Page 1

C

MIT

SUBIS

C

HI ELECTRI

MELSEC System Q

Programmable Logic Controllers

User's Manual

Art. no.: 130383

01 05 2003

SH(NA)-080042

Version L

Digital I/O Modules

QX

MITSUBISHI ELECTRI

/QY

INDUSTRIAL AUTOMATION

Page 2

SAFETY PRECAUTIONS •

•

(Always read these instructions before using this equipment.)

Before using this product, please read this manual and the relevant manuals introduced in this manual

carefully and pay full attention to safety to handle t he product correctly .

The instructions given in this manual are concerned with this product. For the safety instructions of the

programmable controller system, please read the CPU module user's manual.

In this manual, the safety instructions are ranked as "DANGER" and "CAUTION".

DANGER

!

CAUTION

!

Note that the !CAUTION level may lead to a serious consequence according to the circumstances.

Always follow the instructions of both levels because they are important to personal safety .

Please save this manual to make it accessible when required and always forward it to the end user.

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in medium or slight personal injury or physical damage.

[Design Instructions]

!

DANGER

• Install a safety circuit external to the PLC that keeps the ent ire syst em safe if there are problems

with the external power supply or PLC. Not doing so may cause false output or malfunction,

leading to accidents.

(1) Outside the PLC, construct mechanical damage preventing interlock circuits, e.g. emergency

stop circuits, protective circuits, forward/rev erse or other conflicting operation interlocking

circuits, and upper and lower positioning limit switches.

(2) When the PLC detects either of the following problems, it will stop arithmet ic operat ion and

turn off all outputs in the case of (a). In the case of (b) , it will st op arithmet ic operation and

hold or turn off all outputs according to the parameter setting.

(a) The overcurrent protection or overvoltage protection of the pow er supply module is

activated.

(b) The self-diagnostic function of the PLC CPU has detected a fault such as the watchdog

timer error.

In addition, all outputs may be turned on when there are problems undetectable by the PLC

CPU, such as in the I/O controller. Build a fail-safe circuit or provide a mechanism externally

of the PLC to operate the machine safely at such times. Refer to the CPU module user's

manual for fail-safe circuit examples.

(3) Output could be left on or off when there is trouble in the output module's relays, t ransistors,

etc. So build an external monitoring circuit that will monito r any output signal that could lead

to a serious accident.

A - 1 A - 1

Page 3

[Design Instructions]

!

DANGER

• When overcurrent exceeding the rated load current or caused by a shorted load or the like flows

in the output module for a long time, it may cause smoke or fire. To prevent this, configure an

external safety circuit, such as fuses.

• Build a circuit that turns on the external power supply after the PLC pow er supply has been

turned on. If the external power supply is turned on first, it could result in false output or

malfunction.

• When there are communication problems with the data link, refer to the corresponding data link

manual for the operating status of each station. Not doing so could result in false output or

malfunction.

• When connecting a peripheral device to the CPU module or connecting a personal computer or

the like to the intelligent function module to exercise control (data change) on the running PLC,

configure up an interlock circuit in the sequence program to ensure that t he whole sy stem w ill

always operate safely.

Also before exercising other control (program change, operating status change (status control))

on the running PLC, read the manual carefully and fully confirm safety.

Especially for the above control on the remote PLC from an external device, an immediate

action may not be taken for PLC trouble due to a data communication fault.

In addition to configuring up the interlock circuit in the sequence program, corrective and other

actions to be taken as a system for the occurrence of a data communication fault should be

predetermined between the external device and PLC CPU.

!

CAUTION

• Do not bundle the control wires or communication cables with the main circuit or power wires, or

run them close to each other.

They should be run 100mm (3.94in.) or more away from each other.

Not doing so could result in noise that would cause malfunction.

• When the output module is used to control a lamp load, heater, solenoid valve or the like, large

current (approximately 10 times greater than the normal) may flow when the output is turned

from OFF to ON. Choose an output module having a sufficient rated current.

A - 2 A - 2

Page 4

[Installation Instructions]

!

CAUTION

• Use the PLC in the environment that meets the general specifications given in t his manual.

Using this PLC in the environment outside the range of the general specifications could result in

electric shock, fire, malfunction, or damage to, or deterioration of the product.

• Hold down the module-loading lever at the module bottom, and securely insert the module-fixing

hook into the fixing hole in the base unit. Incorrect loading of the module can cause a

malfunction, failure or drop.

When using the PLC in the environment of much vibration, tighten the module with a screw.

Tighten the screw in the specified torque range. Undertightening can cause a drop, short circuit

or malfunction. Overtightening can cause a drop, short circuit or malfunction due to damage to

the screw or module.

• When installing extension cables, be sure that the connectors of base unit are installed correctly.

After installation, check them for looseness. Poor connections could cause an input or output

failure.

• Securely load the memory card by pushing it into the memory card loading connector. After

loading, make a check. Not doing so can cause malfunction due to a contact fault.

• Completely turn off the external power supply before loading or unloading the module. Not doing

so could result in damage to the product.

• Do not directly touch the module's conductive parts.

Doing so could cause malfunction or failure of the module.

[Wiring Instructions]

!

DANGER

• Completely turn off the external power supply before starting wiring. Not doing so could result in

electric shock or damage to the product.

• When turning on the power supply or starting operation after wiring work, always mount the

product with the supplied terminal cover.

Not doing so could result in electric shock.

A - 3 A - 3

Page 5

[Wiring Instructions]

!

CAUTION

• Always ground the FG and LG terminals to the protectiv e ground conductor. Not doing so could

result in electric shock or malfunction.

• Before wiring the module, confirm the rated voltage and terminal layout of the product.

Connecting a power supply that is different from the rating or incorrectly wiring the product could

result in fire or failure.

• External connectors should be crimped or pressure-welded with the specified tools, or correctly

soldered. Imperfect connections could result in short circuit, fires or malfunction.

• Tighten the terminal screws in the specified torque range.

Undertightening could result in short circuit, fire or malfunction.

Overtightening could cause damage to the screws and/or the module, resulting in drop, short

circuit or malfunction.

• Be careful not to allow foreign matter such as chips and wire off-cuts to enter the module.

Foreign matter could cause fire, failure, or malfunction.

• The module has an ingress prevention label on its top to prevent foreign matter, such as wire

offcuts, from entering the module during wiring.

Do not peel this label during wiring.

Before starting system operation, be sure to peel this label because of heat dissipation.

[Startup/Maintenance Instructions]

!

DANGER

• Do not touch the terminals while power is on.

Doing so could cause electric shock.

• Correctly connect the battery. Do not charge, disassemble, heat, place in fire, short circuit, or

solder the battery.

Mishandling of the battery can cause heat generation, burst or ignition which could result in

injury or fire.

• Always turn off the external power supply completely before cleaning the module or retightening

the terminal or module mounting screws.

Not doing so could result in electric shock.

Undertightening of terminal screws can cause a short circuit or malfunction.

Overtightening of screws can cause damage to the screws and/or the module, resulting in drop,

short circuit, or malfunction

A - 4 A - 4

Page 6

[Startup/Maintenance Instructions]

!

CAUTION

• The online operations conducted for the running CPU module by connecting a peripheral device

(especially program modification, forced output, operating status change) should be performed

after you have read the manual carefully read and fully confirmed safety.

Operation mistakes could cause machine damage or accident.

• Do not disassemble or modify the modules.

Doing so could cause failure, malfunction, injury or fire.

• Always switch off the external power supply completely before mounting or removing the

module.

Not doing so can cause failure or malfunction of the module.

• Before touching the module, always touch grounded metal, etc. to discharge st atic elect ricity

from human body, etc.

Not doing so can cause the module to fail or malfunction.

[Disposal Instructions]

!

CAUTION

• When disposing of this product, treat it as industrial waste.

A - 5 A - 5

Page 7

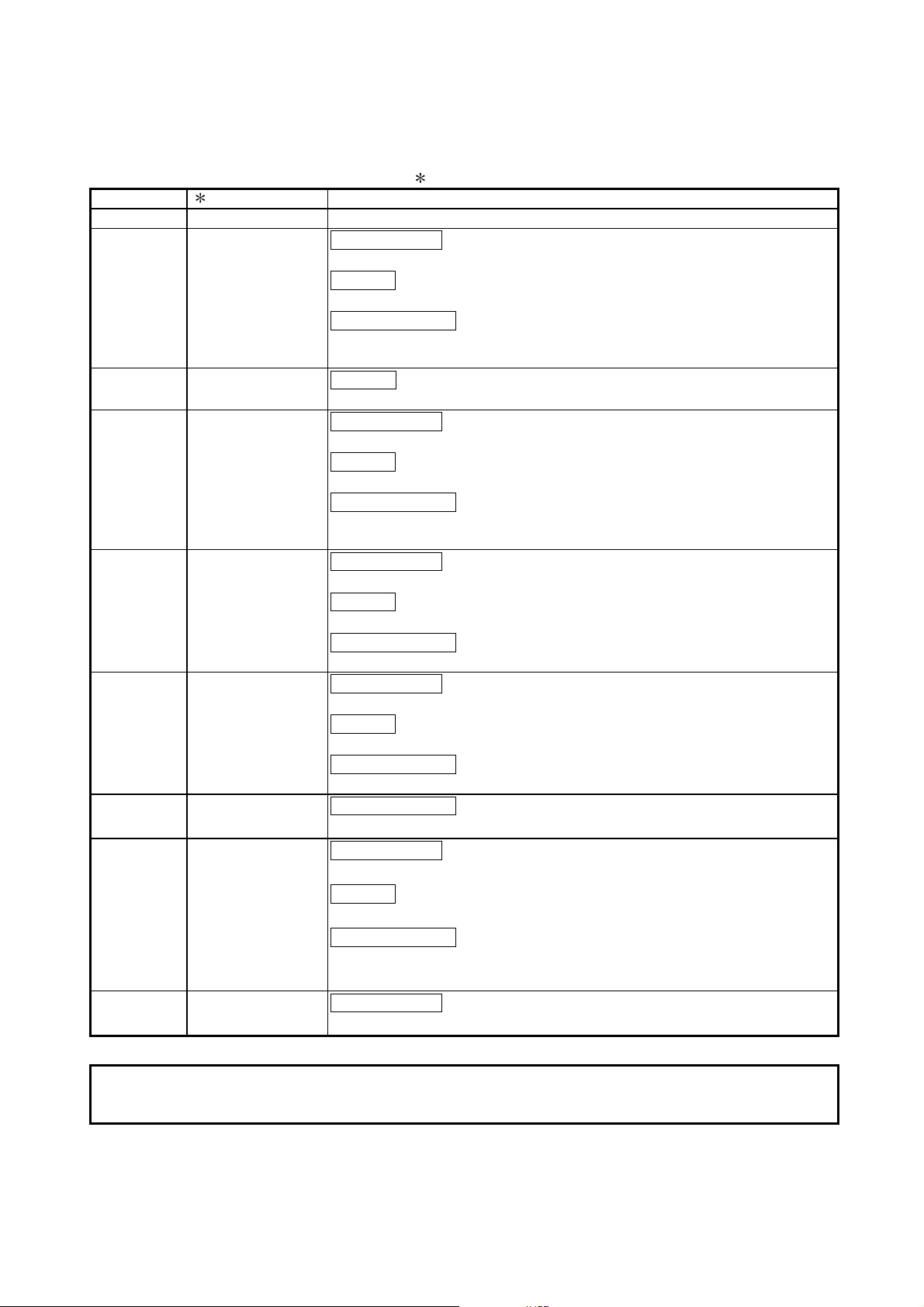

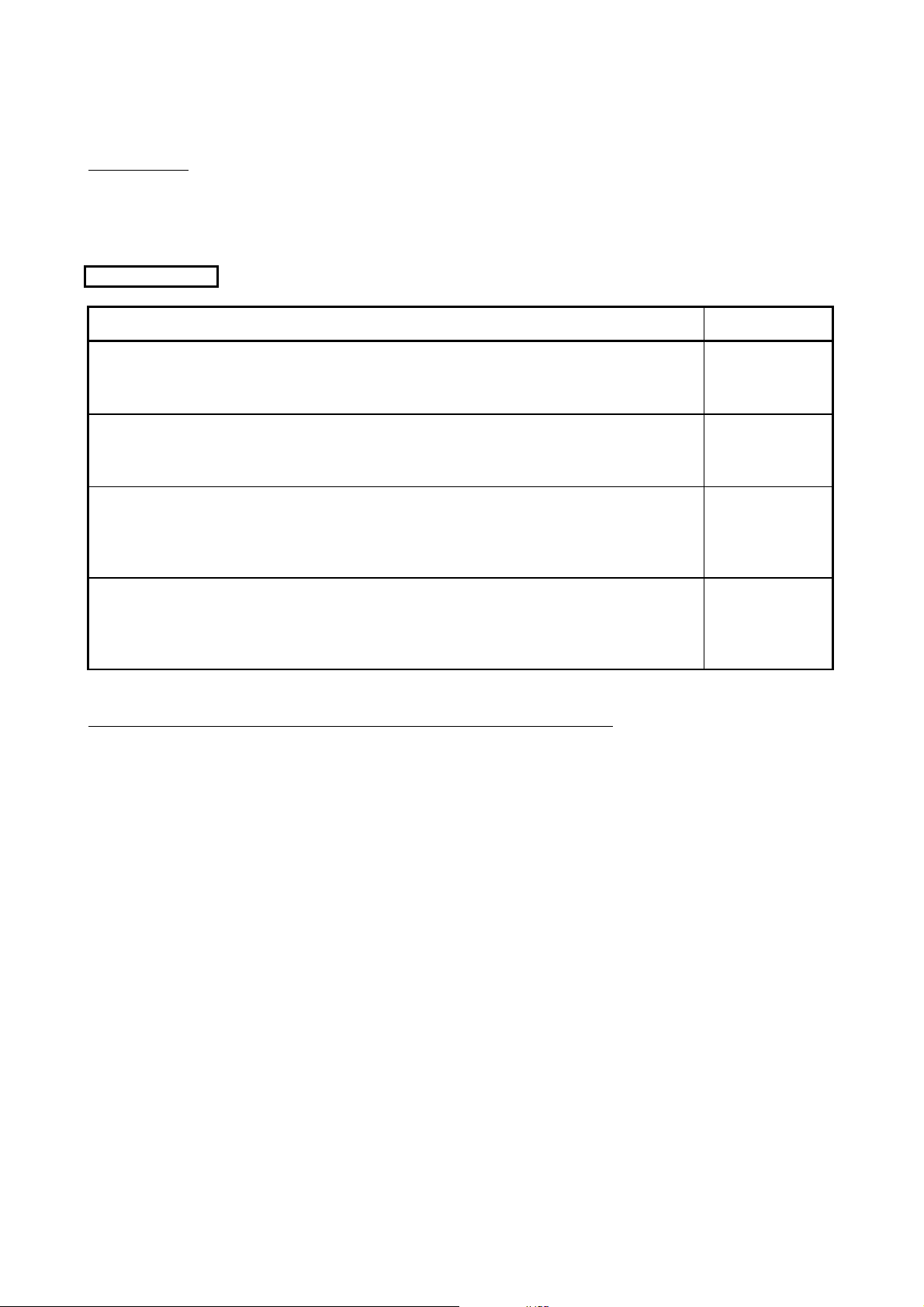

REVISIONS

The manual number is given on the bottom left of the back cover.

Print Date Manual Number Revision

Dec., 1999 SH (NA)-080042-A First edition

Feb., 2000 SH (NA)-080042-B

Addition model

QH42P, QX48Y57, QX70, QX71, QX72, QY18A

Addition

Chapter 4

Partial correction

Section 1.2, Chapter 5, 8.1,

Chapters 4 to 8 (changed into Chapters 5 to 9)

Apr., 2000 SH (NA)-080042-C

Deletion

QY18A

Jul., 2000 SH (NA)-080042-D

Addition model

QX28,QX40-S1,QY18A,QY22,QI60

Addition

Chapter 5

Partial correction

Section 1.2

Chapters 5 to 9 (changed into Chapters 6 to 10)

Nov., 2000 SH (NA)-080042-E

Addition model

QY70, QY71

Addition

Section 1.3

Partial correction

CONTENTS, Section 3.3, 5.1

Jan., 2001 SH (NA)-080042-F

Addition model

QY68A

Addition

Section 10.2

Partial correction

CONTENTS, Section 1.2, 3.3, 5.1, Chapters 7

Mar., 2001 SH (NA)-080042-G

Partial correction

Section 2.4, 8.1

Jul., 2001 SH (NA)-080042-H

Addition model

Q6TE-18S

Addition

Chapter 9, APP 1.3

Partial correction

CONTENTS, Section 2.1, 2.2, 2.4, 5.1

Chapters 9 to 10 (changed into Chapters 10 to 11)

Jul., 2002 SH (NA)-080042-I

Addition model

QX41-S1, QX42-S1, A6CON4

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any patent licenses.

Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property rights which

may occur as a result of using the contents noted in this manual.

1999 MITSUBISHI ELECTRIC CORPORATION

Japanese Manual Version SH-080024-L

A - 6 A - 6

Page 8

Print Date Manual Number Revision

Mar., 2003 SH (NA)-080042-J

Addition model

QX82

May., 2003 SH (NA)-080042-K

Partial correction

Section 1.2, 2.2

May., 2003 SH (NA)-080042-L

Addition model

QX82-S1

Partial correction

Section 1.2, 3.3

Addition

Section 2.15

A - 7 A - 7

Page 9

INTRODUCTION

Thank you for choosing the MITSUBISHI MELSEC-Q Series General-Purpose Programmable Logic Controller.

Before using this product, please read this manual carefully to use the equipment to its optimum.

