Page 1

C

MIT

SUBIS

C

HI ELECTRI

MELSEC System Q

Programmable Logic Controllers

User’s Manual

High Performance Model QCPU

Art. no.: 130000

01 10 2002

SH (NA)-080037-F

Q02CPU, Q02HCPU,

Q06HCPU, Q12HCPU,

Q25HCPU

MITSUBISHI ELECTRI

INDUSTRIAL AUTOMATION

Page 2

SAFETY PRECAUTIONS

(Read these precautions before using.)

When using Mitsubishi equipment, thoroughly read this manual and the associated manuals introduced in

this manual. Also pay careful attention to safety and handle the module properly .

These SAFETY PRECAUTIONS classify the safety precautions int o two cat egories: "DANG ER" and

"CAUTION".

DANGER

!

CAUTION

!

Depending on circumstances, procedures indicated by ! CAUTION may also be linked to serious

results.

In any case, it is important to follow the directions for usage.

Store this manual in a safe place so that you can take it out and read it whenever necessary . Alw ay s

forward it to the end user.

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in medium or slight personal injury or physical damage.

[DESIGN PRECAUTIONS]

!

DANGER

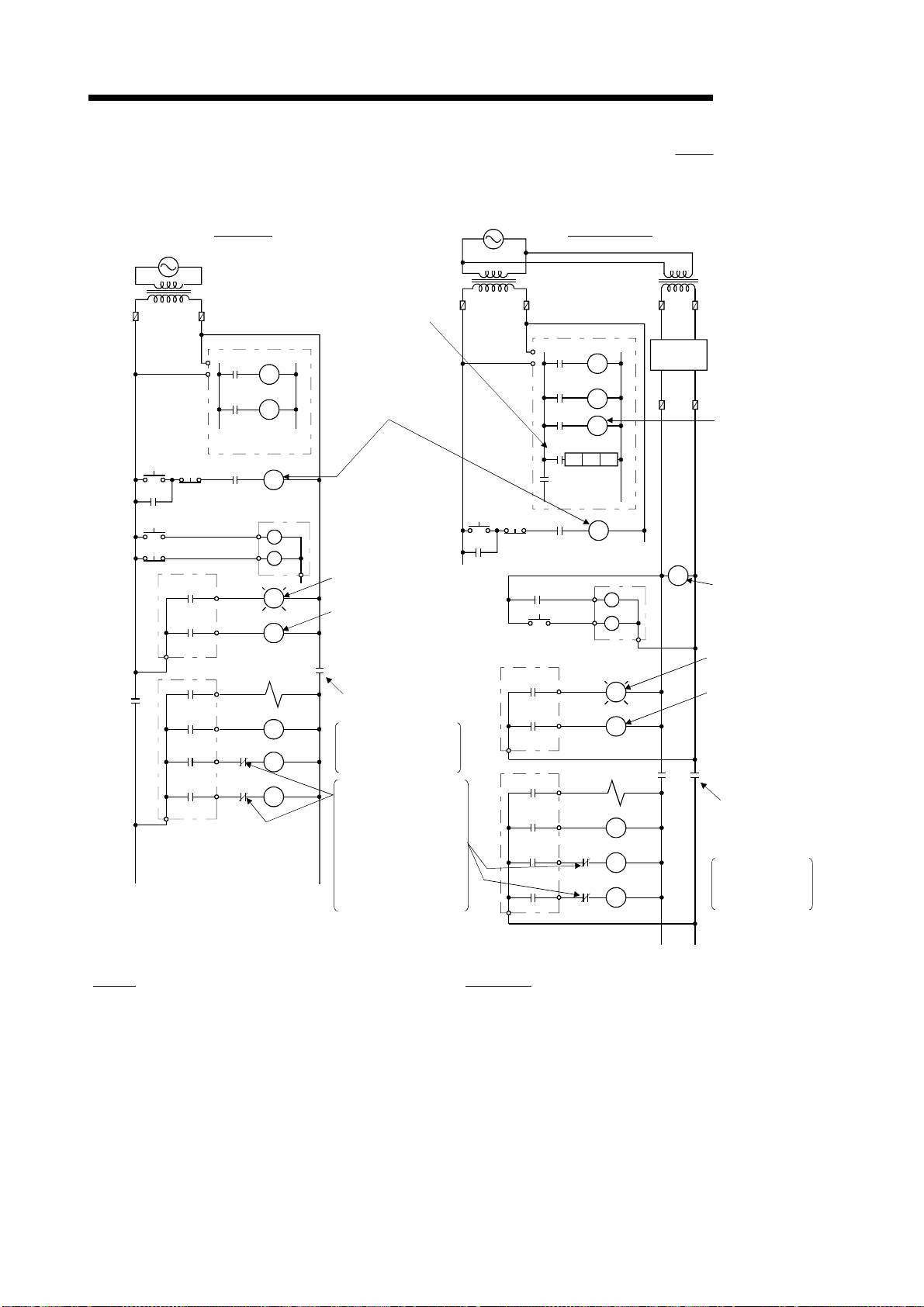

Install a safety circuit external to the PLC that keeps the ent ire syst em safe even when t here

are problems with the external power supply or the PLC module. Otherwise, t rouble could result

from erroneous output or erroneous operation.

(1) Outside the PLC, construct mechanical damage preventing interlock circuits such as

emergency stop, protective circuits, positioning upper and low er limits switches and

interlocking forward/reverse operations.

(2) When the PLC detects the following problems, it will stop calculation and turn off all out put

in the case of (a). In the case of (b), it will st op calculation and hold or t urn off all out put

according to the parameter setting.

Note that the AnS series module will turn off the out put in eit her of cases (a) and (b).

(a) The power supply module has over current protection equipment and over voltage

protection equipment.

(b) The PLC CPUs self-diagnosis functions, such as the watch dog timer error, detect

problems.

In addition, all output will be turned on when t here are pr oblems that t he PLC CPU cannot

detect, such as in the I/O controller. Build a fail safe circuit exterior to the PLC that will make

sure the equipment operates safely at such times. See section 9.1 of this manual for

example fail safe circuits.

(3) Output could be left on or off when there is trouble in the outputs module relay or transist or.

So build an external monitoring circuit that will monit or any single output s that could cause

serious trouble.

A - 1 A - 1

Page 3

[DESIGN PRECAUTIONS]

!

DANGER

When overcurrent which exceeds the rating or caused by short-circuited load flows in the output

module for a long time, it may cause smoke or fire. To prevent this, configure an external safety

circuit, such as fuse.

Build a circuit that turns on the external power supply w hen the PLC main module power is

turned on. If the external power supply is turned on first, it could result in erroneous out put or

erroneous operation.

When there are communication problems with the data link, refer to the corresponding data link

manual for the operating status of each station. Not doing so could result in erroneous output or

erroneous operation.

When connecting a peripheral device to the CPU module or connecting a personal computer or

the like to the intelligent function module to exercise control (data change) on the running PLC,

configure up an interlock circuit in the sequence program to ensure that t he whole sy stem w ill

always operate safely.

Also before exercising other control (program change, operating status change (status control))

on the running PLC, read the manual carefully and fully confirm safety.

Especially for the above control on the remote PLC from an external device, an immediate

action may not be taken for PLC trouble due to a data communication fault.

In addition to configuring up the interlock circuit in the sequence program, corrective and other

actions to be taken as a system for the occurrence of a data communication fault should be

predetermined between the external device and PLC CPU.

!

CAUTION

Do not bunch the control wires or communication cables with the main circuit or power wires, or

install them close to each other. They should be installed 100 mm (3.94 inch) or more from

each other. Not doing so could result in noise that would cause erroneous operation.

When controlling items like lamp load, heater or solenoid valve using an output module, large

current (approximately ten times greater than that present in normal circumstances) may flow

when the output is turned OFF to ON.

Take measures such as replacing the module with one having sufficient rated current.

A - 2 A - 2

Page 4

[INSTALLATION PRECAUTIONS]

!

CAUTION

Use the PLC in an environment that meets the general specifications contained in this manual.

Using this PLC in an environment outside the range of the general specifications could result in

electric shock, fire, erroneous operation, and damage to or deterioration of the product.

Hold down the module loading lever at the module bottom, and securely insert the module

fixing latch into the fixing hole in the base unit.

Incorrect loading of the module can cause a malfunction, failure or drop.

When using the PLC in the environment of much vibration, tighten the module with a screw.

Tighten the screw in the specified torque range. Undertightening can cause a drop, short circuit

or malfunction. Overtightening can cause a drop, short circuit or malfunction due to damage to

the screw or module.

When installing extension cables, be sure that the connectors of base unit are installed

correctly. After installation, check them for looseness. Poor connections could cause an input or

output failure.

Securely load the memory card into the memory card loading connector. After loading, check

for lifting. Lifting can cause a malfunction due to a contact fault.

Completely turn off the external power supply before loading or unloading the module. Not

doing so could result in electric shock or damage to the product.

Do not directly touch the module's conductive parts or electronic components. Touching the

conductive parts could cause an operation failure or give damage to the module.

[WIRING PRECAUTIONS]

!

DANGER

Completely turn off the external pow er supply when inst alling or placing w iring. Not completely

turning off all power could result in electric shock or damage to the product.

When turning on the power supply or operating the module after installation or wiring work, be

sure that the module's terminal covers are correctly attached. Not at taching the t erminal cover

could result in electric shock.

A - 3 A - 3

Page 5

[WIRING PRECAUTIONS]

!

CAUTION

Be sure to ground the FG terminals and LG terminals to the protective ground conductor. Not

doing so could result in electric shock or erroneous operation.

When wiring in the PLC, be sure that it is done correctly by checking the product's rated voltage

and the terminal layout. Connecting a power supply that is different from the rating or incorrectly

wiring the product could result in fire or damage.

External connections shall be crimped or pressure welded with the specified tools, or correctly

soldered. Imperfect connections could result in short circuit, fires, or erroneous operation.

Tighten the terminal screws with the specified torque. If the terminal screws are loose, it could

result in short circuits, fire, or erroneous operation. Tightening the terminal screws too far may

cause damages to the screws and/or the module, resulting in fallout, short circuits, or

malfunction.

Be sure there are no foreign substances such as sawdust or wiring debris inside the module.

Such debris could cause fires, damage, or erroneous operation.

The module has an ingress prevention label on its top to prevent foreign matter, such as wire

offcuts, from entering the module during wiring.

Do not peel this label during wiring.

Before starting system operation, be sure to peel this label because of heat dissipation.

[STARTUP AND MAINTENANCE PRECAUTIONS]

!

DANGER

Do not touch the terminals while power is on.

Doing so could cause shock or erroneous operation.

Correctly connect the battery.

Also, do not charge, disassemble, heat, place in fire, short circuit, or solder the battery .

Mishandling of battery can cause overheating or cracks which could result in injury and fires.

Switch all phases of the external power supply off when cleaning the module or retightening the

terminal or module mounting screws. Not doing so could result in electric shock.

Undertightening of terminal screws can cause a short circuit or malfunction. Overtightening of

screws can cause damages to the screws and/or the module, resulting in fallout, short circuits,

or malfunction.

A - 4 A - 4

Page 6

[STARTUP AND MAINTENANCE PRECAUTIONS]

!

DANGER

The online operations conducted for the CPU module being operated, connecting the peripheral

device (especially, when changing data or operation status), shall be conducted after the

manual has been carefully read and a sufficient check of safety has been conducted.

Operation mistakes could cause damage or problems with of the module.

Do not disassemble or modify the modules.

Doing so could cause trouble, erroneous operation, injury, or fire.

Use any radio communication device such as a cellular phone or a PHS phone more than 25cm

(9.85 inch) away from the PLC.

Not doing so can cause a malfunction.

Switch all phases of the external power supply off before mounting or removing the module.

If you do not switch off the external pow er supply , it will cause failur e or malfunction of t he

module.

Do not drop or give an impact to the battery installed in t he module.

Otherwise the battery w ill be broken, possibly causing inter nal leakage of electrolyt e.

Do not use but dispose of the battery if it has fallen or an impact is given to it .

[DISPOSAL PRECAUTIONS]

!

CAUTION

When disposing of this product, treat it as industrial waste.

A - 5 A - 5

Page 7

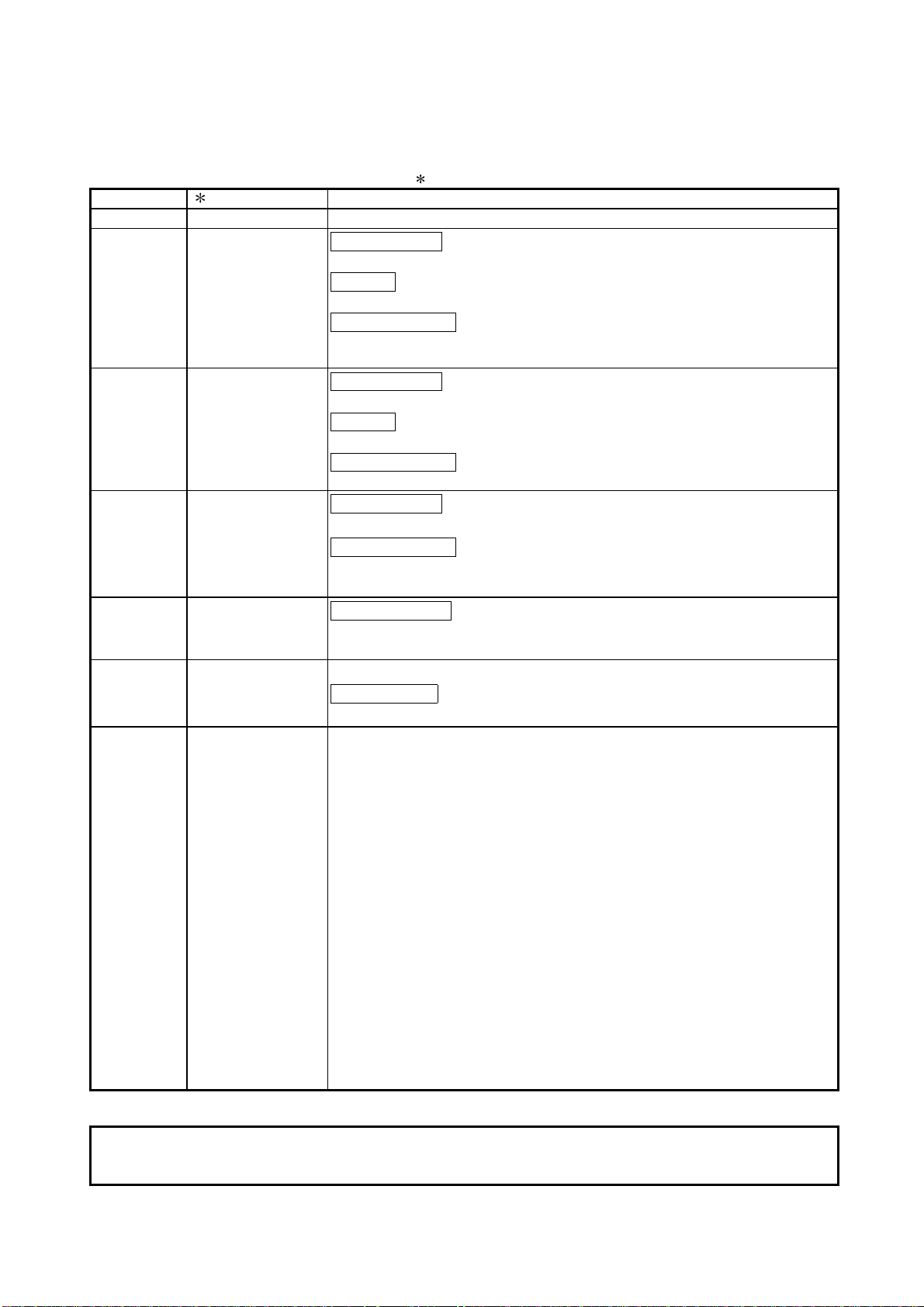

REVISIONS

The manual number is given on the bottom left of the back cover.

