Page 1

SERVICE MANUAL

199419-12120

August 2010

Pub. No. 99419-12120

Page 2

FOREWORD

This service manual describes the maintenance and adjustment procedures, and specifi-

cations for Mitsubishi diesel engines.

To maintain the performance of the engine for many years and to ensure safe operation,

it is important to use the engine correctly and conduct scheduled inspection and mainte-

nance, and it may also be necessary to take appropriate measures which involve in disas-

sembly, inspection, repair and assembly work of the engine and engine parts.

Read through this manual carefully and understand the work procedures fully before dis-

assembling, inspecting, repairing or assembling the engine.

The contents of this manual are based on the engine model produced at the time of publi-

cation. Please note that the contents of this manual may change due to improvements made

thereafter.

I

Page 3

FOREWORD

HOW TO USE THIS MANUAL

This service manual consists of several chapters, which will give you quick references to specifications, maintenance standards,

adjustment and service procedures including practices to disassemble, inspect, repair and assemble the Mitsubishi diesel

engines.

A short summary describing the contents of each chapter is given in the CHAPTER INDEX page, and there is also a detailed

table of contents at the beginning of each chapter.

Regarding the procedures for operation and scheduled maintenance of the engine, refer to the Operation and Maintenance Man-

ual. For information on the engine components and ordering of service parts, refer to the Parts Catalogue. Structure and func-

tion of the engine are described in the relevant training manuals.

If you have an inquiry, please check the engine model and serial number, and contact our service department.

Description format

(1) Index numbers allotted to parts in exploded views are not only a call-out of part names listed in the text but also an indica-

tion of the sequence of disassembly.

(2) Inspections to be conducted during disassembly process are indicated in boxes in the relevant exploded views.

(3) Maintenance standards required for inspection and repair works are indicated in the appropriate positions in the text. They

are also collectively indicated in the Chapter 2.

(4) The tightening torque with engine oil applied on the thread, is specified [Wet]. Unless otherwise specified, the tightening

torque is of dry condition.

(5) In this manual, important safety or other cautionary instructions are emphasized with the following head marks.

Note

Indicates an immediately hazardous situation which, if not avoided, will result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury.

Indicates a potentially hazardous situation which, if not avoided, may result in property

damage.

Emphasizes important matter, or indicates information useful for operation or maintenance

of the engine.

II

Page 4

FOREWORD

Terms used in this manual

Nominal value

means the basic nominal size of a part to be measured.

Standard value

means the quantitative requirement for dimension of a part, clearance between parts and performance. The values are rounded

off for the inspection job, and do not necessarily conform to the design values.

Limit value

means the limit value, which the measured value reaches, the part needs repair or replacement with a new one.

Abbreviations and Standards

BTDC : Before Top Dead Center

ATDC : After Top Dead Center

BBDC : Before Bottom Dead Center

ABDC : After Bottom Dead Center

TIR : Total Indicator Reading

API : American Petroleum Institute

ASTM : American Society for Testing and Materials

JIS : Japanese Industrial Standards

LLC : Long Life Coolant

MIL : Military Specifications and Standards (U.S.A.)

MSDS : Material Safety Data Sheet

SAE : Society of Automotive Engineers (U.S.A.)

P/N : Part Number

Unit of Measurement

Measurements are based on the International System of Units (SI), and their converted metric values are indicated in { } and

U.S. customary values are in [ ]. For metric conversion, the following rates are used.

Pressure :1 MPa = 10.197 kgf/cm

Torque :1 N•m = 0.10197 kgf•m

Force :1 N = 0.10197 kgf

Output power :1 kW = 1.341 HP = 1.3596 PS

Pressure (mercury column) :1 kPa = 0.7 cmHg

Pressure (watercolumn) :1 kPa = 10.197 cmH

-1

Rotation speed: 1 min

= 1 rpm

2

2O (cmAq)

III

Page 5

FOREWORD

Safety Cautions

Fire and Explosion Precautions

Keep Flames Away

Do not use flames near the engine (in

the engine room). The flame is dan-

gerous to ignite combustibles and

cause a fire. Wipe off spilled fuel, oil

and LLC immediately and thoroughly.

Spilled fuel, oil and LLC may ignite and cause a fire.

Store the fuel and engine oil in a well ventilated area.

Make sure that the fuel and engine oil container caps

are tightly fastened.

Keep Engine Surrounding Area Tidy and

Clean

Do not place combustible or explosive material, such

as fuel, engine oil, LLC or explosive powder near the

engine. Such substances can cause a fire or explo-

sion. Thoroughly remove dust, dirt and other foreign

material collected on the engine and the area around

the engine. Such material can cause a fire or the

engine to overheat. In particular, clean the top surface

of the battery thoroughly. Dust can cause a short-cir-

cuit. Always place the engine at a position at least 1 m

[3.28 ft.] apart from buildings and other equipment to

prevent a possible fire caused by engine heat.

Do Not Open Side Covers Until Engine

Cools

Do not try to open the side cover of crankcase before

the engine cools down. Wait at least 10 minutes after

stopping the engine. Opening the cover when the

engine is hot allows fresh air to flow into the crank-

case, which can cause oil mist to ignite and explode.

Pay Attention to Fuel, Oil and Exhaust Gas

Leak

If any fuel, oil or exhaust gas leakage is found, imme-

diately take corrective measures to stop it. Such leak-

ages, if left uncorrected, can cause fuel or engine oil to

reach hot engine surfaces or hot exhaust gas to con-

tact flammable material, may results in a fire, personal

injury and damage to the equipment.

Use Explosion-proof Light

When inspecting fuel, engine oil, coolant, battery elec-

trolyte, etc., use an explosion-proof light. If the lighting

is not an explosion-proof type, it may ignite and cause

an explosion.

Prevent Electrical Wires From Short Circuit

Avoid inspecting or servicing the electrical system with

the battery cable connected to the battery. Otherwise,

a fire could result from short circuit. Be sure to discon-

nect the battery cable from the negative (-) terminal

before starting work. A loose terminal and a damaged

cable or wire may result in a short circuit and a fire.

Inspect, and if any defect is found, repair or replace it

before starting work.

Keep Fire Extinguishers and First-aid Kit

Handy

Keep fire extinguishers handy, and

become familiar with their usage.

Keep a first-aid kit at the designated

place to be ready for use in an emer-

gency. Make counteract procedures

against a fire or an accident. Provide the contact per-

son and means of communication in case of emer-

gency.

IV

Page 6

Stay Away From Rotating and Moving Parts

FOREWORD

Install Protective Covers Over Rotating

Parts After Inspection and Maintenance

Work

Check the covers over engine rotating

parts for correct installation. Repair

any damaged or loosed covers. Never

remove the protective covers over

rotating parts during operation. When

the engine is coupled to a radiator or other equipment,

install protective covers over the exposed connecting

belt and coupling.

Check Work Area for Safety Before Starting

Before starting the engine, make sure that no one is

near the engine and that tools are not left on or near

the engine. Verbally notify persons within the immedi-

ate area when starting the engine. When the starter

device is tagged with the warning sign saying DO NOT

RUN, never start the engine.

Lockout and Tagout

Be sure to lockout and tagout before starting inspec-

tion and maintenance. Lockout and tagout are effec-

tive methods of cutting off machines and equipment

from energy sources. To accomplish the lockout/

tagout, remove the starter switch key, set the battery

switch to OFF position and attach a DO NOT RUN or

equivalent caution tag to the starter switch. The starter

switch key must be kept by the person who performs

inspection and maintenance work.

Be Sure to Stop the Engine Before Inspection and Maintenance

Be sure to stop the engine before proceeding to

inspection and maintenance work. Never try to make

adjustments on the engine parts while the engine is

running. Rotating parts such as belt can reel in your

body and cause serious injuries.

Always Put Back Engine Turning Tool After

Stay Away From Moving Parts While Engine

Operates

Keep away from the rotating parts

during operation. Do not leave any

objects that may get caught in rotating

parts. If clothes or a tool gets caught

in rotating parts, serious injury will

result.

Use

Be sure to remove the turning tool used for inspection

and maintenance work. Make sure to pull back the

turning gear to the engine running position before

starting the engine. If the engine is started with a turn-

ing tool inserted or turning condition, it can not only

cause damage to the engine, but also lead to a per-

sonal injury.

V

Page 7

FOREWORD

Be Careful of Exhaust Gas Poisoning

Be Careful of Ventilation to Operate Engine

If the engine is installed in an

enclosed area, and the exhaust gas is

ducted outside, make sure that duct

joints are free from gas leak. Exhaust

gas from the engine contains harmful

components such as carbon monoxide. Operating the

engine in an ill-ventilated area can cause gas poison-

ing.

Be Careful of Hearing Loss

Wear Ear Plugs

Always wear ear plugs when entering

the machine room (engine room).

Combustion sound and mechanical

noise of engine can cause hearing

loss.

Be Careful of Falling

Lift Engine Carefully

Use slings or wire ropes strong

enough to lift the load considering the

engine weight. To lift the engine, hitch

the proper slings to the lifting hangers

prepared on the engine. To lift the

engine, keep the engine in a well-bal-

anced position, thinking carefully of the engine center

of gravity.

The hangers prepared on the engine are designed for

lifting the weight of engine only. In the case where the

generator, marine gear, and others are installed to the

engine, consideration that the additional weight will not

affect the hangers of the engine.

Keep the angle formed by slings attached to hangers

within 60°. If the angle exceeds this limit, excessive

load may be applied to the hangers and damage the

hangers. If the wire rope contacts the engine directly,

place a cloth or other soft pad to avoid damage to the

engine and sling.

Do Not Climb Onto the Engine

Do not climb onto the engine, nor step on any engine

parts on the engine sides. To work on parts located

high on the engine, use a ladder, footing, and others to

prevent from slipping and falling. Climbing onto the

engine may result in engine part damage and your

injury by falling down.

Always Prepare a Stable Footing

When working on the upper part of

the engine and other hard-to-reach

places, use a stable footing. Stand-

ing on an old footstool or parts box

may result in personal injury. Do not

put any unnecessary objects on a footing.

VI

Page 8

FOREWORD

Be Careful When Handling Fuel,

Engine Oil or LLC

Use Specified Fuel, Engine Oil and LongLife Coolant (LLC) Only

Use the fuel, oil and LLC specified in this manual only,

and handle them carefully. Use of any other fuel, oil or

LLC, or improper handling may cause various engine

defects and malfunctions. Get the MSDS issued by the

fuel, oil and LLC suppliers, and follow the directions in

the MSDS for proper handling.

Handle LLC Carefully

When handling LLC, wear rubber gloves and a protective face mask. If LLC or coolant containing LLC

comes into contact with your skin or eyes, or if it is

swallowed, you would suffer from inflammation, irritation or poisoning. If LLC is accidentally swallowed,

induce vomiting immediately and seek medical attention. If LLC enter your eyes, flush them immediately

with plenty of water and seek medical attention. If LLC

contact your skin or clothing, wash it away immediately with plenty of water. Keep flames away from

LLC. LLC can catch flames and cause a fire. Drained

coolant containing LLC is a hazardous material. Do

not discard it in an unauthorized procedure. Practice

the applicable law and regulations when discard

drained coolant.

Proper Discarding of Waste Oil, LLC and

Coolant

Do not discard waste engine oil, LLC and coolant in an

unauthrized procedure. Such a way of disposal is

strictly prohibited by laws and regulations. Discard

waste oil, LLC, coolant and other environmentally hazardous waste in accordance with the applicable laws

and regulations.

Be Careful of Burns

Do Not Touch the Engine During or Immedi-

ately After Operation

Do not touch any parts of the engine

during or immediately after operation.

You can get burned. Before starting

the maintenance and inspection work,

check the water temperature meter to make sure that

the engine is cooled down.

Be Careful to Open and Close the Radiator

Cap

Never open the radiator cap while the engine is run-

ning or immediately after the engine stops. Stop the

engine and give a sufficient time to allow the coolant to

cool down before opening the cap. When opening the

radiator cap, slowly open the cap so as to release

internal pressure. To prevent hot steam scalds, wear

thick rubber gloves or cover the cap with a cloth. When

closing the radiator cap, tightly close the cap. Do not

open the radiator cap during engine running or imme-

diately after engine stop. Otherwise hot steam and

coolant gush out and can cause burns.

Refill Coolant Only After the Coolant Tem-

perature Dropped

Do not refill coolant immediately after the engine

stops. Wait until the coolant temperature lowers suffi-

ciently to avoid risk of burns.

Do Not Remove Heat Shields

The exhaust system, which becomes extremely hot

while the engine is operating, is provided with various

heat shields. Never remove the heat shields. If any of

these heat shields were inevitably removed for the

inspection and maintenance, be sure to install them

after the work.

Be Careful of Burns When Changing Oil

Wear gloves when draining oil or changing oil filters. If

your skin contacts hot oil or hot parts, you get burn

injury.

VII

Page 9

FOREWORD

Battery

Be Careful with Battery

Never use flames or generate

sparks near the battery. The battery gives off highly flammable

hydrogen gas and oxygen gas.

Any flame or spark near a battery

may cause an explosion.

Do not use the battery if its fluid level is below the

lower limit line. Long use of the battery may result in

an explosion.

Do not short the battery terminals with a tool or other

metal object.

When disconnecting battery cables, always remove

first from negative (-) terminal first. When reconnecting the cables, always connect first to the positive

(+) terminal.

Charge the battery in a well-ventilated area, with all

battery plugs removed.

Make sure the cable clamps are securely fastened to

the battery terminals. A loose terminal can cause

sparks that may result in an explosion.

Before servicing electrical components or conducting

electric welding, set the battery switch to the [Open/

OFF] position or disconnect the cable from the negative (-) battery terminal to cut off the electrical current.

Electrolyte (battery fluid) contains dilute sulfuric acid.

Careless handling of the battery may lead to the loss

of sight and/or skin burns. Also, do not swallow battery fluid.

Wear protective goggles and rubber gloves when

working with the battery (such as adding water or

charging).

If battery electrolyte is spilled onto the skin or cloth-

ing, immediately wash it away with lots of water. Use

soap to clean thoroughly.

Battery fluid can make you blind if splash into your

eyes. Immediately flush it away with plenty of clean

water, and seek immediate medical attention.

If battery fluid is accidentally swallowed, gargle with

plenty of water, then drink lots of water, and seek

immediate medical attention.

When Abnormality Occurs

Do Not Add Coolant Immediately After a

Sudden Stop Due to Overheating

If the engine stops suddenly due to overheating, or

you suddenly stop the engine by any reason, do not

add coolant immediately. If water is added immedi-

ately, parts such as cylinder heads can be damaged

due to the sudden drop of temperature. Add coolant

slowly after the engine becomes cool.

Be Careful to Restart After Abnormal Stop

If the engine stops abnormally, do not restart the

engine immediately. If the engine stops giving an

emergency alert, inspect the engine and correct the

cause of the defect before restarting. If the engine is

kept operating in such a condition, it can result in seri-

ous engine failure.

Immediately Stop the Engine When Engine

Oil Pressure Drops

If the engine oil pressure drops significantly, stop the

engine immediately, and inspect the lubrication sys-

tem to find the cause. Continuous engine operation

with low oil pressure may cause bearings and other

parts to seize.

Stop the Engine Immediately When the Belt

Break

If the belt breaks, stop the engine immediately. Contin-

uous engine operation with the broken belt can cause

the engine to overheat. Steam of boiled coolant may

gush out from the reserve tank or radiator, and results

in burns.

VIII

Page 10

Other Cautions

FOREWORD

Do Not Tamper

If tampered, the warranty is totally void even in the

warranty period. Tampering with the engine can not

only damage the engine but also may lead to personal

injury.

Perform All Specified Pre-operation Inspections and Scheduled Inspections

Conduct the daily inspection and scheduled inspec-

tion/maintenance as described in this manual.

