Page 1

Type QD70 Positioning Module

U

Type QD70 Positioning Module User's Manual

Mitsubishi Programmable

Logic Controller

QD70P4

QD70P8

GX Configurator-PT

(SW1D5C-QPTU-E)

Page 2

A - 1 A - 1

SAFETY INSTRUCTIONS

(Always read these instructions before using this equipment.)

Before using this product, please read this manual and the relevant manuals introduced in this manual

carefully and pay full attention to safety to handle the product correctly.

The instructions given in this manual are concerned with this product. For the safety instructions of the

programmable logic controller system, please read the CPU module User's Manual.

In this manual, the safety instructions are ranked as "DANGER" and "CAUTION".

!

DANGER

CAUTION

!

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury .

Indicates that incorrect handling may cause hazardous conditions,

resulting in medium or slight personal injury or physical damage.

Note that the !CAUTION level may lead to a serious consequence according to the circumstances.

Always follow the instructions of both levels because they are important to personal safety.

Please save this manual to make it accessible when required and always forward it to the end user.

[DESIGN INSTRUCTION]

!

DANGER

Provide a safety circuit outside the programmable logic controller so that the entire system will

operate safely even when an external power supply error or PLC fault occurs.

Failure to observe this could lead to accidents for incorrect outputs or malfunctioning.

(1) Configure an emergency stop circuit and interlock circuit such as a positioning control

upper limit/lower limit to prevent mechanical damage outside the PLC.

(2) The OPR operation is controlled by the OPR direction and OPR speed data. Deceleration

starts when the near-point dog turns ON. Thus, if the OPR direction is incorrectly set,

deceleration will not start and the machine will continue to travel. Configure an interlock

circuit to prevent mechanical damage outside the PLC.

(3) When the module detects an error, deceleration st op will t ake place.

Make sure that the OPR data and positioning data are within the parameter setting values.

Page 3

A - 2 A - 2

!

CAUTION

Do not bundle or adjacently lay the control wire or communication cable with the main circuit or

power wire.

Separate these by 100mm (3.94in.) or more.

Failure to observe this could lead to malfunctioning caused by noise.

[MOUNTING INSTRU CT ION S ]

!

CAUTION

Use the PLC within the general specifications environment given in t his manual.

Using the PLC outside the general specification range environment could lead t o elect ric

shocks, fires, malfunctioning, product damage or deterioration.

Hold down the module loading lever at the bottom of the module and insert the module fixing

hooks into the base unit fixing holes securely to load the module. Improper loading of the

module can cause a malfunction, failure or drop.

For use in vibratory environment, tighten the module with screws.

Tighten the screws within the specified torque range.

Undertightening can cause a drop, short circuit or malfunction.

Overtightening can cause a drop, short circuit or malfunction due to damage to the screws or

module.

Always load or unload the module after switching power off externally in all phases. Not doing

so may damage the product.

[WIRING INSTRUCTIONS]

!

DANGER

Always confirm the terminal layout before connecting the wires to the module.

[STARTUP/MAINTENANCE INSTRUCTIONS]

!

DANGER

Always turn all phases of the power supply OFF externally before cleaning or tightening the

screws.

Failure to turn all phases OFF could lead to electric shocks.

Page 4

A - 3 A - 3

[STARTUP/MAINTENANCE INSTRUCTIONS]

!

CAUTION

Never disassemble or modify the module.

Failure to observe this could lead to trouble, malfunctioning, injuries or fires.

Always turn all phases of the power supply OFF externally before installing or removing the

module.

Failure to turn all phases OFF could lead to module trouble or malfunctioning.

Before starting test operation, set the parameter speed limit value to the slowest value, and

make sure that operation can be stopped immediately if a hazardous state occurs.

[DISPOSAL INSTRUCTIONS]

!

CAUTION

When disposing of the product, handle it as industrial waste.

Page 5

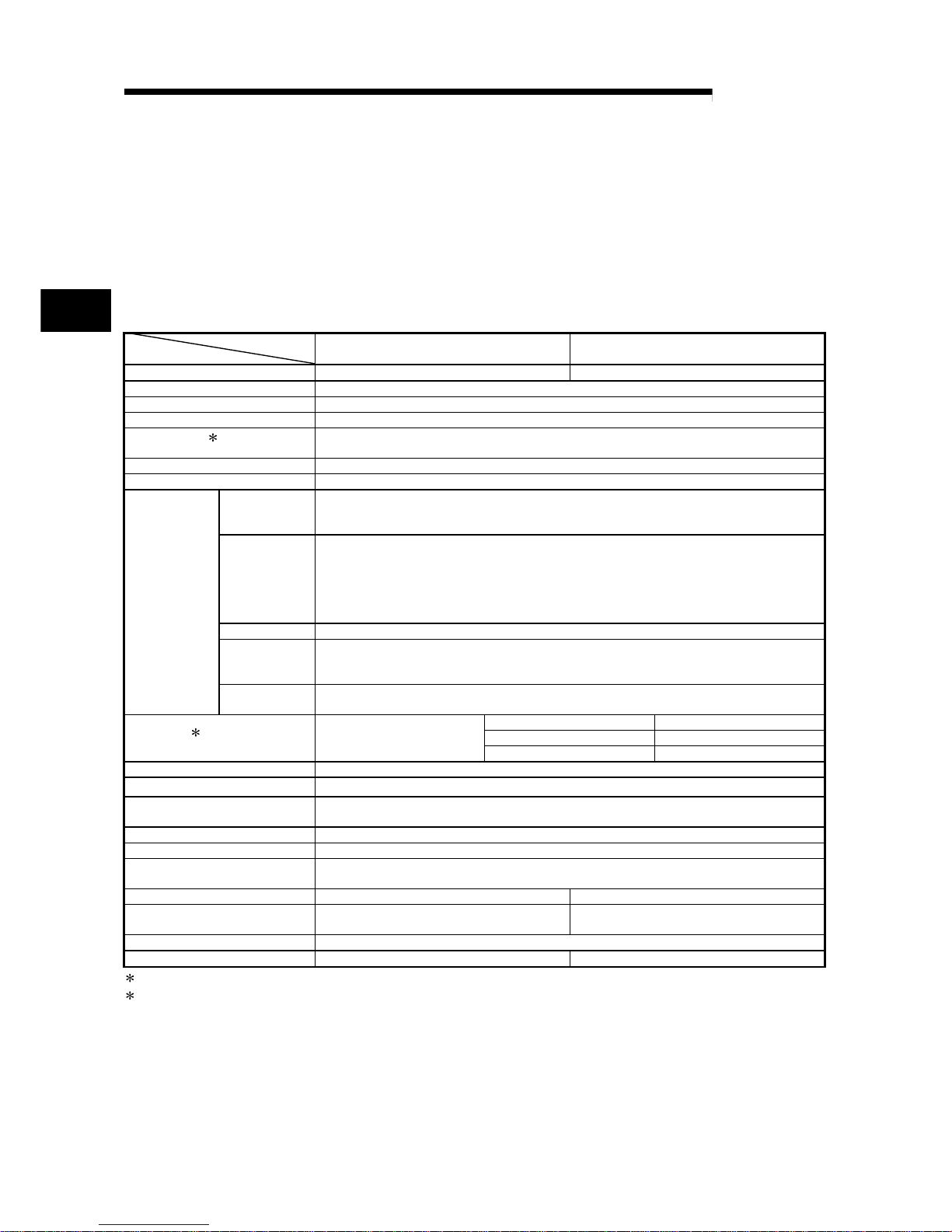

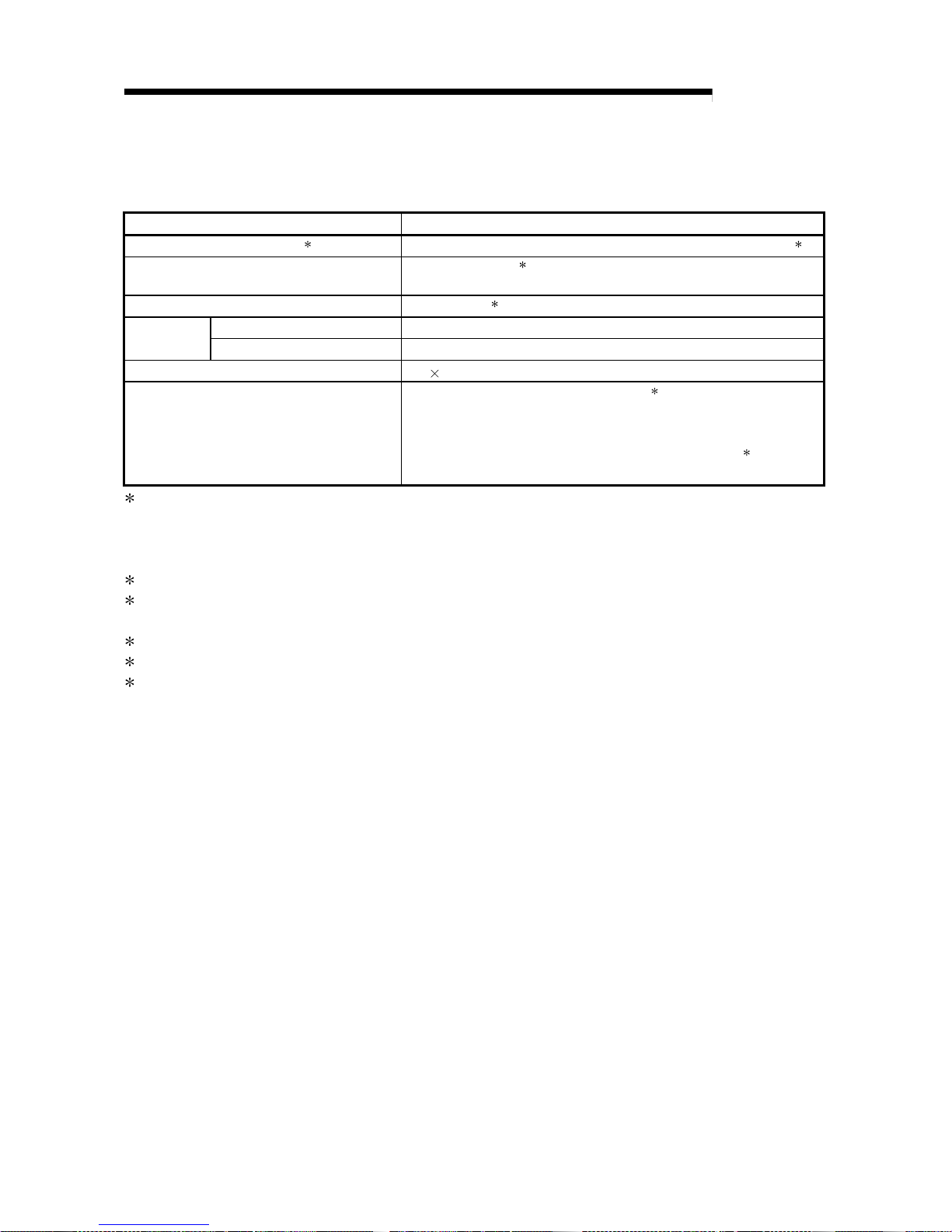

A - 4 A - 4

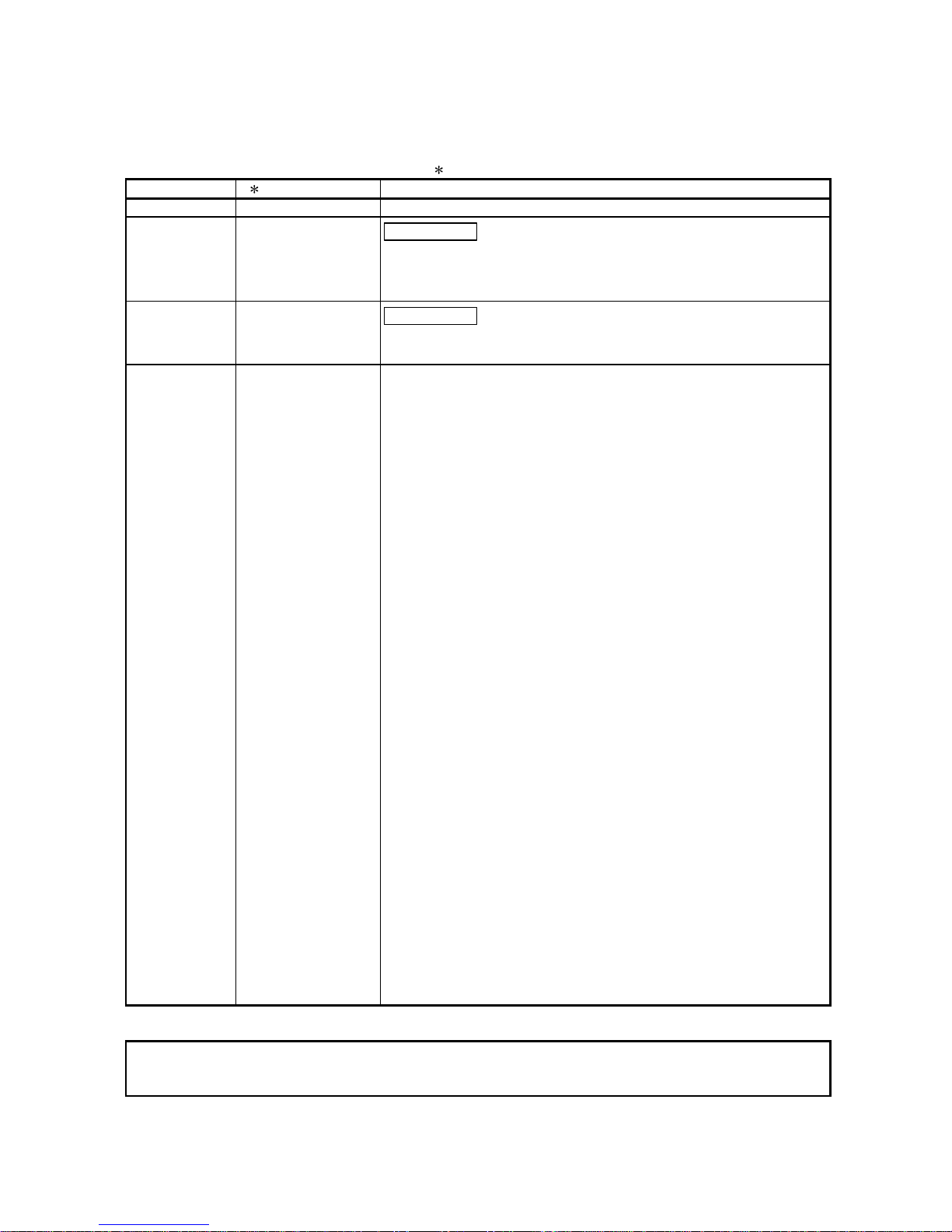

REVISIONS

The manual number is given on the bottom left of the back cover

.

Print Date

Manual Number Revision

Jun., 2001 SH (NA)-080171-A First edition

Feb., 2002 SH (NA)-080171-B

Modifications

About Manuals, Section 2.3, Section 2.4, Section 4.6.1, Section 5.3,

Section 5.7, Section 6.2.2, Section 8.2.3, Section 8.2.4, Section

8.2.5, Section 8.2.6, Section 10.3, Appendix 8

Jul., 2002 SH (NA)-080171-C

Modifications

CONTENS, Section .1.1.1, Section 4.2, Section 11.3, Section 11.4,

Section 11.5, Section 13.2, Appendix 2, Appendix 8, INDEX

Japanese Manual Version SH-080138-D

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any patent

licenses. Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property

rights which may occur as a result of using the contents noted in this manual.

2001 MITSUBISHI ELECTRIC CORPORATION

Page 6

A - 5 A - 5

INTRODUCTION

Thank you for purchasing the Mitsubishi programmable logic controller MELSEC-Q Series.

Always read through this manual, and fully comprehend the functions and performance of the Q Series PLC

before starting use to ensure correct usage of this product.

