Page 1

C

MIT

SUBIS

C

MELSEC System Q

Motion Controller

User's Manual

HI ELECTRI

Art. no.: 143715

01 05 2002

IB(NA)-0300040-B

Q172CPU

Q173CPU

MITSUBISHI ELECTRI

INDUSTRIAL AUTOMATION

Page 2

SAFETY PRECAUTIONS

(Read these precautions before using.)

When using this equipment, thoroughly read this manual and the associated manuals introduced in this

manual. Also pay careful attention to safety and handle the module properly.

These precautions apply only to this equipment. Refer to the Users manual of the CPU module to use for

a description of the PLC system safety precautions.

These SAFETY PRECAUTIONS classify the safety precautions int o two cat egories: "DANG ER" and

"CAUTION".

DANGER

!

CAUTION

!

Depending on circumstances, procedures indicated by ! CAUTION may also be linked to serious

results.

In any case, it is important to follow the directions for usage.

Store this manual in a safe place so that you can take it out and read it whenever necessary . Alw ay s

forward it to the end user.

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in medium or slight personal injury or physical damage.

A - 1

Page 3

For Safe Operations

1. Prevention of electric shocks

!

DANGER

Never open the front case or terminal covers while the power is ON or the unit is running, as

this may lead to electric shocks.

Never run the unit with the front case or terminal cover removed. The high v oltage t erminal and

charged sections will be exposed and may lead to electric shocks.

Never open the front case or terminal cover at times other than wiring work or periodic

inspections even if the power is OFF. The insides of the Motion controller and servo amplifier

are charged and may lead to electric shocks.

When performing wiring work or inspections, turn the power OFF, wait at least ten minutes, and

then check the voltage with a tester, et c.. Failing t o do so may lead to electr ic shocks.

Be sure to ground the Motion controller, servo amplifier and servomotor. (Ground resistance :

or less) Do not ground commonly with other devices.

100

The wiring work and inspections must be done by a qualified technician.

Wire the units after installing the Motion controller, servo amplifier and serv omotor. Failing to do

so may lead to electric shocks or damage.

Never operate the switches with wet hands, as this may lead t o electric shocks.

Do not damage, apply excessive stress, place heavy things on or sandwich t he cables, as t his

may lead to electric shocks.

Do not touch the Motion controller, servo amplifier or servomotor terminal blocks while the

power is ON, as this may lead to electric shocks.

Do not touch the internal power supply, internal grounding or signal wires of the Mot ion

controller and servo amplifier, as this may lead to electric shocks.

2. For fire prevention

!

CAUTION

Install the Motion controller, servo amplifier, servomotor and regenerative resist or on

inflammable material. Direct installation on flammable material or near flammable material may

lead to fires.

If a fault occurs in the Motion controller or servo amplifier, shut the power OFF at the servo

amplifier’s power source. If a large current continues to flow, fires may occur.

When using a regenerative resistor, shut the power OFF with an error signal. The regenerative

resistor may abnormally overheat due to a fault in the regenerative t ransistor, etc., and may

lead to fires.

Always take heat measures such as flame proofing for the inside of the control panel where

the servo amplifier or regenerativ e resistor is installed and for t he wires used. Failing to do so

may lead to fires.

A - 2

Page 4

3. For injury prevention

!

CAUTION

Do not apply a voltage other than that specified in the instruction manual on any terminal.

Doing so may lead to destruction or damage.

Do not mistake the terminal connections, as this may lead to destruction or damage.

Do not mistake the polarity ( + / - ), as this may lead to destruction or damage.

Do not touch the servo amplifier's heat radiating fins, regenerative resistor and servomotor, et c.,

while the power is ON and for a short time after the power is turned OFF. In this timing, these

parts become very hot and may lead to burns.

Always turn the power OFF before touching the servomotor shaft or coupled machines, as

these parts may lead to injuries.

Do not go near the machine during test operations or during operations such as teaching.

Doing so may lead to injuries.

4. Various precautions

Strictly observe the following precautions.

Mistaken handling of the unit may lead to faults, injuries or electric shocks.

(1) System structure

!

CAUTION

Always install a leakage breaker on the Motion controller and servo amplifier power source.

If installation of a magnetic contactor for power shut off during an error, etc., is specified in the

instruction manual for the servo amplifier, etc., always install the magnetic cont actor.

Install the emergency stop circuit externally so that the operat ion can be stopped immediately

and the power shut off.

Use the Motion controller, servo amplifier, servomotor and regenerative resistor with t he combi-

nations listed in the instruction manual. Other combinations may lead to fires or faults.

If safety standards (ex., robot safety rules, etc., ) apply to the sy stem using the Motion cont roller,

servo amplifier and servomotor, make sure that the safety standards are satisfied.

Construct a safety circuit externally of the Motion controller or serv o amplifier if the abnormal

operation of the Motion controller or servo amplifier differ from the safety directive operation in

the system.

In systems where coasting of the serv omotor w ill be a problem during t he emergency stop, the

forced stop, servo OFF or when the power is shut OFF, use dy namic brakes.

Make sure that the system considers the coasting amount even when using dynamic brakes.

A - 3

Page 5

!

CAUTION

In systems where perpendicular shaft dropping may be a problem during the emergency stop,

the forced stop and servo OFF or when the power is shut OFF, use bot h dynamic brakes and

magnetic brakes.

The dynamic brakes must be used only during the emergency stop, the forced stop and errors

where servo OFF occurs. These brakes must not be used for normal braking.

The brakes (magnetic brakes) assembled into the servomotor are for holding applications, and

must not be used for normal braking.

The system must have a mechanical allowance so that the machine itself can stop even if the

stroke limits switch is passed through at the max. speed.

Use wires and cables that have a wire diameter, heat resistance and bending resistance

compatible with the system.

Use wires and cables within the length of the range described in the instruction manual.

The ratings and characteristics of the parts (other than Motion controller, servo amplifier and

servomotor) used in a system must be compatible with the Motion controller, servo amplifier

and servomotor.

Install a cover on the shaft so that the rotary part s of the servomotor are not t ouched during

operation.

There may be some cases where holding by the magnetic brakes is not possible due to the

life or mechanical structure (when the ball screw and servomotor are connected with a timing

belt, etc.). Install a stopping device t o ensure safety on the machine side.

(2) Parameter settings and prog r amming

!

CAUTION

Set the parameter values to those that are compatible with the Motion cont roller, serv o amplifier,

servomotor and regenerative resistor model and the system application. The protect ive functions

may not function if the settings are incorrect.

The regenerative resistor model and capacity parameters must be set to values that conform to

the operation mode, servo amplifier and servo power supply module. The protective functions

may not function if the settings are incorrect.

Set the mechanical brake output and dynamic brake output validity parameters to v alues that

are compatible with the system application. The protective functions may not function if the

settings are incorrect.

Set the stroke limit input validity parameter to a v alue that is compatible with t he sy stem

application. The protective functions may not function if the setting is incorrect.

A - 4

Page 6

!

CAUTION

Set the servomotor encoder type (increment, absolute position ty pe, et c.) parameter to a v alue

that is compatible with the system application. The protect ive functions may not function if the

setting is incorrect.

Set the servomotor capacity and type (standard, low-inert ia, flat, etc.) parameter t o values t hat

are compatible with the system application. The protective functions may not function if the

settings are incorrect.

Set the servo amplifier capacity and type parameters to v alues that are compatible w ith the

system application. The protective functions may not function if the settings are incorrect.

Use the program commands for the program with the conditions specified in the instruction

manual.

Set the sequence function program capacity setting, device capacity, latch validity range, I/O

assignment setting, and validity of continuous operation during error detection to v alues t hat are

compatible with the system application. The protective functions may not function if the settings

are incorrect.

Some devices used in the program have fixed applications, so use these with the conditions

specified in the instruction manual.

The input devices and data registers assigned to the link will hold the dat a prev ious to w hen

communication is terminated by an error, etc. Thus, an error correspondence interlock program

specified in the instruction manual must be used.

Use the interlock program specified in the special function module's instruction manual for the

program corresponding to the special function module.

(3) Transportation and installation

!

CAUTION

Transport the product with the correct method according to the weight.

Use the servomotor suspension bolts only for the transportation of the servomotor. Do not

transport the servomotor with machine installed on it.

Do not stack products past the limit. When transporting the Motion controller or servo amplifier,

never hold the connected wires or cables.

When transporting the servomotor, never hold the cables, shaft or detector.

When transporting the Motion controller or servo amplifier, never hold the front case as it may

fall off.

When transporting, installing or removing the Motion controller or serv o amplifier, nev er hold

the edges.

Install the unit according to the instruction manual in a place where the w eight can be wit hstood.

A - 5

Page 7

!

CAUTION

Do not get on or place heavy objects on the product.

Always observe the installation direction.

Keep the designated clearance between the Motion controller or servo amplifier and control

panel inner surface or the Motion controller and servo amplifier, Motion controller or servo

amplifier and other devices.

Do not install or operate Motion controller, servo amplifiers or servomotors that are damaged or

that have missing parts.

Do not block the intake/outtake ports of the servomotor with cooling fan.

Do not allow conductive matter such as screw or cutting chips or combustible matter such as oil

enter the Motion controller, servo amplifier or servomotor.

The Motion controller, servo amplifier and servomotor are precision machines, so do not drop

or apply strong impacts on them.

Securely fix the Motion controller and servo amplifier to the machine according to the instruction

manual. If the fixing is insufficient, these may come off during operation.

Always install the servomotor with r eduction gears in the designat ed direct ion. Failing to do so

may lead to oil leaks.

Store and use the unit in the following environmental conditions.

Environment

Ambient

temperature

Ambient humidity

Storage

temperature

Atmosphere

Altitude

Vibration

Motion controller/Servo amplifier Servomotor

According to each instruction manual.

According to each instruction manual.

According to each instruction manual.

Indoors (where not subject to direct sunlight).

No corrosive gases, flammable gases, oil mist or dust must exist

1000m (3278.69ft.) or less above sea level

According to each instruction manual

Conditions

0°C to +40°C (With no freezing)

(32°F to +104°F)

80% RH or less

(With no dew condensation)

-20°C to +65°C

(-4°F to +149°F)

When coupling with the synchronization encoder or servomotor shaft end, do not apply impact

such as by hitting with a hammer. Doing so may lead to detector damage.

Do not apply a load larger than the tolerable load onto the servomotor shaft. Doing so may lead

to shaft breakage.

When not using the module for a long time, disconnect the power line from the Motion controller

or servo amplifier.

Place the Motion controller and servo amplifier in static electricity prev enting v inyl bags and

store.

When storing for a long time, please contact with our sales representative.

A - 6

Page 8

(4) Wiring

!

CAUTION

Correctly and securely wire the wires. Reconfirm the connections for mistakes and the terminal

screws for tightness after wiring. Failing to do so may lead to run away of the

servomotor.

After wiring, install the protective covers such as the t erminal covers t o the original positions.

Do not install a phase advancing capacitor, surge absorber or radio noise filter (option FR-BIF)

on the output side of the servo amplifier.

Correctly connect the output side ( terminals U, V, W). Incorrect connections will lead t he

servomotor to operate abnormally.

Do not connect a commercial power supply to the servomotor, as this may lead t o trouble.

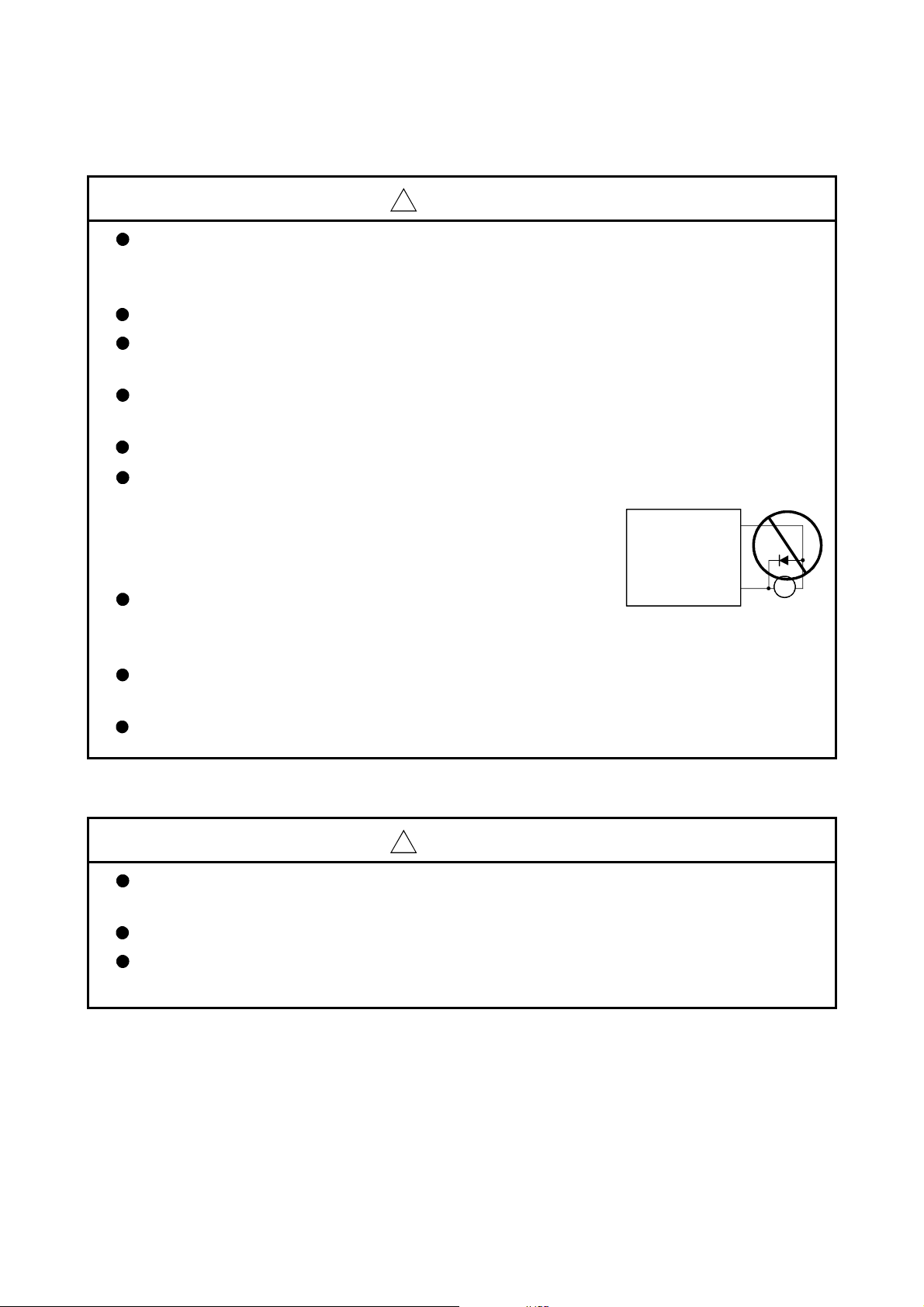

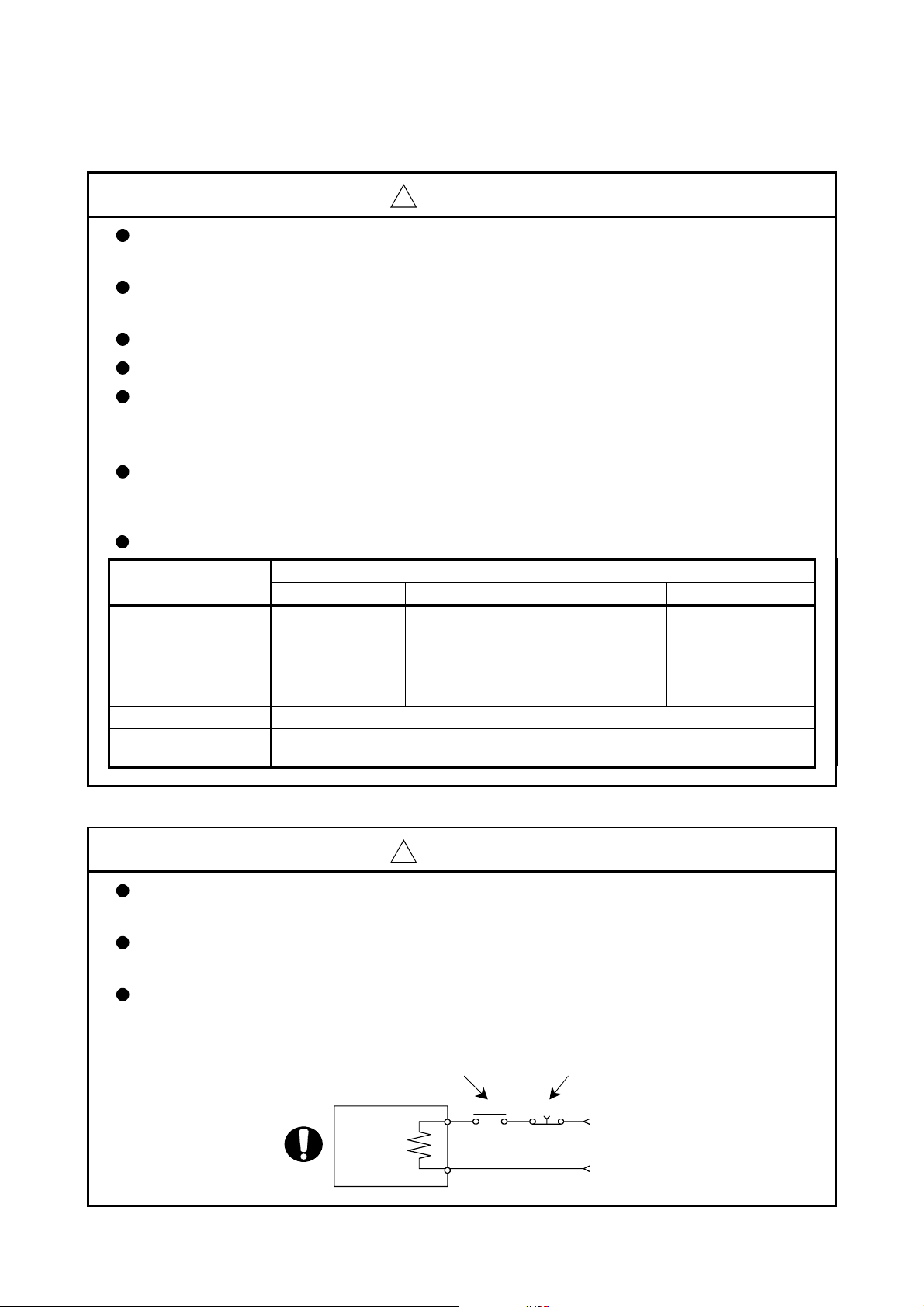

Do not mistake the direction of the surge absorbing diode

installed on the DC relay for the control signal output of

brake signals, etc. Incorrect installation may lead to signals

not being output when trouble occurs or the protective

functions not functioning.

