Mitsubishi Electric SRK05CR-S, SRK05CRP-S, SRK12CR-S, SRK09CR-S, SRK09CRP-S Technical Manual

...Page 1

RESIDENTIAL AIR-CONDITIONING

TECHNICAL MANUAL & PARTS LIST

WALL MOUNTED TYPE

RESIDENTIAL AIR-CONDITIONERS

(Split system, air cooled cooling only type)

SRK05CR-S, S3, S6

SRK05CRP-S, S3

SRK09CR-S, S3, S4, S5

SRK09CRP-S, S3, S5

SRK09CRR-S, S3, S4, S5, S6

SRK12CR-S, S3, S4, S5, S6

Manual No.'15•SRK-T-171

Page 2

Page 3

-

1

-

'15 • SRK-T-171

TECHNICAL MANUAL

Page 4

-

2

-

'15 • SRK-T-171

'10 • SRK-T-099

CONTENTS

1. SPECIFICATIONS .................................................................................... 4

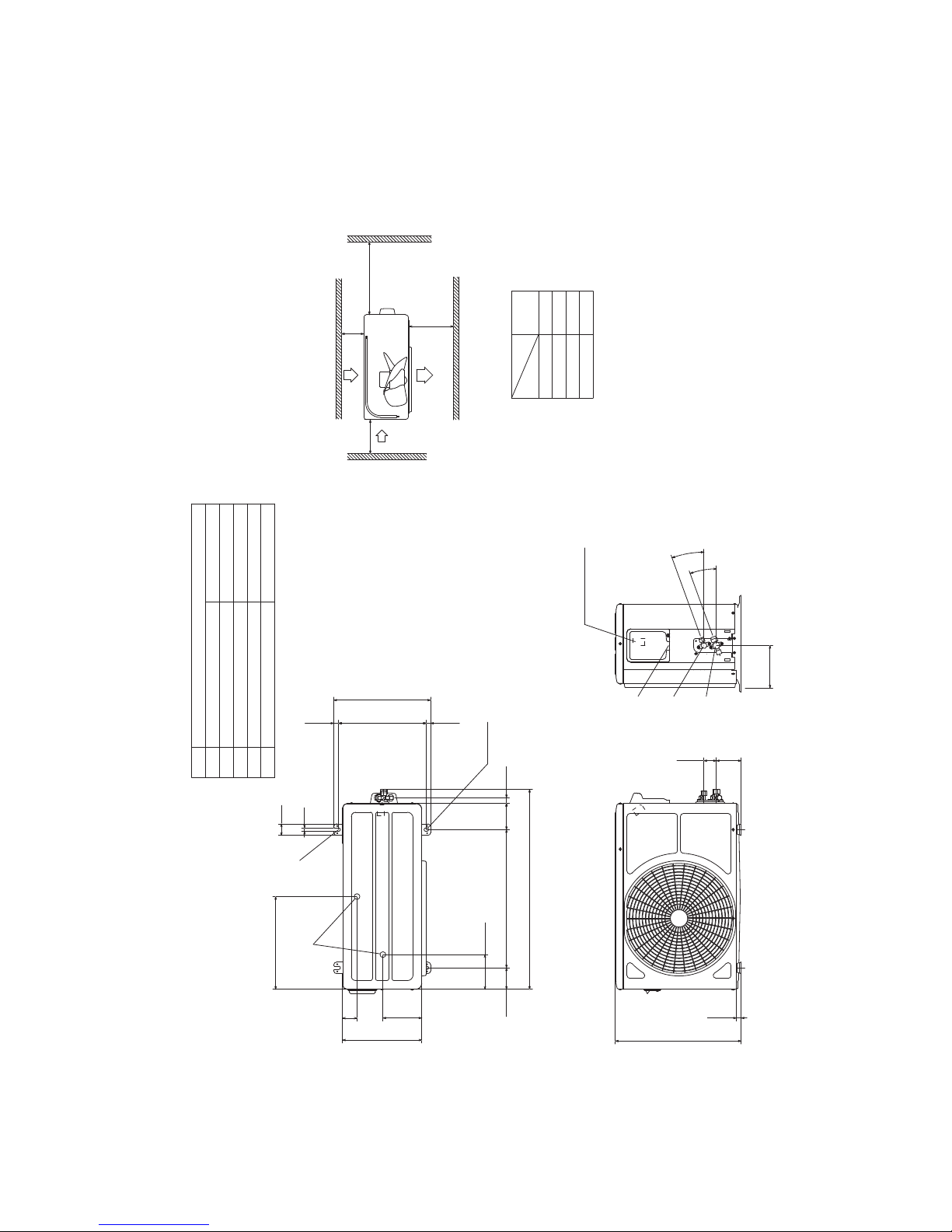

(2) Outdoor units ...................................................................................... 28

(3) Wireless remote control

...................................................................... 30

........................................................................ 26

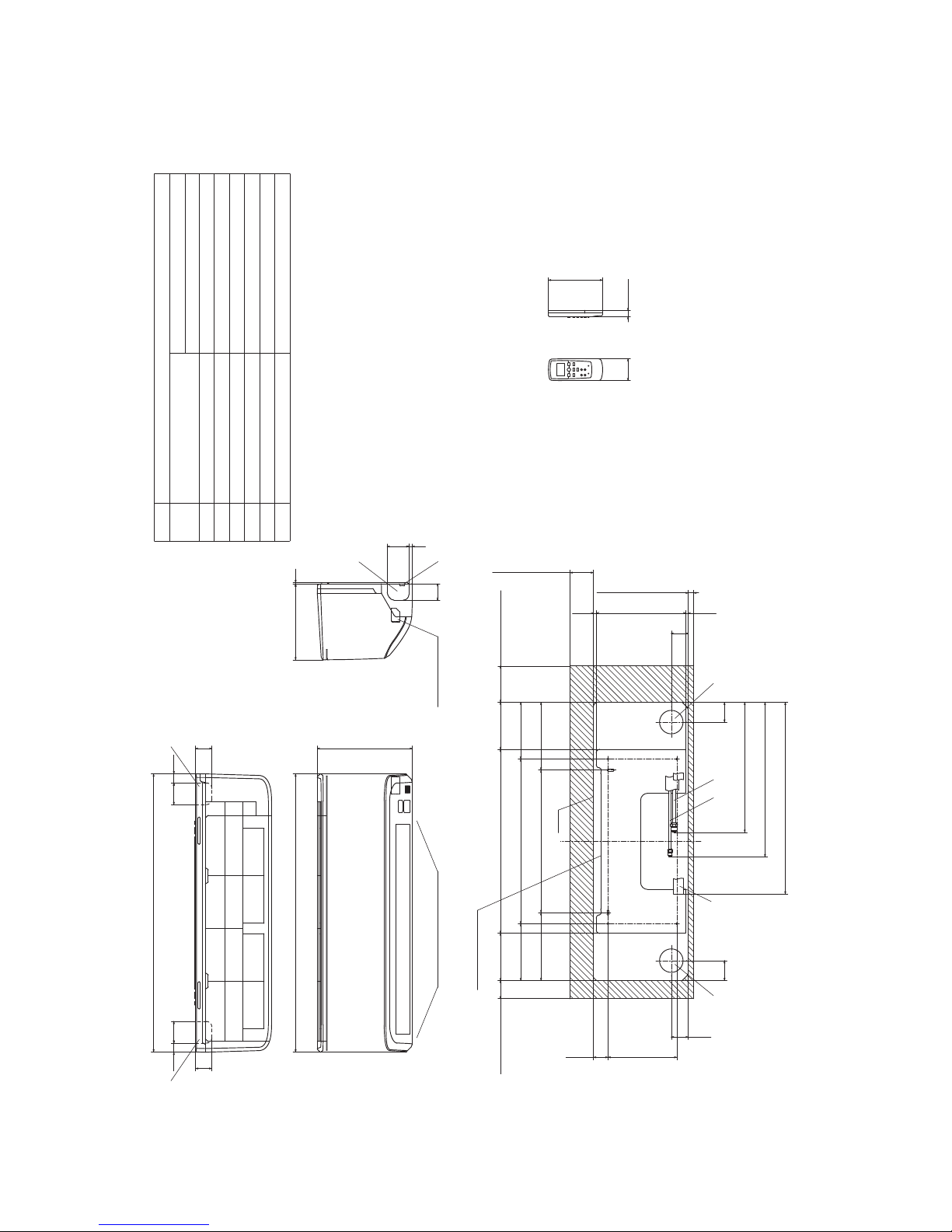

(1) Indoor units ......................................................................................... 26

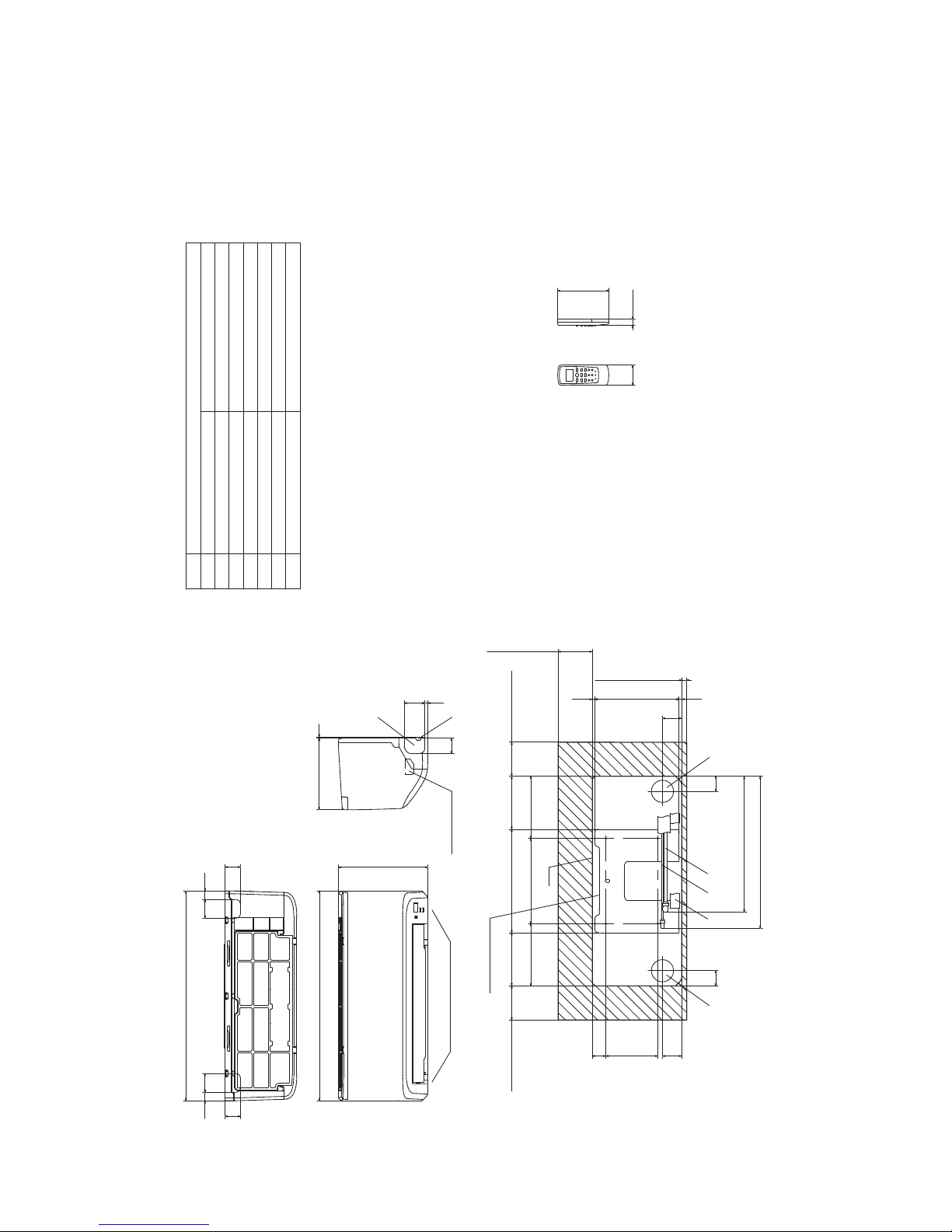

2. EXTERIOR DIMENSIONS

3. ELECTRICAL WIRING ............................................................................. 31

(1) Indoor units ......................................................................................... 31

(2) Outdoor units ...................................................................................... 32

....................................................... 41

6. RANGE OF USAGE & LIMITATIONS

5. PIPING SYSTEM ..................................................................................... 40

4. NOISE LEVEL ..................................................................................... 34

7. CAPACITY TABLES

............................................................................... 46

............................................................................... 43

8. APPLICATION DATA

9. OUTLINE OF OPERATION CONTROL BY MICROCOMPUTER ........... 56

(6) Timer operation

................................................................................. 59

(5) Flap control ....................................................................................... 59

...................................................... 58(4) Custom cord switching procedure

........................................................................ 58(3) Auto restart function

(2) Unit ON/OFF button

.......................................................................... 58

(1) Operation control function by remote control

..................................... 56

(8) Outline of automatic operation .......................................................... 60

(7) Outline of cooling operation .............................................................. 60

(9) Protective control function

.................................................................. 61

.............................................................................. 62

.................... 63

(4) Troubleshooting procedure (If the air-conditioner runs)

(3) Troubleshooting procedure

(If the air-conditioner does not run at all)

....... 62

(1) Cautions

............................................................................................ 62

(2) Items to check before troubleshooting ................................................ 62

(5) Self-diagnosis table ............................................................................ 63

(6) Inspection procedures corresponding to detail of trouble ................... 64

10. MAINTENANCE DATA

Page 5

-

3

-

'15 • SRK-T-171

'10 • SRK-T-099

(7)

Phenomenon observed after shortcircuit, wire breakage on sensor

........ 65

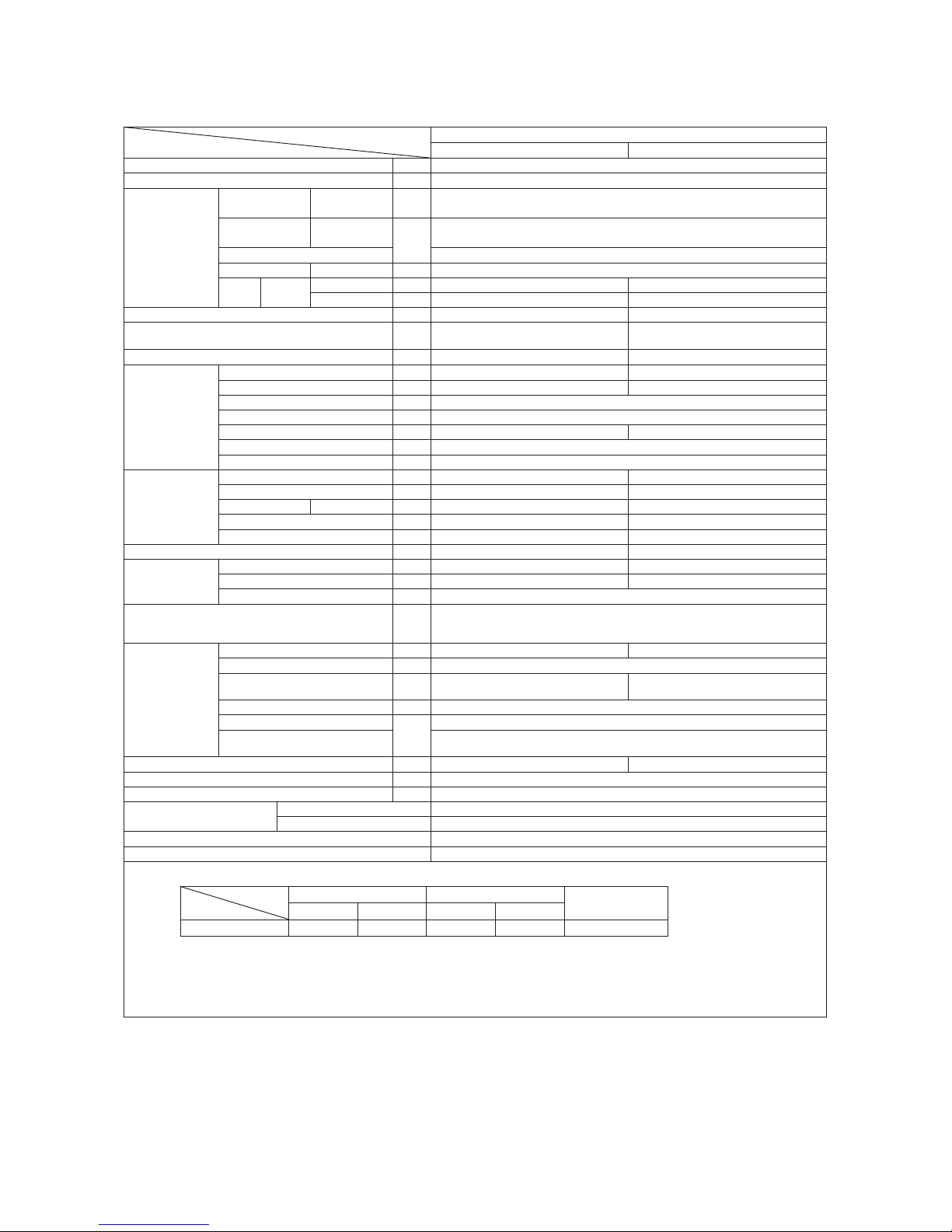

■How to read the model name

Example: SRK 05 C

Series code

Cooling only type

Product capacity

Model name SRK : Wall mounted type

SRC : Outdoor unit

R-S

(8) How to make sure of wireless remote control ..................................... 66

