Mitsubishi PUZ-A12NHA, PUZ-A·NHA-BS, PUZ-A18NHA, PUZ-A24NHA, PUZ-A30NHA Installation Manual

...

Air-Conditioners

PUZ-A

PUY-A

·NHA, PUZ-A·NHA-BS

·NHA, PUY-A·NHA-BS

English

Deutsch

Nederlands

Español

INSTALLATION MANUAL

For safe and correct use, read this manual and the indoor unit installation manual thoroughly before installing

the air-conditioner unit.

MANUAL DE INSTALACIÓN

Para un uso correcto y seguro, lea detalladamente este manual y el manual de instalación de la unidad interior

antes de instalar la unidad de aire acondicionado.

FOR INSTALLER

PARA EL INSTALADOR

Italiano

ППЛУИО¿

Português

Dansk

Svenska

English

Español

Contents

1. Safety precautions ................................................................................... 2

2. Installation location .................................................................................. 3

3. Installing the outdoor unit ......................................................................... 4

4. Installing the refrigerant piping ................................................................. 5

5. Drainage piping work ............................................................................... 7

1. Safety precautions

s Before installing the unit, make sure you read all the “Safety precau-

tions”.

s Please report to or take consent by the supply authority before connec-

tion to the system.

Warning:

Describes precautions that must be observed to prevent danger of injury or

death to the user.

Caution:

Describes precautions that must be observed to prevent damage to the unit.

Warning:

• The unit must not be installed by the user. Ask a dealer or an authorized

technician to install the unit. If the unit is installed incorrectly, water leakage,

electric shock, or fire may result.

• For installation work, follow the instructions in the Installation Manual and use

tools and pipe components specifically made for use with R410A refrigerant.

The R410A refrigerant in the HFC system is pressurized 1.6 times the pressure

of usual refrigerants. If pipe components not designed for R410A refrigerant

are used and the unit is not installed correctly, the pipes may burst and cause

damage or injuries. In addition, water leakage, electric shock, or fire may result.

• The unit must be installed according to the instructions in order to minimize

the risk of damage from earthquakes, typhoons, or strong winds. An incorrectly installed unit may fall down and cause damage or injuries.

• The unit must be securely installed on a structure that can sustain its weight.

If the unit is mounted on an unstable structure, it may fall down and cause

damage or injuries.

• If the air conditioner is installed in a small room, measures must be taken to

prevent the refrigerant concentration in the room from exceeding the safety

limit in the event of refrigerant leakage. Consult a dealer regarding the appropriate measures to prevent the allowable concentration from being exceeded.

Should the refrigerant leak and cause the concentration limit to be exceeded,

hazards due to lack of oxygen in the room may result.

• Ventilate the room if refrigerant leaks during operation. If refrigerant comes

into contact with a flame, poisonous gases will be released.

• All electric work must be performed by a qualified technician according to

local regulations and the instructions given in this manual. The units must be

powered by dedicated power lines and the correct voltage and circuit breakers must be used. Power lines with insufficient capacity or incorrect electrical work may result in electric shock or fire.

6. Electrical work .......................................................................................... 7

7. Test run .................................................................................................... 9

8. Special Functions .................................................................................. 10

9. System control (Fig. 9-1) ........................................................................ 10

After installation work has been completed, explain the “Safety Precautions,” use,

and maintenance of the unit to the customer according to the information in the Operation Manual and perform the test run to ensure normal operation. Both the Installation Manual and Operation Manual must be given to the user for keeping. These

manuals must be passed on to subsequent users.

: Indicates a part which must be grounded.

Warning:

Carefully read the labels affixed to the main unit.

• Use C1220 copper phosphorus, for copper and copper alloy seamless pipes,

to connect the refrigerant pipes. If the pipes are not connected correctly, the

unit will not be properly grounded and electric shock may result.

• Use only specified cables for wiring. The connections must be made securely

without tension on the terminals. If the cables are connected or installed incorrectly, overheating or fire may result.

• The terminal block cover panel of the outdoor unit must be firmly attached. If

the cover panel is mounted incorrectly and dust and moisture enter the unit,

electric shock or fire may result.

• When installing or moving the air conditioner, use only the specified refrigerant (R410A) to charge the refrigerant lines. Do not mix it with any other refrigerant and do not allow air to remain in the lines. Air enclosed in the lines can

cause pressure peaks resulting in a rupture and other hazards.

• Use only accessories authorized by Mitsubishi Electric and ask a dealer or

an authorized technician to install them. If accessories are incorrectly installed, water leakage, electric shock, or fire may result.

• Do not alter the unit. Consult a dealer for repairs. If alterations or repairs are

not performed correctly, water leakage, electric shock, or fire may result.

• The user should never attempt to repair the unit or transfer it to another location. If the unit is installed incorrectly, water leakage, electric shock, or fire

may result. If the air conditioner must be repaired or moved, ask a dealer or

an authorized technician.

• After installation has been completed, check for refrigerant leaks. If refrigerant leaks into the room and comes into contact with the flame of a heater or

portable cooking range, poisonous gases will be released.

1.1. Before installation

Caution:

• Do not use the unit in an unusual environment. If the air conditioner is installed in areas exposed to steam, volatile oil (including machine oil), or sulfuric

gas, areas exposed to high salt content such as the seaside, or areas where

the unit will be covered by snow, the performance can be significantly reduced and the internal parts can be damaged.

• Do not install the unit where combustible gases may leak, be produced, flow,

or accumulate. If combustible gas accumulates around the unit, fire or explosion may result.

• The outdoor unit produces condensation during the heating operation. Make

sure to provide drainage around the outdoor unit if such condensation is

likely to cause damage.

1.2. Before installation (relocation)

Caution:

• Be extremely careful when transporting the units. Two or more persons are

needed to handle the unit, as it weighs 20 kg, 44 Ibs or more. Do not grasp

the packaging bands. Wear protective gloves to remove the unit from the

packaging and to move it, as you can injure your hands on the fins or other

parts.

• Be sure to safely dispose of the packaging materials. Packaging materials, such

as nails and other metal or wooden parts may cause stabs or other injuries.

2

• When installing the unit in a hospital or communications office, be prepared

for noise and electronic interference. Inverters, home appliances, high-frequency medical equipment, and radio communications equipment can cause

the air conditioner to malfunction or breakdown. The air conditioner may also

affect medical equipment, disturbing medical care, and communications equipment, harming the screen display quality.

• The base and attachments of the outdoor unit must be periodically checked

for looseness, cracks or other damage. If such defects are left uncorrected,

the unit may fall down and cause damage or injuries.

• Do not clean the air conditioner unit with water. Electric shock may result.

• Tighten all flare nuts to specification using a torque wrench. If tightened too

much, the flare nut can break after an extended period and refrigerant can

leak out.

1. Safety precautions

D

E

C

B

A

37-13/32

13+1-3/16

37-1/8(53-5/32)

6-7/8

23-5/8

14-9/16

31-1/2

11-13/16+29/32

23-5/8

5-29/32

2-23/32

19-11/16

13

1.3. Before electric work

Caution:

• Be sure to install circuit breakers. If not installed, electric shock may result.

• For the power lines, use standard cables of sufficient capacity. Otherwise, a

short circuit, overheating, or fire may result.

• When installing the power lines, do not apply tension to the cables. If the

connections are loosened, the cables can snap or break and overheating or

fire may result.

1.4. Before starting the test run

Caution:

• Turn on the main power switch more than 12 hours before starting operation.

Starting operation just after turning on the power switch can severely damage the internal parts. Keep the main power switch turned on during the operation season.

• Before starting operation, check that all panels, guards and other protective

parts are correctly installed. Rotating, hot, or high voltage parts can cause

injuries.

• Do not touch any switch with wet hands. Electric shock may result.

1.5. Using R410A refrigerant air conditioners

Caution:

• Use C1220 copper phosphorus, for copper and copper alloy seamless pipes,

to connect the refrigerant pipes. Make sure the insides of the pipes are clean

and do not contain any harmful contaminants such as sulfuric compounds,

oxidants, debris, or dust. Use pipes with the specified thickness. (Refer to

page 5) Note the following if reusing existing pipes that carried R22 refrigerant.

- Replace the existing flare nuts and flare the flared sections again.

- Do not use thin pipes. (Refer to page 5)

• Store the pipes to be used during installation indoors and keep both ends of

the pipes sealed until just before brazing. (Leave elbow joints, etc. in their

packaging.) If dust, debris, or moisture enters the refrigerant lines, oil deterioration or compressor breakdown may result.

• Use ester oil, ether oil, alkylbenzene oil (small amount) as the refrigeration oil

applied to the flared sections. If mineral oil is mixed in the refrigeration oil, oil

deterioration may result.

• Be sure to ground the unit. Do not connect the ground wire to gas or water

pipes, lighting rods, or telephone grounding lines. If the unit is not properly

grounded, electric shock may result.

• Use circuit breakers (ground fault interrupter, isolating switch (+B fuse), and

molded case circuit breaker) with the specified capacity. If the circuit breaker

capacity is larger than the specified capacity, breakdown or fire may result.

• Do not touch the refrigerant pipes with bare hands during operation. The

refrigerant pipes are hot or cold depending on the condition of the flowing

refrigerant. If you touch the pipes, burns or frostbite may result.

• After stopping operation, be sure to wait at least five minutes before turning

off the main power switch. Otherwise, water leakage or breakdown may result.

• Do not use refrigerant other than R410A refrigerant. If another refrigerant is

used, the chlorine will cause the oil to deteriorate.

• Use the following tools specifically designed for use with R410A refrigerant.

The following tools are necessary to use R410A refrigerant. Contact your

nearest dealer for any questions.

Tools (for R410A)

Gauge manifold Flare tool

Charge hose Size adjustment gauge

Gas leak detector Vacuum pump adapter

Torque wrench Electronic refrigerant charging scale

• Be sure to use the correct tools. If dust, debris, or moisture enters the refrigerant lines, refrigeration oil deterioration may result.

• Do not use a charging cylinder. If a charging cylinder is used, the composition of the refrigerant will change and the efficiency will be lowered.

