Page 1

MELSEC iQ-R MODBUS and MODBUS/TCP

Reference Manual

-RJ71C24

-RJ71C24-R2

-RJ71C24-R4

-RJ71EN71

-R04ENCPU

-R08ENCPU

-R16ENCPU

-R32ENCPU

-R120ENCPU

Page 2

Page 3

SAFETY PRECAUTIONS

(1) MELSEC programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major or serious accident;

and

ii) where the backup and fail-safe function are systematically or automatically provided outside of the PRODUCT for the

case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general industries.

MITSUBISHI ELECTRIC SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT LIMITED TO

ANY AND ALL RESPONSIBILITY OR LIABILITY BASED ON CONTRACT, WARRANTY, TORT, PRODUCT

LIABILITY) FOR ANY INJURY OR DEATH TO PERSONS OR LOSS OR DAMAGE TO PROPERTY CAUSED BY the

PRODUCT THAT ARE OPERATED OR USED IN APPLICATION NOT INTENDED OR EXCLUDED BY

INSTRUCTIONS, PRECAUTIONS, OR WARNING CONTAINED IN MITSUBISHI ELECTRIC USER'S, INSTRUCTION

AND/OR SAFETY MANUALS, TECHNICAL BULLETINS AND GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

• Nuclear Power Plants and any other power plants operated by Power companies, and/or any other cases in which the

public could be affected if any problem or fault occurs in the PRODUCT.

• Railway companies or Public service purposes, and/or any other cases in which establishment of a special quality

assurance system is required by the Purchaser or End User.

• Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as Elevator and Escalator,

Incineration and Fuel devices, Vehicles, Manned transportation, Equipment for Recreation and Amusement, and

Safety devices, handling of Nuclear or Hazardous Materials or Chemicals, Mining and Drilling, and/or other

applications where there is a significant risk of injury to the public or property.

Notwithstanding the above restrictions, Mitsubishi Electric may in its sole discretion, authorize use of the PRODUCT in

one or more of the Prohibited Applications, provided that the usage of the PRODUCT is limited only for the specific

applications agreed to by Mitsubishi Electric and provided further that no special quality assurance or fail-safe,

redundant or other safety features which exceed the general specifications of the PRODUCTs are required. For details,

please contact the Mitsubishi Electric representative in your region.

(3) Mitsubishi Electric shall have no responsibility or liability for any problems involving programmable controller trouble and

system trouble caused by DoS attacks, unauthorized access, computer viruses, and other cyberattacks.

(Read these precautions before using this product.)

Before using MELSEC iQ-R series programmable controllers, please read the manuals for the product and the relevant

manuals introduced in those manuals carefully, and pay full attention to safety to handle the product correctly.

Make sure that the end users read this manual and then keep the manual in a safe place for future reference.

CONDITIONS OF USE FOR THE PRODUCT

1

Page 4

INTRODUCTION

Thank you for purchasing the Mitsubishi Electric MELSEC iQ-R series programmable controllers.

This manual describes the frame specifications and MODBUS standard functions to use the MODBUS slave function and

MODBUS/TCP slave function of the following modules.

Before using this product, please read this manual and the relevant manuals carefully and develop familiarity with the

functions and performance of the MELSEC iQ-R series programmable controller to handle the product correctly.

Relevant products

RJ71C24, RJ71C24-R2, RJ71C24-R4

RJ71EN71, R04ENCPU, R08ENCPU, R16ENCPU, R32ENCPU, R120ENCPU

2

Page 5

CONTENTS

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

CONDITIONS OF USE FOR THE PRODUCT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

RELEVANT MANUALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

TERMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

GENERIC TERMS AND ABBREVIATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

CHAPTER 1 FRAME SPECIFICATIONS 6

1.1 MODBUS Protocol Frame Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

RTU mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

ASCII mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

1.2 MODBUS/TCP Protocol Frame Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.3 Protocol Data Unit Formats Grouped by Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

CHAPTER 2 MODBUS STANDARD FUNCTION LIST 13

CHAPTER 3 MODBUS STANDARD FUNCTION DETAILS 14

3.1 Read Coils (FC: 01H). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

3.2 Read Discrete Inputs (FC: 02H) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.3 Read Holding Registers (FC: 03H). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.4 Read Input Registers (FC: 04H) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

3.5 Write Single Coil (FC: 05H). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

3.6 Write Single Register (FC: 06H) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

3.7 Read Exception Status (FC: 07H). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

3.8 Diagnostics (FC: 08H) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Return query data (sub-function code: 00H) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Restart communications option (sub-function code: 01H). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Return diagnostic register (sub-function code: 02H). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Change ASCII input delimiter (sub-function code: 03H) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Force listen only mode (sub-function code: 04H) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Clear counters and diagnostic register (sub-function code: 0AH) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Return bus message count (sub-function code: 0BH). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Return bus communication error count (sub-function code: 0CH) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Return bus exception error count (sub-function code: 0DH) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Return slave message count (sub-function code: 0EH) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Return slave no response count (sub-function code: 0FH). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Return slave NAK count (sub-function code: 10H) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Return slave busy count (sub-function code: 11H) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Return bus character overrun count (sub-function code: 12H) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Return IOP overrun error count (sub-function code: 13H). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Clear overrun counter and flag (sub-function code: 14H) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.9 Get Communications Event Counter (FC: 0BH) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.10 Get Communications Event Log (FC: 0CH) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

3.11 Write Multiple Coils (FC: 0FH) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3.12 Write Multiple Registers (FC: 10H). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

3.13 Report Slave ID (FC: 11H) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3.14 Read File Record (FC: 14H) (SC: 06H). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3.15 Write File Record (FC: 15H) (SC: 06H). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

CONTENTS

3

Page 6

3.16 Mask Write Register (FC: 16H) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

3.17 Read/Write Multiple Registers (FC: 17H). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

CHAPTER 4 EXCEPTION CODES 50

INDEX 52

REVISIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

TRADEMARKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

4

Page 7

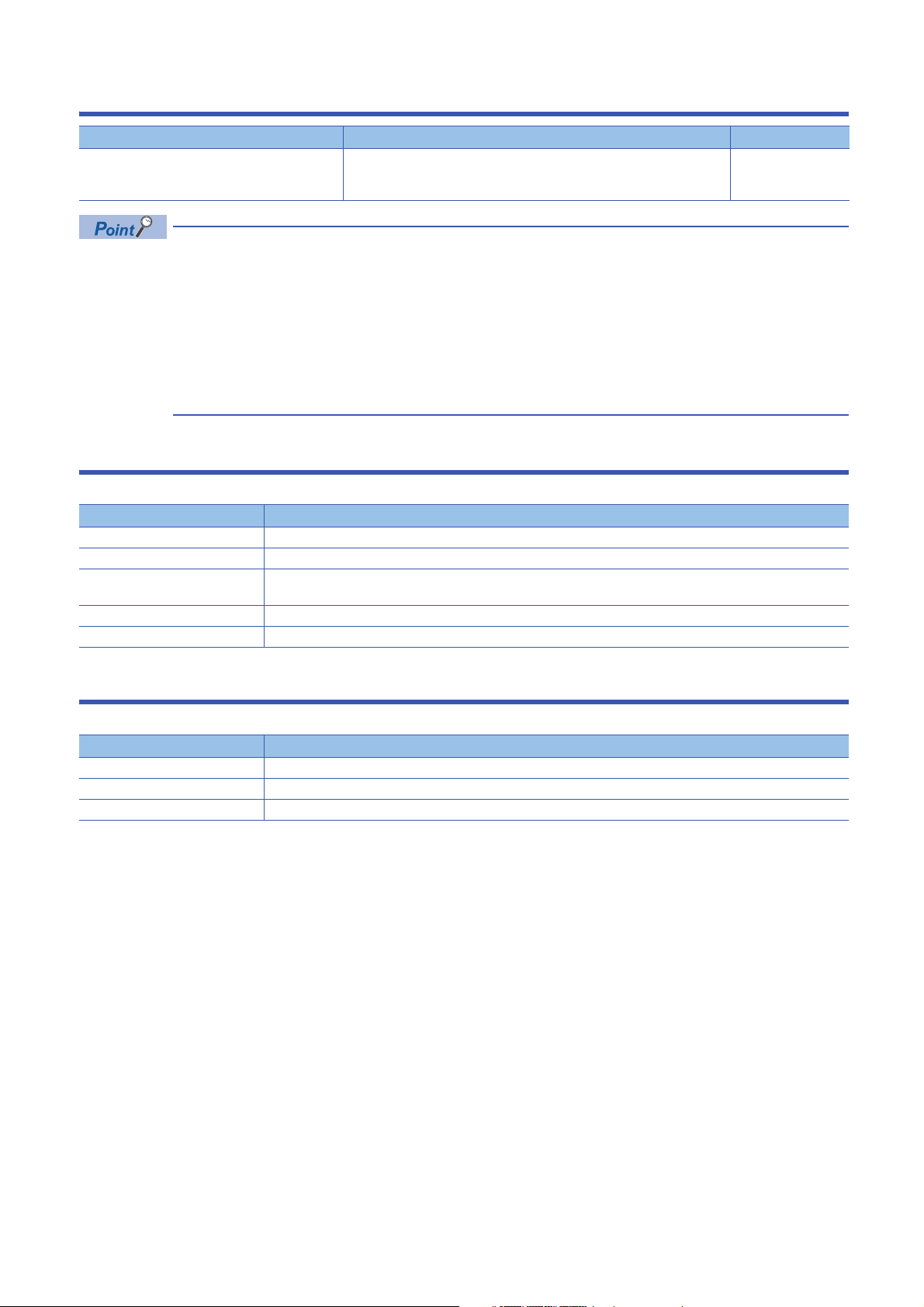

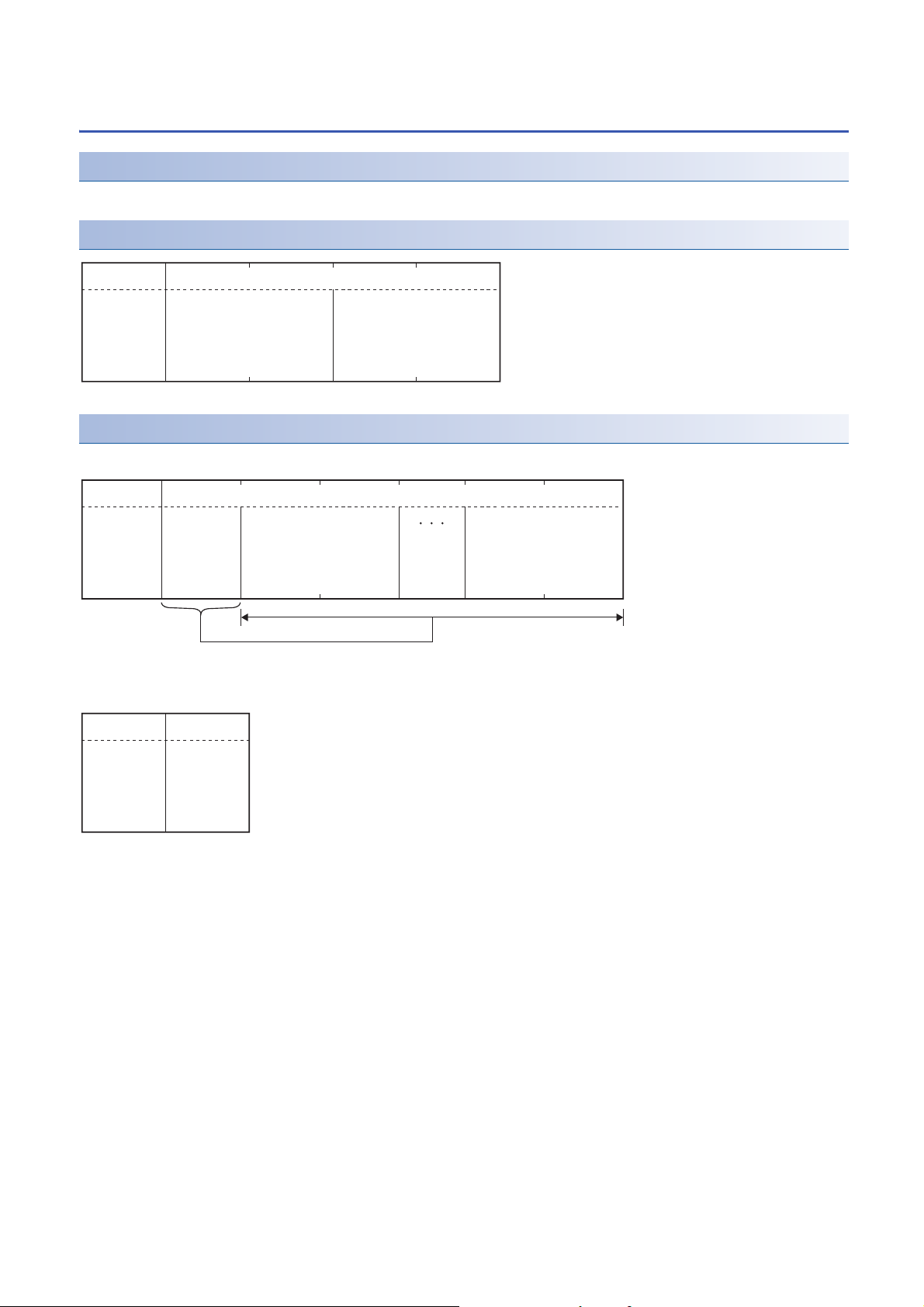

RELEVANT MANUALS

Manual name [manual number] Description Available form

MELSEC iQ-R MODBUS and MODBUS/TCP

Reference Manual

[BCN-P5999-1060] (this manual)

e-Manual refers to the Mitsubishi Electric FA electronic book manuals that can be browsed using a dedicated

tool.

e-Manual has the following features:

• Required information can be cross-searched in multiple manuals.

