Page 1

ROOM AIR-CONDITIONING

TECHNICAL MANUAL & PARTS LIST

WALL MOUNTED TYPE

ROOM AIR-CONDITIONER

(Split system, air cooled cooling only type)

SRK10CFV-4, 13CFV-4

Page 2

TECHNICAL MANUAL

Page 3

CONTENTS

1. GENERAL INFORMATION ............................................................................... 2

1.1 Specific features ........................................................................................ 2

1.2 How to read the model name .................................................................... 2

2. SELECTION DATA............................................................................................ 3

2.1 Specifications............................................................................................. 3

2.2 Range of usage & limitations.................................................................... 5

2.3 Exterior dimensions .................................................................................. 5

2.4 Piping system............................................................................................. 6

2.5 Selection chart ........................................................................................... 7

3. ELECTRICAL DATA ......................................................................................... 8

3.1 Electrical wiring ......................................................................................... 8

4. OUTLINE OF OPERATION CONTROL BY MICROCOMPUTER .................... 9

4.1 Operation control function by remote control switch ............................ 9

4.2 Unit ON/OFF button ................................................................................. 10

4.3 Power blackout auto restart function .................................................... 11

4.4 Custom cord switching procedure......................................................... 11

4.5 Flap and louver control ........................................................................... 12

4.6 3D auto operation .................................................................................... 12

4.7 Timer operation ........................................................................................ 13

4.8 Installation location setting .................................................................... 14

4.9 Outline of cooling operation ................................................................... 15

4.10 Outline of dehumidifying operation ....................................................... 16

4.11 Outline of automatic operation ............................................................... 17

4.12 Outline of fan operation .......................................................................... 17

4.13 Outline of clean operation....................................................................... 17

4.14 Protective control function ..................................................................... 18

5. APPLICATION DATA ...................................................................................... 19

5.1 Selection of location for installation ...................................................... 20

5.2 Installation of indoor unit ........................................................................ 21

5.3 Installation of outdoor unit ..................................................................... 24

5.4 Connection of refrigerant pipings .......................................................... 24

5.5 Installation of remote control switch ..................................................... 25

5.6 Earthing work ........................................................................................... 25

5.7 Test run ...................................................................................................... 26

5.8 Precautions for wireless remote control installation and

operation................................................................................................... 26

6. MAINTENANCE DATA.................................................................................... 27

6.1 Trouble shooting ...................................................................................... 27

6.2 Servicing ................................................................................................... 30

-

-

1

Page 4

1 GENERAL INFORMATION

1.1 Specific features

The “MITSUBISHI HEAVY INDUSTRIES, LTD.” room air-conditioner: SRK series are of split and wall mounted type and the unit

consists of indoor unit and outdoor unit with refrigerant precharged in factory. The indoor unit is composed of room air cooling equip-

ment with operation control switch and the outdoor unit is composed of condensing unit with compressor.

(1) Remote control flap & louver

The flap & louver can be automatically controlled by operating wireless remote control.

¡ Flap swing : The flaps swing up and down successively.

¡ Louver swing : The louvers swing left and right successively.

¡ 3D auto operation : Fan speed and air flow direction are automatically controlled, allowing the entire room to be

efficiently conditioned.

¡ Memory flap : Once the flap & louver position is set, the unit memorizes the position and continues to operate

at the same position from the next time.

(2) Automatic operation

When the remote control switch is set on “auto(

thermal dry, or operate in the operation mode before it has been turned to automatic control.

(3) Self diagnosis function

¡ We are constantly trying to do better service to our customers by installing such judges that show abnormality of operation as

follows.

) ”, it will either automatically decide operation mode such as cooling and

TIMER light

ON

1 time flash

2 time flash

6 time flash

Heat exchanger sensor error

Room temperature sensor error

Indoor fan motor error

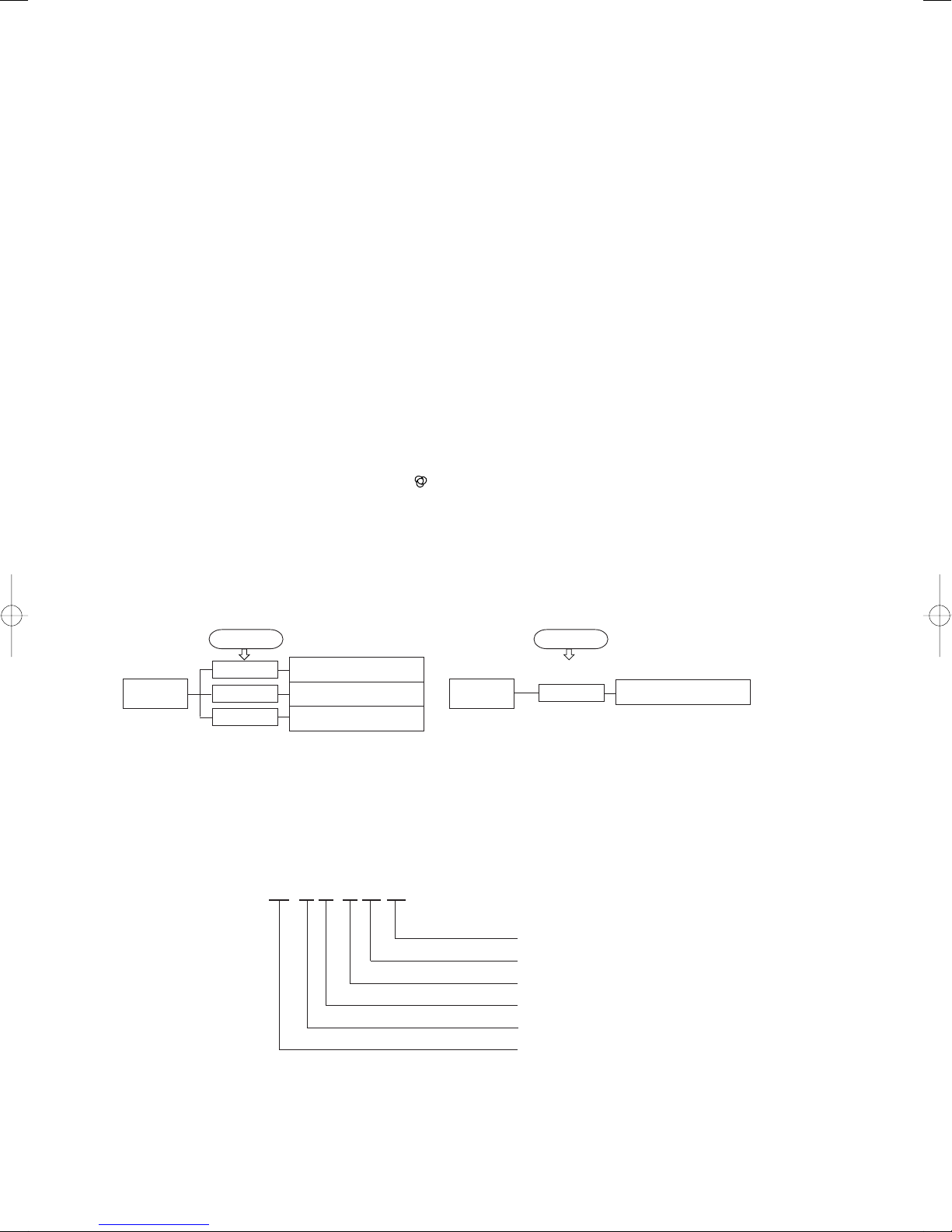

1.2 How to read the model name

Example : SR K 10 C FV -4

RUN light

ON

TIMER lightRUN light

2 time flash

Trouble of outdoor unit

For Asia

Series No.

Cooling only type

Product capacity

Wall mounted type

Split type room air-conditioner

-

-

2

Page 5

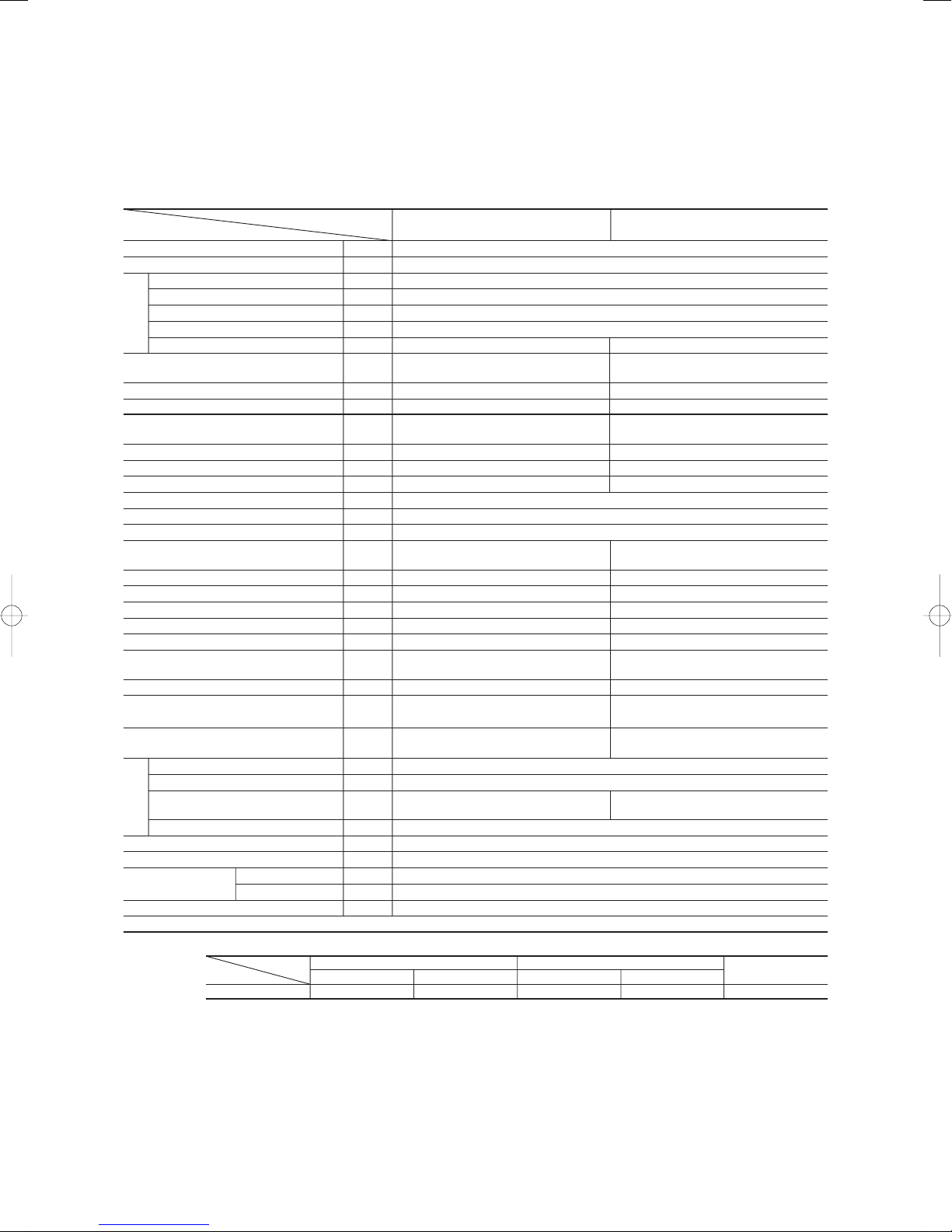

2 SELECTION DATA

2.1 Specifications

Model SRK10CFV-4 (Indoor unit)

Item

Cooling capacity

Power source 1 Phase, 220V, 50Hz

(1)

Operation

data

Exterior dimensions

Color Fine snow Stucco white

Net weight kg 8.5 30

Refrigerant equipment

Compressor types & Q’ty

Heat exchanger Louver fins & inner grooved tubing Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Refrigerant

Refrigerant oil R 0.35 (SUNISO 4GSI or ATMOS NM56)

Air handling equipment

Fan type & Q’ty

Air flow (at High) CMM 9.0 26.5

Air filter, Q’ty Polypropylene net (washable) × 2–

Shock & vibration absorber – Cushion rubber (for compressor)

Electric heater ––

Operation control

Operation switch

Room temperature control Microcomputer thermostat –

Pilot lamp RUN (Green), TIMER (Yellow),

Safety equipment Frost protection,

Refrigerant

piping

Drain hose Connectable

Power source cord 2.5 m (3 cores with Earth)

Connection

wiring

Accessories (included) Mounting kit

Optional parts –

Notes (1) The data are measured at the following conditions.

SRC10CFV-4 (Outdoor unit)

Model

(1)

Cooling input kW 0.73

Running current (Cooling) A 3.4

Inrush current A 18

COP (In cooling) 3.62

Noise level

Height × Width × Depth

Motor kW – 0.69

Starting method – Line starting

Motor W 16 14

O.D mm (in) Liquid line: ø6.35 (1/4") Gas line: ø9.52 (3/8")

Connecting method Flare connecting

Attached length of piping Liquid line: 0.4 m

Insulation Necessary (Both sides)

(4)

(3)

Size × Core number 1.5 mm2 × 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Item Indoor air temperature Outdoor air temperature

Operation DB WB DB WB

Cooling 27°C19°C35°C24°C ISO-T1, JIS C9612

(2) The operation data are applied to the 220 V districts respectively.

(3) The refrigerant quantity to be charged includes the refrigerant in 7.5 m connecting piping.

(Purging is not required even in the short piping.)

If the piping length is longer, when it is 7.5 to 15 m, add 10 g refrigerant per meter.

(4) Expressed in sound pressure level.

