SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

HFC

utilized

R410A

TECHNICAL & SERVICE MANUAL

November 2013

No. OCH502

REVISED EDITION-C

Outdoor unit

[Model Name]

PUMY-P60NKMU

PUMY-P60NKMU-BS

[Service Ref.]

PUMY-P60NKMU

PUMY-P60NKMU-BS

CONTENTS

1. SAFETY PRECAUTION

2. OVERVIEW OF UNITS

3. SPECIFICATIONS

4. DATA

5. OUTLINES AND DIMENSIONS

6. WIRING DIAGRAM

7.

8. TROUBLESHOOTING

9. ELECTRICAL WIRING

10. REFRIGERANT PIPING TASKS

11. DISASSEMBLY PROCEDURE

................................................................

NECESSARY CONDITIONS FOR SYSTEM CONSTRUCTION

..........................................

.........................................

Revision:

• Replaced troubleshooting

table with flow chart in

REVISED EDITION-C.

• Some descriptions have

been modified.

• Please void OCH502

REVISED EDITION-B.

Note :

• This service manual

describes technical data

of outdoor unit. As for

indoor units, refer to its

service manual.

...................................

.....................................

.....................

.....

....................................

.................................

..................

.....................

2

5

10

11

17

18

19

29

100

103

109

Model name

indication

OUTDOOR UNIT

PARTS CATALOG (OCB502)

Use new refrigerant pipes.

Store the piping indoors, and both ends of the

piping sealed until just before brazing.

(Leave elbow joints, etc. in their packaging.)

Avoid using thin pipes.

Charge refrigerant from liquid phase of gas

cylinder.

If the refrigerant is charged from gas phase, composition

change may occur in refrigerant and the efficiency will be

lowered.

Do not use refrigerant other than R410A.

If other refrigerant (R22 etc.) is used, chlorine in refrigerant can cause deterioration of refrigerant oil etc.

Use a vacuum pump with a reverse flow check

valve.

Vacuum pump oil may flow back into refrigerant cycle and

that can cause deterioration of refrigerant oil etc.

Use the following tools specifically designed for

use with R410A refrigerant.

The following tools are necessary to use R410A refrigerant.

Handle tools with care.

If dirt, dust or moisture enters into refrigerant cycle, that can

cause deterioration of refrigerant oil or malfunction of compressor.

Do not use a charging cylinder.

If a charging cylinder is used, the composition of refrigerant will change and the efficiency will be lowered.

Flare tool

Electronic refrigerant

charging scale

Vacuum pump adaptor

Size adjustment gauge

Gauge manifold

Torque wrench

Gas leak detector

Charge hose

Tools for R410A

Contamination inside refrigerant piping can cause deterioration of refrigerant oil etc.

If dirt, dust or moisture enters into refrigerant cycle, that can

cause deterioration of refrigerant oil or malfunction of compressor.

If large amount of mineral oil enters, that can cause deterioration of refrigerant oil etc.

Make sure that the inside and outside of refrigerant piping is clean and it has no contaminants

such as sulfur, oxides, dirt, shaving particles, etc,

which are hazard to refrigerant cycle.

In addition, use pipes with specified thickness.

The refrigerant oil applied to flare and flange

connections must be ester oil, ether oil or

alkylbenzene oil in a small amount.

Ventilate the room if refrigerant leaks during

operation. If refrigerant comes into contact with

a flame, poisonous gases will be released.

Use the specified refrigerant only.

Never use any refrigerant other than that specified.

Doing so may cause a burst, an explosion, or fire when the

unit is being used, serviced, or disposed of.

Correct refrigerant is specified in the manuals and on the

spec labels provided with our products.

We will not be held responsible for mechanical failure,

system malfunction, unit breakdown or accidents caused

by failure to follow the instructions.

1 SAFETY PRECAUTION

OCH502C

CAUTIONS RELATED TO NEW REFRIGERANT

Cautions for units utilizing refrigerant R410A

2

[1] Cautions for service

OCH502C

(1) Perform service after recovering the refrigerant left in unit completely.

(2) Do not release refrigerant in the air.

(3) After completing service, charge the cycle with specified amount of refrigerant.

(4) When performing service, install a filter drier simultaneously.

Be sure to use a filter drier for new refrigerant.

[2] Additional refrigerant charge

When charging directly from cylinder

· Check that cylinder for R410A on the market is syphon type.

Charging should be performed with the cylinder of syphon stood vertically. (Refrigerant is charged from liquid phase.)

·

Unit

Gravimeter

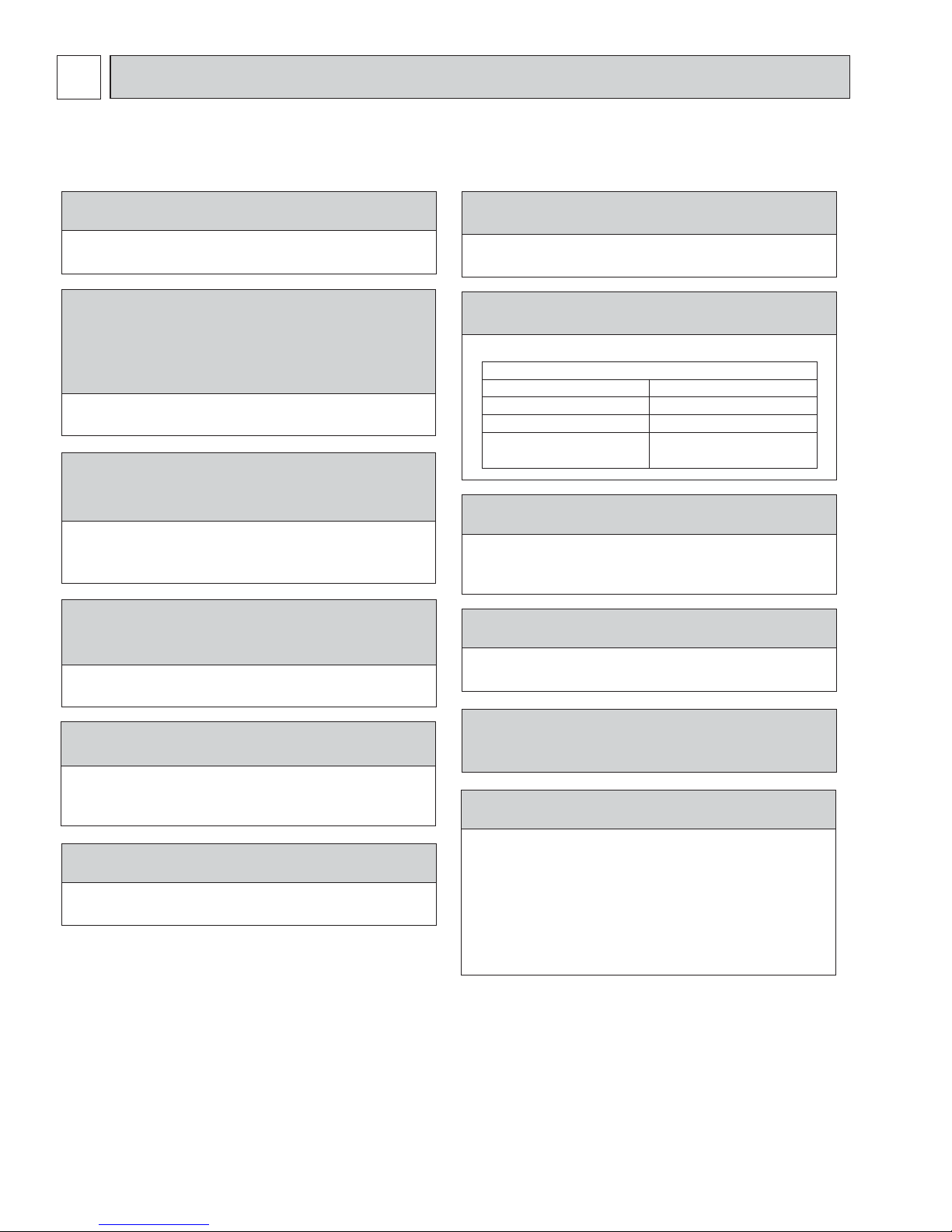

[3] Service tools

Use the below service tools as exclusive tools for R410A refrigerant.

No.

Gauge manifold · Only for R410A

1

Charge hose · Only for R410A

2

Electronic scale

3

Gas leak detector · Use the detector for R134a, R407C or R410A.

4

Adaptor for reverse flow check · Attach on vacuum pump.

5

Refrigerant charge base

6

Refrigerant cylinder · Only for R410A · Top of cylinder (Pink)

7

Refrigerant recovery equipment

8

Tool name Specifications

· Use the existing fitting

· Use high-tension side pressure of 5.3MPa·G or over.

· Use pressure performance of 5.09MPa·G or over.

· Cylinder with syphon

specifications

—

—

—

. (UNF1/2)

33

Cautions for refrigerant piping work

1/4

3/8

1/2

5/8

3/4

6.35

9.52

12.70

15.88

19.05

0.8

0.8

0.8

1.0

1.0

0.8

0.8

0.8

1.0

1.0

Nominal

dimensions(inch)

Diagram below: Piping diameter and thickness

Outside

diameter

(mm)

Thickness

(mm)

R410A R22

*

*

Use 1/2H or H pipes.

1/4

3/8

1/2

5/8

3/4

6.35

9.52

12.70

15.88

19.05

9.1

13.2

16.6

19.7

—

9.0

13.0

16.2

19.4

23.3

Nominal

dimensions(inch)

Flare cutting dimensions

Outside

diamer (mm)

Dimension A

( ) (mm)

+0

-0.4

R410A R22

1/4

3/8

1/2

5/8

3/4

6.35

9.52

12.70

15.88

19.05

17.0

22.0

26.0

29.0

—

17.0

22.0

24.0

27.0

36.0

Nominal

dimensions(inch)

Flare nut dimensions

Outside

diameter(mm)

Dimension B(mm)

R410A R22

Gauge manifold

Charge hose

Gas leak detector

Refrigerant recovery equipment

Refrigerant cylinder

Applied oil

Safety charger

Charge valve

Vacuum pump

Flare tool

Bender

Pipe cutter

Welder and nitrogen gas cylinder

Refrigerant charging scale

Vacuum gauge or thermistor vacuum gauge and

vacuum valve

Charging cylinder

Air purge, refrigerant charge

and operation check

Gas leak check

Refrigerant recovery

Refrigerant charge

Apply to flared section

Prevent compressor malfunction

when charging refrigerant by

spraying liquid refrigerant

Prevent gas from blowing out

when detaching charge hose

Vacuum drying and air

purge

Flaring work of piping

Bend the pipes

Cut the pipes

Weld the pipes

Refrigerant charge

Check the degree of vacuum. (Vacuum

valve prevents back flow of oil and refrigerant to thermistor vacuum gauge)

Refrigerant charge

Tool exclusive for R410A

Tool exclusive for R410A

Tool for HFC refrigerant

Tool exclusive for R410A

Tool exclusive for R410A

Ester oil, ether oil and

alkylbenzene oil (minimum amount)

Tool exclusive for R410A

Tool exclusive for R410A

Tools for other refrigerants can

be used if equipped with adapter for reverse flow check

Tools for other refrigerants

can be used by adjusting

flaring dimension

Tools for other refrigerants can be used

Tools for other refrigerants can be used

Tools for other refrigerants can be used

Tools for other refrigerants can be used

Tools for other refrigerants

can be used

Tool exclusive for R410A

Tools and materials Use R410A tools Can R22 tools be used?

(Usable if equipped

with adapter for rever se flow)

(Usable by adjusting

flaring dimension)

Can R407C tools be used?

Ester oil, ether oil:

Alkylbenzene oil: minimum amount

(Usable if equipped

with adapter for rever se flow)

(Usable by adjusting

flaring dimension)

: Prepare a new tool. (Use the new tool as the tool exclusive for R410A.)

: Tools for other refrigerants can be used under certain conditions.

: Tools for other refrigerants can be used.

OCH502C

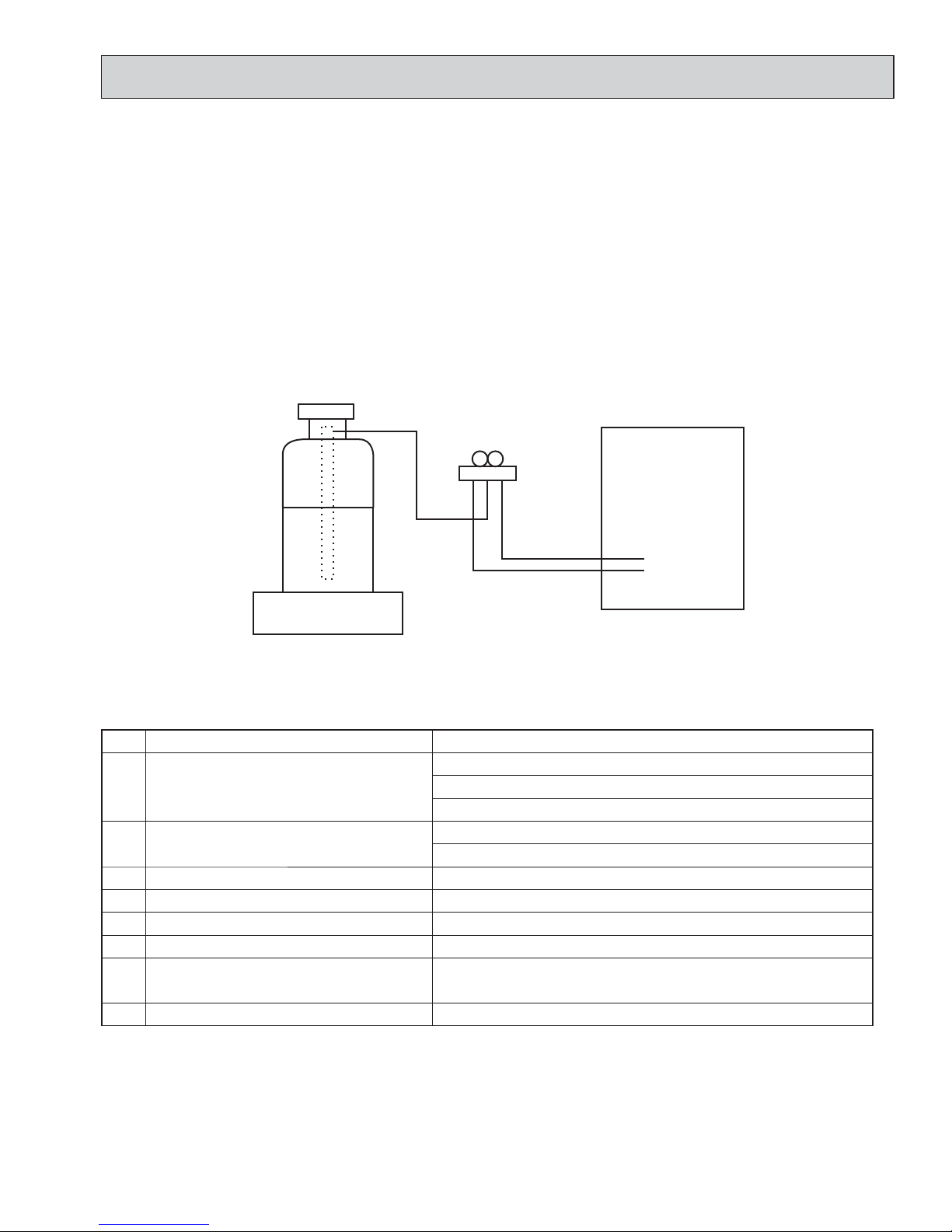

New refrigerant R410A is adopted for replacement inverter series. Although the refrigerant piping work for R410A is same

as for R22, exclusive tools are necessary so as not to mix with different kind of refrigerant. Furthermore as the working

pressure of R410A is 1.6 times higher than that of R22, their sizes of flared sections and flare nuts are different.

1 Thickness of pipes

Because the working pressure of R410A is higher compared to R22, be sure to use refrigerant piping with thickness

shown below. (Never use pipes of 0.7 mm or below.)

2 Dimensions of flare cutting and flare nut

The component molecules in HFC refrigerant are smaller compared to conventional refrigerants. In addition to that,

R410A is a refrigerant, which has higher risk of leakage because its working pressure is higher than that of other refrigerants. Therefore, to enhance airtightness and intensity, flare cutting dimension of copper pipe for R410A has been

specified separately from the dimensions for other refrigerants as shown below. The dimension B of flare nut for R410A

also has partly been changed to increase intensity as shown below. Set copper pipe correctly referring to copper pipe

flaring dimensions for R410A below. For 1/2 and 5/8 inch, the dimension B changes.

Use torque wrench corresponding to each dimension.

Dimension A

3 Tools for R410A (The following table shows whether conventional tools can be used or not.)

4

Dimension B

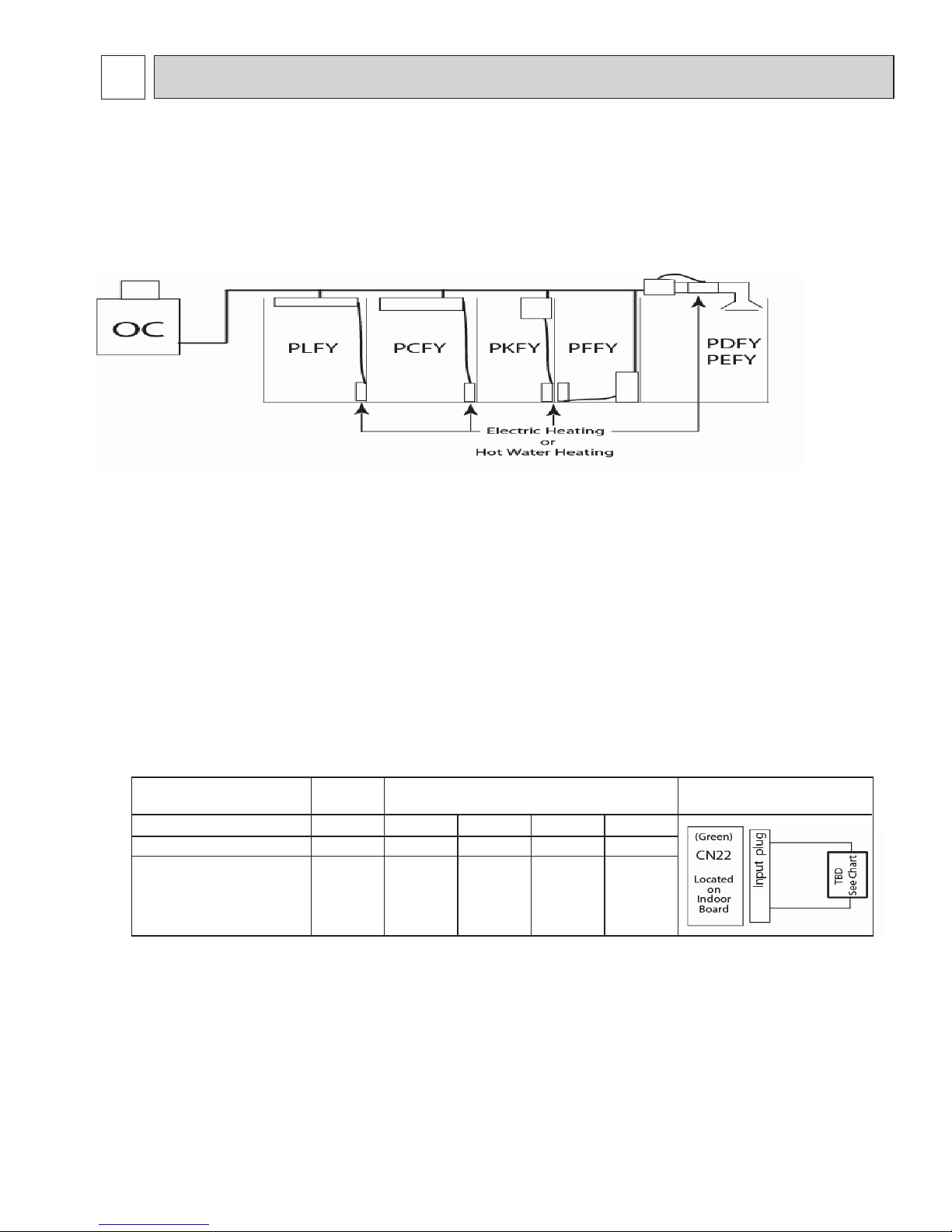

(1) Auxiliary heating operation controls another heat source that depends on the main system's operations,

which means the interlock operation shown in "b)" will be possible.

a)

b) Different Indoor unit applications that can be applied:

(2) Outdoor unit DIPSW5-4 for auxiliary heating control:

Set DIPSW5-4 when power is turned off at unit.

OFF:

Disable auxiliary Heating Function (Initial setting)

ON :

Enable auxiliary Heating Function

Indoor unit must be R410A UL model for this function to operate.

2-1. Auxiliary HEATING ON/OFF CONTROL SET-UP

(3) Determine required indoor fans speed during defrost mode:

0 20k 27k 39k 62K

None Black Blue White Red

Stopped

Setting on

remote

controller

Very Low Low High

Note: The setting will be disabled "when Heater contact signal is OFF".

CN22 input resistance ()

CN22 input (cable color)

Fan speed setting

OFF

Fan airflow rate setting

During defrost operation

ON

Wiring

CN22

a) With no auxiliary heating output the Indoor fan normally goes off to prevent cold drafts during the defrost cycles.

b) With auxiliary heating control the auxiliary heat will be on during defrost mode, thus cold drafts will not be present.

(Ducted units only)

c) For models PEFY and PDFY (Ducted) recommended to use "Black" (20K) connector.

d) For models PLFY, PCFY, PKFY and PFFY (Ductless) recommended "None", no connector required.

e) To set the fan airflow rate to be used during defrost operation, insert the resistance that is packed within the optional

adaptor cable kit (PAC-YU24HT-F) into the CN22 sensor input.

You can choose at what speed the indoor fan operates during defrost cycles bases on chart below.

