Page 1

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

TECHNICAL DATA BOOK

November 2008

No. OCS12

REVISED EDITION-A

<Indoor unit>

[Model names]

<Outdoor unit>

[Model name]

HYPER HEATING INVERTER

PLA-A·BA

PKA-A·GA

PKA-A·GAL

PKA-A·FA

Revision :

• PUZ-HA30NHA is added in

REVISED EDITION-A.

• Some descriptions have

been modifi ed.

• Please void OCS12.

PKA-A·FAL

PUZ-HA30NHA

PUZ-HA36NHA

CONTENTS

1. REFERENCE SERVICE MANUAL ·············································2

2. SPECIFICATIONS ······································································3

3. OUTLINES AND DIMENSIONS ················································· 4

4. WIRING DIAGRAM ·····································································9

5. REFRIGERANT SYSTEM DIAGRAM ······································13

6. PERFORMANCE CURVES ······················································14

7. CORRECTION FACTORS ························································16

8. AIR FLOW DATA ······································································18

9. NOISE CRITERION CURVES ··················································24

10. OPTIONAL PARTS ····································································27

Page 2

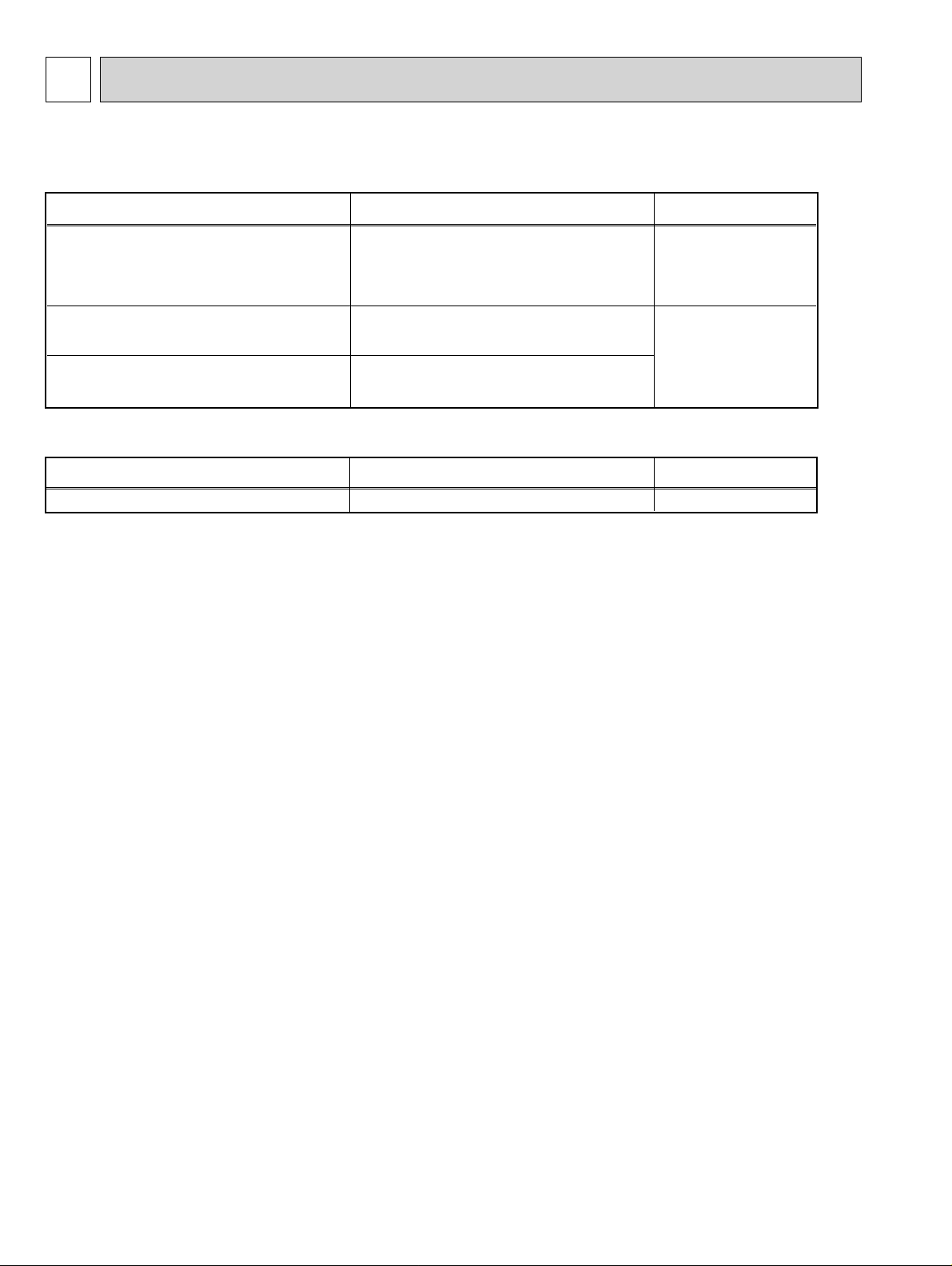

1

REFERENCE SERVICE MANUAL

For information on service, please refer to the service manual as follows.

1-1. INDOOR UNIT

Model name Service Ref.

PLA-A18/30/36BA PLA-A18BA PLA-A18BA

PLA-A30BA

1

PLA-A36BA PLA-A36BA

1

1

Service

Manual No.

OCH420

OCB420

PKA-A18GA PKA-A18GA/GA

PKA-A18GAL PKA-A18GAL/GAL

PKA-A30/36FA PKA-A36FA/FA1/FA

1

/GA

2

1

/GAL

2

PKA-A30/36FAL PKA-A36FAL/FAL1/FAL

1-2. OUTDOOR UNIT

Model name Service Ref.

PUZ-HA30/36NHA PUZ-HA30/36NHA

2

PKA-A30FA

2

PKA-A30FAL

OC369

2

2

Service

Manual No.

OCH426 OCB426

2

Page 3

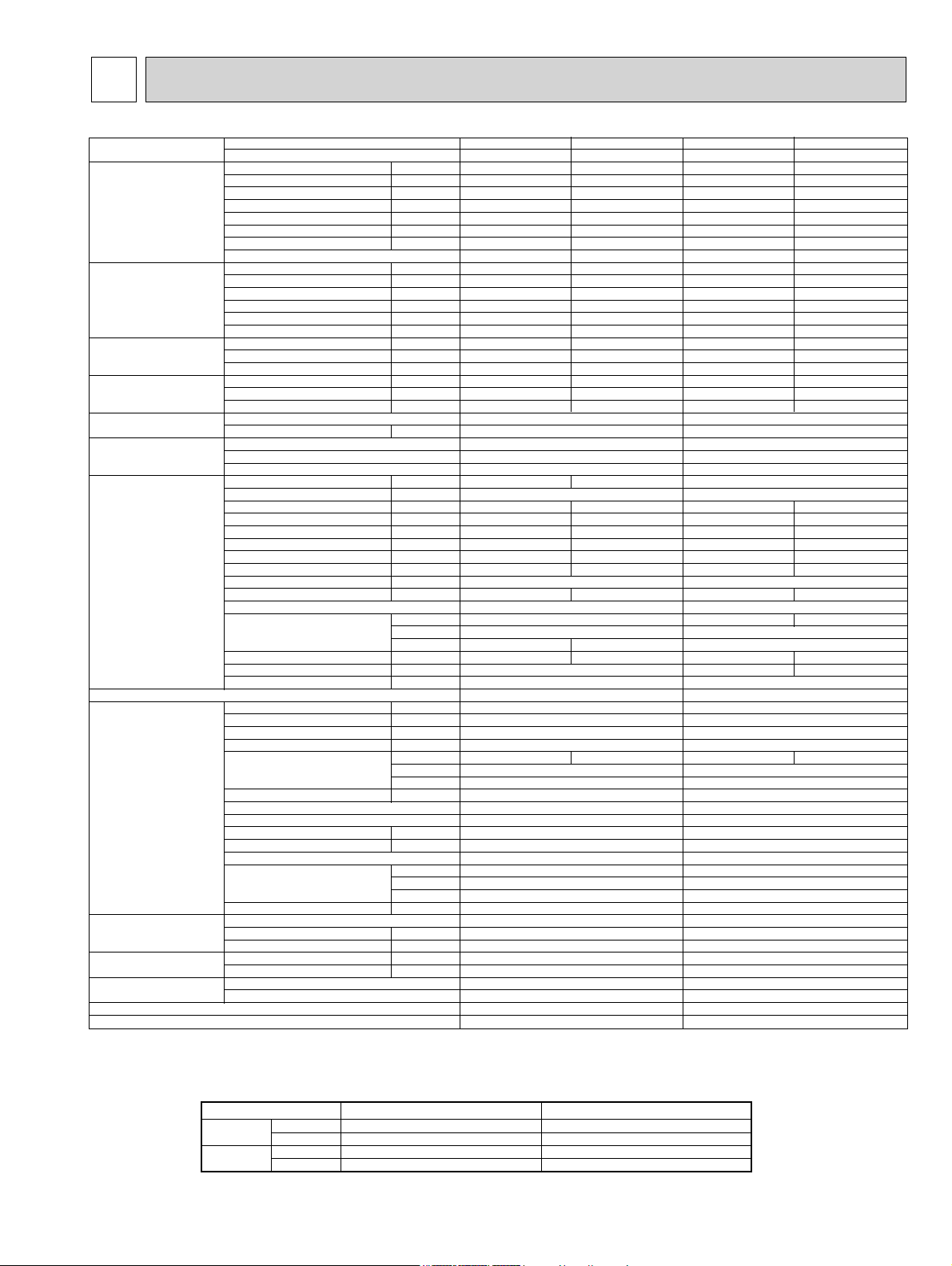

2

SPECIFICATIONS

Model name Indoor unit

Cooling Max. Capacity BTU/h

Heating Max. Capacity BTU/h

Heating at 17°F(-8.3°C) Capacity BTU/h

Heating at 5°F(-15°C) Capacity BTU/h

Power supply Phase, Cycle, Voltage

Voltage Indoor - Outdoor S1 - S2

Indoor unit MCA A

Remote Controller

Outdoor unit MCA A

Refrigerant Type

Refrigerant pipe size Gas side O.D. mm[inch]

Refrigerant pipe length Height difference

Refrigerant Piping Not supplied

Connection Method

Outdoor unit

Rated Capacity BTU/h

Min. Capacity BTU/h

Total Input W

EER BTU/h/W

SEER BTU/h/W

Moisture Removal Pints/h 6.8 7.1

*1 SHF

Rated Capacity BTU/h

Min. Capacity BTU/h

Total Input W

COP W/W

*1 HSPF(4/5) BTU/h/W

Total Input W

*2 COP W/W

Total Input W

*3 COP W/W

Breaker size A

Indoor - Outdoor S2 - S3

Indoor - Remote Controller

MOCP A

Fan Motor F.L.A. 1.00 0.52

Fan Motor Output W

Airflow (Lo-M2-M1-Hi) DRY CMM

Airflow (Lo-M2-M1-Hi) WET CMM

Airflow (Lo-M2-M1-Hi) DRY CFM

Airflow (Lo-M2-M1-Hi) WET CFM

External pressure Pa

Sound level (Lo-M2-M1-Hi) dB(A)

External finish (Grille)

Dimension Unit (Grille) W : mm[inch]

Weight Unit(Grille) kg

Weight Unit(Grille) lbs

Field drain pipe size mm[inch]

MOCP A

Fan Motor F.L.A.

Fan Motor Output W

Compressor Type

Air flow CMM[CFM]

Refrigerant Control

Defrost Method Reverse Cycle

Sound level at cooling dB(A)

Sound level at heating dB(A)

External finish Ivory Munsell 3Y 7.8/1.1

Dimension W : mm[inch]

Weight kg[lbs]

Charge kg[lbs, oz]

Oil L[oz]

Liquid side O.D. mm[inch]

Length

D : mm[inch]

H : mm[inch]

R.L.A.

L.R.A.

