Page 1

QCPU User's Manual

(Hardware Design, Maintenance and Inspection)

-Q00(J)CPU -Q26UD(E)HCPU

-Q01CPU -Q26UDVCPU

-Q02(H)CPU -Q50UDEHCPU

-Q06HCPU -Q100UDEHCPU

-Q12HCPU

-Q25HCPU

-Q02PHCPU

-Q06PHCPU

-Q12PHCPU

-Q25PHCPU

-Q12PRHCPU

-Q25PRHCPU

-Q00U(J)CPU

-Q01UCPU

-Q02UCPU

-Q03UD(E)CPU

-Q03UDVCPU

-Q04UD(E)HCPU

-Q04UDVCPU

-Q06UD(E)HCPU

-Q06UDVCPU

-Q10UD(E)HCPU

-Q13UD(E)HCPU

-Q13UDVCPU

-Q20UD(E)HCPU

Page 2

Page 3

SAFETY PRECAUTIONS

WARNING

CAUTION

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in minor or moderate injury or property damage.

Overcurrent or overvoltage protection of

the power supply module is activated.

The CPU module detects an error such as a

watchdog timer error by the self-diagnostic function.

All outputs are turned off All outputs are turned off

All outputs are turned off

All outputs are held or turned off

according to the parameter setting.

Q series module AnS/A series module

(Read these precautions before using this product.)

Before using this product, please read this manual and the relevant manuals carefully and pay full attention

to safety to handle the product correctly.

In this manual, the safety precautions are classified into two levels: " WARNING" and " CAUTION".

Under some circumstances, failure to observe the precautions given under " CAUTION" may lead to

serious consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this manual and then keep the manual in a safe place for future

reference.

[Design Precautions]

WARNING

● Configure safety circuits external to the programmable controller to ensure that the entire system

operates safely even when a fault occurs in the external power supply or the programmable controller.

Failure to do so may result in an accident due to an incorrect output or malfunction.

(1) Configure external safety circuits, such as an emergency stop circuit, protection circuit, and

protective interlock circuit for forward/reverse operation or upper/lower limit positioning.

(2) The programmable controller stops its operation upon detection of the following status, and the

output status of the system will be as shown below.

All outputs may turn on when an error occurs in the part, such as I/O control part, where the CPU

module cannot detect any error. To ensure safety operation in such a case, provide a safety

mechanism or a fail-safe circuit external to the programmable controller. For a fail-safe circuit

example, refer to Page 670, Appendix 9.

(3) Outputs may remain on or off due to a failure of an output module relay or transistor. Configure an

external circuit for monitoring output signals that could cause a serious accident.

1

Page 4

[Design Precautions]

WARNING

● In an output module, when a load current exceeding the rated current or an overcurrent caused by a

load short-circuit flows for a long time, it may cause smoke and fire. To prevent this, configure an

external safety circuit, such as a fuse.

● Configure a circuit so that the programmable controller is turned on first and then the external power

supply. If the external power supply is turned on first, an accident may occur due to an incorrect output

or malfunction.

● For the operating status of each station after a communication failure, refer to relevant manuals for the

network. Incorrect output or malfunction due to a communication failure may result in an accident.

● When changing data of the running programmable controller from a peripheral connected to the CPU

module or from a personal computer connected to an intelligent function module, configure an

interlock circuit in the sequence program to ensure that the entire system will always operate safely.

For program modification and operating status change, read relevant manuals carefully and ensure

the safety before operation. Especially, in the case of a control from an external device to a remote

programmable controller, immediate action cannot be taken for a problem on the programmable

controller due to a communication failure. To prevent this, configure an interlock circuit in the

sequence program, and determine corrective actions to be taken between the external device and

CPU module in case of a communication failure.

[Design Precautions]

CAUTION

● Do not install the control lines or communication cables together with the main circuit lines or power

cables. Keep a distance of 100mm or more between them. Failure to do so may result in malfunction

due to noise.

● When a device such as a lamp, heater, or solenoid valve is controlled through an output module, a

large current (approximately ten times greater than normal) may flow when the output is turned from

off to on. Take measures such as replacing the module with one having a sufficient current rating.

● After the CPU module is powered on or is reset, the time taken to enter the RUN status varies

depending on the system configuration, parameter settings, and/or program size. Design circuits so

that the entire system will always operate safely, regardless of the time.

2

Page 5

[Installation Precautions]

CAUTION

● Use the programmable controller in an environment that meets the general specifications in this

manual. Failure to do so may result in electric shock, fire, malfunction, or damage to or deterioration of

the product.

● To mount the module, while pressing the module mounting lever in the lower part of the module, fully

insert the module fixing projection(s) into the hole(s) in the base unit and press the module until it

snaps into place. Incorrect mounting may cause malfunction, failure, or drop of the module. When

using the programmable controller in an environment of frequent vibrations, fix the module with a

screw. Tighten the screw within the specified torque range. Undertightening can cause drop of the

screw, short circuit or malfunction. Overtightening can damage the screw and/or module, resulting in

drop, short circuit, or malfunction.

When using an extension cable, connect it to the extension cable connector of the base unit securely.

●

Check the connection for looseness. Poor contact may cause incorrect input or output.

● When using a memory card, fully insert it into the memory card slot. Check that it is inserted

completely. Poor contact may cause malfunction.

● When using an SD memory card, fully insert it into the SD memory card slot. Check that it is inserted

completely. Poor contact may cause malfunction.

● When using an extended SRAM cassette, fully insert it into the connector for cassette connection of

the CPU module. Close the cassette cover after inserting to avoid looseness of the extended SRAM

cassette. Poor contact may cause malfunction.

● Shut off the external power supply (all phases) used in the system before mounting or removing the

module. Failure to do so may result in damage to the product. A module can be replaced online (while

power is on) on any MELSECNET/H remote I/O station or in the system where a CPU module

supporting the online module change function is used. Note that there are restrictions on the modules

that can be replaced online, and each module has its predetermined replacement procedure. For

details, refer to this manual and in the manual for the corresponding module.

● Do not directly touch any conductive part of the module, the memory card, the SD memory card, or

the extended SRAM cassette. Doing so can cause malfunction or failure of the module.

● When using a Motion CPU module and modules designed for motion control, check that the

combinations of these modules are correct before applying power. The modules may be damaged if

the combination is incorrect. For details, refer to the user's manual for the Motion CPU module.

[Wiring Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before wiring. Failure to do so may

result in electric shock or damage to the product.

● After installation and wiring, attach the included terminal cover to the module before turning it on for

operation. Failure to do so may result in electric shock.

3

Page 6

[Wiring Precautions]

CAUTION

● Individually ground the FG and LG terminals of the programmable controller with a ground resistance

of 100 or less. Failure to do so may result in electric shock or malfunction.

● Use applicable solderless terminals and tighten them within the specified torque range. If any spade

solderless terminal is used, it may be disconnected when the terminal screw comes loose, resulting in

failure.

● Check the rated voltage and terminal layout before wiring to the module, and connect the cables

correctly. Connecting a power supply with a different voltage rating or incorrect wiring may cause a fire

or failure.

● Connectors for external connection must be crimped or pressed with the tool specified by the

manufacturer, or must be correctly soldered. Incomplete connections could result in short circuit, fire,

or malfunction.

● Install the connector to the module securely. Poor contact may cause malfunction.

● Do not install the control lines or communication cables together with the main circuit lines or power

cables. Keep a distance of 100mm or more between them. Failure to do so may result in malfunction

due to noise.

● Place the wires or cables in a duct or clamp them. If not, dangling cable may swing or inadvertently be

pulled, resulting in damage to the module or cables or malfunction due to poor connection.

● Connect the cable correctly after confirming the interface type to be connected. Connecting to the

wrong interface or incorrect wiring can result in a failure of the module or external devices.

● Tighten the terminal screw within the specified torque range. Undertightening can cause short circuit,

fire, or malfunction. Overtightening can damage the screw and/or module, resulting in drop, short

circuit, or malfunction.

● Prevent foreign matter such as dust or wire chips from entering the module. Such foreign matter can

cause a fire, failure, or malfunction.

● A protective film is attached to the top of the module to prevent foreign matter, such as wire chips,

from entering the module during wiring. Do not remove the film during wiring. Remove it for heat

dissipation before system operation.

● Do not pull the cable section of a cable for disconnection. When disconnecting a cable with a

connector, hold the connector and pull it. When disconnecting a cable on a terminal block, loosen the

terminal screw before disconnection. Pulling the connected cable can result in malfunction or damage

of the module or the cable.

● Mitsubishi Electric programmable controllers must be installed in control panels. Connect the main

power supply to the power supply module in the control panel through a relay terminal block. Wiring

and replacement of a power supply module must be performed by maintenance personnel who is

familiar with protection against electric shock. (For wiring methods, refer to Page 103, Section 4.8.1.)

4

Page 7

[Startup and Maintenance Precautions]

WARNING

● Do not touch any terminal while power is on. Doing so will cause electric shock.

● Correctly connect the battery connector. Do not charge, disassemble, heat, short-circuit, solder, or

throw the battery into the fire, or apply liquid or a strong shock to the battery. Doing so will cause the

battery to produce heat, explode, ignite, or liquid spill, resulting in injury and fire.

● Shut off the external power supply (all phases) used in the system before cleaning the module or

retightening the terminal screws, connector screws, or module fixing screws. Failure to do so may

result in electric shock or cause the module to fail or malfunction.

[Startup and Maintenance Precautions]

CAUTION

● Before performing online operations (especially, program modification, forced output, and operation

status change) for the running CPU module from the peripheral connected, read relevant manuals

carefully and ensure the safety. Improper operation may damage machines or cause accidents.

● Do not disassemble or modify the modules. Doing so may cause failure, malfunction, injury, or a fire.

● Use any radio communication device such as a cellular phone or PHS (Personal Handy-phone

System) more than 25cm away in all directions from the programmable controller. Failure to do so

may cause malfunction.

● Shut off the external power supply (all phases) used in the system before mounting or removing the

module. Failure to do so may cause the module to fail or malfunction. A module can be replaced

online (while power is on) on any MELSECNET/H remote I/O station or in the system where a CPU

module supporting the online module change function is used. Note that there are restrictions on the

modules that can be replaced online, and each module has its predetermined replacement procedure.

For details, refer to this manual and the manual for the corresponding module.

● After the first use of the product, do not mount/remove the module to/from the base unit, the extended

SRAM cassette to/from the CPU module, or the terminal block to/from the module more than 50 times

(IEC 61131-2 compliant) respectively. Exceeding the limit of 50 times may cause malfunction.

● After the first use of the product, do not mount/remove the SD memory card more than 500 times.

Exceeding the limit of 500 times may cause malfunction.

● Do not drop or apply shock to the battery to be installed in the module. Doing so may damage the

battery, causing the battery fluid to leak inside the battery. If the battery is dropped or any shock is

applied to it, dispose of it without using.

● Before handling the module, touch a grounded metal object to discharge the static electricity from the

human body. Failure to do so may cause the module to fail or malfunction.

5

Page 8

[Disposal Precautions]

CAUTION

● When disposing of this product, treat it as industrial waste. When disposing of batteries, separate

them from other wastes according to the local regulations. (For details of the Battery Directive in EU

countries, refer to Page 678, Appendix 12.)

[Transportation Precautions]

CAUTION

● When transporting lithium batteries, follow the transportation regulations. (For details of the regulated

models, refer to Page 677, Appendix 11.)

6

Page 9

CONDITIONS OF USE FOR THE PRODUCT

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major

or serious accident; and

ii) where the backup and fail-safe function are systematically or automatically provided outside of

the PRODUCT for the case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general

industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT

LIMITED TO ANY AND ALL RESPONSIBILITY OR LIABILITY BASED ON CONTRACT,

WARRANTY, TORT, PRODUCT LIABILITY) FOR ANY INJURY OR DEATH TO PERSONS OR

LOSS OR DAMAGE TO PROPERTY CAUSED BY the PRODUCT THAT ARE OPERATED OR

USED IN APPLICATION NOT INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS,

OR WARNING CONTAINED IN MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY

MANUALS, TECHNICAL BULLETINS AND GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

• Nuclear Power Plants and any other power plants operated by Power companies, and/or any

other cases in which the public could be affected if any problem or fault occurs in the PRODUCT.

• Railway companies or Public service purposes, and/or any other cases in which establishment of

a special quality assurance system is required by the Purchaser or End User.

• Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as

Elevator and Escalator, Incineration and Fuel devices, Vehicles, Manned transportation,

Equipment for Recreation and Amusement, and Safety devices, handling of Nuclear or

Hazardous Materials or Chemicals, Mining and Drilling, and/or other applications where there is a

significant risk of injury to the public or property.

Notwithstanding the above, restrictions Mitsubishi may in its sole discretion, authorize use of the

PRODUCT in one or more of the Prohibited Applications, provided that the usage of the PRODUCT

is limited only for the specific applications agreed to by Mitsubishi and provided further that no

special quality assurance or fail-safe, redundant or other safety features which exceed the general

specifications of the PRODUCTs are required. For details, please contact the Mitsubishi

representative in your region.

7

Page 10

INTRODUCTION

Remark

This manual provides hardware specifications, maintenance and inspection of the system, and troubleshooting of the CPU

modules, power supply modules, and base units required for operating the Q series programmable controllers.

Before using this product, please read this manual and the relevant manuals carefully and develop familiarity with the

functions and performance of the Q series programmable controller to handle the product correctly.

When applying the program examples introduced in this manual to the actual system, ensure the applicability and confirm that

it will not cause system control problems.

