Page 1

AIR CONDITIONING SYSTEMS

For Internal Training

FM 33568 / ISO 9001;2000

Certificate Number EC97J1227

The Air Conditioning & Refrigeration Systems Works acquired ISO 9001 certification under Series

9000 of the International Standard Organization (ISO) based on a review of Quality , management for

the production of refrigeration and air conditioning equipment.

ISO Authorization System

The ISO 9000 series is a plant authorization system relating to quality management as stipulated by

the ISO. ISO 9001 certifies quality management based on the "design, development, production,

installation and auxiliary services" for products built at an authorized plant.

The Air Conditioning & Refrigeration Systems Works acquired environmental management system

standard ISO 14001 certification.

The ISO 14000 series is a set of standards applying to environmental protection set by the

International Standard Organization (ISO).

http://Global.MitsubishiElectric.com

Air to Water Booster unit

Air to Water HEX unit

Sales / Technical Guide

MEE08K021

New publication effective Sep. 2008

Specifications subject to change without notice

Page 2

NEW TECHNOLOGY

CONTENTS

1

THE BASICS

1-1 What is Booster unit?

1-2 What is HEX unit?

With many people spending much of their time

indoors at home or work, it is not surprising that

buildings account for a large percentage of all

energy use. This means that there is great scope for

reducing energy use through better-designed

buildings and more efficient heating, cooling and

hot-water systems.

WE NEED TO

Reduce CO2 emissions

Improve energy performance

Ensure that we heat and cool by the most efficient

means possible.

2

FEATURES

2-1 Comparison between Booster unit, HEX unit,

gas/oil boilers, and electric heaters

2-2 Wide range of applications

2-3 Selecting a model

3

CONTROL

3-1 Control options designed for Booster unit

and HEX unit

As a leading manufacturer of energy efficient heat

pump systems, we constantly strive to meet and

exceed the increasing demands placed on our

industry. The drive to reduce energy consumption

and the impact it’s use has on the environment is

crucial and increasingly important to us all. The need

to be more energy conscious and environmentally

responsible has long driven Mitsubishi Electric to

spend huge amounts of resource on researching and

developing the solutions of the future. As market

leaders, at the forefront of the very latest technology,

we pride ourselves in providing high performance

and competitive systems on which you can rely.

Amongst such developments is the advanced heat

pump technology used in Booster unit and HEX unit.