D : mm[inch]

H : mm[inch]

PLA-A30BA

PUZ-HA30NHA

30,000

30,000

18,000

2,450

12.2

15.6

7.2

0.73

34,000

32,000

18,000

3,440

2.73

8.8 / 7.0

32,000

5,720

1.64

32,000

6,630

1.41 1.90

1phase, 60Hz, 208/230V 1phase, 60Hz, 208/230V

AC208/230V

1

0.51

50

14-16-18-21

13-15-17-20

490-570-640-740

460-530-600-710 700-890 (Lo-Hi)

White Munsell 6.4Y 8.9/0.4 White Munsell 3.4Y 7.7/0.8

840(950) [33-1/16(37-3/8)] 1680 [66-1/8]1400 [55-1/8]

840(950) [33-1/16(37-3/8)] 235 [9-1/4]

258(35) [10-3/16(1-3/8)]

23(6) 28

O.D. 32 [1-1/4] I.D. 20 [13/16]

Attached in Grille Attached in Indoor unit

0.4 + 0.4

100[3,530]

Electronic Expansion Valve

950 [37-3/8]

330 + 30 [13 + 1-3/16]

1,350 [53-1/8]

121 [267]

5.5 [12 lbs]

1.4(FV50S) [45]

15.88 [5/8]

9.52 [3/8]

Max.30m [Max.100ft]

Max.75m [Max.245ft]

PLA-A36BA PKA-A36FA(L)

PUZ-HA36NHA PUZ-HA36NHA

36,000 34,200

36,000 34,200

18,000 18,000

3,120 2,950

11.5 11.6

16.0 16.0

0.79 0.77

40,000 40,000

38,000 38,000

18,000 18,000

3,230 3,100

3.45 3.59

9.4 / 7.3 9.4 / 7.3

38,000 38,000

5,300 5,300

2.10 2.10

38,000 38,000

5,860 5,860

1.90

PKA-A30FA(L)

PUZ-HA30NHA

30,000

30,000

18,000

2,730

11.0

14.5

7.9

0.70

34,000

32,000

18,000

3,460

2.71

8.9 / 7.2

32,000

5,600

1.67

32,000

6,370

1.47

30 30

DC24V DC24V

DC12V DC12V : Wired type

15 15

00

55(13) 62

28

40

60 + 60

18

27.5

21

0.43

120 70

20-23-26-30 22-28 (Lo-Hi)

19-22-25-29 20-25 (Lo-Hi)

710-810-920-1060 780-990 (Lo-Hi)

670-770-880-1030

32-34-37-4028-30-32-34 46-49 (Lo-Hi)

298(35) [11-3/4(1-3/8)]

25(6)

45

15-20 (Lo-Hi)

14-18 (Lo-Hi)

530-705 (Lo-Hi)

480-635 (Lo-Hi)

39-45 (Lo-Hi)

24

53

ANB33FJCMTANB33FJEMT ANB33FJEMT

Electronic Expansion Valve

52

53

Ivory Munsell 3Y 7.8/1.1

330 + 30 [13 + 1-3/16]

R410A

Max.30m [Max.100ft]

Max.75m [Max.245ft]

Flared

NOTES : *1.Rating conditions (cooling)-Indoor : D.B. 26.7°C(80°F), W.B. 19.4°C(67°F) Outdoor : D.B. 35°C(95°F), W.B. 23.9°C(75°F)

(heating)-Indoor : D.B. 21.1°C(70°F), W.B. 15.6°C(60°F) Outdoor : D.B. 8.3°C(47°F), W.B. 6.1°C(43°F)

*2.Rating conditions (heating)-Indoor : D.B. 21.1°C(70°F), W.B. 15.6°C(60°F) Outdoor : D.B. -8.3°C(17°F), W.B. -9.4°C(15°F)

*3.Rating conditions (heating)-Indoor : D.B. 21.1°C(70°F), W.B. 15.6°C(60°F) Outdoor : D.B. -15°C(5°F), W.B. -15°C(5°F)

Operating range

Cooling

Heating

Maximum

Minimum

Maximum

Minimum

Indoor intake air temperature

D.B. 32°C(90°F), W.B. 23°C(73°F)

D.B. 19°C(66°F), W.B. 15°C(59°F)

D.B. 28°C(83°F)

D.B. 17°C(63°F)

Outdoor intake air temperature

D.B. 46°C(115°F)

D.B. -18°C(0°F)*

D.B. 21.1°C(70°F), W.B. 15°C(59°F)

D.B. -25°C(-13°F), W.B. -25°C(-13°F)

* In case that the wind baffle is installed. (In case that the wind baffle is not installed, the minimum temperature will be -5°C(23°F)DB.)

AC208/230V

340 [13-3/8]

28

40

0.4 + 0.4

60 + 60

ANB33FJCMT

18

27.5

100[3,530]

Reverse Cycle

52

53

950 [37-3/8]

1,350 [53-1/8]

121 [267]

R410A

5.5 [12 lbs]

1.4(FV50S) [45]

15.88 [5/8]

9.52 [3/8]

Not supplied

Flared

3

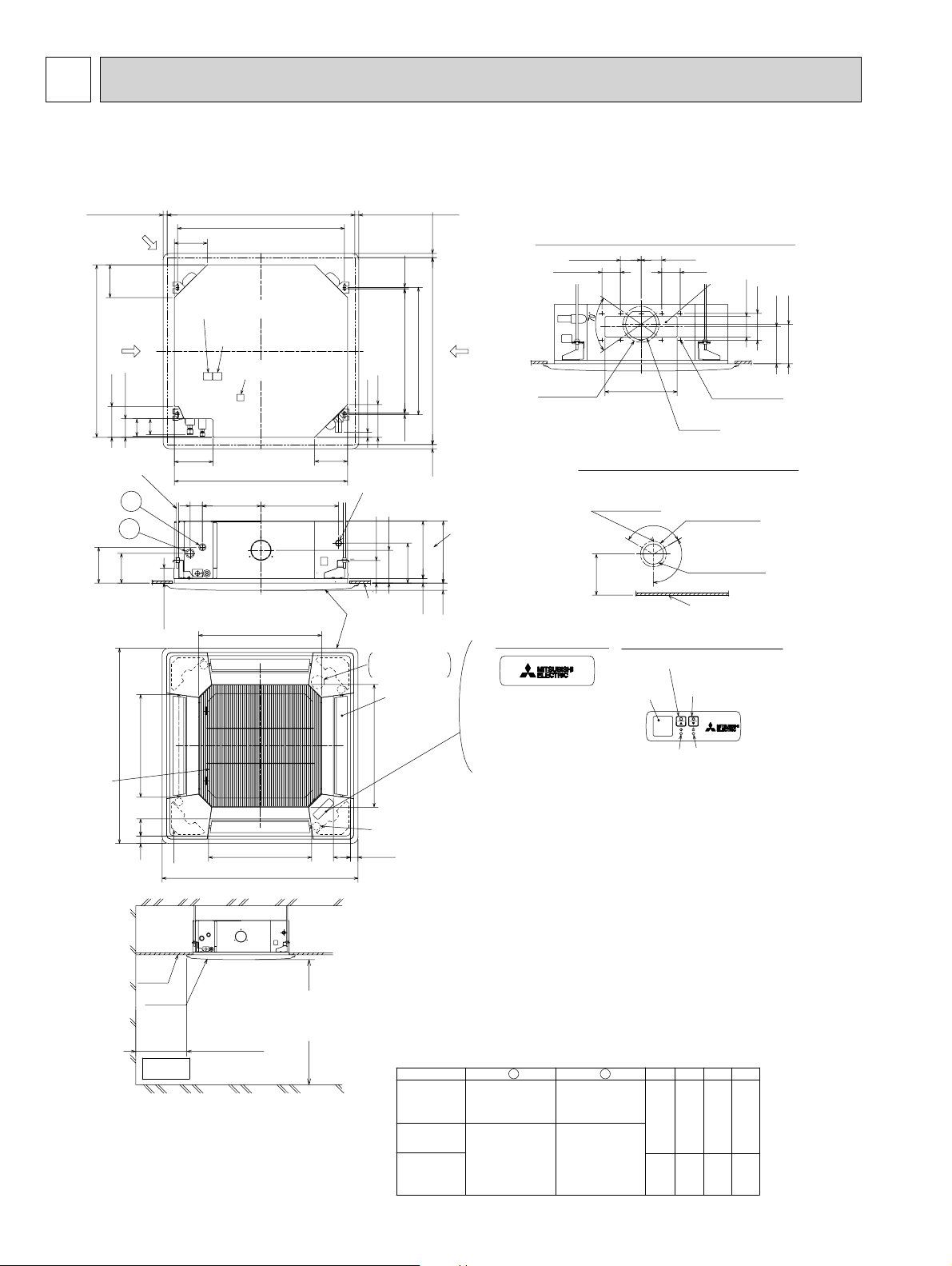

Page 4

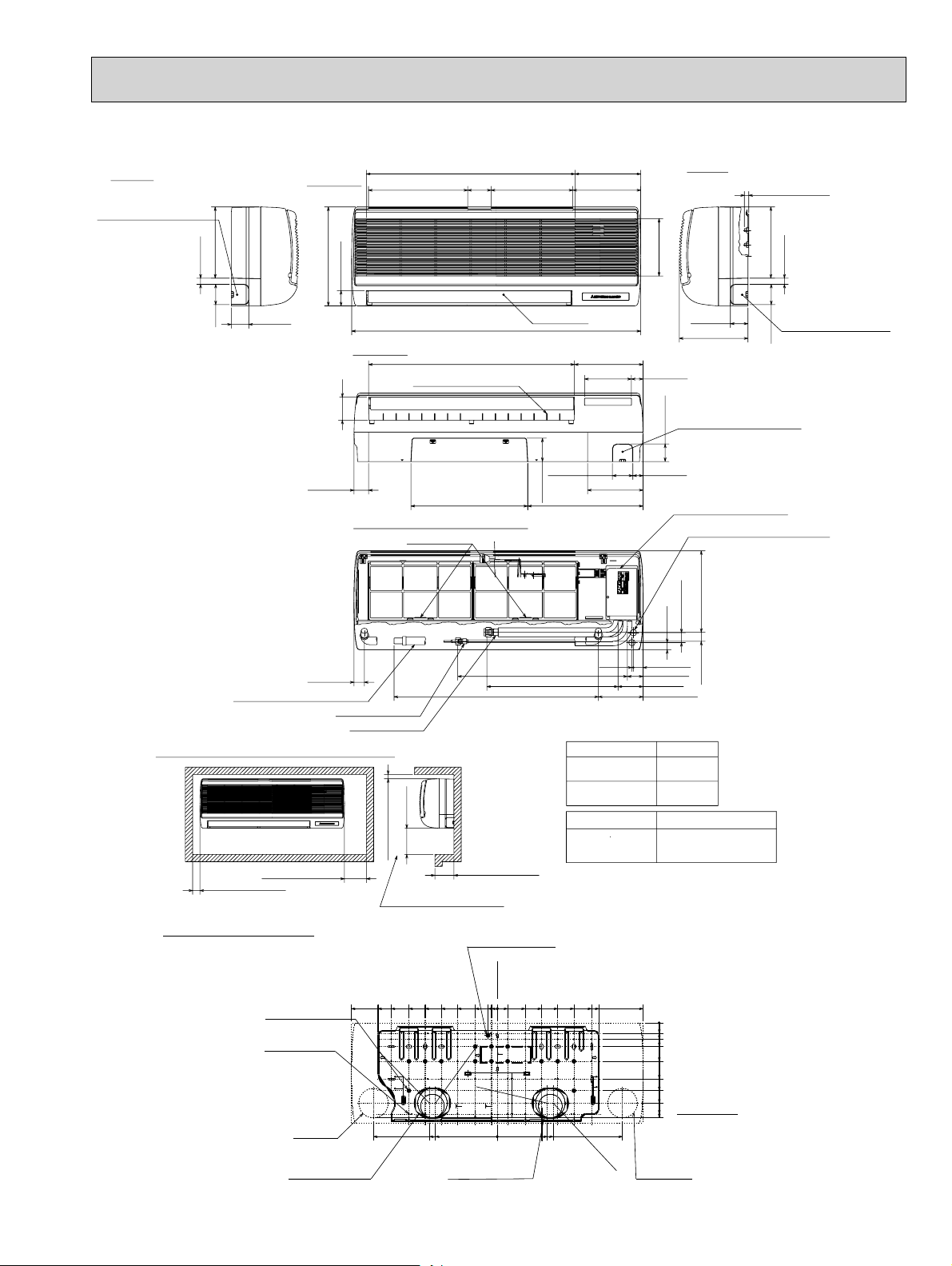

3

OUTLINES AND DIMENSIONS

INDOOR UNIT Unit : inch (mm)

PLA-A18BA PLA-A30BA PLA-A36BA

25/32 to 1-25/32(20~45)

Fresh air

intake hole

33-1/16(840)

Suspension bolt

M10 or W3/8

6-11/16

+

Suspension bolt

lower edge

Air intake grille

(160)

6-5/16

Branch duct hole

(90)

(150)

3-17/32

5-29/32

D

C

1

2

(170)

5-1/2

(140)

+

(50~70)

(500)

(950)

37-3/8

19-11/16

Air outlet hole

(83)

3-17/64

(36)

1-27/64

Ceiling

Grille

Entire

periphery

33-27/32 to 35-13/16(860~910)

Suspension bolt pitch

6-5/16

(160)

For MA-Remote controller

terminal block

Indoor unit/Outdoor unit

connecting terminal block

7-3/8

(187.5)

2-3/8

1-15/16~2-3/4

M

Corner pocket

(60)

33-1/16

(284)

M

Indoor unit

Min.19-11/16(500)

Ceiling hole

31-7/8(810)

For wiring replacement kit

terminal block

(840)

(377)

14-27/3211-3/16

23-1/2

(597)

Air intake hole

(500)

19-11/16

Air outlet hole

(950)

37-3/8

Min.94-1/2(2400)

from floor

Floor

M

6-5/16

(160)

25/32 to 1-25/32(20~45)

Drain pipe

connected to VP-25

Ceiling

Grille

M

1-27/64

3-17/64

(83)

25/32 to

(7.5)

(5/16)(5/16)

+35

-5

(605 )

(620)

-3/16

+1-3/8

24-13/32

(160)

23-13/16

(24)

Suspension bolt pitch

(156)

6-9/64

7-15/32

+

Auto vane

(Air outlet)

Air intake hole

(7.5)

(190)

+3/16

11/ 16

33-27/32 to 35-13/1625/32

A

+5

0

6-5/16

15/16

(105)

4-1/8

++

Drain hole

Drain pump clean hole

and Drain emergency

drainage hole

(597)

23-1/2

Note1. As for drain pipe, please use VP-25(O.D. :32 PVC TUBE).

