PWFY-1PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

PWFY-P-NMU-E-BU/-AU

1. GENERAL DESCRIPTION .................................................................................................................................... PWFY-2

2. SPECIFICATIONS ................................................................................................................................................. PWFY-3

3. EXTERNAL DIMENSIONS .................................................................................................................................... PWFY-6

4. CENTER OF GRAVITY .........................................................................................................................................PWFY-8

5. ELECTRICAL WIRING DIAGRAMS ...................................................................................................................... PWFY-9

6. REFRIGERANT CIRCUIT DIAGRAMS ...............................................................................................................PWFY-11

7. SOUND PRESSURE LEVELS AND NC CURVES .............................................................................................PWFY-12

8. VIBRATION LEVELS ........................................................................................................................................... PWFY-13

9. CAPACITY TABLES .............................................................................................................................................PWFY-14

9-1. Correction by Temperature ........................................................................................................................PWFY-14

9-2. Water Pressure Drop ................................................................................................................................. PWFY-24

10. OPTIONAL PARTS .............................................................................................................................................. PWFY-25

11. SYSTEM DESIGN ............................................................................................................................................... PWFY-26

11-1. Electrical Work .......................................................................................................................................... PWFY-26

11-2. M-NET Control ..........................................................................................................................................PWFY-27

11-3. Installation .................................................................................................................................................PWFY-32

HYDRONIC HEAT EXCHANGER UNITS

PWFY-2

PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

1. GENERAL DESCRIPTION

Unit Conguration

50 to 100%R2/WR2 series

PWFY with

standard indoor units

Only standard

indoor units

50 to 150% 50 to 150%

Only PWFY

<PWFY-P36NMU-E-BU>

50 to 100%R2/WR2 series

PWFY with

standard indoor units

Only standard

indoor units

50 to 150% 50 to 150%

Only PWFY

<PWFY-P36,P72NMU-E-AU>

50 to 100%Y/H2i/WY series

50 to 130% 50 to 130%

Model PWFY-P36NMU-E-BU PWFY-P36NMU-E-AU PWFY-P72NMU-E-AU

Outdoor unit

- PUHY-P*T(S)HMU-A(-BS)/PUHY-P*Y(S)HMU-A(-BS)

- PUHY-P*T(S)JMU-A(-BS)/PUHY-P*Y(S)JMU-A(-BS)

- PUHY-HP*T(S)JMU-A(-BS)

- PQHY-P*T(S)HMU-A/PQHY-P*Y(S)HMU-A

PURY-P*T(S)HMU-A(-BS)/PURY-P*Y(S)HMU-A(-BS) PURY-P*T(S)HMU-A(-BS)/PURY-P*Y(S)HMU-A(-BS)

PURY-P*T(S)JMU-A(-BS)/PURY-P*Y(S)JMU-A(-BS) PURY-P*T(S)JMU-A(-BS)/PURY-P*Y(S)JMU-A(-BS)

PQRY-P*T(S)HMU-A/PQRY-P*Y(S)HMU-A PQRY-P*T(S)HMU-A/PQRY-P*Y(S)HMU-A

BC

Controllers

BC Controllers: CMB-P104,105,106,108,1010,1016NU-G

Main BC Controllers: CMB-P108,1010,1013, 1016-GA / CMB-P1016NU-HA

Sub BC Controllers: CMB-P104,108NU-GB / CMB-P1016NU-HB

Operation Temperature Range

PWFY-P36NMU-E-BU

Only PWFY

PWFY with

standard indoor unit

Only standard indoor units

Heating (WB)

Inlet water temperature R2/WR2 series 50 to 160°F (10 to 71°C) 50 to 160°F (10 to 71°C) ―

Outdoor temperature R2 series -4 to 90°F (-20 to 32°C) -4 to 90°F (-20 to 32°C) -4 to 60°F (-20 to 15.5°C)

Circulating Water

temperature

WR2 series 50 to 113°F (10 to 45°C) 50 to 113°F (10 to 45°C) 50 to 113°F (10 to 45°C)

PWFY-P36, 72NMU-E-AU

Connectable outdoor unit capacity range

Only standard indoor units

Cooling (DB) Heating (WB)

Outdoor temperature

R2 series

23 to 109°F(-5 to 43°C) -4 to 60°F(-20 to 15.5°C)

Y series

23 to 109°F(-5 to 43°C) -4 to 60°F(-20 to 15.5°C)

Circulating Water

temperature

WR2 series 50 to 113°F (10 to 45°C) 50 to 113°F (10 to 45°C)

WY series 50 to 113°F (10 to 45°C) 50 to 113°F (10 to 45°C)

Only PWFY PWFY with standard indoor units

Cooling Heating Cooling Heating

Inlet water temperature

R2/WR2 series

50 to 95°F (10 to 35°C) 50 to 105°F (10 to 41°C) 50 to 95°F (10 to 35°C) 50 to 105°F (10 to 41°C)

Y/H2i/WY series

50 to 95°F (10 to 35°C) 50 to 105°F (10 to 41°C) 50 to 95°F (10 to 35°C) 50 to 105°F (10 to 41°C)

Outdoor temperature

R2 series

23 to 115°F (-5 to 46°C) -4 to 90°F(-20 to 32°C) 23 to 115°F (-5 to 46°C) -4 to 90°F(-20 to 32°C)

Y series

23 to 115°F(-5 to 46°C) -4 to 60°F(-20 to 15.5°C) 23 to 115°F(-5 to 46°C) -4 to 60°F(-20 to 15.5°C)

H2i series

23 to 109°F(-5 to 43°C) -13 to 60°F(-25 to 15.5°C) 23 to 109°F(-5 to 43°C) -13 to 60°F(-25 to 15.5°C)

Circulating Water

temperature

WR2 series 50 to 113°F (10 to 45°C) 50 to 113°F (10 to 45°C) 50 to 113°F (10 to 45°C) 50 to 113°F (10 to 45°C)

WY series 50 to 113°F (10 to 45°C) 50 to 113°F (10 to 45°C) 50 to 113°F (10 to 45°C) 50 to 113°F (10 to 45°C)

PWFY-3PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

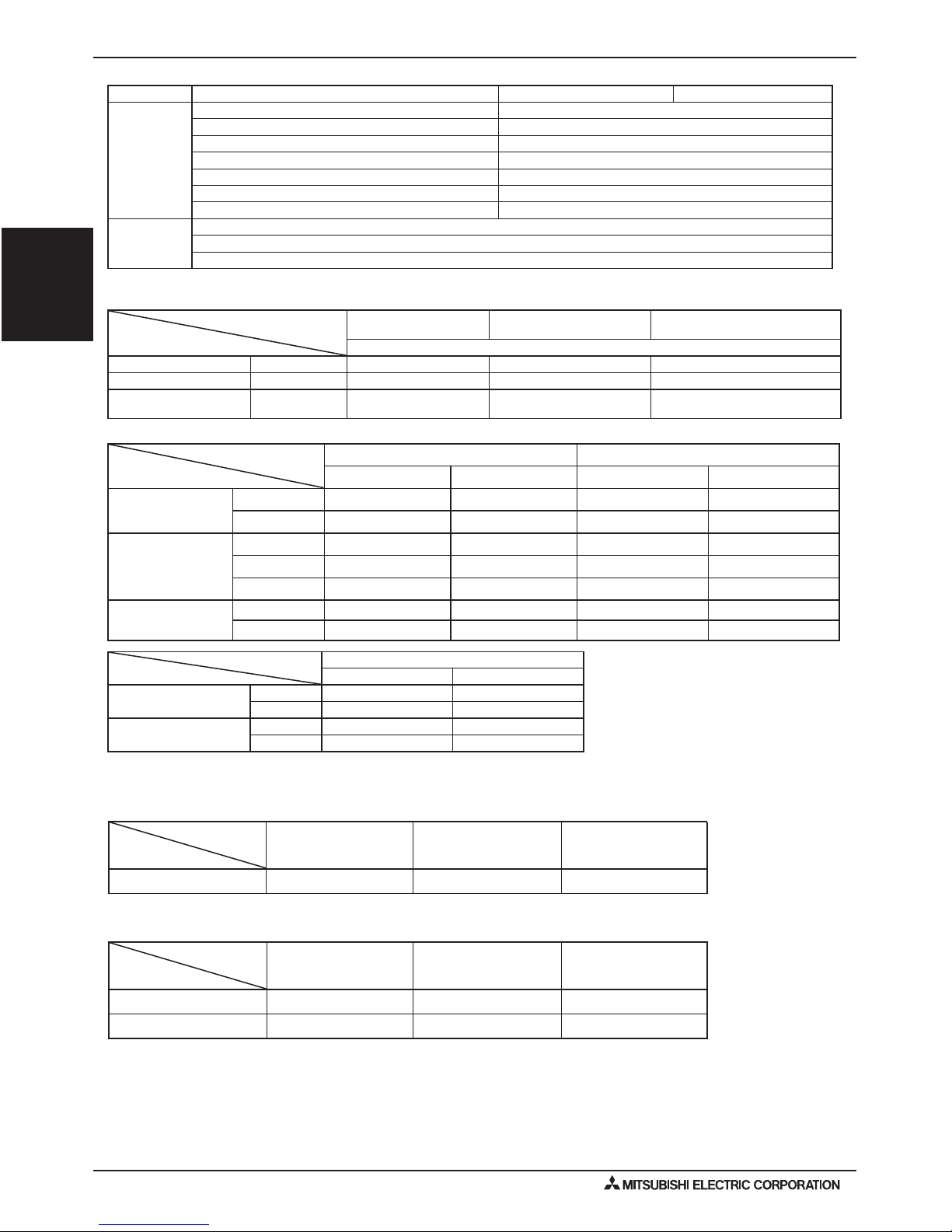

2. SPECIFICATIONS

Model

Power source

kWHeating capacity

kcal / h(Nominal )

BTU / h

kW

A

W.B

dB<A>

in.(mm)

in.(mm)

in.(mm)

in.(mm)

in.(mm)

mm

in.

lbs(kg)

kW

-

Power input

Liquid

Gas

Current input

Outdoor temp.

Inlet Water temp.

Total capacity

Temp. range of

heating

Connectable

outdoor unit Model / Quantity

Sound pressure level (measured in anechoic room)

Diameter of

refrigerant pipe

Diameter of

water pipe

Field drain pipe size

External dimension H × W × D

Net weight

Compressor

Maker

Type

Starting method

Motor output

Circulating water

Range

Protection on Internal circuit

(R134a)

High pressure protection

Inverter circuit (COMP)

Compressor

Type × original chargeRefrigerant

Control

R410ADesign pressure

R134a

Water

ExternalDrawing

Standard attachment

Optional parts

Remark

Note:

*1 Nominal heating conditions

Outdoor Temp. : 47°FDB / 43°FWB (8.3°CDB/6.1°CWB)

kcal = kW x 860

BTU/h = kW x 3,412

cfm = m

3

/min x 35.31

G(us) = L × 0.2642

lbs = kg / 0.4536

psi = MPa×145.038

Pipe length : 7.6 m (25 ft)

Level difference : 0m (0ft)

Inlet water Temp 149°F (65°C) Water flow rate 2.15m

3

/h (555G/h)

* Due to continuing improvement, the above specifications may be subject to change without notice. * Install the unit in an environment where the

wet bulb Temp. will not exceed 90°F (32°C).

* The unit is not designed for outside installations.

* Please don't use steel for the water piping material. * The water circuit must use the closed circuit.

* Please do not use it as a drinking water. Discharge water from unit is not potable. Do not connect the output directly to a potable system.

* Please always make water circulate or add brine to the circulation water when the ambient temperature becomes 32°F (0°C) or less.

* Please do not use groundwater and well water.

* The specification data is subject

to rounding variation.

Unit converter

Lubricant

Operation volume

Inlet

Outlet

Accessory

Wiring

Document

m

3

/h

G/h

G/min

L/min

MPa

MPa

psi

psi

psi

MPa

1.00

Installation Manual, Instruction Book

800 (785 without legs) × 450 × 300

KE94C344

Inverter

1.0

Over-heat protection, Over-current protection

R134a x ( 2lbs + 7oz) ( 1.1kg )

10,100

11.7

WKB94T460

NONE

44

Strainer, Heat insulation material, 2 × Connector sets, 2 × Washer

PWFY-P36NMU-E-BU

1-phase 208-230V 60Hz

PT3/4 (27.2) Screw

MITSUBISHI ELECTRIC CORPORATION

NEO22

Φ1-1/4 (Φ32)

Inverter rotary hermetic compressor

31-1/2" (30-15/16" without legs) × 17-3/4” × 11-13/16”

133 (60)

PT3/4 (27.2) Screw

12.30 - 11.12

50~100% of outdoor unit capacity

PURY-P*T(S)HMU/Y(S)HMU-A(-BS)

PURY-P*T(S)JMU/P*Y(S)JMU-A(-BS)

PQRY-P*T(S)HMU/-P*Y(S)HMU-A(-BS)

Φ5/8 (Φ15.88) Brazed

-4~90°F (-20~32°C)

Φ3/8 (Φ9.52) Brazed

39,900

50~160°F (10~71°C)

2.48

0.6~2.15

156~555

2.6~9.2

10~35

LEV

601

4.15

522

3.60

High pressure sensor, High pressure switch at 3.60 MPa (522 psi)

Discharge thermo protection, Over-current protection

145

Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and

other items shall be referred to the Installation Manual.