Print Date Manual Number Revision

Dec., 1999 SH(NA)-080037-A First edition

Sep., 2000 SH(NA)-080037-B

Addition model

Q33B, Q63B, Q63P

Addition

Section 2.3, 4.5, 11.2.3, 11.2.10, 11.2.11

Partial correction

Section 1.2, 2.2, 4.1, 4.2, 5.1.1, 5.2, 8.1.5, 11.2.1, 11.3.2, 11.5.1, 11.6,

11.7

Jun., 2001 SH(NA)-080037-C

Addition model

Q62P, Q52B, Q55B, QC05B

Addition

Section 6.6

Partial correction

Section 2.1, 2.2, 4.1, 4.2, 5.1.5, 6.1, 6.2, 6.3, 8.1.5, 11.2.4, 11.7

Sep., 2001 SH(NA)-080037-D

Addition model

Q64P

Partial correction

CONTENTS, Section 4.1, 5.1.1, 5.1.2, 5.2, 6.1, 6.2, 8.1.5, 11.5.1,

Appendix1.2, 2.2

Apr., 2002 SH(NA)-080037-E

Partial correction

Chapter 1, Section 1.1, 2.1, 2.2, 2.3, 4.1, 5.1.1, 7.1, 7.2, 7.3, 10.3.1,

10.3.2

Oct., 2002 SH(NA)-080037-F

Complete review

Addition model

Q32SB, Q33SB, Q35SB, Q61SP

Japanese Manual Version SH-080019-I

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any patent

licenses. Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property

rights which may occur as a result of using the contents noted in this manual.

1999 MITSUBISHI ELECTRIC CORPORATION

A - 6 A - 6

Page 8

INTRODUCTION

Thank you for choosing the Mitsubishi MELSEC-Q Series of General Purpose Programmable Controllers.

Please read this manual carefully so that equipment is used to its optimum.

CONTENTS

SAFETY PRECAUTIONS............................................................................................................................A- 1

REVISIONS ..................................................................................................................................................A- 6

CONTENTS ..................................................................................................................................................A- 7

About Manual................................................................................................................................................A-17

How to Use This Manuals ............................................................................................................................A-18

About the Generic Terms and Abbreviations...............................................................................................A-19

1 OVERVIEW 1- 1 to 1- 4

1.1 Features..................................................................................................................................................1- 2

2 SYSTEM CONFIGURATION FOR SINGLE CPU SYSTEM 2- 1 to 2- 8

2.1 System Configuration............................................................................................................................. 2- 1

2.2 Precaution on System Configuration.....................................................................................................2- 6

2.3 Confirming the Serial Number and Function Version............................................................................2- 8

3 GENERAL SPECIFICATIONS 3- 1 to 3- 2

4 HARDWARE SPE CI F I CATI ON O F TH E CPU MODULE 4- 1 to 4 - 9

4.1 Performance Specification .....................................................................................................................4- 1

4.2 Part Names and Settings .......................................................................................................................4- 4

4.3 Switch Operation After Writing in Program............................................................................................4- 7

4.4 Latch Clear Operation ............................................................................................................................4- 8

4.5 Executing Automatic Write to Standard ROM....................................................................................... 4- 8

5 POWER SUPPLY MODULE 5- 1 to 5- 11

5.1 Specification............................................................................................................................................5- 1

5.1.1 Power supply module specifications .............................................................................................. 5- 1

5.1.2 Selecting the power supply module................................................................................................5- 6

5.1.3 Precauti on wh en connect in g th e unin te r rupt ive powe r supply......................................................5- 8

5.2 Names of Parts and Settings .................................................................................................................5- 9

6 BASE UNIT AND EXTENSION CABLE 6- 1 to 6- 11

6.1 Base Unit Specification Table ................................................................................................................ 6- 1

6.2 Extension Cable Specification Table.....................................................................................................6- 3

6.3 Parts Names of Base Unit......................................................................................................................6- 3

6.4 Setting the Extension Base Unit ............................................................................................................6- 6

A - 7 A - 7

Page 9

6.5 I/O Number Allocation ............................................................................................................................6- 7

6.6 Guideline fo r U se o f Ex ten si on Ba se Un it s (Q5B) .............................................................................6- 8

7 MEMORY CARD AND BATTERY 7- 1 to 7- 6

7.1 Memory Card Specifications.................................................................................................................. 7- 1

7.2 Battery Specifications (For CPU Module and SRAM Card)..................................................................7- 2

7.3 Handling the Memory Card....................................................................................................................7- 3

7.4 The Names of The Parts of The Memory Card.....................................................................................7- 4

7.5 Memory Card Loading/Unloading Procedures...................................................................................... 7- 5

7.6 Installation of Battery (For CPU Module and Memory Card)................................................................ 7- 6

8 EMC AND LOW VOLTAGE DIRECTIVE 8- 1 to 8-11

8.1 Requirements for Conformance to EMC Directive................................................................................8- 1

8.1.1 Standards applicable to the EMC Directive....................................................................................8- 1

8.1.2 Installation instructions for EMC Directive......................................................................................8- 2

8.1.3 Cables..............................................................................................................................................8- 3

8.1.4 Power supply module......................................................................................................................8- 5

8.1.5 When using QA1S6

8.1.6 Others..............................................................................................................................................8- 8

8.2 Requirement to Conform to the Low Voltage Directive.........................................................................8- 9

8.2.1 Standard applied for MELSEC-Q series PLC................................................................................8- 9

8.2.2 MELSEC-Q series PLC selection...................................................................................................8- 9

8.2.3 Power supply..................................................................................................................................8- 10

8.2.4 Control box.....................................................................................................................................8- 10

8.2.5 Grounding.......................................................................................................................................8- 11

8.2.6 External wiring................................................................................................................................8- 11

B type base unit ........................................................................................ 8- 5

9 LOADING AND INSTALLATION 9- 1 to 9-26

9.1 General Safety Requirements................................................................................................................ 9- 1

9.2 Calculating Heat Generation by PLC..................................................................................................... 9- 6

9.3 Module Installation..................................................................................................................................9- 9

9.3.1 Precaution on installation................................................................................................................9- 9

9.3.2 Instructions for mounting the base unit ..........................................................................................9-12

9.3.3 Installation and removal of module................................................................................................. 9-15

9.4 How to Set Stage Numbers for the Extension Base Unit......................................................................9-19

9.5 Connection and Disconnection of Extension Cable ..............................................................................9-20

9.6 Wiring......................................................................................................................................................9-23

9.6.1 The precautions on the wiring.........................................................................................................9-23

9.6.2 Connecting to the power supply module ........................................................................................ 9-26

10 MAINTENANCE AND INSPECTION 10- 1 to 10- 8

10.1 Daily Inspection ..................................................................................................................................10- 2

10.2 Periodic Inspection.............................................................................................................................10- 3

10.3 Battery Replacement..........................................................................................................................10- 4

10.3.1 Battery life....................................................................................................................................10- 5

10.3.2 Battery replacement procedure..................................................................................................10- 7

A - 8 A - 8

Page 10

11 TROUBLESHOOTING 11- 1 to 11-99

11.1 Troubleshooting Basics......................................................................................................................11- 1

11.2 Troubleshooting..................................................................................................................................11- 2

11.2.1 Troubleshooting flowchart...........................................................................................................11- 2

11.2.2 Flowchart for when the "MODE" LED is not turned on..............................................................11- 3

11.2.3 Flowchart for when the "MODE" LED is flickering.....................................................................11- 4

11.2.4 Flowchart for when the "POWER" LED is turned off .................................................................11- 5

11.2.5 Flowchart for when the "RUN" LED is turned off .......................................................................11- 6

11.2.6 When the "RUN" LED is flickering..............................................................................................11- 7

11.2.7 Flowchart for when the "ERR." LED is on/flickering ..................................................................11- 7

11.2.8 When the "USER" LED is turned on...........................................................................................11- 8

11.2.9 When the "BAT." LED is turned on.............................................................................................11- 8

11.2.10 Flowchart for when the "BOOT" LED is flickering.................................................................... 11- 9

11.2.11 Flowchart for when output module LED is not turned on ........................................................11-10

11.2.12 Flowchart for when output load of output module does not turn on........................................11-11

11.2.13 Flowchart for when unable to read a program.........................................................................11-12

11.2.14 Flowchart for when unable to write a program.........................................................................11-13

11.2.15 Flowchart for when it is unable to perform boot operation from memory card .......................11-15

11.2.16 Flowchart for when UNIT VERIFY ERR. occurs......................................................................11-16

11.2.17 Flowchart for when CONTROL BUS ERR. occurs..................................................................11-17

11.3 Error Code List....................................................................................................................................11-18

11.3.1 Procedure for reading error codes..............................................................................................11-18

11.3.2 Error code list ..............................................................................................................................11-19

11.4 Canceling of Errors.............................................................................................................................11-37

11.5 I/O Module Troubleshooting...............................................................................................................11-38

11.5.1 Input circuit troubleshooting........................................................................................................11-38

11.5.2 Output circuit troubleshooting.....................................................................................................11-41

11.6 Special Relay List...............................................................................................................................11-42

11.7 Special Register List...........................................................................................................................11-64

APPENDICES App- 1 to App-17

APPENDIX 1 Error Code Return to Origin During General Data Processing........................................App- 1

APPENDIX 1.1 Error code overall explanation ...................................................................................App- 1

APPENDIX 1.2 Description of the errors of the error codes (4000

H

to 4FFFH) .................................App- 2

APPENDIX 2 External Dimensions .........................................................................................................App- 7

APPENDIX 2.1 CPU module ...............................................................................................................App- 7

APPENDIX 2.2 Power supply module.................................................................................................App- 7

APPENDIX 2.3 Main base unit ............................................................................................................App-10

APPENDIX 2.4 Slim type main base unit............................................................................................App-12

APPENDIX 2.5 Extension base unit....................................................................................................App-13

APPENDIX 3 Upgraded Functions of High Performance Model QCPU ................................................App-16

APPENDIX 3.1 Specification comparison ...........................................................................................App-16

APPENDIX 3.2 Function comparison..................................................................................................App-16

APPENDIX 3.3 Added functions and the corresponding GX Developer versions.............................App-17

INDEX Index- 1 to Index- 2

A - 9 A - 9

Page 11

(Related manual) ....................................................High Performance model QCPU (Q Mode) User's Manual

(Function Explanation, Program Fundamentals)

CONTENTS

1 OVERVIEW

1.1 Features

1.2 Programs

1.3 Convenient Programming Devices and Instructions

2 SYSTEM CONFIGURATION FOR SINGLE CPU SYSTEM

2.1 System Configuration

2.2 Precaution on System configuration

2.3 Confirming the Serial Number and Function Version

3 PERFORMANCE SPECIFICATION

4 SEQUENCE PROGRAM CONFIGURATION & EXECUTION CONDITIONS

4.1 Sequence Program

4.1.1 Main routine program

4.1.2 Sub-routine programs

4.1.3 Interrupt programs

4.2 Program Execute Type

4.2.1 Initial execution type program

4.2.2 Scan execution type program

4.2.3 Low speed execution type program

4.2.4 Stand-by type program

4.2.5 Fixed scan execution type program

4.3 Operation processing

4.3.1 Initial processing

4.3.2 I/O refresh (I/O module refresh processing)

4.3.3 Automatic refresh of the intelligent function module

4.3.4 END processing

4.4 RUN, STOP, PAUSE Operation Processing

4.5 Operation Processing during Momentary Power Failure

4.6 Data Clear Processing

4.7 I/O Processing and Response Lag

4.7.1 Refresh mode

4.7.2 Direct mode

4.8 Numeric Values which Can Be Used in Sequence Programs

4.8.1 BIN (Binary code)

4.8.2 HEX (Hexadecimal)

4.8.3 BCD (Binary Coded Decimal)

A - 10 A - 10

Page 12

4.8.4 Real numbers (floating decimal point data)

4.9 Character String Data

5 ASSIGNMENT OF I/O NUMBERS

5.1 Relationship Between the Number of Stages and Slots of the Extension Base Unit

5.2 Installing Extension Base Units and Setting the Number of Stages

5.3 Base Unit Assignment (Base Mode)

5.4 What are I/O Numbers?

5.5 Concept of I/O Number Assignment

5.5.1 I/O numbers of main base unit and extension base units

5.5.2 Remote station I/O number

5.6 I/O Assignment by GX Developer

5.6.1 Purpose of I/O assignment by GX Developer

5.6.2 Concept of I/O assignment using GX Developer

5.7 Examples of I/O Number Assignment

5.8 Checking the I/O Numbers

6 HIGH PERFORMANCE MODEL QCPU FILES

6.1 About the High Performance model QCPU's Memory

6.2 Program Memory

6.3 About the Standard ROM

6.4 About the Standard RAM

6.5 Memory Card

6.6 Writing Data to the Standard ROM or the Flash Card

6.6.1 Writing Data to the standard ROM or to the Flash card using GX Developer

6.6.2 Automatic write to standard ROM

(Auto Down load all data from Memory card to standard ROM)