2

OCH502C

OVERVIEW OF UNITS

55

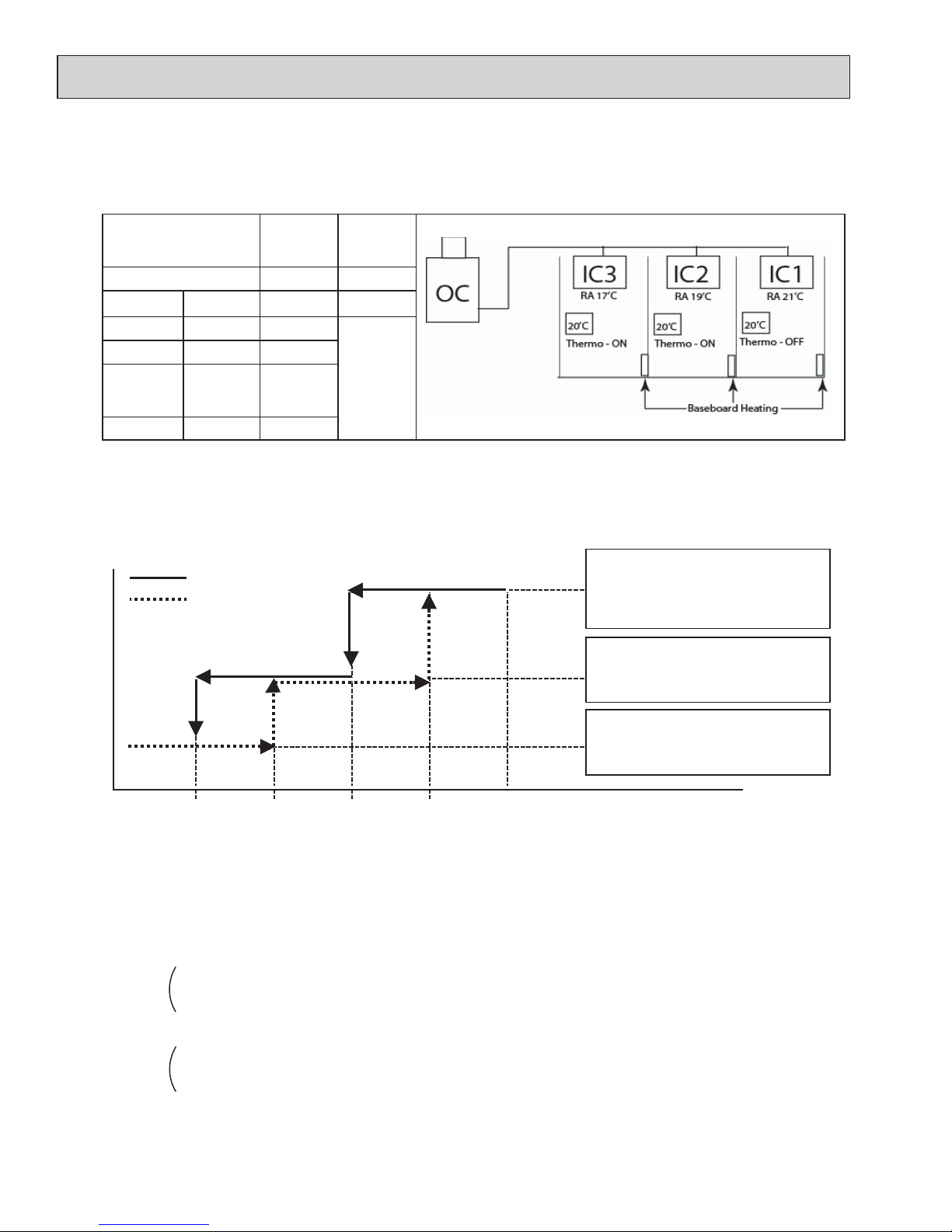

(4) Determine fan airflow setting during indoor thermo-OFF conditions:

A

OCH502C

a) These settings are done within Indoor DIPSW1-7 and DIPSW1-8, see chart below for options.

b) Recommended SW1-7 OFF and SW1-8 ON will determine airflow based on "Setting on the remote controller".

Auxiliary heating

signal

Thermo condition

SW1-7 SW1-8

OFF OFF Very low

ON OFF Low

OFF ON

ON

ON

Fan speed

setting

OFF ON

Setting on

remote

controller

Stopped

Fan speed

setting

Setting on

remote

controller

(5) Setting outdoor unit and auxiliary heat switch over temperatures.

When the DIPSW 5-4 is set to "ON", the outdoor unit and the contact output operates as shown below.

a) Outdoor default setting and operations are shown below:

Stage 1

mb. decreasing - Outdoor unit HP operation

Amb. increasing - Defrost : Heater contact ON signal

- Other than defrost : Contact OFF

Stage 2

- Outdoor unit HP operation

- Heater contact ON signal

a

-12

-C

[10-F]

When the set temperature ranges overlap, the previously set pattern (1,2 or 3) has a priority.

The stage 1 has the highest priority, 2 the second and then 3.

b) Based on above chart listed the sequence of operation on "On ambient decrease"

Stage 1 :(TH7 = > 10

Stage 2 :(TH7 = 10

Stage 3 :(TH7 = < -12

c) Based on above chart listed the sequence of operation on "On ambient increase"

Stage 3 :(TH7 = < 0

Stage 2 :(TH7 = > 0

Stage 1 :(TH7 = > 20

b

-C

0

[32-F]

c

-C

10

[50-F]

:

) : the outdoor unit runs in HP mode.

:

to -12:) : the outdoor unit runs in HP mode with auxiliary heating.

:

) : Auxiliary heating only (Outdoor unit is OFF).

:

) : Auxiliary heating only (Outdoor unit is OFF).

:

to 20:) : Auxiliary heating with outdoor unit in HP mode.

:

) : Outdoor unit in HP mode only.

d

-C

20

[68-F]

TH7 = Outdoor temperature

Stage 3

- Outdoor unit OFF (Standby)

- Heater contact ON signal

6

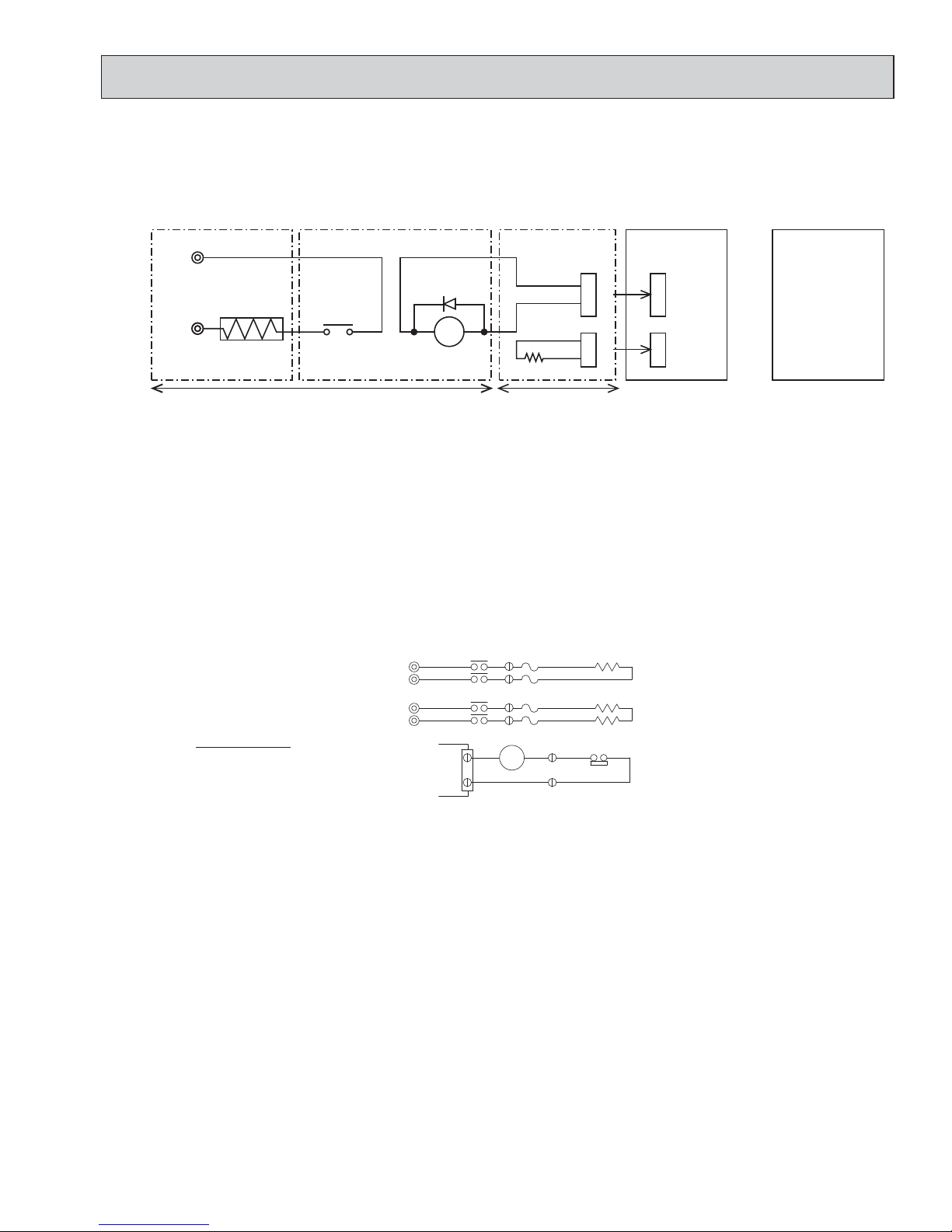

(6) Locally procured wiring

A basic connection method is shown.

(i.e. interlocked operation with the electric heater with the fan speed setting on high)

Recommended circuit

CN24

Remote control Board Relay circuit

Adapter

Indoor unit

control board

Outdoor unit

control board

Electric Heater

power source

Electric

Heater

Red 1

White 2

Dip switch

SW5-4 "ON"

Preparations in the field

Maximum cable length

is 10 m (32ft)

Red 1

Red 2

YellowGreen

1-phase power

supply

208V, 230V/60Hz

Control board

FS1, 2 ----- Thermal fuse

H1, H2 ----- Heater

26H --------- Overheat protection

thermostat

88H --------- Electromagnetic contactor

Wiring diagram

For relay X use the specifications given below operation coil

Rated voltage : 12VDC

Power consumption : 0.9W or less

*Use the diode that is recommended by the relay manufacturer at both ends of the relay coil.

The length of the electrical wiring for the PAC-YU24HT is 2 meters (6-1/2 ft)

To extend this length, use sheathed 2-core cable.

Control cable type : CVV, CVS, CPEV or equivalent.

Cable size : 0.5 mm

2

to 1.25 mm2 (AWG22 to AWG16)

Do not extend the cable more than 10 meters (32ft).