Page 6

-

4

-

'15 • SRK-T-171

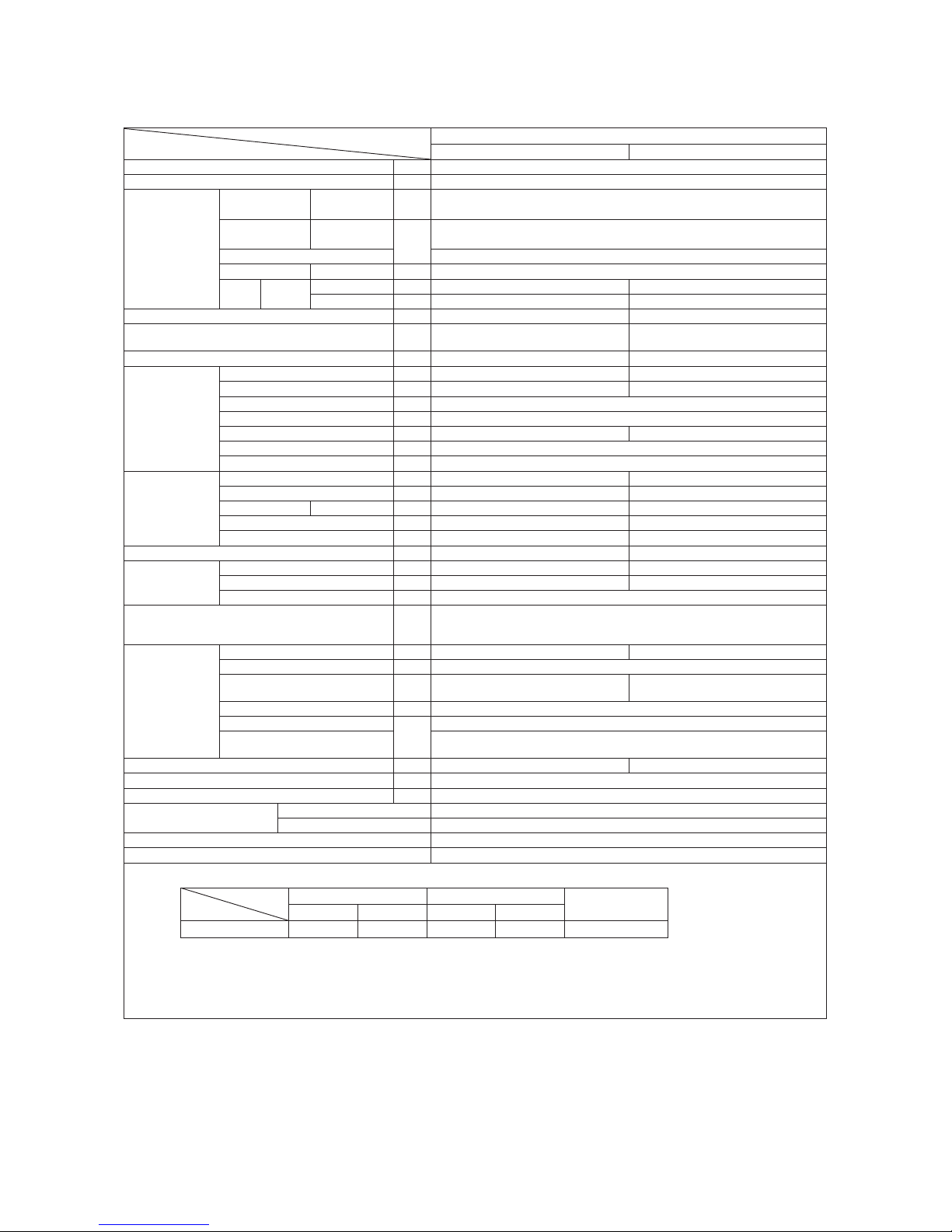

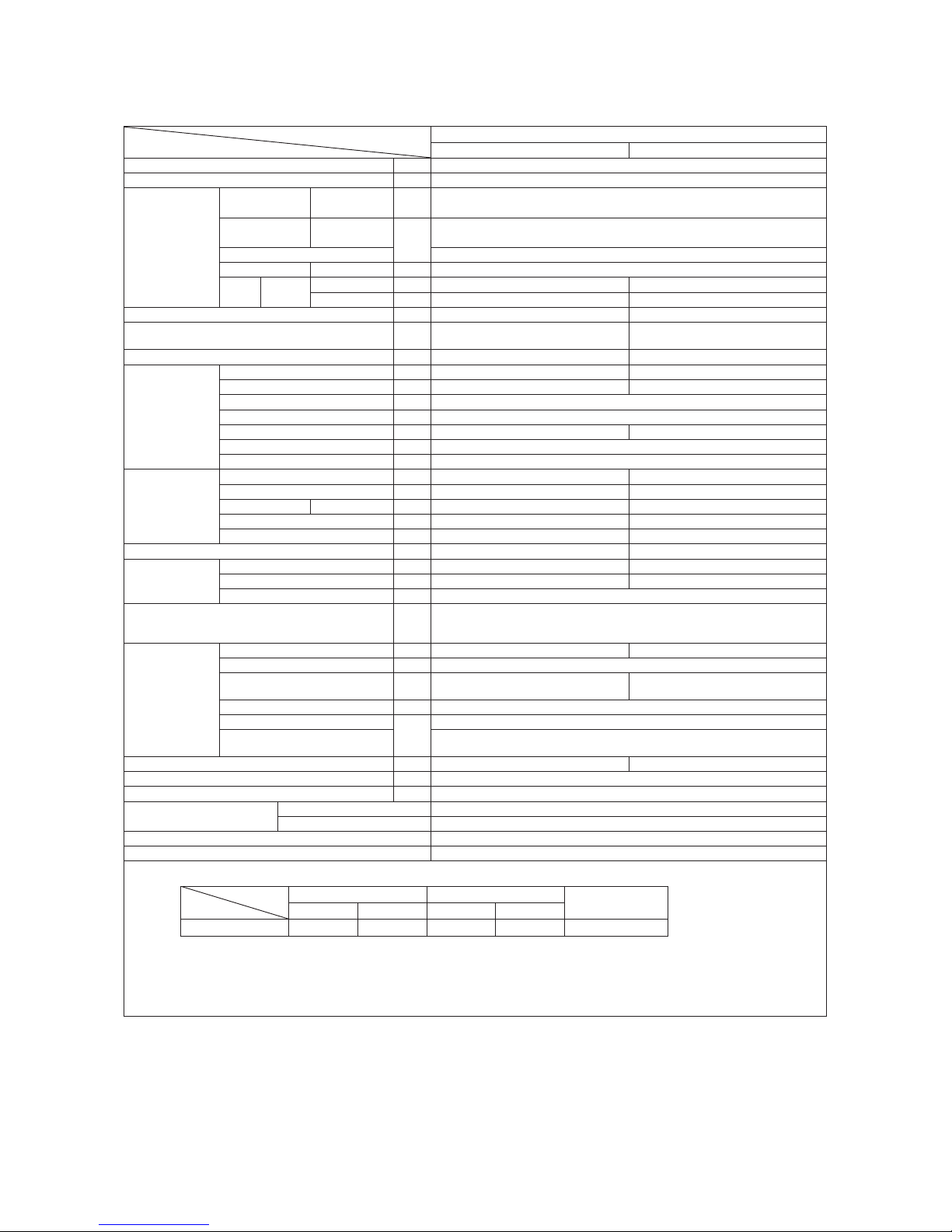

1. SPECIFICATIONS

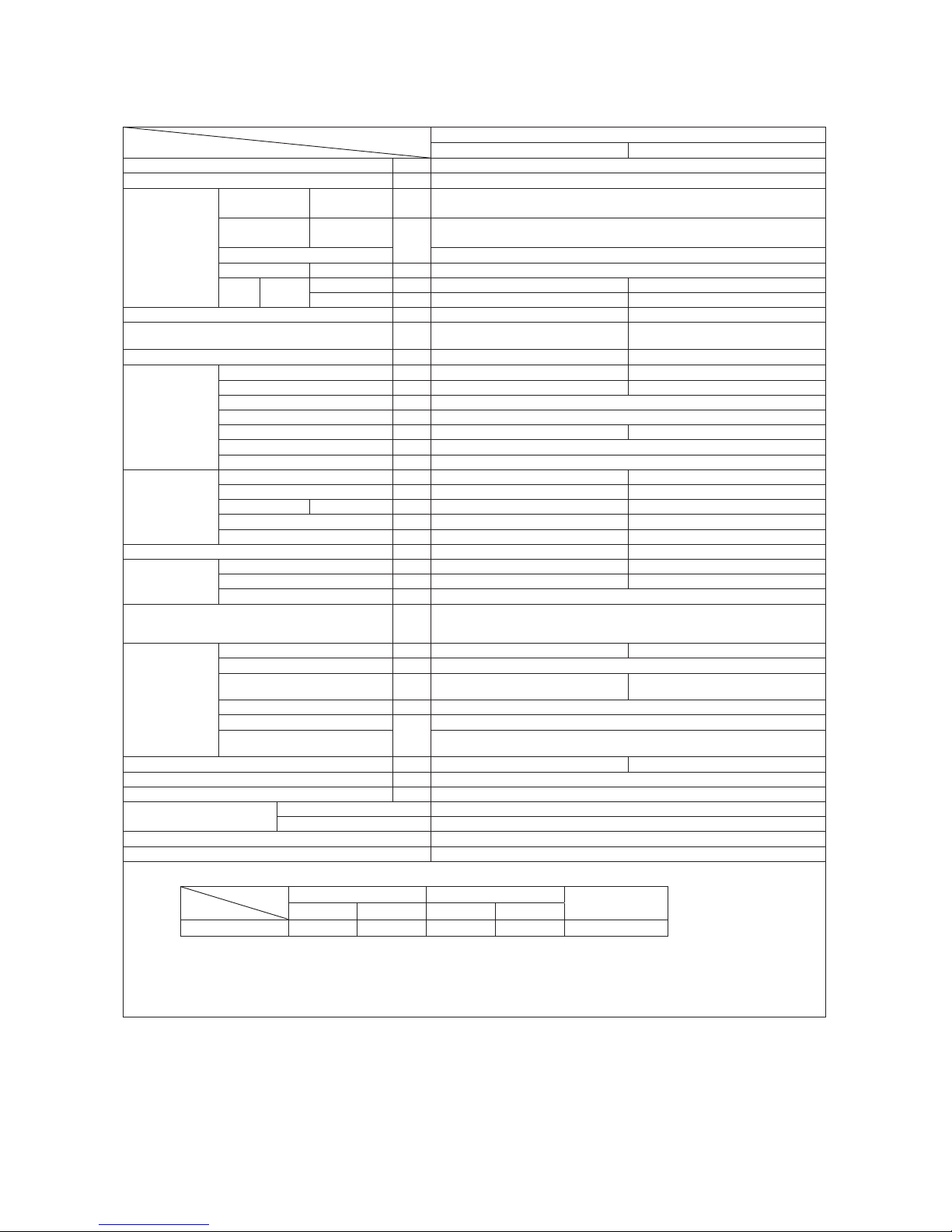

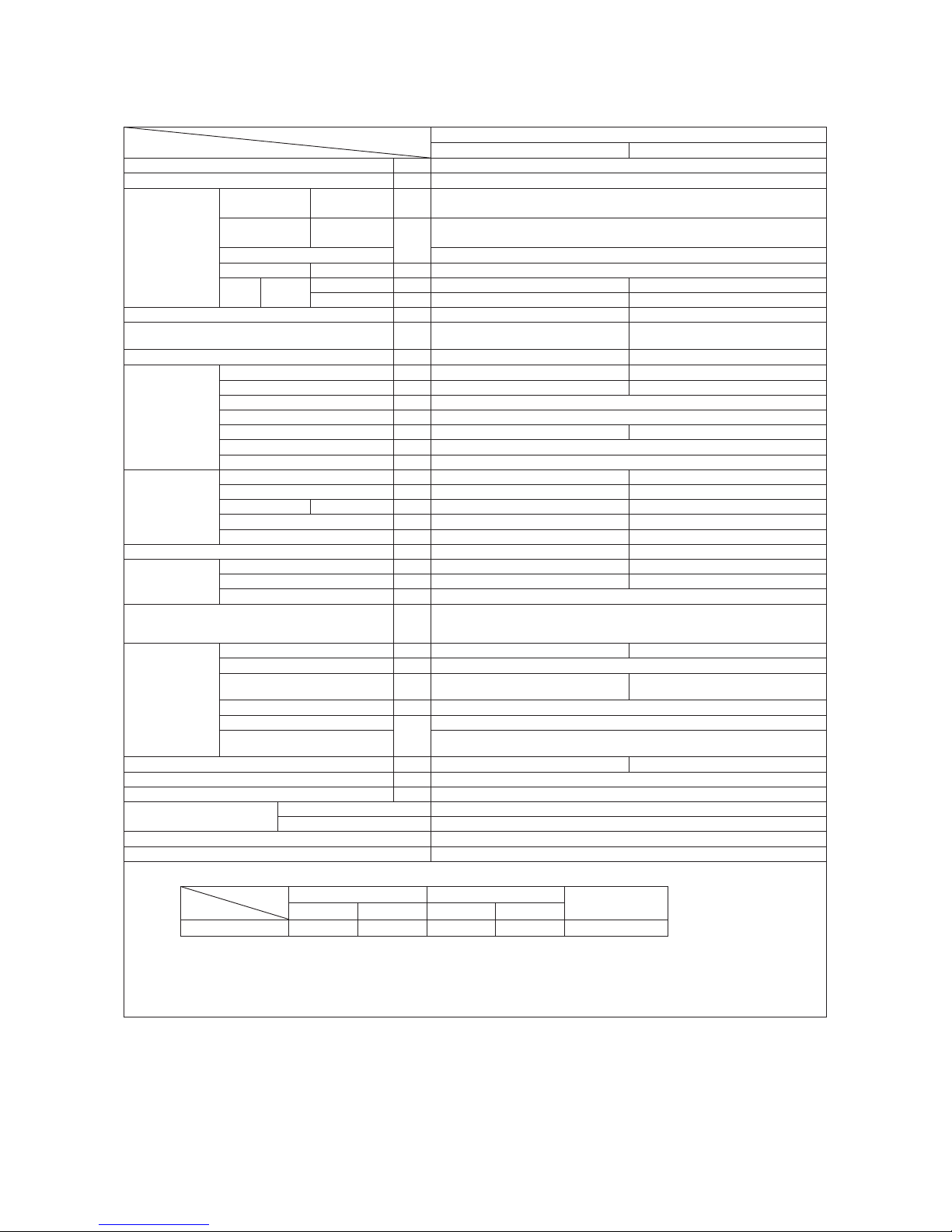

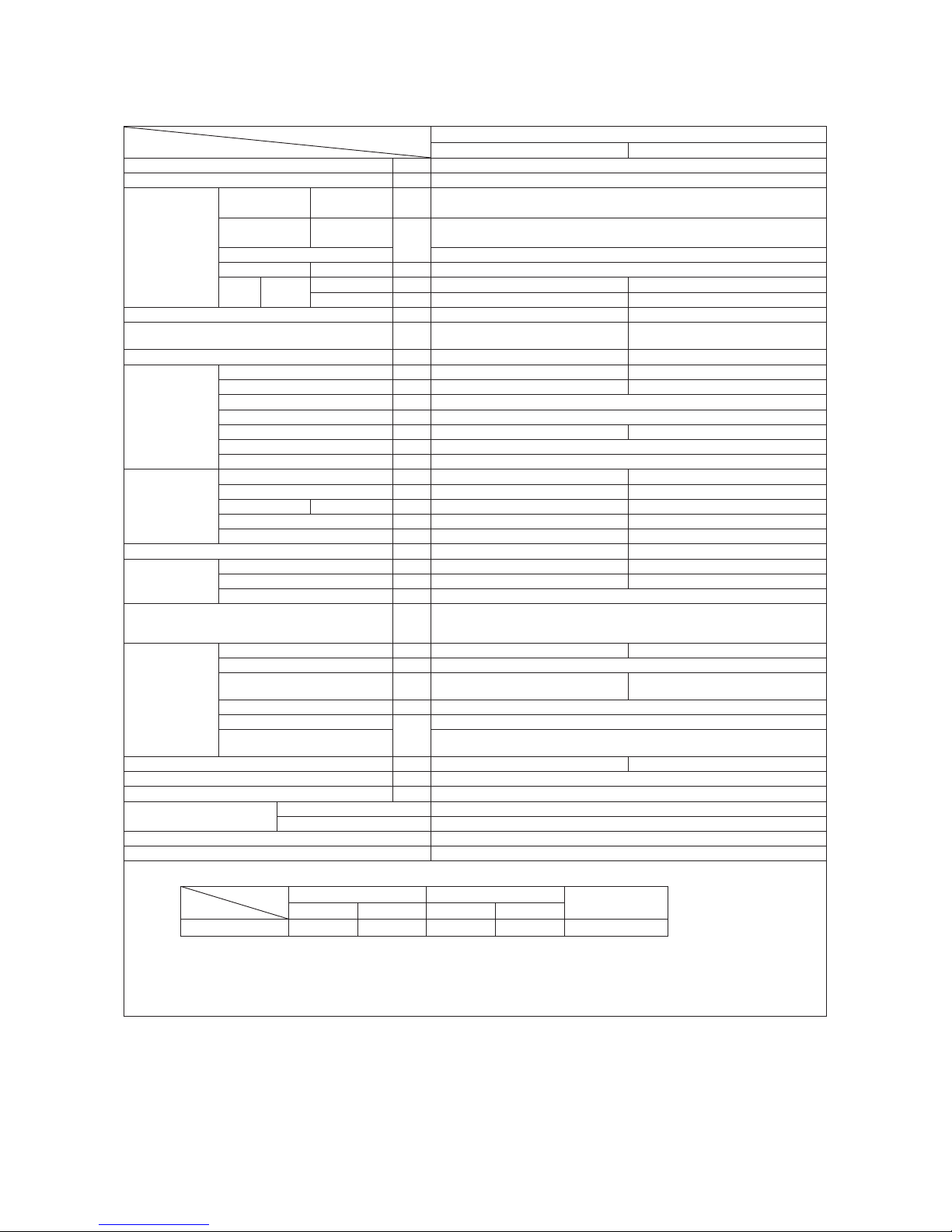

Model

Item

SRK05CR-S

Indoor unit SRK05CR-S Outdoor unit SRC05CR-S

Cooling capacity (1) W 1465

Power source 1 Phase, 220-240V, 50Hz

Operation

data

Power

consumption

Cooling kW 0.375

Running

current

Cooling

A

1.70

Inrush current 10

COP Cooling 3.91

Noise

level

Cooling

Sound level dB(A) 42 48

Power level dB 56 59

Exterior dimensions (Height x Width x Depth) mm 262 x 615 x 210 435 x 645 (+50) x 275

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 6 20

Refrigerant

equipment

Compressor type & Q'ty — GAB046PAA (Rotary type) x 1

Motor (Starting method) kW — PSC

Refrigerant oil

ℓ

0.23 (POE [RB68A] or PVE [FVC68D])

Refrigerant (4) kg R410A 0.46 ( Pre-charged up to the piping length of 5m )

Heat exchanger Louver fins & inner grooved tubing Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Device control Microcomputer control

Air handling

equipment

Fan type & Q'ty Cross flow fan x 1 Propeller fan x 1

Motor W 17 22

Air flow Cooling m3/min 8.5 23

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 1 —

Shock & vibration absorber — Cushion rubber (for compressor)

Operation

control

Operation switch Wireless remote control —

Room temperature control Microcomputer thermostat —

Operation display RUN : Green, TIMER : Yellow

Safety devices

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor Fan motor error protection,

Cooling overload protection

Installation

data

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

Connecting method Flare connecting

Attached length of piping m

Liquid line : 0.46

Gas line : 0.40

—

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

m

Max. 15

Vertical height difference between

outdoor unit and indoor unit

Max.5 (Outdoor unit is higher)

Max.5 (Outdoor unit is lower)

Drain hose Connectable (VP 16) —

Power cable —

Recommended breaker size A 10

Connection wiring

Size x Core number 1.5mm2 x 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Option parts —

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C ISO-T1, JIS C 9612

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 220V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 5m connecting piping.

(Purging is not required even for the short piping.)

If the piping length is 5m to 15m, additional refrigerant is 10g per each 1m longer than 5m.

The pipe length is 5m.

Page 7

-

5

-

'15 • SRK-T-171

Model

Item

SRK05CR-S3

Indoor unit SRK05CR-S3 Outdoor unit SRC05CR-S3

Cooling capacity (1) W 1465

Power source 1 Phase, 220-240V, 50Hz

Operation

data

Power

consumption

Cooling kW 0.375

Running

current

Cooling

A

1.70

Inrush current 10

COP Cooling 3.91

Noise

level

Cooling

Sound level dB(A) 42 48

Power level dB 56 59

Exterior dimensions (Height x Width x Depth) mm 262 x 615 x 210 435 x 645 (+50) x 275

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 6 20

Refrigerant

equipment

Compressor type & Q'ty — GAB046PAA (Rotary type) x 1

Motor (Starting method) kW — PSC

Refrigerant oil

ℓ

0.23 (POE [RB68A] or PVE [FVC68D])

Refrigerant (4) kg R410A 0.46 ( Pre-charged up to the piping length of 5m )

Heat exchanger Louver fins & inner grooved tubing Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Device control Microcomputer control

Air handling

equipment

Fan type & Q'ty Cross flow fan x 1 Propeller fan x 1

Motor W 17 22

Air flow Cooling m3/min 8.5 23

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 1 —