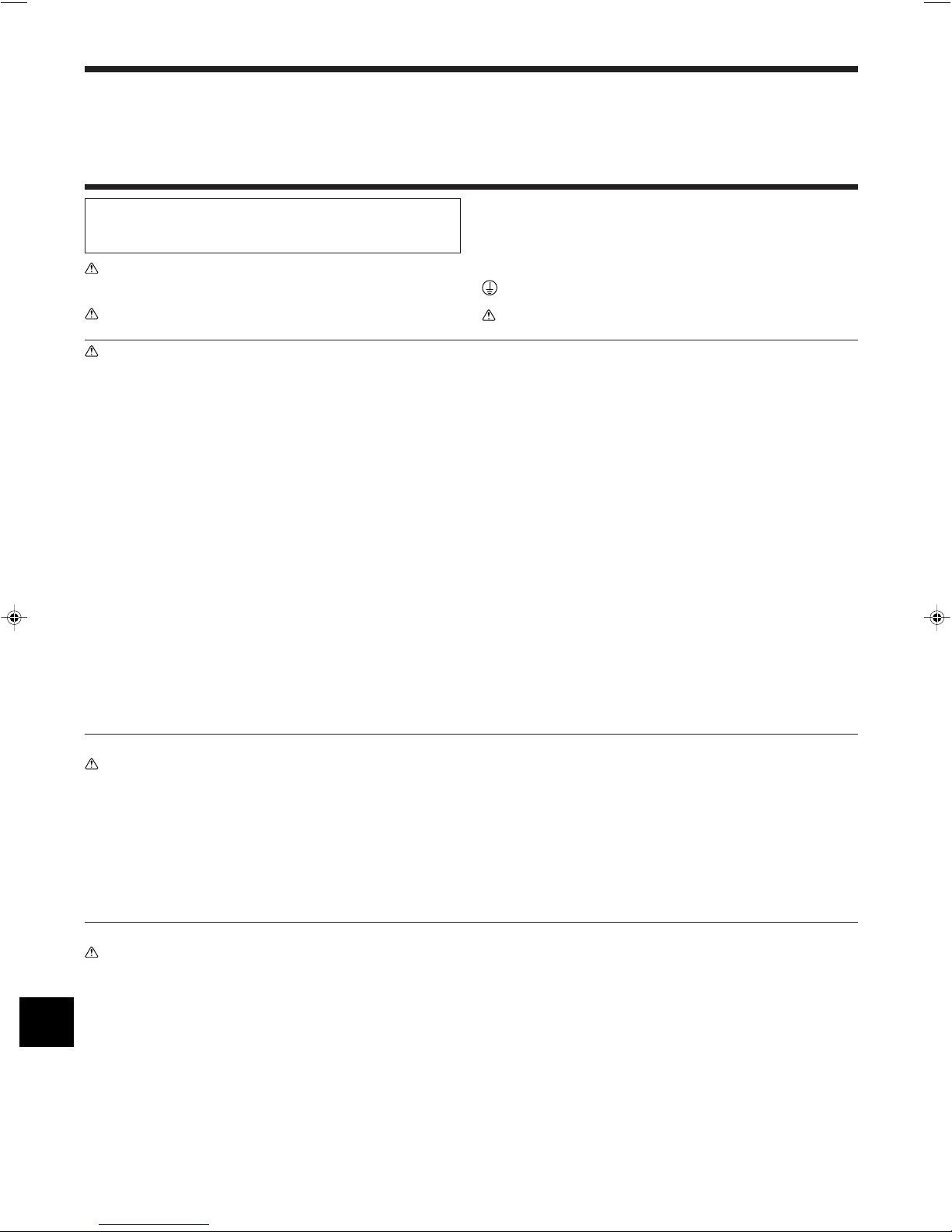

2. Installation location

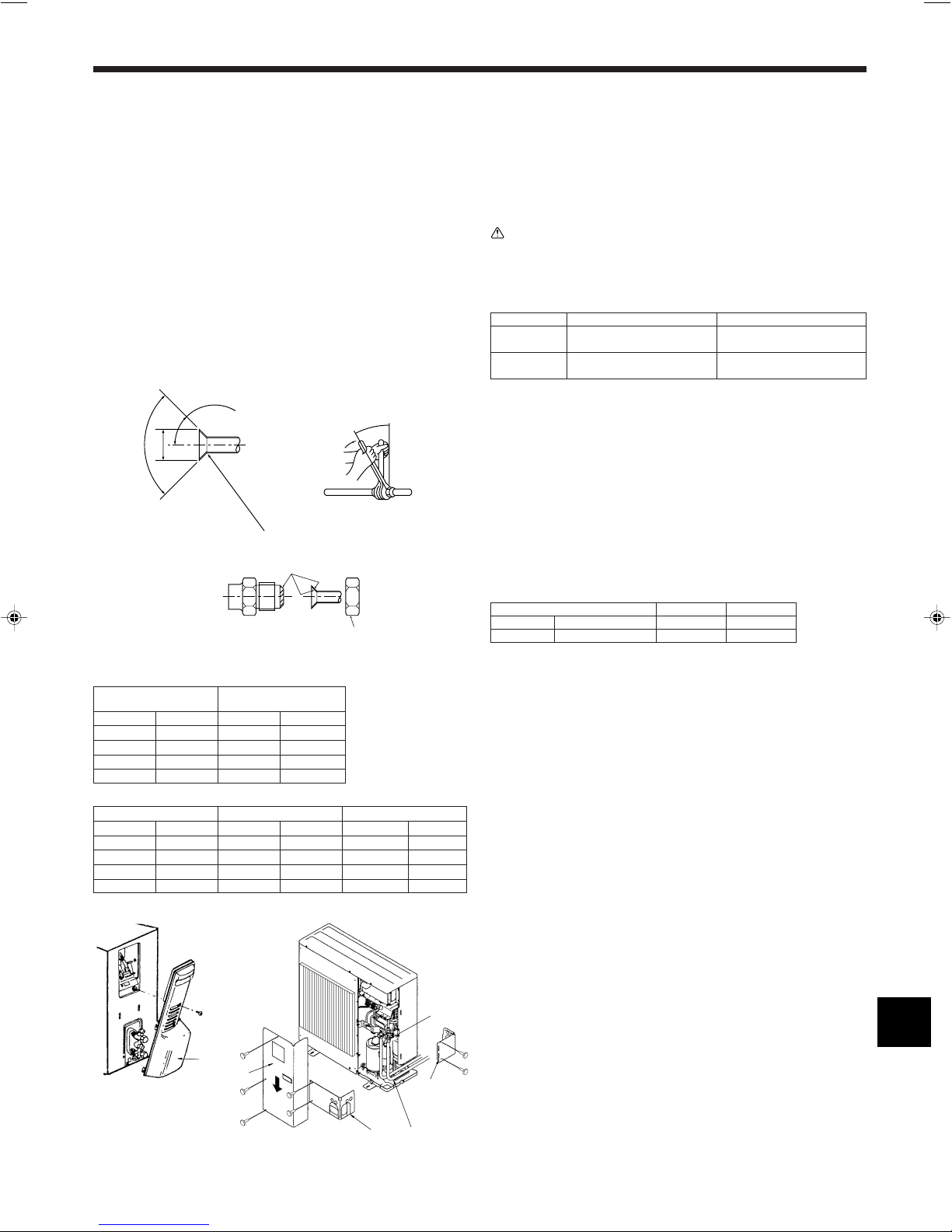

Fig. 2-1

Fig. 2-2

2.1. Refrigerant pipe (Fig. 2-1)

s Check that the difference between the heights of the indoor and outdoor

units, the length of refrigerant pipe, and the number of bends in the pipe are

within the limits shown below.

Models

A12, A18 Max. 30 m, 100 ft Max. 30 m, 100 ft Max. 15

A24, A30, A36, A42

• Height difference limitations are binding regardless of which unit, indoor or outdoor,

is positioned higher.

D Indoor unit

E Outdoor unit

■ A24, A30, A36, A42 (inch)■ A12, A18 (inch)

2.2. Choosing the outdoor unit installation location

• Avoid locations exposed to direct sunlight or other sources of heat.

• Select a location from which noise emitted by the unit will not inconvenience

neighbors.

• Select a location permitting easy wiring and pipe access to the power source and

indoor unit.

• Avoid locations where combustible gases may leak, be produced, flow, or accumulate.

• Note that water may drain from the unit during operation.

• Select a level location that can bear the weight and vibration of the unit.

• Avoid locations where the unit can be covered by snow. In areas where heavy snow

fall is anticipated, special precautions such as raising the installation location or

installing a hood on the air intake must be taken to prevent the snow from blocking

the air intake or blowing directly against it. This can reduce the airflow and a malfunction may result.

• Avoid locations exposed to oil, steam, or sulfuric gas.

• Use the transportation handles of the outdoor unit to transport the unit. If the unit is

carried from the bottom, hands or fingers may be pinched.

A Pipe length B Height C Number of

(one way) difference bends (one way)

Max. 50 m, 165 ft Max. 30 m, 100 ft Max. 15

2.3. Outline dimensions (Outdoor unit) (Fig. 2-2)

The figure in parenthesis is for A42 model.

3

B

2. Installation location

A

B

A

C

D

19-11/16 19-11/16

Min. 25-19/32

5-29/32 5-29/32

Min. 13-25/32

31-1/2

1-9/32

11-13/16

13

23-5/8 23-5/8

Min. 14-3/16

6-7/8 6-7/8

Min. 13/32

37-13/32

1-3/32

13

14-9/16

D

Fig. 2-3

Fig. 2-4

Fig. 2-5

2.4. Ventilation and service space

2.4.1. Windy location installation

When installing the outdoor unit on a rooftop or other location unprotected from the

wind, situate the air outlet of the unit so that it is not directly exposed to strong winds.

Strong wind entering the air outlet may impede the normal airflow and a malfunction

may result.

The following shows three examples of precautions against strong winds.

1 Face the air outlet towards the nearest available wall about 50 cm, 19-11/16 inch

away from the wall. (Fig. 2-3)

2 Install an optional air outlet guide and air guide if the unit is installed in a location

where strong winds from a typhoon, etc. may directly enter the air outlet. (Fig. 2-4)

A Air outlet guide

3 Position the unit so that the air outlet blows perpendicularly to the seasonal wind

direction, if possible. (Fig. 2-5)

B Wind direction

3. Installing the outdoor unit

2.4.2. When installing a single outdoor unit (Refer to the last page)

Minimum dimensions are as follows, except for Max., meaning Maximum dimensions,

indicated.

The figures in parentheses are for A42 models.

Refer to the figures for each case.

1 Obstacles at rear only (Fig. 2-6)

2 Obstacles at rear and above only (Fig. 2-7)

3 Obstacles at rear and sides only (Fig. 2-8)

∗ 350mm, 13-25/32 inch for A12, A18

4 Obstacles at front only (Fig. 2-9)

∗ When using an optional air outlet guide, the clearance for A42 models is 500 mm,

19-11/16 inch or more.

5 Obstacles at front and rear only (Fig. 2-10)

∗ When using an optional air outlet guide, the clearance for A42 models is 500 mm,

19-11/16 inch or more.

6 Obstacles at rear, sides, and above only (Fig. 2-11)

∗ 350 for A12, A18

• Do not install the optional air outlet guides for upward airflow.

2.4.3. When installing multiple outdoor units (Refer to the last page)

Leave 350 mm, 13-25/32 inch for A18 and 10 mm, 13/32 inch for A24-A42 space or

more between the units.

1 Obstacles at rear only (Fig. 2-12)

2 Obstacles at rear and above only (Fig. 2-13)

• No more than three units must be installed side by side. In addition, leave space as shown.

• Do not install the optional air outlet guides for upward airflow.

3 Obstacles at front only (Fig. 2-14)

∗ When using an optional air outlet guide, the clearance for A42 models is 1000 mm,

39-3/8 inch or more.

4 Obstacles at front and rear only (Fig. 2-15)

∗ When using an optional air outlet guide, the clearance for A42 models is 1000 mm,

39-3/8 inch or more.

5 Single parallel unit arrangement (Fig. 2-16)

∗ When using an optional air outlet guide installed for upward airflow, the clearance is 500

(1000) mm, 19-11/16 (39-3/8) inch or more.

6 Multiple parallel unit arrangement (Fig. 2-17)

∗ When using an optional air outlet guide installed for upward airflow, the clearance is 1000

(1500) mm, 39-3/8 (59-1/16) inch or more.

7 Stacked unit arrangement (Fig. 2-18)

• The units can be stacked up to two units high.

• No more than two stacked units must be installed side by side. In addition, leave space as

shown.