BTU 9000

dB 39 45

mm 268 × 790 × 199 540 × 780 × 290

kg R22 0.9 (Pre-Charged up to the piping length of 7.5m)

HI POWER (Green), 3D AUTO (Green)

SRK10CFV-4 SRC10CFV-4

–

Tangential fan × 1 Propeller fan × 1

Wireless-Remote control –

Fan motor error protection

Gas line : 0.33 m

RSA201A018

Internal thermostat (for compressor)

(220V)

–

–

Standards

-

-

3

Page 6

Model SRK13CFV-4 (Indoor unit)

SRC13CFV-4 (Outdoor unit)

(220V)

Item

Cooling capacity

Power source 1 Phase, 220V, 50Hz

Cooling input kW 1.06

Running current (Cooling) A 4.9

(1)

Inrush current A 29

COP (In cooling) 3.45

Operation

data

Noise level

Exterior dimensions

Height × Width × Depth

Color Fine snow Stucco white

Net weight kg 8.5 37

Refrigerant equipment

Compressor types & Q’ty

Motor kW – 1.09

Starting method – Line starting

Heat exchanger Louver fins & inner grooved tubing Straight fins & inner grooved tubing

Refrigerant control Capillary tubes

Refrigerant

Refrigerant oil R 0.41 (SUNISO 4GSI or ATMOS NM56)

Air handling equipment

Fan type & Q’ty

Motor W 16 22

Air flow (at High) CMM 9.5 29.5

Air filter, Q’ty Polypropylene net (washable) × 2–

Shock & vibration absorber – Cushion rubber (for compressor)

Electric heater ––

Operation control

Operation switch

Room temperature control Microcomputer thermostat –

Pilot lamp RUN (Green), TIMER (Yellow),

Safety equipment Frost protection,

O.D mm (in) Liquid line: ø6.35 (1/4") Gas line: ø12.7 (1/2")

Connecting method Flare connecting

Attached length of piping Liquid line: 0.4 m

Refrigerant

piping

Insulation Necessary (Both sides)

Drain hose Connectable

Power source cord 2.5 m (3 cores with Earth)

Connection

wiring

Accessories (included) Mounting kit

Optional parts –

Notes (1) The data are measured at the following conditions.

(1)

(4)

(3)

Size × Core number 1.5 mm2 × 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Item Indoor air temperature Outdoor air temperature

Operation DB WB DB WB

Cooling 27°C19°C35°C24°C ISO-T1, JIS C9612

(2) The operation data are applied to the 220 V districts respectively.

(3) The refrigerant quantity to be charged includes the refrigerant in 7.5 m connecting piping.

(Purging is not required even in the short piping.)

If the piping length is longer, when it is 7.5 to 15 m, add 10 g refrigerant per meter.

(4) Expressed in sound pressure level.

Model

BTU 12500

dB 40 49

mm 268 × 790 × 199 540 × 780 × 290

kg R22 0.93 (Pre-Charged up to the piping length of 7.5m)

HI POWER (Green), 3D AUTO (Green)

SRK13CFV-4 SRC13CFV-4

–

Tangential fan × 1 Propeller fan × 1

Wireless-Remote control –

Fan motor error protection

Gas line : 0.33 m

RSA201A017

Internal thermostat (for compressor)

–

–

Standards

-

-

4

Page 7

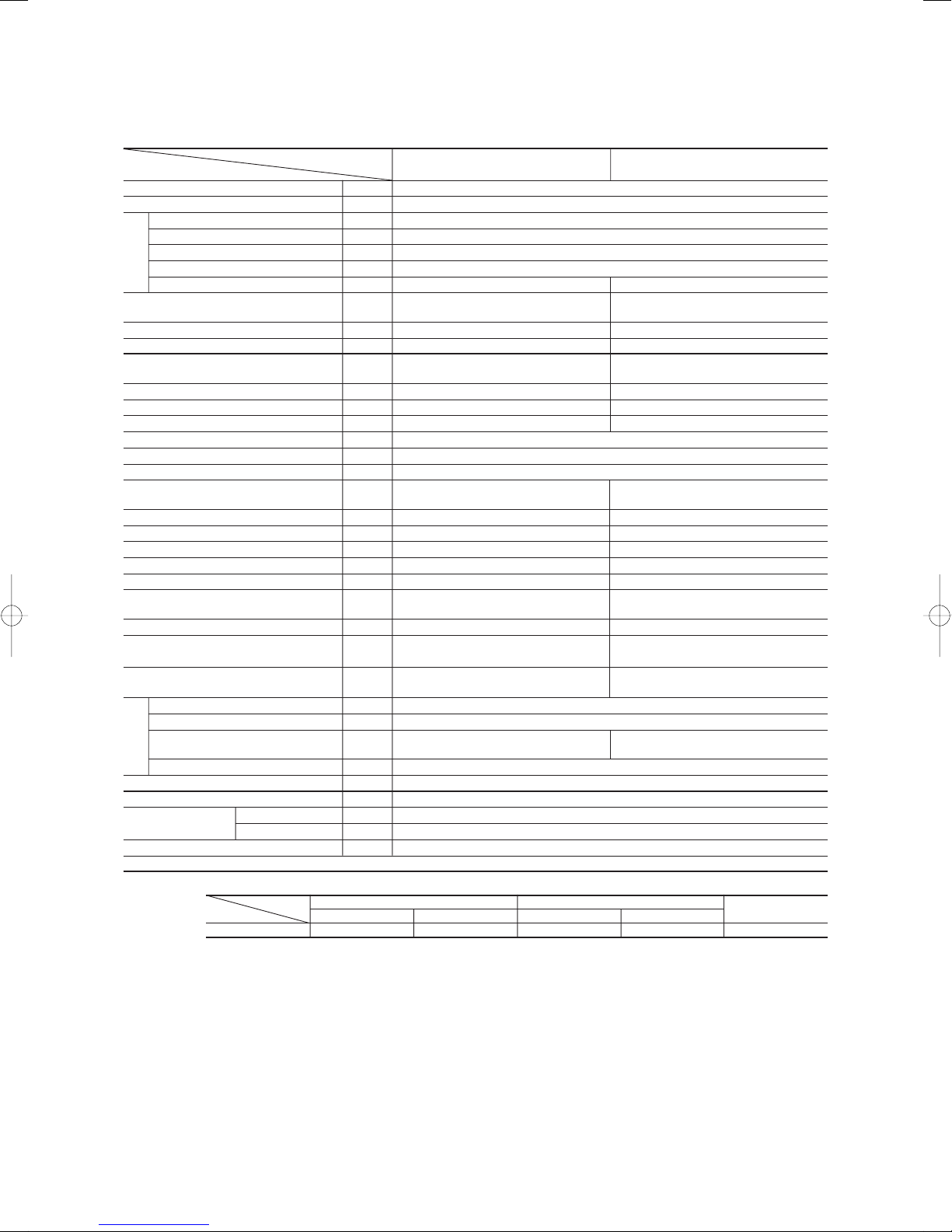

2.2 Range of usage & limitations

Indoor return air temperature

(Upper, lower limits)

Refrigerant line (one way) length Max. 15m

All models

Refer to the selection chart

Power source voltage Rating ± 10%

Voltage at starting Min. 85% of rating

Frequency of ON-OFF cycle Max. 10 times/h

ON and OFF interval Max. 3 minutes

Outdoor air temperature

(Upper, lower limits)

Vertical height difference between

outdoor unit and indoor unit

Max. 5m (Outdoor unit is higher)

Max. 5m (Outdoor unit is lower)

Item

Models

Piping hole (ø65)

( )

Piping hole (ø65)

53.5

380.6

Pipng for Liquid 448.6 (ø6.35)

10 :ø9.52

13 :ø12.7

Pipng for Gas

Drain hose 520 (ø16)

53.5

44.5

252.2

7.5

8.3

102.5

585

102.5

133.5450206.5

202450138

44.5

43.2

39.3

200

45

45

60

17.5

60

27

788

60

9

45

199

3

Terminal block

Piping hole right(left)

268

790

A

VIEW A

→

2.3 Exterior dimensions

(1) Indoor unit

Models SRK10CFV-4, 13CFV-4

Unit: mm

-

-

5

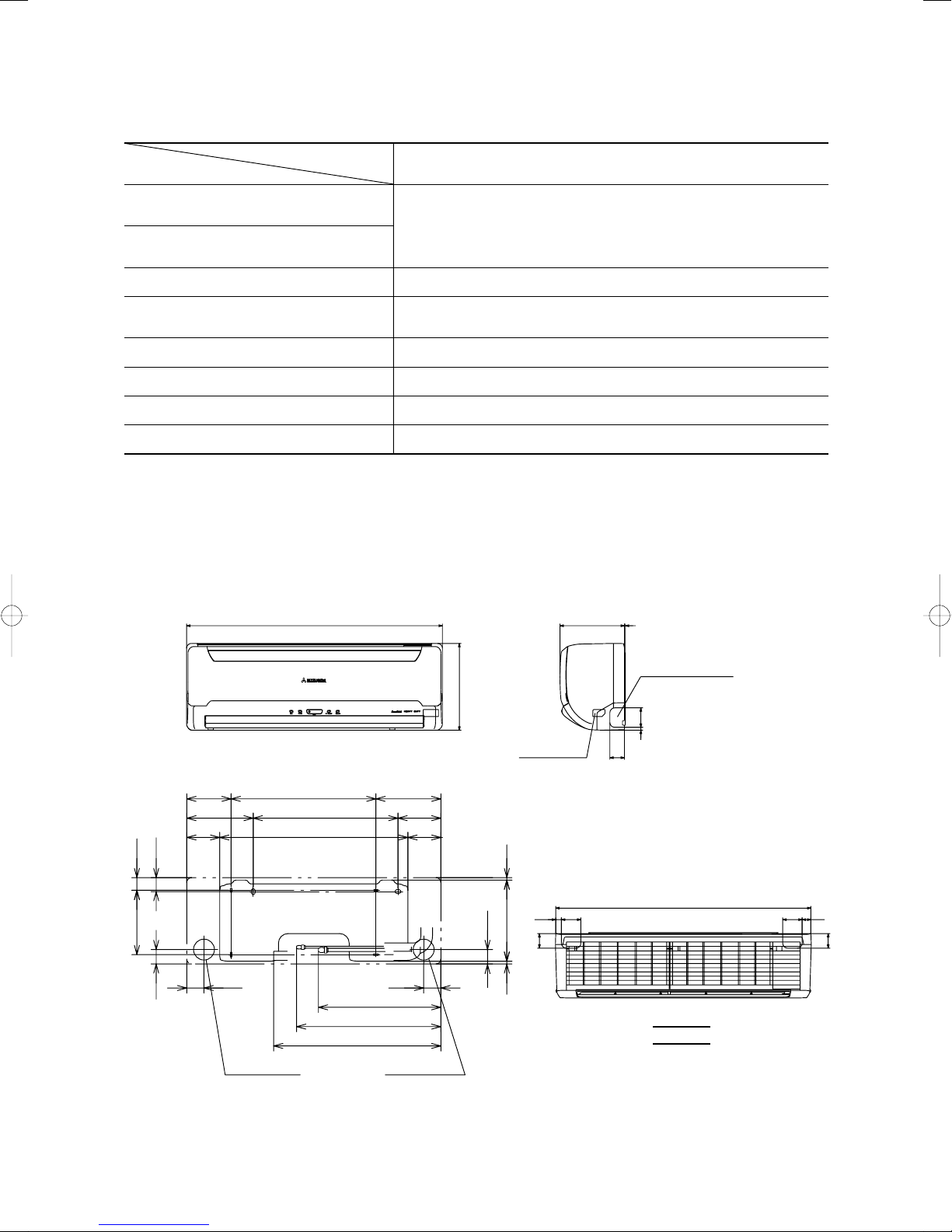

Page 8

(2) Outdoor unit

Outdoor unitIndoor unit

Terminal block

10: ø9.52 (3/8")

13: ø12.7 (1/2")

ø6.35 (1/4")

Flare connecting

Service valve (Gas)

Service valve (Liquid)

Flare connecting

Drain holes

2-16×12

138.4

40°

61.9

18.9165.1510104.9

439.1

111.4

99.4

349.5

313.1

43.1

290

12

50

350

23.5312.514

33.5

40°

42.595.9

14

540

780

Models SRC10CFV-4, 13CFV-S

Unit: mm

2.4 Piping system

Models All models

Room temp.

sensor

Heat

exchanger

Flare connecting

Flare connecting

10 : ø9.52

( )

13 : ø12.7

Heat

exchanger

sensor

Piping

(Gas)

Piping

(Liquid)

ø6.35

Service valve

(Gas)

Check joint

Service valve (Liquid)

