SPLIT-TYPE, HEAT PMUP AIR CONDITIONERS

TECHNICAL & SERVICE MANUAL

R407C

Outdoor unit

[Model name] [Service Ref.]

PUMY-P125VMA PUMY-P125VMA

PUMY-P125YMA PUMY-P125YMA

2003

No.OC272

REVISED EDITION-A

Revision :

•PUMY-P125VMAand

PUMY-P125YMA1 are

added in REVISED

EDITION-A.

•Please void OC272.

PUMY-P125YMA

CONTENTS

1. TECHNICAL CHANGE ·····································2

2. SAFETY PRECAUTION ····································3

3. OVERVIEW OF UNITS······································5

4. SPECIFICATIONS·············································8

5. DATA ·······························································10

6. OUTLINES AND DIMENSIONS······················18

7. WIRING DIAGRAM·········································19

8.

NECESSARY CONDITIONS FOR SYSTEM CONSTRUCTION

9. TROUBLESHOOTING ····································34

10. ELECTRICAL WIRING ····································72

11. REFRIGERANT PIPING TASKS·····················75

12. DISASSEMBLY ···············································80

13. PARTS LIST ····················································86

1

···22

OUTDOOR UNIT

1 TECHNICAL CHANGE

PUMY-P125YMA ➔ PUMY-P125YMA1

1. Addition of new function (Auto Change Over)

PUMY-P125YMA : Not equipped

PUMY-P125YMA1 : Equipped

2. Difference of operation switching logic for the outdoor output connector (CN3D)

PUMY-P125YMA : CN3D 1-2 ······ OPEN : Heating CLOSE : Cooling

PUMY-P125YMA1 : CN3D 1-2 ······ OPEN : Cooling CLOSE : Heating

3. Difference of the role of SW5-1 (function selection switch)

PUMY-P125YMA : Fix the operation frequency ······························ ON : Fix OFF : Normal

PUMY-P125YMA1 : Auto Change Over from Remote Controller ······ ON : Enable OFF : Disable

2

2 SAFETY PRECAUTION

Cautions for using with the outdoor unit which adopts R407C refrigerant.

· Do not use the existing refrigerant piping.

-The old refrigerant and refrigerant oil in the existing piping contains a large amount of chlorine which may cause the refrigerant oil of the new unit to deteriorate.

· Do not use copper pipes which are broken, deformed or discolour .

In addition, be sure that the inner surfaces of the pipes are clean, free of hazardous sulphur and oxides, or have no dust /

dirt, shaving particles, oils, moisture or any other contamination.

-If there is a large amount of residual oil (hydraulic oil, etc.) inside the piping and joints, deterioration of the refrigerant oil will

result.

· Store the piping to be used during installation indoors and keep both ends of the piping sealed until just before

brazing. (Store elbows and other joints in a plastic bag.)

-If dust, dirt, or water enters the refrigerant cycle, deterioration of the oil and compressor trouble may result.

· Use ester oil, ether oil or alkyl benzene (small amount) as the refrigerant oil to coat flares and flange connections.

-The refrigerant oil will degrade if it is mixed with a large amount of mineral oil.

Use liquid refrigerant to fill the system.

-If gas refrigerant is used to fill the system, the composition of the refrigerant in the cylinder will change and performance

may drop.

· Do not use a refrigerant other than R407C.

-If another refrigerant (R22, etc.) is used, the chlorine in the refrigerant may cause the refrigerant oil to deteriorate.

· Use a vacuum pump with a service port.

-The vacuum pump oil may flow back into the refrigerant cycle and cause the refrigerant oil to deteriorate.

· Do not use the following tools that are used with conventional refrigerant.

(Gauge manifold , charge hose, gas leak detector, reverse flow check valve, refrigerant charge base, vacuum gauge,

refrigerant recovery equipment)

-If the conventional refrigerant and refrigerant oil are mixed in the R407C, the refrigerant may deteriorated.

-If water is mixed in the R407C, the refrigerant oil may deteriorate.

-Since R407C does not contain any chlorine, gas leak detectors for conventional refrigerant will not react to it.

· Do not use a charging cylinder.

-Using a charging cylinder may cause the refrigerant to deteriorate.

· Be especially careful when managing the tools.

-if dust, dirt, or water gets in the refrigerant cycle, the refrigerant may deteriorate.

· Do not use the drier which is sold in the field.

-The drier for R407C refrigerant is pre-attached to outdoor unit refrigerant circuit.

-Some drier in the field are not in conformity with R407C refrigerant.

3

Gravimeter

Unit

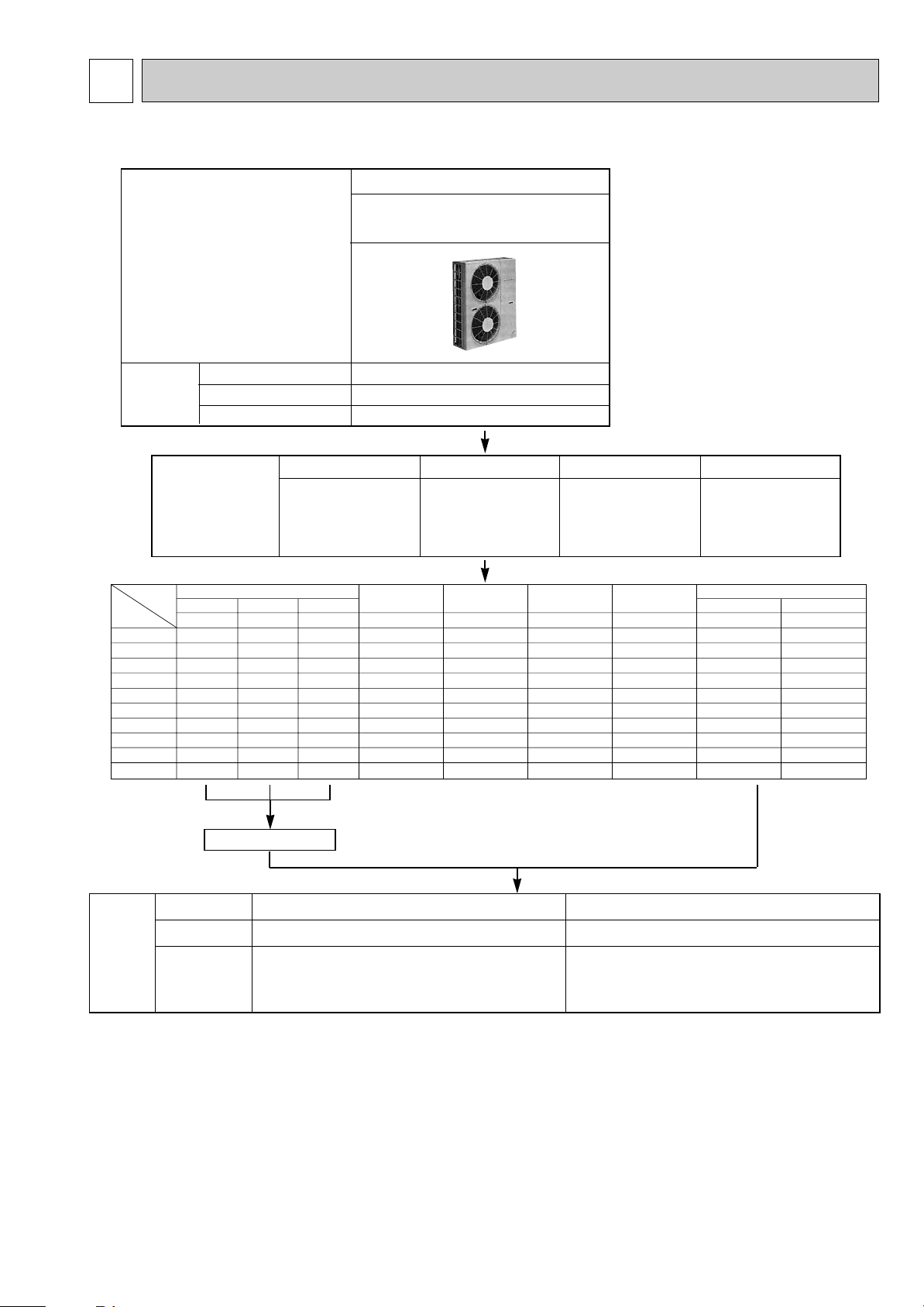

[1] Service tools

Use the below service tools as exclusive tools for R407C refrigerant.

No. Tool name Specifications

1 Gauge manifold ·Only for R407C.

·Use the existing fitting SPECIFICATIONS. (UNF 7/16)

·Use high-tension side pressure of 3.43MPa·G or over.

2 Charge hose ·Only for R407C.

·Use pressure performance of 5.10MPa·G or over.

3 Electronic scale

4 Gas leak detector ·Use the detector for R407C.

5 Adapter for reverse flow check. ·Attach on vacuum pump.

6 Refrigerant charge base.

7 Refrigerant cylinder. ·For R407C ·Top of cylinder (Brown)

·Cylinder with syphon

8 Refrigerant recovery equipment.

[2] Notice on repair service

·After recovering the all refrigerant in the unit, proceed to working.

·Do not release refrigerant in the air.

·After completing the repair service, recharge the cycle with the specified amount of

liquid refrigerant.

[3] Refrigerant recharging

(1) Refrigerant recharging process

1 Direct charging from the cylinder.

·R407C cylinder are available on the market has a syphon pipe.

·Leave the syphon pipe cylinder standing and recharge it.

(By liquid refrigerant)

(2) Recharge in refrigerant leakage case

·After recovering the all refrigerant in the unit, proceed to working.

·Do not release the refrigerant in the air.

·After completing the repair service, recharge the cycle with the specified amount of

liquid refrigerant.

4

3 OVERVIEW OF UNITS

20

25

32

40

50

63

71

80

100

125

–

–

32VKM-A

40VKM-A

50VKM-A

63VKM-A

–

80VAM-A

100VAM-A

125VAM-A

20VLMD-A

25VLMD-A

32VLMD-A

40VLMD-A

50VLMD-A

63VLMD-A

–

80VLMD-A

100VLMD-A

125VLMD-A

20VML-A / VMM-A

25VML-A / VMM-A

32VML-A / VMM-A

40VMH-A / VMM-A

50VMH-A / VMM-A

63VMH-A / VMM-A

71VMH-A / VMM-A

80VMH-A / VMM-A

100VMH-A / VMM-A

125VMH-A / VMM-A

20VM-A

25VM-A

32VM-A

40VM-A

50VM-A

63VM-A

71VM-A

80VM-A

100VM-A

125VM-A

20VAM-A

25VAM-A

32VGM-A

40VGM-A

50VGM-A

63VFM-A

–

–

100VFM-A

–

20VLEM-A

25VLEM-A

32VLEM-A

40VLEM-A

50VLEM-A

63VLEM-A

–

–

–

–

20VLRM-A

25VLRM-A

32VLRM-A

40VLRM-A

50VLRM-A

63VLRM-A

–

–

–

–

–

–

–

40VGM-A

–

63VGM-A

–

–

100VGM-A

125VGM-A

PLFY-P PLFY-P PEFY-P PDFY-P PKFY-P PCFY-P PFFY-P PFFY-P

Capacity

Model

Cassette Ceiling

4-way flow 2-way flow

20VBM-A

25VBM-A

32VBM-A

40VBM-A

–

–

–

–

–

–

PMFY-P

1-way flow

Ceiling

Concealed

Ceiling mounted

built-in

Ceiling

Suspended

Wall Mounted

Floor standing

Exposed Concealed

Remote

controller

Name

Model number

Functions

M-NET remote controller

PAR-F27MEA-E

• A handy remote controller for use in conjunction

with the Melans centralized management system.

• Addresses must be set.

• Addresses setting is not necessary.

•

Only the indoor unit for MA remote controller

(the end of model name is -A) can be used.

