Page 1

C Controller Module User's Manual

(Hardware Design, Function Explanation)

-Q12DCCPU-V(Basic mode)

-Q06CCPU-V

-Q06CCPU-V-B

-SW3PVC-CCPU-E

Page 2

Page 3

SAFETY PRECAUTIONS

WARNING

CAUTION

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in minor or moderate injury or property damage.

(Read these precautions before using this product.)

Before using this product, please read this manual and the relevant manuals carefully and pay full attention

to safety to handle the product correctly.

The precautions given in this manual are concerned with this product only. For the safety precautions of the

programmable controller system, refer to the user's manual for the CPU module used.

In this manual, the safety precautions are classified into two levels: " WARNING" and " CAUTION".

Under some circumstances, failure to observe the precautions under " CAUTION" may lead to serious

consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this manual and then keep the manual in a safe place for future

reference.

[Design Precautions]

WARNING

Configure safety circuits external to the C Controller module to ensure that the entire system

operates safely even when a fault occurs in the external power supply or the C Controller module.

Failure to do so may result in an accident due to an incorrect output or malfunction.

(1) Configure external safety circuits, such as an emergency stop circuit, protection circuit, and

protective interlock circuit for forward/reverse operation or upper/lower limit positioning.

(2) If the following status (a) or (b) occurs, the system will behave accordingly.

(a) When overcurrent or overvoltage protection of the power supply module is activated, the

outputs (Y) from the user program and writing to the buffer memory are disabled, and all

outputs are turned off.

(b) When the C Controller module detects an error such as a watchdog timer error by the self-

diagnostic function, the outputs (Y) from the user program and writing to the buffer memory

are disabled. Whether to hold or turn off all outputs can be set by parameters.

All outputs may turn on when an error occurs in the part, such as I/O control part, where the C

Controller module cannot detect any error.

To ensure safety operation in such a case, provide a safety mechanism or a fail-safe circuit

external to the C Controller module. For a fail-safe circuit example, refer to "CHAPTER 6

PREPARATORY PROCEDURES AND SETTING" in this manual.

A - 1

Page 4

[Design Precautions]

WARNING

(3) Outputs may remain on or off due to a failure of an output module relay or transistor.

Configure an external circuit for monitoring output signals that could cause a serious accident.

In an output module, when a load current exceeding the rated current or an overcurrent caused by a

load short-circuit flows for a long time, it may cause smoke and fire. To prevent this, configure an

external safety circuit, such as a fuse.

Configure a circuit so that the C Controller system is turned on first and then the external power

supply. If the external power supply is turned on first, an accident may occur due to an incorrect

output or malfunction.

For the operating status of each station after a communication failure, refer to the relevant manuals

for the network.

Incorrect output or malfunction may result in an accident.

For the following controls, configure an interlock circuit in the user program to ensure that the entire

system will always operate safely.

(1) Changing data of a running C Controller module from the development environment (personal

computer) connected

(2) Changing the operating status

(3) Operation from the development environment (personal computer)

Especially, in the case of a control from an external device to a remote C Controller module,

immediate action cannot be taken for a problem on the C Controller module due to a communication

failure.

To prevent this, configure an interlock circuit in the user program, and determine corrective actions to

be taken between the external device and C Controller module in case of a communication failure.

To maintain the safety of the C Controller system against unauthorized access from external devices

via the network, take appropriate measures. To maintain the safety against unauthorized access via

the Internet, take measures such as installing a firewall.

When configuring the system, do not leave any slot empty on the base unit.

If a slot is to be left empty, attach a blank cover (QG60).

Failure to do so may cause internal parts of the mounted modules to fly apart during a short-circuit

test or when an excess current or voltage is applied to an external I/O part by mistake.

A - 2

Page 5

[Design Precautions]

CAUTION

Do not install the control lines or communication cables together with the main circuit lines or power

cables.

Keep a distance of 100mm (3.94 inches) or more between them.

Failure to do so may result in malfunction due to noise.

When a device such as a lamp, heater, or solenoid valve is controlled through an output module, a

large current (approximately ten times greater than normal) may flow when the output is turned from

off to on. Take measures such as replacing the module with one having a sufficient current rating.

After the C Controller module is powered on or is reset, the time taken to enter the RUN status varies

depending on the system configuration, parameter setting, and/or program size.

Design circuits so that the entire system will always operate safely, regardless of the time.

[Installation Precautions]

CAUTION

Use the C Controller module in an environment that meets the general specifications in this manual.

Failure to do so may result in an electric shock, fire, malfunction, or damage to or deterioration of the

product.

To mount the module, while pressing the module mounting lever located in the lower part of the

module, fully insert the module fixing projection(s) into the hole(s) in the base unit and press the

module until it snaps into place.

Incorrect mounting may cause malfunction, failure or drop of the module.

When using the module in an environment of frequent vibrations, fix the module with a screw.

Tighten the screw within the specified torque range.

Undertightening can cause drop of the screw, short circuit or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or malfunction.

A - 3

Page 6

[Installation Precautions]

CAUTION

When using an extension cable, connect it to the connector of the base unit or module securely.

Check the connection for looseness.

Poor contact may cause incorrect input or output.

When using a CompactFlash card, fully insert it into the CompactFlash card slot.

Check that it is inserted completely.

Poor contact may cause malfunction.

Shut off the external power supply for the system in all phases before mounting or removing the

module.

Failure to do so may result in damage to the product.

Do not directly touch any conductive part of the module.

Doing so can cause malfunction or failure of the module.

[Wiring Precautions]

WARNING

Shut off the external power supply for the system in all phases before wiring.

Failure to do so may result in electric shock or damage to the product.

After wiring, attach the included terminal cover to the module before turning it on for operation.

Failure to do so may result in electric shock.

A - 4

Page 7

[Wiring Precautions]

CAUTION

Ground the FG and LG terminals to the protective ground conductor dedicated to the programmable

controller.

Failure to do so may result in electric shock or malfunction.

Prevent foreign matter such as dust or wire chips from entering the module.

Such foreign matter can cause a fire, failure, or malfunction.

Check the rated voltage and terminal layout before wiring to the module, and connect the cables

correctly.

Connecting a power supply with a different voltage rating or incorrect wiring may cause a fire or

failure.

Securely connect the Ethernet and RS-232 cables to respective connectors of the C Controller

module.

Do not install the control lines or the communication cables together with the main circuit lines or

power cables.

Doing so may result in malfunction due to noise.

Tighten the terminal screw within the specified torque range.

Undertightening can cause short circuit, fire, or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or malfunction.

Place the communication and power cables in a duct or clamp them.

If not, dangling cable may swing or inadvertently be pulled, resulting in damage to the module or

cables or malfunctions due to poor contact.

When disconnecting a communication or power cable from the module, do not hold and pull the

cable part.

Doing so may cause malfunction or damage to the module or cable.

For a cable with connector, hold the connected connector by hand to disconnect the cable.

For a screw-type cable, loosen the screw to disconnect the cable.

Do not connect outputs of multiple power supply modules in parallel.

The power supply modules may produce heat, causing a fire or failure.

Connectors for external connection must be crimped or pressed with the tool specified by the

manufacturer, or must be correctly soldered.

For the tool, refer to the user's manual for the relevant I/O module.

Incomplete connections could result in short circuit, fire or malfunction.

A - 5

Page 8

[Startup and Maintenance Precautions]

WARNING

Do not touch any terminal while power is on.

Doing so will cause electric shock.

Correctly connect the battery connector.

Do not charge, disassemble, heat, short-circuit, solder, or throw the battery into the fire.

Doing so will cause the battery to produce heat, explode, or ignite, resulting in injury and fire.

Shut off the external power supply for the system in all phases before cleaning the module or

retightening the terminal screws or module fixing screws.

Failure to do so may result in electric shock.

Undertightening the terminal screws can cause short circuit or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or malfunction.

For the following controls, configure an interlock circuit in the user program to ensure that the entire

system will always operate safely.

(1)

Changing data of the running C Controller module from the development environment (personal

computer) connected

(2) Changing the operating status

3) Operation from the development environment (personal computer)

(

Especially, in the case of a control from an external device to a remote C Controller module,

immediate action cannot be taken for a problem on the C Controller module due to a communication

failure.

To prevent this, configure an interlock circuit in the user program, and determine corrective actions to

be taken between the external device and C Controller module in case of a communication failure.

A - 6

Page 9

[Startup and Maintenance Precautions]

CAUTION

Do not disassemble or modify the modules.

Doing so may cause failure, malfunction, injury, or a fire.

Before performing online operations (especially, program modification, forced output, and operation

status change) for the running C Controller module from the peripheral connected, read relevant

manuals carefully and ensure the safety.

Improper operation may damage machines or cause accidents.

Shut off the external power supply for the system in all phases before mounting or removing the

module.

Failure to do so may cause the module to fail or malfunction.

After the first use of the product, do not mount/remove the module to/from the base unit more than

50 times. (IEC 61131-2 compliant)

Exceeding the limit of 50 times may cause malfunction.

Use any radio communication device such as a cellular phone or PHS (Personal Handy-phone

System) more than 25cm (9.85 inches) away in all directions from the C Controller system.

Failure to do so may cause malfunction.

Do not drop or apply shock to the battery to be installed in the module.

Doing so may damage the battery, causing the battery fluid to leak inside the battery.

If the battery is dropped or any shock is applied to it, dispose of it without using.

Before handling the module, touch a grounded metal object to discharge the static electricity from

the human body.

Failure to do so may cause the module to fail or malfunction.

A - 7

Page 10

[Disposal Precautions]

CAUTION

When disposing of this product, treat it as industrial waste.

When disposing of batteries, separate them from other wastes according to the local regulations.

(For details of the Battery Directive in EU countries, refer to Appendix 4.)

[Transportation Precautions]

CAUTION

When transporting lithium batteries, follow the transportation regulations. (For details of the

regulated models, refer to Appendix 3.)

A - 8

Page 11

CONDITIONS OF USE FOR THE PRODUCT

(1) Mitsubishi C Controller system ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major

or serious accident; and

ii) where the backup and fail-safe function are systematically or automatically provided outside of

the PRODUCT for the case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general

industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT

LIMITED TO ANY AND ALL RESPONSIBILITY OR LIABILITY BASED ON CONTRACT,

WARRANTY, TORT, PRODUCT LIABILITY) FOR ANY INJURY OR DEATH TO PERSONS OR

LOSS OR DAMAGE TO PROPERTY CAUSED BY the PRODUCT THAT ARE OPERATED OR

USED IN APPLICATION NOT INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS,

OR WARNING CONTAINED IN MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY

MANUALS, TECHNICAL BULLETINS AND GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

• Nuclear Power Plants and any other power plants operated by Power companies, and/or any

other cases in which the public could be affected if any problem or fault occurs in the PRODUCT.

• Railway companies or Public service purposes, and/or any other cases in which establishment of

a special quality assurance system is required by the Purchaser or End User.

• Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as

Elevator and Escalator, Incineration and Fuel devices, Vehicles, Manned transportation,

Equipment for Recreation and Amusement, and Safety devices, handling of Nuclear or

Hazardous Materials or Chemicals, Mining and Drilling, and/or other applications where there is a

significant risk of injury to the public or property.