4

INSTALLATION

4-1 Installation

5

Q&A

5-1 Booster unit/HEX unit Specification and function

5-2 Booster unit/HEX unit Installation and service

5-3 Sales

1 2

Page 3

1-1

1-2

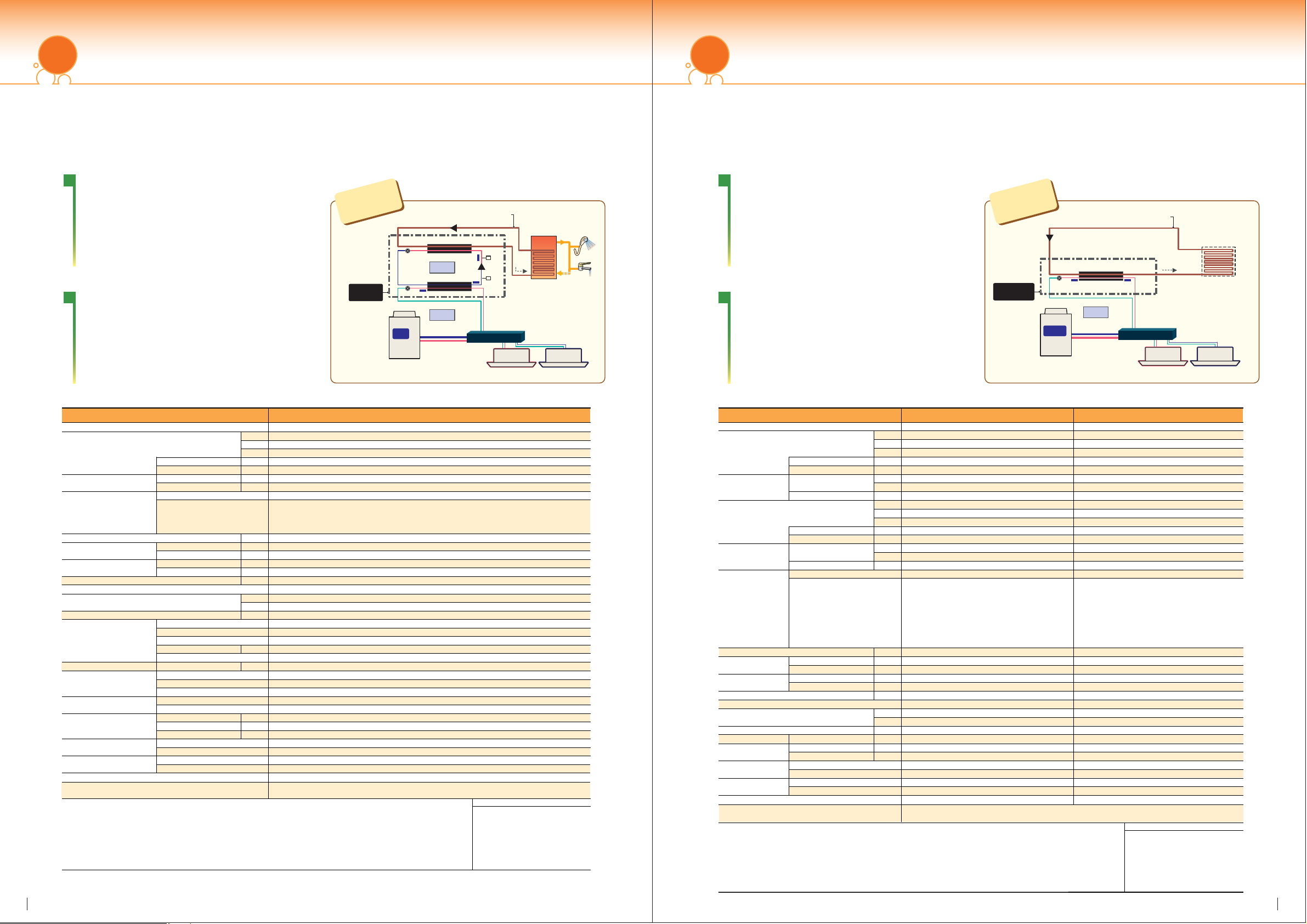

What is Booster unit?

Efficient and technologically advanced, Booster unit takes advantage of proven heat recovery

technology to provide hot water for sanitary use and is one of the most advanced, efficient hot water

systems available today.

TECHNOLOGY

Benefiting from the heat recovery operation of the

CITY MULTI R2 system, Booster unit converts

energy from the air to higher temperatures suitable

for heating water and results in virtually no energy

waste.

HIGH EFFICIENCY

Capable to air condition and supply hot water in a

single system, Booster unit is ideal for use in a

variety of applications. From hotels to restaurants to

gyms, it works perfectly in providing optimum air

environment and hot water to a maximum of 70˚C.

Booster unit

for R2

Booster

Unit

Outdoor

water

LEV

LEV

CITY MULTI

R2

series

Pump

Plate Hex.

R134a

Plate Hex.

R410A

Closed loop circuit

HP

Comp.

LP

BC controller

Indoor

unit

TANK

Indoor

Indoor

unit

What is HEX unit?

With a high COP output achieved, the MITSUBISHI ELECTRIC HEX unit system provides a greater

level of comfort, lower CO

TECHNOLOGY

HEX unit works perfectly to provide heating and

cooling to water fan coil units, panel heaters, or

under floor heating systems. It benefits from the

high-efficient operation of our CITY MULTI and heat

recovery operation when used with R2 system.

FEATURES

HEX unit offers 45˚C in heating and down to 8˚C in

cooling, making it suitable for residential properties,

offices or hotels, providing an optimal environment

while benefiting from reduced running costs and

lessening the impact on our environment.

2 emissions and reduced running costs.

HEX unit

for Y/R2

Pump

HEX Unit

CITY MULTI

R2,Y

series

Outdoor

water

LEV

Plate Hex.

R410A

Closed loop circuit

❈BC controller is only required for

the system with R2 series.

BC controller

Indoor

unit

Indoor

Floor Heating or

Panel Heater

or FAN-coil(AHU)

Indoor

unit

Model

Power source

Power input

Current input

Temp. range of

heating

Connectable

outdoor unit Model / Quantity

Sound pressure level (measured in anechoic room)

Diameter of

refrigerant pipe

Diameter of

water pipe

Field drain pipe size

External finish

External dimension H ✕ W ✕ D

Net weight

Compressor

Circulating water

Protection on Internal circuit

(R134a)

Design pressure

Standard attachment

Optional parts

Remark

Note:

* Due to continuing improvement, the above specifications may be subject to change without notice. * Install the unit in an environment where the

* Please don't use the steel material for the water piping material. * The water circuit must use the closed circuit.

* Please always make water circulate or add the brine to the circulation water when the ambient temperature becomes 0˚C or less.

* Please always make water circulate or pull out the circulation water completely when not using it.

* Please do not use groundwater and well water.

*1 Nominal heating conditions

Outdoor Temp. : 7˚CDB/6˚CWB (45˚FDB / 43˚FWB)

Pipe length : 7.5 m (24-9/16 ft)

Level difference : 0m (0ft)

Inlet water Temp 65˚C Water flow rate 2.15m3/h

Outdoor temp.

Inlet Water temp.

Total capacity

Liquid

Gas

Inlet

Outlet

Type

Maker

Starting method

Motor output

Lubricant

Operation volume Range

High pressure protection

Inverter circuit (COMP)

Compressor

Type ✕ original chargeRefrigerant

Control

R410a

R134a

Water

ExternalDrawing

Wiring

Document

Accessory

kWHeating capacity

kcal / h(Nominal )

BTU / h

kW

A

W.B

-

dB<A>

mm(in.)

mm(in.)

mm(in.)

mm(in.)

mm(in.)

mm

in.

kg(lb)

kW

3

/h

m

MPa

MPa

MPa

PURY-P450YSHM-A(-BS)~PURY-P800YSHM-A(-BS)

PURY-EP200YHM-A(-BS)~PURY-EP300YHM-A(-BS)

PURY-EP400YSHM-A(-BS)~PURY-EP600YSHM-A(-BS)

31-1/2" (30-15/16" without legs) ✕ 17-3/4" ✕ 11-13/16"

High pressure sensor, High pressure switch at 3.60 MPa (601 psi)

Discharge thermo protection, Over-current protection

Strainer, Heat insulation material, 2 ✕ Connector sets

Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and

other items shall be referred to the Installation Manual.

wet bulb Temp. will not exceed 32degC.

* Please do not use it as a drinking water.

* The unit is not designed for outside installations.