OCH502C

X

X

+

R

S

R

S

CN24

88H

88H

FS1

FS2

FS1

FS2

88H

H1

H2

26H

CN22

7

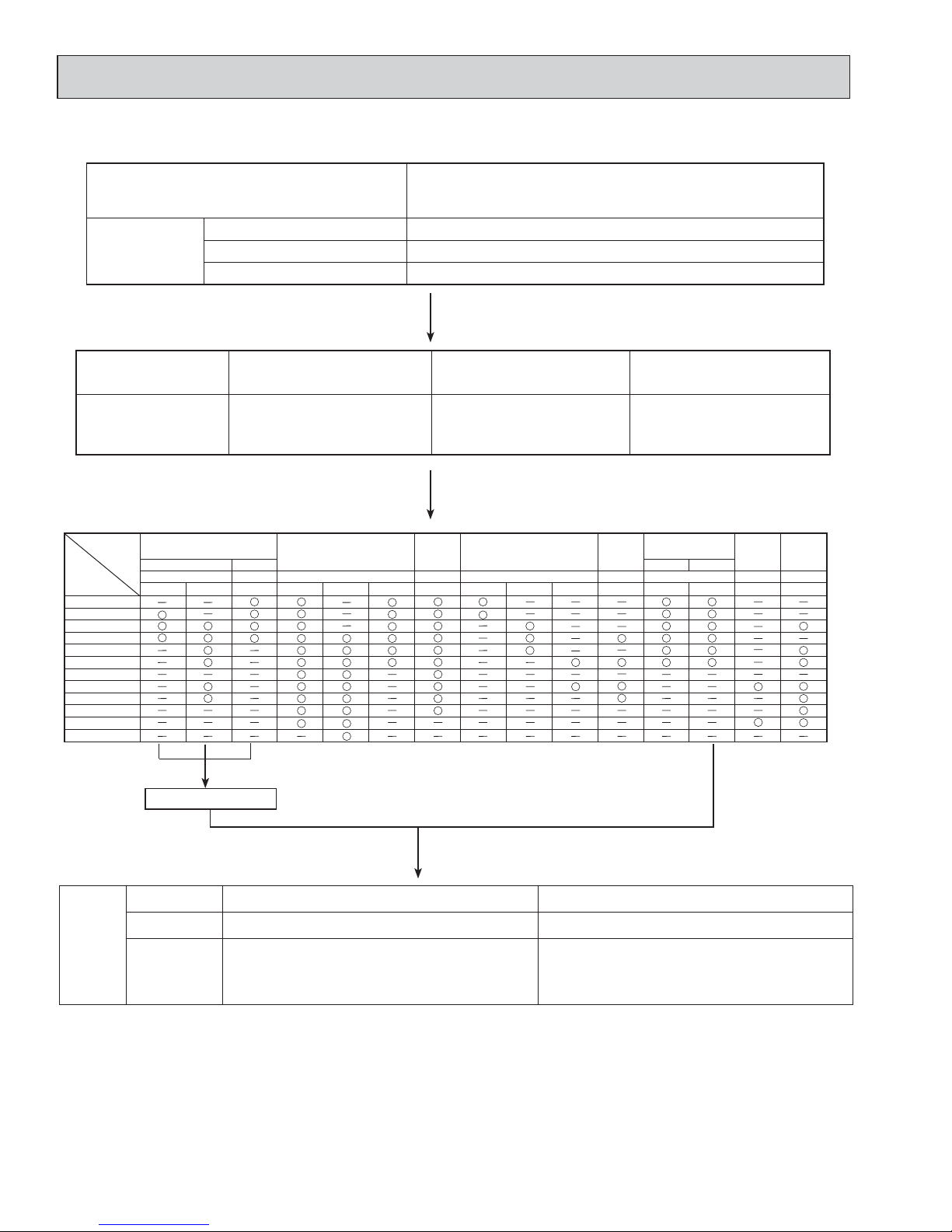

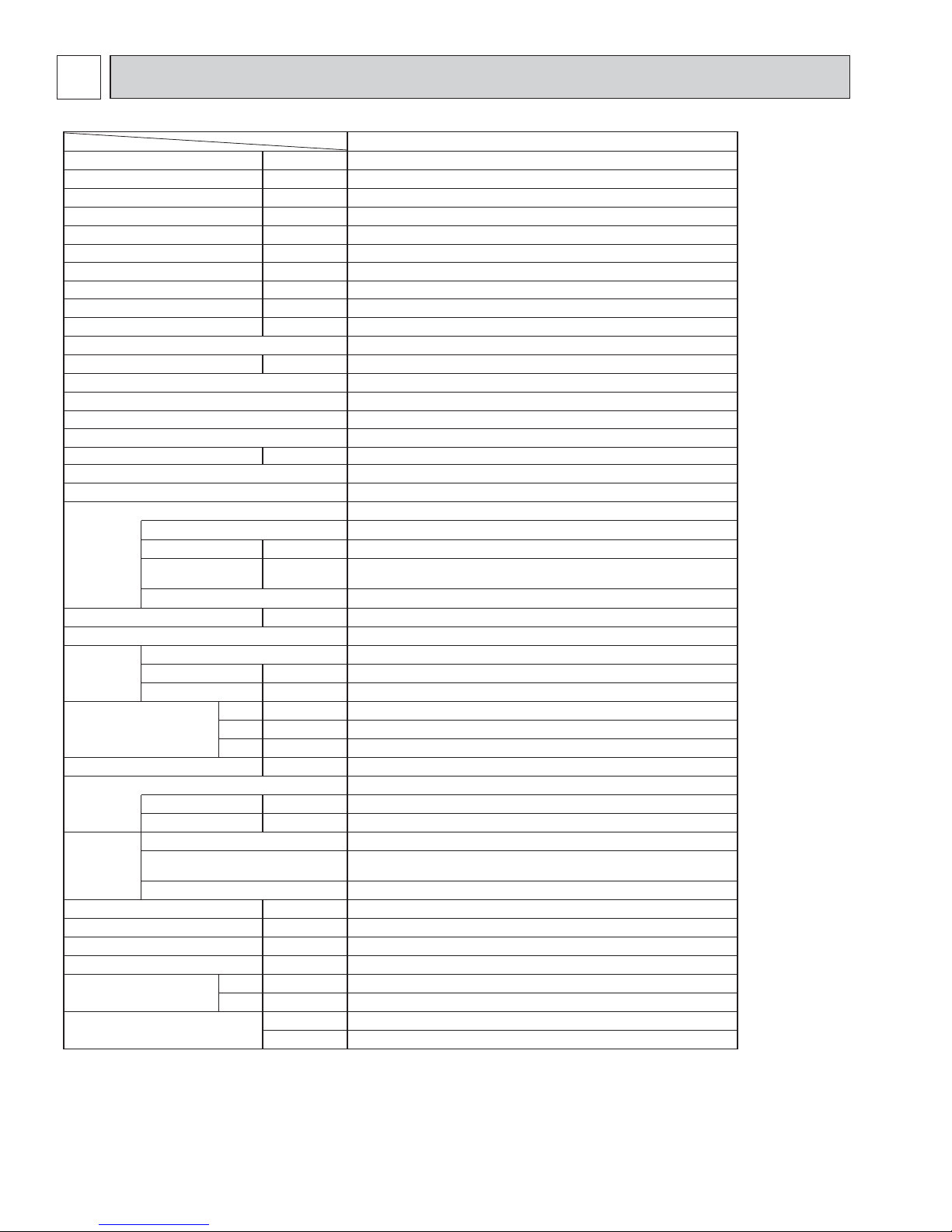

2-2. UNIT CONSTRUCTION

Model

Ceiling

Ceiling

Ceiling Concealed mounted Wall Mounted

Concealed

4-way flow

1-way flow

built-in

Exposed

Concealed

(Fresh Air)*

PLFY-P PMFY-P PEFY-P PDFY-P PKFY-P PCFY-P PFFY-P PEFY-P PVFY-P

Capacity

NCMU-E NBMU-E NBMU-E NMAU-E NMHU-E NMSU-E NMU-E NBMU-E NHMU-E

NKMU-E

NKMU-E NEMU-E

NRMU-E E00A

NMHU-E-F

06

08

12

15

18

24

27

30

36

48

54

72

Ceiling Cassette

Ceiling

Vertical

concealed

Suspended

Floor Standing

OCH502C

Outdoor unit

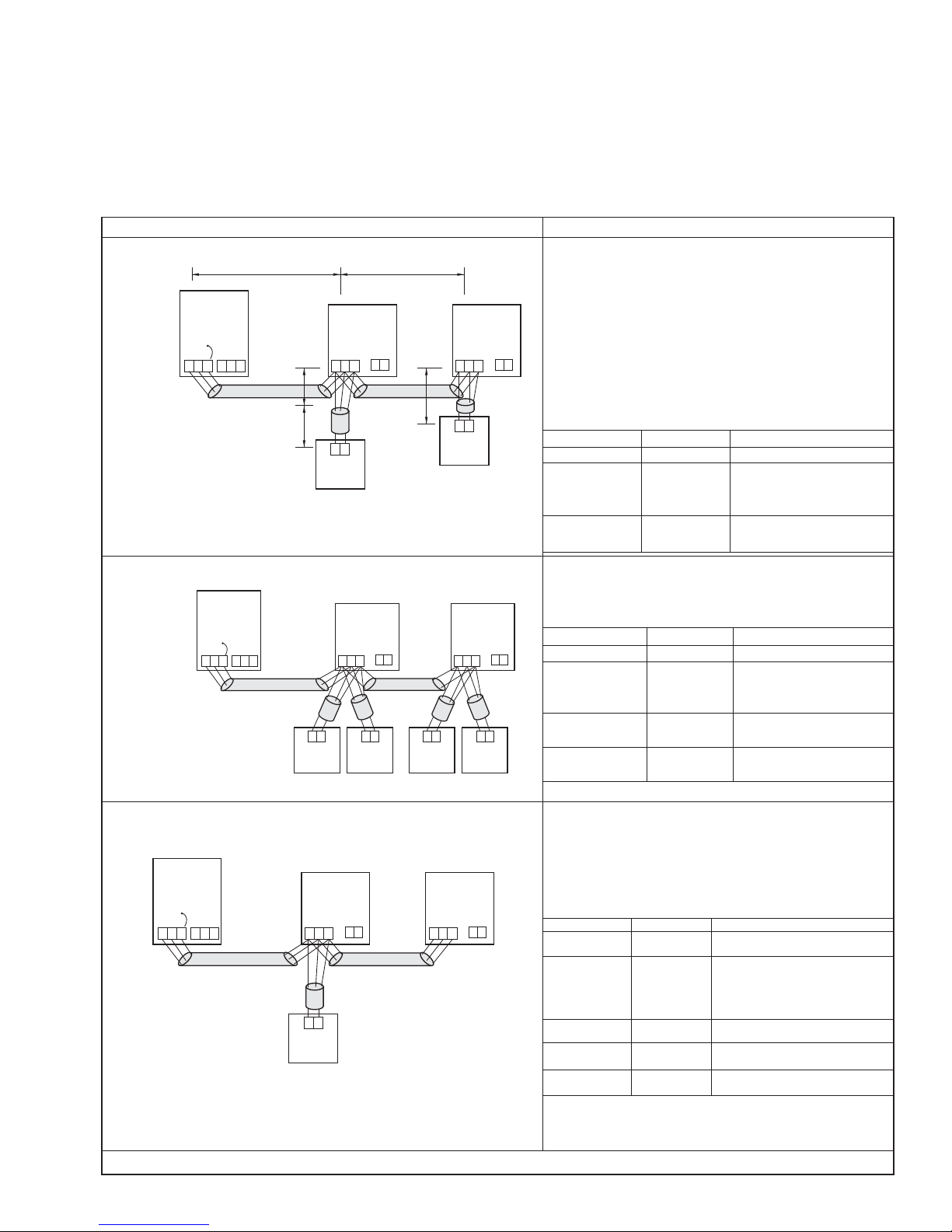

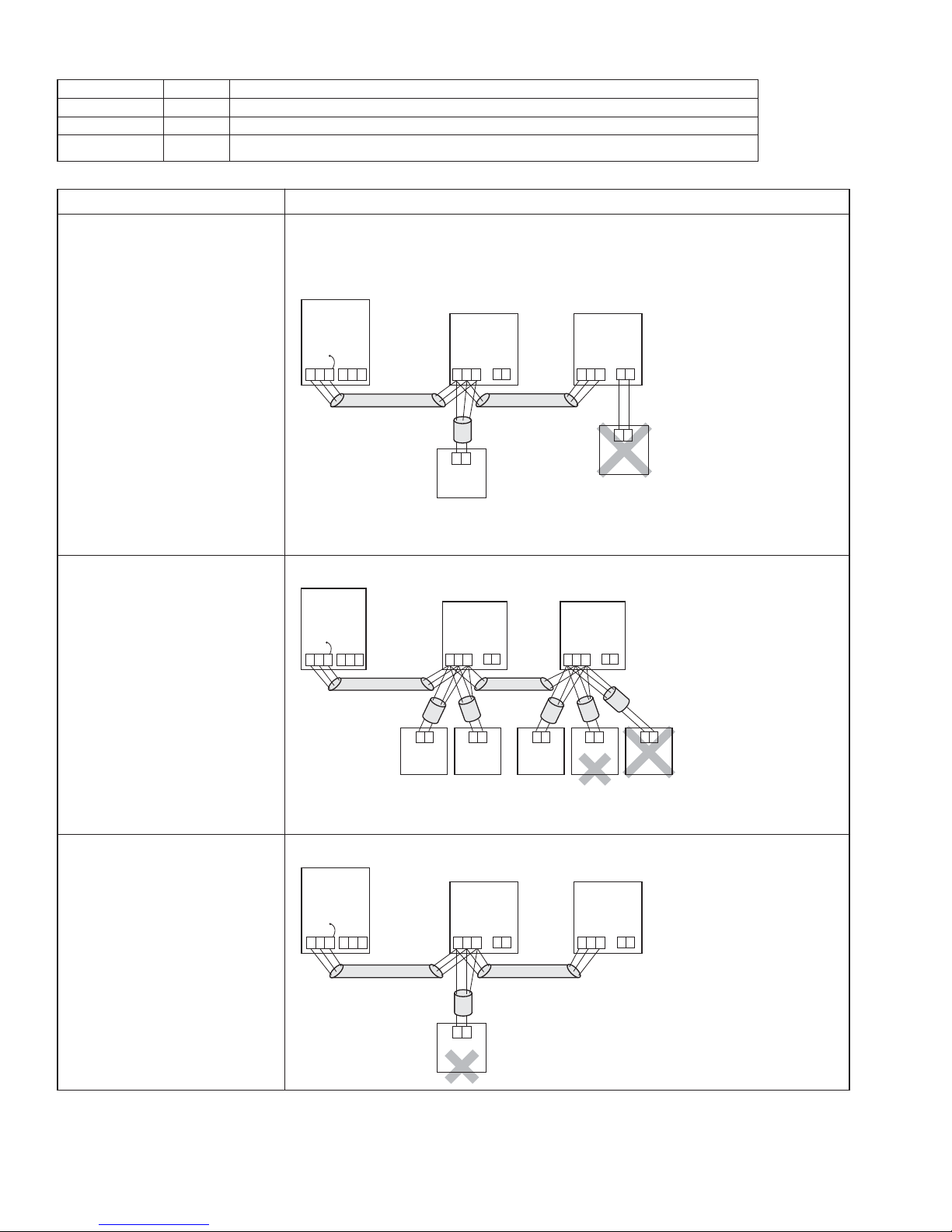

Indoor unit that

can be connected

Branching pipe

components

Capacity

Number of units

Total system wide capacity

CMY-Y62-G-E CMY-Y64-G-E CMY-Y68-G-E

Branch header

(2 branches)

P60

Type 06 ~ Type 72

1~ 12 unit

50% ~130% of outdoor unit capacity

Branch header

(4 branches)

Branch header

(8 branches)

Decorative panel

Remote

controller

Name

Model number

Functions

• A handy remote controller for use in conjunction

with the Melans centralized management system.

M-NET remote controller

• Addresses must be set.

*It is possible only by 1:1 system.

(1 indoor unit of Fresh Air type is connected with 1 outdoor unit.)

Operating temperature range (outdoor temperature) for fresh air type indoor units differ from other indoor units.

Refer to 2-2(2).

PAR-F27MEA-US

MA remote controller

PAR-21MAAU-J, PAR-30MAAU-J

• Address setting is not necessary.

8

2-3. UNIT SPECIFICATIONS

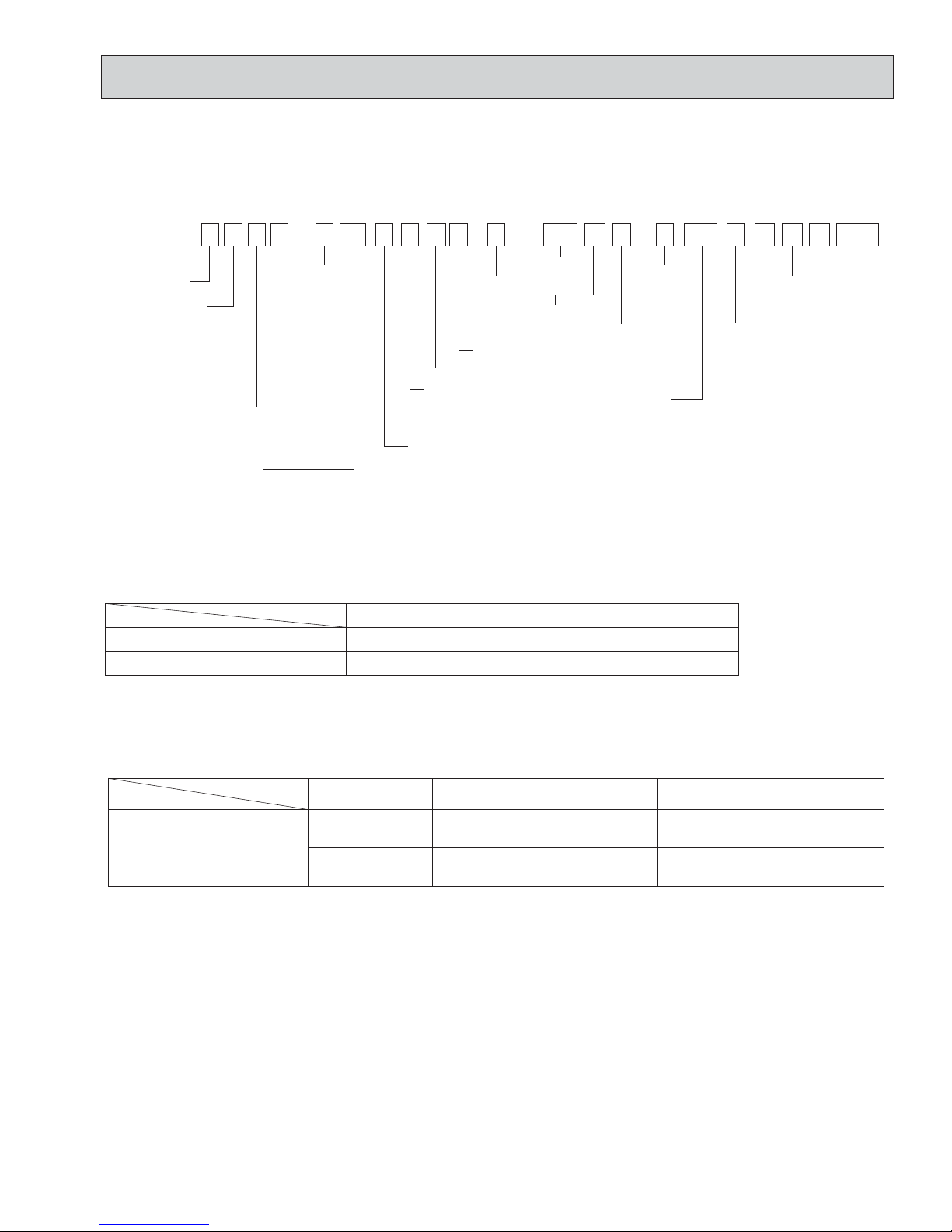

P L F Y - P 30 N B M U - E PU M Y - P 60 N

K M U -BS

PAC ty pe

Frequency

conversion

controller

Refrigerant

R410A/R22

commonness

Refrigerant

R410A

NEW frequency converter

one-to-many air conditioners

(flexible design type)

Indicates equivalent

to Cooling capacity

Indicates equivalent

to Cooling capacity

Power supply

N: Single phase

208/230V 60Hz

Power supply

N: Single phase

208/230V 60Hz

L : Ceiling cassette

K : Wall-mounted type

E : Hidden skylight type

C : Ceiling suspended type

M : Ceiling cassette type

F : Floor standing type

Outdoor unit

model type

Sub-number

Unit model type

UL model

M-NET control

M-NET control

UL model

Salt proof

type

Frequency

conversion

controller

Outdoor unit

MULTI-S

Cooling

W.B. 15 - 24°C [59 - 75°F]

Heating

D.B. 15 - 27°C [59 - 81°F]

:%í&>í)@

Indoor-side intake air temperature

Outdoor-side intake air temperature

'%í&>)@

OCH502C

(1) Method for identifying MULTI-S model

■

Indoor unit < When using Model 30 >

(2) Operating temperature range

■

Outdoor unit <When using model 60 >

Notes D.B. : Dry Bulb Temperature

W.B. : Wet Bulb Temperature

*10 - 46°C DB [50 - 115°FDB] : In the case of connecting PKFY-P06/P08 type indoor unit.

Ŷ In the case of connecting fresh air type indoor unit

Indoor-side and Outdoor-side

intake air temperature

** Thermo-off (FAN-mode) automatically starts if the outdoor temp. is lower than 21:D.B.[70°FD.B.].

***Thermo-off (FAN-mode) automatically starts if the outdoor temp. is higher than 20:D.B.[68°FD.B.].

(3) Guaranteed voltage

198 - 253V, 60Hz

Capacity of Fresh

air type indoor

P30

P54

Cooling

D.B.21 - 43:[70 - 109°F] **

W.B.15.5 - 35:[60 - 95°F]

D.B.21 - 43:[70 - 109°F] **

W.B.15.5 - 35:[60 - 95°F]

9

Heating

'%í - 20:[14 - 68°F] ***

'%í:[23 - 68°F] ***

3

OCH502C

SPECIFICATIONS

Item

Cooling Capacity Btu/h

Heating Capacity Btu/h

***

Input (Cool

Input Current (Cool

Power factor (Cool)

Input (Heat

Input Current (Heat

Power factor (Heat)

EER (Cool

COP (Heat

Connectable indoor units (Max.

Max. Connectable Capacity Btu/h 78,000(130%

Power Supply Single phase , 60Hz , 208/230V

Breaker Size

Max. fuse size

Min.Circuit.Ampacity

Sound level (Cool/Heat

External finish Munsell 3Y 7.8/1.1

Refrigerant control Linear Expansion Valve

Compressor Hermetic

Crankcase heater W —

Heat exchanger Plate fin coil (Anti corrosion fin treatment

Fan Fan(drive

Dimensions (HoWoD

Weight kg [lb

Refrigerant R410A

Protection High pressure protection HP switch

devices

Total Piping length (Max.

Farthest m [ft] 80 [262]

Max Height difference m [ft] 50 [164] *

Chargeless length m [ft] 0 [0]

Guaranteed operation range

)

)

***

***

)

***

***

)

***

)

***

***

)

)

Model

Motor output kW 3.0

Capacity control

Starting method Inverter

) o

No. Propeller fan o 2

Fan motor output kW 0.16 + 0.16

Airflow m

)

Charge kg [lb

Oil (Model

Compressor protection

Fan motor protection Overheating/Voltage protection

Piping diameter

)

)

Liquid [mm[in] 9.52 [3/8

Gas [mm[in] 19.05 [3/4

Service Ref.

kW

A

%

kW

A

%

Btu/h/W

W/W

)

dB 58 / 59

%

3

/min [CFM] 140 [4,940]

W mm [in

D mm [in

H mm [in

L [oz]

m [ft]

(

cool

(

heat

Rating conditions

Cooling Indoor : D.B. 26.7°C / W.B. 19.4°C

[D.B. 80°F / W.B. 67°F]

Outdoor : D.B. 35°C [D.B. 95°F]

Heating Indoor : D.B. 21.1°C [D.B. 70°F]

Outdoor : D.B. 8.3°C / W.B. 6.1°C

[D.B. 47°F / W.B. 43°F]

PUMY-P60NKMU(-BS)

60,000

66,000

4.80

21.5

97.0

6.15

27.6

97.0

12.5

3.14

12

)

40A

42A

25A

ANB66FFZMT

Cooling 38-100

Heating 29-100

)

]

]

]

]

]

)

)

í: DB [23 - 115

1,050 [41-5/16]

330+30 [13+1-3/16

1,338 [52+11/16

142 [313]

5.1 [11.2

2.3 [73] (FV50S

Compressor thermo,

Over current detection

150 [492]

í::%>í

]

]

]

)

]

)

F DB]**

°

F WB]

°

*40m [140ft] : In the case of installing outdoor unit lower than indoor unit.

**

10 - 46°C [50 - 115°F]DB : In the case of connecting PKFY-P06/P08 type

indoor unit.

***Electrical data is for only outdoor unit.

(In case of connecting 4 indoor units of PKFY-P06NBMU×2 and PKFY-

P24NKMU×2)

Btu/h=kW × 3,412 CFM=K/min × 35.31 lbs=kg/ 0.4536

Note: Above specification data is subject to rounding variation.

10

4

OCH502C

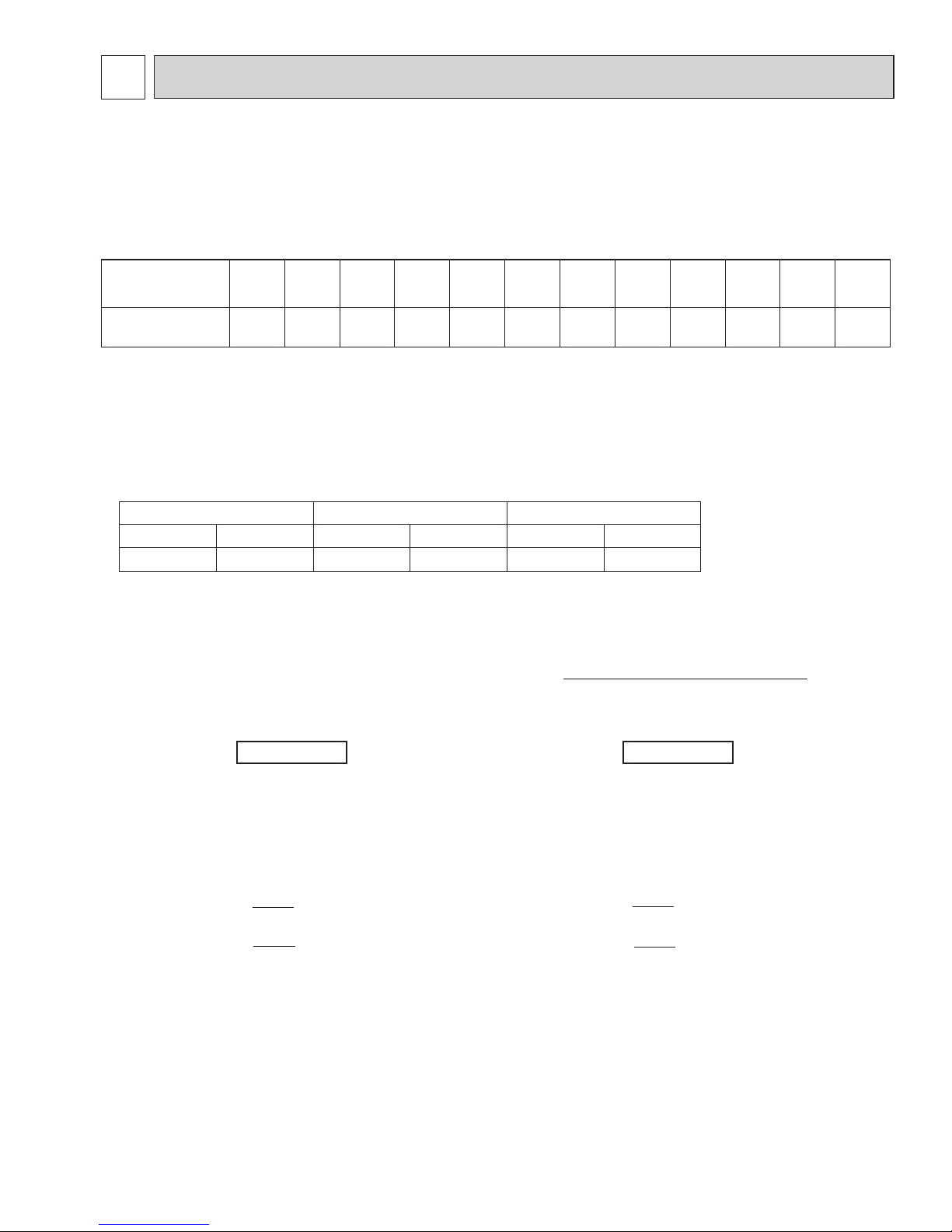

DATA

4-1. COOLING AND HEATING CAPACITY AND CHARACTERISTICS

4-1-1. Method for obtaining system cooling and heating capacity:

To obtain the system cooling and heating capacity and the electrical characteristics of the outdoor unit, first add up the ratings

of all the indoor units connected to the outdoor unit (see table below), and then use this total to find the standard capacity with

the help of the tables on 4-2. STANDARD CAPACITY DIAGRAM.

(1) Capacity of indoor unit

Model number for

indoor unit

Model Capacity 6 8 12 15 18 24 27 30 36 48 54 72

(2) Sample calculation

1 System assembled from indoor and outdoor unit (in this example the total capacity of the indoor units is greater than that of

the outdoor unit)

• Outdoor unit PUMY-P60NKMU

• Indoor unit PKFY-P08NAMU-E o 2 , PLFY-P18NBMU-E o 3

2 According to the conditions in 1, the total capacity of the indoor unit will be: 8 o 2 + 18 o 3 = 70

3 The following figures are obtained from the 52 total capacity row of the standard capacity table (4-2.):

Capacity (Btu/h)

Cooling Heating Cooling Heating Cooling Heating

62,000

A

Model 06 Model 08 Model 12 Model 15 Model 18 Model 24 Model 27 Model 30 Model 36 Model 48 Model 54 Model 72

68,000

B

Outdoor unit power consumption (kW)

4.62 5.91 20.3 26.0

Outdoor unit current (A)/230V

4-1-2. Method for obtaining the heating and cooling capacity of an indoor unit:

(1) The capacity of each indoor unit (Btu/h) = the capacity A (or B) o

(2) Sample calculation (using the system described above in 4-1-1. (2) ):

During cooling: During heating:

• The total model capacity of the indoor unit is:

8000 o 2 + 18000 o 3 = 70000Btu/h

Therefore, the capacity of PKFY-P08NAMU-E and

PLFY-P18NBMU-E will be calculated as follows by

using the formula in 4-1-2. (1):

Model 08= 62,000 o = 7,090 Btu/h

Model 18= 62,000 o = 15,940 Btu/h

8000

70000

18000

70000

• The total model capacity of indoor unit is:

9000 o 2 + 20000 o 3 = 78000 Btu/h

Therefore, the capacity of PKFY-P08NAMU-E and

PLFY-P18NBMU-E will be calculated as follows by

using the formula in 4-1-2. (1):

Model 08= 68,000 o = 7,850 Btu/h

Model 18= 68,000 o = 17,440 Btu/h

total model capacity of all indoor units

model capacity

9000

78000

20000

78000

11

4-2. STANDARD OPERATION DATA (REFERENCE DATA)

OCH502C

Operation

Ambient

temperature

Indoor unit

Operating

conditions

Piping

Fan speed — Hi

Amount of refrigerant kg [lbs-oz] 8.5 [18]

Electric current A 21.4 27.4

Outdoor unit

LEV opening Indoor unit Pulse 171 (P06)/426 (P24) 215 (P06)/534 (P24)

Pressure High pressure/Low pressure MPa [psi] 2.83/0.94 [411/136] 2.93/0.66 [425/95]

Temp. of each

section

Voltage V 230

Compressor frequency Hz 45 56

Outdoor unit

Indoor unit

Indoor

Outdoor 35°C/— [95°F/—] 8.3°C/6.1°C [47°F/43°F]

No. of connected units

No. of units in operation 4

Model — 06×2/24×2

Main pipe

Branch pipe 2.5 [8-1/4]

Total pipe length 15 [49-1/4]

Discharge

Heat exchanger outlet 38 [100] 3 [37]

Accumulator inlet 13 [55] 0 [32]

Compressor inlet 14 [57] −1 [30]

Compressor shell bottom 74 [165] 68 [154]

LEV inlet 27 [81] 40 [104]

Heat exchanger inlet 10 [50] 61 [142]

DB/WB

Unit

m [ft]

°C [°F]

26.7°C/19.4°C [80°F/67°F] 21.1°C/— [70°F/—]

74 [165] 68 [154]

Outdoor unit model

PUMY-P60NKMU(-BS)

4

5 [16-3/8]