CONTENTS

SAFETY INSTRUCTIONS.............................................................................................................................A- 1

REVISIONS....................................................................................................................................................A- 4

CONTENTS....................................................................................................................................................A- 5

About Manuals ...............................................................................................................................................A- 9

Using This Manual..........................................................................................................................................A- 9

Conformation to the EMC Directive and Low Voltage Instruction ................................................................A- 9

Generic Terms and Abbreviations................................................................................................................A- 10

Component List .............................................................................................................................................A- 10

SECTION 1 PRODUCT SPECIFICATIONS AND HANDLING

1 PRODUCT OUTLINE 1- 1 to 1- 10

1.1 Positioning control....................................................................................................................................1- 1

1.1.1 Features of QD70..............................................................................................................................1- 1

1.1.2 Mechanism of positioning control ......................................................................................... ............1- 2

1.1.3 Outline design of positioning control system....................................................................................1- 4

1.1.4 Communicating signals between QD70 and each module..............................................................1- 7

1.2 Positioning control....................................................................................................................................1- 9

1.2.1 Outline of starting ...................................................................................................... ........................1- 9

1.2.2 Outline of stopping ...........................................................................................................................1- 10

2 SYSTEM CONFIGURATION 2- 1 to 2- 5

2.1 General image of system.........................................................................................................................2- 1

2.2 Component list .........................................................................................................................................2- 2

2.3 Applicable system....................................................................................................................................2- 3

2.4 How to check the function version and the software version ................................................................. 2- 4

3 SPECIFICATIONS AND FUNCTIONS 3- 1 to 3- 11

3.1 Performance specifications......................................................................................................................3- 1

3.2 List of functions ........................................................................................................................................3- 2

3.3 Specifications of input/output signal with PLC CPU ...............................................................................3- 4

3.3.1 List of input/output signals with PLC CPU........................................................................................3- 4

3.3.2 Details of input signal (QD70

PLC CPU) .....................................................................................3- 5

3.3.3 Details of output signals (PLC CPU

QD70).................................................................................3- 6

3.4 Specifications of input/output interfaces with external device ................................................................3- 7

3.4.1 Electrical specifications of input/output signals................................................................................ 3- 7

3.4.2 Signal layout for external device connection connector...................................................................3- 9

3.4.3 List of input/output signal details......................................................................................................3- 10

3.4.4 Input/output interface internal circuit................................................................................................3- 11

Page 7

A - 6 A - 6

4 DATA USED FOR POSITIONI NG CON TROL ( LIS T OF BU FFER MEM ORY ADDRE SSES ) 4- 1 to 4- 31

4.1 Type of data .............................................................................................................................................4- 1

4.1.1 Parameters and data required for control.........................................................................................4- 1

4.1.2 Setting items for parameters.............................................................................................................4- 3

4.1.3 Setting items for OPR data...............................................................................................................4- 4

4.1.4 Setting items for JOG data................................................................................................................4- 5

4.1.5 Setting items for positioning data...................................................................................................... 4- 6

4.1.6 Type and roles of monitor data.........................................................................................................4- 7

4.1.7 Type and roles of control data ..........................................................................................................4- 8

4.2 List of parameters ....................................................................................................................................4- 9

4.3 List of OPR data......................................................................................................................................4- 14

4.4 List of JOG data ......................................................................................................................................4- 20

4.5 List of positioning data ............................................................................................................................4- 21

4.6 List of monitor data..................................................................................................................................4- 27

4.6.1 Axis monitor data..............................................................................................................................4- 27

4.6.2 Module information monitor data.....................................................................................................4- 29

4.7 List of control data...................................................................................................................................4- 30

4.7.1 Axis control data...............................................................................................................................4- 30

5 SETUP AND PROCEDURES BEFORE OPERATION 5- 1 to 5- 20

5.1 Handling precautions ...............................................................................................................................5- 1

5.2 Procedures before operation ...................................................................................................................5- 3

5.3 Part identification nomenclature ..............................................................................................................5- 4

5.4 Wiring .......................................................................................................................................................5- 7

5.4.1 Wiring precautions.............................................................................................................................5- 7

5.5 Confirming the wiring ..............................................................................................................................5- 12

5.5.1 Confirmation items at completion of wiring......................................................................................5- 12

5.6 Switch setting for intelligent function module.........................................................................................5- 14

5.7 Simple reciprocating operation...............................................................................................................5- 18

6 UTILITY PACKAGE(GX Configurator-PT) 6- 1 to 6- 17

6.1 Utility package functions .......................................................................................................................... 6- 1

6.2 Installing and uninstalling the utility package..........................................................................................6- 2

6.2.1 User precautions ...............................................................................................................................6- 2

6.2.2 Operating environment......................................................................................................................6- 4

6.3 Explanation of utility package operations................................................................................................6- 5

6.3.1 How to perform common utility package operations........................................................................ 6- 5

6.3.2 Operation overview ...........................................................................................................................6- 7

6.3.3 Starting the intelligent function module utility ................................................................................... 6- 9

6.4 Initial setting.............................................................................................................................................6- 11

6.5 Auto refresh setting.................................................................................................................................6- 13

6.6 Monitor/test..............................................................................................................................................6- 15

6.6.1 Monitor/Test screen..........................................................................................................................6- 15

7 SEQUENCE PROGRAM USED FOR POSITIONING CONTROL 7- 1 to 7- 20

7.1 Precautions for creating program............................................................................................................7- 1

7.2 List of devices used..................................................................................................................................7- 3

Page 8

A - 7 A - 7

7.3 Creating a program ..................................................................................................................................7- 5

7.3.1 General configuration of program.....................................................................................................7- 5

7.3.2 Positioning control operation program..............................................................................................7- 6

7.4 Positioning control program examples....................................................................................................7- 8

7.5 Program details.......................................................................................................................................7- 12

7.5.1 Initialization program ........................................................................................................................7- 12

7.5.2 Start method setting program ..........................................................................................................7- 13

7.5.3 Start program....................................................................................................................................7- 13

7.5.4 Sub program.....................................................................................................................................7- 18

SECTION 2 CONTROL DETAILS AND SETTING

8 OPR CONTROL 8- 1 to 8- 16

8.1 Outline of OPR control.............................................................................................................................8- 1

8.1.1 Two types of OPR control.................................................................................................................8- 1

8.2 Machine OPR control...............................................................................................................................8- 2

8.2.1 Outline of the machine OPR operation.............................................................................................8- 2

8.2.2 Machine OPR method.......................................................................................................................8- 3

8.2.3 OPR method (1): Near-point dog method ........................................................................................8- 4

8.2.4 OPR method (2): Stopper 1 .............................................................................................................. 8- 6

8.2.5 OPR method (3): Stopper 2 .............................................................................................................. 8- 8

8.2.6 OPR method (4): Stopper 3 .............................................................................................................8- 10

8.2.7 OPR method (5): Count 1 ................................................................................................................8- 12

8.2.8 OPR method (6): Count 2 ................................................................................................................8- 14

8.3 Fast OPR control.....................................................................................................................................8- 16

8.3.1 Outline of the fast OPR control operation........................................................................................8- 16

9 POSITIONING CONTROL 9- 1 to 9- 17

9.1 Outline of positioning controls..................................................................................................................9- 1

9.1.1 Data required for positioning control.................................................................................................9- 1

9.1.2 Operation patterns of positioning controls........................................................................................9- 2

9.1.3 Designating the positioning address.................................................................................................9- 8

9.1.4 Confirming the current value.............................................................................................................9- 9

9.2 Setting the positioning data ....................................................................................................................9- 10

9.2.1 Relation between each control and positioning data ......................................................................9- 10

9.2.2 1-axis linear control ..........................................................................................................................9- 11

9.2.3 Speed-position switching control ..................................................................................................... 9- 13

9.2.4 Current value changing....................................................................................................................9- 16

9.3 Multiple axes simultaneous start control ................................................................................................9- 17

10 JOG OPERATION 10- 1 to 10- 6

10.1 Outline of JOG operation.....................................................................................................................10- 1

10.2 JOG operation execution procedure ...................................................................................................10- 3

10.3 JOG operation example.......................................................................................................................10- 4

11 SUB FUNCTIONS 11- 1 to 11- 13

11.1 Outline of sub functions .......................................................................................................................11- 1

Page 9

A - 8 A - 8

11.2 Speed limit function..............................................................................................................................11- 1

11.3 Speed change function........................................................................................................................11- 2

11.4 Software stroke limit function...............................................................................................................11- 5

11.5 Acceleration/deceleration processing function....................................................................................11- 8

11.6 Restart function...................................................................................................................................11- 12

12 COMMON FUNCTIONS 12- 1 to 12- 3

12.1 Outline of common functions ...............................................................................................................12- 1

12.2 External I/O signal switching function..................................................................................................12- 1

12.3 External I/O signal monitor function ....................................................................................................12- 2

13 TROUBLESHOOTING 13- 1 to 13- 14

13.1 Error and warning details.....................................................................................................................13- 1

13.2 List of errors .........................................................................................................................................13- 3

13.3 List of warnings ...................................................................................................................................13- 11

13.4 LED display function...........................................................................................................................13- 13

13.5 Confirming the error definition using system monitor of GX Developer............................................13- 14

APPENDIX App- 1 to App- 18

Appendix 1 External dimension drawing ...................................................................................................App- 1

Appendix 2 Operation timing and processing time in each control ..........................................................App- 2

Appendix 3 Connection examples with servo amplifiers manufactured by MITSUBISHI Electric Corporation

.................................................................................................................................................App- 6

Appendix 3.1 Connection example of QD70P

and MR-H A...........................................................App- 6

Appendix 3.2 Connection example of QD70P

and MR-J2/J2S- A................................................App- 7

Appendix 3.3 Connection example of QD70P

and MR-C A...........................................................App- 8

Appendix 4 Connection examples with stepping motors manufactured by ORIENTALMOTOR Co., Ltd.

.................................................................................................................................................App- 9

Appendix 4.1 Connection example of QD70P

and VEXTA UPD .....................................................App- 9

Appendix 5 Connection examples with servo amplifiers manufactured by Matsushita Electric Industrial Co.,

Ltd...........................................................................................................................................App- 10

Appendix 5.1 Connection example of QD70P

and MINAS A series ...............................................App- 10

Appendix 6 Connection examples with servo amplifiers manufactured by Yamayo Electric Co., Ltd...App- 11

Appendix 6.1 Connection example of QD70P

and PZ series..........................................................App- 11

Appendix 7 Connection examples with servo amplifiers manufactured by Yasukawa Electric Co., Ltd

................................................................................................................................................App- 12

Appendix 7.1 Connection example of QD70P

and Σ- series .........................................................App- 12

Appendix 8 Comparisons with type QD75 positioning module................................................................App- 13

Appendix 9 List of buffer memory addresses...........................................................................................App- 16

INDEX Index- 1 to Index- 5

Page 10

A - 9 A - 9

About Manuals

The following manuals are also related to this product.

In necessary, order them by quoting the details in the tables below.

Detailed Manuals

Manual Name

Manual Number

(Model Code)

Type QD70 Positioning Module User's Manual (Hardware)

Describes the performance, specifications, I/O interface, component names, and startup procedure of

the respective positioning modules: QD70P4 and QD70P8. (The manual is supplied with the module.)

IB-0800169

(13JT42)

Using This Manual

The symbols used in this manual are shown below.

Pr.

...... Symbol indicating positioning parameter and OPR parameter item.

OPR.

....... Symbol indicating OPR data item.

JOG.

....... Symbol indicating JOG data item.

Da.

...... Symbol indicating positioning data item.

Md.

...... Symbol indicating monitor data item.

Cd.

....... Symbol indicating control data item.

(A serial No. is inserted in the

mark. )

Numeric values used in this manual

• The buffer memory addresses, error codes and warning codes are represented

in decimal.

• The X/Y devices are represented in hexadecimal.

• The setting data and monitor data are represented in either decimal or

hexadecimal. The data ended b y "H" are repres en ted in hex a dec imal.

(Example) 10.........10 Decimal

10H......16 Hexadecimal

Conformation to the EMC Directive and Low Voltage Instruction

For details on making Mitsubishi PLC conform to the EMC directive and low

voltage instruction when installing it in your product, please refer to Chapter 3,

“EMC Directive and Low Voltage Instruction” of the using PLC CPU module

User’s Manual (Hardware).

The CE logo is printed on the rating plate on the main body of the PLC that

conforms to the EMC directive and low voltage instruction.

To make this product conform to the EMC directive and low voltage instruction,

please refer to Section 5.4.1 "Wiring precautions".

Page 11

A - 10 A - 10

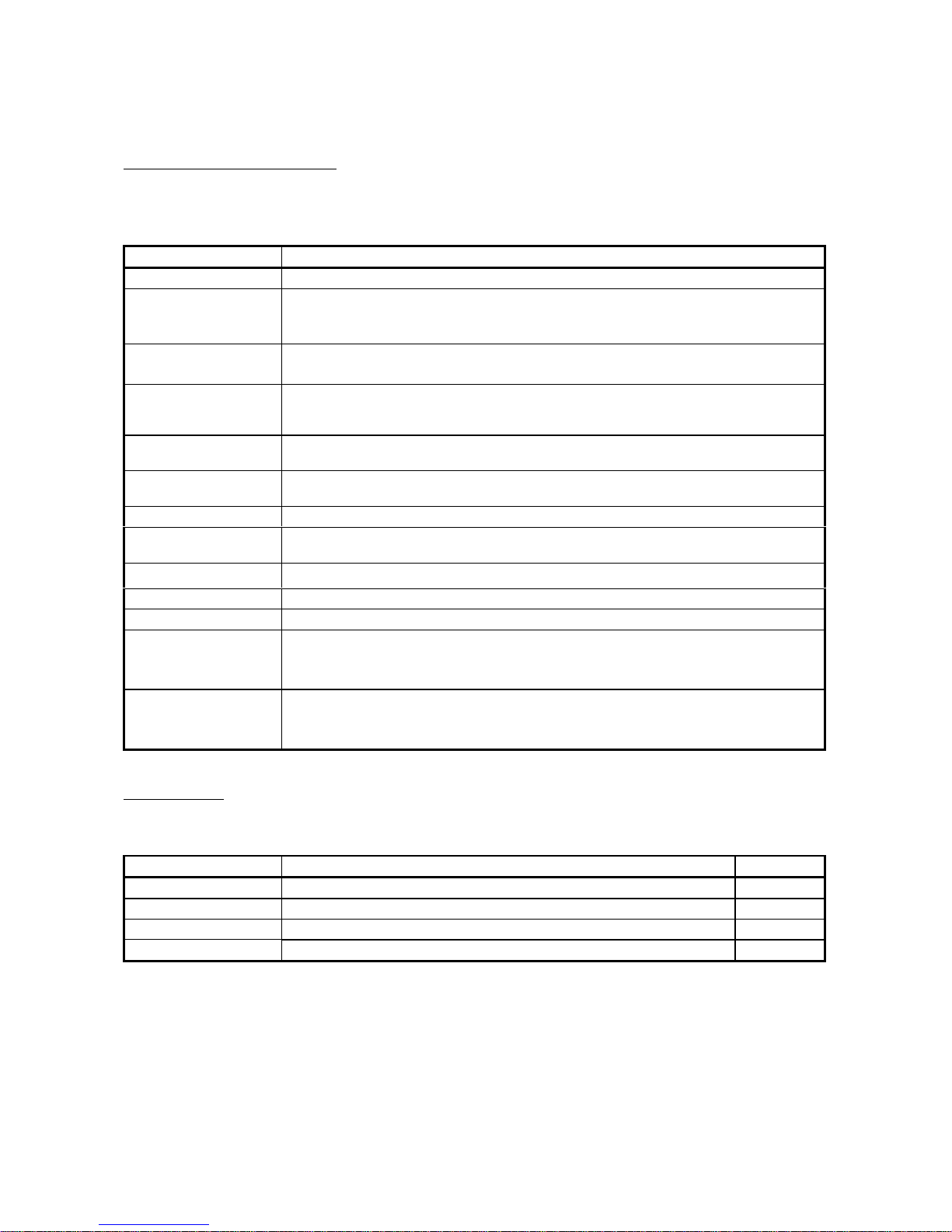

Generic Terms and Abbreviations

Unless specially noted, the following generic terms and abbreviations are used in

this manual.

Generic term/abbreviation Details of generic term/abbreviation

PLC CPU Generic term for PLC CPU on which QD70 can be mounted.

AD75 Generic term for type A1SD75P1-S3/P2-S3/P3-S3, AD75P1-S3/P2-S3/P3-S3 Positioning

module.

The module type is described to indicate a specific modul e.

QD70 Generic term for type QD70 positioning module QD70P4/QD70P8.

The module type is described to indicate a specific modul e.

QD75

Generic term for positioning module QD75P1, QD75P2, QD75P4, QD75D1, QD 75D2, and

QD75D4.

The module type is described to indicate a specific modul e.

Peripheral device

Generic term for DOS/V personal computer where following "GX Configurator-PT" and ""GX

Developer" have been installed.

GX Configurator-PT

Abbreviation for GX Configurator-PT (SW1D5C-QPTU-E) utility package for QD70 positioning

module.

GX Developer Abbreviation for GX Developer (SW4D5C-GPPW-E or later).

Drive unit

Abbreviation for open collector pulse input compatible drive unit (servo amplifier or stepping

motor).

DOS/V personal computer IBM PC/AT® and compatible DOS/V compliant personal computer.

Personal computer Generic term for DOS/V personal computer.

Workpiece Generic term for moving body such as workpiece and tool, and for v arious control targ ets.

Axis 1, axis 2, axis 3,

axis 4, axis 5, axis 6,

axis 7, axis 8

Indicates each axis connected to QD70.

1-axis, 2-axes, 3-axes,

4-axes, 5-axes, 6-axes,

7-axes, 8-axes

Indicates the number of axes. (Example: 2-axes = Indicates two axes such as axis 1 and axis

2, axis 2 and axis 3, and axis 3 and axis 1.)

Component List

The component list of this product is given below.

Type Component Quantity

QD70P4 Type QD70P4 Positioning Module (4-axes open-collector output type) 1

QD70P8 Type QD70P8 Positioning Module (8-axes open-collector output type) 1

SW1D5C-QPTU-E GX Configurator-PT Version 1 (1-license product) (CD-ROM) 1

SW1D5C-QPTU-EA GX Configurator-PT Version 1 (Multiple-license product) (CD-ROM) 1

Page 12

SECTION 1 PRODUCT SPECIFICATIONS

AND HANDLING

Section 1 is configured for the following purposes (1) to (4).

(1) To understand the outline of positioning control, and the QD70 specifications

and functions

(2) To carry out actual work such as installation and wiring

(3) To set parameters and data required for positioning control

(4) To create a sequence program required for positioning control

Read "Section 2" for details on each control.

CHAPTER 1 PRODUCT OUTLINE ................................................................................. 1- 1 to 1- 10

CHAPTER 2 SYSTEM CONFIGURATION..................................................................... 2- 1 to 2- 5

CHAPTER 3 SPECIFICATIONS AND FUNCTIONS...................................................... 3- 1 to 3- 11

CHAPTER 4 DATA USED FOR POSITIONING CONTROL.......................................... 4- 1 to 4- 31

CHAPTER 5 SETUP AND PROCEDURES BEFORE OPERATION............................. 5- 1 to 5- 20

CHAPTER 6 UTILITY PACKAGE.................................................................................... 6- 1 to 6- 17

CHAPTER 7 SEQUENCE PROGRAM USED FOR POSITIONING CONTROL........... 7- 1 to 7- 20

SECTION 1

Page 13

MEMO

SECTION 1

Page 14

1 - 1 1 - 1

MELSEC-Q

1 PRODUCT OUTLINE

CHAPTER 1 PRODUCT OUTLINE

This user's manual provides the specifications, handling, programming methods and

other information of the QD70 positioning module used with the MELSEC-Q series

CPU module.