MA remote controller

PAR-20MAA-E

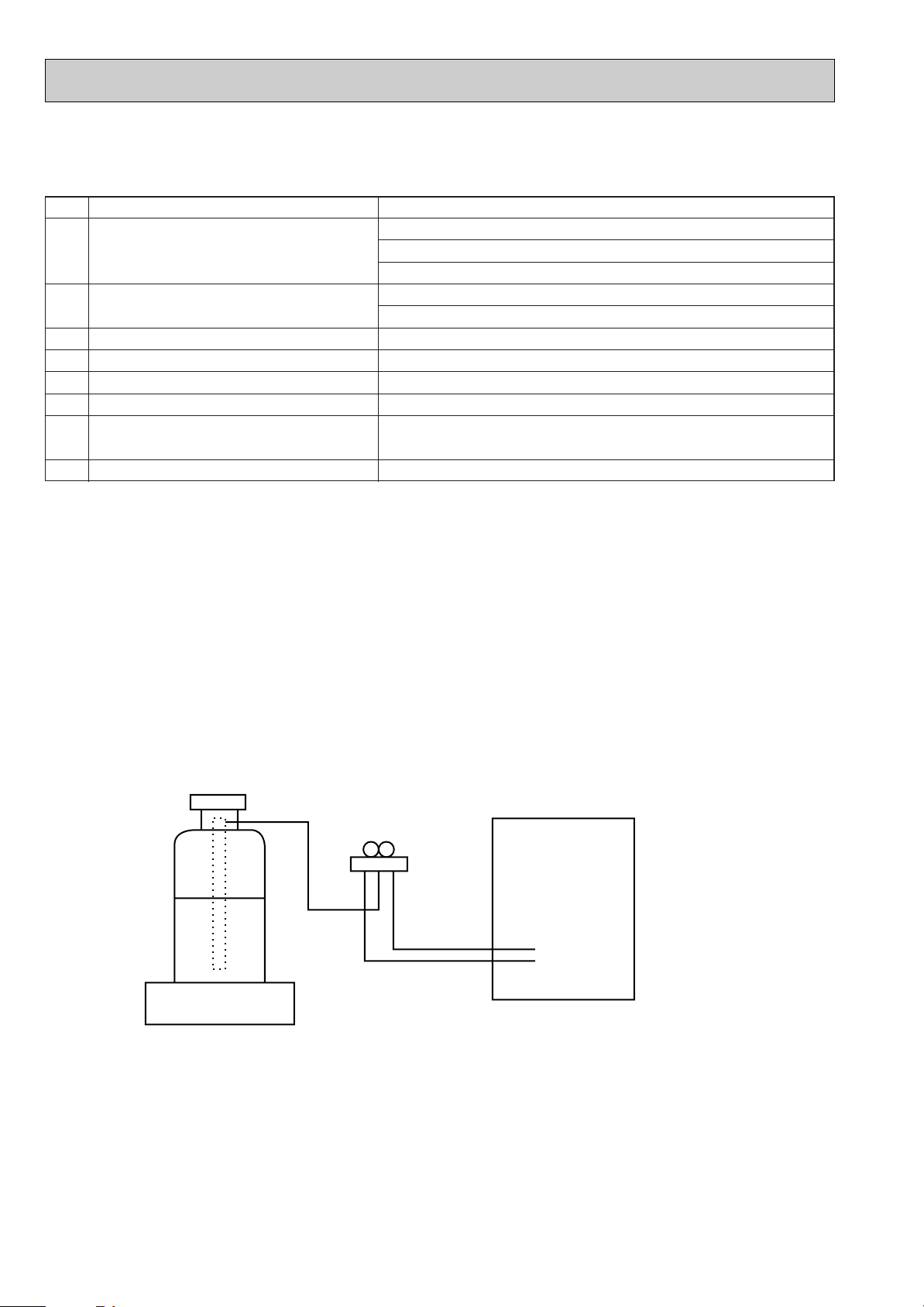

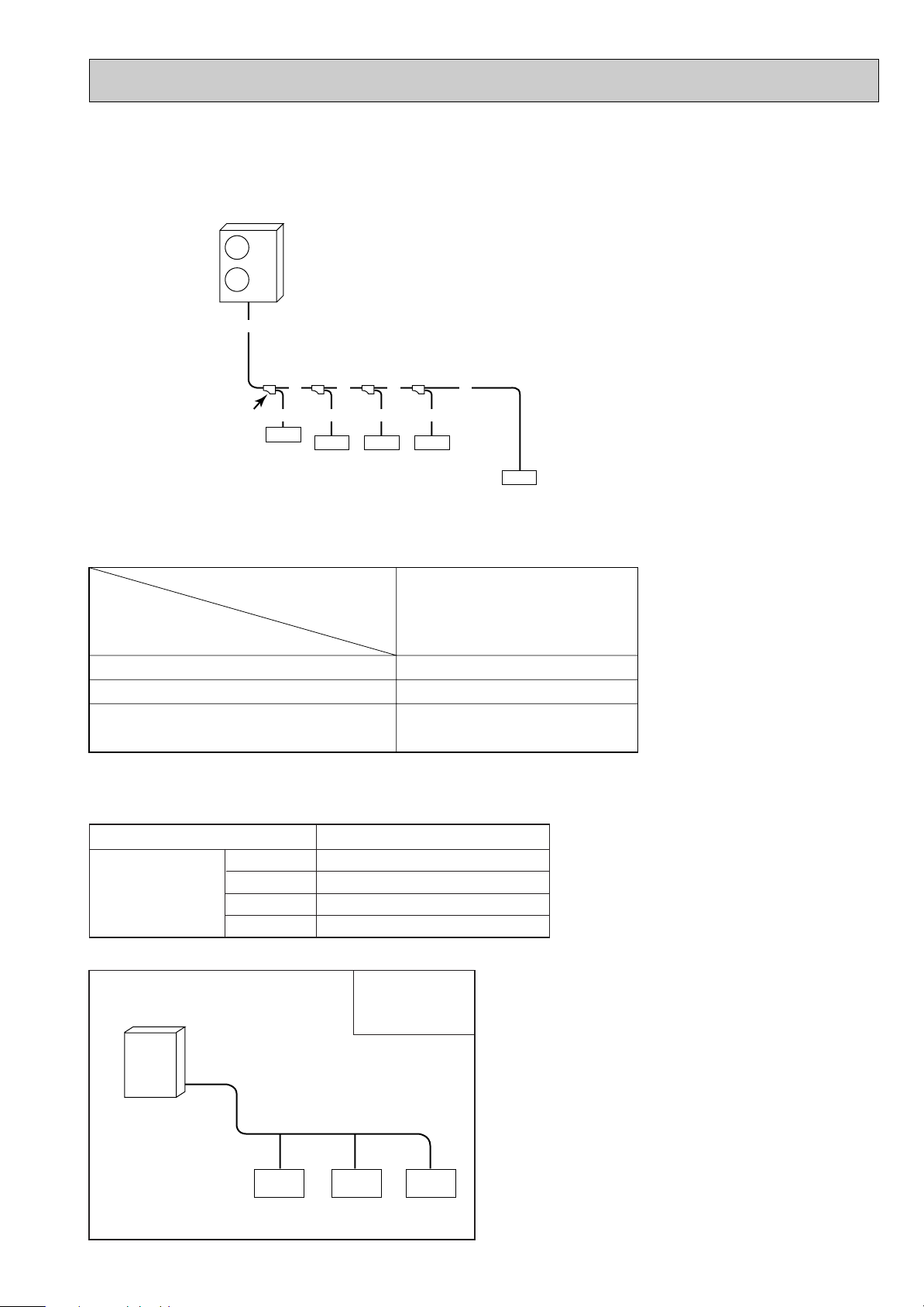

3-1. UNIT CONSTRUCTION

Outdoor unit

5HP

PUMY-P125VMA

PUMY-P125YMA

PUMY-P125YMA

1

Indoor unit

that can be

connected

Branching pipe

components

Capacity

Number of units

Total system wide capacity

CMY-Y62-C-E CMY-Y64-C CMY-Y68

Branch header

(2 branches)

Type 20~Type 125

1~8 units

50~130% of outdoor unit capacity

Branch header

(4 branches)

Branch header

(8 branches)

CMY-S65

Multi distribution

Piping on outdoor

unit

(5 branches)

Decorative panel

5

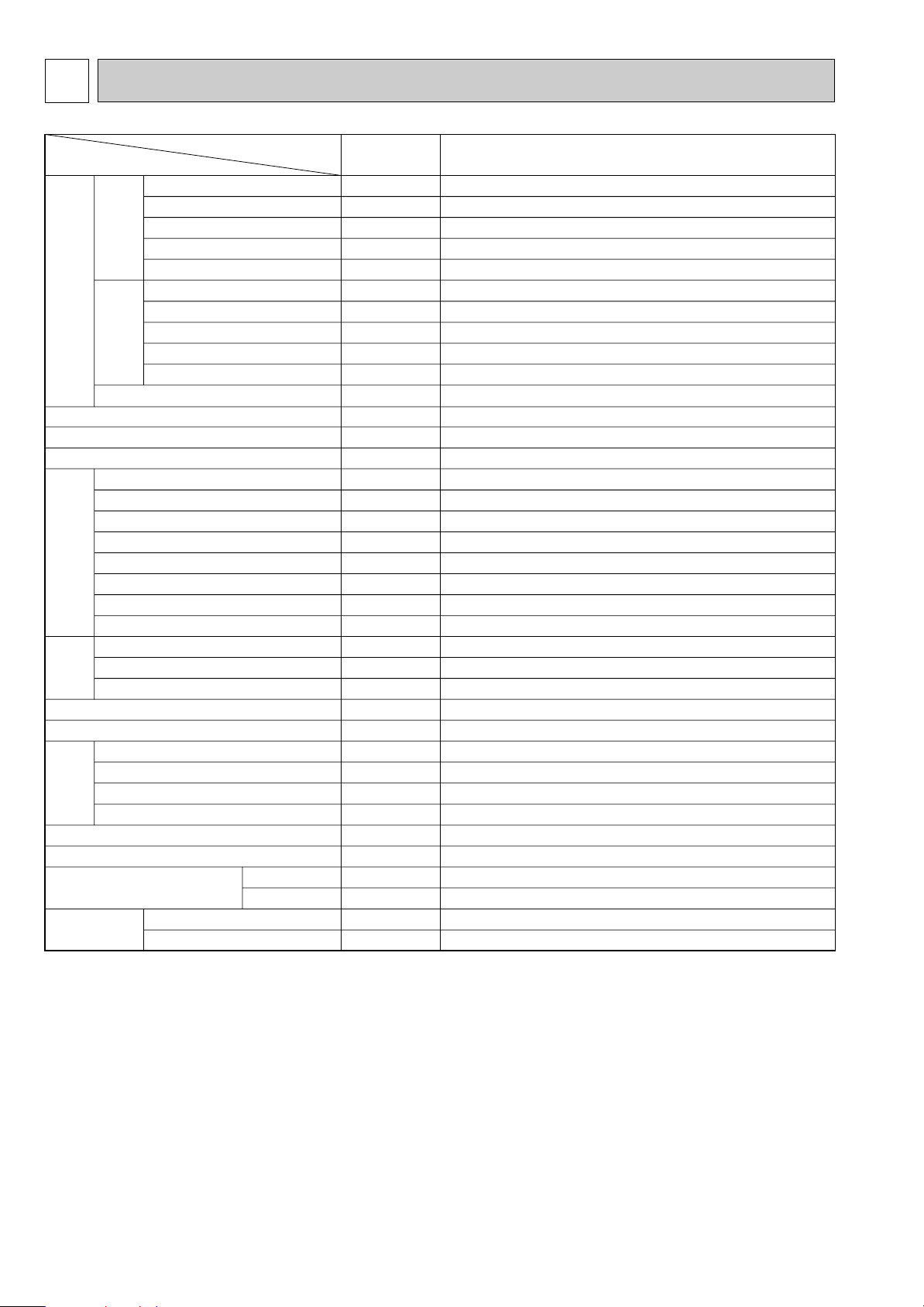

3-2. UNIT SPECIFICATIONS

P L F Y - P 80 V AM - A PU M Y - P 125 V M A

PAC type

AM

KM

M

KM

LMD

Frequency

conversion

controller

Refrigerant

R407C/R22

commonness

Refrigerant

R407C

NEW frequency converter

one-to-many air conditioners

(flexible design type)

Indicates equivalent

to Cooling capacity

Indicates equivalent

to Cooling capacity

Power supply

V: Single phase

220-230-240V 50Hz

220V 60Hz

Power supply

V: Single phase

220-230-240V 50Hz

Y: 3-phase

380-400-415V 50Hz

380V 60Hz

L : Ceiling cassette

K : Wall-mounted type

E : Hidden skylight type

C: Ceiling suspended type

M: Ceiling cassette type

F : Floor standing type

}

M-NET

control

M-NET control

MA control

Sub-number

Frequency

conversion

controller

Outdoor unit

MULTI-S

Service Ref.

w

PUMY-P125VMA

PUMY-P125YMA

PUMY-P125YMA1

Capacity

Cooling (kW)

Heating (kW)

14.0

16.0

3.5Motor for compressor (kW)

Cooling

W.B. 15~24°C

D.B. -5~46°C

Heating

D.B. 15~27°C

W.B. -15~15.5°C

Indoor-side intake air temperature

Outdoor-side intake air temperature

(1) Outdoor Unit

Cooling / Heating capacity indicates the maximum value at operation under the following condition.

w. Cooling Indoor : D.B. 27°C / W.B. 19.0°C

Outdoor : D.B. 35°C

Heating Indoor : D.B. 20°C

Outdoor : D.B. 7°C / W.B. 6°C

(2) Method for identifying MULTI-S model

■ Indoor unit < When using Model 80 >

■ Outdoor unit <When using model 125 >

(3) Operating temperature range

Notes D.B. : Dry Bulb Temperature

W.B. : Wet Bulb Temperature

6

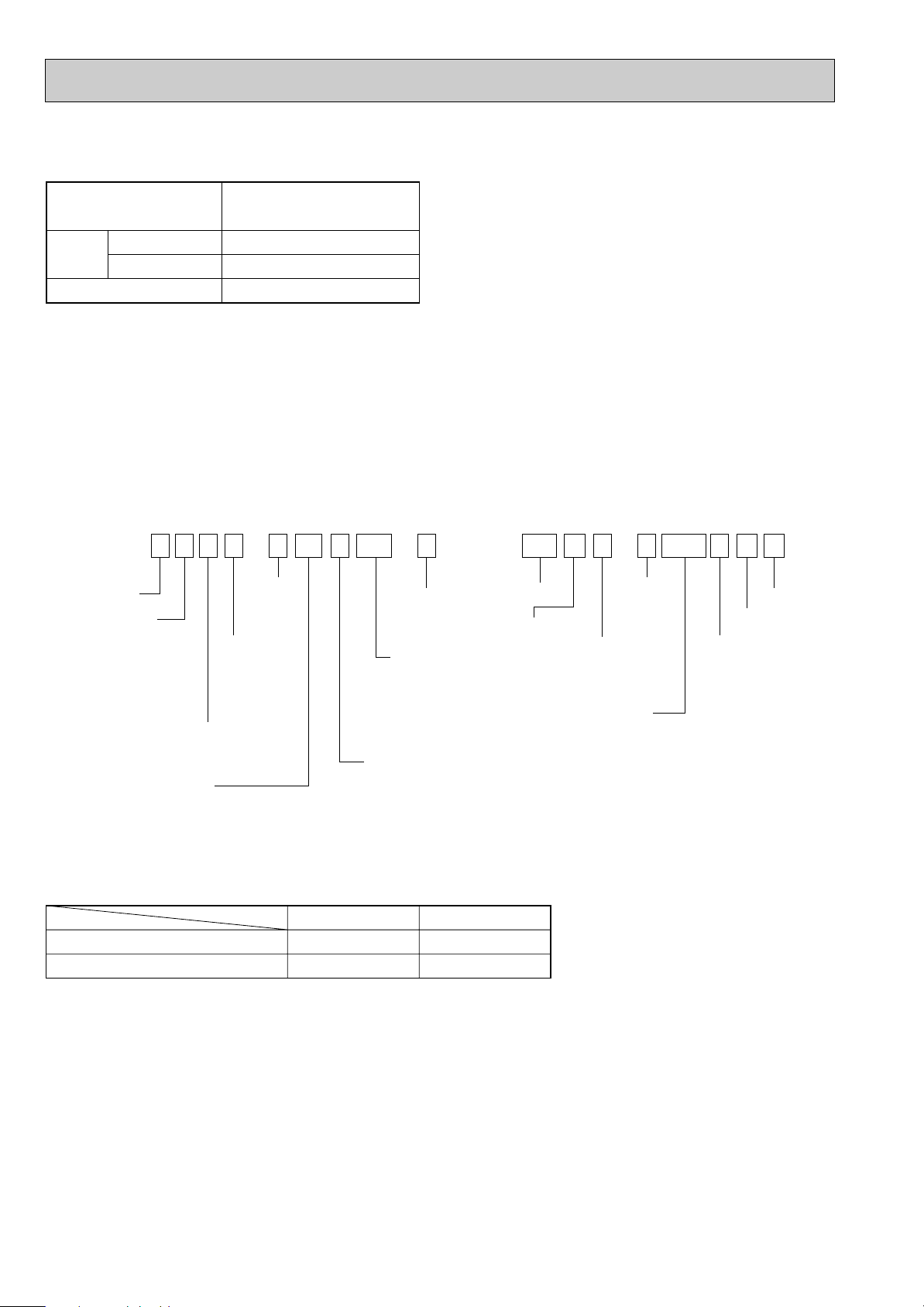

3-3. SYSTEM LAYOUT

A

B

a

indoor

1

C

b

indoor

2

D

c

indoor

3

e

d

indoor

4

indoor

5

First branch

(branching connector)

Outdoor unit

125

80 40 40

Outdoor unit

Indoor unit

Type 20 ~ Type 125

PUMY-P125VMA

PUMY-P125YMA

PUMY-P125YMA

1

1~8 units

63~163

Indoor unit that can connected

Available capacity of indoor unit

Total capacity of units that can be included system

(50-130% of outdoor unit capacity)

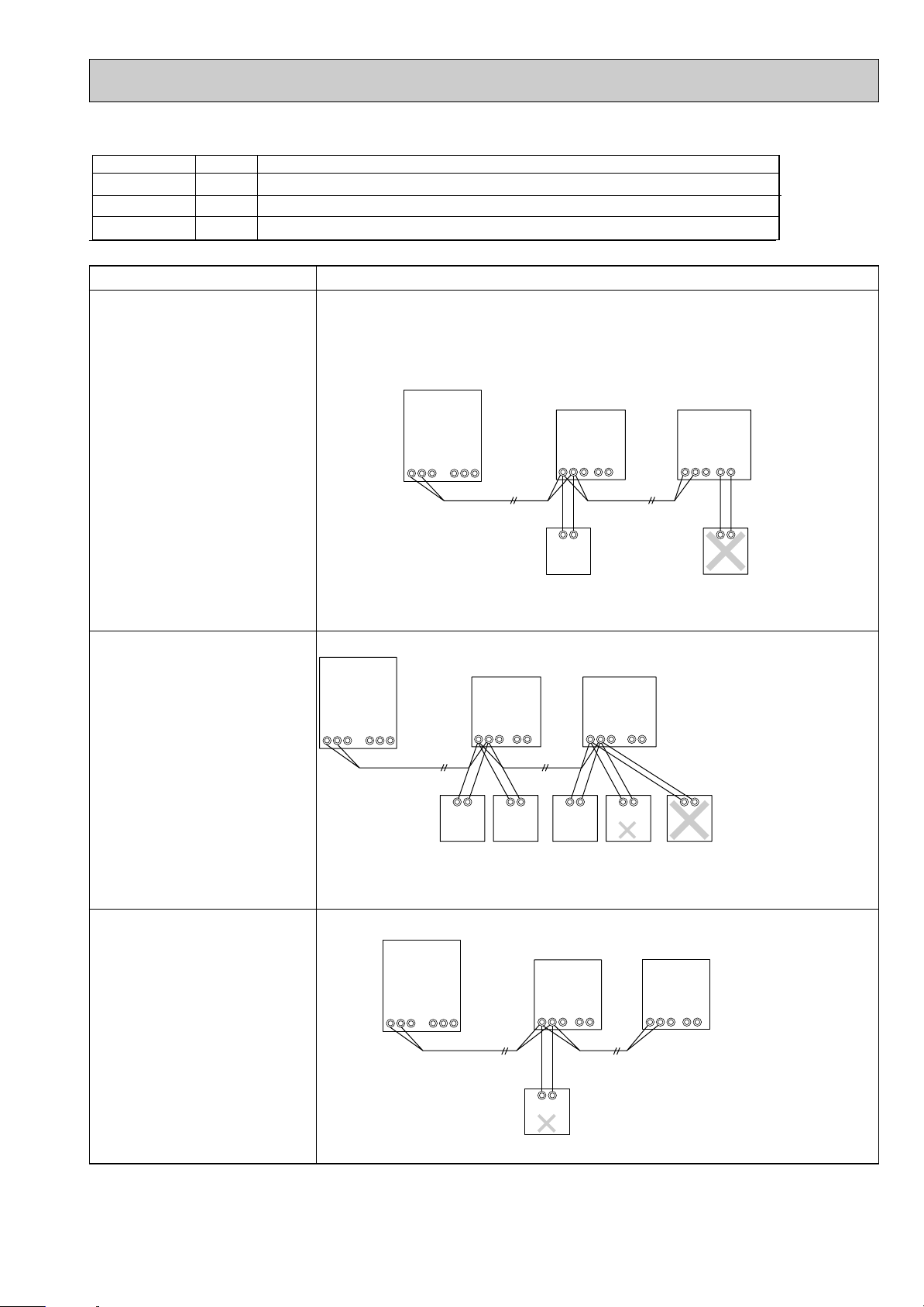

3-3-1. System layout

One outdoor unit using branching connectors can be connected to a maximum of eight indoor units.

