Page 1

October 2003

OPERATION&MAINTENANCE MANUAL

OPERATION &

MAINTENANCE MANUAL

Printed in Japan

Pub.No.

NOTE

The operator and supervisor are requested to read this

Operation and Maintenance Manual carefully before

operating the engine or conducting inspection and

maintenance.

Never operate the engine or conduct maintenance work

without completely understanding this manual.

Pub.No.

October 2003

99080-20120

99080-20120

Page 2

Page 3

INTRODUCTION

This manual contains information for operation, inspection and maintenance of the Mitsubishi Engines.

Please read this manual carefully to understand the operation, inspection and maintenance procedures in

order to use the engine properly.

Failure to follow directions in this manual can lead to serious accidents.

Pub.No.

99080-20120

Page 4

INTRODUCTION

Limited Warranty

The manufacturer, at its option, will repair or replace any parts returned intact to the manufacturer only when

the manufacturer, upon inspection, determines to be defective in material and/or workmanship.

The foregoing shall constitute the limited warranty provided by the manufacturer.

The manufacturer will provide the limited warranty only to the user with whom the manufacturer concludes the

original contract, and shall not provide the limited warranty to a user to whom the ownership of the product

may be transferred.

• The manufacturer makes no warranties, either express or implied, except as provided in this manual, includ-

ing without limitation thereof, warranties as to marketability, merchantability, fitness for a particular purpose

or use, or against infringement of any patent.

• The manufacturer will not be liable for any damages or consequential damages, including without limitation

thereof, damages or other costs resulting from any abuse, misuse, misapplication of the engine and devices

supplied by the manufacturer.

• The manufacturer will not be liable for any damages or personal injuries resulting from any modification,

without the manufacturer's written permission, of the engine and devices supplied by the manufacturer.

• The manufacturer will not be liable for any damages or production losses caused by the use of fuel, engine

oil and/or long life coolant that are not recommended by the manufacturer.

Page 5

Important Information

• To avoid potential hazard, accident prevention

activities must be planned methodically and con-

ducted continually by considering all aspects of

engine operation, maintenance and inspection.

Everyone including managers and supervisors

should actively participate, recognize one's role

and organize oneself and one's work to ensure a

safe environment.

• The foremost safety objective is to prevent acci-

dents which could result in injury or death, or

damage equipment.

• Observe all related federal/national and local

codes and regulations to reduce the possibility of

personal injury.

• The manufacturer cannot foresee all potential

danger of the engine, potential danger resulting

from human error and others, or danger caused

by a specific environment in which the engine is

used.

Since there are many actions that cannot be per-

formed or must not be performed, it is not possi-

ble to indicate every caution in this manual or on

warning labels. As such, it is extremely important

to follow directions in this manual and also to take

general safety measures when operating, main-

taining and inspecting the engine.

• This manual has been prepared for people whose

native language is English. When the engine is

used by individuals whose native language is not

English, the customer is requested to provide

thorough safety guidance to the operators. Also

add safety, caution and operating signs that

describe the original warning label statements in

the native language of the operators.

• The engine must be operated, maintained and

inspected only by qualified persons who have

thorough knowledge of engines and their danger

and also received danger avoidance training.

• To prevent occurrence of an accident, do not

attempt to carry out any operation other than

those described in this manual, or to use the

engine for any unapproved purpose.

• When the ownership of the engine is transferred,

be sure to provide this manual with the engine to

the new owner. Also inform the manufacturer of

INTRODUCTION

the name and address of the new owner of the

engine.

• This manual is copyrighted and all rights are

reserved. The drawings and technical reference,

including this manual, may not, in whole or in

part, be duplicated, photocopied, translated, or

reproduced in any electronic medium or machine

readable form without prior written consent from

the manufacturer.

• The contents in this manual are subject to change

without notice for improvement of the engine.

• Your engine may differ from the photographs and

figures in this manual.

Please note that, depending on specifications,

items described in this manual may differ from

those on your engine in shape, or may not be

installed on your engine.

• If you need more detailed information or have

questions, contact a Mitsubishi dealer.

• If this manual is misplaced, obtain a new copy

from a Mitsubishi dealer as soon as possible.

Page 6

INTRODUCTION

Warnings

The following two methods are used to call the attention of the operators and maintenance personnel to the

potential danger of the engine.

• Warning statements in the manual

• Warning labels affixed on the engine

Warning Statements

The warning statements in this manual describe potential danger in operating, inspecting or maintaining the

engine by using the following five classifications to indicate the degree of potential hazard. Failure to follow

these directions can lead to serious accidents which can result in personal injury, or death in the worst case.

Indicates a highly hazardous situation which, if not avoided, can result in

death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, can result

in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, can result

in minor or moderate injury.

Indicates a potentially hazardous situation which, if not avoided, can result

in property damage.

Note Indicates important information or information which is useful for engine

operation.

Page 7

INTRODUCTION

Explanation of Terms

Abbreviations, Standards and Others

• API = American Petroleum Institute

• ASTM = American Society for Testing and Materials

• JIS = Japanese Industrial Standards

• MIL = Military Specifications and Standards (U.S.)

• MSDS = Material Safety Data Sheet

• SAE = Society of Automotive Engineers (U.S.)

• LLC = Long Life Coolant

Units of Measurement

Measurements are based on the International System of Units (SI), and they are converted to the metric sys-

tem units in this manual based on the following conversion rates.

• Pressure: 1 MPa = 10.197 kgf/cm

• Torque: 1 N⋅m = 0.10197 kgf⋅m

• Force: 1 N = 0.10197 kgf

• Horsepower: 1 kW = 1.341 HP = 1.3596 PS

• Meter of mercury: 1 kPa = 0.7 cmHg

• Meter of water: 1 kPa = 10.197 cmH

-1

• Engine speed: 1 min

= 1 rpm

2

2O (cmAq)