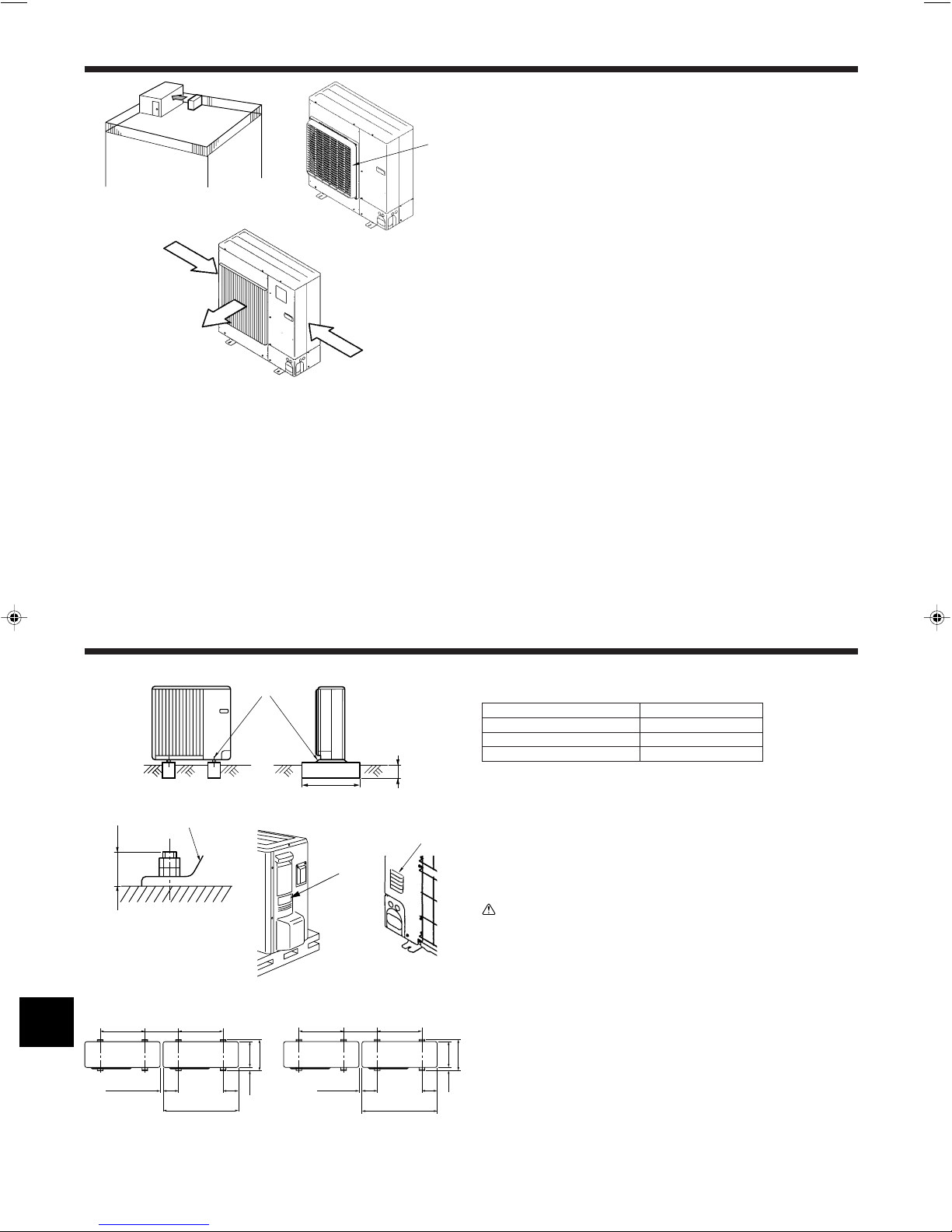

Max. 23/32 for A12, A18

Max. 1-3/16 for A24-A42

A M10 (3/8”) bolt

B Base

C As long as possible.

D Vent

■ A24-A42■ A12, A18

Fig. 3-1

• Be sure to install the unit in a sturdy, level surface to prevent rattling noises during

(inch)

■ A24-A42■ A12, A18

(inch)

operation. (Fig. 3-1)

<Foundation specifications>

Foundation bolt M10 (3/8”)

Thickness of concrete 120 mm, 4-23/32 inch

Length of bolt 70 mm, 2-3/4 ing

Weight-bearing capacity 320 kg, 264 lbs

• Make sure that the length of the foundation bolt is within 30 mm, 1-3/16 inch of the

bottom surface of the base.

• Secure the base of the unit firmly with four-M10 foundation bolts in sturdy locations.

Installing the outdoor unit

• Do not block the vent. If the vent is blocked, operation will be hindered and breakdown may result.

• In addition to the unit base, use the installation holes on the back of the unit to attach

wires, etc., if necessary to install the unit. Use self-tapping screws (ø5 × 15 mm,

ø13/16 × 19/32 inch or more) and install on site.

Warning:

• The unit must be securely installed on a structure that can sustain its weight.

If the unit is mounted on an unstable structure, it may fall down and cause

damage or injuries.

• The unit must be installed according to the instructions in order to minimize

the risk of damage from earthquakes, typhoons, or strong winds. An incorrectly installed unit may fall down and cause damage or injuries.

4

4. Installing the refrigerant piping

90° ±0.5°

øA

R1/64 to R1/32

A

45°±2°

B

C

D

C

B

A

E

D

D

A Flare cutting dimensions

B Flare nut tightening torque

Fig. 4-1

A (Fig. 4-1)

Flare dimensions

øA dimensions

■ A24-A42■ A12, A18

Fig. 4-3

Copper pipe O.D.

(mm) (inch) (mm) (inch)

ø6.35 1/4” 8.7 - 9.1 11/32 - 23/64

ø9.52 3/8” 12.8 - 13.2 1/2 - 33/64

ø12.7 1/2” 16.2 - 16.6 41/64 - 21/32

ø15.88 5/8” 19.3 - 19.7 49/64 - 25/32

B (Fig. 4-1)

Copper pipe O.D. Flare nut O.D. Tightening torque

(mm) (inch) (mm) (inch) (N·m) (ft·lbs)

ø6.35 1/4” 17 43/64 14 - 18 10 - 13

ø9.52 3/8” 22 7/8 34 - 42 25 - 30

ø12.7 1/2” 26 1 - 3/64 49 - 61 35 - 44

ø15.88 5/8” 29 1 - 9/64 68 - 82 49 - 59

A Front piping cover

B Piping cover

C Stop valve

D Service panel

E Band radius : 100 mm, 3-15/16 inch-150 mm, 5-27/32 inch

(inch)

4.1. Precautions for devices that use R410A refrigerant

• Refer to page 3 for precautions not included below on using air conditioners

with R410A refrigerant.

• Use ester oil, ether oil, alkylbenzene oil (small amount) as the refrigeration oil

applied to the flared sections.

• Use C1220 copper phosphorus, for copper and copper alloy seamless pipes,

to connect the refrigerant pipes. Use refrigerant pipes with the thicknesses

specified in the table to the below. Make sure the insides of the pipes are

clean and do not contain any harmful contaminants such as sulfuric compounds, oxidants, debris, or dust.

Warning:

When installing or moving the air conditioner, use only the specified refrigerant (R410A) to charge the refrigerant lines. Do not mix it with any other refrigerant and do not allow air to remain in the lines. Air enclosed in the lines can

cause pressure peaks resulting in a rupture and other hazards.

A12, A18 A24-A42

Liquid pipe

Gas pipe

• Do not use pipes thinner than those specified above.

ø6.35 mm, 1/4inch ø9.52 mm, 3/8 inch

thickness 0.8 mm, 1/32 inch thickness 0.8 mm, 1/32 inch

ø12.7 mm, 1/2 inch ø15.88 mm, 5/8 inch

thickness 0.8 mm, 1/32 inch thickness 1.0 mm, 3/64 inch

4.2. Connecting pipes (Fig. 4-1)

• When commercially available copper pipes are used, wrap liquid and gas pipes

with commercially available insulation materials (heat-resistant to 100 °C, 212 °F or

more, thickness of 12 mm, 1/2 inch or more).

• The indoor parts of the drain pipe should be wrapped with polyethylene foam insu-

lation materials (specific gravity of 0.03, thickness of 9 mm, 23/64 inch or more).

• Apply thin layer of refrigerant oil to pipe and joint seating surface before tightening

flare nut. A

• Use two wrenches to tighten piping connections. B

• Use leak detector or soapy water to check for gas leaks after connections are com-

pleted.

• Apply refrigerating machine oil over the entire flare seat surface. C

• Use the flare nuts for the following pipe size. D

Gas side Pipe size (mm, inch) ø12.7, 1/2”ø15.88, 5/8”

Liquid side Pipe size (mm, inch) ø6.35, 1/4”ø9.52, 3/8”

*1: The flare nut is attached to its pipe.

*2: The flare nut is in the outdoor unit accessory.

Do not use the flare nut attached. If it is used, a gas leakage or even a pipe

extraction may occur.

• When bending the pipes, be careful not to break them. Bend radii of 100 mm,

3-15/16 inch to 150 mm, 5-27/32 inch are sufficient.

• Make sure the pipes do not contact the compressor. Abnormal noise or vibration

may result.

1 Pipes must be connected starting from the indoor unit.

Flare nuts must be tightened with a torque wrench.

2 Flare the liquid pipes and gas pipes and apply a thin layer of refrigeration oil

(Applied on site).

A12, A18 A24, A42

4.3. Refrigerant piping (Fig. 4-3)

■ For A12, A18

Remove the service panel D (one screw).

■ For A24-A42

Remove the service panel D (three screws) and the front piping cover A (two screws)

and rear piping cover B (two screws).

1 Perform refrigerant piping connections for the indoor/outdoor unit when the out-

door unit’s stop valve is completely closed.

2 Vacuum-purge air from the indoor unit and the connection piping.

3 After connecting the refrigerant pipes, check the connected pipes and the indoor

unit for gas leaks. (Refer to 4.4 Refrigerant pipe airtight testing method)

4 Vacuumize the refrigerant lines through the service port of the liquid stop valve

and then open the stop valves completely (for both the liquid and gas stop valves).

This will completely connect the refrigerant lines of the indoor and outdoor units.

• If the stop valves are left closed and the unit is operated, the compressor and

control valves will be damaged.

• Use a leak detector or soapy water to check for gas leaks at the pipe connection sections of the outdoor unit.

• Do not use the refrigerant from the unit to purge air from the refrigerant lines.

• After the valve work is completed, tighten the valve caps to the correct torque:

20 to 25 N·m, 14 to 18 ft·lbs (200 to 250 kgf·cm).

Failure to replace and tighten the caps may result in refrigerant leakage. In

addition, do not damage the insides of the valve caps as they act as a seal to

prevent refrigerant leakage.

5 Use sealant to seal the ends of the thermal insulation around the pipe connection

sections to prevent water from entering the thermal insulation.