■Examples of a branching method

3-3-2. Notes on the connection of indoor and outdoor units

Note: When the total capacity of indoor units exceeds the capacity of the outdoor unit (more than 100%), the rated power of

each indoor unit will be less when they are running simultaneously.

3-3-3. Capacity for outdoor unit

(1) Branching pipe

Model

CMY-Y62C-E

Branching connector

(2) Examples of System Construction (All models)

PIping method

Indoor units

CMY-Y64-C

CMY-Y68

CMY-S65

Outdoor unit

NUMBER OF BRANCHING POINTS

2

4

8

5

Total capacity of

indoor units.

160

7

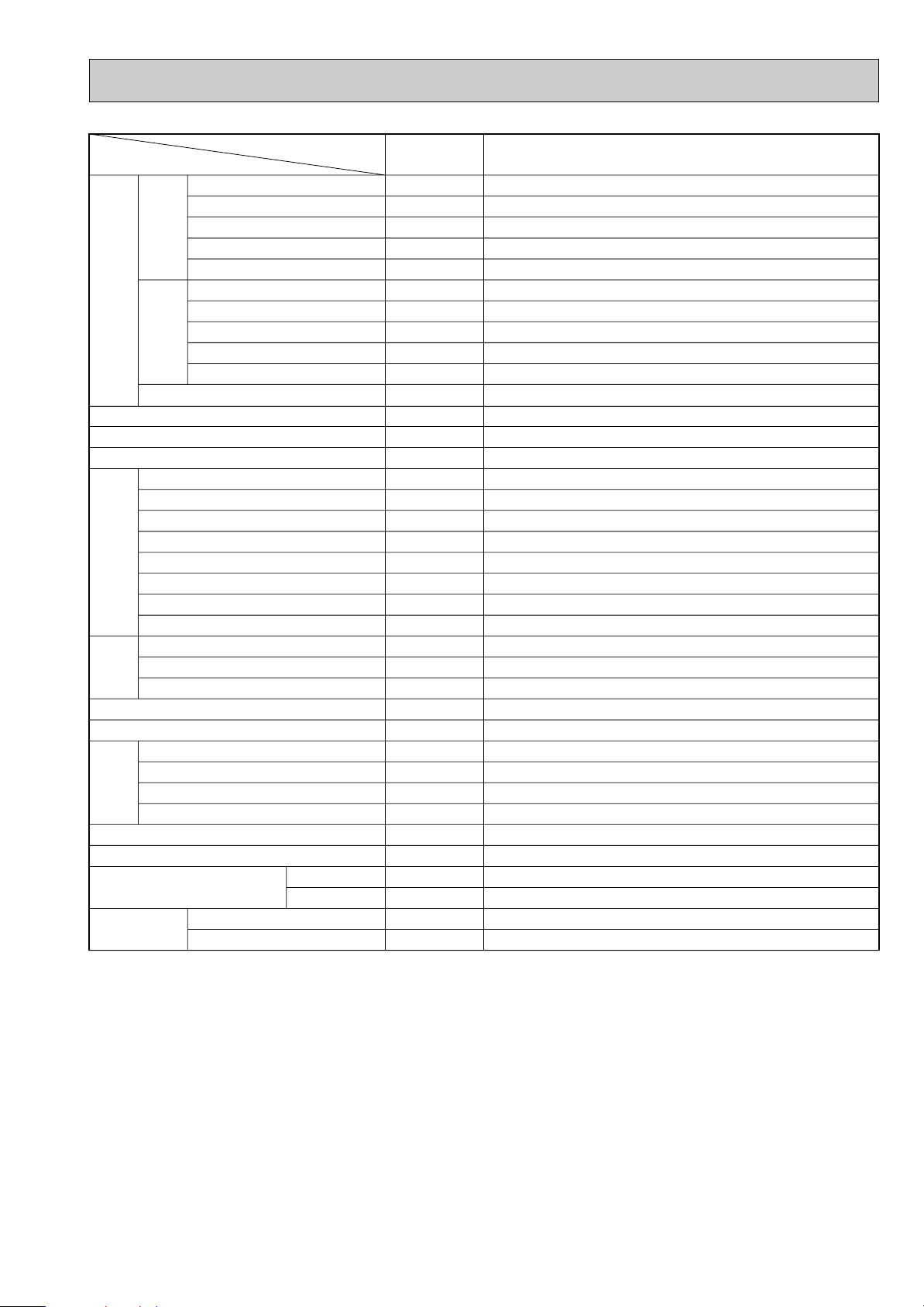

4 SPECIFICATIONS

PUMY-P125VMA

14.0

6.10

28.3-27.1-26.0

98

17

16.0

6.03

28.0-26.7-25.7

98

17

Single phase 220-230-240V 50Hz

Molten-galvanized steel plate (with polyester coating), ivory white <5Y 8/1>

1280 o 1020 o 350 (+30)

Crossover fin

EEV48FAM

Fully enclosed type o 1

Frequency converter start

3.5

Cooling 27-100% Heating 25-100%

1.9 (104Hz)

—

1.4 (MEL32)

Propeller (direct) o 2

90(3,177)

60 o 2

Reverse cycle

—

High pressure pressure sensor (3.0MPa)

Thermal switch

Thermal switch

Overheating, excessive current protection

54

127(280)

19.05

9.52

R407C o 8.5

Expansion valve

Item

Service Ref.

Unit

Standard performance

Heating Cooling

Rated Cooling capacity

Rated power consumption

Operating current

Operating power factor

Starting current

Rated Heating capacity

Rated power consumption

Operating current

Operating power factor

Starting current

Rated power supply

Type o charge amount

Control method

External finish (Munsell colour-coded markings)

Dimensions H o W o D (Note 1)

Heat exchanger type

Defrost method

Pressure gauge

Noise level

Weight

Refrigerant pipe size

Refrigerant

Model

Type o quantity

Starting method

Motor output

Capacity control

Daily cooling capacity

Heater <crankcase>

Refrigerating oil (Model)

Type o quantity

Airflow

Motor output

High pressure protection

Compressor protection

Blower protection

Frequency converter circuit

Compressor

Protection

devices

Gas

Liquid

Fan

kW

kW

A

%

A

kW

kW

A

%

A

mm

kW

%

Legal tons

W

L

k/min(CFM)

W

dB

kg(lbs)

[ mm

[ mm

kg

Note 1: External dimensions in parentheses indicate the dimensions of protruding parts.

Note 2: Rating conditions (JIS B 8616)

Cooling : Indoor : D.B. 27: W.B. 19:

: Outdoor : D.B. 35: W.B. 24:

Heating : Indoor : D.B. 20:

: Outdoor : D.B. 7: W.B. 6:

8

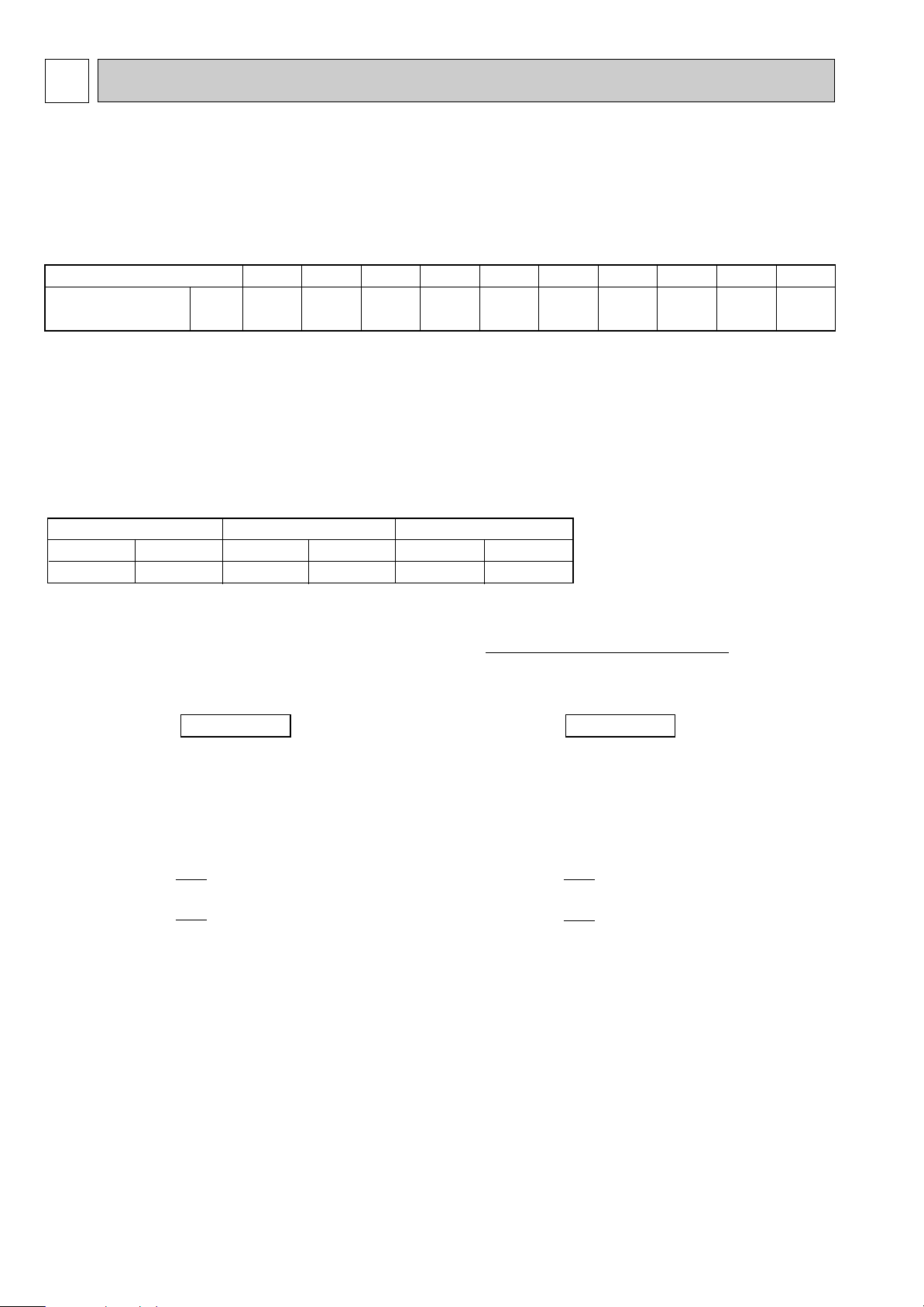

Item

Rated Cooling capacity

Rated power consumption

Operating current

Operating power factor

Starting current

Rated Heating capacity

Rated power consumption

Operating current

Operating power factor

Standard performance

External finish (Munsell colour-coded markings)

Dimensions H o W o D (Note 1)

Heat exchanger type

Compressor

Fan

Defrost method

Pressure gauge

Protection

Noise level

Weight

Refrigerant pipe size

Refrigerant

Note 1: External dimensions in parentheses indicate the dimensions of protruding parts.

Note 2: Rating conditions (JIS B 8616)

Cooling : Indoor : D.B. 27: W.B. 19:

Heating Cooling

Starting current

Rated power supply

Model

Type o quantity

Starting method

Motor output

Capacity control

Daily cooling capacity

Heater <crankcase>

Refrigerating oil (Model)

Type o quantity

Airflow

Motor output

High pressure protection

Compressor protection

Blower protection

devices

Frequency converter circuit

Type o charge amount

Control method

: Outdoor : D.B. 35: W.B. 24:

Heating : Indoor : D.B. 20:

: Outdoor : D.B. 7: W.B. 6:

Service Ref.

Gas

Liquid

Unit

kW

kW

A

%

A

kW

kW

A

%

A

mm

kW

%

Legal tons

W

L

k/min(CFM)

W

dB

kg(lbs)

[ mm

[ mm

kg

3 phase 380-400-415V 50Hz

Molten-galvanized steel plate (with polyester coating), ivory white <5Y 8/1>

1280 o 1020 o 350 (+30)

Fully enclosed type o 1

Frequency converter start

Cooling 27-100% Heating 25-100%

Propeller (direct) o 2

High pressure pressure sensor (3.0MPa)

Overheating, excessive current protection

PUMY-P125YMA

PUMY-P125YMA

14.0

5.95

9.6-9.1-8.8

94

8.0

16.0

5.58

9.2-8.8-8.5

92

8.0

Crossover fin

EEV48FAK

3.5

1.9 (104Hz)

—

1.4 (MEL32)

90(3,177)

60 o 2

Reverse cycle

—

Thermal switch

Thermal switch

54

127(280)

19.05

9.52

R407C o 8.5

Expansion valve

1

9

5 DATA

Model 20

Model Number for indoor unit

Model Capacity

kW

22

Model 2528Model 3236Model 4045Model 5056Model 6371Model 7180Model 8090Model 100

112

Model 125

140

5-1. COOLING AND HEATING CAPACITY AND CHARACTERISTICS

5-1-1. Method for obtaining system cooling and heating capacity:

To obtain the system cooling and heating capacity and the electrical characteristics of the outdoor unit, first add up the ratings

of all the indoor units connected to the outdoor unit (see table below), and then use this total to find the standard capacity with

the help of the tables on page 11 to 14.