PWFY-4

PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

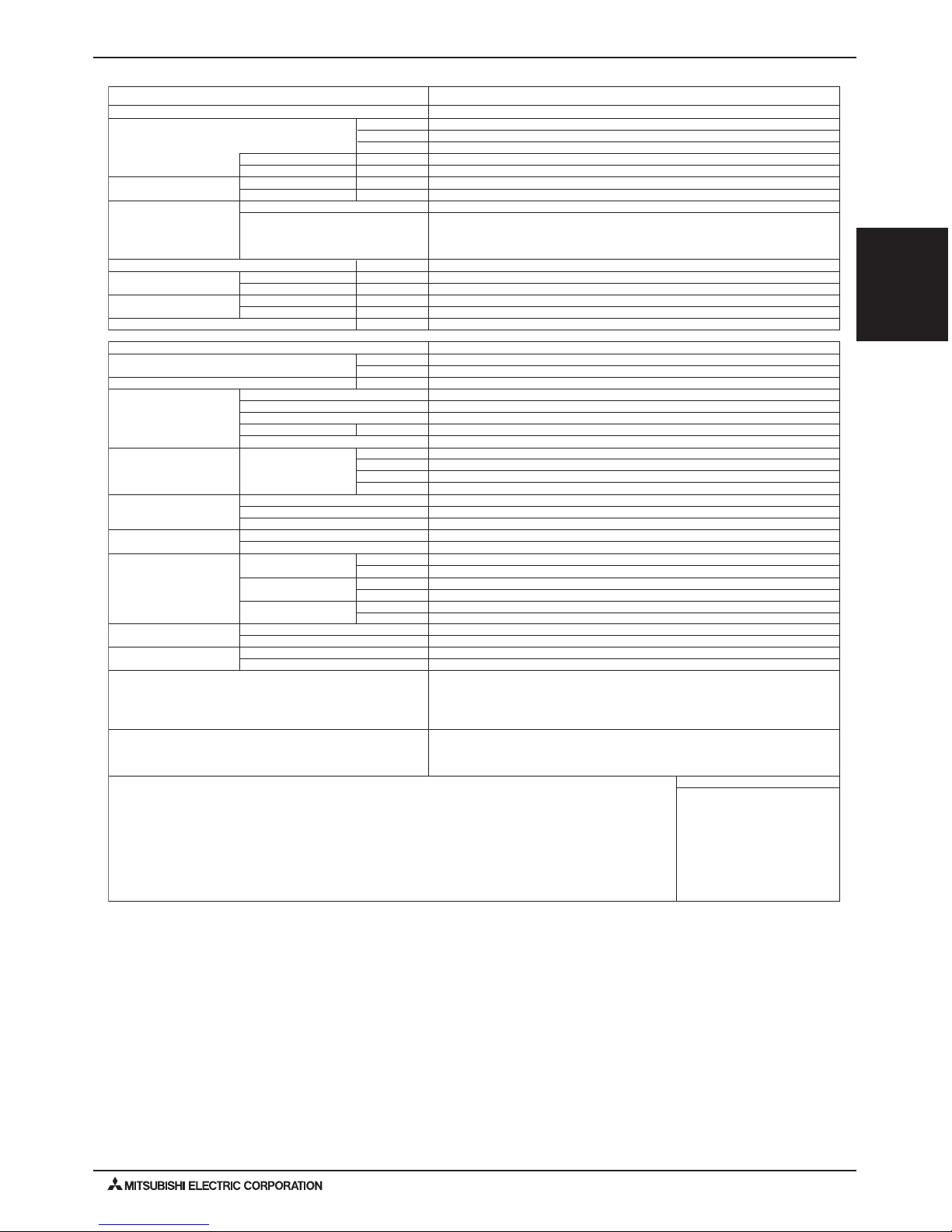

2. SPECIFICATIONS

Model

Power source

kW*1Heating capacity

kcal / h

BTU / h

kW

A

W.B

*1(Nominal)

*1

Power input

Current input

Outdoor temp.

Temp. range of

W.B

-

heating

Inlet Water temp.

kW*2Cooling capacity

kcal / h

BTU / h

kW

A

D.B

*2(Nominal)

*2

Power input

Current input

Outdoor temp.Temp. range of cooling

D.B

-Inlet Water temp.

Total capacity

Model / Quantity

Connectable

outdoor unit

Sound pressure level (measured in anechoic room) dB<A>

in.(mm)

in.(mm)

Diameter of

refrigerant pipe

in.(mm)

in.(mm)

Diameter of

water pipe

in.(mm)

mm

Field drain pipe size

External finish

External dimension H × W × D

in.

lbs(kg)

Net weight

Circulating water

Range

Design pressure

Water

R410A

Drawing

Standard attachment

Optional parts

Remark

Note:

*2 Nominal cooling conditions *1 Nominal heating conditions

Outdoor Temp. : 47°FDB/43°FWB (8.3°CDB / 6.1°CWB) Outdoor Temp. : 95°FDB (35°CDB)

Pipe length : 7.6 m (25 ft)Pipe length : 7.6 m (25 ft)

Level difference : 0m (0ft)Level difference : 0m (0ft)

Inlet water Temp 86°F (30°C)

Water flow rate 2.15m

3

/h (555G/h)

Inlet water Temp 149°F (23°C)

Water flow rate 1.93m

3

/h (498G/h)

* Install the unit in an environment where the

* Due to continuing improvement, the above specifications may be subject to change without notice.

wet bulb Temp. will not exceed 92°F (32°C) * The unit is not designed for outside installations.

* Please don't use steel for the water piping material. * The water circuit must use the closed circuit.

* Please always make water circulate or add the brine to the circulation water when the ambient temperature becomes 32°F (0°C) or less.

Inlet

Outlet

Operation Volume

Liquid

Gas

Accessory

External

Wiring

Document

Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and

other items shall be referred to the Installation Manual.

Unit converter

36,200

50~95°F (10~35°C)

0.015

Φ5/8 (Φ15.88) Brazed

Φ3/8 (Φ9.52) Brazed

PT3/4 (27.2) Screw

Installation Manual, Instruction Book

PT3/4 (27.2) Screw

NO

WKB94T461

0.072 - 0.065

50~100% of outdoor unit capacity

PUHY-P*T(S)HMU/P*Y(S)HMU-A(-BS)

PUHY-P*T(S)JMU/P*Y(S)JMU-A(-BS)

PQHY-P*T(S)HMU/P*Y(S)HMU-A(-BS)

23~109°F (-5~43°C) PURY - series

23~109°F (-5~43°C) PUHY - series

0.6~2.15

2.6~9.2

4.15

145

10~35

156~555

1.00

Strainer, Heat insulation material, 2 × Connector sets , 2 × Washer

Φ1-1/4 (Φ32)

PWFY-P36NMU-E-AU

1-phase 208 - 230 V 60Hz

9,100

10.6

29

11.7

800 (785 without legs) × 450 × 300

KE94C345

601

NONE

10,100

39,900

-4~60°F (-20~15.5°C) PUHY - series

50~105°F (10~41°C)

0.015

0.072 - 0.065

-4~90°F (-20~32°C) PURY - series

31-1/2" (30-15/16" without legs) × 17-3/4” × 11-13/16”

78 (35)

* Please do not use it as a drinking water. Discharge water from unit is not possible. Do not connect the output directly to a potable system.

* Please do not use groundwater and well water.

m3/h

G/h

G/min

L/min

MPa

psi

MPa

psi

kcal = kW x 860

BTU/h = kW x 3,412

cfm = m

3

/min x 35.31

G(us) = L × 0.2642

lbs = kg / 0.4536

psi = MPa×145.038

* The specification data is subject

to rounding variation.

PURY-P*T(S)HMU/Y(S)HMU-A(-BS)

PURY-P*T(S)JMU/P*Y(S)JMU-A(-BS)

PQRY-P*T(S)HMU/-P*Y(S)HMU-A(-BS)

PWFY-5PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

2. SPECIFICATIONS

Model

Power source

kW*1Heating capacity

kcal / h

BTU / h

kW

A

W.B

*1(Nominal)

*1

Power input

Current input

Outdoor temp.

Temp. range of

W.B

-

heating

Inlet Water temp.

kW*2Cooling capacity

kcal / h

BTU / h

kW

A

D.B

*2(Nominal)

*2

Power input

Current input

Outdoor temp.Temp. range of cooling

D.B

-Inlet Water temp.

Total capacity

Model / Quantity

Connectable

outdoor unit

Sound pressure level (measured in anechoic room) dB<A>

in.(mm)

in.(mm)

Diameter of

refrigerant pipe

in.(mm)

in.(mm)

Diameter of

water pipe

in.(mm)

mm

Field drain pipe size

External finish

External dimension H × W × D

in.

lbs(kg)

Net weight

Circulating water

Range

Design pressure

Water

R410A

Drawing

Standard attachment

Optional parts

Remark

Note:

*2 Nominal cooling conditions *1 Nominal heating conditions

Outdoor Temp. : 47°FDB/43°FWB (8.3°CDB / 6.1°CWB) Outdoor Temp. : 95°FDB (35°CDB)

Pipe length : 7.6 m (25 ft)Pipe length : 7.6 m (25 ft)

Level difference : 0m (0ft)Level difference : 0m (0ft)

Inlet water Temp 86°F (30°C)

Water flow rate 4.30m

3

/h (1110G/h)

Inlet water Temp 149°F (23°C)

Water flow rate 3.86m

3

/h (996G/h)

* Install the unit in an environment where the

* Due to continuing improvement, the above specifications may be subject to change without notice.

wet bulb Temp. will not exceed 92°F (32°C) * The unit is not designed for outside installations.

* Please don't use steel for the water piping material. * The water circuit must use the closed circuit.

* Please always make water circulate or add the brine to the circulation water when the ambient temperature becomes 32°F (0°C) or less.

Inlet

Outlet

Operation Volume

Liquid

Gas

Accessory

External

Wiring

Document

Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and

other items shall be referred to the Installation Manual.

Unit converter

72,000

50~95°F (10~35°C)

0.015

Φ3/4 (Φ19.05) Brazed

Φ3/8 (Φ9.52) Brazed

PT 1 ( 34 ) Screw

Installation Manual, Instruction Book

PT 1 ( 34 ) Screw

NO

WKB94T461

0.072 - 0.065

50~100% of outdoor unit capacity

23~109°F (-5~43°C) PURY - series

23~109°F (-5~43°C) PUHY - series

1.2~4.30

5.2~18.4

4.15

145

20~72

312~1110

1.00

Strainer , Connecter , Heat insulation material, 2 × Connector sets , Expansion joint , 2 × Washer

Φ1-1/4 (Φ32)

PWFY-P72NMU-E-AU

1-phase 208 - 230 V 60Hz

18,100

21.1

29

23.4

800 (785 without legs) × 450 × 300

KE94C345

601

NONE

20,100

79,800

-4~60°F (-20~15.5°C) PUHY - series

50~105°F (10~41°C)

0.015

0.072 - 0.065

-4~90°F (-20~32°C) PURY - series

31-1/2" (30-15/16" without legs) × 17-3/4” × 11-13/16”

84 (38)

* Please do not use it as a drinking water. Discharge water from unit is not potable. Do not connect the output directly to a potable system.

* Please do not use groundwater and well water.

m3/h

G/h

G/min

L/min

MPa

psi

MPa

psi

kcal = kW x 860

BTU/h = kW x 3,412

cfm = m

3

/min x 35.31

G(us) = L × 0.2642

lbs = kg / 0.4536

psi = MPa×145.038

* The specification data is subject

to rounding variation.

