Mitsubishi Electric PURY-P-YHM-A, PURY-P-YHM-A-BS, PURY-EP-YHM-A, PURY-EP-YHM-A-BS Installation Manual

Air-Conditioners For Building Application

OUTDOOR UNIT

PURY-P-YHM-A (-BS)

PURY-EP-YHM-A (-BS)

For use with R410A

GB

PO

HG

SV

CZ

TR

RU

GR

P

NL

I

E

F

D

SL

INSTALLATION MANUAL

For safe and correct use, please read this installation manual thoroughly before installing the air-conditioner unit.

INSTALLATIONSHANDBUCH

Zum sicheren und ordnungsgemäßen Gebrauch der Klimageräte das Installationshandbuch gründlich durchlesen.

MANUEL D’INSTALLATION

Veuillez lire le manuel d’installation en entier avant d’installer ce climatiseur pour éviter tout accident et vous assurer d’une utilisation correcte.

MANUAL DE INSTALACIÓN

Para un uso seguro y correcto, lea detalladamente este manual de instalación antes de montar la unidad de aire acondicionado.

MANUALE DI INSTALLAZIONE

Per un uso sicuro e corretto, leggere attentamente questo manuale di installazione prima di installare il condizionatore d’aria.

INSTALLATIEHANDLEIDING

Voor een veilig en juist gebruik moet u deze installatiehandleiding grondig doorlezen voordat u de airconditioner installeert.

MANUAL DE INSTALAÇÃO

Para segurança e utilização correctas, leia atentamente este manual de instalação antes de instalar a unidade de ar condicionado.

E°XEIPI¢IO O¢H°IøN E°KATA™TA™H™

°И· ·ЫК¿ПВИ· О·И ЫˆЫЩ‹ ¯Ъ‹ЫЛ, ·Ъ·О·ПВ›ЫЩВ ‰И·‚¿ЫВЩВ ЪФЫВ¯ЩИО¿ ·˘Щfi ЩФ ВБ¯ВИЪ›‰ИФ ВБО·Щ¿ЫЩ·ЫЛ˜ ЪИУ ·Ъ¯›ЫВЩВ ЩЛУ

ВБО·Щ¿ЫЩ·ЫЛ ЩЛ˜ МФУ¿‰·˜ ОПИМ·ЩИЫМФ‡.

РУКОВОДСТВО ПО УСТАНОВКЕ

Для осторожного и правильного использования прибора необходимо тщательно ознакомиться с данным руководством по

установке до выполнения установки кондиционера.

MONTAJ ELKWTABI

Emniyetli ve doqru biçimde naswl kullanwlacaqwnw öqrenmek için lütfen klima cihazwnw monte etmeden önce bu elkitabwnw dikkatle okuyunuz.

2

(mm)