Page 8

Page 9

CONTENTS

Chapter 1 BASIC SAFETY PRECAUTIONS

Warning Fire and Explosion ...............1-1

Keep flames away............................................ 1-1

Keep engine and surrounding area clean ........ 1-1

Never open crankcase until engine cools ........ 1-1

Check for fuel, oil and exhaust gas leaks......... 1-1

Use flameproof light ......................................... 1-1

Do not short electrical wires ............................. 1-1

Keep fire extinguishers and first-aid kit

nearby .............................................................. 1-1

Warning Stay Clear of All Rotating and

Moving Parts........................................1-2

Install protective covers on rotating parts......... 1-2

Check surrounding area for safety ................... 1-2

Stay clear of all rotating and moving parts while

engine is operating........................................... 1-2

Lock out and Tag out ....................................... 1-2

Always stop engine before inspection and

maintenance..................................................... 1-2

Always return turning tools to original

position............................................................. 1-2

Warning Be Careful of Burns..............1-3

Do not touch engine during operation or

Engine Oil and LLC............................. 1-4

Use only specified fuel, engine oil and coolant

(LLC).............................................................. 1-4

Handle LLC carefully........................................ 1-4

Properly dispose of drained oil and LLC .......... 1-4

Caution Service Battery ..................... 1-5

Handle battery carefully ................................... 1-5

Caution When Abnormality Occurs.... 1-5

If engine overheats, conduct cooling operation

before stopping engine..................................... 1-5

If engine stops due to abnormality, exercise caution

when restarting................................................. 1-5

If engine oil pressure drops, stop engine

immediately ...................................................... 1-5

Caution Other Cautions ..................... 1-6

Never modify engine ........................................ 1-6

Never break seals ............................................ 1-6

Perform all specified pre-operation inspections and

periodic inspections.......................................... 1-6

Perform engine break-in................................... 1-6

Warm up engine before use............................. 1-6

Never operate engine under overload

condition ........................................................... 1-6

Conduct cooling operation before stopping

immediately after operation.............................. 1-3

Open radiator filler cap carefully ...................... 1-3

Add coolant only after coolant temperature

drops ................................................................ 1-3

Do not dismount heat protection covers........... 1-3

Warning Be Careful of Exhaust Fume

Poisoning.............................................1-3

Perform engine operation in a well-ventilated

site ................................................................... 1-3

Warning Protect Ears from Noises .....1-3

Wear earplugs.................................................. 1-3

Warning Be Careful When Lifting

Engine .................................................1-4

Lifting engine carefully ..................................... 1-4

Do not climb onto engine ................................. 1-4

Always watch your footing................................ 1-4

Caution Be Careful of Handling Fuel,

engine .............................................................. 1-6

Do not splash water on engine......................... 1-6

Conduct proper maintenance of air cleaner/pre-

cleaner ............................................................. 1-7

Observe safety rules at workplace ................... 1-7

Wear proper work clothes and protective gear. 1-7

Use appropriate tools for maintenance work.... 1-7

Cautions concerning transportation ................. 1-7

Do not operate engine continuously under low

load .................................................................. 1-7

Ventilate the engine room sufficiently .............. 1-7

Do not touch high-pressure injection fuel ......... 1-7

Caution About Warning Labels .......... 1-8

Maintain and inspect warning labels ................ 1-8

Warning labels ................................................. 1-9

CONTENTS-1

Page 10

CONTENTS

Chapter 2

NAME OF PARTS

Engine External Diagrams...................2-1

S12U Left View ................................................ 2-1

S12U Right View .............................................. 2-1

S16U Left View ................................................ 2-2

S16U Right View ............................................. 2-2

Equipment and Instrument ..................2-3

Starting and Shutdown Devices ....................... 2-3

Start Switch ............................................................. 2-3

Stop Switch ............................................................. 2-3

Start Lever ................................................................ 2-3

M

anual Stop Lever.................................................... 2-3

Instruments..........................................2-4

Tachometer............................................................... 2-4

Hour Meter................................................................ 2-4

Oil Pressure Gage .................................................... 2-4

Oil Temperature Gage.............................................. 2-4

Jacket Coolant Temperature Gage........................... 2-4

Oil Cooler Coolant Temperature Gage..................... 2-4

Air Cooler Coolant Temperature Gage ..................... 2-4

Jacket Coolant Pressure Gage................................. 2-4

Oil Cooler Coolant Pressure Gage ........................... 2-4

Air Cooler Coolant Pressure Gage ........................... 2-4

Exhaust Temperature Gage ..................................... 2-4

Fuel Pressure Gage.................................................. 2-4

Inlet Pressure Gage.................................................. 2-4

Engine Protection Devices ..................2-5

Low Oil Pressure Alarm............................................ 2-5

High Coolant Temperature Alarm ............................. 2-5

Oil Filter Clog Alarm.................................................. 2-5

Overspeed Alarm...................................................... 2-5

Using Turning Gear .............................2-6

Chapter 3 OPERATION

Preparation for Operation of New or

Overhauled Engine..............................3-1

Fuel System ..................................................... 3-1

Pouring fuel............................................................... 3-1

Bleeding Fuel System............................................... 3-2

Bleeding Air from Fuel Filters

(Wire-Element Type)................................................. 3-2

Bleeding Air from Fuel Feed Pipe............................. 3-3

Lubricating System........................................... 3-4

Pouring engine oil..................................................... 3-4

Cooling System ................................................ 3-5

Pouring coolant......................................................... 3-5

Electrical Systems............................................ 3-6

Checking Battery.............................................. 3-6

Electrolyte level..........................................................3-6

Checking specific gravity of electrolyte......................3-6

Checking loosened wire ................................... 3-6

Checking Valves for Open/Closed Position...... 3-7

Test Operation ................................................. 3-7

Normal Engine Operation ................... 3-8

Preparations for Operation

(Pre-Start Inspection) ....................................... 3-8

External Inspection....................................................3-8

Cleaning Fuel Filters (Wire-Element Type)................3-8

Checking Fuel Level in Tank .....................................3-9

Draining Water from Fuel Tank..................................3-9

Checking Engine Oil Level.........................................3-9

Checking Coolant Level...........................................3-10

Inspection of Air Cleaner Indicator...........................3-10

Draining Water from Air Starter Tank ......................3-11

Inspection of Air Tank Air Pressure .........................3-11

Starting.............................................. 3-12

Warming-up Operation ................................... 3-12

Inspection of Oil Pressure........................................3-12

External Inspection during Warming-up...................3-12

Operation ....................................................... 3-13

Inspection During Operation....................................3-13

Stopping ......................................................... 3-14

Emergency Stop............................................. 3-14

Inspection After Stopping ............................... 3-14

Chapter 4 MAINTENANCE

Cautions Concerning Maintenance..... 4-1

Stop the engine before checking or adding fuel, oil or

coolant. ......................................................................4-1

Handle electrolyte carefully........................................4-1

Handle LLC carefully. ................................................4-1

Always wear protective gear......................................4-1

Use recommended fuel, engine oil and coolant.........4-1

Perform all specified pre-start inspections and periodic

inspections.................................................................4-1

Use only genuine Mitsubishi parts.............................4-1

Fuel ..................................................... 4-2

Recommended Fuel ......................................... 4-2

Handling Fuel ................................................... 4-2

Engine Oil ........................................... 4-4

Recommended Engine Oil ............................... 4-4

CONTENTS-2

Page 11

CONTENTS

Selection of Oil Viscosity .......................................... 4-4

Handling Engine Oil ......................................... 4-5

Coolant ................................................4-6

Recommended Coolant ................................... 4-6

Long Life Coolant (LLC)................................... 4-6

Recommended LLC ......................................... 4-7

Features and Performance of Recommended

LLC .................................................................. 4-7

Maintenance of LLC ......................................... 4-7

Replacement timing of LLC ...................................... 4-7

LLC concentration..................................................... 4-7

Importance of LLC............................................ 4-8

Characteristics of LLC Additive and Important

Notes................................................................ 4-8

Examples of Abnormalities Caused by LLC..... 4-8

Pitting on iron parts................................................... 4-8

Corrosion of aluminum parts..................................... 4-8

Pitting and clogging of radiator ................................. 4-8

Filters...................................................4-9

Electrical Parts.....................................4-9

Cautions in Operating Engine in Cold

Weather Season................................4-10

Fuel ................................................................ 4-10

Engine Oil....................................................... 4-10

Coolant........................................................... 4-10

Battery............................................................ 4-10

Maintenance After Cold Season .................... 4-10

General definition of emergency engine....................5-2

General definition of general-purpose engine............5-2

Periodic Maintenance Chart for Engine in

Regular Use ........................................ 5-3

Periodic Maintenance Chart for

Emergency Engine.............................. 5-8

Periodic Maintenance Chart for General-

Purpose Power Supply Engine ......... 5-13

Chapter 6 PERIODIC INSPECTION AND MAINTENANCE PROCEDURES

Fuel System ........................................ 6-1

Draining Water from Fuel Filters

(Wire-Element Type)..................................................6-1

Draining Water from Fuel Filters

(Center-Bolt Type) .....................................................6-1

Draining Water from Fuel Tank..................................6-2

Cleaning inside of Fuel Filters

(Wire-Element Type)..................................................6-2

Changing Fuel Filters (Center-Bolt Type)......... 6-3

Changing Fuel Filters (Cartridge Type) ............ 6-4

Changing Fuel Filters with Engine Stop.....................6-4

Changing Fuel Filters while Engine in

Operation...................................................................6-5

Inspection of Fuel Control Linkage Ball

Joints................................................................ 6-6

Lubricating System ............................. 6-7

Changing Engine Oil, Oil Filters and Bypass Oil

Chapter 5 PERIODIC MAINTENANCE CHART

How to Use Periodic Maintenance

Chart....................................................5-1

Periodic Maintenance Chart............................. 5-1

Periodic maintenance chart for regular-use

engine ....................................................................... 5-1

Periodic maintenance chart for emergency

engine ....................................................................... 5-1

Periodic maintenance chart for general-purpose

engine ....................................................................... 5-1

General Definition of Regular-Use Engine,

Emergency Engine and General-Purpose

Engine .............................................................. 5-2

General definition of regular-use engine................... 5-2

Filter ................................................................. 6-7

Draining Engine Oil....................................................6-7

Changing Oil Filters (S12U).......................................6-7

Changing Oil Filters (Swithover Type)

(S12U) .............................................................. 6-8

Changing Oil Filters with Engine Stop .......................6-8

Changing Oil Filters While Engine in Operation ........6-8

Changing Oil Filters (Swithover Type)