(1) Capacity of indoor unit

(2) Sample calculation

1 System assembled from indoor and outdoor unit (in this example the total capacity of the indoor units is greater than

that of the outdoor unit)

• Outdoor unit PUMY-P125YMA

• Indoor unit PKFY-P25VAM-A o 2 , PLFY-P50VLMD-A o 2

2 According to the conditions in 1 , the total capacity of the indoor unit will be: 28 o 2 +

56 o 2 = 168

Capacity (kW)

Cooling

14.60

AB

Heating

16.33

Outdoor unit power consumption (kW)

Cooling

6.04

Heating

5.14

Outdoor unit current (A)

Cooling

8.9

Heating

7.8

5-1-2. Method for obtaining the heating and cooling capacity of an indoor unit:

(1) The capacity of each indoor unit (kW) = the capacity A (or B ) o

(2) Sample calculation (using the system described above in 4-1-1. (2) ):

During cooling: During heating:

• The total model capacity of the indoor unit is:

2.8 o 2 + 5.6 o 2=16.8kW

Therefore, the capacity of PKFY-P25VAM-A and

PLFY-P50VLMD-A will be calculated as follows by

using the formula in 4-1-2. (1):

Model 25=14.6 o = 2.43kW

Model 50=14.6 o = 4.87kW

2.8

16.8

5.6

16.8

total model capacity of all indoor units

• The total model capacity of indoor unit is:

3.2 o 2 + 6.3 o 2=19.0

Therefore, the capacity of PKFY-P25VAM-A and PLFYP50VLMD-A will be calculated as follows by using the

formula in 4-1-2. (1):

Model 25=16.33 o = 2.75kW

Model 50=16.33 o = 5.41kW

model capacity

3.2

19.0

6.3

19.0

10

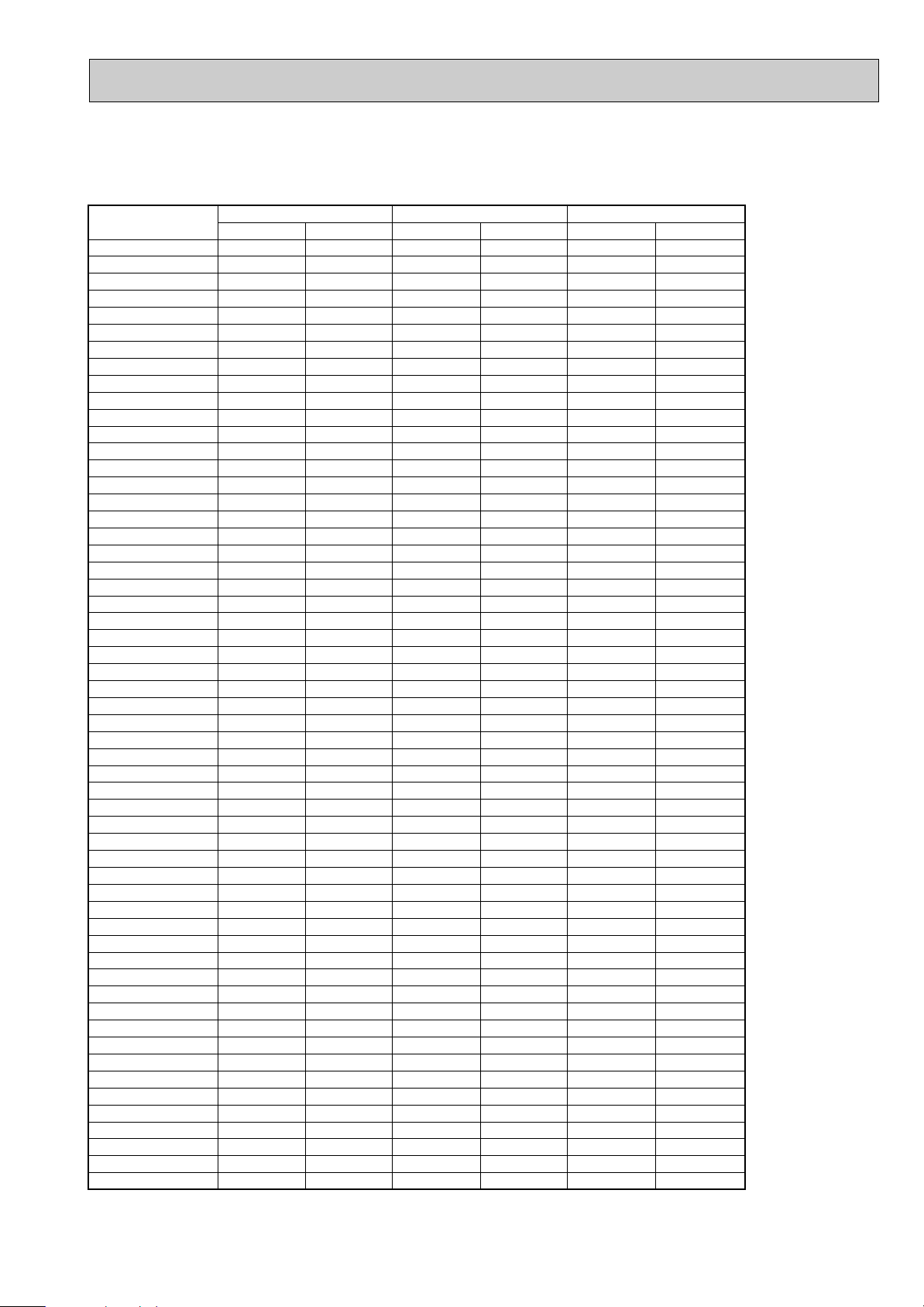

5-2. STANDARD CAPACITY DIAGRAM

Total capacity of

indoor units (kW)

Capacity (kW)

Power consumption (kW) Current (A)

Cooling

Heating

Cooling

Heating

Cooling

Heating

2.58

2.61

2.65

2.69

2.73

2.76

2.80

2.84

2.88

2.92

2.96

3.00

3.04

3.08

3.12

3.16

3.20

3.25

3.29

3.33

3.38

3.42

3.47

3.51

3.56

3.60

3.65

3.69

3.74

3.79

3.84

3.89

3.93

3.98

4.03

4.08

4.13

4.19

4.24

4.29

4.34

4.39

4.45

4.50

4.55

4.61

4.66

4.72

4.77

4.83

4.89

4.94

5.00

5.06

5.12

5.17

2.86

2.89

2.93

2.97

3.01

3.04

3.08

3.12

3.16

3.20

3.23

3.27

3.31

3.35

3.39

3.43

3.47

3.51

3.55

3.59

3.64

3.68

3.72

3.76

3.80

3.85

3.89

3.93

3.98

4.02

4.06

4.11

4.15

4.20

4.24

4.29

4.33

4.38

4.42

4.47

4.52

4.56

4.61

4.66

4.70

4.75

4.80

4.85

4.90

4.94

4.99

5.04

5.09

5.14

5.19

5.24

11.0

11.1

11.3

11.5

11.6

11.8

11.9

12.1

12.3

12.4

12.6

12.8

12.9

13.1

13.3

13.5

13.6

13.8

14.0

14.2

14.4

14.6

14.8

15.0

15.1

15.3

15.5

15.7

15.9

16.1

16.3

16.6

16.8

17.0

17.2

17.4

17.6

17.8

18.0

18.3

18.5

18.7

18.9

19.2

19.4

19.6

19.9

20.1

20.3

20.6

20.8

21.1

21.3

21.5

21.8

22.0

12.2

12.3

12.5

12.6

12.8

13.0

13.1

13.3

13.5

13.6

13.8

13.9

14.1

14.3

14.5

14.6

14.8

15.0

15.1

15.3

15.5

15.7

15.8

16.0

16.2

16.4

16.6

16.8

16.9

17.1

17.3

17.5

17.7

17.9

18.1

18.3

18.5

18.6

18.8

19.0

19.2

19.4

19.6

19.8

20.0

20.2

20.4

20.7

20.9

21.1

21.3

21.5

21.7

21.9

22.1

22.3

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

7.00

7.10

7.20

7.30

7.40

7.50

7.60

7.70

7.80

7.90

8.00

8.10

8.20

8.30

8.40

8.50

8.60

8.70

8.80

8.90

9.00

9.10

9.20

9.30

9.40

9.50

9.60

9.70

9.80

9.90

10.00

10.10

10.20

10.30

10.40

10.50

10.60

10.70

10.80

10.90

11.00

11.10

11.20

11.30

11.40

11.50

11.60

11.70

11.80

11.90

12.00

12.10

12.20

12.30

12.40

12.50

7.88

8.00

8.11

8.22

8.33

8.44

8.56

8.67

8.78

8.89

9.00

9.10

9.20

9.30

9.40

9.50

9.60

9.70

9.80

9.90

10.00

10.10

10.22

10.33

10.45

10.56

10.67

10.79

10.90

11.02

11.13

11.24

11.36

11.47

11.59

11.70

11.81

11.93

12.04

12.16

12.27

12.38

12.50

12.63

12.75

12.88

13.00

13.13

13.25

13.38

13.50

13.63

13.75

13.88

14.00

14.13

w

w Before calculating the sum of total capacity of indoor units, please convert

the valve into the kW model capacity following the formula on page 8.

240V, 50Hz

5-2-1. PUMY-P125VMA STANDARD CAPACITY DIAGRAM

11

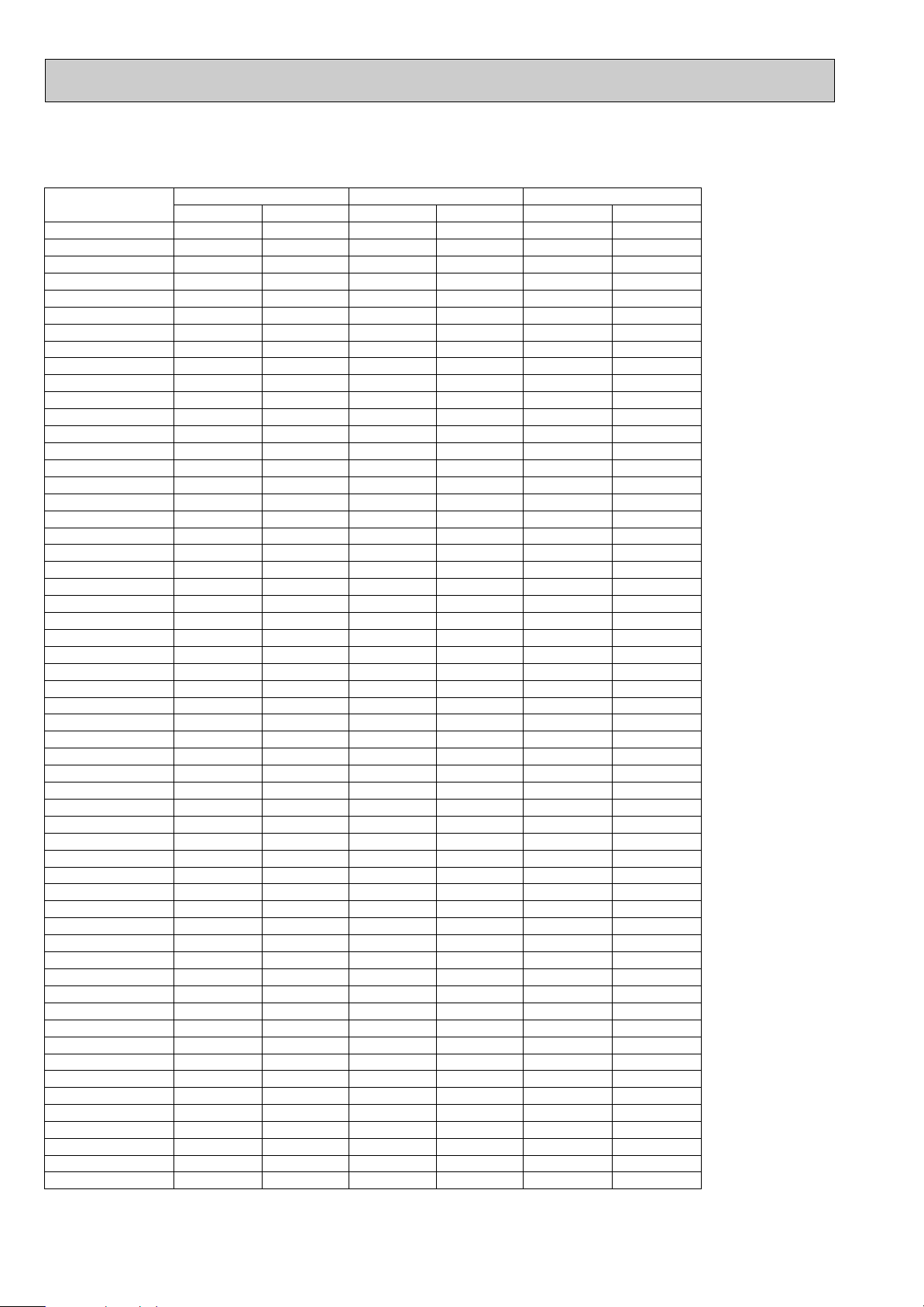

5-2-2. PUMY-P125VMA STANDARD CAPACITY DIAGRAM

Total capacity of

indoor units (kW)

Capacity (kW)

Power consumption (kW) Current (A)

Cooling

Heating

Cooling

Heating

Cooling

Heating

5.23

5.29

5.35

5.41

5.47

5.53

5.59

5.66

5.72

5.78

5.84

5.91

5.97

6.04

6.10

6.11

6.11

6.11

6.12

6.12

6.12

6.13

6.13

6.13

6.14

6.14

6.14

6.15

6.15

6.15

6.15

6.16

6.16

6.16

6.17

6.17

6.17

6.18

6.18

6.18

6.19

6.19

6.19

6.20

6.20

6.20

6.21

6.21

6.21

6.22

6.22

6.22

6.22

6.23

6.23

6.23

6.24

5.29

5.34

5.39

5.45

5.50

5.55

5.60

5.65

5.71

5.76

5.81

5.87

5.92

5.97

6.03

6.02

6.00

5.98

5.96

5.95

5.93

5.91

5.90

5.88

5.86

5.85

5.83

5.81

5.79

5.78

5.76

5.74

5.73

5.71

5.69

5.68

5.66

5.64

5.62

5.61

5.59

5.57

5.56

5.54

5.52

5.51

5.49

5.47

5.46

5.44

5.42

5.40

5.39

5.37

5.35

5.34

5.32

22.3

22.5

22.8

23.1

23.3

23.6

23.8

24.1

24.4

24.6

24.9

25.2

25.4

25.7

26.0

26.0

26.0

26.0

26.1

26.1

26.1

26.1

26.1

26.1

26.1

26.2

26.2

26.2

26.2

26.2

26.2

26.2

26.2

26.3

26.3

26.3

26.3

26.3

26.3

26.3

26.4

26.4

26.4

26.4

26.4

26.4

26.4

26.5

26.5

26.5

26.5

26.5

26.5

26.5

26.5

26.6

26.6

22.6

22.8

23.0

23.2

23.4

23.6

23.9

24.1

24.3

24.5

24.8

25.0

25.2

25.4

25.7

25.6

25.6

25.5

25.4

25.3

25.3

25.2

25.1

25.0

25.0

24.9

24.8

24.8

24.7

24.6

24.5

24.5

24.4

24.3

24.3

24.2

24.1

24.0

24.0

23.9

23.8

23.7

23.7

23.6

23.5

23.5

23.4

23.3

23.2

23.2

23.1

23.0

23.0

22.9

22.8

22.7

22.7

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

177

178

179

180

181

182

12.60

12.70

12.80

12.90

13.00

13.10

13.20

13.30

13.40

13.50

13.60

13.70

13.80

13.90

14.00

14.02

14.04

14.06

14.08

14.10

14.12

14.15

14.17

14.19

14.21

14.23

14.25

14.27

14.30

14.32

14.34

14.36

14.38

14.40

14.42

14.45

14.47

14.49

14.51

14.53

14.55

14.57

14.60

14.62

14.64

14.66

14.68

14.70

14.72

14.75

14.77

14.79

14.81

14.83

14.85

14.87

14.89

14.25

14.38

14.50

14.63

14.75

14.88

15.00

15.13

15.25

15.38

15.50

15.63

15.75

15.88

16.00

16.01

16.02

16.03

16.04

16.06

16.07

16.08

16.09

16.10

16.12

16.13

16.14

16.15

16.16

16.17

16.19

16.20

16.21

16.22

16.23

16.25

16.26

16.27

16.28

16.29

16.31

16.32

16.33

16.34

16.35

16.36

16.38

16.39

16.40

16.41

16.42

16.44

16.45

16.46

16.47

16.48

16.50

w

w Before calculating the sum of total capacity of indoor units, please convert

the valve into the kW model capacity following the formula on page 8.

