Page 1

MELSEC iQ-R Motion Controller

User's Manual

-R16MTCPU

-R32MTCPU

-R64MTCPU

Page 2

Page 3

SAFETY PRECAUTIONS

WARNING

Indicates that incorrect handling may cause hazardous conditions, resulting in

death or severe injury.

CAUTION

Indicates that incorrect handling may cause hazardous conditions, resulting in

minor or moderate injury or property damage.

(Read these precautions before using this product.)

Before using this product, please read this manual and the relevant manuals carefully and pay full attention to safety to handle

the product correctly.

The precautions given in this manual are concerned with this product only. Refer to MELSEC iQ-R Module Configuration

Manual for a description of the PLC system safety precautions.

In this manual, the safety precautions are classified into two levels: " WARNING" and " CAUTION".

Under some circumstances, failure to observe the precautions given under " CAUTION" may lead to serious

consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this manual and then keep the manual in a safe place for future reference.

[Design Precautions]

WARNING

● Configure safety circuits external to the programmable controller to ensure that the entire system

operates safely even when a fault occurs in the external power supply or the programmable controller.

Failure to do so may result in an accident due to an incorrect output or malfunction.

(1) Emergency stop circuits, protection circuits, and protective interlock circuits for conflicting

operations (such as forward/reverse rotations or upper/lower limit positioning) must be configured

external to the programmable controller.

(2) When the programmable controller detects an abnormal condition, it stops the operation and all

outputs are:

• Turned off if the overcurrent or overvoltage protection of the power supply module is activated.

• Held or turned off according to the parameter setting if the self-diagnostic function of the CPU

module detects an error such as a watchdog timer error.

(3) All outputs may be turned on if an error occurs in a part, such as an I/O control part, where the

CPU module cannot detect any error. To ensure safety operation in such a case, provide a safety

mechanism or a fail-safe circuit external to the programmable controller. For a fail-safe circuit

example, refer to "General Safety Requirements" in the MELSEC iQ-R Module Configuration

Manual.

(4) Outputs may remain on or off due to a failure of a component such as a relay and transistor in an

output circuit. Configure an external circuit for monitoring output signals that could cause a

serious accident.

● In an output circuit, when a load current exceeding the rated current or an overcurrent caused by a

load short-circuit flows for a long time, it may cause smoke and fire. To prevent this, configure an

external safety circuit, such as a fuse.

● Configure a circuit so that the programmable controller is turned on first and then the external power

supply. If the external power supply is turned on first, an accident may occur due to an incorrect output

or malfunction.

1

Page 4

[Design Precautions]

WARNING

● For the operating status of each station after a communication failure, refer to manuals relevant to the

network. Incorrect output or malfunction due to a communication failure may result in an accident.

● When connecting an external device with a CPU module or intelligent function module to modify data

of a running programmable controller, configure an interlock circuit in the program to ensure that the

entire system will always operate safely. For other forms of control (such as program modification,

parameter change, forced output, or operating status change) of a running programmable controller,

read the relevant manuals carefully and ensure that the operation is safe before proceeding. Improper

operation may damage machines or cause accidents.

● Especially, when a remote programmable controller is controlled by an external device, immediate

action cannot be taken if a problem occurs in the programmable controller due to a communication

failure. To prevent this, configure an interlock circuit in the program, and determine corrective actions

to be taken between the external device and CPU module in case of a communication failure.

● Do not write any data to the "system area" and "write-protect area" of the buffer memory in the

module. Also, do not use any "use prohibited" signals as an output signal from the CPU module to

each module. Doing so may cause malfunction of the programmable controller system. For the

"system area", "write-protect area", and the "use prohibited" signals, refer to the user's manual for the

module used.

● If a communication cable is disconnected, the network may be unstable, resulting in a communication

failure of multiple stations. Configure an interlock circuit in the program to ensure that the entire

system will always operate safely even if communications fail. Failure to do so may result in an

accident due to an incorrect output or malfunction.

● To maintain the safety of the programmable controller system against unauthorized access from

external devices via the network, take appropriate measures. To maintain the safety against

unauthorized access via the Internet, take measures such as installing a firewall.

● Configure safety circuits external to the programmable controller to ensure that the entire system

operates safely even when a fault occurs in the external power supply or the programmable controller.

Failure to do so may result in an accident due to an incorrect output or malfunction.

● If safety standards (ex., robot safety rules, etc.,) apply to the system using the module, servo amplifier

and servo motor, make sure that the safety standards are satisfied.

● Construct a safety circuit externally of the module or servo amplifier if the abnormal operation of the

module or servo amplifier differs from the safety directive operation in the system.

● Do not remove the SSCNET cable while turning on the control circuit power supply of modules and

servo amplifier. Do not see directly the light generated from SSCNET connector of the module or

servo amplifier and the end of SSCNET cable. When the light gets into eyes, you may feel

something wrong with eyes. (The light source of SSCNET complies with class1 defined in JISC6802

or IEC60825-1.)

2

Page 5

[Design Precautions]

CAUTION

● Do not install the control lines or communication cables together with the main circuit lines or power

cables. Keep a distance of 100mm or more between them. Failure to do so may result in malfunction

due to noise.

● During control of an inductive load such as a lamp, heater, or solenoid valve, a large current

(approximately ten times greater than normal) may flow when the output is turned from off to on.

Therefore, use a module that has a sufficient current rating.

● After the CPU module is powered on or is reset, the time taken to enter the RUN status varies

depending on the system configuration, parameter settings, and/or program size. Design circuits so

that the entire system will always operate safely, regardless of the time.

● Do not power off the programmable controller or reset the CPU module while the settings are being

written. Doing so will make the data in the flash ROM and SD memory card undefined. The values

need to be set in the buffer memory and written to the flash ROM and SD memory card again. Doing

so also may cause malfunction or failure of the module.

● When changing the operating status of the CPU module from external devices (such as the remote

RUN/STOP functions), select "Do Not OPEN in Program" for "Open Method Setting" of "Module

Parameter". If "OPEN in Program" is selected, an execution of the remote STOP function causes the

communication line to close. Consequently, the CPU module cannot reopen the line, and external

devices cannot execute the remote RUN function.

[Installation Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before mounting or removing the

module. Failure to do so may result in electric shock or cause the module to fail or malfunction.

3

Page 6

[Installation Precautions]

CAUTION

● Use the programmable controller in an environment that meets the general specifications in the Safety

Guidelines included with the base unit. Failure to do so may result in electric shock, fire, malfunction,

or damage to or deterioration of the product.

● To mount a module, place the concave part(s) located at the bottom onto the guide(s) of the base unit,

and push in the module until the hook(s) located at the top snaps into place. Incorrect mounting may

cause malfunction, failure, or drop of the module.

● To mount a module with no module fixing hook, place the concave part(s) located at the bottom onto

the guide(s) of the base unit, push in the module, and fix it with screw(s). Incorrect mounting may

cause malfunction, failure, or drop of the module.

● When using the programmable controller in an environment of frequent vibrations, fix the module with

a screw.

● Tighten the screws within the specified torque range. Undertightening can cause drop of the screw,

short circuit, or malfunction. Overtightening can damage the screw and/or module, resulting in drop,

short circuit, or malfunction.

● When using an extension cable, connect it to the extension cable connector of the base unit securely.

Check the connection for looseness. Poor contact may cause malfunction.

● When using an SD memory card, fully insert it into the SD memory card slot. Check that it is inserted

completely. Poor contact may cause malfunction.

● Securely insert an extended SRAM cassette into the cassette connector of the CPU module. After

insertion, close the cassette cover and check that the cassette is inserted completely. Poor contact

may cause malfunction.

● Do not directly touch any conductive parts and electronic components of the module, SD memory

card, extended SRAM cassette, or connector. Doing so may cause malfunction or failure of the

module.

[Wiring Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before installation and wiring.

Failure to do so may result in electric shock or cause the module to fail or malfunction.

● After installation and wiring, attach the included terminal cover to the module before turning it on for

operation. Failure to do so may result in electric shock.

4

Page 7

[Wiring Precautions]

CAUTION

● Individually ground the FG and LG terminals of the programmable controller with a ground resistance

of 100 ohms or less. Failure to do so may result in electric shock or malfunction.

● Use applicable solderless terminals and tighten them within the specified torque range. If any spade

solderless terminal is used, it may be disconnected when the terminal screw comes loose, resulting in

failure.

● Check the rated voltage and signal layout before wiring to the module, and connect the cables

correctly. Connecting a power supply with a different voltage rating or incorrect wiring may cause fire

or failure.

● Connectors for external devices must be crimped or pressed with the tool specified by the

manufacturer, or must be correctly soldered. Incomplete connections may cause short circuit, fire, or

malfunction.

● Securely connect the connector to the module. Poor contact may cause malfunction.

● Do not install the control lines or communication cables together with the main circuit lines or power

cables. Keep a distance of 100mm or more between them. Failure to do so may result in malfunction

due to noise.

● Place the cables in a duct or clamp them. If not, dangling cable may swing or inadvertently be pulled,

resulting in damage to the module or cables or malfunction due to poor contact. Do not clamp the

extension cables with the jacket stripped. Doing so may change the characteristics of the cables,

resulting in malfunction.

● Check the interface type and correctly connect the cable. Incorrect wiring (connecting the cable to an

incorrect interface) may cause failure of the module and external device.

● Tighten the terminal screws or connector screws within the specified torque range. Undertightening

can cause drop of the screw, short circuit, fire, or malfunction. Overtightening can damage the screw

and/or module, resulting in drop, short circuit, fire, or malfunction.

● When disconnecting the cable from the module, do not pull the cable by the cable part. For the cable

with connector, hold the connector part of the cable. For the cable connected to the terminal block,

loosen the terminal screw. Pulling the cable connected to the module may result in malfunction or

damage to the module or cable.

● Prevent foreign matter such as dust or wire chips from entering the module. Such foreign matter can

cause a fire, failure, or malfunction.

● A protective film is attached to the top of the module to prevent foreign matter, such as wire chips,

from entering the module during wiring. Do not remove the film during wiring. Remove it for heat

dissipation before system operation.

● Programmable controllers must be installed in control panels. Connect the main power supply to the

power supply module in the control panel through a relay terminal block. Wiring and replacement of a

power supply module must be performed by qualified maintenance personnel with knowledge of

protection against electric shock. For wiring, refer to the MELSEC iQ-R Module Configuration Manual.

● For Ethernet cables to be used in the system, select the ones that meet the specifications in the user's

manual for the module used. If not, normal data transmission is not guaranteed.

5

Page 8

[Startup and Maintenance Precautions]

WARNING

● Do not touch any terminal while power is on. Doing so will cause electric shock or malfunction.

● Correctly connect the battery connector. Do not charge, disassemble, heat, short-circuit, solder, or

throw the battery into the fire. Also, do not expose it to liquid or strong shock. Doing so may cause the

battery to generate heat, explode, ignite, or leak, resulting in injury or fire.

● Shut off the external power supply (all phases) used in the system before cleaning the module or

retightening the terminal screws, connector screws, or module fixing screws. Failure to do so may

result in electric shock.

[Startup and Maintenance Precautions]

CAUTION

● When connecting an external device with a CPU module or intelligent function module to modify data

of a running programmable controller, configure an interlock circuit in the program to ensure that the

entire system will always operate safely. For other forms of control (such as program modification,

parameter change, forced output, or operating status change) of a running programmable controller,

read the relevant manuals carefully and ensure that the operation is safe before proceeding. Improper

operation may damage machines or cause accidents.

● Especially, when a remote programmable controller is controlled by an external device, immediate

action cannot be taken if a problem occurs in the programmable controller due to a communication

failure. To prevent this, configure an interlock circuit in the program, and determine corrective actions

to be taken between the external device and CPU module in case of a communication failure.