• Other manuals can be accessed from the links in the manual.

• The hardware specifications of each part can be found from the product figures.

• Pages that users often browse can be bookmarked.

• Sample programs can be copied to an engineering tool.

Protocol (MODBUS, MODBUS/TCP) that reads and writes data from a target

device to a module

e-Manual

PDF

TERMS

Unless otherwise specified, this manual uses the following terms.

Ter m Description

Master A name for the side that requests function execution

MODBUS device A device used in communications via the MODBUS protocol

Request message A message that requests function execution to slaves.

Response message A message that returns execution results of functions from a slave to the master

Slave A name for the side that processes execution requests from the master and returns the execution results

In the MODBUS protocol, the master requests function execution to the slaves.

GENERIC TERMS AND ABBREVIATIONS

Unless otherwise specified, this manual uses the following generic terms and abbreviations.

Generic term/abbreviation Description

C24 A MELSEC iQ-R series serial communication module

FC An abbreviation of function code

SC An abbreviation of sub code

5

Page 8

1 FRAME SPECIFICATIONS

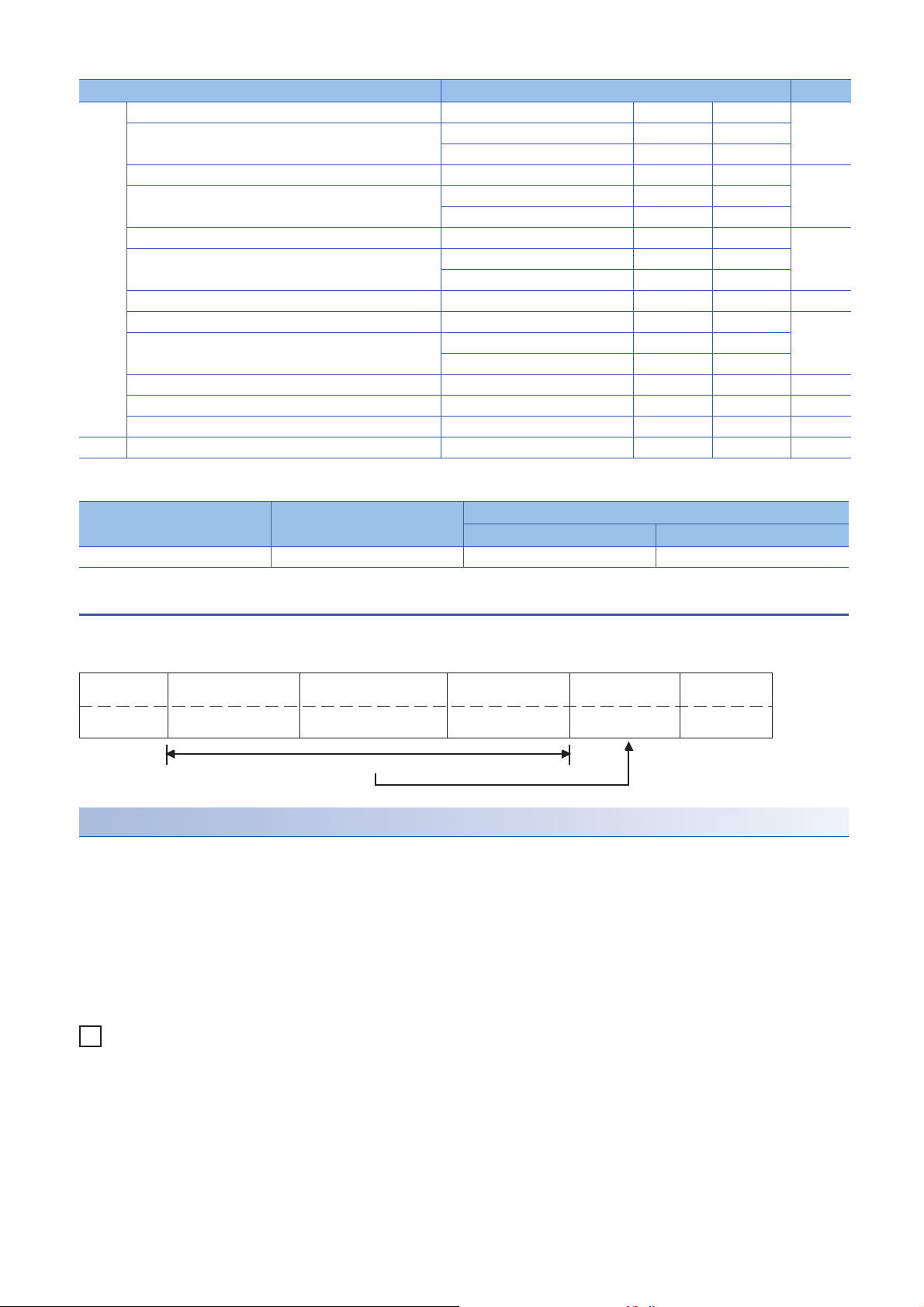

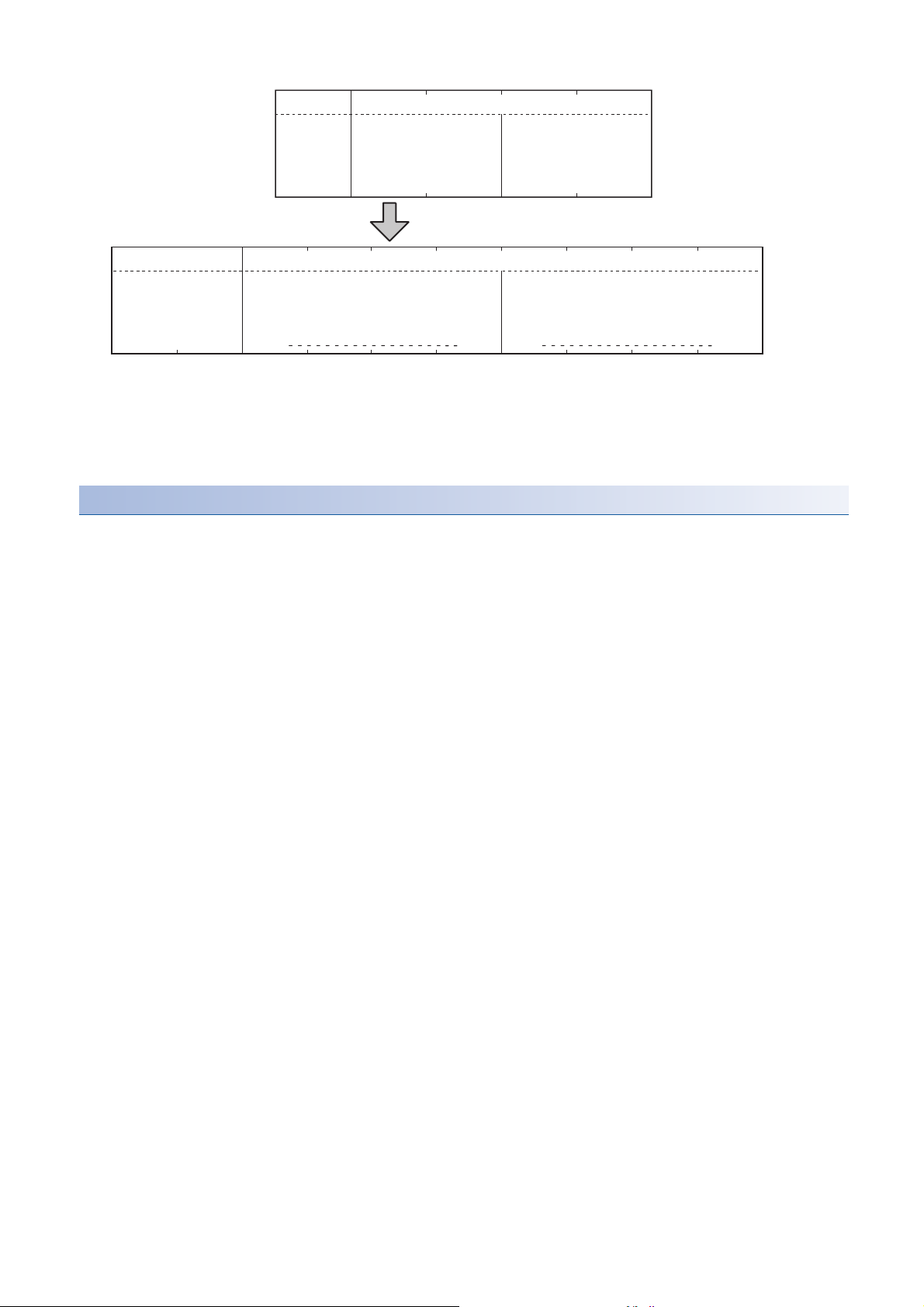

DataAddress field Function code Error check

Protocol data unit

Start

END

(Start)

DataAddress field Function code Error check Address field

3.5 character time

or more

1 byte 1 byte

0 to 252 bytes

2 bytes

3.5 character time

or more

1 byte

Error check calculation range

1.1 MODBUS Protocol Frame Specifications

This section describes the frame specifications of the MODBUS protocol.

Area name Description

Address field ■When request message is sent from the master to a slave

Protocol data unit Function code ■When request message is sent from the master to a slave

Data ■When request message is sent from the master to a slave

Error check The master adds a check code in a request message and transmits the request message.

The following frame modes are available.

• RTU mode

• ASCII mode

The frame mode of C24 must be consistent with that of the target device.

• 0: Sends a request message to all the slaves. (Broadcast)

• 1 to 247: Stores the target slave station number.

■When response message is sent from a slave to the master

The host station number is stored when sending a response message.

Specifies the content of the processing instructed from the master to a slave.

■When response message is sent from a slave to the master

A requested function code is stored in the case of normal completion.

The most significant bit turns ON in the case of error completion.

Stores the request content of the processing.

■When response message is sent from a slave to the master

Stores the execution result of the processing.

The slave, which received the request message, recalculates the check code in the request message

and determines whether the message is correct or not.

The message is discarded if it has an error.

The error check method differs depending on the frame mode.

6

RTU mode

In this mode, frames are received or sent in binary codes.

The frame specifications are compliant with the MODBUS protocol specifications.

Error check in RTU mode

The error check in the RTU mode is conducted by CRC (Cyclic Redundancy Check).

C24 calculates the CRC by the following steps.

Follow the same steps to calculate the CRC when conducting an error check on the target device.

1. Load the 16-bit register whose bits are all '1'.

2. The CRC is calculated every 8 bits from the upper bit of the frame.

Calculate the exclusive OR (XOR) from the 8 bits of the frame and the bits of the step 1.

3. Shift the result of step 2 by 1 bit to the right.

1 FRAME SPECIFICATIONS

1.1 MODBUS Protocol Frame Specifications

Page 9

4. If the least significant bit of the step 2 is '1', calculate the exclusive OR (XOR) from the result of step 3 and the generator

Ex.

polynomial (A001H).

If the least significant bit is '0', do not calculate the exclusive OR (XOR), but shift it by 1 bit to the right.

5. Repeat the step 3 and 4 until the bit is shifted up to 8 times.

6. Calculate the exclusive OR (XOR) from the result of step 5 and the next 8 bits of the frame.

7. Repeat the step 3 to 6.

8. Repeat the above operations until the end of the data unit is reached. The final value is a calculated CRC value.

9. The CRC value is stored in the frame in the order of lower 8 bits to upper 8 bits.

The following is a calculation example in the case where function code 07H is sent to station No.2.

Error check range is as follows:

• Address field (1 byte): 02H

• Function code (1 byte): 07H

• Data (0 bytes)

CRC error checking procedure 16-bit register (MSB) Flag

1 Loa d the 1 6 -b i t reg i ste r w hos e b its a re al l '1' . 16 - bit r egis t er w h o se b i ts a r e all ' 1'. 1111 1111 1111 1111

2 Calculate the exclusive OR (XOR) from the first 8 bits of the

frame and the bits in the above.

3 S h ift b y 1 bi t t o th e rig h t . Sh i ft 1 0111 1111 1111 111 0 1

4 Since the flag is '1', calculate the exclusive OR (XOR) from the

result in 'Shift 1' and generator polynomial (A001H).