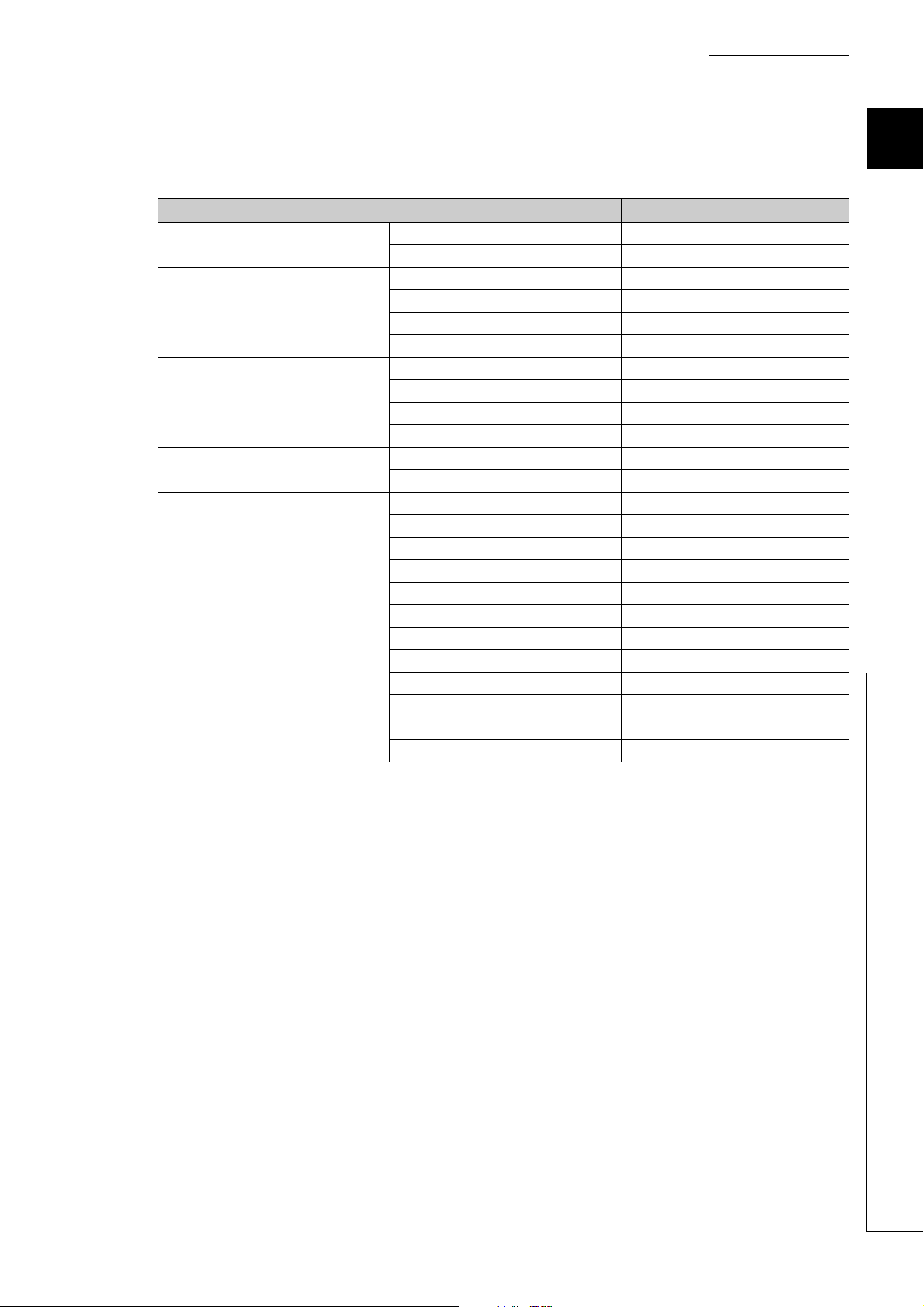

Relevant CPU module

CPU module Model

Basic model QCPU Q00(J)CPU, Q01CPU

High Performance model QCPU Q02(H)CPU, Q06HCPU, Q12HCPU, Q25HCPU

Process CPU Q02PHCPU, Q06PHCPU, Q12PHCPU, Q25PHCPU

Redundant CPU Q12PRHCPU, Q25PRHCPU

Q00U(J)CPU, Q01UCPU, Q02UCPU, Q03UD(E)CPU, Q03UDVCPU,

Universal model QCPU

Q04UD(E)HCPU, Q04UDVCPU, Q06UD(E)HCPU, Q06UDVCPU,

Q10UD(E)HCPU, Q13UD(E)HCPU, Q13UDVCPU, Q20UD(E)HCPU,

Q26UD(E)HCPU, Q26UDVCPU, Q50UDEHCPU, Q100UDEHCPU

Precautions when using the Q series CPU module for the first time

Memory must be formatted using a programming tool before first use of the CPU module.

For details of memory formatting, refer to the following.

Operating manual for the programming tool used

Precautions for batteries

(1) When resuming operation with the CPU module which has been stored without battery:

The CPU module memory must be formatted using a programming tool. ( Page 264, Section 13.4)

This manual does not describe the functions of the CPU module.

For the functions, refer to the following.

Manuals for the CPU module used. (Function Explanation, Program Fundamentals)

For multiple CPU systems, refer to the following.

QCPU User's Manual (Multiple CPU System)

For redundant systems, refer to the following.

QnPRHCPU User's Manual (Redundant System)

8

Page 11

Memo

9

Page 12

CONTENTS

CONTENTS

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

CONDITIONS OF USE FOR THE PRODUCT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

MANUALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

MANUAL PAGE ORGANIZATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

TERMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

PACKING LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

DISCONTINUED MODELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

CHAPTER 1 OVERVIEW 26

1.1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

CHAPTER 2 SYSTEM CONFIGURATION 33

2.1 Overall Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.2 Component List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.3 Precautions for System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2.3.1 Bus connection of GOT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

2.3.2 Peripheral device configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

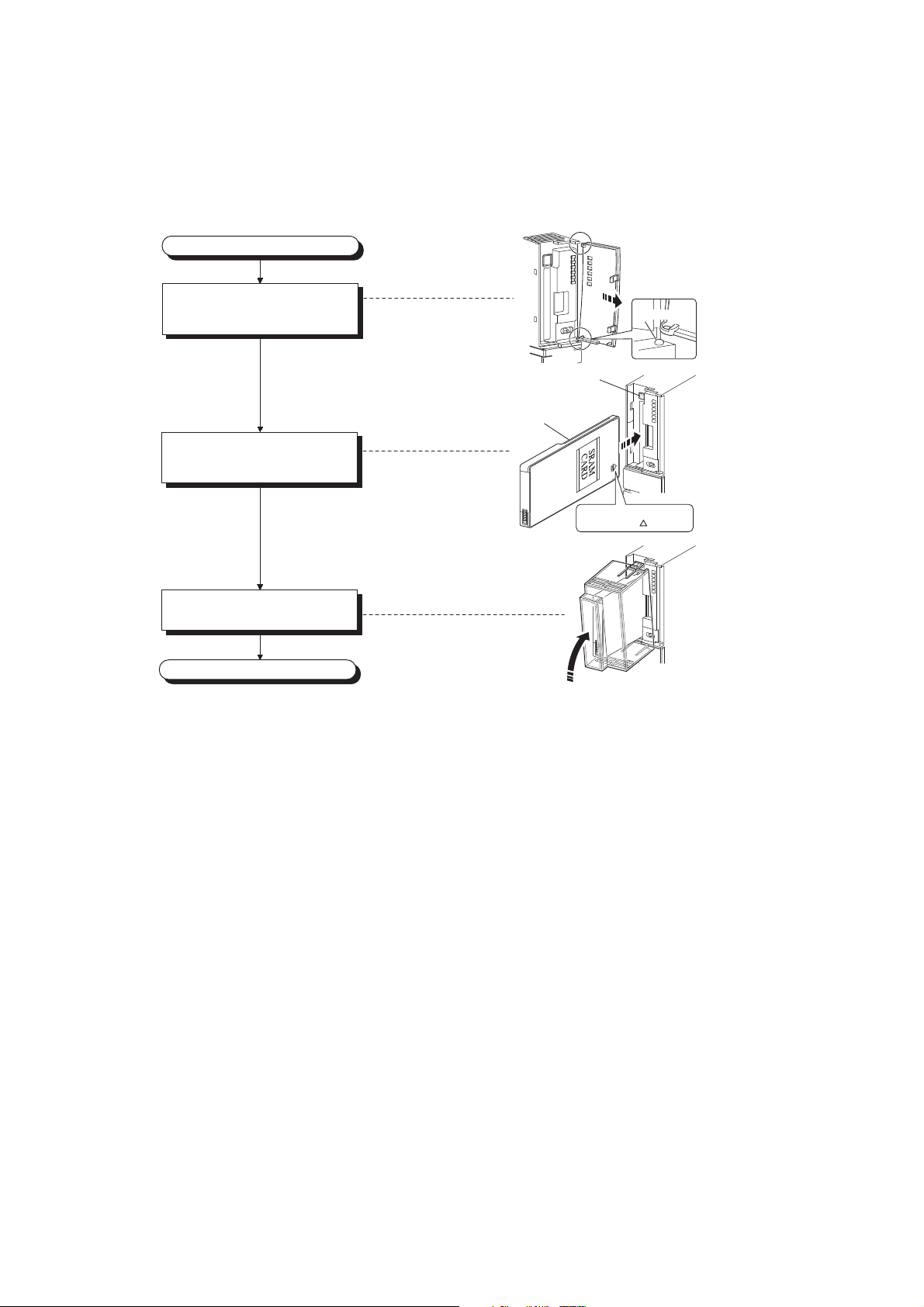

CHAPTER 3 CPU MODULE START-UP PROCEDURES 57

CHAPTER 4 INSTALLATION AND WIRING 59

4.1 Installation Environment and Installation Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4.1.1 Installation environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

4.1.2 Installation position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

4.2 Mounting a Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

4.2.1 Mounting precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

4.2.2 Base unit installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

4.2.3 Installation and removal of module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

4.3 Connecting an Extension Base Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

4.3.1 Setting the extension base number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

4.3.2 Connection and disconnection of extension cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

4.3.3 Extension cable specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

4.3.4 Voltage drop when an extension base unit is used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

4.4 Mounting and Removing a Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

4.5 Installing and Removing a Memory Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

4.6 Installing and Removing an SD Memory Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

4.7 Installing and Removing an Extended SRAM Cassette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

4.8 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

4.8.1 Wiring power supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

4.8.2 Wiring of 18-point screw terminal block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

4.8.3 Wiring to connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

4.8.4 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

CHAPTER 5 GENERAL SPECIFICATIONS 117

10

Page 13

CHAPTER 6 CPU MODULE 119

6.1 Part Names. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

6.1.1 Basic model QCPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

6.1.2 High Performance model QCPU, Process CPU and Redundant CPU . . . . . . . . . . . . . . . . .125

6.1.3 Universal model QCPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .130

6.2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

6.2.1 Basic model QCPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .145

6.2.2 High Performance model QCPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .148

6.2.3 Process CPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .152

6.2.4 Redundant CPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .156

6.2.5 Universal model QCPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .160

6.3 Switch Operation at the Time of Writing Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

6.3.1 Basic model QCPU and Universal model QCPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .180

6.3.2 High Performance model QCPU, Process CPU and Redundant CPU . . . . . . . . . . . . . . . . .181

6.4 Reset Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

6.4.1 Basic model QCPU and Universal model QCPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .182

6.4.2 High Performance model QCPU, Process CPU and Redundant CPU . . . . . . . . . . . . . . . . .183

6.5 Latch Clear Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

6.5.1 Basic model QCPU and Universal model QCPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .184

6.5.2 High Performance model QCPU, Process CPU and Redundant CPU . . . . . . . . . . . . . . . . .184

6.6 Automatic Write to the Standard ROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

CHAPTER 7 POWER SUPPLY MODULE 187

7.1 Part Names and Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

7.1.1 Base unit that can be used in combination with power supply module . . . . . . . . . . . . . . . . .194

7.2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

7.2.1 Power supply module specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .196

7.2.2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .213

7.2.3 Selecting the power supply module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .215

7.2.4 Precautions on power supply capacity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .218

7.2.5 Life detection power supply module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .219

CHAPTER 8 BASE UNIT 223

8.1 Part Names. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

8.2 Extension Base Units that can be Combined with the Main Base Unit. . . . . . . . . . . . . . . . . . 230

8.3 Specification Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

CHAPTER 9 MEMORY CARD 235

9.1 Part Names. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

9.1.1 List of usable memory cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .236

9.2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

9.2.1 Memory card specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .237

9.2.2 Specifications of the memory card battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .239

9.3 Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

11

Page 14

9.3.1 Battery installation into the memory card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .241

CHAPTER 10 SD MEMORY CARD 243

10.1 Part Names. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

10.2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

10.3 Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

10.4 Forcibly Disabling the SD Memory Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

CHAPTER 11 EXTENDED SRAM CASSETTE 246

11.1 Part Names. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

11.2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

11.3 Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

CHAPTER 12 BATTERY 248

12.1 Battery Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

12.2 Battery Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

CHAPTER 13 MAINTENANCE AND INSPECTION 253

13.1 Daily Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

13.2 Periodic Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

13.3 Replacement Procedure of the Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

13.3.1 Replacement procedure of the CPU module battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .255

13.3.2 SRAM card battery replacement procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .261

13.4 Operating the Programmable Controller that Has been Stored . . . . . . . . . . . . . . . . . . . . . . . 264

CHAPTER 14 MODULE CHANGE DURING SYSTEM OPERATION 265

14.1 Online Module Change. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

14.2 Change of Redundant Power Supply Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

CHAPTER 15 TROUBLESHOOTING 276

15.1 Visual Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

15.1.1 When the POWER LED does not turn on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .278

15.1.2 When the POWER LED does not turn on in green . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .278

15.1.3 When the LIFE LED does not turn on in green or orange . . . . . . . . . . . . . . . . . . . . . . . . . . .279

15.1.4 When the MODE LED does not turn on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .280

15.1.5 When the RUN LED does not turn on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .281

15.1.6 When the BOOT LED flickers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .281

15.2 Checking the Error Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

15.3 Checking for Functional Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .285

15.3.1 Write to PLC and Read from PLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .286

15.3.2 Boot operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .287

15.3.3 Errors caused by hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .288

15.3.4 Ethernet communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .289

12

Page 15

15.3.5 Socket communication function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .294

15.3.6 MC protocol function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .295

15.3.7 Predefined protocol function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .296

15.3.8 Transmission from an external device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .297

15.3.9 Operating status of the CPU module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .297

15.3.10 Errors caused by SFC program instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .298

15.3.11 I/O module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .299

15.3.12 Power supply module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .300

15.4 Saving Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

APPENDICES 306

Appendix 1 Error Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

Appendix 1.1 Error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .307

Appendix 1.2 Reading error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .307