CONTENTS

About Manuals ..............................................................................................................................................A- 10

1. GENERAL SPECIFICATIONS OF INPUT AND OUTPUT MODULES AND INSTRUCTIONS FOR

SELECTING THEM 1- 1 to 1- 12

1.1 General Specifications............................................................................................................................1- 1

1.2 Selecting Instructions..............................................................................................................................1- 1

1.3 How to Make Settings on GX Developer.................................................................................................1- 8

1.3.1 Setting of I/O response time .............................................................................................................1- 8

1.3.2 Setting of error-time output mode.....................................................................................................1-10

1.3.3 QI60 switch setting............................................................................................................................1-11

2. INPUT MODULE SPECIFICATIONS 2- 1 to 2-18

2.1 QX10 AC Input Module...........................................................................................................................2- 1

2.2 QX28 AC Input Module...........................................................................................................................2- 2

2.3 QX40 DC Input Module (Positive Common Type).................................................................................2- 3

2.4 QX40-S1 DC Input Module (Positive Common Type)...........................................................................2- 4

2.5 QX41 DC Input Module (Positive Common Type).................................................................................2- 5

2.6 QX41-S1 DC Input Module (Positive Common Type)...........................................................................2- 6

2.7 QX42 DC Input Module (Positive Common Type).................................................................................2- 8

2.8 QX42-S1 DC Input Module (Positive Common Type)...........................................................................2- 9

2.9 QX70 DC Input Module (Positive Common/Negative Common Shared Type)....................................2-11

2.10 QX71 DC Input Module (Positive Common/Negative Common Shared Type)..................................2-12

2.11 QX72 DC Input Module (Positive Common/Negative Common Shared Type)..................................2-13

2.12 QX80 DC Input Module (Negative Common Type)..............................................................................2-14

2.13 QX81 DC Input Module (Negative Common Type)..............................................................................2-15

2.14 QX82 DC Input Module (Negative Common Type)..............................................................................2-16

2.15 QX82-S1 DC Input Module (Negative Common Type) ........................................................................2-17

3. OUTPUT MODULE SPECI FI CA TIO NS 3- 1 to 3- 1 3

3.1 QY10 Contact Output Module ................................................................................................................3- 1

3.2 QY18A Contact Output Module (All Points Independent) .....................................................................3- 2

3.3 QY22 TRIAC Output Module..................................................................................................................3- 3

3.4 QY40P Transistor Output Module (Sink Type) ......................................................................................3- 4

3.5 QY41P Transistor Output Module (Sink Type) ......................................................................................3- 5

3.6 QY42P Transistor Output Module (Sink Type) ......................................................................................3- 6

3.7 QY50 Transistor Output Module (Sink Type).........................................................................................3- 7

3.8 QY68 Transistor Output Module (All Points Independent, Sink/Source Type)..................................... 3- 8

3.9 QY70 Transistor Output Module (Sink Type).........................................................................................3- 9

3.10 QY71 Transistor Output Module (Sink Type)........................................................................................3-10

3.11 QY80 Transistor Output Module (Source Type)...................................................................................3-11

A - 8 A - 8

Page 10

3.12 QY81P Transistor Output Module (Source Type)................................................................................. 3-12

4. INPUT/OUTPUT CONPOSITE MODULE 4- 1 to 4- 4

4.1 QH42P I/O Module..................................................................................................................................4- 1

4.2 QX48Y57 I/O Module..............................................................................................................................4- 3

5. INTERRUPT MODULE 5- 1 to 5- 2

5.1 QI60 Interrupt Module.............................................................................................................................5- 1

6. BLANK COVER MODULE 6- 1 to 6- 2

7. CONNECTORS 7- 1 to 7- 2

8. SPECIFICATIONS OF CONNECTOR/TERMINAL BLOCK CONVERTOR MODULES 8- 1 to 8- 7

8.1 Specifications of Connector/Terminal Block Convertor Modules..........................................................8- 1

8.2 Connector/Terminal Block Convertor Module Connection Diagrams...................................................8- 3

8.2.1 A6TBXY36........................................................................................................................................8- 3

8.2.2 A6TBXY54........................................................................................................................................8- 4

8.2.3 A6TBX70 ..........................................................................................................................................8- 5

8.2.4 A6TBX36-E.......................................................................................................................................8- 5

8.2.5 A6TBY36-E.......................................................................................................................................8- 6

8.2.6 A6TBX54-E.......................................................................................................................................8- 6

8.2.7 A6TBY54-E.......................................................................................................................................8- 7

8.2.8 A6TBX70-E.......................................................................................................................................8- 7

9. SPRING CLAMP TER MINAL BL OCK 9- 1 to 9- 2

9.1 Q6TE-18S.............................................................................................................................................9- 1

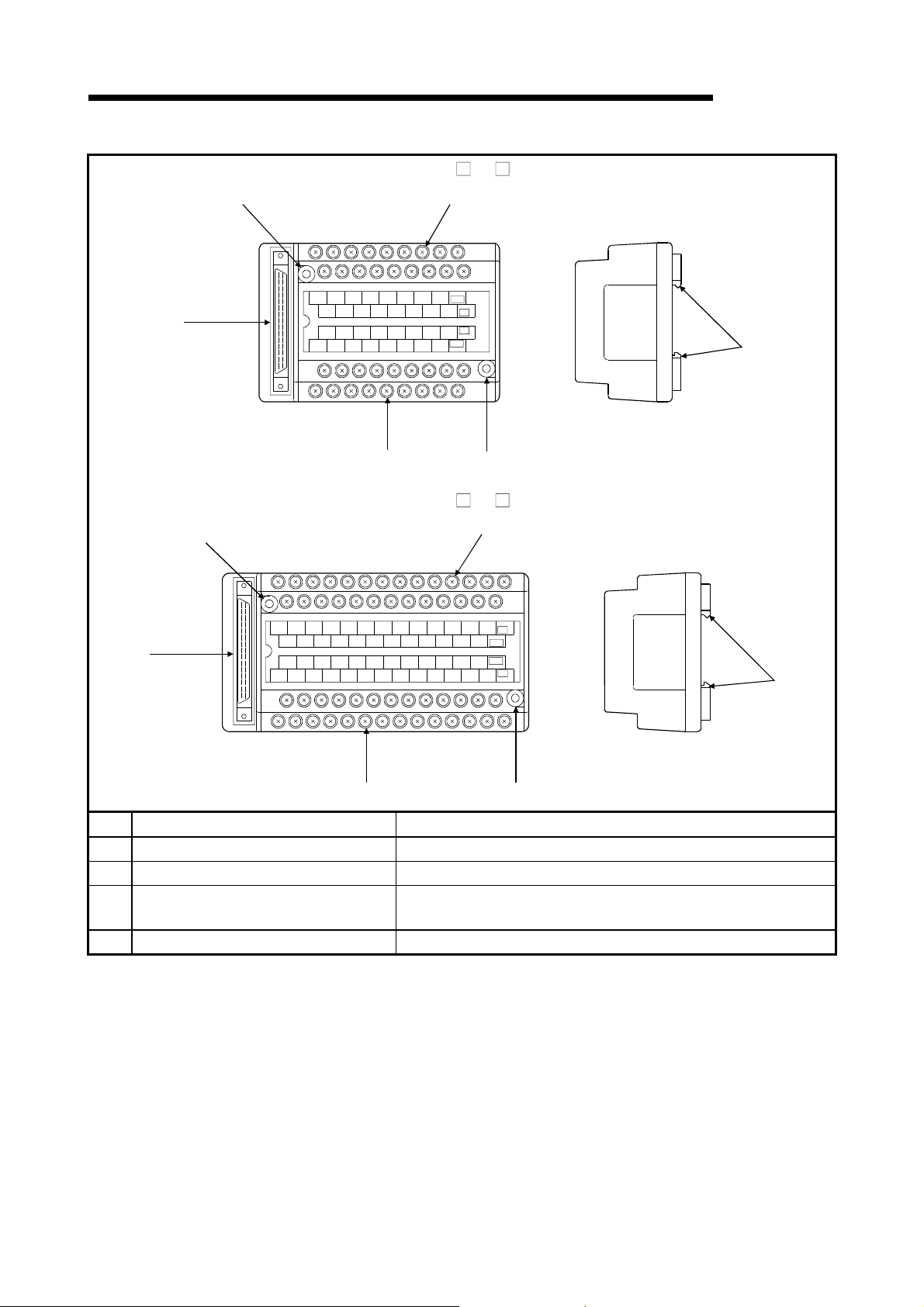

10. NAMES OF MODULE PARTS 10- 1 to 10- 4

11. I/O MODULE TROUBLESHOOTING 11- 1 to 11- 4

11.1 Input Circuit Troubleshooting..............................................................................................................11- 1

11.2 Output Circuit Troubleshooting...........................................................................................................11- 4

APPENDICES App- 1 to App- 9

Appendix 1 External Dimensional Drawings............................................................................................App- 1

Appendix 1.1 I/O modules.....................................................................................................................App- 1

Appendix 1.2 Connectors, connector/terminal block converter modules............................................App- 4

Appendix 1.3 Spring Clamp Terminal Block..........................................................................................App- 7

Appendix 2 Compatibility with MELSEC-AnS Series I/O modules..........................................................App- 8

A - 9 A - 9

Page 11

About Manuals

The following manuals are also related to this product.

In necessary, order them by quoting the details in the tables below.

Related Manuals

Manual Name

Basic model QCPU (Q Mode) User's M anual (Hardware Design/Maintenance and Inspection)

This manual provides the specifications of the CPU modules, power supply modules, base units, extension

cables, memory cards and others. (Optional)

Manual Number

(Model Code)

SH-080187

(13JR43)

Basic model QCPU (Q Mode) User's M anual (Function Explanation/Program Fundamentals)

This manual explains the functions, programming methods, devices and so on necessary to create programs

with the QCPU (Q mode). (Optional)

High Performance model QCPU (Q Mode) User's M anual (H ardw are D esign/Maintenance and

Inspection)

This manual provides the specifications of the CPU modules, power supply modules, base units, extension

cables, memory cards and others. (Optional)

High Performance model QCPU (Q Mode) User's M anual (Function Explanation/Program

Fundamentals)

This manual explains the functions, programming methods, devices and so on necessary to create programs

with the QCPU (Q mode). (Optional)

SH-080188

(13JR44)

SH-080037

(13JL97)

SH-080038

(13JL98)

Conformation to the EMC Directive and Low Voltage Instruction

For details on making Mitsubishi PLC conform to the EMC directive and low voltage instruction when installing

it in your product, please refer to Chapter 3, "EMC Directive and Low Voltage Instruction" of the PLC CPU

User's Manual(Hardware).

The CE logo is printed on the rating plate on the main body of the PLC that conforms to the EMC directive and

low voltage instruction.

A - 10 A - 10

Page 12

1 GENERAL SPECIFICATIONS OF INPUT AND OUTPUT MODULES AND

INSTRUCTIONS FOR SELECTING THEM

MELSEC-Q

1. GENERAL SPECIFICATIONS OF INPUT AND OUTPUT MODULES AND INSTRUCTIONS FOR SELECTING THEM

This chapter describes the general specifications of I/O modules and instructions for

selecting them.

1.1 General Specifications

Refer to the following manual for the general specifications of the I/O modules.

• Basic model QCPU (Q Mode) User's Manual (Hardware Design/Maintenance and

Inspection)

• High Performance model QCPU (Q Mode) User's Manual (Hardware Design/

Maintenance and Inspection)

1.2 Selecting Instructions

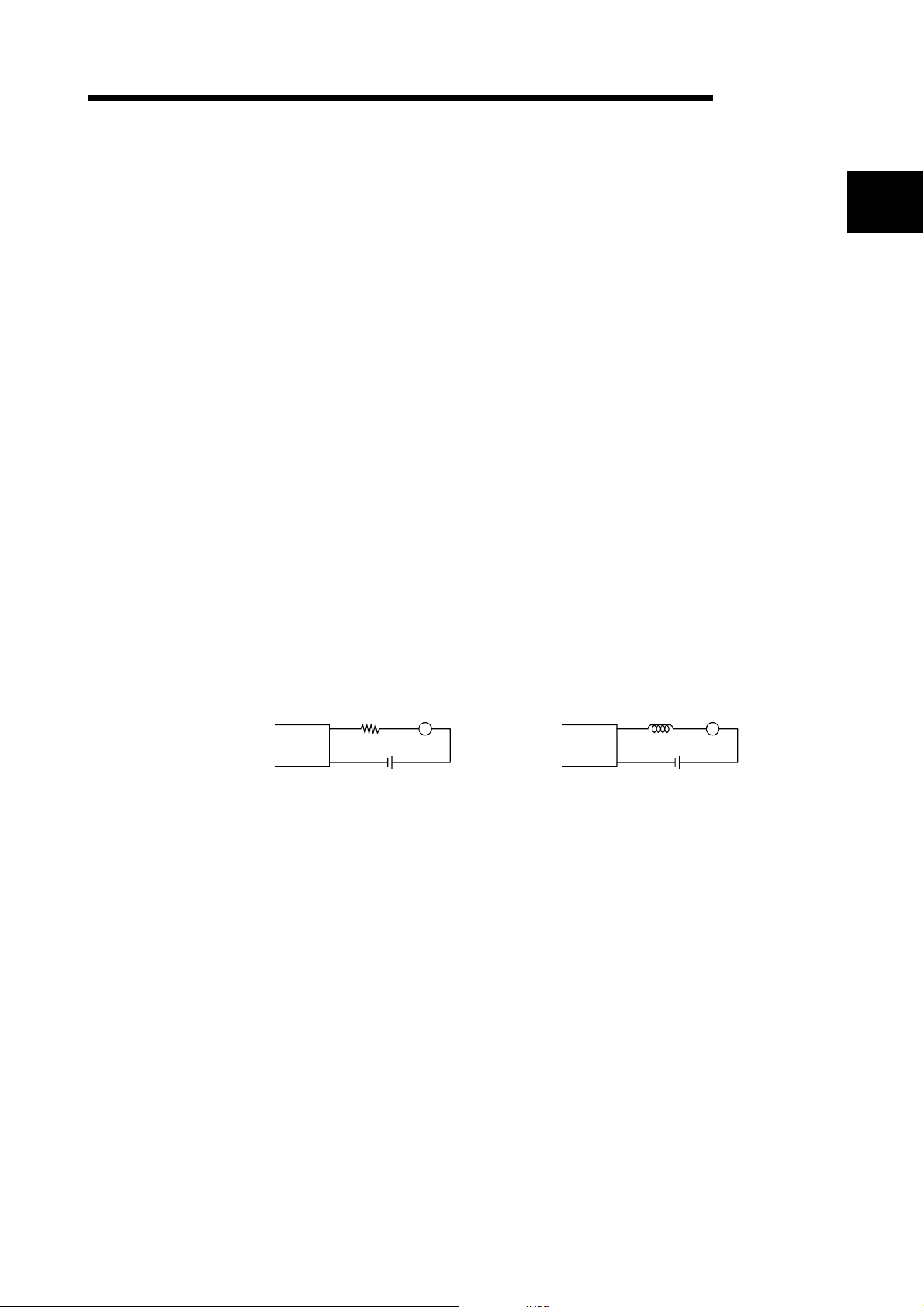

(1) If an output module drives an inductive load, it must be switched ON for 1 second

or longer and switched OFF for 1 second or longer.

(2) If a counter or timer which has a DC-DC converter as a load is used with an output

module, using an average current to choose an output module can cause a fault

due to periodic rush currents when it is turned ON or during operation.

To reduce the influence of rush currents for use of the above load, connect a

resistor or an inductance to the load in series or use a module whose maximum

load current is larger.

Resistor Load Inductance

Output

module

(3) Fuses installed in output modules cannot be replaced. They are designed to protect

external wiring if the module outputs are shorted.

Therefore, output modules may not be protected from a short circuit.

If an output module becomes faulty due to any cause other than a short circuit, its

fuse may not function.

(4) The number of signals, which can be turned ON simultaneously in an input module,

varies according to the input voltage and ambient temperature.

Refer to the corresponding input module specifications.