5 S h ift b y 1 bi t t o th e rig h t . Sh i ft 2 011 0 1111 1111 1111 1

Since the flag is '1', calculate the exclusive OR (XOR) from the

result in 'Shift 2' and generator polynomial (A001H).

Sh i ft b y 1 bit t o the r igh t . Sh i f t 3 0110 0 111 1111 1111 0

Sh i ft b y 1 bit t o the r igh t . Sh i f t 4 0011 0 011 1111 1111 1

Since the flag is '1', calculate the exclusive OR (XOR) from the

result in 'Shift 4' and generator polynomial (A001H).

Sh i ft b y 1 bit t o the r igh t . Sh i f t 5 010 0 100 1 1111 1111 0

Sh i ft b y 1 bit t o the r igh t . Sh i f t 6 001 0 010 0 1111 1111 1

Since the flag is '1', calculate the exclusive OR (XOR) from the

result in 'Shift 6' and generator polynomial (A001H).

Sh i ft b y 1 bit t o the r igh t . Sh i f t 7 010 0 001 0 0111 1111 0

Shift by 1 bit to the right. Shift 8 0010 0001 0011 1111 1

Since the flag is '1', calculate the exclusive OR (XOR) from the

result in 'Shift 8' and generator polynomial (A001H).

6 Calculate the exclusive OR (XOR) from the next 8 bits of the

frame and the bits in the above.

Address field (02H) 0000 0010

Ex c lus i ve OR ( XOR ) 1111 1111 1111 11 0 1

Generator polynomial (A001H) 1010 0000 0000 0001

Ex c lus i ve OR ( XOR ) 110 1 1111 1111 1111

Generator polynomial (A001H) 1010 0000 0000 0001

Ex c lus i ve OR ( XOR ) 110 0 1111 1111 111 0

Generator polynomial (A001H) 1010 0000 0000 0001

Ex c lus i ve OR ( XOR ) 10 0 1 00 11 1111 111 0

Generator polynomial (A001H) 1010 0000 0000 0001

Ex c lus i ve OR ( XOR ) 10 0 0 01 0 0 1111 111 0

Generator polynomial (A001H) 1010 0000 0000 0001

Exclusive OR (XOR) 1000 0001 0011 1110

Function code (07H) 0000 0111

Exclusive OR (XOR) 1000 0001 0011 1001

*1

1

1 FRAME SPECIFICATIONS

1.1 MODBUS Protocol Frame Specifications

7

Page 10

Ex.

CRC error checking procedure 16-bit register (MSB) Flag

Start END

:

(3AH)

CR + LF

(0DH) (0AH)

Address field

2 characters

Function code

2 characters

Data Error check

n x 2 characters

(n = 0 to 252)

2 characters

Error check calculation range

7 Shift by 1 bit to the right. Shift 1 0100 0000 1001 1100 1

Since the flag is '1', calculate the exclusive OR (XOR) from the

result in 'Shift 1' and generator polynomial (A001H).

Shift by 1 bit to the right. Shift 2 0111 0000 0100 1110 1

Since the flag is '1', calculate the exclusive OR (XOR) from the

result in 'Shift 2' and generator polynomial (A001H).

Shift by 1 bit to the right. Shift 3 0110 1000 0010 0111 1

Since the flag is '1', calculate the exclusive OR (XOR) from the

result in 'Shift 3' and generator polynomial (A001H).

Shift by 1 bit to the right. Shift 4 0110 0100 0001 0011 0

Shift by 1 bit to the right. Shift 5 0011 0010 0000 1001 1

Since the flag is '1', calculate the exclusive OR (XOR) from the

result in 'Shift 5' and generator polynomial (A001H).

Shift by 1 bit to the right. Shift 6 0100 1001 0000 0100 0

Shift by 1 bit to the right. Shift 7 0010 0100 1000 0010 0

Shift by 1 bit to the right. Shift 8 0001 0010 0100 0001 0

8 The final value is a calculated CRC value. CRC value 12H 41H

*1 The least significant bit from the previous exclusive OR (XOR)

Generator polynomial (A001H) 1010 0000 0000 0001

Exclusive OR (XOR) 1110 0000 1001 1101

Generator polynomial (A001H) 1010 0000 0000 0001

Ex c lus i ve OR ( XOR ) 110 1 000 0 01 0 0 1111

Generator polynomial (A001H) 1010 0000 0000 0001

Exclusive OR (XOR) 1100 1000 0010 1110

Generator polynomial (A001H) 1010 0000 0000 0001

Exclusive OR (XOR) 1001 0010 0000 1000

Data is stored as follows:

Address field Function code Error check

Lower 8 bits of the CRC value Upper 8 bits of the CRC value

02H 07H 41H 12H

*1

ASCII mode

In this mode, frames are received or sent in units of 2 characters (2 bytes) in ASCII codes.

The frame specifications are compliant with the MODBUS protocol specifications.

Error check in ASCII mode

The error check in the ASCII mode is conducted by LRC (Longitudinal Redundancy Check).

C24 calculates the LRC by the following steps.

Follow the same steps to calculate the LRC when conducting an error check on the target device.

1. To calculate the LRC, convert the ASCII codes within the error check range into the RTU format (binary).

2. Add the figures in units of contiguous 8 bits in the frame. (Excluding carries during addition.)

3. Change the result of step 2 to a 2's complement. (Reverse the bits and add 01H.)

4. Convert the result of step 3 to an ASCII code.

The following are calculation examples in the case where function code 01H is sent to station No.2.

Error check range of the request message is as follows:

• Address field (1 byte): 02H

• Function code (1 byte): 01H

8

1 FRAME SPECIFICATIONS

1.1 MODBUS Protocol Frame Specifications

Page 11

• Data (2 bytes): Start coil number specification (0000H), Number of read points (0008H)

Error check procedure LRC in request message transmission

1 Convert the ASCII codes within the error check range into the RTU format

(binary).

2 Add the figures. (Excluding carries during addition.) Addition result 0000 1011

3 C h ang e the r e sul t t o a 2 ' s com p leme n t. ( R eve r s e th e b its a n d ad d 01H . ) Rev e r sed b it va l ue 1111 010 0

4 Convert the result to an ASCII code. LRC value (ASCII code) F 5

Address field (02H) 0000 0010

Function code (01H) 0000 0001

Start coil number specification (H) 0000 0000

Start coil number specification (L) 0000 0000

Read points (H) 0000 0000

Read points (L) 0000 1000

01H 0000 0001

LR C val u e 1111 010 1

46H 35H

Data is stored in ASCII code as follows:

Data

category

Value 02H 01H 0000H 0008H F5H

Character0 2 0 1 00000008F5

RTU (binary) 0000 0010 0000 0001 0000 0000 0000 0000 0000 0000 0000 1000 1111 0101

ASCII code 30H 32H 30H 31H 30H 30H 30H 30H 30H 30H 30H 38H 46H 35H

Address field Function code Start coil number

specification

Read points Error check

1

The slave, which received the request message, recalculates the check code in the request message and determines

whether the message is correct or not.

Error check procedure LRC check when receiving a request message

1 Convert the ASCII codes within the error check range into the RTU format

(binary).

2 Add the LRC value. (Excluding carries during addition.)

Normally, the addition result is zero.

Address field (02H) 0000 0010

Function code (01H) 0000 0001

Start coil number specification (H) 0000 0000

Start coil number specification (L) 0000 0000

Read points (H) 0000 0000

Read points (L) 0000 1000

LR C val u e 1111 010 1

Addition result 0000 0000

1 FRAME SPECIFICATIONS

1.1 MODBUS Protocol Frame Specifications

9

Page 12

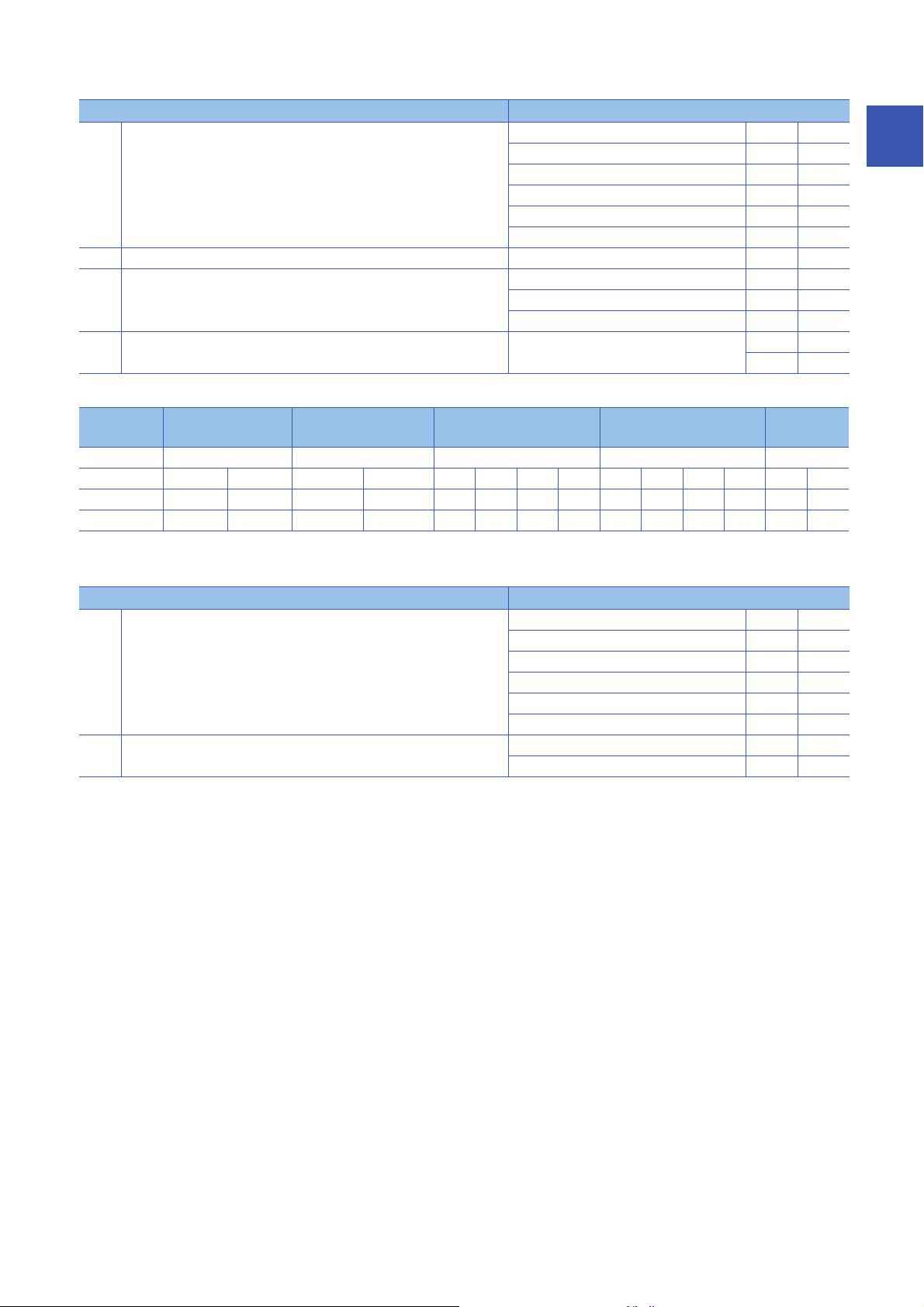

1.2 MODBUS/TCP Protocol Frame Specifications

FCSEthernet

header

Application dataIP header TCP header

(Error check)

MODBUS/TCP frame

MODBUS/TCP application data unit

MODBUS application header

Transaction IDProtocol ID Message

length

Module ID Function code Data

Protocol data unit

This section describes the frame specifications of the MODBUS/TCP protocol.

Area name Area size Description

MODBUS application header Communication ID 2 bytes Used by the master to match response messages from slaves.

Protocol ID 2 bytes Indicates the protocol of the protocol data unit.

For MODBUS/TCP, 0 is stored.

Message length 2 bytes Stores the message size in bytes.

Module ID 1 byte Used when specifying slaves connected to other lines, such as with

Protocol data unit Function code 1 byte Specifies the content of the processing instructed from the master to a

Data 1 to 252 bytes ■When request message is sent from the master to a slave

The stored message length indicates the length of the message in

areas subsequent to this area.

the MODBUS Serial protocol.

slave.

Stores the request content of the processing.

■When response message is sent from a slave to the master

Stores the execution result of the processing.