Appendix 1.3 List of error codes (1000 to 1999) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .308

Appendix 1.4 List of error codes (2000 to 2999) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .328

Appendix 1.5 List of error codes (3000 to 3999) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .357

Appendix 1.6 List of error codes (4000 to 4999) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .375

Appendix 1.7 List of error codes (5000 to 5999) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .391

Appendix 1.8 List of error codes (6000 to 6999) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .393

Appendix 1.9 List of error codes (7000 to 10000) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .402

Appendix 1.10 Clearing an error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .410

Appendix 1.11 Error codes returned to request source during communication with CPU module . .411

Appendix 2 List of Special Relay Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .454

Appendix 3 List of Special Register Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 506

Appendix 4 Battery Life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 600

Appendix 4.1 Display of battery consumption and reduction measures of the consumption . . . . . .601

Appendix 4.2 Battery lives of CPU modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .603

Appendix 4.3 SRAM card battery life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .630

Appendix 5 Checking Serial Number and Function Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 632

Appendix 5.1 Applicable software versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .634

Appendix 5.2 GX Configurator versions applicable to a single CPU system . . . . . . . . . . . . . . . . . .635

Appendix 6 Added or Changed Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 637

Appendix 6.1 Basic model QCPU upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .637

Appendix 6.2 High Performance model QCPU upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 639

Appendix 6.3 Precautions for using older versions of the High Performance model QCPU . . . . . . 641

Appendix 6.4 Process CPU upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .644

Appendix 6.5 Redundant CPU upgrade. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .645

Appendix 6.6 Universal model QCPU upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .646

Appendix 7 Specifications of L1MEM-2GBSD and L1MEM-4GBSD . . . . . . . . . . . . . . . . . . . . . . . . 650

Appendix 8 EMC and Low Voltage Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 651

Appendix 8.1 Requirements for compliance with the EMC Directive . . . . . . . . . . . . . . . . . . . . . . . .651

Appendix 8.1.1 Standards relevant to the EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . .652

Appendix 8.1.2 Installation instructions for EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . 654

Appendix 8.1.3 Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .655

Appendix 8.1.4 Installation environment of the CC-Link/LT module and the AS-i module . . .662

13

Page 16

Appendix 8.1.5 Power supply part of the power supply module, Q00JCPU, and Q00UJCPU

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .662

Appendix 8.1.6 Precautions when using a MELSEC-A series module . . . . . . . . . . . . . . . . . . 663

Appendix 8.1.7 Others. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .665

Appendix 8.2 Requirements to compliance with the Low Voltage Directive. . . . . . . . . . . . . . . . . . .667

Appendix 8.2.1 Standard applied for MELSEC-Q series programmable controller . . . . . . . . .667

Appendix 8.2.2 MELSEC-Q series programmable controller selection . . . . . . . . . . . . . . . . . .667

Appendix 8.2.3 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .668

Appendix 8.2.4 Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .668

Appendix 8.2.5 External wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .669

Appendix 9 General Safety Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 670

Appendix 10Calculating Heat Generation of Programmable Controller . . . . . . . . . . . . . . . . . . . . . . 674

Appendix 11 Precautions for Battery Transportation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 677

Appendix 12Handling of Batteries and Devices with Built-in Batteries in EU Member States . . . . . 678

Appendix 12.1 Disposal precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .678

Appendix 12.2 Exportation precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .679

Appendix 13 External Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 680

Appendix 13.1 CPU modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .680

Appendix 13.2 Power supply modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .686

Appendix 13.3 Main base units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .690

Appendix 13.4 Extension base units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .696

Appendix 13.5 Other optional items. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .703

INDEX 706

REVISIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 709

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 715

TRADEMARKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 716

14

Page 17

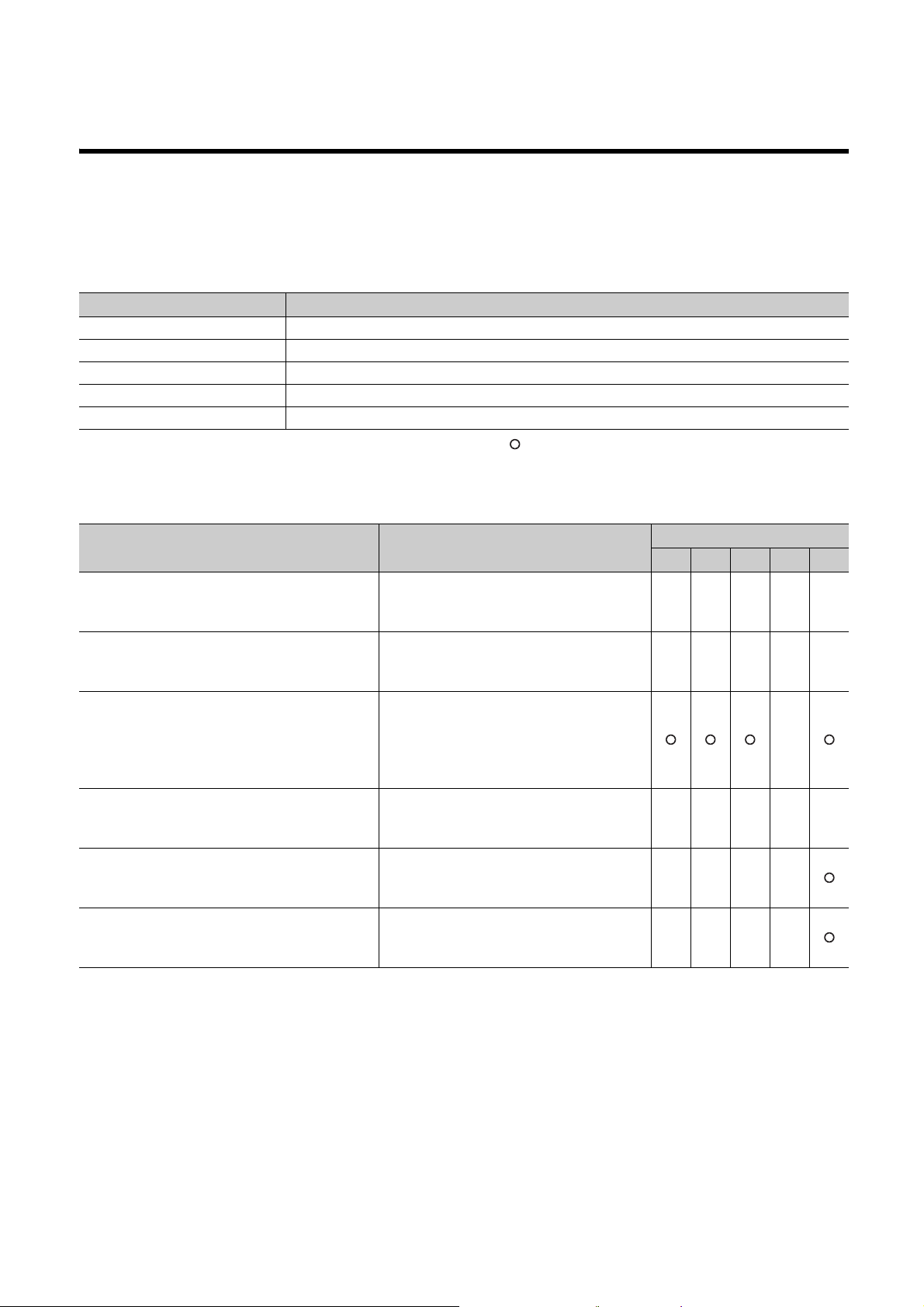

MANUALS

To understand the main specifications, functions, and usage of the CPU module, refer to the basic manuals.

Read other manuals as well when using a different type of CPU module and its functions.

Order each manual as needed, referring to the following lists.

The numbers in the "CPU module" and the respective modules are as follows.

Number CPU module

1) Basic model QCPU

2) High Performance model QCPU

3) Process CPU

4) Redundant CPU

5) Universal model QCPU

● : Basic manual, : Other CPU module manuals/Use them to utilize functions.

(1) CPU module user's manual

Manual name

< Manual number (model code) >

QnUCPU Users Manual (Function Explanation,

Program Fundamentals)

<SH-080807ENG, 13JZ27>

Qn(H)/QnPH/QnPRHCPU User's Manual (Function

Explanation, Program Fundamentals)

<SH-080808ENG, 13JZ28>

QCPU User's Manual (Multiple CPU System)

<SH-080485ENG, 13JR75>

QnPRHCPU User's Manual (Redundant System)

<SH-080486ENG, 13JR76>

QnUCPU User's Manual (Communication via Built-in

Ethernet Port)

<SH-080811ENG, 13JZ29>

MELSEC-Q Programming/Structured Programming

Manual (Process Control Instructions)

<SH-080893ENG, 13JZ39>

Description

Functions, methods, and devices for

programming

Functions, methods, and devices for

programming

Information on building multiple CPU systems

(system configurations, I/O numbers,

communications between CPU modules, and

communications with I/O modules and

intelligent function modules)

Redundant system configuration, functions,

communication with external devices, and

troubleshooting

Detailed description of communication via the

built-in Ethernet ports of the CPU module

Detailed description of the data logging function

of the CPU module

CPU module

1) 2) 3) 4) 5)

●

●●●●

●

15

Page 18

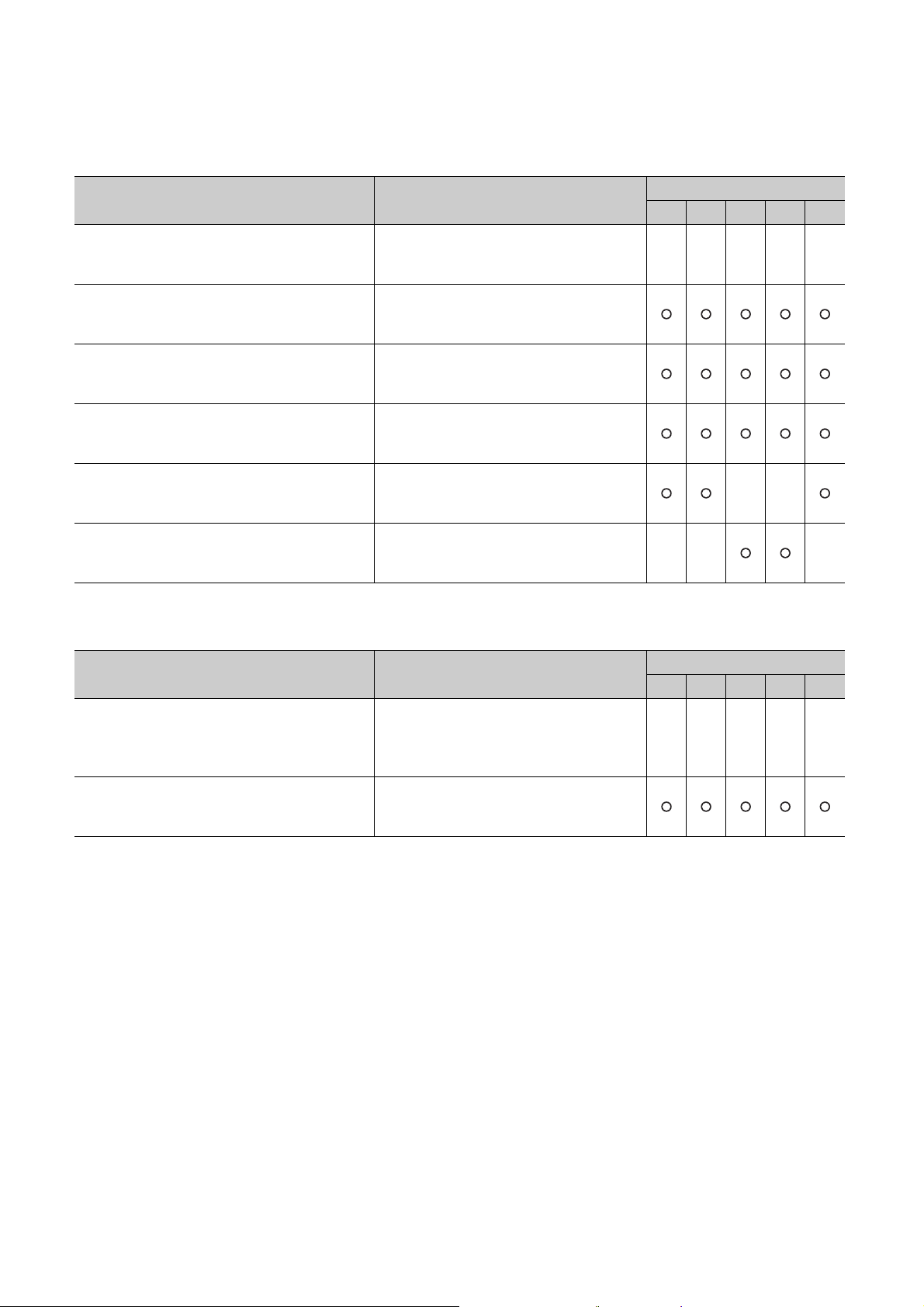

(2) Programming manual

Manual name

< Manual number (model code) >

MELSEC-Q/L Programming Manual (Common

Instruction)

