Mitsubishi SRC208HENF-L, SRK288HENF-L, SRC328HENF-L2, SRK408HENF-L3, SRC408HENF-L3 User Manual

...Page 1

Линейка кондиционеров Mitsubishi Heavy на

сезон 2002 года.

1. Настенные бытовые сплит-системы.

WALL MOUNTED TYPE ROOM AIR CONDITIONER

тепло/холод только охлаждение инвертор

SRK 208 HENF-L SRK 208 СENF-L

SRK 258 СENF-L

SRK 288 HENF-L SRK 288 СENF-L SRK 25 GZ-L1

SRK 328 HENF-L2 SRK 328 СENF-L

SRK 408 HENF-L3 SRK 408 СENF-L SRK 35 GZ-L1

SRK 50 HA SRK 50 СA

SRK 56 HA SRK 56 СA SRK 502 Z-L

поддерживаются в наличии на складе в Москве в течении всего 2002

года.

SRK 501 HENF-L, SRK 561 HENF-L

SRK 501 СENF-L, SRK 561 СENF-L

поставлялись в 2001 году. Сняты с производства, поставки в 2002

году не планируются.

Указанные модели поставляются на фреоне R22. Возможна поставка

на фреоне R407.

Информацию по моделям на R407, а также старым моделям Вы можете

получить в компании Бьюфорт по тел. (095) 755-84-33.

Page 2

1-2

CONTENTS

1.1GENERAL INFORMATION........................................................................53

1.1.1Specific features.................................................................................53

1.1.2How to read the model name.............................................................53

1.2SELECTION DATA.....................................................................................54

1.2.1Specifications......................................................................................54

1.2.2Range of usage & limitations.............................................................58

1.2.3Exterior dimensions............................................................................59

1.2.4Piping system......................................................................................61

1.3ELECTRICAL DATA..................................................................................63

1.3.1Electrical wiring..................................................................................63

1.4OUTLINE OF OPERATION CONTROL BY MICROCOMPUTER.............65

1.4.1Table of operation control..................................................................65

1.4.2Details of operation control...............................................................66

1.5APPLICATION DATA.................................................................................77

1.5.1Selection of location for installation.................................................78

1.5.2Installation of indoor unit...................................................................79

1.5.3Installation of outdoor unit.................................................................81

1.5.4Refrigerant piping...............................................................................82

1.5.5Test run................................................................................................83

1.5.6Precautions for wireless remote controller installation

and operation ......................................................................................84

1.6MAINTENANCE DATA...............................................................................85

1.6.1Trouble shooting.................................................................................85

1.6.2Servicing..............................................................................................89

1.6.3Power supply remote operation........................................................90

Page 3

1-3

1.1 GENERAL INFORMATION

1.1.1 Specific features

The “Mitsubishi Daiya” room air conditioner: SRK series are of split and wall mounted type and the unit consists of indoor unit

and outdoor unit with refrigerant precharged in factory. The indoor unit is composed of room air cooling or heating equipment with

operation control switch and the outdoor unit is composed of condensing unit with compressor.

(1) Remote control flap

The flap can be automatically controlled by operating wireless remote control.

¡ AUTO (Natural flow) : Flap operation is automatically control.

¡ Swing : This will swing the flap up and down.

¡ Memory flap : Once the flap position is set, the unit memorizes the position and continues to

operate at the same position from the next time.

(2) Automatic Operation

When the remote control switch is set on “auto”, it will either automatically decide operation mode such as cooling,

heating and thermal dry, or operate in the operation mode before it has been turned to automatic control.

(3) Self diagnosis Function

We are constantly trying to do better service to our customers by installing such judges that show abnormality of operation

as follows.

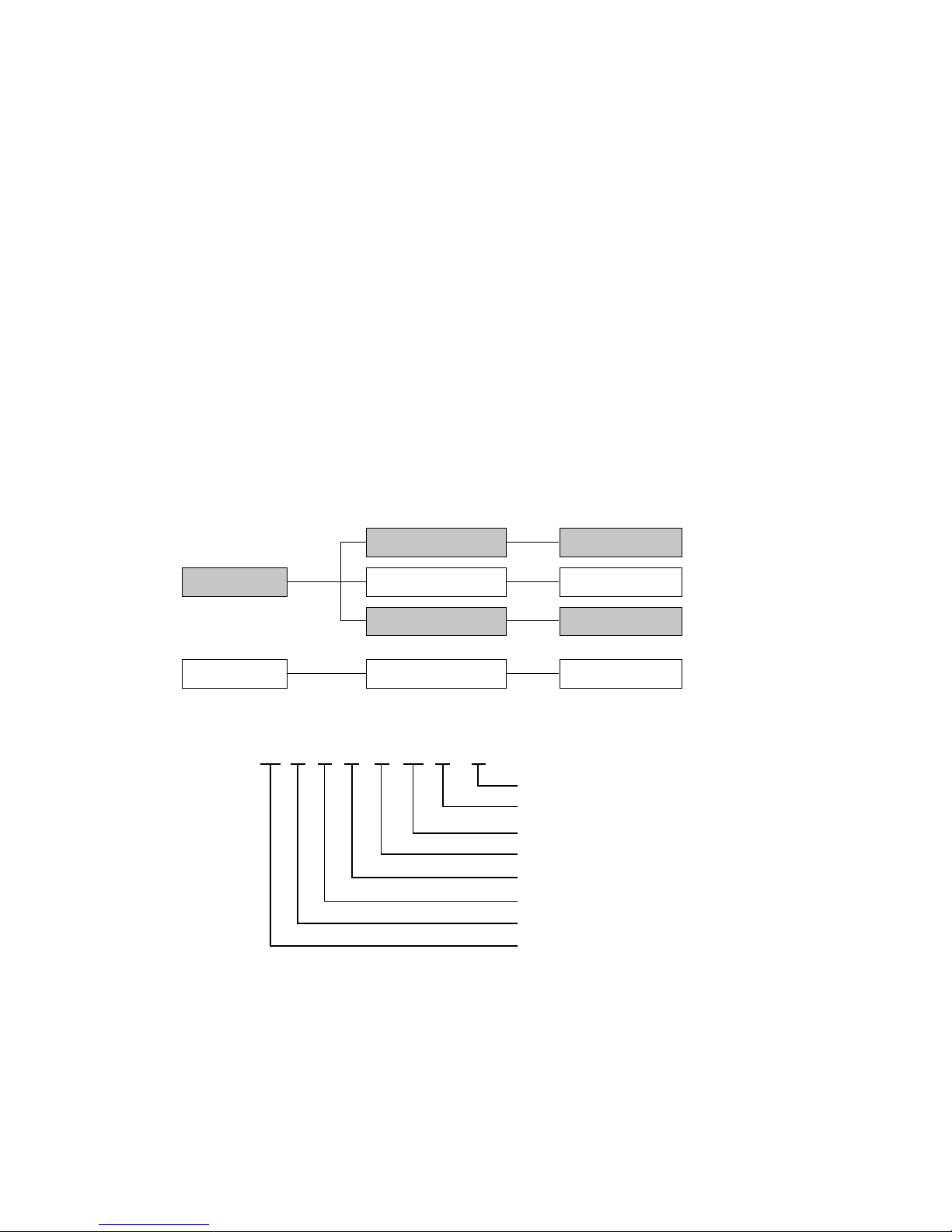

1.1.2 How to read the model name

Example : SR K 32 8 H EN F - L

CE marking model

Flare connecting

Applicable power source …… See the specifications

H-Heat pump type C-Cool only type

Series No.

Product capacity

Wall mounted type room air conditioner

Split type room air conditioner

Abnormality of room

temperature sensor.

TIMER lamp is

light up.

RUN lamp is flashing.

(1 Times/ 8sec.)

RUN lamp is flashing.

(2 Times/ 8sec.)

Abnormality of heat

exchanger sensor.

Abnormality of indoor

fan motor.

RUN lamp is flashing.

(6 Times/ 8sec.)

t

t

t

Abnormality of outdoor

unit.

RUN lamp is light

up.

TIMER lamp is flashing.

(5 Times/ 8sec.)

t

t

No lamps will flashing

when the unit is operating.

