Page 1

MELSEC iQ-R Digital-Analog Converter Module

User's Manual (Application)

-R60DA4

-R60DAV8

-R60DAI8

Page 2

Page 3

SAFETY PRECAUTIONS

WARNING

Indicates that incorrect handling may cause hazardous conditions, resulting in

death or severe injury.

CAUTION

Indicates that incorrect handling may cause hazardous conditions, resulting in

minor or moderate injury or property damage.

(Read these precautions before using this product.)

Before using this product, please read this manual and the relevant manuals carefully and pay full attention to safety to handle

the product correctly.

The precautions given in this manual are concerned with this product only. For the safety precautions of the programmable

controller system, refer to the MELSEC iQ-R Module Configuration Manual.

In this manual, the safety precautions are classified into two levels: " WARNING" and " CAUTION".

Under some circumstances, failure to observe the precautions given under " CAUTION" may lead to serious

consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this manual and then keep the manual in a safe place for future reference.

1

Page 4

[Design Precautions]

WARNING

● Configure safety circuits external to the programmable controller to ensure that the entire system

operates safely even when a fault occurs in the external power supply or the programmable controller.

Failure to do so may result in an accident due to an incorrect output or malfunction.

(1) Emergency stop circuits, protection circuits, and protective interlock circuits for conflicting

operations (such as forward/reverse rotations or upper/lower limit positioning) must be configured

external to the programmable controller.

(2) When the programmable controller detects an abnormal condition, it stops the operation and all

outputs are:

• Turned off if the overcurrent or overvoltage protection of the power supply module is activated.

• Held or turned off according to the parameter setting if the self-diagnostic function of the CPU

module detects an error such as a watchdog timer error.

(3) All outputs may be turned on if an error occurs in a part, such as an I/O control part, where the

CPU module cannot detect any error. To ensure safety operation in such a case, provide a safety

mechanism or a fail-safe circuit external to the programmable controller. For a fail-safe circuit

example, refer to "General Safety Requirements" in the MELSEC iQ-R Module Configuration

Manual.

(4) Outputs may remain on or off due to a failure of a component such as a relay and transistor in an

output circuit. Configure an external circuit for monitoring output signals that could cause a

serious accident.

● In an output circuit, when a load current exceeding the rated current or an overcurrent caused by a

load short-circuit flows for a long time, it may cause smoke and fire. To prevent this, configure an

external safety circuit, such as a fuse.

● Configure a circuit so that the programmable controller is turned on first and then the external power

supply. If the external power supply is turned on first, an accident may occur due to an incorrect output

or malfunction.

● For the operating status of each station after a communication failure, refer to manuals relevant to the

network. Incorrect output or malfunction due to a communication failure may result in an accident.

● When connecting an external device with a CPU module or intelligent function module to modify data

of a running programmable controller, configure an interlock circuit in the program to ensure that the

entire system will always operate safely. For other forms of control (such as program modification,

parameter change, forced output, or operating status change) of a running programmable controller,

read the relevant manuals carefully and ensure that the operation is safe before proceeding. Improper

operation may damage machines or cause accidents.

● Especially, when a remote programmable controller is controlled by an external device, immediate

action cannot be taken if a problem occurs in the programmable controller due to a communication

failure. To prevent this, configure an interlock circuit in the program, and determine corrective actions

to be taken between the external device and CPU module in case of a communication failure.

● Do not write any data to the "system area" and "write-protect area" of the buffer memory in the

module. Also, do not use any "use prohibited" signals as an output signal from the CPU module to

each module. Doing so may cause malfunction of the programmable controller system. For the

"system area", "write-protect area", and the "use prohibited" signals, refer to the user's manual for the

module used.

2

Page 5

[Design Precautions]

WARNING

● If a communication cable is disconnected, the network may be unstable, resulting in a communication

failure of multiple stations. Configure an interlock circuit in the program to ensure that the entire

system will always operate safely even if communications fail. Incorrect output or malfunction due to a

communication failure may result in an accident.

● To maintain the safety of the programmable controller system against unauthorized access from

external devices via the network, take appropriate measures. To maintain the safety against

unauthorized access via the Internet, take measures such as installing a firewall.

● Analog outputs may remain on due to a failure of the module. Configure an external interlock circuit

for output signals that could cause a serious accident.

[Design Precautions]

CAUTION

● Do not install the control lines or communication cables together with the main circuit lines or power

cables. Keep a distance of 100mm or more between them. Failure to do so may result in malfunction

due to noise.

● During control of an inductive load such as a lamp, heater, or solenoid valve, a large current

(approximately ten times greater than normal) may flow when the output is turned from off to on.

Therefore, use a module that has a sufficient current rating.

● After the CPU module is powered on or is reset, the time taken to enter the RUN status varies

depending on the system configuration, parameter settings, and/or program size. Design circuits so

that the entire system will always operate safely, regardless of the time.

● Do not power off the programmable controller or reset the CPU module while the setting values in the

buffer memory are being written to the flash ROM in the module. Doing so will make the data in the

flash ROM undefined. The values need to be set in the buffer memory and written to the flash ROM

again. Doing so also can cause malfunction or failure of the module.

● When changing the operating status of the CPU module (such as remote RUN/STOP) from the

external device, select "Do Not OPEN in Program" for the "Open Method Setting" in the module

parameter. The communication line will be closed when "OPEN in Program" is selected and the

remote STOP is executed from the external device. Consequently, the CPU module cannot reopen

the communication line, and the external device cannot execute the remote RUN.

● Power on or off the external power supply while the programmable controller is on. Failure to do so

may result in incorrect output or malfunction.

● At on/off of the power or external power supply, or at the output range switching, a voltage may occur

or a current may flow between output terminals for a moment. In this case, start the control after

analog outputs become stable.

3

Page 6

[Installation Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before mounting or removing the

module. Failure to do so may result in electric shock or cause the module to fail or malfunction.

[Installation Precautions]

CAUTION

● Use the programmable controller in an environment that meets the general specifications in the Safety

Guidelines included with the base unit. Failure to do so may result in electric shock, fire, malfunction,

or damage to or deterioration of the product.

● To mount a module, place the concave part(s) located at the bottom onto the guide(s) of the base unit,

and push in the module until the hook(s) located at the top snaps into place. Incorrect interconnection

may cause malfunction, failure, or drop of the module.

● When using the programmable controller in an environment of frequent vibrations, fix the module with

a screw.

● Tighten the screws within the specified torque range. Undertightening can cause drop of the screw,

short circuit, or malfunction. Overtightening can damage the screw and/or module, resulting in drop,

short circuit, or malfunction.

● When using an extension cable, connect it to the extension cable connector of the base unit securely.

Check the connection for looseness. Poor contact may cause malfunction.

● When using an SD memory card, fully insert it into the SD memory card slot. Check that it is inserted

completely. Poor contact may cause malfunction. / Failure to do so may cause malfunction.

● Securely insert an extended SRAM cassette into the cassette connector of the CPU module. After

insertion, close the cassette cover and check that the cassette is inserted completely. Poor contact

may cause malfunction.

● Do not directly touch any conductive parts and electronic components of the module, SD memory

card, extended SRAM cassette, or connector. Doing so can cause malfunction or failure of the

module.

[Wiring Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before installation or wiring. Failure

to do so may result in electric shock or cause the module to fail or malfunction.

● After installation and wiring, attach the included terminal cover to the module before turning it on for

operation. Failure to do so may result in electric shock.

4

Page 7

[Wiring Precautions]

CAUTION

● Individually ground the FG and LG terminals of the programmable controller with a ground resistance

of 100 ohms or less. Failure to do so may result in electric shock or malfunction.

● Use applicable solderless terminals and tighten them within the specified torque range. If any spade

solderless terminal is used, it may be disconnected when the terminal screw comes loose, resulting in

failure.

● Check the rated voltage and signal layout before wiring to the module, and connect the cables

correctly. Connecting a power supply with a different voltage rating or incorrect wiring may cause fire

or failure.

● Connectors for external devices must be crimped or pressed with the tool specified by the

manufacturer, or must be correctly soldered. Incomplete connections may cause short circuit, fire, or

malfunction.

● Securely connect the connector to the module. Poor contact may cause malfunction.

● Do not install the control lines or communication cables together with the main circuit lines or power

cables. Keep a distance of 100mm or more between them. Failure to do so may result in malfunction

due to noise.

● Place the cables in a duct or clamp them. If not, dangling cable may swing or inadvertently be pulled,

resulting in damage to the module or cables or malfunction due to poor contact. Do not clamp the

extension cables with the jacket stripped. Doing so may change the characteristics of the cables,

resulting in malfunction.

● Check the interface type and correctly connect the cable. Incorrect wiring (connecting the cable to an

incorrect interface) may cause failure of the module and external device.

● Tighten the terminal screws or connector screws within the specified torque range. Undertightening

can cause drop of the screw, short circuit, fire, or malfunction. Overtightening can damage the screw

and/or module, resulting in drop, short circuit, fire, or malfunction.

● When disconnecting the cable from the module, do not pull the cable by the cable part. For the cable

with connector, hold the connector part of the cable. For the cable connected to the terminal block,

loosen the terminal screw. Pulling the cable connected to the module may result in malfunction or

damage to the module or cable.

● Prevent foreign matter such as dust or wire chips from entering the module. Such foreign matter can

cause a fire, failure, or malfunction.

● A protective film is attached to the top of the module to prevent foreign matter, such as wire chips,

from entering the module during wiring. Do not remove the film during wiring. Remove it for heat

dissipation before system operation.

● Mitsubishi programmable controllers must be installed in control panels. Connect the main power

supply to the power supply module in the control panel through a relay terminal block. Wiring and

replacement of a power supply module must be performed by qualified maintenance personnel with

knowledge of protection against electric shock. For wiring, refer to the MELSEC iQ-R Module

Configuration Manual.

● For Ethernet cables to be used in the system, select the ones that meet the specifications in the user's

manual for each module. If not, normal data transmission is not guaranteed.

5

Page 8

[Startup and Maintenance Precautions]

Warning

● Do not touch any terminal while power is on. Doing so will cause electric shock or malfunction.

● Correctly connect the battery connector. Do not charge, disassemble, heat, short-circuit, solder, or

throw the battery into the fire. Also, do not expose it to liquid or strong shock. Doing so will cause the

battery to produce heat, explode, ignite, or leak, resulting in injury and fire.

● Shut off the external power supply (all phases) used in the system before cleaning the module or

retightening the terminal screws, connector screws, or module fixing screws. Failure to do so may

result in electric shock.

6

Page 9

[Startup and Maintenance Precautions]

CAUTION

● When connecting an external device with a CPU module or intelligent function module to modify data

of a running programmable controller, configure an interlock circuit in the program to ensure that the

entire system will always operate safely. For other forms of control (such as program modification,

parameter change, forced output, or operating status change) of a running programmable controller,

read the relevant manuals carefully and ensure that the operation is safe before proceeding. Improper

operation may damage machines or cause accidents.

● Especially, when a remote programmable controller is controlled by an external device, immediate

action cannot be taken if a problem occurs in the programmable controller due to a communication

failure. To prevent this, configure an interlock circuit in the program, and determine corrective actions

to be taken between the external device and CPU module in case of a communication failure.

● Do not disassemble or modify the modules. Doing so may cause failure, malfunction, injury, or a fire.

● Use any radio communication device such as a cellular phone or PHS (Personal Handy-phone

System) more than 25cm away in all directions from the programmable controller. Failure to do so

may cause malfunction.

● Shut off the external power supply (all phases) used in the system before mounting or removing the

module. Failure to do so may cause the module to fail or malfunction.

● Tighten the screws within the specified torque range. Undertightening can cause drop of the

component or wire, short circuit, or malfunction. Overtightening can damage the screw and/or module,

resulting in drop, short circuit, or malfunction.

● After the first use of the product, do not mount/remove the module to/from the base unit, and the

terminal block to/from the module, and do not insert/remove the extended SRAM cassette to/from the

CPU module more than 50 times (IEC 61131-2 compliant) respectively. Exceeding the limit may cause

malfunction.

● After the first use of the product, do not insert/remove the SD memory card to/from the CPU module

more than 500 times. Exceeding the limit may cause malfunction.

● Do not touch the metal terminals on the back side of the SD memory card. Doing so may cause

malfunction.

● Do not touch the integrated circuits on the circuit board of an extended SRAM cassette. Doing so may

cause malfunction.

● Do not drop or apply shock to the battery to be installed in the module. Doing so may damage the

battery, causing the battery fluid to leak inside the battery. If the battery is dropped or any shock is

applied to it, dispose of it without using.