10

1 FRAME SPECIFICATIONS

1.2 MODBUS/TCP Protocol Frame Specifications

Page 13

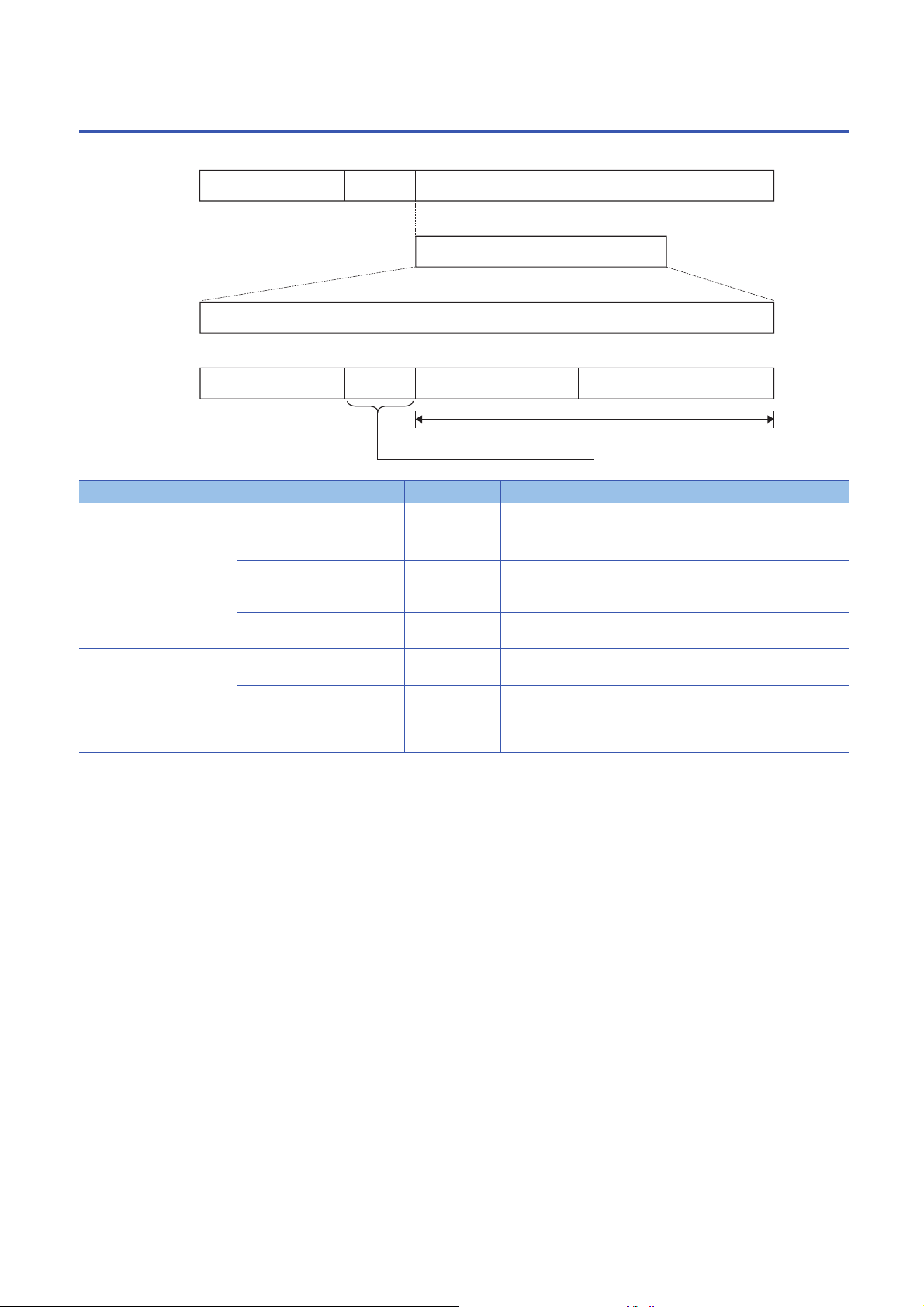

1.3 Protocol Data Unit Formats Grouped by Function

Ex.

(H) (L)

(1)

(H) (L)

02H 001FH 0001H

Start input number specification

Data

Number of read points

Function code

(H) (L) (H) (L)

01H

(1)

(2)

(3)

(4)

Start coil number specification

Data

Number of read points

Function code

1 byte

(8 bits)

1 byte

(8 bits)

(0000H to FFFFH) (0001H to 07D0H)

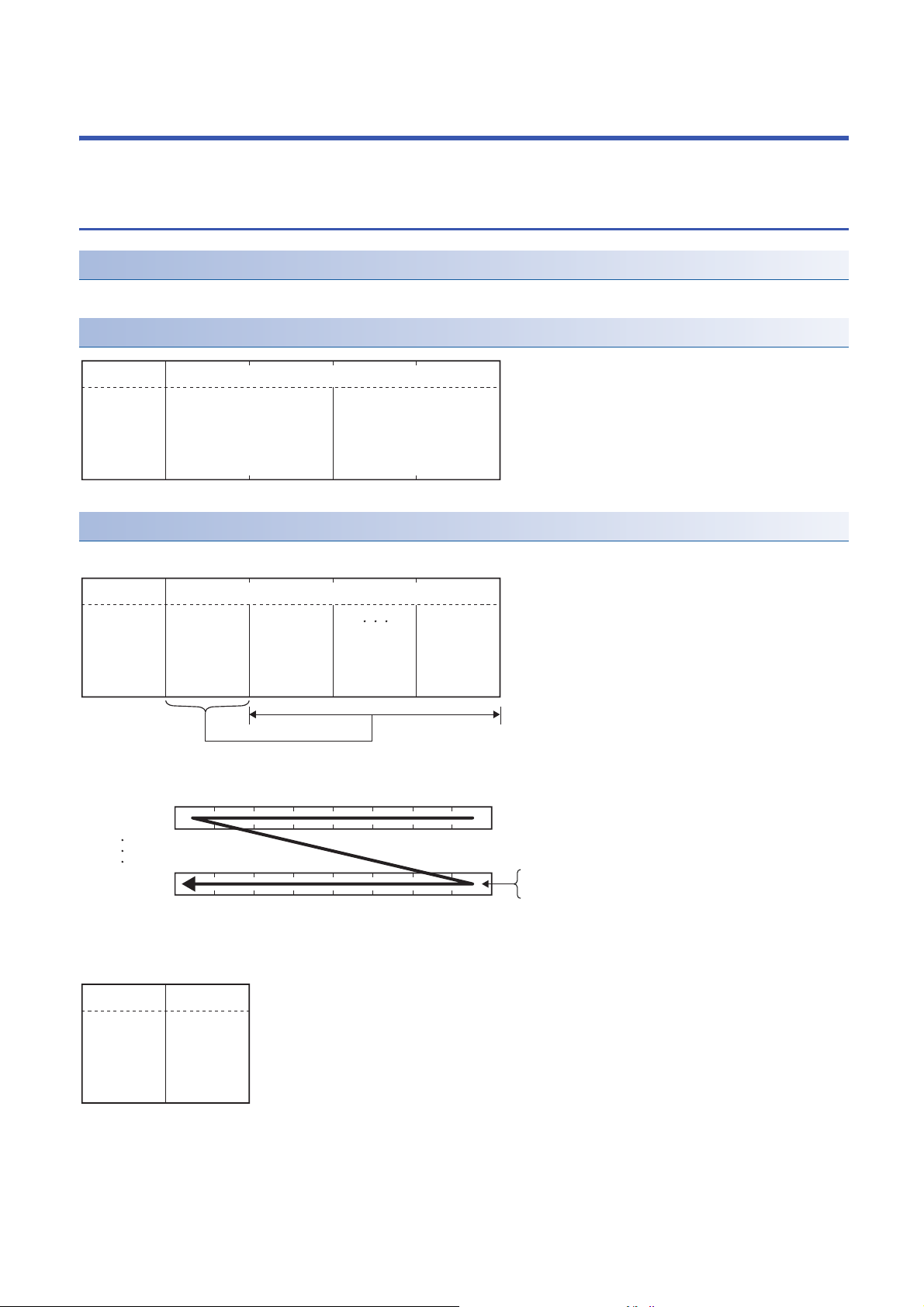

This section describes the protocol data unit formats of the MODBUS standard functions.

When the device number is specified within the message

When specifying the device number within the message, specify "device number - 1".

However, this instruction is not applicable to the file number and the device number specified for reading or writing extended

file register.

When the status of input 32 (100032) is read by the read discrete inputs (function code: 02H)

(1) When reading the status of input 32 (100032), specify 31 (001FH) for the start input number.

The device number stored in the response message is "the device number of the device that actually performed reading/

writing - 1".

Descriptions of request message and response message formats

This section describes descriptions of the request message and response message formats of the MODBUS standard

functions.

1

■ Message format for MODBUS RTU mode and MODBUS/TCP

(1) Area name

(2) Frame description

(3) For request message format: Setting range

For response message format: Value stored in the response message

(4) When one piece of data consists of two bytes, the upper byte (eight bits) is (H) and the lower byte (eight bits) is (L).

■ Message format for MODBUS ASCII mode

The message format shown in Chapter 3 is for RTU mode or MODBUS/TCP.

In the ASCII mode, read the values shown in Chapter 3 in ASCII code.

1 FRAME SPECIFICATIONS

1.3 Protocol Data Unit Formats Grouped by Function

11

Page 14

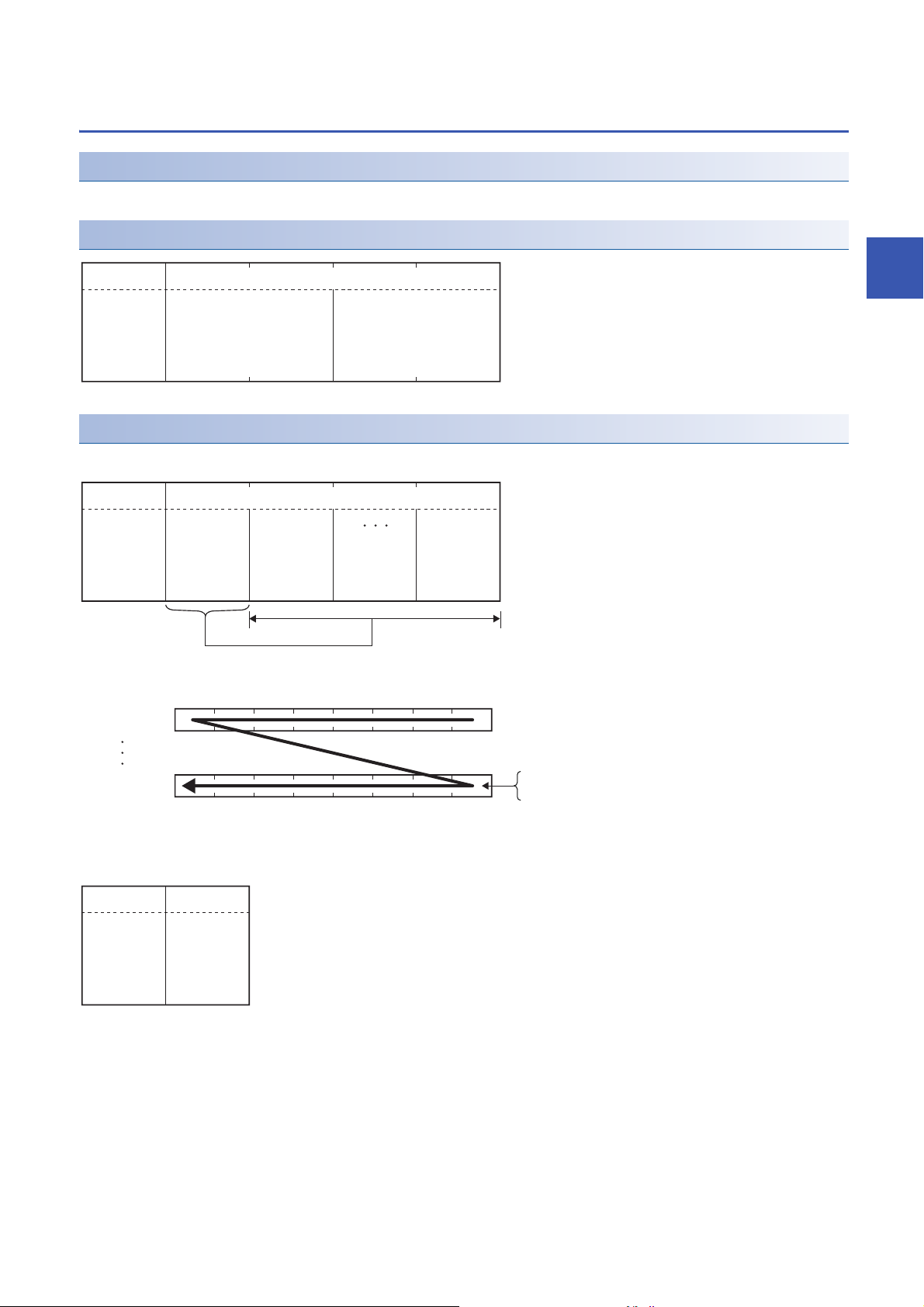

■ Response message format

(H) (L) (H) (L)

01H

(H) (L) (H) (L) (H)

(L)

(30H) (31H) (30H) (30H) (36H) (45H) (30H) (30H) (33H) (46H)

0 FE61 30000

(006EH) (003FH)

Start coil number specification

Data

Number of read points

Function code

Data

Start coil number specification

Number of read points

Function code

(RTU mode)

(ASCII mode)

Convert RTU mode to ASCII mode

The format of the response message sent from a slave to the master varies depending on whether the processing performed

by the slave completed successfully or completed with an error.

