Mitsubishi PUMY-P125VKM3-BS, PUMY-P140YKM3, PUMY-P112YKM3-BS, PUMY-P140VKM3-BS, PUMY-P140YKM3-BS Technical & Service Manual

...

TECHNICAL & SERVICE MANUAL

OUTDOOR UNIT

HFC

utilized

R410A

March 2017

Note:

•

This service manual

describes technical data of

the outdoor units only.

<Outdoor unit>

[Model Name]

Model name

indication

PARTS CATALOG (OCB632)

PUMY-P112VKM3

PUMY-P125VKM3

PUMY-P140VKM3

PUMY-P112YKM3

PUMY-P125YKM3

PUMY-P140YKM3

PUMY-P112VKM3-BS

PUMY-P125VKM3-BS

PUMY-P140VKM3-BS

PUMY-P112YKM3-BS

PUMY-P125YKM3-BS

PUMY-P140YKM3-BS

Salt proof model

PUMY-P112VKM3

PUMY-P125VKM3

PUMY-P140VKM3

PUMY-P112YKM3 PUMY-P112YKME3

PUMY-P125YKM3 PUMY-P125YKME3

PUMY-P140YKM3 PUMY-P140YKME3

PUMY-P112VKM3-BS

PUMY-P125VKM3-BS

PUMY-P140VKM3-BS

PUMY-P112YKM3-BS PUMY-P112YKME3-BS

PUMY-P125YKM3-BS PUMY-P125YKME3-BS

PUMY-P140YKM3-BS PUMY-P140YKME3-BS

[Service Ref.]

CONTENTS

1. SAFETY PRECAUTION

.....................................

2

2. OVERVIEW OF UNITS

.......................................

5

3. SPECIFICATIONS

............................................

10

4. DATA

.................................................................

13

5. OUTLINES AND DIMENSIONS

.......................

27

6. WIRING DIAGRAM

...........................................

29

7.

NECESSARY CONDITIONS FOR SYSTEM CONSTRUCTION

.......

32

8. TROUBLESHOOTING

......................................

50

9. ELECTRICAL WIRING

...................................

132

10. REFRIGERANT PIPING TASKS

....................

139

11. DISASSEMBLY PROCEDURE

.......................

146

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

No. OCH632

REVISED EDITION-A

Revision:

•

Modified the "Ratio of

power input" graph for cooling in "4-2. CORRECTION

BY TEMPERATURE" in

REVISED EDITION-A.

•

Some other descriptions

have been also modified.

OCH632 is void.

2

Cautions for units utilizing refrigerant R410A

1-1. CAUTIONS RELATED TO NEW REFRIGERANT

Use new refrigerant pipes.

Store the piping indoors, and both ends of the

piping sealed until just before brazing.

(Leave elbow joints, etc. in their packaging.)

Avoid using thin pipes.

Charge refrigerant from liquid phase of gas

cylinder.

If the refrigerant is charged from gas phase, composition

change may occur in refrigerant and the efficiency will be

lowered.

Do not use refrigerant other than R410A.

If other refrigerant (R22, etc.) is used, chlorine in refrigerant can cause deterioration of refrigerant oil, etc.

Use a vacuum pump with a reverse flow check

valve.

Vacuum pump oil may flow back into refrigerant cycle and

that can cause deterioration of refrigerant oil, etc.

Use the following tools specifically designed for

use with R410A refrigerant.

The following tools are necessary to use R410A refrigerant.

Handle tools with care.

If dirt, dust or moisture enters into refrigerant cycle, that can

cause deterioration of refrigerant oil or malfunction of compressor.

Do not use a charging cylinder.

If a charging cylinder is used, the composition of refrigerant will change and the efficiency will be lowered.

Flare tool

Electronic refrigerant

charging scale

Vacuum pump adaptor

Size adjustment gauge

Gauge manifold

Torque wrench

Gas leak detector

Charge hose

Tools for R410A

Contamination inside refrigerant piping can cause deterioration of refrigerant oil, etc.

If dirt, dust or moisture enters into refrigerant cycle, that can

cause deterioration of refrigerant oil or malfunction of compressor.

If large amount of mineral oil enters, that can cause deterioration of refrigerant oil, etc.

Make sure that the inside and outside of refrigerant piping is clean and it has no contaminants

such as sulfur, oxides, dirt, shaving particles, etc,

which are hazard to refrigerant cycle.

In addition, use pipes with specified thickness.

The refrigerant oil applied to flare and flange

connections must be ester oil, ether oil or

alkylbenzene oil in a small amount.

Ventilate the room if refrigerant leaks during

operation. If refrigerant comes into contact with

a flame, poisonous gases will be released.

Use the specified refrigerant only.

Never use any refrigerant other than that specified.

Doing so may cause a burst, an explosion, or fire when the

unit is being used, serviced, or disposed of.

Correct refrigerant is specified in the manuals and on the

spec labels provided with our products.

We will not be held responsible for mechanical failure,

system malfunction, unit breakdown or accidents caused

by failure to follow the instructions.

1 SAFETY PRECAUTION

OCH632A

3

Unit

Electronic weighing scale

[3] Service tools

Use the below service tools as exclusive tools for R410A refrigerant.

[1] Cautions for service

(1) Perform service after recovering the refrigerant left in unit completely.

(2) Do not release refrigerant in the air.

(3) After completing service, charge the cycle with specified amount of refrigerant.

(4) If moisture or foreign matter might have entered the refrigerant piping during service, ensure to remove them.

[2] Additional refrigerant charge

When charging directly from cylinder

(1) Check that cylinder for R410A on the market is a syphon type.

(2) Charging should be performed with the cylinder of syphon stood vertically. (Refrigerant is charged from liquid phase.)

Although "-BS" model has been designed to be resistant to salt damage, observe the following precautions to maintain the

performance of the unit.

(1) Avoid installing the unit in a location where it will be exposed directly to seawater or sea breeze.

(2) If the cover panel may become covered with salt, be sure to install the unit in a location where the salt will be washed away

by rainwater. (If a sunshade is installed, rainwater may not clean the panel.)

(3) To ensure that water does not collect in the base of the outdoor unit, make sure that the base is level, not at angle. Water

collecting in the base of the outdoor unit could cause rust.

(4) If the unit is installed in a coastal area, clean the unit with water regularly to remove any salt build-up.

(5) If the unit is damaged during installation or maintenance, be sure to repair it.

(6) Be sure to check the condition of the unit regularly.

(7) Be sure to install the unit in a location with good drainage.

1-2. PRECAUTIONS FOR SALT PROOF TYPE "-BS" MODEL

No.

Tool name Specifications

1

Gauge manifold · Only for R410A

· Use the existing fitting

specifications

. (UNF1/2)

· Use high-tension side pressure of 5.3MPa·G or over.

2

Charge hose · Only for R410A

· Use pressure performance of 5.09MPa·G or over.

3

Electronic weighing scale

—

4

Gas leak detector · Use the detector for R134a, R407C or R410A.

5

Adaptor for reverse flow check · Attach on vacuum pump.

6

Refrigerant charge base

—

7

Refrigerant cylinder · Only for R410A · Top of cylinder (Pink)

· Cylinder with syphon

8

Refrigerant recovery equipment

—

OCH632A

4

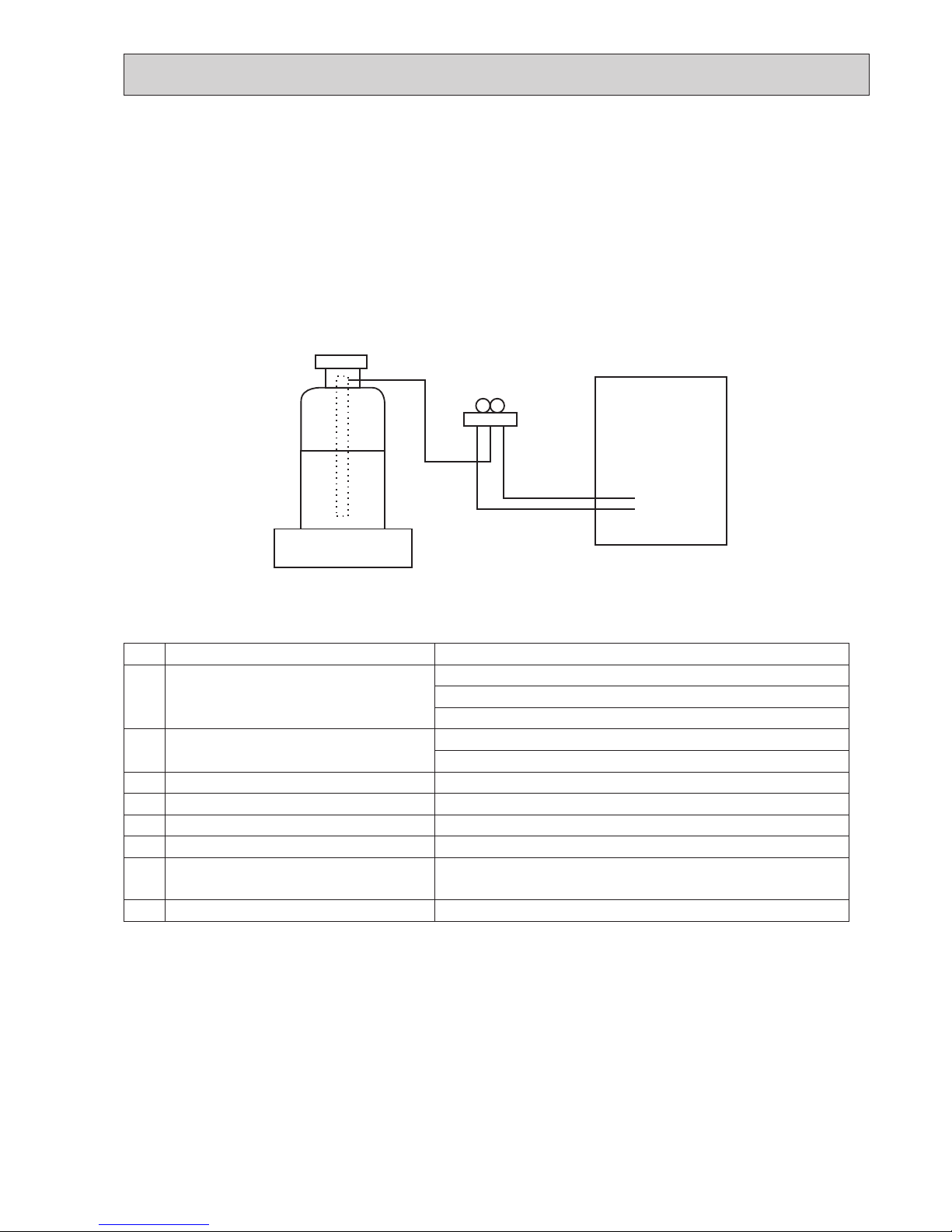

Cautions for refrigerant piping work

New refrigerant R410A is adopted for replacement inverter series. Although the refrigerant piping work for R410A is same

as for R22, exclusive tools are necessary so as not to mix with different kind of refrigerant. Furthermore as the working

pressure of R410A is 1.6 times higher than that of R22, their sizes of flared sections and flare nuts are different.

1 Thickness of pipes

Because the working pressure of R410A is higher compared to R22, be sure to use refrigerant piping with thickness

shown below. (Never use pipes of 0.7 mm or below.)

2 Dimensions of flare cutting and flare nut

The component molecules in HFC refrigerant are smaller compared to conventional refrigerants. In addition to that,

R410A is a refrigerant, which has higher risk of leakage because its working pressure is higher than that of other refrigerants. Therefore, to enhance airtightness and strength, flare cutting dimension of copper pipe for R410A has been

specified separately from the dimensions for other refrigerants as shown below. The dimension B of flare nut for R410A

also has partly been changed to increase strength as shown below. Set copper pipe correctly referring to copper pipe

flaring dimensions for R410A below. For 1/2 and 5/8 inch pipes, the dimension B changes.

Use torque wrench corresponding to each dimension.

3 Tools for R410A (The following table shows whether conventional tools can be used or not.)

1/4

3/8

1/2

5/8

3/4

6.35

9.52

12.70

15.88

19.05

0.8

0.8

0.8

1.0

—

0.8

0.8

0.8

1.0

1.0

Nominal

dimensions (in)

Diagram below: Piping diameter and thickness

Outside

diameter

(mm)

Thickness

(mm)

R410A R22

1/4

3/8

1/2

5/8

3/4

6.35

9.52

12.70

15.88

19.05

9.1

13.2

16.6

19.7

—

9.0

13.0

16.2

19.4

23.3

Nominal

dimensions (in)

Flare cutting dimensions

Outside

diameter

Dimension A

( )

+0

-0.4

(mm)

R410A R22

(mm)

1/4

3/8

1/2

5/8

3/4

6.35

9.52

12.70

15.88

19.05

17.0

22.0

26.0

29.0

—

17.0

22.0

24.0

27.0

36.0

Nominal

dimensions (in)

Flare nut dimensions

Outside

diameter

Dimension B

(mm)

R410A R22

(mm)

Gauge manifold

Charge hose

Gas leak detector

Refrigerant recovery equipment

Refrigerant cylinder

Applied oil

Safety charger

Charge valve

Vacuum pump

Flare tool

Bender

Pipe cutter

Welder and nitrogen gas cylinder

Refrigerant charging scale

Vacuum gauge or thermistor vacuum gauge and

vacuum valve

Charging cylinder

Air purge, refrigerant charge

and operation check

Gas leak check

Refrigerant recovery

Refrigerant charge

Apply to flared section

Prevent compressor malfunction

when charging refrigerant by

spraying liquid refrigerant

Prevent gas from blowing out

when detaching charge hose

Vacuum drying and air

purge

Flaring work of piping

Bend the pipes

Cut the pipes

Weld the pipes

Refrigerant charge

Check the degree of vacuum. (Vacuum

valve prevents back flow of oil and refrigerant to thermistor vacuum gauge)

Refrigerant charge

Tool exclusive for R410A

Tool exclusive for R410A

Tool for HFC refrigerant

Tool exclusive for R410A

Tool exclusive for R410A

Ester oil, ether oil and

alkylbenzene oil (minimum amount)

Tool exclusive for R410A

Tool exclusive for R410A

Tools for other refrigerants can

be used if equipped with adopter for reverse flow check

Tools for other refrigerants

can be used by adjusting

flaring dimension

Tools for other refrigerants can be used

Tools for other refrigerants can be used

Tools for other refrigerants can be used

Tools for other refrigerants can be used

Tools for other refrigerants

can be used

Tool exclusive for R410A

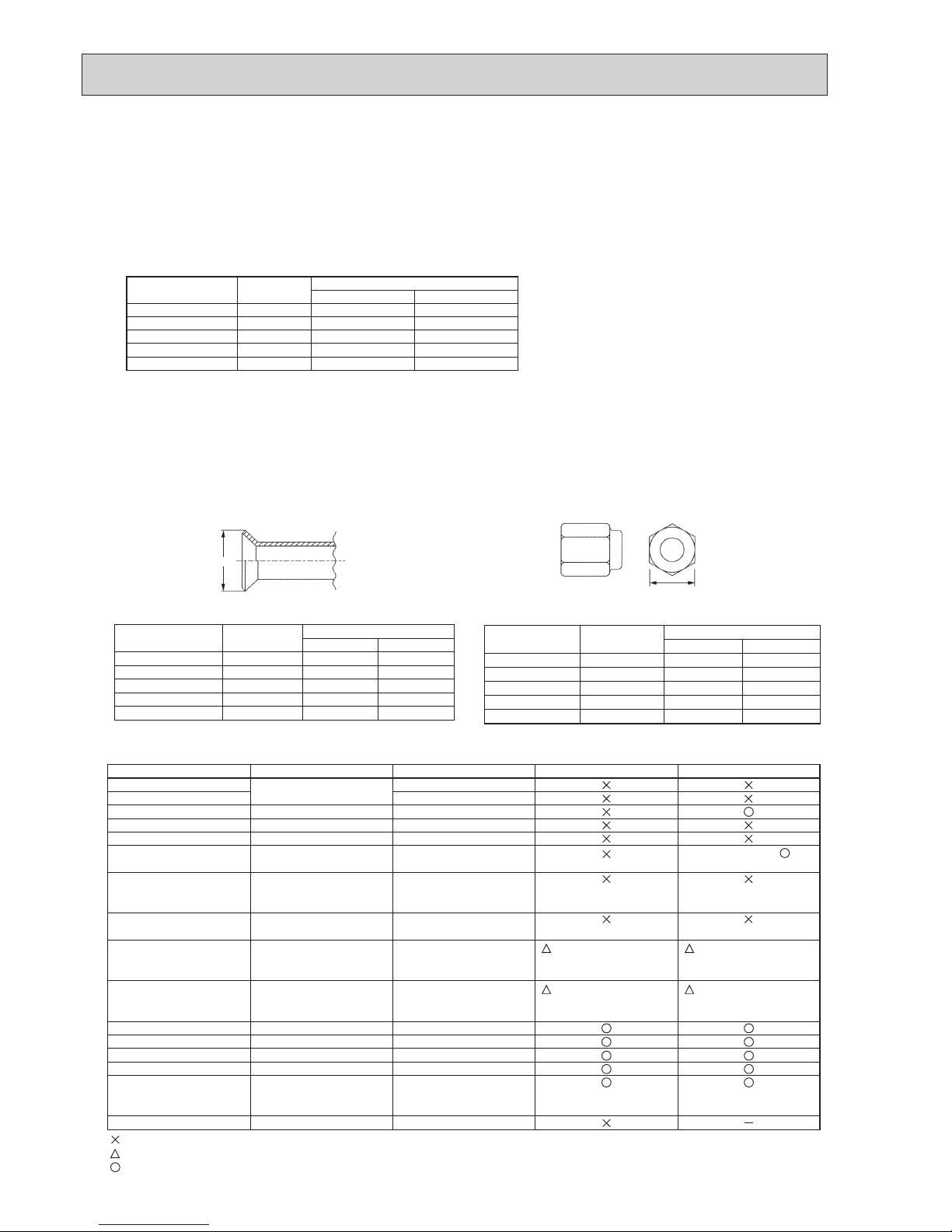

Tools and materials Use R410A tools Can R22 tools be used?

(Usable if equipped

with adopter for rever se flow)

(Usable by adjusting

flaring dimension)

Can R407C tools be used?

Ester oil, ether oil:

Alkylbenzene oil: minimum amount

(Usable if equipped

with adopter for rever se flow)

(Usable by adjusting

flaring dimension)

: Prepare a new tool. (Use the new tool as the tool exclusive for R410A.)

: Tools for other refrigerants can be used under certain conditions.

: Tools for other refrigerants can be used.

Dimension A

Dimension B

OCH632A

5

2

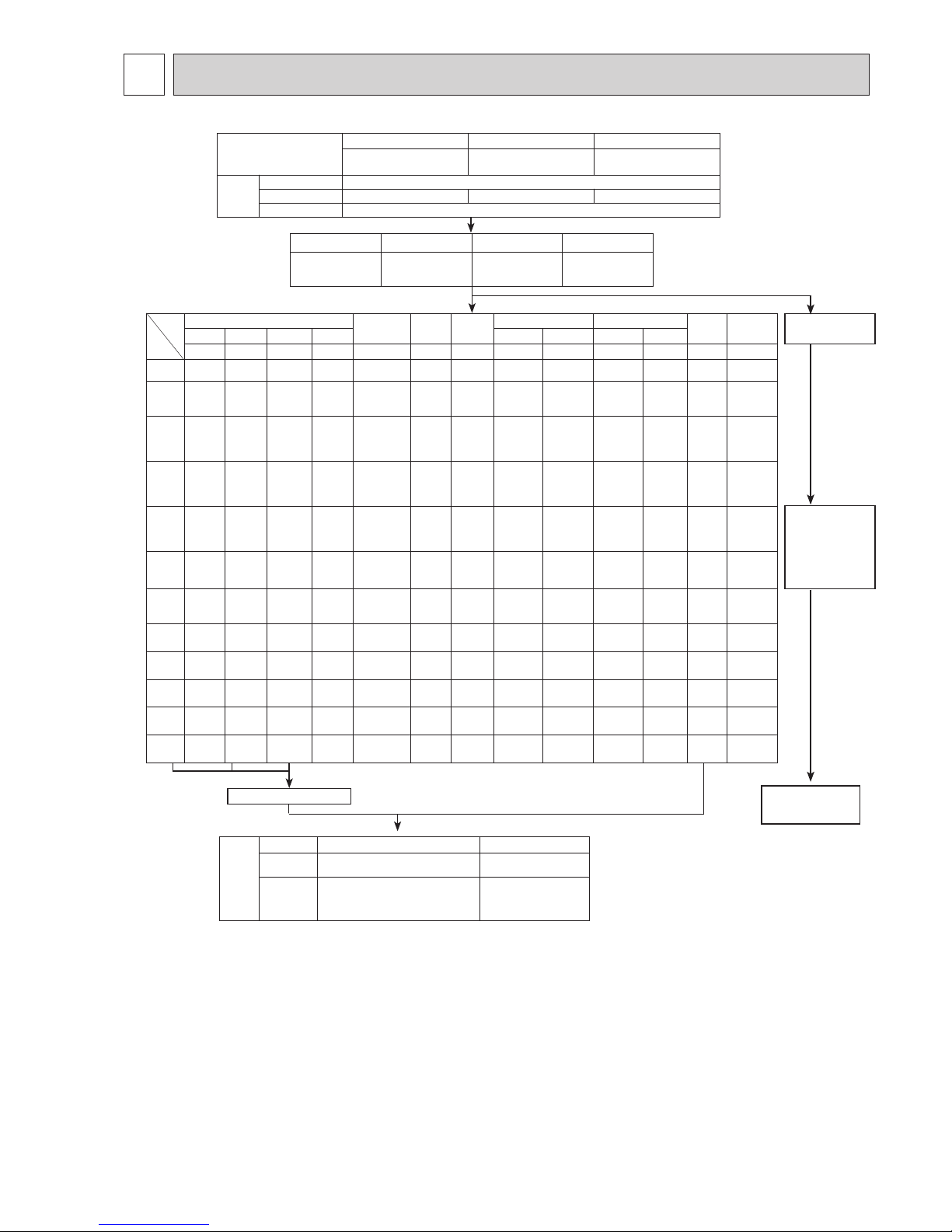

2-1. UNIT CONSTRUCTION

Remote

controller

Name

Model number

Functions

M-NET remote controller

PAR-F27MEA-E,

PAR-U02MEDA

• A handy remote controller for use in

conjunction

with the Melans centralized

management system.