● Startup and maintenance of a control panel must be performed by qualified maintenance personnel

with knowledge of protection against electric shock. Lock the control panel so that only qualified

maintenance personnel can operate it.

● Before handling the module, touch a conducting object such as a grounded metal to discharge the

static electricity from the human body. Failure to do so may cause the module to fail or malfunction.

7

Page 10

[Operating Precautions]

CAUTION

● When changing data and operating status, and modifying program of the running programmable

controller from an external device such as a personal computer connected to an intelligent function

module, read relevant manuals carefully and ensure the safety before operation. Incorrect change or

modification may cause system malfunction, damage to the machines, or accidents.

● Do not power off the programmable controller or reset the CPU module while the setting values in the

buffer memory are being written to the flash ROM in the module. Doing so will make the data in the

flash ROM undefined. The values need to be set in the buffer memory and written to the flash ROM

again. Doing so also can cause malfunction or failure of the module.

[Disposal Precautions]

CAUTION

● When disposing of this product, treat it as industrial waste.

● When disposing of batteries, separate them from other wastes according to the local regulations. For

details on battery regulations in EU member states, refer to the MELSEC iQ-R Module Configuration

Manual.

[Transportation Precautions]

CAUTION

● When transporting lithium batteries, follow the transportation regulations. For details on the regulated

models, refer to the MELSEC iQ-R Module Configuration Manual.

● The halogens (such as fluorine, chlorine, bromine, and iodine), which are contained in a fumigant

used for disinfection and pest control of wood packaging materials, may cause failure of the product.

Prevent the entry of fumigant residues into the product or consider other methods (such as heat

treatment) instead of fumigation. The disinfection and pest control measures must be applied to

unprocessed raw wood.

8

Page 11

CONDITIONS OF USE FOR THE PRODUCT

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major or serious accident;

and

ii) where the backup and fail-safe function are systematically or automatically provided outside of the PRODUCT for the

case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT LIMITED TO ANY AND ALL

RESPONSIBILITY OR LIABILITY BASED ON CONTRACT, WARRANTY, TORT, PRODUCT LIABILITY) FOR ANY

INJURY OR DEATH TO PERSONS OR LOSS OR DAMAGE TO PROPERTY CAUSED BY the PRODUCT THAT ARE

OPERATED OR USED IN APPLICATION NOT INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS, OR

WARNING CONTAINED IN MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY MANUALS, TECHNICAL

BULLETINS AND GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

• Nuclear Power Plants and any other power plants operated by Power companies, and/or any other cases in which the

public could be affected if any problem or fault occurs in the PRODUCT.

• Railway companies or Public service purposes, and/or any other cases in which establishment of a special quality

assurance system is required by the Purchaser or End User.

• Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as Elevator and Escalator,

Incineration and Fuel devices, Vehicles, Manned transportation, Equipment for Recreation and Amusement, and

Safety devices, handling of Nuclear or Hazardous Materials or Chemicals, Mining and Drilling, and/or other

applications where there is a significant risk of injury to the public or property.

Notwithstanding the above restrictions, Mitsubishi may in its sole discretion, authorize use of the PRODUCT in one or

more of the Prohibited Applications, provided that the usage of the PRODUCT is limited only for the specific

applications agreed to by Mitsubishi and provided further that no special quality assurance or fail-safe, redundant or

other safety features which exceed the general specifications of the PRODUCTs are required. For details, please

contact the Mitsubishi representative in your region.

9

Page 12

INTRODUCTION

Thank you for purchasing the Mitsubishi Electric MELSEC iQ-R series programmable controllers.

This manual describes the functions, parameter settings, and troubleshooting of the relevant products listed below.

Before using this product, please read this manual and the relevant manuals carefully and develop familiarity with the

functions and performance of the MELSEC iQ-R series programmable controller to handle the product correctly.

When applying the program examples provided in this manual to an actual system, ensure the applicability and confirm that it

will not cause system control problems.

Please make sure that the end users read this manual.

Unless otherwise specified, this manual describes the program examples in which the I/O numbers of X/Y0 to

X/YF are assigned for a D/A converter module. I/O numbers must be assigned to apply the program examples

introduced in this manual to an actual system. For I/O number assignment, refer to the following.

MELSEC iQ-R CPU Module User's Manual (Application)

Relevant products

R60DA4. R60DAV8, R60DAI8

10

Page 13

MEMO

11

Page 14

CONTENTS

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

CONDITIONS OF USE FOR THE PRODUCT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

RELEVANT MANUALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

TERMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

CHAPTER 1 FUNCTIONS 15

1.1 Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

1.2 Range Switching Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

1.3 D/A Conversion Enable/Disable Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.4 D/A Output Enable/Disable Setting Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

1.5 Analog Output HOLD/CLEAR Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

1.6 Analog Output Test when CPU Module is in STOP Status Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1.7 Scaling Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

1.8 Shift Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1.9 Alert Output Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

1.10 Rate Control Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

1.11 External Power Supply Disconnection Detection Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

1.12 Disconnection Detection Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

1.13 Interrupt Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

1.14 Wave Output Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Initial settings of the wave output function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Execution of the wave output function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Points to use the wave output function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Wave output step action function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

1.15 Inter-Module Synchronization Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

1.16 Error History Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

1.17 Event History Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

1.18 Backing up, Saving, and Restoring Offset/Gain Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

When a module-specific backup parameters is used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

When the module-specific backup parameter is not used. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

1.19 Q Compatible Mode Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

12

CHAPTER 2 PARAMETER SETTING 95

2.1 Basic Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

2.2 Application Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

2.3 Interrupt Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

2.4 Refresh Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

Refresh processing time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

CHAPTER 3 TROUBLESHOOTING 100

3.1 Checking Using LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

3.2 Checking the Status of the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

3.3 Troubleshooting by Symptom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

When the RUN LED flashes or turns off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

When the ERR LED turns on. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

When the ALM LED turns on. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

When an analog value is not output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Page 15

When an analog value is not output with the wave output function being selected. . . . . . . . . . . . . . . . . . . . . .104

When HOLD of analog output value is not available. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

When the synchronization output is not performed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105

When 'External power supply READY flag' (X7) does not turn on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

3.4 Error Code List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106

3.5 Alarm Code List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

APPENDICES 111

Appendix 1 Module Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Appendix 2 I/O Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

List of I/O signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Details of input signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Details of output signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

Appendix 3 Buffer Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .124

List of buffer memory addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .124

Details of buffer memory addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .136

Appendix 4 Dedicated Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .174

Instruction list. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Appendix 5 Operation Examples of When the Remote Head Module Is Mounted . . . . . . . . . . . . . . . . . . . . . . . .175

System configuration example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .175

Setting in the master station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .176

Setting in the intelligent device station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .179

Checking the network status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Program examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Appendix 6 Added or Changed Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

CONTENTS

INDEX 186

REVISIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .188

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .189

TRADEMARK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .190

13

Page 16

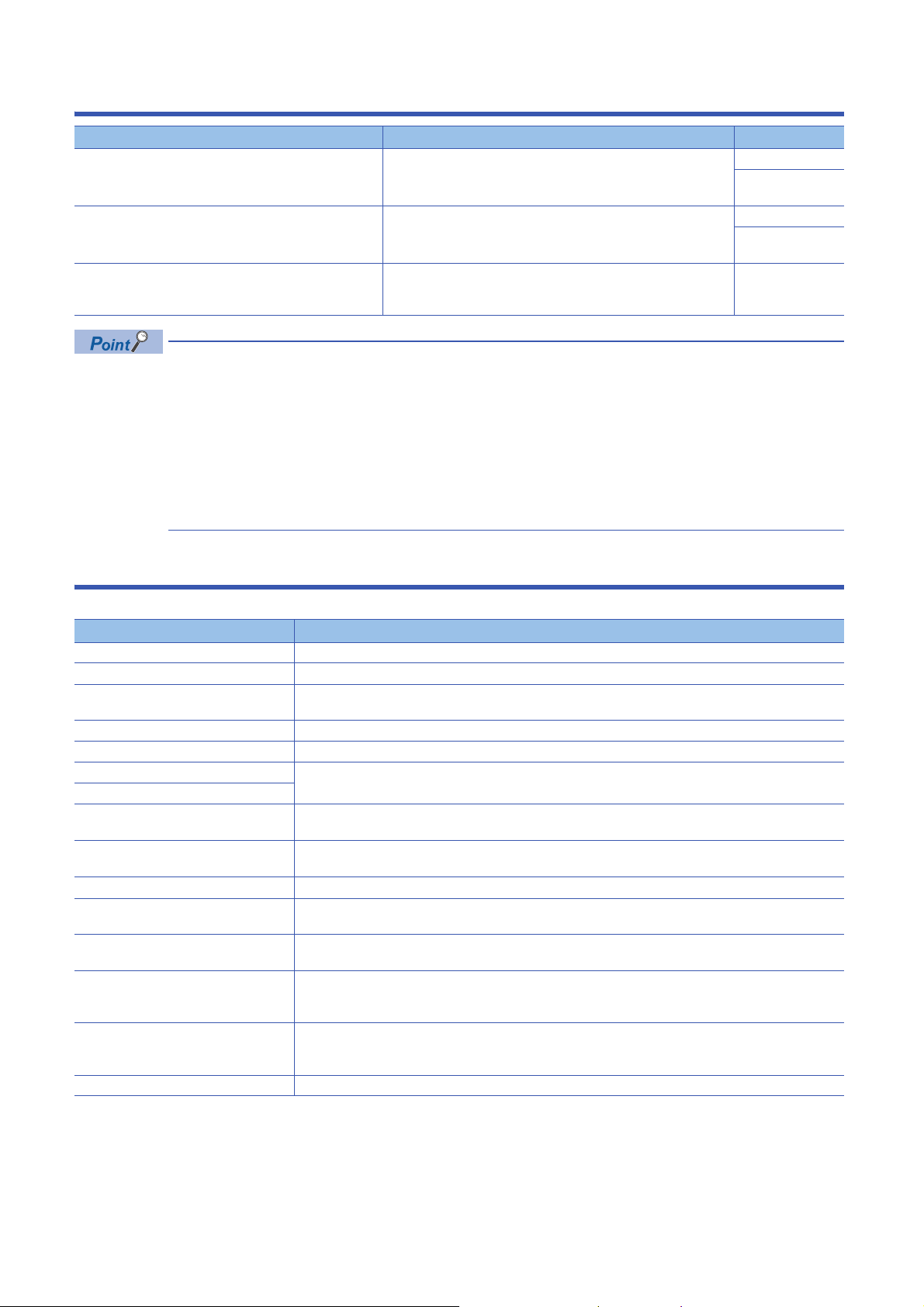

RELEVANT MANUALS

Manual name [manual number] Description Available form

MELSEC iQ-R Digital-Analog Converter Module User's

Manual (Application)

[SH-081237ENG] (this manual)

MELSEC iQ-R Digital-Analog Converter Module User's

Manual (Startup)

[SH-081235ENG]

MELSEC iQ-R Programming Manual (Module Dedicated

Instructions)

[SH-081976ENG]

e-Manuals are electronic book-type manuals for Mitsubishi Electric FA products that can be read with a

dedicated tool.

The following shows the features of e-Manuals.

• Desired information can be searched for from multiple manuals at a time. (Manual cross search)

• Other manuals can be referred to from links in a manual.

• Desired hardware specifications can be checked from each part in the illustrations of products.

• Information frequently referred to can be registered as a favorite.

• Sample programs can be copied to an engineering tool.

Functions, parameter setting, troubleshooting, I/O signals, and buffer

memory of the D/A converter module

Specifications, procedures before operation, wiring, operatio n example,

and offset/gain setting of the D/A converter module

Dedicated instructions for the intelligent function modules e-Manual

Print book

e-Manual

PDF

Print book

e-Manual

PDF

PDF

TERMS

Unless otherwise specified, this manual uses the following terms.

Term Description

D/A converter module The abbreviation for the MELSEC iQ-R series digital-analog converter module

GX Works3 The product name of the software package for the MELSEC programmable controllers

Watchdog timer error An error that occurs if the internal processing of the D/A converter module is abnormal. Watchdog timer enables

Engineering tool A generic term for GX Works3

Factory default setting A generic term for analog output ranges of 0 to 10V, 0 to 5V, 1 to 5V, -10 to 10V, 0 to 20mA, and 4 to 20mA

Normal mode Setting values of the operation mode setting: normal mode and offset/gain setting mode

Offset/gain setting mode

Synchronization normal output mode When the inter-module synchronization function target is enabled, a value is set to CH Synchronization digital

Buffer memory A memory in an intelligent function module, where data (such as setting values and monitoring values)

User range An analog output range where any value can be set. Set the user range in the offset/gain setting.

