Mitsubishi PWFY-P100VM-E-BU, PWFY-P100VM-E-AU, PWFY-P200VM-E-AU, WCB CMB-PW202V-J DATA BOOK

Page 1

DATA BOOK

2nd edition

AIR CONDITIONERS

MODEL

PWFY-P100VM-E-BU

PWFY-P100VM-E-AU

PWFY-P200VM-E-AU

Page 2

• Do not use steel pipes as water pipes.

- Copper pipes are recommended.

• The water circuit should be a closed circuit.

• Ask the dealer or an authorized technician to

install the air conditioner.

- Improper installation by the user may result in water

leakage, electric shock, or re.

• Install the unit in a place that can withstand its

weight.

- Inadequate strength may cause the unit to fall down,

resulting in injuries.

• Do not touch the unit. The unit surface can be hot.

• Do not install the unit where corrosive gas is

generated.

• Usethespeciedcablesforwiring.Makethe

connections securely so that the outside force of

the cable is not applied to the terminals.

- Inadequate connection and fastening may generate

heat and cause a re.

• Prepare for rain and other moisture and

earthquakesandinstalltheunitatthespecied

place.

- Improper installation may cause the unit to topple

and result in injury.

• Always use an strainer and other accessories

speciedbyMitsubishiElectric.

- Ask an authorized technician to install the accesso

-

ries. Improper installation by the user may result in

water leakage, electric shock, or re.

• Never repair the unit. If the air conditioner must

be repaired, consult the dealer.

- If the unit is repaired improperly, water leakage,

electric shock, or re may result.

• Do not touch the refrigerant pipes and Water

pipes.

- Improper handling may result in injury.

• When handling this product, always wear protec

-

tive equipment.

EG:Gloves,fullarmprotectionnamelyboilersuit,

and safety glasses.

- Improper handling may result in injury.

• If refrigerant gas leaks during installation work,

ventilate the room.

- If the refrigerant gas comes into contact with a ame,

poisonous gases will be released.

• InstalltheunitaccordingtothisInstallationManual.

- If the unit is installed improperly, water leakage,

electric shock, or re may result.

• Have all electric work done by a licensed electri

-

cianaccordingto“ElectricFacilityEngineering

Standard” and “Interior Wire Regulations”and the

instructions given in this manual and always use

a special circuit.

- If the power source capacity is inadequate or electric

work is performed improperly, electric shock and re

may result.

• Keep the electric parts away from water (washing

water etc.).

- It might result in electric shock, catching re or

smoke.

• Securely install the heat source unit terminal

cover (panel).

- If the terminal cover (panel) is not installed properly,

dust or water may enter the heat source unit and re

or electric shock may result.

• When installing and moving the air conditioner

to another site, do not charge it with a refrigerant

differentfromtherefrigerant(R410A)speciedon

the unit.

- If a different refrigerant or air is mixed with the origi

nal refrigerant, the refrigerant cycle may malfunction

and the unit may be damaged.

• If the air conditioner is installed in a small room,

measures must be taken to prevent the refriger

ant concentration from exceeding the safety limit

even if the refrigerant should leak.

- Consult the dealer regarding the appropriate meas

ures to prevent the safety limit from being exceeded.

Should the refrigerant leak and cause the safety

limit to be exceeded, hazards due to lack of oxygen

in the room could result.

• When moving and reinstalling the air conditioner,

consult the dealer or an authorized technician.

- If the air conditioner is installed improperly, water

leakage, electric shock, or re may result.

- i -

Page 3

• After completing installation work, make sure that

refrigerant gas is not leaking.

- If the refrigerant gas leaks and is exposed to a fan

heater, stove, oven, or other heat source, it may gen

erate noxious gases.

• Do not reconstruct or change the settings of the

protection devices.

- If the pressure switch, thermal switch, or other

protection device is shorted and operated forcibly,

or parts other than those specied by Mitsubishi

Electric are used, re or explosion may result.

• To dispose of this product, consult your dealer.

• The installer and system specialist shall secure

-

safety against leakage according to local regula

tion or standards.

- Following standards may be applicable if local regu

lation are not available.

• Pay a special attention to the place, such as a

basement, etc. where refrigeration gas can stay,

since refrigeration is heavier than the air.

-

-

• Do not use the existing refrigerant piping.

- The old refrigerant and refrigerant oil in the existing

piping contains a large amount of chlorine which

may cause the refrigerant oil of the new unit to dete

riorate.

- R410A is a high-pressure refrigerant and can cause

the existing piping to burst.

• Use refrigerant piping made of C1220 (CU-DHP)

phosphorusdeoxidizedcopperasspeciedinthe

JIS H3300 “Copper and copper alloy seamless

pipes and tubes”. In addition, be sure that the in

ner and outer surfaces of the pipes are clean and

free of hazardous sulphur, oxides, dust/dirt, shaving particles, oils, moisture, or any other contaminant.

- Contaminants on the inside of the refrigerant piping

may cause the refrigerant residual oil to deteriorate.

• Store the piping to be used during installation

indoors and keep both ends of the piping sealed

until just before brazing. (Store elbows and other

joints in a plastic bag.)

- If dust, dirt, or water enters the refrigerant cycle,

deterioration of the oil and compressor trouble may

result.

• Apply a small amount of ester oil, ether oil, or

alkylbenzenetoares.(forindoorunit)

- Inltration of a large amount of mineral oil may

cause the refrigerant oil to deteriorate.

• Useliquidrefrigeranttollthesystem.

- If gas refrigerant is used to seal the system, the

composition of the refrigerant in the cylinder will

change and performance may drop.

-

• Do not use a refrigerant other than R410A.

- If another refrigerant (R22, etc.) is mixed with

-

R410A, the chlorine in the refrigerant may cause the

refrigerant oil to deteriorate.

• Useavacuumpumpwithareverseowcheck

valve.

- The vacuum pump oil may ow back into the refrig

erant cycle and cause the refrigerant oil to deteriorate.

• Do not use the following tools that are used with

conventional refrigerants.

(Gaugemanifold,chargehose,gasleakdetector,

reverseowcheckvalve,refrigerantchargebase,

refrigerant recovery equipment)

- If the conventional refrigerant and refrigerant oil are

mixed in the R410A, the refrigerant may deterio

rated.

- If water is mixed in the R410A, the refrigerant oil

may deteriorate.

- Since R410A does not contain any chlorine, gas

leak detectors for conventional refrigerants will not

react to it.

• Do not use a charging cylinder.

- Using a charging cylinder may cause the refrigerant

to deteriorate.

• Do not use antioxidant or leak-detection additive.

• Be especially careful when managing the tools.

- If dust, dirt, or water gets in the refrigerant cycle, the

refrigerant may deteriorate.

-

-

- ii -

Page 4

• Do not install the unit where combustible gas may

leak.

- If the gas leaks and accumulates around the unit, an

explosion may result.

• Do not use the air conditioner where food, pets,

plants, precision instruments, or artwork are kept.

- The quality of the food, etc. may deteriorate.

• Do not use the air conditioner in special environ

ments.

- Oil, steam, sulfuric smoke, etc. can signicantly reduce

the performance of the air conditioner or damage its

parts.

-

• When installing the unit in a hospital, communica

tionstation,orsimilarplace,providesufcient

protection against noise.

- The inverter equipment, private power generator,

high-frequency medical equipment, or radio commu

nication equipment may cause the air conditioner to

operate erroneously, or fail to operate. On the other

hand, the air conditioner may affect such equipment

by creating noise that disturbs medical treatment or

image broadcasting.

• Do not install the unit on a structure that may

cause leakage.

- When the room humidity exceeds 80 % or when the

drain pipe is clogged, condensation may drip from

the indoor unit. Perform collective drainage work

together with the unit, as required.

-

-

- iii -

Page 5

• Groundtheunit.

- Do not connect the ground wire to gas or water

pipes, lightning rods, or telephone ground lines.

Improper grounding may result in electric shock.

• Install the power cable so that tension is not

applied to the cable.

- Tension may cause the cable to break and generate

heat and cause a re.

• Install a leak circuit breaker, as required.

- If a leak circuit breaker is not installed, electric shock

may result.

• Usepowerlinecablesofsufcientcurrent

carrying capacity and rating.

- Cables that are too small may leak, generate heat,

and cause a re.

• Use only a circuit breaker and fuse of the

speciedcapacity.

- A fuse or circuit breaker of a larger capacity or a

steel or copper wire may result in a general unit

failure or re.

• Do not wash the air conditioner units.

- Washing them may cause an electric shock.

• Be careful that the installation base is not

damaged by long use.

- If the damage is left uncorrected, the unit may fall

and cause personal injury or damage property.

• Install the drain piping according to this

InstallationManualtoensureproperdrainage.

Wrap thermal insulation around the pipes to

prevent condensation.

- Improper drain piping may cause water leakage and

damage to furniture and other possessions.

• Be very careful about product transportation.

- If the unit weighs more than 20kg, carry the unit with

more than one person.

- Some products use PP bands for packaging. Do not

use any PP bands for a means of transportation. It

is dangerous.

- When transporting the unit, support it at the specied

positions on the unit base. Also support the unit at

four points so that it cannot slip side ways.

• Safely dispose of the packing materials.

- Packing materials, such as nails and other metal or

wooden parts, may cause stabs or other injuries.

- Tear apart and throw away plastic packaging bags

so that it is out of reach of children. If children play

with a plastic bag which was not torn apart, they

face the risk of suffocation.

- iv -

Page 6

• Turn on the power at least 12 hours before

starting operation.

- Starting operation immediately after turning on the

main power switch can result in severe damage

to internal parts. Keep the power switch turned on

during the operational season.

• Donottouchtheswitcheswithwetngers.

- Touching a switch with wet ngers can cause elec

tric shock.

• Do not touch the refrigerant pipes during and im

mediately after operation.

- During and immediately after operation, the

refrigerant pipes are may be hot and may be cold,

depending on the condition of the refrigerant owing

through the refrigerant piping, compressor, and

other refrigerant cycle parts. Your hands may suffer

burns or frostbite if you touch the refrigerant pipes.

• Do not operate the air conditioner with the panels

and guards removed.

- Rotating, hot, or high-voltage parts can cause

injuries.

-

• Do not turn off the power immediately after

stopping operation.

- Always wait at least ve minutes before turning off

the power. Otherwise, water leakage and trouble

may occur.

• Do not touch the surface of the compressor

during servicing.

- If unit is connected to the supply and not running,

crank case heater at compressor is operating.

-

• Do not touch the panels near the fan outlet with

barehands:theycangethotwhiletheunitisin

operation (even if it is stopped) or immediately

after operation to prevent burns. Wear gloves to

protect your hands when it is necessary to touch

the panels.

• While the unit is in operation or immediately after

operation, high-temperature exhaust air may blow

out of the fan exhaust outlet. Do not hold your

hands over the outlet or touch the panels near the

outlet.

• Be sure to provide a pathway for the exhaust air

from the fan.

• Water pipes can get very hot, depending on the

preset temperature. Wrap the water pipes with

insulating materials to prevent burns.

- v -

Page 7

Contents

Safety Precautions

IGeneralEquipmentDescriptions

1. Unit conguration table ············································ 1

2. Operable temperature range ··································· 1

3. Connectable outdoor unit/heat source unit

capacity range ·························································

IIProductSpecications

1. Specications ·························································· 2

(1) PWFY-P100VM-E-BU

(2) PWFY-P100VM-E-AU

(3) PWFY-P200VM-E-AU

(4) CMB-P104V-G

(5) CMB-PW202V-J

2. External Dimensions

(1) PWFY-P100VM-E-BU

(2) PWFY-P100, 200VM-E-AU

(3) CMB-P104,105,106,108,1010,1013,1016V-G

(4) CMB-PW202V-J

3. Electrical Wiring Diagrams ····································

(1) PWFY-P100VM-E-BU

(2) PWFY-P100, 200VM-E-AU

(3) CMB-P104V-G

(4) CMB-PW202V-J

4. Accessories ···························································

(1) PWFY

(2) CMB-P104V-G

(3) CMB-PW202V-J

················································ 6

10

14

III Product Data

1. Capacity tables ······················································ 15

(1) Correction by temperature

(2) Correction by water ow rate

(3) Correction by total indoor

(4) Correction by refrigerant piping length

(5) Correction at frosting and defrosting

(6) Water pressure drop

(7) Operation temperature range

2. Sound pressure levels ··········································· 41

(1) PWFY-P100VM-E-BU

(2) PWFY-P100, 200VM-E-AU

3. Vibration levels ······················································

(1) PWFY-P100VM-E-BU

4. Refrigerant circuit diagrams and

thermal sensors ····················································· 43

(1) PWFY-P100VM-E-BU

(2) PWFY-P100VM-E-AU

(3) PWFY-P200VM-E-AU

42

IV Installation

1. How to calculate the necessary heating capacity ·· 44

(1) Heating capacity calculation

(2) Calculation example

2. Installation ·····························································

(1) Selecting an installation site

1

(2) Installing the unit

(3) Refrigerant pipe and drain pipe specications

(4) Connecting refrigerant pipes and drain pipes

3. Water pipe installation ···········································

(1) Water circuit sample

(2) Selecting a water pump

(3) Installing the strainer

(4) Precautions during installation

(5) Example of unit installation

(6) Insulation installation

(7) Water processing and water quality control

(8) Pump interlock

(9) Anti freeze mode

V System Design

1. Electrical work ······················································· 56

(1) General cautions

(2) Power supply for PWFY unit

(3) Connecting remote controller,

indoor and outdoor transmission cables

(4) Transmission cable specications

(5) Connecting electrical connections

(6) Indoor unit address setting

(7) External input/output function

(8) BC controller piping design

(9) WCB piping design

VI Controller

1. PAR-W21MAA specications ································· 67

2. Dip switch functions ···············································

VIIMaintenanceCycle

1. Routine maintenance checks ································ 69

2. Parts Replacement Cycle ······································ 69

VIII Product Data (additional

information for chapter III.)

1. Outdoor unit capacity tables ·································· 70

(1) Correction by total indoor

(2) Correction by refrigerant piping length

(3) Correction at frosting and defrosting

45

51

68

Page 8

GeneralEquipmentDescriptions

I

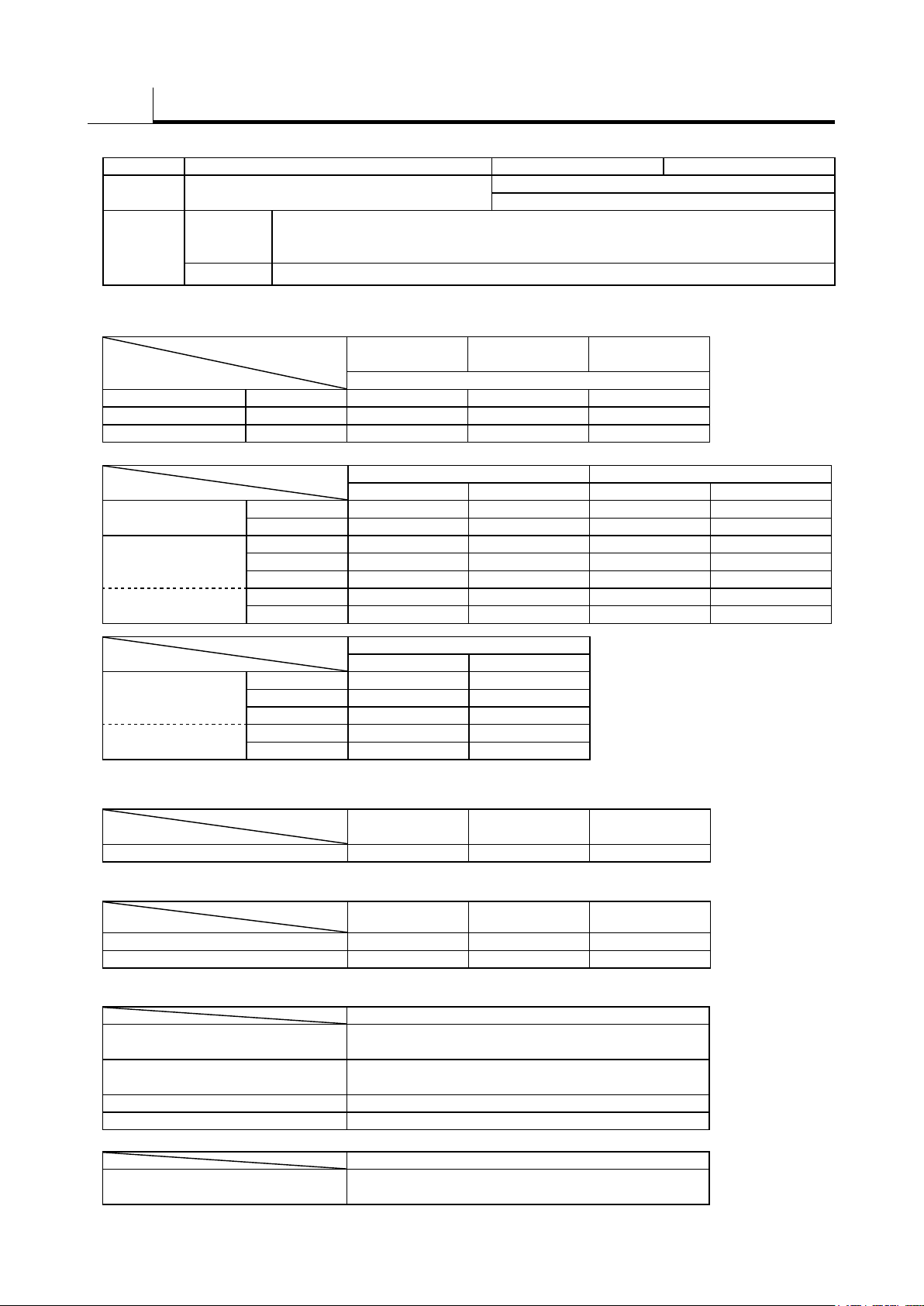

1.Unitcongurationtable

Model PWFY-P100VM-E-BU

Outdoor unit

Connection

PURY-(E)P•Y(S)HM-A(-BS) / PQRY-P•Y(S)HM-A

BC controller

WCB

BC controller: CMB-P104,105,106,108,1010,1013,1016V-G

Main BC controller: CMB-P108,1010,1013,1016V-GA / CMB-P1016V-HA

Sub BC controller: CMB-P104,108V-GB / CMB-P1016V-HB

PWFY-P100VM-E-AU PWFY-P200VM-E-AU

PUHY-(E)/(H)P•Y(S)HM-A(-BS) / PQHY-P•(S)HM-A

PURY-(E)P•Y(S)HM-A(-BS) / PQRY-P•Y(S)HM-A

CMB-PW202V-J

2. Operable temperature range

<PWFY-P100VM-E-BU>

Only PWFY

Inlet water temperature R2/WR2 series 10 to 70ºC 10 to 70ºC ―

Outdoor temperature R2 series -20 to 32ºCWB -20 to 32ºCWB -20 to 15.5ºCWB

Circulating water

temperature

WR2 series 10 to 45ºC 10 to 45ºC 10 to 45ºC

PWFY with

standard indoor unit

Heating

<PWFY-P100,200VM-E-AU>

Only PWFY PWFY with standard indoor units

Cooling Heating Cooling Heating

Inlet water temperature

Outdoor temperature

Circulating water

temperature

R2/WR2 series

Y/HP/WY series

R2 series

Y series

HP series

WR2 series

WYseries

10 to 35ºC 10 to 40ºC 10 to 35ºC 10 to 40ºC

10 to 35ºC 10 to 40ºC 10 to 35ºC 10 to 40ºC

-5 to 43ºCDB -20 to 32ºCWB -5 to 43ºCDB -20 to 32ºCWB

-5 to 43ºCDB

-5 to 43ºCDB -25 to 15.5ºCWB -5 to 43ºCDB -25 to 15.5ºCWB

10 to 45ºC 10 to 45ºC 10 to 45ºC 10 to 45ºC

10 to 45ºC 10 to 45ºC 10 to 45ºC 10 to 45ºC

-20 to 15.5ºCWB -5 to 43ºCDB

Only standard

indoor units

-20 to 15.5ºCWB

Only standard indoor units

Cooling Heating

Outdoor temperature

Circulating water

temperature

R2 series

Y series

HP series

WR2 series

WYseries

-5 to 43ºCDB -20 to 15.5ºCWB

-5 to 43ºCDB -20 to 15.5ºCWB

-5 to 43ºCDB -25 to 15.5ºCWB

10 to 45ºC 10 to 45ºC

10 to 45ºC 10 to 45ºC

3. Connectable outdoor unit/heat source unit capacity range

<PWFY-P100VM-E-BU>

Only PWFY

R2/WR2 series

*1 In case of WCB connection, the capacity range will be "50 to 130%".

