Mitsubishi Electric PURY-80TMU, PURY-100TMU-A, CMB-104, CMB-105, CMB-106 Service Manual

...

AIR CONDITIONERS CITY MULTI

Models PURY-80TMU, 100TMU

PURY-80TMU-A, 100TMU-A

CMB-104, 105, 106, 108, 1010, 1013, 1016NU-F

Service Handbook

–1–

Contents

1 PRECAUTIONS FOR DEVICES .............................................................. 3

[1] Storage of Piping Material ................................................................. 3

[2] Brazing .............................................................................................. 4

[3] Airtightness Test ................................................................................ 5

[4] Vacuuming ........................................................................................ 5

2 COMPONENT OF EQUIPMENT ............................................................. 6

[1] Appearance of Components ............................................................. 6

[2] Refrigerant Circuit Diagram and Thermal Sensor ........................... 13

[3] Electrical Wiring Diagram ................................................................ 14

[4] Standard Operation Data ................................................................ 18

[5] Function of Dip SW and Rotary SW ................................................ 20

3 TEST RUN ............................................................................................. 23

[1] Before Test Run .............................................................................. 23

[2] Test Run Method ............................................................................. 27

4 GROUPING REGISTRATION OF INDOOR UNITS WITH REMOTE

CONTROLLER ....................................................................................... 28

5 CONTROL .............................................................................................. 34

[1] Control of Outdoor Unit ................................................................... 34

[2] Control of BC Controller .................................................................. 37

[3] Operation Flow Chart ...................................................................... 38

[4] List of Major Component Functions ................................................ 44

[5] Resistance of Temperature Sensor ................................................. 47

6 REFRIGERANT AMOUNT ADJUSTMENT ............................................ 48

[1] Refrigerant Amount and Operating Characteristics ........................ 48

[2] Adjustment and Judgement of Refrigerant Amount ........................ 48

7 TROUBLESHOOTING ........................................................................... 54

[1] Principal Parts ................................................................................. 54

[2] BC Controller Disassembly Procedure ........................................... 80

[3] Self-diagnosis and Countermeasures Depending on the Check

Code Displayed ............................................................................... 86

[4] LED Monitor Display ..................................................................... 108

8 PREPARATION, REPAIRS AND REFRIGERANT REFILLING WHEN

REPAIRING LEAKS ............................................................................. 118

[1] Location of leaks: Extension piping or indoor units (when cooling) 118

[2] Location of leaks: Outdoor unit (Cooling mode) ............................. 118

[3] Location of leaks:

Extension piping or indoor units (Heating mode)

119

[4] Location of leaks: Outdoor unit (when heating) ............................. 119

–2–

Safety precautions

Before installation and electric work

Before installing the unit, make sure you read all

the “Safety precautions”.

The “Safety precautions” provide very important

points regarding safety. Make sure you follow

them.

This equipment may not be applicable to

EN61000-3-2: 1995 and EN61000-3-3: 1995.

This equipment may have an adverse effect on

equipment on the same electrical supply system.

Please report to or take consent by the supply.

authority before connection to the system.

Symbols used in the text

Warning:

Describes precautions that should be observed to

prevent danger of injury or death to the user.

Caution:

Describes precautions that should be observed to

prevent damage to the unit.

Symbols used in the illustrations

: Indicates an action that must be avoided.

: Indicates that important instructions must be followed.

: Indicates a part which must be grounded.

: Beware of electric shock (This symbol is displayed on the

main unit label.) <Color: Yellow>

Warning:

Carefully read the labels affixed to the main unit.

Warning:

• Use the specified cables for wiring. Make the connections

securely so that the outside force of the cable is not

applied to the terminals.

- Inadequate connection and fastening may generate heat and

cause a fire.

• Have all electric work done by a licensed electrician

according to “Electric Facility Engineering Standard” and

“Interior Wire Regulations”and the instructions given in

this manual and always use a special circuit.

- If the power source capacity is inadequate or electric work is

performed improperly, electric shock and fire may result.

• Securely install the cover of control box and the panel.

- If the cover and panel are not installed properly, dust or water

may enter the outdoor unit and fire or electric shock may

result.

• After completing service work, make sure that refrigerant

gas is not leaking.

- If the refrigerant gas leaks and is exposed to a fan heater,

stove, oven, or other heat source, it may generate noxious

gases.

• Do not reconstruct or change the settings of the protection

devices.

- If the pressure switch, thermal switch, or other protection

device is shorted and operated forcibly, or parts other than

those specified by Mitsubishi Electric are used, fire or

explosion may result.

*

▲

▲

▲

▲

▲

–3–

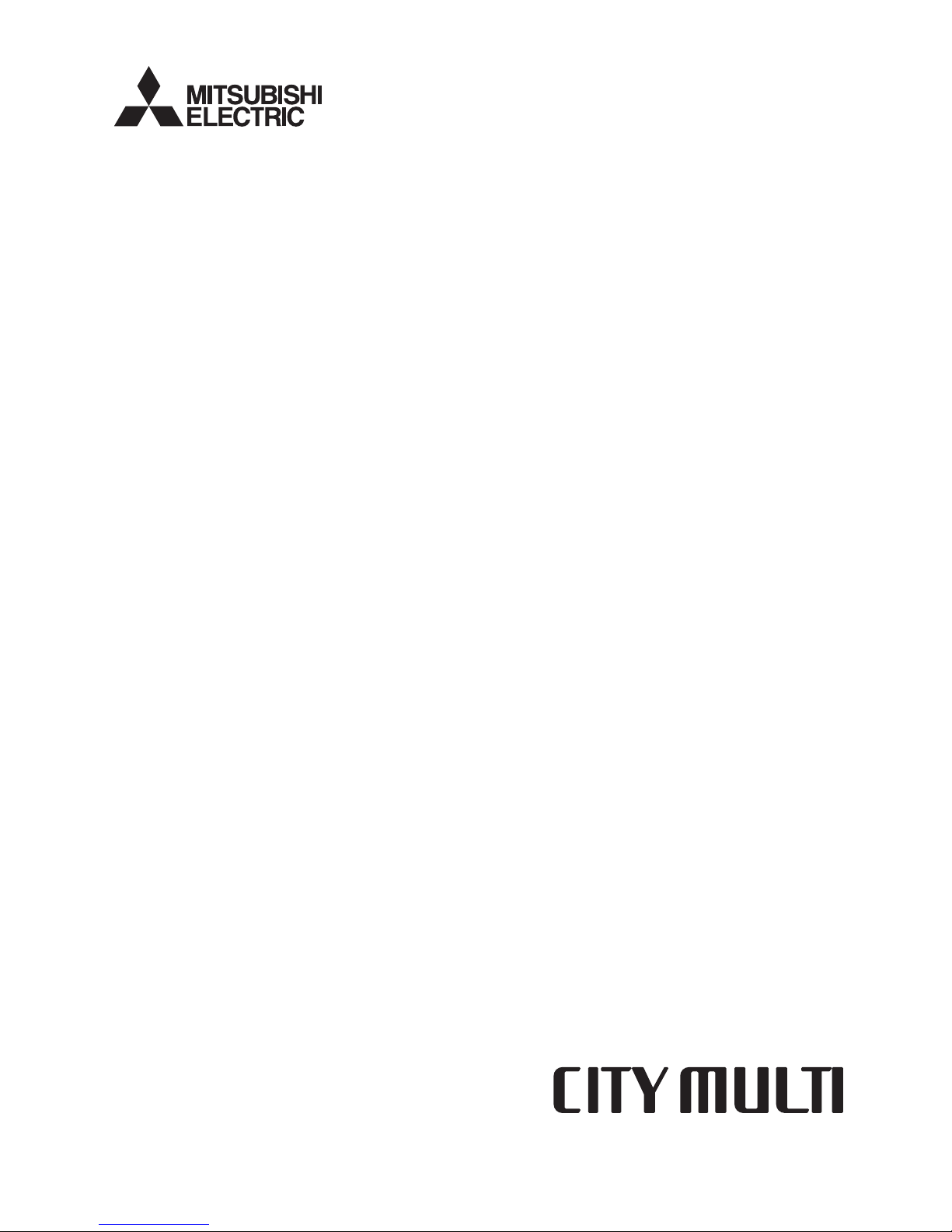

[1] Storage of Piping Material

(1) Storage location

Store the pipes to be used indoors. (Warehouse at site or owner’s warehouse)

Storing them outdoors may cause dirt, waste, or water to infiltrate.

(2) Pipe sealing before storage

Both ends of the pipes should be sealed until immediately before brazing.

Wrap elbows and T’s in plastic bags for storage.

11

11

1 PRECAUTIONS FOR DEVICES

–4–

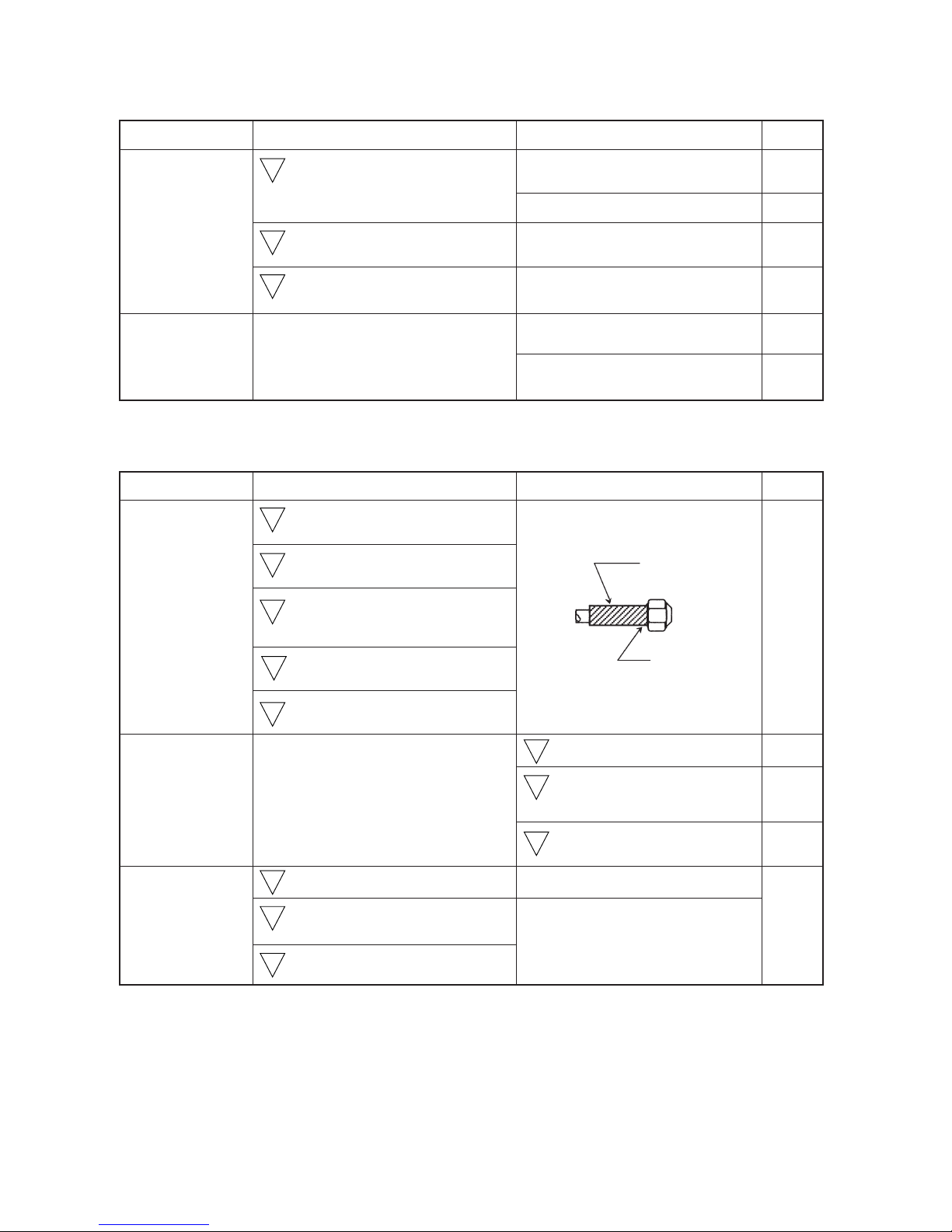

[2] Brazing

No changes from the conventional method, but special care is required so that foreign matter (ie. oxide scale, water, dirt,

etc.) does not enter the refrigerant circuit.

Example : Inner state of brazed section

When non-oxide brazing was not used When non-oxide brazing was used

Items to be strictly observed :

1. Do not conduct refrigerant piping work outdoors on a rainy day.

2. Apply non-oxide brazing.

3. Use a brazing material (Bcup-3) which requires no flux when brazing between copper pipes or between a copper pipe

and copper coupling.

4. If installed refrigerant pipes are not immediately connected to the equipment, then braze and seal both ends of them.

Reasons :

1. A flux generally contains chlorine. A residual flux in the refrigerant circuit may generate sludge.

Note :

• Commercially available antioxidants may have adverse effects on the equipment due to its residue, etc. When

applying non-oxide brazing, use oxygen free nitrogen (OFN).

–5–

[3] Airtightness Test

Items to be strictly observed :

1. Pressurize the equipment with nitrogen up to the design pressure and then judge the equipment’s airtightness, taking

temperature variations into account.

Reasons :

1. Use of oxygen as the pressurized gas may cause an explosion.

[4] Vacuuming

1. Standard degree of vacuum for the vacuum pump

Use a pump which reaches 65 Pa (0.0094 psi) or below after 5 minutes of operation.

In addition, be sure to use a vacuum pump that has been properly maintained and oiled using the specified oil. If the

vacuum pump is not properly maintained, the degree of vacuum may be too low.

2. Required accuracy of the vacuum gauge

Use a vacuum gauge that can measure up to 650 Pa (0.094 psi). Do not use a general gauge manifold since it cannot

measure a vacuum of 650 Pa (0.094 psi).

3. Evacuating time

• Evacuate the equipment for 1 hour after 650 Pa (0.094 psi) has been reached.

• After envacuating, leave the equipment for 1 hour and make sure that the vacuum is not lost.

4. Operating procedure when the vacuum pump is stopped

In order to prevent a backflow of the vacuum pump oil, open the relief valve on the vacuum pump side or loosen the

charge hose to drawn in air before stopping operation.

The same operating procedure should be used when using a vacuum pump with a check valve.