-

6

Capillary tube

-

Compressor

Capillary tube

Cooling cycle

Accumulator

Heat

exchanger

Page 9

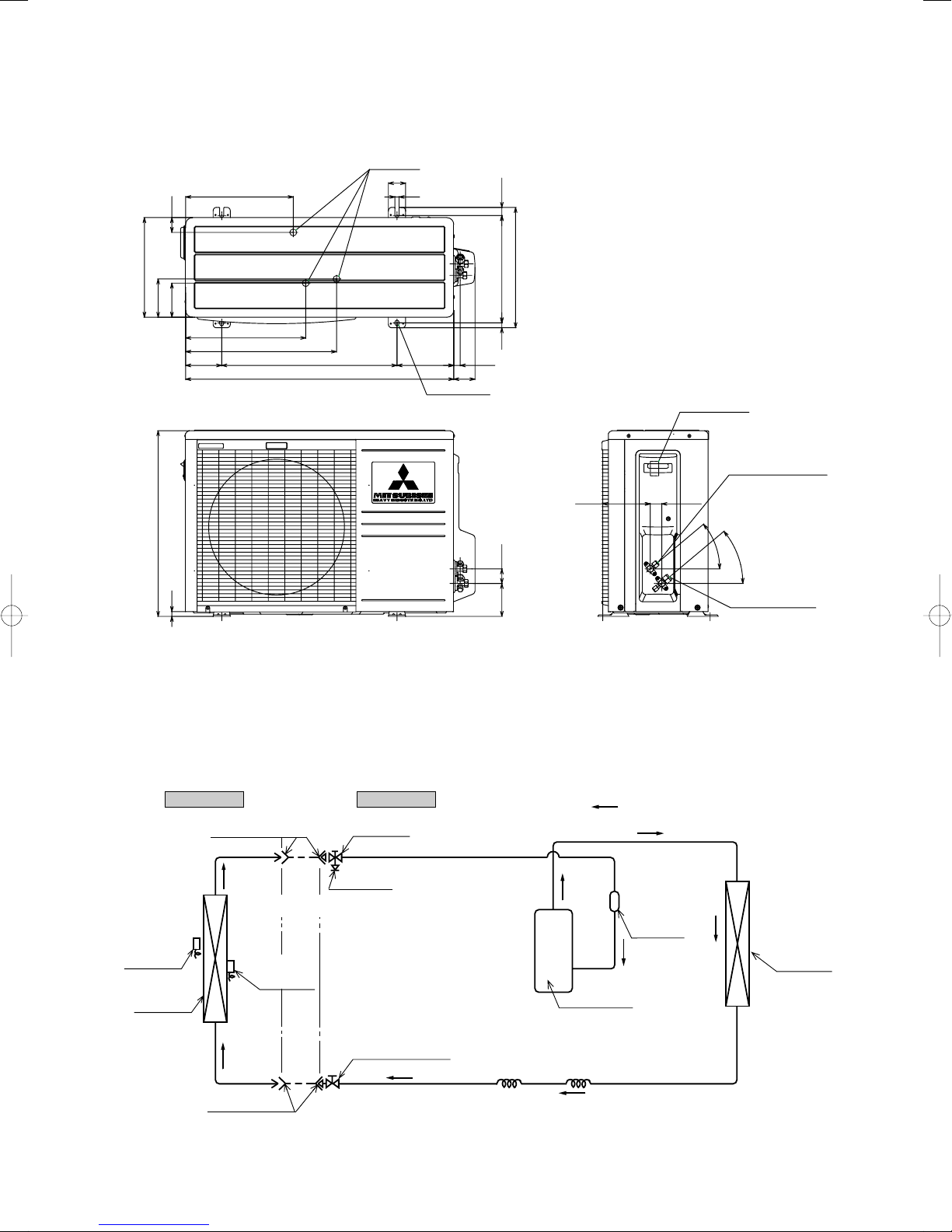

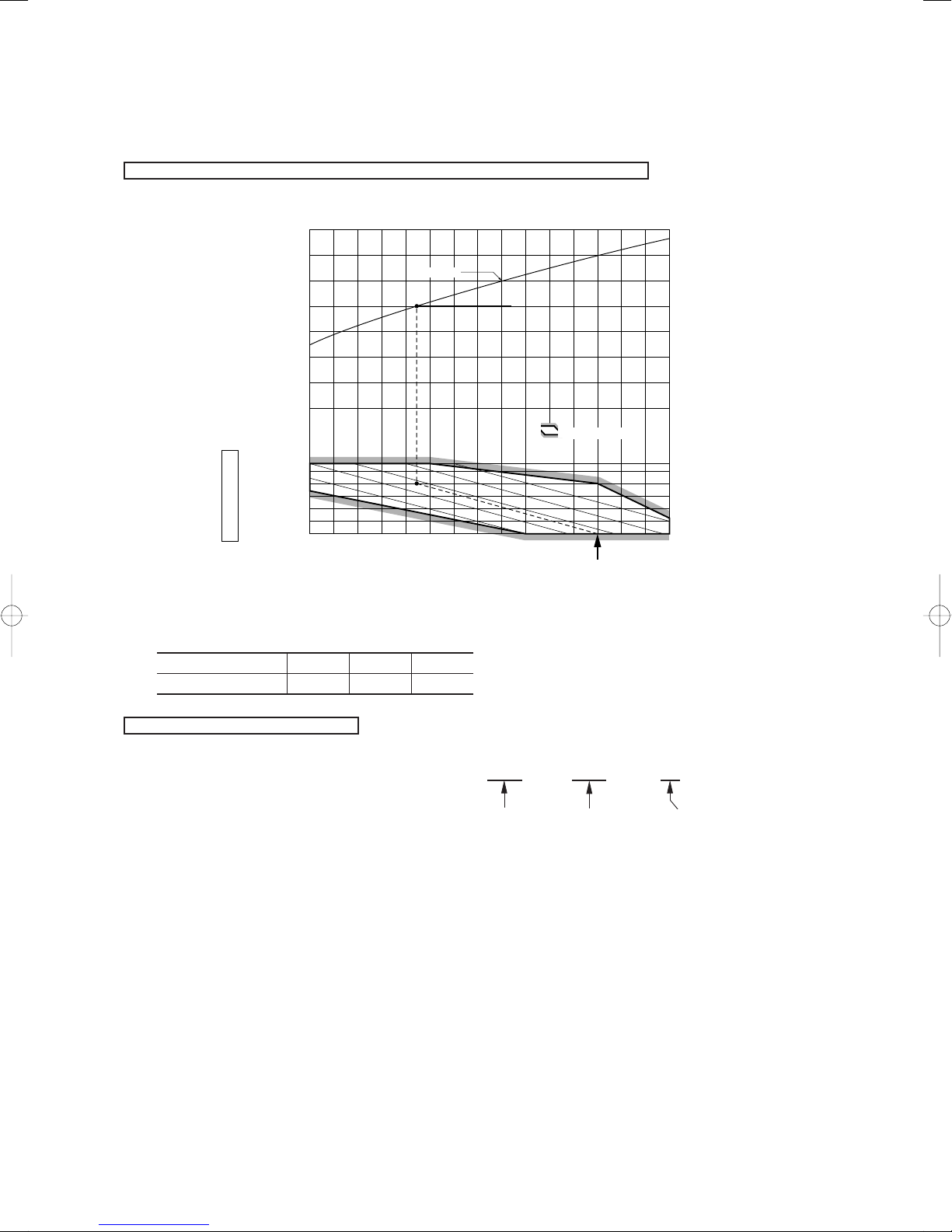

2.5 Selection chart

14 16 18 20 22

15

20

25

30

35

40

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

43

24

ISO-T1 Standard ConditionIndoor air W.B. temperature °C W.B.

Cooling

Applicable range

Coefficient of cooling

capacity in relation

to temperature

Cooling operation

Outdoor air D.B.

temperature

°C D.B.

Piping length [m]

Cooling

7

1.0

10

0.99

15

0.975

Correct the cooling capacity in accordance with the conditions as follows. The net cooling capacity can be obtained in the following way.

Net capacity = Capacity shown on specification ✕ Correction factors as follows.

(1) Coefficient of cooling capacity in relation to temperatures

(2) Correction of cooling capacity in relation to one way length of refrigerant piping

It is necessary to correct the cooling capacity in relation to the one way piping length between the indoor and outdoor units.

How to obtain the cooling capacity

Example : The net cooling capacity of the model SRK13CFV-4 with the piping length of 15m, indoor wet-bulb temperature at 19.0˚C

and outdoor dry-bulb temperature 35˚C is Net cooling capacity = 12500 ✕ 0.975 ✕ 1.0 = 12187 BTU

SRK13CFV-4 Length 15m

Factor by air

temperatures

-

-

7

Page 10

-

8

-

CM

51C

FMo

FM

I

SM

LM1

LM2

BK

BK

Th1

Th2

BKBLLB

Y/GN

Y/GN

TT

BK

BKWH

WH

WHWH BRBR

RD

WH

Y

WH

WH

WH

RD

WH

BK

L2

2

3

1

L3

L1

Sh

CFo

CF

I

ZNR

CONTROL BOX

Printed circuit board

Power source

220V 50Hz

F

(250V 3.15A)

Cc

OR

OR

Outdoor unit

Indoor unit

1

2

~

~

1

2

Wireless

Display

CNE

CNY

CNX

CNM

CNW

52C3N

52C

52C4

1

5

3

CNU

CNG

Back up Sw

R-Amp

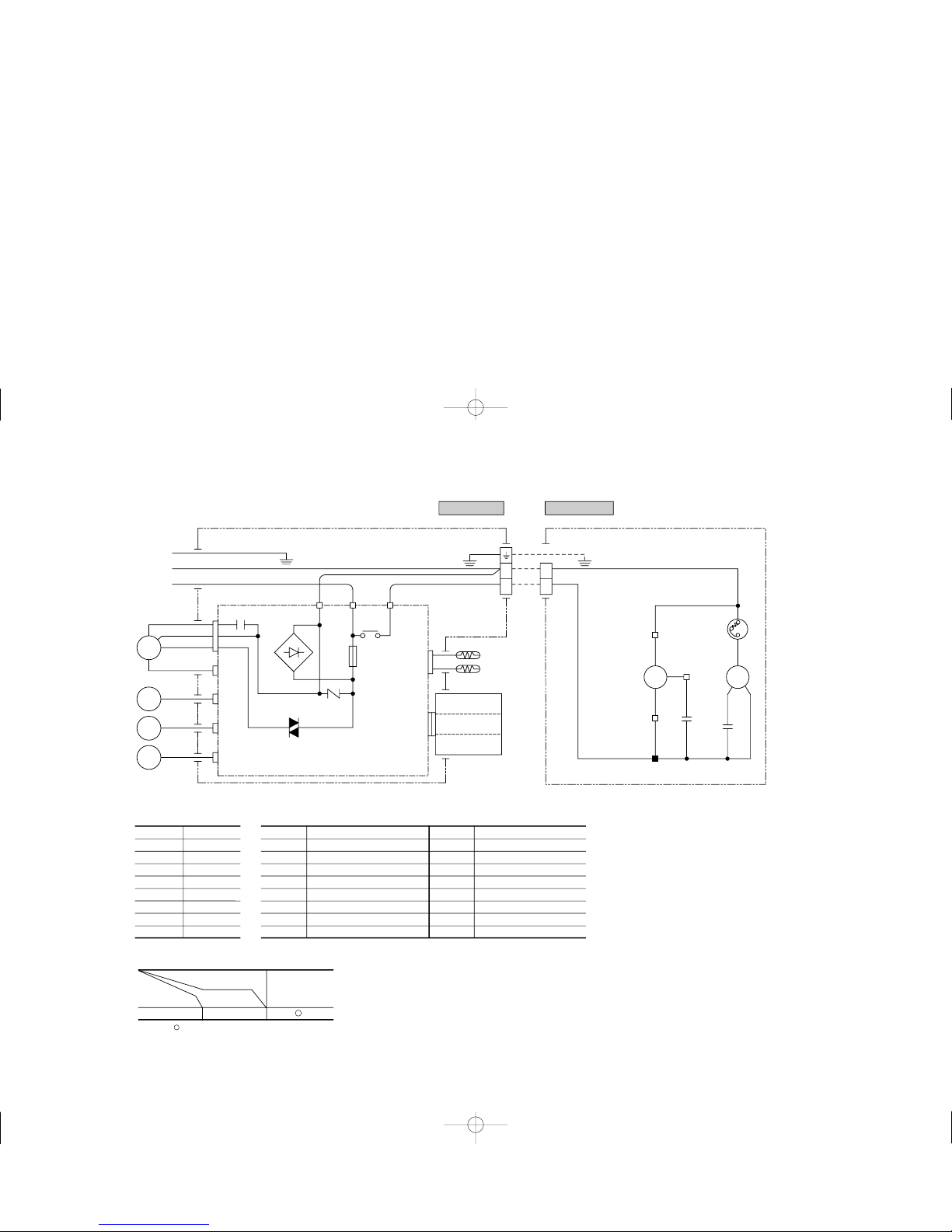

BK Black

BL Blue

BR Brown

LB Light blue

Y Yellow

RD Red

OR Orange

WH White

Y/G Yellow/Green

Color symbol

Symbol

Parts name Symbol Parts name

C

C

Capacitor for CM

SM Flap motor

CF

I

Capacitor for FM

I

Th

1

,

2

Sensor

LM

1

,

2

Louver motor

CF

O

Capacitor for FM

O

T Terminal block

CM Compressor motor

ZNR Varistor

F Fuse

51C Motor protector for CM

FM

I

Fan motor (Indoor unit)

52C Magnetic contactor for CM

FM

O

Fan motor (Outdoor unit)

Meaning of marks

Notes (1) : denotes magnetized relay

×

: denotes demagnetized relay

(2) Th

1

is room temperature sensor. Th2 (the heat exchanger sensor) is frost prevention sensor.

Operation

Cooling

Relay symbol Control part

52C CM

Table of relay operations

3 ELECTRICAL DATA

3.1 Electrical wiring

Models SRK10CFV-4, 13CFV-4

Page 11

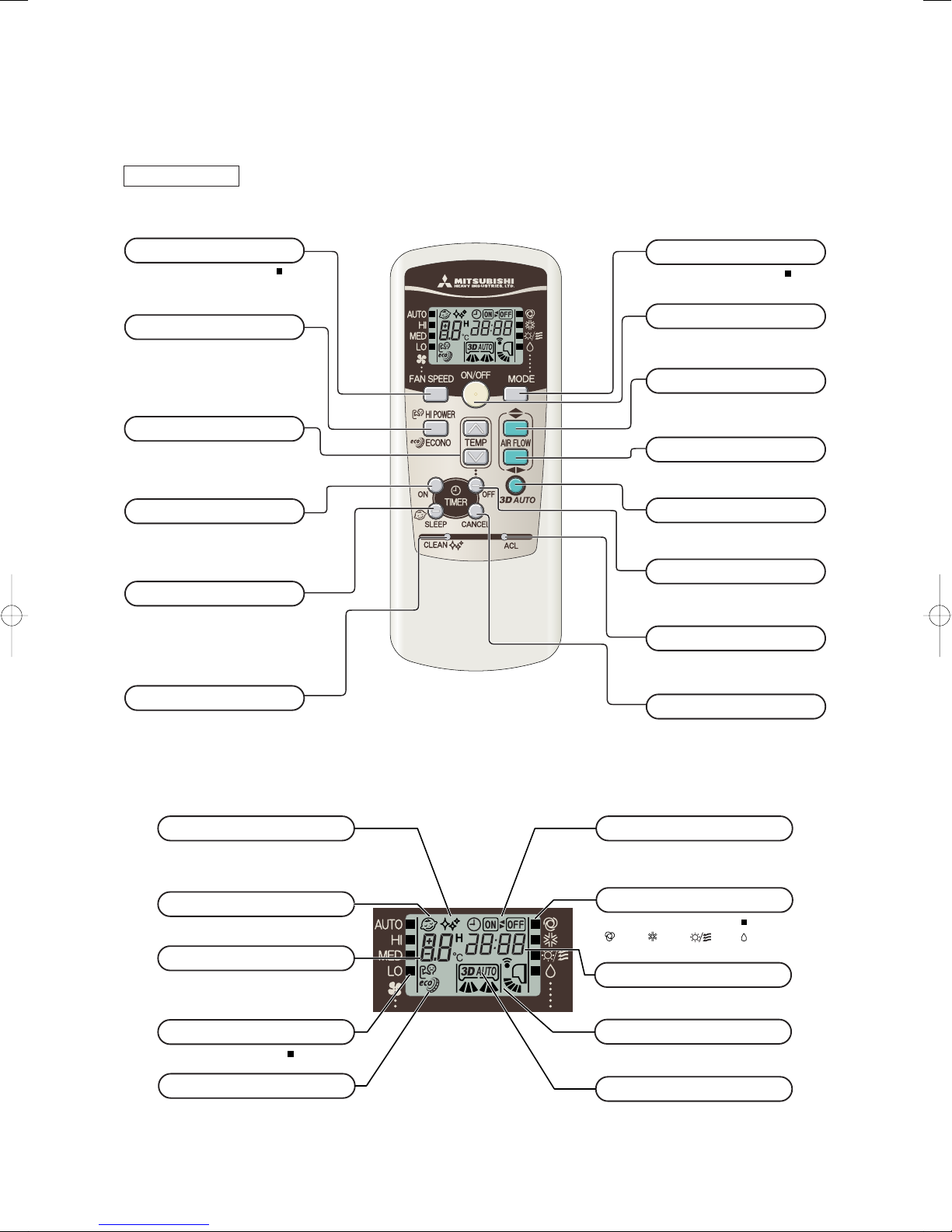

4 OUTLINE OF OPERATION CONTROL BY MICROCOMPUTER

FAN SPEED button

Each time the button is pushed, the

indicator is switched over in turn.

