Mitsubishi PURY-M400YNW-A1, PURY-M250YNW-A1, PURY-M200YNW-A1, PURY-M500YNW-A1, PURY-M450YNW-A1 Data Book

...

AIR CONDITIONING SYSTEMS

MODEL

PURY-M200-500YNW-A1 (-BS)

PURY-EM200-500YNW-A1 (-BS)

GENERAL LINE-UP

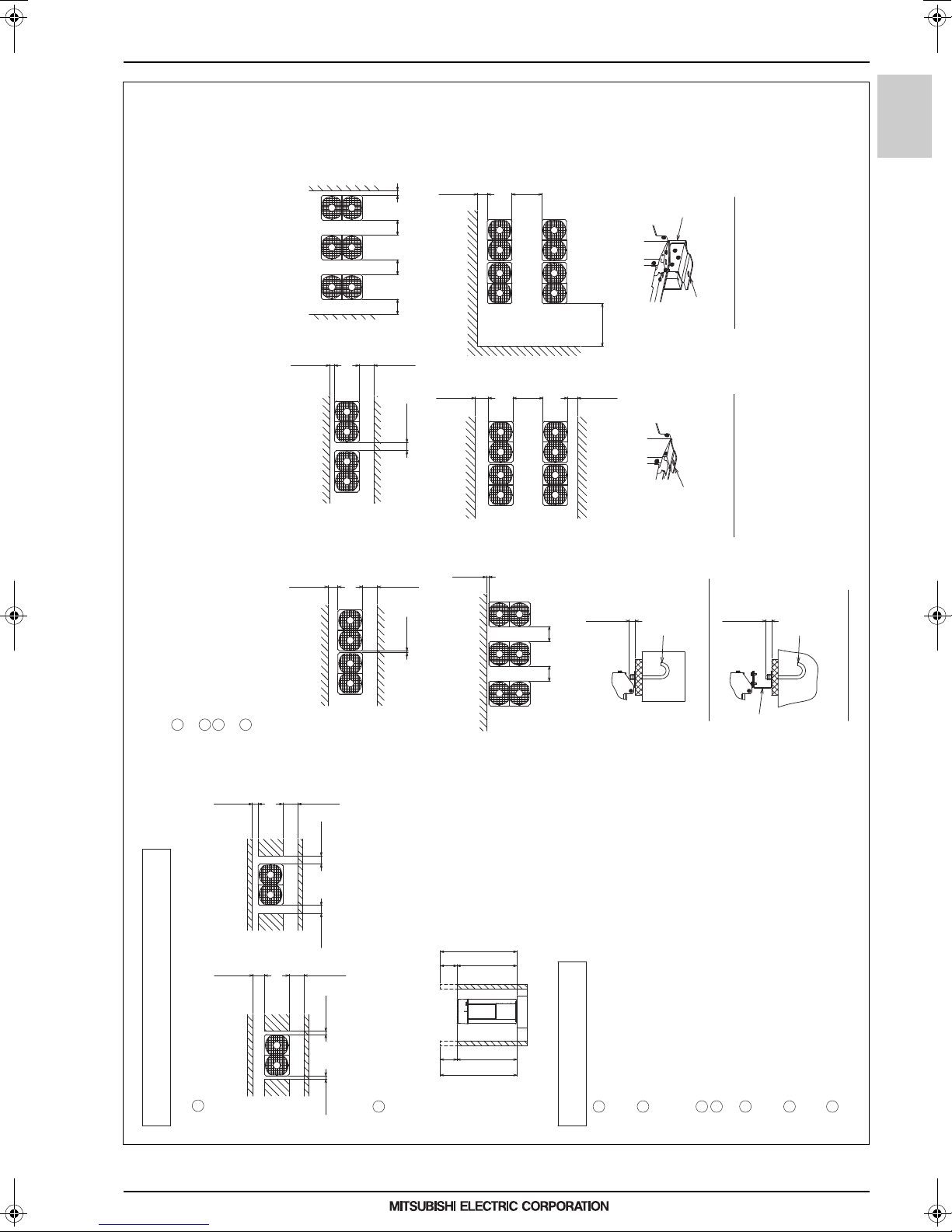

I.GENERAL LINE-UP

GENERAL LINE-UP

Heat Recovery R2-Series

PURY-M300YNW-A1(-BS)

PURY-M500YNW-A1(-BS)

PURY-M250YNW-A1(-BS)PURY-M200YNW-A1(-BS)

8, 10, 12HP

PURY-M450YNW-A1(-BS)

PURY-M400YNW-A1(-BS)PURY-M350YNW-A1(-BS)

14, 16, 18HP

20HP

Heat Recovery High efficiency R2-Series

PURY-EM250YNW-A1(-BS)PURY-EM200YNW-A1(-BS)

PURY-EM300YNW-A1(-BS)

8, 10, 12HP

PURY-EM450YNW-A1(-BS)

PURY-EM400YNW-A1(-BS)PURY-EM350YNW-A1(-BS)

14, 16, 18HP

PURY-EM500YNW-A1(-BS)

20HP

MEES18K068

CONTENTS

PURY-M-YNW-A1, PURY-EM-YNW-A1

I.R2-Series

1. SPECIFICATIONS .................................................................................................................................... 2

2. EXTERNAL DIMENSIONS ....................................................................................................................... 16

3. CENTER OF GRAVITY ............................................................................................................................ 28

4. ELECTRICAL WIRING DIAGRAMS ......................................................................................................... 30

5. SOUND LEVELS ...................................................................................................................................... 33

5-1. Sound levels in cooling mode .......................................................................................................... 33

5-2. Sound levels in heating mode.......................................................................................................... 39

6. VIBRATION LEVEL .................................................................................................................................. 45

7. OPERATION TEMPERATURE RANGE...................................................................................................46

8. CAPACITY TABLES ................................................................................................................................. 47

8-1. Correction by temperature ............................................................................................................... 48

8-2. Correction by total indoor................................................................................................................. 60

8-3. Correction by piping length.............................................................................................................. 64

8-4. Correction at frost and defrost ......................................................................................................... 67

8-5. Correction by antifreeze solution concentration............................................................................... 68

9. ELECTRICAL WORK................................................................................................................................ 69

9-1. Power supply for Outdoor unit ......................................................................................................... 69

9-2. Power cable specifications .............................................................................................................. 70

9-3. Power supply examples ................................................................................................................... 71

10.M-NET CONTROL ................................................................................................................................... 72

10-1.Address setting................................................................................................................................ 72

11.PIPING DESIGN ...................................................................................................................................... 73

11-1.R32 Piping material ......................................................................................................................... 73

11-2.Piping Design .................................................................................................................................. 74

11-3.Refrigerant charging calculation ...................................................................................................... 83

11-4.Water piping .................................................................................................................................... 84

R2-Series

MEES18K068

1

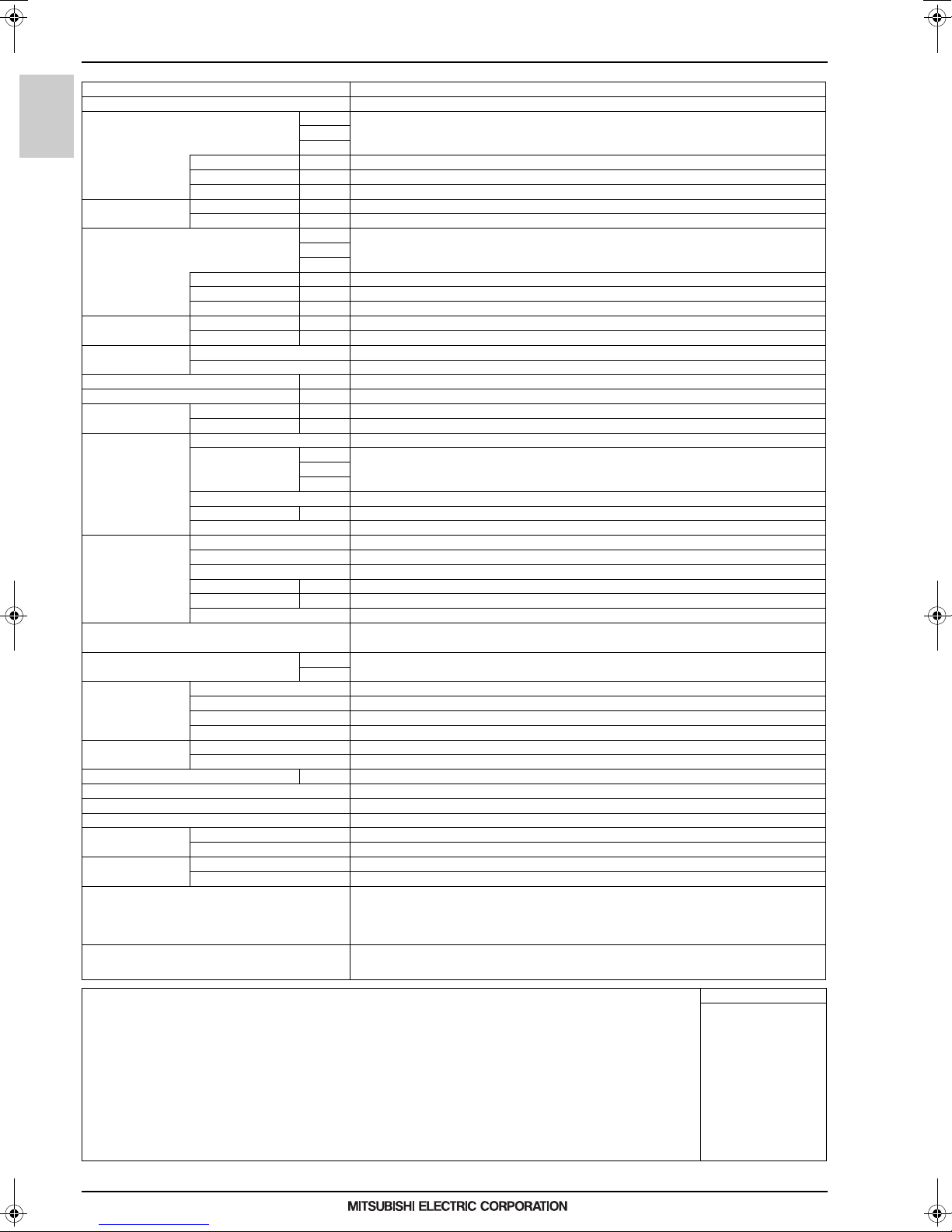

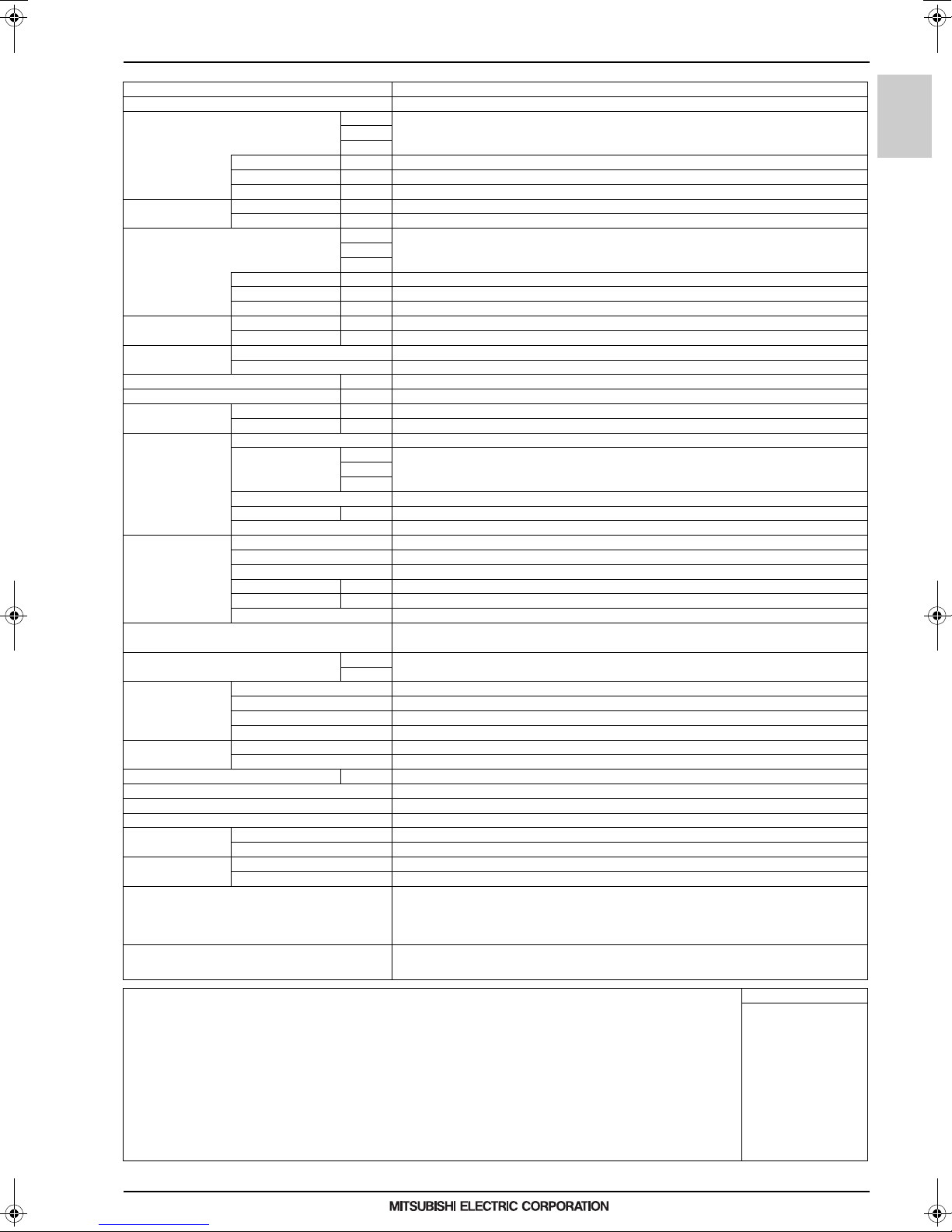

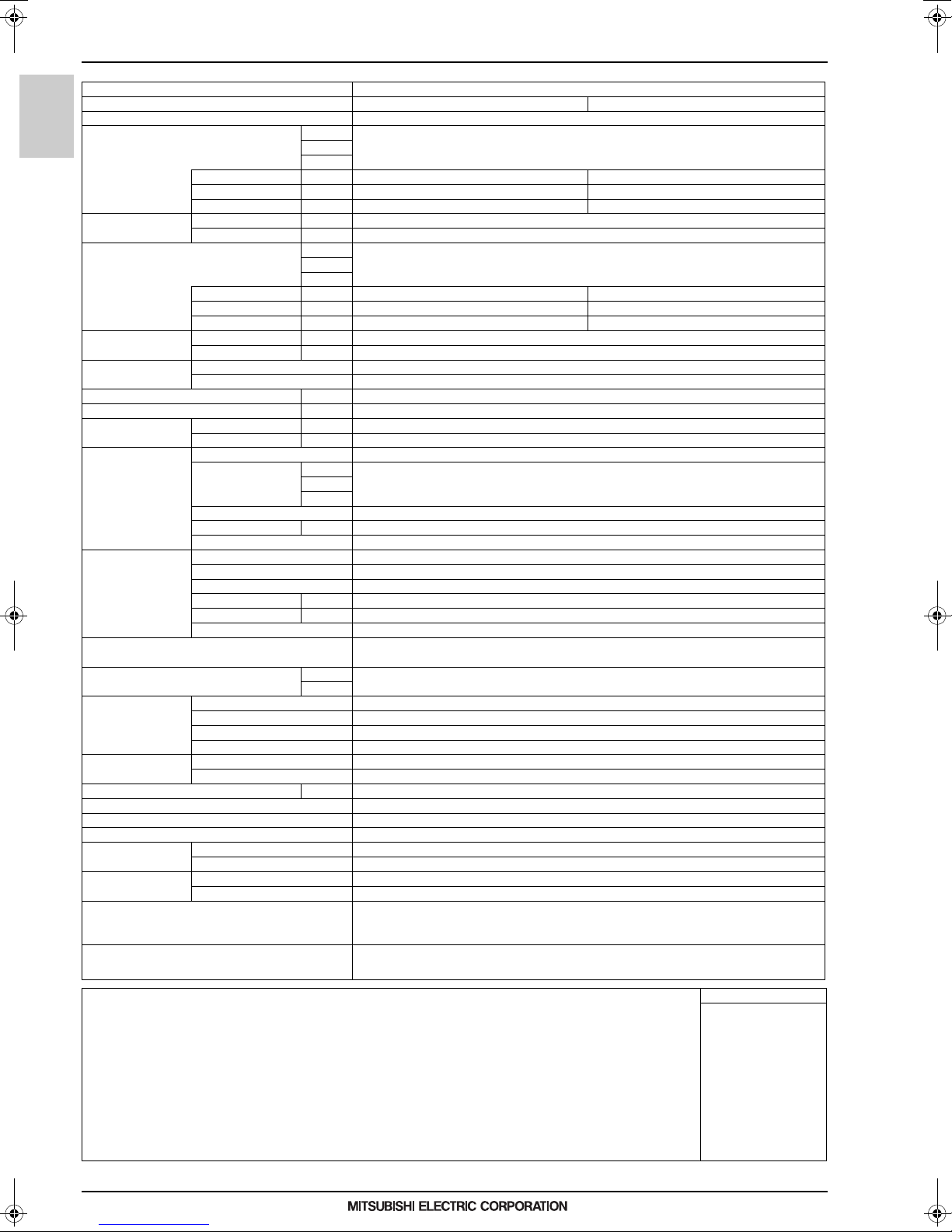

1. SPECIFICATIONS

I.R2-Series1. SPECIFICATIONS

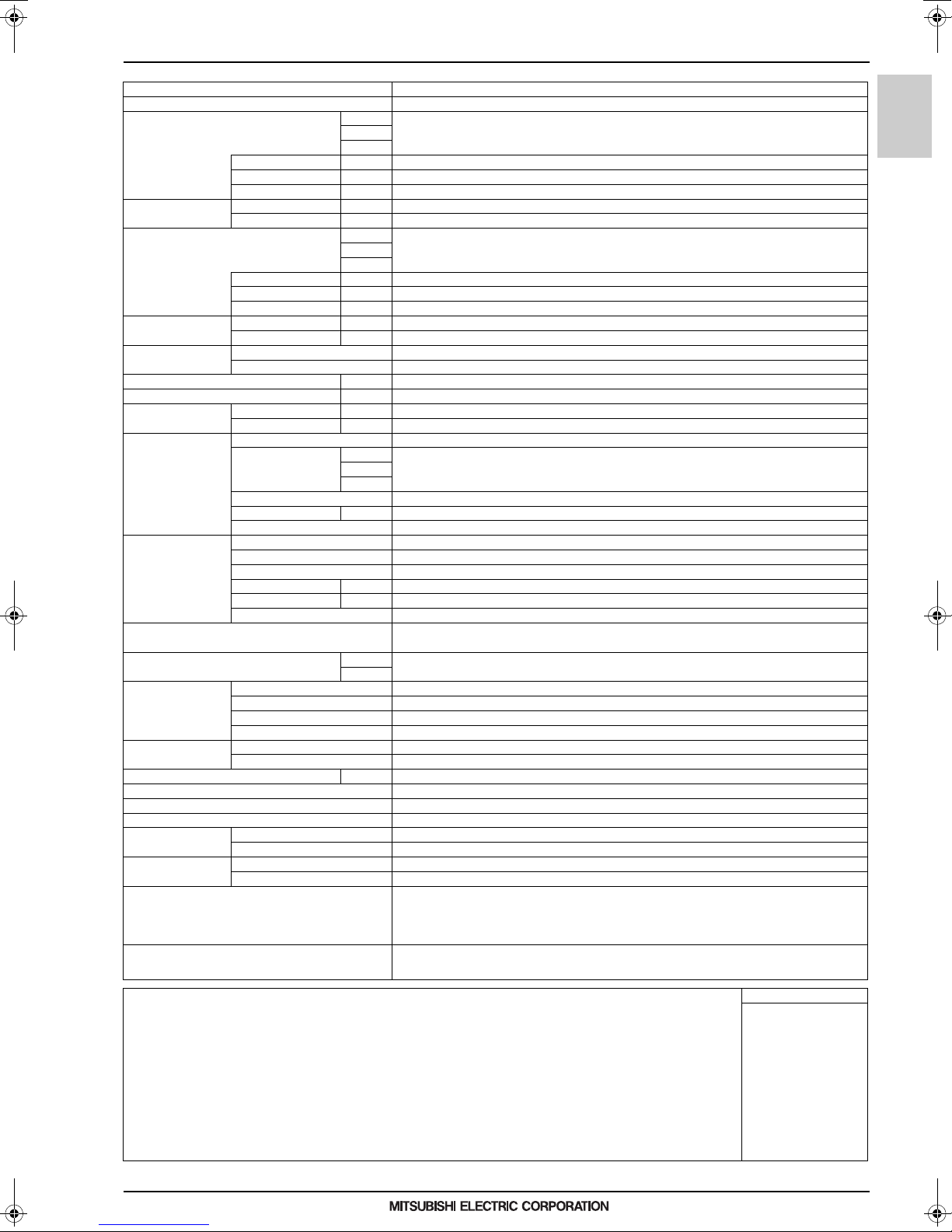

Model PURY-M200YNW-A1 (-BS)