–6–

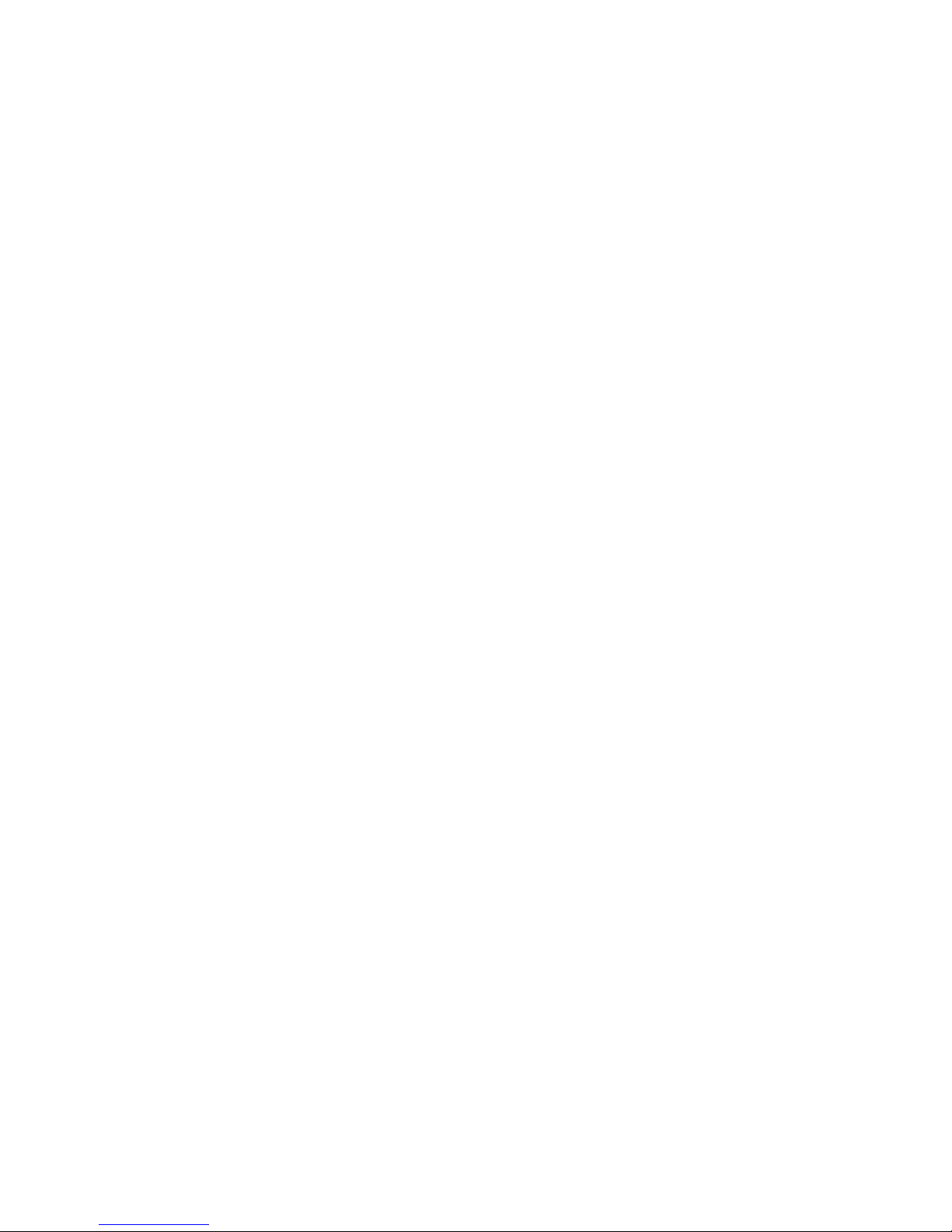

SV block Fusible plug

Accumulator

CV block

Compressor

4-way valve

22

22

2 COMPONENT OF EQUIPMENT

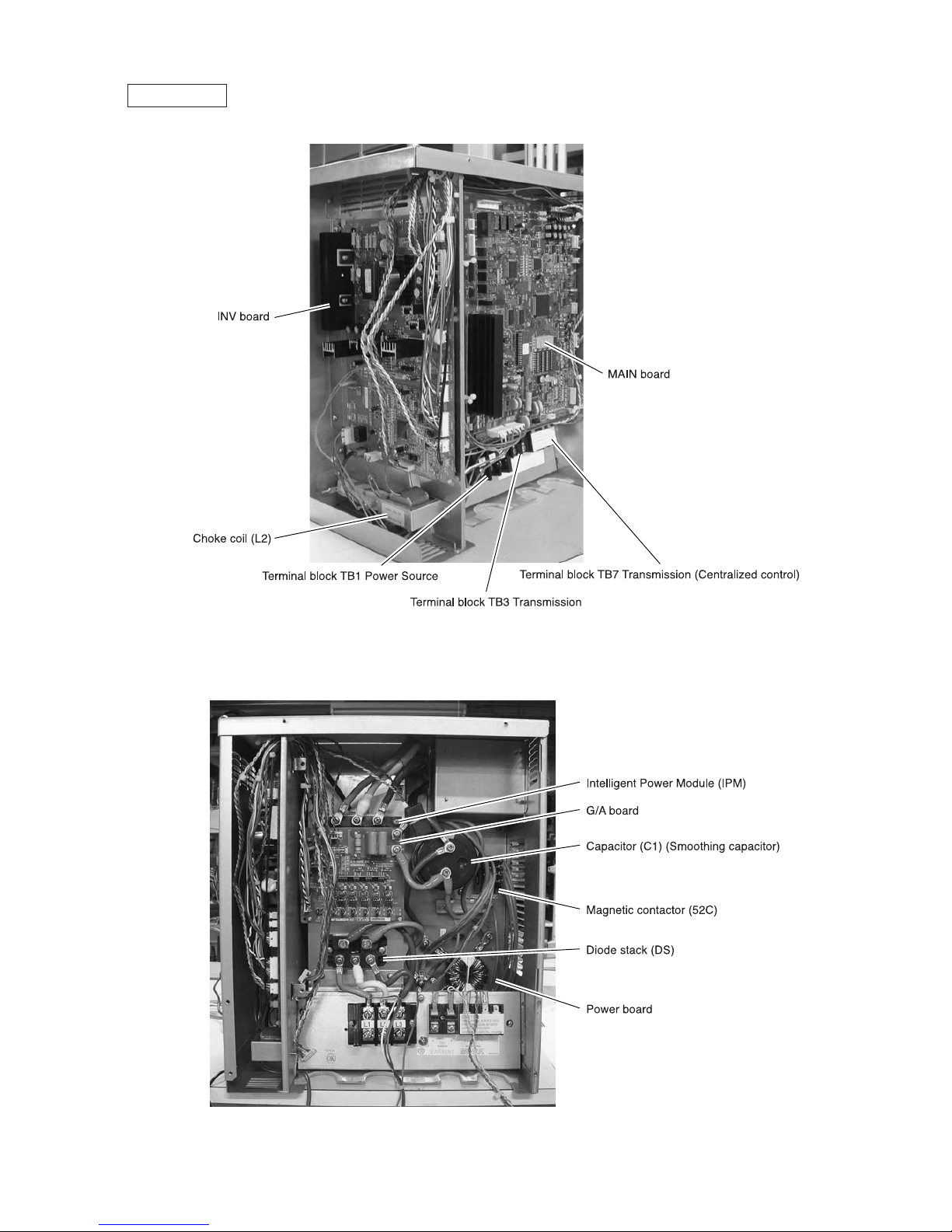

[1] Appearance of Components

In case of -A type.

–7–

Controller Box

–8–

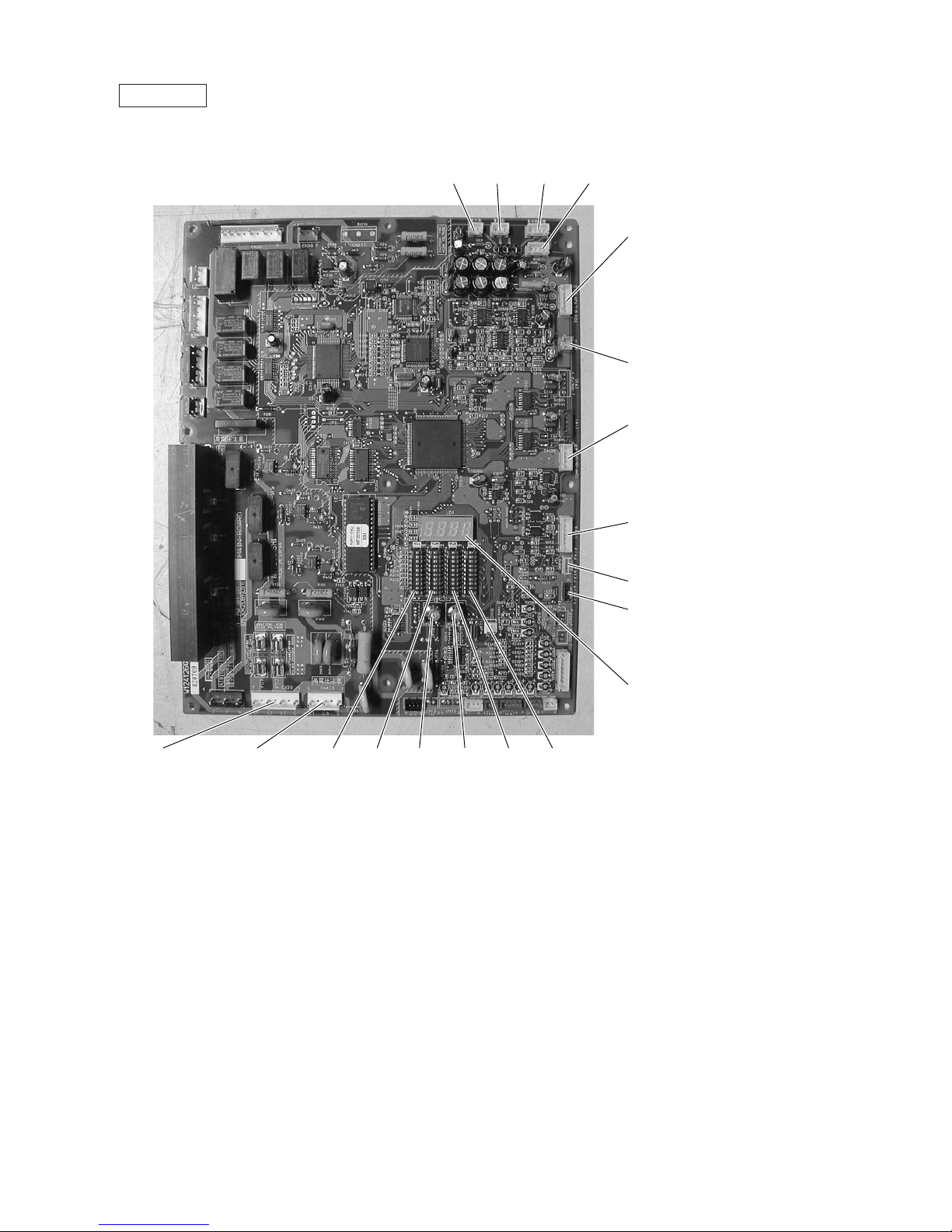

MAIN board

CNS1 CNS2 CN40 CN41

CNVCC3

Power Source

for control

1-2 30V

1-3 30V

4-6 12V

5-6 5V

CN51

Indication distance

3-4 Compressor ON/OFF

3-5 Trouble

CNRS3

Serial transmission to

INV board

CN3D

CN3S

LD1

Service LED

SW1

SW2SWU1SWU2SW3SW4CNAC3

Power Output

5 L1

3 L3

1 G

CN20

Power Input

7 L1

5 L2

3 L3

1 G

CNVCC5

Power Source for control(5V)

–9–

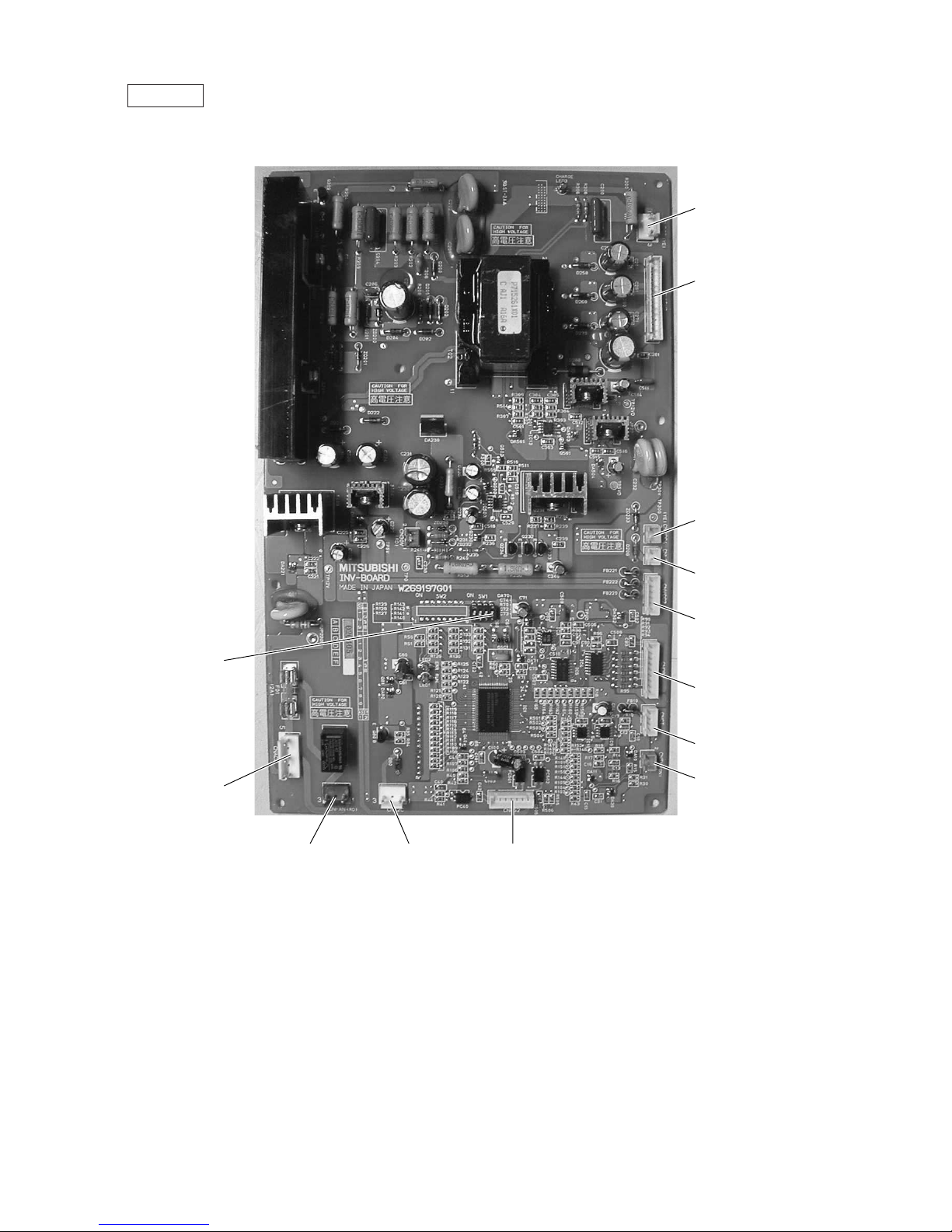

INV board

CNDC2

1-3 DC-325V

CN15V2

Power Output

for IPM control

CNVCC4

Power Output (5V)