•

The above illustration shows all controls, but in practice

only the relevant parts are shown.

OPERATION MODE select button

Each time the button pushed, the

indicator is switched over in turn.

ON/OFF (luminous) button

Press for starting operation, press again

for stopping.

HI POWER/ECONO button

This button changes the HIGH POWER/

ECONOMY mode.

AIR FLOW (UP/DOWN) button

This button changes the air flow (up/down) mode.

This button changes the air flow (left/right) mode.

SLEEP button

This button changes to SLEEP operation.

CLEAN switch

This switch changes the CLEAN mode.

ON TIMER button

This button selects ON TIMER operation.

AIR FLOW (LEFT/RIGHT) button

3D AUTO button

This button sets 3D AUTO operation.

This button cancels the ON timer, OFF

timer, and SLEEP operation.

CANCEL button

RESET switch

Switch for resetting microcomputer and

setting time.

SLEEP indicator

Indicates during SLEEP operation.

TEMPERATURE indicator

Indicates set temperature.

(Does not indicate temperature when operation

mode is on AUTO)

FAN SPEED indicator

Indicates set air flow rate with lamp.

CLEAN indicator

Indicates during CLEAN operation.

ON/OFF TIMER indicator

Indicates during ON/OFF TIMER operation.

AIR FLOW indicator

Shows selected flap and louver mode.

3D AUTO indicator

Indicates during 3D AUTO operation.

HI POWER/ECONO MODE indicator

Indicates during HIGH POWER/ECONOMY

mode operation.

[

OPERATION MODE indicator

Indicates selected operation with lamp.

(Auto)•(Cool)• (Fan) •(Dry)]

OFF TIMER button

This button selects OFF TIMER operation.

TEMPERATURE button

This button sets the room temperature.

(This button changes the present time and

TIMER time.)

TIME indicator

Indicates present time or timer setting time.

4.1 Operation control function by remote control switch

Remote control

Models SRK10CFV-4, 13CFV-4

◆ Operation selection

◆ Indication selection

-

-

9

Page 12

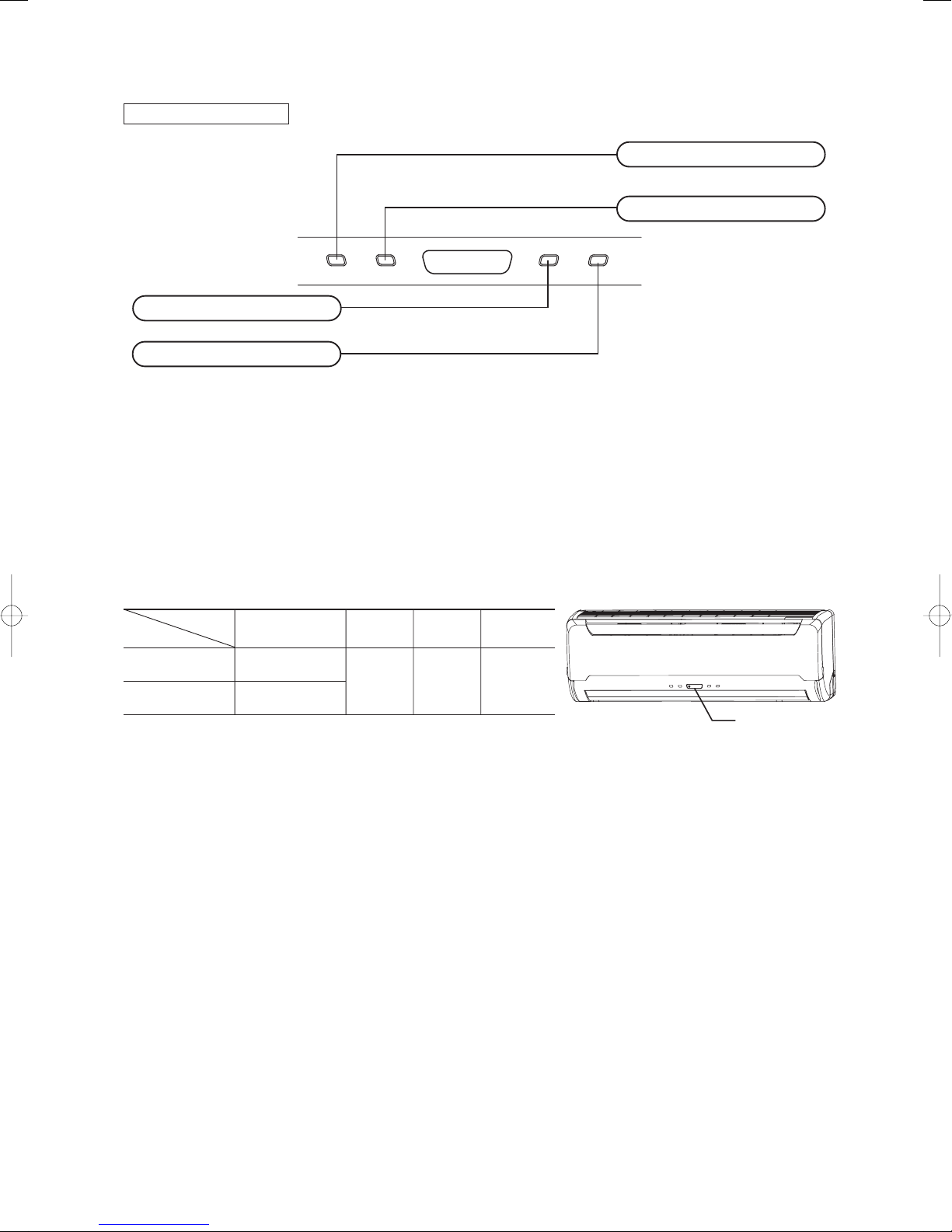

Unit indication selection

3D AUTO light (green)

Illuminates during 3D AUTO operation.

HI POWER light (green)

Illuminates during HIGH POWER operation.

RUN light (green)

Illuminates during operation

and CLEAN operation.

TIMER light (yellow)

Illuminates during TIMER operation.

ECONO light (orange)

Illuminates during ECONOMY operation.

RUN light (green)

Illuminates during operation

and CLEAN operation.

TIMER light (yellow)

Illuminates during TIMER operation.

RUN TIMER

ON / OFF

HI POWER 3D AUTO

RUN TIMER

ON / OFF

HI POWER ECONO

HI POWER light (green)

Illuminates during HIGH POWER operation.

Unit ON/OFF button

Models SRK10CFV-4, 13CFV-4

Models SRK10CFV, 13CFV

4.2 Unit ON/OFF button

When the remote control batteries become weak, or if the remote control is lost or malfunctioning, this button may be used to turn the

unit on and off.

(1) Operation

Push the button once to place the unit in the automatic mode. Push it once more to turn the unit off.

(2) Details of operation

The unit will go into the automatic mode in which it automatically determines, from room temperature (as detected by sensor),

whether to go into the cooling or thermal dry modes.

Function

Operation mode

Room temperature

setting

Fan speed Flap

Timer switch

Cooling About 24ºC

Thermal dry About 24ºC

Auto Auto

Continuous

-

10

-

Page 13

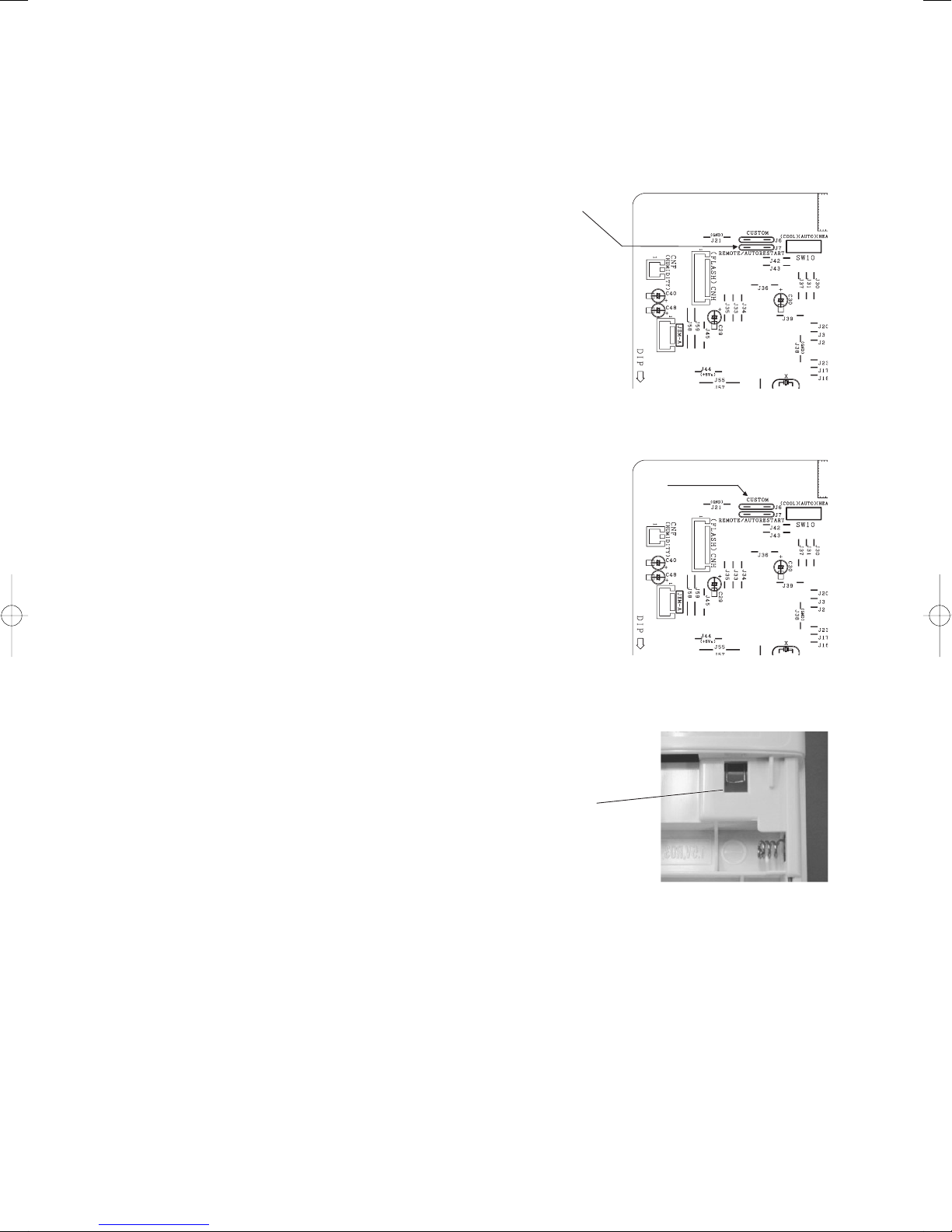

4.3 Power blackout auto restart function

(1) Power blackout auto restart function is a function that records the operational status of the air-conditioner immediately prior to it

being switched off by a power cut, and then automatically resumes operations at that point after the power has been restored.

(2) The following settings will be cancelled:

(a) Timer settings

Jumper wire (J7)

(b) High-power operations

Notes (1) The power blackout auto restart function is set at on when the air-conditioner is shipped from the

factory. Consult with your dealer if this function needs to be switched off.

(2) When power failure ocurrs, the timer setting is cancelled. Once power is resumed, reset the timer.

(3)

If the jumper wire (J7) “AUTO RESTART” is cut, auto restart is disabled. (See the diagram at right)

4.4 Custom cord switching procedure

If two wireless remote controls are installed in one room, in order to prevent wrong operation

due to mixed signals, please modify the printed circuit board in the indoor unit’s control box

and the remote control using the following procedure. Be sure to modify both boards. If only

one board is modified, receiving (and operation) cannot be done.

(1) Modifying the indoor unit’s printed circuit board

Take out the printed circuit board from the control box and cut off jumper wire (J6)

using wire cutters.

After cutting of the jumper wire, take measures to prevent contact with the other the lead

wires, etc.

Jumper wire (J6)

(2) Modifying the wireless remote control

(a) Remove the battery.

(b) Cut the jumper wire shown in the figure at right.

