Mitsubishi Electric Q, Q173DCPU-S1, Q172DCPU, Q172DSCPU, Q172DCPU-S1 Programming Manual

...Page 1

Page 2

SAFETY PRECAUTIONS

(Please read these instructions before using this equipment.)

Before using this product, please read this manual and the relevant manuals introduced in this manual

carefully and pay full attention to safety to handle the product correctly.

These precautions apply only to this product. Refer to the Q173D(S)CPU/Q172D(S)CPU Users manual

for a description of the Motion controller safety precautions.

In this manual, the safety instructions are ranked as "DANGER" and "CAUTION".

Indicates that incorrect handling may cause hazardous

Depending on circumstances, procedures indicated by

results.

In any case, it is important to follow the directions for usage.

Please save this manual to make it accessible when required and always forward it to the end user.

DANGER

CAUTION

conditions, resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous

conditions, resulting in medium or slight personal injury or

physical damage.

CAUTION may also be linked to serious

A - 1

Page 3

For Safe Operations

1. Prevention of electric shocks

DANGER

Never open the front case or terminal covers while the power is ON or the unit is running, as this

may lead to electric shocks.

Never run the unit with the front case or terminal cover removed. The high voltage terminal and

charged sections will be exposed and may lead to electric shocks.

Never open the front case or terminal cover at times other than wiring work or periodic

inspections even if the power is OFF. The insides of the Motion controller and servo amplifier are

charged and may lead to electric shocks.

Completely turn off the externally supplied power used in the system before mounting or

removing the module, performing wiring work, or inspections. Failing to do so may lead to electric

shocks.

When performing wiring work or inspections, turn the power OFF, wait at least ten minutes, and

then check the voltage with a tester, etc. Failing to do so may lead to electric shocks.

Be sure to ground the Motion controller, servo amplifier and servomotor. (Ground resistance :

or less) Do not ground commonly with other devices.

100

The wiring work and inspections must be done by a qualified technician.

Wire the units after installing the Motion controller, servo amplifier and servomotor. Failing to do

so may lead to electric shocks or damage.

Never operate the switches with wet hands, as this may lead to electric shocks.

Do not damage, apply excessive stress, place heavy things on or sandwich the cables, as this

may lead to electric shocks.

Do not touch the Motion controller, servo amplifier or servomotor terminal blocks while the power

is ON, as this may lead to electric shocks.

Do not touch the built-in power supply, built-in grounding or signal wires of the Motion controller

and servo amplifier, as this may lead to electric shocks.

2. For fire prevention

CAUTION

Install the Motion controller, servo amplifier, servomotor and regenerative resistor on

incombustible. Installing them directly or close to combustibles will lead to fire.

If a fault occurs in the Motion controller or servo amplifier, shut the power OFF at the servo

amplifier’s power source. If a large current continues to flow, fire may occur.

When using a regenerative resistor, shut the power OFF with an error signal. The regenerative

resistor may abnormally overheat due to a fault in the regenerative transistor, etc., and may lead

to fire.

Always take heat measures such as flame proofing for the inside of the control panel where the

servo amplifier or regenerative resistor is installed and for the wires used. Failing to do so may

lead to fire.

Do not damage, apply excessive stress, place heavy things on or sandwich the cables, as this

may lead to fire.

A - 2

Page 4

3. For injury prevention

CAUTION

Do not apply a voltage other than that specified in the instruction manual on any terminal.

Doing so may lead to destruction or damage.

Do not mistake the terminal connections, as this may lead to destruction or damage.

Do not mistake the polarity ( + / - ), as this may lead to destruction or damage.

Do not touch the heat radiating fins of controller or servo amplifier, regenerative resistor and

servomotor, etc., while the power is ON and for a short time after the power is turned OFF. In this

timing, these parts become very hot and may lead to burns.

Always turn the power OFF before touching the servomotor shaft or coupled machines, as these

parts may lead to injuries.

Do not go near the machine during test operations or during operations such as teaching.

Doing so may lead to injuries.

4. Various precautions

Strictly observe the following precautions.

Mistaken handling of the unit may lead to faults, injuries or electric shocks.

(1) System structure

CAUTION

Always install a leakage breaker on the Motion controller and servo amplifier power source.

If installation of an electromagnetic contactor for power shut off during an error, etc., is specified in

the instruction manual for the servo amplifier, etc., always install the electromagnetic contactor.

Install the emergency stop circuit externally so that the operation can be stopped immediately and

the power shut off.

Use the Motion controller, servo amplifier, servomotor and regenerative resistor with the correct

combinations listed in the instruction manual. Other combinations may lead to fire or faults.

Use the Motion controller, base unit and motion module with the correct combinations listed in the

instruction manual. Other combinations may lead to faults.

If safety standards (ex., robot safety rules, etc.,) apply to the system using the Motion controller,

servo amplifier and servomotor, make sure that the safety standards are satisfied.

Construct a safety circuit externally of the Motion controller or servo amplifier if the abnormal

operation of the Motion controller or servo amplifier differ from the safety directive operation in the

system.

In systems where coasting of the servomotor will be a problem during the forced stop, emergency

stop, servo OFF or power supply OFF, use dynamic brakes.

Make sure that the system considers the coasting amount even when using dynamic brakes.

In systems where perpendicular shaft dropping may be a problem during the forced stop,

emergency stop, servo OFF or power supply OFF, use both dynamic brakes and electromagnetic

brakes.

A - 3

Page 5

CAUTION

The dynamic brakes must be used only on errors that cause the forced stop, emergency stop, or

servo OFF. These brakes must not be used for normal braking.

The brakes (electromagnetic brakes) assembled into the servomotor are for holding applications,

and must not be used for normal braking.

The system must have a mechanical allowance so that the machine itself can stop even if the

stroke limits switch is passed through at the max. speed.

Use wires and cables that have a wire diameter, heat resistance and bending resistance

compatible with the system.

Use wires and cables within the length of the range described in the instruction manual.

The ratings and characteristics of the parts (other than Motion controller, servo amplifier and

servomotor) used in a system must be compatible with the Motion controller, servo amplifier and

servomotor.

Install a cover on the shaft so that the rotary parts of the servomotor are not touched during

operation.

There may be some cases where holding by the electromagnetic brakes is not possible due to the

life or mechanical structure (when the ball screw and servomotor are connected with a timing belt,

etc.). Install a stopping device to ensure safety on the machine side.

(2) Parameter settings and programming

CAUTION

Set the parameter values to those that are compatible with the Motion controller, servo amplifier,

servomotor and regenerative resistor model and the system application. The protective functions

may not function if the settings are incorrect.

The regenerative resistor model and capacity parameters must be set to values that conform to

the operation mode, servo amplifier and servo power supply module. The protective functions

may not function if the settings are incorrect.

Set the mechanical brake output and dynamic brake output validity parameters to values that are

compatible with the system application. The protective functions may not function if the settings

are incorrect.

Set the stroke limit input validity parameter to a value that is compatible with the system

application. The protective functions may not function if the setting is incorrect.

Set the servomotor encoder type (increment, absolute position type, etc.) parameter to a value

that is compatible with the system application. The protective functions may not function if the

setting is incorrect.

Set the servomotor capacity and type (standard, low-inertia, flat, etc.) parameter to values that

are compatible with the system application. The protective functions may not function if the

settings are incorrect.

Set the servo amplifier capacity and type parameters to values that are compatible with the

system application. The protective functions may not function if the settings are incorrect.

Use the program commands for the program with the conditions specified in the instruction

manual.

A - 4

Page 6

CAUTION

Set the sequence function program capacity setting, device capacity, latch validity range, I/O

assignment setting, and validity of continuous operation during error detection to values that are

compatible with the system application. The protective functions may not function if the settings

are incorrect.

Some devices used in the program have fixed applications, so use these with the conditions

specified in the instruction manual.

The input devices and data registers assigned to the link will hold the data previous to when

communication is terminated by an error, etc. Thus, an error correspondence interlock program

specified in the instruction manual must be used.

Use the interlock program specified in the intelligent function module's instruction manual for the

program corresponding to the intelligent function module.

(3) Transportation and installation

CAUTION

Transport the product with the correct method according to the mass.

Use the servomotor suspension bolts only for the transportation of the servomotor. Do not

transport the servomotor with machine installed on it.

Do not stack products past the limit.

When transporting the Motion controller or servo amplifier, never hold the connected wires or

cables.

When transporting the servomotor, never hold the cables, shaft or detector.

When transporting the Motion controller or servo amplifier, never hold the front case as it may fall

off.

When transporting, installing or removing the Motion controller or servo amplifier, never hold the

edges.

Install the unit according to the instruction manual in a place where the mass can be withstood.

Do not get on or place heavy objects on the product.

Always observe the installation direction.

Keep the designated clearance between the Motion controller or servo amplifier and control panel

inner surface or the Motion controller and servo amplifier, Motion controller or servo amplifier and

other devices.

Do not install or operate Motion controller, servo amplifiers or servomotors that are damaged or

that have missing parts.

Do not block the intake/outtake ports of the Motion controller, servo amplifier and servomotor with

cooling fan.

Do not allow conductive matter such as screw or cutting chips or combustible matter such as oil

enter the Motion controller, servo amplifier or servomotor.

The Motion controller, servo amplifier and servomotor are precision machines, so do not drop or

apply strong impacts on them.

Securely fix the Motion controller, servo amplifier and servomotor to the machine according to

the instruction manual. If the fixing is insufficient, these may come off during operation.

A - 5

Page 7

CAUTION

Always install the servomotor with reduction gears in the designated direction. Failing to do so

may lead to oil leaks.

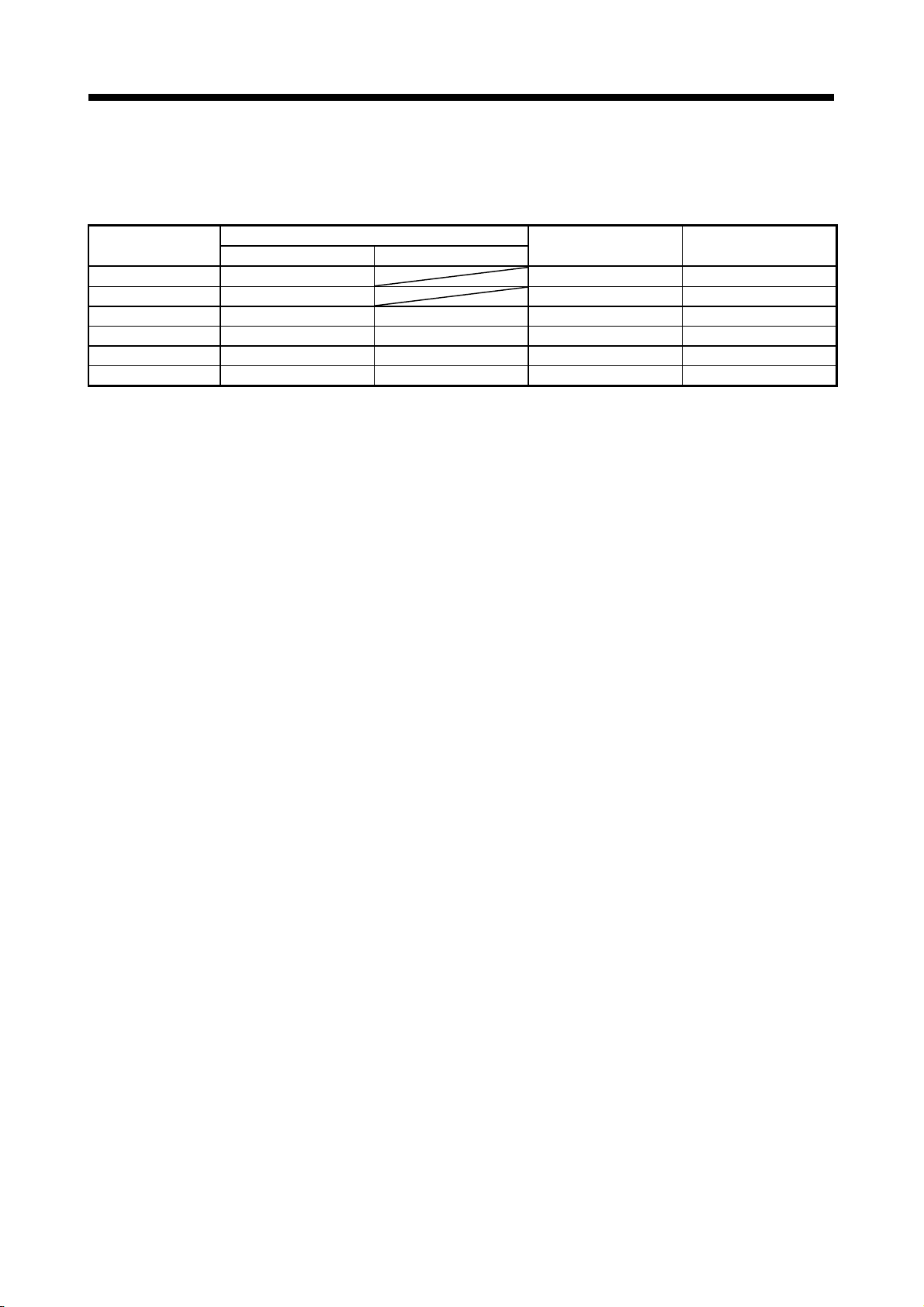

Store and use the unit in the following environmental conditions.