● Do not disassemble or modify the modules. Doing so may cause failure, malfunction, injury, or a fire.

● Use any radio communication device such as a cellular phone or PHS (Personal Handy-phone

System) more than 25cm away in all directions from the programmable controller. Failure to do so

may cause malfunction.

● Shut off the external power supply (all phases) used in the system before mounting or removing the

module. Failure to do so may cause the module to fail or malfunction.

● Tighten the screws within the specified torque range. Undertightening can cause drop of the

component or wire, short circuit, or malfunction. Overtightening can damage the screw and/or module,

resulting in drop, short circuit, or malfunction.

● After the first use of the product, do not mount/remove the module to/from the base unit, and the

terminal block to/from the module, and do not insert/remove the extended SRAM cassette to/from the

CPU module more than 50 times (IEC 61131-2 compliant) respectively. Exceeding the limit of 50 times

may cause malfunction.

● After the first use of the product, do not insert/remove the SD memory card to/from the CPU module

more than 500 times. Exceeding the limit of 500 times may cause malfunction.

● Do not touch the metal terminals on the back side of the SD memory card. Doing so may cause

malfunction or failure.

● Do not touch the integrated circuits on the circuit board of an extended SRAM cassette. Doing so may

cause malfunction or failure.

● Do not drop or apply shock to the battery to be installed in the module. Doing so may damage the

battery, causing the battery fluid to leak inside the battery. If the battery is dropped or any shock is

applied to it, dispose of it without using.

6

Page 9

[Startup and Maintenance Precautions]

CAUTION

● Startup and maintenance of a control panel must be performed by qualified maintenance personnel

with knowledge of protection against electric shock. Lock the control panel so that only qualified

maintenance personnel can operate it.

● Before handling the module, touch a conducting object such as a grounded metal to discharge the

static electricity from the human body. Failure to do so may cause the module to fail or malfunction.

● Before testing the operation, set a low speed value for the speed limit parameter so that the operation

can be stopped immediately upon occurrence of a hazardous condition.

● Confirm and adjust the program and each parameter before operation. Unpredictable movements

may occur depending on the machine.

● When using the absolute position system function, on starting up, and when the module or absolute

position motor has been replaced, always perform a home position return.

● Before starting the operation, confirm the brake function.

● Do not perform a megger test (insulation resistance measurement) during inspection.

● After maintenance and inspections are completed, confirm that the position detection of the absolute

position detection function is correct.

● Lock the control panel and prevent access to those who are not certified to handle or install electric

equipment.

[Operating Precautions]

CAUTION

● When changing data and operating status, and modifying program of the running programmable

controller from an external device such as a personal computer connected to an intelligent function

module, read relevant manuals carefully and ensure the safety before operation. Incorrect change or

modification may cause system malfunction, damage to the machines, or accidents.

● Do not power off the programmable controller or reset the CPU module while the setting values in the

buffer memory are being written to the flash ROM in the module. Doing so will make the data in the

flash ROM and SD memory card undefined. The values need to be set in the buffer memory and

written to the flash ROM and SD memory card again. Doing so also may cause malfunction or failure

of the module.

● Note that when the reference axis speed is specified for interpolation operation, the speed of the

partner axis (2nd, 3rd, or 4th axis) may exceed the speed limit value.

● Do not go near the machine during test operations or during operations such as teaching. Doing so

may lead to injuries.

[Disposal Precautions]

CAUTION

● When disposing of this product, treat it as industrial waste.

● When disposing of batteries, separate them from other wastes according to the local regulations. For

details on battery regulations in EU member states, refer to the MELSEC iQ-R Module Configuration

Manual.

7

Page 10

[Transportation Precautions]

CAUTION

● When transporting lithium batteries, follow the transportation regulations. For details on the regulated

models, refer to the MELSEC iQ-R Module Configuration Manual.

● The halogens (such as fluorine, chlorine, bromine, and iodine), which are contained in a fumigant

used for disinfection and pest control of wood packaging materials, may cause failure of the product.

Prevent the entry of fumigant residues into the product or consider other methods (such as heat

treatment) instead of fumigation. The disinfection and pest control measures must be applied to

unprocessed raw wood.

8

Page 11

CONDITIONS OF USE FOR THE PRODUCT

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major or serious accident;

and

ii) where the backup and fail-safe function are systematically or automatically provided outside of the PRODUCT for the

case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT LIMITED TO ANY AND ALL

RESPONSIBILITY OR LIABILITY BASED ON CONTRACT, WARRANTY, TORT, PRODUCT LIABILITY) FOR ANY

INJURY OR DEATH TO PERSONS OR LOSS OR DAMAGE TO PROPERTY CAUSED BY the PRODUCT THAT ARE

OPERATED OR USED IN APPLICATION NOT INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS, OR

WARNING CONTAINED IN MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY MANUALS, TECHNICAL

BULLETINS AND GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

• Nuclear Power Plants and any other power plants operated by Power companies, and/or any other cases in which the

public could be affected if any problem or fault occurs in the PRODUCT.

• Railway companies or Public service purposes, and/or any other cases in which establishment of a special quality

assurance system is required by the Purchaser or End User.

• Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as Elevator and Escalator,

Incineration and Fuel devices, Vehicles, Manned transportation, Equipment for Recreation and Amusement, and

Safety devices, handling of Nuclear or Hazardous Materials or Chemicals, Mining and Drilling, and/or other

applications where there is a significant risk of injury to the public or property.

Notwithstanding the above, restrictions Mitsubishi may in its sole discretion, authorize use of the PRODUCT in one or

more of the Prohibited Applications, provided that the usage of the PRODUCT is limited only for the specific

applications agreed to by Mitsubishi and provided further that no special quality assurance or fail-safe, redundant or

other safety features which exceed the general specifications of the PRODUCTs are required. For details, please

contact the Mitsubishi representative in your region.

INTRODUCTION

Thank you for purchasing the Mitsubishi Electric MELSEC iQ-R series programmable controllers.

This manual describes the system configuration, specifications, installation, wiring, maintenance and inspection, and

troubleshooting of the relevant products listed below.

Before using this product, please read this manual and the relevant manuals carefully and develop familiarity with the

functions and performance of the MELSEC iQ-R series programmable controller to handle the product correctly.

When applying the program examples provided in this manual to an actual system, ensure the applicability and confirm that it

will not cause system control problems.

Please make sure that the end users read this manual.

Relevant products

R16MTCPU, R32MTCPU, R64MTCPU

9

Page 12

COMPLIANCE WITH EMC AND LOW VOLTAGE DIRECTIVES

Method of ensuring compliance

To ensure that Mitsubishi programmable controllers maintain EMC and Low Voltage Directives when incorporated into other

machinery or equipment, certain measures may be necessary. Please refer to one of the following manuals.

MELSEC iQ-R Module Configuration Manual

Safety Guidelines (This manual is included with the base unit.)

The CE mark on the side of the programmable controller indicates compliance with EMC and Low Voltage Directives.

Additional measures

To ensure that this product maintains EMC and Low Voltage Directives, please refer to the following manual.

MELSEC iQ-R Motion Controller User's Manual

10

Page 13

CONTENTS

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

CONDITIONS OF USE FOR THE PRODUCT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

COMPLIANCE WITH EMC AND LOW VOLTAGE DIRECTIVES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

RELEVANT MANUALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

TERMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

MANUAL PAGE ORGANISATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

CHAPTER 1 SYSTEM CONFIGURATION 16

1.1 Motion System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Equipment configuration in system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Peripheral device configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

R64MTCPU/R32MTCPU/R16MTCPU system overall configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Function explanation of the Motion CPU modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Restrictions on Motion systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.2 System Configuration Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Configuration equipment list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Software packages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1.3 Checking Production Information and Operating System Software Version . . . . . . . . . . . . . . . . . . . . . . .27

Checking production information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Checking operating system software version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

1.4 Restrictions by the Software's Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

1.5 Engineering Software Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

CONTENTS

CHAPTER 2 EQUIPMENT SPECIFICATIONS 31

2.1 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.2 Motion CPU Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Name of parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

LED display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Rotary switch setting and operation mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2.3 Serial Absolute Synchronous Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

2.4 SSCNETIII Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Connection between the Motion CPU module and servo amplifiers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Setting of the axis No. and switch of servo amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Precautions for SSCNETIII cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

CHAPTER 3 INSTALLATION AND WIRING 50

3.1 Mounting Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3.2 Module Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Mounting position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Installation of the base unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Installation and removal of module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3.3 Installation and Removal of SD Memory Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

3.4 Mounting of Serial Absolute Synchronous Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

3.5 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

11

Page 14

Power supply circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Safety circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

CHAPTER 4 START-UP PROCEDURES 56

4.1 Start-up Adjustment Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

CHAPTER 5 INSPECTION AND MAINTENANCE 59

5.1 Daily Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5.2 Periodic Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

5.3 Life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

CHAPTER 6 TROUBLESHOOTING 62

6.1 Troubleshooting Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.2 Troubleshooting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

6.3 Checking LED Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Checking LED display of the Motion CPU module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

6.4 Checking With Engineering Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

6.5 Troubleshooting by Circumstance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

When the READY LED of the Motion CPU module has turned OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

When an error is displayed or flickering in the dot matrix LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

When cannot write to Motion CPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

When cannot read from Motion CPU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

When the servo amplifier does not start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

CHAPTER 7 EMC DIRECTIVES 68

7.1 Requirements for Compliance with the EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Standards relevant to the EMC directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Installation instructions for EMC directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Parts of measure against noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Measure against noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

APPENDICES 74

Appendix 1 Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

SSCNETIII cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Serial absolute synchronous encoder cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

SSCNETIII cables (SC-J3BUS□M-C) manufactured by Mitsubishi Electric System & Service. . . . . . . . . . . . . . 79

Appendix 2 Exterior Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Motion CPU module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Serial absolute synchronous encoder (Q171ENC-W8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

REVISIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

TRADEMARKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

12

Page 15

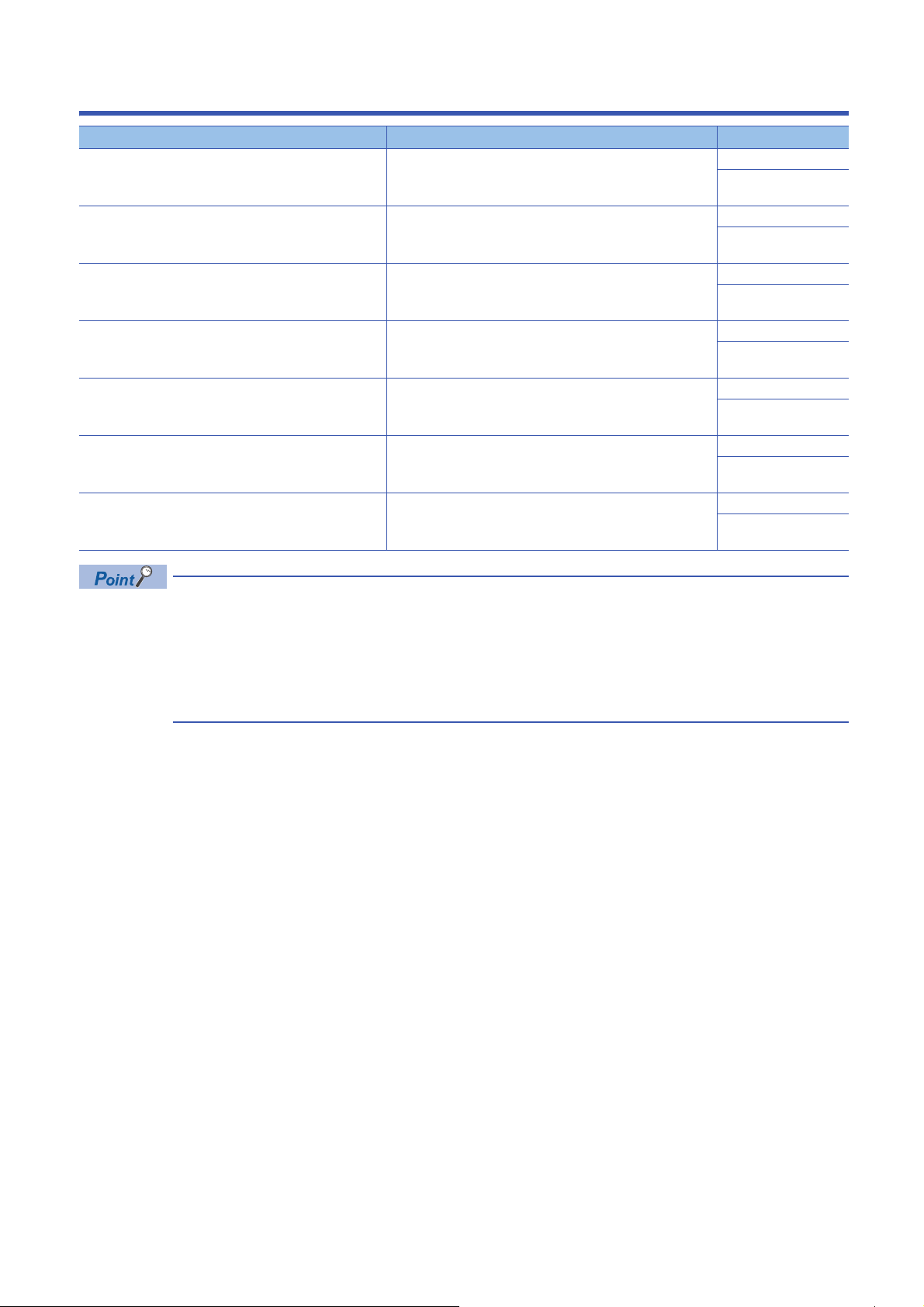

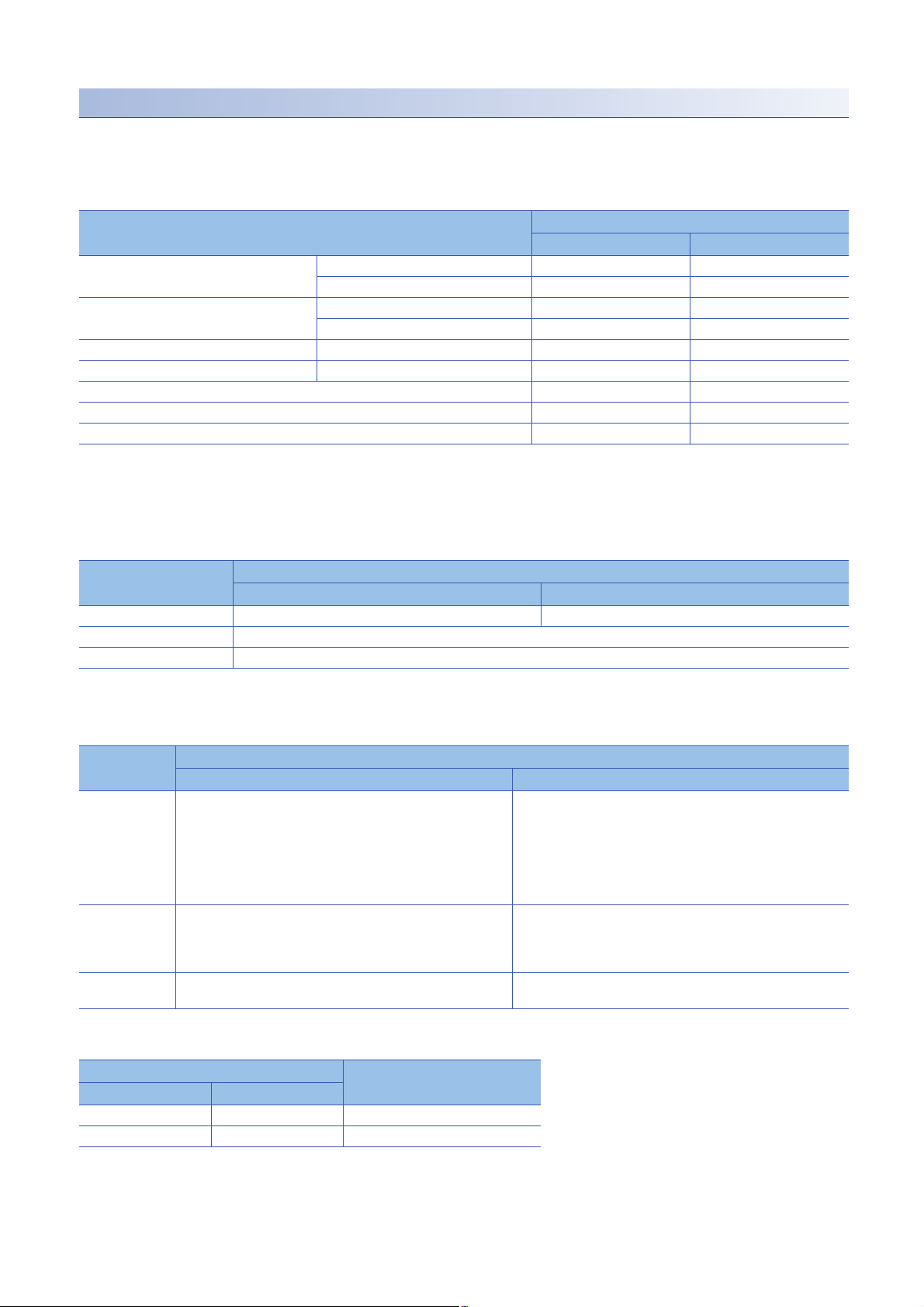

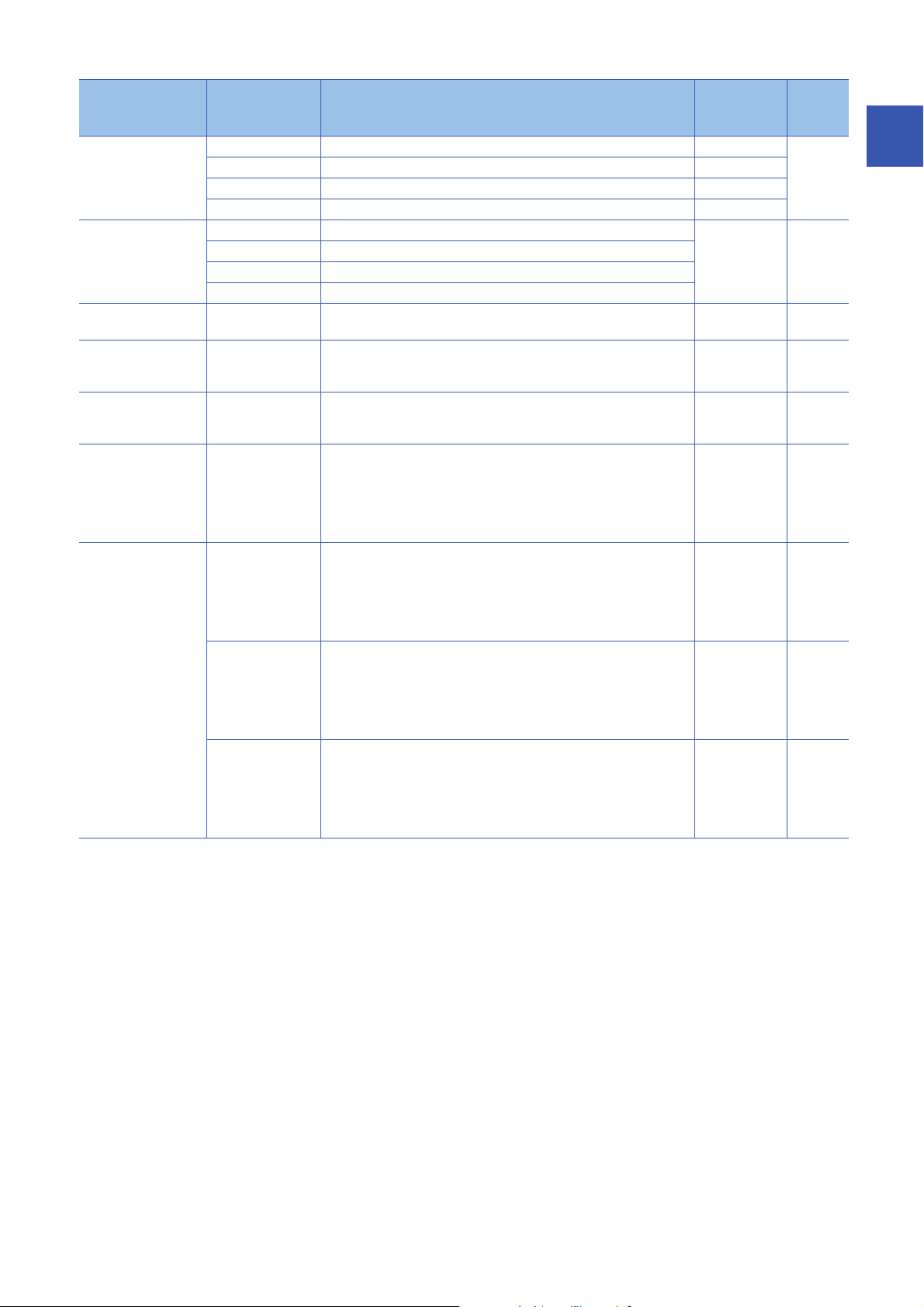

RELEVANT MANUALS

Manual Name [Manual Number] Description Available form

MELSEC iQ-R Motion Controller User's Manual

[IB-0300235] (This manual)

MELSEC iQ-R Motion Controller Programming Manual

(Common)

[IB-0300237]

MELSEC iQ-R Motion Controller Programming Manual

(Program Design)

[IB-0300239]

MELSEC iQ-R Motion Controller Programming Manual

(Positioning Control)

[IB-0300241]

MELSEC iQ-R Motion Controller Programming Manual

(Advanced Synchronous Control)

[IB-0300243]

MELSEC iQ-R Motion Controller Programming Manual

(Machine Control)

[IB-0300309]

MELSEC iQ-R Motion Controller Programming Manual

(G-Code Control)

[IB-0300371]

This manual explains specifications of the Motion CPU modules,

SSCNET cables, synchronous encoder, troubleshooting, and

others.

This manual explains the Multiple CPU system configuration,

performance specifications, common parameters, auxiliary/applied

functions, error lists and others.

This manual explains the functions, programming, debugging for

Motion SFC and others.

This manual explains the servo parameters, positioning

instructions, device lists and others.

This manual explains the dedicated instructions to use

synchronous control by synchronous control parameters, device

lists and others.

This manual explains the dedicated instructions to use machine

control by machine control parameters, machine positioning data,

device lists and others.

This manual explains the dedicated instructions to use G-code

control by G-code control parameters and G-code programs.

Print book

e-Manual

PDF

Print book

e-Manual

PDF

Print book

e-Manual

PDF

Print book

e-Manual

PDF

Print book

e-Manual

PDF

Print book

e-Manual

PDF

Print book

e-Manual

PDF

e-Manual refers to the Mitsubishi FA electronic book manuals that can be browsed using a dedicated tool.

e-Manual has the following features:

• Required information can be cross-searched in multiple manuals.

• Other manuals can be accessed from the links in the manual.

• The hardware specifications of each part can be found from the product figures.

• Pages that users often browse can be bookmarked.