(S16U) .............................................................. 6-9

Changing Oil Filters with Engine Stop .......................6-9

Changing Oil Filters While Engine in Operation ........6-9

Changing Bypass Oil Filter ......................................6-10

Pouring Engine Oil...................................................6-11

Inspection of Engine Oil Leakage After Replacing

Oil Filter .......................................................... 6-11

CONTENTS-3

Page 12

CONTENTS

Inspection of Engine Oil for Mixing of Fuel and

Water.............................................................. 6-11

Analysis of Engine Oil Properties................... 6-12

Engine Oil Sampling Tool Sets and Ordering

Procedure ............................................................... 6-12

Cooling System .................................6-13

Checking LLC Concentration ......................... 6-13

Inspection and Replacement of Zinc Rods .... 6-13

Changing Coolant .......................................... 6-14

Draining Coolant..................................................... 6-14

Cleaning the Cooling System ................................. 6-14

Pouring coolant....................................................... 6-15

Inlet and Exhaust Systems................6-16

Inspection and Draining Water of Exhaust Pipes

and Exhaust Muffler ....................................... 6-16

Draining Water From Air Cooler Chamber and

Inspection for Water Leakage ........................ 6-16

Cleaning, Inspection and Changing

Pre-Cleaner.................................................... 6-16

Cleaning, Inspecting and Changing Air Cleaner

Element .......................................................... 6-17

Chapter 9

TROUBLESHOOTING

General Precautions ........................... 9-1

Contact a Mitsubishi Dealer for Repair

Service ............................................................. 9-1

Examination before Work ................................. 9-1

Notes Regarding Contamination ...................... 9-1

Notes Regarding Parts Handling ...................... 9-1

Work Safety...................................................... 9-1

Conditions Required for Proper Engine

Operation ......................................................... 9-2

Troubleshooting .................................. 9-3

Engine Turns, But It Does Not Start ................. 9-3

Engine Does Not Turn...................................... 9-5

Engine Output is Low.................................................9-6

Engine Knocks ................................................. 9-7

Engine Produces Large Amount of Smoke While in

Operation ......................................................... 9-8

Engine Operates at High Speed and Does Not

Stop.................................................................. 9-8

Malfunction of Lubricating System ................... 9-9

Air Starter System .............................6-18

Draining Water and Cleaning Air Starter

Strainer........................................................... 6-18

Draining Water from Air Starter Compressor . 6-18

Chapter 7 LONG-TERM STORAGE

Storing Engine in Non-Operable Condition for More

Than 3 Months ................................................. 7-1

Preparation for Storage ............................................ 7-1

Maintenance during Storage..................................... 7-1

Using Engine after Storage....................................... 7-1

Storing Engine in Operable Condition for More Than

3 Months .......................................................... 7-2

Operating Engine for Maintenance Purposes........... 7-2

Chapter 8 TRANSPORTATION

Lifting Engine Carefully .................................... 8-1

Chapter 10 MAIN SPECIFICATIONS

Main Specifications........................... 10-1

List of Illustrations

fig.1-1 Warning for flywheel entanglement..............1-9

fig.1-2 Warning for moving parts.............................1-9

fig.1-3 Warning for oil mist ......................................1-9

fig.1-4 Caution for footing........................................1-9

fig.1-5 Caution for electric shock.............................1-9

fig.1-6 Warning for rotating parts.............................1-9

fig.1-7 Caution for burns .........................................1-9

fig.1-8 Warning for rotating parts.............................1-9

fig.1-9 Caution for referring to manual ....................1-9

fig.1-10 Caution for burns .........................................1-9

fig.2-1 S12U engine left view ..................................2-1

fig.2-2 S12U engine right view................................2-1

CONTENTS-4

fig.2-3 S16U engine left view ..................................2-2

fig.2-4 S16U engine right view................................2-2

fig.2-5 Start switch and stop switch.........................2-3

Page 13

CONTENTS

fig.2-6 Start lever.................................................... 2-3

fig.2-7 Manual stop lever........................................ 2-3

fig.2-8 Air cleaner indicator .................................... 2-5

fig.2-9 Preparation for turning ................................ 2-6

fig.2-10 Turning........................................................ 2-6

fig.2-11 Locking turning gear.................................... 2-6

fig.3-1 Priming pump operating method................. 3-2

fig.3-2 Bleeing air from fuel filters

(wire-element type) ..................................... 3-2

fig.3-3 Bleeding air from fuel filters

(center-bolt type)......................................... 3-2

fig.3-4 Bleeding air from fuel filters

(cartridge-type)............................................ 3-3

fig.3-5 Fuel filter switchover cock........................... 3-3

fig.3-6 Bleeding air from fuel feed pipe (1)............. 3-3

fig.3-7 Bleeding air from fuel feed pipe (2)............. 3-3

fig.3-8 Oil filler and oil level gage ........................... 3-4

fig.3-9 Engine oil priming pump.............................. 3-4

fig.3-10 Coolant drain cock on the engine................ 3-5

fig.6-2 Draining water from fuel filter

(center-bolt type)..........................................6-1

fig.6-3 Draining water from fuel tank .......................6-2

fig.6-4 Cleaning inside of fuel filter

(wire-element) type).....................................6-2

fig.6-5 Changing fuel filters (center-bolt type).........6-3

fig.6-6 Fuel filter switchover handle.........................6-4

fig.6-7 Changing fuel filters (cartridge type) ............6-4

fig.6-8 Fuel filter switchover handle.........................6-5

fig.6-9 Changing fuel filters (cartridge type) ............6-5

fig.6-10 Inspection of the ball joints for

looseness.....................................................6-6

fig.6-11 Changing oil filter element (S12U) ...............6-7

fig.6-12 Inspection of oil filter ....................................6-7

fig.6-13 Changing oil filters (switchover type)........ 6-8

fig.6-14 Changing oil filter elements..........................6-9

fig.6-15 Oil filter switchover handle ...........................6-9

fig.6-16 Changing bypass oil filters .........................6-10

fig.6-17 Inspection of bypass oil filter......................6-10

fig.3-11 Coolant drain cock on the water pump........ 3-5

fig.3-12 Water tank coolant level.............................. 3-5

fig.3-13 Inspecting electrolyte level.......................... 3-6

fig.3-14 Inspecting specific gravity of electrolyte...... 3-6

fig.3-15 Checking valves for open/closed

position........................................................ 3-7

fig.3-16 Checking valves for open/closed position... 3-8

fig.3-17 Cleaning fuel filter (wire-element type)........ 3-8

fig.3-18 Draining water from fuel tank ...................... 3-9

fig.3-19 Oil filler and oil level gage ........................... 3-9

fig.3-20 Checking coolant level .............................. 3-10

fig.3-21 Air cleaner indicator .................................. 3-10

fig.3-22 Draining water from air starter tank........... 3-11

fig.3-23 Inspection of air tank air pressure............. 3-11

fig.3-24 Stop button................................................ 3-14

fig.3-25 Manual stop lever...................................... 3-14

fig.4-1 Recommended fuel..................................... 4-2

fig.4-2 Recommended fuel according to air

fig.6-18 Bypass oil filter...........................................6-10

fig.6-19 Oil filler and level gage...............................6-11

fig.6-20 Engine oil priming pump.............................6-11

fig.6-21 Engine oil sampling tool sets......................6-12

fig.6-22 Zinc rod good/bad......................................6-13

fig.6-23 Coolant drain cock (on engine) ..................6-14

fig.6-24 Coolant drain cock (on water pump) ..........6-14

fig.6-25 Coolant drain cock on the engine...............6-15

fig.6-26 Coolant drain cock on the water pump.......6-15

fig.6-27 Water tank coolant level.............................6-15

fig.6-28 Inspection and raining water of exhaust pipes

and exhaust muffler ...................................6-16

fig.6-29 Coolant drain cock on air cooler

chamber .....................................................6-16

fig.6-30 Cleaning pre-cleaner..................................6-16

fig.6-31 Removal of air cleaner element .................6-17

fig.6-32 Cleaning air cleaner element .....................6-17

fig.6-33 Inspecting air cleaner element ...................6-17

temperature................................................. 4-2

fig.4-3 Recommended oil viscosity according to air

temperature................................................. 4-4

fig.6-1 Draining water from fuel filter

(wire-element type) ..................................... 6-1

fig.6-34 Air cleaner indicator ...................................6-17

fig.6-35 Air starter strainer.......................................6-18

fig.6-36 Air starter compressor................................6-18

fig.8-1 Hangers for lifting.........................................8-1

fig.8-2 Lifting the engine..........................................8-1

CONTENTS-5

Page 14

CONTENTS

List of Tables

Table 3-1 Specific gravity of electrolyte.................. 3-6

Table 3-2 Data for rated speed............................. 3-13

Table 4-1 Recomended Fuel .................................. 4-2

Table 4-2 Fuel Use Limit Property Guideline.......... 4-3

Table 4-3 Water quality standards.......................... 4-6

Table 4-4 Recommended brands of LLC................ 4-7

Table 4-5 Recommended LLC concentration (for

reference only)........................................ 4-7

Table 5-1 Periodic maintenance chart for engine in

regular use.............................................. 5-3

Table 5-2 Periodic maintenance chart for emergency

engine..................................................... 5-8

Table 5-3 Periodic maintenance chart for general-

purpose power supply engine............... 5-13

Table 6-1 Engine oil sampling tool sets ................ 6-12

Table 7-1 Recommended rust-preventive

oil and corrosion inhibitor........................ 7-1

Table 9-1 Conditions required for proper engine

operation................................................. 9-2

Table 9-2 Engine turns, but it does not start........... 9-3

Table 9-3 Engine does not turn .............................. 9-5

Table 9-4 Engine output is low ............................... 9-6

Table 9-5 Engine knocks ........................................ 9-7

Table 9-6 Engine produces large amount of smoke while

in operation............................................. 9-8

Table 9-7 Engine operates at high speed and does not

stop......................................................... 9-8

Table 9-8 Malfunction of lubrication system ........... 9-9

Table 10-1 Main specifications table ...................... 10-1

CONTENTS-6

Page 15

Chapter 1 BASIC SAFETY PRECAUTIONS

Warning Fire and Explosion

Keep flames away

Store fuel and engine oil in a

well-ventilated area.

Make sure that the caps of fuel

and engine oil containers are

tightly closed, and store them in

the designated site.

Do not use flames or smoke where fuel or oil is

handled or cleaning solvent is used for washing

parts.

Spilled fuel, oil and LLC should be wiped immedi-

ately and thoroughly. Spilled fuel, oil and LLC can

ignite and cause fire.

Keep engine and surrounding area clean

Do not store combustible (such as fuel, engine oil

and LLC), explosive or dangerous materials near

the engine. Those substances can cause a fire or

explosion.

Keep the engine and the surrounding area free of

dust, dirt and foreign materials, since they can

cause fire or the engine to overheat.

Clean the top surface of the battery after perform-

ing maintenance work. Dust on the battery may

cause a short-circuit.

The engine must be used at least 1 m [3.3 ft.] away

from buildings and other equipment to prevent pos

sible fire caused by engine heat.

Never open crankcase until engine cools

If the cover is opened while the engine is still hot,

fresh air comes into crankcase and oil mist can be

ignited by engine heat, then it may lead to the

explosion of the engine.

Never open the engine crankcase cover before the

engine becomes cool, wait at least 10 minutes after

the engine stops.

Check for fuel, oil and exhaust gas leaks

Inspect fuel, oil and exhaust pipes regularly for

damage and looseness. If a fuel, oil and exhaust

gas leak is found, repair the leakage immediately.

Fuel or oil spilled on a hot surface of the engine,

and exhaust gas blown onto a combustible material

may cause fire and result in personal injury and/or

damage to equipment.

Use flameproof light

When inspecting fuel, engine oil, coolant, battery

electrolyte, etc., use a flameproof light. An ordinary

light may ignite and cause an explosion.

Do not short electrical wires

Before inspecting or servicing any electrical compo-

nent, disconnect the ground cable from the nega-

tive (-) battery terminal to prevent short-circuit and

fire.

Loose terminals or damaged cables/wires can

cause a short-circuit that may result in fire. Before

operating the engine, inspect the cables and wires,

and repair or replace if necessary.

Keep fire extinguishers and firstaid kit nearby

Keep fire extinguishers nearby,

and be familiarized with their

usage.

Keep a first-aid kit at the desig-

nated place, and make sure it is

easily accessible at anytime.

Establish response procedures to follow in the

event of fire or accident, and post information con

cerning emergency contact locations and their con-

tact methods.

-

1-1

Page 16

Chapter 1 BASIC SAFETY PRECAUTIONS

Warning Stay Clear of All Rotating and Moving Parts

Install protective covers on rotating parts

Make sure the protective covers of

the engine are correctly installed.

Repair any damaged or loose covers.

When the engine is coupled to other

equipment or the radiator, install pro

tective covers on the exposed connecting belt and

coupling.

Never remove protective covers for rotating parts

such as the damper cover, camshaft cover or

rocker cover while the engine is operating.

-

Check surrounding area for safety

Before starting the engine, check to make sure no

one is near the engine and tools are not left on or

near the engine. Verbally notify persons within the

immediate area when starting the engine.

When the starter device is posted with a sign that

prohibits startup operation, do not operate the

engine.

