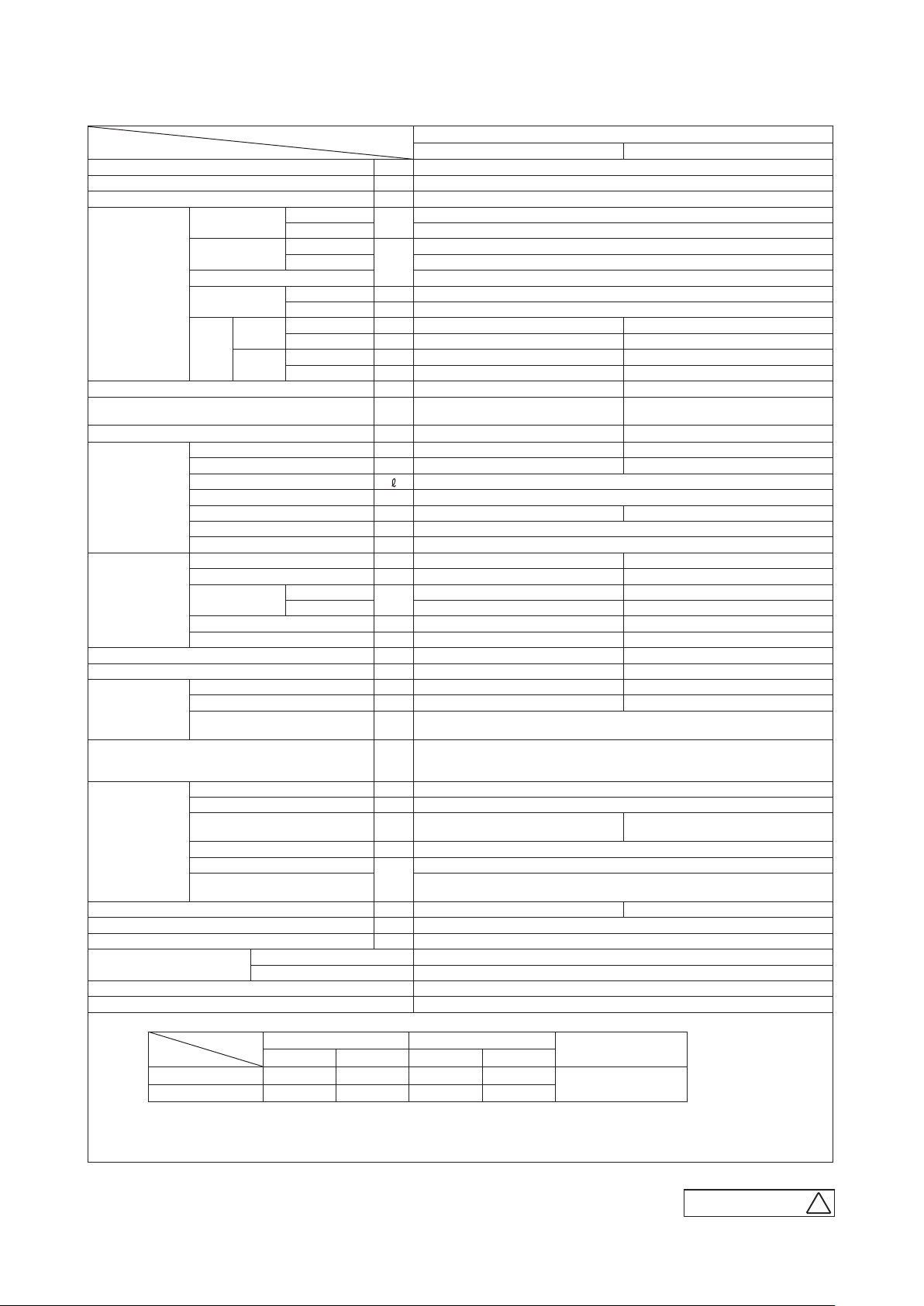

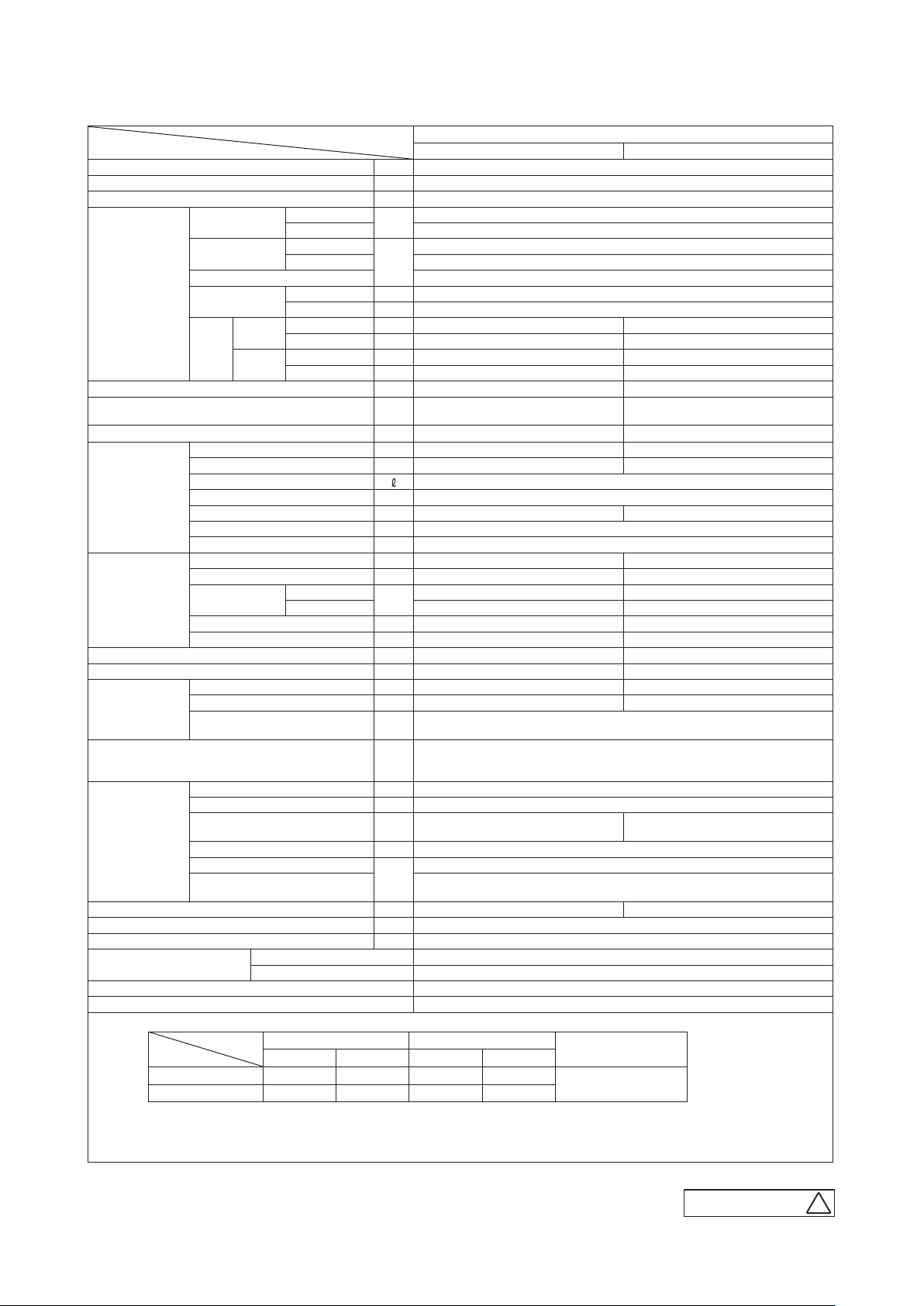

1. SPECIFICATIONS

(1) Wall mounted type (SRK)

Item

Cooling capacity (1) W 5000 (1600 (Min.)~5500 (Max.))

Heating capacity (1) W 5800 (1600 (Min.)~6600 (Max.))

Power supply 1 Phase, 220~240 V, 50Hz

Power

consumption

Running

current

Operation

data (1)

Exterior dimensions (Height x Width x Depth) mm 294 x 798 x 229 640 x 800 (+71) x 290

Exterior appearance

(Munsell color)

Net weight kg 9.5 42

Refrigerant

equipment

Air handling

equipment

Shock & vibration absorber — Cushion rubber (for compressor)

Electric heater — —

Operation

control

Safety devices

Installation

data

Drain hose Connectable (VP16) —

Power cable —

Recommended breaker size A 16

Connection wiring

Accessories (included)

Optional parts Interface kit (SC-BIKN-E)

Note (1) The data are measured at the following conditions.

Inrush current 7.3 / 7.0 / 6.7 (220/ 230/ 240 V)

COP

Cooling

Noise

level

Heating

Compressor type & Q'ty — 5RS132XAB21 (Rotary type) x 1

Motor (Starting method) kW — 0.90 (Line starting)

Refrigerant oil 0.37 (FV50S)

Refrigerant (4) kg R410A 1.35 (Pre-Charged up to the piping length of 15m)

Heat exchanger Louver fins & inner grooved tubing M fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Deice control Microcomputer control

Fan type & Q'ty Tangential fan x 1 Propeller fan x 1

Motor W 38 34

Air flow

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 2 —

Operation switch Wireless-Remote control —

Room temperature control Microcomputer thermostat —

Operation Display RUN : Green, TIMER : Yellow, HI POWER : Green, 3D AUTO : Green

Refrigerant piping size (O.D) mm Liquid line :φ6.35 (1/4") Gas line :φ12.7 (1/2")

Connecting method Flare connecting

Attached length of piping m

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

Vertical height difference between

outdoor unit and indoor unit

Item

Operation

Cooling 27˚C 19˚C 35˚C 24˚C

Heating 20˚C — 7˚C 6˚C

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 220/230/240V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 15m connecting piping.

(Purging is not required even for the short piping.)

Cooling

Heating 1.59 (0.42~2.10)

Cooling

Heating 7.3 / 7.0 / 6.7 (220/ 230/ 240 V)

Cooling 3.23

Heating 3.65

Sound level dB(A) Hi : 46 Me : 37 Lo : 26 51

Power level dB 61 61

Sound level dB(A) Hi : 45 Me : 37 Lo : 31 53

Power level dB 61 63

Cooling

Heating Hi : 13.5 Me : 10.2 Lo : 7.5 36.0

Size x Core number 1.5mm2 x 4 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Indoor air temperature Outdoor air temperature

DB WB DB WB

Model

kW

A

CMM

m

Indoor unit SRK50ZJ-S Outdoor unit SRC50ZJ-S

7.1 / 6.8 / 6.5 (220/ 230/ 240 V)

Fine snow

( 8.0Y 9.3/0.1 ) near equivalent

Hi : 11.3 Me : 7.8 Lo : 5.3 36.0

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Heating overload protection (High pressure control), Cooling overload protection

Liquid line : 0.53

Gas line : 0.40

Max. 15 (Outdoor unit is higher)

Mounting kit, Clean filter (Allergen clear filter x 1, Photocatalytic washable deodorizing filter x 1)

SRK50ZJ-S

1.55 (0.40~2.20)

Max. 25

Max. 15 (Outdoor unit is lower)

The pipe length is 7.5m.

Standards

ISO-T1, JIS C 9612

Adapted to RoHS directive

Stucco white

( 4.2Y 7.5/1.1 ) near equivalent

—

RWA0 0 0 Z225

B

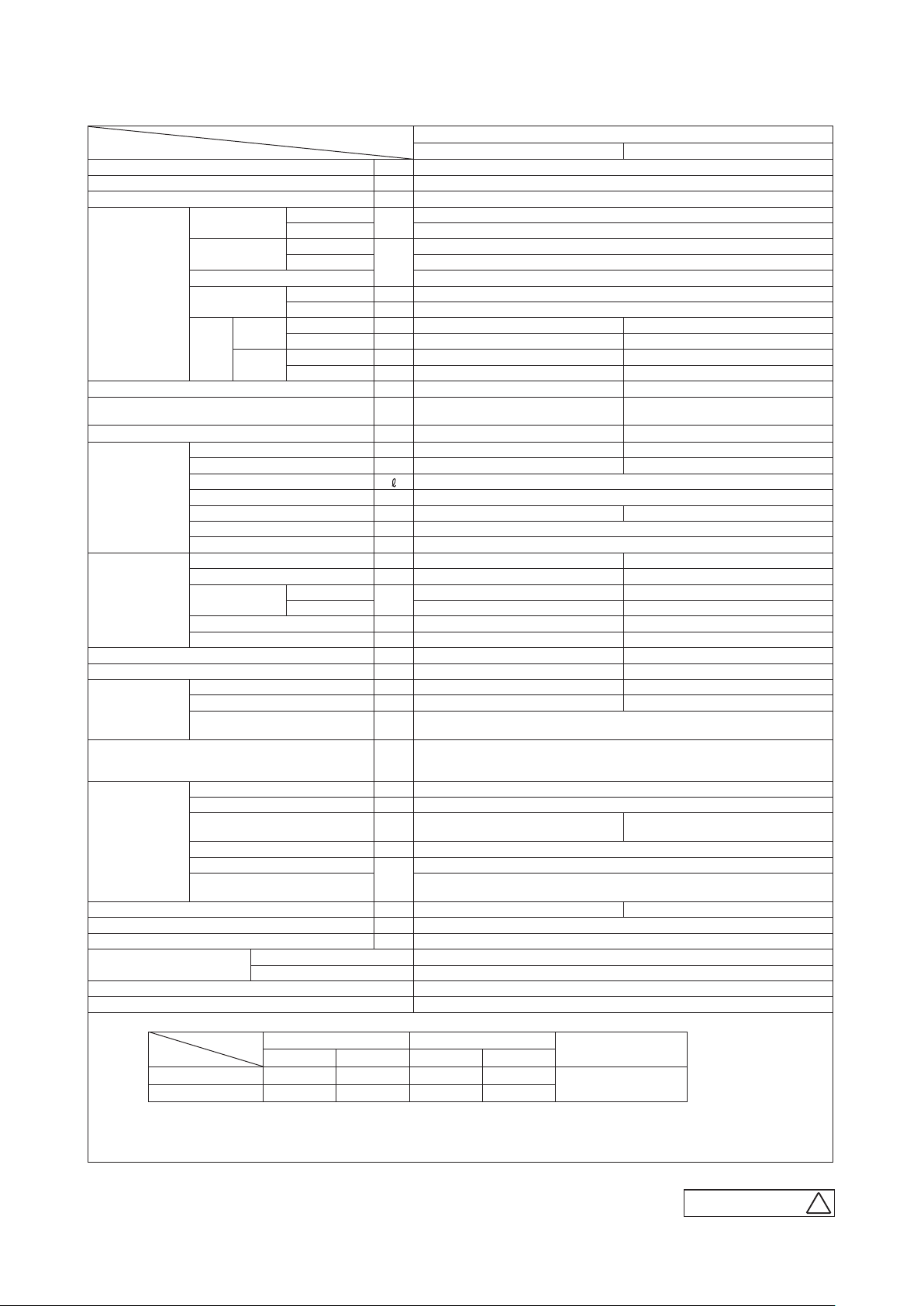

Page 4

'10 • SR-T-091D

Adapted to RoHS directive

Item

Cooling capacity (1) W 2000 (900 (Min.)~3100 (Max.))