Failure to conduct the specified inspections may cause

various engine problems, damage to parts, and a seri-

ous accident.

Wear Proper Work Clothing and Protective

Gears

Wear a hard hat, face shield, safety shoes, dust mask,

gloves and other protective gears as needed. When

using compressed air, wear safety goggles, a hard

hat, gloves and other necessary protective gear.

Works without wearing proper protective gears may

result in serious injury.

Never Break the Seals

To ensure the proper engine operation, the fuel control

link is provided with seals that protect the fuel injection

volume and rotation speed settings against tampering.

If the seal is tampered, no guarantee will be provided.

If the seal is tampered, the defects shown below can

occure.

Rapid wear of moving and rotating parts

Engine troubles such as seizure and damage of

engine parts

Sudden increase of fuel and lubricating oil consump-

tion

Deterioration of engine performance due to improper

balance between fuel injection volume and governor

control, or a serious accident due to overrunning of

the engine

Inspect the Engine After Operation

After the engine operation, inspect each part of engine

once again. If any defect is found, correct immediately.

Break-in the Engine

To break-in a new engine or overhauled engine, oper-

ate the engine at a speed lower than the rated speed

in a light load condition during the first 50 hours of

operation. Operating a new engine or overhauled

engine in a severe condition during the break-in period

shortens the service life of the engine.

IX

Page 11

FOREWORD

Warm-up the Engine Before Use

After starting the engine, run the engine at a low idling

speed for 5 to 10 minutes for warming-up. Start the

work after this operation is completed. Warm-up oper-

ation circulates lubricant in the engine, and works for

the longer service life and economical operation. Do

not continue the warm-up operation for a longer time

than necessary. Long warm-up operation causes car-

bon deposits in the cylinders, and may lead to incom-

plete combustion.

Do Not Operate the Engine in an Overloaded Condition

If the engine shows an overloaded condition such as

black exhaust smoke, reduce the load immediately to

an appropriate load condition. Overloading causes not

only high fuel consumption but also excessive carbon

deposits inside the engine. Carbon deposits cause

various problems and will shorten the service life of the

engine.

Cool Down the Engine Before Stop

Cool down the engine at low idling for five to six min-

utes before stopping it. Stopping the engine immedi-

ately after high-load operation will cause local heat up

of engine parts and shorten the service life of the

engine. During the cooling operation, check the engine

for abnormalities.

Do Not Continue Low Load Operation

Low load continuous operation (less than 30%) must

be limited within one hour. Long warm-up operation

causes carbon deposits in the cylinders, and may lead

to incomplete combustion. Also, after low load opera-

tion for approx one hour, run the engine at a 30% or

higher load for five minutes or more.

Use Care to Protect Engine From Water

Use care to protect engine from water such as rain

entering through the air inlet or exhaust openings. Do

not wash the engine while it is running. Cleaning fluid

or water can be sucked into the engine. Starting the

engine with water inside the combustion chambers

can cause the water hammering, and may result in

engine inner parts damage and serious accident.

Air Cleaner or

Pre-cleaner is to be Properlly Maintained.

With foreign material in the intake air, excessive wear

of the engine can result. Worn parts produce many

problems such as increase of oil consumption,

decrease of output and starting difficulties. For effec-

tive removal of dust from intake air, maintain the air

cleaner/pre-cleaner according to the following instruc-

tions.

Never perform maintenance of the air cleaner or pre-

cleaner during operation. Foreign material enters the

turbocharger and may result in a serious failure.

When removing the air cleaner or pre-cleaner, be

careful to prevent dust and foreign material collected

on the cleaner from entering the engine. After

removing the air cleaner or pre-cleaner, immediately

cover the opening (inlet port of engine or turbo-

charger silencer) with plastic sheet or similar means

to prevent foreign materials from entering the

engine.

An air cleaner with a dust indicator gives an alarm

when it is clogged. Conduct maintenance when the

alarm is given.

X

Page 12

FOREWORD

Observe Safety Rules at Work Site

Observe the safety rules established at the workplace

when operating and maintaining the engine. Do not

operate the engine if you are in bad health. Consult

your supervisor about your condition. Operation of the

engine with decreased attention may cause improper

operation and results in an accident. When working in

a team of two or more people, use specified hand sig-

nals to communicate among workers.

Use Proper Tools for Maintenance Work

Always keep in mind to select most appropriate tools

for the work and use them correctly. If a tool is dam-

aged, replace with new tool.

Do Not Operate Starter for a Long Time

Do not use the starter for more than 10 seconds at a

time. If the engine does not start, wait for at least 1

minute before starting again. Continuous operation of

the starter to start a stubborn engine may lead to a flat

battery or starter burning out.

Cautions for Engine Trans portation

To road-transport the engine, consider the engine

weight, width and height, and obey applicable laws

and regulations such as road traffic laws, vehicle road

acts and vehicle restriction ordinances.

Be Careful of Engine Room Ventilation

Always keep the engine room well-ventilated. Insuffi-

cient intake air amount of the engine can cause an

increase in the engine temperature, and could result in

a decrease in the output power and poor performance.

It is highly recommended to calculate the required

amount of air supply to the engine and install an ade-

quate ventilation system before installing the engine.

Do Not Touch High Pressure Fuel Jet

Do not touch fuel jet leaked or sprayed from the high

pressure injection pipe. Fuel in the fuel injection pipe

has a high pressure and if the fuel impinges your skin,

it goes through the skin and can cause serious injury.

Do Not Turn Off the Battery Switch During

Operation

If the battery switch is turned OFF when the engine is

running, not only various meters will stop working but

also the diodes and transistors in the starter can be

damaged.

XI

Page 13

FOREWORD

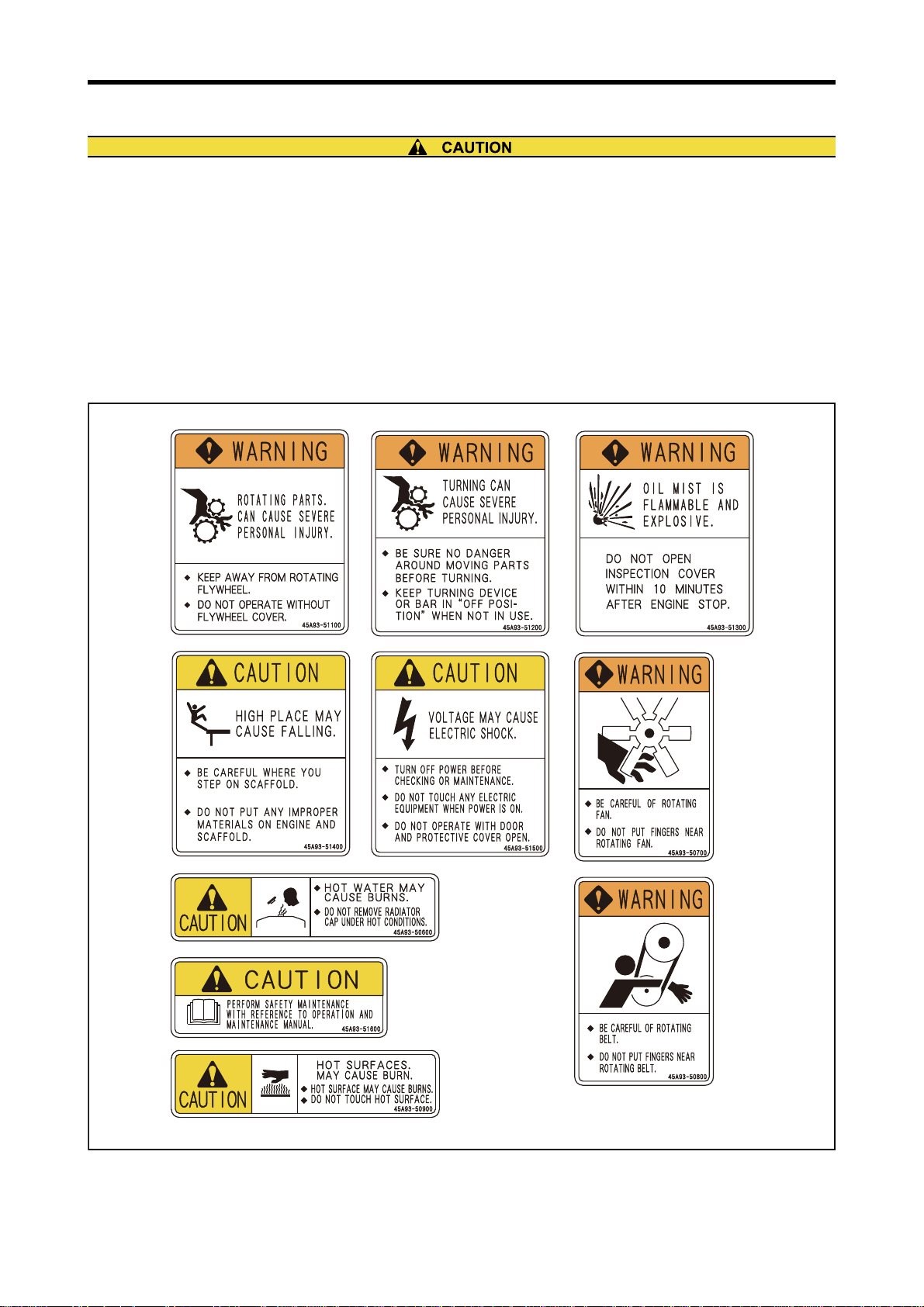

Warning Labels

Maintenance of Warning Labels

Make sure all warning/caution labels are legible.

Clean or replace the warning or caution label when the description or illustration is not clear to read.

For cleaning the warning/caution labels, use a cloth, water and soap. Do not use cleaning solvent, gasoline or other

chemicals to prevent the label from fading and peering.

Replace a damaged or missing label with a new one.

If any engine part sticked with a warning label is replaced with a new one, attach a new identical warning label to the

new part.

To get new warning labels, contact our approved dealer.

XII

Warning labels

Page 14

Points on Disassembling and Assembling

This service manual contains the recommended practices to

service the engine. The manual also contains dedicated spe-

cial tools made for the work, and the basic safety cautions to

obey when working. Note that this manual does not cover

all potential hazards that could occur during maintenance,

inspection and service works of the engine.

When working on the engine, follow the related instructions

in this manual and also be careful of the following:

Points on Disassembling

Use correct tools and instruments. Or serious damage or

accident may result.

Do not use jack bolts having sharp edge, as they may cause

damage to the surface.

Use a footing and workbench to place disassembled parts if

necessary, and obey the disassembling procedures

described in this manual. Do not place the parts on the

floor directly. Place them on a workbench or the like.

Place the engine parts in the order of removal to prevent

from missing. Place the parts in the serial order for reas-

sembling.

When reusing the engine parts, unless there are special rea-

sons, install them to their original positions.

Pay attention to assembling marks. Put your marks on the

parts, if necessary, to ensure correct assembling.

Carefully check each part for defects during disassembling

or cleaning. Do not miss symptoms which can not be

found after disassembling or cleaning.

Pay attention to the safety, especially for the balancing of

disassembled parts and carrying of heavy parts. (Get help,

and use jacks, chain blocks and guide bolts as necessary.)

Use protective gloves when you touch overheated or fro-

zen parts. Touching the part with a bear hand can cause

burns.

Points on Assembling

Wash all engine parts, except such parts as oil seals, O-

rings and rubber seats, in cleaning oil and dry them with

compressed air.

Use correct tools and instruments.

Use only high-quality lubricating oil and grease of the

appropriate type. Be sure to apply oil, grease or adhesive

to specified surfaces.

Use a torque wrench to tighten parts correctly when their

tightening torques are specified. Refer to "Tightening

torque table."

Replace Gaskets, packings and O-rings with new ones.

Apply adhesive as required. Do not apply adhesive too

much.

Use protective gloves when you touch overheated or fro-

zen parts. Touching the part with a bear hand can cause

burns.

FOREWORD

XIII

Page 15

GENERAL CONTENTS

Chapter 1 GENERAL

1. External View

2. Outline of Systems

3. Contents of Plate and Label

4. Specifications

Chapter 2 SERVICE DATA

1. Maintenance Service Data

2. Tightening Torque Table

Chapter 3 SERVICE TOOLS

1. Special Tools

Chapter 4 OVERHAUL INSTRUCTIONS

1. Determining Overhaul Timing

2. Compression Pressure - Measure

Chapter 5 DISASSEMBLY OF BASIC ENGINE

1. Cylinder Heads and Valve Mechanisms - Disassemble and Inspect

2. Rear Mechanism - Disassemble and Inspect

3. Front Mechanism - Disassemble and Inspect

4. Cylinder Liner, Piston and Connecting Rod - Disassemble and Inspect

5. Crankcase, Crankshaft and Main Bearing - Disassemble and Inspect

Chapter 6 INSPECTION AND REPAIR OF BASIC ENGINE

1. Cylinder Head and Valve Mechanism - Inspect and Repair

2. Rear Mechanism - Inspect and Repair

3. Front Mechanism - Inspect and Repair

4. Piston and Connecting Rod - Inspect and Repair

5. Crankcase and Crankshaft - Inspect and Repair

Chapter 7 ASSEMBLY OF BASIC ENGINE

1. Crankshaft and Main Bearing - Install

2. Cylinder Liner, Piston and Connecting Rod - Assemble

3. Front Mechanism - Assemble

4. Rear Mechanism - Assemble

5. Cylinder Head and Valve Mechanism - Assemble

Page 16

Chapter 8 FUEL SYSTEM

1. Fuel System - Remove and Inspect

2. Fuel System - Disassemble, Inspect and Assemble

3. Fuel System - Install

Chapter 9 LUBRICATION SYSTEM

1. Lubrication System - Remove and Inspect

2. Lubrication System - Disassemble, Inspect and Assemble

3. Lubrication System - Install

Chapter 10 COOLING SYSTEM

1. Cooling System - Remove and Inspect

2. Cooling System - Disassemble, Inspect and Assemble

3. Cooling System - Install

Chapter 11 INLET AND EXHAUST SYSTEMS

1. Inlet and Exhaust Systems - Remove and Inspect

2. Inlet and Exhaust Systems - Disassemble, Inspect and Assemble

3. Inlet and Exhaust Systems - Install

Chapter 12 AIR START SYSTEM

1. Air Start System - Remove and Inspect

2. Air Start System - Disassemble, Inspect and Assemble

3. Air Start System - Install

Chapter 13 ADJUSTMENT AND OPERATION

1. Engine - Adjust

2. Break-in Operation

3. Engine-Test and Adjustment

Page 17

Chapter 1 GENERAL

1. External View ...........................................................................................................1-3

2. Outline of Systems................................................................................................1-13

2.1 Outline of Fuel System ........................................................................................................... 1-13

2.2 Outline of Lubrication System................................................................................................. 1-13

2.3 Outline of Cooling System ...................................................................................................... 1-14

2.4 Outline of Inlet and Exhaust System....................................................................................... 1-17

3. Contents of Plate and Label .................................................................................1-19

3.1 Name Plate ............................................................................................................................. 1-19

3.2 Caution Plate .......................................................................................................................... 1-19

3.3 Emissions Certification Label.................................................................................................. 1-19

4. Specifications ........................................................................................................1-20