CNL2

Choke coil

CNVCC2

Power Output

1-2 30V, 1-3 30V

4-6 12V, 5-6 5V

CNDR2

Output to

G/A board

CNCT

CNTH

CNRS2

Serial transmission

to MAIN board

CN52C

Control for 52C

CNFAN

Control for MF1

CNAC2

Power Input

5 L1

3 L3

1 G

SW1

–10–

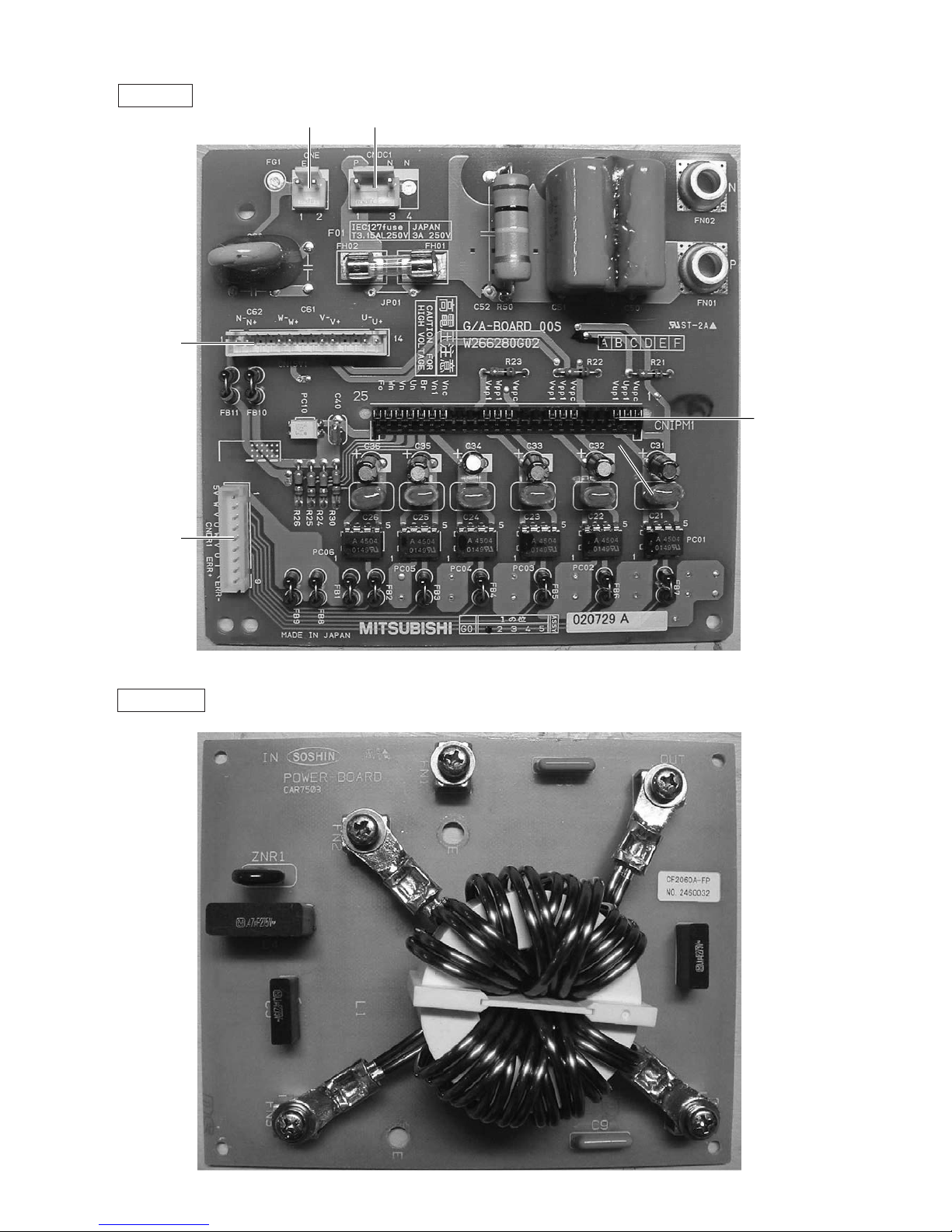

G/A board

CNIPM1

CN15V1

CNDR1

CNE CNDC1

Power board

–11–

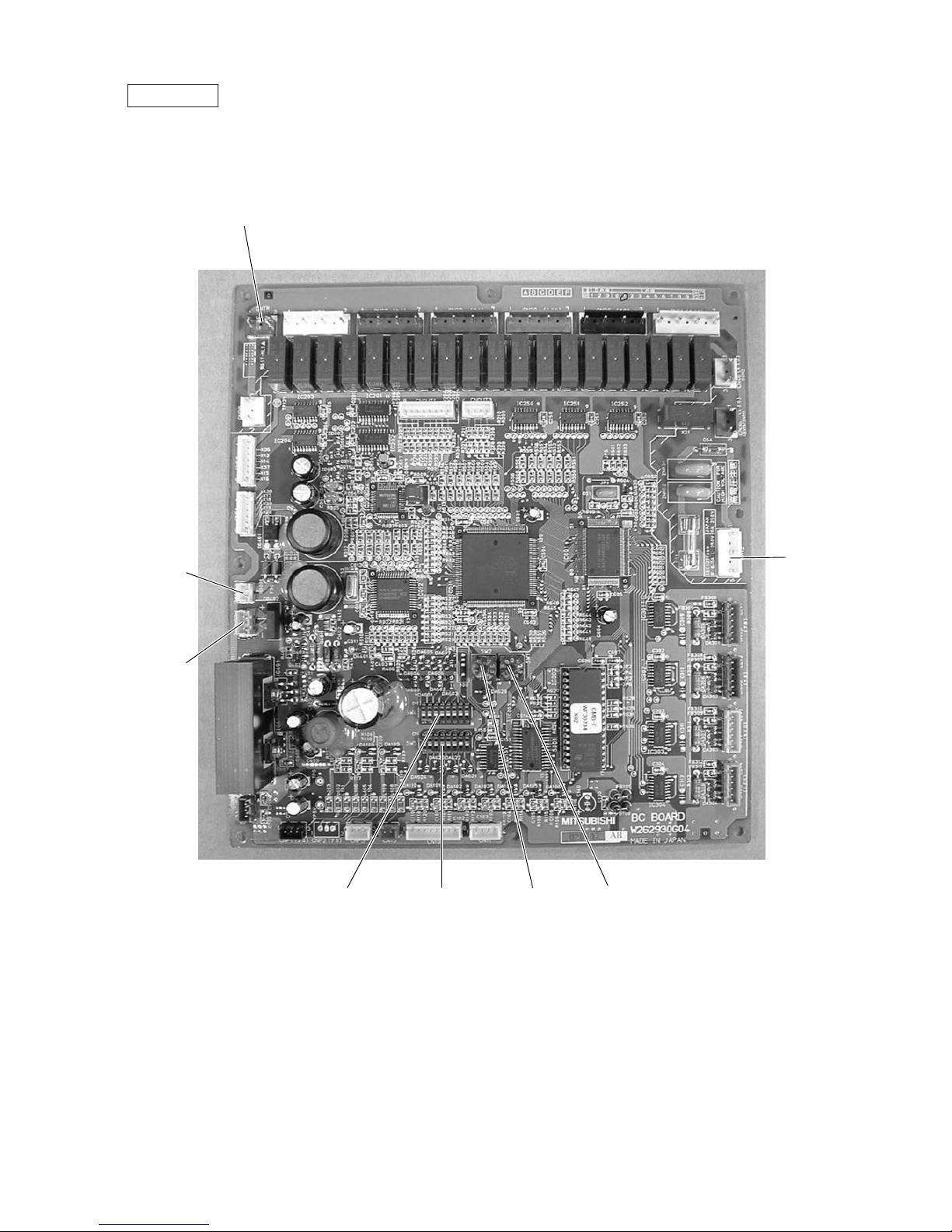

BC controller

CNTR

CN02

M-NET

transmission

CN03

CN12

Power

supply

1 EARTH

3 N

5 L

SW4 SW2 SW1SW5

–12–

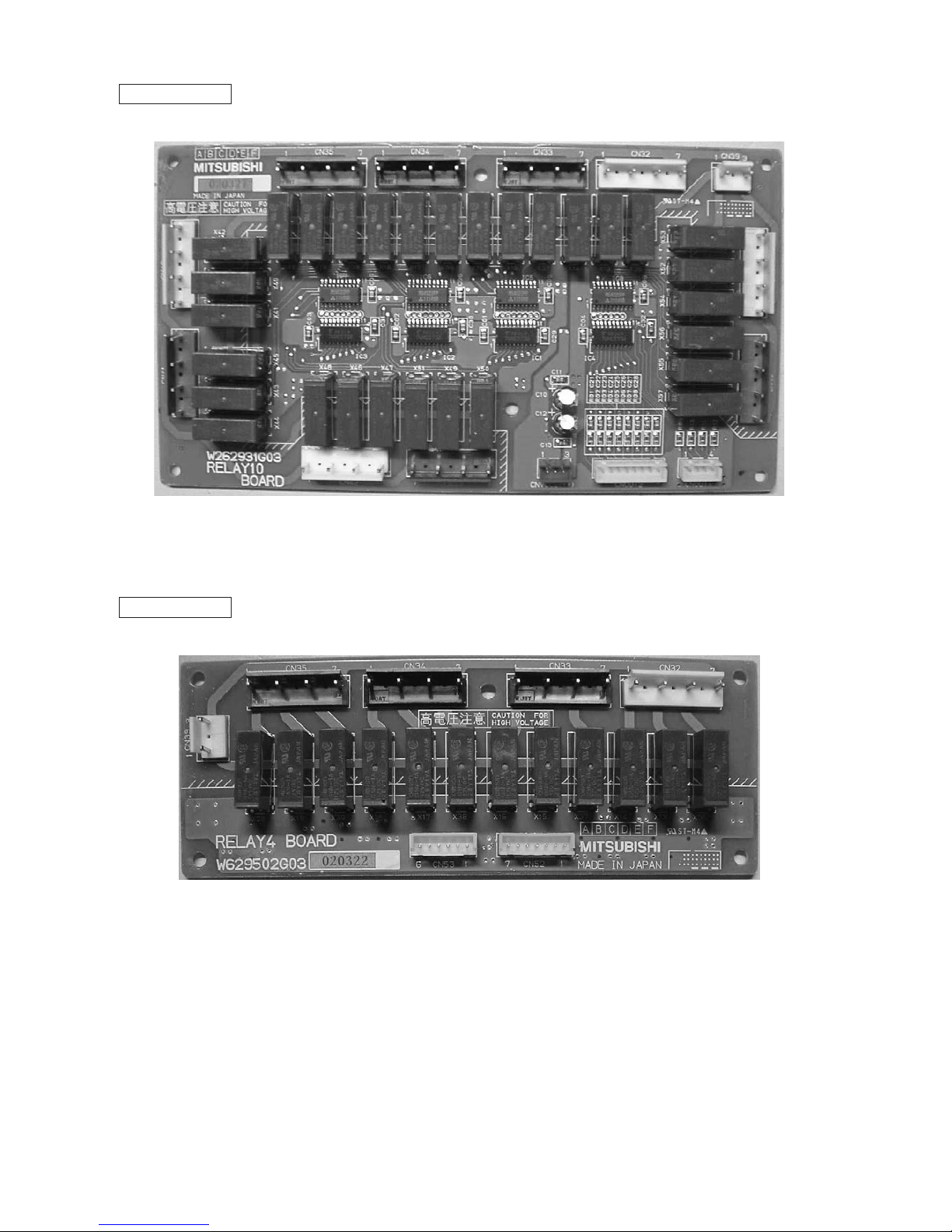

RELAY 10 board

RELAY 4 board

–13–

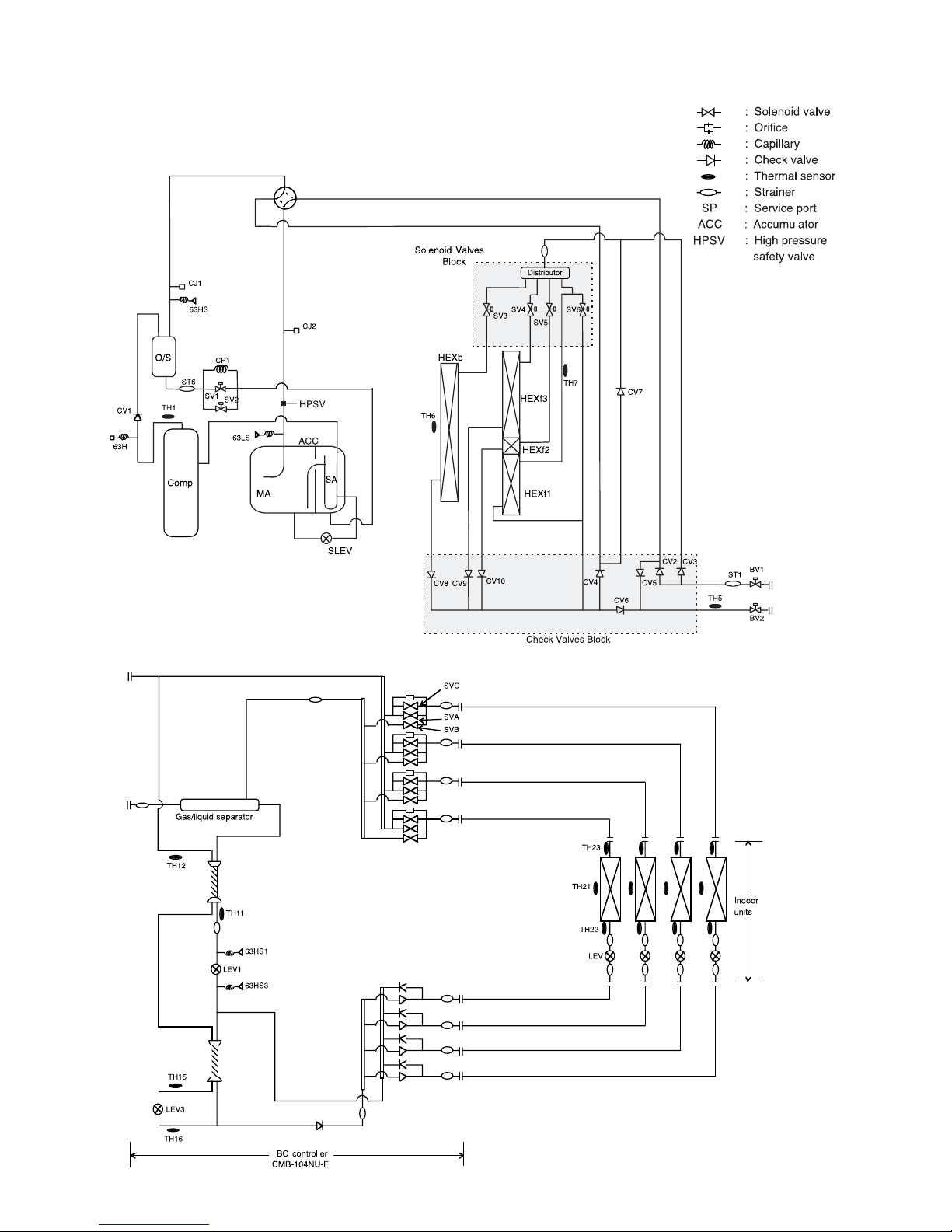

[2] Refrigerant Circuit Diagram and Thermal Sensor

–14–

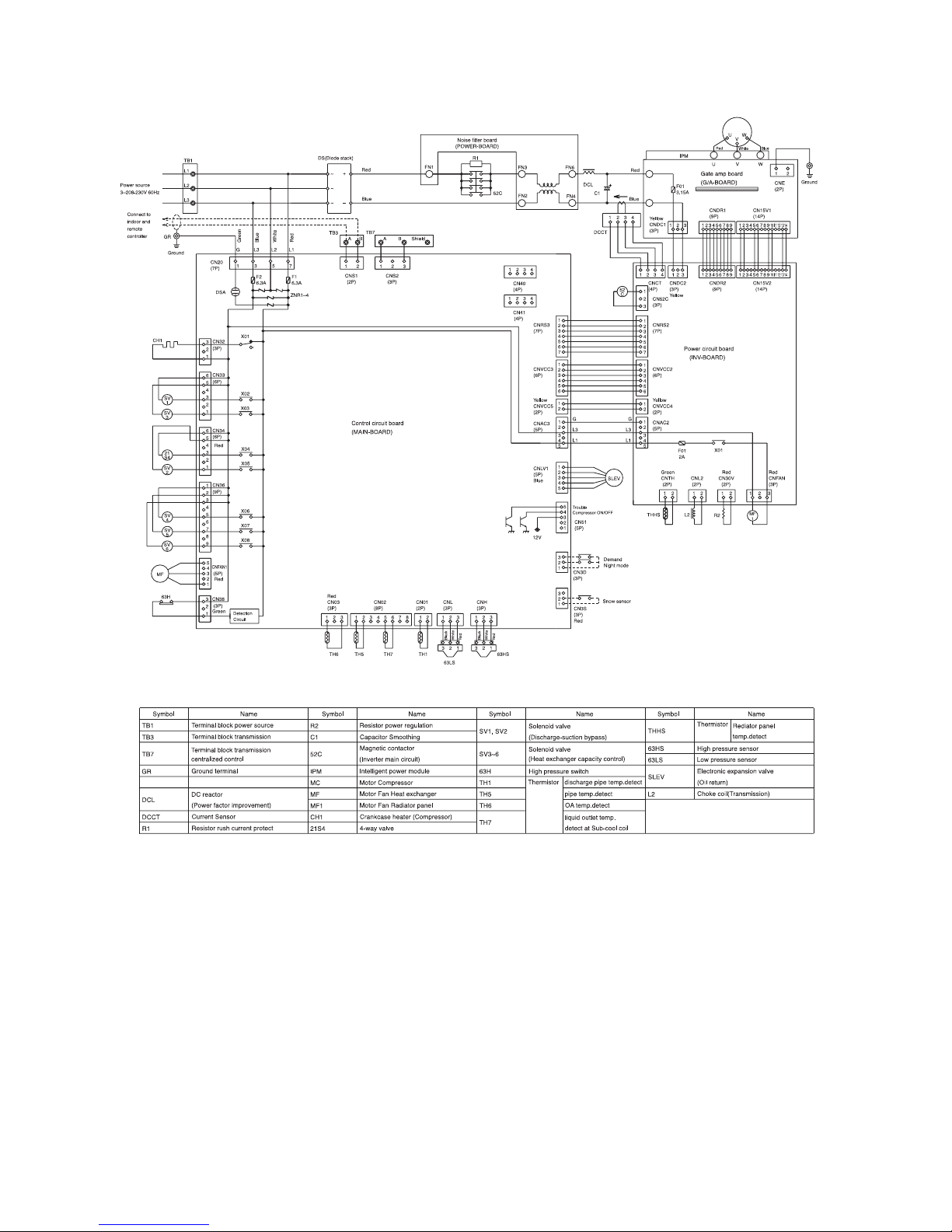

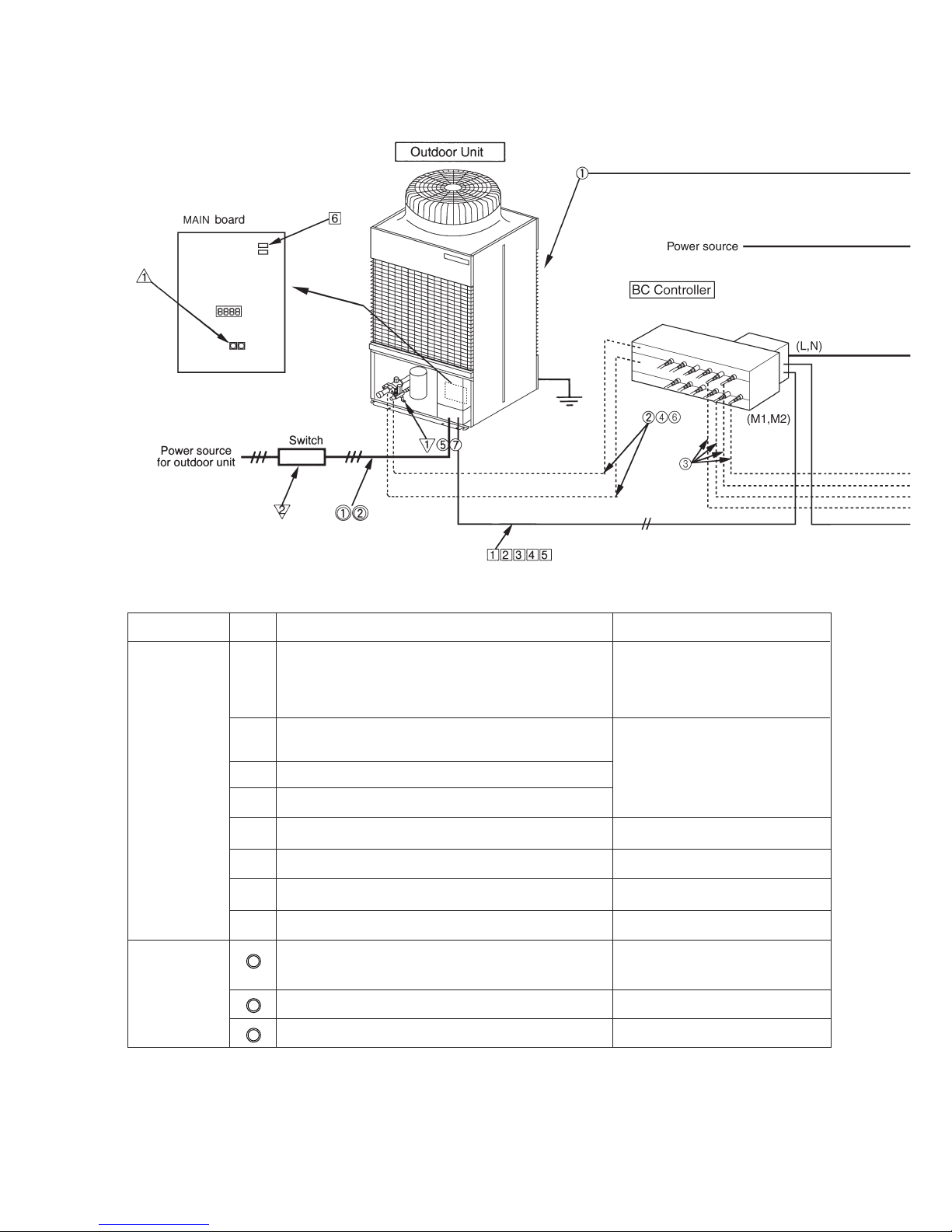

[3] Electrical Wiring Diagram

1

MC

P

N

–15–

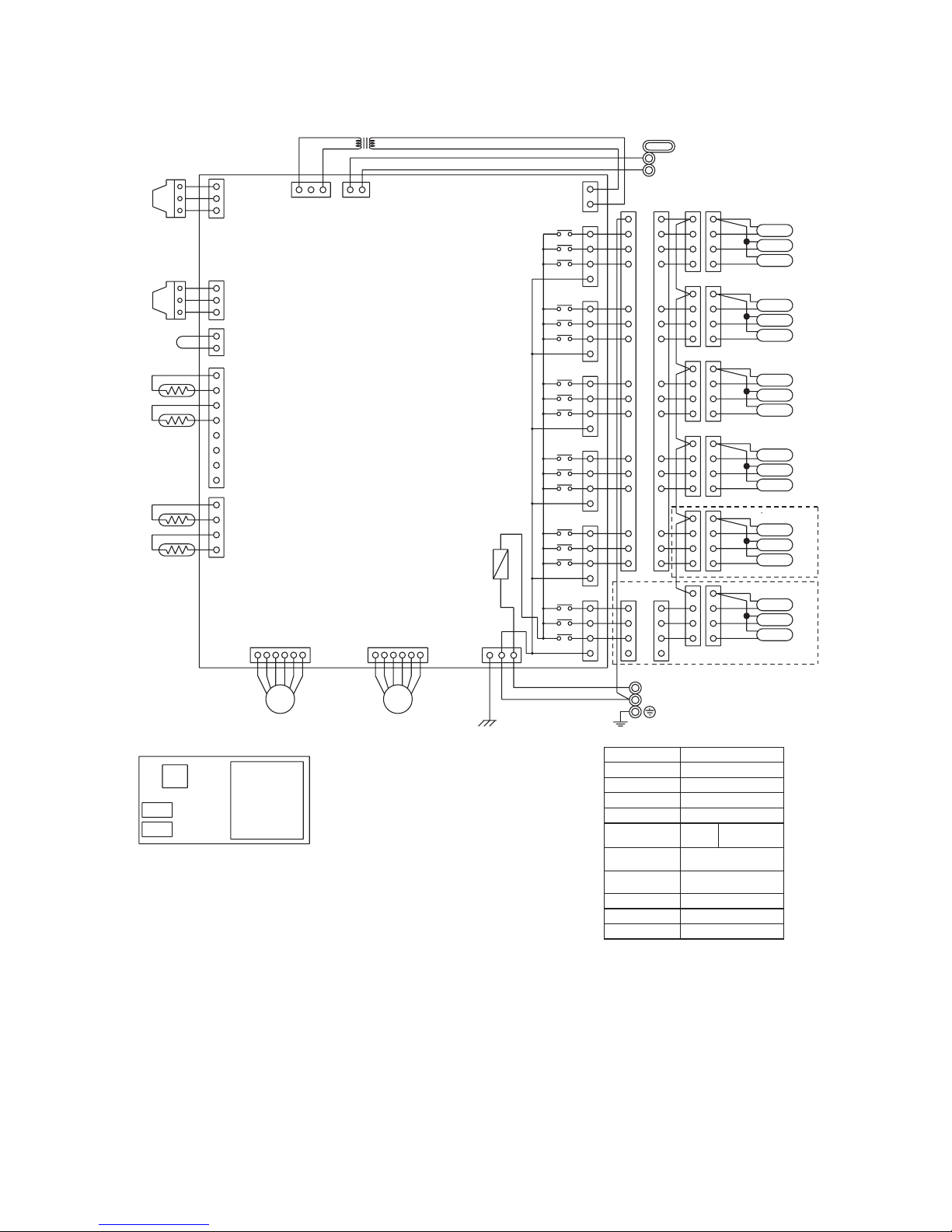

2 CMB-104·105·106NU-F

F01

250VAC

6.3A F

CMB-106NU-F ONLY

Circuit

board

(Symbol explanation)