Conditions

Environment

Ambient

temperature

Ambient humidity According to each instruction manual.

Storage

temperature

Atmosphere

Altitude 1000m (3280.84ft.) or less above sea level

Vibration According to each instruction manual

Motion controller/Servo amplifier Servomotor

According to each instruction manual.

According to each instruction manual.

Indoors (where not subject to direct sunlight).

No corrosive gases, flammable gases, oil mist or dust must exist

0°C to +40°C (With no freezing)

(32°F to +104°F)

80% RH or less

(With no dew condensation)

-20°C to +65°C

(-4°F to +149°F)

When coupling with the synchronous encoder or servomotor shaft end, do not apply impact such

as by hitting with a hammer. Doing so may lead to detector damage.

Do not apply a load larger than the tolerable load onto the synchronous encoder and servomotor

shaft. Doing so may lead to shaft breakage.

When not using the module for a long time, disconnect the power line from the Motion controller

or servo amplifier.

Place the Motion controller and servo amplifier in static electricity preventing vinyl bags and store.

When storing for a long time, please contact with our sales representative.

Also, execute a trial operation.

When you disinfect or protect wooden packing from insects, take measures except by fumigation.

Fumigating the Motion controller and servo amplifier or packing the Motion controller and servo

amplifier with fumigated wooden packing can cause a malfunction of the Motion controller and

servo amplifier due to halogen materials (such as fluorine, chlorine, bromine, and iodine) which

are contained in fumigant.

The Motion controller and servo amplifier must not be used with parts which contain halogen-

series flame retardant materials (such as bromine) under coexisting conditions.

A - 6

Page 8

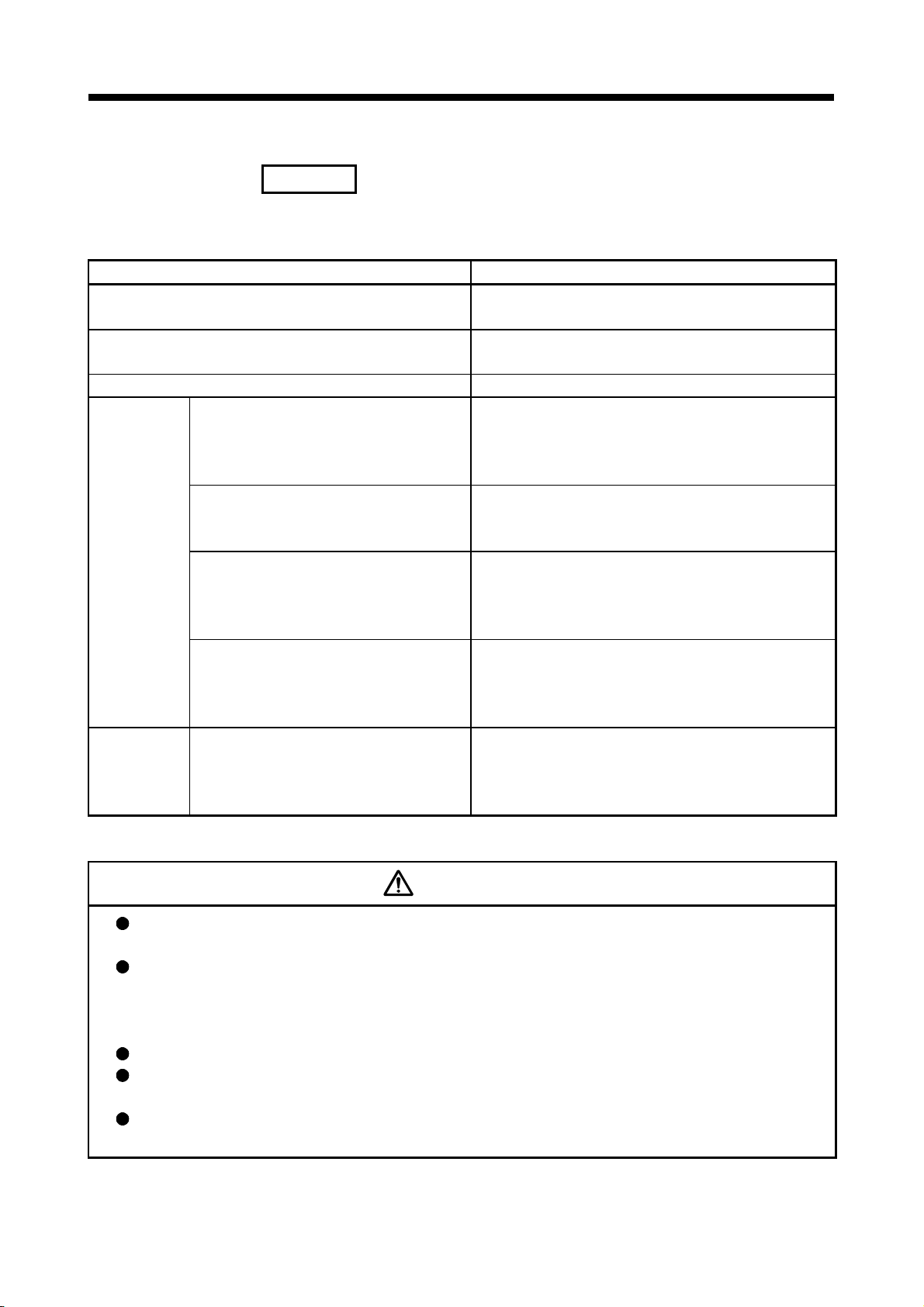

(4) Wiring

CAUTION

Correctly and securely wire the wires. Reconfirm the connections for mistakes and the terminal

screws for tightness after wiring. Failing to do so may lead to run away of the servomotor.

After wiring, install the protective covers such as the terminal covers to the original positions.

Do not install a phase advancing capacitor, surge absorber or radio noise filter (option FR-BIF)

on the output side of the servo amplifier.

Correctly connect the output side (terminal U, V, W) and ground. Incorrect connections will lead

the servomotor to operate abnormally.

Do not connect a commercial power supply to the servomotor, as this may lead to trouble.

