Mitsubishi PUZ-A24NHA, PUZ-A24NHA-BS, PUZ-A30NHA, PUZ-A18NHA-BS, PUZ-A30NHA-BS Service Manual

...

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

SPLIT -TYPE, AIR CONDITIONERS

Outdoor unit

SERVICE MANUAL

R410A

June 2007

No.OC367

REVISED EDITION-C

[model names]

PUZ-A18NHA

PUZ-A24NHA

PUZ-A30NHA

PUZ-A36NHA

PUZ-A42NHA

PUZ-A18NHA-BS

PUZ-A24NHA-BS

PUZ-A30NHA-BS

PUZ-A36NHA-BS

PUZ-A42NHA-BS

PUY-A12NHA

PUY-A18NHA

PUY-A24NHA

PUY-A30NHA

PUY-A36NHA

PUY-A42NHA

PUY-A12NHA-BS

PUY-A18NHA-BS

PUY-A24NHA-BS

PUY-A30NHA-BS

PUY-A36NHA-BS

PUY-A42NHA-BS

[Service Ref.]

PUZ-A18NHA

PUZ-A24NHA

PUZ-A30NHA

PUZ-A36NHA

PUZ-A42NHA

PUZ-A18NHA-BS

PUZ-A24NHA-BS

PUZ-A30NHA-BS

PUZ-A36NHA-BS

PUZ-A42NHA-BS

PUY-A12NHA PUY-A12NHA

PUY-A18NHA PUY-A18NHA1

PUY-A24NHA PUY-A24NHA1

PUY-A30NHA PUY-A30NHA1

PUY-A36NHA PUY-A36NHA1

PUY-A42NHA

PUY-A12NHA

PUY-A18NHA

PUY-A24NHA

PUY-A30NHA

PUY-A36NHA

1-BS

1-BS

1-BS

1-BS

1-BS

PUY-A42NHA-BS

Revision:

• “9-2. SEPARATE INDOOR

UNIT/OUTDOOR UNIT

POWER SUPPLIES” is

deleted in REVISED

EDITION-C.

• Some descriptions have

been modified.

• Please void OC367 REVISED

EDITION-B.

1

NOTE:

• This manual describes only

service data of the outdoor

units.

• RoHS compliant products

have <G> mark on the spec

name plate.

• For servicing RoHS compliant

products, refer to the RoHS

PARTS LIST.

PUZ-A24/30/36NHA

PUY-A24/30/36NHA

CONTENTS

1. TECHNICAL CHANGES ·································2

2. REFERENCE MANUAL··································2

3. SAFETY PRECAUTION··································3

4. FEATURES ·····················································6

5. SPECIFICATIONS···········································7

6. DATA·······························································9

7. OUTLINES AND DIMENSIONS····················13

8. WIRING DIAGRAM·······································16

9. WIRING SPECIFICATIONS··························20

10.

REFRIGERANT SYSTEM DIAGRAM

11. TROUBLESHOOTING···································26

12. EASY MAINTENANCE FUNCTION··············81

13. FUNCTION SETTING····································84

14.

MONITORING THE OPERATION DATA BY THE REMOTE CONTROLLER

15. DISASSEMBLY PROCEDURE ···················102

16. PARTS LIST ················································117

17. RoHS PARTS LIST ·····································126

··············23

············92

1

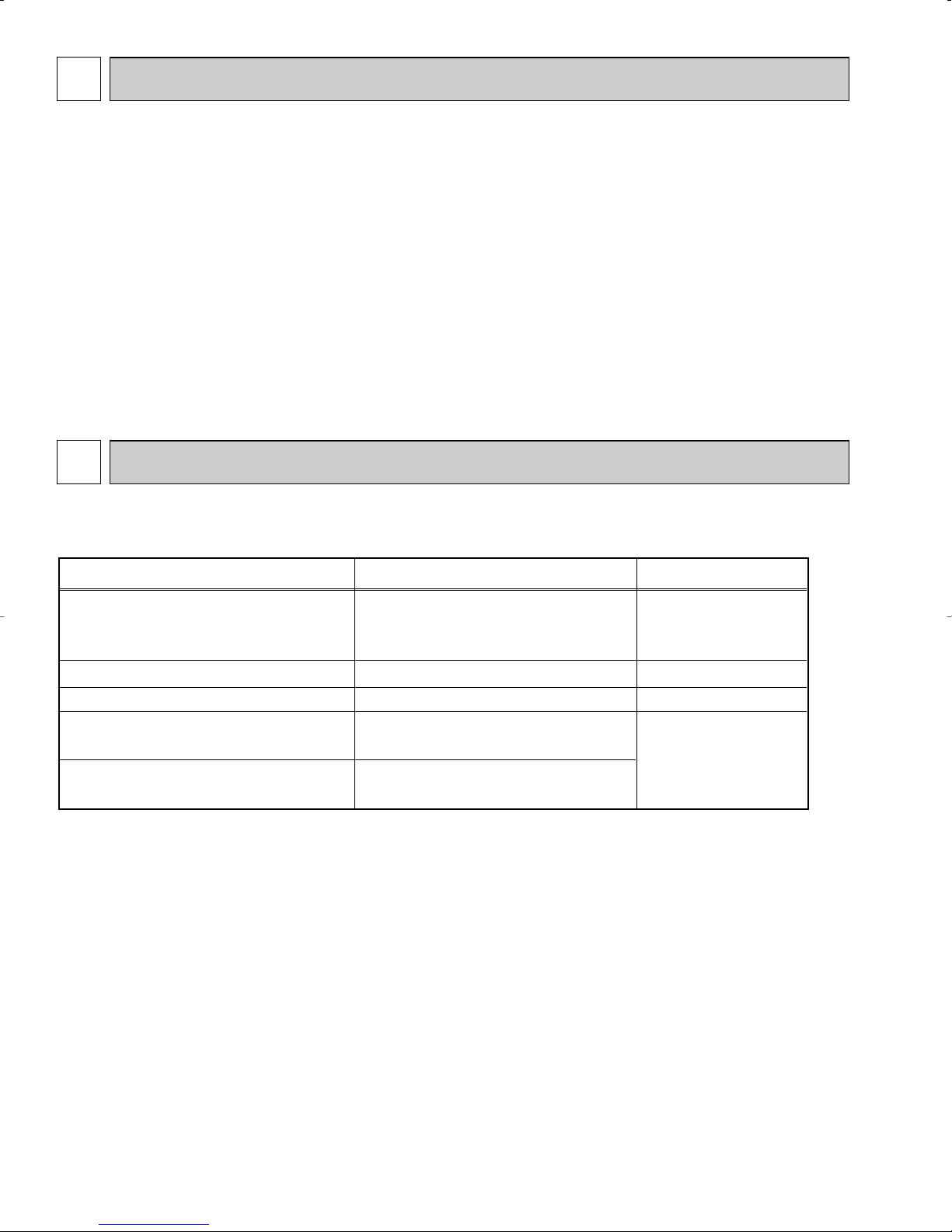

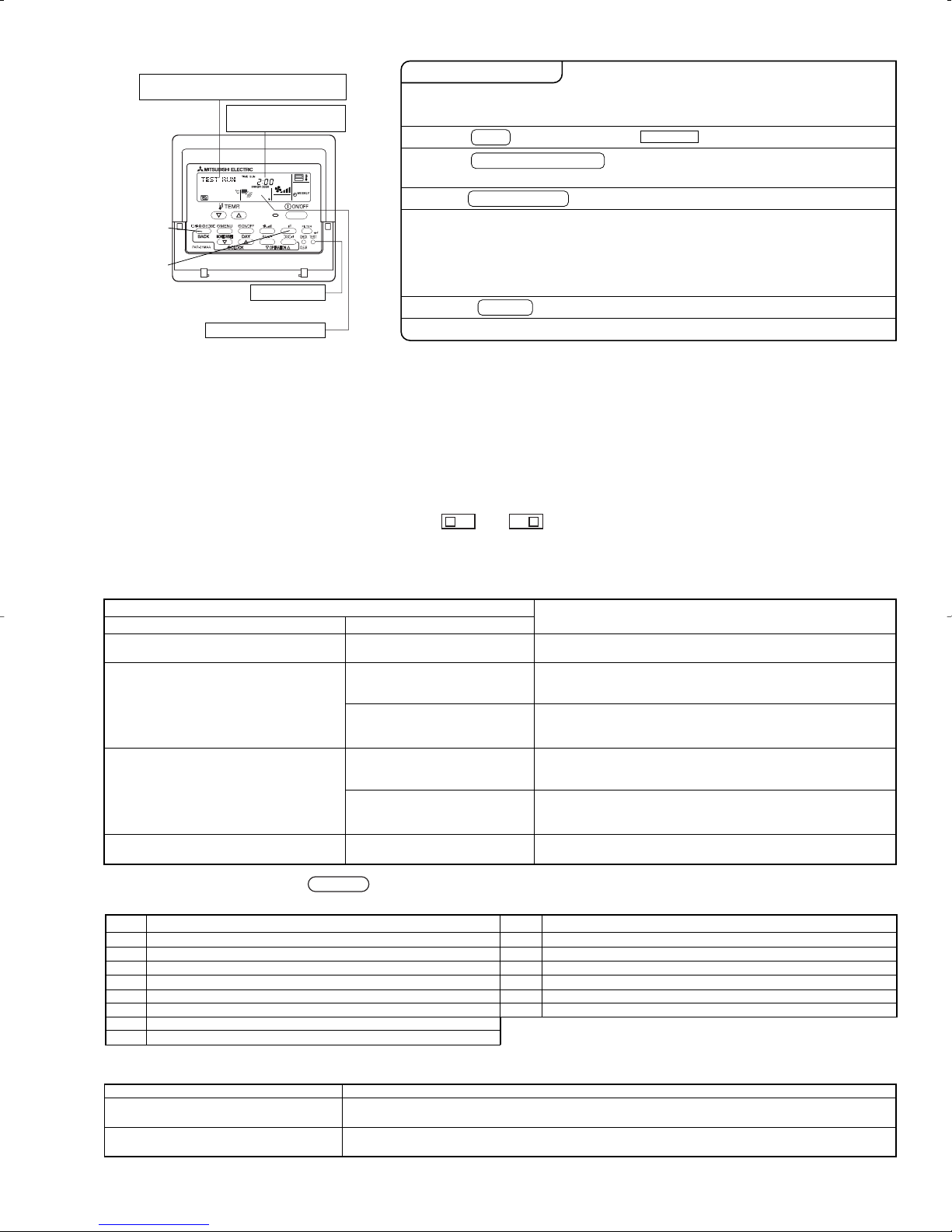

2-1. INDOOR UNIT

Model name Service Ref.

Service

Manual No.

PLA-A12/18/24/30/36/42AA PLA-A12/18/24/30/36/42AA(1) OC370

PLA-A12/18/24/30/36/42BA PLA-A12/18/24/30/36/42BA

OCH420

OCB420

(Issue scheduled in July, 2007)

PCA-A24/30/36/42GA PCA-A24/30/36/42GA(1) OC368

PKA-A12/18GA PKA-A12/18GA(1)

OC369

PKA-A12/18GAL PKA-A12/18GAL(1)

PKA-A24/30/36FA PKA-A24/30/36FA(1)

PKA-A24/30/36FAL PKA-A24/30/36FAL(1)

2-2. TECHNICAL DATA BOOK

Manual No. OCS04

TECHNICAL CHANGES

PUY-A12NHA(-BS) ➔ PUY-A12NHA1(-BS)

PUY-A18NHA(-BS) ➔ PUY-A18NHA1(-BS)

PUY-A24NHA(-BS) ➔ PUY-A24NHA1(-BS)

PUY-A30NHA(-BS) ➔ PUY-A30NHA

1(-BS)

PUY-A36NHA(-BS) ➔ PUY-A36NHA1(-BS)

• Controller circuit board(C.B.) has been changed.

2

REFERENCE MANUAL

2

3 SAFETY PRECAUTION

Use new refrigerant pipes.

Make sure that the inside and outside of refrigerant piping is clean and it has no contamination

such as sulfur hazardous for use, oxides, dirt,

shaving particles, etc.

In addition, use pipes with specified thickness.

Store the piping to be used during installation

indoors and keep both ends of the piping sealed

until just before brazing. (Leave elbow joints, etc.

in their packaging.)

Use ester oil, ether oil or alkylbenzene oil (small

amount) as the refrigerant oil applied to flares

and flange connections.

In case of using the existing pipes for R22, be careful with

the followings.

· Be sure to clean the pipes and make sure that the insides

of the pipes are clean.

· Change flare nut to the one provided with this product.

Use a newly flared pipe.

· Avoid using thin pipes.

Charge refrigerant from liquid phase of gas

cylinder.

If the refrigerant is charged from gas phase, composition

change may occur in refrigerant and the efficiency will be

lowered.

Do not use refrigerant other than R410A.

If other refrigerant (R22 etc.) is used, chlorine in refrigerant can cause deterioration of refrigerant oil etc.

Use a vacuum pump with a reverse flow check

valve.

Vacuum pump oil may flow back into refrigerant cycle and

that can cause deterioration of refrigerant oil etc.

Use the following tools specifically designed for

use with R410A refrigerant.

The following tools are necessary to use R410A refrigerant.

Keep the tools with care.

If dirt, dust or moisture enters into refrigerant cycle, that can

cause deterioration of refrigerant oil or malfunction of compressor.

Do not use a charging cylinder.

If a charging cylinder is used, the composition of refrigerant will change and the efficiency will be lowered.

Flare tool

Electronic refrigerant

charging scale

Vacuum pump adaptor

Size adjustment gauge

Gauge manifold

Torque wrench

Gas leak detector

Charge hose

Tools for R410A

Contamination inside refrigerant piping can cause deterioration of refrigerant oil etc.

If dirt, dust or moisture enters into refrigerant cycle, that can

cause deterioration of refrigerant oil or malfunction of compressor.

If large amount of mineral oil enters, that can cause deterioration of refrigerant oil etc.

Ventilate the room if refrigerant leaks during

operation. If refrigerant comes into contact with

a flame, poisonous gases will be released.

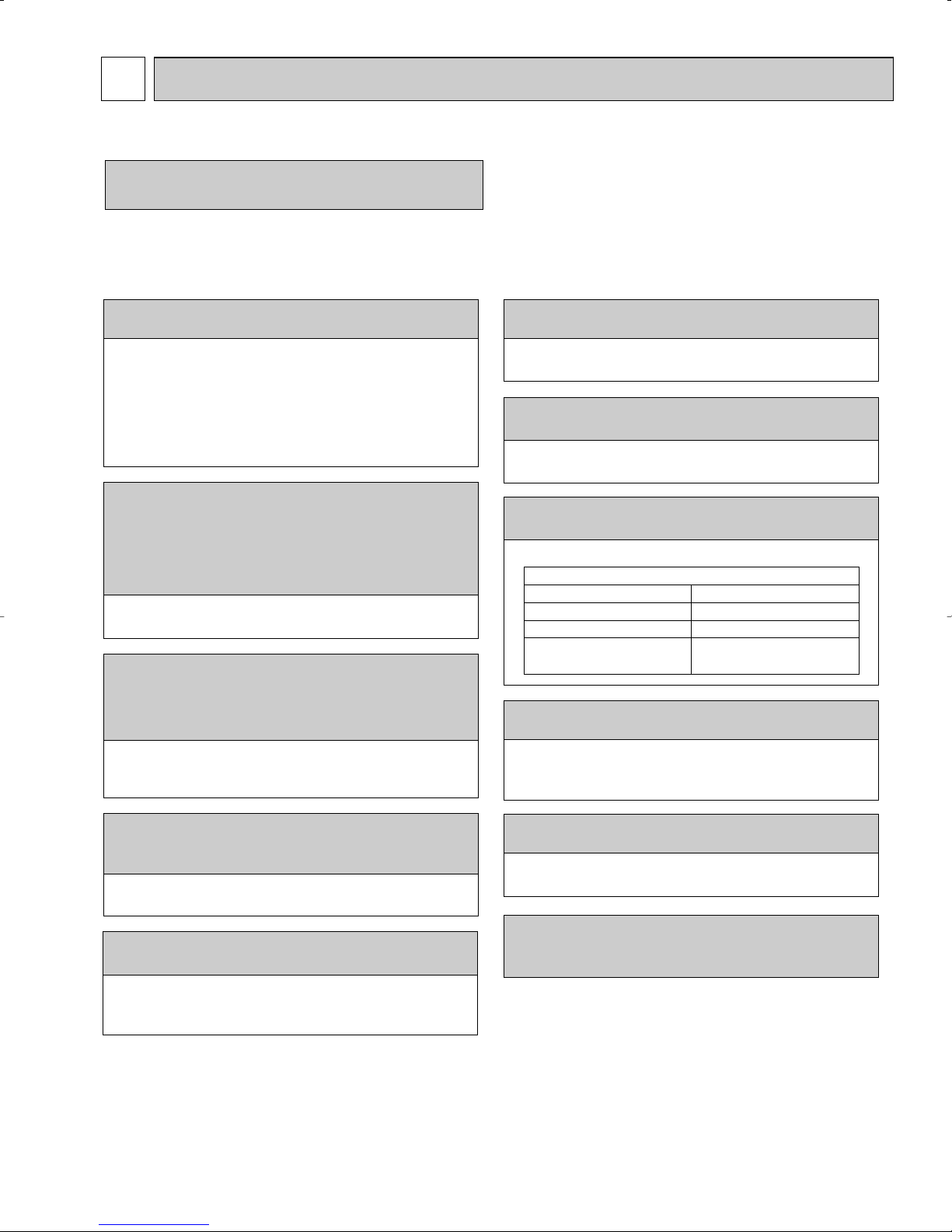

3-1. ALWAYS OBSERVE FOR SAFETY

Before obtaining access to terminals, all supply

circuits must be disconnected.

3-2. CAUTIONS RELATED TO NEW REFRIGERANT

Cautions for units utilizing refrigerant R410A

3

Gravimeter

Unit

[1] Cautions for service

(1) Perform service after collecting the refrigerant left in unit completely.

(2) Do not release refrigerant in the air.

(3) After completing service, charge the cycle with specified amount of refrigerant.

(4) When performing service, install a filter drier simultaneously.

Be sure to use a filter drier for new refrigerant.

[2] Additional refrigerant charge

When charging directly from cylinder

· Check that cylinder for R410A on the market is syphon type.

· Charging should be performed with the cylinder of syphon stood vertically. (Refrigerant is charged from liquid phase.)

[3] Service tools

Use the below service tools as exclusive tools for R410A refrigerant.

No. Specifications

1 Gauge manifold ·Only for R410A

·Use the existing fitting

·Use high-tension side pressure of 5.3MPa·G or over.

2 Charge hose ·Only for R410A

·Use pressure performance of 5.09MPa·G or over.

3 Electronic scale

4 Gas leak detector ·Use the detector for R134a, R407C or R410A.

5 Adaptor for reverse flow check ·Attach on vacuum pump.

6 Refrigerant charge base

7 Refrigerant cylinder ·Only for R410A Top of cylinder (Pink)

8 Refrigerant recovery equipment

specifications

Cylinder with syphon

.