50 to 100% 50 to 150%

PWFY with

standard indoor unit

*1

<PWFY-P100,200VM-E-AU>

Only PWFY

R2/WR2 series

Y/HP/WY series 50 to 100% 50 to 130% 50 to 130%

*1 In case of WCB connection, the capacity range will be "50 to 130%".

50 to 100% 50 to 150%

PWFY with

standard indoor unit

*1

<BC controller>

Connectable unit

CMB-P104/P105/106/107/1010/

1013/1016V-G

CMB-P108/1010/1013/1016V-GA

CMB-P1016V-HA PURY-P700-800YSHM-A(-BS)

CMB-P104/108V-GB, CMB-P1016V-HB CMB-P108/1010/1013/1016V-GA, CMB-P1016V-HA

PURY-(E)P200-350YHM-A(-BS)

PQRY-P200-300YHM-A

PURY-(E)P200-650Y(S)HM-A(-BS)

PQRY-P200-600Y(S)HM-A

<WCB>

Connectable unit

CMB-PW202V-J

PURY-(E)P200-350YHM-A(BS)

PQRY-P200-300YHM-A

Only standard

indoor units

50 to 150%

Only standard

indoor units

50 to 150%

*1

*1

- 1 -

Page 9

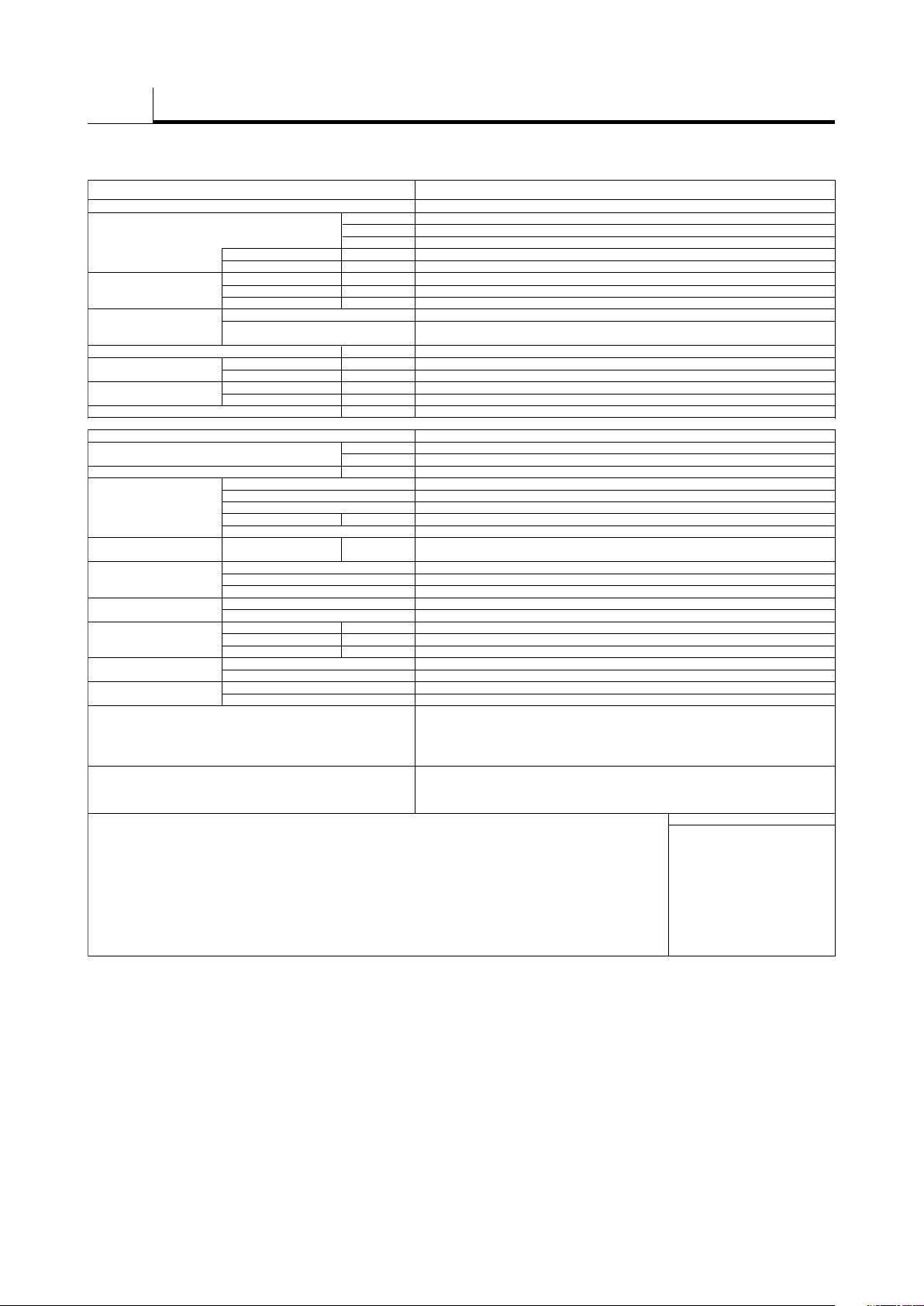

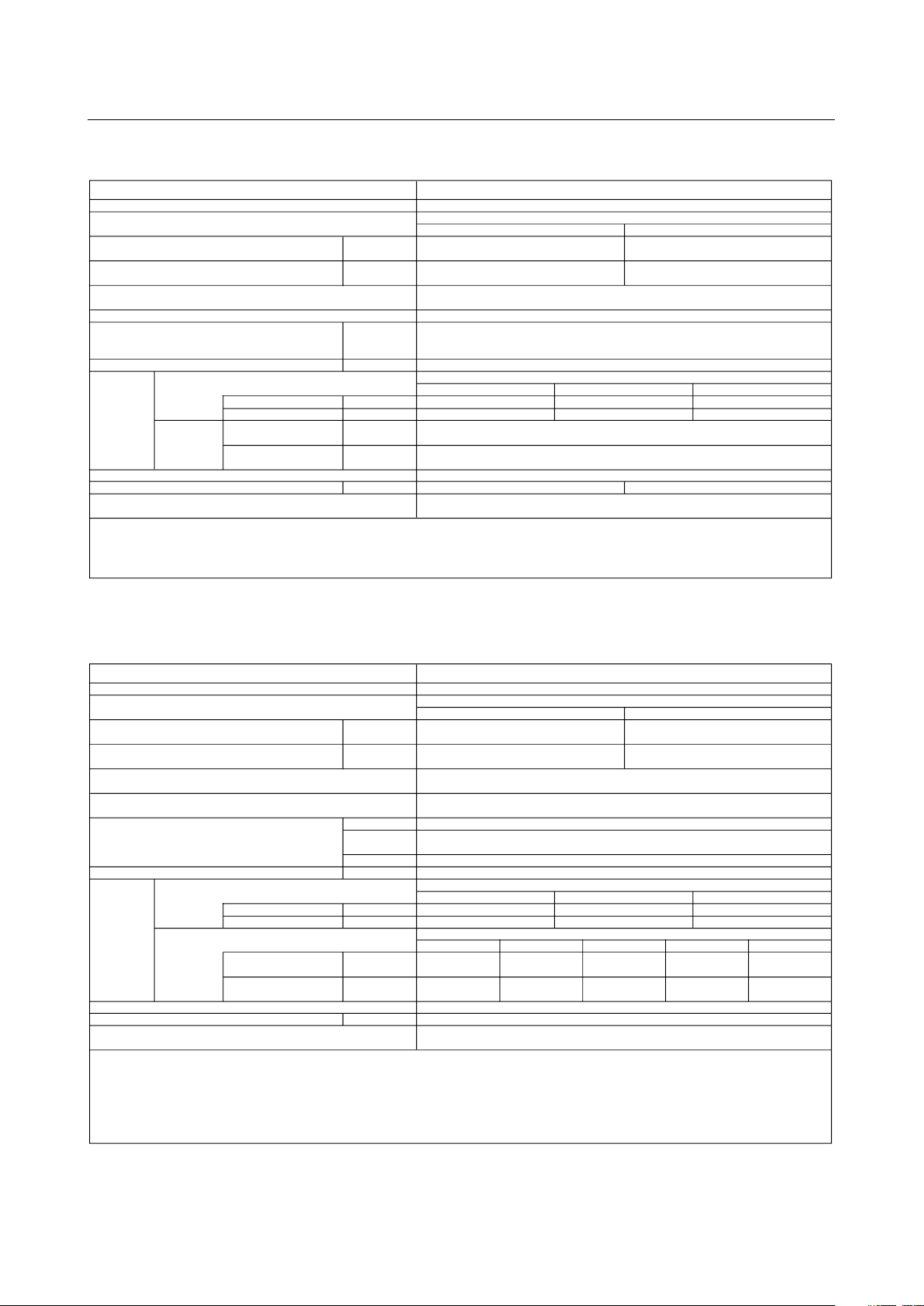

II

Model

Power source

kWHeating capacity

*1

*1*1kcal / h(Nominal )

BTU / h

kW

A

W.B

dB<A>

mm(in.)

mm(in.)

mm(in.)

mm(in.)

mm(in.)

mm

in.

kg(lb)

kW

-

Power input

Liquid

Gas

Current input

Outdoor temp.

Inlet Water temp.

-Circulating Water temp.

Total capacity

Temp. range of

heating

Connectable

outdoor unit

/heat source unit

Model / Quantity

Sound pressure level (measured in anechoic room)

Diameter of

refrigerant pipe

Diameter of

water pipe

Field drain pipe size

External finish

External dimension H × W × D

Net weight

Compressor

Maker

Type

Starting method

Motor output

Circulating water

Range

Protection on Internal circuit

(R134a)

High pressure protection

Inverter circuit (COMP)

Compressor

Type × original charge

Refrigerant

Control

R410a

Design pressure

R134a

Water

External

Drawing

Standard attachment

Optional parts

Remark

Note:

*1 Nominal heating conditions

<PURY-series>

Outdoor Temp. : 7°CDB/6°CWB (45°FDB / 43°FWB)

kcal = kW × 860

Pipe length : 7.5 m (24-9/16 ft)

BTU/h = kW × 3,412

Level difference : 0m (0ft)

cfm = m3/min x 35.31

Inlet water Temp 65°C Water flow rate 2.15m3/h

<PQRY-series>

Circulating water Temp. : 20°C (68°F)

Pipe length : 7.5 m (24-9/16 ft)

Level difference : 0m (0ft)

Inlet water Temp 65°C Water flow rate 2.15m3/h

lb = kg / 0.4536

* Due to continuing improvement, the above specifications may be subject to change without notice. * Install the unit in an environment where the

wet bulb Temp. will not exceed 32degC.

* The unit is not designed for outside installations.

* Please don't use the steel material for the water piping material. * The water circuit must use the closed circuit.

* Please do not use it as a drinking water.

* Please always make water circulate or add the brine to the circulation water when the ambient temperature becomes 0°C or less.

* Please always make water circulate or pull out the circulation water completely when not using it.

* Please do not use groundwater and well water.

* The specification data is subject

to rounding variation.

Unit converter

Lubricant

Operation volume

Inlet

Outlet

Accessory

Wiring

Document

m3/h

MPa

MPa

MPa

1.00

Installation Manual, Instruction Book

800 (785 without legs) × 450 × 300

E64C226X01

Inverter

1.0

Over-heat protection, Over-current protection

R134a × 1.1kg (0.50lb)

10,800

12.5

WKB94L762

NONE

44

NO

Strainer, Heat insulation material, 2 × Connector sets

PWFY-P100VM-E-BU

1-phase 220-230-240V 50/60Hz

PT3/4 Screw

MITSUBISHI ELECTRIC CORPORATION

NEO22

Φ32 (1-1/4'')

Inverter rotary hermetic compressor

31-1/2" (30-15/16" without legs) × 17-3/4” × 11-13/16”

60 (133)

PT3/4 Screw

11.63 - 11.12 - 10.66

50~100% of outdoor unit/heat source unit capacity

PURY-(E)P • Y(S)HM-A(-BS)

PQRY-P • Y(S)HM-A

Φ15.88 (Φ5/8") Brazed

-20~32°C (-4~90°F) PURY-series

10~45°C (50~113°F) PQRY-series

Φ9.52 (Φ3/8") Brazed

42,700

10~70°C (50~158°F)

2.48

0.6~2.15

LEV

4.15

High pressure sensor, High pressure switch at 3.60 MPa (601 psi)

Discharge thermo protection, Over-current protection

3.60

Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and

other items shall be referred to the Installation Manual.