Output

module

Load

1

1 - 1 1 - 1

Page 13

1 GENERAL SPECIFICATIONS OF INPUT AND OUTPUT MODULES AND

INSTRUCTIONS FOR SELECTING THEM

1

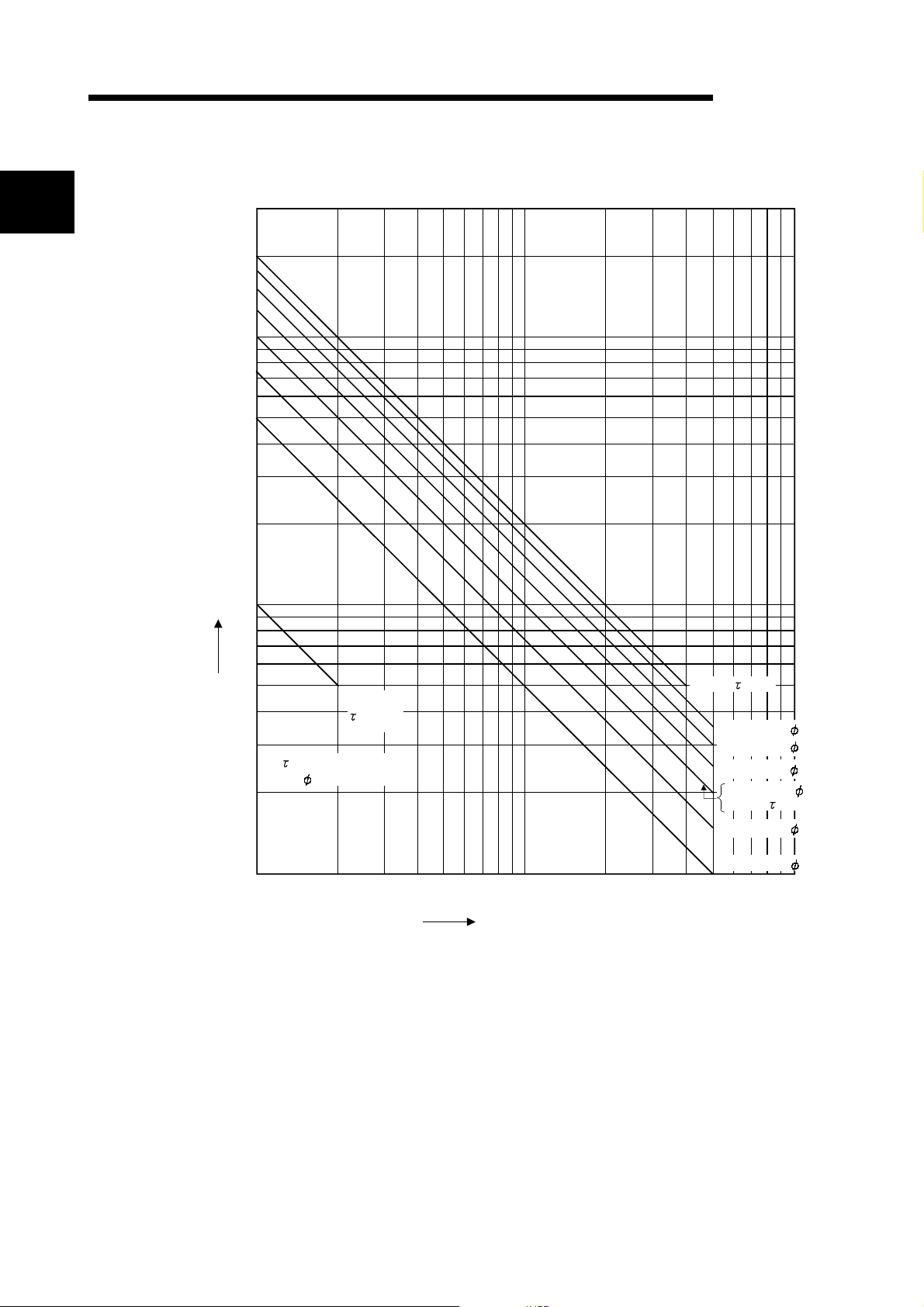

(5) The following chart shows the service life of a relay output module.

Applicable module: QY10, QY18A

MELSEC-Q

200

100

70

50

30

20

10

Switching life (10,000 times)

7

5

3

(L/R): Time constant

cos : Power factor

2

DC100

=7ms

DC30V =0ms

AC100V cos =0.7

AC200V cos =0.7

AC100V cos =0.35

AC200V cos =0.35

DC24V =7ms

AC120V cos =0.2

1

0.1 0.2 0.3 0.5 0.7 1 2 3 5

Switching current (A)

AC240V cos =0.2

1 - 2 1 - 2

Page 14

1 GENERAL SPECIFICATIONS OF INPUT AND OUTPUT MODULES AND

INSTRUCTIONS FOR SELECTING THEM

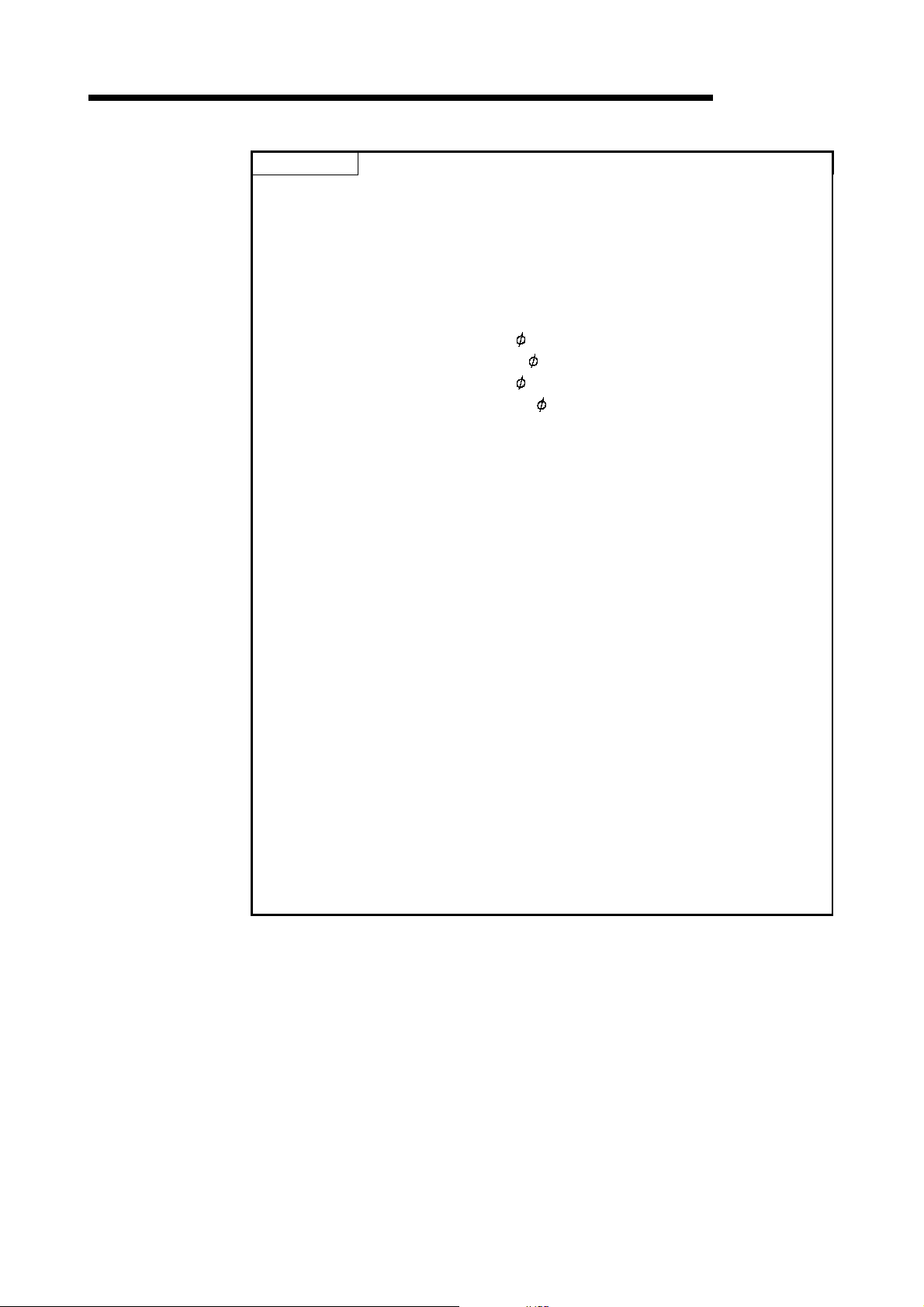

POINT

(1) When using the module for the application in which the relay contact is

frequently switched, the relay life span should be considered. Therefore, it is

recommended to use a triac output module.

(2) The relay life curve shows the value based on actual use, which is not

guaranteed. Therefore, make sure to allow for a margin of error.

The relay life span differs according to the specifications as follows:

Rated switching voltage, current load 100 thousand operations

200V AC 1.5A, 240V AC 1A (COS

200V AC 0.4A, 240V AC 0.3A (COS

200V AC 1A, 240V AC 0.5A (COS

200V AC 0.3A, 240V AC 0.15A (COS

24V DC 1A, 100V DC 0.1A (L/R=7ms) 100 thousand operations

24V DC 0.3A, 100V DC 0.03A (L/R=7ms) 300 thousand operations

(3) Relay life is substantially affected by the load type and inrush current

characteristics.

The inrush current may cause the contact welding. Therefore, consideration

should be given to it as well as constant current.

(a) Inductive load

When the inductive load such as electromagnetic contactor or solenoid is

shut off, high counter-electromotive force is generated between the

contacting materials to produce an arc discharge. Consideration should be

made especially when the power factor is low, as it may decrease the life

period.

In addition, make sure to consider the contact melting, as the inrush current

equivalent to 5 to 15 times of constant current flows when the module is

powered on.

(b) Lamp load

Make sure to consider the contact melting, as the inrush current equivalent

to 10 to 15 times of constant current flows in the lamp circuit.

(c) Capacitive load

Make sure to consider the contact melting when a device such as condenser

is used in a load circuit, as the inrush current equivalent to 20 to 40 times of

constant current may flow in the circuit.

Also, pay full attention to the wire capacity if long length of wire is routed.

(6) Insulation-sleeved crimping terminals cannot be used with the terminal block.

It is recommended to cover the wire connections of the crimping terminals with

mark or insulation tubes.

(7) Use wires of 0.3 to 0.75mm

terminal block.

(8) Do not use I/O modules under pressure higher than the atmospheric pressure of

0m (0ft.) altitude. Doing so can cause a malfunction.

When using I/O modules under pressure, please consult your sales representative.

=0.7) 100 thousand operations

=0.7) 300 thousand operations

=0.35) 100 thousand operations

=0.35) 300 thousand operations

2

core and 2.8mm (0.11in.) OD max. to connect to the

MELSEC-Q

1 - 3 1 - 3

Page 15

1 GENERAL SPECIFICATIONS OF INPUT AND OUTPUT MODULES AND

INSTRUCTIONS FOR SELECTING THEM

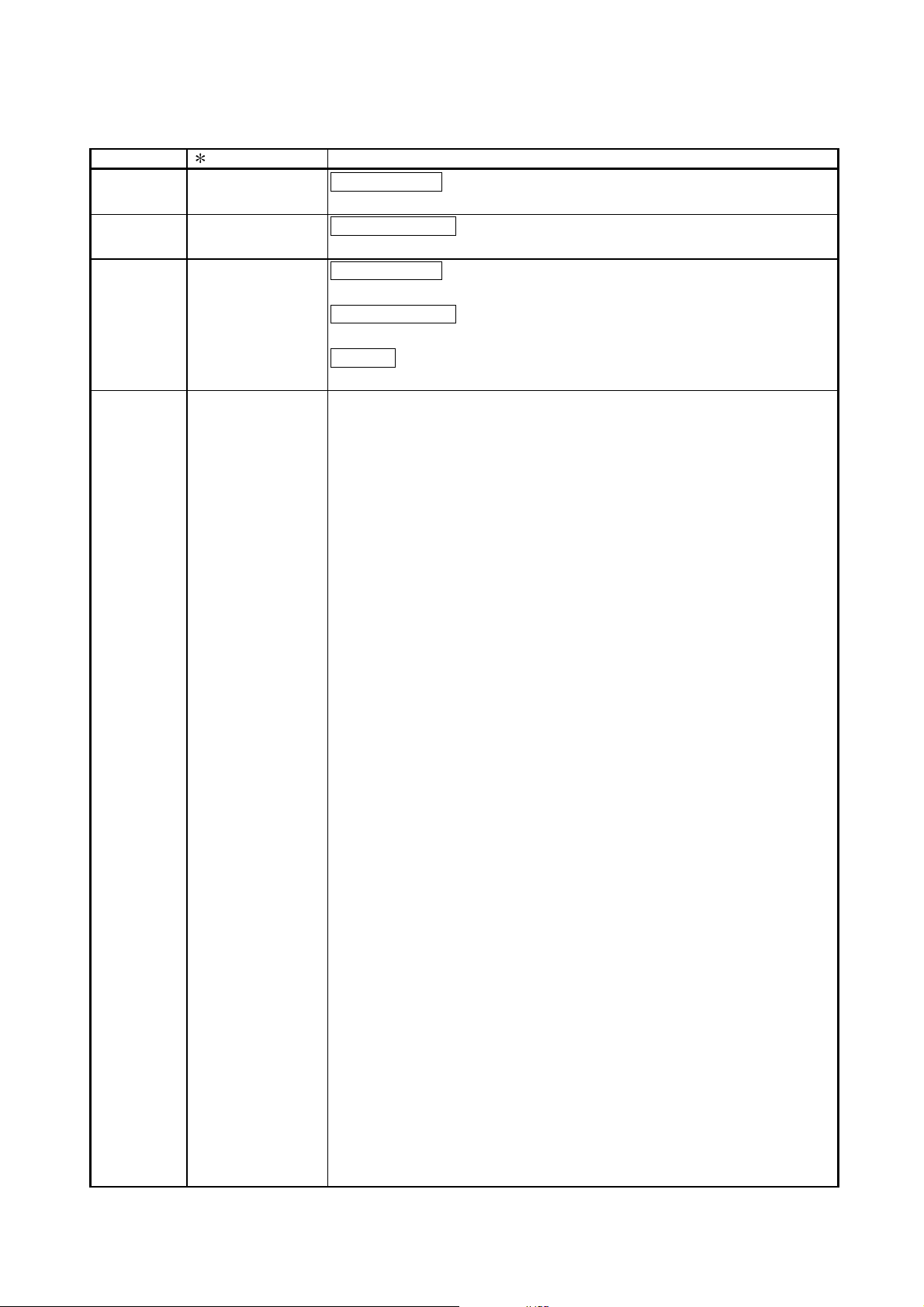

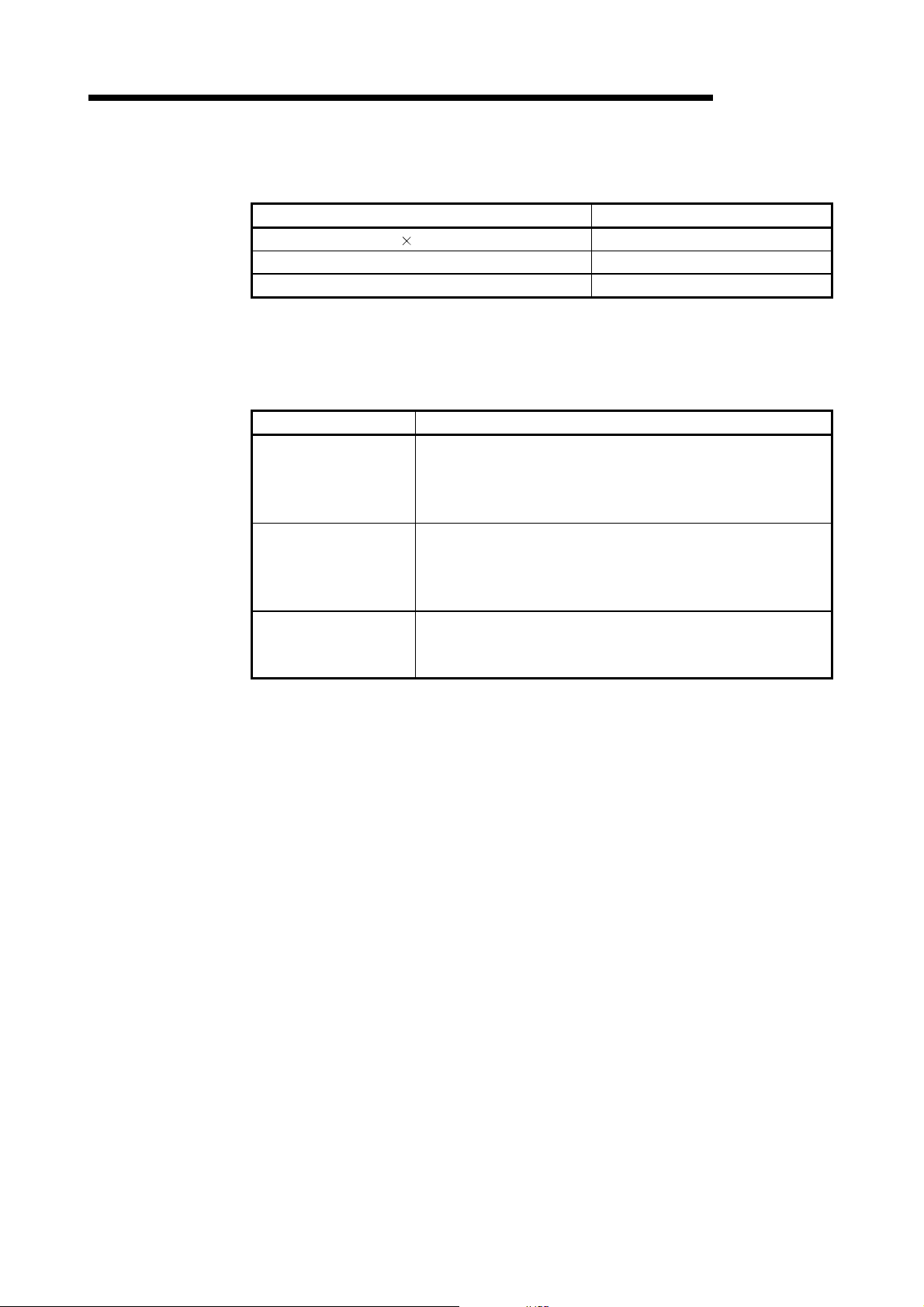

(9) Tighten the module fixing and terminal block screws to the torques in the following

ranges.

Screw Location Tightening Torque Range

Module fixing screw (M3 12 screw) 36 to 48 N•cm

I/O module terminal block screw (M3 screw) 42 to 58 N•cm

I/O module terminal block mounting screw (M3 screw) 66 to 89 N•cm

(10)There are the following restrictions on the thermal protections activated by

protected output modules.

The thermal protections are overload and overheat protective functions.

(a) QY40P, QY41P, QY42P, QH42P

Function Description

Common

(Overload and overheat

protective functions)

Overload protective

function

Overheat protective

function

• If an overcurrent keeps flowing due to overload, heat is generated

to activate the overheat protective function.

• Each protective function is designed to protect the internal

elements of the module, not the external equipment.

• The overload protective function is activated in 1 point increments

in terms of 1A to 3A/point.

• The overload protective function returns operation to normal when

the load becomes a rated load

• The overheat protective function is activated in 1 point increments.

• The overheat protective function automatically returns operation to

normal when heat reduces.