240V, 50Hzw

12

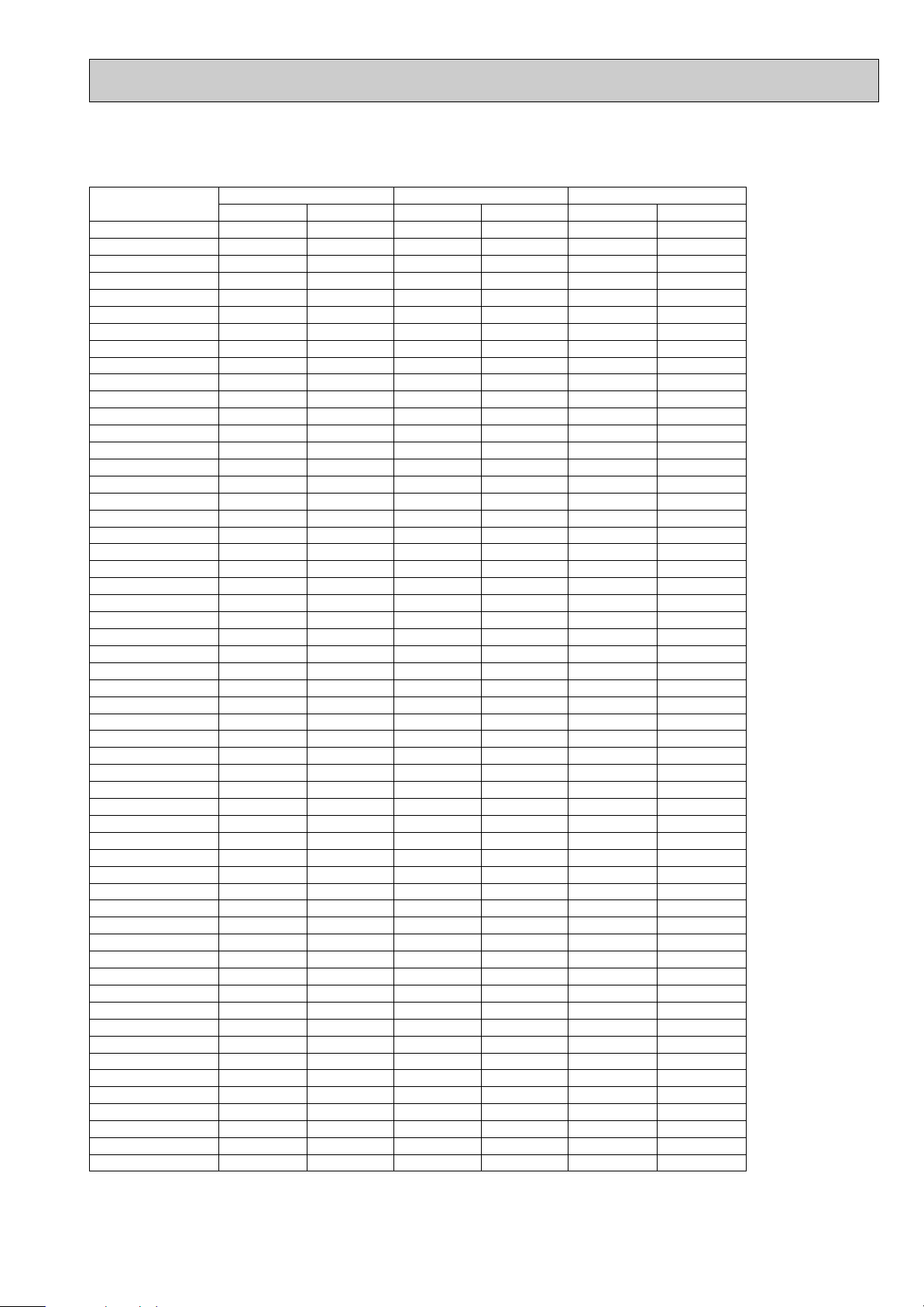

5-2-3. PUMY-P125YMA, PUMY-P125YMA1 STANDARD CAPACITY DIAGRAM

Total capacity of

indoor units (kW)

Capacity (kW)

Power consumption (kW) Current (A)

Cooling

Heating

Cooling

Heating

Cooling

Heating

2.47

2.50

2.54

2.57

2.61

2.64

2.68

2.72

2.76

2.80

2.83

2.87

2.91

2.95

2.99

3.03

3.07

3.12

3.16

3.20

3.24

3.29

3.33

3.37

3.42

3.46

3.51

3.55

3.60

3.65

3.69

3.74

3.79

3.84

3.88

3.93

3.98

4.03

4.08

4.13

4.18

4.24

4.29

4.34

4.39

4.44

4.50

4.55

4.61

4.66

4.72

4.77

4.83

4.88

4.94

5.00

2.63

2.66

2.70

2.73

2.77

2.80

2.84

2.87

2.91

2.94

2.98

3.02

3.05

3.09

3.13

3.16

3.20

3.24

3.27

3.31

3.35

3.39

3.43

3.47

3.51

3.55

3.59

3.62

3.67

3.71

3.75

3.79

3.83

3.87

3.91

3.95

3.99

4.04

4.08

4.12

4.16

4.21

4.25

4.30

4.34

4.38

4.43

4.47

4.52

4.56

4.61

4.65

4.70

4.74

4.79

4.84

3.8

3.9

3.9

4.0

4.0

4.1

4.1

4.2

4.2

4.3

4.3

4.4

4.4

4.5

4.6

4.6

4.7

4.8

4.8

4.9

5.0

5.0

5.1

5.2

5.2

5.2

5.3

5.4

5.4

5.5

5.6

5.7

5.7

5.8

5.9

5.9

6.0

6.1

6.2

6.2

6.3

6.3

6.4

6.5

6.6

6.6

6.7

6.8

6.9

7.0

7.1

7.1

7.2

7.3

7.4

7.5

4.2

4.2

4.3

4.3

4.4

4.4

4.5

4.5

4.5

4.6

4.7

4.7

4.8

4.8

4.9

4.9

5.0

5.1

5.1

5.2

5.2

5.3

5.4

5.4

5.5

5.5

5.5

5.6

5.7

5.7

5.8

5.9

5.9

6.0

6.0

6.1

6.2

6.2

6.3

6.4

6.4

6.4

6.5

6.6

6.6

6.7

6.8

6.8

6.9

7.0

7.0

7.1

7.2

7.2

7.3

7.4

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

7.00

7.10

7.20

7.30

7.40

7.50

7.60

7.70

7.80

7.90

8.00

8.10

8.20

8.30

8.40

8.50

8.60

8.70

8.80

8.90

9.00

9.10

9.20

9.30

9.40

9.50

9.60

9.70

9.80

9.90

10.00

10.10

10.20

10.30

10.40

10.50

10.60

10.70

10.80

10.90

11.00

11.10

11.20

11.30

11.40

11.50

11.60

11.70

11.80

11.90

12.00

12.10

12.20

12.30

12.40

12.50

7.88

8.00

8.11

8.22

8.33

8.44

8.56

8.67

8.78

8.89

9.00

9.10

9.20

9.30

9.40

9.50

9.60

9.70

9.80

9.90

10.00

10.10

10.22

10.33

10.45

10.56

10.67

10.79

10.90

11.02

11.13

11.24

11.36

11.47

11.59

11.70

11.81

11.93

12.04

12.16

12.27

12.38

12.50

12.63

12.75

12.88

13.00

13.13

13.25

13.38

13.50

13.63

13.75

13.88

14.00

14.13

w

w Before calculating the sum of total capacity of indoor units, please convert

the valve into the kW model capacity following the formula on page 8.

415V, 50Hz

13

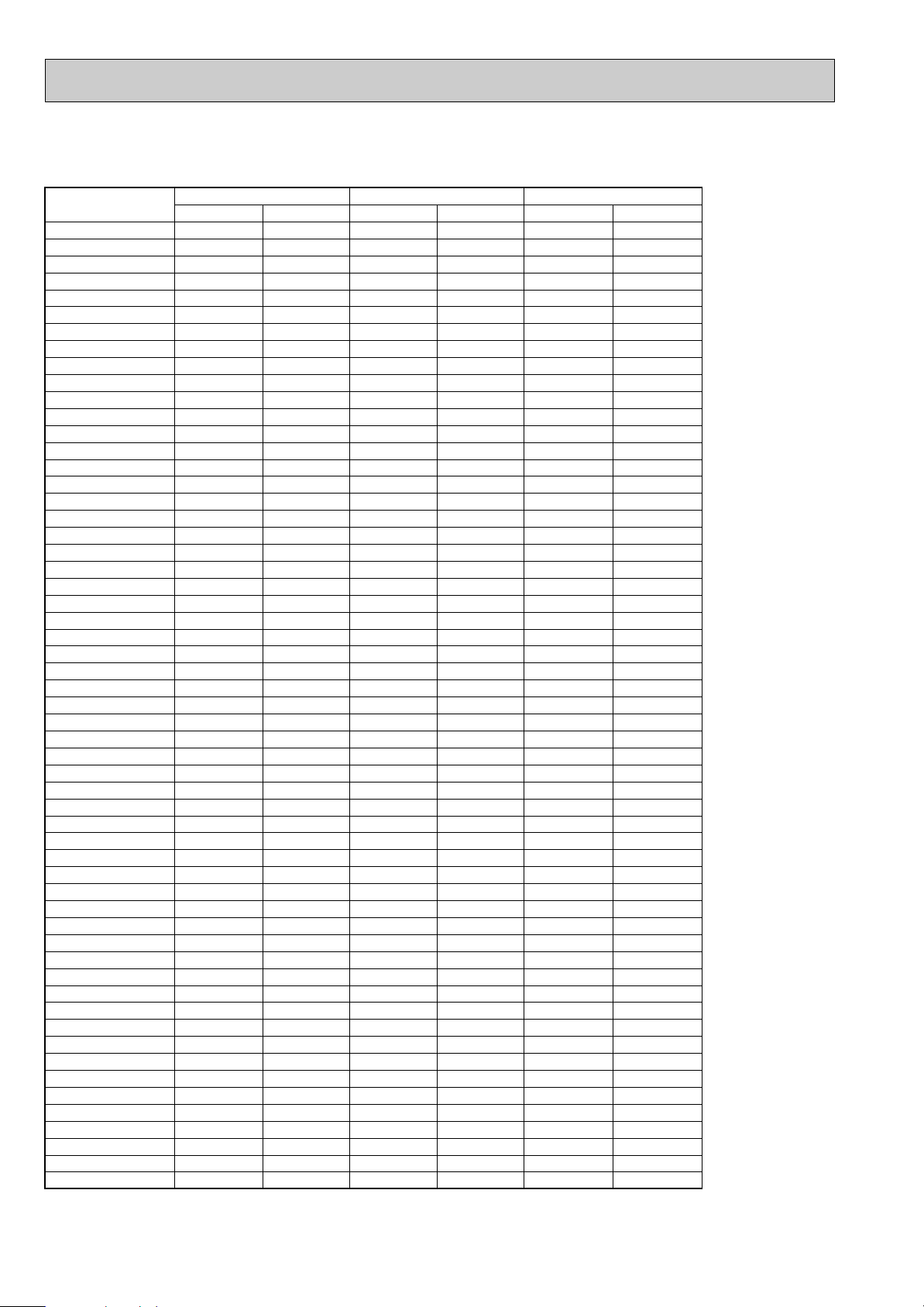

5-2-4. PUMY-P125YMA, PUMY-P125YMA1 STANDARD CAPACITY DIAGRAM

Total capacity of

indoor units (kW)

Capacity (kW)

Power consumption (kW) Current (A)

Cooling

Heating

Cooling

Heating

Cooling

Heating

5.05

5.11

5.17

5.23

5.29

5.35

5.41

5.47

5.53

5.59

5.65

5.71

5.77

5.84

5.95

5.96

5.96

5.96

5.97

5.97

5.97

5.98

5.98

5.98

5.99

5.99

5.99

5.99

6.00

6.00

6.00

6.01

6.01

6.01

6.02

6.02

6.02

6.03

6.03

6.03

6.03

6.04

6.04

6.04

6.05

6.05

6.05

6.06

6.06

6.06

6.07

6.07

6.07

6.07

6.08

6.08

6.08

4.88

4.93

4.98

5.03

5.07

5.12

5.17

5.22

5.27

5.32

5.36

5.41

5.46

5.51

5.58

5.57

5.55

5.53

5.52

5.50

5.49

5.47

5.46

5.44

5.43

5.41

5.39

5.38

5.36

5.35

5.33

5.32

5.30

5.28

5.27

5.25

5.24

5.22

5.21

5.19

5.17

5.16

5.14

5.13

5.11

5.10

5.08

5.06

5.05

5.03

5.02

5.00

4.99

4.97

4.95

4.94

4.92

7.6

7.6

7.7

7.7

7.8

7.9

8.0

8.1

8.2

8.3

8.4

8.5

8.5

8.6

8.8

8.8

8.8

8.8

8.8

8.8

8.8

8.9

8.9

8.9

8.9

8.9

8.9

8.9

8.9

8.9

8.9

8.9

8.9

8.9

8.9

8.9

8.9

8.9

8.9

8.9

8.9

8.9

8.9

8.9

9.0

9.0

9.0

9.0

9.0

9.0

9.0

9.0

9.0

9.0

9.0

9.0

9.0

7.5

7.5

7.5

7.6

7.7

7.7

7.8

7.9

8.0

8.0

8.1

8.2

8.3

8.3

8.4

8.4

8.4

8.4

8.3

8.3

8.3

8.3

8.3

8.2

8.2

8.2

8.2

8.1

8.1

8.1

8.1

8.0

8.0

8.0

8.0

7.9

7.9

7.9

7.9

7.8

7.8

7.8

7.8

7.8

7.8

7.8

7.8

7.7

7.7

7.7

7.7

7.6

7.6

7.6

7.6

7.6

7.5

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

177

178

179

180

181

182

12.60

12.70

12.80

12.90

13.00

13.10

13.20

13.30

13.40

13.50

13.60

13.70

13.80

13.90

14.00

14.02

14.04

14.06

14.08

14.10

14.12

14.15

14.17

14.19

14.21

14.23

14.25

14.27

14.30

14.32

14.34

14.36

14.38

14.40

14.42

14.45

14.47

14.49

14.51

14.53

14.55

14.57

14.60

14.62

14.64

14.66

14.68

14.70

14.72

14.75

14.77

14.79

14.81

14.83

14.85

14.87

14.89

14.25

14.38

14.50

14.63

14.75

14.88

15.00

15.13

15.25

15.38

15.50

15.63

15.75

15.88

16.00

16.01

16.02

16.03

16.04

16.06

16.07

16.08

16.09

16.10

16.12

16.13

16.14

16.15

16.16

16.17

16.19

16.20

16.21

16.22

16.23

16.25

16.26

16.27

16.28

16.29

16.31

16.32

16.33

16.34

16.35

16.36

16.38

16.39

16.40

16.41

16.42

16.44

16.45

16.46

16.47

16.48

16.50

w

w Before calculating the sum of total capacity of indoor units, please convert

the valve into the kW model capacity following the formula on page 8.