1-1

Page 18

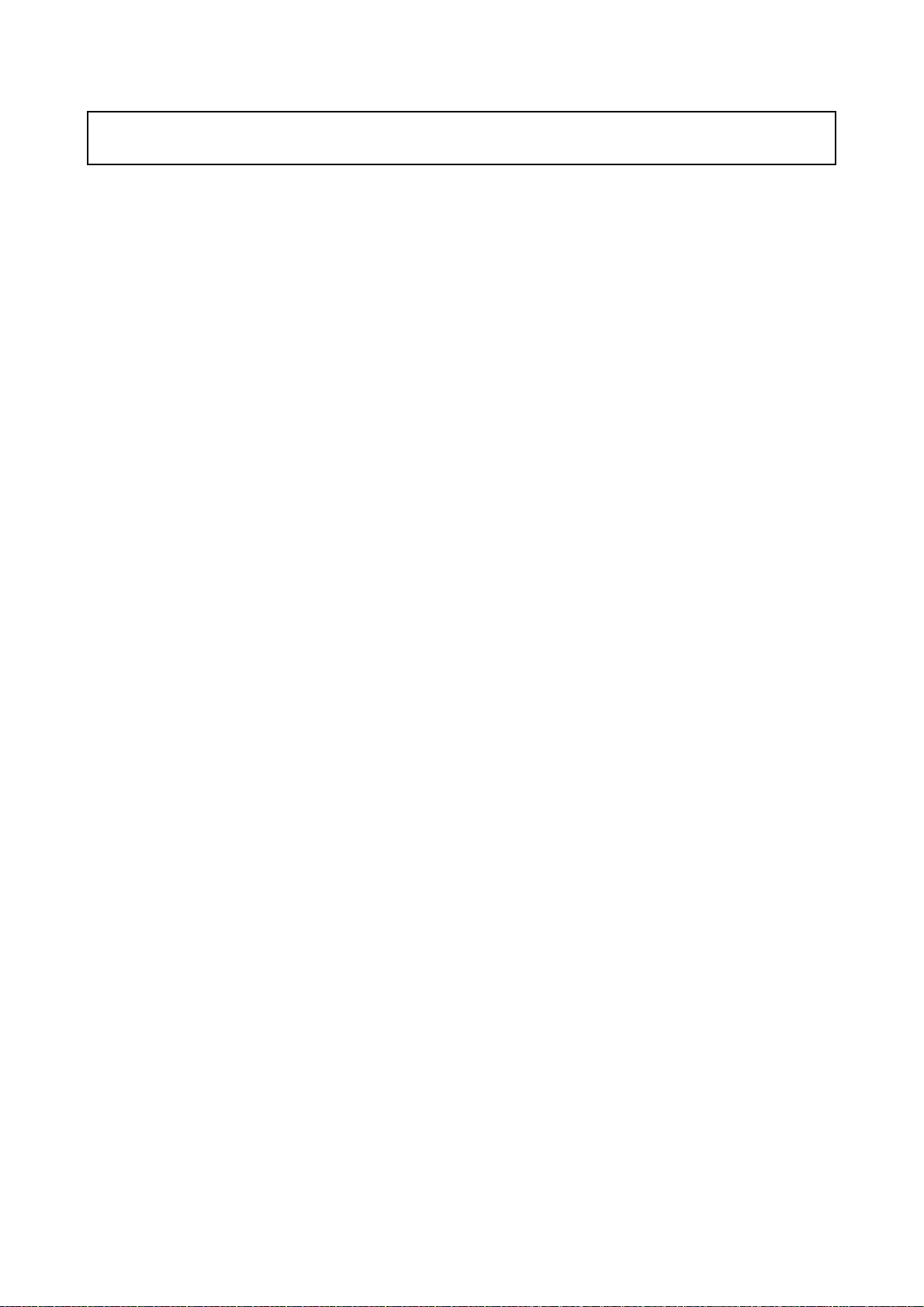

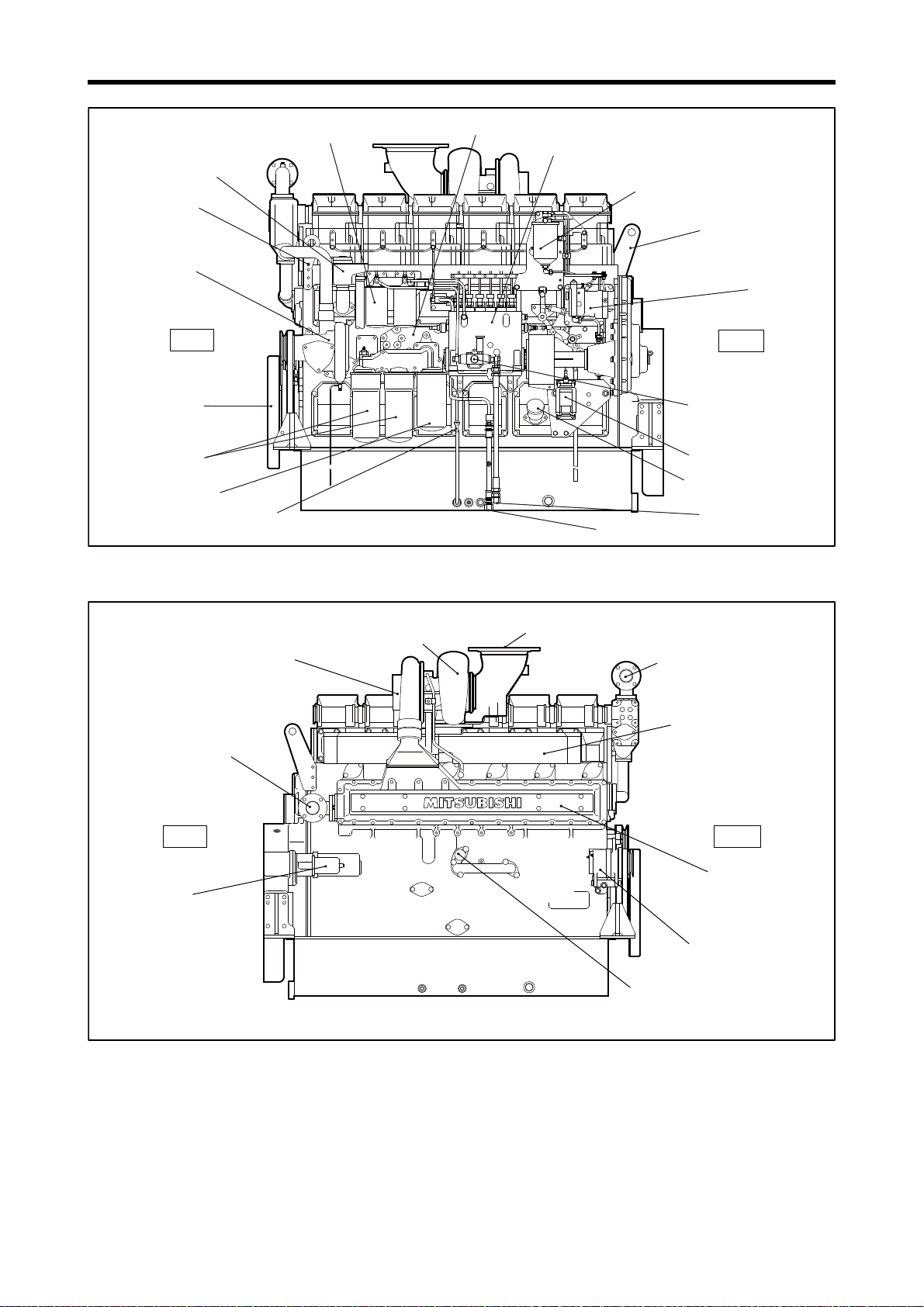

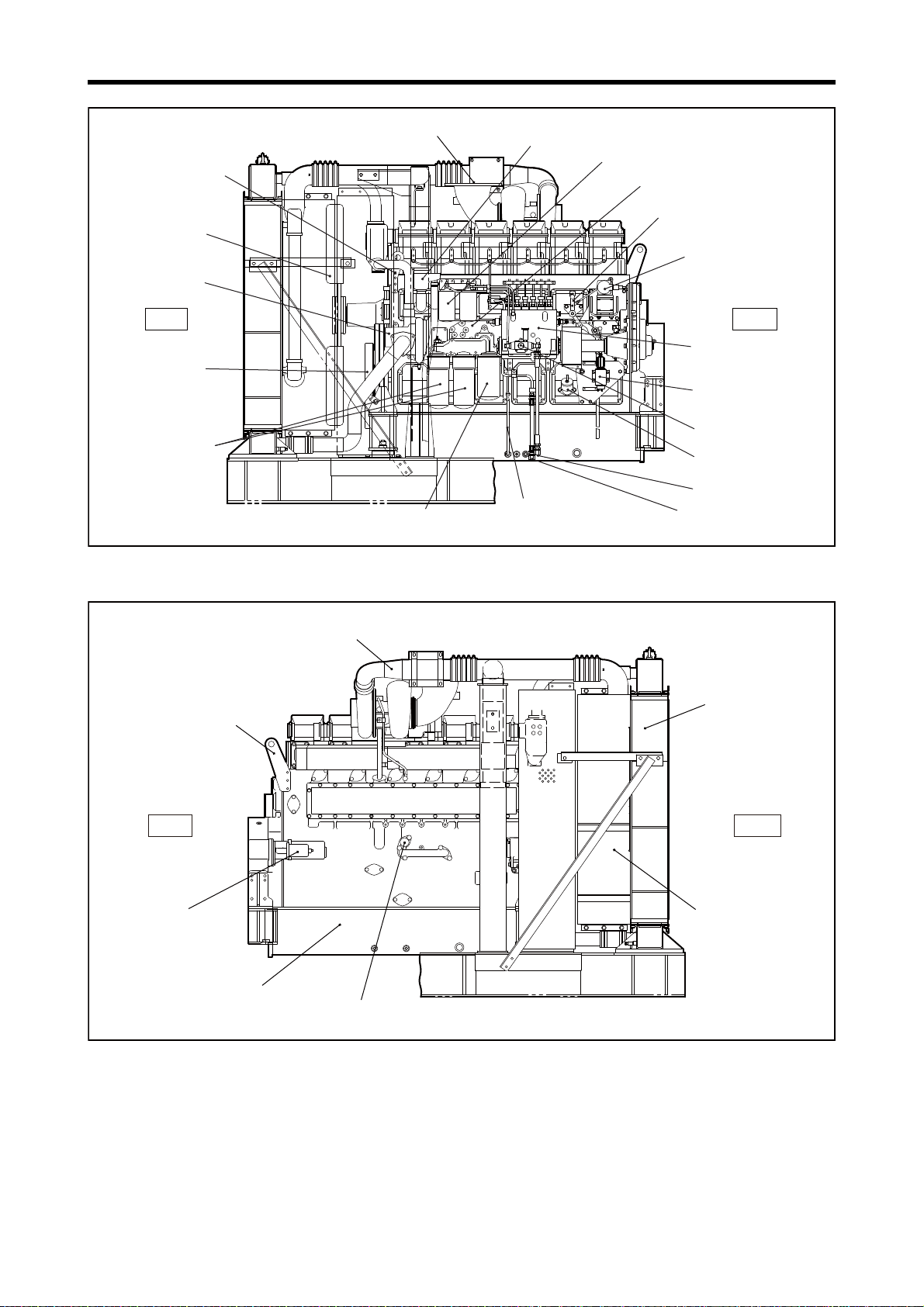

Chapter 1 GENERAL

Tension pulley

Engine coolant outlet

Water pump

S6R-PTA with fan spec

Thermostat case

Oil pan

Note: Configuration varies depending on the destination and specifications.

Damper

Flywheel

Engine oil discharge port

Rotation direction

Rotation direction

Timing gear case

S6R-PTA with fan spec

Note: Configuration varies depending on the destination and specifications.

Rotation direction

1. External View

Chapter 1 GENERAL

Engine Front View

Engine Rear View

1-3

Page 19

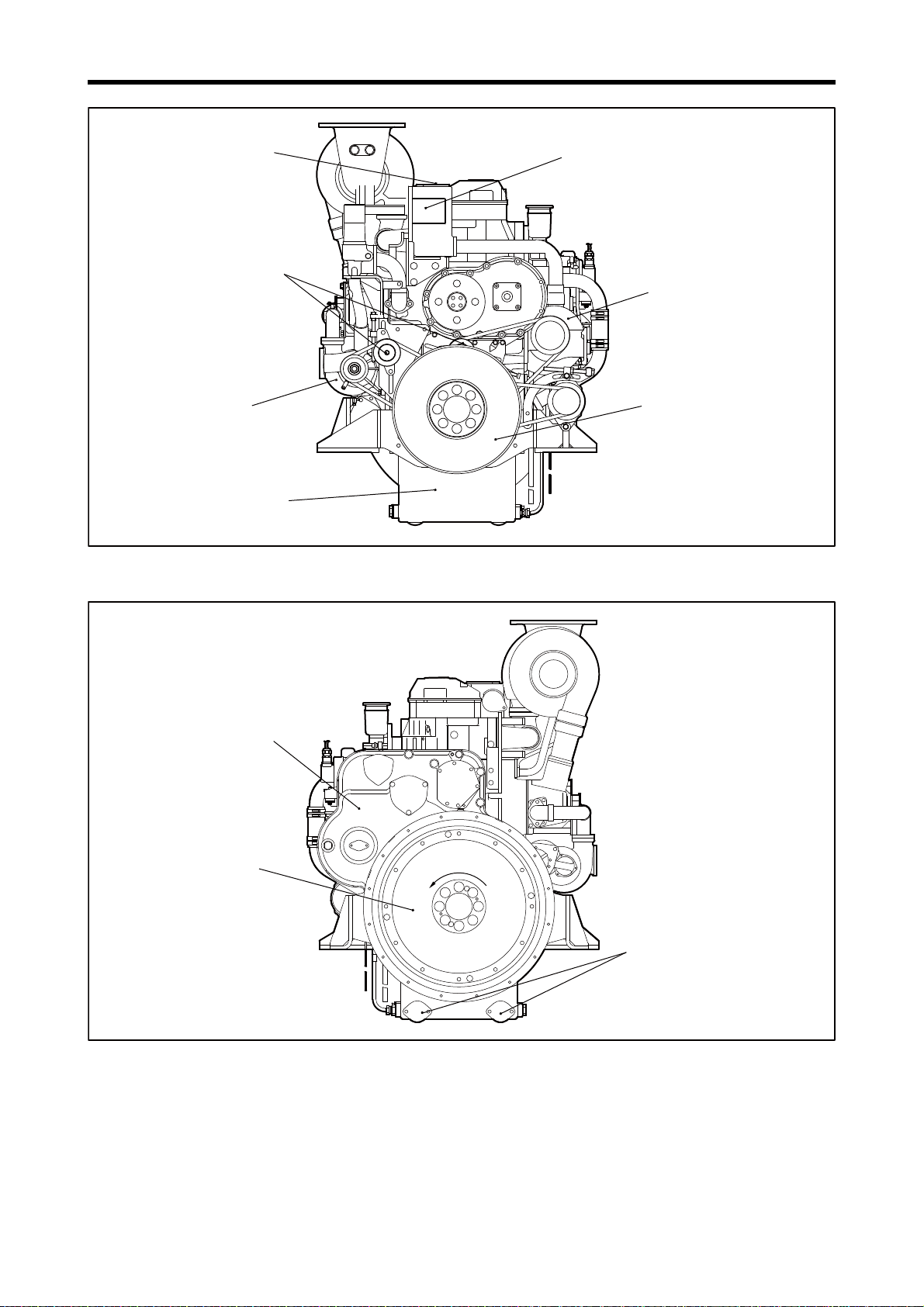

Chapter 1 GENERAL

Oil level gauge

Governor

Governor oil filter

Fuel injection pump

Fuel filter

Oil cooler

Engine coolant inlet

Oil filler

Stop solenoid

Fuel outlet

Fuel inlet

Rear

Front

Damper

Oil filter

Bypass oil filter

Front hanger

Fuel feed pump

Breather

Rear hanger

Water pump

S6R-PTA with fan spec

Note: Configuration varies depending on the destination and specifications.