<SH-080809ENG, 13JW10>

MELSEC-Q/L/QnA Programming Manual (SFC)

<SH-080041, 13JF60>

MELSEC-Q/L Programming Manual (MELSAP-L)

<SH-080076, 13JF61>

MELSEC-Q/L Programming Manual (Structured

Te xt )

<SH-080366E, 13JF68>

MELSEC-Q/L/QnA Programming Manual (PID

Control Instructions)

<SH-080040, 13JF59>

QnPHCPU/QnPRHCPU Programming Manual

(Process Control Instructions)

<SH-080316E, 13JF67>

(3) Operating manual

Description

Detailed description and usage of instructions

used in programs

System configuration, specifications, functions,

programming, and error codes for SFC

(MELSAP3) programs

System configuration, specifications, functions,

programming, and error codes for SFC

(MELSAP-L) programs

System configuration and programming using

structured text language

Dedicated instructions for PID control

Dedicated instructions for process control

CPU module

1) 2) 3) 4) 5)

●●●●●

Manual name

< Manual number (model code) >

GX Works2 Version 1 Operating Manual (Common)

<SH-080779ENG, 13JU63>

GX Developer Version 8 Operating Manual

<SH-080373E, 13JU41>

Description

System configuration, parameter settings, and

online operations of GX Works2, which are

common to Simple projects and Structured

projects

Operating methods of GX Developer, such as

programming, printing, monitoring, and

debugging

CPU module

1) 2) 3) 4) 5)

●●●●●

16

Page 19

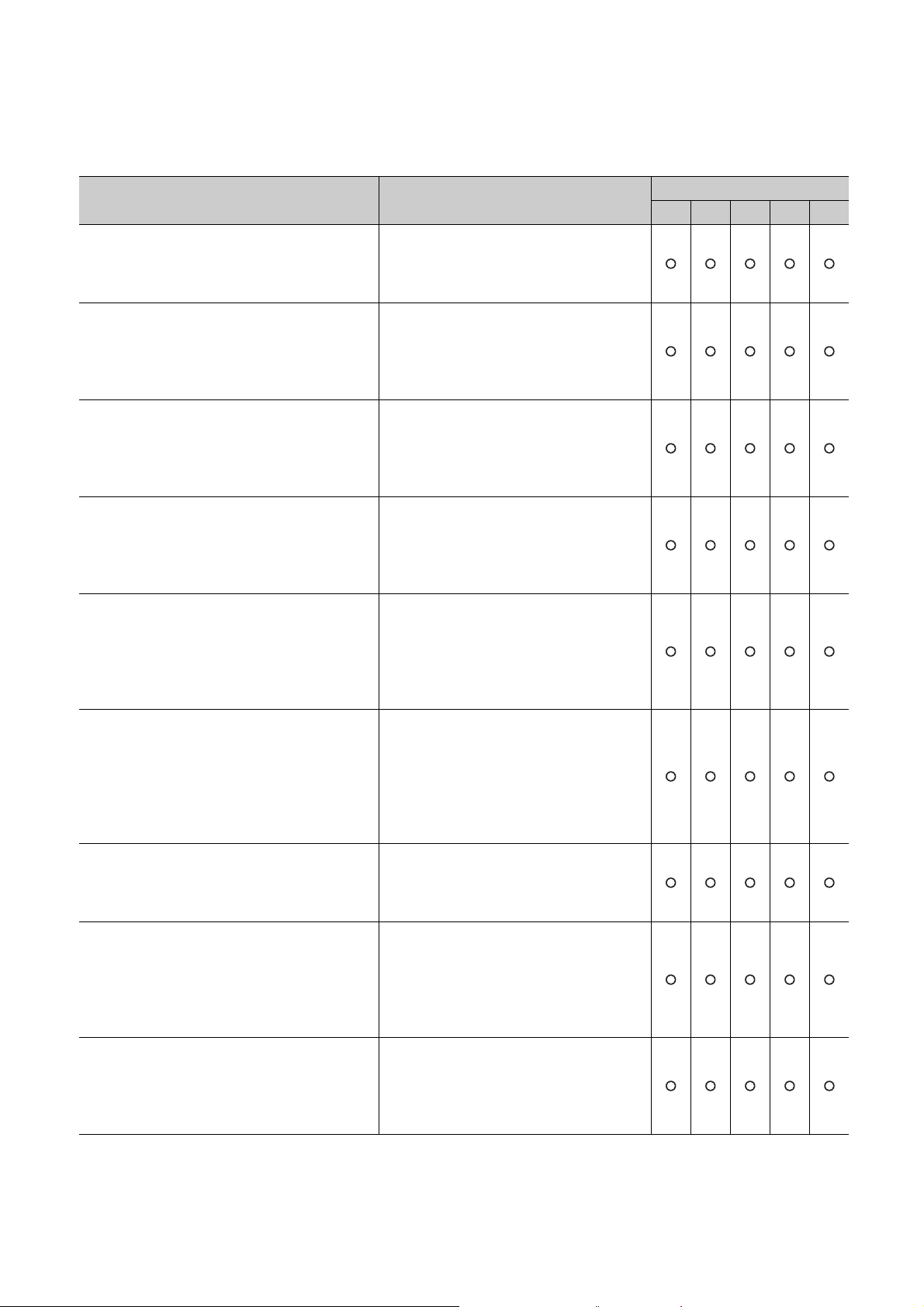

(4) Intelligent function module manual

Manual name

< Manual number (model code) >

CC-Link IE Controller Network Reference Manual

<SH-080668ENG, 13JV16>

MELSEC-Q CC-Link IE Field Network Master/Local

Module User's Manual

<SH-080917ENG, 13JZ47>

Q Corresponding MELSECNET/H Network System

Reference Manual (PLC to PLC network)

<SH-080049, 13JF92>

Q Corresponding MELSECNET/H Network System

Reference Manual (Remote I/O network)

<SH-080124, 13JF96>

Q Corresponding Ethernet Interface Module User's

Manual (Basic)

<SH-080009, 13JL88>

MELSEC-Q/L Ethernet Interface Module User's

Manual (Application)

<SH-080010, 13JL89>

MELSEC-Q CC-Link System Master/Local Module

User's Manual

<SH-080394E, 13JR64>

Q Corresponding Serial Communication Module

User's Manual (Basic)

<SH-080006, 13JL86>

MELSEC-Q/L Serial Communication Module User's

Manual (Application)

<SH-080007, 13JL87>

Description

Specifications, procedures and settings before

system operation, parameter setting,

programming, and troubleshooting of the CC-

Link IE Controller Network module

Specifications, procedures and settings before

system operation, parameter setting,

programming, and troubleshooting of the CC-

Link IE Field Network module

Specifications, procedures and settings before

system operation, parameter setting,

programming, and troubleshooting of a

MELSECNET/H network system (PLC to PLC

network)

Specifications, procedures and settings before

system operation, parameter setting,

programming, and troubleshooting of a

MELSECNET/H network system (remote I/O

network)

Specifications, procedures for data

communication with external devices, line

connection (open/close), fixed buffer

communication, random access buffer

communication, and troubleshooting of the

Ethernet module

E-mail function, programmable controller CPU

status monitoring function, communication via

CC-Link IE Controller Network, CC-Link IE

Field Network, MELSECNET/H, or

MELSECNET/10, communication using the

data link instructions, and file transfer function

(FTP server) of the Ethernet module

System configuration, performance

specifications, functions, handling, wiring, and

troubleshooting of the QJ61BT11N

Overview, system configuration, specifications,

procedures before operation, basic data

communication method with external devices,

maintenance and inspection, and

troubleshooting for using the serial

communication module

Special functions (specifications, usage, and

settings) and data communication method with

external devices of the serial communication

module

CPU module

1) 2) 3) 4) 5)

17

Page 20

(5) Others

Manual name

< Manual number (model code) >

iQ Sensor Solution Reference Manual

<SH-081133ENG, 13JV28>

CC-Link IE Field Network Basic Reference Manual

<SH-081684ENG, 13JX62>

Description

Operating methods of iQ Sensor Solution, such

as programming and monitoring

Specifications, procedures before operation,

system configuration, programming, functions,

parameter settings, and troubleshooting of CC-

Link IE Field Network Basic

CPU module

1) 2) 3) 4) 5)

18

Page 21

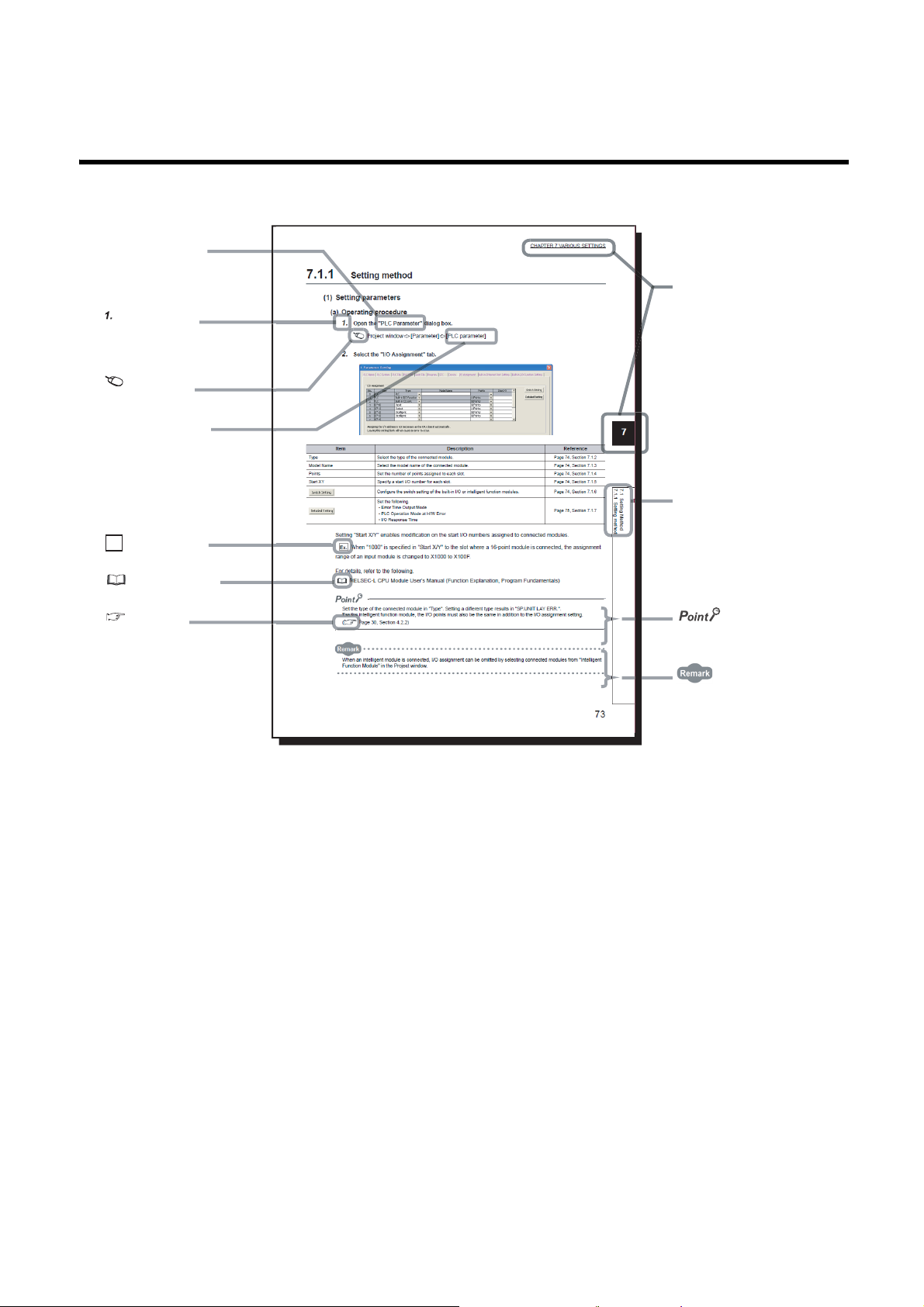

MANUAL PAGE ORGANIZATION

The section of

the current page is shown.

The chapter of

the current page is shown.

"" is used for

screen names and items.

[ ] is used for items

in the menu bar and

the project window.

shows operating

procedures.

shows reference

manuals.

shows notes that

requires attention.

shows mouse

operations.

*1

shows

reference pages.

shows setting or

operating examples.

Ex.

shows useful

information.

In this manual, pages are organized and the symbols are used as shown below.

The following page illustration is for explanation purpose only, and is different from the actual pages.