Drain pump is included.

Max. lifting height is 70-7/18(850mm) from the ceiling.

Vane motor

(36)

2. As for suspension bolt, please use M10 or W3/8.

(Procured at local site)

3. Electrical box may be removed for the service purpose.

Make sure to slack the electrical wire little bit for

control/power wires connection.

4. The height of the indoor unit is able to be adjusted

with the grille attached.

5. For the installation of the optional high efficiency filter

or optional multi-functional casement.

1) Add 5-5/16(135mm) to the dimensions + marked on the figure.

2) The optional high efficiency filter becomes optional

multi-functional casement and concomitant use.

6. When installing the branch ducts, be sure to insulate adequately.

Otherwise condensation and dripping may occur.

(It becomes the cause of dew drops/water dew.)

7. As for necessary installation/service space, please refer to the

left figure.

Models

PLA-A12BA

PLA-A18BA

PLA-A24BA

PLA-A30BA

PLA-A36BA

PLA-A42BA

~45)

1-25/32

(20

(860~910)

Branch duct

Ceiling hole

hole

to 1-25/32

(20~45)

Connected the attached

flexible pipe or socket.

Keep 25/64(10)to 19/32(15)

between unit ceiling

and ceiling slab.

B

+

0

(35)

(17 )

1-3/8

In case of standard grille

Refrigerant pipe

: 6.35mm

····

Flared connection

····1/4

Refrigerant pipe

····

: 9.52mm

Flared connection

····3/8

Detail connecting of branch duct(Both aspects)

3-15/16

3-17/32

(90)

:

6-7/8

(

:

175)

Burring hole pitch

(100)

13-25/32

(350)

3-15/16

3-17/32

:

Cut out hole

(100)

(90)

Cut out hole

5-29/32

3-15/16

14-:1/8

Burring hole

(

:

150)

(100)

(

(130)

5-1/8

14-:2.8

Detail drawing of fresh air intake hole

Burring hole

)(

3-:1/8(3-:2.8)

6-7/32

+

( 158)

+

In case of wireless remote controller

Emergency operation switch<Cooling>

Receiver

Operation lamp

1

2

Refrigerant pipe

····

: 12.7mm

Flared connection

····1/2

Refrigerant pipe

: 15.88mm

····

Flared connection

····5/8

120°

9-1/2

(241)

11-1/16

(281)

Burring hole pitch

:

4-29/32(:125)

Cut out hole

120°

:

3-15/16(:100)

Ceiling

Emergency operation

switch<Heating>

DEFROST/STAND BY lamp

10-3/16

3-5/32

(80)

(258)

3-11/32

11-3/4

(85)

(298)

DCBA

2-29/32

(74)

3-1/32

(77)

(155)

6-3/32

++

)

(167)

6-9/16

44

Page 5

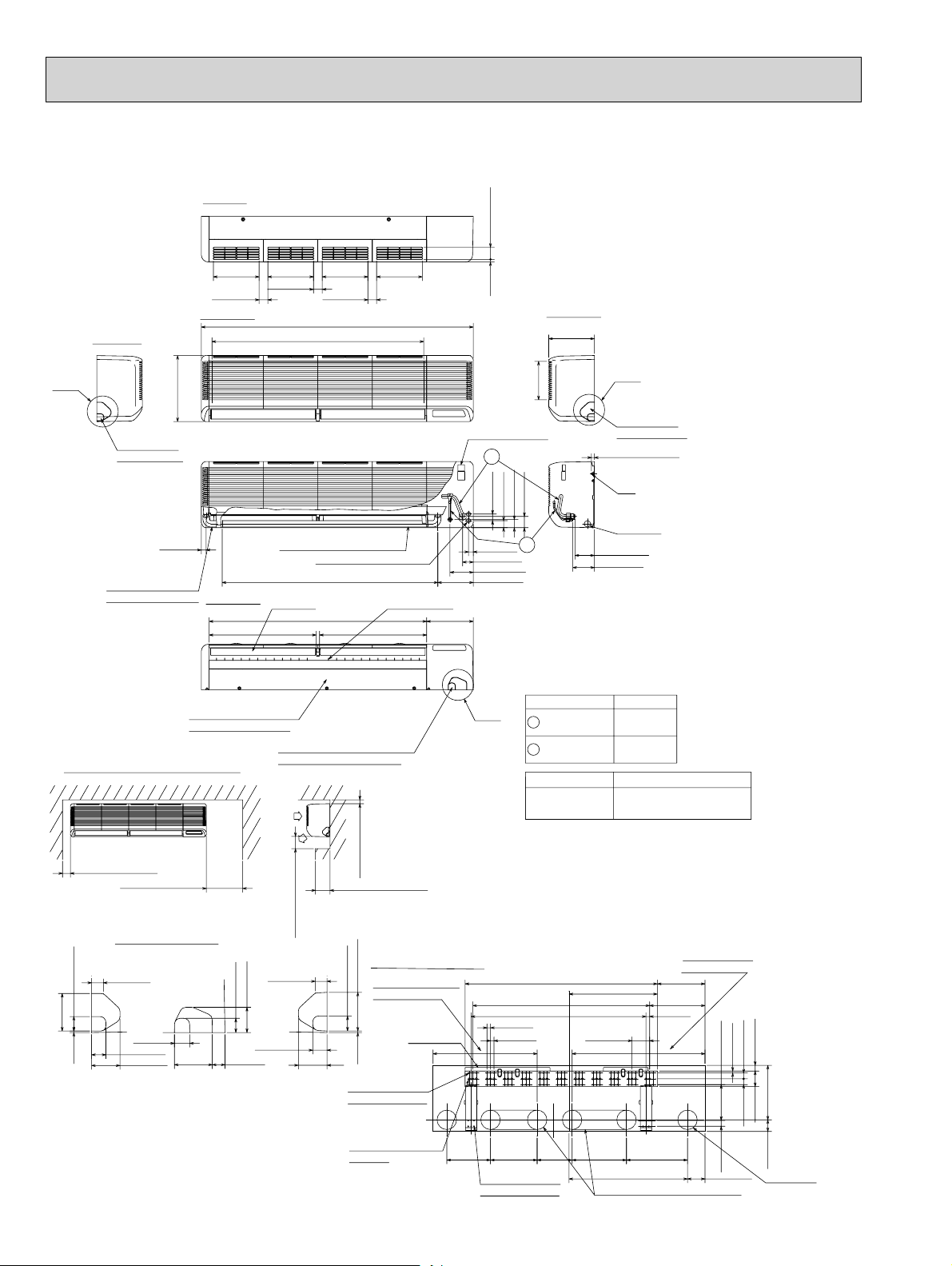

PKA-A18GA PKA-A18GAL Unit : inch (mm)

Left side

Knockout hole for left piping

Refrigerant pipe.Drain pipe.

Wiring hole.

Front view

28-5/32(715) Air intake 8-27/32(225)

13-3/8(340)

Air intake

3-5/32(80)

11-1/32(280) 9-3/16(233)

Air intake

Right side

Less than 19/32(15)

9-21/32(245)

13/16(21)

2-3/8(60)

2-3/4(70)

1-31/32(50)

1-3/8(35)

Drain hose

Service space required around indoor unit

Field drain pipe size

13/ 16 (20=) I.D

13-3/8(340)

2-3/32(53)

Lower side

12-Louvers(manual)

3-1/8(79)

Front view (top open the grille)

Liquid pipe

Gas pipe

Filter grip

39(990)

27-3/4(705) Air outlet 9-1/4(235)

27-9/16(700)

(Flexible hose total length 31-1/2(800))

Right side

Auto vane

6-5/16(160) 1-9/16(40)

2-3/4(70) 1-3/8(35)

3-1/8(80)

22-7/8(581)

17-11/16(449)

7-15/32(190)

15-9/16(395)15-3/4(400)

MODEL 18

Liquid pipe

Gas pipe

3/16(5)

Air intake

7-25/32(198)

2-3/8(60)

9-1/4(235)

Knockout hole for under piping

Refrigerant piping.Drain pipe.

Wiring hole

2-3/8(60)

Service panel

(Power supply access)

Wiring entrance holes

1-11/32(34)

1(25)

1-5/16(33)

2-1/8(54)

3-3/8(86)

6-1/32(153)

(Right side piping installation)

1-7/32(31) 11-1/32(280)

1/4

1/2

9-21/32(245)

13/16(21)

Knockout hole for right piping

Refrigerant pipe.Drain pipe.

Wiring hole

2-3/4(70)

1-31/32(50) or more

Details of installation plate

5-29/32(150) or more

14-:9/16(:14)holes

for bolts

49-:3/16(:5)holes

for tapping screw

Left-rear

piping hole

Knockout hole for

left-rear piping

1-13/16(30) or more

7-3/32(180) or more

(Necessary clearance for

Unit installation)

19-1/2(495)

11-13/16(300)

14-3/16(360)

15-15/16(405)

R2-1/16(R52.5)

16-17/32(420)

Less than 5-1/8(130)

5-5/16(135)

7-15/32(190)

9-21/32(245)

R2-1/16(R52.5)

Knockout hole for

right-rear piping

9-1/16(230)

8-9/32(210)

Installation plate

balance point hole

Unit center

1-1/4(32)

25/32(20)

2-15/16(75)

0

1-3/8(35)

3-3/4(95)

R2-1/16(R52.5)

0

55

Through holeSleeve *1

ø2-15/16(ø75)

ø2-15/16~ø3-5/32

(ø75~ø80)

*1 Sleeves are available on the market.

*2 This size shows the lower end of through hole.

8-1/16(205)

10-1/4(260)

5-29/32(150)

R2-1/16(R52.5)

7-15/32(190)

6-11/16(170)

12-19/32(320)

19-1/2(495)

13-19/32(345)

Right-rear

piping hole

16-23/32(425)

0

0

1-3/8(35)

2-5/32(55)

3-5/32(80)

5-1/8(130)

7-15/32(190)

9-1/16(230)

10-23/32(272)

12-7/32(310)