Engine coolant outlet

Starter

Air cooler

Turbocharger

Front

Rear

Air inlet

Exhaust manifold

Exhaust pipe, exhaust outlet

Relief valve

Alternator

S6R-PTA with fan spec

Note: Configuration varies depending on the destination and specifications.

Left Side View

1-4

Right Side View

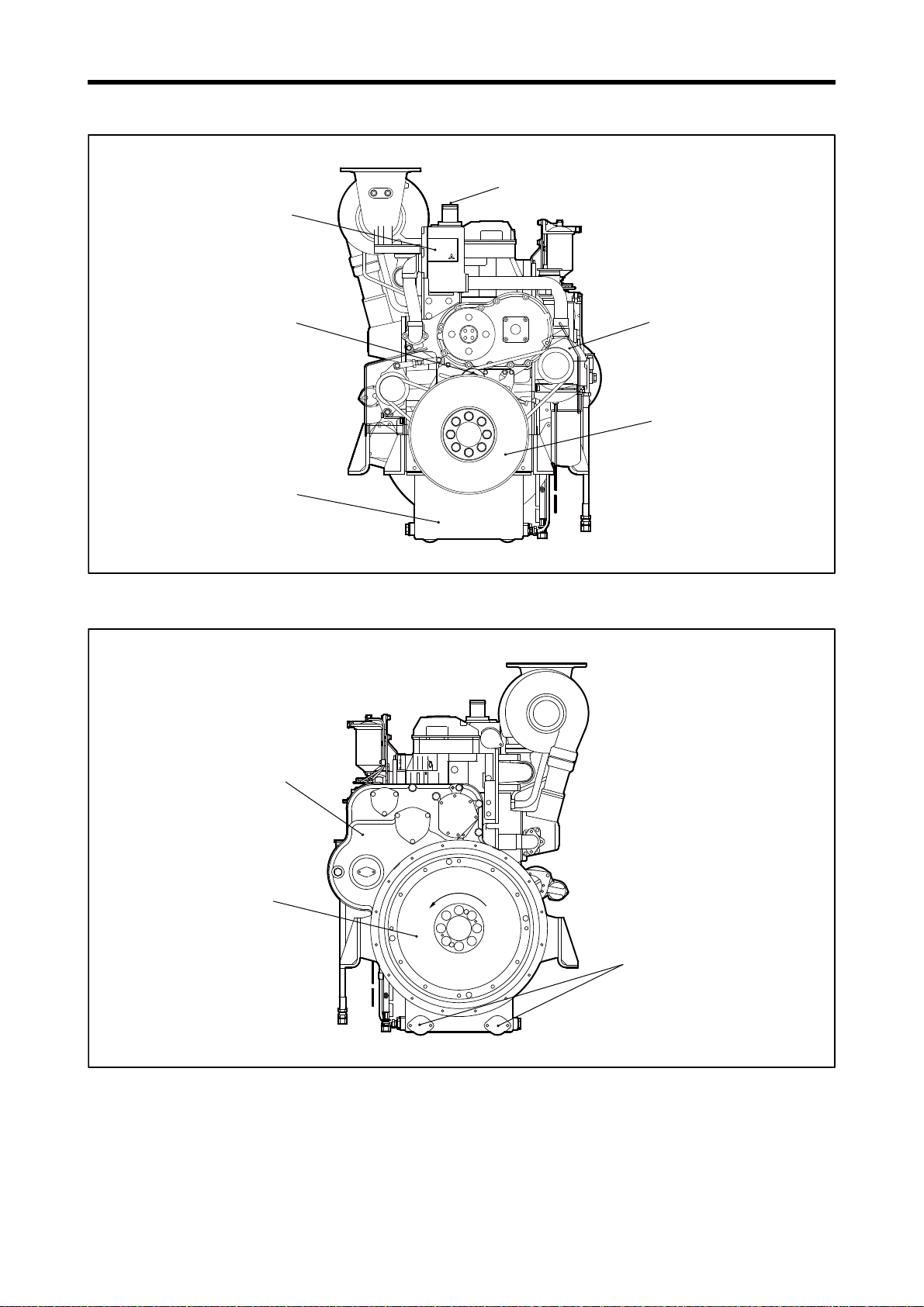

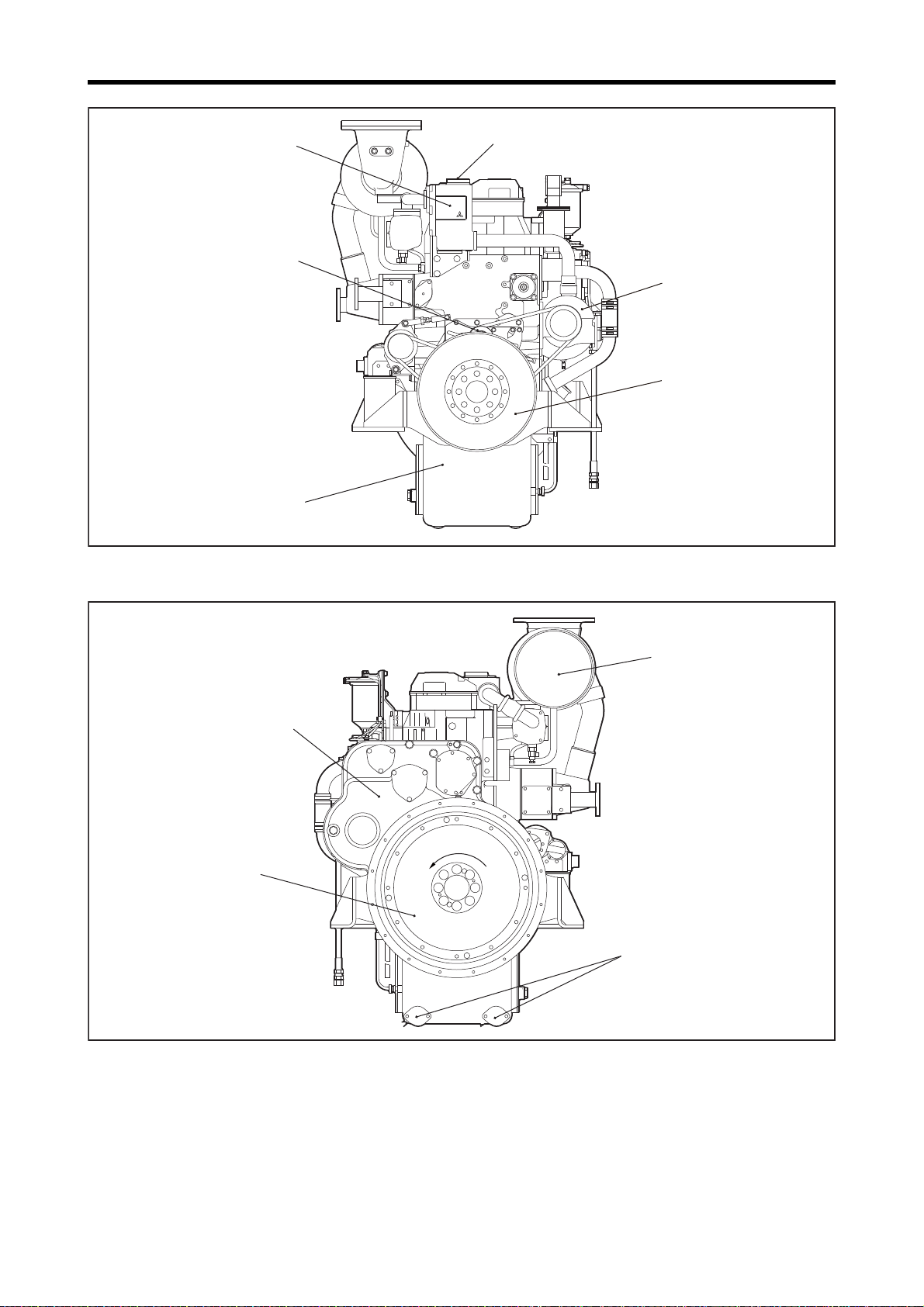

Page 20

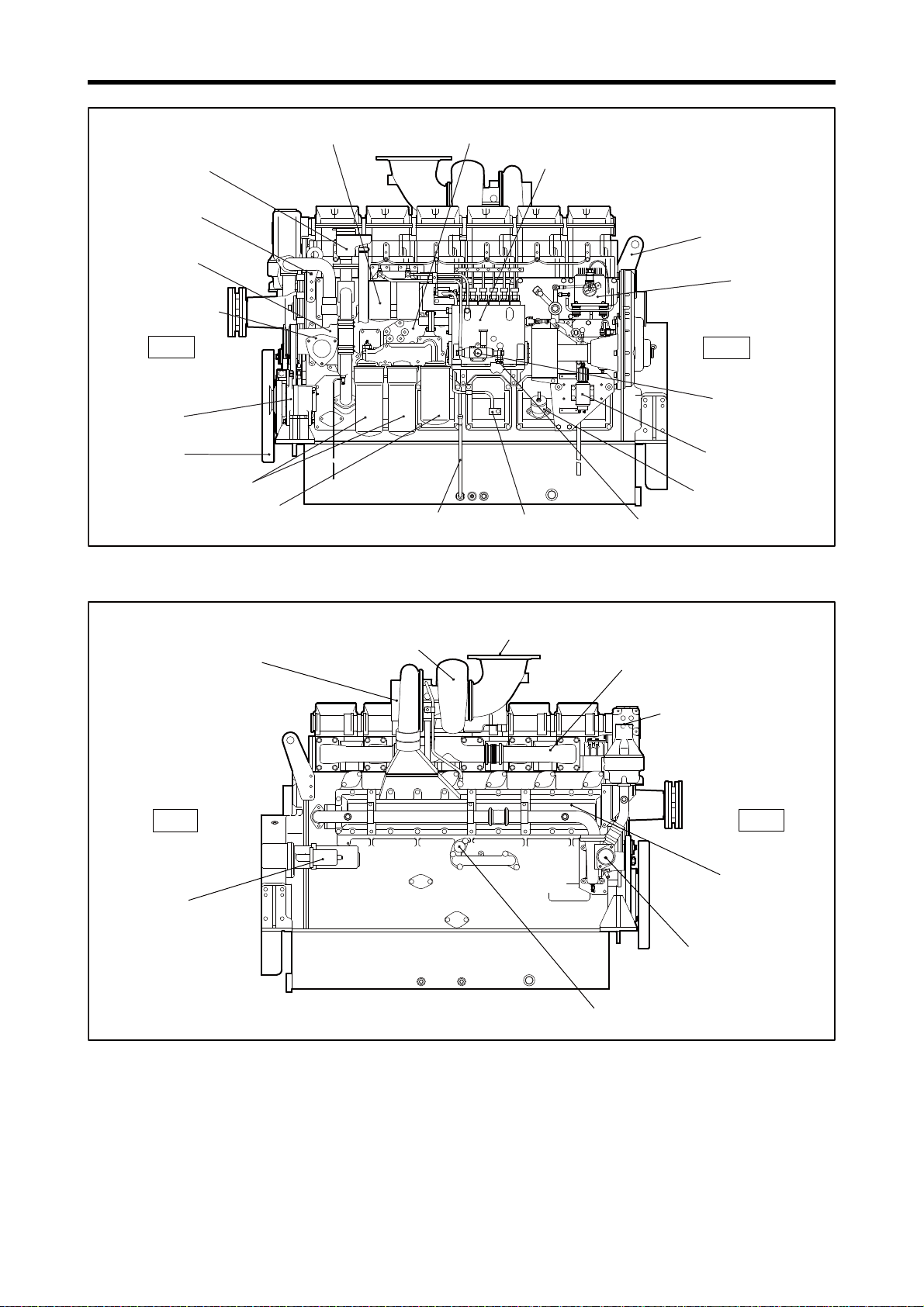

Chapter 1 GENERAL

Tension pulley

Engine coolant outlet

Thermostat case

Oil pan

S6R-PTK

Note: Configuration varies depending

on the destination and specifications.

Water pump

Damper

Flywheel

Timing gear case

Note: Configuration varies depending

on the destination and specifications.

S6R-PTK

Engine oil drain port

Rotation directionRotation directionRotation direction

Engine Front View

Engine Rear View

1-5

Page 21

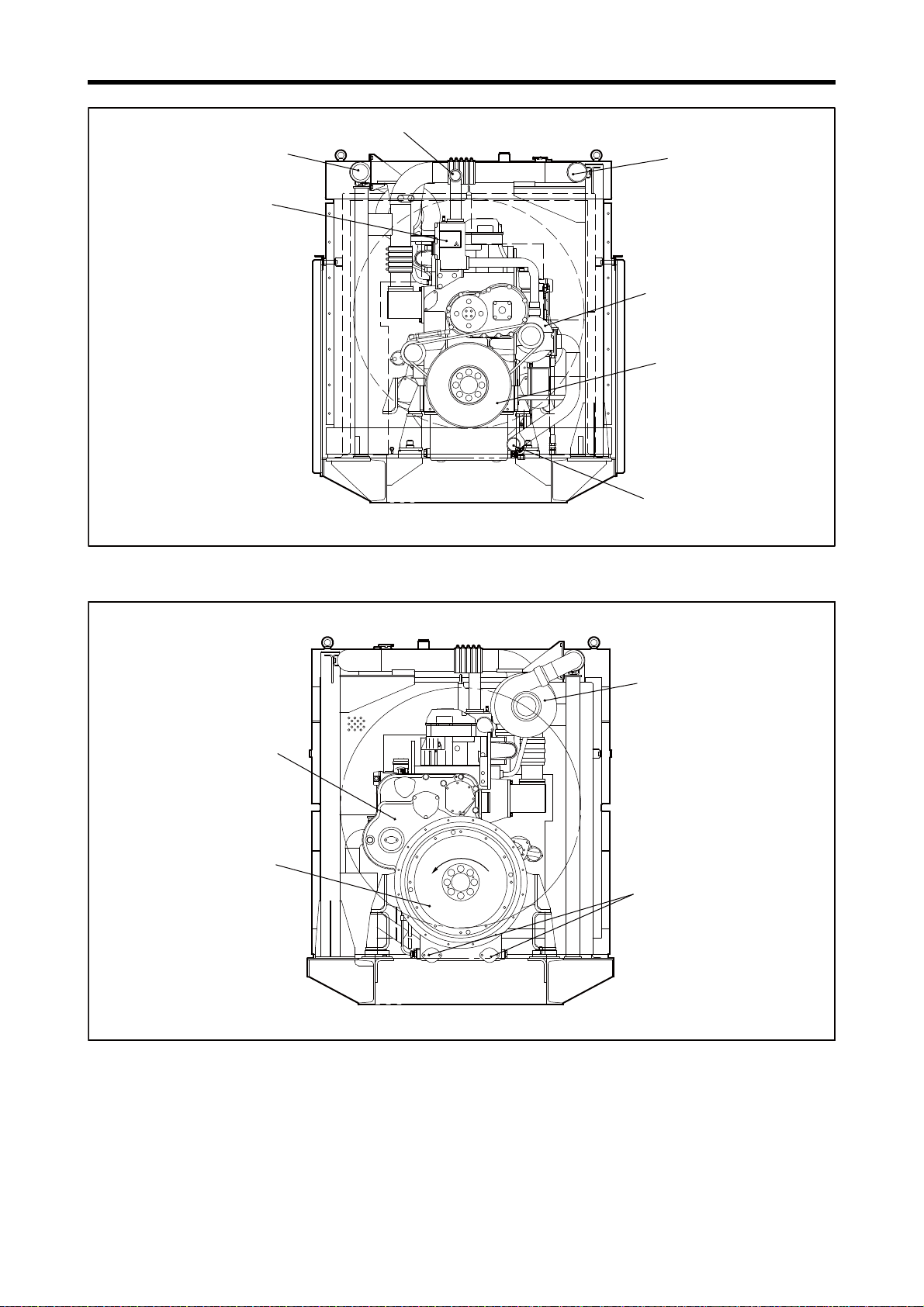

Chapter 1 GENERAL

Governor

Governor oil filter

Fuel injection pump

Fuel filter

Oil cooler

Oil filler

Rear

Front

Front hanger

Breather

Rear hanger

Water pump

Note: Configuration varies depending on the destination and specifications.