PWFY-P100VM-E-BU

1-phase 220-230-240V 50/60Hz

50~100% of outdoor unit capacity

PURY-P200YHM-A(-BS)~PURY-P400YHM-A(-BS)

800 (785 without legs) ✕ 450 ✕ 300

Inverter rotary hermetic compressor

MITSUBISHI ELECTRIC CORPORATION

Over-heat protection, Over-current protection

Installation Manual, Instruction Book

12.5

10,800

42,700

2.48

11.63 - 11.12 - 10.66

-20~32˚C (59~90˚F)

10~70˚C (50~158˚F)

44

ø9.52 (ø3/8") Brazed

ø15.88 (ø5/8") Brazed

PT3/4 Screw

PT3/4 Screw

ø32 (1-1/4")

NO

60 (133)

Inverter

1.0

NEO22

0.6~2.15

R134a ✕ 1.1kg (0.50lb)

LEV

4.15

3.60

1.00

WKB94L762

E64C226X01

NONE

kcal = kW ✕ 860

BTU/h = kW ✕ 3,412

cfm = m3/min ✕ 35.31

lb = kg / 0.4536

* The specification data is subject

to rounding variation.

Unit converter

Model

Power source

Power input

Temp. range of

heating

Connectable

outdoor unit

Sound pressure level (measured in anechoic room) dB<A>

Diameter of

refrigerant pipe

Diameter of

water pipe

Field drain pipe size

External finish

External dimension H ✕ W ✕ D

Net weight

Circulating water

Design pressure

Drawing

Standard attachment

Optional parts

Remark

Note:

Outdoor Temp. : 7˚CDB/6˚CWB (45˚FDB / 43˚FWB) Outdoor Temp. : 35˚CB (95˚FDB)

Inlet water Temp 30˚C

* Due to continuing improvement, the above specifications may be subject to change without notice.

* Please don't use the steel material for the water piping material. * The water circuit must use the closed circuit.

* Please always make water circulate or add the brine to the circulation water when the ambient temperature becomes 0˚C or less.

* Please always make water circulate or pull out the circulation water completely when not using it.

Current input

Outdoor temp.

Inlet Water temp.

Power input

Current input

Outdoor temp.Temp. range of cooling

Total capacity

Model / Quantity

Liquid

Gas

Inlet

Outlet

Operation Volume Range

R410a

Water

External

Wiring

Document

Accessory

Water flow rate 2.15m

3

/h

kW*1Heating capacity

kcal / h

*1(Nominal)

BTU / h

*1

kW

A

W.B

W.B

kW*2Cooling capacity

kcal / h

*2(Nominal)

BTU / h

*2

kW

A

D.B

D.B

-Inlet Water temp.

mm(in.)

mm(in.)

mm(in.)

mm(in.)

mm(in.)

mm

in.

kg(lb)

3

m

/h

MPa

MPa

*2 Nominal cooling conditions *1 Nominal heating conditions

Pipe length : 7.5 m (24-9/16 ft)Pipe length : 7.5 m (24-9/16 ft)

Level difference : 0m (0ft)Level difference : 0m (0ft)

Inlet water Temp 23˚C

PURY-P200YHM-A(-BS)~PURY-P400YHM-A(-BS)

PURY-P450YSHM-A(-BS)~PURY-P800YSHM-A(-BS)

PURY-EP200YHM-A(-BS)~PURY-EP300YHM-A(-BS)

PURY-EP400YSHM-A(-BS)~PURY-EP600YSHM-A(-BS)

PUHY-P200YHM-A(-BS)~PUHY-P450YHM-A(-BS)

PUHY-P500YSHM-A(-BS)~PUHY-P1250YSHM-A(-BS)

PUHY-EP200YHM-A(-BS)~PUHY-EP300YHM-A(-BS)

PUHY-EP400YSHM-A(-BS)~PUHY-EP900YSHM-A(-BS)

31-1/2" (30-15/16" without legs) ✕ 17-3/4" ✕ 11-13/16"

Strainer, Heat insulation material, 2 ✕ Connector sets

PWFY-P100VM-E-AU

1-phase 220-230-240V 50/60Hz

0.068 - 0.065 - 0.063

-20~32˚C (-4~90˚F) PURY - series

-20~15.5˚C (-4~60˚F) PUHY - series

10~40˚C (50~104˚F)

0.068 - 0.065 - 0.063

-5~43˚C (23~110˚F) PURY - series

-5~43˚C (23~110˚F) PUHY - series

10~35˚C (50~95˚F)

50~100% of outdoor unit capacity

ø9.52 (ø3/8") Brazed

ø15.88 (ø5/8") Brazed

800 (785 without legs) ✕ 450 ✕ 300

Installation Manual, Instruction Book

Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and

other items shall be referred to the Installation Manual.

Water flow rate 1.93m3/h

* Install the unit in an environment where the

wet bulb Temp. will not exceed 32degC. * The unit is not designed for outside installations.

* Please do not use it as a drinking water. * Please do not use groundwater and well water.

PWFY-P200VM-E-AU

12.5

10,800

42,700

0.015

11.2

9,600

38,200

0.015

PURY-EP400YSHM-A(-BS)~PURY-EP600YSHM-A(-BS)

29

PT3/4 Screw

PT3/4 Screw

ø32 (1-1/4") ø32 (1-1/4")

NO

35 (78)

0.6~2.15

4.15

1.00

WKB94L763

E00C223

NONE

PUHY-EP400YSHM-A(-BS)~PUHY-EP900YSHM-A(-BS)

Strainer, Connecter, Heat insulation material, 2 ✕ Connector sets, Expansion joint

1-phase 220-230-240V 50/60Hz

-20~32˚C (-4~90˚F) PURY - series

-20~15.5˚C (-4~60˚F) PUHY - series

-5~43˚C (23~110˚F) PURY - series

-5~43˚C (23~110˚F) PUHY - series

50~100% of outdoor unit capacity

PURY-P200YHM-A(-BS)~PURY-P400YHM-A(-BS)