Shock & vibration absorber — Cushion rubber (for compressor)

Operation

control

Operation switch Wireless remote control —

Room temperature control Microcomputer thermostat —

Operation display RUN : Green, TIMER : Yellow

Safety devices

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Cooling overload protection

Installation

data

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

Connecting method Flare connecting

Attached length of piping m

Liquid line : 0.46

Gas line : 0.40

—

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

m

Max. 15

Vertical height difference between

outdoor unit and indoor unit

Max.5 (Outdoor unit is higher)

Max.5 (Outdoor unit is lower)

Drain hose Connectable (VP 16) —

Power cable —

Recommended breaker size A 10

Connection wiring

Size x Core number 1.5mm2 x 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Option parts —

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C ISO-T1, JIS C 9612

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 220V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 5m connecting piping.

(Purging is not required even for the short piping.)

If the piping length is 5m to 15m, additional refrigerant is 10g per each 1m longer than 5m.

The pipe length is 5m.

Page 8

-

6

-

'15 • SRK-T-171

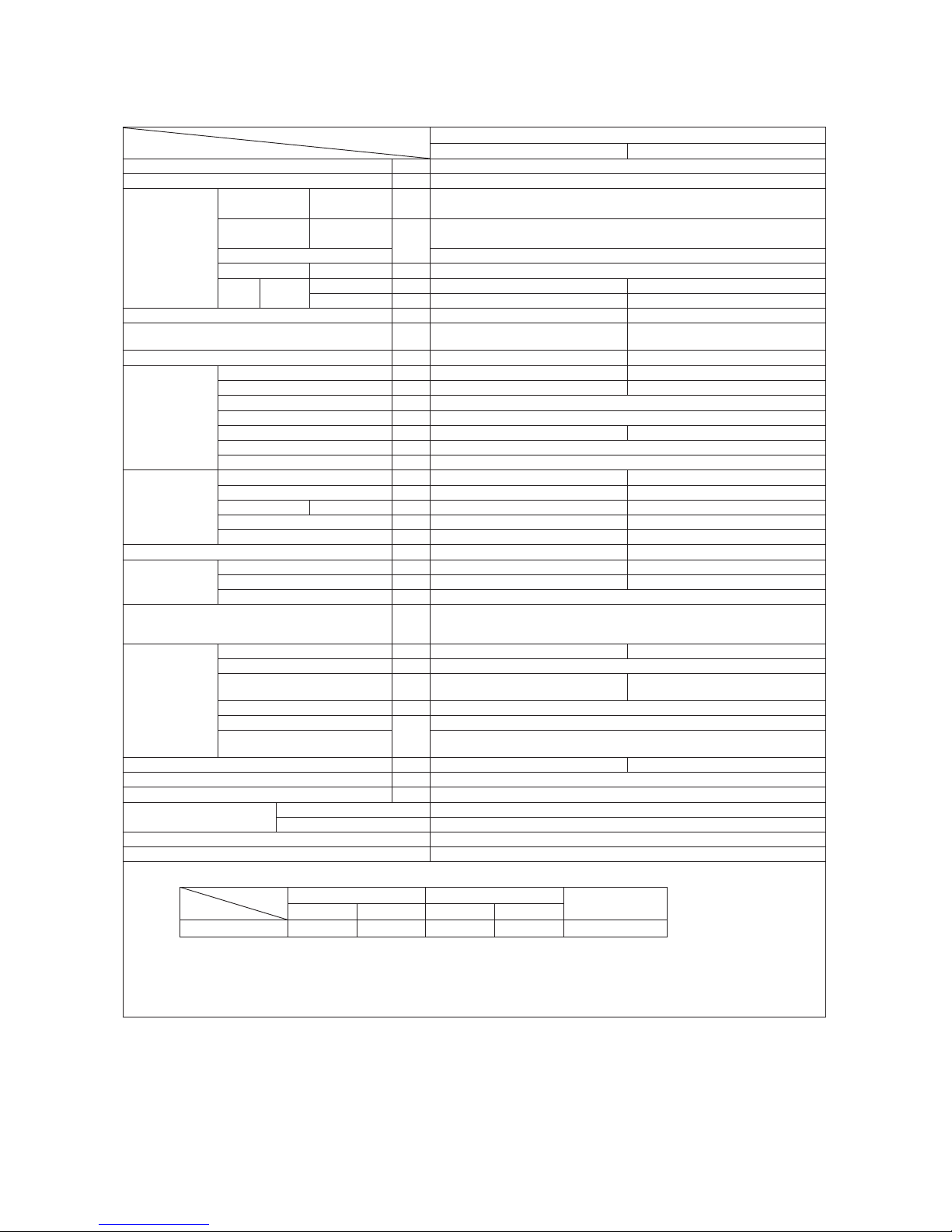

Model

Item

SRK05CR-S6

Indoor unit SRK05CR-S6 Outdoor unit SRC05CR-S6

Cooling capacity (1) W 1465

Power source 1 Phase, 220-240V, 50Hz

Operation

data

Power

consumption

Cooling kW 0.400

Running

current

Cooling

A

1.80

Inrush current 10

COP Cooling 3.66

Noise

level

Cooling

Sound level dB(A) 42 50

Power level dB 56 61

Exterior dimensions (Height x Width x Depth) mm 262 x 615 x 210 435 x 645 (+50) x 275

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 6 20

Refrigerant

equipment

Compressor type & Q'ty — GAB046PAA (Rotary type) x 1

Motor (Starting method) kW — PSC

Refrigerant oil

ℓ

0.23 (POE [RB68A] or PVE [FVC68D])

Refrigerant (4) kg R410A 0.46 ( Pre-charged up to the piping length of 5m )

Heat exchanger Louver fins & inner grooved tubing Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Device control Microcomputer control

Air handling

equipment

Fan type & Q'ty Cross flow fan x 1 Propeller fan x 1

Motor W 17 22

Air flow Cooling m3/min 8.5 23

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 1 —

Shock & vibration absorber — Cushion rubber (for compressor)

Operation

control

Operation switch Wireless remote control —

Room temperature control Microcomputer thermostat —

Operation display RUN : Green, TIMER : Yellow

Safety devices

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor Fan motor error protection,

Cooling overload protection

Installation

data

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

Connecting method Flare connecting

Attached length of piping m

Liquid line : 0.46

Gas line : 0.40

—

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

m

Max. 15

Vertical height difference between

outdoor unit and indoor unit

Max.5 (Outdoor unit is higher)

Max.5 (Outdoor unit is lower)

Drain hose Connectable (VP 16) —

Power cable —

Recommended breaker size A 10

Connection wiring

Size x Core number 1.5mm2 x 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Option parts —

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C ISO-T1, JIS C 9612

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 230V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 5m connecting piping.

(Purging is not required even for the short piping.)

If the piping length is 5m to 15m, additional refrigerant is 10g per each 1m longer than 5m.

The pipe length is 5m.