4

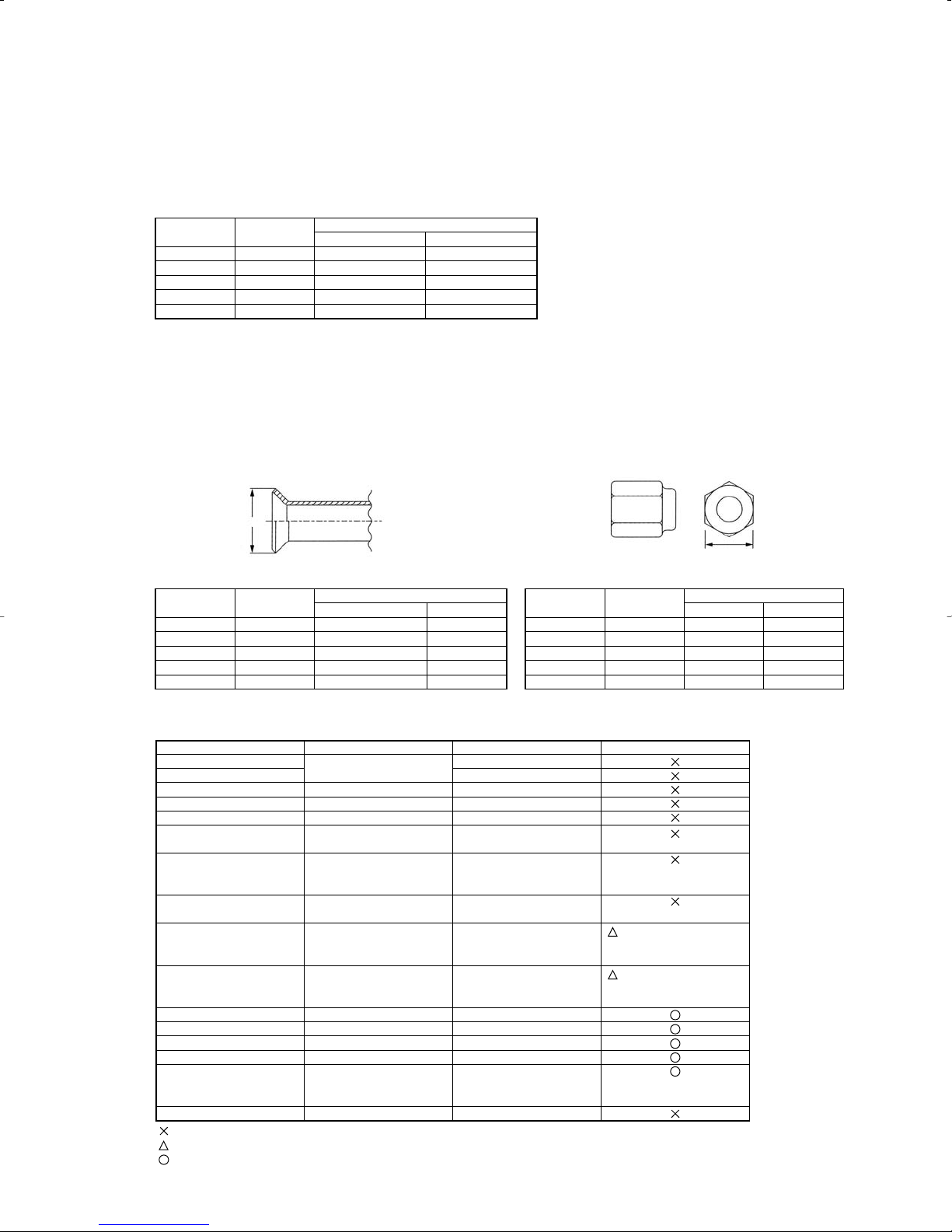

3-3. CAUTIONS FOR REFRIGERANT PIPING WORK

1/4”

3/8”

1/2”

5/8”

3/4”

6.35

9.52

12.70

15.88

19.05

0.8 [1/32"]

0.8 [1/32"]

0.8 [1/32"]

1.0 [5/128"]

—

0.8 [1/32"]

0.8 [1/32"]

0.8 [1/32"]

1.0 [5/128"]

1.0 [5/128"]

Nominal

dimensions

Diagram below: Piping diameter and thickness

Outside

diameter

(mm)

Thickness

: mm [inch]

R410A R22

1/4”

3/8”

1/2”

5/8”

3/4”

6.35

9.52

12.70

15.88

19.05

9.1 [11/32-23/64]

13.2 [1/2-33/64]

16.6 [41/64-21/32]

19.7 [49/64-25/32]

—

9.0

13.0

16.2

19.4

23.3

Nominal

dimensions

Flare cutting dimensions

Outside

diameter

Dimension A

( )

+0

-0.4

Unit : mm [inch]

R410A R22

1/4”

3/8”

1/2”

5/8”

3/4”

6.35

9.52

12.70

15.88

19.05

17.0 [43/64]

22.0 [7/8]

26.0 [1-3/64]

29.0 [1-9/64]

—

17.0

22.0

24.0

27.0

36.0

Nominal

dimensions

Flare nut dimensions

Outside

diameter

Dimension B

Unit : mm [inch]

R410A R22

Gauge manifold

Charge hose

Gas leak detector

Refrigerant recovery equipment

Refrigerant cylinder

Applied oil

Safety charger

Charge valve

Vacuum pump

Flare tool

Bender

Pipe cutter

Welder and nitrogen gas cylinder

Refrigerant charging scale

Vacuum gauge or thermistor vacuum gauge and

vacuum valve

Charging cylinder

Air purge, refrigerant charge

and operation check

Gas leak check

Collection of refrigerant

Refrigerant charge

Apply to flared section

Prevent compressor malfunction

when charging refrigerant by

spraying liquid refrigerant

Prevent gas from blowing out

when detaching charge hose

Vacuum drying and air

purge

Flaring work of piping

Bend the pipes

Cut the pipes

Weld the pipes

Charge refrigerant

Check the degree of vacuum. (Vacuum

valve prevents back flow of oil and refrigerant to thermistor vacuum gauge)

Charge refrigerant

Tool exclusive for R410A

Tool exclusive for R410A

Tool for HFC refrigerant

Tool exclusive for R410A

Tool exclusive for R410A

Ester oil and alkylbenzene

oil (minimum amount)

Tool exclusive for R410A

Tool exclusive for R410A

Tools for other refrigerants can

be used if equipped with adopter for reverse flow check

Tools for other refrigerants

can be used by adjusting

flaring dimension

Tools can be used for other refrigerants

Tools can be used for other refrigerants

Tools can be used for other refrigerants

Tools can be used for other refrigerants

Tools can be used for other

refrigerants

Tool exclusive for R410A

Tools and materials Use R410A tools Can R22 tools be used?

(Usable if equipped

with adopter for rever se flow)

(Usable by adjusting

flaring dimension)

: Prepare a new tool. (Use the new tool as the tool exclusive for R410A.)

: Tools for other refrigerants can be used under certain conditions.

: Tools for other refrigerants can be used.

New refrigerant R410A is adopted for replacement inverter series. Although the refrigerant piping work for R410A is

same as for R22, exclusive tools are necessary so as not to mix with different kind of refrigerant. Furthermore as the

working pressure of R410A is 1.6 time higher than that of R22, their sizes of flared sections and flare nuts are different.

1Thickness of pipes

Because the working pressure of R410A is higher compared to R22, be sure to use refrigerant piping with thickness

shown below. (Never use pipes of 0.7mm [7/256 inch] or below.)

2Dimensions of flare cutting and flare nut

The component molecules in HFC refrigerant are smaller compared to conventional refrigerants. In addition to that,

R410A is a refrigerant, which has higher risk of leakage because of its working pressure is higher than that of other

refrigerants. Therefore, to enhance air tightness and intensity, flare cutting dimension of copper pipe for R410A has

been specified separately from the dimensions for other refrigerants as shown below. The dimension B of flare nut for

R410A also has partly been changed to increase intensity as shown below. Set copper pipe correctly referring to copper pipe flaring dimensions for R410A below. For 1/2” and 5/8”, the dimension B changes.

Use torque wrench corresponding to each dimension.

Dimension A

3Tools for R410A (The following table shows whether conventional tools can be used or not.)

5

Dimension B

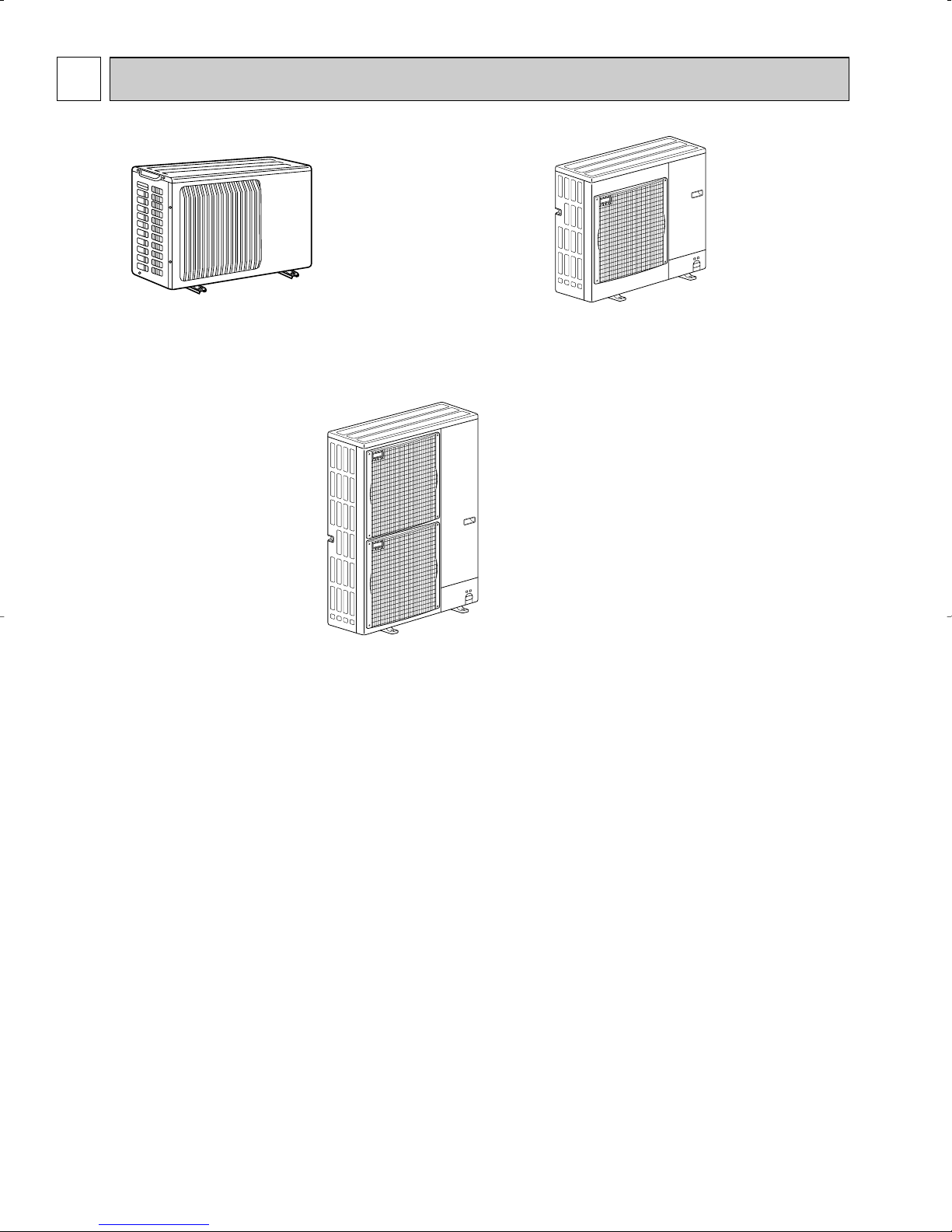

4 FEATURES

PUZ-A18NHA

PUZ-A18NHA-BS

PUY-A12/18NHA

PUY-A12/18NHA

1

PUY-A12/18NHA1-BS

PUZ-A24/30/36NHA

PUZ-A24/30/36NHA-BS

PUY-A24/30/36NHA

PUY-A24/30/36NHA

1

PUY-A24/30/36NHA1-BS

PUZ-A42NHA

PUZ-A42NHA-BS

PUY-A42NHA

PUY-A42NHA-BS

CHARGELESS SYSTEM

PRE-CHARGED REFRIGERANT IS SUPPLIED FOR PIPING LENGTH AT SHIPMENT.

(Max. 100ft, 30m (A42) / Max. 70ft, 20m (A12-36))

The refrigerant circuit with LEV(Linear Expansion Valve) and accumulator always control the optimal refrigerant level

regardless of the length (A42: 100ft, 30m max. / A12-36: 70ft, 20m max. and 16ft, 5m min.) of piping. The additional

refrigerant charging work during installation often causes problems.

It is completely eliminated by chargeless system. This unique system improves the quality and reliability of the work

done. It also helps to speed up the installation time.

6

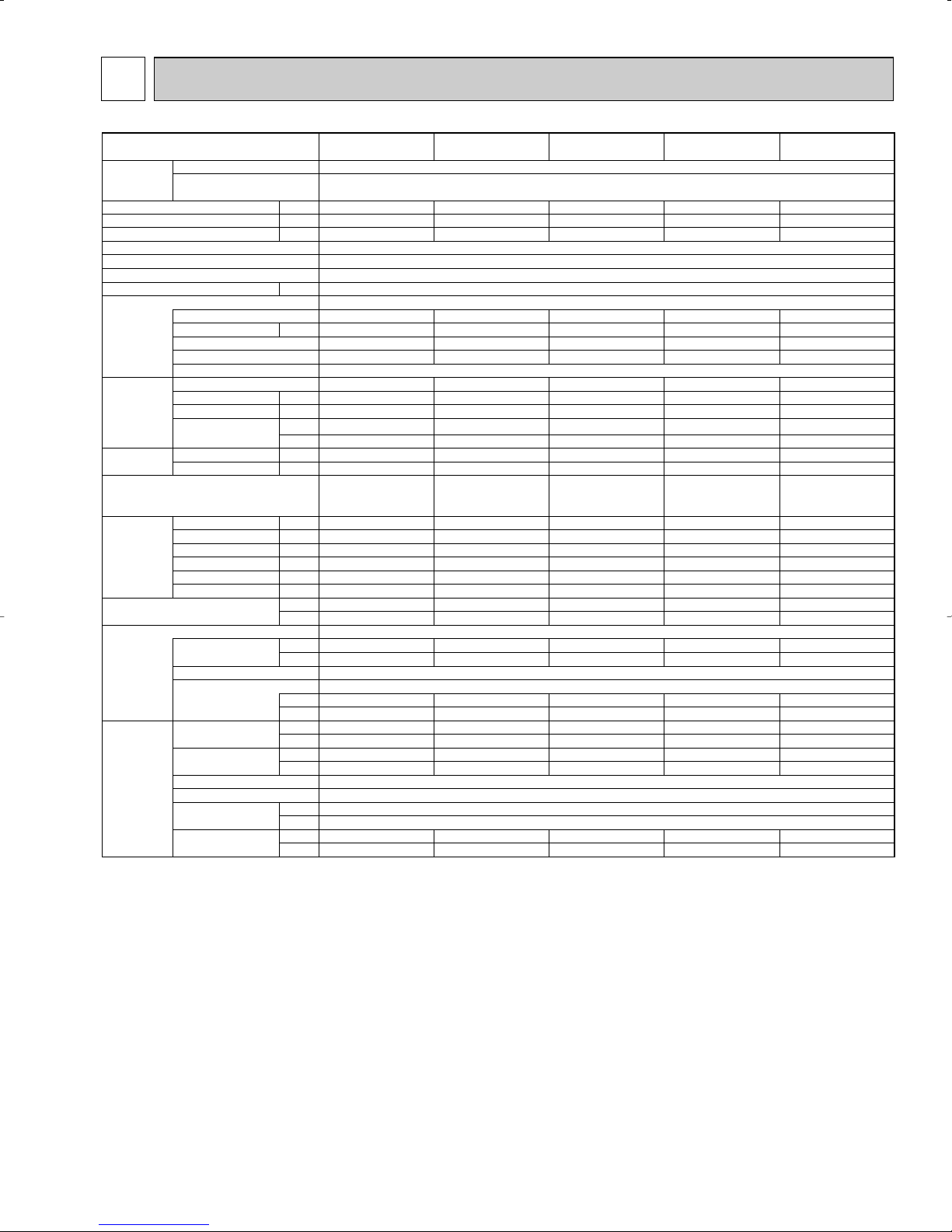

5 SPECIFICATIONS

Service Ref. PUZ-A18NHA PUZ-A24NHA PUZ-A30NHA PUZ-A36NHA PUZ-A42NHA

Power supply Phase Single

MCA A1318252526

MOCP A 20 30 40 40 40

Breaker size A 15 25 30 30 30

External finish Munsell 3Y 7.8/1.1

Heat exchanger Plate fin coil

Defrost method Reverse cycle

Crankcase heater

Compressor Hermetic

Fan Fan(drive) o No. Propeller fan o 1 Propeller fan o 1 Propeller fan o 1 Propeller fan o 1 Propeller fan o 2

Sound level Cooling dB 46 48 48 48 51

Protection devices

Dimension W mm 800 950 950 950 950

Weight kg 45 75 75 75 121

Refrigerant R410A

Refrigerant Pipe size OD mm 6.35 9.52 9.52 9.52 9.52

piping Liquid in. 1/4 3/8 3/8 3/8 3/8

Cycle 60Hz

Voltage 208/230V

Model SNB130FPBM1 TNB220FLDM TNB220FLDM TNB220FLDM ANV33FDDMT

Motor output kW 0.85 1.3 1.3 1.3 2.5

Starter type Line start

Fan motor output

Fan motor

Airflow m

Heating dB 47 50 50 50 55

D mm 300+23 330+30 330+30 330+30 330+30

H mm 600 943 943 943 1350

W in. 31-1/2 37-12/32 37-12/32 37-12/32 37-12/32

D in. 11-13/16 + 7/8 13 + 1-3/16 13 + 1-3/16 13 + 1-3/16 13 + 1-3/16

H in. 23-5/8 37-1/8 37-1/8 37-1/8 53-5/32

Charged kg 1.7 2.7 2.7 2.7 4.5

Control Linear expansion valve

Oil Model Ester (MEL56

Charged L 0.65 0.87 0.87 0.87 1.4

Pipe size OD mm 12.7 15.88 15.88 15.88 15.88

Gas in. 1/2 5/8 5/8 5/8 5/8

Connection method Indoor Flared

Connection method Outdoor Flared

Height difference m Max. 30

IU - OU ft Max. 100

Piping length m Max. 30 Max. 50 Max. 50 Max. 50 Max. 50

R.L.A. 12 12 12 12 20

L.R.A. 14 14 17.5 17.5 27.5

F.L.A.

PUZ-A18NHA-BS PUZ-A24NHA-BS PUZ-A30NHA-BS PUZ-A36NHA-BS PUZ-A42NHA-BS

kW

kW

3

/min 34 55 55 55 100

CFM 1200 1940 1940 1940 3530

lbs 99 165 165 165 267

lbs 3 + 12/16 6 6 6 10

oz 20 28 28 28 45

ft Max. 100 Max. 165 Max. 165 Max. 165 Max. 165

0.040 0.075 0.075 0.075 0.086 + 0.086

0.35 0.75 0.75 0.75 0.40 + 0.40

HP switch HP switch HP switch HP switch HP switch

Discharge thermo Discharge thermo Discharge thermo Discharge thermo Discharge thermo

-

LP switch

)

7

Service Ref. PUY-A12NHA PUY-A18NHA PUY-A24NHA PUY-A30NHA PUY-A36NHA

PUY-A42NHA

PUY-A12NHA

1 PUY-A18NHA1 PUY-A24NHA1 PUY-A30NHA1 PUY-A36NHA1

PUY-A12NHA1-BS PUY-A18NHA1-BS PUY-A24NHA1-BS PUY-A30NHA1-BS PUY-A36NHA1-BS

PUY-A42NHA-BS

Power supply

Phase Single

Cycle 60Hz

Voltage 208/230V

MCA A131318252526

MOCP A 15 20 30 40 40 40

Breaker size A 15 15 25 30 30 30

External finish Munsell 3Y 7.8/1.1

Heat exchanger Plate fin coil

Defrost method Crankcase heater

kW

-

Compressor Hermetic

Model SNB130FPBM1 SNB130FPBM1 TNB220FLDM TNB220FLDM TNB220FLDM ANV33FDDMT

Motor output kW 0.85 0.85 1.3 1.3 1.3 2.5

R.L.A. 12 12 12 12 12 20

L.R.A. 14 14 14 17.5 17.5 27.5

Starter type Line start

Fan

Fan (drive) o No.

Propeller fan

o

1 Propeller fan

o

1 Propeller fan

o

1 Propeller fan

o

1 Propeller fan

o

1 Propeller fan

o

2

Fan motor output

kW

0.040 0.040 0.075 0.075 0.075 0.086 + 0.086

Fan motor

F.L.A.