• Addresses must be set.

• Addresses setting is not

necessary.

MA remote controller

PAR-21MAA, PAR-31/32MAA

PAR-W21MAA(when using PWFY)

Outdoor unit

Capacity

1 to 9 unit

50 to 130% of outdoor unit capacity

*2 *3

Type 15 to Type 140

1 to 10 unit

Applicable

indoor unit

Number of units

Total system wide capacity

4HP 5HP 6HP

PUMY-P112VKM3(-BS)

PUMY-P112YKM(E)3(-BS)

PUMY-P125VKM3(-BS)

PUMY-P125YKM(E)3(-BS)

1 to 12 unit

PUMY-P140VKM3(-BS)

PUMY-P140YKM(E)3(-BS)

Branching pipe

components

Branch header

(2 branches)

Branch header

(4 branches)

Branch header

(8 branches)

CMY-Y62-G-E CMY-Y64-G-E CMY-Y68-G-E

*1. PUMY is connectable to Fresh Air type indoor unit.

It is possible to connect 1 Fresh Air type indoor unit to 1 outdoor unit. (1:1 system)

Operating temperature range (outdoor temperature) for fresh air type indoor units differ from other indoor units.

Refer to "2-4-(3). Operating temperature range".

*2. When the indoor unit of Fresh Air type is connected with the outdoor unit, the maximum connectable total indoor unit capacity is 110% (100%

incaseofheatingbelow−5:.

*3. When connecting PWFY series (Note that the connection is not allowed inside EU countries.)

•Only1PWFY-P100VM-E-AUcanbeconnected.PWFY-P200VM-E-AUandPWFY-P100VM-E-BUcannotbeconnected.

•ThePWFYunitcannotbetheonlyunitconnectedtoanoutdoorunit.Selectanindoorunitsothatthetotalratedcapacityoftheindoor

units, excluding the PWFY unit, is 50 to 100% of the outdoor unit capacity.

*4.

When connecting the CONNECTION KIT (PAC-LV11M-J) and an M-series indoor unit, refer to the installation manual for the CONNECTION KIT.

*5. Authorized connectable indoor units are as follows;

PUMY-P112: PEFY-P25VMA3-E × 2 + PEFY-P32VMA3-E × 2

PUMY-P125: PEFY-P32VMA3-E × 4

PUMY-P140: PEFY-P32VMA3-E × 3 + PEFY-P40VMA3-E × 1

*6. Do not connect Lossnay remote controller(s). (PZ-61DR-E, PZ-60DR-E, PZ-52SF-E, PZ-43SMF-E)

Decorative panel

OVERVIEW OF UNITS

M series remote

controller

Model

Capacity

Cassette Ceiling

Ceiling

Concealed

Wall

Mounted

Ceiling

Suspended

Floor standing Ceiling concealed

Lossnay

Air to Water

unit

*

3

CONNECTION KIT

2 by 2 4-way ow 2-way ow

1-way ow

Exposed

Concealed Fresh air

*

1

Built-in

PAC-LV11M-J

PLFY-P PLFY-P PLFY-P

PMFY-P

PEFY-P

PKFY-P

PCFY-P PFFY-P PFFY-P PEFY-P PDFY GUF*6PWFY-P

15

15VFM-E1

– – –

15VMS1(L)-E

15VBM-E

– – – – – – –

20

20VFM-E1

20VBM-E 20VLMD-E 20VBM-E

20VMS1(L)-E

20VMA(L)-E

20VMR-E-L/R

20VBM-E

–

20VLEM-E

20VKM-E2

20VLRM-E

20VLRMM-E

– 20VM-E – –

25

25VFM-E1

25VBM-E 25VLMD-E 25VBM-E

25VMS1(L)-E

25VMA(L)-E

25VMR-E-L/R

25VMA3-E

*

5

25VBM-E

–

25VLEM-E

25VKM-E2

25VLRM-E

25VLRMM-E

– 25VM-E – –

32

32VFM-E1

32VBM-E 32VLMD-E 32VBM-E

32VMS1(L)-E

32VMA(L)-E

32VMR-E-L/R

32VMA3-E

*

5

32VHM-E

–

32VLEM-E

32VKM-E2

32VLRM-E

32VLRMM-E

– 32VM-E – –

40

40VFM-E1

40VBM-E 40VLMD-E 40VBM-E

40VMS1(L)-E

40VMA(L)-E

40VMH-E

40VMA3-E

*

5

40VHM-E 40VKM-E

40VLEM-E

40VKM-E2

40VLRM-E

40VLRMM-E

– 40VM-E – –

M series indoor unit

*

4

MSZ-GE Series

MSZ-SF Series

MSZ-EF Series

MSZ-FH Series

MFZ-KJ Series

50

50VFM-E1

50VBM-E 50VLMD-E

–

50VMS1(L)-E

50VMA(L)-E

50VMH-E

50VHM-E

–

50VLEM-E

50VLRM-E

50VLRMM-E

– 50VM-E

50RD(H)4

–

63

–

63VBM-E 63VLMD-E

–

63VMS1(L)-E

63VMA(L)-E

63VMH-E

63VKM-E 63VKM-E

63VLEM-E

63VLRM-E

63VLRMM-E

– 63VM-E – –

71

– –

– –

71VMA(L)-E

71VMH-E

– – – – – 71VM-E – –

80

–

80VBM-E 80VLMD-E

–

80VMA(L)-E

80VMH-E

– – – –

80VMH-E-F

80VM-E –

100

–

100VBM-E

100VLMD-E

–

100VMA(L)-E

100VMH-E

100VKM-E 100VKM-E

–

–

– 100VM-E

100RD(H)4

100VM-E1-AU

100VM-E2-AU

125

–

125VBM-E

125VLMD-E

–

125VMA(L)-E

125VMH-E

–

125VKM-E

–

–

– 125VM-E

–

140

– – –

–

140VMA(L)-E

140VMH-E

– – –

– 140VMH-E-F

– –

OCH632A

6

PUMY-P125VKM3(-BS)

PUMY-P125YKM(E)3(-BS)

PUMY-P140VKM3(-BS)

PUMY-P140YKM(E)3(-BS)

6HP

PUMY-P112VKM3(-BS)

PUMY-P112YKM(E)3(-BS)

4HP

Applicable

indoor unit

Branch box

that can be

connected

Capacity

Number of units

Total system wide capacity*

1

Type 15 to Type 100

2 to 8 units

1 to 2 units

24 to 130 % of outdoor unit capacity

(3.0 to 16.2 kW)

Number of units

*

1

Outdoor unit

Ceiling

concealed

4-way

ceiling cassette

Wall

mounted

Model type

Model name

Deluxe

Standard

Compact

Low static pressure

Middle static pressure

2 by 2 type

Standard

MSZ-FH25/35/50VE2

MSZ-SF25/35/42/50VE3

MSZ-GF60/71VE

MSZ-EF18/22/25/35/42/50VE3

MSZ-SF15/20VA

SEZ-KD25/35/50/60/71VAQ(L)

PEAD-RP50/60/71/100JA(L)Q

SLZ-KF25/35/50VA2

PLA-ZRP35/50/60/71/100BA

PLA-RP35/50/60/71/100EA

PCA-RP35/50/60/71/100KAQ

MFZ-KJ25/35/50VE2

MLZ-KA25/35/50VA

Floor standing

Capacity class (kW)

2.2 2.5 3.5 5.0 6.0 7.1 8.0

10.0

Connectable indoor unit lineup (Heat pump inverter type)

Note: The lineup of a connectable indoor unit depends on a district/areas/country.

Branch box

PAC-MK51/52BC(B)

5 branches

(MAX. 5 units)

PAC-MK31/32BC(B)

3 branches

(MAX. 3 units)

Number of branches

Indoor unit that

can be connected

( )

Notes: 1. A maximum of 2 branch boxes can be connected to 1 outdoor unit.

2. When connecting a Cylinder unit or a Hydrobox, use a PAC-MK32/52BC(B) branch box.

Select a model according to the connection method.

2- branch pipe (joint): Optional parts

In case of using 1- branch box

In case of using 2- branch boxes

No need

Model name

Connection method

flare

brazing

MSDD-50AR-E

MSDD-50BR-E

Option

Optional accessories of indoor units and outdoor units are available.

2.01.5

1.8

4.2

1-way ceiling cassette

5HP

21 to 130 % of outdoor unit capacity

(3.0 to 18.2 kW)

19 to 130 % of outdoor unit capacity

(3.0 to 20.2 kW)

Ceiling suspended

Model type

Cylinder unit

Hydrobox

Connectable ecodan unit

Model name

EHST20C series (except EHST20C-MEC)

EHSC series (except EHSC-MEC)

Note: Only 1 Cylinder unit or Hydrobox can be connected.

*

1

When connecting ecodan unit(s), the total capacity of connected

Air to Air indoor units is up to 130% of the outdoor unit. (Air to Air

130% + ecodan). However, when operating Air to Air indoor

unit(s) in heating mode and ecodan unit(s) in DHW or heating

mode at the same time, the total capacity of connected Air to Air

units is below:

· PUMY-P112: 1.3 kW

· PUMY-P125: 2.8 kW

· PUMY-P140: 4.3 kW

However, the following combinations can be connected:

· PUMY-P112: MSZ-SF15VA × 1

· PUMY-P125: MSZ-SF15VA × 2

· PUMY-P140: MSZ-SF15VA × 3

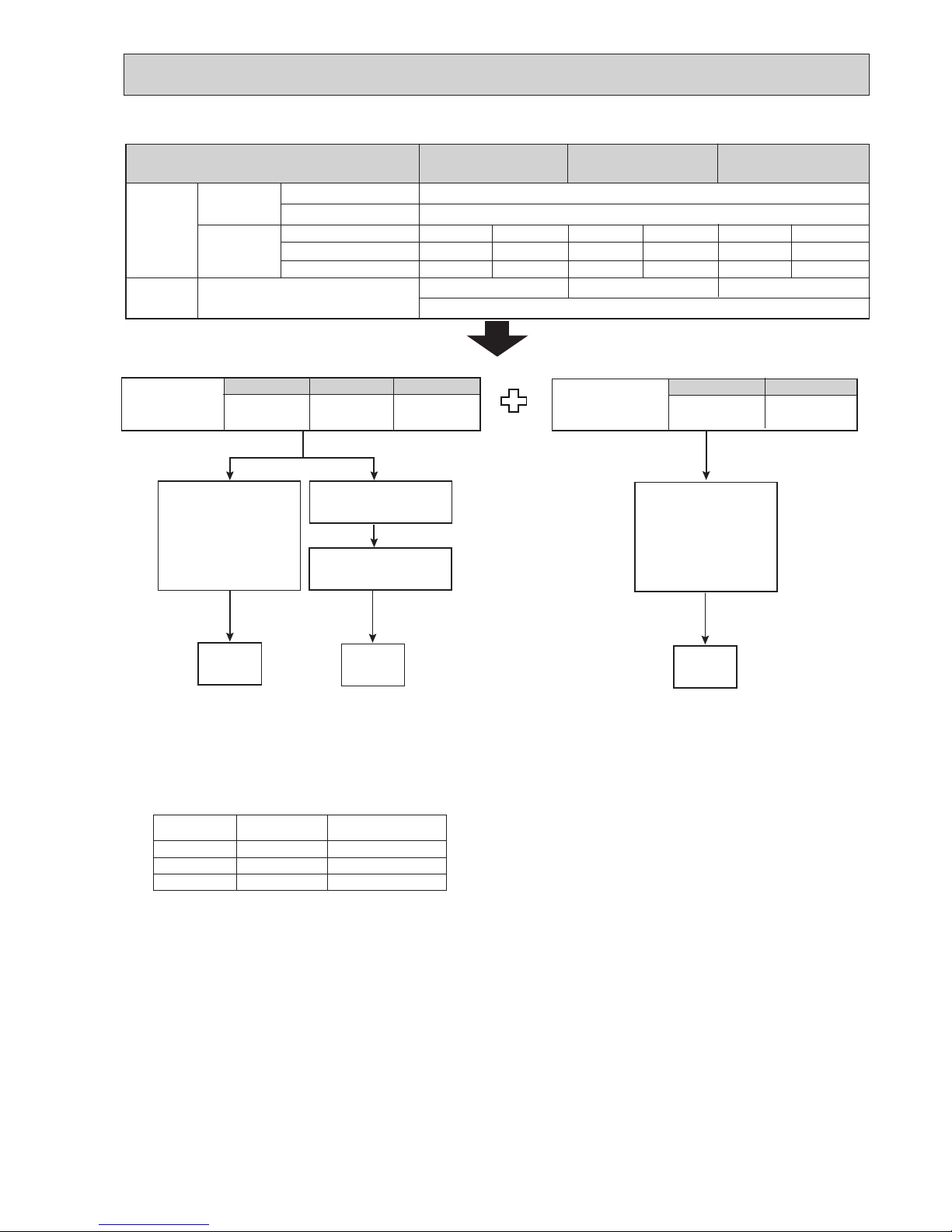

2-2. UNIT CONSTRUCTION (BRANCH BOX SYSTEM)

OCH632A

7

PUMY-P125VKM3(-BS)

PUMY-P125YKM(E)3(-BS)

PUMY-P140VKM3(-BS)

PUMY-P140YKM(E)3(-BS)

Via branch box Citymulti indoor

PUMY-P112VKM3(-BS)

PUMY-P112YKM(E)3(-BS)

Applicable

indoor unit

Capacity

Number

of units*

1

Via branch box Citymulti indoor

5

7 or 8*

2

Outdoor unit

PAC-MK51/52BC(B)

5 branches

(MAX. 5 units)

PAC-MK31/32BC(B)

3 branches

(MAX. 3 units)

Branch box

Number of branches

City multi indoor unit

Via branch box

Type 15 to Type 140

Type 15 to Type 100

1-branch box

2-branch box

Via branch box Citymulti indoor

5

3 or 2*

2

5

8

5

3

5

8

5

3

Total system wide capacity*

1

6.3 to 16.2 kW 7.1 to 18.2 kW 8.0 to 20.2 kW

50 to 130% of outdoor unit capacity

Branching pipe

components

CMY-Y62-G-E

Branch header

(2 branches)

CMY-Y64-G-E

Branch header

(4 branches)

CMY-Y68-G-E

Branch header

(8 branches)

Citymulti indoor units*

3

CONNECTION KIT

PAC-LV11M-J

M series indoor unit

MA

remote

controller

M series

remote

controller

M series

S series

P series

indoor units*

3

Cylinder unit

Hydrobox

MA

remote

controller

*2 When connecting 7 indoor units via branch box, connectable citymulti indoor units are 3; connecting 8 indoor units

via branch box, connectable citymulti indoor units are 2.

*

3

Refer to “2-1. UNIT CONSTRUCTION” or “2-2. UNIT CONSTRUCTION (BRANCH BOX SYSTEM)”, for more detail.

*

1

When connecting ecodan unit, the total capacity of connected Air to Air indoor units is up to 130% of the outdoor

unit. (Air to Air 130% + ecodan). However, when operating Air to Air indoor unit(s) in heating mode and ecodan unit

in DHW or heating mode at the same time, the maximum connectable Air to Air indoor unit is below.

2-3. UNIT CONSTRUCTION (MIXED SYSTEM)

Model ATA total capacity

Can be exceptionally

connected

PUMY-P112 1.3 kW MSZ-SF15VE × 1

PUMY-P125 2.8 kW MSZ-SF15VE × 2

PUMY-P140 4.3 kW MSZ-SF15VE × 3

OCH632A

8

2-4. UNIT SPECIFICATIONS

(2) Method for identifying MULTI-S model

(1) Outdoor Unit

Outdoor unit <When using model 125 >

PU M Y - P 125 Y K M E 3 - BS

Refrigerant

R410A

Indicates equivalent

to Cooling capacity

Power supply

V: Single phase

220/230/240 V, 50 Hz

Y: 3-phase

380/400/415 V, 50 Hz

380 V, 60 Hz (YKM3 only)

Outdoor unit

model type

M-NET

control

Frequency

conversion

controller

Outdoor unit

MULTI-S

(kcal/ h)

Salt proof

type

sub

number

Electrical

box

Service Ref.

Capacity

Cooling (kW)

Heating (kW)

12.5

14.0

2.9

14.0

16.0

3.5

15.5

18.0

3.9

Compressor (kW)

PUMY-P112VKM3(-BS)

PUMY-P112YKM(E)3(-BS)

PUMY-P125VKM3(-BS)

PUMY-P125YKM(E)3(-BS)

PUMY-P140VKM3(-BS)

PUMY-P140YKM(E)3(-BS)

Cooling/Heating capacity indicates the maximum value at operation under the following condition.

*Cooling Indoor : D.B. 27°C/W.B. 19.0°C

Outdoor : D.B. 35°C

Heating Indoor : D.B. 20°C

Outdoor : D.B. 7°C/W.B. 6°C

(3) Operating temperature range

Notes: D.B. : Dry Bulb Temperature

W.B. : Wet Bulb Temperature

*

1

10 to 52°C D.B. : When connecting PKFY-P15/P20/P25VBM, PFFY-P20/25/32VKM, PFFY-P20/25/32VLE(R)M, PEFY-P25/32/40VMA3-E;

and M series, S series, and P series type indoor unit.

Cooling

W.B. 15 to 24°C

D.B. −5 to 52°C

*

1

Heating

D.B. 15 to 27°C

W.B. −20 to 15°C

Indoor-side intake air temperature

Outdoor-side intake air temperature

■

When connecting fresh air type indoor unit

air type indoor

Capacity of Fresh

Cooling

Heating

Indoor-side and Outdoor-side

P80

D.B. 21 to 43:

*

2

W.B. 15.5 to 35:

D.B.−10 to 20:

*

3

intake air temperature

P140

D.B. 21 to 43:

*

2

W.B. 15.5 to 35:

D.B. −5 to 20:

*

3

*2 Thermo-OFF (FAN-mode) automatically starts if the outdoor temp. is lower than 21 : D.B..

*

3

Thermo-OFF (FAN-mode) automatically starts if the outdoor temp. is higher than 20 : D.B..

■ When connecting PWFY unit

Cooling

Heating

Indoor-side intake water temperature

Outdoor-side intake air temperature

• PWFY series can operate in Heating mode but not in Cooling mode. An indoor unit other than that of PWFY series can

operate in Cooling mode.

• A PWFY series and other series cannot operate simultaneously.

• The operation of PWFY series takes precedence over other series. While a PWFY series is operating, other series do not operate.

• The set temperature on the remote controller represents the target temperature of the outlet water.

*

4

*

4

D.B. 10 to 45:

*

4

W.B. −20 to 15:

OCH632A

9

■ When connecting Cylinder unit or Hydrobox

*5 ATA unit: Air to Air unit (other than PWFY, Cylinder unit or Hydrobox)

*

6

Cylinder unit and Hydrobox can not operate Cooling mode in connecting PUMY.

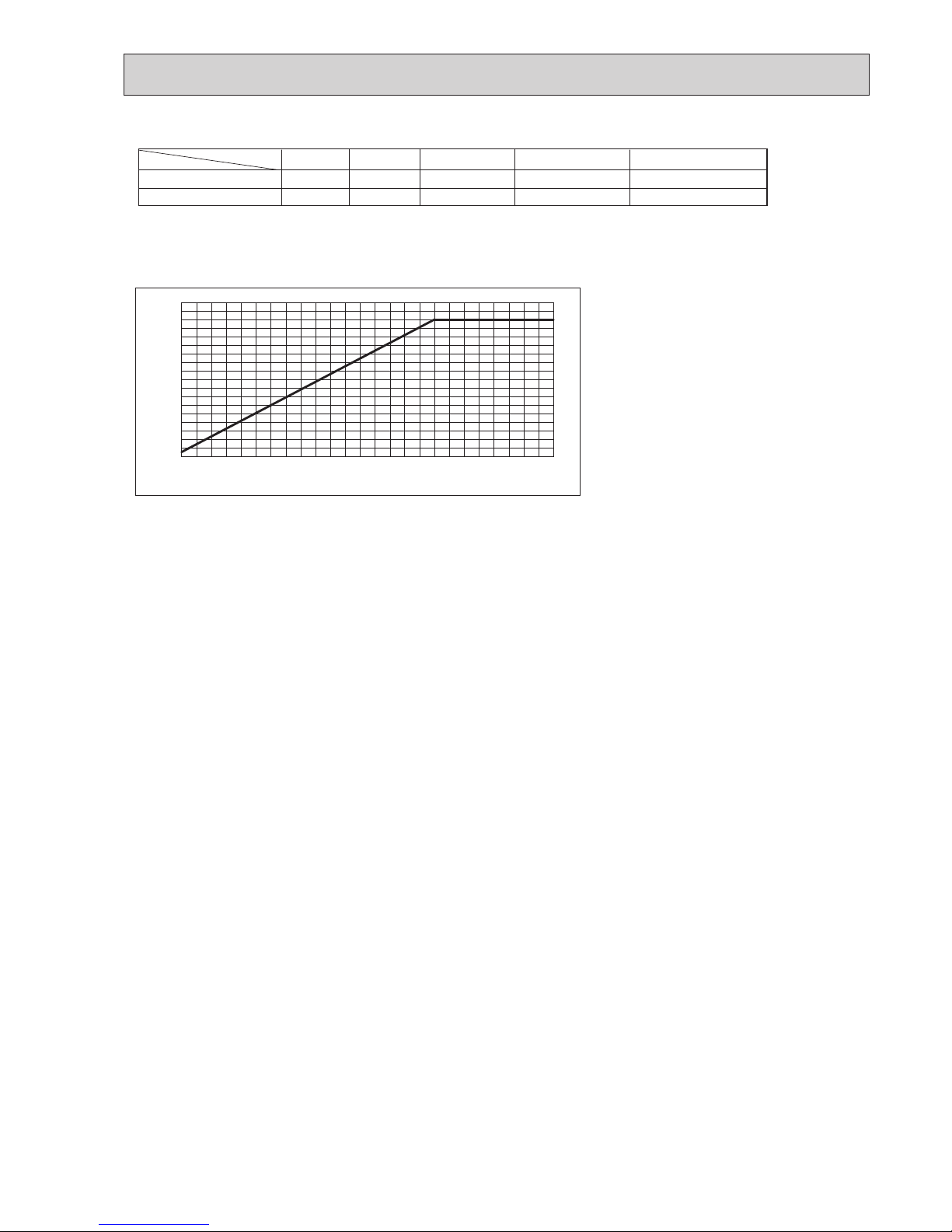

*7 When outdoor temp. is less than 7:, outlet water temp. is lowered (Refer to Figure 1).