PURY-P*T(S)HMU/Y(S)HMU-A(-BS)

PURY-P*T(S)JMU/P*Y(S)JMU-A(-BS)

PQRY-P*T(S)HMU/-P*Y(S)HMU-A(-BS)

PUHY-P*T(S)HMU/P*Y(S)HMU-A(-BS)

PUHY-P*T(S)JMU/P*Y(S)JMU-A(-BS)

PQHY-P*T(S)HMU/P*Y(S)HMU-A(-BS)

PWFY-6

PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

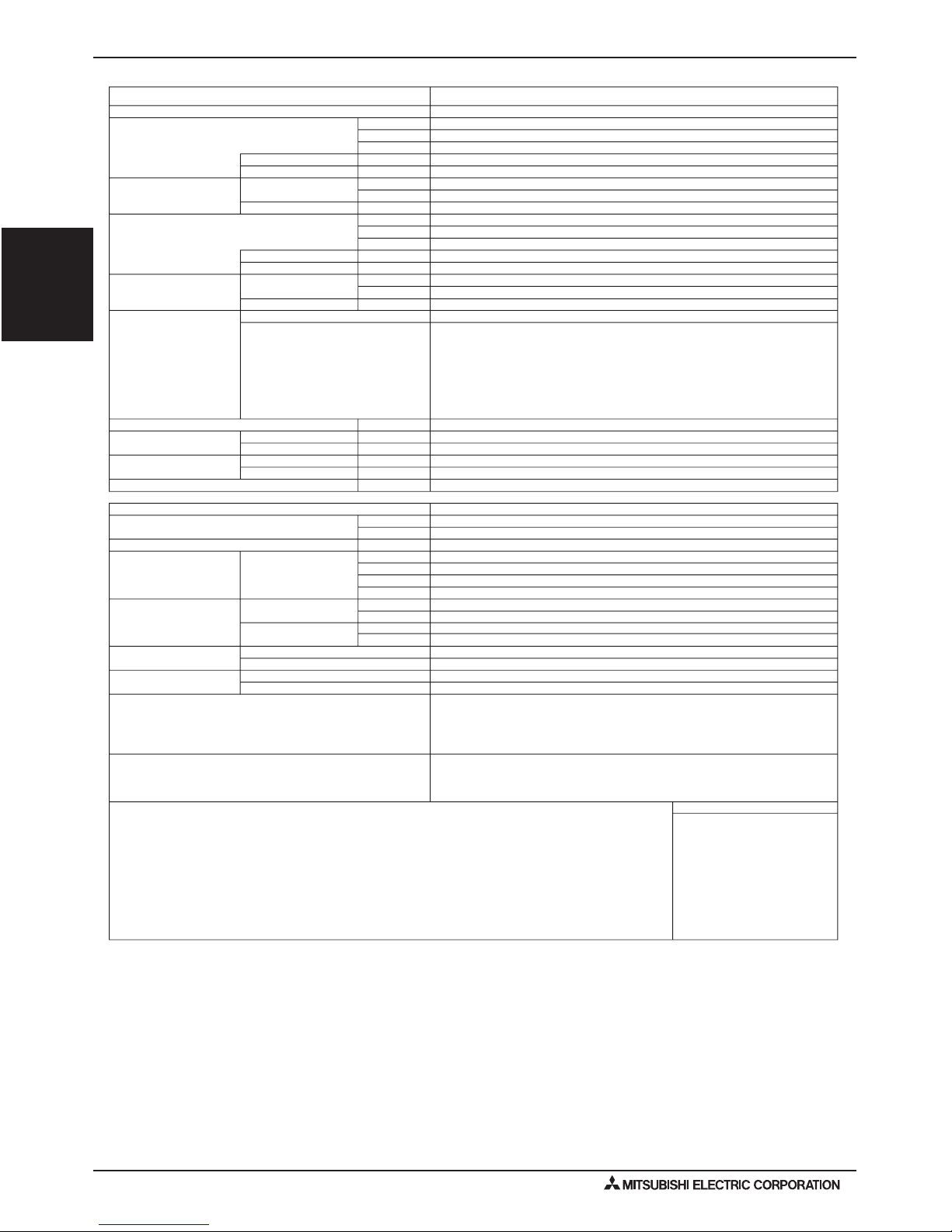

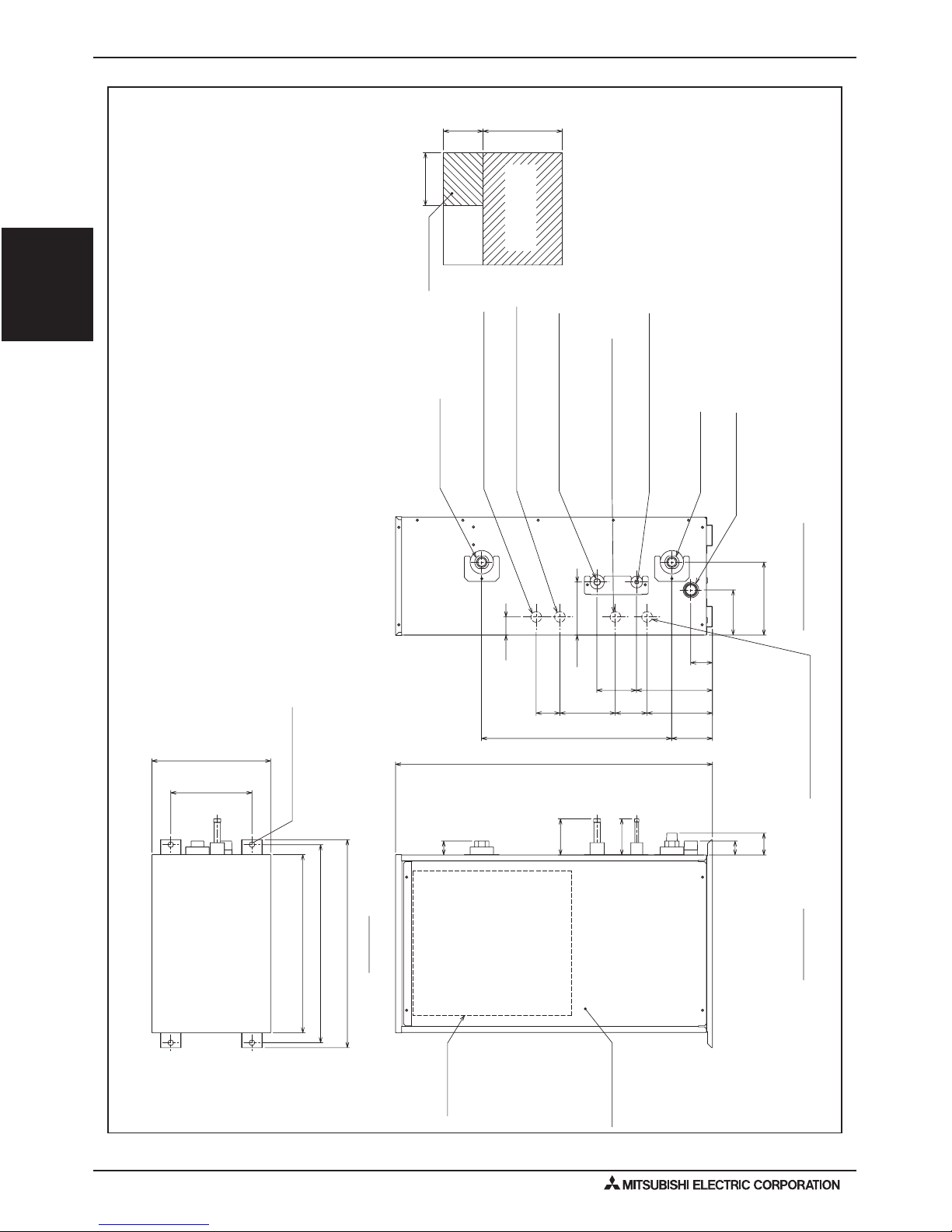

3. EXTERNAL DIMENSIONS

(11-13/16)(23-5/8)

Piping space

(right side)

Top view

Fig. A

Service space

(front side)

300

400(15-3/4)

600

Drain (R1 screw)

Control box

Water outlet

(RC3/4 screw)

ø27(1-3/32) Knockout hole

<Hole for external wiring input>

ø27(1-3/32) Knockout hole

<Hole for external wiring output>

ø27(1-3/32) Knockout hole

<Hole for power supply>

ø27(1-3/32) Knockout hole

<Hole for control wiring>

Service panel

Top view

Right side view

Front view

2X2-ø14(9/16) Hole

Connection pipe of outdoor unit

(Liquid)

ø15.88(5/8) <Brazed>

ø9.52(3/8) <Brazed>

Connection pipe of outdoor unit

(Gas)

Water inlet

(R3/4 screw)

Note 1. Ensure no water or debris can enter the unit through any gaps around

wiring or piping.

2. Ensure adequate service space is right around the unit, according to Fig A.

3. Please always make water circulate or add the brine to the circulation water

when the ambient temperature becomes 0degC(32°F )or less.

4. The unit is not designed for outside installations.

5. Install the unit in an environment where the wet bulb Temp.

will not exceed 32degC(90°F).

6. The water circuit must use the closed circuit.

7. Please don't use the steel material for the water piping material.

8. Connect the strainer which is put as accessory to water inlet pipe.

<Accessories>

• Y-type strainer (RC3/4) ················ 1pc.

•

Heat Insulation material ·············· 1pc.

•

Connector set ······························ 2set

•

Washer ········································ 2pcs.

(4-1/32)

(3-15/16)

(3-5/32) (5-17/32) (2-3/8)

(6-1/2)

(2-5/32)

(7-17/32)

102

(1-13/32)

(1-13/16)

(5-9/32)

(4-1/2)

(7-1/4)

(2-3/16)

525(20-11/16)

55

35(1-13/32)

35

91(3-19/32)

91(3-19/32)

134

480(18-29/32)

46

60

140

100

191

80

165

54

184

114

(Mounting pitch)

(Mounting pitch)

205(8-3/32)

800(31-1/2)

300(11-13/16)

450(17-23/32)

500(19-11/16)

<Unit:mm(in)>

PWFY-P36NMU-E-BU

PWFY-7PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

3. EXTERNAL DIMENSIONS

(23-5/8)

(11-13/16)

300

600

Fig. A

Service space

(front side)

Top view

400(15-3/4)

Piping space

(right side)

Drain (R1 screw)

ø9.52(3/8) <Brazed>

P72:Use the Expansion joint of accessories

ø27(1-3/32) Knockout hole

<Hole for control wiring>

ø27(1-3/32) Knockout hole

<Hole for power supply>

Water outlet

(RC3/4 screw)

Water inlet

(R3/4 screw)

P36:ø15.88(5/8) <Brazed>

P72:ø19.05(3/4) <Brazed>

ø27(1-3/32) Knockout hole

<Hole for external wiring input>

ø27(1-3/32) Knockout hole

<Hole for external wiring output>

Connection pipe of outdoor unit

(Gas)

Connection pipe of outdoor unit

(Liquid)

Front view

Right side view

Control box

Service panel

Top view

2X2-ø14(9/16) Hole

<Accessories>

• Y-type strainer (RC3/4) ················ 1pc.

•

Heat Insulation material ·············· 1pc.

•

Connector set ······························ 2set

•

Washer ········································ 2pcs.

•

Expansion joint(P72) ··················· 2pcs.

[From RC3/4 to RC1]

(3-15/16)

(8-1/8)

(4-1/2)

(2-3/8)

(3-5/32)

(5-17/32)

(5-9/32)

(1-13/16)

(7-17/32)

(6-1/2)

(2-5/32)

(4-1/32)

(1-13/32)

(2-3/16)

525(20-11/16)

91(3-19/32)

91(3-19/32)

35(1-13/32)

55

35

480(18-29/32)

102

206

134

114

100

191

46

6014080

165

54

(Mounting pitch)

450(17-23/32)

300(11-13/16)

(Mounting pitch)

205(8-3/32)

800(31-1/2)

500(19-11/16)

<Unit:mm(in)>

Note 1. Ensure no water or debris can enter the unit through any gaps around

wiring or piping.

2. Ensure adequate service space is right around the unit, according to Fig A.

3. Please always make water circulate or add the brine to the circulation water

when the ambient temperature becomes 0degC(32°F )or less.

4. The unit is not designed for outside installations.

5. Install the unit in an environment where the wet bulb Temp.

will not exceed 32degC(90°F).