0.35 0.35 0.75 0.75 0.75 0.40 + 0.40

Airflow m

3

/min 34 34 55 55 55 100

CFM 1200 1200 1940 1940 1940 3530

Sound level Cooling dB 46 46 48 48 48 51

Heating dB – – – – – –

Protection devices HP switch HP switch HP switch HP switch HP switch HP switch

LP switch

Discharge thermo Discharge thermo Discharge thermo Discharge thermo Discharge thermo Discharge thermo

Dimension W mm 800 800 950 950 950 950

D mm 300+23 300+23 330+30 330+30 330+30 330+30

H mm 600 600 943 943 943 1350

W in. 31-1/2 31-1/2 37-12/32 37-12/32 37-12/32 37-12/32

D in. 11-13/16 + 7/8 11-13/16 + 7/8 13 + 1-3/16 13 + 1-3/16 13 + 1-3/16 13 + 1-3/16

H in. 23-5/8 23-5/8 37-1/8 37-1/8 37-1/8 53-5/32

Weight kg 41 44 74 74 74 120

lbs 90 97 163 163 163 265

Refrigerant R410A

Charged kg 1.3 1.7 2.7 2.7 2.7 4.5

lbs 2 +14/16 3 + 12/16 6 6 6 10

Control Linear expansion valve

Oil Model Ester (MEL56

)

Charged L 0.65 0.65 0.87 0.87 0.87 1.4

oz 20 20 28 28 28 45

Refrigerant Pipe size OD mm 6.35 6.35 9.52 9.52 9.52 9.52

piping Liquid in. 1/4 1/4 3/8 3/8 3/8 3/8

Pipe size OD mm 12.7 12.7 15.88 15.88 15.88 15.88

Gas in. 1/2 1/2 5/8 5/8 5/8 5/8

Connection method Indoor Flared

Connection method Outdoor

Flared

Height difference m Max. 30 Max. 30 Max. 30 Max. 30 Max. 30 Max. 30

IU - OU ft Max. 100 Max. 100 Max. 100 Max. 100 Max. 100 Max. 100

Piping length m Max. 30 Max. 30 Max. 50 Max. 50 Max. 50 Max. 50

ft Max. 100 Max. 100 Max. 165 Max. 165 Max. 165 Max. 165

8

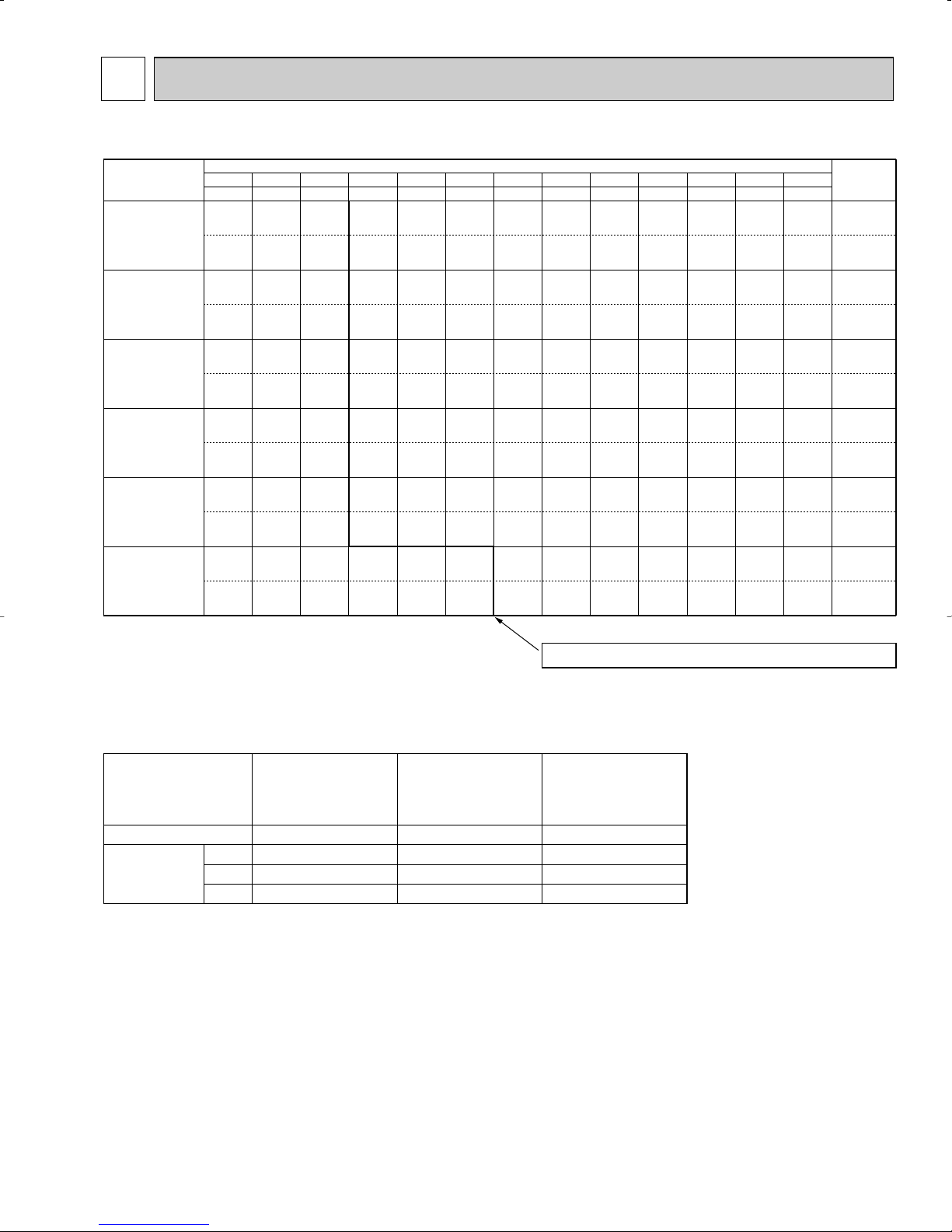

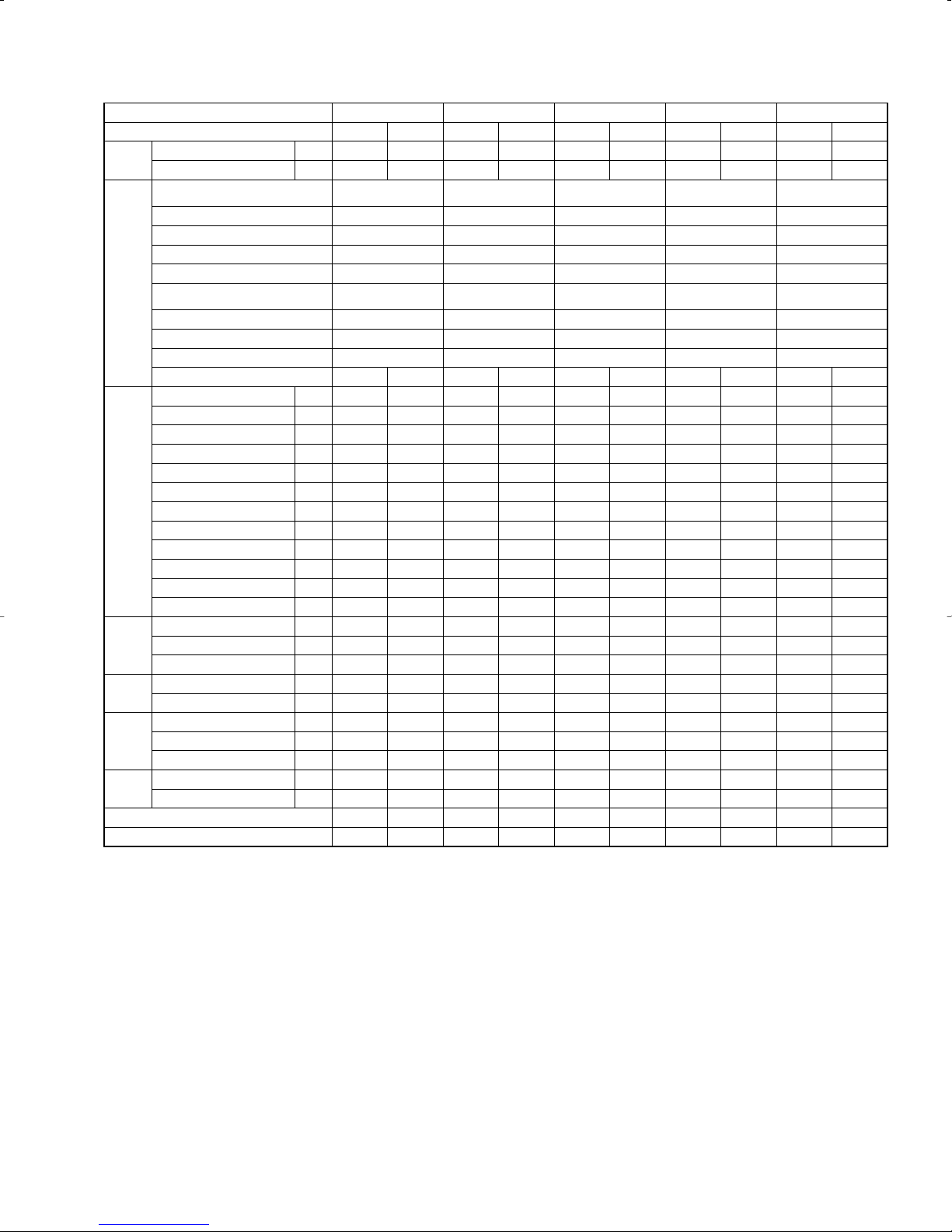

Piping Length (one way

)

Charged

Factory

Service Ref. 50ft 60ft 70ft 80ft 90ft 100ft 110ft 120ft 130ft 140ft 150ft 160ft 165ft

15m 18m 21m 24m 27m 30m 33m 37m 40m 43m 46m 49m 50m

PUY-A12NHA

1-BS

PUY-A12NHA

PUY-A12NHA

1

42 oz 44 oz 46 oz 48 oz 50 oz 52 oz - - - - - - - 46 oz

1.2 kg 1.2 kg 1.3 kg 1.4 kg 1.4 kg 1.5 kg - - - - - - - 1.3 kg

PUY-A18NHA

1-BS

PUY-A18NHA

PUY-A18NHA

1

PUZ-A18NHA-BS

PUZ-A18NHA

56 oz 58 oz 60 oz 62 oz 64 oz 66 oz - - - - - - - 60 oz

1.6 kg 1.6 kg 1.7 kg 1.8 kg 1.8 kg 1.9 kg - - - - - - - 1.7 kg

PUY-A24NHA

1-BS

PUY-A24NHA

PUY-A24NHA

1

PUZ-A24NHA-BS

PUZ-A24NHA

84 oz 90 oz 96 oz 102 oz 108 oz 114 oz 120 oz 126 oz 132 oz 138 oz 144 oz 150 oz 156 oz 96 oz

2.4 kg 2.6 kg 2.7kg 2.9 kg 3.1 kg 3.2 kg 3.4 kg 3.6 kg 3.7 kg 3.9 kg 4.1 kg 4.3 kg 4.4 kg 2.7 kg

PUY-A30NHA

1-BS

PUY-A30NHA

PUY-A30NHA

1

PUZ-A30NHA-BS

PUZ-A30NHA

84 oz 90 oz 96 oz 102 oz 108 oz 114 oz 120 oz 126 oz 132 oz 138 oz 144 oz 150 oz 156 oz 96 oz

2.4 kg 2.6 kg 2.7kg 2.9 kg 3.1 kg 3.2 kg 3.4 kg 3.6 kg 3.7 kg 3.9 kg 4.1 kg 4.3 kg 4.4 kg 2.7 kg

PUY-A36NHA

1-BS

PUY-A36NHA

PUY-A36NHA

1

PUZ-A36NHA-BS

PUZ-A36NHA

84 oz 90 oz 96 oz 102 oz 108 oz 114 oz 120 oz 126 oz 132 oz 138 oz 144 oz 150 oz 156 oz 96 oz

2.4 kg 2.6 kg 2.7kg 2.9 kg 3.1 kg 3.2 kg 3.4 kg 3.6 kg 3.7 kg 3.9 kg 4.1 kg 4.3 kg 4.4 kg 2.7 kg

PUY-A42NHA-BS

PUY-A42NHA

PUZ-A42NHA-BS

PUZ-A42NHA

132 oz 136 oz 142 oz 148 oz 154 oz 160 oz 166 oz 172 oz 178 oz 184 oz 190 oz 196 oz 202 oz 160 oz

3.7 kg 3.9 kg 4.0 kg 4.2 kg 4.4 kg 4.5 kg 4.7 kg 4.9 kg 5.0 kg 5.2 kg 5.4 kg 5.6 kg 5.7 kg 4.5 kg

Longer pipe than 70 or 100 ft, additional charge is required.

PUZ-A42NHA

Service Ref.

PUZ-A42NHA-BS

PUY-A42NHA

PUY-A42NHA-BS

Compressor model SNB130FPBM1 TNB220FLDM ANV33FDDMT

(')

Winding Registance

U-V 0.320 0.880 0.266

U-W 0.320 0.880 0.266

W-V 0.320 0.880 0.266

(

at 20;, 68˚F

)

PUY-A12,18NHA1-BS

PUY-A12,18NHA

PUY-A12,18NHA

1

PUZ-A18NHA-BS

PUZ-A18NHA

PUY-A24,30,36NHA

1-BS

PUY-A24,30,36NHA

PUY-A24,30,36NHA

1

PUZ-A24,30,36NHA-BS

PUZ-A24,30,36NHA

6

DATA

6-1. REFILLING REFRIGERANT CHARGE (R410A : oz, kg)

6-2. COMPRESSOR TECHNICAL DATA

9

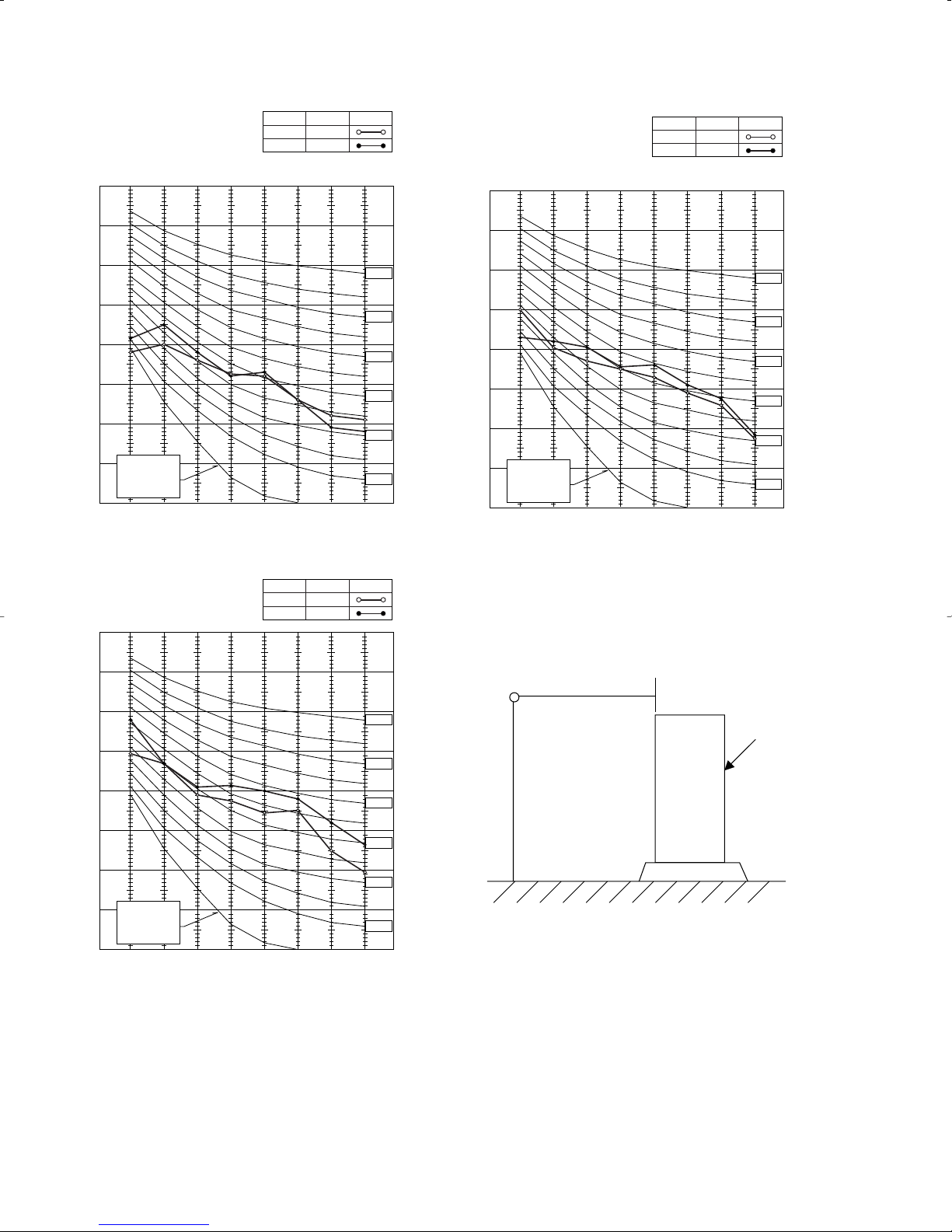

6-3. NOISE CRITERION CURVES

5ft

3.3ft

MICROPHONE

UNIT

GROUND

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

BAND CENTER FREQUENCIES, Hz

PUY-A12/18NHA

PUY-A12/18NHA1

PUY-A12/18NHA1-BS

PUZ-A18NHA

PUZ-A18NHA-BS

COOLING

MODE

HEATING

46

SPL(dB)

47

LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

BAND CENTER FREQUENCIES, Hz

PUY-A24/30/36NHA

PUY-A24/30/36NHA

1

PUY-A24/30/36NHA1-BS

PUZ-A24/30/36NHA

PUZ-A24/30/36NHA-BS

COOLING

MODE

HEATING

48

SPL(dB)

50

LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

BAND CENTER FREQUENCIES, Hz

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

PUY-A42NHA

PUY-A42NHA-BS

PUZ-A42NHA

PUZ-A42NHA-BS

COOLING

MODE

HEATING

51

SPL(dB)

