INSTALLATION INSTRUCTIONS

PHOTOVOLTAIC MODULE

1.INTRODUCTION

• BEFORE INSTALLATION, OPERATION, AND MAINTENANCE, BE SURE TO READ THESE INSTRUCTIONS IN ORDER TO USE

THE PV MODULES SAFELY.

• FOR INSTALLATIONS IN THE USA, REFER TO THE NATIONAL ELECTRIC CODE (NEC) AND ALL APPLICABLE LOCAL CODES.

FOR INSTALLATIONS IN CANADA, REFER TO THE CANADIAN ELECTRIC CODE (CEC) AND ALL APPLICABLE LOCAL CODES.

•

FAILURE TO OBSERVE THE FOLLOWING INSTRUCTIONS MAY RESULT IN DEATH OR PERSONAL INJURY AND PROPERTY DAMAGE.

• KEEP THIS MANUAL FOR FUTURE REFERENCE.

En-1

WARNING

1. GENERAL USE

• Avoid touching the front surface of the module with bare

hands.

• DO NOT handle except for installation and maintenance.

• Ensure that unauthorised personnel, including children,

are not allowed to access the modules.

2. GENERAL HANDLING

• DO NOT alter or remove any component.

• DO NOT stand or step on the modules.

• DO NOT damage the front or rear surface of the PV

modules. The rear surface can be damaged by sharp

objects.

• DO NOT throw or drop the PV modules.

• DO NOT lift the modules by the connectors or cables.

3. INSTALLATION

• Only licensed professionals should handle the modules.

• Secure yourself to avoid falling from the installation area.

• DO NOT use damaged PV modules.

A damaged PV module may cause fire and/or an

electrical shock resulting in personal injury or even

death.

• DO NOT expose the PV modules to artificially

concentrated sunlight.

• Cover the front surfaces of the PV modules with an

opaque cloth to prevent the generation of high voltage

and electric current during installation.

• Securely fasten the PV modules to the mounting

framework to prevent them from falling due to wind or

snow loads. The modules should be installed as

instructed in this installation manual.

• Securely ground the PV module frame and the mounting

framework following local regulations.

• Install a residual current device (RCD) as prescribed by

local regulations.

• DO NOT expose the backside of the module to sunlight.

• DO NOT install the modules in places where they can be

shaded by objects such as buildings or trees.