Notwithstanding the above, restrictions Mitsubishi may in its sole discretion, authorize use of the

PRODUCT in one or more of the Prohibited Applications, provided that the usage of the PRODUCT

is limited only for the specific applications agreed to by Mitsubishi and provided further that no

special quality assurance or fail-safe, redundant or other safety features which exceed the general

specifications of the PRODUCTs are required. For details, please contact the Mitsubishi

representative in your region.

A - 9

Page 12

REVISIONS

Partial correction

Partial correction

Addition

Modification

Partial correction

Addition

Modification

Partial correction

Partial correction

Partial correction

*The manual number is given on the bottom left of the back cover.

Print date *Manual number Revision

Jun., 2009 SH(NA)-080766ENG-A First edition

Jan., 2010 SH(NA)-080766ENG-B

PRECAUTIONS

Aug., 2010 SH(NA)-080766ENG-C

SAFETY PRECAUTIONS, ABOUT MANUALS, HOW TO USE THIS MANUAL,

GENERIC TERMS AND ABBREVIATIONS, GLOSSARY, Section 1.1, 2.1.3,

2.1.4, 2.2.1, 2.2.2, 2.3, 2.4, 3.2, 3.4.2, 4.1, 4.4, 4.5, 4.13, 5.2 to 5.4, 6.2, 6.11.2,

8.1.1, 8.2.2, 10.1, 11.1.4, 11.3, 13.1, 13.2, 13.6, 14.1, 15.2.4, 16.3, 16.4.1,

16.5.1, Appendix 8, Appendix 9.1, Appendix 10, Appendix 11

CONDITIONS OF USE FOR THE PRODUCT, Section 2.1.5, 4.4, 4.16, 6.8.5,

Chapter 9, Section 16.4.2, Appendix 6, Appendix 7, Appendix 9

Section 2.1.5 Section 2.1.6, Section 4.4 to 4.14 Section 4.5 to 4.15,

Chapter 9 to 15 Chapter10 to 16,

Appendix 6 to 8, Appendix7 to 8 Appendix10 to 11

Mar., 2011 SH(NA)-080766ENG-D

OPERATING PRECAUTIONS, Section 1.1, 2.1.3, 2.3, 2.4, 3.3.1, 3.3.2, 4.3.3,

4.15, 4.16, 5.3.2, 5.4.2, 6.3, 8.2.2, 16.4.1, Appendix 7, Appendix 9, Appendix 12

Jul., 2011 SH(NA)-080766ENG-E

Jan., 2012 SH(NA)-080766ENG-F

Dec., 2012

SH(NA)-080766ENG-G

Appendix 10

Appendix 10 to 11 Appendix 11 to 12

ABOUT MANUALS, GENERIC TERMS AND ABBREVIATIONS, Section 2.1.2,

2.1.4, 2.2.1, 2.2.2, 11.1.4

Section 2.2.1, 2.2.2, 2.4, 3.1

GENERIC TERMS AND ABBREVIATIONS, OPERATING PRECAUTIONS,

Section 2.2.1, 2.3, 3.2, 3.3.2, 4.5, 6.3, 6.4.1, 6.6, 10.1, 11.1, 11.2.1, 11.3, 12.1,

13.3.3, 13.3.4, 13.9, 16.2.3

A - 10

Page 13

Print date *Manual number Revision

Partial correction

Addition

Delete

Modification

Partial correction

Partial correction

Partial correction

Partial correction

Partial correction

Partial correction

Addition

Partial correction

Oct., 2013

SH(NA)-080766ENG-H

ABOUT MANUALS, HOW TO USE THIS MANUAL,

GENERIC TERMS AND ABBREVIATIONS, GLOSSARY, PACKING LIST,

CHAPTER 1, Section 1.1, 2.1.2, 2.2.1, 2.2.2, 2.3, 2.4, 2.5, 2.5.1, 4.14, 6.3, 6.4.1,

6.7, 6.10, 6.10.1, 6.10.2, 6.12.1, 8.2.1, 10.1, 11.1, 12.1, 13.3.1, 16.2, 16.2.2,

16.2.7, 16.2.8, 16.2.11, 16.5.1, Appendix7

PRODUCT ORGANIZATION

Appendix 11

Appendix 12 Appendix 11

Dec., 2013

Mar., 2014

Jul., 2014 SH(NA)-080766ENG-K

Feb., 2015 SH(NA)-080766ENG-L

Dec., 2015

Jun., 2016

Oct., 2017

SH(NA)-080766ENG-I

SH(NA)-080766ENG-J

SH(NA)-080766ENG-M

SH(NA)-080766ENG-N

SH(NA)-080766ENG-O

GENERIC TERMS AND ABBREVIATIONS, Section 10.1

GENERIC TERMS AND ABBREVIATIONS, Section 11.2.1, Section 12.1,

Section 12.7, Section 13.3.2, Section 13.3.3, Section 13.3.4, Section 13.9,

Appendix11

ABOUT MANUALS, GENERIC TERMS AND ABBREVIATIONS, CHAPTER 1,

Section 11.1, Section 11.3

Section 2.2.2, Section 6.7.1

PACKING LIST, Section 2.1.3, Section 2.5.1, Section 3.2, Section 6.4.1,

Appendix 2.1, WARRANTY

SAFETY PRECAUTIONS, GENERIC TERMS AND ABBREVIATIONS,

Section 6.6, Section 6.11

DISCONTINUED MODELS

ABOUT MANUALS, GENERIC TERMS AND ABBREVIATIONS, CHAPTER 1,

Section 6.7.1, Section 11.1, Appendix 11

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any patent licenses.

Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property rights which may

occur as a result of using the contents noted in this manual.

Japanese manual version SH-080764-Q

© 2009 MITSUBISHI ELECTRIC CORPORATION

A - 11

Page 14

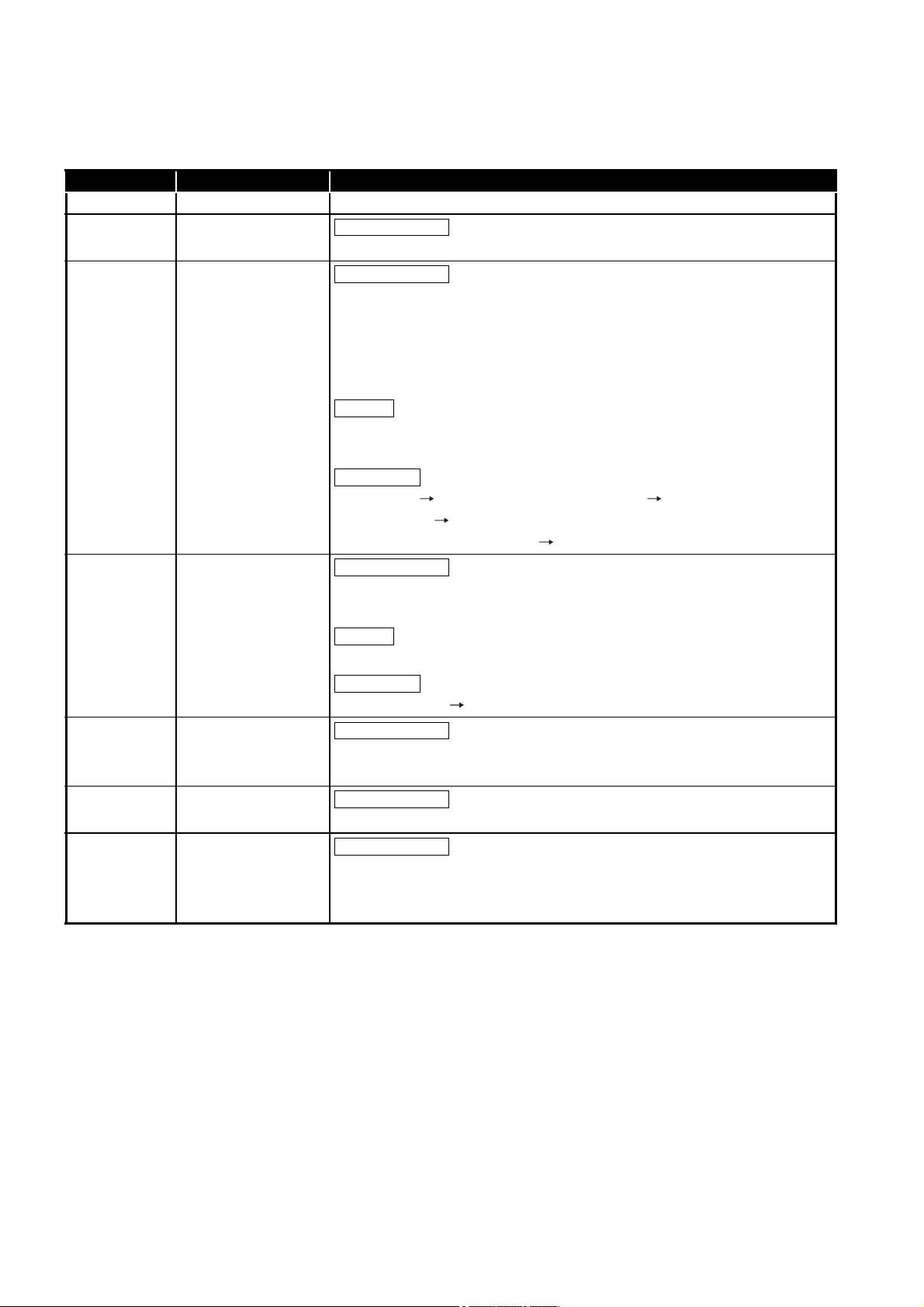

OPERATING PRECAUTIONS

This section provides the following precautions.

System configurations

Standard RAM, standard ROM, and CompactFlash card

Battery

Clock setting

Starting the C Controller module

Network configurations

Relation between system tasks and the system watchdog timer, user

watchdog timer, and link device refresh cycles

For the Wind River Systems product

(1) Precautions for system configurations

(a) Supported modules

Precautions for Refer to

Page A-12

Page A-13

Page A-15

Page A-16

Page A-16

Page A-17

Page A-17

Page A-17

In a system configuration where a C Controller module is used, some main and

extension base units cannot be used ( Page 2-16, Section 2.1.6), and also

use of some modules is restricted by their function versions ( Page 2-17,

Section 2.2).

(b) Multiple CPU system

1) Applicable CPU modules

For the CPU modules that can be used with a C Controller module in a multiple

CPU system, refer to the following.

Page 11-11, Section 11.2.1

2) MT Developer connection (Version 00Y or earlier) in a multiple CPU system

When a multiple CPU system includes a C Controller module set as CPU No.1

and a Motion CPU, a communication test of MT Developer (Version 00Y or

earlier) cannot be performed. (The Motion CPU communication test error

(error code: 12288) will occur.)

To perform the communication test from MT Developer, use either of the

following methods.

• Use MT Developer Version 00Z or later.

• When using MT Developer Version 00Y or earlier, modify the multiple

CPU system configuration so that CPU No.1 is a programmable controller

CPU.

