Page 1

SERVICE MANUAL

HFC

utilized

R410A

R410A REFRIGERANT

No. OBR01

CONTENTS

1. INFORMATION FOR THE AIR CONDITIONER

WITH R410A REFRIGERANT ···························2

2. TOOLS DEDICATED FOR THE AIR

CONDITIONER WITH R410A REFRIGERANT ·3

3. REFRIGERANT PIPING·····································3

4. REFRIGERANT OIL ·····················BACK COVER

5. ADDITIONAL CHARGE ···············BACK COVER

NOTE:

This service manual describes treatment of the air conditioner with R410A refrigerant.

Page 2

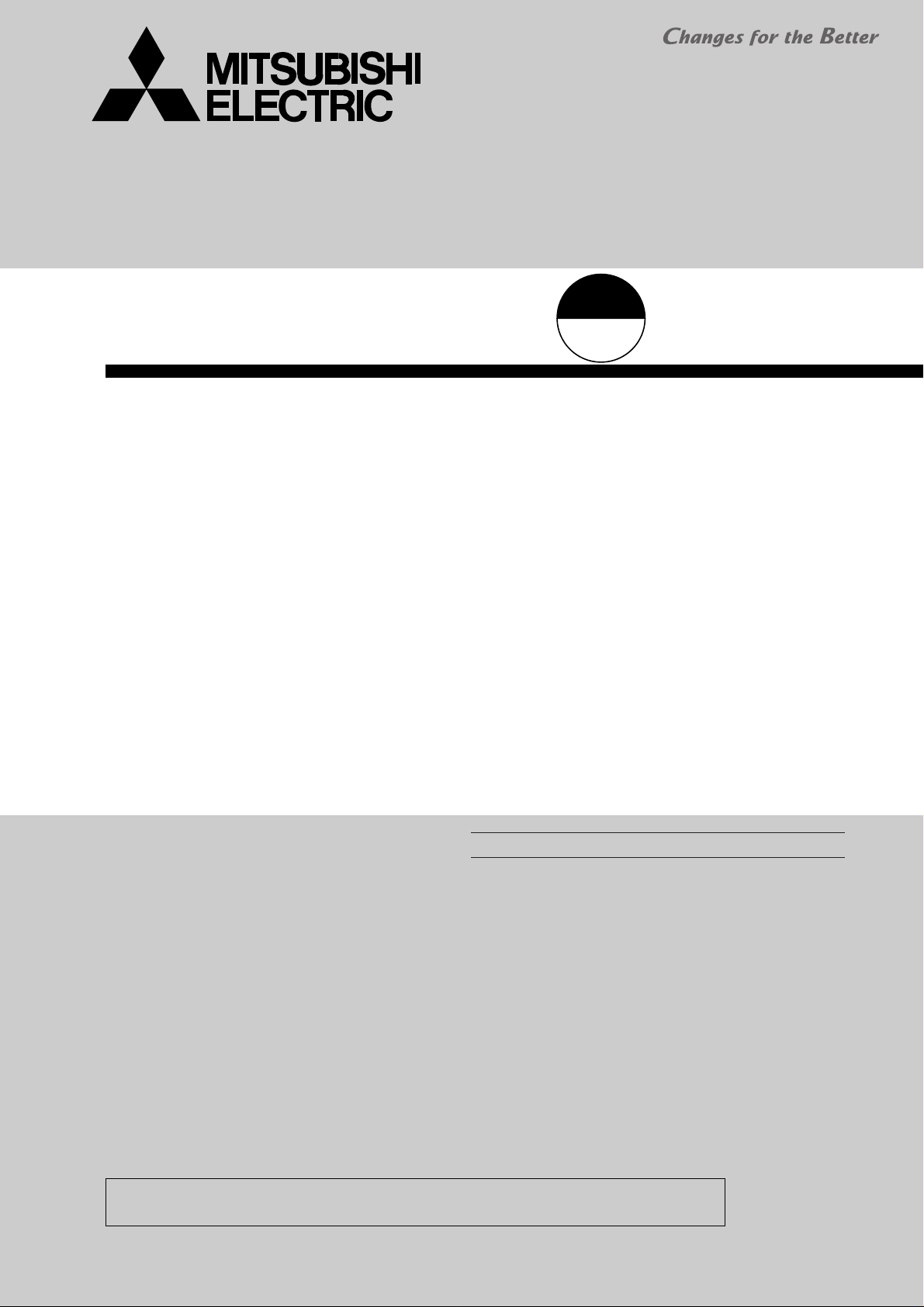

New Specification Current Specification

The incompatible refrigeration oil easily separates from

refrigerant and is in the upper layer inside the suction muffler.

Raising position of the oil back hole enables to back the

refrigeration oil of the upper layer to flow back to the

compressor.

Since refrigerant and refrigeration oil are compatible each,

refrigeration oil goes back to the compressor through the

lower position oil back hole.

Compressor

Suction muffler

Oil back hole

refrigeration oil

Refrigerant

Compressor

Suction muffler

Oil back hole

refrigeration oil /Refrigerant

Compressor

Refrigeration

oil

Refrigerant

New refrigerant

R410A

HFC-32: HFC-125 (50%:50%)

Pseudo-azeotropic refrigerant

Not included

A1/A1

72.6

-51.4

1.557

64

Non combustible

0

1730

From liquid phase in cylinder

Possible

Incompatible oil

Non

Non

Previous refrigerant

R22

R22 (100%)

Single refrigerant

Included

A1

86.5

-40.8

0.94

44.4

Non combustible

0.055

1700

Gas phase

Possible

Compatible oil

Light yellow

Non

Refrigerant

Composition (Ratio)

Refrigerant handling

Chlorine

Safety group (ASHRAE)

Molecular weight

Boiling point (:)

Steam pressure [25:](Mpa)

Saturated steam density [25:](Kg/K)