R mode A mode that the module operates w ith the buffer memory map that memory areas have been newly laid out in the

Q compatible mode A mode that the module operates with the buffer memory map converted to the equivalent map of the MELSEC-

Global label A label that is valid for all program data created in the project. The global label has two types: a module specific

Module label A label that represents a memory (I/O signals and buffer memory areas) specific to each module in a given

Remote head module The abbreviation for the RJ72GF15-T2 CC-Link IE Field Network remote head module

the module to monitor its own internal processing.

value using a synchronous interrupt program and the value is output on the set synchronization cycle.

exchanged with a CPU module are stored

MELSEC iQ-R series.

Q series.

label (module label) generated automatically by GX Works3, and an optional label for which any device can be

specified.

character string. Through the module used, GX Works3 automatically generates this label, which can be used as

a global label.

14

Page 17

1 FUNCTIONS

This chapter describes the functions of the D/A converter module and the setting procedures for those functions.

For details of the I/O signals and the buffer memory, refer to the following.

Page 114 Details of input signals

Page 121 Details of output signals

Page 136 Details of buffer memory addresses

• This chapter describes I/O signals and buffer memory addresses for CH1. For details on the I/O signals and

buffer memory addresses for CH2 or later, refer to the following.

Page 113 List of I/O signals

Page 124 List of buffer memory addresses

• in error codes and alarm codes indicates a channel where an error or alarm has occurred. A numerical

value corresponding to the error comes in . For details, refer to the following.

Page 106 Error Code List

Page 110 Alarm Code List

1

1 FUNCTIONS

15

Page 18

1.1 Modes

The D/A converter module has the normal mode and offset/gain setting mode. Change the mode according to the function

used.

The following describes each mode.

In each operation mode, the Q compatible mode function that is executed with the buffer memory layout of the

D/A converter module converted to the equivalent of the Q series can also be selected.

Normal mode

The normal mode is classified into the normal output mode and wave output mode. In this manual, the normal mode means

both of the normal output mode and waveform output mode.

■Normal output mode

This output mode is for performing the normal D/A conversion. The value set in 'CH1 Digital value' (Un\G460) is output in

analog after the D/A conversion.

■Wave output mode

This output mode is for performing the wave output. The value set in 'Wave data registry area' (Un\G10000 to Un\G89999) is

output in analog after the D/A conversion.

For details of the wave output function, refer to the following.

Page 38 Wave Output Function

Offset/gain setting mode

This mode is for performing the offset/gain setting.

For details on the offset/gain setting, refer to the following.

MELSEC iQ-R Digital-Analog Converter Module User's Manual (Startup)

16

1 FUNCTIONS

1.1 Modes

Page 19

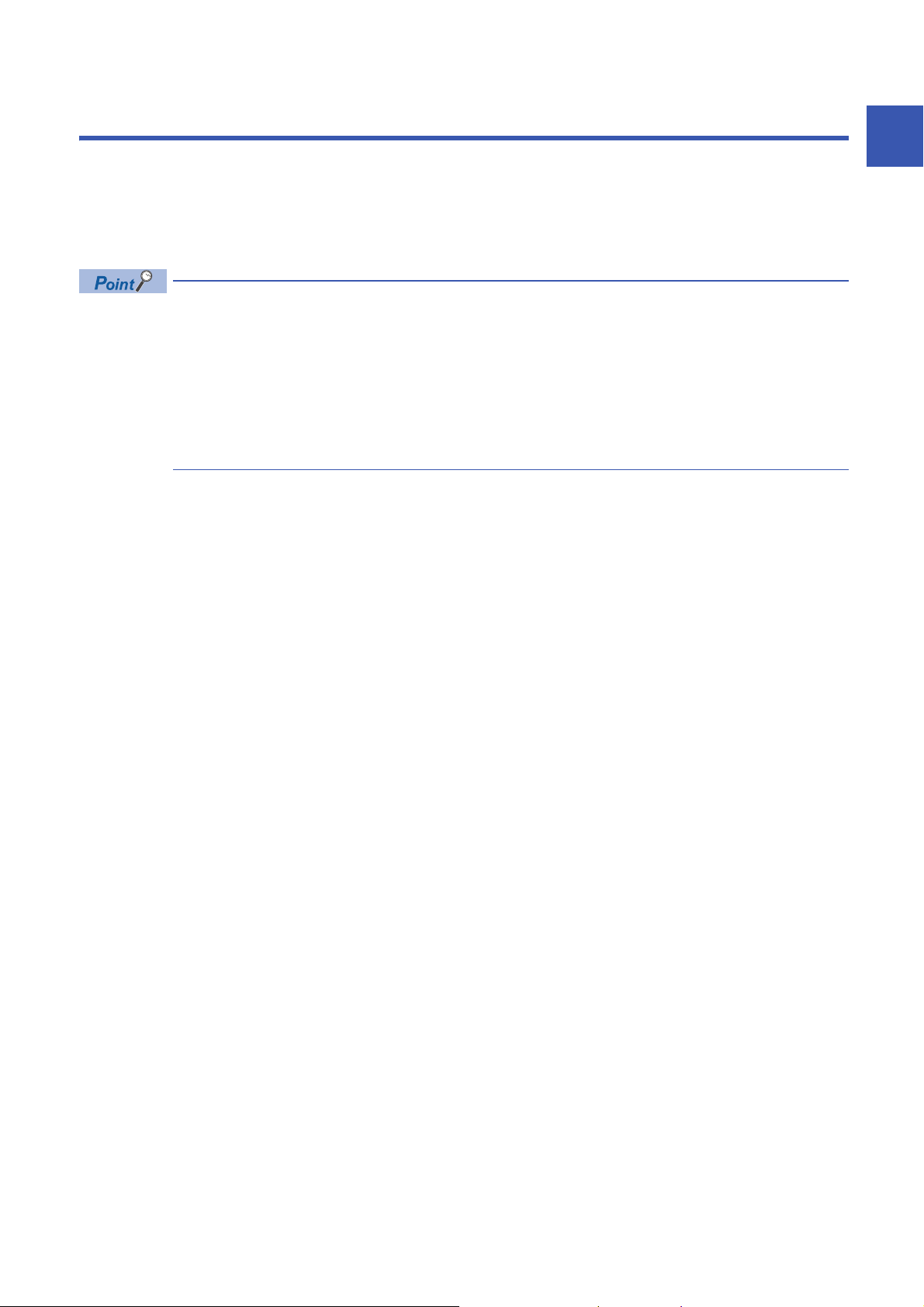

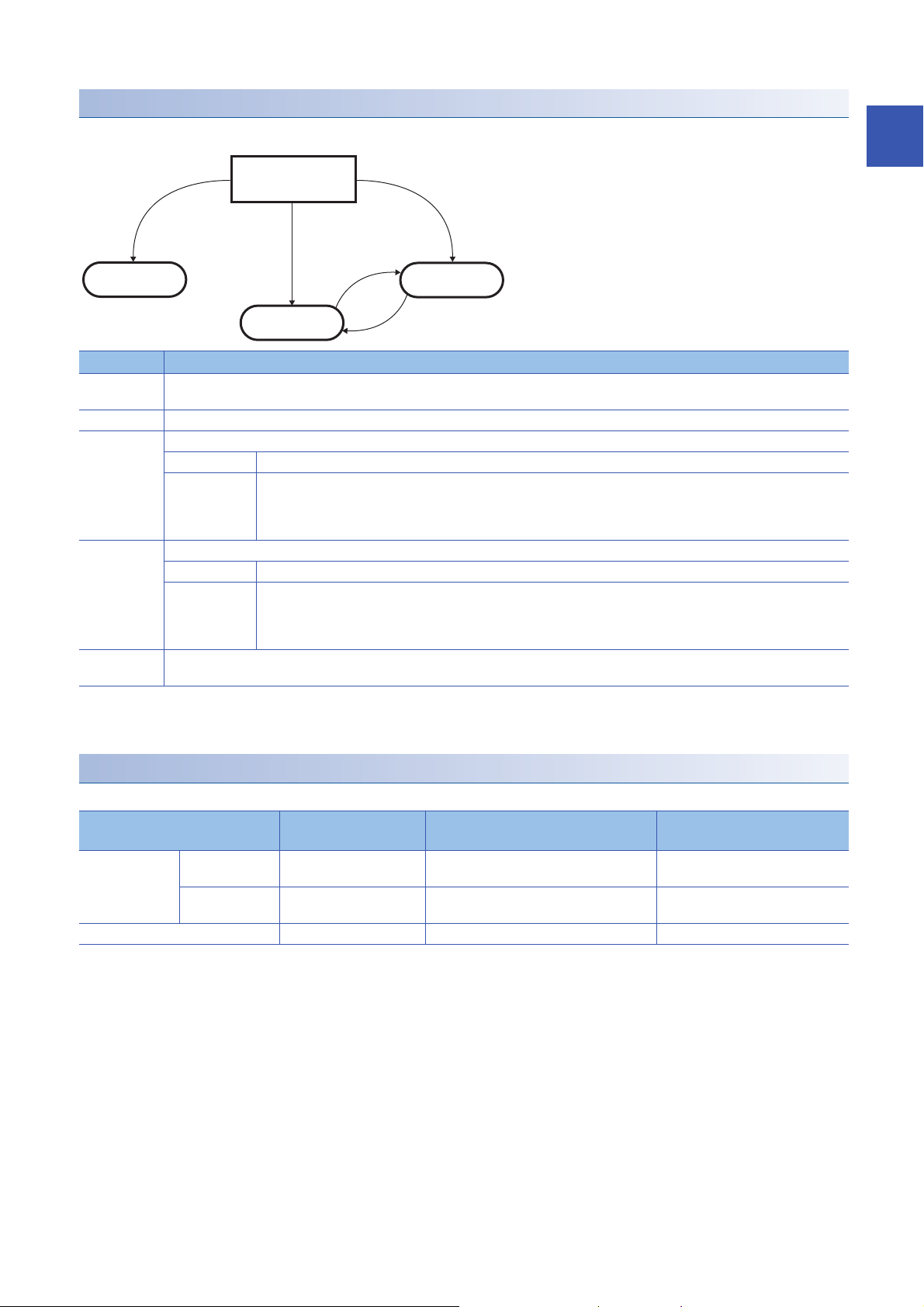

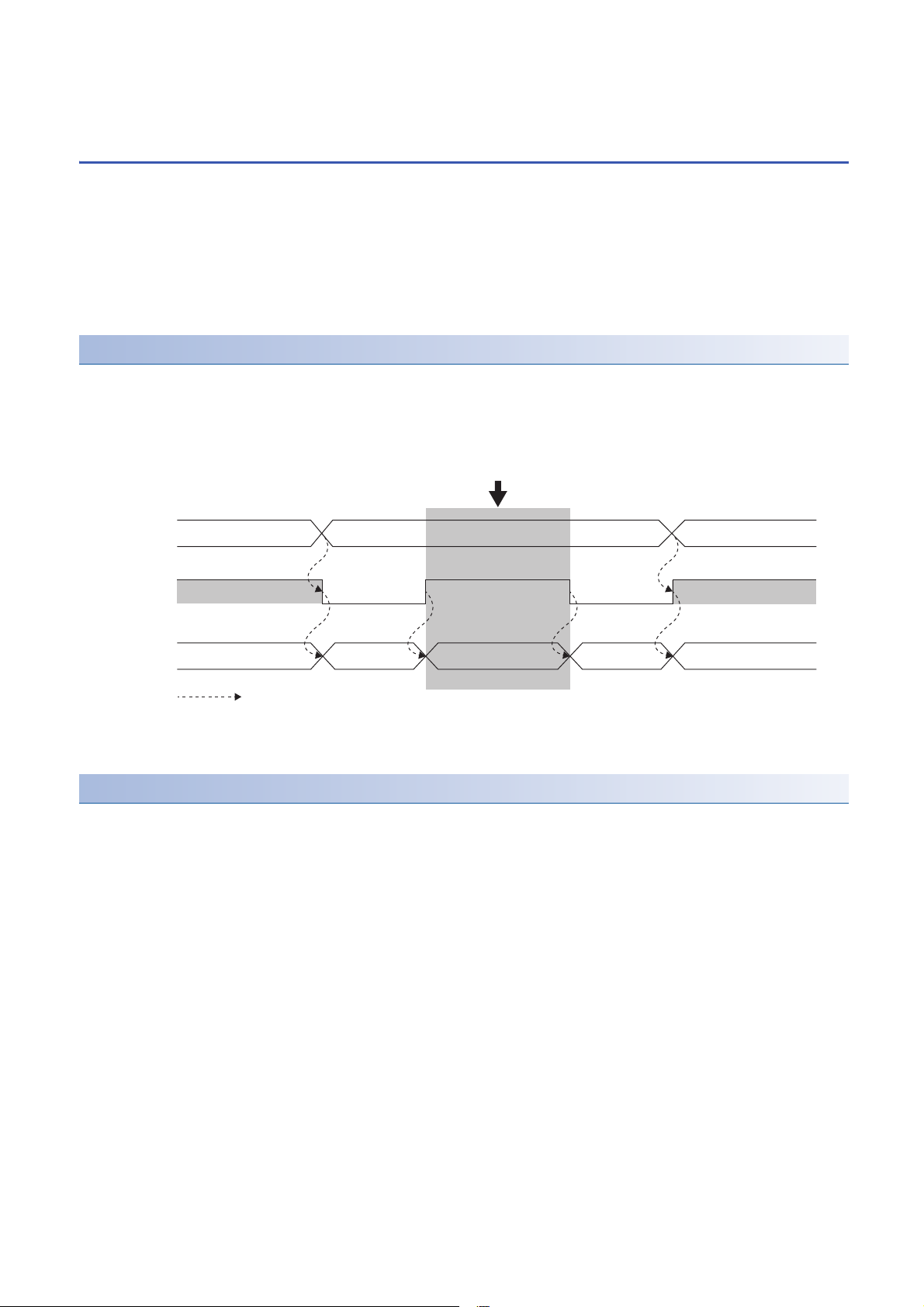

Mode transitions

At the power-on or at the

reset of the CPU module

(5)

(2)

(1)

(4)

(3)

Normal mode

Wave output mode

Offset/gain

setting mode

*1

The following figure and table describe the transition condition for each mode.