(c) Time adjustment and time notification of GOT

In a multiple CPU system configuration, when time adjustment or time notification

is performed in a GOT connected to C Controller modules for CPU No. 2 to No. 4,

it is executed to CPU No. 1.

In this case, to match the clock data between the C Controller modules assigned

to CPU No. 2 to No. 4 and the GOT, use the multiple CPU clock synchronization

function.

Page 4-33, Section 4.7.1

A - 12

(d) Connection with GX Works2/GX Developer

For the connection with GX Works2/GX Developer, refer to the following.

Page 2-29, Section 2.4 (7)

Page 15

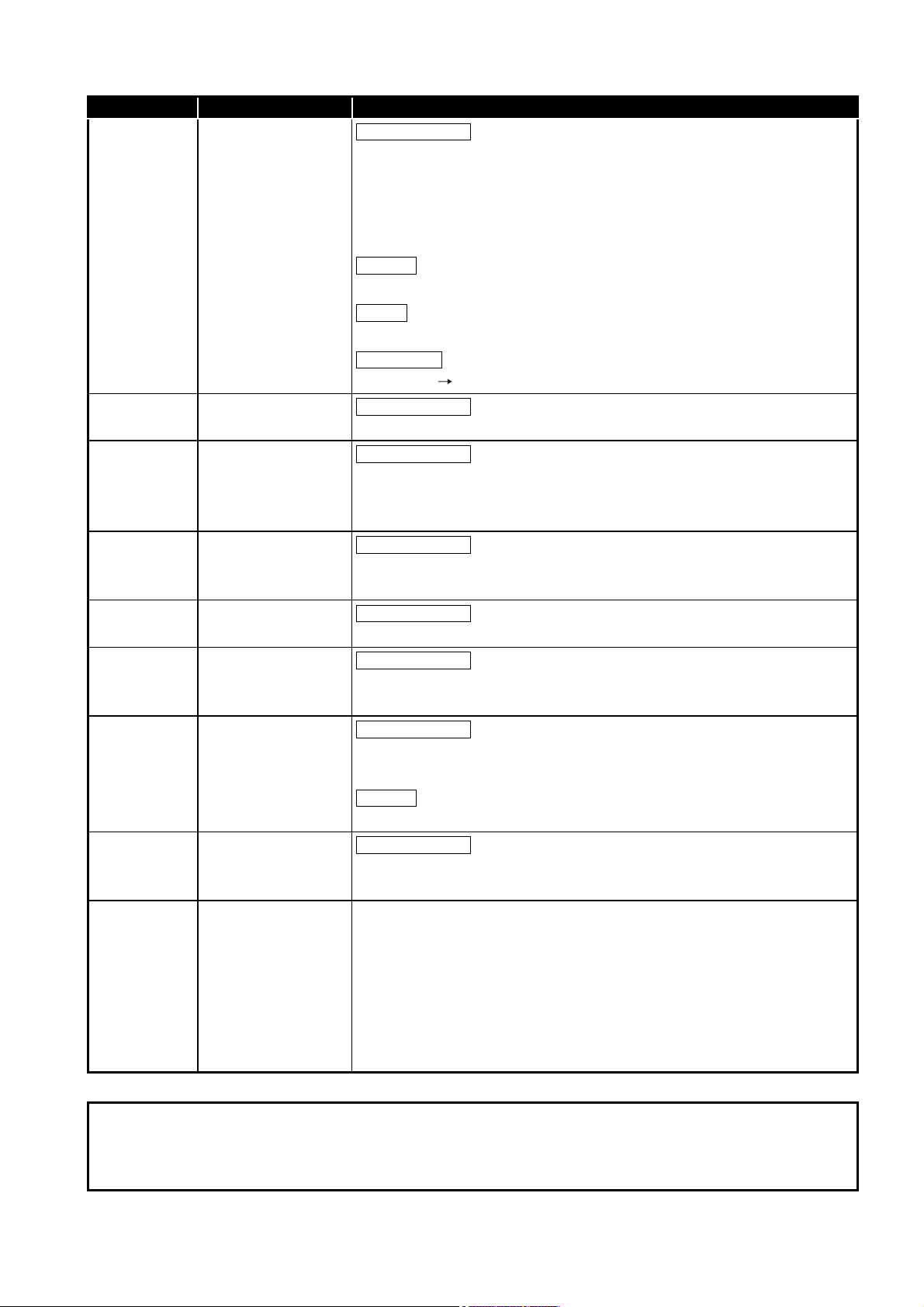

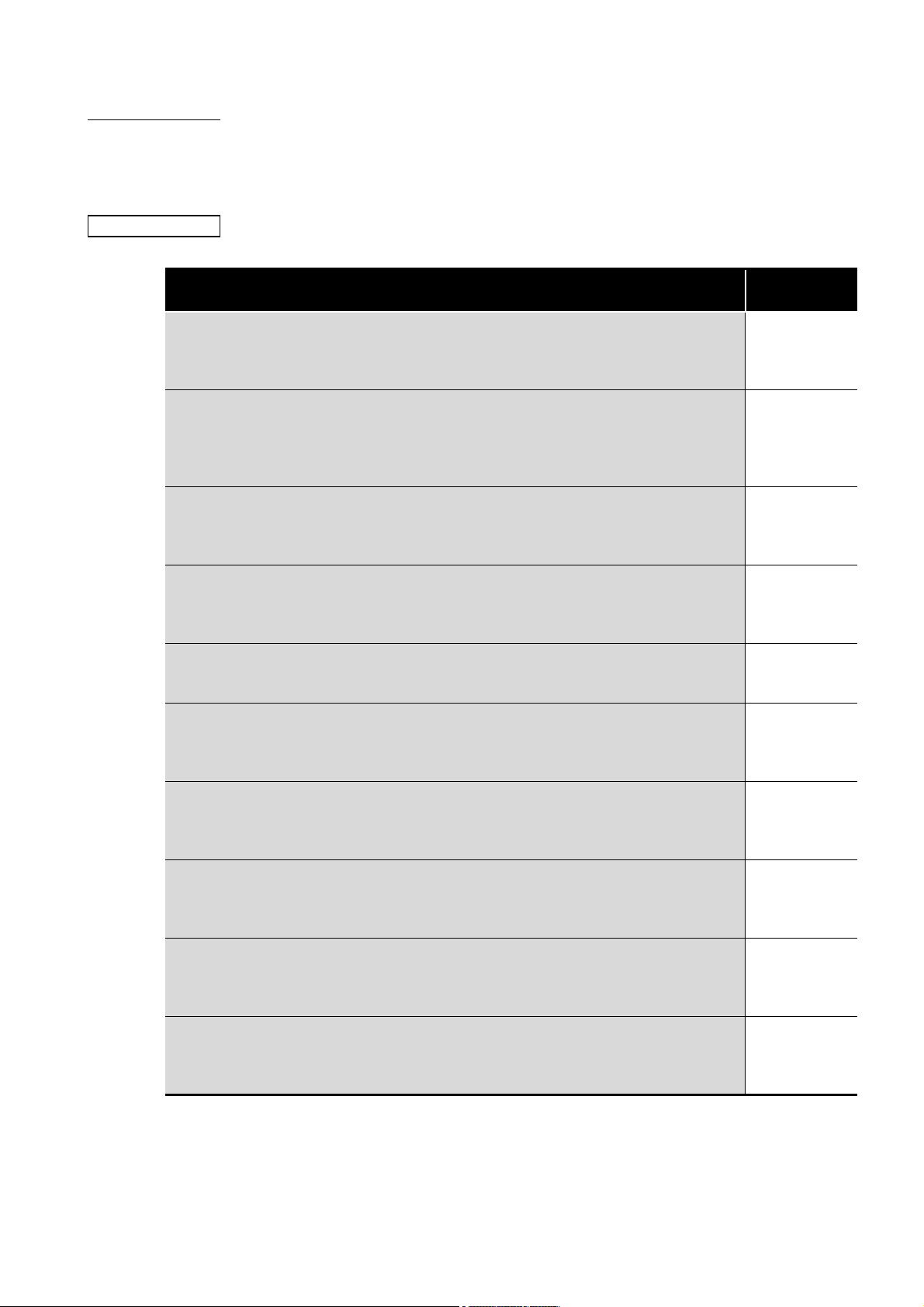

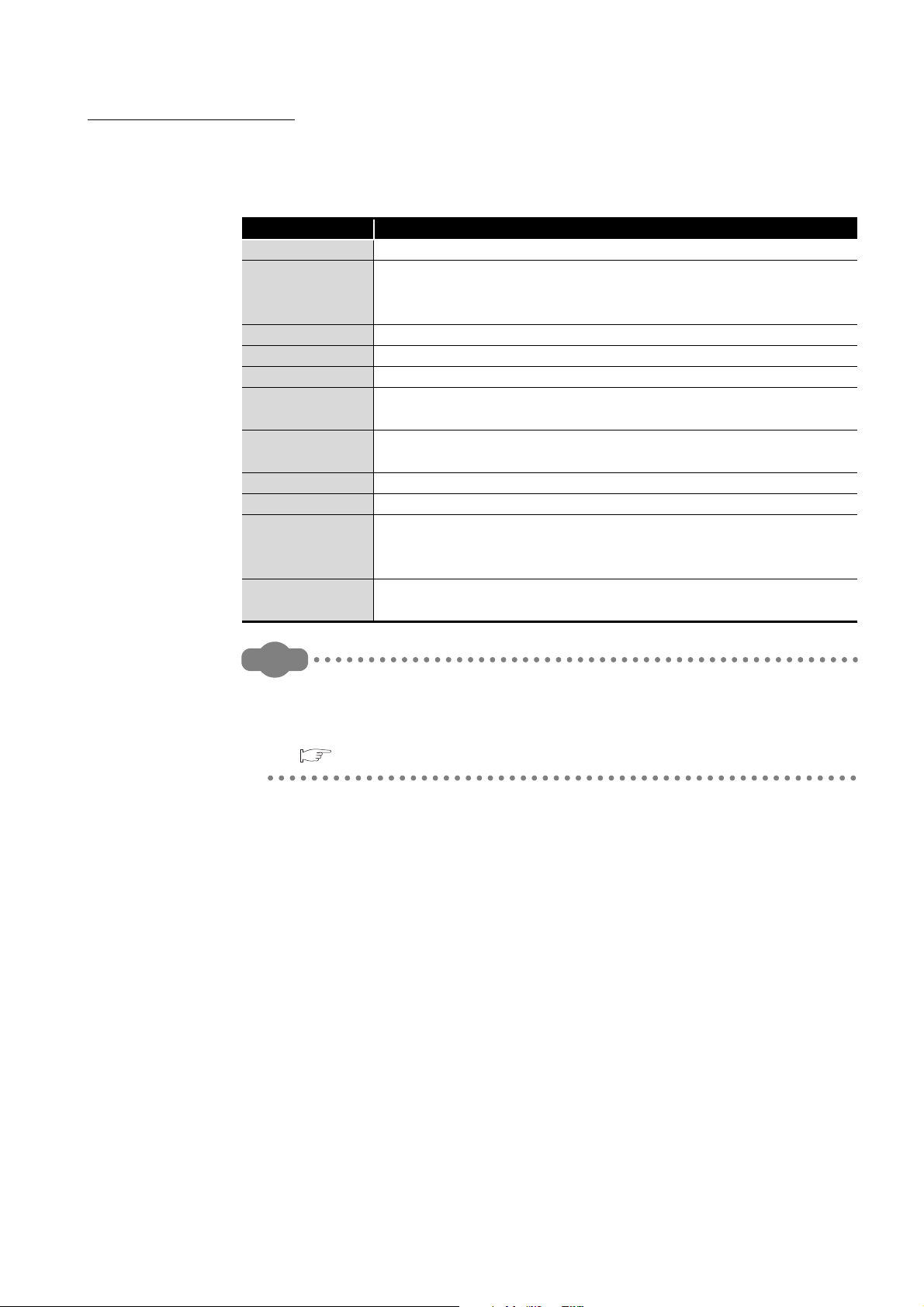

(2) Precautions for standard RAM, standard ROM, and CompactFlash card

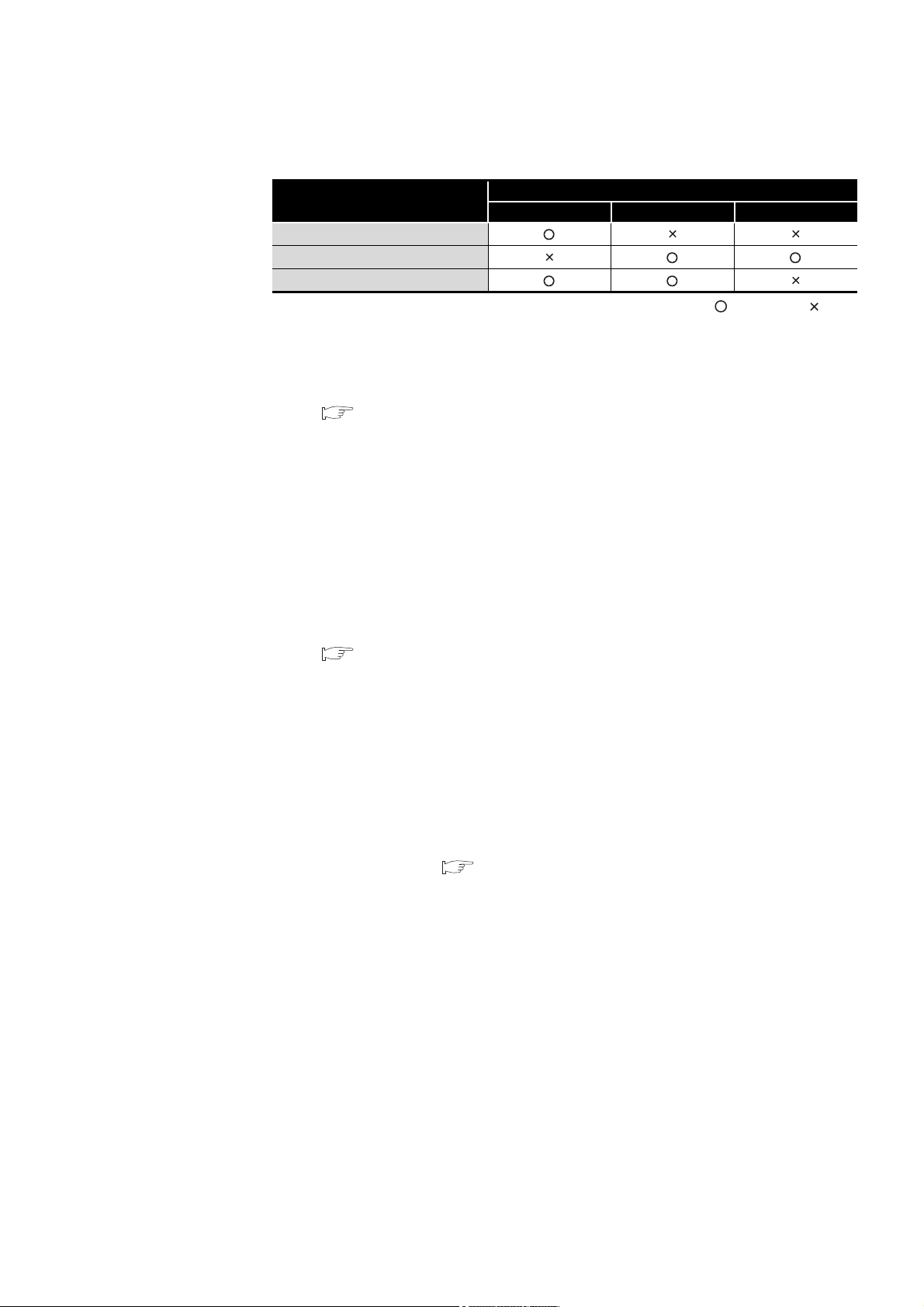

Table A.1 Memory availability

Memory

Standard RAM

Standard ROM

CompactFlash card

(a) Standard RAM formatting

1) When formatting the standard RAM

Be sure to perform the method described in the following section.

Page 6-77, Section 6.10.1 (6)

Do not format it by using a command from Workbench Shell.

2) During standard RAM formatting

Do not power off or reset the C Controller module during standard RAM

formatting.

Doing so causes the standard RAM to be formatted again when the C

Controller module is started the next time.

(b) Standard ROM formatting

Q12DCCPU-V Q06CCPU-V Q06CCPU-V-B

Availability

: Available, : N/A

1) When formatting the standard ROM

Be sure to perform the method described in the following section.

Page 6-85, Section 6.10.2 (4)

Do not format it by using a command from Tornado Shell.

2) During standard ROM formatting

Do not power off or reset the C Controller module during standard ROM

formatting.

Doing so causes the standard ROM to be formatted again when the C

Controller module is started the next time.

(c) Allowable number of writes to the standard ROM (service life)

A flash ROM is used for the standard ROM and it has a limit in the number of

writes (service life). ( Page 6-71, Section 6.9)

A - 13

Page 16

(d) Allowable number of writes to a CompactFlash card (service life)

• For the live of the QD81MEM and GT05-MEM, refer to the following.

Page 6-70, Section 6.8.5

• For the live of commercially available CompactFlash cards, refer to the

specifications of each product.

(e) CompactFlash card replacement

Do not power off or reset the system or remove the CompactFlash card while

writing file data to the CompactFlash card.

Doing so can cause corruption of the CompactFlash card data or a file system

error.

• To remove a CompactFlash card during file writing:

Page 6-64, Section 6.8.2

• To power off or reset the system:

Page 8-9, Section 8.2.2

(f) File name and directory name

Use alphanumeric characters and special characters (excluding \, /, *, ?, <, >, |, :,

and ") for the names of a file and a directory stored in the following memories in

the C Controller module:

• Standard RAM

• Standard ROM

• CompactFlash card

If a file or a directory with a name including characters other than alphanumeric

characters and special characters (excluding \, /, *, ?, <, >, |, :, and ") is stored in

the memories above in the C Controller module, the following phenomena may

occur:

• Character corruption on file names and directory names

• Loss of files and directories

(g) Unmounting a CompactFlash card by the RESET/SELECT switch

1) When unmounting during access

Unmounting a CompactFlash card by the RESET/SELECT switch during file

writing to the CompactFlash card can cause corruption of the CompactFlash

card data or a file system error.

Stop the access to the CompactFlash card before removing the card.

( Page 6-64, Section 6.8.2)

2) When powering off or resetting the system

Before powering off or resetting the system, refer to the following.

Page 8-9, Section 8.2.2

3) Switch operation

If the RESET/SELECT switch is held in the RESET position by mistake, the C

Controller module will be reset.

Be careful when unmounting a CompactFlash card by operating the RESET/

SELECT switch. ( Page 6-67, Section 6.8.3)

A - 14

Page 17