6

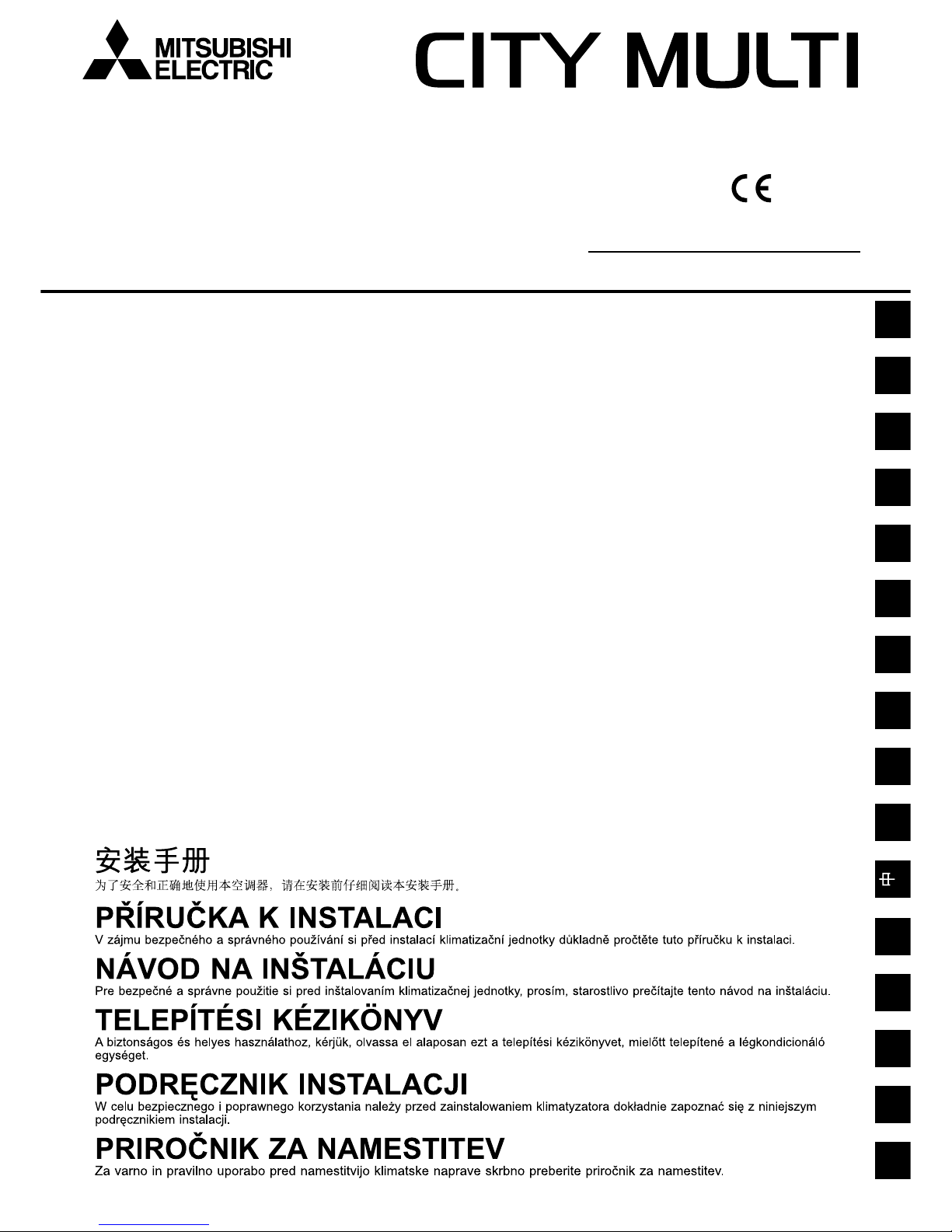

[Fig. 6.0.1]

(2)

(1)

(3)

(4)

[Fig. 6.0.2]

<A> : Top view

<B> : Side view

<C> : When there is little space up to an obstruction

A : Front

B : Unit height

C : Back

D : Air outlet guide (Procured at the site)

A : Front

B : Must be open

C : Wall height (H)

15

*

15

*

450

*

300

*

<A>

A

100

*

450

*

50

*

50

*

<A>

A

A

B

<B>

500

H

h

h

H

240

45°

A

D

C

50

<C>

1000

30

450

*

300

*

C

B B

C

A

100

450

*

100

*

B B

C

C

A

450

*

100*

C C

B

A

A

A

B

450 450

15

*

C

AAA

450 450

900

300

*

300

*

B B

C

C

A

1000

*

900 300

*

B

B

C

A

(mm)

