Mitsubishi Electric PWFY-P-NMU-E-AU, PWFY-P-NMU-E-BU Engineering Manual

PWFY-1PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

PWFY-P-NMU-E-BU/-AU

1. GENERAL DESCRIPTION .................................................................................................................................... PWFY-2

2. SPECIFICATIONS ................................................................................................................................................. PWFY-3

3. EXTERNAL DIMENSIONS .................................................................................................................................... PWFY-6

4. CENTER OF GRAVITY .........................................................................................................................................PWFY-8

5. ELECTRICAL WIRING DIAGRAMS ...................................................................................................................... PWFY-9

6. REFRIGERANT CIRCUIT DIAGRAMS ...............................................................................................................PWFY-11

7. SOUND PRESSURE LEVELS AND NC CURVES .............................................................................................PWFY-12

8. VIBRATION LEVELS ........................................................................................................................................... PWFY-13

9. CAPACITY TABLES .............................................................................................................................................PWFY-14

9-1. Correction by Temperature ........................................................................................................................PWFY-14

9-2. Water Pressure Drop ................................................................................................................................. PWFY-24

10. OPTIONAL PARTS .............................................................................................................................................. PWFY-25

11. SYSTEM DESIGN ............................................................................................................................................... PWFY-26

11-1. Electrical Work .......................................................................................................................................... PWFY-26

11-2. M-NET Control ..........................................................................................................................................PWFY-27

11-3. Installation .................................................................................................................................................PWFY-32

HYDRONIC HEAT EXCHANGER UNITS

PWFY-2

PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

1. GENERAL DESCRIPTION

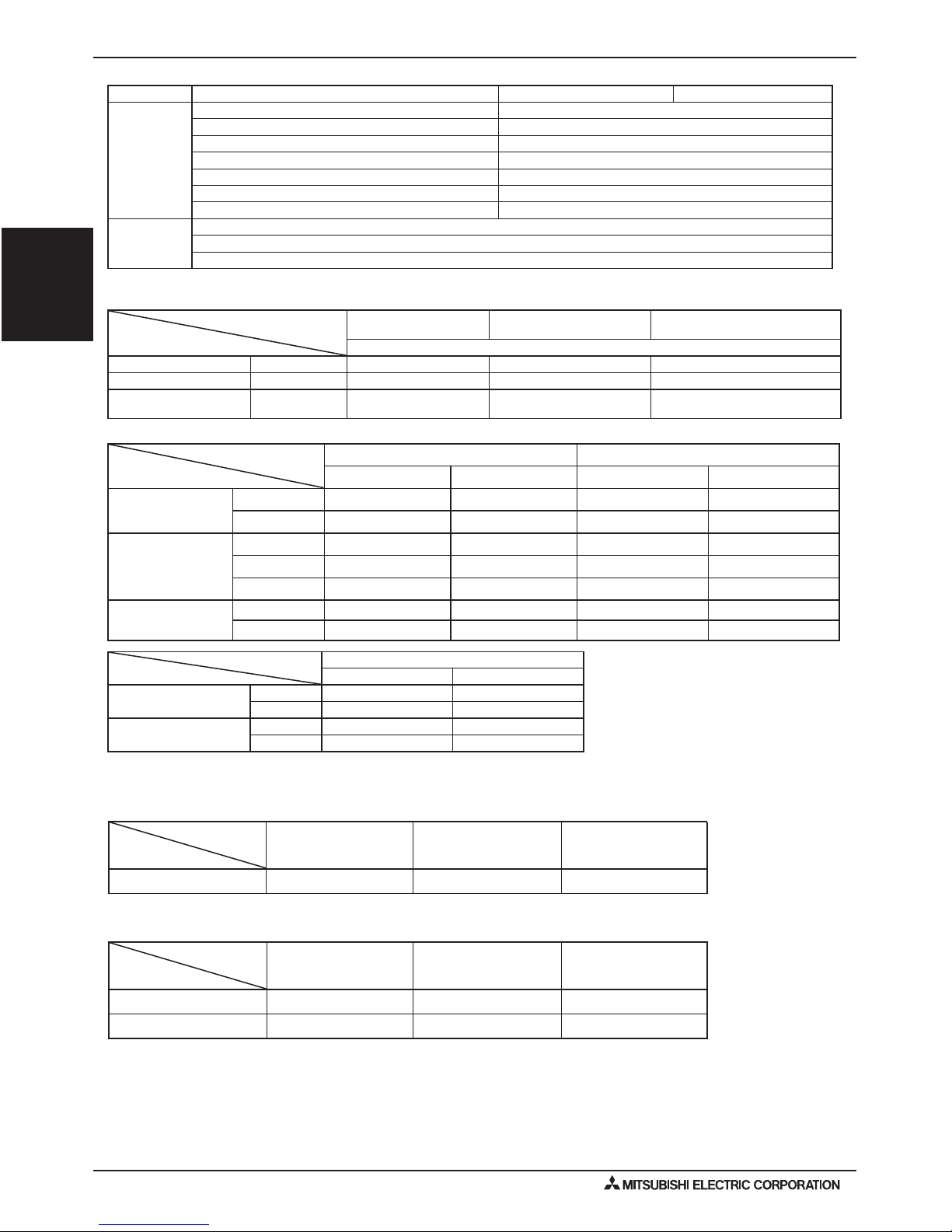

Unit Conguration

50 to 100%R2/WR2 series

PWFY with

standard indoor units

Only standard

indoor units

50 to 150% 50 to 150%

Only PWFY

<PWFY-P36NMU-E-BU>

50 to 100%R2/WR2 series

PWFY with

standard indoor units

Only standard

indoor units

50 to 150% 50 to 150%

Only PWFY

<PWFY-P36,P72NMU-E-AU>

50 to 100%Y/H2i/WY series

50 to 130% 50 to 130%

Model PWFY-P36NMU-E-BU PWFY-P36NMU-E-AU PWFY-P72NMU-E-AU

Outdoor unit

- PUHY-P*T(S)HMU-A(-BS)/PUHY-P*Y(S)HMU-A(-BS)

- PUHY-P*T(S)JMU-A(-BS)/PUHY-P*Y(S)JMU-A(-BS)

- PUHY-HP*T(S)JMU-A(-BS)

- PQHY-P*T(S)HMU-A/PQHY-P*Y(S)HMU-A

PURY-P*T(S)HMU-A(-BS)/PURY-P*Y(S)HMU-A(-BS) PURY-P*T(S)HMU-A(-BS)/PURY-P*Y(S)HMU-A(-BS)

PURY-P*T(S)JMU-A(-BS)/PURY-P*Y(S)JMU-A(-BS) PURY-P*T(S)JMU-A(-BS)/PURY-P*Y(S)JMU-A(-BS)

PQRY-P*T(S)HMU-A/PQRY-P*Y(S)HMU-A PQRY-P*T(S)HMU-A/PQRY-P*Y(S)HMU-A

BC

Controllers

BC Controllers: CMB-P104,105,106,108,1010,1016NU-G

Main BC Controllers: CMB-P108,1010,1013, 1016-GA / CMB-P1016NU-HA

Sub BC Controllers: CMB-P104,108NU-GB / CMB-P1016NU-HB

Operation Temperature Range

PWFY-P36NMU-E-BU

Only PWFY

PWFY with

standard indoor unit

Only standard indoor units

Heating (WB)

Inlet water temperature R2/WR2 series 50 to 160°F (10 to 71°C) 50 to 160°F (10 to 71°C) ―

Outdoor temperature R2 series -4 to 90°F (-20 to 32°C) -4 to 90°F (-20 to 32°C) -4 to 60°F (-20 to 15.5°C)

Circulating Water

temperature

WR2 series 50 to 113°F (10 to 45°C) 50 to 113°F (10 to 45°C) 50 to 113°F (10 to 45°C)

PWFY-P36, 72NMU-E-AU

Connectable outdoor unit capacity range

Only standard indoor units

Cooling (DB) Heating (WB)

Outdoor temperature

R2 series

23 to 109°F(-5 to 43°C) -4 to 60°F(-20 to 15.5°C)

Y series

23 to 109°F(-5 to 43°C) -4 to 60°F(-20 to 15.5°C)

Circulating Water

temperature

WR2 series 50 to 113°F (10 to 45°C) 50 to 113°F (10 to 45°C)

WY series 50 to 113°F (10 to 45°C) 50 to 113°F (10 to 45°C)

Only PWFY PWFY with standard indoor units

Cooling Heating Cooling Heating

Inlet water temperature

R2/WR2 series

50 to 95°F (10 to 35°C) 50 to 105°F (10 to 41°C) 50 to 95°F (10 to 35°C) 50 to 105°F (10 to 41°C)

Y/H2i/WY series

50 to 95°F (10 to 35°C) 50 to 105°F (10 to 41°C) 50 to 95°F (10 to 35°C) 50 to 105°F (10 to 41°C)