Combustibility

ODP w1

GWP w2

Refrigerant charge method

Additional charge on leakage

Kind

Color

Smell

w1:Ozone Destruction Parameter : based on CFC-11

w2 :Global Warmth Parameter : based on CO

2

1. INFORMATION FOR THE AIR CONDITIONER WITH R410A REFRIGERANT

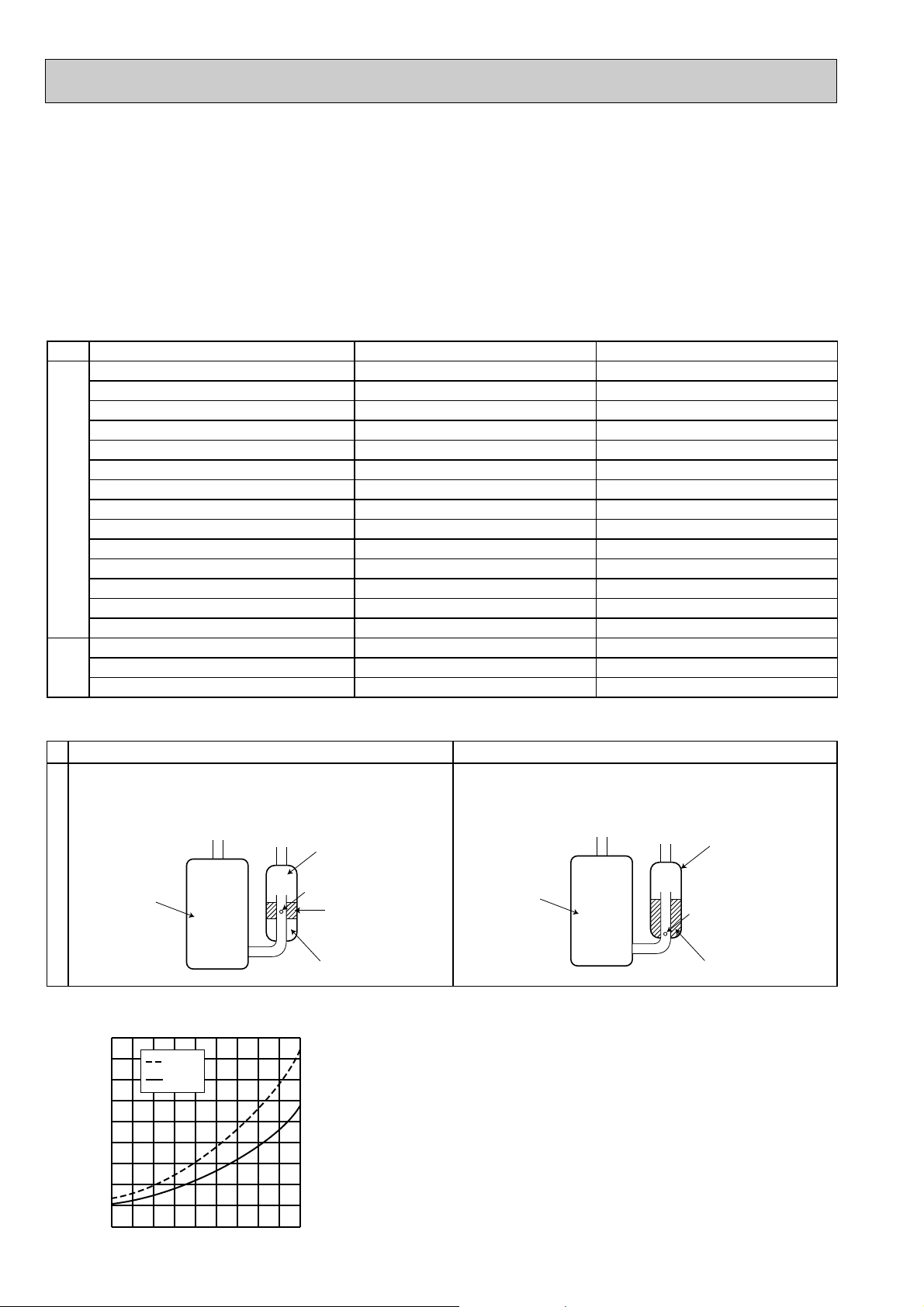

-30 -20 -10 0 10 203040 50 60

-0.5

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

(MPa [Gauge])

R410A

R22

Conversion chart of refrigerant temperature and pressure

Saturated liquid pressure

(:)

• This room air conditioner adopts HFC refrigerant (R410A) which never destroys the ozone layer.

• Pay particular attention to the following points, though the basic installation procedure is same as that for R22 air

conditioners.

1 As R410A has working pressure approximate 1.6 times as high as that of R22, some special tools and piping parts/

materials are required. Refer to the table below.

2 Take sufficient care not to allow water and other contaminations to enter the R410Arefrigerant during storage and

installation, since it is more susceptible to contaminations than R22.