6. The water circuit must use the closed circuit.

7. Please don't use the steel material for the water piping material.

8. Connect the strainer which is put as accessory to water inlet pipe.

PWFY-P36,72NMU-E-AU

PWFY-8

PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

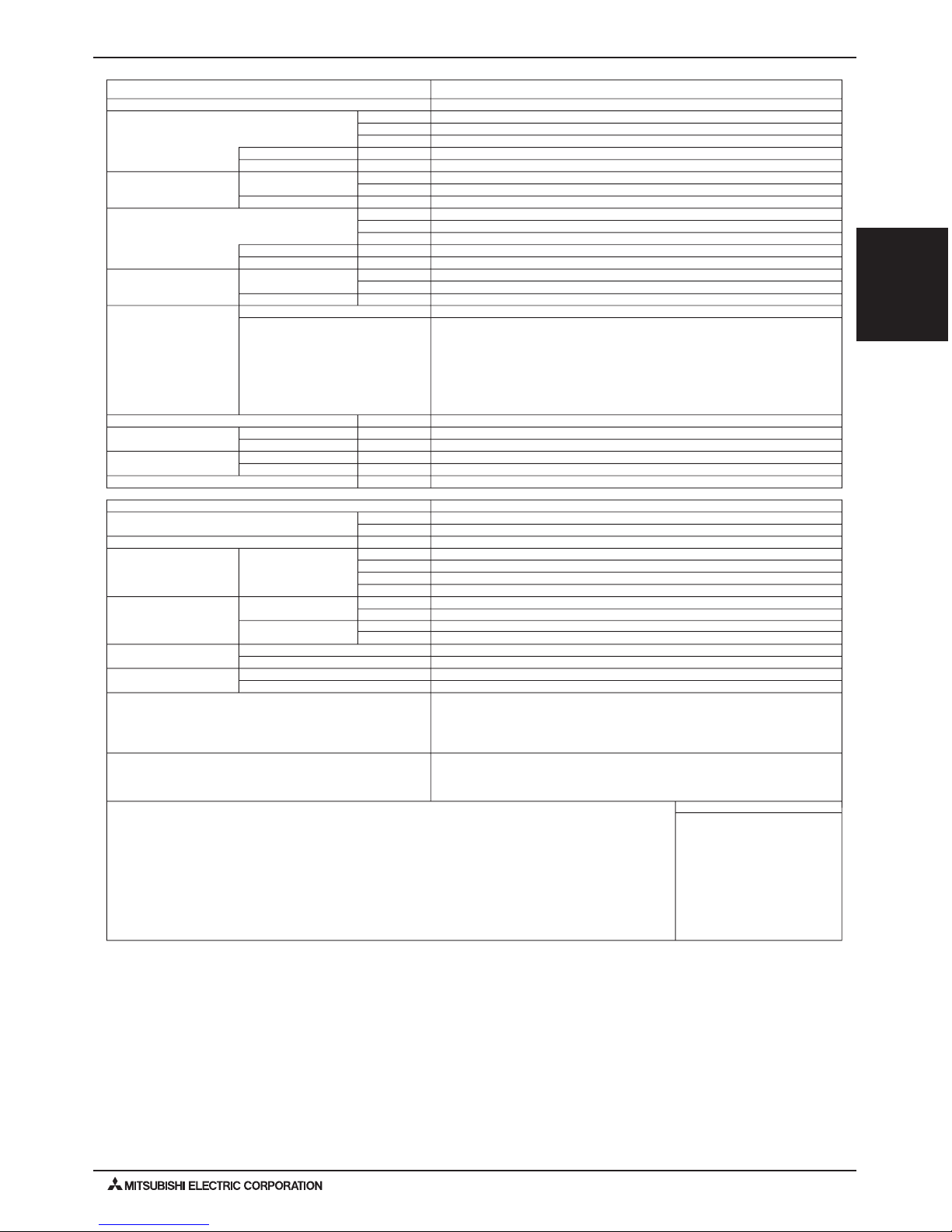

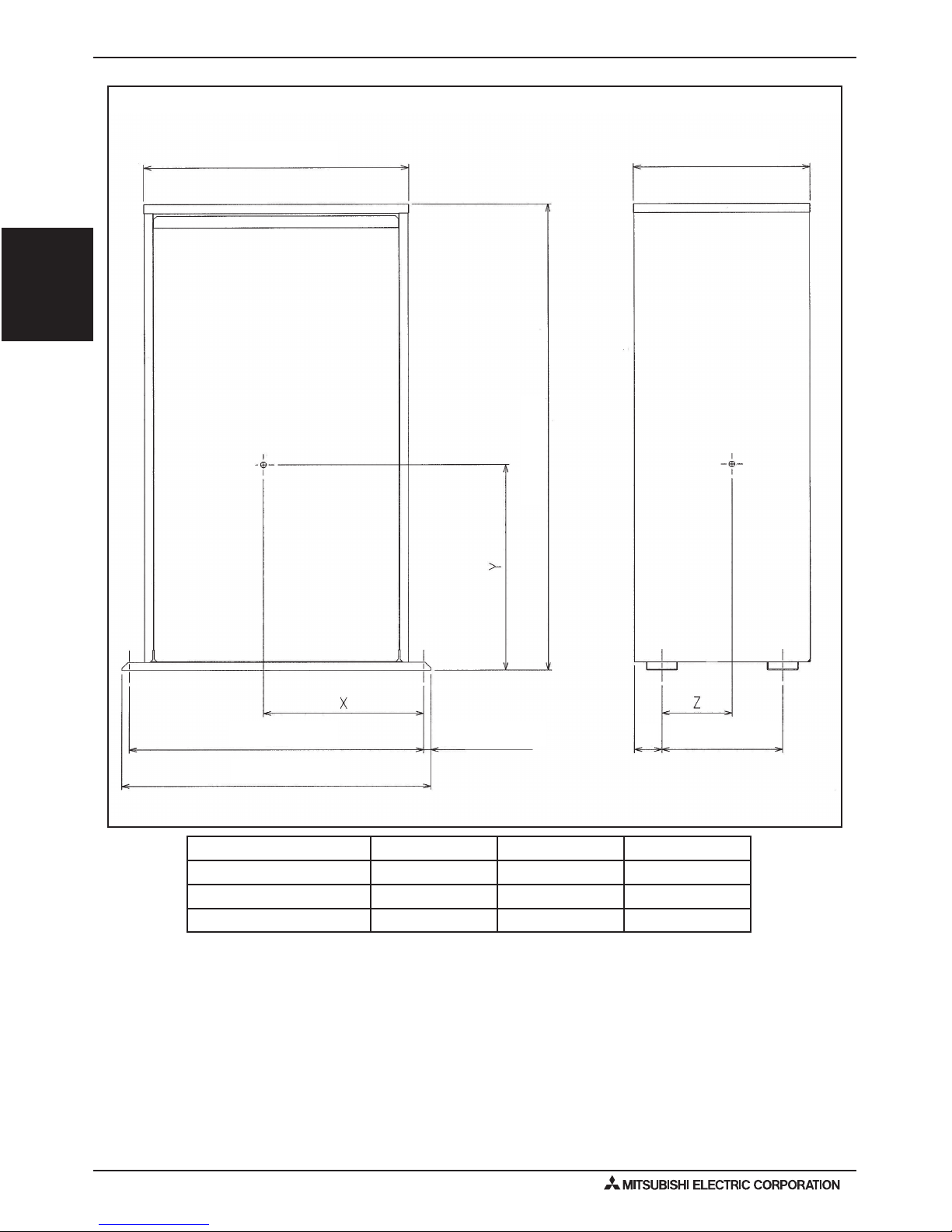

4. CENTER OF GRAVITY

17-23/32 (450) 11-13/16 (300)

31-1/2 (800)

17/32 (13)19-11/16 (500)

20-11/16 (525)

8-3/32 (205)

1-7/8 (47)

in. (mm)

Model X Y Z

PWFY-P36NMU-E-BU 10-23/32 (272) 13 (355) 4-11/16 (119)

PWFY-P36NMU-E-AU 11-13/32 (289) 13-5/8 (346) 4-1/16 (103)

PWFY-P72NMU-E-AU 10-29/32 (277) 13-11/16 (347) 3-29/32 (99)

PWFY-9PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

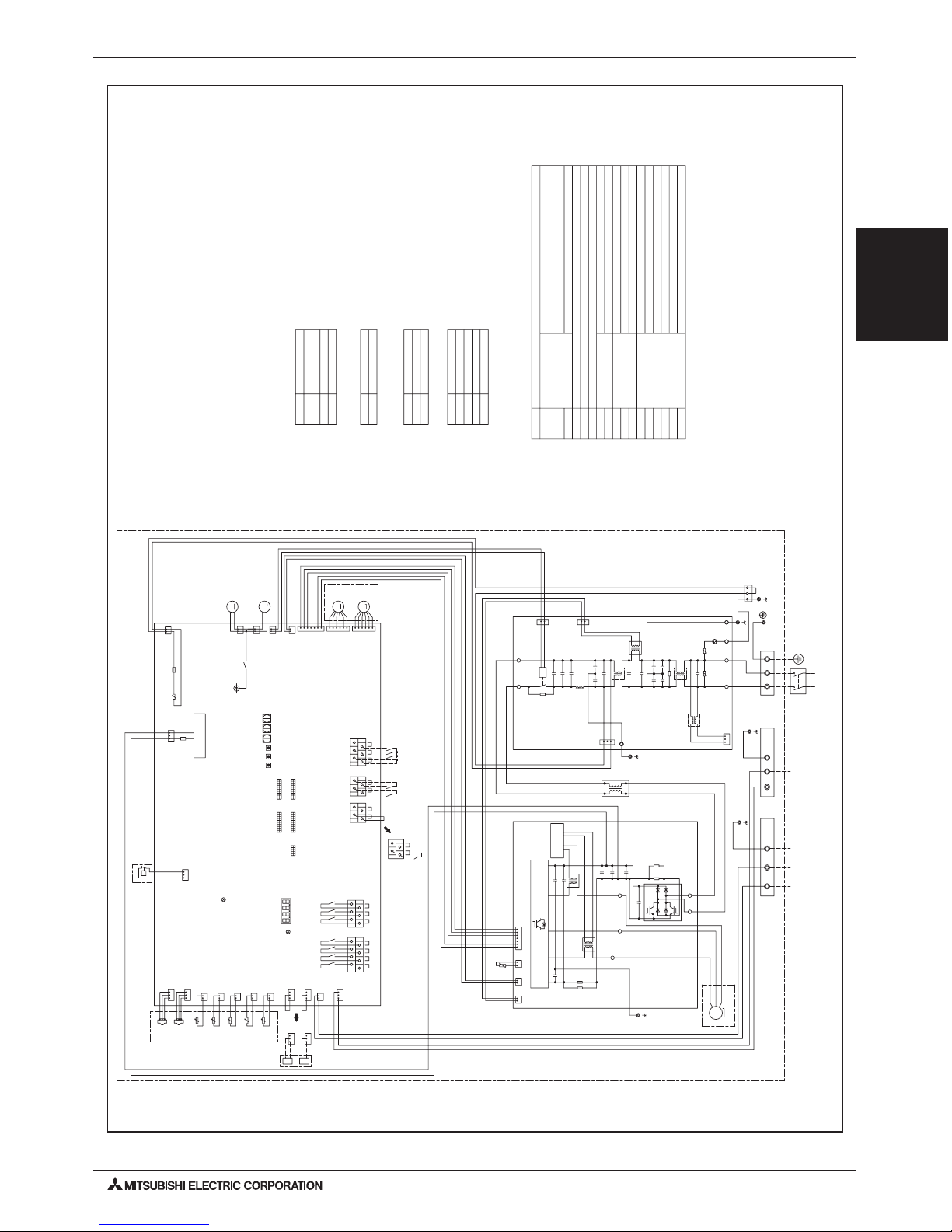

5. ELECTRICAL WIRING DIAGRAMS

gray

2

1

gray

black

To outdoor unit/

BC controller

To MA remote

controller

Power Supply

~208/230V

60Hz

3

2

1

blue

red

yellow/green

bluered

CN4

63LS

CN63HS

1

1

3

2

2

3

THHS

12

CN63LS

123

TH8

2

1

CN403

red

TH6

1

2

CN404

black

31

CT1

Moter

3~

CYN

RS4

MS

RS3

(Compressor)

CN3A

blue

U

t

t

t

t

t

red

yellow

TH22

CN405

IPM

W

V

U

black

1

63HS

7

2

1

3

1

2

CN3

2

1

t

CN401

CN2

256

red

CN5

2

1

TH11

1

2

TH13

2

1

white

CN402

green

red

5

6

RS1

black

2

CN52C

R1

LO

U

CNAC2

red

2

CN5

1

1

2

red

blue red

LEV2W

M

M

LI

24V

blue

+

CB3

Z2

1

U

CT1

LEV1W

1

CN2

63H1

6

5

CNAC

2

red

1

CX2

L1

CN506A

L3

L2 G

6

5

N

CN-E1

CN631

DSA

pink

E2

3

1

E1

432

1

CY4

P

CY3

31

L4

Z1

NI

CB1

+

1

TB2

CN661

2L23

X506

W

4

CN4

blue

U

CN52C

1

2

+

CX3

INV control

circuit

PFC

E3

1

L1

2

M

ZNR01

ACL

CY1CY2

CT2

Noise

Filter

red

Fan motor

1

3

(DC)

CX5

CYP

CIS

CX6

1

2

7

V

yellow

LED3:Lit when powered

INV Board

Control Board

CB2

(DC)

CY6

S

CX4

R

CNAC1

M

CNLVA

NO

Fan motor

3

1

2

RS2

CY5

P

CNLVB

blue

CX1

CX7

CN506B

CPS

+

RS

F01

AC250V

6.3A T

F631

DC700V

4A T

Power

Supply circuit

bluered

TB5

M1 M2 S(SHIELD)

S(SHIELD)

TB15

yellow

purple

black

orange

green

red

black

white

green

gray

52C

1

2

CN2M

blue

31

*4

*8

IN2

TB141B

TB142B

IN6

COM+

OUT5

TB142C

OUT7

OUT6

X515 X517

X516

IN8

IN5IN7

TB142A

X514

OUT2

X512

X511 X513

OUT1 OUT3

OUT4

TB141A

*5 *6 *7

IN3 IN4

COM+

LED4:Remote controller

when powered

At factory

shipment

At factory

shipment

SWU1

10

SW1

5

ON

OFF

1

Unit address setting(SWU1,SWU2)

Connection No.(SWU3)

LED1 Display setting(SW2)

Function setting(SW1,SW3,SW4)

SWP3

SW5

SWP1

SWU3

SWP2

SWU2

OFF

ON

1

10

SW4

OFF

ON

110

LED1

OFF

ON

1

SW3

OFF

ON

110

SW2

IN1

gray

CN421

black

31

CN422

blue

IN1

IN2

31

CN421

4-20mA

4-20mA

black

31

CN422

blue

2

2

2

2

AC reactor

Pressure

switch

High pressure switch

(High pressure protection for the booster unit)

Discharge pressure

Low pressure

TB2

LEV1W

TB5

LEV2W

TB15

TH11

OUT1

IN1

IN3

COM+

IN4

IN5

IN6

IN7

TH13

OUT2

TH22

OUT3

TH6

OUT4

TH8

CT1,CT2

ACL

THHS

Magnetic relay(main circuit)

Current sensor(AC)

Explanation

Function

Function

Function

Function

Terminal

block

Linear

expansion valve

Power supply

BC controller/outdoor unit

Outdoor unit/BC controller

Booster unit

MA remote controller

Compressor discharge temp

Operation ON/OFF

Pump interlock

Connection demand

Common

Operation ON/OFF

Hot water/Heating

Heating ECO

Anti-freeze

Evaporator outlet temp

Defrost

liquid pipe temp

Compressor

water inlet temp

Error signal

water outlet temp

IGBT temp

Pressure

sensor

Symbol

Symbol

Symbol

Symbol

Symbol

63H1

*4 TB141A(output)

*5 TB142A(input)

*6 TB142B(input)

*7 TB142C(input)

*8. Use copper supply wires.