Stay clear of all rotating and moving parts while engine is operating

Do not approach rotating and moving

parts of the engine while the engine is

in operation.

Rotating parts can entangle your

body or tools and result in serious

injury.

Keep items that can be easily entangled by rotating

parts away from the engine.

If your body or tool contacts rotating and moving

parts, serious injury may occur as a result.

Lock out and Tag out

Be sure to lock out and tag out before starting

inspection and maintenance.

Lockout and tagout are effective methods of cutting

off machines and equipment from energy sources.

To lock out and tag out, pull out the key from the

starter switch, turn off the battery switch, and post a

tag on the starter switch indicating “Do Not Oper

ate.” The starter key switch should be kept by the

person performing the inspection and maintenance.

For the air starter system, close the main valve of

the air tank, and post a tag indicating “Do Not Open

the Valve.”

-

Always stop engine before inspection and maintenance

Be sure to stop the engine before conducting

inspection and maintenance. Never attempt to

adjust the engine parts while the engine is running.

Conducting inspection and maintenance on an

operating engine can result in a serious accident of

entanglement by rotating parts.

Always return turning tools to original position

Be sure to remove all turning tools used during

maintenance and inspection.

Starting the engine with the turning tools inserted or

turning gears engaged may not only cause engine

damage but personal injury as well.

1-2

Page 17

Chapter 1 BASIC SAFETY PRECAUTIONS

Warning Be Careful of

Burns

Do not touch engine during operation or immediately after operation

Do not touch the main and exhaust

parts of the engine during operation

or immediately after operation to

prevent burns.

To conduct maintenance and

inspection, wait until the engine cools sufficiently as

indicated with the temperature gage.

Open radiator filler cap carefully

Never open the radiator filler cap while the engine

is operating or immediately after it is stopped.

The engine coolant is hot during engine operation

and immediately after operation. If the radiator filler

cap is opened when the coolant is at operating tem

perature, steam and hot coolant may blow out,

causing skin burns as a result.

When opening the cap, stop the engine and allow

the coolant temperature to drop sufficiently. Cover

the cap with a cloth or use thick rubber glove, and

then slowly open the cap.

When closing the cap, be sure to tighten securely.

Add coolant only after coolant temperature drops

Do not add coolant immediately after the engine

stops. Wait until the coolant temperature lowers

sufficiently to prevent burns.

Warning Be Careful of

Exhaust Fume Poisoning

Perform engine operation in a well-ventilated site

Exhaust gas from the engine

contains carbon monoxide and

other harmful substances.

Do not operate the engine in an

enclosed area (inside a ware

house, tunnel, etc.) or in a site where all sides are

blocked, since exhaust fumes can cause gas poi

soning.

If the engine must be operated in an enclosed area,

discharge the exhaust gas to the outside and pro

vide adequate ventilation.

Connect an exhaust duct to the exhaust pipe to

lead exhaust gas to the outside, and make sure

exhaust gas does not leak from the duct joints.

-

Make sure the exhaust gas does not blow in the

direction of plants or animals.

-

-

-

Warning Protect Ears

from Noises

Wear earplugs

Be sure to wear earplugs when

entering into the engine room.

The earplugs can be quite use

ful to protect ears from various

engine noises.

-

Do not dismount heat protection covers

The high-temperature exhaust components are

installed with heat protection covers. Do not dis

mount these heat protection covers. If they must be

removed during inspection and maintenance, be

sure to reinstall them after completing the inspec

tion and maintenance.

-

-

1-3

Page 18

Chapter 1 BASIC SAFETY PRECAUTIONS

Warning Be Careful

When Lifting Engine

Lifting engine carefully

To lift the engine, use slings capa-

ble of supporting the weight of the

engine.

Attach appropriate slings to the

hangers on the engine.

Keep the engine balanced during lifting by consid-

ering the center of gravity of the engine.

Keep the angle formed by slings attached to hang-

ers within 60°. If the angle exceeds this limit, exces-

sive load is applied on the hangers and may

damage the hangers.

If wire ropes contact the engine, place a cloth or

other soft padding to prevent damage to the engine

and wire ropes.

Do not climb onto engine

Never climb onto the engine.

To work on parts located on the upper section, use

a ladder, stand, etc.

Climbing on the engine can not only damage entire

parts, but also cause parts to fall off and result in

injury.

Always watch your footing

Use a stable work platform to

stand on when working on the

upper part of the engine and

other hard-to-reach places.

Standing on a decrepit stand or

parts box may result in personal injury.

Do not put obstacles on the stand.

Caution Be Careful of Handling Fuel, Engine Oil and LLC

Use only specified fuel, engine oil and coolant (LLC)

Use fuel, oil and LLC specified in this manual, and

handle them carefully.

Use of any other fuel, oil or LLC, and improper han-

dling may cause various engine problems and mal-

functions.

Obtain the MSDSs issued by the fuel, oil and LLC

suppliers, and follow the directions on the MSDSs

for proper handling.

Handle LLC carefully

Wear safety mask and rubber gloves when han-

dling LLC. Avoid contact with skin and eyes to pre-

vent personal injury.

Should LLC be accidentally swallowed, induce

vomiting immediately and seek medical attention.

Should LLC enter eyes, flush immediately with

plenty of water and seek medical attention. If LLC is

spilled on skin or clothes, wash immediately with lot

of water.

Keep flammable materials away from LLC to pre-

vent fire. Never use flames or generate sparks near

LLC since flames or sparks can cause fire.

Drained LLC is harmful. Do not dispose of into con-

ventional sewage. Contact a Mitsubishi dealer for

the disposal of drained LLC.

Properly dispose of drained oil and LLC

Do not dispose of engine oil, used cleaning oil or

LLC into conventional sewage.

Prepare drip pan or other containers to receive oil

and LLC drained from the engine. Do not drain

them directly onto the ground.

For disposal of drained oil and LLC, consult a Mit-

subishi dealer.

1-4

Page 19

Chapter 1 BASIC SAFETY PRECAUTIONS

Caution Service Bat-

tery

Handle battery carefully

• Batteries release flammable

hydrogen gas and oxygen.

Never use flames or generate

sparks near the battery since

flames or sparks can cause

an explosion.

• Do not use the battery when the fluid surface is

lower than the minimum required level. Using a

battery with a low electrolyte level can result in an

explosion.

• Do not short the battery terminals with a tool or

other metal object.

• When disconnecting battery cables, remove the

cable from the negative (-) terminal first. When

reconnecting cables, attach the cable to the posi-

tive (+) terminal first.

• Charge the battery in a well-ventilated area, with

all filling hole plugs removed.

• Make sure the cable clamps are securely

installed on the battery terminals. A loose cable

clamp can cause sparks that may result in an

explosion.

• Before servicing electrical components or con-

ducting electric welding, set the battery switch to

the [OFF] position or disconnect the cable from

the negative (-) battery terminal to cut off the

electrical current.

• Electrolyte contains dilute sulfuric acid. Careless

handling of the battery can cause loss of sight

and burns.

• Wear safety goggles and rubber gloves when

working with the battery (replenishment of fluid,

charging, etc.)

• If electrolyte is spilled on skin or clothes, wash

immediately with lots of water. Then, use soap to

clean thoroughly.

• If electrolyte enters eyes, flush immediately with

lots of fresh water and see a physician as soon as

possible.

• Should you accidentally swallow electrolyte, gar-

gle with plenty of water, then drink lots of water.

Consult a physician immediately.

Caution When Abnormality Occurs

If engine overheats, conduct cooling operation before stopping

engine

If the engine overheats, do not stop the engine

immediately. Abrupt stopping of an overheated

engine may cause the coolant temperature to rise,

resulting in seizing of the engine. If the engine over

heats, operate the engine at low idling speed (cool-

ing operation), and stop the engine after the coolant

temperature lowers sufficiently.

Do not add coolant immediately after stopping the

engine. Adding coolant to a hot engine may cause

damage to the cylinder head from sudden change

in temperature. Add coolant gradually after the

engine cools to room temperature.

If engine stops due to abnormality, exercise caution when restarting

If the engine stops due to an abnormality, do not

restart the engine immediately. If the engine stops

with an alarm, check and correct the cause of the

problem before restarting. Operating the engine

without correcting the problem may result in serious

engine problems.

If engine oil pressure drops, stop engine immediately

If the engine oil pressure decreases, stop the

engine immediately, and inspect the lubricating sys

tem including the oil level and pump. Operating the

engine with low oil pressure may cause seizing of

bearings and other parts.

-

-

1-5

Page 20

Chapter 1 BASIC SAFETY PRECAUTIONS

Caution Other Cautions

Never modify engine

Unauthorized modification of the engine will void

the maker's warranty.

Modification of the engine may not only cause

engine damage but may result in personal injury as

well.

If there is a need to modify the engine, please con-

tact a Mitsubishi dealer.

Never break seals

To ensure proper engine operation, the fuel control

links are attached with seals that prevent accidental

change of the injection volume and rotation speed

settings. Operating the engine without these seals

in place can result in the following problems, and

also invalidates the warranty.

• Rapid wear of moving and rotating parts

• Engine damage such as seizing of engine parts

• Increased consumption of fuel and lubricating oil

• Degradation of engine performance due to

improper balance between fuel injection volume

and governor operation.

Perform all specified pre-operation inspections and periodic

inspections

Conduct the pre-operation inspections and periodic

inspections as described in this manual.

Failure to conduct the specified inspections may

cause various engine problems and damage to

parts, as well as serious accidents.

Perform engine break-in

Break in a new engine by operating it with a light

load and at a speed lower than normal during the

first 50 hours of operation.

Operating a new engine under high load or severe

conditions during the break-in period can shorten

the service life of the engine.

Warm up engine before use

If the auxiliary devices for the starter (water heater,

engine oil priming pump etc.) are not installed, let

the engine idle for 5 to 10 minutes before using the

engine for work.