1.1 Positioning control

1.1.1 Features of QD70

The following are the features of the QD70.

(1) Wide assortment of 4-axes and 8-ax es modul es

The QD70 is a positioning module used in a multi-axes system that does not

need complex control.

It is not compatible with the MELSEC-A series AD70 positioning module in I/O

signals, functio n s, et c.

(2) About positioning control functions

(a) The QD70 has a number of functions required for a positioning control

system, such as posi ti oni ng cont r ol to any po sit io n an d equa l - spee d contr ol .

1) You can set up to 10 pieces of positioning data, which include

positioning address, control method, operation pattern and like, per axis.

These positioning data are used to exercise positioning control axis-byaxis.

2) Axis-by-axis positioning control allows linear control (up to 8 axes can be

controlled simul tane ou sly ) .

This control can perform positioning termination with one piece of

positioning data or exercise continuous positioning control by continuous

execution of multi pl e pi e ces of po sit ion in g da ta.

(b) As the control method, any of position control, speed-position switching

control and current value changing may be specified in each positioning

data.

(c) The following six different OPR methods are available for "machine OPR

control": nea r-p oi nt do g meth od (o ne met h od ), stop pe r (t hree met h od s) an d

count (two methods).

(d) Varying finely in speed to ensure smooth acceleration/deceleration, the

QD70 is suitable fo r co nne ctio n t o a st epping motor.

(e) You can change the I/O signal logic according to the specifications of the

external device.

This allows the input signals to be used with either of "normally open" and

"normally closed" contacts, and the output signals to be used according to

the specifications of the drive unit.

(3) Fast start processing

Processing at a position control start has been speeded up to shorten the start

processing time of one axis to 0.1ms.

At a simultaneous start of multiple axes (the positioning start signals are turned

ON at the same time within one scan), there are no starting delays between the

axes.

(4) Ease of maintenance

In the QD70, error definitions have been subdivided to improve maintenance

performance.

(5) Ease of utility package settings

The optionally available utility package (GX Configurator-PT) allows initial setting

and auto refresh setting to be made on the screen, reducing sequence programs

and facilitating the confirmation of the setting status and operating status.

1

Page 15

1 - 2 1 - 2

MELSEC-Q

1 PRODUCT OUTLINE

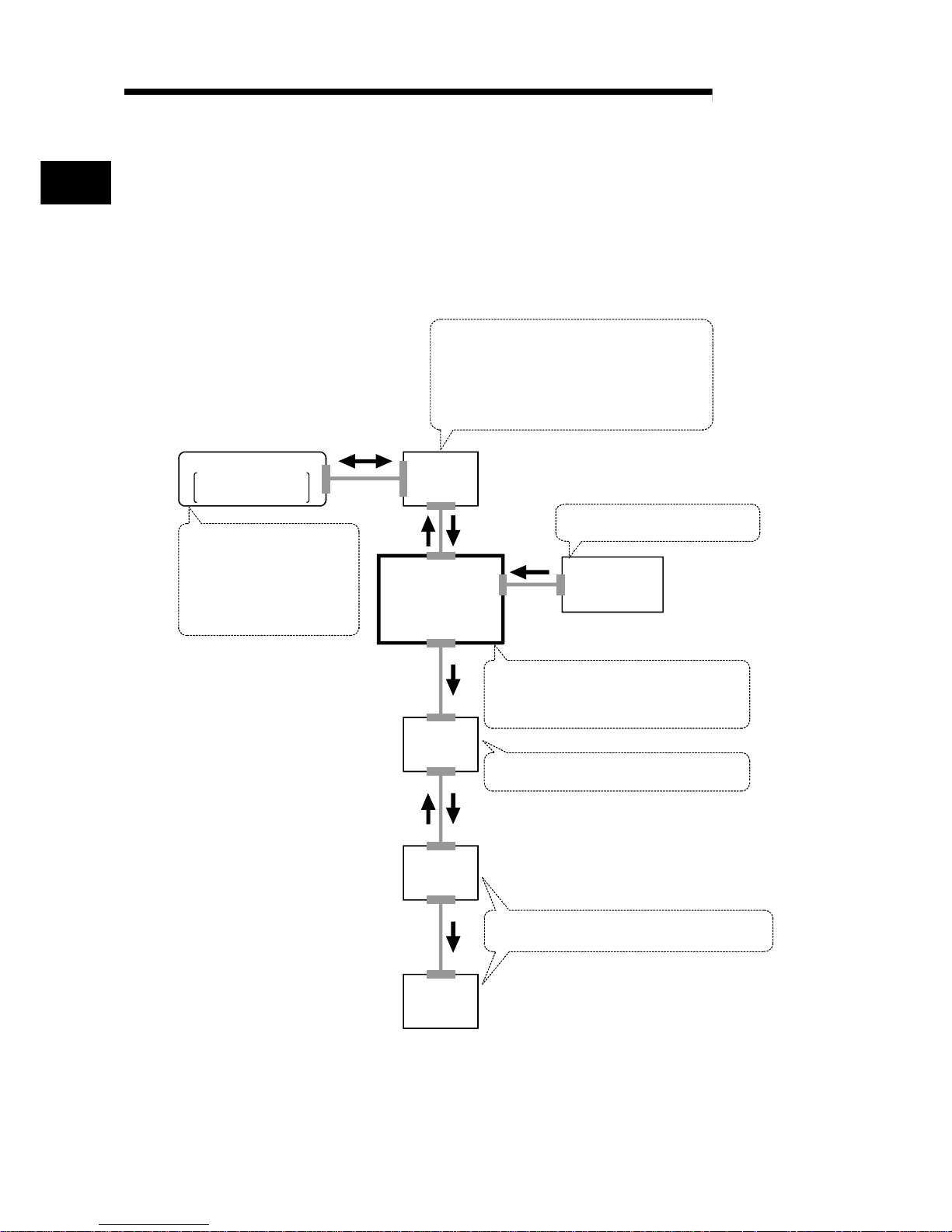

1.1.2 Mechanism of positioning control

Positioning control using the QD70 is exercised using "pulse signals". (The QD70 is a

module that outputs pulses.)

In a positioning control system using the QD70, a variety of software and external

devices are used to play their roles as shown below.

The QD70 imports various signals, parameters and data, and exercises control with

the PLC CPU to realiz e co mpl e x po siti oni ng con tro l.

Stores the created program.

The QD70 outputs the positioning start signal and

axis stop signal following the stired program.

QD70 errors, etc., are detected.

PLC CPU

Peripheral device

GX Developer/

GX Configurator-PT

QD70

positioning

module

Drive

unit

Stores the parameter and data

Outputs to the drive unit according to the

instructins from the PLC CPU.

Receives pulses commands from QD70,

and drives the motor.

Carries out the actual work according to

commands from the drive unit

Motor

Workpiece

Using GX Developer, create

control sequence and conditions

as sequence program.

Adding in GX Configurator-PT

enables initial setting of

parameters and data.

Input near-point dog signal and speed

-position switching signal to QD70.

Mechanical

system inputs

(Switches)

1

Page 16

1 - 3 1 - 3

MELSEC-Q

1 PRODUCT OUTLINE

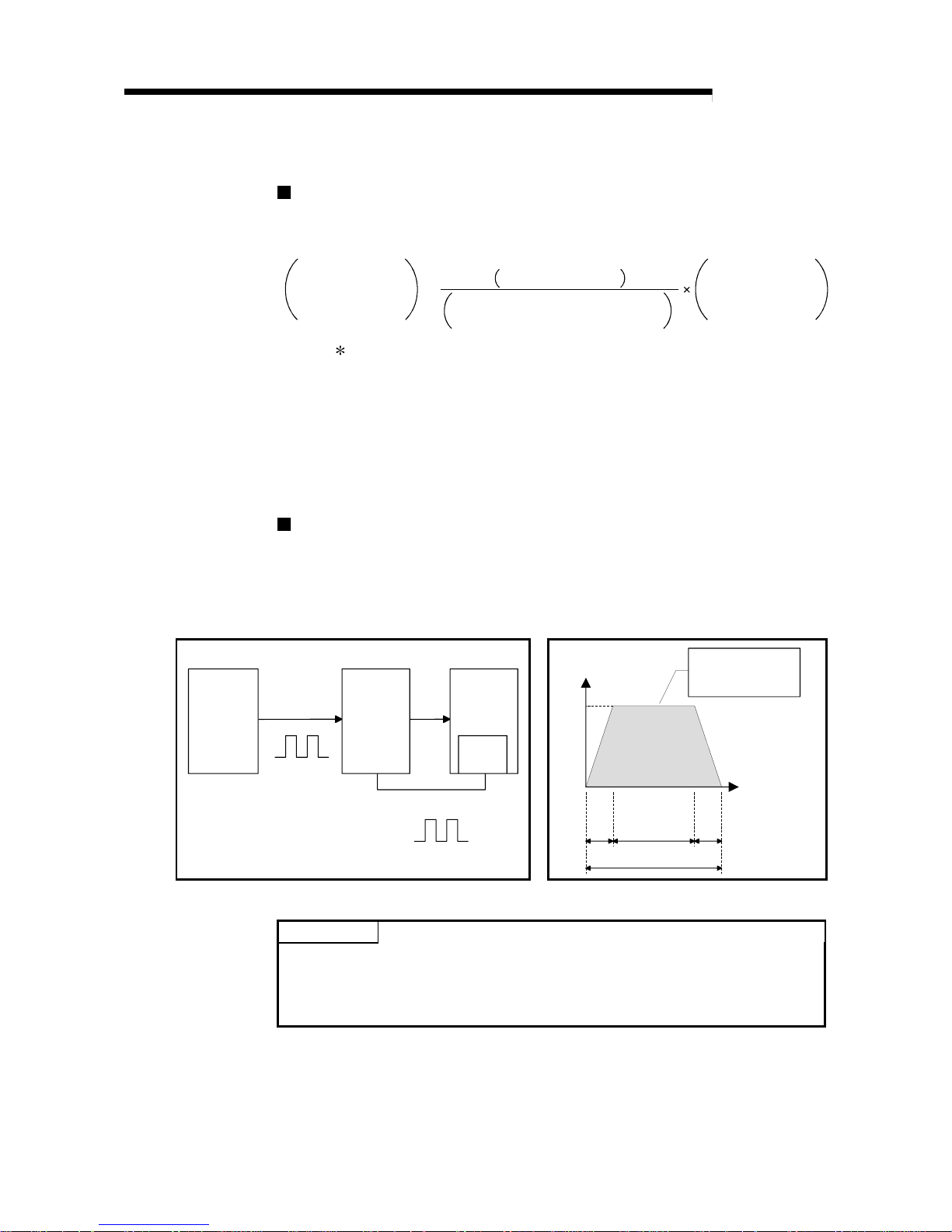

The principle of "position control" and "speed control" operation is shown below.

Position control

The total No. of pulses required to move the designated distance is obtained in the

following manner.

Total No. of pulses

required to move

designated distance

Designated distance

Movement amount of machine (load)

side when motor rotates once

No. of pulses

required for motor to

rotate once

=

The No. of pulses required for the motor to rotate once is the "encoder resolution"

described in the motor catalog specification list.

When this total No. of pulses is issued from the QD70 to the drive unit, control to move

the designated distance can be executed.

The machine side movement amount when one pulse is issued to the drive unit is

called the "movement amount per pulse". This value is the min. value for the workpiece

to move, and is also the electrical positioning control precision.

Speed control

Though the above "total No. of pulses" is an element needed to control the

movement amount, speed must be controlled to perform equal-speed operation.

This "speed" is controlled by the "pulse frequency" output from the QD70 to the drive

unit.

Speed=Pulses frequency

Movement amount=No. of puleses

Feedback pulses=

Pulses generated by detector

Positioning

module

Servo

amplifiter

Servo

motor

Detector

Pulses generated by detector

A

ta td

0.4 0.41.2

(s)

Pulse frequency

[pps]

This area is hte total

No. of commanded

pulses.

Movement amount t = 2

Fig. 1.1 Relationship between position control and speed control

POINT

• The "movement amount per pulse" is the value determined on the machine side.

(Refer to Section 1.1.3.)

• The QD70 uses the "total No. of pulses" to control the position, and uses the

"pulse frequency" to control the speed.

Page 17

1 - 4 1 - 4

MELSEC-Q

1 PRODUCT OUTLINE

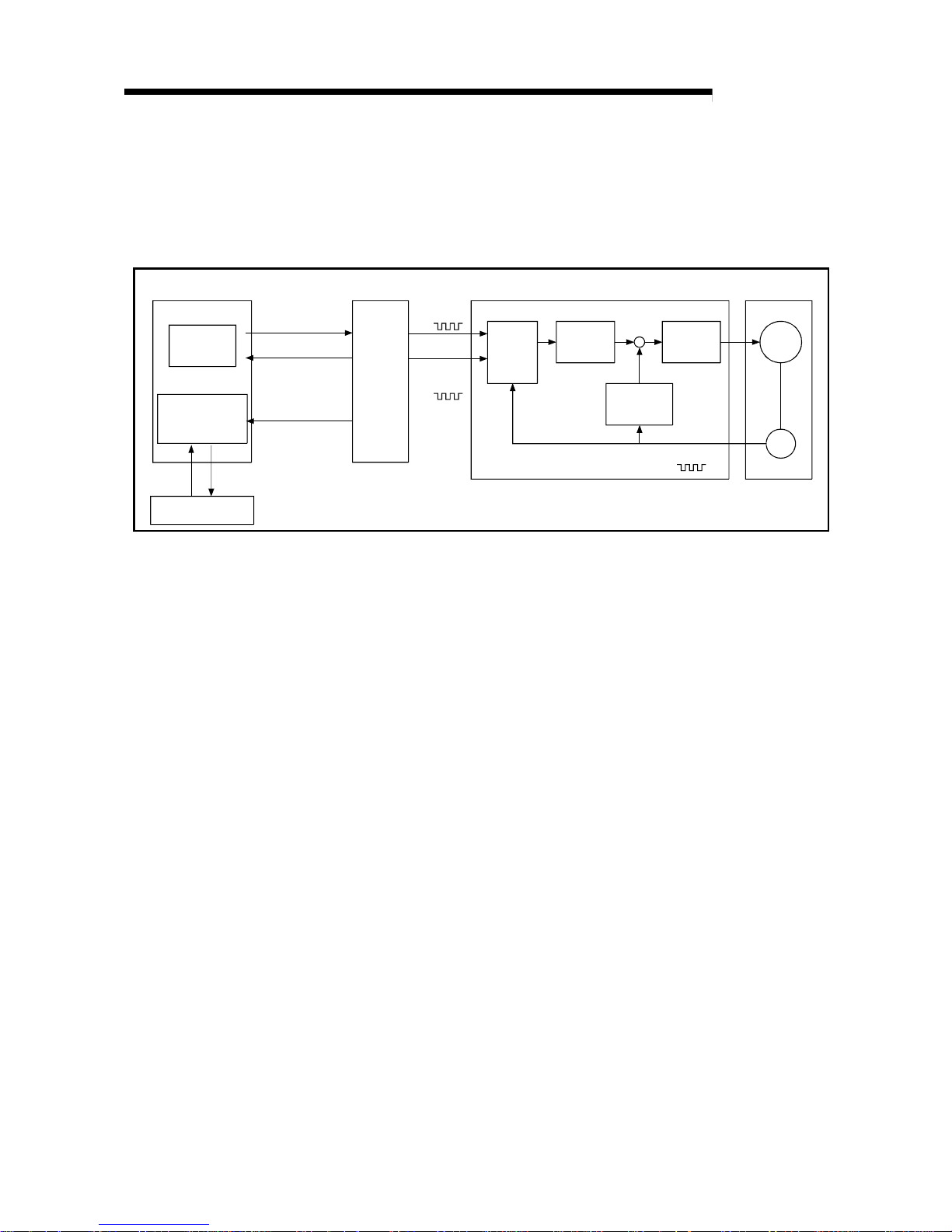

1.1.3 Outline design of positioning control sy stem

The outline of the positioning control system operation and design, using the QD70, is

shown below.

(1) Positioning control system using QD70

Positioning module

QD70

PLC CPU

M

PG

GX Configurator-PT

Program

Intelligent

function module

parameter

Read, write, etc.

Monitor date read

Initial setteng /Auto rofresh setting/Monitor

Drive unit

Buffer

memories

/XY

device

Forward run

pulse train

Reverse run

pulse train

Deviation

counter

D/A

converter

Speed

command

Servo

amplifiter

Interface

Feedback pulse

Servomotor

Fig. 1.2 Outline of the operation of positioning control system using QD70

(a) Positioning operation by the QD70

1) The QD70 output is a pulse train.

The pulse train output by the QD70 is counted by and stored in the

deviation counter in the drive unit.

The D/A converter outputs an analog DC current proportionate to the

count maintained by the deviation counter (called "pulse droop"). The

analog DC current serves as the servo motor speed control signal.

2) The servo motor rotation is controlled by the speed control signal from

the drive unit.

As the servo motor rotates, the pulse generator (PG) attached to the

servo motor generates feedback pulses, the frequency of which is

proportionate to the rotation speed.

The feedback pulses are fed back to the drive unit and decrements the

pulse droop, the pulse count maintained by the deviation counter.

The motor keeps on rotating as the pulse droop is maintained at a

certain level.

3) When the QD70 terminates the output of a pulse train, the servo motor

decelerates as the pulse droop decreases and stops when the count

drops to zero.