Outdoor temperature

R2 series

23 to 115°F (-5 to 46°C) -4 to 90°F(-20 to 32°C) 23 to 115°F (-5 to 46°C) -4 to 90°F(-20 to 32°C)

Y series

23 to 115°F(-5 to 46°C) -4 to 60°F(-20 to 15.5°C) 23 to 115°F(-5 to 46°C) -4 to 60°F(-20 to 15.5°C)

H2i series

23 to 109°F(-5 to 43°C) -13 to 60°F(-25 to 15.5°C) 23 to 109°F(-5 to 43°C) -13 to 60°F(-25 to 15.5°C)

Circulating Water

temperature

WR2 series 50 to 113°F (10 to 45°C) 50 to 113°F (10 to 45°C) 50 to 113°F (10 to 45°C) 50 to 113°F (10 to 45°C)

WY series 50 to 113°F (10 to 45°C) 50 to 113°F (10 to 45°C) 50 to 113°F (10 to 45°C) 50 to 113°F (10 to 45°C)

PWFY-3PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

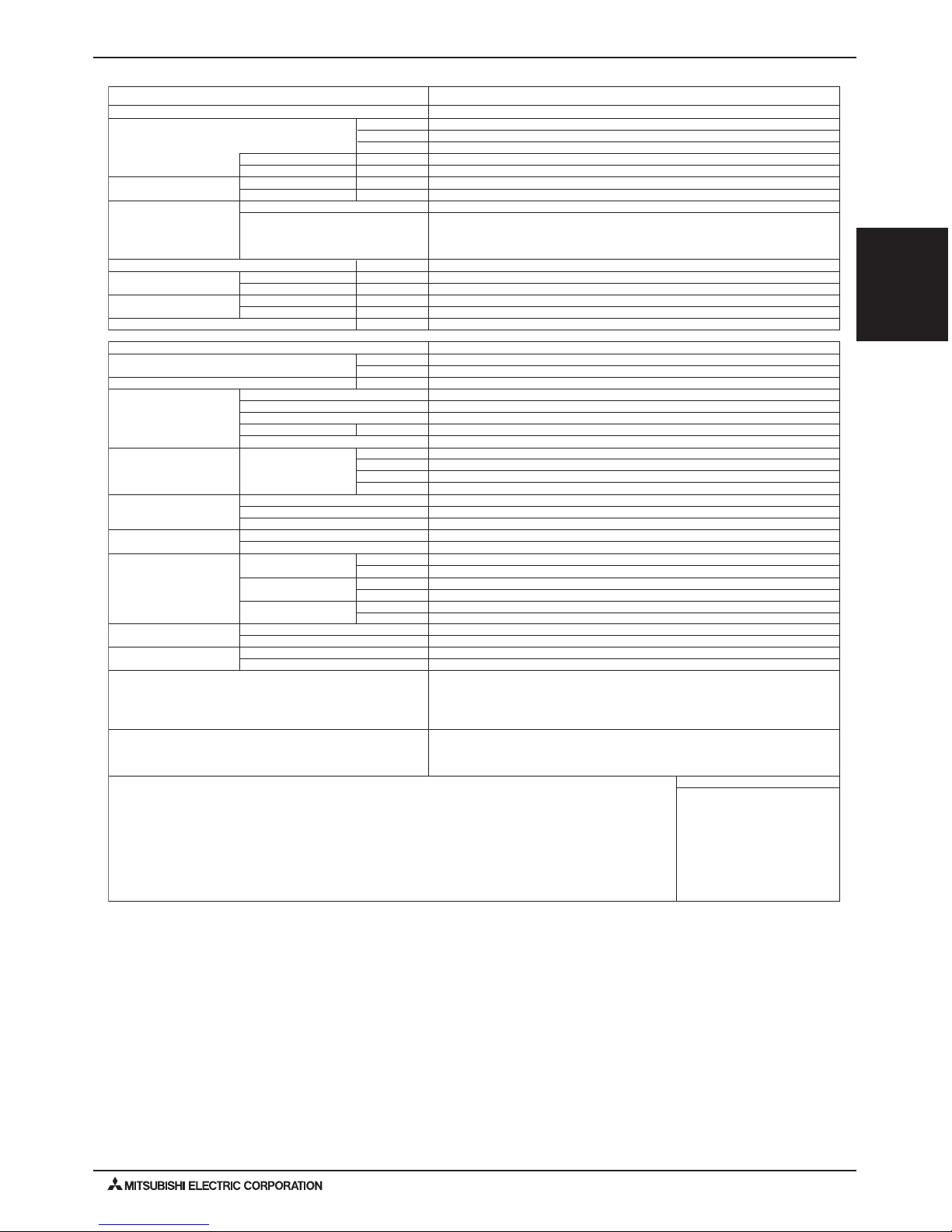

2. SPECIFICATIONS

Model

Power source

kWHeating capacity

kcal / h(Nominal )

BTU / h

kW

A

W.B

dB<A>

in.(mm)

in.(mm)

in.(mm)

in.(mm)

in.(mm)

mm

in.

lbs(kg)

kW

-

Power input

Liquid

Gas

Current input

Outdoor temp.

Inlet Water temp.

Total capacity

Temp. range of

heating

Connectable

outdoor unit Model / Quantity

Sound pressure level (measured in anechoic room)

Diameter of

refrigerant pipe

Diameter of

water pipe

Field drain pipe size

External dimension H × W × D

Net weight

Compressor

Maker

Type

Starting method

Motor output

Circulating water

Range

Protection on Internal circuit

(R134a)

High pressure protection

Inverter circuit (COMP)

Compressor

Type × original chargeRefrigerant

Control

R410ADesign pressure

R134a

Water

ExternalDrawing

Standard attachment

Optional parts

Remark

Note:

*1 Nominal heating conditions

Outdoor Temp. : 47°FDB / 43°FWB (8.3°CDB/6.1°CWB)

kcal = kW x 860

BTU/h = kW x 3,412

cfm = m

3

/min x 35.31

G(us) = L × 0.2642

lbs = kg / 0.4536

psi = MPa×145.038

Pipe length : 7.6 m (25 ft)

Level difference : 0m (0ft)

Inlet water Temp 149°F (65°C) Water flow rate 2.15m

3

/h (555G/h)

* Due to continuing improvement, the above specifications may be subject to change without notice. * Install the unit in an environment where the

wet bulb Temp. will not exceed 90°F (32°C).

* The unit is not designed for outside installations.

* Please don't use steel for the water piping material. * The water circuit must use the closed circuit.

* Please do not use it as a drinking water. Discharge water from unit is not potable. Do not connect the output directly to a potable system.

* Please always make water circulate or add brine to the circulation water when the ambient temperature becomes 32°F (0°C) or less.

* Please do not use groundwater and well water.

* The specification data is subject

to rounding variation.

Unit converter

Lubricant

Operation volume

Inlet

Outlet

Accessory

Wiring

Document

m

3

/h

G/h

G/min

L/min

MPa

MPa

psi

psi

psi

MPa

1.00

Installation Manual, Instruction Book

800 (785 without legs) × 450 × 300

KE94C344

Inverter

1.0

Over-heat protection, Over-current protection

R134a x ( 2lbs + 7oz) ( 1.1kg )

10,100

11.7

WKB94T460

NONE

44

Strainer, Heat insulation material, 2 × Connector sets, 2 × Washer

PWFY-P36NMU-E-BU

1-phase 208-230V 60Hz

PT3/4 (27.2) Screw

MITSUBISHI ELECTRIC CORPORATION

NEO22

Φ1-1/4 (Φ32)

Inverter rotary hermetic compressor

31-1/2" (30-15/16" without legs) × 17-3/4” × 11-13/16”

133 (60)

PT3/4 (27.2) Screw

12.30 - 11.12

50~100% of outdoor unit capacity

PURY-P*T(S)HMU/Y(S)HMU-A(-BS)

PURY-P*T(S)JMU/P*Y(S)JMU-A(-BS)

PQRY-P*T(S)HMU/-P*Y(S)HMU-A(-BS)

Φ5/8 (Φ15.88) Brazed

-4~90°F (-20~32°C)

Φ3/8 (Φ9.52) Brazed

39,900

50~160°F (10~71°C)

2.48

0.6~2.15

156~555

2.6~9.2

10~35

LEV

601

4.15

522

3.60

High pressure sensor, High pressure switch at 3.60 MPa (522 psi)

Discharge thermo protection, Over-current protection

145

Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and

other items shall be referred to the Installation Manual.