Heating capacity (1) W 2500 (900 (Min.)~4300 (Max.))

Power supply 1 Phase, 220~240 V, 50Hz

Power

consumption

Running

current

Operation

data (1)

Exterior dimensions (Height x Width x Depth) mm 309 x 890 x 220 595 x 780 (+62) x 290

Exterior appearance

(Munsell color)

Net weight kg 15 38

Refrigerant

equipment

Air handling

equipment

Shock & vibration absorber — Cushion rubber (for compressor)

Electric heater — —

Operation

control

Safety devices

Installation

data

Drain hose Connectable (VP16) —

Power cable —

Recommended breaker size A 16

Connection wiring

Accessories (included)

Optional parts Interface kit (SC-BIKN-E)

Note (1) The data are measured at the following conditions.

Inrush current 2.4 / 2.3 / 2.2 (220/ 230/ 240 V)

COP

Cooling

Noise

level

Heating

Compressor type & Q'ty — RM-B5077MDE1 (Rotary type) x 1

Motor (Starting method) kW — 0.75 (Line starting)

Refrigerant oil 0.35 (DIAMOND FREEZE MA68)

Refrigerant (4) kg R410A 1.2 (Pre-Charged up to the piping length of 15m)

Heat exchanger Louver fins & inner grooved tubing M fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Deice control Microcomputer control

Fan type & Q'ty Tangential fan x 1 Propeller fan x 1

Motor 27 24

Air flow

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 2 —

Operation switch Wireless-Remote control —

Room temperature control Microcomputer thermostat —

Operation Display

Refrigerant piping size (O.D) mm Liquid line :φ6.35 (1/4") Gas line :φ9.52 (3/8")

Connecting method Flare connecting

Attached length of piping m

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

Vertical height difference between

outdoor unit and indoor unit

Item

Operation

Cooling 27˚C 19˚C 35˚C 24˚C

Heating 20˚C — 7˚C 6˚C

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 220/230/240V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 15m connecting piping.

(Purging is not required even for the short piping.)

Cooling

Heating 0.45 (0.23~1.00)

Cooling

Heating 2.4 / 2.3 / 2.2 (220/ 230/ 240 V)

Cooling 5.71

Heating 5.56

Sound level dB(A) Hi : 39 Me : 30 Lo : 21 47

Power level dB 53 60

Sound level dB(A) Hi : 38 Me : 33 Lo : 25 47

Power level dB 54 59

Cooling

Heating Hi : 12.0 Me : 9.5 Lo : 7.0 27.0

Size x Core number 1.5mm2 x 4 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Indoor air temperature Outdoor air temperature

DB WB DB WB

Model

kW

A

CMM

m

Indoor unit SRK20ZJX-S Outdoor unit SRC20ZJX-S

Fine snow

( 8.0Y 9.3/0.1 ) near equivalent

Hi : 11.5 Me : 8.0 Lo : 5.0 29.5

RUN : Green, TIMER : Yellow, HI POWER : Green,

3D AUTO : Green, ECONO : Blue

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Heating overload protection (High pressure control), Cooling overload protection

Liquid line : 0.55

Gas line : 0.49

Mounting kit, Clean filter (Allergen clear filter x 1, Photocatalytic washable deodorizing filter x 1)

SRK20ZJX-S

0.35 (0.19~0.70)

1.9 / 1.8 / 1.7 (220/ 230/ 240 V)

Stucco white

( 4.2Y 7.5/1.1 ) near equivalent

—

Max. 15

Max. 10 (Outdoor unit is higher)

Max. 10 (Outdoor unit is lower)

The pipe length is 7.5m.

Standards

ISO-T1, JIS C 9612

RWA0 0 0 Z229

-

-

3

B

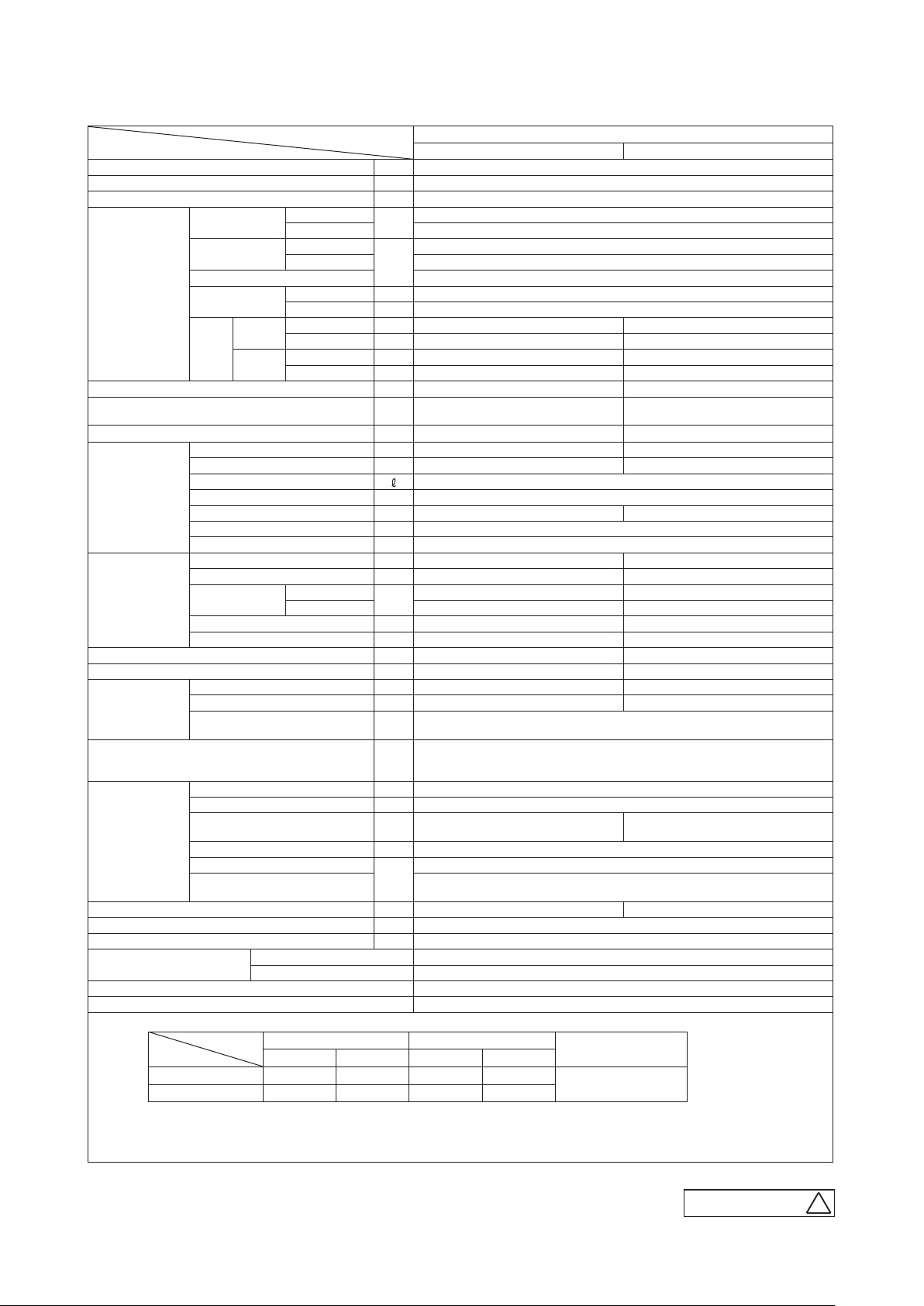

Page 5

-

4

-

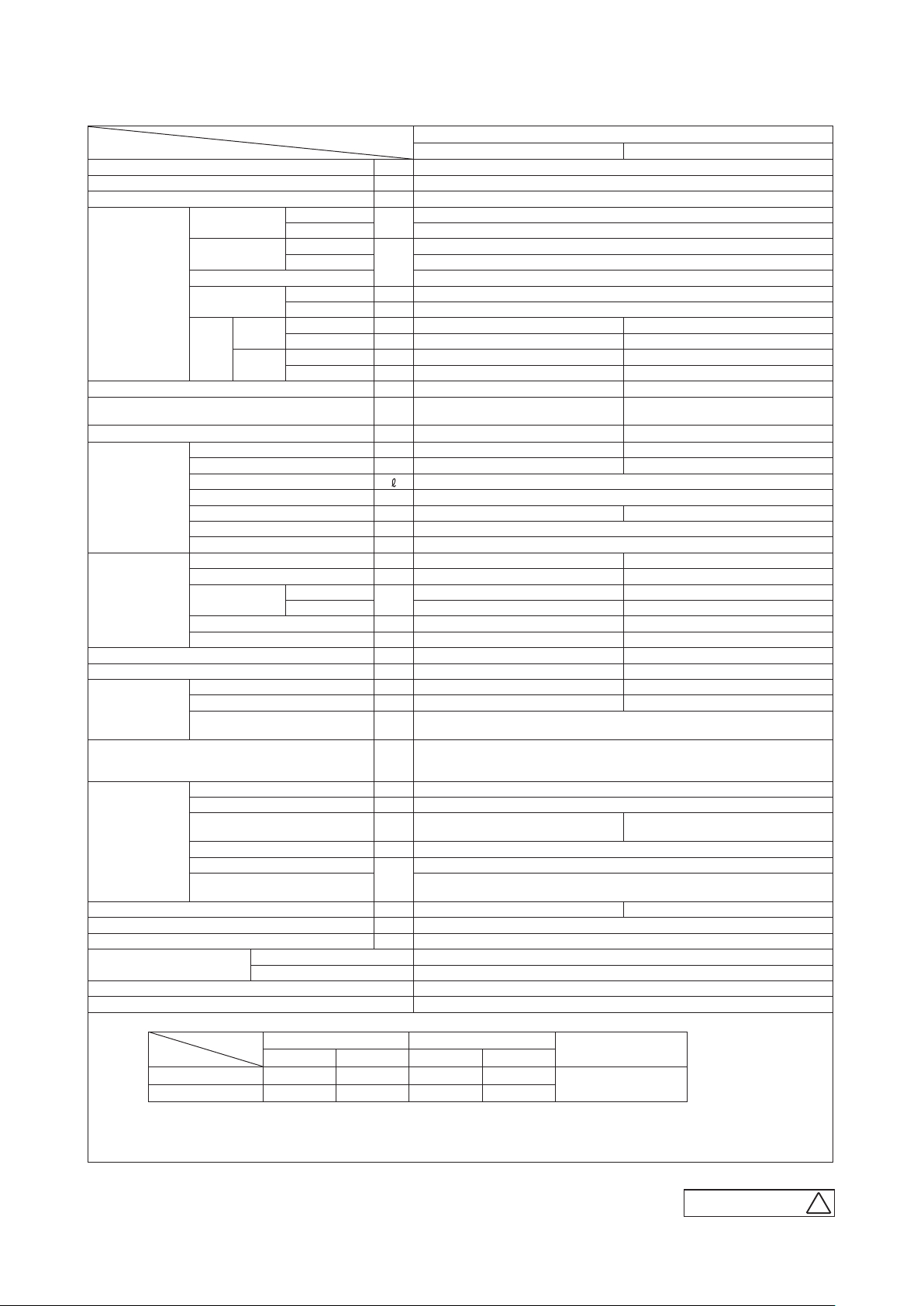

'10 • SR-T-091D

Adapted to RoHS directive

Item

Cooling capacity (1) W 2550 (900 (Min.)~3200 (Max.))

Heating capacity (1) W 3130 (900 (Min.)~4700 (Max.))

Power supply 1 Phase, 220~240 V, 50Hz

Power

consumption

Running

current

Operation

data (1)

Exterior dimensions (Height x Width x Depth) mm 309 x 890 x 220 595 x 780 (+62) x 290

Exterior appearance

(Munsell color)

Net weight kg 15 38

Refrigerant

equipment

Air handling

equipment

Shock & vibration absorber — Cushion rubber (for compressor)

Electric heater — —

Operation

control

Safety devices

Installation

data

Drain hose Connectable (VP16) —

Power cable —

Recommended breaker size A 16

Connection wiring

Accessories (included)

Optional parts Interface kit (SC-BIKN-E)

Note (1) The data are measured at the following conditions.