No. Transition condition

(1) Set "Operation mode setting" to "Normal mode (D/A conversion process)" in "Basic settig" of the engineering tool and set "Output mode

setting" to "Normal output mode".

(2) Set "Operation mode setting" to "Offset/gain setting mode” in "Basic settig" of the engineering tool.

(3) Perform the mode transition by either of the following methods.

Method 1 Execute the G(P).OFFGAN instruction (Argument "S": 0: Transition to the normal output mode).

Method 2 Set the following values for 'Mode switching setting' (Un\G296, Un\G297) and turn on and off 'Operating condition setting

request' (Y9).

• Un\G296: 5260H

• Un\G297: 4441H

(4) Perform the mode transition by either of the following methods.

Method 1 Execute the G(P).OFFGAN instruction (Argument "S": 1: Transition to the offset/gain setting mode).

Method 2 Set the following values for 'Mode switching setting' (Un\G296, Un\G297) and turn on and off 'Operating condition setting

request' (Y9).

• Un\G296: 4441H

• Un\G297: 5260H

(5) Set "Operation mode setting" to "Normal mode (D/A conversion process)" in "Basic settig" of the engineering tool and set "Output mode

setting" to "Wave output mode".

*1 The wave output mode is independent of the other modes. After the module is powered on in the wave output mode, the transition to the

other modes is disabled.

After the module is powered on in any mode other than the wave output mode, the transition to the wave output mode is also disabled.

1

Checking method

The currently selected mode can be checked with the following items.

Mode RUN LED status Stored value of 'Output mode'

Normal mode Normal output

Offset/gain setting mode Flashing 0 ON

*1 When 'User range write request' (YA) is off

'Offset/gain setting mode

(Un\G60)

mode

Wave output

mode

ON 0 OFF

ON 1 OFF

status flag' (XA)

*1

*1

1 FUNCTIONS

1.1 Modes

17

Page 20

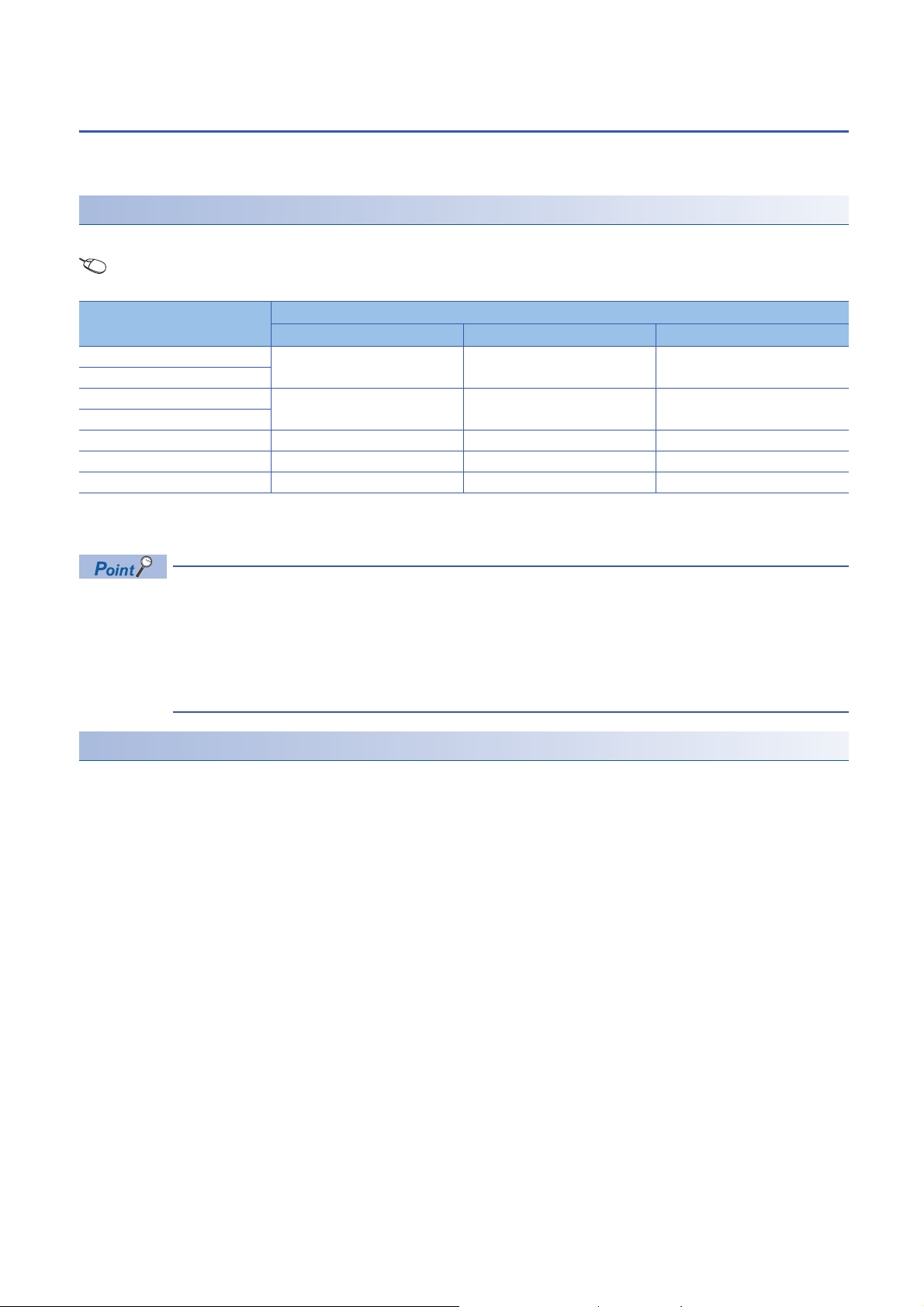

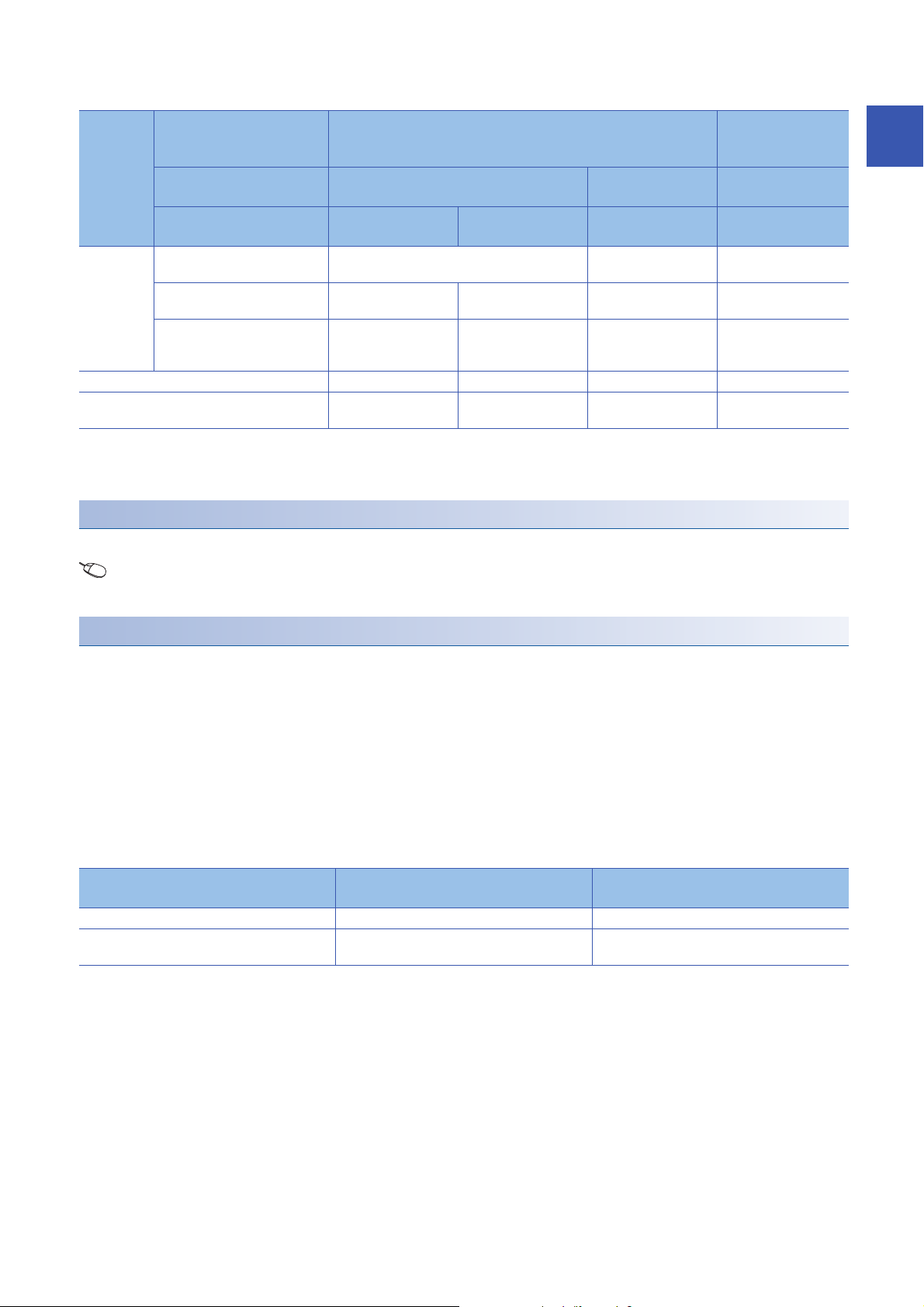

1.2 Range Switching Function

The output range of the analog output can be switched for each channel.

Switching the range makes it possible to change the I/O conversion characteristic.

Setting procedure

Set the output range to be used in "Output range setting".

Navigation window [Parameter] [Module Information] Module name [Module parameter] "Basic settig"

"Range switching function"

Output range setting Digital input range

R60DA4 R60DAV8 R60DAI8

4 to 20mA 0 to 32000 0 to 32000

0 to 20mA

1 to 5V 0 to 32000 0 to 32000

0 to 5V

-10 to 10V -32000 to 32000 -32000 to 32000

User range (Voltage) -32000 to 32000 -32000 to 32000

User range (Current) -32000 to 32000 -32000 to 32000

After the data is written, the range is switched when the programmable power supply is turned off and on or when the CPU

module is reset.

The following buffer memory areas are used to monitor the range setting and to switch the range.

• 'CH1 Range setting' (Un\G598)

• 'CH1 Range setting monitor' (Un\G430)

For details on the buffer memory areas, refer to the following.

Page 164 CH1 Range setting

Page 145 CH1 Range setting monitor

Precautions

The output range cannot be changed for channels set to D/A conversion disabled. To change the output range, set "D/A

conversion enable/disable setting" to "D/A conversion enabled" and 'CH1 Output enable/disable flag' (Y1) to OFF.

18

1 FUNCTIONS

1.2 Range Switching Function

Page 21

1.3 D/A Conversion Enable/Disable Function

Set whether to enable or disable the D/A conversion for each channel.