3 For refrigerant piping, use clean, pressure-proof parts/materials specifically designed for R410A.

(Refer to 3. REFRIGERANT PIPING.)

4 Composition change may occur in R410A since it is a mixed refrigerant. When charging, charge liquid refrigerant to prevent

composition change.

NOTE : The unit of pressure has been changed to MPa on the

international system of units(SI unit system).

The conversion factor is: 1(MPa [Gauge]) =10.2(kgf/

2

ff

[Gauge])

Page 3

2. TOOLS DEDICATED FOR THE AIR CONDITIONER WITH R410A REFRIGERANT

Wall thickness

(mm)

(mm)

6.35

9.52

12.7

15.88

0.8

0.8

0.8

1.0

Heat resisting foam plastic

Specific gravity 0.045 Thickness 8 mm

Insulation material

Outside diameter

of pipe

R410A

6.35

9.52

12.7

15.88

17

22

26

29

R22

17

22

24

27

R410A

Outside diameter

of pipe

6.35

9.52

12.7

15.88

9.1

13.2

16.6

19.7

B (mm)

R22

9

13

16.2

19.4

Pipe dimension for flaring work

Dimension of flare nut

( )

+0

-4

C (mm)

Outside diameter

of pipe

Outside diameter

of pipe

Carry out flaring work using flaring tool as shown below.