ProductSpecications

1.Specications

(1) PWFY-P100VM-E-BU

- 2 -

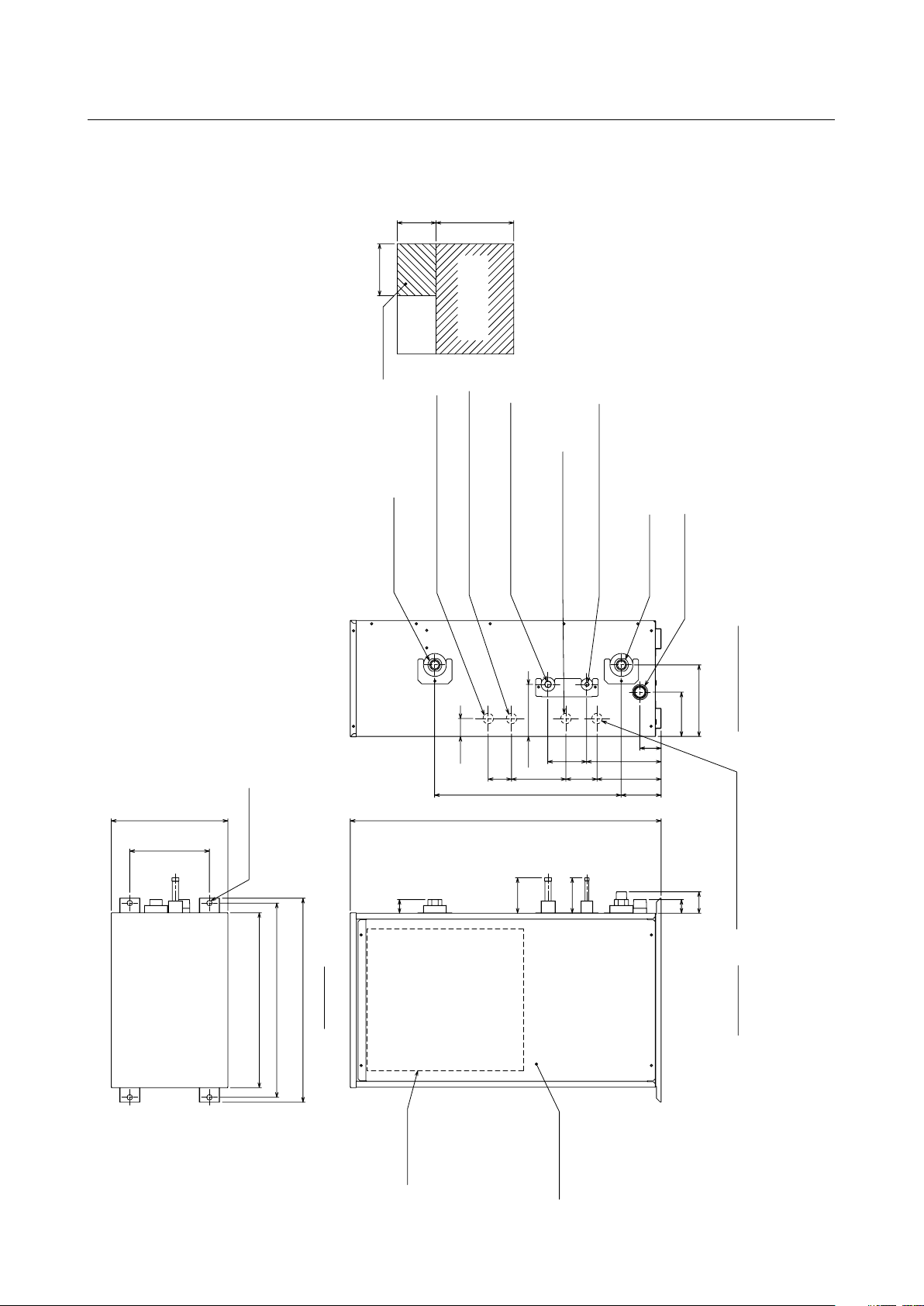

Page 10

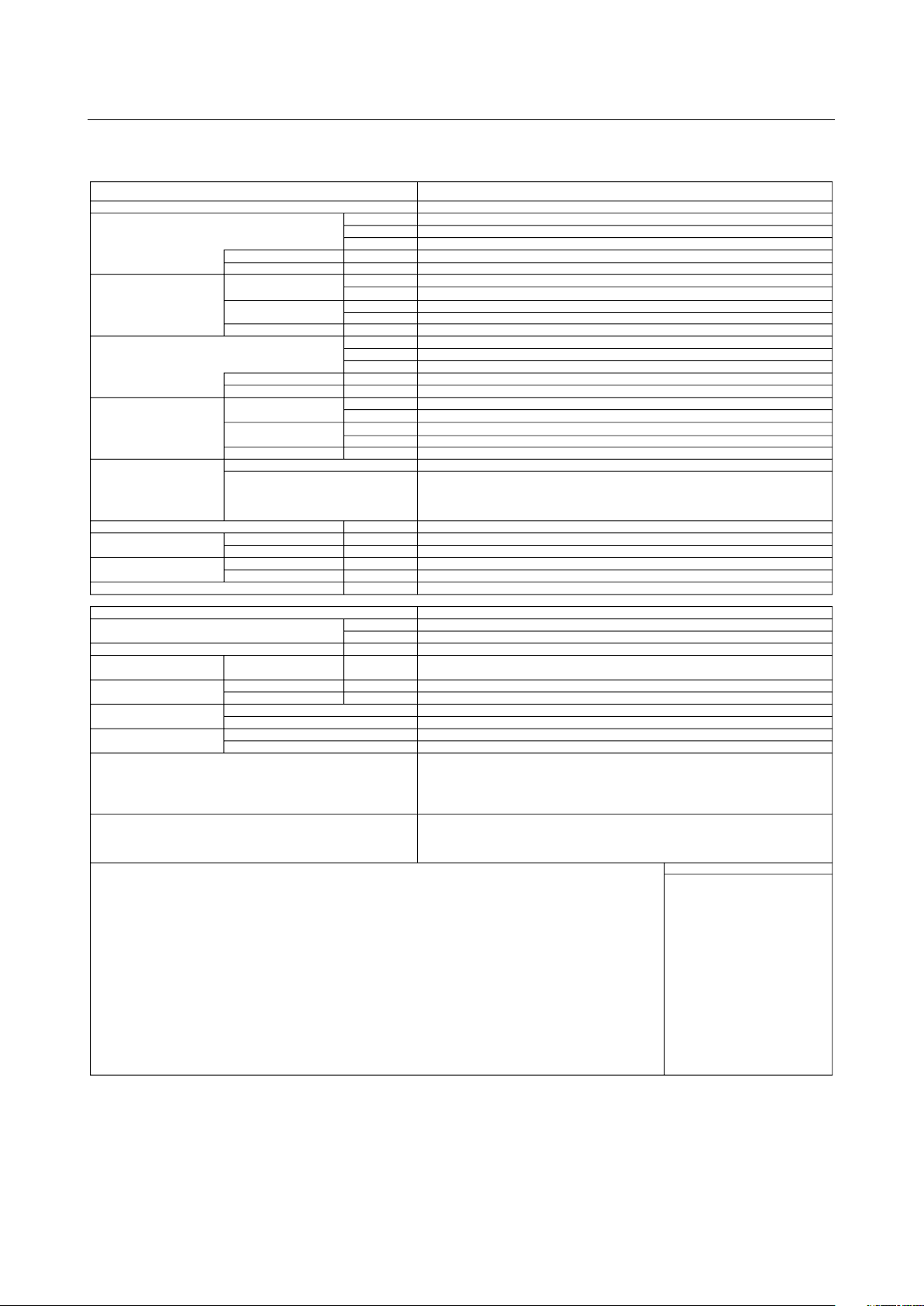

Model

Power source

kW*1Heating capacity

kcal / h

BTU / h

kW

A

W.B

*1(Nominal)

*1

Power input

Current input

Outdoor temp.

Temp. range of

W.B

-

-

-

heating

Inlet Water temp.

Circulating Water temp.

kW*2Cooling capacity

kcal / h

BTU / h

kW

A

D.B

*2(Nominal)

*2

Power input

Current input

Outdoor temp.

Temp. range of cooling

D.B

-Inlet Water temp.

Total capacity

Model / Quantity

Connectable

outdoor unit

/heat source unit

Sound pressure level (measured in anechoic room) dB<A>

mm(in.)

mm(in.)

Diameter of

refrigerant pipe

mm(in.)

mm(in.)

Diameter of

water pipe

mm(in.)

mm

Field drain pipe size

External finish

External dimension H × W × D

in.

kg(lb)

Net weight

Circulating water

Range

Design pressure

Water

R410a

Drawing

Standard attachment

Optional parts

Remark

Note:

*2 Nominal cooling conditions

*1 Nominal heating conditions

Outdoor Temp. : 7°CDB/6°CWB (45°FDB / 43°FWB)

Outdoor Temp. : 35°CB (95°FDB)

kcal = kW × 860

BTU/h= kW × 3,412

Pipe length : 7.5 m (24-9/16 ft)

Pipe length : 7.5 m (24-9/16 ft)

Level difference : 0m (0ft)

Level difference : 0m (0ft)

<PUHY/PURY-series>

<PUHY/PURY-series>

Circulating water Temp. : 20°C (68°F)

Pipe length : 7.5 m (24-9/16 ft)

Level difference : 0m (0ft)

<PQHY/PQRY-series>

<PQHY/PQRY-series>

cfm = m3/min × 35.31

Inlet water Temp 30°C

Water flow rate 2.15m3/h

Inlet water Temp 30°C

Water flow rate 2.15m3/h

Inlet water Temp 23°C

Water flow rate 1.93m3/h

Circulating water Temp. : 30°C (86°F)

Pipe length : 7.5 m (24-9/16 ft)

Level difference : 0m (0ft)

Inlet water Temp 23°C

Water flow rate 1.93m3/h

* Install the unit in an environment where the

lb = kg / 0.4536

* Due to continuing improvement, the above specifications may be subject to change without notice.

wet bulb Temp. will not exceed 32degC. * The unit is not designed for outside installations.

* Please don't use the steel material for the water piping material. * The water circuit must use the closed circuit.

* Please always make water circulate or add the brine to the circulation water when the ambient temperature becomes 0°C or less.

* Please always make water circulate or pull out the circulation water completely when not using it.

Inlet

Outlet

Operation Volume

Liquid

Gas

m3/h

MPa

MPa

Accessory

External

Wiring

Document

Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and

other items shall be referred to the Installation Manual.

Unit converter

* The specification data is subject

to rounding variation.

38,200

10~35°C (50~95°F)

0.015

Φ15.88 (Φ5/8") Brazed

Φ9.52 (Φ3/8") Brazed

PT3/4 Screw

Installation Manual, Instruction Book

PT3/4 Screw

NO

WKB94L763

0.068 - 0.065 - 0.063

50~100% of outdoor unit/heat source unit capacity

PUHY-(E)/(H)P • Y(S)HM-A(-BS)

PQHY-P • Y(S)HM-A

PURY-(E)P • Y(S)HM-A(-BS)

PQRY-P • Y(S)HM-A

-5~43°C (23~110°F) PURY - series

-5~43°C (23~110°F) PUHY - series

0.6~2.15

1.00

Strainer, Heat insulation material, 2 × Connector sets

Φ32 (1-1/4'')

PWFY-P100VM-E-AU

1-phase 220-230-240V 50/60Hz

9,600

11.2

29

12.5

800 (785 without legs) × 450 × 300

E00C223

4.15

NONE

10,800

42,700

-20~15.5°C (-4~60°F) PUHY - series

10~45°C (50~113°F) PQRY - series

10~45°C (50~113°F) PQHY - series

-

-

Circulating Water temp.

10~45°C (50~113°F) PQRY - series

10~45°C (50~113°F) PQHY - series

10~40°C (50~104°F)

0.015

0.068 - 0.065 - 0.063

-20~32°C (-4~90°F) PURY - series

31-1/2" (30-15/16" without legs) × 17-3/4” × 11-13/16”

35 (78)

* Please do not use it as a drinking water.

* Please do not use groundwater and well water.

(2) PWFY-P100VM-E-AU

- 3 -

Page 11

Model

Power source

kW*1Heating capacity

kcal / h

BTU / h

kW

A

W.B

*1(Nominal)

*1

Power input

Current input

Outdoor temp.

Temp. range of

W.B

-

heating

Inlet Water temp.

kW*2Cooling capacity

kcal / h

BTU / h

kW

A

D.B

*2(Nominal)

*2

Power input

Current input

Outdoor temp.

Temp. range of cooling

D.B

-Inlet Water temp.

Total capacity

Model / Quantity

Connectable

outdoor unit

/heat source unit

Sound pressure level (measured in anechoic room) dB<A>

mm(in.)

mm(in.)

Diameter of

refrigerant pipe

mm(in.)

mm(in.)

Diameter of

water pipe

mm(in.)

mm

Field drain pipe size

External finish

External dimension H × W × D

in.

kg(lb)

Net weight

Circulating water

Range

Design pressure

Water

R410a

Drawing

Standard attachment

Optional parts

Remark

Note:

Inlet

Outlet

Operation Volume

Liquid

Gas

m3/h

MPa

MPa

Accessory

External

Wiring

Document

Unit converter

*2 Nominal cooling conditions

*1 Nominal heating conditions

Outdoor Temp. : 7°CDB/6°CWB (45°FDB / 43°FWB)

Outdoor Temp. : 35°CDB (95°FDB)

Pipe length : 7.5 m (24-9/16 ft)

Pipe length : 7.5 m (24-9/16 ft)

Level difference : 0m (0ft)

Level difference : 0m (0ft)

Inlet water Temp 30°C Water flow rate 4.30m3/h Inlet water Temp 30°C Water flow rate 4.30m3/h

Inlet water Temp 23°C

Water flow rate 3.86m3/h

Inlet water Temp 23°C

Water flow rate 3.86m3/h

* Due to continuing improvement, the above specifications may be subject to change without notice.

* Install the unit in an environment where the

wet bulb Temp. will not exceed 32degC.

* The unit is not designed for outside installations.

* Please don't use the steel material for the water piping material. * The water circuit must use the closed circuit.

* Please always make water circulate or add the brine to the circulation water when the ambient temperature becomes 0°C or less.

* Please always make water circulate or pull out the circulation water completely when not using it.

Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and

other items shall be referred to the Installation Manual.

10~40°C (50~104°F)

0.015

0.068 - 0.065 - 0.063

-20~32°C (-4~90°F) PURY - series

21,500

85,300

-20~15.5°C (-4~60°F) PUHY - series

E94C228X01

NONE

Φ32 (1-1/4'')

PWFY-P200VM-E-AU

1-phase 220-230-240V 50/60Hz

19,300

22.4

29

25.0

1.2~4.30

1.00

Strainer, Connecter, Heat insulation material, 2 × Connector sets, Expansion joint

PT 1 Screw

Installation Manual, Instruction Book

NO

WKB94L763

31-1/2" (30-15/16" without legs) × 17-3/4” × 11-13/16”

38 (84)

800 (785 without legs) × 450 × 300

4.15

0.015

Φ19.05 (Φ3/4") Brazed

Φ9.52 (Φ3/8") Brazed

PT 1 Screw

0.068 - 0.065 - 0.063

76,400

10~35°C (50~95°F)

50~100% of outdoor unit/heat source unit capacity

PUHY-(E)/(H)P • Y(S)HM-A(-BS)

PQHY-P • Y(S)HM-A

PURY-(E)P • Y(S)HM-A(-BS)

PQRY-P • Y(S)HM-A

-5~43°C (23~110°F) PURY - series

-5~43°C (23~110°F) PUHY - series

kcal = kW × 860

BTU/h = kW × 3,412

cfm = m3/min × 35.31

lb = kg / 0.4536

* The specification data is subject

to rounding variation.

-

-

Circulating Water temp.

10~45°C (50~113°F) PQRY - series

10~45°C (50~113°F) PQHY - series

-

-

Circulating Water temp.

10~45°C (50~113°F) PQRY - series

10~45°C (50~113°F) PQHY - series

<PUHY/PURY-series>

<PUHY/PURY-series>

Circulating water Temp. : 20°C (68°F)

Pipe length : 7.5 m (24-9/16 ft)

Level difference : 0m (0ft)

<PQHY/PQRY-series>

<PQHY/PQRY-series>

Circulating water Temp. : 30°C (86°F)

Pipe length : 7.5 m (24-9/16 ft)

Level difference : 0m (0ft)

* Please do not use it as a drinking water.

* Please do not use groundwater and well water.

(3) PWFY-P200VM-E-AU

- 4 -

Page 12

Model

Power source

Number of branch

Power input

Current

External finish

Connectable outdoor unit/heat source unit

Indoor unit capacity connectable to 1 branch

External dimension H x W x D

Field drain pipe size

Net weight

Accessories

kW

A

kW

mm(in.)

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lb)

Refrigerant

piping

diameter

To

outdoor unit

/heat source

unit

To

indoor

unit

High press. pipe

Low press. pipe

Liquid pipe

Gas pipe

Note:

*1. Installation/foundation work, electrical connection work, duct work, insulation work, power source switch, and other items shall be referred to the Installation Manual.

*2. The equipment is for R410A refrigerant.

*3. Install this product in a location where noise (refrigerant noise) emitted by the unit will not disturb the neighbors.

(For use in quiet environments with low background noise, position the BC CONTROLLER at least 5m away from any indoor units.)

*4. Indoor units P100,P125,P140 can be connected to 1 branch. (In this case, cooling capacity decrease a little.)

PURY-(E)P200/250/300/350YHM-A(-BS) / PQRY-P200/250/300YHM-A

Cooling : 0.067/0.076/0.085

Heating : 0.030/0.034/0.038

Cooling : 0.054/0.061/0.067

Heating : 0.024/0.027/0.030

Cooling : 0.31/0.34/0.36

Heating : 0.14/0.15/0.16

Cooling : 0.25/0.27/0.28

Heating : 0.11/0.12/0.13

Galvanized steel plate

(Lower part drain pan painting N1.5)

CMB-P104V-G

1N ~ 220/230/240V

50Hz 60Hz

24 (53) 27 (60)

4

Model P80 or smaller

(Use optional joint pipe combining 2 branches when the total capacity exceeds 81.)

(Use the reducer (standard accessory) when the indoor unit Model 50 or smaller is connected.)

O.D. 32mm (1-1/4)

284 x 648 x 432 (11-3/16 x 25-9/16 x 17-1/16)

Connectable outdoor unit capacity

ø19.05 (ø3/4) Brazed

ø9.52 (ø3/8) Flare

(ø6.35 (ø1/4) with attached reducer used, ø12.7 (ø1/2) with optional joint pipe used.)

·Drain Connection pipe (with flexible hose and insulation)

·Reducer

ø15.88 (ø5/8) Flare

(ø12.7 (ø1/2) with attached reducer used, ø19.05 (ø3/4) with optional joint pipe used.)

P200

ø15.88 (ø5/8) Brazed

ø22.2 (ø7/8) Brazed

P250/P300

ø19.05 (ø3/4) Brazed

ø28.58 (ø1-1/8) Brazed

P350

ø19.05 (ø3/4) Brazed

(4) CMB-P104V-G

Model

Power source

Number of branch

Power input

Current

External finish

Connectable outdoor unit

Connectable unit capacity

External dimension H x W x D

Field drain pipe size

Net weight

Accessories

kW

A

Total

Indoor / PWFY

branch

PWFY branch

mm(in.)

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lb)

Refrigerant

piping

diameter

To

outdoor unit

/heat source

unit

To

indoor/

PWFY unit

High press. pipe

Low press. pipe

Liquid pipe

Gas pipe

Note:

*1. For installation/foundation work, electrical connection work, insulation work, and power source switch etc., refer to the Installation Manual.

*2. The equipment is for R410A refrigerant.

*3. Install this product in a location where noise (refrigerant noise) emitted by the unit will not disturb the neighbors.

(For use in quiet environments with low background noise, position the Water system Connection Box at least 5m away from any indoor units.)

*4. Install the unit horizontally.

*5. The indoor / PWFY unit branch is for cooling / heating. The indoor / PWFY unit cannot be simultaneously operated in different operation modes.

*6. The PWFY unit branch is for the heating only.

*7. Seal the unused branch using the optional cover cap (CMY-S202-J).