BC controller

(Box internal layout)

T5

T4

T6

T1

T3

T2

1

3

1

1

2

3

1

2

1

2

1

2

3

4

1

123456 123456 1 3 5

2

3

4

5

6

7

8

3

321 21

1

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

3

3

5

7

1

3

5

7

1

3

5

7

1

3

5

7

1

3

5

7

1

3

5

7

X2

X1

X30

X4

X3

X31

X6

X5

X32

X8

X7

X33

X10

X9

X34

X12

X11

X35

3

G

2

2

Fuse AC250V 6.3A T

F01

Terminal

T1~6

CN31

CN30

CN29

SV6B

SV6A

SV6C

SV4A

SV4C

SV5B

SV4B

SV5C

SV5A

CN28

CN27

SV1B

SV1A

SV1C

SV2A

SV2C

SV3C

SV2B

SV3B

SV3A

CONT.B

TR

Terminal block

(for Transmission)

TB02

Terminal block

(for power source)

TB01

Solenoid valve

SV1~6A,B,C

Expansion valve

Thermistor sensor

Transformer

Name

Symbol

TR

TH11,12,15,16

LEV1,3

PS1,3

Pressure sensor

CONT.B

Note : 1.TB02 is transmission

terminal block.

Never connect power

line to it.

2.The initial set values

of switch on CONT.B

are as follows.