-

11

Cut

-

Page 14

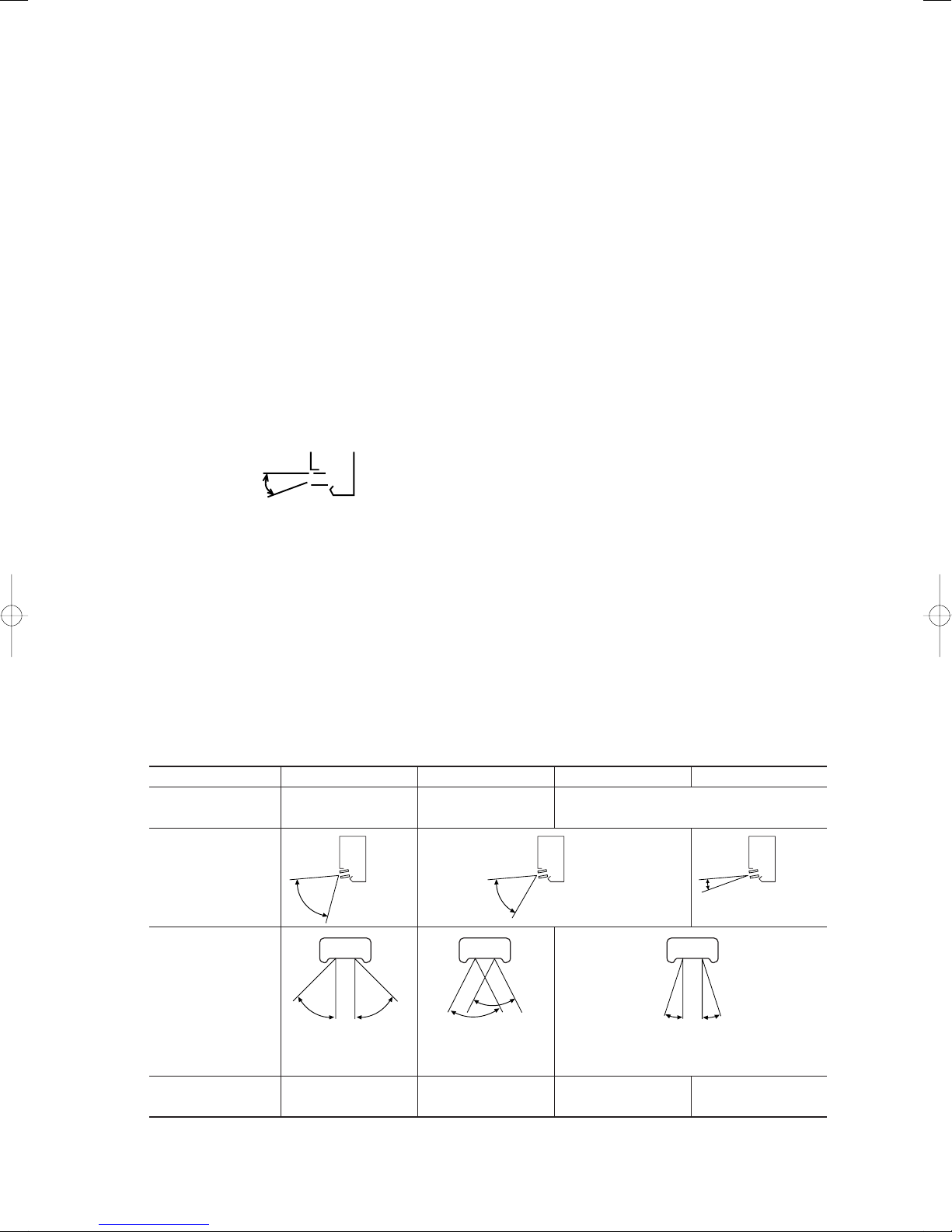

4.5 Flap and louver control

Operation step

Flap

Louver

Conditions for

jumping to next STEP

Fan speed Setting fan speed

_

20 cycle 60 cycle 60 cycle

Auto : HIGH POWER

Other than Auto: Setting fan speed

Setting fan speed

STEP1 STEP2 STEP3 STEP4

Left louver

The left louver and right louver

operate in the same direction

left and right.

The left louver and right louver

operate in opposite directions to

each other on the left and right sides.

The left louver and right louver operate in opposite directions to

each other on the left and right sides.

Right louver

Left louver Right louver

Left louver Right louver

Control the flap and louver by AIRFLOW

(1) Swing flap

Flap moves in upward and downward directions continuously.

(2) Swing louver

Louver moves in left and right directions continuously.

(3) When not operating

The flap returns to the position of air flow directly below, when operation has stopped.

(4) Memory flap (Flap or Louver stopped)

When you press the AIRFLOW (UP/DOWN or LEFT/RIGHT) button once while the flap or louver is operating, it stops swinging

at an angle. Since this angle is memorized in the microcomputer, the flap or louver will automatically be set at this angle when the

next operation is started.

¡ Recommendable stopping angle of the flap

(UP/DOWN) and

(LEFT/RIGHT) button on the wireless remote control.

COOL•DRY

4.6 3D auto operation

Control the flap and louver by 3D AUTO button on the wireless remote control.

Fan speed and air flow direction are automatically controlled, allowing the entire room to efficiently conditioned.

(1) Detail of operation

(a) Perform STEP1 → STEP2 → STEP3 → STEP4 one time.

(b) After performing STEP4 in (a) above, the next steps to be carried out are determined by the difference between the room

temperature and the setting temperature.

1) Room temperature – Setting temperature > 5ºC: STEP2 → STEP3 → STEP4 are performed.

2) Room temperature – Setting temperature

Horizontal

blowing

<

5ºC: STEP3 → STEP4 are performed.

=

-

-

12

Page 15

4.7 Timer operation

(1) Comfortable timer setting (ON timer)

If the timer is set at ON when the operation select switch is set at the cooling, or the cooling in auto mode operation is selected, the

comfortable timer starts and determines the starting time of next operation based on the initial value of 15 minutes and the relationship

between the room temperature at the setting time (temperature of room temperature sensor) and the setting temperature. (Max. 60

minutes)

Operation mode Operation start time correction value (Min.)

At cooling

Notes (1) At 5 minutes before the timer ON time, operation starts regardless of the temperature of the room temperature sensor (Th1).

(2) This function does not actuate when the operation select switch is set at the dehumidifying as well as the dehumidifying in the auto mode.

However, the operation of item (1) above is performed during the dehumidifying in the auto mode.

(3) During the comfortable timer operation, both the run light and timer light illuminate and the timer light goes off after expiration of the timer, ON setting time.

(Example) Cooling

3 < Room temp. – Setting temp. 1 < Room temp. – Setting temp.

+5 No change –5

<

3 Room temp. – Setting temp.

=

<

1

=

Room temperature

Setting temperature

Operation starting time

Time

15 min. 10 min. 5 min.

earlier earlier earlier

Corrects the starting time of next operation by

calculating the temperature difference.

¡ If the difference (= Room temperature – Setting tempera-

ture) is 4°C, the correction value is found to be +5 minutes from the table shown above so that the starting time

of next operation is determined as follows:

15 min. earlier + 5 min. = 20 min. earlier

↑↑

Current operation

Setting time

start time

Correction value

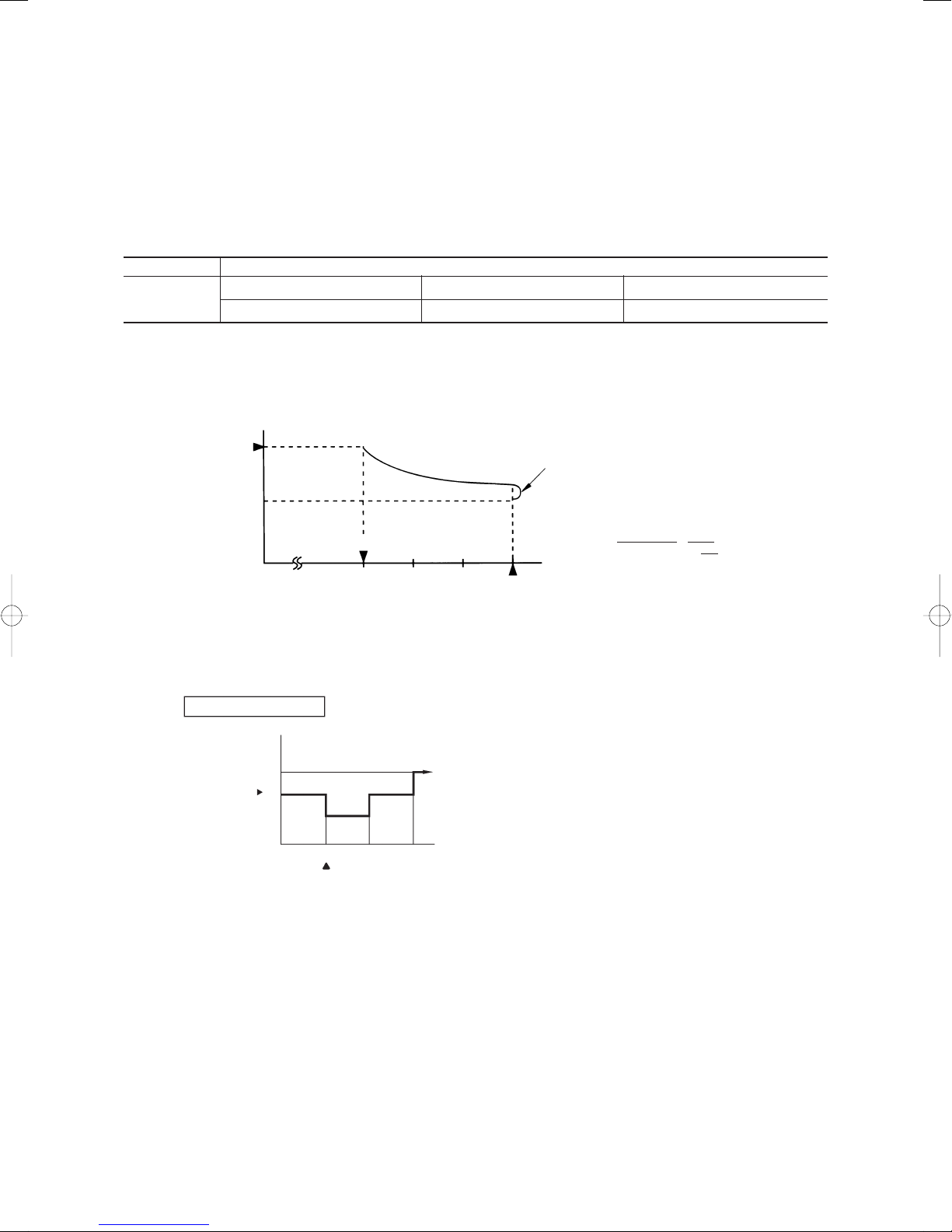

(2) Sleep timer operation

Pressing the SLEEP button causes the temperature to be controlled as shown in the following chart with respect to the set temperature.

Cooling, DRY

+

1.0

Temperature

setting (˚C)

Timer operation

(time)

0

-1.0

0 1.0 2.0

Start

(3) OFF timer operation

The Off timer can be set at a specific time (in 10-minute units) within a 24-hour period.

-

13

-

Page 16

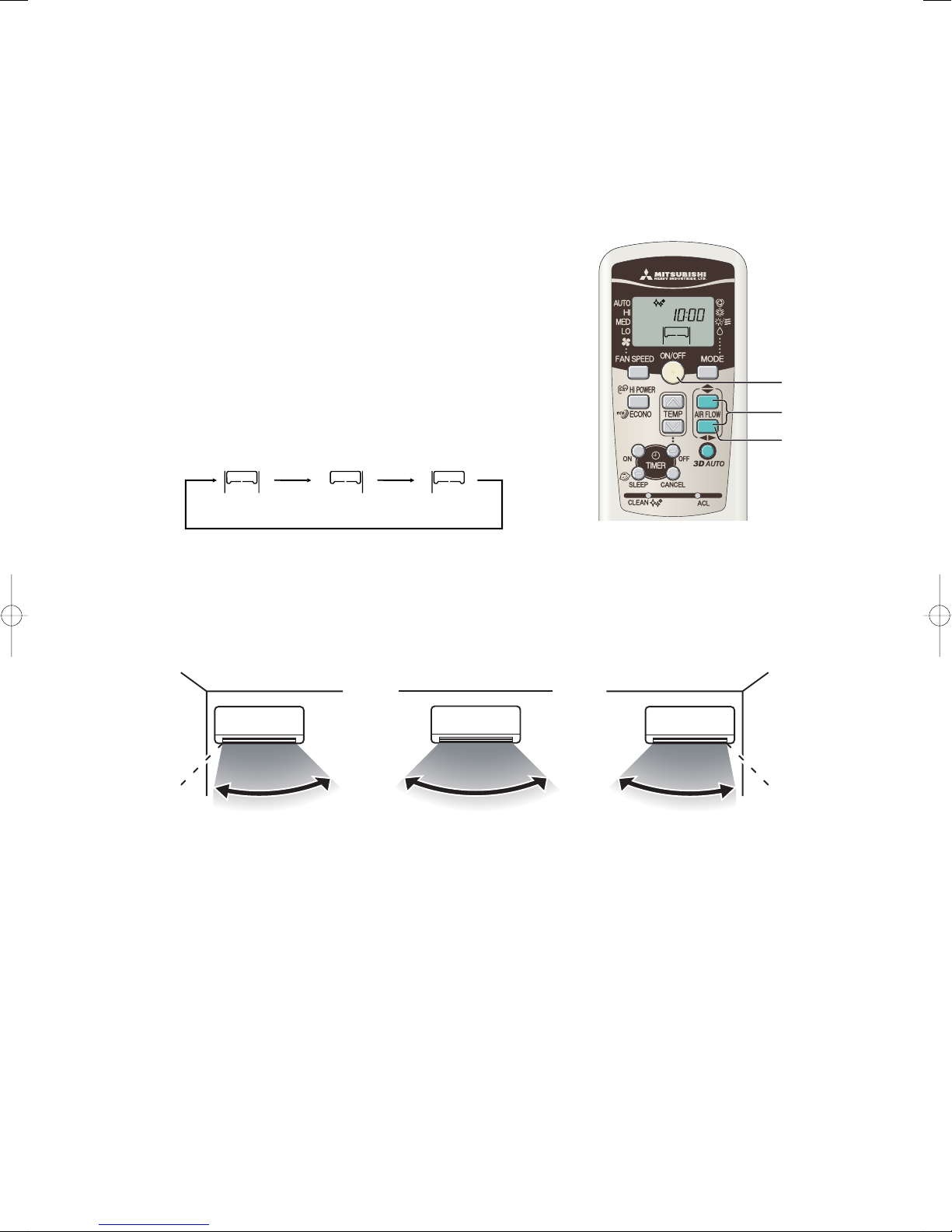

4.8 Installation location setting

Airflow range Airflow range Airflow range

(Left End Installation) (Center Installation) (Right End Installation)

1, 4

2

3

(Center Installation) (Right End Installation) (Left End Installation)

When the indoor unit is installed at the end of a room, control the air flow direction so that it is not toward the side walls. If you set the

remote control’s installation position, keep it so that the air flow is within the range shown in the following figure.