}

Page 4

1-4

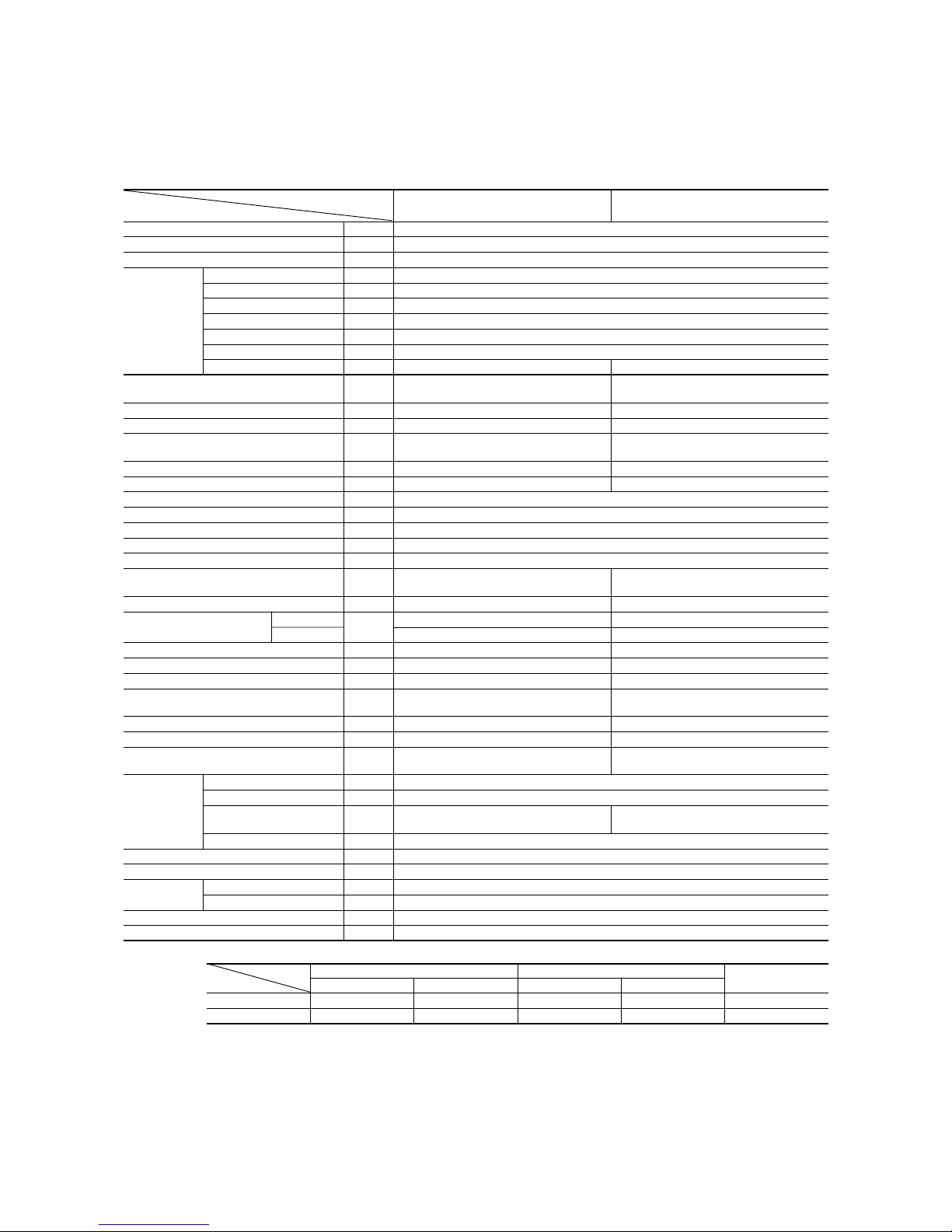

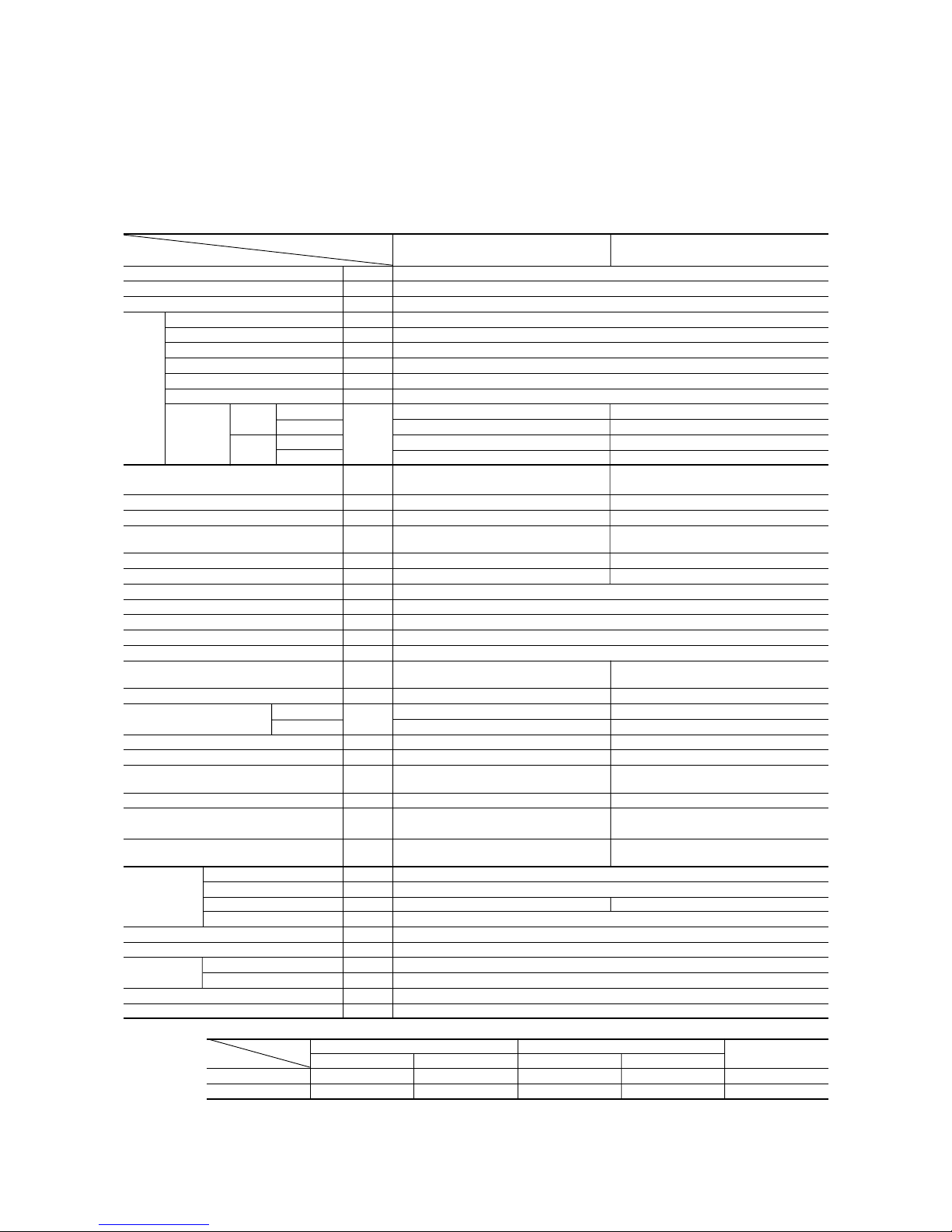

1.2 SELECTION DATA

1.2.1 Specifications

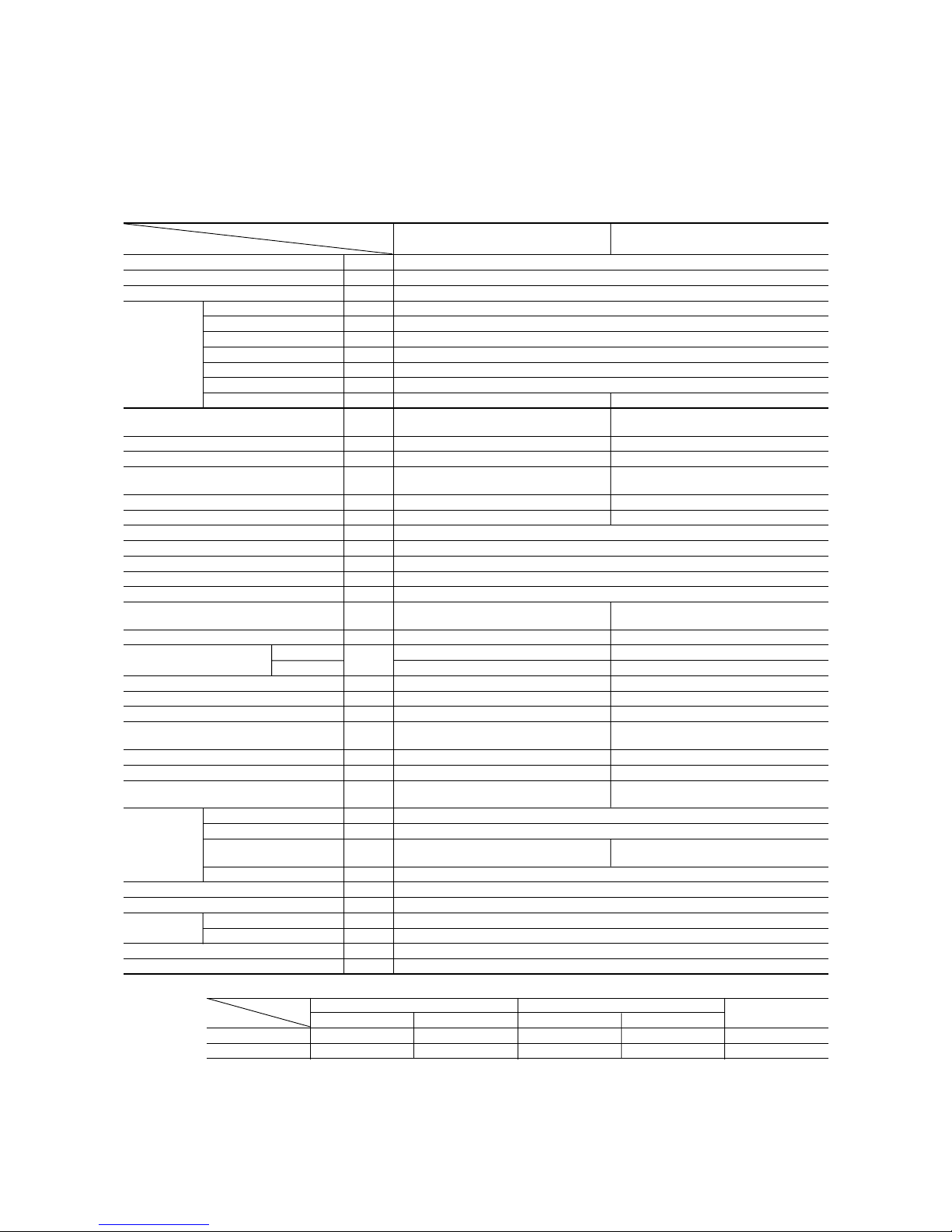

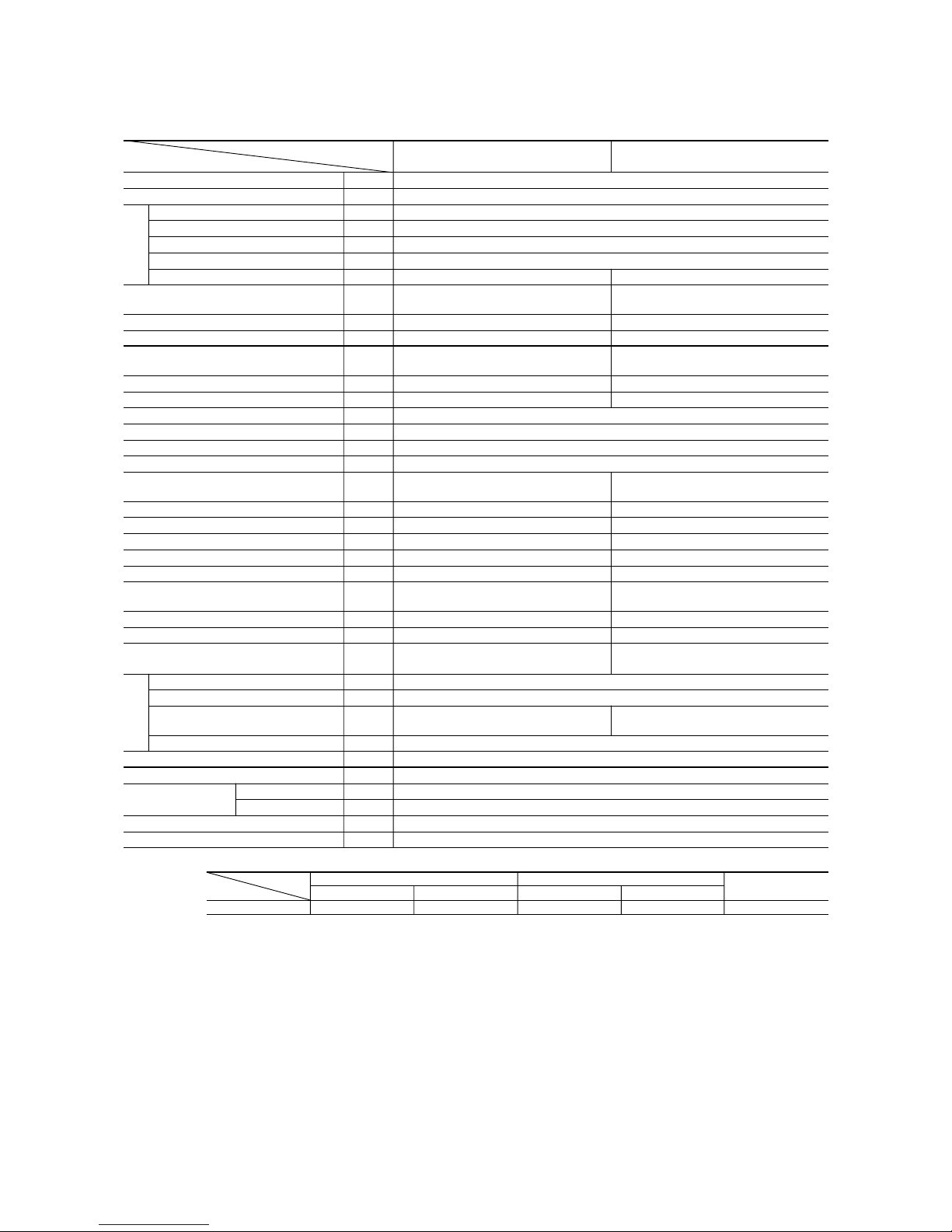

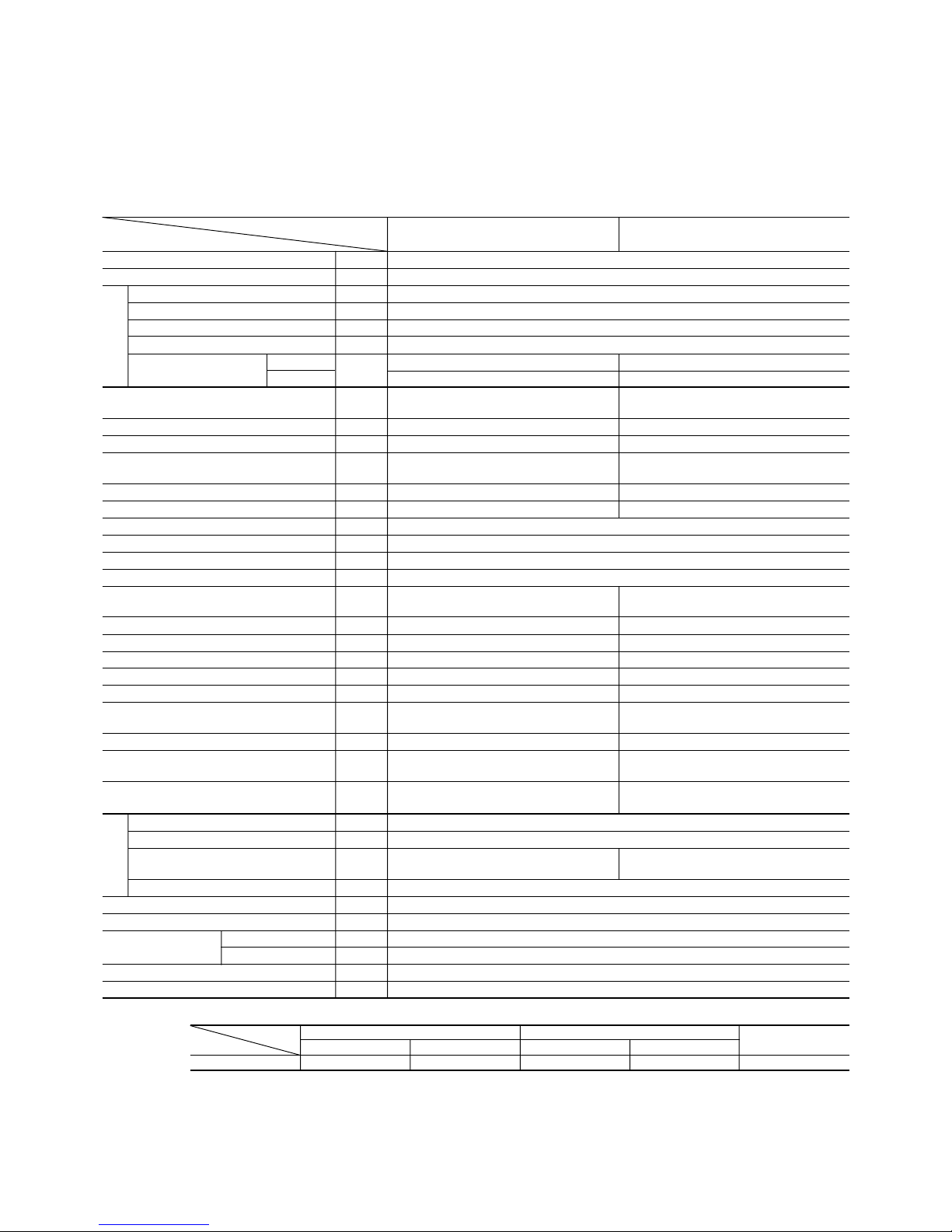

Model SRK208HENF-L (Indoor unit)

SRC208HENF-L (Outdoor unit)

Item

Model

SRK208HENF-L SRC208HENF-L

Cooling capacity

(1)

W 1800/1850

Heating capacity

(1)

W 2000/2050

Power source 1 Phase, 220/240V, 50Hz

Cooling input kW 0.690/0.775

Running current (Cooling) A 3.4/3.6

Heating input kW 0.620/0.735

Running current (Heating) A 3.0/3.4

Inrush current A 17.3/18.9

COP (In cooling) 2.61/2.39

Noise level

(5)

dB(A) Cooling: 36/37 Heating: 38/39 Cooling: 46/47 Heating: 47/48

Exterior dimensions

Height x Width x Depth

mm 275 x 790 x 174 492 x 750 x 220

Color Ivory white Polar white

Net weight kg 7.5 27

Refrigerant equipment

Compressor type & Q’ty

– RM5485GNE2 (Rotary type) x 1

Motor kW – 0.65

Starting method – Line starting

Heat exchanger Louver fins & bare tubing

Refrigerant control Capillary tubes

Refrigerant

(4)

kg R22 0.62

Refrigerant oil R 0.35 (BARREL FREEZE 32SAM)

Defrost control MC control

Air handling equipment

Fan type & Q’ty

Tangential fan x 1 Propeller fan x 1

Motor W 16 17

Air flow (at High) (Cooling) 7.0/7.0 21/22

(Heating)

CMM

7.5/7.5 21/22

Air filter, Q’ty Polypropylene net (washable) x 2 –

Shock & vibration absorber – Cushion rubber (for compressor)

Electric heater ––

Operation control

Operation switch

Wireless–Remote controller –

Room temperature control MC. Thermostat –

Pilot lamp RUN (Green), TIMER (Yellow) –

Safety equipment

–

Dome mounted protector (for compressor)

Internal thermostat (for fan motor)

O.D mm(in) Liquid line: ø6.35 (1/4") Gas line: ø9.52 (3/8")

Connecting method Flare connecting

Attached length of piping Liquid line: 0.4m

Gas line: 0.35m

–

Insulation Necessary (Both sides)

Drain hose Connectable

Power source cord 2.5m (3 cores with Earth)

Connection Size x Core number 1.5mm2 x 5 cores (Including earth cable)

wiring

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Optional parts –

Notes (1) The data are measured at the following conditions.

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27ºC 19ºC 35ºC 24ºC JIS C9612, ISO-T1

Heating 20ºC – 7ºC 6ºC JIS C9612, ISO-T1

(2) The operation data are applied to the 220V or 240V districts respectively

(3) Limitation of Voltage application Minimum: 198V Maximum: 264V

(4) The refrigerant quantity to be charged includes the refrigerant in 7.5m connecting piping.

(Purging is not required even in the short piping.)

If the piping length is longer, (when it is less than 10 m, add 20g refrigerant per meter and when it is 10 to 15m, add 30g

refrigerant per meter.)

(5) Expressed in sound pressure level.

Operation data

(1)