MELSEC-Q

1 - 4 1 - 4

Page 16

1 GENERAL SPECIFICATIONS OF INPUT AND OUTPUT MODULES AND

INSTRUCTIONS FOR SELECTING THEM

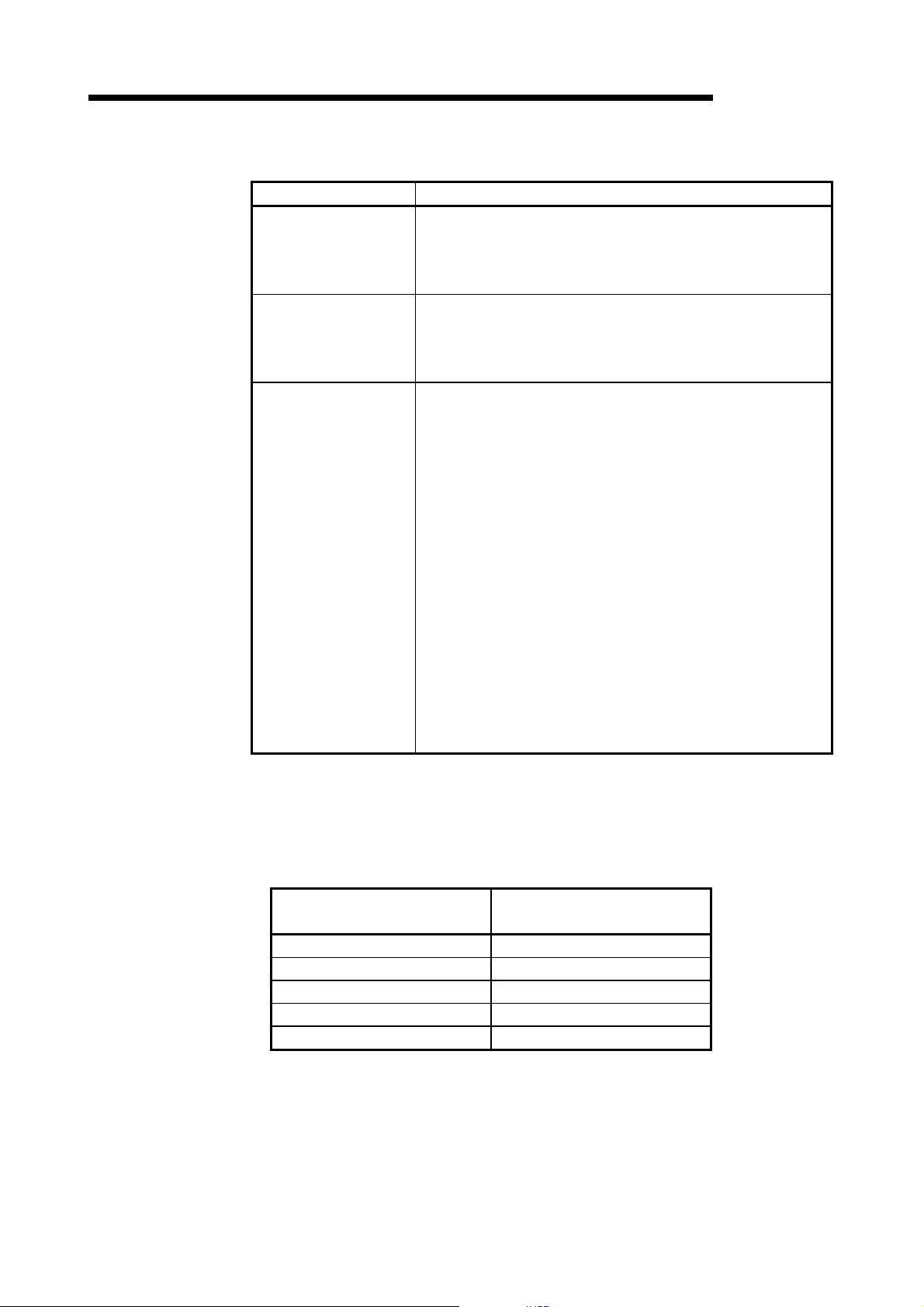

(b) QY81P

Function Description

Common

(Overload and overheat

protective functions)

Overload protective

function

Overheat protective

function

• If an overcurrent keeps flowing due to overload, heat is generated

to activate the overheat protective function.

• Each protective function is designed to protect the internal

elements of the module, not the external equipment.

• The overload protective function is activated in 1 point increments

in terms of 1A to 3A/point.

• The overload protective function returns operation to normal when

the load becomes a rated load.

• The overheat protective function is activated in 2 point increments.

(It is activated in 2 point increments of Y0/Y1, Y2/Y 3, ..., and w hen

overheat protection is activated, that of 2 points is activated

simultaneously. If an overheat condition persists, heat transferred

may activate the other overheat protective function.)

• If an output turns ON at the activation of the overheat protective

function, the actual output voltage oscillates between 0V and load

voltage.

At the load voltage of 24V, the average voltage during oscillation is

approx. 7V.

No oscillation is encountered when the output is OFF at the

activation of the overheat protective function.

To ensure that the output is turned OFF at the activation of the

overheat protective function, use an external load which sw itches

OFF at 7V or more.

• The overheat protective function automatically returns operation to

normal when heat reduces.

(11)Input modules may import noise or the like as an input depending on the pulse

width of a signal.

This pulse width has a value as listed below depending on the parameter-set

response time. The operating environment should be fully considered when making

the response time setting.

Response Time Setting (ms)

1 0.3

5 3

10 6

20 12

70 45

Minimum Value of Pulse Width

That May Be Imported (ms)

MELSEC-Q

1 - 5 1 - 5

Page 17

1 GENERAL SPECIFICATIONS OF INPUT AND OUTPUT MODULES AND

INSTRUCTIONS FOR SELECTING THEM

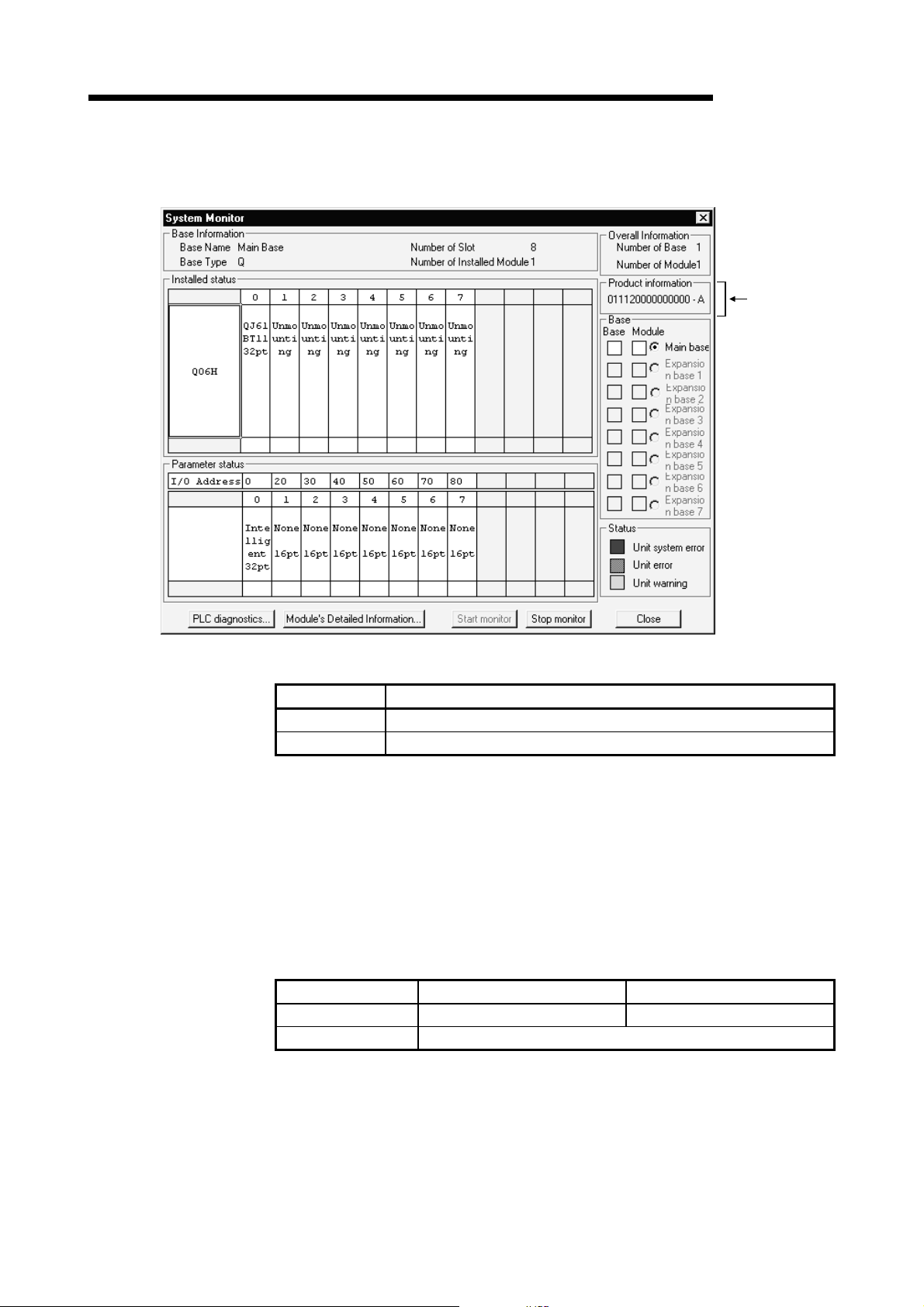

(12)When confirming the product information on the CPU PLC, observe the system

monitor in the DIAGNOSIS menu of the GX Developer.

MELSEC-Q

Confirm by

observing here.

(13)When using the QH42P or QX48Y57, configure it with the following devices.

Part name Detail

CPU PLC Product of product information [011120000000000-A] or later

GX Developer

SW5D5C-GPPW or later

The CPU PLCs other than those listed above cannot be used.

When the SW4D5C-GPPW is used, the response time cannot be set

(fixed at 10ms).

Set OUTPUT for the I/O allocation.

(14)Instructions for use of QY22

It is recommended to fit a fuse to each external terminal in order to prevent the

external device and module from being burnt if a load short-circuit occurs.

The fuse recommended for fitting is the one conforming to IEC60127 Sheet 1.

The following fuses have been confirmed by Mitsubishi to operate properly.

Fuse Model 216 02.5 216 002

Rated current 2.5A 2A

Manufacturer Littelfuse, Inc

1 - 6 1 - 6

Page 18

1 GENERAL SPECIFICATIONS OF INPUT AND OUTPUT MODULES AND

INSTRUCTIONS FOR SELECTING THEM

(15) Caution points when using QY68A

Installing a fuse to the external terminal to prevent burn out of external devices and

modules in the case of a load short is recommended.

A rated voltage 3A fast type fuse is recommended.

Fuses confirmed for operation by this company are listed below.

Fuse Model 216 3.15 312 003

Rated current 3.15A 3A

Manufacturer Littelfuse, Inc

(16) Possible constructions for QI60 compatible time settings

When setting compatible times for QI60, use the constructions listed below.

If using other constructions, compatible times can not be set. (Fixed at 0.2 ms)

Product name Contents

PLC CPU Product information "021120000000000-B" or later

GX Developer SW6D5C-GPPW or later

MELSEC-Q

1 - 7 1 - 7

Page 19

1 GENERAL SPECIFICATIONS OF INPUT AND OUTPUT MODULES AND

INSTRUCTIONS FOR SELECTING THEM

1.3 How to Make Settings on GX Developer

This section describes how to make settings using GX Developer.

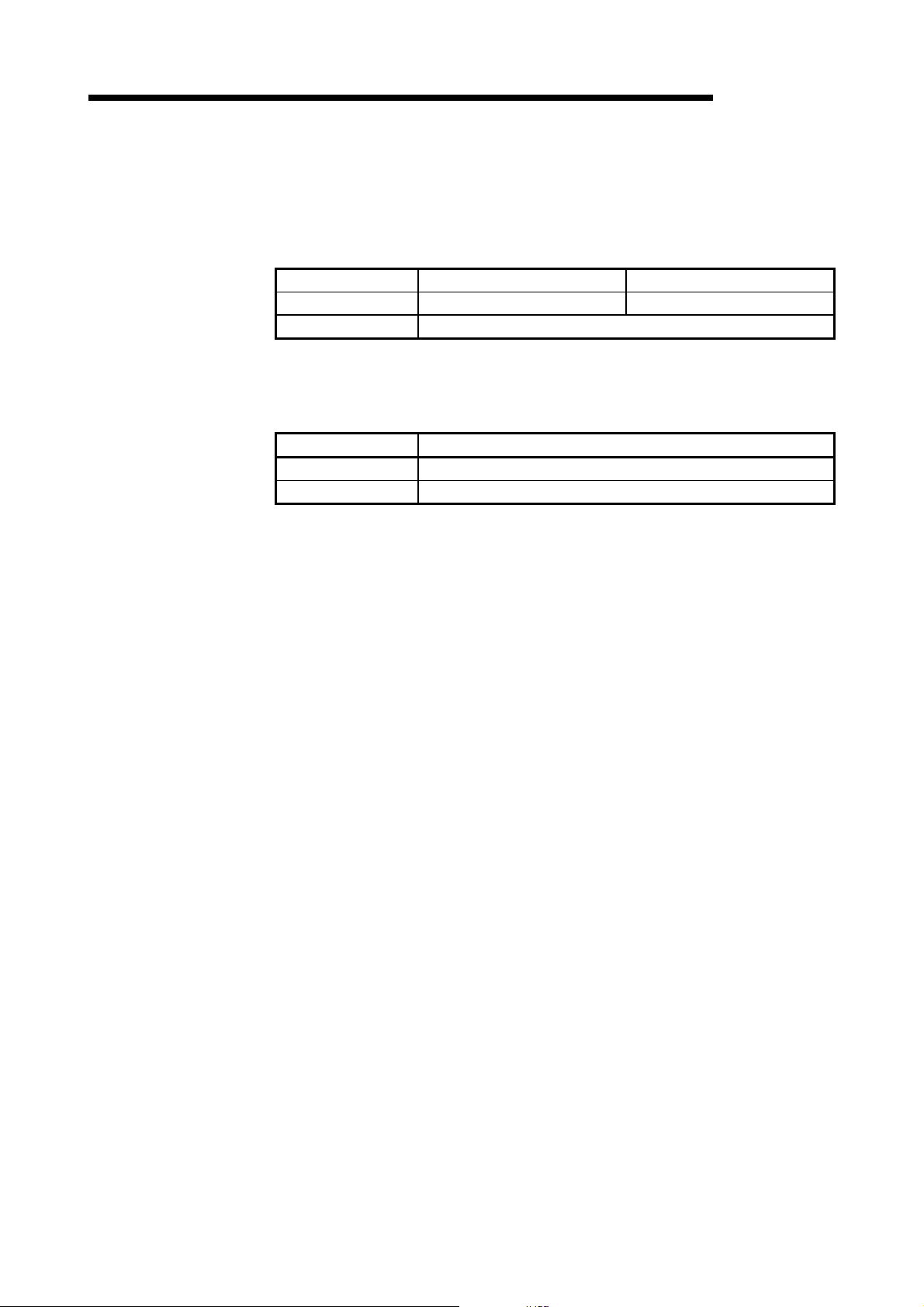

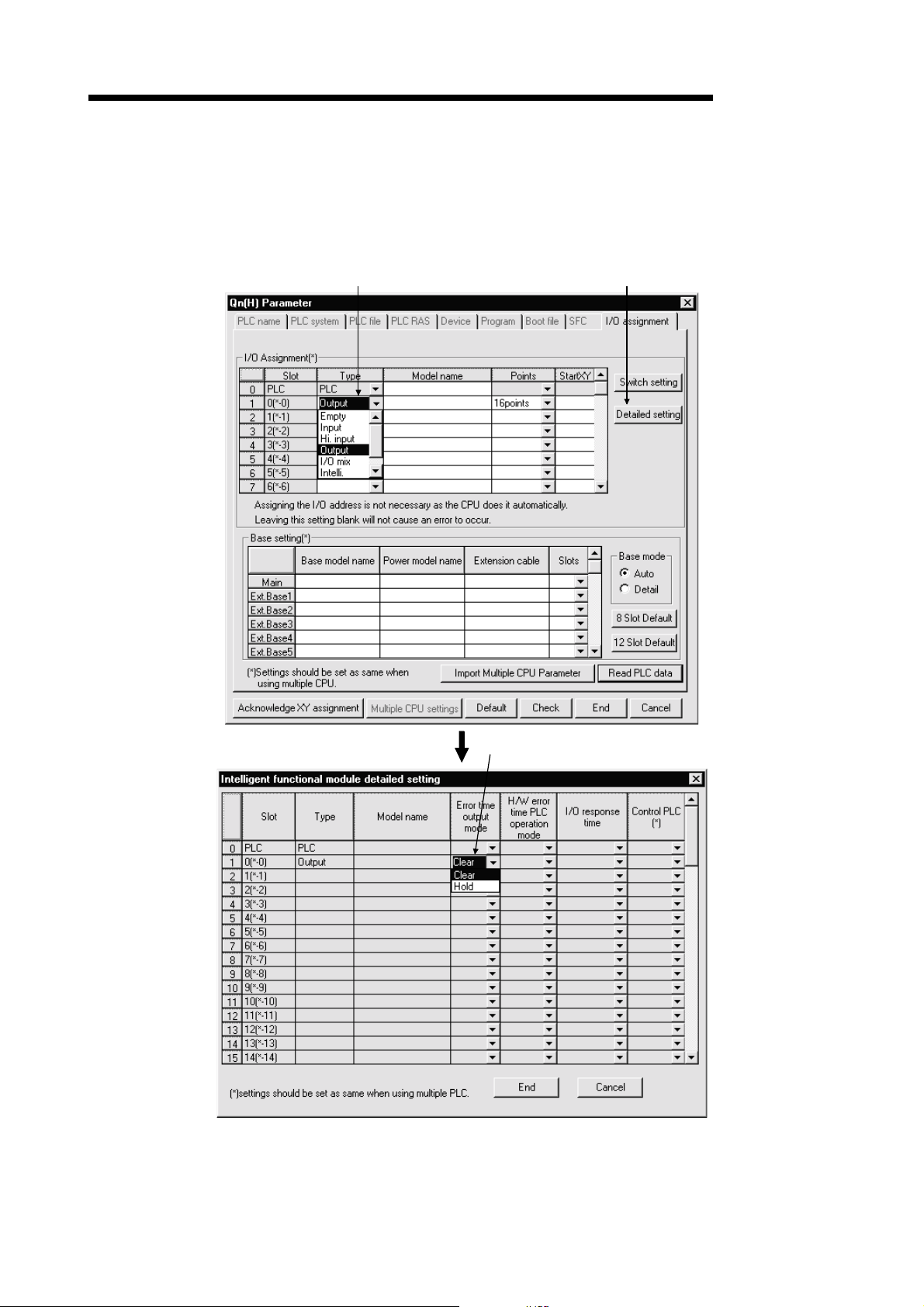

1.3.1 Setting of I/O response time

Set the I/O response time in I/O assignment of PLC Parameter.