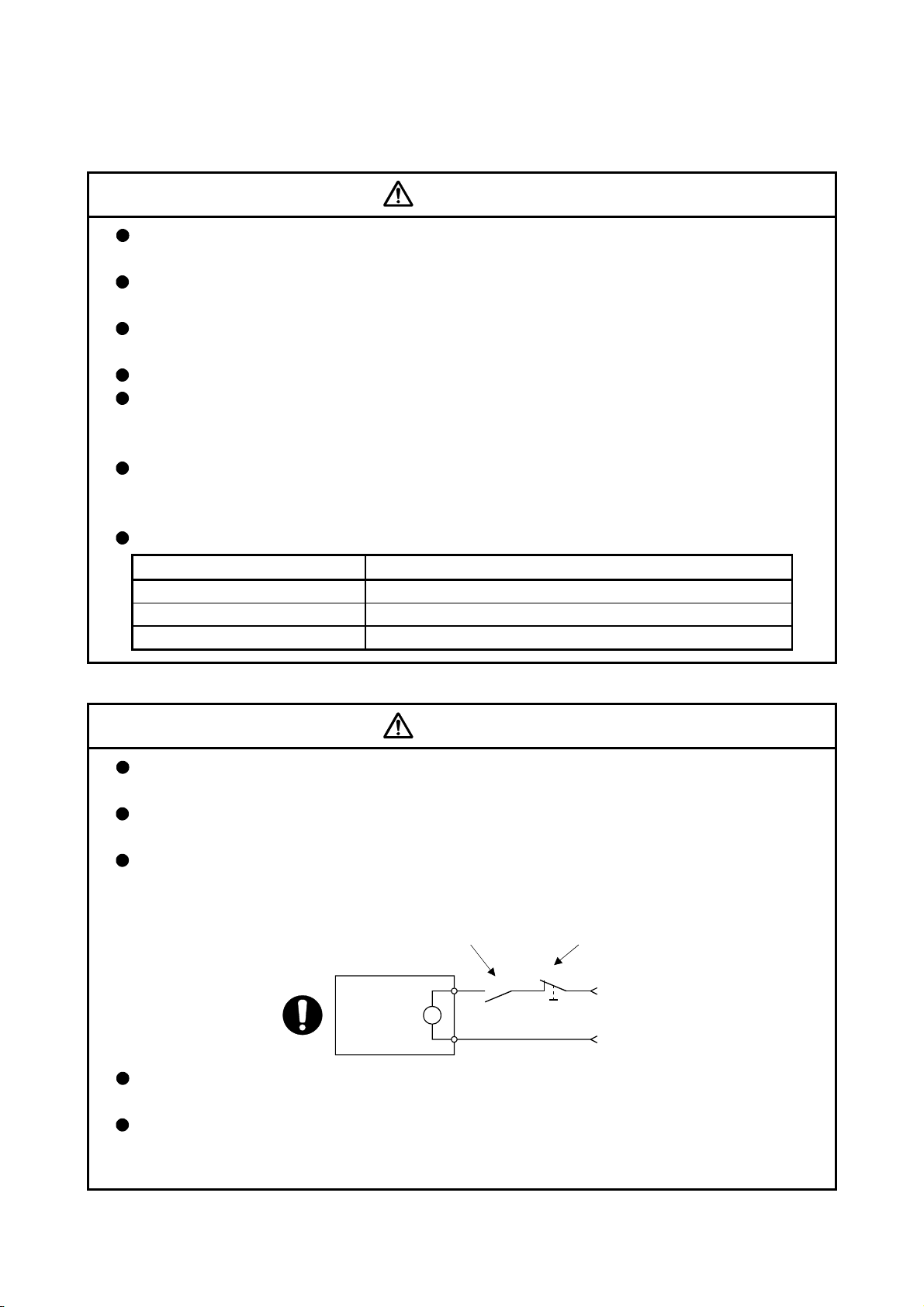

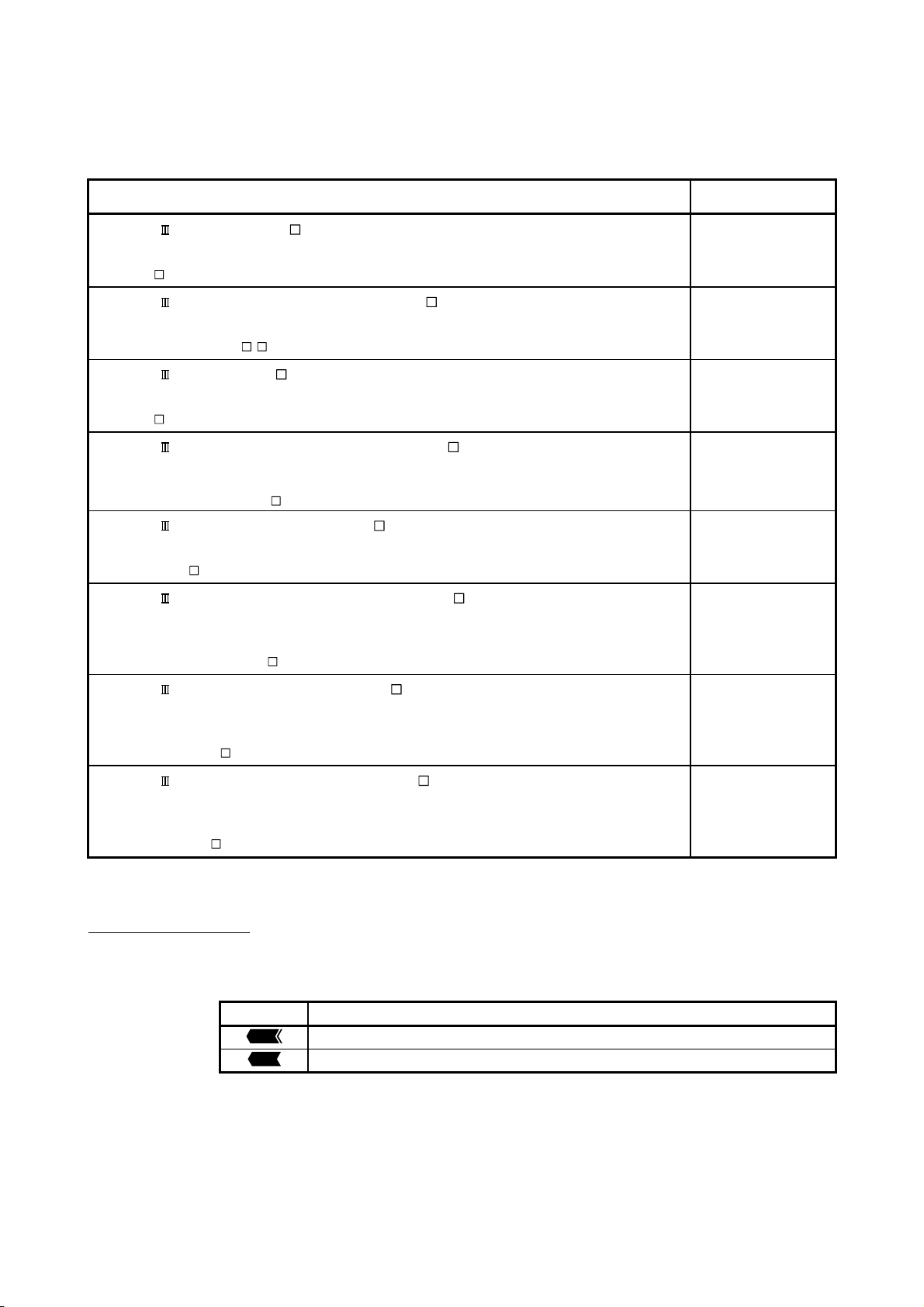

Do not mistake the direction of the surge absorbing diode installed on the DC relay for the control

signal output of brake signals, etc. Incorrect installation may lead to signals not being output

when trouble occurs or the protective functions not functioning.

Servo amplifier

DOCOM

Control output

signal

DICOM

For the sink output interface For the source output interface

24VDC

RA

Servo amplifier

DOCOM

Control output

signal

DICOM

24VDC

RA

Do not connect or disconnect the connection cables between each unit, the encoder cable or

PLC expansion cable while the power is ON.

Securely tighten the cable connector fixing screws and fixing mechanisms. Insufficient fixing may

lead to the cables combing off during operation.

Do not bundle the power line or cables.

(5) Trial operation and adjustment

CAUTION

Confirm and adjust the program and each parameter before operation. Unpredictable

movements may occur depending on the machine.

Extreme adjustments and changes may lead to unstable operation, so never make them.

When using the absolute position system function, on starting up, and when the Motion controller

or absolute value motor has been replaced, always perform a home position return.

Before starting test operation, set the parameter speed limit value to the slowest value, and

make sure that operation can be stopped immediately by the forced stop, etc. if a hazardous

state occurs.

A - 7

Page 9

(6) Usage methods

CAUTION

Immediately turn OFF the power if smoke, abnormal sounds or odors are emitted from the

Motion controller, servo amplifier or servomotor.

Always execute a test operation before starting actual operations after the program or

parameters have been changed or after maintenance and inspection.

Do not attempt to disassemble and repair the units excluding a qualified technician whom our

company recognized.

Do not make any modifications to the unit.

Keep the effect or electromagnetic obstacles to a minimum by installing a noise filter or by using

wire shields, etc. Electromagnetic obstacles may affect the electronic devices used near the

Motion controller or servo amplifier.

When using the CE Mark-compliant equipment, refer to the User's manual for the Motion

controllers and refer to the corresponding EMC guideline information for the servo amplifiers,

inverters and other equipment.

Use the units with the following conditions.

Item Conditions

Input power According to each instruction manual.

Input frequency According to each instruction manual.

Tolerable momentary power failure According to each instruction manual.

(7) Corrective actions for errors

CAUTION

If an error occurs in the self diagnosis of the Motion controller or servo amplifier, confirm the

check details according to the instruction manual, and restore the operation.

If a dangerous state is predicted in case of a power failure or product failure, use a servomotor

with electromagnetic brakes or install a brake mechanism externally.

Use a double circuit construction so that the electromagnetic brake operation circuit can be

operated by emergency stop signals set externally.

Shut off with servo ON signal OFF,

alarm, electromagnetic brake signal.

Servo motor

RA1

Electromagnetic

brakes

B

Shut off with the

emergency stop

signal (EMG).

EMG

24VDC

If an error occurs, remove the cause, secure the safety and then resume operation after alarm

release.

The unit may suddenly resume operation after a power failure is restored, so do not go near the

machine. (Design the machine so that personal safety can be ensured even if the machine

restarts suddenly.)

A - 8

Page 10

(8) Maintenance, inspection and part replacement

CAUTION

Perform the daily and periodic inspections according to the instruction manual.

Perform maintenance and inspection after backing up the program and parameters for the Motion

controller and servo amplifier.

Do not place fingers or hands in the clearance when opening or closing any opening.

Periodically replace consumable parts such as batteries according to the instruction manual.

Do not touch the lead sections such as ICs or the connector contacts.

Before touching the module, always touch grounded metal, etc. to discharge static electricity from

human body. Failure to do so may cause the module to fail or malfunction.

Do not directly touch the module's conductive parts and electronic components.

Touching them could cause an operation failure or give damage to the module.

Do not place the Motion controller or servo amplifier on metal that may cause a power leakage

or wood, plastic or vinyl that may cause static electricity buildup.

Do not perform a megger test (insulation resistance measurement) during inspection.

When replacing the Motion controller or servo amplifier, always set the new module settings

correctly.

When the Motion controller or absolute value motor has been replaced, carry out a home

position return operation using one of the following methods, otherwise position displacement

could occur.

1) After writing the servo data to the Motion controller using programming software, switch on the

power again, then perform a home position return operation.

2) Using the backup function of the programming software, load the data backed up before

replacement.

After maintenance and inspections are completed, confirm that the position detection of the

absolute position detector function is correct.

Do not drop or impact the battery installed to the module.

Doing so may damage the battery, causing battery liquid to leak in the battery. Do not use the

dropped or impacted battery, but dispose of it.

Do not short circuit, charge, overheat, incinerate or disassemble the batteries.

The electrolytic capacitor will generate gas during a fault, so do not place your face near the

Motion controller or servo amplifier.

The electrolytic capacitor and fan will deteriorate. Periodically replace these to prevent secondary

damage from faults. Replacements can be made by our sales representative.

Lock the control panel and prevent access to those who are not certified to handle or install

electric equipment.

Do not burn or break a module and servo amplifier. Doing so may cause a toxic gas.

A - 9

Page 11

(9) About processing of waste

When you discard Motion controller, servo amplifier, a battery (primary battery) and other option

articles, please follow the law of each country (area).

CAUTION

This product is not designed or manufactured to be used in equipment or systems in situations

that can affect or endanger human life.

When considering this product for operation in special applications such as machinery or systems

used in passenger transportation, medical, aerospace, atomic power, electric power, or

submarine repeating applications, please contact your nearest Mitsubishi sales representative.

Although this product was manufactured under conditions of strict quality control, you are strongly

advised to install safety devices to forestall serious accidents when it is used in facilities where a

breakdown in the product is likely to cause a serious accident.

(10) General cautions

All drawings provided in the instruction manual show the state with the covers and safety

partitions removed to explain detailed sections. When operating the product, always return the

covers and partitions to the designated positions, and operate according to the instruction

manual.

A - 10

Page 12

REVISIONS

The manual number is given on the bottom left of the back cover.

Print Date Manual Number Revision

Sep., 2007 IB(NA)-0300137-A First edition

Nov., 2009 IB(NA)-0300137-B [Additional model]

MR-J3W-

B, MR-J3- B-RJ080W, MR-J3- BS

[Additional correction/partial correction]

Safety precautions, About Manuals, Restrictions by the software's

version or serial number, Servo amplifier display servo error code

(#8008+20), Amplifier-less operation status flag (SM508), SSCNET

control (Status_SD508), SSCNET control (Command_SD803),

Advanced S-curve acceleration/deceleration, Error code list, Warranty

Sep., 2011 IB(NA)-0300137-C [Additional model]

Q173DCPU-S1, Q172DCPU-S1, GX Works2, MR Configurator2

[Additional correction/partial correction]

Safety precautions, About Manuals, Restrictions by the software's

version, Error code list

Mar., 2012 IB(NA)-0300137-D [Additional model]

Q173DSCPU, Q172DSCPU, Q171ENC-W8, MR-J4-

[Additional function]

Speed-torque control

[Additional correction/partial correction]

About Manuals, Manual page organization, Restrictions by the

software's version, Programming software version, PI-PID switching

command (M3217+20n), Parameter error number (#8009+20n), Servo

status 1 (#8010+20n), Servo status 2 (#8011+20n), Servo status 3

(#8012+20n), Maximum motion operation cycle (SD524), System

setting error information (SD550, SD551), Error code list, Processing

time of the Motion CPU

Sep., 2012 IB(NA)-0300137-E [Additional correction/partial correction]

About Manuals, Restrictions by the software's version, Programming

software version, External forced stop input ON latch flag (SM506),

Operation method (SD560), Error code list, Processing time of the

Motion CPU

Apr., 2013 IB(NA)-0300137-F [Additional correction/partial correction]

About Manuals, Restrictions by the software's version, Error code list

B, MR-J4W- B

Japanese Manual Number IB(NA)-0300129

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any patent

licenses. Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property

rights which may occur as a result of using the contents noted in this manual.

© 2007 MITSUBISHI ELECTRIC CORPORATION

A - 11

Page 13

INTRODUCTION

Thank you for choosing the Mitsubishi Motion controller Q173D(S)CPU/Q172D(S)CPU.

Before using the equipment, please read this manual carefully to develop full familiarity with the functions

and performance of the Motion controller you have purchased, so as to ensure correct use.