5

4. Installing the refrigerant piping

A

B

H

I

C

D

E

F

G

D

B

A

C

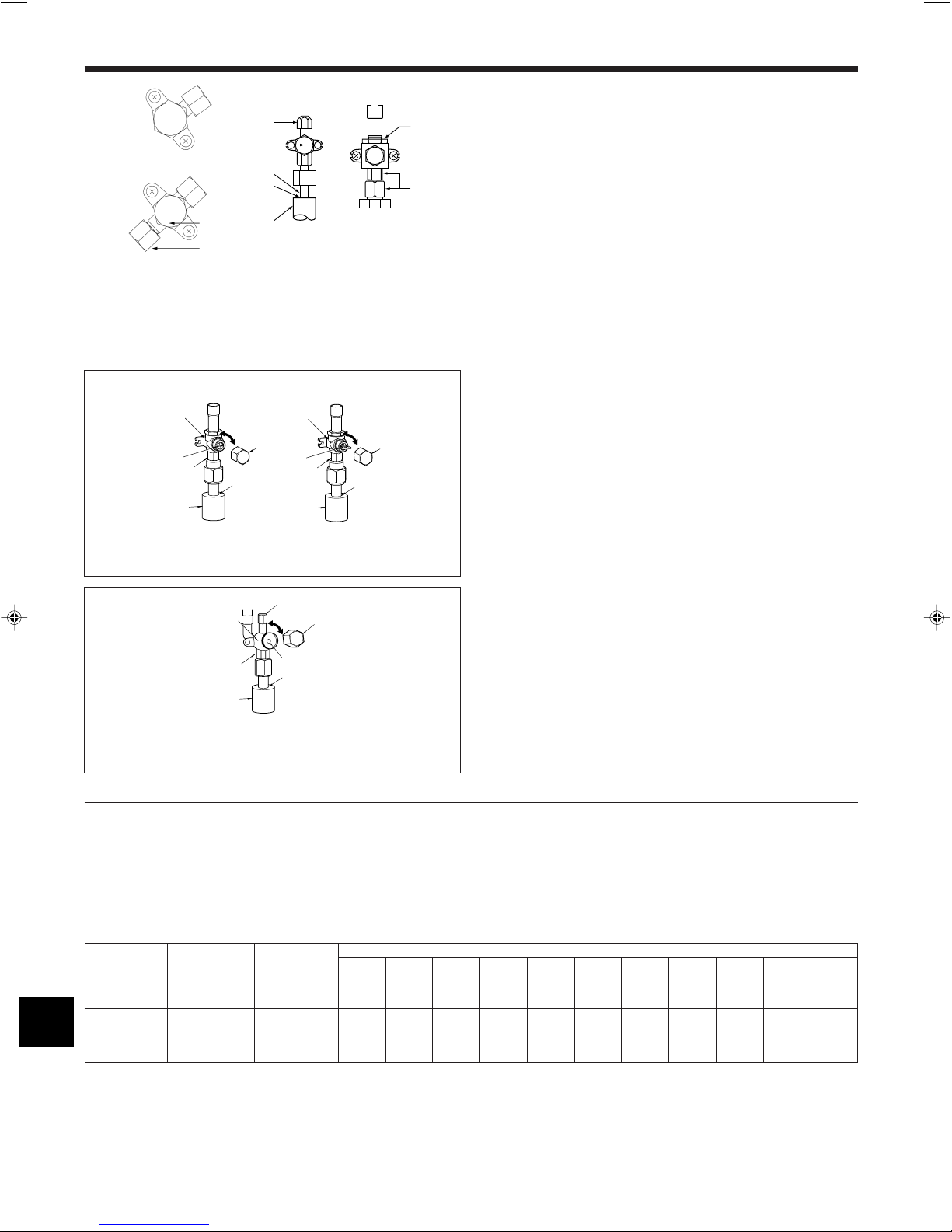

Fig. 4-5

A

B

C

D

E

F

I

J

J

A

B

K

D

E

F

I

Type A Type B

Fig. 4-6

B

G

H

E

D

A

I

J

F

E Local pipe

A Stop valve <Liquid side>

B Stop valve <Gas side>

C Service port

D Open/Close section

(1)

(2)

F Sealed, same way for gas side

G Pipe cover

H Do not use a wrench here.

Refrigerant leakage may result.

I Use two wrenches here.

Fig. 4-4

4.4. Refrigerant pipe airtight testing method

(1) Connect the testing tools.

• Make sure the stop valves A B are closed and do not open them.

• Add pressure to the refrigerant lines through the service port C of the liquid

stop valve D.

(2) Do not add pressure to the specified pressure all at once; add pressure little by little.

1 Pressurize to 0.5 MPa (5 kgf/cm

pressure does not decrease.

2 Pressurize to 1.5 MPa (15 kgf/cm2G), wait five minutes, and make sure the

pressure does not decrease.

3 Pressurize to 4.15 MPa (41.5 kgf/cm

perature and refrigerant pressure.

(3) If the specified pressure holds for about one day and does not decrease, the pipes

have passed the test and there are no leaks.

• If the surrounding temperature changes by 1 °C, the pressure will change by

about 0.03 MPa (0.3 kgf/cm

(4) If the pressure decreases in steps (2) or (3), there is a gas leak. Look for the

source of the gas leak.

2

G), wait five minutes, and make sure the

2

G) and measure the surrounding tem-

2

G). Make the necessary corrections.

4.5. Stop valve opening method

(1) Gas side of A24-A42 (Fig. 4-5)

Type A

1 Remove the cap, then turn one-quarter rotation counter-clockwise with a flat-bladed

screwdriver to complete open.

2 Check that the valves are fully open, then return the cap to its original state and

tighten it down.

Type B

1 Remove the cap, pull the handle toward you and rotate 1/4 turn in a counterclock-

wise direction to open.

2 Make sure that the stop valve is open completely, push in the handle and rotate

the cap back to its original position.

(2) Liquid side of A24-A42 and Gas/Liquid side of A12, A18 (Fig. 4-6)

1 Remove the cap and turn the valve rod counterclockwise as far as it will go with

the use of a 4 mm hexagonal wrench. Stop turning when it hits the stopper.

(ø6.35, 1/4 inch: Approximately 4.5 revolutions) (ø9.52, 3/8 inch: Approximately

10 revolutions)

2 Make sure that the stop valve is open completely, push in the handle and rotate

the cap back to its original position.

A Valve

B Unit side

C Operation section

D Cap

E Local pipe side

F Pipe cover

G Service port

H Wrench hole

Refrigerant pipes are protectively wrapped for A24-A42

• The pipes can be protectively wrapped up to a diameter of ø90 mm, 3-35/64 inch

before or after connecting the pipes. Cut out the knockout in the pipe cover following the groove and wrap the pipes.

Pipe inlet gap for A24-A42

• Use putty or sealant to seal the pipe inlet around the pipes so that no gaps remain.

(If the gaps are not closed, noise may be emitted or water and dust will enter the

unit and breakdown may result.)

I Double spanner section

(Do not apply a spanner other than to this section. Doing so would cause coolant leaks.)

J Seal section

(Seal the end of the heat insulation material at

the pipe connection section with whatever seal

material you have on hand so that water does

not infiltrate the heat insulation material.)

K Handle

4.6. Addition of refrigerant

• Additional charging is not necessary if the pipe length does not exceed 20 m, 70 ft

for A12-A36, 30 m 100 ft for A42.

• If the pipe length exceeds the specified length above, charge the unit with additional R410A refrigerant according to the permitted pipe lengths in the chart below.

* When the unit is stopped, charge the unit with the additional refrigerant through

the liquid stop valve after the pipe extensions and indoor unit have been

vacuumized.

When the unit is operating, add refrigerant to the gas check valve using a

safety charger. Do not add liquid refrigerant directly to the check valve.

Max height

difference

Max pipe

length

Model

A12, A18 30 m, 100 ft 30 m, 100 ft 0

A24, A30, A36 50 m, 165 ft 30 m, 100 ft 0

A42 50 m, 165 ft 30 m, 100 ft 0 0 0 0

6

* After charging the unit with refrigerant, note the added refrigerant amount on

the service label (attached to the unit).

Refer to the “1.5. Using R410A refrigerant air conditioners” for more information.

• Be careful when installing multiple units. Connecting to an incorrect indoor unit can

lead to abnormally high pressure and have a serious effect on operation performance.

20 m 25 m 27 m 30 m 33.5 m 36.6 m 40 m 43 m 45.5 m 48.8 m 50 m

70 ft 80 ft 90 ft 100 ft 110 ft 120 ft 130 ft 140 ft 150 ft 160 ft 165 ft

0.06 kg 0.11 kg 0.17 kg

2 oz 4 oz 6 oz

0.17 kg 0.34 kg 0.51 kg 0.68 kg 0.85 kg 1.02 kg 1.19 kg 1.36 kg 1.53 kg 1.70 kg

6 oz 12 oz 18 oz 24 oz 30 oz 36 oz 42 oz 48 oz 54 oz 60 oz

Additional refrigerant charging amount (kg/oz)

–––––––

0.17 kg 0.34 kg 0.51 kg 0.68 kg 0.85 kg 1.02 kg 1.19 kg

6 oz 12 oz 18 oz 24 oz 30 oz 36 oz 42 oz

4. Installing the refrigerant piping

A

A

C

E

D

B

C

A

B

A

B

C

D

E

A

C

B

S3

S3

S2

S1

S2S1L1 L2

GR

D

E

E

D

E

C

B

A A

E E

L1GRL2 S1 S2 S3

E

B

A

F

C

L1GRL2 S1 S2 S3

B–C ≤ 8 m, 26 ftA24, A36 : A+B+C ≤ 50 m, 165 ft

Fig. 4-7

5. Drainage piping work

Outdoor unit drainage pipe connection

When drain piping is necessary, use the drain socket or the drain pan (option).

A12, A18 A24-A42

Drain socket PAC-SG61DS-E

Drain pan PAC-SG63DP-E PAC-SG64DP-E

4.7. For twin combination (For A24, A36 only)

Refrigerant piping limitation of length, height difference are shown in the figure. (Fig.

4-7)

A Indoor unit

B Outdoor unit

C Multi distribution pipe (option)