415V, 50Hzw

14

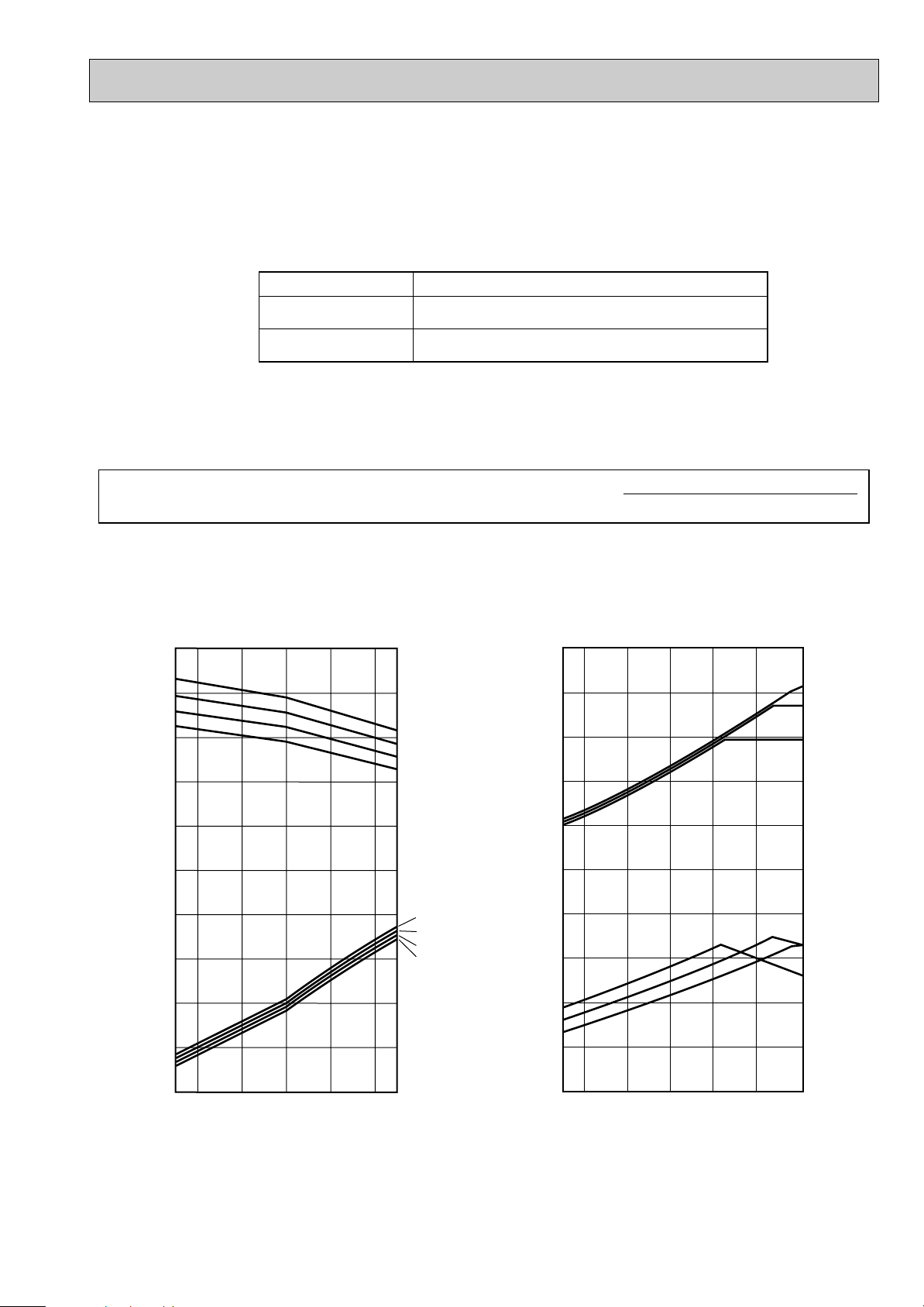

5-3. CORRECTING COOLING AND HEATING CAPACITY

Service Ref. PUMY-P125VMA PUMY-P125YMA PUMY-P125YMA1

Rated cooling capacity

Rated heating capacity

Indoor D.B. 27°C / W.B. 19°C

Outdoor D.B. 35°C

Indoor D.B. 20°C

Outdoor D.B. 7°C / W.B. 6°C

0.4

-5 0 10 20 30 40 46

0.6

0.8

1.0

1.2

1.4

0.6

0.8

1.0

1.2

1.4

22

20

18

16

22

20

18

16

0.4

-12 -10 0 105-5 15

0.6

0.8

1.0

1.2

1.4

0.6

0.8

1.0

1.2

1.4

15

20

25

20

15

25

5-3-1. Correcting Changes in Air Conditions

(1)The performance curve charts (Figure 1, 2) show the rated capacity (total capacity) under the stated conditions when standard

length for piping (5m) is used. The rated power is derived from the capacity ratio and power ratio obtained for the indoor and

outdoor intake temperatures at time 1.

• Standard conditions:

• Use the rated capacity and rated power values given in the characteristics table for each indoor unit.

• The capacity is the single value on the side of the outdoor unit; the capacity on the sides of each indoor unit must be

added to obtain the total capacity.

(2)The capacity of each indoor unit may be obtained by multiplying the total capacity obtained in (1) by the ratio between the

individual capacity at the rated time and the total capacity at the rated time.

Individual capacity under stated conditions = total capacity under the stated conditions o

(3)Capacity correction factor curve

individual capacity at the rated time

total capacity at the rated time

Figure 1. PUMY-P125VMA PUMY-P125YMA

PUMY-P125YMA

Cooling performance curve

Cooling

Capacity

(ratio)

Cooling

Power

consumption

(ratio)

1

INDOOR

<W.B. :>

INDOOR

<W.B. :>

Figure 2. PUMY-P125VMA PUMY-P125YMA

PUMY-P125YMA

Heating performance curve

Heating

Capacity

(ratio)

Heating

Power

consumption

(ratio)

1

INDOOR

<D.B. :>

INDOOR

<D.B. :>

Outdoor <D.B. ::>

Outdoor <W.B. ::>

15

5-3-2. Correcting Capacity for Changes in the Length of Refrigerant Piping

1.0

0.95

0.9

5 10152025303540455055

1.0

63 (50%)

94 (75%)

125 (100%)

163 (130%)

0.95

0.9

0.85

0.8

5 10152025303540455055

(1) During cooling, to obtain the ratio (and the equivalent piping length) of the outdoor units rated capacity and the total

in-use indoor capacity, first find the capacity ratio corresponding to the standard piping length (5m) from Figures 3

at first, and then multiply by the cooling capacity from Figure 1 to obtain the actual capacity.

(2) During heating, to find the equivalent piping length, first find the capacity ratio corresponding to standard piping length (5m)

from Figure 4, and then multiply by the heating capacity from Figure 2 to obtain the actual capacity.

(1) Cooling capacity correction factor

Figure 3. PUMY-P125VMA PUMY-P125YMA PUMY-P125YMA1

Cooling capacity correction curve

Total capacity for indoor unit

Cooling

Capacity

(ratio)

piping length (m)

(2) Heating capacity correction factor

Figure 4. PUMY-P125VMA PUMY-P125YMA PUMY-P125YMA1

Heating capacity correction curve

Heating

Capacity

(ratio)

piping length (m)

(3) Method for Obtaining the Equivalent Piping Length

Equivalent length for type 125 = (length of piping to farthest indoor unit) + (0.35 o number of bends in the piping) (m)

Length of piping to farthest indoor unit: type 125.....70m

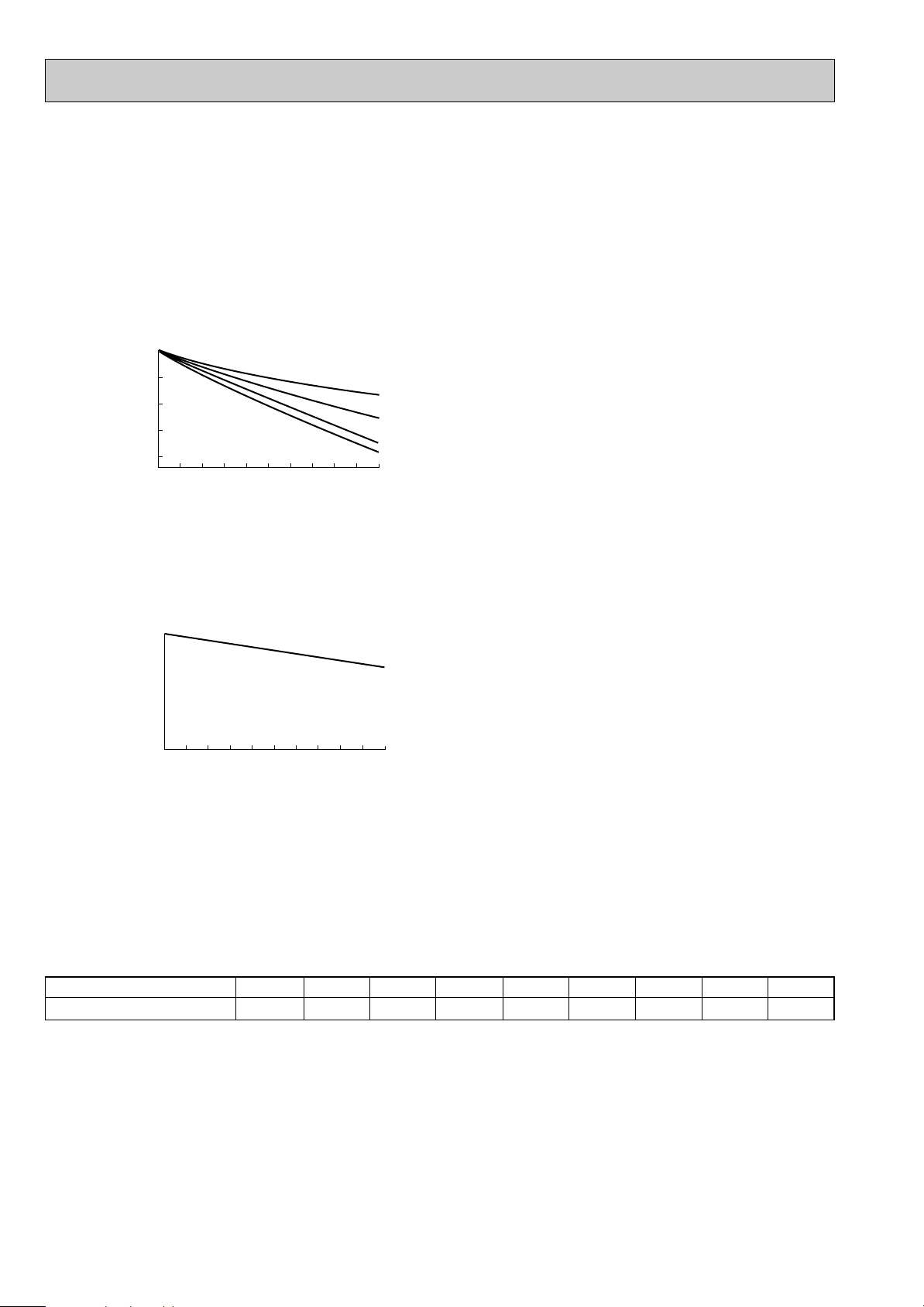

5-3-3. Correction of Heating Capacity for Frost and Defrosting

If heating capacity has been reduced due to frost formation or defrosting, multiply the capacity by the appropriate correction

factor from the following table to obtain the actual heating capacity.

Correction factor diagram

Outdoor Intake temperature (W.B.°C)

Correction factor

6

1.0

4

0.98

2

0.89

0

0.88

-2

0.89

-4

0.9

-6

0.95

-8

0.95

-10

0.95

16

PUMY-P125VMA

PUMY-P125YMA

PUMY-P125YMA

90

80

NOTCH

SPL(dB) LINE

Hi 54

1

70

NC-70

60

NC-60

50

NC-50

40

NC-40

30

NC-30

APPROXIMATE

20

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

10

63 125 250 500 1000 2000 4000 8000

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

NC-20

1m

MICROPHONE

1m

17

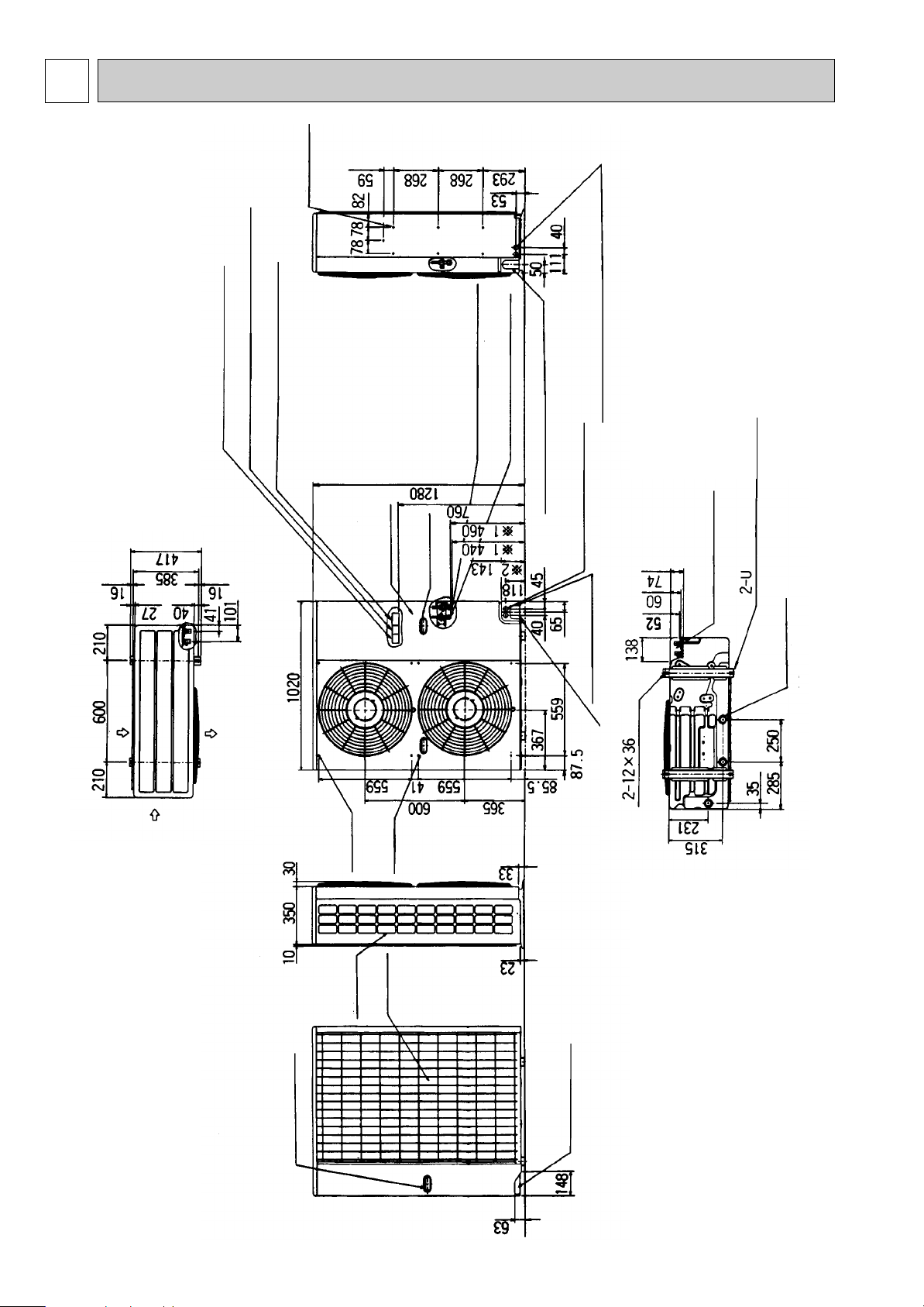

6 OUTLINES AND DIMENSIONS

• OUTDOOR UNITS

PUMY-P125VMA

PUMY-P125YMA

PUMY-P125YMA1

Optional parts

(base branching

pipe) installation

hole

Terminal block for transmission

Terminal block for central control

Terminal block for power source

Liquid refrigerant pipe

connection {9.52 (3/8F)

Gas refrigerant-pipe

connection {19.05 (3/4F)

Knock out hole for right piping

Knock out holes for

power line 2-{27

Knock out holes for power line 2-{29

unit : mm

shaped notched holes

(standard bolt M10)

Air intake

Air outlet

Handle for

Optional parts

installation hole

Rear air intake

Side air intake

moving

Knock out hole for

front piping

Oval holes

Piping cover

(standard bolt M10)

Bottom piping hole

Drain hole

(3-{33 hole)

Handle for moving

18

Rear piping hole

when a piping cover is used for aesthetic reasons.

✻1...Indicates the dimensions of the cutoff valve connector.