Page 9

-

7

-

'15 • SRK-T-171

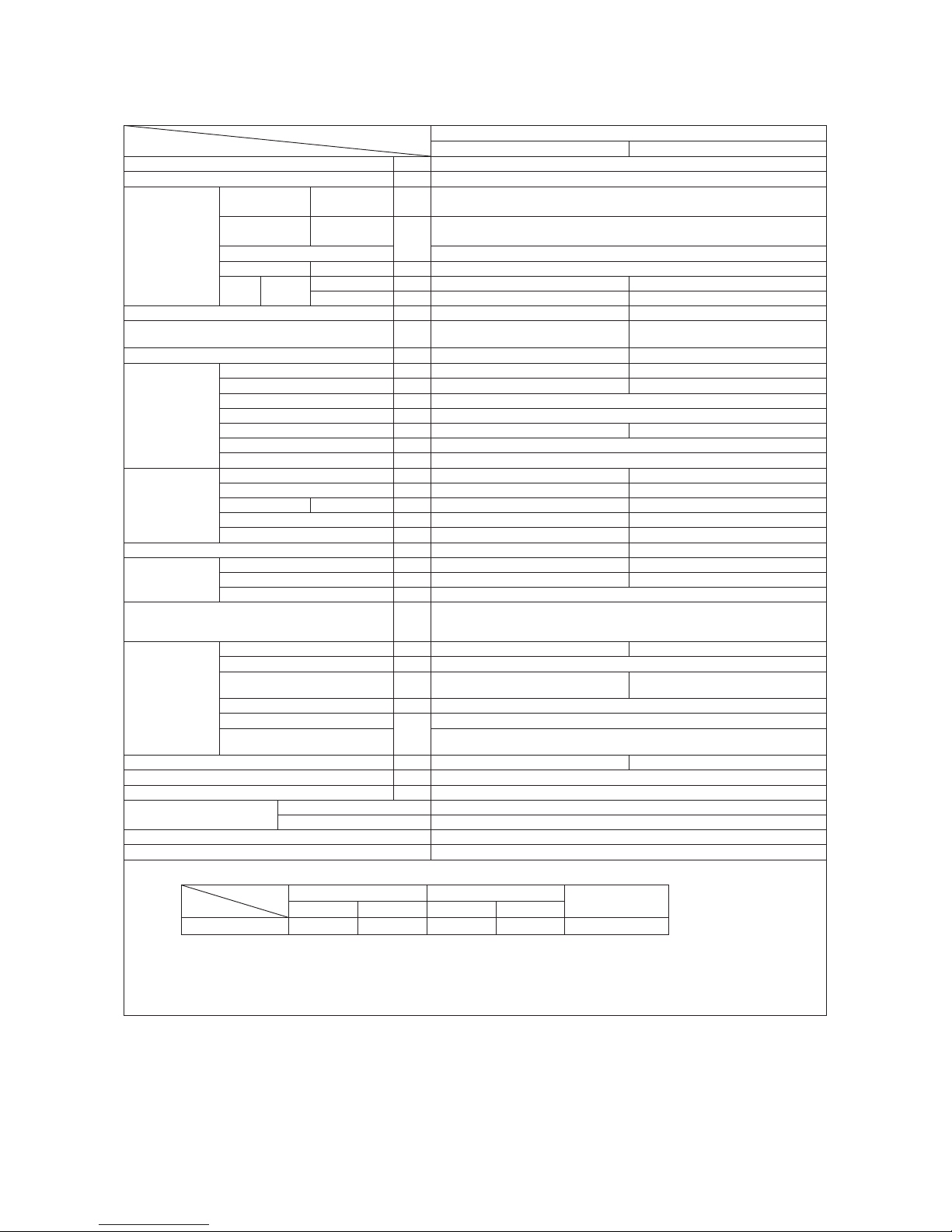

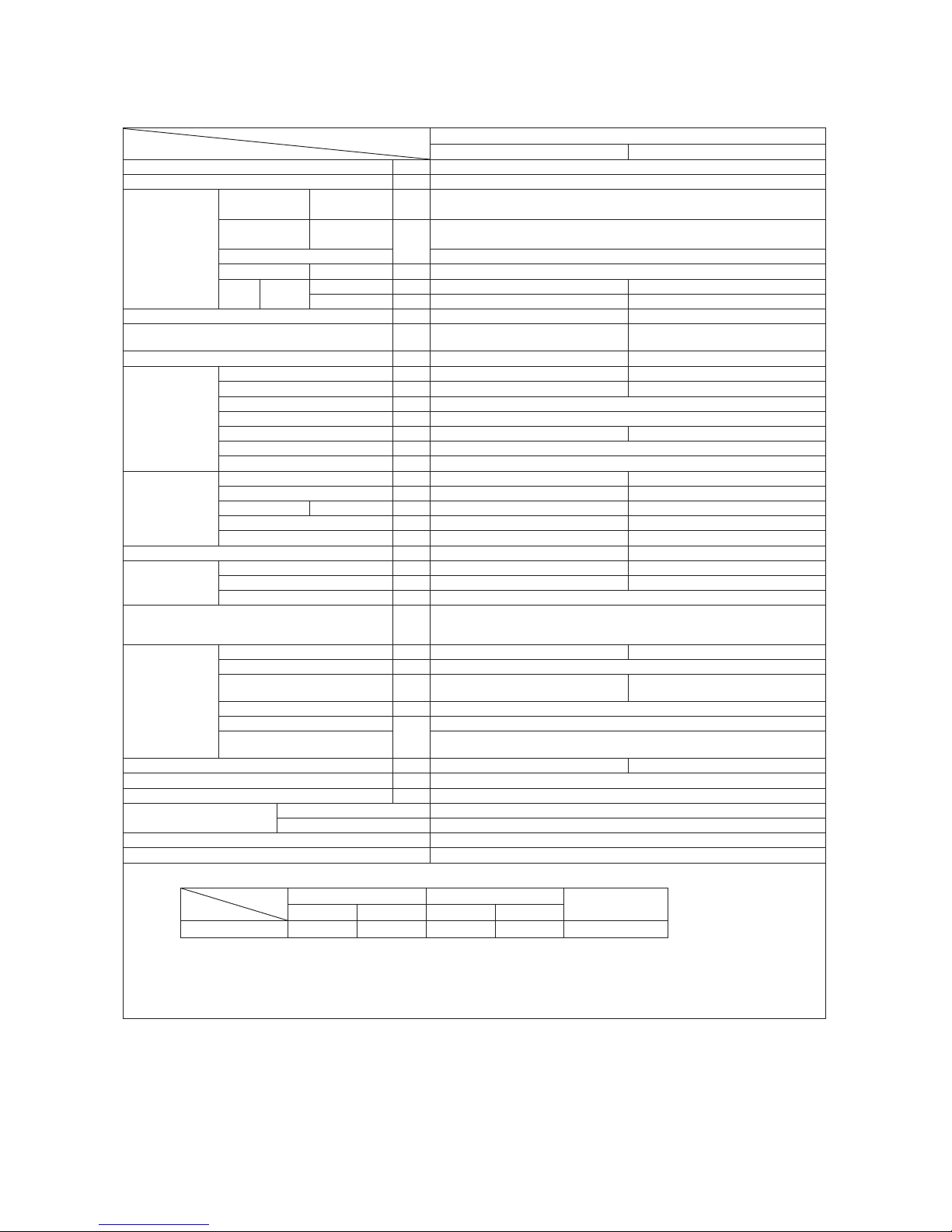

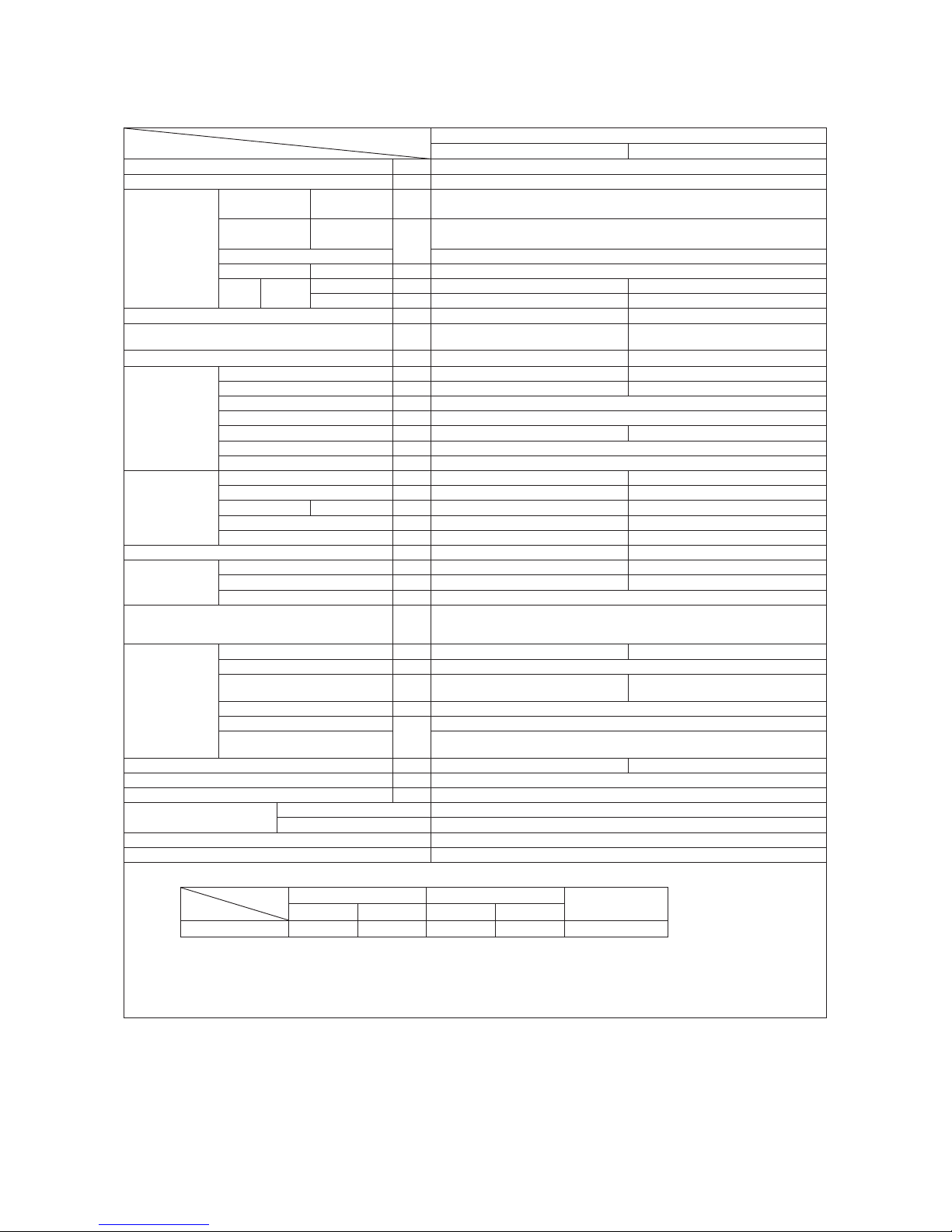

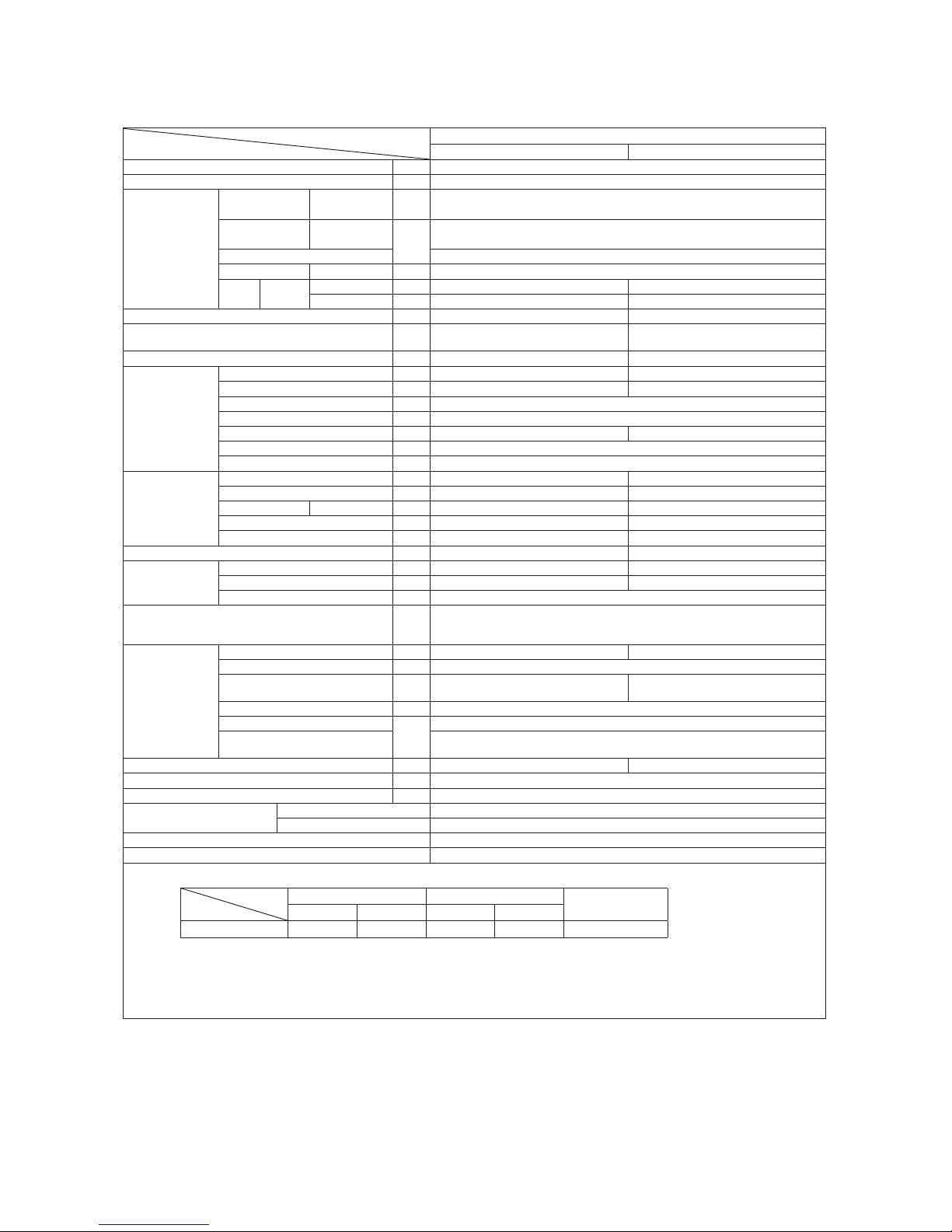

Model

Item

SRK05CRP-S

Indoor unit SRK05CRP-S Outdoor unit SRC05CRP-S

Cooling capacity (1) W 1465

Power source 1 Phase, 220-240V, 50Hz

Operation

data

Power

consumption

Cooling kW 0.490

Running

current

Cooling

A

2.30

Inrush current 10

COP Cooling 2.99

Noise

level

Cooling

Sound level dB(A) 42 50

Power level dB 56 61

Exterior dimensions (Height x Width x Depth) mm 262 x 615 x 210 435 x 645 (+50) x 275

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 6 19.5

Refrigerant

equipment

Compressor type & Q'ty — GAB046PAA (Rotary type) x 1

Motor (Starting method) kW — PSC

Refrigerant oil

ℓ

0.23 (POE [RB68A] or PVE [FVC68D])

Refrigerant (4) kg R410A 0.44 ( Pre-charged up to the piping length of 5m )

Heat exchanger Louver fins & inner grooved tubing Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Device control Microcomputer control

Air handling

equipment

Fan type & Q'ty Cross flow fan x 1 Propeller fan x 1

Motor W 17 22

Air flow Cooling m3/min 8.5 20

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 1 —

Shock & vibration absorber — Cushion rubber (for compressor)

Operation

control

Operation switch Wireless remote control —

Room temperature control Microcomputer thermostat —

Operation display RUN : Green, TIMER : Yellow

Safety devices

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor Fan motor error protection,

Cooling overload protection

Installation

data

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

Connecting method Flare connecting

Attached length of piping m

Liquid line : 0.46

Gas line : 0.40

—

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

m

Max. 15

Vertical height difference between

outdoor unit and indoor unit

Max.5 (Outdoor unit is higher)

Max.5 (Outdoor unit is lower)

Drain hose Connectable (VP 16) —

Power cable —

Recommended breaker size A 10

Connection wiring

Size x Core number 1.5mm2 x 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Option parts —

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C ISO-T1, JIS C 9612

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 220V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 5m connecting piping.

(Purging is not required even for the short piping.)

If the piping length is 5m to 15m, additional refrigerant is 10g per each 1m longer than 5m.

The pipe length is 5m.

Page 10

-

8

-

'15 • SRK-T-171

Model

Item

SRK05CRP-S3

Indoor unit SRK05CRP-S3 Outdoor unit SRC05CRP-S3

Cooling capacity (1) W 1465

Power source 1 Phase, 220-240V, 50Hz

Operation

data

Power

consumption

Cooling kW 0.490

Running

current

Cooling

A

2.30

Inrush current 10

COP Cooling 2.99

Noise

level

Cooling

Sound level dB(A) 42 50

Power level dB 56 61

Exterior dimensions (Height x Width x Depth) mm 262 x 615 x 210 435 x 645 (+50) x 275

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 6 19.5

Refrigerant

equipment

Compressor type & Q'ty — GAB046PAA (Rotary type) x 1

Motor (Starting method) kW — PSC

Refrigerant oil

ℓ

0.23 (POE [RB68A] or PVE [FVC68D])

Refrigerant (4) kg R410A 0.44 ( Pre-charged up to the piping length of 5m )

Heat exchanger Louver fins & inner grooved tubing Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Device control Microcomputer control

Air handling

equipment

Fan type & Q'ty Cross flow fan x 1 Propeller fan x 1

Motor W 17 22

Air flow Cooling m3/min 8.5 20

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 1 —

Shock & vibration absorber — Cushion rubber (for compressor)

Operation

control

Operation switch Wireless remote control —

Room temperature control Microcomputer thermostat —

Operation display RUN : Green, TIMER : Yellow

Safety devices

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor Fan motor error protection,

Cooling overload protection

Installation

data

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

Connecting method Flare connecting

Attached length of piping m

Liquid line : 0.46

Gas line : 0.40

—

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

m

Max. 15

Vertical height difference between

outdoor unit and indoor unit

Max.5 (Outdoor unit is higher)

Max.5 (Outdoor unit is lower)

Drain hose Connectable (VP 16) —

Power cable —

Recommended breaker size A 10

Connection wiring

Size x Core number 1.5mm2 x 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Option parts —

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C ISO-T1, JIS C 9612

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 220V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 5m connecting piping.

(Purging is not required even for the short piping.)

If the piping length is 5m to 15m, additional refrigerant is 10g per each 1m longer than 5m.

The pipe length is 5m.