PURY-(E)P200/250/300/350YHM-A (-BS)

PQRY-P200/250/300YHM-A

Cooling : 0.019/0.020/0.021

Heating : 0.020/0.022/0.024

Cooling : 0.018/0.019/0.019

Heating : 0.019/0.020/0.021

Cooling : 0.09/0.09/0.09

Heating : 0.10/0.10/0.10

Cooling : 0.09/0.09/0.09

Heating : 0.09/0.09/0.09

Galvanized steel plate

(Lower part drain pan painting N1.5)

CMB-PW202V-J

1N ~ 220/230/240V

50Hz 60Hz

20 (45)

2

O.D. 32mm (1-1/4" )

284 x 648 x 432 (11-3/16" x 25-9/16" x 17-1/16" )

50% ~ 130% of outdoor unit/heat source unit

up to 130% of outdoor unit/heat source unit

up to 100% of outdoor unit/heat source unit

Total down-stream Indoor unit capacity

Connectable outdoor unit capacity

ø19.05 (ø3/4" ) Brazed

·Drain Connection pipe (with flexible hose and insulation)

·Refrigerant connection pipe

P200

ø15.88 (ø5/8" ) Brazed

ø15.88 (ø5/8" )

Brazed

~P140

ø9.52 (ø3/8" )

Brazed

ø19.05 (ø3/4" )

Brazed

P141~P200

ø9.52 (ø3/8" )

Brazed

ø22.2 (ø7/8" )

Brazed

P201~P300

ø9.52 (ø3/8" )

Brazed

ø28.58 (ø1-1/8" )

Brazed

P301~P400

ø12.70 (ø1/2" )

Brazed

ø28.58 (ø1-1/8" )

Brazed

P401~

ø15.88 (ø5/8" )

Brazed

ø22.2 (ø7/8" ) Brazed

P250/P300

ø19.05 (ø3/4" ) Brazed

ø28.58 (ø1-1/8" ) Brazed

P350

ø19.05 (ø3/4" ) Brazed

*Other models of BC controller are available. For unit information, refer to the Data Book.

(5) CMB-PW202V-J

- 5 -

Page 13

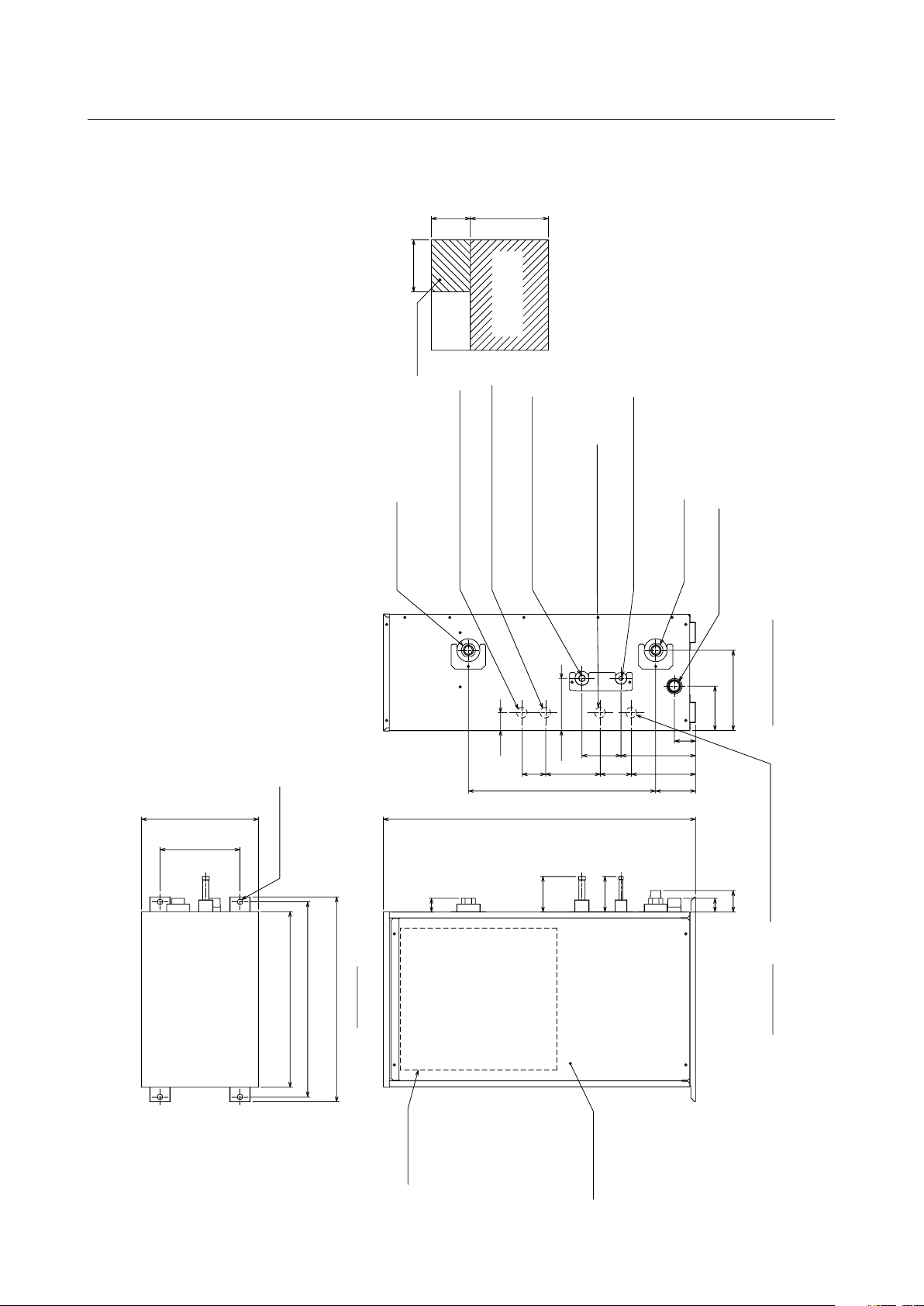

2.ExternalDimensions

Piping space

(right side)

Fig. A

Service space

(front side)

Top view

300

400

600

ø27 Knockout hole

<Hole for external wiring output>

Drain (R1 screw)

Control box

Water outlet

(RC3/4 screw)

ø27 Knockout hole

<Hole for external wiring input>

ø27 Knockout hole

<Hole for power supply>

ø27 Knockout hole

<Hole for control wiring>

Service panel

Top view

Right side view

Front view

2X2-ø14 Hole

Connection pipe of outdoor unit

(Liquid)

ø15.88 <Brazed>

ø9.52 <Brazed>

Connection pipe of outdoor unit

(Gas)

Water inlet

(R3/4 screw)

525

(Mounting pitch)

(Mounting pitch)

205

800 300

450

500

55

35

35

91

91

134

480

46

60140

100191

80165

102

54

184

114

Note 1.Ensure no rain water or debris can enter the unit through any gaps around

wiring or piping.

2.Ensure adequate service space is right around the unit, according to Fig A.

3.Please always make water circulate or add the brine to the circulation water

when the ambient temperature becomes 0°C or less.

4.The unit is not designed for outside installations.

5.Install the unit in an environment where the wet bulb Temp.

will not exceed 32degC.

6.Please always make water circulate or pull out the circulation

water completely when not using it.

7.The water circuit must use the closed circuit.

8.Please don't use the steel material for the water piping material.

9.Connect the strainer which is put as accessory to water inlet pipe.

<Accessories>

●Y-type strainer (RC3/4) ·························· 1pc.

●Heat Insulation material ························· 1pc.

●Connector set ········································ 2set

<Unit:mm>

(1) PWFY-P100VM-E-BU

- 6 -

Page 14

(2) PWFY-P100, 200VM-E-AU

300600

Fig. A

Service space

(front side)

Top view

400

Piping space

(right side)

P200:Use the Expansion joint

of accessories

Drain (R1 screw)

ø9.52 <Brazed>

ø27 Knockout hole

<Hole for control wiring>

ø27 Knockout hole

<Hole for power supply>

Water outlet

(RC3/4 screw)

Water inlet

(R3/4 screw)

P100:ø15.88 <Brazed>

P200:ø19.05 <Brazed>

ø

27 Knockout hole

<Hole for external wiring input>

ø27 Knockout hole

<Hole for external wiring output>

Connection pipe of outdoor unit

(Gas)

Connection pipe of outdoor unit

(Liquid)

Front view

Right side view

Control box

Service panel

Top view

2X2-ø14 Hole

525

(Mounting pitch)

450

(Mounting pitch)

300800

205

500

<Accessories>

●Y-type strainer (RC3/4) ····························· 1pc.

●Heat Insulation material

····························

1pc.

●Connector set

············································

2set

●Expansion joint (P200) ······························ 2pcs.

[From RC3/4 to RC1]

Note 1.Ensure no rain water or debris can enter the unit through any gaps around

wiring or piping.

2.Ensure adequate service space is right around the unit, according to Fig A.

3.Please always make water circulate or add the brine to the circulation water

when the ambient temperature becomes 0°C or less.

4.The unit is not designed for outside installations.

5.Install the unit in an environment where the wet bulb Temp.

will not exceed 32degC.

6.Please always make water circulate or pull out the circulation

water completely when not using it.

7.The water circuit must use the closed circuit.

8.Please don't use the steel material for the water piping material.

9.Connect the strainer which is put as accessory to water inlet pipe.

91

91

35

55

35

480102

206

134

114

100191

46

6014080165

54

<Unit:mm>

- 7 -

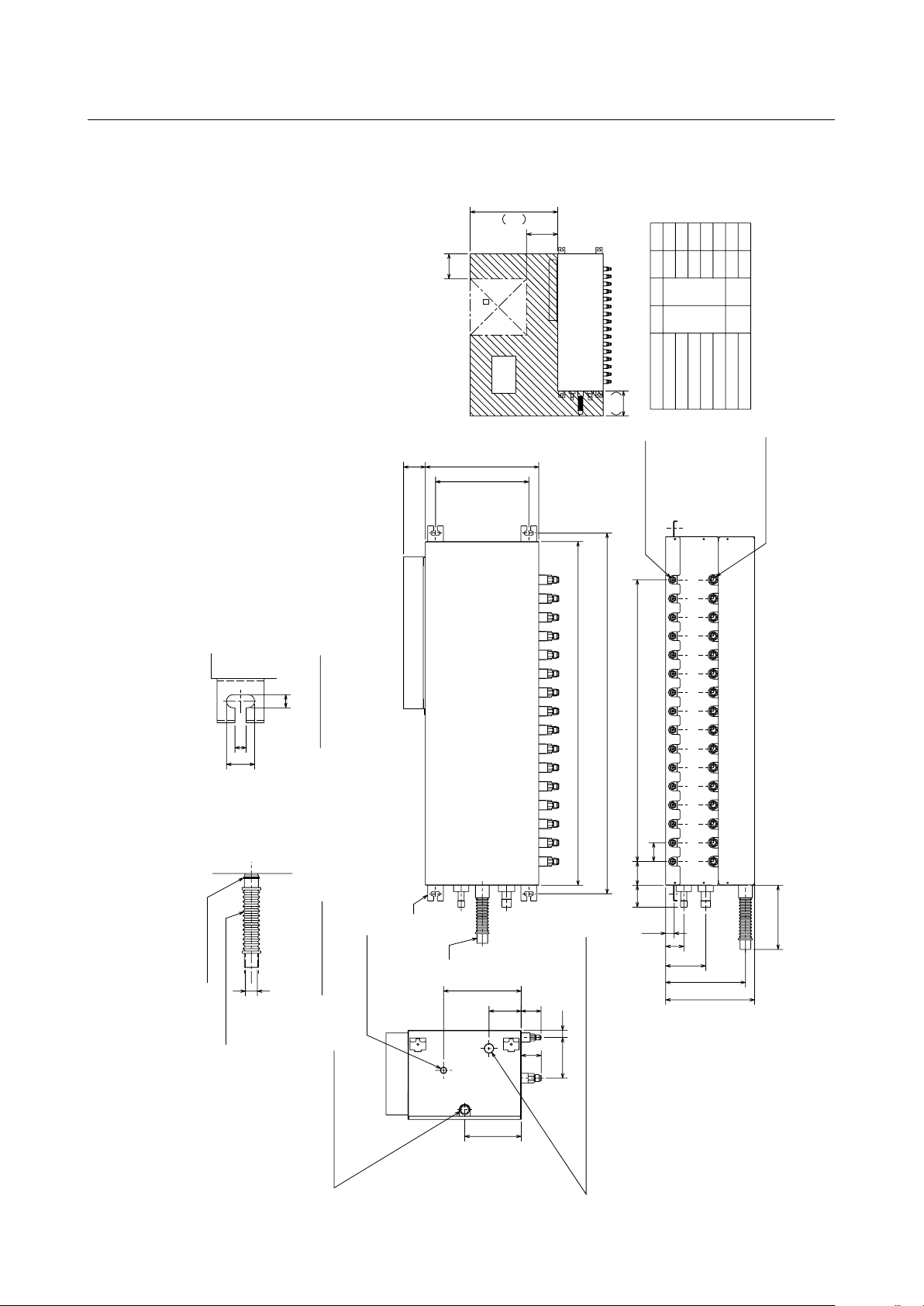

Page 15

<Accessories>

• Refrigerant<Low pressure> conn. pipe ··············· 2pcs.

• Refrigerant<High pressure> conn. pipe ·············· 1pc.

• Reducer(Large,Small) ········································· Quantity for all connections

• Drain hose I.D. 32 (1-1/4") ··································· 1pc.

• Hose band ··························································· 1pc.

• Tie band ······························································ 1pc.

Note1. Suspension bolt(

ø10),washer(M10),and nut(M10)

prepare in the field.

2. Take notice of service space as follows.

(Please give attention not to occupy service

space by letting ducts and pipes through.)

PURY-P200 : ø

19.05 <Brazed> (use attachment pipe)

PURY-P250, P300 :

ø

22.2 <Brazed>

PURY-P350 :

ø

28.6 <Brazed> (use attachment pipe)

Service

space

ø19.05 <Brazed>

Detail of X section

Detail of Y section

Control box

12

14

30

Drain pipe O.D. 32 (1-1/4")

B

A

Connection pipe of outdoor unit (Low pressure)

103

Connection pipe of

outdoor unit

(High pressure)

248

ø31

A B C D

ø9.52 <Flare>

161514

1312

11

109

876543

2

1

ø15.88 <Flare>

Access

door

450

(Lifting bolt pitch)

(Lifting bolt pitch)

345

7

9

12

15

180

240

300

420

540

720

900

702

1152

648

1098

CMB-P104V-G

CMB-P105V-G

CMB-P108V-G

CMB-P106V-G

CMB-P1010V-G

CMB-P1016V-G

CMB-P1013V-G

298

181

200

130 23

60

Y

362 70

Drain hose I.D. 32 (1-1/4")

Band (Accessory)

X

70

200

27

700

250

Connection pipe of

indoor unit (Gas)

Connection pipe of

indoor unit (Liquid)

64

64

58

128

255

284

200

60XC=D76

<Unit:mm>

(3) CMB-P104,105,106,108,1010,1013,1016V-G

- 8 -

Page 16

(4) CMB-PW202V-J

Connection pipe of

PWFY (Gas)

Connection pipe of

PWFY (Liquid)

Connection pipe of

indoor unit/PWFY (Liquid)

Connection pipe of

indoor unit/PWFY (Gas)

Liquid line

Indoor unit/PWFY

(Cooling/Heating)

PWFY(Heating only)

Gas line

Liquid line

Gas line

(Lifting bolt pitch)

(Lifting bolt pitch)

250

700

200

200

Access

door

450

~P300: ø9.52<Brazed>(use attachment pipe)

P301~P400: ø12.7<Brazed>(use attachment pipe)

P401~: ø15.88<Brazed>

~P140: ø15.88<Brazed>(use attachment pipe)

P141~P200: ø19.05<Brazed>(use attachment pipe)

P201~P300: ø22.2<Brazed>(use attachment pipe)

P301~: ø28.58<Brazed>(use attachment pipe)

~P140: ø15.88<Brazed>(use attachment pipe)

P141~P200: ø19.05<Brazed>

P201~P300: ø22.2<Brazed>(use attachment pipe)

~P300: ø9.52<Brazed>

Drain hose(Accessory)

Band(Accessory)

Connection pipe of outdoor unit (Low pressure)

Connection pipe of outdoor unit (High pressure)

12

14

30

ø

31

27

Y

X

Dtail of Y section

284

648

90

Drain piping

VP-25 connection

Control box

200

255

Detail of X section

298

702

190423

300

252

103

58

90

127 21

90 181

255

70362

103

PURY-P200: ø19.05<Brazed>(use attachment pipe)

PURY-P250,P300: ø22.2<Brazed>

PURY-P350: ø28.58<Brazed>(use attachment pipe)

PURY-P200: ø15.88<Brazed>(use attachment pipe)

PURY-P250,P300,P350: ø19.05<Brazed>

<Accessories>

Refrigerant<Low pressure> conn. pipe

Refrigerant<High pressure> conn. pipe

Refrigerant<Gas> conn. pipe

Refrigerant<Liquid> conn. pipe

Drain hose(VP-25 connection)

Hose band

Tie band

2pcs.

1pc.

6pcs.

2pcs.

1pc.

1pc.

1pc.

Note1. Suspension bolt (ø10), washer (M10), and nut (M10)

prepare in the field.

2. Take notice of service space as follows.

(Please give attention not to occupy service

space by letting ducts and pipes through.)

3. Install this product in a location where noise (refrigerant noise)

emitted by the unit will not disturb the neighbors.

(For use in quiet enviroments with low background noise, position

the BC CONTROLLER at least 5m away from any indoor units.)

4. Install the unit horizontally.

5. The indoor unit/PWFY branch is for cooling/heating.The indoor unit/PWFY

cannot be simultaneously operated in different operation modes.