Furthermore, outlet air temperature is lowered.

Cooling

—

*

6

—

*

6

Outlet water temperature

Outdoor temperature

DHW only

ATW Heating only

DHW + ATA Heating

*

5

ATW Heating + ATA Heating

*

5

−20 to 35:

−20 to 21:

7 to 35:

−10 to 35:

*

7

55: Max. 55: Max. 55: Max. 45 to 55: Max.

-10 -5 0 5 10 15

39

41

43

45

47

49

51

53

55

57

Outdoor temp. [°CDB]

Max. outlet water temp. [°C]

Figure 1 Temperature change of max. outlet water temp. according to outdoor temperature

OCH632A

10

3

SPECIFICATIONS

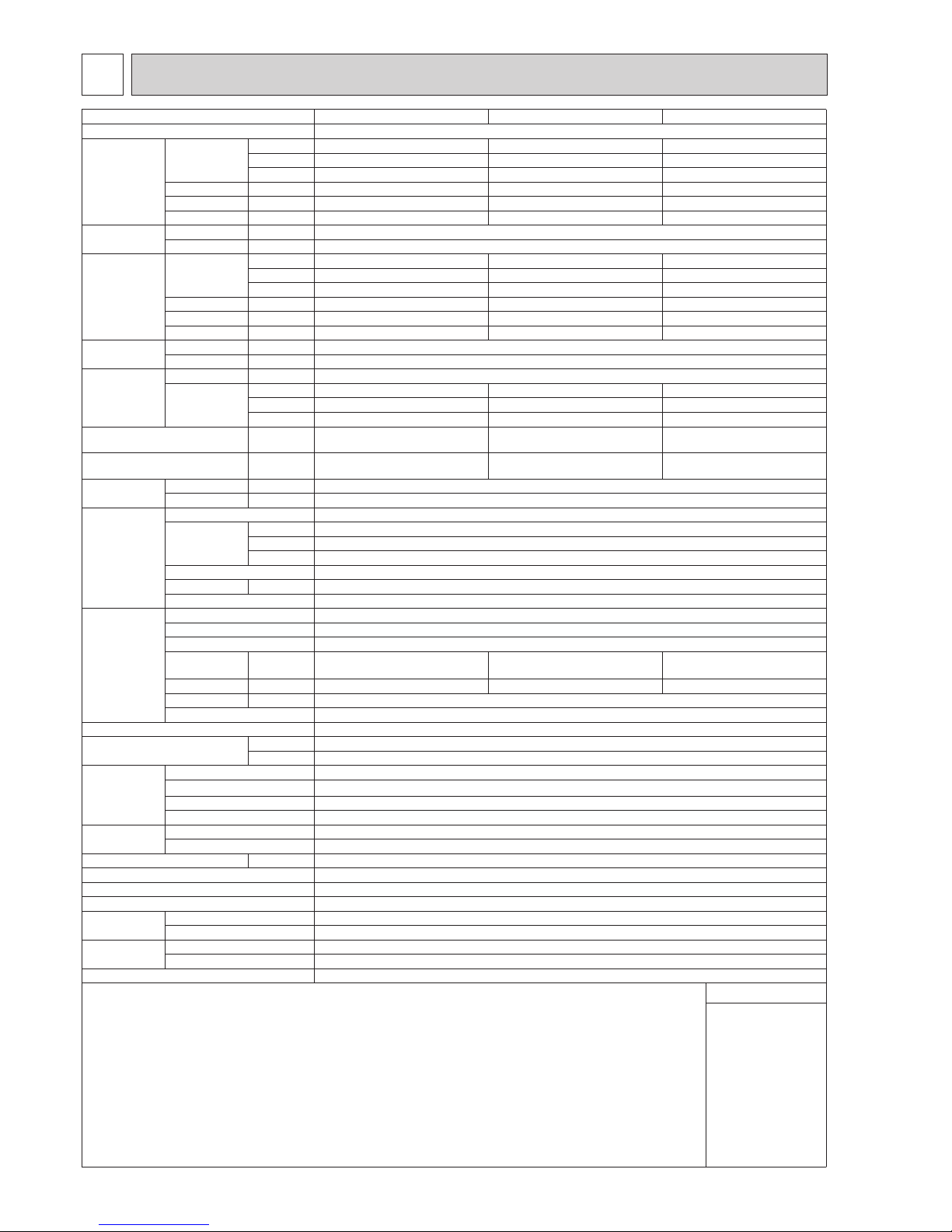

Model PUMY-P112VKM3(-BS) PUMY-P125VKM3(-BS) PUMY-P140VKM3(-BS)

Power source

1-phase 220/230/240 V, 50 Hz; 1-phase 220 V, 60 Hz

Cooling capacity

(Nominal)

kW*

1

12.5 14.0 15.5

kcal/h*

1

10,750 12,040 13,330

BTU/h*

1

42,650 47,768 52,886

Power input kW 2.79 3.46 4.52

Current input A 12.87/12.32/11.80, 12.87 15.97/15.27/14.64, 15.97 20.86/19.95/19.12, 20.86

COP kW/kW 4.48 4.05 3.43

Temp. range of

cooling

Indoor temp. W.B. 15 to 24°C

Outdoor temp. D.B. −5to52°C

*3, *4

Heating capacity

(Nominal)

kW*

2

14.0 16.0 18.0

kcal/h*

2

12,040 13,760 15,480

BTU/h*

2

47,768 54,592 61,416

Power input kW 3.04 3.74 4.47

Current input A 14.03/13.42/12.86, 14.03 17.26/16.51/15.82, 17.26 20.63/19.73/18.91, 20.63

COP kW/kW 4.61 4.28 4.03

Temp. range of

heating

Indoor temp. D.B. 15 to 27°C

Outdoor temp. W.B. −20to15°C

Indoor unit

connectable

Total capacity 50 to 130% of outdoor unit capacity

Model/ Quantity Citymulti 15 - 140/9 15 - 140/10 15 - 140/12

Branch box 15 - 100/8 15 - 100/8 15 - 100/8

Mixed system

15 - 140*5/10 15 - 140*5/10*

6

15 - 140*5/10*

6

Sound pressure level

(measured in anechoic room)

dB <A>

49/51 50/52 51/53

Power pressure level

(measured in anechoic room)

dB <A>

69/71 70/72 71/73

Refrigerant

piping diameter

Liquid pipe mm (inch) 9.52 (3/8)

Gas pipe mm (inch) 15.88 (5/8)

FAN *2 Type × Quantity Propeller Fan x 2

Airowrate m³/min 110

L/s 1,833

cfm 3,884

Control, Driving mechanism DC control

Motor output kW 0.06+0.06

External static press. 0

Compressor Type × Quantity Scroll hermetic compressor x 1

Manufacture Mitsubishi Electric Corporation

Starting method Inverter

Capacity control % Cooling 26 to 100

Heating 20 to 100

Cooling 24 to 100

Heating 18 to 100

Cooling 21 to 100

Heating 17 to 100

Motor output kW 2.9 3.5 3.9

Case heater kW 0

Lubricant FV50S (2.3litter)

Externalnish Galvanized Steel Sheet Munsell No. 3Y 7.8/1.1

External dimension H × W × D mm 1,338 × 1,050 × 330(+25)

inch 52-11/16 × 41-11/ 32 × 13 (+1)

Protection

devices

High pressure protection High pressure Switch

Inverter circuit (COMP./FAN)

Overcurrent detection, Overheat detection(Heat sink thermistor)

Compressor Compressor thermistor, Overcurrent detection

Fan motor Overheating, Voltage protection

Refrigerant Type × original charge R410A 4.8 kg

Control Electronic expansion valve

Net weight kg (lb) 122 (269)

Heat exchanger Cross Fin and Copper tube

HIC circuit (HIC: Heat Inter-Changer) HIC circuit

Defrosting method Reversed refrigerant circuit

Drawing External BK01N346

Wiring BH78B813

Standard

attachment

Document Installation Manual

Accessory Grounded lead wire x2

Optional parts Joint: CMY-Y62-G-E, Header: CMY-Y64/68-G-E, Branch box: PAC-MK31/32/51/52BC(B)

Remarks

Unit converter

kcal/h = kW × 860

BTU/h = kW × 3,412

cfm = m³/min × 35.31

lb = kg/0.4536

Abovespecicationdatais

subject to rounding

variation.

*1 Nominal cooling conditions *2 Nominal heating conditions

Indoor :

27°C D.B./19°C W.B. [81°F D.B/66°F W.B.]

20°C D.B. [68°F D.B.]

Outdoor : 35°C D.B. [95°F D.B.]

7°C DB/6°C W.B. [45°F D.B./43°F W.B.]

Pipe length : 7.5 m [24-9/16 ft] 7.5 m [24-9/16 ft]

Level difference : 0 m [0 ft] 0 m [0 ft]

Notes : 1. Nominal conditions *

1

, *2 are subject to ISO 15042.

2.Duetocontinuingimprovement,abovespecicationsmaybesubjecttochangewithoutnotice.

*3 10 to 52:D.B. [50 to 126_F D.B.], when connecting following models: PKFY-P15/20/25VBM, PFFY-P20/25/32VLE(R)M, PFFY-

P20/25/32VKM, PEFY-P25/32/40VMA3; and M series, S series, and P series type indoor unit.

*4−15to52:D.B. [50 to 126_F D.B.], when using an optional air protect guide [PAC-SH95AG-E]. However, this condition does not

apply to the indoor unit listed in *3.

*5

Up to P100 when connecting via branch box.

*6

Up to 11 units when connecting via 2 branch boxes.

OCH632A

11

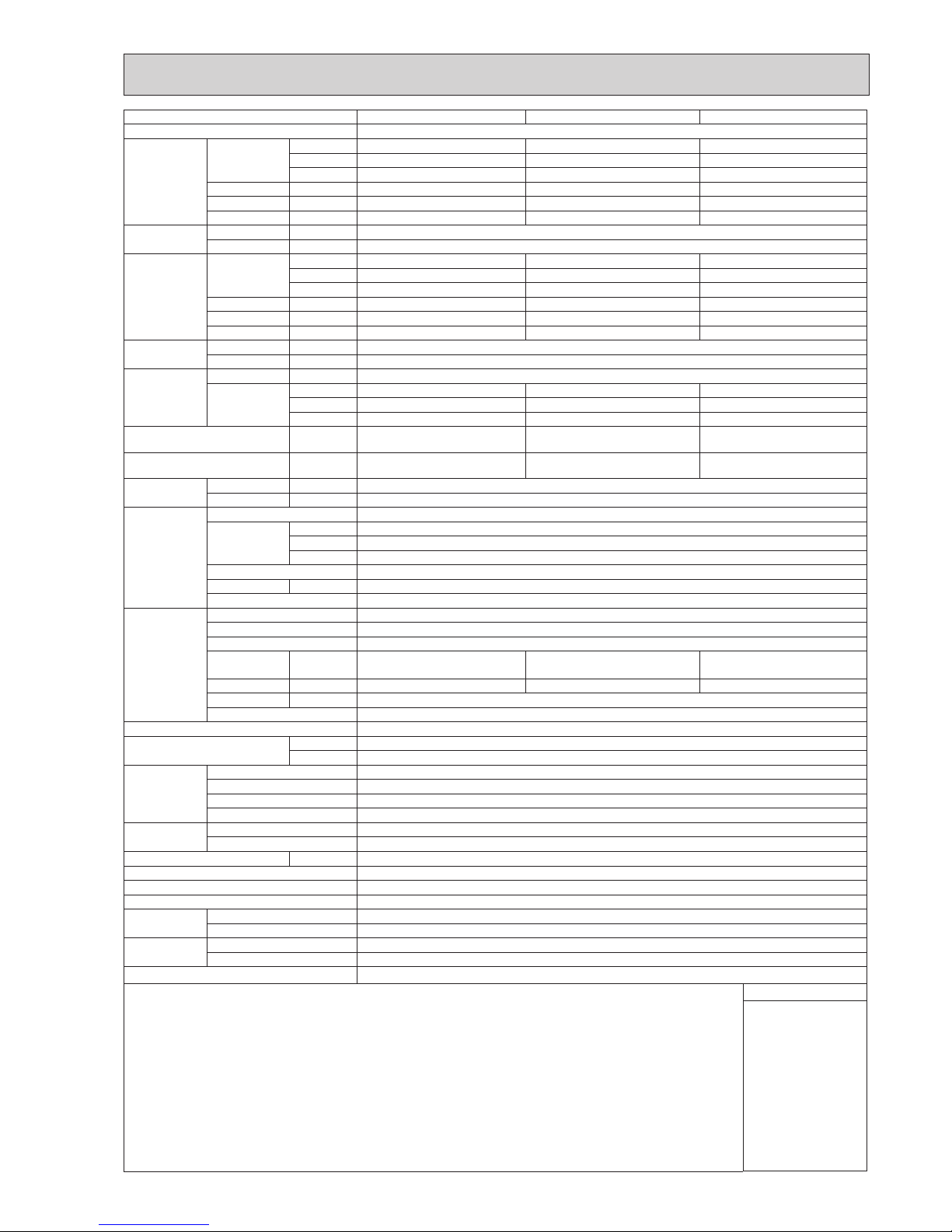

Model PUMY-P112YKM3(-BS) PUMY-P125YKM3(-BS) PUMY-P140YKM3(-BS)

Power source 3-phase 380/400/415 V, 50 Hz; 3-phase 380 V, 60 Hz

Cooling capacity

(Nominal)

kW *

1

12.5 14.0 15.5

kcal/h *

1

10,750 12,040 13,330

BTU/h *

1

42,650 47,768 52,886

Power input kW 2.79 3.46 4.52

Current input A 4.99/4.74/4.57, 4.99 5.84/5.55/5.35, 5.84 7.23/6.87/6.62, 7.23

COP kW/kW 4.48 4.05 3.43

Temp. range of

cooling

Indoor temp. W.B.

15 to 24°C

Outdoor temp. D.B. −5to52°C

*3, *4

Heating capacity

(Nominal)

kW *

2

14.0 16.0 18.0

kcal/h *

2

12,040 13,760 15,480

BTU/h *

2

47,768 54,592 61,416

Power input kW 3.04 3.74 4.47

Current input A 5.43/5.16/4.98, 5.43 6.31/6.00/5.78, 6.31 7.15/6.79/6.55, 7.15

COP kW/kW 4.61 4.28 4.03

Temp. range of

heating

Indoor temp. D.B. 15 to 27°C

Outdoor temp. W.B. −20to15°C

Indoor unit

connectable

Total capacity 50 to 130% of outdoor unit capacity

Model/Quantity Citymulti 15 - 140/9 15 - 140/10 15 - 140/12

Branch box 15 - 100/8 15 - 100/8 15 - 100/8

Mixed system

15 - 140*5/10 15 - 140*5/10*

6

15 - 140*5/10*

6

Sound pressure level

(measured in anechoic room)

dB <A>

49/51 50/52 51/53

Power pressure level

(measured in anechoic room)

dB <A>

69/71 70/72 71/73

Refrigerant

piping diameter

Liquid pipe mm (inch) 9.52 (3/8)

Gas pipe mm (inch) 15.88 (5/8)

FAN *2 Type × Quantity Propeller Fan × 2

Airowrate K/min 110

L/s 1,833

cfm 3,884

Control, Driving mechanism DC control

Motor output kW 0.06+0.06

External static press. 0

Compressor Type x Quantity Scroll hermetic compressor × 1

Manufacture Mitsubishi Electric Corporation

Starting method Inverter

Capacity control % Cooling 26 to 100

Heating 20 to 100

Cooling 24 to100

Heating 18 to 100

Cooling 21 to 100

Heating 17 to 100

Motor output kW 2.9 3.5 3.9

Case heater kW 0

Lubricant FV50S(2.3litter)

Externalnish Galvanized Steel Sheet Munsell No. 3Y 7.8/1.1

External dimension H × W × D mm 1338 × 1050 × 330(+25)

inch 52-11/16 × 41-11/32 × 13 (+1)

Protection

devices

High pressure protection High pressure Switch

Inverter circuit (COMP./FAN) Overcurrent detection, Overheat detection(Heat sink thermistor)

Compressor Compressor thermistor, Over current detection

Fan motor Overheating, Voltage protection

Refrigerant Type × original charge R410A 4.8 kg

Control

Electronic expansion valve

Net weight kg (lb) 125 (276)

Heat exchanger Cross Fin and Copper tube

HIC circuit (HIC: Heat Inter-Changer) HIC circuit

Defrosting method Reversed refrigerant circuit

Drawing External BK01N339

Wiring BH78B814

Standard

attachment

Document Installation Manual

Accessory Grounded lead wire x2

Optional parts

Joint: CMY-Y62-G-E, Header: CMY-Y64/68-G-E, Branch box: PAC-MK31/32/51/52BC(B)

Unit converter

kcal/h = kW × 860

BTU/h = kW × 3,412

cfm = m³/min × 35.31

lb = kg/0.4536

Abovespecicationdatais

subject to rounding

variation

.

*1 Nominal cooling conditions *2 Nominal heating conditions

Indoor :

27°C D.B./19°C W.B. [81°F D.B/66°F W.B.]

20°C D.B. [68°F D.B.]

Outdoor : 35°C D.B. [95°F D.B.]

7°C DB/6°C W.B. [45°F D.B./43°F W.B.]

Pipe length : 7.5 m [24-9/16 ft] 7.5 m [24-9/16 ft]

Level difference : 0 m [0 ft] 0 m [0 ft]

Remarks:

Notes : 1. Nominal conditions *

1

, *2 are subject to ISO 15042.

2.Duetocontinuingimprovement,abovespecicationsmaybesubjecttochangewithoutnotice.

*3 10 to 52:D.B. [50 to 126_F D.B.], when connecting following models: PKFY-P15/20/25VBM, PFFY-P20/25/32VLE(R)M, PFFY-

P20/25/32VKM, PEFY-P25/32/40VMA3; and M series, S series, and P series type indoor unit.

*4−15to52:D.B. [50 to 126_F D.B.], when using an optional air protect guide [PAC-SH95AG-E]. However, this condition does not

apply to the indoor unit listed in *3.

*5

Up to P100 when connecting via branch box.

*6

Up to 11 units when connecting via 2 branch boxes.