Refrigerant

piping

Page 5

1-5

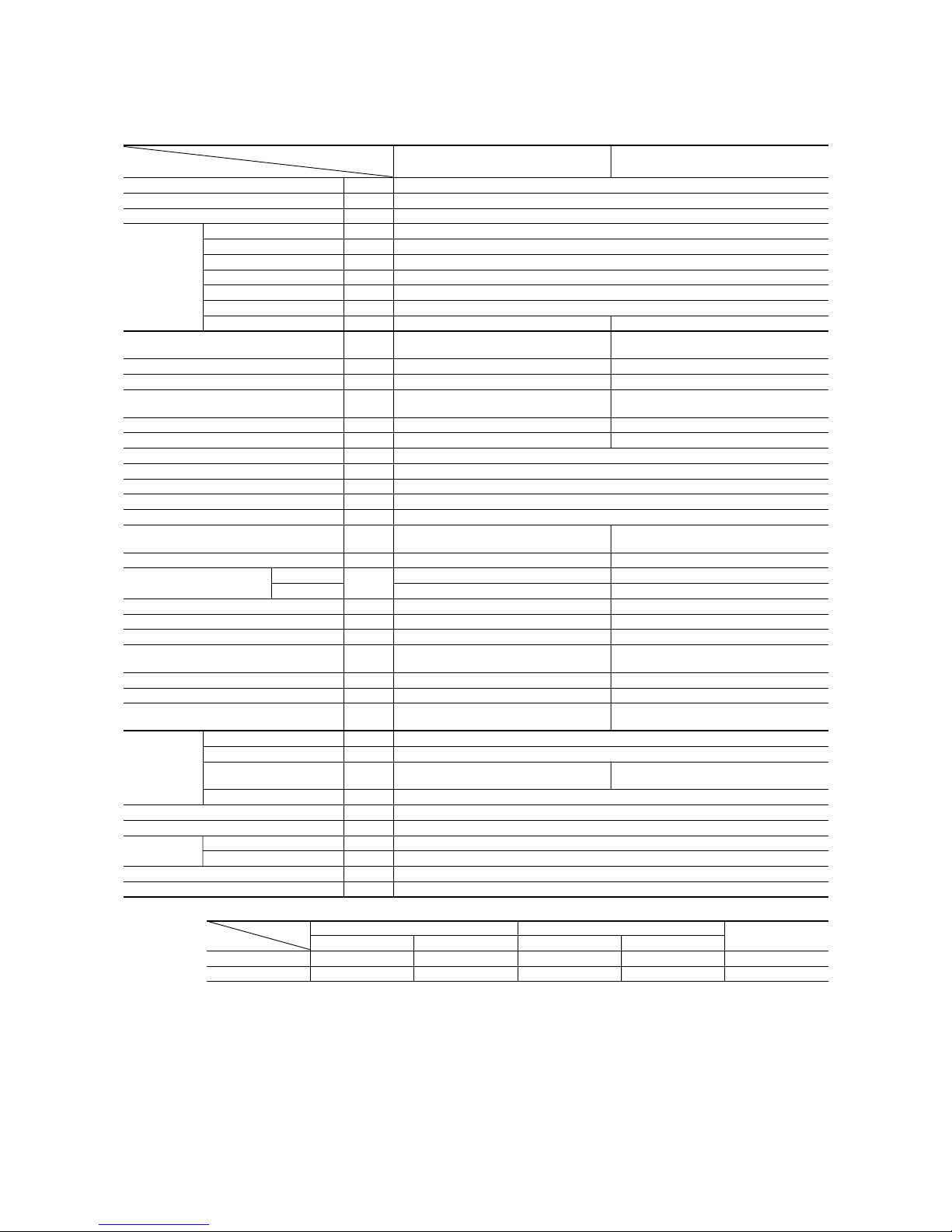

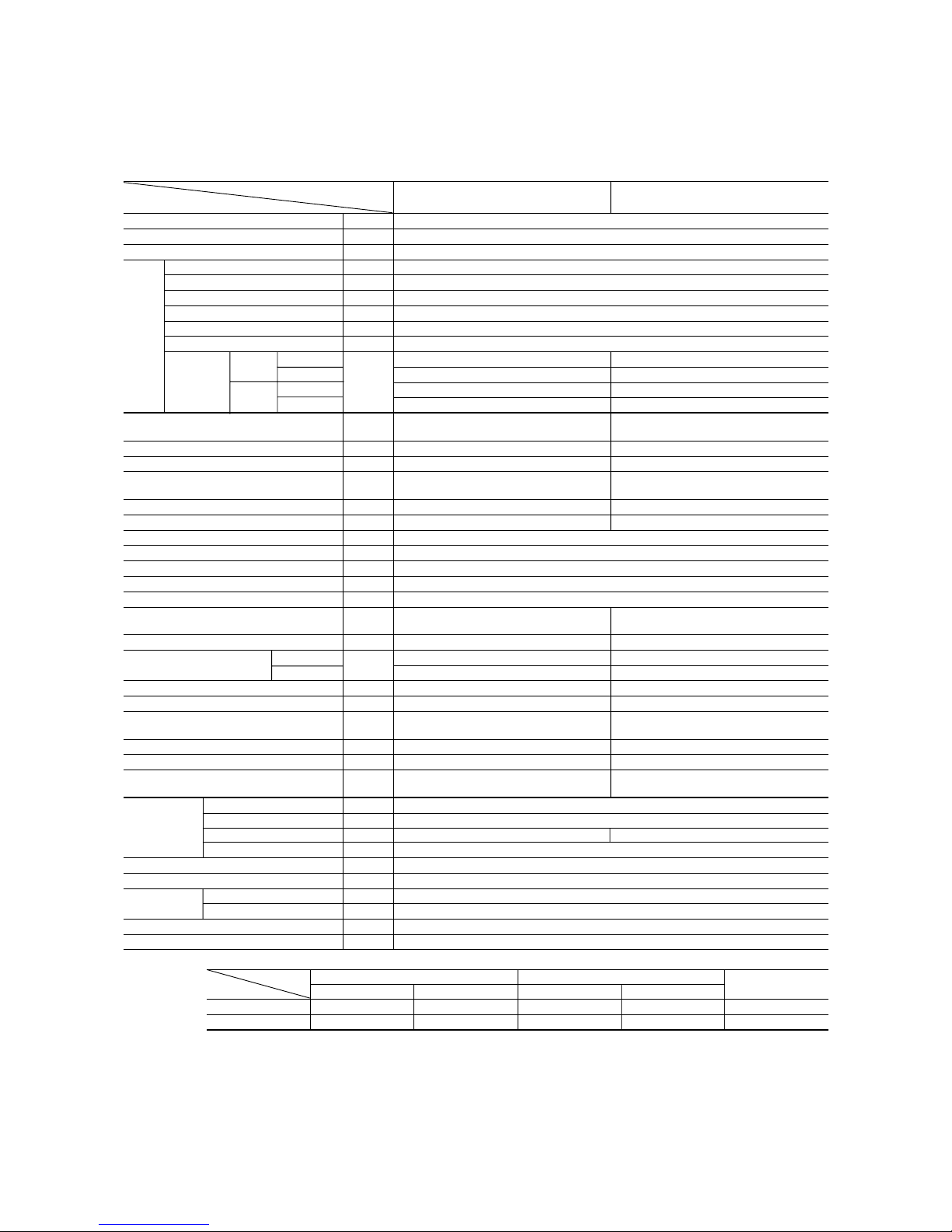

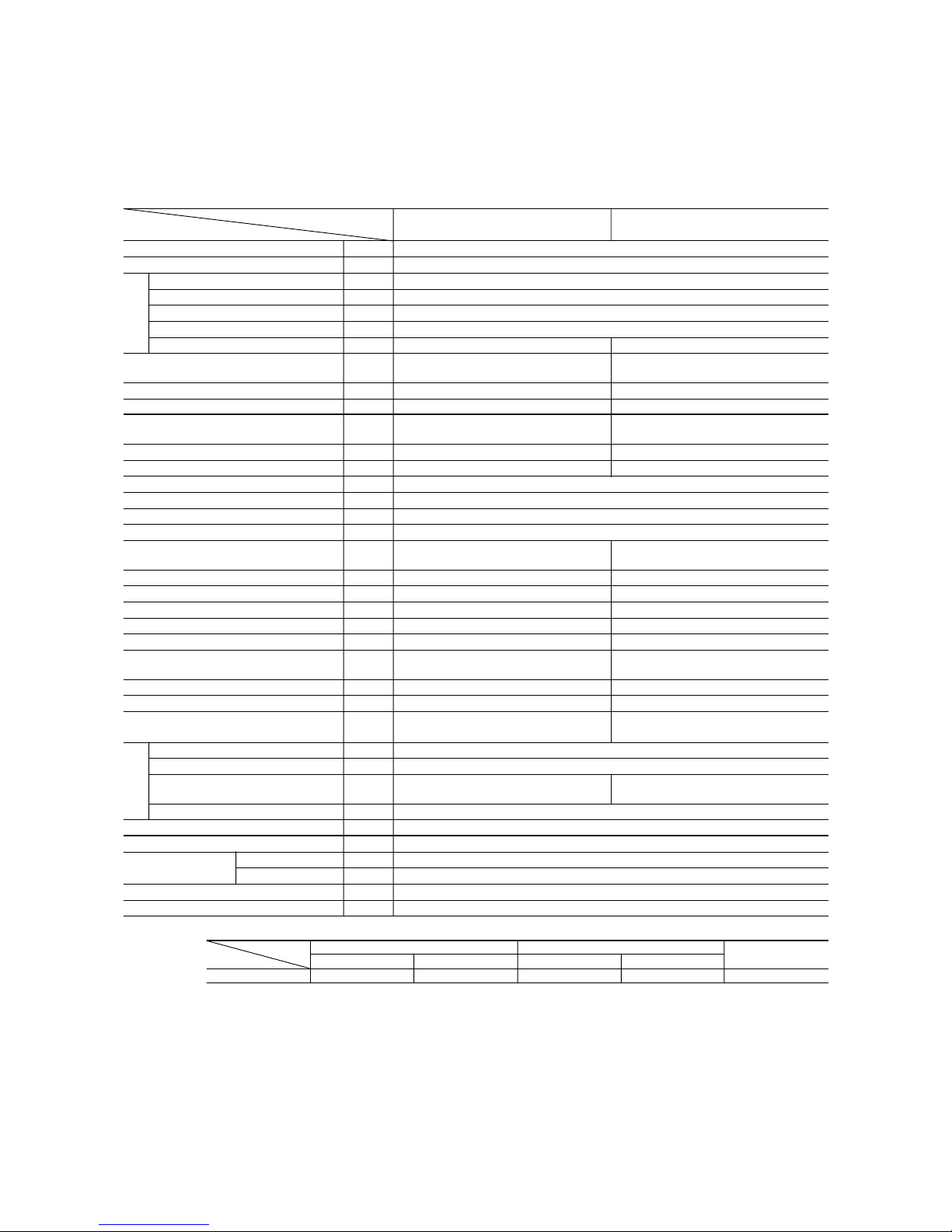

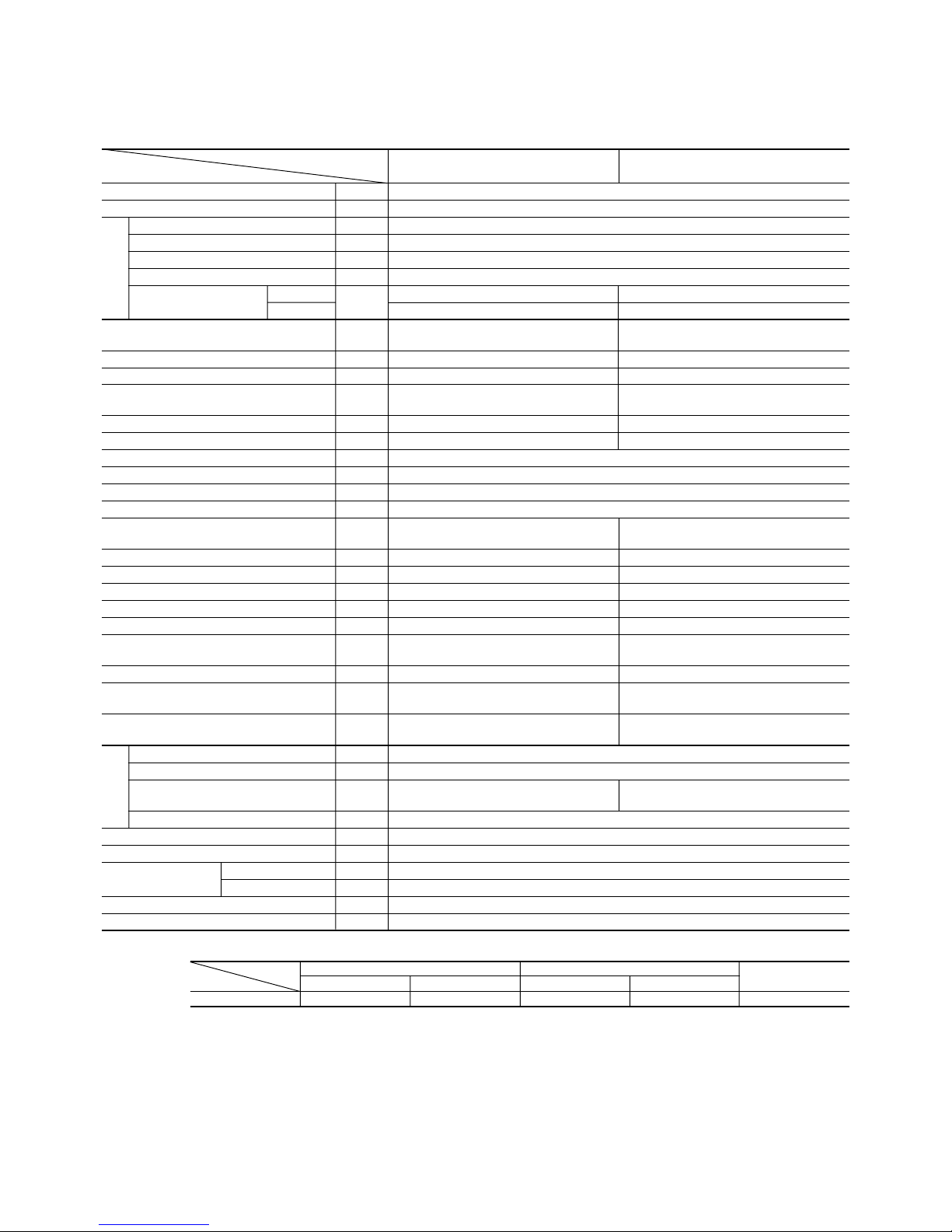

Model SRK288HENF-L (Indoor unit)

SRC288HENF-L (Outdoor unit)

Item

Model

SRK288HENF-L SRC288HENF-L

Cooling capacity

(1)

W 2500/2500

Heating capacity

(1)

W 2900/3000

Power source 1 Phase, 220/240V, 50Hz

Cooling input kW 0.930/1.005

Running current (Cooling) A 4.5/4.6

Heating input kW 0.83/0.91

Running current (Heating) A 4.0/4.1

Inrush current A 18.2/19.6

COP (In cooling) 2.69/2.49

Noise level

(5)

dB(A) Cooling:38/39 Heating:38/41 Cooling:41/42 Heating:42/43

Exterior dimensions

Height x Width x Depth

mm 275 x 790 x 174 542 x 795 x 255

Color Off white Polar white

Net weight kg 7.5 33

Refrigerant equipment

Compressor type & Q’ty

– RM5512GNE1 (Rotary type) x 1

Motor kW – 0.9

Starting method – Line starting

Heat exchanger Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Refrigerant

(4)

kg R22 0.88

Refrigerant oil R 0.35 (SUNISO Z300HDS)

Defrost control MC control

Air handling equipment

Fan type & Q’ty

Tangential fan x 1 Propeller fan x 1

Motor W 16 11

Air flow (at High) (Cooling) 7.5/7.5 23

(Heating)

CMM

8.0/8.0 23

Air filter, Q’ty Polypropylene net (washable) x 2 –

Shock & vibration absorber – Cushion rubber (for compressor)

Electric heater ––

Operation control

Operation switch

Wireless–Remote controller –

Room temperature control MC. Thermostat –

Pilot lamp RUN (Green), TIMER (Yellow) –

Safety equipment

–

Dome mounted protector (for compressor)

Internal thermostat (for fan motor)

O.D mm(in) Liquid line: ø6.35 (1/4") Gas line: ø9.52 (3/8")

Connecting method Flare connecting

Attached length of piping Liquid line: 0.4m

Gas line: 0.35m

–

Insulation Necessary (Both sides)

Drain hose Connectable

Power source cord 2.5m (3 cores with Earth)

Connection Size x Core number 1.5mm2 x 5 cores (Including earth cable)

wiring

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Optional parts –

Notes (1) The data are measured at the following conditions.

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27ºC 19ºC 35ºC 24ºC JIS C9612, ISO-T1

Heating 20ºC – 7ºC 6ºC JIS C9612, ISO-T1

(2) The operation data are applied to the 220V or 240V districts respectively

(3) Limitation of Voltage application Minimum: 198V Maximum: 264V

(4) The refrigerant quantity to be charged includes the refrigerant in 7.5m connecting piping.

(Purging is not required even in the short piping.)

If the piping length is longer, (when it is less 10 m, add 20g refrigerant per meter and when it is 10 to 15m, add 30g refrigerant

per meter.)

(5) Expressed in sound pressure level.

Operation data

(1)