55

LINE

10

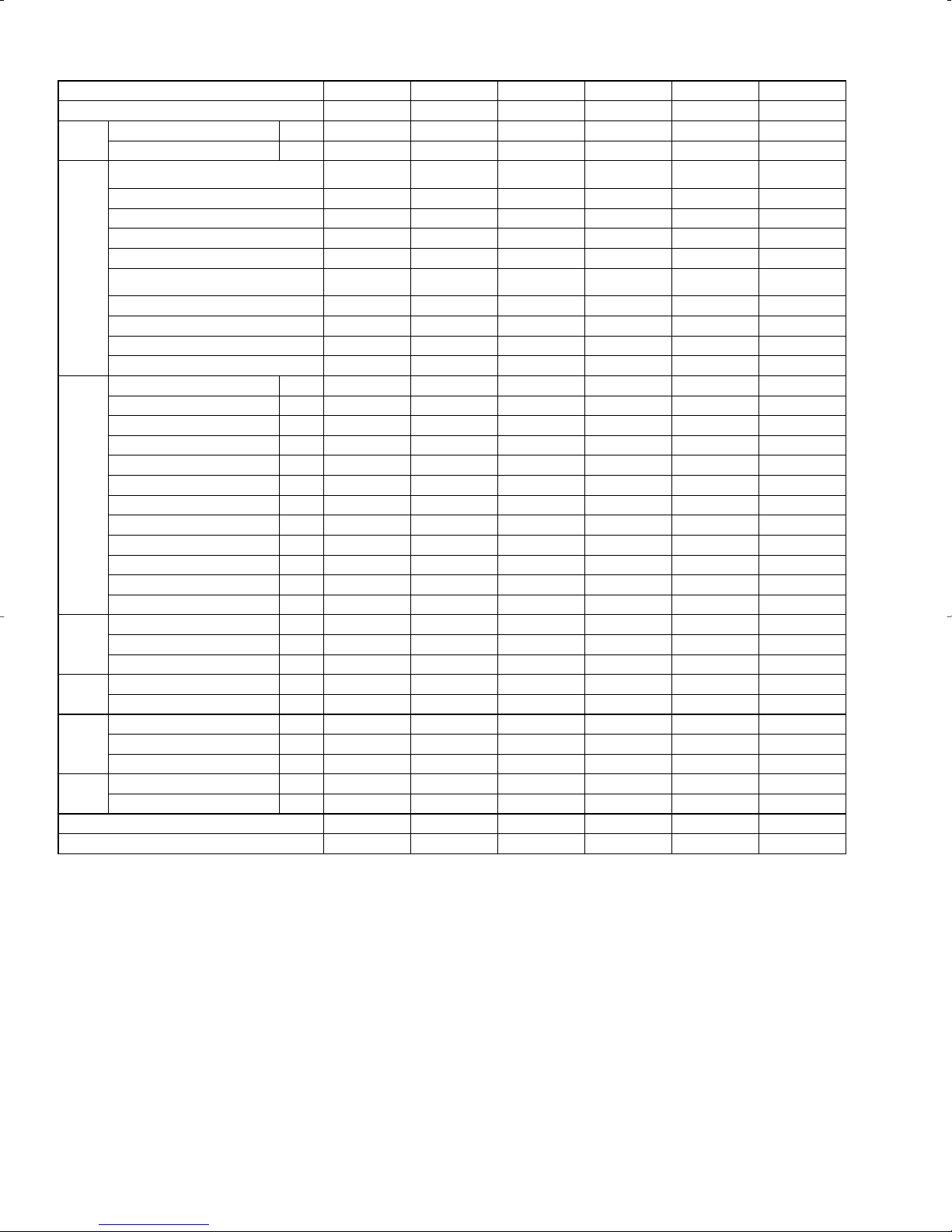

6-4. STANDARD OPERATION DATA

6-4-1. Heat pump

Representative matching

PKA-A18GA PKA-A24FA PKA-A30FA PKA-A36FA PLA-A42AA

Mode

COOLING HEATING COOLING HEATING COOLING HEATING COOLING HEATING COOLING HEATING

Total Capacity BTU/h

18,000 19,000 24,000 26,000 30,000 32,000 34,200 37,000 42,000 45,000

Input W

2,240 2,130 2,650 2,570 4,400 3,660 5,030 3,610 4,820 5,070

Electrical circuit

Indoor unit model

PKA-A18GA PKA-A24FA PKA-A30FA PKA-A36FA PLA-A42AA

Phase

Single Single Single Single Single

Cycle

60Hz 60Hz 60Hz 60Hz 60Hz

Voltage

230V 230V 230V 230V 230V

Current

0.33A 0.43A 0.43A 0.52A 1.25A

Outdoor unit model

PUZ-A18NHA PUZ-A24NHA PUZ-A30NHA PUZ-A36NHA PUZ-A42NHA

Phase

Single Single Single Single Single

Cycle

60Hz 60Hz 60Hz 60Hz 60Hz

Voltage

230V 230V 230V 230V 230V

Current

9.71A 9.22A 11.45A 11.09A 19.29A 15.98A 22.03A 15.66A 20.35A 21.48A

Refrigerant circuit

Discharge pressure MPa 3.14 3.38 2.85 3.03 2.99 3.50 3.22 2.95 2.85 3.28

Suction pressure MPa 0.81 0.64 0.86 0.69 0.72 0.65 0.76 0.60 0.83 0.71

Discharge temperature : 81.6 89.0 72.6 79.3 83.7 92.4 88.8 83.0 72.9 86.1

Condensing temperature : 52.0 51.6 46.8 49.6 49.1 55.9 51.5 48.0 46.8 52.3

Suction temperature : 4.8 -1.2 7.0 -0.3 1.2 -1.6 3.3 -2.0 4.6 0.1

Ref. Pipe length m 7.6 7.6 7.6 7.6 7.6 7.6 7.6 7.6 7.6 7.6

Discharge pressure PSIG 455 490 414 440 434 508 467 428 414 475

Suction pressure PSIG 118 93 125 99 104 94 110 87 121 103

Discharge temperature ˚F 179 192 163 175 183 198 192 181 163 187

Condensing temperature ˚F 126 125 116 121 120 133 125 118 116 126

Suction temperature ˚F 41 30 45 31 34 29 38 28 40 32

Ref. Pipe length ft 25 25 25 25 25 25 25 25 25 25

side

Indoor

Intake air temperature DB : 26.7 21.1 26.7 21.1 26.7 21.1 26.7 21.1 26.7 21.1

Intake air temperature WB : 19.4 15.6 19.4 15.6 19.4 15.6 19.4 15.6 19.4 15.6

Discharge air temperature DB : 12.2 45.4 13.7 40.5 12.1 45.7 13.7 40.9 12.0 45.8

side

Outdoor

Intake air temperature DB : 35 8.3 35 8.3 35 8.3 35 8.3 35 8.3

Intake air temperature WB : 23.9 6.1 23.9 6.1 23.9 6.1 23.9 6.1 23.9 6.1

side

Indoor

Intake air temperature DB ˚F 80 70 80 70 80 70 80 70 80 70

Intake air temperature WB ˚F 67 60 67 60 67 60 67 60 67 60

Discharge air temperature DB ˚F 54 114 57 105 54 114 57 106 54 114

side

Outdoor

Intake air temperature DB ˚F 95 47 95 47 95 47 95 47 95 47

Intake air temperature WB ˚F 75 43 75 43 75 43 75 43 75 43

SHF 0.70 0.78 0.70 0.77 0.71

BF 0.12

–

–

–

–

–

–

–

–

–

– 0.10 0.11 0.11 0.09

11

Representative matching

PKA-A12GA PKA-A18GA PKA-A24FA PKA-A30FA PKA-A36FA PLA-A42AA

Mode

COOLING COOLING COOLING COOLING COOLING COOLING

Total Capacity BTU/h

12,000 18,000 24,000 30,000 34,200 42,000

Input W

1,210 2,240 2,650 4,400 5,030 4,820

Electrical circuit

Indoor unit model

PKA-A12GA PKA-A18GA PKA-A24FA PKA-A30FA PKA-A36FA PLA-A42AA

Phase

Single Single Single Single Single Single

Cycle

60Hz 60Hz 60Hz 60Hz 60Hz 60Hz

Voltage

230V 230V 230V 230V 230V 230V

Current

0.33A 0.33A 0.43A 0.43A 0.52A 1.25A

Outdoor unit model

PUY-A12NHA PUY-A18NHA PUY-A24NHA PUY-A30NHA PUY-A36NHA PUY-A42NHA

Phase

Single Single Single Single Single Single

Cycle

60Hz 60Hz 60Hz 60Hz 60Hz 60Hz

Voltage

230V 230V 230V 230V 230V 230V

Current

5.09A 9.71A 11.45A 19.29A 22.03A 20.35A

Refrigerant circuit

Discharge pressure MPa 2.99 3.14 2.85 2.99 3.22 2.85

Suction pressure MPa 1.00 0.81 0.86 0.72 0.76 0.83

Discharge temperature : 72.8 81.6 72.6 83.7 88.8 72.9

Condensing temperature : 50.7 52.0 46.8 49.1 51.5 46.8

Suction temperature : 11.1 4.8 7.0 1.2 3.3 4.6

Ref. Pipe length m 7.6 7.6 7.6 7.6 7.6 7.6

Discharge pressure PSIG 434 455 414 434 467 414

Suction pressure PSIG 145 118 125 104 110 121

Discharge temperature F 163 179 163 183 192 163

Condensing temperature F 123 126 116 120 125 116

Suction temperature F 52 41 45 34 38 40

Ref. Pipe length ft 25 25 25 25 25 25

side

Indoor

Intake air temperature DB : 26.7 26.7 26.7 26.7 26.7 26.7

Intake air temperature WB : 19.4 19.4 19.4 19.4 19.4 19.4

Discharge air temperature DB : 14.8 12.2 13.7 12.1 13.7 12.0

side

Outdoor

Intake air temperature DB : 35 35 35 35 35 35

Intake air temperature WB : 23.9 23.9 23.9 23.9 23.9 23.9

side

Indoor

Intake air temperature DB ˚F 80 80 80 80 80 80

Intake air temperature WB ˚F 67 67 67 67 67 67

Discharge air temperature DB ˚F 59 54 57 54 57 54

side

Outdoor

Intake air temperature DB ˚F 95 95 95 95 95 95

Intake air temperature WB ˚F 75 75 75 75 75 75

SHF 0.86 0.70 0.78 0.70 0.77 0.71

BF 0.09 0.12 0.10 0.11 0.11 0.09

6-4-2. Cooling only

12

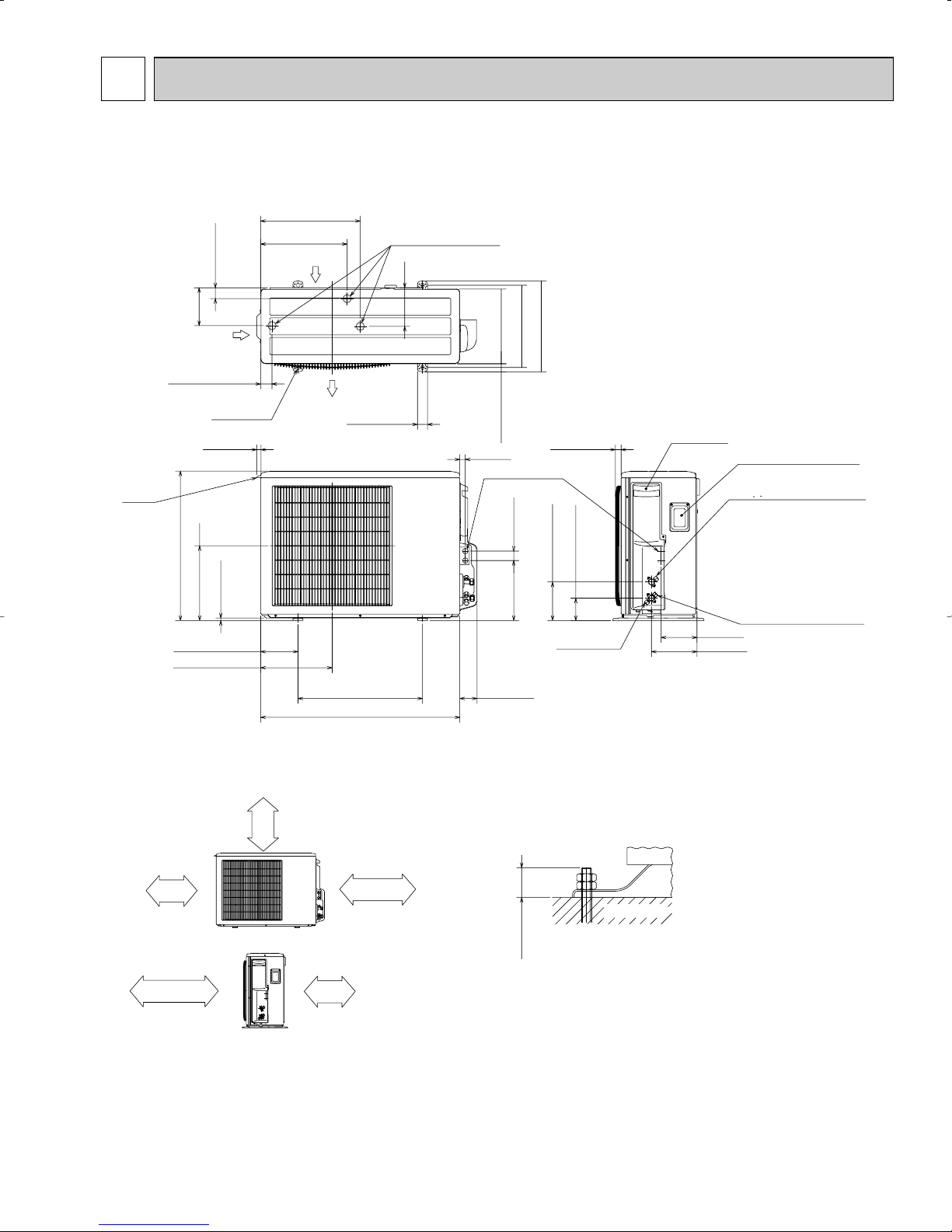

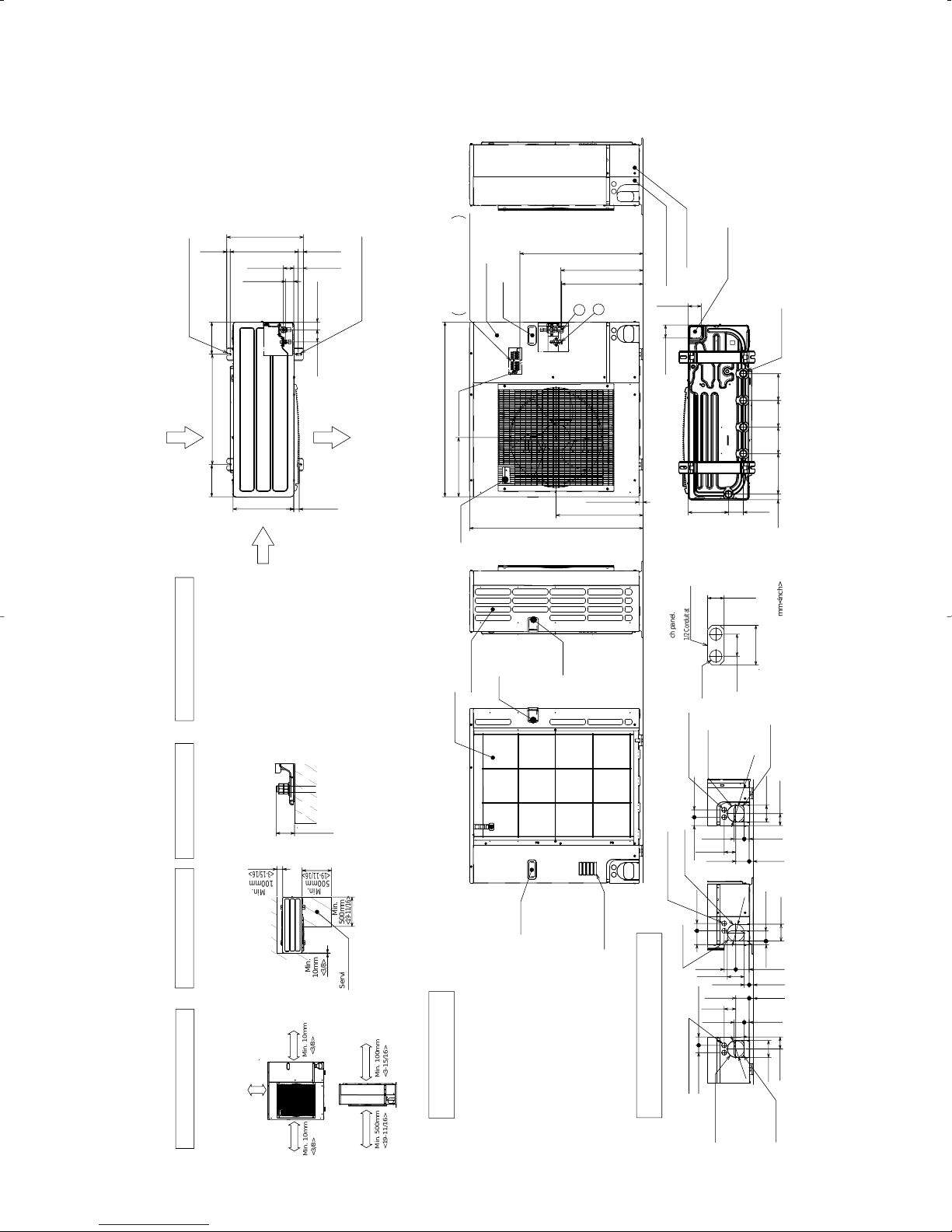

1/2 conduit hole

144<5-21/32>

2-ø22.2<7/8>

22<7/8>

38<1-1/2>241<9-1/2>

Min.100mm<3-15/16>

Piping and wiring connection can

be made from the rear direction only.

*1 In the place where short cycle tends to occur,cooling and heating

capacity and power consumption might get lowered by 10%. Air outlet

guide (optional PAC-SG58SG-E) will help them improve.

*2 If air is discharged to the wall, the surface might get stained.

2 sides should be open in

the right, left and rear side.

Min.100mm<3-15/16> as long as

no obstacle is placed on the

rear and light-and-left sides

of the unit

*1

*2

*1

Air intake

Air outlet

4-oval hole

Air intake

Service panel

Connection for liquid pipe

Service panel for charge plug

Service port

Connection for gas pipe

Min.100mm<3-15/16>

Min.500mm<19-11/16>

Min.350mm<13-25/32>

Basically

open

Max.

<Foundation bolt height>

FOUNDATION

Please secure the unit firmly

with 4 foundation M10<W3/8> bolts.

(Bolts, washers and nut must

be purchased locally.)

18mm<23/32>

[33<1-5/16> drain hole

43.6<1-23/32>

152<6>

155

400<15-25/32>

347.5<13-11/16>

45.4<1-25/32>

365<14-3/8>

330<13>

300<11-13/16>

40<1-9/16>

Handle

600<23-5/8>

10<3/8>

300<11-13/16>

150<5-29/32>

287.5<11-11/32>

500<19-11/16>

800<31-1/2>

69<2-23/32>

183<7-7/32>

90<3-17/32>

155<6-3/32>

23<29/32>

32.5<1-9/32>

18<23/32>

FLARE [12.7<1/2F>

FLARE [6.35<1/4F>

Installation bolt pitch

PIPING-WIRING DIRECTION

Minimum installation space for outdoor unit

Free space around the outdoor unit

(basic example)

FOUNDATION BOLTS

7

OUTLINES AND DIMENSIONS

OUTDOOR UNIT

Unit : mm<inch>

PUZ-A18NHA PUZ-A18NHA-BS PUY-A12/18NHA PUY-A12/18NHA1 PUY-A12/18NHA1-BS

13

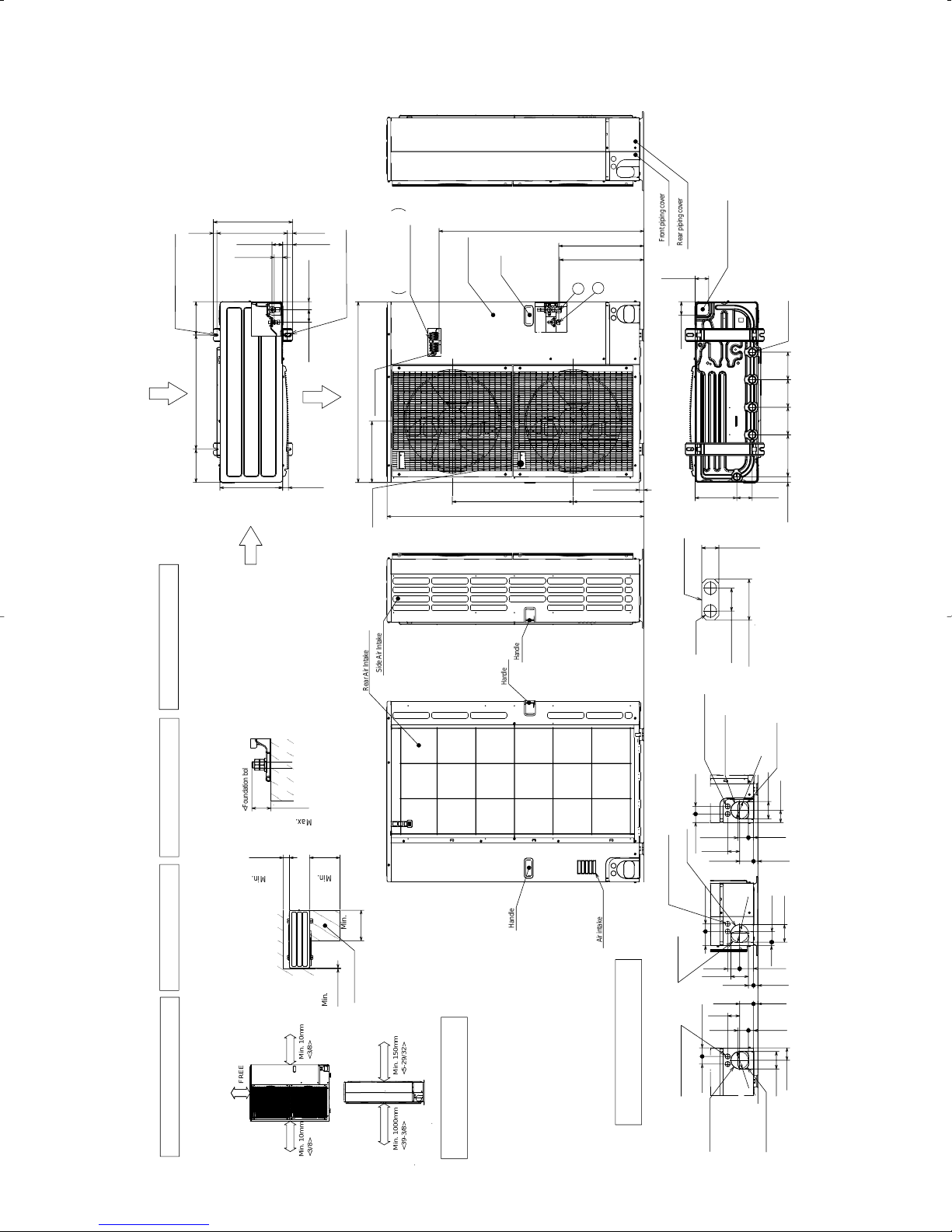

PUZ-A24/30/36NHA PUZ-A24/30/36NHA-BS

,

,,,,

,,,,,,

,,,,,

,,,,,,

,,,,,

,,

,,,,

,

,

,

,,

,,,

,

,,

,

,,

,

,

,,

,,,

,,

,

,

,,,

,

,,

,

,

,

,

,

,

,,

,,

,

,

,

,

,

,,,

,

,

,

,,,

,,,,

,

,

,

,,

,,

,,

,

,

,,

,

,

,

,

,,

,,

,

,,

,

,,

Min. 10mm

<3/8>

Min. 10mm

<3/8>

Min. 100mm

<3-15/16>

Min. 500mm

<19-11/16>

mm<inch>

100mm

Min.