13

Page 16

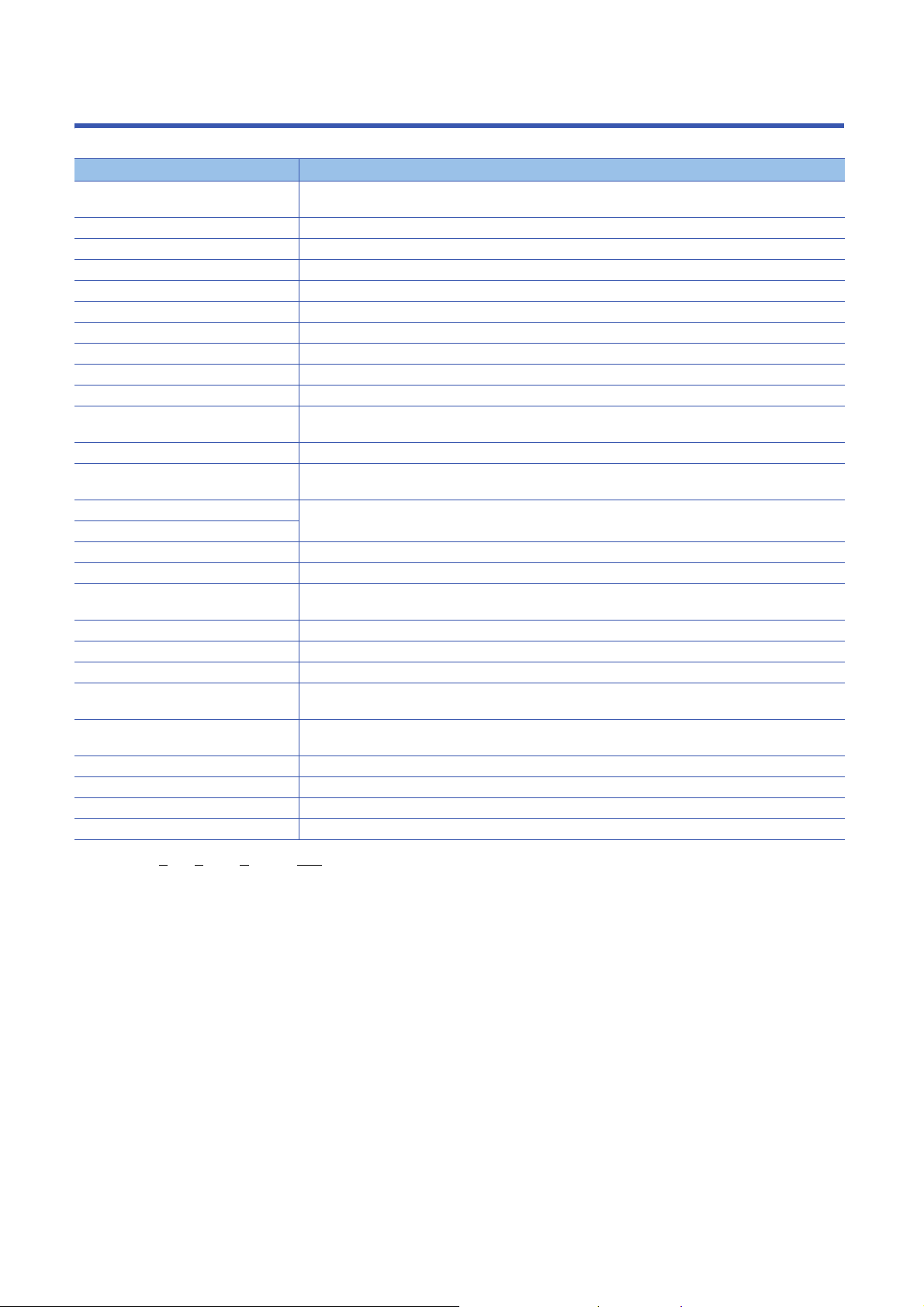

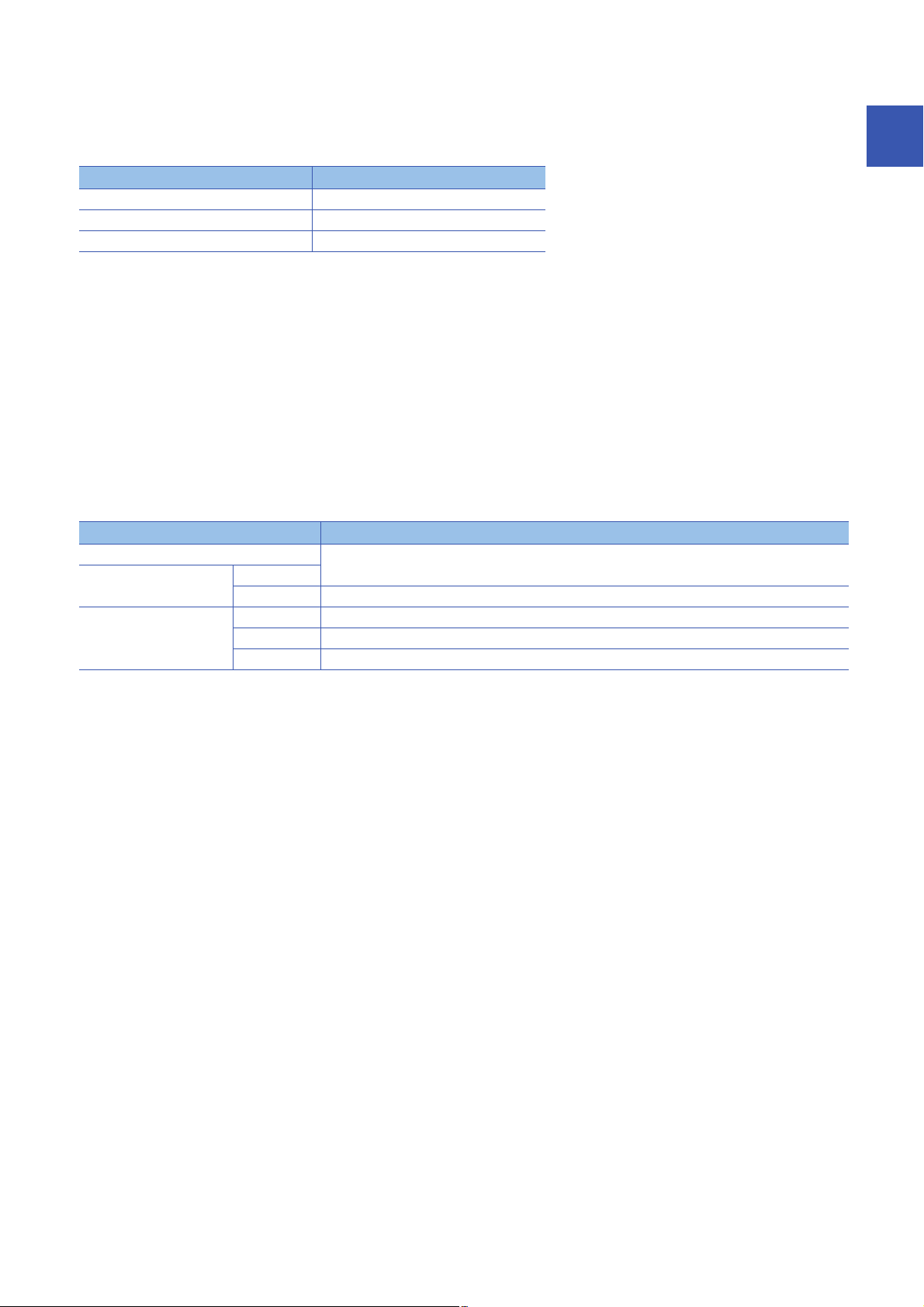

TERMS

Unless otherwise specified, this manual uses the following terms.

Ter m Description

R64MTCPU/R32MTCPU/R16MTCPU or

Motion CPU (module)

MR-J4(W)-B Servo amplifier model MR-J4-B/MR-J4W-B

MR-J3(W)-B Servo amplifier model MR-J3-B/MR-J3W-B

AMP or Servo amplifier General name for "Servo amplifier model MR-J4-B/MR-J4W-B/MR-J3-B/MR-J3W-B"

RnCPU, PLC CPU or PLC CPU module Abbreviation for MELSEC iQ-R series CPU module

Multiple CPU system or Motion system Abbreviation for "Multiple PLC system of the R series"

CPUn Abbreviation for "CPU No.n (n = 1 to 4) of the CPU module for the Multiple CPU system"

Operating system software General name for "SW10DNC-RMTFW"

Engineering software package General name for MT Developer2/GX Works3

MELSOFT MT Works2 General product name for the Motion controller engineering software "SW1DND-MTW2"

MT Developer2 Abbreviation for the programming software included in the "MELSOFT MT Works2" Motion controller

GX Works3 General product name for the MELSEC PLC software package "SW1DND-GXW3"

Serial absolute synchronous encoder or

Q171ENC-W8

SSCNET/H

SSCNET

SSCNET(/H) General name for SSCNET/H, SSCNET

Absolute position system General name for "system using the servomotor and servo amplifier for absolute position"

Intelligent function module General name for module that has a function other than input or output such as A/D converter module and D/A

SSCNET/H head module

Optical hub unit or MR-MV200 Abbreviation for SSCNET/H Compatible Optical Hub Unit (MR-MV200)

Sensing module General name for SSCNET/H compatible sensing module MR-MT2000 series

Sensing SSCNET/H head module

MR-MT2010

Sensing extension module General name for I/O module (MR-MT2100), pulse I/O module (MR-MT2200), analog I/O module (MR-

Sensing I/O module or MR-MT2100 Abbreviation for I/O module (MR-MT2100)

Sensing pulse I/O module or MR-MT2200 Abbreviation for pulse I/O module (MR-MT2200)

Sensing analog I/O module or MR-MT2300 Abbreviation for analog I/O module (MR-MT2300)

Sensing encoder I/F module or MR-MT2400 Abbreviation for encoder I/F module (MR-MT2400)

*1

*1

*1

*1

Abbreviation for MELSEC iQ-R series Motion controller

engineering software

Abbreviation for "Serial absolute synchronous encoder (Q171ENC-W8)"

High speed synchronous network between Motion controller and servo amplifier

converter module.

Abbreviation for "MELSEC-L series SSCNET/H head module (LJ72MS15)"

or

Abbreviation for SSCNET/H head module (MR-MT2010)

MT2300), encoder I/F module (MR-MT2400)

*1 SSCNET: Servo System Controller NETwork

14

Page 17

MANUAL PAGE ORGANISATION

Representation of device No. used in this manual

The "R" and "Q" beside the device No. of positioning dedicated signals such as "[Rq.1140] Stop command (R: M34480+32n/

Q: M3200+20n)" indicate the device No. for the device assignment methods shown below. When "R" and "Q" are not beside

the device No., the device No. is the same for both device assignment methods.