Refrigerant

piping

Page 6

1-6

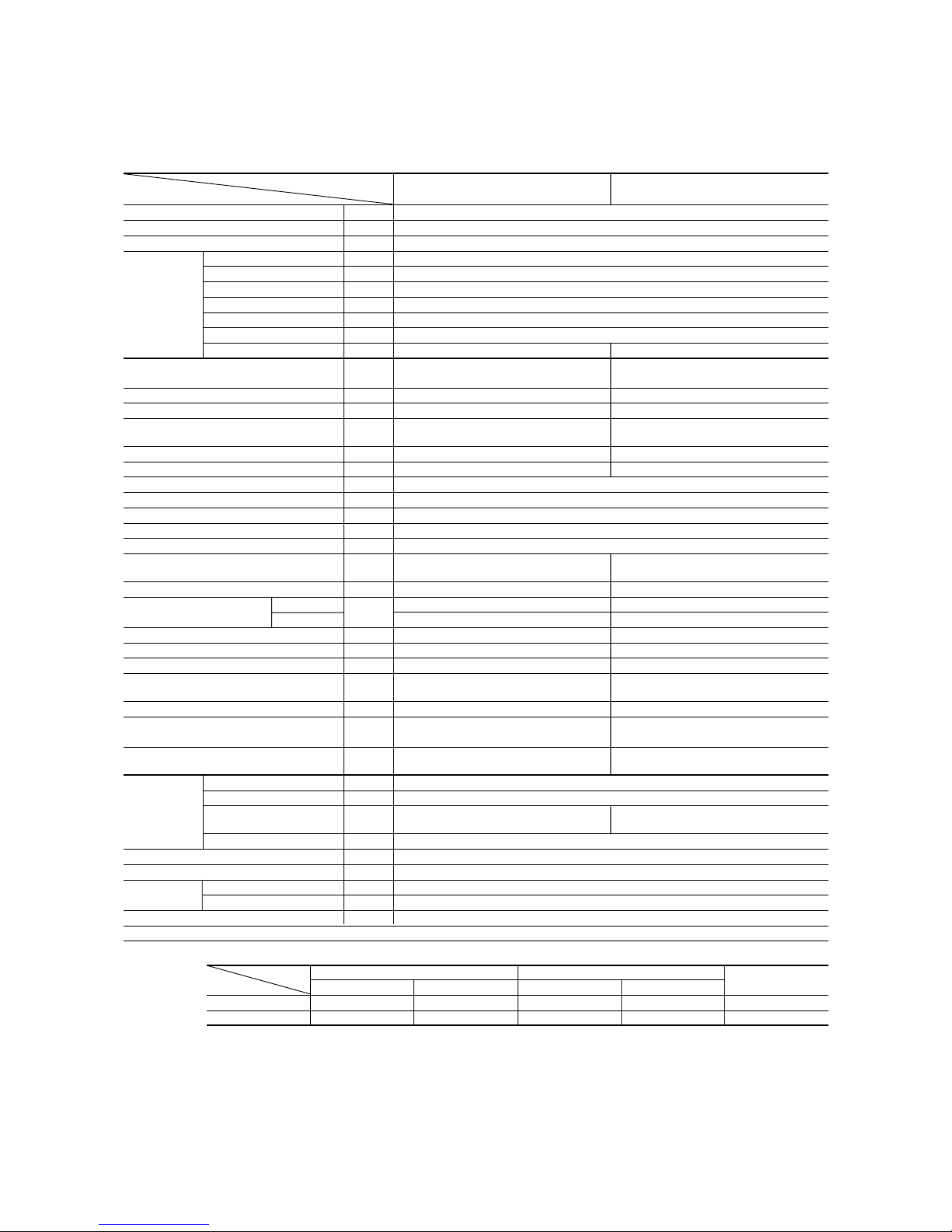

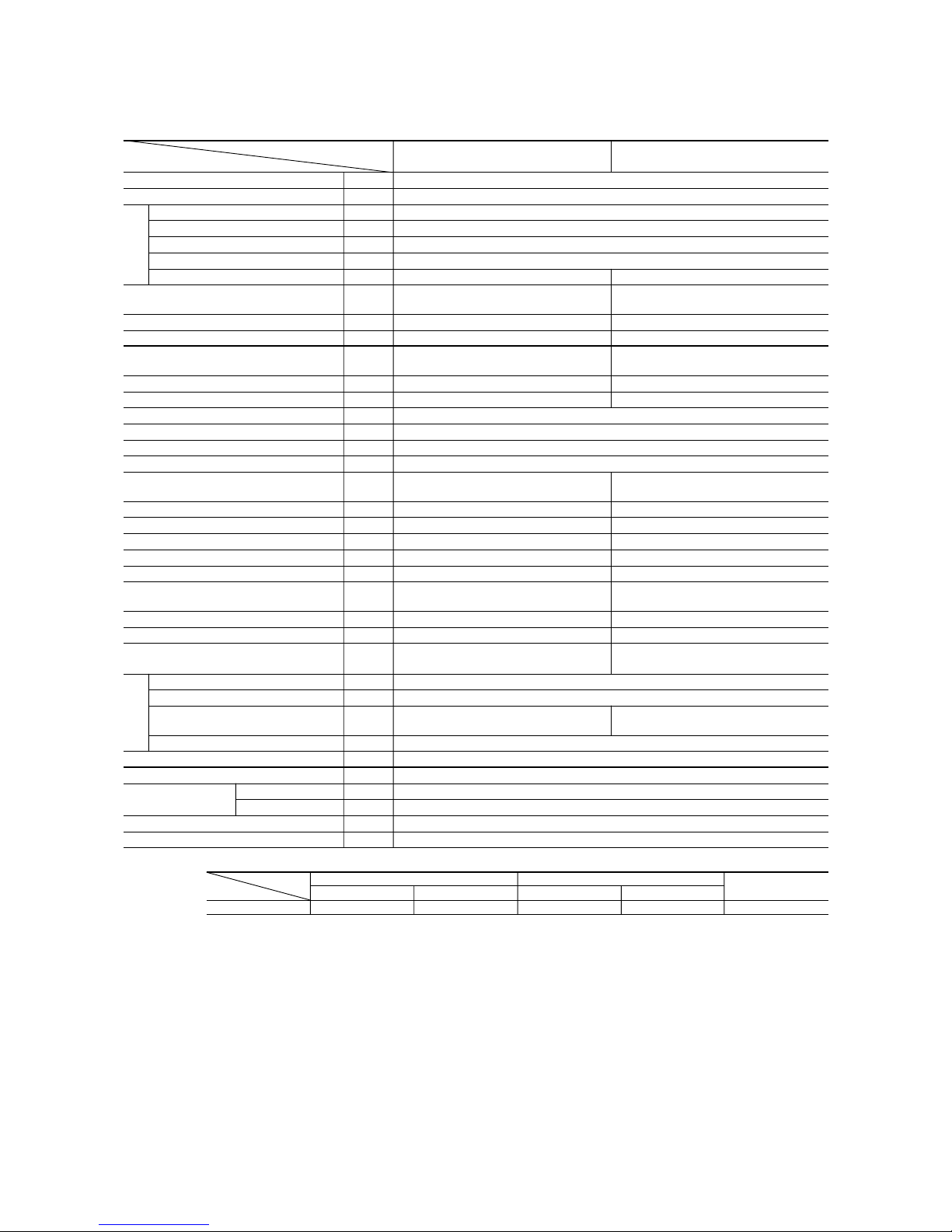

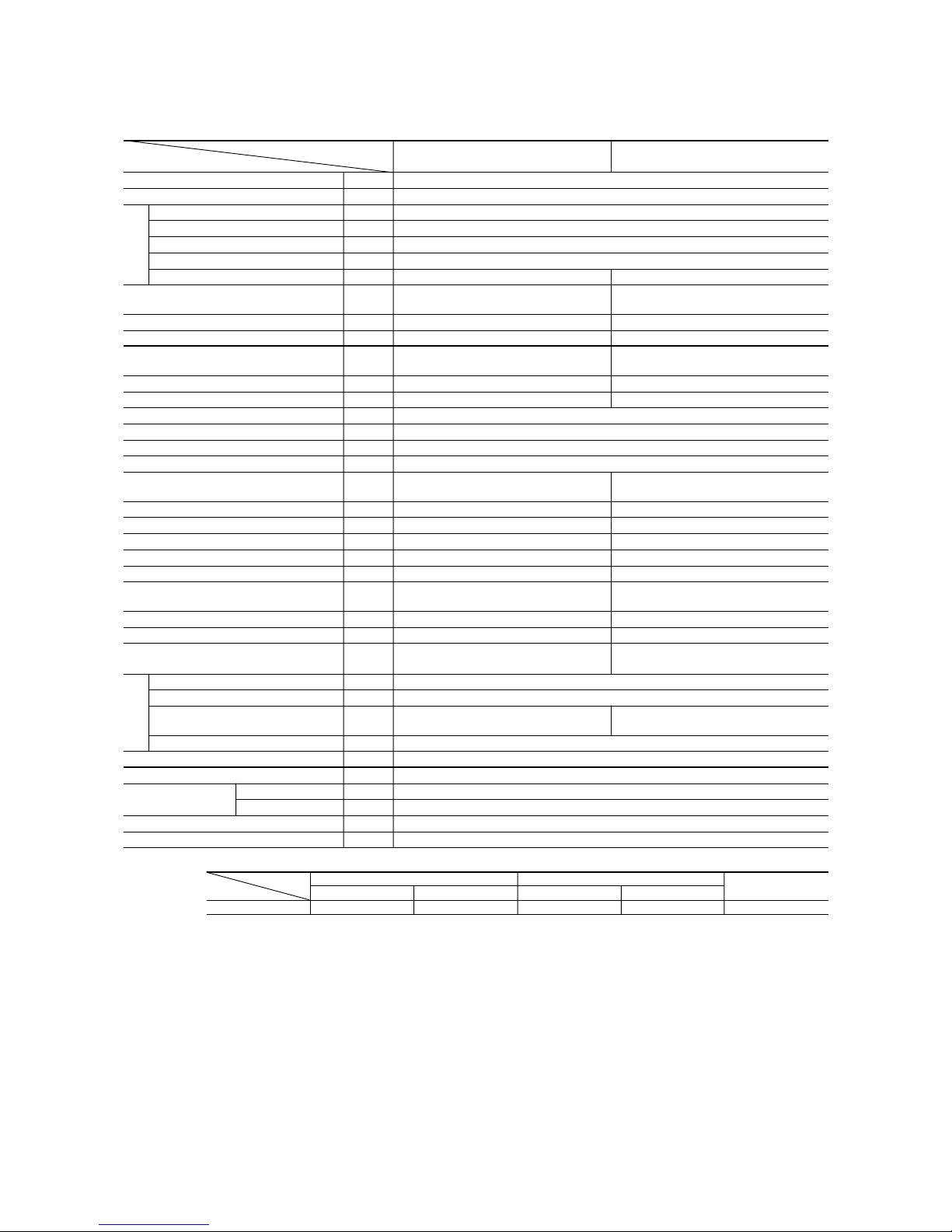

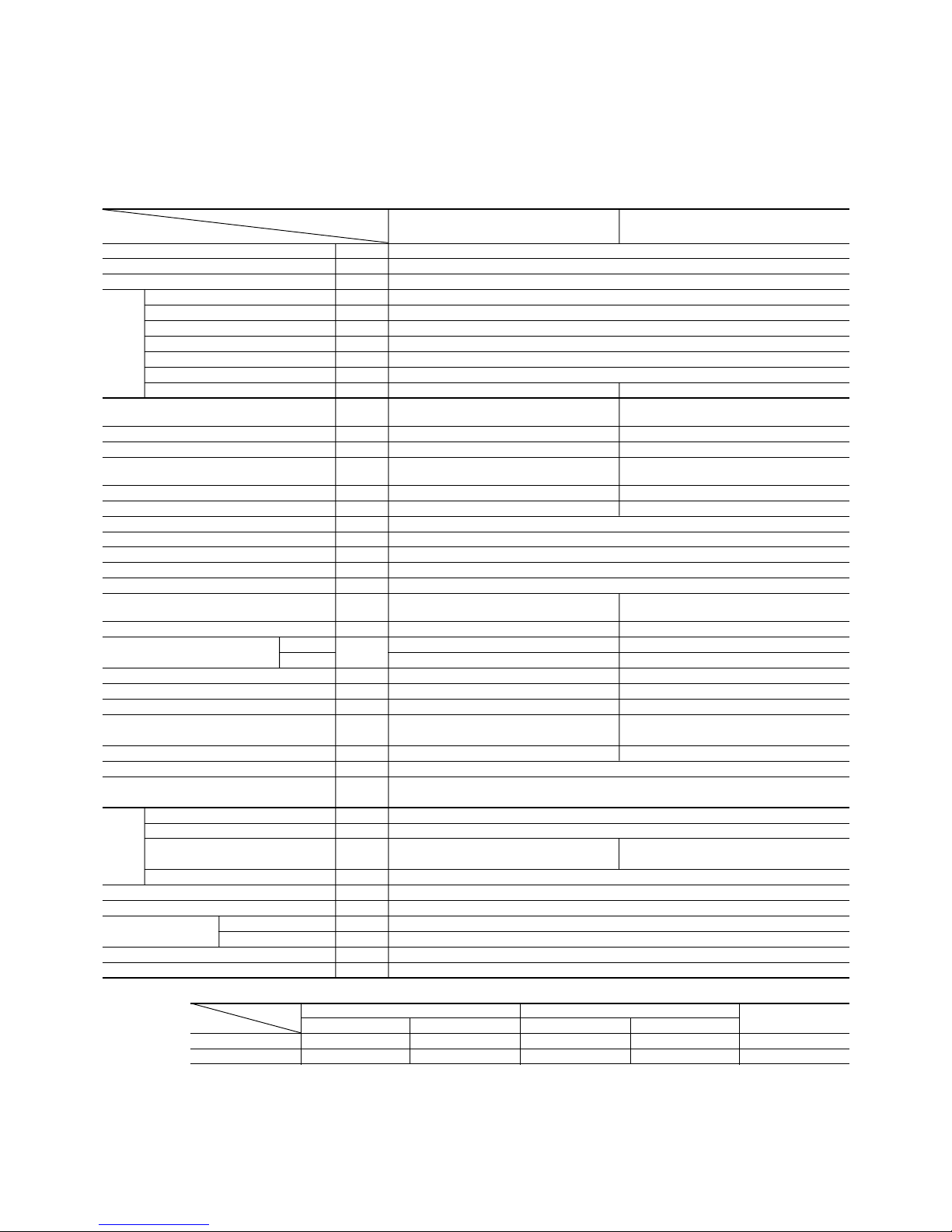

Model SRK328HENF-L2 (Indoor unit)

SRC328HENF-L2 (Outdoor unit)

Item

Model

SRK328HENF–L2 SRC328HENF–L2

Cooling capacity

(1)

W 3000/3000

Heating capacity

(1)

W 3800/3800

Power source 1 Phase, 220/240V, 50Hz

Cooling input kW 1.39/1.49

Running current (Cooling) A 6.9/6.9

Heating input kW 1.19/1.32

Running current (Heating) A 6.1/6.1

Inrush current A 33.6/36.6

COP (In cooling) 2.16/2.01

Noise level

(5)

dB(A) Cooling: 40/42 Heating: 41/43 Cooling: 44/46 Heating: 45/47

Exterior dimensions

Height x Width x Depth

mm 275 x 790 x 174 542 x 795 x 255

Color Ivory white Polar white

Net weight kg 8 37

Refrigerant equipment

Compressor type & Q’ty

– RM5517GNE2 (Rotary type) x 1

Motor kW – 1.3

Starting method – Line starting

Heat exchanger Louver fins & bare tubing

Refrigerant control Capillary tubes

Refrigerant

(4)

kg R22 0.74

Refrigerant oil R 0.6 (BARREL FREEZE 32SAM)

Defrost control MC control

Air handling equipment

Fan type & Q’ty

Tangential fan x 1 Propeller fan x 1

Motor W 16 15

Air flow (at High) (Cooling) 8.5/8.5 24/24.5

(Heating)

CMM

9.5/9.5 24/24.5

Air filter, Q’ty Polypropylene net (washable) x 2 –

Shock & vibration absorber – Cushion rubber (for compressor)

Electric heater ––

Operation control

Operation switch

Wireless–Remote controller –

Room temperature control MC. Thermostat –

Pilot lamp RUN (Green), TIMER (Yellow) –

Safety equipment

–

Dome mounted protector (for compressor)

Internal thermostat (for fan motor)

O.D mm(in) Liquid line: ø6.35 (1/4") Gas line: ø12.7 (1/2")

Connecting method Flare connecting

Attached length of piping Liquid line: 0.4m

Gas line : 0.35m

–

Insulation Necessary (Both sides)

Drain hose Connectable

Power source cord 2.5m (3 cores with Earth)

Connection Size x Core number 1.5mm2 x 5 cores (Including earth cable)

wiring

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Optional parts –

Notes (1) The data are measured at the following conditions.

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27ºC 19ºC 35ºC 24ºC JIS C9612, ISO-T1

Heating 20ºC – 7ºC 6ºC JIS C9612, ISO-T1

(2) The operation data are applied to the 220V or 240V districts respectively

(3) Limitation of Voltage application

Minimum: 198V Maximum: 264V

(4) The refrigerant quantity to be charged includes the refrigerant in 7.5m connecting piping.

(Purging is not required even in the short piping.)

If the piping length is longer, when it is 10 m, add 20g refrigerant per meter and when it is 10 to 15m, add 30g refrigerant per meter.

(5) Expressed in sound pressure level.

Operation data

(1)