6.7 Executing Standard ROM/Memory Card Programs (Boot Run)

6.8 Program File Configuration

6.9 GX Developer File Operation and File Handling Precautions

6.9.1 File operation

6.9.2 File handling precautions

6.9.3 File size

7 FUNCTION

7.1 Function List

7.2 Constant Scan

7.3 Latch Functions

7.4 Setting the Output (Y) Status when Changing from/to STOP Status to/from RUN Status

7.5 Clock Function

A - 11 A - 11

Page 13

7.6 Remote Operation

7.6.1 Remote RUN/STOP

7.6.2 Remote PAUSE

7.6.3 Remote RESET

7.6.4 Remote latch clear

7.6.5 Relationship of the remote operation and High Performance model QCPU RUN/STOP switch

7.7 Changing the Input Response Speed of the Q Series Compatible Module (I/O Response Time)

7.7.1 Selecting the response time of the input module

7.7.2 Selecting the response time of the high speed input module

7.7.3 Selecting the response time of the interrupt module

7.8 Setting the Switches of the Intelligent Function Module

7.9 Monitoring Function

7.9.1 Monitor condition setting

7.9.2 Monitoring test for local device

7.9.3 Forced ON/OFF of external I/O

7.10 Writing in Program during High Performance model QCPU RUN

7.10.1 Writing data in the circuit mode during the RUN status

7.10.2 Writing a batch of files during RUN

7.11 Execution Time Measurement

7.11.1 Program monitor list

7.11.2 Interrupt program monitor list

7.11.3 Scan time measurement

7.12 Sampling Trace Function

7.13 Debug Function with Multiple Users

7.13.1 Multiple-user monitoring function

7.13.2 Multiple-user RUN write function

7.14 Watch dog timer (WDT)

7.15 Self-Diagnosis Function

7.15.1 Interrupt due to error occurrence

7.15.2 LED display when error occurs

7.15.3 Cancel error

7.16 Failure History

7.17 System Protect

7.17.1 Password registration

7.17.2 Remote password

7.18 Monitoring High Performance model QCPU System Status from GX Developer (System Monitor)

7.19 LED Display

7.19.1 LED display

7.19.2 Priority setting

7.20 High Speed Interrupt Function

7.21 Module Service Interval Time Reading

A - 12 A - 12

Page 14

8 COMMUNICATION WITH INTELLIGENT FUNCTION MODULE/SPECIAL FUNCTION MODULE

8.1 Communication Between High Performance model QCPU and Q-series Intelligent Function Modules

8.1.1 Initial setting and automatic refresh setting using GX Configurator

8.1.2 Communication using device initial value

8.1.3 Communication using FROM/TO instruction

8.1.4 Communication using the intelligent function module device

8.1.5 Communication using the instructions dedicated for intelligent function modules

8.2 Request from Intelligent Function Module to High Performance model QCPU

8.2.1 Interrupt from the intelligent function module

8.3 Communication Between High Performance model QCPU and AnS-Series Special Function Modules

8.3.1 Communication using device initial value

8.3.2 Communication using FROM/TO instruction

8.3.3 Communication using the intelligent function module device

8.3.4 Effects of quicker access to the special function module and countermeasures against them

9 PARAMETER LIST

10 DEVICES

10.1 Device List

10.2 Internal User Devices

10.2.1 Inputs (X)

10.2.2 Outputs (Y)

10.2.3 Internal relays (M)

10.2.4 Latch relays (L)

10.2.5 Anunciators (F)

10.2.6 Edge relay (V)

10.2.7 Link relays (B)

10.2.8 Link special relays (SB)

10.2.9 Step relays (S)

10.2.10 Timers (T)

10.2.11 Counters (C)

10.2.12 Data registers (D)

10.2.13 Link registers (W)

10.2.14 Link special registers (SW)

10.3 Internal System Devices

10.3.1 Function devices (FX, FY, FD)

10.3.2 Special relays (SM)

10.3.3 Special registers (SD)

10.4 Link Direct Devices (J

\ )

A - 13 A - 13

Page 15

10.5 Intelligent Function Module Devices (U

10.6 Index Registers (Z)

10.6.1 Switching between scan execution type programs and low speed execution type programs

10.6.2 Switching between scan/low speed execution programs and interrupt/fixed scan execution type

programs

10.7 File Registers (R)

10.7.1 File register capacity

10.7.2 Differences in memory card access method by memory card type

10.7.3 Registering the file registers

10.7.4 File register designation method

10.7.5 Precautions in using file registers

10.8 Nesting (N)

10.9 Pointers

10.9.1 Local pointers

10.9.2 Common pointers

10.10 Interrupt Pointers (I)

10.11 Other Devices

10.11.1 SFC block device (BL)

10.11.2 SFC transition device (TR)

10.11.3 Network No. designation device (J)

10.11.4 I/O No. designation device (U)

10.11.5 Macro instruction argument device (VD)

10.12 Constants

10.12.1 Decimal constants (K)

10.12.2 Hexadecimal constants (H)

10.12.3 Real numbers (E)

10.12.4 Character string ( " " )

10.13 Convenient Uses for Devices

10.13.1 Global devices & local devices

10.13.2 Device initial values

\G )

11 HIGH PERFORMANCE MODEL QCPU PROCESSING TIME

11.1 Reading High Performance model QCPU's Scan Time

11.2 Factors Responsible for Extended Scan Time

Factors Responsible for Shortened Scan Time

12 PROCEDURE FOR WRITING PROGRAMS TO HIGH PERFORMANCE MODEL QCPU

12.1 Writing Procedure for 1 Program

12.1.1 Items to consider when creating one program

12.1.2 Procedure for writing programs to the High Performance model QCPU

12.2 Procedure for Multiple Programs

12.2.1 Items to consider when creating multiple programs

12.2.2 Procedure for writing programs to the High Performance model QCPU

A - 14 A - 14

Page 16

13 OUTLINE OF MULTIPLE CPU SYSTEMS

13.1 Features

13.2 Outline of Multiple CPU Systems

13.3 Differences with Single CPU Systems

14 SYSTEM CONFIGURATION OF MULTIPLE CPU SYSTEMS

14.1 System Configuration

14.2 Precautions During Multiple CPU System Configuration

14.2.1 Function versions of High Performance model QCPU , motion CPUs and PC CPU module that

can be sued, and their mounting positions

14.2.2 Precautions when using Q series corresponding I/O modules and intelligent function modules

14.2.3 Limitations when mounting AnS series corresponding I/O modules and special function modules

14.2.4 Modules that have mounting restrictions

14.2.5 Usable GX Developers and GX Configurators

14.2.6 Parameters that enable the use of multiple CPU systems

14.2.7 Resetting the multiple CPU system

14.2.8 Processing when High Performance model QCPU stop errors occur

14.2.9 Reducing the time required for multiple CPU system processing

15 ALLOCATING MULTIPLE CPU SYSTEM I/O NUMBERS

15.1 Concept behind Allocating I/O Numbers

15.1.1 I/O modules and intelligent function module I/O numbers

15.1.2 I/O number of High Performance model QCPU, Motion CPU and PC CPU module

15.2. Purpose of PC Parameter I/O Allocations with the GX Developer

16 COMMUNICATION BETWEEN THE MULTIPLE CPU SYSTEM'S QCPUS AND MOTION CPUs

16.1 Automatic Refresh of Common CPU Memory

16.2 Communication with Multiple CPU Commands and Intelligent Function Module Devices

16.3 Interactive Communications between The High Performance model QCPU and Motion CPU

16.3.1 Control instructions from the High Performance model QCPU to the Motion CPU

16.3.2 Reading and writing device data

16.4 Common CPU Memory

17 COMMUNICATIONS BETWEEN THE MULTIPLE CPU SYSTEM'S I/O MODULES AND

INTELLIGENT FUNCTION MODULES

17.1 Range of Control PLC Communications

17.2 Range of Non-control PLC Communications

A - 15 A - 15

Page 17

18 PROCESSING TIME FOR MULTIPLE CPU SYSTEM HIGH PERFORMANCE MODEL

QCPUs

18.1 Concept behind QCPU Scanning Time

18.2 Factor to Prolong the Scan Time

19 STARTING UP THE MULTIPLE CPU SYSTEM

19.1 Flow-chart for Starting Up the Multiple CPU System

19.2 Setting Up the Multiple CPU System Parameters (Multiple PLC Settings, Control PLC Settings)

19.2.1 System configuration

19.2.2 Creating new systems

19.2.3 Using existing preset multiple CPU settings and I/O allocations

APPENDICES

APPENDIX 1 Special Relay List

APPENDIX 2 Special Register List

APPENDIX 3 List of Interrupt Pointer Nos. and Interrupt Factors

INDEX

A - 16 A - 16

Page 18

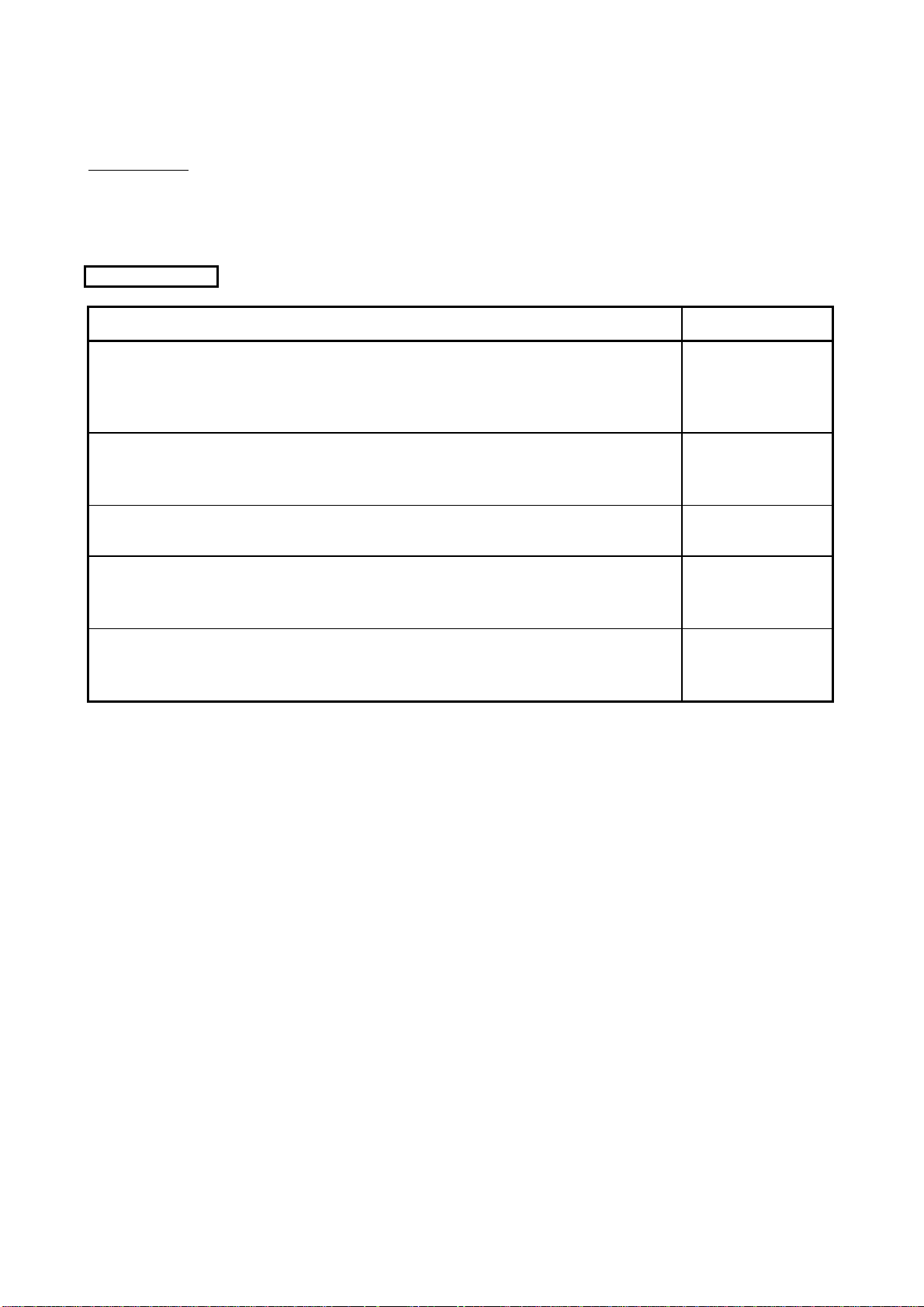

About Manuals

The following manuals are related to this product.

Referring to this list, please request the necessary manuals.

Related Manuals

Manual Name

High Performance model QCPU (Q Mode) User's M anual (Function Explanation, Program

Fundamentals)

This manual explains the functions, programming methods, devices and so on necessary to create

programs with the High Performance model QCPU. (sold separately)

Manual Number

(Model Code)

SH-080038

(13JL98)

QCPU (Q Mode)/QnACPU Programming Manual (Common Instructions)

This manual describes how to use the sequence instructions, basic instructions and application

instructions. (sold separately)

QCPU (Q Mode)/QnACPU Programming Manual (PID Control Instructions)

This manual describes the dedicated instructions used to exercise PID control. (sold separately)

QCPU (Q Mode)/QnACPU Programming Manual (SFC)

This manual explains the system configuration, performance specifications, functions, programming,

debugging, error codes and others of MELSAP3. (sold separately)

QCPU (Q Mode) Programming Manual (MELSAP-L)

This manual describes the programming methods, specifications, functions, and so on that are

necessary to create the MELSAP-L type SFC programs. (sold separately)

SH-080039

(13JF58)

SH-080040

(13JF59)

SH-080041

(13JF60)

SH-080076

(13JF61)

A - 17 A - 17

Page 19

How to Use This Manual

This manual is prepared for users to understand the hardware specifications of those modules such as the

CPU modules, power supply modules, and base units, maintenance and inspections of the system, and

troubleshooting required when you use MELSEC-Q series PLCs.