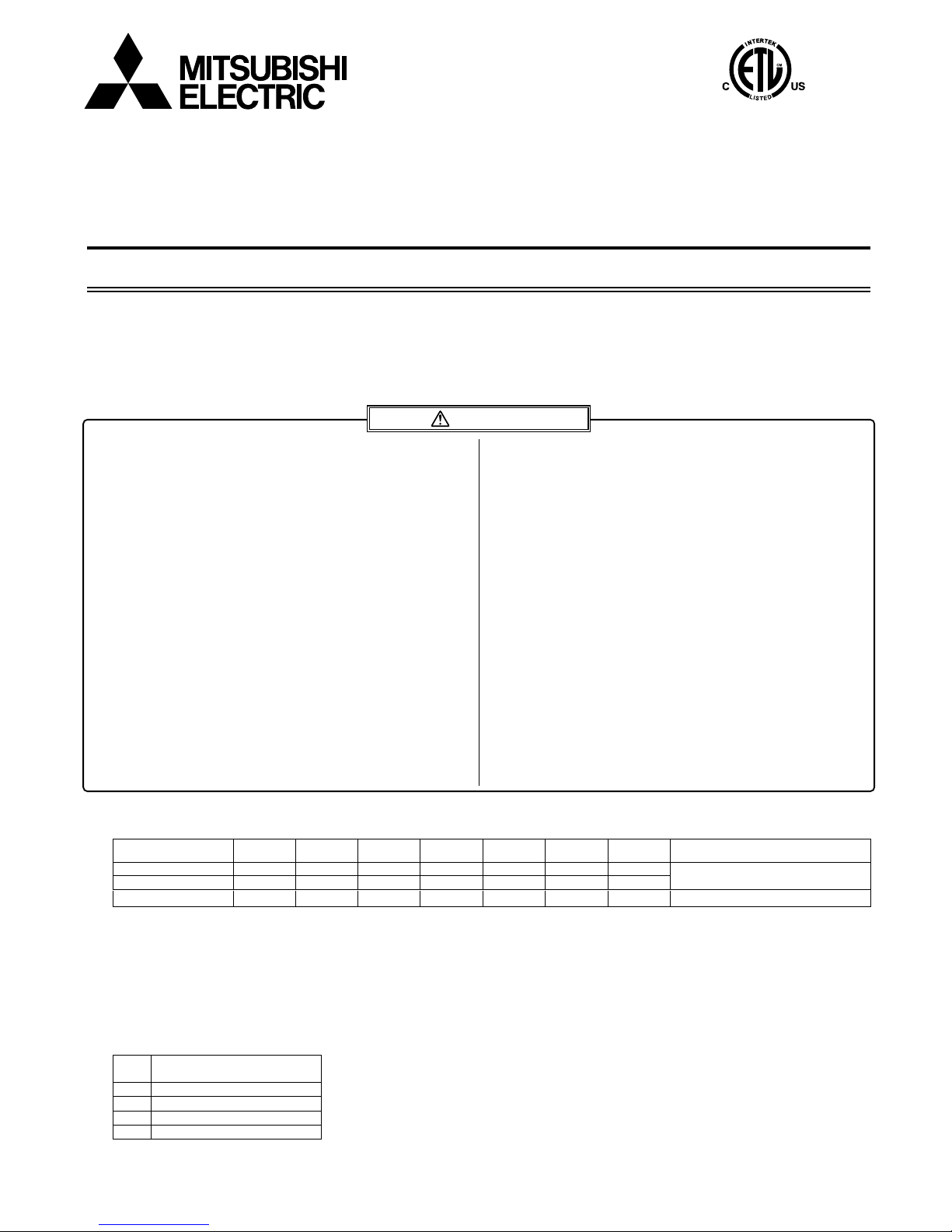

ELECTRICAL SPECIFICATIONS

The electrical characteristics are within ±10% of the indicated values of Isc, Voc, and within +5/-0% of Pmax under

standard test conditions (irradiance of 1000 W/m

2

, AM1.5 spectrum, and a cell temperature of 25°C (77°F)).

Standard: IEC61215 ed. 2 (2005), IEC61730 ed. 1 (2004) Application Class A, UL1703

MODEL

PV-MJE265FB

PV-MJE270FB

Pmax

265 W

270 W

Voc

38.0 V

38.2 V

Isc

9.10 A

9.23 A

Vmp

30.9 V

31.1 V

Imp

8.59 A

8.69 A

*1 [A]

15

15

*2 [A]

12.5

12.5

MAXIMUM SYSTEM VOLTAGE

ETL LISTED

CONFORMS TO STANDARD UL 1703

CERTIFIED TO ULC ORD C1703

*1 FUSE RATING BASED ON MAX. BYPASS DIODE AMPACITY WITHIN THE PV MODULE

*2 MINIMUM BYPASS DIODE RATING

*3 +5/-0% OF NOMINAL VALUE

SYMBOL DEFINITIONS

Pmax

Voc

Isc

Vmp

Imp

MAXIMUM POWER

OPEN CIRCUIT VOLTAGE

SHORT CIRCUIT CURRENT

MAXIMUM POWER VOLTAGE

MAXIMUM POWER CURRENT

TOLERANCE *3 - - - - - -

1000V

(IEC61215,IEC61730,UL1703)