63HS

63LS

Thermistor

52C

<Symbol explanation>

<HIGH VOLTAGE WARNING>

· Control box houses high-voltage parts.

Before inspecting the inside of the control box, turn off the power,

keep the unit off for at least 10 minutes, and confirm that the voltage

CN631 on Control Board has dropped to DC20V or less.

<CAUTION FOR INSTALLATION>

· Prior to installation, read the Installation Manual carefully.

*1. Single-dotted lines indicate wiring not supplied with the unit.

*2. Dot-dash lines indicate the control box boundaries.

*3. Faston terminals have a locking function.

Make sure the terminals are securely locked in place after insertion.

Press the tab on the terminals to removed them.

°

°

°

°

°

°

PWFY-P36NMU-E-BU

PWFY-10

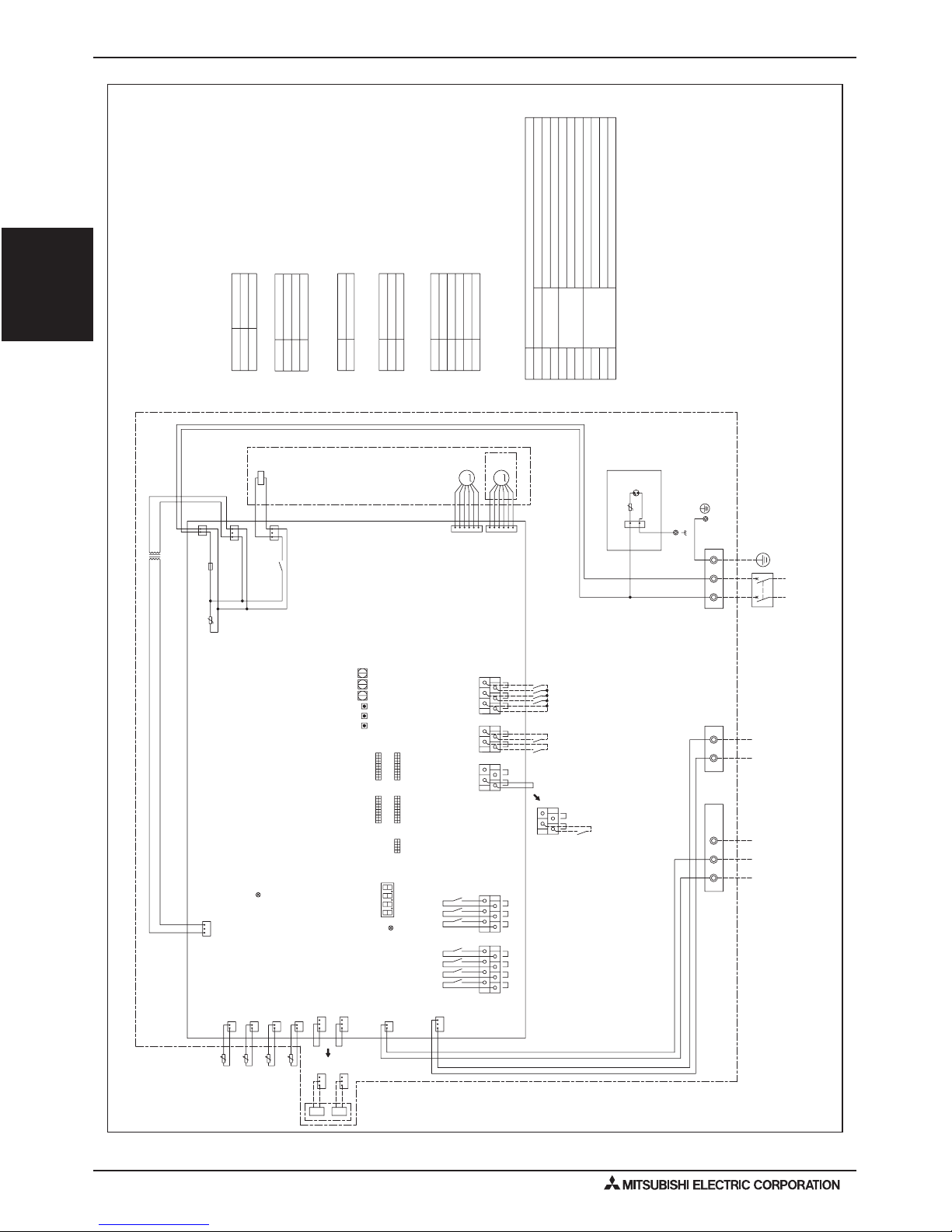

PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

TH8

TH6

TH23

blue

CN2M

2

1

2

1

CN402

green

2

1

CN403

red

1

2

CN404

black

yellow

CN405

t

TH22

1

2

S(SHIELD)

2

M2

1

M1

To MA remote

controller

To outdoor unit/

BC controller/

Power Supply

~208/230V

60Hz

L2 G

L1

Unit address setting(SWU1,SWU2)

Connection No.(SWU3)

LED1

TB15TB5

ZNR1

U

DSA1

CN1

1

3

SWU2

SWU1

SWP3

SWP2

SWP1

OFF

ON

110

SW4

OFF

ON

110

SW3

OFF

ON

110

SW1

OFF

ON

110

SW2

LED4:Remote controller

when powered

At factory

shipment

At factory

shipment

5

CNLVC

6

1

LEV1Wb

1223344

X502

CN507

3

1

M

M

5

5

6

ON

OFF

1

SW5

SWU3

LED3:Lit when powered

Control Board

CNLVB

LEV1Wa

TB2

SV1

*3

*8

DSA Board

CN3T

red

13

T01

ZNR01

3

1

CN502

black

1

2

CNAC

red

U

F01

AC250V

6.3A T

LED1 Display setting(SW2)

Function setting(SW1,SW3,SW4)

OUT4

OUT3

OUT2

X514

X513

X512

TB141A

OUT1

X511

3

33

33

22

22

1

11

11

CN3A

CN421

CN421

4-20mA

4-20mA

CN422CN422

blue

black

black

blue

blue

TB142C

COM+ IN6 IN8

COM+ IN5 IN7

TB142B

X516

X517X515

OUT6

OUT7OUT5

TB141B

red

red

green

blue

yellow/green

TB142A

IN2

IN1

IN1

IN3IN4

*4

*5 *6 *7

orange

yellow

black

purple

TB2

LEV1Wa

SV1

TB5

LEV1Wb

TB15

OUT1

IN1

IN3

P36

COM+

IN4

P72

IN5

IN6

IN7

IN8

OUT2

TH22

TH23

TH6

OUT4

TH8

Explanation

Function

Function

Function

Function

Appliance

Terminal

block

Linear

expansion valve

Solenoid valve

Power supply

BC controller/outdoor unit

For opening/closing the bypass circuit

Outdoor unit/BC controller

BC controller/outdoor unit

*3

MA remote controller

Operation ON/OFF

Pump interlock

Connection demand

*3 do not exist

Common

Operation ON/OFF

*3 exist

Heating

Heating ECO

Anti-freeze

Cooling

Defrost

liquid pipe temp

gas pipe temp

water inlet temp

Error signal

water outlet temp

Symbol

Symbol

Symbol

Symbol

Model name

Symbol

Thermistor

<Symbol explanation>

<CAUTION FOR INSTALLATION>

· Prior to installation, read the Installation Manual carefully.

*1. Single-dotted lines indicate wiring not supplied with the unit.

*2. Dot-dash lines indicate the control box boundaries.

*3. Difference of appliance

*4 TB141A(output)

*5 TB142A(input)

*6 TB142B(input)

*7 TB142C(input)

*8. Use copper supply wires.