The manual is classified roughly into three sections as shown below.

1) Chapters 1 and 2 Describe the outline of the CPU module and the system

configuration.

The basics of the system configuration of CPU module are

described.

2) Chapters 3 to 7 Describe the general specifications indicating the operating

environments of the CPU module, power supply module, and

base units, and the performance specifications of these

modules.

3) Chapters 8 to 10 Describe the overall maintenance such as the installation of the

CPU module, daily inspections, and troubleshooting.

REMARK

This manual does not explain the functions of the CPU module.

For these functions, refer to the manual shown below.

• High Performance model QCPU (Q Mode) User's Manual (Function Explanation,

Program Fundamentals)

A - 18 A - 18

Page 20

About the Generic Terms and Abbreviations

This manual uses the following general names and abbreviations in the descriptions of the High

Performance model QCPU unless otherwise specified.

Generic Term/Abbreviation Description

High Performance model

QCPU

Q Series Abbreviation for Mitsubishi MELSEC-Q Series Programmable Logic Controller.

AnS Series

GX Developer General name for GX Developer Version 4 or later.

Q3 B

Q3 SB

Q5 B

Q6 B

QA1S6 B

Main base unit

Slim type main base unit

Extension base unit General name for Q5 B, Q6 B and QA1S6 B.

SRAM card Abbreviation for Q2MEM-1MBS, Q2MEM-2MBS type SRAM card.

Flash card General name for Q2MEM-2MBF and Q2MEM-4MBF types Flash card.

ATA card

Memory card General name for SRAM card, Flash card and ATA card.

Power supply module

Slim type power supply module General name for Q61SP slim type power supply module

Battery

Extension cable

General name for Q02CPU, Q02HCPU, Q06HCPU, Q12HCPU, and Q25HCPU

modules.

Abbreviation for small types of Mitsubishi MELSEC-A Series Programmable Logic

Controller.

General name for Q33B, Q35B, Q38B, Q312B type main base unit with High

Performance model QCPU and Q Series power supply module, I/O module and

intelligent function module attachable.

General name for Q32SB, Q33SB, Q35SB slim type main base unit with High

Performance model QCPU and slim type power supply module, I/O module and

intelligent function module attachable.

General name for Q52B and Q55B type extension base unit with Q Series I/O module

and intelligent function module attachable.

General name for Q63B, Q65B, Q68B and Q612B type extension base unit with Q

Series power supply module, I/O module and intelligent function module attachable.

General name for QA1S65B and QA1S68B type extension base unit with AnS Series

power supply module, I/O module and special function module attachable.

General name for Q33B, Q35B, Q38B, Q312B type main base unit with High

Performance model QCPU and Q Series power supply module, I/O module and

intelligent function module attachable.

General name for Q32SB, Q33SB, Q35SB slim type main base unit with High

Performance model QCPU and slim type power supply module, I/O module and

intelligent function module attachable.

General name for Q2MEM-8MBA, Q2MEM-16MBA and Q2MEM-32MBA types ATA

card.

General name for Q61P-A1, Q61P-A2, Q62P, Q63P, Q64P, A1S61PN, A1S62P and

A1S63P types power supply module.

General name for battery for Q6BAT type CPU module and Q2MEM-BAT type SRAM

card.

General name for QC05B, QC06B, QC12B, QC30B, QC50B, QC100B type extension

cable.

A - 19 A - 19

Page 21

1 OVERVIEW

1 OVERVIEW

MELSEC-Q

1

This Manual describes the hardware specifications and handling methods of the High

Performance model QCPU.

The Manual also describes those items related to the specifications of the power

supply module, main base unit, extension base unit, extension cable, memory card

and battery.

Functions are added when the High Performance model QCPU is updated.

The added functions can be discriminated by the function version/serial number of the

CPU module.

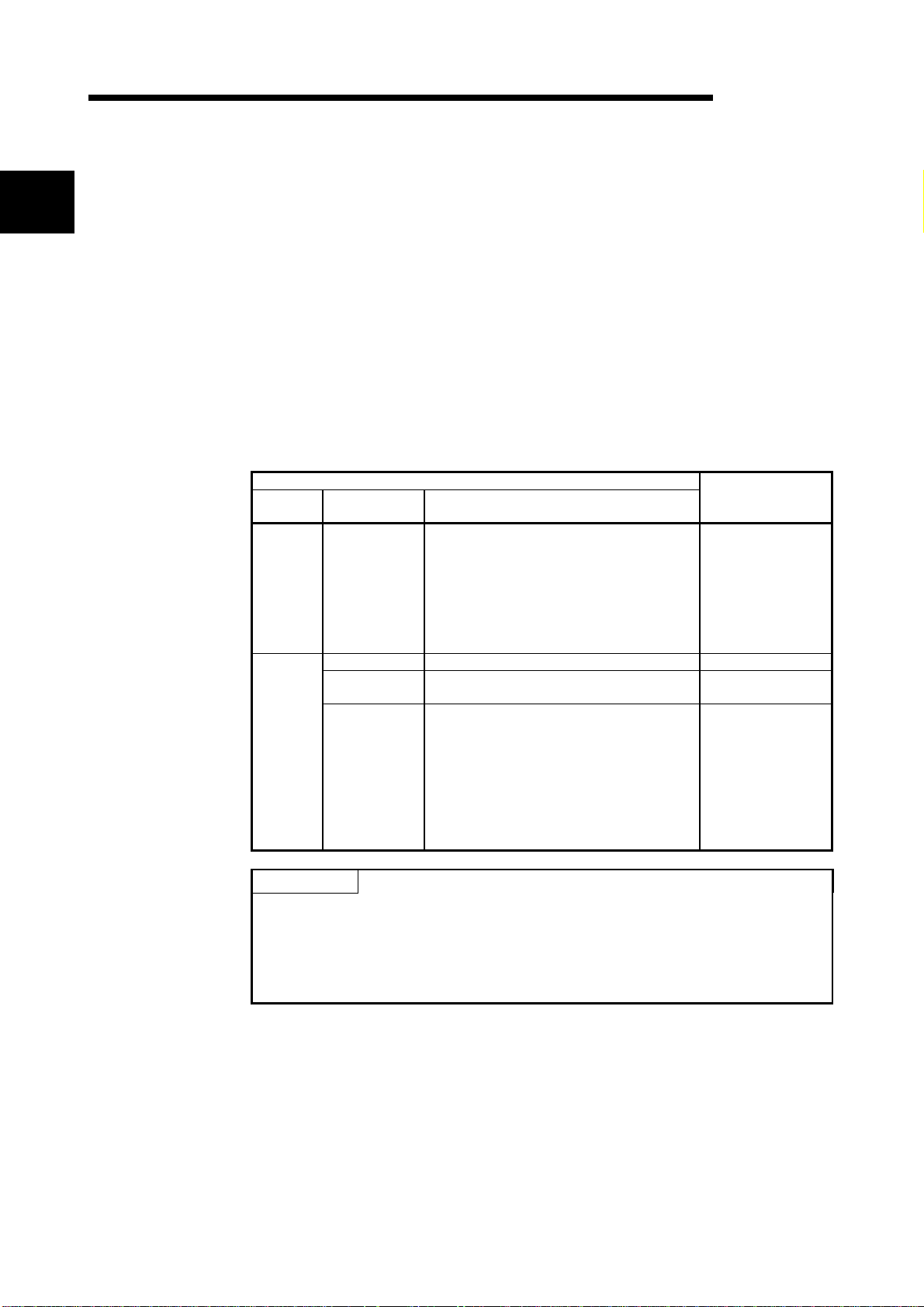

Table 1.1 gives the added functions and the corresponding GX Developer versions.

When using the added function, confirm the function version/serial number and the GX

Developer version.

Table 1.1 List of Functions Added to High Performance Model QCPU and Function

Versions/Serial Numbers

Function

version

A

B

Update Details of High Performance Model QCPU

Serial No. Added functions

• Automatic write to standard ROM

• Enforced ON/OFF for external I/O

• Remote password setting

02092" or later

"

— • Compatibility with the multiple CPU system Version 6 or later

03051" or later

"

04012" or later

"

• Increased standard RAM capacity of

Q12HCPU, Q25HCPU

• Compatibility with MELSECN ET /H remote

I/O network

• Interrupt module (QI60) compatibility

• Installation of PC CPU module into the

multiple CPU system

• High speed interrupt function

• Compatibility with index modification for

module designation of dedicated instruction

• Selection of refresh item for COM

instruction

• Extended life battery of SRAM card

• Compatibility with 2Mbyte SR AM card

• Increased standard RAM capacity of

Q02HCPU, Q06HCPU

Corresponding

GX Developer

Version 6 or later

Version 7 or later

Version 7.10L

or later

POINT

(1) For the details of the added functions in Table 1.1, refer to the High

Performance model QCPU (Q mode) User's Manual (Function Explanation,

Program Fundamentals).

(2) Refer to Section 2.3 for the serial No. and function version of the High

Performance model QCPU.

1 - 1 1 - 1

Page 22

1 OVERVIEW

MELSEC-Q

1.1 Features

High Performance model QCPU has the following new features:

(1) Controllable multiple I/O points

All High Performance model QCPUs support 4096 points (X/Y0 to FFF) as the

number of actual I/O points capable of getting access to the I/O module installed

on the base unit.

They also support 8192 points max. (X/YO to 1FFF) as the number of I/O

devices which can be used in the remote I/O stations such as MELSECNET/H

remote I/O NET, CC-Link data link and MELSECNET/MINI-S3 data link.

(2) Lineup according to progr am capaci ty

The optimum CPU module for the program capacity to be used can be selected.

Q02CPU, Q02HCPU : 28k step

Q06HCPU : 60k step

Q12HCPU : 124k step

Q25HCPU : 252k step

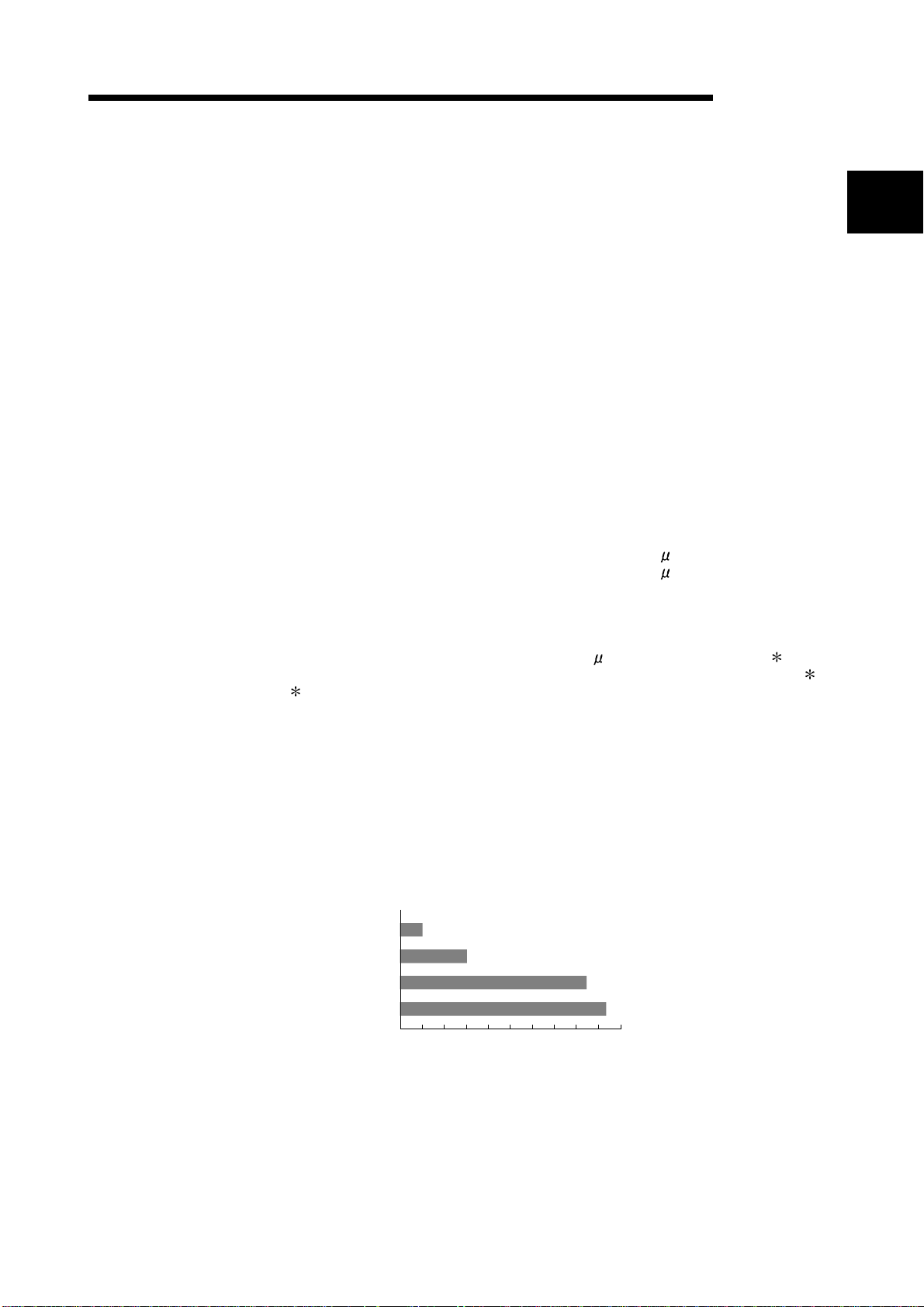

(3) Realised high speed processing

Depending on the type of the sequencer, high speed processing has been

realized.(Example: when LD instruction is used)

Q02CPU : 0.079

Q02HCPU, Q06HCPU, Q12HCPU, Q25HCPU : 0.034

In addition, an access to the intelligent function module or an increase in speed

of the link refresh of the network have been realized by the connection system

(System bus connection) of the newly developed base unit.