12

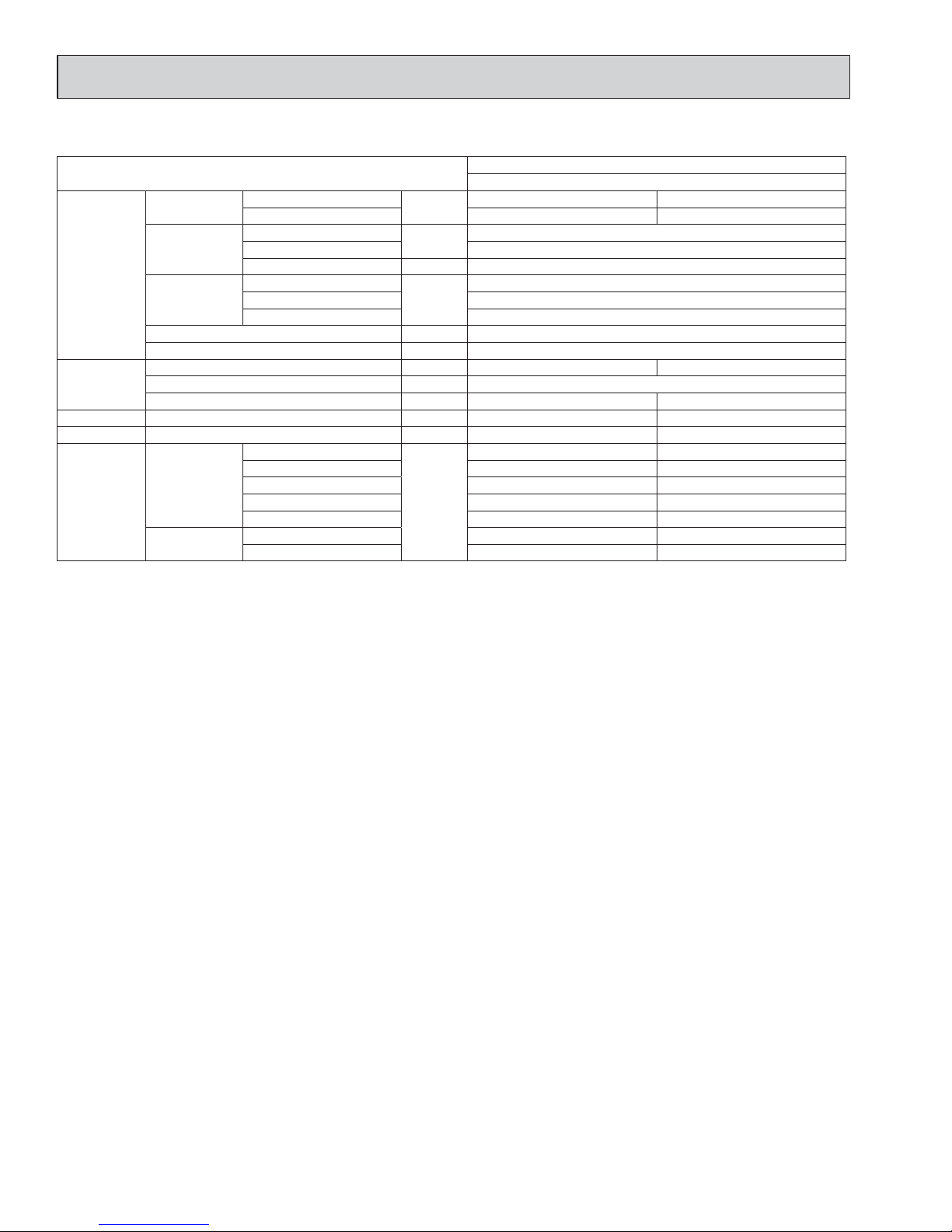

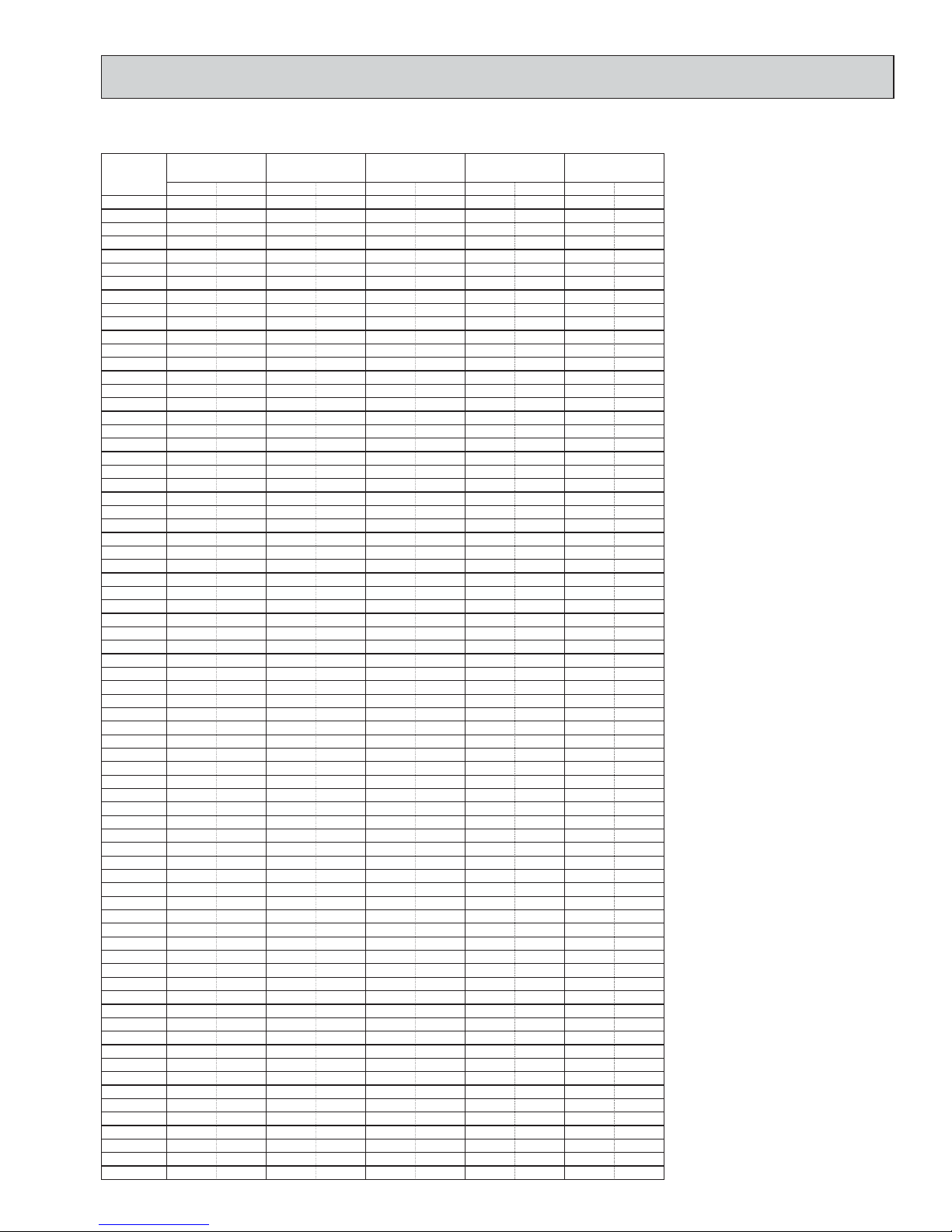

4-3. STANDARD CAPACITY DIAGRAM

OCH502C

PUMY-P60NKMU PUMY-P60NKMU-BS

Total capacity

of indoor units

Capacity

(Btu/h)

Cooling Heating Cooling Heating Cooling Heating Cooling Heating Cooling Heating

6 6000 7000 0.71 1.06 8.45 1.94 3.1 4.6 3.4 5.1

7 7000 8100 0.82 1.15 8.56 2.06 3.6 5.1 4.0 5.6

8 8000 9200 0.92 1.24 8.67 2.18 4.0 5.4 4.5 6.0

9 9000 10300 1.03 1.32 8.77 2.28 4.5 5.8 5.0 6.4

10 10000 11400 1.13 1.40 8.86 2.38 5.0 6.2 5.5 6.8

11 11000 12500 1.23 1.48 8.95 2.47 5.4 6.5 6.0 7.2

12 12000 13600 1.33 1.56 9.04 2.56 5.8 6.8 6.5 7.6

13 13000 14700 1.43 1.63 9.12 2.64 6.3 7.2 6.9 7.9

14 14000 15800 1.52 1.71 9.20 2.71 6.7 7.5 7.4 8.3

15 15000 16900 1.62 1.78 9.27 2.77 7.1 7.8 7.9 8.7

16 16000 18000 1.71 1.86 9.34 2.83 7.5 8.2 8.3 9.0

17 17000 19100 1.81 1.94 9.40 2.89 7.9 8.5 8.8 9.4

18 18000 20200 1.90 2.02 9.46 2.94 8.3 8.9 9.2 9.8

19 19000 21300 2.00 2.09 9.52 2.98 8.8 9.2 9.7 10.2

20 20000 22400 2.09 2.18 9.58 3.02 9.2 9.6 10.1 10.6

21 21000 23500 2.18 2.26 9.63 3.05 9.6 9.9 10.6 11.0

22 22000 24600 2.27 2.34 9.68 3.08 10.0 10.3 11.0 11.4

23 23000 25700 2.36 2.43 9.73 3.10 10.4 10.7 11.5 11.8

24 24000 26800 2.45 2.51 9.78 3.12 10.8 11.0 11.9 12.2

25 25000 27900 2.54 2.60 9.82 3.14 11.2 11.4 12.3 12.6

26 26000 29000 2.63 2.70 9.87 3.15 11.6 11.8 12.8 13.1

27 27000 30100 2.72 2.79 9.92 3.16 11.9 12.3 13.2 13.5

28 28000 31200 2.81 2.88 9.96 3.17 12.3 12.7 13.6 14.0

29 29000 32300 2.90 2.98 10.01 3.17 12.7 13.1 14.1 14.5

30 30000 33400 2.98 3.08 10.05 3.18 13.1 13.5 14.5 15.0

31 31000 34500 3.07 3.18 10.10 3.18 13.5 14.0 14.9 15.5

32 32000 35600 3.15 3.29 10.14 3.17 13.8 14.4 15.3 16.0

33 33000 36700 3.24 3.39 10.19 3.17 14.2 14.9 15.7 16.5

34 34000 37800 3.32 3.50 10.24 3.16 14.6 15.4 16.1 17.0

35 35000 38900 3.40 3.61 10.29 3.16 14.9 15.9 16.5 17.5

36 36000 40000 3.48 3.72 10.35 3.15 15.3 16.4 16.9 18.1

37 37000 41100 3.56 3.84 10.40 3.14 15.6 16.9 17.3 18.6

38 38000 42200 3.63 3.95 10.46 3.13 15.9 17.4 17.6 19.2

39 39000 43200 3.71 4.06 10.52 3.12 16.3 17.8 18.0 19.7

40 40000 44300 3.78 4.17 10.59 3.11 16.6 18.3 18.4 20.3

41 41000 45400 3.85 4.29 10.65 3.10 16.9 18.8 18.7 20.8

42 42000 46500 3.92 4.41 10.73 3.09 17.2 19.4 19.0 21.4

43 43000 47600 3.98 4.52 10.80 3.08 17.5 19.9 19.3 22.0

44 44000 48700 4.04 4.64 10.88 3.08 17.7 20.4 19.6 22.5

45 45000 49800 4.10 4.75 10.97 3.07 18.0 20.9 19.9 23.1

46 46000 50900 4.16 4.86 11.06 3.07 18.3 21.4 20.2 23.6

47 47000 52000 4.21 4.98 11.15 3.06 18.5 21.8 20.4 24.2

48 48000 53100 4.26 5.08 11.25 3.06 18.7 22.3 20.7 24.7

49 49000 54200 4.31 5.18 11.36 3.06 18.9 22.8 20.9 25.2

50 50000 55300 4.36 5.28 11.48 3.07 19.1 23.2 21.2 25.7

51 51000 56400 4.40 5.38 11.59 3.07 19.3 23.6 21.4 26.1

52 52000 57500 4.44 5.46 11.72 3.08 19.5 24.0 21.6 26.5

53 53000 58600 4.47 5.55 11.86 3.10 19.6 24.4 21.7 26.9

54 54000 59700 4.50 5.62 12.00 3.11 19.8 24.7 21.9 27.3

55 55000 60800 4.53 5.69 12.14 3.13 19.9 25.0 22.0 27.6

56 56000 61900 4.55 5.75 12.30 3.15 20.0 25.2 22.1 27.9

57 57000 63000 4.57 5.80 12.47 3.18 20.1 25.5 22.2 28.2

58 58000 64100 4.59 5.84 12.64 3.21 20.2 25.7 22.3 28.4

59 59000 65200 4.60 5.87 12.82 3.25 20.2 25.8 22.3 28.5

60 60000 66000 4.60 5.95 13.04 3.25 20.2 26.1 22.3 28.9

61 60200 66200 4.61 5.90 13.05 3.29 20.2 25.9 22.4 28.6

62 60400 66400 4.61 5.90 13.09 3.30 20.2 25.9 22.4 28.6

63 60600 66600 4.61 5.90 13.13 3.31 20.2 25.9 22.4 28.7

64 60800 66800 4.62 5.90 13.17 3.31 20.3 25.9 22.4 28.7

65 61000 67000 4.62 5.91 13.21 3.32 20.3 25.9 22.4 28.7

66 61200 67200 4.62 5.91 13.26 3.33 20.3 26.0 22.4 28.7

67 61400 67400 4.62 5.91 13.30 3.34 20.3 26.0 22.4 28.7

68 61600 67600 4.62 5.91 13.34 3.35 20.3 26.0 22.4 28.7

69 61800 67800 4.62 5.91 13.38 3.36 20.3 26.0 22.4 28.7

70 62000 68000 4.62 5.91 13.42 3.37 20.3 26.0 22.4 28.7

71 62200 68200 4.62 5.91 13.47 3.38 20.3 26.0 22.4 28.7

72 62400 68400 4.62 5.91 13.51 3.39 20.3 26.0 22.4 28.7

73 62600 68600 4.62 5.91 13.56 3.40 20.3 26.0 22.4 28.7

74 62800 68800 4.62 5.91 13.60 3.41 20.3 26.0 22.4 28.7

75 63000 69000 4.62 5.91 13.64 3.42 20.3 26.0 22.4 28.7

76 63200 69200 4.62 5.91 13.69 3.43 20.3 26.0 22.4 28.7

77 63400 69400 4.62 5.91 13.74 3.44 20.3 26.0 22.4 28.7

78 63600 69600 4.61 5.91 13.78 3.45 20.2 25.9 22.4 28.7

Power consumption

(kW)

EER / COP

Current (A) / 230V Current (A) / 208V

13

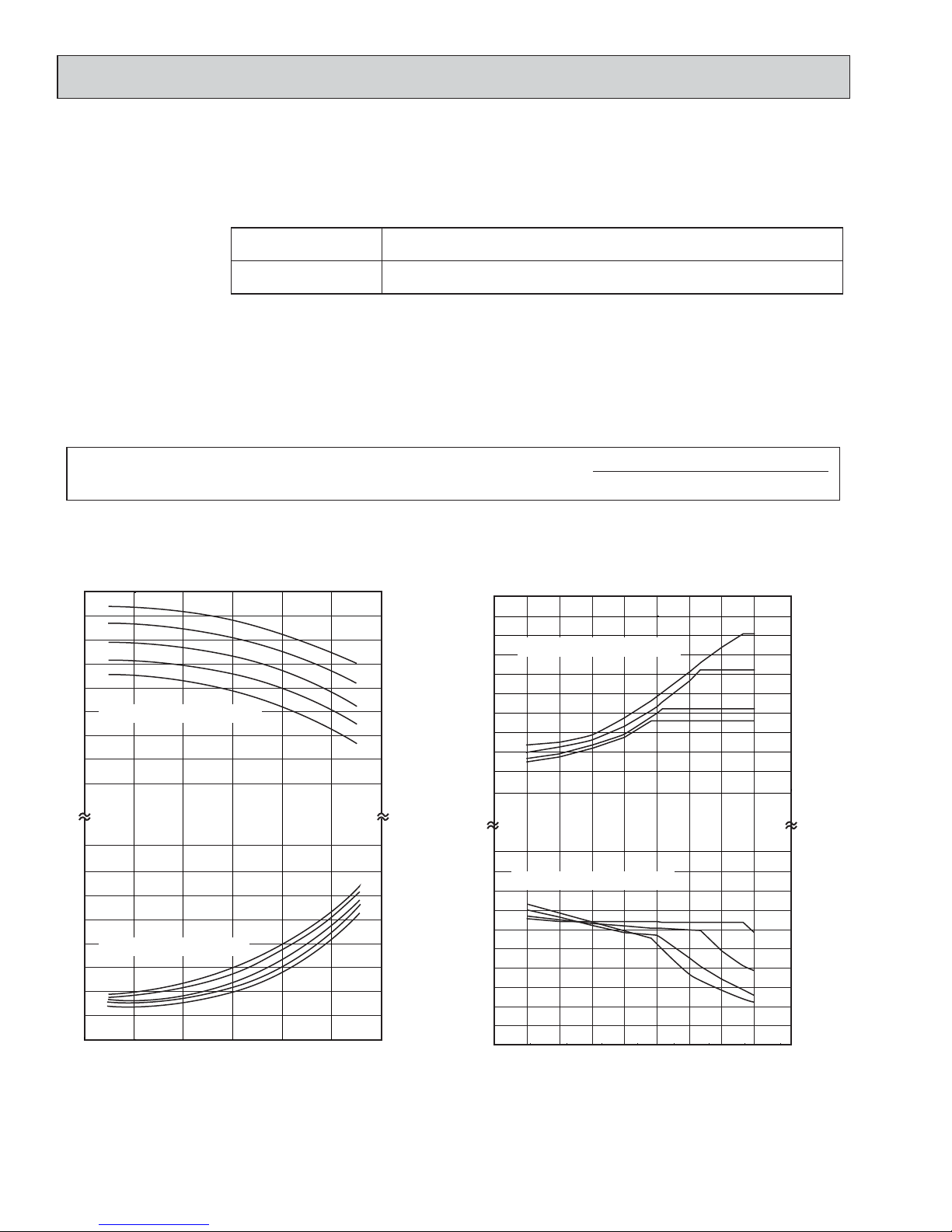

4-4. CORRECTING COOLING AND HEATING CAPACITY

OCH502C

4-4-1. Correcting changes in air conditions

(1) The performance curve charts (Figure 1, 2) show the ratio by the temperature condition change when the rated capacity (total

capacity) and the rated input are presumed 1, under standard length (7.6 m [25 ft]) and standard temperature condition.

• Standard conditions:

Rated cooling capacity

Rated heating capacity

• Use the rated capacity and rated input given in “4-2.”.

• The input is the single value on the side of the outdoor unit; the input on the sides of each indoor unit must be added to

obtain the total input.

(2) The capacity of each indoor unit may be obtained by multiplying the total capacity obtained in (1) by the ratio between the

individual capacity at the rated time and the total capacity at the rated time.