D Height difference (Indoor unit-Outdoor unit) Max. 30 m, 100 ft

E Height difference (Indoor unit-Indoor unit) Max. 1 m, 3 ft

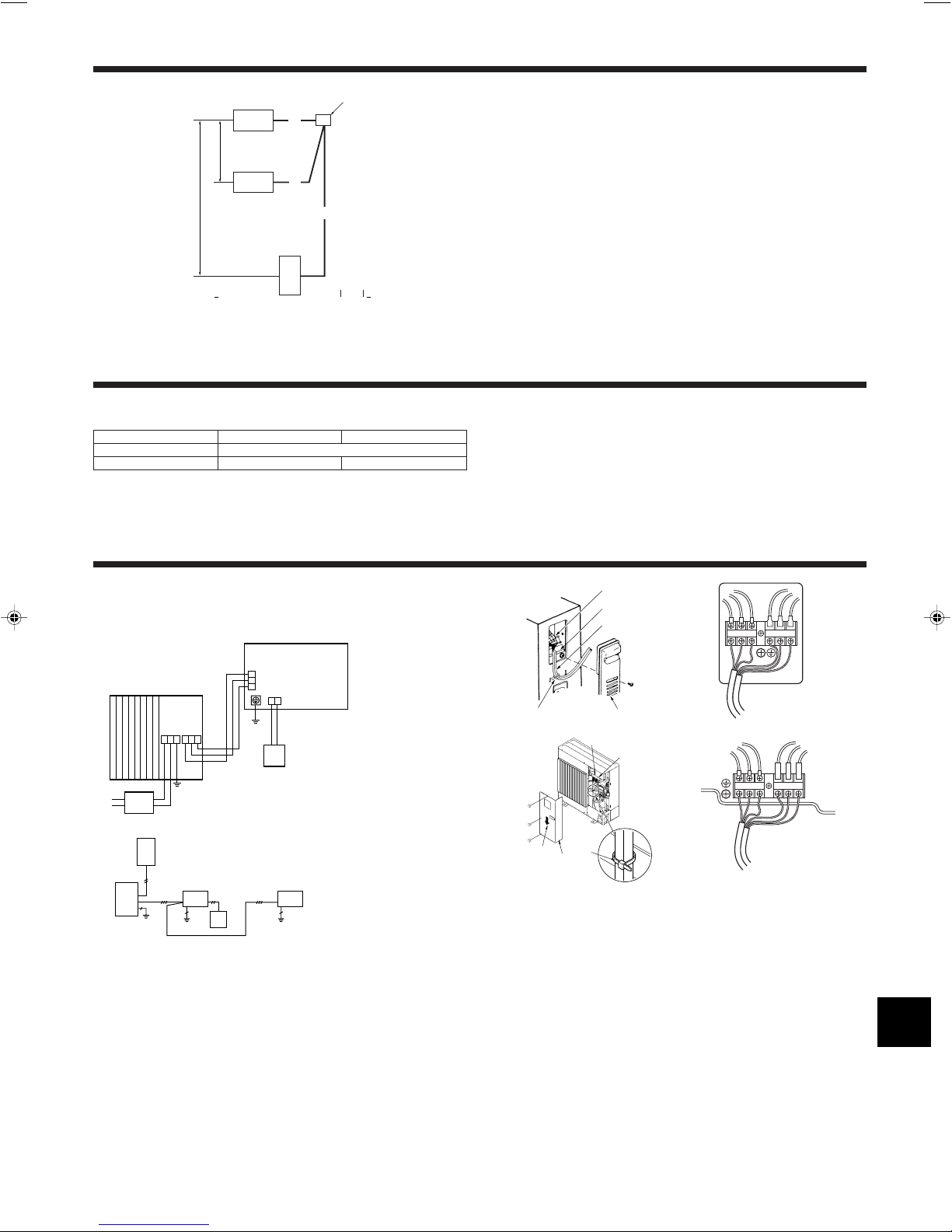

6. Electrical work

6.1. Outdoor unit (Fig. 6-1, Fig. 6-2)

1 Remove the service panel.

2 Wire the cables referring to the Fig. 6-1 and the Fig. 6-2.

For Power

For Power

Fig. 6-1

A Indoor unit

B Outdoor unit

C Remote controller

D Main switch (Breaker)

E Earth

■ A12, A18

■ A24-A42

A Earth terminal

B Terminal block

C Clamp

D Service panel

E Wire the cables so that they do not

contact the center of the service

panel or the gas valve.

Fig. 6-2

7

■ A12, A18

CORD COVER

CONDUIT COVER

CABLE STRAP

TERMINAL BED

SERVICE PANEL

CONDUIT PLATE : accessory

GRL2L1 S1 S2 S3

■ A24–42

8

6. Electrical work

S1

S2

S3

S1

S2

S3

6.2. Field electrical wiring

Outdoor unit model

Outdoor unit power supply

Breaker size

Minimum circuit ampacity

Maximum rating of overcurrent protective device

Outdoor unit power supply

Outdoor unit power supply earth

Indoor unit-Outdoor unit *1

size

Wiring

Indoor unit earth *1

Wire No. ×

Remote controller-Indoor unit *2

Outdoor unit L1-L2 *3

Indoor unit-Outdoor unit S1-S2 *3

Indoor unit-Outdoor unit S2-S3 *3

rating

Circuit

Remote controller-Indoor unit *3

*1. Max. 50 m, 165 ft

*2. The 10 m, 30 ft wire is attached in the remote controller accessory. Max 1500 ft

*3. The figures are NOT always against the ground.

S3 terminal has DC 24 V against S2 terminal. However between S3 and S1, these terminals are NOT electrically insulataed by the transformer or other device.

Notes: 1. Wiring size must comply with the applicable local and national code.

2. Use copper supply wires.

3. Use wires rated 300V ro more for the power supply cables and the indoor/outdoor unit connecting cables.

4. Install an earth longer than other cables.

208/230V

Single phase

A12 A18 A24 A30 A36 A42

Single, 208/230 V, 60 Hz Single, 208/230 V, 60 Hz Single, 208/230 V, 60 Hz Single, 208/230 V, 60 Hz Single, 208/230 V, 60 Hz Single, 208/230 V, 60 Hz

15A 15A 25A 30A 30A 30A

13A 13A 18A 25A 25A 26A

15A 20A 30A 40A 40A 40A

2 × Min. AWG 14 2 × Min. AWG 14 2 × Min. AWG 12 2 × Min. AWG 10 2 × Min. AWG 10 2 × Min. AWG 10

1 × Min. AWG 14 1 × Min. AWG 14 1 × Min. AWG 12 1 × Min. AWG 10 1 × Min. AWG 10 1 × Min. AWG 10

3 × AWG 16 (polar) 3 × AWG 16 (polar) 3 × AWG 16 (polar) 3 × AWG 16 (polar) 3 × AWG 16 (polar) 3 × AWG 16 (polar)

1 × Min. AWG 16 1 × Min. AWG 16 1 × Min. AWG 16 1 × Min. AWG 16 1 × Min. AWG 16 1 × Min. AWG 16

2 × AWG 22 (Non-polar) 2 × AWG 22 (Non-polar) 2 × AWG 22 (Non-polar) 2 × AWG 22 (Non-polar) 2 × AWG 22 (Non-polar) 2 × AWG 22 (Non-polar)

AC 208/230 V AC 208/230 V AC 208/230 V AC 208/230 V AC 208/230 V AC 208/230 V

AC 208/230 V AC 208/230 V AC 208/230 V AC 208/230 V AC 208/230 V AC 208/230 V

DC 24 V DC 24 V DC 24 V DC 24 V DC 24 V DC 24 V

DC 12 V DC 12 V DC 12 V DC 12 V DC 12 V DC 12 V

Isolator

A-Control

Outdoor Unit

3 poles isolator

A-Control

Indoor Unit

Warning:

In case of A-control wiring, there is high voltage potential on the S3 terminal caused by electrical circuit design that has no electrical insulation between power line

and communication signal line. Therefore, please turn off the main power supply when servicing. And do not touch the S1, S2, S3 terminals when the power is

energized. If isolator should be used between indoor unit and outdoor unit, please use 3-poles type.

7. Test run

7.1. Before test run

s After completing installation and the wiring and piping of the indoor and outdoor

units, check for refrigerant leakage, looseness in the power supply or control

wiring, wrong polarity, and no disconnection of one phase in the supply.

s Use a 500-volt megohmmeter to check that the resistance between the power

supply terminals and ground is at least 1.0M

s Do not carry out this test on the control wiring (low voltage circuit) terminals.

Warning:

Do not use the air conditioner if the insulation resistance is less than 1.0M

Insulation resistance

After installation or after the power source to the unit has been cut for an extended

period, the insulation resistance will drop below 1 MΩ due to refrigerant accumulating in the compressor. This is not a malfunction. Perform the following procedures.

1. Remove the wires from the compressor and measure the insulation resistance of

the compressor.

2. If the insulation resistance is below 1 MΩ, the compressor is faulty or the resist-

ance dropped due the accumulation of refrigerant in the compressor.

3. After connecting the wires to the compressor, the compressor will start to warm

up after power is supplied. After supplying power for the times indicated below,

measure the insulation resistance again.

• The insulation resistance drops due to accumulation of refrigerant in the compressor. The resistance will rise above 1 MΩ after the compressor is warmed

up for two to three hours.

(The time necessary to warm up the compressor varies according to atmospheric conditions and refrigerant accumulation.)

ΩΩ

Ω.

ΩΩ

ΩΩ

Ω.

ΩΩ

• To operate the compressor with refrigerant accumulated in the compressor,

the compressor must be warmed up at least 12 hours to prevent breakdown.

4. If the insulation resistance rises above 1 MΩ, the compressor is not faulty.

Caution:

• The compressor will not operate unless the power supply phase connection

is correct.

• Turn on the power at least 12 hours before starting operation.

- Starting operation immediately after turning on the main power switch can result in

severe damage to internal parts. Keep the power switch turned on during the operational season.

s The followings must be checked as well.

• The outdoor unit is not faulty. LED1 and LED2 on the control board of the outdoor

unit flash when the outdoor unit is faulty.

• Both the gas and liquid stop valves are completely open.

• A protective sheet covers the surface of the DIP switch panel on the control board of

the outdoor unit. Remove the protective sheet to operate the DIP switches easily.

• Make sure that the all of the SW5 DIP switches for function changes on the control

board of the outdoor unit are set to OFF. If all of the SW5 switches are not set to

OFF, record the settings and then set all of the switches to OFF. Begin recovering

the refrigerant. After moving the unit to a new location and completing the test run,

set the SW5 switches to the previously recorded settings.

9

7. Test run

ON

123456

OFF

TB4

TB5

TB1

TB4

TB5

TB4

TB1

TB4

TB1

TB4

TB5

1

1

2

2

AA

BBBBB

CD

AFGE

ON

OFF

3456

ON

OFF

3456

ON

OFF

3456

SW1

CNDM

Red

Brown

Orange

BCD

E

3

1

7.2. Test run

7.2.1. Using SW4 in outdoor unit

1) PUH Type, PUZ Type

SW4-1 ON

SW4-2 OFF

SW4-1 ON

SW4-2 ON

2) PUY Type

SW4-1 ON

SW4-2 ON or OFF

* After performing the test run, set SW4-1 to OFF.

Cooling operation

Heating operation

Cooling operation

8. Special Functions

A

Fig. 8-1

A Circuit diagram example (low noise mode)

B On-site arrangement

C External input adapter (PAC-SC36NA)

D Outdoor unit control board

E Max. 10 m, 33 ft

8.2. Refrigerant collecting (pump down)

Perform the following procedures to collect the refrigerant when moving the indoor

unit or the outdoor unit.

1 Before collecting the refrigerant, first make sure that the all of the SW5 DIP switches

for function changes on the control board of the outdoor unit are set to OFF. If all of the

SW5 switches are not set to OFF, record the settings and then set all of the switches

to OFF. Start collecting the refrigerant. After moving the unit to a new location and

completing the test run, set the SW5 switches to the previously recorded settings.

2 Supply power (circuit breaker).

* When power is supplied, make sure that “CENTRALLY CONTROLLED” is not

displayed on the remote controller. If “CENTRALLY CONTROLLED” is displayed, the refrigerant collecting (pump down) cannot be completed normally.

3 After the gas stop valve is closed, set the SWP switch on the control board of the

outdoor unit to ON. The compressor (outdoor unit) and ventilators (indoor and

outdoor units) start operating and refrigerant collecting operation begins. LED1

and LED2 on the control board of the outdoor unit are lit.

9. System control (Fig. 9-1)

• After power is supplied, a small clicking noise may be heard from the inside of the outdoor

unit. The electronic expansion valve is opening and closing. The unit is not faulty.

• A few seconds after the compressor starts, a clanging noise may be heard from the

inside of the outdoor unit. The noise is coming from the check valve due to the small

difference in pressure in the pipes. The unit is not faulty.

The test run operation mode cannot be changed by DIP switch SW4-2 during

the test run. (To change the test run operation mode during the test run, stop

the test run by DIP switch SW4-1. After changing the test run operation mode,

resume the test run by switch SW4-1.)