In the MODBUS standard function, the formats when completed successfully and completed with an error are described in the

response message format.

Storage locations of exception code and error code

When processing on a slave is completed with an error, an exception code is sent to the master.

For details on exception codes, refer to the following.

Page 50 EXCEPTION CODES

Exception codes are also stored in the buffer memory of modules.

The detailed cause is detected as an error by modules.

For details on the buffer memory and errors of modules, refer to the following.

MELSEC iQ-R Ethernet User's Manual (Application)

MELSEC iQ-R Serial Communication Module User's Manual(Application)

12

1 FRAME SPECIFICATIONS

1.3 Protocol Data Unit Formats Grouped by Function

Page 15

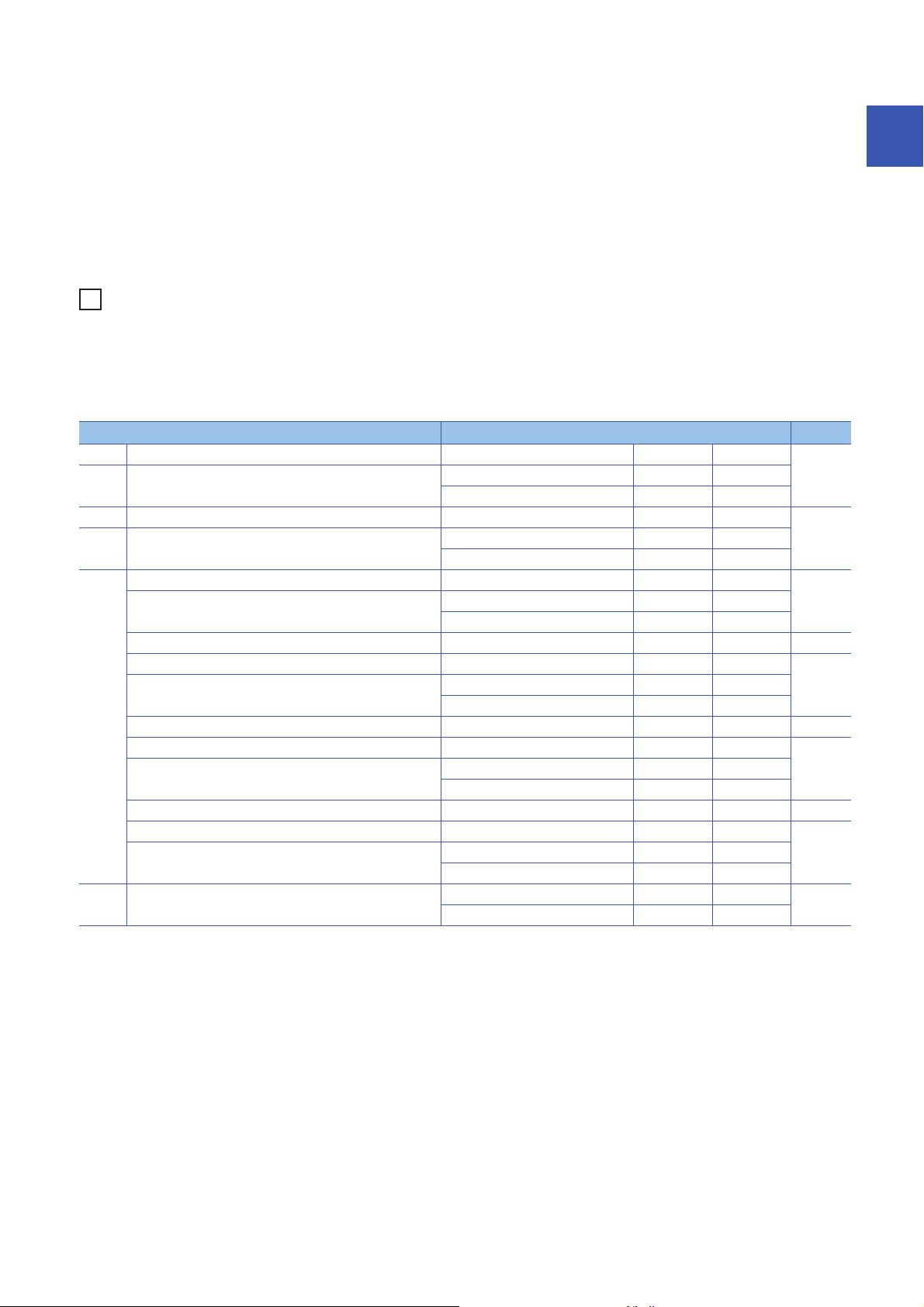

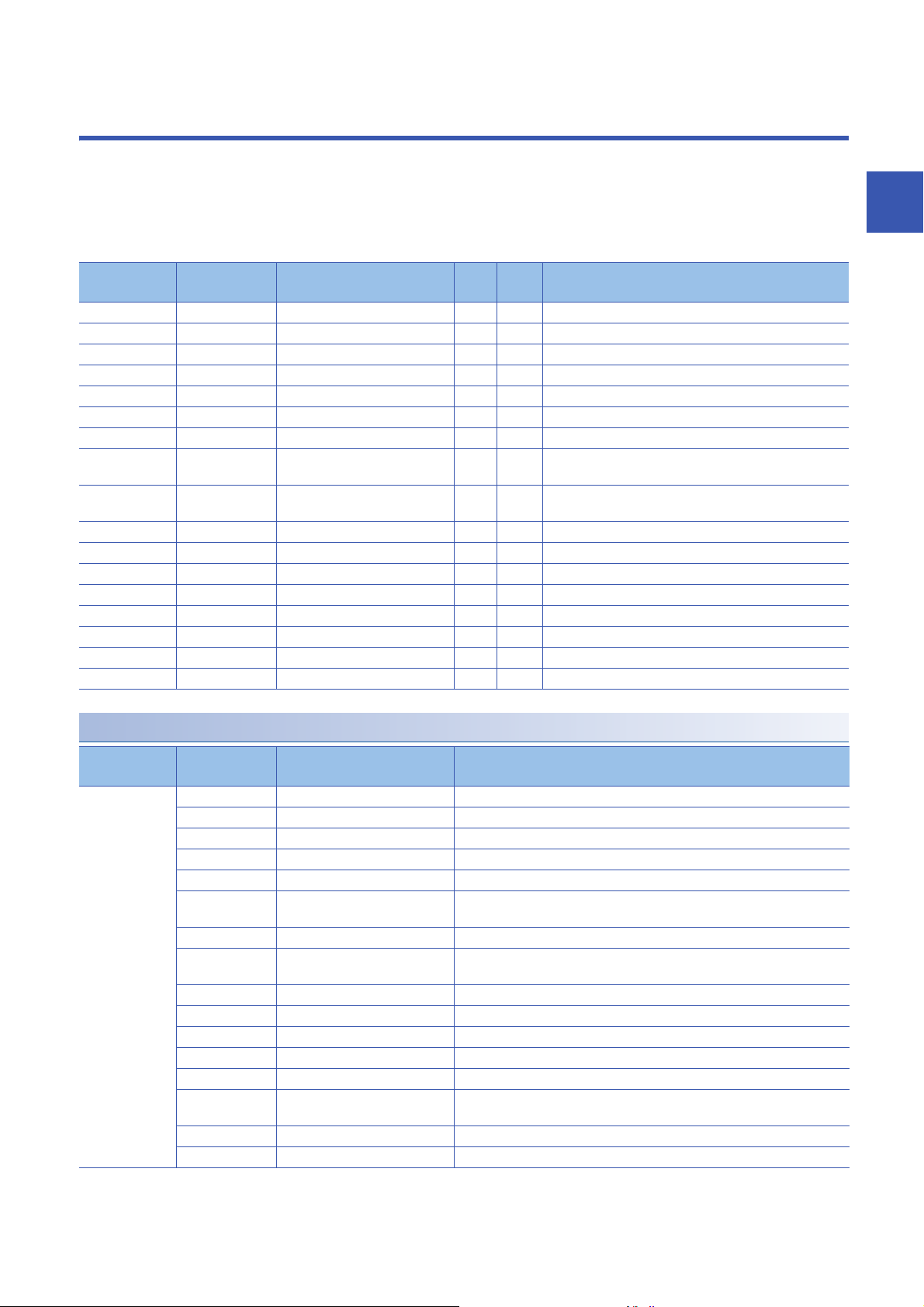

2 MODBUS STANDARD FUNCTION LIST

This chapter lists the MODBUS standard functions and availability for modules when using the slave function.

The modules are abbreviated as follows:

• C24: RJ71C24, RJ71C24-R2, RJ71C24-R4

• E71: RJ71EN71, R04ENCPU, R08ENCPU, R16ENCPU, R32ENCPU, R120ENCPU

: Available, : Not available

Function code

(FC)

01H Read coils Page 14 Read Coils (FC: 01H)

02H Read discrete inputs Page 15 Read Discrete Inputs (FC: 02H)

03H Read holding registers Page 16 Read Holding Registers (FC: 03H)

04H Read input registers Page 17 Read Input Registers (FC: 04H)

05H Write single coil Page 18 Write Single Coil (FC: 05H)

06H Write single register Page 19 Write Single Register (FC: 06H)

07H Read exception status Page 20 Read Exception Status (FC: 07H)

08H Page 13 Diagnosis function

0BH Get communications event

0CH Get communications event log Page 39 Get Communications Event Log (FC: 0CH)

0FH Write multiple coils Page 41 Write Multiple Coils (FC: 0FH)

10H Write multiple registers Page 42 Write Multiple Registers (FC: 10H)

11H Report slave ID Page 43 Report Slave ID (FC: 11H)

14H 06H Read file record Page 45 Read File Record (FC: 14H) (SC: 06H)

15H 06H Write file record Page 47 Write File Record (FC: 15H) (SC: 06H)

16H Mask write register Page 48 Mask Write Register (FC: 16H)

17H Read/Write multiple registers Page 49 Read/Write Multiple Registers (FC: 17H)

Sub code (SC) Function name C24 E71 Reference

Page 21 Diagnostics (FC: 08H)

details

Page 38 Get Communications Event Counter (FC: 0BH)

counter

2

Diagnosis function details

Function code

(FC)

08H 0000H Return query data Page 22 Return query data (sub-function code: 00H)

Sub-function

code

0001H Restart communications option Page 23 Restart communications option (sub-function code: 01H)

0002H Return diagnostic register Page 24 Return diagnostic register (sub-function code: 02H)

0003H Change ASCII input delimiter Page 25 Change ASCII input delimiter (sub-function code: 03H)

0004H Force listen only mode Page 26 Force listen only mode (sub-function code: 04H)

000AH Clear counters and diagnostic

000BH Return bus message count Page 28 Return bus message count (sub-function code: 0BH)

000CH Return bus communication error

000DH Return bus exception error count Page 30 Return bus exception error count (sub-function code: 0DH)

000EH Return slave message count Page 31 Return slave message count (sub-function code: 0EH)

000FH Return slave no response count Page 32 Return slave no response count (sub-function code: 0FH)

0010H Return slave NAK count Page 33 Return slave NAK count (sub-function code: 10H)

0011H Return slave busy count Page 34 Return slave busy count (sub-function code: 11H)

0012H Return bus character overrun

0013H Return IOP overrun error count Page 36 Return IOP overrun error count (sub-function code: 13H)

0014H Clear overrun counter and flag Page 37 Clear overrun counter and flag (sub-function code: 14H)

Function name Reference

Page 27 Clear counters and diagnostic register (sub-function code: 0AH)

register

Page 29 Return bus communication error count (sub-function code: 0CH)

count

Page 35 Return bus character overrun count (sub-function code: 12H)

count

2 MODBUS STANDARD FUNCTION LIST

13

Page 16

3 MODBUS STANDARD FUNCTION DETAILS

(H) (L) (H) (L)

01H

Data

Number of read pointsStart coil number specification

Function code

(0000H to FFFFH) (0001H to 07D0H)

01H

DataFunction code

Number of read

bytes n

Device data 1 Device data n

Number of read bytes n

b0b1b2b3b4b5b6b7

0: OFF

1: ON

Device data 1

Device data n

Bit device storage order

81H

Data

Exception code

Function code

This chapter describes protocol data unit formats.

3.1 Read Coils (FC: 01H)

Operation description

Reads the status (ON/OFF) of one or multiple coils.

Request message format (from master to slave)

Response message format (from slave to master)

■ When completed successfully

14

• Device data 1 to n

• The read coil status is stored in the order of lower bit to higher bit.

• If the number of read points is not a multiple of eight, the remaining bits are all set to 0.

■ When completed with an error

3 MODBUS STANDARD FUNCTION DETAILS

3.1 Read Coils (FC: 01H)

Page 17

3.2 Read Discrete Inputs (FC: 02H)

(H) (L) (H) (L)

02H

Start input number specification

Data

Number of read points

Function code

(0000H to FFFFH) (0001H to 07D0H)

02H

DataFunction code

Number of read

bytes n

Device data 1 Device data n

Number of read bytes n

b0b1b2b3b4b5b6b7

0: OFF

1: ON

Device data 1

Device data n

Bit device storage order

82H

Data

Exception code

Function code

Operation description

Reads the status (ON/OFF) of one or multiple inputs.