PURY-P450YSHM-A(-BS)~PURY-P800YSHM-A(-BS)

PURY-EP200YHM-A(-BS)~PURY-EP300YHM-A(-BS)

PUHY-P200YHM-A(-BS)~PUHY-P450YHM-A(-BS)

PUHY-P500YSHM-A(-BS)~PUHY-P1250YSHM-A(-BS)

PUHY-EP200YHM-A(-BS)~PUHY-EP300YHM-A(-BS)

800 (785 without legs) ✕ 450 ✕ 300

31-1/2" (30-15/16" without legs) ✕ 17-3/4" ✕ 11-13/16"

Installation Manual, Instruction Book

25.0

21,500

85,300

0.015

0.068 - 0.065 - 0.063

10~40˚C (50~104˚F)

22.4

19,300

76,400

0.015

0.068 - 0.065 - 0.063

10~35˚C (50~95˚F)

29

ø9.52 (ø3/8") Brazed

ø19.05 (ø3/4") Brazed

PT 1 Screw

PT 1 Screw

NO

38 (84)

1.2~4.30

4.15

1.00

WKB94L763

E94C228X01

NONE

Unit converter

kcal = kW ✕ 860

BTU/h = kW ✕ 3,412

cfm = m3/min ✕ 35.31

lb = kg / 0.4536

* The specification data is subject

to rounding variation.

3 4

Page 4

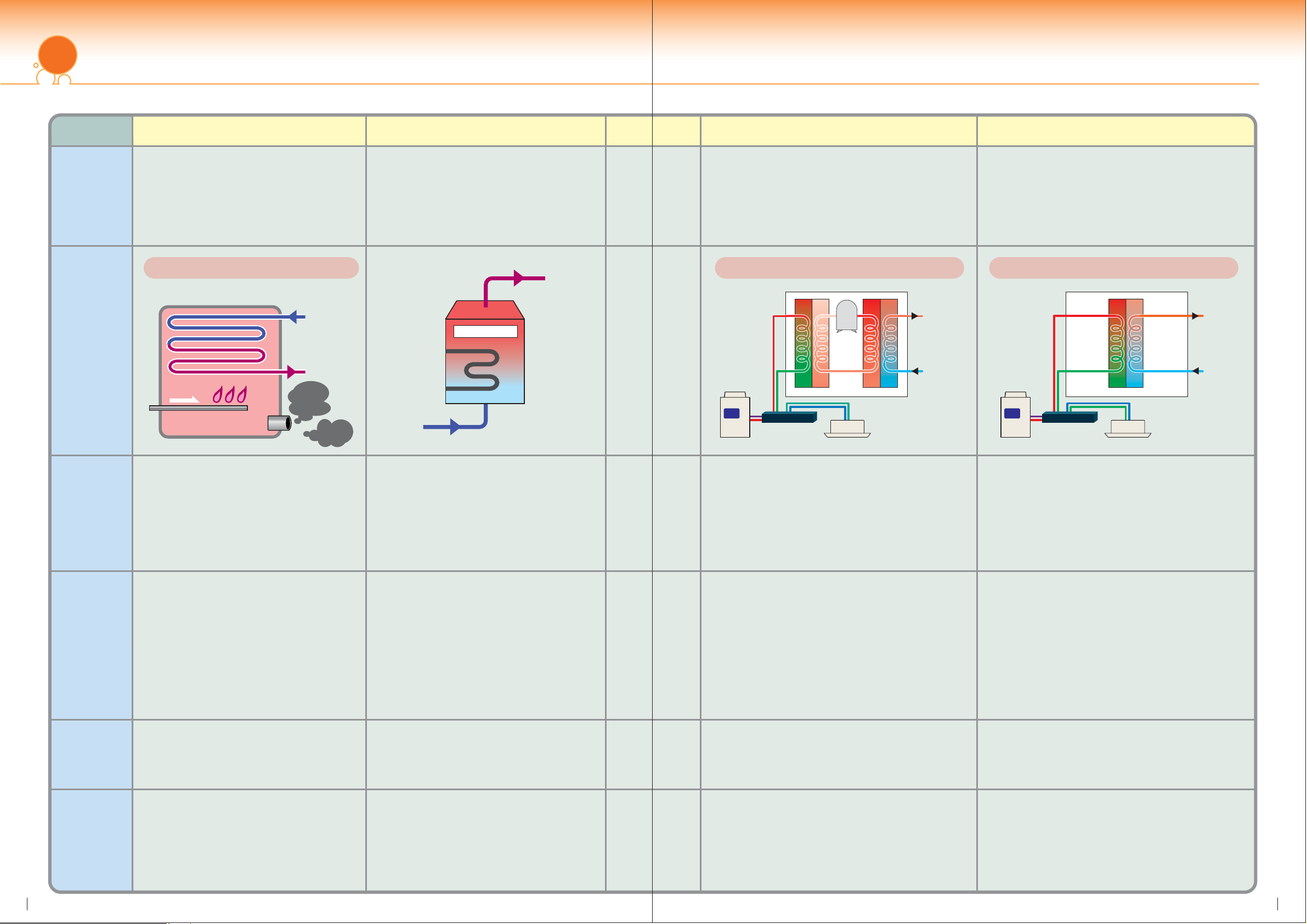

2-1

Comparison among Booster unit, HEX unit, gas/oil boilers, and electric heaters

System

outline

System

structure

Gas/oil boiler

Heats water using the energy

released by combustion.

Water supply

Hot-water supply

Gas, oil etc.