OCH632A

12

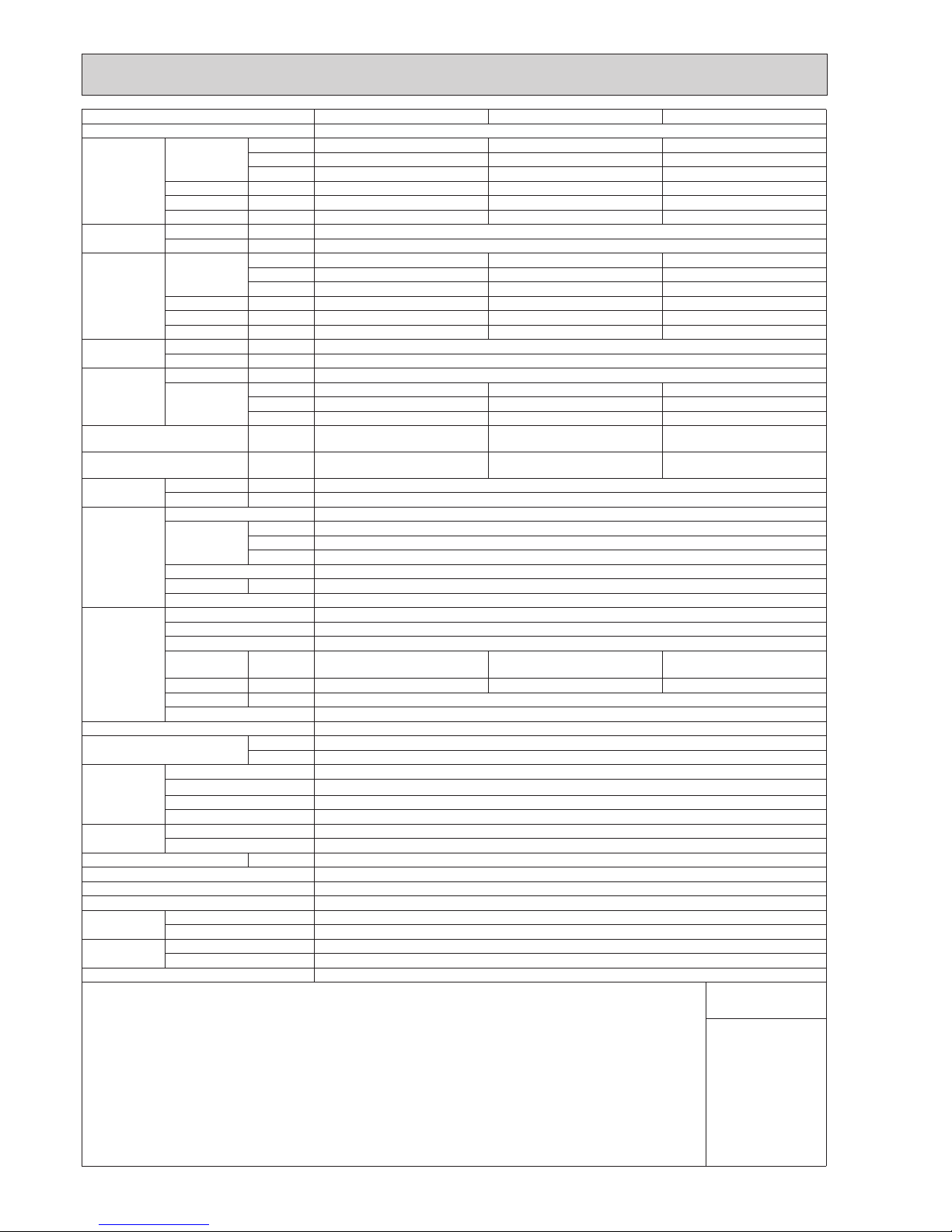

Model PUMY-P112YKME3(-BS) PUMY-P125YKME3(-BS) PUMY-P140YKME3(-BS)

Power source 3-phase 380/400/415 V, 50 Hz

Cooling capacity

(Nominal)

kW*

1

12.5 14.0 15.5

kcal/h*

1

10,750 12,040 13,330

BTU/h*

1

42,650 47,768 52,886

Power input kW 2.79 3.46 4.52

Current input A 4.46/4.24/4.09 5.53/5.26/5.07 7.23/6.87/6.62

COP kW/kW 4.48 4.05 3.43

Temp. range of

cooling

Indoor temp. W.B. 15 to 24°C

Outdoor temp. D.B. −5to52°C

*3, *4

Heating capacity

(Nominal)

kW*

2

14.0 16.0 18.0

kcal/h*

2

12,040 13,760 15,480

BTU/h*

2

47,768 54,592 61,416

Power input kW 3.04 3.74 4.47

Current input A 4.86/4.62/4.45 5.98/5.68/5.48 7.15/6.79/6.55

COP kW/kW 4.61 4.28 4.03

Temp. range of

heating

Indoor temp. D.B. 15 to 27°C

Outdoor temp. W.B. −20to15°C

Indoor unit

connectable

Total capacity 50 to 130% of outdoor unit capacity

Model/Quantity Citymulti 15 - 140/9 15 - 140/10 15 - 140/12

Branch box 15 - 100/8 15 - 100/8 15 - 100/ 8

Mixed system

15 - 140*

5

/10 15 - 140*5/10*

6

15 - 140*5/10*

6

Sound pressure level

(measured in anechoic room)

dB <A>

49/51 50/52 51/ 53

Power pressure level

(measured in anechoic room)

dB <A>

69/71 70/72 71/73

Refrigerant

piping diameter

Liquid pipe mm (inch) 9.52 (3/8)

Gas pipe mm (inch) 15.88 (5/8)

FAN *2 Type × Quantity Propeller Fan × 2

Airowrate K/min 110

L/s 1,833

cfm 3,884

Control, Driving mechanism DC control

Motor output kW 0.06+0.06

External static press. 0

Compressor Type × Quantity Scroll hermetic compressor × 1

Manufacture Mitsubishi Electric Corporation

Starting method Inverter

Capacity control % Cooling 26 to 100

Heating 20 to 100

Cooling 24 to 100

Heating 18 to 100

Cooling 21 to 100

Heating 17 to 100

Motor output kW 2.9 3.5 3.9

Case heater kW 0

Lubricant FV50S(2.3litter)

Externalnish Galvanized Steel Sheet Munsell No. 3Y 7.8/1.1

External dimension HxWxD mm 1,338 × 1,050 × 330(+25)

inch 52-11/16 × 41-11/32 × 13 (+1)

Protection

devices

High pressure protection High pressure Switch

Inverter circuit (COMP./FAN)

Overcurrent detection, Overheat detection(Heat sink thermistor)

Compressor Compressor thermistor, Over current detection

Fan motor Overheating, Voltage protection

Refrigerant Type × original charge R410A 4.8kg

Control Electronic expansion valve

Net weight kg (lb) 136 (300)

Heat exchanger Cross Fin and Copper tube

HIC circuit (HIC: Heat Inter-Changer) HIC circuit

Defrosting method Reversed refrigerant circuit

Drawing External BK01N339

Wiring BH78J358

Standard

attachment

Document Installation Manual

Accessory Grounded lead wire x2

Optional parts Joint: CMY-Y62-G-E, Header: CMY-Y64/68-G-E, Branch box: PAC-MK31/32/51/52BC(B)

Remarks

Unit converter

kcal/h = kW × 860

BTU/h = kW × 3,412

cfm = m³/min × 35.31

lb = kg/0.4536

Abovespecicationdatais

subject to rounding

variation.

*1 Nominal cooling conditions *2 Nominal heating conditions

Indoor :

27°C D.B./19°C W.B. [81°F D.B/66°F W.B.]

20°C D.B. [68°F D.B.]

Outdoor : 35°C D.B. [95°F D.B.]

7°C DB/6°C W.B. [45°F D.B./43°F W.B.]

Pipe length : 7.5 m [24-9/16 ft] 7.5 m [24-9/16 ft]

Level difference : 0 m [0 ft] 0 m [0 ft]

Notes : 1. Nominal conditions *

1

, *2 are subject to ISO 15042.

2.Duetocontinuingimprovement,abovespecicationsmaybesubjecttochangewithoutnotice.

*3 10 to 52:D.B. [50 to 126_F D.B.], when connecting following models: PKFY-P15/20/25VBM, PFFY-P20/25/32VLE(R)M, PFFY-

P20/25/32VKM, PEFY-P25/32/40VMA3; and M series, S series, and P series type indoor unit.

*4−15to52:D.B. [50 to 126_F D.B.], when using an optional air protect guide [PAC-SH95AG-E]. However, this condition does not

apply to the indoor unit listed in *3.

*5

Up to P100 when connecting via branch box.

*6

Up to 11 units when connecting via 2 branch boxes.

OCH632A

13

4

Capacity of indoor unit

Model 20

Model Number

for indoor unit

Model

Capacity

2.2

Model 15

1.7

Model 25

2.8

Model 32

3.6

Model 40

4.5

Model 50

5.6

Model 63

7.1

Model 71

8.0

Model 80

9.0

Model 100

11.2

Model 125

14.0

Model 140

16.0

Model

Capacity

2.01.5 2.2 2.5 3.5 4.2 5.0 6.0 7.1

P•FY Series

M Series

S Series

P Series

Model 20

Model Number

for indoor unit

Model 15 Model 22 Model 25 Model 35 Model 42 Model 50 Model 60 Model 71

1.8

Model 18

8.0

Model 80

10.0

Model 100

DATA

Indoor Temperature [°CW.B.]

Ratio of cooling capacity

15 16 17 18 19 20 21 22 23 24

0.4

0.6

0.8

1.0

1.2

<Cooling>

Design Condition

Outdoor Design Dry Bulb Temperature 40ºC

Total Cooling Load 9.0 kW

Room1

Indoor Design Dry Bulb Temperature 27ºC

Indoor Design Wet Bulb Temperature 20ºC

Cooling Load 4.0 kW

Room2

Indoor Design Dry Bulb Temperature 24ºC

Indoor Design Wet Bulb Temperature 18ºC

Cooling Load 4.5 kW

<Other>

Indoor/Outdoor Equivalent Piping Length 100 m

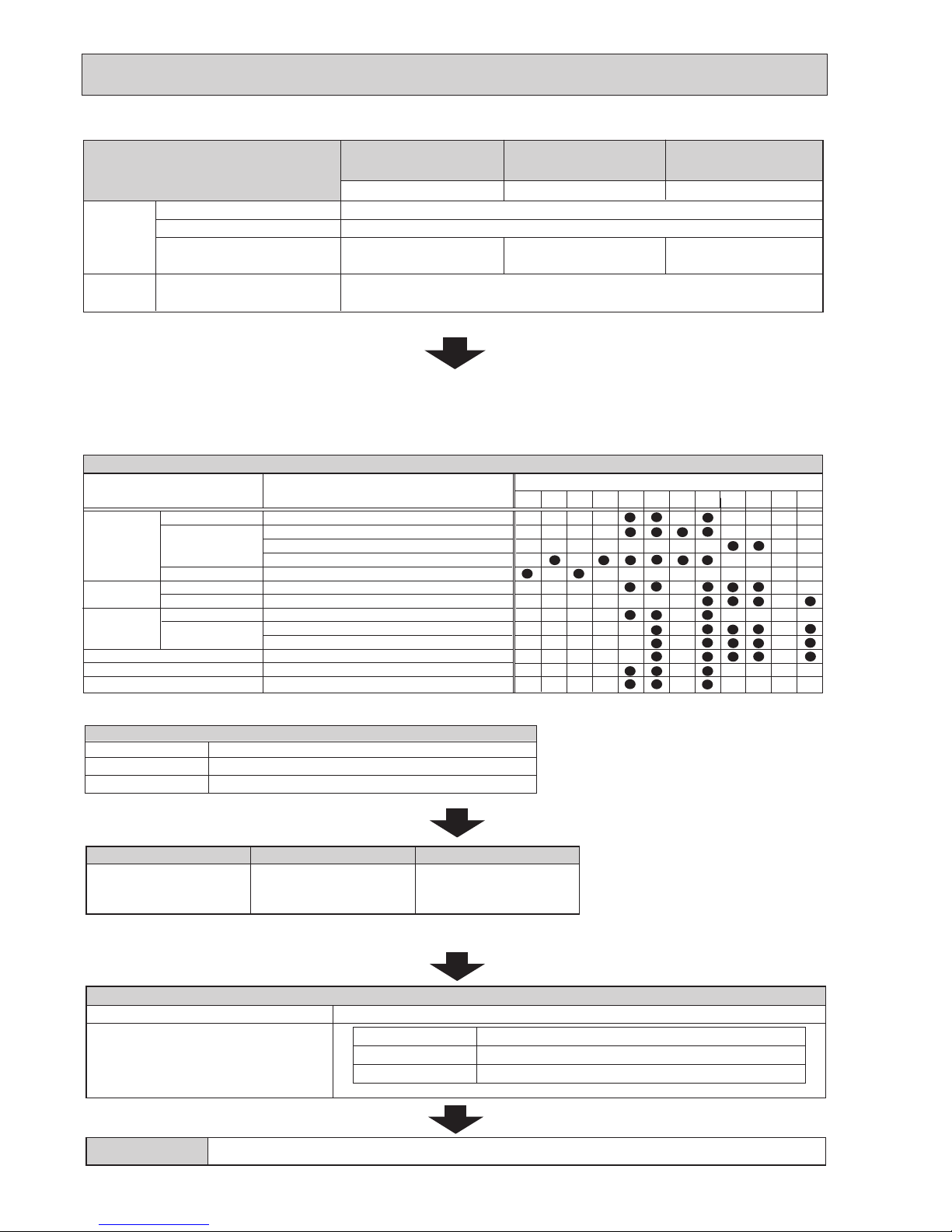

1. Cooling Calculation

(1) Temporary Selection of Indoor Units

Room1

PEFY-P40 4.5 kW (Rated)

Room2

PEFY-P50 5.6 kW (Rated)

(2) Total Indoor Units Capacity

P40 + P50 = P90

(3) Selection of Outdoor Unit

The P112 outdoor unit is selected as total indoor units capacity is P90

PUMY-P112 12.5 kW

(4) Total Indoor Units Capacity Correction Calculation

Room1

Indoor Design Wet Bulb Temperature Correction (20ºC)

1.04 (Refer to Figure 1)

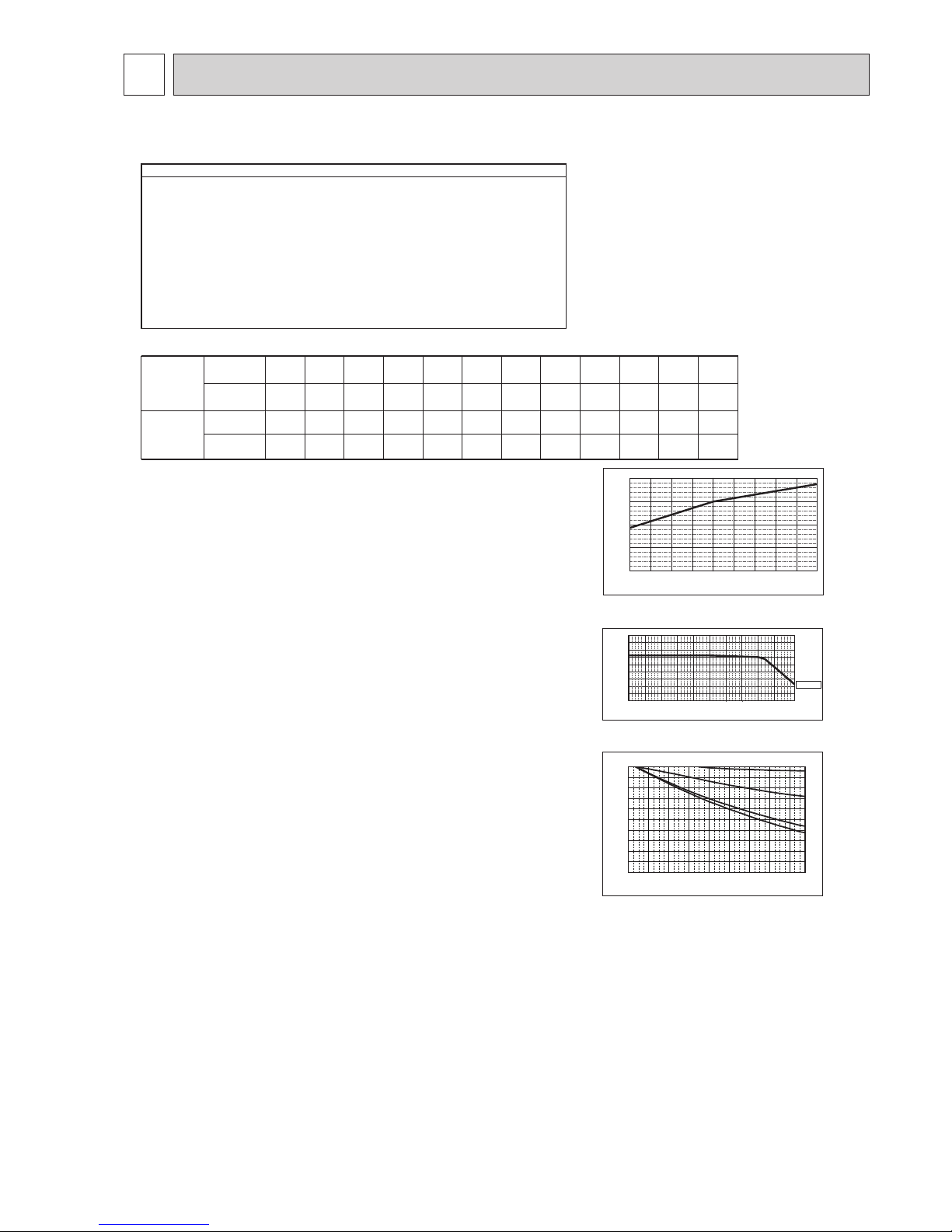

Figure 1

Indoor unit temperature correction

To be used to correct indoor unit only

Figure 2 Outdoor unit temperature correction

To be used to correct outdoor unit only

Figure 3

Correction of refrigerant piping length

Room2

Indoor Design Wet Bulb Temperature Correction (18ºC)

0.90 (Refer to Figure 1)

CTi = Σ (Indoor Unit Rating × Indoor Design Temperature Correction)

= 4.5 × 1.04 + 5.6 × 0.90

= 9.7 kW

(5) Outdoor Unit Correction Calculation

Outdoor Design Dry Bulb Temperature Correction (40ºC)

0.86 (Refer to Figure 2)

Piping Length Correction (160 m)

0.85 (Refer to Figure 3)

Total Outdoor Unit Capacity (CTo)

Total Indoor Units Capacity (CTi)

CTo = Outdoor Rating × Outdoor Design Temperature Correction × Piping Length Correction

= 12.5 × 0.86 × 0.85

= 9.14 kW

(6) Determination of Maximum System Capacity

Comparison of Capacity between Total Indoor Units Capacity (CTi) and Total Outdoor Unit Capacity (CTo)

CTi = 9.7 > CTo = 9.14, thus, select CTo.

CTx = CTo = 9.14 kW

(7) Comparison with Essential Load

Against the essential load 9.0kW, the maximum system capacity is 9.14 kW: Proper outdoor units have been selected.

(8) Calculation of Maximum Indoor Unit Capacity of Each Room

CTx = CTo, thus, calculate by the calculation below

Room1

Maximum Capacity × Room1 Capacity after the Temperature Correction/(Room1,2 Total Capacity after the Temperature Correction

= 9.14 × (4.5 × 1.04)/(4.5 × 1.04 + 5.6 × 0.90)

= 4.4 kW

OK: fulfills the load 4.0 kW

Room2

Maximum Capacity × Room2 Capacity after the Temperature Correction/(Room1,2 Total Capacity after the Temperature Correction)

= 9.14 × (5.60 × 0.90)/(4.5 × 1.04 + 5.6 × 0.90)

= 4.7 kW OK: fulfills the load 4.5 kW

Go on to the heating trial calculation since the selected units fulfill the cooling loads of Room 1, 2.

Ratio of cooling capacity

°CD.B.

19°C W.B.

Indoor

Temperature

Total capacity of indoor unit

Outdoor Temperature

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

−5 0 5 10 15 20 25 3 0 35

40

45

Cooling capacity correction factor

0.50

0.55

0.60

0.65

0.70

0.75

0.80

0.85

0.90

0.95

1.00

0 20 40 60 80 1 00 120 140 160

Piping equivalent length (m)

6.3

12.5

9.4

16.2

Note: If CTx = CTi, please refer to the <Heating> section to calculate the Maximum Indoor Unit Capacity of Each Room.

4-1. SELECTION OF COOLING/HEATING UNITS

OCH632A

14

Capacity of indoor unit

Model 20

Model Number

for indoor unit

Model

Capacity

2.5

Model 15

1.9

Model 25

3.2

Model 32

4.0

Model 40

5.0

Model 50

6.3

Model 63

8.0

Model 71

9.0

Model 80

10.0

Model 100

12.5

Model 125

16.0

Model 140

18.0

Model

Capacity

2.31.7 2.5 2.9 4.0 4.8 5.7 6.9 8.1

P•FY Series

M Series

S Series

P Series

Model 20

Model Number

for indoor unit

Model 15 Model 22 Model 25

Model 35

Model 42 Model 50 Model 60 Model 71

2.1

Model 18

9.3

Model 80

11.2

Model 100

<Hea ting>

Design Condition

Outdoor Design Wet Bulb Temperature 2ºC

Total Heating Load 10.3 kW

Room1

Indoor Design Dry Bulb Temperature 21ºC

Heating Load

4.8 kW

Room2

Indoor Design Dry Bulb Temperature 23ºC

Heating Load

5.5 kW

<Other>

Indoor/Outdoor Equivalent Piping Length 100 m

2. Hea ting Calcula tion

(1) Temporary Selection of Indoor Units

Room1

PEFY-P40 5.0 kW (Rated)

Room2

PEFY-P50 6.3 kW (Rated)

(2) Total Indoor Units Capacity

P40 + P50 = P90

(3) Selection of Outdoor Unit

The P112 outdoor unit is selected as total indoor units capacity is P90

PUMY-P112 14.0 kW

(4) Total Indoor Units Capacity Correction Calculation

Room1

Indoor Design Dry Bulb Temperature Correction (21ºC)

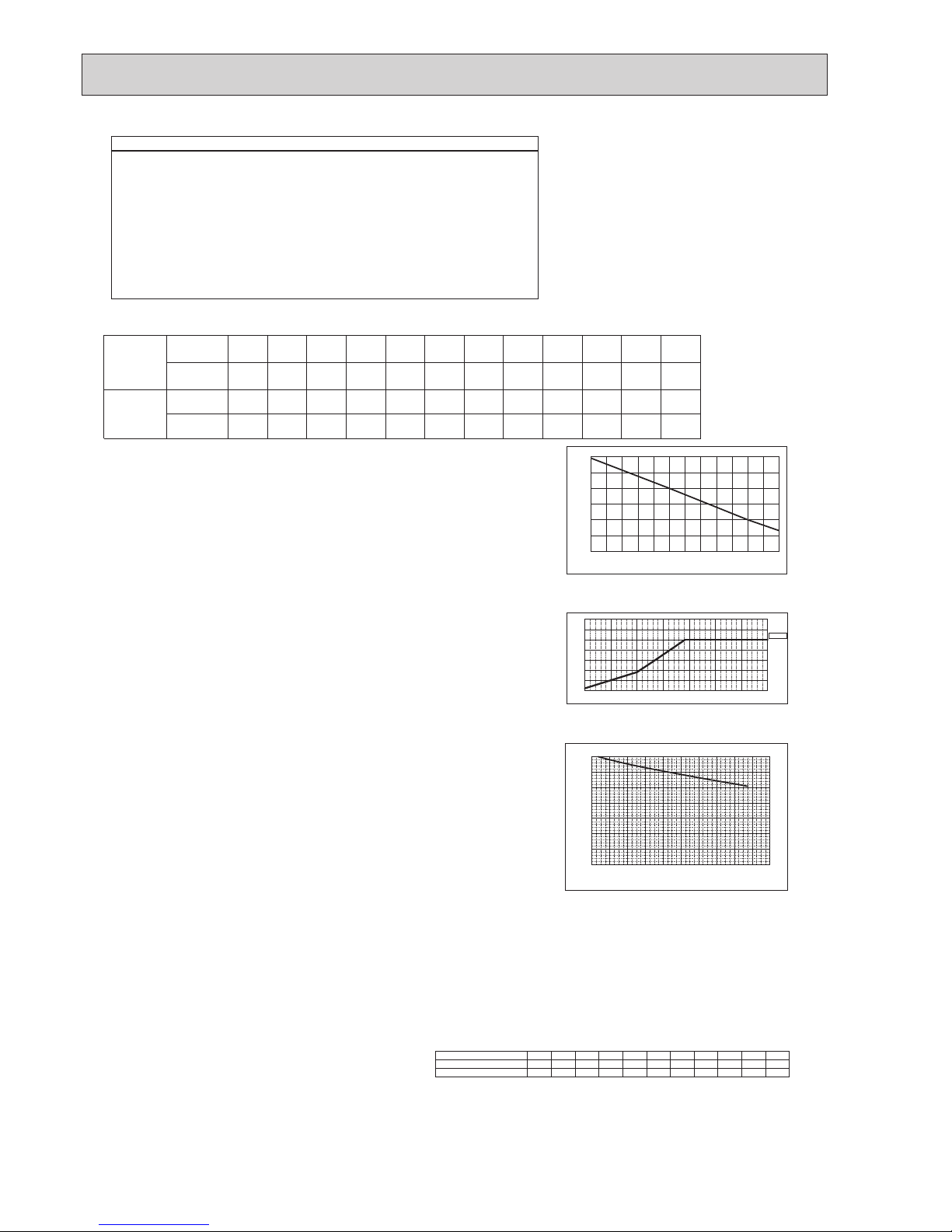

0.96 (Refer to Figure 4)

Table 1 Table of correction factor at frost and defrost

Room2

Indoor Design Dry Bulb Temperature Correction (23ºC)

0.88 (Refer to Figure 4)

CTi = Σ (Indoor Unit Rating × Indoor Design Temperature Correction)

= 5.0 × 0.96 + 6.3 × 0.88

= 10.3 kW

(5) Outdoor Unit Correction Calculation

Outdoor Design Wet Bulb Temperature Correction (2ºC)

1.0 (Refer to Figure 5)

Piping Length Correction (100 m)

Defrost Correction

0.94 (Refer to Figure 6)

0.89 (Refer to Table 1)

Total Outdoor Unit Capacity (CTo)

Total Indoor Units Capacity (CTi)

CTo = Outdoor Unit Rating × Outdoor Design Temperature Correction × Piping Length

Correction × Defrost Correction

= 14.0 × 1.0 × 0.94 × 0.89

= 11.7 kW

(6) Determination of Maximum System Capacity

Comparison of Capacity between Total Indoor Units Capacity (CTi) and Total Outdoor Unit Capacity (CTo)

CTi = 10.3 < CTo = 11.7, thus, select CTi.