PWFY-4

PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

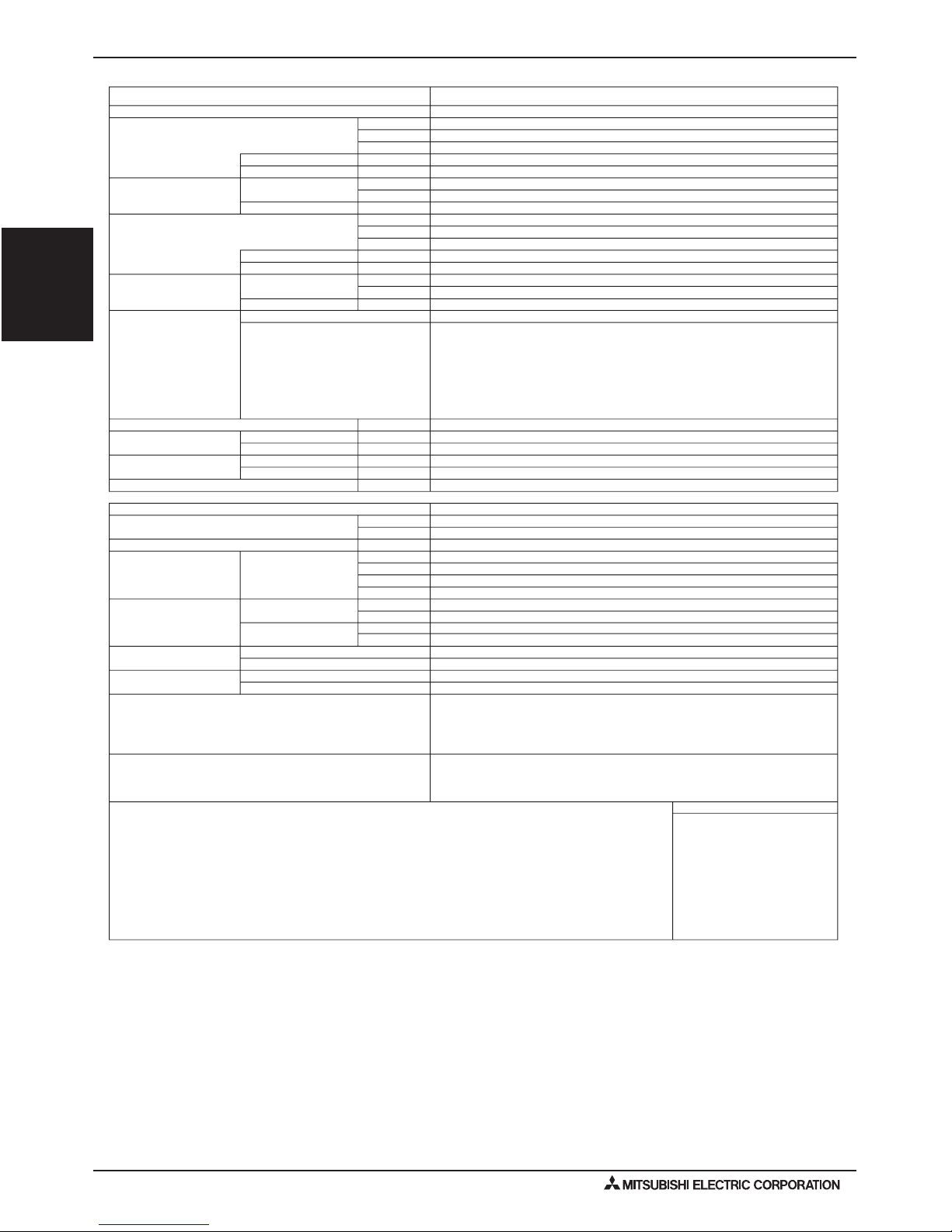

2. SPECIFICATIONS

Model

Power source

kW*1Heating capacity

kcal / h

BTU / h

kW

A

W.B

*1(Nominal)

*1

Power input

Current input

Outdoor temp.

Temp. range of

W.B

-

heating

Inlet Water temp.

kW*2Cooling capacity

kcal / h

BTU / h

kW

A

D.B

*2(Nominal)

*2

Power input

Current input

Outdoor temp.Temp. range of cooling

D.B

-Inlet Water temp.

Total capacity

Model / Quantity

Connectable

outdoor unit

Sound pressure level (measured in anechoic room) dB<A>

in.(mm)

in.(mm)

Diameter of

refrigerant pipe

in.(mm)

in.(mm)

Diameter of

water pipe

in.(mm)

mm

Field drain pipe size

External finish

External dimension H × W × D

in.

lbs(kg)

Net weight

Circulating water

Range

Design pressure

Water

R410A

Drawing

Standard attachment

Optional parts

Remark

Note:

*2 Nominal cooling conditions *1 Nominal heating conditions

Outdoor Temp. : 47°FDB/43°FWB (8.3°CDB / 6.1°CWB) Outdoor Temp. : 95°FDB (35°CDB)

Pipe length : 7.6 m (25 ft)Pipe length : 7.6 m (25 ft)

Level difference : 0m (0ft)Level difference : 0m (0ft)

Inlet water Temp 86°F (30°C)

Water flow rate 2.15m

3

/h (555G/h)

Inlet water Temp 149°F (23°C)

Water flow rate 1.93m

3

/h (498G/h)

* Install the unit in an environment where the

* Due to continuing improvement, the above specifications may be subject to change without notice.

wet bulb Temp. will not exceed 92°F (32°C) * The unit is not designed for outside installations.

* Please don't use steel for the water piping material. * The water circuit must use the closed circuit.

* Please always make water circulate or add the brine to the circulation water when the ambient temperature becomes 32°F (0°C) or less.

Inlet

Outlet

Operation Volume

Liquid

Gas

Accessory

External

Wiring

Document

Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and

other items shall be referred to the Installation Manual.

Unit converter

36,200

50~95°F (10~35°C)

0.015

Φ5/8 (Φ15.88) Brazed

Φ3/8 (Φ9.52) Brazed

PT3/4 (27.2) Screw

Installation Manual, Instruction Book

PT3/4 (27.2) Screw

NO

WKB94T461

0.072 - 0.065

50~100% of outdoor unit capacity

PUHY-P*T(S)HMU/P*Y(S)HMU-A(-BS)

PUHY-P*T(S)JMU/P*Y(S)JMU-A(-BS)

PQHY-P*T(S)HMU/P*Y(S)HMU-A(-BS)

23~109°F (-5~43°C) PURY - series

23~109°F (-5~43°C) PUHY - series

0.6~2.15

2.6~9.2

4.15

145

10~35

156~555

1.00

Strainer, Heat insulation material, 2 × Connector sets , 2 × Washer

Φ1-1/4 (Φ32)

PWFY-P36NMU-E-AU

1-phase 208 - 230 V 60Hz

9,100

10.6

29

11.7

800 (785 without legs) × 450 × 300

KE94C345

601

NONE

10,100

39,900

-4~60°F (-20~15.5°C) PUHY - series

50~105°F (10~41°C)

0.015

0.072 - 0.065

-4~90°F (-20~32°C) PURY - series

31-1/2" (30-15/16" without legs) × 17-3/4” × 11-13/16”

78 (35)

* Please do not use it as a drinking water. Discharge water from unit is not possible. Do not connect the output directly to a potable system.

* Please do not use groundwater and well water.

m3/h

G/h

G/min

L/min

MPa

psi

MPa

psi

kcal = kW x 860

BTU/h = kW x 3,412

cfm = m

3

/min x 35.31

G(us) = L × 0.2642

lbs = kg / 0.4536

psi = MPa×145.038

* The specification data is subject

to rounding variation.

PURY-P*T(S)HMU/Y(S)HMU-A(-BS)

PURY-P*T(S)JMU/P*Y(S)JMU-A(-BS)

PQRY-P*T(S)HMU/-P*Y(S)HMU-A(-BS)