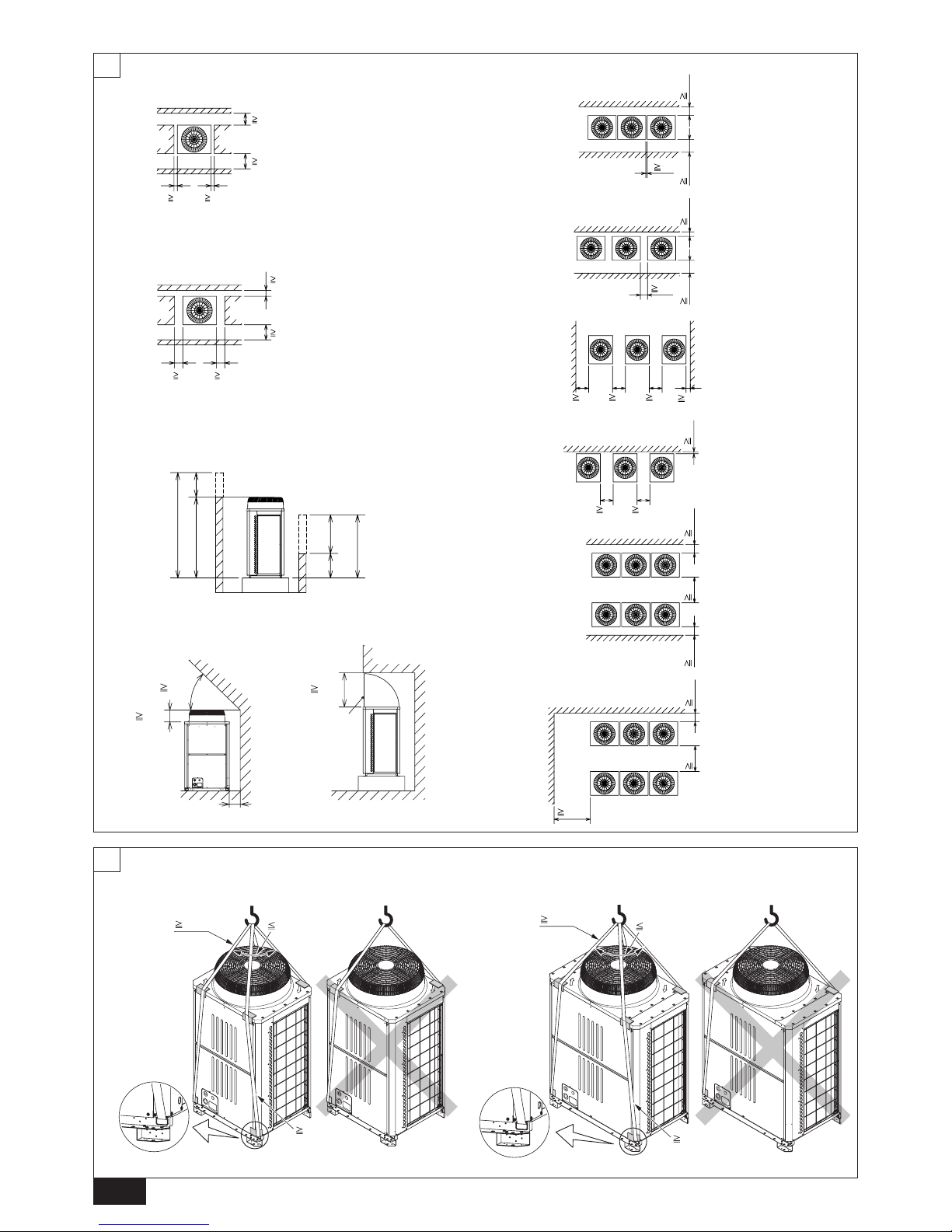

[Fig. 7.0.1]

1 P200 ~ P300

EP200

7

2 P350 ~ P400

EP250 ~ EP300

8m

8m

40°

8m

40°

8m

3

8

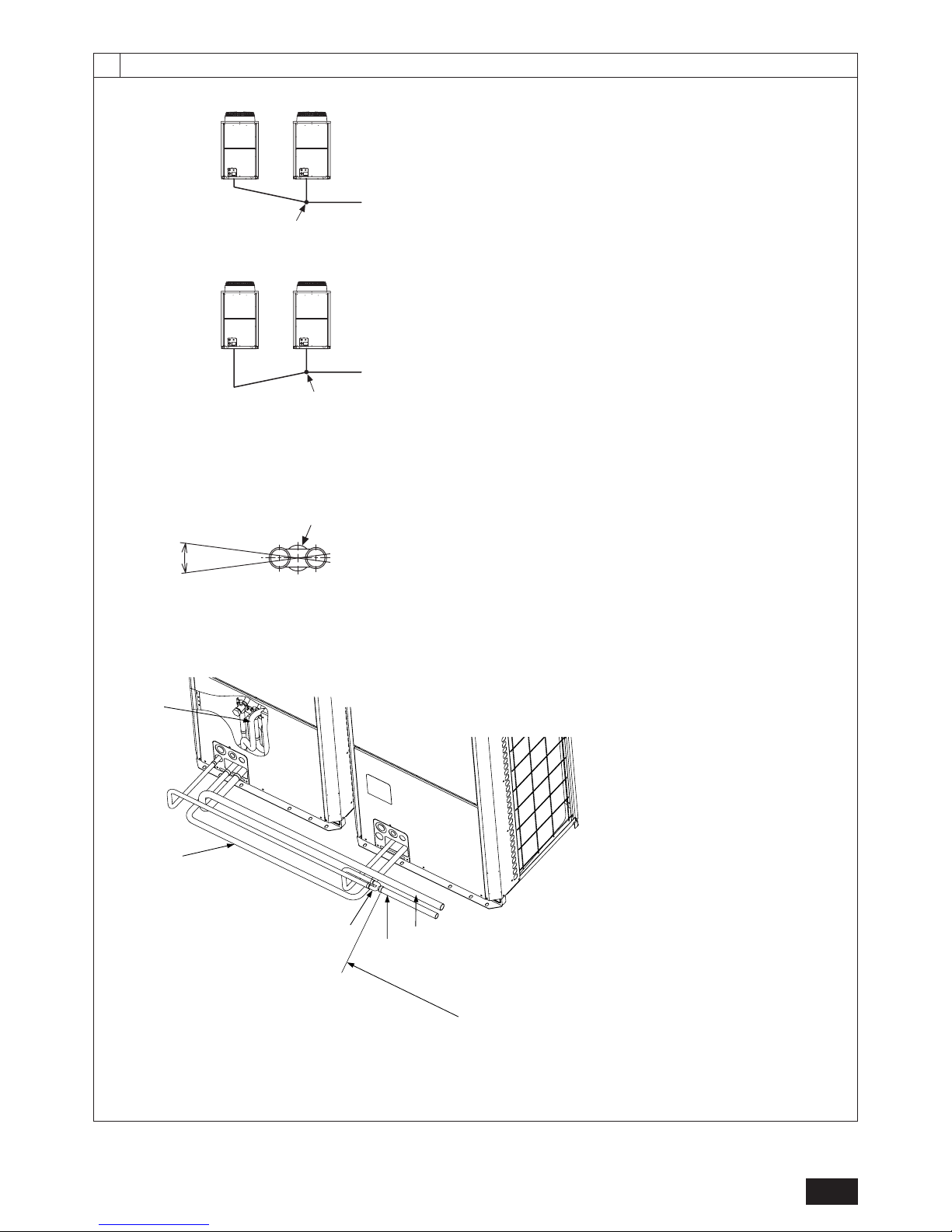

[Fig. 8.1.1]

<A> Without detachable leg A : M10 anchor bolt procured at the site.

B : Corner is not seated.

C : Fixing bracket for hole-in anchor bolt (3 locations to fix

with screws).