CTx = CTi = 10.3 kW

(7) Comparison with Essential Load

Against the essential load 10.3kW, the maximum system capacity is 10.3 kW: Proper indoor units have been selected.

(8) Calculation of Maximum Indoor Unit Capacity of Each Room

CTx = CTo, thus, calculate by the calculation below

Room1

Indoor Unit Rating × Indoor Design Temperature Correction

= 5.0 × 0.96

= 4.8 kW OK: fulfills the load 4.8 kW

Room2

Indoor Unit Rating

× Indoor Design Temperature Correction

= 6.3× 0.88

= 5.5 kW OK: fulfills the load 5.5 kW

Completed selecting units since the selected units fulfill the heating loads of Room 1, 2.

Figure 4 Indoor unit temperature correction

To be used to correct indoor unit only

Figure 5 Outdoor unit temperature correction

To be used to correct outdoor unit only

Figure 6 Correction of refrigerant piping length

1

0.90

0.80

0.95

0.85

0.75

0.65

0.70

200 40 60 80 100 120 140 160 180 200

Heating capacity correction factor

Piping equivalent length (m)

15 16 17 18 19 20 21 22 23 24 25 26 27

0.6

0.7

0.8

0.9

1.0

1.1

1.2

Ratio of heating capacity

Indoor Temperature [°CD.B.]

−20 −15 −10 −5 0 5 10 15

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

Ratio of heating capacity

Outdoor Temperature [°C W.B.]

20°C D.B

Note: If CTx = CTo, please refer to the <Cooling> section to calculate the Maximum Indoor Unit Capacity of Each Room.

Outdoor inlet air temp. °C 6 4 2 0

−2 −4 −6 −8 −10 −15 −20

PUMY-P112,125,140VKM3 1.0 0.98 0.89 0.88 0.89 0.90 0.95 0.95 0.95 0.95 0.95

PUMY-P112,125,140YKM(E)3 1.0 0.98 0.89 0.88 0.89 0.90 0.95 0.95 0.95 0.95 0.95

OCH632A

15

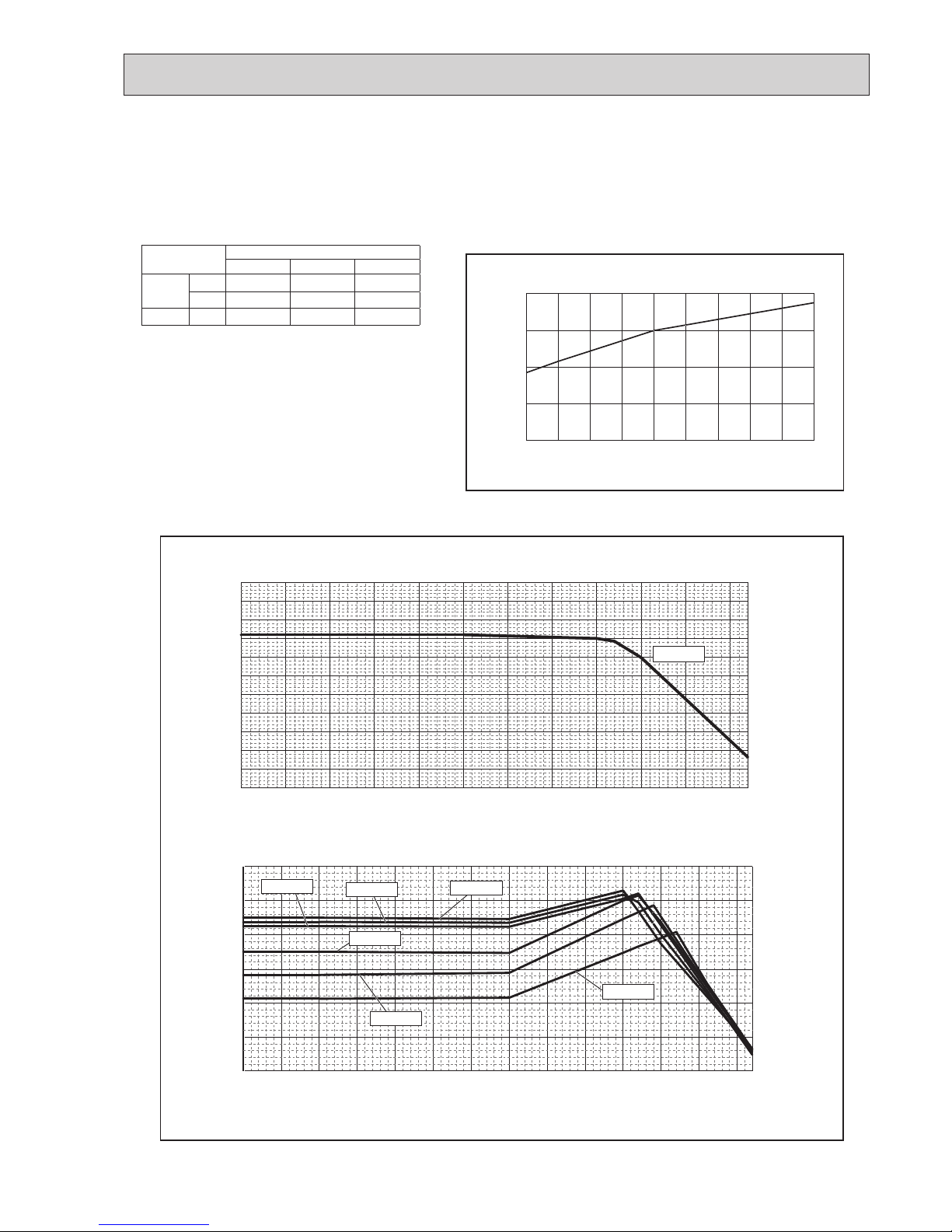

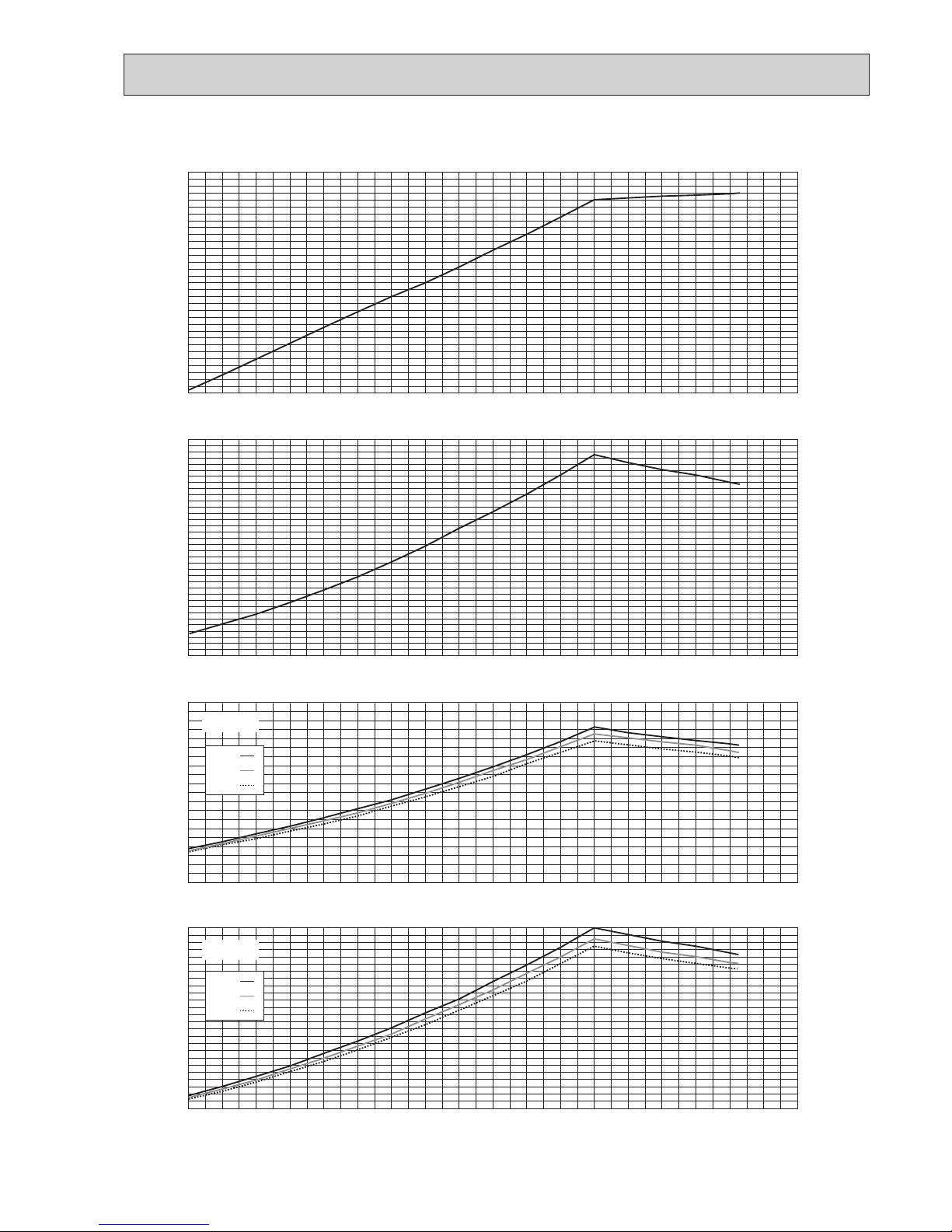

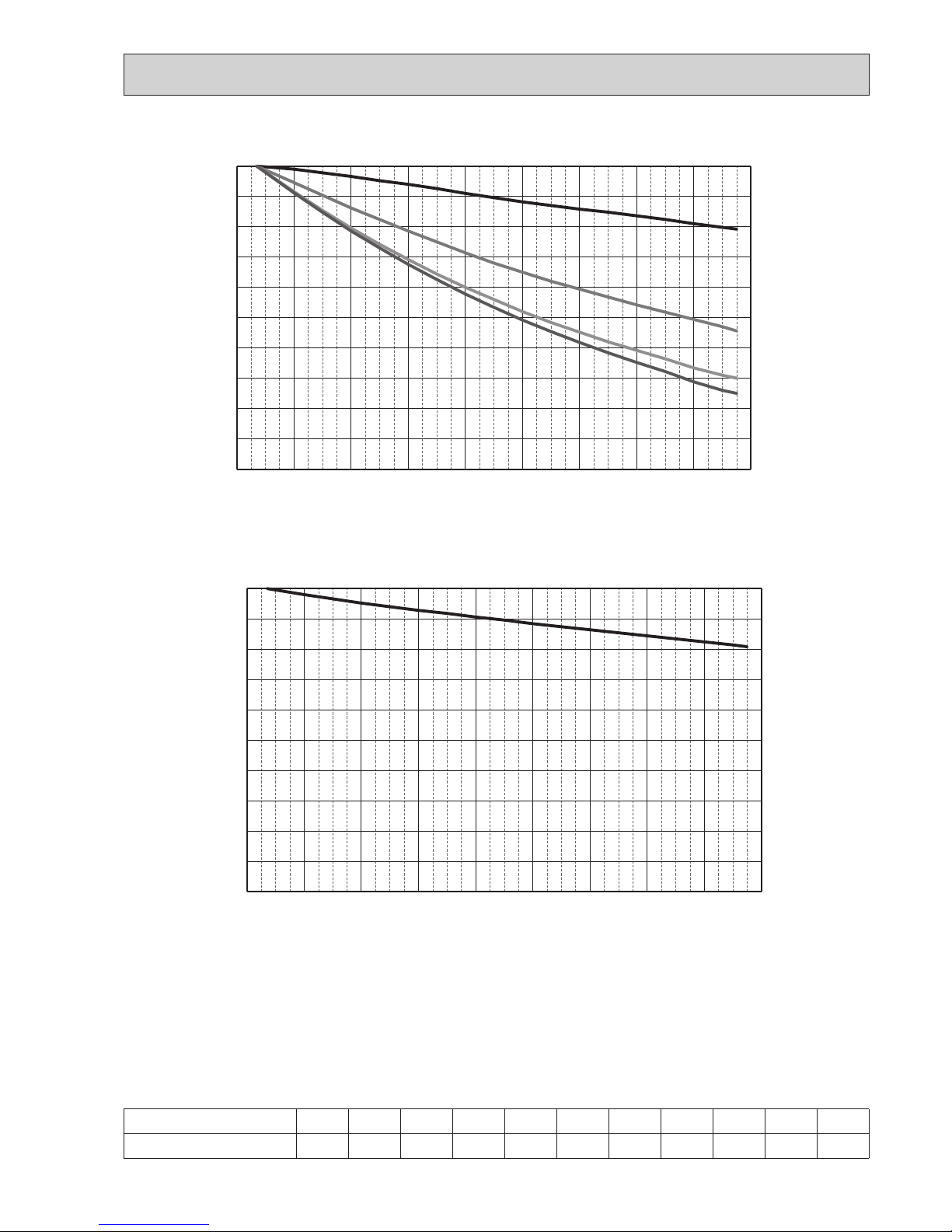

4-2. CORRECTING BY TEMPERATURE

15 16 17 18 19 20 21 22 23 24

0.4

0.6

0.8

1.0

1.2

Ratio of cooling capacity

Indoor Temperature [°CW.B.]

Ratio of cooling capacity

Outdoor Temperature [°C D.B.]

Indoor Temperature

-5.0 0.0 5.0 10.0 15.0 20.0 25.0 30.0 35.0 40.0 45.0

50.0 52.0

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

19°C W.B

Ratio of power input

Outdoor Temperature [°C D.B.]

Indoor Temperature

-15.0 -10.0 -5.0 0.0 5.0 10.0 15.0 20.0 25.0 30.0 35.0 40.0 45.0

50.0 52.0

0.0

0.2

0.4

0.6

0.8

1.0

1.2

16°C W.B

18°C W.B

19°C W.B

20°C W.B

22°C W.B

24°C W.B

CITY MULTI could have varied capacity at different designing temperature. Using the nominal cooling/heating capacity value

and the ratio below, the capacity can be observed at various temperature.