(1) Setting

1 If the air conditioning unit is running, press the ON/OFF button to stop.

The installation location setting cannot be made while the unit is running.

2 Press the AIR FLOW

AIRFLOW

or more.

The installation location display illuminates.

3 Setting the air-conditioning installation location.

Press the AIR FLOW

location.

Each time the AIR FLOW

indicator is switched in the order of:

4 Press the ON/OFF button.

The air-conditioner's installation location is set.

Press within 60 seconds of setting the installation location (while the

installation location setting display illuminates).

(LEFT/RIGHT) button together for 5 seconds

(UP/DOWN) button and the

(LEFT/RIGHT) button and adjust to the desired

(LEFT/RIGHT) button is pressed, the

-

14

-

Page 17

4.9 Outline of cooling operation

Indoor fan motor

Flap and louver

Display

52C

Outdoor fan motor

ON

ON or OFF

Lights up

OFF

OFF

ON

ON or OFF

Lights up

ON

ON

OFF

Stop position control

Lights up or flashes

OFF

OFF

When the compressor

command is OFF

When the compressor

command is ON

When the compressor goes

OFF due to an anomalous stop.

Functional

components

Item

Swing flap or louver

Swing stop

Auto fan control

Speed 5

Speed 5

Speed 3

Speed 3

AUTO HIGH MED

Speed 2

Speed 2

LOW

Flow control

Fan speed switching

Speed 4

Speed 3

Speed 2

Thermostat setting point

Speed 5

+1 +2 +3 +4

OFF

ON

Set temp.

-1

Room temp.

Compressor

Outdoor fan

Indoor unit fan

Outdoor unit fan

Compressor

Speed 6 fixed

ON

ON

Running time

Running start ~ 1 hour

1~2 hours

2 hours ~

Set temperature compensation

Set temperature +0.5

Set temperature +1.0

Set temperature +1.5

(1) Operation of major fanctinal components

(2) Fan speed switching

(a) Auto fan control

The indoor fan is automatically controlled in accordance with the difference between the room temperature (detected by the

room temperature sensor) and the termostat setting as shown below.

(3) Thermostat operation

The compressor and outdoor fan and turned on and off as shown below according to the temperature setting.

(4) HIGH POWER operation ( “HI POWER” button on the remote control : ON)

The following operation is performed for 15 minutes without relation to the set temperature or fan speed setting.

(5) ECONOMY operation ( “ECONO” button on the remote control : ON)

The set temperature changes as shown at right, and the

indoor unit fan speed is set on speed 2.

Notes (1) Room temperature is not adjusted during the HIGH POWER operation.

(2) Protective functions will actuate with priority even during the HIGH POWER

operation.

-

15

-

Page 18

4.10 Outline of dehumidifying operation

ON

OFF

OFF

0

3

6

912

ON

OFF

OFF

0

12

ON

OFF

OFF

0

4

8

ON

OFF

OFF

0

8

OFF

OFF

0

8

ON

OFF

OFF

0

3

8

Running time

Running start ~ 1 hour

1~2 hours

2 hours ~

Set temperature compensation

Set temperature +0.5

Set temperature +1.0

Set temperature +1.5

(1) Choose the appropriate operation block area by the difference between room temperature and thermostat setting temperature as

shown below.

¡ Operation block area

D Block C Block B Block A Block

–2 0 +3

Room temp. – Setting temp.(deg)

(2) Start up operation

Compressor

and

outdoor fan

Indoor fan

Speed 2

Speed 1

C.D Block

20

seconds

Compressor

and

outdoor fan

Indoor fan

A.B Block

Speed 2

minutes

Start Temperature check

Note (1) Thermostat operation is performed in A, B Block. When compressor and indoor fan stop by thermostat operation within 12 minutes from start, temperature

check is performed by operating indoor fan at speed 1 for 20 seconds before finishing 12 minutes and allowing decision of next operation block.

Start

Operation block decision

Temperature check

(3) DRY operation

After finishing start up operation described in (2) above, thermal dry operation is performed at 8 minutes intervals, according to the

difference between room temperature and thermostat setting temperature as shown below.

Beside, 1 cycle of this operating time consists of 8 minutes, 7 cycle operation is performed then.

Compressor

and

outdoor fan

Indoor fan

Compressor

and

outdoor fan

Indoor fan

D Block

Speed 1

20 seconds

minutes

Start Temperature check Start Temperature check

B Block

Speed 2

Speed 1

20 seconds

minutes

Start Temperature check Temperature check

Compressor

and

outdoor fan

Indoor fan

Compressor

and

outdoor fan

Indoor fan

C Block

Speed 2

Speed 1

Operation block decision

A Block

Speed 2

Start

20 seconds

minutes

minutes

minutes

(4) ECONOMY operation ( “ECONO” button on the remote control : ON)

The set temperature changes as shown at right, and the

indoor unit fan speed is set on speed 2.

Operation block decision

-

-

16

Page 19

4.11 Outline of automatic operation

52C

Indoor fan motor

Outdoor fan motor

Flap and louver

Speed 6 Speed 5 Speed 4

OFF

OFF

ON or OFF

Speed 3 Speed 2 Speed 1

HIGH

POWER

AUTO HIGH MED LOW ECONOMY

Functional

components

Fan speed switching

Indoor unit fan

Outdoor unit fan

Compressor

Speed 6 fixed

OFF

OFF

(1) Determination of operation mode

The blow operation of the indoor fan is carried out at the 1st speed for 20 seconds and the room temperature is checked to

determine the operation mode automatically. (When the unit is operated by the turn-on timer, the blow operation is not carried out.)

Room temperature<26°C26°C

<

Room temperature

=

Operation mode Dry Cooling

(2) Within 30 minutes after either auto or manual operation stops, if auto operation is started, or if you switch to auto operation during

manual operation, the system runs in the previous operation mode.

(3) The temperature is checked 1 time in 30 minutes after the start of operation, and if the judgment differs from the previous operation

mode, the operation mode changes.

(4) Setting temperature can be adjusted within the following range. There is the relationship as shown below between the signals of the

wireless remote control and the setting temperature.

Signals of wireless remote control (Display)

–6 –5 –4 –3 –2 –1 ±0+1+2+3+4+5+6

Setting Cooling 16 17 18 19 20 21 22 23 24 25 26 27 28

temperature Dehumidifying 17 18 19 20 21 22 23 24 25 26 27 28 29

4.12 Outline of fan operation

(1) Operation of major fanctional components

(2) HIGH POWER operation (“HI POWER” button on the remote control : ON)

The following operation is performed for 15 minutes without relation to the set fan speed.

4.13 Outline of clean operation

COOL,DRY,AUTO (COOL,DRY); after operation has stopped, the moisture inside the dryer air conditioner, controls the production of

fungus etc.

(1) Operating condition

‘Clean’ is switched ON, when the air conditioner receives a STOP signal.

(2) Detail of operation

Compressor OFF

Indoor fan motor Speed 1

Outdoor fan motor OFF

Flap and louver Fully closed

(3) Reset condition

When control finishes 120 minutes after the Clean operation starts. When the stop signal is received from the remote control.

Note (1) Protective functions will actuate with priority even during the HIGH POWER operation.

-

-

17

Page 20

4.14 Protective control function

(1) Frost prevention for indoor heat exchanger [Preventing frost accumulation on the indoor heat exchanger]

During the Cooling or Dry operation in low room air temp. condition, evaporating temperature will decrease and consequently

indoor heat exchanger sometimes gets clogged with frost (or ice).

In order to prevent this trouble, compressor is stopped by under mentioned condition by indoor heat exchanger sensor (Th

timer (built into microcomputer circuit) functions.

Also indoor fan is changed over to protects the fan tap just before frost prevention control.

2) and

CM, FM

1 Temperature of heat exchanger is

O stoppage condition

2.5˚C or lower.

CM, FMO re-starting condition

1 Temperature of heat exchanger is

8˚C or higher.

2 As least 3 minutes has passed since

the compressor started.

Protects

the fan

tap just

before

frost

prevention

control

2.5 8

Indoor heat exchanger

temperature (˚C)

Set fan

speed

(2) Three-minute forced operation

When the compressor begins operating the thermal operation is not effective for 3 minutes, so operation continues as is in the

operation mode. (After 3 minutes has passed the thermal operation is effective.)

However, stopping the compressor via a stop signal or protection control has priority.

(3) Self diagnosis function

When something abnormal happens on the outdoor unit, indoor unit fan motor and each sensor (heat exchanger, room temperature),

it will be indicated by flashing lights.

(a) Abnormality of outdoor unit: When the indoor heat exchanger temperature does not fall to 25°C or below for 40 minutes

(b) Abnormality of indoor fan motor: The indoor fan motor revolves at a rate under 300 rpm for 30 seconds or longer, the

(c) Abnormality of heat exchanger sensor: RUN light will flashing when the input temperature of the heat exchanger

(d) Abnormality room temperature sensor: RUN light will flashing when the input temperature of the room temperature

Note (1) If the above abnormalities happen concurrently, the light will flashing in the order of item number (a) through (d) above.

after 5 minutes have elapsed since the compressor operation start, the abnormality stop

occurs. (The timer light flashes 2 times.)

RUN light will flash.

sensor measures less than –20°C for more than 15 seconds with the air

conditioner “OFF”. (will not flashing during operation)

sensor measures less than –20°C for more than 15 seconds with the air

conditioner “OFF”. (will not flashing during operation)

-

-

18

Page 21

5 APPLICATION DATA

SAFETY PRECAUTIONS

¡ Please read these “Safety Precautions” first then accurately execute the installation work.

¡ Though the precautionary points indicated herein are divided under two headings, WARNING and CAUTION , those points

which are related to the strong possibility of an installation done in error resulting in death or serious injury are listed in the

WARNING section. However, there is also a possibility of serious consequences in relationship to the points listed in the

CAUTION section as well. In either case, important safety related information is indicated, so by all means, properly observe all

that is mentioned.

¡ After completing the installation, along with confirming that no abnormalities were seen from the operation tests, please explain

operating methods as well as maintenance methods to the user (customer) of this equipment, based on the owner’s manual.

Moreover, ask the customer to keep this sheet together with the owner’s manual.

WARNING

¡ To disconnect the appliance from the mains supply this appliance must be connected to the mains by means of

a circuit breaker or a switch (use a recognized 20A) with a contact separation of at least 3mm.

¡ The appliance shall be installed in accordance with national wiring regulations.

¡ This system should be applied to places as households, residences and the like. Application to inferior environ-

ment such as engineering shop could cause equipment malfunction.

¡ Please entrust installation to either the company which sold you the equipment or to a professional contractor.

Defects from improper installations can be the cause of water leakage, electric shocks and fires.

¡ Execute the installation accurately, based on following the installation manual. Again, improper installations can

result in water leakage, electric shocks and fires.

¡ For installation, confirm that the installation site can sufficiently support heavy weight. When strength is insuffi-

cient, injury can result from a falling of the unit.

¡ For electrical work, please see that a licensed electrician executes the work while following the safety standards

related to electrical equipment, and local regulations as well as the installation instructions, and that only exclusive use circuits are used.

Insufficient power source circuit capacity and defective installment execution can be the cause of electric shocks

and fires.

¡ Accurately connect wiring using the proper cable, and insure that the external force of the cable is not conducted

to the terminal connection part, through properly securing it improper connection or securing can result in heat

generation or fire.

¡ Ta ke care that wiring does not rise upward, and accurately install the lid/service panel.It’s improper installation

can also result heat generation or fire.

¡ When setting up or moving the location of the air conditioner, do not mix air etc. or anything other than the

designated refrigerant (R22) within the refrigeration cycle.

Rupture and injury caused by abnormal high pressure can result from such mixing.

¡ Always use accessory parts and authorized parts for installation construction. Using parts not authorized by this

company can result in water leakage, electric shock, fire and refrigerant leakage.

¡ Ventilate the work area when refrigerant leaks during the operation.

Coming in contact with fire, refrigerant could generate toxic gas.

¡ Confirm after the foundation construction work that refrigerant does not leak.

If coming in contact with fire of a fan heater, a stove or movable cooking stove, etc., refrigerant leaking in the

room could generate toxic gas.

¡ Execute proper grounding. Do not connect the ground wire to a gas pipe, water pipe, lightning rod or a telephone

ground wire.

Improper placement of ground wires can result in electric shock.

¡ The installation of an earth leakage breaker is necessary depending on the established location of the unit.

No installing an earth leakage breaker may result in electric shock.

¡ Do not install the unit where there is a concern about leakage of combustible gas.

The rare even of leaked gas collecting around the unit could result in an outbreak of fire.

¡ For the drain pipe, follow the installation manual to insure that it allows proper drainage and thermally insulate it

to prevent condensation. Inadequate plumbing can result in water leakage and water damage to interior items.

¡ Install the outdoor unit so that the aluminum fins on the air heat exchanger cannot be touched. Failure to

observe this may result in injury.

¡ Do not place objects near the outdoor unit or allow leaves to gather around the unit. If there are objects or leaves

around the outdoor unit, small animals may enter unit and contact electrical parts resulting in break down,

emission of smoke or flame.

CAUTION

-

-

19

Page 22

5.1 Selection of location for installation

6.5 cm

5 cm

10 cm

60 cm MIN

Air intake

10 cm MIN

10 cm

MIN

Air outlet

Air

intake

No obstacles

(Service

space for

electrical

parts)

r

h

(1) Indoor unit

(a) Where there is no obstructions to the air flow and where the cooled

air can be evenly distributed.

(b) A solid place where the unit or the wall will not vibrate.