PWFY-5PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

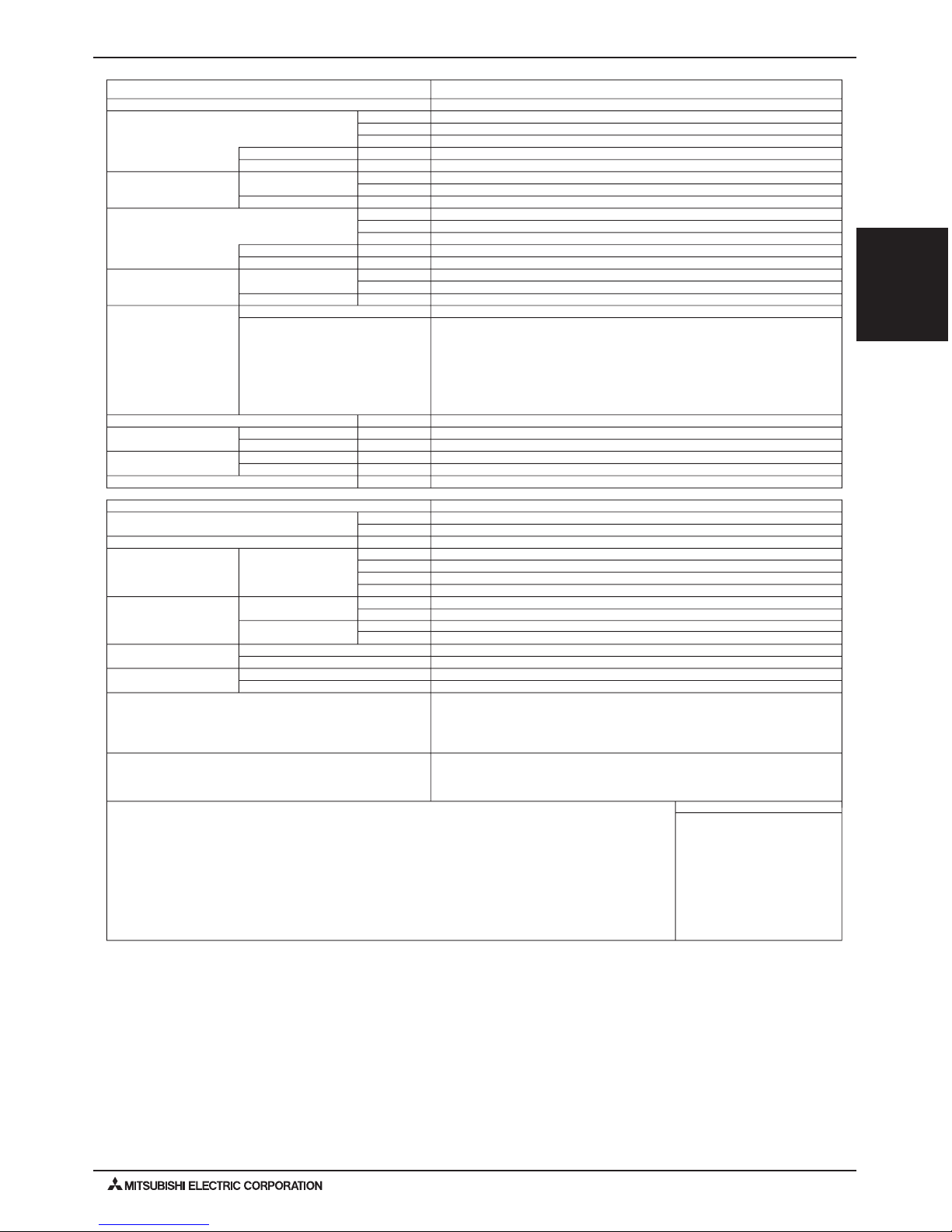

2. SPECIFICATIONS

Model

Power source

kW*1Heating capacity

kcal / h

BTU / h

kW

A

W.B

*1(Nominal)

*1

Power input

Current input

Outdoor temp.

Temp. range of

W.B

-

heating

Inlet Water temp.

kW*2Cooling capacity

kcal / h

BTU / h

kW

A

D.B

*2(Nominal)

*2

Power input

Current input

Outdoor temp.Temp. range of cooling

D.B

-Inlet Water temp.

Total capacity

Model / Quantity

Connectable

outdoor unit

Sound pressure level (measured in anechoic room) dB<A>

in.(mm)

in.(mm)

Diameter of

refrigerant pipe

in.(mm)

in.(mm)

Diameter of

water pipe

in.(mm)

mm

Field drain pipe size

External finish

External dimension H × W × D

in.

lbs(kg)

Net weight

Circulating water

Range

Design pressure

Water

R410A

Drawing

Standard attachment

Optional parts

Remark

Note:

*2 Nominal cooling conditions *1 Nominal heating conditions

Outdoor Temp. : 47°FDB/43°FWB (8.3°CDB / 6.1°CWB) Outdoor Temp. : 95°FDB (35°CDB)

Pipe length : 7.6 m (25 ft)Pipe length : 7.6 m (25 ft)

Level difference : 0m (0ft)Level difference : 0m (0ft)

Inlet water Temp 86°F (30°C)

Water flow rate 4.30m

3

/h (1110G/h)

Inlet water Temp 149°F (23°C)

Water flow rate 3.86m

3

/h (996G/h)

* Install the unit in an environment where the

* Due to continuing improvement, the above specifications may be subject to change without notice.

wet bulb Temp. will not exceed 92°F (32°C) * The unit is not designed for outside installations.

* Please don't use steel for the water piping material. * The water circuit must use the closed circuit.

* Please always make water circulate or add the brine to the circulation water when the ambient temperature becomes 32°F (0°C) or less.

Inlet

Outlet

Operation Volume

Liquid

Gas

Accessory

External

Wiring

Document

Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and

other items shall be referred to the Installation Manual.

Unit converter

72,000

50~95°F (10~35°C)

0.015

Φ3/4 (Φ19.05) Brazed

Φ3/8 (Φ9.52) Brazed

PT 1 ( 34 ) Screw

Installation Manual, Instruction Book

PT 1 ( 34 ) Screw

NO

WKB94T461

0.072 - 0.065

50~100% of outdoor unit capacity

23~109°F (-5~43°C) PURY - series

23~109°F (-5~43°C) PUHY - series

1.2~4.30

5.2~18.4

4.15

145

20~72

312~1110

1.00

Strainer , Connecter , Heat insulation material, 2 × Connector sets , Expansion joint , 2 × Washer

Φ1-1/4 (Φ32)

PWFY-P72NMU-E-AU

1-phase 208 - 230 V 60Hz

18,100

21.1

29

23.4

800 (785 without legs) × 450 × 300

KE94C345

601

NONE

20,100

79,800

-4~60°F (-20~15.5°C) PUHY - series

50~105°F (10~41°C)

0.015

0.072 - 0.065

-4~90°F (-20~32°C) PURY - series

31-1/2" (30-15/16" without legs) × 17-3/4” × 11-13/16”

84 (38)

* Please do not use it as a drinking water. Discharge water from unit is not potable. Do not connect the output directly to a potable system.

* Please do not use groundwater and well water.

m3/h

G/h

G/min

L/min

MPa

psi

MPa

psi

kcal = kW x 860

BTU/h = kW x 3,412

cfm = m

3

/min x 35.31

G(us) = L × 0.2642

lbs = kg / 0.4536

psi = MPa×145.038

* The specification data is subject

to rounding variation.

PURY-P*T(S)HMU/Y(S)HMU-A(-BS)

PURY-P*T(S)JMU/P*Y(S)JMU-A(-BS)

PQRY-P*T(S)HMU/-P*Y(S)HMU-A(-BS)

PUHY-P*T(S)HMU/P*Y(S)HMU-A(-BS)

PUHY-P*T(S)JMU/P*Y(S)JMU-A(-BS)

PQHY-P*T(S)HMU/P*Y(S)HMU-A(-BS)

PWFY-6

PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

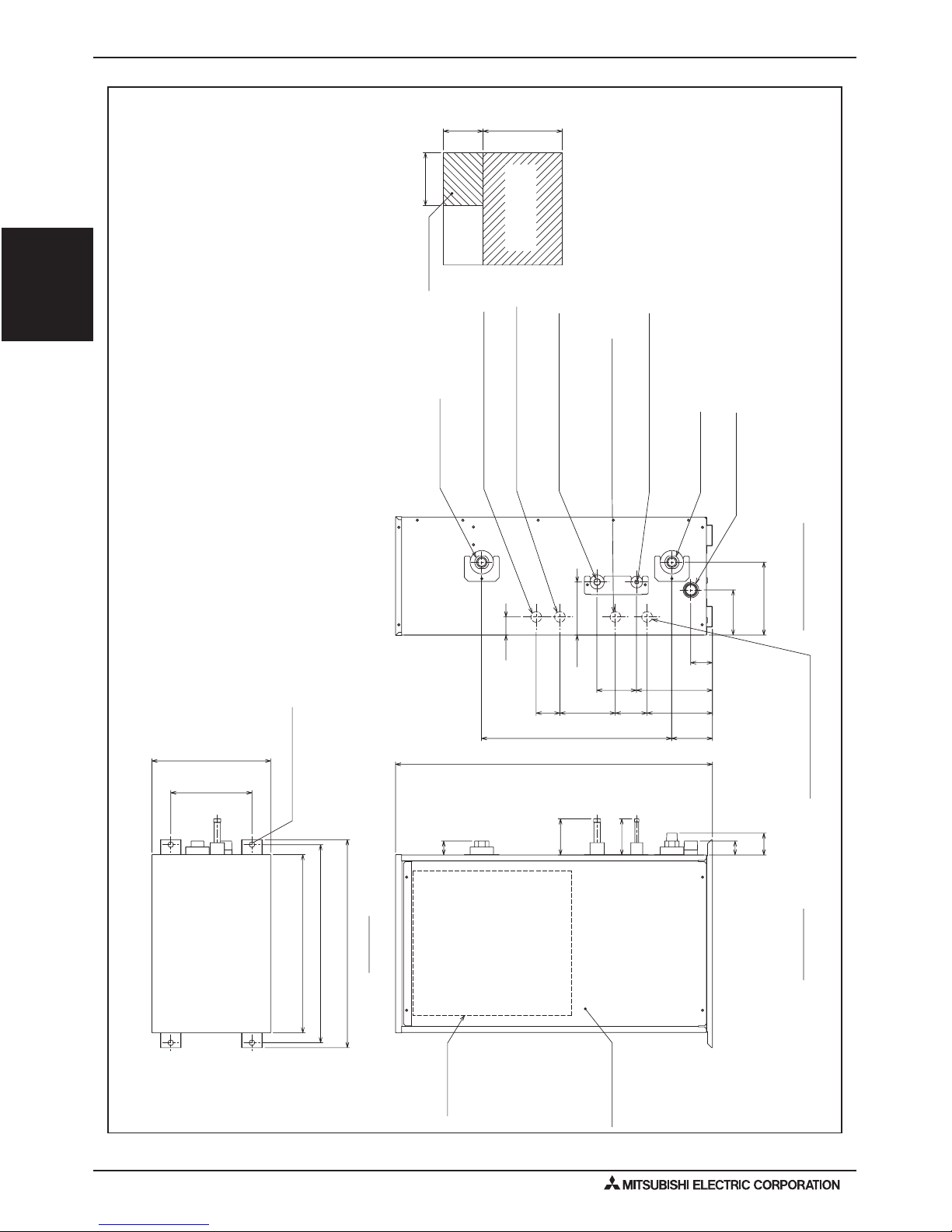

3. EXTERNAL DIMENSIONS

(11-13/16)(23-5/8)