S6R-PTK

Fuel feed pump

Stop solenoid

Oil level gauge

Fuel return port

Fuel inlet

Damper

Oil filter

Bypass oil filter

Starter

Engine air cooler

coolant outlet

Air cooler

Engine air cooler

coolant inlet

Turbocharger

Front

Rear

Exhaust manifold

Alternator

S6R-PTK

Note: Configuration varies depending on the destination and specifications.

Exhaust pipe, exhaust outlet

Air inlet

Relief valve

Left Side View

Right Side View

1-6

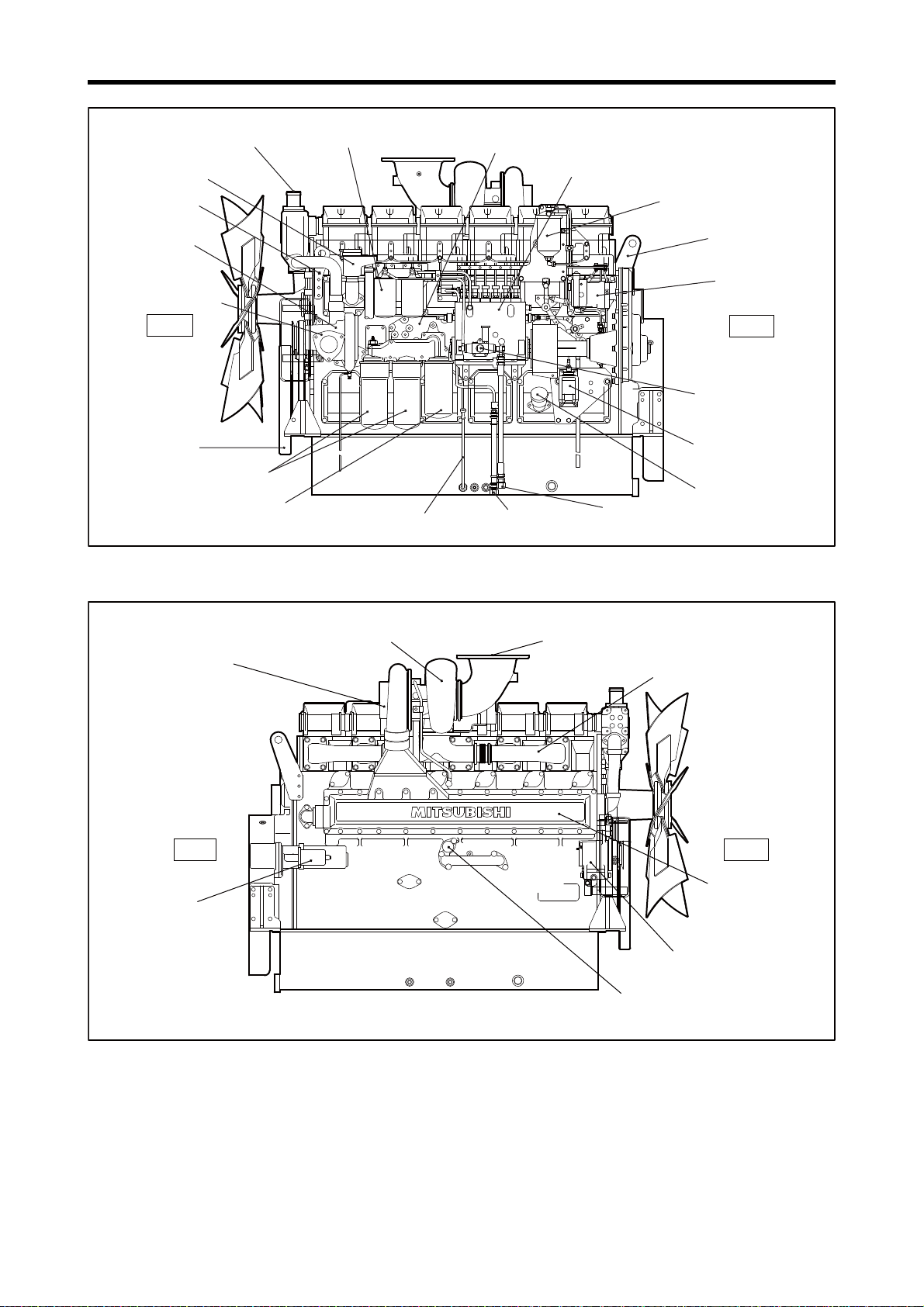

Page 22

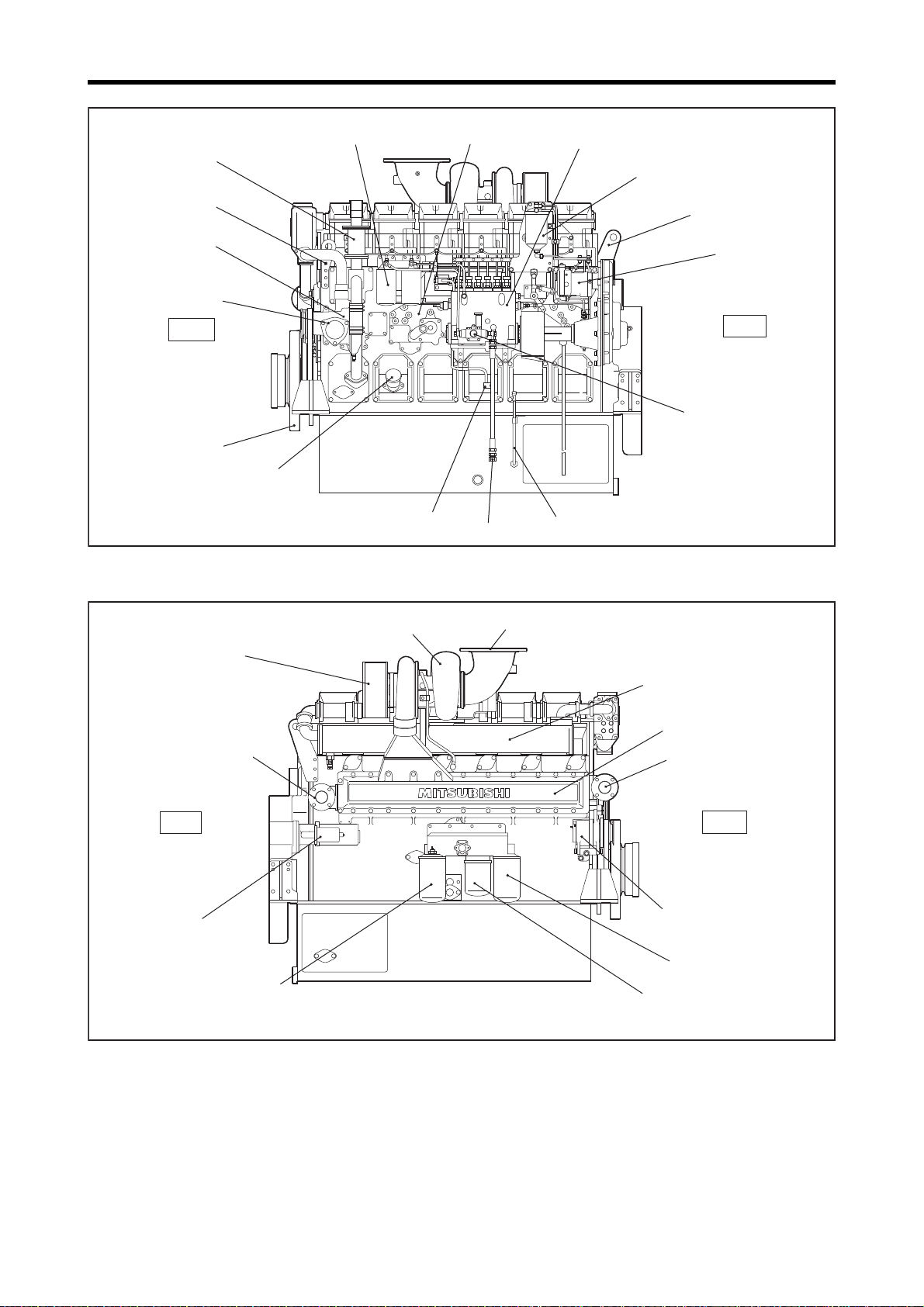

Chapter 1 GENERAL

Tension pulley

Engine coolant outlet

Thermostat case

Oil pan

Note: Configuration varies depending on the destination and specifications.

S6R-Y2PTAW

Water pump

Damper

Water pump

for air cooler cooling

Flywheel

Timing gear case

S6R-Y2PTAW

Note: Configuration varies depending on the destination and specifications.

Engine oil drain port

Rotation directionRotation direction

Rotation direction

Engine Front View

Engine Rear View

1-7

Page 23

Chapter 1 GENERAL

Oil level gauge

Governor

Fuel injection pump

Fuel filter

Oil cooler

Engine coolant inlet

Oil filler

Fuel return port

Fuel inlet

Rear

Front

Front hanger

Breather

Rear hanger

Water pump

S6R-Y2PTAW

Note: Configuration varies depending on the destination and specifications.

Fuel feed pump

Stop solenoid

Damper

Oil filter

Bypass oil filter

Alternator

Starter

Air cooler coolant outlet

Air cooler

Turbocharger

Front

Rear

Exhaust manifold

S6R-Y2PTAW

Note: Configuration varies depending on the destination and specifications.

Exhaust pipe, exhaust outlet

Air inlet

Relief valve

Air cooler coolant inlet

Left Side View

Right Side View

1-8

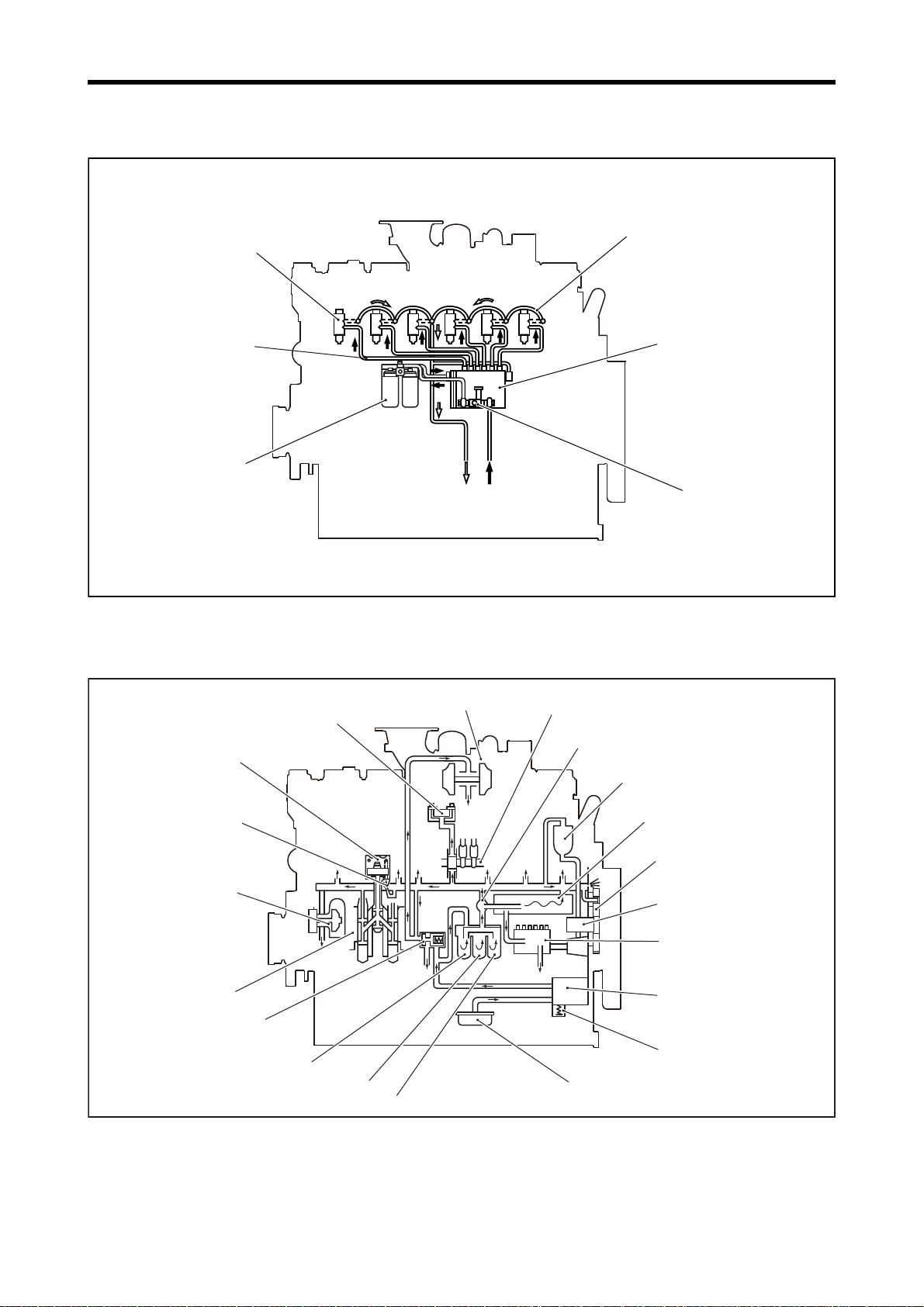

Page 24

Chapter 1 GENERAL

Thermostat case

Note: Configuration varies depending on the destination and specifications.

S6R2-PTAA

Water pump

Damper

Coolant inlet

Coolant outlet

Air outlet for air cooler

Air inlet for air cooler

Flywheel

Timing gear case

S6R2-PTAA

Note: Configuration varies depending on the destination and specifications.

Engine oil drain port

Rotation directionRotation direction

Rotation direction

Turbocharger

Engine Front View

Engine Rear View

1-9

Page 25

Chapter 1 GENERAL

Fuel return port

Oil level gauge

Fuel inlet

Breather

Stop lever

Actuator (governor)

Fuel injection pump

Fuel feed pump

Stop solenoid

Water pump

Damper

Bypass oil filter

Oil filter

Oil filler

Oil cooler

Fuel filter

Fan

Front hanger

Front

Rear

Exhaust pipe, exhaust outlet

S6R2-PTAA

Note: Configuration varies depending on the destination and specifications.

Starter

Relief valve

Radiator

Air cooler

Air duct

Front

Rear

Rear hanger

S6R2-PTAA

Note: Configuration varies depending on the destination and specifications.