Symbol Device assignment method

R MELSEC iQ-R Motion device assignment

Q Q series Motion compatible device assignment

15

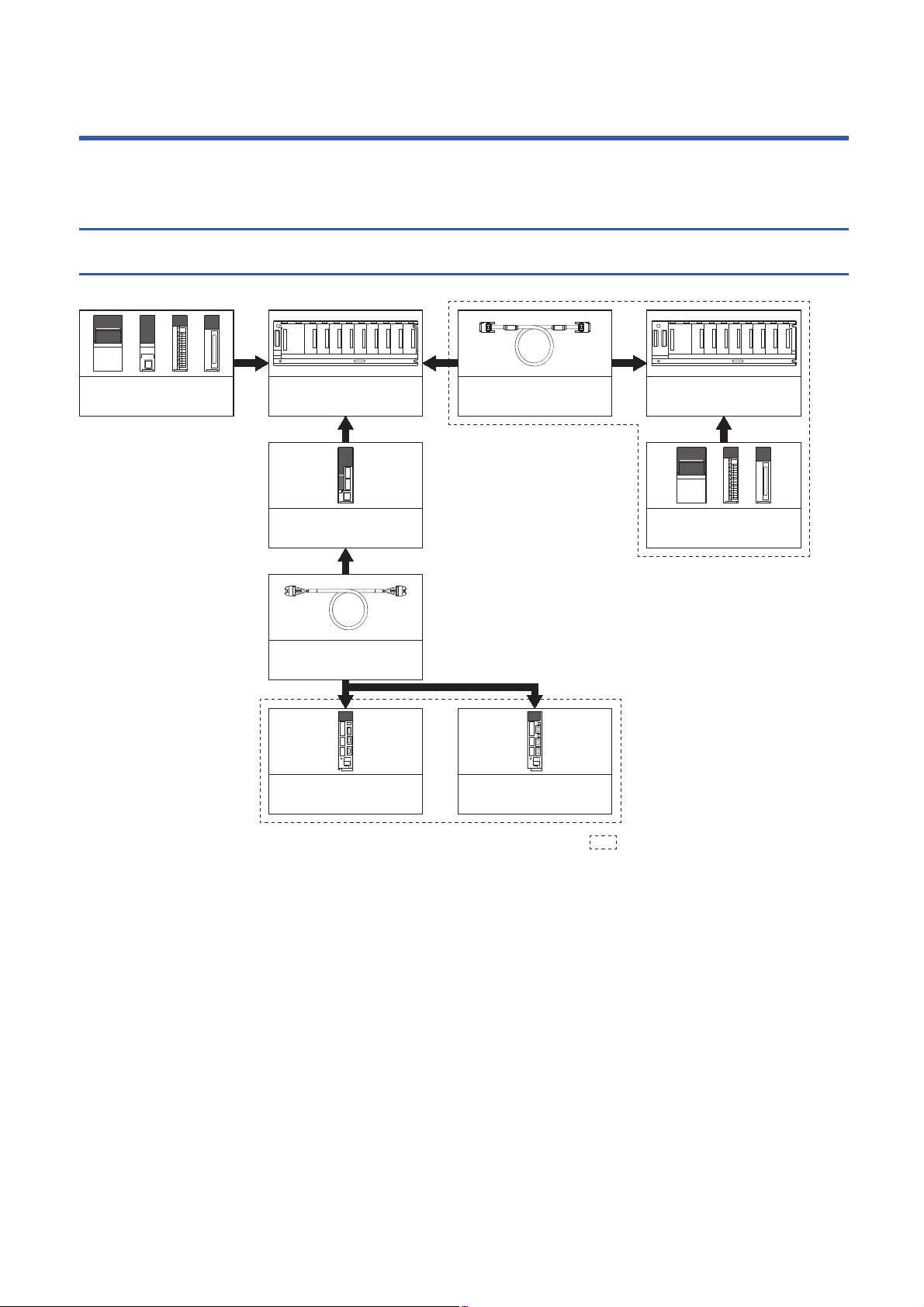

Page 18

1 SYSTEM CONFIGURATION

Extension of the R series module

Motion CPU module

(R64MTCPU/R32MTCPU/

R16MTCPU)

: Selected according to the system

Main base unit

(R35B, R38B, R312B)

Power supply module/RnCPU/

I/O module/Intelligent function

module of the R series

Power supply module/

I/O module/Intelligent function

module of the R series

Extension cable

(RCB)

Servo amplifier

(MR-J4(W)-B)

Servo amplifier

(MR-J3(W)-B)

R6B extension base unit

(R65B, R68B, R312B)

SSCNETµcable

(MR-J3BUSM(-A/-B))

This section describes the Motion controller system configuration, precautions on use of system and configured equipment.

1.1 Motion System Configuration

Equipment configuration in system

16

1 SYSTEM CONFIGURATION

1.1 Motion System Configuration

Page 19

Peripheral device configuration

Ethernet cable

*1

Personal computer

Motion CPU module

(R64MTCPU/R32MTCPU/

R16MTCPU)

Ethernet configuration

*1 Corresponding Ethernet cables

Part name Connection type Cable type Ethernet standard Specification

Ethernet cable Connection with HUB Straight cable 10BASE-T Compliant with Ethernet standards, category 5 or

100BASE-TX

Direct connection Straight cable

Crossover cable

10BASE-T

100BASE-TX

■Selection criterion of cable

• Category : 5 or higher

• Diameter of lead: AWG26 or higher

• Shield: Copper braid shield and drain wire or copper braid shield and aluminium layered type shield

higher.

• Shielded twisted pair cable (STP cable)

1

1 SYSTEM CONFIGURATION

1.1 Motion System Configuration

17

Page 20

R64MTCPU/R32MTCPU/R16MTCPU system overall configuration

RMT

CPU

RCPU

R61P

PLC CPU/

Motion CPU

Main base unit

(R3B)

Extension base unit

(R6B)

Extension cable

(RCB)

Up to 7 extensions

RX

Line 1

SSCNETµ(/H)

(CN1)

Line 2

SSCNETµ(/H)

(CN2)

SSCNETµ cable

(MR-J3BUSM(-A/-B))

RY

Motion CPU controlled modules

RD62R6AD

/

R6DA

P Manual pulse generator x2/module

Incremental synchronous encoder x2/module

Intelligent

function module

E

I/O module/

Intelligent function module

Analog Input/Output

Input/Output

(Up to 4096 points)

External input signals

d01

M

E

d02 d16

M

E

d01

M

E

d02

M

E

M

E

d16

M

E

Power supply

module

Personal computer

GOT

USB/Ethernet

PERIPHERAL I/F

Cognex Corporation

vision system

Sensing module

MR-MT2000 series

*3

I/O module,

Intelligent

function module

L61P LJ72MS15

MELSEC-L series SSCNETµ/H

head module (LJ72MS15)

*3

Sensing module

MR-MT2000 series

*3

R64MTCPU: 2 lines (Up to 8 stations (Up to 4 stations/line))

R32MTCPU: 2 lines (Up to 8 stations (Up to 4 stations/line))

R16MTCPU: 1 line (Up to 4 stations)

I/O module,

Intelligent

function module

L61P LJ72MS15

R64MTCPU: 2 lines (Up to 64 axes (Up to 32 axes/line))

*2

R32MTCPU: 2 lines (Up to 32 axes (Up to 16 axes/line))

R16MTCPU: 1 line (Up to 16 axes)

External input signals of servo amplifier

Serial absolute synchronous

encoder

*1

(Q171ENC-W8)

Serial absolute synchronous

encoder cable

(Q170ENCCBLM-A)

E

MR-J3(W)-B/MR-J4(W)-B model servo

amplifier

Optical hub unit (MR-MV200)

Inverter FR-A800/FR-A700 series

VC´ series/VPH series servo driver

manufactured by CKD Nikki Denso Co., Ltd.

Stepping motor module AlphaStep/5-phase

manufactured by ORIENTAL MOTOR Co., Ltd.

IAI electric actuator controller manufactured

by IAI Corporation

Upper stroke limit

Lower stroke limit

Stop signal

Proximity dog/Speed-position switching

Upper stroke limit

Lower stroke limit

Proximity dog/Speed-position switching

18

*1 MR-J4-B-RJ only

*2 Up to 16 axes per line for R64MTCPU when communication type is SSCNET.

*3 SSCNET/H only

CAUTION

• Construct a safety circuit externally of the Motion controller or servo amplifier if the abnormal operation of the Motion controller or servo amplifier differ from

the safety directive operation in the system.

• The ratings and characteristics of the parts (other than Motion controller, servo amplifier and servomotor) used in a system must be compatible with the

Motion controller, servo amplifier and servomotor.

• Set the parameter values to those that are compatible with the Motion controller, servo amplifier, servomotor and regenerative resistor model and the system

application. The protective functions may not function if the settings are incorrect.

1 SYSTEM CONFIGURATION

1.1 Motion System Configuration

Page 21

Function explanation of the Motion CPU modules

• The following servo amplifiers can be controlled in Motion CPU module.

Motion CPU Servo amplifier control

R64MTCPU Up to 64 axes per 2 lines (up to 32 axes per 1 line)

R32MTCPU Up to 32 axes per 2 lines (up to 16 axes per 1 line)

R16MTCPU Up to 16 axes per 1 line

• It is possible to set the program which synchronized with the motion operation cycle and executed at fixed cycle (Min.

0.222ms).

• It is possible to execute a download of servo parameters to servo amplifier, servo ON/OFF to servo amplifier and position

commands, etc. by connecting between the Motion CPU module and servo amplifier with SSCNET cable.

• I/O modules and intelligent function modules (excluding some modules) can be controlled with the Motion CPU module.

(Page 24 PLC module which can be controlled by Motion CPU)

• Data exchange between CPU modules is possible by CPU buffer memory in the Multiple CPU system.

• Wiring is reduced by issuing the external signal (upper/lower stroke limit signal, proximity dog signal) via the servo amplifier.

• Battery is not required for the Motion CPU.

Restrictions on Motion systems

Combination of Multiple CPU system

• Motion CPU module cannot be used as standalone module. Be sure to install the MELSEC iQ-R series PLC CPU module

to CPU No.1. Refer to the following for the configurations in a Multiple CPU system with the PLC CPU module as CPU

No.1.

MELSEC iQ-R Module Configuration Manual

• Up to four modules of MELSEC iQ-R series PLC CPU modules/Motion CPU modules can be installed from the CPU slot

(the slot on the right side of power supply module) to the I/O slot 6 of the main base unit. CPU modules are called CPU

No.1 to CPU No.4 from the left sequentially. There is no restriction on the installation order of CPU No.2 to No.4. For CPU

module other than CPU No.1, CPU reservation setting (allocating a CPU No. without actually installing a CPU module) can

be made.

• It takes about 10 seconds to startup (a state where it can be controlled) the Motion CPU. After startup, each CPU requires

time for initializing. For a system that begins executing programs without waiting for the startup of other CPUs, change the

Multiple CPU synchronous startup setting.

1

Motion CPU module restrictions

• The Motion CPU module only controls MELSEC iQ-R series modules. It cannot control MELSEC Q series modules.

• To execute the forced stop input, use a device set in the forced stop input setting ([Motion CPU Common Parameter]

[Basic Setting])

• Refer to the following for details of installing Motion CPU module to a DIN rail.

MELSEC iQ-R Module Configuration Manual

• Use the Graphic Operation Terminal (GOT) that supports Motion CPU (R64MTCPU/R32MTCPU/R16MTCPU).

1 SYSTEM CONFIGURATION

1.1 Motion System Configuration

19

Page 22

SSCNET communication restrictions

• Set "SSCNET/H" or "SSCNET" for every line in the SSCNET setting ([Motion CPU Common Parameter] [Servo

Network Setting]) to communicate with the servo amplifiers and SSCNET compatible equipment. The following shows the

servo amplifiers and SSCNET compatible equipment that can be used when "SSCNET/H" and "SSCNET" are set.

: Usable, : Unusable

Servo amplifier/SSCNETIII compatible equipment SSCNET setting

SSCNETIII/H SSCNETIII

Servo amplifier MR-J4(W)-B

MR-J3(W)-B

Inverter FR-A800 series

FR-A700 series

Sensing module MR-MT2000 series

SSCNET/H head module LJ72MS15

VC series/VPH series servo driver manufactured by CKD Nikki Denso Co., Ltd

Stepping motor module AlphaStep/5-phase manufactured by ORIENTAL MOTOR Co., Ltd

IAI electric actuator controller manufactured by IAI Corporation

*1 Operated in J3 compatibility mode

• The maximum No. of control axes per line for the Motion CPU (R64MTCPU/R32MTCPU/R16MTCPU) are shown below by

the communication type set in SSCNET setting. Settings that exceed the maximum No. of control axes per line cannot be

made.

Motion CPU Communication type

SSCNETIII/H SSCNETIII

R64MTCPU 32 axes 16 axes

R32MTCPU 16 axes

R16MTCPU 16 axes

*1

• The following are restrictions for the communication type depending on the operation cycle.