Disabling the D/A conversion for unused channels reduces the D/A conversion cycles.

Setting procedure

Set "D/A conversion enable/disable setting" to "D/A conversion enable” or "D/A conversion disable".

Navigation window [Parameter] [Module Information] Module name [Module parameter] "Basic settig"

"D/A conversion enable/disable function"

1.4 D/A Output Enable/Disable Setting Function

Specify whether to output the D/A conversion value or offset value for each channel.

The conversion speed is a constant, regardless of the output enable/disable state.

Setting procedure

Set to enable or disable the D/A output for each channel with 'CH1 Output enable/disable flag' (Y1).

'CH1 Output enable/disable flag' (Y1) Analog output

Enable (ON) The D/A conversion value is output.

Disable (OFF) The offset value is output.

1

1 FUNCTIONS

1.3 D/A Conversion Enable/Disable Function

19

Page 22

1.5 Analog Output HOLD/CLEAR Function

Set whether to hold or clear the analog output value that has been output when the operating status of the CPU module is

RUN, STOP, or stop error.

The HOLD/CLEAR setting can be checked with 'CH1 HOLD/CLEAR function setting monitor' (Un\G431).

Operation

When the operating status of the CPU module is RUN, STOP, or stop error, the analog output status changes as shown in the

following table, depending on the combination of the settings of the analog output HOLD/CLEAR setting, 'CH1 D/A conversion

enable/disable setting' (Un\G500), and 'CH1 Output enable/disable flag' (Y1).

■In the normal output mode

Execution

status

Analog output produced when the CPU module

is in the RUN status

Analog output produced when the CPU module

is in the STOP state

Analog output produced when the CPU module

is in the stop error state

Analog output produced when a watchdog timer

*1

error

CH1 D/A conversion

enable/disable setting

(Un\G500)

CH1 Output enable/disable

flag (Y1)

Analog output HOLD/

CLEAR setting

occurs

Enable Disable

Enable Disable Enable or disable

HOLD CLEAR HOLD or CLEAR HOLD or CLEAR

The digital value converted in analog is output. Offset value 0V/0mA

Hold Offset value Offset value

Hold Offset value Offset value 0V/0mA

0V/0mA 0V/0mA 0V/0mA 0V/0mA

*2

0V/0mA

*1 The error occurs due to a hardware failure of the D/A converter module or other causes. 'Module READY' (X0) and the RUN LED of the

D/A converter module turn off.

When a watchdog timer error occurs, 'Module READY' (X0) and the RUN LED of the D/A converter module turn off.

*2 The following operation is performed when the CPU module is in the STOP state, the D/A conversion enable/disable setting is set to D/

A conversion enable (0) for the channel where HOLD is set, and 'Operating condition setting request' (Y9) is turned on and off.

When Output enable/disable flag is off: Outputs 0V/0mA.

When Output enable/disable flag is turned on: Outputs the offset value.

■In the wave output mode

Execution

status

Analog output produced when the CPU module is

in the RUN status

Analog output produced when the CPU module is

in the STOP state

Analog output produced when the CPU module is

in the stop error state

Analog output produced when a watchdog timer

*1

error

CH1 D/A conversion

Enable Disable

enable/disable setting

(Un\G500)

CH1 Output enable/disable

Enable Disable Enable or

flag (Y1)

Analog output HOLD/

HOLD CLEAR HOLD or

CLEAR setting

Wave output status Output Stop Pause Output Stop Pause

Wave

data

Hold Offset value Offset value 0V/0mA

Hold Offset value Offset value 0V/0mA

0V/0mA 0V/0mA 0V/0mA 0V/0mA

occurs

*2

Hold Wave

data

disable

HOLD or

CLEAR

*2

Offset

value

Offset value 0V/0mA

CLEAR

*1 The error occurs due to a hardware failure of the D/A converter module or other causes. 'Module READY' (X0) and the RUN LED of the

D/A converter module turn off.

When a watchdog timer error occurs, 'Module READY' (X0) and the RUN LED of the D/A converter module turn off.

*2 The output set in 'CH1 Output setting during wave output stop' (Un\G524).

1 FUNCTIONS

20

1.5 Analog Output HOLD/CLEAR Function

Page 23

■In the synchronization normal output mode

Execution

status

External

power

supply

READY flag

(X7): On

External power supply READY flag (X7): Off 0V/0mA 0V/0mA 0V/0mA 0V/0mA

Analog output produced when a watchdog timer

*1

error

*1 The error occurs due to a hardware failure of the D/A converter module or other causes. 'Module READY' (X0) and the RUN LED of the

D/A converter module turn off.

When a watchdog timer error occurs, 'Module READY' (X0) and the RUN LED of the D/A converter module turn off.

CH1 D/A conversion

enable/disable setting

(Un\G500)

CH1 Output enable/disable

flag (Y1)

Analog output HOLD/

CLEAR setting

Analog output produced when the

CPU module is in the RUN status

Analog output produced when the

CPU module is in the STOP state

Analog output produced when the

CPU module is in the stop error

state

occurs

Enable Disable

Enable Disable Enable or disable

HOLD CLEAR HOLD or CLEAR HOLD or CLEAR

CH1 Synchronization digital value (Un\G9500) Offset value 0V/0mA

Hold Offset value Offset value

Hold Offset value Offset value 0V/0mA

0V/0mA 0V/0mA 0V/0mA 0V/0mA

*2

0V/0mA

Setting procedure

Set "Analog output HOLD/CLEAR setting" to "HOLD" or "CLEAR".

Navigation window [Parameter] [Module Information] Module name [Module parameter] "Basic settig"

"Output mode setting function"

1

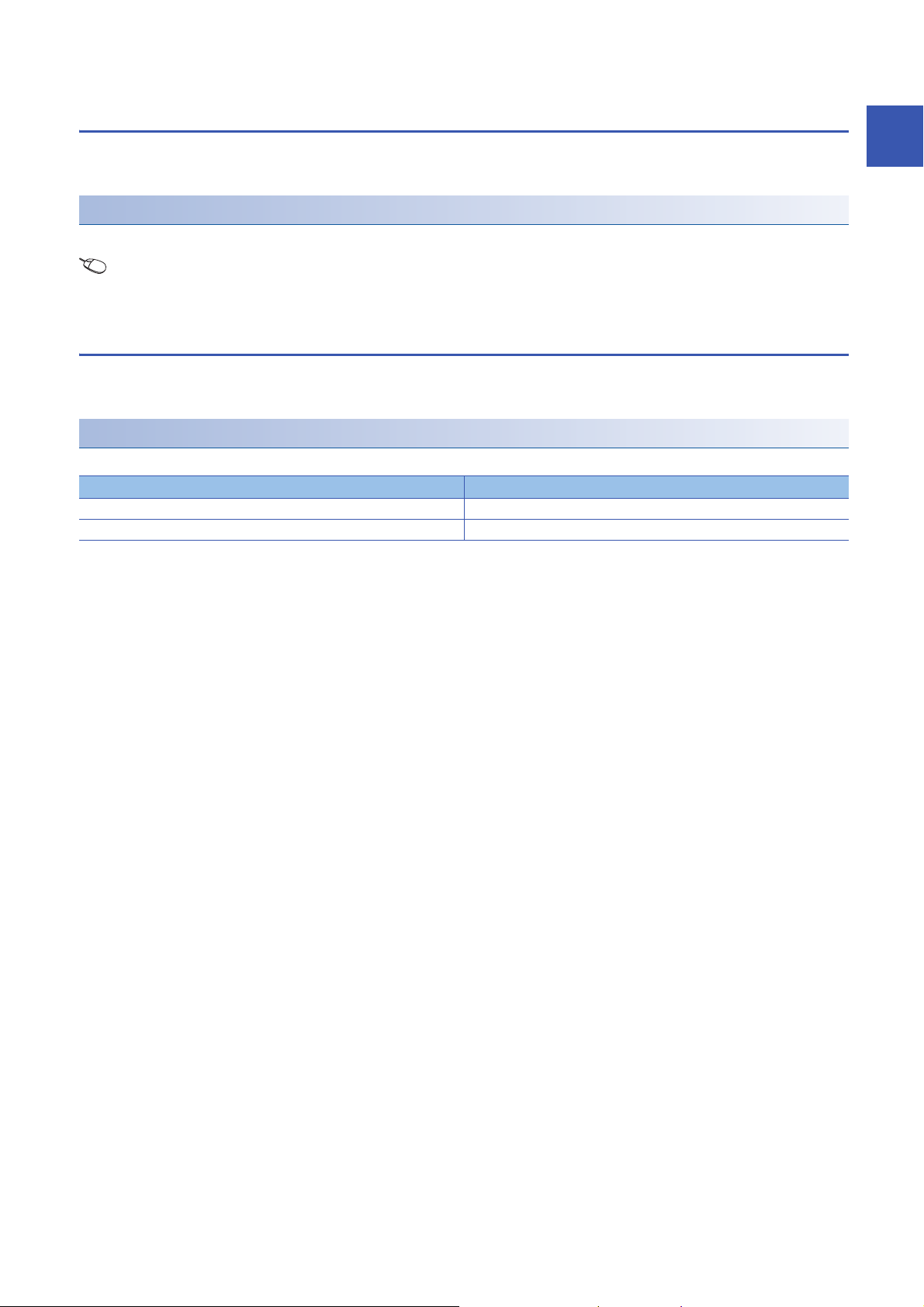

Precautions for when the remote head module has been mounted

When the D/A converter module has been mounted on the remote head module, set whether to hold or clear the analog

output value that has been output when the host station is disconnected with "CPU error output mode setting" of the module

parameter.

The following describes the settings required for using "CPU error output mode setting".

• Enable the station-based block data assurance for cyclic data on the sending side.

• To hold the analog output value, set "CPU error output mode setting" to "Hold". The analog output HOLD/CLEAR function

setting is disabled.

This setting is enabled for each module and cannot be set for each channel. To match the output status of when a stop error

occurs or the CPU module is in the STOP state and that of when the host station is disconnected, set "Analog output HOLD/

CLEAR setting" to the same value in all the channels.

Operating status CPU error output mode setting

The analog output value is held. Hold HOLD

The analog output value is cleared.

(The offset value is output.)

*1 "CPU error output mode setting" is enabled in the following cases.

When the host station is disconnected due to a network error

When the data link is stopped by the CC-Link IE Field Diagnostics of the engineering tool

Clear CLEAR

*1

Analog output HOLD/CLEAR setting

(Set the same value in all the channels.)

1 FUNCTIONS

1.5 Analog Output HOLD/CLEAR Function

21

Page 24

1.6 Analog Output Test when CPU Module is in STOP

RUN

Offset value

OFF

*1

OFF

ON

*2

ON

Offset value

RUNSTOP

D/A-converted value is output even when the CPU module is in STOP status.

Analog output value

converted from digital value

Analog output value

converted from digital value

Analog output value

converted from digital value

CH1 Output

enable/disable

flag (Y1)

Analog output

value status

CPU module

status

Controlled by the D/A converter module

Status Function

Analog output tests can be carried out when the CPU module is in the STOP status.

The following functions are enabled during the analog output test.

• Scaling function (Page 23 Scaling Function)

• Shift function (Page 26 Shift Function)

• Alert output function (Page 28 Alert Output Function)

When a digital value that is out of the setting range is written, a digital value setting range error (error code: 191H) occurs

and the corresponding check code is stored in 'CH1 Setting value check code' (Un\G400).

Operation

By forcibly turning on 'CH1 Output enable/disable flag' (Y1) when the CPU module is in the STOP state, the analog output

value is changed from the offset value to the D/A-converted analog output value.

The following figure shows the relation between 'CH1 Output enable/disable flag' (Y1) and the analog output value of the CPU

module in the STOP state when the analog output HOLD/CLEAR setting is set to CLEAR (0).

*1 'CH1 Output enable/disable flag' (Y1) turns off when the status of the CPU module is changed into STOP.

*2 By forcibly turning on 'CH1 Output enable/disable flag' (Y1), the analog output value is changed from the offset value to the D/A-

converted analog output value.

Setting procedure

To perform an analog output test, configure the settings in the device test of the engineering tool following the procedure

shown below.

1. Set 'CH1 D/A conversion enable/disable setting' (Un\G500) of the buffer memory to D/A conversion enabled (0).

2. Turn on 'Operating condition setting request' (Y9).

3. Check that 'Operating condition setting completed flag' (X9) turns off, and turn off 'Operating condition setting request'

(Y9).

4. Set the digital value equivalent to the analog value to be output for 'CH1 Digital value' (Un\G460) in the buffer memory.