<3-15/16>

500mm

Min.

<19-11/16>

500mm

Min.

<19-11/16>

10mm

Min.

<3/8>

Service space

,,

,,,

,,,,

,,,,

,,,,

,,,

Max.

30mm<1-3/16>

FOUNDATION

<Foundation bolt height>

31<1-7/32>

74<2-19/32>

40<1-9/16>

When installing the conduit,

set the attachment to the

inner side of each panel.

1/2 Conduit attachment

2-

[

22.2<7/8>

330 <13>

175 <6-7/8>

600 <23-5/8>

175 <6-7/8>

53 <2-3/32>

28 <1-3/32> 370 <14-9/16>

19 <3/4>

56 <2-7/32>

45 <1-25/32>

42 <1-21/32>66 <2-5/8>

417 <16-13/32>

2-U Shaped notched hole

(Foundfation Bolt M10<W3/8>)

Side Air Intake

Rear Air Intake

Air outlet

2-12*36 oval hole

(Foundation Bolt M10<W3/8>)

30 <1-3/16>

Side Air Intake

Handle

Rear piping cover

Front piping cover

81<3-3/16>

219 <8-5/8>

145

<5-23/32>

220

<8-21/32>

30 <1-3/16>

145

<5-23/32>

71 <2-13/16>

71 <2-13/16>

145

<5-23/32>

Bottom piping hole

(Knockout)

Drain hole

(5-

[

33<1-5/16>)

Handle

Handle

Rear Air Intake

Air Intake

670 <26-3/8>

*1 443<17-7/16>

*1 447<17-19/32>

322 <12-11/16>

950 <37-13/32>

473 <18-5/8>

943 <37-1/8>

23<29/32>

2

1

Handle

Handle

Service panel

Earth terminal

Left . . . Power supply wiring

Reight . . Indoor/Outdoor wiring

Terminal Block

63<2-1/2>

73<2-7/8>

75

<2-31/32>

40 <1-9/16>

92<3-5/8>

92<3-5/8>

27<1-1/16>23<29/32>

55<2-3/16>

19<3/4>

Conduit hole

(2-

[

27<1-1/16>Knockout)

Right trunking hole

(Knockout)

Right piping hole

(Knockout)

[

92

<

3-5/8>

45<1-25/32>

65<2-9/16>

92<3-5/8>

40 <1-9/16>

63

<2-1/2>

23<29/32>

73<2-7/8>

55<2-3/16>

27<1-1/16>

Conduit hole

(2-

[

27<1-1/16>Knockout)

Front trunking hole

(Knockout)

Front piping hole

(Knockout)

[92

<3-5/8>

40 <1-9/16>45<1-25/32>

63<2-1/2>

73<2-7/8>23<29/32

55<2-3/16>

27<1-1/16>

92<3-5/8>

65<2-9/16>

Conduit hole

(2-

[

27<1-1/16>Knockout)

Rear trunking hole

(Knockout)

Rear piping hole

(Knockout)

[

92

<3-5/8>

FREE

Piping and wiring connections

can be made from 4 directions:

front, right, rear and below.

Dimensions of space needed

for service access are

shown in the below diagram.

Please secure the unit firmly

with 4 foundation (M10<W3/8>)

bolts. (Bolts and washers must

be purchased locally.)

The diagram below shows a

basic example.

Explantion of particular details are

given in the installation manuals etc.

1

····Refrigerant GAS pipe connction (FLARE) [15.88(5/8F)

2

····Refrigerant LIQUID pipe connection (FLARE) [ 9.52(3/8F)

*1···· Indication of STOP VALVE connection location.

Example of Notes

Piping Knockout Hole Details

1 FREE SPACE (Around the unit)

2 SERVICE SPACE

3 FOUNDATION BOLTS

4 PIPING-WIRING DIRECTIONS

PUY-A24/30/36NHA PUY-A24/30/36NHA1-BS

PUY-A24/30/36NHA1

Unit : mm<inch>

,,

14

PUZ-A42NHA PUZ-A42NHA-BS

Terminal Block

Left ··· Power supply wiring

Right ··· Indoor/Outdoor wiring

Earth terminal

Service panel

Handle

1

2

1350<53-5/32>

23<29/32>

950<37-13/32>

1076<42-3/8>

* 1 447<17-19/32>

* 1 443<17-7/16>

371<14-19/32>

635<25>

322<12-11/16>

Handle

,,

,

,

,,,

,,

,

,,,

,,

,

,,,,

,,

,,

,

,

,

,,,

,

,

,

,,,

,

,,,

,

,

,,

,

,

,

,

,,

,

,

,,

,

,,,

,

,

,

,,

,

,,

,

,,

,

,,

,,

,

,,

,

,

,,,,

,,,,

,,,,,

,,,,

,,,,

,,,

,,,,,

,,,,,,

,,,,,,

,,,,,,

,,,

,,,,,

,,

,,

,,,

,,,

,

,

,

,,,,,

,

,,

,,,

Min. 1000mm

<39-3/8>

Min. 150mm

<5-29/32>

Min. 10mm

<3/8>

Min. 10mm

<3/8>

FREE

Max.

Min.

Min.

Min.

Min.

Handle

Side Air Intake

Front piping cover

Rear piping cover

Air intake

Rear Air Intake

Handle

Handle

<Foundation bolt height>

Air outlet

Rear Air Intake

Side Air Intake

30mm<1-3/16>

FOUNDATION

150mm

<5-29/32>

500mm

<19-11/16>

500mm

<19-11/16>

10mm<3/8>

Service space

40<1-9/16>

74<2-19/32>

31<1-7/32>

When installing the conduit.

set the attachment to the

inner side of each panel.

2-

[

22.2<7/8>

1/2 Conduit attachment

600<23-5/8>

175

<6-7/8>

175

<6-7/8>

330<13>

417<16-13/32>

42<1-21/32>

66<2-5/8>

53<2-3/32> 56<2-7/32>

45<1-25/32>

19<3/4>

28<1-3/32> 370<14-9/16>

2-U Shaped notched hole

(Foundation Bolt M10<W3/8>)

2-12*36 Oval hole

(Foundation Bolt M10<W3/8>)

30<1-3/16>

45<1-25/32>

40<1-9/16>

65<2-9/16>

92<3-5/8>

27<1-1/16>

55<2-3/16>

23<29/32> 73<2-7/8>

63<2-1/2>

Rear piping hole

(Knockout)

Rear trunking hole

(Knockout)

Conduit hole

(2-[27<1-1/16>Knockout)

[92

<3-5/8>

19<3/4>

55<2-3/16>

92<3-5/8>

75

<2-31/32>

40<1-9/16>

73<2-7/8>

63<2-1/2>

23<29/32> 27<1-1/16>

92<3-5/8>

Right piping hole

(Knockout)

Right trunking hole

(Knockout)

Conduit hole

(2-[27<1-1/16>Knockout)

[92

<3-5/8>

92<3-5/8>

65<2-9/16>

45<1-25/32>40<1-9/16>

27<1-1/16>

55<2-3/16>

23<29/32> 73<2-7/8>

63

<2-1/2>

Front piping hole

(Knockout)

Front trunking hole

(Knockout)

Conduit hole

(2-[27<1-1/16>Knockout)

[92

<3-5/8>

145

<5-23/32>

145

<5-23/32>

220

<8-21/32>

30<1-3/16>

145

<5-23/32>

81<3-3/16>

219<8-5/8>

71<2-13/16>

71<2-13/16>

Bottom piping hole

(Knockout)

Drain hole

5-

[

33<1-5/16>

The diagram below shows a

basic example.

Explantion of particular details are

given in the installation manuals etc.

Dimensions of space needed

for service access are

shown in the below diagram.

Please secure the unit firmly

with 4 foundation (M10<W3/8>)

bolts. (Bolts and washers must

be purchased locally.)

1 . . .Refrigerant GAS pipe connction (FLARE) [15.88(5/8F)

2 . . .Refrigerant LIQUID pipe connection (FLARE) [ 9.52(3/8F)

*1 . . .Indication of STOP VALVE connection location.

Piping and wiring connections

can be made from 4 directions:

front, right, rear and below.

Example of Notes

1 FREE SPACE (Around the unit)

2 SERVICE SPACE

3 FOUNDATION BOLTS

4 PIPING-WIRING DIRECTIONS

Piping Knockout Hole Details

PUY-A42NHA PUY-A42NHA-BS

Unit : mm<inch>

,

15

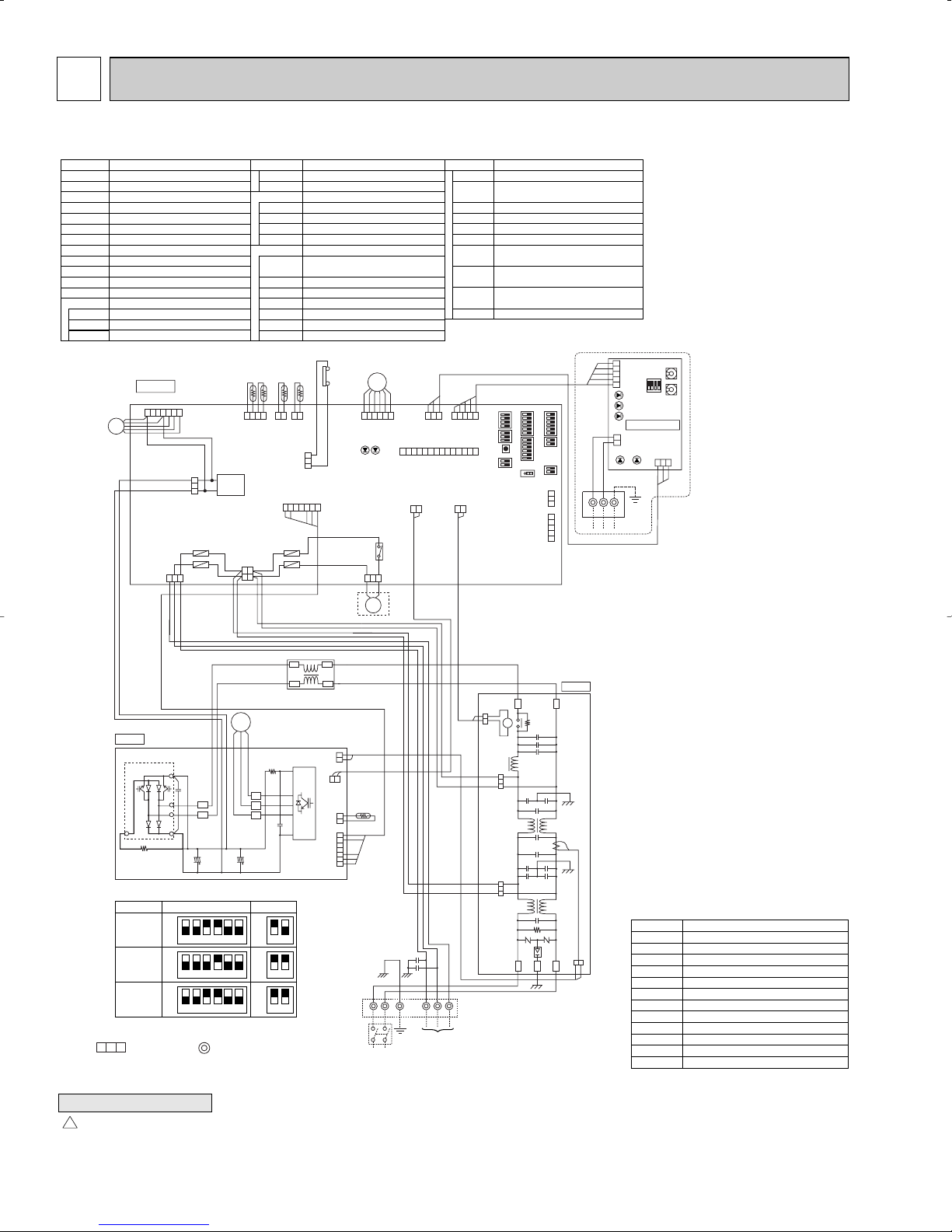

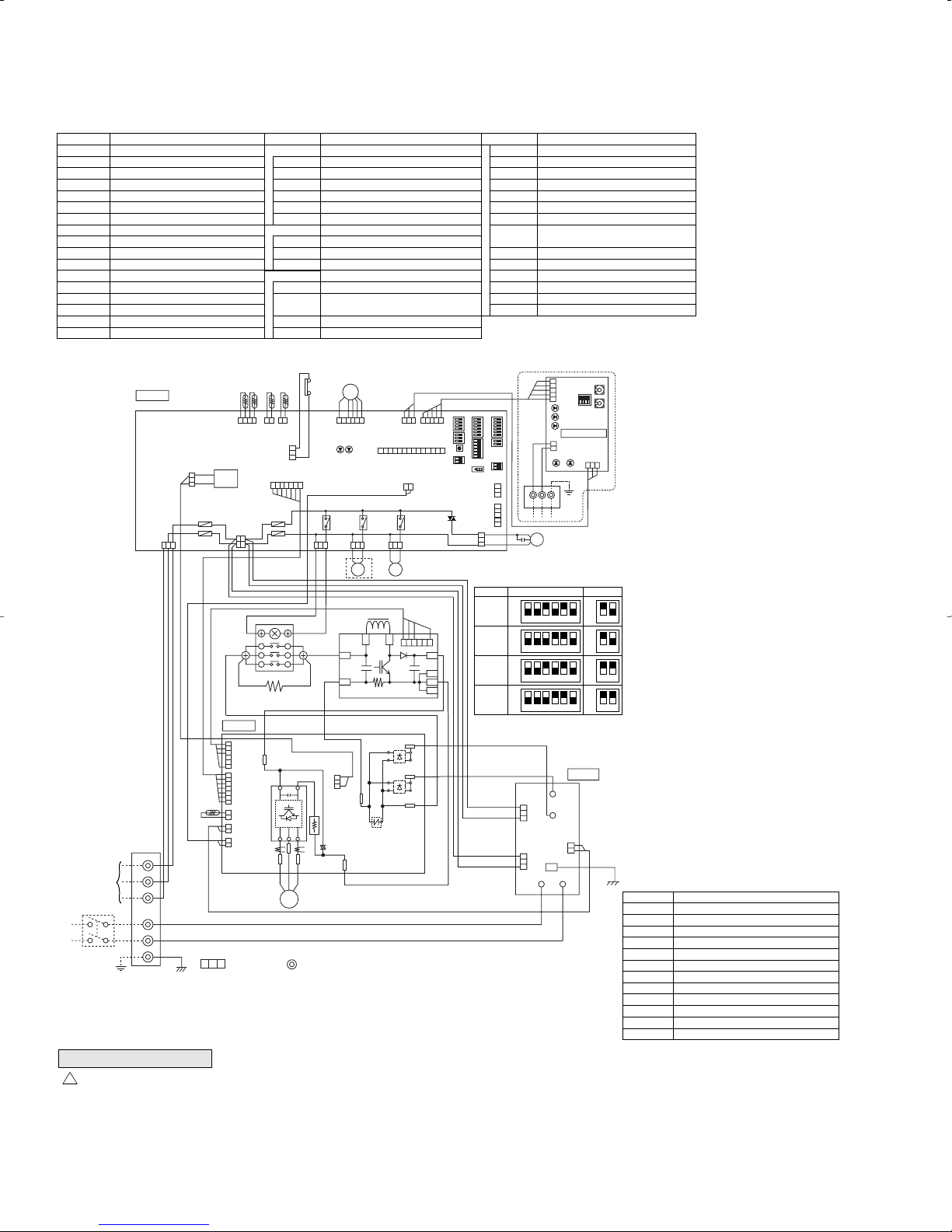

8

WIRING DIAGRAM

PUZ-A18NHA PUZ-A18NHA-BS PUY-A12/18NHA PUY-A12/18NHA1 PUY-A12/18NHA1-BS

SYMBOL

TB1

MC

MF1

21S4

63H

TH3

TH4

TH6

TH7

TH8

LEV-A

ACL

P.B.

R/S

U/V/W

PFC

Terminal Block<Power Supply, Indoor/Outdoor>

Motor for Compressor

Fan Motor

Solenoid Valve (Four-Way Valve)

High Pressure Switch

Thermistor<Outdoor Pipe>

Thermistor<Discharge>

Thermistor<Outdoor 2-Phase Pipe>

Thermistor<Outdoor>

Thermistor<Heat Sink>

Electronic Expansion Valve

Reactor

Power Circuit Board

Connection Terminal<L1/L2-Phase>

Connection Terminal<U/V/W-Phase>

Converter

MF1

NAME SYMBOL NAME SYMBOL NAME

N.F.

C.B.

F2

F1

TH7 TH6 TH3 TH4

TH7/6

(RED)

TRANS

21

43

CNAC

(WHT)

C.B.

CNS

(WHT)

CNF1

65714

(WHT)

3

1

CNDC

(PNK)

132

Power moduleIPM

Main Smoothing Capacitor

CB1~CB2

Noise Filter Circuit Board

Connection Terminal<L1-Phase>

LI/LO

Connection Terminal<L2-Phase>

NI/NO

E

Connection Terminal<Ground>

52C Relay

52C

Controller Circuit Board

SW1

Switch<Forced defrost, Defect history

record reset, Refrigerant address>

SW4

Switch<Test Operation>

SW5

Switch<Function Switch>

SW6

Switch<Model Select>

SW7

Switch<Function Setup>

SW8

Switch

SW9

Switch

43212121

TH3

TH4

(WHT)

(WHT)

13

63H

YLW)

CN2

(WHT)

567

43221

F3

F4

LED2

LEV-A

LEV-A

(WHT)

21S4

456321

LED1

21S4

13

(GRN)

PUZ only

SW10

Switch<Model Select>

LED1,

Light Emitting Diodes

<Operation Inspection Indicators>

LED2

F1~4

Fuse<6.3 A>

SWP

Switch<Pump Down>

CN31

Connector<Emergency Operation>

CNM

Connector<A-Control Service Inspection Kit>

Connector

CNMNT

<Connected to Optional M-NET Adapter Board>

Connector

CNVMNT

<Connected to Optional M-NET Adapter Board>

Connector

CNDM

<Connected for Option (Contact Input)>

X52

Relay

321

45321

CNVMNT

CNMNT

(WHT)

(WHT)

1110 12 13 14

657891234

CNM

(WHT)

CN4

CN52C

(WHT)

(RED)

21

1

X52

SW5SW8SW4 SWP

*1

SW6SW1

CN31

CNDM

CN51

SW7

SW9SW10

*1

(WHT)

(WHT)

321

54213

Optional M-NET adaptor

45321

SW1

CN5

(WHT)

LED2

LED3

LED4

M-NET SUBSTRATE

21

CN2M

(WHT)

LED1

LED5

TB7

ABS

M-NET

123

SW11

SW12

CND

(WHT)

N.F.