Refrigerant

piping

Page 7

1-7

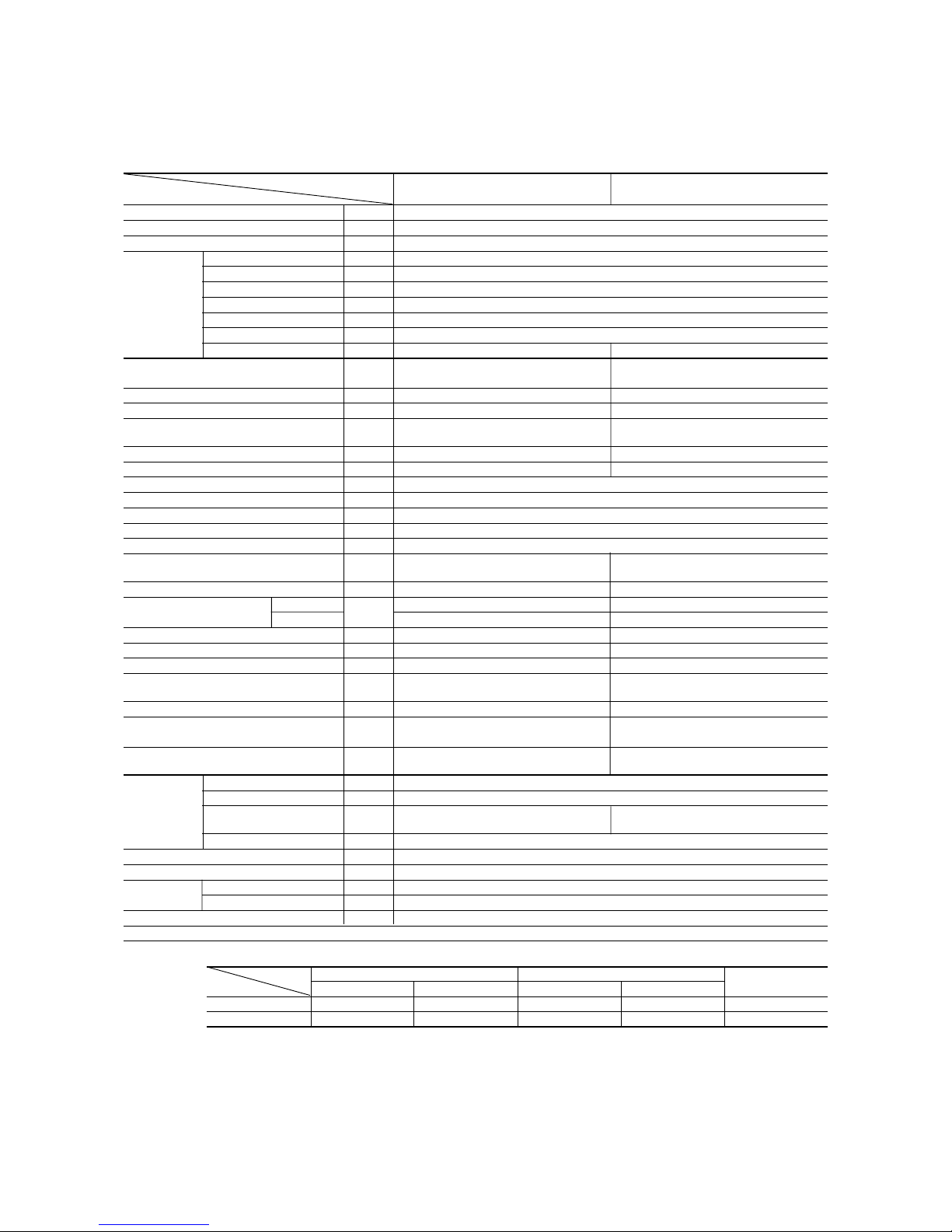

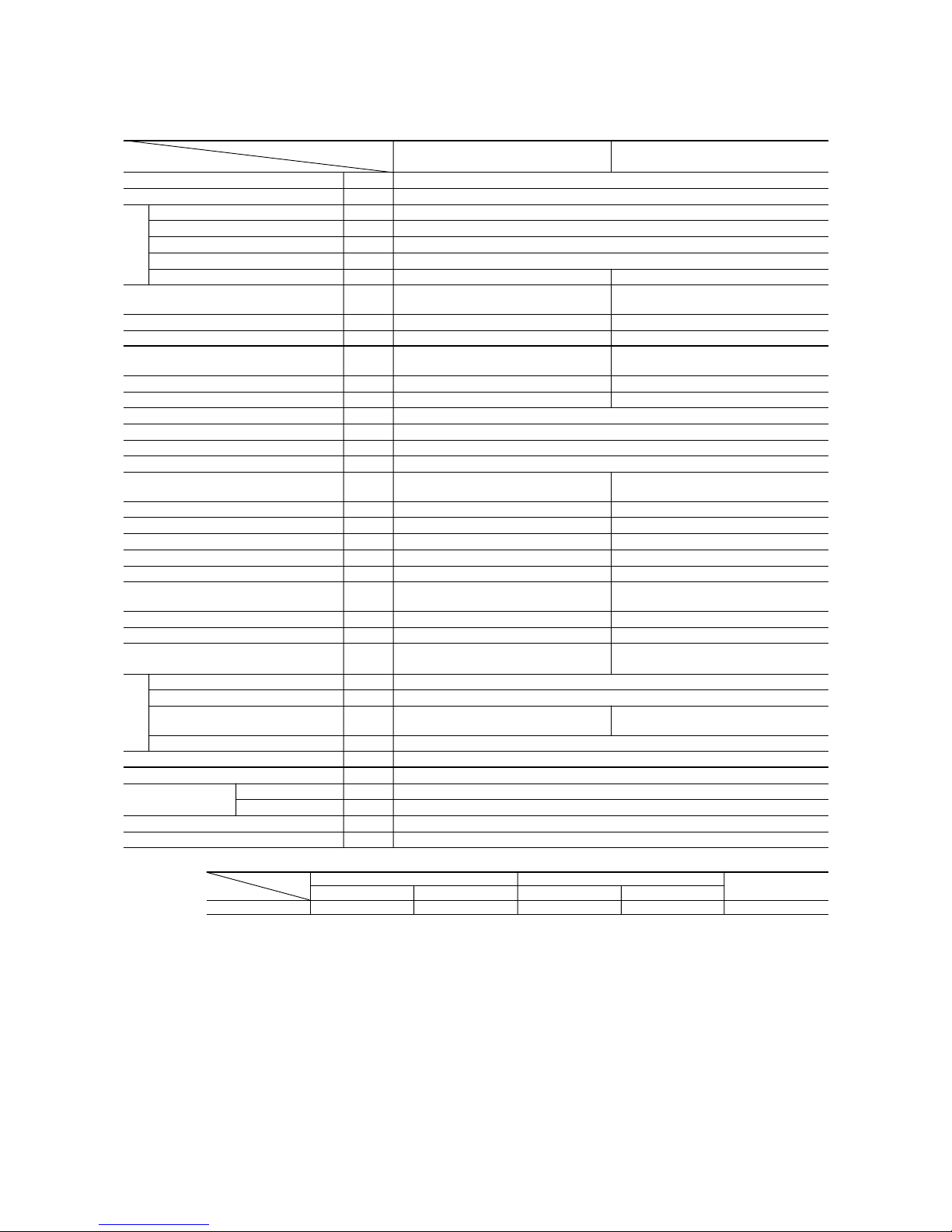

Model SRK408HENF-L3 (Indoor unit)

SRC408HENF-L3 (Outdoor unit)

Item

Model

SRK408HENF-L3 SRC408HENF-L3

Cooling capacity

(1)

W 3500/3500

Heating capacity

(1)

W 4100/4100

Power source 1 Phase, 220/240V, 50Hz

Cooling input kW 1.320/1.405

Running current (Cooling) A 6.4/6.4

Heating input kW 1.335/1.460

Running current (Heating) A 6.5/6.5

Inrush current A 33.6/36.6

COP (In cooling) 2.65/2.49

Cooling

Sound level Hi : 40/42 Lo : 31/32 47/49

Noise level

Power level

dB

Hi : 54/56 Lo : 45/46 61/63

Heating

Sound level Hi : 41/43 Lo : 39/40 48/50

Power level Hi : 55/57 Lo : 53/54 62/64

Exterior dimensions

Height x Width x Depth

mm 275 x 790 x 174 542 x 795 x 255

Color Ivory white Polar white

Net weight kg 8 37

Refrigerant equipment

Compressor type & Q’ty

– RM5516GNVE4 (Rotary type) x 1

Motor kW – 1.3

Starting method – Line starting

Heat exchanger Louver fins & bare tubing

Refrigerant control Capillary tubes

Refrigerant

(4)

kg R22 1.3

Refrigerant oil R 0.6 (BARREL FREEZE 32SAM)

Defrost control MC control

Air handling equipment

Fan type & Q’ty

Tangential fan x 1 Propeller fan x 1

Motor W 16 18

Air flow (at High) (Cooling) 8.5/8.5 22/22.5

(Heating)

CMM

9.5/9.5 22/22.5

Air filter, Q’ty Polypropylene net (washable) x 2 –

Shock & vibration absorber – Cushion rubber (for compressor)

Operation control

Operation switch

Wireless–Remote controller –

Room temperature control MC. Thermostat –

Pilot lamp RUN (Green), TIMER (Yellow) –

Safety equipment

–

Dome mounted protector (for compressor)

Internal thermostat (for fan motor)

O.D mm(in) Liquid line: ø6.35 (1/4") Gas line: ø12.7 (1/2")

Connecting method Flare connecting

Attached length of piping Liquid line: 0.4m Gas line : 0.35m –

Insulation Necessary (Both sides)

Drain hose Connectable

Power source cord 2.5m (3 cores with Earth)

Connection Size x Core number 1.5mm2 x 5 cores (Including earth cable)

wiring

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Optional parts –

Notes (1) The data are measured at the following conditions.

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27ºC 19ºC 35ºC 24ºC ISO-T1, JIS C9612

Heating 20ºC – 7ºC 6ºC ISO-T1, JIS C9612

(2) The operation data are applied to the 220V or 240V districts respectively

(3) The refrigerant quantity to be charged includes the refrigerant in 7.5m connecting piping. (Purging is not required even in the short piping.)

If the piping length is longer, when it is 10 m, add 20g refrigerant per meter and when it is 10 to 15m, add 30g refrigerant per meter.

(4) When the unit is operated in cooling or dehumidification mode at the outside air temperature of 1ºC and less, there is a possibility that water leakage

occurs at the indoor unit.

Operation data

(1)

Refrigerant

piping

Page 8

1-8

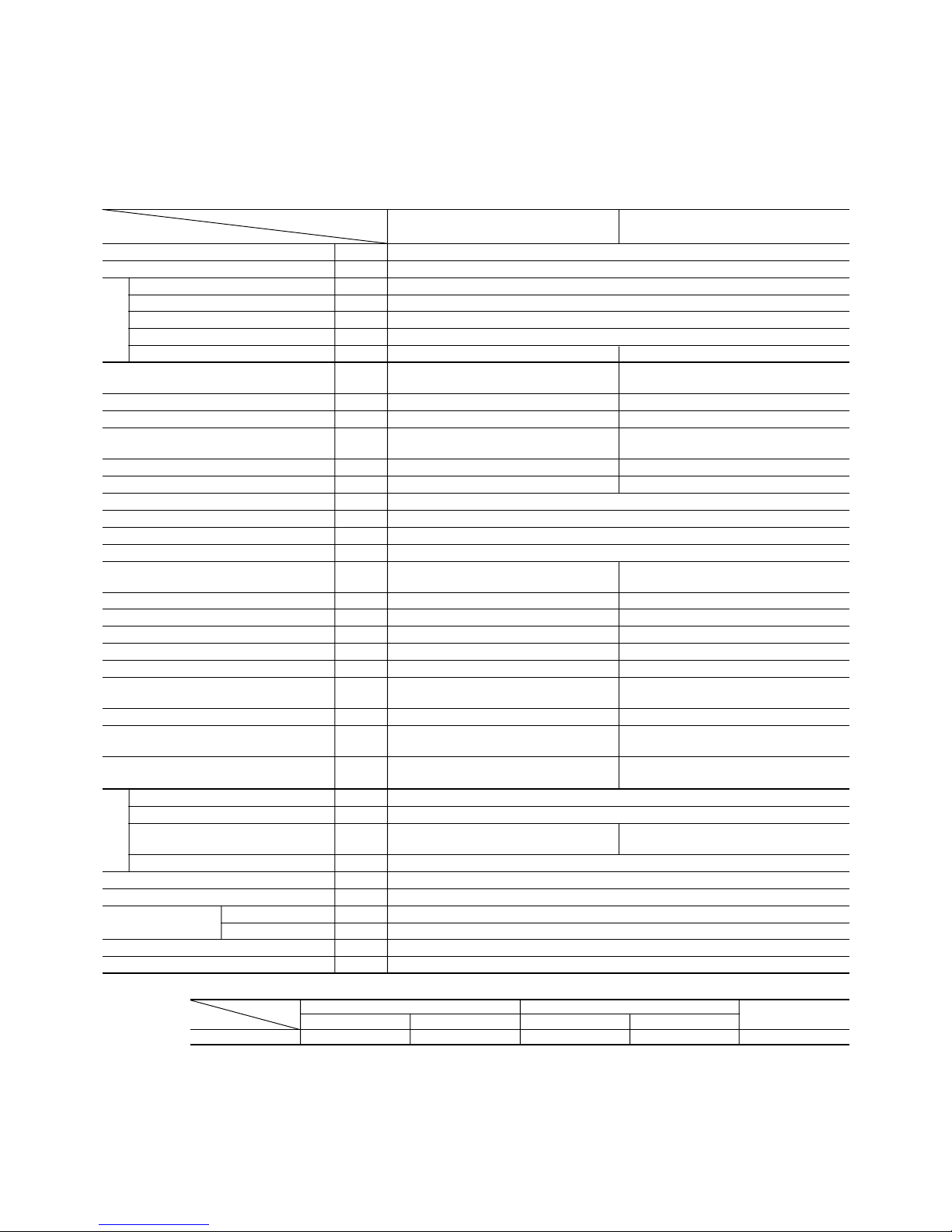

Item

Model

SRK501HENF–L SRC501HENF–L

Cooling capacity

(1)

W 4500/4500

Heating capacity

(1)

W 5700/5800

Power source 1 Phase, 220/240V, 50Hz

Cooling input kW 1.78/1.88

Running current (Cooling) A 8.4/8.2

Heating input kW 1.76/1.89

Running current (Heating) A 8.5/8.3

Inrush current A 39/42

COP (In cooling) 2.53/2.39

Noise level

(5)

dB(A) Cooling: 44/44 Heating: 45/45 Cooling: 50/51 Heating: 53/54

Exterior dimensions

Height x Width x Depth

mm 275‚790‚189 615‚850‚290 + 30

Color Ivory white Polar white

Net weight kg 9 53

Refrigerant equipment

Compressor type & Q’ty

– RM5523GNE4 (Rotary type) x 1

Motor kW – 1.7

Starting method – Line starting

Heat exchanger Louver fins & bare tubing

Refrigerant control Capillary tubes

Refrigerant

(4)

kg R22 1.28

Refrigerant oil R 0.7 (BARREL FREEZE 32SAM)

Defrost control MC control

Air handling equipment

Fan type & Q’ty

Tangential fan x 1 Propeller fan x 1

Motor W 23 40

Air flow (at High) (Cooling) 11/11 34/34

(Heating)

CMM

12/12 34/34

Air filter, Q’ty Polypropylene net (washable) x 2 –

Shock & vibration absorber – Cushion rubber (for compressor)

Electric heater ––

Operation control

Operation switch

Wireless–Remote controller –

Room temperature control MC. Thermostat –

Pilot lamp RUN (Green), TIMER (Yellow),

–

ECONO (Orange), HI POWER (Green)

Safety equipment

–

Dome mounted protector (for compressor)

Internal thermostat (for fan motor)

O.D mm(in) Liquid line: ø6.35 (1/4") Gas line: ø12.7 (1/2")

Connecting method Flare connecting

Attached length of piping Liquid line: 0.4m

Gas line: 0.35m

–

Insulation Necessary (Both sides)

Drain hose Connectable

Power source cord 2.5m (3 cores with Earth)

Connection Size x Core number 1.5mm2 x 5 cores (With Earth)

wiring

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Optional parts –

Notes (1) The data are measured at the following conditions.

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27ºC 19ºC 35ºC 24ºC JIS C9612, ISO-T1

Heating 20ºC – 7ºC 6ºC JIS C9612, ISO-T1

(2) The operation data are applied to the 220V or 240V districts respectively

(3) Limitation of Voltage application Minimum: 198V Maximum: 264V

(4) The refrigerant quantity to be charged includes the refrigerant in 7.5m connecting piping.

(Purging is not required even in the short piping.)

If the piping length is longer, (when it is 10 m, add 20g refrigerant per meter and when it is 10 to 15m, add 30g refrigerant per

meter.)

(5) Expressed in sound pressure level.

Operation data

(1)

Refrigerant

piping

Model SRK501HENF-L (Indoor unit)

SRC501HENF-L (Outdoor unit)

Page 9

1-9

Model SRK561HENF-L (Indoor unit)

SRC561HENF-L (Outdoor unit)

Item

Model

SRK561HENF–L SRC561HENF–L

Cooling capacity

(1)

W 5000/5000

Heating capacity

(1)

W 6200/6300

Power source 1 Phase, 220/240V, 50Hz

Cooling input kW 2.08/2.18

Running current (Cooling) A 10.2/9.53

Heating input kW 2.02/2.15

Running current (Heating) A 10.5/9.95

Inrush current A 44/48

COP (In cooling) 2.40/2.29

Noise level

(5)

dB(A) Cooling: 45/45 Heating: 46/46 Cooling: 53/54 Heating: 54/56

Exterior dimensions

Height x Width x Depth

mm 275‚790‚189 615‚850‚290 + 30

Color Ivory white Polar white

Net weight kg 9 53

Refrigerant equipment

Compressor type & Q’ty

– RM5526GNE4 (Rotary type) x 1

Motor kW – 1.9

Starting method – Line starting

Heat exchanger Louver fins & bare tubing

Refrigerant control Capillary tubes

Refrigerant

(4)

kg R22 1.35

Refrigerant oil R 0.7 (BARREL FREEZE 32SAM)

Defrost control MC control

Air handling equipment

Fan type & Q’ty

Tangential fan x 1 Propeller fan x 1

Motor W 23 40

Air flow (at High) (Cooling) 12/12 34/34

(Heating)

CMM

13/13 34/34

Air filter, Q’ty Polypropylene net (washable) x 2 –

Shock & vibration absorber – Cushion rubber (for compressor)

Electric heater ––

Operation control

Operation switch

Wireless–Remote controller –

Room temperature control MC. Thermostat –

Pilot lamp RUN (Green), TIMER (Yellow),

–

ECONO (Orange), HI POWER (Green)

Safety equipment – Dome mounted protector (for compressor)

Internal thermostat (for fan motor)

O.D mm(in) Liquid line: ø6.35 (1/4") Gas line: ø12.7 (1/2")

Connecting method Flare connecting

Attached length of piping Liquid line: 0.4m

Gas line: 0.35m

–

Insulation Necessary (Both sides)

Drain hose Connectable

Power source cord 2.5m (3 cores with Earth)

Connection Size x Core number 1.5mm2 x 5 cores (With Earth)

wiring

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Optional parts –

Notes (1) The data are measured at the following conditions.

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27ºC 19ºC 35ºC 24ºC JIS C9612, ISO-T1

Heating 20ºC – 7ºC 6ºC JIS C9612, ISO-T1

(2) The operation data are applied to the 220V or 240V districts respectively

(3) Limitation of Voltage application Minimum: 198V Maximum: 264V

(4) The refrigerant quantity to be charged includes the refrigerant in 7.5m connecting piping.

(Purging is not required even in the short piping.)

If the piping length is longer, (when it is 10 m, add 20g refrigerant per meter and when it is 10 to 15m, add 30g refrigerant per

meter.)

(5) Expressed in sound pressure level.