Oil pan

Left Side View

Right Side View

1-10

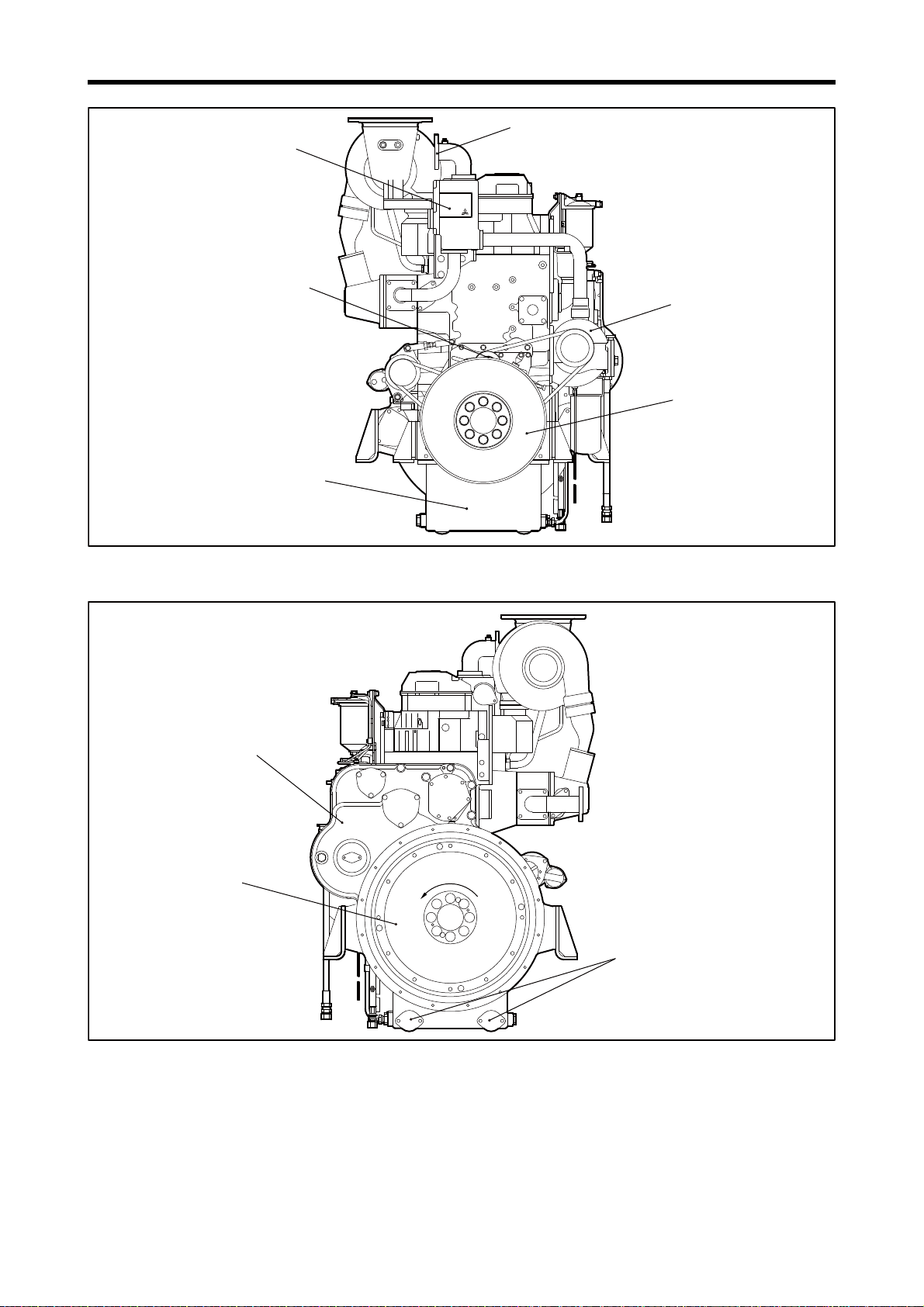

Page 26

Chapter 1 GENERAL

Tension pulley

Thermostat case

Oil pan

Water pump

Damper

Note: Configuration varies depending on the destination and specifications.

S6R-Z3MPTAW

Engine coolant outlet

Flywheel

Timing gear case

Silencer

S6R-Z3MPTAW

Note: Configuration varies depending on

the destination and specifications.

Engine oil drain port

Rotation directionRotation directionRotation direction

Engine Front View

Engine Rear View

1-11

Page 27

Chapter 1 GENERAL

Oil level gauge

Governor

Governor oil filter

Fuel injection pump

Fuel filter Oil cooler

Engine coolant inlet

Oil filler

Fuel return port

Fuel inlet

Rear

Front

Damper

Front hanger

Fuel feed pump

Breather

Rear hanger

Water pump

S6R-Z3MPTAW

Note: Configuration varies

depending on the destination

and specifications.

Starter

Oil filter

Oil filter

Bypass oil filter

Air cooler coolant outlet

Air cooler

Air cooler coolant inlet

Turbocharger

Front

Rear

Pre-cleaner air inlet

Exhaust manifold

Exhaust pipe, exhaust outlet

Alternator

S6R-Z3MPTAW

Note: Configuration varies depending on the destination and specifications.

Left Side View

1-12

Right Side View

Page 28

2. Outline of Systems

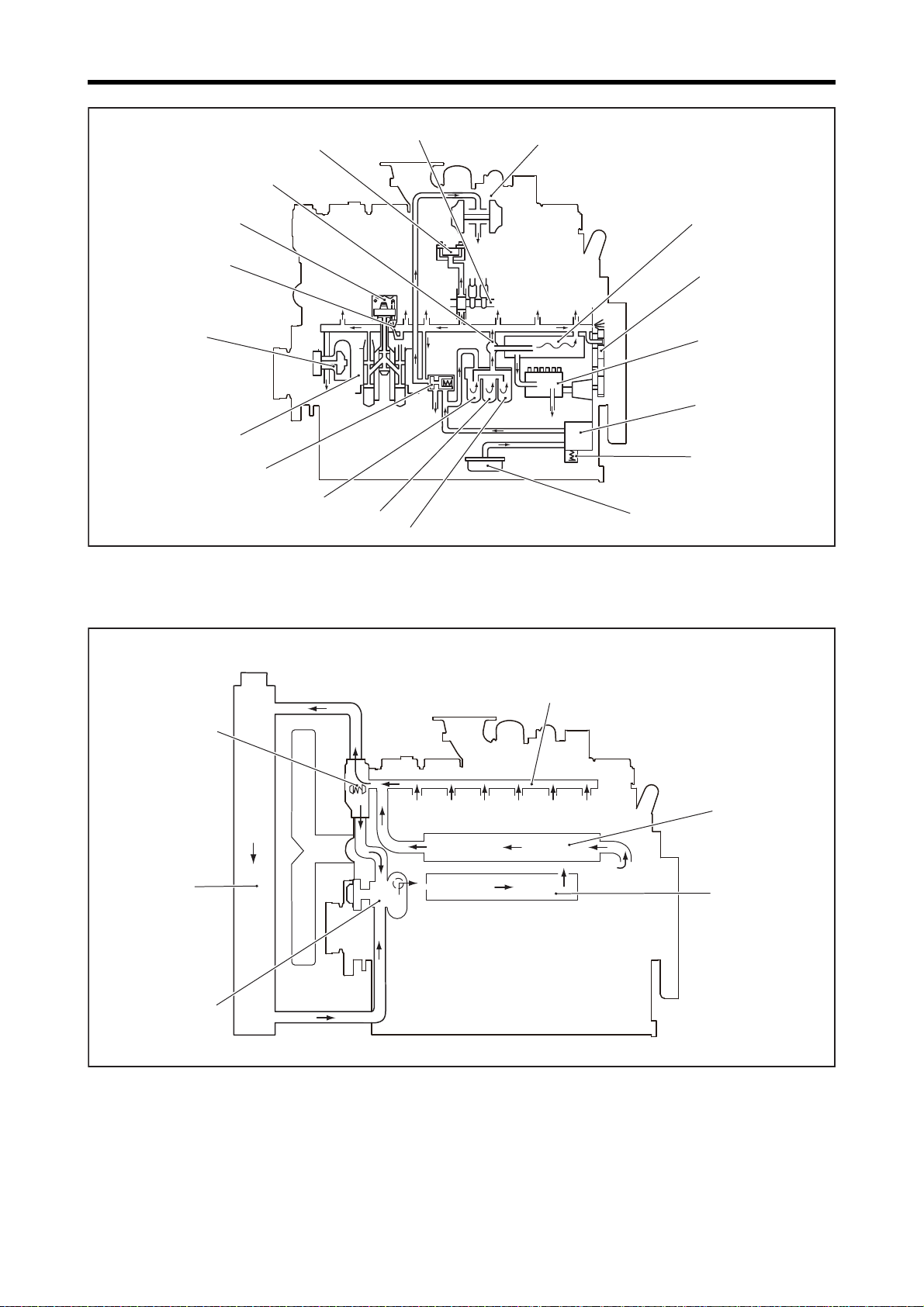

Fuel injection nozzle

Fuel leak-off pipe

Fuel injection pump

Fuel feed pump

From fuel tank

To fuel tank

Fuel filter

Fuel injection pipe

Oil pressure governor spec

Governor

Turbocharger

Camshaft

Oil thermostat

Oil cooler

Timing gear

Fuel injection pump

Oil pump

Safety valve

Bypass oil filter

Oil strainer

Oil filter

Relief valve

Crankshaft

Water pump

Piston

cooling nozzle

Piston

Rocker shaft

Oil filter

Governor oil filter

2.1 Outline of Fuel System

Chapter 1 GENERAL

2.2 Outline of Lubrication System

Outline of Fuel System

Outline of Lubrication System

1-13

Page 29

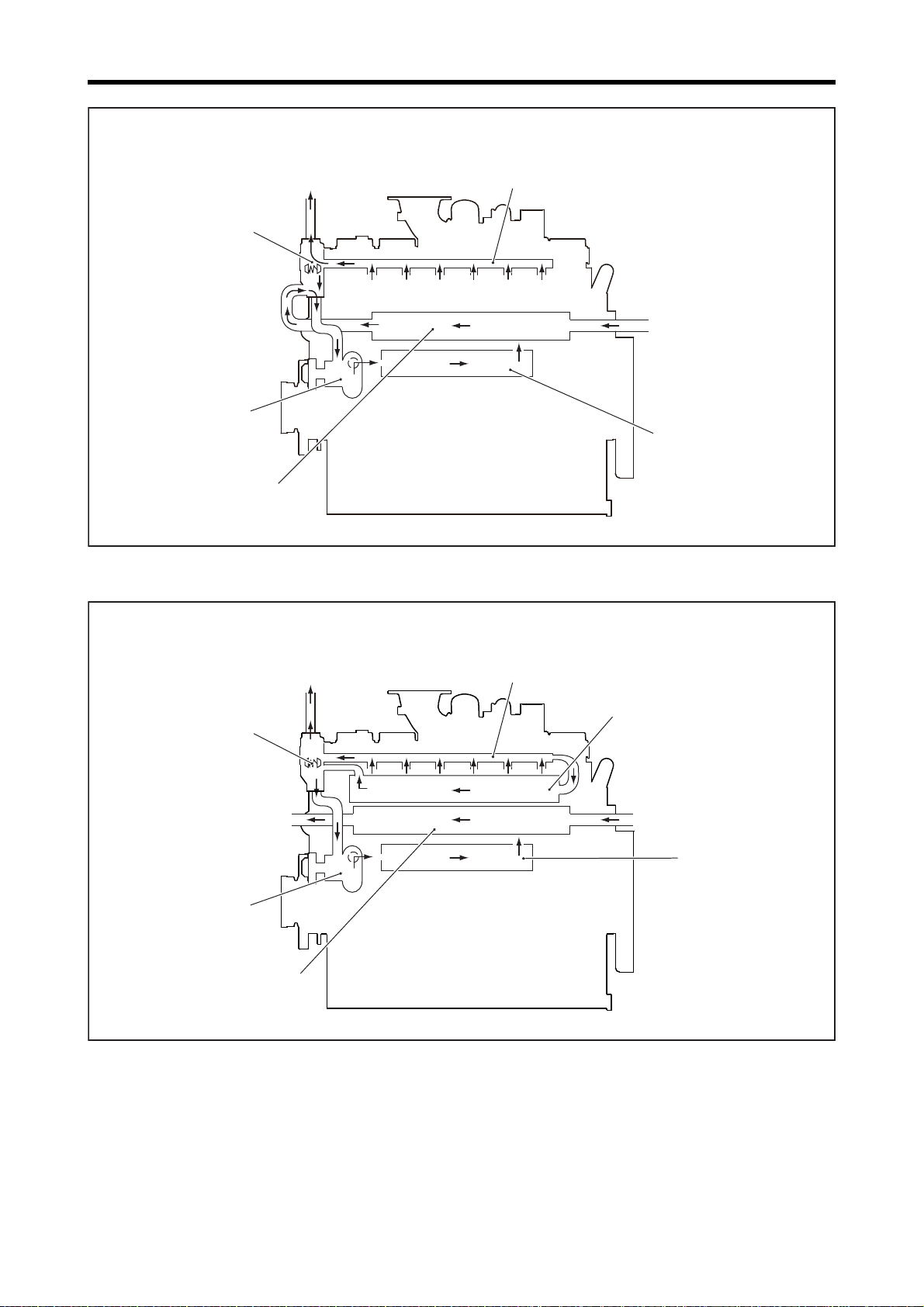

Chapter 1 GENERAL

Turbocharger

Camshaft

Oil thermostat

Oil cooler

Electronic governor spec

Timing gear

Fuel injection pump

Oil pump

Safety valve

Bypass oil filter

Oil strainer

Oil filter

Relief valve

Crankshaft

Water pump

Piston

cooling nozzle

Piston

Rocker shaft

Oil filter

Water outlet pipe (rocker case)

Oil cooler

Air cooler

PTA spec

Thermostat

Radiator

Water pump

2.3 Outline of Cooling System

Outline of Lubrication System

1-14

Outline of Cooling System

Page 30

Chapter 1 GENERAL

Water outlet pipe (rocker case)

Oil cooler

PTK spec

Thermostat

Air cooler

Water pump

Air cooler,

Engine coolant inlet

Air cooler,

engine coolant outlet

Water outlet pipe (rocker case)

Oil cooler

PTAW spec (Outside of water pump for air cooler cooling)

Thermostat

Air cooler

Water pump

Exhaust manifold

Air cooler coolant inlet Air cooler coolant outlet

Engine coolant outlet

Outline of Cooling System

Outline of Cooling System

1-15

Page 31

Chapter 1 GENERAL

Water outlet pipe (rocker case)

Oil cooler

Thermostat

Air cooler

Water pump

Air cooler water pump

Engine coolant inlet

Air cooler coolant outlet

Engine coolant

outlet

Air cooler

coolant outlet

PTAW spec (Water pump for air cooler cooling mounted)

Water outlet pipe (rocker case)

Oil cooler

Air cooler

PTAA spec

Thermostat

Radiator

Water pump

Outline of Cooling System

1-16

Outline of Cooling System

Page 32

Chapter 1 GENERAL

Water outlet pipe (rocker case)

Oil cooler

Marine gear

oil cooler

MTK, MPTK spec

Thermostat

Heat exchanger

Water pump

Sea water pump

Sea water

outlet port

Sea water inlet port

Exhaust manifold

Exhaust outlet

Air cooler

Exhaust air

Charging air

Turbocharger

Exhaust pipe

Internal air cooler spec

From air-cleaner

Cylinder

2.4 Outline of Inlet and Exhaust System

Outline of Cooling System

Outline of Inlet and Exhaust System

1-17

Page 33

Chapter 1 GENERAL

Exhaust outlet

Air cooler

Exhaust air

Charging air

Turbocharger

Exhaust pipe

External air cooler spec

From air-cleaner

Cylinder

Outline of Inlet and Exhaust System

1-18

Page 34

3. Contents of Plate and Label

3.1 Name Plate

The name plate is attached on the lateral side of the engine,

and shows the following information:

Engine serial number

Manufactured date

Total displacement

Engine output

Rated speed

Right side

Chapter 1 GENERAL

RearFront

3.2 Caution Plate

The caution plate is attached to the top face of the rocker

cover of No. 1 cylinder and shows the following informa-

tion:

Valve clearance

Firing order

Fuel injection timing

Connecting rod weight rank

3.3 Emissions Certification Label

The emission certification label that shows compliance with

emission requirements is attached to the engine.

Left side

Cylinder No.

Name Plate

VALVE CLEARANCE(COLD)

INLET

FUEL INJECTION TIMING

mm

0.6

FIRING ORDER

1-5-3-6-2-4

CON-ROD RANK

EXHAUST

0.8

mm

°

BTDC

Caution Plate

1-19

Page 35

Chapter 1 GENERAL

4. Specifications

Engine model S6R S6R2

Type Water cooled, four stroke cycle diesel, turbo charged

No. of cylinders - Arrangement 6 cylinders, in-line

Combustion system Direct injection system

Valve mechanism Overhead

Cylinder bore × stroke 170×180 mm [6.69×7.09 in.] 170×220 mm [6.69×8.66 in.]