Piping space

(right side)

Top view

Fig. A

Service space

(front side)

300

400(15-3/4)

600

Drain (R1 screw)

Control box

Water outlet

(RC3/4 screw)

ø27(1-3/32) Knockout hole

<Hole for external wiring input>

ø27(1-3/32) Knockout hole

<Hole for external wiring output>

ø27(1-3/32) Knockout hole

<Hole for power supply>

ø27(1-3/32) Knockout hole

<Hole for control wiring>

Service panel

Top view

Right side view

Front view

2X2-ø14(9/16) Hole

Connection pipe of outdoor unit

(Liquid)

ø15.88(5/8) <Brazed>

ø9.52(3/8) <Brazed>

Connection pipe of outdoor unit

(Gas)

Water inlet

(R3/4 screw)

Note 1. Ensure no water or debris can enter the unit through any gaps around

wiring or piping.

2. Ensure adequate service space is right around the unit, according to Fig A.

3. Please always make water circulate or add the brine to the circulation water

when the ambient temperature becomes 0degC(32°F )or less.

4. The unit is not designed for outside installations.

5. Install the unit in an environment where the wet bulb Temp.

will not exceed 32degC(90°F).

6. The water circuit must use the closed circuit.

7. Please don't use the steel material for the water piping material.

8. Connect the strainer which is put as accessory to water inlet pipe.

<Accessories>

• Y-type strainer (RC3/4) ················ 1pc.

•

Heat Insulation material ·············· 1pc.

•

Connector set ······························ 2set

•

Washer ········································ 2pcs.

(4-1/32)

(3-15/16)

(3-5/32) (5-17/32) (2-3/8)

(6-1/2)

(2-5/32)

(7-17/32)

102

(1-13/32)

(1-13/16)

(5-9/32)

(4-1/2)

(7-1/4)

(2-3/16)

525(20-11/16)

55

35(1-13/32)

35

91(3-19/32)

91(3-19/32)

134

480(18-29/32)

46

60

140

100

191

80

165

54

184

114

(Mounting pitch)

(Mounting pitch)

205(8-3/32)

800(31-1/2)

300(11-13/16)

450(17-23/32)

500(19-11/16)

<Unit:mm(in)>

PWFY-P36NMU-E-BU

PWFY-7PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

3. EXTERNAL DIMENSIONS

(23-5/8)

(11-13/16)

300

600

Fig. A

Service space

(front side)

Top view

400(15-3/4)

Piping space

(right side)

Drain (R1 screw)

ø9.52(3/8) <Brazed>

P72:Use the Expansion joint of accessories

ø27(1-3/32) Knockout hole

<Hole for control wiring>

ø27(1-3/32) Knockout hole

<Hole for power supply>

Water outlet

(RC3/4 screw)

Water inlet

(R3/4 screw)

P36:ø15.88(5/8) <Brazed>

P72:ø19.05(3/4) <Brazed>

ø27(1-3/32) Knockout hole

<Hole for external wiring input>

ø27(1-3/32) Knockout hole

<Hole for external wiring output>

Connection pipe of outdoor unit

(Gas)

Connection pipe of outdoor unit

(Liquid)

Front view

Right side view

Control box

Service panel

Top view

2X2-ø14(9/16) Hole

<Accessories>

• Y-type strainer (RC3/4) ················ 1pc.

•

Heat Insulation material ·············· 1pc.

•

Connector set ······························ 2set

•

Washer ········································ 2pcs.

•

Expansion joint(P72) ··················· 2pcs.

[From RC3/4 to RC1]

(3-15/16)

(8-1/8)

(4-1/2)

(2-3/8)

(3-5/32)

(5-17/32)

(5-9/32)

(1-13/16)

(7-17/32)

(6-1/2)

(2-5/32)

(4-1/32)

(1-13/32)

(2-3/16)

525(20-11/16)

91(3-19/32)

91(3-19/32)

35(1-13/32)

55

35

480(18-29/32)

102

206

134

114

100

191

46

6014080

165

54

(Mounting pitch)

450(17-23/32)

300(11-13/16)

(Mounting pitch)

205(8-3/32)

800(31-1/2)

500(19-11/16)

<Unit:mm(in)>

Note 1. Ensure no water or debris can enter the unit through any gaps around

wiring or piping.

2. Ensure adequate service space is right around the unit, according to Fig A.

3. Please always make water circulate or add the brine to the circulation water

when the ambient temperature becomes 0degC(32°F )or less.

4. The unit is not designed for outside installations.

5. Install the unit in an environment where the wet bulb Temp.

will not exceed 32degC(90°F).

6. The water circuit must use the closed circuit.

7. Please don't use the steel material for the water piping material.

8. Connect the strainer which is put as accessory to water inlet pipe.

PWFY-P36,72NMU-E-AU

PWFY-8

PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

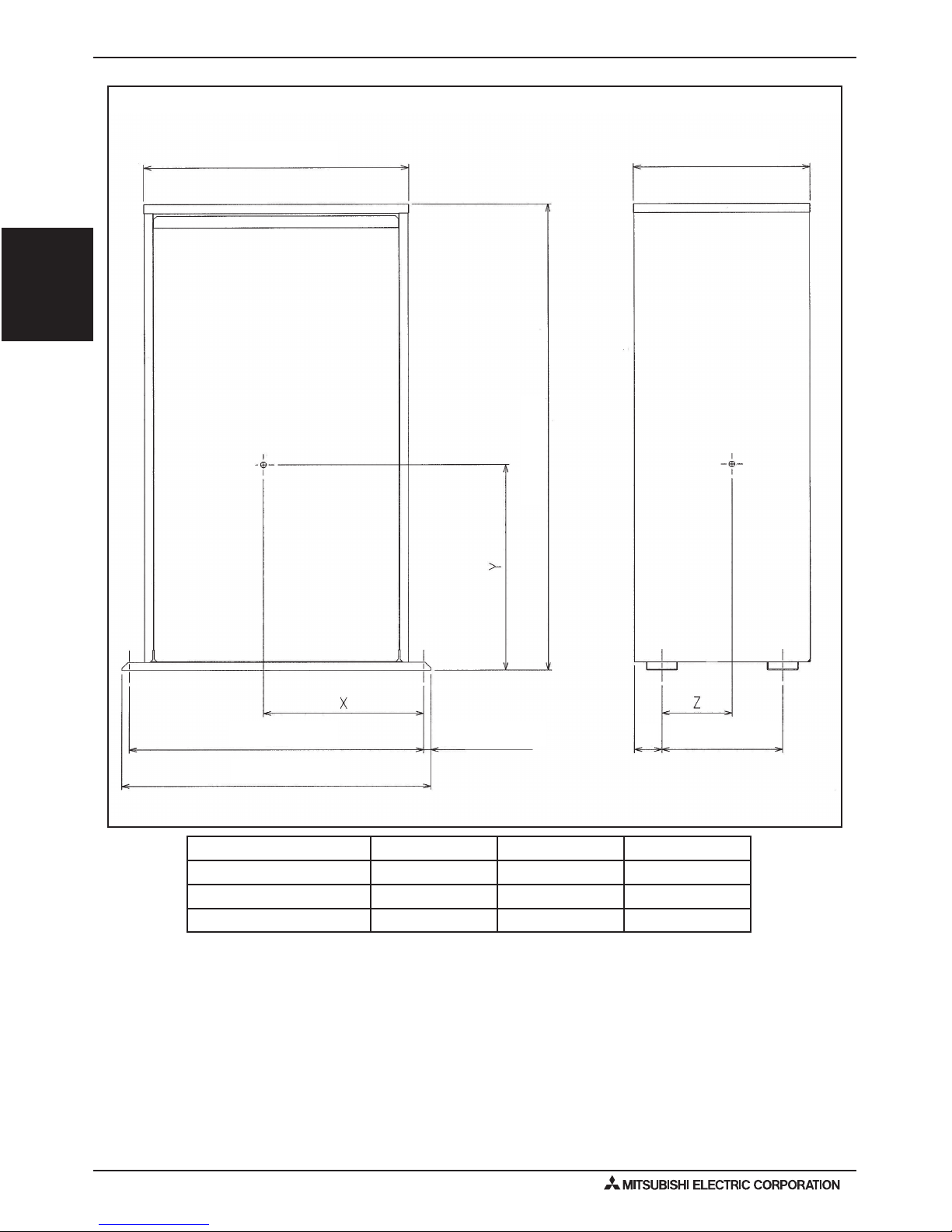

4. CENTER OF GRAVITY

17-23/32 (450) 11-13/16 (300)