Do not connect or disconnect the connection cables between

each unit, the encoder cable or PLC expansion cable while the

power is ON.

Servo amplifier

VIN

(24VDC)

Controll output

signal

RA

Securely tighten the cable connector fixing screws and fixing mechanisms. Insufficient fixing

may lead to the cables combing off during operation.

Do not bundle the power line or cables.

(5) Trial operation and adjustment

!

CAUTION

Confirm and adjust the program and each parameter before operation. Unpredictable

movements may occur depending on the machine.

Extreme adjustments and changes may lead to unstable operation, so never make them.

When using the absolute position system function, on starting up, and when the Motion

controller or absolute value motor has been replaced, always perform a home position return.

A - 7

Page 9

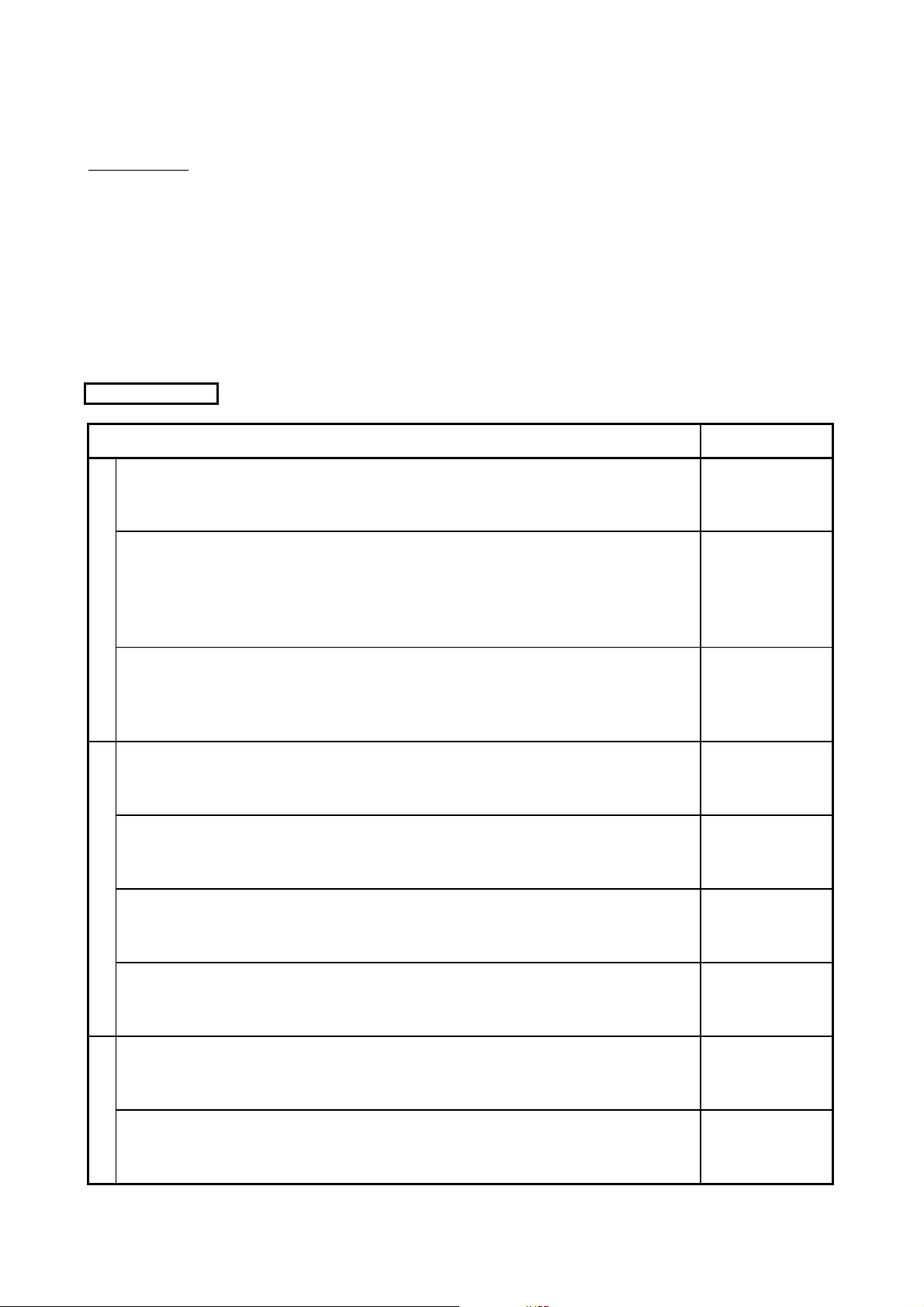

Conditions

(6) Usage methods

!

CAUTION

Immediately turn OFF the power if smoke, abnormal sounds or odors are emitted from the

Motion controller, servo amplifier or servomotor.

Always execute a test operation before starting actual operations after the program or

parameters have been changed or after maintenance and inspection.

The units must be disassembled and repaired by a qualified technician.

Do not make any modifications to the unit.

Keep the effect or magnetic obstacles to a minimum by inst alling a noise filter or by using wire

shields, etc. Magnetic obstacles may affect the electronic devices used near t he Motion

controller or servo amplifier.

When using the CE Mark-compliant equipment, refer to the "EMC Installation Guidelines"

(data number IB(NA)-67339) for the Motion controllers and refer to the corresponding EMC

guideline information for the servo amplifiers, inverters and other equipment.

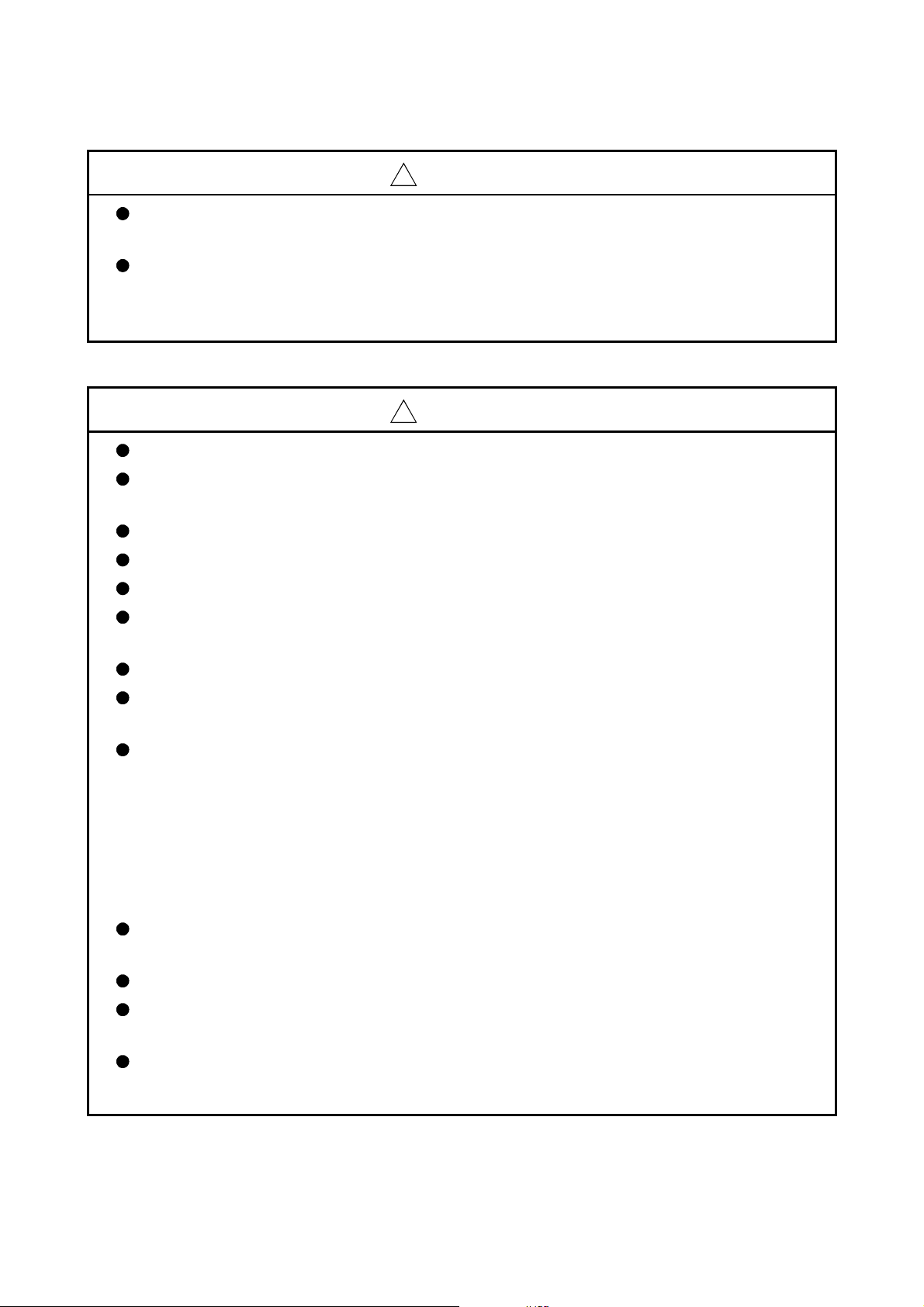

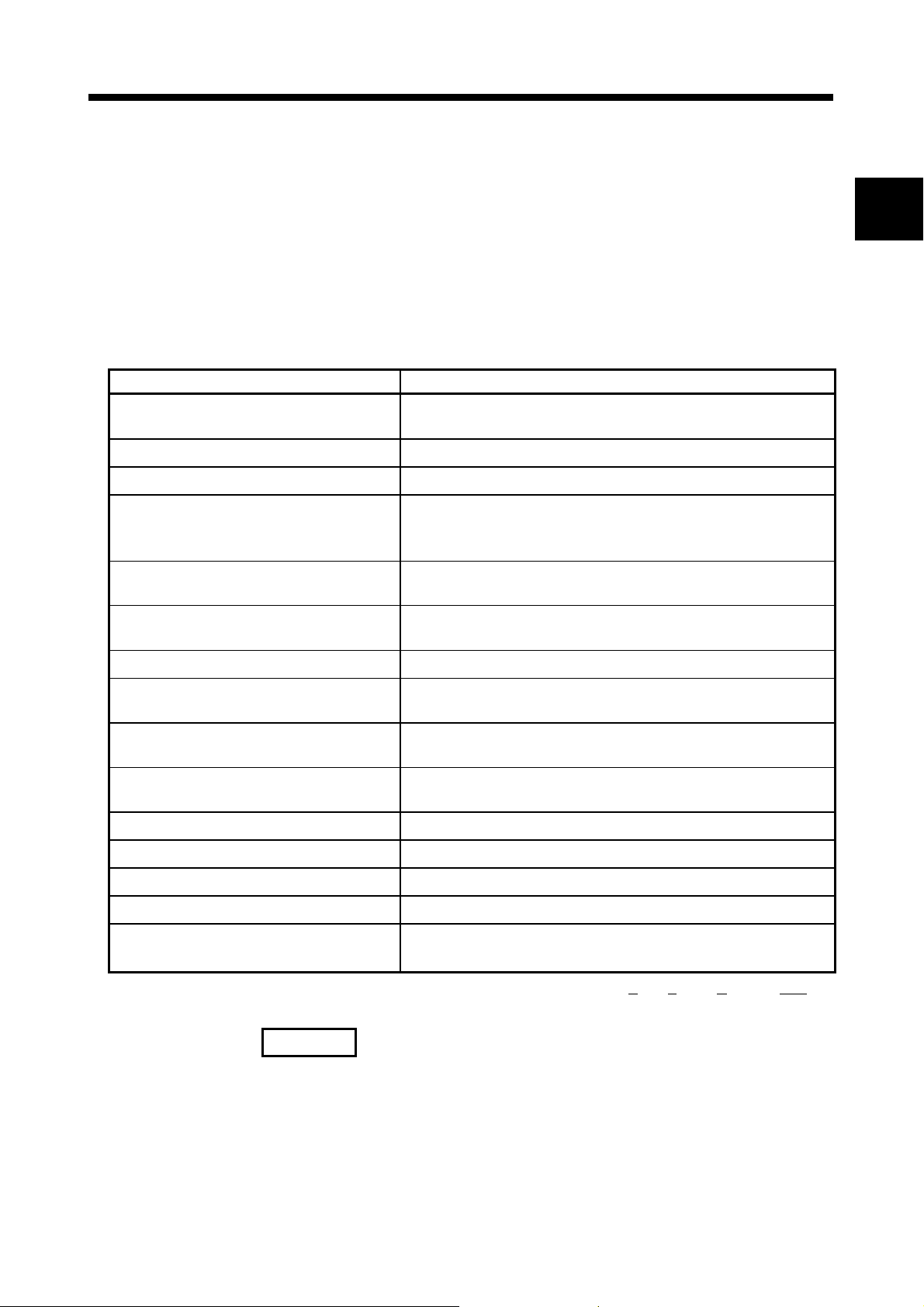

Use the units with the following conditions.

Item

Input power

Input frequency 50/60Hz ±5%

Tolerable momentary

power failure

Q61P-A1 Q61P-A2 Q63P Q64P

100 to 120VAC

(85 to 132VAC) (170 to 264VAC) (15.6 to 31.2VDC)

+10% +10% +30% +10%

200 to 240VAC

-15%

-15%

20ms or less

24VDC

-35%

100 to 120VAC

200 to 240VAC

(85 to 132VAC/

170 to 264VAC)

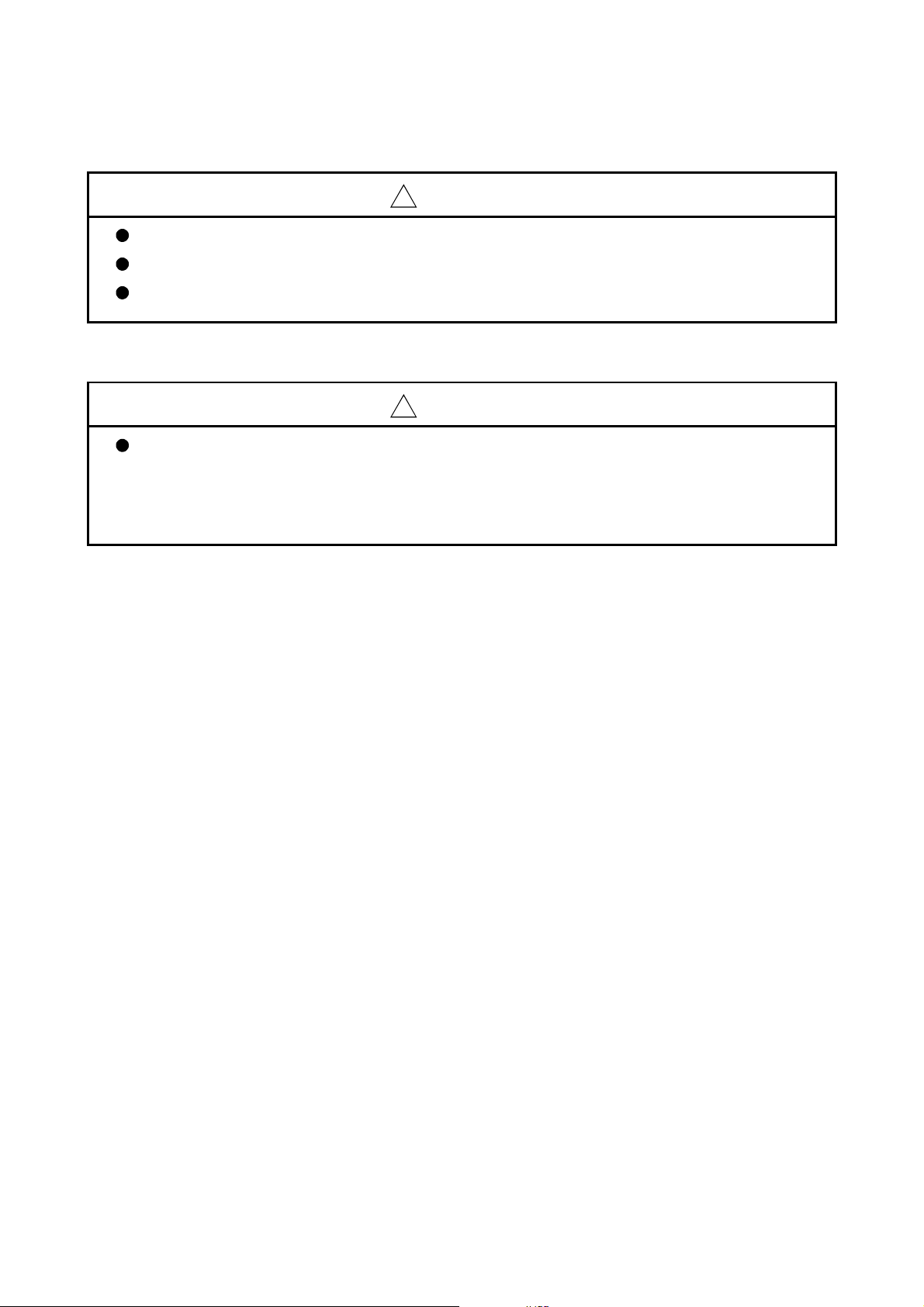

(7) Corrective actions for errors

!