: No restriction

Operation

cycle

0.222ms • Maximum 12 control axes per line.

0.444ms • Maximum 24 control axes per line.

0.888ms or more • Up to 4 stations per line can be set with the SSCNET/H head

*1 When the number of control axes per line setting exceeds the maximum number of control axes per line, operation is carried out at the

following operation cycles.

Maximum number of control axes per line Operation cycle

SSCNETIII/H SSCNETIII

13 to 24 axes 5 to 8 axes 0.444ms

25 axes or more 9 axes or more 0.888ms

Communication type

SSCNETIII/H SSCNETIII

*1

• MR-J4W3-B (software version A2 or earlier) cannot be used.

• 1 station per line can be set with the SSCNET/H head module

or sensing module.

• AlphaStep/5-phase cannot be used.

• Up to 2 axes per IAI electric actuator controller can be set.

• Up to 2 stations per line can be set with the SSCNET/H head

module and/or the sensing module.

• Up to 4 axes per IAI electric actuator controller can be set.

module and/or the sensing module.

*3

*4

*6

*1

*3

*6

*3

• The maximum number of control axes per line is 4 control axes.

*2

• Set the axis select rotary switch of the servo amplifier to "0 to 3".

If the axis select rotary switch of servo amplifier is set to "4 to F",

the servo amplifiers are not recognized.

• MR-J4W3-B (software version A2 or earlier) cannot be used.

•MR-J3W-B cannot be used.

• FR-A700 series, VC series, and VPH series cannot be used.

• The maximum number of control axes per line is 8 axes.

• Set the axis select rotary switch of the servo amplifier to "0 to 7".

If the axis select rotary switch of servo amplifier is set to "8 to F",

the servo amplifiers are not recognized.

*1

*1

*2

*5

*2 MR-J4W3-B (Software version "A3" or later) supports operation cycle 0.222ms. However, when using operation cycle 0.222ms, some

functions are restricted. Refer to the following for details.

Servo amplifier Instruction Manual

1 SYSTEM CONFIGURATION

20

1.1 Motion System Configuration

Page 23

*3 When using the sensing module in axis mode, there are no restrictions on the number of stations for the sensing module.

*4 When AlphaStep/5-phase is present, operation is carried out at 0.444ms operation cycle.

*5 When FR-A700 series, VC series, or VPH series are present, operation is carried out at 0.444ms operation cycle.

*6 When the setting exceeds the number of control axes per controller, a minor error (error code: 1C83H) occurs.

Set the operation cycle as follows according to the number of control axes per controller.

Number of control axes per controller Operation cycle

1 to 2 axes 0.222ms or more

3 to 4 axes 0.444ms or more

5 axes or more 0.888ms or more

• When using MR-J4W-B, if there is at least one axis which has not been set in servo network setting, all axes of the

applicable servo amplifier cannot be connected, and all servo amplifiers after the applicable servo amplifier cannot be

connected. Set "Not used" to the applicable axis with a dip switch for the axis which is not used by MR-J4W-B.

• When using a multi-axis servo amplifier (MR-J4W-B), there is a restriction on the number of connectable units (servo

amplifier (MR-J4(W)-B), SSCNET/H head module, other drivers etc.) between the Motion CPU and the multi-axis servo

amplifier. The number of connectable units are shown below. When more than the number of connectable units are

connected, a warning (error code: 0C82H) occurs. While communication with MR-J4W-B is still possible when the

warning occurs, communication becomes unstable, therefore the unit configuration should be reviewed. Furthermore, when

an optical hub unit is used, the number of connectable units is reduced. Refer to the following for details of when an optical

hub unit is connected.

MELSEC iQ-R Motion Controller Programming Manual (Common)

Servo amplifier Number of connectable units

MR-J4-B No restriction

MR-J4W2-B 1 axis set

2 axes set 14 units or less

MR-J4W3-B 1 axis set No restriction

2 axes set 14 units or less

3 axes set 13 units or less

1

1 SYSTEM CONFIGURATION

1.1 Motion System Configuration

21

Page 24

1.2 System Configuration Equipment

Configuration equipment list

Motion controller related module

Part name Model name

Motion CPU module R64MTCPU Up to 64 axes control, Operation cycle 0.222[ms] or more, Built-in Ethernet 1.20

R32MTCPU Up to 32 axes control, Operation cycle 0.222[ms] or more, Built-in Ethernet 1.20

R16MTCPU Up to 16 axes control, Operation cycle 0.222[ms] or more, Built-in Ethernet 1.20

*2

PLC CPU module

C Controller module

Power supply module

Main base unit

*2

R00CPU Program capacity 10k steps, LD instruction processing speed 31.3ns,

R01CPU Program capacity 15k steps, LD instruction processing speed 31.3ns,

R02CPU Program capacity 20k steps, LD instruction processing speed 3.92ns,

R04CPU Program capacity 40k steps, LD instruction processing speed 0.98ns,

R08CPU Program capacity 80k steps, LD instruction processing speed 0.98ns,

R16CPU Program capacity 160k steps, LD instruction processing speed 0.98ns,

R32CPU Program capacity 320k steps, LD instruction processing speed 0.98ns,

R120CPU Program capacity 1200k steps, LD instruction processing speed 0.98ns,

R04ENCPU Program capacity 40k steps, LD instruction processing speed 0.98ns,

R08ENCPU Program capacity 80k steps, LD instruction processing speed 0.98ns,

R16ENCPU Program capacity 160k steps, LD instruction processing speed 0.98ns,

R32ENCPU Program capacity 320k steps, LD instruction processing speed 0.98ns,

R120ENCPU Program capacity 1200k steps, LD instruction processing speed 0.98ns,

R08PCPU Program capacity 80k steps, LD instruction processing speed 0.98ns,

R16PCPU Program capacity 160k steps, LD instruction processing speed 0.98ns,

R32PCPU Program capacity 320k steps, LD instruction processing speed 0.98ns,

R120PCPU Program capacity 1200k steps, LD instruction processing speed 0.98ns,

*2

R12CCPU-V Endian format: Little endian, OS: VxWorks Version 6.9 1.26

*3

R61P 100 to 240VAC input, 5VDC 6.5A output

R62P 100 to 240VAC input, 5VDC 3.5A/24VDC 6.0A output

R63P 24VDC input, 5VDC 6.5A output

R64P 100 to 240VAC input, 5VDC 9A output

R35B Number of I/O modules: 5 slots 0.58

R38B Number of I/O modules: 8 slots 0.71

R312B Number of I/O modules: 12 slots 0.88

R310B-HT Number of I/O modules: 10 slots, extended temperature range 0.82

*1

Description Current

Built-in Ethernet port

Built-in Ethernet port

Built-in Ethernet port

Built-in Ethernet port

Built-in Ethernet port

Built-in Ethernet port

Built-in Ethernet port

Built-in Ethernet port

Built-in Ethernet port, Built-in CC-Link IE

Built-in Ethernet port, Built-in CC-Link IE

Built-in Ethernet port, Built-in CC-Link IE

Built-in Ethernet port, Built-in CC-Link IE

Built-in Ethernet port, Built-in CC-Link IE

Built-in Ethernet port

Built-in Ethernet port

Built-in Ethernet port

Built-in Ethernet port

Remark

consumption

5VDC[A]

0.67

0.67

0.67

0.67

0.67

0.67

0.67

0.67

1.49

1.49

1.49

1.49

1.49

0.76

0.76

0.76

0.76

22

1 SYSTEM CONFIGURATION

1.2 System Configuration Equipment

Page 25

Part name Model name

*1

Description Current

Remark

consumption

5VDC[A]

Extension base unit *2R65B Number of I/O modules: 5 slots 0.70

R68B Number of I/O modules: 8 slots 0.81

R612B Number of I/O modules: 12 slots 0.92

R610B-HT Number of I/O modules: 10 slots, extended temperature range 0.85

Extension cable RC06B Length 0.6m(1.97ft.)

RC12B Length 1.2m(3.94ft.)

RC30B Length 3m(9.84ft.)

RC50B Length 5m(16.40ft.)

DIN rail installation

adaptor

Serial absolute

synchronous encoder

Serial absolute

synchronous encoder

cable

Connector set for serial

absolute synchronous

encoder cable

SSCNET cable MR-J3BUSM • R64MTCPU/R32MTCPU/R16MTCPU MR-J4(W)-B/

R6DIN1 Length 5m(16.40ft.)

Q171ENC-W8 Resolution: 4194304pulse/rev

Q170ENCCBLM-A Serial absolute synchronous encoder Q171ENC-W8 MR-J4-B-RJ

MR-J3CN2 MR-J4-B-RJ side connector

MR-J3BUSM-A • R64MTCPU/R32MTCPU/R16MTCPU MR-J4(W)-B/

MR-J3BUSM-B

For connection of R35B/R38B/R312B/R65B/R68B/R612B

Permitted axial loads Radial load: Up to 19.6N, Thrust load: Up to 9.8N

Permitted speed: 3600r/min

2m(6.56ft.), 5m(16.40ft.), 10m(32.81ft.), 20m(65.62ft.), 30m(98.43ft.),

50m(164.04ft.)

Plug: 36210-0100PL

Shell: 36310-3200-008

Q171ENC-W8 side connector

Plug: D/MS3106B22-14S

Cable clamp: D/MS3057-12A

MR-J4(W)-B MR-J4(W)-B/MR-J4(W)-B LJ72MS15

• R64MTCPU/R32MTCPU/R16MTCPU MR-J3(W)-B/

MR-J3(W)-B MR-J3(W)-B

• Standard cord for inside panel

0.15m(0.49ft.), 0.3m(0.98ft.), 0.5m(1.64ft.), 1m(3.28ft.), 3m(9.84ft.)

MR-J4(W)-B MR-J4(W)-B/MR-J4(W)-B LJ72MS15

• R64MTCPU/R32MTCPU/R16MTCPU MR-J3(W)-B/

MR-J3(W)-B MR-J3(W)-

tandard cable for outside panel

S

•

5m(16.40ft.), 10m(32.81ft.), 20m(65.62ft.)

*4

• R64MTCPU/R32MTCPU/R16MTCPU MR-J4(W)-B/

MR-J4(W)-B MR-J4(W)-B/MR-J4(W)-B LJ72MS15

• R64MTCPU/R32MTCPU/R16MTCPU MR-J3(W)-B/

MR-J3(W)-B MR-J3(W)-B

• Long distance cable

30m(98.43ft.), 40m(131.23ft.), 50m(164.04ft.)

B

0.25

*1 =Cable length

(015: 0.15m(0.49ft.), 03: 0.3m(0.98ft.), 05: 0.5m(1.64ft.), 1: 1m(3.28ft.), 2: 2m(6.56ft.), 3: 3m(9.84ft.), 5: 5m(16.40ft.), 10: 10m(32.81ft.),

20: 20m(65.62ft.), 25: 25m(82.02ft.), 30: 30m(98.43ft.), 40: 40m(131.23ft.), 50:50m(164.04ft.)

*2 5VDC internal current consumption of shared equipment with PLC might be changed. Be sure to refer to the MELSEC iQ-R series PLC

Manuals.

*3 Be sure to use the power supply module within the range of power supply capacity.

*4 Please contact your nearest Mitsubishi sales representative for the cable of less than 30m(98.43ft.).