(3) Precautions for battery

(a) For the Q12DCCPU-V

1) About file corruption

The battery must be installed before operation.

• If the C Controller system is operated without a battery and then is

powered off or reset

The data in the standard RAM and battery-backed-up RAM may be

damaged, or a file system error may occur.

• When the battery is not replaced even after a battery error

The standard RAM or battery-backed-up RAM data or clock data may be

corrupted, or a file system error may occur.

2) Battery replacement

For battery replacement, observe the procedures described in this manual.

( Page 6-53, Section 6.7.3 (4))

(b) For the Q06CCPU-V(-B)

1) About file corruption

• When the battery is not replaced even after a battery error

The standard ROM and battery-backed-up RAM data being accessed and

clock data may be corrupted, or a file system error may occur.

• If the C Controller system is operated without a battery and then shut

down improperly

The standard ROM and battery-backed-up RAM data being accessed

may be corrupted, or a file system error may occur.

• When the procedures shown in Page 6-54, Section 6.7.4 are not observed

The standard ROM and battery-backed-up RAM data being accessed

may be corrupted, or a file system error may occur.

2) Restrictions on operations without a battery

• Powering on the system without a battery

If the C Controller system is powered on with no battery installed in the C

Controller module, the system will start with unreliable clock data.

Set clock data in this case. Otherwise, event history files and programs

using clock data cannot function properly. ( Page 6-54, Section 6.7.4)

• Operating the system without a battery

If the system was operated with no battery installed in the C Controller

module, perform the shutdown operation before powering off or resetting

the C Controller system. ( Page 6-55, Section 6.7.4 (2))

3) Battery replacement

For battery replacement, observe the procedures described in this manual.

( Page 6-53, Section 6.7.3 (4))

A - 15

Page 18

(4) Precautions for clock setting

(a) Clock setting

1) Setting method

Set the clock of the C Controller module as described in Page 4-30, Section

4.7 (4) (a).

If the year 2100 is exceeded after clock setting, clock data of the year 2100

and later can be used until the C Controller module is restarted.

At the time of restart, year data of the C Controller module will be reset to those

of 2000 to 2099.

2) Condition for the setting

The clock of the C Controller module must be set with the QBF_WaitEvent and

QBF_WaitUnitEvent functions not being executed.

(5) Precautions for starting the C Controller module

(a) Time required for connection from each utility to the C Controller module

After power-on or reset, the C Controller module is ready to connect to each utility

at the following timing.

• When executing the script file, "STARTUP.CMD":

Upon completion of the RUN LED flashing

• When not executing the script file, "STARTUP.CMD":

Fifteen (15) seconds after completion of the start or reset process

Do not attempt a connection before the above timing after power-on or reset.

Changing "Priority" to a larger value in the Option tab of C Controller setting utility

increases the time after which the C Controller module can be connected.

(b) Flashing "01" or "02" of the 7-segment LED (Q12DCCPU-V only)

At start-up of the C Controller module, "01" or "02" flashes on the 7-segment LED

in the following cases.

• When the C Controller module is in factory-default state

(Because the standard RAM is not initialized)

• When the C Controller module is left unused for a long period of time with no

battery installed

(Because the standard and battery-backed-up RAM data are corrupted)

If "01" or "02" flashes on the 7-segment LED, install a battery and perform the

module initialization setting procedure. ( Page 6-77, Section 6.10.1 (6))

A - 16

Page 19

(6) Precautions for network configurations

(a) Precautions for using two Ethernet channels (Q12DCCPU-V only)

When using two channels as Ethernet ports, two different network addresses

must be set for CH1 and CH2 of the C Controller module.