Warm-up operation circulates lubricants in the

engine and contributes to a longer service life and

economical operation.

Do not conduct warm-up operation for an extended

period of time. Prolonged warm-up operation

causes carbon build-up in the cylinders that leads

to incomplete combustion.

Never operate engine under overload condition

If the engine shows an overload condition such as

the emmision of exhaust smoke, decrease the load

immediately so that the engine operates at appro

priate output and load.

Overloading the engine causes not only high fuel

consumption but also excessive carbon deposits

inside the engine. Carbon deposits cause various

problems and can shorten the service life of the

engine.

-

Conduct cooling operation before stopping engine

Before stopping the engine, let it idle at low speed

for 5 to 6 minutes to cool.

Stopping the engine immediately after high-speed

operation can cause engine parts to heat up and

shorten the service life of the engine.

During cooling operation, check the engine for

abnormalities.

Do not splash water on engine

Do not allow rainwater, etc., to enter the engine

through the air inlet or exhaust openings.

Do not wash the engine while it is in operation,

since the engine may suck in the cleaning fluid

(water). If the engine is started with water inside the

combustion chambers, water hammer action can

damage the engine and result in serious accidents.

1-6

Page 21

Chapter 1 BASIC SAFETY PRECAUTIONS

Conduct proper maintenance of air cleaner/pre-cleaner

The major cause of abnormal wear on engine parts

is dust entering with intake air. Worn parts result in

an increase of oil consumption, decrease of output,

and starting difficulties. Conduct maintenance of

the air cleaner/pre-cleaner according to the follow

ing directions to ensure optimum air filtering perfor-

mance.

• Do not conduct maintenance of the air cleaner/

pre-cleaner while the engine is operating.

Without the air cleaner/pre-cleaner in place, the

turbocharger can suck foreign particles into the

engine, decrease the load immediately so that

the engine operates at appropriate output and

load.

• When removing the air cleaner, do not allow dust

attached on the air cleaner/pre-cleaner to enter

into the engine.

• If equipped with a dust indicator, conduct mainte-

nance only when the clog warning sign appears.

While servicing the air cleaer/pre-cleaner, do not

let dust enter into the air cleaner/pre-cleaner,

damage or deform the element.

Observe safety rules at workplace

Observe the safety rules established at your work-

place when operating and maintaining the engine.

Do not operate the engine if you are feeling ill.

Operation of the engine with reduced awareness

may cause accidental operations that may result in

accidents. In such case, you should inform your

supervisor of your condition.

When working in a team of two or more persons,

use specified hand signals to communicate among

the workers.

Wear proper work clothes and protective gear

Wear the work clothes specified by your workplace.

Wear a hardhat, face shield, safety shoes, dust pro-

tective mask, gloves and other protective gear as

needed.

When handling compressed air, wear safety gog-

gles, hardhat, gloves and other necessary protec-

tive gear. Compressed air may cause personal

injury when not wearing the proper protective gear.

Use appropriate tools for maintenance work

Use appropriate tools according to the type of

maintenance work, and use them correctly.

If tools are damaged, replace with new tools.

-

Cautions concerning transportation

When transporting the engine using a truck, con-

sider the engine weight, width and height to ensure

safety. Abide by the pertinent laws and regulations.

Do not operate engine continuously under low load

When operating the engine with a 30 % load or

lower, limit each operation to 10 minutes. Operating

the engine under low load tends to result in

unburned fuel, which can adhere on internal engine

parts to cause malfunctions and shorten the engine

service life.

Ventilate the engine room sufficiently

Be sure to provide sufficient ventilation in the

engine room. Insufficient air in the room can cause

the engine temperature to rise and the output

power and performance to lower.

It is highly recommended to calculate the required

amount of air supply to the engine and install an

appropriate ventilation system before installing an

engine.

Do not touch high-pressure injection fuel

Should injected fuel leak from a fuel injection pipe,

do not touch the spurting fuel.

Fuel in the fuel injection pipes is under high pres-

sure. Touching high-pressure fuel can cause the

fuel to penetrate the skin and result in gangrene.

1-7

Page 22

Chapter 1 BASIC SAFETY PRECAUTIONS

Caution About Warning Labels

Maintain and inspect warning labels

Make sure all warning labels are legible.

If the description and/or illustration on a warning

label cannot be seen clearly, clean or replace the

label.

To clean warning labels, use a cloth, water and

soap. Do not use solvents, gasoline or other chemi

cals to clean warning labels. Cleaning with chemi-

cals may cause the labels to peel off.

If warning labels are damaged or missing, replace

with new labels.

If a part of the engine with warning label is replaced

with new part, also attach new warning label to the

new part.

To obtain replacement warning labels, contact a

Mitsubishi dealer.