CAUTION

If an error occurs in the self diagnosis of the Motion controller or servo amplifier, confirm the

check details according to the instruction manual, and restore the operation.

If a dangerous state is predicted in case of a power failure or product failure, use a servomotor

with magnetic brakes or install a brake mechanism externally.

Use a double circuit construction so that the magnetic brake operation circuit can be operated

by emergency stop signals set externally.

Shut off w ith the

Shot off with servo ON signal OFF,

alarm,magnetic brake signal.

emergency stop

signal(EMG).

-15%

+10%

-15%

/

Servo motor

Magnetic

brakes

A - 8

RA1

EMG

24VDC

Page 10

!

CAUTION

If an error occurs, remove the cause, secure the safety and then resume operation after alarm

seleasl.

The unit may suddenly resume operation after a power failure is restored, so do not go near the

machine. (Design the machine so that personal safety can be ensured even if the machine

restarts suddenly.)

(8) Maintenance, inspection and part replacement

!

CAUTION

Perform the daily and periodic inspections according to the instruction manual.

Perform maintenance and inspection after backing up the program and parameters for the

Motion controller and servo amplifier.

Do not place fingers or hands in the clearance when opening or closing any opening.

Periodically replace consumable parts such as batteries according to the instruction manual.

Do not touch the lead sections such as ICs or the connector contacts.

Do not place the Motion controller or servo amplifier on metal that may cause a power leakage

or wood, plastic or vinyl that may cause st atic electr icity buildup.

Do not perform a megger test (insulation resistance measurement) during inspection.

When replacing the Motion controller or servo amplifier, always set the new module settings

correctly.

When the Motion controller or absolute value motor has been replaced, carry out a home

position return operation using one of the following methods, otherwise position displacement

could occur.

1) After writing the servo data to the Motion controller using programming software, switch on

the power again, then perform a home position return operation.

2) Using the backup function of the programming software, load the data backed up before

replacement.

After maintenance and inspections are completed, confirm that the position detection of the

absolute position detector function is correct.

Do not short circuit, charge, overheat, incinerate or disassemble the batt eries.

The electrolytic capacitor will generate gas dur ing a fault, so do not place y our face near t he

Motion controller or servo amplifier.

The electrolytic capacitor and fan will deter iorate. Periodically replace these t o prev ent

secondary damage from faults. Replacements can be made by our sales representative.

A - 9

Page 11

(9) Disposal

!

CAUTION

Dispose of the product as general industrial waste.

Do not disassemble the parts of the Motion controller, servo amplifier or servomotor.

Dispose of the battery according to local laws and regulations.

(10) General cautions

!

CAUTION

All drawings provided in the instruction manual show the state w ith the cov ers and safety

partitions removed to explain detailed sections. When operating the product, always return the

covers and partitions to the designated positions, and operate according to the inst ruction

manual.

A - 10

Page 12

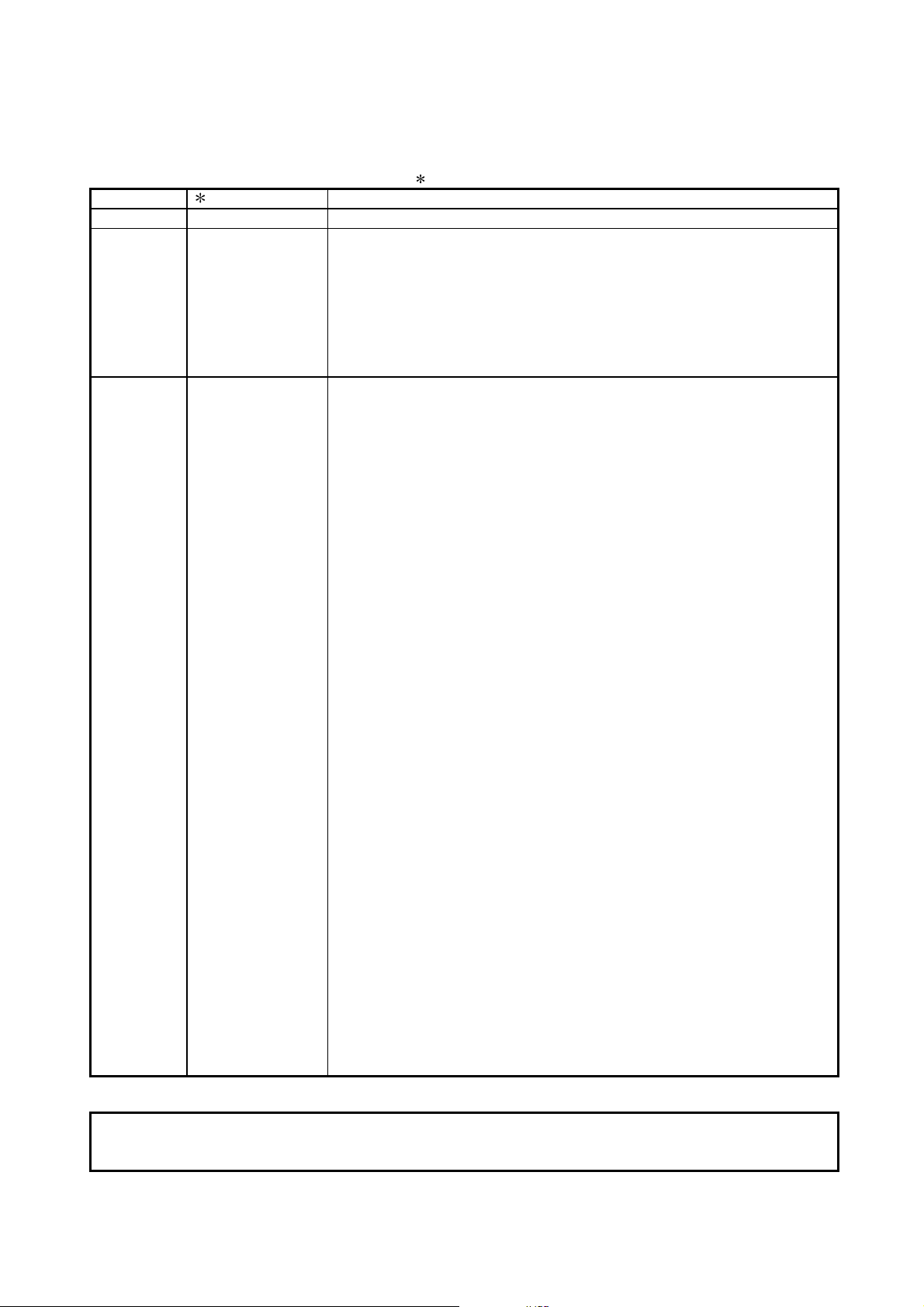

REVISIONS

The manual number is given on the bottom left of the back cover.

Print Date Manual Number Revision

Nov., 2001 IB(NA)-0300040-A First edition

May., 2002 IB(NA)-0300040-B

[Addition model]

Q173CPUN/Q172CPUN, MR-J2M-B, A10BD-PCF

[Addition function]

•

For Windows 2000

•

ROM operation

•

MODE LED Installation mode/ROM writing mode

•

BOOT LED Installation mode/ROM writing mode

[Partial correction]

Japanese Manual Number IB(NA)-0300021

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any patent

licenses. Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property

rights which may occur as a result of using the contents noted in this manual.

© 2001 MITSUBISHI ELECTRIC CORPORATION

A - 11

Page 13

INTRODUCTION

Thank you for choosing the Q173CPU(N)/Q172CPU(N) Motion Controller.

Please read this manual carefully so that equipment is used to its optimum.

CONTENTS

Safety Precautions.........................................................................................................................................A- 1

Revisions ........................................................................................................................................................A-11

Contents .........................................................................................................................................................A-12

About Manuals ...............................................................................................................................................A-15

1. OVERVIEW 1- 1 to 1- 2

1.1 Overview...................................................................................................................................................1- 1

2. SYSTEM CONFIGURATION 2- 1 to 2-70

2.1 Motion System Configuration ..................................................................................................................2- 1

2.1.1 Q173CPU(N) System overall configuration...................................................................................... 2- 8

2.1.2 Q172CPU(N) System overall configuration...................................................................................... 2- 9

2.1.3 Function explanation of the Q173CPU(N)/Q172CPU(N) Motion CPU modules ............................2-10

2.1.4 Restrictions on motion systems........................................................................................................2-11

2.2 System Configuration Equipment............................................................................................................ 2-13

2.3 General Specifications.............................................................................................................................2-20

2.4 Specifications of Equipment and Settings...............................................................................................2-22

2.4.1 Q173CPU(N)/Q172CPU(N)..............................................................................................................2-22

2.4.2 Power supply module........................................................................................................................2-28

2.4.3 Base unit and extension cable..........................................................................................................2-34

2.4.4 Q172LX Servo external signals interface module............................................................................2-37

2.4.5 Q172EX Serial absolute synchronous encoder interface module................................................... 2-42

2.4.6 Q173PX Manual pulse generator interface module.........................................................................2-49

2.4.7 Manual pulse generator/Serial absolute synchronous encoder ......................................................2-56

2.4.8 Connection method with SSCNET cables and termination connector............................................2-57

2.4.9 External battery .................................................................................................................................2-67

2.4.10 Cooling fan unit (Q170FAN) (Q173CPU/Q172CPU only).............................................................2-69

3. DESIGN 3- 1 to 3-16

3.1 System Designing Procedure..................................................................................................................3- 1

3.2 External Circuit Design ............................................................................................................................3- 4

3.2.1 Power supply circuit design .............................................................................................................. 3- 8

3.2.2 Safety circuit design ..........................................................................................................................3- 9

3.3 Layout Design within The Control Panel.................................................................................................3-11

3.3.1 Installation environment....................................................................................................................3-11

3.3.2 Layout design of the base units........................................................................................................3-12

3.3.3 Calculating heat generation by Motion controller.............................................................................3-13

3.4 Design Checklist ......................................................................................................................................3-16

A - 12

Page 14

4. INSTALLATION AND WIRING 4- 1 to 4-16

4.1 Module Installation ...................................................................................................................................4- 1

4.1.1 Instructions for handling....................................................................................................................4- 1

4.1.2 Instructions for installation of the base unit ...................................................................................... 4- 3

4.1.3 Installation and removal of module...................................................................................................4- 5

4.2 Installation and Removal of Cable........................................................................................................... 4- 7

4.2.1 Installation and removal of the SSCNET cable................................................................................4- 7

4.2.2 2 Installation and removal of the battery cable.................................................................................4- 8

4.3 Installation of the Serial Absolute Synchronous Encoder....................................................................... 4- 9

4.4 Replacement of the Cooling fan unit (Q170FAN) (Q173CPU/Q172CPU only).....................................4-11

4.5 Wiring........................................................................................................................................................4-12

4.5.1 Instructions for wiring ........................................................................................................................4-12

4.5.2 Wiring to the power supply module ..................................................................................................4-15

4.6 Installation/Wiring Checklist.....................................................................................................................4-16

5. TRIAL RUN AND ADJUSTMENT 5- 1 to 5- 8

5.1 Checklist before Trial Operation..............................................................................................................5- 1

5.2 Trial Run and Adjustment Procedure ...................................................................................................... 5- 2

5.3 Operating System Installation Procedure................................................................................................5- 7

5.4 Trial Run and Adjustment Checklist ........................................................................................................5- 8

6. INSPECTION AND MAINTENANCE 6- 1 to 6-26

6.1 Maintenance Works ................................................................................................................................. 6- 2

6.1.1 Inspection and maintenance.............................................................................................................6- 2

6.2 Daily Inspection........................................................................................................................................6- 4

6.3 Periodic Inspection...................................................................................................................................6- 6

6.4 External Battery........................................................................................................................................6- 7

6.4.1 Battery service life time.....................................................................................................................6- 8

6.4.2 Battery replacement procedure ........................................................................................................6- 9

6.5 Troubleshooting .......................................................................................................................................6-11

6.5.1 Basics of troubleshooting..................................................................................................................6-11

6.5.2 Troubleshooting of Motion CPU module and I/O modules..............................................................6-12

6.5.3 I/O modules troubleshooting.............................................................................................................6-22

6.6 Error Code................................................................................................................................................6-25

6.6.1 Procedure for reading error codes....................................................................................................6-25

A - 13

Page 15

APPENDICES App- 1 to App-23

APPENDIX 1 Cables..................................................................................................................................App- 1

APPENDIX 1.1 SSCNET cables............................................................................................................App- 1

APPENDIX 1.2 Serial absolute synchronous encoder cable................................................................App-11

APPENDIX 2 Exterior Dimensions Diagram.............................................................................................App-13

APPENDIX 2.1 CPU module .................................................................................................................App-13

APPENDIX 2.2 Servo external signals interface module (Q172LX) ....................................................App-16

APPENDIX 2.3 Serial absolute synchronous encoder interface module (Q172EX) ...........................App-16

APPENDIX 2.4 Manual pulse generator interface module (Q173PX) .................................................App-17

APPENDIX 2.5 Power supply module (Q61P-A1, Q61P-A2, Q63P, Q64P)........................................App-18

APPENDIX 2.6 Dividing unit (Q173DV), Battery unit (Q170BAT)........................................................App-19

APPENDIX 2.7 Connector .....................................................................................................................App-20

APPENDIX 2.8 Manual pulse generator (MR-HDP01).........................................................................App-22

APPENDIX 2.9 Serial absolute synchronous encoder (MR-HENC) ....................................................App-22

APPENDIX 2.10 Cooling fan unit (Q170FAN) (Q173CPU/Q172CPU only) ........................................App-23

A - 14

Page 16

About Manuals

This manual is only to explain hardware of the Motion controller.

The following manuals are related to this product.

Referring to this list, please request the necessary manuals.

This User's Manual do not describes hardware specification and handling methods of the PLC CPU

modules, power supply modules, base unit and I/O module in details.

The above contents, refer to the QCPU (Q Mode) User's Manual and Building Block I/O Module User's

Manual.

Related Manuals

Manual Name

Q173CPU/Q172CPU Motion controller (SV13/SV22) Programming M anual (Real)

This manual explains the servo parameter, positioning instructions, device list and error list.

(Optional)

Manual Number

(Model Code)

IB-0300043

(1CT782)

Q173CPU/Q172CPU Motion controller (SV22) Programming M anual (Virtual)

This manual describes the dedicated instructions use to the synchronous control by virtual main shaft,

mechanical system program create mechanical module.

This manual explains the servo parameter, positioning instructions, device list and error list.

(Optional)

Q173CPU/Q172CPU Motion controller (SV13/SV22) Programming M anual (Motion SFC)

Software of Motion CPU

This manual explains the Multiple CPU system configuration, performance specifications, functions,

programming, debugging and error codes.

(Optional)

QCPU (Q Mode) User's M anual (Function Explanation/Program Fundamentals)

This manual explains the functions, programming methods and devices and so on necessary to create

programs with the QCPU (Q mode). (Optional)

QCPU (Q Mode)/QnA Programming M anual (Common Instructions)

This manual describes how to use the sequence instructions, basic instructions, application instructions

and micro computer program. (Optional)

QCPU (Q Mode)/QnA Programming M anual (PID Control)

This manual describes the dedicated instructions used to exercise PID control. (Optional)

Software of PLC

QCPU (Q Mode)/QnA Programming M anual (SFC)

This manual explains the system configuration, performance specifications, functions, programming,

debugging, error codes and others of MELSAP3. (Optional)

IB-0300044

(1CT783)

IB-0300042

(1CT781)

SH-080038

(13JL98)

SH-080039

(13JF58)

SH-080040

(13JF59)

SH-080041

(13JF60)

QCPU (Q Mode) User's M anual (Hard ware Design/Maintenance and inspection)

This manual provides the specifications of the CPU modules, power supply modules, base modules,

extension cables, memory cards and others. (Optional)

Building Block I/O Module User's Manual

This manual provides the specifications of the I/O modules, connector, connector/terminal block

Hardware of PLC

conversion modules and others. (Optional)

A - 15

SH-080037

(13Jl97)

SH-080042

(13JL99)

Page 17

MEMO

A - 16

Page 18

1 OVERVIEW

1. OVERVIEW

1.1 Overview

This User's Manual describes the hardware specifications and handling methods of the

Motion Controller's Model Q173CPU(N)/Q172CPU(N) for the Q series PLC Multiple

CPU system.

The Manual also describes those items related to the specifications of the option

module for the Motion controller, Manual pulse generator, Synchronous encoder, and

cable.

Generic term/ Abbreviation Description

Q173CPU(N)/Q172CPU(N), Motion CPU or

Motion CPU module

MR-H-BN or Servo amplifier Servo amplifier model MR-H!BN

MR-J2!-B or Servo amplifier Servo amplifier model MR-J2S-!B/MR-J2M-B/MR-J2-!B/MR-J2-03B5

Q172LX/Q172EX/Q173PX or

Motion module

QCPU, PLC CPU or

PLC CPU module

Multiple CPU system or

Motion system

Programming S/W package SW6RN-GSV!P and GX Developer software package

Manual pulse generator or

MR-HDP01

Serial absolute synchronous encoder or

MR-HENC

SSCNET

Cooling fan unit Cooling fan unit (Q170FAN)

(Note)

In this manual, the following abbreviations are used.

Q173CPUN/Q172CPUN/Q173CPU/Q 172CPU Motion CPU module

Q172LX Servo external signals interface module/

Q172EX Serial absolute synchronous encoder interface module/

Q173PX Manual pulse generator interface module

Qn(H)CPU

General name for Multiple PLC system of the Q series

General name for Manual pulse generator (MR-HDP 01)

General name for Serial absolute synchronous encoder (MR-HENC)

High speed synchronous communication network between M otion

controller and servo amplifier.