-

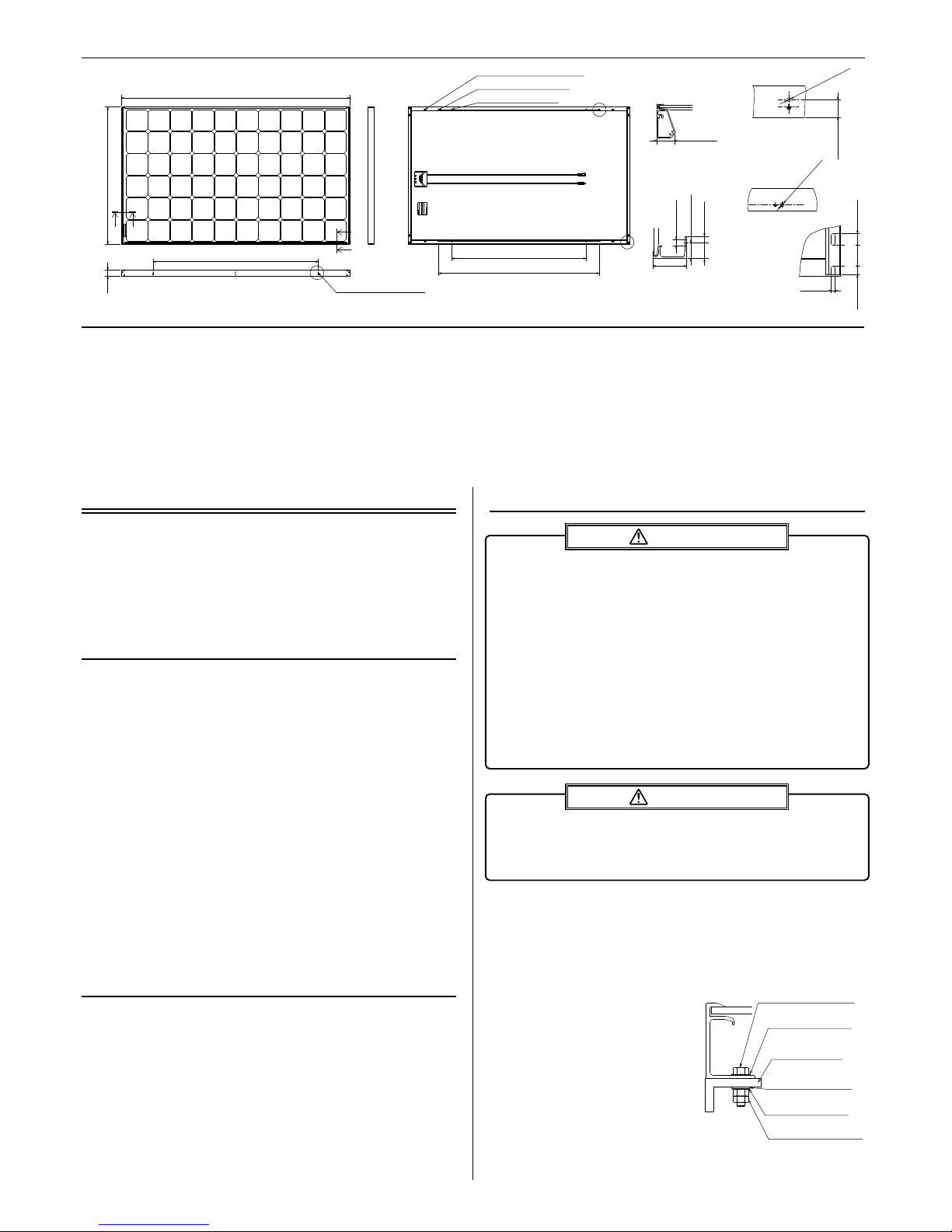

2-3-2. Mounting using the "Clipping method"

"The clipping method" is a way to secure modules on steady

base profiles (rail structures. etc.,) with "clipping" materials to

hold the top of the frame, without directly securing it with bolts

and nuts on the back of the module.

Mitsubishi Electric Corp.

doesn't specify or

warrant any materials,

e.g. base profile and

clipping materials etc.,

related to the clipping

method.

• The base profile should be perpendicular to the longer side

of the module (see figure below).

• The

•

Refer to the figure for the proper attachment.

• Secure the clips using M6 (1/4”) or larger (M8 (5/16”)) bolts

for where heavy snow loads are expected.

• Make to use clips that reach at least 5mm in from the edge

of the module frame.

• Use clipping material with sufficient strength and proper

form that can withstand forces from wind pressure and

snowfall pressure specific to the local climate.

• Secure bolts with the appropriate torque to avoid

deformation of the module frame.

• Take precaution in utilizing locking fasteners to avoid

loosening of the panel from its original anchored position.

• Note that the drainage holes at each corner of module

should not be blocked by the base profile.

En-2

2-3. MOUNTING

• Use mounting framework that can withstand forces from wind

pressure and snowfall pressure specific to your local climate.