SW1 : 0

SW2 : 0

TB01

TB02

L1

L2

~208V-230V 60Hz

⎫

⎬

⎭

⎫

⎬

⎭

Power source

M1

M2

Shield wire

Transmission line

DC 30V

LEV1LEV3

TB01

LEV1

PS3

PS1

TH16

TH15

TH12

TH11

CN07

CN11

CN10

CN13

CN03

CNP3

CNP1

CN02

CONT.B

CN05

CN12

CNTR

CN26

TB02

TR

CMB-105 106NU-F ONLY

–16–

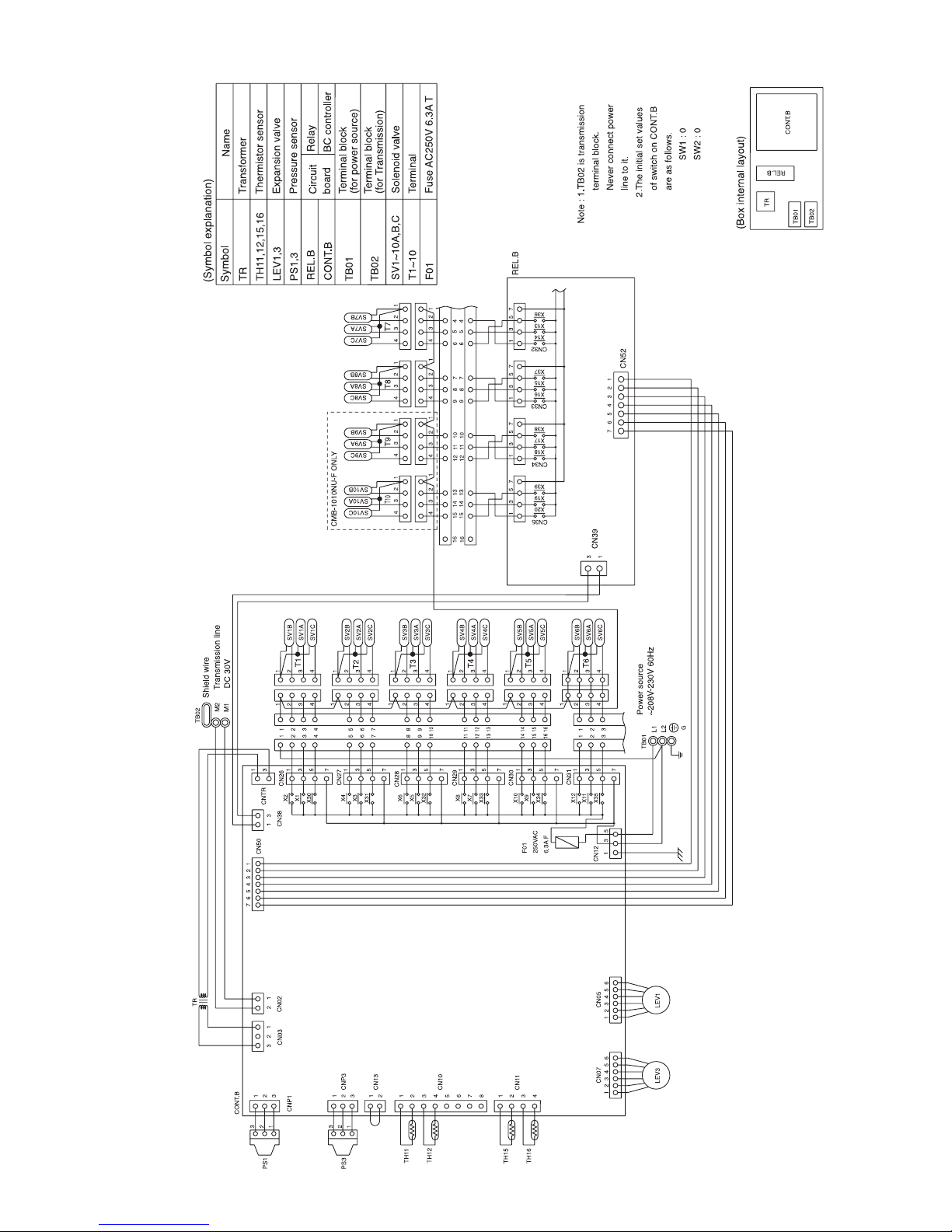

3 CMB-108·1010NU-F

⎫

⎬

⎭

⎫

⎬

⎭

–17–

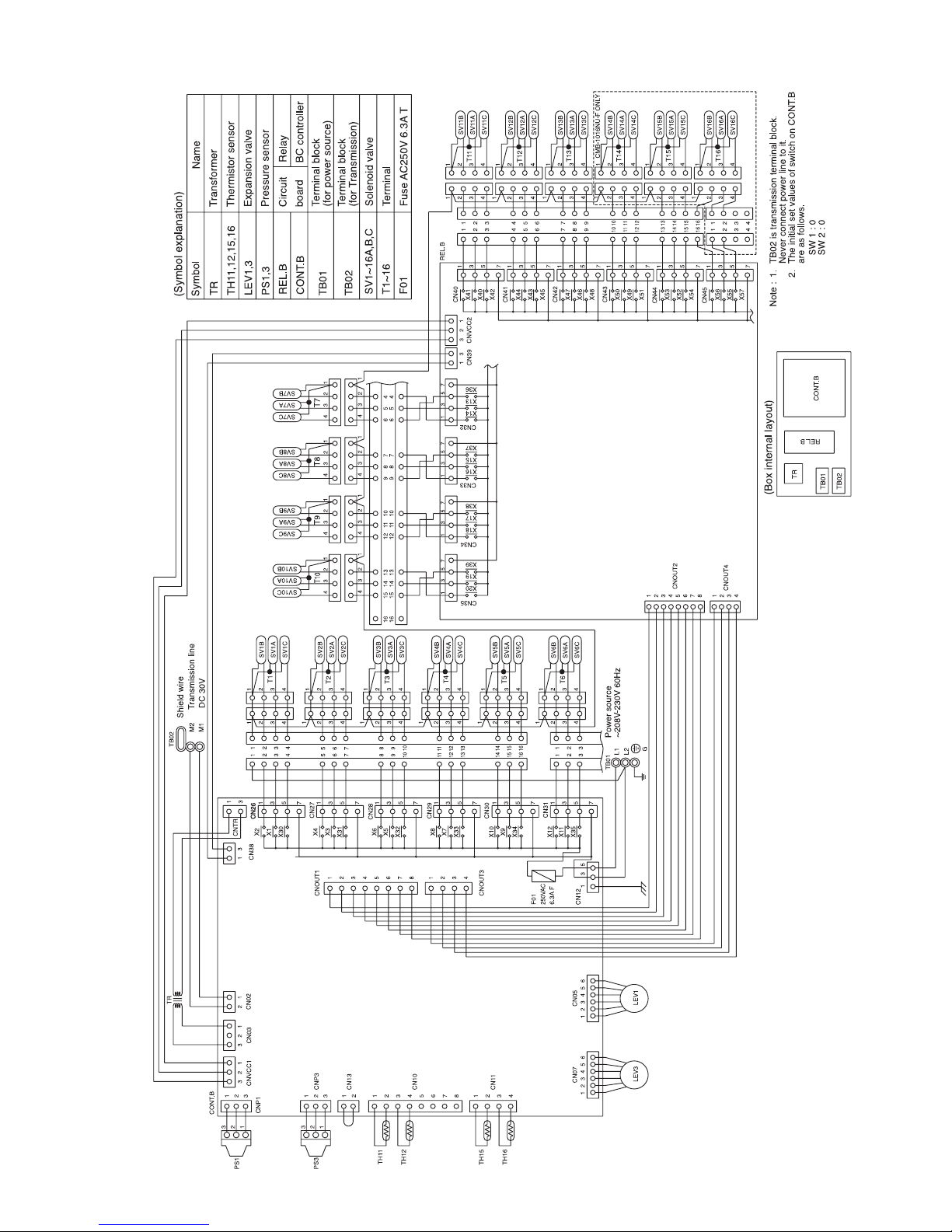

4 CMB-1013·1016NU-F

⎫

⎬

⎭

⎫

⎬

⎭

–18–

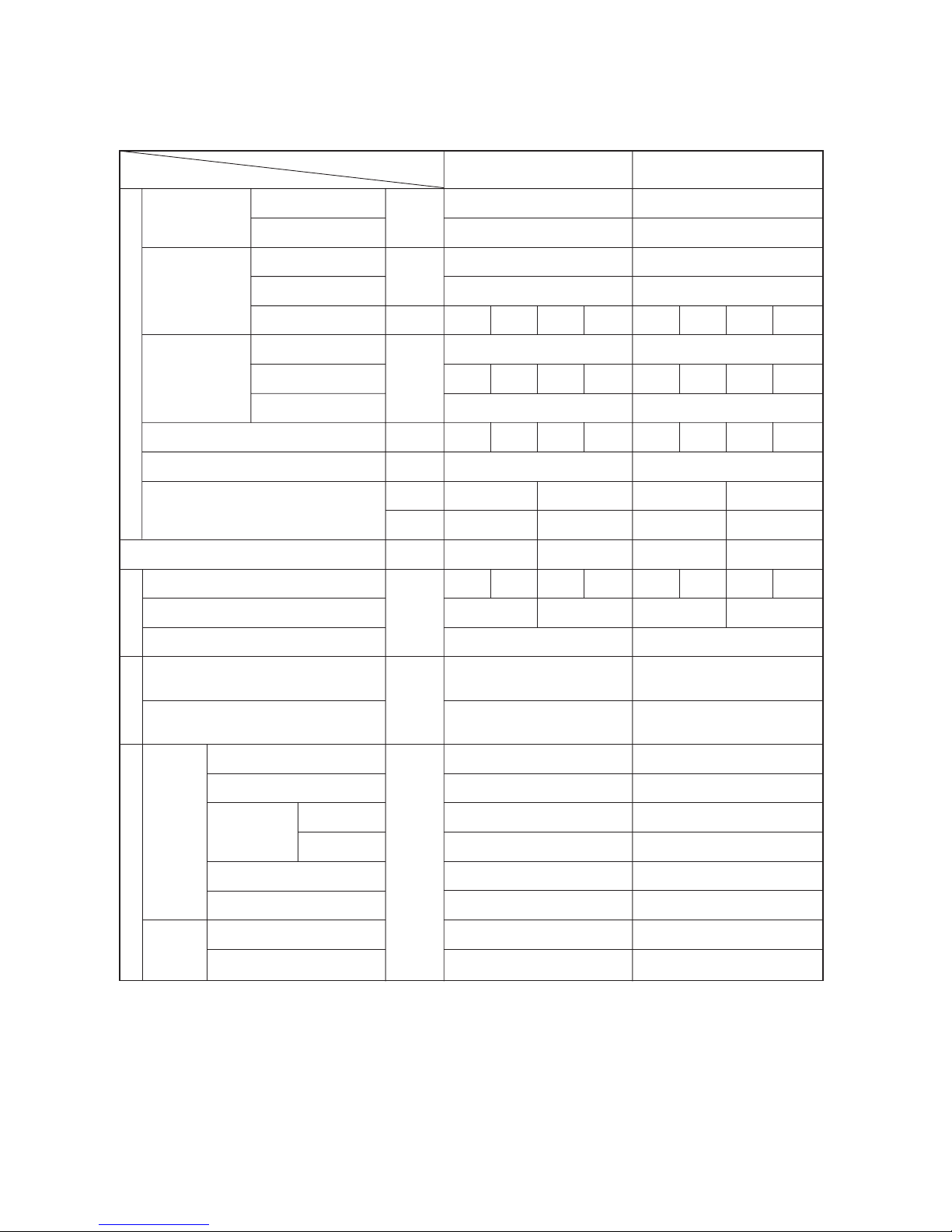

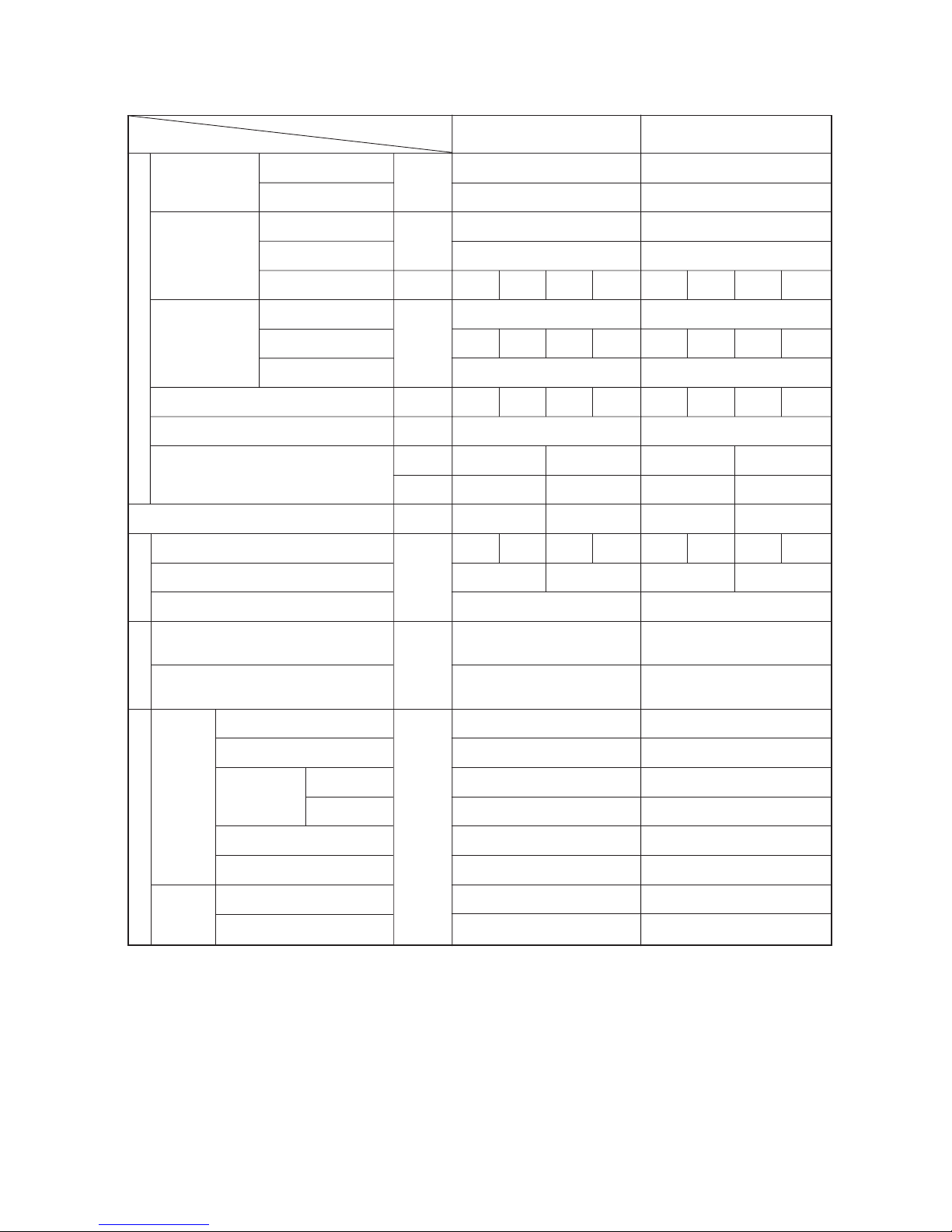

[4] Standard Operation Data

1 Cooling

Outdoor unit

Items

PURY-80TMU(-A) PURY-100TMU(-A)