Combustion chamber

Exhaust

gas

CO

NOx

2

Electric heater Booster unit HEX unit

Heats water by immersing an electric

heater inside the water tank, which

directly heats the water.

Hot-water supply

Hot-water cylinder

Heater

Water supply

By utilizing waste heat from the R2 outdoor

unit for the booster unit, it is possible to

supply hot water with high efficiency

operation.

Booster Unit for R2Trans Flux type

CITY MULTI

R2

series

Outdoor

BC controller

COMP

Indoor

unit

Hot water

supply

Water supply

By Utilizing waste heat from the R2 outdoor

unit for heating operation in HEX unit, it is

possible to supply hot water with high

efficiency. (No efficiency when in cooling or

connected with Y series)

HEX unit for Y/R2

Hot water

supply

Water supply

CITY MULTI

R2

series

Outdoor

BC controller

Indoor

unit

Safety

Energy

saving

CO2

emission

Operation involves combustion. Due to

special requirements, a boiler room is

necessary. Proper installation is required

to ensure safe operation, i.e.ventilation.

Due to high voltage, careful handling

and installation of power lines are

required.

Only consumes energy at the time

and place where it is needed.

Continuous running of the system

required to keep load of buffer tank.

Efficiency is low as COP of 1, as part

of the embedded energy is lost

through exhaust and emission

losses.

CO2 and NOx may generate at the

installation site. The volume will be

larger than an electric system.

Relatively safe. Due to high voltage,

careful handling and installation of

power lines are required.

Only consumes energy at the time

and place where it is needed.

Consumed energy is entirely

converted into effective heat at the

point of use.

Efficiency is low as COP of 1, as part

of the embedded energy is lost

through exhaust and emission losses.

2 and NOx will not generate at

CO

the installation site.

Relatively safe. Due to high voltage, careful

handling and installation of power lines are

required.

If refrigerant leaks, there is a possibility of

suffocation.

Highly efficient, as it utilizes waste heat from

cooling to supply hot water.

2 and NOx will not generate at the

CO

installation site.

Relatively safe. Due to high voltage, careful

handling and installation of power lines are

required.

If refrigerant leaks, there is a possibility of

suffocation.

Highly efficient, as it utilizes waste heat from

cooling to supply hot water.

CO2 and NOx will not generate at the

installation site.

Maintenance

Regular maintenance and chimney

sweeping required.

Remote operation and monitoring is

possible.

Easy maintenance, no chimney sweeping,

no purging of the pipes. Remote operation

and monitoring is possible.

May require regular replacement of

Easy maintenance, no need for regular

servicing by an expert, no chimney

sweeping, no purging of the pipes. Remote

operation and monitoring is possible.

Easy maintenance, no need for regular

servicing by an expert, no chimney

sweeping, no purging of the pipes. Remote

operation and monitoring is possible.

electric heater.

5 6

Page 5

2-2

Proposal examples/Application examples

Restaurant

HEX unit

From Outdoor Unit

Hot Water

Outdoor Unit

Heating / Cooling

Fan coil units

Panel heaters

Floor heating

Residence

HOT water up to 45˚C

Easy operation by remote

controller

Both hot and cool water available.

(Depends on outdoor unit’s

operation mode)

Heating/Cooling

Hot water up to 70˚C

High COP operation with heat recovery

technology

High COP operation with double inverter

technology

From Outdoor Unit

Booster unit

Healthcare facilities Hotels Hospitals Factories Gyms

Supermarkets Apartments Restaurants Offices

7 8

Page 6

2-3

Selecting a model

(1) Model selection calculation (2) Model selection calculation example

A

A. For Air conditioning using such as Panel Heaters,

. For Air conditioning using such as Panel Heaters,

Floor Heating and Fan coil units

Required total heating capacity kW

Safety factor; %

B. For Sanitary use such as Shower and Bathrooms

Conditions

Tank inlet water Temp.; °C

Tank outlet water Temp.; °C

(Set Temp -5 °C)

Safety factor for Heat Loss; %

Operating time; Hours

For Shower; /Person x Person =

(Water Temp. Condition °C)

For Bathrooms; /Person x Person =

(Water Temp. Condition

PWFY unit

°C)

Tank

Floor Heating and Fan coil units

Required total heating capacity 20

4

7

3 3

3

For Shower; 60 /Person x Person =

(Water Temp. Condition °C)

For Bathrooms; 8 /Person x Person =

(Water Temp. Condition

3

B. For Sanitary use such as Shower and Bathrooms

20

30

Safety factor; %

Conditions

Tank inlet water Temp.; °C

Tank outlet water Temp.; °C

[ (Set Temp) -5°C ]

Safety factor for Heat Loss; %

Operating time; Hours

1,200

40

240

45

°C)

10

10

60

15

8

kW

(The examples of water volume might be need to be changed as you need.)

The conversion of water volume to °C

x(

+x( - )/( -)

= /day

Heating Capacity Calculation for sanitary usage

/

1,000 x ( - ) = M cal / day

The conversion of M cal to kW

/ 860 x 1,000 /

C.

Total (A+B)

Total Heating Capacity

(100%

x

D. No. of units required

Safety factor; %

(100%

+

+x

-

=kW

%) +

%) / 12.5 kW = units

)/( - )

x (100% %) = kW

+

(The examples of water volume might be need to be changed as you need.)

The conversion of water volume to °C

1,200

+x( - )/( -)

240

= /day

888

Heating Capacity Calculation for sanitary usage

888

The conversion of M cal to kW

44.4

Total (A+B)

C.