✻2...Make sure that the panel can be easily removed for maintenance

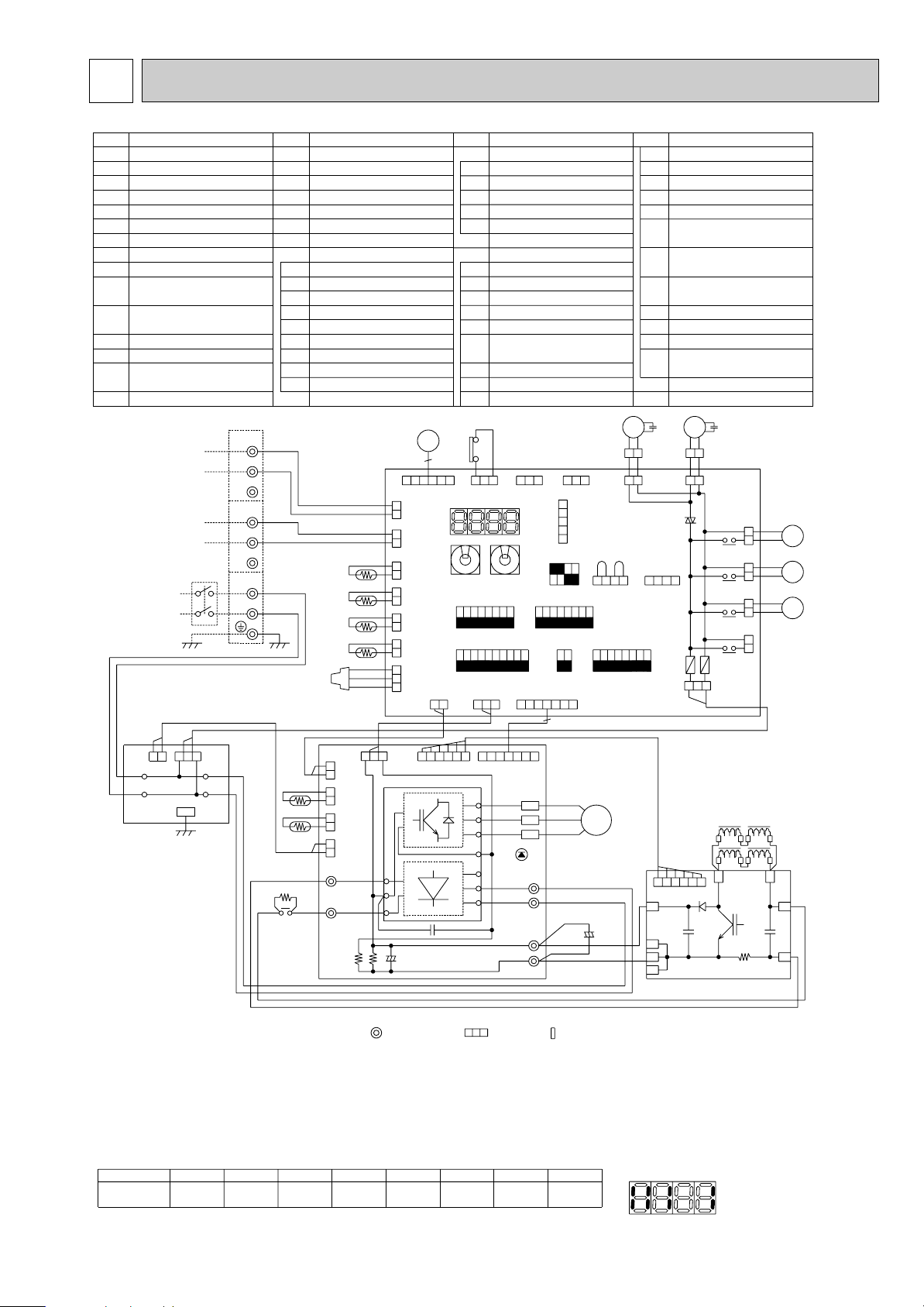

7 WIRING DIAGRAM

PUMY-P125VMA

SYMBOL

TB1 Terminal Block(Power Supply)

Terminal Block(Transmission)TB3 4-Way Valve21S4

Terminal Block(Centralized Control)

TB7

CE

Smoothing Capacitor

C1,C2

Fan Motor Capacitor

DCL1~4

Reactor

Resistor(Rush Current Protection)

RS

ACTM Active Filter Module

Thermistor(Discharge Temperature Detection)

TH1

TH2

Thermistor

(Low Pressure Saturated Temp.Detection)

TH5

Thermistor

(Pipe Temp.Detection / Judging Defrost)

Thermistor(Outdoor Temp.Detection)

TH6

THHS A/B

Thermistor(Radiator Panel) A;ACTM,B;IGBT

63HS

High Pressuer Sensor

(Discharge Pressure Detection)

Thermal Switch(Compressor)49C

TO INDOOR UNIT

CONNECTING WIRES

DC 30V (Non-polar)

FOR CENTRALIZED

CONTROL

DC 30V (Non-polar)

NO FUSE BREAKER 32A

POWER SUPPLY

~ / N

220-230-240V

NAME

L

N

SYMBOL

SV

LEV(A) Expansion Valve

MF1,MF2

MC

P.B. Power Circuit Board

U/V/W

CN2~6

CNDC

CNAF

IGBT

LED1

SC-S,R

SC-P1,P2

SC-N1,N2

*1 The address automatically

TB3

M1

M2

S

TB7

M1

M2

S

TB1

L

N

becomes "100" if it is

set as "01~50".

BRN

BRN

ORN

ORN

Magnetic Contactor52C

NAME

Solenoide Valve(Hot Gas Bypass)

Fan Motor(Inner Thermostat)

Compressor(Inner Thermostat)

Connection Terminal(U/V/W Phase)

Connector

Connector

Connector

Converter,Inverter

Light Emitting Diode(Inverter Control Status)

Screw Type Terminal(L./N-Phase)

Screw Type Terminal(DC Voltage)

Screw Type Terminal(DC Voltage)

< M.B.>

TH2

TH5

TH6

TH1

63HS

LEV

65432

LEV-A (WHT)

CNS1

2

(RED)

1

CNS2

2

(YLW)

1

TH2

2

(WHT)

1

TH5

2

(GRN)

1

TH6

2

(RED)

1

TH1

2

(WHT)

1

3

63HS

2

(WHT)

1

(WHT)

SYMBOL

Noise Filter Circuit BoardN.F.

LI/LO

Connection Lead(L-Phase)

NI/NO

Connection Lead(N-Phase)

Connection Terminal(Ground)

EI

CNAC2

Connector

Connector

CN5

Multi Circuit BoardM.B.

F1,F2

Fuse(6.3A)

SW1 Switch(Display Selection)

Switch(Function Selection)

SW2

Switch(Test Run)

SW3

Switch(Model Selection)

SW4

Switch(Function Selection)

SW5

SW5-1 Auto Change Over

OFF;disabled ON;enabled

Switch(Function Selection)SW6

Switch(Unit Address Selection,1st digit)

SWU1

Switch(Unit Address Selection,2nd digit)

SWU2

49C

6

YLW YLW

1

31

49C(GRY)

0

1

9

*1

8

7

6

5

SWU2 SWU1

ON

OFF

1

ON

OFF

12345678910

CN4

CNDC(PNK)

1

2

2

4

321

CN3S(WHT)

LED2LED1

(WHT)

0

1

9

2

8

3

3

7

4

6

5

(1st digit)(2nd digit)

SW1

3456782 1 3456782

ON

OFF

SW2

CN2 (WHT)

131432 567

CN51

ON

OFF

OFF

ON

NAME

321

CN3D(WHT)

1

2

3

3.12V

4

4.COMP. ON

5

5.Error

SW4

4321

SW5

SW3

21

7

SYMBOL

MF2

WHT

31

WHT

13 13

MF2

(WHT)

1234 1234

SW6

ON

OFF

1 3456782

Connector(Multi system)

NAME

CNS1

Connector(Centralized Control)

CNS2

Connector

CN4

Connector(Centralized Control Power Supply)

CN40

CN41

Connector(For String Jumper Connector)

CN51

Connector(Connected for Option)

Compressor drive signal,Error signal

CN3D

Connector(Connected for Option)

Auto Change Over Signal

CN3S

Connector(Connected for Option)

Demand Signal

Relay(Magnetic Contactor)

X500

Relay(4-Way Valve)

X501

Relay(Solenoid Valve)

X502

Digital Indication LED

LED1,2

Operation Inspection Indication

WHT

WHT

F.C

F1

MF1

RED

ORN

BLU

31

BLU

MF1

(WHT)

X500

21S4(GRN)

X501

X502

F2

CNAC

31

(RED)

C2

52C(ORG)

1

3

1

3

SV(BLK)

1

3

CH(BLU)

1

3

YLW

YLW

BLU

BLU

BLK

BLK

52C

21S4

SV1

RED

C2

ORN

BLU

BLU

CN40(WHT)CN41(WHT)

(6.3A) (6.3A)

W

V

U

LED1

< P.B.>

BLK

WHT

RED

MC

CE

+

CN5

(RED)

LI

NI

< N.F.>

21

31

CNAC2

(RED)

LO

NO

EI

THHS_A

THHS_B

RS

52C

2

1

2

1

2

1

2

1

CN4

(WHT)

CN3

(WHT)

CN6

(WHT)

CN5

(RED)

SCR-N1

SCR-P1

13

IGBT

CNDC

(PNK)

+

-

+

+

51234

CNAF (WHT)

743215

66

CN2 (WHT)

SCR-S

SCR-R

SCR-P2

SCR-N2

NOTES: 1. Refer to the wiring diagrams of the indoor units for details on wiring of each indoor unit.

2. Symbols used in wiring diagram above are. :Terminal block, :Connector, :Insertion tab.

3. Self-diagnosis function

The indoor and outdoor units can be diagnosed automatically using the self-diagnosis switch(SW1) and LED1,2

(LED indication)found on the multi-controller of the outdoor unit.

LED indication : Set all contacts of SW1 to OFF.

4. For the system utilizing R-converter units(PAC-SF29LB),the following functions are not available.

SW3;TEST RUN SW5-1;AUTO CHANGE OVER CN3D;AUTO CHANGE OVER(external singnal)

5. The input for CN3D 1-2(AUTO CHANGE OVER EXTERNAL SIGNEL)is as follows.

Short;heating Open;Cooling(It differs from Service ref.PUMY-P125YMA)

•During normal operation

The LED indicates the drive state of the controller in the outdoor unit.

Bit

Indication

1 876543

Compressor

operated

2

52C

Always lit---SV121S4

•When fault requiring inspection has occurred

The LED alternately indicates the inspection code and the location of the unit in which the fault has occurred.

L2

652341

P

N1

N2

I

L1

ACTM

(Example)

When the compressor and SV1 are

turned during cooling operation.

78563421

DCL3DCL4

DCL1DCL2

+

-

19

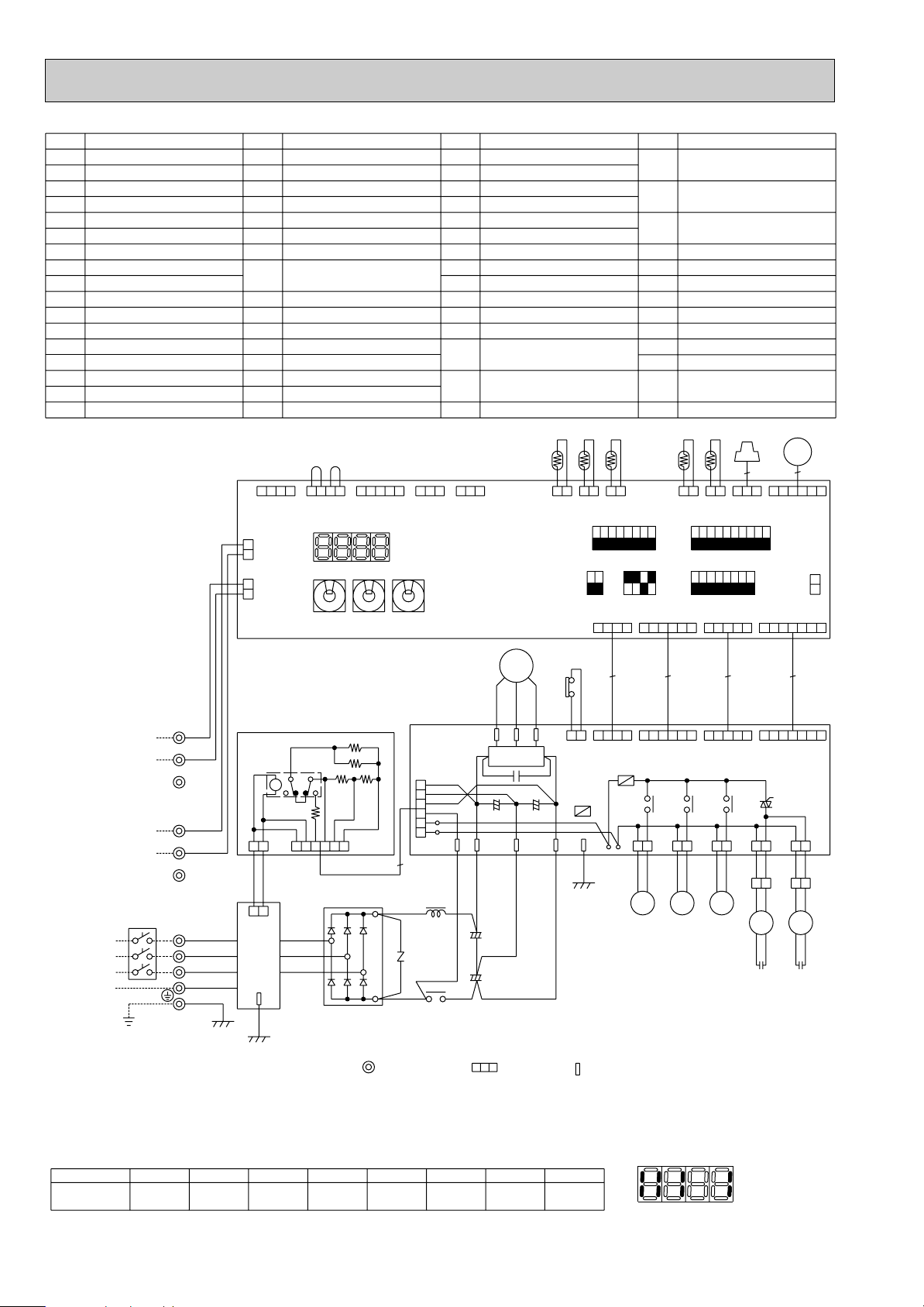

PUMY-P125YMA

9

8

7

6

5

4

3

2

1

0

9

8

7

6

5

4

3

2

1

0

9

8

7

6

5

4

3

2

1

0

RD2

123

CN3S

(RED)

CN3S CONNECTOR <DEMAND SIGNAL>

operated

NOTES : 1. Refer to the wiring diagrams of the indoor units for details on wiring of each indoor unit.

2. Symbols used in wiring diagram above are. : Terminal block, : Connector, :Insertion tab.

3. Self-diagnosis function

The indoor and outdoor units can be diagnosed automatically using the self-diagnosis switch (SW1) and LD1(LED indication)

found on the multi-controller of the outdoor unit.

LED indication : Set all contacts of SW1 to OFF.

7

8

5

634

2

1

(Example)

When the compressor and SV1 are

turned during cooling operation.

Always lit---SV121S4

1 876543

52C

2

Compressor

Indication

Bit

•During normal operation

The LED indicates the drive state of the controller in the outdoor unit.

•When fault requiring inspection has occurred

The LED alternately indicates the inspection code and the location of the unit in which the fault has occurred.