Inrush current 3.1 / 2.9 / 2.8 (220/ 230/ 240 V)

COP

Cooling

Noise

level

Heating

Compressor type & Q'ty — RM-B5077MDE1 (Rotary type) x 1

Motor (Starting method) kW — 0.75 (Line starting)

Refrigerant oil 0.35 (DIAMOND FREEZE MA68)

Refrigerant (4) kg R410A 1.2 (Pre-Charged up to the piping length of 15m)

Heat exchanger Louver fins & inner grooved tubing M fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Deice control Microcomputer control

Fan type & Q'ty Tangential fan x 1 Propeller fan x 1

Motor W 27 24

Air flow

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 2 —

Operation switch Wireless-Remote control —

Room temperature control Microcomputer thermostat —

Operation Display

Refrigerant piping size (O.D) mm Liquid line :φ6.35 (1/4") Gas line :φ9.52 (3/8")

Connecting method Flare connecting

Attached length of piping m

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

Vertical height difference between

outdoor unit and indoor unit

Item

Operation

Cooling 27˚C 19˚C 35˚C 24˚C

Heating 20˚C — 7˚C 6˚C

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 220/230/240V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 15m connecting piping.

(Purging is not required even for the short piping.)

Cooling

Heating 0.595 (0.23~1.12)

Cooling

Heating 3.1 / 2.9 / 2.8 (220/ 230/ 240 V)

Cooling 5.20

Heating 5.26

Sound level dB(A) Hi : 41 Me : 31 Lo : 22 47

Power level dB 55 60

Sound level dB(A) Hi : 41 Me : 34 Lo : 27 47

Power level dB 58 60

Cooling

Heating Hi : 13.0 Me : 10.0 Lo : 7.5 27.0

Size x Core number 1.5mm2 x 4 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Indoor air temperature Outdoor air temperature

DB WB DB WB

Model

kW

A

CMM

m

Indoor unit SRK25ZJX-S Outdoor unit SRC25ZJX-S

Fine snow

( 8.0Y 9.3/0.1 ) near equivalent

Hi : 12.5 Me : 9.0 Lo : 5.0 29.5

RUN : Green, TIMER : Yellow, HI POWER : Green,

3D AUTO : Green, ECONO : Blue

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Heating overload protection (High pressure control), Cooling overload protection

Liquid line : 0.55

Gas line : 0.49

Mounting kit, Clean filter (Allergen clear filter x 1, Photocatalytic washable deodorizing filter x 1)

SRK25ZJX-S

0.49 (0.19~0.82)

2.5 / 2.4 / 2.3 (220/ 230/ 240 V)

Stucco white

( 4.2Y 7.5/1.1 ) near equivalent

—

Max. 15

Max. 10 (Outdoor unit is higher)

Max. 10 (Outdoor unit is lower)

The pipe length is 7.5m.

Standards

ISO-T1, JIS C 9612

RWA0 0 0 Z229

B

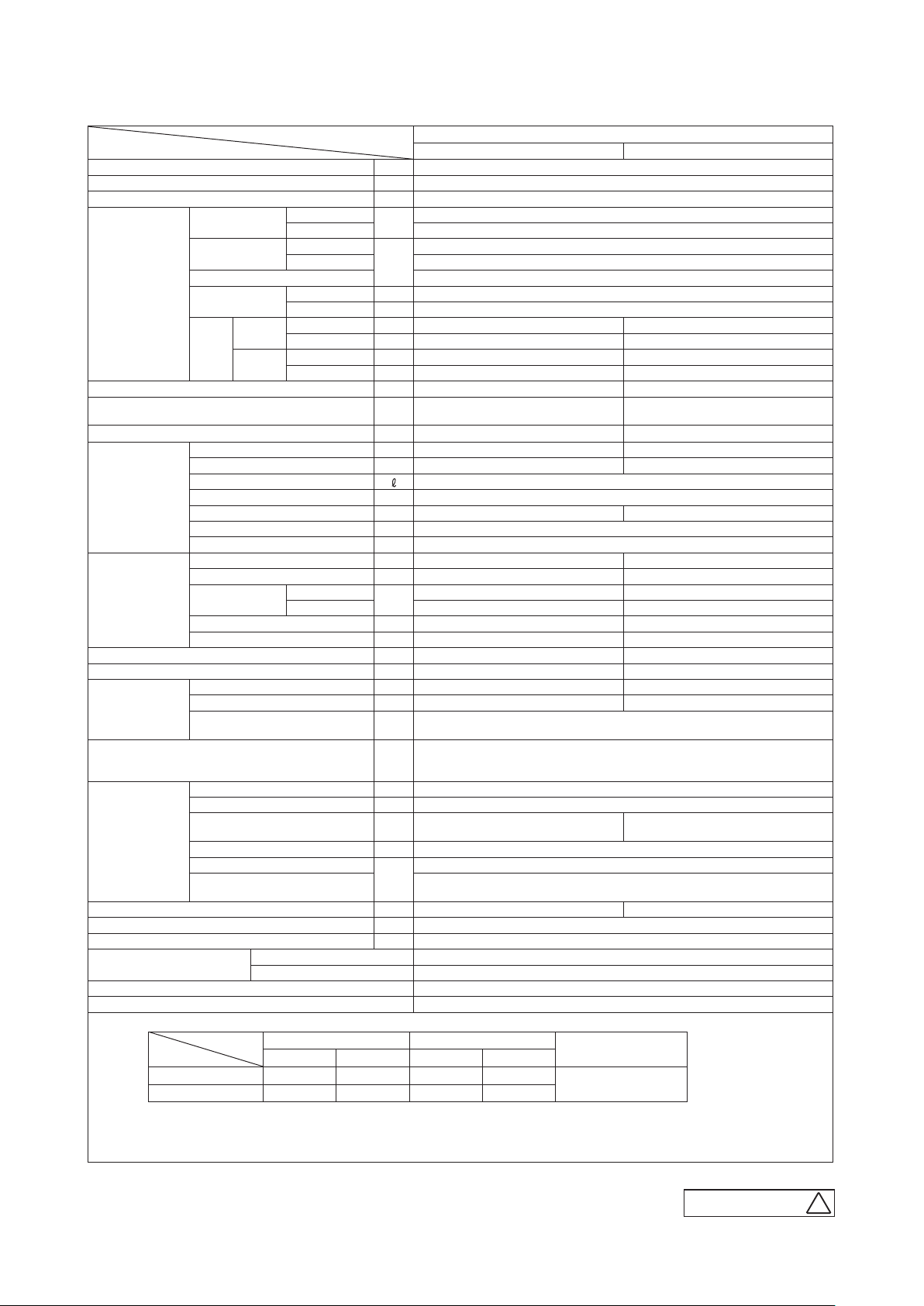

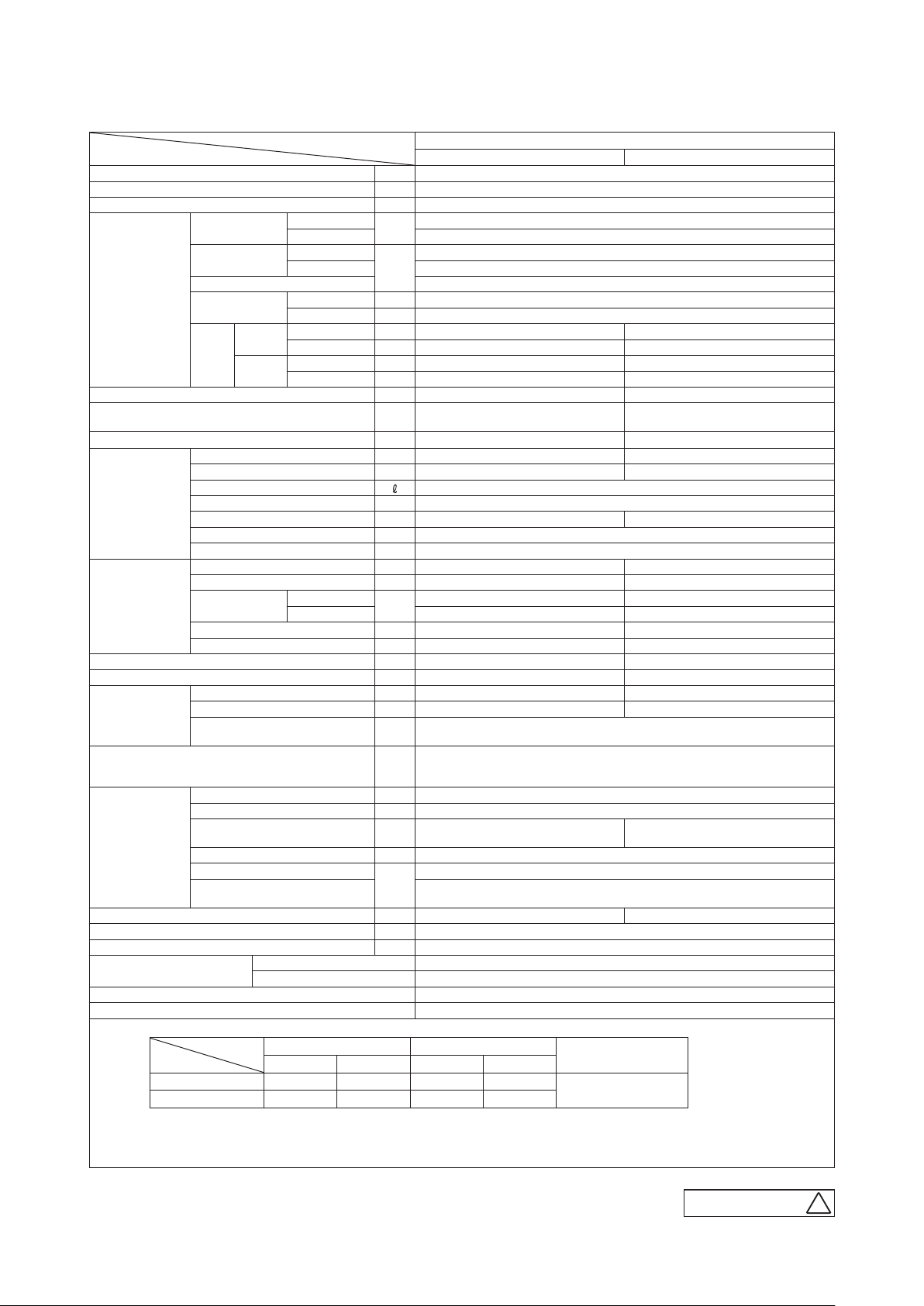

Page 6

'10 • SR-T-091D

Adapted to RoHS directive

Item

Cooling capacity (1) W 3500 (900 (Min.)~4100 (Max.))

Heating capacity (1) W 4300 (900 (Min.)~5100 (Max.))

Power supply 1 Phase, 220~240 V, 50Hz

Power

consumption

Running

current

Operation

data (1)

Exterior dimensions (Height x Width x Depth) mm 309 x 890 x 220 595 x 780 (+62) x 290

Exterior appearance

(Munsell color)

Net weight kg 15 38

Refrigerant

equipment

Air handling

equipment

Shock & vibration absorber — Cushion rubber (for compressor)

Electric heater — —

Operation

control

Safety devices

Installation

data

Drain hose Connectable (VP16) —

Power cable —

Recommended breaker size A 16

Connection wiring

Accessories (included)

Optional parts Interface kit (SC-BIKN-E)

Note (1) The data are measured at the following conditions.

Inrush current 4.6 / 4.4 / 4.2 (220/ 230/ 240 V)

COP

Cooling

Noise

level

Heating

Compressor type & Q'ty — RM-B5077MDE1 (Rotary type) x 1

Motor (Starting method) kW — 0.90 (Line starting)

Refrigerant oil 0.35 (DIAMOND FREEZE MA68)

Refrigerant (4) kg R410A 1.2 (Pre-Charged up to the piping length of 15m)

Heat exchanger Louver fins & inner grooved tubing M fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Deice control Microcomputer control

Fan type & Q'ty Tangential fan x 1 Propeller fan x 1

Motor W 27 24

Air flow

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 2 —

Operation switch Wireless-Remote control —

Room temperature control Microcomputer thermostat —

Operation Display

Refrigerant piping size (O.D) mm Liquid line :φ6.35 (1/4") Gas line :φ9.52 (3/8")

Connecting method Flare connecting

Attached length of piping m

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

Vertical height difference between

outdoor unit and indoor unit

Item

Operation

Cooling 27˚C 19˚C 35˚C 24˚C

Heating 20˚C — 7˚C 6˚C

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 220/230/240V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 15m connecting piping.

(Purging is not required even for the short piping.)

Cooling

Heating 0.960 (0.23~1.35)

Cooling

Heating 4.6 / 4.4 / 4.2 (220/ 230/ 240 V)

Cooling 4.14

Heating 4.48

Sound level dB(A) Hi : 43 Me : 33 Lo : 22 50

Power level dB 58 63

Sound level dB(A) Hi : 42 Me : 35 Lo : 27 50

Power level dB 59 62

Cooling

Heating Hi : 14.0 Me : 11.0 Lo : 8.0 29.5

Size x Core number 1.5mm2 x 4 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Indoor air temperature Outdoor air temperature

DB WB DB WB

Model

kW

A

CMM

m

Indoor unit SRK35ZJX-S Outdoor unit SRC35ZJX-S

Fine snow

( 8.0Y 9.3/0.1 ) near equivalent

Hi : 13.5 Me : 9.5 Lo : 5.0 32.5

RUN : Green, TIMER : Yellow, HI POWER : Green,

3D AUTO : Green, ECONO : Blue

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Heating overload protection (High pressure control), Cooling overload protection

Liquid line : 0.55

Gas line : 0.49

Mounting kit, Clean filter (Allergen clear filter x 1, Photocatalytic washable deodorizing filter x 1)

SRK35ZJX-S

0.845 (0.19~1.01)

4.0 / 3.8 / 3.6 (220/ 230/ 240 V)

Stucco white

( 4.2Y 7.5/1.1 ) near equivalent

—

Max. 15

Max. 10 (Outdoor unit is higher)

Max. 10 (Outdoor unit is lower)

The pipe length is 7.5m.