Request message format (from master to slave)

Response message format (from slave to master)

■ When completed successfully

3

• Device data 1 to n

• The read input status is stored in the order of lower bit to higher bit.

• If the number of read points is not a multiple of eight, the remaining bits are all set to 0.

■ When completed with an error

3 MODBUS STANDARD FUNCTION DETAILS

3.2 Read Discrete Inputs (FC: 02H)

15

Page 18

3.3 Read Holding Registers (FC: 03H)

(H) (L) (H) (L)

03H

Start holding register number

specification

Data

Number of read points

Function code

(0000H to FFFFH) (0001H to 007DH)

03H

(H) (L) (H) (L)

DataFunction code

Number of read

bytes n×2

Device data 1 Device data n

Number of read bytes n×2

83H

Data

Exception code

Function code

Operation description

Reads one or multiple holding register values.

Request message format (from master to slave)

Response message format (from slave to master)

■ When completed successfully

• For example, when n = 4, the number of read bytes is 4 2 = 8.

■ When completed with an error

16

3 MODBUS STANDARD FUNCTION DETAILS

3.3 Read Holding Registers (FC: 03H)

Page 19

3.4 Read Input Registers (FC: 04H)

(H) (L) (H) (L)

04H

Data

Number of read pointsStart input register number

specification

Function code

(0000H to FFFFH) (0001H to 007DH)

04H

(H) (L) (H) (L)

DataFunction code

Number of read

bytes n×2

Device data 1 Device data n

Number of read bytes n×2

84H

Data

Exception code

Function code

Operation description

Reads one or multiple input register values.

Request message format (from master to slave)

Response message format (from slave to master)

■ When completed successfully

3

• For example, when n = 4, the number of read bytes is 4 2 = 8.

■ When completed with an error

3 MODBUS STANDARD FUNCTION DETAILS

3.4 Read Input Registers (FC: 04H)

17

Page 20

3.5 Write Single Coil (FC: 05H)

(H) (L) (H) (L)

05H

FF00H: ON

0000H: OFF

Coil number specification

Data

ON/OFF specification

Function code

(0000H to FFFFH)

85H

Data

Exception code

Function code

Operation description

Writes a value (ON/OFF) to one coil.

Request message format (from master to slave)

Response message format (from slave to master)

■ When completed successfully

The slave returns the request message received from the master as-is.

■ When completed with an error

18

3 MODBUS STANDARD FUNCTION DETAILS

3.5 Write Single Coil (FC: 05H)

Page 21

3.6 Write Single Register (FC: 06H)

(H) (L) (H) (L)

06H

Holding register number

specification

Data

Write data

Function code

(0000H to FFFFH) (0000H to FFFFH)

86H

Data

Exception code

Function code

Operation description

Writes a value to one holding register area.

Request message format (from master to slave)

Response message format (from slave to master)

■ When completed successfully

The slave returns the request message received from the master as-is.

■ When completed with an error

3

3 MODBUS STANDARD FUNCTION DETAILS

3.6 Write Single Register (FC: 06H)

19

Page 22

3.7 Read Exception Status (FC: 07H)

07H

Function code

07H

Data

Error information

Function code

87H

Data

Exception code

Function code

Operation description

Reads the error status.

Request message format (from master to slave)

Response message format (from slave to master)

■ When completed successfully

In the error information, the specified device data by "Specifying the error status" of the parameter is stored.

MELSEC iQ-R Serial Communication Module User's Manual(Application)

■ When completed with an error

20

3 MODBUS STANDARD FUNCTION DETAILS

3.7 Read Exception Status (FC: 07H)

Page 23

3.8 Diagnostics (FC: 08H)

Executes the various diagnostics and checks the C24 status and communication status.

In the diagnostics, a sub-function code is specified after a function code with a request message.

Checking communication conditions using a diagnostic counter

When using the MODBUS slave function, the number of error occurrences during communication is stored in a diagnostic

counter.

The communication status of MODBUS can be checked by a diagnostic counter of the MODBUS standard function.

■ Diagnostic counter

Counter Buffer memory MODBUS standard function

Typ e Description CH1 CH2

Bus message count

Bus communication error

*1

count

Exception error count Counts the number of exception error occurrences.

Slave message count Counts the number of times that messages addressed to the

Slave no-response count Counts the number of times that broadcast request messages

Slave NAK count Refers to the number of times that NAK responses were

Slave busy count Refers to the number of times that busy responses were

Character overrun count Counts the number of times that the request message size

*1

Counts the number of messages detected on the line. 32512

Counts the number of the following error messages detected on

the line.

• CRC/LRC error message

• Overrun/parity error

• Short frame (less than 3 bytes)

• Character overrun (256 bytes or more)

Messages other than the above are counted by the bus

message count.

(Including broadcast messages)

host were processed.

(Including when broadcast request messages were received)

were received.

received in a master device.

It is always '0' in C24s.

received in a master device.

It is always '0' in C24s.

exceeded the upper limit.

(7F00H)

32513

(7F01H)

32522

(7F0AH)

32518

(7F06H)

32519

(7F07H)

32520

(7F08H)

32521

(7F09H)

32514

(7F02H)

32576

(7F40H)

32577

(7F41H)

32586

(7F4AH)

32582

(7F46H)

32583

(7F47H)

32584

(7F48H)

32585

(7F49H)

32578

(7F42H)

Page 28 Return bus message

count (sub-function code: 0BH)

Page 29 Return bus

communication error count (subfunction code: 0CH)

Page 30 Return bus exception

error count (sub-function code: 0DH)

Page 31 Return slave message

count (sub-function code: 0EH)

Page 32 Return slave no response

count (sub-function code: 0FH)

Page 33 Return slave NAK count

(sub-function code: 10H)

Page 34 Return slave busy count

(sub-function code: 11H)

Page 35 Return bus character

overrun count (sub-function code: 12H)

Page 36 Return IOP overrun error

count (sub-function code: 13H)

3

*1 The bus message count is in an exclusive relationship with the bus communication error count.

■ Count range

0000H to FFFFH are counted.

The count is stopped if it has reached FFFFH. To continue, clear the counter.

■ Methods for clearing a counter

A counter can be cleared by any of the following methods:

• Turning the power OFF and ON

• Resetting a CPU module

• Clearing the buffer memory to '0' by using a sequence program

• Receiving the following MODBUS standard functions

Counter to be cleared MODBUS standard function

All diagnostic counters shown above Page 23 Restart communications option (sub-function code: 01H)

Page 27 Clear counters and diagnostic register (sub-function code: 0AH)

Character overrun count Page 37 Clear overrun counter and flag (sub-function code: 14H)

3 MODBUS STANDARD FUNCTION DETAILS

3.8 Diagnostics (FC: 08H)

21

Page 24

Return query data (sub-function code: 00H)

(H) (L)

08H (0000H)

DataFunction code Sub-function code

Arbitrary data

88H

Data

Exception code

Function code

Operation description

Returns the contents of the request message without change.

Used to check if the network or the target device is operating normally. (Loopback test)

Request message format (from master to slave)

Response message format (from slave to master)

■ When completed successfully

The slave returns the request message received from the master as-is.

■ When completed with an error

22

3 MODBUS STANDARD FUNCTION DETAILS

3.8 Diagnostics (FC: 08H)

Page 25

Restart communications option (sub-function code: 01H)

(H) (L)

08H (0001H)

(H) (L)

DataFunction code Sub-function code

Clear setting of

Communications event log

FF00H: Clear

0000H: Not clear

88H

Data

Exception code

Function code

Operation description

Initializes the communication port of the receiving channel side and restarts the slave function.

Restart is performed after returning the response message corresponding to a request message.

The operation status returns to online mode when it was in the listen only mode.

The following data are cleared when executing the restart communications option.

• Data being received

• 'CH1/2 side LED lighting status and communication error status' of the buffer memory (Un\G513/Un\G514)

• 'CH1/2 side exception code storage area' of the buffer memory (Un\G28674/Un\G28676)

*1

• Diagnostic counter (Page 21 Checking communication conditions using a diagnostic counter)

• ERR LED and C ERR LED OFF

*2

• Communications event count (Page 38 Get Communications Event Counter (FC: 0BH))

*1 Clears only the receiving channel side area.

*2 Clears the errors of the channel that has received the request message.

As the errors of other channels are not cleared, the LED will not turn OFF if an error has occurred on any other channel.

Clears the the following data when "Clear setting of the communications event log" is specified with "FF00H (clear)" in the

request message.

• Communications event log (Page 39 Get Communications Event Log (FC: 0CH))

Request message format (from master to slave)

*1

3

Response message format (from slave to master)

■ When completed successfully

The slave returns the request message received from the master as-is.

■ When completed with an error

3 MODBUS STANDARD FUNCTION DETAILS

3.8 Diagnostics (FC: 08H)

23

Page 26

Return diagnostic register (sub-function code: 02H)

(H) (L)

08H (0002H) (0000H)

(H) (L)

DataFunction code Sub-function code

(H) (L)

08H (0002H)

(H) (L)

b0b1b2b3b4b5b6b7b8b9b10b11b12b13b14b15

0 0 0 1/0 1/0 1/0 1/0 1/0 0 0 0 1/0 1/0 1/0 1/0 1/0

CH1 C/N

CH1 P/S

CH1 PRO.

CH1 SIO

CH1 ERR.

CH2 C/N

CH2 P/S

CH2 PRO.

CH2 SIO

CH2 ERR.

DataFunction code Sub-function code

Diagnostic register value

CH1 side Detailed

LED status

(0: OFF, 1: ON)

CH2 side Detailed

LED status

(0: OFF, 1: ON)

Unused (Fixed to 0)

Unused (Fixed to 0)

88H

Data

Exception code

Function code

Operation description

Reads out the detailed LED status of C24 to the master.

Request message format (from master to slave)

Response message format (from slave to master)

■ When completed successfully

In the C24, the detailed LED status of 'CH1/2 side LED lighting status and communication error status' of the buffer memory

(Un\G513/Un\G514) is stored as the diagnostic register.

■ When completed with an error

24

3 MODBUS STANDARD FUNCTION DETAILS

3.8 Diagnostics (FC: 08H)

Page 27

Change ASCII input delimiter (sub-function code: 03H)

Start END

CR + LF

(0DH) (0AH)

:

(3AH)

Address field

2 characters

Function code

2 characters

Data Error check

n x 2 characters

(n = 0 to 252)

2 characters

Change this into a specified data.

(H) (L)

08H (0003H) (00H)

DataFunction code Sub-function code

Input delimiter

setting

(00H to FFH)

88H

Data

Exception code

Function code

Operation description

Changes the 2nd byte (LF(0AH)) of the end code in the ASCII mode to a specified data.

The specified data is stored in '2nd byte of end code' of the buffer memory (Un\G32524/Un\G32588).

Request message format (from master to slave)

Response message format (from slave to master)

3

■ When completed successfully

The slave returns the request message received from the master as-is.

■ When completed with an error

This function is used only for 1:1 connections.

Do not use this function for 1:n connections.

3 MODBUS STANDARD FUNCTION DETAILS

3.8 Diagnostics (FC: 08H)

25

Page 28

Force listen only mode (sub-function code: 04H)

(H) (L)

08H (0004H) (0000H)

(H) (L)

DataFunction code Sub-function code

88H

Data

Exception code

Function code

Operation description

Places a slave into the offline mode.

Used when disconnecting a slave from the network.

When C24 is set in the listen only mode, the status is as follows:

• Ignores all request messages except for those of restart communications option. (Page 23 Restart communications

option (sub-function code: 01H))

• Stops counting of the diagnostic counter. (Page 21 Checking communication conditions using a diagnostic counter)

• Continues recording with the communications event log. (Page 39 Get Communications Event Log (FC: 0CH))

Request message format (from master to slave)

Response message format (from slave to master)

■ When completed successfully

No response message is returned because the listen only mode (offline status) is active.

■ When completed with an error

Whether the C24 has been switched to listen only mode or not can be checked in the 'Communications mode'

of the buffer memory (Un\G32525/32589).

• 0000H: Online mode

• 0001H: Listen only mode

The listen only mode can be changed to online mode by either of the following:

• Restart communications option (Page 23 Restart communications option (sub-function code: 01H))

• Turn the power OFF and ON, or reset the programmable controller CPU.

26

3 MODBUS STANDARD FUNCTION DETAILS

3.8 Diagnostics (FC: 08H)

Page 29

Clear counters and diagnostic register (sub-function code: 0AH)

(H) (L)

08H (000AH) (0000H)

(H) (L)

DataFunction code Sub-function code

88H

Data

Exception code

Function code

Operation description

Clears counters (e.g. message count).

Also, clears the diagnostic register and the error of the channel where the request message has been received.

The following counters will be cleared.