(1) For Input/I/O mix module

Choose [Input/I/O mix] in Type, choose [Detailed setting], and choose [I/O response

time] in I/O response time.

Choose Input/I/O mix.

Choose Detailed setting.

MELSEC-Q

Choose I/O response time

1 - 8 1 - 8

(default: 10ms).

Page 20

1 GENERAL SPECIFICATIONS OF INPUT AND OUTPUT MODULES AND

INSTRUCTIONS FOR SELECTING THEM

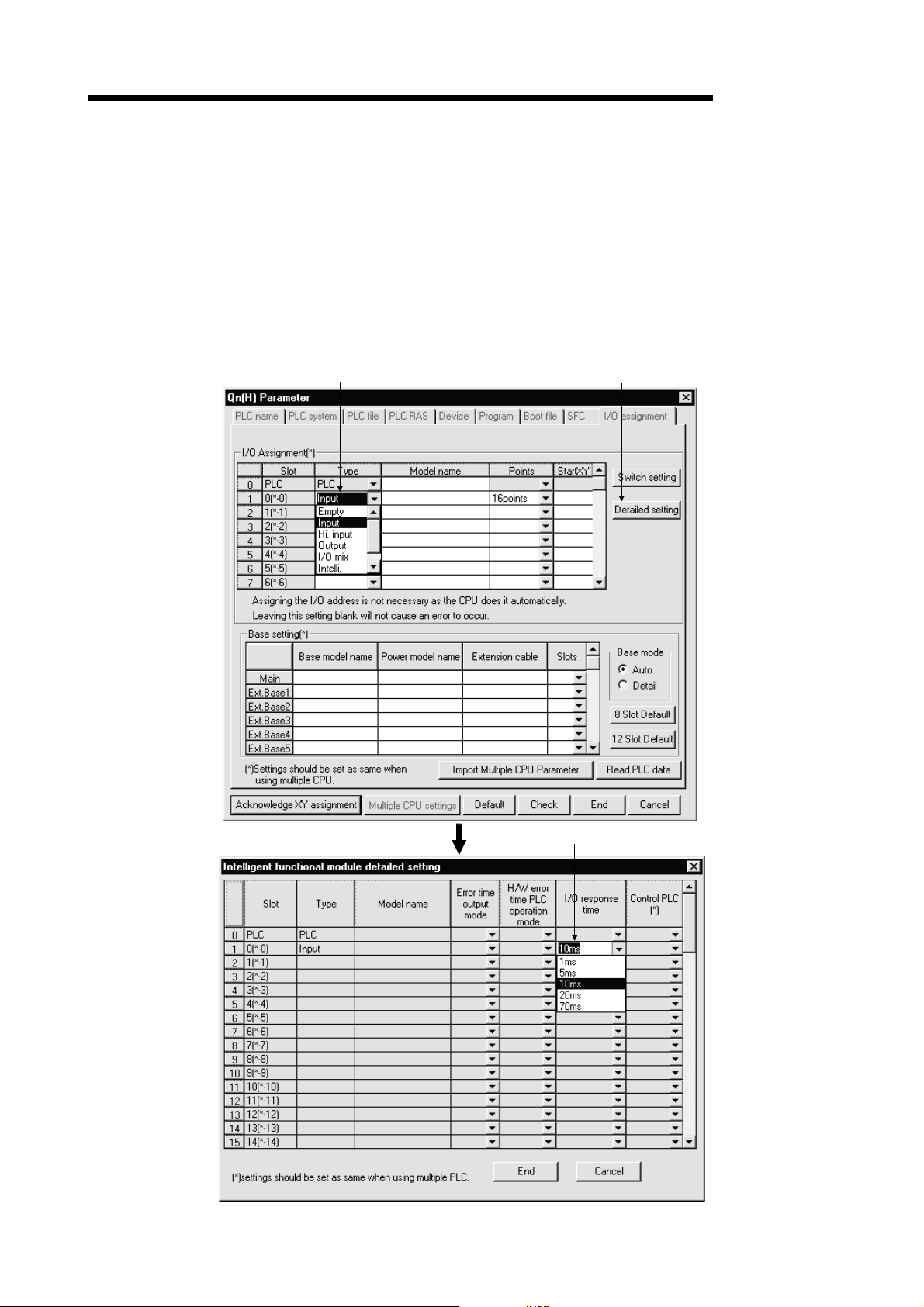

(2) For high-speed input module/QI60

Choose [Hi. input/Interrupt] in Type, choose [Detailed setting], and choose [I/O

response time] in I/O response time.

Choose Hi. input/Interrupt. Choose Detailed setting.

MELSEC-Q

Choose I/O response time

(default: 0.2ms).

1 - 9 1 - 9

Page 21

1 GENERAL SPECIFICATIONS OF INPUT AND OUTPUT MODULES AND

INSTRUCTIONS FOR SELECTING THEM

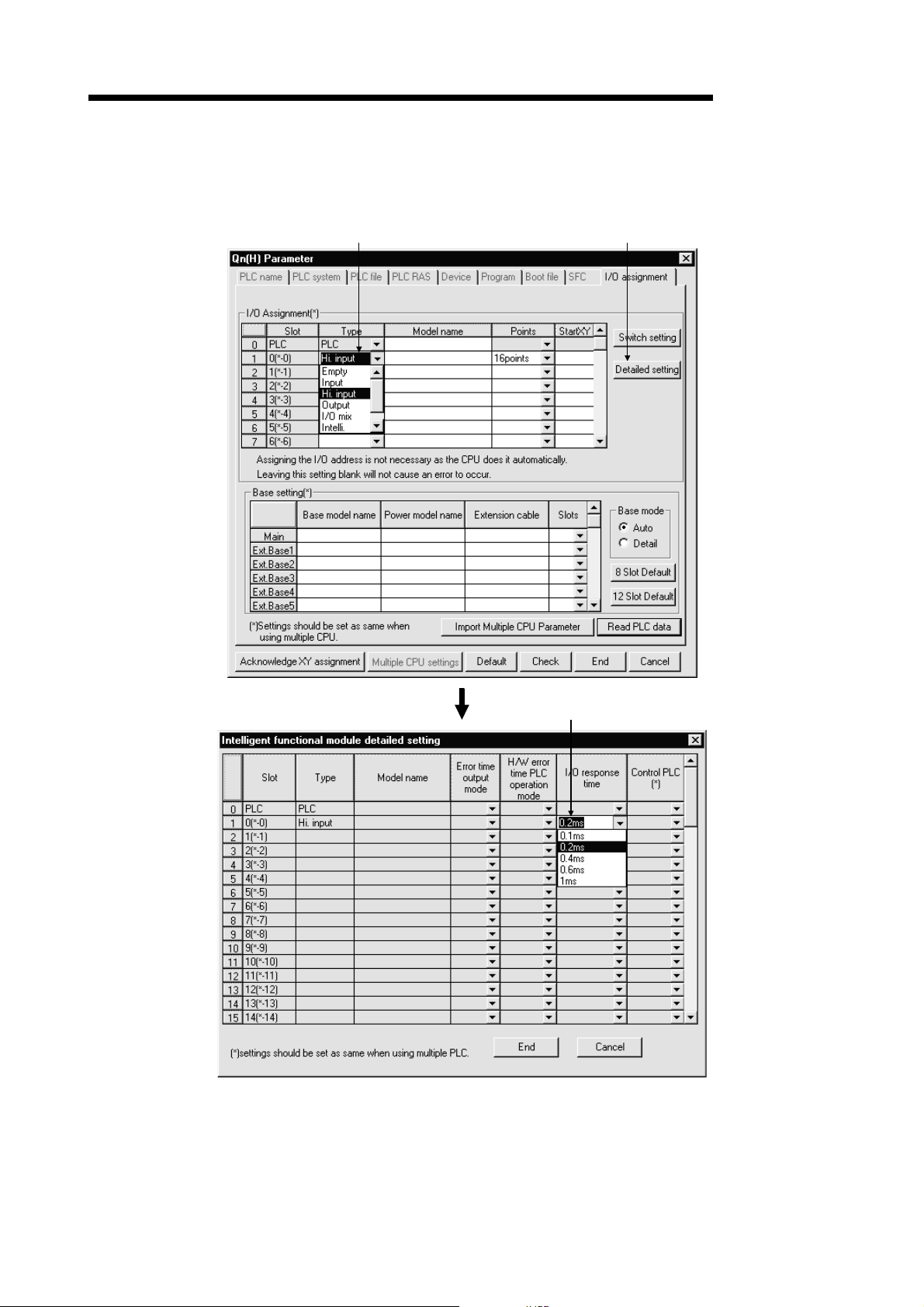

1.3.2 Setting of error-time output mode

Set the error-time output mode in I/O assignment of PLC Parameter.

Choose [Output/I/O mix] in Type, choose [Detailed setting], and choose [Clear/Hold] in

Error time output mode.

Choose Output/I/O mix. Choose Detailed setting.

MELSEC-Q

Choose Clear/Hold

(default: Clear).

1 - 10 1 - 10

Page 22

1 GENERAL SPECIFICATIONS OF INPUT AND OUTPUT MODULES AND

INSTRUCTIONS FOR SELECTING THEM

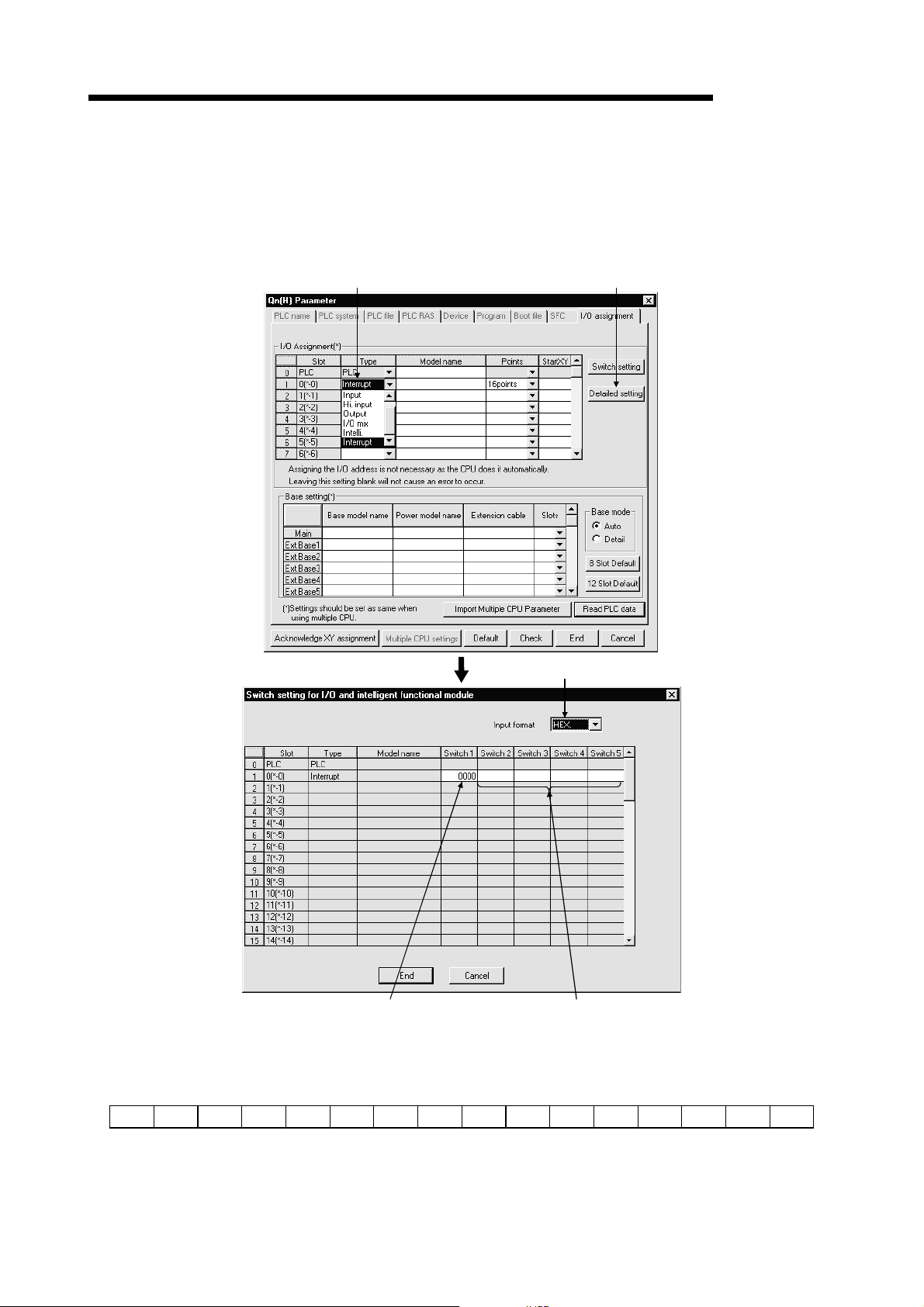

1.3.3 QI60 switch setting

Set the QI60 switches in I/O assignment of PLC Parameter.

Choose [Interrupt] in Type, choose [Switch setting], choose [HEX.] in Input format, and

set the interrupt processing conditions in Switch 1.

Choose Interrupt. Choose Switch setting.

MELSEC-Q

Choose HEX.

Set the interrupt processing conditions

(leading edge/trailing edge) of CH1 to CH16.

Setting inhibited.

Set the interrupt processing condition with switch 1. The relationships between bits and inputs are as indicated

below.