7.2.2. Using remote controller

Refer to the indoor unit installation manual.

8.1. Low noise mode (on-site modification) (Fig. 8-1)

By performing the following modification, operation noise of the outdoor unit can be

reduced by about 3-4 dB.

The low noise mode will be activated when a commercially available timer or the

contact input of an ON/OFF switch is added to the CNDM connector (option) on the

control board of the outdoor unit.

• The capacity may be insufficient according to the outdoor temperature and conditions, etc.

1 Complete the circuit as shown when using the external input adapter (PAC-

SC36NA). (Option)

2 SW1 ON: Low noise mode

SW1 OFF: Normal operation

* Only set the SWP switch (push-button type) to ON if the unit is stopped. How-

ever, even if the unit is stopped and the SWP switch is set to ON less than

three minutes after the compressor stops, the refrigerant collecting operation

cannot be performed. Wait until compressor has been stopped for three minutes and then set the SWP switch to ON again.

4 Because the unit automatically stops in about two to three minutes after the refrig-

erant collecting operation (LED1 and LED2 are lit), be sure to quickly close the

gas stop valve. When LED1 and LED2 are lit and the outdoor unit is stopped, open

the liquid stop valve completely, and then repeat step 3 after three minutes have

passed.

* If the refrigerant collecting operation has been completed normally (LED1 and

LED2 are lit), the unit will remain stopped until the power supply is turned off.

5 Turn off the power supply (circuit breaker).

E SW 1 - 3 ~ 6

F SW 1 - 3 ~ 6

G SW 1 - 3 ~ 6

A Outdoor unit

B Indoor unit

C Master remote controller

D Subordinate remote controller

E Standard 1:1 (Refrigerant address = 00)

F Simultaneous twin (Refrigerant address = 01)

G Simultaneous twin (Refrigerant address = 02)

Fig. 9-1

10

* Set the refrigerant address using the DIP switch of the outdoor unit.

1 Wiring from the Remote Control

This wire is connected to TB5 (terminal board for remote controller) of the indoor unit

(non-polar).

2 When a Different Refrigerant System Grouping is Used.

Up to 16 refrigerant systems can be controlled as one group using the slim MA remote controller.

Note:

In single refrigerant system (twin/triple), there is no need of wiring

SW1

Function table

<SW1>

SW1

function

settings

Function

1 Compulsory de-

frosting

2 Error history clear

Refrigerant sys-

3

tem address set-

4

ting

5

6

Operation according to switch setting

ON OFF

Start Normal

Clear Normal

Settings for outdoor unit addresses 0 to 15

22

2.

22

3-15/16

(

7-7/8

)

7-7/8

(

11-13/16

)

3-15/16

(

7-7/8

)

3-15/16

(

5-29/32

)

7-7/8

(

11-13/16

)

39-3/8

Max. 19-11/16

19-11/16

(

39-3/8

)

3-15/16

(

5-29/32

)

19-11/16 (39-3/8)

7-7/8

(

11-13/16

)

39-3/8

(

59-1/16

)

11-13/16

(

19-11/16

)

39-3/8

(

59-1/16

)

Max. 11-13/16

39-3/8

(

59-1/16

)

39-3/8

(

59-1/16

)

11-13/16

(

19-11/16

)

19-11/16

(

39-3/8

)

15-3/4

(

23-5/8

)

39-3/8

(

78-23/32

)

3-15/16

(

5-29/32

)

39-3/8

(

59-1/16

)

19-11/16

(

31-1/2

)

5-29/32

39-3/8

(

59-1/16

)

15-3/4

(

23-5/8

)

78-23/32

(

118-3/32

)

11-13/16

(

19-11/16

)

Fig. 2-6 Fig. 2-7

5-29/32

(

9-27/32

)

5-29/32

(

9-27/32

)

39-3/8 (59-1/16

)

11-13/16 (19-11/16

)

Max. 19-11/16

inch

Fig. 2-8 Fig. 2-9

Fig. 2-12 Fig. 2-13

Fig. 2-10 Fig. 2-11

Fig. 2-14

Fig. 2-15

Fig. 2-17 Fig. 2-18

Fig. 2-16

11

Contenido

1. Medidas de Seguridad ........................................................................... 12

2. Lugar en que se instalará ...................................................................... 13

3. Instalación de la unidad exterior ............................................................ 14

4. Instalación de los tubos del refrigerante ................................................ 15

5. Tubería de drenaje ................................................................................. 17

1. Medidas de Seguridad

s Antes de instalar la unidad, asegúrese de haber leído el capítulo de “Me-

didas de seguridad”.

s Antes de conectar el sistema, informe al servicio de suministro o pídale

permiso para efectuar la conexión.

Atención:

Describe las precauciones que deben tenerse en cuenta para evitar el riesgo

de lesiones o muerte del usuario.

Cuidado:

Describe las precauciones que deben tenerse en cuenta para evitar daños en

la unidad.

Atención:

• El usuario no debe instalar la unidad. La instalación del aire acondicionado

debe correr a cargo del distribuidor o técnico autorizado. La instalación incorrecta de la unidad puede provocar escapes de agua, descargas eléctricas o

incendios.

• Para la instalación, siga las instrucciones del Manual de instalación y utilice

las herramientas y piezas de fontanería específicamente diseñados para utilizar con el refrigerante R410A. El refrigerante R410A en el sistema de HFC

puede asimilar una presión 1,6 veces superior a la de los refrigerantes convencionales. Si los accesorios de fontanería que se instalan no están fabricados para el refrigerante R410A, los tubos se pueden quemar y causar daños o lesiones. Además, pueden producirse escapes de agua, descargas eléctricas o incendios.

• La unidad debe instalarse según las instrucciones para reducir posibles da-

ños en caso de terremoto, huracán o vientos fuertes. Si no se instala correctamente, la unidad podría caerse y provocar daños o lesiones.

• La unidad debe instalarse firmemente sobre una estructura capaz de sopor-

tar su peso. Si la unidad se instala sobre una estructura inestable, podría

caerse y provocar daños o lesiones.

• Si el equipo de aire acondicionado se instala en una sala pequeña deberán

tomarse medidas para prevenir que la concentración de refrigerante exceda

los límites de seguridad en caso de fugas. Pregunte a un distribuidor por las

medidas adecuadas para evitar que la concentración exceda los límites. Si

se produce una fuga de refrigerante que sobrepase los límites de concentración, la estancia en la sala puede ser peligrosa por falta de oxígeno.

• Si se produce una fuga de refrigerante durante el funcionamiento, ventile la

sala. Si el refrigerante entra en contacto con una llama, se desprenderán

gases nocivos.

• Todas las conexiones eléctricas deberán ser realizadas por un técnico cuali-

ficado según la normativa local y las instrucciones de este manual. Cada

unidad debe tener su línea eléctrica y se deben usar disyuntores y un voltaje

correcto. El uso de líneas eléctricas con una capacidad insuficiente o una

conexión eléctrica incorrecta puede provocar descargas eléctricas o incendios.

6. Trabajo eléctrico ..................................................................................... 17

7. Prueba de funcionamiento ..................................................................... 19

8. Funciones especiales ............................................................................ 20

9. Sistema de control (Fig. 9-1) .................................................................. 20

Después de terminar la instalación, explique las “Medidas de Seguridad”, funcionamiento y mantenimiento de la unidad al cliente según el Manual de instrucciones y

realice una prueba para asegurarse de que funciona correctamente. Entregue una

copia del Manual de instalación y del Manual de instrucciones al usuario. Estos manuales deben pasar a usuarios posteriores del equipo.

: Indica una pieza que debe estar conectada a tierra.

Atención:

Lea atentamente las etiquetas adheridas a la unidad principal.

• Utilice tubos de cobre fosforoso del tipo C1220 y tubos de aleación de cobre

sin costuras para conectar los tubos del refrigerante.Si los tubos no se conectan correctamente, la unidad no estará bien puesta a tierra y puede provocar descargas eléctricas.

• Utilice sólo cables especificados para el cableado. Las conexiones se deben

realizar con seguridad sin corriente en los terminales. Si los cables no están

bien conectados o no se han instalado correctamente, puede producirse

sobrecalentamiento o un incendio.

• La cubierta del bloque de terminales de la unidad exterior tiene que estar

bien sujeta.

Si la cubierta no se instala correctamente y el polvo y la humedad entran en

la unidad, se pueden producir una descarga eléctrica o un incendio.

• Cuando instale o mueva el equipo de aire acondicionado, utilice sólo el refrigerante indicado (R410A) para cargar los tubos de refrigerante. No lo mezcle

con otro tipo de refrigerante y vacíe completamente de aire los tubos. El aire

que quede en los tubos puede provocar picos de presión que causarían su

rotura y otros daños.

• Utilice sólo accesorios autorizados por Mitsubishi Electric y pida a su distribuidor o a un técnico autorizado que se los instale. Si los accesorios no se

instalan correctamente, pueden producirse escapes de agua, descargas eléctricas o incendios.

• No modifique la unidad. Para las reparaciones, acuda a su distribuidor. Si las

modificaciones o las reparaciones no se realizan correctamente, pueden producirse escapes de agua, descargas eléctricas o incendios.

• El usuario nunca debe intentar reparar la unidad o moverla de sitio. Si la

unidad no se instala correctamente, pueden producirse escapes de agua,

descargas eléctricas o incendios. Si debe reparar o mover el equipo de aire

acondicionado, acuda a su distribuidor o técnico autorizado.

• Tras haber realizado la instalación, compruebe si hay fugas de refrigerante.

Si en caso de fuga el refrigerante entra en contacto con las llamas de un

calentador o de un equipo de cocina portátil, se desprenderán gases nocivos.

1.1. Cuestiones previas a la instalación

Cuidado:

• No utilice la unidad en un ambiente enrarecido. Este aire acondicionado no

se puede instalar en áreas expuestas a vapor, aceite esencial (incluyendo el

aceite para máquinas) o al humo sulfúrico, ni en áreas con alto contenido en

sal, como playas, o en zonas donde la nieve pueda cubrir la unidad, ya que

pueden reducir significativamente su rendimiento y dañar las piezas internas.

• No instale la unidad donde se puedan verter, producir, circular o acumular

gases inflamables. Si se acumula gas inflamable en zonas próximas a la unidad, se podría producir un incendio o una explosión.

1.2. Cuestiones previas a la instalación (reubicación)

Cuidado:

• Tenga mucho cuidado cuando mueva las unidades. Se necesitan dos o más

personas para llevar la unidad porque pesa 20 kg, 44 lbs o más. No la sujete

por las bandas de embalaje. Utilice guantes protectores para sacar la unidad

de la caja y para moverla, ya que se podría lesionar con las aletas u otras

partes.

• Guarde los embalajes en un lugar seguro. Los materiales de embalaje, como

clavos y otras piezas de metal o de madera pueden producir pinchazos y

otras lesiones.

12

• La unidad exterior produce condensación cuando funciona como calefacción. Asegúrese de habilitar drenaje alrededor de la unidad exterior si la condensación puede provocar daños.

• Si instala la unidad en un hospital o en un centro de comunicaciones, recuerde que la unidad produce ruidos e interferencias electrónicas. Los conmutadores, aparatos domésticos, equipos médicos de alta frecuencia y las comunicaciones de radio pueden provocar un mal funcionamiento o la avería del

equipo de aire acondicionado. El equipo de aire acondicionado también puede

afectar los equipos médicos e interrumpir los cuidados médicos, así como

los equipos de comunicación y dañar la calidad de la pantalla.