D : Detachable leg

30mm

A

B

C

A

[Fig. 8.1.2]

A : Screws

30mm

A

D

B

C D

<B> With detachable leg

9

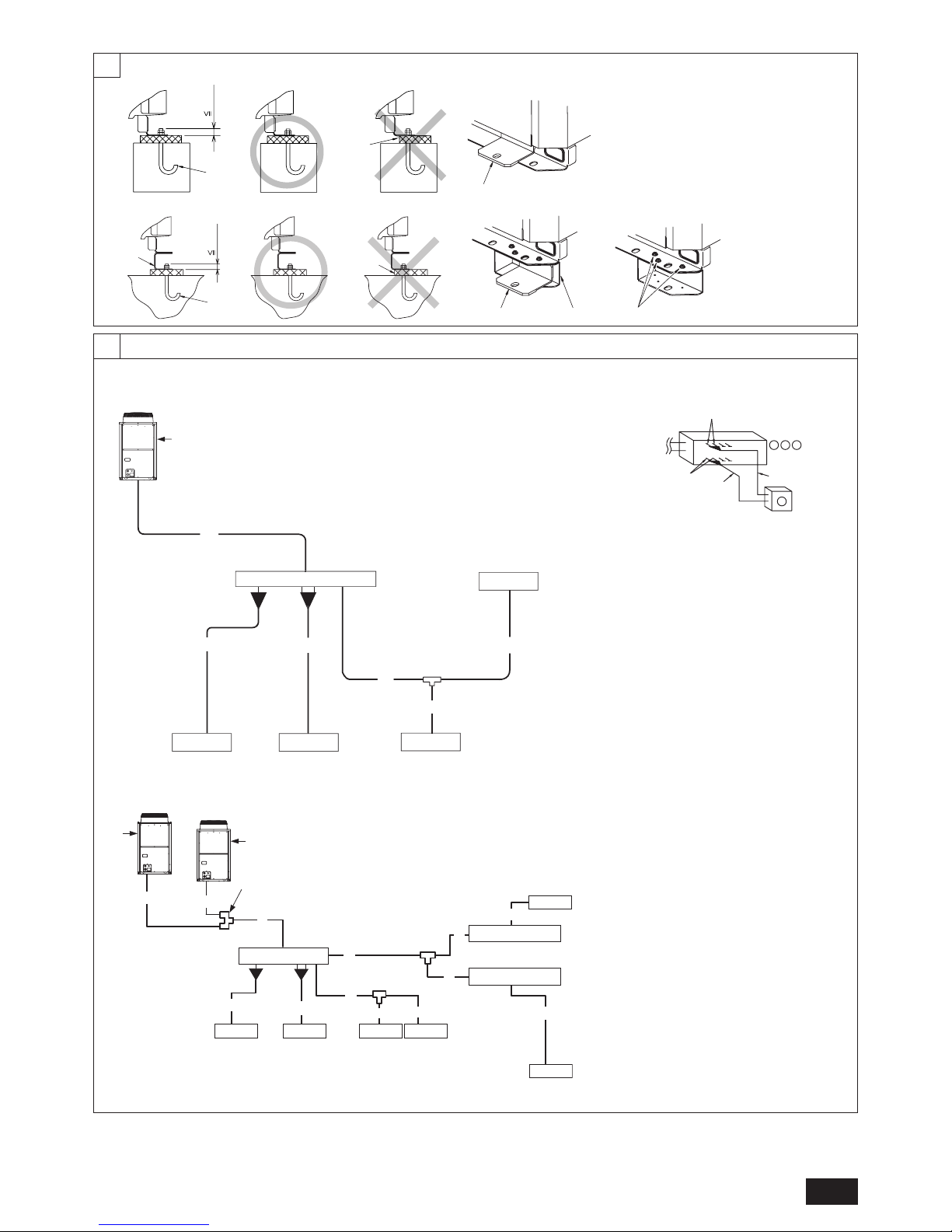

9.2

[Fig. 9.2.1]

[P200 ~ P400]

[EP200 ~ EP300]

[P450 ~ P800]

[EP400 ~ EP600]

a

C

b

B

c d

f

D

E

A

e

A1

unit1

unit2

A2

A

G

C

E E E

D

E

D

E

F

A

*

NOTE1

a

b

c

d

A

B C

EFE

E

(*Note1)

E

B C D

g

i

j

h

A : Outdoor unit

B : BC controller (standard)

C : BC controller (main)

D : BC controller (sub)

E : Indoor unit (15 ~ 80)

F : Indoor unit (100 ~ 250)

G: Outdoor twinning kit

4

*1 The pipe sizes listed in columns A1 to A2 in this table correspond to the

sizes for the models listed in the unit 1 and 2 columns. When the order of

unit 1 and 2 is changed, make sure to use the appropriate pipe size for the

model.