Standards

ISO-T1, JIS C 9612

RWA0 0 0 Z229

-

-

5

B

Page 7

-

6

-

'10 • SR-T-091D

Adapted to RoHS directive

Item

Cooling capacity (1) W 5000 (700 (Min.)~6200 (Max.))

Heating capacity (1) W 6000 (700 (Min.)~8800 (Max.))

Power supply 1 Phase, 220~240 V, 50Hz

Power

consumption

Running

current

Operation

data (1)

Exterior dimensions (Height x Width x Depth) mm 309 x 890 x 220 640 x 800 (+71) x 290

Exterior appearance

(Munsell color)

Net weight kg 15 43

Refrigerant

equipment

Air handling

equipment

Shock & vibration absorber — Cushion rubber (for compressor)

Electric heater — —

Operation

control

Safety devices

Installation

data

Drain hose Connectable (VP16) —

Power cable —

Recommended breaker size A 16

Connection wiring

Accessories (included)

Optional parts Interface kit (SC-BIKN-E)

Note (1) The data are measured at the following conditions.

Inrush current 6.2 / 5.9 / 5.7 (220/ 230/ 240 V)

COP

Cooling

Noise

level

Heating

Compressor type & Q'ty — 5CS130XGB04 (Scroll type) x 1

Motor (Starting method) kW — 0.9 (Line starting)

Refrigerant oil 0.48 (RB68A or Freol Alpha 68M)

Refrigerant (3) kg R410A 1.4 (Pre-Charged up to the piping length of 15m)

Heat exchanger Louver fins & inner grooved tubing M fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Deice control Microcomputer control

Fan type & Q'ty Tangential fan x 1 Propeller fan x 1

Motor W 27 34

Air flow

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 2 —

Operation switch Wireless-Remote control —

Room temperature control Microcomputer thermostat —

Operation Display

Refrigerant piping size (O.D) mm Liquid line :φ6.35 (1/4") Gas line :φ12.7 (1/2")

Connecting method Flare connecting

Attached length of piping m

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

Vertical height difference between

outdoor unit and indoor unit

Item

Operation

Cooling 27˚C 19˚C 35˚C 24˚C

Heating 20˚C — 7˚C 6˚C

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 220/230/240V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 15m connecting piping.

(Purging is not required even for the short piping.)

Cooling

Heating 1.35 (0.2~2.26)

Cooling

Heating 6.2 / 5.9 / 5.7 (220/ 230/ 240 V)

Cooling 3.85

Heating 4.44

Sound level dB(A) Hi : 45 Me : 38 Lo : 26 48

Power level dB 60 62

Sound level dB(A) Hi : 45 Me : 38 Lo : 32 48

Power level dB 62 62

Cooling

Heating Hi : 16.5 Me : 14.5 Lo : 10.5 33.0

Size x Core number 1.5mm2 x 4 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Indoor air temperature Outdoor air temperature

DB WB DB WB

Model

kW

A

CMM

m

Indoor unit SRK50ZJX-S Outdoor unit SRC50ZIX-S

Fine snow

( 8.0Y 9.3/0.1 ) near equivalent

Hi : 13.5 Me : 11 Lo: 8 36.0

RUN : Green, TIMER : Yellow, HI POWER : Green,

3D AUTO : Green, ECONO : Blue

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Heating overload protection (High pressure control), Cooling overload protection

Liquid line : 0.55

Gas line : 0.49

Mounting kit, Clean filter (Allergen clear filter x 1, Photocatalytic washable deodorizing filter x 1)

SRK50ZJX-S

1.30 (0.2~2.20)

6.0 / 5.7 / 5.5 (220/ 230/ 240 V)

Stucco white

( 4.2Y 7.5/1.1 ) near equivalent

—

Max. 30

Max. 20 (Outdoor unit is higher)

Max. 20 (Outdoor unit is lower)

The pipe length is 7.5m.

Standards

ISO-T1, JIS C 9612

RWA0 0 0 Z229

B

Page 8

'10 • SR-T-091D

Adapted to RoHS directive

Item

Cooling capacity (1) W 6000 (800 (Min.)~6800 (Max.))

Heating capacity (1) W 6800 (800 (Min.)~9700 (Max.))

Power supply 1 Phase, 220~240 V, 50Hz

Power

consumption

Running

current

Operation

data (1)

Exterior dimensions (Height x Width x Depth) mm 309 x 890 x 220 640 x 800 (+71) x 290

Exterior appearance

(Munsell color)

Net weight kg 15 43

Refrigerant

equipment

Air handling

equipment

Shock & vibration absorber — Cushion rubber (for compressor)

Electric heater — —

Operation

control

Safety devices

Installation

data

Drain hose Connectable (VP 16) —

Power cable —

Recommended breaker size A 16

Connection wiring

Accessories (included)

Optional parts Interface kit (SC-BIKN-E)

Note (1) The data are measured at the following conditions.

Inrush current 8.5 / 8.2 / 7.8 (220/ 230/ 240 V)

COP

Cooling

Noise

level

Heating

Compressor type & Q'ty — 5CS130XGB04 (Scroll type) x 1

Motor (Starting method) kW — 0.9 (Line starting)

Refrigerant oil 0.48 (RB68A or Freol Alpha 68M)

Refrigerant (3) kg R410A 1.4 (Pre-Charged up to the piping length of 15m)

Heat exchanger Louver fins & inner grooved tubing M fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Deice control Microcomputer control

Fan type & Q'ty Tangential fan x 1 Propeller fan x 1

Motor W 27 34

Air flow

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 2 —

Operation switch Wireless-Remote control —

Room temperature control Microcomputer thermostat —

Operation Display

Refrigerant piping size (O.D) mm Liquid line :φ6.35 (1/4") Gas line :φ12.7 (1/2")

Connecting method Flare connecting

Attached length of piping m

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

Vertical height difference between

outdoor unit and indoor unit

Item

Operation

Cooling 27˚C 19˚C 35˚C 24˚C

Heating 20˚C — 7˚C 6˚C

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 220/230/240V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 15m connecting piping.

(Purging is not required even for the short piping.)

Cooling

Heating 1.67 (0.25~2.70)

Cooling

Heating 7.7 / 7.3 / 7.0 (220/ 230/ 240 V)

Cooling 3.23

Heating 4.07

Sound level dB(A) Hi : 47 Me : 38 Lo : 26 51

Power level dB 62 65

Sound level dB(A) Hi : 45 Me : 39 Lo : 33 51

Power level dB 62 65

Cooling

Heating Hi : 17.0 Me : 15.0 Lo : 11.0 36.0

Size x Core number 1.5mm2 x 4 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Indoor air temperature Outdoor air temperature

DB WB DB WB

Model

kW

A

CMM

m

Indoor unit SRK60ZJX-S Outdoor unit SRC60ZIX-S

Fine snow

( 8.0Y 9.3/0.1 ) near equivalent

Hi : 14.5 Me : 12.5 Lo : 8.5 41.5

RUN : Green, TIMER : Yellow, HI POWER : Green,

3D AUTO : Green, ECONO : Blue

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Heating overload protection (High pressure control), Cooling overload protection

Liquid line : 0.55

Gas line : 0.49

Mounting kit, Clean filter (Allergen clear filter x 1, Photocatalytic washable deodorizing filter x 1)

SRK60ZJX-S

1.86 (0.25~2.30)

8.5 / 8.2 / 7.8 (220/ 230/ 240 V)

Stucco white

( 4.2Y 7.5/1.1 ) near equivalent

—

Max. 30

Max. 20 (Outdoor unit is higher)

Max.20 (Outdoor unit is lower)

The pipe length is 7.5m.

Standards

ISO-T1, JIS C 9612

RWA0 0 0 Z229

-

-

7

B

Page 9

-

8

-

'10 • SR-T-091D

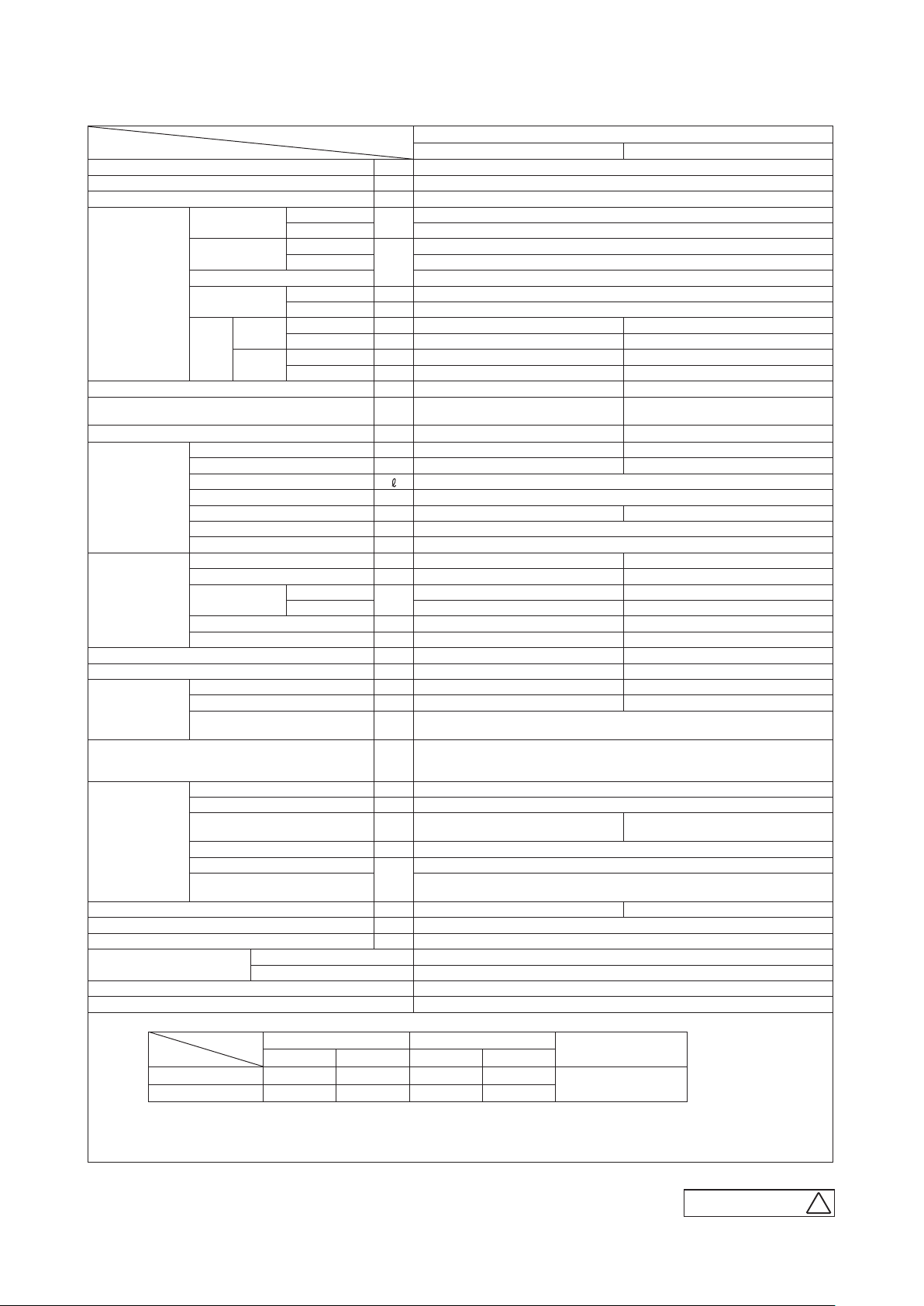

(2) Floor standing type (SRF)

Item

Cooling capacity (1) W 2500 (900 (Min.)~3200 (Max.))

Heating capacity (1) W 3400 (900 (Min.)~4700 (Max.))

Power supply 1 Phase, 220~240 V, 50Hz

Power

consumption

Running

current

Operation

data (1)

Exterior dimensions (Height x Width x Depth) mm 600 x 860 x 238 595 x 780 x 290

Exterior appearance

( Munsell color )

Net weight kg 18 38

Refrigerant

equipment

Air handling

equipment

Shock & vibration absorber — Cushion rubber (for compressor)

Electric heater — —

Operation

control

Safety devices

Installation

data

Drain hose Connectable (VP16) —

Power cable —

Recommended breaker size A 16

Connection wiring

Accessories (included)

Optional parts Interface kit (SC-BIKN-E)

Note (1) The data are measured at the following conditions.

Inrush current 3.6 / 3.4 / 3.3 (220/ 230/ 240 V)

COP

Cooling

Noise

level

Heating

Compressor type & Q'ty — RM-B5077MDE1 (Rotary type) x 1

Motor (Starting method) kW — 0.75 (Line starting)

Refrigerant oil 0.35 (DIAMOND FREEZE MA68)

Refrigerant (3) kg R410A 1.2 (Pre-Charged up to the piping length of 15m)

Heat exchanger Louver fins & inner grooved tubing M fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Deice control Microcomputer control

Fan type & Q'ty Turbo fan x 1 Propeller fan x 1

Motor W 40 24

Air flow

Fresh air intake Impossible —

Air filter, Quality / Quantity Polypropylene net (washable) x 1 —

Operation switch Wireless-Remote control —

Room temperature control Microcomputer thermostat —

Operation Display

Refrigerant piping size (O.D) mm Liquid line :φ6.35 (1/4") Gas line :φ9.52 (3/8")

Connecting method Flare connecting

Attached length of piping m — —

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

Vertical height difference between

outdoor unit and indoor unit

Item

Operation

Cooling 27˚C 19˚C 35˚C 24˚C

Heating 20˚C — 7˚C 6˚C

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 220/230/240V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 15m connecting piping.

(Purging is not required even for the short piping.)