• Use mounting framework and brackets that can withstand the

environment where the PV modules are to be used. Select

proper corrosion resistant materials and coatings.

• Use appropriate safeguards and components to install the

modules.

• PV modules shall be mounted over a fire resistant roof

covering rated for the application and on any slope less than

5in/ft (127mm/305mm) to maintain a fire Class rating.

• Installing the modules at an angle less than 2°can result in

decreased module output due to dirt and dust accumulating

on the module surface.

• Make sure there is enough space for air circulation behind

the PV modules to dissipate heat.

• DO NOT open any additional holes in the modules.

• The module is Type 2 of Fire Performance.

2-3-1. Mounting using bolt holes

Mounting examples:

• Fasten the corner holes of the PV module with M8 (5/16”)

stainless steel bolts to the mounting framework with a

torque of 4.5 to 6N·m (3.3 to 4.4 ft-lb).

•

Use spring washers and flat washers to fasten the PV module as

shown in figure1.

• Install the PV module securely

by fastening the appropriate

bolts with double nuts and

locking washers.

• Make sure that there is more

than a 5 mm gap between

modules to prevent buckling

caused by thermal expansion.

CAUTION

WARNING

2.INSTALLATION

Refer to Local Code (US: National Electrical Code) standards,

construction rules and safety instructions regarding installation

of the PV modules.

Electrical installations in Canada shall be in accordance with

CSA. C22. 1, Safety Standard for Electrical Installations,

Canadian Electrical Code, Part1.

2-1. CLIMATE CONDITIONS

Install the PV module within the following conditions:

•

Ambient monthly mean temperature: -20°C to 40°C (-4 to 104 °F)

• Operating temperature: -30°C to 83°C (-22 to 181 °F)

• Allowable pressure: up to +2400/-3000Pa

• Water resistance/damage: The PV modules shall not be

immersed in water and shall not be continually exposed to

a source of water, such as a sprinkler, fountain, etc.

• Corrosion warning: The PV modules shall not be installed in

corrosive areas such as:

-- Salty areas: areas where salty water such as ocean

spray comes in direct contact with the module, or

-- Sulfurous areas: areas near sulfurous volcanos and

sulfurous springs.

Note

In case of installation in Asian countries, PV modules shall

not be installed in corrosive areas within 500m from a body

of salt water and/or areas where there is direct contact with

salty wind.

2-2. ORIENTATION

• Install the PV modules facing South in the Northern

Hemisphere or North in the Southern Hemisphere.

• PV modules connected in series should be installed in the

same orientation and angle. Different orientation or angles

may cause loss of output power due to the different

amount of sunlight being absorbed by the modules.

• Do not allow the modules to be shaded at anytime.

Shade causes loss of electrical output, even though the

factory fitted bypass diode will reduce such loss to some

extent.

1-2. MULTIPLYING FACTOR

Under normal conditions, the PV module is likely to experience conditions that produce more current and/or voltage than reported

under Standard Test Conditions. Accordingly, the values of Isc and Voc marked on this module should be multiplied by a factor of

1.25 when determining component voltage ratings, conductor capacities (cross sectional area), fuse sizes, and size of controls

connected to the PV output. Customers in US should refer to article 690.8 the National Electrical Code for an additional multiplying

factor of 125 percent (80 percent derating), which may be applicable. Customers in other locations should refer to the codes relevant to

the location of installation for further guidance. Voc should be increased by a factor based on the lowest ambient temperature

recorded for the location. To determine the corrected value for Maximum System Voltage follow the guidelines in article 690.7 of the

NEC or applicable section in the CEC. The voltage temperature coefficient for the module in use should be used when determining

Maximum System Voltage.

1-1. STRUCTURE

Fig. 1 Module mounting

2-4. GROUNDING

• The grounding method should satisfy the Local Codes and

the NEC or CEC accordingly.

• Securely ground the PV modules and the mounting

framework.