B (mm)

A2 *1

Î Total capacity of indoor units

~ 80

‰ Liquid pipe

ø9.52

Ï Gas pipe

ø15.88

a, b, c, d, e, f (mm)

Ô Model number

15,20,25,32,40,50

63,71,80,100,125,140

200

250

‰ Liquid pipe

ø6.35

ø9.52

ø9.52

ø9.52

Ï Gas pipe

ø12.7

ø15.88

ø19.05

ø22.2

C, D (mm)

Downstream

unit model total

~ 200

201 ~ 300

301 ~ 350

351 ~ 400

401 ~ 450

Ì

High-pressure

gas pipe

ø15.88

ø19.05

ø19.05

ø22.2

ø22.2

Ó

Low-pressure

gas pipe

ø19.05

ø22.2

ø28.58

ø28.58

ø28.58

È Liquid pipe

ø9.52

ø9.52

ø12.7

ø12.7

ø15.88

A [Standard] (mm)

9.2

9

g, h, i, j (mm)

Ô Model number

100

125

140

200

250

g

ø9.52

ø9.52

ø9.52

ø9.52

ø9.52

h

ø9.52

ø9.52

ø9.52

ø9.52

ø9.52

i

ø15.88

ø15.88

ø15.88

ø19.05

ø22.2

j

ø15.88

ø15.88

ø15.88

ø15.88

ø15.88

‰ Liquid pipe Ï Gas pipe

Å Outdoor model

P450 ~ P650

EP400 ~ EP600

P700 ~ P800

Outdoor twinning kit

CMY-R100VBK

CMY-R200VBK

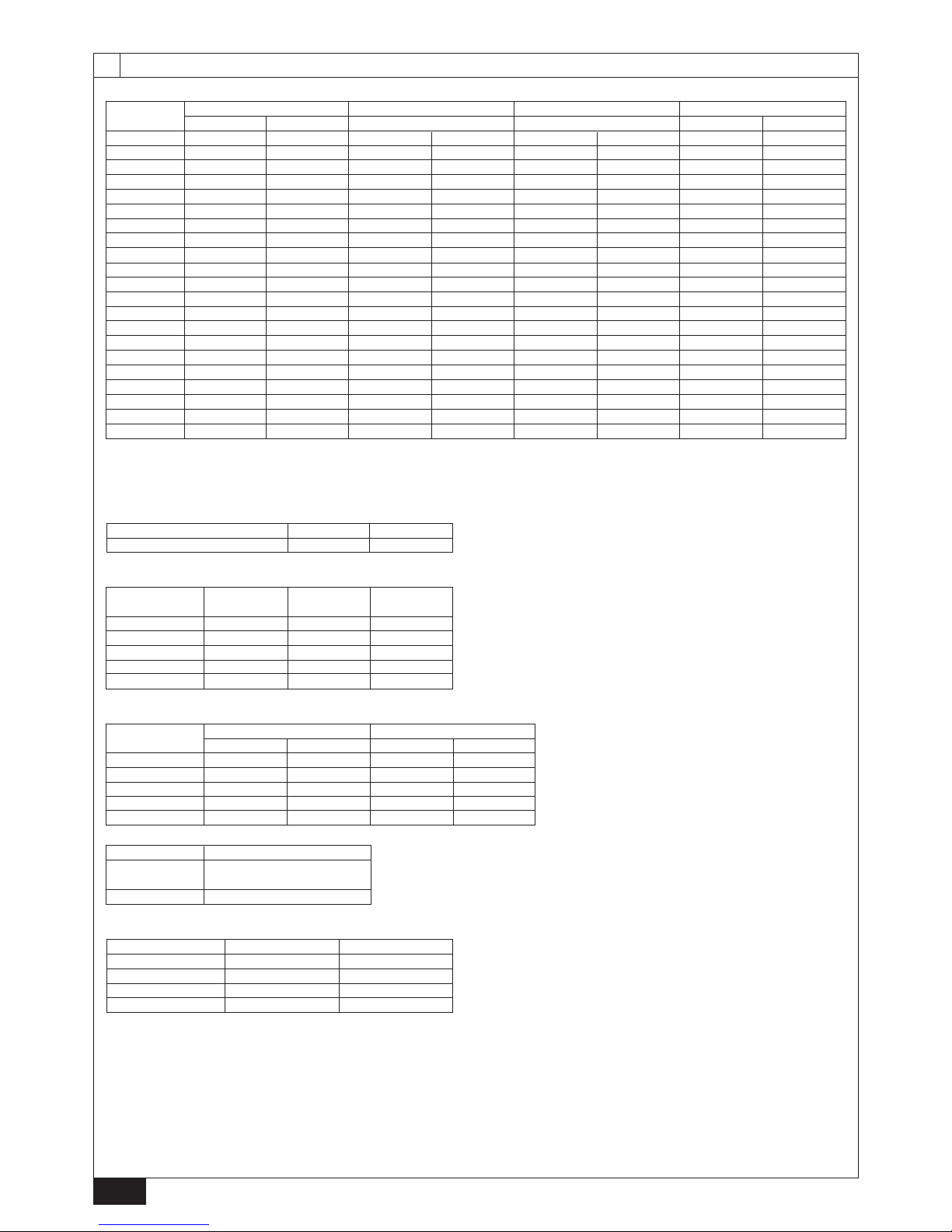

Å Outdoor model

P200

P250

P300

P350

P400

P450

P500

P550

P600

P650

P700

P750

P800

EP200

EP250

EP300

EP400

EP450

EP500

EP550

EP600

ı

High-pressure side

ø15.88

ø19.05

ø19.05

ø19.05

ø22.2

ø22.2

ø22.2

ø28.58

ø28.58

ø28.58

ø28.58

ø28.58

ø28.58

ø15.88

ø19.05

ø19.05

ø22.2

ø22.2

ø22.2

ø28.58

ø28.58

Ç

Low-

pressure side

ø19.05

ø22.2

ø22.2

ø28.58

ø28.58

ø28.58

ø28.58

ø28.58

ø28.58

ø28.58

ø34.93

ø34.93

ø34.93

ø19.05

ø22.2

ø22.2

ø28.58

ø28.58

ø28.58

ø28.58

ø28.58

ı

High-pressure side

-

-

-

-

ø19.05

ø19.05

ø19.05

ø19.05

ø19.05

ø22.2

ø22.2

ø22.2

-

-

ø15.88

ø19.05

ø19.05

ø19.05

ø19.05

Ç

Low-

pressure side

-

-

-

-

ø22.2

ø22.2

ø22.2

ø22.2

ø28.58

ø28.58

ø28.58

ø28.58

-

-

-

ø19.05

ø22.2

ø22.2

ø22.2