X15 X14 X13 X12 X11 X10 X9 X8 X7 X6 X5 X4 X3 X2 X1 X0

b0b15 to

0: Leading edge, 1: Trailing edge

1 - 11 1 - 11

Page 23

1 GENERAL SPECIFICATIONS OF INPUT AND OUTPUT MODULES AND

INSTRUCTIONS FOR SELECTING THEM

MELSEC-Q

MEMO

1 - 12 1 - 12

Page 24

2 INPUT MODULE SPECIFICATIONS

MELSEC-Q

2. INPUT MODULE SPECIFICATIONS

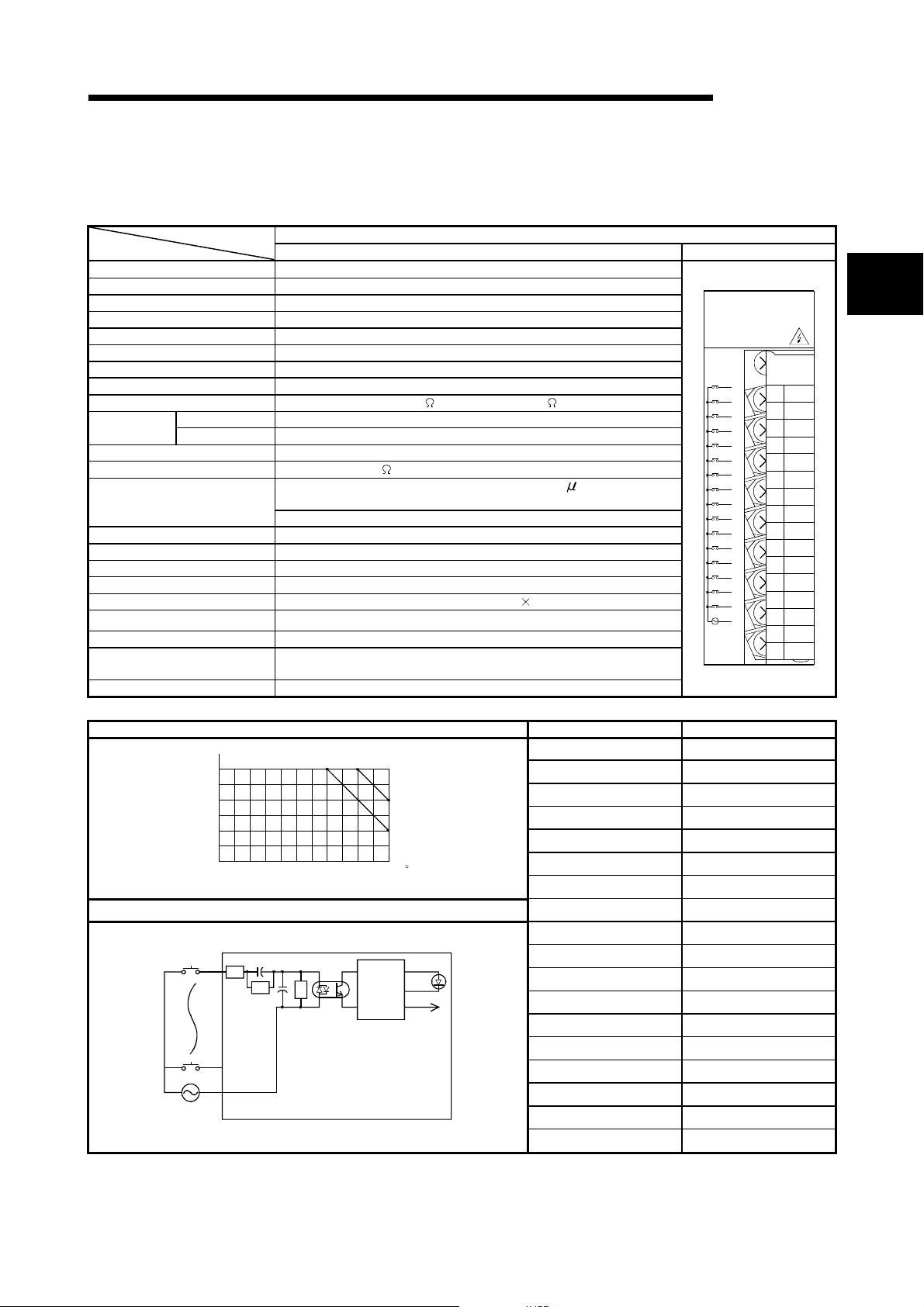

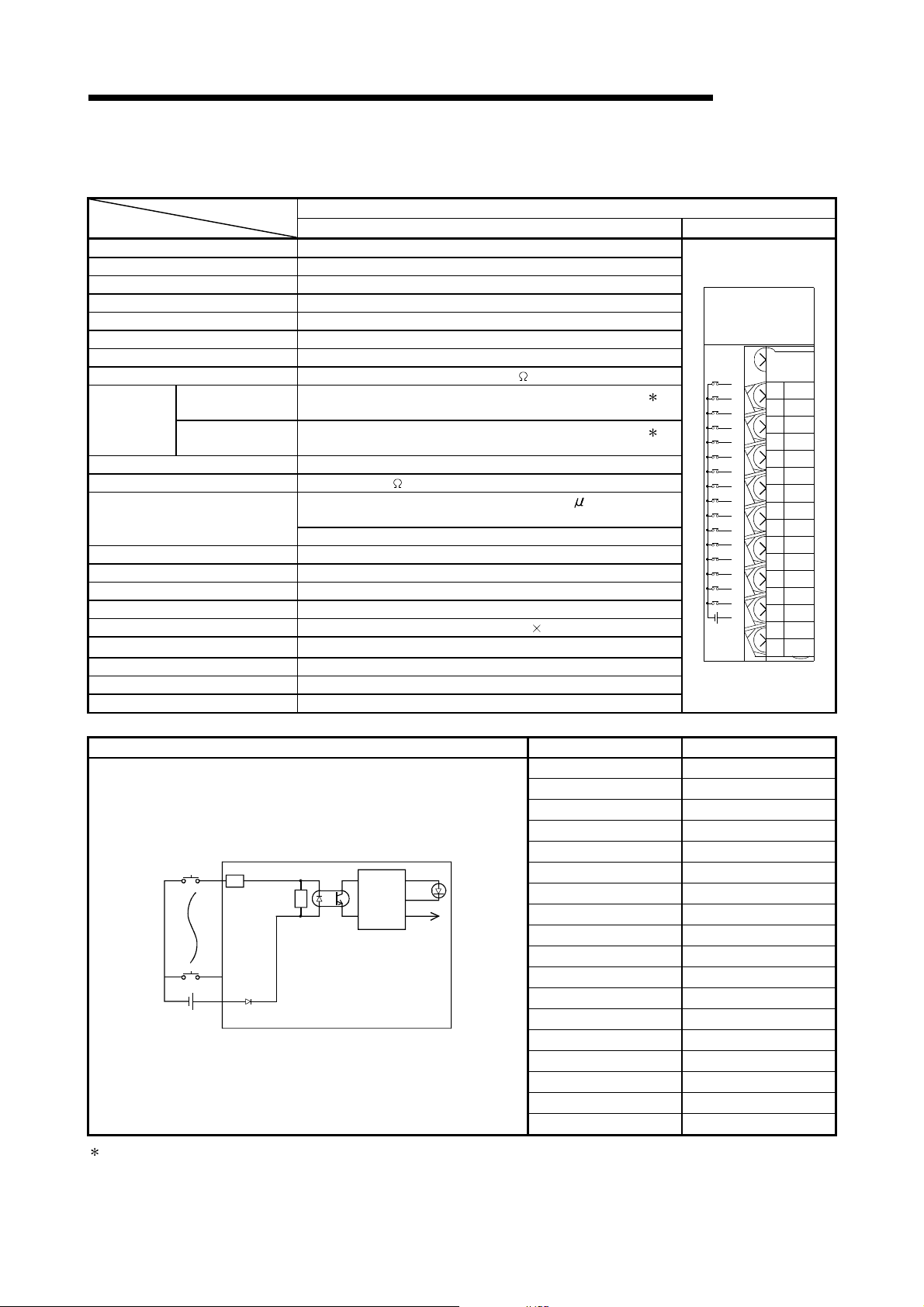

2.1 QX10 AC Input Module

Specifications

Number of input points 16 points

Isolation method Photocoupler

Rated input voltage, frequency 100-120VAC (+10/-15%) 50/60Hz (±3Hz) (distortion factor within 5%)

Rated input current Approx . 8mA (100VAC, 60Hz), approx. 7mA (100VAC, 50Hz)

Input derating Refer to the derating chart.

Inrush current Max. 200mA within 1ms (at 132VAC)

ON voltage/ON current 80VAC or higher/5mA or higher (50Hz, 60Hz)

OFF voltage/OFF current 30VAC or lower/1.7mA or lower (50Hz, 60Hz)

Input impedance Approx. 12k (60Hz), approx. 15k (50Hz)

time

Dielectric withstand voltage 1780VAC rms/3 cycles (altitude 2000m (6557.38ft.))

Insulation resistance 10M or more by insulation resistance tester

Noise immunity

Protection of degree IP1X

Common terminal arrangement 16 points/common (common terminal: TB17)

Number of I/O points 16 (I/O allocation is set as a 16-points input module)

Operation indicator ON indication (LED)

External connections 18-point terminal block (M3 6 screws)

Applicable wire size

Applicable crimping terminal R1.25-3 (sleeved crimping terminals cannot be used.)

5VDC internal current

consumption

OFF to ON 15ms or less (100VAC 50Hz, 60Hz) Response

ON to OFF 20ms or less (100VAC 50Hz, 60Hz)

By noise simulator of 1500Vp-p noise voltage, 1 s noise width

and 25 to 60Hz noise frequency

First transient noise IEC61000-4-4: 1kV

0.3 to 0.75mm

50mA (TYP. all points ON)

Weight 0.17kg

QX10 Appearance

2

core (2.8mm (0.11in.) OD max.)

Derating Chart Terminal Block Number Signal Name

(%)

100

90

80

ON

ratio

70

60

50

40

0102030405055

Ambient temperature

External Connections TB8 X07

TB 1

R

R

R

TB16

TB17

100VAC

Internal

circuit

120VAC

132VAC

( )

C

LED

AC Input Module Type

TB1 X00

TB2 X01

TB3 X02

TB4 X03

TB5 X04

TB6 X05

TB7 X06

TB9 X08

TB10 X09

TB11 X0A

TB12 X0B

TB13 X0C

TB14 X0D

TB15 X0E

TB16 X0F

TB17 COM

TB18 Vacant

QX10

01234567

89 ABCDEF

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

COM

NC

100VAC

8mA60Hz

7mA50Hz

2

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

2 - 1 2 - 1

Page 25

V

V

2 INPUT MODULE SPECIFICATIONS

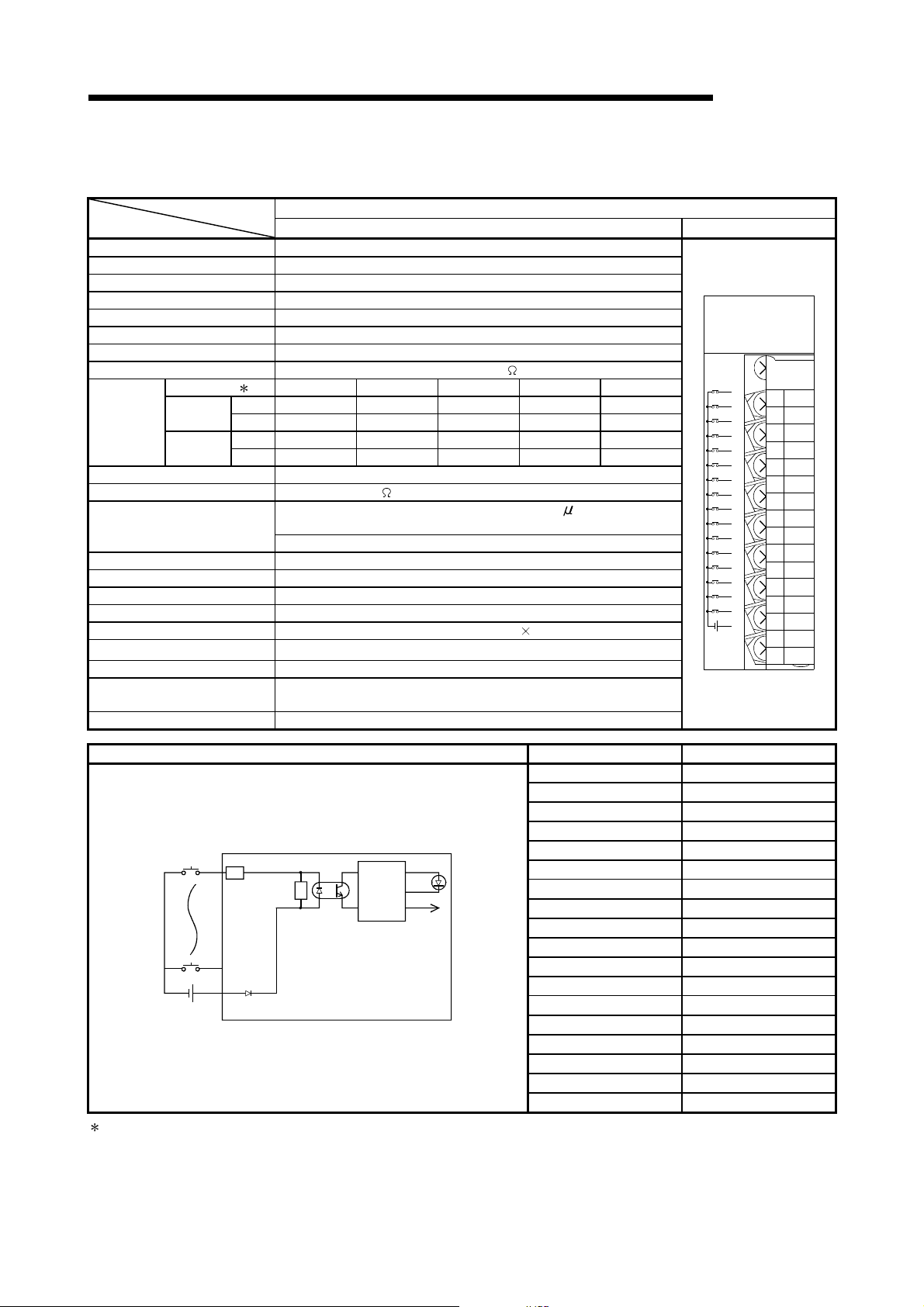

2.2 QX28 AC Input Module

MELSEC-Q

2

AC Input Module Type

Specifications

QX28 Appearance

Number of input points 8 points

Isolation method Photocoupler

Rated input voltage, frequency 100-240VAC (+10/-15%) 50/60Hz (±3Hz) (distortion factor within 5%)

Rated input current

Approx. 17mA (200VAC, 60Hz), approx. 14mA (200VAC, 50Hz)

Approx. 8mA (100VAC, 60Hz), approx. 7mA (100VAC, 50Hz)

Input derating Refer to the derating chart.

Inrush current Max. 500mA within 1ms (at 264VAC)

ON voltage/ON current 80VAC or higher/5mA or higher (50Hz, 60Hz)

OFF voltage/OFF current 30VAC or lower/1.7mA or lower (50Hz, 60Hz)

Input impedance Approx. 12k (60Hz), approx. 15k (50Hz)

OFF to ON 10ms or less (100VAC 50Hz, 60Hz) Response

time

ON to OFF 20ms or less (100VAC 50Hz, 60Hz)

Dielectric withstand voltage 2830VAC rms/3 cycles (altitude 2000m (6557.38ft.))

Insulation resistance 10M or more by insulation resistance tester

By noise simulator of 1500Vp-p noise voltage, 1 s noise width

Noise immunity

and 25 to 60Hz noise frequency

First transient noise IEC61000-4-4: 1kV

Protection of degree IP1X

Common terminal arrangement 8 points/common (common terminal: TB17)

Number of I/O points 16 (I/O allocation is set as a 16-points input module)

Operation indicator ON indication (LED)

External connections 18-point terminal block (M3 6 screws)

Applicable wire size

0.3 to 0.75mm

2

core (2.8mm (0.11in.) OD max.)

Applicable crimping terminal R1.25-3 (sleeved crimping terminals cannot be used.)

5VDC internal current

consumption

50mA (TYP. all points ON)

Weight 0.20kg

Derating Chart Terminal Block Number Signal Name

ON

ratio

(%)

100

90

80

70

100% 45 C

100% 55 C

87.5% 55

240

264

C

60

50

40

0102030405055

Ambient temperature

( )

C

External Connections TB8 Vacant

TB 1

TB15

TB17

100/200AC

R

R

R

Internal

circuit

LED

TB1 X00

TB2 Vacant

TB3 X01

TB4 Vacant

TB5 X02

TB6 Vacant

TB7 X03

TB9 X04

TB10 Vacant

TB11 X05

TB12 Vacant

TB13 X06

TB14 Vacant

TB15 X07

TB16 Vacant

TB17 COM

TB18 Vacant

QX28

01234567

0

NC

1

NC

2

NC

3

NC

4

NC

5

NC

6

NC

7

MC

COM

NC

200VAC

17mA60Hz

14mA50Hz

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

2 - 2 2 - 2

Page 26

2 INPUT MODULE SPECIFICATIONS

2.3 QX40 DC Input Module (Positive Common Type)

DC Input Module (Positive Common Type) Type

Specifications

Number of input points 16 points

Isolation method Photocoupler

Rated input voltage 24VDC (+20/-15%, ripple ratio within 5%)

Rated input current Approx. 4mA

Input derating No

ON voltage/ON current 19V or higher/3mA or higher

OFF voltage/OFF current 11V or lower/1.7mA or lower

Input impedance Approx. 5.6k

1ms/5ms/10ms/20ms/70ms or less (CPU parameter setting)

1ms/5ms/10ms/20ms/70ms or less (CPU parameter setting)

Response

time

OFF to ON

ON to OFF

Dielectric withstand voltage 560VAC rms/3 cycles (altitude 2000m (6557.38ft.))

Insulation resistance 10M or more by insulation resistance tester

By noise simulator of 500Vp-p noise voltage, 1 s noise width

Noise immunity

and 25 to 60Hz noise frequency

First transient noise IEC61000-4-4: 1kV

Protection of degree IP2X

Common terminal arrangement 16 points/common (common terminal: TB17)

Number of I/O points 16 (I/O allocation is set as a 16-points input module)

Operation indicator ON indication (LED)

External connections 18-point terminal block (M3 6 screws)

Applicable wire size

0.3 to 0.75mm

Applicable crimping terminal R1.25-3 (sleeved crimping terminals cannot be used.)

5VDC internal current consumption 50mA (TYP. all points ON)

Weight 0.16kg

External Connections Terminal Block Number Signal Name

TB 1

R

R

TB16

TB17

24VDC

Internal

circuit

: For the setting method, refer to the section 1.3.1.

QX40 Appearance

Initial setting is 10ms.

Initial setting is 10ms.

2

core (2.8mm (0.11in.) OD max.)

LED

MELSEC-Q

QX40

01234567

89ABCDEF

0

0

1

2

2

4

3

4

6

5

6

8

7

A

8

9

C

A

B

E

C

D

E

F

+-

COM

24VDC

4mA

1

3

5

7

9

B

D

F

NC

TB1 X00

TB2 X01

TB3 X02

TB4 X03

TB5 X04

TB6 X05

TB7 X06

TB8 X07

TB9 X08

TB10 X09

TB11 X0A

TB12 X0B

TB13 X0C

TB14 X0D

TB15 X0E

TB16 X0F

TB17 COM

TB18 Vacant

2 - 3 2 - 3

Page 27

2 INPUT MODULE SPECIFICATIONS

2.4 QX40-S1 DC Input Module (Positi ve Common Type)

DC Input Module (Positive Common Type) Type

Specifications

Number of input points 16 points

Isolation method Photocoupler

Rated input voltage 24VDC (+20/-15%, ripple ratio within 5%)

Rated input current Approx. 6mA

Input derating No

ON voltage/ON current 19V or higher/4.0mA or higher

OFF voltage/OFF current 11V or lower/1.7mA or lower

Input impedance Approx. 3.9k

Set value 1 0.1 0.2 0.4 0.6 1

Response

time

OFF to ON

ON to OFF

Typ 0.05ms 0.15ms 0.30ms 0.55ms 1.05ms

max 0.10ms 0.20ms 0.40ms 0.60ms 1.20ms

Typ 0.15ms 0.20ms 0.35ms 0.60ms 1.10ms

max 0.20ms 0.30ms 0.50ms 0.70ms 1.30ms

Dielectric withstand voltage 560VAC rms/3 cycles (altitude 2000m (6557.38ft.))