CONTENTS

Safety Precautions .........................................................................................................................................A- 1

Revisions ........................................................................................................................................................A-11

Contents .........................................................................................................................................................A-12

About Manuals ...............................................................................................................................................A-15

Manual Page Organization ............................................................................................................................A-17

1. OVERVIEW 1- 1 to 1-10

1.1 Overview................................................................................................................................................... 1- 1

1.2 Motion Control in SV13/SV22 Real Mode............................................................................................... 1- 4

1.3 Motion Control in SV22 Virtual Mode ......................................................................................................1- 5

1.4 Restrictions by the Software's Version .................................................................................................... 1- 6

1.5 Programming Software Version .............................................................................................................. 1-10

2. STARTING UP THE SYSTEM 2- 1 to 2- 8

2.1 Starting Up the Virtual Mode System ......................................................................................................2- 1

2.2 Starting Up the Incremental System and Absolute System ................................................................... 2- 3

2.2.1 Operation for incremental system..................................................................................................... 2- 3

2.2.2 Operation for absolute (absolute position) system........................................................................... 2- 4

2.3 Differences Between Real Mode and Virtual Mode................................................................................ 2- 5

2.3.1 Positioning data ................................................................................................................................. 2- 5

2.3.2 Positioning devices............................................................................................................................ 2- 5

2.3.3 Servo programs................................................................................................................................. 2- 6

2.3.4 Control change (Current value change/speed change/target position change) ............................. 2- 7

2.3.5 Switching of control mode (Speed-torque control) ........................................................................... 2- 8

3. PERFORMANCE SPECIFICATIONS 3- 1 to 3- 2

4. POSITIONING DEDICATED SIGNALS 4- 1 to 4-90

4.1 Internal Relays ......................................................................................................................................... 4- 3

4.1.1 Axis statuses ..................................................................................................................................... 4-14

4.1.2 Axis command signals ...................................................................................................................... 4-22

4.1.3 Virtual servomotor axis statuses....................................................................................................... 4-27

4.1.4 Virtual servomotor axis command signals ......................................................................................4-31

4.1.5 Synchronous encoder axis statuses ............................................................................................... 4-36

4.1.6 Synchronous encoder axis command signals.................................................................................. 4-37

4.1.7 Common devices .............................................................................................................................. 4-38

4.2 Data Registers.......................................................................................................................................... 4-53

A - 12

Page 14

4.2.1 Axis monitor devices ......................................................................................................................... 4-61

4.2.2 Control change registers ................................................................................................................... 4-63

4.2.3 Virtual servomotor axis monitor devices........................................................................................... 4-64

4.2.4 Current value after virtual servomotor axis main shaft's differential gear ....................................... 4-66

4.2.5 Synchronous encoder axis monitor devices..................................................................................... 4-68

4.2.6 Current value after synchronous encoder axis main shaft's differential gear ................................. 4-69

4.2.7 Cam axis monitor devices .................................................................................................................4-71

4.2.8 Common devices .............................................................................................................................. 4-72

4.3 Motion Registers(#).................................................................................................................................. 4-75

4.4 Special Relays (SM) ................................................................................................................................ 4-80

4.5 Special Registers (SD)............................................................................................................................. 4-83

5. MECHANICAL SYSTEM PROGRAM 5- 1 to 5-10

5.1 Mechanical Module Connection Diagram ............................................................................................... 5- 2

5.2 Mechanical Module List ........................................................................................................................... 5- 6

6. DRIVE MODULE 6- 1 to 6-24

6.1 Virtual Servomotor ................................................................................................................................... 6- 2

6.1.1 Operation description ........................................................................................................................ 6- 2

6.1.2 Parameter list .................................................................................................................................... 6- 8

6.1.3 Virtual servomotor axis devices (Internal relays, data registers) ..................................................... 6-13

6.2 Synchronous Encoder.............................................................................................................................. 6-14

6.2.1 Operation description ........................................................................................................................ 6-14

6.2.2 Parameter list .................................................................................................................................... 6-19

6.2.3 Synchronous encoder axis devices (Internal relays, data registers) ............................................... 6-20

6.3 Virtual Servomotor/Synchronous Encoder Control Change................................................................... 6-21

6.3.1 Virtual servomotor control change .................................................................................................... 6-21

6.3.2 Synchronous encoder control change.............................................................................................. 6-23

7. TRANSMISSION MODULE 7- 1 to 7-38

7.1 Gear.......................................................................................................................................................... 7- 3

7.1.1 Operation........................................................................................................................................... 7- 3

7.1.2 Parameters ........................................................................................................................................ 7- 3

7.2 Clutch........................................................................................................................................................ 7- 5

7.2.1 Operation........................................................................................................................................... 7-11

7.2.2 Parameters ........................................................................................................................................ 7-25

7.3 Speed Change Gear ................................................................................................................................ 7-34

7.3.1 Operation........................................................................................................................................... 7-34

7.3.2 Parameters ........................................................................................................................................ 7-35

7.4 Differential Gear .......................................................................................................................................7-37

7.4.1 Operation........................................................................................................................................... 7-37

7.4.2 Parameters ....................................................................................................................................... 7-37

8. OUTPUT MODULE 8- 1 to 8-44

8.1 Rollers....................................................................................................................................................... 8- 5

8.1.1 Operation........................................................................................................................................... 8- 5

A - 13

Page 15

8.1.2 Parameter list .................................................................................................................................... 8- 6

8.2 Ball Screw................................................................................................................................................. 8- 9

8.2.1 Operation........................................................................................................................................... 8- 9

8.2.2 Parameter list .................................................................................................................................... 8-10

8.3 Rotary Tables ........................................................................................................................................... 8-13

8.3.1 Operation........................................................................................................................................... 8-13

8.3.2 Parameter list .................................................................................................................................... 8-14

8.4 Cam .......................................................................................................................................................... 8-21

8.4.1 Operation........................................................................................................................................... 8-22

8.4.2 Settings items at cam data creating ................................................................................................. 8-25

8.4.3 Parameter list .................................................................................................................................... 8-29

8.4.4 Cam curve list.................................................................................................................................... 8-41

8.5 Phase Compensation Function ...............................................................................................................8-42

9. REAL MODE/VIRTUAL MODE SWITCHING AND STOP/RE-START 9- 1 to 9-12

9.1 Switching from the Real Mode to Virtual Mode....................................................................................... 9- 1

9.2 Switching from the Virtual Mode to Real Mode....................................................................................... 9- 5

9.2.1 Switching by user ..............................................................................................................................9- 5

9.2.2 Switching by the operating system software .................................................................................... 9- 5

9.2.3 Continuous operation on servo error in virtual mode .......................................................................9- 6

9.3 Precautions at Real Mode/Virtual Mode Switching................................................................................. 9- 7

9.4 Stop and Re-start ..................................................................................................................................... 9- 9

9.4.1 Stop operation/stop causes during operation and re-starting operation list.................................... 9-10

10. AUXILIARY AND APPLIED FUNCTIONS 10- 1 to 10-10

10.1 Mixed Function of Virtual Mode/Real Mode ........................................................................................ 10- 1

10.2 Speed-Torque Control .........................................................................................................................10- 7

APPENDICES APP- 1 to APP-82

APPENDIX 1 Error Codes Stored Using the Motion CPU .....................................................................APP- 1

APPENDIX 1.1 Expression method for word data axis No..................................................................APP- 4

APPENDIX 1.2 Related systems and error processing .......................................................................APP- 5

APPENDIX 1.3 Servo program setting errors (Stored in SD517)........................................................APP- 6

APPENDIX 1.4 Drive module errors .....................................................................................................APP-11

APPENDIX 1.5 Servo errors.................................................................................................................APP-17

APPENDIX 1.6 Output module errors ..................................................................................................APP-51

APPENDIX 1.7 Errors at real mode/virtual mode switching ................................................................APP-60

APPENDIX 2 Setting Range for Indirect Setting Devices........................................................................APP-62

APPENDIX 3 Processing Times of the Motion CPU ...............................................................................APP-64

APPENDIX 4 Device List ..........................................................................................................................APP-66

A - 14

Page 16

About Manuals

The following manuals are also related to this product.

In necessary, order them by quoting the details in the tables below.

Related Manuals

(1) Motion controller

Q173D(S)CPU/Q172D(S)CPU Motion controller User's Manual

This manual explains specifications of the Motion CPU modules, Q172DLX Servo external signal interface

module, Q172DEX Synchronous encoder interface module, Q173DPX Manual pulse generator interface

module, Power supply modules, Servo amplifiers, SSCNET

maintenance/inspection for the system, trouble shooting and others.

Q173D(S)CPU/Q172D(S)CPU Motion controller Programming Manual (COMMON)

This manual explains the Multiple CPU system configuration, performance specifications, common

parameters, auxiliary/applied functions, error lists and others.

Manual Name

cables and Synchronous encoder, and the

Manual Number

(Model Code)

IB-0300133

(1XB927)

IB-0300134

(1XB928)

Q173D(S)CPU/Q172D(S)CPU Motion controller (SV13/SV22) Programming Manual

(Motion SFC)

This manual explains the functions, programming, debugging, error lists for Motion SFC and others.

Q173D(S)CPU/Q172D(S)CPU Motion controller (SV13/SV22) Programming Manual

(REAL MODE)

This manual explains the servo parameters, positioning instructions, device lists, error lists and others.

Q173D(S)CPU/Q172D(S)CPU Motion controller (SV22) Programming Manual

(VIRTUAL MODE)

This manual explains the dedicated instructions to use the synchronous control by virtual main shaft,

mechanical system program create mechanical module, servo parameters, positioning instructions, device

lists, error lists and others.

Q173DSCPU/Q172DSCPU Motion controller (SV22) Programming Manual

(Advanced Synchronous Control)

This manual explains the dedicated instructions to use the synchronous control by synchronous control

parameters, device lists, error lists and others.

Q173D(S)CPU/Q172D(S)CPU Motion controller Programming Manual (Safety Observation)

This manual explains the details, safety parameters, safety sequence program instructions, device lists

and error lists and others for safety observation function by Motion controller.

Motion controller Setup Guidance (MT Developer2 Version1)

This manual explains the items related to the setup of the Motion controller programming software

MT Developer2.

IB-0300135

(1XB929)

IB-0300136

(1XB930)

IB-0300137

(1XB931)

IB-0300198

(1XB953)

IB-0300183

(1XB945)

IB-0300142

( — )

A - 15

Page 17

(2) PLC

QCPU User's Manual (Hardware Design, Maintenance and Inspection)

This manual explains the specifications of the QCPU modules, power supply modules, base units,

extension cables, memory card battery, and the maintenance/inspection for the system, trouble shooting,

error codes and others.

Manual Name

Manual Number

(Model Code)

SH-080483ENG

(13JR73)

QnUCPU User's Manual (Function Explanation, Program Fundamentals)

This manual explains the functions, programming methods and devices and others to create programs

with the QCPU.

QCPU User's Manual (Multiple CPU System)

This manual explains the Multiple CPU system overview, system configuration, I/O modules,

communication between CPU modules and communication with the I/O modules or intelligent function

modules.

QnUCPU User's Manual (Communication via Built-in Ethernet Port)

This manual explains functions for the communication via built-in Ethernet port of the CPU module.

MELSEC-Q/L Programming Manual (Common Instruction)

This manual explains how to use the sequence instructions, basic instructions, application instructions and

micro computer program.

MELSEC-Q/L/QnA Programming Manual (PID Control Instructions)

This manual explains the dedicated instructions used to exercise PID control.

MELSEC-Q/L/QnA Programming Manual (SFC)

This manual explains the system configuration, performance specifications, functions, programming,

debugging, error codes and others of MELSAP3.

I/O Module Type Building Block User's Manual

This manual explains the specifications of the I/O modules, connector, connector/terminal block

conversion modules and others.