Power source 3-phase 4-wire 380-400-415 V 50/60 Hz

Cooling capacity *1 kW 22.4

(Nominal) kcal/h 20,000

Power input kW 5.53

Current input A 9.3-8.8-8.5

Temp. range of Indoor W.B. 15.0~24.0°C (59~75°F)

cooling *3 Outdoor D.B. -5.0~52.0°C (23~126°F)

Heating capacity *2 kW 25.0

(Nominal) kcal/h 21,500

Temp. range of Indoor D.B. 15.0~27.0°C (59~81°F)

PURY-M-YNW-A1, EM-YNW-A1

heating *3 Outdoor W.B. -20.0~15.5°C (-4~60°F)

Indoor unit Total capacity 50~150% of outdoor unit capacity

connectable Model/Quantity WP10~125, W10~125/1~30

Sound pressure level (measured in anechoic room) *4 dB <A> 59.0/59.0

Sound power level (measured in anechoic room) *4 dB <A> 76.0/78.0

Refrigerant High pressure mm (in.) 15.88 (5/8) Brazed

piping diameter Low pressure mm (in.) 19.05 (3/4) Brazed

FAN Type x Quantity Propeller fan x 1

Compressor Type Inverter scroll hermetic compressor

External finish Pre-coated galvanized steel sh eets (+powder coating for -BS type)

External dimension H x W x D mm 1,858 (1,798 without legs) x 920 x 740

Protection devices High pressure protection High pressure sensor, High pressure switch at 4.15 MPa (601 psi)

Refrigerant Type x original charge R32 x 5.2 kg (12 lbs)

Net weight kg (lbs) 227 (501)

Heat exchanger Salt-resistant cross fin & copper tube

HIC circuit (HIC: Heat Inter-Changer) -

Defrosting method Auto-defrost mode (Reversed refrigerant cycle, Hot gas)

Drawing External WKL94T598

Standard attachment Document Installation Manual

Optional parts

EER kW/kW 4.05

Power input kW 6.39

Current input A 10.7-10.2-9.8

COP kW/kW 3.91

Air flow rate m3/min 170

Control, Driving mechanism Inverter-control, Direct-driven by motor

Motor output kW 0.92 x 1

*5 External static press. 0 Pa (0 mmH2O)

Manufacture AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Inverter

Motor output kW 4.6

Case heater kW - (- V)

Lubricant MEL46EH

Inverter circuit (COMP./FAN) Over-heat protection, Over-current protection

Compressor -

Fan motor -

Control HBC controller

Wiring WKE94G769

Accessory -

BTU/h 76,400

BTU/h 85,300

L/s 2,833

cfm 6,003

<MUNSELL 5Y 8/1 or similar>

in. 73-3/16 (70-13/16 without legs) x 36-1/4 x 29-3/16

Main HBC controller: CMB-WM108,1016V-AA

Sub HBC controller: CMB-WM108,1016V-AB

R2-Series

Remarks Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be

Notes: Unit converter

1.Nominal cooling conditions (subject to JIS B8615-2)

Indoor: 27°CD.B./19°CW.B. (81°FD.B./66°FW.B.), Outdoor: 35°CD.B./24°CW.B. (95°FD.B./75°FW.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

2.Nominal heating conditions (subject to JIS B8615-2)

Indoor: 20°CD.B. (68°FD.B.), Outdoor: 7°CD.B./6°CW.B. (45°FD.B./43°FW.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

3.-5°CD.B. (23°FD.B.)/-6°CW.B. (21°FW.B.) to 21°CD.B. (70°FD.B.)/15.5°CW.B. (60°FW.B.)

with cooling/heating mixed operat ion.

4.Cooling mode/Heating mode

5.External static pressure option is available (30 Pa, 60 Pa, 80 Pa/3.1 mmH2O, 6.1 mmH2O, 8.2 mmH2O).

Consult your dealer about the specification when setting External static pressure option.

6.R32 is flammable, and certain restrictions apply to the installation of units.

When installing new units, moving the existing units, or changing the layout of the room,

ensure that installation restrictions are observed.

For detail, refer to the section in the Databook on installation restrictions.

MEES18K068

referred to the Installation Manual.

Due to continuing improvement, above specifications may be subje ct to change without notice.

BTU/h =kW x 3,412

cfm =m3/min x 35.31

lbs =kg/0.4536

*Above specification data is

subject to rounding variatio n.

2

1. SPECIFICATIONS

Model PURY-M250YNW-A1 (-BS)

Power source 3-phase 4-wire 380-400-415 V 50/60 Hz

Cooling capacity *1 kW 28.0

(Nominal) kcal/h 25,000

BTU/h 95,500

Power input kW 8.40

Current input A 14.1-13.4-12.9

EER kW/kW 3.33

Temp. range of Indoor W.B. 15.0~24.0°C (59~75°F)

cooling *3 Outdoor D.B. -5.0~52.0°C (23~126°F)

Heating capacity *2 kW 31.5

(Nominal) kcal/h 27,100

BTU/h 107,500

Power input kW 9.15

Current input A 15.4-14.6-14.1

COP kW/kW 3.44

Temp. range of Indoor D.B. 15.0~27.0°C (59~81°F)

heating *3 Outdoor W.B. -20.0~15.5°C (-4~60°F)

Indoor unit Total capacity 50~150% of outdoor unit capacity

connectable Model/Quantity WP10~125, W10~125/1~37

Sound pressure level (meas ured in anechoic room) *4 dB <A> 60.5/61.0

Sound power level (measured in anechoic room) *4 dB <A> 78.5/80.0

Refrigerant High pressure mm (in.) 15.88 (5/8) Brazed

piping diameter Low pressure mm (in.) 22.2 (7/8) Brazed

FAN Type x Quantity Propeller fan x 1

Air flow rate m3/min 185

L/s 3,083

cfm 6,532

Control, Driving mechanism Inverter-control, Direct-driven by motor

Motor output kW 0.92 x 1

*5 External static press. 0 Pa (0 mmH2O)

Compressor Type Inverter scroll hermetic compressor

Manufacture AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Inverter

Motor output kW 7 .0

Case heater kW - (- V)

Lubricant MEL46EH

External finish Pre-coated galvanized steel sheets (+powder coating for -BS type)

<MUNSELL 5Y 8/1 or similar>

External dimension H x W x D mm 1,858 (1,798 without legs) x 920 x 740

in. 73-3/16 (70-13/16 without legs) x 36-1/4 x 29-3/16

Protection devices High pressure protection High pressure sensor, High pressure switc h at 4.15 MPa (601 psi)

Inverter circuit (COMP./FA N) Ove r-heat protection, Over-cur rent protection

Compressor -

Fan motor -

Refrigerant Type x original charge R32 x 5.2 kg (12 lbs)

Control HBC controller

Net weight kg (lbs) 227 (501)

Heat exchanger Salt-resistant cross fin & copper tube

HIC circuit (HIC: Heat Inter-Changer) -

Defrosting method Auto-defrost mode (Reversed refrigerant cycle, Hot gas)

Drawing External WKL94T598

Wiring WKE94G769

Standard attachment Document Installation Manual

Accessory -

Optional parts

Main HBC controller: CMB-WM108,1016V-AA

Sub HBC controller: CMB-WM108,1016V-AB

R2-Series

PURY-M-YNW-A1, EM-YNW-A1

Remarks Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be

Notes: Unit converter

1.Nominal cooling conditions (subject to JIS B8615-2)

Indoor: 27°CD.B./19°CW.B. (81°FD.B./66°FW.B.), Outdoor: 35°CD.B./24°CW.B. (95°FD.B./75°FW.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

2.Nominal heating conditions (subj ect to JIS B8615-2)

Indoor: 20°CD.B. (68°FD.B.), Outdoor: 7°CD.B./6°CW.B. (45°FD.B./43°FW.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

3.-5°CD.B. (23°FD.B.)/-6°CW.B. (21°FW.B.) to 21°CD.B. (70°FD.B.)/15.5°CW.B. (60°FW.B.)

with cooling/heating mixed operation.

4.Cooling mode/Heating mode

5.External static pressure option is available (30 Pa, 60 Pa, 80 Pa/3.1 mmH2O, 6.1 mmH2O, 8.2 mmH2O).

Consult your dealer about the specification when setting External static pressure option.

6.R32 is flammable, and certain rest rictions apply to the installation of units.

When installing new units, moving the existing units, or changing the layout of the room,

ensure that installation restrictions are observed.

For detail, refer to the section in the Databook on installation restrictions.

MEES18K068

referred to the Installation Manual.

Due to continuing improvement, a bove specifications may be subject to change without notice.

BTU/h =kW x 3,412

cfm =m3/min x 35.31

lbs =kg/0.4536

*Above specification data is

subject to rounding variation.

3

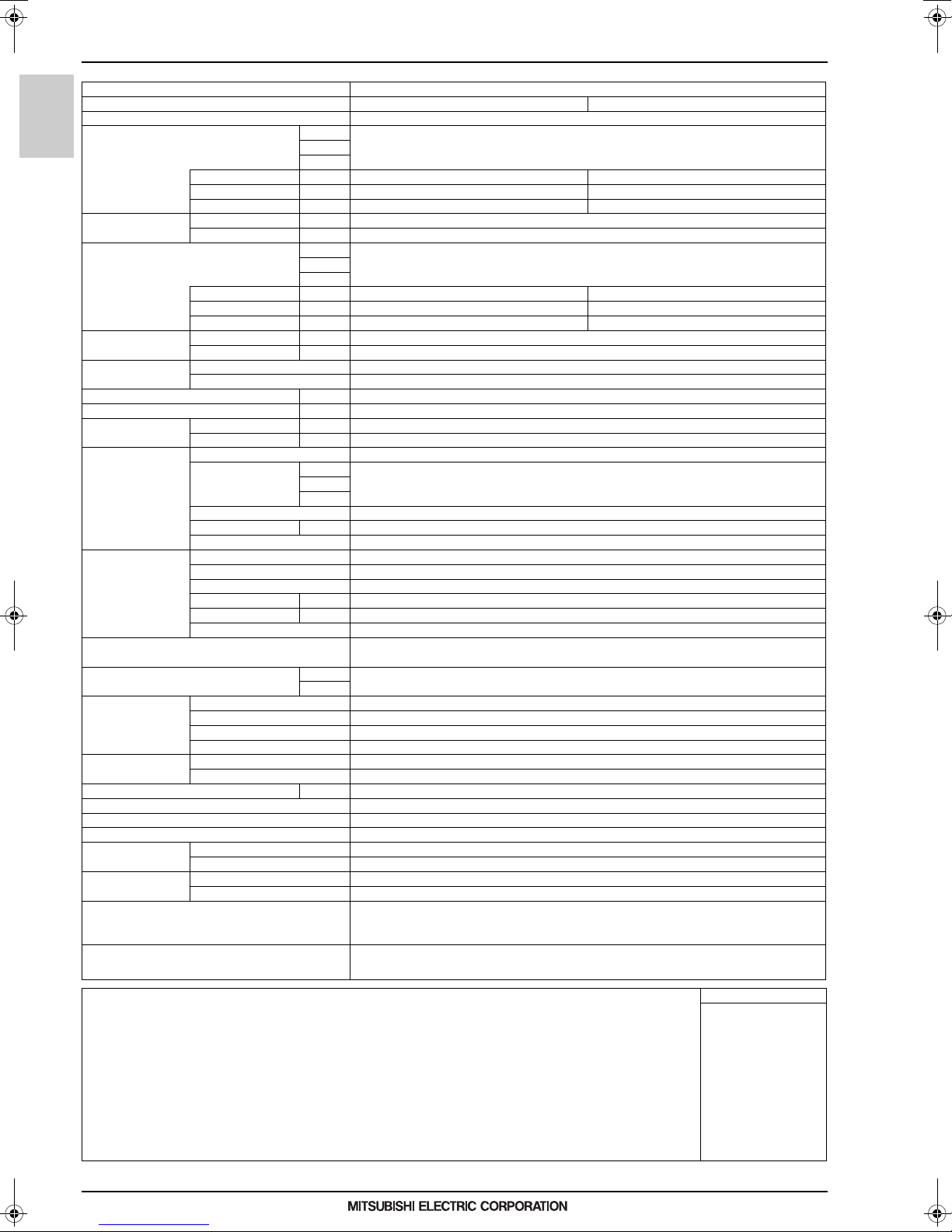

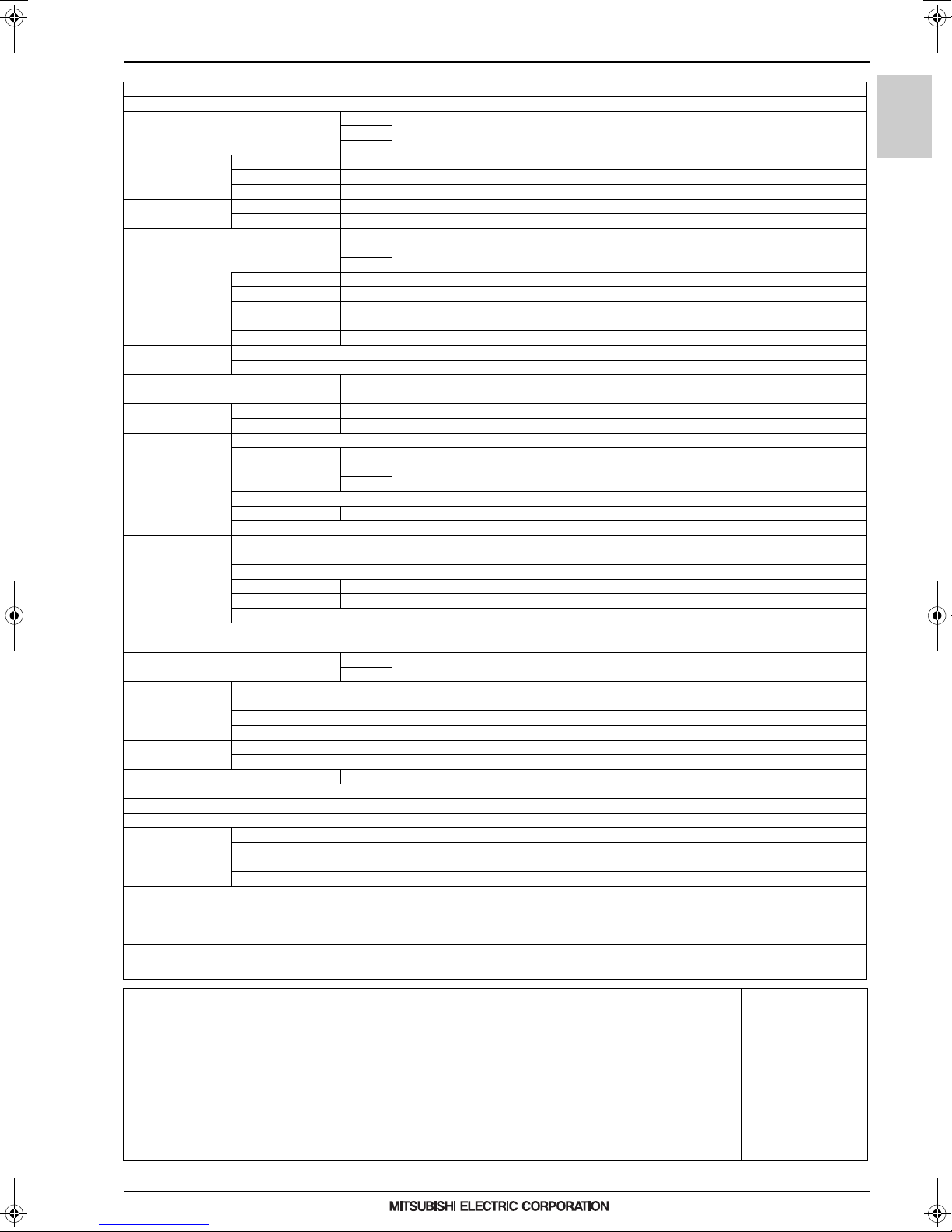

1. SPECIFICATIONS

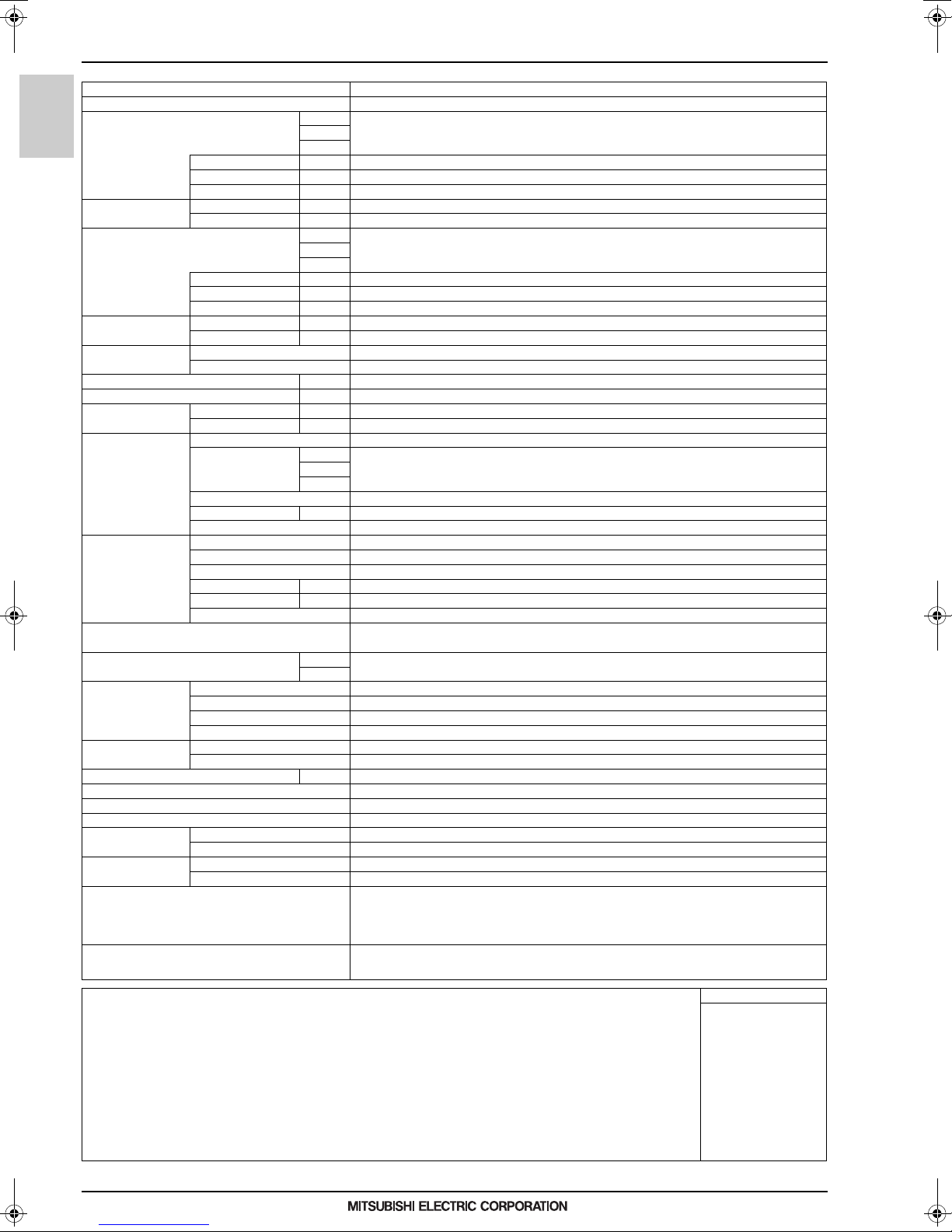

Model PURY-M300YNW-A1 (-BS)