-

1-8

Page 23

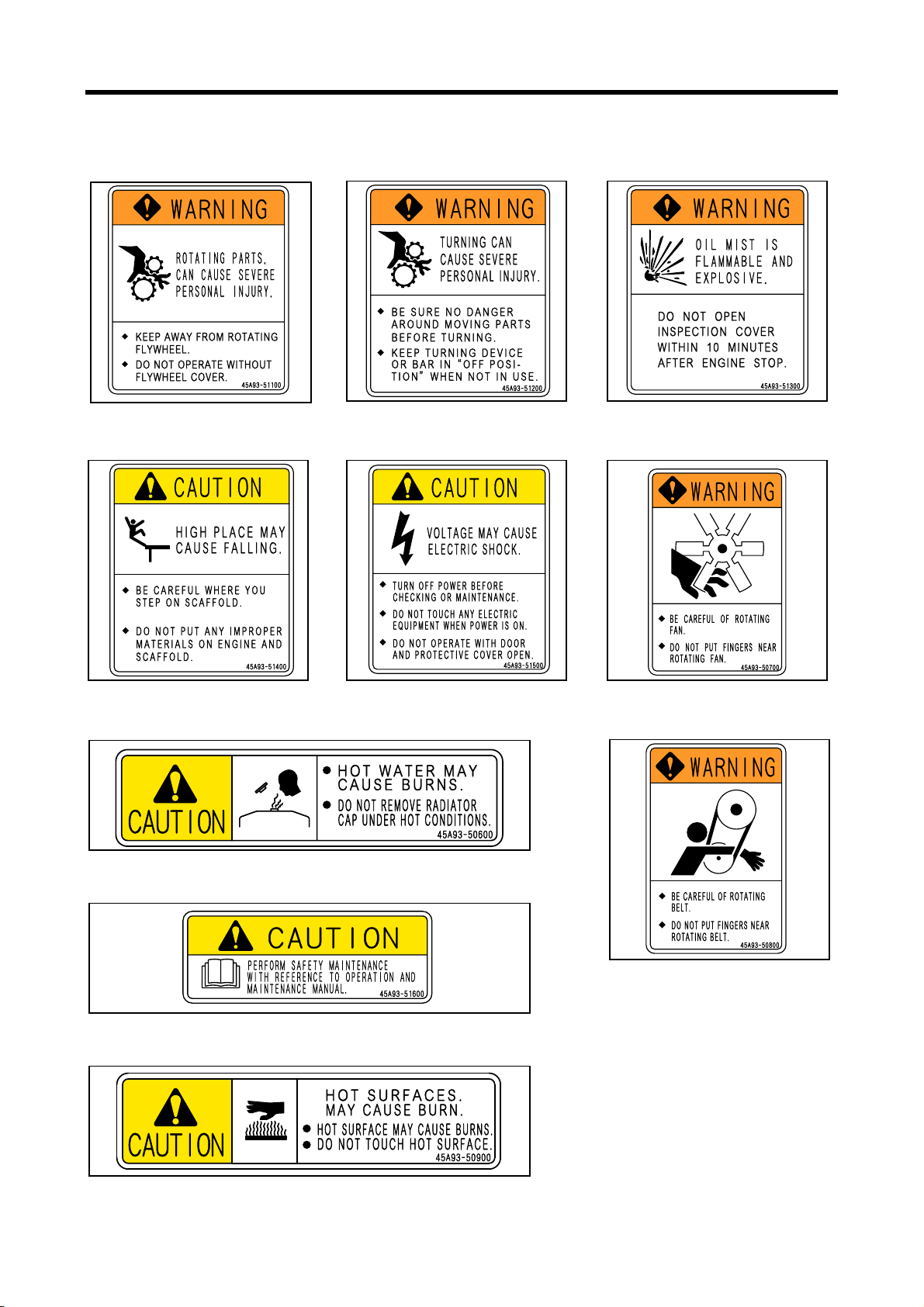

Warning labels

Chapter 1 BASIC SAFETY PRECAUTIONS

fig.1-1 Warning for flywheel

entanglement

fig.1-4 Caution for footing fig.1-5 Caution for electric shock

fig.1-2 Warning for moving parts fig.1-3 Warning for oil mist

fig.1-6 Warning for rotating parts

fig.1-7 Caution for burns

fig.1-9 Caution for referring to manual

fig.1-10 Caution for burns

fig.1-8 Warning for rotating parts

1-9

Page 24

Page 25

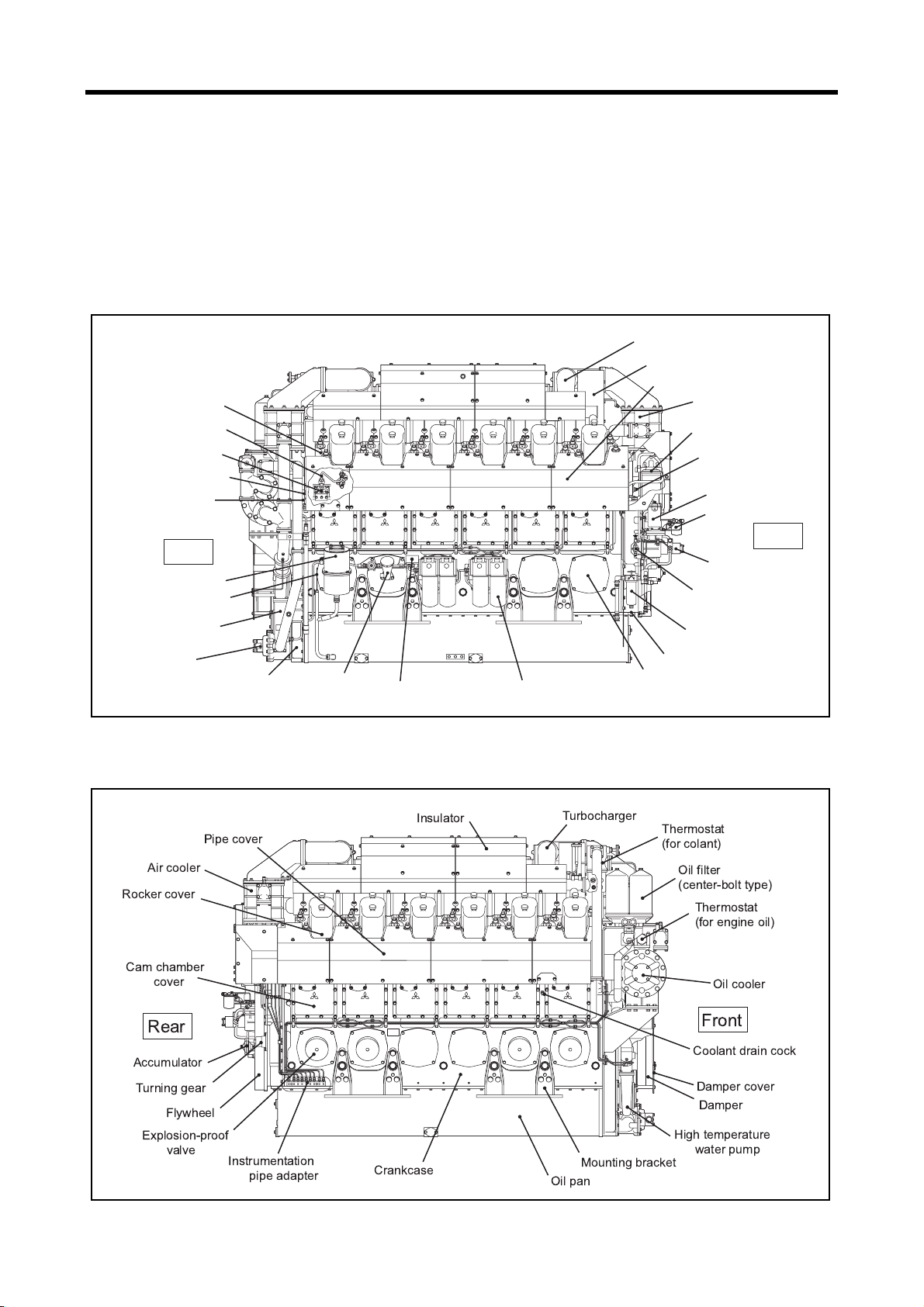

Chapter 2 NAME OF PARTS

Engine External Diagrams

The external diagram is for standard type of S12U/S16U engine.

The installed equipment and shapes differ on the engine type.

S12U Left View

Cylinder head

Fuel injection pipe

Fuel injection pump

Air starter main pipe

Distributor

Front

Breather

Oil level gage

Low temoerature

water pump

Oil pump

Front gear case

Oil filler

Nameplate

Bypass oil filter

Turbocharger

Silencer, pre-cleaner

Pipe cover

Air cooler

Fuel filter

(center-bolt type)

Air cooler chamber

water drain cock

Governor

Governor oil filter

Rear

Fuel feed pump

Fuel priming pump

Fuel filter

(wire-element type)

Timing gear case

Crankcase side cover

S12U Right View

%

!"

&'$

#

fig.2-1 S12U engine left view

$ "

!

#

fig.2-2 S12U engine right view

2-1

Page 26

Chapter 2 NAME OF PARTS

r

S16U Left View

Fuel injection pipe

Turbocharger

Silencer

Pre-cleaner

Air starter

main pipe

Damper cover

Front

Damper

Breather

Oil filler

Low temperature

water pump

Front gear case

S16U Right View

Nameplate

Oil level gage

Bypass oil filter

fig.2-3 S16U engine left view

Fuel injection pump

Pipe cover

Cylinder head

Fuel filter

(center-bolt type)

Coolant drain cock

Governor

Rear

Governor oil filte

Fuel feed pump

Fuel priming pump

Fuel filter

(wire-element type)

Crankcase side cover

!

"

!

#$%

fig.2-4 S16U engine right view

#

&

%

2-2

Page 27

Chapter 2 NAME OF PARTS

Equipment and Instrument

Starting and Shutdown Devices

The shape and type of the starting and shutdown devices may vary from those described below depending on

the engine specifications.

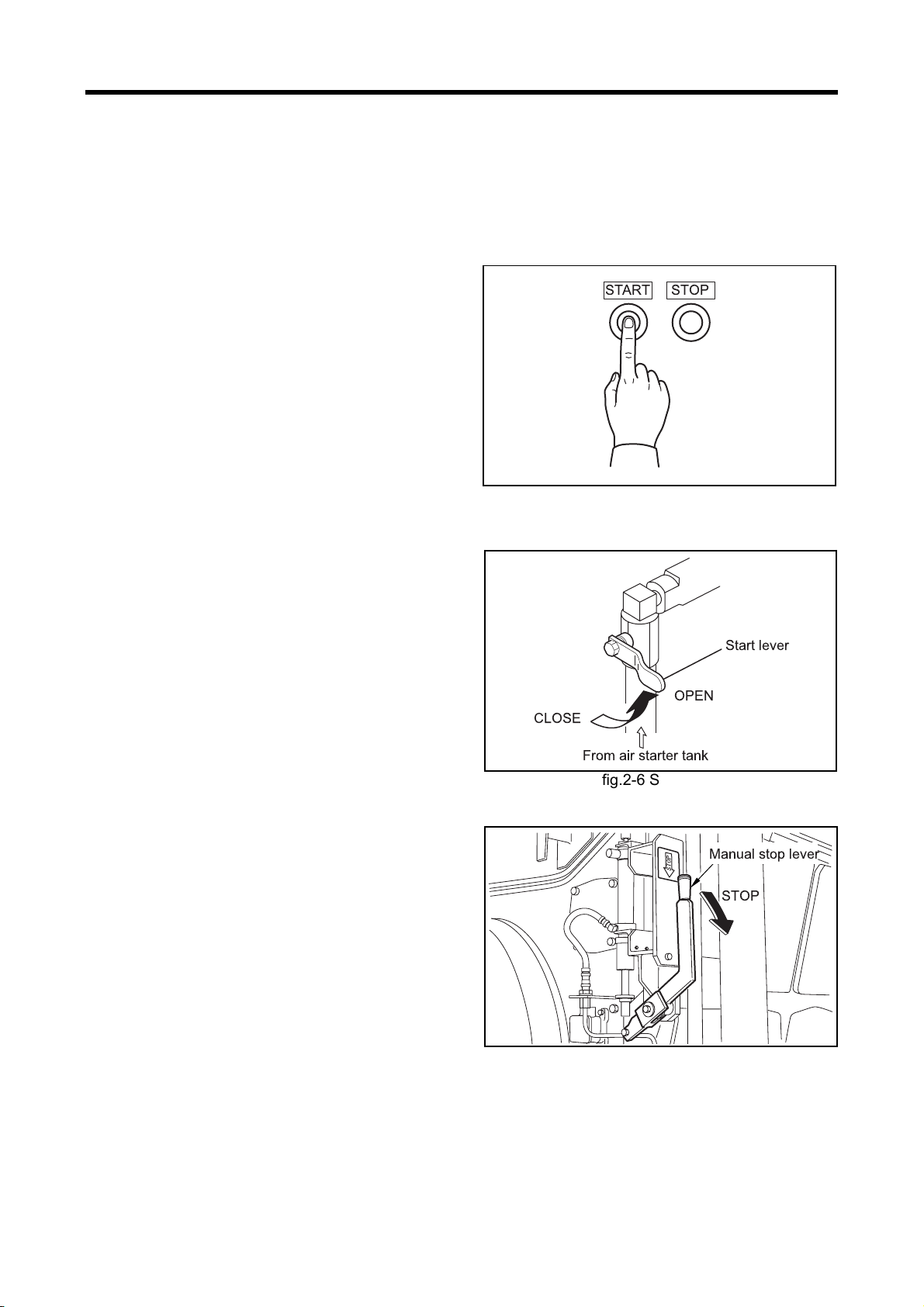

Start Switch

When the start switch on the operation panel is

pressed, starting air is supplied to the air starter

system and cranks the engine.

Stop Switch

When the stop switch on the operation panel is

pressed, the shutdown cylinder operates and

moves the control shaft of the fuel injection pump to

the no-injection position to shut down the engine

operation.

fig.2-5 Start switch and stop switch

STOPSTART

Start Lever

The start lever is provided on the air starter pipe.

When the lever is moved toward the OPEN posi

tion, air flows and cranks the engine. Once the

engine starts, return the lever to the CLOSE posi

tion immediately.

Manual Stop Lever

Use the manual stop lever to shut down the engine

in the event of an emergency.

If the stop button is not working, use the manual

stop lever. The lever is installed to the fuel control

link and when the lever is moved in the STOP

direction, the engine stops operation.

Should the engine continue operating even after

the manual stop lever is operated, cut off the fuel

supply to stop the engine.

-

-

Start lever

OPEN

CLOSE

From air starter tank

fig.2-6 Start lever

fig.2-7 Manual stop lever

2-3

Page 28

Chapter 2 NAME OF PARTS

Instruments

The instruments indicate the internal conditions of

the engine in operation. In normal operation, record

the numerical values indicated on the instruments

at regular intervals. If the numerical value is far dif

ferent from that in normal operation, the indications

of the instruments allow prompt judgment of engine

problems.