5. Turn on 'CH1 Output enable/disable flag' (Y1).

22

1 FUNCTIONS

1.6 Analog Output Test when CPU Module is in STOP Status Function

Page 25

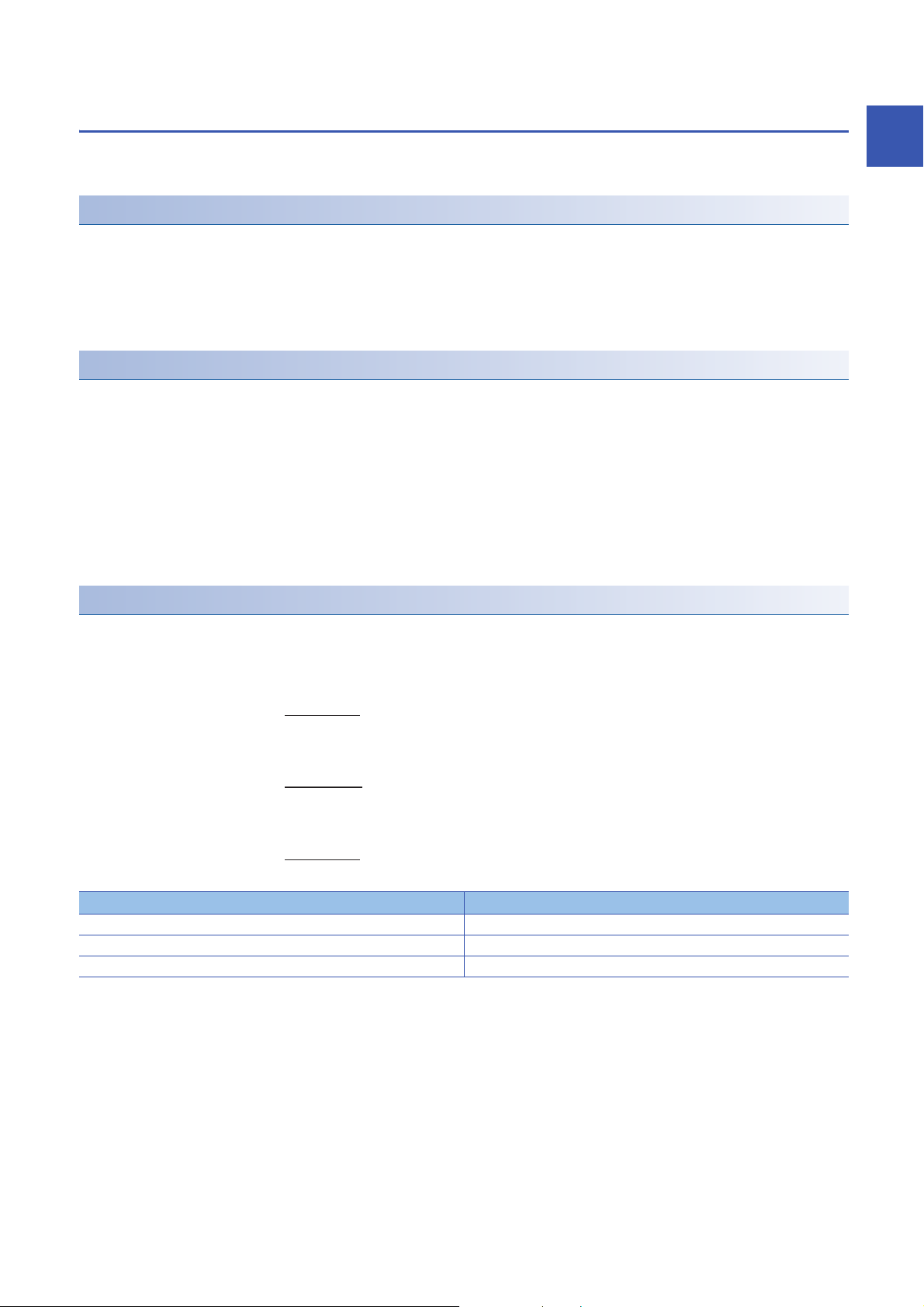

1.7 Scaling Function

× (DX - SL)

SH - S

L

32000

=

Digital value used for D/A

conversion

SH - S

L

64000

× (DX - SL) - 32000

Digital value used for D/A

conversion

=

× (DX - SL)

SH - S

L

32000

=

Digital value used for D/A

conversion

This function performs the scale conversion on digital values within a specified range between a scaling upper limit value and

a scaling lower limit value. The program for scale conversion can be omitted.

Operation

The scale conversion is performed for the set 'CH1 Digital value' (Un\G460) using 'CH1 Scaling upper limit value' (Un\G504)

and 'CH1 Scaling lower limit value' (Un\G506), and the value after the scale conversion is used for the D/A conversion. (In the

scale conversion, values after the decimal point are rounded off.)

When the relation between the set upper limit value and lower limit value is Scaling lower limit value > Scaling upper limit

value, the scale conversion can be performed according to a negative slope.

Concept of scaling setting

The necessary settings for the scaling lower limit value and scaling upper limit value depend on whether the factory default

setting or the user range setting is used for the analog output range.

■When the factory default setting is used for the analog output range

• For the scaling upper limit value, set a value corresponding to the upper limit value of the set analog output value.

• For the scaling lower limit value, set a value corresponding to the lower limit value of the set analog output value.

■When the user range setting is used for the analog output range

• Set a value corresponding to the gain value for the scaling upper limit value.

• Set a value corresponding to the offset value for the scaling lower limit value.

1

Calculating the scaling value

For D/A conversion, the scaling value is calculated based on the following equations.

■When the factory default setting is used for the output range

• When the voltage is 1 to 5V or 0 to 5V and the current is 4 to 20mA or 0 to 20mA

• When the voltage is -10 to 10V

■When the user range setting is used for the output range

Item Description

D

X

S

H

S

L

Digital value

Scaling upper limit value

Scaling lower limit value

1 FUNCTIONS

1.7 Scaling Function

23

Page 26

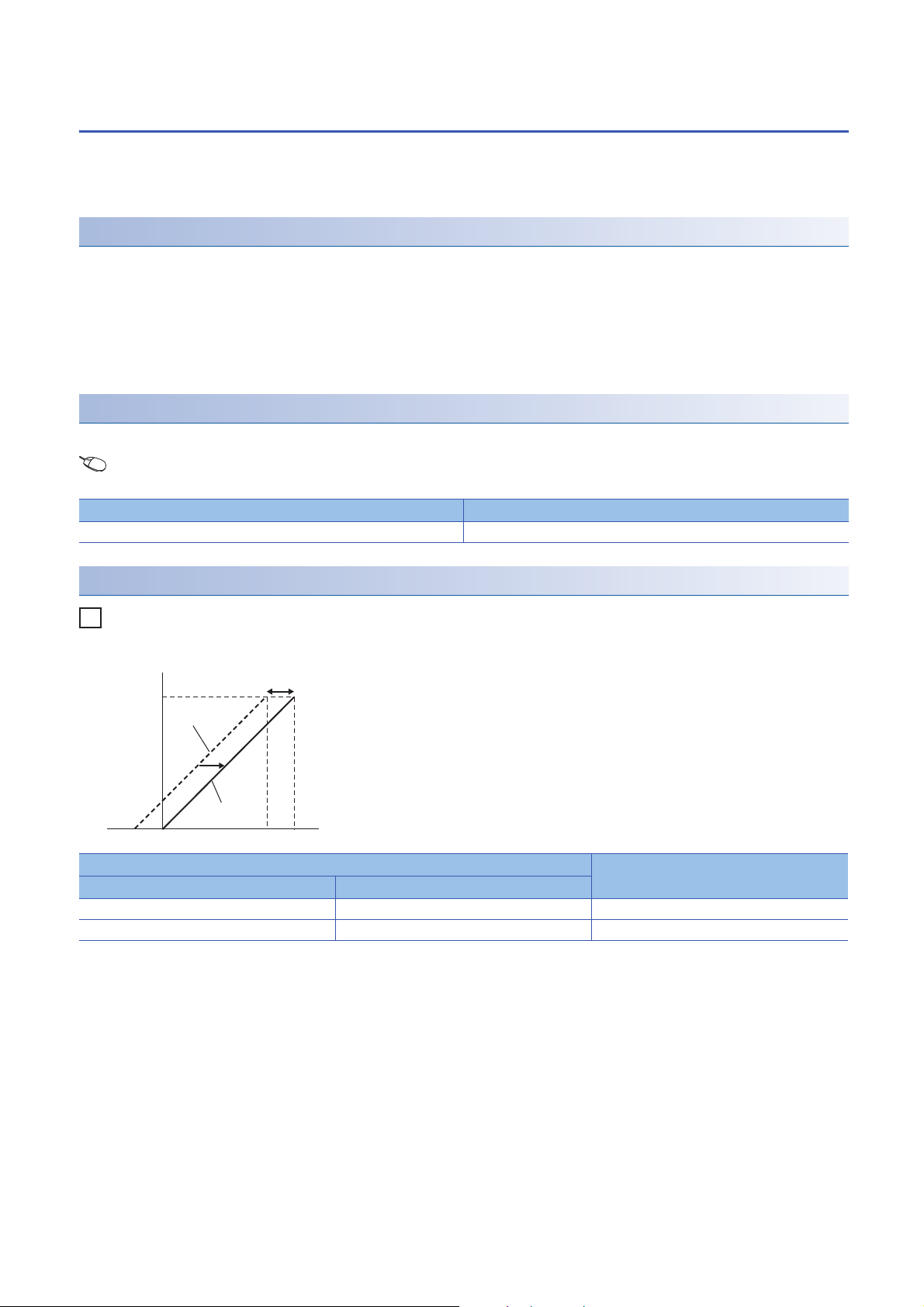

Setting procedure

Ex.

0

5

0

32000

Analog output voltage (V)

Scaling lower limit

value 4000

Scaling upper limit

value 14000

Digital value

1. Set "D/A conversion enable/disable setting" to "D/A conversion enable".

Navigation window [Parameter] [Module Information] Module name [Module parameter] "Basic settig"

"D/A conversion enable/disable function"

2. Set "Scaling enable/disable setting" to "Enable".

Navigation window [Parameter] [Module Information] Module name [Module parameter] "Application

setting" "Scaling setting"

3. Set values for "Scaling upper limit value" and "Scaling lower limit value".

Set the values to satisfy the following relation.

Scaling upper limit value Scaling lower limit value

Item Setting range

Scaling upper limit value -32000 to 32000

Scaling lower limit value

Example of scaling setting

When 14000 is set to the scaling upper limit value and 4000 is set to the scaling lower limit value for the channel with the

output range of 0 to 5V

Digital value Digital value after scaling Output voltage (V)

4000 0 0

6000 6400 1

8000 12800 2

10000 19200 3

12000 25600 4

14000 32000 5

24

1 FUNCTIONS

1.7 Scaling Function

Page 27

Precautions

• When the scaling function is used, the digital value can be set to a value out of the range between the scaling upper limit

value and scaling lower limit value (in the dotted lines in the I/O characteristics graph) before being scaled. However, use

the scaling function within the range of the analog output practical range (in the solid line in the I/O characteristics graph). If

the value exceeds the analog output practical range, the maximum resolution and accuracy may not fall within the range of

the performance specifications.

• The default digital value "0" may not be appropriate, depending on the scaling function setting.

In particular in the examples of when the output range is 0 to 5V, an out-of-range digital value error occurs if 'CH1 Output

enable/disable flag' (Y1) is turned on with the digital value "0".

A digital value setting range error (error code: 191H) occurs and 'Error flag' (XF) turns on, and the ERR LED lights.

Therefore, set an appropriate digital value within the scaling range before turning on 'CH1 Output enable/disable flag' (Y1).

• When using the user range, note that the scaling lower limit value is equal to the offset value.

• When the scaling function is enabled and the digital value after the scaling conversion is out of the digital setting range, a

digital value setting range error (error code: 191H) occurs and the corresponding check code is stored in 'CH1 Setting

value check code' (Un\G400).

• The scaling function is enabled only for the normal output. When the scaling function is enabled while the wave output

function is used, a scaling setting error in wave output mode (error code: 0B1H) occurs and 'Alert output signal' (XE) turns

on.