Total displacement 24.51 L [1495.9 cu in] 29.96 L [1828.5 cu in.]

Firing order 1-5-3-6-2-4

Direction of rotation Counterclockwise as viewed from flywheel side

Engine oil Class CF or CH-4 (API service classification)

Specification table

The mark "○" in the table represents the installed equipment of each engine type.

Note:(a) This table shows the general information. The installation of equipment differs in accordance with the customization

and specifications.

(b) The specification and part number may be changed with the design progress without prior notice.

Equipment name Specification name

Single spring

Valve mechanism

Camshaft

Cylinder liner

Piston

cooling nozzle

Oil pan

Connecting rod

Rod

(Inlet side)

Double spring

(Exhaust side)

Overlap 61°

(37505-40100)

Overlap 93°

(37505-34100)

Overlap 93° advanced by 4°

(37505-04300)

(37507-22700) ○○○○○○○○○○○○○○○○

(37507-55600) ○○○○○○○○○○○○

One jet ○○○ ○○○○○○○○○○○○○○○○○○○○○○

Two jets ○○○○

Standard oil pan

(37513-60101)

Deep type oil pan

(Hi 145L, Low114L)

[38.3, 30.1 USgal]

(37513-20602)

Bolt identification mark

"AU""AL"

(37519-31020)

Bolt identification mark "2"

(37519-75020 to 76010)

S6R S6R2

V2PTK-1

Y2PTAW

Y1PTA-4

Y1PTA-5

PTA-S

PTA

PT

○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○ ○○○○○ ○ ○ ○○○

○○○ ○ ○○ ○○○ ○○○○○○○○○○

○ ○○○○○ ○ ○ ○ ○

○○○○○○○○○○ ○○○○○○○○

○ ○ ○○○○○○○ ○ ○○○○○○○

○○○○○○○○○○○○○○○○

PTK

TA

Z3MPTAW

MPTA

Y1MPTA-3

Y1MPTK-3

MPTK

Y2MPTK-3

MPT

PTA

PT

○○○○○○○○○○○○

PTAA

PTA-S

PTAA-S

PTK

MPTA

MPTK

MTK

MTK2

MTK3

○○

MTK2L

1-20

Page 36

Chapter 1 GENERAL

Equipment name Specification name

Overlap 61°

Compression ratio 14

(37517-30101)

Overlap 93°

Compression ratio 15

(37517-10401)

Overlap 93°

Compression ratio 14.5

(37517-00900)

Piston

Flywheel

Front pulley,

Crankshaft pulley

Overlap 61°

Compression ratio 14

(37517-25100)

Overlap 91°

Compression ratio 14

(37517-05300)

Overlap 93°

4°advance, compression

ratio14

(37517-05500)

Standard (37521-00012) ○○○○○○○○ ○○○○○○

FCD spec (37521-00060) ○○○○○○○ ○○○○○○

Land clutch (37521-12012) ○

(37525-12201) ○○○○○ ○○○○○○○○○○○○○○○○○○○○○○

(37525-04501) ○

(37525-18800) ○○

(37320-22600) ○○○

(37525-28101) ○ ○○ ○○○○○○

(37525-18600) ○○

(37525-02800) ○

S6R S6R2

V2PTK-1

Y2PTAW

Y1PTA-4

Y1PTA-5

PTA-S

PTA

PT

○○○ ○ ○○ ○○○ ○

○○○○○

PTK

○○○

TA

Z3MPTAW

MPTA

Y1MPTA-3

Y1MPTK-3

MPTK

Y2MPTK-3

MPT

PTAA-S

PTA-S

PTAA

PTA

PT

○○○○○○○○○

PTK

MPTK

MPTA

MTK

MTK2L

MTK2

MTK3

○○

○○

1-21

Page 37

Chapter 1 GENERAL

Equipment name Specification name

TD10L-42F-34 ○

TD10L-42F-43 ○○○○

TD13L-47F-40 ○○○○○○○

TD13L-47F-47 ○○○○○ ○○○

TD13L-47F-55 ○○

TD13L-54QRC-47 ○○

TD13L-54QRC-47

Water cool exhaust manifold

TD13L-57V-55 ○

TD13M1-48QRC-40 ○

TD15-50B-49 ○○ ○○

TD15-50B-54 ○○○

TD15-55B-54 ○○○

Turbocharger

Fan

TD15-55B-54 Classification

JG

TD15-55B-54 Classification

NK

TD15-55B-59 ○○

TD15-55B-66 ○

TF15L-60QV-49 ○

TF15M-60QV-49 ○○○○

TF15M-60QVRC-49 ○○○

TF15M-67QVRC-49

(Flange connection type)

TF15M-67QVRC-54 ○○

TF15M1-67QVRC-49 ○

TF15M1-60QVRC-49

Water cool exhaust manifold

D1010, PUSHER

(46648-02300)

D1016, PUSHER

(46648-22600)

S6R S6R2

V2PTK-1

Y2PTAW

Y1PTA-4

Y1PTA-5

PTA-S

PTA

PT

○○○○ ○○ ○○○ ○ ○

PTK

TA

Z3MPTAW

MPTA

○

○

Y1MPTA-3

Y1MPTK-3

MPTK

Y2MPTK-3

MPT

PT

PTA-S

PTAA

PTA

○○

PTAA-S

PTK

MPTA

MPTK

○

○

MTK

MTK2

MTK3

○○

MTK2L

1-22

Page 38

Chapter 1 GENERAL

Equipment name Specification name

Fresh water (internal cooling)

air cool exhaust manifold

(37555-30030)

Fresh water

(external cooling)

air cool exhaust manifold

(37555-30040)

Fresh water (internal cooling)

Water cool exhaust manifold

(37555-10054)

Sea water (37555-30083) ○○ ○○

Air cooler

Fuel injection

nozzle

Fresh water (internal cooling)

air cool exhaust manifold

Classification JG

(37555-30J30)

Fresh water (two system)

air cool exhaust manifold

(37555-30030)

Fresh water (two system)

Water cool exhaust manifold

(37555-00060)

MTK2(37555-33013) ○○

MTK3(37555-05012) ○○

MPTK(37555-30083) ○

T model, screw adjust

opening pressure type

(37560-35000)

T model, screw adjust

opening pressure type

(37560-37000)

T model, screw adjust

opening pressure type

(37560-39000)

T model, screw adjust

opening pressure type

(37560-22010)

T model, screw adjust

opening pressure type

(37560-41000)

T model, screw adjust

opening pressure type

(37561-44000)

T model, shim adjust

opening pressure type

(37560-32000)

TE model, screw adjust

opening pressure type

(37860-06000)

S model, screw adjust

opening pressure type

(37760-22001)

S6R S6R2

V2PTK-1

Y2PTAW

Y1PTA-4

Y1PTA-5

PTA-S

PTA

PT

○○○○ ○○ ○○ ○ ○

○○○○○

○○ ○ ○ ○

○ ○ ○○ ○○○ ○○○ ○○○○

○○ ○○○○○○ ○○○

PTK

○○ ○

○

○○

Z3MPTAW

MPTA

TA

○○ ○

○○

○○

Y1MPTA-3

Y1MPTK-3

MPTK

Y2MPTK-3

MPT

PT

○

PTAA-S

PTA-S

PTAA

PTA

○

MPTK

MPTA

PTK

○○○○

MTK

MTK2

MTK2L

MTK3

○

1-23

Page 39

Chapter 1 GENERAL

Equipment name Specification name

Diesel oil ○○○○○○○○ ○ ○○ ○○○○

Diesel oil, changover type ○○ ○ ○○

Fuel filter

Governor

Starter

Alternator

Stop solenoid

Start restriction

solenoid

A diesel oil ○○ ○○○○○○○○○○○○○

Diesel oil, changeover type ○○ ○○

Primary filter ○○ ○

Changeover type (VOLVO) ○○

Woodward make

PSG type governor

Woodward make

SG type governor

TOHO SEISAKUSHO Co.,

LTD .

SG4017 type actuator

Woodward make

DYNA8000 type Actuator

Woodward make

PROACT type Actuator

Land use self starter motor

(37566-30200)

Land use self starter motor

(37566-40300)×2

Marine use self starter motor

(37566-45200)

Marine use self starter motor

(37566-45200)×2

Air motor (04065-61001) ○○○

30A (04343-38000) ○○○○○○○○ ○○○○○○

35A, brushless

(04343-35500)

35A, brushless, JG

(04343-35600)

35A, JG (04344-05100) ○ ○ ○ ○ ○○○○

130A (04344-08001) ○

RUN-OFF ○○ ○ ○○○○○○○○○○ ○○○○○○○

RUN-ON ○○○○○○○ ○○○○○

RUN-OFF ○○

S6R S6R2

V2PTK-1

Y2PTAW

Y1PTA-4

Y1PTA-5

PTA-S

PTA

PT

○○ ○ ○○○○○○○ ○○ ○○○○○○○

○○ ○ ○○○○○

○○

○○○○

○○○○○○○○○ ○○○○○○

○ ○○ ○○○ ○○

PTK

Z3MPTAW

MPTA

TA

○○ ○

○○○○○○○ ○○○○○○

○○○ ○○

Y1MPTA-3

Y1MPTK-3

MPTK

Y2MPTK-3

MPT

PT

PTAA-S

PTA-S

PTAA

PTA

PTK

MPTK

MPTA

MTK

○

MTK2

MTK3

MTK2L

1-24

Page 40

Chapter 2 SERVICE DATA

1. Maintenance Service Data ......................................................................................2-3

1.1 Maintenance Service Data of Engine General.......................................................................... 2-3

1.2 Maintenance Service Data of Basic Engine.............................................................................. 2-4

1.3 Maintenance Service Data of Fuel System............................................................................... 2-9

1.4 Maintenance Service Data of Lubrication System .................................................................. 2-11

1.5 Maintenance Service Data of Cooling System ....................................................................... 2-12

1.6 Maintenance Service Data of Electrical System ..................................................................... 2-14

1.7 Air Start System...................................................................................................................... 2-17

2. Tightening Torque Table.......................................................................................2-18

2.1 Tightening Torque Spec for Basic Engine .............................................................................. 2-18

2.2 Tightening Torque Spec for Fuel System ............................................................................... 2-19

2.3 Tightening Torque Spec for Lubrication System..................................................................... 2-19

2.4 Tightening Torque Spec for Cooling System.......................................................................... 2-20

2.5 Tightening Torque Spec for Inlet and Exhaust System .......................................................... 2-20

2.6 Tightening Torque Spec for Electrical System........................................................................ 2-21

2.7 Tightening Torque Spec for Air Start System ......................................................................... 2-21

2.8 Tightening Torque for Standard Bolts..................................................................................... 2-22

2.9 Tightening Torque for Standard Eyebolts ............................................................................... 2-23

2.10 Tightening Torque for Standard Union Nuts........................................................................... 2-23

2.11 Tightening Torque for Fuel Injection Pipe............................................................................... 2-23

2-1

Page 41

Chapter 2 SERVICE DATA

1. Maintenance Service Data

1.1 Maintenance Service Data of Engine General

Item

Compression pressure

At rated

Engine oil pressure

When idling

Open BTDC 37°

Close ABDC 44°

Open BBDC 57°

Close ATDC 24°

Open BTDC 2.5°

Close BBDC 13°

Open BBDC 26°

Close BTDC 10.5°

Open BTDC 53°

Close ABDC 44°

Open BBDC 57°

Close ATDC 40°

Open BTDC 14°

Close ABDC 12.5°

Open BBDC 25.5°

Close ATDC 1°

Open BBDC 57°

Close ABDC 40°

Open BBDC 61°

Close ABDC 36°

Open BTDC 18°

Close ABDC 8.5°

Open BBDC 29.5°

Close BTDC 3°

Overlap 61°

camshaft

P/N:37505-40100

Overlap 93°

Valve timing

camshaft

P/N:37505-34100

Overlap 93°

advanced by 4°

camshaft

P/N:37505-04300

Valve clearance (when cold)

Fuel injection timing

Inlet

Exhaust

Inlet

Exhaust

Inlet

Exhaust

Inlet

Exhaust

Inlet

Exhaust

Inlet

Exhaust

Inlet 0.6 mm [0.024 in.]

Exhaust 0.8 mm [0.031 in.]

Nominal

value

Standard value Limit value Remarks

}

}

}

1.27 MPa

{13 kgf/cm2}

[189 psi]

0.29 MPa

{300 kgf/cm2}

[4267 psi]

0.15 MPa

{300 kgf/cm2}

[4267 psi]

Cranking

(approx 120 min

When oil temperature is

90 to 100º C [194 to 212°F]

1.8 MPa

{18.5 kgf/cm

2

[263 psi]

0.49 to 0.64 MPa

{300 kgf/cm

2

[4267 psi]

0.20 to 0.29 MPa

{300 kgf/cm

2

[4267 psi]

Valve clearance 0 mm

±2°(Crank angle)

Valve clearance 2 mm

[0.08 in.]

Valve clearance 0 mm

±2°(Crank angle)

Valve clearance 2 mm

[0.08 in.]

Valve clearance 0 mm

±2°(Crank angle)

Valve clearance 2 mm

[0.08 in.]

Check the caution plate on

No. 1 rocker cover.

-1

Chapter 2 SERVICE DATA

)

2-3

Page 42

Chapter 2 SERVICE DATA

B

Lf

A

B

Lf

A

B

Lf

A

1.2 Maintenance Service Data of Basic Engine

Item

Rocker bushing inside diameter ø36 [1.42]

Rockers

Rocker shaft outside diameter ø36 [1.42]

Valve stem outside diameter ø10 [0.39]

Valve guide inside diameter ø10 [0.39]

Va l ve

Clearance

Intake side

between the bottom face of valve

bridge and top

face of valve

rotator

Exhaust

side

Single valve spring spec

Double valve spring

spec

Valve seat angle 30°

Valve sinkage 0

Seat width

Valve margin

Valve seat

Inside diameter of valve seat counterbore

and valve

Standard

Valve seat outside

diameter

0.03

0.06

Valve seat interference

Free length 73 [2.87] 71 [2.80]

Single

valve

spring

P/N:

37504-10400

Squareness

Installed length/load

(mm [in.]/N {kgf} [lbf])

Free length

P/N:

37504-10600

Inner

spring

Squareness

Set length / load

Double

valve

spring

P/N:

37504-20500

Outer

spring

(mm [in.]/N{kgf} [lbf])

Free length 96.57

Squareness

Set length / load

(mm [in.]/N{kgf} [lbf])

Push rod Runout 0.50 [0.0197] or less TIR

Nominal

value

2.3

[0.091]

3.0

[0.118]

Standard value Limit value Remarks

36.000 to 36.040

[1.4173 to 1.4189]

35.966 to 35.991

[1.4160 to 1.4170]

9.940 to 9.960

[0.3913 to 0.3921]

10.000 to 10.015

[0.3937 to 0.3943]

2.1

[0.083]

36.090

[1.4209]

35.940

[1.4150]

9.910

[0.3902]

10.060

[0.3961]

Same for both inlet and

exhaust valves.