PUMY

P112 P125 P140

Nominal

cooling

capacity

kW

12.5 14.0 15.5

BTU/h

42,650 47,768 52,886

Input kW

2.79 3.46 4.52

Figure 7 Indoor unit temperature correction

To be used to correct indoor unit capacity only

Figure 8 Outdoor unit temperature correction

To be used to correct outdoor unit capacity only

<Cooling>

OCH632A

16

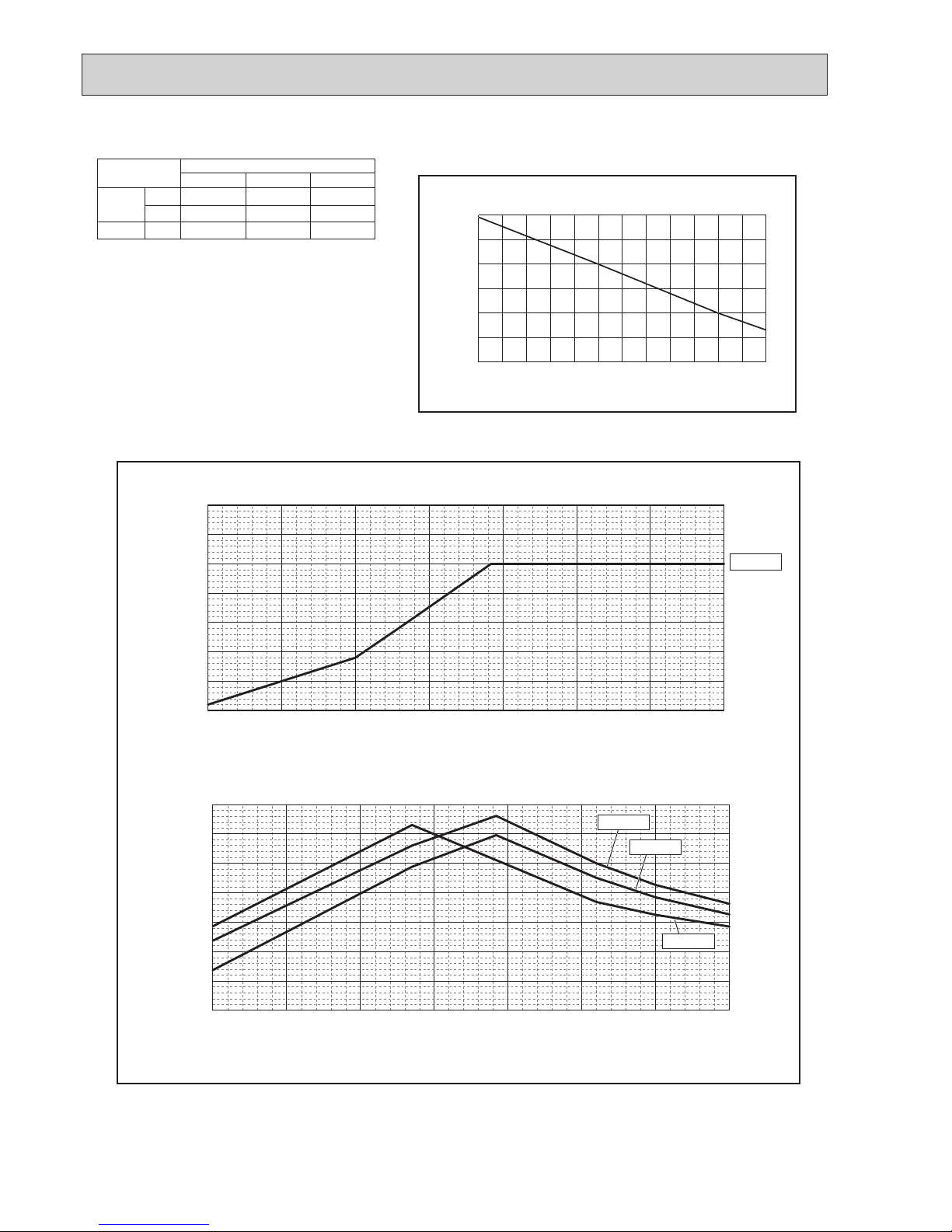

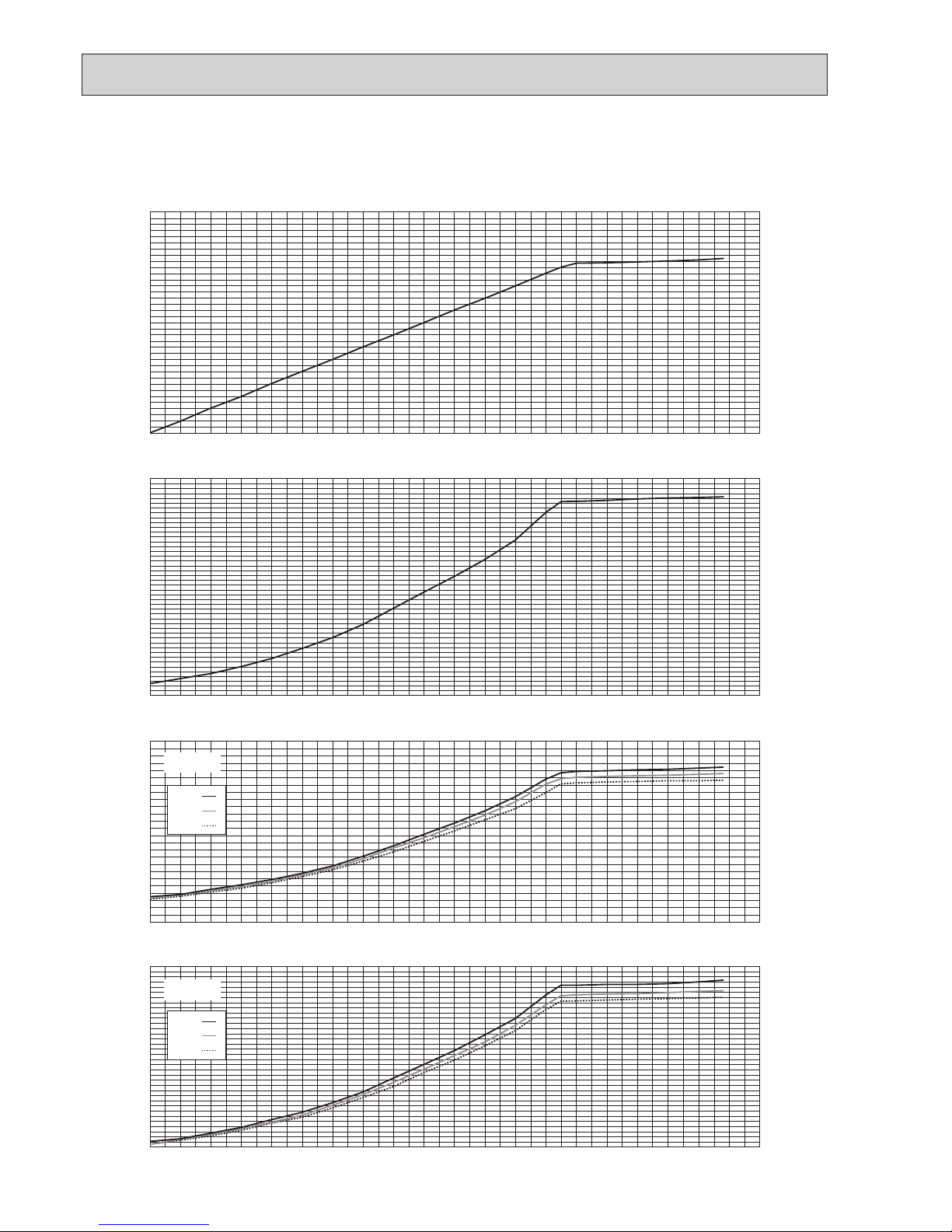

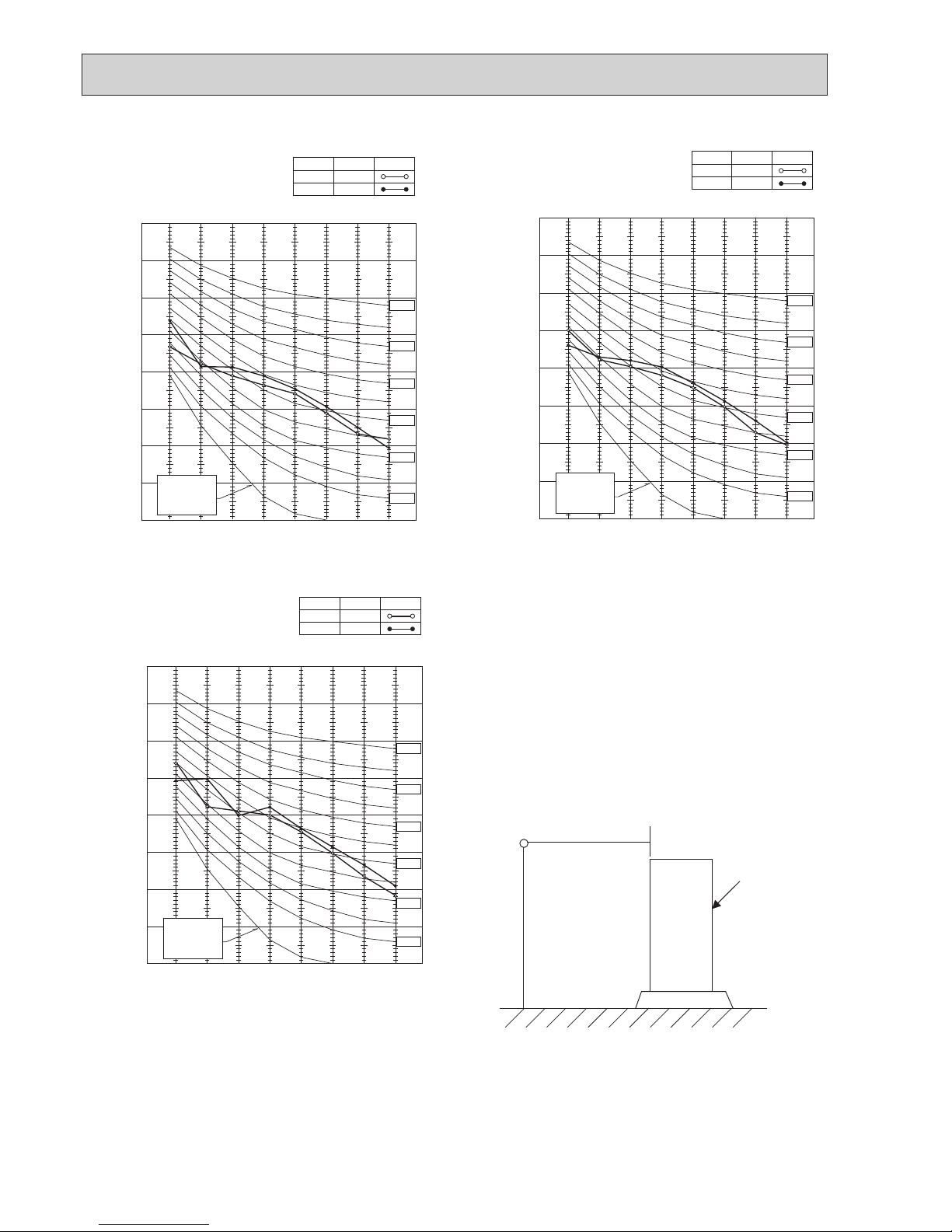

<Heating>

15 16 17 18 19 20 21 22 23 24 25 26 27

0.6

0.7

0.8

0.9

1.0

1.1

1.2

Ratio of heating capacity

Indoor Temperature [°CD.B.]

Ratio of heating capacity

Outdoor Temperature [°C W.B.]

20°C D.B

-20.0 -15.0 -10.0

-5.0 0.0 5.0 10.0 15.0

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

Ratio of power input

Outdoor Temperature [°C W.B.]

Indoor Temperature

-20.0 -15.0 -10.0 -5.0 0.0 5.0 10.0 15.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

25°C D.B

15°C D.B

20°C D.B

Figure 9 Indoor unit temperature correction

To be used to correct indoor unit capacity only

Figure 10 Outdoor unit temperature correction

To be used to correct outdoor unit capacity only

PUMY

P112 P125 P140

Nominal

heating

capacity

kW

14.0 16.0 18.0

BTU/h

47,768 54,592 61,416

Input kW

3.04 3.74 4.47

OCH632A

17

Operation

PUMY-P112VKM3(-BS)

PUMY-P112YKM3(-BS)

PUMY-P112YKME3(-BS)

PUMY-P125VKM3(-BS)

PUMY-P125YKM3(-BS)

PUMY-P125YKME3(-BS)

PUMY-P140VKM3(-BS)

PUMY-P140YKM3(-BS)

PUMY-P140YKME3(-BS)

Operating

conditions

Ambient

temperature

Indoor

DB/

WB

27°C/19°C 20°C/— 27°C/19°C 20°C/— 27°C/19°C 20°C/—

Outdoor 35°C 7°C/6°C 35°C 7°C/6°C 35°C 7°C/6°C

Indoor unit

No. of connected units

Unit

2 2 2

No. of units in operation 2 2 2

Model — 50 x 1/63 x 1 63 × 2 63 x 1/80×1

Piping

Main pipe

m

5 5 5

Branch pipe 2.5 2.5 2.5

Total pipe length 10 10 10

Fan speed — Hi Hi Hi

Amount of refrigerant kg 7.2 7.2 7.2

Outdoor unit

Electric current A 16.17/5.26 17.38/5.67 21.67/7.12 21.91/7.22 25.84/8.58 25.54/8.48

Voltage V 230/400 230/400 230/400

Compressor frequency Hz 67 69 84 86 96 96

LEV

opening

Indoor unit Pulse 357 421 447 525 511 586

Pressure High pressure/Low pressure

MPa G

2.70/0.94 2.86/0.70 2.86/0.88 2.87/0.67 2.95/0.85 2.95/0.65

Temp. of

each section

Outdoor

unit

Discharge

°C

67.0 71.9 69.7 72.1 70.7 73.2

Heat exchanger outlet 40.2 2.0 40.8 1.3 43.7 0.9

Accumulator inlet 8.7 1.0 8.0 0.2 5.6 −0.6

Compressor inlet 10.7 1.3 9.1 0.1 7.8 −0.7

Indoor unit

LEV inlet 18.9 32.4 17.7 33.0 17.0 33.4

Heat exchanger inlet 12.3 55.5 11.1 55.7 10.4 56.8

4-3. STANDARD OPERATION DATA (REFERENCE DATA)

OCH632A

18

4-4. STANDARD CAPACITY DIAGRAM

Before calculating the sum of total capacity of indoor units, please convert the value into the kW model capacity following the formula on

"4-1-1. Method for obtaining system cooling and heating capacity".

Y-Type

V-Type

1.0

2.0

3.0

4.0

5.0

6.0

Current(A)

2.0

2.0

4.0

6.0

8.0

12.0

10.0

16.0

14.0

4.0 6.0 8.0 10.0 12.0 14.0 16.0 18.0 20.0

Capacity(kW)

Total capacity of indoor units(kW)

2.0 4.0 6.0 8.0 10.0 12.0 14.0 16.0 18.0 20.0

Total capacity of indoor units(kW)

2.0 4.0 6.0 8.0 10.0 12.0 14.0 16.0 18.0 20.0

Total capacity of indoor units(kW)

2.0 4.0 6.0 8.0 10.0 12.0 14.0 16.0 18.0 20.0

Total capacity of indoor units(kW)

0.0

5.0

10.0

15.0

20.0

Current(A)

0.5

1.0

1.5

2.0

2.5

3.0

3.5

Input(kW)

220V

230V

240V

380V

400V

415V

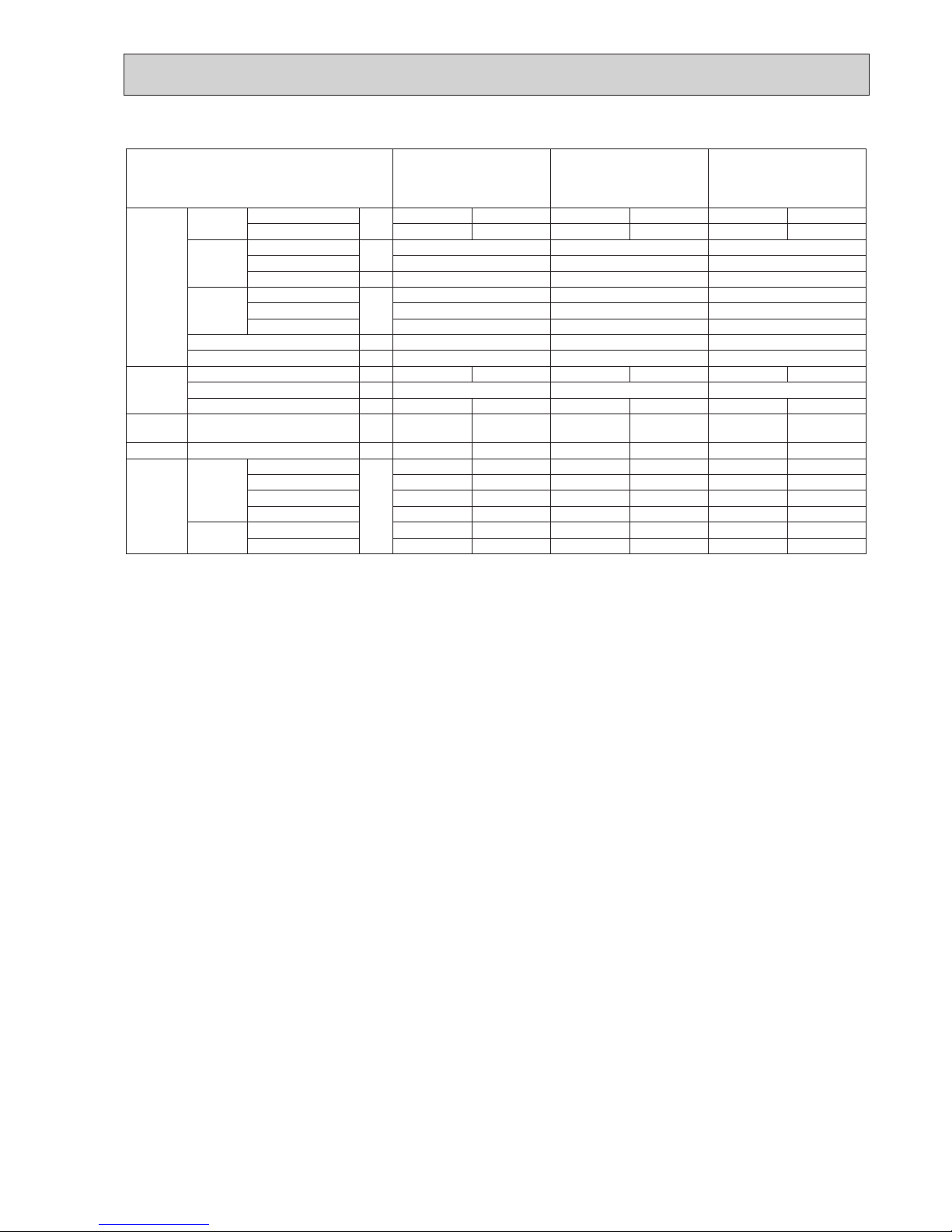

4-4-1. PUMY-P112VKM3(-BS) PUMY-P112YKM(E)3(-BS) <cooling>

OCH632A

19

Y-Type

V-Type

1.0

2.0

3.0

4.0

5.0

6.0

Current(A)

2.0

2.0

4.0

6.0

8.0

12.0

10.0

16.0

14.0

4.0 6.0 8.0 10.0 12.0 14.0 16.0 18.0 200.

Capacity(kW)

Total capacity of indoor units(kW)

2.0 4.0 6.0 8.0 10.0 12.0 14.0 16.0 18.0 20.0

Total capacity of indoor units(kW)

2.0 4.0 6.0 8.0 10.0 12.0 14.0 16.0 18.0 20.0

Total capacity of indoor units(kW)

Current(A)

0.5

1.0

1.5

2.0

2.5

3.0

3.5

Input(kW)

2.0 4.0 6.0 8.0 10.0 12.0 14.0 16.0 18.0 20.0

0.0

5.0

10.0

15.0

20.0

Total capacity of indoor units(kW)

PUMY-P112VKM

220V

230V

240V

380V

400V

415V

4-4-2. PUMY-P112VKM3(-BS) PUMY-P112YKM(E)3(-BS) <heating>

OCH632A

20

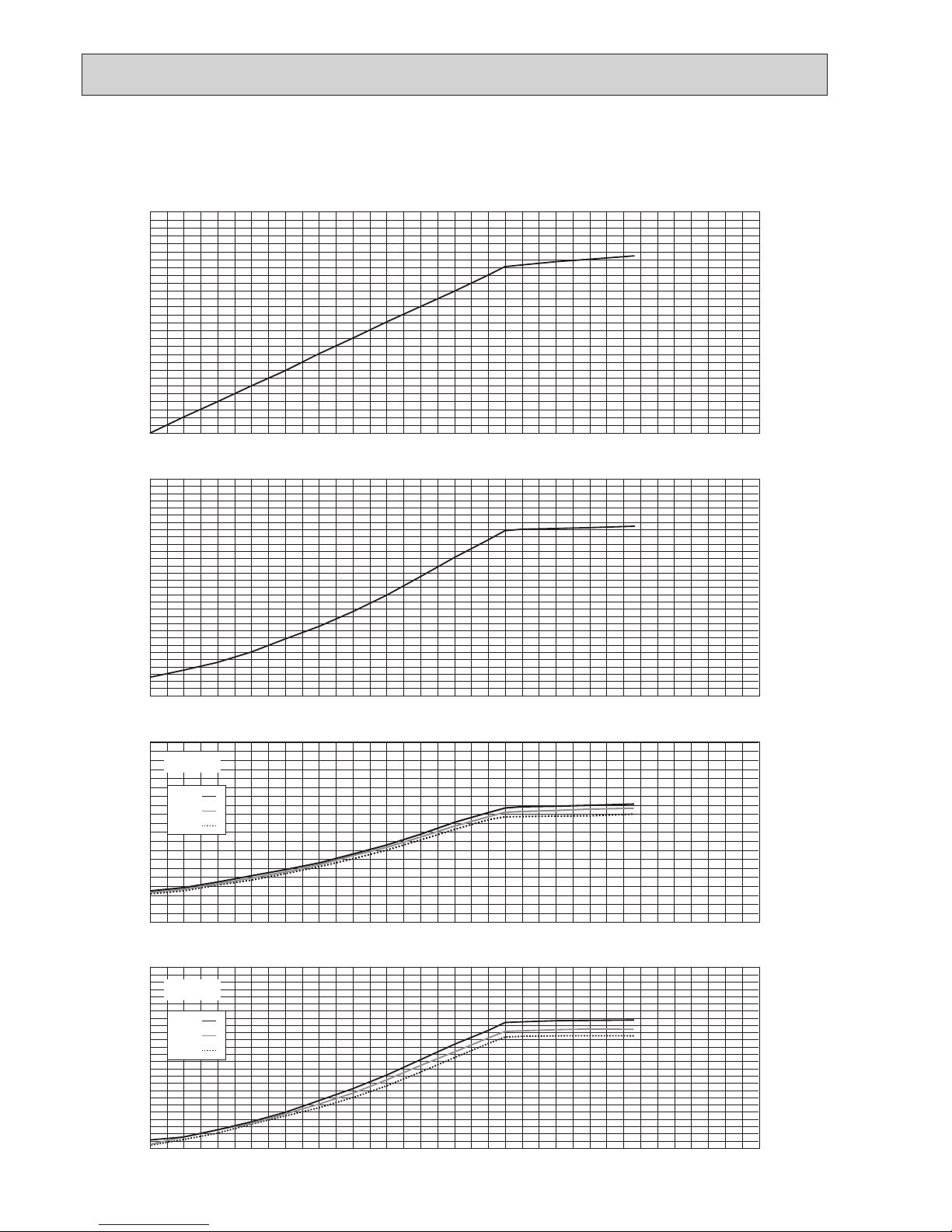

4-4-3. PUMY-P125VKM3(-BS) PUMY-P125YKM(E)3(-BS) <cooling>

Before calculating the sum of total capacity of indoor units, please convert the value into the kW model capacity following the formula on

"4-1-1. Method for obtaining system cooling and heating capacity".

Y-Type

1.0

2.0

3.0

4.0

5.0

6.0

Current(A)

2.0 4.0 6.0 8.0 10.0 12.0 14.0 16.0 18.0 20.0

Total capacity of indoor units(kW)

Current(A) Input(kW)

2.0 4.0 6.0 8.0 10.0 12.0 14.0 16.0 18.0 20.0

Total capacity of indoor units(kW)

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

2.0

2.0

4.0

6.0

8.0

12.0

10.0

16.0

18.0

14.0

4.0 6.0 8.0 10.0 12.0 14.0 16.0 18.0 20.0

Capacity(kW)

Total capacity of indoor units(kW)

V-Type

Total capacity of indoor units(kW)

2.0 4.0 6.0 8.0 10.0 12.0 14.0 16.0 18.0 20.0

0.0

5.0

10.0

15.0

20.0

220V

230V

240V

380V

400V

415V

OCH632A

21

Y-Type

1.0

2.0

3.0

4.0

5.0

6.0

Current(A)

2.0 4.0 6.0 8.0 10.0 12.0 14.0 16.0 18.0 20.0

Total capacity of indoor units(kW)

Current(A) Input(kW)

2.0 4.0 6.0 8.0 10.0 12.0 14.0 16.0 18.0 20.0

Total capacity of indoor units(kW)

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

2.0

2.0

4.0

6.0

8.0

12.0

10.0

16.0

18.0

14.0

4.0 6.0 8.0 10.0 12.0 14.0 16.0 18.0 20.0

Capacity(kW)

Total capacity of indoor units(kW)

V-Type

Total capacity of indoor units(kW)

2.0 4.0 6.0 8.0 10.0 12.0 14.0 16.0 18.0 20.0

0.0

5.0

10.0

15.0

20.0

220V

230V

240V

380V

400V

415V

4-4-4. PUMY-P125VKM3(-BS) PUMY-P125YKM(E)3(-BS) <heating>

OCH632A

22

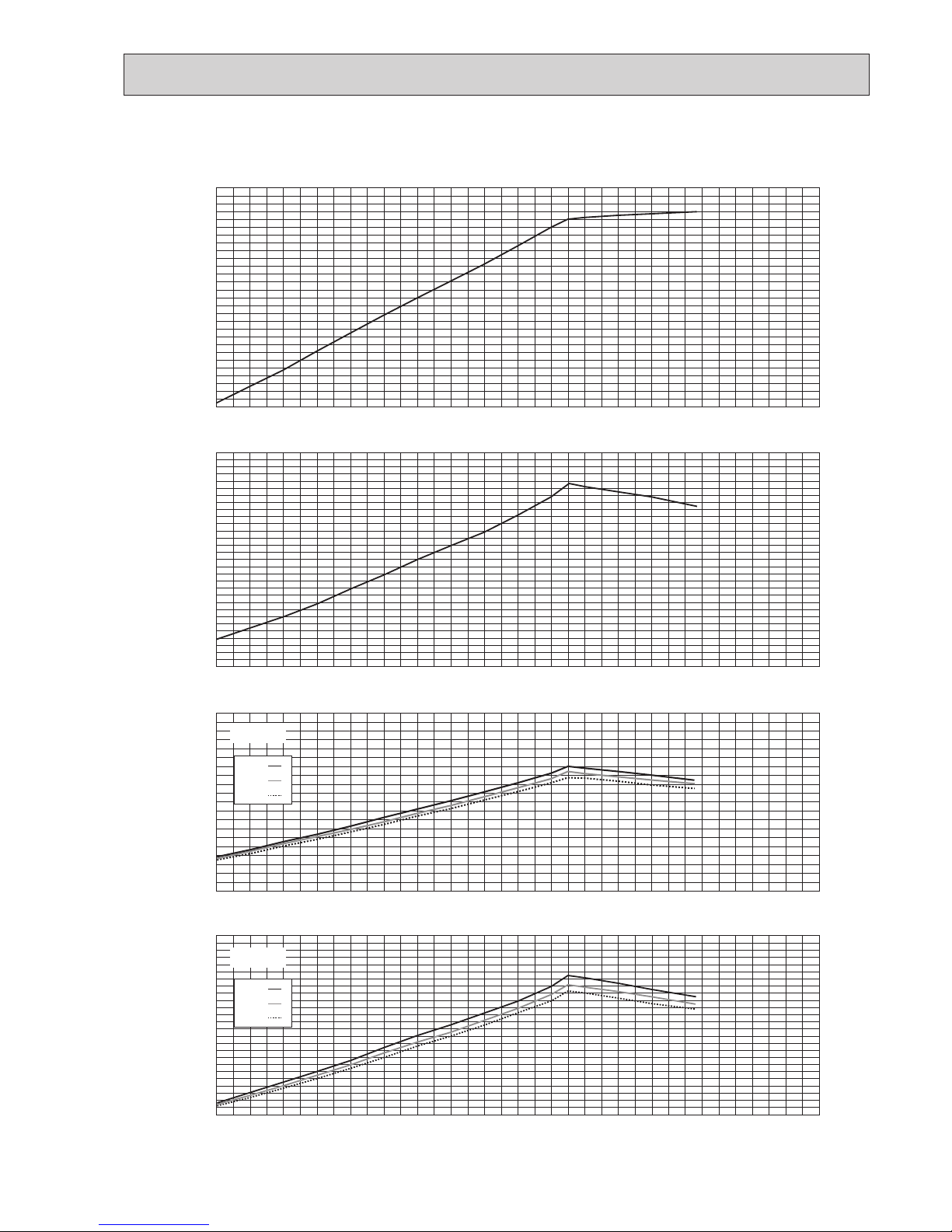

4-4-5. PUMY-P140VKM3(-BS) PUMY-P140YKM(E)3(-BS) <cooling>

Before calculating the sum of total capacity of indoor units, please convert the value into the kW model capacity following the formula on

"4-1-1. Method for obtaining system cooling and heating capacity".