12-11/16(322)+1

Page 6

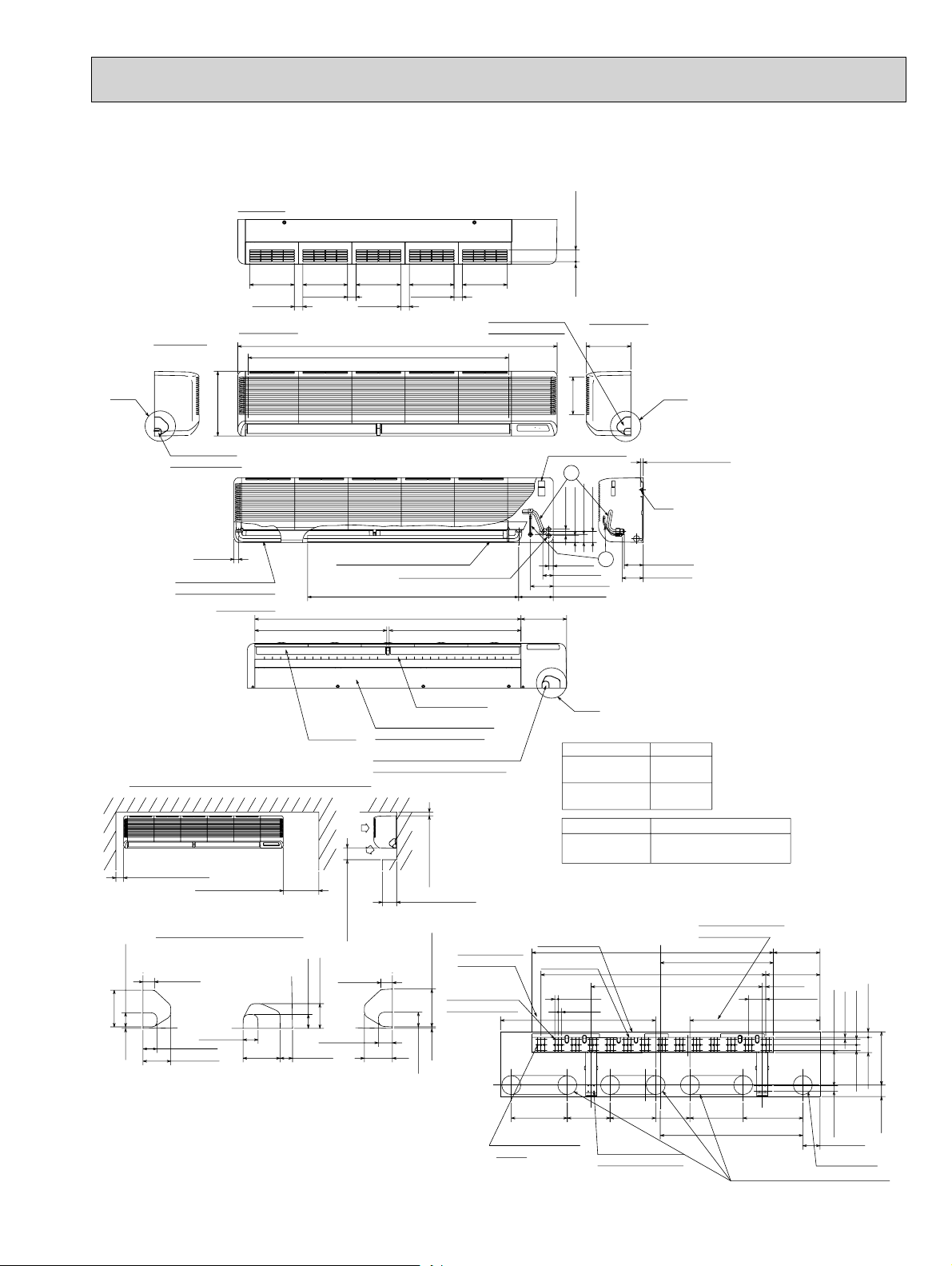

PKA-A30FA PKA-A30FAL Unit : inch (mm)

Top side

9-1/4(235)

1-25/32(45)

Front view

Left side

A

13-3/8(340)

Knockout hole

for left piping

31/32(25)

Drain hose for

left-hand side piping

Lower side

21-23/32(552) Air outlet

Under panel(Removable at

left-hand side piping)

Service space required around indoor unit

1-31/32(50) or more

9-27/32(250) or more

9-1/4(235)

1-25/32(45)

42-29/32(1090) Air intake

Auto vanes

Knockout hole for under-piping

Refrigerant pipe /Drain pipe

Air

intake

Air

outlet

9-1/4(235)

1-25/32(45)

55-1/8(1400)

Field drain pipe size

Drain hose

13/16 (20mm) I.D

Wiring entrance holes

43-11/16(1110) Drain hose

44-3/32(1120)

21-23/32(552) Air outlet

1-3/16(30) or more

Less than 9-27/32(250)

9-1/4(235)

Louvers(Manual)

9-7/16(240)

1/2(13) 2-15/32(62.5)

Terminal blockTerminal block

2

1-5/16(34)

1-7/16(36)

1-21/32(42)

15/16(24)

2-5/32(55)

4-23/32(120)

7-7/32(183)

B

Right side

9-1/4(235)

C

7-3/4(197)

Knockout hole

for right piping

Less than 19/32(15)

Bolt

2-9/32(58)

Drain hose

1

MODEL

1

Liquid pipe

2

Gas pipe

Sleeve

ø3-17/32

(ø90)

*1

4-7/32(107)

4-3/8(111)

24/30

3/8

5/8

Through hole

ø3-17/32~ø3-15/16

(ø90~ø100)

*1 Sleeves are available on the market.

Knockout hole for wiring

AB C

1-3/16(30)

1-17/32(39)

3-15/16(100)

5/32(4)

1-9/16(39)

1-15/32(37)

2-29/32(74)

3-27/32(98)

2-9/16(65)

1-15/32(37)

1-1/4(32)

9-27/32(250) or more

1-3/16(30)

1-15/32(37)

2-29/32(74)

Details of installation plate

Drainage range on

3-15/16(100)

1-17/32(39)

left hand side

Wall fixture

5/32(4)

66-ø1/4(ø6) holes

for tapping screws

32-ø15/32(ø12) holes

for bolts

Unit center

38-31/32(990)

13/32*3-19/32=(35-13/16) (10*91=(910))

35-7/16(900)

23/32(18)

23/32(18)

8-27/32(225)

9-7/16(240)

7-3/32(180)

12-ø1/4(ø6) holes

for tapping screws

6

17-29/32(455)

3-19/32(91)

11-1/32(280) 12-3/8(314)

24-1/32(610)

Range for left rear piping hole

9-21/32(245)

11-7/32(285)

3/4(19)

Drainage range on

right-hand side

13/32(10)

1-3/16(30)

7-1/4(184)

1-3/16(30)

1-3/16(30)

3-17/32(90)

1-5/32(29)

11-1/32(280)

3-1/8(80)

2-3/8(60)

Rear piping hole

Page 7

PKA-A36FA PKA-A36FAL Unit : inch (mm)

Top side

2-15/32(62.5)

9-1/4(235)

1-25/32(45)

Left side

A

Knockout hole

for left piping

Drain hose for

left-hand side piping

Service space required around indoor unit

1-31/32(50) or more

Knockout hole for wiring

ACB

1-3/16(30)

3-15/16(100)

5/32(4) 1-17/32(39)

1-15/32(37)

2-29/32(74)

Front view

13-3/8(340)

31/32(25)

Lower side

9-27/32(250) or more

1-17/32(39)

3-27/32(98)

9-1/4(235)

1-25/32(45)

53-15/16(1370) Air intake

Drain hose

27-5/16(694) Air outlet

Auto vanes

Air

intake

9-27/32(250) or more

1-3/16(30)

2-9/16(65)

1-15/32(37)

1-15/32(37)

1-1/4(32)

9-1/4(235)

1-25/32(45)

Air

outlet

9-1/4(235)

1-25/32(45)

66-1/8(1680)

Field drain pipe size

13/16 (20mm) I.D

Wiring entrance holes

43-11/16(1110) Drain hose

55-1/8(1400)

27-5/16(694) Air outlet

Louvers(Manual)

Under panel(Removable at

left-hand side piping)

Knockout hole for under-piping

Refrigerant pipe /Drain pipe

1-3/16(30) or more

Less than 5-29/32(150)

Drainage range on

left hand side

3-15/16(100)

84-ø1/4(ø6) holes

for tapping screws

2-29/32(74)

5/32(4)

1-17/32(39)

9-1/4(235)

Knockout hole

for right piping

1/2(13)

Right side

9-1/4(235)

C

7-3/4(197)

Terminal block

15/16(24)

2-5/32(55)

4-23/32(120)

7-7/32(183)

9-7/16(240)

2

2-9/32(58)

1-5/16(34)

1-7/16(36)

1-21/32(42)

B

1

Less than 9/16(15)

Bolt

4-1/32(102)

4-3/8(111)

MODEL 36

Liquid pipe

Gas pipe

Sleeve *1

ø3-17/32

(ø90)

3/8

5/8

Through hole

ø3-17/32~ø3-15/16

(ø90~ø100)

*1 Sleeves are available on the market.

Drainage range on

Unit out line

Wall fixture

23/32(18)

23/32(18)

Unit center

50(1270)

1/2*3-19/32=(46-9/16) (13*91=(1183))

right-hand side

23-7/16(595)

35-7/16(900)

9-21/32(245)

11-7/32(285)

3/4(19)

3-19/32(91)

13/32(10)

1-3/16(30)1-3/16(30)

1-5/32(29)

3-5/32(80)

11-1/32(280)

11-5/8(295) 8-27/32(225)

41-ø15/32(ø12) holes

for bolts

7

9-7/16(240) 7-3/32(180) 11-1/32(280)

12-ø1/4(ø6) holes

for tapping screws

12-3/8(314)

29-17/32(750)

Range for left rear piping hole

1-3/16(30) 7-1/4(184)

3-9/16(90)

Rear piping hole

2-3/8(60)

Page 8

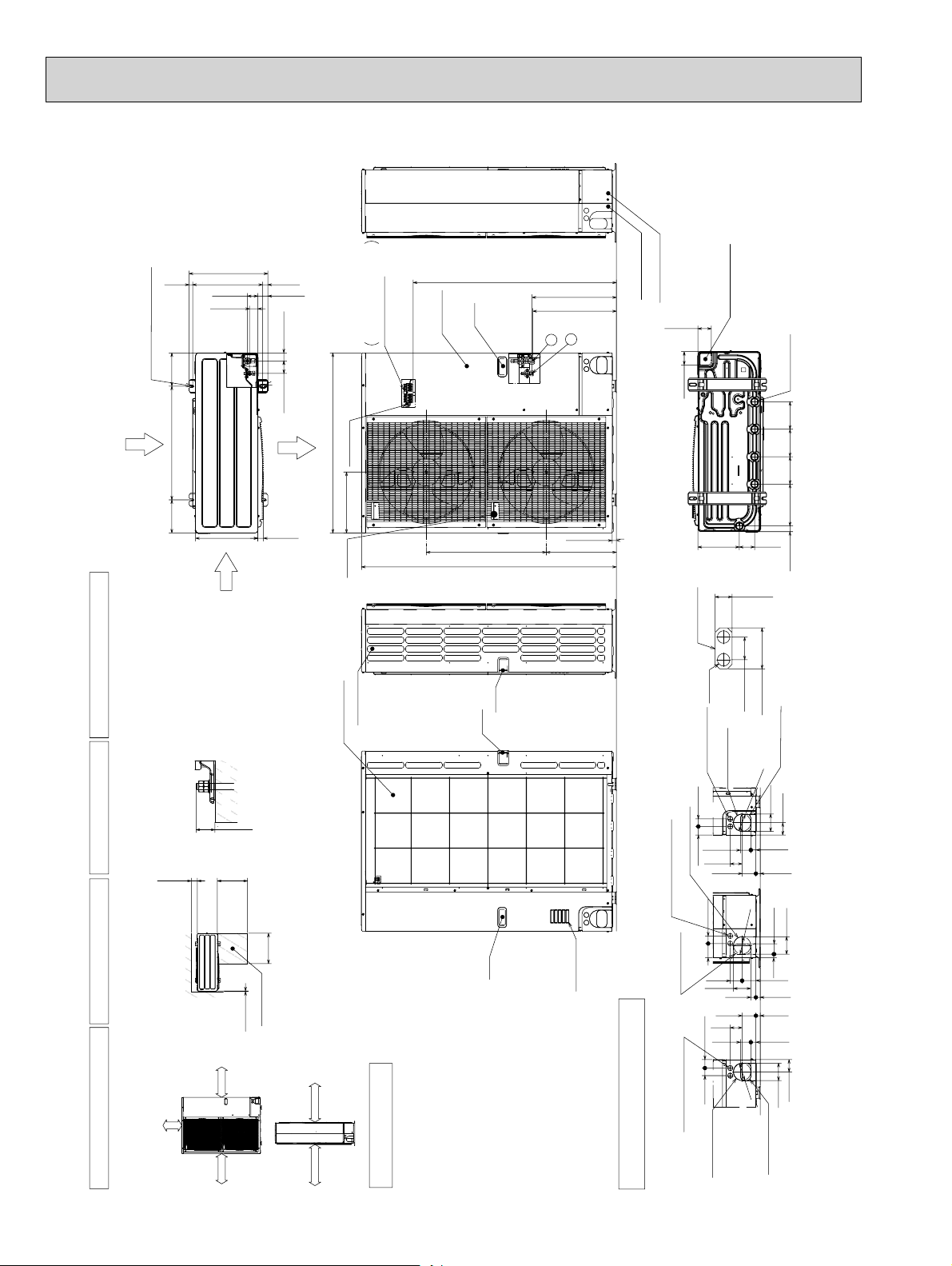

PUZ-HA30NHA PUZ-HA36NHA Unit : mm<inch>

19<3/4>

2-U Shaped notched hole

(Foundation Bolt M10<W3/8>)

175<6-7/8>

600<23-5/8>

Rear Air Intake

175<6-7/8>

417<16-13/32>

370<14-9/16>

56<2-7/32>

45<1-25/32>

330<13>30<1-3/16>

28<1-3/32>

53<2-3/32>

42<1-21/32>66<2-5/8>

2-12%36 Oval hole

(Foundation Bolt M10<W3/8>)

Air Discharge

Side Air Intake

Piping and wiring connections

can be made from 4 directions:

front, right, rear and below.