Thus, the servo motor rotation speed is proportionate to the pulse

frequency, while the overall motor rotation angle is proportionate to the

total number o f pu l ses ou tp ut by the QD70.

Therefore, when a movement amount per pulse is given, the overall

movement amount can be determined by the number of pulses in the

pulse train.

The pulse frequency, on the other hand, determines the servo motor

rotation speed (feed speed).

Page 18

1 - 5 1 - 5

MELSEC-Q

1 PRODUCT OUTLINE

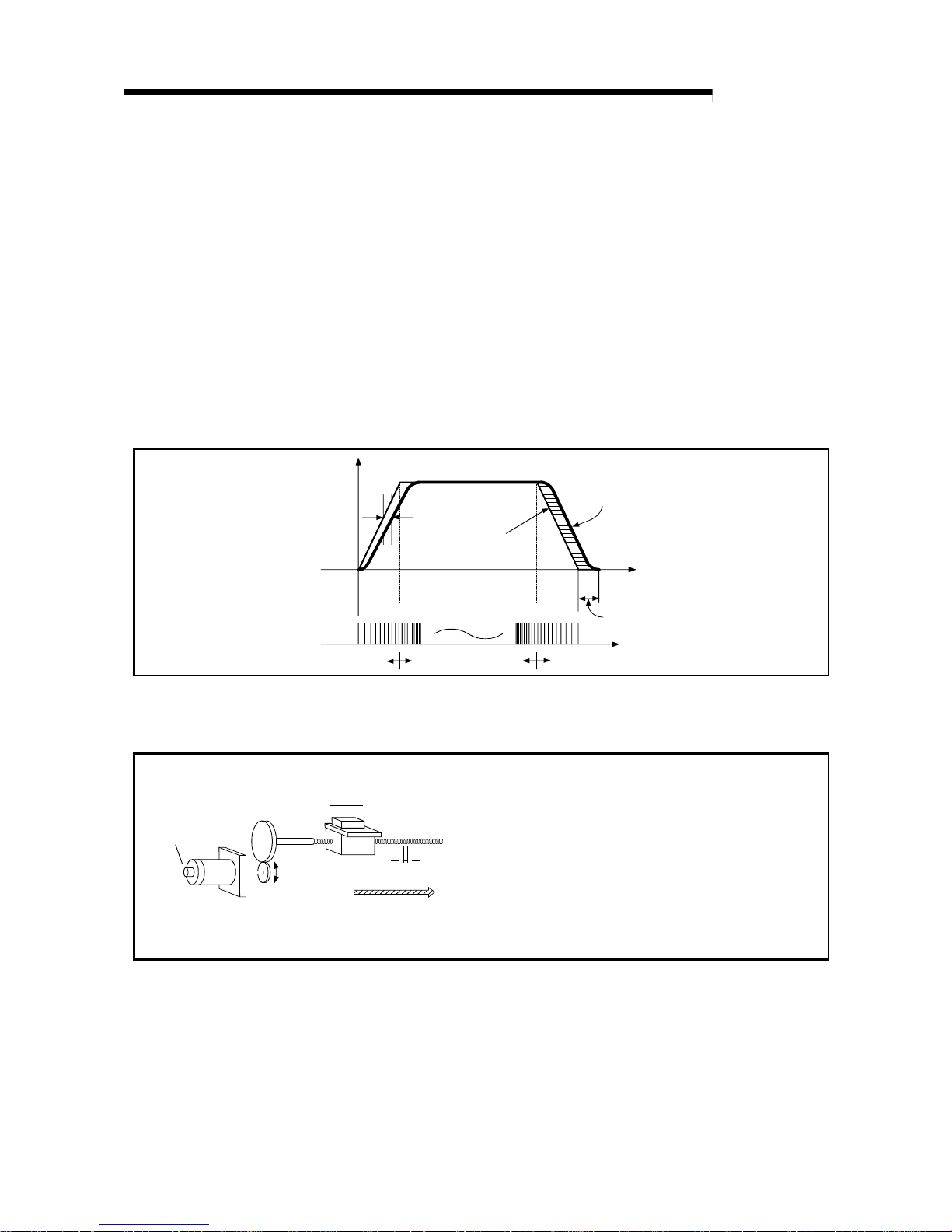

(b) Pulse train output from the QD70

1) As shown in Fig. 1.3, the pulse frequency increases as the servo motor

accelerates. The pulses are sparse when the servo motor starts and

more frequent when the servo motor speed comes close to the target

speed.

2) The pulse frequency stabilizes when the motor speed equals the target

speed.

3) The QD70 decreases the pulse frequency (sparser pulses) to

decelerate the servo motor before it finally stops the output.

There will be a little difference in timing between the decrease in the

pulse frequency and the actual deceleration and stopping of the servo

motor.

This difference, called "the stop settling time", is required for gaining a

stopping accuracy.

Speed V Pulse droop

amount

Pulse

distribution

Servomotor

speed

Acceleration

Deceleration

Time t

Stop

setting time

Pulse train Rough Dense

Rough

Fig. 1.3 QD70 output pulses

(2) Movement amount and speed in a system usi ng w orm g ear s

V

L

P0

P

Workpiece

Worm pear

Table

Pulse

generator

(PG)

Servomotor

A : Movement amount per pulse (mm/pulse)

Vs : Command pulse frequency (pulse/s)

n : No. of pulse generator slits

"

No. of pulses" (pulse/rev)

L : Worm gear lead (mm/rev)

R : Deceleration ratio

V : Movable section speed (mm/s)

N : Motor speed (r/min)

K : Position loop gain (1/s)

ε

: Deviation counter droop pulse amount

P0 : OP (pulse)

P : Address (pulse)

Fig. 1.4 System using worm gears

Page 19

1 - 6 1 - 6

MELSEC-Q

1 PRODUCT OUTLINE

In the system shown in Fig. 1.4, the movement amount per pulse,

command pulse frequency, and the deviation counter droop pulser amount

are determined as follows:

1) Movement amount per pulse

The movement amount per pulse is determined by the worm gear lead,

deceleration ratio, and the No. of pulse generator slites.

The movement amount, therefore, is given as follows: (Number of

pulses output) × (Movement amount per pulse).

L

A =

R

×

n

[mm/pulse]

2) Command pulse frequency

The command pulse frequency is determined by the speed of the

moving part and movement amount per pulse.

V

Vs =

A

[pulse/s]

3) Deviation counter droop pulser amount.

The deviation counter droop pulser amount is determined by the

command pulse frequency and position loop gain.

Vs

ε

=

K

[pulse]

Page 20

1 - 7 1 - 7

MELSEC-Q

1 PRODUCT OUTLINE

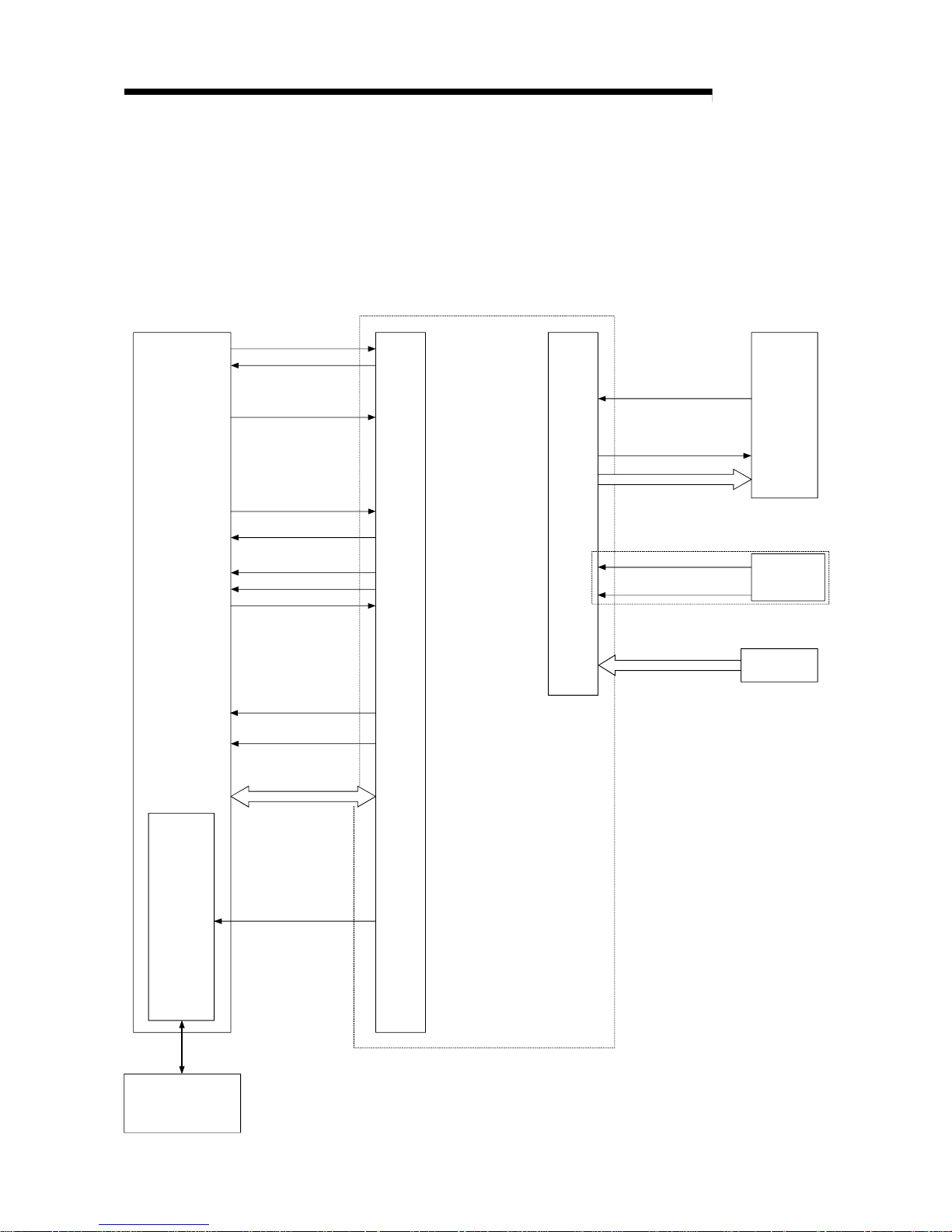

1.1.4 Communicating signals between QD 70 and each mo dul e

The outline of the signal communication between the QD70 (positioning module) and

PLC CPU, peripheral device (GX Configurator-PT) and drive unit, etc., is shown below.

(A peripheral device communicates with the QD70 via the PLC CPU to which it is

connected)

Refer to Chap te r 3 fo r de tails of the I/O si gn al s.

PLC READY signal

Module READY signal

JOG start signal

BUSY signal

Drive

unit

Deviation counter clear

Pulse train

QD70

Y0

X0

PLC CPU

Near-point dog singal

Monitor data

Y18 to Y1F

X10 to X17

Y10 to Y17

X1

Y8 to YF

X18 to X1F

X8 to XF

X2

Axis warning occurrence

signal

24VDC

Power supply

Peripheral device

(GX Configurator-PT)

Initial setting/ Auto refresh/

Operation monitor

Positioning start

Start comple te signal

Axis stop signal

Positioning complete

signal

Axis error occurrence

signal

Mechanical

system inputs

(Switches)

Speed-position switching

signal

(For pulse train output)

Zero signal

Date write/read

Interface

with

PLC CPU

Peripheral

device

interface

External

interface

Page 21

1 - 8 1 - 8

MELSEC-Q

1 PRODUCT OUTLINE

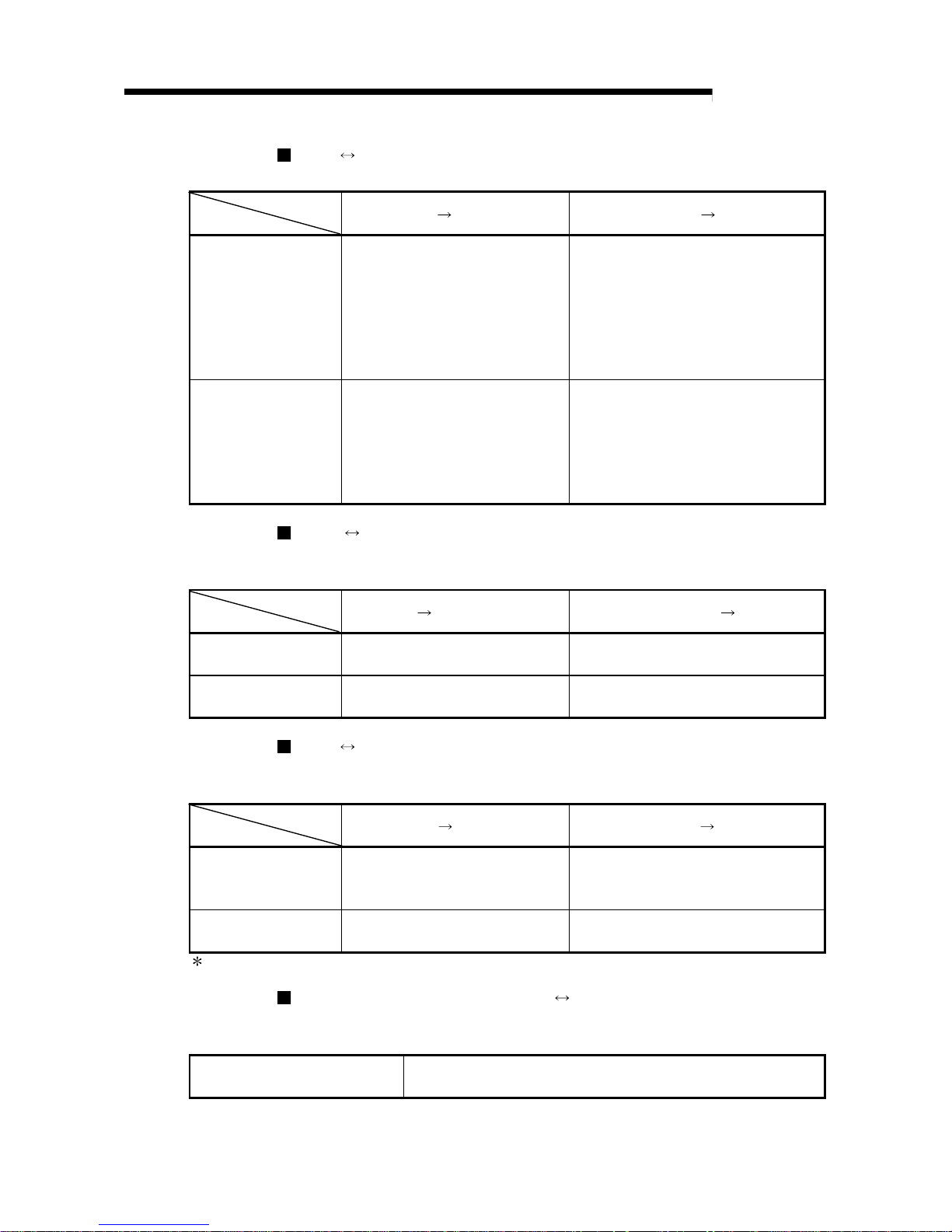

QD70 PLC CPU

The QD70 and PLC CPU communicate the following data via the base unit.

Direction

Communication

QD70

PLC CPU PLC CPU QD70

Control signal

Signal indication QD70 state.

•

Module READY (X0)

•

Axis error occurrence (X1)

•

Axis warning occurrence (X2)

•

BUSY (X8 to XF)

•

Start complete (X10 to X17)

•

Positioning complete (X18 to X1F)

Signal related to commands.

•

PLC READY (Y0)

•

Positioning start (Y8 to YF)

•

Axis stop (Y10 to Y17)

•

JOG start (Y18 to Y1F)

Data (read/write)

•

Parameter

•

OPR data

•

JOG data

•

Positioning data

•

Control data

•

Monitor data

•

Parameter

•

OPR data

•

JOG data

•

Positioning data

•

Control data

QCPU Peripheral device (GX Configurator-PT)

The QCPU and peripheral device make the following communications. (Refer to

Chapter 6 for de ta il s. )

Direction

Communication

QCPU

Peripheral device Peripheral device QCPU

Data –

•

Initial setting

•

Auto refresh setting

Operation monitor

•

Monitor data (QD70 buffer

memory/XY devices)

–

QD70 Drive unit

The QD70 and drive unit communicate the following data via the external device

connection connector.

Direction

Communication

QD70

Drive unit Drive unit QD70

Control signal

Signals related to commands

•

Deviation counter clear signal

(CLEAR)

Signal indicating OP

•

Zero signal (PG0)

Pulse train

•

Pulse train output (PULSE F/

PULSE R)

–

: External 24VDC must be supplied to output the pulse train.

Mechanical system inputs (switches) QD70

The input signals from the mechanical system inputs (switches) are entered into the

QD70 via the exte r nal dev i c e con ne cti on conn e cto r .