Number of HBC controller Single HBC Double HBC

Power source 3-phase 4-wire 380-400-415 V 50/60 Hz

Cooling capacity *1 kW 33.5

(Nominal) kcal/h 30,000

Power input kW 11.65 9.88

Current input A 19.6-18.6-18.0 16.6-15.8-15.2

Temp. range of Indoor W.B. 15.0~24.0°C (59~75°F)

cooling *3 Outdoor D.B. -5.0~52.0°C (23~126°F)

Heating capacity *2 kW 37.5

(Nominal) kcal/h 32,300

PURY-M-YNW-A1, EM-YNW-A1

Temp. range of Indoor D.B. 15.0~27.0°C (59~81°F)

heating *3 Outdoor W.B. -20.0~15.5°C (-4~60°F)

Indoor unit Total capacity 50~150% of outdoor unit capacity

connectable Model/Quantity WP10~125, W10 ~125/2~45

Sound pressure level (measured in anechoic room) *4 dB <A> 61.0/67.0

Sound power level (measured in anechoic room) *4 dB <A> 80.0/86.5

Refrigerant High pressure mm (in.) 15.88 (5/ 8) Brazed

piping diameter L ow pressure mm (in.) 22.2 (7/8) Brazed

FAN Type x Quantity Propeller fan x 1

Compressor Type Inverter scroll hermetic compressor

External finish Pre-coated galvanized steel sh eets (+powder coating for -BS type)

External dimension H x W x D mm 1,858 (1,798 without legs) x 920 x 740

Protection devices High pressure protection High pressure sensor, High pressure switch at 4.15 MPa (601 psi)

Refrigerant Type x original charge R32 x 5.2 kg (12 lbs)

Net weight kg (lbs) 227 (501)

Heat exchanger Salt-resistant cross fin & copper tube

HIC circuit (HIC: Heat Inter-Changer) -

Defrosting method Auto-defrost mode (Reversed refrigerant cycle, Hot gas)

Drawing External WKL94T598

Standard attachment Document Installation Manual

Optional parts Main HBC controller: CMB-WM108,1016V-AA

EER kW/kW 2.87 3.39

Power input kW 11.00 10.33

Current input A 18.5-17.6-17.0 17.4-16.5-15.9

COP kW/kW 3.40 3.63

Air flow rate m

Control, Driving mechanism Inverter-control, Direct-driven by motor

Motor output kW 0.92 x 1

*5 External static press. 0 Pa (0 mmH

Manufacture AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Inverter

Motor output kW 8.0

Case heater kW - (- V)

Lubricant MEL46EH

Inverter circuit (COMP./FAN) Over-heat protection, Over-current protection

Compressor -

Fan motor -

Control HBC controller

Wiring WKE94G769

Accessory -

BTU/h 114,300

BTU/h 128,000

3

/min 240

L/s 4,000

cfm 8,474

O)

2

<MUNSELL 5Y 8/1 or similar>

in. 73-3/16 (70-13/16 without legs) x 36-1/4 x 29-3/16

Sub HBC controller: CMB-WM108,1016V-AB

R2-Series

Remarks Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be

Notes: Unit converter

1.Nominal cooling conditions (subject to JIS B8615-2)

Indoor: 27°CD.B./19°CW.B. (81°FD.B./66°FW.B.), Outdoor: 35°CD.B./24°CW.B. (95°FD.B./75°FW.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

2.Nominal heating conditions (subject to JIS B8615-2)

Indoor: 20°CD.B. (68°FD.B.), Outdoor: 7°CD.B./6°CW.B. (45°FD.B./43°FW.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

3.-5°CD.B. (23°FD.B.)/-6°CW.B. (21°FW.B.) to 21°CD.B. (70°FD.B.)/15.5°CW.B. (60°FW.B.)

with cooling/heating mixed operat ion.

4.Cooling mode/Heating mode

5.External static pressure option is available (30 Pa, 60 Pa, 80 Pa/3.1 mmH2O, 6.1 mmH2O, 8.2 mmH2O).

Consult your dealer about the specification when setting External static pressure option.

6.R32 is flammable, and certain restrictions apply to the installation of units.

When installing new units, moving the existing units, or changing the layout of the room,

ensure that installation restrictions are observed.

For detail, refer to the section in the Databook on installation restrictions.

MEES18K068

referred to the Installation Manual.

Due to continuing improvement, above specifications may be subje ct to change without notice.

BTU/h =kW x 3,412

cfm =m3/min x 35.31

lbs =kg/0.4536

*Above specification data is

subject to rounding variatio n.

4

1. SPECIFICATIONS

Model PURY-M350YNW-A1 (-BS)

Number of HBC controller Single HBC Double HBC

Power source 3-phase 4-wire 380-400-415 V 50/60 Hz

Cooling capacity *1 kW 40.0

(Nominal) kcal/h 35,000

Power input kW 14.93 12.15

Current input A 25.2-2 3.9-23.0 20.5-19.4-18.7

EER kW/kW 2.67 3.29

Temp. range of Indoor W.B. 15.0~24.0°C (59~75°F)

cooling *3 Outdoor D.B. -5.0~52.0°C (23~126°F)

Heating capacity *2 kW 45.0

(Nominal) kcal/h 38,700

Power input kW 13.14 12.16

Current input A 22.1-2 1.0-20.3 20.5-19.5-18.7

COP kW/kW 3.42 3.70

Temp. range of Indoor D.B. 15.0~27.0°C (59~81°F)

heating *3 Outdoor W.B. -20.0~15.5°C (-4~60°F)

Indoor unit Total capacity 50~150% of outdoor unit capacity

connectable Model/Quantity WP10~125, W10~125/1~35

Sound pressure level (meas ured in anechoic room) *4 dB <A> 62 .5/64.0

Sound power level (measured in anechoic room) *4 dB <A> 81.0/83.0

Refrigerant High pressure mm (in.) 15.88 (5/8) Brazed

piping diameter Low pressure mm (in.) 28.58 (1-1/8) Brazed

FAN Type x Quantity Propeller fan x 2

Air flow rate m

Control, Driving mechanism Inverter-control, Direct-driven by motor

Motor output kW 0.46 x 2

*5 External static press. 0 Pa (0 mmH

Compressor Type Inverter scroll hermetic compressor

Manufacture AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Inverter

Motor output kW 9.6

Case heater kW - (- V)

Lubricant MEL46EH

External finish Pre-coated galvanized steel sheets (+powder coating for -BS type)

External dimension H x W x D mm 1,858 (1,798 without legs) x 1,240 x 740

Protection devices High pressure protection High pressure sensor, High pressure switch at 4.15 MPa (601 psi)

Inverter circuit (COMP./FAN) Over-heat protection, Over-current protection

Compressor -

Fan motor -

Refrigerant Type x original charge R32 x 8.0 kg (18 lbs)

Control HBC controller

Net weight kg (lbs) 270 (596)

Heat exchanger Salt-resistant cross fin & copper tube

HIC circuit (HIC: Heat Inter-Changer) -

Defrosting method Auto-defrost mode (Reversed refrigerant cycle)

Drawing External WKL94T599

Wiring WKE94G770

Standard attachment Document Installation Manual

Accessory -

Optional parts Main HBC controller: CMB-WM108,1016V-AA

BTU/h 136,500

BTU/h 153,500

3

/min 250

L/s 4,167

cfm 8,828

O)

2

<MUNSELL 5Y 8/1 or similar>

in. 73-3/16 (70-13/16 without legs) x 48-7/8 x 29-3/16

Sub HBC controller: CMB-WM108,1016V-AB

R2-Series

PURY-M-YNW-A1, EM-YNW-A1

Remarks Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be

Notes: Unit converter

1.Nominal cooling conditions (subject to JIS B8615-2)

Indoor: 27°CD.B./19°CW.B. (81°FD.B./66°FW.B.), Outdoor: 35°CD.B./24°CW.B. (95°FD.B./75°FW.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

2.Nominal heating conditions (subj ect to JIS B8615-2)

Indoor: 20°CD.B. (68°FD.B.), Outdoor: 7°CD.B./6°CW.B. (45°FD.B./43°FW.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

3.-5°CD.B. (23°FD.B.)/-6°CW.B. (21°FW.B.) to 21°CD.B. (70°FD.B.)/15.5°CW.B. (60°FW.B.)

with cooling/heating mixed operation.

4.Cooling mode/Heating mode

5.External static pressure option is available (30 Pa, 60 Pa, 80 Pa/3.1 mmH2O, 6.1 mmH2O, 8.2 mmH2O).

Consult your dealer about the specification when setting External static pressure option.

6.R32 is flammable, and certain rest rictions apply to the installation of units.

When installing new units, moving the existing units, or changing the layout of the room,

ensure that installation restrictions are observed.

For detail, refer to the section in the Databook on installation restrictions.

MEES18K068

referred to the Installation Manual.

Due to continuing improvement, a bove specifications may be subject to change without notice.

BTU/h =kW x 3,412

cfm =m3/min x 35.31

lbs =kg/0.4536

*Above specification data is

subject to rounding variation.

5

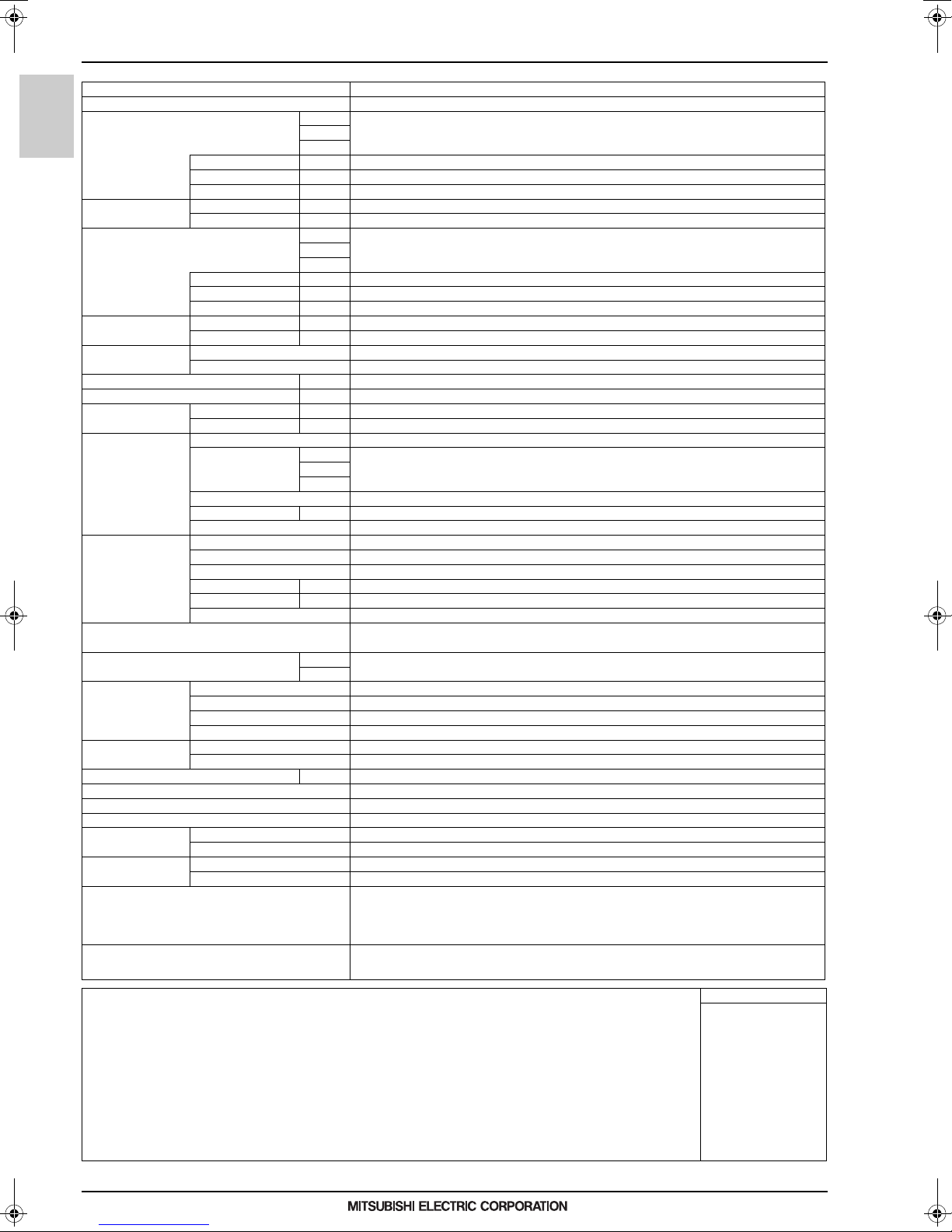

1. SPECIFICATIONS

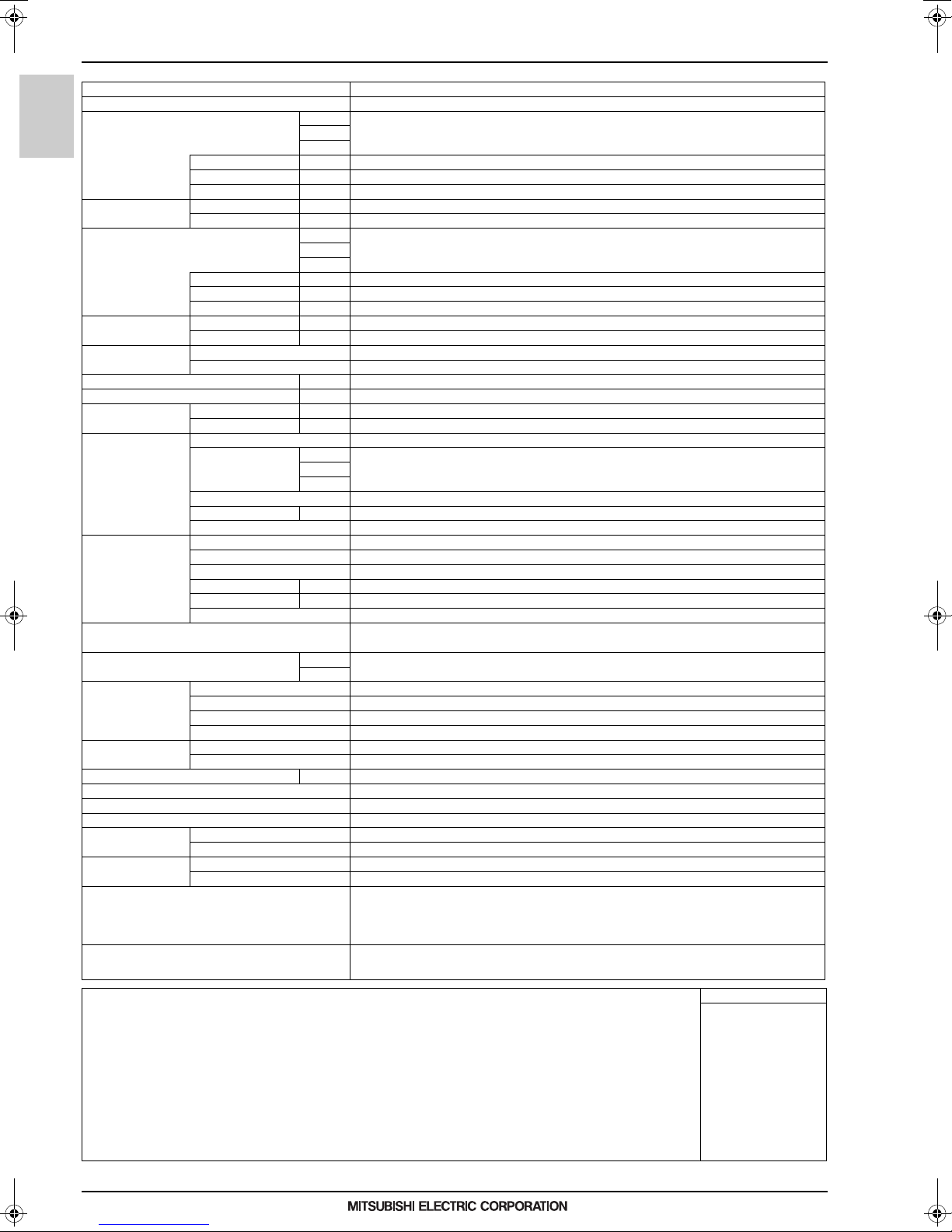

Model PURY-M400YNW-A1 (-BS)

Power source 3-phase 4-wire 380-400-415 V 50/60 Hz

Cooling capacity *1 kW 45.0

(Nominal) kcal/h 40,000

Power input kW 15.15

Current input A 25.5-24.2-23.4

Temp. range of Indoor W.B. 15.0~24.0°C (59~75°F)

cooling *3 Outdoor D.B. -5.0~52.0°C (23~126°F)

Heating capacity *2 kW 50.0

(Nominal) kcal/h 45,000

Temp. range of Indoor D.B. 15.0~27.0°C (59~81°F)

PURY-M-YNW-A1, EM-YNW-A1

heating *3 Outdoor W.B. -20.0~15.5°C (-4~60°F)

Indoor unit Total capacity 50~150% of outdoor unit capacity

connectable Model/Quantity WP10~125, W10~125/1~40

Sound pressure level (measured in anechoic room) *4 dB <A> 65.0/69.0

Sound power level (measured in anechoic room) *4 dB <A> 83.0/88.0

Refrigerant High pressure mm (in.) 19.05 (3/4) Brazed

piping diameter L ow pressure mm (in.) 28.58 (1-1/8) Brazed

FAN Type x Quantity Propeller fan x 2

Compressor Type Inverter scroll hermetic compressor

External finish Pre-coated galvanized steel sheets (+powder coating for -BS type)

External dimension H x W x D mm 1,858 (1,798 without legs) x 1,240 x 740

Protection devices High pressure protection High pressure sensor, High pressure switch at 4.15 MPa (601 psi)

Refrigerant Type x original charge R32 x 8.0 kg (18 lbs)

Net weight kg (lbs) 273 (602)

Heat exchanger Salt-resistant cross fin & copper tube

HIC circuit (HIC: Heat Inter-Changer) -

Defrosting method Auto-defrost mode (Reversed refrigerant cycle)

Drawing External WKL94T599

Standard attachment Document Installation Manual

Optional parts

EER kW/kW 2.97

Power input kW 14.08

Current input A 23.7-22.5-21.7

COP kW/kW 3.55

Air flow rate m3/min 315

Control, Driving mechanism Inverter-control, Direct-dri ven by motor

Motor output kW 0.46 x 2

*5 External static press. 0 Pa (0 mmH2O)

Manufacture AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Inverter

Motor output kW 12.2

Case heater kW - (- V)

Lubricant MEL46EH

Inverter circuit (COMP./FAN) Over-heat protection, Over-current protection

Compressor -

Fan motor -

Control HBC controller

Wiring WKE94G770

Accessory -

BTU/h 153,500

BTU/h 170,600

L/s 5,250

cfm 11,123

<MUNSELL 5Y 8/1 or similar>

in. 73-3/16 (70-13/16 without legs) x 48-7/8 x 29-3/16

Main HBC controller: CMB-WM108,1016V-AA

Sub HBC controller: CMB-WM108,1016V-AB

R2-Series

Remarks Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be

Notes: Unit converter

1.Nominal cooling conditions (subject to JIS B8615-2)

Indoor: 27°CD.B./19°CW.B. (81°FD.B./66°FW.B.), Outdoor: 35°CD.B./24°CW.B. (95°FD.B./75°FW.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

2.Nominal heating conditions (subject to JIS B8615-2)

Indoor: 20°CD.B. (68°FD.B.), Outdoor: 7°CD.B./6°CW.B. (45°FD.B./43°FW.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

3.-5°CD.B. (23°FD.B.)/-6°CW.B. (21°FW.B.) to 21°CD.B. (70°FD.B.)/15.5°CW.B. (60°FW.B.)

with cooling/heating mixed operat ion.