Insulation resistance 10M or more by insulation resistance tester

By noise simulator of 500Vp-p noise voltage, 1 s noise width

Noise immunity

and 25 to 60Hz noise frequency

First transient noise IEC61000-4-4: 1kV

Protection of degree IP2X

Common terminal arrangement 16 points/common (common terminal: TB17)

Number of I/O points 16 (I/O allocation is set as a 16-points Hi. input module)

Operation indicator ON indication (LED)

External connections 18-point terminal block (M3 6 screws)

Applicable wire size

0.3 to 0.75mm

Applicable crimping terminal R1.25-3 (sleeved crimping terminals cannot be used.)

5VDC internal current

consumption

Weight 0.20kg

External Connections Terminal Block Number Signal Name

TB 1

R

R

TB16

TB17

24VDC

Internal

circuit

1: CPU parameter setting. (Initial setting is 0.2ms)

Response time can be changed on SW5D5C-GPPW or later.

For the setting method, refer to the section 1.3.1.

QX40-S1 Appearance

2

core (2.8mm (0.11in.) OD max.)

60mA (TYP. all points ON)

LED

MELSEC-Q

QX40-S1

01234567

89ABCDEF

0

0

1

2

2

4

3

4

6

5

6

8

7

A

8

9

C

A

B

E

C

D

E

F

+-

COM

24VDC

6mA

1

3

5

7

9

B

D

F

NC

TB1 X00

TB2 X01

TB3 X02

TB4 X03

TB5 X04

TB6 X05

TB7 X06

TB8 X07

TB9 X08

TB10 X09

TB11 X0A

TB12 X0B

TB13 X0C

TB14 X0D

TB15 X0E

TB16 X0F

TB17 COM

TB18 Vacant

2 - 4 2 - 4

Page 28

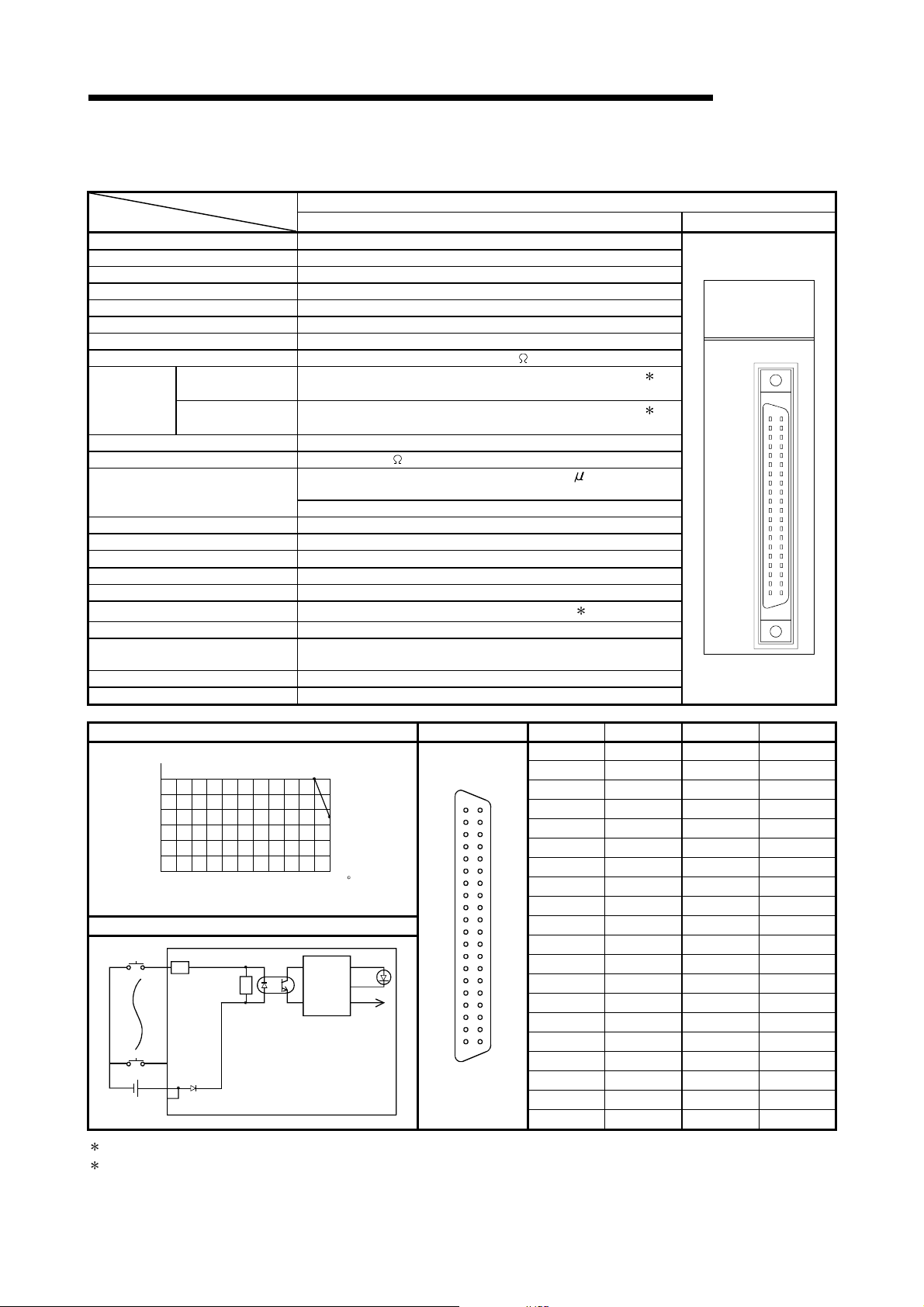

2 INPUT MODULE SPECIFICATIONS

2.5 QX41 DC Input Module (Positive Common Type)

DC Input Module (Positive Common Type) Type

Specifications

Number of input points 32 points

Isolation method Photocoupler

Rated input voltage 24VDC (+20/-15%, ripple ratio within 5%)

Rated input current Approx. 4mA

Input derating Refer to the derating chart.

ON voltage/ON current 19V or higher/3mA or higher

OFF voltage/OFF current 11V or lower/1.7mA or lower

Input impedance Approx. 5.6k

1ms/5ms/10ms/20ms/70ms or less (CPU parameter setting)

1ms/5ms/10ms/20ms/70ms or less (CPU parameter setting)

Response

time

OFF to ON

ON to OFF

Dielectric withstand voltage 560VAC rms/3 cycles (altitude 2000m (6557.38ft.))

Insulation resistance 10M or more by insulation resistance tester

By noise simulator of 500Vp-p noise voltage, 1 s noise width

Noise immunity

and 25 to 60Hz noise frequency

First transient noise IEC61000-4-4: 1kV

Protection of degree IP2X

Common terminal arrangement 32 points/common (common terminal: B01, B02)

Number of I/O points 32 (I/O allocation is set as a 32-points input module)

Operation indicator ON indication (LED)

External connections 40-pin connector

Applicable wire size

0.3mm

2

External wiring connector A6CON1, A6CON2, A6CON3, A6CON4 (optional)

Applicable connector/terminal block

conversion module

A6TBXY36, A6TBXY54, A6TBX70

5VDC internal current consumption 75mA (TYP. all points ON)

Weight 0.15kg

Derating Chart Pin-Outs Pin No. Signal No. Pin No. Signal No.

(%)

100

90

80

ON

ratio

70

28.8VDC

60

50

40

0102030405055

Ambient temperature

( )

C

External Connections B11 X09 A11 X19

LED

Module front view

24VDC

B20

A05

B02

B01

R

R

Internal

circuit

: For the setting method, refer to the section 1.3.1.

1

: When using A6CON2 or A6CON3, refer to Chapter 7.

2

QX41 Appearance

Initial setting is 10ms.

Initial setting is 10ms.

(For A6CON1 or A6CON4) 2

B20 X00 A20 X10

B19 X01 A19 X11

B18 X02 A18 X12

B20

B19

B18

B17

B16

B15

B14

B13

B12

B11

B10

B9

B8

B7

B6

B5

B4

B3

B2

B1

A20

A19

A18

A17

A16

A15

A14

A13

A12

A11

A10

A9

A8

A7

A6

A5

A4

A3

A2

A1

B17 X03 A17 X13

B16 X04 A16 X14

B15 X05 A15 X15

B14 X06 A14 X16

B13 X07 A13 X17

B12 X08 A12 X18

B10 X0A A10 X1A

B09 X0B A09 X1B

B08 X0C A08 X1C

B07 X0D A07 X1D

B06 X0E A06 X1E

B05 X0F A05 X1F

B04 Vacant A04 Vacant

B03 Vacant A03 Vacant

B02 COM A02 Vacant

B01 COM A01 Vacant

MELSEC-Q

QX41

01234567

89ABCDEF

01234567

89ABCDEF

24VDC

4mA

1

1

QX41

2 - 5 2 - 5

Page 29

2 INPUT MODULE SPECIFICATIONS

2.6 QX41-S1 DC Input Module (Positi ve Common Type)

DC Input Module (Positive Common Type) Type

Specifications

Number of input points 32 points

Isolation method Photocoupler

Rated input voltage 24VDC (+20/-15%, ripple ratio within 5%)

Rated input current Approx. 4mA

Input derating Refer to the derating chart.

ON voltage/ON current 19V or higher/3.0mA or higher

OFF voltage/OFF current 9.5V or lower/1.5mA or lower

Input impedance Approx. 5.6k

Set value 1 0.1 0.2 0.4 0.6 1

Response

time

Dielectric withstand voltage 560VAC rms/3 cycles (altitude 2000m (6557.38ft.))

Common terminal arrangement 32 points/common (common terminal: B01, B02)

External wiring connector A6CON1, A6CON2, A6CON3, A6CON4 (optional)

Applicable connector/terminal

block conversion module

1: CPU parameter setting. (Initial setting is 0.2ms)

Response time can be changed on SW5D5C-GPPW or later.

For the setting method, refer to the section 1.3.1.

: When using A6CON2 or A6CON3, refer to Chapter 7.

2

OFF to ON

ON to OFF

Insulation resistance 10M or more by insulation resistance tester

Noise immunity

Protection of degree IP2X

Number of I/O points 32 (I/O allocation is set as a 32-points Hi. input module)

Operation indicator ON indication (LED)

External connections 40-pin connector

Applicable wire size

5VDC internal current

consumption

Weight 0.15kg

Typ 0.05ms 0.15ms 0.30ms 0.55ms 1.05ms

max 0.12ms 0.20ms 0.40ms 0.60ms 1.20ms

Typ 0.15ms 0.20ms 0.35ms 0.60ms 1.10ms

max 0.20ms 0.30ms 0.50ms 0.70ms 1.30ms

By noise simulator of 500Vp-p noise voltage, 1 s noise width

and 25 to 60Hz noise frequency

First transient noise IEC61000-4-4: 1kV

0.3mm

A6TBXY36, A6TBXY54, A6TBX70

QX41-S1 Appearance

2

(For A6CON1 or A6CON4) 2

75mA (TYP. all points ON)

MELSEC-Q

QX41-S1

01234567

89ABCDEF

01234567

89ABCDEF

24VDC

4mA

QX41-S1

2 - 6 2 - 6

Page 30

2 INPUT MODULE SPECIFICATIONS

Derating Chart Pin-Outs Pin No. Signal No. Pin No. Signal No.

(%)

100

90

80

ON

ratio

70

28.8VDC

60

50

40

0102030405055

Ambient temperature

( )

C

External Connections B11 X09 A11 X19

LED

24VDC

B20

A05

B02

B01

R

R

Internal

circuit

B20

B19

B18

B17

B16

B15

B14

B13

B12

B11

B10

B9

B8

B7

B6

B5

B4

B3

B2

B1

A20

A19

A18

A17

A16

A15

A14

A13

A12

A11

A10

A9

A8

A7

A6

A5

A4

A3

A2

A1

Module front view

MELSEC-Q

B20 X00 A20 X10

B19 X01 A19 X11

B18 X02 A18 X12

B17 X03 A17 X13

B16 X04 A16 X14

B15 X05 A15 X15

B14 X06 A14 X16

B13 X07 A13 X17

B12 X08 A12 X18

B10 X0A A10 X1A

B09 X0B A09 X1B

B08 X0C A08 X1C

B07 X0D A07 X1D

B06 X0E A06 X1E

B05 X0F A05 X1F

B04 Vacant A04 Vacant

B03 Vacant A03 Vacant

B02 COM A02 Vacant

B01 COM A01 Vacant

2 - 7 2 - 7

Page 31

2 INPUT MODULE SPECIFICATIONS

2.7 QX42 DC Input Module (Positive Common Type)

MELSEC-Q

Specifications

QX42 Appearance

Number of input points 64 points

DC Input Module (Positive Common Type) Type

Isolation method Photocoupler

Rated input voltage 24VDC (+20/-15%, ripple ratio within 5%)

Rated input current Approx. 4mA

Input derating Refer to the derating chart.

ON voltage/ON current 19V or higher/3mA or higher

OFF voltage/OFF current 11V or lower/1.7mA or lower

Input impedance Approx. 5.6k

Response

time

OFF to ON

ON to OFF

1ms/5ms/10ms/20ms/70ms or less (CPU parameter setting)

Initial setting is 10ms.

1ms/5ms/10ms/20ms/70ms or less (CPU parameter setting)

Initial setting is 10ms.

1

1

QX42

01234567

89ABCDEF

01234567

89ABCDEF

24VDC

4mA

DISPLAY

F L

QX42

Dielectric withstand voltage 560VAC rms/3 cycles (altitude 2000m (6557.38ft.))

Insulation resistance 10M or more by insulation resistance tester

By noise simulator of 500Vp-p noise voltage, 1 s noise width

Noise immunity

and 25 to 60Hz noise frequency

First transient noise IEC61000-4-4: 1kV

Protection of degree IP2X

Common terminal arrangement 32 points/common (common terminal: 1B01, 1B02, 2B01, 2B02)

Number of I/O points 64 (I/O allocation is set as a 32-points input module)

Operation indicator ON indication (LED), 32 point switch-over using switch

External connections 40-pin connector

Applicable wire size

0.3mm

2

(For A6CON1 or A6CON4) 4

External wiring connector A6CON1, A6CON2, A6CON3, A6CON4 (optional)

Applicable connector/terminal block

conversion module

A6TBXY36, A6TBXY54, A6TBX70

5VDC internal current consumption 90mA (TYP. all points ON)

(%)

100

ON

ratio

24VDC

The above diagram shows the first half of 32 points

(F).

The latter half of 32 points (L) are similar.

Weight 0.18kg

Derating Chart Pin-Outs

90

80

70

60

50

40

30

20

0102030405055

Ambient temperature

External Connections

1B20

+-

1A5

1B2

1B1

R

R

Left side

(first half)

Right side

(latter half)

SW

3

Internal

circuit

Indication

selector

circuit

24VDC

26.4VDC

28.8VDC

( )

C

LED

B20

B19

B18

B17

B16

B15

B14

B13

B12

B11

B10

B9

B8

B7

B6

B5

B4

B3

B2

B1

Module front view

Sig-

Pin

nal

No.

No.

1B20 X00 1A20 X10 2B20 X20 2A20 X30

1B19 X01 1A19 X11 2B19 X21 2A19 X31

1B18 X02 1A18 X12 2B18 X22 2A18 X32

1B17 X03 1A17 X13 2B17 X23 2A17 X33

A20

1B16 X04 1A16 X14 2B16 X24 2A16 X34

A19

A18

1B15 X05 1A15 X15 2B15 X25 2A15 X35

A17

A16

1B14 X06 1A14 X16 2B14 X26 2A14 X36

A15

1B13 X07 1A13 X17 2B13 X27 2A13 X37

A14

A13

1B12 X08 1A12 X18 2B12 X28 2A12 X38

A12

A11

1B11 X09 1A11 X19 2B11 X29 2A11 X39

A10

A9

1B10 X0A 1A10 X1A 2B10 X2A 2A10 X3A

A8

A7

1B09 X0B 1A09 X1B 2B09 X2B 2A09 X3B

A6

1B08 X0C 1A08 X1C 2B08 X2C 2A08 X3C

A5

A4

1B07 X0D 1A07 X1D 2B07 X2D 2A07 X3D

A3

A2

1B06 X0E 1A06 X1E 2B06 X2E 2A06 X3E

A1

1B05 X0F 1A05 X1F 2B05 X2F 2A05 X3F

1B04 Vacant 1A04 Vacant 2B04 Vacant 2A04 Vacant

1B03 Vacant 1A03 Vacant 2B03 Vacant 2A03 Vacant

1B02 COM 1A02 Vacant 2B02

1B01 COM 1A01 Vacant 2B01

Pin

No.

Sig-

nal

No.

Pin

No.

Sig-

nal

No.

COM2

COM2

Pin

No.

2A02 Vacant

2A01 Vacant

1: For the setting method, refer to the section 1.3.1.

2: Pin number of 1 indicates that of the left-hand side connector, and pin number of 2 indicates that of the right-hand

side connector.

3: Selection of left-hand (F) side provides the first half (X00 to X1F) LED indications, and selection of right-hand (L) side provides the

latter half (X20 to X3F) LED indications.

: When using A6CON2 or A6CON3, refer to Chapter 7.

4

Sig-

nal

No.

2 - 8 2 - 8

Page 32

2 INPUT MODULE SPECIFICATIONS

MELSEC-Q

2.8 QX42-S1 DC Input Module (Positi ve Common Type)

DC Input Module (Positive Common Type) Type

Specifications

Number of input points 64 points

Isolation method Photocoupler

Rated input voltage 24VDC (+20/-15%, ripple ratio within 5%)

Rated input current Approx. 4mA

Input derating

ON voltage/ON current 19V or higher/3.0mA or higher

OFF voltage/OFF current 9.5V or lower/1.5mA or lower

Input impedance Approx. 5.6k

Set value 1 0.1 0.2 0.4 0.6 1

Response

time

Dielectric withstand voltage 560VAC rms/3 cycles (altitude 2000m (6557.38ft.))