Mechanical system inputs (switches)

•

Near-point dog signal (DOG)

•

Speed-position switching signal (CHG)

Page 22

1 - 9 1 - 9

MELSEC-Q

1 PRODUCT OUTLINE

1.2 Positioning control

1.2.1 Outline of starting

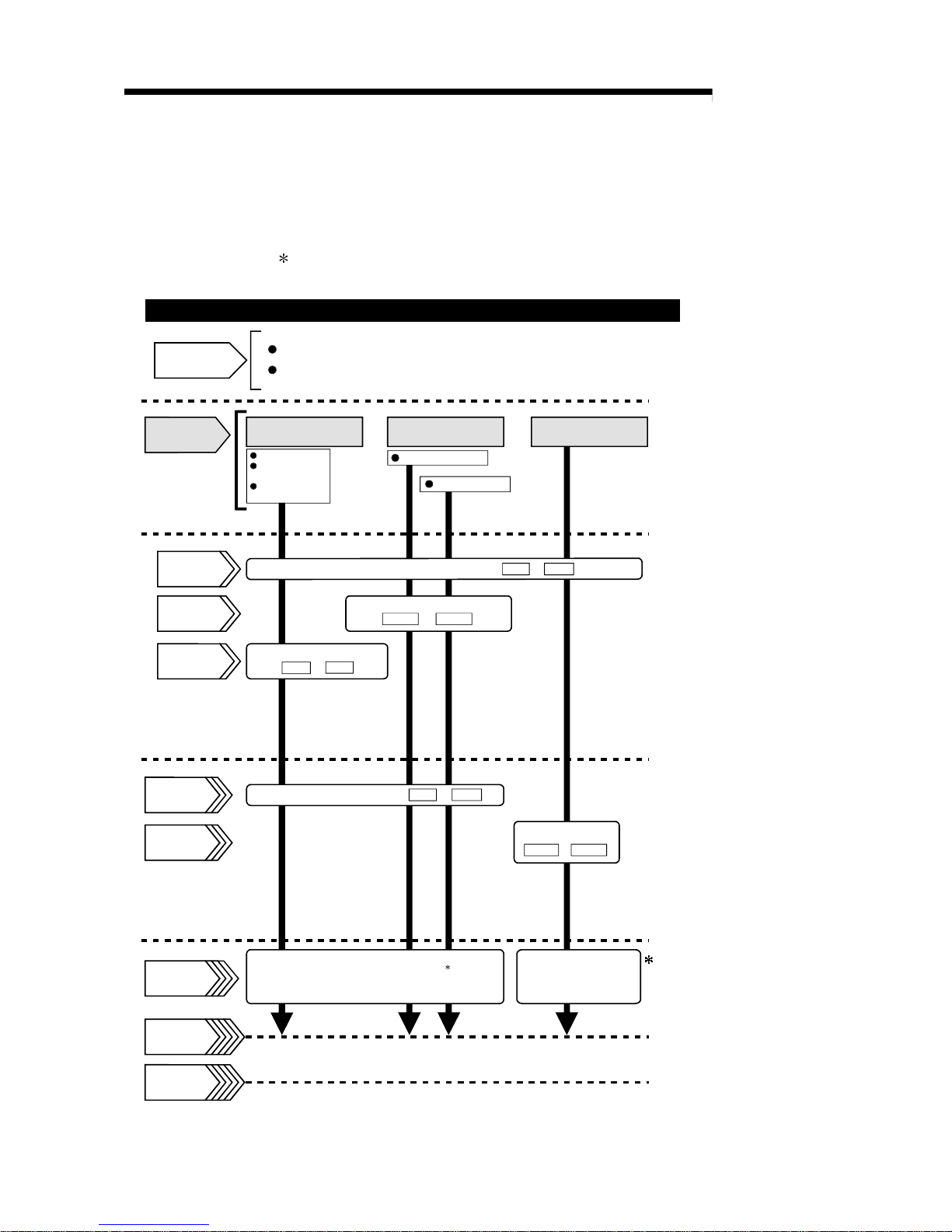

The outline for starting each control is shown with the following flowchart.

It is assumed that each module is installed, and the required system configuration,

etc., has been prepared.

Machine OPR control

Fast OPR control

OPR control

Set the OPR data.

OPR. 1 to

OPR. 9

Preparation

Control

functions

Flow of starting

Installation and connection of module

Setting of hardware

Position control

Speed-position

switching control

Current value

changing

Positioning control

JOG operation

Parameter

Positioning

data

OPR data

Control data

Start signal

Control start

Control end

Set the parameters.

Set the start method.( Da. 1 to Da. 7 )

Operation

Stop

Turn ON the QD70 start signal

from the PLC CPU

Set the positioning data.

( Da. 1 to Da. 7 )

Set the JOG data

( JOG. 1 to JOG. 4 )

JOG data

( Pr. 1 to Pr. 10 )

: Positioning control can make a

multiple axes simultaneous start.

(Refer to "Section 9.3" for details.)

Turn the QD70 JOG

start signal ON from

the PLC CPU

Page 23

1 - 10 1 - 10

MELSEC-Q

1 PRODUCT OUTLINE

1.2.2 Outline of stopping

The possible causes of a control stop are as follows.

(1) Control ended normally

(2) An error occurred in the PLC CPU

(3) An error occurred in the QD70

(4) The axis stop signal from the PLC CPU turned ON

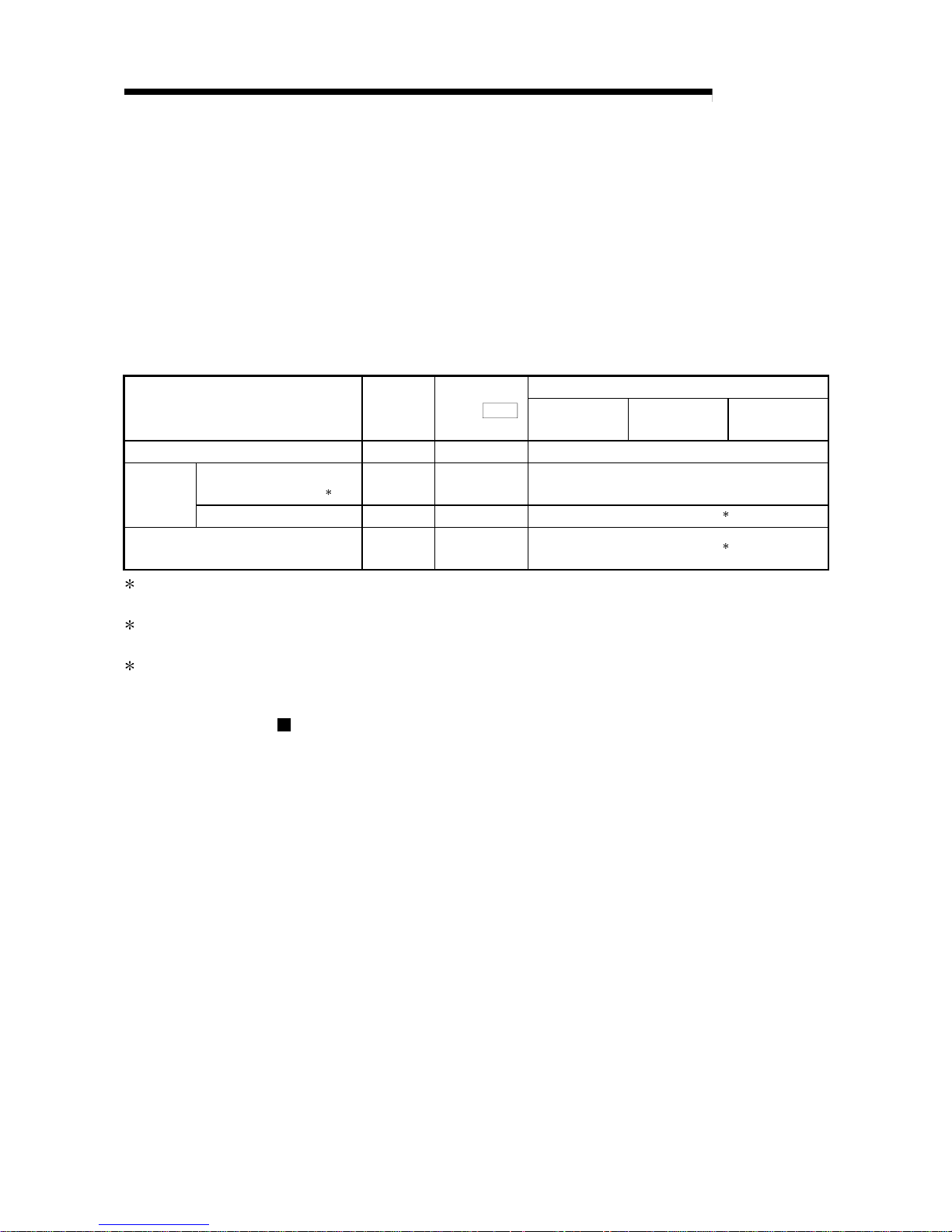

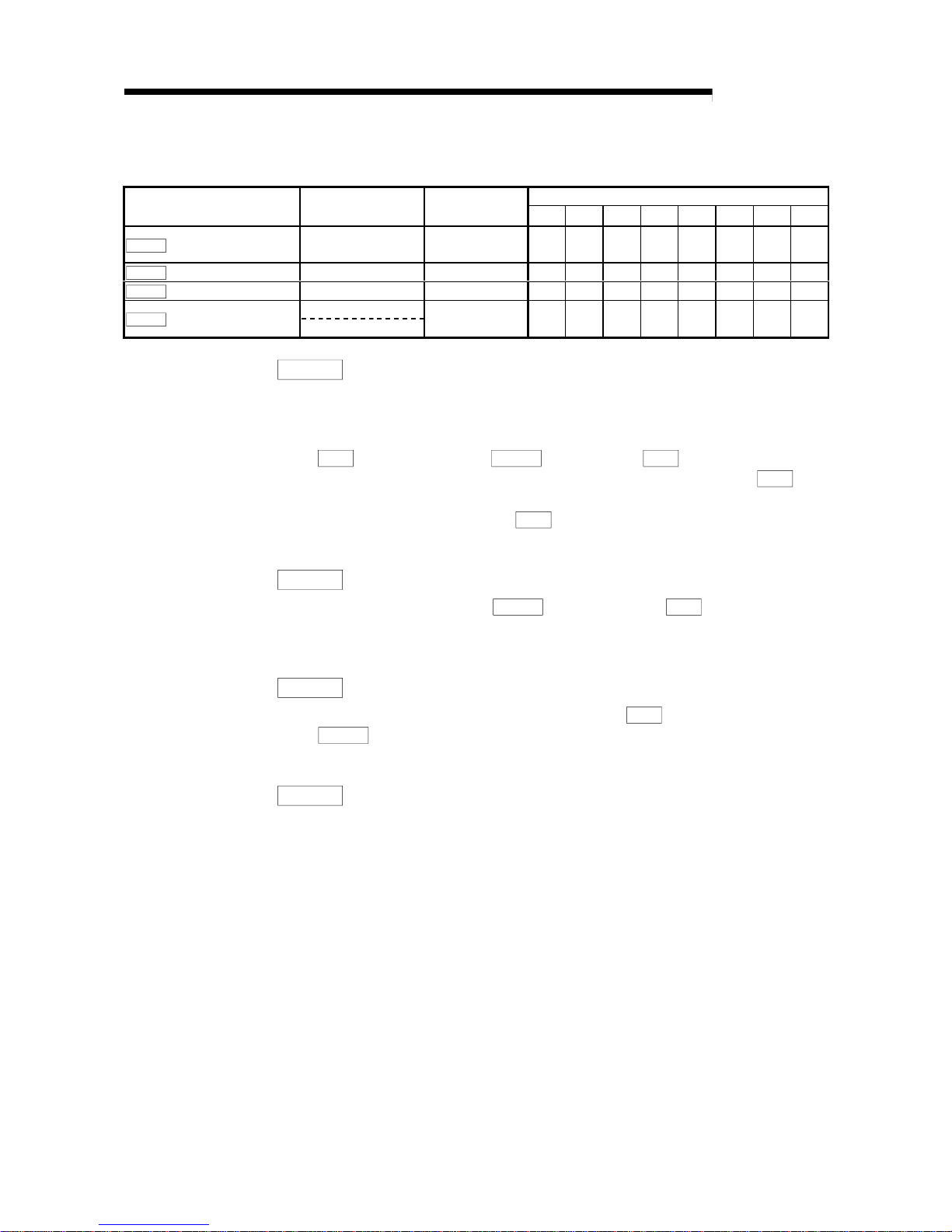

Stop processings performed in the above cases are outlined in the following table.

(Except the case (1) where control sto pped normally)

Stop processing

Stop factor

Stopped

axis

Axis operation

status (

Md. 4

)

after stop

OPR control

Positioning

control

JOG operation

PLC CPU error All axes Error Deceleration stop

Software stroke limit

upper/lower limit error

1

Axis by axis Error Deceleration stop

QD70 error

Other error Axis by axis Error

Deceleration stop

2

"Axis stop signal" from PLC CPU turned

ON

Axis by axis Stopped

Deceleration stop

3

1: By making parameter setting, you can set the software stroke limit valid/invalid. When the stroke limit is set invalid, a

deceleration stop is not made. (Refer to Section 4.2.)

2: If an illegal positioning data setting value caused an error during posit ion control (operation pattern: continuous path

control), an immediate stop is made at the positioning data prec eding th at illega l setting v alue. (R efer to Secti on 9.1.2.)

3: For position control (operation pattern: continuous path control), you can make parameter setting to select the

stopping method (position match stop or deceleration stop). (Refer to Section 4.2.)

Stop after multiple axes simultaneous start under positioning control

The axes started will not stop simultaneously. The stop command (axis stop signal

ON) must be given to each axis.

Page 24

2 - 1 2 - 1

MELSEC-Q

2 SYSTEM CONFIGURATION

CHAPTER 2 SYSTEM CONFIGURATION

This chapter explains the system configuration of the QD70.

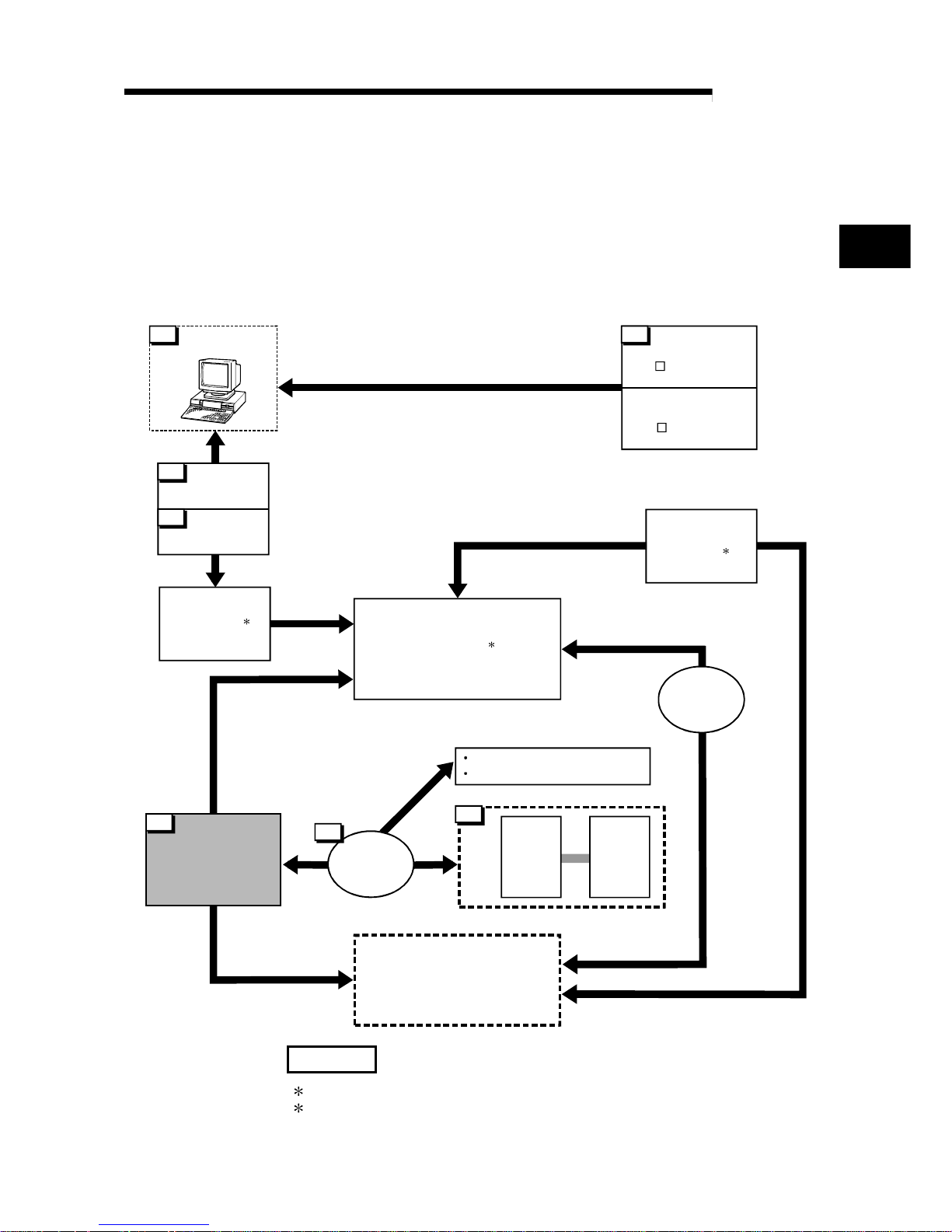

2.1 General image of system

The following is the general configuration including the QD70, PLC CPU, peripheral

device and others.

(The numbers in the sketch correspond to the "Nos." in the table in "Section 2.2

Component list" on the next page.)

Extension system

6

Drive

unit

Motor

4

5

RS-232

cable

USB cable

1

Positioning module

QD70P4/QD70P8

7

Connection

cable

Mechanical system inputs (switches)

Near-point dog signal

Speed-position switching signal

Extension

cable

Power supply

module

Main base unit

CPU module

3 2

GX Developer

(SW D5C-GPPW-E)

GX Configurator-PT

(SW D5C-QPTU-E)

Peripheral device

Personal

computer

1

2

2

REMARK

1: For the usable CPU module, refer to "Section 2.3 Applicable system".

2: For the usable base unit and power supply module, refer to the CPU Module

User's Manual.

2

Page 25

2 - 2 2 - 2

MELSEC-Q

2 SYSTEM CONFIGURATION

2.2 Component list

A positioning system using the QD70 consists of the following components.