6. The PWFY unit branch is for the heating only.

Service

space

<Unit:mm>

- 9 -

Page 17

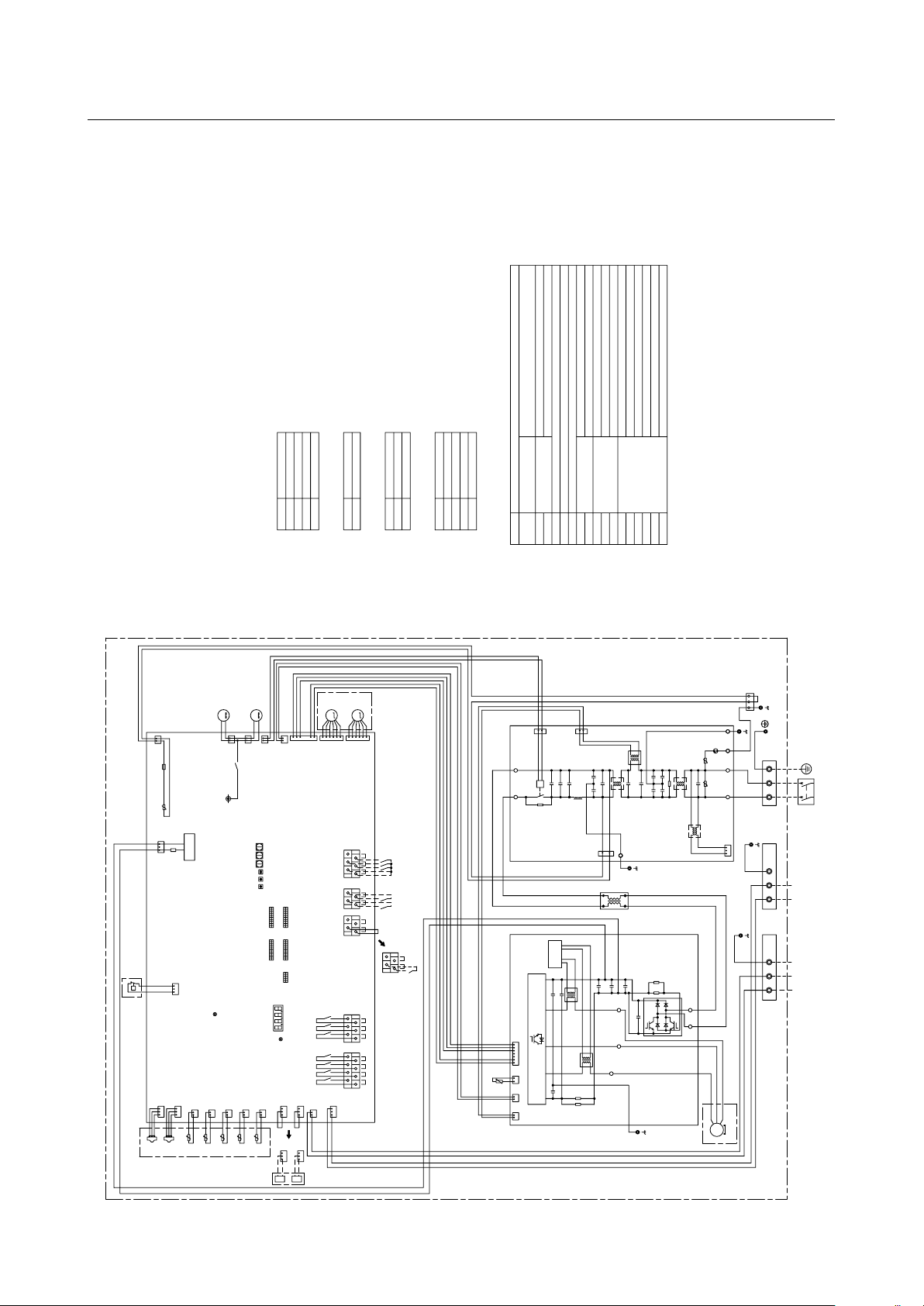

3.ElectricalWiringDiagrams

M

4-20mA

4-20mA

gray

2

1

gray

black

To outdoor unit/

BC controller/WCB

To MA remote

controller

Power Supply

~220/230/240V

50Hz/60Hz

3

2

1

blue

red

yellow/green

bluered

CN4

63LS

CN63HS

1

1

3

2

2

3

THHS

12

CN63LS

123

t°

TH8

2

1

CN403

red

t°

TH6

1

2

CN404

black

t°

3 1

CT1

Moter

3~

CYN

RS4

MS

RS3

(Compressor)

CN3A

blue

U

t°

red

yellow

TH22

CN405

IPM

W

V

U

black

1

63HS

7

2

1

3

1

2

CN3

2

1

t°

CN401

CN2

2 5 6

t°

red

CN5

2

1

TH11

1

2

TH13

2

1

white

CN402

green

red

5

6

RS1

black

2

CN52C

R1

LO

U

CNAC2

red

2

CN5

1

1

2

red

blue

red

LEV2W

M

LI

24V

blue

+

CB3

Z2

1

U

CT1

LEV1W

1

CN2

63H1

6

5

CNAC

2

red

1

CX2

L

CN506A

L3

N

6

5

N

CN-E1

CN631

DSA

pink

E2

3

1

E1

432

1

CY4

P

CY3

31

L4

Z1

NI

CB1

+

1

TB2

CN661

2L23

X506

W

4

CN4

blue

U

CN52C

1

2

+

CX3

INV control

circuit

PFC

E3

1

L1

2

M

ZNR01

ACL

CY1CY2

CT2

Noise

Filter

red

Fan motor

1

3

(DC)

CX5

CYP

CIS

CX6

1

2

7

V

yellow

LED3:Lit when powered

INV Board

Control Board

CB2

(DC)

CY6

S

CX4

R

CNAC1

M

CNLVA

NO

Fan motor

3

1

2

RS2

CY5

P

CNLVB

blue

CX1

CX7

CN506B

CPS

+

RS

F01

AC250V

6.3A

F631

DC700V

4A

Power

Supply circuit

blue

red

TB5

M1 M2

S(SHIELD) S(SHIELD)

TB15

yellow

purple

black

orange

gray

red

black

white

gray

gray

52C

1

2

CN2M

blue

3 1

*4

IN2

TB141B

TB142B

IN6

COM+

OUT5

TB142C

OUT7

OUT6

X515 X517

X516

IN8

IN5 IN7

TB142A

X514

OUT2

X512

X511 X513

OUT1 OUT3

OUT4

TB141A

*5 *6 *7

IN3 IN4

COM+

LED4:Remote controller

when powered

SWU1

10

SW1

5

ON

OFF

1

Unit address setting(SWU1,SWU2)

Connection No.(SWU3)

LED1 Display setting(SW2)

Function setting(SW1,SW3,SW4)

SWP3

SW5

SWP1

SWU3

SWP2

SWU2

OFF

ON

1 10

SW4

OFF

ON

1 10

LED1

OFF

ON

1

SW3

OFF

ON

1 10

SW2

IN1

gray

CN421

black

3 1

CN422

blue

IN1

IN2

3 1

CN421

black

3 1

CN422

blue

2

2

2

2

BC controller/WCB/outdoor unit

Booster unit

Linear

expansion valve

LEV1W

LEV2W

IN7 Anti-freeze

IN6 Heating ECO

Symbol

Function

COM+ Common

IN5 Hot water

IN4 Operation ON/OFF

Connection demand

Symbol

IN3

Function

Symbol

Pump interlock

Function

IN1

*4 TB141A(output)

*5 TB142A(input)

*6 TB142B(input)

*7 TB142C(input)

Function

Symbol

OUT1 Operation ON/OFF

OUT2 Defrost

OUT3 Compressor

OUT4 Error signal

<HIGH VOLTAGE WARNING>

·Control box houses high-voltage parts.

Before inspecting the inside of the control box, turn off the power,

keep the unit off for at least 10 minutes,and confirm that the voltage

CN631 on Control Board has dropped to DC20V or less.

<CAUTION FOR INSTALLATION>

·Prior to installation,read the Installation Manual carefully.

*1.Single-dotted lines indicate wiring not supplied with the unit.

*2.Dot-dash lines indicate the control box boundaries.

*3.Faston terminals have a locking function.

Make sure the terminals are securely locked in place after insertion.

Press the tab on the terminals to removed them.

TH8 water outlet temp

TH6 water inlet temp

TH22 liquid pipe temp

TH13 Evaporator outlet temp

Compressor discharge tempTH11 Thermistor

TB15 MA remote controller

TB5 Outdoor unit/BC controller/WCB

AC reactor

Pressure

switch

High pressure switch

(High pressure protection for the booster unit)

Discharge pressure

Low pressure

TB2

CT1,CT2

ACL

THHS

Magnetic relay(main circuit)

Current sensor(AC)

Explanation

Terminal

block

Power supply

IGBT temp

Pressure

sensor

Symbol

63H1

63HS

63LS

52C

<Symbol explanation>

(1) PWFY-P100VM-E-BU

- 10 -

Page 18

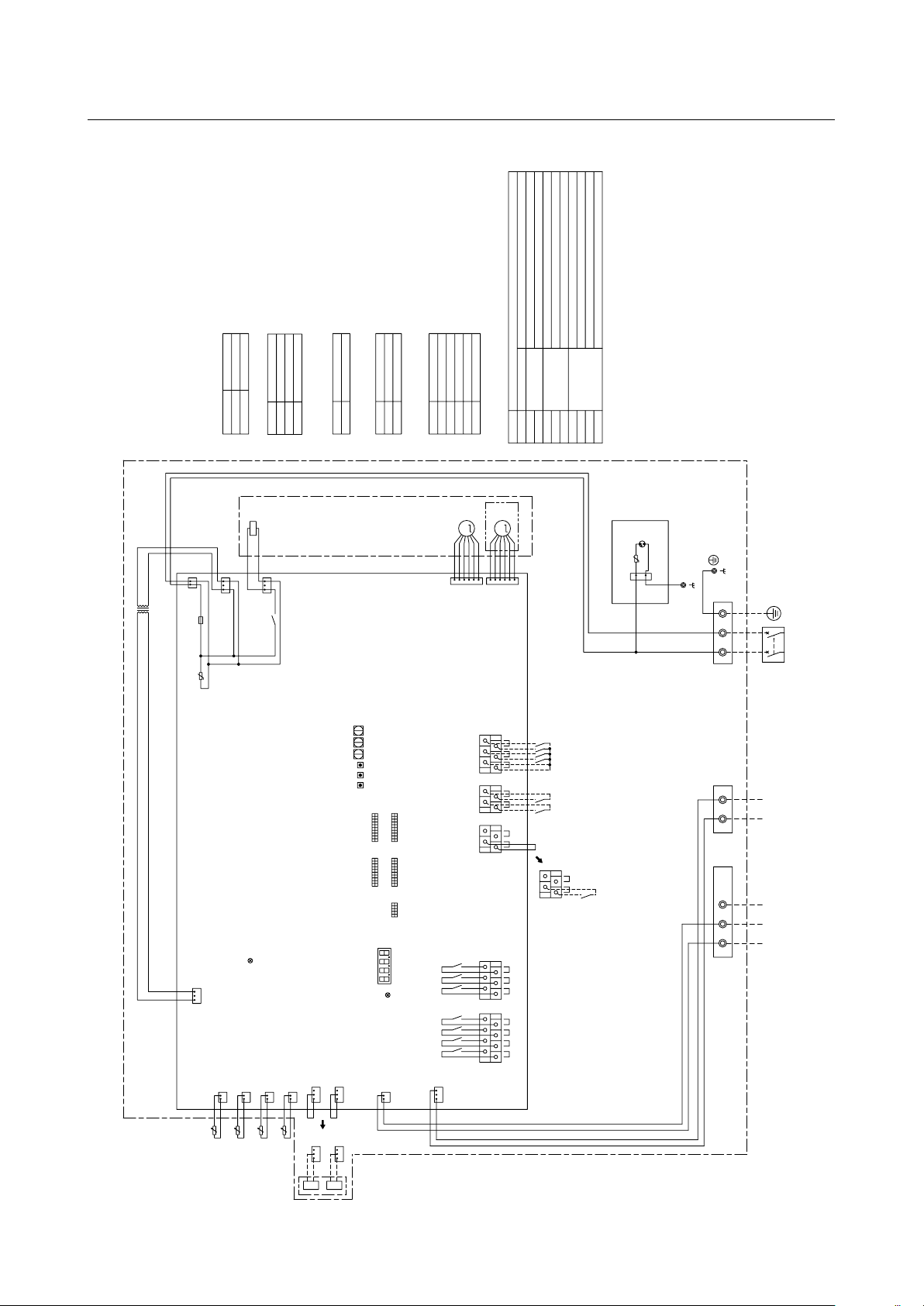

(2) PWFY-P100, 200VM-E-AU

gray

red

M

For opening/closing the bypass circuit

Solenoid valve

SV1

IN1

TB5

M1 M2

S(SHIELD)

To outdoor unit/

BC controller/

WCB

4-20mA

4-20mA

132

CN421

black

132

CN422

blue

132

CN422

blue

2

black

CN421

13

IN1

234

5

yellow/green

LEV1Wa

LEV1Wb

Linear

expansion valve

BC controller/WCB/outdoor unit

BC controller/WCB/outdoor unit

Function

Function

Function

black

yellow purple

bluered

NL

IN7

IN8IN6

IN5COM+

IN4IN3

orange

*3.Difference of appliance

*4 TB141A(output)

*5 TB142A(input)

*6 TB142B(input)

*7 TB142C(input)

Model name

Appliance

P100 *3 do not exist

P200 *3 exist

*7*6*5

*4

Cooling

TH23 gas pipe temp

CN502

black

COM+

TH8

TH6

TH23

t°

t°

t°

blue

CN2M

2

1

2

1

CN402

green

2

1

CN403

red

1

2

CN404

black

yellow

CN405

t°

TH22

1

2

21

To MA remote

controller

Power Supply

~220/230/240V

50Hz/60Hz

Unit address setting(SWU1,SWU2)

Connection No.(SWU3)

LED1

TB15

ZNR1

U

DSA1

CN1

1

3

SWU2

SWU1

SWP3

SWP2

SWP1

OFF

ON

1 10

SW4

OFF

ON

1 10

SW3

OFF

ON

1 10

SW1

OFF

ON

1 10

SW2

LED4:Remote controller

when powered

5

CNLVC

6

1

LEV1Wb

123

4

X502

CN507

3

1

M

5

6

ON

OFF

1

SW5

SWU3

LED3:Lit when powered

Control Board

CNLVB

LEV1Wa

TB2

SV1

*3

DSA Board

CN3T

red

13

T01

ZNR01

3

1

1

2

CNAC

red

U

F01

AC250V

6.3A

LED1 Display setting(SW2)

Function setting(SW1,SW3,SW4)

OUT4

OUT3

OUT2

X514

X513

X512

TB141A

OUT1

X511

3 1

CN3A

blue

TB142CTB142B

X516

X517X515

OUT6

OUT7OUT5

TB141B

TB142A

IN2

IN8

IN7 Anti-freeze

IN6 Heating ECO

Symbol

COM+ Common

IN5 Heating

IN4 Operation ON/OFF

Connection demand

Symbol

IN3

Symbol

Pump interlockIN1

Function

Symbol

OUT1 Operation ON/OFF

OUT2 Defrost

OUT4 Error signal

<CAUTION FOR INSTALLATION>

·

Prior to installation,read the Installation Manual carefully.

*1.Single-dotted lines indicate wiring not supplied with the unit.

*2.Dot-dash lines indicate the control box boundaries.

TH8 water outlet temp

TH6 water inlet temp

TH22 liquid pipe temp

Thermistor

TB15 MA remote controller

TB5 Outdoor unit/WCB/BC controller

TB2

Explanation

Terminal

block

Power supply

Symbol

<Symbol explanation>

- 11 -

Page 19

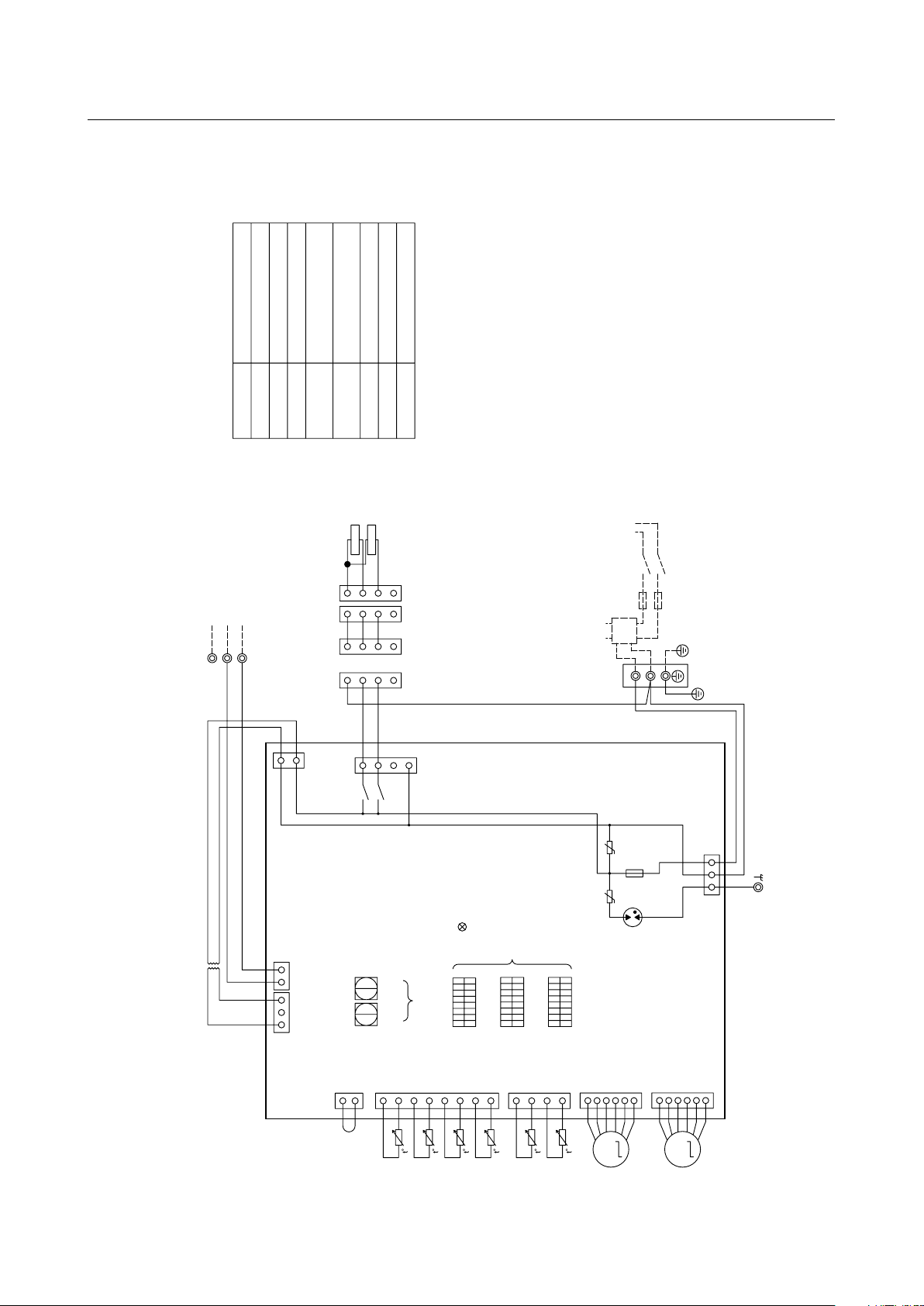

(3) CMB-P104V-G

CONT.B

Pressure sensor

TR

TH11,12,15,16

LEV1,3

PS1,3

Symbol Name

Transformer

Thermistor sensor

Expansion valve

SV1

~

4A,B,C Solenoid valve

TB01

Terminal block

(for power source)

TB02

Terminal block

(for Transmission)

T1~4 Terminal

F01

Fuse AC250V 6.3A F

Solenoid valve

SVM1

TR

TB02

CN26

3

1

CN12

1

5

3

CN05

6

5

4

3

2

1

CONT.B

1

2

CN02

3

CNP1

1

2

3

CNP3

211

2

3

4

567

8

4

3

2

1

123 2 1

CN03

CN13

CN10

CN11

CN07

TH11

TH12

TH15

TH16

PS1

PS3

6

5

4

3

2

1

TB01

1VEL

3

VEL

S(SHIELD)

M2

M1

220V~240V

20V

~

22V

L

1

234

10

9

8

423

10

2

143

SV3A

SV3B

SV2B

SV3C

SV2C

SV2A

243

756

4

3

2

1

2

3

4

1

234

2

3

4

9

8

7

6

5

SV1C

SV1A

SV1B

7

5

3

1

7

5

3

1

7

5

3

1

X2

X1

X30

X4

X3

X31

X6

X5

X32

CN27(Red)

CN28(Blue)

1

1

1

1

234

13

12

11

16

15

14

13

12

11

SV4B

SV4C

SV4A

15

16

14

1

2

3

4

1

7

5

3

1

X8

X7

X33

CN29(Green)

SVM1

123

1

2

3

1

3

CN36(Green)

X21

N

ZNR01

ZNR02

CNTR

(Red)

2

2

PE

3

1

3

1

T2

T3

T1

T4

PE

TO NEXT INDOOR UNIT

PULL BOX

FUSE(16A)

BREAKER(16A)

POWER SUPPLY

~220V-240V

50Hz/60Hz

Indoor/outdoor

Transmission Line

ON

OFF

1

SW5

OFF

8

SW4

ON

1

8

BC controller

Circuit

board

SW2 SW1

1

10

F01

250VAC

6.3A F

(Black)

(Red)

(Yellow)

(Red)

(Yellow)

DSA

Note:1.TB02 is transmission terminal block.