The instrument shape (round, square) and indica-

tion type (analog, digital) can vary depending on

the engine specifications.

Tachometer

This indicates the engine revolutions per minute

(rpm).

Note: The tachometer may have a built-in hour

meter.

Hour Meter

This indicator shows cumulative engine operating

hours.

Use the meter indication as a guigeline for deter-

mining the need for regular inspection and servic-

ing.

Oil Cooler Coolant Pressure Gage

This indicates the coolant pressure in the oil cooler.

-

Air Cooler Coolant Pressure Gage

This indicates the coolant pressure in the air cooler.

Exhaust Temperature Gage

This indicates the temperature of exhaust gas at

the cylinder outlets or turbocharger inlet or outlet.

Fuel Pressure Gage

This indicates the pressure of fuel supplied to the

fuel injection pump by the fuel feed pump.

Inlet Pressure Gage

This indicates the pressure of inlet supplied to the

air cooler.

Oil Pressure Gage

This indicates the engine oil pressure.

Oil Temperature Gage

This indicates the engine oil temperature.

Jacket Coolant Temperature Gage

This indicates coolant temperature inside of the

crankcase.

Oil Cooler Coolant Temperature Gage

This indicates coolant temperature in the oil cooler.

Air Cooler Coolant Temperature Gage

This indicates coolant temperature in the air cooler.

Jacket Coolant Pressure Gage

This indicates the pressure of coolant in the crank-

case, cylinder heads and other parts.

2-4

Page 29

Chapter 2 NAME OF PARTS

Engine Protection Devices

The engine protection devices activate an alarm when an abnormality occurs in the engine in order to protect

the engine and prevent serious problems and accidents. When a protection device is activated, stop the

engine, examine the cause of the abnormality, and take corrective measures.

If the cause of the problem is unknown, contact a Mitsubishi dealer.

Protection devices installed on the engine and their types (setting values) and shapes vary depending on the

engine specifications. The following describes the typical protection devices installed in a Mitsubishi engine.

Low Oil Pressure Alarm

The oil pressure switch activates an alarm when the engine oil pressure drops to an abnormally low level.

High Coolant Temperature Alarm

The high coolant temperature alarm device generates a warning or stops the engine when the coolant tem-

perature rises to an abnormally high level due to an engine malfunction or other reason.

Oil Filter Clog Alarm

The oil filter clog detector generates a warning when the oil filter becomes clogged and causes an abnormally

large pressure difference between before and after the oil filter. When it generates an alarm, replace it with a

new filter immediately and change engine oil, as well.

Overspeed Alarm

The overspeed alarm device generates a warning and stops the engine operation when the engine speed

starts operating at abnormally high speed due to an engine malfunction or other reason.

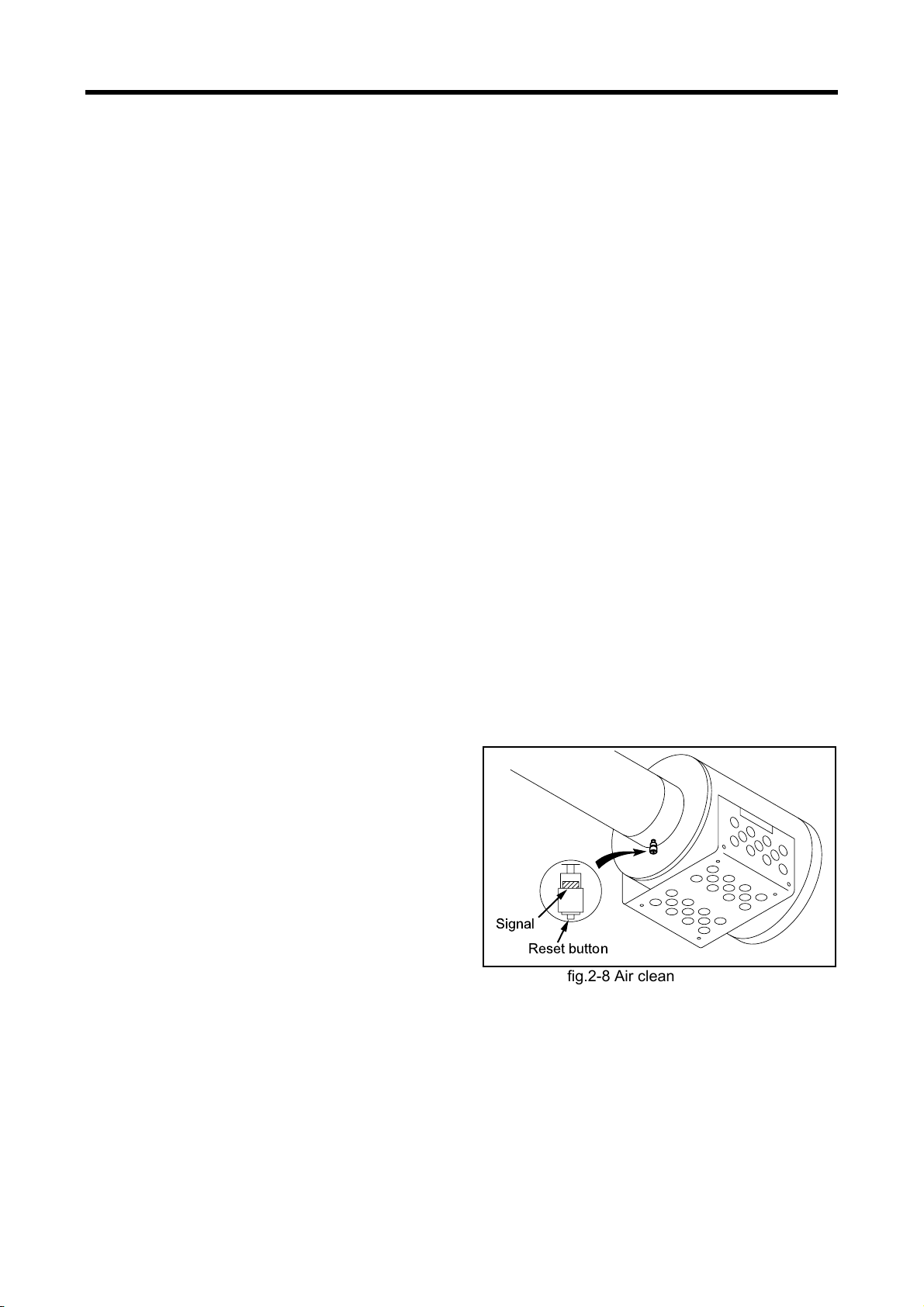

Air Cleaner Clog Alarm (Air Cleaner Indicator)

A red signal appears as a warning when the air cleaner

element becomes clogged and causes an abnormally

large pressure difference between before and after the

air cleaner. When a red signal appears, clean the air

cleaner element immediately or replace it with a new

element.

After the element is cleaned or replaced, press the

reset button located at the upper part of the indicator to

cancel the red signal.

While serving the air cleaner, do not enter dust into the

air cleaner or damage the element.

Signal

Reset button

fig.2-8 Air cleaner indicator

2-5

Page 30

Chapter 2 NAME OF PARTS

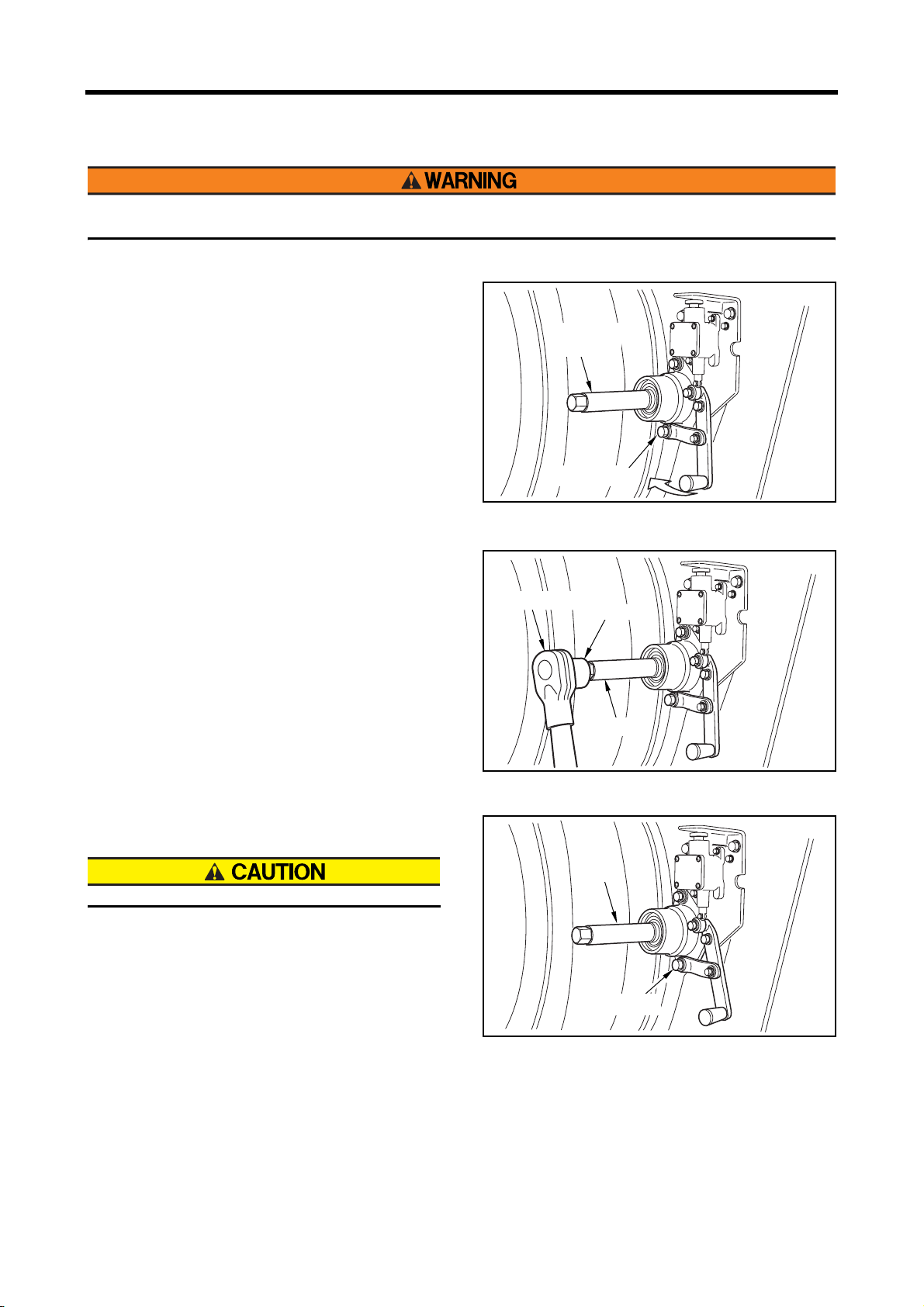

Using Turning Gear

Before starting the engine, return (pull out) the turning gear to the original position. Starting the engine with the

turning gear pushed in not only damages the ring gear but also may result in personal injury.