No. Product Type Remarks

1 Positioning module

QD70P4

QD70P8

QD70P

No. of control axes

Open collector output typeP

GX Developer SW D5C-GPPW-E

2

GX Configurator-PT SW

D5C-QPTU-E

For details, refer to the GX Developer Operating Manual and

"CHAPTER 6 UTILITY PACKAGE (GX Configurator-PT)".

3 Personal computer

DOS/V personal

computer

(User-prepared)

Refer to the GX Developer Operating Manual for details.

4 RS-232 cable QC30R2

(User-prepared)

RS-232 cable for connection of the CPU module and DOS/V personal

computer.

Refer to the GX Developer Operating Manual for details.

5 USB cable –

(User-prepared)

USB cable for connection of the CPU module and DOS/V personal

computer.

Refer to the GX Developer Operating Manual for details.

6 Drive unit –

(User-prepared)

Refer to the drive unit manual for details.

7

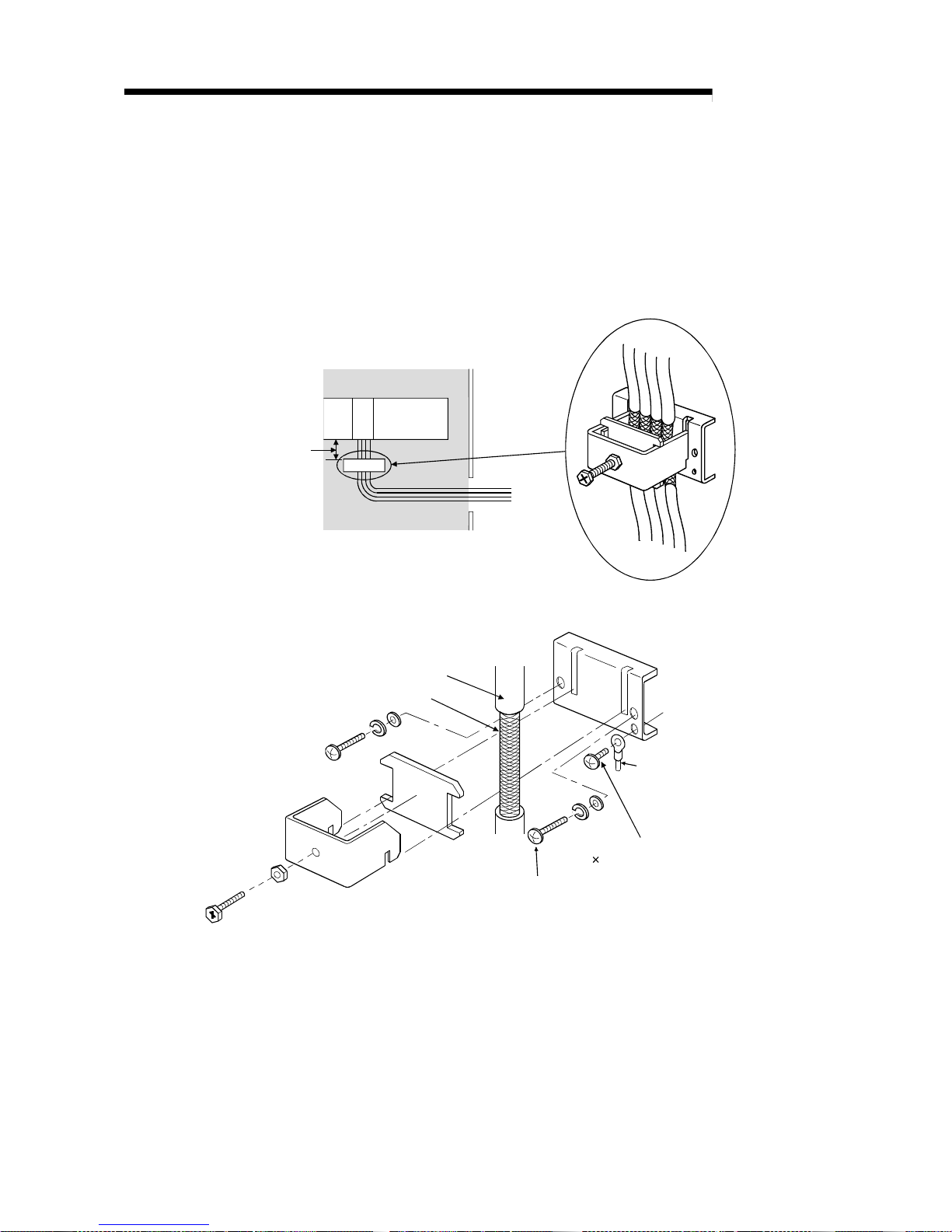

Connection cable

(for connection of

QD70 and drive unit)

–

(User-prepared)

Cable for connection of the QD70 and drive unit or mechanical system

input signals.

(To be fabricated in reference to the connected device manual and

Section 3.4.2)

2

Page 26

2 - 3 2 - 3

MELSEC-Q

2 SYSTEM CONFIGURATION

2.3 Applicable system

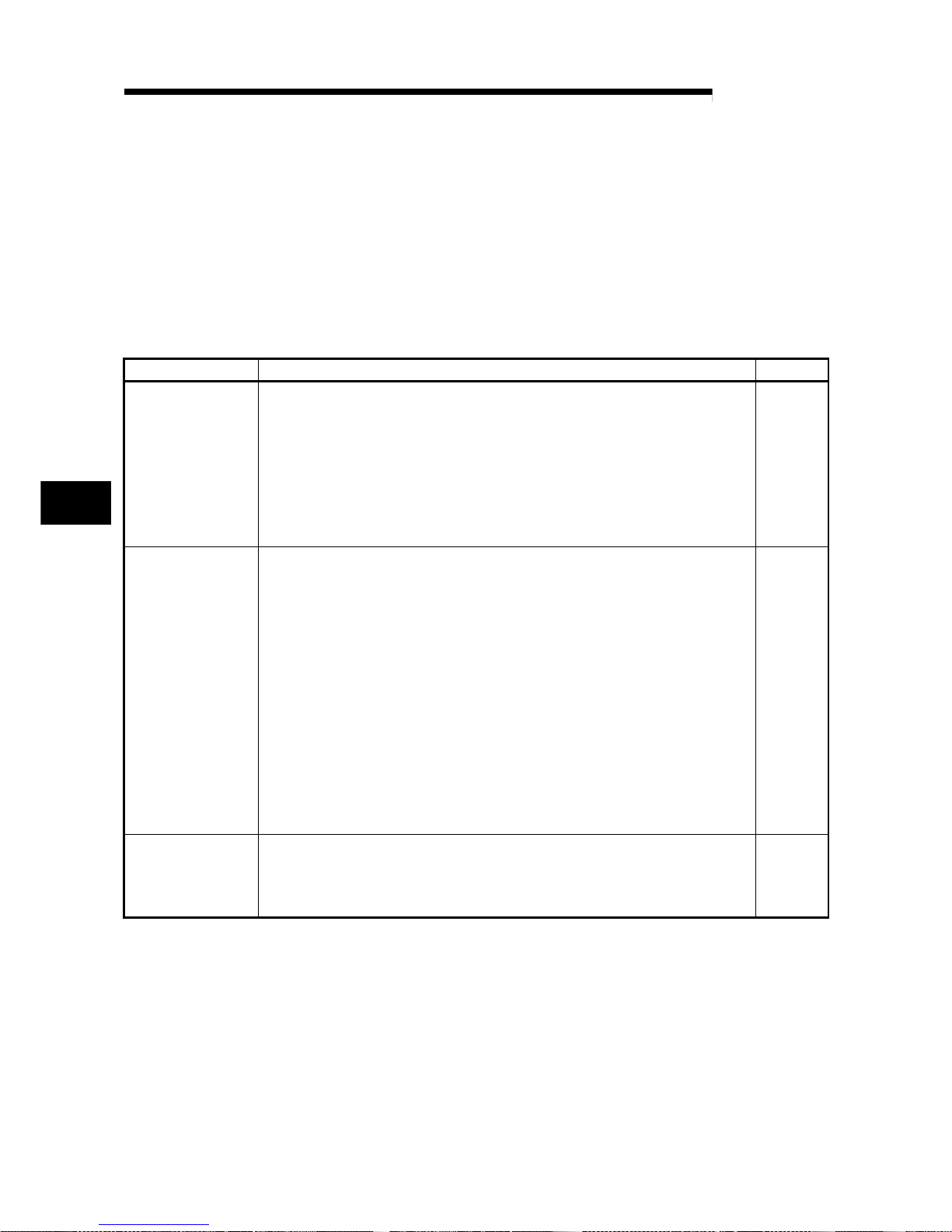

The QD70 is usable with the following system.

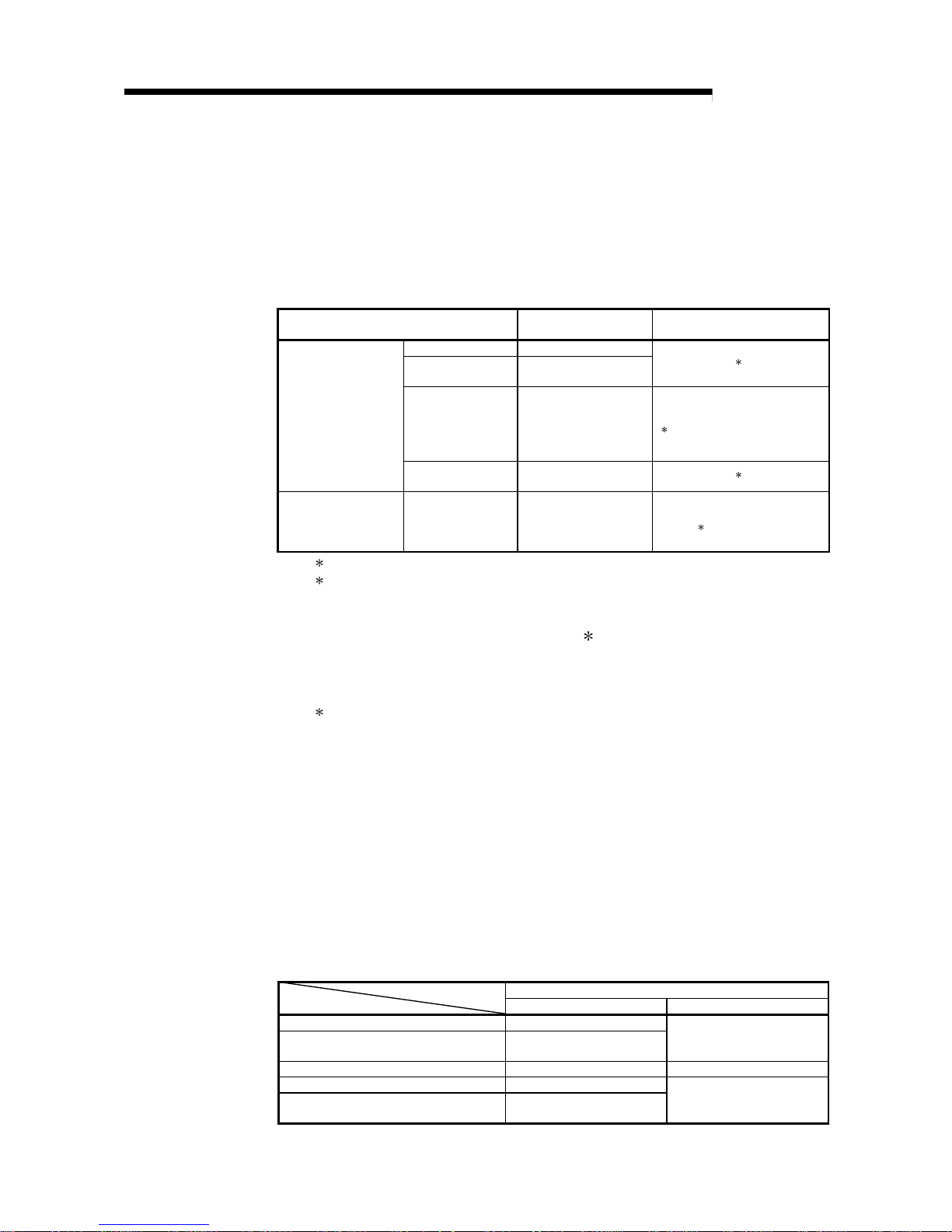

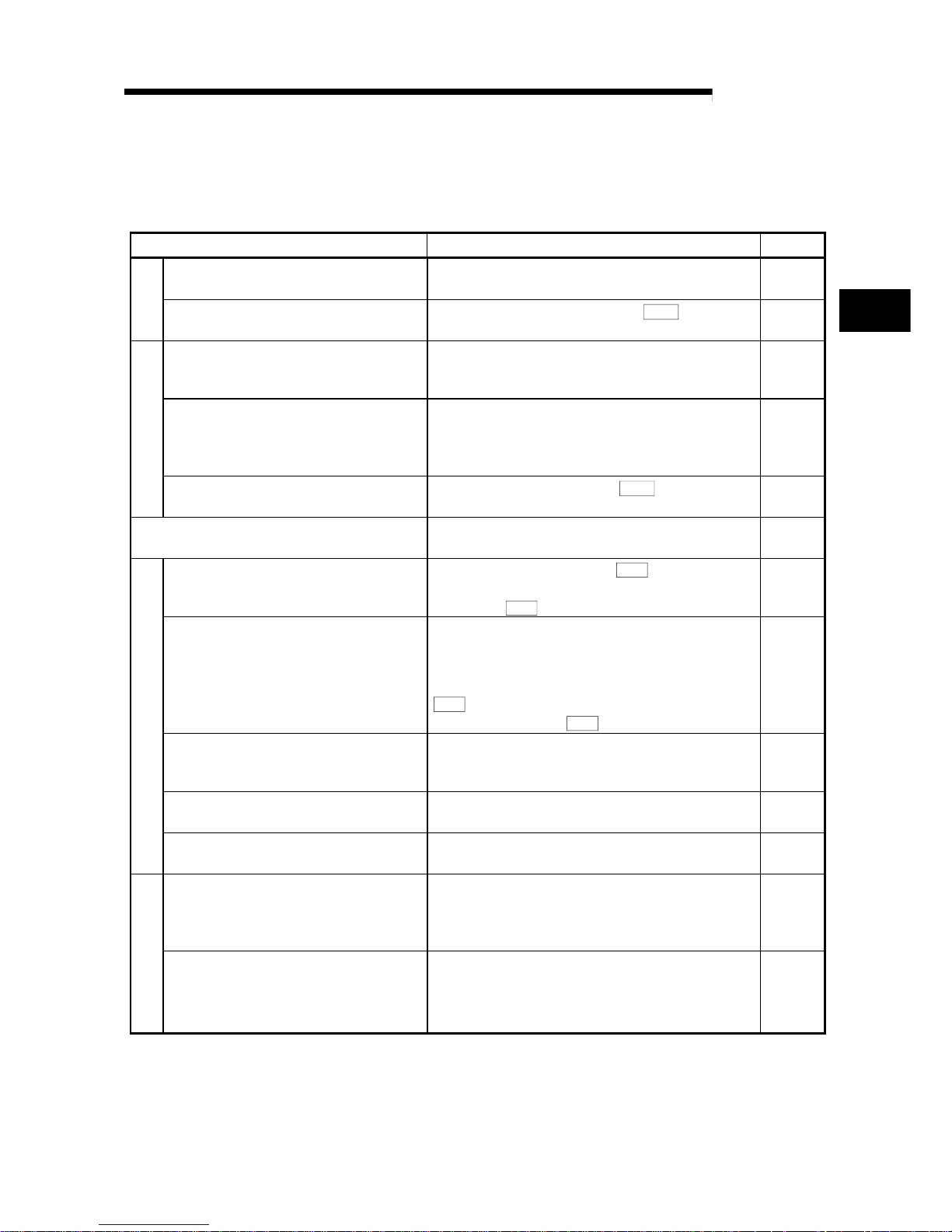

(1) Applicable module and the number o f modules that ca n be i nstal led

The following are the CPU module and network module (for remote I/O stations)

in which the QD70 can be installed and the number of modules that can be

installed.

Applicable module

Number of modules that

can be installed

Remarks

Q00JCPU Maximum 16

Q00CPU

Q01CPU

Maxi mum 24

(

1

)

Q02CPU

Q02HCPU

Q06HCPU

Q12HCPU

Q25HCPU

Maxi mum 64

Can be installed in Q mode only

(

1

)

CPU module

Q12PHCPU

Q25PHCPU

Maxi mum 64

(

1

)

Network module

QJ72LP25-25

QJ72BR15

QJ72LP25G

QJ71LP25GE

Maxi mum 64

MELSECNET/H Remote I/O

station (

2

)

1 See User's Manual (Function Explanation, Program Fundamentals) for the CPU module to use.

2 See Q Corresponding MELSECNET/H Network System Reference Manual (Remote I/O

network).