Common terminal arrangement

External wiring connector A6CON1, A6CON2, A6CON3, A6CON4 (optional)

Applicable connector/terminal

block conversion module

1: CPU parameter setting. (Initial setting is 0.2ms)

Response time can be changed on SW5D5C-GPPW or later.

For the setting method, refer to the section 1.3.1.

2: Pin number of 1 indicates that of the left-hand side connector, and pin number of 2 indicates that of the right-hand

side connector.

3: Selection of left-hand (F) side provides the first half (X00 to X1F) LED indications, and selection of right-hand (L) side provides the

latter half (X20 to X3F) LED indications.

: When using A6CON2 or A6CON3, refer to Chapter 7.

4

OFF to ON

ON to OFF

Insulation resistance 10M or more by insulation resistance tester

Noise immunity

Protection of degree IP2X

Number of I/O points 64 (I/O allocation is set as a 64-points Hi. input module)

Operation indicator ON indication (LED)

External connections

Applicable wire size

5VDC internal current

consumption

Weight 0.18kg

Typ 0.05ms 0.15ms 0.30ms 0.55ms 1.05ms

max 0.12ms 0.20ms 0.40ms 0.60ms 1.20ms

Typ 0.15ms 0.20ms 0.35ms 0.60ms 1.10ms

max 0.20ms 0.30ms 0.50ms 0.70ms 1.30ms

By noise simulator of 500Vp-p noise voltage, 1 s noise width

and 25 to 60Hz noise frequency

First transient noise IEC61000-4-4: 1kV

32 points/common (common terminal: 1B01, 1B02, 2B01, 2B02)

0.3mm

A6TBXY36, A6TBXY54, A6TBX70

QX42-S1 Appearance

Refer to the derating chart.

40-pin connector

2

(For A6CON1 or A6CON4) 4

90mA (TYP. all points ON)

QX42-S1

01234567

89ABCDEF

01234567

89ABCDEF

24VDC

4mA

DISPLAY

F L

QX42-S1

2 - 9 2 - 9

Page 33

2 INPUT MODULE SPECIFICATIONS

Derating Chart Pin-Outs

(%)

100

90

80

ON

70

ratio

60

50

40

30

20

0102030405055

Ambient temperature

External Connections

24VDC

1B20

+-

1A5

1B2

1B1

R

R

Left side

(first half)

Right side

(latter half)

SW

The above diagram shows the first half of 32 points

(F).

The latter half of 32 points (L) are similar.

3

Internal

circuit

Indication

selector

circuit

24VDC

26.4VDC

28.8VDC

( )

C

LED

B20

B19

B18

B17

B16

B15

B14

B13

B12

B11

B10

B9

B8

B7

B6

B5

B4

B3

B2

B1

Module front view

MELSEC-Q

Pin

No.

Sig-

nal

No.

Sig-

Pin

nal

No.

No.

1B20 X00 1A20 X10 2B20 X20 2A20 X30

1B19 X01 1A19 X11 2B19 X21 2A19 X31

1B18 X02 1A18 X12 2B18 X22 2A18 X32

1B17 X03 1A17 X13 2B17 X23 2A17 X33

A20

1B16 X04 1A16 X14 2B16 X24 2A16 X34

A19

A18

1B15 X05 1A15 X15 2B15 X25 2A15 X35

A17

A16

1B14 X06 1A14 X16 2B14 X26 2A14 X36

A15

1B13 X07 1A13 X17 2B13 X27 2A13 X37

A14

A13

1B12 X08 1A12 X18 2B12 X28 2A12 X38

A12

A11

1B11 X09 1A11 X19 2B11 X29 2A11 X39

A10

A9

1B10 X0A 1A10 X1A 2B10 X2A 2A10 X3A

A8

A7

1B09 X0B 1A09 X1B 2B09 X2B 2A09 X3B

A6

1B08 X0C 1A08 X1C 2B08 X2C 2A08 X3C

A5

A4

1B07 X0D 1A07 X1D 2B07 X2D 2A07 X3D

A3

A2

1B06 X0E 1A06 X1E 2B06 X2E 2A06 X3E

A1

1B05 X0F 1A05 X1F 2B05 X2F 2A05 X3F

1B04 Vacant 1A04 Vacant 2B04 Vacant 2A04 Vacant

1B03 Vacant 1A03 Vacant 2B03 Vacant 2A03 Vacant

1B02 COM 1A02 Vacant 2B02

1B01 COM 1A01 Vacant 2B01

Pin

No.

Sig-

nal

No.

COM2

COM2

Sig-

Pin

nal

No.

No.

2A02 Vacant

2A01 Vacant

2 - 10 2 - 10

Page 34

2 INPUT MODULE SPECIFICATIONS

MELSEC-Q

2.9 QX70 DC Input Module (Positive Common/Negative Common Shared Type)

DC Input Module (Positive Common/Negative Common Shared Type) Type

Specifications

Number of input points 16 points

Insulation method Photocoupler

Rated input voltage

(+20/-15%, ripple ratio within 5%)

5VDC

Rated input current Approx. 1.2mA Approx. 3.3mA

Input derating None

ON voltage/ON current 3.5V or higher/1mA or higher

OFF voltage/OFF current 1V or lower/0.1mA or lower

Input resistance Approx. 3.3k

1ms/5ms/10ms/20ms/70ms or less (CPU parameter setting)

1ms/5ms/10ms/20ms/70ms or less (CPU parameter setting)

Response

time

OFF ON

ON

OFF

Dielectric maximum voltage 560VAC rms/3 cycles (altitude 2000m)

Insulation resistance 10M or more by insulation resistance tester

By noise simulator of 500Vp-p noise voltage,

s noise width and 25 to 60Hz noise frequency

Noise immunity

1

First transient noise IEC61000-4-4: 0.25kV

Protection of degree IP2X

Common terminal arrangement 16 points/common (common terminal: TB17)

Number of I/O points 16 (I/O allocation is set as a 16-points input module)

Operation indicator ON indication (LED)

External connections 18-point terminal block (M3 6 screw)

Applicable wire size

Core cable: 0.3 to 0.75mm

Applicable connector terminal R1.25-3 (Terminals with sleeve cannot be used)

5VDC internal current

consumption

55mA (TYP, all points ON)

Weight 0.14kg

External Connections Terminal Block No. Signal Name

For open collector (positive common) connect io n

TB 1

R

TB17

5/12VDC

For TTL, LS-TTL, CMO S buf f er

(positive common) connections

TB 1

TB17

R

For sensor (negative common)

connections

LED

Internal

circuit

: For the setting method, refer to the section 1.3.1.

QX70 Appearance

12VDC

(+20/-15%, ripple ratio within 5%)

Initial setting is 10ms

Initial setting is 10ms

2

(Outside diameter: 2.8mm or smaller)

QX70

01234567

89ABCDEF

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

+-

COM

NC

5/12VDC

1.2mA

3.3mA

TB1 X00

TB2 X01

TB3 X02

TB4 X03

TB5 X04

TB6 X05

TB7 X06

TB8 X07

TB9 X08

TB10 X09

TB11 X0A

TB12 X0B

TB 1

TB13 X0C

TB14 X0D

TB15 X0E

TB16 X0F

TB17

TB17 COM

TB18 Vacant

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

2 - 11 2 - 11

Page 35

2 INPUT MODULE SPECIFICATIONS

MELSEC-Q

2.10 QX71 DC Input Module (Positive Common/Negative Common Shared Type)

DC Input Module (Positive Common/Negative Common Shared Type) Type

Specifications

Number of input points 32 points

Insulation method Photocoupler

Rated input voltage

(+20/-15%, ripple ratio within 5%)

5VDC

Rated input current Approx. 1.2mA Approx. 3.3mA

Input derating None

ON voltage/ON current 3.5V or higher/1mA or higher

OFF voltage/OFF current 1V or lower/0.1mA or lower

Input resistance Approx. 3.3k

1ms/5ms/10ms/20ms/70ms or less (CPU parameter setting)

1ms/5ms/10ms/20ms/70ms or less (CPU parameter setting)

Response

time

OFF ON

ON

OFF

Dielectric maximum voltage 560VAC rms/3 cycles (altitude 2000m)

Insulation resistance 10M or more by insulation resistance tester

By noise simulator of 500Vp-p noise voltage,

s noise width and 25 to 60Hz noise frequency

Noise immunity

1

First transient noise IEC61000-4-4: 0.25kV

Protection of degree IP2X

Common terminal arrangement 32 points/common (common terminal: B01, B02)

Number of I/O points 32 (I/O allocation is set as a 32-points input module)

Operation indicator ON indication (LED)

External connections 40-pin connector

Applicable wire size

0.3mm

2

External wiring connector A6CON1, A6CON2, A6CON3, A6CON4 (optional)

5VDC internal current

consumption

70mA (TYP, all points ON)

Weight 0.12kg

External Connections Pin-Outs Pin No.

For open collector (positive common) connection

B20

R

B02

B01

5/12VDC

For TTL, LS-TTL, CMOS buffer

(positive common) connections

: For the setting method, refer to the section 1.3.1.

1

: When using A6CON2 or A6CON3, refer to Chapter 7.

2

B20

B02

R

For sensor (negative common)

connections

LED

Internal

circuit

B20

B02

QX71 Appearance

12VDC

(+20/-15%, ripple ratio within 5%)

1

QX71

01234567

89ABCDEF

01234567

89ABCDEF

5/12VDC

1.2 / 3.3mA

Initial setting is 10ms

1

Initial setting is 10ms

(For A6CON1 or A6CON4) 2

Signal

No.

Pin No.

B20 X00 A20 X10

B20

B19

B18

B17

B16

B15

B14

B13

B12

B11

B10

B9

B8

B7

B6

B5

B4

B3

B2

B1

Module front view

A20

A19

A18

A17

A16

A15

A14

A13

A12

A11

A10

A9

A8

A7

A6

A5

A4

A3

A2

A1

B19 X01 A19 X11

B18 X02 A18 X12

B17 X03 A17 X13

B16 X04 A16 X14

B15 X05 A15 X15

B14 X06 A14 X16

B13 X07 A13 X17

B12 X08 A12 X18

B11 X09 A11 X19

B10 X0A A10 X1A

B09 X0B A09 X1B

B08 X0C A08 X1C

B07 X0D A07 X1D

B06 X0E A06 X1E

B05 X0F A05 X1F

B04 Vacant A04 Vacant

B03 Vacant A03 Vacant

B02 COM A02 Vacant

B01 COM A01 Vacant

QX71

Signal

No.

2 - 12 2 - 12

Page 36

2 INPUT MODULE SPECIFICATIONS

MELSEC-Q

2.11 QX72 DC Input Module (Positive Common/Negative Common Shared Type)

Specifications

QX72 Appearance

Number of input points 64 points

Insulation method Photocoupler

DC Input Module (Positive Common/Negative Common Shared Type) Type

Rated input voltage

(+20/-15%, ripple ratio within

5%)

(+20/-15%, ripple ratio within 5%)

Rated input current Approx. 1.2mA Approx. 3.3mA

Input derating None

ON voltage/ON current 3.5V or higher/3mA or higher

OFF voltage/OFF current 1V or lower/0.1mA or lower

5VDC

12VDC

QX72

01234567

89ABCDEF

01234567

89ABCDEF

5/12VDC

1.2/3.3mA

DISPLAY

F L

Input resistance Approx. 3.3k

Response

time

OFF ON

ON

OFF

1ms/5ms/10ms/20ms/70ms or less (CPU parameter setting)

Initial setting is 10ms

1ms/5ms/10ms/20ms/70ms or less (CPU parameter setting)

Initial setting is 10ms

1

1

Dielectric maximum voltage 560VAC rms/3 cycles (altitude 2000m)

Insulation resistance 10M or more by insulation resistance tester

By noise simulator of 500Vp-p noise voltage,

s noise width and 25 to 60Hz noise frequency

Noise immunity

1

First transient noise IEC61000-4-4: 0.25kV

Protection of degree IP2X

Common terminal arrangement 32 points/common (common terminal: 1B01, 1B02, 2B01, 2B02)

Number of I/O points 64 (I/O allocation is set as a 64-points input module)

Operation indicator ON indication (LED), 32-point switchover using switch

External connections 40-pin connector

Applicable wire size 0.3mm2 (For A6CON1 or A6CON4) 4

External wiring connector A6CON1, A6CON2, A6CON3, A6CON4 (optional)

5VDC internal current consumption 85mA (TYP, all points ON)

Weight 0.13kg

External Connections Pin-Outs Pin No.

For open collector (positive common) connection

1B20

R

R

3

SWLeft side

(first half)

Right side

1B20

1B02

(latter half)

For sensor

(negative common)

connections

1B02

1B01

5/12VDC

For TTL, LS-TTL, CMOS buffer

(positive common) connections

The above diagram shows the first half of

32 points (F).

The latter half of 32 points (L) are similar.

Internal

circuit

Indication

selector

circuit

1B20

1B02

LED

LED

B20

B19

B18

B17

B16

B15

B14

B13

B12

B11

B10

B9

B8

B7

B6

B5

B4

B3

B2

B1

Module

front view

A20

A19

A18

A17

A16

A15

A14

A13

A12

A11

A10

A9

A8

A7

A6

A5

A4

A3

A2

A1

Signal

Pin No.

No.

1B20 X00 1A20 X10 2B20 X20 2A20 X30

1B19 X01 1A19 X11 2B19 X21 2A19 X31

1B18 X02 1A18 X12 2B18 X22 2A18 X32

1B17 X03 1A17 X13 2B17 X23 2A17 X33

1B16 X04 1A16 X14 2B16 X24 2A16 X34

1B15 X05 1A15 X15 2B15 X25 2A15 X35

1B14 X06 1A14 X16 2B14 X26 2A14 X36

1B13 X07 1A13 X17 2B13 X27 2A13 X37

1B12 X08 1A12 X18 2B12 X28 2A12 X38

1B11 X09 1A11 X19 2B11 X29 2A11 X39

1B10 X0A 1A10 X1A 2B10 X2A 2A10 X3A

1B09 X0B 1A09 X1B 2B09 X2B 2A09 X3B

1B08 X0C 1A08 X1C 2B08 X2C 2A08 X3C

1B07 X0D 1A07 X1D 2B07 X2D 2A07 X3D

1B06 X0E 1A06 X1E 2B06 X2E 2A06 X3E

1B05 X0F 1A05 X1F 2B05 X2F 2A05 X3F

1B04 Vacant 1A04 Vacant 2B04 Vacant 2A04 Vacant

1B03 Vacant 1A03 Vacant 2B03 Vacant 2A03 Vacant

1B02 COM1 1A02 Vacant 2B02 COM2 2A02 Vacant

1B01 COM1 1A01 Vacant 2B01 COM2 2A01 Vacant

1: For the setting method, refer to the section 1.3.1.

2: Pin number of 1 indicates that of the left-hand side connector, and pin number of 2 indicates that of the right-hand

side connector.

3: Selection of left-hand (F) side provides the first half (X00 to X1F) LED indications, and selection of right-hand (L) side provides the

latter half (X20 to X3F) LED indications.

4: When using A6CON2 or A6CON3, refer to Chapter 7.

Signal

No.

Pin No.

Signal

No.

Pin No.

QX72

Signal

No.

2 - 13 2 - 13

Page 37

2 INPUT MODULE SPECIFICATIONS

2.12 QX80 DC Input Module (Neg ati v e C ommon Ty pe)

DC Input Module (Negative Common Type) Type

Specifications

Number of input points 16 points

Isolation method Photocoupler

Rated input voltage 24VDC (+20/-15%, ripple ratio within 5%)

Rated input current Approx. 4mA

Input derating No

ON voltage/ON current 19V or higher/3mA or higher

OFF voltage/OFF current 11V or lower/1.7mA or lower

Input impedance Approx. 5.6k

1ms/5ms/10ms/20ms/70ms or less (CPU parameter setting)

1ms/5ms/10ms/20ms/70ms or less (CPU parameter setting)

Response

time

OFF to ON

ON to OFF

Dielectric withstand voltage 560VAC rms/3 cycles (altitude 2000m (6557.38ft.))

Insulation resistance 10M or more by insulation resistance tester

By noise simulator of 500Vp-p noise voltage, 1 s noise width

Noise immunity

and 25 to 60Hz noise frequency

First transient noise IEC61000-4-4: 1kV

Protection of degree IP2X

Common terminal arrangement 16 points/common (common terminal: TB18)

Number of I/O points 16 (I/O allocation is set as a 16-points input module)

Operation indicator ON indication (LED)

External connections 18-point terminal block (M3 6 screws)

Applicable wire size

0.3 to 0.75mm

Applicable crimping terminal R1.25-3 (sleeved crimping terminals cannot be used.)

5VDC internal current consumption 50mA (TYP. all points ON)

Weight 0.16kg

External Connections Terminal Block Number Signal Name

TB 1

R

R

TB16

TB18

24VDC

Internal

circuit

: For the setting method, refer to the section 1.3.1.

QX80 Appearance

Initial setting is 10ms.

Initial setting is 10ms.

2

core (2.8mm (0.11in.) OD max.)

LED

MELSEC-Q

QX80

01234567

89ABCDEF

0

0

1

2

2

4

3

4

6

5

6

8

7

A

8

9

C

A

B

E

C

D

E

F

COM

24VDC

4mA

1

3

5

7

9

B

D

F

NC

TB1 X00

TB2 X01

TB3 X02

TB4 X03

TB5 X04

TB6 X05

TB7 X06

TB8 X07