ø22.2

ı

High-pressure side

-

-

-

-

ø15.88

ø19.05

ø19.05

ø19.05

ø19.05

ø19.05

ø19.05

ø22.2

-

-

ø15.88

ø15.88

ø15.88

ø19.05

ø19.05

Ç

Low-

pressure side

-

-

-

-

-

ø19.05

ø22.2

ø22.2

ø22.2

ø22.2

ø22.2

ø28.58

ø28.58

-

-

ø19.05

ø19.05

ø19.05

ø22.2

ø22.2

Unit combination A A1 *1

Unit 1

-

-

-

-

P250

P250

P300

P300

P350

P400

P400

P400

-

-

-

EP200

EP250

EP300

EP300

EP300

Unit 2

-

-

-

-

P200

P250

P250

P300

P300

P300

P350

P400

-

-

-

EP200

EP200

EP200

EP250

EP300

5

9.2

9

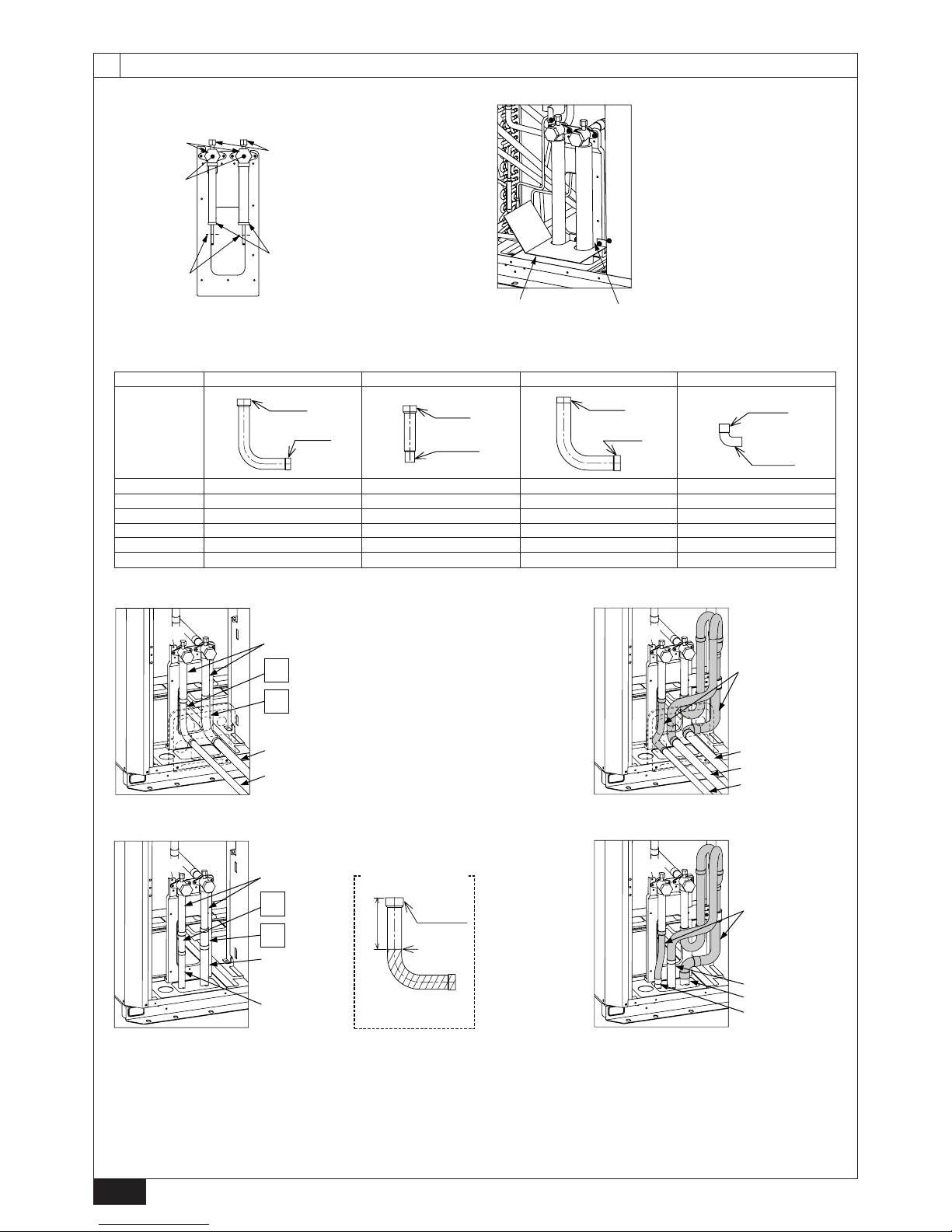

[Fig. 9.2.2]

A

C

D

B

C

D

<A> The piping from the outdoor units to twinning pipe must be made to slope

downwards the twinning pipe. (high-pressure side only)

<B> Slope of twinning pipe (high pressure side only)

±15°

D

E

<C> Pipe connection example

F

H

G

J

K

I

A : Downward slope

B : Upward slope

C : BC controller (standard or main)

D : Twinning pipe

E :

Slope of the

twinning

pipe is at an angle within ±15° to the gro

und

F : Twinning pipe (low-pressure side)

G : Twinning pipe (high-pressure side)

H : On-site piping (low-pressure connecting pipe: between outdoor units)

I : On-site piping (low-pressure main pipe: to BC controller)

J : On-site piping (high-pressure main pipe: to BC controller)

K: Straight run of pipe that is 500 mm or more

6

10.2

10

[Fig. 10.2.1]

A

C

B

E

D

[Fig. 10.2.3]

A

B

A : Example of closure materials (field supply)

B : Fill the gap at the site

No.

A Shape

A : Shaft

B : Service port

C : Cap

D : Pinched connecting pipe severing portion

E : Pinched connecting pipe brazing portion

<A> Front pipe routing <B> Bottom pipe routing <C> Low-pressure side

<D> High-pressure side <E> Severing portion referral figure