Never connect power line to it.

2.The initial set values of switch on

CONT.B are as follows.

SW1:0

SW2:0

Symbol explanation

*Other models of BC controller are available. For unit information, refer to the Data Book.

- 12 -

Page 20

(4) CMB-PW202V-J

TB01

M1

M2

WCB Board

Note:1. TB02 is transmission terminal block.

Never connect power line to it.

2. The initial set values of switch on

WCB Board are as follows.

SW1:0

SW2:0

Expansion valve

Thermistor sensor

Transformer

(Symbol explanation)

Name

Symbol

TB01

Terminal block

(for power source)

Terminal block

(for Transmission)

TB02

Solenoid valve

SVM1

21S4a

4-way valve

TO NEXT

INDOOR UNIT

PULL BOX

FUSE(16A)

BREAKER(16A)

50Hz/60Hz

POWER SUPPLY

~220V-240V

S(SHIELD)

TB02

Indoor/outdoor

Transmission line

1

2

3

6

5

4

CN05

CN07

1

2

3

6

5

4

TH16

TH15

123

4

CN11

TH12

TH11

112

CN13

2

3

CN10

45678

F01

AC250V

6.3A F

ZNR01

ZNR02

CN12

1

3 5

1

3

20V~22V

TR

220V~240V

1 13 2 2

CN02

CN03

F01

Fuse AC250V 6.3A F

TH13

TH14

TR

TH11~16

LEV1,3

Yellow

Red

Red

Yellow

SW1SW2

ON

OFF

ON

OFF

ON

OFF

81

81

81

SW4

SW5

SW6

1

3

X02

CN26

5

7

X01

SVM1

21S4a

123

4

4

3

2

1

1132

4

324

T1

CNTR

Red

N

L

DSA

UU

LEV3

LEV1

M

M

LD1:CPU in

operation

1's

digit

Unit address

setting

10's

digit

Function

setting

317

5

- 13 -

Page 21

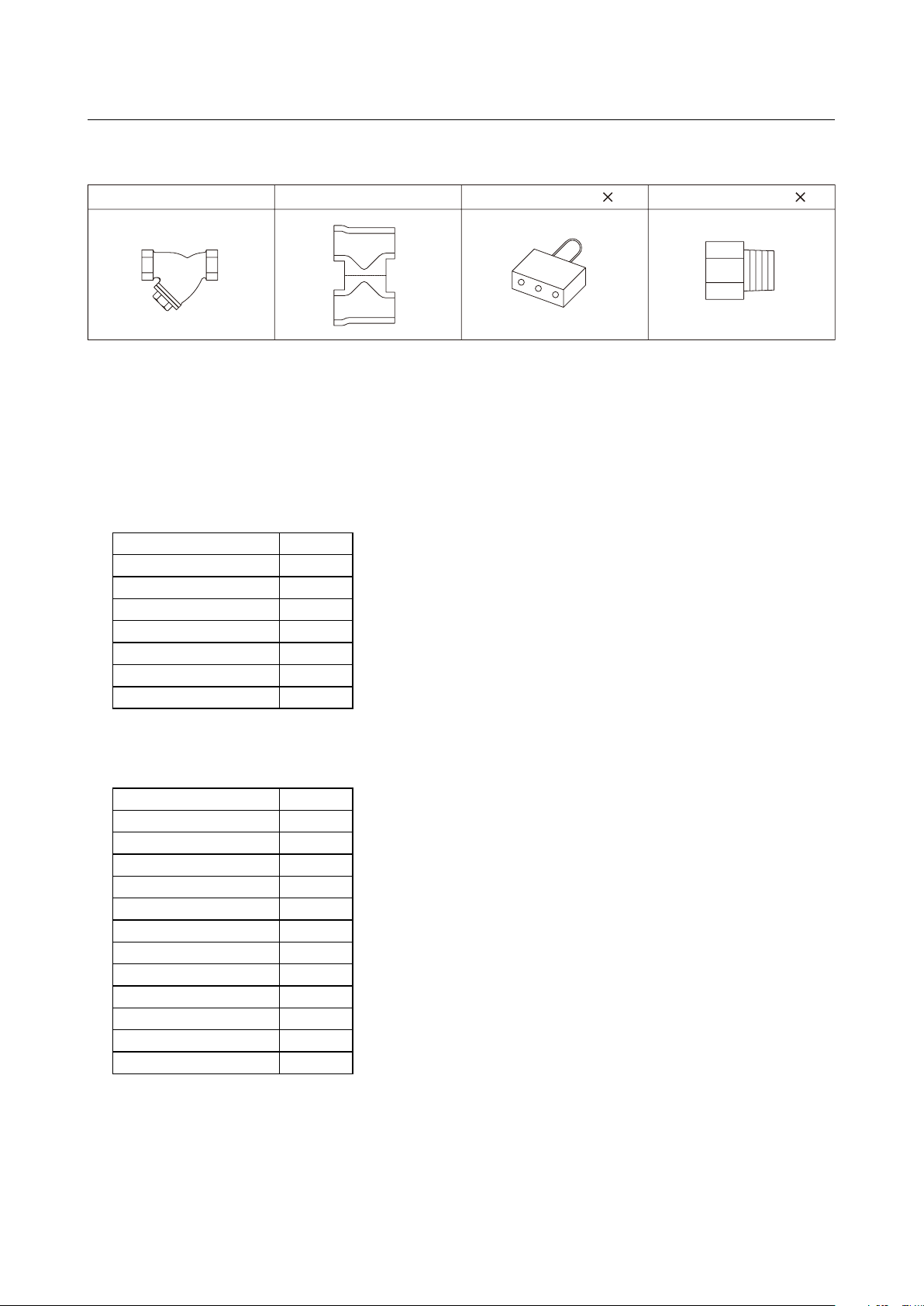

4. Accessories

(A) Strainer (B) Heat insulation material

*1

*1. PWFY-P200VM-E-AU only

(C) Connecter sets 2 (D) Expansion joint 2

(1) PWFY

(A) Install the strainer at the water pipe inlet.

(B) This insulation is for exclusive use with the strainer. Wrap the strainer with the insulation after water pipes are

installed.

(C) These are analog input connectors. Cut the wire before using.

(D) Supplied only with the PWFY-P200VM-E-AU. Install them at the strainer inlet. Refer to P53 for details.

(2) CMB-P104V-G

SIZE Unit

ø15.88 are - IDø12.8 4

ø9.52 are - IDø6.45 4

ODø19.05 - IDø15.88 1

ODø22.2 - IDø19.05 1

ODø22.2 - IDø28.6 1

Drain hose set

Installation Manual 1

1set

(3) CMB-PW202V-J

SIZE Unit

ODø19.05 - IDø15.88 2

ODø22.2 - IDø19.05 1

ODø15.88 - IDø9.52 1

ODø15.88 - IDø12.7 1

ODø25.4 - IDø19.05 1

ODø25.4 - IDø22.2 1

ODø19.05 - IDø22.2 1

ODø25.4 - IDø28.6 1

ODø22.2 - IDø28.6 1

ODø25.4 - IDø15.88 1

Drain hose set

Installation Manual 1

1 set

- 14 -

Page 22

III

PURY- P200,250YHM-A(-BS)

EP200,250YHM-A(-BS)

0.5

0.6

0.7

0.8

0.9

1.0

1.1

Outdoor temp. [°CWB]

Ratio of heating capacity

30°C

20°C

10°C

40°C

50°C

60°C

65°C

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.1

Outdoor temp. [°CWB]

Ratio of booster unit input

65°C

60°C

50°C

40°C

30°C

20°C

10°C

0.5

0.6

0.7

0.8

0.9

1.0

1.1

Outdoor temp. [°CWB]

Ratio of outdoor unit input

40°C

50°C

60°C

65°C

30°C

20°C

10°C

-20

-15 -10 -5

0

5

10

15 20 25 30

-20

-15 -10 -5

0

5

10

15 20 25 30

-20

-15

-10 -5

0

5

10

15 20 25 30

Booster unit inlet-water temp. [°C]

Booster unit inlet-water temp. [°C]

Booster unit inlet-water temp. [°C]