Page 11

-

9

-

'15 • SRK-T-171

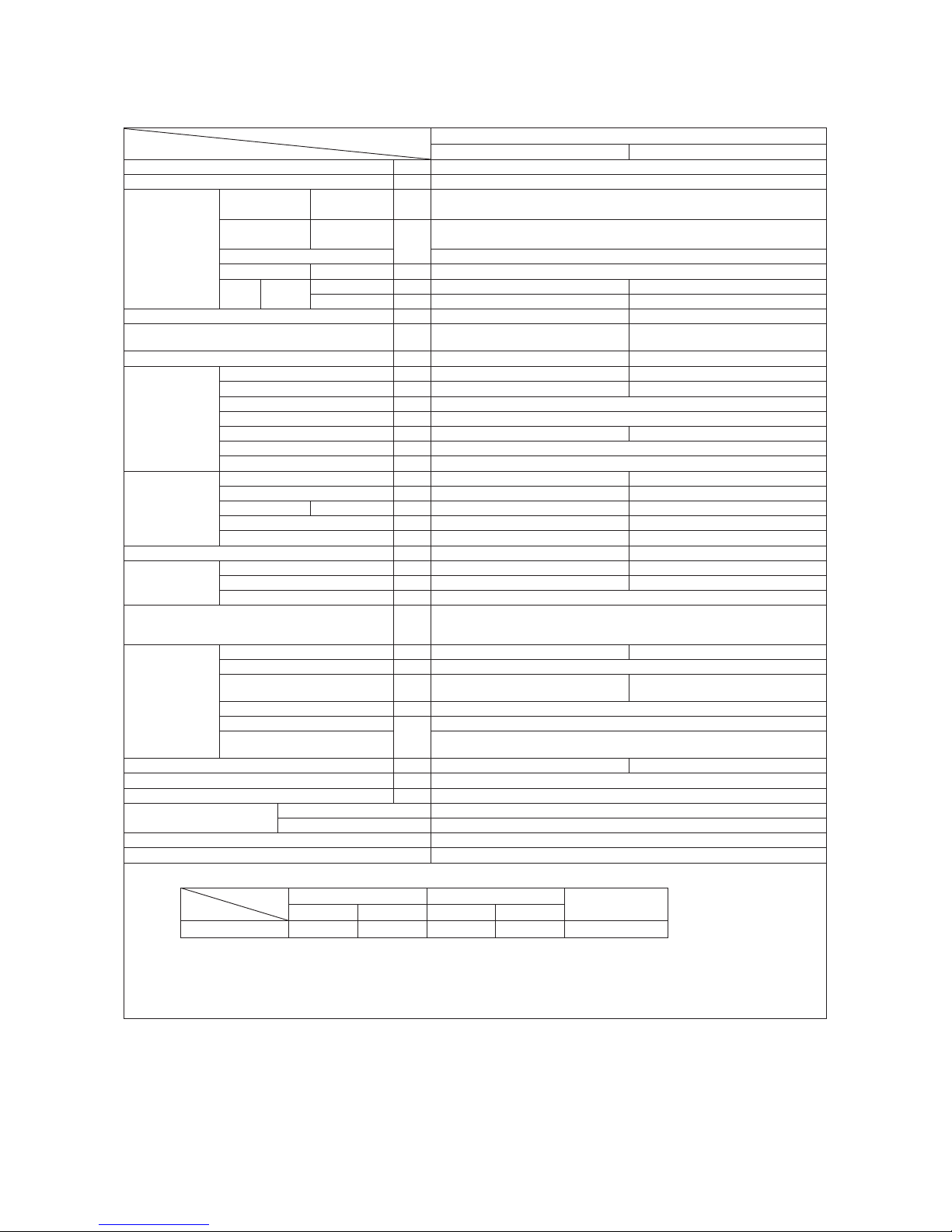

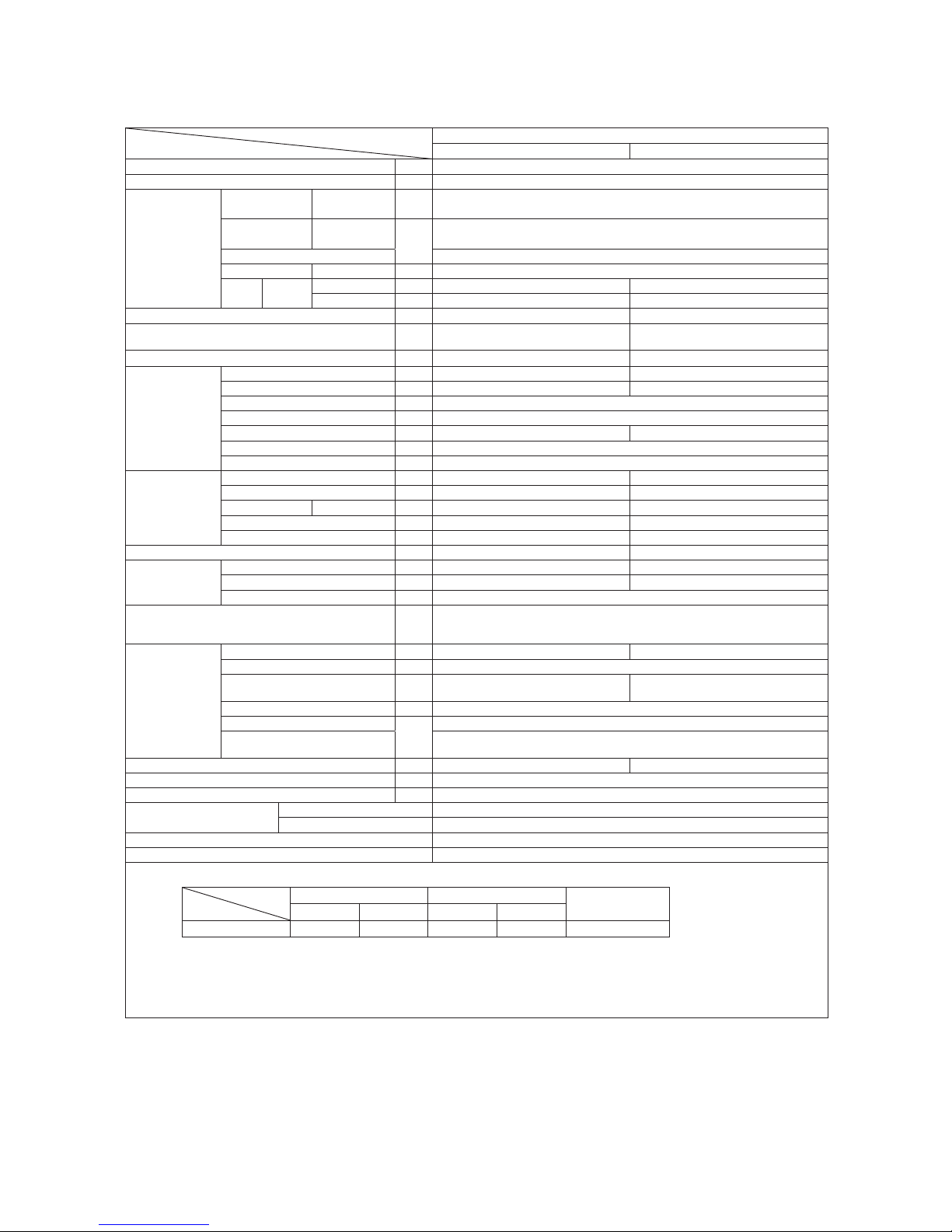

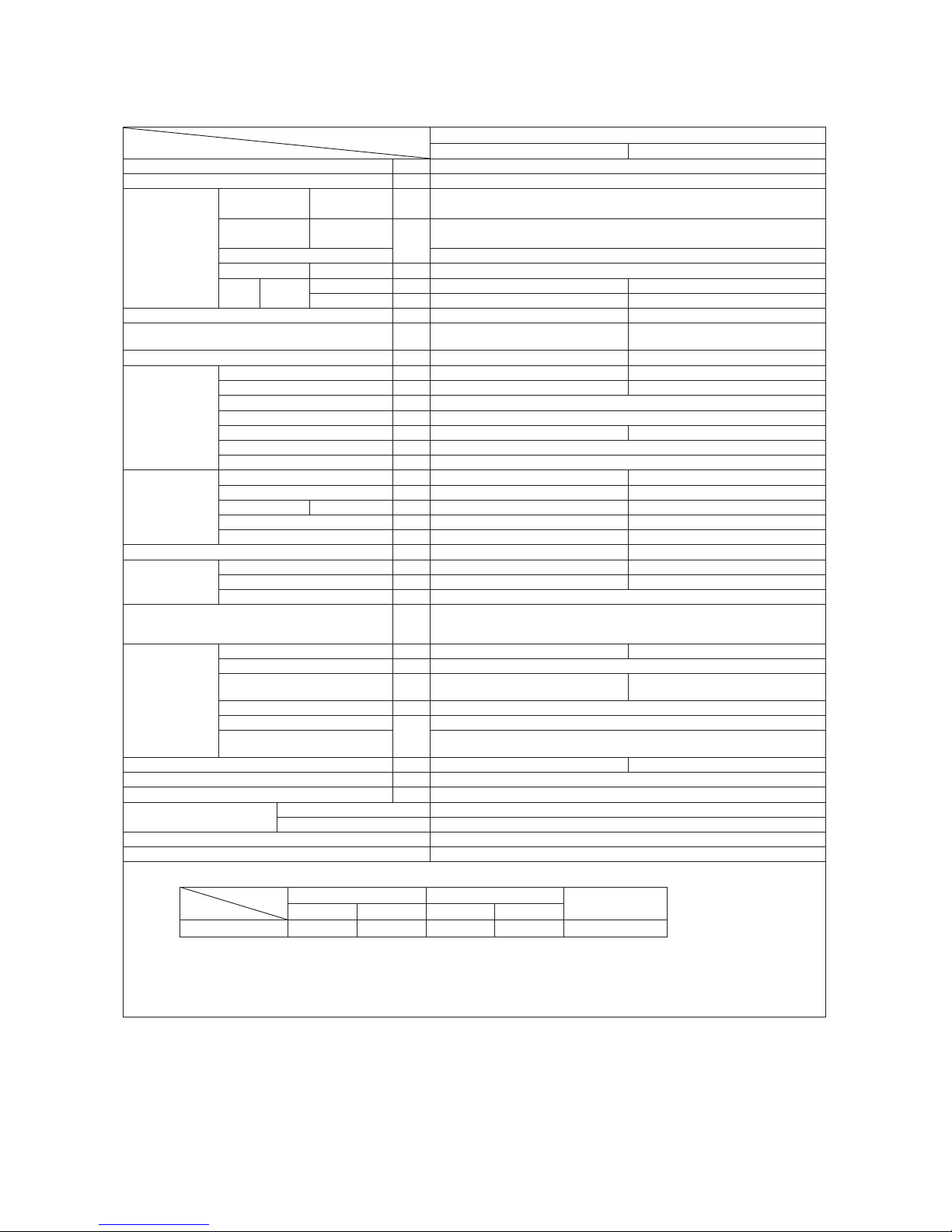

Model

Item

SRK09CR-S

Indoor unit SRK09CR-S Outdoor unit SRC09CR-S

Cooling capacity (1) W 2500

Power source 1 Phase, 220-240V, 50Hz

Operation

data

Power

consumption

Cooling kW 0.893

Running

current

Cooling

A

4.1 / 3.9

Inrush current 15

COP Cooling 2.80

Noise

level

Cooling

Sound level dB(A) 43 50

Power level dB 57 61

Exterior dimensions (Height x Width x Depth) mm 262 x 615 x 210 435 x 645 (+50) x 275

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 6 24.5

Refrigerant

equipment

Compressor type & Q'ty — GKS102PAB (Rotary type) x 1

Motor (Starting method) kW — PSC

Refrigerant oil

ℓ

0.30 (POE [RB68A] or PVE [FVC68D])

Refrigerant (4) kg R410A 0.52 ( Pre-charged up to the piping length of 5m )

Heat exchanger Louver fins & inner grooved tubing Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Device control Microcomputer control

Air handling

equipment

Fan type & Q'ty Cross flow fan x 1 Propeller fan x 1

Motor W 17 22

Air flow Cooling m3/min 9 23

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 1 —

Shock & vibration absorber — Cushion rubber (for compressor)

Operation

control

Operation switch Wireless remote control —

Room temperature control Microcomputer thermostat —

Operation display RUN : Green, TIMER : Yellow

Safety devices

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor Fan motor error protection,

Cooling overload protection

Installation

data

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

Connecting method Flare connecting

Attached length of piping m

Liquid line : 0.46

Gas line : 0.40

—

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

m

Max. 15

Vertical height difference between

outdoor unit and indoor unit

Max.5 (Outdoor unit is higher)

Max.5 (Outdoor unit is lower)

Drain hose Connectable (VP 16) —

Power cable —

Recommended breaker size A 10

Connection wiring

Size x Core number 1.5mm2 x 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Option parts —

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C ISO-T1, JIS C 9612

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 220/230V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 5m connecting piping.

(Purging is not required even for the short piping.)

If the piping length is 5m to 15m, additional refrigerant is 10g per each 1m longer than 5m.

The pipe length is 5m.

Page 12

-

10

-

'15 • SRK-T-171

Model

Item

SRK09CR-S3

Indoor unit SRK09CR-S3 Outdoor unit SRC09CR-S3

Cooling capacity (1) W 2500

Power source 1 Phase, 220-240V, 50Hz

Operation

data

Power

consumption

Cooling kW 0.893

Running

current

Cooling

A

4.1 / 3.9

Inrush current 15

COP Cooling 2.80

Noise

level

Cooling

Sound level dB(A) 43 50

Power level dB 57 61

Exterior dimensions (Height x Width x Depth) mm 262 x 615 x 210 435 x 645 (+50) x 275

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 6 24.5

Refrigerant

equipment

Compressor type & Q'ty — GKS102PAB (Rotary type) x 1

Motor (Starting method) kW — PSC

Refrigerant oil

ℓ

0.30 (POE [RB68A] or PVE [FVC68D])

Refrigerant (4) kg R410A 0.52 ( Pre-charged up to the piping length of 5m )

Heat exchanger Louver fins & inner grooved tubing Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Device control Microcomputer control

Air handling

equipment

Fan type & Q'ty Cross flow fan x 1 Propeller fan x 1

Motor W 17 22

Air flow Cooling m3/min 9 23

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 1 —

Shock & vibration absorber — Cushion rubber (for compressor)

Operation

control

Operation switch Wireless remote control —

Room temperature control Microcomputer thermostat —

Operation display RUN : Green, TIMER : Yellow

Safety devices

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor Fan motor error protection,

Cooling overload protection

Installation

data

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

Connecting method Flare connecting

Attached length of piping m

Liquid line : 0.46

Gas line : 0.40

—

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

m

Max. 15

Vertical height difference between

outdoor unit and indoor unit

Max.5 (Outdoor unit is higher)

Max.5 (Outdoor unit is lower)

Drain hose Connectable (VP 16) —

Power cable —

Recommended breaker size A 10

Connection wiring

Size x Core number 1.5mm2 x 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Option parts —

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C ISO-T1, JIS C 9612

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 220/230V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 5m connecting piping.

(Purging is not required even for the short piping.)

If the piping length is 5m to 15m, additional refrigerant is 10g per each 1m longer than 5m.

The pipe length is 5m.

Page 13

-

11

-

'15 • SRK-T-171

Model

Item

SRK09CR-S4

Indoor unit SRK09CR-S4 Outdoor unit SRC09CR-S4

Cooling capacity (1) W 2500

Power source 1 Phase, 220-240V, 50Hz

Operation

data

Power

consumption

Cooling kW 0.893

Running

current

Cooling

A

4.1 / 3.9

Inrush current 15

COP Cooling 2.80

Noise

level

Cooling

Sound level dB(A) 43 50

Power level dB 57 61

Exterior dimensions (Height x Width x Depth) mm 262 x 615 x 210 435 x 645 (+50) x 275

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 6 24.5

Refrigerant

equipment

Compressor type & Q'ty — GKS102PAB (Rotary type) x 1

Motor (Starting method) kW — PSC

Refrigerant oil

ℓ

0.30 (POE [RB68A] or PVE [FVC68D])

Refrigerant (4) kg R410A 0.52 ( Pre-charged up to the piping length of 5m )

Heat exchanger Louver fins & inner grooved tubing Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Device control Microcomputer control

Air handling

equipment

Fan type & Q'ty Cross flow fan x 1 Propeller fan x 1

Motor W 17 22

Air flow Cooling m3/min 9 23

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 1 —

Shock & vibration absorber — Cushion rubber (for compressor)

Operation

control

Operation switch Wireless remote control —

Room temperature control Microcomputer thermostat —

Operation display RUN : Green, TIMER : Yellow

Safety devices

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor Fan motor error protection,

Cooling overload protection

Installation

data

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

Connecting method Flare connecting

Attached length of piping m

Liquid line : 0.46

Gas line : 0.40

—

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

m

Max. 15

Vertical height difference between

outdoor unit and indoor unit

Max.5 (Outdoor unit is higher)

Max.5 (Outdoor unit is lower)

Drain hose Connectable (VP 16) —

Power cable —

Recommended breaker size A 10

Connection wiring

Size x Core number 1.5mm2 x 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Option parts —

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C ISO-T1, JIS C 9612

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 220/230V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 5m connecting piping.

(Purging is not required even for the short piping.)

If the piping length is 5m to 15m, additional refrigerant is 10g per each 1m longer than 5m.

The pipe length is 5m.

Page 14

-

12

-

'15 • SRK-T-171

Model

Item

SRK09CR-S5

Indoor unit SRK09CR-S5 Outdoor unit SRC09CR-S5

Cooling capacity (1) W 2500

Power source 1 Phase, 220-240V, 50Hz

Operation

data

Power

consumption

Cooling kW 0.893

Running

current

Cooling

A

4.1 / 3.9

Inrush current 15

COP Cooling 2.80

Noise

level

Cooling

Sound level dB(A) 43 50

Power level dB 57 61

Exterior dimensions (Height x Width x Depth) mm 262 x 615 x 210 435 x 645 (+50) x 275

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 6 24.5

Refrigerant

equipment

Compressor type & Q'ty — GKS102PAB (Rotary type) x 1

Motor (Starting method) kW — PSC

Refrigerant oil

ℓ

0.30 (POE [RB68A] or PVE [FVC68D])

Refrigerant (4) kg R410A 0.52 ( Pre-charged up to the piping length of 5m )

Heat exchanger Louver fins & inner grooved tubing Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Device control Microcomputer control

Air handling

equipment

Fan type & Q'ty Cross flow fan x 1 Propeller fan x 1

Motor W 17 22

Air flow Cooling m3/min 9 23

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 1 —

Shock & vibration absorber — Cushion rubber (for compressor)

Operation

control

Operation switch Wireless remote control —

Room temperature control Microcomputer thermostat —

Operation display RUN : Green, TIMER : Yellow

Safety devices

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor Fan motor error protection,

Cooling overload protection

Installation

data

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

Connecting method Flare connecting

Attached length of piping m

Liquid line : 0.46

Gas line : 0.40

—

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

m

Max. 15

Vertical height difference between

outdoor unit and indoor unit

Max.5 (Outdoor unit is higher)

Max.5 (Outdoor unit is lower)

Drain hose Connectable (VP 16) —

Power cable —

Recommended breaker size A 10

Connection wiring

Size x Core number 1.5mm2 x 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Option parts —

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C ISO-T1, JIS C 9612

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 220/230V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 5m connecting piping.