Cooling

Heating 0.723 (0.23~1.20)

Cooling

Heating 3.6 / 3.4 / 3.3 (220/ 230/ 240 V)

Cooling 4.80

Heating 4.70

Sound level dB(A) Hi : 40 Me : 32 Lo : 26 47

Power level dB 51 60

Sound level dB(A) Hi : 40 Me : 35 Lo : 28 47

Power level dB 51 60

Cooling

Heating Hi : 10.5 Me : 8.2 Lo : 6.6 27.0

Size x Core number 1.5mm2 x 4 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Indoor air temperature Outdoor air temperature

DB WB DB WB

Model

kW

A

CMM

m

Indoor unit SRF25ZJX-S Outdoor unit SRC25ZJX-S

Fine snow

( 8.0Y 9.3/0.1 ) near equivalent

Hi : 9.0 Me : 7.6 Lo : 5.8 29.5

RUN : Green, TIMER : Yellow, HI POWER : Green,

AIR OUTLET SELECTION : Green, ECONO : Green

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Heating overload protection (High pressure control), Cooling overload protection

Mounting kit, Clean filter (Natural enzyme filter x 1, Photocatalytic washable deodorizing filter x 1)

SRF25ZJX-S

0.521 (0.19~0.82)

2.6 / 2.5 / 2.4 (220/ 230/ 240 V)

Max. 15

Max. 10 (Outdoor unit is higher)

Max. 10 (Outdoor unit is lower)

The pipe length is 7.5m.

Standards

ISO-T1, JIS C 9612

Adapted to RoHS directive

Stucco white

( 4.2Y 7.5/1.1 ) near equivalent

RW B 000Z0 5 3

A

Page 10

'10 • SR-T-091D

Adapted to RoHS directive

Item

Cooling capacity (1) W 3500 (900 (Min.)~4100 (Max.))

Heating capacity (1) W 4500 (900 (Min.)~5100 (Max.))

Power supply 1 Phase, 220~240 V, 50Hz

Power

consumption

Running

current

Operation

data (1)

Exterior dimensions (Height x Width x Depth) mm 600 x 860 x 238 595 x 780 x 290

Exterior appearance

( Munsell color )

Net weight kg 19 38

Refrigerant

equipment

Air handling

equipment

Shock & vibration absorber — Cushion rubber (for compressor)

Electric heater — —

Operation

control

Safety devices

Installation

data

Drain hose Connectable (VP16) —

Power cable —

Recommended breaker size A 16

Connection wiring

Accessories (included)

Optional parts Interface kit (SC-BIKN-E)

Note (1) The data are measured at the following conditions.

Inrush current 5.2 / 4.9 / 4.7 (220/ 230/ 240 V)

COP

Cooling

Noise

level

Heating

Compressor type & Q'ty — RM-B5077MDE1 (Rotary type) x 1

Motor (Starting method) kW — 0.90 (Line starting)

Refrigerant oil 0.35 (DIAMOND FREEZE MA68)

Refrigerant (3) kg R410A 1.2 (Pre-Charged up to the piping length of 15m)

Heat exchanger Louver fins & inner grooved tubing M fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Deice control Microcomputer control

Fan type & Q'ty Turbo fan x 1 Propeller fan x 1

Motor W 40 24

Air flow

Fresh air intake Impossible —

Air filter, Quality / Quantity Polypropylene net (washable) x 1 —

Operation switch Wireless-Remote control —

Room temperature control Microcomputer thermostat —

Operation Display

Refrigerant piping size (O.D) mm Liquid line :φ6.35 (1/4") Gas line :φ9.52 (3/8")

Connecting method Flare connecting

Attached length of piping m — —

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

Vertical height difference between

outdoor unit and indoor unit

Item

Operation

Cooling 27˚C 19˚C 35˚C 24˚C

Heating 20˚C — 7˚C 6˚C

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 220/230/240V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 15m connecting piping.

(Purging is not required even for the short piping.)

Cooling

Heating 1.124 (0.23~1.43)

Cooling

Heating 5.2 / 4.9 / 4.7 (220/ 230/ 240 V)

Cooling 3.93

Heating 4.00

Sound level dB(A) Hi : 41 Me : 34 Lo : 28 50

Power level dB 52 63

Sound level dB(A) Hi : 41 Me : 36 Lo : 31 50

Power level dB 52 62

Cooling

Heating Hi : 10.7 Me : 8.3 Lo : 7.4 29.5

Size x Core number 1.5mm2 x 4 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Indoor air temperature Outdoor air temperature

DB WB DB WB

Model

kW

A

CMM

m

Indoor unit SRF35ZJX-S Outdoor unit SRC35ZJX-S

Fine snow

( 8.0Y 9.3/0.1 ) near equivalent

Hi : 9.2 Me : 7.8 Lo : 6.4 32.5

RUN : Green, TIMER : Yellow, HI POWER : Green,

AIR OUTLET SELECTION : Green, ECONO : Green

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Heating overload protection (High pressure control), Cooling overload protection

Mounting kit, Clean filter (Natural enzyme filter x 1, Photocatalytic washable deodorizing filter x 1)

SRF35ZJX-S

0.890 (0.19~1.26)

4.1 / 3.9 / 3.7 (220/ 230/ 240 V)

Stucco white

( 4.2Y 7.5/1.1 ) near equivalent

Max. 15

Max. 10 (Outdoor unit is higher)

Max.10 (Outdoor unit is lower)

The pipe length is 7.5m.

Standards

ISO-T1, JIS C 9612

RW B 000Z0 5 3

-

-

9

A

Page 11

-

10

-

'10 • SR-T-091D

Adapted to RoHS directive

Item

Cooling capacity (1) W 5000 (700 (Min.)~5500 (Max.))

Heating capacity (1) W 6000 (700 (Min.)~7000 (Max.))

Power supply 1 Phase, 220~240 V, 50Hz

Power

consumption

Running

current

Operation

data (1)

Exterior dimensions (Height x Width x Depth) mm 600 x 860 x 238 640 x 800 x 290

Exterior appearance

(Munsell color)

Net weight kg 19 43

Refrigerant

equipment

Air handling

equipment

Shock & vibration absorber — Cushion rubber (for compressor)

Electric heater — —

Operation

control

Safety devices

Installation

data

Drain hose Connectable (VP16) —

Power cable —

Recommended breaker size A 16

Connection wiring

Accessories (included)

Optional parts Interface kit (SC-BIKN-E)

Note (1) The data are measured at the following conditions.

Inrush current 7.1 / 6.8 / 6.5 (220/ 230/ 240 V)

COP

Cooling

Noise

level

Heating

Compressor type & Q'ty — 5CS130XGB04 (Scroll type) x 1

Motor (Starting method) kW — 0.9 (Line starting)

Refrigerant oil 0.48 (RB68A or Freol Alpha 68M)

Refrigerant (3) kg R410A 1.4 (Pre-Charged up to the piping length of 15m)

Heat exchanger Louver fins & inner grooved tubing M fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Deice control Microcomputer control

Fan type & Q'ty Turbo fan x 1 Propeller fan x 1

Motor W 40 34

Air flow

Fresh air intake Impossible —

Air filter, Quality / Quantity Polypropylene net (washable) x 1 —

Operation switch Wireless-Remote control —

Room temperature control Microcomputer thermostat —

Operation Display

Refrigerant piping size (O.D) mm Liquid line :φ6.35 (1/4") Gas line :φ12.7 (1/2")

Connecting method Flare connecting

Attached length of piping m — —

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

Vertical height difference between

outdoor unit and indoor unit

Item

Operation

Cooling 27˚C 19˚C 35˚C 24˚C

Heating 20˚C — 7˚C 6˚C

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 220/230/240V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 15m connecting piping.

(Purging is not required even for the short piping.)

Cooling

Heating 1.540 (0.2~2.25)

Cooling

Heating 7.1 / 6.8 / 6.5 (220/ 230/ 240 V)

Cooling 3.60

Heating 3.90

Sound level dB(A) Hi : 47 Me : 39 Lo : 30 48

Power level dB 58 62

Sound level dB(A) Hi : 47 Me : 39 Lo : 32 48

Power level dB 58 62

Cooling

Heating Hi : 12.0 Me : 10.0 Lo : 7.6 33.0

Size x Core number 1.5mm2 x 4 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Indoor air temperature Outdoor air temperature

DB WB DB WB

Model

kW

A

CMM

m

Indoor unit SRF50ZJX-S Outdoor unit SRC50ZIX-S

Fine snow

( 8.0Y 9.3/0.1 ) near equivalent

Hi : 11.5 Me : 9.6 Lo : 6.6 36.0

RUN : Green, TIMER : Yellow, HI POWER : Green,

AIR OUTLET SELECTION : Green, ECONO : Green

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Heating overload protection (High pressure control), Cooling overload protection

Mounting kit, Clean filter (Natural enzyme filter x 1, Photocatalytic washable deodorizing filter x 1)

SRF50ZJX-S

1.390 (0.2~1.80)

6.4 / 6.1 / 5.8 (220/ 230/ 240 V)

Stucco white

( 4.2Y 7.5/1.1 ) near equivalent

Max. 30

Max. 20 (Outdoor unit is higher)

Max. 20 (Outdoor unit is lower)

The pipe length is 7.5m.

Standards

ISO-T1, JIS C 9612

RW B 000Z0 5 3

A

Page 12

'10 • SR-T-091D

(3) Ceiling concealed type (SRR)

Item

Cooling capacity (1) W 2500 ( 900 (Min.)~3200 (Max.))

Heating capacity (1) W 3400 ( 900 (Min.)~4700 (Max.))

Power supply 1 Phase, 220~240 V, 50Hz

Power

consumption

Running

current

Operation

data (1)

Exterior dimensions (Height x Width x Depth) mm 230 x 740 x 455 595 x 780 x 290

Exterior appearance

(Munsell color)

Net weight kg 22 38

Refrigerant

equipment

Air handling

equipment

Shock & vibration absorber — Cushion rubber (for compressor)

Electric heater — —

Operation

control

Safety devices

Installation

data

Drain hose Connectable (VP16) —

Power cable —

Recommended breaker size A 16

Connection wiring

Accessories (included)

Optional parts Wired remote control, Interface kit (SC-BIKN-E)

Note (1) The data are measured at the following conditions.

Inrush current 3.7 / 3.6 / 3.4 (220/ 230/ 240 V)

COP

Cooling

Noise

level

Heating

Compressor type & Q'ty — RM-B5077MDE1 (Rotary type) x 1

Motor (Starting method) kW — 0.75 (Line starting)

Refrigerant oil 0.35 (DIAMOND FREEZE MA68)

Refrigerant (3) kg R410A 1.2 ( Pre-Charged up to the piping length of 15m )

Heat exchanger Louver fins & inner grooved tubing M fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Deice control Microcomputer control

Fan type & Q'ty Centrifugal fan x 2 Propeller fan x 1

Motor W 51 24

Air flow

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net x 1 —

Operation switch Wireless-Remote control —

Room temperature control Microcomputer thermostat —

Operation Display

Refrigerant piping size (O.D) mm Liquid line :φ6.35 (1/4") Gas line :φ9.52 (3/8")

Connecting method Flare connecting

Attached length of piping m — —

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

Vertical height difference between

outdoor unit and indoor unit

Item

Operation

Cooling 27˚C 19˚C 35˚C 24˚C

Heating 20˚C — 7˚C 6˚C

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 220/230/240V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 15m connecting piping.

(Purging is not required even for the short piping.)

Cooling

Heating 0.750 ( 0.23~1.20 )

Cooling

Heating 3.7 / 3.6 / 3.4 (220/ 230/ 240 V)

Cooling 4.31

Heating 4.53

Sound level dB(A) Hi : 40 Me : 35 Lo : 29 47

Power level dB 54 60

Sound level dB(A) Hi: 41 Me: 38 Lo: 31 47

Power level dB 55 60

Cooling

Heating Hi : 10.0 Me : 9.0 Lo : 6.5 27.0

Size x Core number 1.5mm2 x 4 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Indoor air temperature Outdoor air temperature

DB WB DB WB

Model

kW

A

CMM

m

Indoor unit SRR25ZJ-S Outdoor unit SRC25ZJX-S

2.9 / 2.8 / 2.7 (220/ 230/ 240 V)

—

Hi : 8.5 Me : 7.0 Lo : 5.0 29.5

HI POWER : Green, ECONO : Green

Compressor overheat protection, Overcurrent protection, Drain error protection

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Heating overload protection( High pressure control ), Cooling overload protection

Max. 10 (Outdoor unit is higher)

SRR25ZJ-S

0.580 ( 0.19~0.82 )

RUN : Green, TIMER : Yellow,

Max. 15

Max. 10 (Outdoor unit is lower)

Mounting kit

The pipe length is 7.5m.

Standards

ISO-T1, JIS C 9612

Adapted to RoHS directive

Stucco white

( 4.2Y 7.5/1.1 ) near equivalent

-

11

RWA0 0 0 Z231

A

-

Page 13

-

12

-

'10 • SR-T-091D

Adapted to RoHS directive

Item

Cooling capacity (1) W 3500 ( 900 (Min.)~4100 (Max.))

Heating capacity (1) W 4200 ( 900 (Min.)~5100 (Max.))

Power supply 1 Phase, 220~240 V, 50Hz

Power

consumption

Running

current

Operation

data (1)

Exterior dimensions (Height x Width x Depth) mm 230 x 740 x 455 595 x 780 x 290

Exterior appearance

(Munsell color)

Net weight kg 22 38

Refrigerant

equipment

Air handling

equipment

Shock & vibration absorber — Cushion rubber (for compressor)

Electric heater — —

Operation

control

Safety devices

Installation

data

Drain hose Connectable (VP16) —

Power cable —

Recommended breaker size A 16

Connection wiring

Accessories (included)

Optional parts Wired remote control, Interface kit (SC-BIKN-E)

Note (1) The data are measured at the following conditions.