4.Cooling mode/Heating mode

5.External static pressure option is available (30 Pa, 60 Pa, 80 Pa/3.1 mmH2O, 6.1 mmH2O, 8.2 mmH2O).

Consult your dealer about the specification when setting External static pressure option.

6.R32 is flammable, and certain restrictions apply to the installation of units.

When installing new units, moving the existing units, or changing the layout of the room,

ensure that installation restrictions are observed.

For detail, refer to the section in the Databook on installation restrictions.

MEES18K068

referred to the Installation Manual.

Due to continuing improvement, above specifications may be subje ct to change without notice.

BTU/h =kW x 3,412

cfm =m3/min x 35.31

lbs =kg/0.4536

*Above specification data is

subject to rounding variatio n.

6

1. SPECIFICATIONS

Model PURY-M450YNW-A1 (-BS)

Power source 3-phase 4-wire 380-400-415 V 50/60 Hz

Cooling capacity *1 kW 50.0

(Nominal) kcal/h 45,000

BTU/h 170,600

Power input kW 15.47

Current input A 26.1-24.8-23.9

EER kW/kW 3.23

Temp. range of Indoor W.B. 15.0~24.0°C (59~75°F)

cooling *3 Outdoor D.B. -5.0~52.0°C (23~126°F)

Heating capacity *2 kW 56.0

(Nominal) kcal/h 50,000

BTU/h 191,100

Power input kW 16.18

Current input A 27.3-25.9-25.0

COP kW/kW 3.46

Temp. range of Indoor D.B. 15.0~27.0°C (59~81°F)

heating *3 Outdoor W.B. -20.0~15.5°C (-4~60°F)

Indoor unit Total capacity 50~150% of outdoor unit capacity

connectable Model/Quantity WP10~125, W10~125/1~45

Sound pressure level (meas ured in anechoic room) *4 dB <A> 65.5/70.0

Sound power level (measured in anechoic room) *4 dB <A> 83.0/89.0

Refrigerant High pressure mm (in.) 19.05 (3/4) Brazed

piping diameter Low pressure mm (in.) 28.58 (1-1/8) Brazed

FAN Type x Quantity Propeller fan x 2

Air flow rate m3/min 317

L/s 5,283

cfm 11,193

Control, Driving mechanism Inverter-control, Direct-driven by motor

Motor output kW 0.46 x 2

*5 External static press. 0 Pa (0 mmH2O)

Compressor Type Inverter scroll hermetic compressor

Manufacture AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Inverter

Motor output kW 13.1

Case heater kW - (- V)

Lubricant MEL46EH

External finish Pre-coated galvanized steel sheets (+powder coating for -BS type)

<MUNSELL 5Y 8/1 or similar>

External dimension H x W x D mm 1,858 (1,798 without le gs) x 1,240 x 740

in. 73-3/16 (70-13/16 without legs) x 48-7/8 x 29-3/16

Protection devices High pressure protection High pressure sensor, High pressure switc h at 4.15 MPa (601 psi)

Inverter circuit (COMP./FA N) Ove r-heat protection, Over-cur rent protection

Compressor -

Fan motor -

Refrigerant Type x original charge R32 x 10.8 kg (24 lbs)

Control HBC controller

Net weight kg (lbs) 293 (646)

Heat exchanger Salt-resistant cross fin & copper tube

HIC circuit (HIC: Heat Inter-Changer) -

Defrosting method Auto-defrost mode (Reversed refrigerant cycle)

Drawing External WKL94T599

Wiring WKE94G770

Standard attachment Document Installation Manual

Accessory -

Optional parts

Main HBC controller: CMB-WM108,1016V-AA

Sub HBC controller: CMB-WM108,1016V-AB

R2-Series

PURY-M-YNW-A1, EM-YNW-A1

Remarks Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be

Notes: Unit converter

1.Nominal cooling conditions (subject to JIS B8615-2)

Indoor: 27°CD.B./19°CW.B. (81°FD.B./66°FW.B.), Outdoor: 35°CD.B./24°CW.B. (95°FD.B./75°FW.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

2.Nominal heating conditions (subj ect to JIS B8615-2)

Indoor: 20°CD.B. (68°FD.B.), Outdoor: 7°CD.B./6°CW.B. (45°FD.B./43°FW.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

3.-5°CD.B. (23°FD.B.)/-6°CW.B. (21°FW.B.) to 21°CD.B. (70°FD.B.)/15.5°CW.B. (60°FW.B.)

with cooling/heating mixed operation.

4.Cooling mode/Heating mode

5.External static pressure option is available (30 Pa, 60 Pa, 80 Pa/3.1 mmH2O, 6.1 mmH2O, 8.2 mmH2O).

Consult your dealer about the specification when setting External static pressure option.

6.R32 is flammable, and certain rest rictions apply to the installation of units.

When installing new units, moving the existing units, or changing the layout of the room,

ensure that installation restrictions are observed.

For detail, refer to the section in the Databook on installation restrictions.

MEES18K068

referred to the Installation Manual.

Due to continuing improvement, a bove specifications may be subject to change without notice.

BTU/h =kW x 3,412

cfm =m3/min x 35.31

lbs =kg/0.4536

*Above specification data is

subject to rounding variation.

7

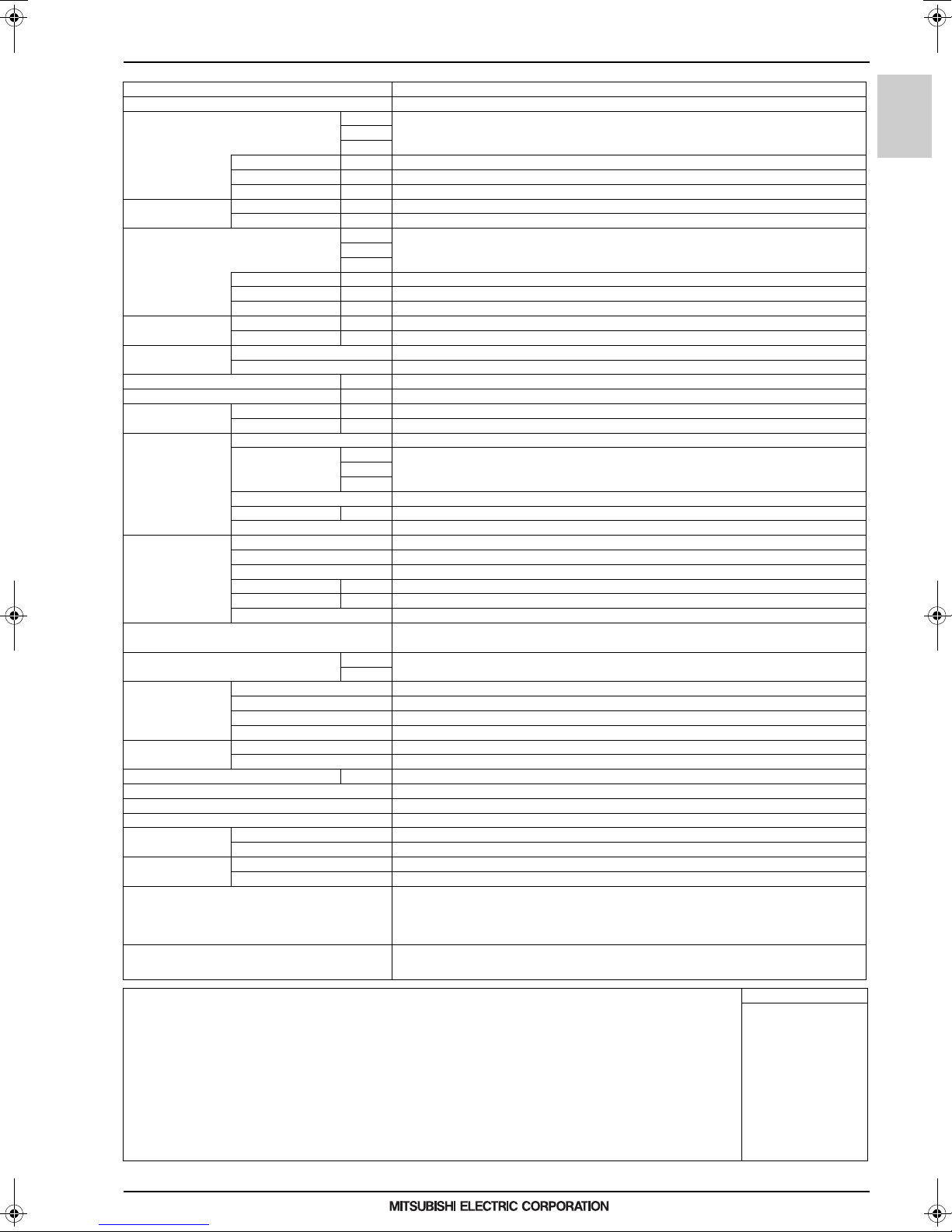

1. SPECIFICATIONS

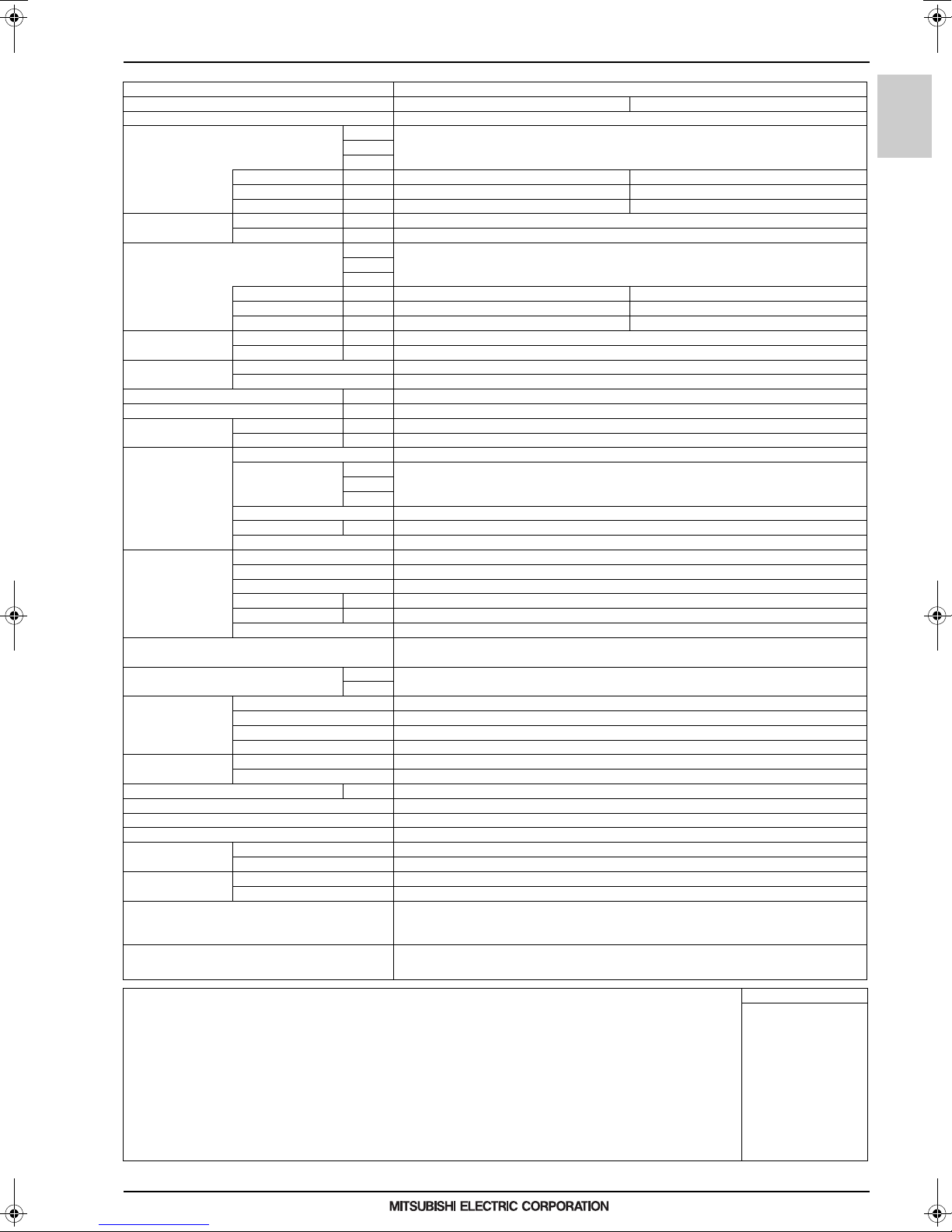

Model PURY-M500YNW-A1 (-BS)

Power source 3-phase 4-wire 380-400-415 V 50/60 Hz

Cooling capacity *1 kW 56.0

(Nominal) kcal/h 50,000

Power input kW 22.25

Current input A 37.5-35.6-34.3

Temp. range of Indoor W.B. 15.0~24.0°C (59~75°F)

cooling *3 Outdoor D.B. -5.0~52.0°C (23~126°F)

Heating capacity *2 kW 63.0

(Nominal) kcal/h 54,200

Temp. range of Indoor D.B. 15.0~27.0°C (59~81°F)

PURY-M-YNW-A1, EM-YNW-A1

heating *3 Outdoor W.B. -20.0~15.5°C (-4~60°F)

Indoor unit Total capacity 50~150% of outdoor unit capacity

connectable Model/Quantity WP10~125, W10~125/1~50

Sound pressure level (measured in anechoic room) *4 dB <A> 63.5/64.5

Sound power level (measured in anechoic room) *4 dB <A> 82.0/84.0

Refrigerant High pressure mm (in.) 19.05 (3/4) Brazed

piping diameter L ow pressure mm (in.) 28.58 (1-1/8) Brazed

FAN Type x Quantity Propeller fan x 2

Compressor Type Inverter scroll hermetic compressor

External finish Pre-coated galvanized steel sheets (+powder coating for -BS type)

External dimension H x W x D mm 1,858 (1,798 without legs) x 1,750 x 740

Protection devices High pressure protection High pressure sensor, High pressure switch at 4.15 MPa (601 psi)

Refrigerant Type x original charge R32 x 10.8 kg (24 lbs)

Net weight kg (lbs) 337 (743)

Heat exchanger Salt-resistant cross fin & copper tube

HIC circuit (HIC: Heat Inter-Changer) -

Defrosting method Auto-defrost mode (Reversed refrigerant cycle)

Drawing External WKL94T600

Standard attachment Document Installation Manual

Optional parts

EER kW/kW 2.51

Power input kW 18.26

Current input A 30.8-29.2-28.2

COP kW/kW 3.45

Air flow rate m3/min 295

Control, Driving mechanism Inverter-control, Direct-dri ven by motor

Motor output kW 0.92 x 2

*5 External static press. 0 Pa (0 mmH2O)

Manufacture AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Inverter

Motor output kW 17.4

Case heater kW - (- V)

Lubricant MEL46EH

Inverter circuit (COMP./FAN) Over-heat protection, Over-current protection

Compressor -

Fan motor -

Control HBC controller

Wiring WKE94G771

Accessory -

BTU/h 191,100

BTU/h 215,000

L/s 4,917

cfm 10,416

<MUNSELL 5Y 8/1 or similar>

in. 73-3/16 (70-13/16 without legs) x 68-15/16 x 29-3/16

Main HBC controller: CMB-WM108,1016V-AA

Sub HBC controller: CMB-WM108,1016V-AB

R2-Series

Remarks Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be

Notes: Unit converter

1.Nominal cooling conditions (subject to JIS B8615-2)

Indoor: 27°CD.B./19°CW.B. (81°FD.B./66°FW.B.), Outdoor: 35°CD.B./24°CW.B. (95°FD.B./75°FW.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

2.Nominal heating conditions (subject to JIS B8615-2)

Indoor: 20°CD.B. (68°FD.B.), Outdoor: 7°CD.B./6°CW.B. (45°FD.B./43°FW.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

3.-5°CD.B. (23°FD.B.)/-6°CW.B. (21°FW.B.) to 21°CD.B. (70°FD.B.)/15.5°CW.B. (60°FW.B.)

with cooling/heating mixed operat ion.

4.Cooling mode/Heating mode

5.External static pressure option is available (30 Pa, 60 Pa, 80 Pa/3.1 mmH2O, 6.1 mmH2O, 8.2 mmH2O).

Consult your dealer about the specification when setting External static pressure option.

6.R32 is flammable, and certain restrictions apply to the installation of units.

When installing new units, moving the existing units, or changing the layout of the room,

ensure that installation restrictions are observed.

For detail, refer to the section in the Databook on installation restrictions.

MEES18K068

referred to the Installation Manual.

Due to continuing improvement, above specifications may be subje ct to change without notice.

BTU/h =kW x 3,412

cfm =m3/min x 35.31

lbs =kg/0.4536

*Above specification data is

subject to rounding variatio n.