Indoor D.B. 26.7°C / W.B. 19.4°C [D.B.80°F / W.B.67°F]

Outdoor D.B. 35°C [D.B.95°F]

Indoor D.B. 21.1°C [D.B.70°F]

Outdoor D.B. 8.3°C / W.B. 6.1°C [D.B.47°F / W.B.43°F]

Individual capacity under stated conditions = total capacity under the stated conditions o

(3) Capacity correction coefficient curve

Figure 1 Cooling performance curve

1.4

1.3

1.2

1.1

1.0

0.9

Ratio of cooling capacity

0.8

0.7

0.6

1.4

1.3

1.2

1.1

1.0

0.9

0.8

0.7

0.6

Ratio of power input

-10 0 10 20 30 40 50

14 32 50 68 86 104 122

OUTDOOR

:WB (°FWB)

24 (75.2)

22 (71.6)

20 (68)

18 (64.4)

16 (60.8)

INDOOR

:WB(°FWB)

24 (75.2)

22 (71.6)

20 (68)

18 (64.4)

16 (60.8)

INDOOR

[°CDB]

[°FDB]

Figure 2 Heating performance curve

1.4

1.3

1.2

1.1

1.0

0.9

0.8

0.7

0.6

0.5

0.4

1.4

1.3

1.2

1.1

1.0

0.9

0.8

0.7

0.6

0.5

0.4

Ratio of heating capacity

Ratio of power input

-25 -20 -15 -10 -5 0 1510520

-13 -4 5 14 23 32 595041 68

individual capacity at the rated time

total capacity at the rated time

:DB (°FDB)

15 (59)

21.1 (70)

25 (77)

27.2 (81)

INDOOR

:DB(°FDB)

15 (59)

21.1 (70)

25 (77)

27.2 (81)

INDOOR

[°CWB]

[°FWB]

OUTDOOR

14

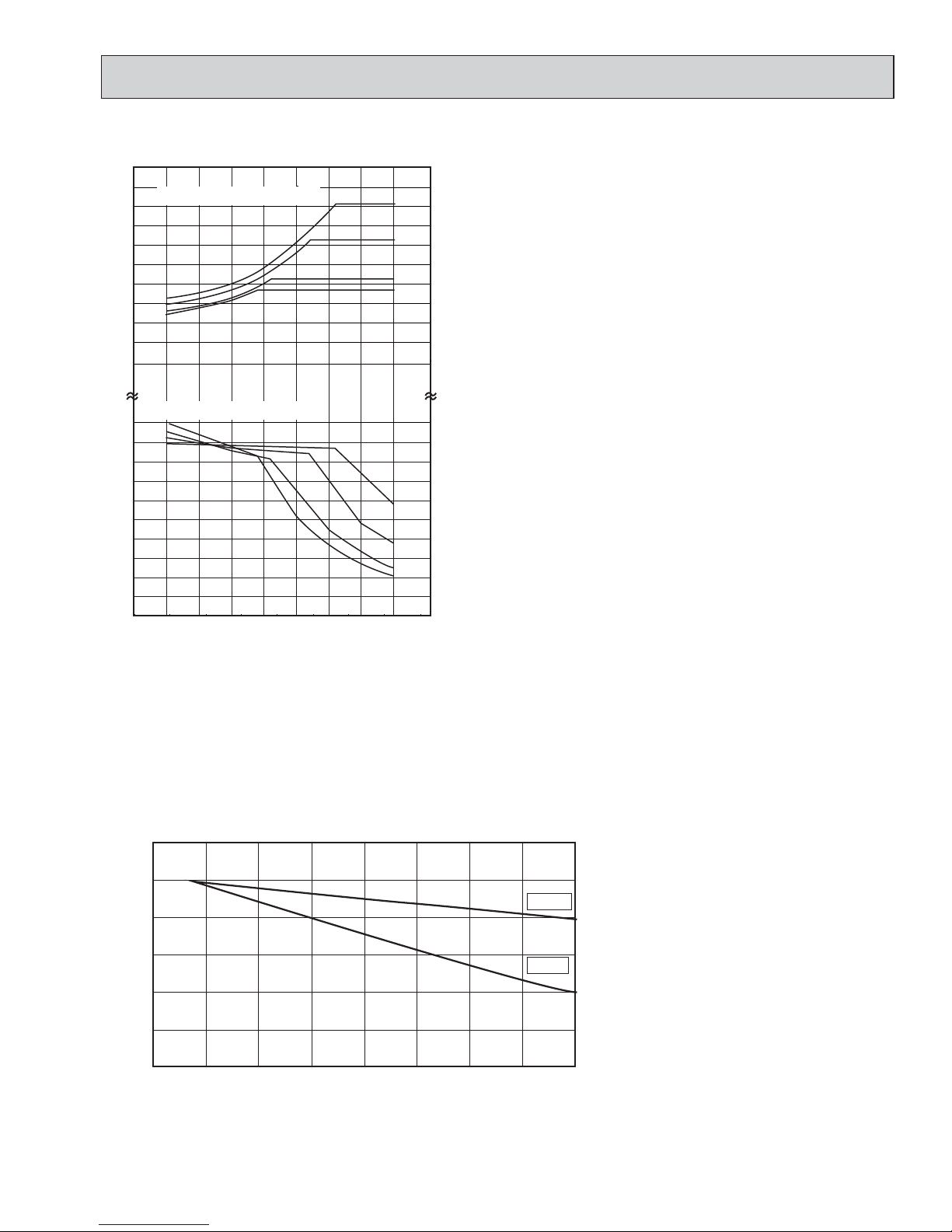

Figure 3 High heating performance curve

OCH502C

1.4

1.3

1.2

1.1

1.0

0.9

0.8

0.7

0.6

0.5

0.4

Ratio of heating capacity

:DB (°FDB)

15 (59)

21.1 (70)

25 (77)

27.2 (81)

INDOOR

1.4

1.3

1.2

1.1

1.0

0.9

0.8

0.7

0.6

0.5

0.4

-25 -20 -15 -10 -5 0 1510520

-13 -4 5 14 23 32 595041 68

OUTDOOR

:DB (°FDB)

15 (59)

21.1 (70)

25 (77)

27.2 (81)

INDOOR

[°CWB]

[°FWB]

4-4-2. Correcting capacity for changes in the length of refrigerant piping

(1) During cooling, obtain the ratio (and the equivalent piping length) of the outdoor units rated capacity and the total in-use

indoor capacity, and find the capacity ratio corresponding to the standard piping length from Figure 3. Then multiply by

the cooling capacity from Figure 1 to obtain the actual capacity.

(2) During heating, find the equivalent piping length, and find the capacity ratio corresponding to standard piping length from

Figure 3. Then multiply by the heating capacity from Figure 2 to obtain the actual capacity.

Figure 3 Capacity correction curve

105

Ratio of power input

100

95

90

85

Capacity ratio [%]

80

75

0 10203040506070 80 [m]

0 33 66 98 131 164 197 230 263 [ft]

Corrected pipe length

• Method for obtaining the equivalent piping length

Equivalent length for type P60 = (length of piping to farthest indoor unit) + (0.3 o number of bends in the piping) (m)

Length of piping to farthest indoor unit: 80 m [262 ft]

Heating

Cooling

15

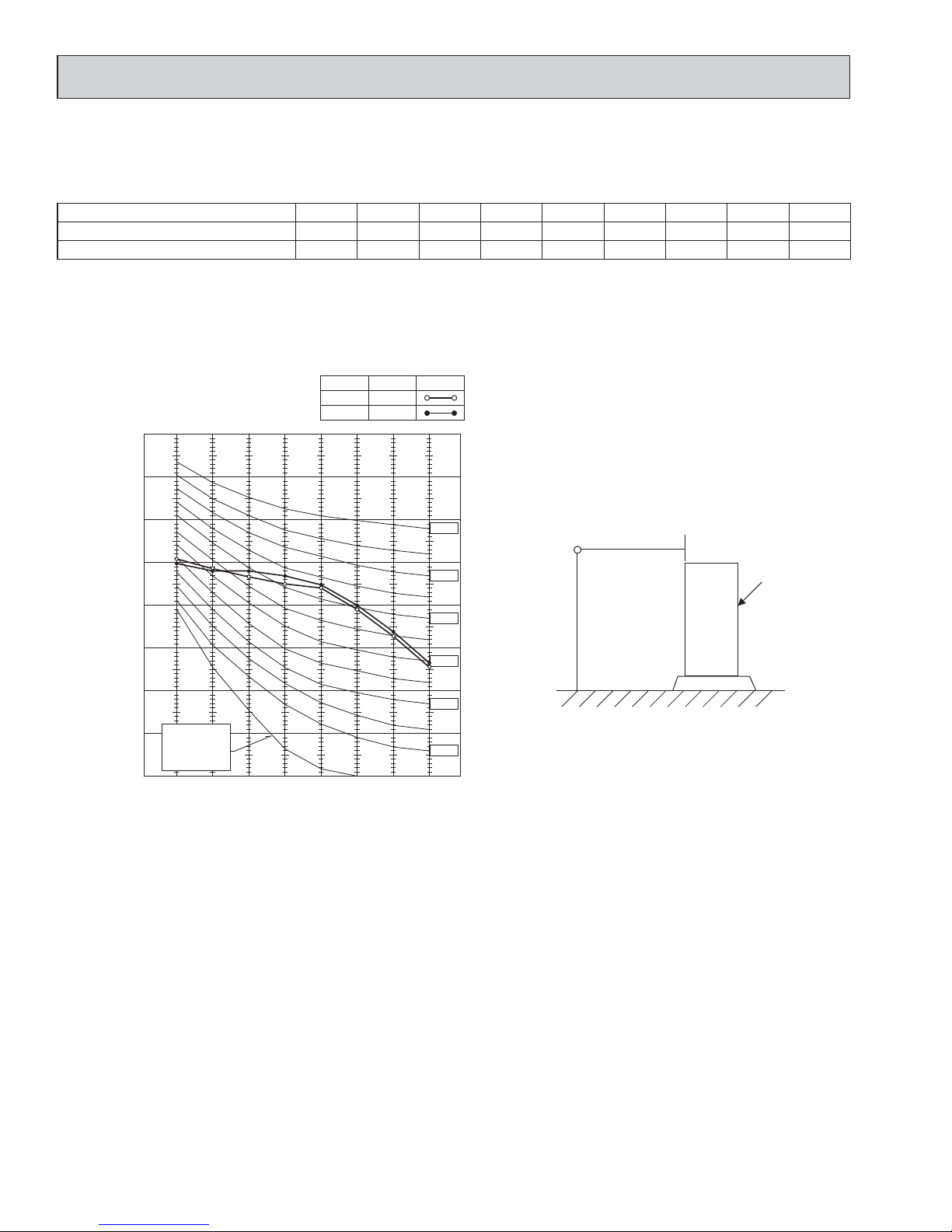

4-4-3. Correction of heating capacity for frost and defrosting

1.5m

[4.9 ft]

1m [3.3 ft]

MICROPHONE

UNIT

GROUND

OCH502C

If heating capacity has been reduced due to frost formation or defrosting, multiply the capacity by the appropriate correction

factor from the following table to obtain the actual heating capacity.

Correction factor diagram

Outdoor Intake temperature (W.B.°F)

Outdoor Intake temperature (W.B.°C)

Correction factor

43 39 36 32 28 25 21 18 14

6420-2-4-6-8-10

1.0 0.98 0.89 0.88 0.89 0.9 0.95 0.95 0.95

4-5. NOISE CRITERION CURVES

SPL(dB)

PUMY-P60NKMU

PUMY-P60NKMU-BS

90

80

MODE

COOLING

HEATING

LINE

58

59

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 μbar)

70

60

50

40

30

APPROXIMATE

20

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

10

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

16

5

OCH502C

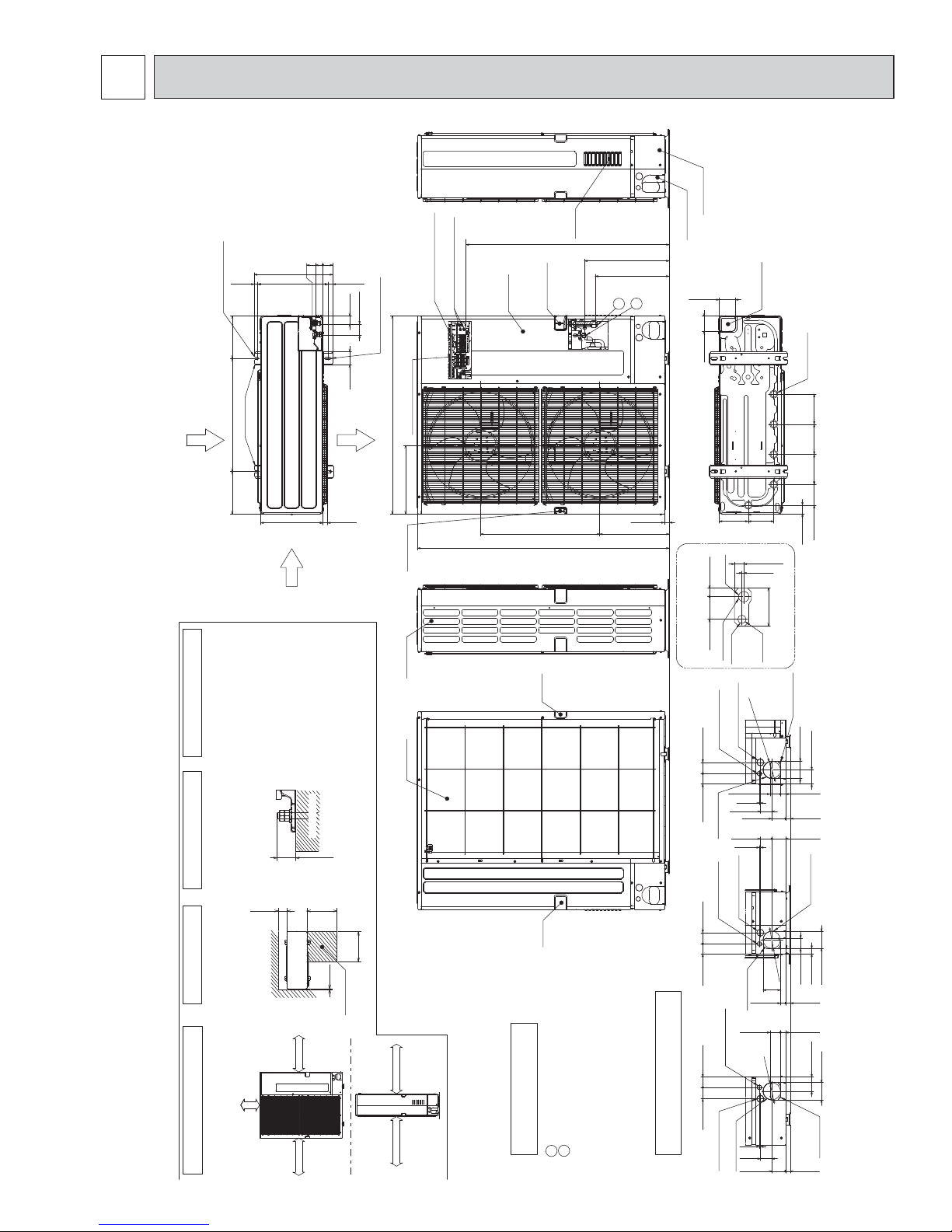

OUTLINES AND DIMENSIONS

PUMY-P60NKMU

PUMY-P60NKMU-BS

2-U Shaped notched holes

(Foundation Bolt M10<W3/8>)

225

<8-27/32>

Rear Air Intake

600<23-5/8>

Installation Feet

225

<8-27/32>

4 PIPING-WIRING DIRECTIONS

Piping and wiring connections

can be made from 4 directions:

FRONT, Right, Rear and Below.

Side Air Intake

56<2-7/32>

40<1-9/16>

417<16-13/32>

330<13>

0

53<2-3/32>

42

70

<1-21/32>

61<2-13/32>

<2-3/4>

25<31/32>

28<1-3/32> 19<3/4>370<14-9/16>

Terminal connection

LeftFor the power supply

2-12×36 Oval holes

(Foundation Bolt M10<W3/8>)

Air Discharge

Ground for the power supply

("GR"marking position)

1050<41-11/32>

362<14-1/4>

Handle for moving

Side Air IntakeRear Air Intake

CenterFor the transmission line

RightFor concentration control

Ground for the transmission line

Ground for concentration control

( )

Service panel

Handle for moving

632<24-7/8>

Handle for

moving

1338<52-11/16>

Air intake

1079<42-15/32>

Unit : mm <inch>

Rear piping cover

Front piping cover

+

1ޓ450<17-23/32>

+

1ޓ393<15-15/32>

2

1

26<1-1/32>

369<14-17/32>

86<3-3/8>

81<3-3/16>

<6-1/16>

154

22.5<7/8>

3/4 Conduit

attachment

When installing the conduit.

Set the attachment to the

inner side of each panel.

60<2-3/8>

27.8<1-3/32>

22.2<7/8>

:

:

92

:

37<1-15/32>Knockout)

24<15/16>Knockout)

:

:

Conduit hole

(

Conduit hole

(

60<2-3/8>

Bottom piping hole

(Knockout)

<5-11/32>

136

24.7<31/32>

5<3/16>

100

Scale 1:5

<3-15/16>

1/2 Conduit

attachment

Rear piping hole

(Knockout)

<3-5/8>

33<1-5/16>)

:

Drain hole

㧔5-

160

<6-5/16>

160

<6-5/16>

160

<6-5/16>

110<4-11/32>

45<1-25/32>

92<3-5/8>

75<2-15/16>

<Foundation bolt height>

3 FOUNDATION BOLTS

Please secure the unit firmly

with 4 foundation (M10<W3/8>) bolts.

(Bolts and washers must be

purchased locally.)

<5-29/32>

150

Min.

2 SERVICE SPACE

Dimensions of space needed

for service access are

shown in the below diagram.

Min. 10mm<3/8>Min. 10mm<3/8>

FREE

1 FREE SPACE (Around the unit)

The diagram below shows a basic example.

Explantion of particular details are

given in the installation manuals etc.

FOUNDATION

30<1-3/16>

Max.

<19-11/16>

500

Min.

Min.

10<3/8>

Min.

500

<19-11/16>

Service space

Min. 1000mm<39-3/8> Min. 150mm<5-29/32>

1717

Handle for

moving

Example of Notes

2

1

ޓޓRefrigerant GAS pipe connection (FLARE):19.05㧔3/4F)

ޓޓRefrigerant LIQUID pipe connection (FLARE): 9.52㧔3/8F㧕

+㧝Indication of STOP VALVE connection location.

55<2-3/16>27<1-1/16>

55<2-3/16>

53<2-3/32> 60<2-3/8>

55<2-3/16>

60<2-3/8>

Piping Knockout Hole Details

5<3/16>

60<2-3/8>

Rear trunking hole

(Knockout)

5<3/16>

24<15/16>Knockout)

37<1-15/32>Knockout)

:

:

Conduit hole

(

Conduit hole

(

Right piping hole

(Knockout)

:24<15/16>Knockout)

Conduit hole

(

5

37<1-15/32>Knockout)

60

:

Conduit hole

(

Front trunking hole

(Knockout)

<3/16>

<2-3/8>

92

:

73<2-7/8>

73<2-7/8>

92

:

92

27<1-1/16>

<3-5/8>

<3-5/8>

<3-5/8>

26<1-1/32>

73<2-7/8> 60<2-3/8>

Right trunking hole

(Knockout)

29<1-5/32>

55<2-3/16>

92<3-5/8>

26<1-1/32>

27<1-1/16> 55<2-3/16>

75<2-15/16>

92<3-5/8>

Front piping hole

(Knockout)

26<1-1/32>

6

OCH502C

WIRING DIAGRAM

PUMY-P60NKMU

PUMY-P60NKMU-BS

MULTI.B.

17

MF1

MS

~

3

MF2

17

MS

~

3

52C

(

BLK

31313

TB3

2

RED

M1

M2

RED

S

TO INDOOR UNIT

CONNECTING WIRES

DC 30V(Non-polar)

TB7

2

YLW

M1

M2

YLW

S

FOR CENTRALIZED

CONTROL

DC 30V(Non-polar)

POWER SUPPLY

~

/N

AC208/230V 60Hz

X505

CN4

(WHT)

12

2

2

CN3N

(BLU)

1

CNS1

(RED)

13

BLK

LEV-A LEV-B

MM

6

6

1

CNLVB

CNLVA

(RED)

(WHT)

2

22

3

5

1

CN51

(WHT)

CNS2

CN41

(YLW)

(WHT)

1214 1441

CN52C

(RED)

3117

52C

52C

E4

E I

N I L I

BLK

* MODEL SELECT 1:ON 0:OFF

PUMY-P60NKMU(-BS)

The black square ( ) indicates

a switch position.

SWU2 SWU1

CN40

(WHT)

M-P.B.

MODEL

SW5

SW4

*

LED1

CN102

(WHT)

41

CN2

(WHT)

CN1

(WHT)

P. B .

BLK

E3

(RED)

CNAC2

1

3

BLK

E2

1

3

(WHT)

CNAC1

1234561

011000020

SW6

SW2?SW8SW1

SW7SW3

LED2

41

TP1

(BLK)

135

2

2

2

SW4 SW8

63HS63LS

TH7 TH6 TH3 TH4 TH2

t° t° t° t° t°

CNF1

(WHT)

CNF2

(WHT)

3

1

2

CNDC

(PNK)

X504

21S4

)

(

GRN

)

(

1

21S4

WHT

CB

RED

TB1

RED

L1

BLU

L2

GRN/YLW

GR

141

3121212

63HS

TH7/6

TH3

(

SV1

WHT

SV1

12

(WHT)

WHT

CN4

U

X502

)

2

RED

WHT

(RED)

63H

(YLW)

1

3

71

X501

SS

(

WHT

)

131

7

TH8

t°

SV2

BLU

X503

)

W

(WHT)

13

63LS

(BLU)

TRANS

(

2

WVU

BLK

V

MS

3~

MC

63H

CN3D

CN3S

(WHT)

TH2

BLK

)

12

CNAC

(RED

2

N2

WHT

DCL

(RED)

131313

CN52C

(RED)

13

3

LED3

)

CNDC

(PNK)

IGBT

WHT

TH4

)

(

WHT

)

(

CN2

(WHT)

7

F1

F2

CN2

(WHT)

P2

DCL2 DCL1

SYMBOL NAME SYMBOL NAME SYMBOL NAME

TB1 Terminal Block <Power Supply

TB3 Terminal Block <Comunication Line

TB7 Terminal Block <

MC Motor For Compressor

MF1,MF2 Fan Motor

21S4 Solenoid Valve <Four-Way Valve

63H High Pressure Switch

High Pressure Sensor

63HS

63LS Low Pressure Sensor

SV1 Solenoid Valve <Bypass Valve

TH2

Thermistor <HIC Pipe

TH3

Thermistor <Outdoor Pipe

TH4 Thermistor <Compressor

TH6 Thermistor <Low Pressure Saturated

TH7

Thermistor <Outdoor

Thermistor <Heat Sink

TH8

Electronic Expansion Valve

LEV-A,LEV-B

Cautions when servicing

!

• WARNING: When the main supply is turned off, the voltage [340 V] in the main capacitor will drop to 20 V in approx. 2

minutes (input voltage: 230 V). When servicing, make sure that LED1, LED2 on the outdoor circuit board goes out, and then

wait for at least 1 minute.

• Components other than the outdoor board may be faulty: Check and take corrective action, referring to the service manual.

Do not replace the outdoor board without checking.

NOTES:

1.Refer to the wiring diagrams of the indoor units for details on wiring of each indoor unit.

Self-diagnosis function

The indoor and outdoor units can be diagnosed automatically using the self-diagnosis switch

(SW1) and LED1, LED2 (LED indication) found on the multi-controller of the outdoor unit.

LED indication : Set all contacts of SW1 to OFF.

• During normal operation

• The LED indicates the drive state of the controller in the outdoor unit.

Bit

Compressor

Indication

operated

• When fault requiring inspection has occurred

The LED alternately indicates the inspection code and the location of the unit in which

the fault has occurred.

>

Centralized Control Line

>

>

>

>

>

>

>

1

2

52C321S44SV15(SV2)

Reactor

DCL

>

CB Main Smoothing Capacitor

>

P.B. Power Circuit Board

Connection Terminal <U/V/W-Phase

TABU/V/W

TABLI/NI

Connection Terminal <L/N-Phase

Connection Terminal <DC Voltage

TABP2

Connection Terminal <DC Voltage

TABN2

Connection Terminal <Reactor

DCL1,DCL2

Power Module

IGBT

Connection Terminal <Ground

EI,E2,E3,E4

MULTI.B.