Inrush current 5.1 / 4.8 / 4.6 (220/ 230/ 240 V)

COP

Cooling

Noise

level

Heating

Compressor type & Q'ty — RM-B5077MDE1 (Rotary type) x 1

Motor (Starting method) kW — 0.75 ( Line starting )

Refrigerant oil 0.35 (DIAMOND FREEZE MA68)

Refrigerant (3) kg R410A 1.2 (Pre-Charged up to the piping length of 15m)

Heat exchanger Louver fins & inner grooved tubing M fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Deice control Microcomputer control

Fan type & Q'ty Centrifugal fan x 2 Propeller fan x 1

Motor W 51 24

Air flow

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net x 1 —

Operation switch Wireless-Remote control —

Room temperature control Microcomputer thermostat —

Operation Display

Refrigerant piping size (O.D) mm Liquid line :φ6.35 (1/4") Gas line :φ9.52 (3/8")

Connecting method Flare connecting

Attached length of piping m — —

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

Vertical height difference between

outdoor unit and indoor unit

Item

Operation

Cooling 27˚C 19˚C 35˚C 24˚C

Heating 20˚C — 7˚C 6˚C

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 220/230/240V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 15m connecting piping.

(Purging is not required even for the short piping.)

Cooling

Heating 1.100 ( 0.23~1.43 )

Cooling

Heating 5.1 / 4.8 / 4.6 (220/ 230/ 240 V)

Cooling 3.24

Heating 3.82

Sound level dB(A) Hi: 42 Me : 37 Lo: 30 50

Power level dB 56 62

Sound level dB(A) Hi : 43 Me : 40 Lo : 32 50

Power level dB 57 62

Cooling

Heating Hi : 11.0 Me : 9.5 Lo : 7.0 29.5

Size x Core number 1.5mm2 x 4 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Indoor air temperature Outdoor air temperature

DB WB DB WB

Model

kW

A

CMM

m

Indoor unit SRR35ZJ-S Outdoor unit SRC35ZJX-S

—

Hi : 9.0 Me : 7.5 Lo : 5.5 32.5

HI POWER : Green, ECONO : Green

Compressor overheat protection, Overcurrent protection, Drain error protection

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Heating overload protection (High pressure control), Cooling overload protection

Max. 10 (Outdoor unit is higher)

SRR35ZJ-S

1.080 ( 0.19~1.26 )

5.0 / 4.7 / 4.5 (220/ 230/ 240 V)

Stucco white

(4.2Y 7.5/1.1) near equivalent

RUN : Green, TIMER : Yellow,

Max. 15

Max. 10 (Outdoor unit is lower)

Mounting kit

The pipe length is 7.5m.

Standards

ISO-T1, JIS C 9612

RWA0 0 0 Z231

A

Page 14

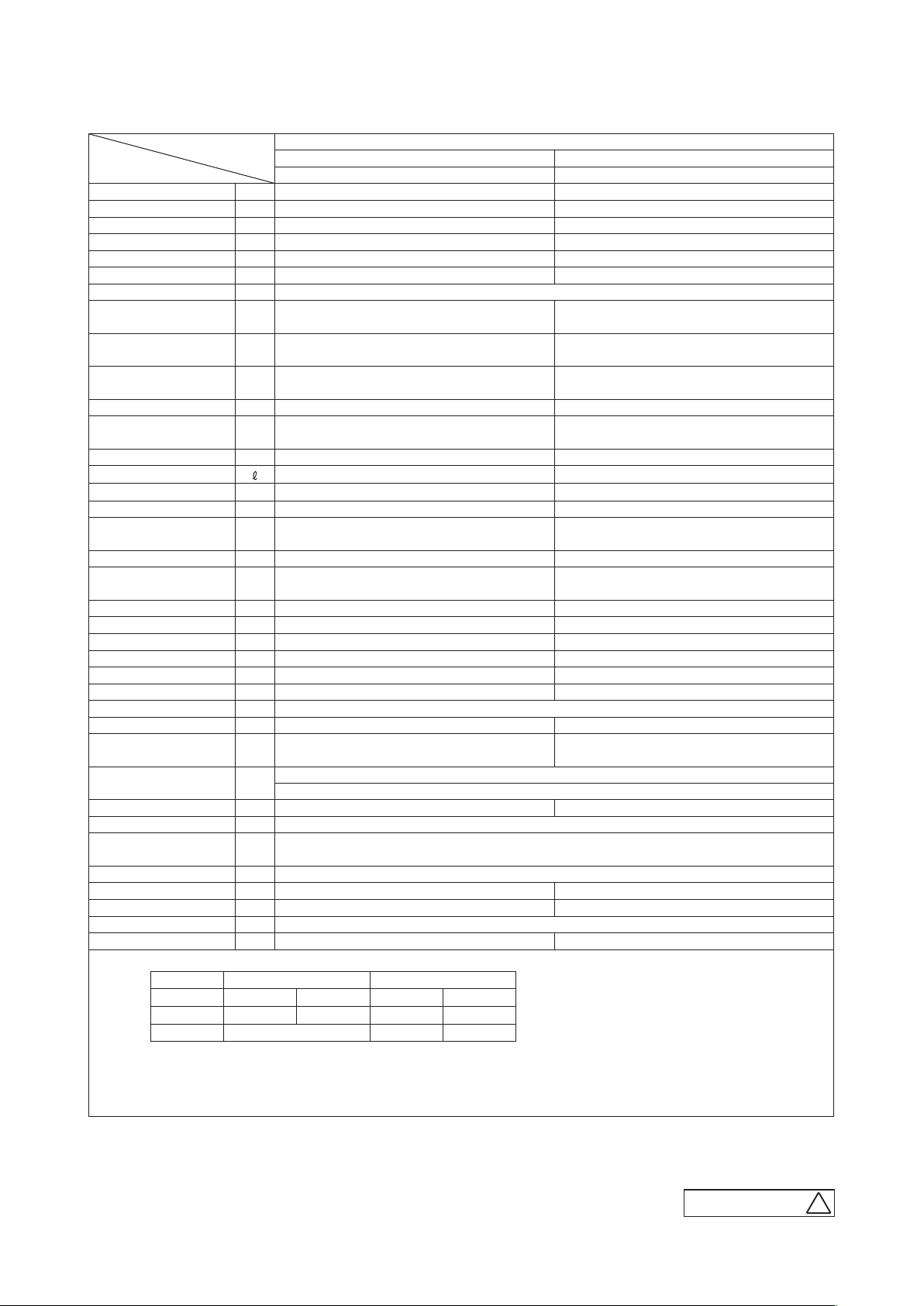

'10 • SR-T-091D

(4) Ceiling cassette-4way compact type (FDTC)

Model

Item

Power source 220/230/240V~50Hz

Operation data Cooling Heating

Nominal capacity kW 2.55 [ 0.9 (Min.)~3.2 (Max.)] 3.45 [ 0.9 (Min.)~4.7 (Max.)]

Power consumption kW 0.6 0.84

Running current A 3.0/2.9/2.8 4.1/4.0/3.8

Power factor % 91 92

Inrush current A 4.1

Sound Pressure Level dB(A)

Exterior dimensions

Height x Width x Depth

Exterior appearance

(Munsell color)

Net weight kg UNIT 15 PANEL 3.5 38

Refrigerant equipment

Compressor type & Q'ty

Starting method — Direct line start

Refrigerant oil — 0.35 (DIAMOND FREEZE MA68)

Heat exchanger Louver fin & inner grooved tubing M shape fin & inner grooved tubing

Refrigerant control — Electronic expansion valve

Air handling equipment

Fan type & Q'ty

Motor <Starting method> W 33 <Direct line start> 24 <Direct line start>

Air flow (Standard) CMM

Available static pressure Pa 0 —

Outdoor air intake Not possible —

Air filter, Q'ty Pocket plastic net × 1 (Washable) —

Shock & vibration absorber Rubber sleeve (for fan motor) Rubber sleeve (for Compressor)

Insulation (noise & heat) Polyurethane form —

Electric heater W — —

Remote controller wired : RC-E4 (option) wireless : RCN-TC-24W-ER (option)

Room temperature control Thermostat by electronics —

Safety equipment

Installation data

Refrigerant piping size

Connecting method Flare piping Flare piping

Refrigerant line (one way) length

Vertical height difference between

outdoor unit and indoor unit

Refrigerant Quantity R410A 1.2kg in outdoor unit (incl. the amount for the piping of : 15m)

Drain pump Built-in Drain pump —

Drain Hose Connectable with VP20 —

Insulation for piping Necessary (Both liquid & Gas lines)

Standard Accessories Mounting kit, Drain hose Drain elbow, Drain hole grommet

Notes (1) The data are measured at the following conditions when the air flow is high mode.

Item Indoor air temperature Outdoor air temperature

Operation DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C

Heating 20˚C 7˚C 6˚C

(2) This packaged air-conditioner is manufactured and tested in conformity with the ISO.

(3) Sound pressure level indicates the value in an anechoic chamber. During operation these value are somewhat higher due to

ambient temperature.

(4) The operation data indicates when the air-conditioner is operated at 220/230/240V 50Hz.

(5) When wireless remote controller is used, fan is 3 speed setting (Hi-Me-Lo) only.

mm

mm

Heating P-Hi : 39 Hi : 38 Me : 33 Lo : 29.5

Heating P-Hi : 10.5 Hi : 9.5 Me : 8.5 Lo : 7

Indoor unit FDTC25VD Outdoor unit SRC25ZJX-S

Panel TC-PSA-25W-E

Cooling P-Hi : 38 Hi : 36 Me : 32 Lo : 29

Unit 248 × 570 × 570

Panel 35 × 700 × 700

Plaster White

( 6.8Y8.9/0.2 ) near equivalent

— RM-B5077MDE1 (Rotary type) x 1

Turbo fan × 1 Propeller fan × 1

Cooling P-Hi : 10 Hi : 9 Me : 8 Lo : 6.5

Overload protection for fan motor

Frost protection thermostat

Liquid line : I/U φ6.35 (1/4") Pipe φ6.35 (1/4") × 0.8 O/U φ6.35 (1/4")

Gas line :

φ9.52 (3/8")

Max. 10m (Outdoor unit is higher)

Max. 10m (Outdoor unit is lower)

FDTC25VD

( 4.2Y7.5/1.1 ) near equivalent

Internal thermostat for fan motor

Abnormal discharge temperature protection.

φ9.52 (3/8") × 0.8 φ9.52 (3/8")

Max. 15m

Adapted to RoHS directive

47

595 x 780 x 290

Stucco White

Cooling 29.5

Heating 27.0

-

13

RWA0 0 0 Z234

A

-

Page 15

'10 • SR-T-091D

Adapted to RoHS directive

Model

Item

Power source 220/230/240V~50Hz

Operation data Cooling Heating

Nominal capacity kW 3.6 [ 0.9 (Min.)~4.1 (Max.)] 4.25 [ 0.9 (Min.)~5.1 (Max.)]

Power consumption kW 1.07 1.16

Running current A 4.9/4.7/4.5 5.3/5.1/4.9

Power factor % 99 99

Inrush current A 5.3

Sound Pressure Level dB(A)

Exterior dimensions

Height x Width x Depth

Exterior appearance

( Munsell color )

Net weight kg UNIT 15 PANEL 3.5 38

Refrigerant equipment

Compressor type & Q'ty

Starting method — Direct line start

Refrigerant oil — 0.35 (DIAMOND FREEZE MA68)

Heat exchanger Louver fin & inner grooved tubing M shape fin & inner grooved tubing

Refrigerant control — Electronic expansion valve

Air handling equipment

Fan type & Q'ty

Motor <Starting method> W 33 <Direct line start> 24 <Direct line start>

Air flow (Standard) CMM

Available static pressure Pa 0 —

Outdoor air intake Not possible —

Air filter, Q'ty Pocket plastic net × 1 (Washable) —

Shock & vibration absorber Rubber sleeve (for fan motor) Rubber sleeve (for Compressor)

Insulation (noise & heat) Polyurethane form —

Electric heater W — —

Remote controller wired : RC-E4 (option) wireless : RCN-TC-24W-ER (option)

Room temperature control Thermostat by electronics —

Safety equipment

Installation data

Refrigerant piping size

Connecting method Flare piping Flare piping

Refrigerant line (one way) length

Vertical height difference between

outdoor unit and indoor unit

Refrigerant Quantity R410A 1.2kg in outdoor unit (incl. the amount for the piping of : 15m)

Drain pump Built-in Drain pump —

Drain Hose Connectable with VP20 —

Insulation for piping Necessary (Both liquid & Gas lines)

Standard Accessories Mounting kit, Drain hose Drain elbow, Drain hole grommet

Notes (1) The data are measured at the following conditions when the air flow is high mode.

Item Indoor air temperature Outdoor air temperature

Operation DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C

Heating 20˚C 7˚C 6˚C

(2) This packaged air-conditioner is manufactured and tested in conformity with the ISO.

(3) Sound pressure level indicates the value in an anechoic chamber. During operation these value are somewhat higher due to

ambient temperature.

(4) The operation data indicates when the air-conditioner is operated at 220/230/240V 50Hz.

(5) When wireless remote controller is used, fan is 3 speed setting (Hi-Me-Lo) only.

mm

Heating P-Hi : 11.5 Hi : 10.0 Me : 9 Lo : 8

mm

Indoor unit FDTC35VD Outdoor unit SRC35ZJX-S

Panel TC-PSA-25W-E

Cooling P-Hi : 41 Hi : 40 Me : 36 Lo : 30

Heating P-Hi : 43 Hi : 42 Me : 35 Lo : 32

Unit 248 × 570 × 570

Panel 35 × 700 × 700

Plaster White

( 6.8Y8.9/0.2 ) near equivalent

— RM-B5077MDE1 (Rotary type) x 1

Turbo fan × 1 Propeller fan × 1

Cooling P-Hi : 11 Hi : 9.5 Me : 9 Lo : 7

Overload protection for fan motor

Frost protection thermostat

Liquid line : I/U φ6.35 (1/4") Pipe φ6.35 (1/4") × 0.8 O/U φ6.35 (1/4")

Gas line :

φ9.52 (3/8")

Max. 10m (Outdoor unit is higher)

Max. 10m (Outdoor unit is lower)

FDTC35VD

50

595 x 780 x 290

Stucco White

( 4.2Y7.5/1.1 ) near equivalent

Cooling 32.5

Heating 29.5

Internal thermostat for fan motor

Abnormal discharge temperature protection.