(Purging is not required even for the short piping.)

If the piping length is 5m to 15m, additional refrigerant is 10g per each 1m longer than 5m.

The pipe length is 5m.

Page 15

-

13

-

'15 • SRK-T-171

Model

Item

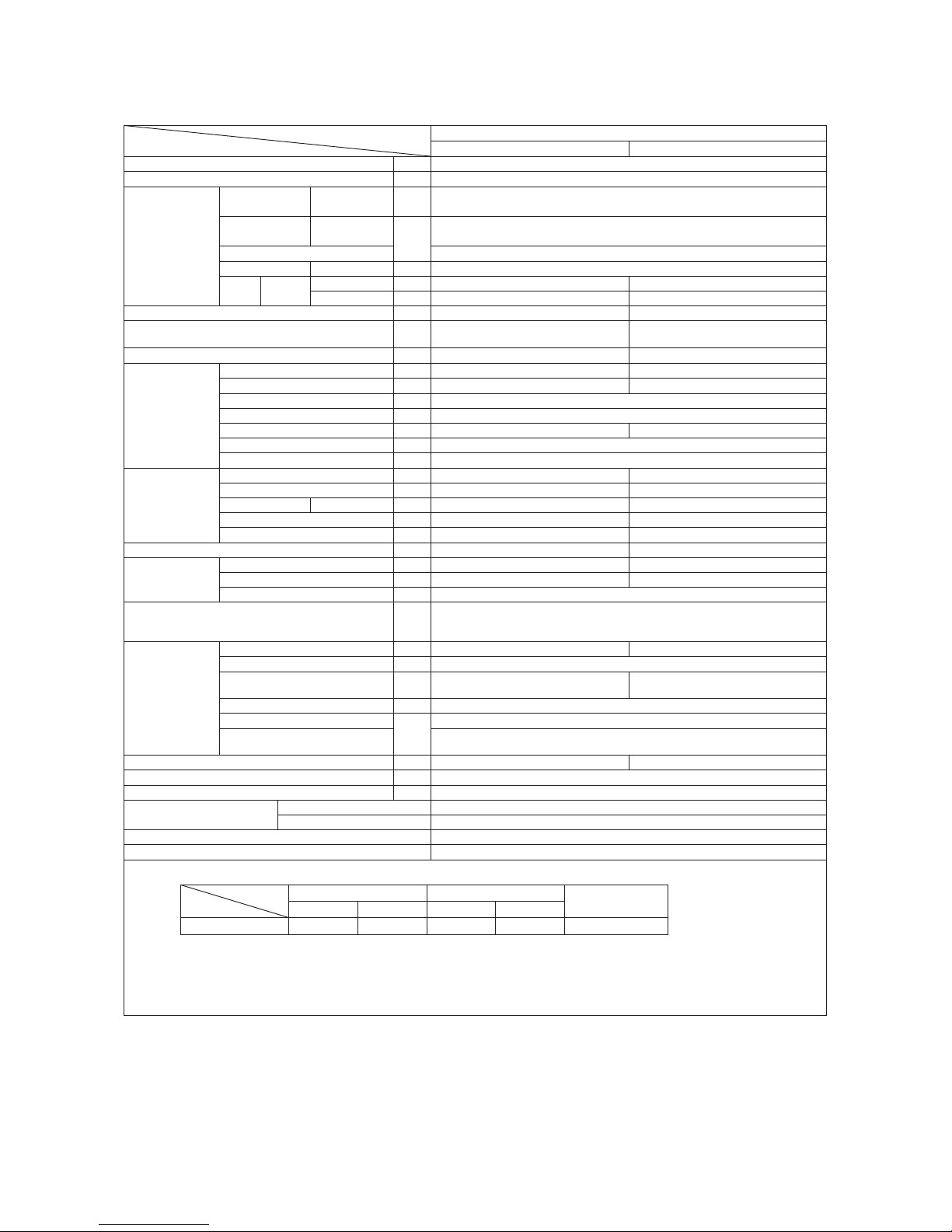

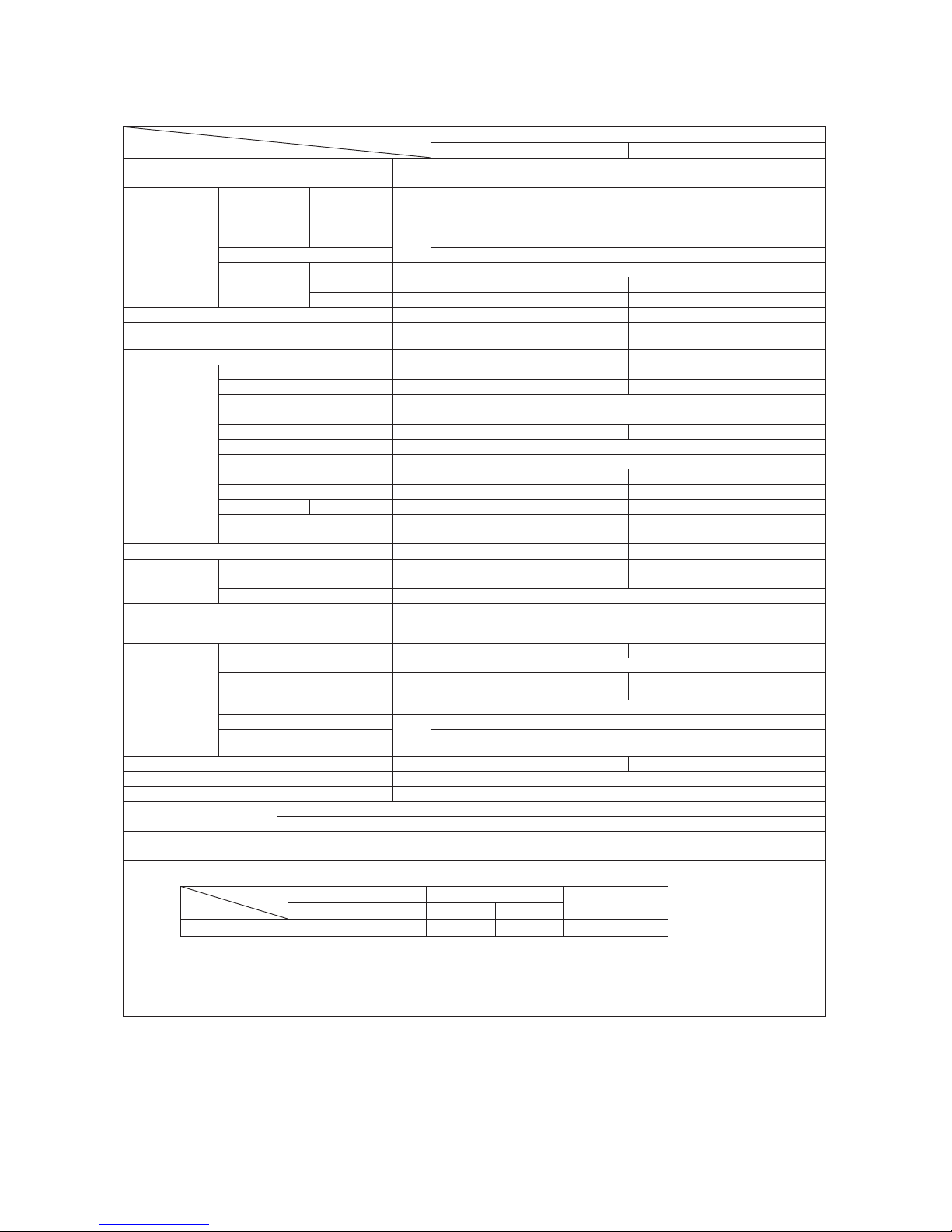

SRK09CRP-S

Indoor unit SRK09CRP-S Outdoor unit SRC09CRP-S

Cooling capacity (1) W 2500

Power source 1 Phase, 220-240V, 50Hz

Operation

data

Power

consumption

Cooling kW 0.925

Running

current

Cooling

A

4.3

Inrush current 15

COP Cooling 2.70

Noise

level

Cooling

Sound level dB(A) 43 51

Power level dB 57 62

Exterior dimensions (Height x Width x Depth) mm 262 x 615 x 210 435 x 645 (+50) x 275

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 6 24

Refrigerant

equipment

Compressor type & Q'ty — GKS102PAB (Rotary type) x 1

Motor (Starting method) kW — PSC

Refrigerant oil

ℓ

0.30 (POE [RB68A] or PVE [FVC68D])

Refrigerant (4) kg R410A 0.48 ( Pre-charged up to the piping length of 5m )

Heat exchanger Louver fins & inner grooved tubing Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Device control Microcomputer control

Air handling

equipment

Fan type & Q'ty Cross flow fan x 1 Propeller fan x 1

Motor W 17 22

Air flow Cooling m3/min 9 23

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 1 —

Shock & vibration absorber — Cushion rubber (for compressor)

Operation

control

Operation switch Wireless remote control —

Room temperature control Microcomputer thermostat —

Operation display RUN : Green, TIMER : Yellow

Safety devices

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor Fan motor error protection,

Cooling overload protection

Installation

data

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

Connecting method Flare connecting

Attached length of piping m

Liquid line : 0.46

Gas line : 0.40

—

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

m

Max. 15

Vertical height difference between

outdoor unit and indoor unit

Max.5 (Outdoor unit is higher)

Max.5 (Outdoor unit is lower)

Drain hose Connectable (VP 16) —

Power cable —

Recommended breaker size A 10

Connection wiring

Size x Core number 1.5mm2 x 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Option parts —

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C ISO-T1, JIS C 9612

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 220V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 5m connecting piping.

(Purging is not required even for the short piping.)

If the piping length is 5m to 15m, additional refrigerant is 10g per each 1m longer than 5m.

The pipe length is 5m.

Page 16

-

14

-

'15 • SRK-T-171

Model

Item

SRK09CRP-S3

Indoor unit SRK09CRP-S3 Outdoor unit SRC09CRP-S3

Cooling capacity (1) W 2500

Power source 1 Phase, 220-240V, 50Hz

Operation

data

Power

consumption

Cooling kW 0.925

Running

current

Cooling

A

4.3

Inrush current 15

COP Cooling 2.70

Noise

level

Cooling

Sound level dB(A) 43 51

Power level dB 57 62

Exterior dimensions (Height x Width x Depth) mm 262 x 615 x 210 435 x 645 (+50) x 275

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 6 24

Refrigerant

equipment

Compressor type & Q'ty — GKS102PAB (Rotary type) x 1

Motor (Starting method) kW — PSC

Refrigerant oil

ℓ

0.30 (POE [RB68A] or PVE [FVC68D])

Refrigerant (4) kg R410A 0.48 ( Pre-charged up to the piping length of 5m )

Heat exchanger Louver fins & inner grooved tubing Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Device control Microcomputer control

Air handling

equipment

Fan type & Q'ty Cross flow fan x 1 Propeller fan x 1

Motor W 17 22

Air flow Cooling m3/min 9 23

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 1 —

Shock & vibration absorber — Cushion rubber (for compressor)

Operation

control

Operation switch Wireless remote control —

Room temperature control Microcomputer thermostat —

Operation display RUN : Green, TIMER : Yellow

Safety devices

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor Fan motor error protection,

Cooling overload protection

Installation

data

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

Connecting method Flare connecting

Attached length of piping m

Liquid line : 0.46

Gas line : 0.40

—

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

m

Max. 15

Vertical height difference between

outdoor unit and indoor unit

Max.5 (Outdoor unit is higher)

Max.5 (Outdoor unit is lower)

Drain hose Connectable (VP 16) —

Power cable —

Recommended breaker size A 10

Connection wiring

Size x Core number 1.5mm2 x 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Option parts —

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C ISO-T1, JIS C 9612

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 220V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 5m connecting piping.

(Purging is not required even for the short piping.)

If the piping length is 5m to 15m, additional refrigerant is 10g per each 1m longer than 5m.

The pipe length is 5m.

Page 17

-

15

-

'15 • SRK-T-171

Model

Item

SRK09CRP-S5

Indoor unit SRK09CRP-S5 Outdoor unit SRC09CRP-S5

Cooling capacity (1) W 2500

Power source 1 Phase, 220-240V, 50Hz

Operation

data

Power

consumption

Cooling kW 0.925

Running

current

Cooling

A

4.3

Inrush current 15

COP Cooling 2.70

Noise

level

Cooling

Sound level dB(A) 43 51

Power level dB 57 62

Exterior dimensions (Height x Width x Depth) mm 262 x 615 x 210 435 x 645 (+50) x 275

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 6 24

Refrigerant

equipment

Compressor type & Q'ty — GKS102PAB (Rotary type) x 1

Motor (Starting method) kW — PSC

Refrigerant oil

ℓ

0.30 (POE [RB68A] or PVE [FVC68D])

Refrigerant (4) kg R410A 0.48 ( Pre-charged up to the piping length of 5m )

Heat exchanger Louver fins & inner grooved tubing Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Device control Microcomputer control

Air handling

equipment

Fan type & Q'ty Cross flow fan x 1 Propeller fan x 1

Motor W 17 22

Air flow Cooling m3/min 9 23

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 1 —

Shock & vibration absorber — Cushion rubber (for compressor)

Operation

control

Operation switch Wireless remote control —

Room temperature control Microcomputer thermostat —

Operation display RUN : Green, TIMER : Yellow

Safety devices

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor Fan motor error protection,

Cooling overload protection

Installation

data

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

Connecting method Flare connecting

Attached length of piping m

Liquid line : 0.46

Gas line : 0.40

—

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

m

Max. 15

Vertical height difference between

outdoor unit and indoor unit

Max.5 (Outdoor unit is higher)

Max.5 (Outdoor unit is lower)

Drain hose Connectable (VP 16) —

Power cable —

Recommended breaker size A 10

Connection wiring

Size x Core number 1.5mm2 x 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Option parts —

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C ISO-T1, JIS C 9612

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 220V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 5m connecting piping.

(Purging is not required even for the short piping.)

If the piping length is 5m to 15m, additional refrigerant is 10g per each 1m longer than 5m.

The pipe length is 5m.

Page 18

-

16

-

'15 • SRK-T-171

Model

Item

SRK09CRR-S

Indoor unit SRK09CRR-S Outdoor unit SRC09CRR-S

Cooling capacity (1) W 2638

Power source 1 Phase, 220-240V, 50Hz

Operation

data

Power

consumption

Cooling kW 0.868

Running

current

Cooling

A

4.0 / 3.8

Inrush current 15

COP Cooling 3.04

Noise

level

Cooling

Sound level dB(A) 43 50

Power level dB 57 61

Exterior dimensions (Height x Width x Depth) mm 262 x 769 x 210 435 x 645 (+50) x 275

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 7 24.5

Refrigerant

equipment

Compressor type & Q'ty — GKS102PAB (Rotary type) x 1

Motor (Starting method) kW — PSC

Refrigerant oil

ℓ

0.30 (POE [RB68A] or PVE [FVC68D])

Refrigerant (4) kg R410A 0.54 ( Pre-charged up to the piping length of 5m )

Heat exchanger Louver fins & inner grooved tubing Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Device control Microcomputer control

Air handling

equipment

Fan type & Q'ty Cross flow fan x 1 Propeller fan x 1

Motor W 17 22

Air flow Cooling m3/min 10 23

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 1 —

Shock & vibration absorber — Cushion rubber (for compressor)

Operation

control

Operation switch Wireless remote control —

Room temperature control Microcomputer thermostat —

Operation display RUN : Green, TIMER : Yellow

Safety devices

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor Fan motor error protection,

Cooling overload protection

Installation

data

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

Connecting method Flare connecting

Attached length of piping m

Liquid line : 0.45

Gas line : 0.41

—

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

m

Max. 15

Vertical height difference between

outdoor unit and indoor unit

Max.5 (Outdoor unit is higher)

Max.5 (Outdoor unit is lower)

Drain hose Connectable (VP 16) —

Power cable —

Recommended breaker size A 10

Connection wiring

Size x Core number 1.5mm2 x 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Option parts —

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C ISO-T1, JIS C 9612

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 220/230V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 5m connecting piping.

(Purging is not required even for the short piping.)

If the piping length is 5m to 15m, additional refrigerant is 10g per each 1m longer than 5m.

The pipe length is 5m.