LO

NO

M-NET ADAPTER

SYMBOL

TB7

(RED)

CN5

12

E

LI

NI

CN5

CND

CN2M

SW1

SW11

SW12

LED1

LED2

LED3

LED4

LED5

Terminal Block<M-net connection>

Connector<Transmission>

Connector<Power Supply>

Connector<M-NET communication>

Switch<Status of communication>

Switch<Address setting : 1st digit>

Switch<Address setting : 2nd digit>

LED<Power Supply : DC5V>

LED<Connection to Outdoor Unit>

LED<Transmission : Sending>

LED<Transmission : Recelving>

LED<Power Supply : DC12V>

NAME

MC

P.B.

PFC

*1 MODEL SELECT

MODEL

ON

PUZ-A18N

OFF

123456

ON

PUY-A12N

OFF

123456

ON

PUY-A18N

OFF

123456

R

S

CB1 CB2

SW6

BLK

RED

WHT

U

V

W

SW10

ON

OFF

12

ON

OFF

12

ON

OFF

12

Symbols used in wiring diagram above are,

: Connector, : Terminal(block).

ACL

CN5

12

(RED)

IPM

21

CN4

(WHT)

TH8

CN3

12

(WHT)

CN2

1672345

(WHT)

TB1

NO FUSE

BREAKER

POWER SUPPLY

208/230V 60Hz

*Use copper supply wire.

L1 GRL2

S1 S2 S3

INDOOR

UNIT

21

CN52C

(BLK)

CNAC2

(RED)

CNAC1

(WHT)

52C

13

13

Cautions when Servicing

!

WARNING: When the main supply is turned off, the voltage [340 V] in the main capacitor will drop to 20 V in approx. 2 minutes (input voltage: 230 V). When servicing, make sure that

LED1 (green) on the outdoor circuit board goes out, and then wait for at least 1 minute.

Components other than the outdoor board may be faulty: Check and take corrective action.

Do not replace the outdoor board without checking.

16

SYMBOL

M-NET ADAPTER

NAME

TB7

CN5

CND

CN2M

SW1

SW11

Terminal Block<M-net connection>

Connector<Transmission>

Connector<Power Supply>

Connector<M-NET communication>

Switch<Status of communication>

Switch<Address setting : 1st digit>

SW12

LED1

LED2

LED3

LED4

LED5

Switch<Address setting : 2nd digit>

LED<Power Supply : DC5V>

LED<Connection to Outdoor Unit>

LED<Transmission : Sending>

LED<Transmission : Recelving>

LED<Power Supply : DC12V>

123456

OFF

ON

PUZ-A24N

PUY-A24N

MODEL

SW6

*1 MODEL SELECT

SW10

12

OFF

ON

123456

OFF

ON

12

OFF

ON

CN3

(WHT)

CN5

(RED)

CN2

(WHT)

CN4

(WHT)

21

12

CN52C

(BLK)

52C

21

TH8

12

1672345

N.F.

LO

NO

CNAC2

(RED)

13

CNAC1

(WHT)

13

12

(RED)

CN5

NI

E

LI

ACL

U

V

W

R

S

PFC

CB1 CB2

IPM

P.B.

CN5

(WHT)

123

LED2

SW1

SW11

SW12

LED3

LED4

TB7

LED1

LED5

45321

21

CND

(WHT)

CN2M

(WHT)

M-NET SUBSTRATE

M-NET

ABS

CNVMNT

(WHT)

321

CNDM

(WHT)

CN51

(WHT)

IC51

321

MF1

(WHT)

13

54213

CNMNT

(WHT)

CNM

(WHT)

45321

LEV-A

(WHT)

LEV-A

C.B.

456321

TH7/6

(RED)

63H

(YLW)

63H

TRANS

TH3

(WHT)

CNDC

(PNK)

TH4

(WHT)

TH7 TH6 TH3 TH4

43212121

SW7

SW6SW1

SW9SW10

CN31

1110 12 13 14

657891234

CN2

(WHT)

CNS

(WHT)

CNAC

(WHT)

CN4

(WHT)

21S4

(GRN)

43221

1

CN52C

(RED)

21

567

LED1

LED2

3

13

X52

52C

(BLK)

13

X53

F1

F2

F4

F3

*1

*1

132

21

43

SW5SW8SW4 SWP

13

21S4

SV2

(BLU)

13

X55

SV

MF1

C1

PUZ only

1

CB3

L1 GRL2

S1 S2 S3

INDOOR

UNIT

TB1

MC

Optional M-NET adaptor

RED

BLK

WHT

POWER SUPPLY

208/230V 60Hz

NO FUSE

BREAKER

Symbols used in wiring diagram above are,

: Connector, : Terminal(block).

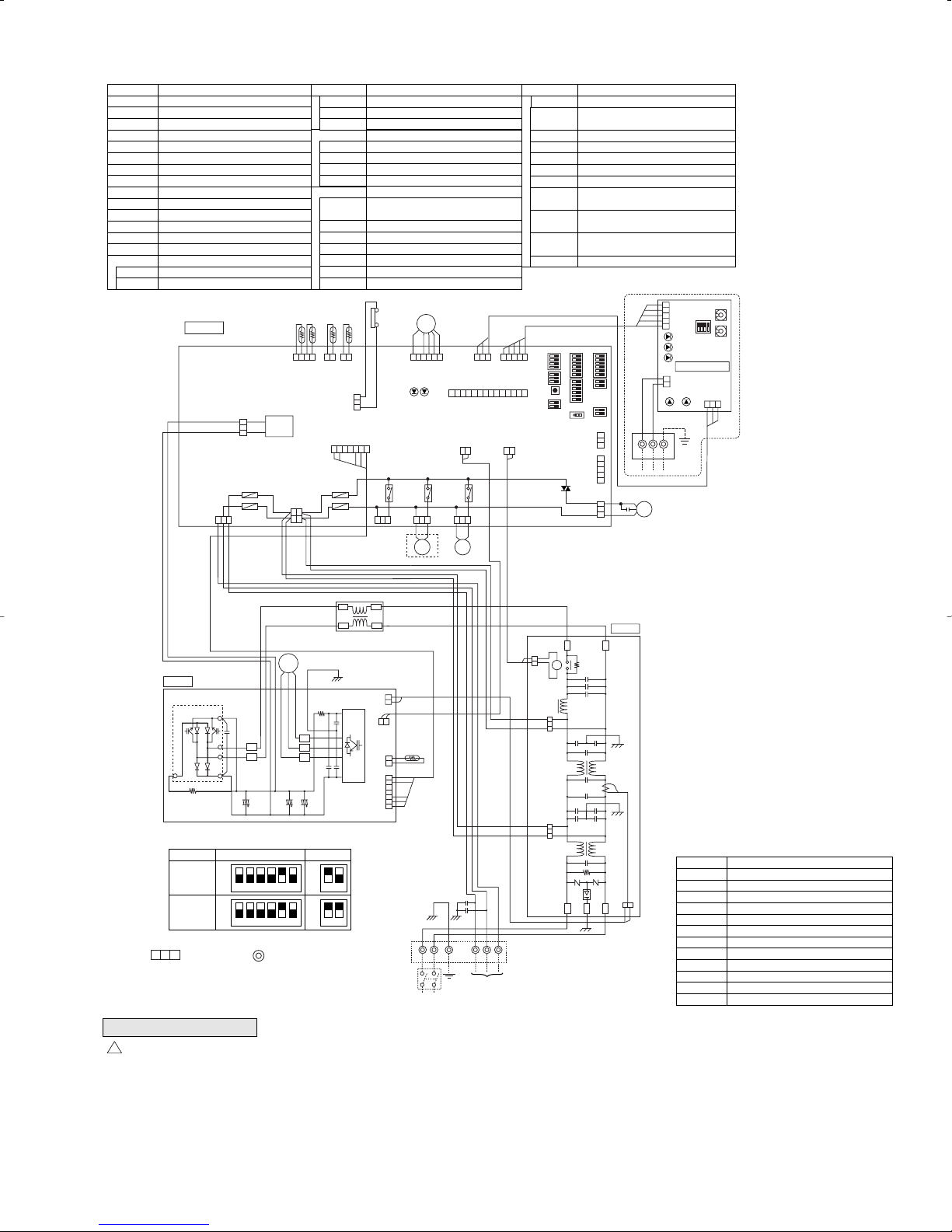

TB1

MC

MF1

21S4

63H

TH3

TH4

TH6

TH7

TH8

LEV-A

ACL

Terminal Block<Power Supply, Indoor/Outdoor>

Motor for Compressor

Fan Motor

C1 Fan Capacitor

Solenoid Valve (Four-Way Valve)

High Pressure Switch

SV Solenoid Valve (Bypass Valve)

Thermistor<Outdoor Pipe>

Thermistor<Discharge>

Thermistor<Outdoor 2-Phase Pipe>

Thermistor<Outdoor>

Thermistor<Heat sink>

Electronic Expansion Valve

Reactor

Power Circuit Board

Connection Terminal<U/V/W-Phase>

P.B.

U/V/W

Noise Filter Circuit Board

Connection Terminal<L1-Phase>

Connection Terminal<Ground>

N.F.

LI/LO

Connection Terminal<L2-Phase>

NI/NO

E

Fuse<6.3 A>

Controller Circuit Board

Switch<Forced defrost, Defect history

record reset, Refrigerant address>

Switch<Test Operation>

Switch<Function Switch>

Switch<Function Setup>

Switch<Pump Down>

Connector<Emergency Operation>

F1~4

SW1

SW4

SW5

SW7

Switch

SW8

SWP

CN31

CNM

CNVMNT

CNDM

LED1,

LED2

Light Emitting Diodes

<Operation Inspection Indicators>

Connector<A-Control Service Inspection Kit>

Connector

<Connected to Optional M-NET Adapter Board>

Connector

<Connected for Option (Contact Input)>

C.B.

Converter

PFC

52C Relay

52C

SYMBOL

NAME SYMBOL NAME SYMBOL NAME

Connection Terminal<L1/L2-Phase>

R/S

CNMNT

Connector

<Connected to Optional M-NET Adapter Board>

Switch<Model Select>

SW6

Solid State Relay<SSR>

IC51

Switch

SW9

Switch<Model Select>

SW10

X53,X52,X55

Relay

Power module

IPM

Main Smoothing CapacitorCB1~CB3

Cautions when Servicing

!

WARNING: When the main supply is turned off, the voltage [340 V] in the main capacitor will drop to 20 V in approx. 2 minutes (input voltage: 230 V). When servicing, make sure that

LED1 (green) on the outdoor circuit board goes out, and then wait for at least 1 minute.

Components other than the outdoor board may be faulty: Check and take corrective action.

Do not replace the outdoor board without checking.

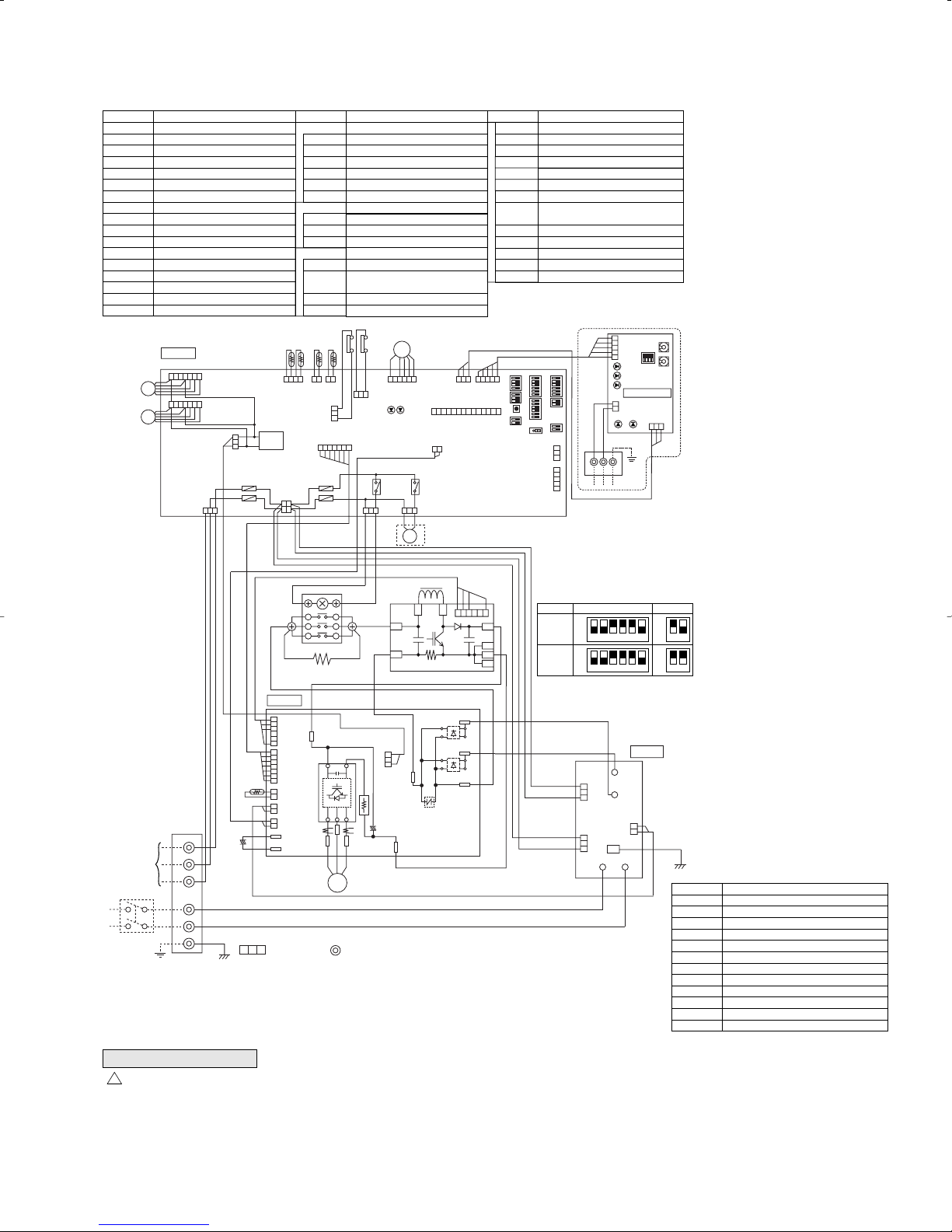

PUZ-A24NHA PUZ-A24NHA-BS PUY-A24NHA PUY-A24NHA1 PUY-A24NHA1-BS

17

SYMBOL

M-NET ADAPTER

NAME

TB7

CN5

CND

CN2M

SW1

SW11

Terminal Block<M-net connection>

Connector<Transmission>

Connector<Power Supply>

Connector<M-NET communication>

Switch<Status of communication>

Switch<Address setting : 1st digit>

SW12

LED1

LED2

LED3

LED4

LED5

Switch<Address setting : 2nd digit>

LED<Power Supply : DC5V>

LED<Connection to Outdoor Unit>

LED<Transmission : Sending>

LED<Transmission : Recelving>

LED<Power Supply : DC12V>

123456

OFF

ON

PUZ-A30N

PUZ-A36N

MODEL SW6

*1 MODEL SELECT

SW10

12

OFF

ON

123456

OFF

ON

12

OFF

ON

123456

OFF

ON

PUY-A30N

PUY-A36N

12

OFF

ON

123456

OFF

ON

12

OFF

ON

CN5

(WHT)

123

LED2

SW1

SW11

SW12

LED3

LED4

TB7

LED1

LED5

45321

21

CND

(WHT)

CN2M

(WHT)

M-NET SUBSTRATE

M-NET

ABS

Optional M-NET adaptor

CNVMNT

(WHT)

321

CNDM

(WHT)

CN51

(WHT)

321

54213

CNMNT

(WHT)

CNM

(WHT)

45321

LEV-A

(WHT)

LEV-A

C.B.

456321

TH7/6

(RED)

63H

(YLW)

TRANS

TH3

(WHT)

CNDC

(PNK)

TH4

(WHT)

TH7 TH6 TH3 TH4

43212121

SW7

SW6SW1

SW9SW10

CN31

1110 1213 14

657891234

CN2

(WHT)

CNS

(WHT)

CNAC

(WHT)

CN4

(WHT)

21S4

(GRN)

52C

(BLK)

432211567

LED1

LED2

13

13

X52

X55

X53

F1

F2

F4

F3

*1

*1

132

21

43

SW5SW8SW4 SWP

13

P.B.

13

MC

CNDC(PNK)

+

-

~

~

+

-

~

~

+

+

-

TABU

RED

BLK

WHT

TABV

TABW

TABS

TABT

TABP1

TABN2

TABN1

TABP2

432156

CN3

(WHT)

CNAF

(WHT)

4321567

CN2

(WHT)

CN4

(WHT)

CN5

(RED)

TH8

212121

U

V

W

21S4

13

12

(RED)

CNAC2

CN5

(RED)

(WHT)

CNAC1

LO

LI

NI

NO

EI

N.F.

31 31

63H

123456

-

+

DCL

ACTM

L1

L2

P

N1

N2

I

SV

PUZ only

IC51

MF1

(WHT)

SV2

(BLU)

MF1

C1

13

13

POWER SUPPLY

208/230V 60Hz

INDOOR

UNIT

NO FUSE

BREAKER

L1

L2

S3

S2

S1

TB1

GR

52C

RS

Symbols used in wiring diagram above are,

: Connector, : Terminal(block).

*Use copper supply wire.

TB1

MC

MF1

21S4

63H

TH3

TH4

TH6

TH7

TH8

LEV-A

DCL

52C

Terminal Block<Power Supply, Indoor/Outdoor >

Motor for Compressor

Fan Motor

C1 Fan Capacitor

Solenoid Valve (Four-Way Valve)

High Pressure Switch

SV Solenoid Valve (Bypass Valve)

Thermistor<Outdoor Pipe>

Thermistor<Discharge>

Thermistor<Outdoor 2-Phase Pipe>

Thermistor<Outdoor>

Thermistor<Heat Sink>

Electronic Expansion Valve

Reactor

52C Relay

RS

Rush Current Protect Resistor

ACTM

Active Filter Module

Power Circuit Board

Connection Terminal<U/V/W-Phase>

Diode Bridge

P.B.

TABU/V/W

Noise Filter Circuit Board

Connection Lead<L1-Phase>

Connection Terminal<Ground>

N.F.

LI/LO

Connection Lead<L2-Phase>

NI/NO

EI

Controller Circuit Board

Switch<Model Select>

Switch<Pump Down>

Connector<Emergency Operation>

Switch

SW8

SW10

SWP

CN31

C.B.

DS2,3

Power ModuleIPM

SYMBOL

NAME SYMBOL NAME SYMBOL NAME

Connection Terminal<L1/L2-Phase>

Connection Terminal<DC Voltage>

TABS/T

TABP1/P2

Connection Terminal<DC Voltage>

TABN1/N2

Switch

SW9

Fuse<6.3 A>

Switch<Forced defrost, Defect history record

reset, Refrigerant address>

Switch<Test Operation>

Switch<Function Switch>

Switch<Model Select>

F1~4

SW1

SW4

SW5

SW6

Switch<Function Setup>

SW7

LED1,

LED2

Light Emitting Diodes

<Operation Inspection Indicators>

CNM

CNMNT

CNVMNT

CNDM

Connector<A-Control Service Inspection Kit>

Connector<Connected to Optional M-NET Adapter Board>

Connector<Connected to Optional M-NET Adapter Board>

Connector

X52,X53,X55

Relay

IC51

Solid State Relay<SSR>

Cautions when Servicing

!

WARNING: When the main supply is turned off, the voltage [340 V] in the main capacitor will drop to 20 V in approx. 2 minutes (input voltage: 230 V). When servicing, make sure that

LED1 (green) on the outdoor circuit board goes out, and then wait for at least 1 minute.