.

Firmly hold copper pipe in a die in the dimension shown in the table above.

A (mm)

Conventional flare tool

(mm)

Clutch type

[6.35

[9.52

[12.7

[15.88

0 to 0.5

0 to 0.5

0 to 0.5

0 to 0.5

1.0 to 1.5

1.0 to 1.5

1.0 to 1.5

1.0 to 1.5

Flare tool for R410A

Clutch type

A

Die

Copper pipe

Flaring tool

Clutch type

(mm)

Flare nut

Copper pipe

C

B

2 Flaring work and flare nut

(mm)

The following tools are required for R410A refrigerant. Some R22 tools can be substituted for R410A tools.

The diameter of the service port on the stop valve in outdoor unit has been changed to prevent any other refrigerant being

charged into the unit. Cap size has been changed from 7/16 UNF with 20 threads to 1/2 UNF with 20 threads.

R410A tools Can R22 tools be used?

Description

R410A has high pressures beyond the measurement range of existing

Gauge manifold

No

gauges. Port diameters have been changed to prevent any other refrigerant

from being charged into the unit.

Charge hose

Gas leak detector

Torque wrench

No

No

Yes

Hose material and cap size have been changed to improve the pressure

resistance.

Dedicated for HFC refrigerant.

6.35 mm and 9.52 mm

No 12.7 mm and 15.88 mm

Flare tool

Flare gauge

Vacuum pump

adapter

Electronic scale for

refrigerant charging

Yes

New

New

New

Clamp bar hole has been enlarged to reinforce the spring strength in the tool.

Provided for flaring work (to be used with R22 flare tool).

Provided to prevent the back flow of oil. This adapter enables you to use

vacuum pumps.

It is difficult to measure R410A with a charging cylinder because the

refrigerant bubbles due to high pressure and high-speed vaporization

No : Not Substitutable for R410A Yes : Substitutable for R410A

3. REFRIGERANT PIPING

1 Specifications

Use the copper or copper-alloy seamless pipe for refrigerant that meet the following specifications.

3

Page 4

4. REFRIGERANT OIL

Apply the special refrigeration oil (accessories: packed with indoor unit) to the flare and the union seat surfaces.

CAUTION

• Do not discharge the refrigerant into the atmosphere.

Take care not to discharge refrigerant into the atmosphere during installation, reinstallation, or repairs to the refrigerant

circuit.

• Use the vacuum pump for air purging for the purpose of environmental protection.

5. ADDITIONAL CHARGE

For additional charging, charge the refrigerant from liquid phase of the gas cylinder.

If the refrigerant is charged from the gas phase, composition change may occur in the refrigerant inside the cylinder and the

outdoor unit. In this case, ability of the refrigeration cycle decreases or normal operation can be impossible. However,

charging the liquid refrigerant all at once may cause the compressor to be locked. Thus, charge the refrigerant slowly.

Union

Stop valve

Indoor unit

Refrigerant gas

cylinder

operating valve

Charge hose (for R410A)

Refrigerant gas cylinder

for R410A with siphon

Liquid pipe

Gas pipe

Service port

Gauge manifold

valve (for R410A)

Outdoor unit

Refrigerant (liquid)

Electronic scale for refrigerant charging

HEAD OFFICE: TOKYO BLDG., 2-7-3, MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN

CC

Copyright 2006 MITSUBISHI ELECTRIC ENGINEERING CO.,LTD

Distributed in Mar. 2006. No. OBR01 6

Made in Japan

New publication, effective Mar. 2006

Specifications subject to change without notice.

Loading...

Loading...