In the above case, a response to the message received through each channel is

sent as follows:

• Messages (including response packets such as ping) to the device having the

same network address as CH1 are sent from CH1.

• Messages (including response packets such as ping) to the device having the

same network address as CH2 are sent from CH2.

(7) Relation between system tasks and the system watchdog timer, user

watchdog timer, and link device refresh cycles

When using any of the following functions, set a sufficiently long time for each of the

system watchdog timer, user watchdog timer, and link device refresh cycles.

• Shell command

• Workbench/Tornado connection

• File access

• Mount/unmount of CompactFlash card

• Ethernet communications

• NFS server communication

If any of the above is used, CPU utilization for a system task with high priority may

increase and a system watchdog timer error, a user watchdog timer error, and link

refresh timeout may occur more frequently.

For the link refresh timeout, the rate of occurrence may also increase when bus

interface driver processing (connections with peripheral devices or communication

with an intelligent function module, etc.) is used.

(8) Precautions for the Wind River Systems product

The C Controller module has an embedded real-time operating system, VxWorks,

made and sold by Wind River Systems, Inc. in the United States.

We, Mitsubishi, make no warranty for the Wind River Systems product and will not be

liable for any problems and damages caused by the Wind River Systems product

during use of the C Controller module.

For the problems or specifications of the Wind River Systems product, refer to the

corresponding manual or consult Wind River Systems, Inc.

Contact information is available on the following website.

www.windriver.com

A - 17

Page 20

INTRODUCTION

Thank you for purchasing the Mitsubishi C Controller module.

Before using the product, please read this manual carefully to understand the features and performance of

the C Controller module and use it correctly.

CONTENTS

SAFETY PRECAUTIONS············································································································ A - 1

CONDITIONS OF USE FOR THE PRODUCT ················································································· A - 9

REVISIONS ··························································································································· A - 10

OPERATING PRECAUTIONS···································································································· A - 12

INTRODUCTION····················································································································· A - 18

CONTENTS ··························································································································· A - 18

ABOUT MANUALS ·················································································································· A - 25

MANUAL PAGE ORGANIZATION ······························································································ A - 26

HOW TO USE THIS MANUAL ··································································································· A - 27

GENERIC TERMS AND ABBREVIATIONS ·················································································· A - 28

GLOSSARY ··························································································································· A - 33

PACKING LIST ······················································································································· A - 34

DISCONTINUED MODELS ······································································································· A - 34

CHAPTER 1 OVERVIEW 1 - 1 to 1 - 16

1.1 Features ··················································································································· 1 - 4

CHAPTER 2 SYSTEM CONFIGURATION 2 - 1 to 2 - 38

2.1 System Configuration··································································································· 2 - 1

2.1.1 Devices used for each base unit··············································································· 2 - 2

2.1.2 Connection with a development environment ······························································ 2 - 5

2.1.3 Connection with peripheral devices··········································································· 2 - 7

2.1.4 System configuration overview················································································· 2 - 9

2.1.5 Connecting a GOT in a bus topology········································································2 - 14

2.1.6 Precautions for system configuration········································································2 - 16

2.2 Applicable Modules ····································································································2 - 17

2.2.1 Applicable I/O modules and intelligent function modules···············································2 - 17

2.2.2 Precautions for using I/O modules and intelligent function modules ································2 - 19

2.3 Software Packages ····································································································2 - 24

2.4 Applicable Devices ·····································································································2 - 25

2.5 Checking Function Version, Serial No., and Software Version ·············································2 - 35

2.5.1 Checking the function version and serial No. of the C Controller module··························2 - 35

2.5.2 Checking the software version of software package ····················································2 - 38

CHAPTER 3 SPECIFICATIONS 3 - 1 to 3 - 9

3.1 General Specifications ································································································· 3 - 1

A - 18

Page 21

3.2 Performance Specifications ···························································································3 - 2

3.3 RS-232 Connector Specifications····················································································3 - 4

3.3.1 RS-232 connector specifications for the Q12DCCPU-V ·················································3 - 4

3.3.2 RS-232 connector specifications for the Q06CCPU-V(-B)···············································3 - 5

3.4 Operation Processing ···································································································3 - 6

3.4.1 Initial processing····································································································3 - 6

3.4.2 I/O access timing ···································································································3 - 7

3.4.3 RUN, STOP and PAUSE status operation processing ···················································3 - 8

3.4.4 Operation processing during momentary power failure ··················································3 - 9

CHAPTER 4 FUNCTIONS 4 - 1 to 4 - 55

4.1 Function List ···············································································································4 - 1

4.2 I/O Module and Intelligent Function Module Access Function ················································4 - 4

4.3 Remote Operation Function ···························································································4 - 5

4.3.1 Remote RUN/STOP ·······························································································4 - 6

4.3.2 Remote PAUSE ····································································································4 - 9

4.3.3 Remote RESET··································································································· 4 - 11

4.3.4 Relation between remote operation and RUN/STOP status ··········································4 - 16

4.4 Device Function ········································································································ 4 - 18

4.5 Self-Diagnostic Function ····························································································· 4 - 20

4.6 Output (Y) Status Setting for Switching STOP to RUN ······················································· 4 - 26

4.7 Clock Function ·········································································································· 4 - 29

4.7.1 Multiple CPU Clock Synchronization Function···························································· 4 - 33

4.8 Input Response Time Selection (I/O Response Time)························································ 4 - 34

4.9 Error Time Output Mode Setting ··················································································· 4 - 36

4.10 Hardware Error Time CPU Operation Mode Setting ·························································· 4 - 37

4.11 Switch Settings for I/O and Intelligent Function Modules ····················································4 - 38

4.12 Watchdog Timer (WDT) ······························································································ 4 - 40

4.13 Interrupt from Intelligent Function Module ······································································· 4 - 42

4.14 Connection Between C Controller Module and GOT (Microcomputer Connection) ··················· 4 - 47

4.15 Telnet Function ········································································································· 4 - 48

4.16 Functions for Communicating with Peripheral Devices through an Ethernet Port ·····················4 - 53

CHAPTER 5 ACCESS VIA NETWORK MODULES 5 - 1 to 5 - 64

5.1 Network Module Access Function List ··············································································5 - 1

5.2 CC-Link Module Access Function····················································································5 - 2

5.2.1 Block data assurance per station ··············································································5 - 3

5.3 MELSECNET/H Module Access Function ······································································· 5 - 10

5.3.1 Message communication······················································································· 5 - 11

5.3.2 Link device access ······························································································· 5 - 15

5.3.3 Parameter settings ······························································································· 5 - 20

5.3.4 Link device refresh setting ····················································································· 5 - 21

5.3.5 Link data transfer processing time specifications ························································ 5 - 31

A - 19

Page 22

5.4 CC-Link IE Controller Network Module Access Function ····················································5 - 38

5.4.1 Message communication ·······················································································5 - 39

5.4.2 Link device access ·······························································································5 - 42

5.4.3 Parameter settings ·······························································································5 - 47

5.4.4 Link device refresh setting ·····················································································5 - 48

5.4.5 Link data transfer processing time specifications ························································5 - 58

CHAPTER 6 PREPARATORY PROCEDURES AND SETTING 6 - 1 to 6 - 95

6.1 Handling Precautions··································································································· 6 - 2

6.2 Fail-Safe Circuit ·········································································································· 6 - 4

6.3 Preparatory Procedure and Setting ················································································6 - 11

6.4 Part Names and Functions ···························································································6 - 24

6.4.1 Part names and functions of the Q12DCCPU-V··························································6 - 24

6.4.2 Part names and functions of the Q06CCPU-V(-B) ·······················································6 - 31

6.5 Cable Connection ······································································································6 - 37

6.5.1 Compliance of the C Controller module with the EMC Directive ·····································6 - 38

6.6 Network Settings for 1:1 Connection ··············································································6 - 39

6.7 Specifications, Installation, and Replacement of the Battery ················································6 - 47

6.7.1 Battery specifications ····························································································6 - 47

6.7.2 Battery installation ································································································6 - 48

6.7.3 Battery replacement ·····························································································6 - 49

6.7.4 When the module has been operated without battery···················································6 - 54

6.7.5 Removing a battery before storage ··········································································6 - 57

6.8 Inserting/Removing a CompactFlash Card and Access Stop ···············································6 - 60

6.8.1 Inserting/removing the CompactFlash card································································6 - 60

6.8.2 Stopping access to the CompactFlash card ·······························································6 - 64

6.8.3 Unmounting the CompactFlash card by the RESET/SELECT switch·······························6 - 67

6.8.4 Measures against static electricity for commercially available CompactFlash cards in

compliance with the EMC directives ·········································································6 - 68

6.8.5 Life of CompactFlash card ·····················································································6 - 70

6.9 Checking the Number of Erasures on the Standard ROM ···················································6 - 71

6.10 Initializing/Changing Mode of C Controller Module ····························································6 - 72

6.10.1 Initializing/Changing mode of Q12DCCPU-V······························································6 - 72

6.10.2 Setting the Q06CCPU-V(-B) back to the factory-set status············································6 - 81

6.11 Login User Setting and Restriction·················································································6 - 88

6.11.1 Functions that can be restricted by login user setting···················································6 - 88

6.11.2 Setting a login user·······························································································6 - 89

6.12 Maintenance and Inspection ·························································································6 - 92

6.12.1 Daily inspection ···································································································6 - 94

6.12.2 Periodical inspection ·····························································································6 - 95

CHAPTER 7 I/O NUMBER ASSIGNMENT 7 - 1 to 7 - 28

7.1 Number of Base Units and Number of Slots······································································ 7 - 1

7.2 Connecting Extension Base Units and Setting the Number of Stages····································· 7 - 3

7.3 Base Unit Assignment (Base Mode)················································································ 7 - 7

A - 20

Page 23

7.4 What is I/O Number? ·································································································· 7 - 13

7.5 I/O Number Assignment ······························································································ 7 - 14

7.5.1 I/O numbers of a base unit····················································································· 7 - 14

7.6 I/O Assignment by C Controller Setting Utility ·································································· 7 - 17

7.6.1 Purposes of I/O assignment by C Controller setting utility············································· 7 - 17

7.6.2 Details of I/O assignment by C Controller setting utility ················································ 7 - 19

7.7 I/O Assignment Example ····························································································· 7 - 24

7.8 Checking I/O Numbers································································································ 7 - 28

CHAPTER 8 MEMORIES AND FILES 8 - 1 to 8 - 10

8.1 Memories of the C Controller Module ···············································································8 - 1

8.1.1 User memories······································································································8 - 1

8.1.2 System memory ····································································································8 - 6

8.2 File Operation and Handling Precautions ··········································································8 - 7

8.2.1 File operation ········································································································8 - 7

8.2.2 Precautions for handling files ···················································································8 - 9

CHAPTER 9 DEVICE DESCRIPTION 9 - 1 to 9 - 5

9.1 Applicable Devices with C Controller Modules ···································································9 - 1

9.2 I/O Device ··················································································································9 - 2

9.2.1 Input (X)···············································································································9 - 2