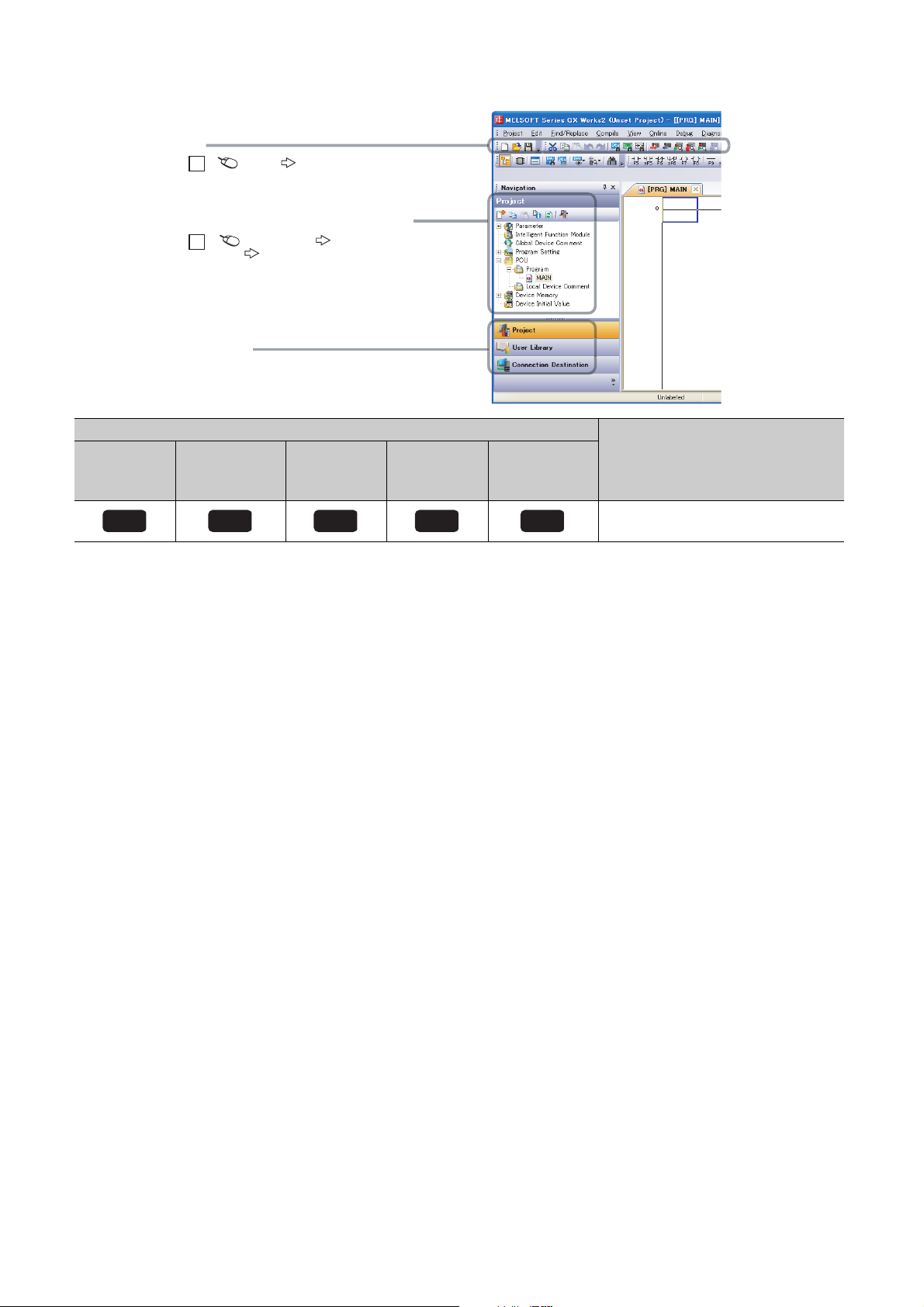

*1 The mouse operation example is provided below. (For GX Works2)

19

Page 22

Basic model

A window selected in the view selection area is displayed.

View selection area

[Online] [Write to PLC...]

Select [Online] on the menu bar,

and then select [Write to PLC...].

Project window

[Parameter]

[PLC Parameter]

Select [Project] from the view selection

area to open the Project window.

Menu bar

Ex.

Ex.

In the Project window, expand [Parameter] and

select [PLC Parameter].

Basic

QCPU

High

Performance

model QCPU

High

performance

Icon

Process

CPU

Process

Redundant

CPU

Redundant

Universal model

QCPU

Universal

Description

Icons indicate that specifications described

on the page contain some precautions.

20

Page 23

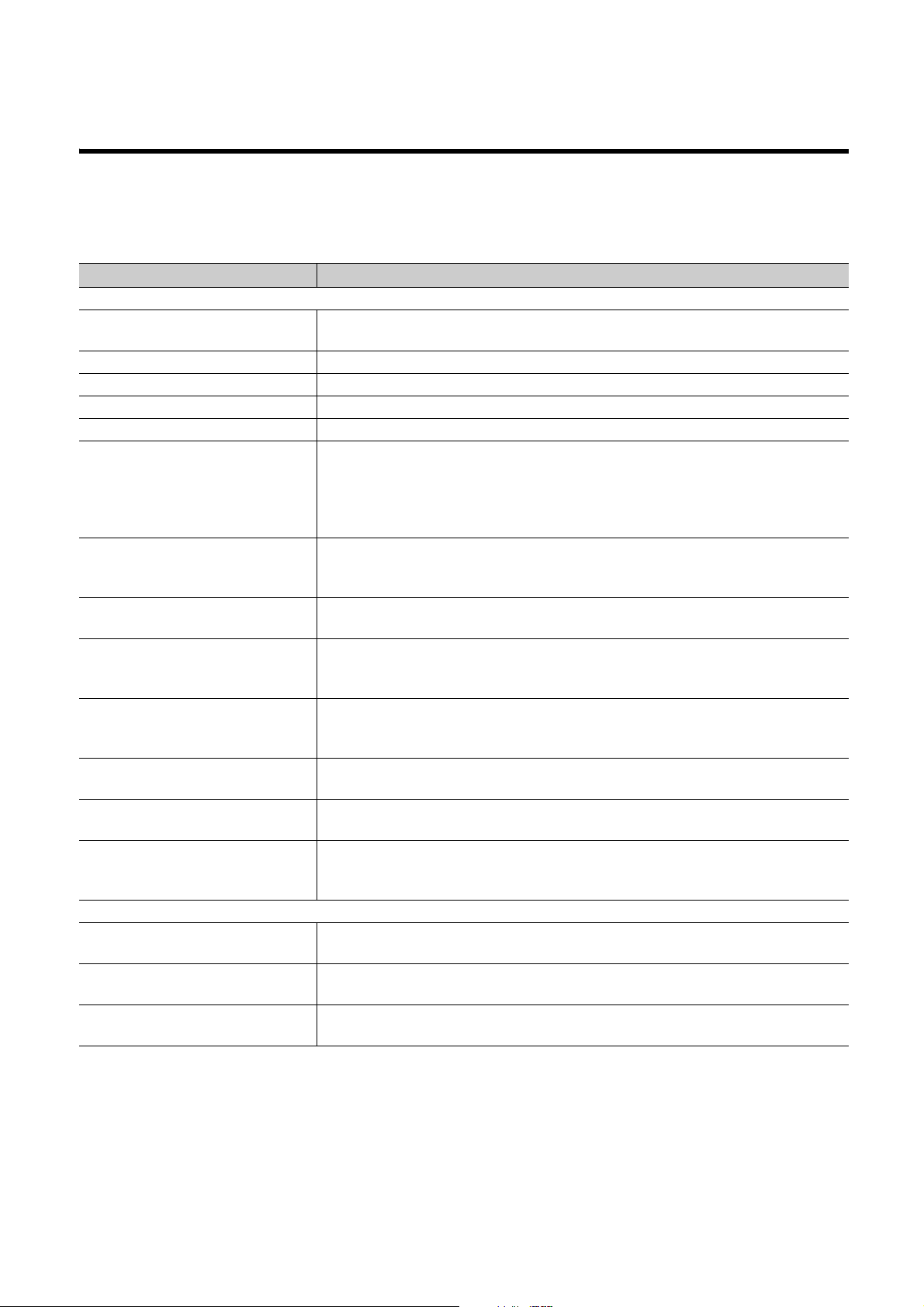

TERMS

Unless otherwise specified, this manual uses the following generic terms and abbreviations.

* indicates a part of the model or version.

(Example): Q33B, Q35B, Q38B, Q312B Q3B

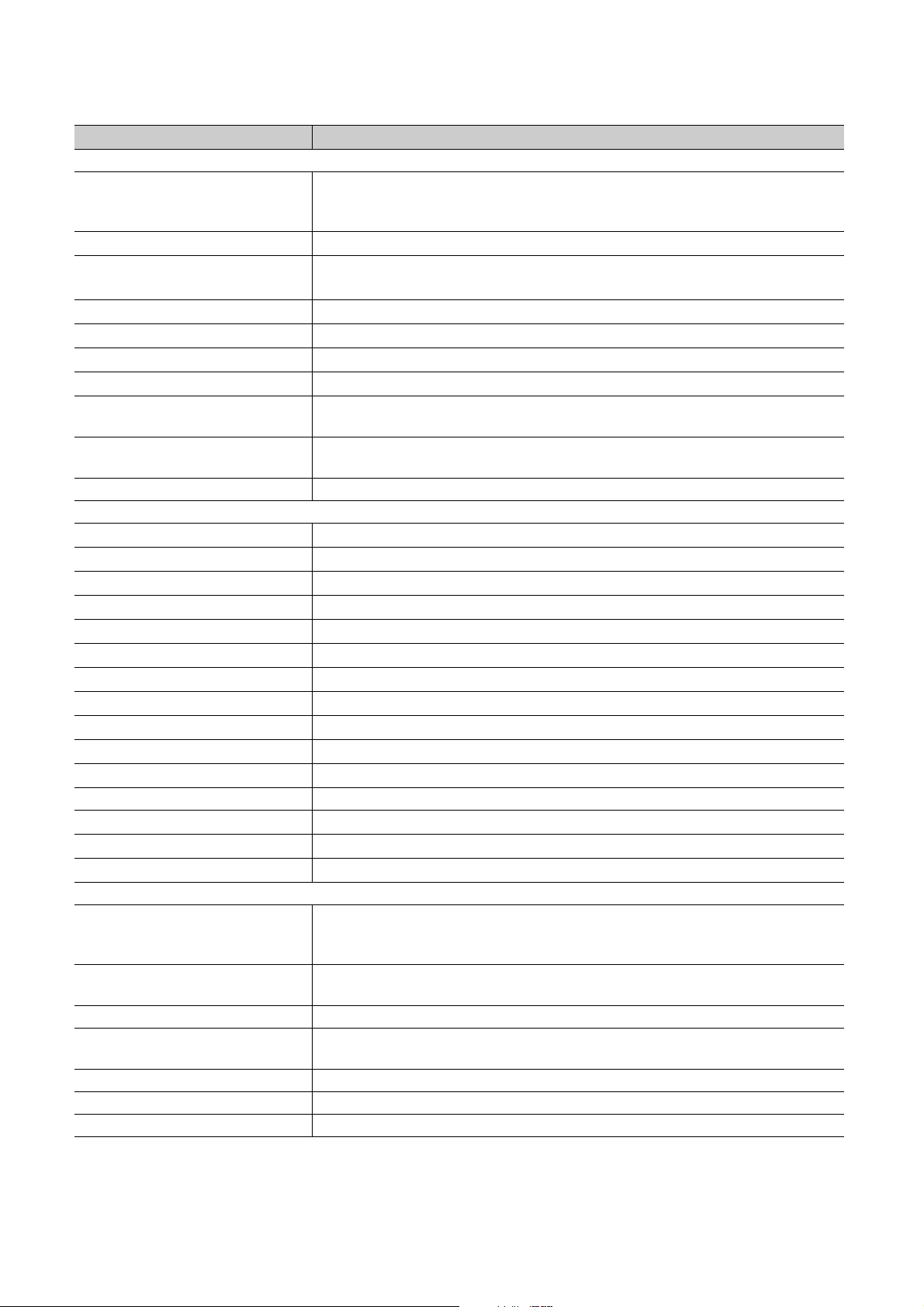

Ter m Description

CPU module type

CPU module

Basic model QCPU Generic term for the Q00JCPU, Q00CPU, and Q01CPU

High Performance model QCPU Generic term for the Q02CPU, Q02HCPU, Q06HCPU, Q12HCPU, and Q25HCPU

Process CPU Generic term for the Q02PHCPU, Q06PHCPU, Q12PHCPU, and Q25PHCPU

Redundant CPU Generic term for the Q12PRHCPU and Q25PRHCPU

Universal model QCPU

Built-in Ethernet port QCPU

High-speed Universal model QCPU

Motion CPU

PC CPU module

C Controller module

High-speed Universal model QCPU

Built-in Ethernet port QCPU

CPU module model

QnU(D)(H)CPU

QnUDVCPU

QnUDE(H)CPU

Generic term for the Basic model QCPU, High Performance model QCPU, Process CPU,

Redundant CPU, and Universal model QCPU

Generic term for the Q00UJCPU, Q00UCPU, Q01UCPU, Q02UCPU, Q03UDCPU,

Q03UDVCPU, Q03UDECPU, Q04UDHCPU, Q04UDVCPU, Q04UDEHCPU, Q06UDHCPU,

Q06UDVCPU, Q06UDEHCPU, Q10UDHCPU, Q10UDEHCPU, Q13UDHCPU, Q13UDVCPU,

Q13UDEHCPU, Q20UDHCPU, Q20UDEHCPU, Q26UDHCPU, Q26UDVCPU, Q26UDEHCPU,

Q50UDEHCPU, and Q100UDEHCPU

Generic term for the Q03UDVCPU, Q03UDECPU, Q04UDVCPU, Q04UDEHCPU,

Q06UDVCPU, Q06UDEHCPU, Q10UDEHCPU, Q13UDVCPU, Q13UDEHCPU,

Q20UDEHCPU, Q26UDVCPU, Q26UDEHCPU, Q50UDEHCPU, and Q100UDEHCPU

Generic term for the Q03UDVCPU, Q04UDVCPU, Q06UDVCPU, Q13UDVCPU, and

Q26UDVCPU

Generic term for the Mitsubishi Electric motion controllers: Q172CPUN, Q173CPUN,

Q172HCPU, Q173HCPU, Q172CPUN-T, Q173CPUN-T, Q172HCPU-T, Q173HCPU-T,

Q172DCPU, Q173DCPU, Q172DCPU-S1, Q173DCPU-S1, Q172DSCPU, and Q173DSCPU

Generic term for the MELSEC-Q series-compatible PC CPU modules manufactured by

CONTEC Co., Ltd.: PPC-CPU686(MS)-64, PPC-CPU686(MS)-128, and PPC-CPU852(MS)-

512

Generic term for the C Controller modules: Q06CCPU-V, Q06CCPU-V-B, Q12DCCPU-V,

Q24DHCCPU-V, and Q24DHCCPU-LS

Generic term for the Q03UDVCPU, Q04UDVCPU, Q06UDVCPU, Q13UDVCPU, and

Q26UDVCPU

Generic term for the Q03UDVCPU, Q03UDECPU, Q04UDVCPU, Q04UDEHCPU,

Q06UDVCPU, Q06UDEHCPU, Q10UDEHCPU, Q13UDVCPU, Q13UDEHCPU,

Q20UDEHCPU, Q26UDVCPU, Q26UDEHCPU, Q50UDEHCPU, and Q100UDEHCPU

Generic term for the Q00UJCPU, Q00UCPU, Q01UCPU, Q02UCPU, Q03UDCPU,

Q04UDHCPU, Q06UDHCPU, Q10UDHCPU, Q13UDHCPU, Q20UDHCPU, and Q26UDHCPU

Generic term for the Q03UDVCPU, Q04UDVCPU, Q06UDVCPU, Q13UDVCPU, and

Q26UDVCPU

Generic term for the Q03UDECPU, Q04UDEHCPU, Q06UDEHCPU, Q10UDEHCPU,

Q13UDEHCPU, Q20UDEHCPU, Q26UDEHCPU, Q50UDEHCPU, and Q100UDEHCPU

21

Page 24

Term Description

Base unit type

Generic term for the main base unit, extension base unit, slim type main base unit, redundant