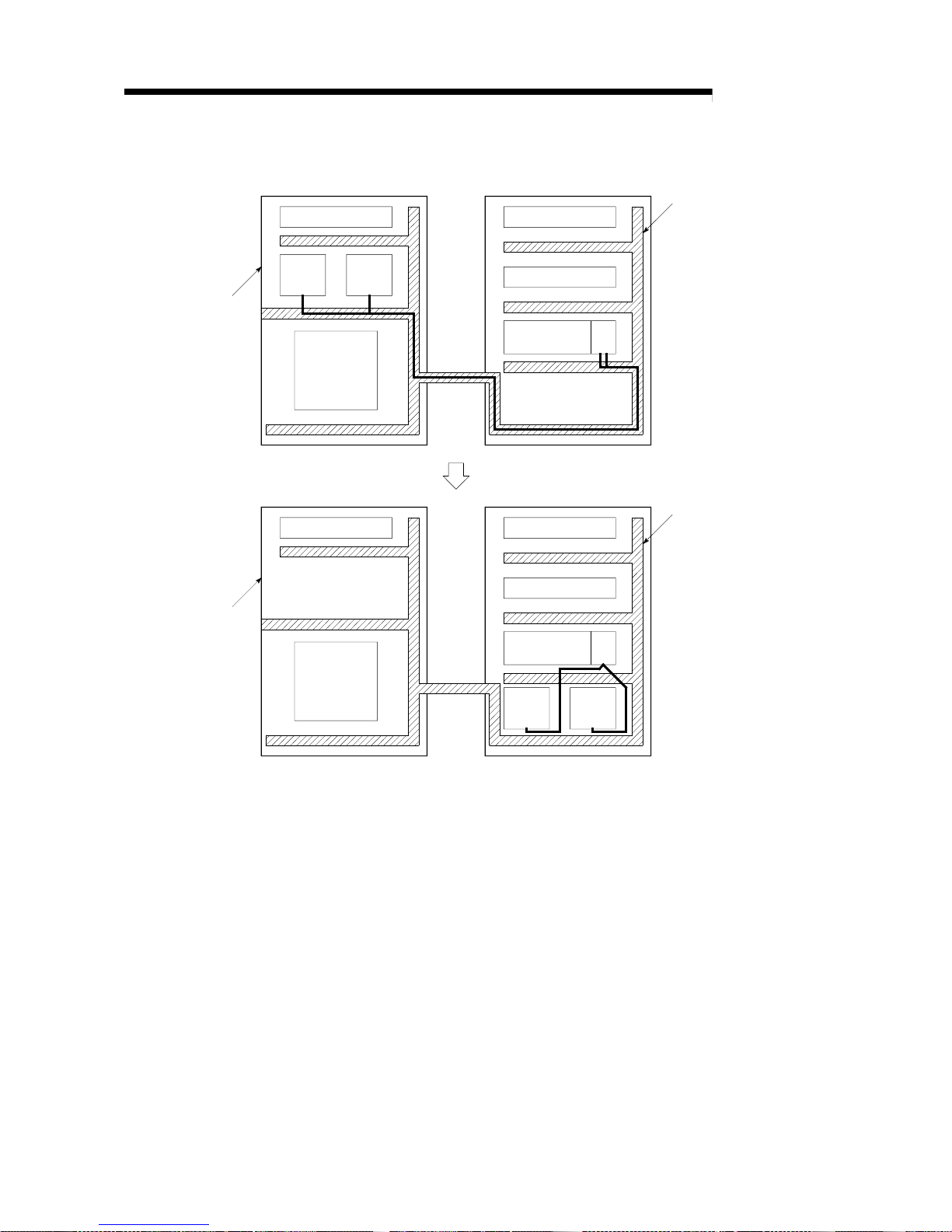

(2) Base unit in which the QD70 can be installed

The QD70 can be installed in any I/O slot ( 3) of the base unit. However, a

power shortage may occur depending on the combination with other installed

modules and the number of modules used, so always take into consideration the

power supply capa city when installing mod ule s.

3 Limited to the range of the number of I/O points in the CPU module and network module (for

remote I/O stations) .

(3) Compatibility with a multiple PLC system

First read the QCPU (Q mode) User's Manual (Function Explanation, Program

Fundamentals) if the QD70 is used with a multiple PLC system.

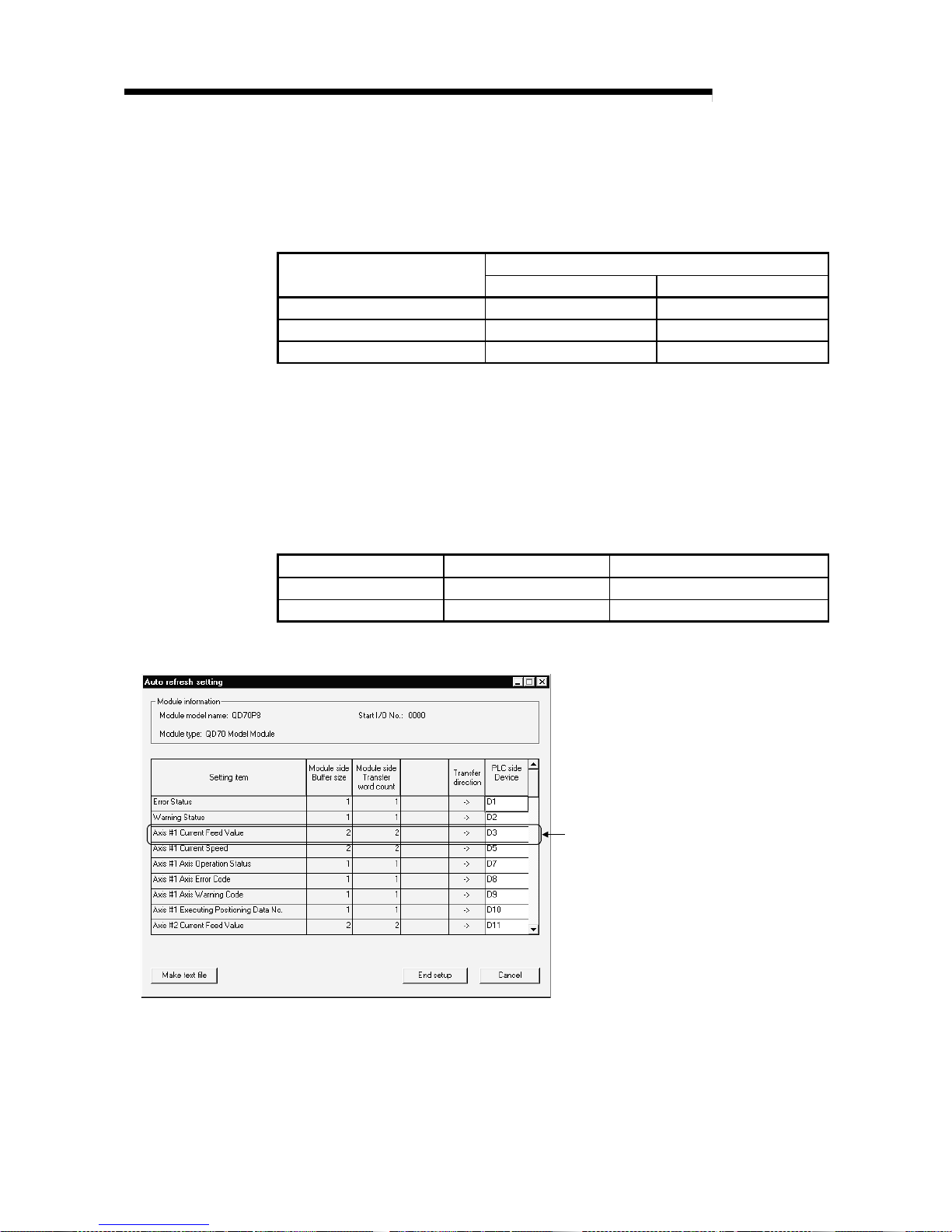

Intelligent function module parameters

Perform PLC write of the intelligent function module parameters to the

control PLC of the QD70 only.

(4) Software packages supported

Correspondence between systems which use a QD70 and software packages

are as shown below.

The GX Developer is necessary when using a QD70.

Software version

GX Developer GX Configurator-PT

If installed in the Q00J/Q00/Q01CPU Version 7 or later

If installed in the Q02/Q02H/Q06H/Q12H/

Q25HCPU

Version 4 or later

Version 1.10L or later

If installed in the Q12PH/Q25PHCPU Version 7.10L or later Version 1.13P or later

If installed in a multiple PLC sy stem Version 6 or later

If installed in a MELSEC N ET/H r e mote I/O

station

Version 6 or later

Version 1.10L or later

Page 27

2 - 4 2 - 4

MELSEC-Q

2 SYSTEM CONFIGURATION

2.4 How to check the function version and the softwar e v ersion

The function version of the QD70 and the software version of the GX Configurator-PT

can be checked in the following methods.

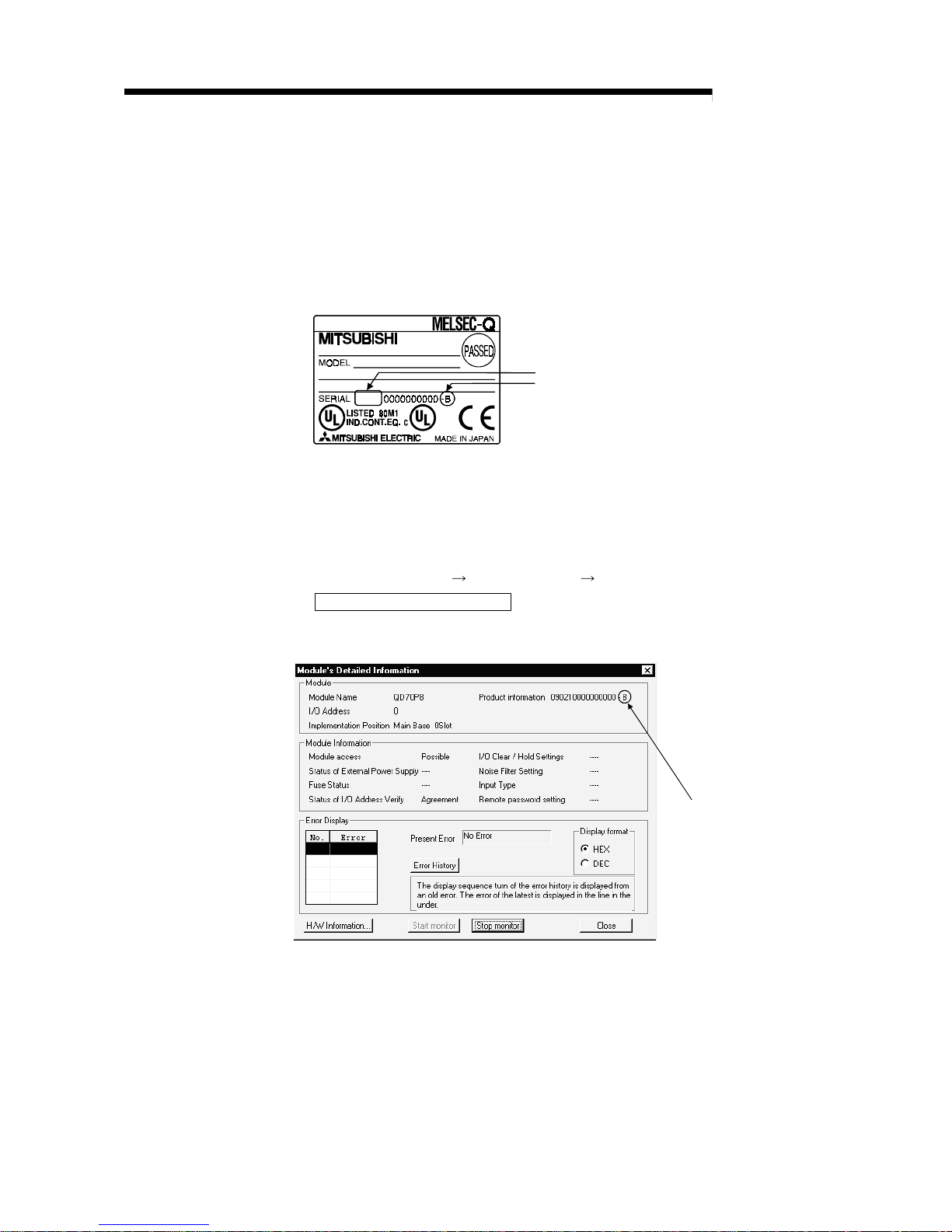

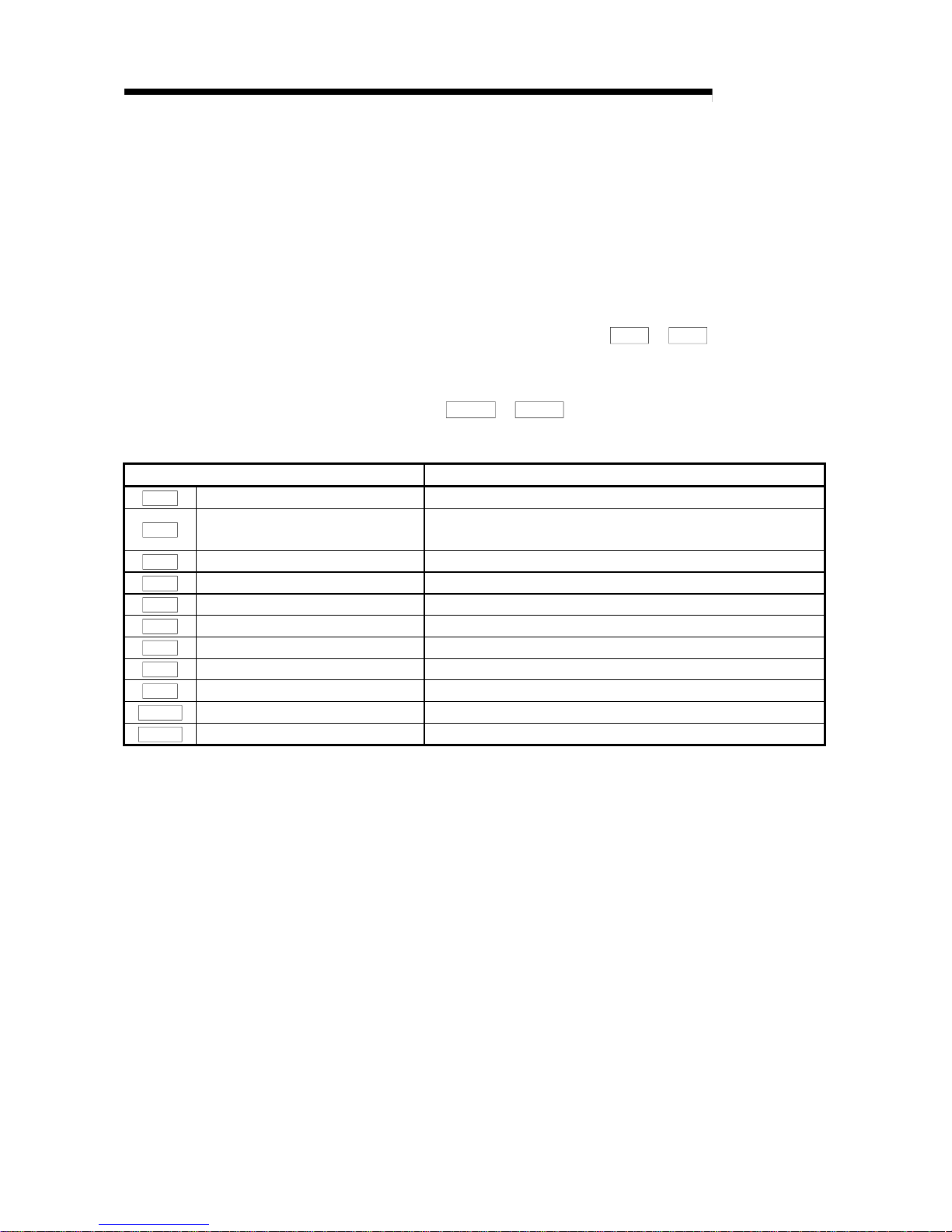

[1] How to check the function version of the QD70

(a) Method using the rated plate on the module side face

Check the alphabet at the end of "SERIAL".

09021

SERIAL No. (The first five digits)

Function version

(b) Method using the peripheral device

Check the alphabet at the end of "Product information" displayed on

System monitor "Module's Detailed Information" of GX Developer.

[Operation of GX Developer]

Choose [Diagnostics] [System monitor] "QD70 module" and choose

Module's Detailed Information

.

<GX Developer display screen>

Function version

Page 28

2 - 5 2 - 5

MELSEC-Q

2 SYSTEM CONFIGURATION

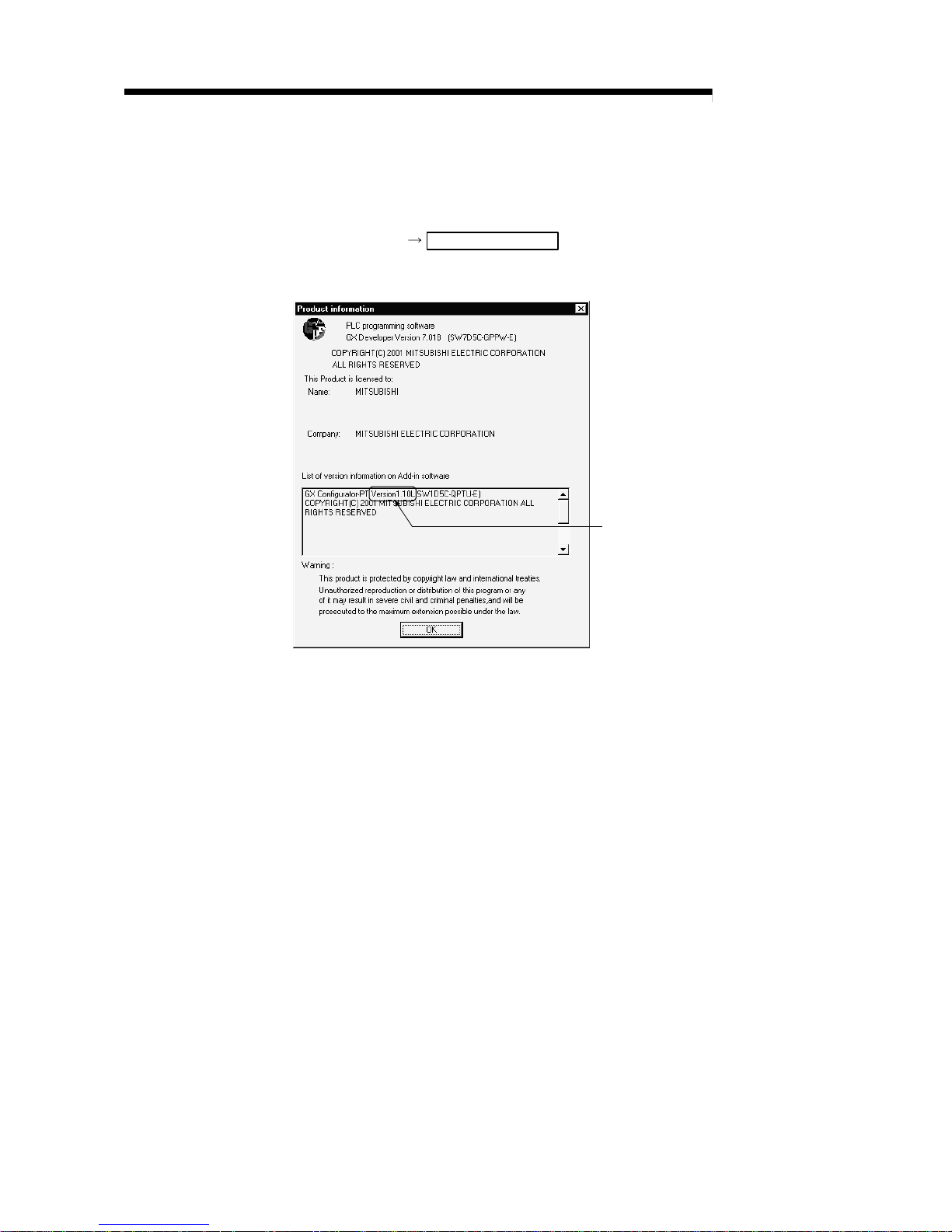

[2] How to check the software version of the GX Configur ator -PT

Check the "Product information" displayed on "Help" of GX Developer.