Controller Circuit Board

SW1

Switch <Display Selection

SW2

Switch <Function Selection

SW3

SW4

SW5

SW6

Switch <Test Run

Switch <Model Selection

Switch <Function Selection

Switch <Function Selection

>

18

SW7

SW8

SWU1

>

SWU2

SS

>

>

CN3D

>

CN3S

>

CN3N

CN51

>

LED1,LED2

>

>

>

>

>

>

LED3

F1,F2

X501

M-P.B.

TP1

~

505

678

Always lit

Switch <Function Selection

Switch <Model Selection

Switch <Unit Address Selection, 1st digit

Switch <Unit Address Selection, 2nd digit>

Connector <Connection For Option

Connector <Connection For Option

Connector <Connection For Option

Connector <Connection For Option

Connector <Connection For Option

LED <Operation Inspection Display

LED <Power Supply to Main Microcomputer>

Fuse <T6. 3AL250V

Relay

M-NET Power Circuit Board

ConnectionTerminal <Ground>

[Example]

When the compressor and

SV1 are turned during cooling

operation.

12345678

>

>

>

>

>

>

>

>

>

>

7

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

051

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

056

001

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

010

101

1

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

002

102 104 154

1111

11

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

009

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

008

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

003

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

007

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

006

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

004

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

005

A transmission wire must be

connected to each refrigerant

system (outdoor and indoor).

Set addresses:

Outdoor unit ..............051-100

Indoor unit .................001-050

Remote controller .....101-200

PUMY has no 100ths digit switch.

The address automatically become

"100" if it is set as "01~50".

Remote

controller

Remote

controller

Remote

controller

Remote

controller

105

Remote

controller

157

Remote

controller

107

Remote

controller

For centralized

management

For remote

controller

Address SW Address SW Address SW Address SW Address SW

Piping

Outdoor unit

Outdoor unit

Indoor unit Indoor unit Indoor unit Indoor unit Indoor unit

Indoor unitIndoor unitIndoor unitIndoor unitIndoor unit

Address SW Address SW Address SW Address SW Address SW

Address SWAddress SWAddress SWAddress SWAddress SW

Address SWAddress SW

For centralized

management

For remote

controller

Transmission wire

OCH502C

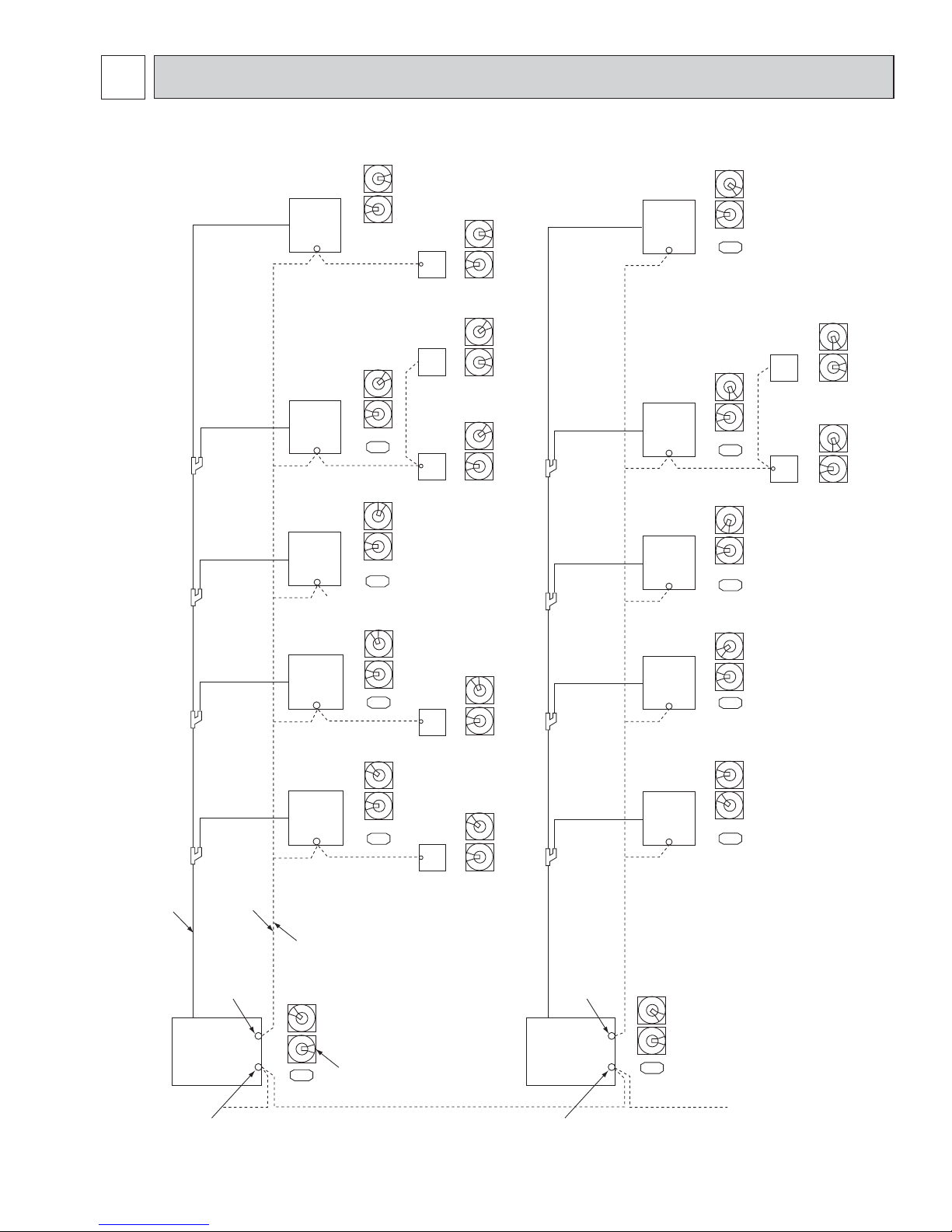

NECESSARY CONDITIONS FOR SYSTEM CONSTRUCTION

7-1. TRANSMISSION SYSTEM SETUP

19

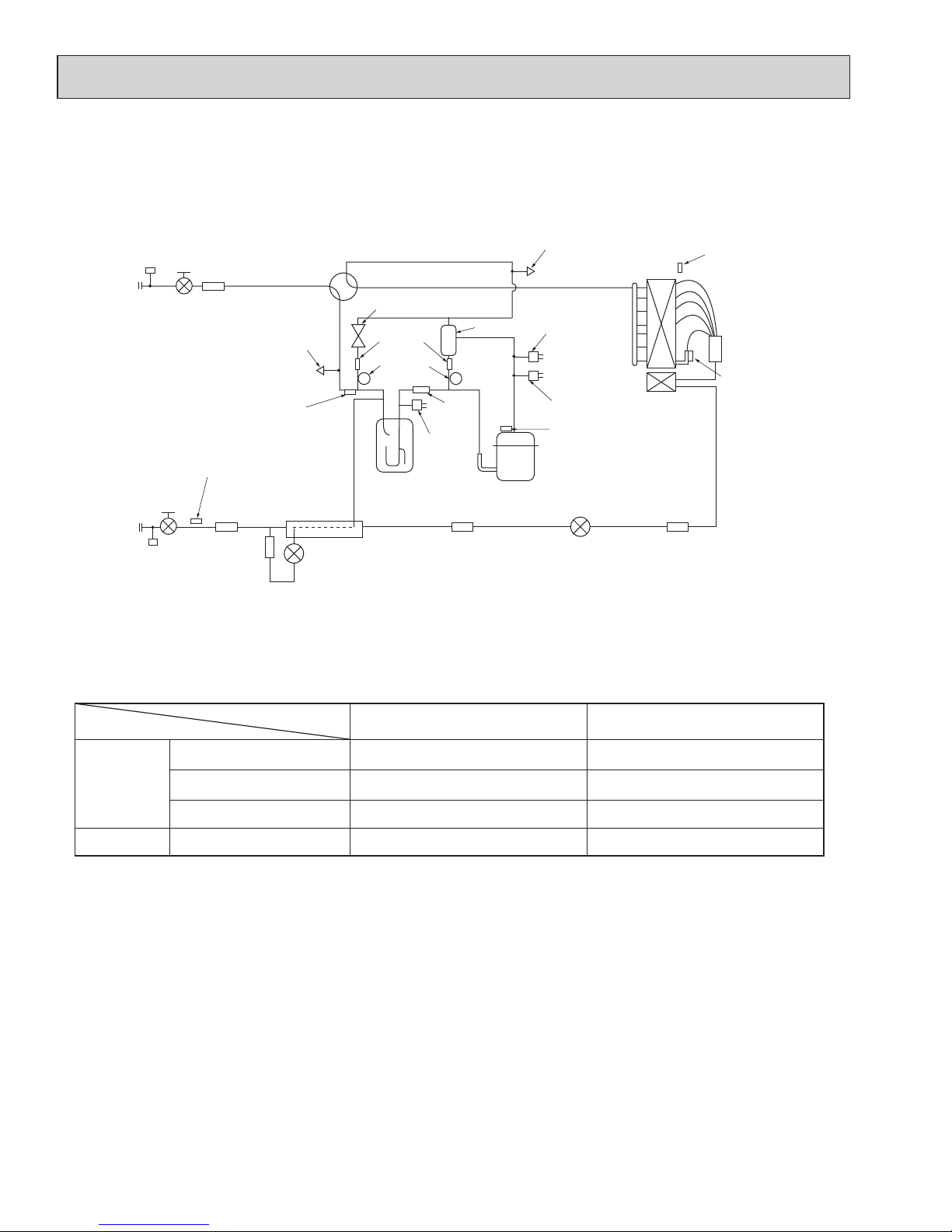

7-2. REFRIGERANT SYSTEM DIAGRAM

Refrigerant

Gas pipe

<3/4>

Refrigerant

Liquid pipe

<3/8>

Accumulator

Thermistor (TH6)

(Saturation temperature

of suction pressure)

Solenoid

valve (SV1)

Check valve

(High pressure)

Check valve

(Low pressure)

High pressure

sensor (63HS)

High pressure

switch (63H)

Low pressure

sensor (63LS)

Thermistor (TH7)

(Outdoor temperature)

(Pipe temperature)

Thermistor (TH4)

Thermistor (TH3)

Oil separator

Service port

Service

port

4-way valve

Strainer

Strainer

Capillary

tube

Strainer

Strainer

Ball valve

Stop valve

Distributor

Strainer Strainer

Compressor

Strainer

Refrigerant piping specifications <dimensions of flared connector>

Capillary tube for oil separator : :2.5 % :0.8 % L800

Capillary tube for solenoid valve : :4.0 % :3.0 % L500

Capacity

Item

Liquid piping

Gas piping

P06, P08, P12, P15, P18

P24, P30, P36, P48, P54

P60

Indoor unit

Outdoor unit

:6.35 <1/4>

:9.52 <3/8>

:9.52 <3/8>

:12.7 <1/2>

:15.88 <5/8>

:19.05 <3/4>

P72 :9.52 <3/8> :19.05 <3/4>

Thermistor (TH2)

(HIC)

(

Compressor

)

HIC

LEV-B

LEV-A

OCH502C

PUMY-P60NKMU

PUMY-P60NKMU-BS

Unit: mm <inch>

20

7-3. SYSTEM CONTROL

TB5

TB15

01

101

RC

(Main)

151

IC

TB3

TB7

51

OC

TB5

TB15

02

IC

RC

(Sub)

102

RC

(Main)

152

RC

(Sub)

12

M1M2

S

M1M2

S

M1M2

S

12

M1M2

S

AB AB AB AB

TB5

12

TB15

01

101

IC

AB

M1 M2

TB3

S

TB7

51

OC

L

1

L3

L2

TB5

TB15

02

IC

102

RC

l1

l2

M1 M2

S

M1 M2

S

12

M1 M2

S

AB

OCH502C

Example for the System

• Example for wiring control cables, wiring method and address setting, permissible lengths, and the prohibited items are listed

in the standard system with detailed explanation.

The explanation for the system in this section : Use 1 single outdoor unit and multiple outdoor units for M-NET remote control

system.

Use 1 single outdoor unit and multiple indoor units in the multiple outdoor

units for the M-NET remote control system.

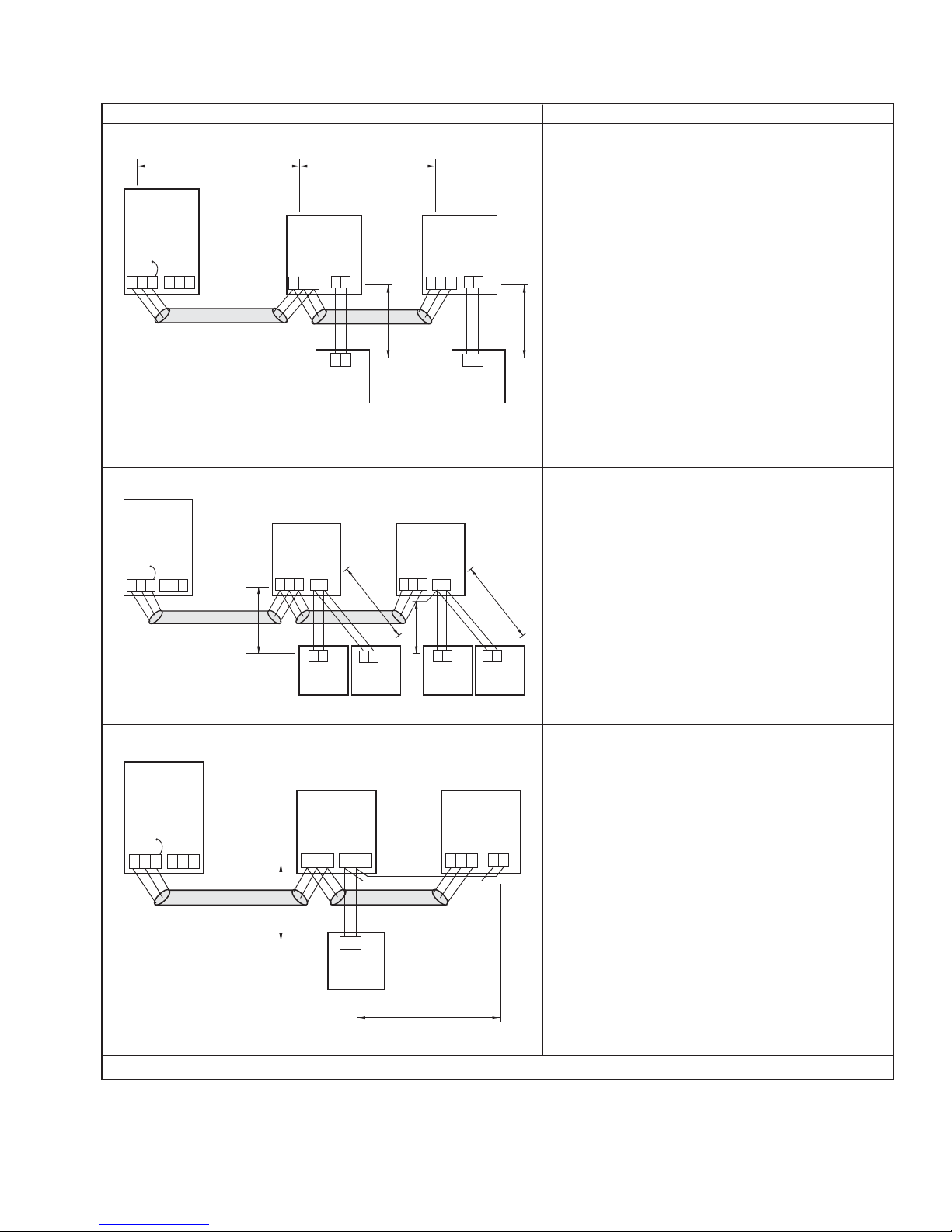

A. Example of a M-NET remote controller system (address setting is necessary.)

Example of wiring control cables Wiring Method and Address Setting

1. Standard operation

• 1 remote controller for each

indoor unit.

• There is no need for setting

the 100 position on the remote

controller.

2. Operation using 2 remote controllers

• Using 2 remote controllers

for each indoor unit.

a. Use feed wiring to connect terminals M1 and M2 on

transmission cable block (TB3) for the outdoor unit

(OC) to terminals M1 and M2 on the transmission

cable block (TB5) of each indoor unit (IC). Use nonpolarized 2 wire.

b. Connect terminals M1 and M2 on transmission cable

terminal block (TB5) for each indoor unit with the

terminal block (TB6) for the remote controller (RC).

c. Set the address setting switch (on outdoor unit P.C.B)

as shown below.

Unit

Indoor unit (IC)

Outdoor unit

(OC)

Remote

controller (RC)

Range

001 to 050

051 to 100

101 to 150

Setting Method

—

Use the smallest

address of all the indoor

unit plus 50.

Indoor unit address plus

100.

a. Same as above.

b. Same as above.

c. Set address switch (on outdoor unit P.C.B) as

shown below.

Unit

Indoor Unit (IC)

Outdoor unit

(OC)

Main Remote

Controller (RC)

Sub Remote

Controller (RC)

Range

001 to 050

051 to 100

101 to 150

151 to 200

Setting Method

—

Use the smallest

address of all the indoor

units plus 50.

Indoor unit address plus

100.

Indoor unit address plus

150.

3. Group operation

OC

51

101

TB5

M1 M2

AB

RC

TB3

TB7

M1 M2

S

M1 M2

S

• Multiple indoor units operated

Combinations of 1 through 3 above are possible.

together by 1 remote controller

IC(Main)

01

S

TB15

12

TB5

M1 M2

IC(Sub)

02

S

21

TB15

12

a. Same as above.

b. Connect terminals M1 and M2 on transmission cable

terminal block (TB5) of the IC main unit with the most

recent address within the same indoor unit (IC) group

to terminal block (TB6) on the remote controller.

c. Set the address setting switch (on outdoor unit P.C.B)

as shown below.

Unit

IC (Main)

IC (Sub)

Outdoor Unit

Main Remote

Controller

Sub Remote

Controller

Range

001 to 050

001 to 050

051 to 100

101 to 150

151 to 200

Use the smallest address within the

same group of indoor units.

Use an address, other than that of

the IC (Main) from among the units

within the same group of indoor

units. This must be in sequence with

the IC (Main).

Use the smallest address of all the

indoor units plus 50.

Set at an IC (Main) address within

the same group plus 100.

Set at an IC (Main) address within

the same group plus 150.

Setting Method

d. Use the indoor unit (IC) within the group with the

most functions as the IC (Main) unit.

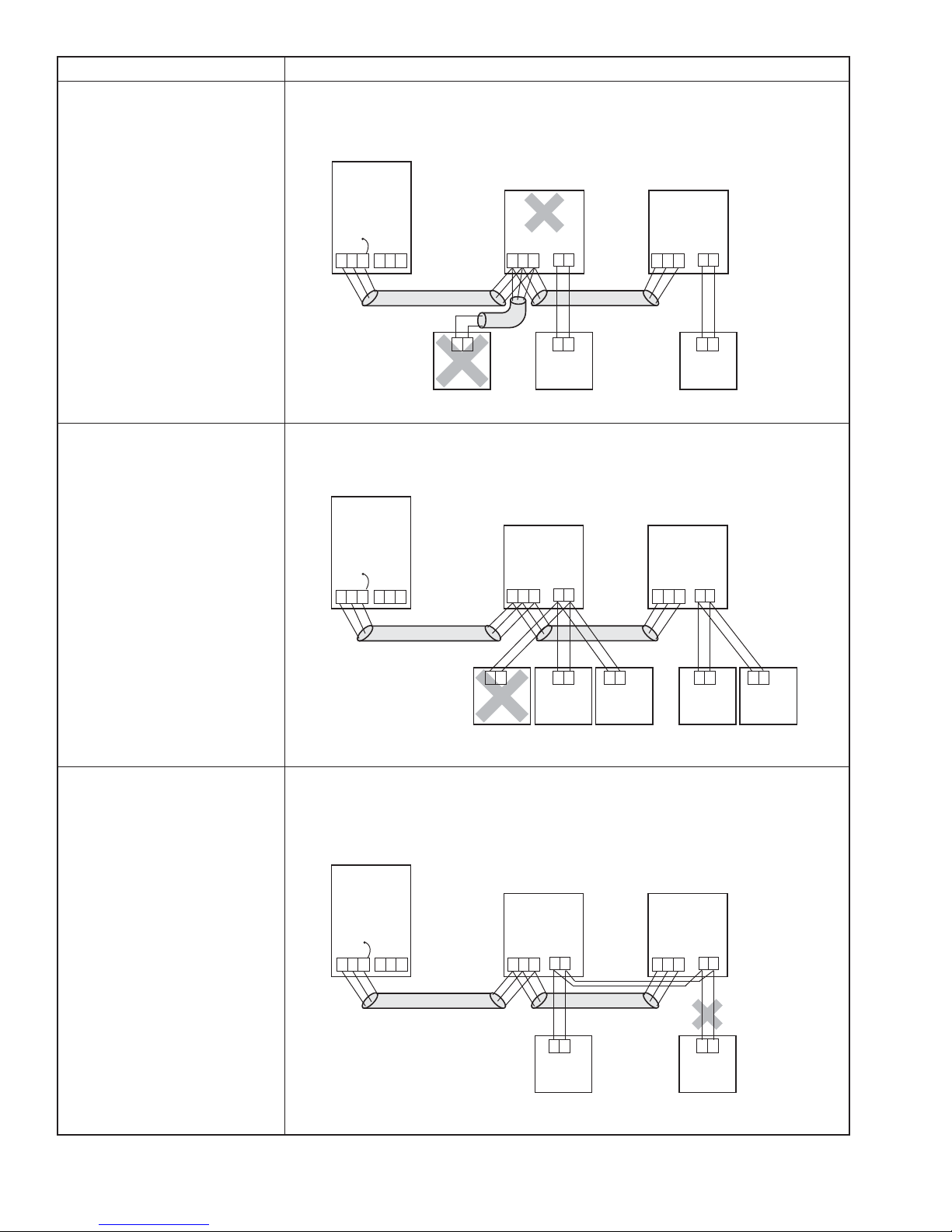

• Name, Symbol and the Maximum Remote controller Units for Connection

OCH502C

Name Symbol Maximum units for connection

Outdoor unit OC —

Indoor unit IC 1 OC unit can be connected to 1-12 IC units

M-NET remote

controller

RC

Maximum 2 RC for 1 indoor unit, Maximum 12 RC for 1 OC

Permissible Lengths Prohibited items

Longest transmission cable length

(1.25 mm² [AWG16])

L1 + L2, L2 + L3, L3 + L1 [ 200m [656ft]

Remote controller cable length

1.