4 PIPING-WIRING DIRECTIONS

FOUNDATION

<1-3/16>

<Foundation bolt height>

Please secure the unit firmly

with 4 foundation (M10<W3/8>)

bolts. (Bolts and washers must

3 FOUNDATION BOLTS

be purchased locally.)

<5-29/32>

150mm

Min.

Dimensions of space needed

for service access are

shown in the below diagram.

2 SERVICE SPACE

30mm

Min.

<19-11/16>

500mm

Min.

Min.

10mm<3/8>

Min.

500mm

<19-11/16>

Service space

Terminal Block

Left···Power supply wiring

950<37-13/32>

Earth terminal

322<12-11/16>

Handle

Side Air Intake

Rear Air Intake

Right····Indoor/Outdoor wiring

Service panel

Handle

Handle

635<25>

Handle

Handle

1076<42-3/8>

1350<53-5/32>

1

* 1 447<17-19/32>

2

Air intake

Front piping cover

* 1 443<17-7/16>

23<29/32>

371<14-19/32>

Rear piping cover

71<2-13/16>

71<2-13/16>

Bottom piping hole

(Knockout)

219<8-5/8>

1/2 Conduit attachment

When installing the conduit.

Set the attachment to the

inner side of each panel.

2-:22.2<7/8>

Conduit hole

(2-:27<1-1/16>Knockout)

Rear trunking hole

(Knockout)

40<1-9/16>

55<2-3/16>

63<2-1/2>

45<1-25/32>

Right trunking hole

(Knockout)

Conduit hole

(2-:27<1-1/16>Knockout)

40<1-9/16>

75

<2-31/32>

63<2-1/2>

<2-1/2>

63

55<2-3/16>

45<1-25/32>

92<3-5/8>

73<2-7/8>

Right piping hole

(Knockout)

40<1-9/16>

:92

<3-5/8>

73<2-7/8>

92

/8>

:

<3-5

27<1-1/16>

Drain hole

5-:33<1-5/16>

145

<5-23/32>

145

<5-23/32>

145

<5-23/32>

220

<8-21/32>

81<3-3/16>

30<1-3/16>

31<1-7/32>

74<2-19/32>

Rear piping hole

(Knockout)

92<3-5/8>

65<2-9/16>

92<3-5/8>

55<2-3/16>

19<3/4>

27<1-1/16>

23<29/32>

73<2-7/8>

23<29/32>

23<29/32>

27<1-1/16>

Min. 10mm

<3/8>

FREE

The diagram below shows a

basic example.

Explantion of particular details are

1 FREE SPACE (Around the unit)

given in the installation manuals etc.

<3/8>

Min. 10mm

Min. 150mm

<5-29/32>

<39-3/8>

Min. 1000mm

Example of Notes

····Refrigerant GAS pipe connction (FLARE):15.88<5/8>

····Refrigerant LIQUID pipe connection (FLARE): 9.52<3/8>

*1 ····Indication of STOP VALVE connection location.

8

/8>

92

:

(Knockout)

<3-5

65<2-9/16>

92<3-5/8>

Front piping hole

(Knockout)

40<1-9/16>

Conduit hole

(2-:27<1-1/16>Knockout)

Piping Knockout Hole Details

Front trunking hole

Page 9

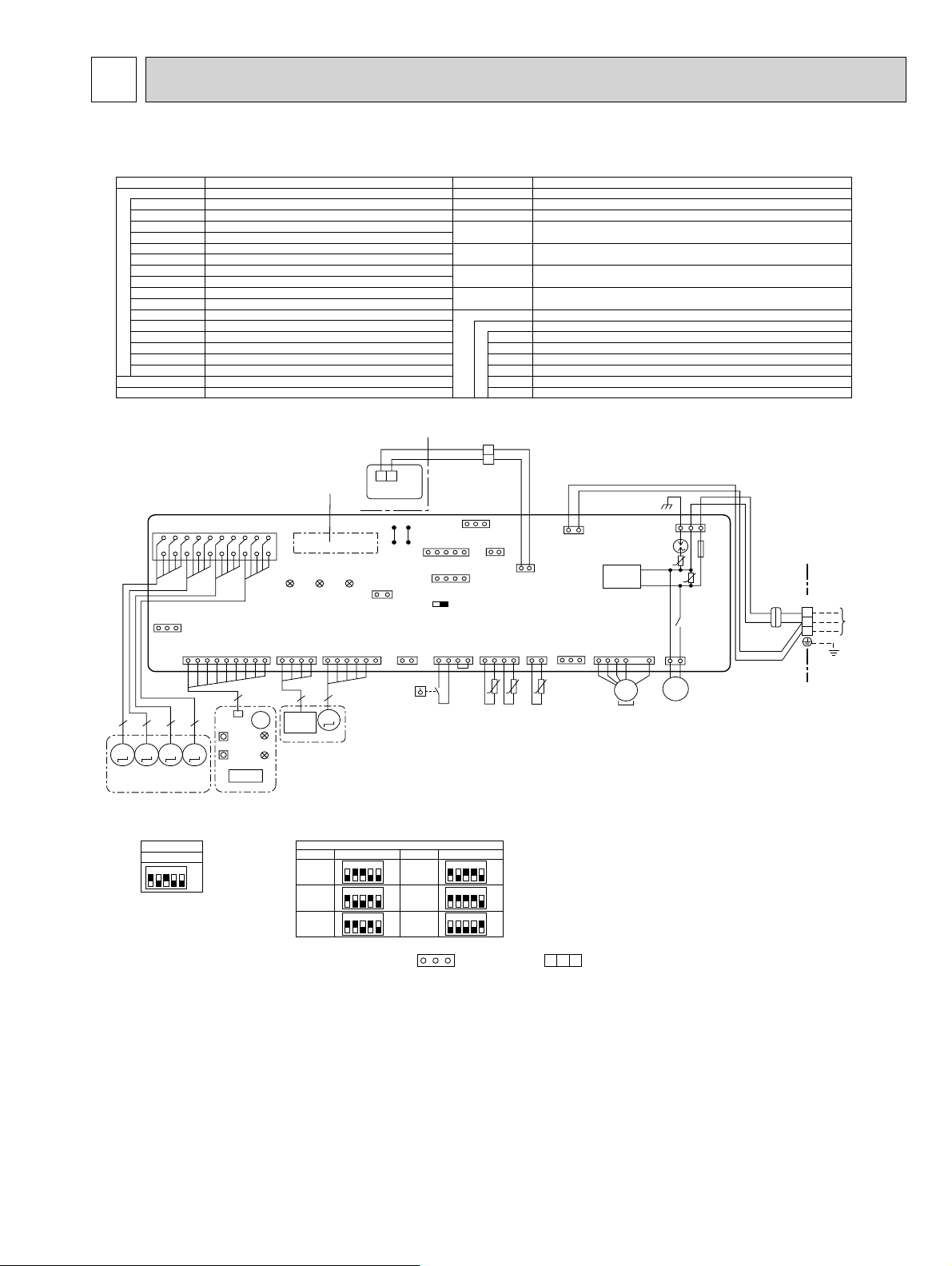

4

WIRING DIAGRAM

PLA-A18BA PLA-A30BA PLA-A36BA

[LEGEND]

SYMBOL SYMBOLNAME NAME

I.B INDOOR CONTROLLER BOARD

CN2L

CN24 CONNECTOR<BACK-UP HEATING>

CN30 CONNECTOR<LLC>

CN32

CN41

CN51

DSA

FUSE

LED1

LED2

LED3

SW1

SW2

SWE

X1

ZNR01, 02

DP

FS

I.B

13

CN3G

(BLK)

CONNECTOR (LOSSNAY)

CONNECTOR (REMOTE SWITCH)

CONNECTOR (HA TERMINAL-A)

CONNECTOR (CENTRALLY CONTROL)

SURGE ABSORBER

FUSE (T6.3AL250V)

POWER SUPPLY (I.B)

POWER SUPPLY (R.B)

TRANSMISSION (INDOOR-OUTDOOR)

SWITCH (MODEL SELECTION) +See table 1.

SWITCH (CAPACITY CODE) +See table 2.

CONNECTOR (EMERGENCY OPERATION)

RELAY (DRAIN PUMP)

VAR IST OR

DRAIN-UP MACHINE

DRAIN FLOAT SWITCH

Refer to tables 1 and 2.

VAN E

CNV

(WHT)

1011121314151617181920

123456789

LED3 LED2 LED1

I-SEE

SENSOR

CN4Y

(WHT)

4

I-SEE

BZ

SENSOR

LED2

I-SEE SENSOR

CORNER PANEL

LED1

RU

(OPTIONAL PART)

W.B

GRILLE

5555

MMMM

MVMVMVMV

WIRELESS

CN90

(WHT)

9

CNB

SW1

SW2

SENSOR MOTOR

5

M

MT

SW2SW1

I-SEE

CN6Y

(RED)

21

TB6

R.B

J42J41

Pair No.

CN2L

21

CNAC

(WHT)

36141911

MF

MV

TB4

TB5, TB6

TH1

TH2

TH5

OPTION PART

W.B

TB5

TRANSMISSION

WIRES

DC12V

CN32

(WHT)

1

CN51

(WHT)

CN24

51

CN41

(WHT)

41

SWE

ON OFF

FLOAT SW

LIQUID/PIPE

CN4F

(WHT)

FS

FAN MOTOR

VANE MOTOR

TERMINAL BLOCK (INDOOR/OUTDOOR CONNECTING LINE)

TERMINAL BLOCK (REMOTE CONTROLLER

TRANSMISSION LINE)

ROOM TEMP. THERMISTOR

(32˚F/15kΩ, 77˚F/5.4kΩ DETECT)

PIPE TEMP. THERMISTOR/LIQUID

(32˚F/15kΩ, 77˚F/5.4kΩ DETECT)

COND. / EVA. TEMP. THERMISTOR

(32˚F/15kΩ, 77˚F/5.4kΩ DETECT)

PCB FOR WIRELESS REMOTE CONTROLLER

BZ

BUZZER

LED1

LED (OPERATION INDICATION: GREEN)

LED2

LED (PREPARATION FOR HEATING: ORANGE)

RECEIVING UNIT

RU

SW1

EMERGENCY OPERATION (HEAT/DOWN)

SW2

EMERGENCY OPERATION (COOL/UP)

2

1

3

(YLW)

2

CN44

(WHT)

REMOCON

t˚t˚

TH5TH2

INDOOR/OUTDOOR

COMMUNICATION

112

CN22

(BLU)

INTAKE

CN20

(RED)

t˚

TH1

13

CN3C

(BLU)

DC280V

RECTIFICATION

FAN

CN30

(GRN)

13

CNMF

(WHT

71121414 4 31

MS

MF

3~

+Be sure to turn off the power source

and then disconnect fan motor connector.

(Failure to do so will cause trouble in fan motor.)

OUTDOOR

CN01

(BLK)

DSA

ZNR02

)

135

U

M

1~

DP

U

ZNR01

X1

D.U.M

CNP

(BLU)

FUSE

YLW

ORN

ORN

BRN

YLW

ORN

TB4

+1

S1

TO

S2

OUTDOOR

UNIT

S3

<Table 1>SW1(MODEL SELECTION)

SW1

Service

12345

ON

OFF

Notes:

1. SymboIs used in wiring diagram above are, : Connector, : Terminal block.

<Table 2>SW2(CAPACITY CODE)

MODELS

PLA-A12BA

PLA-A18BA

PLA-A24BA

Service

12345

12345

12345

ON

OFF

ON

OFF

ON

OFF

SW2

MODELS

PLA-A30BA

PLA-A36BA

PLA-A42BA

Service

12345

12345

12345

ON

OFF

ON

OFF

ON

OFF

2. Indoor and outdoor connecting wires have poIarities, make sure to match terminal numbers (S1, S2, S3) for correct wiring.

3. Since the outdoor side electric wiring may change, be sure to check the outdoor unit electric wiring for servicing.

+1. Use copper supply wires.

[Self-diagnosis]

1. For details on how to operate self-diagnosis with the wireless remote control, refer to the technical manuals etc.

2. For the wired remote control: When you quickly press twice the CHECK switch on the remote control, the unit begins self-diagnosis,

and Check Codes generated in the past appear on the display.