• Diagnostic counter (Page 21 Checking communication conditions using a diagnostic counter)

• Communications event count (Page 38 Get Communications Event Counter (FC: 0BH))

The following diagnostic resisters will be cleared.

• 'CH1/2 side LED lighting status and communication error status' of the buffer memory (Un\G513/Un\G514)

• 'CH1/2 side exception code storage area' of the buffer memory (Un\G28674/Un\G28676)

*1 Clears only the receiving channel side area.

*1

Request message format (from master to slave)

*1

3

Response message format (from slave to master)

■ When completed successfully

The slave returns the request message received from the master as-is.

■ When completed with an error

3 MODBUS STANDARD FUNCTION DETAILS

3.8 Diagnostics (FC: 08H)

27

Page 30

Return bus message count (sub-function code: 0BH)

(H) (L)

08H (000BH) (0000H)

(H) (L)

DataFunction code Sub-function code

(H) (L)

(H) (L)

08H (000BH)

Function code Sub-function code

Bus message count value

Data

(0000H to FFFFH)

88H

Data

Exception code

Function code

Operation description

Reads out the number of messages detected on the line to the master.

Request message format (from master to slave)

Response message format (from slave to master)

■ When completed successfully

Returns the count value of the buffer memory listed below to the master.

• 'Bus message count' (Un\G32512/Un\G32576)

Refer to the following for the counter descriptions, count range, and count clear methods.

Page 21 Checking communication conditions using a diagnostic counter

■ When completed with an error

28

3 MODBUS STANDARD FUNCTION DETAILS

3.8 Diagnostics (FC: 08H)

Page 31

Return bus communication error count (sub-function code: 0CH)

(H) (L)

08H (000CH) (0000H)

(H) (L)

DataFunction code Sub-function code

(H) (L)

(H) (L)

08H (000CH)

Function code Sub-function code

Bus communication

error count value

Data

(0000H to FFFFH)

88H

Data

Exception code

Function code

Operation description

Reads out the number of error messages detected on the line to the master.

Request message format (from master to slave)

Response message format (from slave to master)

■ When completed successfully

3

Returns the count value of the buffer memory listed below to the master.

• 'Bus communication error count' (Un\G32513/Un\G32577)

Refer to the following for the counter descriptions, count range, and count clear methods.

Page 21 Checking communication conditions using a diagnostic counter

■ When completed with an error

3 MODBUS STANDARD FUNCTION DETAILS

3.8 Diagnostics (FC: 08H)

29

Page 32

Return bus exception error count (sub-function code: 0DH)

(H) (L)

08H (000DH) (0000H)

(H) (L)

DataFunction code Sub-function code

(H) (L)

(H) (L)

08H (000DH)

Function code Sub-function code

Exception error count value

Data

(0000H to FFFFH)

88H

Data

Exception code

Function code

Operation description

Reads out the frequency of exception errors to the master.

Request message format (from master to slave)

Response message format (from slave to master)

■ When completed successfully

Returns the count value of the buffer memory listed below to the master.

• 'Exception error count' (Un\G332522/Un\G32586)

Refer to the following for the counter descriptions, count range, and count clear methods.

Page 21 Checking communication conditions using a diagnostic counter

■ When completed with an error

30

3 MODBUS STANDARD FUNCTION DETAILS

3.8 Diagnostics (FC: 08H)

Page 33

Return slave message count (sub-function code: 0EH)

(H) (L)

08H (000EH) (0000H)

(H) (L)

DataFunction code Sub-function code

(H) (L)

(H) (L)

08H (000EH)

Function code Sub-function code

Slave message count value

Data

(0000H to FFFFH)

88H

Data

Exception code

Function code

Operation description

Reads out the number of the slave message processing to the master (including receive of request messages from

broadcast).

Request message format (from master to slave)

Response message format (from slave to master)

■ When completed successfully

3

Returns the count value of the buffer memory listed below to the master.

• 'Slave message count' (Un\G32518/Un\G32582)

Refer to the following for the counter descriptions, count range, and count clear methods.

Page 21 Checking communication conditions using a diagnostic counter

■ When completed with an error

3 MODBUS STANDARD FUNCTION DETAILS

3.8 Diagnostics (FC: 08H)

31

Page 34

Return slave no response count (sub-function code: 0FH)

(H) (L)

08H (000FH) (0000H)

(H) (L)

DataFunction code Sub-function code

(H) (L)

(H) (L)

08H (000FH)

Function code Sub-function code

Slave no-response count value

Data

(0000H to FFFFH)

88H

Data

Exception code

Function code

Operation description

Reads to out the number of broadcast request messages received to the master.

Request message format (from master to slave)

Response message format (from slave to master)

■ When completed successfully

Returns the count value of the buffer memory listed below to the master.

• 'Slave no-response count' (Un\G32519/Un\G32583)

Refer to the following for the counter descriptions, count range, and count clear methods.

Page 21 Checking communication conditions using a diagnostic counter

■ When completed with an error

32

3 MODBUS STANDARD FUNCTION DETAILS

3.8 Diagnostics (FC: 08H)

Page 35

Return slave NAK count (sub-function code: 10H)

(H) (L)

08H (0010H) (0000H)

(H) (L)

DataFunction code Sub-function code

(H) (L)

(H) (L)

08H (0010H)

Function code Sub-function code

Slave NAK count value

Data

(0000H)

88H

Data

Exception code

Function code

Operation description

Reads out the number of NAK responses to the master.

Request message format (from master to slave)

Response message format (from slave to master)

■ When completed successfully

3

Returns the count value of the buffer memory listed below to the master.

• 'Slave NAK count' (Un\G32520/Un\G32584)

It is always '0' in C24s.

■ When completed with an error

3 MODBUS STANDARD FUNCTION DETAILS

3.8 Diagnostics (FC: 08H)

33

Page 36

Return slave busy count (sub-function code: 11H)

(H) (L)

08H (0011H) (0000H)

(H) (L)

DataFunction code Sub-function code

(H) (L)

(H) (L)

08H (0011H)

Function code Sub-function code

Slave busy count value

Data

(0000H)

88H

Data

Exception code

Function code

Operation description

Reads out the number of busy responses to the master.

Request message format (from master to slave)

Response message format (from slave to master)

■ When completed successfully

Returns the count value of the buffer memory listed below to the master.

• 'Slave busy count' (Un\G32521/Un\G32585)

It is always '0' in C24s.

■ When completed with an error

34

3 MODBUS STANDARD FUNCTION DETAILS

3.8 Diagnostics (FC: 08H)

Page 37

Return bus character overrun count (sub-function code: 12H)

(H) (L)

08H (0012H) (0000H)

(H) (L)

DataFunction code Sub-function code

(H) (L)

(H) (L)

08H (0012H)

Function code Sub-function code

Bus character overrun

count value

Data

(0000H to FFFFH)

88H

Data

Exception code

Function code

Operation description

To the master, reads out the number of times the request message size exceeds the upper limit.

Request message format (from master to slave)

Response message format (from slave to master)

■ When completed successfully

3

Returns the count value of the buffer memory listed below to the master.

• 'Character overrun count' (Un\G32514/Un\G32578)

Refer to the following for the counter descriptions, count range, and count clear methods.

Page 21 Checking communication conditions using a diagnostic counter

■ When completed with an error

3 MODBUS STANDARD FUNCTION DETAILS

3.8 Diagnostics (FC: 08H)

35

Page 38

Return IOP overrun error count (sub-function code: 13H)

(H) (L)

08H (0013H) (0000H)

(H) (L)

DataFunction code Sub-function code

(H) (L)

(H) (L)

08H (0013H)

Function code Sub-function code Data

(0000H to FFFFH)

Bus character overrun

count value

88H

Data

Exception code

Function code

Operation description

Reads the IOP overrun error count value to the master.

C24 returns to the master the number of times the request message size exceeds the upper limit. (Same as the Return bus

character overrun count)

Request message format (from master to slave)

Response message format (from slave to master)

■ When completed successfully

Returns the count value of the buffer memory listed below to the master.

• 'Character overrun count' (Un\G32514/Un\G32578)

Refer to the following for the counter descriptions, count range, and count clear methods.

Page 21 Checking communication conditions using a diagnostic counter

■ When completed with an error

36

3 MODBUS STANDARD FUNCTION DETAILS

3.8 Diagnostics (FC: 08H)

Page 39

Clear overrun counter and flag (sub-function code: 14H)

(H) (L)

08H (0014H) (0000H)

(H) (L)

DataFunction code Sub-function code

88H

Data

Exception code

Function code

Operation description

Clears the overrun error counter and flag.

C24 clears the character overrun count value.

Request message format (from master to slave)

Response message format (from slave to master)

■ When completed successfully

The slave returns the request message received from the master as-is.

■ When completed with an error

3

3 MODBUS STANDARD FUNCTION DETAILS

3.8 Diagnostics (FC: 08H)

37

Page 40

3.9 Get Communications Event Counter (FC: 0BH)

0BH

Function code

(H) (L) (H) (L)

0BH

(0000H)

Program command status

Data

Communications

event count value

Function code

(0000H to FFFFH)

8BH

Data

Exception code

Function code

Operation description

Acquires the number of messages whose requested actions (read/write, diagnostics, etc.) have been normally completed.

Whether the action corresponding to the request message is normally completed or not can be checked.

Request message format (from master to slave)

Response message format (from slave to master)

■ When completed successfully

Since C24 does not support any program commands, 0000H is stored in the program command status.

Returns the count value of the buffer memory listed below to the master.

• 'Communications event count' (Un\G32523 to Un\G32587)

The count is stopped if it has reached FFFFH.

Reset the counter by any of the following methods when restarting the count.

• Restart communications option (Page 23 Restart communications option (sub-function code: 01H))

• Clear counters and diagnostic register (Page 27 Clear counters and diagnostic register (sub-function code: 0AH))

• Turn the power OFF and ON, or reset the programmable controller CPU.

■ When completed with an error

38

3 MODBUS STANDARD FUNCTION DETAILS

3.9 Get Communications Event Counter (FC: 0BH)

Page 41

3.10 Get Communications Event Log (FC: 0CH)

0CH

Function code

0CH

(H) (L) (H) (L) (H) (L)

(0000H)

DataFunction code

Communications event

count value

Program command status

Communications

event log No. 0

Bus message count value

Communications

event log No. 63

(0000H

to

FFFFH)

(0000H to FFFFH)

Number of

read bytes

Number of read bytes

8CH

Data

Exception code

Function code

Operation description

Acquires the communications event log into the master.

Request message format (from master to slave)

Response message format (from slave to master)

■ When completed successfully

3

Since C24 does not support any program commands, 0000H is stored in the program command status.

Returns the count values of the buffer memory listed below to the master.

• 'Communications event count' (Un\G32523 to Un\G32587)

• 'Bus message count' (Un\G32512/Un\G32576)

• 'Communications event log 1 to 64' (Un\G32544 to Un\G32575/Un\G32608 to Un\G32639)

Refer to the following for the counter descriptions, count range, and count clear methods.

Page 21 Checking communication conditions using a diagnostic counter

Page 38 Get Communications Event Counter (FC: 0BH)

For details on the communications event log, refer to the following.