Base unit

Main base unit

Extension base unit

Slim type main base unit

Redundant power main base unit

Redundant power extension base unit

Redundant type extension base unit

Multiple CPU high speed main base

unit

Redundant base unit

Redundant power supply base unit Generic term for the redundant power main base unit and redundant power extension base unit

Base unit model

Q3B

Q3SB

Q3RB

Q3DB

Q5B

Q6B

Q6RB

Q6

WRB

QA1S5

B

QA1S6

B

QA6

B

A5B Generic term for the A52B, A55B, and A58B extension base units

A6

B

QA6ADP+A5

QA1S6ADP+A1S5

Power supply module

Power supply module

Q series power supply module

AnS series power supply module Generic term for the A1S61PN, A1S62PN, and A1S63P power supply modules

A series power supply module

Slim type power supply module Abbreviation for the Q61SP slim type power supply module

Redundant power supply module Generic term for the Q63RP, Q64RPN and Q64RP redundant power supply modules

Life detection power supply module Abbreviation for the Q61P-D life detection power supply module

B/A6B

B/A1S6B

power main base unit, redundant power extension base unit, redundant type extension base

unit base unit, and multiple CPU high speed main base unit

Generic term for the Q3

Generic term for the Q5

QA1S6ADP+A1S5

Another term for the Q3

Another term for the Q3

Another term for the Q6

Another term for the Q6

Another term for the Q3

Generic term for the redundant power main base unit, redundant power extension base unit,

and redundant type extension base unit

Generic term for the Q33B, Q35B, Q38B, and Q312B main base units

Generic term for the Q32SB, Q33SB, and Q35SB slim type main base units

Another term for the Q38RB main base unit for redundant power supply system

Generic term for the Q35DB, Q38DB and Q312DB multiple CPU high speed main base units

Generic term for the Q52B and Q55B extension base units

Generic term for the Q63B, Q65B, Q68B, and Q612B extension base units

Another term for the Q68RB extension base unit for redundant power supply system

Another term for Q65WRB extension base unit for redundant system

Another term for the QA1S51B extension base unit

Generic term for the QA1S65B and QA1S68B extension base units

Generic term for the QA65B and QA68B extension base units

Generic term for the A62B, A65B, and A68B extension base units

Abbreviation for A large type extension base unit where the QA6ADP is mounted

Abbreviation for A small type extension base unit where the QA1S6ADP is mounted

Generic term for the Q series power supply module, AnS series power supply module, A series

power supply module, slim type power supply module, redundant power supply module, and life

detection power supply module

Generic term for the Q61P-A1, Q61P-A2, Q61P, Q61P-D, Q62P, Q63P, Q64P, and Q64PN

power supply modules

Generic term for the A61P, A61PN, A62P, A63P, A68P, A61PEU, and A62PEU power supply

modules

B, Q3SB, Q3RB, and Q3DB

B, Q6B, Q6RB, Q6WRB, QA1S5B, QA1S6B,

B/A1S6B, QA6B, and QA6ADP+A5B/A6B

SB

RB

RB

WRB

DB

22

Page 25

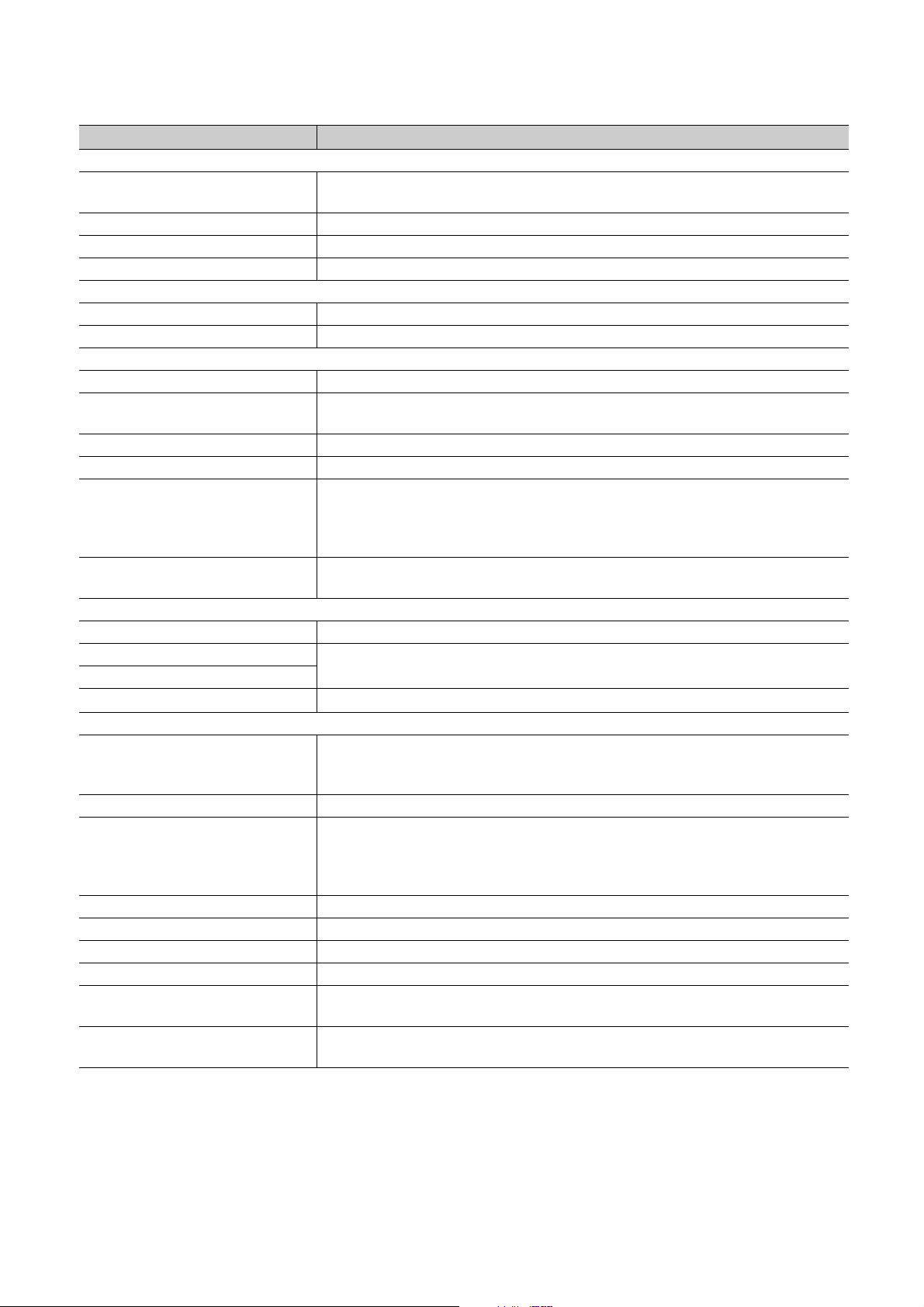

Ter m Description

Network module

CC-Link IE module

MELSECNET/H module Abbreviation for the MELSECNET/H network module

Ethernet module Abbreviation for the Ethernet interface module

CC-Link module Abbreviation for the CC-Link system master/local module

Network

CC-Link IE Generic term for the CC-Link IE Controller Network and the CC-Link IE Field Network

MELSECNET/H Abbreviation for the MELSECNET/H network system

Memory extension

Memory card Generic term for the SRAM card, Flash card, and ATA cards

SRAM card

Flash card Generic term for the Q2MEM-2MBF and Q2MEM-4MBF Flash cards

ATA card Generic term for the Q2MEM-8MBA, Q2MEM-16MBA, and Q2MEM-32MBA ATA cards

SD memory card

Extended SRAM cassette

Software package

Programming tool Generic term for GX Works2 and GX Developer

GX Works2

GX Developer

PX Developer

Others

Control CPU

Controlled module I/O modules and intelligent function modules which are controlled by a control CPU

MC protocol

QA6ADP Abbreviation for the QA6ADP QA conversion adapter module

QA1S6ADP Generic term for the QA1S6ADP and QA1S6ADP-S1 Q-AnS base unit conversion adapters

Extension cable Generic term for the QC05B, QC06B, QC12B, QC30B, QC50B, and QC100B extension cables

Tracking cable Generic term for the QC10TR and QC30TR tracking cables for the Redundant CPU

Battery

GOT

Generic term for the CC-Link IE Controller Network module and the CC-Link IE Field Network

module

Generic term for the Q2MEM-1MBS, Q2MEM-2MBS, Q3MEM-4MBS, and Q3MEM-8MBS

SRAM cards

Generic term for the NZ1MEM-2GBSD, NZ1MEM-4GBSD, NZ1MEM-8GBSD, NZ1MEM-

16GBSD, L1MEM-2GBSD, and L1MEM-4GBSD SD memory cards.

A memory device which consists of flash memory (abbreviation for Secure Digital Memory

Card)

Generic term for the Q4MCA-1MBS, Q4MCA-2MBS, Q4MCA-4MBS, and Q4MCA-8MBS

extended SRAM cassette

Product name for the MELSEC programmable controller software package

Product name for SW

A CPU module which controls each I/O module and intelligent function module

In a multiple CPU system, the CPU module which executes the control can be set for each

module.

Abbreviation for the MELSEC communication protocol. The MELSEC communication protocol

is a communication method to access from an external device to the CPU module according to

the communication procedure for the Q series programmable controller (such as a serial

communication module, Ethernet module).

Generic term for the Q6BAT, Q7BAT, and Q8BAT CPU module batteries, Q2MEM-BAT SRAM

card battery, and Q3MEM-BAT SRAM card battery

Generic term for Mitsubishi Electric Graphic Operation Terminal, GOT-A*** series, GOT-F***

series, GOT1000 series, and GOT2000 series

D5C-FBDQ process control FBD software package

23

Page 26

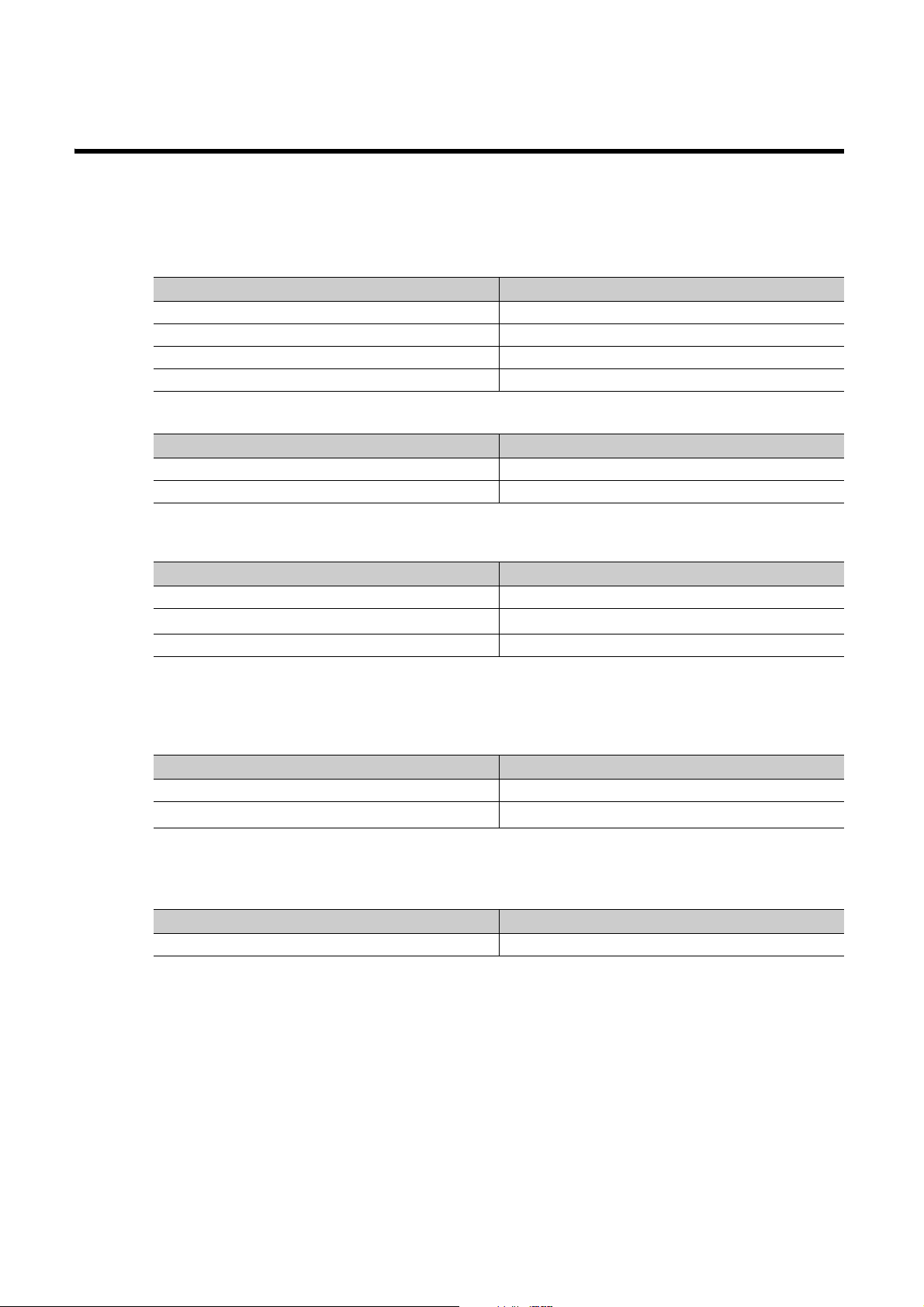

PACKING LIST

The following items are included in the package of this product. Before use, check that all the items are included.