9

Page 10

PKA-A18GA PKA-A18GAL

SYMBOL NAME

P.B

I.B

P. B

INDOOR POWER BOARD

INDOOR CONTROLLER BOARD

FUSE FUSE (6.3A/250V)

ZNR VARISTOR

CN2L CONNECTOR <LOSSNAY>

CN24 CONNECTOR <BACK-UP HEATING>

CN30 CONNECTOR <LLC>

CN32 CONNECTOR <REMOTE SWITCH>

CN41 CONNECTOR <HA TERMINAL-A>

CN51 CONNECTOR <CENTRALLY CONTROL>

SW1 SWITCH <MODEL SELECTION>

SW2 SWITCH <CAPACITY CODE>

SWE

SWITCH <EMERGENCY OPERATION>

X4 RELAY <FAN MOTOR>

FAN CONTROL ELEMENT

BCR

LED1 POWER SUPPLY <I.B>

CNSK

(RED)

1

3

DC13.1V

CN2S

(WHT)

1

2

+

See Table 1.

+

See Table 2.

Please set the voltage

using the remote controller.

For the setting method,

please refer to the indoor

unit Installation Manual.

SYMBOL NAME

POWER SUPPLY <R.B>

LED2

C

MF

MV

TB4

TB5, TB6

TH1

TH2

TH5

R.B

TRANSMISSION <INDOOR-OUTDOOR>LED3

CAPACITOR <FAN MOTOR>

FAN MOTOR

VANE MOTOR

TERMINAL BLOCK <INDOOR/OUTDOOR

CONNECTING LINE>

TERMINAL BLOCK <REMOTE CONTROLLER

TRANSMISSION LINE >

ROOM TEMP.THERMISTOR

<32˚F/15kΩ, 77˚F/5.2kΩ DETECT>

PIPE TEMP.THERMISTOR/LIQUID

<32˚F/15kΩ, 77˚F/5.2kΩ DETECT>

COND./EVA.TEMP.THERMISTOR

<32˚F/15kΩ, 77˚F/5.2kΩ DETECT>

WIRED REMOTE CONTROLLER BOARD

SYMBOL

W.B

Table 2

MODELS

PKAA12GA(L)

WIRELESS REMOTE CONTROLLER BOARD

RECEIVING UNIT

RU

BZ

BUZZER

LED1

LED<RUN INDICATOR >

LED2

LED<HOT ADJUST>

SW1

SWITCH<HEATING ON/OFF>

SW2

SWITCH<COOLING ON/OFF>

NAME

Table 1

SW1

Service board

1 2 3 4 5

SW2

Service board Service board

1 2 3 4 5

ON

OFF

MODELS

PKAA18GA(L)

1 2 3 4 5

ON

OFF

ON

OFF

YLW

ORN

YLW

ORN

BRN

TB4

S1

S2

S3

+1

TO

OUTDOOR

UNIT

MF

M

1~

1

32

C

BLK

WHT

RED

I.B

FAN

(

)

WHT

5

3

1

BCR

SW2 SW1

SWE

ON

OFF

Refer to tables 1 and 2

for service PCB.

POWER

X4

CNDK

(RED)

WHT

RED

3

11

POWER

CND

(ORN)

ZNR

U

YLW

LED3 LED2 LED1

LIQUID

YLW

INTAKE

CN20

)

(

)

RED

12

2121212

1

CN24

(

t˚ t˚ t˚

ORN

BLK

WHT

1

3

POWER

CN2D

FUSE

(WHT)

CN41

CN51

51

PIPE

CN21

CN29

(

)

(

WHT

BLK

TH2

TH5TH1

BRN

1

2

A-CONTROL

CN3C

(BLU)

(

)

WHT

14

(

)

WHT

REMOCON

CN22

)

(

)

BLU

ORN

3

(

CN2L

RED

12

(

CN32

WHT

13

CN30

(

BLK

6

VANE

CN6V

(GRN)

)

1

6

1

)

WIRELESS

CN90

(WHT)

)

9

13

1

TRANSMISSION WIRES DC12V

2

TB5

M

MV

99

RU

RECEIVER

BZ

LED1 LED2 SW2 SW1

R.B

NOTES:

1. Since the outdoor side electric wiring may change, be sure to check the outdoor unit electric wiring for servicing.

2. Indoor and outdoor connecting wires have polarities, make sure to match terminal numbers (S1, S2, S3) for correct wiring.

3. Symbols used in wiring diagram above are, : Connector, : Terminal (block).

4. This diagram shows the wiring of Indoor and Outdoor connecting wires (specification of 230V), adopting superimposed system of

power and signal.

+1. Use copper supply wires.

For A12/18GAL

CNB

W.B

1

2

TB6

For A12/18GA

[Self-diagnosis]

Please refer to technical manuals etc.

10

Page 11

PKA-A30FA PKA-A30FAL PKA-A36FA PKA-A36FAL

[LEGEND]

P.B

I.B

P.B

INDOOR POWER BOARD

INDOOR CONTROLLER BOARD

FUSE FUSE (6.3A/250V)

ZNR VARISTOR

CN2L CONNECTOR <LOSSNAY>

CN24 CONNECTOR <BACK-UP HEATING>

CN30 CONNECTOR <LLC>

CN32 CONNECTOR <REMOTE SWITCH>

CN41 CONNECTOR <HA TERMINAL-A>

CN51 CONNECTOR <CENTRALLY CONTROL>

SW1 SWITCH <MODEL SELECTION>+See Table 1.

SW2 SWITCH <CAPACITY CODE>+See Table 2.

SWE SWITCH <EMERGENCY OPERATION>

X4 RELAY <FAN MOTOR>

FAN CONTROL ELEMENT

BCR

LED1 POWER SUPPLY <I.B>

CNSK

(RED)

1

DC13.1V

3

CN2S

(WHT)

1

2

NAME

Please set the voltage

using the remote controller.

For the setting method,

please refer to the indoor

unit Installation Manual.

MF

M

1~

SYMBOL NAME

POWER SUPPLY <R.B>

LED2

TRANSMISSION <INDOOR-OUTDOOR>LED3

C

MF

MV

TB4

TB5,TB6

TH1

TH2

TH5

R.B

CAPACITOR <FAN MOTOR>

FAN MOTOR

VANE MOTOR

TERMINAL BLOCK <INDOOR/OUTDOOR

CONNECTING LINE>

TERMINAL BLOCK <REMOTE CONTROLLER

TRANSMISSION LINE >

ROOM TEMP.THERMISTOR

<32˚F/15kΩ, 77˚F/5.2kΩ DETECT>

PIPE TEMP.THERMISTOR/LIQUID

<32˚F/15kΩ, 77˚F/5.2kΩ DETECT>

COND./EVA.TEMP.THERMISTOR

<32˚F/15kΩ, 77˚F/5.2kΩ DETECT>

WIRED REMOTE CONTROLLER BOARD

YLW

ORN

YLW

ORN

BRN

TB4

S1

S2

S3

SYMBOL

W.B

+

1

TO

OUTDOOR

UNIT

WIRELESS REMOTE CONTROLLER BOARD

RECEIVING UNIT

RU

BZ

BUZZER

LED1

LED <RUN INDICATOR >

LED2

LED <HOT ADJUST>

SW1

SWITCH <HEATING ON/OFF>

SW2

SWITCH <COOLING ON/OFF>

NAME

Table 1

SW1

Service board

1 2 3 4 5

ON

OFF

Table 2

SW2

MODELS

PKAA24FA(L)

MODELS

PKAA30FA(L)

MODELS

PKAA36FA(L)

Service board

1 2 3 4 5

Service board

1 2 3 4 5

Service board

1 2 3 4 5

ON

OFF

ON

OFF

ON

OFF

1

32

C

BLK

WHT

RED

I.B

FAN

(

)

WHT

5

3

1

BCR

SW2 SW1

SWE

ON

OFF

Refer to tables 1 and 2

for service PCB.

POWER

CNDK

(RED)

X4

WHT

RED

3

11

POWER

CND

(ORN)

ZNR

U

YLW

LED3 LED2 LED1

INTAKE

CN24

(

YLW

CN20

)

(

)

RED

12

2121212

1

tº tº tº

ORN

BLK

1

3

POWER

CN2D

(WHT)

FUSE

CN41

CN51

51

LIQUID

PIPE

CN21

CN29

(

)

(

WHT

BLK

TH2

TH5TH1

WHT

1

2

A-CONTROL

CN3C

(BLU)

(

)

WHT

14

(

)

WHT

REMOCON

CN22

)

(

BLU

BRN

ORN

3

CN2L

CN32

13

)

(

RED

12

(

WHT

CN30

(

BLK

)

6

VANE

CN6V

(GRN)

6

1

1

)

WIRELESS

CN90

(WHT)

)

9

13

1

TRANSMISSION WIRES DC12V

2

TB5

M

MV

99

RU

RECEIVER

For A24/30/36FAL

CNB

BZ

LED1 LED2 SW2 SW1

W.B

R.B

1

2

TB6

For A24/30/36FA

Notes:

1. SymboIs used in wiring diagram above are, : Connector, : Terminal block.

2. Indoor and outdoor connecting wires have poIarities, make sure to match terminal numbers (S1, S2, S3) for correct wiring.

3. Since the outdoor side electric wiring may change, be sure to check the outdoor unit electric wiring for servicing.

4. This diagram shows the wiring of Indoor and Outdoor connecting wires (specification of 230V), adopting superimposed system of

power and signal.

+1. Use copper supply wires.

[Self-diagnosis]

Please refer to technical manuals etc.

11

Page 12

PUZ-HA30NHA PUZ-HA36NHA

[LEGEND]

SYMBOL

TB1

MC

MF1, MF2

21S4

63H

63L Low Pressure Switch

SV

TH3,TH32,TH33

TH4

TH6

TH7

TH8

LEV-A, LEV-B,LEV-C

DCL

ACTM

CB

CY1, CY2

Terminal Block<Power Supply, Indoor/Outdoor >

Motor for Compressor

Fan Motor

Solenoid Valve (Four-Way Valve)

High Pressure Switch

Solenoid Valve (Bypass Valve)

Thermistor <Outdoor Pipe>

Thermistor <Discharge>

Thermistor <Outdoor 2-Phase Pipe>

Thermistor <Outdoor>

Thermistor <Heatsink>

Electronic Expansion Valve

Reactor

Active Filter Module

Main Smoothing Capacitor

Capacitor

C. B.

MF1

MS

3~

MF2

MS

3~

NAME

TH7 TH6 TH3 TH4

TH32

TH33

°

°

t

7

1

1

CNF1

(WHT)

7

CNF2

(WHT)

3

2

CNDC

1

(PNK)

CNS

(WHT)

t

2

121

3

1

TH32

TH33

)

)

(BLK

(YLW

TRANS

F2

F1

31

SYMBOL NAME SYMBOL NAME

P.B.

TABU/V/W

TABS/T

TABP1/P2/P

TABN1/N2/N

DS2, DS3

IPM

N.F.

LI/LO

NI/NO

EI, E2

52C

C.B.

SW1

SW4

SW5

t°t°t°t

°

4121

TH7/6

TH3

TH4

)

(RED)

(WHT

(WHT

CNAC

(WHT)

21

43

P. B.

4

1

CNAF

(WHT)

6

7

1

CN2

IPM

(WHT)

7

1

2

(WHT)

1

2

(RED)

1

2

(WHT)

TABN

TABP

CN3

CN5

CN4

TABP2

RED

TABU

RED

UVW

MS

3~

TABV

WHT

BLK

MC

TH8

t

°

2

2

WHT

CB

RED

)

(YLW)

F3

F4

TABW

Power Circuit Board

Connection Terminal <U/V/W-Phase>

Connection Terminal <L/N-Phase>

Connection Terminal <DC Voltage>

Connection Terminal <DC Voltage>

Diode Bridge

Power Module

Noise Filter Circuit Board

Connection Terminal <L-Phase>

Connection Terminal <N-Phase>

Connection Terminal <Ground>

52C Relay

Controller Circuit Board

Switch <Forced Defrost, Defect History Record

Reset, Refrigerant Address>

Switch <Test Operation>

Switch <Function Switch>

LEV-C

63H

63H

31

CN2

(WHT)

CNDC

(PNK)

1

3

LEV-A

63L

MM

LEV-A

(WHT)

31

63L

LED2

(RED)

71

2

7

21S4

(GRN)

2

U

TABN1

BLK

61

CN4

(WHT)

21

DS3

DS2

TABN2

WHT

LED1

M

LEV-B

5

6

1

LEV-B

(RED)

5

1

LEV-C

(BLU)

X52

13 13 13

TABT

BLU

TABS

WHT

TABP1

RED

CNVMNT

(WHT)

6

SV21S4

3

31

CNM

(WHT)

X55

SV2

(BLU)

CNMNT

(WHT)

CN52C

(RED)

SW6

SW7

SW8

SW9

SWP

CN31

SS

CNM

CNMNT

CNVMNT

CNDM

LED1, LED2

F1~F4

X51,X52,X55

5

+1+

1

51

SW5SW8SW4 SWP

SW6SW1

141

CN31

221

(WHT)