Indoor

Outdoor

Quantity

Quantity in operation

Model

Main pipe

Branch pipe

Total piping length

26.7˚C(80˚F)/19.4˚C(67˚F) 26.7˚C(80˚F)/19.4˚C(67˚F)

35˚C(95˚F) 35˚C(95˚F)

44

44

24 24 20 10 48 16 24 10

5(16.4) 5(16.4)

5(16.4) 5(16.4) 5(16.4) 5(16.4) 5(16.4) 5(16.4) 5(16.4) 5(16.4)

25(82) 25(82)

Hi Hi Hi Hi Hi Hi Hi Hi

10 kg(67 oz) 12 kg(86 oz)

330 460 430 300 410 330 460 300

2000 140 2000 150

235 235

2.03/0.49 1.90/0.39

(294/71) (276/57)

1.92/1.92 1.79/1.79

(279/279) (25/25)

107(225) 110(230)

50(122) 47(117)

7(45) 7(45)

10(50) 10(50)

12(54) 12(54)

75(167) 70(158)

26(79) 30(86)

15(59) 15(59)

Indoor unit fan notch

Refrigerant volume

Compressor volts / Frequency

Outdoor unit

Indoor unit

BC controller (1, 3)

Oil return

High pressure/Low pressure

BC controller liquid/Intermediate

Pressure

DB/WB

Q’ty

–

m

(Ft)

–

kg(oz)

V

V/Hz

A

Pulse

MPa

(psi)

˚C

(˚F)

Condition

Sectional temperature

LEV opening

Discharge (TH1)

Heat exchanger outlet (TH5)

Accumulator

Suction (Comp)

Shell bottom (Comp)

LEV inlet

Heat exchanger outlet

Inlet

Outlet

Outdoor

unit

Indoor

unit

Ambient temp.

Indoor unit

Piping

208 230 208 230

134/76 134/76 171/98 171/98

27.4 24.8 35.2 31.8

–19–

2 Heating

Outdoor unit

Items

PURY-80TMU(-A) PURY-100TMU(-A)

Indoor

Outdoor

Quantity

Quantity in operation

Model

Main pipe

Branch pipe

Total piping length

21.1˚C(70˚F) 21.1˚C(70˚F)

8.3˚C(47˚F)/6.1˚C(43˚F) 8.3˚C(47˚F)/6.1˚C(43˚F)

44

44

24 24 20 10 48 16 24 10

5(16.4) 5(16.4)

5(16.4) 5(16.4) 5(16.4) 5(16.4) 5(16.4) 5(16.4) 5(16.4) 5(16.4)

25(82) 25(82)

Hi Hi Hi Hi Hi Hi Hi Hi

10 kg(67 oz) 12 kg(86 oz)

600 950 750 400 750 600 950 400

60 700 60 800

150 235

1.81/0.35 1.76/0.36

(263/51) (256/53)

1.72/1.37 1.67/1.37

(249/199) (242/199)

100(212) 95(203)

–2(28) –1(30)

–1(30) –1(30)

–4(25) –2(28)

–1(30) –1(30)

45(113) 40(104)

38(100) 40(104)

80(176) 85(185)

208 230 208 230

149/85 149/85 174/100 174/100

27.5 24.9 35.6 32.2

Indoor unit fan notch

Refrigerant volume

Compressor volts / Frequency

Outdoor unit total current

Indoor unit

BC controller (1, 3)

Oil return

High pressure/Low pressure

BC controller liquid/Intermediate

Pressure

DB/WB

Q’ty

–

m

(Ft)

–

kg(oz)

V

V/Hz

A

Pulse

MPa

(psi)

˚C

(˚F)

Condition

Sectional temperature

LEV opening

Discharge (TH1)

Heat exchanger outlet (TH5)

Accumulator

Suction (Comp)

Shell bottom (Comp)

LEV inlet

Heat exchanger outlet

Inlet

Outlet

Outdoor

unit

Indoor

unit

Ambient temp.

Indoor unit

Piping

–20–

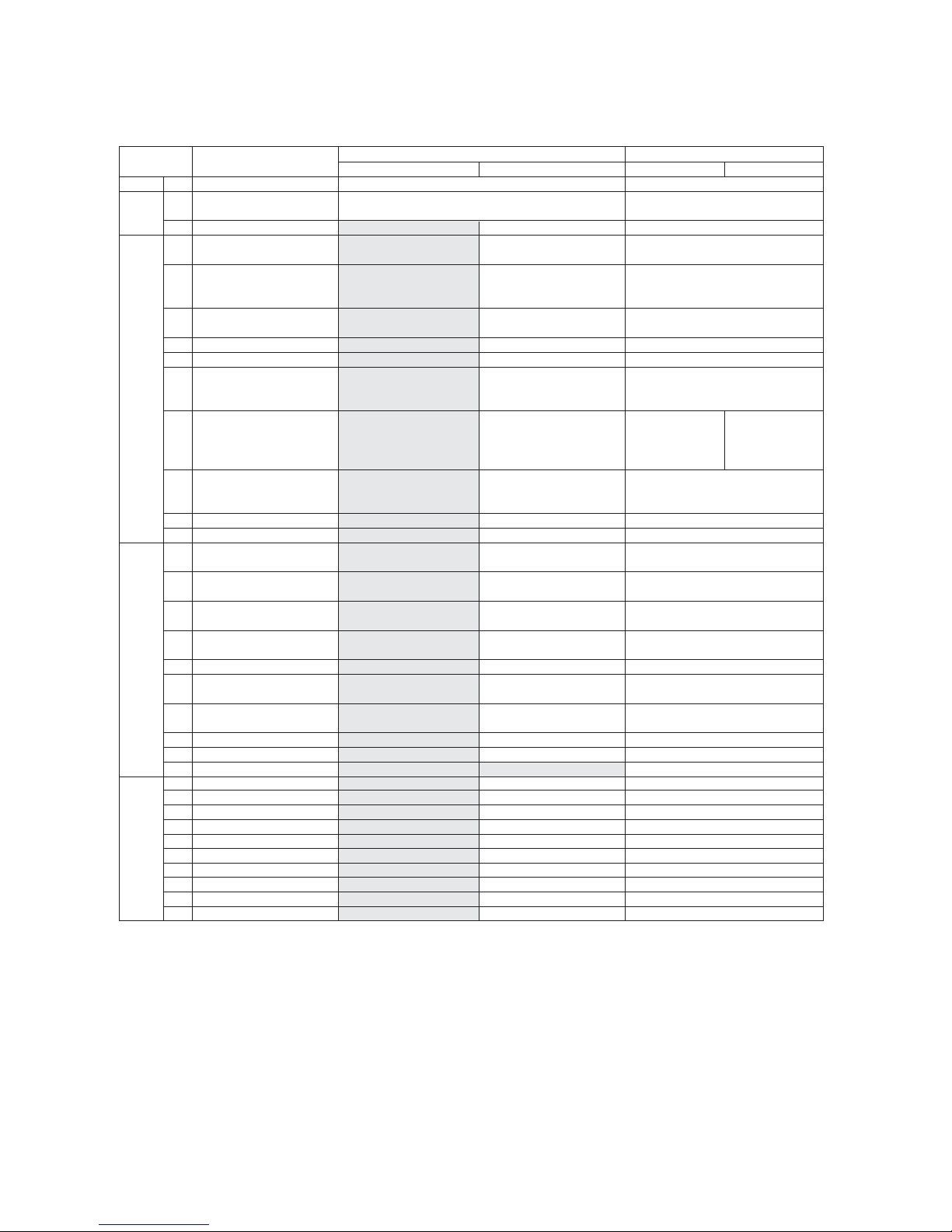

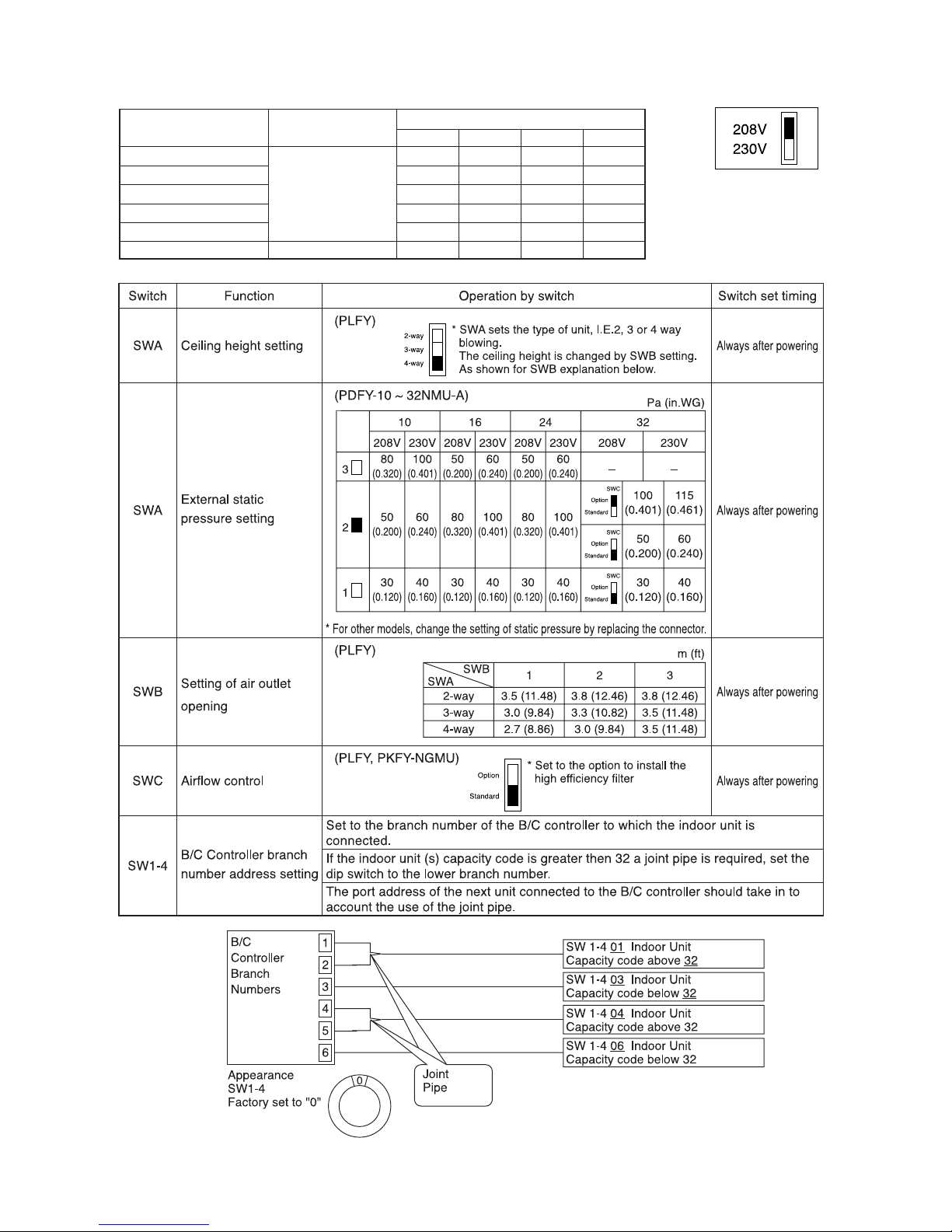

[5] Function of Dip SW and Rotary SW

(1) Outdoor unit

SWU

SW1

SW2

SW3

SW4

1~2

1~8

9~10

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

Unit address setting

For self diagnosis/

operation monitoring

–

Centralized control switch

Deletion of connection

information.

Deletion of error history.

–

–

Disregard ambient air

sensor errors, liquid

overflow errors.

Forced defrosting

Defrost prohibited timer

–

–

SW3-2 Function valid/

invalid

Indoor unit test operation

Defrosting start temperature of TH7.

Defrosting end temperature of TH5.

–

Pump down operation

Target Td (High pressure)

at Heating

–

–

Models

–

–

–

–

LED Display

–

–

–

–

–

Set on 51~100 with the dial switch.

LED monitering display

–

Centralized control not

connected.

Storing of refrigeration

system connection

information.

–

–

–

Errors valid.

Ordinary control

50 min.

–

–

SW3-2 Function invalid

Stop all indoor units.

–6°C

(21˚F)

8°C

(46˚F)

–

Invalid

49˚C

(120˚F)

–

–

Model 80

–

–

–

–

“˚F” “psig” Display

–

–

–

–

–

–

Centralized control

connected.

Deletion of refrigeration

system connection

information.

Deletion

–

–

Disregard errors.

Start forced defrosting.

90 min.

–

–

SW3-2 Function valid

All indoor units test

operation ON.

–3°C

(27˚F)

15°C

(59˚F)

–

Valid

53˚C

(127˚F)

–

–

Model 100

–

–

–

–

“˚C” “kgf/amG” Display

–

–

–

–

–

Before power is turned on.

During normal operation when power

is on.

Should be set on OFF.

Before power is turned on.

Before power is turned on.

During normal operation when power

is on.

–

–

During normal operation when power

is on.

During normal operation when power

is on. (Except during defrosting)

–

–

During normal operation when power

is on.

When SW3-1 is ON after power is

turned on.

During normal operation when power

is on.

During normal operation when power

is on. (Except during defrosting)

–

During compressor stop when power

is on.

During normal operation when power

is on.

–

–

When switching on the power.

–

–

–

–

When switching on the power

–

–

–

–

–

During normal

operation when

power is on.

10 minutes or

more after

compressor

starts.

Switch Function

Function according to switch operation Switch set timing

When off When on When off When on

Note:

• SWU1~2=00 when shipped from the factory. Other factory settings are indicated by shaded portions.

• If the address is set from 01 to 50, it automatically becomes 100.