31-1/2 (800)

17/32 (13)19-11/16 (500)

20-11/16 (525)

8-3/32 (205)

1-7/8 (47)

in. (mm)

Model X Y Z

PWFY-P36NMU-E-BU 10-23/32 (272) 13 (355) 4-11/16 (119)

PWFY-P36NMU-E-AU 11-13/32 (289) 13-5/8 (346) 4-1/16 (103)

PWFY-P72NMU-E-AU 10-29/32 (277) 13-11/16 (347) 3-29/32 (99)

PWFY-9PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

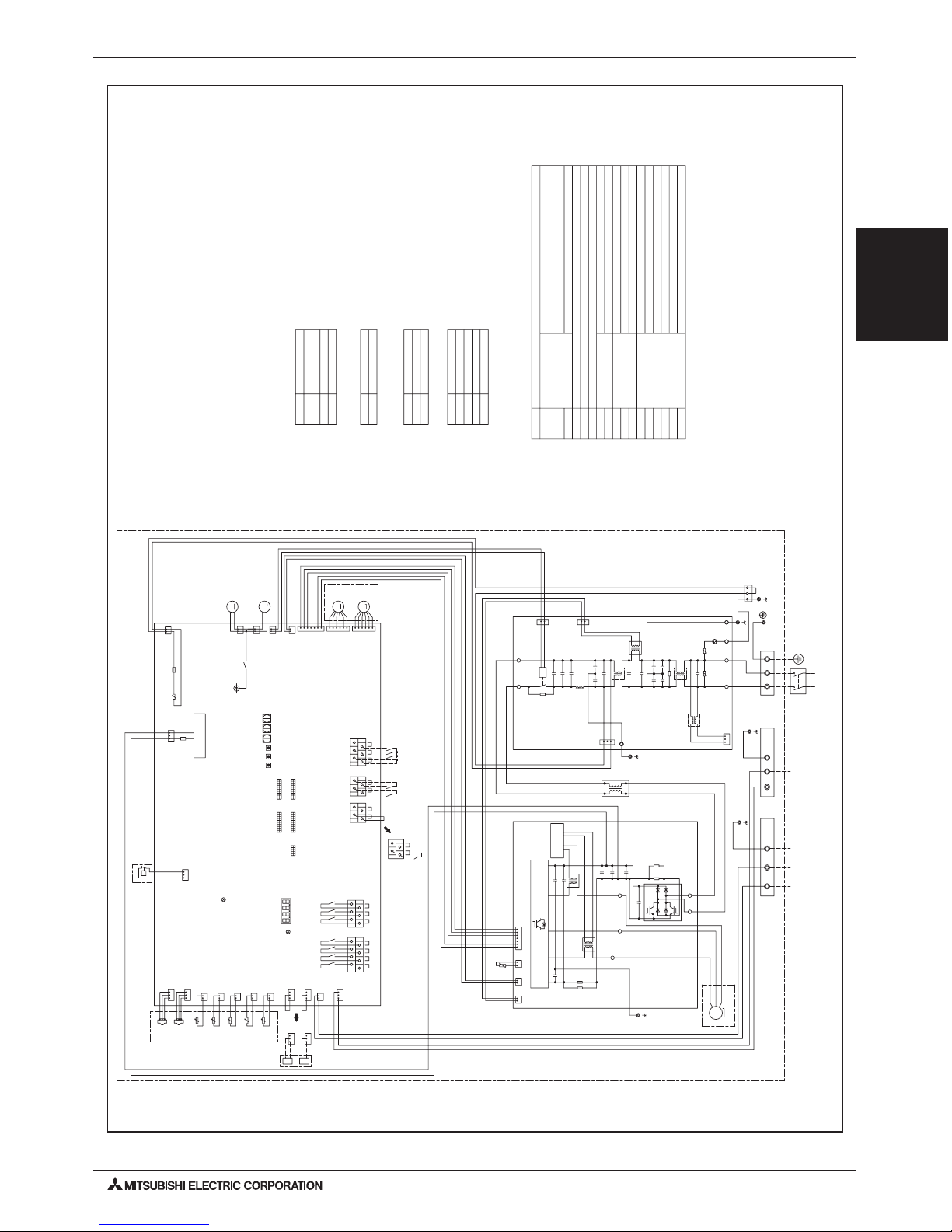

5. ELECTRICAL WIRING DIAGRAMS

gray

2

1

gray

black

To outdoor unit/

BC controller

To MA remote

controller

Power Supply

~208/230V

60Hz

3

2

1

blue

red

yellow/green

bluered

CN4

63LS

CN63HS

1

1

3

2

2

3

THHS

12

CN63LS

123

TH8

2

1

CN403

red

TH6

1

2

CN404

black

31

CT1

Moter

3~

CYN

RS4

MS

RS3

(Compressor)

CN3A

blue

U

t

t

t

t

t

red

yellow

TH22

CN405

IPM

W

V

U

black

1

63HS

7

2

1

3

1

2

CN3

2

1

t

CN401

CN2

256

red

CN5

2

1

TH11

1

2

TH13

2

1

white

CN402

green

red

5

6

RS1

black

2

CN52C

R1

LO

U

CNAC2

red

2

CN5

1

1

2

red

blue red

LEV2W

M

M

LI

24V

blue

+

CB3

Z2

1

U

CT1

LEV1W

1

CN2

63H1

6

5

CNAC

2

red

1

CX2

L1

CN506A

L3

L2 G

6

5

N

CN-E1

CN631

DSA

pink

E2

3

1

E1

432

1

CY4

P

CY3

31

L4

Z1

NI

CB1

+

1

TB2

CN661

2L23

X506

W

4

CN4

blue

U

CN52C

1

2

+

CX3

INV control

circuit

PFC

E3

1

L1

2

M

ZNR01

ACL

CY1CY2

CT2

Noise

Filter

red

Fan motor

1

3

(DC)

CX5

CYP

CIS

CX6

1

2

7

V

yellow

LED3:Lit when powered

INV Board

Control Board

CB2

(DC)

CY6

S

CX4

R

CNAC1

M

CNLVA

NO

Fan motor

3

1

2

RS2

CY5

P

CNLVB

blue

CX1

CX7

CN506B

CPS

+

RS

F01

AC250V

6.3A T

F631

DC700V

4A T

Power

Supply circuit

bluered

TB5

M1 M2 S(SHIELD)

S(SHIELD)

TB15

yellow

purple

black

orange

green

red

black

white

green

gray

52C

1

2

CN2M

blue

31

*4

*8

IN2

TB141B

TB142B

IN6

COM+

OUT5

TB142C

OUT7

OUT6

X515 X517

X516

IN8

IN5IN7

TB142A

X514

OUT2

X512

X511 X513

OUT1 OUT3

OUT4

TB141A

*5 *6 *7

IN3 IN4

COM+

LED4:Remote controller

when powered

At factory

shipment

At factory

shipment

SWU1

10

SW1

5

ON

OFF

1

Unit address setting(SWU1,SWU2)

Connection No.(SWU3)

LED1 Display setting(SW2)

Function setting(SW1,SW3,SW4)

SWP3

SW5

SWP1

SWU3

SWP2

SWU2

OFF

ON

1

10

SW4

OFF

ON

110

LED1

OFF

ON

1

SW3

OFF

ON

110

SW2

IN1

gray

CN421

black

31

CN422

blue

IN1

IN2

31

CN421

4-20mA

4-20mA

black

31

CN422

blue

2

2

2

2

AC reactor

Pressure

switch

High pressure switch

(High pressure protection for the booster unit)

Discharge pressure

Low pressure

TB2

LEV1W

TB5

LEV2W

TB15

TH11

OUT1

IN1

IN3

COM+

IN4

IN5

IN6

IN7

TH13

OUT2

TH22

OUT3

TH6

OUT4

TH8

CT1,CT2

ACL

THHS

Magnetic relay(main circuit)

Current sensor(AC)

Explanation

Function

Function

Function

Function

Terminal

block

Linear

expansion valve

Power supply

BC controller/outdoor unit

Outdoor unit/BC controller

Booster unit

MA remote controller

Compressor discharge temp

Operation ON/OFF

Pump interlock

Connection demand

Common

Operation ON/OFF

Hot water/Heating

Heating ECO

Anti-freeze

Evaporator outlet temp

Defrost

liquid pipe temp

Compressor

water inlet temp

Error signal

water outlet temp

IGBT temp

Pressure

sensor

Symbol

Symbol

Symbol

Symbol

Symbol

63H1

*4 TB141A(output)

*5 TB142A(input)

*6 TB142B(input)

*7 TB142C(input)

*8. Use copper supply wires.