8

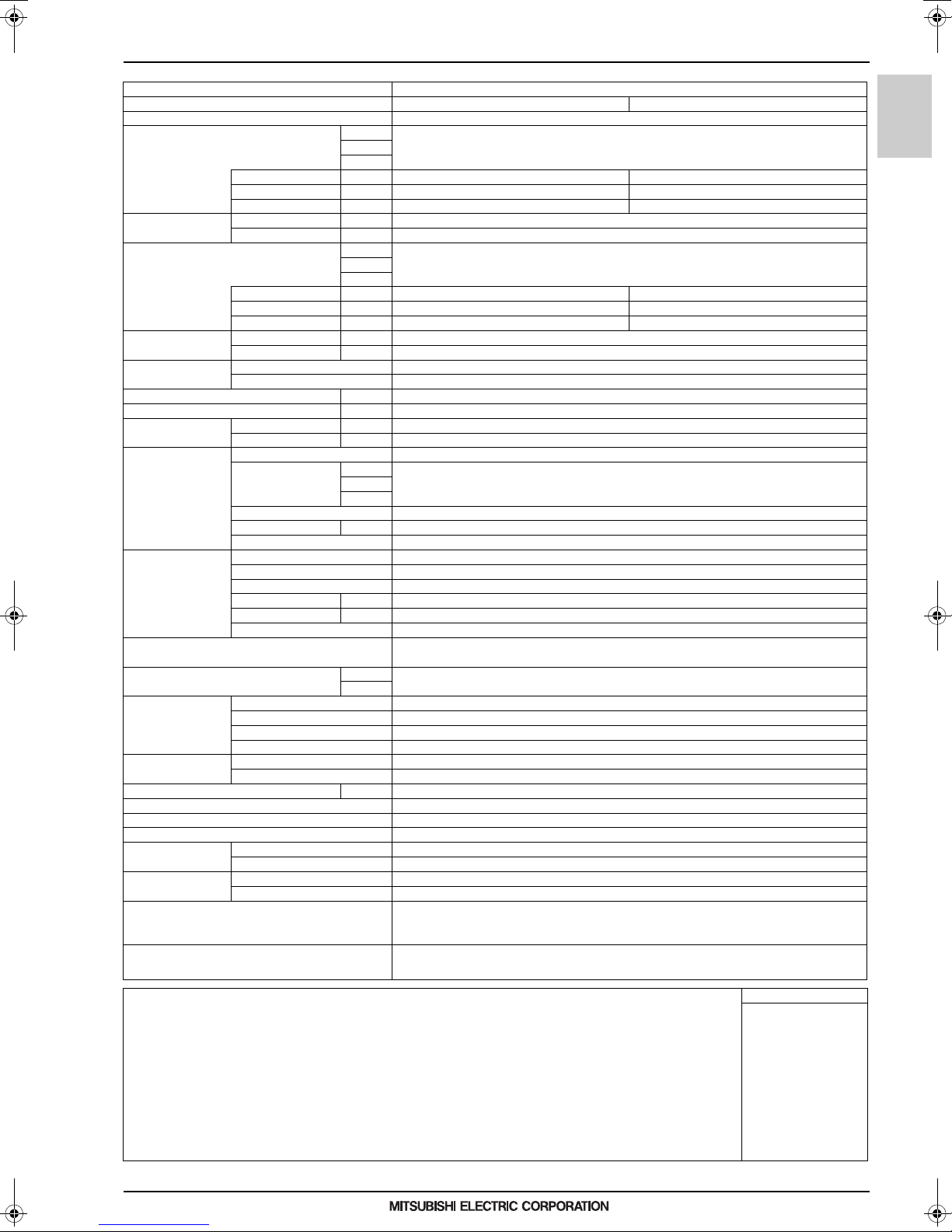

1. SPECIFICATIONS

Model PURY-EM200YNW-A1 (-BS)

Power source 3-phase 4-wire 380-400-415 V 50/60 Hz

Cooling capacity *1 kW 22.4

(Nominal) kcal/h 20,000

BTU/h 76,400

Power input kW 5.13

Current input A 8.6-8.2-7.9

EER kW/kW 4.36

Temp. range of Indoor W.B. 15.0~24.0°C (59~75°F)

cooling *3 Outdoor D.B. -5.0~52.0°C (23~126°F)

Heating capacity *2 kW 25.0

(Nominal) kcal/h 21,500

BTU/h 85,300

Power input kW 6.23

Current input A 10.5-9.9-9.6

COP kW/kW 4.01

Temp. range of Indoor D.B. 15.0~27.0°C (59~81°F)

heating *3 Outdoor W.B. -20.0~15.5°C (-4~60°F)

Indoor unit Total capacity 50~150% of outdoor unit capacity

connectable Model/Quantity WP10~125, W10~125/1~30

Sound pressure level (meas ured in anechoic room) *4 dB <A> 59.0/59.0

Sound power level (measured in anechoic room) *4 dB <A> 76.0/78.0

Refrigerant High pressure mm (in.) 15.88 (5/8) Brazed

piping diameter Low pressure mm (in.) 19.05 (3/4) Brazed

FAN Type x Quantity Propeller fan x 1

Air flow rate m3/min 170

L/s 2,833

cfm 6,003

Control, Driving mechanism Inverter-control, Direct-driven by motor

Motor output kW 0.92 x 1

*5 External static press. 0 Pa (0 mmH2O)

Compressor Type Inverter scroll hermetic compressor

Manufacture AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Inverter

Motor output kW 4 .5

Case heater kW - (- V)

Lubricant MEL46EH

External finish Pre-coated galvanized steel sheets (+powder coating for -BS type)

<MUNSELL 5Y 8/1 or similar>

External dimension H x W x D mm 1,858 (1,798 without legs) x 920 x 740

in. 73-3/16 (70-13/16 without legs) x 36-1/4 x 29-3/16

Protection devices High pressure protection High pressure sensor, High pressure switc h at 4.15 MPa (601 psi)

Inverter circuit (COMP./FA N) Ove r-heat protection, Over-cur rent protection

Compressor -

Fan motor -

Refrigerant Type x original charge R32 x 5.2 kg (12 lbs)

Control HBC controller

Net weight kg (lbs) 231 (510)

Heat exchanger Salt-resistant cross fin & aluminium tube

HIC circuit (HIC: Heat Inter-Changer) -

Defrosting method Auto-defrost mode (Reversed refrigerant cycle, Hot gas)

Drawing External WKL94T601

Wiring WKE94G769

Standard attachment Document Installation Manual

Accessory -

Optional parts

Main HBC controller: CMB-WM108,1016V-AA

Sub HBC controller: CMB-WM108,1016V-AB

R2-Series

PURY-M-YNW-A1, EM-YNW-A1

Remarks Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be

Notes: Unit converter

1.Nominal cooling conditions (subject to JIS B8615-2)

Indoor: 27°CD.B./19°CW.B. (81°FD.B./66°FW.B.), Outdoor: 35°CD.B./24°CW.B. (95°FD.B./75°FW.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

2.Nominal heating conditions (subj ect to JIS B8615-2)

Indoor: 20°CD.B. (68°FD.B.), Outdoor: 7°CD.B./6°CW.B. (45°FD.B./43°FW.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

3.-5°CD.B. (23°FD.B.)/-6°CW.B. (21°FW.B.) to 21°CD.B. (70°FD.B.)/15.5°CW.B. (60°FW.B.)

with cooling/heating mixed operation.

4.Cooling mode/Heating mode

5.External static pressure option is available (30 Pa, 60 Pa, 80 Pa/3.1 mmH2O, 6.1 mmH2O, 8.2 mmH2O).

Consult your dealer about the specification when setting External static pressure option.

6.R32 is flammable, and certain rest rictions apply to the installation of units.

When installing new units, moving the existing units, or changing the layout of the room,

ensure that installation restrictions are observed.

For detail, refer to the section in the Databook on installation restrictions.

MEES18K068

referred to the Installation Manual.

Due to continuing improvement, a bove specifications may be subject to change without notice.

BTU/h =kW x 3,412

cfm =m3/min x 35.31

lbs =kg/0.4536

*Above specification data is

subject to rounding variation.

9

1. SPECIFICATIONS

Model PURY-EM250YNW-A1 (-BS)

Power source 3-phase 4-wire 380-400-415 V 50/60 Hz

Cooling capacity *1 kW 28.0

(Nominal) kcal/h 25,000

Power input kW 7.69

Current input A 12.9-12.3-11.8

Temp. range of Indoor W.B. 15.0~24.0°C (59~75°F)

cooling *3 Outdoor D.B. -5.0~52.0°C (23~126°F)

Heating capacity *2 kW 31.5

(Nominal) kcal/h 27,100

Temp. range of Indoor D.B. 15.0~27.0°C (59~81°F)

PURY-M-YNW-A1, EM-YNW-A1

heating *3 Outdoor W.B. -20.0~15.5°C (-4~60°F)

Indoor unit Total capacity 50~150% of outdoor unit capacity

connectable Model/Quantity WP10~125, W10~125/1~37

Sound pressure level (measured in anechoic room) *4 dB <A> 60.5/61.0

Sound power level (measured in anechoic room) *4 dB <A> 78.5/80.0

Refrigerant High pressure mm (in.) 15.88 (5/8) Brazed

piping diameter Low pressure mm (in.) 22.2 (7/8) Brazed

FAN Type x Quantity Propeller fan x 1

Compressor Type Inverter scroll hermetic compressor

External finish Pre-coated galvanized steel sheets (+po wder coating for -BS type)

External dimension H x W x D mm 1,858 (1,798 without legs) x 920 x 740

Protection devices High pressure protection High pressure sensor, High pressure switch at 4.15 MPa (601 psi)

Refrigerant Type x original charge R32 x 5.2 kg (12 lbs)

Net weight kg (lbs) 231 (510)

Heat exchanger Salt-resistant cross fin & aluminium tube

HIC circuit (HIC: Heat Inter-Changer) -

Defrosting method Auto-defrost mode (Reversed refrigerant cycle, Hot gas)

Drawing External WKL94T601

Standard attachment Document Installation Manual

Optional parts

EER kW/kW 3.64

Power input kW 8.84

Current input A 14.9-14.1-13.6

COP kW/kW 3.56

Air flow rate m3/min 185

Control, Driving mechanism Inverter-control, Direct-driven by motor

Motor output kW 0.92 x 1

*5 External static press. 0 Pa (0 mmH2O)

Manufacture AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Inverter

Motor output kW 6.7

Case heater kW - (- V)

Lubricant MEL46EH

Inverter circuit (COMP./FAN) Over-heat protection, Over-current protection

Compressor -

Fan motor -

Control HBC controller

Wiring WKE94G769

Accessory -

BTU/h 95,500

BTU/h 107,500

L/s 3,083

cfm 6,532

<MUNSELL 5Y 8/1 or similar>

in. 73-3/16 (70-13/16 without legs) x 36-1/4 x 29-3 /16

Main HBC controller: CMB-WM108,1016V-AA

Sub HBC controller: CMB-WM108,1016V-AB

R2-Series

Remarks Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be

Notes: Unit converter

1.Nominal cooling conditions (subject to JIS B8615-2)

Indoor: 27°CD.B./19°CW.B. (81°FD.B./66°FW.B.), Outdoor: 35°CD.B./24°CW.B. (95°FD.B./75°FW.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

2.Nominal heating conditions (subject to JIS B8615-2)

Indoor: 20°CD.B. (68°FD.B.), Outdoor: 7°CD.B./6°CW.B. (45°FD.B./43°FW.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

3.-5°CD.B. (23°FD.B.)/-6°CW.B. (21°FW.B.) to 21°CD.B. (70°FD.B.)/15.5°CW.B. (60°FW.B.)

with cooling/heating mixed operat ion.

4.Cooling mode/Heating mode

5.External static pressure option is available (30 Pa, 60 Pa, 80 Pa/3.1 mmH2O, 6.1 mmH2O, 8.2 mmH2O).

Consult your dealer about the specification when setting External static pressure option.

6.R32 is flammable, and certain restrictions apply to the installation of units.

When installing new units, moving the existing units, or changing the layout of the room,

ensure that installation restrictions are observed.

For detail, refer to the section in the Databook on installation restrictions.

MEES18K068

referred to the Installation Manual.

Due to continuing improvement, above specifications may be subje ct to change without notice.

BTU/h =kW x 3,412

cfm =m3/min x 35.31

lbs =kg/0.4536

*Above specification data is

subject to rounding variatio n.

10

1. SPECIFICATIONS

Model PURY-EM300YNW-A1 (- BS)

Number of HBC controller Single HBC Double HBC

Power source 3-ph ase 4-wire 380-400-415 V 50/60 Hz

Cooling capacity *1 kW 33.5

(Nominal) kcal/h 30,000

Power input kW 10.03 8.52

Current input A 16.9-16.0-15.5 14.3-13.6-13.1

EER kW/kW 3.33 3.93

Temp. range of Indoor W.B. 15.0~24 .0°C (59~75°F)

cooling *3 Outdoor D.B. -5.0~52.0°C (23~126°F)

Heating capacity *2 kW 37.5

(Nominal) kcal/h 32,300

Power input kW 10.46 9.93

Current input A 17.6-16.7-16.1 16.7-15.9-15.3

COP kW/kW 3.58 3.77

Temp. range of Indoor D.B. 15.0~27.0° C (59~81°F)

heating *3 Outdoor W.B. -20.0~15.5°C (-4~60°F)

Indoor unit Total capacity 50~150% of outdoor unit capacity

connectable Model/Quantity WP10~125, W10~125/2~45

Sound pressure level (measured in anechoic room) *4 dB <A> 61.0/67.0

Sound power level (measured in anechoic room) *4 dB <A> 80.0/86.5

Refrigerant High pressure mm (in.) 15.88 (5/8) Brazed

piping diameter Low pressure mm (in.) 22.2 (7/8) Brazed

FAN Type x Quantity Propeller fan x 1

Air flow rate m

Control, Driving mechanism Inverter-control, Direct-driven by motor

Motor output kW 0.92 x 1

*5 External static press. 0 Pa (0 mmH

Compressor Type Inverter scroll hermetic compressor

Manufacture AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Inverter

Motor output kW 7.7

Case heater kW - (- V)

Lubricant MEL46EH

External finish Pre-coate d galvanized steel sheets (+powder co ating for -BS type)

External dimension H x W x D mm 1,858 (1,798 without legs) x 920 x 740

Protection devices High pressure protection High pressure sensor, High pre ssure switch at 4.15 MPa (601 psi)

Inverter circuit (COMP./FA N) Over-heat protection, Over-current protectio n

Compressor -

Fan motor -

Refrigerant Type x original charge R32 x 5.2 kg (12 lbs)

Control HBC controller

Net weight kg (lbs) 23 1 (510)

Heat exchanger Salt-resistant cross fin & aluminium tube

HIC circuit (HIC: Heat Inter-Changer) -

Defrosting method Auto-defrost mode (Reversed refrigerant cycle, Hot gas)

Drawing External WKL94T601

Wiring WKE94G769

Standard attachment Document Installation Manual

Accessory -

Optional parts Main HBC controller: CMB -WM108,1016V-AA

BTU/h 114,300

BTU/h 128,000

3

/min 240

L/s 4,000

cfm 8,474

O)

2

<MUNSELL 5Y 8/1 or similar>

in. 73-3/16 (70-13/16 without legs) x 36-1/4 x 29-3/16

Sub HBC controller: CMB-WM108,1016V-AB

R2-Series

PURY-M-YNW-A1, EM-YNW-A1

Remarks Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be

Notes: Unit converter

1.Nominal cooling conditions (subject to JIS B8615-2)

Indoor: 27°CD.B./19°CW.B. (81°FD.B./66°FW.B.), Outdoor: 35°CD.B./24°CW.B. (95°FD.B./75°FW.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

2.Nominal heating conditions (subj ect to JIS B8615-2)

Indoor: 20°CD.B. (68°FD.B.), Outdoor: 7°CD.B./6°CW.B. (45°FD.B./43°FW.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

3.-5°CD.B. (23°FD.B.)/-6°CW.B. (21°FW.B.) to 21°CD.B. (70°FD.B.)/15.5°CW.B. (60°FW.B.)

with cooling/heating mixed operation.

4.Cooling mode/Heating mode

5.External static pressure option is available (30 Pa, 60 Pa, 80 Pa/3.1 mmH2O, 6.1 mmH2O, 8.2 mmH2O).

Consult your dealer about the specification when setting External static pressure option.

6.R32 is flammable, and certain rest rictions apply to the installation of units.

When installing new units, moving the existing units, or changing the layout of the room,

ensure that installation restrictions are observed.

For detail, refer to the section in the Databook on installation restrictions.

MEES18K068

referred to the Installation Manual.

Due to continuing improvement, above specifications may be subject to change without notice.

BTU/h =kW x 3,412

cfm =m3/min x 35.31

lbs =kg/0.4536

*Above specification data is

subject to rounding variation.

11

1. SPECIFICATIONS

Model PURY-EM350YNW-A1 (-BS)

Number of HBC controller Single HBC Double HBC

Power source 3-phase 4-wire 380-400-415 V 50/60 Hz

Cooling capacity *1 kW 40.0

(Nominal) kcal/h 35,000

Power input kW 13.91 11.33

Current input A 23.4-22.3-21.5 19.1-18.1-17.5

Temp. range of Indoor W.B. 15.0 ~24.0°C (59~75°F)

cooling *3 Outdoor D.B. -5.0~52.0°C (23~126°F)

Heating capacity *2 kW 45.0

(Nominal) kcal/h 38,700

PURY-M-YNW-A1, EM-YNW-A1

Temp. range of Indoor D.B. 15.0~27. 0°C (59~81°F)

heating *3 Outdoor W.B. -20.0~15.5°C (-4~60°F)

Indoor unit Total capacity 50~150% of outdoor unit capacity

connectable Model/Quantity WP10~125, W10~125/1~35

Sound pressure level (measured in anechoic room) *4 dB <A> 62.5/64.0

Sound power level (measured in anechoic room) *4 dB <A> 81.0/83.0

Refrigerant High pressure mm (in.) 1 5.88 (5/8) Brazed

piping diameter Low pressure mm (in.) 28.58 (1-1/8) Brazed

FAN Type x Quantity Propeller fan x 2

Compressor Type Inverter scroll hermetic compressor

External finish Pre-coated galvanized steel sheets (+powder coating for -BS type)

External dimension H x W x D mm 1,858 (1,798 without legs) x 1,240 x 740

Protection devices High pressure protection High pressure sensor, High pressure switch at 4.15 MPa (601 psi)

Refrigerant Type x original charge R32 x 8.0 kg (18 lbs)

Net weight kg (lbs) 276 (609)

Heat exchanger Salt-resistant cross fin & aluminium tube

HIC circuit (HIC: Heat Inter-Changer) -

Defrosting method Auto-defrost mode (Reversed refrigerant cycle, Hot gas)

Drawing External WKL94T602

Standard attachment Document Installation Manual

Optional parts Main HBC contro ller: CMB-WM108,1016V-AA

EER kW/kW 2.87 3.53

Power input kW 13.10 12.16

Current input A 22.1-21.0-20.2 20.5-19.5-18.7

COP kW/kW 3.43 3.70

Air flow rate m

Control, Driving mechanism Inverter-control, Direct-driven by motor

Motor output kW 0.46 x 2

*5 External static press. 0 Pa (0 mmH

Manufacture AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Inverter

Motor output kW 9.6

Case heater kW - (- V)

Lubricant MEL46EH

Inverter circuit (COMP./FAN) Over-heat protection, Over-current protection

Compressor -

Fan motor -

Control HBC controller

Wiring WKE94G770

Accessory -

BTU/h 136,500

BTU/h 153,500

3

/min 250

L/s 4,167

cfm 8,828

O)

2

<MUNSELL 5Y 8/1 or similar>

in. 73-3/16 (70-13/16 without legs) x 48-7/8 x 29-3/16

Sub HBC controller: CMB-WM108,1016V-AB

R2-Series

Remarks Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be

Notes: Unit converter

1.Nominal cooling conditions (subject to JIS B8615-2)

Indoor: 27°CD.B./19°CW.B. (81°FD.B./66°FW.B.), Outdoor: 35°CD.B./24°CW.B. (95°FD.B./75°FW.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

2.Nominal heating conditions (subject to JIS B8615-2)

Indoor: 20°CD.B. (68°FD.B.), Outdoor: 7°CD.B./6°CW.B. (45°FD.B./43°FW.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

3.-5°CD.B. (23°FD.B.)/-6°CW.B. (21°FW.B.) to 21°CD.B. (70°FD.B.)/15.5°CW.B. (60°FW.B.)

with cooling/heating mixed operat ion.