CNDM

CN51

(WHT)

X51

SS

(WHT)

Switch <Model Select>

Switch <Function Setup>

Switch <Function Setup>

Switch

Switch <Pump Down>

Connector <Emergency Operation>

Connector <Connection for Option>

Connector <A-Control Service Inspection Kit>

Connector

<Connected to Optional M-NET Adapter Board>

Connector

<Connected to Optional M-NET Adapter Board>

Connector

< Connected for Option (Contact Input)>

LED <Operation Inspection Indicators>

Fuse<T6.3AL250V

Relay

When M-NET adapter is connected

5

SW7

SW9

1

3

1

5

3

1

CNAC2

(RED)

3

1

CNAC1

(WHT)

WHT

LO NO

LI NI

RED

ABS

52C

U

BLU

5

CN5

SW1

(WHT)

1

LED2

LED3

LED4

M-NET SUBSTRATE

2

CN2M

(WHT)

1

LED1

LED5

TB7

M-NET

N. F.

1

2

CN52C

(BLK)

E2

1

2

CN5

(RED)

EI

U

BLU

>

SW11

SW12

CND

(WHT)

31

3

BLK

BLK

2

2

M-NET ADAPTER

SYMBOL

TB7

CN5

CND

CN2M

SW1

SW11

SW12

LED1

LED2

LED3

LED4

LED5

Terminal Block <M-net connection>

Connector <Transmission>

Connector <Power Supply>

Connector <M-NET communication>

Switch <Status of communication>

Switch <Address setting: 1s digit>

Switch <Address setting: 10ths digit>

LED <Power Supply: DC5V>

LED <Connection to Outdoor Unit>

LED <Transmission: Sending>

LED <Transmission: Recelving>

LED <Power Supply: DC12V>

NAME

DCL

RED

BLK

ACTM

+1MODEL SELECT

MODEL SW6

ON

30N

OFF

12345678

ON

36N

OFF

12345678

BLK

4

WHT

L1

L2

61

RED

P

N1

N2

WHT

Io

SW5-6+2

ON

OFF

123456

ON

OFF

123456

RED

L1 L2 GR S1 S2 S3

POWER SUPPLY

~/N 208/230V 60Hz

2. SW5 -1 to 5: Function Switch

+

YLW

ORN

BLU

GRN

INDOOR

UNIT

+

Use copper supply wires.

BRN

CY1

CY2

TB1

12

Page 13

5

REFRIGERANT SYSTEM DIAGRAM

5-1. INDOOR UNIT

PLA-A·BA PKA-A·GA PKA-A·GAL PKA-A·FA PKA-A·FAL

Strainer(#50)

Heat exchanger

Refrigerant GAS pipe connection

(Flare)

Thermistor TH5

(Cond./Eva. temperature)

Refrigerant flow in cooling

Refrigerant flow in heating

Refrigerant LIQUID pipe connection

Distributor

with strainer(#50)

Thermistor TH1

(Room temperature)

Thermistor TH2

Pipe temperature (Liquid)

(Flare)

Strainer(#50)

5-2. OUTDOOR UNIT

PUZ-HA30NHA PUZ-HA36NHA

Refrigerant

GAS pipe

connection

:15.88 (5/8)

Ball valve

Strainer

#50

Electronic

expansion valve B

Charge plug

(Low pressure)

Strainer

#100

Power

receiver

Solenoid valve

(Four-way valve)

Charge plug

(High pressure)

Low pressure

switch 63L

Strainer

#100

Strainer

#100

Muffler

Compressor

Heat exchanger

High pressure

switch 63H

Thermistor

TH32

(Outdoor pipe)

Thermistor TH4

(Discharge)

Electronic expansion valve A

Injection port

Strainer

#100

unit : mm (inch)

Thermistor TH7

(Outdoor)

Thermistor

TH6

(Outdoor

2-phase pipe)

Thermistor TH3

(Outdoor pipe)

Distributor

Thermistor TH33

(Outdoor pipe)

Bypass

valve

Replace

filter

Refrigerant

LIQUID pipe

connection

:9.52

(3/8)

Stop valve

(with service port)

Strainer

#100

Electronic

expansion valve C

13

Heat inter change circuit

Restrictor

valve

Strainer

#100

Refrigerant flow in cooling

Refrigerant flow in heating

Page 14

6

PERFORMANCE CURVES

FOR THE COMBINATION OF OUTDOOR UNIT PUZ-HA·NHA

Cooling performance curve

1.4

1.2

INDOOR

W.B.

CAPACITY (RATIO)TOTAL INPUT (RATIO)

1.0

0.8

1.2

1.0

72°F (22°C)

68°F (20°C)

64°F (18°C)

61°F (16°C)

INDOOR

W.B.

72°F (22°C)

68°F (20°C)

64°F (18°C)

61°F (16°C)

0.8

0.6

0.4

23

(-5°C)

Note : This diagram shows the case where the operation frequency of a compressor is fixed.

30

(-1°C)

50

(10°C)

OUTDOOR D.B.(°F)

70

(21°C)

90

(32°C)

(43°C)

14

110

Page 15

Rated heating capacity

1.40

1.20

1.00

0.80

0.60

-15 -10 -5 0 5 10 15 20 25 30 35 40 45 50 55 60

-26 -23 -21 -18 -15 -12 -9 -7 -4 -1 2 4 7 10 13 16

Rated heating performance curve

60˚F (16˚C)

70˚F (21˚C)

80˚F (27˚C)

Indoor intake air dry-bulb temperature (˚F DB)

(˚FWB)

(˚CWB)

Outdoor ambient temp.

Heating input

2.00

1.50

1.00

INPUT (RATIO) CAPACITY (RATIO)

0.50

-15 -10 -5 0 5 10 15 20 25 30 35 40 45 50 55 60

-26 -23 -21 -18 -15 -12 -9 -7 -4 -1 2 4 7 10 13 16

80˚F (27˚C)

70˚F (21˚C)

60˚F (16˚C)

Indoor intake air dry-bulb temperature (˚F DB)

(˚FWB)

(˚CWB)

Outdoor ambient temp.

15

Page 16

7

CORRECTION FACTORS

7-1. COOLING CAPACITY CORRECTION FACTORS

Outdoor unit

PUZ-HA30NHA

PUZ-HA36NHA

20m (70ft)10m (33ft)5m (16ft)

1.00 0.985 0.957 0.931 0.908 0.886 0.876 0.865 0.846 0.829

Refrigerant piping length (one way)

30m (100ft) 40m (130ft) 50m (165ft) 55m (180ft) 60m (195ft) 70m (230ft) 80m (260ft)

7-2. HEATING CAPACITY CORRECTION FACTORS

Outdoor unit

PUZ-HA30NHA

PUZ-HA36NHA

20m (70ft)10m (33ft)5m (16ft)

1.00 0.997 0.991 0.985 0.979 0.973 0.970 0.967 0.961 0.955

Refrigerant piping length (one way)

30m (100ft) 40m (130ft) 50m (165ft) 55m (180ft) 60m (195ft) 70m (230ft) 80m (260ft)

7-3. CAPACITY CORRECTION

Cooling and heating capacity is lowered according to pipe length. Capacity can be obtained by referring to the capacity

curves below.

Corrected pipe length (m) = actual pipe length (m) + number of bends x 0.3 (m)

Corrected pipe length (ft) = actual pipe length (ft) + number of bends x 1 (ft)

100

95

90

85

Capacity ratio [%]

80

75

Note: The permitted pipe length is up to 80m<260ft>.

70

5

<16>10<33>15<50>20<70>25<80>

30

<100>35<115>40<130>45<150>50<165>55<180>60<195>65<215>70<230>75<245>80<260>m<ft>

Heating HA30,36

Cooling HA30,36 model

Cooling

Heating

Corrected pipe length [m]

When gas pipe is one size larger than standard size, capacity can be obtained by referring to capacity curves of

standard size.

16

Page 17

7-4. ADDITION OF REFRIGERANT

• Additional charging is not necessary if the pipe length does not exceed 30 m (100 ft).

• If the pipe length exceeds the specified length above, charge the unit with additional R410A refrigerant according to the

permitted pipe lengths in the chart below.

* When the unit is stopped, charge the unit with the additional refrigerant through the liquid stop valve after the pipe

extensions and indoor unit have been vacuumized.

* When the unit is operating, add refrigerant to the gas check valve using a safety charger. Do not add liquid refrigerant

directly to the check valve.

* After charging the unit with refrigerant, note the added refrigerant amount on the service label (attached to the unit).

• Be careful when installing multiple units. Connecting to an incorrect indoor unit can lead to abnormally high pressure and have

a serious effect on operation performance.

Model

HA30,36

Max. pipe

length

75 m

245 ft

Max. height

difference

30 m

100 ft

30 m 33 m 37 m 40 m 43 m 46 m 49 m 52 m 55 m 58 m 61 m 64 m 67 m 70 m 73 m 75 m

100 ft 110 ft 120 ft 130 ft 140 ft 150 ft 160 ft 170 ft 180 ft 190 ft 200 ft 210 ft 220 ft 230 ft 240 ft 245 ft

0 oz 6 oz 12 oz 18 oz 24 oz 30 oz 36 oz 42 oz 48 oz 54 oz 60 oz 66 oz 72 oz 78 oz 84 oz 86 oz

0 kg 0.2 kg 0.4 kg 0.5 kg 0.7 kg 0.9 kg 1.0 kg 1.2 kg 1.4 kg 1.5 kg 1.7 kg 1.9 kg 2.0 kg 2.2 kg 2.3 kg 2.4 kg

Additional refrigerant charging amount

17

Page 18

8

AIR FLOW DATA

8-1. OUTLET AIR SPEED AND COVERAGE RANGE

PLA-A18BA

Airflow

Air speed

Coverage range

Airflow

Air speed

Coverage range

Airflow

Air speed

Coverage range

The air coverage range is the distance to which the 0.8 ft/sec. air can reach, when air is blown out horizontally from the unit at

the High notch position.

The coverage range should be used only as a general guideline since it varies according to the size of the room and the furniture inside the room.

ft/sec.(m/sec.)

ft/sec.(m/sec.)

ft/sec.(m/sec.)

CFM

ft (m)

CFM

ft (m)

CFM

ft (m)

640

10.5 (3.2)

15 (4.8)

PKA-A18GA

PKA-A18GAL

17.4 (5.3)

33 (10)

PKA-A30FA

PKA-A30FAL

705

16.1 (4.9)

41 (12.4)

PLA-A30BA

740

12.1 (3.7)

18 (5.6)

425

PKA-A36FA

PKA-A36FAL

990

17.7 (5.4)

50 (15.3)

PLA-A36BA

1060

17.4 (5.3)

26 (8.0)

18

Page 19

8-2. PLA-A·BA

8-2-1 FRESH AIR INTAKE AND BRANCH DUCT

1. Branch duct hole and fresh air intake hole (Fig. 1)

At the time of installation, use the duct holes (cut out) located at the positions shown in Fig.1, as and when required.

• A fresh air intake hole for the optional multi function casement can also be made.

Note:

The figure marked with * in the drawing represent the dimensions of the main unit excluding those of the optional

multi function casement.

When installing the optional multi function casement, add 5-5/16 to the dimensions marked on the figure.

When installing the branch ducts, be sure to insulate adequately.

Otherwise condensation and dripping may occur.

Unit : inch(mm)

[Fig. 1]

Fresh air intake hole

Indoor unit

Branch duct hole

3-:1/8(:2.8) burring hole

Fresh air intake hole diagram

:4-29/32(:125) burring hole pitch

120

3-:15/16(:100) cut out hole

(*158)

6-7/32

120

Ceiling

Branch duct hole diagram

Drain pipe

Refrigerant pipe

:6-7/8(:175) burring hole pitch

(view from either side)

3-17/32

(90)

70

3-15/16

3-15/16

(100)

(90)

13-25/32(350)

3-17/32

(90)

3-15/16(100)

14-:1/8(:2.8) burring hole

:5-29/32(:150) cut out hole

5-1/8(130)

*6-3/32(155)

*6-9/16(167)

2. Fresh air intake (Installation at site)

By mounting the optional multi-function casement to the indoor unit main body, and mounting the duct flange (option) onto it

further, fresh exterior air intake can be accomplished.

(The mounting of the multi-function casement increases the height of the ceiling plenum by 5-5/16 (135mm).)