63HS

63LS

Thermistor

52C

<Symbol explanation>

<HIGH VOLTAGE WARNING>

· Control box houses high-voltage parts.

Before inspecting the inside of the control box, turn off the power,

keep the unit off for at least 10 minutes, and confirm that the voltage

CN631 on Control Board has dropped to DC20V or less.

<CAUTION FOR INSTALLATION>

· Prior to installation, read the Installation Manual carefully.

*1. Single-dotted lines indicate wiring not supplied with the unit.

*2. Dot-dash lines indicate the control box boundaries.

*3. Faston terminals have a locking function.

Make sure the terminals are securely locked in place after insertion.

Press the tab on the terminals to removed them.

°

°

°

°

°

°

PWFY-P36NMU-E-BU

PWFY-10

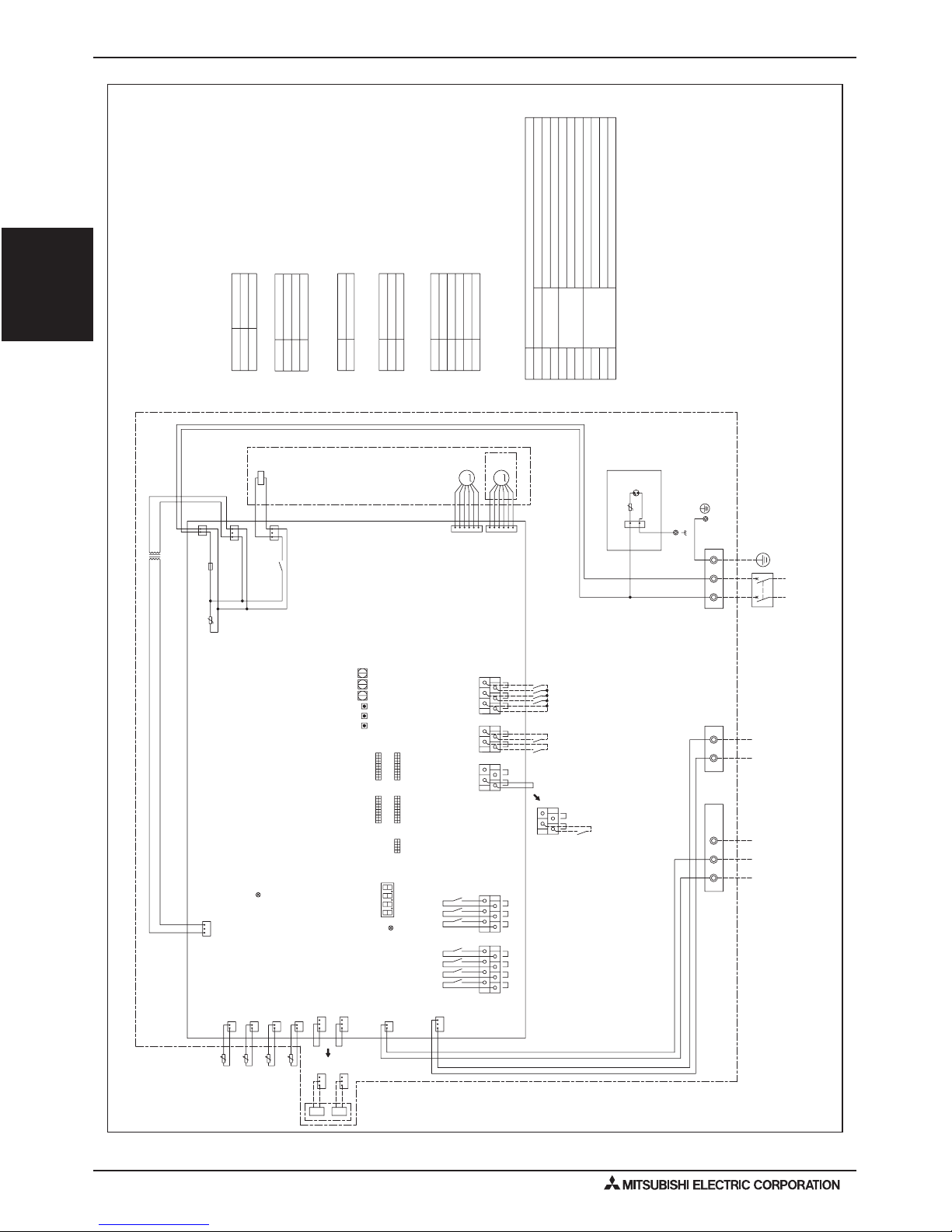

PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

TH8

TH6

TH23

blue

CN2M

2

1

2

1

CN402

green

2

1

CN403

red

1

2

CN404

black

yellow

CN405

t

TH22

1

2

S(SHIELD)

2

M2

1

M1

To MA remote

controller

To outdoor unit/

BC controller/

Power Supply

~208/230V

60Hz

L2 G

L1

Unit address setting(SWU1,SWU2)

Connection No.(SWU3)

LED1

TB15TB5

ZNR1

U

DSA1

CN1

1

3

SWU2

SWU1

SWP3

SWP2

SWP1

OFF

ON

110

SW4

OFF

ON

110

SW3

OFF

ON

110

SW1

OFF

ON

110

SW2

LED4:Remote controller

when powered

At factory

shipment

At factory

shipment

5

CNLVC

6

1

LEV1Wb

1223344

X502

CN507

3

1

M

M

5

5

6

ON

OFF

1

SW5

SWU3

LED3:Lit when powered

Control Board

CNLVB

LEV1Wa

TB2

SV1

*3

*8

DSA Board

CN3T

red

13

T01

ZNR01

3

1

CN502

black

1

2

CNAC

red

U

F01

AC250V

6.3A T

LED1 Display setting(SW2)

Function setting(SW1,SW3,SW4)

OUT4

OUT3

OUT2

X514

X513

X512

TB141A

OUT1

X511

3

33

33

22

22

1

11

11

CN3A

CN421

CN421

4-20mA

4-20mA

CN422CN422

blue

black

black

blue

blue

TB142C

COM+ IN6 IN8

COM+ IN5 IN7

TB142B

X516

X517X515

OUT6

OUT7OUT5

TB141B

red

red

green

blue

yellow/green

TB142A

IN2

IN1

IN1

IN3IN4

*4

*5 *6 *7

orange

yellow

black

purple

TB2

LEV1Wa

SV1

TB5

LEV1Wb

TB15

OUT1

IN1

IN3

P36

COM+

IN4

P72

IN5

IN6

IN7

IN8

OUT2

TH22

TH23

TH6

OUT4

TH8

Explanation

Function

Function

Function

Function

Appliance

Terminal

block

Linear

expansion valve

Solenoid valve

Power supply

BC controller/outdoor unit

For opening/closing the bypass circuit

Outdoor unit/BC controller

BC controller/outdoor unit

*3

MA remote controller

Operation ON/OFF

Pump interlock

Connection demand

*3 do not exist

Common

Operation ON/OFF

*3 exist

Heating

Heating ECO

Anti-freeze

Cooling

Defrost

liquid pipe temp

gas pipe temp

water inlet temp

Error signal

water outlet temp

Symbol

Symbol

Symbol

Symbol

Model name

Symbol

Thermistor

<Symbol explanation>

<CAUTION FOR INSTALLATION>

· Prior to installation, read the Installation Manual carefully.

*1. Single-dotted lines indicate wiring not supplied with the unit.

*2. Dot-dash lines indicate the control box boundaries.

*3. Difference of appliance

*4 TB141A(output)

*5 TB142A(input)

*6 TB142B(input)

*7 TB142C(input)

*8. Use copper supply wires.