(c) A place where there will be enough space for servicing. (Where

space mentioned right can be secured)

(d) Where wiring and the piping work will be easy to conduct.

(e) The place where receiving part is not exposed to the direct rays of

the sun or the strong rays of the street lighting.

(f) A place where it can be easily drained.

(g) A place separated at least 1m away from the television or the radio.

(To prevent interfence to images and sounds.)

(2) Outdoor unit

(a) A place where good air circulation can be obtained and where rain, snow or sunshine will not directly strike the unit.

(b) A place where discharged hot air or unit’s operating sound will not be a nuisance to the neighborhood.

(c) A place where servicing space can be secured.

(d) A place where vibration will not be enlarged.

* Avoid installing in the following places.

•A place near the bedroom and the like, so that the operation noise will cause no trouble.

•A place where there is possibility of flammable gas leakage.

•A place exposed to strong wind.

Left

side

Right

side

(e) Do not install the unit near the seaside, or where there is possibility of chlorine gas generation.

Notes (1) Blowing out port and suction port on the back side of the unit can be

installed at a distance of 10cm from walls.

In case the barrier is 1.2m or above in height, or is overhead, the

(

sufficient space between the unit and wall shall be secured.

(2) When the unit is installed, the space of the following dimension and

above shall be secured.

(3) Limitations for one way piping length and vertical

height difference.

Model

Item

One way piping length (R) 15 m

Outdoor

Vertical height

difference (h)

unit is lower

Outdoor unit

is higher

All models

5 m

5 m

)

-

20

-

Page 23

5.2 Installation of indoor unit

Look for the inside wall structures (Intersediate support or

pillar and firaly install the unit after level surface has been

checked.)

Mating mark for level surface

450

INSTALLATION SPACE (INDOOR UNIT) (FRONT VIEW)

Unit : mm

Piping hole( 65) Piping hole( 65)

Installation board

Indoor unit

53.5

Piping for Gas 380.6

Piping for Liquid 448.6

Drain hose 520( 16)

53.5

Space *

for service

Space

for service

44.5

252.2

7.5

8.3

Space for

service

50

Space for

service

100

102.5

585

102.5

133.5

450206.5

202450138

44.5

43.2

39.3

200

65

15

(1) Installation of installation board

(a) Fixing of installation board

Adjustment of the installation board in the horizontal

direction is to be conducted with four screws in a

temporary tightened state.

Standard hole

Adjust so that board will be level by turning the board

with the standard hole as the center.

* Leave extra space on the right side to enable removal of the lid screw.

(2) Drilling of holes and fixture sleeve (Option Parts)

When drilling the wall that contains a metal lath, wire lath or metal plate, be sure to use pipe hole sleeve sold separately.

(a) Drill a hole with ø65

whole core drill

Indoor side Outdoor side

Note (1) Drill a hole with incline of 5 degree from

indoor side to outdoor side.

(c) Install the sleeve

(Inserting sleeve) (*Sleeve + *Inclined + *Sealing plate)

Turn to

tighten

Paste

Indoor side Outdoor side

(b) Adjusting sleeve length

Cut off the sleeve

collar in case of

drawing piping out

to rear.

Cut off the sleeve

collar that can be

seen from beneath

the unit.

View of sleeve when installed

Sleeve

Indoor side Outdoor side

Inclined

flange

Sealing

plate

Wall thickness

+ 1.5 cm

-

21

-

Page 24

(3) Preparation of indoor unit

Pipe

Drain hose

1. Remove the drain hose. 2. Remove the drain cap. 3. Insert the drain cap. 4. Connect the drain hose.

Left Side Piping Right Side Piping

Lid

Screw *

Clamp

Terminal block

Left downward

Right

Rear

Downward

Left rear

Left

Wall

Gutter

Pipes storage area

(a) Mounting of connecting wires

1) Remove the lid.

2) Remove the wiring clamp.

3) Connect the connecting wire securely to the terminal block.

Use cable for interconnection wiring to avoid loosening

of the wires.

CENELEC code for cables Required field cables.

H05RNR3G1.5 (Example) or 245IEC57

H Harmonized cable type

05 300/500 volts

R Natural-and/or synth. rubber wire insulation

N Polychloroprene rubber conductors insulation

R Standed core

4or5 Number of conductors

G One conductor of the cables is the earth conductor

(yellow/green)

1.5 Section of copper wire (mm

2

)

• Connect the connection wire securely to the terminal

block. If the wire is not affixed completely, contact will

be poor, and it is dangerous as the terminal block may

heat up and catch fire.

• Take care not to confuse the terminal numbers for indoor

and outdoor connections.

• Affix the connection wire using the wiring clamp.

4) Fix the connecting wire by wiring clamp.

5) Attach the lid.

6) Close the air inlet panel.

1 Brown

2 Blue

For power supply, indoor outdoor

For power supply, indoor outdoor

(d) Cautions when piping from the left and the rear center of the unit

[ Top View ]

*Leave space to allow removal of this screw after installation.

(b) Shaping the pipe

• Hold the bottom of the pipe and change its direction

before stretching it and shaping it.

(c) Taping of the exterior

• Tape only the portion that runs through the wall.

Always tape the crossover wires with the pipe.

Piping is possible in the rear, left,

left rear, left downward, right or

downward direction.

Left rear piping

Left side piping Right side piping

Right rear piping

[ Procedure for exchanging the drain hose ]

• Loosen and remove the

spring-type clamp.

• Do not place the power supply cords above the gutter, because the

air conditioner is structured in a way where condensation on the

back side is collected in to the drain pan before drainage.

• Remove with your hand or

a pair of pliers.

• Use a hexagonal wrench to

correctly insert the drain cap

which was removed in 2.

Caution: Be careful because

if the cap is not inserted

property, water leak may

occur.

• Do not make traps in the drain hose line.

Declining slope

• Loosen the spring-type clamp

and securely insert the drain

hose.

Caution: Be careful because if

the cap is not inserted properly,

water leak may occur.

Inverted slipe

Trap

-

22

-

Page 25

(e) Securing the indoor unit to the installation board

Installing steps

1.Hook the upper part

of the indoor unit to

the installation board.

2.The unit can be installed

simply by gently pushing in the lower part.

The marked portion of the

Indoor unit bese lower latch

Lid

Indoor unit

Installation

Latch (2 locations)

Installation

board

Indoor unit

base lower latch

How to remove the indoor unit from the installation board

•

Wall

board

1) Push up at the marked portion of the indoor unit base lower

latch, and slightly pull it toward you.

(both right and left hand sides)

(The indoor unit base lower latch can be removed from the in-

stallation board)

2) Push up the indoor unit upward. So the indoor unit will be

removed from the installation board.

(4) Removal and installation of the front panel

(a) Removing

(b) Fitting

(5) Open/close and detachment/attachment of air inlet panel

(a) To open, pull the panel at both ends of lower part and release

(b) To close, hold the panel at both ends of lower part to lower

(c) To remove, pull up the panel to the position shown in right

(d) To install, insert the air inlet panel arm into the slot on the front

• Remove the 2 set screws.

• Move the lower part of the panel forward and push upwards to

remove. (Remove the 3 latches in the upper section.)

• Do remove the air filter.

• Cover the body with the front panel.

• Push the circled portion at the front.

• Tighten the 2 set screws.

• Fit the air filter. Carry out in the above order.

latches, then pull up the panel until you feel resistance. (The

air inlet panel stops at approx. 60˚ open position.)

downward and push it slightly until the latch works, then push

the center portion slightly.

illustration and pull it toward you.

panel from the position shown in right illustration, hold the

panel at both ends of lower part, lower it downward slowly,

then push it slightly until the latch works and further push the

center portion slightly.

Set screws

-

23

-

Page 26

1 2

5.3 Installation of outdoor unit

(1) Make sure that the unit is stable in installation. Fix the unit to

stable base.

(2) Perfrom wiring, making wire terminal numbers conform to ter-

minal numbers of indoor unit terminal block.

1 Brown

2 Blue

For power supply, indoor outdoor

For power supply, indoor outdoor

5.4 Connection of refrigerant pipings

(1) Preparation

Keep the openings of the pipes covered with tapes etc. to prevent dust, sand, etc. from entering them.

(a) Indoor unit side

(Do not

turn)

¡ Remove the flared nuts.

(on both liquid and gas sides)

Remove

(2) Connection of refrigerant piping

(a) Indoor unit side

• Connect firmly gas and liquid side

pipings by Torque wrench.

(b) Outdoor unit side

Remove

¡ Remove the flared nuts.

(on both liquid and gas sides)

(b) Outdoor unit side

• Connect firmly gas and liquid side

Press

¡ Install the removed flared nuts to the pipes to be

pipings by Torque wrench.

Terminal block

Interconnecting wire

Dimension A

Liquid side

(ø6.35): 9.0 dia

Gas side

(ø9.52): 13.0 dia

(ø12.7): 16.2 dia

connected, then flare the pipes.

Spanner

for fixing

the piping)

Torque

wrench

• Specified torquing value:

Liquid side (ø6.35) : 14~18N·m (1.4~1.8kgf·m)

Gas side (ø9.52) : 34~42N·m (3.4~4.2kgf·m)

Gas side (ø12.7) : 49~61N·m (4.9~6.1kgf·m)

• Specified torquing value:

Liquid side (ø6.35) : 14~18N·m (1.4~1.8kgf·m)

Gas side (ø9.52) : 34~42N·m (3.4~4.2kgf·m)

Gas side (ø12.7) : 49~61N·m (4.9~6.1kgf·m)

• Use one more spanner to fix the valve.

• Always use a Torque wrench and back up spanner to tighten the flare nut.

(3) Air purge

(a) Tighten all flare nuts in the pipings both indoor and outside wall so as not to cause leak.

(b) Connect service valve, charge hose, manifold valve and vacuum pump as is illustrated below.

(c) Open manifold valve handle Lo to its full width, and perform vacuum or evacuation.

Continue the vacuum or evacuation operation for 15 minutes or more and check to see that the vacuum gauge reads – 0.1 MPa

(– 76 cmHg).

(d) After completing vacuum operation, fully open service valve (Both gas and liquid sides) with hexagon headed wrench.

(e) Detach the charge hoses.

(f) Check for possible leakage of gas in the connection parts of both indoor and outdoor.

Stop valve

(Two-way valve)

Service port

Compound

(Gauge)

-76 cm Hg

Handle Lo

(pressure)

Stop value

(Three-way

value)

Charge hose

Pressure

gauge

Manifold

Valve

Handle Hi

(pressure)

Charge hose

Vacuum pump

-

24

-

Page 27

♦ Additional refrigerant charge

-

-

+

+

Screws

When refrigerant piping exceeds 7.5m conduct additional refrigerant charge after refrigerant sweeping.

7.5m over 15m:Additional charge amount per meter = 10g/m

[Example]

How much amount of additional charge for 15m piping?

(15 – 7.5)m × 10g/m=75g 75g for additional charge

(4) Insulation of connecting portion

(a) Cover the connection portion of the refrigerant piping with the

pipe cover and seal them.

If neglecting to do so, moisture occurs on the piping and water

will drip out.

(b) Finishing and fixing

1) Tie up the piping with wrapping tape, and shape it so that it

conforms to which the pipe is attached.

2) Fix them with clamps as right figure.

5.5 Installation of remote control switch

(1) Mounting method of battery

• Uncover the remote control switch, and mount the batteries [R03(AAA, Micro)×2 pieces] in the body regularly.

(Fit the poles with the indication marks, , & . without fail)

Battery

To cover the connecting portion with insula-

Vinyl tape

tion materials, cut upper portion and then seal

it with insulation materials.

Insulation

Refrigerant piping

Electrical wiring

Covering tape

Drain hose

Tapping screw

Cover the exterior portion with covering tape and shape the piping so it

will match the contours of the route

that the piping to take. Also fix the

wiring and pipings to the wall with

clamps.

(b) Fixing to pillar or wall

• Conventionally, operate the wireless remote control by

holding in your hand.

• Avoid installing it on a clay wall etc.

Cover

5.6 Earthing work

• Earth work shall be carried out without fail in order to prevent electric shock and noise generation.

• The connection of the earth cable to the following substances causes dangerous failures, therefore it shall never be done.

City water pipe, Town gas pipe, TV antenna, lightning conductor, telephone line, etc.

-

25

-

Page 28

5.7 Test run

(1) Conduct trial run after confirming that there is no gas leaks.

(2) When conducting trial run set the remote control thermostat to continuous operation position. However when the power source is

cut off or when the unit’s operation switch is turned off or was turned to fan operation position, the unit will not go into operation

in order to protect the compressor.

(3) Explain to the customer on the correct usage of the air conditioner in simple layman’s terms.

(4) Make sure that drain flows properly.

(5) Standard operation data

Model

Item

Low pressure (MPa) 0.46~0.66 0.41~0.61

Temp. difference between

return air and supply air (°C)

Running current (A) 3.4 4.9

Note (1) The data are measured at following conditions

Ambient air temperature

Indoor side: Cooling ... 27˚C DB, 19˚C WB

Outdoor side: Cooling ... 35˚C DB, 24˚C WB

SRK10CFV-4 SRK13CFV-4

10~12 13~15

(220V)

5.8 Precautions for wireless remote control installation and operation

(1) Wireless remote control covers the following distances:

(a) When operating facing the air conditioner:

7 m or less

or less

Wireless remote

control

7 m or less

or less

or less

If the distances exceed the area indicated above, be sure to check

the receiver status.

(b) When manipulating the remote control mounted on a

wall:

Make sure that it works normally (i.e., transmission/reception

signal is audible) before mounting.

Notes (1) The remote control is correctly facing the

sensing element of the air conditioner when being

manipulated.

(2) The typical coverage is indicated (in the left

illustration). It may be more or less depending on

the installation.

(3) The coverage may be less or even nil. If the sensing

element is exposed to strong light, such as direct

sunlight, illumination, etc., or dust is deposited on

it or it is used behind a curtain, etc.

Receiver

Remote control

available in this area.