If 0.5 to 1.25 mm² [AWG20 to AWG16]

R1, R2 [10m [33ft]

2. If the length exceeds 10 meters

[33ft], the exceeding section

should be 1.25 mm² [AWG16]

and that section should be a

value within the total extension

length of the transmission cable

and maximum transmission

cable length. (L

3)

Same as above

•

M-NET remote controller (RC) and MA remote controller (MA) cannot be used together.

• Do not connect anything with TB15 of indoor unit (IC).

TB3

M1 M2

TB3

M1M2

S

OC

51

S

OC

51

M1 M2

TB7

M1M2

TB7

S

S

TB5

M1M2

TB5

M1 M2

AB

101

RC

IC

01

TB15

12

S

IC

01

TB15

12

S

TB5

M1M2

TB5

M1 M2

S

02

IC

02

TB15

12

S

AB

TB15

MA

IC

• Use the indoor unit (IC)

TB15

12

address plus 150 as the

sub remote controller

address. In this case, it

should be 152.

• 3 or more remote con-

AB

101

RC

(Main)

AB AB ABAB

151

RC

(Sub)

102

RC

(Main)

103

(Sub)

RC

104

RC

troller (RC) cannot be

connected to 1 indoor

unit.

Same as above

TB3

M1 M2

S

OC

51

TB7

M1 M2

IC(Main)

01

TB5

TB15

12

M1 M2

S

S

TB5

M1 M2

IC(Sub)

02

S

TB15

12

• The remote controller

address is the indoor

unit main address plus

AB

102

RC

100. In this case, it

should be 101.

22

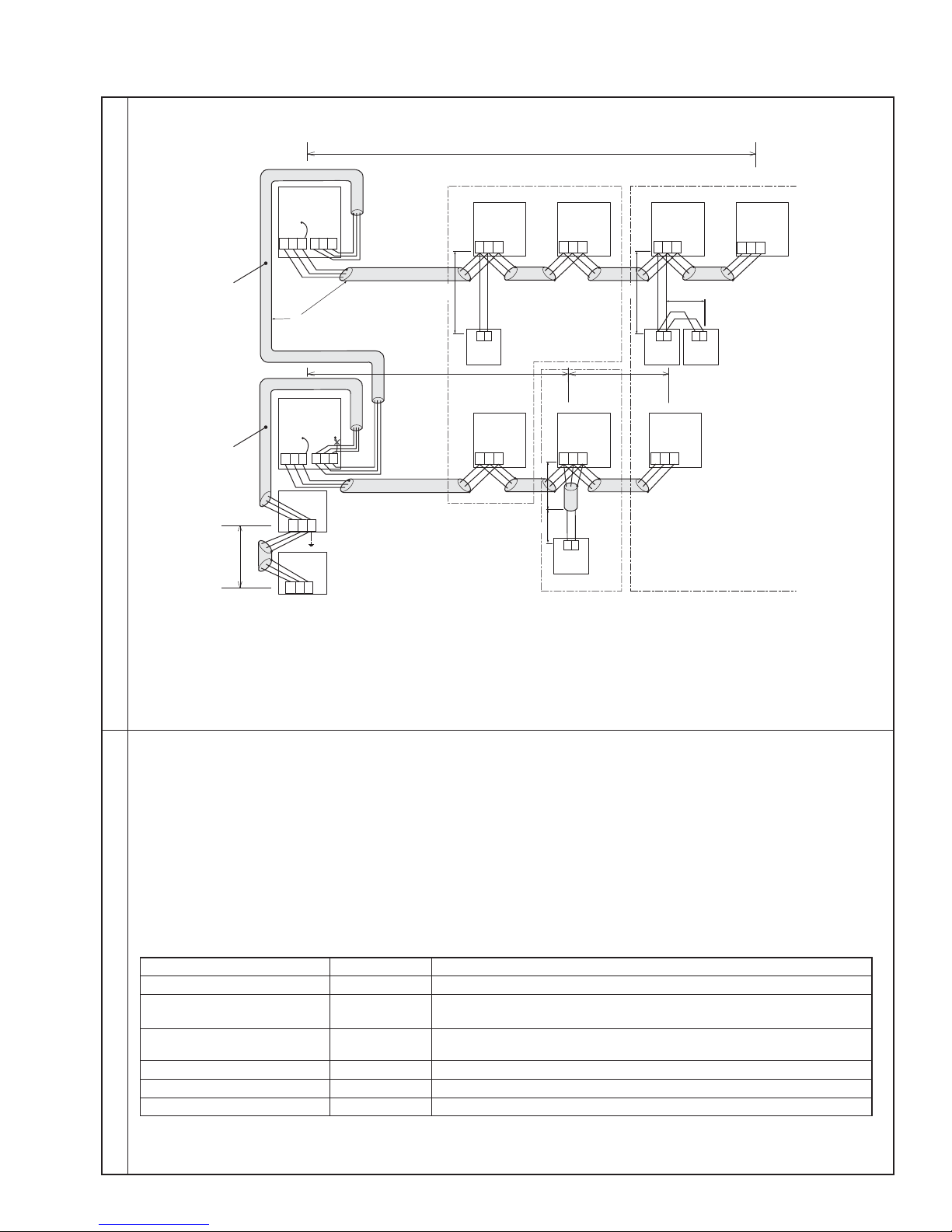

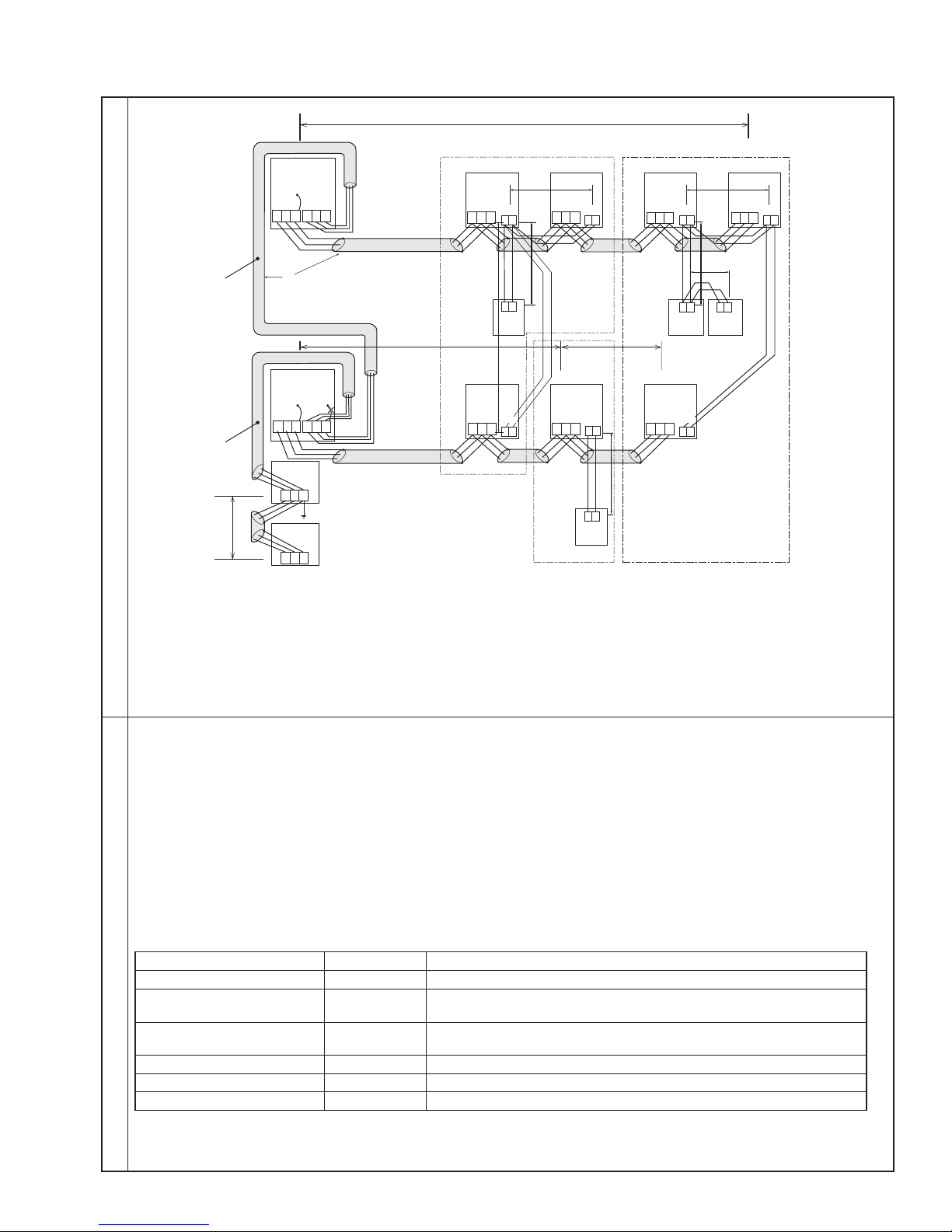

B. Example of a group operation system with 2 or more outdoor units and a M-NET remote controller.

TB7

TB3

IC

(51)

TB5

RC

(01)

IC

TB5

(03)

IC

TB5

(02)

IC

TB5

(04)

IC

TB5

(05)

IC

TB5

(07)

IC

TB5

(06)

L2

L1

(101)

RC

(105)

RC

(104)

RC

(155)

OC

TB7

(53)

OC

3

Power Supply

Unit

System

controller

L3

L6

L7

L4

L5

2

4

1

: Group

: Group

: Group

: Shielded Wire

: Sub Remote Controller

N

N

N

N

M1M2

S

M1M2

S

M1 M2

S

M1 M2

S

ABABAB

M1 M2

S

M1 M2

S

M1 M2

S

S

M1M2

S

TB3

M1M2

S

M1M2

S

AB

M1M2

M1 M2

S

M1 M2

S

OCH502C

(Address settings are necessary.)

Examples of Transmission Cable WiringWiring Method Address Settings

a. Always use shielded wire when making connections between the outdoor unit (OC) and the indoor unit (IC), as well

for all OC-OC, and IC-IC wiring intervals.

b. Use feed wiring to connect terminals M1 and M2 and the ground terminal on the transmission cable terminal block (TB3)

of each outdoor unit (OC) to terminals M1 and M2 on the terminal S on the transmission cable block of the indoor unit

(IC).

c. Connect terminals M1 and M2 on the transmission cable terminal block of the indoor unit (IC) that has the most

recent address within the same group to the terminal block on the remote controller (RC).

d. Connect together terminals M1, M2 and terminal S on the terminal block for central control (TB7) for the outdoor unit

(OC).

e. DO NOT change the jumper connector CN41 on MULTI controller board.

f. The earth processing of S terminal for the centralized control terminal block (TB7) is unnecessary. Connect the termi-

nal S on the power supply unit with the earth.

g. Set the address setting switch as follows.

Unit Range Setting Method

IC (Main) 01 to 00

IC (Sub) 01 to 50

Outdoor Unit 51 to 100

Main Remote Controller 101 to 150

Sub Remote Controller 151 to 200

MA Remote Controller —

h. The group setting operations among the multiple indoor units are done by the remote controller (RC) after the electri-

cal power has been turned on.

Use the smallest address within the same group of indoor units.

Use an address, other than the IC (Main) in the same group of indoor units.

This must be in sequence with the IC (Main).

Use the smallest address of all the indoor units plus 50.

*The address automatically becomes “100” if it is set as “01 - 50”.

Set at an IC (Main) address within the same group plus 100.

Set at an IC (Main) address within the same group plus 150.

Unnecessary address setting (Necessary main/ sub setting)

23

• Name, Symbol, and the Maximum Units for Connection

OCH502C

• Longest length via outdoor units : L1+L2+L3+L4, L1+L2+L3+L5, L1+L2+L6+L7 [ 500 meters [1450 ft] (1.25 mm² [AWG16])

• Longest transmission cable length : L

• Remote controller cable length : R

1, L3+L4, L3+L5, L6, L2+L6, L7 [ 200 meters [656 ft] (1.25 mm² [AWG16])

1,R2, R2+R3, R4 [ 10 meters [33 ft] (0.5 to 1.25 mm² [AWG20 to AWG16])

If the length exceeds 10 meters [33 ft], use a 1.25 mm² [AWG16] shielded wire. The

Permissible Length

length of this section (L

and overall length.

8) should be included in the calculation of the maximum length

Prohibited items

OC

(51)

TB7TB3

M1 M2

S

M1 M2

S

OC

(53)

TB7

TB3

M1 M2

S

Unit

M1M2

S

System

controller

M1M2

S

S

M1M2

Power Supply

: Group

: Group

: Group

: Shielded Wire

: Sub Remote Controller

( ): Address

TB5

M1 M2

TB5

M1 M2

AB

RC

(104)

(02)

(04)

IC

S

IC

S

TB5

M1 M2

(105)

RC

TB5

M1 M2

(05)

(07)

IC

S

IC

S

IC

(01)

TB5

M1 M2

S

AB AB AB

(101)

RC

IC

(03)

TB5

M1 M2

S

(155)

RC

IC

(06)

TB5

M1 M2

S

• Never connect together the terminal blocks (TB5) for transmission wires for indoor units (IC) that have been connected to

different outdoor units (OC).

• Set all addresses to ensure that they are not overlapped.

• M-NET remote controller and MA remote controller cannot be connected with the indoor unit of the same group wring

together

24

C. Example of a MA remote controller system (address setting is not necessary.)

OCH502C

NOTE : In the case of same group operation, need to set the address that is only main indoor unit.

Example of wiring control cables Wiring Method and Address Setting

1. Standard operation

L

1 L2

OC

00

TB3

TB7

M1 M2SM1 M2

S

TB5

M1 M2

IC

00

TB15

12

S

N1

AB

TB5

M1 M2

IC

00

TB15

12

S

AB

a. Use feed wiring to connect terminals M1 and M2

on transmission cable block (TB3) for the outdoor

unit (OC) to terminals M1 and M2 on the transmission cable block (TB5) of each indoor unit (IC). Use

non-polarized 2 wire.

b. Connect terminals 1 and 2 on transmission cable

terminal block (TB15) for each indoor unit with the

terminal block for the MA remote controller (MA).

N2

• 1 remote controller for each

indoor unit.

2. Operation using two remote controllers

OC

00

IC

00

TB5

TB3

TB7

M1 M2SM1 M2

S

N3

• Using 2 remote controllers

for each indoor unit.

M1 M2

TB15

S

12

AB

MA

3. Group operation

OC

00

IC

00

TB3

TB7

M1 M2SM1 M2

S

N7

TB5

TB15

M1 M2SM1 M2

AB

MAMA

IC

00

TB5

TB15

M1 M2

S

N4

AB

MA MA MA

12

N5

AB AB

IC

00

TB5

S

M1 M2

S

N6

TB15

12

a. The same as above.

b. The same as above.

c. In the case of using 2 remote controllers, connect

terminals 1 and 2 on transmission cable terminal

block (TB15) for each indoor unit with the terminal

block for 2 remote controllers.

· Set the sub remote controller position for one of

MA remote controller’s main switch.

Refer to the installation manual of MA remote con-

troller

a. The same as above.

b. The same as above.

c. Connect terminals 1 and 2 on transmission cable

terminal block (TB15) of each indoor unit, which is

doing group operation with the terminal block the MA

remote controller. Use non-polarized 2 wire.

d. In the case of same group operation, need to set the

address that is only main indoor unit. Please set the

smallest address within number 01-50 of the indoor

unit with the most functions in the same group.

• Multiple indoor units operated

together by 1 remote controller

Combinations of 1 through 3 above are possible.

MA

N8

25

Permissible Lengths Prohibited items

OCH502C

Longest transmission cable length

L

1 + L2 [ 200 m [656 ft] (1.25 mm²

[AWG16])

MA remote controller cable length

R

1, R2 [ 200 m [656 ft] (0.3 ~ 1.25

mm² [AWG22 to AWG16])

Longest transmission cable length

The same as above.

MA remote controller cable length

R

3 +R4, R5 +R6 [ 200 m [656 ft]

(0.3 ~ 1.25 mm² [AWG22 to

AWG16])

TB3

M1 M2

S

OC

00

OC

00

TB7

M1 M2

The MA remote controller and the

M-NET remote controller cannot be

used together with the indoor unit

of the same group.

IC

00

TB5

TB15

S

M1 M2

12

S

AB

TB5

M1 M2

IC

00

TB15

12

S

ABAB

MAMARC

3 MA remote controller or more

cannot be connected with the

indoor unit of the same group.

IC

00

IC

00

Longest transmission cable length

The same as above.

MA remote controller cable length

R

7 +R8 [ 200 m [656 ft] (0.3 ~ 1.25

mm² [AWG22 to AWG16])

TB3

M1 M2

TB3

M1 M2

S

S

OC

TB7

M1 M2

TB7

M1 M2

TB5

TB15

S

M1 M2

AB AB AB AB AB

12

S

MA

TB5

TB15

12

M1 M2

S

MA MA MAMA

The second MA remote controller is

connected with the terminal block

(TB15) for the MA remote controller

of the same indoor unit (IC) as the

first remote control.

IC00

00

TB5

TB15

12

M1 M2

S

S

TB5

M1 M2

S

IC

00

TB15

12

26

AB

MA

AB

MA

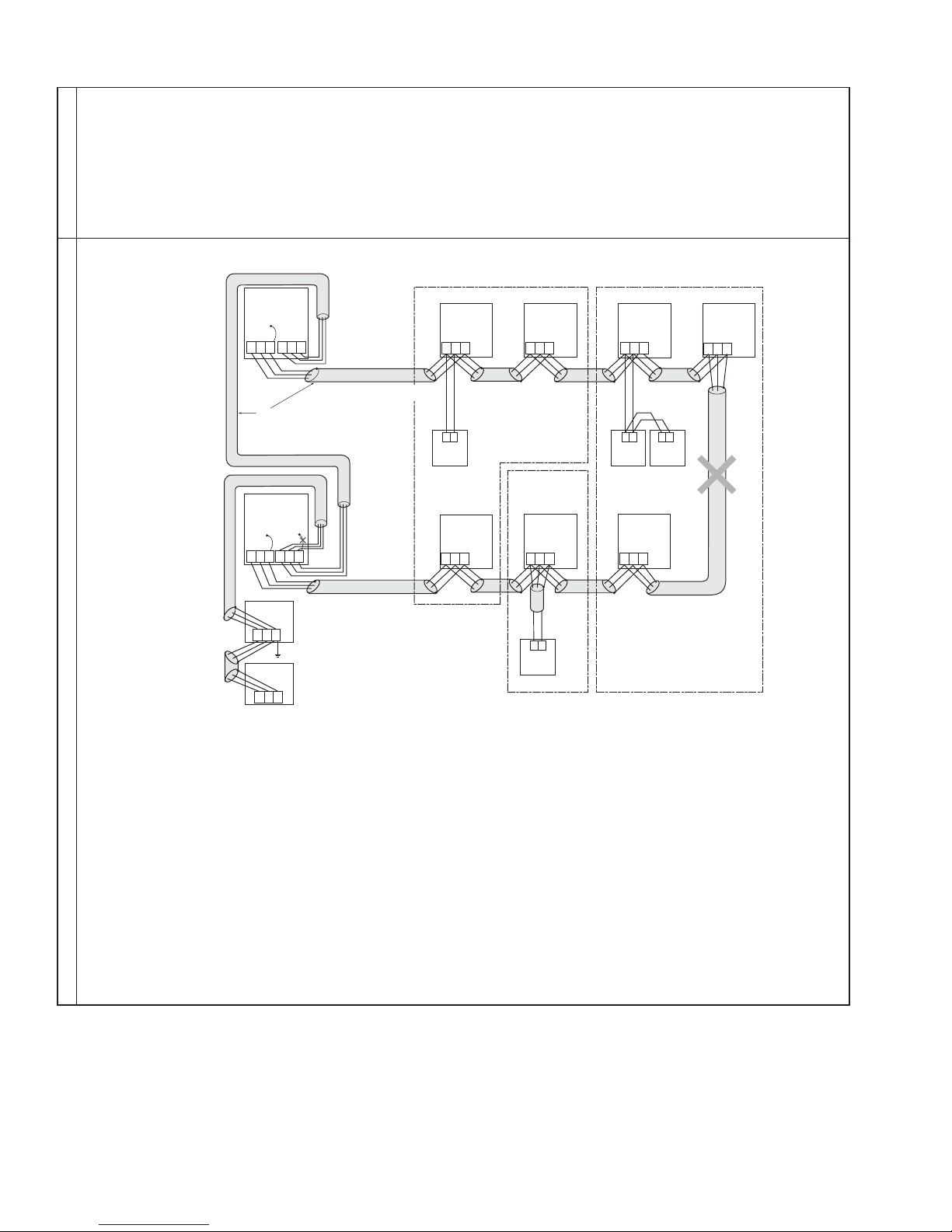

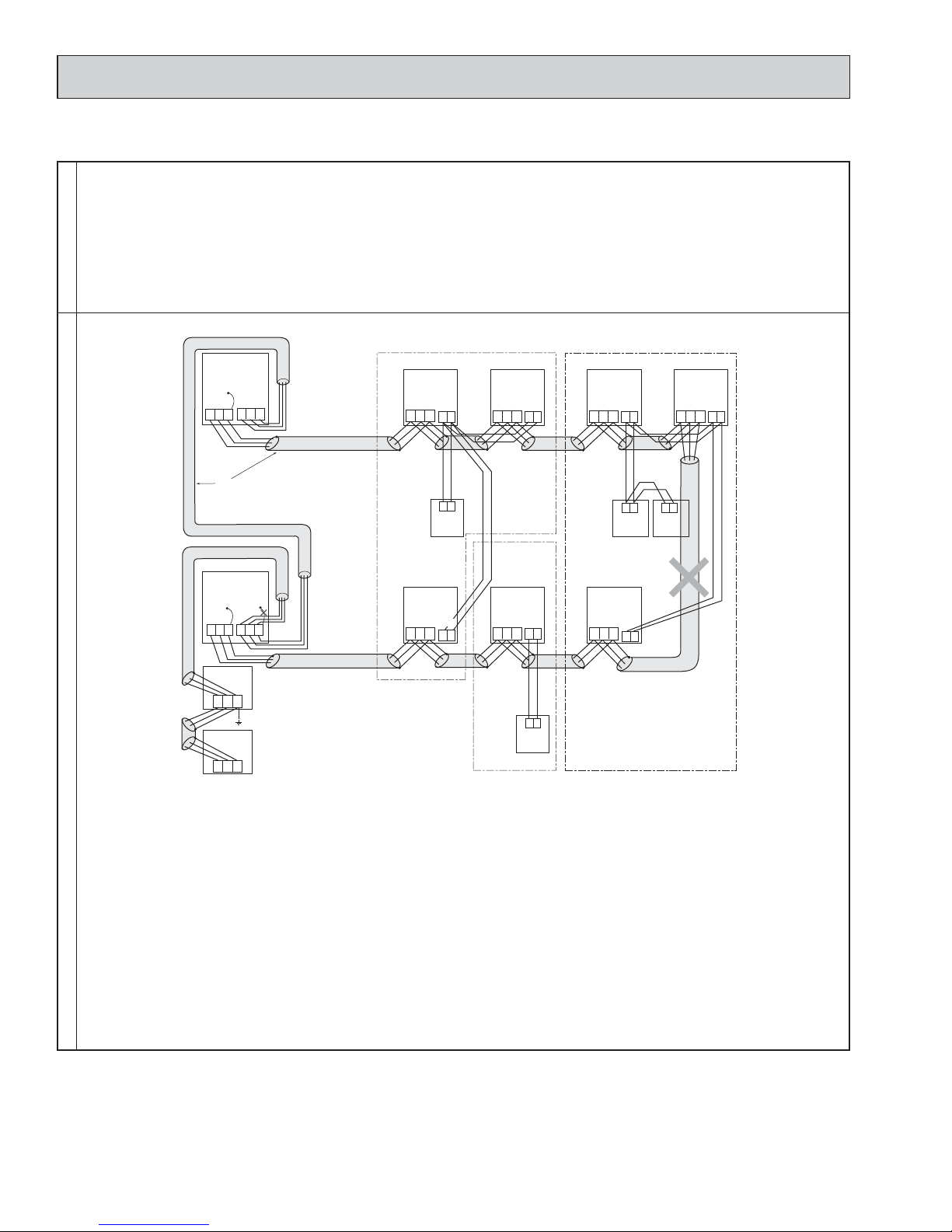

D. Example of a group operation with 2 or more outdoor units and a MA remote controller.

OCH502C

(Address settings are necessary.)