Access to the intelligent function module : 20

MELSECNET/H link refresh processing : 4.6ms/8k word (approx. 4.3 times)

1: Where Q02HCPU is compared with Q2ASHCPU-S1.

s /word (approx. 7 times) 1

s

s

(4) Increase in debugging efficiency thr oug h high speed

communication with GX Dev el oper

In the High Performance model QCPU, a time required for writing/reading of a

program or monitoring has been reduced through the high speed communication

at a speed of 115.2kbps max. by the RS-232, and a communication time

efficiency at the time of debugging has been increased.

In the Q02HCPU, Q06HCPU, Q12HCPU, and Q25HCPU, a high speed

communication at a speed of 12Mbps is allowed through the USB.

26k step program transfer time

1

1

Q25HCPU(USB)

Q25HCPU(RS-232)

Q2ASHCPU

A2USHCPU-S1

12

30

0 1020304050607080

86

94

90 100

(Unit:s)

(5) AnS series I/O module or special function module are available.

For Q series, if an appropriate module is not available, the AnS series I/O

module or special function module can also be used for the High Performance

model QCPU through the use of the QA1S65B/QA1S68B extension base unit.

1 - 2 1 - 2

Page 23

1 OVERVIEW

Comparison of installation space

98mm

(3.86

inch)

(6) Saved space by a reduction in si z e

The installation space for Q series has been reduced by approx. 60 % of the

space for AnS series.

1SX10 1SY50 1SX41 1SY41 1SX81 1SY81 1SX42 1SY42

PULL

MELSEC-Q

5 Slot Main Base Unit 245mm(9.65inch)

8 Slot Main Base Unit 328mm(12.92inch)

12 Slot Main Base Unit 439mm(17.30inch)

(depth:98mm(3.86inch))

(7) Connection of up to seven extension base units.

(a) The High Performance model QCPU can connect to seven extension base

units (eight base units including the main) and accept up to 64 modules.

(b) The overall distance of the extension cables is up to 13.2m to ensure high

degree of extension base unit arrangement.

(8) Memory extension by memory card

The High Performance model QCPU is provided with a memory card installation

connector to which a memory card of 32 Mbyte max. can be connected (32

Mbyte is available when a ATA card is used).

When a memory card of large capacity is installed, a large capacity of file can be

controlled, comments to all data devices can be set up, and the programs in the

past can be stored in the memory as they are in the form of the corrected

histories.

If a memory card is not installed, a program can be stored onto the standard

ROM built in the CPU module, and file registers can be handled by the standard

RAM.

REMARK

• The number of file registers that can be handled changes depending on the

function version/serial number of the CPU module used.

CPU Module Type Number of File Registers

Q02CPU 32k points

First 5 digits of serial number are "04011" or earlier 32k points Q02HCPU

Q06HCPU

Q25HCPU

First 5 digits of serial number are "04012" or later 64k points

First 5 digits of serial number are "02091" or earlier 32k points Q12HCPU

First 5 digits of serial number are "02092" or later 128k points

Refer to Section 2.3 to confirm the function version and serial number of the High

Performance model QCPU.

1 - 3 1 - 3

Page 24

1 OVERVIEW

MELSEC-Q

(9) Data can be written automatical ly to standard ROM

You need not use GX Developer to write parameters/programs on a memory

card to the standard ROM of the High Performance model QCPU.

When the standard ROM is used to perform ROM operation, you can load a

memory card into the High Performance model QCPU and write

parameters/programs on the memory card to the standard ROM. Hence, you

need not carry GX Developer (personal computer) to rewrite the

parameters/programs.

(10) External I/O can be turned ON/OFF forcibly

If the High Performance model QCPU is in the RUN mode, you can operate GX

Developer to turn external inputs/outputs ON/OFF forcibly, independently of the

program execution status.

You need not put the High Performance model QCPU in the STOP mode to

perform wiring/operation tests by forced ON/OFF of outputs.

(11) Remote password can be set

When access to an Ethernet module or serial communication module is made

externally, whether access to the High Performance model QCPU can be made

or not can be selected with a remote password.

(12) Remote I/O network of MELSECNET/H can be configured

You can load the remote master station of the MELSECNET/H to configure an

MELSECNET/H remote I/O system.

REMARK

• Features (9) to (12) are functions added to the High Performance model QCPU

whose serial number is "02092" or later in its upper 5 digits.

• The remote password facility can be executed when the Ethernet module or serial

communication module of function version B and GX Developer Version 6 or later

are used.

• In addition to the remote password, there are the following protection facilities for

the High Performance model QCPU.

(a) Protection of the whole CPU module by making system protection settings of

the High Performance model QCPU

(b) Protection of the memory card by setting the write protect switch of the memory

card

(c) File-by-file protection using password

• The MELSECNET/H remote I/O network facility can be executed when the

MELSECNET/H network module of function version B and GX Developer (Version

6 or later) are used.

1 - 4 1 - 4

Page 25

2 SYSTEM CONFIGURATION FOR SINGLE CPU SYSTEM

2 SYSTEM CONFIGURATION FOR SINGLE CPU SYSTEM

MELSEC-Q

2.1 System Configuration

2

Memory card

(Q2MEM-1MBS,Q2MEM-2MBS,

Q2MEM-2MBF,Q2MEM-4MBF,

Q2MEM-8MBA,Q2MEM-16MBA,

Q2MEM-32MBA)

This section describes the system configuration of the High Performance model

QCPU, cautions on use of the system, and configured equipment.

The outline of the equipment configuration, configuration with peripheral devices, and

system configuration in the High Performance model QCPU system is described below.

(1) Equipment configuration

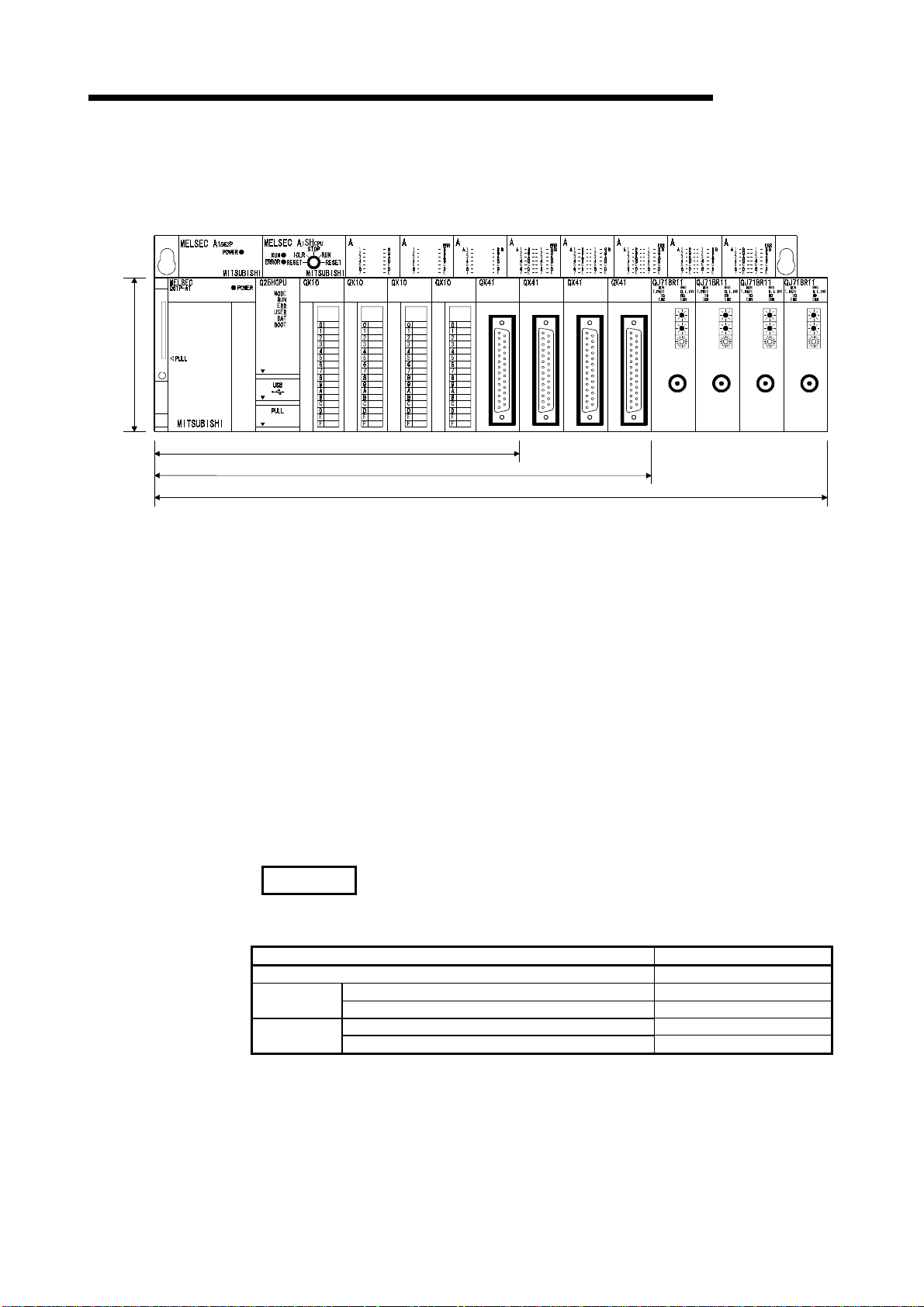

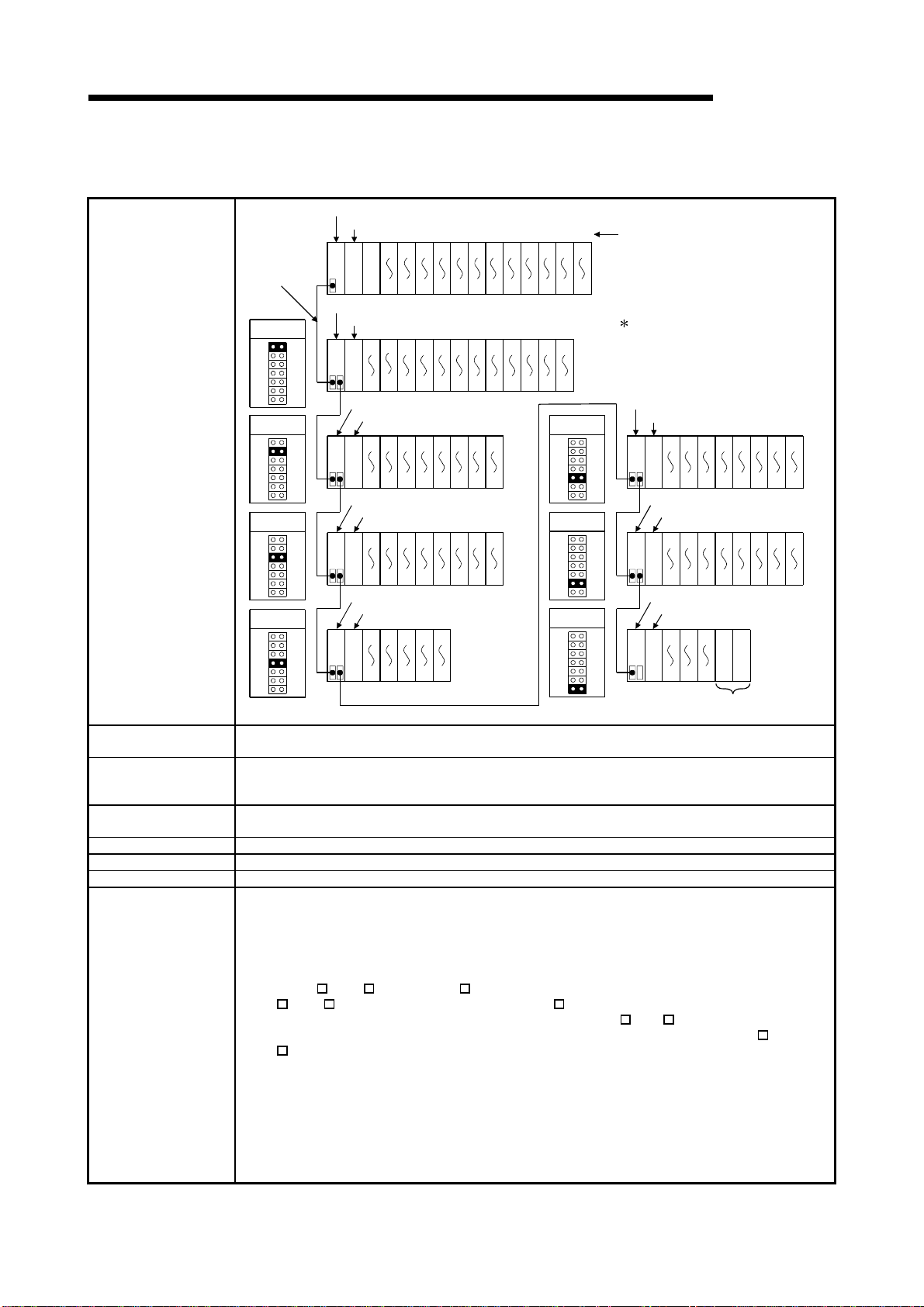

(a) If the main base unit (Q3B) is used

MITSUBISHI

MITSUBISHI

LITHIUM BAT TERY

1

High Performance model QCPU

(Q02CPU,Q02HCPU,Q06HCPU,

Q12HCPU,Q25HCPU)

Main base unit

(Q33B, Q35B,Q38B,Q312B)

Battery

(Q6BAT)

Power supply module ,

I/O module , Inte l l igent function

module of the Q Series

Extension of the AnS Series module Extension of the Q Series module

2

QA1S6 extension base unit

(QA1S65B,QA1S68B)

Extension cable

(QC05B,QC06B,QC12B,

QC30B, QC50B,QC100B)

Q5 B extension base unit

(Q52B, Q55B)

Q6 B extension base unit

(Q63B, Q65B,Q68B,Q612B)

Power supply module ,

I/O module , Intelligent function

module of the AnS Series

POINTS

1: The number of memory cards to be installed is one sheet.