1

1 SYSTEM CONFIGURATION

1.2 System Configuration Equipment

23

Page 26

PLC module which can be controlled by Motion CPU

Part name Model name Description Current

consumption

*1

Remark

5VDC[A]

Input module RX10 AC input, input 16 points 0.11 Refer to the MELSEC

RX40C7 DC input, plus common/minus common shared type, input 16 points 0.11

RX41C4 DC input, plus common/minus common shared type, input 32 points 0.15

RX42C4 DC input, plus common/minus common shared type, input 64 points 0.18

RX40PC6H DC input, plus common type, input 16 points 0.10

RX40NC6H DC input, minus common type, input 16 points 0.10

RX41C6HS DC input, plus common/minus common shared type, input 32 points 0.15

RX61C6HS DC input, plus common/minus common shared type, input 32 points 0.15

Output module RY10R2 Contact output, output 16 points 0.45

RY40NT5P Transistor output, sink type, output 16 points 0.14

RY41NT2P Transistor output, sink type, output 32 points 0.18

RY41NT2H Transistor output, sink type, output 32 points 0.42

RY42NT2P Transistor output, sink type, output 64 points 0.25

RY40PT5P Transistor output, source type, output 16 points 0.13

RY41PT1P Transistor output, source type, output 32 points 0.19

RY41PT2H Transistor output, source type, output 32 points 0.41

RY42PT1P Transistor output, source type, output 64 points 0.29

Input/Output

composite

module

Analogue input

module

Analogue

output module

High-speed

counter module

Temperature

input module

RH42C4NT2P DC input, plus common/ minus common shared type, input 32 points,

transistor output, sink type, output 32 points

R60AD4 Voltage/current input, 4ch 0.22

R60ADV8 Voltage input, 8ch 0.23

R60ADI8 Current input, 8ch 0.22

R60AD8-G Voltage/current input, 8ch, channel isolated 0.33

R60AD16-G Voltage/current input, 16ch, channel isolated 0.52

R60DA4 Voltage/current output, 4ch 0.16

R60DAV8 Voltage output, 8ch 0.16

R60DAI8 Current output, 8ch 0.16

R60DA8-G Voltage/current output, 8ch, channel isolated 0.18

R60DA16-G Voltage/current output, 16ch, channel isolated 0.25

R60ADH4 Voltage/current output, 4ch 0.73

RD62P2 DC input, sink output type, 2ch 0.11

RD62P2E DC input, source type, 2ch 0.20

RD62D2 Differential input, sink output type, 2ch 0.17

R60TD8-G Thermocouple (B, R, S, K, E, J, T, N) input, 8ch, channel isolated 0.36

R60RD8-G RTD (Pt100, JPt100, Ni100, Pt50) input, 8ch, channel isolated 0.35

0.22

iQ-R series manuals for

each module.

*1 5VDC internal current consumption of shared equipment with PLC might be changed. Be sure to refer to the manuals for each module.

24

1 SYSTEM CONFIGURATION

1.2 System Configuration Equipment

Page 27

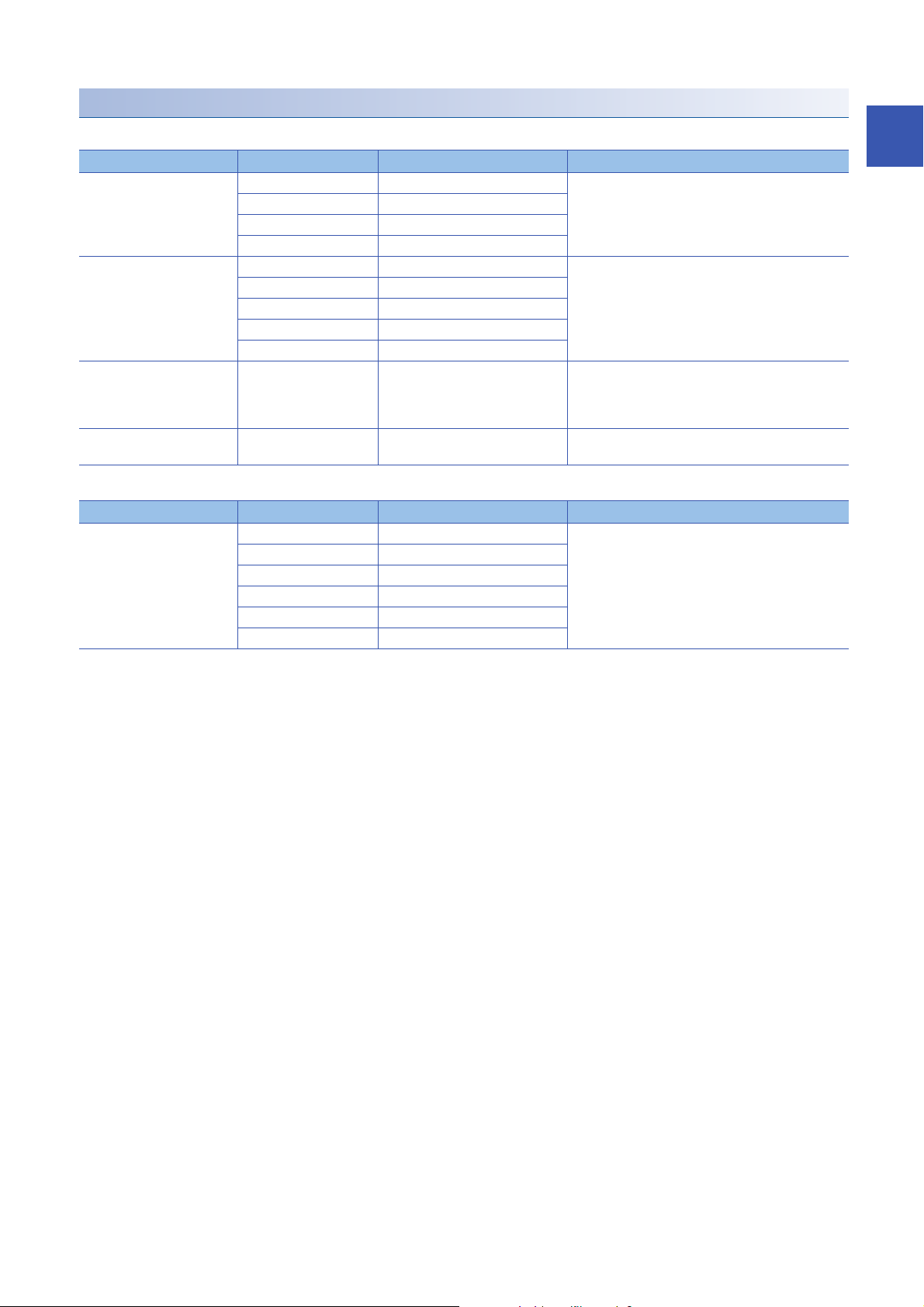

SSCNETIII(/H) compatible equipment

■SSCNETIII/H compatible equipment

Part name Model name Description Remarks

MR-J4 series servo amplifier MR-J4-B Refer to the servo amplifier instruction manuals.

MR-J4-B-RJ

MR-J4-B-LL

MR-J4W-B For 2-axis type, 3-axis type

Sensing module MR-MT2010 Sensing SSCNET/H head module Refer to the sensing module instruction manuals.

MR-MT2100 Sensing I/O module

MR-MT2200 Sensing pulse I/O module

MR-MT2300 Sensing analog I/O module

MR-MT2400 Sensing encoder I/F module

SSCNET/H head module LJ72MS15 Maximum link points: Input 64 bytes,

Output 64 bytes

Transmission cycle: 0.222ms,

0.444ms, 0.888ms

Optical hub unit MR-MV200 3 branches, 1 unit, 24VDC power

supply connector is attached

Refer to the MELSEC-L series PLC manuals.

■SSCNETIII compatible equipment

Part name Model name Description Remarks

MR-J3 series servo amplifier MR-J3-B Refer to the servo amplifier instruction manuals.

MR-J3W-B For 2-axis type

MR-J3-B-RJ006 For fully closed control

MR-J3-B-RJ004 For linear servo motor

MR-J3-B-RJ080W For direct drive motor

MR-J3-B Safety For drive safety servo

1

1 SYSTEM CONFIGURATION

1.2 System Configuration Equipment

25

Page 28

Software packages

Operating system software

Motion CPU Model name

R64MTCPU SW10DNC-RMTFW

R32MTCPU

R16MTCPU

*1 The operating system software is installed at the time of product purchases.

Engineering software

■Motion controller engineering software

Part name Model name

MELSOFT MT Works2

• MT Developer2

• MR Configurator2

*1 Included in Motion controller engineering software "MELSOFT MT Works2".

*2 The servo setup software "MR Configurator2" is included with MELSOFT MT Works2.

*1

*2

■PLC engineering software

Part name Model name

MELSOFT GX Works3 SW1DND-GXW3-E

SW1DND-MTW2-E

26

1 SYSTEM CONFIGURATION

1.2 System Configuration Equipment

Page 29

1.3 Checking Production Information and Operating

Rating plate

Production information

Production information

Marks of compliant standards

System Software Version

This section explains checking for the production information of Motion CPU module and the operating system software

version.

Checking production information

Checking with the Motion CPU module

■Rating plate

The rating plate is situated on the side face of the Motion CPU module. The SERIAL line displays the Motion CPU module

production information.

■Production information marking

The production information of the Motion CPU module is found on the production information marking on the front of the

Motion CPU module.

1

■Checking with GX Works3

The production information can be checked on the system monitor screen in GX Works3. (Page 28 Checking with GX

Works3)

■Checking with MT Developer2

Production information can be checked with MT Developer2 in the CPU information. (Page 28 Checking with MT

Developer2)

1 SYSTEM CONFIGURATION

1.3 Checking Production Information and Operating System Software Version

27

Page 30

Checking operating system software version

Operating system

software version

Production information

of Motion CPU module

Operating system

software version

Production information

of Motion CPU module

The operating system software version can be checked with MT Developer2 or GX Works3.

Checking with GX Works3

Check on the product information list screen.

[Diagnostics] [System monitor] [Product Information List] button

Checking with MT Developer2

■Installation screen

Check on the installation screen.

■CPU information screen

Check on the CPU information screen.

[Help] [CPU information]

■Device

Check with the special register "Operating system software version (SD740 to SD747)". Refer to for details on special

registers.

MELSEC iQ-R Motion Controller Programming Manual (Common)