SH-080807ENG

(13JZ27)

SH-080485ENG

(13JR75)

SH-080811ENG

(13JZ29)

SH-080809ENG

(13JW10)

SH-080040

(13JF59)

SH-080041

(13JF60)

SH-080042

(13JL99)

MELSEC-L SSCNET /H Head Module User's Manual

This manual explains specifications of the head module, procedures before operation, system

configuration, installation, wiring, settings, and troubleshooting.

A - 16

SH-081152ENG

(13JZ78)

Page 18

(3) Servo amplifier

SSCNET /H interface MR-J4- B Servo amplifier Instruction Manual

This manual explains the I/O signals, parts names, parameters, start-up procedure and others for

MR-J4-

B Servo amplifier.

Manual Name

Manual Number

(Model Code)

SH-030106

(1CW805)

SSCNET /H interface Multi-axis AC Servo MR-J4W- B Servo amplifier Instruction Manual

This manual explains the I/O signals, parts names, parameters, start-up procedure and others for Multi-

axis AC Servo MR-J4W

- B Servo amplifier.

SSCNET interface MR-J3- B Servo amplifier Instruction Manual

This manual explains the I/O signals, parts names, parameters, start-up procedure and others for

MR-J3-

B Servo amplifier.

SSCNET interface 2-axis AC Servo Amplifier MR-J3W- B Servo amplifier Instruction

Manual

This manual explains the I/O signals, parts names, parameters, start-up procedure and others for 2-axis

AC Servo Amplifier MR-J3W-

B Servo amplifier.

SSCNET Compatible Linear Servo MR-J3- B-RJ004 Instruction Manual

This manual explains the I/O signals, parts names, parameters, start-up procedure and others for Linear

Servo MR-J3-

B-RJ004 Servo amplifier.

SSCNET Compatible Fully Closed Loop Control MR-J3- B-RJ006 Servo amplifier

Instruction Manual

This manual explains the I/O signals, parts names, parameters, start-up procedure and others for Fully

Closed Loop Control MR-J3-

B-RJ006 Servo amplifier.

SSCNET Interface Direct Drive Servo MR-J3- B-RJ080W Servo amplifier Instruction

Manual

This manual explains the I/O signals, parts names, parameters, start-up procedure and others for Direct

Drive Servo MR-J3-

B-RJ080W Servo amplifier.

SH-030105

(1CW806)

SH-030051

(1CW202)

SH-030073

(1CW604)

SH-030054

(1CW943)

SH-030056

(1CW304)

SH-030079

(1CW601)

SSCNET interface Drive Safety integrated MR-J3- B Safety Servo amplifier Instruction

Manual

This manual explains the I/O signals, parts names, parameters, start-up procedure and others for safety

integrated MR-J3-

B Safety Servo amplifier.

Manual Page Organization

The symbols used in this manual are shown below.

Symbol Description

QDS

Symbol that indicates correspondence to only Q173DSCPU/Q172DSCPU.

QD

Symbol that indicates correspondence to only Q173DCPU(-S1)/Q172DCPU(-S1).

A - 17

SH-030084

(1CW205)

Page 19

MEMO

A - 18

Page 20

1 OVERVIEW

1. OVERVIEW

1.1 Overview

This programming manual describes the dedicated instructions, positioning control

parameters and positioning dedicated devices for mechanical system program

comprised of a virtual main shaft or mechanical module required to execute the

synchronous control in the Motion controller (SV22 virtual mode).

The following positioning control is possible in the Motion controller (SV22 virtual

Generic term/Abbreviation Description

Q173D(S)CPU/Q172D(S)CPU or

Motion CPU (module)

Q172DLX/Q172DEX/Q173DPX/

Q173DSXY or Motion module

MR-J4(W)- B Servo amplifier model MR-J4- B/MR-J4W- B

MR-J3(W)- B Servo amplifier model MR-J3- B/MR-J3W- B

AMP or Servo amplifier

QCPU, PLC CPU or PLC CPU module QnUD(E)(H)CPU/QnUDVCPU

Multiple CPU system or Motion system Abbreviation for "Multiple PLC system of the Q series"

CPUn

Operating system software General name for "SW7DNC-SV Q /SW8DNC-SV Q "

SV13

SV22

Programming software package General name for MT Developer2/GX Works2/GX Developer/MR Configurator

MELSOFT MT Works2

MT Developer2

GX Works2

GX Developer

MR Configurator

(Note-2)

mode).

Applicable CPU Number of positioning control axes

Q173DSCPU

Q173DCPU (-S1)

Q172DSCPU Up to 16 axes

Q172DCPU (-S1) Up to 8 axes

Up to 32 axes

In this manual, the following abbreviations are used.

Q173DSCPU/Q172DSCPU/Q173DCPU/Q172DCPU/Q173DCPU-S1/

Q172DCPU-S1 Motion CPU module

Q172DLX Servo external signals interface module/

Q172DEX Synchronous encoder interface module

Q173DPX Manual pulse generator interface module/

Q173DSXY Safety signal module

General name for "Servo amplifier model MR-J4- B/MR-J4W- B/MR-J3- B/

MR-J3W-

Abbreviation for "CPU No.n (n= 1 to 4) of the CPU module for the Multiple CPU

system"

Operating system software for conveyor assembly use (Motion SFC) :

SW8DNC-SV13Q

Operating system software for automatic machinery use (Motion SFC) :

SW8DNC-SV22Q

Abbreviation for "Motion controller engineering environment MELSOFT

MT Works2"

(Note-2)

General name for "MR Configurator/MR Configurator2"

Abbreviation for "Motion controller programming software MT Developer2

(Version 1.00A or later)"

Abbreviation for "Programmable controller engineering software

MELSOFT GX Works2 (Version 1.15R or later)"

Abbreviation for "MELSEC PLC programming software package

GX Developer (Version 8.48A or later)"

B"

(Note-1)

/

1

1 - 1

Page 21

1 OVERVIEW

Generic term/Abbreviation Description

MR Configurator

MR Configurator2

Manual pulse generator or MR-HDP01 Abbreviation for "Manual pulse generator (MR-HDP01)"

Serial absolute synchronous encoder

or Q171ENC-W8/Q170ENC

SSCNET /H

SSCNET

SSCNET (/H)

(Note-3)

(Note-3)

(Note-3)

General name for SSCNET /H, SSCNET

Absolute position system

Battery holder unit Battery holder unit (Q170DBATC)

Intelligent function module

SSCNET /H head module

(Note-3)

(Note-1): Q172DEX can be used in SV22.

(Note-2): This software is included in Motion controller engineering environment "MELSOFT MT Works2".

(Note-3): SSCNET: S

Abbreviation for "Servo setup software package

MR Configurator (Version C0 or later)"

Abbreviation for "Servo setup software package

MR Configurator2 (Version 1.01B or later)"

Abbreviation for "Serial absolute synchronous encoder (Q171ENC-W8/

Q170ENC)"

High speed synchronous network between Motion controller and servo amplifier

General name for "system using the servomotor and servo amplifier for absolute

position"

General name for module that has a function other than input or output such as

A/D converter module and D/A converter module.

Abbreviation for "MELSEC-L series SSCNET /H head module (LJ72MS15)"

ervo System Controller NETwork

1 - 2

Page 22

1 OVERVIEW

REMARK

For information about each module, design method for program and parameter, refer

Motion CPU module/Motion unit

PLC CPU, peripheral devices for sequence program design,

I/O modules and intelligent function module

Operation method for MT Developer2 Help of each software

• Multiple CPU system configuration

• Performance specification

• Design method for common parameter

• Auxiliary and applied functions (common)

• Design method for Motion SFC program

• Design method for Motion SFC parameter

• Motion dedicated PLC instruction

SV13/SV22

SV22

(Advanced

synchronous

control)

• Design method for positioning control

program in the real mode

• Design method for positioning control

parameter

• Design method for safety observation

parameter

• Design method for user made safety

sequence program

• Design method for synchronous control

parameter

to the following manuals relevant to each module.

Item Reference Manual

Q173D(S)CPU/Q172D(S)CPU Motion controller User’s

Manual

Manual relevant to each module

Q173D(S)CPU/Q172D(S)CPU Motion controller

Programming Manual (COMMON)

Q173D(S)CPU/Q172D(S)CPU Motion controller

(SV13/SV22) Programming Manual (Motion SFC)

Q173D(S)CPU/Q172D(S)CPU Motion controller

(SV13/SV22) Programming Manual (REAL MODE)

Q173D(S)CPU/Q172D(S)CPU Motion controller

Programming Manual (Safety Observation)

Q173DSCPU/Q172DSCPU Motion controller (SV22)

Programming Manual (Advanced Synchronous Control)

CAUTION

When designing the system, provide external protective and safety circuits to ensure safety in

the event of trouble with the Motion controller.

There are electronic components which are susceptible to the effects of static electricity

mounted on the printed circuit board. When handling printed circuit boards with bare hands you

must ground your body or the work bench.

Do not touch current-carrying or electric parts of the equipment with bare hands.

Make parameter settings within the ranges stated in this manual.

Use the program instructions that are used in programs in accordance with the conditions

stipulated in this manual.

Some devices for use in programs have fixed applications: they must be used in accordance

with the conditions stipulated in this manual.