The memory card must be selected from SRAM card, Flash card, and ATA

Power supply module ,

I/O module , Inte l l igent function

module of the Q Series

3

4

card according to the application and capacity.

With commercial memory cards, the Operation is not assured.

2: QA1S65B and QA1S68B extension base units are used for the power supply

module, I/O module, and special function module of the AnS series.

3: The Q series power supply module is not required for the Q5 B type

extension base unit.

4: Q61SP cannot be used for the power supply module.

Use Q61P-A1, Q61P-A2, Q62P, or Q64P for the power supply module.

2 - 1 2 - 1

Page 26

2 SYSTEM CONFIGURATION FOR SINGLE CPU SYSTEM

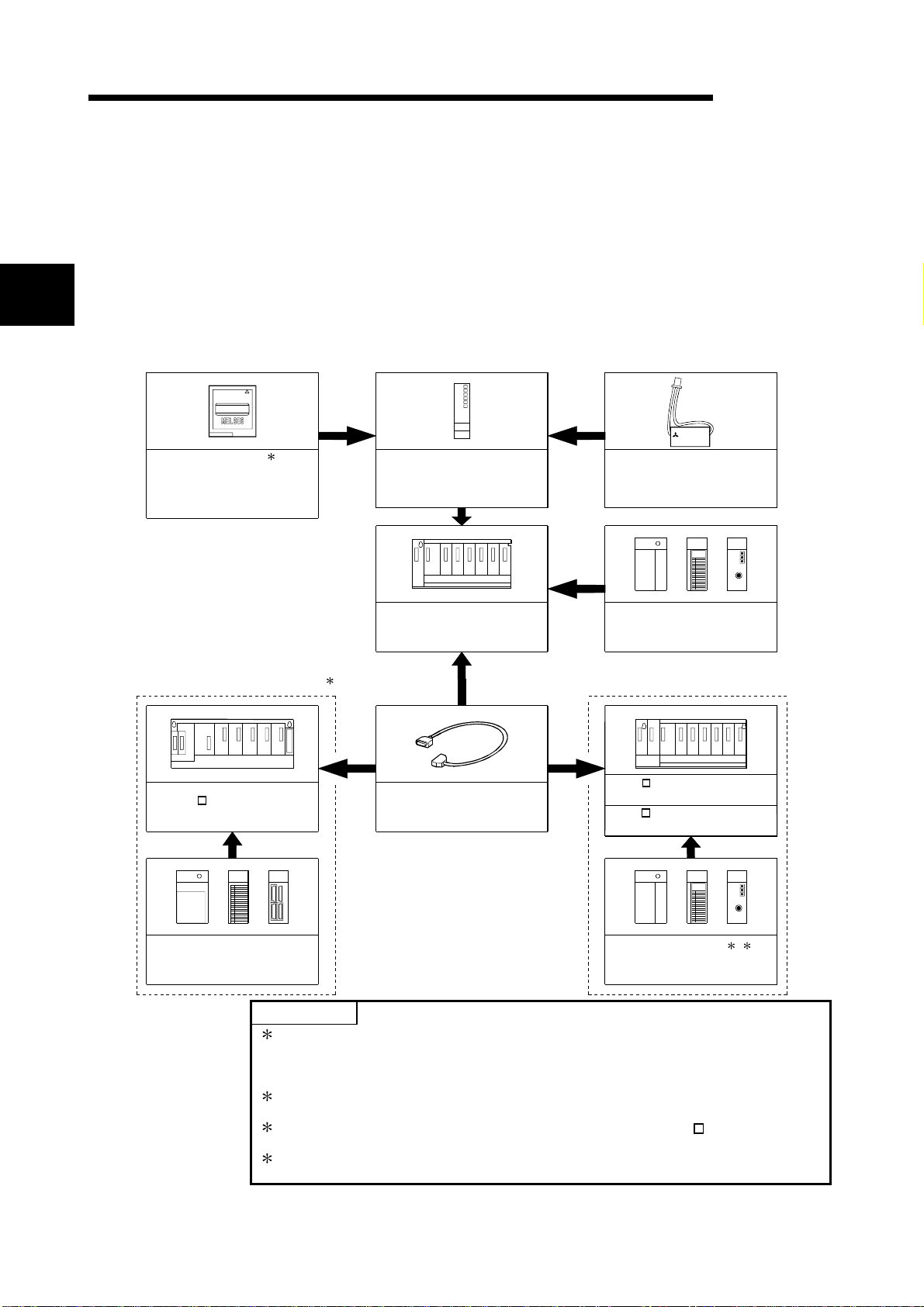

(b) If the slim type main base unit (Q3SB) is used

MITSUBISHI

(Q2MEM-1MBS,Q2MEM-2MBS,

Memory card

Q2MEM-2MBF,Q2MEM-4MBF,

Q2MEM-8MBA,Q2MEM-16MBA,

Q2MEM-32MBA)

*1

High Performance model QCPU

(Q02CPU,Q02HCPU,Q06HCPU,

Q12HCPU,Q25HCPU)

MELSEC-Q

MITSUBISHI

LITHIUM BATTERY

Battery

(Q6BAT)

Slim type main base unit

(Q32SB,Q33SB,Q35SB)

*2

Slim type power supply module,

I/O module ,

Intelligent function module

POINTS

*3

1: The number of memory cards to be installed is one sheet.

The memory card must be selected from SRAM card, Flash card, and ATA

card according to the application and capacity.

With commercial memory cards, the Operation is not assured.

2: The slim type main base unit does not have an extension cable connector. The

extension base unit and GOT cannot be connected.

3: Q61P-A1, Q61P-A2, Q62P, or Q64P cannot be used for the power supply

module.

Use Q61SP for the power supply module.

2 - 2 2 - 2

Page 27

2 SYSTEM CONFIGURATION FOR SINGLE CPU SYSTEM

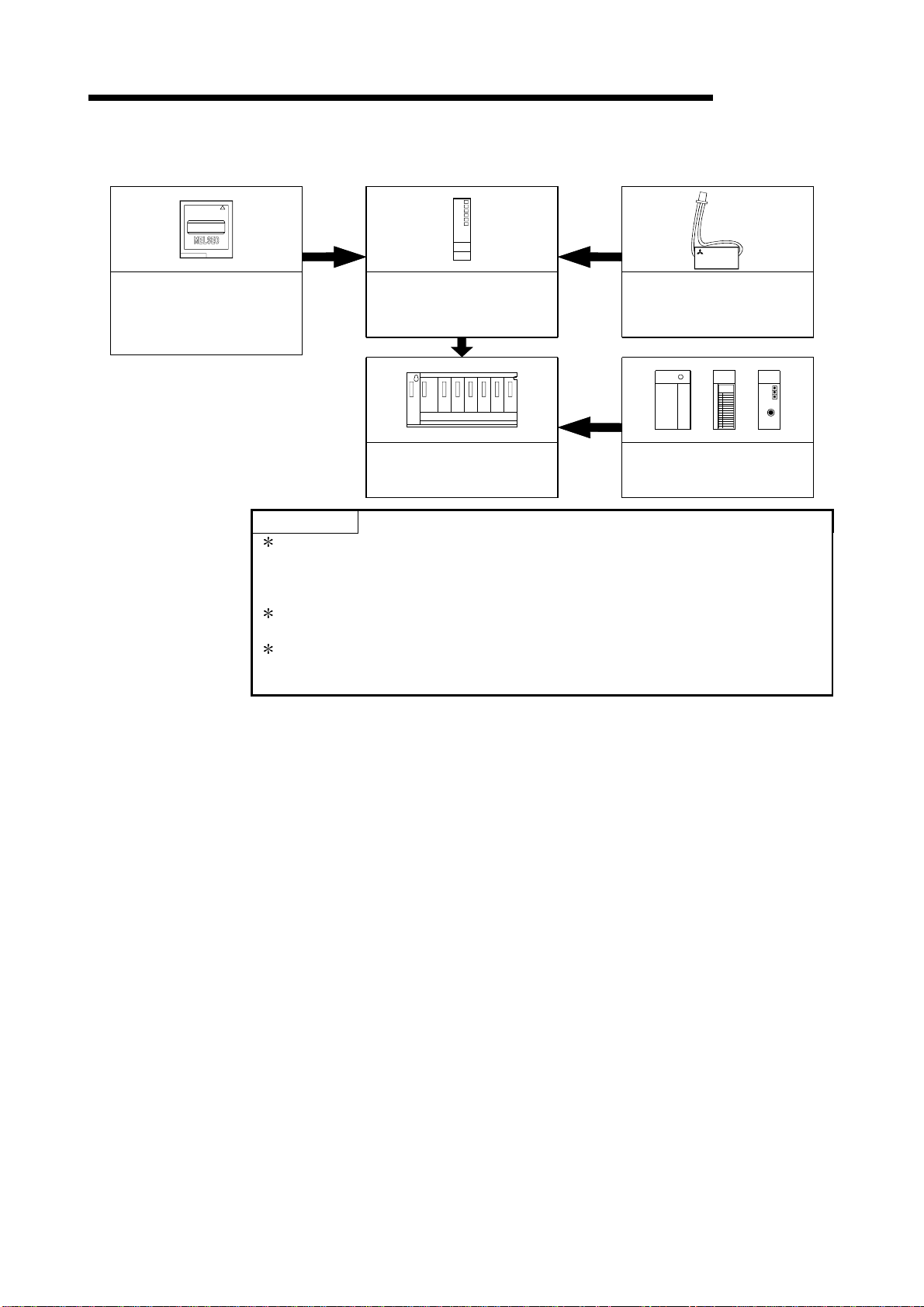

(2) Configuration of peripheral devices

MITSUBISHI

MELSEC-Q

Memory card 1

(Q2MEM-1MBS,Q2MEM-2MBS,

Q2MEM-2MBF,Q2MEM-4MBF,

Q2MEM-8MBA,Q2MEM-16MBA,

Q2MEM-32MBA)

PC card adapter

(Q2MEM-ADP)

High Performance model QCPU

(Q02CPU,Q02HCPU,Q06HCPU,

Q12HCPU,Q25HCPU)

RS-232 cable

(QC30R2)

Personal Computer

GX Developer Version 4 or later

(SW4D5C-GPPW-E or later)

USB cable 1

(To be procured yourself)

Only Q02HCPU, Q06HCPU

Q12HCPU and Q25HCPU

can be used.

1: For how to write data to the memory card and the details of the USB cable, refer to

the GX Developer Operating Manual.

2 - 3 2 - 3

Page 28

2 SYSTEM CONFIGURATION FOR SINGLE CPU SYSTEM

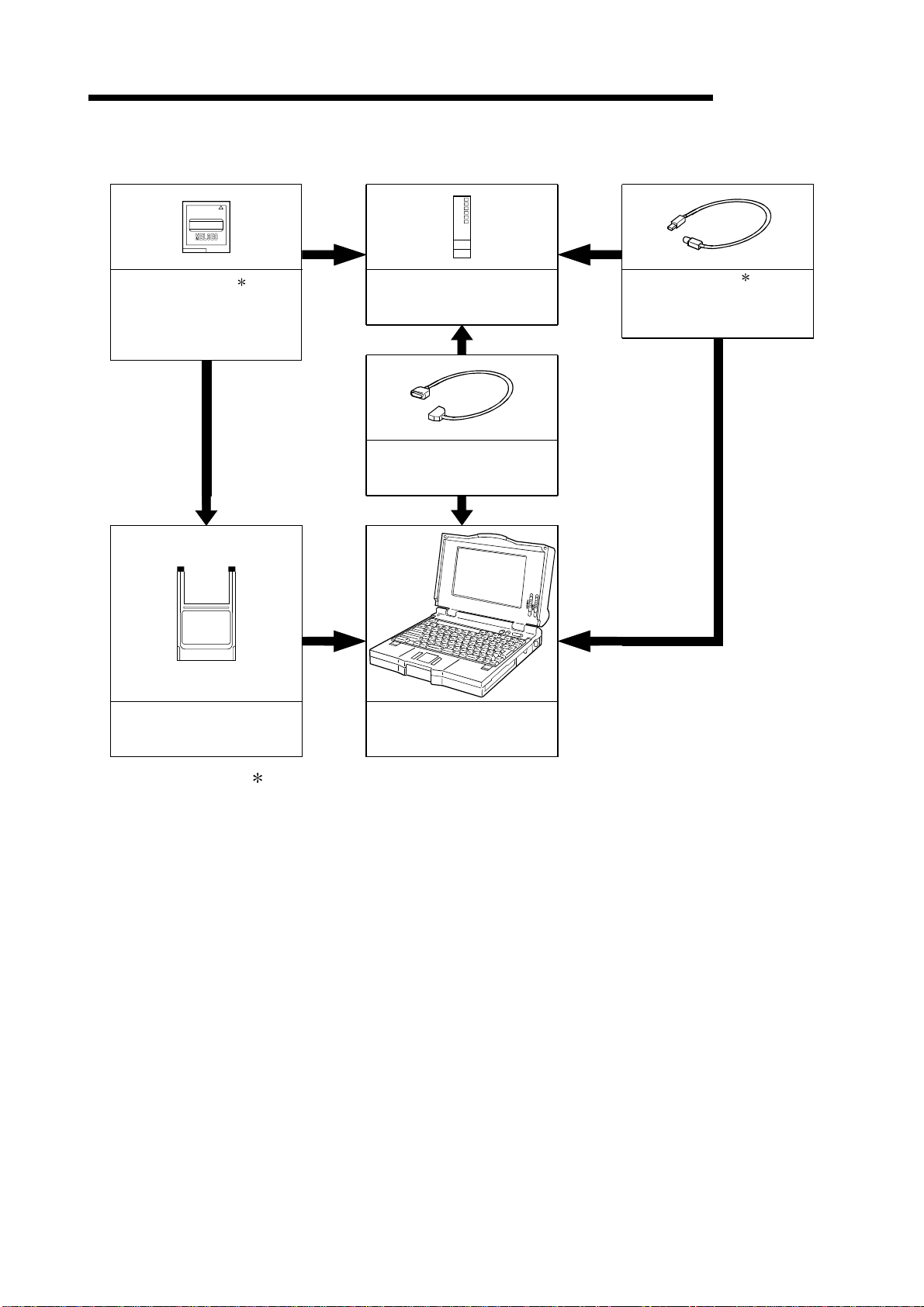

(3) Outline of system configuration

(a) If the main base unit (Q3B) is used

Main base unit(Q312B)

Power supply module

01234567891011

Extension

cable

O

U

T

001F203F405F607F809FA0BFC0DFE0FF100

CPU module

11F

120

13F

140

15F

Extension base unit(Q612B)

1st extension

stage

Power supply module

1E0

1C0

180

1A0

O

I

U

N

T

19F

1BF

1DF

1FF

200

21F

220

23F

240

25F

260

27F

280

29F

2A0

2BF

2221201918171615141312

2C0

2DF

23

2E0

2FF

Extension base unit(Q68B)

Power supply module

320

300

O

I

U

N

T

33F

31F

340

35F

360

37F

380

39F

3A0

3BF

3C0

3DF

3130292827262524

3E0

3FF

5th extension

stage

System configuration

2nd extension

stage

Extension base unit(Q68B)

3rd extension

stage

Power supply module

420

400

O

I

U

N

T

43F

41F

440

45F

460

47F

480

49F

4A0

4BF

4C0

4DF

3938373635343332

4E0

4FF

6th extension

stage

Extension base unit(Q65B)

Maximum number of

Extension Stages

4th extension

stage

Power supply module

520

500

O

I

U

N

T

53F

51F

540

55F

4443424140

580

560

59F

57F

Seven Extension Stages

7th extension

stage

Maximum number of

I/O modules to be

64 modules

installed

Maximum number of

occupied I/O points

4096

Main base unit Q33B, Q35B, Q38B, Q312B

Extension base unit Q52B, Q55B, Q63B, Q65B, Q68B, Q612B, QA1S65B, QA1S68B

Extension cable QC05B, QC06B, QC12B, QC30B, QC50B, QC100B

(1) Extension bases unit of up to seven stages can be used.