Single valve spring spec

only

3.4

[0.134]

2.1

[0.083]

- 0.1 to 0.1

[-0.004 to 0.004]

2.18 to 2.42

[0.0858 to 0.0953]

2.8 to 3.2

[0.110 to 0.126]

60.000 to 60.030

[2.3622 to 2.3634]

60.100 to 60.130

[2.3661 to 2.3673]

60.130 to 60.160

[2.3673 to 2.3685]

60.160 to 60.190

[2.3685 to 2.3697]

1.0

[0.039]

2.8

[0.110]

2.5

[0.098]

60.09

[2.3657]

Valve

seat angle

2 lines, brown

3 lines, brown

4 lines, brown

0.070 to 0.130

[0.0028 to 0.0051]

A=1.5° or less

B=1.9 [0.075] or less

Lf=73 [2.87]

B=2.2

[0.087] over

entire length

66.0 [2.60]/289 to 319

{29.45 to 32.55}

[65 to 72]

90.6

[3.567]

A=2.0° or less

B=3.2 [0.126] or less

Lf=90.6 [3.567]

88.12

[3.469]

B=3.7

[0.146] over

entire length

56.0 [2.20]/137 to 152

{14 to 15.5}

[31 to 34]

93.92

[3.8020]

A=2.5° or less

B=4.2 [0.165] or less

Lf=96.57 [3.8020]

[3.698]

B=4.9

[0.193] over

entire length

62.0 [2.44]/496 to 549

{50.6 to 56.0}

[112 to 123]

Unit: mm [in.]

Seat width

Valve

sinkage

Valve

margin

2-4

Page 43

Cylinder

head

Cylinder

liner

Piston

Cylinder

head

gasket

Piston

cooling

nozzle

Piston and

cylinder

head

Piston ring End gap

Distortion of bottom surface 0.03 [0.0012] or less

Height (reference)

Inside diameter

Roundness 0.02 [0.0008] or less

Cylindricity 0.02 [0.0008] or less

Flange protrusion

Flange thickness

Top ridge height

Outside diameter

Weight difference

per engine

Piston pin bore inside diameter ø70 [2.76]

protrusion

Thickness when tightened

Valve opening

pressure

Top clearance

Item

P/N: 37507-22700 (S6R)

P/N: 37507-55600 (S6R2)

P/N:

37517-30101 ("30101" stamp)

37517-10401 ("10401" stamp)

37517-00900 ("00900" stamp)

37517-25100 ("25100" stamp)

37517-05500 ("05500" stamp)

37517-05300 ("05300" stamp)

P/N:

37517-07800 ("07800" stamp)

37517-07900 ("07900" stamp)

P/N:

37517-00800 ("00800" stamp)

P/N:

37517-30101 ("30101" stamp)

37517-10401 ("10401" stamp)

37517-00900 ("00900" stamp)

37517-25100 ("25100" stamp)

37517-05500 ("05500" stamp)

37517-05300 ("05300" stamp)

37517-07800 ("07800" stamp)

37517-07900 ("07900" stamp)

P/N:

37517-00800 ("00800" stamp)

One jet spec

Two jet spec

No. 1 compression

No. 2 compression

Oil

Nominal

value

ø170

[6.69]

ø170

[6.69]

ø170

[6.69]

ø170

[6.69]

ø170

[6.69]

1.8

[0.071]

Chapter 2 SERVICE DATA

Unit: mm [in.]

Standard value Limit value Remarks

0.07

[0.003]

154.9 to 155.1

[6.098 to 6.106]

170.02 to 170.04

[6.6937 to 6.6945]

170.00 to 170.04

[6.6929 to 6.6945]

0.11 to 0.20

[0.0043 to 0.0079]

14.16 to 14.20

[0.5575 to 0.5591]

0.16 to 0.24

[0.0063 to 0.0094]

169.760 to 169.800

[6.6835 to 6.6850]

169.739 to 169.779

[6.6826 to 6.6842]

169.760 to 169.780

[6.6835 to 6.6842]

within 10 g [0.35 oz]

within ±15 g [0.53 oz]

70.002 to 70.015

[2.7560 to 2.7565]

0.04 to 0.64

[0.0016 to 0.0252]

1.77 to 1.83

[0.0697 to 0.0720]

0.26 to 0.32 MPa

{2.7 to 3.3 kgf/cm

[38 to 47 psi]

0.10 to 0.15 MPa

{1.0 to 1.5 kgf/cm

[14 to 21 psi]

1.24 to 1.99

[0.0488 to 0.0783]

0.6 to 0.8

[0.024 to 0.032]

0.6 to 0.8

[0.024 to 0.032]

0.3 to 0.45

[0.0118 to 0.0177]

170.100

[6.6968]

Measure the outside

169.660

[6.6795]

169.639

[6.6787]

169.660

[6.6795]

70.040

[2.7575]

2

}

2

}

1.0

[0.039]

0.6

[0.024]

diameter from lower end

of piston at 40 mm [1.57

in.] with right angles to

the piston pin.

2-5

Page 44

Chapter 2 SERVICE DATA

Item

Piston pin Outside diameter ø70 [2.76]

Inside diameter of connecting rod bushing ø70 [2.76]

Bend and twist

End play

Connecting rod

Connecting rod

rod

bearing

Flywheel

Damper

Rear mechanism

Camshaft

Inside diameter of big end bore

Roundness for inside diameter of big end bore

Big end side (Width)

Standard

0.25

Thickness at

center

Face runout (Reference) 0.285 [0.0112] or less

Radial runout (Reference) 0.127 [0.0050] or less

Face runout (Reference) 0.5 [0.0197] or less

Radial runout (Reference) 0.5 [0.0197] or less

Backlash between crank gear and idler gear

Backlash between idler gear and camshaft gear

Backlash between idler gear and fuel injection pump

gear

Idler bushing inside diameter ø50 [1.97]

Idler shaft outside diameter ø50 [1.97]

Idler gear end play

Cam lift

(Major axis minor axis)

Runout 0.05 [0.0020] or less

Journal diameter ø84 [3.30]

Camshaft bushing inside diameter

(As installed in crankcase)

End play

Under

size

37505-34100 (Overlap 93°)

37505-40100 (Overlap 61°)

0.50

0.75

1.00

Nominal

value

ø131

[5.16]

3.000

[0.1181]

3.125

[0.1230]

3.250

[0.1280]

3.375

[0.1329]

3.500

[0.1378]

ø84 [3.30]

Unit: mm [in.]

Standard value Limit value Remarks

69.987 to 70.000

[2.7554 to 2.7559]

70.020 to 70.040

[2.7567 to 2.7575]

0.05/100 [0.0020/3.94]

or less

0.4 to 0.6

[0.016 to 0.024]

131.000 to 131.025

[5.1575 to 5.1585]

66.7 to 66.8

[2.626 to 2.620]

2.957 to 2.970

[0.1164 to 0.1169]

3.082 to 3.095

[0.1213 to 0.1219]

3.207 to 3.220

[0.1263 to 0.1268]

3.332 to 3.345

[0.1312 to 0.1317]

3.457 to 3.470

[0.1361 to 0.1366]

0.11 to 0.28

[0.0043 to 0.0110]

0.12 to 0.18

[0.0047 to 0.0071]

0.12 to 0.18

[0.0047 to 0.0071]

50.000 to 50.025

[1.9685 to 1.9695]

49.950 to 49.975

[1.9665 to 1.9675]

0.2 to 0.4

[0.008 to 0.016]

9.207 to 9.287

[0.3625 to 0.3656]

9.207 to 9.287

[0.3625 to 0.3656]

83.92 to 83.94

[3.3039 to 3.3047]

84.020 to 84.095

[3.3079 to 3.3108]

0.10 to 0.25

[0.0039 to 0.0098]

69.970

[2.7547]

70.070

[2.7587]

1.0

[0.039]

Minimum:

130.950

[5.1555]

Maximum:

131.050

[5.1594]

0.100

[0.0039]

2.930

[0.1154]

3.055

[0.1203]

3.180

[0.1252]

3.305

[0.1301]

3.430

[0.1350]

0.50

[0.197]

0.50

[0.197]

0.50

[0.197]

50.060

[1.9709]

49.900

[1.9646]

0.6

[0.0236]

8.45

[0.3327]

8.45

[0.3327

0.08

[0.0031]

83.87

[3.3020]

84.100

[3.3110]

0.40

[0.0157]

TIR

2-6

Page 45

Crank

shaft

Item

Standard

0.25

Crankpin outside

diameter

Crank main

journal outside

diameter

Parallelism of journal and crankpin

Circularity of journal and crankpin

Cylindricity of journal and crankpin

Fillet radius of pin

Fillet radius of journals

Hardness of journals and crankpins Hv > 620

Finishing surface roughness Ra 0.2 μm [0.008 µin.]

Angular deviation between pins ±20'

Crankpin width

Rearmost

crank main

journal width

Runout 0.04 [0.0016] or less

End play (width between web and thrust bearing)

Under

size

Standard

Under

size

Standard

Over

size

0.50

0.75

1.00

0.25

0.50

0.75

1.00

0.25

0.50

0.75

1.00

1.25

1.50

Nominal

value

ø125

[4.92]

ø140

[5.51]

R7

[0.28]

R7

[0.28]

67

[2.64]

66

[2.60]

Standard value Limit value Remarks

124.930 to 124.950

[4.9185 to 4.9193]

124.680 to 124.700

[4.9084 to 4.9094]

124.430 to 124.450

[4.8988 to 4.8996]

124.180 to 124.200

[4.8890 to 4.8898]

123.930 to 123.950

[4.8791 to 4.8799]

139.930 to 139.950

[5.5090 to 5.5098]

139.680 to 139.700

[5.4992 to 5.5000]

139.430 to 139.450

[5.4894 to 5.4901]

139.180 to 139.200

[5.4795 to 5.4803]

138.930 to 138.950

[5.5090 to 5.5098]

Deviation of 0.01

[0.0004] or less over

entire pin length

Diameter difference

0.01 [0.0004] or less

Diameter difference

0.01 [0.0004] or less

6.8 to 7.0

[0.268 to 0.276]

6.8 to 7.0

[0.268 to 0.276]

67.20 to 67.30

[2.6457 to 2.6496]

66.00 to 66.05

[2.5984 to 2.6004]

66.25 to 66.30

[2.6083 to 2.6102]

66.50 to 66.55

[2.6181 to 2.6201]

66.75 to 66.80

[2.6279 to 2.6299]

67.00 to 67.05

[2.6378 to 2.6398]

67.25 to 67.30

[2.6476 to 2.6496]

67.50 to 67.55

[2.6575 to 2.6594]

0.300 to 0.520

[0.0118 to 0.0205]

Chapter 2 SERVICE DATA

Unit: mm [in.]

124.890

[4.9169]

124.640

[4.9071]

124.390

[4.8972]

124.140

[4.8874]

123.890

[4.8775]

139.890

[5.5075]

139.640

[5.4976]

139.390

[5.4878]

139.140

[5.4779]

138.890

[5.4681]

0.03

[0.012]

0.03

[0.012]

0.03

[0.012]

0.10

[0.0039]

0.600

[0.0236]

TIR

2-7

Page 46

Chapter 2 SERVICE DATA

Item

Standard

Main

bearing

Trust

plate

Crankcase

Thickness at

center

Thickness

Distortion of top surface 0.1 [0.004] or less

Inside diameter of main bearing bore

Depth of counterbore in crankcase

Height from journal center to top face

(Reference value)

Under

size

Standard

Over

size

0.25

0.50

0.75

1.00

0.25

0.50

0.75

Nominal

value

3.500

[0.1378]

3.625

[0.1427]

3.750

[0.1476]

3.875

[0.1526]

4.000

[0.1575]

5.00

[0.1969]

5.25

[0.2067]

5.50

[0.2165]

5.75

[0.2264]

ø147

[5.79]

Unit: mm [in.]

Standard value Limit value Remarks

3.467 to 3.480

[0.1365 to 0.1370]

3.592 to 3.605

[0.1414 to 0.1419]

3.717 to 3.730

[0.1463 to 0.1469]

3.842 to 3.855

[0.1513 to 0.1518]

3.967 to 3.980

[0.1562 to 0.1567]

4.78 to 4.85

[0.1882 to 0.1909]

5.03 to 5.10

[0.1980 to 0.2008]

5.28 to 5.35

[0.2079 to 0.2106]

5.53 to 5.60

[0.2177 to 0.2189]

147.000 to 147.025

[5.7874 to 5.7884]

14.00 to 14.05

[0.5512 to 0.5531]

549.45 to 549.55

[21.6318 to 21.6358]

3.425

[0.1348]

3.550

[0.1398]

3.675

[0.1447]

3.800

[0.1496]

3.925

[0.1545]

4.71

[0.1854]

4.96

[0.1953]

5.21

[0.2051]

5.46

[0.2150]

0.2

[0.008]

147.035

[5.7888]

2-8

Page 47

1.3 Maintenance Service Data of Fuel System

Item Nominal value Standard value Limit value Remarks

Free length of nozzle

spring

Squareness of nozzle

spring

Nozzle spring

parallelism of top and

bottom surfaces

Fuel injection starting

pressure

Orifice cone angle

Fuel injection

nozzle

Orifice diameter

Number of orifices

P/N:37561-26400

P/N:48726-00402

P/N:37561-26400 0.6 [0.0236] or less

P/N:48726-00402 1.25°or less

P/N:37561-26400 0.1 [0.004] or less

P/N:48726-00402 0.65°or less

P/N:

37760-14001

37760-22001

P/N: 37560-32000

P/N:

37561-44000

37860-06000

37560-35000

37560-39000

37560-22010

P/N:

37561-44000 ("K" mark)

P/N:

37860-06000 ("XX" mark)

37760-14001 ("SS" mark)

37760-22001 ("RS" mark)

P/N:

37560-35000 ("M" mark)

37560-37000 ("F" mark)

37560-39000 ("H" mark)

37560-32000 ("N" mark)

37560-22010 ("N" mark)

P/N:

37760-14001 ("SS" mark)

P/NP/N:

37860-06000 ("XX" mark)

P/N:

37560-35000 ("M" mark)

37760-22001 ("RS" mark)

P/N:

37560-32000 ("N" mark)

37561-44000 ("K" mark)

37560-22010 ("N" mark)

P/N:

37560-39000 ("H" mark)

P/N:

37560-37000 ("F" mark)

P/N:

37760-14001 ("SS" mark)

37760-22001 ("RS" mark)

P/N:

37860-06000 ("XX" mark)

37560-35000 ("M" mark)

37560-32000 ("N" mark)

37561-44000 ("K" mark)

37560-22010 ("N" mark)

37560-39000 ("H" mark)

37560-41000 ("P" mark)

37560-37000 ("F" mark)

30.40 MPa

{310 kgf/cm

[4267 psi]

34.32 MPa

{350 kgf/cm

[4978 psi]

34.32 MPa

{350 kgf/cm

[4978 psi]

155°

158°

160°

ø0.26

[0.012]

ø0.27

[0.0106]

ø0.29

[0.0114]

ø0.31

[0.0122]

ø0.325

[0.0128]

ø0.35

[0.0138]

9

10

30

[1.18]

26.8

[1.055]

30.40 to 30.89 MPa

{310 to 315 kgf/cm

2

}

[4409 to 4480 psi]

(the value when it is new)

33.83 to 35.79 MPa

{345 to 365 kgf/cm

2

}

[4907 to 5192 psi]

(the value when it is new)

34.32 to 34.81 MPa

{350 to 355 kgf/cm

2

}

[4978 to 5049 psi]

(the value when it is new)

Chapter 2 SERVICE DATA

Unit: mm [in.]

2

}

2

}

2

}

2-9

Page 48

Chapter 2 SERVICE DATA

Inside diameter of case bearing housing

Fuel injection

pump accessory

drive

Governor drive

For injection pump

drive shaft bearing

Outside diameter of drive shaft bearing fit

Inside diameter of drive shaft case bearing housing ø52 [2.05]

Drive shaft side bearing

Outside diameter of drive shaft bearing fit ø25 [0.98 in.]

Outside diameter of drive shaft gear fit ø26 [1.02]

Inside diameter of drive gear fit ø26 [1.02]