°t°

t

°

t

°

5. ELECTRICAL WIRING DIAGRAMS

PWFY-P36,72NMU-E-AU

PWFY-11PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

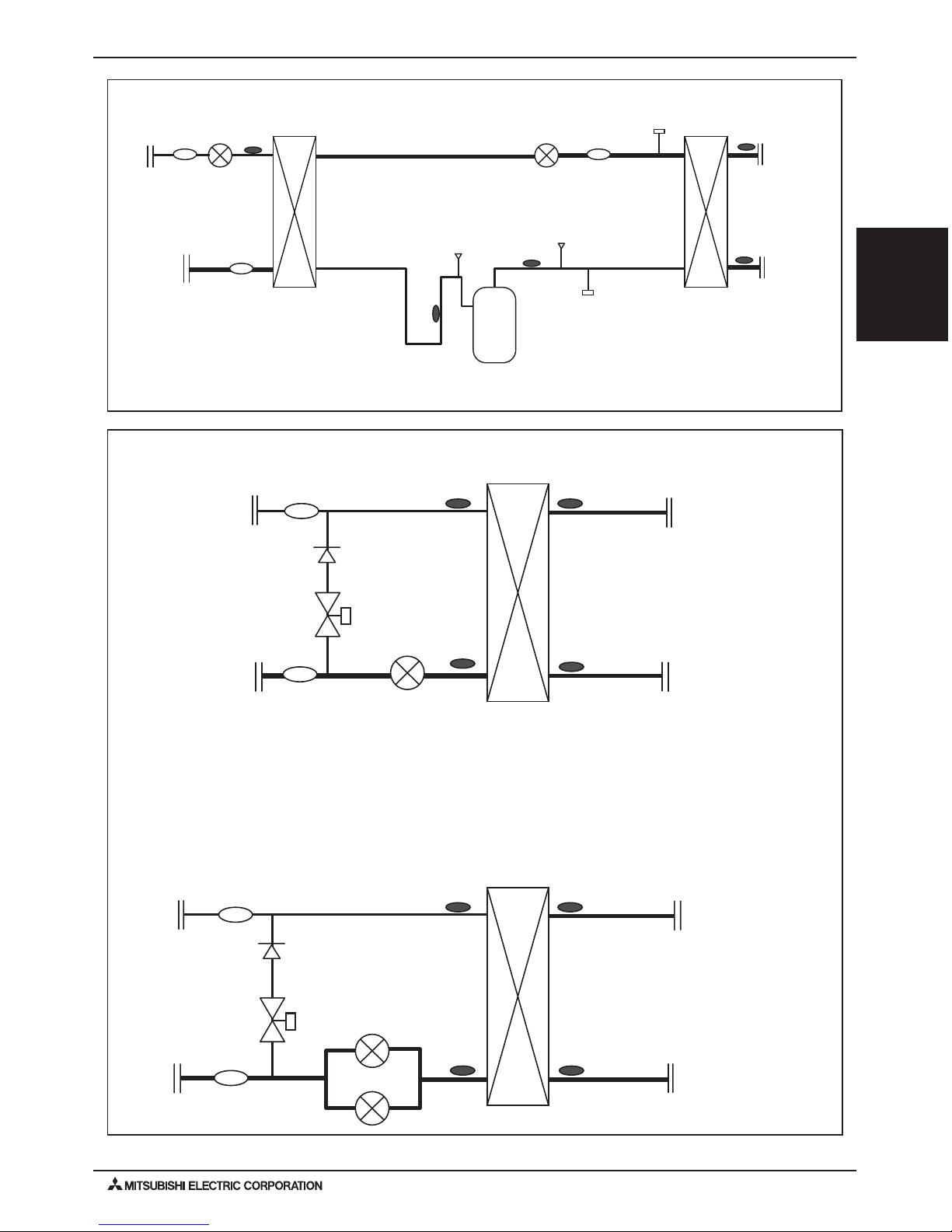

6. REFRIGERANT CIRCUIT DIAGRAMS

TH6

TH23

LEV1Wa

TH8

TH22

SV

CV1

ST2

ST3

Water inlet

Water outlet

screw

screw

Brazed

Brazed

TH6

TH23

LEV1Wa

TH8

TH22

LEV1Wb

SV

ST2

ST4

CV1

Water inlet

Water outlet

screw

screw

Brazed

Brazed

PWFY-P36NMU-E-AU

PWFY-P72NMU-E-AU

PWFY-P36NMU-E-BU

TH11

63H1

63HS

63LS

TH13

TH22

LEV1W

LEV2W

COMP

Water outlet

TH6

TH8

ST3

ST1

ST2

CJ

Brazed

Brazed

screw

screw

Water inlet

Hex

Hex

PWFY-12

PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

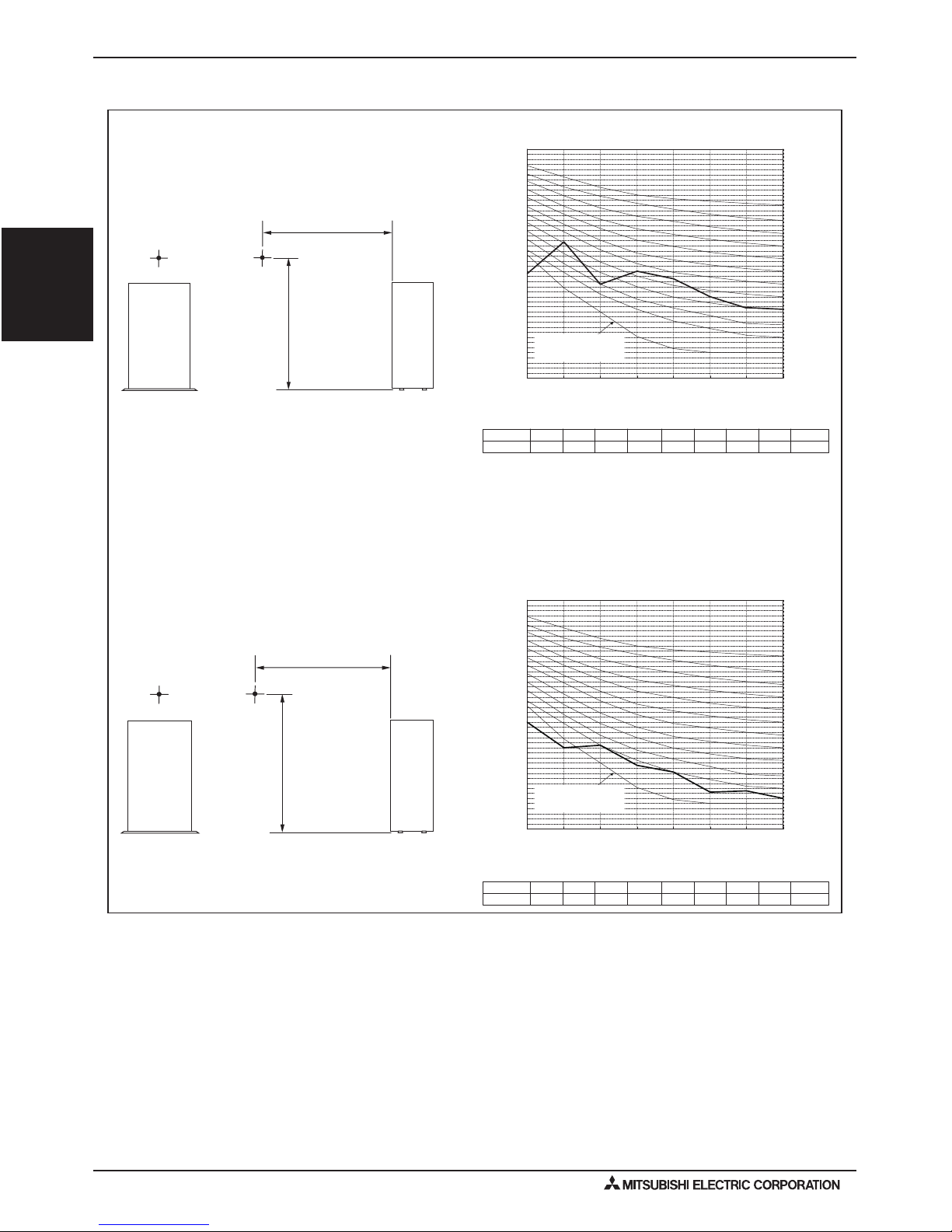

7. SOUND PRESSURE LEVELS

0

10

30

20

40

50

60

70

80

90

63 125 250 500 1k 2k 4k 8k

NC-40

NC-30

NC-20

NC-60

NC-50

NC-70

Octave band sound level (dB)

Sound pressure level of PWFY-P36NMU-E-BU

Measurement condition

PWFY-P36NMU-E-BU

60Hz

Octave band center frequencies <Hz>

Octave band sound level (dB)

Sound pressure level of PWFY-P36, 72NMU-E-AU

dB(A)

29.0

8k

12.0

4k

15.0

2k

14.5

1k

22.5

500

25.0

250

33.0

125

32.0

63

42.0

60Hz

dB(A)

44.0

8k

27.0

4k

27.5

2k

32.0

1k

39.0

500

42.0

250

37.0

125

53.5

63

41.0

Measurement condition

PWFY-P36, 72NMU-E-AU

Measurement

location

3-1/4 ft. (1m)

3-1/4 ft. (1m)

Measurement

location

3-1/4 ft. (1m)

3-1/4 ft. (1m)

Octave band center frequencies <Hz>

Approximate minimum

audible limit on

continuous noise

0

10

30

20

40

50

60

70

80

90

63 125 250 500 1k 2k 4k 8k

NC-40

NC-30

NC-20

NC-60

NC-50

NC-70

Approximate minimum

audible limit on

continuous noise

7-1. Sound Pressure Levels and NC Curves

PWFY-13PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

8. VIBRATION LEVELS

PWFY-P36NMU-E-BU

PWFY-P36NMU-E-BU

Model Vibration Levels[dBA]

34

3-15/16 in (100mm)

7-7/8 in (200mm)

Measurement

location

Service

panel

Concrete

VIBRATION LEVELS

PWFY-14

PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

9. CAPACITY TABLES

9-1. Correction by Temperature

Y-Series + PWFY-P36/72NMU-E-AU

PUHY-P72,96T(Y)JMU-A-BS

Cooling

0. 4

0. 6

0. 8

1. 0

1. 2

1. 4

20 30 40 50 60 70 80 90 100 110 120

Outdoor Temperature(FDB)

Inlet water Temperature(F)

Ratio of cooling capacity

0. 5

0. 6

0. 7

0. 8

0. 9

1. 0

1. 1

1. 2

1. 3

1. 4

20 30 40 50 60 70 80 90 100 110 120

Outdoor Temperature(FDB)

Ratio of cooling input

Inlet water Temperature(F)

Heating

0. 2

0. 4

0. 6

0. 8

1. 0

1. 2

-5 0 5 10 15 20 25 30 35 40 45 50 55 60

Inlet Water Temperature(F)

Ratio of heating capacity

Outdoor Temperature(FDB)

0. 4

0. 5

0. 6

0. 7

0. 8

0. 9

1. 0

1. 1

1. 2

-5 0 5 10 15 20 25 30 35 40 45 50 55 60

Outdoor Temperature(FWB)

Ratio of heating input

Inlet water Temperature(F)

PUHY-P120,144Y(T)JMU-A-BS

Cooling

Heating

0. 4

0. 6

0. 8

1. 0

1. 2

1. 4

20 30 40 50 60 70 80 90 100 110 120

Inlet Water Temperature(F)

Ratio of cooling capacity

95

86

77

68

59

50

Outdoor Temperature(FWB)

0. 2

0. 4

0. 6

0. 8

1. 0

1. 2

-5 0 5 10 15 20 25 30 35 40 45 50 55 60

Outdoor Temperature(FWB)

Inlet Water Temperature(F)

Ratio of heating capacity

50

68

86

95

105

0. 5

0. 6

0. 7

0. 8

0. 9

1. 0

1. 1

1. 2

1. 3

1. 4

20 30 40 50 60 70 80 90 100 110 120

Outdoor Temperature(FDB)

Inlet Water Temperature(F)

Ratio of cooling input

95

86

77

68

59

50

0. 4

0. 5

0. 6

0. 7

0. 8

0. 9

1. 0

1. 1

1. 2

-5 0 5 10 15 20 25 30 35 40 45 50 55 60

Outdoor Temperature(FWB)

Inlet Water Temperature(F)

Ratio of heating input

105

95

86

68

50

95

86

77

68

59

50

50

68

86

95

105

95

86

77

68

59

50

105

95

86

68

50

PWFY-15PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

9. CAPACITY TABLES

PUHY-P168,192,216,240Y(T)SJMU-A-BS

HeatingCooling

0. 4

0. 6

0. 8

1. 0

1. 2

1. 4

20 30 40 50 60 70 80 90 100 110 120

Outdoor Temperature(FDB)

Inlet Water Temperature(F)

Ratio of cooling capacity

95

86

77

68

59

50

0. 4

0. 6

0. 8

1. 0

1. 2

1. 4

-5 0 5 10 15 20 25 30 35 40 45 50 55 60

Outdoor Temperature(FWB)

Inlet Water Temperature(F)

Ratio of heating capacity

50

68

86

95

105

0. 5

0. 6

0. 7

0. 8

0. 9

1. 0

1. 1

1. 2

1. 3

1. 4

20 30 40 50 60 70 80 90 100 110 120

Outdoor Temperature(FDB)

Inlet Water Temperature(F)

Ratio of cooling input

95

86

77

68

59

50

0. 4

0. 5

0. 6

0. 7

0. 8

0. 9

1. 0

1. 1

1. 2

-5 0 5 10 15 20 25 30 35 40 45 50 55 60

Outdoor Temperature(FWB)

Inlet Water Temperature(F)

Ratio of heating input

105

95

86

68

50

PUHY-P264,288T(Y)SJMU-A-BS

HeatingCooling

0. 4

0. 6

0. 8

1. 0

1. 2

1. 4

20 30 40 50 60 70 80 90 100 110 120

Outdoor Temperature(FDB)

Inlet Water Temperature(F)

Ratio of cooling capacity

95

86

77

68

59

50

0. 4

0. 5

0. 6

0. 7

0. 8

0. 9

1. 0

1. 1

1. 2

1. 3

-5 0 5 10 15 20 25 30 35 40 45 50 55 60

Outdoor Temperature(FWB)

Inlet Water Temperature(F)

Ratio of heating capacity

50

68

86

95

105

0. 5

0. 6

0. 7

0. 8

0. 9

1. 0

1. 1

1. 2

1. 3

1. 4

20 30 40 50 60 70 80 90 100 110 120

Outdoor Temperature(FDB)

Inlet Water Temperature(F)

Ratio of cooling input

95

86

77

68

59

50

0. 4

0. 5

0. 6

0. 7

0. 8

0. 9

1. 0

1. 1

1. 2

1. 3

-5 0 5 10 15 20 25 30 35 40 45 50 55 60

Outdoor Temperature(FWB)

Inlet Water Temperature(F)

Ratio of heating input

105

95

86

68

50

PWFY-16

PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

9. CAPACITY TABLES

PUHY-P312,336,360T(Y)SJMU-A-BS

HeatingCooling

0. 4

0. 5

0. 6

0. 7

0. 8

0. 9

1. 0

1. 1

1. 2

1. 3

-5 0 5 10 15 20 25 30 35 40 45 50 55 60

Outdoor Temperature(FWB)

Inlet Water Temperature(F)

Ratio of heating capacity

50

68

86

95

105

0. 5

0. 6

0. 7

0. 8

0. 9

1. 0

1. 1

1. 2

1. 3

1. 4

20 30 40 50 60 70 80 90 100 110 120

Outdoor Temperature(FDB)

Inlet Water Temperature(F)

Ratio of cooling input

95

86

77

68

59

50

0. 4

0. 6

0. 8

1. 0

1. 2

1. 4

20 30 40 50 60 70 80 90 100 110 120

Outdoor Temperature(FDB)

Inlet Water Temperature(F)

Ratio of cooling capacity

95

86

77

68

59

50

0. 4

0. 5

0. 6

0. 7

0. 8

0. 9

1. 0

1. 1

1. 2

-5 0 5 10 15 20 25 30 35 40 45 50 55 60

Outdoor Temperature(FWB)

Inlet Water Temperature(F)

Ratio of heating input

105

95

86

68

50

PWFY-17PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

9. CAPACITY TABLES

R2-Series + PWFY-P36/72NMU-E-AU

PURY-P72,96T(Y)JMU-A-BS

Cooling

Heating

0. 4

0. 6

0. 8

1. 0

1. 2

1. 4

20 30 40 50 60 70 80 90 100 110 120

Outdoor Temperature(FDB)

Inlet water Temperature(F)

Ratio of cooling capacity

95

86

77

68

59

50

0. 4

0. 5

0. 6

0. 7

0. 8

0. 9

1. 0

1. 1

1. 2

1. 3

-5 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90

Outdoor Temperature(FWB)

Inlet Water Temperature(F)

Ratio of heating capacity

50

68

86

95

105

0. 5

0. 6

0. 7

0. 8

0. 9

1. 0

1. 1

1. 2

1. 3

1. 4

20 30 40 50 60 70 80 90 100 110 120

Outdoor Temperature(FDB)

Inlet water Temperature(F)

Ratio of cooling input

95

86

77

68

59

50

0. 4

0. 5

0. 6

0. 7

0. 8

0. 9

1. 0

1. 1

1. 2

-5 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90

Outdoor Temperature(FWB)

Inlet Water Temperature(F)

Ratio of heating input

105

95

86

68

50

PURY-P120,144T(Y)JMU-A-BS

Cooling

Heating

0. 4

0. 6

0. 8

1. 0

1. 2

1. 4

20 30 40 50 60 70 80 90 100 110 120

Outdoor Temperature(FDB)

Inlet Water Temperature(F)

Ratio of cooling capacity

95

86

77

68

59

50

0. 2

0. 4

0. 6

0. 8

1. 0

1. 2

-5 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90

Outdoor Temperature(FWB)

Inlet Water Temperature(F)

Ratio of heating capacity

50

68

86

95

105

0. 5

0. 6

0. 7

0. 8

0. 9

1. 0

1. 1

1. 2

1. 3

1. 4

20 30 40 50 60 70 80 90 100 110 120

Outdoor Temperature(FDB)

Inlet Water Temperature(F)

Ratio of cooling input

95

86

77

68

59

50

0. 4

0. 5

0. 6

0. 7

0. 8

0. 9

1. 0

1. 1

1. 2

1. 3

-5 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90

Outdoor Temperature(FWB)

Inlet Water Temperature(F)

Ratio of heating input

105

95

86

68

50

PWFY-18

PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

9. CAPACITY TABLES

PURY-P168,192,216,240T(Y)JMU-A-BS

Cooling

Heating

0. 4

0. 6

0. 8

1. 0

1. 2

1. 4

20 30 40 50 60 70 80 90 100 110 120

Outdoor Temperature(FDB)

Inlet Water Temperature(F)

Ratio of cooling capacity

95

86

77

68

59

50

0. 2

0. 4

0. 6

0. 8

1. 0

1. 2

-5 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90

Outdoor Temperature(FWB)

Inlet Water Temperature(F)