Total Heating Capacity

20

D. No. of units required

Safety factor; %

29.42 20

x(

/1,000 x ( - ) = M cal / day

/ 860 x 1,000 /

x (100%

20

(100%

40

45

60 44.4

+

10

+x

60

-

8 6.45

%) +

%) / 12.5 kW = units

10

10

10

=kW

6.45 15 29.42

)/( - )

x (100% %) = kW

2.82

+

60

60

10

10

units are required

9 10

3

units are required

Page 7

3-1

Control design for Booster unit and HEX unit

Function

Item Description Operations Display

ON/OFF Runs and stops the operation of a group of units

Operation mode switching ❈ Available operation modes vary depending on the unit to be connected.

❈ Switching limit setting can be made via a remote controller.

Water temperature setting

Preset temperature range limit Preset temperature range setting can be limited via a remote controller.

Water temperature display (in increments of 1˚C or 1˚F)

Permit / Prohibit

local operation

Weekly scheduler

Error When an error is currently occurring on a unit, the afflicted unit and the error code are displayed.

Self check (Error history) Searches the latest error history by pressing the CHECK button twice.

Test run

Circulating water

replacement warning

Language setting

Operation locking function ·All-switch locking

Switches between Hot Water / Heating / Heating ECO / Anti-freeze / Cooling

Temperature can be set within the ranges below. (in increments of 1˚C or 1˚F)

Hot Water 30 / 35 / 40 / 45˚C min. ~ 30 ~ 70˚C

Heating (in increments of 1˚C or 2˚F)

Heating ECO Temperature within the following range can be set depending on the outside air

temperature. 30˚C min. ~ 45˚C max.

Anti-freeze 10˚C min. ~ 45˚C max. (in increments of 5˚C or 10˚F)

Cooling 10˚C min. ~ 30˚C max. (in increments of 5˚C or 10˚F)

❈ The settable range varies depending on the unit to be connected.

10˚C min. ~ 90˚C max.

❈ The settable range varies depending on the unit to be connected.

Individually prohibits operations of each local remote control function :ON/OFF, Operation modes,

water temperature setting, Circulating water replacement warning reset.

❈ Upper level controller may not be connected depending on the unit to be connected.

ON / OFF / Water temperature setting can be done up to 6 times one day in the week.

(in increments of a minute)

Enables the Test run mode by pressing the TEST button twice.

❈ Test run mode is not available depending on the unit to be connected.

Displays the circulating water replacement warning via the unit message.

Clears the display by pressing the CIR.WATER button twice.

❈ Circulating water replacement warning is not available depending on the unit to be connected.

The language on the dot matrix LCD can be changed. (Seven languages)

English/German/Spanish/Russian/Italian/French/Swedish

Remote controller operation can be locked or unlocked.

·Locking except ON/OFF switch

Control priorities

1. External input signal 2. Centralized controller 3. Remote controller

Heating ECO mode

Set temp.

Tf12

Tf11

Initial setting

Tf11

Tf12

Ta11

Ta12

Booster/Hex unit icon shown on

AG-150A and TG-2000A screen

(Dip SW4-3 ON)

Ta11

30˚C

40˚C

0˚C

10˚C

Remote Controller :

PAR-W21MAA

Heating ECO is for energy saving.

When this function is effective, outlet water

temp. will automatically change based on

ambient temp. Contribute to energy saving

by controlling capacity especially in cases

where ambient temp. is high and there is low

demand for hot water or heating.

Ta12

oudoor temp.

Possible to change by remote

controller <PAR-W21MAA>

Output/Input Functions

TB141A (Output)

Symbol

OUT1

OUT2

OUT3

OUT4

TB142A (Input)

Symbol

IN1

TB142B (Input)

Symbol

IN3

IN4

TB142C (Input)

Symbol

+

COM

IN5

IN6

IN7

❈

IN8

Analog input

Symbol

CN421

CN422

Function

Operation ON/OFF

Defrost

Compressor

Error signal

Function

Pump interlock No setting when shipped from factory. ON=in operation. OFF=invalid.

Function

Connection demand

Operation ON/OFF

Function

Common

Hot water/Heating

Heating ECO

Anti-freeze

Cooling

Function

Set water temperature

Set water temperature

Outputs the ON/OFF signal

Outputs the Defrost signal

Outputs the Compressor signal

Outputs the Error signal

Mandatory STOP with demand input ON

For external ON/OFF operation.

Common wiring

Hot water operation

Outlet water temp. will automatically change based on ambient temp.

Unit will atutomatically maintain set water temp.

Cooling operation

❈ HEX unit only

Capable with accessory connector

Capable with accessory connector

❈ CN421 priority

Anti freeze mode (Dip SW4-4 ON)

Anti freeze mode is to prevent

water pipe from freezing.

When this function is effective,

Control

Box

Measurement

point of

Operation signal

Pump interlock

Water Temp.

is available to

choose by

Dip SW1-1

Strainer

Water Pump

Water temperature is changeable by remote controller <PAR-W21MAA>

the unit will automatically

maintain set water temp. (Field

supply control board for water

pump operation necessary.)

Broken lines are field

supply products.

11 12

Page 8

4-1

Installation

The unit must be installed inside a building. The unit is not designed for

outdoor installation.

For water pipes, do NOT use steel pipes. Copper pipes are

recommended.

Drain pipe

Install the drain pipe with an inclination of between 1/100 and 1/200 to provide a downward

flow of drain water.For cold climate installation, take an appropriate measures (e.g., drain

heater) to prevent the drain water from freezing.

Strainer

Install a strainer near the PWFY unit to keep foreign materials from entering the water-side

heat exchanger.

Do not touch the unit, the unit surface can be hot.

Back up system is recommended in case of PWFY unit breakdown.