φ9.52 (3/8") × 0.8 φ9.52 (3/8")

Max. 15m

-

14

RWA0 0 0 Z234

A

-

Page 16

2. EXTERIOR DIMENSIONS

Space for installation and service when viewing from the front

Wired - remote controller

㧔Option㧕

Notes㧔1㧕The model name label is attached

ޓޓ ޓ on the underside of the panel.

Wireless remote controller

ޓ 㧔2㧕It takes the interface kit 㧔SC-BIKN-E㧕

ޓޓ ޓ to connect the wired remote controller.

Outlet for down piping

㧔Refer to the above view㧕

Hole on wall for right rear piping

Hole on wall for left rear piping

Gas piping

Outlet for wiring

Drain hose

Liquid piping

F

E

C

D

B

Symbol

A

㧔Ǿ65㧕

VP16

Ǿ6.35㧔1㧛4"㧕㧔Flare㧕

Content

㧔Ǿ65㧕

20㨪35 Ǿ9.52㧔3㧛8"㧕㧔Flare㧕

Outlet for piping㧔on both side㧕

G

50 Ǿ12.7㧔1㧛2"㧕㧔Flare㧕

Model

Unit:mm

غ120

19

60

150

17.3

G

790

6014.5

45

3160

45

798

294

229 3

45

609

100106.5585106.5

50

48.9

55

47

47

55

403.6

471.6

531.8

F

139 450 209

Unit

D

C

A

E

B

65

15

7.7279.17.2

㧔Service space㧕

㧔Service space㧕

㧔Service space㧕

㧔Service space㧕

Installation plate

(1) Indoor units

Model SRK50ZJ-S

-

15

-

RLA0 0 0 Z051

'10 • SR-T-091D

Page 17

-

16

-

'10 • SR-T-091D

Models SRK20ZJX-S, 25ZJX-S, 35ZJX-S, 50ZJX-S, 60ZJX-S

G

F

Hole on wall for right rear piping

Hole on wall for left rear piping

Gas piping

Outlet for wiring

Drain hose

Liquid piping

F

E

C

D

B

Symbol

A

㧔Ǿ65㧕

VP16

Ǿ6.35㧔1㧛4"㧕㧔Flare㧕

Content

㧔Ǿ65㧕

Unit:mm

Space for installation and service when viewing from the front

Outlet for down piping

㧔Refer to the above view㧕

Outlet for piping㧔on both side㧕

G

D C

A

E

B

Wired - remote controller

㧔Option㧕

Notes㧔1㧕The model name label is attached

ޓޓ ޓ on the underside of the panel.

Wireless remote controller

ޓ 㧔2㧕It takes the interface kit 㧔SC-BIKN-E㧕

ޓޓ ޓ to connect the wired remote controller.

Terminal block

Ǿ9.52㧔3㧛8"㧕㧔Flare㧕

Ǿ12.7㧔1㧛2"㧕㧔Flare㧕

Model 20,25,35

Model 50,60

881.9

59.926 20.959.9

46.5

61.5

46.5

61.5

890

309

9 61.5

3220

50 120 650 120 100

220 450 220

35 35

48.9222.5

48

48

5.7 295.4 7.9

15

㧔Service space㧕

65

Unit

54

46.5

㧔Service space㧕

㧔Service space㧕 㧔Service space㧕

Installation plate

491.1

520.8

559.1

58

غ

120

19

61.5

60

150

17.3

RKY0 0 0 Z053

Page 18

(b) Floor standing type (SRF)

600

Unit:mm

Hole on wall for right rear piping

Hole on wall for left rear piping

Gas piping

Drain hose

Liquid piping

F

E

C

D

B

Symbol

A

㧔Ǿ65㧕

VP16

Ǿ6.35㧔1㧛4"㧕㧔Flare㧕

Content

㧔Ǿ65㧕

25,35 : Ǿ9.52㧔3㧛8"㧕㧔Flare㧕

50 : Ǿ12.7㧔1㧛2"㧕㧔Flare㧕

Model

Outlet for piping㧔on both side㧕

D E

G

Outlet for down piping

㧔Refer to the above view㧕

Space for installation and service when viewing from the front

㧔Option㧕

Wired remote controllerWireless remote controller

A

B

C

F

F

FF

G

Screw point fasten the indoor unit

Ǿ5

860 238

15 60

60

100 60

55

157.276.3 85.3 22.7

185

25.530.5

198

804

6565

45

585

30.5 103.5

585

45

83.5 620 156.5

5.2

726

Notes

㧔1㧕 The model name label is attached on the rightside of the unit.

ޓ㧔2㧕 It takes the interface kit 㧔SC-BIKN-E㧕 to connect the wired remote controller.

㧔3㧕 In case of wall installation, leave the unit 150mm or less from the floor.

514.8 80

211.5255255138.5

544.8 20

482.8

156.2

203

50

70

1084010

50+Service space

㧔Service space㧕

35

㧔Service space㧕

125

6

100

12

Unit

Installation plate

غ120

19

60

150

17.3

Models SRF25ZJX-S, 35ZJX-S, 50ZJX-S

-

17

-

RFB0 0 0 Z004

'10 • SR-T-091D

Page 19

-

18

-

'10 • SR-T-091D

8-φ2.8

Holes for tapping screws(φ4)

455

253

325.4

67035

35

515

3030

740 105.7

230

150

135

75

38

11.2

10522090220105

41 170 19

Terminal block

Air inlet

Air outlet

(Suspension bolts pitch)

(Suspension bolts pitch)

Control Box

B

A

C

D

E

FIG.A

FIG.B

Unit:mm

DCB

Suspension bolts

Drain piping

Liquid piping

VP16

φ6.35(1/4")(Flare)

Gas piping

A

Symbol

Content

φ9.52(3/8")

(M8)

(Flare)

E

Power supply intake

(φ35)

(Option)

Wired remote controllerWireless remote controller

Note(1)The model name label is attached

on the lid of the control box.

□120

19

60

150

17.3

(2)It takes the interface kit (SC-BIKN-E)

to connect the wired remote controller.

236

30

100540100

52 148 30

9-φ2.8

Holes for tapping screws(φ4)

11-φ2.8

Holes for tapping screws(φ4)

Holes for tapping screws(φ4)

6-M4

For hanger plate

☆

☆ ☆

☆

☆

710

710

174.4

177

168 168 168 168

69423

10 10

10 24

168 168 168 168

160 40

190

30.3

703

23

21

82 574 84

670

20120

32

2424

20 80 80 40

150

4040

15 15

203.711.3

15

15 15

18.5

11 13

18.5

1024

35 35

5-φ3.3(

☆

Mark only)

FIG.A

FIG.B

In case of filter guide taken off

(Air inlet from lower)

In case of filter guide installed

(normal condition)

(Air inlet from rear)

In case of filter guide installed

(option)

In case of rear panel taken off

(c) Ceiling concealed type (SRR)

Models SRR25ZJ-S, 35ZJ-S

RJ D00 0Z5 02

A

Page 20

(d) Ceiling cassette-4way compact type (FDTC)

D

G

F

C

B

Hole for wiring

Suspension bolts

Drain piping

Liquid piping

(

M10 or M8

)

VP20 (I.D.20,O.D.26) Note (2

)

φ

6.35(1/4")(Flare

)

Gas pipingA

Symbol

φ

9.52(3/8")(Flare

)

Content

(

Knock out

)

φ

25

Unit:mm

(2)

Prepare the connecting socket(VP20)on site.

Notes

(1)

The model name label is attached on the control box lid.

(3)

This unit is designed for 2x2 grid ceiling.

provide an inspection port on the control box side.

If it is installed on a ceiling other than 2x2 grid ceiling,

Obstacle

Remote controller

Space for installation and service

(

Option

)

Make a space of 4000 or more between

the units when installing more than one.

Ducting for air outlet

6-φ4

Holes for

Hole

tapping screws

Hanger plate for

suspension bolt

Drain hose piece

(

Accessory

)

Control

box

(

Installed on site

)

Decorative panel

Air supply

Air return

grille

G

G

G

G

D

A

C

B

F

1000

or more

1000

or more

19

□

120

600

or less

(

Max. Drain lift

)

60

140

100

100

88

140

145

325

□

570

45

or more

132

192

35

88

210

248

185

190 223

326

350

530

(

Suspension bolts pitch

)

530

(

Suspension bolts pitch

)

556

67

200 48

□

413

□

700

21

35

295 325

Models FDTC25VD, 35VD

-

19

-

PJA 0 0 3Z338

B

'10 • SR-T-091D

Page 21

-

20

-

'10 • SR-T-091D

L2

Intake

Outlet

Intake

L3

L1

Minimum installation space

Service

space

( )

L4

L2

L3

L4

L1

100

100

250

Open

I II

Open

250

80

280

III

280

Open

80

75

Examples of

Dimensions

installation

IV

180

Open

80

Open

φ12.7(1/2")(Flare)

Content

C Pipe/cable draw-out hole

D

E Anchor bolt hole

Drain discharge hole

Symbol

B

A Service valve connection(gas side)

M10 × 4places

φ20 × 5places

Service valve connection(liquid side)

φ6.35(1/4")(Flare)

Notes

(1) It must not be surrounded by walls on the four sides.

(2) The unit must be fixed with anchor bolts. An anchor bolt must not

protrude more the 15mm.

(3) Where the unit is subject to strong winds, lay it in such

a direction that the blower outlet faces perpendicularly

to the dominant wind direction.

(4) Leave 1m or more space above the unit.

(5) A wall in front of the blower outlet must not exceed the units height.

(6) The model name label is attached on the right side of the unit.

A

C

Terminal block

B

93 42.5

640

800

89 510 201

327.3

83.5

290

43.5

327.3 50.6

12

24.3312.514.8

71.2

17.9

40°

40°

33.5148.4

12.4

351.6

38.6

90.6

520.6 161

35.6

D

E

Unit:mm

(2) Outdoor units

Model SRC50ZJ-S

RCT0 0 0 Z005

Page 22

L2

Intake

Outlet

Intake

L3

L1

Minimum installation space

Service

space

( )

L4

L2

L3

L4

L1

100

100

250

Open

I II

Open

250

80

280

III

280

Open

80

75

Examples of

Dimensions

installation

IV

180

Open

80

Open

Notes

(1) It must not be surrounded by walls on the four sides.

(2) The unit must be fixed with anchor bolts. An anchor bolt must not

protrude more the 15mm.

(3) Where the unit is subject to strong winds, lay it in such

a direction that the blower outlet faces perpendicularly

to the dominant wind direction.

(4) Leave 1m or more space above the unit.

(5) A wall in front of the blower outlet must not exceed the units height.

(6) The model name label is attached on the lower right corner of the front panel.

φ9.52(3/8")(Flare)

Content

C Pipe/cable draw-out hole

E Anchor bolt hole

Drain discharge hole

Symbol

B

A Service valve connection(gas side)

M10 × 4places

φ20 × 2places

Service valve connection(liquid side)

φ6.35(1/4")(Flare)

D

40°

40°

138.4 33.5

Terminal block

C

B

A

97.7

42.5

15.8

595

63.4

390.6

390.6

69.4

111.6 510 158.4

780 61.9

17.9

14.8 312.5 24.3

351.6

50.6

12

290

E

D

Unit:mm

-

21

-

RC V000Z 007

Models SRC20ZJX-S, 25ZJX-S, 35ZJX-S

'10 • SR-T-091D

A

Page 23

-

22

-

'10 • SR-T-091D

Terminal block

L2

Intake

Outlet

Intake

L3

L1

L4

Service

space

( )

Minimum installation space

Notes

(1) It must not be surrounded by walls on the four sides.

(2) The unit must be fixed with anchor bolts. An anchor bolt must not

protrude more the 15mm.

(3) Where the unit is subject to strong winds, lay it in such

a direction that the blower outlet faces perpendicularly

to the dominant wind direction.

(4) Leave 1m or more space above the unit.

(5) A wall in front of the blower outlet must not exceed the units height.

(6) The model name label is attached on the lower right corner of the front panel.