L1

L2

L6

Examples of Transmission Cable Wiring

L7

: Group

: Group

: Group

: Shielded Wire

: Sub Remote Controller

( ): Address

OC

(51)

TB7

TB3

M1 M2SM1 M2

OC

(53)

TB7

TB3

M1 M2

M1M2

S

Power Supply

Unit

M1M2

S

System

controller

M1M2

S

IC

(05)

TB15

S

12

AB AB

MAMAMA

IC

(07)

TB15

S

12

IC

2

m

(06)

TB5

TB15

M1M2

S

12

1

m4

m

3

m

IC

(01)

S

TB15 TB15

M1 M2

S

12

AB

m3

MA

L3

IC

(03)

TB15

S

M1 M2

TB5

S

12

IC

2

m

(02)

TB5TB5

M1 M2

S

12

1

m

M1M2

TB5

L4

IC

(04)

TB5

M1 M2

TB15

S

12

AB

TB5

M1 M2

1

m

a. Always use shielded wire when making connections between the outdoor unit (OC) and the indoor unit (IC), as well

for all OC-OC, and IC-IC wiring intervals.

b. Use feed wiring to connect terminals M1 and M2 and the ground terminal on the transmission cable terminal block (TB3)

of each outdoor unit (OC) to terminals M1 and M2 on the terminal S on the transmission cable block of the indoor unit

(IC).

c. Connect terminals M1 and M2 on the transmission cable terminal block of the indoor unit (IC) that has the most

recent address within the same group to the terminal block on the remote controller (RC).

d. Connect together terminals M1, M2 and terminal S on the terminal block for central control (TB7) for the outdoor unit

(OC).

e. DO NOT change the jumper connector CN41 on MULTI controller board.

f. The earth processing of S terminal for the centralized control terminal block (TB7) is unnecessary. Connect the termi-

nal S on the power supply unit with the earth.

g. Set the address setting switch as follows.

Unit Range Setting Method

IC (Main) 01 to 00

IC (Sub) 01 to 50

Wiring Method Address Settings

Outdoor Unit 51 to 100

Main Remote Controller 101 to 150

Sub Remote Controller 151 to 200

MA Remote Controller —

Use the smallest address within the same group of indoor units.

Use an address, other than the IC (Main) in the same group of indoor units.

This must be in sequence with the IC (Main).

Use the smallest address of all the indoor units plus 50.

*The address automatically becomes “100” if it is set as “01 - 50”.

Set at an IC (Main) address within the same group plus 100.

Set at an IC (Main) address within the same group plus 150.

Unnecessary address setting (Necessary main/ sub setting)

h. The group setting operations among the multiple indoor units are done by the remote controller (RC) after the electri-

cal power has been turned on.

27

• Name, Symbol, and the Maximum Units for Connection

OCH502C

Longest length via outdoor unit (M-NET cable):

L

1+L2+L3+L4

and L1+L2+L6+L7 [ 500 m [1640 ft] (1.25 e [AWG16] or more)

Longest transmission cable length (M-NET cable):

L

1

and L3+L4 and L6 and L2+L6 and L7 [ 200 m

Remote controller cable length:

m1

Permissible LengthProhibited items

and m1+m2+m3 and m1+m2+m3+m4

[ 200 m

[656 ft]

[656 ft]

(1.25 e

[AWG16]

(0.3 to 1.25 e

or more)

[AWG22 to AWG16]

)

OC

(51)

TB7TB3

M1M2

M1M2

S

S

OC

(53)

TB7

TB3

M1M2

S

Unit

M1 M2

S

System

controller

M1 M2

S

S

M1M2

Power Supply

: Group

: Group

: Group

: Shielded Wire

: Sub Remote Controller

( ): Address

IC

(01)

TB5 TB15 TB15

M1 M2

S

12

AB

MA

IC

(03)

TB15

TB5

M1 M2

S

12

TB5

M1 M2

TB5

M1 M2

IC

(02)

IC

(04)

S

S

IC

(05)

TB15TB5

M1 M2

TB5

M1 M2

S

12

AB AB

MAMAMA

IC

(07)

S

12

12

TB15 TB15

12

AB

IC

(06)

TB15TB5

M1 M2

S

12

• Never connect together the terminal blocks (TB5) for transmission wires for indoor units (IC) that have been connected to

different outdoor units (OC).

• M-NET remote controller and MA remote controller cannot be connected with the indoor unit of the same group wring

together.

28

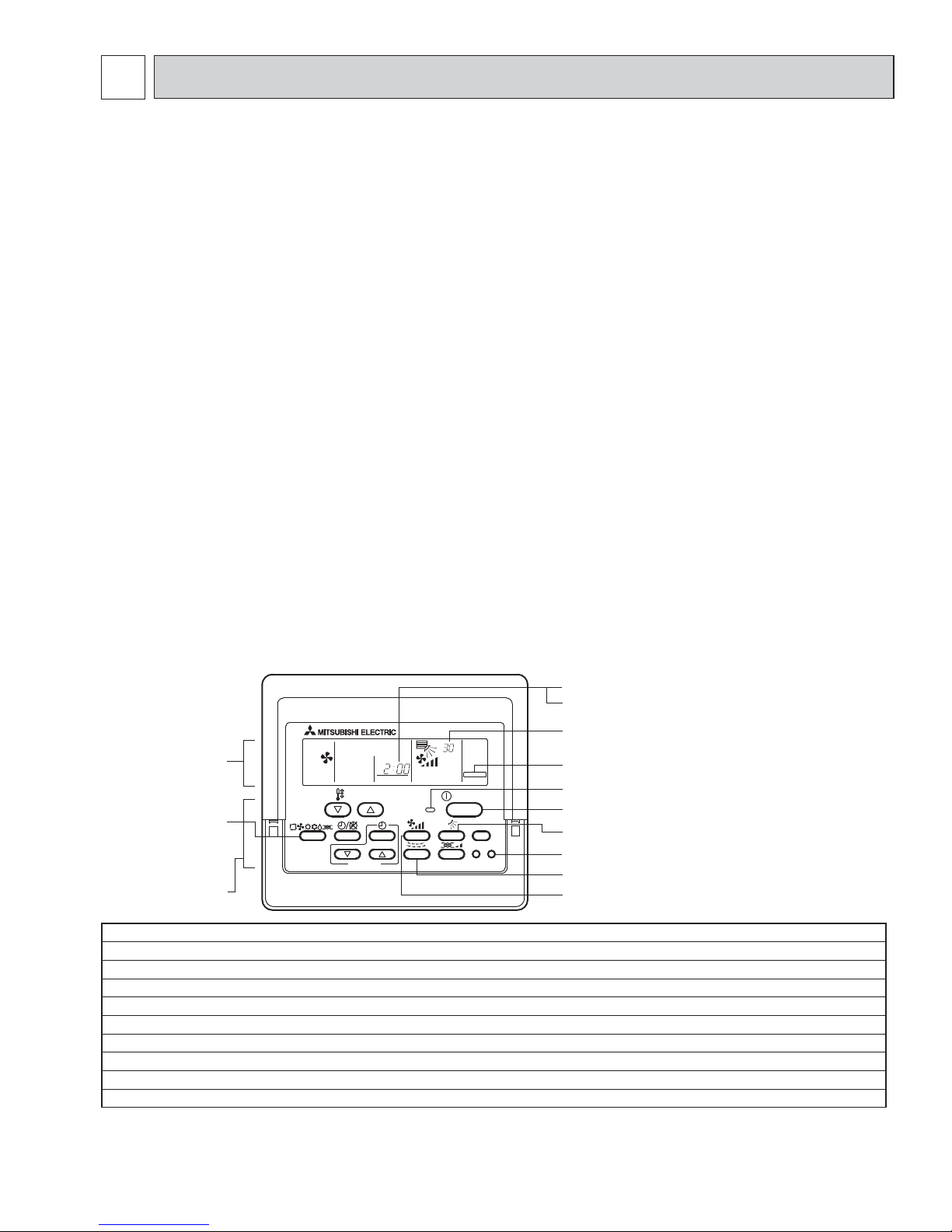

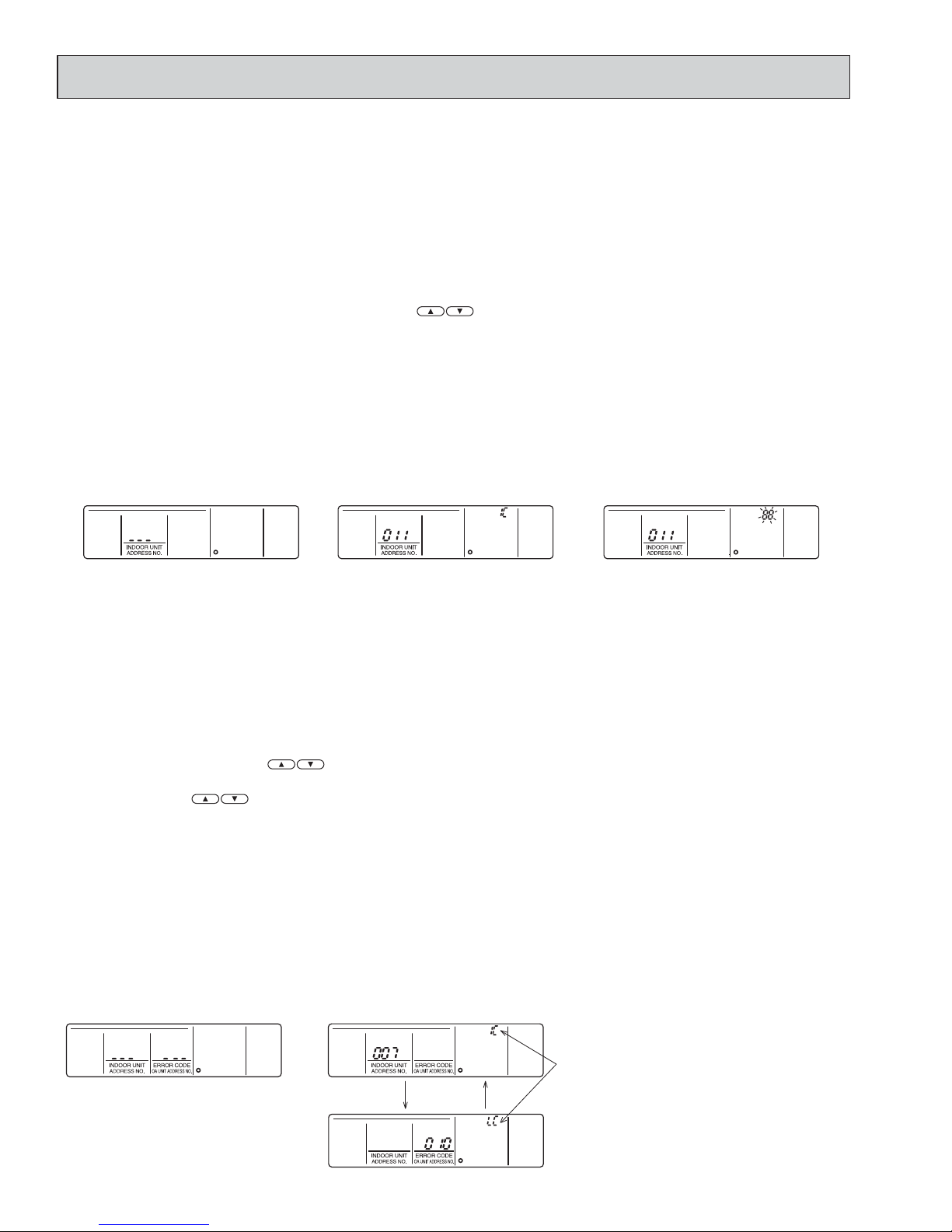

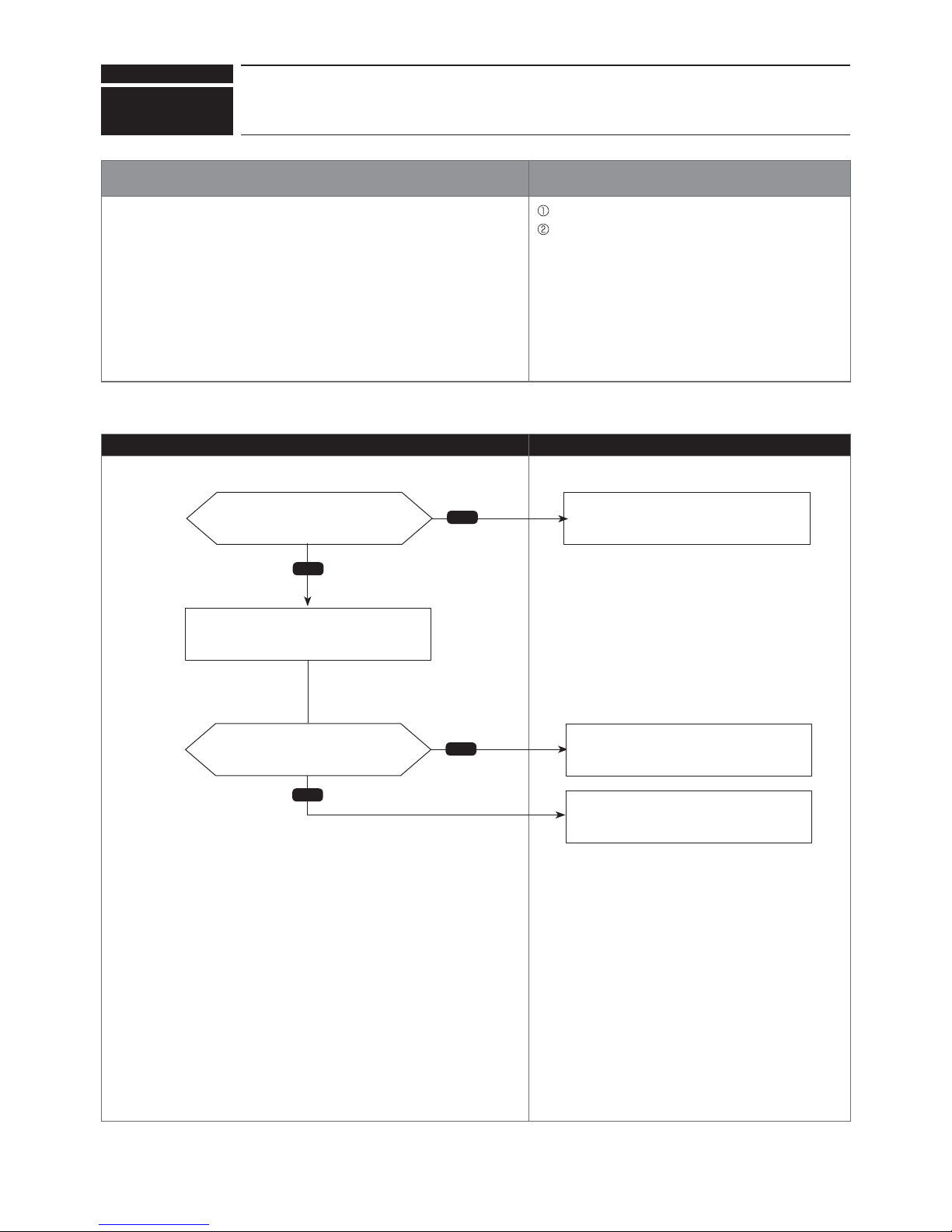

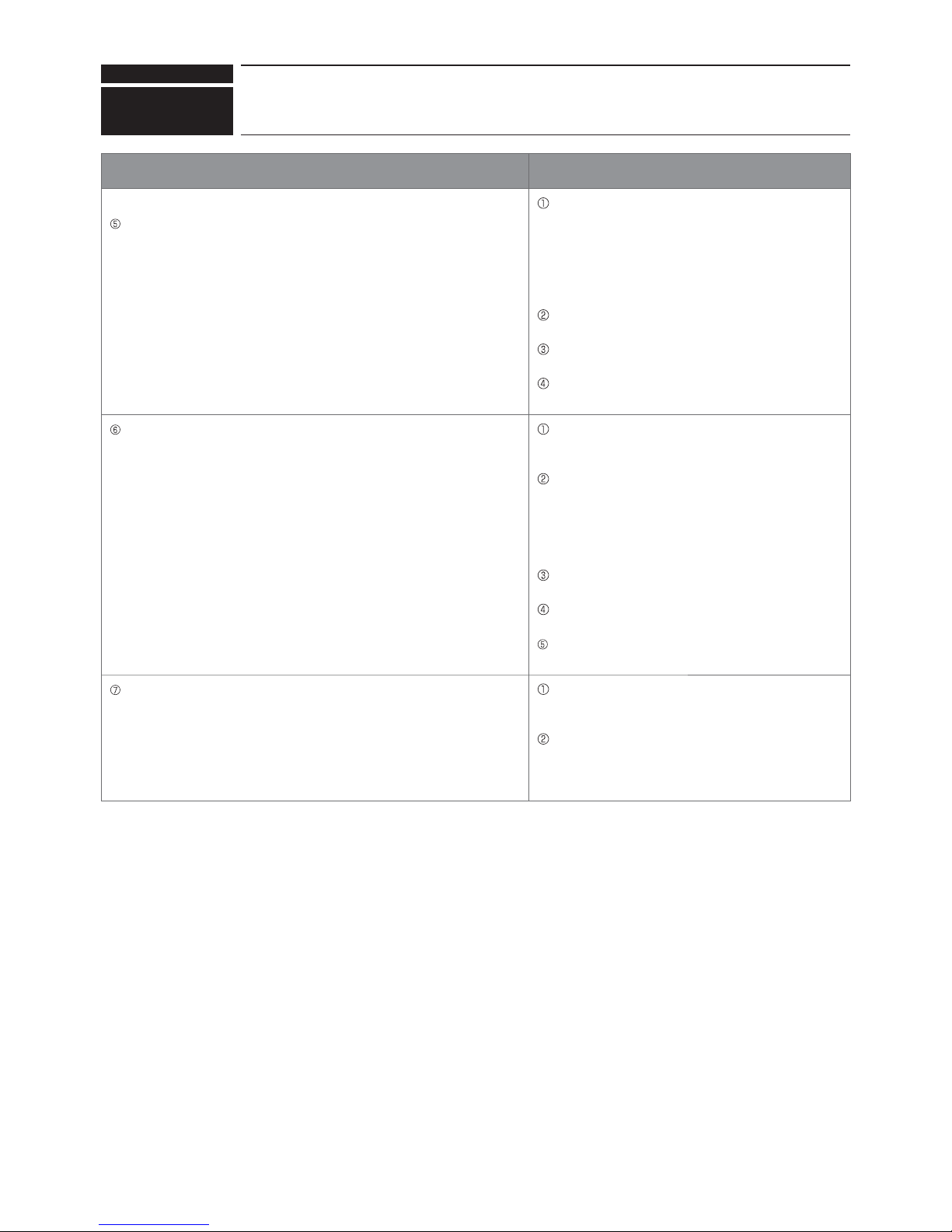

8 TROUBLESHOOTING

ON/OFF

TEST RUN

°C

1Hr.

FILTER

CHECK TEST

TEMP.

TIMER SET

Check code indicator (see NOTE 1)