1

Dividing unit Dividing unit (Q173DV)

Battery unit Battery unit (Q170BAT)

A!0BD-PCF A10BD-PCF/A30BD-PCF SSC I/F board

Intelligent function module

General name for MELSECNET/H module/Ethernet module/C C-Link

module/Serial communication module

(Note) SSCNET: Servo System Controller NETwork

REMARK

For information about the QCPU, peripheral devices for PLC program creation, I/O

modules and intelligent function module, refer to the manual relevant to each

module. Also, refer to the programming manual of the operating system for

information about creating motion programs, and refer to the help of each software

for information about operation of each programming software package.

1 - 1

Page 19

1 OVERVIEW

MEMO

1 - 2

Page 20

2 SYSTEM CONFIGURATION

2. SYSTEM CONFIGURATION

This section describes the system configuration of the Q173CPU(N)/Q172CPU(N),

2.1 Motion System Configuration

Q173CPU(N) System configuration

(Note)

cautions on use of the system, and configured equipment.

The outline of the equipment configuration, configuration with peripheral devices, and

system configuration in the Q173CPU(N)/Q172CPU(N) system is described below.

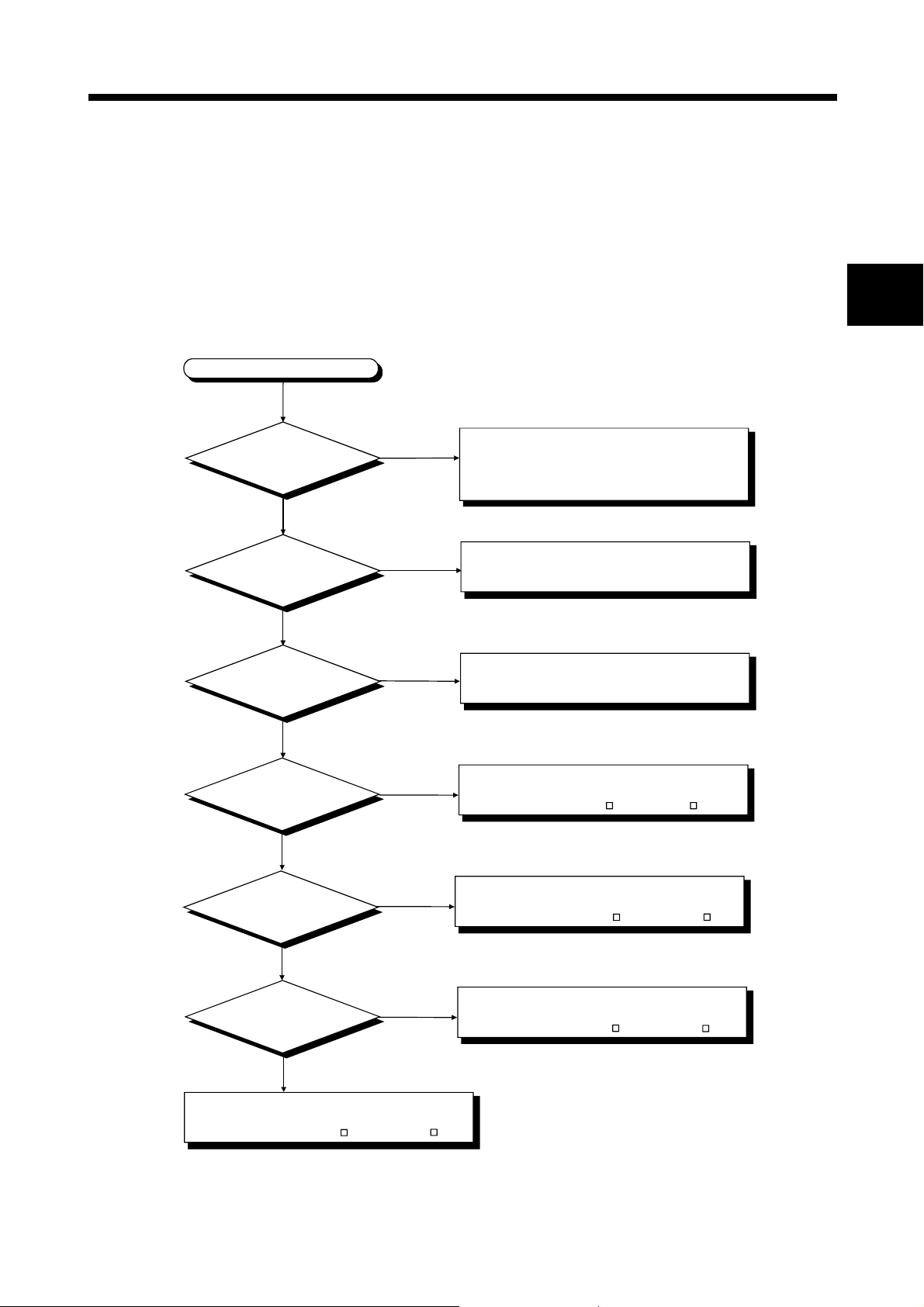

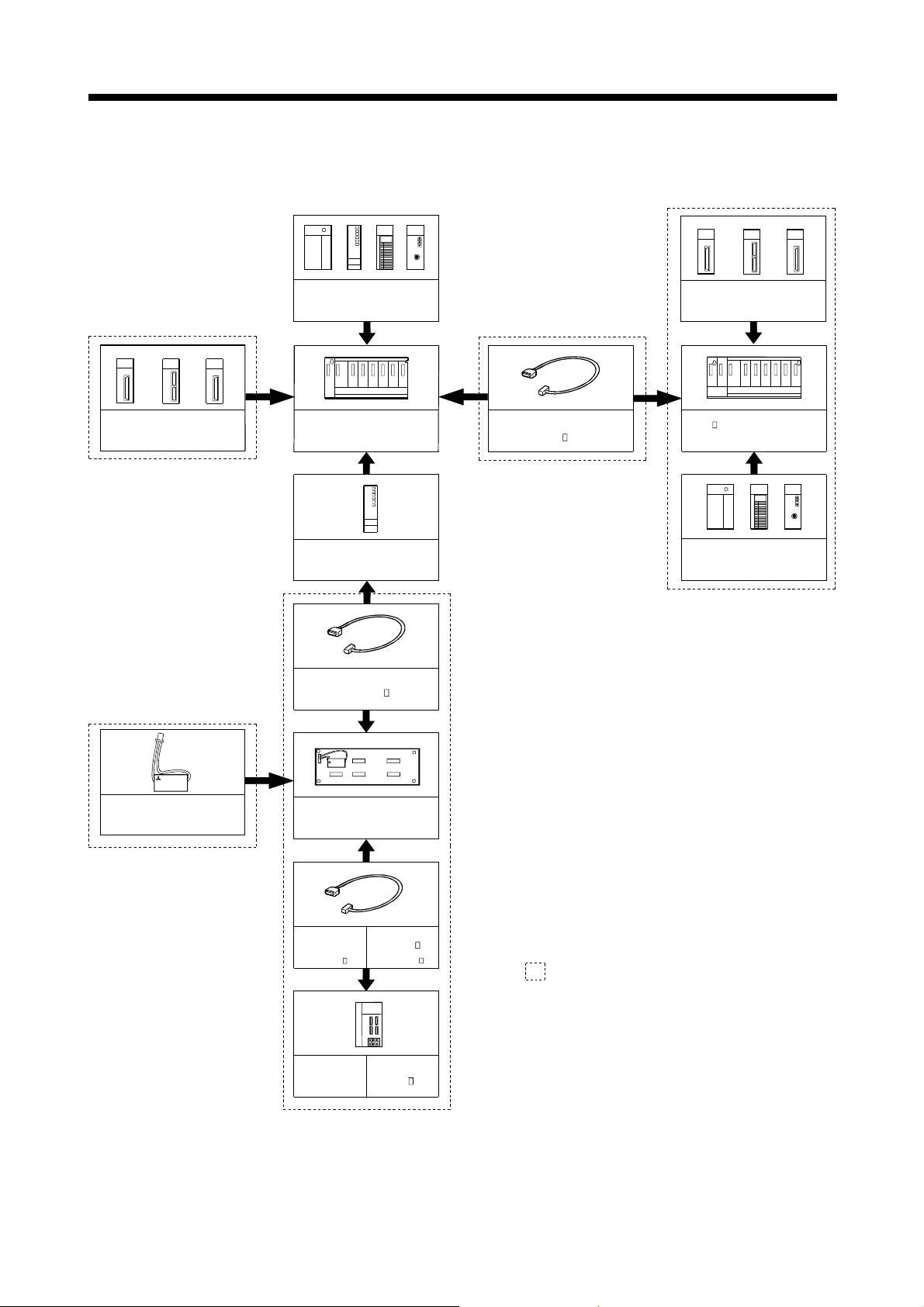

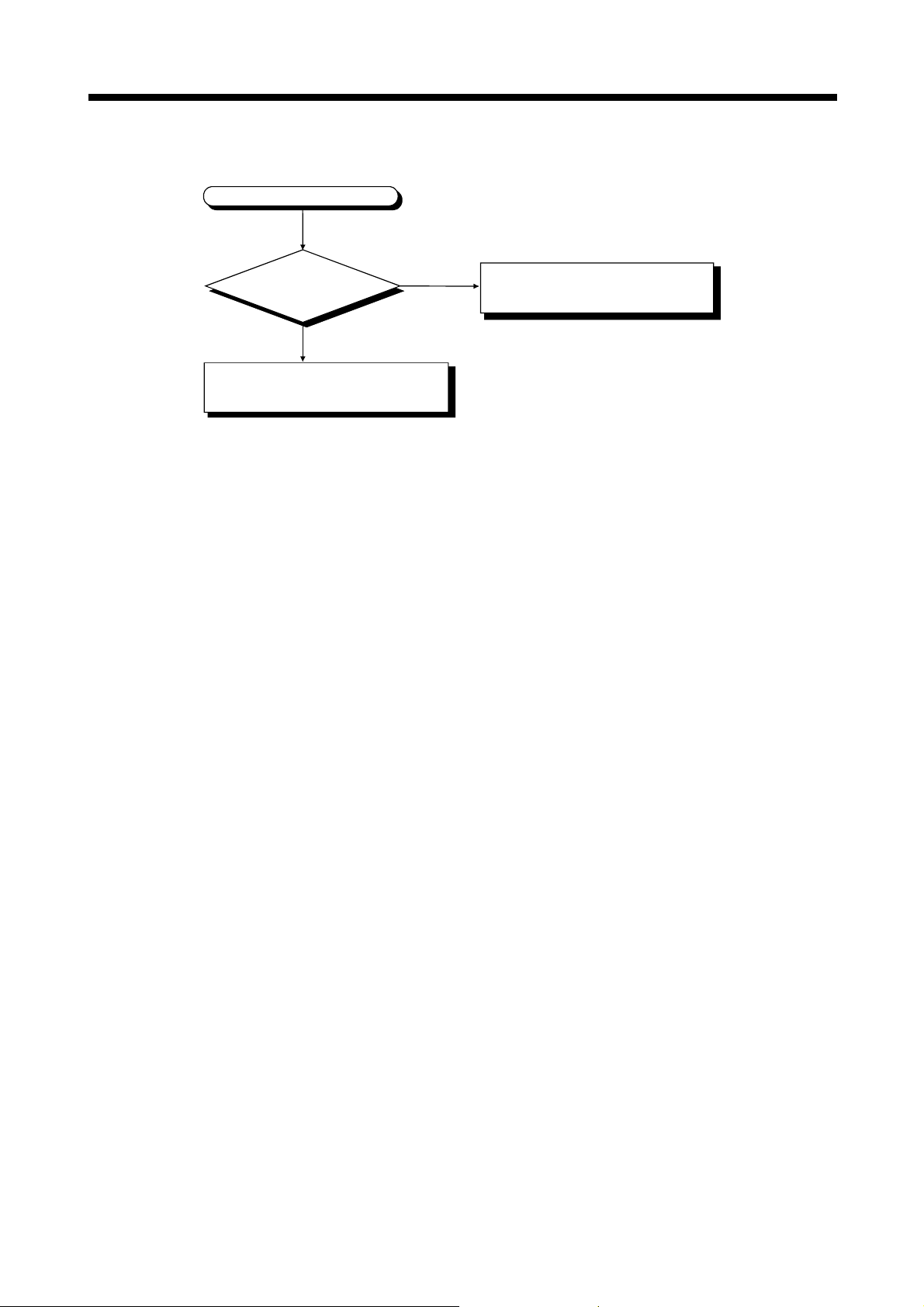

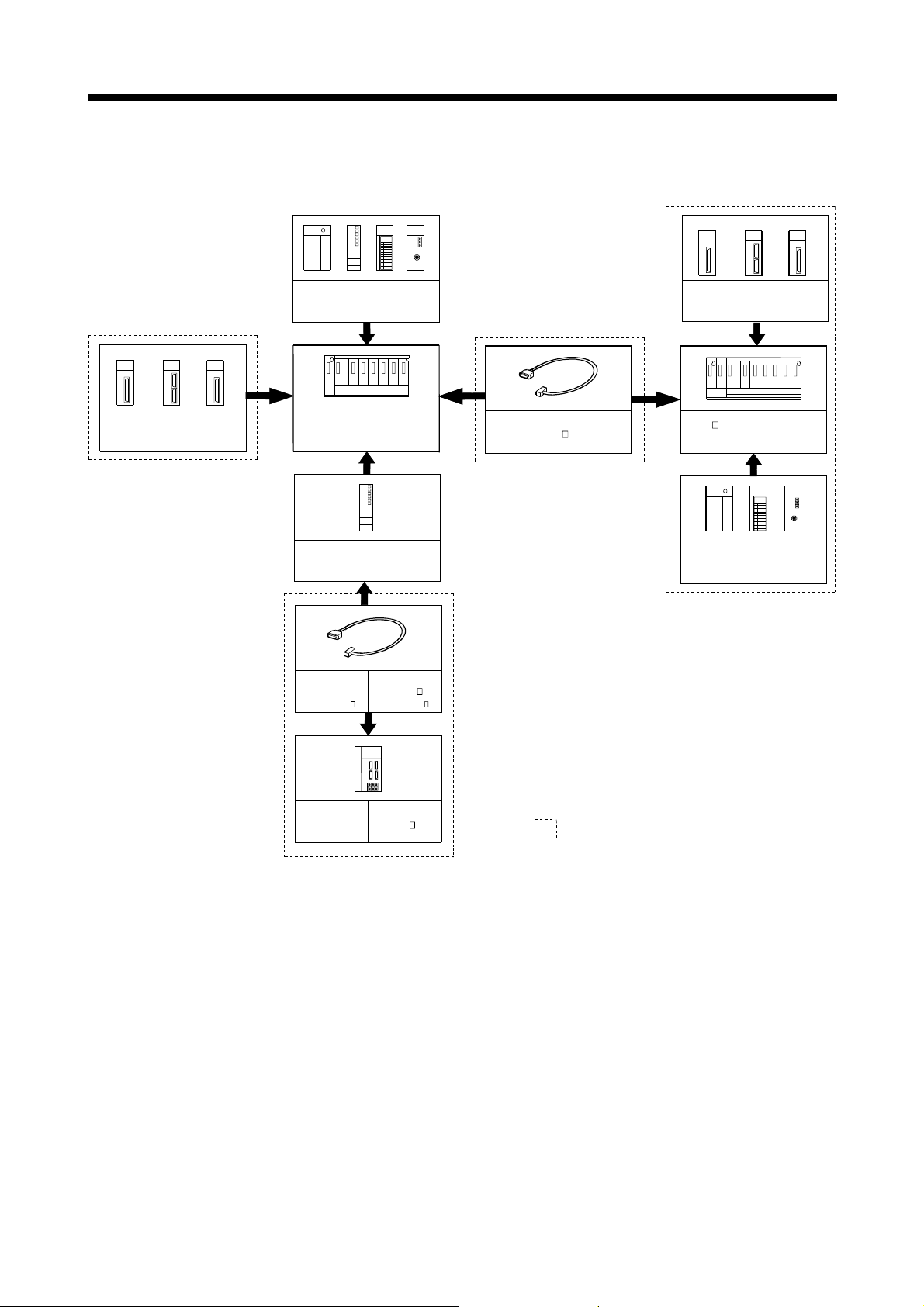

(1) Equipment configuration in Q173CPU ( N) system

Is this system

continuously power off for 1000

hours or more running?

NO

Should the

Dividing unit be used to divide

SSCNET Lines?

YES

YES

Refer to equipment configuration of "(a) When using

the Dividing unit/external battery".

Note : Set the battery (A6BAT/MR-BAT) to the Dividing

unit (Q173DV).

Refer to equipment configuration of "(a) When using

the Dividing unit/external battery".

2

NO

of the amplifier used at 1st axis

Is the type

of each SSCNET line

the same?

YES

Is it possible

to use only 1st

SSCNET Line?

NO

Is it possible

to use 1st and 2nd

SSCNET Line?

NO

Is it possible

to use 1st to 3rd

SSCNET Line?

NO

Refer to equipment configuration of "(b) When using

the Dividing cable".

Note : Use a Q173J2B4CBL M/Q173HB4CBL M.

NO

YES

YES

YES

Refer to equipment configuration of "(a) When using

the Dividing unit/external battery".

Refer to equipment configuration of "(b) when using

the Dividing cable".

Note : Use a Q173J2BCBL M/Q173HBCBL M.

Refer to equipment configuration of "(b) When using

the Dividing cable".

Note : Use a Q173J2B2CBL M/Q173HB2CBL M.

Refer to equipment configuration of "(b) When using

the Dividing cable".