Page 19

-

17

-

'15 • SRK-T-171

Model

Item

SRK09CRR-S3

Indoor unit SRK09CRR-S3 Outdoor unit SRC09CRR-S3

Cooling capacity (1) W 2638

Power source 1 Phase, 220-240V, 50Hz

Operation

data

Power

consumption

Cooling kW 0.868

Running

current

Cooling

A

4.0 / 3.8

Inrush current 15

COP Cooling 3.04

Noise

level

Cooling

Sound level dB(A) 43 50

Power level dB 57 61

Exterior dimensions (Height x Width x Depth) mm 262 x 769 x 210 435 x 645 (+50) x 275

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 7 24.5

Refrigerant

equipment

Compressor type & Q'ty — GKS102PAB (Rotary type) x 1

Motor (Starting method) kW — PSC

Refrigerant oil

ℓ

0.30 (POE [RB68A] or PVE [FVC68D])

Refrigerant (4) kg R410A 0.54 ( Pre-charged up to the piping length of 5m )

Heat exchanger Louver fins & inner grooved tubing Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Device control Microcomputer control

Air handling

equipment

Fan type & Q'ty Cross flow fan x 1 Propeller fan x 1

Motor W 17 22

Air flow Cooling m3/min 10 23

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 1 —

Shock & vibration absorber — Cushion rubber (for compressor)

Operation

control

Operation switch Wireless remote control —

Room temperature control Microcomputer thermostat —

Operation display RUN : Green, TIMER : Yellow

Safety devices

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor Fan motor error protection,

Cooling overload protection

Installation

data

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

Connecting method Flare connecting

Attached length of piping m

Liquid line : 0.45

Gas line : 0.41

—

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

m

Max. 15

Vertical height difference between

outdoor unit and indoor unit

Max.5 (Outdoor unit is higher)

Max.5 (Outdoor unit is lower)

Drain hose Connectable (VP 16) —

Power cable —

Recommended breaker size A 10

Connection wiring

Size x Core number 1.5mm2 x 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Option parts —

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C ISO-T1, JIS C 9612

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 220/230V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 5m connecting piping.

(Purging is not required even for the short piping.)

If the piping length is 5m to 15m, additional refrigerant is 10g per each 1m longer than 5m.

The pipe length is 5m.

Page 20

-

18

-

'15 • SRK-T-171

Model

Item

SRK09CRR-S4

Indoor unit SRK09CRR-S4 Outdoor unit SRC09CRR-S4

Cooling capacity (1) W 2638

Power source 1 Phase, 220-240V, 50Hz

Operation

data

Power

consumption

Cooling kW 0.868

Running

current

Cooling

A

4.0 / 3.8

Inrush current 15

COP Cooling 3.04

Noise

level

Cooling

Sound level dB(A) 43 50

Power level dB 57 61

Exterior dimensions (Height x Width x Depth) mm 262 x 769 x 210 435 x 645 (+50) x 275

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 7 24.5

Refrigerant

equipment

Compressor type & Q'ty — GKS102PAB (Rotary type) x 1

Motor (Starting method) kW — PSC

Refrigerant oil

ℓ

0.30 (POE [RB68A] or PVE [FVC68D])

Refrigerant (4) kg R410A 0.54 ( Pre-charged up to the piping length of 5m )

Heat exchanger Louver fins & inner grooved tubing Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Device control Microcomputer control

Air handling

equipment

Fan type & Q'ty Cross flow fan x 1 Propeller fan x 1

Motor W 17 22

Air flow Cooling m3/min 10 23

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 1 —

Shock & vibration absorber — Cushion rubber (for compressor)

Operation

control

Operation switch Wireless remote control —

Room temperature control Microcomputer thermostat —

Operation display RUN : Green, TIMER : Yellow

Safety devices

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor Fan motor error protection,

Cooling overload protection

Installation

data

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

Connecting method Flare connecting

Attached length of piping m

Liquid line : 0.45

Gas line : 0.41

—

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

m

Max. 15

Vertical height difference between

outdoor unit and indoor unit

Max.5 (Outdoor unit is higher)

Max.5 (Outdoor unit is lower)

Drain hose Connectable (VP 16) —

Power cable —

Recommended breaker size A 10

Connection wiring

Size x Core number 1.5mm2 x 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Option parts —

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C ISO-T1, JIS C 9612

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 220/230V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 5m connecting piping.

(Purging is not required even for the short piping.)

If the piping length is 5m to 15m, additional refrigerant is 10g per each 1m longer than 5m.

The pipe length is 5m.

Page 21

-

19

-

'15 • SRK-T-171

Model

Item

SRK09CRR-S5

Indoor unit SRK09CRR-S5 Outdoor unit SRC09CRR-S5

Cooling capacity (1) W 2638

Power source 1 Phase, 220-240V, 50Hz

Operation

data

Power

consumption

Cooling kW 0.868

Running

current

Cooling

A

4.0 / 3.8

Inrush current 15

COP Cooling 3.04

Noise

level

Cooling

Sound level dB(A) 43 50

Power level dB 57 61

Exterior dimensions (Height x Width x Depth) mm 262 x 769 x 210 435 x 645 (+50) x 275

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 7 24.5

Refrigerant

equipment

Compressor type & Q'ty — GKS102PAB (Rotary type) x 1

Motor (Starting method) kW — PSC

Refrigerant oil

ℓ

0.30 (POE [RB68A] or PVE [FVC68D])

Refrigerant (4) kg R410A 0.54 ( Pre-charged up to the piping length of 5m )

Heat exchanger Louver fins & inner grooved tubing Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Device control Microcomputer control

Air handling

equipment

Fan type & Q'ty Cross flow fan x 1 Propeller fan x 1

Motor W 17 22

Air flow Cooling m3/min 10 23

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 1 —

Shock & vibration absorber — Cushion rubber (for compressor)

Operation

control

Operation switch Wireless remote control —

Room temperature control Microcomputer thermostat —

Operation display RUN : Green, TIMER : Yellow

Safety devices

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor Fan motor error protection,

Cooling overload protection

Installation

data

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

Connecting method Flare connecting

Attached length of piping m

Liquid line : 0.45

Gas line : 0.41

—

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

m

Max. 15

Vertical height difference between

outdoor unit and indoor unit

Max.5 (Outdoor unit is higher)

Max.5 (Outdoor unit is lower)

Drain hose Connectable (VP 16) —

Power cable —

Recommended breaker size A 10

Connection wiring

Size x Core number 1.5mm2 x 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Option parts —

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C ISO-T1, JIS C 9612

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 220/230V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 5m connecting piping.

(Purging is not required even for the short piping.)

If the piping length is 5m to 15m, additional refrigerant is 10g per each 1m longer than 5m.

The pipe length is 5m.

Page 22

-

20

-

'15 • SRK-T-171

Model

Item

SRK09CRR-S6

Indoor unit SRK09CRR-S6 Outdoor unit SRC09CRR-S6

Cooling capacity (1) W 2638

Power source 1 Phase, 220-230V, 50Hz

Operation

data

Power

consumption

Cooling kW 0.868

Running

current

Cooling

A

4.0 / 3.8

Inrush current 15

COP Cooling 3.04

Noise

level

Cooling

Sound level dB(A) 43 50

Power level dB 57 61

Exterior dimensions (Height x Width x Depth) mm 262 x 769 x 210 435 x 645 (+50) x 275

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 7 24.5

Refrigerant

equipment

Compressor type & Q'ty — GKS102PAB (Rotary type) x 1

Motor (Starting method) kW — PSC

Refrigerant oil

ℓ

0.30 (POE [RB68A] or PVE [FVC68D])

Refrigerant (4) kg R410A 0.54 ( Pre-charged up to the piping length of 5m )

Heat exchanger Louver fins & inner grooved tubing Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Device control Microcomputer control

Air handling

equipment

Fan type & Q'ty Cross flow fan x 1 Propeller fan x 1

Motor W 17 22

Air flow Cooling m3/min 10 23

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 1 —

Shock & vibration absorber — Cushion rubber (for compressor)

Operation

control

Operation switch Wireless remote control —

Room temperature control Microcomputer thermostat —

Operation display RUN : Green, TIMER : Yellow

Safety devices

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor Fan motor error protection,

Cooling overload protection

Installation

data

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

Connecting method Flare connecting

Attached length of piping m

Liquid line : 0.45

Gas line : 0.41

—

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

m

Max. 15

Vertical height difference between

outdoor unit and indoor unit

Max.5 (Outdoor unit is higher)

Max.5 (Outdoor unit is lower)

Drain hose Connectable (VP 16) —

Power cable —

Recommended breaker size A 10

Connection wiring

Size x Core number 1.5mm2 x 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Option parts —

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C ISO-T1, JIS C 9612

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 220/230V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 5m connecting piping.

(Purging is not required even for the short piping.)

If the piping length is 5m to 15m, additional refrigerant is 10g per each 1m longer than 5m.

The pipe length is 5m.