1

1 FUNCTIONS

1.7 Scaling Function

25

Page 28

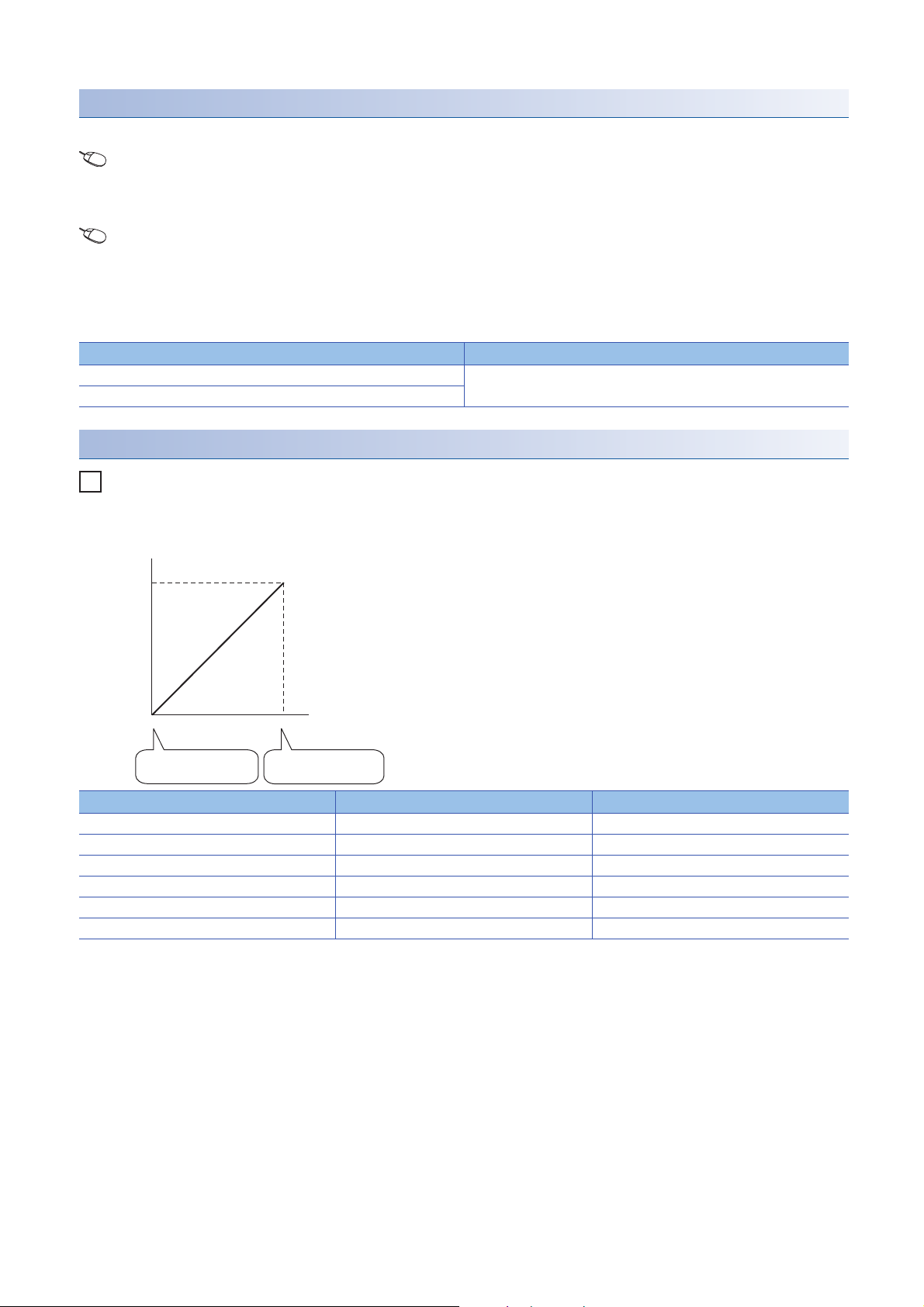

1.8 Shift Function

Ex.

0

5

0

32000

31950

-50

Analog output voltage (V)

Input value

shift

After

adjustment

Before

adjustment

digital value

This function adds the set input value shift amount to the digital input value.

The analog output value reflects the change in the input value shift amount on a realtime basis. Therefore, fine adjustment

can be easily performed when the system starts.

Operation

When the D/A conversion is performed on the digital value, the value obtained by adding 'CH1 Input value shift amount'

(Un\G480) to 'CH1 Digital value' (Un\G460) is used for the D/A conversion.

When the digital value after the addition exceeds the range of -32768 to 32767 as the result of the shift processing, the value

is fixed with the lower limit value (-32768) or the upper limit value (32767).

When a value is written to 'CH1 Input value shift amount' (Un\G480), the set value is added to the digital input value

regardless of the ON/OFF state of 'Operating condition setting request' (Y9).

Setting procedure

Set the shift amount to "Input value shift amount".

Navigation window [Parameter] [Module Information] Module name [Module parameter] "Application

setting" "Shift function"

Item Setting range

Input value shift amount -32768 to 32767

Setting example

When the output range is 0 to 5V and the input value shift amount is +50

Digital value Analog output voltage (V)

Before adjustment After adjustment

-50 0 0

31950 32000 5

1 FUNCTIONS

1.8 Shift Function

26

Page 29

Precautions

• Based on the digital value on which the shift-and-add is performed, the alert output function, scaling function, and rate

control function are executed.

• When the value obtained by adding 'CH1 Input value shift amount' (Un\G480) to 'CH1 Digital value' (Un\G460) is out of the

digital setting range, a digital value setting range error (error code: 191H) occurs and the corresponding check code is

stored in 'CH1 Setting value check code' (Un\G400).

• The shift function is enabled only for the normal output. When a value other than 0 is set in 'CH1 Input value shift amount'

(Un\G480) while the wave output function is used, an input value shift amount setting error in wave output mode (alarm

code: 0B2H) occurs and 'Alert output signal' (XE) turns on. Although the wave output continues, 'CH1 Input value shift

amount' (Un\G480) is not added to the wave data to be output.

• Even though 0 is set for 'CH1 Input value shift amount' (Un\G480) after an input value shift amount setting error in wave

output mode has occurred, 'Alert output signal' (XE) does not turn off. Turn on and off 'Alert output clear request' (YE) to

turn off 'Alert output signal' (XE). By this operation, 'Alert output signal' (X8) and the ALM LED turn off, and Latest alarm

code is cleared.

1

1 FUNCTIONS

1.8 Shift Function

27

Page 30

1.9 Alert Output Function

CH1 Alert output upper limit value

OFF ON

Alert output signal (XE)

OFF

OFF ON

CH1 Alert output lower limit value

20000

-2000

Digital value

Alert output upper flag

Alert output lower flag

Alert output clear request (YE)

OFF

Digital value

Analog output value

ON ON

ON OFF

OFF

OFF

Controlled by the D/A converter module

This function outputs an alert when the digital value is larger than the alert output upper limit value or is smaller than the alert

output lower limit value.

Operation

■Alert output notification

When 'CH1 Digital value' (Un\G460) is larger than 'CH1 Alert output upper limit value' (Un\G510) or is smaller than 'CH1 Alert

output lower limit value' (Un\G512), either of 'Alert output upper limit flag' (Un\G36) or 'Alert output lower limit flag' (Un\G37),

'Alert output signal' (XE), and the ALM LED turn on to output an alert. In addition, an alarm code (080H or 081H) is stored

in 'Latest alarm code' (Un\G2) when an alert has occurred.

When an alert has occurred, the set value of the alert output upper limit value or the alert output lower limit value is used as

the digital value for the D/A conversion.

When 'CH1 Digital value' (Un\G460) is changed to a value smaller than 'CH1 Alert output upper limit value' (Un\G510) and

larger than 'CH1 Alert output lower limit value' (Un\G512) after an alert has occurred, the analog output value returns to a

normal value. However, 'Alert output upper limit flag' (Un\G36), 'Alert output lower limit flag' (Un\G37), and 'Alert output signal'

(XE) are not cleared.

28

1 FUNCTIONS

1.9 Alert Output Function

Page 31

Clearing a warning

The alert output can be cleared in the following two methods:

After 'CH1 Digital value' (Un\G460) is set to be smaller than 'CH1 Alert output upper limit value' (Un\G510) and larger than

'CH1 Alert output lower limit value' (Un\G512)

• Turning on and off 'Alert output clear request' (YE)

• Turning on and off 'Operating condition setting request' (Y9)

The D/A converter module arranges the following status when an alert output is cleared.

• Clearing 'Alert output upper limit flag' (Un\G36) and 'Alert output lower limit flag' (Un\G37)

• Turning off 'Alert output signal' (XE)

• Turning off the ALM LED

• Clearing the alarm code stored in 'Latest alarm code' (Un\G2)

Setting procedure

1. Set "Alert output setting" to "Enable".

Navigation window [Parameter] [Module Information] Module name [Module parameter] "Application

setting" "Alert output function"

2. Set values for "Alert output upper limit value" and "Alert output lower limit value".

Set the values to satisfy the following relation.

Alert output upper limit value > Alert output lower limit value

Item Setting range

Alert output upper limit value -32768 to 32767

Alert output lower limit value

1

Precautions

• When the shift function is used in the normal mode, 'CH1 Digital value' (Un\G460) on which the shift-and-add is performed

is the alert detection target. Set the alert output upper/lower limit values in consideration of the shift-and-add.

1 FUNCTIONS

1.9 Alert Output Function

29

Page 32

1.10 Rate Control Function

The increment/decrement of the analog output value per 80s is restricted to prevent the sudden change of the analog output

value.

When the inter-module synchronization function is enabled, the rate control function cannot be used.

Operation

When the change amount of 'CH1 Digital value' (Un\G460) is larger than the value set in 'CH1 Increase digital limit value'

(Un\G514) or 'CH1 Decrease digital limit value' (Un\G516), this function changes 'CH1 Digital value' (Un\G460) by the limit

values set for each digital limit value.

The increment/decrement values per 80s are set for 'CH1 Increase digital limit value' (Un\G514) and 'CH1 Decrease digital

limit value' (Un\G516). However, the actual update cycle of the output value of the corresponding channel is (80s Number

of conversion-enabled channels).

Therefore, the analog output value increases or decreases per update cycle as follows:

First time: The D/A conversion value of the increase/decrease digital limit value

Second time or later: The D/A conversion value of (Increase/decrease digital limit value Number of conversion-enabled

channels)

Setting procedure

1. Set "Rate control enable/disable setting" to "Enable".

Navigation window [Parameter] [Module Information] Module name [Module parameter] "Application

setting" "Rate control function"