Note : Use a Q173J2B3CBL M/Q173HB3CBL M.

(Note) : Continuous powe r failure time which can be backed up on the internal battery is

different depending on the charge time. It is possible to continuously power off for

1100 hours because of charge of 40 hours. Refer to the section 2.3(5) for details.

2 - 1

Page 21

2 SYSTEM CONFIGURATION

(a) When using the Dividing unit/external batter y

Extension of the Q series module

Motion module

(Q172LX, Q172EX, Q173PX)

(Note)

Power supply module/

Q CPU/ I/O module/ Intelligent

function module of the Q series

CPU base unit

(Q33B, Q35B, Q38B, Q312B)

Motion CPU module

(Q173CPU(N))

SSCNET cable

(Q173DVC BL M)

Extension cable

(QC B)

Motion module

(Q172LX, Q172EX, Q173PX)

Q6 B extension base unit

(Q63B, Q65B, Q68B, Q612B)

Power supply module/

I/O module/Intelligent function

module of the Q series

SSCNET CN1

MITSUBISHI

LITHIUM BATTERY

Battery

(A6BAT/MR-BAT)

MITSUBISHI

LITHIUM BATTE RY

Q173CPU

SSCNET cable

for MR-H-BN

(MR-J2HBUS M-A) (MR-J2HBUS M)

SSCNET CN2

Dividin g u n i t

(Q173DV)

SSCNET cable

for MR-J2 -B

SSCNET CN3

SSCNET CN4

It is possible to select the best according to the system.

MITSUBISHI

(Note) : When using the external battery, be

sure to set the Battery(A6BAT/MR-BAT)

to the Dividing unit(Q173DV).

Battery(A6BAT/MR-BAT) is optional.

Servo amplifier

(MR-H-BN)

Servo amplifier

(MR-J2 -B)

2 - 2

Page 22

2 SYSTEM CONFIGURATION

(b) When using the Dividing cable

Extension of the Q series module

Motion module

(Q172LX, Q172EX, Q173 PX)

Power supply module/

Q CPU/ I/O module/ Intelligent

function module of the Q series

CPU base unit

(Q33B, Q35B, Q38B, Q312B)

Motion CPU module

(Q173CPU(N))

SSCNET cable

for MR-H-BN

(Q173HB CBL M)

SSCNET cable

for MR-J2 -B

(Q173J2B CBL M)

(Note)

Extension cable

(QC B)

Motion module

(Q172LX, Q172EX, Q173PX)

Q6 B extension base unit

(Q63B, Q65B, Q68B, Q612B)

Power supply module/

I/O module/Intelligent function

module of the Q series

MITSUBISHI

It is possible to select the best according to the system.

Servo amplifier

(MR-H-BN)

Servo amplifier

(MR-J2 -B)

(Note) : When using the external battery,

be sure to use the Dividing unit(Q173DV).

2 - 3

Page 23

2 SYSTEM CONFIGURATION

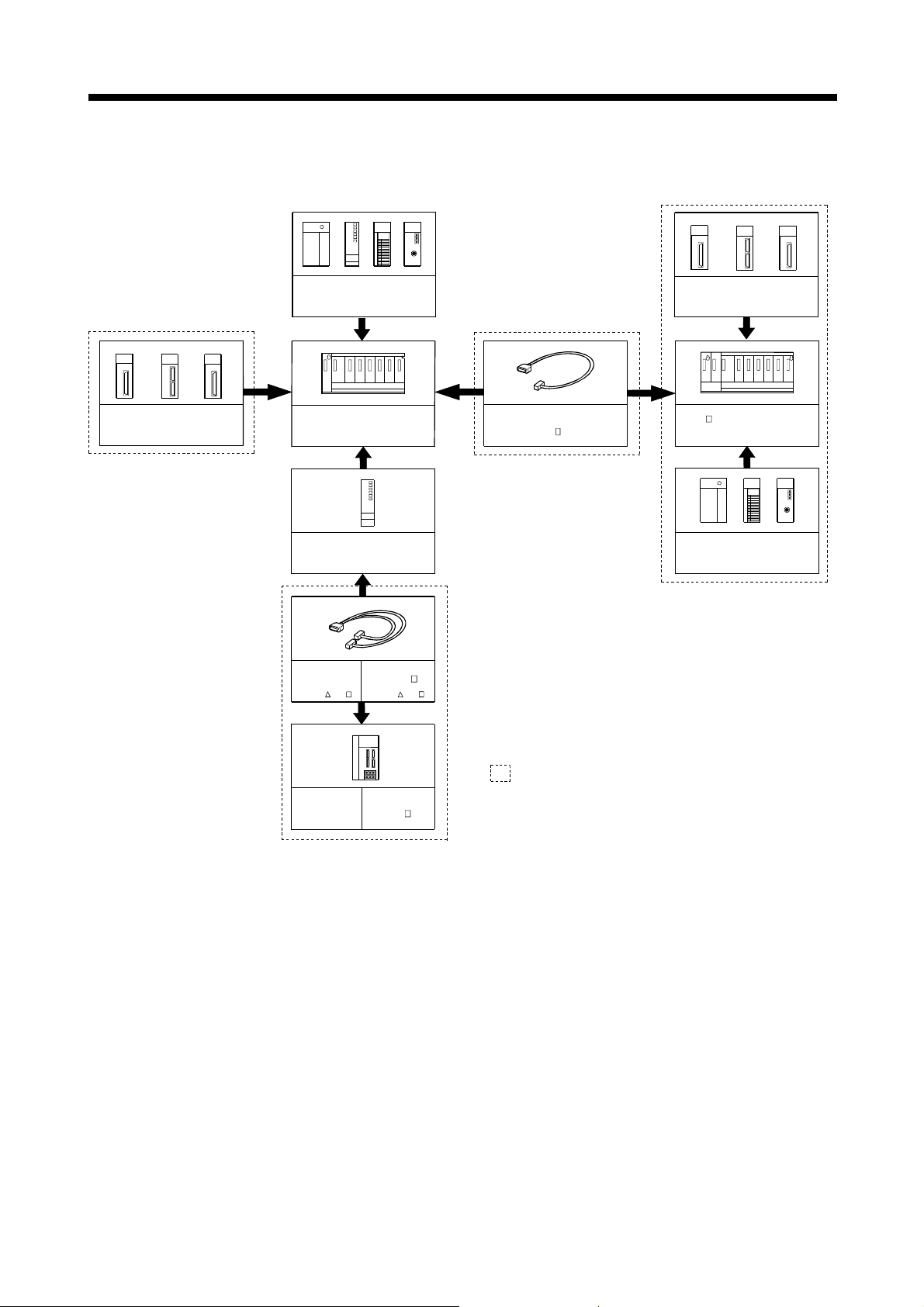

(2) Equipment configuration in Q172CPU ( N) system

Q172CPU(N) System configuration

(Note)

Refer to equipment configuration of

"(b) When not using the external battery".

Is this system

continuously power off for 1000

hours or more running?

NO

YES

Refer to equipment configuration of

"(a) When using the external battery".

(Note) : Continuous power off time which can be backed up on the internal

battery is different depending on the charge time. It is possible to

continuously power off for 1100 hours because of charge of 40 hours.

Refer to the section 2.3 (5) for details.

2 - 4

Page 24

2 SYSTEM CONFIGURATION

(a) When using the external battery

Extension of the Q series module

Motion module

(Q172LX, Q172EX, Q173PX)

(Note)

MITSUBISHI

BAT

LITHIUM BATTERY

CPU

PASSED

Battery unit

(Q170BAT)

Power supply module/

Q CPU/ I/O module/ Intelligent

function module of the Q series

CPU base unit

(Q33B, Q35B, Q38B, Q312B)

Motion CPU module

(Q172CPU(N))

Q17BAT

DATE

SSCNET cable

for MR-H-BN

(Q172HBC BL M-B)

SSCNET cable

for MR-J2 -B

(Q172J2BCBL M-B)

Extension cable

(QC B)

Motion module

(Q172LX, Q172EX, Q173PX)

Q6 B extension base unit

(Q63B, Q65B, Q68B, Q612B)

Power supply module/

I/O module/Intelligent function

module of the Q series

MITSUBISHI

LITHIUM BATT ERY

Battery

(A6BAT/MR-BAT)

Servo amplifier

(MR-H-BN)

MITSUBISHI

Servo amplifier

(MR-J2 -B)

It is possible to select the best according to the system.

(Note) : When using the external battery, be sure to use the

SSCNET cable(Q172J2BCBL M-B/Q172H BCBL M-B)

and to set the battery (A6BAT/MR-BAT). Also in stall

the battery(A6BAT/MR-BAT)in the Battery unit(Q170B AT).

Battery(A6BAT/MR-BAT) is optional.

2 - 5

Page 25

2 SYSTEM CONFIGURATION

(b) When not using the external battery

Extension of the Q series module

Motion module

(Q172LX, Q172EX, Q173PX)

Power supply module/

Q CPU/ I/O module/ Intelligent

function module of the Q series

CPU base unit

(Q33B, Q35B, Q38B, Q312B)

Motion CPU module

(Q172CPU(N))

SSCNET cable

for MR-H-BN

(Q172HBCBL M) (Q172J2BCBL M)

SSCNET cable

for MR-J2 -B

Extension cable

(QC B)

Motion module

(Q172LX, Q172EX, Q173PX)

Q6 B extension base unit

(Q63B, Q65B, Q68B, Q612B)

Power supply module/

I/O module/Intelligent function

module of the Q series

Servo ampli fi er

(MR-H-BN)

MITSUBIS HI

Servo ampli fi er

(MR-J2 -B)

It is possible to select the best according to the system.

2 - 6

Page 26

2 SYSTEM CONFIGURATION

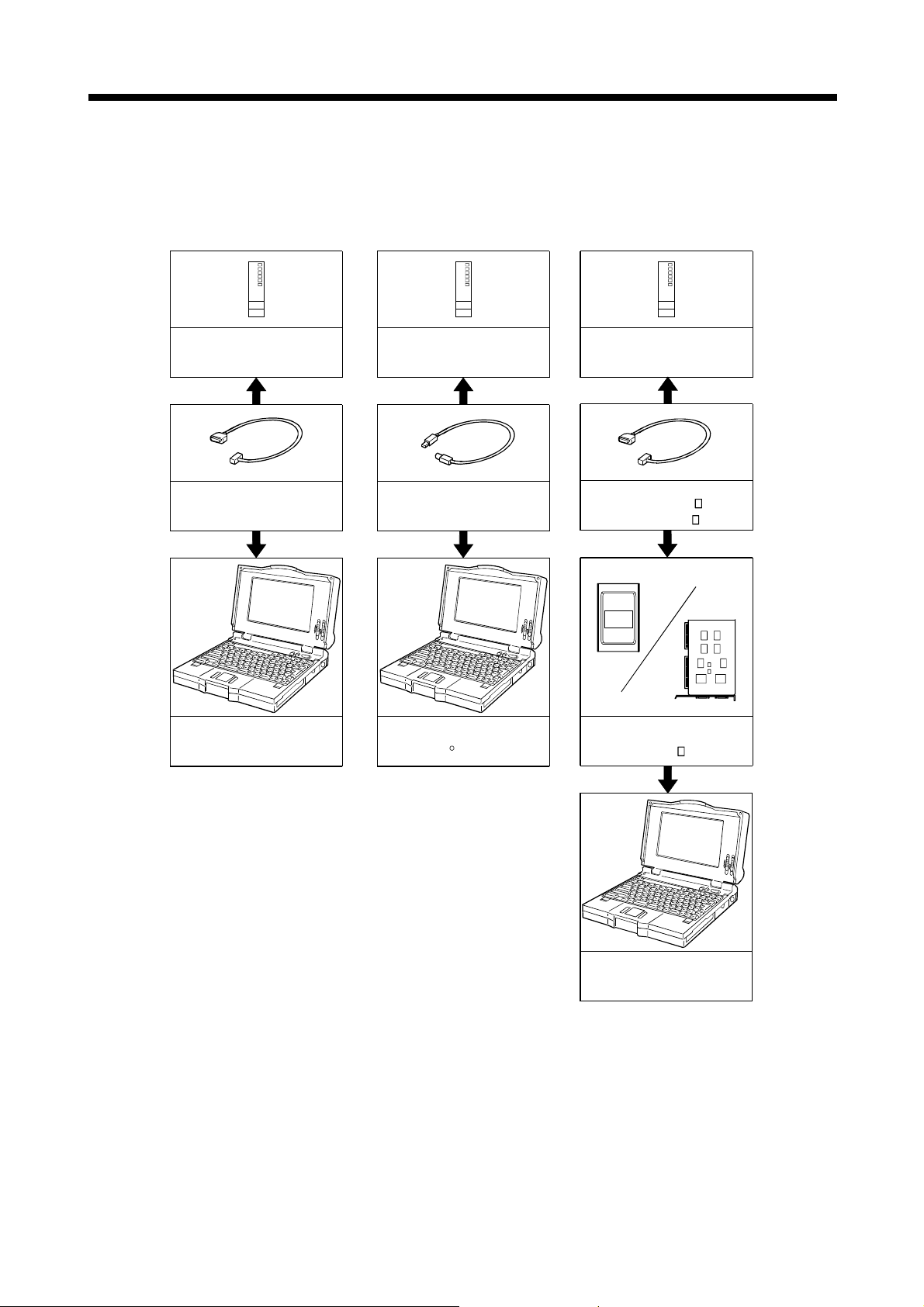

(3) Configuration of peripheral devices for the Q173CPU(N)/

Q172CPU(N)

(a) RS232 configration

The following (a) (b) (c) can be used.

(b) USB configration

(c) SSCNET configration

Motion CPU module

(Q173CPU(N), Q172CPU(N))

RS-232 cable

(QC30R2)

Personal computer

Motion CPU module

(Q173CPU(N), Q172CPU(N))

USB cable

Personal computer

(Windows 98/2000 only)

R

Motion CPU module

(Q173CPU(N), Q172CPU(N))

SSCNET cable

(Q170CDCBL M,

Q170BDCBL M)

MITSUBISHI

SSCNET

CARD

A30CD-PCF

SSC I/F Card/B o a r d

(A30CD-PCF/A 0BD-PCF)

Personal computer

(Note) : For information about GPP functions of QCPU, refer to the operating manual

of PLC. Also, refer to the programming manual of the operating system for

information about creating motion programs, and refer to the help of each

software for information about operation of each programming software

package.