Components other than the outdoor board may be faulty: Check and take corrective action.

Do not replace the outdoor board without checking.

PUZ-A30/36NHA PUZ-A30/36NHA-BS

PUY-A30/36NHA PUY-A30/36NHA1-BS

PUY-A30/36NHA1

18

SYMBOL

M-NET ADAPTER

NAME

TB7

CN5

CND

CN2M

SW1

SW11

Terminal Block<M-net connection>

Connector<Transmission>

Connector<Power Supply>

Connector<M-NET communication>

Switch<Status of communication>

Switch<Address setting : 1st digit>

SW12

LED1

LED2

LED3

LED4

LED5

Switch<Address setting : 2nd digit>

LED<Power Supply : DC5V>

LED<Connection to Outdoor Unit>

LED<Transmission : Sending>

LED<Transmission : Recelving>

LED<Power Supply : DC12V>

123456

OFF

ON

PUZ-A42N

PUY-A42N

MODEL SW6

*1 MODEL SELECT

SW10

12

OFF

ON

123456

OFF

ON

12

OFF

ON

CN5

(WHT)

123

LED2

SW1

SW11

SW12

LED3

LED4

TB7

LED1

LED5

45321

21

CND

(WHT)

CN2M

(WHT)

M-NET SUBSTRATE

M-NET

ABS

Optional M-NET adaptor

CNVMNT

(WHT)

321

CNDM

(WHT)

CN51

(WHT)

321

54213

CNMNT

(WHT)

CNM

(WHT)

45321

LEV-A

(WHT)

LEV-A

C.B.

456321

TH7/6

(RED)

63H

(YLW)

TRANS

TH3

(WHT)

CNDC

(PNK)

CNF1

(WHT)

CNF2

(WHT)

TH4

(WHT)

TH7 TH6 TH3 TH4

43212121

SW7

SW6SW1

SW9SW10

CN31

1110 1213 14

657891234

65714

MF1

MF2

65714

CN2

(WHT)

CNS

(WHT)

CNAC

(WHT)

CN4

(WHT)

21S4

(GRN)

52C

(BLK)

432211567

LED1

LED2

13

13

X52

X53

F1

F2

F4

F3

*1

*1

132

21

43

SW5SW8SW4 SWP

13

31

P.B.

13

MC

CNDC(PNK)

+

+

-

~

~

+

-

~

~

+

+

-

TABU

TABN

TABP

TABV

TABW

TABS

TABT

TABP1

TABN2

TABN1

TABP2

432156

CN3

(WHT)

CNAF

(WHT)

4321567

CN2

(WHT)

CN4

(WHT)

CN5

(RED)

TH8

212121

U

CB

V

W

21S4

13

12

(RED)

CNAC2

CN5

(RED)

(WHT)

CNAC1

LO

LI

NI

NO

EI

N.F.

31 31

63L

(RED)

63H 63L

POWER SUPPLY

208/230V 60Hz

INDOOR

UNIT

NO FUSE

BREAKER

L1

L2

S3

S2

S1

TB1

GR

123456

-

+

DCL

52C

RS

ACTM

L1

L2

P

N1

N2

I

PUZ only

RED

BLK

WHT

Symbols used in wiring diagram above are,

: Connector, : Terminal(block).

*Use copper supply wire.

TB1

MC

MF1,MF2

21S4

63H

63L

TH3

TH4

TH6

TH7

TH8

LEV-A

DCL

52C

Terminal Block<Power Supply, Indoor/Outdoor >

Motor for Compressor

Fan Motors

Solenoid Valve (Four-Way Valve)

High Pressure Switch

Low Pressure Switch

Thermistor<Outdoor Pipe>

Thermistor<Discharge>

Thermistor<Outdoor 2-Phase Pipe>

Thermistor<Outdoor>

Thermistor<Heat Sink>

Electronic Expansion Valve

Reactor

52C Relay

RS

Rush Current Protect Resistor

ACTM

Active Filter Module

CB

Main Smoothing Capacitor

Power Circuit Board

Connection Terminal<U/V/W-Phase>

Diode Bridge

P.B.

TABU/V/W

Noise Filter Circuit Board

Connection Lead<L1-Phase>

Connection Terminal<Ground>

N.F.

LI/LO

Connection Lead<L2-Phase>

NI/NO

EI

Controller Circuit Board

Switch<Model Select>

Switch<Pump Down>

Connector<Emergency Operation>

SW10

SWP

CN31

C.B.

DS2,3

Power ModuleIPM

SYMBOL

NAME SYMBOL NAME SYMBOL NAME

Connection Terminal<L1/L2-Phase>

TABS/T

Connection Terminal<DC Voltage>

TABP1/P2/P

Connection Terminal<DC Voltage>

TABN1/N2/N

Switch

SW8

Switch

SW9

Fuse<6.3 A>

Switch<Forced defrost, Defect history record

reset, Refrigerant address>

Switch<Test Operation>

Switch<Function Switch>

Switch<Model Select>

F1~4

SW1

SW4

SW5

SW6

Switch<Function Setup>

SW7

LED1,

LED2

Light Emitting Diodes

<Operation Inspection Indicators>

CNM

CNMNT

CNVMNT

CNDM

Connector<A-Control Service Inspection Kit>

Connector<Connected to Optional M-NET Adapter Board>

Connector<Connected to Optional M-NET Adapter Board>

Connector< Connected for Option (Contact Input)>

X52,X53

Relay

Cautions when Servicing

!

WARNING: When the main supply is turned off, the voltage [340 V] in the main capacitor will drop to 20 V in approx. 2 minutes (input voltage: 230 V). When servicing, make sure that

LED1 (green) on the outdoor circuit board goes out, and then wait for at least 1 minute.

Components other than the outdoor board may be faulty: Check and take corrective action.

Do not replace the outdoor board without checking.

PUZ-A42NHA PUZ-A42NHA-BS

PUY-A42NHA PUY-A42NHA-BS

19

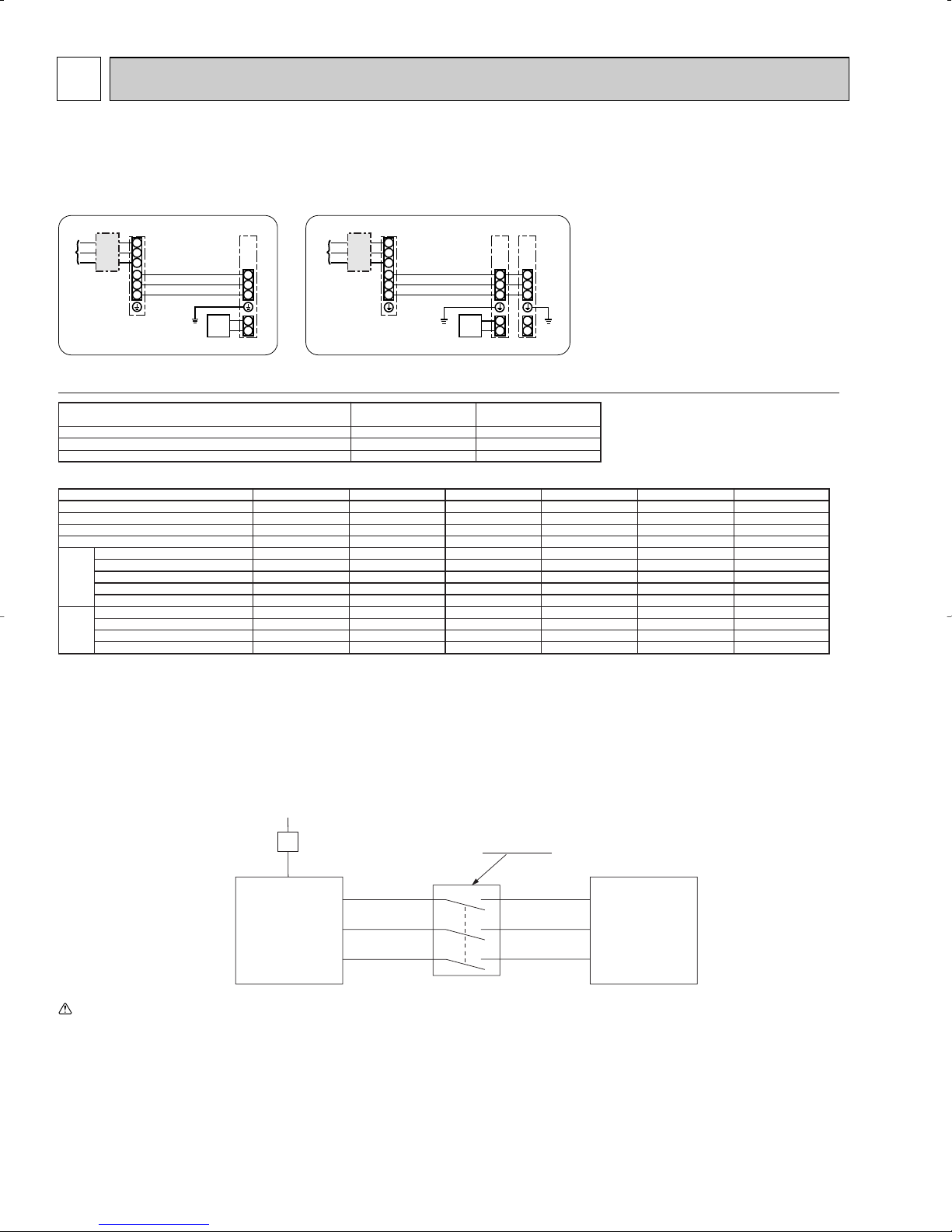

9

9-1. INDOOR UNIT POWER SUPPLIED FROM OUTDOOR UNIT (A-control application)

The following connection patterns are available.

The outdoor unit power supply patterns vary on models.

1:1 System Simultaneous twin system

A Outdoor unit power supply

B Wiring circuit breaker or isolating switch

C Outdoor unit

D Indoor unit/outdoor unit connecting cords

E Remote controller

F Indoor unit

G Indoor unit earth

S1

S2

L1

L2

GR

1

2

S1

S2

S3

S3

S1

S2

L1

L2

GR

1

2

S1

S2

S3

1

2

S1

S2

S3

S3

Warning:

In case of A-control wiring, there is high v oltage potential on the S3 terminal caused by electrical circuit design that has no electrical insulation between po wer line

and communication signal line. Therefore, please turn off the main power supply when servicing. And do not touch the S1, S2, S3 terminals when the power is

energized. If isolator should be used between indoor unit and outdoor unit, please use 3-pole type.

* Affix a label A that is included with the manuals near each wiring diagram for the indoor and outdoor units.

Indoor unit model

PLA-A12, 18, 24, 30

PCA, PKA

PLA-A36, 42

1A 2A

15A 15A

––

ACB

D

E

ACB

D

E

FFF

GG G

Indoor unit power supply

Minimum circuit ampacity

Maximum rating of overcurrent protective device

*1. Max. 50 m, 165 ft

*2. The 10 m, 30 ft wire is attached in the remote controller accessory. Max 1500 ft

*3. The figures are NOT always against the ground.

S3 terminal has DC 24 V against S2 terminal. However between S3 and S1, these terminals are NOT electrically insulataed by the transformer or other device.

1.Wiring size must comply with the applicable local and national code.

2.Use copper supply wires.

3.Use wires rated 300V or more for the power supply cables and the indoor/outdoor unit connecting cables.

4.Install an earth longer than other cables.

Notes:

Outdoor unit model

Outdoor unit power supply

Breaker size

Minimum circuit ampacity

Maximum rating of overcurrent protective device

Outdoor unit power supply

Outdoor unit power supply earth

Indoor unit-Outdoor unit *1

Indoor unit earth *1

Remote controller-Indoor unit *2

Outdoor unit L1-L2 *3

Indoor unit-Outdoor unit S1-S2 *3

Indoor unit-Outdoor unit S2-S3 *3

Remote controller-Indoor unit *3

A12 A18 A24 A30 A36 A42

Single, 208/230 V, 60 Hz Single, 208/230 V, 60 Hz Single, 208/230 V, 60 Hz Single, 208/230 V, 60 Hz Single, 208/230 V, 60 Hz Single, 208/230 V, 60 Hz

15A 15A 25A 30A 30A 30A

13A 13A 18A 25A 25A 26A

15A 20A 30A 40A 40A 40A

2 o Min. AWG 14 2 o Min. AWG 14 2 o Min. AWG 12 2 o Min. AWG 10 2 o Min. AWG 10 2 o Min. AWG 10

1 o Min. AWG 14 1 o Min. AWG 14 1 o Min. AWG 12 1 o Min. AWG 10 1 o Min. AWG 10 1 o Min. AWG 10

3 o AWG 16 (polar) 3 o AWG 16 (polar) 3 o AWG 16 (polar) 3 o AWG 16 (polar) 3 o AWG 16 (polar) 3 o AWG 16 (polar)

1 o Min. AWG 16 1 o Min. AWG 16 1 o Min. AWG 16 1 o Min. AWG 16 1 o Min. AWG 16 1 o Min. AWG 16

2 o AWG 22 (Non-polar) 2 o AWG 22 (Non-polar) 2 o AWG 22 (Non-polar) 2 o AWG 22 (Non-polar) 2 o AWG 22 (Non-polar) 2 o AWG 22 (Non-polar)

AC 208/230 V AC 208/230 V AC 208/230 V AC 208/230 V AC 208/230 V AC 208/230 V

AC 208/230 V AC 208/230 V AC 208/230 V AC 208/230 V AC 208/230 V AC 208/230 V

DC 24 V DC 24 V DC 24 V DC 24 V DC 24 V DC 24 V

DC 12 V DC 12 V DC 12 V DC 12 V DC 12 V DC 12 V

Wiring

Wire No. o

size

Circuit

rating

S1

S2

S3

S1

S2

S3

A-Control

Outdoor Unit

3 poles isolator

230V

Single phase

Isolator

A-Control

Indoor Unit

WIRING SPECIFICATIONS

20

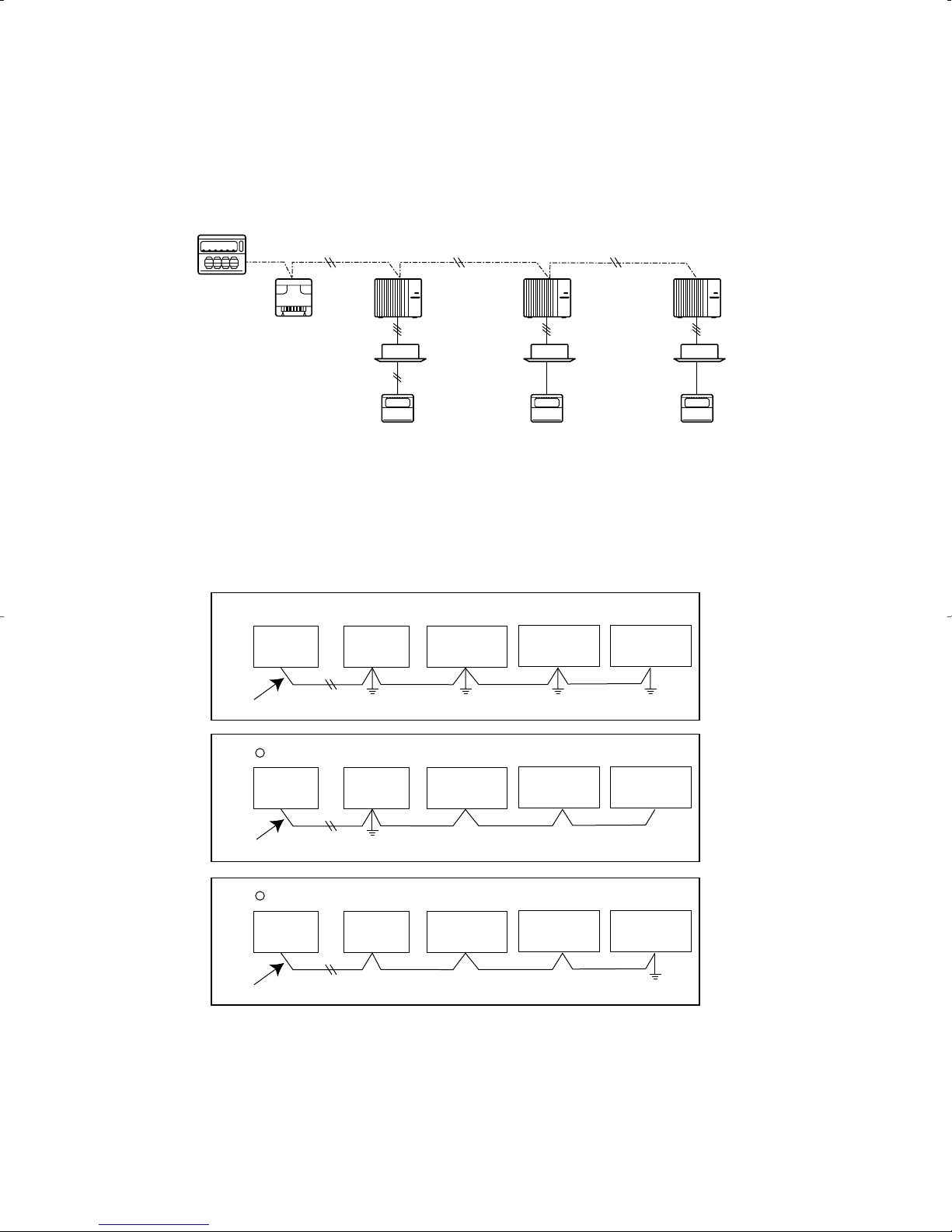

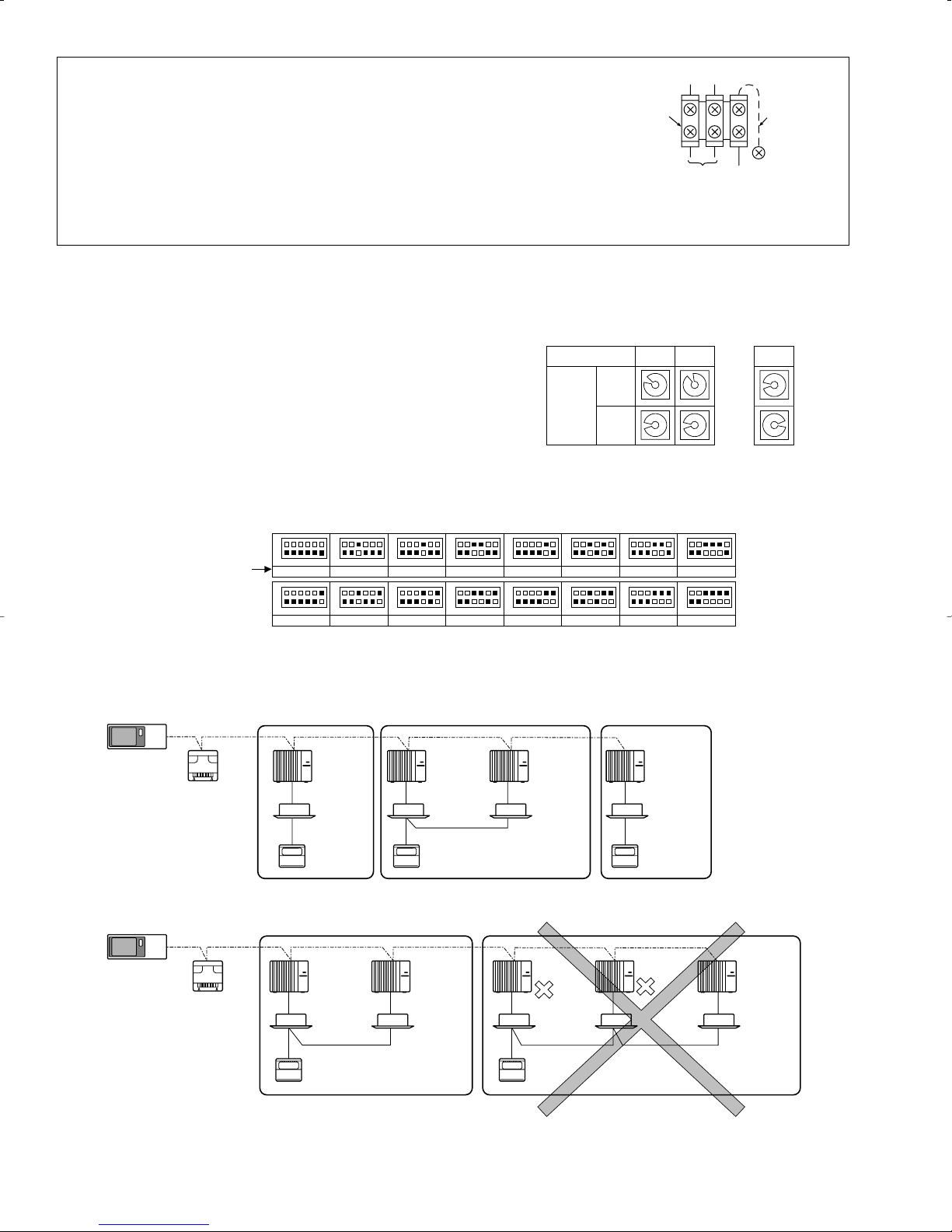

9-2. M-NET WIRING METHOD

Group

remote

controller

Refrigerant

address 00

M-NET

address 01

A-control

remote

controller

A-control

remote

controller

A-control

remote

controller

Refrigerant

address 00

M-NET

address 02

Refrigerant

address 00

M-NET

address 03

Power

supply

unit for

transmission

wire

Central

remote

controller

M-NET transmission wire

✕ Bad example (Multi spot grounding of shield wire)

Good example 1 (Single spot grounding of shield wire)

Power

supply

appliance

M-NET type

outdoor unit

Central

remote

controller

Power

supply

appliance

M-NET type

outdoor unit

M-NET type

outdoor unit

M-NET type

outdoor unit

M-NET transmission wire

M-NET type

outdoor unit

M-NET type

outdoor unit

Central

remote

controller

Power

supply

appliance

M-NET type

outdoor unit

M-NET transmission wire

M-NET type

outdoor unit

M-NET type

outdoor unit

Good example 2 (Single spot grounding of shield wire)

(Points to notice)

(1) Outside the unit, transmission wires should stay away from electric wires in order to prevent electromagnetic noise from

making an influence on the signal communication. Place them at intervals of more than 5cm. Do not put them in the same

conduit tube.