Examples of proper grounding technique:

2 Nuts

(Stainless steel, 5/16(M8))

Spring washer

(Stainless steel, 5/16)

Flat Washer

(Stainless steel, 5/16)

Mounting structure

(Alminium)

Flat Washer

(Stainless steel, 5/16)

Bolt

(Stainless steel, 5/16(M8))

E(4 PLACES)

Drainage holes

15[0.59]

20[0.79]

6[0.24]

35[1.38]

1657[65.2]

1000[39.4]

1200[47.2]

1199[47.2]

994[39.1]

46[1.81]

A A

B

B

C

φ4.09[φ0.16](4 PLACES)

6[0.24]×20[0.79](4 PLACES)

φ4.09[φ0.16](4 PLACES)

φ9[φ0.35](4 PLACES)

D

E

(+)(–)

994 (39.1)

φ9[φ0.35]

21.5[0.85]

30[1.18]

46[1.81]

φ4.09

[φ0.16]

D(4 PLACES)

φ4.09

[φ0.16]

Grounding Mark

25.3[1.00]

Grounding Mark

25.3[1.00]

C(4 PLACES)

A−A

B−B

24.5[0.96]

2-3-2. Mounting using the "Clipping method"

"The clipping method" is a way to secure modules on steady

base profiles (rail structures. etc.,) with "clipping" materials to

hold the top of the frame, without directly securing it with bolts

and nuts on the back of the module.

Mitsubishi Electric Corp.

doesn't specify or

warrant any materials,

e.g. base profile and

clipping materials etc.,

related to the clipping

method.

• The base profile should be perpendicular to the longer side

of the module (see figure below).

• The

module shall be attached at 4 points or more on the frames.

•

Refer to the figure for the proper attachment.

• Secure the clips using M6 (1/4”) or larger (M8 (5/16”)) bolts

for where heavy snow loads are expected.

• Make to use clips that reach at least 5mm in from the edge

of the module frame.

• Use clipping material with sufficient strength and proper

form that can withstand forces from wind pressure and

snowfall pressure specific to the local climate.

• Secure bolts with the appropriate torque to avoid

deformation of the module frame.

• Take precaution in utilizing locking fasteners to avoid

loosening of the panel from its original anchored position.

• Note that the drainage holes at each corner of module

should not be blocked by the base profile.

En-3

CAUTION

5mm min.

Frame (longer side)

bolt

Clipping material

Framework (base profile)

Module

(in principle)

Fig. 5 Grounding method #3

2-4-1. Method #1 (use of self-tapping screws)

• Install a stainless steel screw (M5 or No.10) with 32 threads

per inch to the grounding hole with a torque of 2.3N·m

(20lbf-in).

• Ensure that at least 2 threads are engaged in the module

frame.

• As shown in the figure 3, the copper wire should be

compressed by the screw head.

• A stainless steel washer with an appropriate corrosion

resistant coating should be inserted between the copper

wire and screwhead.

• A proper cupped washer should be inserted between the

copper wire and frame to avoid galvanic corrosion.

• The copper wire must be #14 AWG or thicker, and be

secured to the module frame.

Fig. 3 Grounding method #1

2-4-2. Method #2 (use of a ground lug)

• An appropriate device such as UL Listed ILSCO ground lug,

Cat. No. GBL4-DBT should be secured by a stainless steel

screw (M5 or No.10) with 32 threads per inch with a torque

of 2.3N·m (20lbf-in) as shown in the figure 4.

• A star or toothed washer shall be inserted between the

ground lug and module frame.

• The copper wire must be #14 AWG or thicker, and be

secured to the ground lug screw.

Fig. 4 Grounding method #2

2-4-3. Method #3 (use of bolts and nuts)

• A No.8 stainless steel bolt and nut with 32 threads per inch

can be used instead of a No.10 self-tapping screw in

Method #2 under the following conditions:

- Torque to secure the bolt: 1.8N·m (16lb-in)

- A lock or spring washer shall be inserted between the

nut and toothed washer.

Fig. 2 Clipping method

Required mounting area to be fixed

2-4. GROUNDING

• The grounding method should satisfy the Local Codes and

the NEC or CEC accordingly.

• Securely ground the PV modules and the mounting

framework.