-

26

-

Page 29

6 MAINTENANCE DATA

6.1 Trouble shooting

(1) Trouble shooting to be performed prior to exchanging PCB, (Printed circuit board) [Common to all models]

All the models described in this chapter are controlled by a microcomputer. When providing maintenance service to customers it

is necessary to understand the function controlled by a microcomputer thoroughly, so as not to mistakenly identify correct opera-

tions as mis-operations. It is also necessary to perform the following simple checks before conducting detailed checks or exchang-

ing printed circuit board.

Before exchanging Printed circuit board

Claim call from the user

Ascertain the nature of the claim.

Ascertain the operation status.

Is this nonsense claim?

No

Operate the unit.

Does the trouble occur again?

YES

Temporarily turn off the power source and

turn it on again in about 1 min. and turn the

unit on again.

Does the trouble occur again?

YES

Disconnect connectors and connect them

again.

Operate the unit again after confirming that the fuse

and the varistor equipped on PCB does not burn out.

YES

No

No

Unit did not cool, etc.

¡ Is the power on?

¡ Is the thermostat setting correct?

(Not too high?)

¡ Is the unit in a timer operation?

¡ Does user understand function?

etc.

¡ Explain the function of the unit to user.

No need for PCB change

Check further the status when the trouble occured

(such as the timer of occurence, power failures, thunder, use status of other electrical appliances, etc).

Clarify the reason for the problem and explain it thoroughly to the user.

No need for PCB change

Microcomputer runaway due to power source

conditions is a possible cause.

Does the trouble occur again?

YES

Carry out checks according to detailed

check process (See later page)

-

No

27

No need for PCB change

The cause is defective connector contact.

-

Page 30

(2) Indication of Self Diagnosis (Indoor unit)

RUN light is flashing.

(1 Time flash.)

TIMER light is

lights

continuously.

RUN light is flashing.

(2 Time flash.)

RUN light is flashing.

(6 Time flash.)

Connect of Defect

Abnormality of heat

exchanger sensor.

Abnormality of room

temperature sensor.

Abnormality of indoor

fan motor.

Place of defect

¡ Disconnection of heat exchanger sensor.

¡ Disconnection of room temperature

sensor.

¡ Fan motor is defective.

¡ Printed circuit board is defective.

RUN light is

lights

continuously.

TIMER light is flashing.

(2 Time flash.)

Abnormality of outdoor

unit.

¡ Compressor is defective.

¡ Capacitor is defective.

¡ Gas is short.

(3) Troubleshooting

Abnormality of outdoor unit [Compressor malfunction of insufficient gas (refrigerant)]

Does compressor operate?

Yes

Is refrigerant circulation

volume normal?

Yes

Is abnormality the same after

gas charging?

Yes

Clogging of capillary tube. etc.

No

No

Insufficient gas.

Is protective device normal?

Ye s

Is capacitor normal?

Ye s

Replace compressor.

No

No

Replace protective device.

Replace capacitor.

Abnormality of indoor fan motor (Fan motor defective, printed circuit board defective)

Is the connector connection

good?

Yes

Is voltage being applied to the

fan motor?

Yes

The fan motor is defective.

No

No

Repair the connector.

The indoor circuit board

is defective.

Abnormality of sensor Disconnection of sensor and defective connection of connector

Is connection to connector

good?

Ye s

Is sensor resistance value

normal?

Ye s

Replace PCB.

No

No

Repair connector.

Replace sensor.

-

28

Chart for sensor temperature

resistance characteristics

(Disconnection)

Resistance value

(kΩ)

(Short circuit)

Temperature (°C)

-

Page 31

(4) Trouble Diagnostic Procedures

Unit malfunctions or

does not stop.

Indoor light of

indoor unit does not

illuminate.

Outdoor fan does not

operate.

Runaway of micro-

computer

Check receptacle voltage.

Check if PCB fuse is blown.

Check varistor

Replace PCB.

Check voltage with fan

connector.

No

Remove receptacle.

Insert it after 3 min.

and operate.

Replace fuse.

Replace varistor.

Ye s

Normal operation.

Check capacitor.

Normal

Replace fan motor.

No change.

Abnormal

Replace PCB.

Microcomputer rarely

mis-starts even during

times or power supply

or power failure, but, it

can sometimes occur

during those times. If it

occurs, check the operation, when the result is

positive then proceed as

normal.

Replace capacitor.

Replace PCB.

(5) Trouble shooting chart for the room temperature sensor (Th1), heat exchanger sensor (Th2)

Unit sensor Operation

Room temperature

(1)

sensor

(Th1) except for

“continuous” thermal

setting.

Indoor unit

Heat exchanger

sensor (Th

Note (1) When the room temperature sensor (Th

2)

Cooling

Cooling

1) will not operate normally. Cooling operation may be run continuously by putting the thermostat setting on “CONTINUOUS”

Short circuit Broken connection

Continuous Cooling operation

¡ Cannot be turned ON/OFF by thermostat

¡ When FM

Cooling will not operate.

I is on. “AUTO” is continuously

Hi

Function

Cooling will not operate

I : continuous operation

¡ FM

¡ CM,FMo: stopped

Cooling will operate

¡ Heat exchanger frost preventer begins to operate

¡ Cools alternately for 10 minutes, stopping for 3

minutes.

-

29

-

Page 32

(6) How to make sure of remote control

(1)

Is remote

control

normal?

YES

Again pushing

operating switch

NO

Remote control

defects

Note (1) How to check the remote control.

(a) Press the reset switch of remote control.

(b) If the almost normal if entire display of remote control is shown after 1

indication.

Operating the

unit?

NO

Does operating Unit

ON/OFF button

Operating the unit?

YES

Replace the

display

Operating the

unit by remote

control?

NO

Remote control

defects

YES

NO

YES

Abnormal is not

fount

Control unit defects

It is normal

6.2 Servicing

(1) Evacuation

The evacuation is an procedure to purge impurities ...... noncondensable gas, air, moisture from the refrigerant equipment by using

a vacuum pump. Since the refrigerant R22 is very insoluble in water, even a small amount of moisture left in the refrigerant

equipment will freeze, causing what is called water clogging.

¡ Evacuation procedure

(a) Check to ensure that there is no internal pressure in the unit. If there is an internal pressure, it

should be relieved through the check joint.

(b) Connect the service hoses of the gauge manifold to the check joint of the gas & liquid piping.

(c) Connect a vacuum pump to the charge hose A. Repeat evacuation in the following sequence.

Start the vacuum pump

Operate the vacuum pump for more than 15 minutes after –0.1MPa

(–76 cmHg) is indicated.

Check joint

Close low pressure valve 1 of gauge manifold.

Stop the vacuum pump.

Notes (1) Do not use the refrigerant pressure to expel air.

(2) Do not use the compressor for evacuation.

(3) Do not operate the compressor in the vacuum condition.

Service hose

Charge hose

Vacuum

pump

Liquid side

Gas side

Gauge

manifold

Refrigerant

cylinder

-

30

-

Page 33

(2) Refrigerant charge

(a) Discharge refrigerant entirely from the unit and evacuate the unit.

Note: Addition of refrigerant without evacuation is unreasonable, because it will result in low charge or overcharge.

(b) Keep the gauge manifold and connect a refrigerant cylinder to the unit.

(c) Record the weight of the refrigerant cylinder on the balance. This is necessary for making sure of the charged refrigerant

amount.

(d) Purge air from the charge hose A .

Firstly loose the connecting portion of the charge hose A at the gauge manihold side and open the valve 3 for a few

seconds, and then immediately retighten it after observing that gas is blow out from the loosened portion.

(e) Open the valve 1 and 3 after discharging air from the charge hose A , then the gas refrigerant begins flowing from the

cylinder into the unit. Be sure to erect the refrigerant cylinder upright to let gas refrigerant flow into the unit.

(f) When refrigerant has been charged into the system to some extent, refrigerant flow becomes stagnant, when that happens,

start the compressor in cooling cycle until the unit is filled with gas to the specified weight.

(g) Making sure of the refrigerant amount, close the valve 3.

(h) Disconnect the charge hose from the unit. Cover the valve ports of the refrigerant piping with caps and tighten them securely.

(i) Check for gas leakage applying a gas leak detector along the piping line.

(j) Start the air conditioner and make sure of its operating condition ...... high side and low side pressures and temperature

difference between return air and supply air.

-

31

-

Page 34

PARTS LIST

INDOOR UNIT

SRK10CFV-4, SRK13CFV-4

OUTDOOR UNIT

SRC10CFV-4, SRC13CFV-4

Page 35

CRAE0175

14

14

9

8

14

10

10

12

12

18

20

24

15

22

11

21

17

22

13

2

4

5

5

1

31

28

30

35

35

6

3

4

16

22

25

21

19

23

7

27

26

32

34

33

29

PANEL&FANASSY

- 33 -

Page 36

SRK10CFV-4

END ITEM NO. : RWA002F050D

Recommendable Purchased Q't

y

10 30 50 100 500 1000

1-6 RKX 102A 001B PANEL ASSY,FRONT 1 1112

1 RKX 122A 001B PANEL,FRONT 1

2 RKX 435A 004 PANEL ASSY,AIR IN 1 1123

3 RKX 437A 001 FILTER,AIR 2 1112W315×H294.3(t2)

4 RKX 129A 013 CAP 2

5 RKX 129A 014 HOLDER,FILTER 2 1112

6 RKX 133A 001 PLATE,ORNAMENT 1 1112

7-27 RKX 435A 002 GRILLE ASSY,AIR OUT 1 1123

7 RKX 435A 003 GRILLE,AIR OUTLET 1

8 RKX 436A 001 FLAP(A) 1

UPPER

9 RKX 436A 002 FLAP(B) 1

LOWER

10・11 RKX 436A 003 LOUVER ASSY(R) 1 1122

10 RKX 436A 005 LOUVER 6

11 RKX 129A 008 PLATE,CONNECTING(R) 1

12・13 RKX 436A 004 LOUVER ASSY(L) 1 1122

12 RKX 436A 005 LOUVER 6

13 RKX 129A 009 PLATE,CONNECTING(L) 1

14 RKW 935C 200 COLLAR 6

15 RKX 129A 010 BRACKET,MOTOR(A) 1 1112

16 RKX 129A 011 BRACKET,MOTOR(B) 1 1112

17 RKX 129A 012 BRACKET,MOTOR(C) 1 1112

18 RKX 144A 001 LINK 1 1112

19 RKX 144A 002 CRANK(A) 1 1112

20 RKX 144A 003 CRANK(B) 1 1112

21 RKW 144A 204 CRANK(C) 2 1112

22 SSA 512T 052 MOTOR,STEPPING 3 1112FOR FLAP/LOUVER(R,L)

23 RKS 504A 100G HARNESS ASSY 1 1112FOR FLAP

24 RKS 504A 100 HARNESS ASSY 1 1112FOR LOUVER(R)

25 RKS 504A 100L HARNESS ASSY 1 1112FOR LOUVER(L)

26 SSA 423A 094 HOSE,DRAIN 1

27 SSA 326A 047 PLUG 1

28 RKX 111A 001 BASE ASSY 1 1112

29 SSA 511J 218 MOTOR,AC 1 1112FOR IMPELLER

30 SSA 431G 044 IMPELLER 1 1124

31 SSA 923C 114 BEARING,PLANE 1 1112

32 RKX 129A 005 COVER(MOTOR) 1 1112

33 RKX 032A 001 PLATE,INSTALLATION 1 1112

34 RKX 132A 001A LID 1 1124

35 SSA 913A 007A SCREW,TAP 4 4×14

NoteNo. Part No. Part Name RE.Q

- 34 -

Page 37

CRAE0176

20

17

18

21

23

22

24

25

14

15

16

9

10

11

12

13

1

8

5

7

6

4

2

3

19

HEATEXCH.&CONTROL

- 35 -

Page 38

SRK10CFV-4

END ITEM NO. : RWA002F050D

Recommendable Purchased Q't

y

10 30 50 100 500 1000

1-4 RKX 301A 002A HEAT EXCH ASSY(AIR) 1 1112

2 RKX 315D 001 HEADER ASSY 1

3 RKX 129A 016 BRACKET(L) 1

4 RKX 315A 001 DISTRIBUTOR ASSY 1

5-7 RKX 321A 001 PIPE ASSY 1

6 SSA 323F 082 UNION(SLD) 1 FOR GAS

7 SSA 323F 082A UNION(SLD) 1 FOR LIQ.

8 RKX 129A 001 PLATE ASSY,BAFFLE 1 1112

9 RKX 142A 001 BOX,CONTROL 1

10-12 RKX 505A 001B PWB ASSY 1 2248

11 SSA 555B 050C VARISTOR 1 1112

12 SSA 564A 132 FUSE(CURRENT) 1 1124F 3.15A

13 SSA 551A 163L SENSOR ASSY 1 1124

INCL.SENSOR(ROOM TEMP.& HEAT EXCH.)

14 RKV 504A 500 HARNESS ASSY(POWER) 1 1112

15 SSA 561B 713 BLOCK,TERMINAL 1 1122

16 RKX 011G 001 LABEL,WIRING 1

17 RKX 503A 001 DISPLAY ASSY 1 1123

18 RKX 505A 003 PWB ASSY(DISPLAY) 1 2248

19 RKJ 941F 001 SPRING,LEAF 1

20 RKX 008A 003B PARTS,STANDARD 1

21 RKX 502A 001 CONTROL ASSY,REMOTE 1 2 3 5 10

22 RKT 437A 011 FILTER,CLEAN 1 2248

23 RKT 437A 005 FILTER,LIGHT CLEAN 1 2248

24 RMA 012A 017 MANUAL,INSTRUCTION 1

25 RKN 032A 002B HOLDER(REMO-CON) 1 1112

(26) RMA 011F 003A

T

LABEL,MODEL NAME 1

NoteNo. Part No. Part Name RE.Q

- 36 -

Page 39

CRAE0175

14

14

9

8

14

10

10

12

12

18

20

24

15

22

11

21

17

22

13

2

4

5

5

1

31

28

30

35

35

6

3

4

16

22

25

21

19

23

7

27

26

32

34

33

29

PANEL&FANASSY

- 37 -

Page 40

SRK13CFV-4

END ITEM NO. : RWA002F050F

Recommendable Purchased Q't

y

10 30 50 100 500 1000

1-6 RKX 102A 001B PANEL ASSY,FRONT 1 1112