4.Cooling mode/Heating mode

5.External static pressure option is available (30 Pa, 60 Pa, 80 Pa/3.1 mmH2O, 6.1 mmH2O, 8.2 mmH2O).

Consult your dealer about the specification when setting External static pressure option.

6.R32 is flammable, and certain restrictions apply to the installation of units.

When installing new units, moving the existing units, or changing the layout of the room,

ensure that installation restrictions are observed.

For detail, refer to the section in the Databook on installation restrictions.

MEES18K068

referred to the Installation Manual.

Due to continuing improvement, above specifications may be subject to change without notice.

BTU/h =kW x 3,412

cfm =m3/min x 35.31

lbs =kg/0.4536

*Above specification data is

subject to rounding variatio n.

12

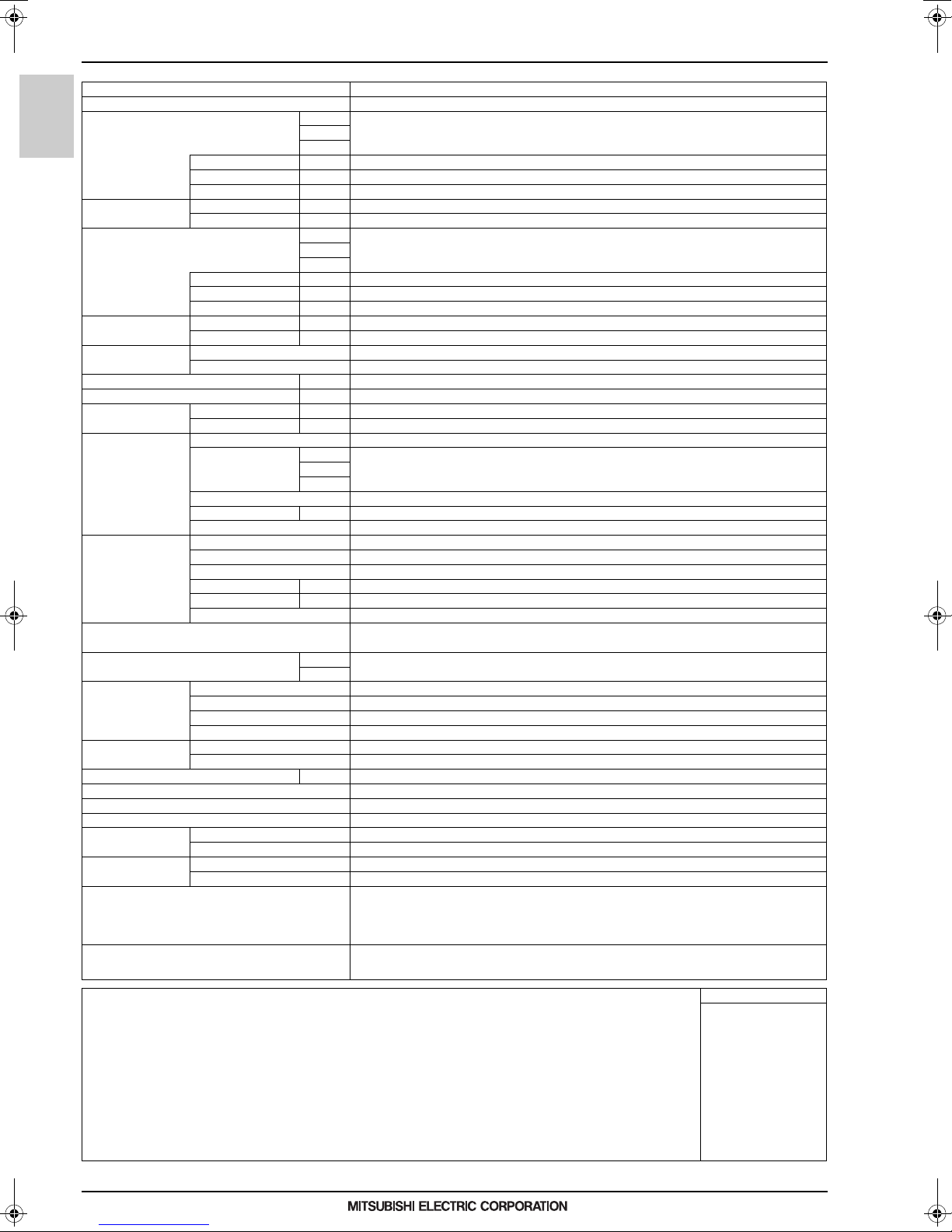

1. SPECIFICATIONS

Model PURY-EM400YNW-A1 (-BS)

Power source 3-phase 4-wire 380-400-415 V 50/60 Hz

Cooling capacity *1 kW 45.0

(Nominal) kcal/h 40,000

BTU/h 153,500

Power input kW 13.84

Current input A 23.3-22.1-21.3

EER kW/kW 3.25

Temp. range of Indoor W.B. 15.0~24.0°C (59~75°F)

cooling *3 Outdoor D.B. -5.0~52.0°C (23~126°F)

Heating capacity *2 kW 50.0

(Nominal) kcal/h 45,000

BTU/h 170,600

Power input kW 13.88

Current input A 23.4-22.2-21.4

COP kW/kW 3.60

Temp. range of Indoor D.B. 15.0~27.0°C (59~81°F)

heating *3 Outdoor W.B. -20.0~15.5°C (-4~60°F)

Indoor unit Total capacity 50~150% of outdoor unit capacity

connectable Model/Quantity WP10~125, W10~1 25/1~40

Sound pressure level (meas ured in anechoic room) *4 dB <A> 65.0/69.0

Sound power level (measured in anechoic room) *4 dB <A> 83.0/88.0

Refrigerant High pressure mm (in.) 19.05 (3/4) Brazed

piping diameter Low pressure mm (in.) 28.58 (1-1/8) Brazed

FAN Type x Quantity Propeller fan x 2

Air flow rate m3/min 315

L/s 5,250

cfm 11,123

Control, Driving mechanism Inverter-control, Direct-driven by motor

Motor output kW 0.46 x 2

*5 External static press. 0 Pa (0 mmH2O)

Compressor Type Inverter scroll hermetic compressor

Manufacture AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Inverter

Motor output kW 11.1

Case heater kW - (- V)

Lubricant MEL46EH

External finish Pre-coated galvanized steel sheets (+powder coating for -BS type)

<MUNSELL 5Y 8/1 or similar>

External dimension H x W x D mm 1,858 (1,798 without legs) x 1,240 x 740

in. 73-3/16 (70-13/16 without legs) x 48-7/8 x 29-3/16

Protection devices High pressure protection High pressure sensor, High pressure switch at 4.15 MPa (601 psi)

Inverter circuit (COMP./FAN) Over-heat protection, Over-current protection

Compressor -

Fan motor -

Refrigerant Type x original charge R32 x 8.0 kg (18 lbs)

Control HBC con troller

Net weight kg (lbs) 280 (618)

Heat exchanger Salt-resistant cross fin & aluminium tube

HIC circuit (HIC: Heat Inter-Changer) -

Defrosting method Auto-defrost mode (Reversed refrigerant cycle)

Drawing External WKL94T602

Wiring WKE94G770

Standard attachment Document Installation Manual

Accessory -

Optional parts

Main HBC controller: CMB-WM108,1016V-A A

Sub HBC controller: CMB-WM108,1016V-AB

R2-Series

PURY-M-YNW-A1, EM-YNW-A1

Remarks Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be

Notes: Unit converter

1.Nominal cooling conditions (subject to JIS B8615-2)

Indoor: 27°CD.B./19°CW.B. (81°FD.B./66°FW.B.), Outdoor: 35°CD.B./24°CW.B. (95°FD.B./75°FW.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

2.Nominal heating conditions (subj ect to JIS B8615-2)

Indoor: 20°CD.B. (68°FD.B.), Outdoor: 7°CD.B./6°CW.B. (45°FD.B./43°FW.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

3.-5°CD.B. (23°FD.B.)/-6°CW.B. (21°FW.B.) to 21°CD.B. (70°FD.B.)/15.5°CW.B. (60°FW.B.)

with cooling/heating mixed operation.

4.Cooling mode/Heating mode

5.External static pressure option is available (30 Pa, 60 Pa, 80 Pa/3.1 mmH2O, 6.1 mmH2O, 8.2 mmH2O).

Consult your dealer about the specification when setting External static pressure option.

6.R32 is flammable, and certain rest rictions apply to the installation of units.

When installing new units, moving the existing units, or changing the layout of the room,

ensure that installation restrictions are observed.

For detail, refer to the section in the Databook on installation restrictions.

MEES18K068

referred to the Installation Manual.

Due to continuing improvement, a bove specifications may be subject to change without notice.

BTU/h =kW x 3,412

cfm =m3/min x 35.31

lbs =kg/0.4536

*Above specification data is

subject to rounding variation.

13

1. SPECIFICATIONS

Model PURY-EM450YNW-A1 (-BS)

Power source 3-phase 4-wire 380-400-415 V 50/60 Hz

Cooling capacity *1 kW 50.0

(Nominal) kcal/h 45,000

Power input kW 15.24

Current input A 25.7-24.4-23.5

Temp. range of Indoor W.B. 15.0~24.0°C (59~75°F)

cooling *3 Outdoor D.B. -5.0~52.0°C (23~126°F)

Heating capacity *2 kW 56.0

(Nominal) kcal/h 50,000

Temp. range of Indoor D.B. 15.0~27.0°C (59~81°F)

PURY-M-YNW-A1, EM-YNW-A1

heating *3 Outdoor W.B. -20.0~15.5°C (-4~60°F)

Indoor unit Total capacity 50~150% of outdoor unit capacity

connectable Model/Quantity WP10~125, W10~125/1~45

Sound pressure level (measured in anechoic room) *4 dB <A> 65.5/70.0

Sound power level (measured in anechoic room) *4 dB <A> 83.0/89.0

Refrigerant High pressure mm (in.) 19.05 (3/4) Brazed

piping diameter L ow pressure mm (in.) 28.58 (1-1/8) Bra zed

FAN Type x Quantity Propeller f an x 2

Compressor Type Inverter scroll hermetic compressor

External finish Pre-coated galvanized steel sheets (+po wder coating for -BS type)

External dimension H x W x D mm 1,858 (1,798 without legs) x 1,240 x 740

Protection devices High pressure protection High pressure sensor, High pressure switch at 4.15 MPa (601 psi)

Refrigerant Type x original charge R32 x 10.8 kg (24 lbs)

Net weight kg (lbs) 305 (673)

Heat exchanger Salt-resistant cross fin & aluminium tube

HIC circuit (HIC: Heat Inter-Changer) -

Defrosting method Auto-defrost mode (Reversed refrigerant cycle)

Drawing External WKL94T602

Standard attachment Document Installation Manual

Optional parts

EER kW/kW 3.28

Power input kW 15.77

Current input A 26.6-25.2-24.3

COP kW/kW 3.55

Air flow rate m3/min 315

Control, Driving mechanism Inverter-control, Direct-driven by motor

Motor output kW 0.46 x 2

*5 External static press. 0 Pa (0 mmH2O)

Manufacture AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Inverter

Motor output kW 12.7

Case heater kW - (- V)

Lubricant MEL46EH

Inverter circuit (COMP./FAN) Over-heat protection, Over-current protection

Compressor -

Fan motor -

Control HBC controller

Wiring WKE94G770

Accessory -

BTU/h 170,600

BTU/h 191,100

L/s 5,250

cfm 11,123

<MUNSELL 5Y 8/1 or similar>

in. 73-3/16 (70-13/16 without legs) x 48-7/8 x 29-3 /16

Main HBC controller: CMB-WM108,1016V-AA

Sub HBC controller: CMB-WM108,1016V-AB

R2-Series

Remarks Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be

Notes: Unit converter

1.Nominal cooling conditions (subject to JIS B8615-2)

Indoor: 27°CD.B./19°CW.B. (81°FD.B./66°FW.B.), Outdoor: 35°CD.B./24°CW.B. (95°FD.B./75°FW.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

2.Nominal heating conditions (subject to JIS B8615-2)

Indoor: 20°CD.B. (68°FD.B.), Outdoor: 7°CD.B./6°CW.B. (45°FD.B./43°FW.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

3.-5°CD.B. (23°FD.B.)/-6°CW.B. (21°FW.B.) to 21°CD.B. (70°FD.B.)/15.5°CW.B. (60°FW.B.)

with cooling/heating mixed operat ion.

4.Cooling mode/Heating mode

5.External static pressure option is available (30 Pa, 60 Pa, 80 Pa/3.1 mmH2O, 6.1 mmH2O, 8.2 mmH2O).

Consult your dealer about the specification when setting External static pressure option.

6.R32 is flammable, and certain restrictions apply to the installation of units.

When installing new units, moving the existing units, or changing the layout of the room,

ensure that installation restrictions are observed.

For detail, refer to the section in the Databook on installation restrictions.

MEES18K068

referred to the Installation Manual.

Due to continuing improvement, above specifications may be subje ct to change without notice.

BTU/h =kW x 3,412

cfm =m3/min x 35.31

lbs =kg/0.4536

*Above specification data is

subject to rounding variatio n.

14

1. SPECIFICATIONS

Model PURY-EM500YNW-A1 (-BS)

Power source 3-phase 4-wire 380-400-415 V 50/60 Hz

Cooling capacity *1 kW 56.0

(Nominal) kcal/h 50,000

BTU/h 191,100

Power input kW 18.06

Current input A 30.4-28.9-27.9

EER kW/kW 3.10

Temp. range of Indoor W.B. 15.0~24.0°C (59~75°F)

cooling *3 Outdoor D.B. -5.0~52.0°C (23~126°F)

Heating capacity *2 kW 63.0

(Nominal) kcal/h 54,200

BTU/h 215,000

Power input kW 17.45

Current input A 29.4-27.9-26.9

COP kW/kW 3.61

Temp. range of Indoor D.B. 15.0~27.0°C (59~81°F)

heating *3 Outdoor W.B. -20.0~15.5°C (-4~60°F)

Indoor unit Total capacity 50~150% of outdoor unit capacity

connectable Model/Quantity WP10~125, W10~1 25/1~50

Sound pressure level (meas ured in anechoic room) *4 dB <A> 63.5/64.5

Sound power level (measured in anechoic room) *4 dB <A> 82.0/84.0

Refrigerant High pressure mm (in.) 19.05 (3/4) Brazed

piping diameter Low pressure mm (in.) 28.58 (1-1/8) Brazed

FAN Type x Quantity Propeller fan x 2

Air flow rate m3/min 295

L/s 4,917

cfm 10,416

Control, Driving mechanism Inverter-control, Direct-driven by motor

Motor output kW 0.92 x 2

*5 External static press. 0 Pa (0 mmH2O)

Compressor Type Inverter scroll hermetic compressor

Manufacture AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Inverter

Motor output kW 13.8

Case heater kW - (- V)

Lubricant MEL46EH

External finish Pre-coated galvanized steel sheets (+powder coating for -BS type)

<MUNSELL 5Y 8/1 or similar>

External dimension H x W x D mm 1,858 (1,798 without legs) x 1,750 x 740

in. 73-3/16 (70-13/16 without legs) x 68-15/16 x 29-3/16

Protection devices High pressure protection High pressure sensor, High pressure switch at 4.15 MPa (601 psi)

Inverter circuit (COMP./FAN) Over-heat protection, Over-current protection

Compressor -

Fan motor -

Refrigerant Type x original charge R32 x 10.8 kg (24 lbs)

Control HBC con troller

Net weight kg (lbs) 348 (768)

Heat exchanger Salt-resistant cross fin & aluminium tube

HIC circuit (HIC: Heat Inter-Changer) -

Defrosting method Auto-defrost mode (Reversed refrigerant cycle)

Drawing External WKL94T603

Wiring WKE94G771

Standard attachment Document Installation Manual

Accessory -

Optional parts

Main HBC controller: CMB-WM108,1016V-A A

Sub HBC controller: CMB-WM108,1016V-AB

R2-Series

PURY-M-YNW-A1, EM-YNW-A1

Remarks Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be

Notes: Unit converter

1.Nominal cooling conditions (subject to JIS B8615-2)

Indoor: 27°CD.B./19°CW.B. (81°FD.B./66°FW.B.), Outdoor: 35°CD.B./24°CW.B. (95°FD.B./75°FW.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

2.Nominal heating conditions (subj ect to JIS B8615-2)

Indoor: 20°CD.B. (68°FD.B.), Outdoor: 7°CD.B./6°CW.B. (45°FD.B./43°FW.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

3.-5°CD.B. (23°FD.B.)/-6°CW.B. (21°FW.B.) to 21°CD.B. (70°FD.B.)/15.5°CW.B. (60°FW.B.)

with cooling/heating mixed operation.

4.Cooling mode/Heating mode

5.External static pressure option is available (30 Pa, 60 Pa, 80 Pa/3.1 mmH2O, 6.1 mmH2O, 8.2 mmH2O).

Consult your dealer about the specification when setting External static pressure option.

6.R32 is flammable, and certain rest rictions apply to the installation of units.

When installing new units, moving the existing units, or changing the layout of the room,

ensure that installation restrictions are observed.

For detail, refer to the section in the Databook on installation restrictions.

MEES18K068

referred to the Installation Manual.

Due to continuing improvement, a bove specifications may be subject to change without notice.

BTU/h =kW x 3,412

cfm =m3/min x 35.31

lbs =kg/0.4536

*Above specification data is

subject to rounding variation.