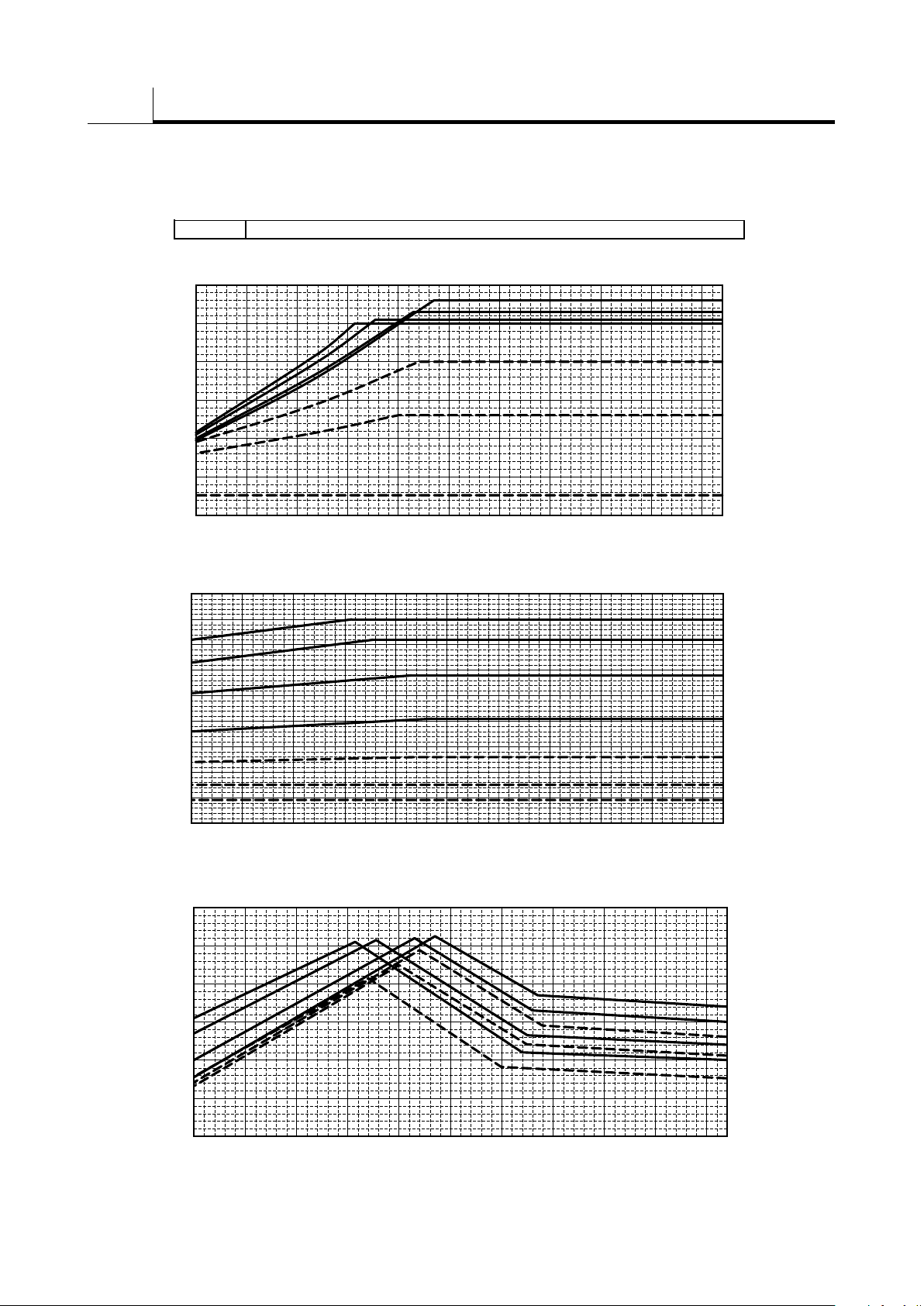

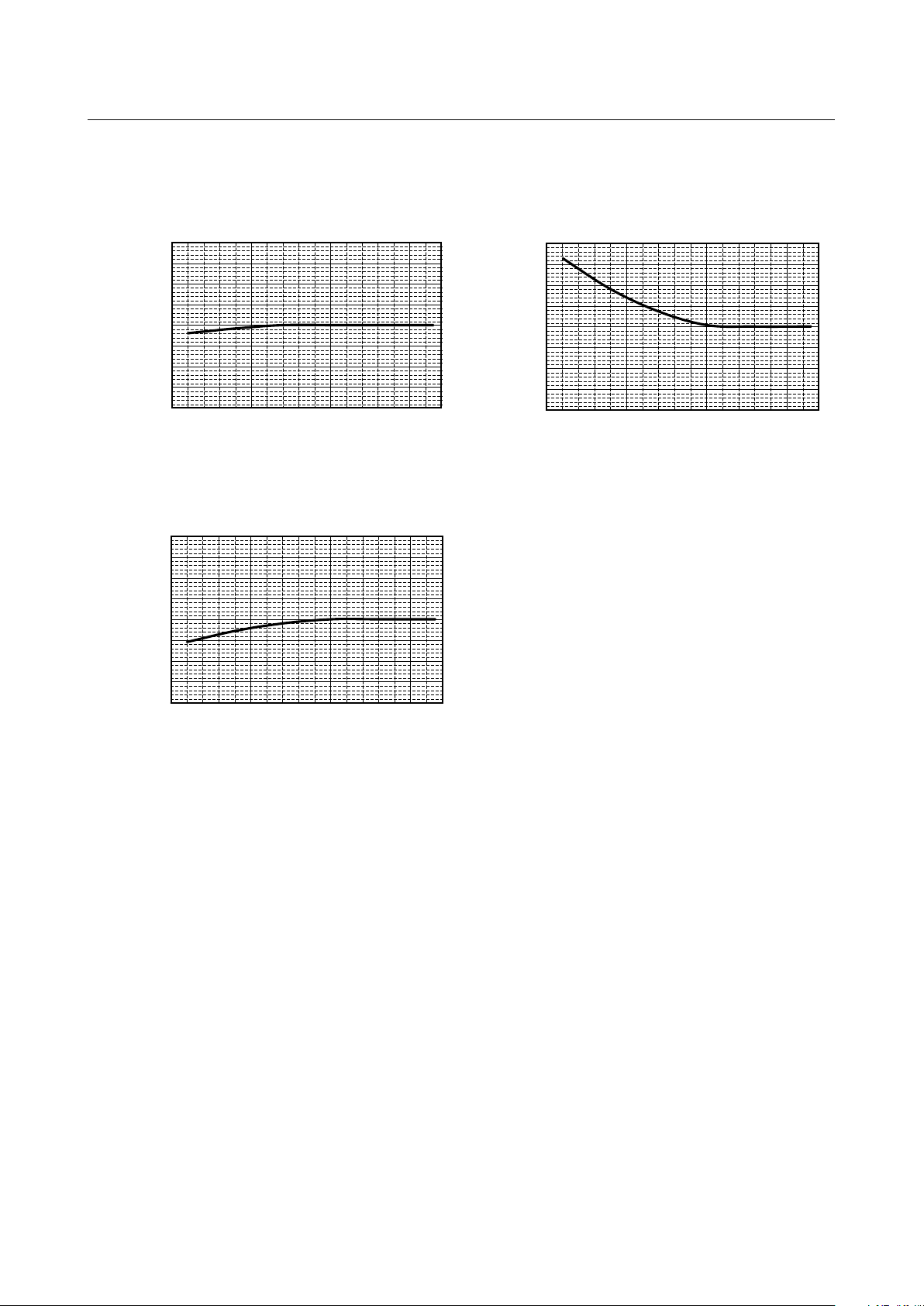

Product Data

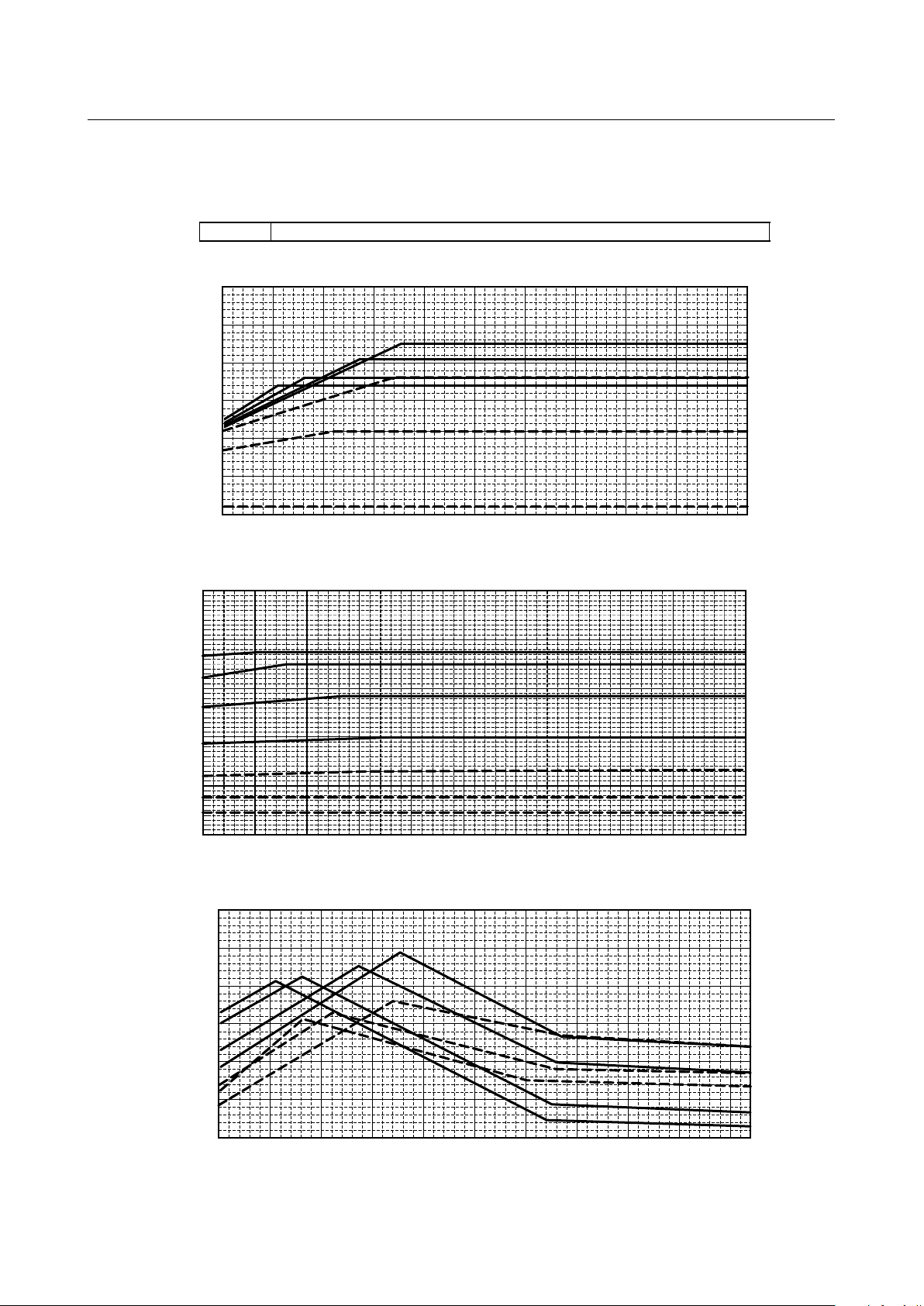

1. Capacity tables

(1) Correction by temperature

(1)-1 R2 series + PWFY-P100VM-E-BU

- 15 -

Page 23

PURY- P300,350,400YHM-A(-BS) EP300,400Y(S)HM-A(-BS)

Outdoor temp. [°CWB]

Ratio of heating capacity

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.1

Outdoor temp. [°CWB]

Ratio of booster unit input

65°C

60°C

50°C

40°C

30°C

20°C

10°C

0.5

0.6

0.7

0.8

0.9

1.0

1.1

Outdoor temp. [°CWB]

Ratio of outdoor unit input

40°C

50°C

60°C

65°C

30°C

20°C

10°C

0.5

0.6

0.7

0.8

0.9

1.0

1.1

30°C

20°C

10°C

40°C

50°C

60°C

65°C

-20

-15

-10 -5

0

5

10

15 20 25 30

-20

-15 -10 -5

0

5

10

15 20 25 30

-20

-15 -10 -5

0

5

10

15 20 25 30

Booster unit inlet-water temp. [°C]

Booster unit inlet-water temp. [°C]

Booster unit inlet-water temp. [°C]

- 16 -

Page 24

30°C

20°C

10°C

40°C

50°C

60°C

65°C

PURY-

P450,500,550,600,650YSHM-A(-BS) EP450,500,550,600YSHM-A(1)(-BS)

0.5

0.6

0.7

0.8

0.9

1.0

1.1

Outdoor temp. [°CWB]

Ratio of heating capacity

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.1

Outdoor temp. [°CWB]

Ratio of booster unit input

65°C

60°C

50°C

40°C

30°C

20°C

10°C

0.5

0.6

0.7

0.8

0.9

1.0

1.1

Outdoor temp. [°CWB]

Ratio of outdoor unit input

40°C

50°C

60°C

65°C

30°C

20°C

10°C

-20

-15 -10 -5

0

5

10

15 20 25 30

-20

-15 -10 -5

0

5

10

15 20 25 30

-20

-15 -10 -5

0

5

10

15 20 25 30

Booster unit inlet-water temp. [°C]

Booster unit inlet-water temp. [°C]

Booster unit inlet-water temp. [°C]

- 17 -

Page 25

PURY- P700,750,800YSHM-A(-BS)

0.5

0.6

0.7

0.8

0.9

1.0

1.1

Ratio of heating capacity

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.1

Ratio of booster unit input

65°C

60°C

50°C

40°C

30°C

20°C

10°C

0.5

0.6

0.7

0.8

0.9

1.0

1.1

Ratio of outdoor unit input

40°C

50°C

60°C

65°C

30°C

20°C

10°C

Outdoor temp. [°CWB]

Outdoor temp. [°CWB]

Outdoor temp. [°CWB]

30°C

20°C

10°C

40°C

50°C

60°C

65°C

-20

-15 -10 -5

0

5

10

15 20 25 30

-20

-15

-10 -5

0

5

10

15 20 25 30

-20

-15 -10 -5

0

5

10

15 20 25 30

Booster unit inlet-water temp. [°C]

Booster unit inlet-water temp. [°C]

Booster unit inlet-water temp. [°C]

- 18 -

Page 26

PURY- P200,250YHM-A(-BS) EP200,250YHM-A(-BS)

Outdoor temp. [°CWB]

Ratio of heating capacity

0.2

0.4

0.6

0.8

1.0

1.2

Outdoor temp. [°CWB]

Ratio of booster unit input

65°C

60°C

50°C

40°C

30°C

20°C

10°C

0.4

0.5

0.6

0.7

0.8

0.9

1.0

Outdoor temp. [°CWB]

Ratio of outdoor unit input

40°C

50°C

60°C

65°C

30°C

20°C

10°C

0.5

0.6

0.7

0.8

0.9

1.0

1.1

30°C

20°C

10°C

40°C

50°C

60°C

65°C

-20

-15

-10 -5

0

5

10

15 20 25 30

-20

-15 -10 -5

0

5

10

15 20 25 30

-20

-15 -10 -5

0

5

10

15 20 25 30

Booster unit inlet-water temp. [°C]

Booster unit inlet-water temp. [°C]

Booster unit inlet-water temp. [°C]

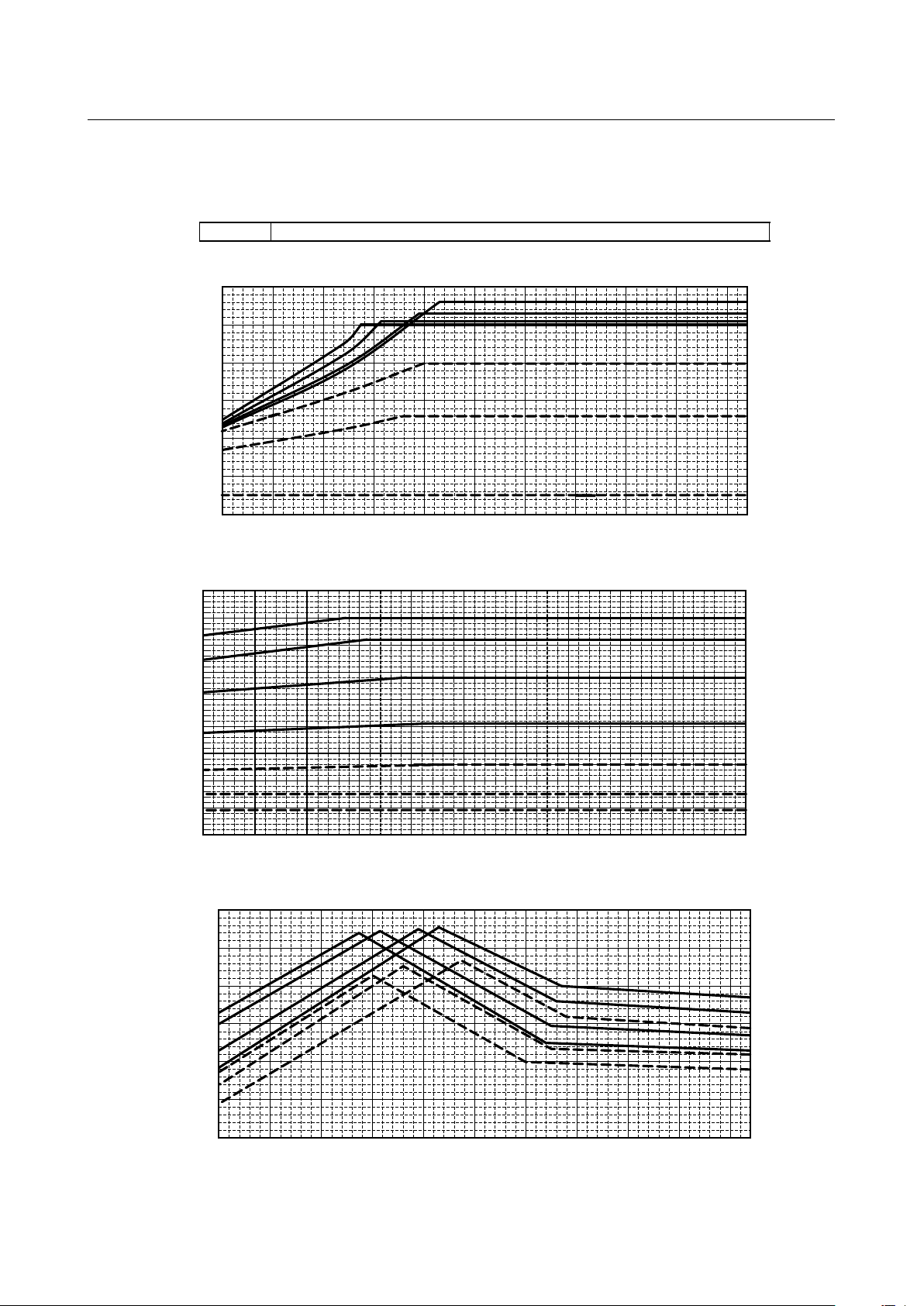

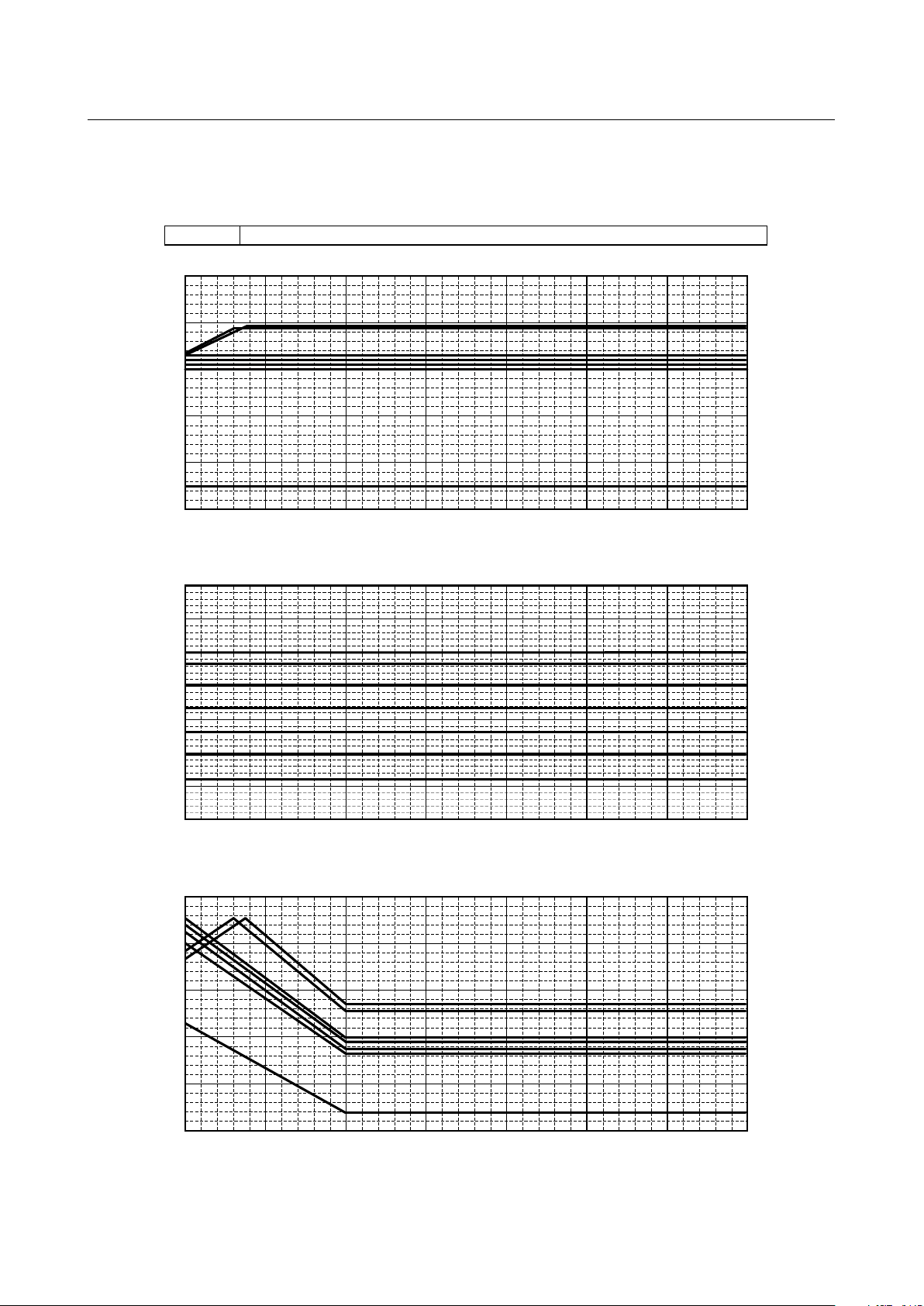

(1)-2 R2 series + PWFY-P100VM-E-BU + WCB Energy saving mode*

*For energy saving mode, set WCB DIP SW 6-5 ON.

- 19 -

Page 27

PURY- P300,350YHM-A(-BS) EP300YHM-A(-BS)

Outdoor temp. [°CWB]

Ratio of heating capacity

0.2

0.4

0.6

0.8

1.0

1.2

Outdoor temp. [°CWB]

Ratio of booster unit input

65°C

60°C

50°C

40°C

30°C

20°C

10°C

0.5

0.6

0.7

0.8

0.9

1.0

1.1

Outdoor temp. [°CWB]

Ratio of outdoor unit input

40°C

50°C

60°C

65°C

30°C

20°C

10°C

0.5

0.6

0.7

0.8

0.9

1.0

1.1

30°C

20°C

10°C

40°C

50°C

60°C

65°C

-20

-15

-10 -5

0

5

10

15 20 25 30

-20

-15 -10 -5

0

5

10

15 20 25 30

-20

-15 -10 -5

0

5

10

15 20 25 30

Booster unit inlet-water temp. [°C]

Booster unit inlet-water temp. [°C]

Booster unit inlet-water temp. [°C]