(2) Terminal block (TB7) for transmission wires should never be connected to 208/230V power supply. If it is connected,

electronic parts on M-NET P.C. board may be burnt out.

(3) Use 2-core x 1.25mm2[AWG16] shield wire (CVVS, CPEVS) for the transmission wire. Transmission signals may not be

sent or received normally if different types of transmission wires are put together in the same multi-conductor cable. Never

do this because this may cause a malfunction.

It would be ok if M-NET wire (non-polar, 2-cores) is arranged in addition to the wiring for A-control.

(4) Ground only one of any appliances through M-NET transmission wire (shield wire). Communication error may occur due to

the influence of electromagnetic noise.

If there are more than two grounding spots on the shield wire, noise may enter into the shield wire because the ground

wire and shield wire form one circuit and the electric potential difference occurs due to the impedance difference among

grounding spots. In case of single spot grounding, noise does not enter into the shield wire because the ground wire and

shield wire do not form one circuit.

To avoid communication errors caused by noise, make sure to observe the single spot grounding method described in the

installation manual.

“Ed” error will appear on the LED display of outdoor unit.

“0403” error will appear on the central-control remote controller.

21

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

12

~

50

M-NET Address No.

<Setting example>

Switching

setting

SW11

ones

digit

SW12

tens

digit

OFF

ON

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

0

Refrigerant

address

OFF

ON

8

OFF

ON

1

OFF

ON

9

OFF

ON

10

OFF

ON

11

OFF

ON

12

OFF

ON

13

OFF

ON

14

OFF

ON

15

OFF

ON

2

OFF

ON

3

OFF

ON

4

OFF

ON

5

OFF

ON

6

OFF

ON

7

System

controller

A-control

remote

controller

Group A Group B Group C

A-control

remote

controller

TB5

A-control

remote

controller

Refrigerant

address 00

M-NET

address 01

Refrigerant

address 00

M-NET

address 02

Refrigerant

address 01

M-NET

address 03

Refrigerant

address 00

M-NET

address 04

Power

supply

unit for

transmission

wire

A-control

remote

controller

A-control

remote

controller

TB5

Group A Group B

Refrigerant

address 00

M-NET

address 01

Refrigerant

address 01

M-NET

address 02

Refrigerant

address 00

M-NET

address 04

Refrigerant

address 01

M-NET

address 03

Refrigerant

address 02

M-NET

address 05

System

controller

Power

supply

unit for

transmission

wire

● M-NET wiring

(1) Use 2-core x 1.25mm

2

[AWG16] shield wire for electric wires.

(Excluding the case connecting to system controller.)

(2) Connect the wire to the M-NET terminal block. Connect one core of the

transmission wire (non-polar) to Aterminal and the other to B. Peel the

shield wire, twist the shield part to a string and connect it to S terminal.

(3) In the system which several outdoor units are being connected, the terminal

(A, B, S) on M-NET terminal block should be individually wired to the other

M-NET

terminal

block

ABS

Transmission

wire

Shield

part

Ground

wire

outdoor unit’s terminal, i.e. Ato A, B to B and S to S. In this case, choose one of those outdoor units and drive a screw

to fix an ground wire on the plate as shown on the right figure.

9-3-1. M-NET address setting

In A-control models, M-NET address and refrigerant address should be set only for the outdoor unit. Similar to CITY MULTI

series, there is no need to set the address of outdoor unit and remote controller. To construct a central control system, the

setting of M-NET address should be conducted only upon the outdoor unit. The setting range should be 1 to 50 (the same as

that of the indoor unit in CITY MULTI system), and the address number should be consecutively set in a same group.

Address number can be set by using rotary switches

(SW11 for ones digit and SW12 for tens digit), which

is located on the M-NET board of outdoor unit.

(Initial setting: all addresses are set to “0”.)

9-3-2. Refrigerant address setting

In case of multiple grouping system (multiple refrigerant circuits in one group), indoor units should be connected by remote

controller wiring (TB5) and the refrigerant address needs to be set. Leave the refrigerant addresses to “00” if the group setting is not conducted. Set the refrigerant address by using DIP SW1-3 to -6 on the outdoor controller board. [Initial setting: all

switches are OFF. (All refrigerant addresses are “00”.)]

9-3-3. Regulations in address settings

In case of multiple grouping system, M-NET and refrigerant address settings should be done as explained in the above section. Set the lowest number in the group for the outdoor unit whose refrigerant address is “00” as its M-NET address.

w Refrigerant addresses can be overlapped if they are in the different group.

w In group B, M-NET address of the outdoor unit whose refrigerant address is “00” is not set to the minimum in the group. As

“03” is right for this situation, the setting is wrong. Taking group A as a good sample, set the minimum M-NET address in

the group for the outdoor unit whose refrigerant address is “00”.

22

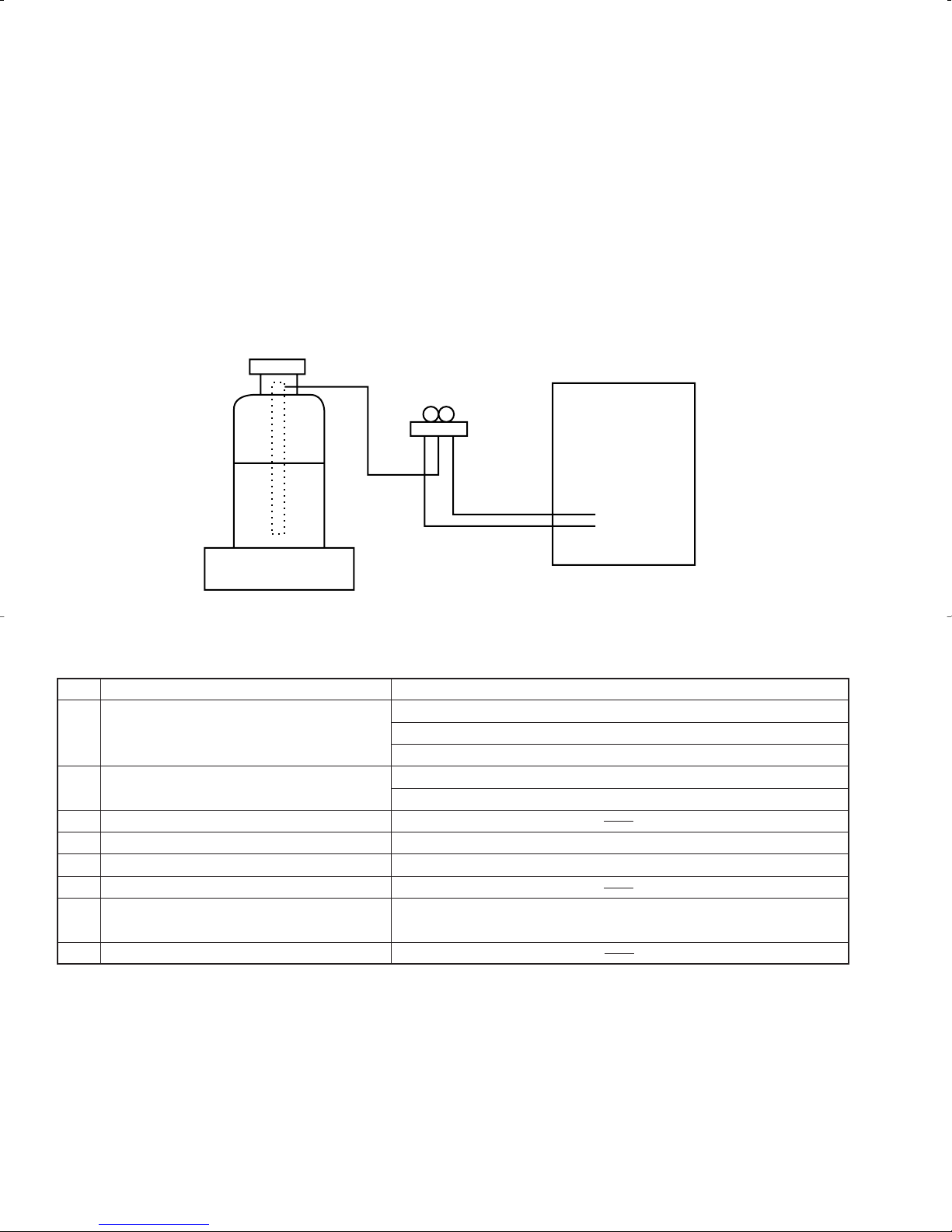

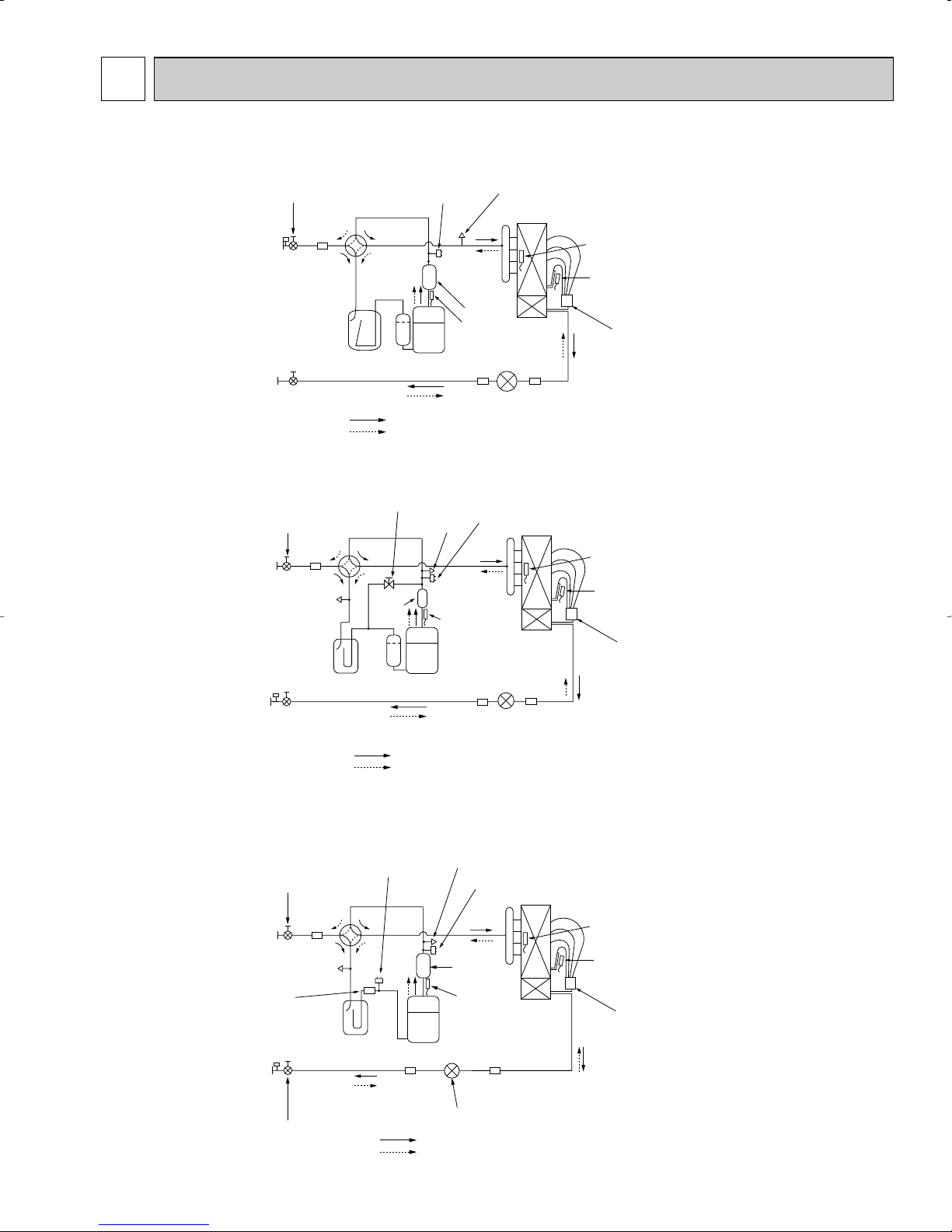

10

Outdoor heat exchanger

Thermistor

(TH3)

Thermistor

(TH6)

Distributor

Service

port

(check)

Accumulator

Compressor

Refrigerant GAS pipe

15.88A({5/8")

Refrigerant LIQUID pipe

9.52A({3/8")

Stop valve

(with service port)

4-way valve

Service

port

(check)

High pressure

protect switch

Refrigerant flow in cooling

Refrigerant flow in heating

Linear expansion valve

Thermistor

(TH4)

Muffler

Ball valve

Bypass valve

(#50)

Strainer

(#100)

Strainer

(#100)

Strainer

Accumulator

Stop valve

(with service port)

Compressor

Refrigerant GAS pipe

12.7A({1/2")

Refrigerant LIQUID pipe

6.35A({1/4")

Stop valve

4-way valve

Service

port(check)

High pressure

protect switch

Outdoor heat exchanger

Thermistor

(TH3)

Thermistor

(TH6)

Distributor

Muffler

Thermistor(TH4)

Linear expansion valve

Refrigerant flow in cooling

Refrigerant flow in heating

(#50)

Strainer

(#100)

Strainer

(#100)

Strainer

Service

port

(check)

Accumulator

Compressor

Refrigerant GAS pipe

15.88A({5/8")

Refrigerant LIQUID pipe

9.52A({3/8")

4-way

valve

Service

port

(check)

High pressure protect switch

Linear expansion valve

Muffler

Thermistor

(TH4)

Refrigerant flow in cooling

Refrigerant flow in heating

Ball valve

(#50)

Strainer

Strainer

(#100)

Strainer

(#100)

Strainer

(#100)

Low pressure protect

switch

Stop valve

(with service port)

Outdoor heat exchanger

Thermistor

(TH3)

Thermistor

(TH6)

Distributor

REFRIGERANT SYSTEM DIAGRAM

PUZ-A18NHA PUZ-A18NHA-BS

PUZ-A24/30/36NHA PUZ-A24/30/36NHA-BS

Unit : mm

<4-way valve solenoid coil>

Heating : ON

Cooling : OFF

PUZ-A42NHA PUZ-A42NHA-BS

23

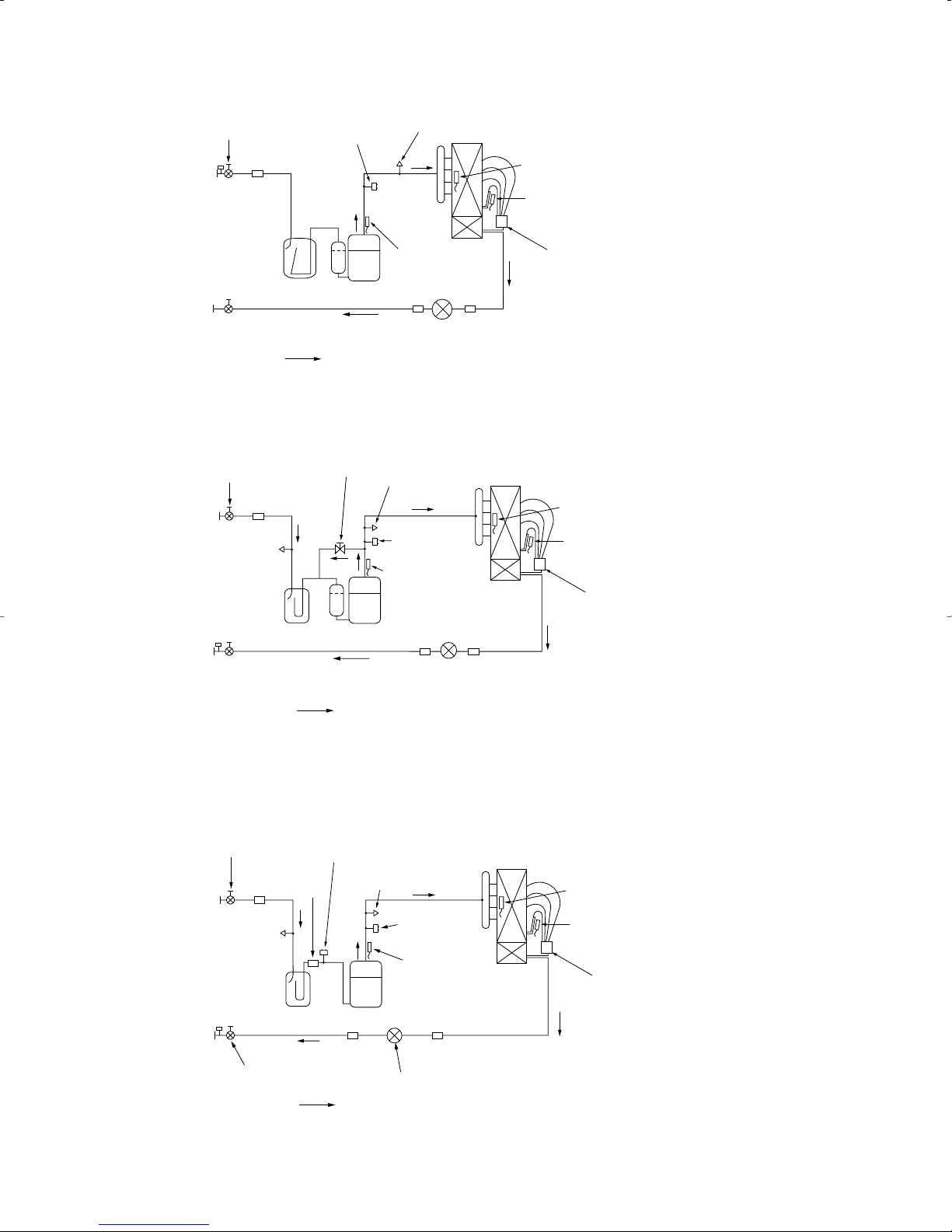

Outdoor heat exchanger

Thermistor

(TH3)

Thermistor

(TH6)

Distributor

Service

port

(check)

Accumulator

Compressor

Refrigerant GAS pipe

15.88A({5/8")

Refrigerant LIQUID pipe

9.52A({3/8")

Stop valve