2 - 7

Page 27

2 SYSTEM CONFIGURATION

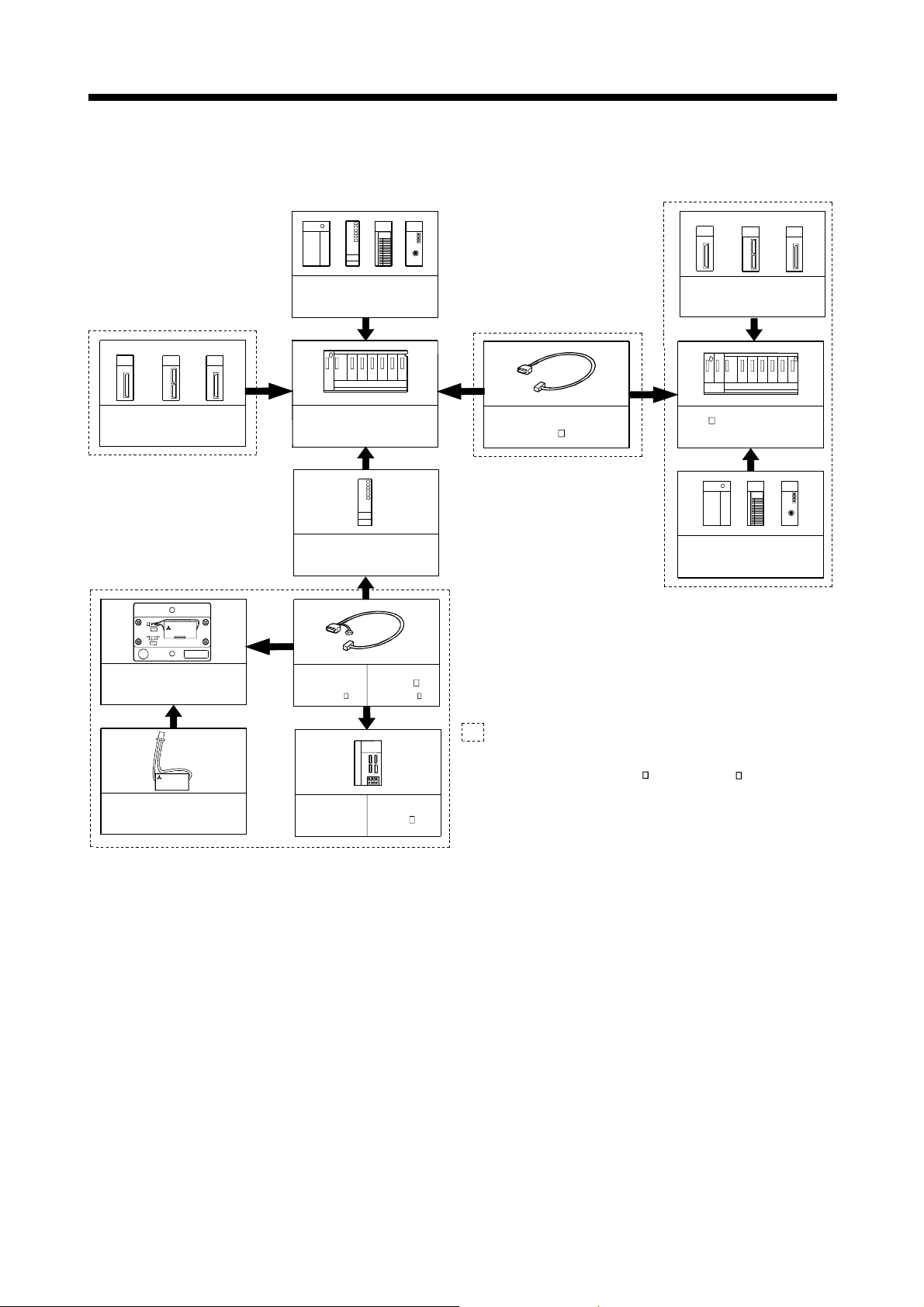

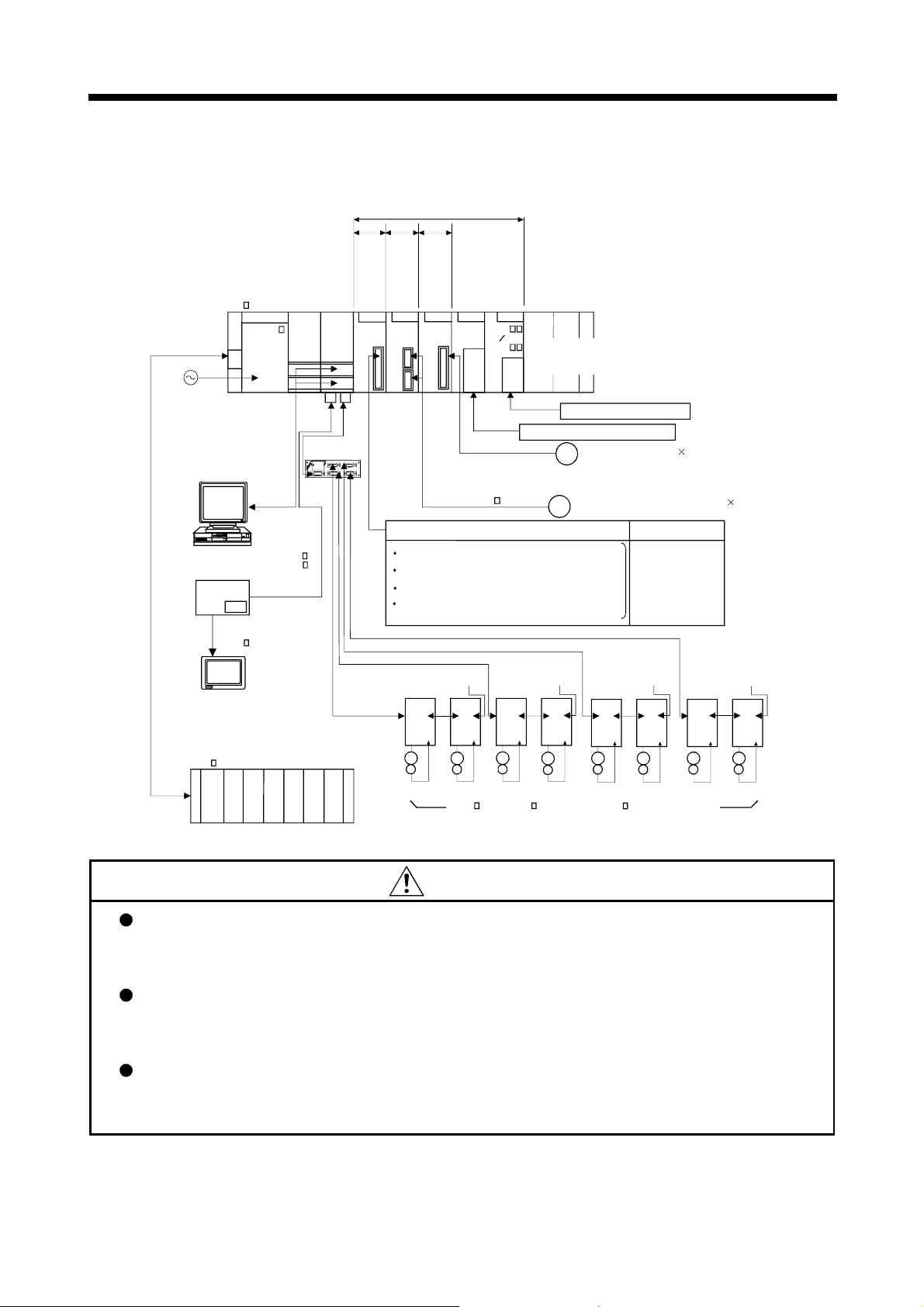

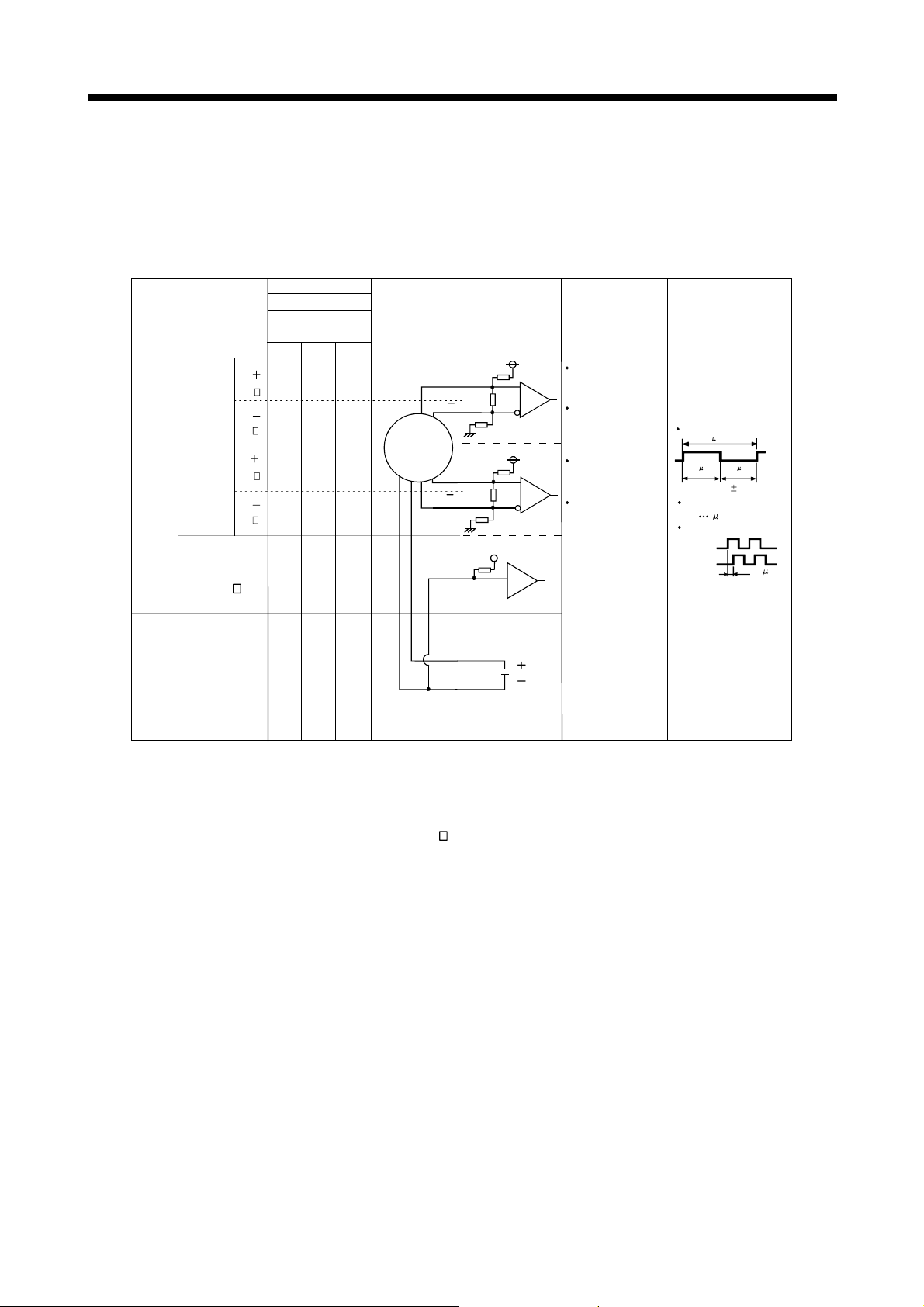

2.1.1 Q173CPU(N) System ov eral l config urati on

Motion CPU contol module

100/200VAC

Personal Computer

IBM PC/AT

Panel Personal Computer

(WinNT/Win98/Win2000)

Computer link SSC

CPU base

unit

(Q3 B)

Q61P-A

(Q170CDCBL M/

SSC I/F Card/Board

(A30CD-PCF/

A 0BD-PCF)

Qn(H)

CPU

USB/

RS232

Communication

cable

Q170BDCBL M)

SSCNET

PLC CPU/

Motion CPU

Q173

CPU

(N)

Dividing unit

(Q173DV)

MITSUBISHI

LITHIUM BATTERY

interface module

Servo external

signals

Q172

LX

SSCNET cable

SSCNET LINE1

generator

interface module

Manual pulse

Synchronous

interface module

encoder

Q172

EX

QI73

PX

QI60

QX

I/O module of the Q Series or

QY

Special function module

Input/output(Max. 256)

Interrupt signals (16 points)

Manual pulse generator 3/module

P

(MR-HDP01)

Serial absolute synchronous

encoder cable

(MR-JHSCBL M-H)

External input signals

FLS : Upper stroke limit

RLS : Lower stroke limit

STOP : Stop signal

DOG/CHANGE : Proximity dog/

Speed-position switching

SSCNET LINE2

Termination

connector

SSCNET LINE3

d8d1

Serial absolute synchronous encoder 2/module

E

(MR-HENC)

Termination

connector

d8d1

(Max. 1 module)

(Max. 6 modules)

Number of Inputs

8 axes/module

(Max. 4 module )

SSCNET LINE4

Termination

connector

d1

d8

d1

Termination

connector

d8

(Q6 B)

Extension

cable

Power supply

UP to 7 Extension base units

M

M

E

MR-H BN/MR-J2S- B/MR-J2M-B/MR-J2- B/MR-J2-03B5 model

module

Servo amplifier, Max.32 axes

M

M

E

E

E

M

M

E

E

M

E

CAUTION

Construct a safety circuit externally of the Motion controller or serv o amplifier if the abnormal

operation of the Motion controller or servo amplifier differ from the safety directive operation in

the system.

The ratings and characteristics of the parts (other than Motion controller, servo amplifier and

servomotor) used in a system must be compatible with the Motion controller, servo amplifier

and servomotor.

Set the parameter values to those that are compatible with the Motion cont roller, serv o amplifier,

servomotor and regenerative resistor model and the system application. The protect ive

functions may not function if the settings are incorrect.

M

E

2 - 8

Page 28

2 SYSTEM CONFIGURATION

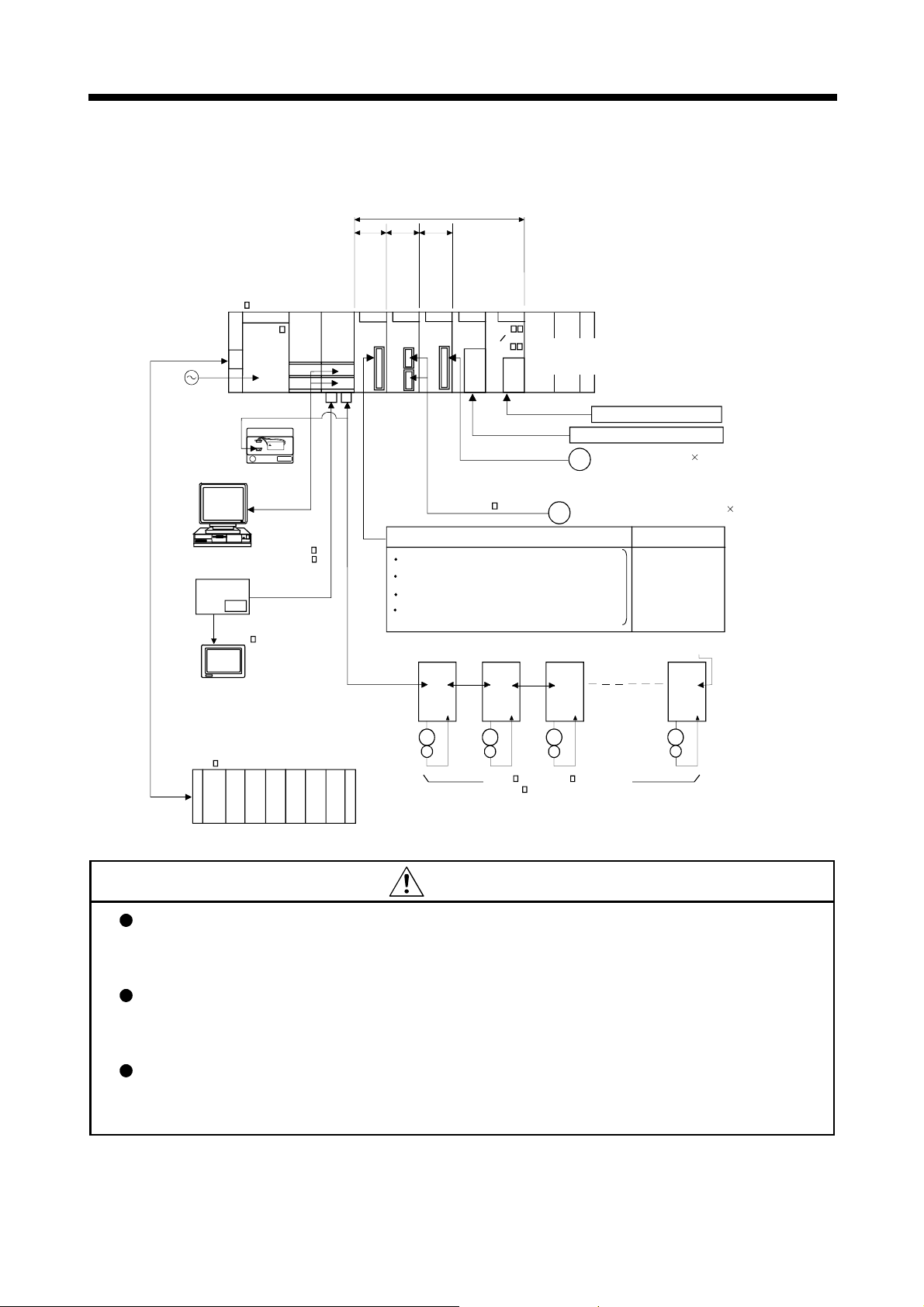

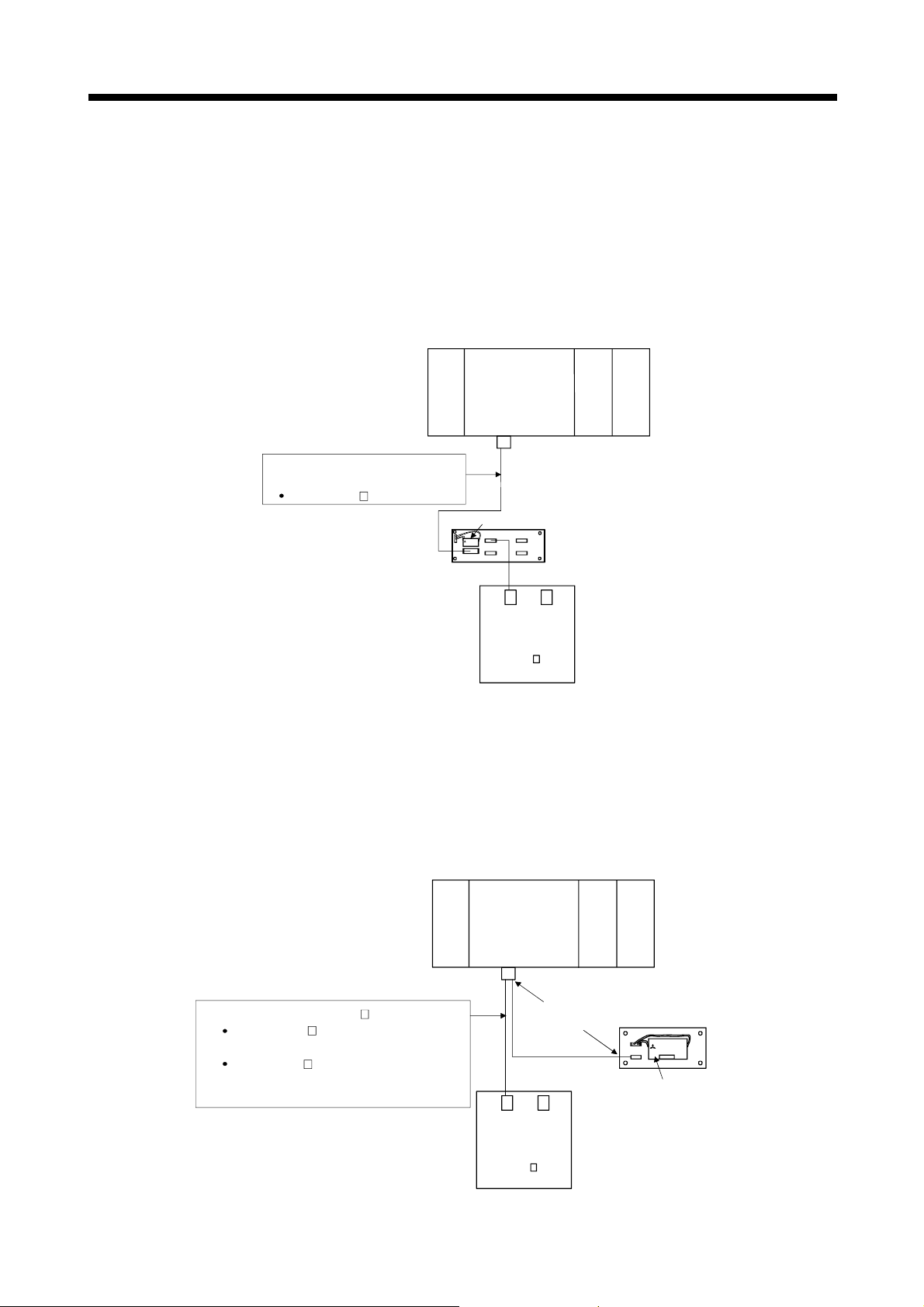

2.1.2 Q172CPU(N) System ov eral l config urati on

Motion CPU contol module

100/200VAC

Battery unit

(Q170BAT)

Personal Computer

IBM PC/AT

Panel Personal Computer

(WinNT/Win98/Win2000)

Computer link SSC

CPU base

unit

(Q3 B)

Qn(H)

Q61P-A

CPU

MITSUBISHI

LITHIUM BATTERY

USB/

RS232

Communication

cable

(Q170CDCBL M/

Q170BDCBL M)

SSCNET

SSC I/F card/board

(A30CD-PCF/

A 0BD-PCF)

PLC CPU/

Motion CPU

Q172

CPU

(N)

Manual pulse

generator

interface module

interface module

Synchronous

Servo external

encoder

signals

interface module

Q172

LX

Q172EXQI73

PX

Serial absolute synchronous

encoder cable

(MR-JHSCBL M-H)

QI60

QX

QY

External input signals

FLS : Upper stroke limit

RLS : Lower stroke limit

STOP : Stop signal

DOG/CHANGE : Proximity dog/

Speed-position switching

SSCNET cable

SSCNET LINE1

d1 d2 d3

I/O module of the Q Series or

Special function module

Input/output(Max. 256)

Interrupt signals (16 points)

Manua l pulse ge nerat o r 3/m o dule

P

(MR-HDP01)

Serial absolute synchronous encoder 2/module

E

(Max.1 module)

(Max. 4 modules) (MR-HENC)

Number of Inputs

8 axes/module

(Max. 1 module)

Termination

connector

d8

(Q6 B)

Extension

cable

Power supply

Up to 7 Extension base units

M

E

module

M

E

MR-H BN/MR-J2S- B/MR-J2M-B

/MR-J2- B/MR-J2-03B5 model

Servo amplifier, Max.8 axes

M

E

M

E

CAUTION

Construct a safety circuit externally of the Motion controller or serv o amplifier if the abnormal

operation of the Motion controller or servo amplifier differ from the safety directive operation in

the system.