A

C

D

B

E

φ12.7(1/2")(Flare)

Content

C Pipe/cable draw-out hole

D

E Anchor bolt hole

Drain discharge hole

Symbol

B

A Service valve connection(gas side)

M10 × 4places

φ20 × 5places

Service valve connection(liquid side)

φ6.35(1/4")(Flare)

Unit:mm

93 42.5

640

800

89 510 201

327.3

83.5

290

43.5

327.3 50.6

12

24.3312.514.8

71.2

17.9

40°

40°

33.5148.4

12.4

351.6

L2

L3

L4

L1

100

100

250

Open

I II

Open

250

80

280

III

280

Open

80

75

Examples of

Dimensions

installation

IV

180

Open

80

Open

38.6

90.6

520.6 161

35.6

Models SRC50ZIX-S, 60ZIX-S

RCT0 0 0 Z004

Page 24

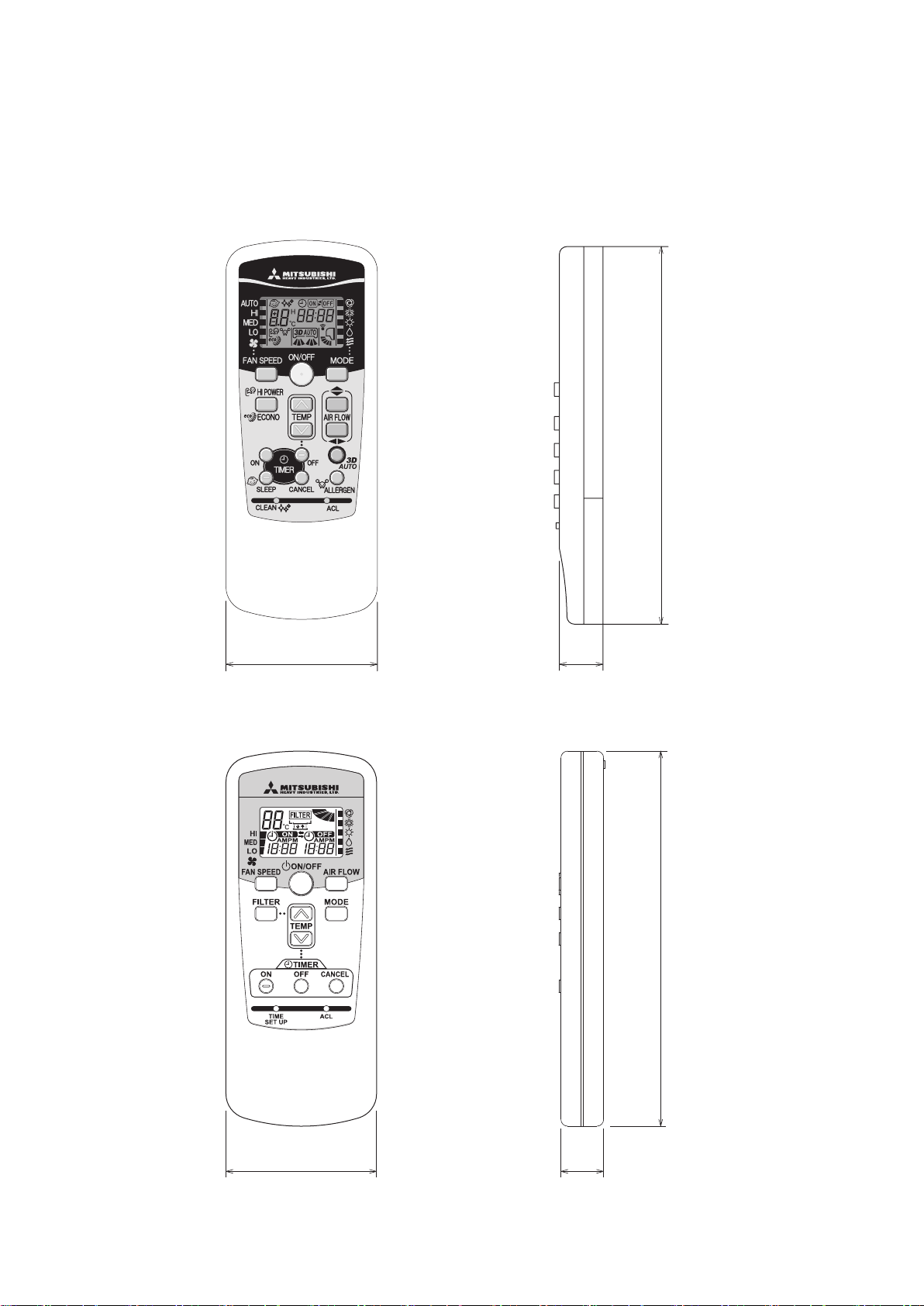

(3) Remote controller

60

17

150

Unit: mm

60

17.3

150

٨

The wireiess remote controller in the following figure shows for the SRK-50ZJ-S type.

(a) Wireless remote controller

Models SRK, SRF, SRR

'10 • SR-T-091D

Model FDTC (Option parts)

-

-

23

Page 25

-

24

-

'10 • SR-T-091D

(b) Wired remote controller (option parts)

TEMP ON/OFF

48

غ120

L C D

Wall surface

Wiring

Electrical box

䋨Not included䋩

19

Wiring specifications

Exposed mounting

23

46

11.5 11

Remote

control

outline

120

45

83.5

42

120

Remote control installation dimensions

Wiring oulet

Installation hole

12×7 Slot hole

9.5×5 Slot hole 䋨4places䋩

䋨1䋩 Installation screw for remote control

M4 Screw (2 pieces)

44

(1) If the prolongation is over 100m, change to the size below.

But, wiring in the remote controller case should be under 0.5mm2. Change the wire size outside of

the case according to wire connecting. Waterproof treatment is necessary at the wire connecting

section. Be careful about contact failure.

Length Wiring thickness

100 to 200m

0.5mm2×2 cores

0.75mm2×2 cores

1.25mm2×2 cores

2.0mm2×2 cores

Under 300m

Under 400m

Under 600m

Upper part

Lower part

Lower case

Sheath

Upper cace

Board

Wiring

Upper

Lower

X Y

Sheath

Upper cace

Board

Wiring

Upper

Lower

YX

Tighten the screws after

cutting off the thin part of

screw mounting part.

Embedded mounting

The peeling-off length of sheath

The peeling-off length

of sheath

In case of pulling out from

upper left

In case of pulling out

from upper left

In case of pulling out

from upper left

X wiring : 170mm

Y wiring : 190mm

Pulling out from center

X wiring : 215mm

Y wiring : 195mm

Pulling out from upper left

In case of pulling out from center

In case of pulling out

from center

In case of pulling out

from center

Wiring outlet

Cut off the upper thin part of remote control lower case with a nipper or knife,

and grind burrs with a file etc.

0.3mm2×2 cores.

X, Y Terminal block

Attach M3 screw

with washer

Unit:mm

PJZ0 0 0 Z274

Page 26

250V 3.15A

PRINTED

CNF CNE

CNX

CNG

4

CNU

1 3 65

35,50

CNY

M M M

5 5

U

2 8

2

t

o

CNS

CNM

M

5

TO OUTDOOR

S/N

J

L

G

1

CIRCUIT

BOARD

INTERFACE KIT

RDBKWHYBL

WIRELESS

DISPLAY

BACK-UP SW

UNIT

BK

WH

RD

Y/G

HEAT

EXCHANGER

2/N

3

Y/G

HD

ONLY

t

o

2

t

o

R-AMP

2

HEAT

EXCHANGER

5

FM

I

SM

I

LM

1

LM

2

F

Va

Th

I

Th

2

Th

3

T

DS

㨪

㨪

Blue

BlackBK

Red

BL

RD

WhiteWH

Yellow㧛GreenY㧛G

ColorMark

Heat exch. sensor

Fan motor

Room temp. sensor

Flap motor

Diode stackDS

FuseF

Connector

CNE-CNY

FM

I

Terminal blockT

Description

Item

VaristorVa

LM

1,2

SM

I

Louver motor

Th

I

Th

2,3

YellowY

Humidity sensor

HD

Power Source

1 Phase

220㧛230㧛240V 50Hz

-

25

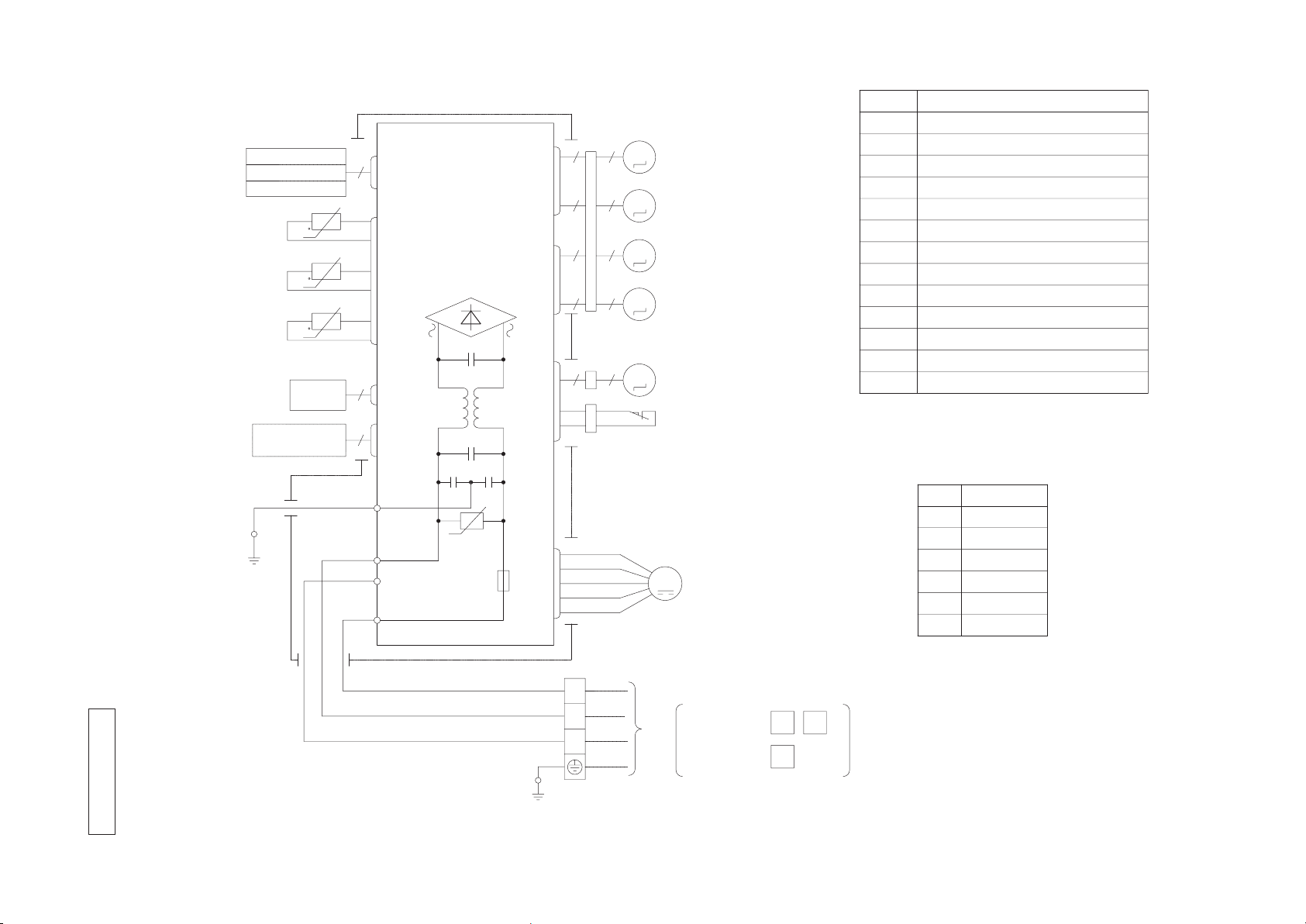

3. ELECTRICAL WIRING

(1) Indoor units

(a) Wall mounted type (SRK)

Model SRK50ZJ-S

-

RWA000Z22 6

'10 • SR-T-091D

Page 27

-

26

-

'10 • SR-T-091D

Models SRK20ZJX-S, 25ZJX-S, 35ZJX-S, 50ZJX-S, 60ZJX-S

250V

F

G

3.15A

S㧛N

Va

CNU

CNS

INTERFACE KIT

SC-BIKN-E

CNG

CNE

DISPLAY

WIRELESS RECEIVER

J

CNF

U

M

HEAT

1

3

4

5

6

BACK-UP SW

5

2

12

EXCHANGER

L

Th1

BOARD

CIRCUIT

PRINTED

LS

CNY

CNX2

CNX1

M

M

M

M

M

5

5

5

5

5

5

5

5

5 5

IM

RD

WH

RD

WH

BK

BL

Y

Y㧛G

BK

t

Th2 1

Th2 2

Th3

LM

1

LM

2

SM

1

SM

2

FM

I

DS

t

t

TO OUTDOOR UNIT

HEAT

EXCHANGER

1

2㧛N

3

POWER WIRES

SIGNAL WIRE

1

2/N

3

Power source

1 phase 220 - 240 V 50Hz

T

Color Marks

Blue

BlackBK

Red

BL

RD

WhiteWH

Yellow㧛GreenY㧛G

YellowY

ColorMark

Heat exch. sensor

Humidity sensor 㧔50,60 only㧕

Fan motor

Room temp. sensor

Flap motor

Th1

Th2

Th3

Diode stackDS

FuseF

Connector

CNE-CNY

FM

I

Terminal blockT

Louver motor

LM

1,2

SM

1,2

1,2

Limit switchLS

Inlet motor

IM

Description

Item

VaristorVa

RWA000Z22 7

Page 28

(b) Floor standing type (SRF)

Color Marks

Blue

BlackBK

Red

BL

RD

WhiteWH

Yellow㧛GreenY㧛G

YellowYE

ColorMark

Heat exch. sensor

Humidity sensor

Fan motor

Room temp. sensor

Flap motor

Th1

Th2

Th3

Diode stackDS

FuseF

Connector

CNE-CNX2

FM

I

Terminal blockT

Damper motor

DM

1

SM

1,2

1,2

Damper arm motor

Description

Item

VaristorVa

DM

2

250V

F

G

3.15A

S㧛N

Va

CNU

CNS

INTERFACE KIT

SC-BIKN-E

CNG

CNE

DISPLAY

WIRELESS RECEIVER

J

CNF

U

M

HEAT

1

3

4

5

6

BACK-UP SW

5

2

10

EXCHANGER

L

Th1

BOARD

CIRCUIT

PRINTED

CNX2

CNX1

M

M

M

M

5

5

5

5

5

5

5

5

RD

WH

RD

WH

BK

BL

YE

Y㧛G

BK

t

Th2

1

Th2

2

Th3

DM

1

DM

2

SM

1

SM

2

FM

I

DS

t

t

TO OUTDOOR UNIT

HEAT

EXCHANGER

1

2㧛N

3

POWER WIRES

SIGNAL WIRE

1

2/N

3

Power source

1 phase 220 - 240 V 50Hz

T

AIR SELECTION SW

Models SRF25ZJX-S, 35ZJX-S, 50ZJX-S

-

27

-

RWB000Z0 52

'10 • SR-T-091D

Page 29

-

28

-

'10 • SR-T-091D

Item

Meaning of Marks

Description Item Description

Color Marks

Mark Color Mark Color

T

TO OUTDOOR UNIT

RECEIVER