15

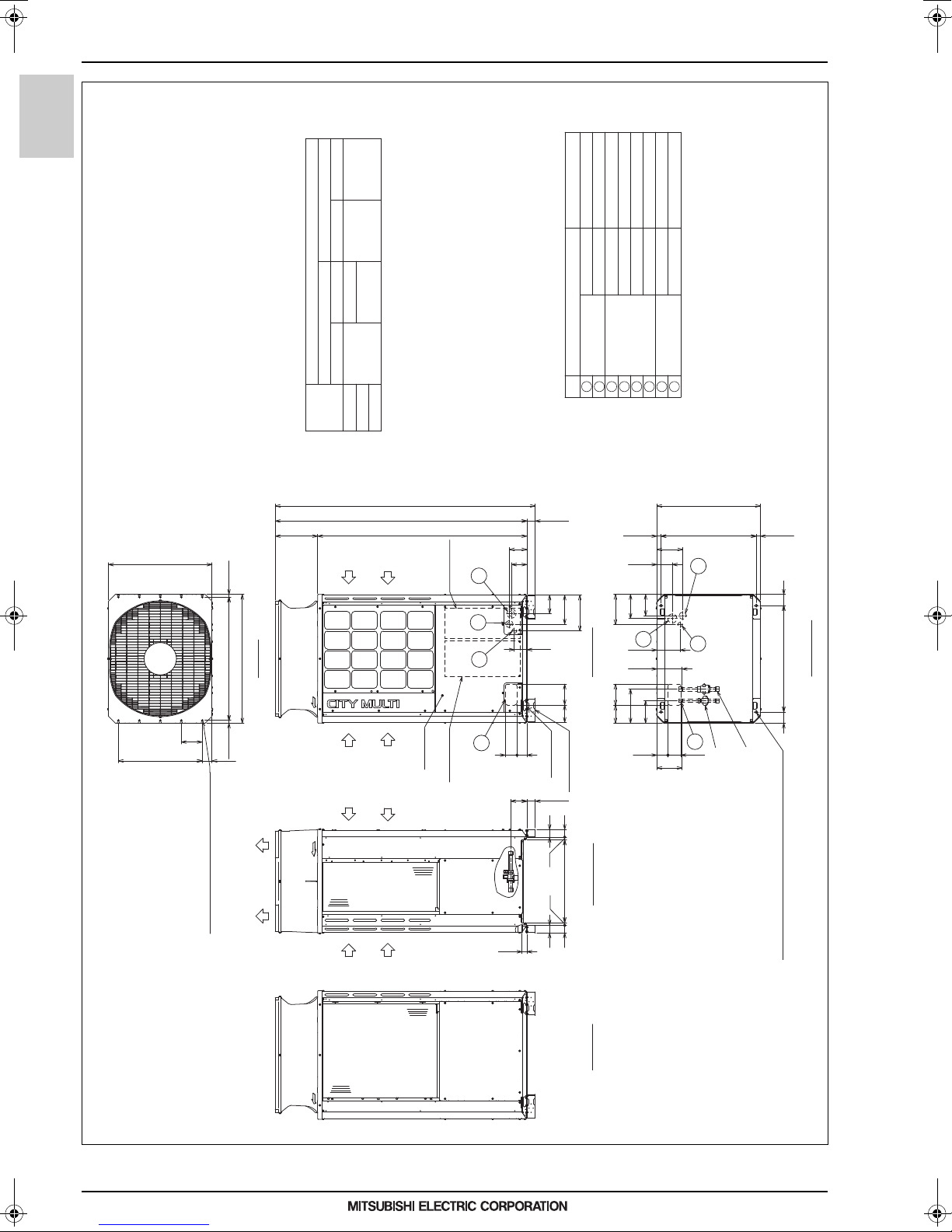

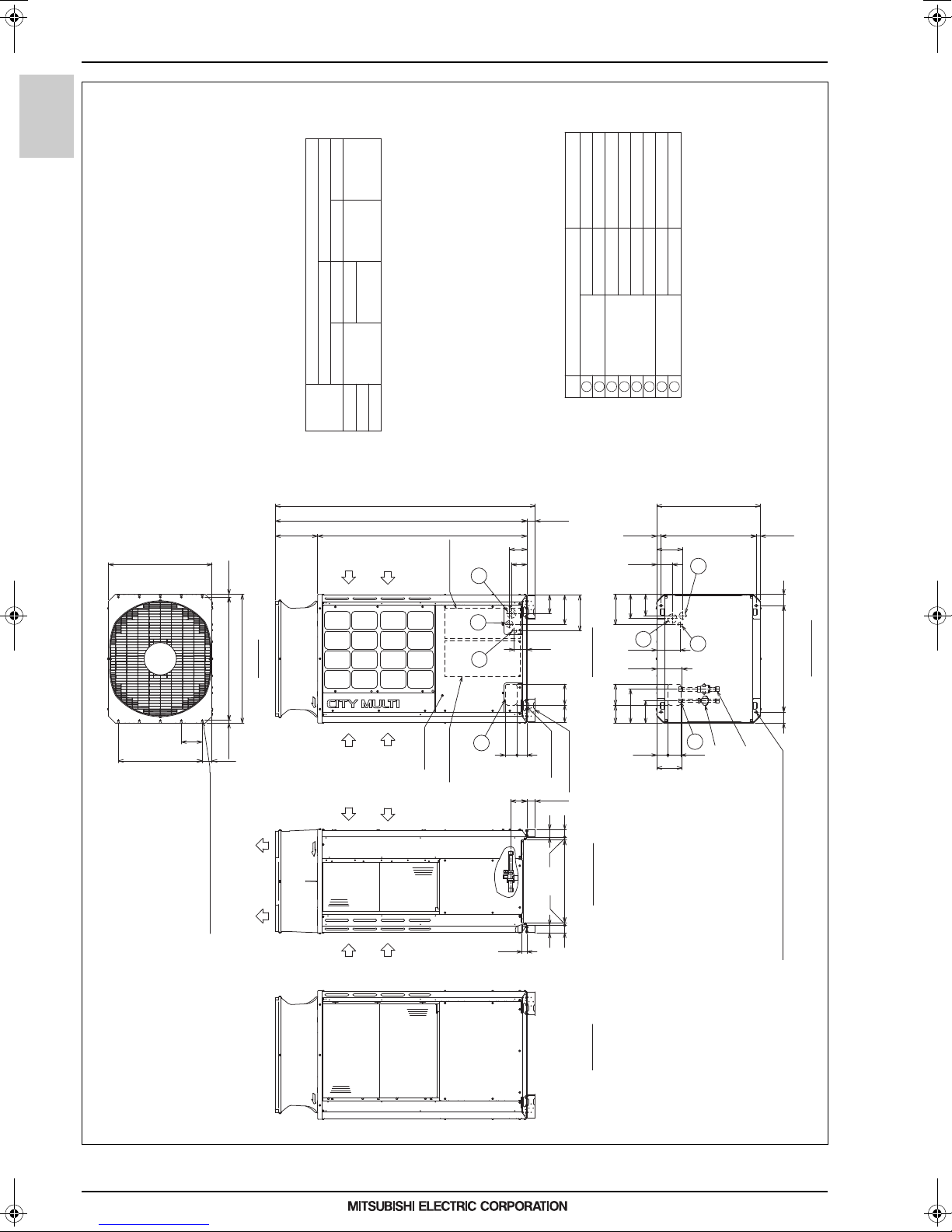

2. EXTERNAL DIMENSIONS

PURY-M200, 250, 300YNW-A1(-BS)

Unit: mm

1

3

4

7

Intake

air

Front view

Intake

air

Intake

air

Discharge air

Left side view

Rear view

2

5

6

8

(Mounting pitch)

Bottom view

(Mounting pitch)

2×5-ø4.6 Hole

(Make hole at the plastic fan guard

for snow hood attachment)

<Snow hood attachment hole>

Top view

Sling hole

Detachable leg

(front and back, 2 points)

Note 2*

2×2-14×31 Oval hole

2×2-14×20 Oval hole(without detachable leg)

Intake

air

Refrigerant

service valve

<High pressure>

Refrigerant

service valve

<Low pressure>

Service

panel

Control box

(INV Box)

Control box

(MAIN Box)

For transmission cables

For wires

For pipes

NO.

Usage Specifications

Front through hole

Bottom through hole

Front through hole

Front through hole

Bottom through hole

Bottom through hole

Front through hole

148 × 84 Knockout hole

ø65 or ø40 Knockout hole

ø52 or ø27 Knockout hole

ø65 Knockout hole

ø52 Knockout hole

ø34 Knockout hole

150 × 94 Knockout hole

Connecting pipe specifications

ø34 Knockout hole

Note 1.Please refer to the next page for information regarding necessary

spacing around the unit and foundation work.

2.The detachable leg can be removed at site.

3.At brazing of pipes, wrap the refrigerant service valve

with wet cloth and keep the temperature of refrigerant

service valve under 120°C.

4.This unit has restrictions for the safety, so refer to

SAFETY HANDLING FOR R32 or the Installation Manual.

*1 Connect the refrigerant pipe to the service valve

according to the Installation Manual.

Bottom through hole

Model

Diameter

Refrigerant pipe

Service valve

M250

ø22.2

ø22.2 Brazed *1

ø15.88 Brazed *1

ø28.58

M200

High pressure Low pressure

M300

High pressure Low pressure

ø19.05 Brazed *1

132

207

256

148125

90

110

125

1495 303

1798

(60)

1858

5656

20

54

592

110

185

681(678~684)

29.5

(740)

80760

80

166

181

152

172

216

160

243

150128

94 79

181

29.5

84

71

35

920

19.519.5 881

740

150

600=150×470

54

20

116

(60)

1

243

567

8

2. EXTERNAL DIMENSIONS

R2-Series

PURY-M-YNW-A1, EM-YNW-A1

MEES18K068

16

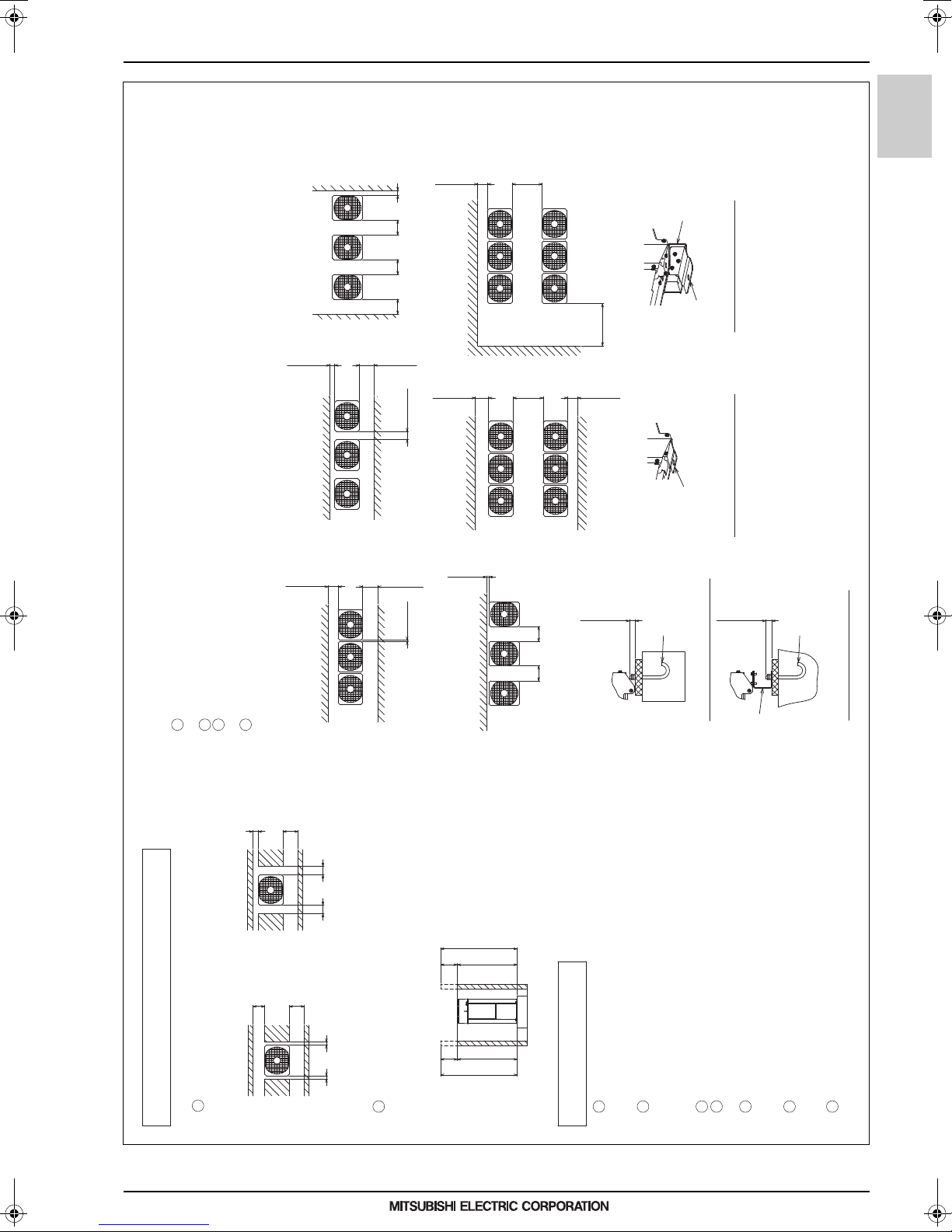

2. EXTERNAL DIMENSIONS

Unit: mm

PURY-M200, 250, 300YNW-A1(-BS)

Front

Front

<Top view>

*

<Unit:mm>

<Top view>

M10 anchor bolt

<field supply required>

Fixing plate

<field supply required>

<To be left open>

Front

Wall <H>

<To be left open>

Front

<Unit:mm>

Fixing plate

<field supply required>

M10 anchor bolt

<field supply required>

Wall <H>

<To be left open>

<To be left open>

<To be left open>

Front

Wall <H>

Wall <H>

Wall <H>

Wall <H>

Front

Front

<To be left open>

Wall <H>

Front

Wall <H>

<To be left open>

<To be left open>

Front

Front

Front

Wall <H>

Wall <H>

Front

<To be left open>

<To be left open>

Detachable leg

Fig.A (without detachable legs)

Fig.B (with detachable legs)

Fig.C (without detachable legs) Fig.D (with detachable legs)

Detachable leg

<Wall height limit> Front :Up to the unit height

Back :Up to the unit height

Side :Up to the unit height

<Side view>

Front

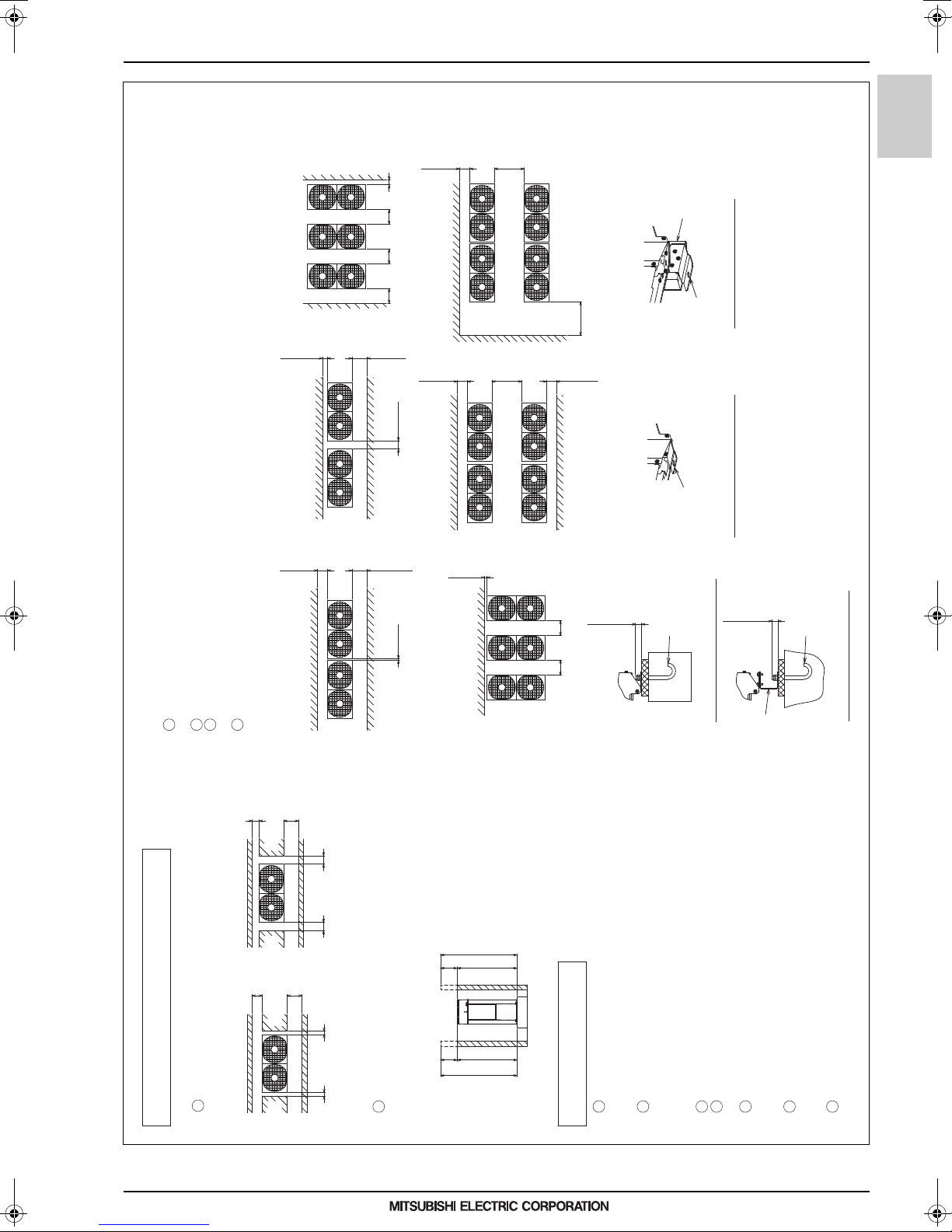

1. Required space around the unit

●In case of single installation

1 Secure enough space around the unit as shown in the figure below.

· With a space of at least

300mm to the wall on

the back of the unit

2 When the height of the walls on the front, back or on the sides<H>

exceeds the wall height limit as defined below

add the height that exceeds the height limit <h> to the figures that

are marked with an asterisk.

2. Foundation work

1 Take into consideration the surface strength, water drainage route,

piping route, and wiring route when preparing the installation site.

<Note that the drain water comes out of the unit during operation.>

2 Build the foundation in such way that the corner of the installation leg is

securely supported as shown in the right figure.(Fig.A,B)

When using a rubber isolating cushion, please ensure it is large enough

to cover the entire width of each of the unit's legs.

3 The protrusion length of the anchor bolt must not exceed 30mm.(Fig.A,B)

4 Use four fixing plates as shown in the right figure <field supply required>

when using post-installed anchor bolts.(Fig.C,D)

5

To prevent small animals and water and snow from entering the unit and damaging its parts,

close the gap around the edges of through holes for pipes and wires with

filler plates <field supply required>.

6 When the pipes or cables are routed at the bottom of the unit,

make sure that the through hole at the base of the unit does not get blocked

with the installation base.

7 Refer to the Installation Manual when installing units on an installation base.

●In case of collective installation

· With a space of at least

100mm to the wall on

the back of the unit

15 min.

50 min.* 50 min.*

100 min.*

450 min.*

300 min.*

100 min.30 min.

450 min.450 min.* 450 min. 100 min.*

450 min.* 100 min.*

450 min.*

1000 min.*

900 min.

300 min.*

900 min.

300 min.*300 min.*

15 min.*

450 min.450 min.

450 min.* 300 min.*

15 min.*

30mm max.30mm max.

Unit height

h

H

Unit height

h

H

1 When multiple units are installed adjacent to each other, secure enough space to allow

for air circulation and walkway between groups of units as shown in the figures below.

2 At least two sides must be left open.

3 As with the single installation, add the height that exceeds the height limit<h>

to the figures that are marked with an asterisk.

4 If there is a wall at both the front and the rear of the unit, install up to six units

consecutively in the side direction and provide a space of 1000mm or more as inlet space/

passage space for each six units.