°t°

t

°

t

°

5. ELECTRICAL WIRING DIAGRAMS

PWFY-P36,72NMU-E-AU

PWFY-11PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

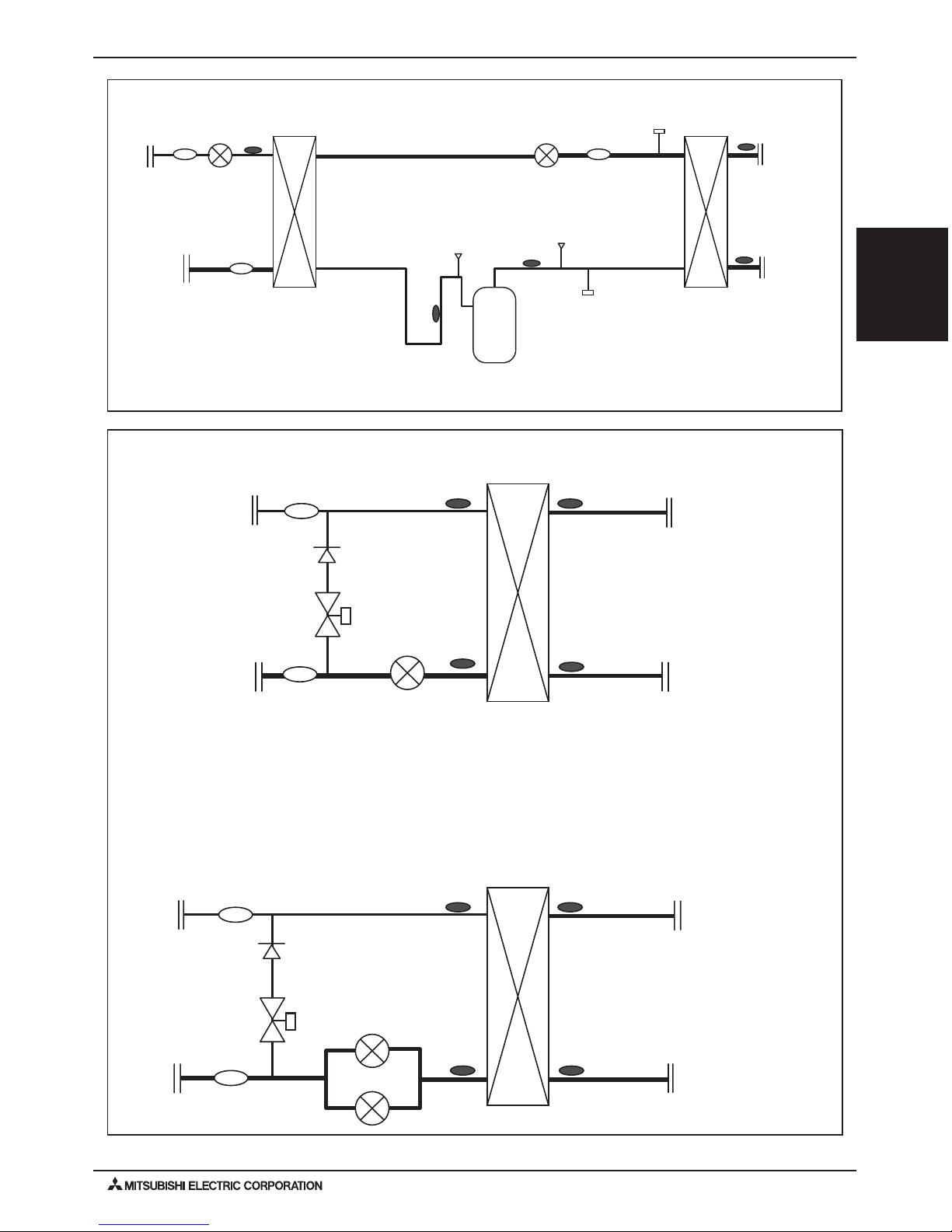

6. REFRIGERANT CIRCUIT DIAGRAMS

TH6

TH23

LEV1Wa

TH8

TH22

SV

CV1

ST2

ST3

Water inlet

Water outlet

screw

screw

Brazed

Brazed

TH6

TH23

LEV1Wa

TH8

TH22

LEV1Wb

SV

ST2

ST4

CV1

Water inlet

Water outlet

screw

screw

Brazed

Brazed

PWFY-P36NMU-E-AU

PWFY-P72NMU-E-AU

PWFY-P36NMU-E-BU

TH11

63H1

63HS

63LS

TH13

TH22

LEV1W

LEV2W

COMP

Water outlet

TH6

TH8

ST3

ST1

ST2

CJ

Brazed

Brazed

screw

screw

Water inlet

Hex

Hex

PWFY-12

PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

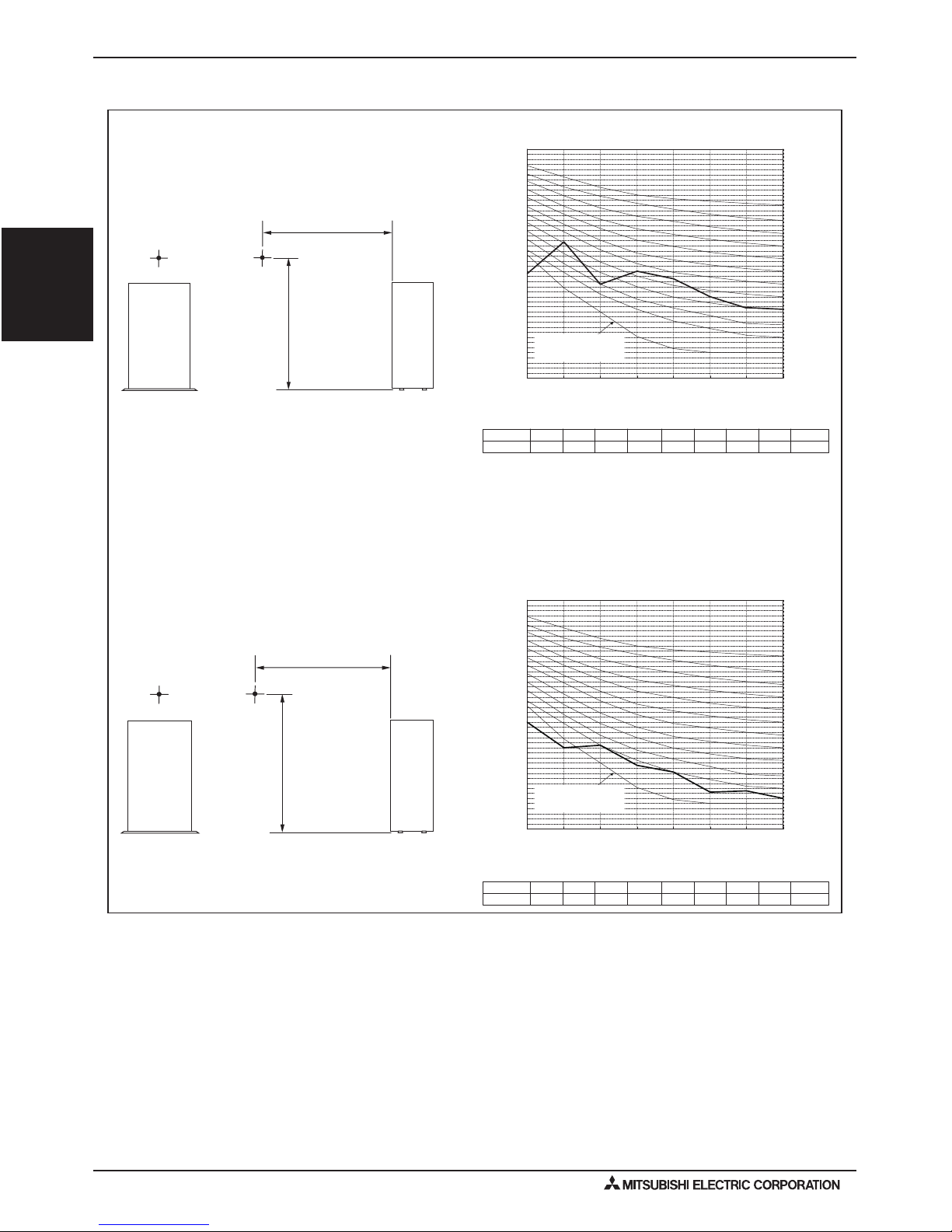

7. SOUND PRESSURE LEVELS

0

10

30

20

40

50

60

70

80

90

63 125 250 500 1k 2k 4k 8k

NC-40

NC-30

NC-20

NC-60

NC-50

NC-70

Octave band sound level (dB)

Sound pressure level of PWFY-P36NMU-E-BU

Measurement condition

PWFY-P36NMU-E-BU

60Hz

Octave band center frequencies <Hz>

Octave band sound level (dB)

Sound pressure level of PWFY-P36, 72NMU-E-AU

dB(A)

29.0

8k

12.0

4k

15.0

2k

14.5

1k

22.5

500

25.0

250

33.0

125

32.0

63

42.0

60Hz

dB(A)

44.0

8k

27.0

4k

27.5

2k

32.0

1k

39.0

500

42.0

250

37.0

125

53.5

63

41.0

Measurement condition

PWFY-P36, 72NMU-E-AU

Measurement

location

3-1/4 ft. (1m)

3-1/4 ft. (1m)

Measurement

location

3-1/4 ft. (1m)

3-1/4 ft. (1m)

Octave band center frequencies <Hz>

Approximate minimum

audible limit on

continuous noise

0

10

30

20

40

50

60

70

80

90

63 125 250 500 1k 2k 4k 8k

NC-40

NC-30

NC-20

NC-60

NC-50

NC-70

Approximate minimum

audible limit on

continuous noise

7-1. Sound Pressure Levels and NC Curves

Loading...

Loading...