A Shape B When not attaching a low-pressure twinning pipe C When attaching a low-pressure twinning pipe

D Refrigerant service valve piping E On-site piping (low-pressure connecting pipe) F On-site piping (high-pressure connecting pipe)

G Twinning kit (sold separately)

H On-site piping (low-pressure connecting pipe: to BC controller)

I On-site piping (low-pressure connecting pipe: to outdoor unit)

J 75 mm (reference measurement) K ID ø25.4 side L Severing portion

*1 For the attachment of the Twinning pipe (sold separately), refer to the instructions included in the kit.

*2 Connection pipe is not used when the Twinning kit is attached.

*3 Use a pipe cutter to sever.

* When not attaching a low-pressure twinning pipe.

[Fig. 10.2.2]

ø22.2

ID ø25.4

ID ø22.2

OD ø19.05

ø22.2

ID ø25.4

ID ø28.58

ø28.58

ID ø25.4

ID ø19.05

OD ø19.05

F

E

<C>

<D>

D

A

B

G

H

I

F

<C>

<D>

<A> Front pipe routing

B When not attaching a low-pressure twinning pipe

C When attaching a low-pressure twinning pipe *1,*2

D

E

F

<C>

<D>

C

D

*3

K

L

J

F

H

I

G

<C>

<D>

B When not attaching a low-pressure twinning pipe C When attaching a low-pressure twinning pipe *1,*2

1 2 3 4

1 <C> Low-pressure side

1 <C> Low-pressure side

1 <C> Low-pressure side

1 <C> Low-pressure side

-

1 <D> High-pressure side

-

1 <D> High-pressure side

1 <D> High-pressure side

1 <D> High-pressure side

-

-

-

-

1 <C> Low-pressure side

1 <C> Low-pressure side

-

1 <D> High-pressure side

1 <D> High-pressure side

1 <D> High-pressure side

-

<E> Severing portion

referral figure

<B> Bottom pipe routing

<B> Refrigerant service valve

(Low-pressure side/brazed type)

<A> Refrigerant service valve

(High-pressure side/brazed type)