- 20 -

Page 28

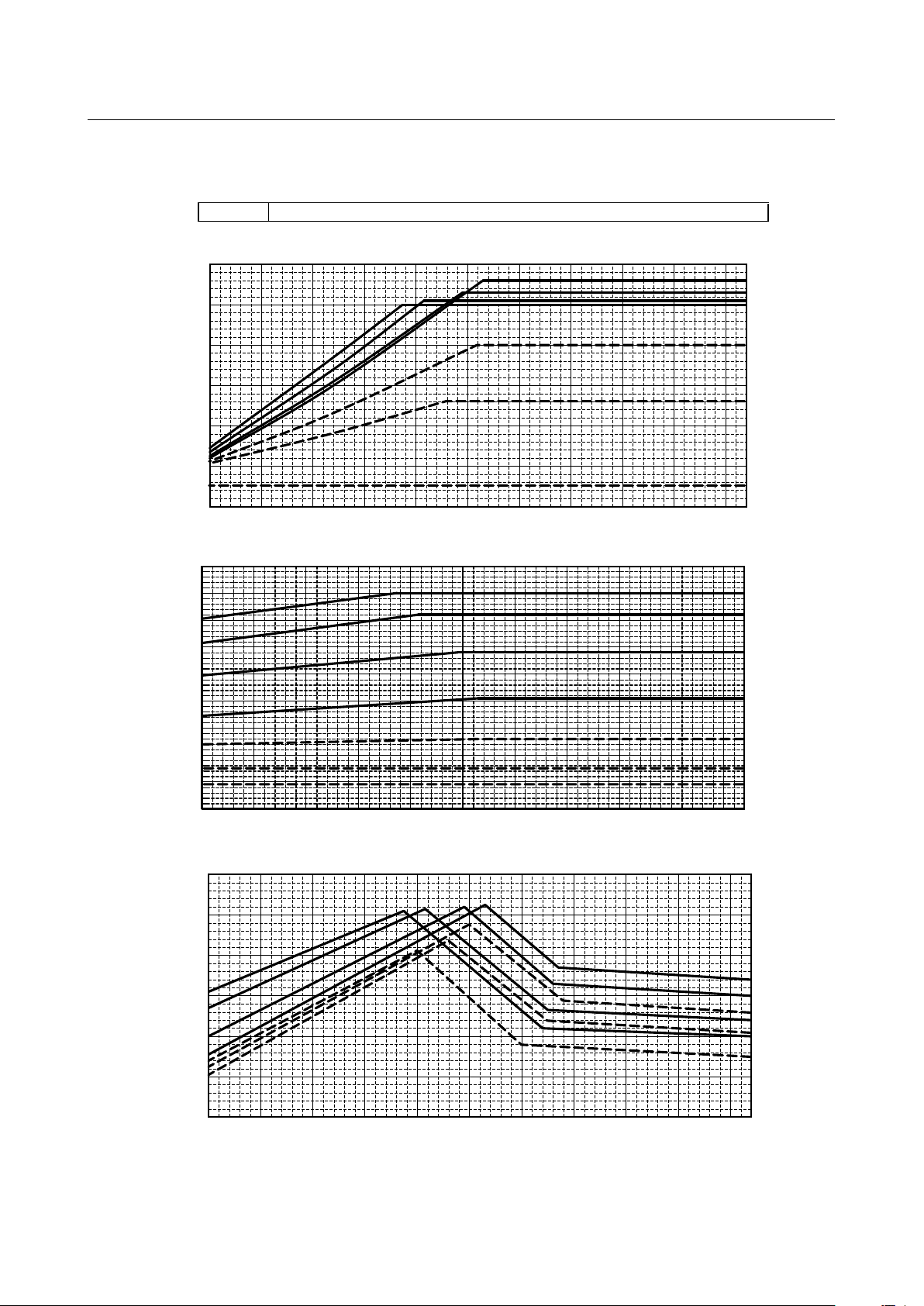

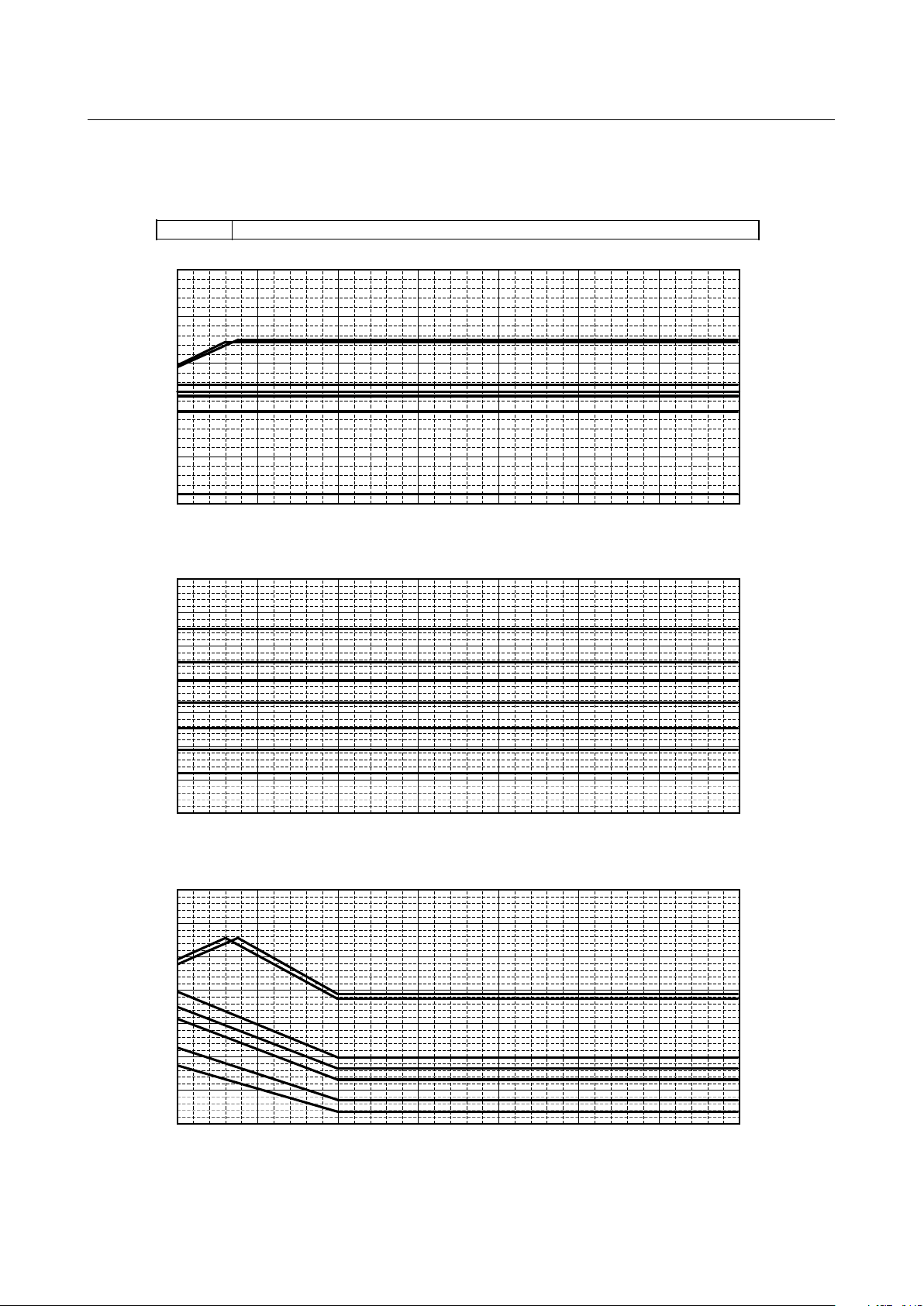

(1)-3 WR2 series + PWFY-P100VM-E-BU

Booster unit inlet-water temp. [°C]

Booster unit inlet-water temp. [°C]

Booster unit inlet-water temp. [°C]

Heat source unit (WR2) inlet-water temp. [°C]

Ratio of Heat source unit input

40°C

50°C

60°C

65°C

10°C

30°C

20°C

0.2

0.0

0.4

0.6

0.8

1.0

1.2

1.4

Heat source unit (WR2) inlet-water temp. [°C]

Ratio of Booster unit input

40°C

30°C

20°C

10°C

50°C

60°C

65°C

0.7

0.8

0.9

1.0

1.1

1.2

Heat source unit (WR2) inlet-water temp. [°C]

Ratio of Booster unit capacity

40°C

50°C

10°C

10

15 20 25 30 35 40 45

0.7

0.8

0.9

1.0

1.1

1.2

10

15 20 25 30 35 40 45

10

15 20 25 30 35 40 45

60°C

65°C

30°C

20°C

PQRY- P200,250,300,400,450,500,550,600Y(S)HM-A

- 21 -

Page 29

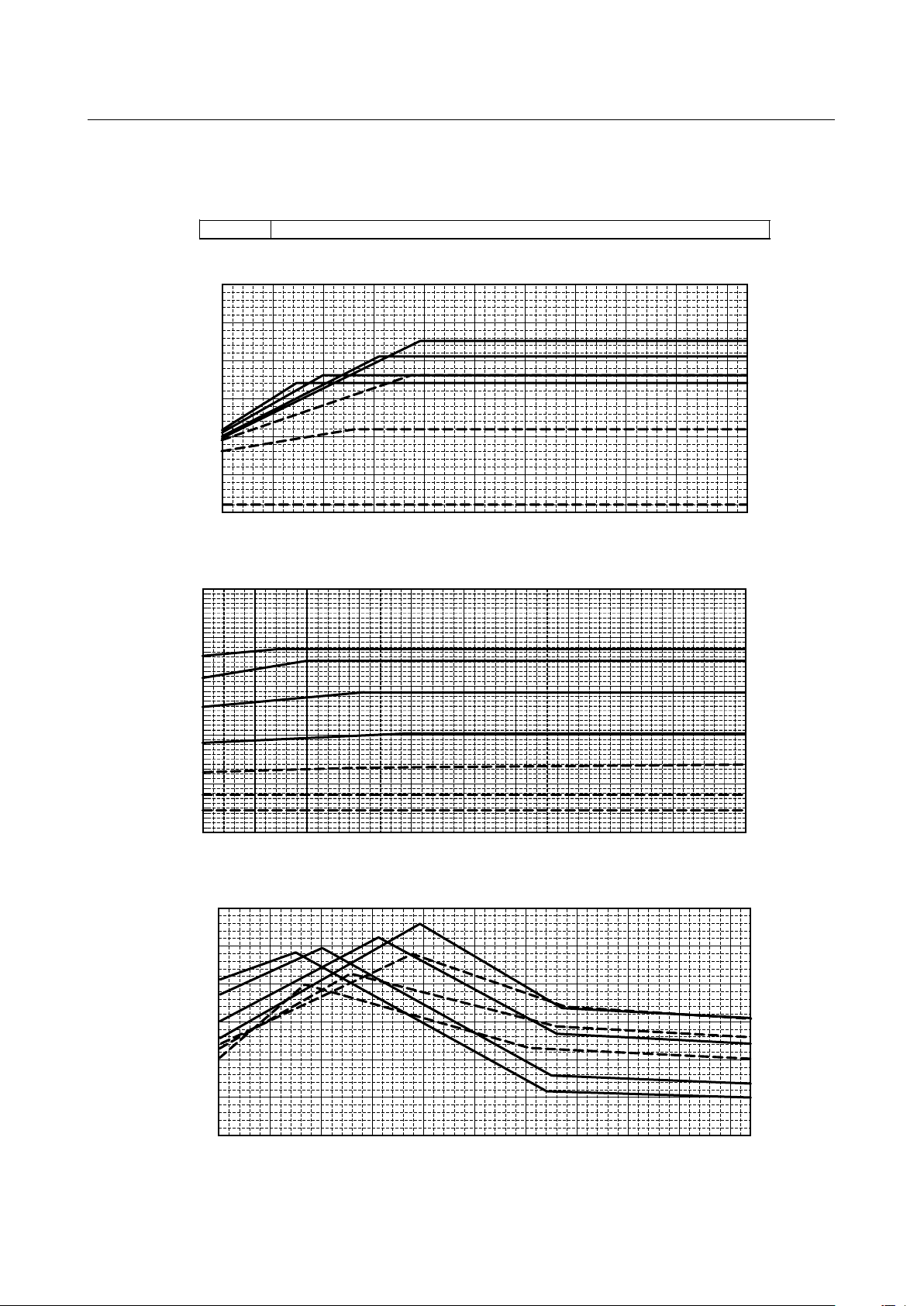

(1)-4 WR2 series + PWFY-P100VM-E-BU + WCB Energy saving mode*

Booster unit inlet-water temp. [°C]

Booster unit inlet-water temp. [°C]

Booster unit inlet-water temp. [°C]

Heat source unit (WR2) inlet-water temp. [°C]

Ratio of Heat source unit input

40°C

50°C

60°C

65°C

10°C

30°C

20°C

0.2

0.0

0.4

0.6

0.8

1.0

1.2

1.4

Heat source unit (WR2) inlet-water temp. [°C]

Ratio of Booster unit input

40°C

30°C

20°C

10°C

50°C

60°C

65°C

0.7

0.8

0.9

1.0

1.1

1.2

Heat source unit (WR2) inlet-water temp. [°C]

Ratio of Booster unit capacity

40°C

50°C

60°C

65°C

30°C

20°C

10°C

10

15 20 25 30 35 40 45

10

15 20 25 30 35 40 45

10

15 20 25 30 35 40 45

0.6

0.5

0.7

0.8

0.9

1.0

1.1

1.2

PQRY- P200,250,300,400,450,500,550,600Y(S)HM-A

*For energy saving mode, set WCB DIP SW 6-5 ON.

- 22 -

Page 30

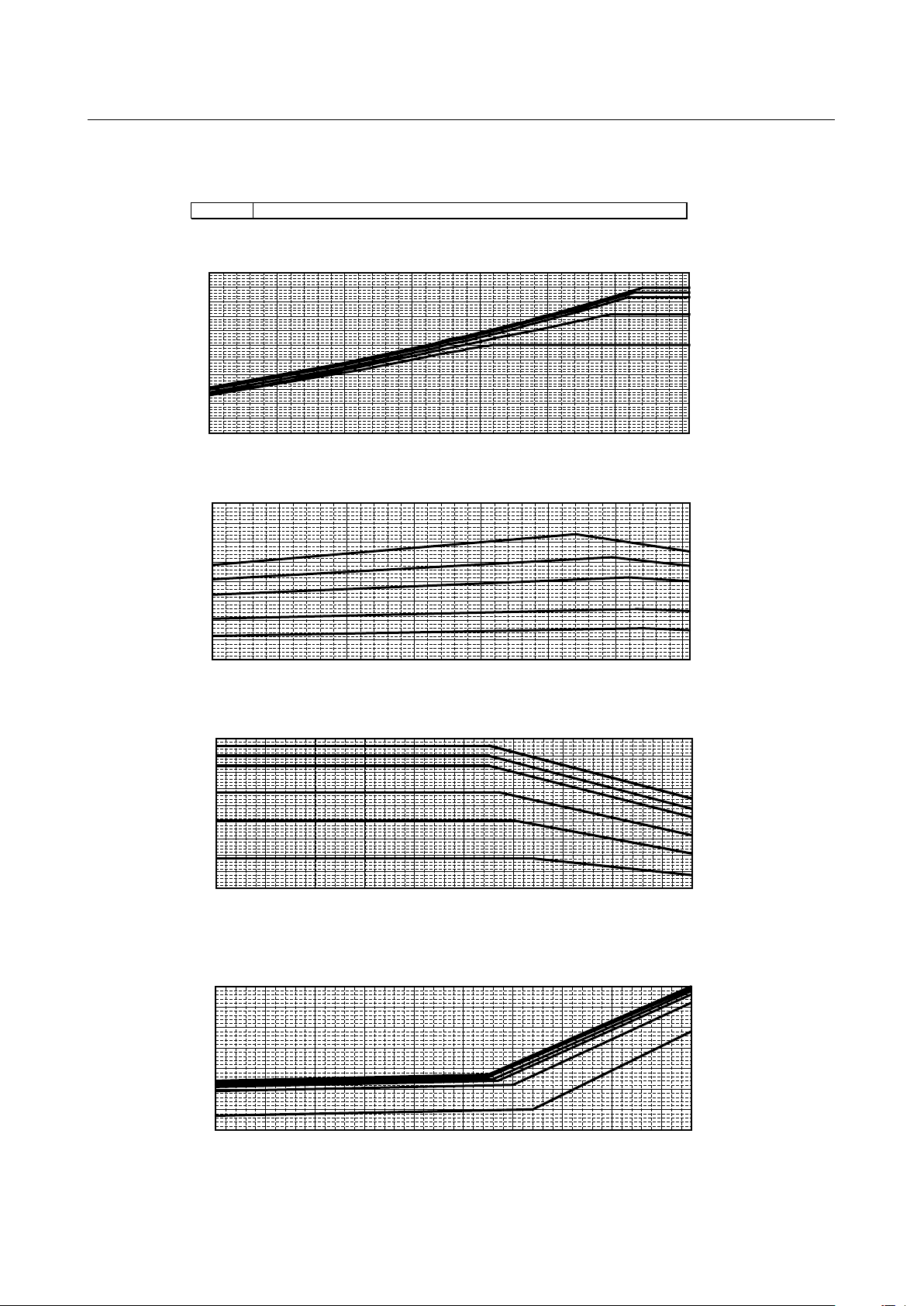

(1)-5 Y series + PWFY-P100,200VM-E-AU

PUHY- P200,250YHM-A(-BS) EP200,250YHM-A(-BS)

Heating

Cooling

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.2

1.1

Outdoor temp. [°CWB]

Ratio of outdoor unit input

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

Outdoor temp. [°CWB]

Ratio of heating capacity

10°C

20°C

30°C

35°C

40°C

10°C

20°C

30°C

35°C

40°C

HEX unit inlet-water temp. [°C]

HEX unit inlet-water temp. [°C]

HEX unit inlet-water temp. [°C]

HEX unit inlet-water temp. [°C]

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

1.4

Outdoor temp. [°CDB]

Ratio of cooling capacity

35°C

30°C

25°C

20

°C

15°C

10°C

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

Outdoor temp. [°CDB]

Ratio of outdoor unit input

35°C

30°C

25°C

20°C

15°C

10

°C

-20

-15

-10 -5

0

5

10

15

-20

-15

-10 -5

0

5

10

15

-5

0

5

10

15

20

25

30

35

40

-5

0

5

10

15

20

25

30

35

40

- 23 -

Page 31

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.2

1.1

Heating

Cooling

Outdoor temp. [°CWB]

Ratio of outdoor unit input

40°C

30°C

35°C

20°C

10°C

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

Outdoor temp. [°CWB]

Ratio of heating capacity

10°C

20°C

30°C

35°C

40°C

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

1.4

Outdoor temp. [°CDB]

Ratio of cooling capacity

35°C

30°C

25°C

20

°C

15°C

10°C

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

Outdoor temp. [°CDB]

Ratio of outdoor unit input

35°C

30°C

25°C

20°C

15°C

10

°C

EP300,400Y(S)HM-A(-BS)PUHY- P300,350,400YHM-A(-BS)

-20

-15

-10 -5

0

5

10

15

-20

-15

-10 -5

0

5

10

15

-5

0

5

10

15

20

25

30

35

40

-5

0

5

10

15

20

25

30

35

40

HEX unit inlet-water temp. [°C]

HEX unit inlet-water temp. [°C]

HEX unit inlet-water temp. [°C]

HEX unit inlet-water temp. [°C]

- 24 -

Page 32

PUHY-

Heating

Cooling

Outdoor temp. [°CWB]

Ratio of outdoor unit input

Outdoor temp. [°CWB]

Ratio of heating capacity

Outdoor temp. [°CDB]

Ratio of cooling capacity

Outdoor temp. [°CDB]

Ratio of outdoor unit input

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

1.4

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.1