Service space

Top view

400525

Piping space (right side)

Installation image

Wall mounted Ceiling Suspended

Floor standing

Hot-blast

up to 55°C

Service space

(front side)

Example of Water pipe installation

Solid arrows in the figure indicate the direction of water flow.

Mains water

PWFY

Water-side

heat exchanger

13 14

Field supply

T

T

PWFY

Water overflow

To drain outlet

P

P

Sample of water circuit for HWS/ATW

P

300

600

Roof

Tank Outlet

Inlet

Unit [mm]

R2

PURY-P400YHM-A

BC controller

PWFY-P100VM-E-BU PWFY-P100VM-E-BU PWFY-P100VM-E-AU PEFY-P32VMR-E-R PEFY-P63VMS1-E

* Note: If any medicinal substance is used for Heating (AHU, FCU, Floor Heating, etc), part the water circuit for sanitary use.

PWFY

PWFY

Counter flow water circuit

We have no regulation for water flow way. Therefore customers can choose

either counter flow or parallel flow due to their demand.

Cold Water Tank

Hot Water Tank

Cold Water Tank

Hot Water Tank Hot Water Tank

PWFY

PWFY

Parallel flow water circuit

Cold Water Tank

Water Supply

For Cooling

(AHU, FCU, etc)

For Heating

(AHU, FCU,

Floor Heating, etc)

Water Supply

For Sanitaty use

(Shower, Bath, etc)

Page 9

5-1

Q & A

5-1

Booster unit/HEX unit Specification and function Booster unit/HEX unit Specification and function

Q & A

Q1

Q2

Q3

Q4

Q5

Q6

Q7

What kinds of compressors are used in Booster unit?

Mitsubishi Electric Rotary compressors

What is the temperature range on controller for heating?

Booster unit:35˚C-70˚C (95F-158F)

HEX unit :30˚C-45˚C (86F-113F) (Heating)

HEX unit :10˚C-30˚C (50F-86F) (Cooling)

What is the hydraulic pressure?

1.0MPa (Maximum range)

Is the water pump embedded?

Water pumps are field supplied and need to be selected depending on field system.

How do you interlock the pumps?

TB142A

Short circuiting of TB142A will start the unit

and opening of circuit will stop operation. (nonvoltage A contact)

IN1

What are the new technologies?

Booster units and HEX units operate on high COP with heat recovery function (with

R2 system). Booster unit is able to supply high temperature hot water up to 70˚C

without electric heater.

What is Anti-freeze?

Anti-freeze mode (Dip SW3-4 ON) to prevent water pipe from freezing. When Antifreeze mode is effective, the unit will sustain set water temperature. The field supply

control board for water pump interlock is necessary.

Q9

External analog input

Method

Input T(A), T(B)

4mA :T(A)

20mA:T(B)

Conversion equation:To=[{T(B) - T(A)}/16] ✕ Ia + [ T(A) - {T(B) - T(A)}/4]

To: set temperature, Ia: analogue input value (mA)

Calculation example: T(A)=30˚C, T(B)=70˚C, Ia=10mA

Conversion equation: To=2.5 ✕ Ia+20 To=45˚C

Q10

Remote controller specifications

What is external analog input?

T(B)˚C

Changeable with

PAR-W21MAA

T(A)˚C

4mA 20mA

What are the functions with the controllers?

Item Description

ON/OFF

Operation mode switching

Water temperature setting

Preset temperature range

Water temperature display

Permit / Prohibit

local operation

Weekly scheduler

Error

Self check (Error history)

Test run

Circulating water

replacement warning

Language setting

Operation locking function

Runs and stops the operation of a group of units

Switches between Hot Water / Heating / Heating ECO / Anti-freeze / Cooling

* Available operation modes vary depending on the unit to be connected.

* Switching limit setting can be made via a remote controller.

Temperature can be set within the ranges below. (in increments of 1˚C or 1˚F)

Hot Water 35˚C min. ~ 70˚C max. (in increments of 1˚C or 2˚F)

Heating 30˚C min. ~ 45˚C max. (in increments of 1˚C or 2˚F)

Anti-freeze 10˚C min. ~ 45˚C max. (in increments of 1˚C or 1˚F)

Cooling 10˚C min. ~ 30˚C max. (in increments of 1˚C or 1˚F)

* The settable range varies depending on the unit to be connected.

Preset temperature range setting can be limited via a remote controller.

10˚C min. ~ 90˚C max. (in increments of 1˚C or 1˚F)

* The settable range varies depending on the unit to be connected.

Individually prohibits operations of each local remote control function :ON/OFF,

Operation modes,water temperature setting, Circulating water replacement

warning reset.

*

Upper level controller may not be connected depending on the unit to be connected.

ON / OFF / Water temperature setting can be done up to 6 times one day in the week.

(in increments of a minute)

When an error is currently occurring on a unit, the afflicted unit and the error code

are displayed.

Searches the latest error history by pressing the CHECK button twice.

Enables the Test run mode by pressing the TEST button twice.

* Test run mode is not available depending on the unit to be connected.

Displays the circulating water replacement warning via the unit message.

Clears the display by pressing the CIR.WATER button twice.

* Circulating water replacement warning is not available depending on the unit to

be connected.

The language on the dot matrix LCD can be changed. (Seven languages)

English/German/Spanish/Russian/Italian/French/Swedish

Remote controller operation can be locked or unlocked.

.

All-switch locking . Locking except ON/OFF switch

S/W default

T(A)=10˚C

T(B)=70˚C.

*All setting with a controller.

la

Operations

Display

Q8

What is heating Eco?

Heating ECO (Dip SW4-3 ON) is an energy saving function. When this mode is

effective, the outlet water temperature will automatically change based on ambient

temperature.