P250

EP250

P300

EP300

P350

P400

7

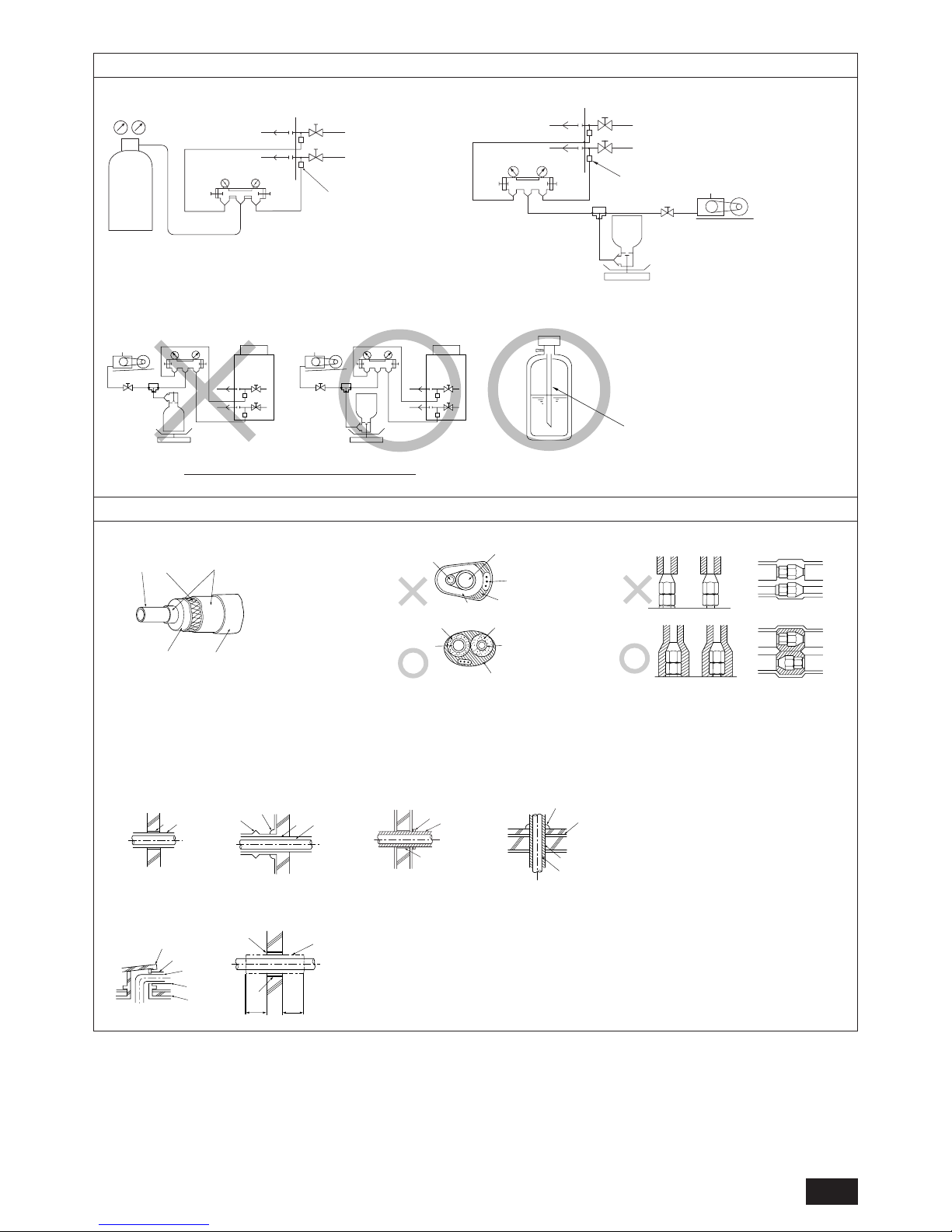

[Fig. 10.3.1]

[Fig. 10.3.3]

10.3

A

A : Nitrogen gas

B : To indoor unit

C : System analyzer

D : Low knob

E : Hi knob

F : Valve

G : Low-pressure pipe

H : High-pressure pipe

I : Outdoor unit

J : Service port

A : System analyzer

B : Low knob

C : Hi knob

D : Valve

E : Low-pressure pipe

F : High-pressure pipe

G : Service port

H : Three-way joint

I : Valve

J : Valve

K : R410A cylinder

L : Scale

M : Vacuum pump

N : To indoor unit

O : Outdoor unit

A : Syphon pipe

D

C

C

B

B

E

F

G

H

I

J

A

LOW

HI

10.4

[Fig. 10.4.4]

[Fig. 10.4.3][Fig. 10.4.2]

C

A

B

D

E

[Fig. 10.4.1]

B

A

D

C

E

E

E

D

A

B

A B

<A> Inner wall (concealed)

A B

D

C

<B> Outer wall

A : Steel wire B : Piping

C : Asphaltic oily mastic or asphalt

D : Heat insulation material A

E : Outer covering B

A : High-pressure pipe B : Low-pressure pipe

C : Electric wire D : Finishing tape

E : Insulator

D

F

G

B

<D> Floor (waterproofing)

E

A

B

<C> Outer wall (exposed)

F

H

D

B

G

<E> Roof pipe shaft

I

A

J

1m1m

<F> Penetrating portion on fire

limit and boundary wall

A : Sleeve B : Heat insulating material

C : Lagging D : Caulking material

E : Band F : Waterproofing layer

G : Sleeve with edge H : Lagging material

I : Mortar or other incombustible caulking

J : Incombustible heat insulation material

B In case of the R410A cylinder having no syphon pipe.

[Fig. 10.3.2]

LOW

HI

B

A

K

J

L

H

M

C

D

EN

N

O

F

G

I

Loading...

Loading...