• La base y los aditamentos de fijación de la unidad exterior deben comprobarse periódicamente para detectar posibles roturas, tuercas flojas o cualquier

otro daño que hayan podido sufrir. Si no se solucionan esos problemas, la

unidad podría caerse y causar daños o lesiones.

• No limpie con agua el equipo de aire acondicionado. Puede sufrir una descarga eléctrica.

• Apriete las tuercas de abocardado a los niveles recomendados mediante una

llave dinamométrica. Si las aprieta demasiado, se pueden romper al cabo de

un tiempo y producirse fugas de refrigerante.

1. Medidas de Seguridad

D

E

C

B

A

37-13/32

13+1-3/16

37-1/8(53-5/32)

6-7/8

23-5/8

14-9/16

31-1/2

11-13/16+29/32

23-5/8

5-29/32

2-23/32

19-11/16

13

1.3. Antes de la instalación eléctrica

Cuidado:

• Asegúrese de instalar disyuntores. Si no se instalan, se podrían producir

descargas eléctricas.

• Use cables estándar de suficiente capacidad para las líneas eléctricas. Si no

lo hace así, se podría producir un cortocircuito, un sobrecalentamiento o un

incendio.

• Cuando instale las líneas eléctricas, los cables no deben tener corriente. Si

las conexiones se aflojan, los cables se podrían cruzar o romper y se podría

producir un incendio o un sobrecalentamiento.

1.4. Antes de realizar las pruebas de funcionamiento

Cuidado:

• Conecte la corriente al menos 12 horas antes de que empiece a funcionar el

equipo. Si se acciona inmediatamente después de haberlo conectado a la

corriente, pueden producirse daños graves en las piezas internas. Mantenga

la unidad conectada a la corriente durante la temporada de funcionamiento.

• Antes de que comience a funcionar el equipo, compruebe que todos los paneles y protectores están instalados correctamente. Las piezas giratorias,

calientes o de alto voltaje pueden provocar lesiones.

• No toque ningún interruptor con las manos mojadas. Puede sufrir una descarga eléctrica.

1.5. Utilización del refrigerante R410A para equipos de

aire acondicionado

Cuidado:

• Utilice tubos de cobre fosforoso del tipo C1220 y tubos de aleación de cobre

sin costuras para conectar los tubos del refrigerante. Asegúrese de que el

interior de las tuberías está limpio y que no contienen ningún contaminante

dañino como compuestos sulfúricos, oxidantes, impurezas o polvo. Utilice

tuberías con el grosor especificado. (Consulte la página 15) Tenga en cuenta

lo siguiente si reutiliza tuberías que contenían refrigerante R22.

- Sustituya las tuercas de abocardado existentes y vuelva a abocardar las secciones abocardadas.

- No use tuberías de poco grosor. (Consulte la página 15)

• Almacene las tuberías que se deban instalar en el interior y mantenga los

orificios tapados hasta el momento de instalarlas. (Deje las juntas articuladas y otras piezas en sus embalajes.) Si el polvo, los restos o la humedad

entran en las tuberías de refrigeración, se puede producir el deterioro del

aceite o una avería en el aparato.

• Utilice aceite de éster, de éter o alquilobenceno (en pequeñas cantidades)

para recubrir las secciones abocardadas. Si se mezcla aceite mineral con

aceite de refrigeración se puede deteriorar el aceite.

• Asegúrese de instalar una toma de tierra. No conecte el cable de tierra a las

tomas de tierra de las tuberías de gas o de agua, de postes de iluminación o

de teléfono. Si la unidad no está bien conectada a la línea de tierra, se puede

producir una descarga eléctrica.

• Utilice disyuntores (interruptor de falta de tierra, interruptor aislante (+fusible B) e interruptores en caja moldeada) con la potencia especificada. Si la

potencia del interruptor es mayor que la especificada, puede ocurrir un incendio o una avería.

• No toque la tubería del refrigerante sin guantes mientras durante el funcionamiento. La tubería del refrigerante está caliente o frío según las condiciones de la corriente de refrigerante. Si toca la tubería puede sufrir quemaduras por el calor o por el frío.

• Una vez deje de funcionar el aparato, espere cinco minutos antes de apagar

el interruptor principal. De lo contrario, se puede producir un goteo de agua

o una avería.

• No utilice otro refrigerante que no sea R410A. Si utiliza otro refrigerante, el

cloro provocará el deterioro del aceite.

• Utilice las siguientes herramientas especialmente diseñadas para usar con

el refrigerante R410A. Se necesitan las siguientes herramientas para utilizar

el refrigerante R410A. Si tiene alguna duda, consulte con su distribuidor más

cercano.

Manómetro Abocardador

Manguera de carga Ajustador del tamaño

Detector de fugas de gas Adaptador de la bomba de vacío

Llave dinamométrica

• Asegúrese de utilizar las herramientas adecuadas. Si el polvo, los restos o la

humedad entran en las tuberías de refrigeración, se puede producir el deterioro del aceite de refrigeración.

• No utilice un cilindro de carga. Si utiliza un cilindro de carga, variará la composición del refrigerante y no será tan eficaz.

Herramientas (para R410A)

Báscula electrónica de carga del refrigerante

2. Lugar en que se instalará

Fig. 2-1

■ A24, A30, A36, A42 (inch)■ A12, A18 (inch)

Fig. 2-2

2.1. Tubería de refrigerante (Fig. 2-1)

s Compruebe que la diferencia de altura entre las unidades interior y exterior,

la longitud del tubo de refrigerante y la cantidad de codos en la tubería se

encuentren dentro de los límites que se indican a continuación.

Modelos

A12, A18 Máx. 30 m, 100 ft Máx. 30 m, 100 ft Máx. 15

A24, A30, A36, A42

• Las limitaciones de diferencia de altura son obligatorias sin importar qué unidad, la

interior o la exterior, está colocada más alta.

D Unidad interior

E Unidad exterior

A Longitud de las B Diferencia C Número de

tuberías (un sentido)

Máx. 50 m, 165 ft Máx. 30 m, 100 ft Máx. 15

de altura codos (un sentido)

2.2. Elección del lugar de instalación de la unidad exte-

rior

• No instale la unidad en lugares expuestos directamente al sol o a otras fuentes de

calor.

• Escoja un lugar donde el ruido de la unidad no moleste a los vecinos.

• Escoja un lugar donde sea fácil instalar el cableado y las tuberías y acceder a la

fuente de alimentación y a la unidad exterior.

• No instale la unidad donde se puedan verter, producir, circular o acumular gases

inflamables.

• Durante el funcionamiento, la unidad puede perder agua.

• Escoja un lugar nivelado que pueda soportar el peso y la vibración de la unidad.

• No instale la unidad en lugares donde la pueda cubrir la nieve. En zonas propensas a las nevadas intensas, se deben tomar medidas de precaución, como por

ejemplo, situar la unidad elevada o instalar una protección en la entrada de aire

para evitar que la nieve la obstruya o fluya directamente contra ésta. Esto reduce la

corriente de aire e impide que la unidad funcione correctamente.

• No instale la unidad en lugares expuestos a aceite, vapor o humo sulfúrico.

• Utilice las asas de transporte de la unidad exterior parar transportarla. Si transporta la unidad tomándola por la parte inferior se podría lesionar las manos o los

dedos.

2.3. Dimensiones exteriores (Unidad exterior) (Fig. 2-2)

La cifra que aparece en paréntesis es para los modelos A42.

13

23-5/8 23-5/8

Min. 14-3/16

6-7/8 6-7/8

Min. 13/32

37-13/32

1-3/32

13

14-9/16

2. Lugar en que se instalará

A

B

A

C

B

D

D

19-11/16 19-11/16

Min. 25-19/32

5-29/32 5-29/32

Min. 13-25/32

31-1/2

1-9/32

11-13/16

13

Fig. 2-3

Fig. 2-4

Fig. 2-5

2.4. Ventilación y espacio de servicio

2.4.1. Instalación en lugares expuestos al viento

Cuando instale una unidad en el tejado o en otros lugares desprotegidos del viento,

la salida de aire de la unidad no debe quedar expuesta directamente al viento fuerte.

Si el viento fuerte entra en la salida de aire puede impedir la circulación normal del

aire y causar un mal funcionamiento.

A continuación se muestran tres ejemplos de precauciones a tomar contra el viento

fuerte.

1 Coloque la salida de aire de frente a la pared más próxima a una distancia de

unos 50 cm, 19-11/16 inch de ella. (Fig. 2-3)

2 Si la unidad está situada en un lugar expuesto a vientos fuertes como huracanes

que puedan entrar en la salida de aire coloque una guía para la salida de aire o

una guía de aire. (Fig. 2-4)

A Guía para la salida de aire

3 Coloque la unidad de manera que la salida de aire sople en dirección perpendicu-

lar a la dirección estacional del viento, si la conoce. (Fig. 2-5)

B Dirección del viento

3. Instalación de la unidad exterior

2.4.2. Cuando se instala una unidad exterior simple (Consulte la página anterior)

Las dimensiones mínimas son las siguientes, excepto para máx. (dimensiones máxi-

mas), las cuales también están indicadas.

Las cifras que aparecen en paréntesis son para los modelos A42.

Consulte los números correspondientes para cada caso.

1 Obstáculos sólo en la parte trasera (Fig. 2-6)

2 Obstáculos sólo en la parte trasera y superior (Fig. 2-7)

3 Obstáculos sólo en la parte trasera y los laterales (Fig. 2-8)

∗ 350mm, 13-25/32 inch para A12, A18

4 Obstáculos sólo en la parte delantera (Fig. 2-9)

∗ Si utiliza una guía para salida de aire opcional, el espacio libre para los modelos A42 debe

ser de 500 mm, 19-11/16 inch o más.

5 Obstáculos sólo en la parte delantera y trasera (Fig. 2-10)

∗ Si utiliza una guía para salida de aire opcional, el espacio libre para los modelos A42 debe

ser de 500 mm, 19-11/16 inch o más.

6 Obstáculos sólo en la parte trasera, los laterales y superior (Fig. 2-11)

∗ 350 para A12, A18

• No utilice las guías para salida de aire opcionales para corriente de aire hacia arriba.

2.4.3. Cuando instale varias unidades exteriores (Consulte la página

anterior)

Deje 350 mm, 13-25/32 inch para A18 y 10 mm, 13/32 inch para A24-A42 de holgura

o más entre las unidades.

1 Obstáculos sólo en la parte trasera (Fig. 2-12)

2 Obstáculos sólo en la parte trasera y superior (Fig. 2-13)

• No se deben instalar más de tres unidades correlativas. Además, se debe dejar el espacio

indicado.

• No utilice las guías para salida de aire opcionales para corriente de aire hacia arriba.

3 Obstáculos sólo en la parte delantera (Fig. 2-14)

∗ Si utiliza una guía para salida de aire opcional, el espacio libre para los modelos A42 debe

ser de 1000 mm, 39-3/8 inch o más.

4 Obstáculos sólo en la parte delantera y trasera (Fig. 2-15)

∗ Si utiliza una guía para salida de aire opcional, el espacio libre para los modelos A42 debe

ser de 1000 mm, 39-3/8 inch o más.