1 - 3

Page 23

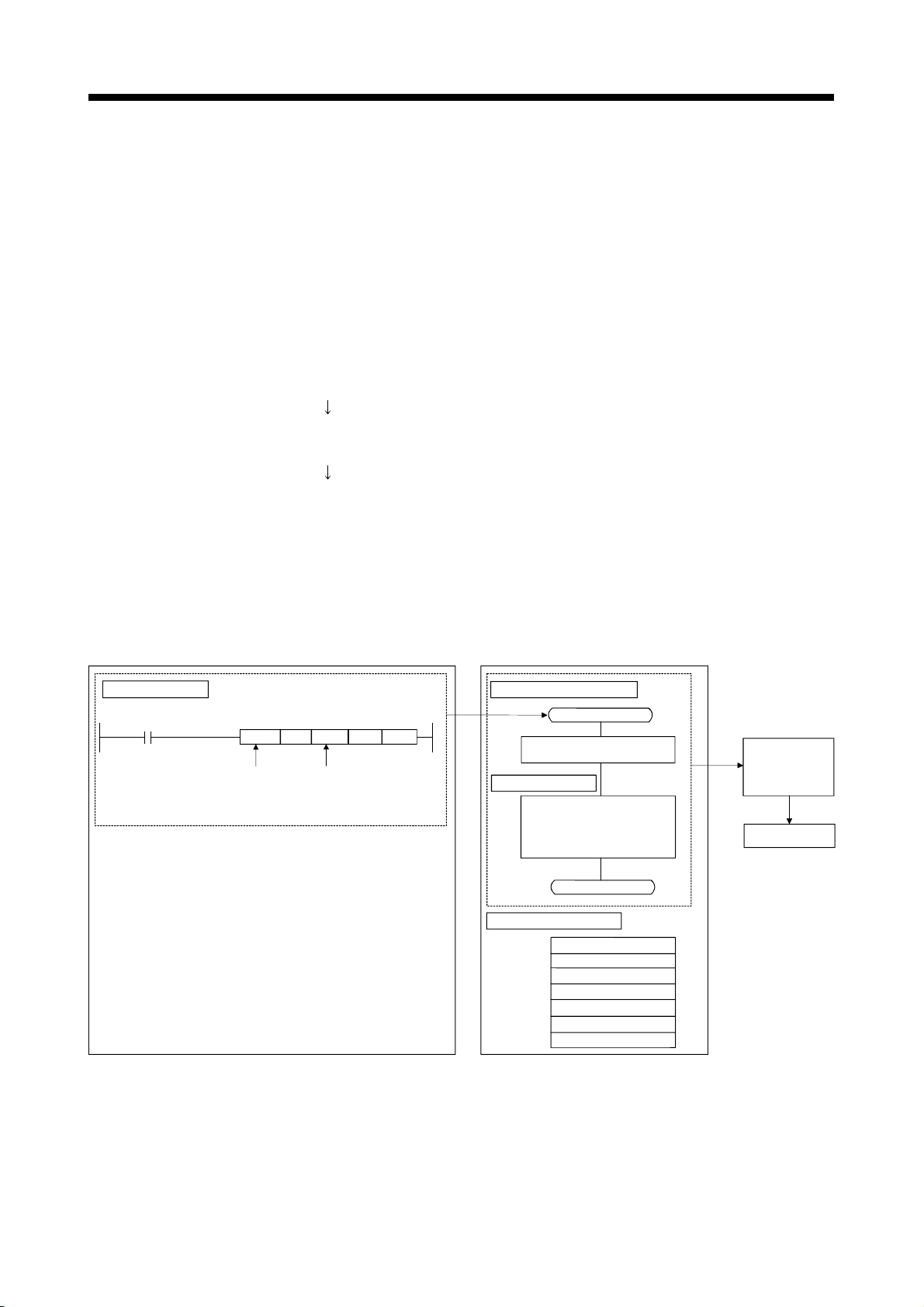

1 OVERVIEW

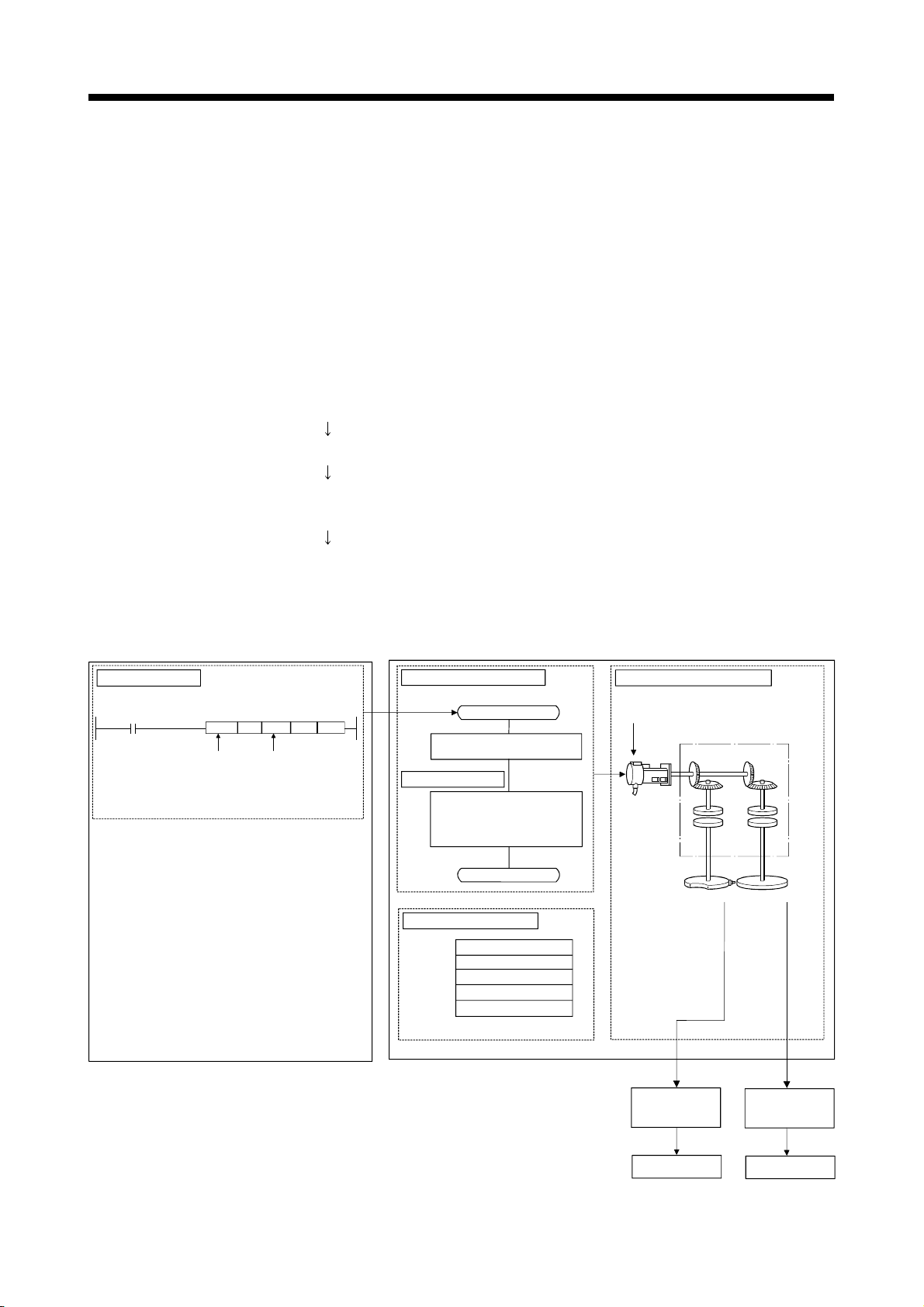

1.2 Motion Control in SV13/SV22 Real Mode

(1) System with servomotor is controlled directly using the servo program in

(SV13/SV22) real mode.

(2) Setting of the positioning parameter and creation of the servo

program/Motion SFC program are required.

(3) The procedure of positioning control is shown below:

1) Motion SFC program is requested to start using the D(P). SFCS

instruction of the sequence program.

(Motion SFC program can also be started automatically by parameter

setting.)

2) Execute the positioning control using the specified Motion SFC program.

(Output to the servo amplifier)

Program structure in SV13/SV22 real mode

3) The servomotor is controlled.

<PLC CPU>

Sequence program

DP.SFCS

Motion SFC

program start

request instruction

(Note) : Motion SFC program can also be started automatically

by parameter setting.

K0

••••

•••• ••••

Specification of starting

program No.

<Motion CPU>

Motion SFC program

1)

[G100]

M2049//servo ON accept ?

Servo program

[K10: real]

1 INC-2

Axis 1, 10000 PLS

Axis 2, 20000 PLS

Vector speed 30000 PLS/s

Positioning control parameters

Transfer

END

System settings

Fixed parameters

Servo parameters

Parameter blocks

Home position return data

JOG operation data

Limit switch output data

2)

3)

Servo amplifier

Servomotor

1 - 4

Page 24

1 OVERVIEW

1.3 Motion Control in SV22 Virtual Mode

(1) Synchronous control with software is performed using the mechanical

system program comprised by virtual main shaft and mechanical module in

(SV22) virtual mode.

(2) Mechanical system programs is required in addition to the positioning

parameter, servo program/Motion SFC program used in real mode.

(3) The procedure of positioning control in virtual mode is shown below:

1) Motion SFC program for virtual mode is requested to start using the

D(P). SFCS instruction of the sequence program.

(Motion SFC program can also be started automatically by parameter

setting.)

2) The virtual servomotor of the mechanical system program is started.

3) Output the operation result obtained through the transmission module to

the servo amplifier set as the output module.

4) The servomotor is controlled.

Program structure in SV22 virtual mode

<PLC CPU>

Sequence program

DP.SFCS

•••• K0

Motion SFC

program star t

request inst ruction

(Note) : Motion SFC program can also be started automatically

by parameter setting.

• Home position return data is not used, since home position return cannot be executed in virtual mode.

(Home position return is executed in real mode.)

• JOG operation in virtual mode is controlled using the JOG operation data set by drive module parameters.

•••• ••••

Specification of starting

program No.

<Motion CPU>

Motion SFC program

1)

[G200]

M2044//on virt ual mode?

Servo program

[K100: virtual]

1 VF

Axis 1

Speed # 0 PLS/s

Positioning con trol parameter s

Transfer

END

System settings

Fixed parameters

Servo parameters

Parameter blocks

Limit switch output data

Mechanical system program

Drive module

(Virtual servomotor)

Transmission module

2)

(Axis 1)

Output module

3)

Servo amplifier

3)

Servo amplifier

1 - 5

4)

Servomotor

4)

Servomotor

Page 25

1 OVERVIEW

1.4 Restrictions by the Software's Version

There are restrictions in the function that can be used by the version of the operating

system software and programming software.

The combination of each version and a function is shown in Table1.1.

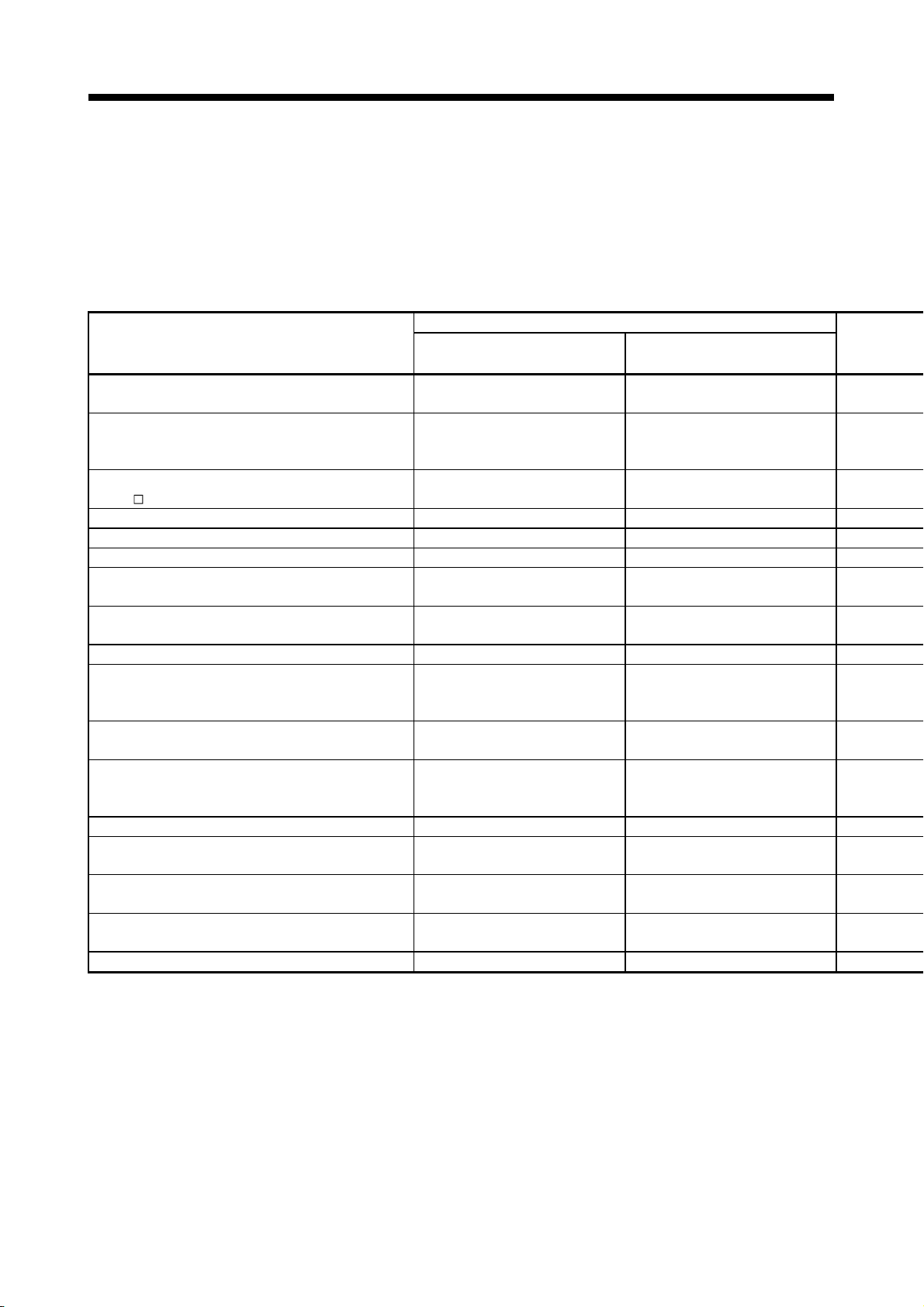

Table 1.1 Restrictions by the Software's Version

Operating system software version

Function

Checking Motion controller's serial number and operating

system software version in GX Developer

Advanced S-curve acceleration/deceleration

(Except constant-speed control (CPSTART) of servo

program.)