Operation data

(1)

Refrigerant

piping

Page 10

1-10

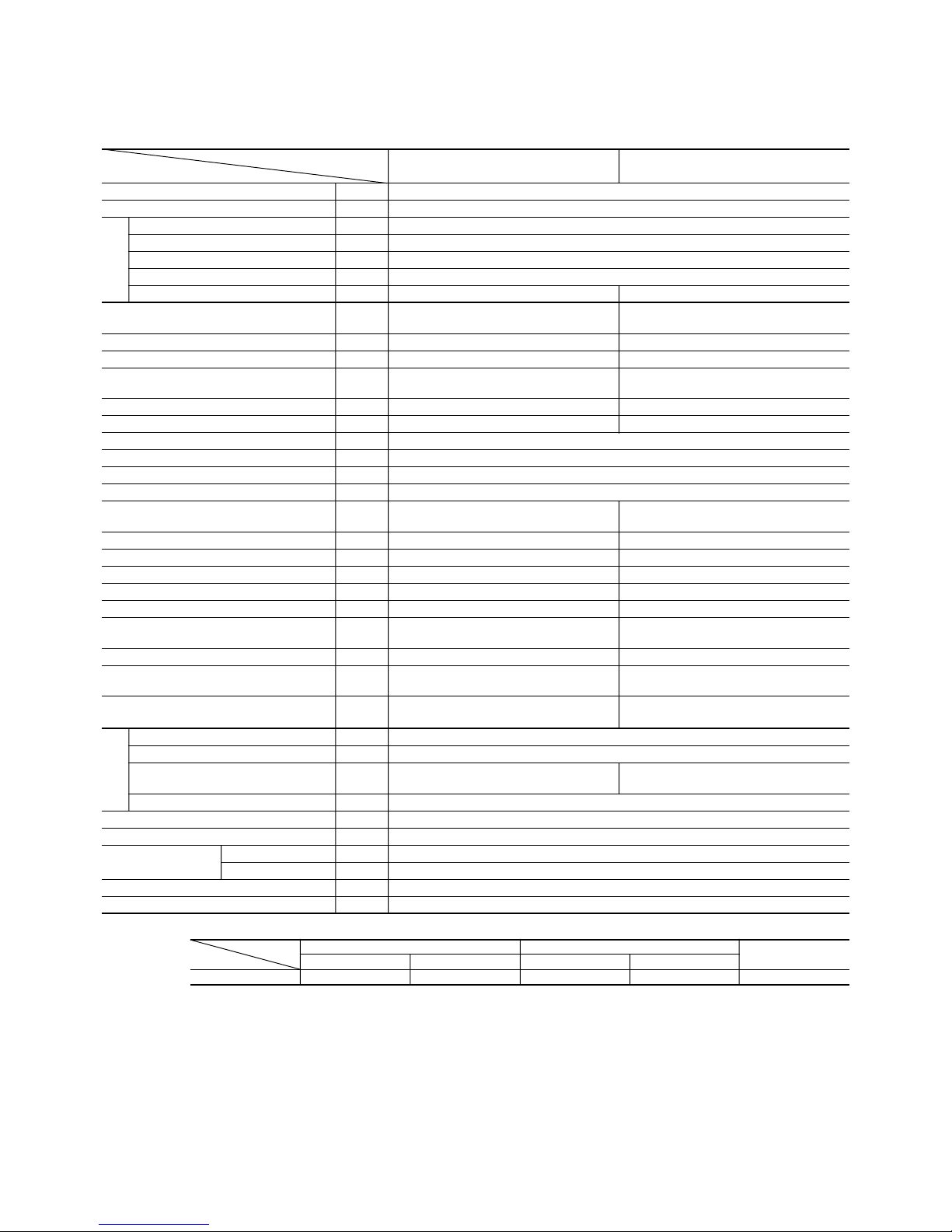

Model SRK50A (Indoor unit)

SRC50HA (Outdoor unit)

Item

Model

SRK50A SRC50HA

Cooling capacity

(1)

W 4500

Heating capacity

(1)

W 5700

Power source 1 Phase, 220/230/240V, 50Hz

Cooling input kW 1.79

Running current (Cooling) A 8.4/8.0/7.7

Heating input kW 1.83

Running current (Heating) A 8.5/8.1/7.9

Inrush current A 39/41/42

COP (In cooling) 2.51

Cooling

Sound level Hi : 44 Lo : 37 51

Noise level

Power level

dB

Hi : 58 Lo : 51 65

Heating

Sound level Hi : 45 Lo : 38 53

Power level Hi : 59 Lo : 52 67

Exterior dimensions

Height x Width x Depth

mm 298‚798‚203 640‚850‚290

Color Stucco white Stucco white

Net weight kg 10 45

Refrigerant equipment

Compressor type & Q’ty

– RM5523GNE4 (Rotary type) x 1

Motor kW – 1.7

Starting method – Line starting

Heat exchanger Louver fins & grooved tubing

Refrigerant control Capillary tubes

Refrigerant

(3)

kg R22 1.45

Refrigerant oil R 0.7 (BARREL FREEZE 32SAM)

Defrost control MC control

Air handling equipment

Fan type & Q’ty

Tangential fan x 1 Propeller fan x 1

Motor W 23 35

Air flow (at High) (Cooling) 11 39

(Heating)

CMM

13 39

Air filter, Q’ty Polypropylene net (washable) x 2 –

Shock & vibration absorber – Cushion rubber (for compressor)

Operation control

Operation switch

Wireless–Remote controller –

Room temperature control MC. Thermostat –

Pilot lamp RUN (Green), TIMER (Yellow),

–

ECONO (Orange), HI POWER (Green)

Safety equipment

–

Dome mounted protector (for compressor)

Internal thermostat (for fan motor)

O.D mm(in) Liquid line: ø6.35 (1/4") Gas line: ø12.7 (1/2")

Connecting method Flare connecting

Attached length of piping Liquid line: 0.5m Gas line: 0.43m –

Insulation Necessary (Both sides)

Drain hose Connectable

Power source cord 3m (3 cores with Earth)

Connection Size x Core number 1.5mm2 x 5 cores (With Earth)

wiring

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Optional parts –

Notes (1) The data are measured at the following conditions.

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27ºC 19ºC 35ºC 24ºC ISO-T1, JIS C9612

Heating 20ºC – 7ºC 6ºC ISO-T1, JIS C9612

(2) The operation data are applied to the 220V, 230V or 240V districts respectively

(3) The refrigerant quantity to be charged includes the refrigerant in 7 m connecting piping. (Purging is not required even in the short piping.)

If the piping length is longer. (When it is 7 to 15 m, add 20 g refrigerant per meter.)

(4) When the unit is operated in cooling or dehumidification mode at the outside air temperature of 1ºC and less, there is a possibility that water leakage

occurs at the indoor unit.

Operation data

(1)

Refrigerant

piping

Page 11

1-11

Model SRK56A (Indoor unit)

SRC56HA (Outdoor unit)

Item

Model

SRK56A SRC56HA

Cooling capacity

(1)

W 5000

Heating capacity

(1)

W 6200

Power source 1 Phase, 220/230/240V, 50Hz

Cooling input kW 2.08

Running current (Cooling) A 9.7/9.3/8.9

Heating input kW 2.10

Running current (Heating) A 9.8/9.4/9.0

Inrush current A 44/46/48

COP (In cooling) 2.40

Cooling

Sound level Hi : 45 Lo : 38 51

Noise level

Power level

dB

Hi : 59 Lo : 52 65

Heating

Sound level Hi : 45 Lo : 38 53

Power level Hi : 59 Lo : 52 67

Exterior dimensions

Height x Width x Depth

mm 298‚798‚203 640‚850‚290

Color Stucco white Stucco white

Net weight kg 10 45

Refrigerant equipment

Compressor type & Q’ty

– RM5526GNE4 (Rotary type) x 1

Motor kW – 1.9

Starting method – Line starting

Heat exchanger Louver fins & grooved tubing

Refrigerant control Capillary tubes

Refrigerant

(3)

kg R22 1.45

Refrigerant oil R 0.7 (BARREL FREEZE 32SAM)

Defrost control MC control

Air handling equipment

Fan type & Q’ty

Tangential fan x 1 Propeller fan x 1

Motor W 23 35

Air flow (at High) (Cooling) 11 39

(Heating)

CMM

13 39

Air filter, Q’ty Polypropylene net (washable) x 2 –

Shock & vibration absorber – Cushion rubber (for compressor)

Operation control

Operation switch

Wireless–Remote controller –

Room temperature control MC. Thermostat –

Pilot lamp RUN (Green), TIMER (Yellow),

–

ECONO (Orange), HI POWER (Green)

Safety equipment – Dome mounted protector (for compressor)

Internal thermostat (for fan motor)

O.D mm(in) Liquid line: ø6.35 (1/4") Gas line: ø12.7 (1/2")

Connecting method Flare connecting

Attached length of piping Liquid line: 0.5m Gas line: 0.43m –

Insulation Necessary (Both sides)

Drain hose Connectable

Power source cord 3m (3 cores with Earth)

Connection Size x Core number 1.5mm2 x 5 cores (With Earth)

wiring

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Optional parts –

Notes (1) The data are measured at the following conditions.

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27ºC 19ºC 35ºC 24ºC ISO-T1, JIS C9612

Heating 20ºC – 7ºC 6ºC ISO-T1, JIS C9612

(2) The operation data are applied to the 220V, 230V or 240V districts respectively

(3) The refrigerant quantity to be charged includes the refrigerant in 7 m connecting piping. (Purging is not required even in the short piping.)

If the piping length is longer. (When it is 7 to 15 m, add 20 g refrigerant per meter.)

(4) When the unit is operated in cooling or dehumidification mode at the outside air temperature of 1ºC and less, there is a possibility that water leakage

occurs at the indoor unit.

Operation data

(1)

Refrigerant

piping

Page 12

1-12

(2) The operation data are applied to the 220 V or 240 V districts respectively.

(3) Limitation of Voltage application

Minimum: 198 V Maximum: 264 V

(4) The refrigerant quantity to be charged includes the refrigerant in 7.5 m connecting piping.

(Purging is not required even in the short piping.)

If the piping length is longer, (when it is less than 10 m, add 10 g refrigerant per meter and when it is 10 to 15 m, add 30 g refrigerant per meter.)

(5) Expressed in sound pressure level.

Notes (1) The data are measured at the following conditions.

Model SRK208CENF-L (Indoor unit)

SRC208CENF-L (Outdoor unit)

Item

Model

SRK208CENF-L SRC208CENF-L

Cooling capacity

(1)

W 1800/1850

Power source 1 Phase, 220/240 V, 50 Hz

Cooling input kW 0.54/0.58

Running current (Cooling) A 2.5/2.6

Inrush current A 11.7/12.8

COP (In cooling) 3.33/3.19

Noise level

(5)

dB (A) 36/37 44/45

Exterior dimensions mm

275 × 790 × 174 492 × 750 × 220

Height × Width × Depth

Color Ivory white Polar white

Net weight kg 7.5 24

Refrigerant equipment

– RM5470GNE5 (Rotary type) × 1

Compressor types & Q’ty

Motor kW – 0.55

Starting method – Line starting

Heat exchanger Louver fins & tubing

Refrigerant control Capillary tubes

Refrigerant

(4)

kg R22 0.57

Refrigerant oil R 0.3 (BARREL FREEZE 32SAM)

Air handling equipment

Tangential fan × 1 Propeller fan × 1

Fan type & Q’ty

Motor W 16 17

Air flow (at High) CMM 7/7 19.5/20.5

Air filter, Q’ty Polypropylene net (washable) × 2–

Shock & vibration absorber – Cushion rubber (for compressor)

Electric heater ––

Operation control

Wireless-Remote controller –

Operation switch

Room temperature control MC. Thermostat –

Pilot lamp RUN (Green), TIMER (Yellow) –

Safety equipment

–

Dome mounted protector (for compressor)

Internal thermostat (for fan motor)

O.D mm (in) Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

Connecting method Flare connecting

Attached length of piping Liquid line: 0.4 m

–

Gas line : 0.35 m

Insulation Necessary (Both sides)

Drain hose Connectable

Power source cord 2.5 m (3 cores with Earth)

Size × Core number 1.5 mm2 × 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Optional parts –

Connection

wiring

Operation

data

(1)

Refrigerant

piping

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27°C19°C35°C24°C JIS C9612, ISO-T1

Page 13

1-13

(2) The operation data are applied to the 220 V or 240 V districts respectively.

(3) Limitation of Voltage application

Minimum: 198 V Maximum: 264 V

(4) The refrigerant quantity to be charged includes the refrigerant in 7.5 m connecting piping.

(Purging is not required even in the short piping.)

If the piping length is longer, (when it is less than 10 m, add 10 g refrigerant per meter and when it is 10 to 15 m, add 30 g refrigerant per meter.)

(5) Expressed in sound pressure level.

Notes (1) The data are measured at the following conditions.

Model SRK258CENF-L (Indoor unit)

SRC258CENF-L (Outdoor unit)

Item

Model

SRK258CENF-L SRC258CENF-L

Cooling capacity

(1)

W 2200/2250

Power source 1 Phase. 220/240 V, 50 Hz

Cooling input kW 0.66/0.74

Running current (Cooling) A 3.3/3.4

Inrush current A 17.3/18.9

COP (In cooling) 3.33/3.04

Noise level

(5)

dB (A) 38/39 41/42

Exterior dimensions mm

275 × 790 × 174 542 × 795 × 255

Height × Width × Depth

Color Ivory white Polar white

Net weight kg 7.5 31

Refrigerant equipment

– RM5485GNE1 (Rotary type) × 1

Compressor types & Q’ty

Motor kW – 0.6

Starting method – Line starting

Heat exchanger Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Refrigerant

(4)

kg R22 0.71

Refrigerant oil R 0.3 (BARREL FREEZE 32SAM)

Air handling equipment

Tangential fan × 1 Propeller fan × 1

Fan type & Q’ty

Motor W 16 11

Air flow (at High) CMM 7.5/7.5 22/22

Air filter, Q’ty Polypropylene net (washable) × 2–

Shock & vibration absorber – Cushion rubber (for compressor)

Electric heater ––

Operation control

Wireless-Remote controller –

Operation switch

Room temperature control MC. Thermostat –

Pilot lamp RUN (Green), TIMER (Yellow) –

Safety equipment

–

Dome mounted protector (for compressor)

Internal thermostat (for fan motor)

O.D mm (in) Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

Connecting method Flare connecting

Attached length of piping Liquid line: 0.4 m

–

Gas line : 0.35 m

Insulation Necessary (Both sides)

Drain hose Connectable

Power source cord 2.5 m (3 cores with Earth)

Size × Core number 1.5 mm2 × 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Optional parts –

Connection

wiring

Operation

data

(1)

Refrigerant

piping

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27°C19°C35°C24°C JIS C9612, ISO-T1

Page 14

1-14

(2) The operation data are applied to the 220 V or 240 V districts respectively.

(3) Limitation of Voltage application

Minimum: 198 V Maximum: 264 V

(4) The refrigerant quantity to be charged includes the refrigerant in 7.5 m connecting piping.

(Purging is not required even in the short piping.)

If the piping length is longer, (when it is less than 10 m, add 10 g refrigerant per meter and when it is 10 to 15 m, add 30 g refrigerant per meter.)

(5) Expressed in sound pressure level.

Notes (1) The data are measured at the following conditions.

Model SRK288CENF-L (Indoor unit)

SRC288CENF-L (Outdoor unit)

Item

Model

SRK288CENF-L SRC288CENF-L

Cooling capacity

(1)

W 2500/2550

Power source 1 Phase, 220/240 V, 50 Hz

Cooling input kW 0.87/0.95

Running current (Cooling) A 4.1/4.2

Inrush current A 18.2/19.6

COP (In cooling) 2.87/2.68

Noise level

(5)

dB (A) 38/39 41/42

Exterior dimensions mm

275 × 790 × 174 542 × 795 × 255

Height × Width × Depth

Color Ivory white Polar white

Net weight kg 7.5 33

Refrigerant equipment

– RM5512GNE1 (Rotary type) × 1

Compressor types & Q’ty

Motor kW – 0.9

Starting method – Line starting

Heat exchanger Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Refrigerant

(4)

kg R22 0.75

Refrigerant oil R 0.35 (BARREL FREEZE 32SAM)

Air handling equipment

Tangential fan × 1 Propeller fan × 1

Fan type & Q’ty

Motor W 16 11

Air flow (at High) CMM 7.5/7.5 22/22

Air filter, Q’ty Polypropylene net (washable) × 2–

Shock & vibration absorber – Cushion rubber (for compressor)

Electric heater ––

Operation control

Wireless-Remote controller –

Operation switch

Room temperature control MC. Thermostat –

Pilot lamp RUN (Green), TIMER (Yellow) –

Safety equipment

–

Dome mounted protector (for compressor)

Internal thermostat (for fan motor)

O.D mm (in) Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

Connecting method Flare connecting

Attached length of piping Liquid line: 0.4 m

–

Gas line : 0.35 m

Insulation Necessary (Both sides)

Drain hose Connectable

Power source cord 2.5 m (3 cores with Earth)

Size × Core number 1.5 mm2 × 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Optional parts –

Connection

wiring

Operation

data

(1)

Refrigerant

piping

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27°C19°C35°C24°C JIS C9612, ISO-T1

Page 15

1-15

(2) The operation data are applied to the 220 V or 240 V districts respectively.

(3) Limitation of Voltage application

Minimum: 198 V Maximum: 264 V

(4) The refrigerant quantity to be charged includes the refrigerant in 7.5 m connecting piping.

(Purging is not required even in the short piping.)

If the piping length is longer, (when it is less than 10 m, add 10 g refrigerant per meter and when it is 10 to 15 m, add 30 g refrigerant per meter.)