Y-Type

Current(A)

Total capacity of indoor units(kW)

Current(A) Input(kW)

Total capacity of indoor units(kW)

V-Type

2.0

2.0

4.0

6.0

8.0

12.0

10.0

16.0

18.0

20.0

14.0

4.0 6.0 8.0 10.0 12.0 14.0 16.0 18.0 20.0 22.0

2.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

4.0 6.0 8.0 10.0 12.0 14.0 16.0 18.0 20.0 22.0

2.0

5.0

0.0

10.0

15.0

20.0

25.0

4.0 6.0 8.0 10.0 12.0 14.0 16.0 18.0 20.0 22.0

2.0

2.0

1.0

3.0

4.0

5.0

6.0

7.0

8.0

4.0 6.0 8.0 10.0 12.0 14.0 16.0 18.0 20.0 22.0

Total capacity of indoor units(kW)

Capacity(kW)

Total capacity of indoor units(kW)

220V

230V

240V

380V

400V

415V

OCH632A

23

Y-Type

Current(A)

Total capacity of indoor units(kW)

Current(A) Input(kW)

Total capacity of indoor units(kW)

2.0

2.0

4.0

6.0

8.0

12.0

10.0

16.0

18.0

20.0

14.0

4.0 6.0 8.0 10.0 12.0 14.0 16.0 18.0 20.0 22.0

2.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

4.0 6.0 8.0 10.0 12.0 14.0 16.0 18.0 20.0 22.0

2.0

2.0

1.0

3.0

4.0

5.0

6.0

7.0

8.0

4.0 6.0 8.0 10.0 12.0 14.0 16.0 18.0 20.0 22.0

Total capacity of indoor units(kW)

Capacity(kW)

Total capacity of indoor units(kW)

Current(A)

V-Type

2.0

5.0

0.0

10.0

15.0

20.0

25.0

4.0 6.0 8.0 10.0 12.0 14.0 16.0 18.0 20.0 22.0

220V

230V

240V

380V

400V

415V

4-4-6. PUMY-P140VKM3(-BS) PUMY-P140YKM(E)3(-BS) <heating>

OCH632A

24

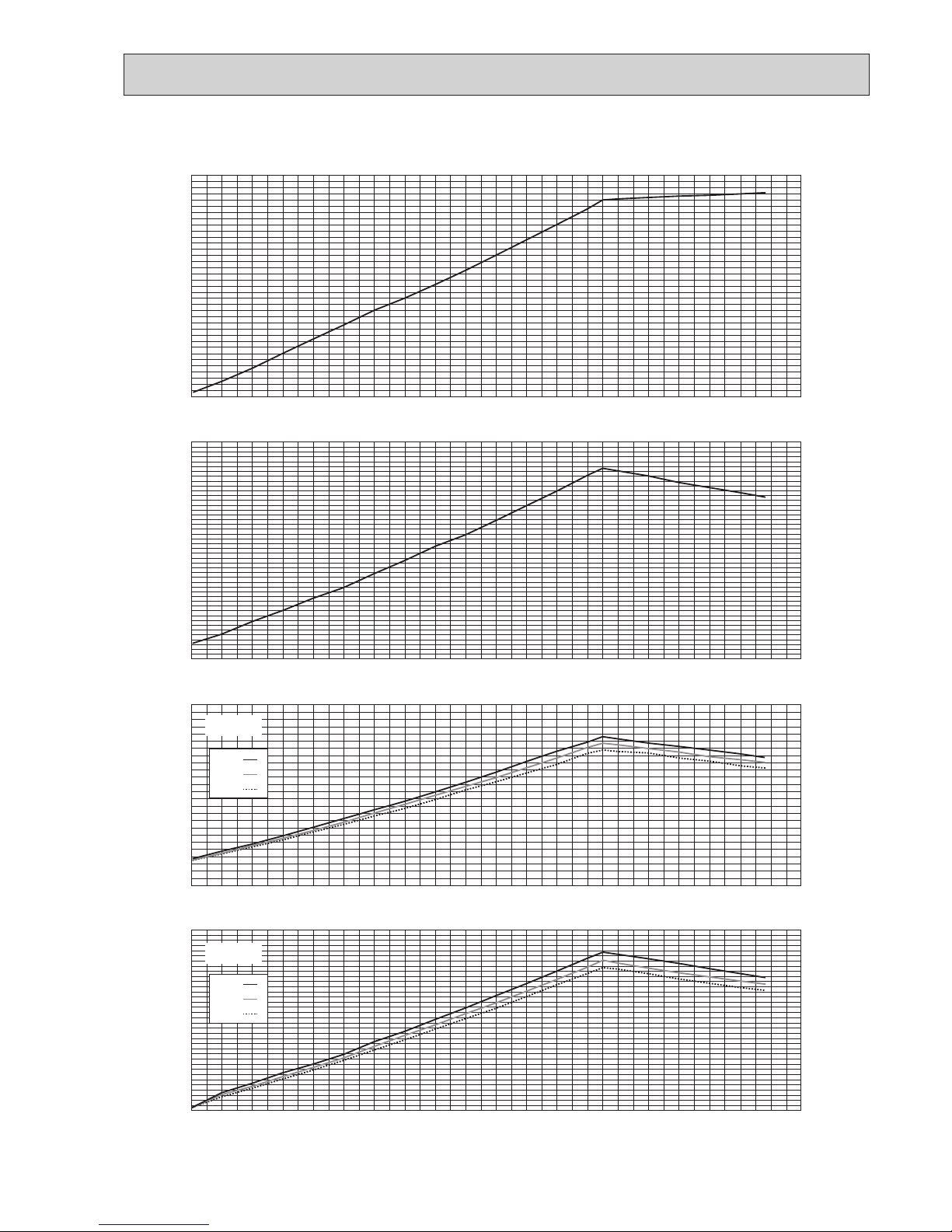

4-5.

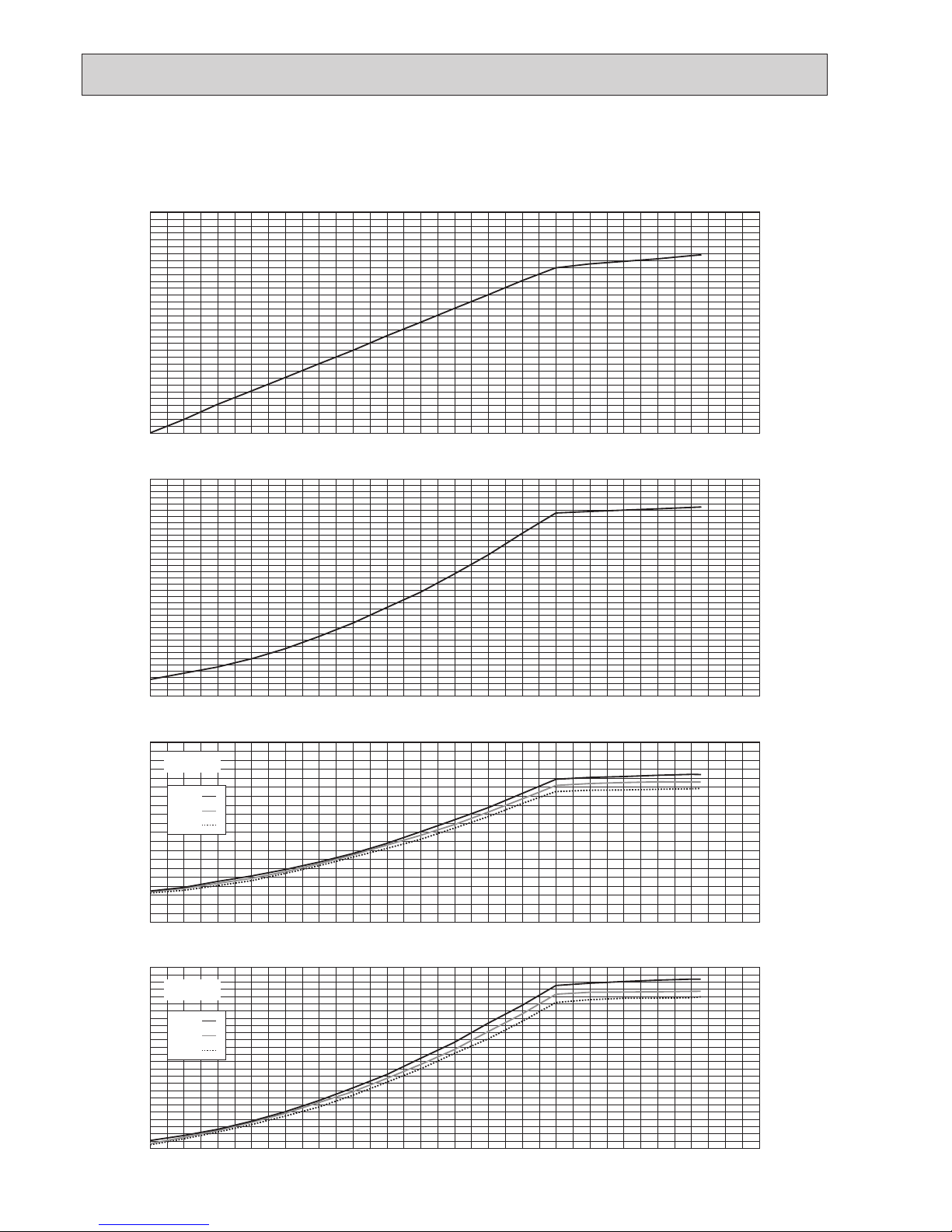

CORRECTING CAPACITY FOR CHANGES IN THE LENGTH OF REFRIGERANT PIPING

(1) During cooling, obtain the ratio (and the equivalent piping length) of the outdoor units rated capacity and the total in-use

indoor capacity, and find the capacity ratio corresponding to the standard piping length from Figure 11 to 13. Then multiply

by the cooling capacity from Figure 7 and 8 in "4-2. CORRECTION BY TEMPERATURE" to obtain the actual capacity.

(2) During heating, find the equivalent piping length, and find the capacity ratio corresponding to standard piping length from

Figure 14. Then multiply by the heating capacity from Figure 9 and 10 in "4-2. CORRECTION BY TEMPERATURE" to

obtain the actual capacity.

(1) Capacity Correction Curve

0 20 40 60 80 100 120 140 160 180

0.50

0.55

0.60

0.65

0.70

0.75

0.80

0.85

0.90

0.95

1.00

9.4

6.3

12.5

16.2

Capacity ratio

Piping equivalent length (m)

Total capacity of indoor unit

Total capacity of indoor unit

0 20 40 60 80 100 120 140 160 180

0.50

0.55

0.60

0.65

0.70

0.75

0.80

0.85

0.90

0.95

1.00

10.5

7.0

14.0

18.2

Capacity ratio

Piping equivalent length (m)

Figure 11 PUMY-P112VKM3(-BS) PUMY-P112YKM(E)3(-BS) <Cooling>

Figure 12 PUMY-P125VKM3(-BS) PUMY-P125YKM(E)3(-BS) <Cooling>

OCH632A

25

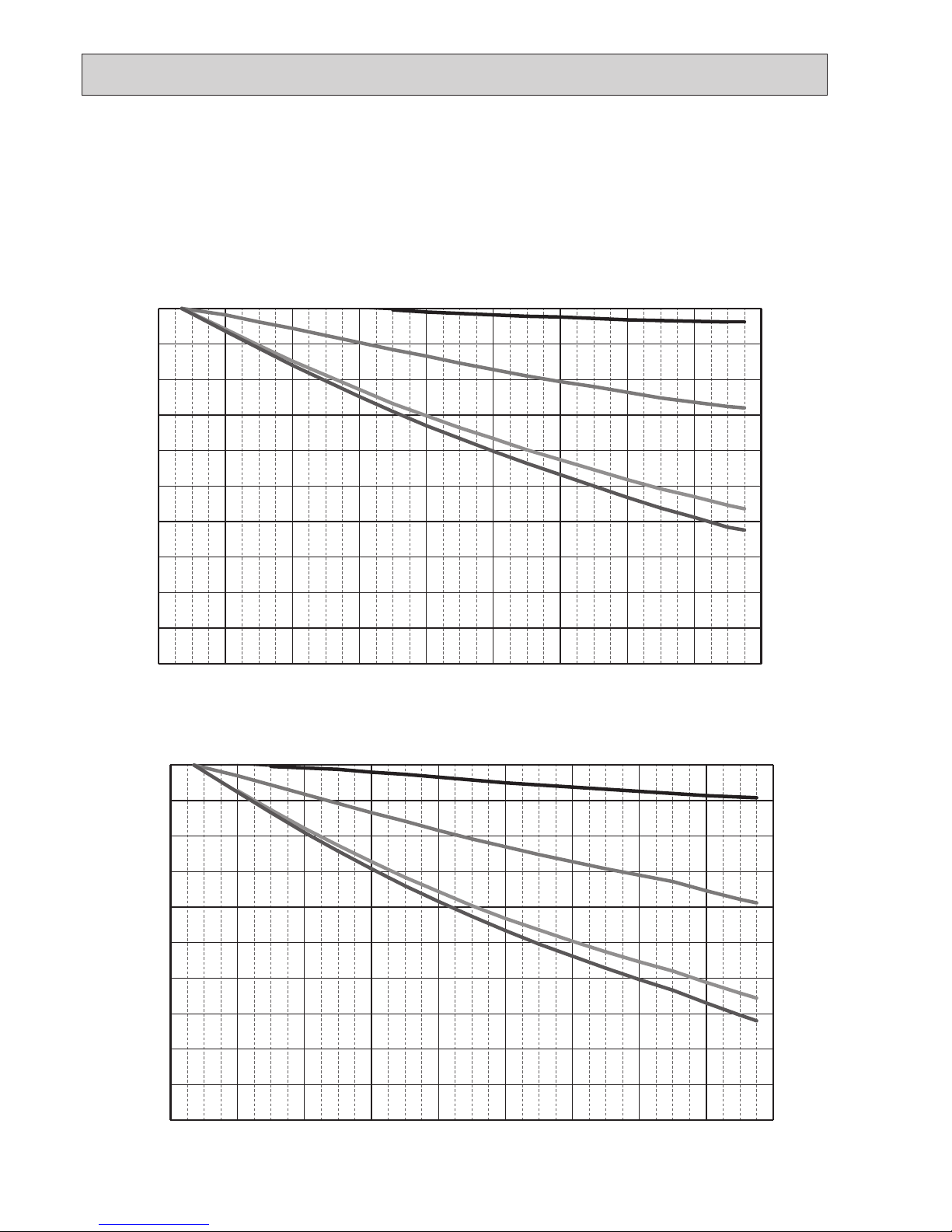

(2) Method for Obtaining the Equivalent Piping Length

Equivalent length for type P112·125·140 = (length of piping to farthest indoor unit) + (0.3 o number of bends in the piping) (m)

Length of piping to farthest indoor unit: type P112–P140.....150 m

4-5-1. Correction of Heating Capacity for Frost and Defrosting

If heating capacity has been reduced due to frost formation or defrosting, multiply the capacity by the appropriate correction

factor from the following table to obtain the actual heating capacity.

Correction factor diagram

Outdoor Intake temperature (W.B.°C)

6 4 2 0 −2 −4 −6 −8 −10 −15 −20

Correction factor

1.0 0.98 0.89 0.88 0.89 0.9 0.95 0.95 0.95 0.95 0.95

0 20 40 60 80 100 120 140 160 180

0.50

0.55

0.60

0.65

0.70

0.75

0.80

0.85

0.90

0.95

1.00

11.6

7.8

15.5

20.2

Capacity ratio

Piping equivalent length (m)

0 20 40 60 80 100 120 140 160 180

0.50

0.55

0.60

0.65

0.70

0.75

0.80

0.85

0.90

0.95

1.00

Capacity ratio

Piping equivalent length (m)

Total capacity of indoor unit

Figure 13 PUMY-P140VKM3(-BS) PUMY-P140YKM(E)3(-BS) <Cooling>

Figure 14 PUMY-P112/125/140VKM3(-BS) <Heating>

PUMY-P112/125/140YKM3(-BS) <Heating>

PUMY-P112/125/140YKME3(-BS) <Heating>

OCH632A

26

1.5 m

1 m

MICROPHONE

UNIT

GROUND

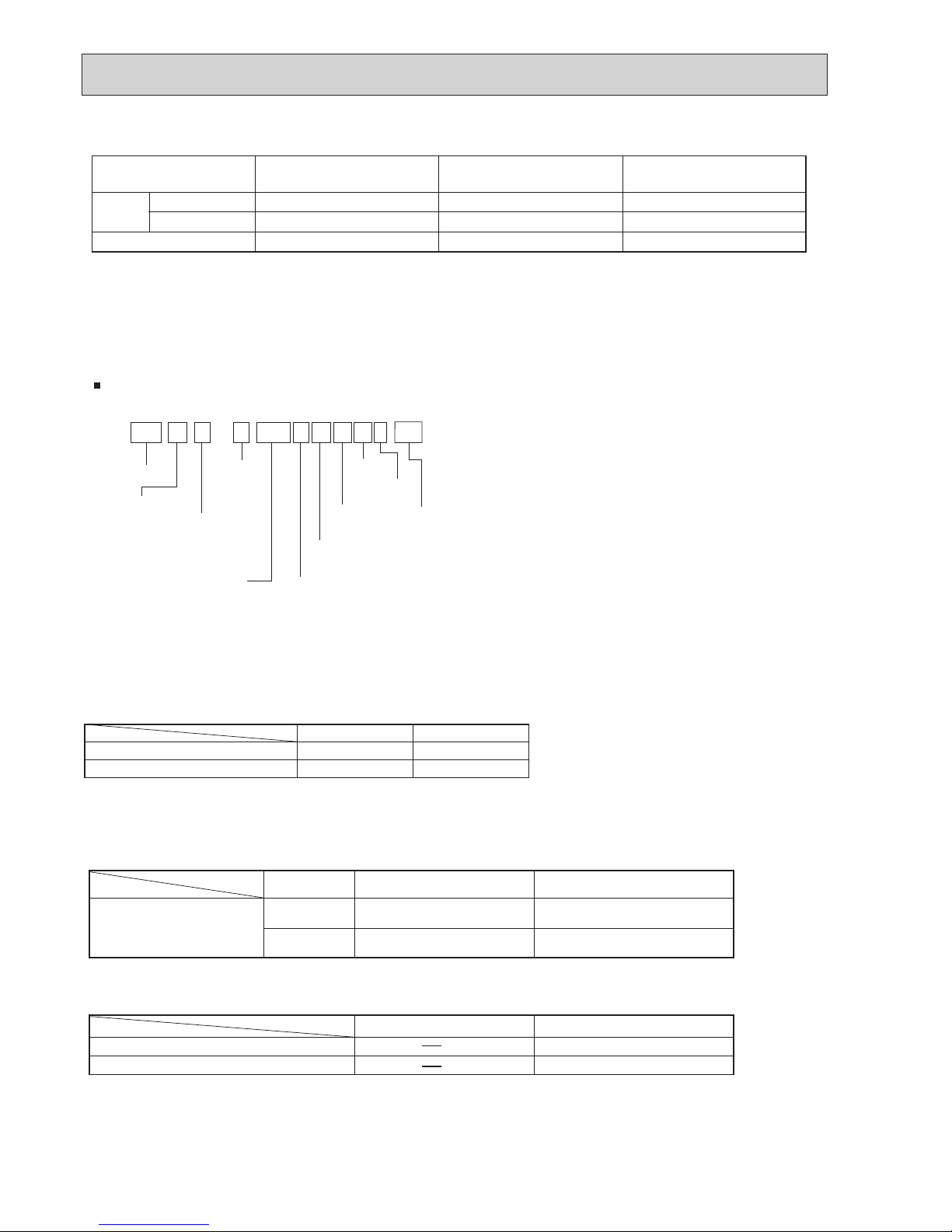

4-6. NOISE CRITERION CURVES

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

BAND CENTER FREQUENCIES, Hz

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

PUMY-P112VKM3(-BS)