Page 23

-

21

-

'15 • SRK-T-171

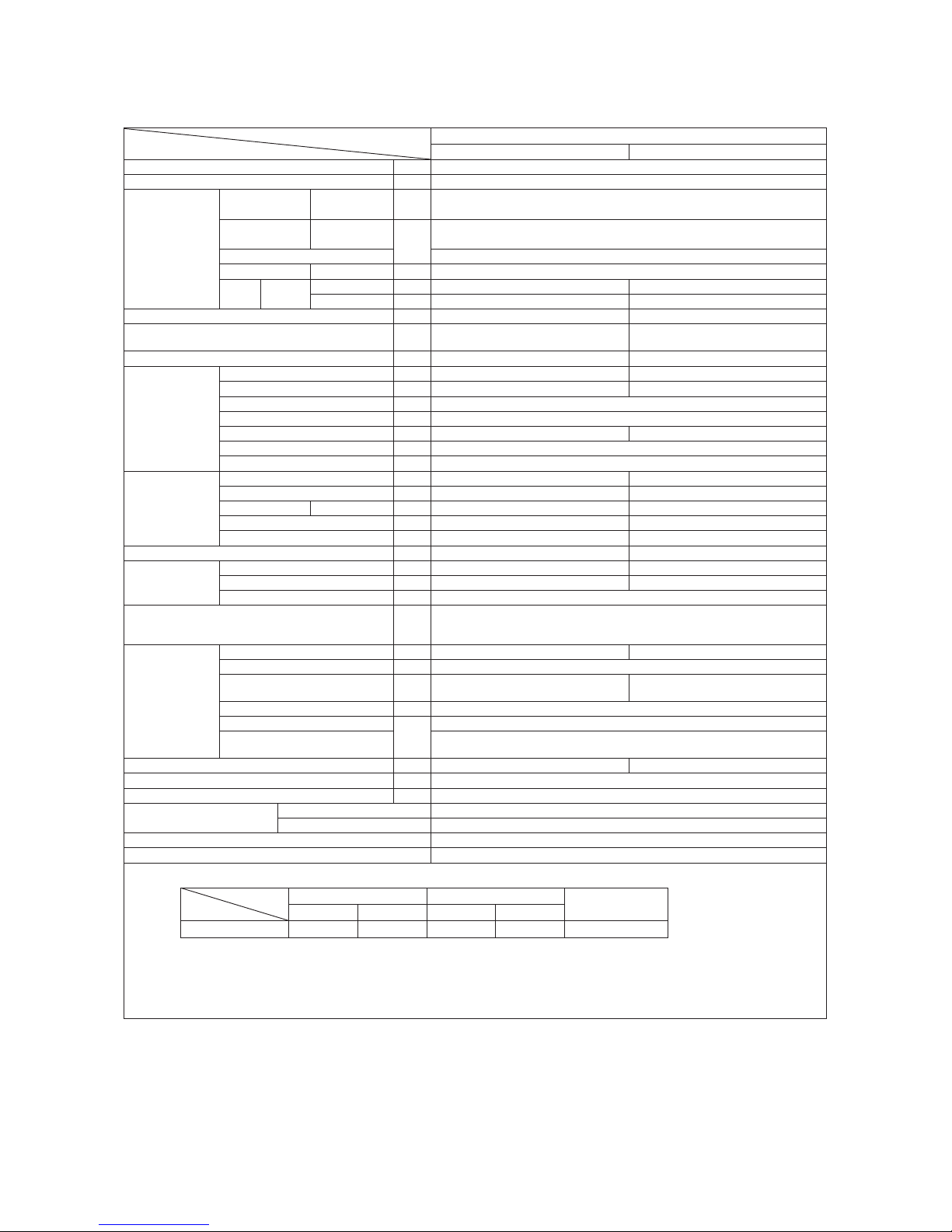

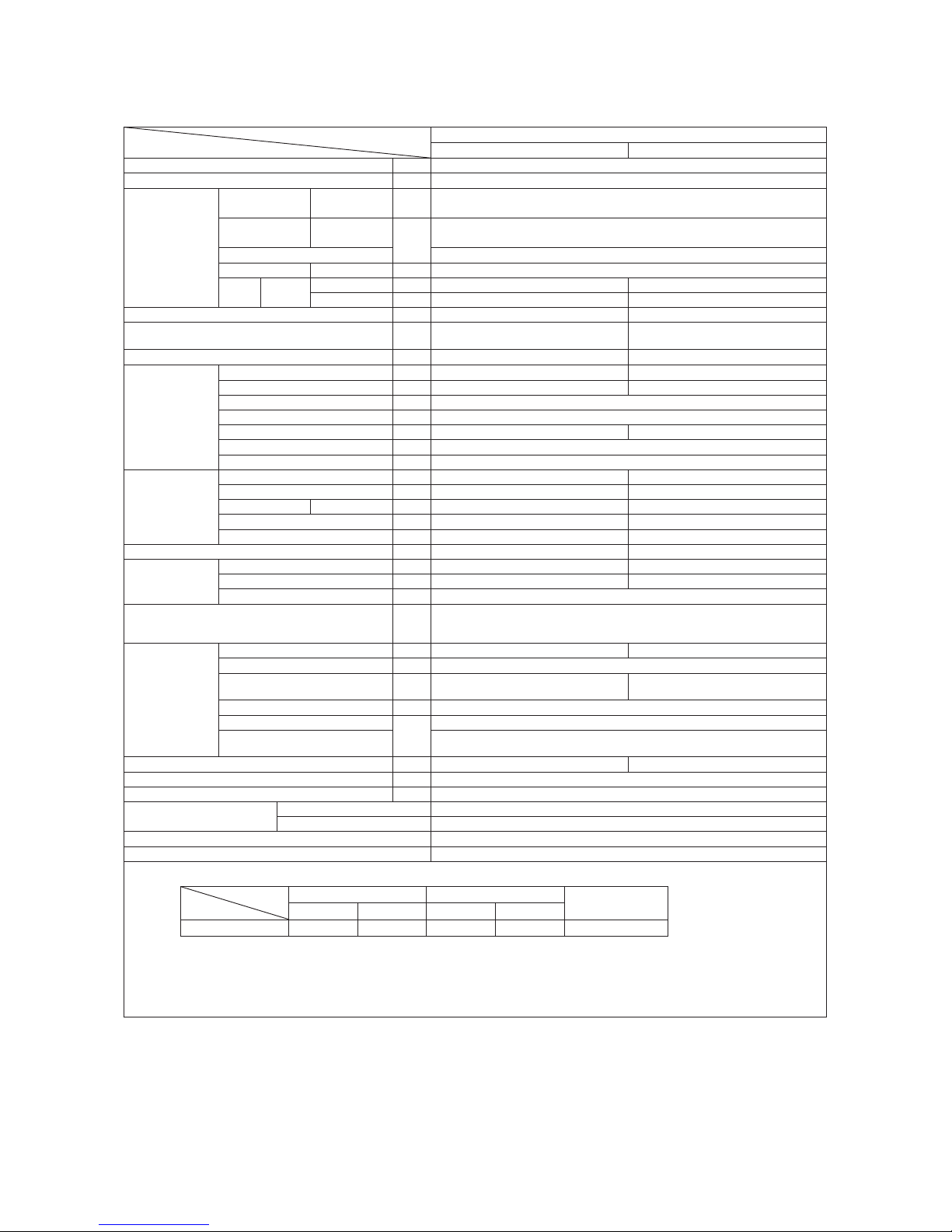

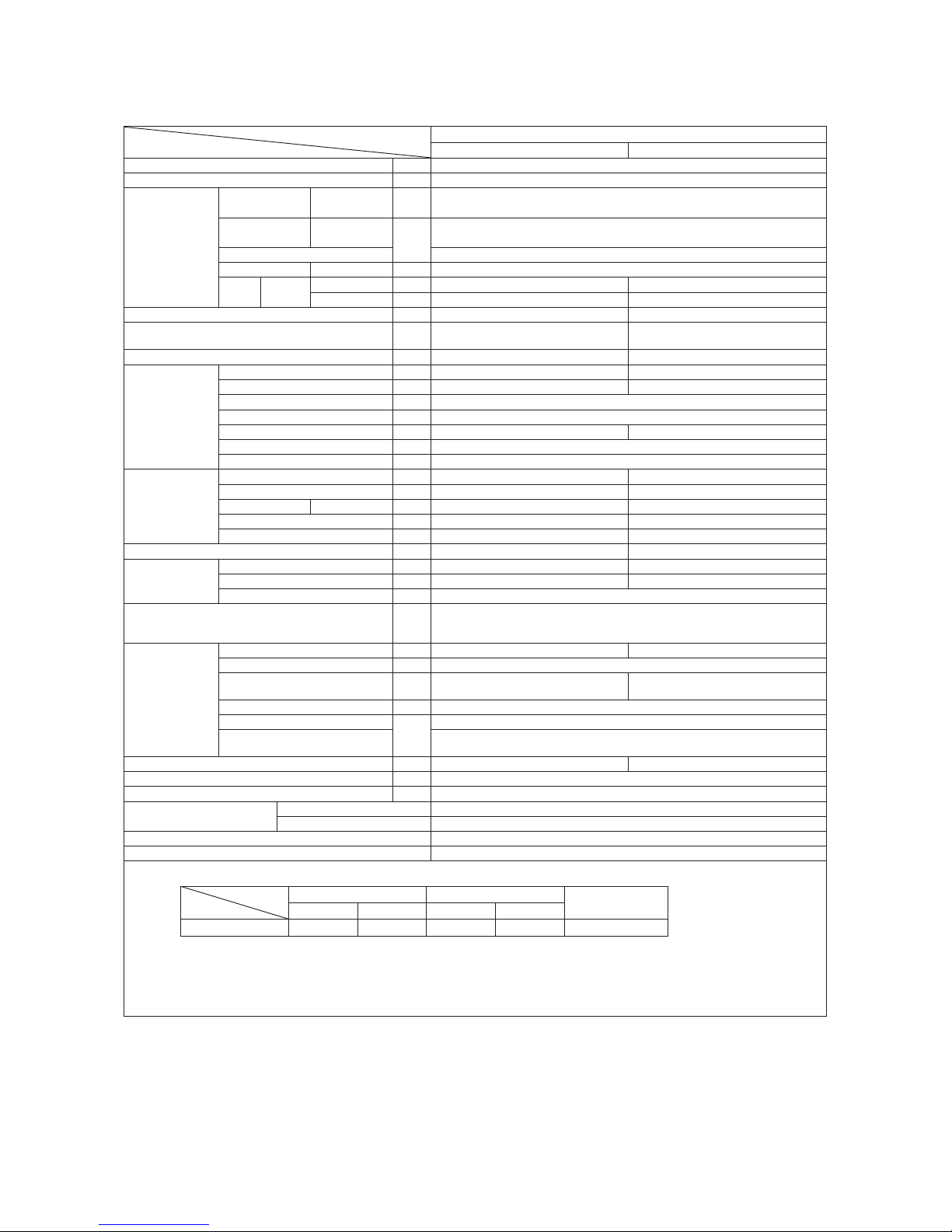

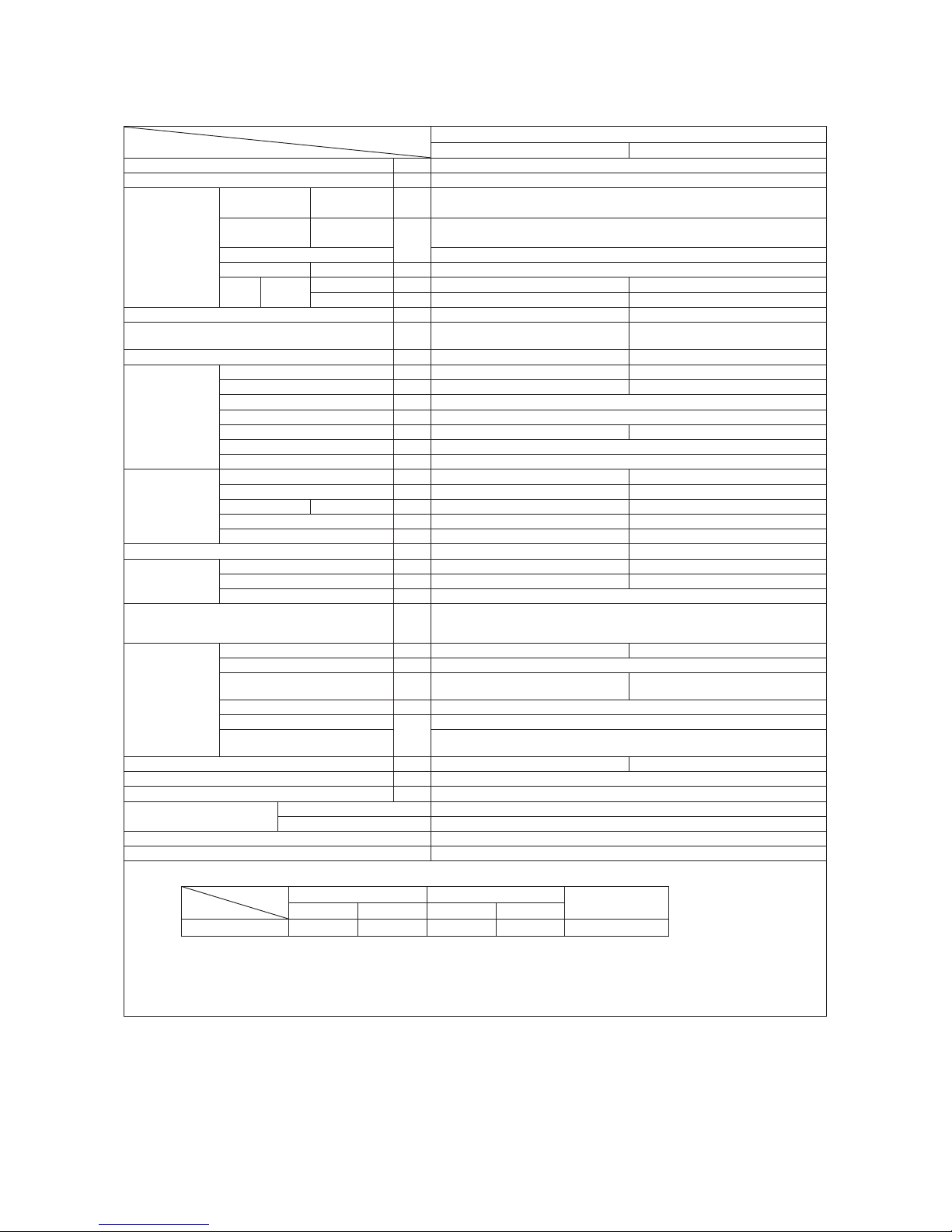

Model

Item

SRK12CR-S

Indoor unit SRK12CR-S Outdoor unit SRC12CR-S

Cooling capacity (1) W 3450

Power source 1 Phase, 220-240V, 50Hz

Operation

data

Power

consumption

Cooling kW 1.120

Running

current

Cooling

A

5.1

Inrush current 7.5

COP Cooling 3.08

Noise

level

Cooling

Sound level dB(A) Hi : 43 Me : 39 Lo : 36 50

Power level dB 57 61

Exterior dimensions (Height x Width x Depth) mm 268 x 790 x 222 595 x 780 (+62) x 290

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 7 31

Refrigerant

equipment

Compressor type & Q'ty — GKS139PAA ( Rotary type ) x 1

Motor (Starting method) kW — PSC

Refrigerant oil

ℓ

0.30 ,POE(RB68A) or PVE(FVC68D)

Refrigerant (4) kg R410A 0.78 ( Pre-charged up to the piping length of 5m )

Heat exchanger Louver fins & inner grooved tubing Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Device control Microcomputer control

Air handling

equipment

Fan type & Q'ty Tangential fan x 1 Propeller fan x 1

Motor W 17 25

Air flow Cooling m3/min 15 38

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 2 —

Shock & vibration absorber — Cushion rubber (for compressor)

Operation

control

Operation switch Wireless remote control —

Room temperature control Microcomputer thermostat —

Operation display RUN : Green, TIMER : Yellow

Safety devices

Compressor overheat protection,

Frost protection, Serial signal error protection, Fan motor error protection,

Installation

data

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ12.7 (1/2")

Connecting method Flare connecting

Attached length of piping m

Liquid line : 0.57

Gas line : 0.55

—

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

m

Max. 15

Vertical height difference between

outdoor unit and indoor unit

Max.5 (Outdoor unit is higher)

Max.5 (Outdoor unit is lower)

Drain hose Connectable (VP 16) —

Power cable 2m (3 Cores wih Earth)

Recommended breaker size A 20

Connection wiring

Size x Core number 1.5mm2 x 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Option parts —

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C JIS C 9612, TISI 1155, 2134, 812

(2) This air-conditioner is manufactured and tested in conformity with the TISI.

(3) The operation data are applied to the 230V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 5m connecting piping.

(Purging is not required even for the short piping.)

If the piping length is 5m to 15m, additional refrigerant is 10g per each 1m longer than 5m.

The pipe length is 5m.

Page 24

-

22

-

'15 • SRK-T-171

Model

Item

SRK12CR-S3

Indoor unit SRK12CR-S3 Outdoor unit SRC12CR-S3

Cooling capacity (1) W 3450

Power source 1 Phase, 220-240V, 50Hz

Operation

data

Power

consumption

Cooling kW 1.12

Running

current

Cooling

A

5.1

Inrush current 7.5

COP Cooling 3.08

Noise

level

Cooling

Sound level dB(A) Hi : 43 Me : 39 Lo : 36 50

Power level dB 57 61

Exterior dimensions (Height x Width x Depth) mm 268 x 790 x 222 595 x 780 (+62) x 290

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 7 31

Refrigerant

equipment

Compressor type & Q'ty — GKS139PAA ( Rotary type ) x 1

Motor (Starting method) kW — PSC

Refrigerant oil

ℓ

0.30 ,POE(RB68A) or PVE(FVC68D)

Refrigerant (4) kg R410A 0.78 ( Pre-charged up to the piping length of 5m )

Heat exchanger Louver fins & inner grooved tubing Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Device control Microcomputer control

Air handling

equipment

Fan type & Q'ty Tangential fan x 1 Propeller fan x 1

Motor W 17 25

Air flow Cooling m3/min 15 38

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 2 —

Shock & vibration absorber — Cushion rubber (for compressor)

Operation

control

Operation switch Wireless remote control —

Room temperature control Microcomputer thermostat —

Operation display RUN : Green, TIMER : Yellow

Safety devices

Compressor overheat protection,

Frost protection, Serial signal error protection, Fan motor error protection,

Installation

data

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ12.7 (1/2")

Connecting method Flare connecting

Attached length of piping m

Liquid line : 0.57

Gas line : 0.55

—

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

m

Max. 15

Vertical height difference between

outdoor unit and indoor unit

Max.5 (Outdoor unit is higher)

Max.5 (Outdoor unit is lower)

Drain hose Connectable (VP 16) —

Power cable 2m (3 Cores wih Earth)

Recommended breaker size A 20

Connection wiring

Size x Core number 1.5mm2 x 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Option parts —

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C ISO-T1, JIS C 9612

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 230V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 5m connecting piping.

(Purging is not required even for the short piping.)

If the piping length is 5m to 15m, additional refrigerant is 10g per each 1m longer than 5m.

The pipe length is 5m.

Page 25

-

23

-

'15 • SRK-T-171

Model

Item

SRK12CR-S4

Indoor unit SRK12CR-S4 Outdoor unit SRC12CR-S4

Cooling capacity (1) W 3450

Power source 1 Phase, 220-240V, 50Hz

Operation

data

Power

consumption

Cooling kW 1.12

Running

current

Cooling

A

5.1

Inrush current 7.5

COP Cooling 3.08

Noise

level

Cooling

Sound level dB(A) Hi : 43 Me : 39 Lo : 36 50

Power level dB 57 61

Exterior dimensions (Height x Width x Depth) mm 268 x 790 x 222 595 x 780 (+62) x 290

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 7 31

Refrigerant

equipment

Compressor type & Q'ty — GKS139PAA ( Rotary type ) x 1

Motor (Starting method) kW — PSC

Refrigerant oil

ℓ

0.30 ,POE(RB68A) or PVE(FVC68D)

Refrigerant (4) kg R410A 0.78 ( Pre-charged up to the piping length of 5m )

Heat exchanger Louver fins & inner grooved tubing Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Device control Microcomputer control

Air handling

equipment

Fan type & Q'ty Tangential fan x 1 Propeller fan x 1

Motor W 17 25

Air flow Cooling m3/min 15 38

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 2 —

Shock & vibration absorber — Cushion rubber (for compressor)

Operation

control

Operation switch Wireless remote control —

Room temperature control Microcomputer thermostat —

Operation display RUN : Green, TIMER : Yellow

Safety devices

Compressor overheat protection,

Frost protection, Serial signal error protection, Fan motor error protection,

Installation

data

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ12.7 (1/2")

Connecting method Flare connecting

Attached length of piping m

Liquid line : 0.57

Gas line : 0.55

—

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

m

Max. 15

Vertical height difference between

outdoor unit and indoor unit

Max.5 (Outdoor unit is higher)

Max.5 (Outdoor unit is lower)

Drain hose Connectable (VP 16) —

Power cable 2m (3 Cores wih Earth)

Recommended breaker size A 20

Connection wiring

Size x Core number 1.5mm2 x 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Option parts —

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C ISO-T1, JIS C 9612

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 230V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 5m connecting piping.

(Purging is not required even for the short piping.)

If the piping length is 5m to 15m, additional refrigerant is 10g per each 1m longer than 5m.

The pipe length is 5m.

Page 26

-

24

-

'15 • SRK-T-171

Model

Item

SRK12CR-S5

Indoor unit SRK12CR-S5 Outdoor unit SRC12CR-S5

Cooling capacity (1) W 3450

Power source 1 Phase, 220-240V, 50Hz

Operation

data

Power

consumption

Cooling kW 1.12

Running

current

Cooling

A

5.1

Inrush current 7.5

COP Cooling 3.08

Noise

level

Cooling

Sound level dB(A) Hi : 43 Me : 39 Lo : 36 50

Power level dB 57 61

Exterior dimensions (Height x Width x Depth) mm 268 x 790 x 222 595 x 780 (+62) x 290

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 7 31

Refrigerant

equipment

Compressor type & Q'ty — GKS139PAA ( Rotary type ) x 1

Motor (Starting method) kW — PSC

Refrigerant oil

ℓ

0.30 ,POE(RB68A) or PVE(FVC68D)

Refrigerant (4) kg R410A 0.78 ( Pre-charged up to the piping length of 5m )

Heat exchanger Louver fins & inner grooved tubing Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Device control Microcomputer control

Air handling

equipment

Fan type & Q'ty Tangential fan x 1 Propeller fan x 1

Motor W 17 25

Air flow Cooling m3/min 15 38

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 2 —

Shock & vibration absorber — Cushion rubber (for compressor)

Operation

control

Operation switch Wireless remote control —

Room temperature control Microcomputer thermostat —

Operation display RUN : Green, TIMER : Yellow

Safety devices

Compressor overheat protection,

Frost protection, Serial signal error protection, Fan motor error protection,

Installation

data

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ12.7 (1/2")

Connecting method Flare connecting

Attached length of piping m

Liquid line : 0.57

Gas line : 0.55

—

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

m

Max. 15

Vertical height difference between

outdoor unit and indoor unit

Max.5 (Outdoor unit is higher)

Max.5 (Outdoor unit is lower)

Drain hose Connectable (VP 16) —

Power cable 2m (3 Cores wih Earth)

Recommended breaker size A 20

Connection wiring

Size x Core number 1.5mm2 x 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Option parts —

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C ISO-T1, JIS C 9612

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 230V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 5m connecting piping.

(Purging is not required even for the short piping.)

If the piping length is 5m to 15m, additional refrigerant is 10g per each 1m longer than 5m.

The pipe length is 5m.

Page 27

-

25

-

'15 • SRK-T-171

Model

Item

SRK12CR-S6

Indoor unit SRK12CR-S6 Outdoor unit SRC12CR-S6

Cooling capacity (1) W 3450

Power source 1 Phase, 220-240V, 50Hz

Operation

data

Power

consumption

Cooling kW 1.12

Running

current

Cooling

A

5.1

Inrush current 7.5

COP Cooling 3.08

Noise

level

Cooling

Sound level dB(A) Hi : 43 Me : 39 Lo : 36 50

Power level dB 57 61

Exterior dimensions (Height x Width x Depth) mm 268 x 790 x 222 595 x 780 (+62) x 290

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 7 31

Refrigerant

equipment

Compressor type & Q'ty — GKS139PAA ( Rotary type ) x 1

Motor (Starting method) kW — PSC

Refrigerant oil

ℓ

0.30 ,POE(RB68A) or PVE(FVC68D)

Refrigerant (4) kg R410A 0.78 ( Pre-charged up to the piping length of 5m )

Heat exchanger Louver fins & inner grooved tubing Louver fins & inner grooved tubing

Refrigerant control Capillary tubes