(5) Expressed in sound pressure level.

Notes (1) The data are measured at the following conditions.

Model SRK328CENF-L (Indoor unit)

SRC328CENF-L (Outdoor unit)

Item

Model

SRK328CENF-L SRC328CENF-L

Cooling capacity

(1)

W 2750/2750

Power source 1 Phase, 220/240 V, 50 Hz

Cooling input kW 0.93/0.99

Running current (Cooling) A 4.3/4.4

Inrush current A 18.2/19.6

COP (In cooling) 2.96/2.78

Noise level

(5)

dB (A) 40/42 42/44

Exterior dimensions mm

275 × 790 × 174 542 × 795 × 255

Height × Width × Depth

Color Ivory white Polar white

Net weight kg 8 33

Refrigerant equipment

– RM5512GNE1 (Rotary type) × 1

Compressor types & Q’ty

Motor kW – 0.9

Starting method – Line starting

Heat exchanger Louver fins & tubing

Refrigerant control Capillary tubes

Refrigerant

(4)

kg R22 0.7

Refrigerant oil R 0.35 (BARREL FREEZE 32SAM)

Air handling equipment

Tangential fan × 1 Propeller fan × 1

Fan type & Q’ty

Motor W 16 9

Air flow (at High) CMM 8.5/8.5 22/22.5

Air filter, Q’ty Polypropylene net (washable) × 2–

Shock & vibration absorber – Cushion rubber (for compressor)

Electric heater ––

Operation control

Wireless-Remote controller –

Operation switch

Room temperature control MC. Thermostat –

Pilot lamp RUN (Green), TIMER (Yellow) –

Safety equipment

–

Dome mounted protector (for compressor)

Internal thermostat (for fan motor)

O.D mm (in) Liquid line: φ6.35 (1/4") Gas line: φ12.7 (1/2")

Connecting method Flare connecting

Attached length of piping Liquid line: 0.4 m

–

Gas line : 0.35 m

Insulation Necessary (Both sides)

Drain hose Connectable

Power source cord 2.5 m (3 cores with Earth)

Size × Core number 1.5 mm2 × 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Optional parts –

Connection

wiring

Operation

data

(1)

Refrigerant

piping

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27°C19°C35°C24°C JIS C9612, ISO-T1

Page 16

1-16

(2) The operation data are applied to the 220 V or 240 V districts respectively.

(3) Limitation of Voltage application

Minimum: 198 V Maximum: 264 V

(4) The refrigerant quantity to be charged includes the refrigerant in 7.5 m connecting piping.

(Purging is not required even in the short piping.)

If the piping length is longer, (when it is less than 10 m, add 10 g refrigerant per meter and when it is 10 to 15 m, add 30 g refrigerant per meter.)

(5) Expressed in sound pressure level.

Notes (1) The data are measured at the following conditions.

Model SRK408CENF-L (Indoor unit)

SRC408CENF-L (Outdoor unit)

Item

Model

SRK408CENF-L SRC408CENF-L

Cooling capacity

(1)

W 3500/3500

Power source 1 Phase, 220/240 V, 50 Hz

Cooling input kW 1.320/1.405

Running current (Cooling) A 6.4/6.4

Inrush current A 33.6/36.6

COP (In cooling) 2.65/2.49

Noise level

(5)

dB (A) 40/42 47/49

Exterior dimensions mm

275 × 790 × 174 542 × 795 × 255

Height × Width × Depth

Color Ivory white Polar white

Net weight kg 8 37

Refrigerant equipment

– RM5517GNE4 (Rotary type) × 1

Compressor types & Q’ty

Motor kW – 1.3

Starting method – Line starting

Heat exchanger Louver fins & tubing

Refrigerant control Capillary tubes

Refrigerant

(4)

kg R22 1.3

Refrigerant oil R 0.6 (BARREL FREEZE 32SAM)

Air handling equipment

Tangential fan × 1 Propeller fan × 1

Fan type & Q’ty

Motor W 16 18

Air flow (at High) CMM 8.5/8.5 22/22.5

Air filter, Q’ty Polypropylene net (washable) × 2–

Shock & vibration absorber – Cushion rubber (for compressor)

Electric heater ––

Operation control

Wireless-Remote controller –

Operation switch

Room temperature control MC. Thermostat –

Pilot lamp RUN (Green), TIMER (Yellow) –

Safety equipment

–

Dome mounted protector (for compressor)

Internal thermostat (for fan motor)

O.D mm (in) Liquid line: φ6.35 (1/4") Gas line: φ12.7 (1/2")

Connecting method Flare connecting

Attached length of piping Liquid line: 0.4 m

–

Gas line : 0.35 m

Insulation Necessary (Both sides)

Drain hose Connectable

Power source cord 2.5 m (3 cores with Earth)

Size × Core number 1.5 mm2 × 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Optional parts –

Connection

wiring

Operation

data

(1)

Refrigerant

piping

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27°C19°C35°C24°C JIS C9612, ISO-T1

Page 17

1-17

Model SRK501CENF-L (Indoor unit)

SRC501CENF-L (Outdoor unit)

(2) The operation data are applied to the 220 V or 240 V districts respectively.

(3) Limitation of Voltage application

Minimum: 198 V Maximum: 264 V

(4) The refrigerant quantity to be charged includes the refrigerant in 7.5 m connecting piping.

(Purging is not required even in the short piping.)

If the piping length is longer, (when it is less than 10 m, add 10 g refrigerant per meter and when it is 10 to 15 m, add 30 g refrigerant per meter.)

(5) Expressed in sound pressure level.

Notes (1) The data are measured at the following conditions.

Item

Model

SRK501CENF-L SRC501CENF-L

Cooling capacity

(1)

W 4500/4500

Power source 1 Phase, 220/240V, 50 Hz

Cooling input kW 1.78/1.88

Running current (Cooling) A 8.4/8.2

Inrush current A 39/42

COP (In cooling) 2.53/2.39

Noise level

(5)

dB (A) 44/44 50/51

Exterior dimensions mm

275 × 790 × 189 615 × 850 × 290 + 30

Height × Width × Depth

Color Ivory white Polar white

Net weight kg 9 52

Refrigerant equipment

– RM5523GNE4 (Rotary type) × 1

Compressor types & Q’ty

Motor kW – 1.7

Starting method – Line starting

Heat exchanger Louver fins & tubing

Refrigerant control Capillary tubes

Refrigerant

(4)

kg R22 1.28

Refrigerant oil R 0.7 (BARREL FREEZE 32SAM)

Air handling equipment

Tangential fan × 1 Propeller fan × 1

Fan type & Q’ty

Motor W 23 40

Air flow (at High) CMM 11/11 34/34

Air filter, Q’ty Polypropylene net (washable) × 2 –

Shock & vibration absorber – Cushion rubber (for compressor)

Electric heater ––

Operation control

Wireless-Remote controller –

Operation switch

Room temperature control MC. Thermostat –

Pilot lamp RUN (Green), TIMER (Yellow),

–

ECONO (Orange), HI POWER (Green)

Safety equipment – Dome mounted protector (for compressor)

Internal thermostat (for fan motor)

O.D mm (in) Liquid line: φ6.35 (1/4") Gas line: φ12.7 (1/2")

Connecting method Flare connecting

Attached length of piping Liquid line: 0.4m

–

Gas line : 0.35m

Insulation Necessary (Both sides)

Drain hose Connectable

Power source cord 2.5 m (3 cores with Earth)

Size × Core number 1.5 mm2 × 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Optional parts –

Connection

wiring

Operation

data

(1)

Refrigerant

piping

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27°C19°C35°C24°C JIS C9612, ISO-T1

Page 18

1-18

(2) The operation data are applied to the 220 V or 240 V districts respectively.

(3) Limitation of Voltage application

Minimum: 198 V Maximum: 264 V

(4) The refrigerant quantity to be charged includes the refrigerant in 7.5 m connecting piping.

(Purging is not required even in the short piping.)

If the piping length is longer, (when it is less than 10 m, add 10 g refrigerant per meter and when it is 10 to 15 m, add 30 g refrigerant per meter.)

(5) Expressed in sound pressure level.

Notes (1) The data are measured at the following conditions.

Model SRK561CENF-L (Indoor unit)

SRC561CENF-L (Outdoor unit)

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27°C19°C35°C24°C JIS C9612, ISO-T1

Item

Model

SRK561CENF-L SRC561CENF-L

Cooling capacity

(1)

W 5000/5000

Power source 1 Phase, 220/240V, 50 Hz

Cooling input kW 2.08/2.18

Running current (Cooling) A 10.2/9.53

Inrush current A 44/48

COP (In cooling) 2.40/2.29

Noise level

(5)

dB (A) 45/45 53/54

Exterior dimensions mm

275 × 790 × 189 615 × 850 × 290 + 30

Height × Width × Depth

Color Ivory white Polar white

Net weight kg 9 52

Refrigerant equipment

– RM5526GNE4 (Rotary type) × 1

Compressor types & Q’ty

Motor kW – 1.9

Starting method – Line starting

Heat exchanger Louver fins & tubing

Refrigerant control Capillary tubes

Refrigerant

(4)

kg R22 1.35

Refrigerant oil R 0.7 (BARREL FREEZE 32SAM)

Air handling equipment

Tangential fan × 1 Propeller fan × 1

Fan type & Q’ty

Motor W 23 40

Air flow (at High) CMM 12/12 34/34

Air filter, Q’ty Polypropylene net (washable) × 2 –

Shock & vibration absorber – Cushion rubber (for compressor)

Electric heater ––

Operation control

Wireless-Remote controller –

Operation switch

Room temperature control MC. Thermostat –

Pilot lamp RUN (Green), TIMER (Yellow),

–

ECONO (Orange), HI POWER (Green)

Safety equipment

–

Dome mounted protector (for compressor)

Internal thermostat (for fan motor)

O.D mm (in) Liquid line: φ6.35 (1/4") Gas line: φ12.7 (1/2")

Connecting method Flare connecting

Attached length of piping Liquid line: 0.4m

–

Gas line : 0.35m

Insulation Necessary (Both sides)

Drain hose Connectable

Power source cord 2.5 m (3 cores with Earth)

Size × Core number 1.5 mm2 × 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Optional parts –

Connection

wiring

Operation

data

(1)

Refrigerant

piping

Page 19

1-19

Model SRK50A (Indoor unit)

SRC50CA (Outdoor unit)

(2) The operation data are applied to the 220V, 230V or 240V districts respectively.

(3) The refrigerant quantity to be charged includes the refrigerant in 7 m connecting piping.

(Purging is not required even in the short piping.)

If the piping length is longer, (When it is 7 to 15 m, add 20 g refrigerant per meter.)

(4) When the unit is operated in cooling or dehumidification mode at the outside air temperature of 1ºC and less, there is a possibility that water leakage

occurs at the indoor unit.

Notes (1) The data are measured at the following conditions.

Item

Model

SRK50A SRC50CA

Cooling capacity

(1)

W 4500

Power source 1 Phase, 220/230/240V, 50 Hz

Cooling input kW 1.79

Running current (Cooling) A 8.4/8.0/7.7

Inrush current A 39/41/42

COP (In cooling) 2.51

Noise level

Sound level

dB

Hi : 44 Lo : 37 51

Power level Hi : 58 Lo : 51 65

Exterior dimensions mm

298 × 798 × 203 640 × 850 × 290

Height × Width × Depth

Color Noble white Stucco white

Net weight kg 10 44

Refrigerant equipment

– RM5523GNE4 (Rotary type) × 1

Compressor types & Q’ty

Motor kW – 1.7

Starting method – Line starting

Heat exchanger Louver fins & grooved tubing

Refrigerant control Capillary tubes

Refrigerant

(3)

kg R22 1.45

Refrigerant oil R 0.7 (BARREL FREEZE 32SAM)

Air handling equipment

Tangential fan × 1 Propeller fan × 1

Fan type & Q’ty

Motor W 23 35

Air flow (at High) CMM 11 39

Air filter, Q’ty Polypropylene net (washable) × 2–

Shock & vibration absorber – Cushion rubber (for compressor)

Electric heater ––

Operation control

Wireless-Remote controller –

Operation switch

Room temperature control MC. Thermostat –

Pilot lamp RUN (Green), TIMER (Yellow),

–

ECONO (Orange), HI POWER (Green)

Safety equipment

–

Dome mounted protector (for compressor)

Internal thermostat (for fan motor)

O.D mm (in) Liquid line: φ6.35 (1/4") Gas line: φ12.7 (1/2")

Connecting method Flare connecting

Attached length of piping Liquid line: 0.5m

–

Gas line : 0.43m

Insulation Necessary (Both sides)

Drain hose Connectable

Power source cord 3 m (3 cores with Earth)

Size × Core number 1.5 mm2 × 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Optional parts –

Connection

wiring

Operation data

(1)

Refrigerant

piping

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27°C19°C35°C24°C ISO-T1, JIS C9612

Page 20

1-20

(2) The operation data are applied to the 220V, 230V or 240V districts respectively.

(3) The refrigerant quantity to be charged includes the refrigerant in 7 m connecting piping.

(Purging is not required even in the short piping.)

If the piping length is longer, (When it is 7 to 15 m, add 20 g refrigerant per meter.)

(4) When the unit is operated in cooling or dehumidification mode at the outside air temperature of 1ºC and less, there is a possibility that water leakage

occurs at the indoor unit.

Notes (1) The data are measured at the following conditions.

Model SRK56A (Indoor unit)

SRC56CA (Outdoor unit)

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27°C19°C35°C24°C ISO-T1, JIS C9612

Item

Model

SRK56A SRC56CA

Cooling capacity

(1)

W 5000

Power source 1 Phase, 220/230/240V, 50 Hz

Cooling input kW 2.08

Running current (Cooling) A 9.7/9.3/8.7

Inrush current A 44/46/48

COP (In cooling) 2.40

Noise level

Sound level

dB

Hi : 45 Lo : 38 54

Power level Hi : 59 Lo : 52 68

Exterior dimensions mm

298 × 798 × 203 640 × 850 × 290

Height × Width × Depth

Color Noble white Stucco white

Net weight kg 10 44

Refrigerant equipment

– RM5526GNE4 (Rotary type) × 1

Compressor types & Q’ty

Motor kW – 1.9

Starting method – Line starting

Heat exchanger Louver fins & grooved tubing

Refrigerant control Capillary tubes

Refrigerant

(3)

kg R22 1.45

Refrigerant oil R 0.7 (BARREL FREEZE 32SAM)

Air handling equipment

Tangential fan × 1 Propeller fan × 1

Fan type & Q’ty

Motor W 23 35

Air flow (at High) CMM 11 39

Air filter, Q’ty Polypropylene net (washable) × 2–

Shock & vibration absorber – Cushion rubber (for compressor)

Electric heater ––

Operation control

Wireless-Remote controller –

Operation switch

Room temperature control MC. Thermostat –

Pilot lamp RUN (Green), TIMER (Yellow),

–

ECONO (Orange), HI POWER (Green)

Safety equipment

–

Dome mounted protector (for compressor)

Internal thermostat (for fan motor)

O.D mm (in) Liquid line: φ6.35 (1/4") Gas line: φ12.7 (1/2")

Connecting method Flare connecting

Attached length of piping Liquid line: 0.5m

–

Gas line : 0.43m

Insulation Necessary (Both sides)

Drain hose Connectable

Power source cord 3 m (3 cores with Earth)

Size × Core number 1.5 mm2 × 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Optional parts –

Connection

wiring

Operation data

(1)

Refrigerant

piping

Page 21

1-21

1.2 SELECTION DATA

1.2.1 Specifications

Model SRK25GZ-L1 (Indoor unit)

SRC25GZ-L1 (Outdoor unit)

Item

Model

SRK25GZ-L1 SRC25GZ-L1

Cooling capacity

(1)

W 2500 [900~2900]

Heating capacity

(1)

W 3400 [900~4000]

Power source 1 Phase, 220/240V, 50Hz

Cooling input kW 0.96 [0.31~1.22]

Running current (Cooling) A 4.8

Heating input kW 1.17 [0.28~1.35]

Running current (Heating) A 5.8

Inrush current A 5.8

COP (In cooling) 2.60

Noise level dB (A) Cooling: 38 Heating: 39 Cooling: 46 Heating: 46

Exterior dimensions

Height × Width × Depth mm

250 × 750 × 178 540 × 645 × 245

Color Ivory white Polar white

Net weight kg 7.5 28

Refrigerant equipment

Compressor type & Q’ty

– RM5465GA1 (Rotary type) × 1

Motor kW – 0.75

Starting method – Line starting

Heat exchanger Louver fins & bare tubing

Refrigerant control Capillary tubes

Refrigerant

(4)

kg R22 0.64 (Pre-Charged up to the piping length of 5m)

Refrigerant oil R 0.35 (BARREL FREEZE 32SAM)

Deice control MC control

Air handling equipment

Fan type & Q’ty

Tangential fan × 1 Propeller fan × 1

Motor W 18 20

(Cooling) 7.0 21

Air flow (at High)

(Heating)

CMM

7.5 21

Air filter, Q’ty Polypropylene net (washable) × 2–

Shock & vibration absorber – Cushion rubber (for compressor)

Electric heater ––

Operation control

Operation switch

Wireless-Remote controller –

Room temperature control MC. Thermostat –

Pilot lamp RUN (Green), TIMER (Yellow)

Safety equipment

O.D mm (in) Liquid line: φ6.35 (1/4″) Gas line: φ9.52 (3/8″)

Connecting method Flare connecting

Attached length of piping Liquid line: 0.4 m

Gas line : 0.35 m

–

Insulation Necessary (Both sides)

Drain hose Connectable

Power source cord 2.5 m (3 cores with Earth)

Size × Core number 1.5 mm2 × 4 cores (Including earth cable)

Connection wiring

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Optional parts –

Notes (1) The data are measured at the following conditions.