5 Disposición en paralelo de unidades simples (Fig. 2-16)

∗ Si utiliza un guía para salida de aire opcional instalada para que el aire salga hacia arriba, el

espacio libre debe ser de 500 (1000) mm, 19-11/16 (39-3/8) inch o más.

6 Disposición en paralelo de varias unidades (Fig. 2-17)

∗ Si utiliza un guía para salida de aire opcional instalada para que el aire salga hacia arriba, el

espacio libre debe ser de 1000 (1500) mm, 39-3/8 (59-1/16) inch o más.

7 Disposición de unidad apilada (Fig. 2-18)

• Se pueden apilar hasta dos unidades de altura.

• No se deben instalar más de dos unidades correlativas. Además, se debe dejar el espacio

indicado.

Máx. 23/32 para A12, A18

Máx. 1-3/16 para A24-A42

A Perno M10 (3/8”)

B Base

C Lo más largo posible.

D Salida de aire

■ A24-A42■ A12, A18

MÍn. 25-19/32

MÍn. 13-25/32

14

Fig. 3-1

MÍn. 13/32

■ A24-A42■ A12, A18

MÍn. 14-11/64

(inch)

• Cerciórese de instalar la unidad en una superficie robusta y nivelada para evitar los

(inch)

ruidos de traqueteo durante la operación. (Fig. 3-1)

<Especificaciones de la cimentación>

Perno de cimentación M10 (3/8”)

Grosor del hormigón 120 mm, 4-23/32 inch

Longitud del perno 70 mm, 2-3/4 ing

Capacidad de soporte de peso 320 kg, 264 lbs

• Cerciórese de que la longitud del perno de cimentación esté dentro de 30 mm,

1-3/16 inch de la superficie inferior de la base.

• Asegure firmemente la base de la unidad con cuatro pernos de cimentación M10

en lugares robustos.

Instalación de la unidad exterior

• No obstruya la salida de aire. Si se obstruye la salida de aire, se puede dificultar el

funcionamiento del aparato y puede causar una avería.

• Además de la base de la unidad, utilice los orificios de instalación situados en la

parte trasera de la unidad para añadirle cables u otros elementos necesarios para

instalar la unidad. Utilice tirafondos (ø5 × 15 mm, ø13/16 × 19/32 inch o más) para

instalar el equipo.

Atención:

• La unidad debe instalarse firmemente sobre una estructura capaz de soportar su peso. Si la unidad se instala sobre una estructura inestable, podría

caerse y provocar daños o lesiones.

• La unidad debe instalarse según las instrucciones para reducir posibles daños en caso de terremoto, huracán o vientos fuertes. Si no se instala correctamente, la unidad podría caerse y provocar daños o lesiones.

4. Instalación de los tubos del refrigerante

90° ±0.5°

øA

R1/64 to R1/32

A

45°±2°

B

C

D

C

B

A

E

D

D

90˚±0,5˚

a

A Dimensiones del corte abocinado

B Torsión de apriete de la tuerca abocardada

Fig. 4-1

A (Fig. 4-1)

Tubo de cobre O.D.

(mm) (inch) (mm) (inch)

ø6,35 1/4” 8,7 - 9,1 11/32 - 23/64

ø9,52 3/8” 12,8 - 13,2 1/2 - 33/64

ø12,7 1/2” 16,2 - 16,6 41/64 - 21/32

ø15,88 5/8” 19,3 - 19,7 49/64 - 25/32

B (Fig. 4-1)

Tubo de cobre O.D.

(mm) (inch) (mm) (inch) (N·m) (ft·lbs)

ø6,35 1/4” 17 43/64 14 - 18 10 - 13

ø9,52 3/8” 22 7/8 34 - 42 25 - 30

ø12,7 1/2” 26 1 - 3/64 49 - 61 35 - 44

ø15,88 5/8” 29 1 - 9/64 68 - 82 49 - 59

A Cubierta de la tubería frontal

B Cubierta de la tubería

C Válvula de parada

D Panel de servicio

E Radio del codo: 100 mm, 3-15/16 inch-150 mm, 5-27/32 inch

Dimensiones de abocinado

dimensiones øA

Tuerca de abocardado

O.D.

■ A24-A42■ A12, A18

Fig. 4-3

(inch)

Torsión de apriete

4.1. Precauciones a tomar en equipos que utilicen el

refrigerante R410

• Consulte la página 13 para las precauciones a tomar en equipos que utilicen

el refrigerante R410A y que no se encuentren a continuación.

• Utilice aceite de éster, de éter o alquilobenceno (en pequeñas cantidades)

para recubrir las secciones abocardadas.

• Utilice tubos de cobre fosforoso del tipo C1220 y tubos de aleación de cobre

sin costuras para conectar los tubos del refrigerante. Utilice tuberías para

refrigerante del grosor especificado en la tabla siguiente. Asegúrese de que

el interior de las tuberías está limpio y que no contienen ningún contaminante nocivo como compuestos sulfúricos, oxidantes, restos o polvo.

Atención:

Cuando instale o mueva el equipo de aire acondicionado, utilice sólo el refrigerante indicado (R410A) para cargar los tubos de refrigerante. No lo mezcle con otro

tipo de refrigerante y vacíe completamente de aire los tubos. El aire que quede en

los tubos puede provocar picos de presión que causarían su rotura y otros daños.

A12, A18 A24-A42

Tubo de líquido

Tubo de gas

• No utilice tubos con un grosor menor del especificado a continuación.

ø6,35 mm, 1/4inch ø9,52 mm, 3/8 inch

grosor 0,8 mm, 1/32 inch grosor 0,8 mm, 1/32 inch

ø12,7 mm, 1/2 inch ø15,88 mm, 5/8 inch

grosor 0,8 mm, 1/32 inch grosor 1,0 mm, 3/64 inch

4.2. Tubos de conexión (Fig. 4-1)

• Si se utilizan tubos de cobre convencionales, envuelva los tubos de gas y líquido

con materiales aislantes (resistente al calor hasta 100 °C, 212 °F o más, espesor

de 12 mm 1/2 inch o más).

• Las piezas interiores del tubo de drenaje tienen que estar envueltas en materiales

aislantes de espuma de polietileno (gravedad específica de 0,03 y espesor de

9 mm, 23/64 inch o más).

• Aplique una capa delgada de aceite refrigerante a la superficie tubo y de la junta

de asiento antes de apretar la tuerca de abocardado. A

• Utilice dos llaves de apriete para apretar las conexiones de los tubos. B

• Utilice un detector de fugas o agua jabonosa para comprobar posibles fugas de

gas una vez realizadas las conexiones.

• Aplique aceite refrigerante para máquinas en toda la superficie abocinada. C

• Utilice las tuercas abocardadas para el siguiente tamaño de tubería. D

Gasseite

Flüssigkeitsseite

*1: La tuerca abocardada está acoplada a su tubería.

*2: La tuerca abocardada está en el accesorio de la unidad exterior.

No use la tuerca abocardada adjunta. Si se usa, podría ocurrir una fuga de gas o

incluso la extracción de una tubería.

• Cuando doble los tubos, tenga cuidado de no romperlos. Un radio de curvatura de

100 mm, 3-15/16 inch a 150 mm, 5-27/32 inch es suficiente.

• Asegúrese de que las tuberías no tocan el compresor. Podría producir ruidos o

vibraciones extrañas.

1 Las tuberías se deben conectar empezando por la unidad interior.

Las tuercas abocardadas se deben apretar con una llave dinamométrica.

2 Caliente el tubo de líquido y el tubo de gas y aplique una fina capa de aceite de

refrigeración (aplicado directamente).

Tamaño de la tubería (mm, inch)

Tamaño de la tubería (mm, inch)

A12, A18 A24, A42

ø12,7, 1/2”ø15,88, 5/8”

ø6,35, 1/4”ø9,52, 3/8”

4.3. Tubos de refrigerante (Fig. 4-3)

■ Para A12, A18

Elimine el panel de servicio D (un tornillo).

■ Para A24-A42

Quite el panel de servicio D (tres tornillos) y la cubierta de la tubería frontal A (dos

tornillos) y cubierta de la tubería posterior B (dos tornillos).

1 Realice las conexiones de los tubos de refrigerante de la unidad interior/exterior

con la válvula de parada de la unidad exterior completamente cerrada.

2 Purgue el aire del sistema por succión en la unidad interior y tubos de conexión.

3 Tras conectar las tuberías de refrigerante con la unidad interior, compruebe que

no haya fugas de gas. (Consulte apartado 4.4. Prueba de fuga de gas del tubo de

refrigerante.)

44

4 Aspire las líneas de refrigerante a través del punto de reparaciones de la válvula

44

de parada de líquido y a continuación, abra completamente las válvulas de para-

da (tanto las de líquido como las de gas). Esta operación le permitirá conectar

completamente las líneas refrigerantes de las unidades interiores y exteriores.

• Si deja cerradas las válvulas de parada y pone en marcha la unidad, el compresor y la válvula de control sufrirán daños.

• Utilice un detector de fugas o jabón y agua para detectar las fugas de gas en

las juntas de las conexiones de los tubos de la unidad exterior.

• No utilice el refrigerante desde la unidad para purgar el aire de las líneas de

refrigerante.

• Tras haber realizado los trabajos en las válvulas, ajuste las tuercas de las

válvulas a la presión adecuada: 20 a 25 N·m, 14 a 18 ft·lbs (200 a 250 kgf·cm).

Si no sustituye o aprieta bien las tuercas puede provocar una fuga de refrigerante. Además, evite dañar el interior de las válvulas ya que funcionan como

selladoras para evitar fugas de refrigerante.

55

5 Utilice un sellador para proteger las conexiones de los tubos y los extremos del

55

material aislante no se impregnen de agua.

15

4. Instalación de los tubos del refrigerante

A

B

H

I

C

D

E

F

G

D

B

A

C

Fig. 4-5

A

B

C

D

E

F

I

J

J

A

B

K

D

E

F

I

Type A Type B

Fig. 4-6

B

G

H

E

D

A

I

J

F

E Tubo local

A Válvula de retención <Lado de líquido>

B Válvula de retención <Lado de gas>

C Puerto de servicio

D Sección Abierto/Cerrado

(1)

(2)

F Sellado, igual para lado de gas

G Cubierta del tubo

H No utilice una llave aquí.

Podría producirse una pérdida de refrigerante.

I Utilice dos llaves aquí.

Fig. 4-4

4.4. Prueba de fuga de gas del tubo de refrigerante

(1) Conecte las herramientas para pruebas.

• Asegúrese de que las válvulas de parada A B están cerradas y no las abra.

• Añada presión a las líneas de refrigerante a través del punto C para repara-

ciones de válvula de parada de líquido D.

(2) No añada presión al nivel especificado de golpe; hágalo poco a poco.

1 Presurice a 0,5 MPa (5 kgf/cm

presión no se ha reducido.

2 Presurice a 1,5 MPa (15 kgf/cm2G), espere cinco minutos y compruebe que la

presión no se ha reducido.

3 Presurice a 4,15 MPa (41,5 kgf/cm

presión del refrigerante.

(3) Si la presión especificada se mantiene estable durante un día y no se reduce, las

tuberías han pasado la prueba y no existe riesgo de fugas.

• Si la temperatura ambiental cambia 1 °C, la presión variará unos 0,03 MPa

(0,3 kgf/cm

(4) Si la presión se reduce en los pasos (2) o (3), hay una fuga de gas. Busque el

punto de fuga del gas.

2

G). Haga las correcciones necesarias.

2