15 16

Page 10

5-1

Q & A

5-1

Booster unit /HEX unit Specification and function Booster unit /HEX unit Specification and function

Q & A

Q11

Refer to the table below for the maintenance schedule.

Replacement cycle may be shortened depending on the usage.

What is the durability of Booster unit and HEX unit?

Refrigerant circuit

Water circuit

Components

Compressor

Solenoid valve

Check valve

Linear expansion valve

Strainer

Pipes

Sensor (Temperature sensor, Pressure sensor)

Pressure switch

Drain pan

Electronic board

Strainer

Water pipe

Water-side heat exchanger

Refrigerant-side heat exchanger

Replacement cycle

20,000 hours

20,000 hours

20,000 hours

20,000 hours

20,000 hours

20,000 hours

25,000 hours

25,000 hours

20,000 hours

5 Years

8 Years

10 Years

5 Years

5 Years

Q16

Even if the total connectable capacity is 100% or more, PWFY is only connectable

within 100%.

What is the connectable capacity when connecting with

standard indoor units? And what is the temperature range of

operation for outdoor units?

Ambient (outdoor) temperature range of heating mode for PWFY combination (WB)

Only PWFY

R2 series

Y series

Outdoor unit will change its software to PWFY connection version automatically when PWFY is connected.

R2 series allows a higher temperature range than Y series, the reason is that R2 has an effective heat exchanger bypass circuit

against high-pressure error.

(*1) Some cooling operated by standard indoor units is necessary against high-pressure error, if standard indoor units are to be

worked near the high temperature range (32˚C or less).

Connectable outdoor unit capacity range for PWFY combination (WB)

R2 series

Y series

-20~32˚C

-20~15.5˚C

Only PWFY

50~100%

50~100%

PWFY with

standard indoor units

-20~32˚C (*1)

-20~15.5˚C

PWFY with

standard indoor units

50~150%

50~130%

Only standard

indoor units

-20~15.5˚C

-20~15.5˚C

Only standard

indoor units

50~150%

50~130%

Connectable

PWFY type

BU, AU

AU

Connectable

PWFY type

BU, AU

AU

Q12

Booster unit :10˚C~70˚C

HEX unit :10˚C~40˚C (Heating)

10˚C~35˚C (Cooling)

Q13

Even when the outdoor temperature is low, water temperature of supplied hot water

will not decrease.

Q14

Yes, it will be shown on the controller display.

Q15

What is the water temperature operation range?

Will the temperature of the hot water decrease during winter?

In case of malfunction, will the controller show an error?

Can HEX unit/Booster unit be connected to standard indoor units?

OK R2 + (PWFY: 100%) + (Standard indoor units: 50%) = 150%

NG R2 + (PWFY: 130%) + (Standard indoor units: 20%) = 150%

Q17

R2 outdoor units have a stronger tolerance for high-pressure error when heating

compared to Y series.

Why can the R2 outdoor units operate at an outdoor

temperature of 32˚C when connecting with Booster unit ?

Yes, it can be connected to the standard indoor models.

17 18

Page 11

5-2

Q & A

Booster unit/ HEX unit Installation and service

5-2

Q & A

Booster unit/ HEX unit Installation and service

Q1

Q2

Q3

Q4

Are there any regulations to installation location?

The HEX unit/Booster unit can only be installed indoors.

Is it possible to operate a multiple number of units at the

same time?

Controller: Possible with MA wiring.

Output: Possible with setting sequence relay on site.

Is a drain pipe required?

Yes. For condensation caused by inlet water temperature.

Is it possible to use ground water?

No. Ground water, rain, and sea water cannot be used.

Q8

Q9

Is the hot water suitable for drinking?

No, we do not recommend hot water for drinking.

The hot water is circulating and not supplied for drinking purposes.

What are the considerations when setting address?

Do not group Booster unit and HEX unit together.

OSOC

# #

TB3

TB3

BC

TB02

#!

TB5

Booster

TB5

TB15

HEX

TB5

!

TB15

Q5

Q6

Q7

Can a unit be directly connected to mains water?

The water circuit must be a closed circuit. (to prevent scaling of pipes, heat

exchanger etc. )

What materials are used for water piping?

Copper, stainless steel, polybuten and polyethylene water piping can be used. (it

must withstand 90˚C). Steel piping cannot be used.

If there is a possibility of steel usage in existing equipment, be sure to part the water circuit.

What is a recommended maintenance schedule?

For maintenance, sales offices will be able to handle replacements of functional

parts (compressor, heat exchanger, valves). Please refer to the Parts List.

BC

TB02

BC

TB02

#"

#$

TB5

TB5

$

"

W MA R/C W MA R/C

#

TB5

%

HEXHEX

TB5

TB15

TB5

&

TB15

W MA R/C

Transmission line

19 20

Page 12

5-3

Q & A

Q & A

Sales

Q1

Q2

Q3

Q4

What applications are suitable?

It is best for facilities that require a large amount of hot water such as, healthcare

facilities, hotels, hospitals, sports facilities (gyms, golf courses) and restaurants.

How many people can the unit provide hot water for?

Hotels, healthcare facilities, and hospitals: 10-20 people/unit.

* It varies depending on the purposes. Refer to “2-3 Selecting a model” section for

calculation.

Can it be used for air conditioning and space heating?

Yes, it can be used for both applications.

Why is the running cost low?

Because of the high efficient heat pump and heat recovery technology.

Q5

What is the difference between ATW Booster unit & HEX unit

and electric heaters.

Booster unit and HEX unit COP is 3.0 or more and therefore the running cost is 1/3

compared to electric heaters.

21

Loading...

Loading...