Direct drive servo

MR-J3-

Servo amplifier display servo error code (#8008+20n) — 00H

0.44ms fixed-cycle event task — 00H

444μs coasting timer (SD720, SD721) — 00H

Synchronous encoder current value monitor in real mode — 00H

Display of the past ten times history in current value history

monitor

Amplifier-less operation — 00H

Servo instruction (Home position return (ZERO), high

speed oscillation (OSC)) and manual pulse generator

operation in mixed function of virtual mode/real mode

Advanced S-curve acceleration/deceleration in constant-

speed control (CPSTART) of servo program.

External input signal (DOG) of servo amplifier in home

position return of count type and speed/position switching

control

Communication via PERIPHERAL I/F

Motion SFC operation control instruction

Type conversion (DFLT, SFLT)

Vision system dedicated function (MVOPEN, MVLOAD,

MVTRG, MVPST, MVIN, MVFIN, MVCLOSE, MVCOM)

Home position return of scale home position signal

detection type

Real time display function in digital oscilloscope function

B-RJ080W

Q173DSCPU/Q172DSCPU Q173DCPU(-S1)/Q172DCPU(-S1)

— 00D

— 00H

— 00H

— 00H

— 00H

— 00K

— 00G

— 00H

— 00L

— 00L

— 00L

— 00N

(Note-1), (Note-2)

1 - 6

Page 26

1 OVERVIEW

Programming software version

MELSOFT MT Works2 (MT Developer2)

Q173DSCPU/Q172DSCPU Q173DCPU(-S1)/Q172DCPU(-S1)

— — — — Section 4.3

1.39R 1.06G — — (Note-3)

— — — — (Note-5)

— — — — (Note-5)

1.39R 1.15R — — (Note-5)

1.39R 1.17T — —

(Note-1): SV13/SV22 is the completely same version.

(Note-2): The operating system software version can be confirmed in the operating system software (CD-ROM), MT Developer2 or

(Note-3): Q173D(S)CPU/Q172D(S)CPU Motion controller (SV13/SV22) Programming Manual (Motion SFC)

(Note-4): Q173D(S)CPU/Q172D(S)CPU Motion controller (SV13/SV22) Programming Manual (REAL MODE)

(Note-5): Q173D(S)CPU/Q172D(S)CPU Motion controller Programming Manual (COMMON)

(Note-6): Q173D(S)CPU/Q172D(S)CPU Motion controller Programming Manual (Safety Observation)

(Note-7): Q173DSCPU/Q172DSCPU Motion controller (SV22) Programming Manual (Advanced Synchronous Control)

— — — — (Note-2)

1.39R 1.06G — — (Note-4)

1.39R 1.06G 1.01B C2

— — — —

1.39R 1.06G — — (Note-5)

1.39R 1.09K — — Section 10.1

1.39R 1.09K — — (Note-4)

1.39R 1.15R — —

1.39R 1.15R — — (Note-3)

1.39R 1.15R — — (Note-3)

1.39R 1.15R — — (Note-4)

GX Works2/GX Developer. (Refer to "Q173D(S)CPU/Q172D(S)CPU Motion controller Programming Manual (COMMON) Section

1.3, 1.4".)

MR Configurator2 MR Configurator

—: There is no restriction by the version.

Section of reference

Section 6.2

Section 6.3

1 - 7

Page 27

1 OVERVIEW

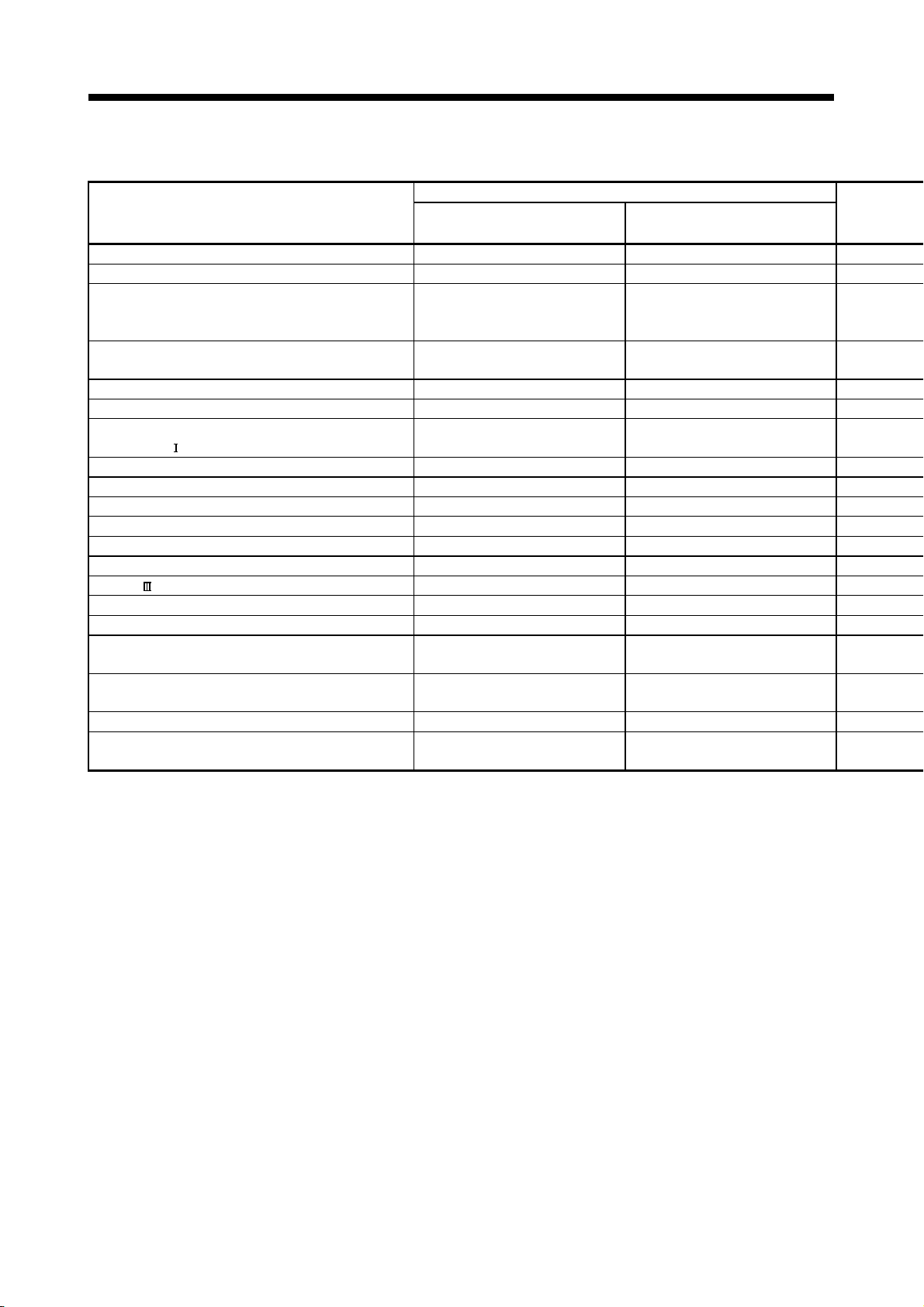

Table 1.1 Restrictions by the Software's Version (continued)

Operating system software version

Function

Rapid stop deceleration time setting error invalid function

Vision system dedicated function (MVOUT)

Motion SFC operation control instruction

Program control (IF - ELSE - IEND, SELECT -CASE -

SEND, FOR -NEXT, BREAK)

Display format depending on the error setting data

information of motion error history device (#8640 to #8735)

Product information list device (#8736 to #8751) — 00S

Safety observation function — 00S

Feed current value update command (M3212+20n) valid in

speed control (

External forced stop input ON latch (SM506) 00B 00S

Operation method (SD560) 00B Not support

Advanced synchronous control 00B Not support

Limit switch output function expansion 00B Not support

Driver communication function 00C Not support

Intelligent function module support 00C Not support

SSCNET /H head module connection 00C Not support

Cam auto-generation (CAMMK) easy stroke ratio cam 00C Not support

Acceleration/deceleration time change function 00C Not support

Home position return of dogless home position signal

reference type

Setting range expansion of backlash compensation

amount

Multiple CPU synchronous control 00C Not support

Cam axis length per cycle change during synchronous

control

)

Q173DSCPU/Q172DSCPU Q173DCPU(-S1)/Q172DCPU(-S1)

— 00S

— 00S

— 00R

— 00S

00B Not support

00C Not support

00C Not support

00C Not support

(Note-1), (Note-2)

1 - 8

Page 28

1 OVERVIEW

Programming software version

MELSOFT MT Works2 (MT Developer2)

Q173DSCPU/Q172DSCPU Q173DCPU(-S1)/Q172DCPU(-S1)

— — — — (Note-4)

1.39R 1.39R — — (Note-3)

— — — — Section 4.3

1.39R 1.39R — — (Note-6)

— — — — (Note-5)

— Not support — — (Note-5)

1.47Z Not support — — (Note-7)

1.47Z Not support — — (Note-5)

— Not support — — (Note-5)

1.56J Not support — — (Note-5)

1.56J Not support — — (Note-5)

1.56J Not support — — (Note-3)

1.56J Not support — — (Note-4)

1.56J Not support — — (Note-7)

(Note-1): SV13/SV22 is the completely same version.

(Note-2): The operating system software version can be confirmed in the operating system software (CD-ROM), MT Developer2 or

(Note-3): Q173D(S)CPU/Q172D(S)CPU Motion controller (SV13/SV22) Programming Manual (Motion SFC)

(Note-4): Q173D(S)CPU/Q172D(S)CPU Motion controller (SV13/SV22) Programming Manual (REAL MODE)

(Note-5): Q173D(S)CPU/Q172D(S)CPU Motion controller Programming Manual (COMMON)

(Note-6): Q173D(S)CPU/Q172D(S)CPU Motion controller Programming Manual (Safety Observation)

(Note-7): Q173DSCPU/Q172DSCPU Motion controller (SV22) Programming Manual (Advanced Synchronous Control)

1.39R 1.39R — — (Note-3)

— — — — (Note-3)

— Not support — — (Note-4)

1.56J Not support — — (Note-4)

1.56J Not support — — (Note-4)

1.56J Not support — — (Note-7)

GX Works2/GX Developer. (Refer to "Q173D(S)CPU/Q172D(S)CPU Motion controller Programming Manual (COMMON) Section

1.3, 1.4".)

MR Configurator2 MR Configurator

—: There is no restriction by the version.