28

1 SYSTEM CONFIGURATION

1.3 Checking Production Information and Operating System Software Version

Page 31

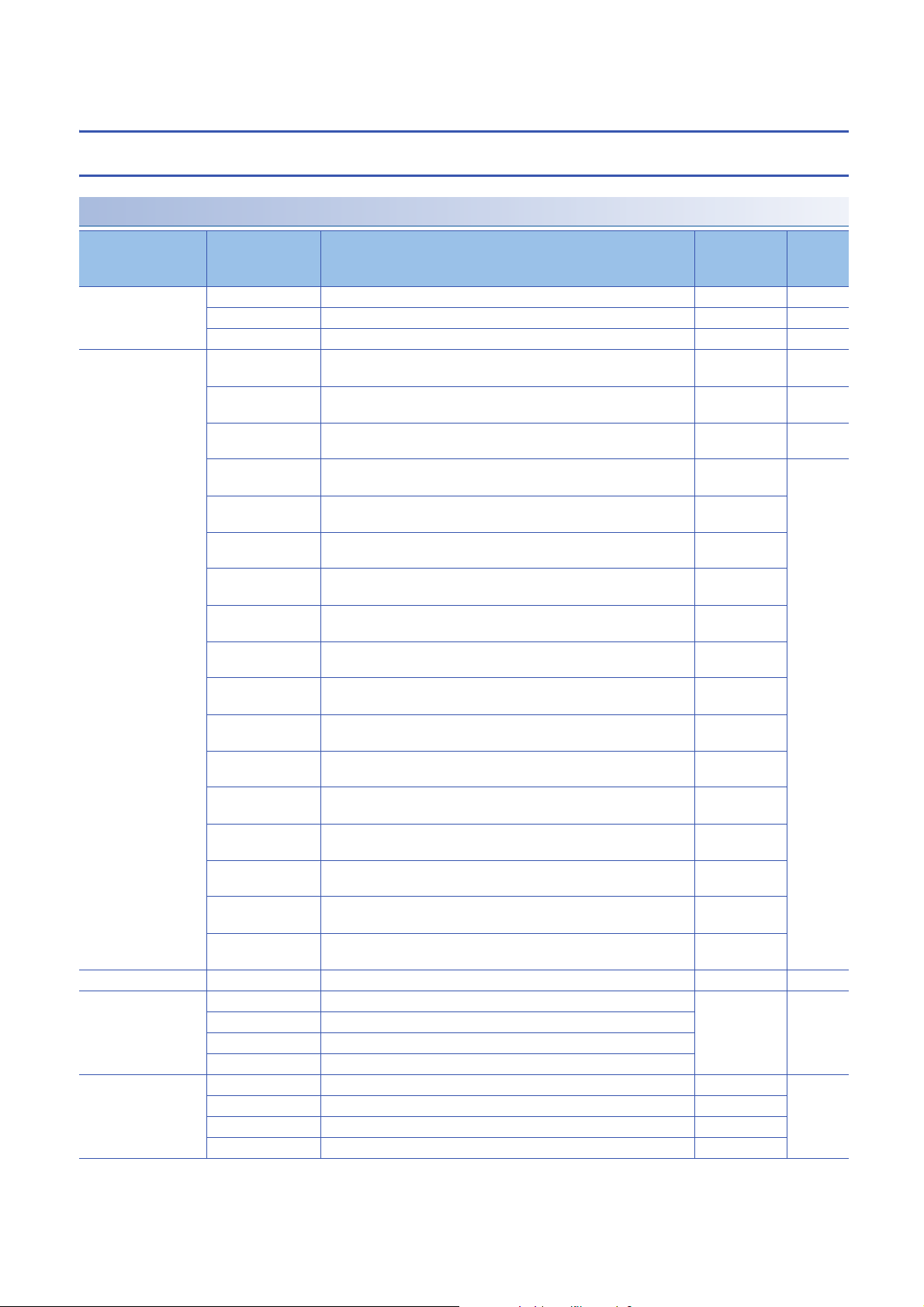

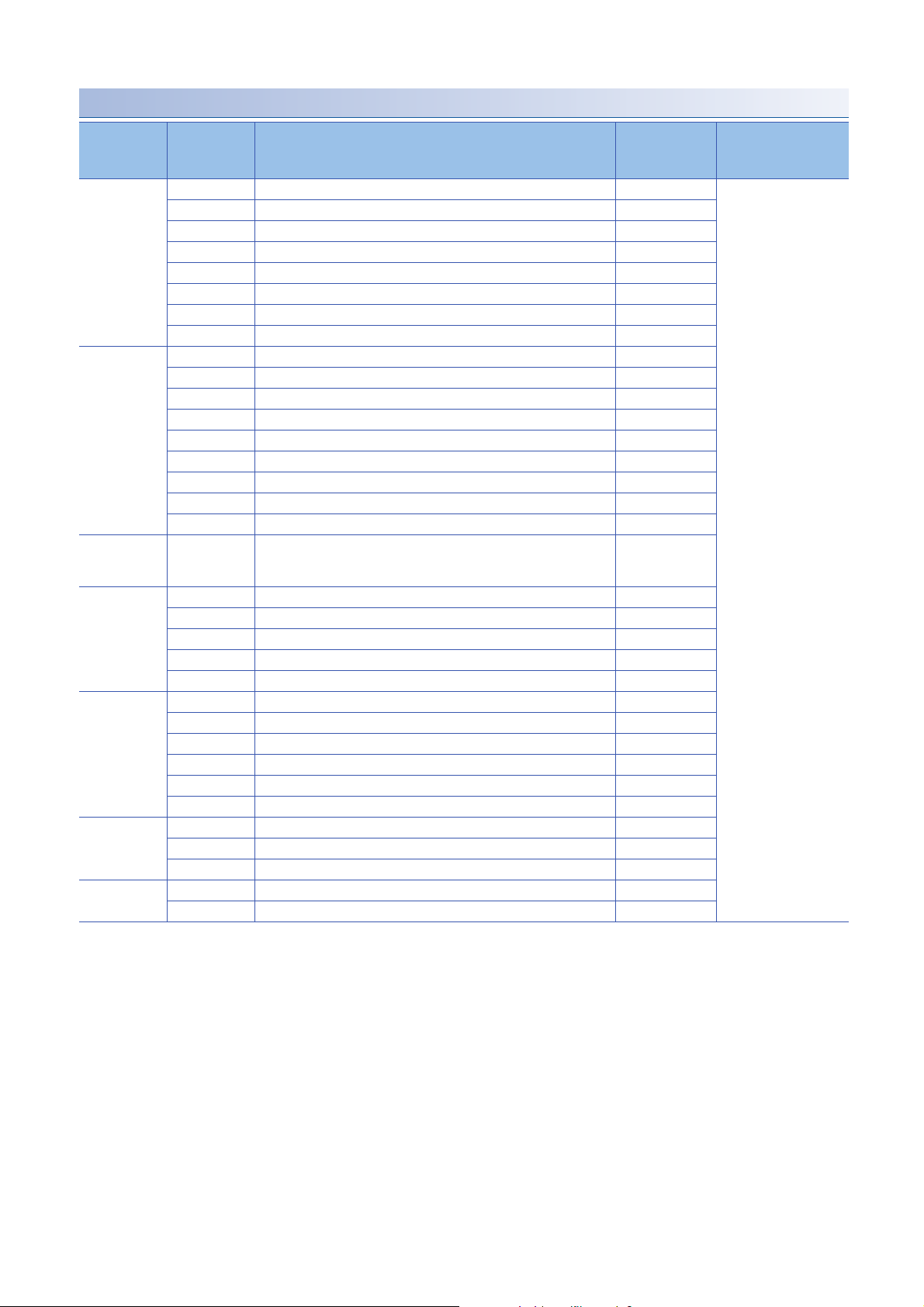

1.4 Restrictions by the Software's Version

There are restrictions in the function that can be used by the version of the operating system software and engineering

software. The combination of each version and a function is shown below.

: There is no restriction by the version.

Function Operating

system

software

version

Label access from external device 02 1.105K

File transmission at boot 03 1.111R

Event history 03 1.111R

ABS direction in degrees 03 1.111R

Clutch smoothing slippage method(Linear: Input value follow up) 03 1.111R

Pressure control 03 1.111R 1.37P

Optional data monitor (transient command) 03 1.111R

Optical hub unit connection 03 1.111R

Multiple CPU advanced synchronous control 03 1.111R

Extension of the number of vision system connections 03 1.111R

Motion dedicated PLC instructions (M(P).CHGA, M(P).CHGAS,

M(P).CHGV, M(P).CHGVS, M(P).CHGT)

Motion dedicated PLC instructions (M(P).BITWR, D(P).BITWR) 03 1.007H

Add-on function 03 1.111R

Add-on dedicated function (MCFUN) 03 1.111R

Servo amplifier (MR-J4-B-LL) compatible 03 1.111R 1.37P

Vibration suppression command filter 04 1.115V

Override function 04 1.115V

Test mode expansion 04 1.115V 1.41T

SD memory card compatible label function 04 1.115V

Parameter change function 05

Stepping motor module AlphaStep/5-phase manufactured by ORIENTAL

MOTOR Co., Ltd.

Home position return of driver home position return method 05 1.118Y

Device assignment method 07 1.120A

Machine control 07 1.120A

Motion dedicated function (MCNST) 07 1.120A

Multiple CPU advanced synchronous control (192 axis synchronization)*707 1.120A

Servo driver VPH series manufactured by CKD Nikki Denso Co., Ltd. 07 1.120A

Inverter FR-A800 series 07 1.120A

Override function compatible in machine control 08 1.120A

Sequential coordinate command control for machine control 08 1.120A

Data set method 3 home position return 08 1.125F

Indirect specification expansion for Motion SFC program 08 1.125F

IAI electric actuator controller manufactured by IAI Corporation 08 1.125F

Compatible with cam conversion data 08 1.125F

Motion dedicated PLC instructions (M(P).MCNST/D(P).MCNST) 07 1.025B

Sensing module connection 09 1.128J 1.55H

Expansion of the number of Motion SFC multi active steps 09 1.128J

Improvement of absolute positioning operation for servo driver VC/VPH

series manufactured by CKD Nikki Denso Co., Ltd., and stepping motor

module AlphaStep/5-phase manufactured by ORIENTAL MOTOR Co.,

Ltd.

Expansion of the number of positioning points for the Motion dedicated

function (MCNST)

1.007H

05 1.118Y

09

10 1.120A

Engineering software version Section

MELSOFT MT Works2 GX

*1

MT

Developer2

MR

Configurator2

Works3

of

reference

*2

*2

*2

*4

*4

*4

*2

*2

*5

*2

*3

*3

*2

*3

*4

*4

*2

*2

*2

*2

*4

*2

*6

*3

*5

*2

*2

*4

*6

*4

*3

*2

*3

*2

*3

*2

*6

1

1 SYSTEM CONFIGURATION

1.4 Restrictions by the Software's Version

29

Page 32

Function Operating

system

software

version

Expansion of the number of Motion SFC programs and servo programs 10 1.130L

Synchronous encoder via sensing module 10 1.130L 1.55H

Mixed operation cycle function 10 1.130L

RnENCPU Multiple CPU system compatible 10 1.118Y 1.032J

Actual coordinate value (world coordinate system) monitor for machine

control

Virtual servo amplifier function 12 1.137T

G-code control

Add-on library license authentication 14 1.140W

RnCPU (R00CPU, R01CPU, R02CPU) Multiple CPU system compatible 1.140W 1.040S

*8

11 1.135R

14 1.140W

Engineering software version Section

MELSOFT MT Works2 GX

*1

MT

Developer2

MR

Configurator2

Works3

of

reference

*3*4

*5

*2

*6

*2

*9

*2

*1 The operating system software version can be confirmed in MT Developer2, or GX Works3. (Page 28 Checking operating system

software version)

*2 MELSEC iQ-R Motion Controller Programming Manual (Common)

*3 MELSEC iQ-R Motion Controller Programming Manual (Program Design)

*4 MELSEC iQ-R Motion Controller Programming Manual (Positioning Control)

*5 MELSEC iQ-R Motion Controller Programming Manual (Advanced Synchronous Control)

*6 MELSEC iQ-R Motion Controller Programming Manual (Machine Control)

*7 Because the device assignment of status device settings are changed, the device assignment must be reviewed when updating the

operating system software to version "07" or later from version "05" or earlier

*8 Requires add-on library "SW10DND-GCD".

*9 MELSEC iQ-R Motion Controller Programming Manual (G-Code Control)

1.5 Engineering Software Version

The operating system software and engineering software versions that support Motion CPU are shown below.

Motion CPU Operating system software MELSOFT MT Works2

(MT Developer2)

R16MTCPU 01 or later 1.100E or later 1.000A or later

R32MTCPU

R64MTCPU 07 or later 1.120A or later 1.019V or later

GX Works3

30

1 SYSTEM CONFIGURATION

1.5 Engineering Software Version

Page 33

2 EQUIPMENT SPECIFICATIONS

2.1 General Specifications

General specifications of the Motion controller are shown below.

Item Specification

Operating ambient temperature 0 to 55 (32 to 131)

Storage ambient temperature -25 to 75 (-13 to 167)

Operating ambient humidity 5 to 95%RH, non-condensing

Storage ambient humidity 5 to 95%RH, non-condensing

Vibration resistance Compliant with

Shock resistance Compliant with JIS B 3502 and IEC 61131-2 (147m/s2 , 3 times in each of 3 directions X, Y, Z)

Operating ambience No corrosive gases

Operating altitude

Mounting location Inside control panel

Overvoltage category

Pollution level

Equipment class Class

*3

*4

*5

JIS B 3502 and

IEC 61131-2

0 to 2000m(0 to 6561.68ft.)