9.2.2 Output (Y) ············································································································9 - 2

9.3 Internal User Device ·····································································································9 - 3

9.3.1 Internal relay (M) ···································································································9 - 3

9.3.2 Data register (D) ····································································································9 - 3

9.4 Internal System Device ·································································································9 - 3

9.4.1 Special relay (SM) ·································································································9 - 3

9.4.2 Special register (SD) ······························································································9 - 3

9.5 Link Direct Device ········································································································9 - 4

9.6 Module Access Device··································································································9 - 5

9.6.1 Intelligent function module device··············································································9 - 5

9.6.2 Multiple CPU area device ························································································9 - 5

CHAPTER 10 MULTIPLE CPU SYSTEM OVERVIEW 10 - 1 to 10 - 3

10.1 What is the Multiple CPU System? ················································································ 10 - 1

CHAPTER 11 MULTIPLE CPU SYSTEM CONFIGURATION 11 - 1 to 11 - 15

11.1 System Configuration ································································································· 11 - 1

11.1.1 Devices used for each base unit ············································································· 11 - 2

11.1.2 Connection with a development environment····························································· 11 - 5

11.1.3 Connection with peripheral devices ········································································· 11 - 5

11.1.4 System configuration overview (when CPU No.1 is a C Controller module) ······················ 11 - 6

11.2 Applicable Modules ·································································································· 11 - 11

A - 21

Page 24

11.2.1 Applicable CPU modules ····················································································· 11 - 11

11.2.2 Precautions for using I/O modules and intelligent function modules ······························ 11 - 13

11.3 Precautions for System Configuration··········································································· 11 - 14

CHAPTER 12 CONCEPT OF MULTIPLE CPU SYSTEM 12 - 1 to 12 - 24

12.1 Mounting Positions of CPU Modules ··············································································12 - 1

12.2 CPU No. of CPU Module ·····························································································12 - 9

12.3 I/O Number Assignment ···························································································· 12 - 11

12.3.1 I/O number assignment for the module ··································································· 12 - 11

12.3.2 I/O number of each CPU module··········································································· 12 - 12

12.4 Access Ranges Between a CPU Module and Other Modules ············································ 12 - 13

12.4.1 Access to controlled modules ··············································································· 12 - 13

12.4.2 Access to non-controlled modules ········································································· 12 - 13

12.5 Access to Link Devices ····························································································· 12 - 20

12.6 Resetting CPU Modules ···························································································· 12 - 21

12.7 When a CPU Module Stop Error Occurs ······································································· 12 - 22

CHAPTER 13 COMMUNICATIONS BETWEEN CPU MODULES 13 - 1 to 13 - 49

13.1 Data Communications by MELSEC Data Link Functions ····················································13 - 2

13.2 Interrupt from Another CPU··························································································13 - 3

13.2.1 Multiple CPU synchronous interrupt function···························································· 13 - 11

13.3 Data Communications Using CPU Shared Memory ························································· 13 - 12

13.3.1 CPU shared memory structure·············································································· 13 - 14

13.3.2 Data communications using auto refresh································································· 13 - 17

13.3.3 Communication using the multiple CPU high speed transmission area and auto refresh ··· 13 - 24

13.3.4 Data communications without using auto refresh ······················································ 13 - 32

13.4 Programmable Controller Remote Control Function ························································ 13 - 42

13.5 Sequence Program Control Function············································································ 13 - 43

13.6 Issuing an Interrupt to Another CPU············································································· 13 - 44

13.7 Motion CPU Control Instruction ··················································································· 13 - 46

13.8 Motion CPU Device Access························································································ 13 - 47

13.9 Multiple CPU Synchronized Boot-Up············································································ 13 - 48

CHAPTER 14 PARAMETERS ADDED FOR MULTIPLE CPU SYSTEMS 14 - 1 to 14 - 7

14.1 Parameter List···········································································································14 - 1

14.1.1 Setting the number of CPUs (required) ·····································································14 - 4

14.1.2 Operation mode setting (optional) ············································································14 - 6

14.1.3 Online module change (optional) ·············································································14 - 6

14.1.4 I/O sharing when using Multiple CPUs (optional) ························································14 - 6

14.1.5 Communication area setting (refresh setting) (optional)················································14 - 6

14.1.6 Control CPU settings (required) ··············································································14 - 7

14.1.7 Multiple CPU synchronous startup setting (optional) ····················································14 - 7

14.1.8 Multiple CPU high speed transmission area setting (required) ·······································14 - 7

A - 22

Page 25

CHAPTER 15 STARTING A MULTIPLE CPU SYSTEM 15 - 1 to 15 - 17

15.1 Flowchart for Starting a Multiple CPU System·································································· 15 - 1

15.2 Setting Parameters Added for Multiple CPU Systems ························································ 15 - 4

15.2.1 System configuration ···························································································· 15 - 4

15.2.2 Parameters required for the multiple CPU system······················································· 15 - 5

15.2.3 When creating a new system ················································································· 15 - 7

15.2.4 Importing existing multiple CPU parameters ···························································· 15 - 14

CHAPTER 16 TROUBLESHOOTING 16 - 1 to 16 - 93

16.1 Troubleshooting Basics ······························································································· 16 - 2

16.2 Troubleshooting ········································································································ 16 - 3

16.2.1 When the POWER LED on the power supply module turned off ···································· 16 - 4

16.2.2 When the MODE LED is not lit················································································ 16 - 5

16.2.3 When the ERR. LED is on or flashing······································································· 16 - 7

16.2.4 When the RUN LED remains flashing ······································································ 16 - 8

16.2.5 When UNIT VERIFY ERR. occurred ········································································ 16 - 9

16.2.6 When CONTROL-BUS.ERR. occurred ··································································· 16 - 10

16.2.7 When no communication is available between the development environment

(personal computer) and C Controller module ·························································· 16 - 12

16.2.8 When a file (program) cannot be written ································································· 16 - 15

16.2.9 When an error occurs during user program execution················································ 16 - 16

16.2.10 When a file system error occurred ········································································· 16 - 18

16.2.11 When no LED on an output module turn on ····························································· 16 - 20

16.2.12 When an output load device of an output module does not turn on ······························· 16 - 21

16.2.13 When operation is not normal due to script file execution ··········································· 16 - 22

16.2.14 When an error occurred during user program download or ld command execution ·········· 16 - 25

16.2.15 When unable to read from or write to the specified device ·········································· 16 - 27

16.2.16 When an error occurred during reading from or writing to the standard RAM,

standard ROM, CompactFlash card, or RAM disk using FTP ······································ 16 - 28

16.2.17 When unable to make a Telnet connection ······························································ 16 - 30

16.2.18 When unable to make an FTP connection ······························································· 16 - 32

16.3 Actions to be Taken When the ERR. LED is On or Flashing·············································· 16 - 34

16.4 Error Code List ········································································································ 16 - 59

16.4.1 Error codes and actions (for errors occurred in function execution)······························· 16 - 59

16.4.2 Error codes and actions (for errors occurred in communication)··································· 16 - 73

16.5 Hardware Self-Diagnostic Function·············································································· 16 - 75

16.5.1 Hardware self-diagnostic test and initialization setting of the Q12DCCPU-V ··················· 16 - 75

16.5.2 Hardware self-diagnostic test and initialization setting of the Q06CCPU-V(-B) ················ 16 - 84

16.6 Diagnostics and Restoration of the Standard RAM, Standard ROM, and CompactFlash Card

Drives ··················································································································· 16 - 91

APPENDICES APPX - 1 to APPX - 48

Appendix 1 Function Processing Time ············································································· APPX - 1

Appendix 2 External Dimensions ···················································································· APPX - 6

Appendix 2.1 Q12DCCPU-V ····················································································· APPX - 6

Appendix 2.2 Q06CCPU-V························································································ APPX - 8

A - 23

Page 26

Appendix 2.3 Q06CCPU-V-B ····················································································· APPX - 9

Appendix 3 Transportation Precautions·········································································· APPX - 10

Appendix 3.1 Regulated models··············································································· APPX - 10

Appendix 3.2 Handling for transportation···································································· APPX - 10

Appendix 4 Handling of Batteries and Devices with Built-in Batteries in EU Member States ······ APPX - 11

Appendix 4.1 Disposal precautions ··········································································· APPX - 11

Appendix 4.2 Exportation precautions········································································ APPX - 12

Appendix 5 Characters Applicable to User Names and Passwords ······································ APPX - 13

Appendix 6 List of Special Relays ················································································· APPX - 15

Appendix 7 List of Special Registers·············································································· APPX - 16

Appendix 8 Parameter Number List··············································································· APPX - 22

Appendix 9 Connection with GX Works2/GX Developer····················································· APPX - 25

Appendix 9.1 When accessing another CPU of a multiple CPU system ···························· APPX - 25

Appendix 9.2 Accessing other stations······································································· APPX - 34

Appendix 10 Connection with MX Component··································································· APPX - 37

Appendix 10.1 Accessing the host station ···································································· APPX - 37

Appendix 10.2 Accessing other stations······································································· APPX - 43

Appendix 11 Functions Added by Version Upgrade ···························································· APPX - 45

INDEX INDEX - 1 to INDEX - 2

A - 24

Page 27

ABOUT MANUALS

Relevant Manuals

The following manuals are relevant to this product.

Order each manual as needed, referring to the table below.

Manual name

C Controller Module User's Manual (Utility Operation, Programming)

Describes the installation and uninstallation of VxWorks-based setting and monitoring tool for C

Controller module (SW3PVC-CCPU), utility operations, and functions and programming.

(Sold separately)

MELSEC-Q C Controller Module User's Manual

Describes the system configuration, specifications, functions, handling methods, wiring,

troubleshooting, and programming and function of C Controller module (Q24DHCCPU-V,

Q24DHCCPU-VG, Q24DHCCPU-LS, Q26DHCCPU-LS, and Q12DCCPU-V (Extended mode)).

(Sold separately)

Setting/Monitoring Tools for the C Controller Module Version 4 Operating Manual

Describes the system configuration and operation method of Setting/Monitoring Tools for the C

Controller Module (SW4PVC-CCPU).

(Sold separately)

CW Workbench Operating Manual

Describes the system configuration, installation/uninstallation, specifications, functions, and

troubleshooting of the product.

(Sold separately)

CW-Sim Operating Manual

Describes the system configuration, specifications, functions, and troubleshooting of CW-Sim.

(Sold separately)

QCPU User's Manual (Hardware Design, Maintenance and Inspection)

Describes the specifications of CPU modules, power supply modules, base units, extension cables,

memory cards, and others.

(Sold separately)

QCPU User's Manual (Multiple CPU System)

Describes the multiple CPU system overview, system configurations, I/O numbers, communications

between CPU modules, and communication with I/O modules or intelligent function modules.

(Sold separately)

MELSEC-Q CC-Link System Master/Local Module User's Manual

Describes the system configurations, performance specifications, functions, handling instructions,

wiring, and troubleshooting of CC-Link modules.

(Sold separately)

Q Corresponding MELSECNET/H Network System Reference Manual (PLC to PLC network)

Describes the PLC-to-PLC network specifications, preparatory procedures and settings, parameter

setting, programming, and troubleshooting of the MELSECNET/H network system.