Section of reference

1 - 9

Page 29

1 OVERVIEW

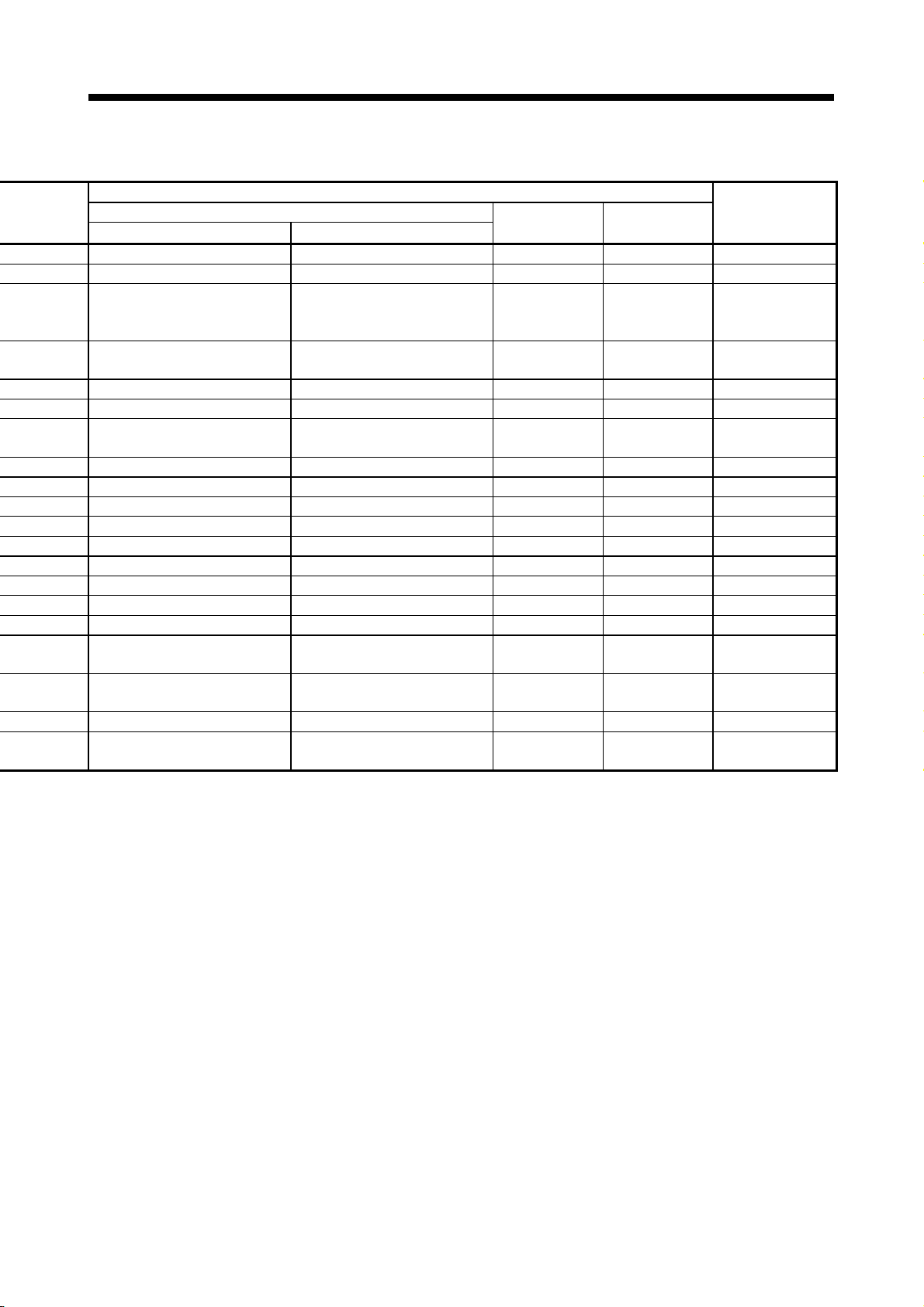

1.5 Programming Software Version

Motion CPU

Q173DSCPU

Q172DSCPU

Q173DCPU-S1

Q172DCPU-S1

Q173DCPU 1.00A 1.03D 1.00A

Q172DCPU 1.00A 1.03D 1.00A

The programming software versions that support Motion CPU are shown below.

MELSOFT MT Works2 (MT Developer2)

SV13/SV22 SV43

(Note-1)

1.39R

1.39R

1.00A

1.00A

(Note-1)

(Note-2)

1.03D

(Note-2)

1.03D

(Note-1): Use version 1.47Z or later to use advanced synchronous control method.

(Note-2): Use version 1.12N or later to communicate via PERIPHERAL I/F.

(Note-3): Use version 1.23Z or later to communicate via PERIPHERAL I/F.

(Note-4): Use version C1 or later to use MR Configurator combination with MT Developer2.

1.10L Not support

1.10L Not support

(Note-3)

(Note-3)

MR Configurator2 MR Configurator

1.00A

1.00A

C0

C0

C0

C0

(Note-4)

(Note-4)

(Note-4)

(Note-4)

1 - 10

Page 30

2 STARTING UP THE SYSTEM

2. STARTING UP THE SYSTEM

The procedure for virtual mode positioning control is shown below.

2.1 Starting Up the Virtual Mode System

The procedure to start up for virtual mode system is shown below.

START

Install the MT Developer2

Start the MT Developer2

System setting/Multiple CPU

settings/Automatic refresh

setting

Set the following positioning

parameters

Fixed parameters

Servo parameters

Parameter blocks

Limit switch output data

Refer to the "Q173D(S)CPU/Q172D(S)CPU

Motion controller Programming Manual (COMMON)".

Refer to the "Q173D(S)CPU/Q172D(S)CPU

Motion controller (SV13/SV22) Programming

Manual (REAL MODE)".

Refer to the "Q173D(S)CPU/Q172D(S)CPU

Motion controller Programming Manual (COMMON)".

2

Execute the relative check, and

correct the errors

Will cam be used ?

Set the cam data

NO

YES

Create the mechanical system

program

Refer to Chapter "5 MECHANICAL SYSTEM

PROGRAM".

Check the mechanical system

program, and correct the errors

1)

2 - 1

Page 31

2 STARTING UP THE SYSTEM

Create the Motion SFC program

and servo program

Turn the power supply of

Multiple CPU system ON

Write the following data to the

Motion CPU using

MT Developer2

System setting data

Servo setting data

Motion SFC parameter

Motion SFC program

Servo program

Mechanical system program

Cam data (Cam use)

1)

Starting up the servo amplifier

using MT Developer2

Execute the JOG operation,

manual pulse generator

operation and home position

return test

Adjust cam setting axis

(Cam use)

(Bottom dead point, stroke value,

etc.)

Align the virtual mode operation

start position

Set data in the parameter

setting device

Switch from real mode to virtual

mode

Start drive module operation

Real mode

Check operation state with the

servo monitor or mechanical

system monitor

END

2 - 2

Virtual mode

Page 32

2 STARTING UP THE SYSTEM

2.2 Starting Up the Incremental System and Absolute System

When incremental system or absolute system is used, the procedure for virtual mode

operation is shown below.

2.2.1 Operation for incremental system

The operation procedure for incremental system is shown below.

START

Turn the power supply of

Multiple CPU system ON

Execute the all axes servo

start request (Turn M2042 on)

Execute the home position

return

Align the virtual mode

operation start position

Set data in the parameter

setting device

Switch from real mode to

virtual mode

Set the operation start address

by the current value change

Real mode

Virtual mode

Execute virtual mode operation

2 - 3

Page 33

2 STARTING UP THE SYSTEM

2.2.2 Operation for absolute (absolute position) system

The operation procedure for absolute system is shown below.

START

Turn the power supply of

Multiple CPU system ON

Execute the all axes servo

start request (Turn M2042 on)

Is the home

position return request

signal ON ?

YES

Execute the home position

return

Align the virtual mode

operation start position

Set data in the parameter

setting device

NO

YES

Is the

continuation

disabled warning

signal ON ?

NO

Real mode

Switch from real mode to

virtual mode

Set the operation start address

by the current value change

Execute virtual mode operation

Virtual mode

2 - 4

Page 34

2 STARTING UP THE SYSTEM

2.3 Differences Between Real Mode and Virtual Mode

Specifications of the positioning data, positioning devices and servo programs, etc.

used in the real mode differ in part in the virtual mode.

When using them in the virtual mode, refer to the "Q173D(S)CPU/Q172D(S)CPU

Motion controller (SV13/SV22) Programming Manual (REAL MODE)" after checking

about a different point in the real mode.

2.3.1 Positioning data

Positioning data used in the virtual mode are shown in Table 2.1 below.

Table 2.1 Positioning Data List

Item Real mode Virtual mode Remark

System settings

Fixed parameters

Servo parameters

Parameter blocks

Home position return data

JOG operation data

Limit switch output data

(Note): Refer to Section 10.1 for the real mode axis at virtual mode.

2.3.2 Positioning devices

Usable units differ according to the

output module.

Only [PLS] usable.

: Used

: Used (Restrictions in part)

: Not used

The operating ranges of positioning devices used in virtual mode are shown in Table

2.2 below.

Table 2.2 Operating Range of Positioning Devices

Device name Real mode Virtual mode

M2000 to M3839

Internal relays

Special relays SM0 to SM2255

Data registers

Motion registers #8000 to #8751

Special registers SD0 to SD2255

M4640 to M4687

M5440 to M5487

D0 to D799

D1120 to D1239

2 - 5

M2000 to M5487

D0 to D1559

Page 35

2 STARTING UP THE SYSTEM

2.3.3 Servo programs

(1) Servo program area

(a) The same servo program (Kn) No. cannot be used in both the real mode and

virtual modes. The range of servo program (Kn) used in the virtual mode

must be set using MT Developer2 in advance.

(2) Servo instructions

(a) The home position return, speed control (

high-speed oscillation control and speed control with fixed position stop

among the controls which can be used in the real mode cannot be used in

(3) Differences of the servo instruction between real mode and virtual mode are

the virtual mode.

(b) Control units of the parameter block and the torque limit value among the

positioning data which can be set using the servo program are not used.

shown in Table 2.3 below.

), speed/position switching control,

Table 2.3 Differences of Servo Instruction List

Item

VPF

Speed/position

control

Speed control ( )

Servo

instruction

Positioning

data

(Note-1): Instruction not listed in the table above are common instructions in real mode and virtual

(Note-2): Refer to Section 10.1 for the real mode axis at virtual mode.

Home position

return

High-speed

oscillation

Speed control

with fixed position

stop

Control units

Parameter block

Torque limit value

mode.

VPR

VPSTART

ZERO

VVF

VVR

OSC

PVF

PVR

Real

mode

Virtual

mode

Fixed as

"PLS"

: Used, : Unusable, : Not used

Remark

Switch to virtual mode

after home position

return in the real

mode.

The torque limit value

is set with the "output

module parameter".

2 - 6

Page 36

2 STARTING UP THE SYSTEM

2.3.4 Control change (Current value change/speed change/target position change)

When a control change is executed in the virtual mode, the feed current value/speed of

the drive module is changed.

Control changes are not possible for the output module (except for cam).

Differences between control changes in the real mode and virtual modes are shown in

Table 2.4 below.

Table 2.4 Differences List of Control Change

Real mode Virtual mode

Item

Current value

change

Speed change

Target position

change

(Note-1): If the output module is a roller which uses a speed change gear, a speed change can be executed by

QDS

changing the speed change gear ratio.

Servo motor

Synchronous

encoder

Ver.!

Virtual servo

Drive module Output module

Synchronous

motor

encoder

Roller

Ball

Rotary

screw

table

(Note-1)

: Used, : Unusable

Cam

REMARK

Refer to the following Chapters for details of the drive and output modules.

• Drive module : Chapter 5 and 6

• Output module : Chapter 5 and 8

Ver.!

: Refer to Section 1.4 for the software version that supports this function.

2 - 7

Page 37

2 STARTING UP THE SYSTEM

2.3.5 Switching of control mode (Speed-torque control)

When a speed-torque control is executed in the virtual mode, the control mode of the

output module (except for cam) and real mode axis is switched.

Differences between speed-torque control in the real mode and virtual modes are

shown in Table 2.5 below.

Table 2.5 Differences List of Control Mode Switching

Real mode Virtual mode

Item

Speed-torque

control

Servo motor

Synchronous

encoder

Drive module Output module

Virtual servo

motor

Synchronous