Ratio of heating capacity

50

68

86

95

105

0. 5

0. 6

0. 7

0. 8

0. 9

1. 0

1. 1

1. 2

1. 3

1. 4

20 30 40 50 60 70 80 90 100 110 120

Outdoor Temperature(FDB)

Inlet Water Temperature(F)

Ratio of cooling input

95

86

77

68

59

50

0. 2

0. 4

0. 6

0. 8

1. 0

1. 2

-5 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90

Outdoor Temperature(FWB)

Inlet Water Temperature(F)

Ratio of heating input

105

95

86

68

50

PURY-P264,288T(Y)JMU-A-BS

Cooling

Heating

0. 4

0. 6

0. 8

1. 0

1. 2

1. 4

20 30 40 50 60 70 80 90 100 110 120

Ratio of cooling capacity

Outdoor Temperature(FDB)

Inlet Water Temperature(F)

95

86

77

68

59

50

0. 4

0. 5

0. 6

0. 7

0. 8

0. 9

1. 0

1. 1

1. 2

1. 3

-5 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90

Outdoor Temperature(FWB)

Inlet Water Temperature(F)

Ratio of heating capacity

50

68

86

95

105

0. 5

0. 6

0. 7

0. 8

0. 9

1. 0

1. 1

1. 2

1. 3

1. 4

20 30 40 50 60 70 80 90 100 110 120

Outdoor Temperature(FDB)

Inlet Water Temperature(F)

Ratio of cooling input

95

86

77

68

59

50

0. 4

0. 5

0. 6

0. 7

0. 8

0. 9

1. 0

1. 1

1. 2

1. 3

-5 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90

Outdoor Temperature(FWB)

Inlet Water Temperature(F)

Ratio of heating input

105

95

86

68

50

PWFY-19PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

9. CAPACITY TABLES

H2I Series + PWFY-P36/72NMU-E-AU

PUHY-HP72,96Y(T)JMU-A-BS

PUHY-HP144,192Y(T)SJMU-A-BS

0. 4

0. 6

0. 8

1. 0

1. 2

1. 4

20 30 40 50 60 70 80 90 100 110 120

Outdoor Temperature(FDB)

Inlet Water Temperature(F)

Ratio of cooling capacity

95

86

77

68

59

50

0. 2

0. 4

0. 6

0. 8

1. 0

1. 2

- 15 - 10 -5 0 5 10 15 20 25 30 35 40 45 50 55 60

Outdoor Temperature(FWB)

Inlet Water Temperature(F)

Ratio of heating capacity

50

68

86

104

0. 5

0. 6

0. 7

0. 8

0. 9

1. 0

1. 1

1. 2

1. 3

1. 4

20 30 40 50 60 70 80 90 100 110 120

Outdoor Temperature(FDB)

Inlet Water Temperature(F)

Ratio of cooling input

95

86

77

68

59

50

0. 4

0. 6

0. 8

1. 0

1. 2

1. 4

1. 6

1. 8

- 15 - 10 -5 0 5 10 15 20 25 30 35 40 45 50 55 60

Outdoor Temperature(FWB)

Inlet Water Temperature(F)

Ratio of heating input

86

68

50

104

PWFY-20

PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

9. CAPACITY TABLES

0.5

0.6

0.7

0.8

0.9

1.0

1.1

-5 5 15 25 35 45 55 65 75 85

Outdoor temp. [ FWB]

Ratio of heat i ng capacity

68

50

86

104

122

140

149

Booster uni t inlet - water t emp. [F]

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.1

-5 5 15 25 35 45 55 65 75 85

Outdoor temp. [ FWB]

Ratio of boos t er uni t input

685086

104

Booster uni t inlet - water t emp.[F]

122

140

149

0.6

0.7

0.8

0.9

1.0

1.1

-5 5 15 25 35 45 55 65 75 85

Outdoor temp. [ FWB]

Ratio of out door unit input

104

122

86

140

68

149

50

Booster uni t inlet - water t emp. [F]

R2-Series + PWFY-P36NMU-E-BU

PURY-P72,96T(Y)JMU-A-BS

PWFY-21PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

9. CAPACITY TABLES

0.5

0.6

0.7

0.8

0.9

1.0

1.1

-5 5 15 25 35 45 55 65 75 85

Outdoor temp. [ FWB]

Ratio of heati ng capacity

Booster uni t inlet - wat er t emp. [F]

68

50

86

104

122

140

149

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.1

-5 5 15 25 35 45 55 65 75 85

Outdoor temp. [ FWB]

Ratio of boost er uni t input

Booster uni t inlet - wat er t emp. [F]

68

50

86

104

122

140

149

0.5

0.6

0.7

0.8

0.9

1.0

1.1

-5 5 15 25 35 45 55 65 75 85

Out door t emp. [FWB]

Ratio of outdoor unit input

Booster uni t inlet - wat er t emp. [F]

104

122

86

140

68

149

50

0.5

0.6

0.7

0.8

0.9

1.0

1.1

-5 5 15 25 35 45 55 65 75 85

Outdoor temp. [ FWB]

Ratio of heati ng capacity

Booster uni t inlet - wat er t emp. [F]

685086

104

122

140

149

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.1

-5 5 15 25 35 45 55 65 75 85

Outdoor temp. [ FWB]

Ratio of boost er uni t input

Booster uni t inlet - wat er t emp. [F]

68

50

86

104

122

140

149

0.5

0.6

0.7

0.8

0.9

1.0

1.1

-5 5 15 25 35 45 55 65 75 85

Outdoor temp. [ FWB]

Ratio of outdoor unit input

Booster uni t inlet - wat er t emp. [F]

104

122

86

140

68

149

50

0.5

0.6

0.7

0.8

0.9

1.0

1.1

-5 5 15 25 35 45 55 65 75 85

Outdoor temp. [ FWB]

Ratio of heati ng capacity

Booster uni t inlet - wat er t emp. [F]

685086

104

122

140

149

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.1

-5 5 15 25 35 45 55 65 75 85

Outdoor temp. [ FWB]

Ratio of boost er uni t input

Booster uni t inlet - wat er t emp. [F]

68

50

86

104

122

140

149

0.6

0.7

0.8

0.9

1.0

1.1

-5 5 15 25 35 45 55 65 75 85

Outdoor temp. [ FWB]

Ratio of outdoor unit input

Booster uni t inlet - wat er t emp. [F]

104

122

86

140

68

149

50

R2-Series + PWFY-P36NMU-E-BU

PURY-P120,144T(Y)JMU-A-BS

PWFY-22

PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

0.5

0.6

0.7

0.8

0.9

1.0

1.1

-5 5 15 25 35 45 55 65 75 85

Outdoor temp. [ FWB]

Ratio of heati ng capacity

Booster uni t inlet - wat er t emp. [F]

68

50

86

104

122

140

149

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.1

-5 5 15 25 35 45 55 65 75 85

Outdoor temp. [ FWB]

Ratio of boost er uni t input

Booster uni t inlet - wat er t emp. [F]

68

50

86

104

122

140

149

0.5

0.6

0.7

0.8

0.9

1.0

1.1

-5 5 15 25 35 45 55 65 75 85

Outdoor temp. [ FWB]

Ratio of outdoor unit input

Booster uni t inlet - wat er t emp. [F]

104

122

86

140

68

149

50

0.5

0.6

0.7

0.8

0.9

1.0

1.1

-5 5 15 25 35 45 55 65 75 85

Outdoor temp. [ FWB]

Ratio of heati ng capacity

Booster uni t inlet - wat er t emp. [F]

68

50

86

104

122

140

149

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.1

-5 5 15 25 35 45 55 65 75 85

Outdoor temp. [ FWB]

Ratio of boost er uni t input

Booster uni t inlet - wat er t emp. [F]

68

50

86

104

122

140

149

0.6

0.7

0.8

0.9

1.0

1.1

-5 5 15 25 35 45 55 65 75 85

Outdoor temp. [ FWB]

Ratio of outdoor unit input

Booster uni t inlet - wat er t emp. [F]

104

122

86

140

68

149

50

R2-Series + PWFY-P36NMU-E-BU

PURY-P168,192,216,240T(Y)JMU-A-BS

9. CAPACITY TABLES

PWFY-23PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

0.5

0.6

0.7

0.8

0.9

1.0

1.1

-5 5 15 25 35 45 55 65 75 85

Outdoor temp. [ FWB]

Ratio of heati ng capacity

Booster uni t inlet - wat er t emp. [F]

68

50

86

104

122

140

149

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.1

-5 5 15 25 35 45 55 65 75 85

Outdoor temp. [ FWB]

Ratio of boost er uni t input

Booster uni t inlet - wat er t emp. [F]

68

50

86

104

122

140

149

0.6

0.7

0.8

0.9

1.0

1.1

-5 5 15 25 35 45 55 65 75 85

Outdoor temp. [ FWB]

Ratio of outdoor unit input

Booster uni t inlet - wat er t emp. [F]

104

122

86

140

68

149

50

9. CAPACITY TABLES

R2-Series + PWFY-P36NMU-E-BU

PURY-P264,288T(Y)JMU-A-BS

PWFY-24

PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

9. CAPACITY TABLES

9-2. Water Pressure Drop

PWFY-P36NMU-E-BU

0

3.3 (10)

6.6 (20)

10 (30)

13.3 (40)

16.6 (50)

2.2 (0.5) 4.4 (1) 6.6 (1.5

)8

.8 (2)

Water flow rate (GPM [m3/h])

Water-pressure drop (ft. [kPa])

PWFY-P36,72NMU-E-AU

0

3.3 (10)

6.6 (20)

10 (30)

13.6 (40)

16.6 (50)

20 (60)

23.3 (70)

26.6 (80)

30 (90)

33.3 (100)

Water flow rate (GPM [m3/h])

Water-pressure drop (ft. [kPa])

PWFY-P36NMU-E-AU

PWFY-P72NMU-E-AU

2.2 (0.5)

4.4 (1)

6.6 (1.5)

8.8 (2)

11 (2.5)

13.2 (3)

15.4 (3.5)

17.6 (4)

19 (4.5)

PWFY-25PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

10. OPTIONAL PARTS

Optional Parts Line Up for the Indoor Unit

(A) Strainer (B)

Heat insulation material

*1. PWFY-P72NMU-E-AU only

(C) Connecter sets 2(D) Washer 2

*1

(E) Expansion joint 2

(A) Install the strainer at the water pipe inlet.

(B) This insulation is for exclusive use with the strainer. Wrap the strainer with the insulation after water

pipes are installed.

(C) These are analog input connectors. Cut the wire before using.

(D) Fix power source wiring to terminal bed box by using buffer bushing for tensile force. (Conduit or the like.)

Connect transmission wiring to transmission terminal bed through the knockout hole of terminal bed box using

ordinary bushing.

(E) Supplied only with the PWFY-P72NMU-E-AU. Install them at the strainer inlet.

PWFY-26

PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

11-1-2. Electrical characteristics of Indoor unit

• Provideaswitchwithatleast3mm(1/8in)contactseparationineachpolewheninstallingtheairconditioner.

Model

Unit

Hz Volts

Voltage

range

RLA(A) MCA(A)

Max.

Fuse(A)

PWFY-P36NMU-E-AU

PWFY-P72NMU-E-AU

60Hz 208/230V 188 to 253V 0.072/0.065 0.09 15

Model

Unit Compressor

Hz Volts

Voltage

range

RLA(A) MCA(A)

Max.

Fuse(A)

SC(A)

PWFY-P36NMU-E-BU 60Hz 208/230V 188 to 253V 12.30/11.12 25 25 1.25

Symbols: MCA: Min. Circuit Amps (=1.25 x FLA)

11. SYSTEM DESIGN

11-1. Electrical Work

11-1-1. General Cautions

Warning:

Electricalworkshouldbeperformedbyqualiedelectricalengineersinaccordancewith“EngineeringStandardsForElectrical

Installation” and the supplied installation manuals. Special circuits should also be used. If the power circuit lacks capacity or has an

installationfailure,itmaycauseariskofelectricshockorre.

1. Follow ordinances of your government organization for technical standard related to electrical equipment, wiring regulations,

and guidances of each electrical power company.

2. Power should be taken from the special branch circuit.

3. Install a ground breaker to the power.

4. Install the unit so that the control circuit cables (remote controller, transmission cables, or external input/output line) is not

in direct contact with the power cable outside the unit.

5. Ensure that there is no slack on all wire connections.

6. Vermin may have access to and damage the power, remote controller, and transmission cables. To prevent damage, insert

cables into metal piping.

7. Do not connect the power cables to the transmission cable leads.

8. Connect control cables to the indoor unit, remote controller, and the outdoor unit.

9. Ground the unit.

10. Select control cables following instructions.

Caution:

Be sure to put the unit to the ground on the outdoor unit side. Do not connect the ground cable to any gas pipe, water pipe,

lightening rod, or telephone cable. Improper grounding may cause electric shock.