Examples of proper grounding technique:

WARNING

Stainless steel washer

(#10)

Self-tapping screw

(Stainless steel, #10-32TPI)

Cupped washer

Copper wire (14AWG or thicker)

Module frame

(Stainless steel)

Copper wire

(14AWG or thicker)

(Stainless steel)

Stainless steel washer(#10)

Cupped washer

Module frame

Self-tapping screw

(Stainless steel, #10-32TPI)

Self-tapping screw

(Stainless steel, #10-32TPI)

Copper wire

(14AWG or thicker)

Toothed washer

(Stainless steel, #10)

Grounding lug

(ex. ILSCO GBL4-DBT)

Copper wire

(14AWG or thicker)

Grounding lug

(ex. ILSCO GBL4-DBT)

Self-tapping screw

(Stainless steel, #10-32TPI)

Toothed washer

(Stainless steel, #10)

Bolt

(Stainless steel, #8)

Nut (Stainless steel, #8)

Grounding lug

(ex. ILSCO GBL4-DBT)

Spring washer

(Stainless steel, #8)

Copper wire

(14AWG or thicker)

Toothed washer

(Stainless steel, #8)

Mounting area (4 places)

Framework (base profile)

up to +2400/-3000Pa

up to +2000/-2400Pa

up to +2000/-2000Pa

1657 (65.2)

594 (23.4)

994 (39.1)

600 (23.6)

900 (35.4)

1400 (55.1)

INSTALLATION INSTRUCTIONS

PHOTOVOLTAIC MODULE

1506876HC2701

All Rights Reserved. Copyright ©2015: MITSUBISHI ELECTRIC CORPORATION

Printed in Japan

1.INTRODUCTION

• BEFORE INSTALLATION, OPERATION, AND MAINTENANCE, BE SURE TO READ THESE INSTRUCTIONS IN ORDER TO USE

THE PV MODULES SAFELY.

• FOR INSTALLATIONS IN THE USA, REFER TO THE NATIONAL ELECTRIC CODE (NEC) AND ALL APPLICABLE LOCAL CODES.

FOR INSTALLATIONS IN CANADA, REFER TO THE CANADIAN ELECTRIC CODE (CEC) AND ALL APPLICABLE LOCAL CODES.

•

FAILURE TO OBSERVE THE FOLLOWING INSTRUCTIONS MAY RESULT IN DEATH OR PERSONAL INJURY AND PROPERTY DAMAGE.

• KEEP THIS MANUAL FOR FUTURE REFERENCE.

En-4

1. GENERAL USE

• Avoid touching the front surface of the module with bare

hands.

• DO NOT handle except for installation and maintenance.

• Ensure that unauthorised personnel, including children,

are not allowed to access the modules.

2. GENERAL HANDLING

• DO NOT alter or remove any component.

• DO NOT stand or step on the modules.

• DO NOT damage the front or rear surface of the PV

modules. The rear surface can be damaged by sharp

objects.

• DO NOT throw or drop the PV modules.

• DO NOT lift the modules by the connectors or cables.

3. INSTALLATION

• Only licensed professionals should handle the modules.

• Secure yourself to avoid falling from the installation area.

• DO NOT use damaged PV modules.

A damaged PV module may cause fire and/or an

electrical shock resulting in personal injury or even

death.

CAUTION

WARNING

• Connect the required number of PV modules to meet the

voltage specification of the equipment used in the system.

- Max. in series: 20pcs due to max. system voltage

- Max. in parallel: 2 strings due to fuse rating

• Connect the output cable connectors so that they do not

exert any strain on the base of the cable at the junction box.

Secure the cable to the mounting framework using approved

fasteners.

The connectors should be placed behind the mounting

framework so that the connectors are not directly exposed to

sunlight, wind or rain.

• DO NOT apply external force (stepping on, etc.) to the

connector.

• The PV module has a pair of male and female waterproof

connectors. For an electrical connection in series, connect

the positive (+) connector of the first PV module to the

negative (-) connector of the following module.

• These modules employ UL Recognized connectors for output

wiring. Final output field wiring should be done with

CCT9901-3301F (R51-27) (male), CCT9901-3511F (R51-27)

(female) connectors from SMK using minimum 14 AWG

copper wire cables rated for 90°C (194°F).

These products provide final system output wiring in

accordance with the U.S. National Electrical Code, NFPA

70-2008 or CEC accordingly.

Please refer to Article 690 of the NEC for additional guidance.

• To extend the cable, use proper commercial cables and

connectors rated for at least 1000V that can withstand

outdoor use for long periods. Select the appropriate cable

size according to its length to avoid excessive voltage drop.