(2) Do not use extension cable longer than an overall extension length of 13.2m(43.31ft.).

(3) When using an extension cable, do not bind it together with the main circuit (high voltage and

heavy current) line or do not lay down them closely to each other.

(4) When setting the No. of the expansion stages, set it in the ascending order so that the same

No. is not set simultaneously by two extension base units.

(5) When Q5

B, Q6 B and QA1S6 B types of extension base units are mix ed, first connect the

Q5 B, Q6 B type and then connect the QA1S6 B type.

When setting the No. of the extension stages, set it from Q5

Notes

Although there are no particular restrictions in the order of the installation of the Q5

Q6 B, refer to Section 6.6 for usability.

(6) Connect the extension cable from OUT of the ex tension cable connector of the base unit to IN

of the extension base unit on the next stage.

(7) If 65 or more modules are installed, an error will occur.

(8) When the GOT is bus-connected, it occupies one extension stage and one slot.

(9) The High Performance model QCPU processes the GOT as a 16-point intelligent function

module. Hence, connecting one GOT decreases 16 points available for the base unit.

(10) Q61SP cannot be used for the power supply module.

Use Q61P-A1, Q61P-A2, Q62P, or Q64P for the power supply module.

160

17F

Slot No.

The figure shows the configuration

when 32-I/O modules are

loaded to each slot.

Extension base unit(QA1S68B)

Power supply module

600

5E0

5C0

5A0

O

I

U

N

T

5BF

5DF

5FF

61F

Extension base unit(QA1S68B)

Power supply module

700

6E0

6C0

6A0

O

I

U

N

T

6BF

6DF

6FF

71F

Extension base unit(QA1S65B)

Power supply module

636261

7E0

7C0

7A0

O

I

U

N

T

7FF

7DF

7BF

When module is installed,

an error occurs.

B/Q6 B in order.

MELSEC-Q

5251504948474645

680

660

640

620

69F

67F

65F

63F

6059585756555453

780

760

740

720

79F

77F

75F

73F

Prohibit

Prohibit

B and

2 - 4 2 - 4

Page 29

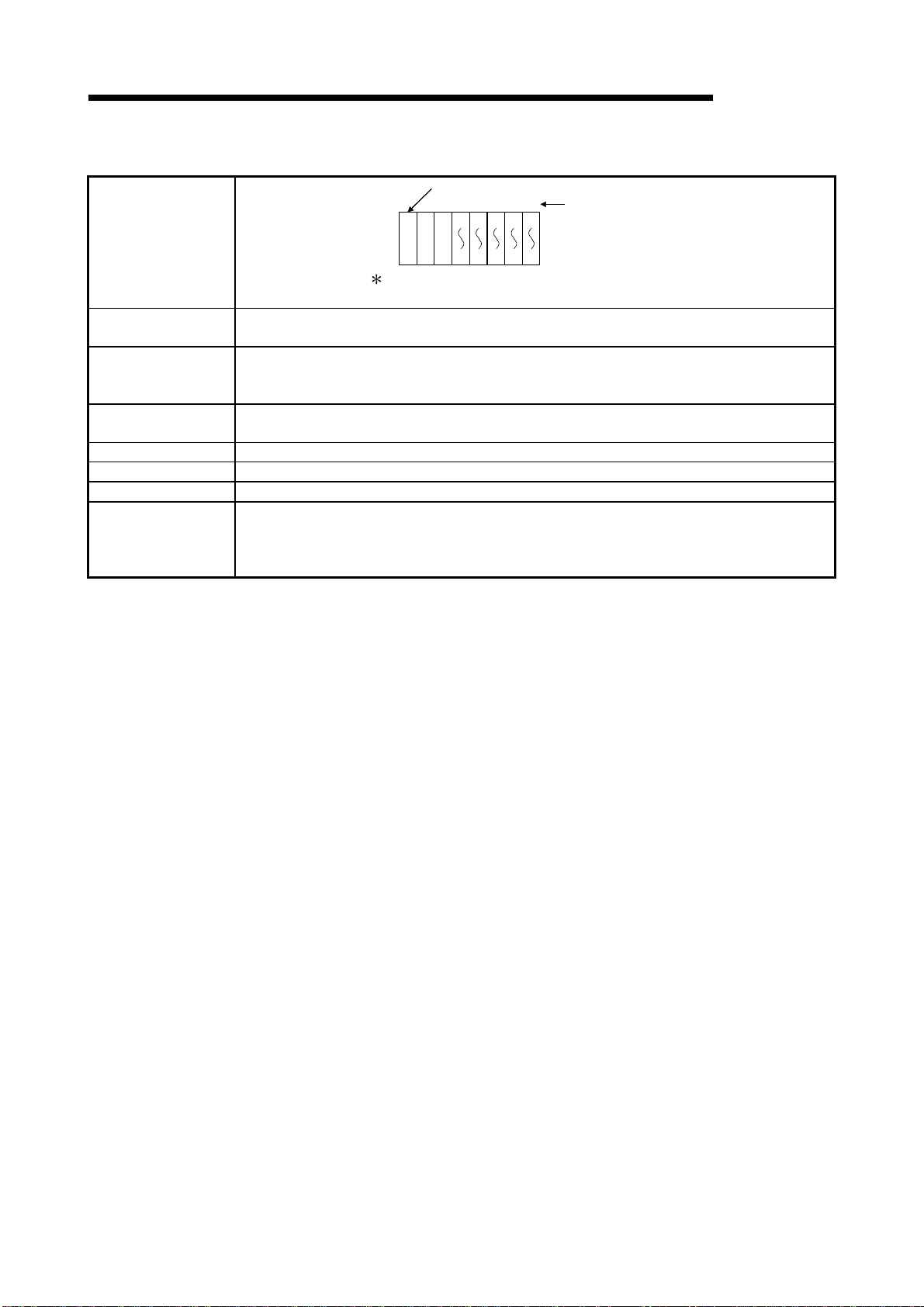

2 SYSTEM CONFIGURATION FOR SINGLE CPU SYSTEM

(b) If the slim type main base unit (Q3SB) is used

Slim type main base unit (Q35SB)

01234

001F203F405F607F80

Slot No.

MELSEC-Q

System configuration

The above system assumes that each slot is loading with

a 32-point module.

Maximum number of

Extension Stages

CPU module

Power supply

module

No extension allowed

9F

Maximum number of

I/O modules to be

5 modules

installed

Maximum number of

occupied I/O points

4096

Main base unit Q32SB, Q33SB, Q35SB

Extension base unit Cannot be connected.

Extension cable C annot be connected.

(1) Q61P-A1, Q61P-A2, Q62P, or Q64P cannot be used for the power supply module.

Notes

Use Q61SP for the power supply module.

(2) The slim type main base unit does not have an extension cable connector.

The extension base unit and GOT cannot be connected.

2 - 5 2 - 5

Page 30

2 SYSTEM CONFIGURATION FOR SINGLE CPU SYSTEM

MELSEC-Q

2.2 Precaution on System Configuration

This section describes hardware and software packages compatible with QCPU.

(1) Hardware

(a) The number of modules to be installed and functions are limited depending on

the type of the modules.

Applicable Module Type

• QJ71LP21

Q Series MELSECNET/H

network module

Q series Ethernet interface

module

Q series CC-Link system

master local module

MELSECNET/MIN I-S3 data

link module

AnS series special function

module shown on the right

Interrupt module

• QJ71BR11

• QJ71LP21-25

• QJ71LP21G

• QJ71LP21GE

• QJ71E71

• QJ71E71-B2

• QJ71E71-100

• QJ61BT11 No limit

• A1SJ71PT32-S3

• A1SJ71T32-S3

• A1SD51S

• A1SD21-S1

• A1SJ71J92-S3

(When GET/PUT service is used)

• A1SI61

• QI60

1: A maximum of 4 modules if the network parameters for CC-Link are set and

controlled by the GX Developer. There is no restriction in the number of modules

when the parameters are set by the special-purpose instructions for the CC-Link.

For details on the CC-Link System Master Local Unit that can set parameters with

the special-purpose instructions, refer to the user's manual for the CC-Link Master

Local module.

(b) When the AnS series special-function modules shown below are used, a

limitation is given to an accessible device range.

• A1SJ71J92-S3 type JEMANET interface module

• A1SD51S type intelligent communication

Device Accessible device range

Input (X), Output (Y) X/Y0 to 7FF

Internal relay (M), Latch relay (L) M0 to 8191

Link relay (B) B0 to FFF

Timer (T) T0 to 2047

Counter (C) C0 to 1023

Data register (D) D0 to 6143

Link register (W) W0 to FFF

Annunciator (F) F0 to 2047

(c) A graphic operation terminal can be used only for the GOT900 series (Basic

OS matching Q mode and communication driver must be installed).

The GOT800 series, A77GOT, and A64GOT cannot be used.

2 - 6 2 - 6

Limit of number of modules

to be installed

Up to 4 in total of inter-PLC

network and remote I/O

network modules

Up to 4 units

1

No limit

(setting of automatic refresh

function not allowed)

Total of 6 units

One unit only

Page 31

2 SYSTEM CONFIGURATION FOR SINGLE CPU SYSTEM

(d) The modules shown below cannot be used.

Module Name Type

MELSECNET/10 network

module

MELSECNET (II), /B data link

module

Ethernet interface module

Serial communication module,

computer link module

CC-Link master-local module A1SJ61QBT11, A1SJ61BT11

Modem interface module A1SJ71CMO-S3

ME-NET interface module A1SJ71ME81

A1SJ71LP21, A1SJ71BR11, A1SJ71QLP21,

A1SJ71QLP21S, A1SJ71QLP21GE, A1SJ71QBR11

A1SJ71AP21, A1SJ71AR21, A1SJ71AT21B

A1SJ71QE71-B2-S3(-B5-S3),

A1SJ71E71-B2-S3(-B5-S3)

A1SJ71QC24(N), A1SJ71UC24-R2(-R4/-PRF)

(e) A dedicated instruction for the next module which was present in the QnA/A

series program instruction cannot be used for the High Performance model

QCPU.

Re-writing using FROM/TO instruction is required.

Module Name Type

High speed counter module A1SD61, A1SD62, A1SD62D(-S1), A1SD62E

MELSECNET/MINI-S3 A1SJ71PT32-S3, A1SJ71T32-S3

Positioning module A1SD75P1-S3(P2-S3/P3-S3)

ID module A1SJ71ID1-R4, A1SJ71ID2-R4

(f) Some system configurations and functions are restricted when writing the

parameter of the "High speed interrupt fixed scan interval" setting.

Refer to the following manual for the restrictions when the parameter of the

"High speed interrupt fixed scan interval" setting has been written.

•

High Performance model QCPU (Q mode) User's Manual

(Function Explanation, Program Fundamentals)

Note that the above restrictions do not apply to the High Performance model

QCPU of serial number "04011" or earlier since it ignores the "High speed

interrupt fixed scan interval" setting.

(2) Software package

GX Developer that can use the functions added to the High Performance model

QCPU changes depending on the function version/serial number of the CPU

module.