The ratings and characteristics of the parts (other than Motion controller, servo amplifier and

servomotor) used in a system must be compatible with the Motion controller, servo amplifier

and servomotor.

Set the parameter values to those that are compatible with the Motion cont roller, serv o amplifier,

servomotor and regenerative resistor model and the system application. The protect ive

functions may not function if the settings are incorrect.

2 - 9

Page 29

2 SYSTEM CONFIGURATION

2.1.3 Function explanation of the Q173CPU(N)/Q172CPU ( N ) M oti on CPU modul es

(1) It is possible to download servo parameters to servo amplifier, turn the servo

ON/OFF, and send the position commands by connecting the Motion CPU

(Q173CPU(N)/Q172CPU(N)) and the servo amplifier with the SSCNET cable.

(2) It is possible to select the servo control functions/programming languages by

installing the corresponding operating system software on the Q173CPU(N)/

Q172CPU(N).

(3) It is possible to use stroke limit signals connected to Q172LX and signals of serial

encoders connected to Q172EX, etc. for the purpose of motion control by setting

the Q173CPU(N)/Q172CPU(N) as the control CPU of various motion modules

(Q172LX/Q172EX, etc.) .

(4) It is possible to perform not only servo control but also DI/O input/output control

according to programs implemented in the Motion SFC program by setting the

Q173CPU(N)/Q172CPU(N) as the control CPU of the Q series PLC I/O module

(When using the Motion SFC as the operating system software).

(For information about the Q series PLC I/O modules that can be controlled by the

Motion CPUs, refer to section 2.2 (2). )

(5) It is possible to exchange data such as automatic refresh among CPU as the Q

series PLC multiple CPU system.

(6) There is no restriction on the positions at which the modules controlled by the

Motion CPU (Q172LX/Q172EX, etc.) may be installed. Specify the installation

position in the system settings.

2 - 10

Page 30

2 SYSTEM CONFIGURATION

2.1.4 Restrictions on motion systems

(1) It is not allowed to use the Motion CPU as the control CPU of a module installed

on the QA1S6!B extension base unit. A PLC CPU must be used as the control

CPU.

(2) The connector for installation of memory card on the Motion CPU module is for

future function expansion.

(3) The Motion CPU module cannot be used as standalone module. It must always be

used in combination with a PLC CPU (of a version that supports Multiple CPU

systems). Moreover, it must be installed on the right side of the PLC CPU module.

A PLC CPU cannot be installed in a position to the right of a Motion CPU.

(4) Use the PLC CPU in the “Q mode.”

(5) The Motion CPU cannot be set as the control CPU of the intelligent function

module or the Graphic Operation Terminal (GOT).

(6) The SSCNET cable that connects the Motion CPU and the servo amplifiers can

be pulled out from the lower part. Make sure to secure sufficient space for pulling

out the cable when designing the board.

(7) The Motion CPU is one module element of the Q series multiple PLC system. It is

necessary to set the parameters of the Q series multiple PLC system for each

PLC CPU. The Motion CPU module must also be set to support the multiple

system by system setting s.

(8) Make sure to use the Motion CPU as the control CPU of motion modules

dedicated for the Motion CPU (Q172LX, Q172EX, Q173PX, etc.). They will not

operate correctly if a PLC CPU is set and installed as the control CPU by mistake.

The Motion CPU is treated as a 32-point intelligent module by PLC CPUs of other

machines.

It cannot be accessed from other machines.

(9) When a Multiple CPU system is configured, make sure to configure the modules

so that the total current consumption of the individual modules on the CPU base

does not exceed the 5VDC output capacity of the power supply module.

(Refer to section 2.4.2 (3), (4) Power supply module.)

2 - 11

Page 31

2 SYSTEM CONFIGURATION

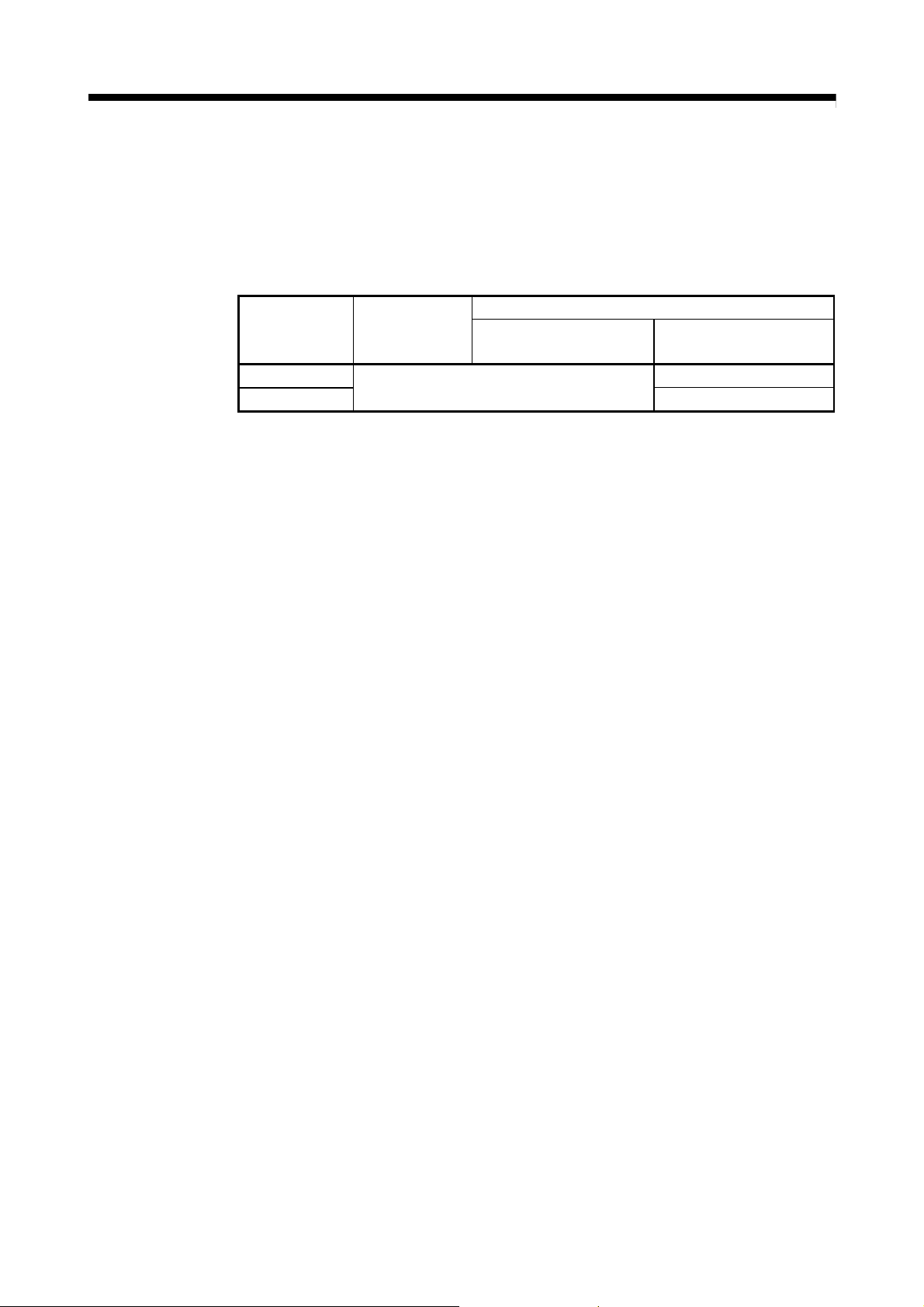

(10) Number of Motion CPU modules and temperature conditions

(Q173CPU/Q172CPU only)

(a) It is possible to remove the Cooling fan unit(Q170FAN) in order to disperse

heat from inside the Motion CPU module according to the number of the

Motion CPU module and ambient temperature conditions.

Removable/Not removable of the Cooling fan unit (Q170FAN) by number of

Motion CPU modules and ambient temperature is as follows.

1) When using only one Motion CPU module

2) When using two or more Motion CPU modules

Ambient temperature

of the Motion CPU

Number of the Motion CPU

1 module Removable Not removable

It is possible to remove the Cooling fan unit if the ambient temperature

in which the Motion CPU module will be operating is 0 to 40°C (32 to

104°F).

Do not remove the Cooling fan unit(Q170FAN).

0 to 40

(

32 to 104

°C

°F)

Over 40 to 55

(Over

104 to 131

°C

°F)

2 modules or more Not removable

(11) When the internal battery of the Motion CPU is charged for 40 hours of normal

operation, it will be able to provide backup power for the IC-RAM memory for

1100 hours (Guaranteed time)/4300 hours (Actual time) .

Battery backup by the external battery will be necessary if there is a possibility

that a continuous power off that lasts longer than the continuous power off hours

for the internal battery. (Refer to section 2.4.9 External battery)

Item

Charging time of

Internal rechargeable

battery only

External battery 60000 240000

8 hours or more

Charging time of

40 hours or more

Guaranteed time (MIN) [ h ] Actual time (TYP) [ h ]

Continuous power off time

200 500

1100 4300

2 - 12

Page 32

2 SYSTEM CONFIGURATION

2.2 System Configuration Equipment

Part name Model name Description

Motion CPU module

Servo external signals

interface module

Serial absolute

synchronous encoder

interface module

Manual pulse generator

interface module

PLC CPU module

Power supply module

CPU base unit

Extension base unit

Extension cable

Manual pulse generator MR-HDP01

Serial absolute

synchronous

encoder

(1) Table of motion module

Q172CPUN Max.8 axes control 1.14

Q172CPU Max.8 axes control, with Cooling fan unit 1.62

Q173CPUN Max.32 axes control 1.25

Q173CPU Max.32 axes control, with Cooling fan unit 1.75

Q172LX Servo external signal 8 axes (FLS, RLS, STOP, DOG/CHANGE×8) 0.05

Q172EX

Q173PX

Q02CPU Program capacity 28k 0.60

Q02HCPU Program capacity 28k 0.64

Q06HCPU Program capacity 60k 0.64

Q12HCPU Program capacity 124k 0.64

Q25HCPU Program capacity 252k 0.64

Q61P-A1 100 to 120VAC input/ 5VDC 6A output ——

Q61P-A2 200 to 240VAC input/ 5VDC 6A output ——

Q63P 24VDC Input/ 5VDC 6A output ——

Q64P 100 to 120VAC/200 to 240VAC Input/ 5VDC 8.5A output ——

Q33B Number of I/O modules installed 3 slots

Q35B Number of I/O modules installed 5 slots

Q38B Number of I/O modules installed 8 slots

Q312B Number of I/O modules installed 12 slots 0.121

Q63B Number of I/O modules installed 3 slots 0.105

Q65B Number of I/O modules installed 5 slots 0.110

Q68B Number of I/O modules installed 8 slots 0.114

Q612B Number of I/O modules installed 12 slots 0.121

QC05B Length 0.45m(1.48ft.)

QC06B Length 0.6m(1.97ft.)

QC12B Length 1.2m(3.9ft.)

QC30B Length 3m(9.8ft.)

QC50B Length 5m(16.4ft.)

QC100B Length 10m(32.8ft.)

MR-HENC

Serial absolute synchronous MR-HENC interface×2

Tracking input 2 points

Manual pulse generator MR-HDP01/

Synchronous encoder interface ×3, Tracking input 3 points

Pulse resolution: 25PLS/rev(100PLS/rev after magnification by 4)

Permitted axial loads Radial load: Max.19.6N

Thrust load: Max. 9.8N

Permitted speed: 200r/min(Normal rotation)

Resolution: 16384PLS/rev

Permitted axial loads Radial load: Max.98N

Thrust load: Max.49N

Permitted speed: 4300r/min

Current

consumption

5VDC[A]

0.07

0.11

0.105

0.110

0.114

——

0.06

0.15

Remark

2 - 13

Page 33

2 SYSTEM CONFIGURATION

Table of motion module(continued)

Part name Model name Description

Connection between Serial absolute synchronous encoder and

Serial absolute

synchronous

encoder cable

SSCNET cable

SSC I/F board

MR-JHSCBL!M-H

Q170BDCBL!M

Q170CDCBL!M

Q172J2BCBL!M

Q172J2BCBL!M-B

Q172HBCBL!M

Q172HBCBL!M-B

Q173J2B CBL!M

Q173HB CBL!M

Q173DVCBL!M

A10BD-PCF PCI bus loading type, 2 ch/board

A30BD-PCF ISA bus loading type, 2 ch/board

Q172EX

2m(6.56ft.), 5m(16.4 ft.) , 1 0 m(3 2 .8 ft.) , 2 0 m(6 5 .6 ft.) , 3 0 m(9 8 .4 ft.)

(Same as encoder cables for HC-SFS/RFS/UFS(2000r/min) series

motors)

Connection between Q173CPU(N)/Q172CPU(N) and SSC I/F board

3m(9.84ft.), 5m(16.4 ft.) , 1 0 m(3 2 .8 ft.)

Connection between Q173CPU(N)/Q172CPU(N) and SSC I/F card

3m(9.84ft.), 5m(16.4 ft.) , 1 0 m(3 2 .8 ft.)

Connection between Q172CPU(N) and Battery unit (Q170BAT),

Q172CPU(N) and servo amplifier (MR-J2S-!B/MR-J2M-B/

MR-J2-!B/MR-J2-03B5)

0.5m(1.64ft.), 1m(3.2 8 ft.) , 5 m(1 6 .4 ft.)

Connection between Q172CPU(N) and Battery unit (Q170BAT),

Q172CPU(N) and servo amplifier (MR-H!BN)

0.5m(1.64ft.), 1m(3.2 8 ft.) , 5 m(1 6 .4 ft.)

Connection between Q173CPU(N) and servo amplifier

(MR-J2S-!B/MR-J2M-B/MR-J2-!B/MR-J2-03B5)

0.5m(1.64ft.), 1m(3.2 8 ft.) , 5 m(1 6 .4 ft.)

Connection between Q173CPU(N) and servo amplifier

(MR-H!BN)

0.5m(1.64ft.), 1m(3.2 8 ft.) , 5 m(1 6 .4 ft.)

Connection between Q173CPU(N) and Q173DV

0.5m(1.64ft.), 1m(3.2 8 ft.)

Current

consumption

5VDC[A]

——

——

——

——

——

Remark

Battery

unit

needs to

use “-B”

type

cable.

SSC I/F card A3 0 C D - PC F PCMCIA TYPE II, 1 ch/card

Dividing unit Q173DV

Battery unit Q170BAT For IC-RAM memory backup of Q172CPU(N) ——

Battery A6BAT

Cooling fan unit Q170FAN Cooling fan of the Motion CPU module 0.08

Q172CPU(N)

connector set

Q173CPU(N)

connector set

Q172CON

Q173CON

For dividing the SSCNET lines of Q173CPU(N) into 4.

(Attachment: Battery h o l d e r fo r IC-RAM memory backu p )

For IC-RAM memory backup of Q173CPU(N)/Q172CPU(N) module

(SFC programs, Servo programs, Parameters)

Connector for Q172CPU(N)

Connector : HDR-E14MG1

Case : HDR-E14LPA5

Q173CPU(N) side connector set

Connector : HDR-E26MG1

Case : HDR-E26LPA5

(Note-1)

(Note-1)

——

——

——

——

2 - 14

Page 34

2 SYSTEM CONFIGURATION

Table of motion module(continued)

Current

Part name Model name Description

Q173CPU(N) side connector set

Connector : HDR-E26MG1

Q173DV connector set Q173DVCON

=Number of lines (none: 1 Line, 2: 2 Lines, 3: 3 Lines, 4: 4 Lines)

=Cable length (0.5: 0.5m(1.64ft.), 1: 1m(3.28ft.), 2: 2m(6.56ft.), 3: 3m(9.84ft.), 4: 4m(13.12ft.), 5: 5m(16.4ft.) )

!