–21–

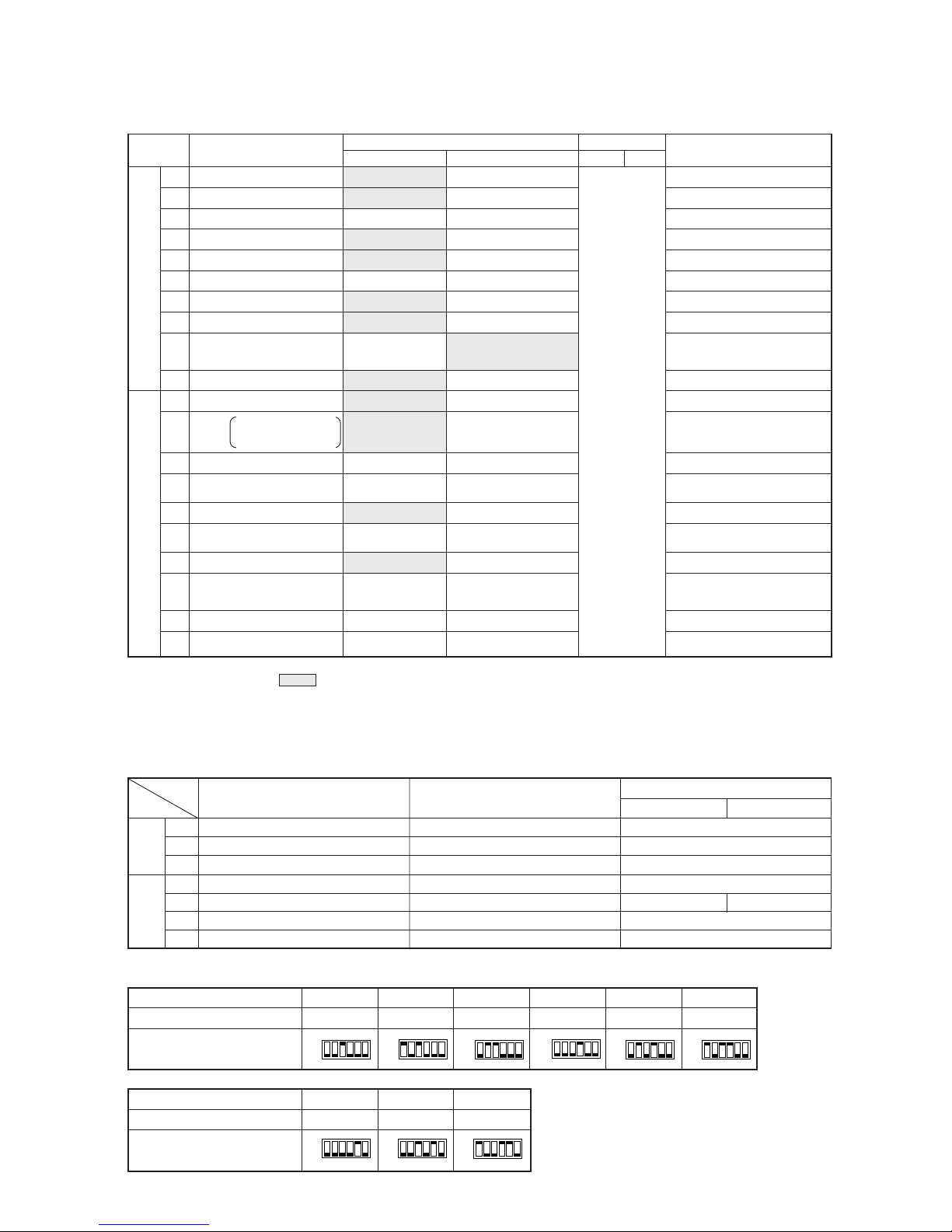

(2) Indoor unit

DIP SW1, 3

Model 32 40 48

Capacity (model name) code

16 20 25

SW2 setting

Model 08 10 12 16 20 24

Capacity (model name) code

45 681013

SW2 setting

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Note 1: The shaded part indicates the setting at factory shipment. (For the SW not being shaded, refer to the

table below.)

2: The DipSW setting is only effective during unit stopping (remote controller OFF) for SW1, 2, 3 and 4 commonly

and the power source is not required to reset.)

3: When both SW1-7 and SW1-8 are being set to ON, the fan stops at the heating thermostat of OFF.

Setting of DIP SW2

Model

Switch

SW1

SW3

3

6

7

3

4

6

8

PLFY-NAMU-A

ON

ON

OFF

ON

ON

OFF

OFF

Indoor unit inlet

None

100h

Ineffective

Fan output display

At stationary heating

Very low speed

SW1-7 setting

Ineffective

–

Heat pump

None

None

None

1st setting

Down blow B, C

–

Effective

–

–

Built in remote controller

Provided

2500h

Effective

Thermo. ON signal display

Always at heat.

Low speed

Set airflow

Effective

–

Cool.only

Provided

Provided

Provided

2nd setting

Horizontal

–

Ineffective

–

–

Room temp. sensor position

Clogged filter detect.

Filter duration

OA intake

Remote display select.

Humidifier control

Heating thermo. OFF airflow

Heating thermo. OFF airflow

Power failure automatic

return

–

Model selection

Louver

Vane

Vane swing function

Vane horizontal angle

Vane angle set for cooling

–

Heating 4deg (7.2 deg) up

Note : °C scale (°F scale)

–

–

Always ineffective for PKFY-NAMU

Not provided for PKFY-NAMU

Provided for PLFY-NGMU (ON) setting

Always down blow B,C for

PKFY-NAMU

SW1

SW3

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

Switch SW name

Operation by SW

Switch set timing

OFF ON OFF ON

Remarks

At unit stopping

(at remote

controller OFF)

Cooling capacity saving

for PKFY-NAMU,

effective/ineffective

PDFY-NMU-A

ON

ON

OFF

OFF

OFF

OFF

OFF

PKFY

OFF

OFF

OFF

ON

OFF

OFF

NAMU-A NGMU-A

OFF ON

–22–

Setting of DIP SW4 Setting of DIP SW5

1234

ON OFF ON OFF

OFF OFF OFF ON

ON OFF OFF ON

OFF OFF ON ON

––––

OFF OFF ON –

PDFY-10 ~ 32

PLFY-12 ~ 24

PLFY-32 ~ 48

PKFY-P-8

PKFY-P-12

PDFY-40, 48

Model Circuit board used

SW4

Phase control

Relay selection

–23–

33

33

3 TEST RUN

[1] Before Test Run

(1) Check points before test run

1 Neither refrigerant leak nor loose power source/ transmission lines should be found, if found correct immediately.

2 Confirm that the resistance between the power source terminal block and the ground exceeds 2MΩ by measur-

ing it with a DC500V megger. Do not run if it is lower than 2MΩ.

Note : Never apply the megger to the MAIN board. If applied, the MAIN board will be broken.

3 Confirm that the Ball valve at both gas and liquid sides are fully opened.

Note : Close the cap.

4 Be sure that the crankcase heater has been powered by turning the main power source on at least 12 hours

before starting the test run. The shorter powering time causes compressor trouble.

(2) Caution at inverter check

Because the inverter power portion in outdoor unit electrical part box have a lot of high voltage portion, be sure to follow

the instructions shown below.

During energizing power source, never touch inverter power portion because high voltage (approx. 580V) is

applied to inverter power portion.

When checking,

Shut off main power source, and check it with tester, etc.

Allow 10 minutes after shutting off main power source.

Open the MAIN board mounting panel, and check whether voltage of both ends of electrolytic capacitor is

20V or less.

1

2

1

2

3

–24–

(3) Check points for test run when mounting options

(4) Attention for mounting drain water lifting-up mechanism

Check point

Local remote controller displays code

No. “2503”, and the mechanism stops.

No overflow from drain pan.

Drain water comes out by operation of

drain pump.

Sound of pump operations is heard, and

drain water comes out.

No water leak from connecting portions

of each water piping.

Water is supplied to water supply tank,

and float switch is operating.

Built-in optional parts

Mounting of drain

water lifting-up

mechanism

Mounting of permeable film humidifier

Content of test run

Release connector of pump circuit,

check error detection by pouring

water into drain pan water inlet.

After that, connect connector of

circuit.

Check pump operations and drainage status in cooling (test run) mode.

Check humidifier operations and water

supply status in heating (test run) mode.

1

2

3

4

5

Result

1

2

3

Work

Disassembling and

assembling of drain

water lifting-up

mechanism

Mounting of float

switch

Electric wiring

Float switch moves smoothly.

Float switch is mounted on

mounting board straight without

deformation.

Float switch does not contact the

copper pipe.

Wiring procedure is exactly followed.

Connector portion is tightly hooked.

Content of test run

Lead wire from control box not

damaged.

Rubber cap properly inserted in to

drain water outlet of drain pan?

Insulation pipe of gas and liquid

pipes dealt with as shown in the right

figure?

Drain pan and piping cover mounted

without gap?

Drain pan hooked on cut projection

of the mechanism?

Float switch installed without contacting the

drain pan?

No mistakes in wiring?

Connectors connected securely and

tightly?

No tension on lead wire when sliding

control box?

1

2

3

1

2

3

Check point Result

Insulation pipe

No gap

–25–

(5) Check points for system structure

Check points from installation work to test run.

Trouble

Not operate.

Not cool (at cooling).

Not heat (at heating).

Not cool, not heat, error stop.

Condensation drip in piping.

Not cool, not heat, error stop.

Water leak, condensation drip in drain piping.

Error stop, not operate.

Electric shock.

Error stop, not operate.

Classification

Installation and

piping

Power source

wiring

Portion

1

2

3

4

5

6

7

8

1

2

3

Check item

Instruction for selecting combination of outdoor unit,

and indoor unit followed? (Maximum number of indoor

units which can be connected, connecting model name,

and total capacity.)

Follow limitation of refrigerant piping length? For example,

70m (229ft) or less (total length : 220m (721ft)) at the farthest.

Connecting piping size of branch piping correct?

Refrigerant piping diameter correct?

Refrigerant leak generated at connection?

Insulation work for piping properly done?

Specified amount of refrigerant replenished?

Pitch and insulation work for drain piping properly done?

Specified switch capacity and wiring diameter of main

power source used?

Proper grounding work done on outdoor unit?

The phases of the L line (L1, L2, L3) correct?

–26–

Classification

Transmission

line

Portion Check item

1

Limitation of transmission line length followed? For example,

200m (656ft) or less (total length : 500m (1640ft)) at the farthest.

2 1.25mm2 (AWG16) or more transmission line used?

(Remote controller 10m (32ft) or less 1.25mm2 (AWG16))

3 2-core cable used for transmission line?

4

Transmission line apart from power source line by 5cm (2in) or more?

5 One refrigerant system per transmission line?

6

The short circuit connector is changed form CN41 to

CN40 on the MAIN board when the system is centralized

control? (Just one outdoor unit. Not all outdoor units.)

7 • No connection trouble in transmission line?

8 Connection of wrong remote controller line terminals?

• MA Remote controller : TB15

• M-NET Remote controller : TB5

Trouble

Erroneous operation, error stop.

Erroneous operation, error stop.

Error stop in case multiple-core

cable is used.

Erroneous operation, error stop.

Not operate.

Not operate.

Error stop or not operate.

Never finish the initial mode.

System set

Before starting

Error stop or not operate.

Can not be properly set with power

source turned on.

Not operate.

Set temperature not obtained at

heating operations (Thermostat

stop is difficult)

Error stop.

Error stop, compressor trouble.

1

2

1

2

3

4

Address setting properly done? (M-NET Remote

controller, indoor unit and outdoor unit.)

Setting of address No. done when shutting off power

source?

Address numbers not duplicated?

Turned on SW3-8 on indoor unit circuit board when

mounting room thermistor sensor?

Refrigerant piping ball valve (Liquid pressure pipe, gas

pressure pipe) opened?

Turn on power source 12 hours before starting operations?

2 31

SET TEMP. ON/OFF

PAR-F27MEA-US

FILTER

CHECKTEST

CLOCK ON OFF

MODE

DRY COOL

DAILY

TIMER

CHECK

AUTO

ONCLOCK

SET TEMP.

REMAINDER

NOT AVAILABLE

SENSOR

INSIDE

FILTER

TEST RUN

VENTILATION

EROR CODE

AUTO

OFF

CENTRALLY CONTROLLED

AUTO FAN

HEAT

STAND BY

DEFROST

FAN

SPEED

TIMER FAN SPEED

LOUVER VENTILATION

AIR DIRECTION

TIMER SET

SET TEMP. ON/OFF

PAR-F27MEA-US

FILTER

CHECKTEST

CLOCK ON OFF

MODE

DRY COOL

DAILY

TIMER

CHECK

AUTO

ONCLOCK

SET TEMP.

REMAINDER

NOT AVAILABLE

SENSOR

INSIDE

FILTER

TEST RUN

VENTILATION

EROR CODE

AUTO

OFF

CENTRALLY CONTROLLED

AUTO FAN

HEAT

STAND BY

DEFROST

FAN

SPEED

TIMER FAN SPEED

LOUVER VENTILATION

AIR DIRECTION

TIMER SET

–27–

[2] Test Run Method

Operation procedure

1

Turn on universal power supply at least 12 hours before starting → Displaying “HO” on display panel for about two

minutes

2 Press

TEST

button twice → Displaying “TEST RUN’’ on display panel

3 Press

MODE

button → Make sure that air is blowing out

4

Press

MODE

button to change from cooling to heating operation, and vice versa → Make sure that warm or cold

air is blowing out

5 Press

FAN SPEED

adjust button → Make sure that air blow is changed

6

Press

AIR DIRECTION

or

LOUVER

button to change direction of air blowing make sure that horizontal or

downward blow is adjustable.

7 Make sure that indoor unit fans operate normally

8 Make sure that interlocking devices such as ventilator operate normally if any

9 Press button to cancel test run → Stop operation

Note 1: If check code is displayed on remote controller or remote controller does not operate normally.

2: Test run automatically stops operating after two hours by activation of timer set to two hours.

3: During test run, test run remaining time is displayed on time display section.

4: During test run, temperature of liquid pipe in indoor unit is displayed on remote controller room temperature

display section.

5: When pressing

FAN SPEED

adjust button, depending on the model, “NOT AVAILABLE” may be displayed on

remote controller. However, it is not a malfunction.

6: When pressing

AIR DIRECTION

or

LOUVER

button, depending on the model, “NOT AVAILABLE” may be

displayed on remote controller. However, it is not a malfunction.