PUMY-P112YKM3(-BS)

PUMY-P112YKME3(-BS)

COOLING

MODE

HEATING

49

SPL(dB)

51

LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

BAND CENTER FREQUENCIES, Hz

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

PUMY-P125VKM3(-BS)

PUMY-P125YKM3(-BS)

PUMY-P125YKME3(-BS)

COOLING

MODE

HEATING

50

SPL(dB)

52

LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

BAND CENTER FREQUENCIES, Hz

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

PUMY-P140VKM3(-BS)

PUMY-P140YKM3(-BS)

PUMY-P140YKME3(-BS)

COOLING

MODE

HEATING

51

SPL(dB)

53

LINE

OCH632A

27

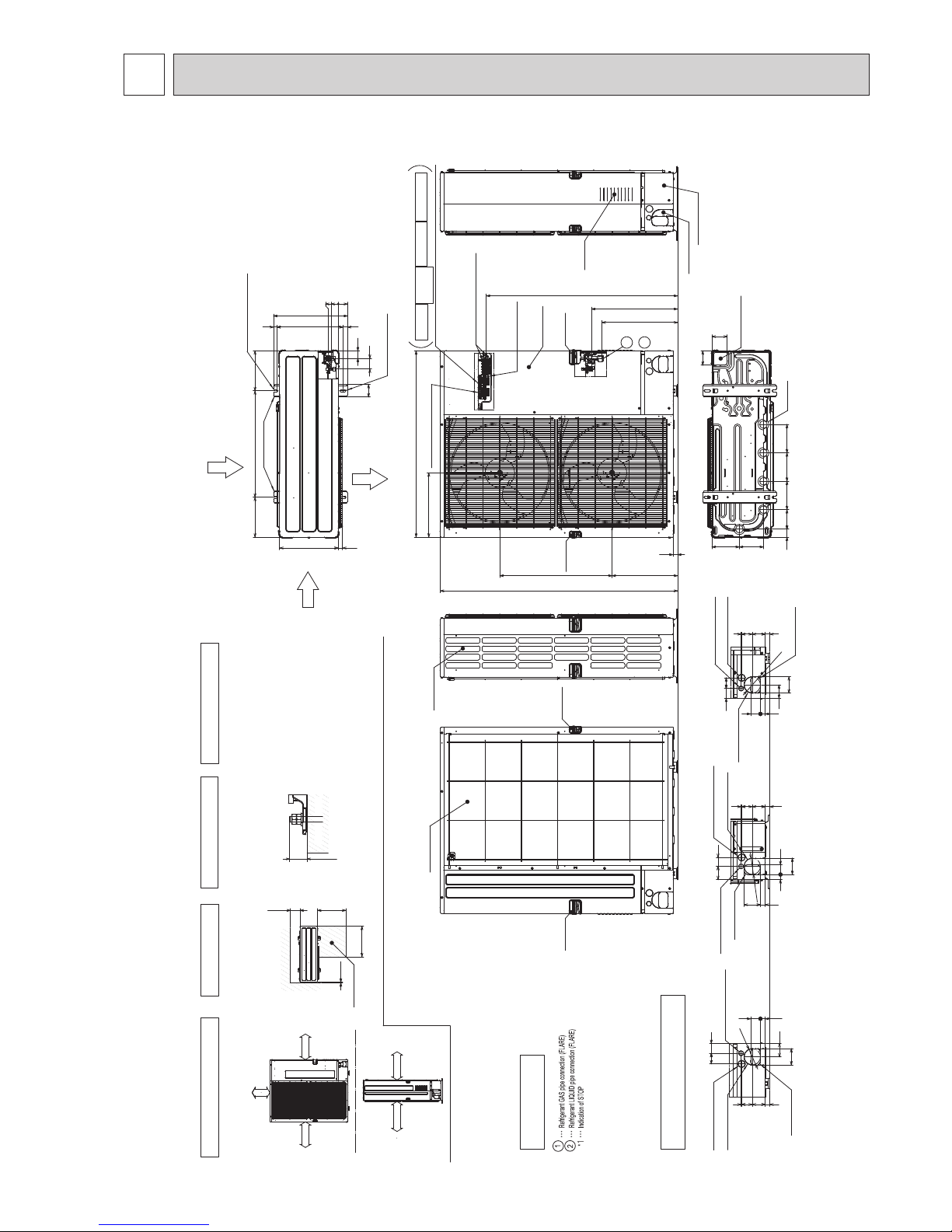

5

OUTLINES AND DIMENSIONS

PUMY-P112VKM3 PUMY-P125VKM3 PUMY-P140VKM3

PUMY-P112VKM3-BS PUMY-P125VKM3-BS PUMY-P140VKM3-BS

Unit: mm

For the

power supply

Terminal connection

For the

branch box

power supply

For the

transmission line

For concentration

control

From left to right

2

1

*1

*1

Service panel

Ground for the power supply

Ground for the transmission line

Ground for concentration control

Handle for

moving

Handle for

moving

Ground for

the branch box

power supply

483

426

1338

26

1050

362

1078

369

632

Bottom piping hole

(Knock-Out)

Drain hole

(5-{33)

81

86

154136

45 160160160110

Handle for

moving

Handle for

moving

Rear Air Intake

Side Air Intake

Rear trunking hole

(Knock-Out)

Power supply wiring hole

({ 40 Knock-Out)

Rear piping hole

(Knock-Out)

Power supply wiring hole

({ 27 Knock-Out)

75

92

55 60

326 73 60

27

55

{

92

Power supply wiring hole

({ 40 Knock-Out)

Front piping hole

(Knock-Out)

Power supply wiring hole

({ 27 Knock-Out)

Front trunking hole

(Knock-Out)

92

75

60 55

27 55

32673

60

{

92

Power supply wiring hole

({ 27 Knock-Out)

Power supply wiring hole

({ 40 Knock-Out)

Right piping hole

(Knock-Out)

Right trunking hole

(Knock-Out)

92

32673

60

75 50

29 55

27

92

{

92

Air Intake

Front piping cover

Rear piping cover

Air Discharge

Rear Air Intake

Side Air Intake

2-12×36 Oval holes

(Foundation Bolt M10)

2-U Shaped notched holes

(Foundation Bolt M10)

Installation Feet

225

417

42

70

61

28

19

370

600 225

25 330

53

56

40

0

Min.15

Min.500

Min.500

Min.150

Min. 15mm

Min. 1000mm Min. 150mm

Min. 15mm

FREE

Piping and wiring connections

can be made from 4 directions:

FRONT, Right, Rear and Below.

4 PIPING-WIRING DIRECTIONS

2 SERVICE SPACE

1 FREE SPACE (Around the unit)

Please secure the unit firmly

with 4 foundation (M10<W3/8>) bolts.

(Bolts and washers must be

purchased locally.)

Dimensions of space needed

for service access are

shown in the below diagram.

The diagram below shows a basic example.

Explantion of particular details are

given in the installation manuals etc.

<Foundation bolt height>

FOUNDATION

Service space

Max.30

Example of Notes

VALVE connection location.

Piping Knock-Out Hole Details

3 FOUNDATION BOL TS

{

15.88(5/8F)

{

9.52(3/8F)

OCH632A

28

Power supply wiring hole

({27Knock-Out)

Power supply wiring hole

({40Knock-Out)

Right trunking hole

(Knock-Out)

Right piping hole

(Knock-Out)

92

2726

92

29 55

373 60

75 50

{

92

Power supply wiring hole

({27Knock-Out)

Power supply wiring hole

({40Knock-Out)

Front piping hole

(Knock-Out)

Front trunking hole

(Knock-Out)

5527

75

92

26

73

60 3

5560

{

92

Power supply wiring hole

({40Knock-Out)

Power supply wiring hole

({27Knock-Out)

Rear trunking hole

(Knock-Out)

Rear piping hole

(Knock-Out)

92

75

55 60

5527

326

73

60

{

92

Side Air Intake

Handle for

moving

Handle for

moving

Rear Air Intake

Air Discharge

Side Air Intake

Rear Air Intake

2-12×36 Oval holes

(Foundation Bolt M10)

2-U Shaped notched holes

(Foundation Bolt M10)

Installation Feet

70 61

42

25 330

417

225 225600

370

28

19

40

53

56

0

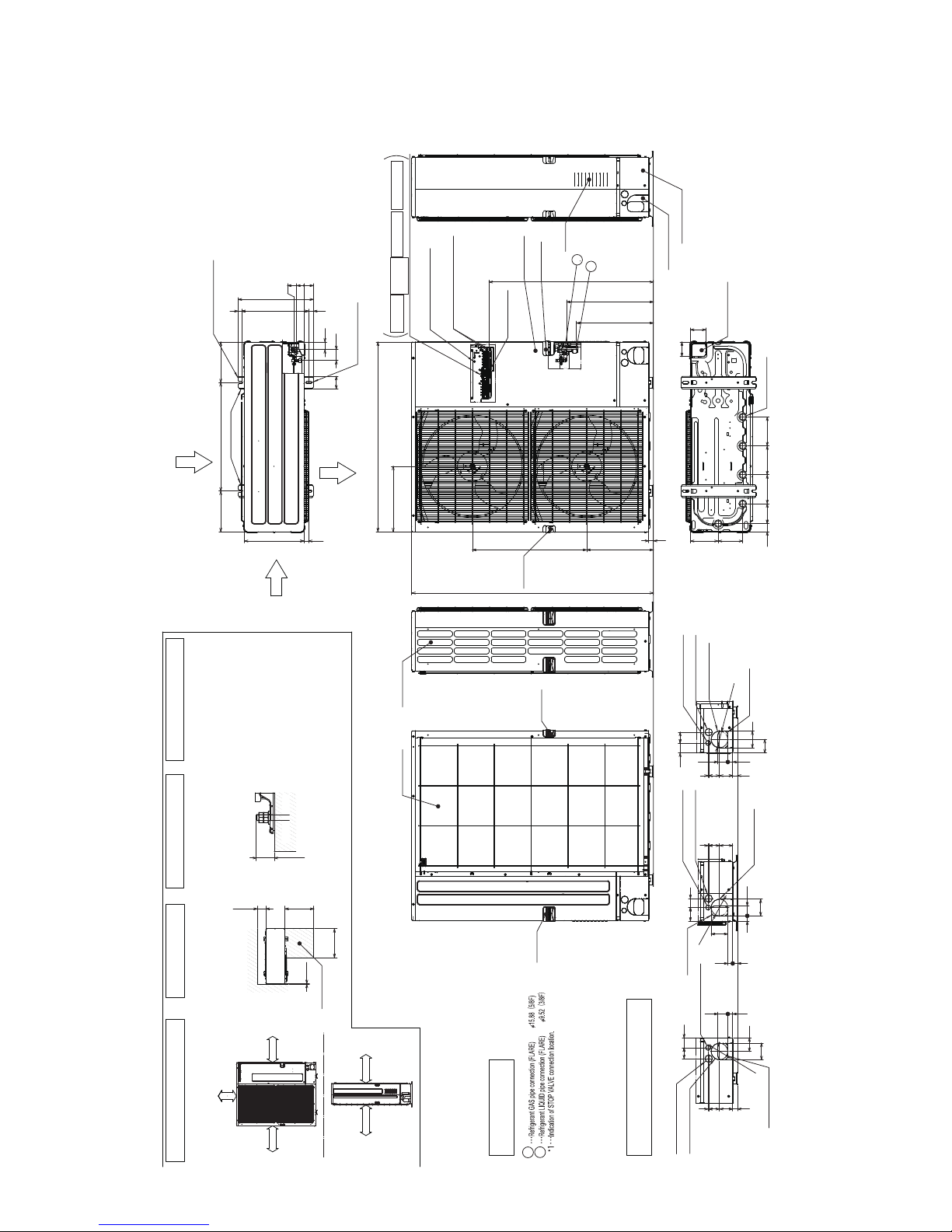

From left to right

For concentration

control

For the

transmission line

For the

branch box

power supply

For the

power supply

Terminal connection

1

2

Ground for

the branch box

power supply

Ground for the transmission line

Ground for concentration control

Ground for the power supply

*1

Handle for

moving

Handle for

moving

Service panel

*1

1338

26

1050

362

909

426

483

369

632

Air Intake

Drain hole(5-{33)

Bottom piping hole

(Knock-Out)

81

86

154136

45 160160160110

Min. 15mm

Min. 1000mm Min. 150mm

Min. 15mm

FREE

Service space

FOUNDATION

<Foundation bolt height>

The diagram below shows a basic example.

Explanation of particular details are

given in the installation manuals etc.

Dimensions of space needed

for service access are

shown in the below diagram.

Please secure the unit firmly

with 4 foundation (M10<W3/8>) bolts.

(Bolts and washers must be

purchased locally.)

1 FREE SPACE (Around the unit)

2 SERVICE SPACE

3 FOUNDATION BOLTS

4 PIPING-WIRING DIRECTIONS

Piping and wiring connections

can be made from 4 directions:

FRONT, Right, Rear and Below.

Min.15

Max.30

Min.150Min.500

Min.500

2

1

Example of Notes

Piping Knock-Out Hole Details

Front piping cover

Rear piping cover

Unit: mm

PUMY-P112YKM3 PUMY-P125YKM3 PUMY-P140YKM3

PUMY-P112YKM3-BS PUMY-P125YKM3-BS PUMY-P140YKM3-BS

PUMY-P112YKME3 PUMY-P125YKME3 PUMY-P140YKME3

PUMY-P112YKME3-BS PUMY-P125YKME3-BS PUMY-P140YKME3-BS

OCH632A

29

6

WIRING DIAGRAM

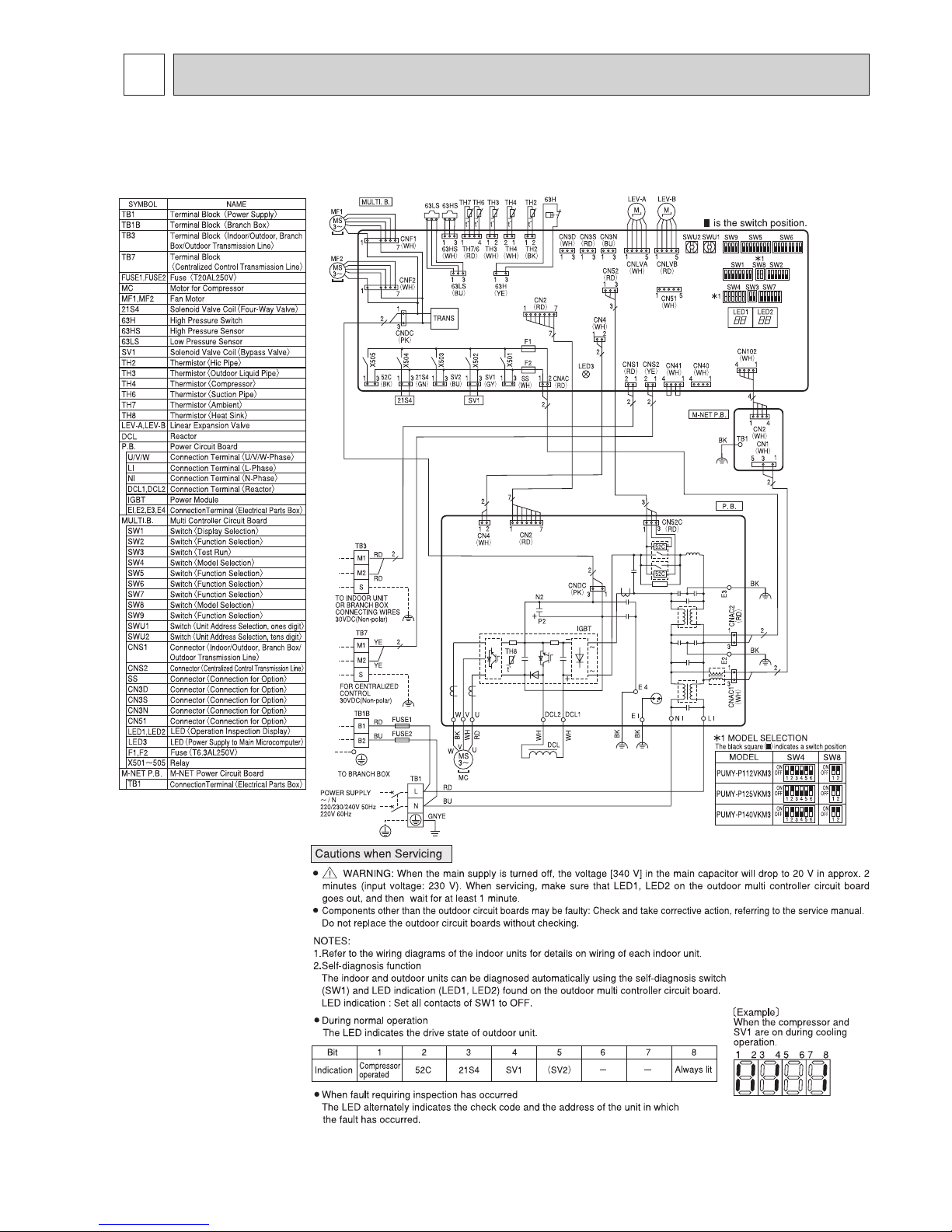

PUMY-P112VKM3 PUMY-P125VKM3 PUMY-P140VKM3

PUMY-P112VKM3-BS PUMY-P125VKM3-BS PUMY-P140VKM3-BS

OCH632A

30

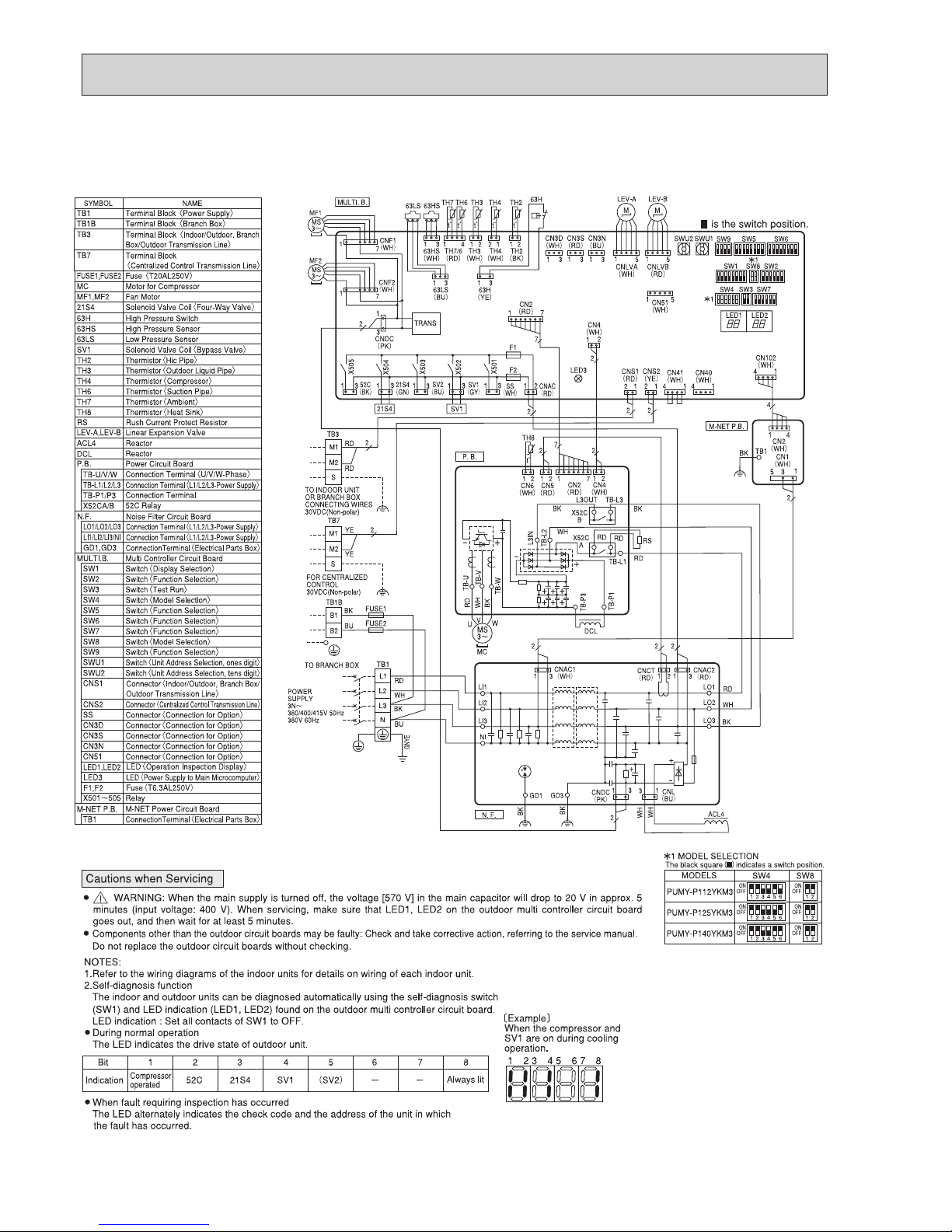

PUMY-P112YKM3 PUMY-P125YKM3 PUMY-P140YKM3

PUMY-P112YKM3-BS PUMY-P125YKM3-BS PUMY-P140YKM3-BS

OCH632A

Loading...

Loading...