Follow the cable manufacturer's instructions.

3.MAINTENANCE

• Maintenance must be done only by qualified personnel.

• Be sure the circuit breaker is switched off, if applicable.

Always use appropriate safety equipment (insulated tools,

insulating gloves, etc.).

• Be sure to cover the front surface of the PV modules with an

opaque cloth to block sunlight when connecting or

disconnecting modules.

ANNUAL INSPECTION

• Check if the nuts and bolts of the mounting framework are

secure. Tighten all loose components.

• Check the connections of cables, including grounding cables

and connectors.

• Check that all electrical and mechanical connections are

free of corrosion.

• Check the ground resistance of metal parts such as the

module frames and the mounting framework.

Others

• Clean the glass surface of the modules when dirty. (Wash

or wipe only the glass surface of module without using

detergent.)

2-4-4. Method #4 (use of the bolts and nuts in the mounting hole)

• All hardware used in this method must be stainless steel.

- Examples of

acceptable grades of

stainless steel are:

18-8, 316, and 410.

• A 1 1/4” bolt and double

nuts of No.5/16 diameter

(or M8) shall be used to

mount the PV module to

the mounting structure

through the 9mm

diameter mounting hole.

• Torque to secure the bolt:

5N·m (3.7 ft-lb)

• External toothed stainless steel washers shall be inserted

between the module frame and ring washer, and also

between the mounting structure and ring washer.

• A spring washer shall be used to avoid loosening of the bolt.

• All 4 mounting holes of each PV module must be secured to

the mounting structure.

• At least 2 of the 4 locations must have external toothed

washers.

• All four locations shall have 2 nuts installed.

• A grounding electrode system for the mounting structure

must be provided in accordance with the NEC or CEC

standards.

• Recommended mounting structure characteristics:

- Alloys with resistivity less than 1.61 micro-ohms / inch

- Wall thickness of at least 1/8”

2-4-5. Method #5 (WEEB clips/ barbed washers and associated

racking)

• Barbed washers listed under UL467 intended for use in

bonding photovoltaic modules to mounting structures may

be used for grounding as described in the NEC or CEC

standards.

• When installing the WEEB UMC Clip or UniRac UGC-1 Clip

as a means of grounding the modules, tighten the mounting

bolt to 13.5N·m (10lb-ft).

• Barbed washers identified for grounding must be installed in

accordance with the manufacturer's specified instructions.

• Recommended mounting structures that accommodate

barbed washers are manufactured by UNIRAC.

• Approved options of WEEB clips/ barbed washers to be

used in conjunction with UNIRAC racking solution are:

o WEEB UMC clip

o UNIRAC UGC-1 clip

Note: Barbed washers are intended for one time use only.

If a module is removed, replaced, repositioned or

remounted, the associated barbed washer(s) must be

replaced. Follow instructions of the manufacturer.

ELECTRICAL SPECIFICATIONS

The electrical characteristics are within ±10% of the indicated values of Isc, Voc, and within +5/-0% of Pmax under

standard test conditions (irradiance of 1000 W/m

Standard: IEC61215 ed. 2 (2005), IEC61730 ed. 1 (2004) Application Class A, UL1703

2-5. WIRING

• DO NOT short the positive and

negative cables.

• Make sure connectors are fully

engaged and locked without any

gap between the insulators. In

case there is a gap, a fire and/or

an electrical shock may occur.

• Use the appropriate tool provided by SMK for disconnecting.

WARNING

Fig. 6 Grounding method #4

2 Nuts (Stainless steel, 5/16(M8))

Ring washer

(Stainless steel, 5/16)

Toothed Washer

(Stainless steel, 5/16)

Mounting structure (Alminium)

Toothed Washer

(Stainless steel, 5/16)

Ring washer

(Stainless steel, 5/16)

Spring washer (Stainless steel, 5/16)

Bolt (Stainless steel, 5/16 (M8))

* 8 7 6 H C 2 7 0 1 *

*1 FUSE RATING BASED ON MAX. BYPASS DIODE AMPACITY WITHIN THE PV MODULE

*2 MINIMUM BYPASS DIODE RATING

*3 +5/-0% OF NOMINAL VALUE

SYMBOL DEFINITIONS

Pmax

Vmp

Loading...

Loading...