(1) CPU module

(a) Q00JCPU or Q00UJCPU

Item Quantity

Module 1

Battery (Q6BAT) 1

Base unit installation screw (M4 × 14 screw) 4

Safety Guidelines (IB-0800423) 1

(b) Other than Q00JCPU and Q00UJCPU

Item Quantity

Module 1

Battery (Q6BAT) 1

(2) Main base unit

Item Quantity

Unit 1

*1

Base unit installation screw (M4 × 14 screw

Safety Guidelines (IB-0800423) 1

)4/5

*2

*1 For the slim type main base unit, M4 × 12 screws are supplied.

*2 Screws as many as the number of installation holes are supplied.

(3) Extension base unit

Item Quantity

Unit 1

Base unit installation screw (M4 × 14 screw)

*3 Screws as many as the number of installation holes are supplied.

(4) Power supply module or I/O module

Item Quantity

Module 1

4/5

*3

24

Page 27

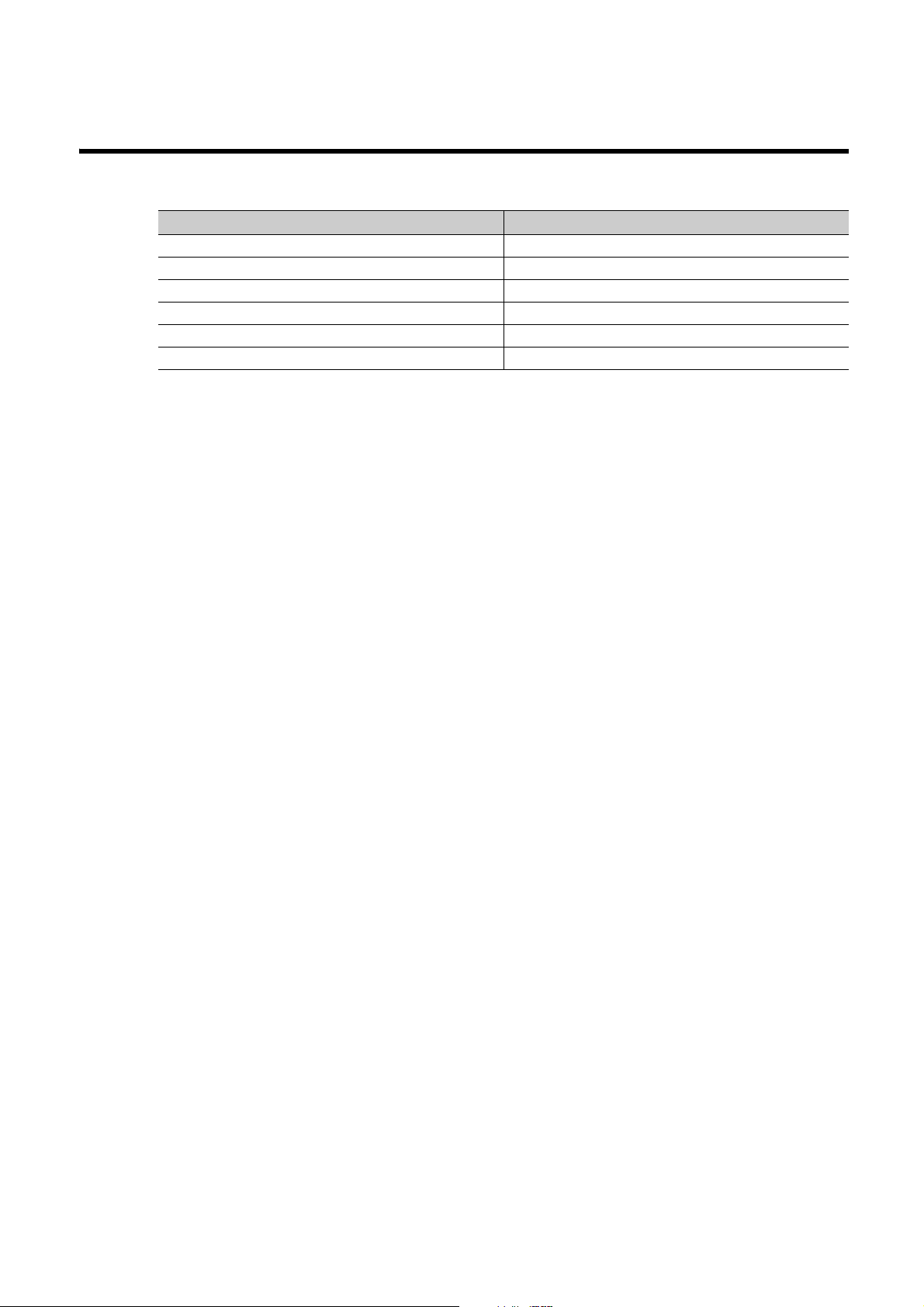

DISCONTINUED MODELS

The following models are described in this manual, but have no longer been produced.

For the onerous repair term after discontinuation of production, refer to "WARRANTY".

Model Production discontinuation

Q61P-A1 March 2009

Q61P-A2 March 2009

Q64P February 2010

L1MEM-2GBSD July 2015

L1MEM-4GBSD July 2015

Q64RP September 2015

25

Page 28

CHAPTER 1 OVERVIEW

1.1 Features

This section describes the features of Q series CPU modules.

(1) Large number of I/O points

The Q Series CPU module supports the following number of actual I/O points accessible to the I/O modules

mounted on the base unit.

(a) Basic model QCPU

• Q00JCPU: 256 points (X/Y0 to FF)

• Q00CPU, Q01CPU: 1024 points (X/Y0 to 3FF)

Up to 2048 points (X/Y0 to 7FF) are supported as the number of I/O device points usable for refreshing the

remote I/O of the CC-Link and link I/O (LX, LY) of the MELSECNET/H.

(b) High Performance model QCPU

One module can support 4096 points (X/Y0 to FFF).

Up to 8192 points (X/Y0 to 1FFF) are supported as the number of I/O device points usable for the remote I/O

stations in the MELSECNET/H remote I/O network, the CC-Link data link, and the MELSECNET/MINI-S3 data

link.

(c) Process CPU and Redundant CPU

One module can support 4096 points (X/Y0 to FFF).

Up to 8192 points (X/Y0 to 1FFF) are supported as the number of I/O device points usable for the remote I/O

stations in the MELSECNET/H remote I/O network and CC-Link data link.

(d) Universal model QCPU

• Q00UJCPU: 256 points (X/Y0 to FF)

• Q00UCPU, Q01UCPU: 1024 points (X/Y0 to 3FF)

• Q02UCPU: 2048 points (X/Y0 to 7FF)

• Q03UD(E)CPU, Q03UDVCPU,

Q04UD(E)HCPU, Q04UDVCPU,

Q06UD(E)HCPU, Q06UDVCPU,

Q10UD(E)HCPU, Q13UD(E)HCPU,

Q13UDVCPU, Q20UD(E)HCPU,

Q26UD(E)HCPU, Q26UDVCPU,

Q50UDEHCPU, Q100UDEHCPU: 4096 points (X/Y0 to FFF)

Up to 8192 points (X/Y0 to 1FFF) are supported as the number of I/O device points usable for the remote I/O

stations in the MELSECNET/H remote I/O network and CC-Link data link.

26

Page 29

CHAPTER 1 OVERVIEW

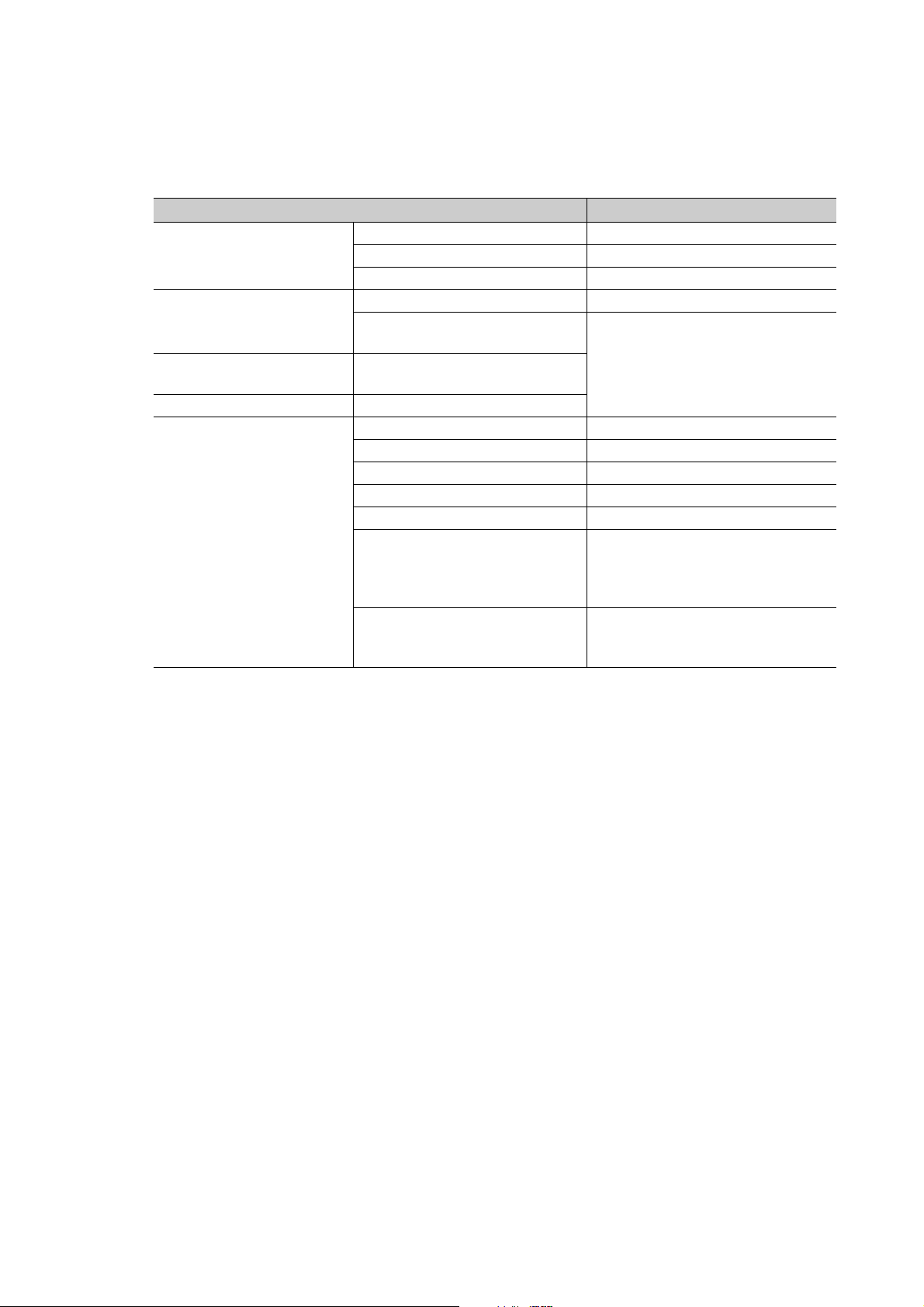

(2) Large selection of CPU modules

The following lists the lineup of CPU available for various program size.