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27ºC 19ºC 35ºC 24ºC JIS C9612, ISO-T1

Heating 20ºC – 7ºC 6ºC JIS C9612, ISO-T1

(2) The values for performance and power consumption shown in brackes [~] indicate the range from minimum to maximum.

(3) The operation data are applied to the 220/240V districts respectively.

(4) Limitation of Voltage application Minimum: 198V Maximum: 264V

(5) The refrigerant quantity to be charged includes the refrigerant in 5 m connecting piping.

(Purging is not required even in the short piping.)

If the piping length is longer,

(When it is 5 to 15 m, add 20 g refrigerant per meter.)

Operation data

(1)

Refrigerant

piping

Compressor: Overheat protection, heating overload protection (High pressure control), overcurrent protection, serial signal error protection, indoor fan motor error protection

Page 22

1-22

Item

Model

SRK35GZ-L1 SRC35GZ-L1

Cooling capacity

(1)

W 3650 [900~3900]

Heating capacity

(1)

W 4800 [900~6100]

Power source 1 Phase, 220/240V, 50Hz

Cooling input kW 1.24 [0.35~1.60]

Running current (Cooling) A 6.3

Heating input kW 1.52 [0.35~2.10]

Running current (Heating) A 7.7

Inrush current A 7.7

COP (Cooling) 2.94

Noise level dB (A) Cooling: 39 Heating: 42 Cooling: 46 Heating: 47

Exterior dimensions

Height × Width × Depth mm

275 × 790 × 174 542 × 795 × 255

Color Ivory white Polar white

Net weight kg 8 35

Refrigerant equipment

Compressor type & Q’ty

– RM5485GAE3 [Rotary type] × 1

Motor kW – 0.75

Starting method – Line starting

Heat exchanger Louver fins & bare tubing

Refrigerant control Capillary tubes

Refrigerant

(4)

kg R22 1.1 (Pre-Charged up to the piping length of 5m)

Refrigerant oil R 0.35 (BARREL FREEZE 32SAM)

Deice control MC control

Air handling equipment

Fan type & Q’ty

Tangential fan × 1 Propeller fan × 1

Motor W 16 18

(Cooling) 7 24

Air flow (at High)

(Heating)

CMM

10 24

Air filter, Q’ty

Polypropylene net (washable) × 2

–

Shock & vibration absorber – Cushion rubber (for compressor)

Electric heater ––

Operation control

Operation switch

Wireless-Remote controller –

Room temperature control MC. Thermostat –

Pilot lamp RUN (Green), TIMER (Yellow)

Safety equipment

O.D mm (in) Liquid line: φ6.35 (1/4″) Gas line: φ12.7 (1/2″)

Connecting method Flare connecting

Attached length of piping Liquid line: 0.4 m

Gas line : 0.35 m

–

Insulation Necessary (Both sides)

Drain hose Connectable

Power source cord 2.5 m (3 cores with Earth)

Size × Core number 1.5 mm2 × 4 cores (Including earth cable)

Connection wiring

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Optional parts –

Notes (1) The data are measured at the following conditions.

Model SRK35GZ-L1 (Indoor unit)

SRC35GZ-L1 (Outdoor unit)

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27ºC 19ºC 35ºC 24ºC JIS C9612, ISO-T1

Heating 20ºC – 7ºC 6ºC JIS C9612, ISO-T1

(2) The values for performance and power consumption shown in brackets [~] indicate the range from minimum to maximum.

(3) The operation data are applied to the 220/240V districts respectively.

(4) Limitation of Voltage application Minimum: 198V Maximum: 264V

(5) The refrigerant quantity to be charged includes the refrigerant in 5 m connecting piping.

(Purging is not required even in the short piping.)

If the piping length is longer,

(When it is 5 to 15 m, add 20 g refrigerant per meter.)

Operation data

(1)

Refrigerant

piping

Compressor: Overheat protection, heating overload protection (High pressure control), overcurrent

protection, frosting protection, serial signal error protection, indoor fan motor error protection

Page 23

1-23

Item

Model

SRK502Z-L SRC502Z-L

Cooling capacity

(1)

W 5000 [900~5600]

Heating capacity

(1)

W 6700 [900~7900]

Power source 1 Phase, 220/240V, 50Hz

Cooling input kW 2.22 [0.17~2.65]

Running current (Cooling) A 10.2

Heating input kW 2.50 [0.145~2.55]

Running current (Heating) A 11.5

Inrush current A 11.5

COP (Cooling) 2.25

Noise level dB (A) Cooling: 43 Heating: 43 Cooling: 48 Heating: 48

Exterior dimensions

Height × Width × Depth mm

275 × 790 × 189 595 × 720 × 290

Color Ivory white Polar white

Net weight kg 9 36

Refrigerant equipment

Compressor type & Q’ty

– GR5490FD4 [Scroll type] × 1

Motor kW – 1.5

Starting method – Line starting

Heat exchanger Louver fins & bare tubing

Refrigerant control Electric expansion valve

Refrigerant

(4)

kg R22 1.24 (Pre-Charged up to the piping length of 7m)

Refrigerant oil R 0.35 (BARREL FREEZE 32SAM)

Deice control MC control

Air handling equipment

Fan type & Q’ty

Tangential fan × 1 Propeller fan × 1

Motor W 26 35

(Cooling) 10 26

Air flow (at High)

(Heating)

CMM

10.5 30

Air filter, Q’ty

Polypropylene net (washable) × 2

–

Shock & vibration absorber – Cushion rubber (for compressor)

Electric heater ––

Operation control

Operation switch

Wireless-Remote controller –

Room temperature control MC. Thermostat –

Pilot lamp RUN (Green), TIMER (Yellow), ECONO (Orange), HI POWER (Green)

Safety equipment

O.D mm (in) Liquid line: φ6.35 (1/4″) Gas line: φ12.7 (1/2″)

Connecting method Flare connecting

Attached length of piping Liquid line: 0.4 m

Gas line : 0.35 m

–

Insulation Necessary (Both sides)

Drain hose Connectable

Power source cord 2.5 m (3 cores with Earth)

Size × Core number 1.5 mm2 × 4 cores (Including earth cable)

Connection wiring

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Optional parts –

Notes (1) The data are measured at the following conditions.

Model SRK502Z-L (Indoor unit)

SRC502Z-L (Outdoor unit)

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27ºC 19ºC 35ºC 24ºC JIS C9612, ISO-T1

Heating 20ºC – 7ºC 6ºC JIS C9612, ISO-T1

(2) The values for performance and power consumption shown in brackets [~] indicate the range from minimum to maximum.

(3) The operation data are applied to the 220/240V districts respectively.

(4) Limitation of Voltage application Minimum: 198V Maximum: 264V

(5) The refrigerant quantity to be charged includes the refrigerant in 7 m connecting piping.

(Purging is not required even in the short piping.)

If the piping length is longer,

(When it is 7 to 25 m, add 20 g refrigerant per meter.)

Operation data

(1)

Refrigerant

piping

Compressor: Overheat protection, heating overload protection (High pressure control), overcurrent protection,

frosting protection, serial signal error protection, indoor fan motor error protection, Comp. rotor lock

Page 24

1-24

1.2.2Range of usage & limitations

(1) Inlet air temperature

(a) Cooling operation (b) Heating operating

Outdoor air temp. ºC D. B.

Indoor air temp. ºC D. B.

Note: The chart is the result from the continu-

ous operation under constant air temperature conditions, however, excludes the

initial pull-down stage.

Note: The chart is the result from the continuous

operation under constant air temperature conditions, however, excludes the initial pulldown stage and any possible defrost cycles.

(2) Total one way piping length and vertical height difference.

(3) Voltage application

Models

All models

Item

Minimum (V) 198

Maximum (V) 264

Outdoor air temp. ºC W. B.

Indoor air temp. ºC W. B.

Applicable temp.

range

JIS-Cooling

Applicable temp. range

JIS-Heating

Models

All models

Item

Total one way piping length (m) 15

Vertical height Outdoor unit is higher 5

difference (m)

Outdoor unit is lower 5

Page 25

1-25

1.2.3 Exterior dimensions

(1) Indoor unit

Models SRK 208, 288, 328, 408 -HENF, -CENF, 258CENF

A

790

15

67

51

390

60

62 18

16

780

*

VIEW A

Remote controller

15 760

170

450 170

Room temp. sensor

Terminal block

20, 28, 32, 40 models 41 models

Piping for Liquid (

Ø

6.35) 440

NOTE(1) Models 20 and 28 have no inlet opening indicated by * mark.

Drain hose 600 (Ø16)

Piping hole

(

Ø

65)

Piping hole

(

Ø

65)

Piping hole right (left)

Unit: mm

174 3

275

187.5 61

46

9260

117

60

20.5

161.5

37

6

36

569

49

Piping for Gas

20, 28:

Ø

9.52

32, 40, 41, Ø12.7

( )

Models SRK501H(C)ENF-L, 561H(C)ENF-L

Page 26

Models SRK50A, 56A

Page 27

1-27

(2) Outdoor unit

Model SRC208 H(C) ENF-L

Models SRC 288, 328, 408 -HENF -CENF, 258 CENF

60

250

120

510

120 30

65 78

45˚

45˚

750

Drain holes

Terminal block

Unit: mm

MAX 61

Service valve (Gas)

Flare fitting

Ø

9.52 (3/8˝)

Service

valve (Liquid)

Flare fitting

Ø

6.35 (1/4˝)

Oval holes (4–16x12)

50

68

14

237

265

14

44

220

492

80

15

300

1414

272

58 44

142.5

142.5

510

32

115

40

33

265

795

50

45˚

45˚

Drain holes

Drain holes

Terminal block

Unit: mm

MAX 80

Service

valve (Liquid)

Service

valve (Gas)

55

22

14

255

272

5844

23

9365

14

413

50

542

539

15

65

16x12 (Oval holes)

for unit fixing

2 places

Flare fitting

Ø

6.35 (1/4˝)

Flare fitting

28:

Ø

9.52 (3/8˝)

32, 40,41:

Ø

12.7 (1/2˝)

Page 28

1-28

Models SRC501H(C)ENF, 561H(C)ENF

170

Oval (M10x4) holes

for Anchor bolt

Drain pipe

87

15

55

850

70.5

30

100

290

60

87

15

25

19

307

615

25

17

475

345

30

19

510 170

Unit: mm

Service

valve (Gas)

Ø12.7 (1/2˝)

Lebel model

name

Service valve (Liquid)

Ø6.35 (1/4˝)

Page 29

1-29

Models SRC50C(H)A, 56C(H)A

42.7

Drain hole

Elogated hole

(2-12X16)

Terminal block

Service valve (Liquide)

Ø6.35 (1/4'')

Service valve (Gas)

Ø12.7 (1/2'')

Ground

terminal

314

14

12

850

203.1

510

136.9

476

286.4

12

50

290

49.6

43.5

328

100.3

15

640

124

34.6

20˚

20˚

Page 30

1-30

A

750

75

92

40

60

746.9

7.5

62

62 7.5

16

VIEW A

75615

150

450 150

Room temp.

thermistor

Terminal

block

Piping for Gas (

Ø

9.52) 370

Piping for Liquid (Ø6.35) 420

Piping hole

(

Ø

65)

Piping hole

(Ø65)

Piping hole right (left)

178 3

250

4615

19

9236.5

4.5

36

117

40

37

36

569

49

A

790

15

67

51

60

62

18

16

780

VIEW A

15 760

170

450 170

Room temp.

thermistor

Terminal block

Piping for Gas

(

Ø

12.7) 390

Piping for Liquid (

Ø

6.35) 440

Drain hose 600 (

Ø

16)

Piping hole

(

Ø

65)

Piping hole

(Ø65)

Piping hole right (left)

Unit: mm

174 3

275

187.5 61

46

9260

117

37

6

36

56

9

49

1.2.3 Exterior dimensions

(1) Indoor unit

Model SRK25GZ-L1

Unit: mm

Model SRK35GZ-L1

Remote controller

Remote controller

Page 31

1-31

(2) Outdoor unit

Model SRC25GZ-L1

192.5

372.5

82.5

480

82.5

61.5

2

-

Ø

12

Terminal

block

127.7

33.3

40˚

40˚

645

Drain holes

Service valve (Gas)

Flare connecting

Ø

9.52 (3/8˝)

Service valve (Liquid)

Flare connecting

Ø

6.35 (1/4˝)

50

12

42

13.5

274.5

300

12

23

44

245

540

100.3 39.7

14.4

Remote controller

Unit: mm

Model SRK502Z-L

Unit: mm

Page 32

1-32

Model SRC35GZ-L1

50

55

Drain holes MAX.80

265

795

58

65

255

272

22

14

23

14

93

44

142.5 510 33142.5

40

32

115

45°

45°

Service

Valve

(Liquid)

Flare connecting

Ø

6.35 (1/4¨)

Service

Valve (Gas)

Flare connecting

Ø

12.7 (1/2¨)

Terminal block

Drain holes

542

539

413

65

15

300

27214

58 44

16 12 (Oval holes)

for unit fixing

2 places

14

50

Unit : mm

Model SRC502Z-L

Unit: mm

Page 33

1-33

Cooling cycle

Heating cycle

Heat exchanger

Strainer

Service valve (Liquid)

Flare connecting

Service valve (Gas)

Room

temperature

sensor

Piping (Gas)

Ø12.7

Piping (Liquid)

Ø6.35

Flare connecting

Check

joint

4way valve

Suction

Capillary tube

Heat exchanger

Compressor Accumulator

Discharge

Heat

exchanger

sensor

Indoor unit

Outdoor unit

Defrost

thermostat

High pressure switch (63H)

(for fan motor control)

Model SRK408HENF-L2

Heat exchanger

Strainer

Service valve (Liquid)

Flare connecting

Service valve (Gas)

Room

temperature

sensor

Piping (Gas)

Ø12.7

Piping (Liquid)

Ø6.35

Flare connecting

Check

joint

4way valve

Suction

Capillary tube

Check valve

Heat exchanger

Compressor

Accumulator

Discharge

Heat

exchanger

sensor

Cooling cycle

Heating cycle

Indoor unit Outdoor unit

Defrost

thermostat

High pressure switch (63H)

(for fan motor control)

1.2.4 Piping system

Model SRK328HENF-L2

Page 34

1-34

Models SRK501HENF-L, 561HENF-L

Heat exchanger

Strainer

Service valve (Liquid)

Flare connecting

Service valve (Gas)

High pressure switch(63H)

(for fan motor control)

Room

temperature

thermistor

Piping (Gas)

Ø12.7

Piping (Liquid)

Ø6.35

Flare connecting

Check

joint

4way valve

Suction

Muffler

Capillary tube

Deicer

thermostat

Heat exchanger

Compressor

Accumulator

Discharge

Heat

exchanger

thermistor

Cooling cycle

Heating cycle

Indoor unit Outdoor unit

Models SRK50HA, 56HA

Heat exchanger

Strainer

Service valve (Liquid)

Flare connecting

Service valve (Gas)

High pressure switch(63H)

(for fan motor control)

Room

temperature

thermistor

Piping (Gas)

Ø12.7

Piping (Liquid)

Ø6.35

Flare connecting

Check

joint

4way valve

Suction

Muffler

Capillary tube

Deicer

thermostat

Heat exchanger

Compressor

Accumulator

Discharge

Heat

exchanger

thermistor

Cooling cycle

Heating cycle

Indoor unit Outdoor unit

Page 35

1-35

Models SRK501CENF-L, 561CENF-L

Heat

exchanger

Heat

exchanger

Room

temperature

thermistor

Flare connecting

Piping (Gas)

ø12.7

Piping (Liquid) ø6.35

Flare connecting

Service valve (Gas)

Service valve (Liquid)

Check joint

Compressor

Capillary tube

Suction

Accumulator

Cooling cycle

Discharge

Heat

exchanger

thermistor

Indoor unit Outdoor unit

Model SRK408HENF-L

Heat exchanger

Strainer

Service valve (Liquid)

Flare connecting

Service valve (Gas)

Room

temperature

sensor

Piping (Gas)

Ø12.7

Piping (Liquid)

Ø6.35

Flare connecting

Check

joint

4way valve

Suction

Capillary tube

Check valve

Heat exchanger

Compressor

Accumulator

Discharge

Heat

exchanger

sensor

Cooling cycle

Heating cycle

Indoor unit Outdoor unit

Page 36

1-36

Model SRK408HENF-L3

Heat exchanger

Strainer