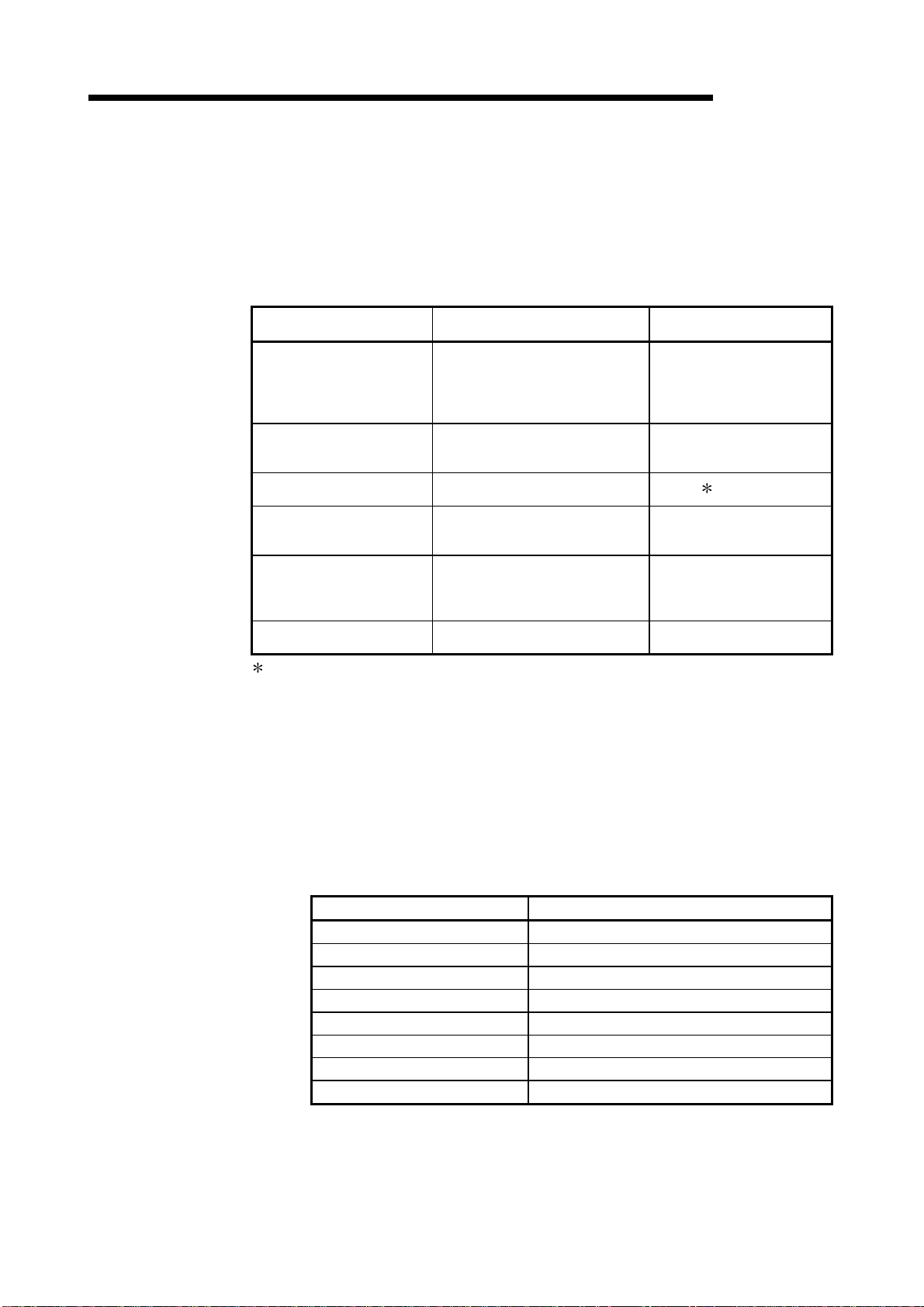

Function Version Serial Number GX Dev eloper

A — Version 4 (SW4D5C-GPPW-E) or later

— Functions added to "02092"

B —

— Functions added to "03052" Version 7 (SW7D5C-GPPW-E) or later

— Functions added to "04012"

Refer to Section 2.3 to confirm the function version and serial number of the High

Performance model QCPU.

MELSEC-Q

Version 6 (SW6D5C-GPPW-E) or later

Version 7.10L (SW7D5C-GPPW-E)

or later

2 - 7 2 - 7

Page 32

2 SYSTEM CONFIGURATION FOR SINGLE CPU SYSTEM

2.3 Confirming the Serial Number and Functi on Ver si on

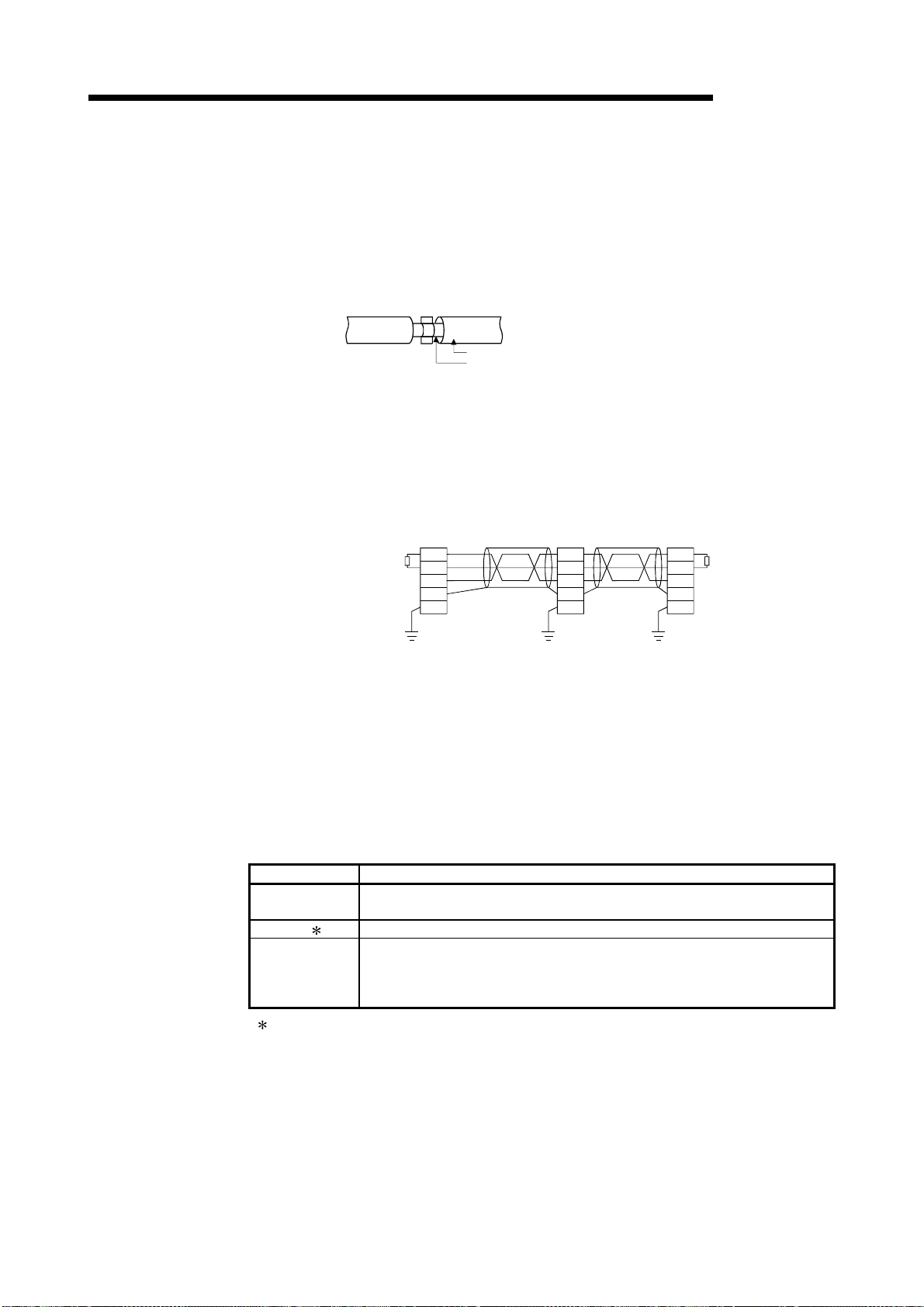

The CPU module serial No. can be confirmed on the rated plate and GX Developer's

system monitor.

(1) Confirming the serial N o. on the r ated plate

The serial No. and function version can be confirmed on the rating plate.

MELSEC-Q

MODEL

SERIAL 020920000000000-B

LISTED 80M1

IND. CONT. EQ.

MADE IN JAPAN

Serial No. (First five digits)

Function version

(2) Confirming the serial N o. on the sy stem moni tor ( li st of product

information)

The CPU module serial No. and function version can be confirmed with the list of

product information on the GX Developer (Version 6 or later) system monitor.

Serial Nos. and function versions of the intelligent function module and CPU

module can also be confirmed.

Serial number Function version

2 - 8 2 - 8

Page 33

3 GENERAL SPECIFICATIONS

3 GENERAL SPECIFICATIONS

MELSEC-Q

Item Specifications

Operating ambient

temperature

Storage ambient

temperature

3

Operating ambient

humidity

Storage ambient

humidity

Vibration resistance

Shock resistance

Operating ambience No corrosive gases

Operating altitude 2000m (6562ft.) max.

Installation location Inside control panel

Overvoltage

category

Pollution level 2 2 max.

1

Performance specification of PLC is as follows:

0 to 55°C

-25 to 75°C

5 to 95%RH

5 to 95%RH

Frequency Acceleration Amplitude Sweep count

Conforming

to

JIS B 3502,

IEC 61131-2

Conforming to JIS B 3502, IEC 61131-2 (147 m/s

Under

intermittent

vibration

Under

continuous

vibration

10 to 57Hz ———

57 to 150Hz

10 to 57Hz ———

57 to 150Hz

4, non-condensing

4, non-condensing

II max.

3

0.075mm

(0.003inch)

———

0.035mm

(0.001inch)

———

2

9.8m/s

2

4.9m/s

2

, 3 times in each of 3 directions X, Y, Z)

10 times each in

X, Y, Z directions

(for 80 min.)

1 : This indicates the section of the power supply to which the equipment is assumed to be connected

between the public electrical power distribution network and the machinery within premises. Category II

applies to equipment for which electrical power is supplied from fixed facilities.

The surge voltage withstand level for up to the rated voltage of 300 V is 2500 V.

2 : This index indicates the degree to which conductive material is generated in terms of the environment in

which the equipment is used.

Pollution level 2 is when only non-conductive pollution occurs. A temporary conductivity caused by

condensing must be expected occasionally.

3 : The storage ambient temperature is -20 to 75°C if the system includes the AnS series modules.

4 : The operating ambient humidity and storage ambient humidity are 10 to 90%RH if the system includes the

AnS series modules.

5 : Do not use or store the PLC under pressure higher than the atmospheric pressure of altitude 0m.

Doing so can cause a malfunction.

When using the PLC under pressure, please contact your sales representative.

3 - 1 3 - 1

Page 34

3 GENERAL SPECIFICATIONS

MELSEC-Q

MEMO

3

3 - 2 3 - 2

Page 35

4 HARDWARE SPECIFICATION OF THE CPU MODULE

4 HARDWARE SPECIFICATION OF THE CPU MODULE

4.1 Performance Specification

MELSEC-Q

The table below shows the performance specifications of the CPU module.

Performance Specifications

Item

Control method Repetitive operation of stored program

I/O control mode Refresh mode

Q02CPU Q02HCPU Q06HCPU Q12HCPU Q25HCPU

Programming language

(Sequence control dedicated language)

(Sequence instruction)

4

Total number of instructions

Constant scan

(Function for setting the scan timer to fixed

settings)

Program 2

capacity

Memory

capacity

Maximum number

of stored files

Program memory

(Drive 0)

Program memory

(Drive 0)

Memory card (RAM)

(Drive 1)

Memory card (ROM)

(Drive 2)

Standard RAM

(Drive 3)

Standard ROM

(Drive 4)

CPU shared memory

4

Program memory 28 60 124 252 1

Memory card (RAM) 256

card

(ROM)

LD X0 0.079 s 0.034 s

MOV D0 D1 0.237

Flash card 288

ATA card 512

Relay symbol language, logic symbolic language,

MELSAP3 (SFC), MEL SAP- L , Fu n ction b lo ck

s 0.102 s

(excluding intelligent function module dedicated instructions)

0.5 to 2000 ms (configurable in increments of 0.5 ms)

28k step 60k step 124k step 252k step

112 kbyte 240 kbyte 496 kbyte 1008 kbyte

Capacity of loading memory cards(2Mbyte max.)

Installed memory card capacity

(Flash card: 4 Mbyte max., ATA card: 32 Mbyte max.)

64kbyte 128kbyte

112 kbyte 240 kbyte 496 kbyte 1008 kbyte

Standard RAM 2

Standard ROM number of writings Max. 100000 times

Number of I/O device points 8192 points (X/Y0 to 1FFF)

Number of occupied I/O points 4096 points (X/Y0 to FFF)

1:124 is the maximum number of programs that can be executed on High Performance model QCPU.

2: The maximum number of sequence steps that can be executed for one program by the High Performance model QCPU with the

parameters stored in another drive is calculated with the following expression.

(Program size) - (File header size (default: 34 steps))

Refer to the High Performance model QCPU User's Manual (Function Explanation, Program Fundamentals) for details on the program

size and file.

3: The memory capacity of the Q12HCPU or Q25HCPU whose first five digits of serial No. are "02091" or earlier is 64K bytes.

(Refer to Section 2.3 for the way to confirm the serial No.)

4:The CPU shared memory is not latched. The CPU shared memory is cleared when the power is turned on to the PLC or when the CPU

module is reset.

5:The memory capacity of the Q02HCPU or Q06HCPU whose first five digits of serial No. are "04011" or earlier is 64K bytes.

(Refer to Section 2.3 for the way to confirm the serial No.)

Standard ROM 28 60 124 252

Model

360

5 256kbyte 3

8 kbyte

Remark

Direct I/O is possible by

direct I/O specification

(DX

, DY )

——

Processing speed

——

——

——

Set parameter values to

specify

——

——

For memory capacity,

refer to Section 7.1.

——

——

——

——

——

Memory

——

——

Only one file register and

one local device

——

——

Number of devices

usable on program

Number of points

accesible to actual I/O

modules

4 - 1 4 - 1

Page 36

4 HARDWARE SPECIFICATION OF THE CPU MODULE

Performance Specifications (continued)

MELSEC-Q

Internal relay [M]

Latch relay [L]

Link relay [B]

Timer [T]

Retentive timer [ST]

Counter [C]

Data register [D ]

Link register [W]

Annunciator [F]

Edge relay [V]

Number of device points

File register

Item

[R]

[ZR]

Model

Q02CPU Q02HCPU Q06HCPU Q12HCPU Q25HCPU

Default 8192 points (M0 to 8191)

Default 8192 points (L0 to 8191)

Default 8192points (B0 to 1FFF)

Default 2048 points (T0 to 2047) (for low / high speed timer)

Select between low / high speed timer by instructions.

The measurement unit of the low / high speed timer is set with

parameters.

(Low speed timer : 1 to 1000ms, 1ms

(High speed timer : 0.1 to 100ms, 0.1ms

Default 0 point(for low / high speed retentive timer)