PWFY-27PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

11. SYSTEM DESIGN

11-2. M-NET Control

11-2-1. Transmission Cable Specications

*1 Connected with simple remote controller. CVVS, MVVS: PVC insulated PVC jacketed shielded control cable

CVV, MVV : PVC insulated PVC sheathed control cable

CPEVS : PE insulated PVC jacketed shielded communication cable

PWFY-P36NMU-E-BU

Transmission Cables MA Remote Controller Cables External Input External Output

Type of

Cable

Shielding wire (2-core)

CVVS, CPEVS or MVVS

Sheathed 2-core cable (shielded)

CVVS

Sheathed multi-core cable

(shielded)

CVVS or MVVS

Sheathed multi-core cable (unshielded)

CVV or MVV

Cable

Diameter

More than 1.25 mm

2

[AWG16]

1.25 mm

2

[AWG16]

(1.25 mm

2

[AWG16]

)*1

1.25 mm

2

[AWG16]

1.25 mm

2

[AWG16]

Remarks -

Max.length: 200 m [656 ft] Max. length: 100 m [328 ft]

Rated voltage: L1-N: 220

~240 V

Rated load: 0.6 A

Transmission Cables MA Remote Controller Cables External Input External Output

Type of

Cable

Shielding wire (2-core)

CVVS, CPEVS or MVVS

Sheathed 2-core cable CVV

(unshielded)

Sheathed multi-core cable

CVV or MVV (unshielded)

Sheathed multi-core cable

(unshielded) CVV or MVV

Cable

Diameter

More than 1.25 mm

2

[AWG16]

1.25 mm

2

[AWG16]

(1.25 mm

2

[AWG16]

)*1

1.25 mm

2

[AWG16]

1.25 mm

2

[AWG16]

Remarks -

Max.length: 200 m [656 ft] Max. length: 100 m [328 ft]

Rated voltage: L1-N: 220

~240 V

Rated load: 0.6 A

PWFY-P36,72NMU-E-AU

11-2-2. Address Setting

Switch Operation

Operate with the main power turned OFF

•Therearetwotypesofrotaryswitchsettingavailable:settingaddresses1to9andover10,andsettingbranchnumbers.

a) How to set addresses

Example:IfAddressis“3”,remainSWU2(forover10)at“0”,andmatchSWU1(for1to9)with“3”.

b) How to set branch numbers SWU3 (Series R2 only)

Matchtheindoorunit’srefrigerantpipewiththeBCcontroller’sendconnectionnumber.RemainotherthanR2at“0”.

•Therotaryswitchesareallsetto“0”whenshippedfromthefactory.Theseswitchescanbeusedtosetunitaddressesand

branch numbers at will.

SWU2 SWU3

SWU1

PWFY-28

PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

11. SYSTEM DESIGN

11-2-3. Setting Addresses

Unit

PWFY unit

Standard indoor unit

ME, LOSSNAY

Remote controller

(Main)

ME, LOSSNAY

Remote controller

(Sub)

Address setting

01 ~ 50

52 ~ 99, 100

101 ~ 150

151 ~ 199, 200

NoteExample

The address of outdoor unit + 1

Please reset one of them to an address between 52

and 99 when two addresses overlap.

The address automatically becomes "100" if it is set

as "01~ 50"

The smallest address of indoor unit in the group + 100

The place of "100" is fixed to "1"

System remote

controller

ON/OFF remote

controller

AG-150

GB-50

000, 201 ~ 250

000, 201 ~ 250

000, 201 ~ 250

Local remote controller

System controller

The address of main remote controller + 50

The address automatically becomes "200" if it is set

as "00"

10 1

10 1

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

10 1

10 1

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

10 1

10 1100

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

10 1100

10 1100

LMAP03U

201 ~ 250

1

1

Fixed

Fixed

Group remote

controller

201 ~ 250

The smallest group No. to be managed + 200

10 1

2

Fixed

2

Fixed

Outdoor unit

BC controller

(Main)

53 ~ 99, 100

Lowest address within the indoor units connected to

the BC controller (Sub) plus 50.

10 1

BC controller

(Sub)

51 ~ 99, 100

The smallest address of indoor unit in same refrigerant

system + 50

Assign sequential address numbers to the outdoor

units in one refrigerant circuit system. OC and OS are

automatically detected. (Note 2)

Please reset one of them to an address between 51

and 99 when two addresses overlap.

The address automatically becomes "100" if it is set

as "01~ 50"

Use the most recent address within the same group of

indoor units. Make the indoor units address connected

to the BC controller (Sub) larger than the indoor units

address connected to the BC controller (Main).

If applicable, set the sub BC controllers in an PURY

system in the following order:

(1)

Indoor unit to be connected to the BC controller (Main)

(2)

Indoor unit to be connected to the BC controller (No.1 Sub)

(3)

Indoor unit to be connected to the BC controller (No.2 Sub)

Set the address so that (1)<(2)<(3)

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

10 1

(Note1)

0,2 0~50~9

BAC-HD150

000, 201 ~ 250

10 1100

0,20~5 0~9

Settings are made with setting tool of BM ADAPTER.

Note1: To set the address to "100", set it to "50"

Note2: Outdoor units OC and OS in one refrigerant circuit system are automatically detected.

OC and OS are ranked in descending order of capacity. If units are the same capacity, they are ranked in ascending

order of their address.

PWFY-29PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

11-2-4. System Examples

11. SYSTEM DESIGN

2. Address should be set to Indoor units, LOSSNAY and central controller.

3. M-NET power is supplied by the Outdoor unit at TB3, while Indoor unit and MA RC consume the M-NET power for transmission

use. For details, refer System configuration restrictions".

NOTE:

1. Outdoor units OC and OS in one refrigerant circuit system are automatically detected.

OC and OS are ranked in descending order of capacity. If units are the same capacity, they are ranked in ascending order

of their address.

Indoor unit

Indoor unit

PWFY-P36NMU-E-BU

PWFY-P36NMU-E-AU

PWFY-P72NMU-E-AU

PWFY-P36NMU-E-BU

PWFY-P36NMU-E-AU

PWFY-P72NMU-E-AU

C/R AMWMA

(Main) (Sub)

MA R/C

SRU

Wireless R/C

*1

*2 System controller should connect to TB7 at Outdoor and use power supply unit together in Multi-Refrigerant-System.

*1

01

BC controller

53

BC controller

(Main)

93

033020

TB15

TB5 5BT20BT 2BT5BT

Transmission Booster

PAC-SF46EPA

TB5

3BT51BT51BT

TB15

MA R/C

(Main) (Sub)

MA R/C

TB15

ME R/C

MA R/C

PZ-52SF

SRU

Wireless R/C

*1

*1 142 143

41 42

43

95

45 46

TB15

TB5 5BT20BT

LOSSNAY

5BT5BT5BT

TB15

*1 For Wireless R/C and Signal receiver unit (SRU), channel 1, 2 and 3 are selectable and should be set to same channel.

BC controller

(Sub1)

Group 2

12 puorG1 puorG

Group 32 43 puorG33 puorG13 puorG

TB3

TB7 7BT7BT7BT

TB7

TB3

201

PSU

5251

OC OS

PURY-P-TSHMU/YSHMU

SC

TB3TB3

9291

OC OS

PURY-P-TSHMU/YSHMU

TB3

97

OC

CN41CN40CN41CN40 CN41CN40CN41 14NC04NC CN40

ON

DipSW2-1

ON

DipSW2-1

ON

DipSW2-1

ON

DipSW2-1

ON

DipSW2-1

PURY-P-TSHMU/YSHMU

4. Indoor units should be set with a branch number.

5. Assign an address to each of the sub BC controllers (SC1 and SC2) which equals the sum of the smallest address of the indoor

units that are connected to each sub BC controller and 50.

*2

MA Remote Controller, Multi-refrigerant system, System Controller at TB7 side.

PWFY-P36NMU-E-BU/PWFY-P36,72NMU-E-AU with R2-Series Outdoor Units

PWFY-30

PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

PWFY-P36,72NMU-E-AU with Y-Series Outdoor Units

11. SYSTEM DESIGN

2. Address should be set to Indoor units, LOSSNAY and central controller.

3. M-NET power is supplied by the Outdoor unit at TB3, while Indoor unit and MA consume the M-NET power for transmission use.

For details, refer to "System configuration restrictions".

NOTE:

1. Outdoor units OC, OS1 and OS2 in one refrigerant circuit system are automatically detected.

OC, OS1 and OS2 are ranked in descending order of capacity. If units are the same capacity, they are ranked in ascending order

of their address.

Indoor unit

PWFY-P36NMU-E-AU

PWFY-P72NMU-E-AU

PWFY-P36NMU-E-AU

PWFY-P72NMU-E-AU

MA

(Main)

WMA

MA

*2 System controller should connect to TB7 at Outdoor and use power supply unit together in Multi-Refrigerant-System.

03302010

TB15

5BT5B

T2

BT5BT

Transmission Booster

PAC-SF46EPA

TB5

3BT51BT51BT

TB15

MA

(Main)MA(Sub)

TB15

PWFY-P36NMU-E-AU

PWFY-P72NMU-E-AU

WMA MA

41 42

43

45 46

TB15

5BT5BT

LOSSNAY

5BT5BT5BT

TB15

SRU

Wireless R/C

*1

*1

*1 For Wireless R/C and Signal receiver unit (SRU), channel 1, 2 and 3 are selectable and should be set to same channel.

Group 2

12 puorG1 puorG

Group 32 43 puorG33 puorG13 puorG

TB3 TB3

TB7 7BT7BT7BT7BT

TB7

TB3

201

PSU

*2

535251

OC OS1 OS2

PUHY-P-YSHMU

SC

TB3TB3

9291

OC OS1

PUHY-P-YSHMU

TB3

97

OC

CN41CN40CN41CN40CN41CN40 CN41CN40CN4114NC04NC CN40

ON

DipSW2-1

ON

DipSW2-1

ON

DipSW2-1

ON

DipSW2-1

ON

DipSW2-1

ON

DipSW2-1

PUHY-P-YHMU

Wireless R/C

*1

*1

PWFY-31PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

11. SYSTEM DESIGN

11-2-5. External Input/Output Function

Preset temperature input (external analog input: 4mA-20mA)

External input is input through CN421, CN422 on the circuit board. (Fig. 1)

[Fig. 1]

Use the supplied connector.

If no temperature settings are made via the MA remote controller, the temperature changes with the current of generator.

Refer to the instructions manual that came with the MA remote controller for how to make the settings.

4 mA → 50 °F (10 °C) 20 mA → 160 °F (71 °C)

External output terminal

External output terminal (refer to Fig. 2) is ineffective when the circuit is open.

Refer to Table 1 for information about each contact.

The current in the circuit to be connected to the external output terminal must be 0.6A or less.

External input terminal

Wiring length must be within 328 ft. (100 m).

External input terminal (refer to Fig. 2).

Refer to Table 2 through Table 4 for information about each contact.

Onlythe“pumpinterlock”functionisineffectivewhenthecircuitisshort-circuited.

Connect a relay circuit to the external output terminal as shown in Fig. 3.

Thespecicationsoftherelaycircuittobeconnectedmustmeetthefollowingconditions.

Contact rating voltage >= DC15V

Contact rating current >= 0.1A

Minimum applicable load =< 1mA at DC

*1 PWFY-P36NMU-E-BU: Hot Water

PWFY-P36, 72NMU-E-AU: Heating

*2 Effective when SW 4-3 is set to ON.

*3 Effective when SW 4-4 is set to ON.

*4 PWFY-P36, 72NMU-E-AU only

*5 When Heating ECO mode is effective, the outlet water temp. will be changed based on ambient temp. automatically.

*6 When Anti-freeze mode is effective, the unit will work for keeping set water temp. automatically.

Note: Dip S/W 1-1 OFF: Water Inlet Temp.

Dip S/W 1-1 ON : Water Outlet Temp.

The factory setting for Dip SW 1-1 is OFF.

Signal priority = External input > centralized controller > remote controller

CN421

(BK)

(BU)

CN422

3

2

+

211

3

current

direction

Current generator

External

analog input

+

current

direction

CN421

(BK)(BU)

CN422

32211

3

[Fig. 2]

OUT4OUT3OUT2

TB141A

OUT1

IN1 IN2 IN3 IN4

IN5IN6 IN7 IN8

TB142CTB142BTB142A

COM+

[Table. 1]

OUT1 Operation ON/OFF

OUT2 Defrost

OUT3 Compressor

OUT4 Error Signal

IN1 Pump Interlock

[Table 2 TB142A]

IN3 Connection Demand

IN4 Operation ON/OFF

[Table 3 TB142B]

[Fig. 3]

COM+ Common

IN5 *1 Hot Water/Heating

IN6 *2 Heating ECO *5

IN7 *3 Antifreeze *6

IN8 *4 Cooling Operation

[Table 4 TB142C]

PWFY-32

PWFY-P-NMU-E-BU/PWFY-P-NMU-E-AU (Sept. 2010)

PWFY-P-NMU-E-BU

PWFY-P-NMU-E-AU

11. SYSTEM DESIGN

11-3-1. Installation

Selecting an installation site

• Do not install outdoors. The unit is not waterproof.

• Back up system is recommended in case of PWFY unit breakdown.

• The unit will get hot. Do not install in a location where heat gets trapped inside.

• Be sure to install unit in a place strong enough to withstand its weight.

Any lack of strength may cause unit to fall down, resulting in a personal injury.

• Do not install the unit where corrosive gas is generated.

• Have installation work in order to protect against earthquake.

Any installation deciency may cause unit to fall down, resulting in a personal injury.

• Pay a special attention to the place, such as a basement, etc. where refrigeration gas can stay, since refrigeration is

heavier than the air.

• Do not install the unit where combustible gas may leak.

- If the gas leaks and accumulates around the unit, an explosion may result.

• When installing the unit in a hospital, communication station, or similar place, provide sufcient protection against

noise.