(Sold separately)

MELSEC-Q CC-Link IE Controller Network Reference Manual

Describes the system configurations, performance specifications, functions, handling instructions,

wiring, and troubleshooting of the CC-Link IE controller network system.

(Sold separately)

Manual number

(code)

SH-080767ENG

(13JZ18)

SH-081130ENG

(13JZ75)

SH-081131ENG

(13JU76)

SH-080982ENG

(13JU71)

SH-081159ENG

(13JU77)

SH-080483ENG

(13JR73)

SH-080485ENG

(13JR75)

SH-080394E

(13JR64)

SH-080049

(13JF92)

SH-080668ENG

(13JV16)

A - 25

Page 28

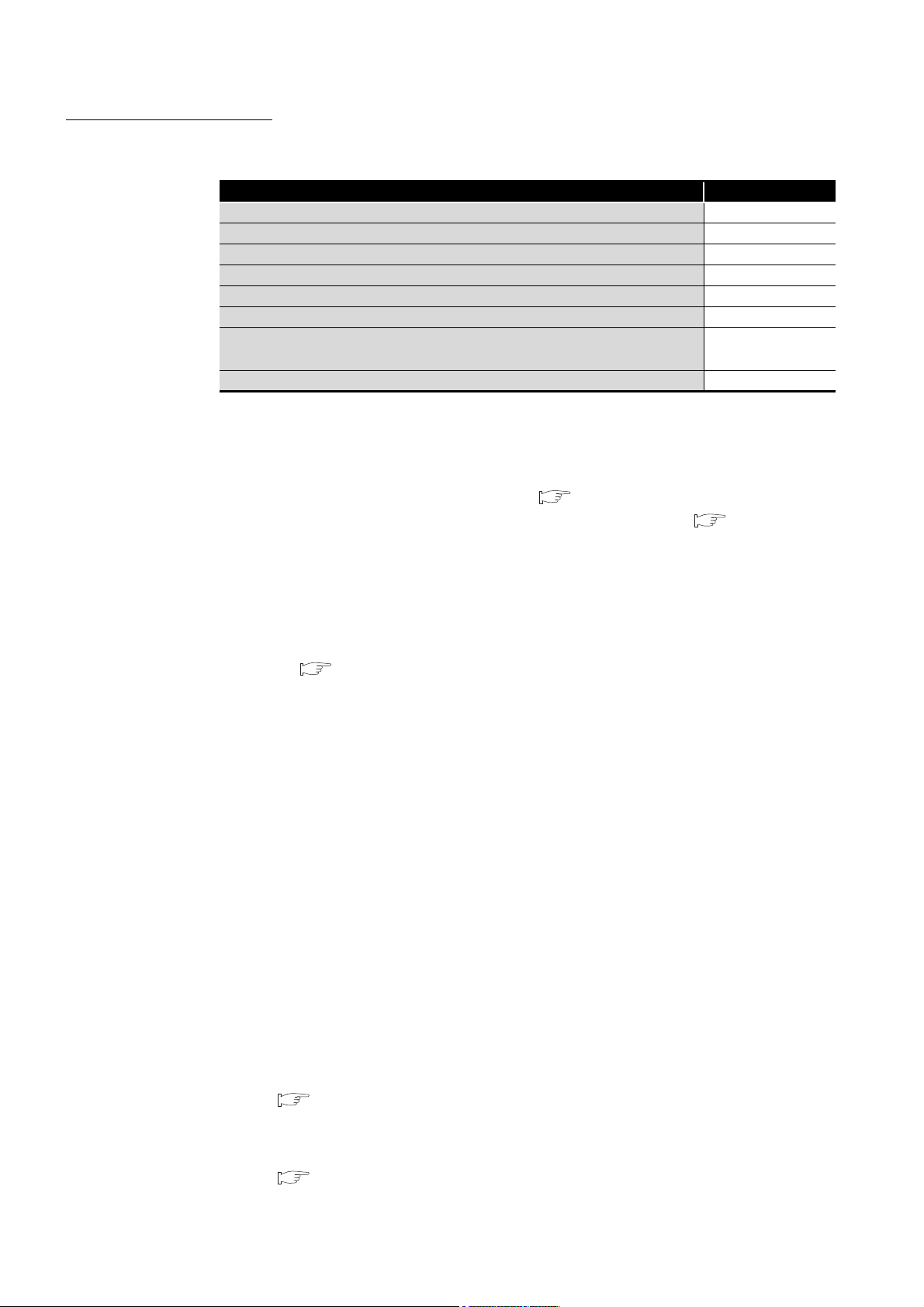

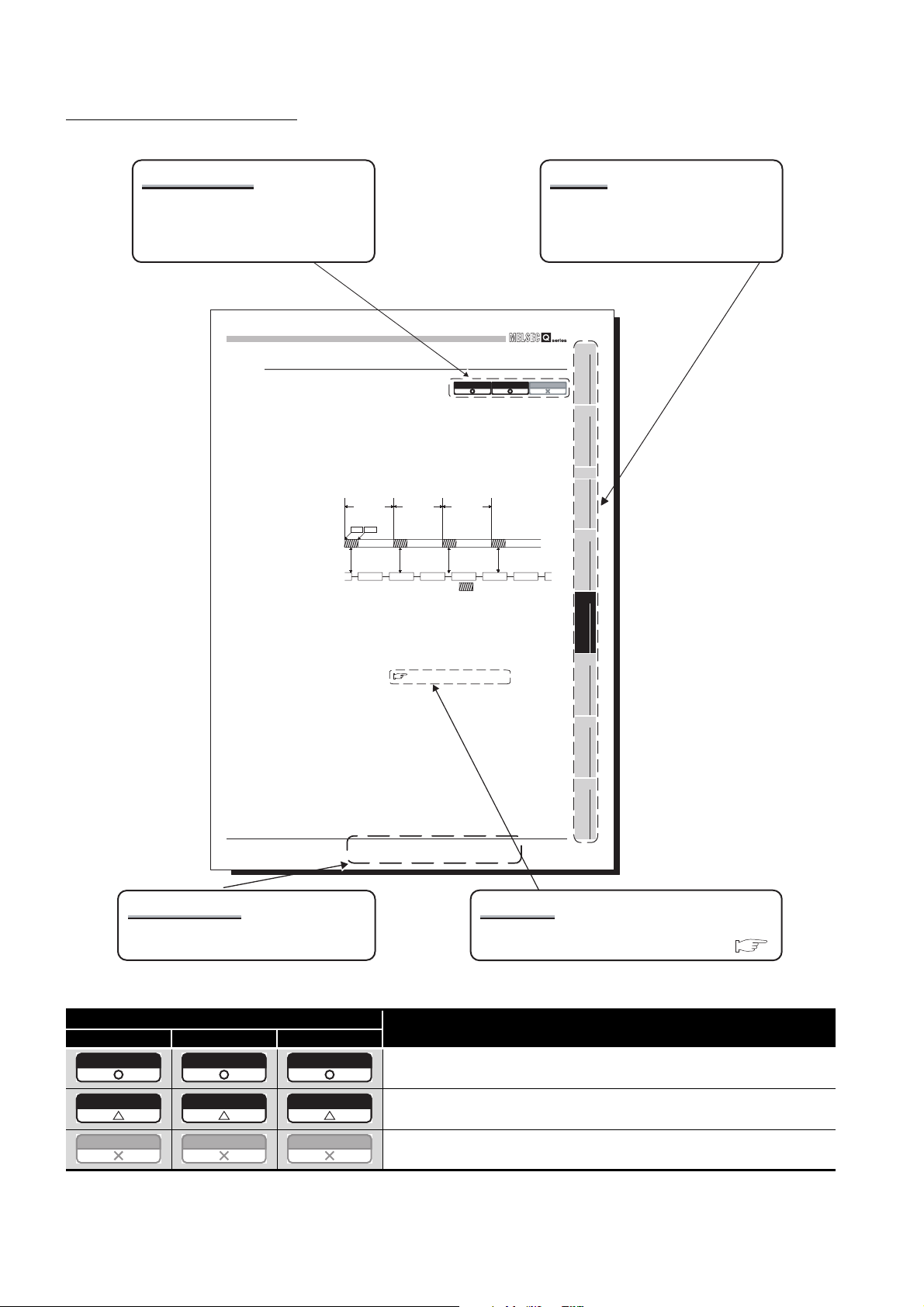

MANUAL PAGE ORGANIZATION

Q06CCPU-V

Relevant model

Whether the description of the section

applies to each model or not is shown as

in the table below.

ACCESS VIA NETWORK MODULES

5

5.4.4 Link device refresh setting

Link device refresh setting is required when using the internal buffer access in user

programs.

To enable the link device refresh, set a link device refresh cycle and refresh parameters in

CC IE Control utility.

(1) Link device refresh cycle

The link device refresh cycle is an interval of time during which the internal link device

buffers of the C Controller module and link devices of a CC-Link IE controller network

module are refreshed.

The concept of the link device refresh cycle is shown below.

C Controller

module processing

(a) Total link device refresh time

Link device

refresh cycle

Link device

refresh

Start End

Link device

refresh

Link scan

Figure 5.45 Conceptual diagram of link device refresh cycle

1) What is total link device refresh time?

This is a processing time for refreshing the link devices of all CC-Link IE

controller network modules that are controlled by the C Controller module.

2) How to obtain the total link device refresh time

A theoretical value for the total link device refresh time can be obtained by a

calculation formula. ( Page 5-59, Section 5.4.5 (1) (b))

Link device

refresh

Link device

refresh cycle

Link device

refresh

Q12DCCPU-V

Link device

refresh cycle

Link device

refresh

Total link device refresh time

Chapter

The chapter of the current page can be

easily identified by this indication on the

right side.

1

Q06CCPU-V-B

OVERVIEW

2

SYSTEM

CONFIGURATION

3

SPECIFICATIONS

4

FUNCTIONS

5

ACCESS VIA NETWORK

MODULES

6

5.4 CC-Link IE Controller Network Module Access Function

Section and title

The section number and title of the current

page can be easily identified.

* The above page illustration is for explanation purpose only, and is different from the actual page.

Icon

Q12DCCPU-V Q06CCPU-V Q06CCPU-V-B

Q12DCCPU-V Q06CCPU-V Q06CCPU-V-B

Q12DCCPU-V Q06CCPU-V Q06CCPU-V-B

Q12DCCPU-V Q06CCPU-V Q06CCPU-V-B

PREPARATORY

PROCEDURES AND

SETTING

7

I/O NUMBER

ASSIGNMENT

8

MEMORIES AND FILES

5.4.4 Link device refresh setting

5 - 48

Reference

The section in this manual or another relevant

manual that can be referred to is shown after .

Description

All or part of the description applies to each model.

The description applies to each model with some restrictions.

The description does not apply to each model.

A - 26

Page 29

HOW TO USE THIS MANUAL

Remark

This manual is intended to help you understand the system configurations, specifications,

functions, preparatory procedures, and troubleshooting of the C Controller module.

Utilize this manual, referring to the following.

CHAPTER 1 Describes the features of the C Controller module.