–28–

4

GROUPING REGISTRATION OF INDOOR UNITS WITH M-NET REMOTE CONTROLLER

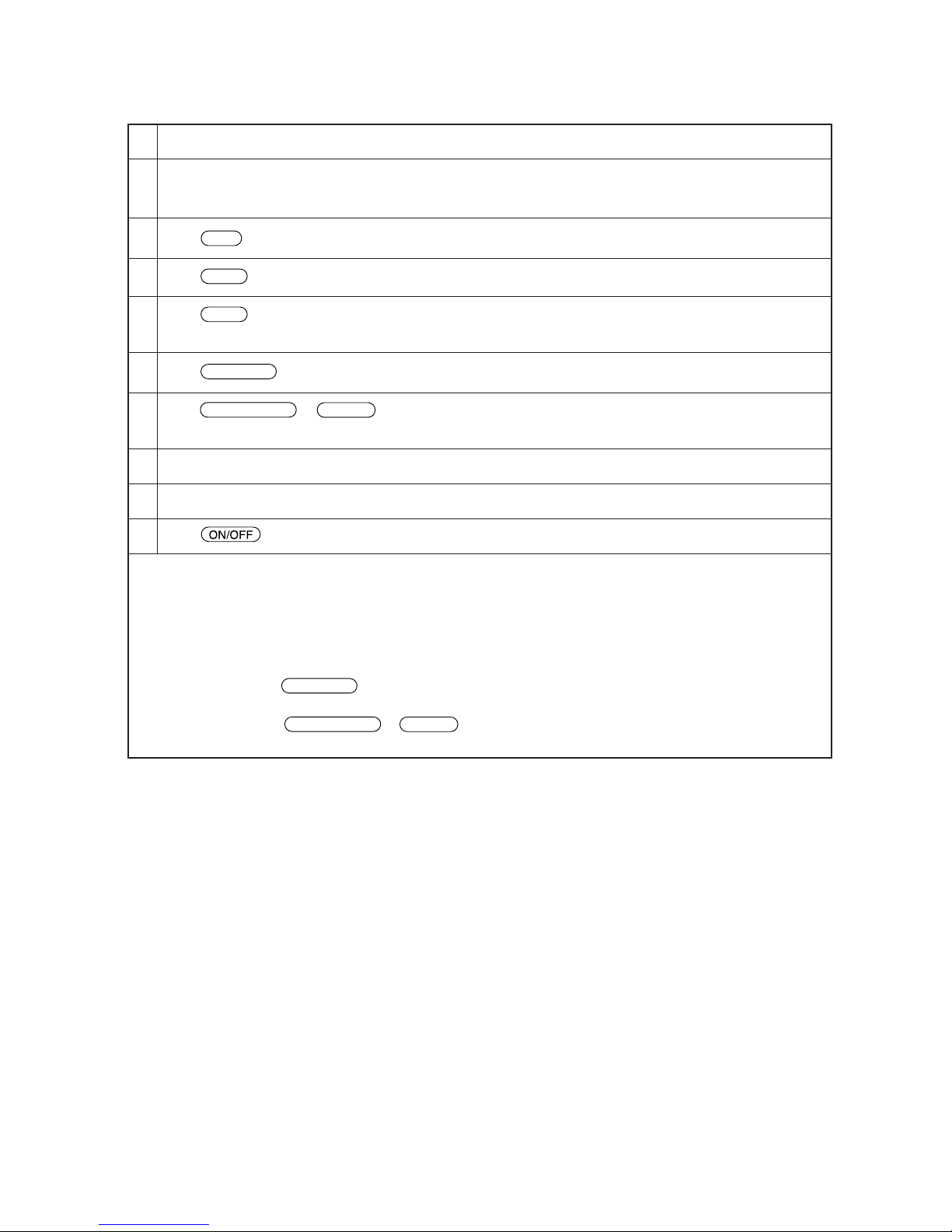

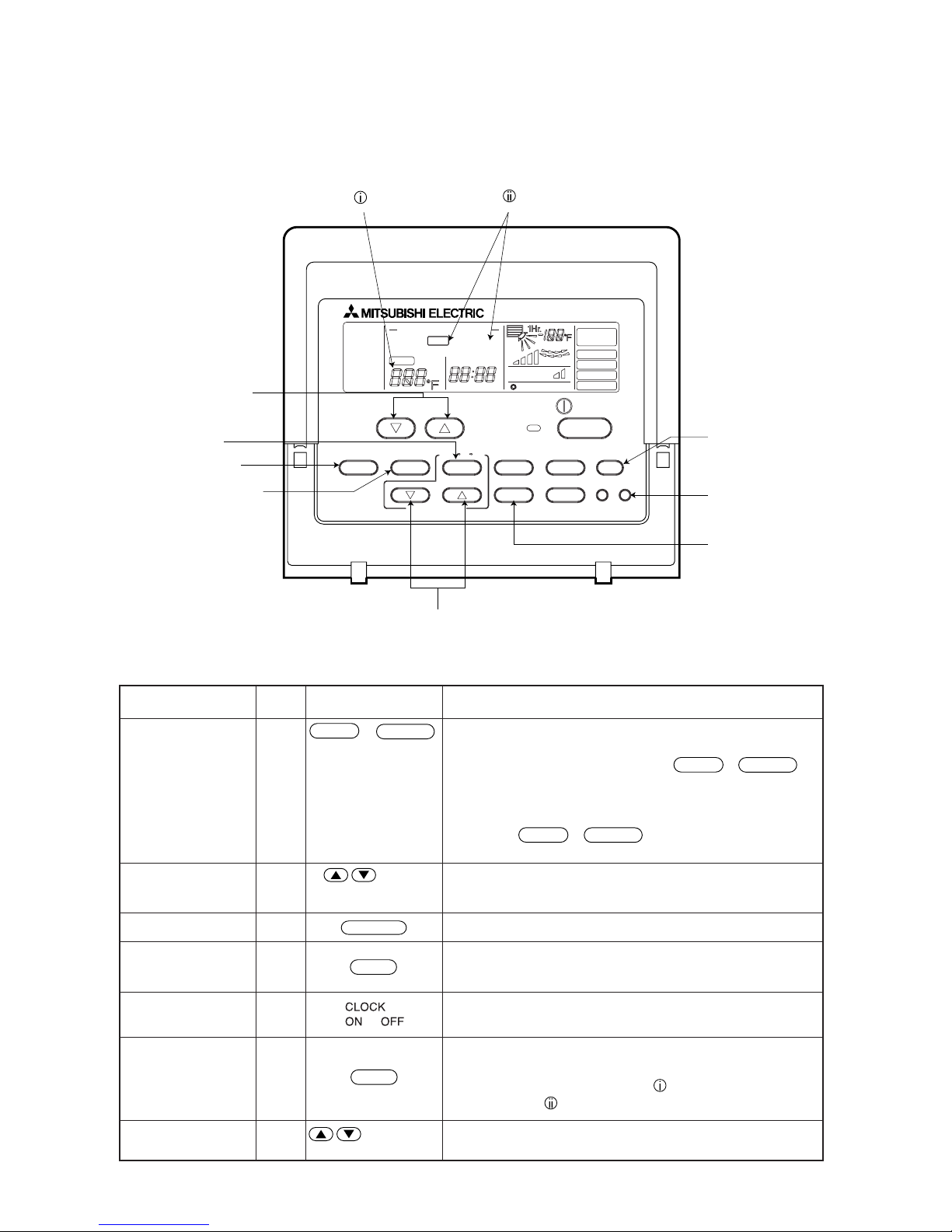

(1) Switch function

• The switch operation to register with the remote controller is shown below:

Registration/

ordinary mode

selector switch

Registration/ordinary

mode selection switch

Switch to assign indoor

unit address

Registration switch

Confirmation switch

Delete switch

Registered mode

selector switch

Switch to assign

interlocked unit address

A + B

C

D

E

F

G

H

This switch selects the ordinary mode or registered mode (ordinary

mode represents that to operate indoor units).

* To select the registered mode, press the

FILTER

+

LOUVER

button continuously for over 2 seconds under stopping state.

[Note] The registered mode can not be obtained for a while after

powering.

Pressing the

FILTER

+

LOUVER

button displays “CENTRALLY

CONTROLLED”.

This button assigns the unit address for “INDOOR UNIT ADDRESS

NO.”

This button is used for group/interlocked registration.

This button is used to retrieve/identify the content of group and

interlocked (connection information) registered.

This button is used to retrieve/identify the content of group and

interlocked (connection information) registered.

This button selects the case to register indoor units as group (group

setting mode) or that as interlocked (interlocked setting mode).

*The unit address is shown at one spot for the group setting mode

while at two spots for the interlocked setting mode.

This button assigns the unit address of “OA UNIT ADDRESS NO.”

Symbol

of switch

G Registered mode

selector switch

E Confirmation switch

C Switch to assign

indoor unit address

H Switch to assign inter-

locked unit address

D Registration switch

A

+

FILTER

TEST RUN

Name Name of actual switch Description

of TEMP

of TIMER SET

B

Registration/

ordinary mode

selector switch

SET TEMP. ON/OFF

PAR-F27MEA-US

FILTER

CHECK TEST

CLOCK ON OFF

MODE

DRY COOL

DAILY

TIMER

CHECK

AUTO

ONCLOCK

SET TEMP.

REMAINDER

NOT AVAILABLE

SENSOR

INSIDE

FILTER

TEST RUN

VENTILATION

EROR CODE

AUTO

OFF

CENTRALLY CONTROLLED

AUTO FAN

HEAT

STAND BY

DEFROST

FAN

SPEED

TIMER FAN SPEED

LOUVER VENTILATION

AIR DIRECTION

TIMER SET

F Delete switch

LOUVER

TIMER

MODE

→

→

–29–

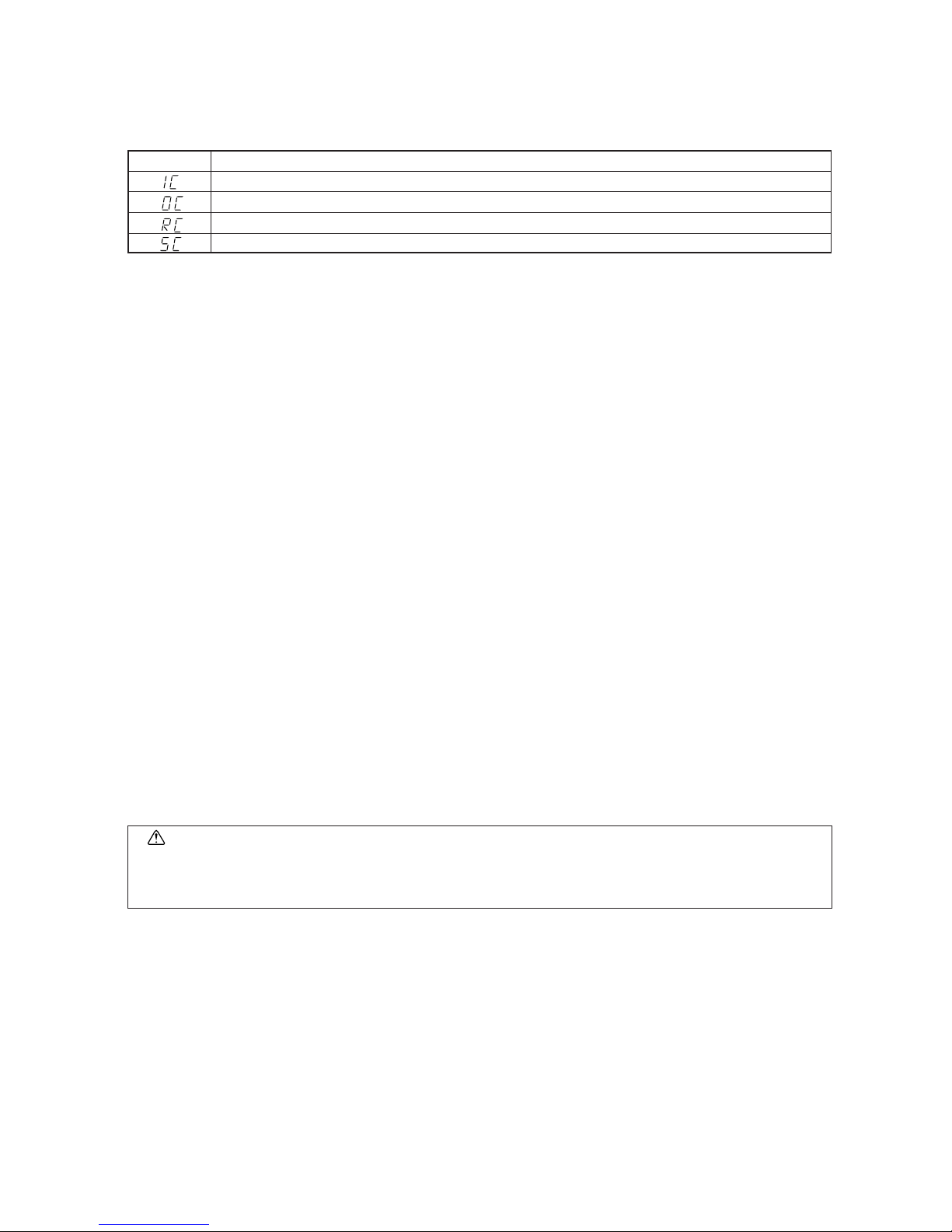

(2) Attribute display of unit

• At the group registration and the confirmation/deletion of registration/connection information, the type (attribute) of the

unit is displayed with two English characters.

Display Type (Attribute) of unit/controller

Indoor unit connectable to remote controller

Outdoor unit

Local remote controller

System controller (MJ)

[Description of registration/deletion/retrieval]

• The items of operation to be performed by the remote controller are given below. Please see the relating paragraph for

detail.

1 Group registration of indoor unit

• The group of the indoor units and operating remote controller is registered.

• It is usually used for the group operation of indoor units with different refrigerant system.

2 Retrieval/identification of group registration information of indoor units

• The address of the registered indoor units in group is retrieved (identified).

3 Retrieval/identification of registration information

• The connection information of any unit (indoor/outdoor units, remote controller or the like) is retrieved (identified).

4 Deletion of group registration information of indoor units

• The registration of the indoor units under group registration is released (deleted).

5 Deletion of the address not existing

• This operation is to be conducted when “6607” error (No ACK error) is displayed on the remote controller caused by

the miss setting at test run, or due to the old memory remained at the alteration/modification of the group composition.

Caution:

When MELANS (MJ-103MTRA for example) is being connected, do not conduct the group/pair registration using

the remote controller. The group/pair registration should be conducted by MELANS. (For detail, refer to the instruction exclusively prepared for MELANS.)

Loading...

Loading...