[Operation of GX Developer]

Choose [Help] Product information

<GX Developer display screen>

Software version

Page 29

3 - 1 3 - 1

MELSEC-Q

3 SPECIFICATIONS AND FUNCTIONS

CHAPTER 3 SPECIFICATIONS AND FUNCTIONS

This chapter describes the performance specifications of the QD70 and the

specifications of the I/O signals transferred to/from the PLC CPU and external device.

For the general specifications of the QD70, refer to the user's manual (hardware) of the

CPU module used.

3.1 Performance specifications

Model

Item

QD70P4 QD70P8

No. of control axes 4 axes 8 axes

Interpolation function No

Control method PTP (Point To Point) control, path control (linear only), speed-position switching control

Control unit pulse

Positioning data

1

10 pieces of data (positioning data No. 1 to 10)/axis

(can be set using GX Configurator-PT or sequence program)

Peripheral device/utility package GX Configurator-PT (option)

Data backup No

Positioning

control method

PTP control : Incremental system/absolute system

Speed-position switching control : Incremental system

Path control : Incremental system/absolute system

Positioning

control range

[Absolute system]

-2147483648 to 2147483647pulse

[Incremental system]

-2147483648 to 2147483647pulse

[Speed-position switching control]

0 to 2147483647pulse

Speed command 0 to 200000pulse/s

Acceleration/

deceleration

processing

Trapezoidal acceleration/deceleration

Positioning

control

Acceleration/

deceleration time

0 to 32767ms

1-axis start 0.1ms

4-axes simultaneous start 0.2ms

Starting time

2

Position control

8-axes simultaneous start 0.4ms

External wiring connection system 40-pin connector

Applicable wire size 0.3mm2 (for use of A6CON1), AWG#24 (for use of A6CON2)

External device connection

connector

A6CON1, A6CON2 (option)

Pulse output method Open collector output

Max. output pulse 200kpps

Max. connection distance between

QD70 and drive unit

2m

Internal current consumption (5VDC) 0.55A 0.74A

External 24V current consumption

(24VDC)

0.065A 0.12A

No. of occupied I/O points 32 points (I/O assignment: Intelligent function module 32 points)

Weight 0.15kg 0.17kg

1

: Positioning data can be started from No.1 only. (Cannot be started from any of No.2 to No.10.)

2

: A delay may occur depending on the operating conditions and starting conditions (control method, bias speed, ACC/DEC time, etc.) of

the other axes.

3

Page 30

3 - 2 3 - 2

MELSEC-Q

3 SPECIFICATIONS AND FUNCTIONS

3.2 List of functions

The following table lists the functions of the QD70.

(Read "SECTION 2 CONTROL DETAILS AND SETTING" for details of the functions.)

Function name Description Reference

Machine OPR control

Mechanically establishes the positioning control start

point using a near-point dog or stopper.

Section

8.2

OPR control

Fast OPR control

Positions a target to the OP address (

Md. 1

Current feed

value) stored in the QD70 using machine OPR control.

Section

8.3

Position control (1-axis linear control)

Positions a target using a linear path to the address set in

the positioning data or to the position designated with the

movement amount.

Section

9.2.2

Speed-position switching control

First, carries out speed control, and then carries out

position control (positioning control with designated

address or movement amount) by turning the "speedposition switching signal" ON.

Section

9.2.3

Positioning control

Current value changing

Changes the Current feed value (

Md. 1

) to the address

set in the positioning data.

Section

9.2.4

JOG operation

Outputs a pulse to drive unit while the JOG start signal is

ON.

Chapter

10

Speed limit function

If the command speed exceeds "

Pr. 5

Speed limit value"

during control, this function limits the commanded speed

to within the "

Pr. 5

Speed limit value" setting range.

Section

11.2

Speed change function

This function changes the speed at any point during

speed control of speed-position switching control or

during JOG operation.

Set the new speed in the speed change buffer memory

(

Pr. 7

New speed value), and change the speed with the

Speed change request (

Pr. 6

).

Section

11.3

Software stroke limit function

If a command outside of the upper/lower limit stroke limit

setting range, set in the parameters, is issued, this

function will not execute positioning for that command.

Section

11.4

Acceleration/deceleration processing function

This function adjusts the acceleration/deceleration

processing of control.

Section

11.5

Sub function

Restart function

This function resumes positioning control during a stop of

the axis from where it had stopped.

Section

11.6

External I/O signal logic switching function

This function changes the external I/O signal logic to

match the externally connected device.

It can be changed by making the intelligent function

module switch setting.

Section

12.2

Common function

External I/O signal monitor function

This function monitors the external I/O signal states using

GX Developer.

Section

5.5

Section

12.3

3

Page 31

3 - 3 3 - 3

MELSEC-Q

3 SPECIFICATIONS AND FUNCTIONS

With the "positioning control", whether or not to continuously execute the positioning

data can be set with the "operation pattern". Outlines of the "operation patterns" are

given below.

Da.1

Operation pattern

Description Reference

Positioning termination

When "Positioning termination" is set for the operation pattern

of the started positioning data, only the designated positioning

data will be executed, and then the positioning control will end.

Continuous positioning control

When "continuous positioning control" is set for the operation

pattern of the started positioning data, after the designated

positioning data is executed, the program will stop once, and

then the next following positioning data will be ex ecuted.

Continuous path control

When "continuous path control" is set for the operation pattern

of the started positioning data, the designated positioning data

will be executed, and then without decelerating, the next

following positioning data will be executed.

9.1.2

Page 32

3 - 4 3 - 4

MELSEC-Q

3 SPECIFICATIONS AND FUNCTIONS

3.3 Specifications of input/output signal w ith PLC CPU

3.3.1 List of input/output signals with PLC CPU

The QD70 uses 32 input points and 32 output points for exchanging data with the PLC

CPU.

The input/output signals when the QD70 is mounted in slot No. 0 of the main base unit

are shown below.

Device X refers to the signals input from the QD70 to the PLC CPU, and device Y

refers to the signals output from the PLC CPU to the QD70.

Signal direction: QD70 PLC CPU Signal direction: PLC CPU QD70

Device No. Signal name Device No. Signal name

X0 Module READY Y0 PLC READY

X1 Axis error occurrence Y1

X2 Axis warning occurrence Y2

X3 Y3

X4 Y4

X5 Y5

X6 Y6

X7

Use prohibited

Y7

Use prohibited

X8 Axis 1 Y8 Axis 1

X9 Axis 2 Y9 Axis 2

XA Axis 3 YA Axis 3

XB Axis 4 YB Axis 4

XC Axis 5 YC Axis 5

XD Axis 6 YD Axis 6

XE Axis 7 YE Axis 7

XF Axis 8

BUSY

YF Axis 8

Positioning start

X10 Axis 1 Y10 Axis 1

X11 Axis 2 Y11 Axis 2

X12 Axis 3 Y12 Axis 3

X13 Axis 4 Y13 Axis 4

X14 Axis 5 Y14 Axis 5

X15 Axis 6 Y15 Axis 6

X16 Axis 7 Y16 Axis 7

X17 Axis 8

Start complete

Y17 Axis 8

Axis stop

X18 Axis 1 Y18 Axis 1

X19 Axis 2 Y19 Axis 2

X1A Axis 3 Y1A Axis 3

X1B Axis 4 Y1B Axis 4

X1C Axis 5 Y1C Axis 5

X1D Axis 6 Y1D Axis 6

X1E Axis 7 Y1E Axis 7

X1F Axis 8

Positioning complete

Y1F Axis 8

JOG start

Important

[Y1 to Y7], and [X3 to X7] are used by the system, and cannot be used by the user.

If these devices are used, the operation of the QD70 will not be guaranteed.

Page 33

3 - 5 3 - 5

MELSEC-Q

3 SPECIFICATIONS AND FUNCTIONS

3.3.2 Details of input signal (QD70 PLC CPU)

The ON/OFF timing and conditions of the input signals are shown below.

Device

No.

Signal name Description

X0 Module READY ON: Prepared

OFF: Not

prepared

watch dog

timer error

•

When the PLC READY signal [Y0] turns from OFF to ON, the parameter and the

OPR data setting range is checked. If no error is found, this signal turns ON. (When

the axis error occurrence signal [X1] is ON, this signal does not turn ON if the PLC

READY signal [Y0] is turned from OFF to ON.)

•

When the PLC READY signal [Y0] turns OFF, this signal turns OFF.

•

When a watch dog timer (WDT) error occurs, this signal turns OFF.

•

This signal is used for interlock in a sequence program, etc.

OFF

ON

OFF

ON

PLC READY signal [Y0]

Module READY signal [X0]

X1 Axis error

occurrence

OFF: No error

ON: Error

occurrence

•

This signal turns ON if an error occurs in any of axes 1 to 8, and turns OFF when

"

Cd. 1

Axis error rese t" is set for all axe s.

(Use "

Md. 10

Error status" to confirm the error status of the corresponding axis.)

X2 Axis warning

occurrence

OFF: No warning

ON: Warning

occurrence

•

This signal turns ON if a warning occurs in any of axes 1 to 8, and turns OFF when

"

Cd. 1

Axis error rese t" is set for all axe s.

(Use "

Md. 11

Warning status" to confirm the warning status of the corresponding

axis.)

X8

X9

XA

XB

XC

XD

XE

XF

Axis 1

Axis 2

Axis 3

Axis 4

Axis 5

Axis 6

Axis 7

Axis 8

BUSY OFF: Not BUSY

ON: BUSY

•

This signal turns ON at the start of positioning control, OPR control or JOG operation.

It turns OFF when the "

Da. 7

Dwell time" has passed after positioning control stops.

(This signal remains ON during positioning control.)

•

This signal turns OFF at error or stop.

X10

X11

X12

X13

X14

X15

X16

X17

Axis 1

Axis 2

Axis 3

Axis 4

Axis 5

Axis 6

Axis 7

Axis 8

Start

complete

OFF: Start

incomplete

ON: Start

complete

•

This signal turns ON when the positioning start signal turns ON and the QD70 starts

the positioning control process.

(The start complete signal also turns ON during OPR control.)

OFF

ON

OFF

ON

Positioning start signal [Y8]

Start complete signal [X10]

X18

X19

X1A

X1B

X1C

X1D

X1E

X1F

Axis 1

Axis 2

Axis 3

Axis 4

Axis 5

Axis 6

Axis 7

Axis 8

Positioning

complete

OFF: Positioning

incomplete

ON: Positioning

complete

(Refer to

"Important")

•

This signal turns ON for the time set in "

Pr. 7

Positioning complete signal output

time" from completion of position control of the corresponding axis.

(It does not turn ON if 0 is set in "

Pr. 7

Positioning complete signal output time".)

•

While ON, this signal turns OFF if a positioning control start (including OPR control)

or JOG operation start is made.

•

This signal does not turn ON at the termination of JOG operation.

•

This signal does not turn ON if position control is stopped midway.

Important

: "Position control c o mpl e te" o f the Q D70 re fe r s to th e po i nt w hen th e pu l se ou tp ut fro m

QD70 is completed.

Thus, even if the QD70's positioning complete signal turns ON, the system may continue

operation.

Page 34

3 - 6 3 - 6

MELSEC-Q

3 SPECIFICATIONS AND FUNCTIONS

3.3.3 Details of output signals (PLC CPU QD70)

The ON/OFF timing and conditions of the output signals are shown below.

Device No. Signal name Description

Y0 PLC READY OFF:

PLC READY OFF

ON:

PLC READY ON

(a) This signal notifies the QD70 that the PLC CPU is normal.

•

It is turned ON/OFF with the sequence program.

•

The PLC READY signal is turned ON during positioning

control, OPR control and JOG operation.

(b) When parameters and OPR data are changed, the PLC READY

signal is turned OFF.

(c) The following processes are carried out when the PLC READY

signal turns from OFF to ON.

•

The parameter and OPR data setting range is checked.

•

The module READY signal [X0] turns ON.

(d) The following processes are carried out when the PLC READY

signal turns from ON to OFF.

In these cases, the OFF time should be set to 100ms or more.

•

The module READY signal [X0] turns OFF.

•

The operating axis stops.

Y8

Y9

YA

YB

YC

YD

YE

YF

Axis 1

Axis 2

Axis 3

Axis 4

Axis 5

Axis 6

Axis 7

Axis 8

Positioning start OFF:

Positioning start not

requested

ON:

Positioning start

requested

•

OPR control and positioning control is started.

•

The positioning start signal is valid at the rising edge, and the

operation is started.

•

When the positioning start signal turns ON during BUSY, the

operation starting warning will occur (warning code: 10).

Y10

Y11

Y12

Y13

Y14

Y15

Y16

Y17

Axis 1

Axis 2

Axis 3

Axis 4

Axis 5

Axis 6

Axis 7

Axis 8

Axis stop OFF:

Axis stop not

requested

ON:

Axis stop requested

•

When the axis stop signal turns ON, the OPR control, positioning

control and JOG operation. In these cases, the ON time should be

set to 4ms or mor e.

•

Turning ON the axis stop signal during operation decelerates the

axis to a stop. At this time, "

Md. 4

Axis operation status" changes

from "Deceleration (Axis Stop ON)" to "Stopped".

Y18

Y19

Y1A

Y1B

Y1C

Y1D

Y1E

Y1F

Axis 1

Axis 2

Axis 3

Axis 4

Axis 5

Axis 6

Axis 7

Axis 8

JOG start OFF:

JOG not started

ON:

JOG started

•

When the JOG start signal is ON, JOG operation will be carried

out at the "

JOG. 1

JOG speed". When the JOG start signal turns

OFF, the operation will decelerate and stop. At this time, "

Md. 4

Axis operation status" changes from "Deceleration (JOG Start

OFF)" to "Standby".

•

Set the rotation direction in "

JOG. 4

JOG direction flag". (Refer to

Chapter 10.)

Page 35

3 - 7 3 - 7

MELSEC-Q

3 SPECIFICATIONS AND FUNCTIONS

3.4 Specifications of input/output interfaces w ith exter nal devi ce

3.4.1 Electrical specifications of input/output sig nal s

Input specifications

Signal name

Rated input

voltage/current

Working voltage

range

ON voltage/

current

OFF voltage/

current

Input resistance Response time

5VDC/18mA 4.5 to 5.5VDC

2.7VDC or more/

5.5mA or more

1.0VDC or less/

0.5mA or less

Approx. 270

Ω

0.1ms or less

Zero signal (PG0)

3µs or less

1ms or mo re

3µs or less

Near-point dog signal

(DOG)

Speed-position switching

signal (CHG)

24VDC/5mA 19.2 to 26.4VDC

17.5VDC or

more/3mA or

more

7VDC or less/

0.9mA or less

Approx. 6.8k

Ω

1ms or less

Output specifications

Signal name

Rated load

voltage

Working load

voltage range

Max. load

current/rush

current

Max. voltage

drop at ON

Leakage current

at OFF

Response time

•

Set the pulse output mode and pulse output logic selection in "intelligent function module switch setting"

(Refer to Section 5.6).

•

The following are the relationships between pulse outputs depending on the "pulse output mode" and "pulse

output logic selection".

Pulse output logic selection

Positive logic Negative logic

Pulse output

mode

Forward run Reverse run Forward run Reverse run

CW

CCW

PULSE

SIGN

High Low

Low High

The table next page shows the rising/falling edge time and duty ratio.

tr

OFF

tf

ON

Pulse output

(CW/PULSE/A phase)

Pulse sign

(CCW/SIGN/B phase)

5 to 24VDC 4.75 to 30VDC

50mA/1 point/

200mA 10ms or

less

0.5VDC (TYP) 0.1mA or less —

Deviation counter clear

(CLEAR)

5 to 24VDC 4.75 to 30VDC

0.1A/1 point/0.4A

10ms or less

1VDC (TYP)

2.5VDC (MAX)

0.1mA or less

2ms or less

(resistance load)

Page 36

3 - 8 3 - 8

MELSEC-Q

3 SPECIFICATIONS AND FUNCTIONS

: Pulse rising/falling edge time (Unit for "tr" and "tf": µs, unit for "Duty": %)

... When ambient temperature is room temperature.