1 Untighten the retaining bolt.

2 Move the turning gear fully to engage the ring gear

and tighten the bolt.

Turning gear

shaft

Retaining bolt

fig.2-9 Preparation for turning

3 Turn the shaft using the socket wrench and the

rachet handle.

4 After turning, move the turning gear, disengage the

turning gear with the ring gear and tighten the retain-

ing bolt.

Make sure the lock pin is securely inserted.

Rachet handle

Socket

Shaft

fig.2-10 Turning

Shaft

Retaining bolt

fig.2-11 Locking turning gear

2-6

Page 31

Chapter 3 OPERATION

Preparation for Operation of New or Overhauled Engine

Before operating a new or overhauled engine, do the following inspection. For second operation onward, do

the following normal operation outlined on page

Fuel System

When handling fuel, make sure there are no flames near the engine.

Wipe any spilled fuel completely. Spilled fuel can ignite and cause fire.

Do not remove the strainer when filling the fuel tank.

Use fuel specified in "Fuel" (4-2).

Pouring fuel

3-8 "Normal Engine Operation".

1 Make sure the insides of the fuel tank and fuel pipes are clean.

2 Pour fuel into the fuel tank.

3 Remove the fuel feed pipe and drain plug from the fuel inlet of the engine, and check the discharged fuel

for dust particles.

4 Reinstall the drain plug and fuel feed pipe.

5 Add fuel until the fuel level gage indicates "FULL."

3-1

Page 32

Chapter 3 OPERATION

Bleeding Fuel System

When fuel overflows from the air vent plug, wipe

thoroughly with a cloth. Spilled fuel is a fire haz-

ard.

After bleeding, lock the priming pump cap

securely. If the cap is not locked tightly, the

priming pump can be damaged, causing fuel

leakage that may lead to a fire.

Closing all air vent plugs before locking the priming

pump cap disallows the priming pump cap from

returning to the original position due to internal pres-

sure.

Bleed air from the location closest to the fuel tank

that are the fuel filter (wire-element type), fuel filter

(center-bolt type), then the fuel feed pipe.

Bleeding Air from Fuel Filters (Wire-Element Type)

[Unlock]

Turn counterclockwise

[Priming]

Move back and force

Priming pump cap

[Lock]

Press the cap

and turn clockwise

fig.3-1 Priming pump operating method

Replace to a new part if there is a damage on the air

vent plug, thread area of bracket or sealing washer.

1 Loosen the air vent plug on the fuel filter (wire-

element type) by rotating about 1.5 turns.

2 Loosen the priming pump cap by turning counter-

clockwise and move it back and forth.

3 When there are no air bubbles in the fuel flowing

from the air vent plug, tighten the air vent plug to

the specified torque.

Bleeding Air from Fuel Filters

(Center-Bolt Type)

Replace to a new part if there is a damage on the air

vent plug, thread area of bracket or sealing washer.

1 Loosen the air vent plug on the fuel filter (center-

bolt type) by rotating about 1.5 turns.

2 Move its priming pump cap back and forth.

3 When there are no air bubbles in the fuel flowing

from the air vent plug, tighten the air vent plug to

the specified torque.

Bracket

fig.3-2 Bleeing air from fuel filters

Air vent plug and

sealing washer

Air vent plug and

sealing washer

(wire-element type)

Air vent plug and

sealing washer

3-2

fig.3-3 Bleeding air from fuel filters

(center-bolt type)

Page 33

Chapter 3 OPERATION

Bleeding Air from Fuel Filters

(Cartridge-Type)

1 Set the handle of the fuel filters (cartridge-type)

to the "Left - Open, Right - Bleed position, and

loosen the right-side air vent plug by rotating it

about 1.5 turns.

2 Move the priming pump cap back and forth.

When the fuel flowing from the right-side air vent

plug no longer contains air bubbles, tighten the

air vent plug.

3 Set the handle to the "Right - Open, Left - Bleed

position, and open the left-side air vent plug.

4 Move the priming pump cap back and forth.

When the fuel flowing from the left side air vent

plug no longer contains air bubbles, tighten the

air vent plug.

5 Return the handle to the normal position.

Replace to a new part if there is a damage on the

air vent plug, thread area of bracket or sealing

washer.

Right side air vent plug

and sealing washer

Bracket

Handle

Left side

air vent plug and

sealing washer

Left side fuel filters

Right side fuel filters

fig.3-4 Bleeding air from fuel filters (cartridge-type)

Right side

bleeding position

Normal position

(Fuel flows through

left side fuel filters only.)

Left side

bleeding position

Left side filter

replacement position

(Fuel flows through

right-side fuel filter only)

fig.3-5 Fuel filter switchover cock

Bleeding Air from Fuel Feed Pipe

1 Loosen the air vent cock on the fuel feed pipe by

rotating about 1.5 turns.

2 Move the priming pump cap back and forth

repeatedly. When there are no air bubbles in the

fuel flowing from the air vent cock, press the

priming pump cap and turn the cap clockwise to

lock.

3 Tighten the air vent cock on the fuel feed pipe.

Tighten the priming cap before closing the air vent

plug.

Closing all air vent plugs before the priming pump

cap disalllows the priming pump cap from returning

to the original position due to internal pressure.

When fuel overflows from the air vent plug, wipe

throughly with a cloth. Spilled fuel causes fire haz-

ard.

Air vent cock

Fuel feed pipe

fig.3-6 Bleeding air from fuel feed pipe (1)

Air vent cock

Fuel feed pipe

fig.3-7 Bleeding air from fuel feed pipe (2)

3-3

Page 34

Chapter 3 OPERATION

Lubricating System

Pouring engine oil

1 Remove the cap from the oil filler.

2 Pour engine oil of the specified type.

Specified engine oil:Class CD or CF

(API Service Classification)

Engine oil capacity (oil pan)

S12U: approx. 450 L [118.88 U. S. gal.]

S16U: approx. 600 L [158.50 U. S. gal.]

Note: Regarding engine oil, refer to "Engine Oil" (4-

4).

3 Check the oil level with the oil level gage.

If the automatic oil feeder is installed, check if it

works normally.

The oil level should be between the MAXIMUM

and MINIMUM marks on the oil level gage.

If the oil level is low, add specified type of engine

oil.

4 Check the oil pan and other parts for oil leaks.

Repair any oil leakage found.

5 Operate the engine oil priming pump to circulate

oil in the engine.

6 Remove the rocker cover, and make sure that oil

is supplied to the valve mechanisms.

7 Stop the priming pump. After about 30 minutes,

add engine oil until the oil level reaches the Maximum line on the oil level gage.

8 Reinstall the cap on the oil filler.

Oil filler

fig.3-8 Oil filler and oil level gage

Engine oil

priming pump

fig.3-9 Engine oil priming pump

Oil level gage

3-4

Page 35

Cooling System

Pouring coolant

1 Make sure the drain cocks on the engine and

water pump are closed firmly.

2 Remove the cap from the water supply inlet of

the coolant tank, and pour undiluted LLC.

Note:(a) Determine the amounts of LLC and water

to be poured by using the LLC concentra-

tion chart.

(b) Regarding coolant, refer to "Coolant" (4-6).

Coolant capacity (engine only)

S12U: approx. 520 L [137.37 U. S. gal]

S16U: approx. 700 L [184.92 U. S. gal]

3 Pour soft water with minimal impurities slowly to

the full level.

4 When coolant reaches the full level securely,

close the water supply inlet cap of the coolant

tank.

5 To release air from the water pump and coolant

pipes, pull the manual stop lever fully to the

STOP position and hold it in that position to keep

the fuel injection pump in no-injection condition,

then supply starting air and crank the engine for

about 10 seconds.

6 Wait for about 1 minute, then repeat the above

cranking operation twice to remove air from the

water pump.

7 Check the level gage on the coolant tank to make

sure there is sufficient coolant (surface level at

about the center of the level gage). If the coolant

level is low, add coolant.

8 Start the engine, and operate it under light load

until the thermostat opens the valve to allow soft

water and LLC to mix thoroughly.

9 Stop the engine, check the level gage on the

coolant tank again. If the coolant level is low, add

coolant (so that the surface level rises to about

the center of the level gage).

Note: Always add coolant having the same LLC con-

centration.

10 Check the pipe joint and other parts for coolant

leaks.

Chapter 3 OPERATION

fig.3-10 Coolant drain cock on the engine

Coolant drain cocks

fig.3-11 Coolant drain cock on the water pump

Water supply inlet

Fluid level gage

fig.3-12 Water tank coolant level

3-5

Page 36

Chapter 3 OPERATION

Electrical Systems

Checking Battery

If electrolyte is spilled on the eyes, skin or clothes, wash immediately with plenty of water. If electrolyte enters