CHAPTER 2

CHAPTER 3 Describes the specifications and performance of the C Controller module.

CHAPTER 4 Describes the functions of the C Controller module.

CHAPTER 5 Describes the network module access function of the C Controller module.

CHAPTER 6

CHAPTER 7

CHAPTER 8 Describes the memories of the C Controller module.

CHAPTER 9 Describes devices that can be used with C Controller modules.

CHAPTER 10 to

CHAPTER 15

CHAPTER 16

Item Description

Describes system configurations that include the C Controller module, and

provides a list of the modules that are accessible from the C Controller

module.

Explains the procedures for starting the system operation using the C

Controller module.

Describes the stage number setting for extension base units and I/O number

assignment.

Describes multiple CPU system configurations, I/O numbers,

communications among programmable controller CPUs, I/O modules, and

intelligent function modules, and how to start a multiple CPU system.

Provides corrective actions to be taken for respective errors, and the error

codes that may be generated during function execution.

This manual does not explain the SW3PVC-CCPU installation and uninstallation

procedures, utility operations, functions, and programming.

For details, refer to the following.

C Controller Module User's Manual (Utility Operation, Programming)

A - 27

Page 30

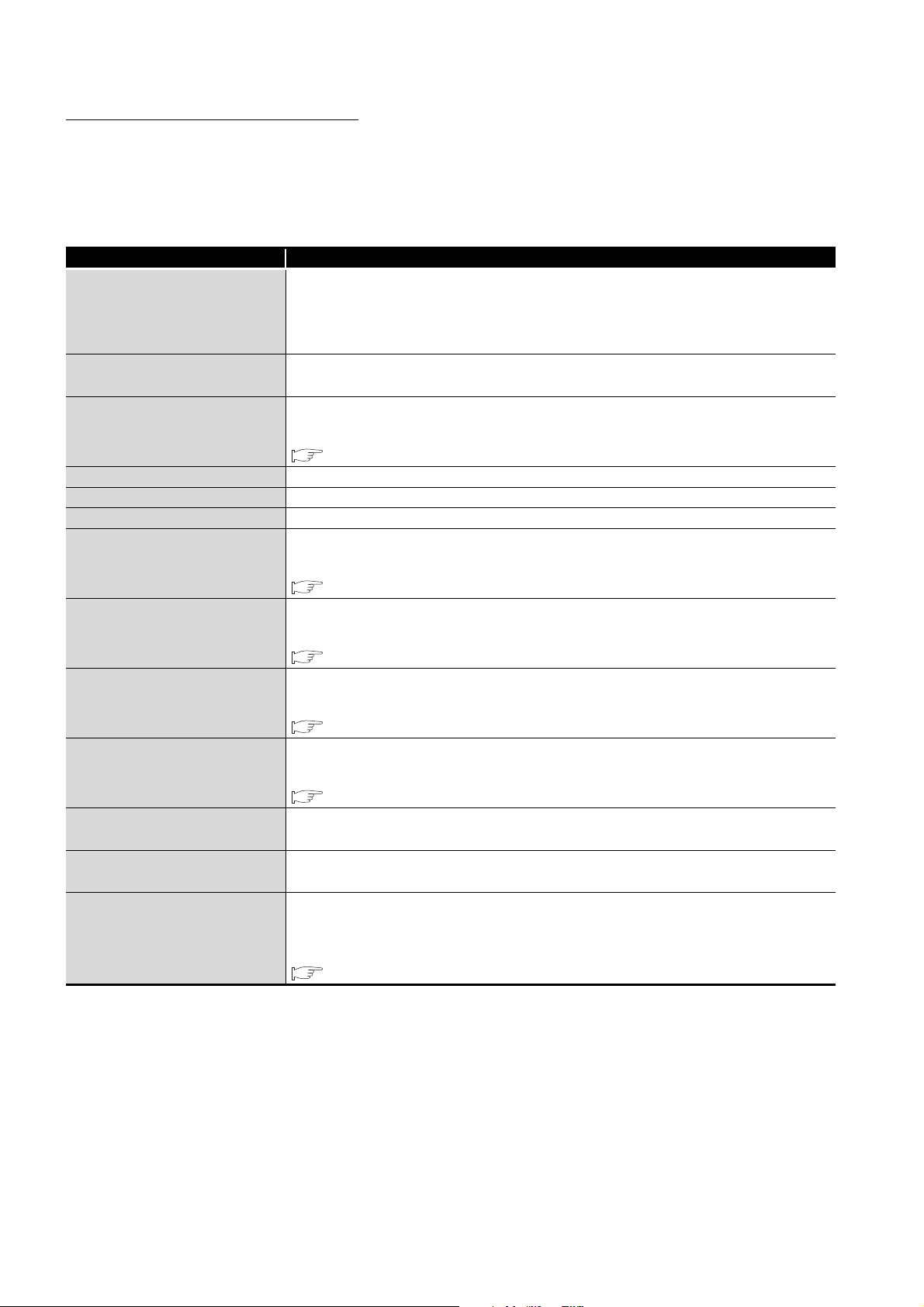

GENERIC TERMS AND ABBREVIATIONS

Unless otherwise specified, this manual uses the following generic terms and

abbreviations to explain the C Controller module.

(1) C Controller modules and SW3PVC-CCPU

Generic term/abbreviation Description

Abbreviation for the Q12DCCPU-V C Controller module

Q12DCCPU-V

Q12DCCPU-V

(Basic mode)

Q12DCCPU-V

(Extended mode)

Q06CCPU-V Abbreviation for the Q06CCPU-V C Controller module

Q06CCPU-V-B Abbreviation for the Q06CCPU-V-B C Controller module

Q06CCPU-V(-B) Generic term for the Q06CCPU-V and Q06CCPU-V-B

Q24DHCCPU-V

Q24DHCCPU-VG

Q24DHCCPU-LS

Q26DHCCPU-LS

C Controller module

SW3PVC-CCPU

SW4PVC-CCPU

In principle, 'Q12DCCPU-V' indicates Q12DCCPU-V (Basic mode).

When the classification is needed for such as comparison with other modules,

'Q12DCCPU-V (Basic mode)' and ‘Q12DCCPU-V (Extended mode)’ are mentioned.

Status that Q12DCCPU-V is initialized with the basic mode

Status that Q12DCCPU-V is initialized with the extended mode

For Q12DCCPU-V (Extended mode), refer to the following manual.

MELSEC-Q C Controller Module User's Manual

Abbreviation for the Q24DHCCPU-V C Controller module

For Q24DHCCPU-V, refer to the following manual.

MELSEC-Q C Controller Module User's Manual

Abbreviation for the Q24DHCCPU-VG C Controller module

For Q24DHCCPU-VG, refer to the following manual.

MELSEC-Q C Controller Module User's Manual

Abbreviation for the Q24DHCCPU-LS C Controller module

For Q24DHCCPU-LS, refer to the following manual.

MELSEC-Q C Controller Module User's Manual

Abbreviation for the Q26DHCCPU-LS C Controller module

For Q26DHCCPU-LS, refer to the following manual.

MELSEC-Q C Controller Module User's Manual

Generic term for the Q06CCPU-V, Q06CCPU-V-B, Q12DCCPU-V, Q24DHCCPU-V,

Q24DHCCPU-VG, Q24DHCCPU-LS, and Q26DHCCPU-LS

Abbreviation for the Setting/Monitoring Tools for the C Controller Module

(SW3PVC-CCPU-E)

Abbreviation for the Setting/Monitoring Tools for the C Controller Module

(SW4PVC-CCPU-E)

For SW4PVC-CCPU, refer to the following manual.

A - 28

Setting/Monitoring Tools for the C Controller Module Version 4 Operating Manual

Page 31

(2) CPU modules

Generic term/abbreviation Description

QnACPU

Basic model QCPU Generic term for the Q00CPU and Q01CPU

High Performance model QCPU Generic term for the Q02CPU, Q02HCPU, Q06HCPU, Q12HCPU, and Q25HCPU

Process CPU Generic term for the Q02PHCPU, Q06PHCPU, Q12PHCPU, and Q25PHCPU

Redundant CPU Generic term for the Q12PRHCPU and Q25PRHCPU

Universal model QCPU

QCPU (Q mode)

Motion CPU

CPU module Generic term for C Controller modules, QCPUs (Q mode), and Motion CPUs

Single CPU system Control system where a C Controller module is mounted in the CPU slot

Multiple CPU system Control system where multiple CPU modules are mounted on a main base unit

Control CPU

Controlled module

Non-controlled module

(Module outside an I/O sharing

group)

Non-control CPU

Battery Generic term for the Q6BAT and Q7BAT batteries for CPU modules

PC CPU module

Generic term for the Q2ACPU, Q2ACPU-S1, Q2ASCPU, Q2ASCPU-S1, Q2ASHCPU,

Q2ASHCPU-S1, Q3ACPU, Q4ACPU, and Q4ARCPU

Generic term for the Q00UJCPU, Q00UCPU, Q01UCPU, Q02UCPU, Q03UDCPU,

Q04UDHCPU, Q06UDHCPU, Q10UDHCPU, Q13UDHCPU, Q20UDHCPU,

Q26UDHCPU, Q03UDECPU, Q04UDEHCPU, Q06UDEHCPU, Q10UDEHCPU,

Q13UDEHCPU, Q20UDEHCPU, Q26UDEHCPU, Q50UDEHCPU, Q100UDEHCPU,

Q03UDVCPU, Q04UDVCPU, Q06UDVCPU, Q13UDVCPU, and Q26UDVCPU

Generic term for the Basic model QCPUs, High Performance model QCPUs, Process

CPUs, Redundant CPUs, and Universal model QCPUs

Generic term for the Q172CPUN, Q172CPUN-T, Q172HCPU, Q172HCPU-T,

Q173CPUN, Q173CPUN-T, Q173HCPU, Q173HCPU-T, Q172DCPU, and Q173DCPU

CPU module that can control I/O modules and intelligent function modules on main and

extension base units.

For example, when CPU No.2 controls a module mounted in Slot 3, CPU No.2 is a

control CPU of the module in Slot 3.

I/O module or intelligent function module that is controlled by a control CPU.

For example, when CPU No.2 controls a module mounted in Slot 3, the module in Slot 3

is a controlled module of CPU No.2.

I/O module or intelligent function module other than controlled modules of a CPU.

For example, when CPU No.2 controls a module mounted in Slot 3, the module in Slot 3

is a non-controlled module of CPUs No.1 and No.3.

CPU module that is not a control CPU.

For example, when CPU No.2 controls a module mounted in Slot 3, CPUs No.1 and

No.3 are non-control CPUs of the module in Slot 3.

Abbreviation for the MELSEC-Q series PC CPU module manufactured by CONTEC

CO., Ltd.

A - 29

Page 32

(3) Network modules and PC boards

Generic term/abbreviation Description

CC-Link module Generic term for the QJ61BT11 and QJ61BT11N

CC-Link/LT module Generic term for the QJ61CL12

Abbreviation for the Q81BD-J61BT11 or Q80BD-J61BT11N CC-Link system master/

CC-Link board

CC-Link IE controller network

module

CC-Link IE controller network

interface board

CC-Link IE field network master/

local module