CPU module type Program size

Basic model QCPU

High Performance model QCPU

Process CPU

Redundant CPU

Universal model QCPU

Q00(J)CPU 8K steps

Q01CPU 14K steps

Q02(H)CPU 28K steps

Q06HCPU 60K steps

Q12HCPU 124K steps

Q25HCPU 252K steps

Q02PHCPU 28K steps

Q06PHCPU 60K steps

Q12PHCPU 124K steps

Q25PHCPU 252K steps

Q12PRHCPU 124K steps

Q25PRHCPU 252K steps

Q00U(J)CPU 10K steps

Q01UCPU 15K steps

Q02UCPU 20K steps

Q03UD(E)CPU, Q03UDVCPU 30K steps

Q04UD(E)HCPU, Q04UDVCPU 40K steps

Q06UD(E)HCPU, Q06UDVCPU 60K steps

Q10UD(E)HCPU 100K steps

Q13UD(E)HCPU, Q13UDVCPU 130K steps

Q20UD(E)HCPU 200K steps

Q26UD(E)HCPU, Q26UDVCPU 260K steps

Q50UDEHCPU 500K steps

Q100UDEHCPU 1000K steps

1

1.1 Features

27

Page 30

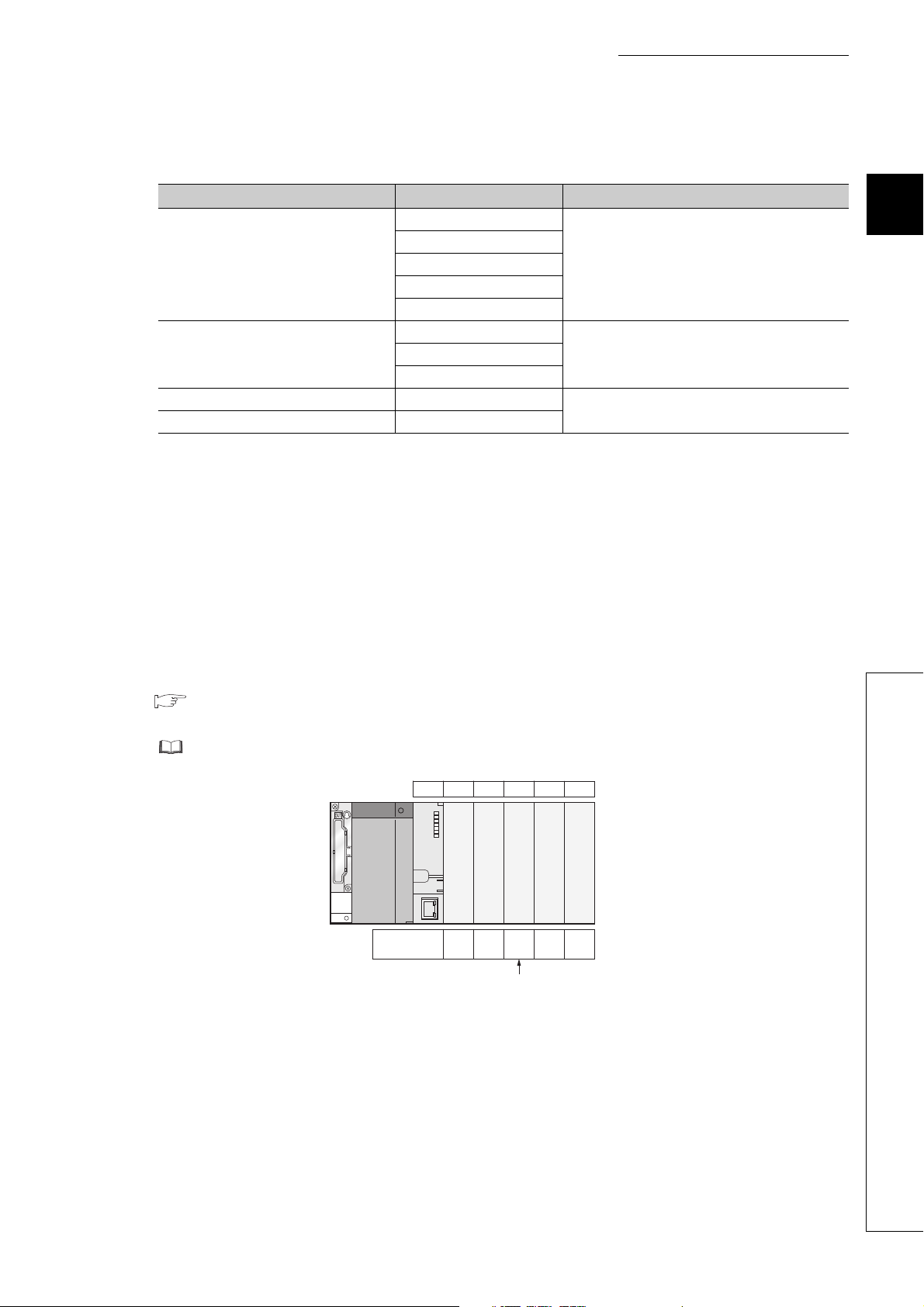

(3) High-speed processing

High speed processing has been achieved.

CPU module type LD instruction processing speed

Q00JCPU 200ns

Basic model QCPU

High Performance model QCPU

Process CPU

Redundant CPU Q12PRHCPU, Q25PRHCPU

Universal model QCPU

The MELSEC Q series base unit high-speed system bus has achieved faster access to an intelligent function

module and link refresh with a network module.

Q00CPU 160ns

Q01CPU 100ns

Q02CPU 79ns

Q02HCPU, Q06HCPU, Q12HCPU,

Q25HCPU

Q02PHCPU, Q06PHCPU, Q12PHCPU,

Q25PHCPU

Q00UJCPU 120ns

Q00UCPU 80ns

Q01UCPU 60ns

Q02UCPU 40ns

Q03UD(E)CPU 20ns

Q04UD(E)HCPU, Q06UD(E)HCPU,

Q10UD(E)HCPU, Q13UD(E)HCPU,

Q20UD(E)HCPU, Q26UD(E)HCPU,

Q50UDEHCPU, Q100UDEHCPU

Q03UDVCPU, Q04UDVCPU,

Q06UDVCPU, Q13UDVCPU,

Q26UDVCPU

34ns

9.5ns

1.9ns

(a) Basic model QCPU

MELSECNET/H link refreshing: 2.2ms/2K words

*1 The Q01CPU is used without using SB and SW, and the MELSECNET/H network module is mounted on the main base

unit.

*1

(b) High Performance model QCPU, Process CPU, Redundant CPU or

Universal model QCPU

Access to the intelligent function module: 20µs/word (approximately 7 times*2)

*2

MELSECNET/H link refreshing: 4.6ms/8K words (approximately 4.3 times

*2 These are the values resulted from the following comparison:

• Comparing Q02HCPU with Q2ASHCPU-S1

• Comparing Q25PHCPU with Q4ARCPU

• Comparing Q25PRHCPU with Q4ARCPU

)

28

Page 31

CHAPTER 1 OVERVIEW

0 1020304050607080

Q25HCPU(USB)

Q25HCPU(RS-232)

Q2ASHCPU

A2USHCPU-S1

12

30

86

94

90 100

(Unit:s)

(4) Increase in debugging efficiency through high-speed communication with a

programming tool

High-speed communications at 115.2Kbps maximum are available by using RS-232 which reducing the time

required for writing and reading of programs and monitoring. Also, the communication time efficiency of

debugging has been increased.

In addition, High Performance model QCPUs (except for the Q02CPU), Process CPUs, Redundant CPUs and

Universal model QCPUs support USB, so that high-speed communications of 12Mbps are available.

(5) Use of AnS/A series I/O modules and special function modules

The AnS/A series compatible extension base units (QA1S5B, QA1S6B, QA1S6ADP+A1S5B/A1S6B,

QA6B, and QA6ADP+A5B/A6B) can be connected to the main base unit where the High Performance

model QCPU or Universal model QCPU

special function modules.

*1 The Universal model QCPU whose serial number (first five digits) is "13102" or later is applicable.

*1

is mounted. This enables the use of AnS/A series I/O modules and

1

(6) Miniaturized modules (space-saving size)

The installation space for the Q series has been reduced by approx. 60% compared with the AnS series.

98mm

5-slot main base unit: 245mm

8-slot main base unit: 328mm

12-slot main base unit: 439mm

(Depth: 98mm)

AnS series

Q series

1.1 Features

29

Page 32

(7) Connection of up to 7 extension base units

Remark

Up to seven extension base units can be connected to the Q series CPU module.

The overall extension cable length is 13.2m, which allows flexible layout of base units.

(8) Memory extension

By extending the memory capacity of a CPU module, large size files can be managed. Comments can be set to

all data devices and old programs can be saved as correction history.

(a) Memory card

A memory card (maximum 32M bytes) can be installed. (The maximum size is available only for ATA cards.)

Memory cards are used for the following operations.

• Boot operation

• Restoring backup data

• Writing programs to the ROM

Data that cannot be stored in the built-in memory of the CPU module, such as sampling trace data and file

register data, can be stored as well.

(b) SD memory card

SD memory cards are used for the following operations.

• Boot operation

• Restoring backup data

• Data backup

• Data logging

(c) Extended SRAM cassette

An extended SRAM cassette extends the capacity of the standard RAM in a CPU module.

• An extended SRAM cassette can be used together with an SD memory card, allowing users to store data

separately (for example, boot data in an SD memory card and device data in an extended SRAM

cassette). This improves maintainability.

• With existing CPU modules, file register areas in the standard RAM and an SRAM card cannot be

accessed sequentially, and the boundary needs to be considered at programming. If the standard RAM

capacity is extended using an extended SRAM cassette, the device area can be extended without

considering the boundary.

Memory extension methods differ depending on the CPU module. ( Page 35, Section 2.2)

30

Page 33

CHAPTER 1 OVERVIEW

Note 1.1, Note 1.2

Note 1.1

Note 1.1

(9) Automatic write to the standard ROM Note 1.1 Note 1.2

Parameters and programs in a memory card or SD memory card can be written to the standard ROM of the CPU

module without using a programming tool.

If the boot operation is being performed from the standard ROM, parameters and programs in a memory card or

SD memory card can be written to the standard ROM by inserting it to the CPU module. Users do not need a

programming tool (personal computer) on hand to modify parameters and programs.

(10)External input/output forced on/off

Forced on and off of external input and output is available using a programming tool even when the CPU module

is running or program is being processed.

Also, wiring test and operation test can be conducted without halting the CPU module by forcibly turning on or off

the I/O.

(11)Remote password function

When the built-in Ethernet port QCPU, Ethernet module, or serial communication module is externally accessed,

an access to the CPU module can be controlled by setting a remote password.

(12)Remote I/O network of MELSECNET/H

A MELSECNET/H remote I/O system can be configured by installing a MELSECNET/H remote master station.

1

● The remote password can be set up when the Ethernet module, or serial communication module of function version B or

later is used.

● The MELSECNET/H remote I/O network can be implemented when the MELSECNET/H network module of function

version B or later is used.

(13)Support of multiple CPU systems

CPU module supports the multiple CPU system.

Multiple CPU systems can be constructed in combination with CPU modules, motion CPU(s), PC CPU module(s),

and C Controller module.

For details of the multiple CPU system, refer to the following.

QCPU User's Manual (Multiple CPU System)

Note 1.1

Basic

The Basic model QCPU does not support the following functions.

• Automatic write to the standard ROM

• External input/output forced on/off

• MELSECNET/H remote I/O network

1.1 Features

Note 1.2

Universal

The Universal model QCPU does not support the following function.

• Parameter setting of automatic write to the standard ROM

31

Page 34

(14)Support of redundant power supply systems

Note 1.3

The redundant power supply system can be configured using a redundant base unit and redundant power supply

modules.

The system can continue operation even if one of the power supply modules fails, since the other will supply the

power.

(15)Direct connection to Ethernet Note 1.3

The Built-in Ethernet port QCPU module allows direct connections to Ethernet.

For details of the functions, refer to the following.

QnUCPU User's Manual (Communication via Built-in Ethernet Port)

Note 1.3

Universal

Only the Built-in Ethernet port QCPU supports this function.

32

Page 35

CHAPTER 2 SYSTEM CONFIGURATION

CHAPTER 2 SYSTEM CONFIGURATION

This chapter describes system configurations, precautions, and components of the Q Series CPU module.

This section describes system configurations for a single CPU system with the Basic model QCPU, High Performance

model QCPU, Process CPU, or Universal model QCPU, and a system configuration when using GOT by bus

connection.

For a multiple CPU system and redundant system (when using the Redundant CPU), refer to the following.

QCPU User's Manual (Multiple CPU System)

QnPRHCPU User's Manual (Redundant System)

2

33

Page 36

2.1 Overall Configuration

Extended SRAM cassette

Memory card, SD memory card

Battery for QCPU (Q6BAT)

Q7BAT-SET

Battery holder

Q8BAT-SET

Q8BAT connection cable

Battery for QCPU (Q7BAT)

Extension cable

Battery for QCPU (Q8BAT)

Basic model QCPU

High Performance model QCPU

Process CPU

Universal model QCPU

Q3 B main base unit

Q3 RB redundant power main base unit

Q3 SB slim type main base unit

Q3 DB multiple CPU high speed main base unit

Power supply module/I/O module/Intelligent function module/Special function module

Q5 B extension base unit

Q6 B extension base unit

Q6 RB redundant power extension base unit

QA1S5 B extension base unit

QA1S6 B extension base unit

QA6 B extension base unit

The combination of modules depends on the devices used in the configuration.

For the applicable combinations, refer to the following.

• CPU modules and base units, batteries, memory cards, SD memory cards, and/or extended SRAM

cassettes ( Page 35, Section 2.2)

• Base units and power supply modules ( Page 187, CHAPTER 7)

• Main base units and extension base units ( Page 223, CHAPTER 8)

• CPU modules and intelligent function modules or special function modules

( User's manual for each module)

34

To correctly configure a system, observe precautions described in Page 39, Section 2.3.

Page 37

CHAPTER 2 SYSTEM CONFIGURATION

2.2 Component List

(1) Basic model QCPU

Item Description

Main base unit Q33B, Q35B, Q38B, Q312B

Applicable main base

*1

unit

Applicable extension base

unit

Maximum number of

connectable extension

base units

Maximum number of

mountable modules

Extension cable QC05B, QC06B, QC12B, QC30B, QC50B, QC100B

Total length of extension

cables

Memory extension ----

Applicable battery Q6BAT

*1 The Q00JCPU does not require a power supply module and the main base unit since the module is an integrated

combination of a power supply module and the main base unit.

Redundant power main base unit Q38RB

Slim type main base unit Q32SB, Q33SB, Q35SB

Multiple CPU high speed main base unit Q35DB, Q38DB, Q312DB

Model requiring no power supply module Q52B, Q55B

Model requiring a Q series power supply module Q63B, Q65B, Q68B, Q612B

Redundant power extension base unit Q68RB

Q00JCPU: 2

Q00CPU, Q01CPU: 4

Q00JCPU: 16 (max. 16 slots)