(Note-1) : Crimping terminal is not sold in Mitsubishi. The following terminal is requested to be procured by customers.

Specified tool (Honda Connectors make) : FHAT-0029/FHPT-0004C

Case : HDR-E26LPA5

Q173DV side connector set

Connector : 10126-3000VE

Case : 10326-52F0-008

(Note-1)

consumption

5VDC[A]

——

(2) Q series PLC module whic h can be control by Motion CPU

Part name

AC QX10 100-120VAC, 7-8mA, 16 points, Terminal block

Input

module

Output

module

Input/Output

composite

module

Interrupt module QI60 DC24V/4mA, Positive common, 16 points, Terminal block

DC

Contact output

module

Sink Type

Transistor

Source Type

TTL•CMOS(Sink)

DC Input/

Transistor output

Model

name

QX40 24VDC/4mA, Positive common, 16 points, Terminal block

QX41 24VDC/4mA, Positive common, 32 points, Connector

QX42 24VDC/4mA, Positive common, 64 points, Connector

QX70

QX71

QX72

QX80 24VDC/4mA, Negative common, 16 points, Terminal block

QX81 24VDC/4mA, Negative common, 32 points, Connector

QY10 240VAC/24VDC, 2A/point, 8A/common, 16 points/common, Terminal block

QY40P 12V/24VDC, 0.1A/point, 1.6A/common, 16 points/common Terminal block

QY41P 12V/24VDC, 0.1A/point, 2A/common, 32 points/common Connector

QY42P

QY50

QY80

QY81P

QY70 5/12VDC, 16mA/point, 16 points(16 points/common), Terminal block

QY71 5/12VDC, 16mA/point, 32 points(32 points/common), Connector

QH42P

QX48Y57

12VDC/5V, Positive common/Negative common shared, 16 points,

Terminal block

12VDC/5V, Positive common/Negative common shared, 32 points,

Terminal block

12VDC/5V, Positive common/Negative common shared, 64 points,

Terminal block

12V/24VDC, 0.1A/point, 2A/common, 64 points(32 points/common),

Connector

12V/24VDC, 0.5A/point, 4A/common, 16 points(16 points/common),

Terminal block

12V/24VDC, 0.5A/point, 4A/common, 64 points(32 points/common),

Terminal block

12V/24VDC, 0.1A/point, 2A/common, 32 points(32 points/common),

Connector

24VDC Positive common: 32 points

DC12-24V/0.1A Output Sink type: 32 points, Connector,

Provided (Thermal protectors, protector against short circuit)

24VDC Positive common: 8 points

DC12-24V/0.5A Output Sink type: 7 points, Terminal block,

Provided (When face is broken, LED lights and signal is output to CPU)

Description

Marked " " connectors are not provided.

Remark

Remark

2 - 15

Page 35

2 SYSTEM CONFIGURATION

(3) Table of servo amplifier

Part name Model name Description

MR-H!BN MR-H series

servo amplifier

Battery MR-BAT Back-up for the absolute position detection.

Termination connector MR-TM Connected to the last servo amplifier (MR-H!BN) by SSCNET.

Regenerative resistor

SSCNET cable MR-HBUS!M

Encoder cable

Encoder connector set

MR-H!!KBN

MR-RB!

MR-H!

MR-RB!-4

MR-HSCBL!M

MR-EN1CBL!M-H

MR-JCCBL!M-L

MR-JCCBL!M-H

MR-JSCNS

MR-EN1CNS

The following servo amplifier series can be used.

(a) MR-H!BN

Refer to catalogue of the servo amplifier about the output capacity of the servomotor.

Refer to catalogue of the servo amplifier about the regenerative resistance.

Connection between MR-H!BN and MR-H!BN

0.5m(1.64ft.), 1m(3.2 8 ft.) , 5 m(1 6 .4 ft.)

Connection between HA-LH!K, HC-SF/RF/UF(2000r/min) series motor and MR-H!BN.

2m(6.56ft.), 5m(16.4 ft.) , 1 0 m(3 2 .8 ft.) , 2 0 m(6 5 .6 ft.) , 3 0 m(9 8 .4 ft.)

Connection between HA-FF, HC-MF/UF(3000r/min) and MR-H!BN

Servo amplifier side connector for HA-LH!K, HC-SF/RF/UF(2000r/min) series motor,

Encoder side connector set

2 - 16

Page 36

2 SYSTEM CONFIGURATION

Part name Model name Description

MR-J2S-!B MR-J2-Super series

servo amplifier

MR-J2M series

servo amplifier

MR-J2 series

servo amplifier

MR-J2-Jr se r i e s

servo amplifier

Battery MR-BAT Back-up for the absolute position detection.

Termination connector MR-A-TM

SSCNET cable

Encoder cable

Encoder connector set

MR-J2S-!B1

MR-J2M-!DU Drive unit

MR-J2M-P8B Interface unit

MR-J2M-BU! Base unit

MR-J2-!B

MR-J2-03B5

MR-J2HBUS!M-A

MR-J2HBUS!M

MR-JHSCBL!M-L Standard cable

MR-JHSCBL!M-H

MR-ENCBL!M-H

MR-JCCBL!M-L Standard cable

MR-JCCBL!M-H

MR-JCCBL!M-H

MR-JRBRCBL!M-H

MR-J2CNS

MR-ENCNS

MR-JRCNM Servo amplifier and Junction connector set for HC-AQ series motor.

MR-JRBRCNM

MR-JRBRCN Electromagnetic brake contact connector for HC-AQ series motor.

MR-J2CNM

(b) MR-J2S-!B/MR-J2M-B/MR-J2-!B/MR-J2-03B5

Refer to catalogue of the servo amplifier about the output capacity of the servomotor.

Refer to catalogue of the servo amplifier about the output capacity of

the servomotor.

Refer to catalogue of the servo amplifier about the output capacity of the servomotor.

Connected to the last servo amplifier(MR-J2S-!B/MR-J2M-B/MR-J2-!B/MR-J2-03B5)

by SSCNET

Connection between Q173DV and MR-H!BN.

Connection between MR-H!BN and (MR-J2S-!B/MR-J2M-B/MR-J2-!B/

MR-J2-03B5).

0.5m(1.64ft.), 1m(3.2 8 ft.) , 5 m(1 6 .4 ft.)

Connection between Q173DV and (MR-J2S-!B/MR-J2M-B/MR-J2-!B/MR-J2-03B5).

Connection between (MR-J2S-!B/MR-J2M-B/MR-J2-!B/MR-J2-03B5) and

(MR-J2S-!B/MR-J2M-B/MR-J2-!B/MR-J2-03B5).

0.5m(1.64ft.), 1m(3.2 8 ft.) , 5 m(1 6 .4 ft.)

Connection between HC-SFS/RFS/UFS(2000r/min) series motor and

MR-J2S-!B/MR-J2M-B.

Long fixing life

encoder cable

Long fixing life

encoder cable

Servo amplifier and junction side connector set for HC-SFS/RFS/UFS(2000r/min)

series motor, HC-SF/RF/UF(2000r/min) series motor.

Servo amplifier side(Motor cable for servomotor with electro magnetic brake) and HCAQ series motor. (Need MR-JRBRCN for electromagnetic brake contact)

Servo amplifier and junction side connector set for HC-MFS/KFS/UFS(3000r/min)

series and HA-FF, HC-MF/UF(3000r/min) series motor.

Connection between HC-SF/RF/UF(2000r/min) series motor and

MR-J2-!B.

2m(6.56ft.), 5m(16.4 ft.) , 1 0 m(3 2 .8 ft.) , 2 0 m(6 5 .6 ft.) , 3 0 m(9 8 .4 ft.)

Connection between HC-MFS/KFS/UFS(3000r/min) series motor and

MR-J2S-!B/MR-J2M-B.

Connection between HC-MF/UF(3000r/min) and HA-FF series motor

and MR-J2-!B.

2m(6.56ft.), 5m(16.4 ft.) , 1 0 m(3 2 .8 ft.) , 2 0 m(6 5 .6 ft.) , 3 0 m(9 8 .4 ft.)

Connection between HC-AQ series motor and MR-J2-03B5.

2m(6.56ft.), 5m(16.4 ft.) , 1 0 m(3 2 .8 ft.) , 2 0 m(6 5 .6 ft.) , 3 0 m(9 8 .4 ft.)

Connection between HC-AQ series motor and MR-J2-03B5.

2m(6.56ft.), 5m(16.4 ft.) , 1 0 m(3 2 .8 ft.) , 2 0 m(6 5 .6 ft.) , 3 0 m(9 8 .4 ft.)

(Motor cable for servomotor with electro magnetic brake)

2 - 17

Page 37

2 SYSTEM CONFIGURATION

(4) Software packages

Application

For conveyor assembly

(Motion SFC)

For automatic machinery

(Motion SFC)

SV13

SV22

Model name Details Remark

SW6RNC-GSVE

(Integrated start-up support software

SW6RN-GSVPROE

SW6RNC-GSVSETE

(1 CD-ROM) )

Model name PLC software package Remark

(a) OS software packages

OS software package

Q173CPU(N) Q172CPU(N)

SW6RN-SV13QB SW6RN-SV13QD

SW6RN-SV22QA SW6RN-SV22QC

(b) Integrated start-up support software packag es

Conveyor assembly software : SW6RN-GSV13P

Automatic machinery software : SW6RN-GSV22P

Cam data creation software : SW3RN-CAMP

Digital oscilloscope software : SW6RN-DOSCP

Communication system software : SW6RN-SNETP

Document print software : SW3RN-DOCPR N P,

SW20R N-DOCPRNP

SW6RNC-GSVHELPE(Operation manual(1 CD-ROM) )

Installation manual

SW6RNC-GSVPROE

A30CD-PCF(SSC I/F ca r d ( PC MCIA TYPE II 1CH/card) )

Q170CDCBL3M(A30CD-PCF cable 3m(9.84ft.) )

(Note) : Operating environment of the programming software is WindowsNTR4.0/

Windows

R

98/WindowsR2000 English version) only.

(c) PLC software packages

Remark

GX Developer SW!D5C-GPPW-E

(Note) : !=used "6" or later.

2 - 18

Page 38

2 SYSTEM CONFIGURATION

(5) Operating envir onment of the personal computer

Operating environment is as follows.

Item

CPU Pentium133MHz or more Pentium II 233MHz or more

Memory capacity Recommended 32MB or more Recommended 64MB or more

Hard disk free space Hard disk free space is as following list.

Disk drive 3.5inch (1.44MB) floppy disk drive, CD-RO M disk drive

Display 800×600 pixels, 256 colors or more

Model name Size

SW6RN-GSV13P 15MB

SW6RN-GSV22P 15MB

SW3RN-CAMP 1MB

SW6RN-DOSCP 3MB

SW6RN-SNETP

SW3RN-DOCPRNP, SW20RN-DOCPRNP 7MB

Model name Size

SW6RN-GSV13P 23MB

SW6RN-GSV22P 30MB

SW3RN-CAMP 2MB

SW6RN-DOSCP 2MB

SW6RN-SNETP 1MB

SW3RN-DOCPRNP, SW20RN-DOCPRNP 2MB

(Note-1) : Pentium Rare trademarks or registered trademarks of Intel Corporation or its subsidiaries in the United States and other

countries.

(Note-2) : WindowsNT

other countries.

R

, WindowsRare either registered trademarks or trademarks of Microsoft Corporation in the United States and/or

IBM PC/AT with w hich WindowsNT4.0/98/2000 English version operates normally.

WindowsNT

R

4.0(Service Pack 2 or later)

Windows

R

98

(Note)

or

(Note) : Impossible to use USB connection.

Windows

R

It is necessary the following capacity depending on the installed software.

SW6RNC-GSVE

Standard 1.5MB

Custom (When all selection) 2MB

SW6RNC-GSVHELPE

POINT

(1) When the operation of Windows is not unclear in the operation of this

software, refer to the manual of Windows or guide-book from the

other supplier.

(2) The screen might not be correctly displayed depending on the

R

system font size of WindowsNT

4.0/WindowsR98/WindowsR2000.

Be sure to use the small size fonts.

2000

2 - 19

Page 39

2 SYSTEM CONFIGURATION

2.3 General Specifications

General specifications of Q173CPU(N)/Q172CPU(N) module is as follows.

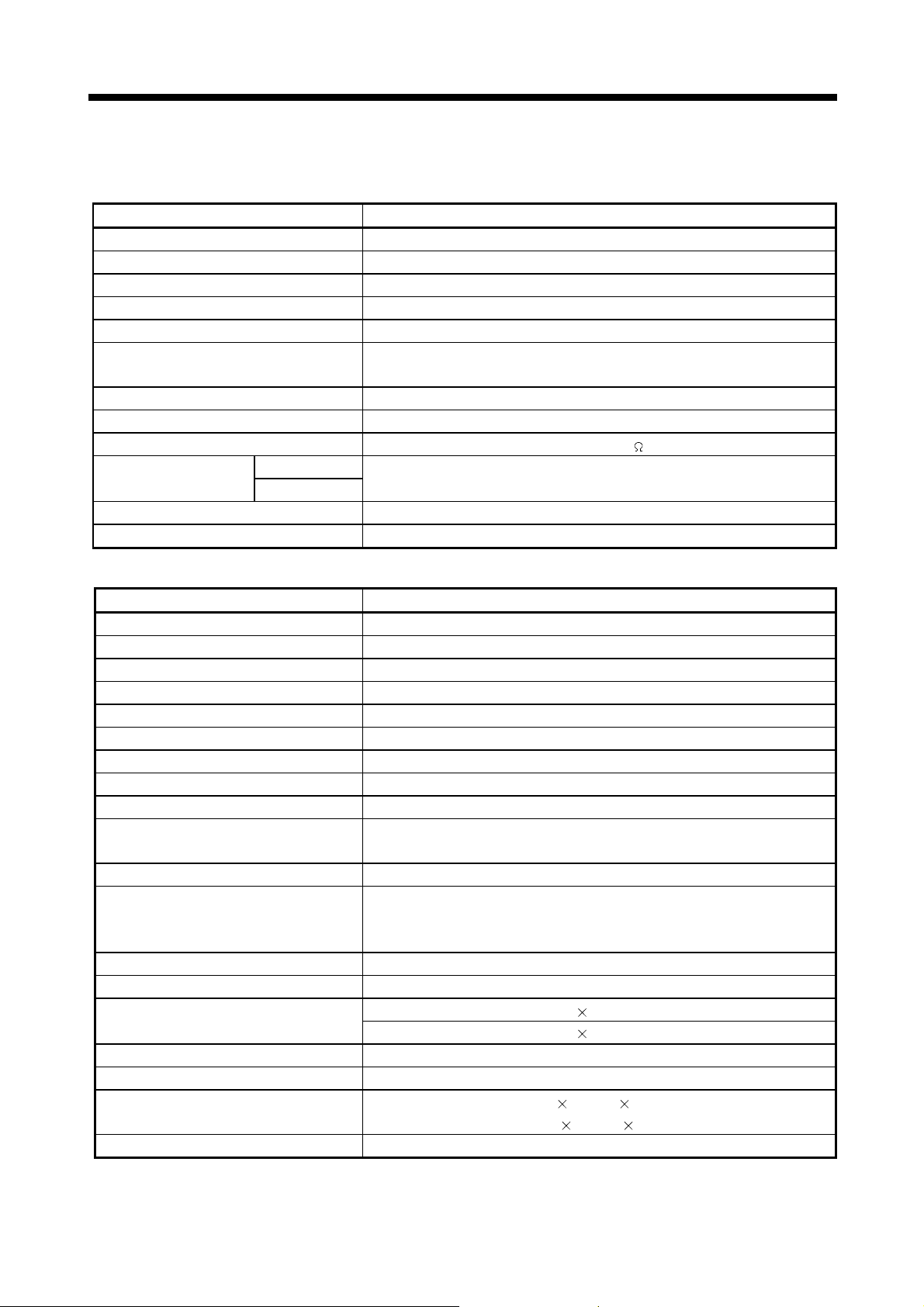

Item Specification

Operating ambient

temperature

Storage ambient

temperature

Operating ambient

humidity

Storage ambient

humidity

Vibration resistance Conforming

JIS B 3501,

IEC 61131-2

Under

intermittent

vibration

Under

continuous

vibration

0 to 55°C

(32 to 131°F)

-25 to 75°C

(Note-3)

(-13 to 167°F)

5 to 95% RH

5 to 95% RH

,

non-condensing

,

non-condensing

Frequency Acceleration Amplitude Sweep count

10 to 57Hz ——

0.075mm

(0.003inch)

10 times each

57 to 150Hz 9.8m/s2 ——

10 to 57Hz ——

57 to 150Hz 4.9m/s

2

——

0.035mm

(0.001inch)

in X, Y, Z

directions

(For 80 min.)

Shock resistance Conforming to JIS B 3501, IEC 61131-2(147m/s2 , 3 times in each of 3 directions X, Y, Z)

Operating ambience No corrosive gases

Operating altitude 2000m(6562ft.) or less

Installation location Inside control panel

Overvoltage category

(Note-1)

Pollution level

(Note-2

)

2 or less

II or less

(Note-1) : This indicates the section of the power supply to which the equipment is assumed to be connected between the

public electrical power distribution network and the machinery within premises.

Category II applies to equipment for which electrical power is supplied from fix ed facilities.

The surge voltage withstand level for up to the rated voltage of 300V is 2500V.

(Note-2) : This index indicates the degree to which conductive material is generated in terms of the env ironment in which

the equipment is used.

Pollution level 2 is when only non-conductive pollution occurs. A temporary conductivity caused by condensing

must be expected occasionally.

(Note-3) : Do not use or store the Motion CPU module under pressure higher than the atmospheric pressure of altitude 0m.