2. Set values for "Increase digital limit value" and "Decrease digital limit value".

Item Setting range

Increase digital limit value 0 to 64000

Decrease digital limit value

30

1 FUNCTIONS

1.10 Rate Control Function

Page 33

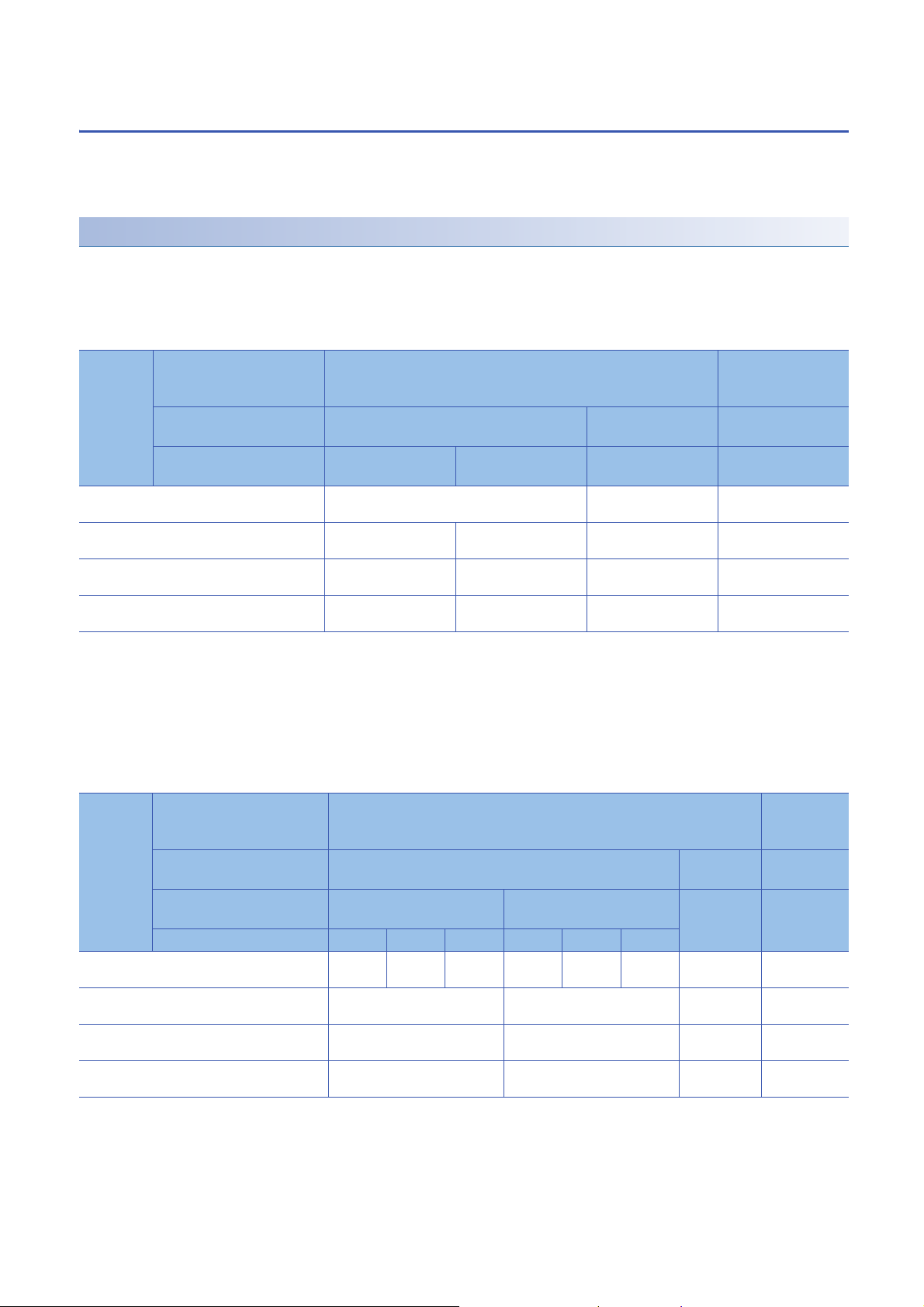

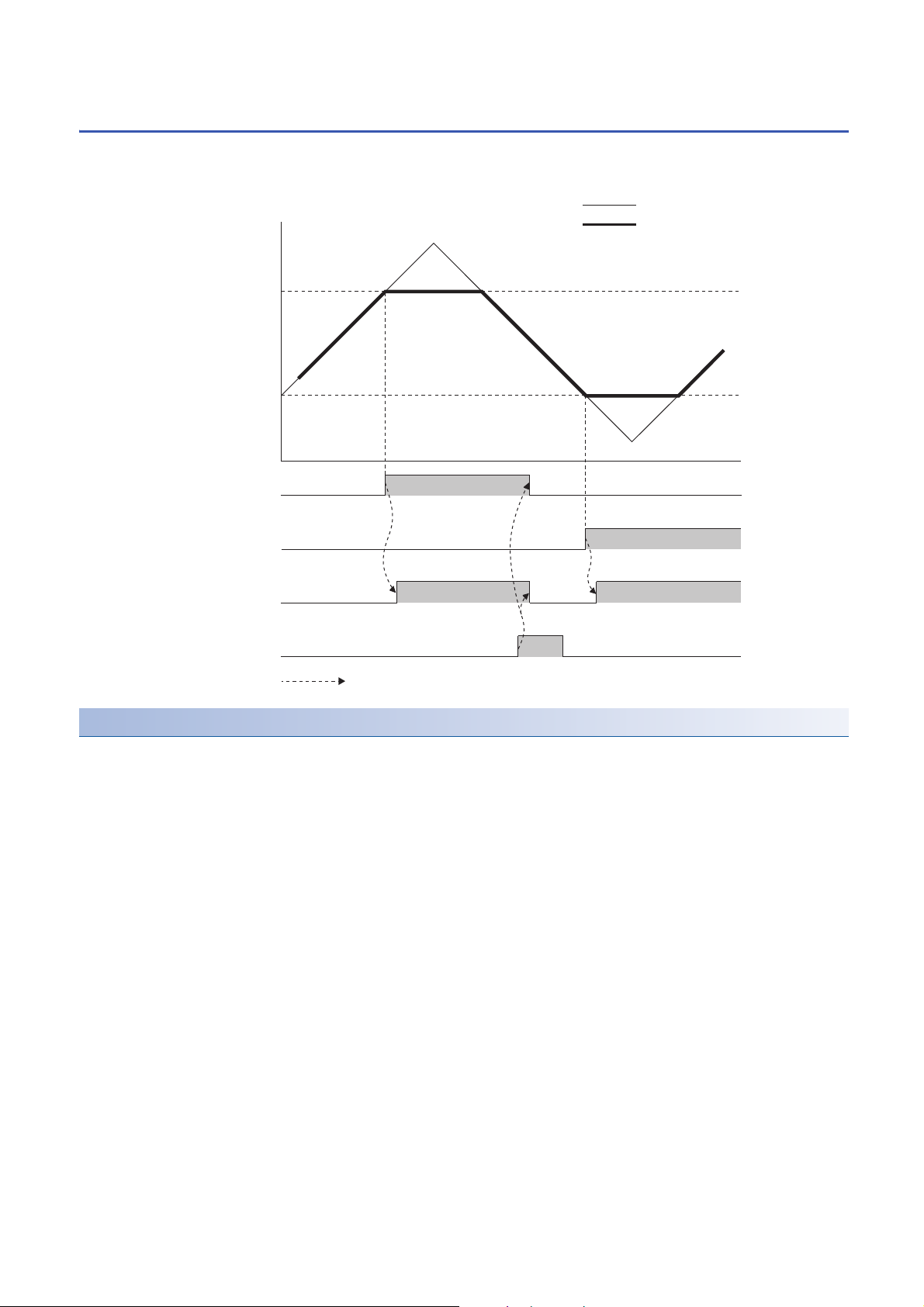

Operation example of the rate control function

<CH1>

1.25V

V

t

2.50V

1.25V

V

t

2.50V

1.25V

V

t

2.50V

4400

4200

4600 6400 80004000

5600 6800 8000

4800 5400 6000 6600 7200 7800 8000

4000 (1.25V) 8000 (2.5V)

600

4000 (1.25V) 8000 (2.5V)

4000 (1.25V) 8000 (2.5V)

400

200

123123123123123123121231231232 3

<CH2>

<CH3>

+600 +1800 +1600

+400 +1200 +1200 +1200

+600+200 +200+600 +600 +600 +600 +600

4000

4000

(Buffer memory)

analog output

Change in the digital

value of internal

CH1 Digital value

CH1 Increase digital limit value

CH2 Digital value

CH3 Digital value

CH2 Increase digital limit value

CH3 Increase digital limit value

Conversion speed = 80µs

Change in the digital

value of internal

Change in the digital

value of internal

Difference

between

the change

Difference

between

the change

Difference

between

the change

Conversion channel

Refresh cycle of output value = 240µs

The following figure shows an operation example when CH1 Rate control enable/disable setting to CH3 Rate control enable/

disable setting are set to Enable (0) and each increase digital limit value is set to 600, 400, and 200.

1

1 FUNCTIONS

1.10 Rate Control Function

31

Page 34

Precautions

RUN

STOP

RUN

Analog output value

The digital input value

converted in analog

Offset value

Rate control enabled

The digital input value

converted in analog

CPU module status

(error)

RUN

STOP

RUN

Analog output value

The digital input value

converted in analog

Offset value

Rate control enabled

The digital input value

converted in analog

CPU module status

(error)

• The setting of the shift function is enabled during the rate control.

• When the alert output function is enabled, the alert determination is performed to the set 'CH1 Digital value' (Un\G460).

Note that an alert does not occur at the timing when the digital value changed by the rate control function exceeds the

upper/lower limit value.

• The rate control does not function during the analog output test for when the CPU module is in the STOP state.

• With Analog output HOLD/CLEAR setting set to a value other than HOLD, the analog output value changes when the CPU

module is in the STOP state but the rate control function does not function.

• When the CPU module status changes while the D/A conversion and D/A output are enabled and the analog output HOLD/

CLEAR setting is set to CLEAR, the rate control function operates as follows:

When the CPU module status changes from RUN to STOP (error), the rate control does not function. When the CPU

module status changes from STOP (error) to RUN, the rate control functions.

• When the CPU module status is changed from STOP (error) to RUN while the D/A conversion is enabled, the D/A output is

enabled, analog output is set to HOLD, and the rate control is enabled, the analog output is restarted from the offset value.

• When the D/A conversion is enabled and the D/A output is disabled, the rate control does not function.

• When a value out of the setting range is written to 'CH1 Digital value' (Un\G460) during the rate control, the rate control is

performed with the upper or lower limit value of the setting range.

In addition, the check result is stored in 'CH1 Setting value check code' (Un\G400).

• When the external power supply is turned off during the rate control, the rate control does not function and the analog

output value changes to 0V/0mA. When the external power supply is recovered, the rate control is restarted from the offset

value.

• The rate control function is enabled only for the normal output. When the rate control function is enabled while the wave

output function is used, a rate control setting error in wave output mode (alarm code: 0B3H) occurs and 'Alert output

signal' (XE) turns on.

32

1 FUNCTIONS

1.10 Rate Control Function

Page 35

1.11 External Power Supply Disconnection Detection

Function

This function detects that the external power supply 24VDC is not supplied or the supply stops.

When the external power supply disconnection is detected, 'External power supply READY flag' (X7) turns off, and the analog

output value becomes 0V/0mA regardless of the other settings.

Operation

When the external power supply is not input or when 200ms has not yet elapsed after the power supply is input, the power

supply is regarded as disconnected and 'External power supply READY flag' (X7) turns off.

When the external power supply input stops, the external power supply is regarded as disconnected and 'External power

supply READY flag' (X7) turns off.

Precautions

When the external power supply does not satisfy the requirements of the performance specifications, the external power

supply is regarded as disconnected.

For the performance specifications of the external power supply, refer to the following.

MELSEC iQ-R Digital-Analog Converter Module User's Manual (Startup)

1

1 FUNCTIONS

1.11 External Power Supply Disconnection Detection Function

33

Page 36

1.12 Disconnection Detection Function

ON

ON

ON

OFF

OFF

OFF

0mA

OFF

OFF

OFF

Analog output value

Time

Disconnection detection

signal (XD)

Disconnection detection

flag (Un\G38.b0)

Error clear request (YF)

Resume output

Disconnection

detection

Controlled by the D/A converter module

Controlled by the program

Threshold of

disconnection detection

Within the detection range

Outside the detection range

Included

CH1 Analog

output value

Was removed and

the disconnection

cause

The R60DA4 and R60DAI8 can detect a disconnection by monitoring the analog output value. This function is enabled only

when the analog output range is 4 to 20mA. A disconnection can be detected for each channel.

Operation

■Disconnection detection

A disconnection can be detected when the analog output range is 4 to 20mA and 'CH1 D/A conversion enable/disable setting'

(Un\G500) is set to D/A conversion enabled (0).

■Operations performed when a disconnection is detected

When a disconnection is detected, the disconnection is notified by turning on 'Disconnection detection flag' (Un\G38),

'Disconnection detection signal' (XD), and the ERR LED.

In addition, an error code (1C4H) is stored in 'Latest error code' (Un\G0).

Even if the disconnection cause is eliminated, the analog output does not restart automatically to prevent an incorrect output.

To restart the analog output, check 'CH1 Digital value' (Un\G460) and turn on and off 'Error clear request' (YF). According to

the status of 'CH1 Output enable/disable flag' (Y1), the analog output restarts.

When the analog output restarts, 'Disconnection detection flag' (Un\G38) of the corresponding channel is cleared. When the

analog output of all the channels restarts, 'Disconnection detection signal' (XD) is cleared.

34

1 FUNCTIONS

1.12 Disconnection Detection Function

Page 37

1.13 Interrupt Function

The D/A converter module executes the interrupt program of the CPU module when an interrupt factor such as a

disconnection or alert output is detected.

For the D/A converter module, the maximum number of interrupt pointers available is 16 per module.

Operation

■Detecting an interrupt factor

When an interrupt factor occurs, an interrupt request is sent to the CPU module at the same time as 'Interrupt factor detection

flag [n]' (Un\G4 to Un\G19) is turned to Interrupt factor (1).

■How to reset an interrupt factor

When Reset request (1) is set to 'Interrupt factor reset request [n]' (Un\G156 to Un\G171) corresponding to the interrupt factor,

the specified interrupt factor is reset and 'Interrupt factor detection flag [n]' (Un\G4 to Un\G19) changes to No interrupt factor

(0).

Setting procedure

To use the interrupt function, set "Condition target setting", "Condition target channel setting", "Interrupt factor transaction

setting", and "Interrupt pointer" in the engineering tool. After completing the settings, write the project to enable the settings.

Navigation window [Parameter] [Module Information] Module name [Module parameter] "Interrupt setting"

The following table shows the setting items on the interrupt setting window.

Item Description

Condition target setting Select a factor of the target for the interrupt detection.

Condition target channel setting Select a target channel when the condition target setting for the interrupt

detection is channel specification.