19

Page 20

3. Fresh air intake amount & static pressure characteristics

1 PLA-A18BA PLA-A30BA

Multifunction casement + High efficiency filter Multifunction casement + Standard filter

50(20)

)]

-2

0

-50(-20)

-100(-40)

-150(-60)

Static pressure [Pa(in.W.G.%10

-200(-80)

012

50 100 150 200

Taking air into the unit

50(20)

)]

-2

0

-50(-20)

-100(-40)

-150(-60)

Static pressure [Pa(in.W.G.%10

-200(-80)

012

50 100 150 200

2 PLA-A36BA

2 - inlet

1 - inlet

6

345

Airflow rate Airflow rate

3456

Airflow rate

[CMM]

[CFM]

[CMM]

[CFM]

50(20)

)]

-2

0

-50(-20)

-100(-40)

-150(-60)

Static pressure [Pa(in.W.G.%10

-200(-80)

012

How to read curves

Curve in the

1

graphs

0

Q

2

Q

3

Q

Qa

2 - inlet

1 - inlet

50 100 150 200

Duct characteristics

at site

A

C

B

345

Q…Designed amount of fresh air intake

A…Static pressure loss of fresh air intake

duct system with airflow amount Q

<Pa(in.W.G.o10-2)>

B…Forced static pressure at air condi-

A

EC

tioner inlet with airflow amount Q

<Pa(in.W.G.o10-2)>

C…Static pressure of booster fan with air-

flow amount Q <Pa(in.W.G.o10-2)>

D…Static pressure loss increase amount

of fresh air intake duct system for air-

flow amount Q <Pa(in.W.G.o10

E…Static pressure of indoor unit with air-

AD

flow amount Q <Pa(in.W.G.o10

Qa…Estimated amount of fresh air intake

without D <CMM(CFM)>

<CMM(CFM)>

Multifunction casement + Standard filter Multifunction casement + High efficiency filter

[CMM]

6

[CFM]

-2

-2

)>

)>

50(20)

)]

-2

0 0

-50(-20)

-100(-40)

-150(-60)

Static pressure [Pa(in.W.G.%10

-200(-80)

02

50 100 150 200 250

Taking air into the unit

50(20)

)]

-2

0

-50(-20)

-100(-40)

-150(-60)

Static pressure [Pa(in.W.G.%10

-200(-80)

02

50 100 150 200 250

50(20)

)]

-2

-50(-20)

2 - inlet

1 - inlet

48

Airflow rate

48

Airflow rate

6

6

[CMM]

[CFM]

[CMM]

[CFM]

-100(-40)

-150(-60)

Static pressure [Pa(in.W.G.%10

-200(-80)

1 - inlet

02

50 100 150 200 250

48

Airflow rate

2 - inlet

6

[CMM]

[CFM]

20

Page 21

4. Change of outlet numbers

The optional air outlet is necessary.

To change the air outlet number to 3-, or 2-way outlet, the

outlet number should be closed with the operational air

outlet shutter.

When the air outlets are closed, close the vane by

removing the vane connector.

Indoor unit

Button

Vane motor

Up/down vanes

Connector

Vane motor

Connector

Button

5. Branch duct and change of outlet numbers

<4- way air flow and branch duct>

Branch

duct

Air intake

+ Branch duct should be connected to one of the branch duct holes on the main unit.

Air

outlet

Outlet concave

portion

Air outlet shutter plate

(Option)

<3- way air flow and branch duct>

Branch

duct

Air

outlet

closed

position

<2- way air flow and branch duct>

Branch

duct

Air

Air

outlet

outlet

closed

closed

position

position

Air intake

Air intake

+ Close the outlet on the side of branch duct and air flows in 3 directions.

Air

outlet

+ The outlet on the side of branch duct and one of the other outlets are closed.

Air flows in 2 directions.

Air

outlet

closed

position

21

Page 22

• Airflow rate of PLA-A18BA can be calculated from the airflow rate based on the characteristic of the duct for PLA-A30BA.

PLA-A30BA

30(12)

4-way airflow (horizontal vane) Round duct

)]Static pressure [Pa(in.W.G%10

-2

Duct

20(8)

4-way airflow (horizontal vane) Rectangular duct

30(12)

)]Static pressure [Pa(in.W.G%10

-2

Duct

20(8)

10(4)

10(4)

High

Static pressure [Pa(in.W.G%10

Low

0

0

0 50 100 150 200 250 [CFM]

2

4 6 8[CMM]

Airflow rate Airflow rate

80(32)

70(28)

)]Static pressure [Pa(in.W.G%10

-2

60(24)

50(20)

40(16)

30(12)

20(8)

10(4)

3-way airflow (horizontal vane) Round duct

Duct

Close

Low

0

0 2 4 6 8 10[CMM]

0 50 100 150 200 250 300 [CFM]

High

Airflow rate Airflow rate

2-way airflow (horizontal vane) Round duct

80(32)

70(28)

)]

-2

60(24)

50(20)

40(16)

30(12)

20(8)

Low

10(4)

0

024681012[CMM]

0 50 100 150 200 250 300 [CFM]

• Use 1 of the 2 duct holes on the indoor unit.

• Use the optional air outlet shutter plate (PAC-SH51SP-E) for 3-way and 2-way airflow.

Close

High

Airflow rate

Duct

Close

350 400

Static pressure [Pa(in.W.G%10

0

0

0 50 100 150 200 250 [CFM]

3-way airflow (horizontal vane) Rectangular duct

80(32)

70(28)

)]

-2

60(24)

50(20)

40(16)

30(12)

20(8)

10(4)

0

0 2 4 6 8 10[CMM]

0 50 100 150 200 250 300 [CFM]

2-way airflow (horizontal vane) Rectangular duct

80(32)

70(28)

)]

-2

60(24)

50(20)

40(16)

30(12)

20(8)

Static pressure [Pa(in.W.G%10

10(4)

0

024681012[CMM]

0 50 100 150 200 250 300 [CFM]

Low

2 4 6 8[CMM]

High

Duct

Close

High

Low

Duct

Close

Low

High

350 400

Airflow rate

Close

22

Page 23

• Airflow rate of PLA-A36BA can be calculated from the airflow rate based on the characteristic of the duct for PLA-A42BA.

PLA-A42BA

4-way airflow (horizontal vane) Round duct

30(12)

)]Static pressure [Pa(in.W.G%10

-2

)]

-2

4-way airflow (horizontal vane) Rectangular duct

30(12)

Duct

20(8)

10(4)

Static pressure [Pa(in.W.G%10

Low

0

0

0 50 100 150

3-way airflow (horizontal vane) Round duct 3-way airflow (horizontal vane) Rectangular duct

80(32)

70(28)

)]Static pressure [Pa(in.W.G%10

-2

60(24)

50(20)

40(16)

30(12)

20(8)

10(4)

2 4 6 8[CMM]

Low

High

Airflow rate

Duct

Close

High

200

250 [CFM]

20(8)

10(4)

Static pressure [Pa(in.W.G%10

0

0

0 50 100 150

80(32)

70(28)

)]

-2

60(24)

50(20)

40(16)

30(12)

20(8)

Static pressure [Pa(in.W.G%10

10(4)

2 4 6 8[CMM]

Duct

Low

Airflow rate

Duct

Close

Low

200

High

High

250 [CFM]

0

0246810[CMM]

0 50 100 150 200 250 300 [CFM]

2-way airflow (horizontal vane) Round duct

100(40)

90(36)

80(32)

70(28)

)]

-2

60(24)

50(20)

40(16)

30(12)

20(8)

10(4)

0

Low

0 2 4 6 8 10 12[CMM]

0 50 100 150 200 250 300 [CFM]

Airflow rate Airflow rate

100(40)

Duct

Close

Close

High

90(36)

80(32)

70(28)

)]

-2

60(24)

50(20)

40(16)

30(12)

Static pressure [Pa(in.W.G%10

350 400

Airflow rate Airflow rate

• Use 1 of the 2 duct holes on the indoor unit.

• Use the optional air outlet shutter plate (PAC-SH51SP-E) for 3-way and 2-way airflow.

0

0 2 4 6 8 10[CMM]

0 50 100 150 200 250 300 [CFM]

2-way airflow (horizontal vane) Rectangular duct

Duct

Close

High

Low

20(8)

10(4)

0

0 2 4 6 8 10 12[CMM]

0 50 100 150 200 250 300 [CFM]

Close

350 400

23

Page 24

9

NOISE CRITERION CURVES

9-1. INDOOR UNIT

PLA-A18BA

NOTCH SPL(dB) LINE

High 32

Medium1 31

Medium2 29

Low 28

PLA-A30BA

NOTCH SPL(dB) LINE

High 34

Medium1 32

Medium2 30

Low 28

90

80

70

60

50

40

30

APPROXIMATE

20

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 bar)

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

10

63 125 250 500 1000 2000 4000 8000

PLA-A36BA

BAND CENTER FREQUENCIES, Hz

NOTCH SPL(dB) LINE

High 40

Medium1 37

Medium2 34

Low 32

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

90

80

70

60

50

40

30

APPROXIMATE

20

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 bar)

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

10

63 125 250 500 1000 2000 4000 8000

CEILING

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

BAND CENTER FREQUENCIES, Hz

UNIT

90

80

70

60

50

40

30

APPROXIMATE

20

THRESHOLD OF

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 bar)

HEARING FOR

CONTINUOUS

NOISE

10

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

5ft

MICROPHONE

24

Page 25

PKA-A18GA

PKA-A18GAL

NOTCH

High

Medium1

Medium2

Low

SPL(dB)

43

41

38

36

LINE

PKA-A30FA

PKA-A30FAL

NOTCH

High

Low

SPL(dB)39LINE

45

90

)

bar

80

70

60

50

40

30

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0dB= 0.0002

APPROXIMATE

20

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

10

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

90

80

70

60

50

40

30

APPROXIMATE

20

THRESHOLD OF

OCTAVE BAND SOUND PRESSURE LEVEL, dB(0dB=0.0002 bar)

PKA-A36FA

PKA-A36FAL

HEARING FOR

CONTINUOUS

NOISE

10

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

NOTCH

High

Low

SPL(dB)46LINE

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

49

UNIT

3.3ft

3.3ft

MICROPHONE

WALL

25

90

)

80

bar

70

60

50

40

30

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0dB= 0.0002

APPROXIMATE

20

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

10

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

Page 26

9-2. OUTDOOR UNIT

PUHZ-HA30NHA

PUHZ-HA36NHA

90

80

70

60

MODE

COOLING

HEATING

SPL(dB)

52

53

LINE

NC-70

NC-60

MICROPHONE

3.3 ft

UNIT

50

40

30

APPROXIMATE

20

THRESHOLD OF

HEARING FOR

CONTINUOUS

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 bar)

NOISE

10

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

NC-50

NC-40

NC-30

NC-20

5 ft

GROUND

26

Page 27

10

OPTIONAL PARTS

10-1. INDOOR UNIT

Part Name Model Name Applicable model

Remote sensor (extensible) PAC-SE41TS-E

Connector for CN51

(output for remote display + pulse12V input)

Connector for CN32 (remote ON/OFF)

Connector for CN24 (Back up heating)

Connector for CN30 (LLC)

Power supply terminal kit

Decoration panel with Wired remote controller

Decoration panel

Multi-function casement

Flange for fresh air intake

High-efficiency filter element

(PAC-SH53TM-E is needed.)

i-see sensor corner panel

Wireless signal receiver

Wireless remote controller kit

Space panel

Air outlet shutter plate

L shape connection pipe

PAC-88HA-E(1pc.)

PAC-725AD(10pcs.)

PAC-SE55RA-E

PAC-SE56RA-E

PAC-SE57RA-E

PAC-SH55HR-E

PAC-SH98HR-E

PLP-42BAMD

PLP-40BAU

PAC-SH53TM-E

PAC-SH65OF-E

PAC-SH59KF-E

PAC-SA1ME-E

PAR-SA9FA-E

PAR-SW96U-E

PAC-SH48AS-E

PAC-SH51SP-E

PAC-SC84PI-E

All models

PLA-A·BA

PKA-A·GA(L)/FA(L)

PLA-A·BA

PKA-A30/36FA(L)

27

Page 28

10-2. OUTDOOR UNIT FOR PUZ-HA30/36NHA

Part Name Model Name

M-NET adapter PAC-SF80MA-E

A-control service tool PAC-SK52ST

Drain socket PAC-SG61DS-E

Air outlet guide(HA30/36 needs 2 pieces.)

Air protect guide(HA30/36 needs 2 pieces.)

Drain pan

Distribution pipe for twin use MSDD-50SR-E

PAC-SG59SG-E

PAC-SH63AG-E

PAC-SG64DP-E

HEAD OFFICE : TOKYO BLDG., 2-7-3, MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN

CCopyright 2007 MITSUBISHI ELECTRIC ENGINEERING CO., LTD.

Distributed in Nov. 2008 No.OCS12 REVISED EDITION-A PDF 6

Distributed in Oct. 2007 No.OCS12 PDF 7

Made in Japan

New publication, effective Nov. 2008

Specifications subject to change without notice.

Loading...

Loading...