Page 40 Communications event log

■ When completed with an error

3 MODBUS STANDARD FUNCTION DETAILS

3.10 Get Communications Event Log (FC: 0CH)

39

Page 42

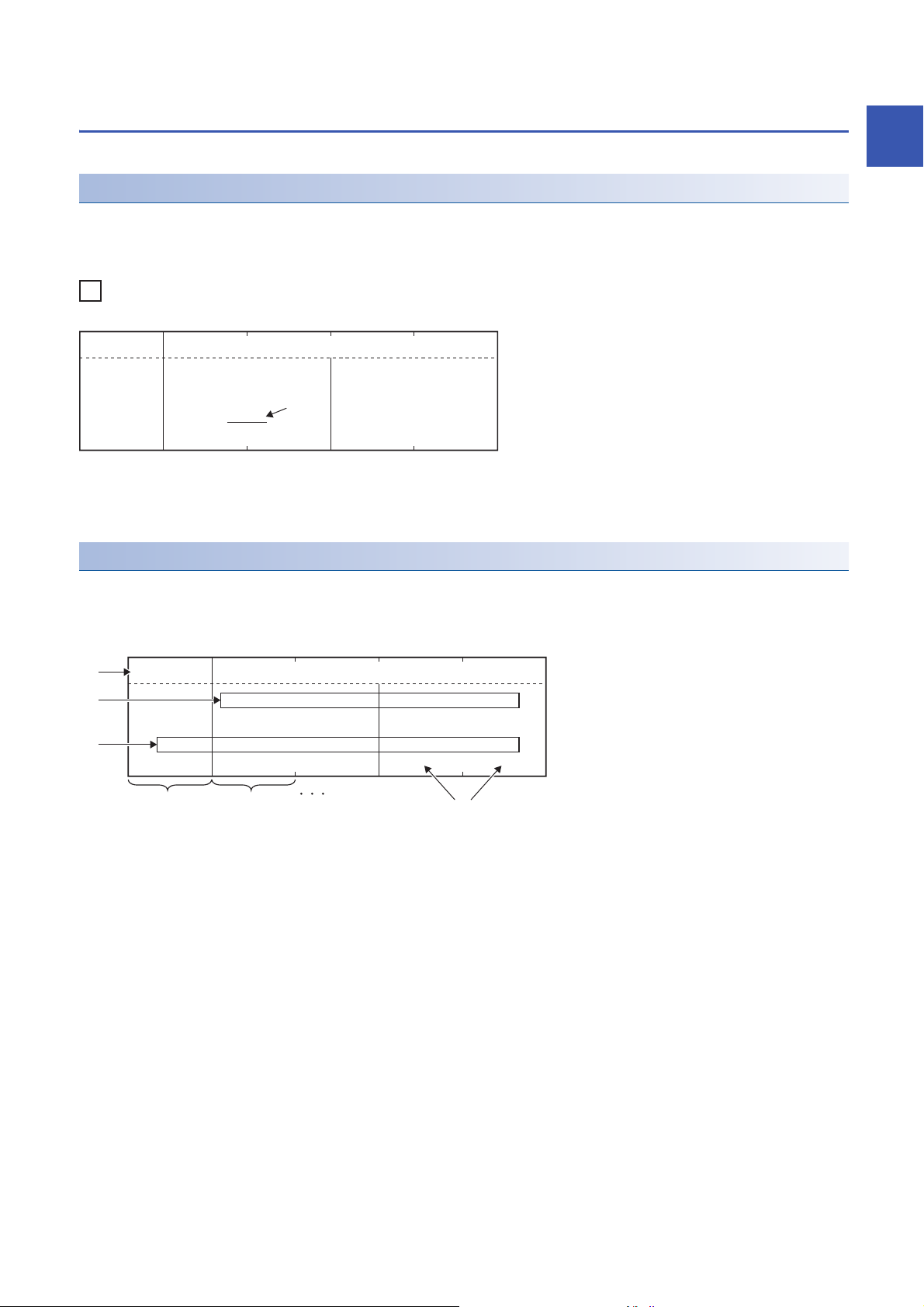

Communications event log

10001/0 1/0 1/0 1/0

b0b1b2b3b4b5b6b7

When the get communications event log (FC: 0CH) is received from the master, C24 returns the following data of the buffer

memory.

• 'Communications event log 1 to 64' (Un\G32544 to Un\G32575/Un\G32608 to Un\G32639)

The number of communications event logs can be checked in the buffer memory 'Communications event log count'

(Un\G32543/Un\G32607).

If the number of communications event logs exceeds 64, the oldest log is deleted and the latest log is stored to

Communications event log 0.

Communications event logs are stored in the buffer memory at the following timing.

Timing to be stored in the buffer

memory

When receiving a request message C24 stores the communications event log before executing the processing of the request message.

When sending a response message C24 stores the communications event log after sending the response message.

When switching to the listen only mode C24 stores the communications event log when switching to the listen only mode.

When processing restart communications option C24 stores the communications event log when processing the restart communications option.

Description

For the relevant communications event, '1' is stored.

• b0: Unused (Fixed to 0)

• b1: Communication error

• b2, b3: Unused (Fixed to 0)

• b4: Bus character overrun error

• b5: In listen only mode

• b6: Broadcast message reception

• b7: Fixed to 1

For the relevant communications event, '1' is stored.

b0b1b2b3b4b5b6b7

0001001/01/0

• b0: Message error (exception code 01H to 03H)

• b1: Processing interruption (exception code 04H)

• b2 to b5: Unused (Fixed to 0)

While the occurrence of busy status (exception code 05H to 07H) is stored for the MODBUS protocol, '0' is

stored for C24 because this kind of events does not occur in it.

• b6: Fixed to 1

• b7: Unused (Fixed to '0')

04H is stored to the communications event log.

00H is stored to the communications event log.

The communications event can be cleared by either of the following:

• Clear setting of the communications event log with the restart communications option. (Page 23 Restart

communications option (sub-function code: 01H))

• Turn the power OFF and ON, or reset the programmable controller CPU.

40

3 MODBUS STANDARD FUNCTION DETAILS

3.10 Get Communications Event Log (FC: 0CH)

Page 43

3.11 Write Multiple Coils (FC: 0FH)

0FH

(H) (L) (H) (L)

DataFunction code

Number of write pointsStart coil number specification Device data 1Number of bytes

n

Device data n

Number of bytes n

(0000H to FFFFH) (0001H to 07B0H) (01H to F6H)

b0b1b2b3b4b5b6b7

0: OFF

1: ON

Device data 1

Device data n

Bit device storage order

(H) (L) (H) (L)

0FH

Data

Number of write pointsStart coil number

Function code

8FH

Data

Exception code

Function code

Operation description

Writes values (ON/OFF) to multiple coils.

Request message format (from master to slave)

• Device data 1 to n

3

• The values (ON/OFF) stored in device data 1 to n are written to the coils in the order of lower bit to higher bit of the device data.

Ensure that the specified number of write points matches the number of bits specified with the number of

bytes.

For example, when the specified number of write points is 16, set the number of bytes to 2 bytes (= 16 bits).

Response message format (from slave to master)

■ When completed successfully

• Start coil number: Stores the same value as the start coil number of the request message.

• Number of write points: Stores the same value as the number of write points of the request message.

■ When completed with an error

3 MODBUS STANDARD FUNCTION DETAILS

3.11 Write Multiple Coils (FC: 0FH)

41

Page 44

3.12 Write Multiple Registers (FC: 10H)

10H

(H) (L) (H) (L) (H) (L) (H) (L)

DataFunction code

Number of write points nStart holding register number

specification

Device data 1Number of

bytes n×2

Device data n

Number of bytes n×2

(0000H to FFFFH) (0001H to 007BH) (01H to F6H)

(H) (L) (H) (L)

10H

Start holding register number

Data

Number of write points

Function code

90H

Data

Exception code

Function code

Operation description

Writes values to multiple holding register areas.

Request message format (from master to slave)

Ensure that the specified number of write points matches the number of bits specified with the number of

bytes.

Response message format (from slave to master)

■ When completed successfully

• Start holding register number: Stores the same value as the start holding register number of the request message.

• Number of write points: Stores the same value as the number of write points of the request message.

■ When completed with an error

42

3 MODBUS STANDARD FUNCTION DETAILS

3.12 Write Multiple Registers (FC: 10H)

Page 45

3.13 Report Slave ID (FC: 11H)

11H

Function code

11H

(02H)

DataFunction code

Number of

bytes

Programmable

controller CPU

STOP/RUN

state

Programmable

controller

CPU type

91H

Data

Exception code

Function code

Operation description

Acquires the information of C24 mounted station into the master.

Request message format (from master to slave)

Response message format (from slave to master)

■ When completed successfully

3

• Programmable controller CPU type: Page 43 Programmable controller CPU type

• Programmable controller CPU STOP/RUN: STOP (00H), RUN (FFH)

■ When completed with an error

Programmable controller CPU type

C24 will return any of the following programmable controller CPU type data.

The programmable controller CPU type is the original for C24s.

Module name Model Programmable controller CPU type returned to Master

Programmable controller CPU R00CPU A0H

R01CPU A1H

R02CPU A2H

R04CPU 00H

R08CPU 01H

R16CPU 02H

R32CPU 03H

R120CPU 04H

R04ENCPU 05H

R08ENCPU 06H

R16ENCPU 07H

R32ENCPU 08H

R120ENCPU 09H

3 MODBUS STANDARD FUNCTION DETAILS

3.13 Report Slave ID (FC: 11H)

43

Page 46

Module name Model Programmable controller CPU type returned to Master

Process CPU R08PCPU 41H

R16PCPU 42H

R32PCPU 43H

R120PCPU 44H

SIL2 process CPU R08PSFCPU 51H

R16PSFCPU 52H

R32PSFCPU 53H

R120PSFCPU 54H

Safety CPU R08SFCPU 91H

R16SFCPU 92H

R32SFCPU 93H

R120SFCPU 94H

C Controller module R12CCPU-V 20H

Remote head module RJ72GF15-T2 60H

RJ72GF15-T2(SR) 61H

RJ72GF15-T2(LR) 62H

44

3 MODBUS STANDARD FUNCTION DETAILS

3.13 Report Slave ID (FC: 11H)

Page 47

3.14 Read File Record (FC: 14H) (SC: 06H)

(H) (L)

14H

(H) (L) (H) ( L)

(H) (L) (H) (L) (H) (L)

(06H)

(06H)

Number of

bytes m×7

Data

File number specification

Function code

Read start device number

Sub-request 1

Reference

number

Number of read points n1

Data

File number specification

Read start device number

Sub-request m

Reference

number

Number of read points nm

Number of bytes m×7

Number of bytes m×7

(0000H to FFFFH) (0000H to 270FH) (0001H to 007CH)

(0000H to FFFFH) (0000H to 270FH) (0001H to 007CH)

Operation description

Reads the values of multiple extended file register areas.

Request message format (from master to slave)

3

• File number specification: The upper limit of the file numbers that can be received by an Ethernet-equipped module is the file register size of the mounted

CPU module.

• Specify the number of sub requests, m, so that the size of the protocol data unit of the request message

does not exceed 253 bytes. The request message will be discarded if the following condition is not met.

[Conditional formula] 253 2 + (m 7)

• Specify the total number of read points of each sub request, N (n1 + ... + nm), so that the size of the protocol

data unit of the response message does not exceed 253 bytes. The slave will return an abnormal response

if the following condition is not met.

[Conditional formula] 253 2 + (m 2) + (N 2)

3 MODBUS STANDARD FUNCTION DETAILS

3.14 Read File Record (FC: 14H) (SC: 06H)

45

Page 48

Response message format (from slave to master)

14H

(L)(H) (H) (L)

(L)(H) (H) (L)

(06H)

(06H)

Number of

response data

bytes

m×2+N×2

Device data 1Number of

read bytes

n1×2+1

Number of read bytes n1×2+1

Reference

number

Device data n1

Number of response data bytes m×2+N×2

Device data 1

Number of

read bytes

nm×2+1

Reference

number

Device data nm

Number of response data bytes m×2+N×2

Number of read bytes nm×2+1

DataFunction code

Sub-request 1

Data

Sub-request m

94H

Data

Exception code

Function code

■ When completed successfully

N shown below is the total of the device data (n1 + ... + nm).

■ When completed with an error

46

3 MODBUS STANDARD FUNCTION DETAILS

3.14 Read File Record (FC: 14H) (SC: 06H)

Page 49

3.15 Write File Record (FC: 15H) (SC: 06H)

(H) (L) (H) (L) (H) (L) (H) (L) (H) (L)

(H) (L) (H) (L) (H) (L) (H) (L) (H) (L)

15H

(06H)

(06H)

Number of

bytes

m×7+N×2

Data

File number

specification

Function code

Write start device

number

Sub-request 1

Reference

number

Number of write points

n1

Number of bytes m×7+N×2

Number of bytes m×7+N×2

Device data 1 Device data n1

Data

File number

specification

Write start device

number

Reference

number

Number of write pointsnmDevice data 1 Device data nm

Sub-request m

(0001H to 007AH)(0000H to 270FH)(0000H to FFFFH)

(0000H to FFFFH) (0000H to 270FH) (0001H to 007AH)

95H

Data

Exception code

Function code

Operation description

Writes a value to one extended file register area or values to multiple extended file register areas.

Request message format (from master to slave)

N shown below is the total of the device data (n1 + ... + nm).

3

• File number specification: The upper limit of the file numbers that can be received by an Ethernet-equipped module is the file register size of the mounted

CPU module.

Specify the number of sub requests, m, and the total number of write points of each sub request, N (n1 + ... +

nm), so that the size of the protocol data unit of the request message does not exceed 253 bytes. The request

message will be discarded if the following condition is not met.

[Conditional formula] 253 2 + (m 7) + (N 2)

Response message format (from slave to master)

■ When completed successfully

The slave returns the request message received from the master as-is.

■ When completed with an error

3 MODBUS STANDARD FUNCTION DETAILS

3.15 Write File Record (FC: 15H) (SC: 06H)

47

Page 50

3.16 Mask Write Register (FC: 16H)

(H) (L) (H) (L)

16H

(H) (L)

Target holding register number

DataFunction code

AND mask value OR mask value

(0000H to FFFFH)(0000H to FFFFH)(0000H to FFFFH)

96H

Data

Exception code

Function code

Operation description

Writes the masked value obtained by performing AND and OR operations on the value stored in one holding register area.

The value is written to the holding register as shown below.

Write value = (current value of target register AND mask value) (OR mask value AND mask value

If the OR mask value is 0000H, only the AND processing of the AND mask value will be performed.

If the AND mask value is 0000H, the OR mask value will be the write value.

Request message format (from master to slave)

Response message format (from slave to master)

■ When completed successfully

The slave returns the request message received from the master as-is.

)

■ When completed with an error

With this function, the value stored in the holding register is read from the slave, the AND/OR processing is