R2-Series

PURY-M-YNW-A1, EM-YNW-A1

MEES18K068

17

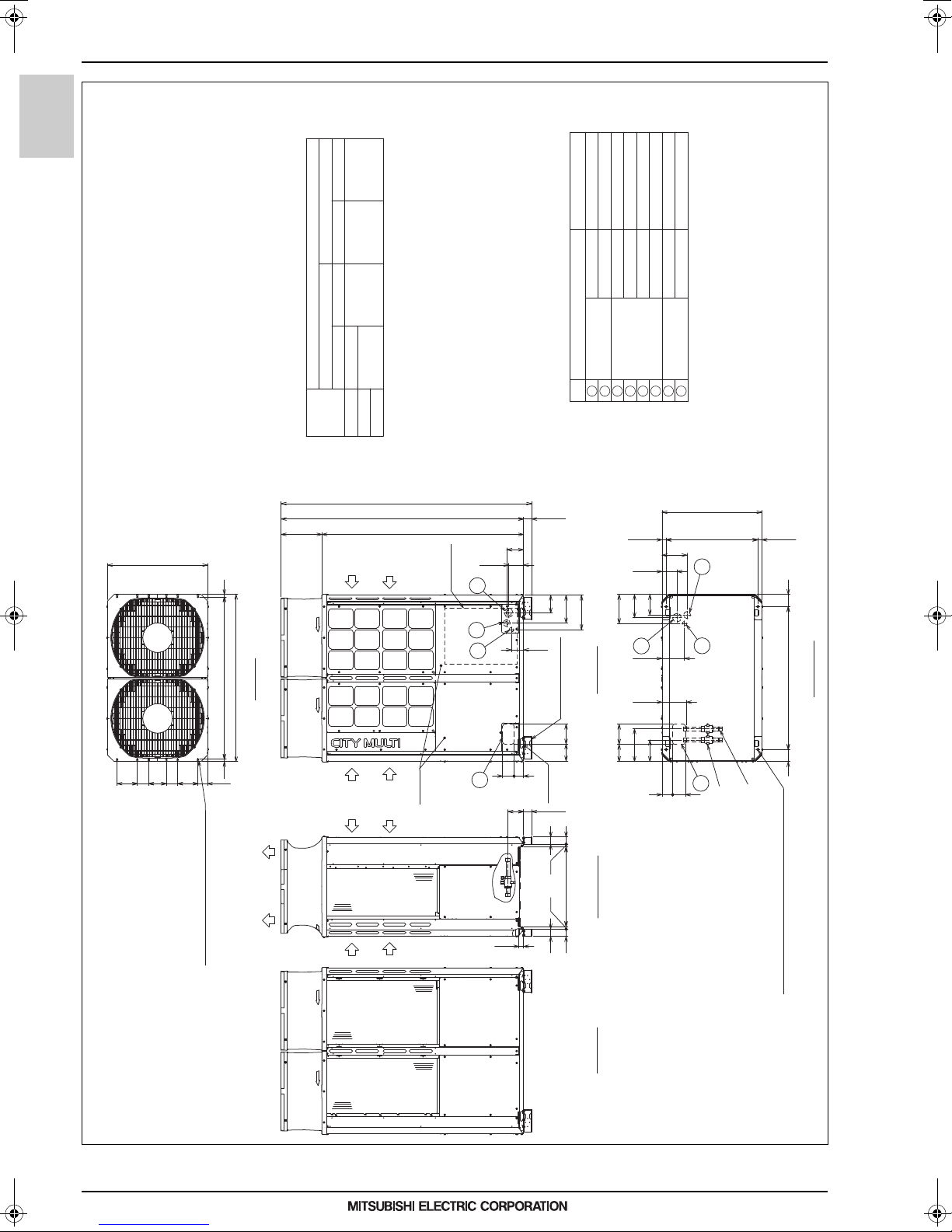

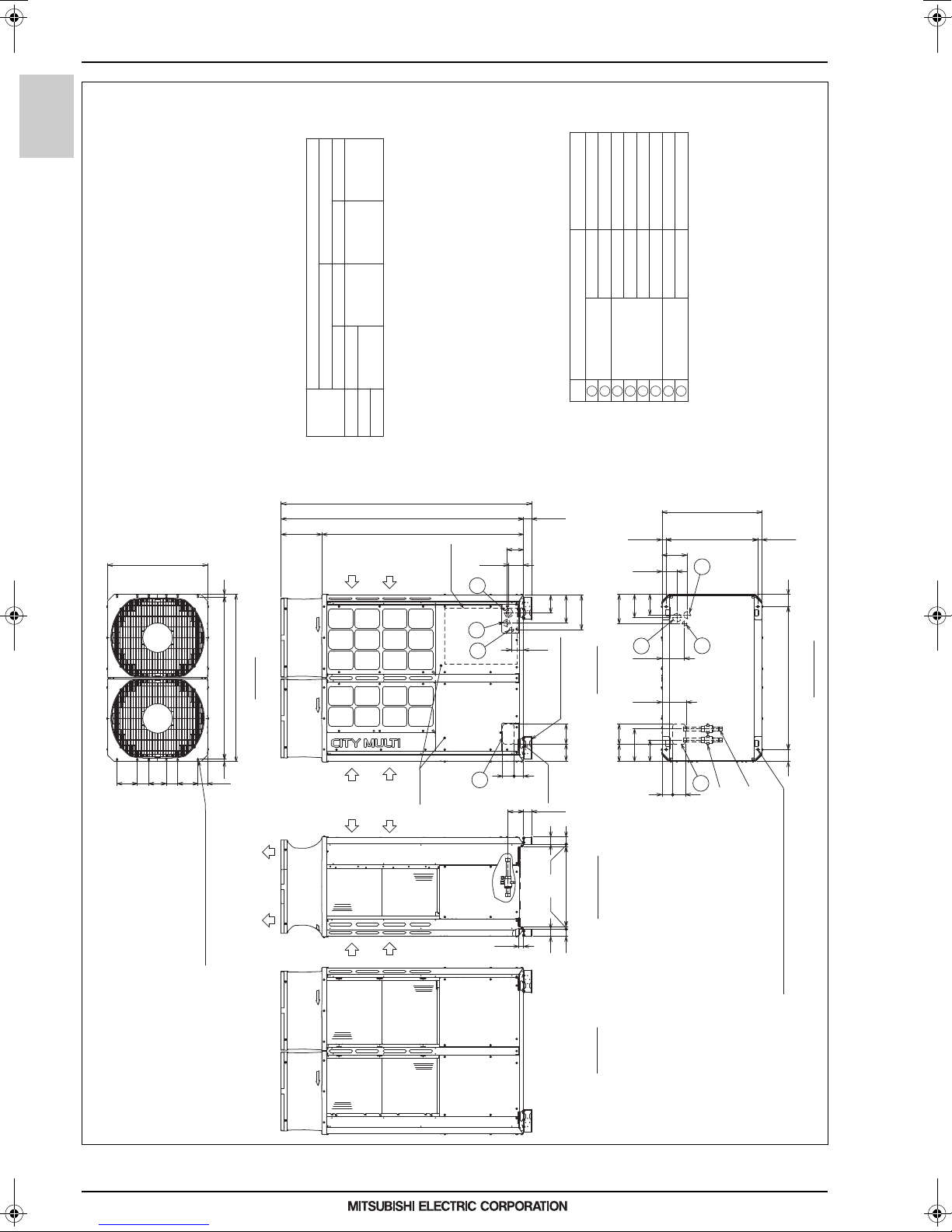

2. EXTERNAL DIMENSIONS

PURY-M350,400,450YNW-A1(-BS)

Unit: mm

Note 1.Please refer to the next page for information regarding necessary

spacing around the unit and foundation work.

2.The detachable leg can be removed at site.

3.At brazing of pipes, wrap the refrigerant service valve

with wet cloth and keep the temperature of refrigerant

service valve under 120°C.

4.This unit has restrictions for the safety, so refer to

SAFETY HANDLING FOR R32 or the Installation Manual.

NO.

1

243

567

8

740

70

150 85 85130 150

18

1204181240

110

(740)

185

29.5

681(678~684)

29.5

94

79

181

160

243

150

128

125

132

207

256

90

110

8471

35

56

116

(60)

20

54

592

54

20

56

148

152

216

166

125

(60)

3031495

1798

1858

90

1060

90

172

2

5

68

(Mounting pitch)

Bottom view

(Mounting pitch)

2×2-14×31 Oval hole

2×2-14×20 Oval hole(without detachable leg)

1

Sling hole

Detachable leg

(front and back, 2 points)

Note 2*

Control box

3

4

7

Service

panel

Intake

air

Intake

air

Discharge air

Intake

air

Intake

air

2×6-ø4.6 Hole

(Make hole at the plastic fan guard

for snow hood attachment)

<Snow hood attachment hole>

Top view

Front view

Left side view

Rear view

Refrigerant

service valve

<High pressure>

Refrigerant

service valve

<Low pressure>

For transmission cables

For wires

For pipes

Usage

Specifications

Front through hole

Bottom through hole

Front through hole

Front through hole

Bottom through hole

Bottom through hole

Front through hole

148 × 84 Knockout hole

ø65 or ø40 Knockout hole

ø52 or ø27 Knockout hole

ø65 Knockout hole

ø52 Knockout hole

ø34 Knockout hole

150 × 94 Knockout hole

Connecting pipe specifications

ø34 Knockout hole

*1 Connect the refrigerant pipe to the service valve

according to the Installation Manual.

Bottom through hole

Model

Diameter

Refrigerant pipe

Service valve

M400

ø28.58

ø15.88 Brazed *1

ø28.58

M350

High pressure Low pressure

ø28.58 Brazed

ø19.05 Brazed *1

M450

High pressure Low pressure

R2-Series

PURY-M-YNW-A1, EM-YNW-A1

MEES18K068

18

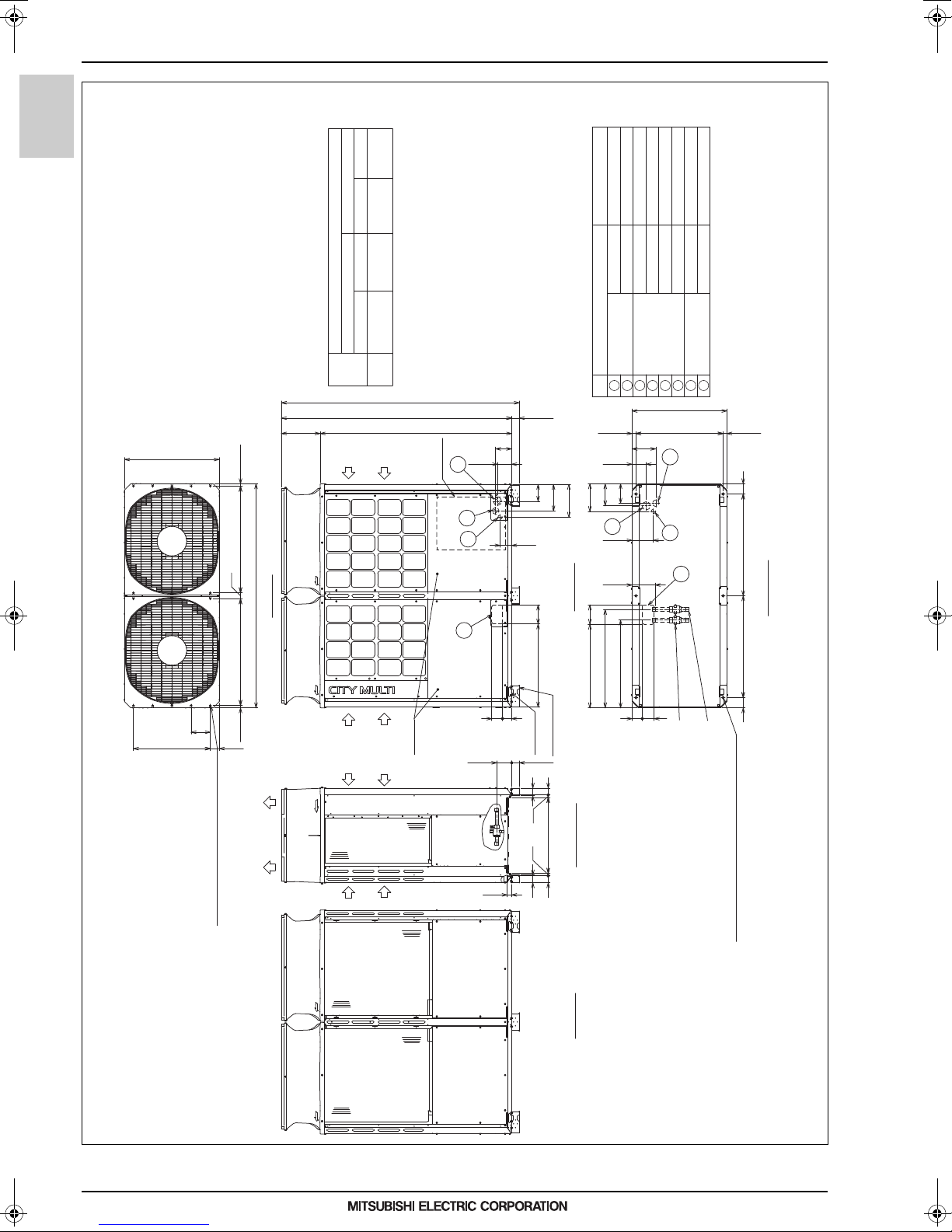

2. EXTERNAL DIMENSIONS

Unit: mm

PURY-M350,400,450YNW-A1(-BS)

<Wall height limit> Front :Up to the unit height

Back :Up to the unit height

Side :Up to the unit height

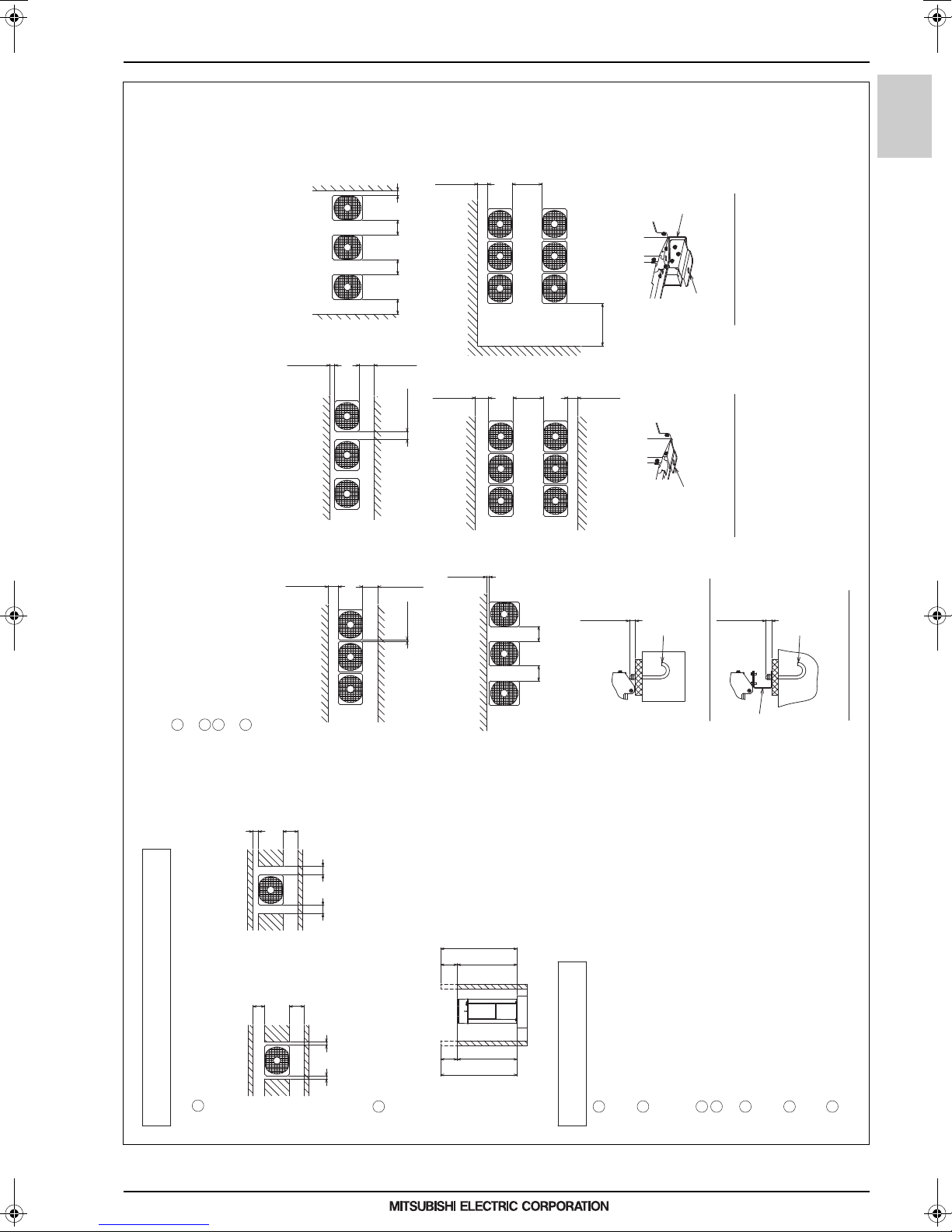

1. Required space around the unit

●In case of single installation

1 Secure enough space around the unit as shown in the figure below.

· With a space of at least

300mm to the wall on

the back of the unit

2 When the height of the walls on the front, back or on the sides<H>

exceeds the wall height limit as defined below

add the height that exceeds the height limit <h> to the figures that

are marked with an asterisk.

2. Foundation work

1 Take into consideration the surface strength, water drainage route,

piping route, and wiring route when preparing the installation site.

<Note that the drain water comes out of the unit during operation.>

2 Build the foundation in such way that the corner of the installation leg is

securely supported as shown in the right figure.(Fig.A,B)

When using a rubber isolating cushion, please ensure it is large enough

to cover the entire width of each of the unit's legs.

3 The protrusion length of the anchor bolt must not exceed 30mm.(Fig.A,B)

4 Use four fixing plates as shown in the right figure <field supply required>

when using post-installed anchor bolts.(Fig.C,D)

5

To prevent small animals and water and snow from entering the unit and damaging its parts,

close the gap around the edges of through holes for pipes and wires with

filler plates <field supply required>.

6 When the pipes or cables are routed at the bottom of the unit,

make sure that the through hole at the base of the unit does not get blocked

with the installation base.

7 Refer to the Installation Manual when installing units on an installation base.

●In case of collective installation

· With a space of at least

100mm to the wall on

the back of the unit

1 When multiple units are installed adjacent to each other, secure enough space to allow

for air circulation and walkway between groups of units as shown in the figures below.

2 At least two sides must be left open.

3 As with the single installation, add the height that exceeds the height limit<h>

to the figures that are marked with an asterisk.

4 If there is a wall at both the front and the rear of the unit, install up to six units

consecutively in the side direction and provide a space of 1000mm or more as inlet space/

passage space for each six units.

Front

Front

<Top view>

<Unit:mm>

<Top view>

M10 anchor bolt

<field supply required>

Fixing plate

<field supply required>

<To be left open>

Front

Wall <H>

<To be left open>

Front

<Unit:mm>

Fixing plate

<field supply required>

M10 anchor bolt

<field supply required>

Wall <H>

<To be left open>

<To be left open>

<To be left open>

Front

Wall <H>

Wall <H>

Wall <H>

Wall <H>

Front

Front

<To be left open>

Wall <H>

Front

Wall <H>

<To be left open>

<To be left open>

Front

Front

Front

Wall <H>

Wall <H>

Front

<To be left open>

<To be left open>

Detachable leg

Fig.A (without detachable legs)

Fig.B (with detachable legs)

Fig.C (without detachable legs) Fig.D (with detachable legs)

Detachable leg

<Side view>

Front

15 min.*

50 min.* 50 min.*

100 min.*450 min.*

300 min.*

100 min.

30 min.

450 min.450 min.* 450 min.

100 min.*

450 min.* 100 min.*

450 min.*

1000 min.*

900 min.

300 min.*

900 min.

300 min.*300 min.*

15 min.*

450 min.450 min.

450 min.* 300 min.*

15 min.*

30mm max.

30mm max.