NO FUSE BREAKER

25A

L1

L2

L3

N

X

X

1

1

(WHT)

CN3D

(WHT)

CN51

(WHT)

CN41

(WHT)

CN40

5321432143214321

YLW

CB2

CB1

CNR

(WHT)

CNR

(WHT)

(RED)

CNA

<POWER SUPPLY BOARD>

(YLW)

49C

(RED)

CN1

FUSE1

(6.3A)

FUSE2

(2A)

SLEV

6

1

2

5764

49C

YLW

31 1234567

1234567

123671234561236

123671236

CN4CN3CN2

CN4CN3CN2

(YLW)(YLW) (WHT)

(YLW)(RED) (YLW) (WHT)

24321 12345678

109876543212876543

SW3 SW5

OFF

ON

OFF

ON

SW4

SW1 SW2

OFF

ON

1

1

ON

OFF

ON

OFF

(YLW)

ACCT

654321

132

CN1

3

63HS

654132123113 2121

THHS

TH1TH2TH5TH6

63HS

THHS

TH2TH6 TH5 TH1

(BLK) (WHT) (GRN)(GRN) (WHT) (WHT)

SLEV

(WHT)

BLU

~

~

~

LO1

LO2

LO3

LI3

E

N

LI2

LI1

(RED)

31

CNA

13

GRN

6

YLW

YLW

WHT

BLK

RS1

RB2 RB1

RD1

BLK

RED

BLU

WHT

GRN

E

P

N

C03

C02C01

NP1PN1

10

3

5

6

8

10

3568

+

–

IPM

WV

-

+

+

-

RED

WHT

BLK

31 13

31

(BLU)

52C

X71

YLW

YLW

52C

31

(GRN)

21S4

X72

BLU

BLU

21S4

SV1

BLK

BLK

13

(BLK)

SV1

(WHT)

MF2

(WHT)

MF1

MF1

C1

31

WHT

BLU

WHT

BLURED

ORN

RED

ORN

BLU

WHT

31

BLU

52C

N

BLU

L3

BLK

L1

RED

S

M1

M2

S

M2

M1

LD1

SWU1

(1st digit)

SWU2

(2nd digit)(3rd digit)

SWU3

<RESISTOR BOARD>

CNS1

(RED)

CNS2

(YLW)

F.C

2

1

1

GRN/YLW

ZNR

–

+

–

+

BLU

BLK

2

FOR CENTRALIZED

CONTROL

DC 30V (Non-polar)

WHT

BLK

WHT

RED

WHT

ORN

ORN

BRN

BRN

GROUND

TO INDOOR UNIT

CONNECTING WIRES

DC 30V (Non-polar)

POWER SUPPLY

3N~

380/220-415/240V

50Hz

W

V

U

U

X73

TB3

TB7

L2

TB1

MF2

C2

MC

DCL

DM

NF

<MULTI CONTROLLER BOARD>

<IPM RADIATOR PANEL

TEMPERATURE DETECTION>

<DISCHARGE TEMPERATURE

DETECTION>

<OUTDOOR TEMPERATURE DETECTION>

<LOW PRESSURE SATURATED

TEMPERATURE DETECTION>

<PIPE TEMPERATURE DETECTION

• JUDGING DEFROST>

THERMISTOR

SYMBOL

TERMINAL BLOCK <TRANSMISSION>

SWITCH <UNIT ADDRESS SELECTION,3RD DIGIT>

SWITCH <UNIT ADDRESS SELECTION,2ND DIGIT>

SWITCH <UNIT ADDRESS SELECTION,1ST DIGIT>

SWITCH <FUNCTION SELECTION>

SWITCH <MODEL SELECTION>

SWITCH <TEST RUN>

THERMISTOR

NAME

SWITCH <FUNCTION SELECTION>

SWITCH <DISPLAY SELECTION>

TERMINAL BLOCK <CENTRALIZED CONTROL>

SOLENOID VALVE <HOT GAS BYPASS>

TERMINAL BLOCK <POWER SUPPLY>

THERMISTOR

SYMBOL

SMOOTHING CAPACITOR

C03 CAPACITOR <FILTER>

C01,C02

CONNECTOR <DISCHARGE CIRCUIT, POWER SUPPLY>

CNR

RESISTOR <RUSH CURRENT PROTECT>

RS1

RESISTOR <DISCHARGE>

RB1,RB2

RESISTOR <VOLTAGE BALANCE ADJUSTMENT>

RD1,RD2

RELAYX

X73 RELAY <SOLENOID VALVE>

X72 RELAY <4-WAY VALVE>

C1,C2 FAN MOTOR CAPACITOR

SWU3

SWU2

SWU1

SW5

SW4

SW3

THHS

INTELLIGENT POWER MODULEIPM

FAN CONTROLF.C

CONNECTOR <CENTRALIZED CONTROL POWER SUPPLY>

CN40

CONNECTOR <FOR STORING JUMPER CONNECTOR>

CN41

CONNECTOR <COMPRESSOR DRIVE SIGNAL OUTPUT>

CN51

CONNECTOR <INVERTER SIGNAL 5V>

CN4

CONNECTOR <POWER SUPPLY 30V,12V,5V>

CN3

CONNECTOR <POWER SYNC SIGNAL, PROTECTION>

CN2

CONNECTOR <CONTROLLER DRIVE CONTROL>

CN1

CONNECTOR <POWER SUPPLY>CNA

CONNECTOR <CURRENT DETECTION>

ACCT

NAME

SYMBOL

NAME

SW2

SW1

CONNECTOR <AUTO CHANGE OVER SIGNAL>

CN3D

REACTOR

THERMAL SWITCH <COMPRESSOR>

TH2

TH5

TH6

63HS

52C

21S4

TH1

SV1

SLEV

MF1,MF2

LD1 X71

CNS1

CNS2

ZNR

FUSE2

TB7

TB3

TB1

MC

DCL

NF

FUSE1

49C

CONNECTOR <MULTI SYSTEM>

CONNECTOR <CENTRALIZED CONTROL>

FUSE (2A)

DIGITAL INDICATION LED

<OPERATION INSPECTION INDICATION>

FAN MOTOR <INNER THERMOSTAT>

EXPANSION VALVE

HIGH PRESSURE SENSOR

<DISCHARGE PRESSURE DETECTION>

MAGNETIC CONTACTOR

4-WAY VALVE

RELAY <MAGNETIC CONTACTOR>

VARISTOR

FUSE (6.3A)

COMPRESSOR <INNER THERMOSTAT>

NOISE FILTER

THERMISTOR

THERMISTOR

CB1,CB2DMSMOOTHING CAPACITOR

DIODE MODULE

NAME

SYMBOL

20

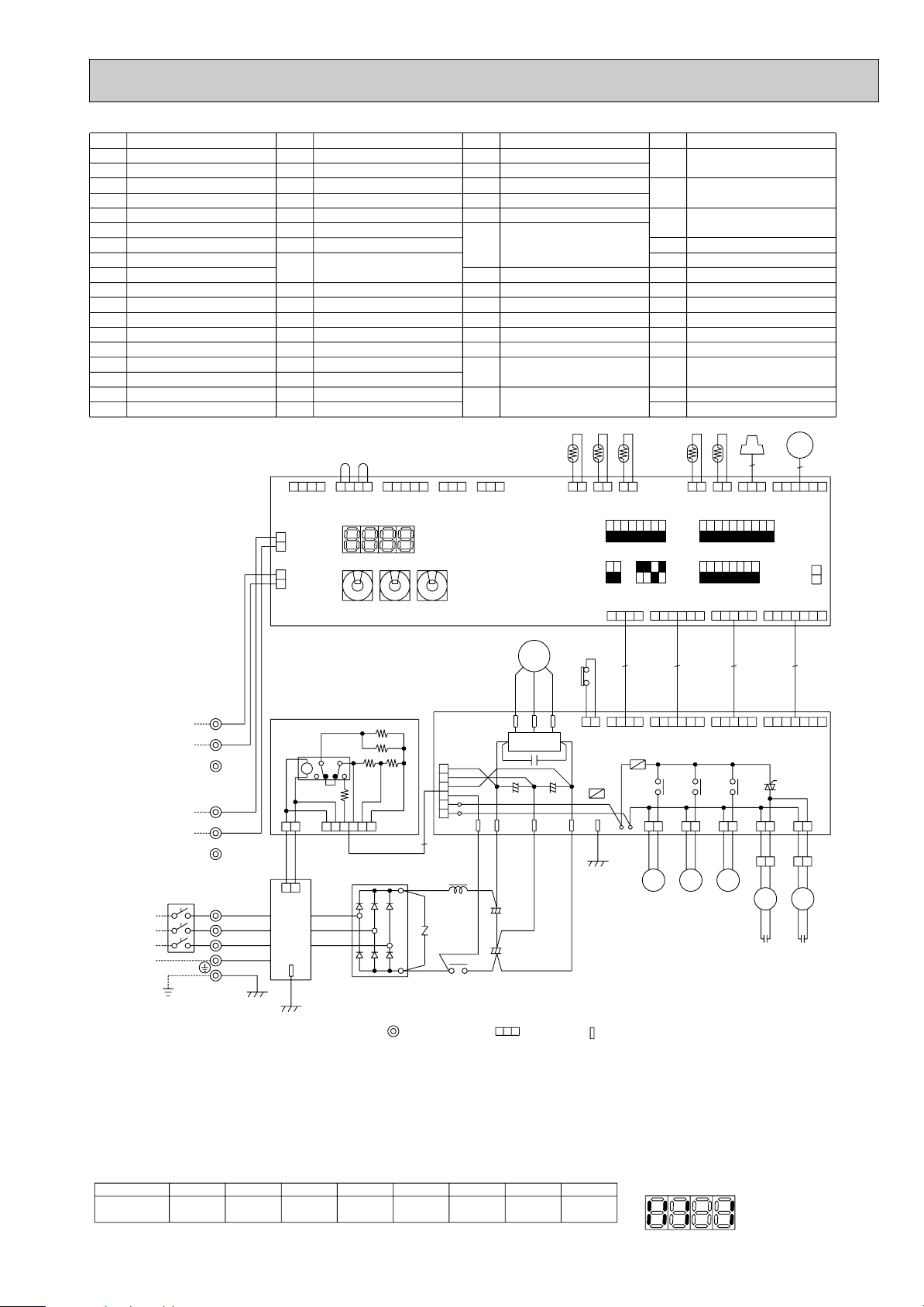

PUMY-P125YMA1

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

9

8

7

6

5

4

3

2

1

0

RD2

123

CN3S

(WHT)

CN3S

CONNECTOR <DEMAND SIGNAL>

operated

NOTES: 1.Refer to the wiring diagrams of the indoor units for details on wiring of each indoor unit.

2.Symbols used in wiring diagram above are. :Terminal block, :Connector, :Insertion tab.

3.Self-diagnosis function

The indoor and outdoor units can be diagnosed automatically using the self-diagnosis switch(SW1) and LD1(LED indication)

found on the multi-controller of the outdoor unit.

LED indication : Set all contacts of SW1 to OFF.

4.For the system utilizing R-converter units(PAC-SF29LB), the following functions are not available.

SW3 : TEST RUN SW5-1 : AUTO CHANGE OVER CN3D : AUTO CHANGE OVER(external singnal)

5.The input for CN3D 1-2(AUTO CHANGE OVER EXTERNAL SIGNEL)is as follows.

Short : heating Open : Cooling(It differs from Service ref. PUMY-P125YMA)

78563421

(Example)

When the compressor and SV1 are

turned during cooling operation.

Always lit---SV121S4

1 876543

52C

2

Compressor

Indication

Bit

• During normal operation

The LED indicates the drive state of the controller in the outdoor unit.

• When fault requiring inspection has occurred

The LED alternately indicates the inspection code and the location of the unit in which the fault has occurred.

50Hz

380/220-415/240V

3N~

NO FUSE BREAKER

25A

L1

L2

L3

N

X

X

1

1

(WHT)

CN3D

(WHT)

CN51

(WHT)

CN41

(WHT)

CN40

5321432143214321

YLW

CB2

CB1

CNR

(WHT)

CNR

(WHT)(RED)

CNA

<POWER SUPPLY BOARD>

(YLW)

49C

(RED)

CN1

FUSE1

(6.3A)

FUSE2

(2A)

SLEV

6

1

2

5764

49C

YLW

31 1234567

1234567

123671234561236

123671236

CN4CN3CN2

CN4CN3CN2

(YLW)(YLW) (WHT)

(YLW)(RED) (YLW) (WHT)

24321 12345678

109876543212876543

SW3 SW5

OFF

ON

OFF

ON

SW4

SW1 SW2

OFF

ON

1

1

ON

OFF

ON

OFF

(YLW)

ACCT

654321

132

CN1

3

63HS

654132123113 2121

THHS

TH1TH2TH5TH6

63HS

THHS

TH2TH6 TH5 TH1

(BLK) (WHT) (GRN)(GRN) (WHT) (WHT)

SLEV

(WHT)

BLU

–

+

~

~

~

LO1

LO2

LO3

LI3

E

N

LI2

LI1

(RED)

31

CNA

13

GRN

6

YLW

YLW

WHT

BLK

RS1

RB2 RB1

RD1

BLK

RED

BLU

WHT

GRN

E

P

N

C03

C02C01

NP1PN1

10

3

5

6

8

10

3568

+

-

IPM

WV

-

+

+

-

RED

WHT

BLK

31 13

31

(BLU)

52C

X71

YLW

YLW

52C

31

(GRN)

21S4

X72

BLU

BLU

21S4

SV1

BLK

BLK

13

(BLK)

SV1

(WHT)

MF2

(WHT)

MF1

MF1

C1

31

WHT

BLU

WHT

BLURED

ORN

RED

ORN

BLU

WHT

31

BLU

52C

N

BLU

L3

BLK

L1

RED

S

M1

M2

S

M2

M1

LD1

SWU1

(1st digit)

SWU2

(2nd digit)(3rd digit)

SWU3

<RESISTOR BOARD>

CNS1

(RED)

CNS2

(YLW)

F.C

2

1

1

GRN/YLW

ZNR

-

+

BLU

BLK

2

FOR CENTRALIZED

CONTROL

DC 30V (Non-polar)

WHT

BLK

WHT

RED

WHT

ORN

ORN

BRN

BRN

GROUND

TO INDOOR UNIT

CONNECTING WIRES

DC 30V (Non-polar)

POWER SUPPLY

W

V

U

U

X73

TB3

TB7

L2

TB1

MF2

C2

MC

DCL

DM

NF

<MULTI CONTROLLER BOARD>

<IPM RADIATOR PANEL TEMP. DETECTION>

<DISCHARGE TEMP. DETECTION>

<OUTDOOR TEMP. DETECTION>

THERMISTOR

<LOW PRESSURE SATURATED TEMP. DETECTION>

TERMINAL BLOCK <TRANSMISSION>

SWITCH <UNIT ADDRESS SELECTION,3RD DIGIT>

SWITCH <UNIT ADDRESS SELECTION,2ND DIGIT>

SWITCH <UNIT ADDRESS SELECTION,1ST DIGIT>

SWITCH <FUNCTION SELECTION>

SW5-1 AUTO CHANGE OVER

OFF : disabled ON : enabled

SWITCH <MODEL SELECTION>

SWITCH <TEST RUN>

THERMISTOR

NAME

SWITCH <FUNCTION SELECTION>

SWITCH <DISPLAY SELECTION>

TERMINAL BLOCK <CENTRALIZED CONTROL>

SOLENOID VALVE <HOT GAS BYPASS>

TERMINAL BLOCK <POWER SUPPLY>

THERMISTOR

SMOOTHING CAPACITOR

C03 CAPACITOR <FILTER>

C01,C02

CONNECTOR <DISCHARGE CIRCUIT,POWER SUPPLY>

CNR

RESISTOR <RUSH CURRENT PROTECT>

RS1

RESISTOR <DISCHARGE>

RB1,RB2

RESISTOR <VOLTAGE BALANCE ADJUSTMENT>

RD1,RD2

RELAY

X

X73

RELAY <SOLENOID VALVE>

X72

RELAY <4-WAY VALVE>

C1,C2 FAN MOTOR CAPACITOR

SWU3

SWU2

SWU1

SW5

SW4

SW3

THHS

INTELLIGENT POWER MODULE

IPM

FAN CONTROLF.C

CONNECTOR <CENTRALIZED CONTROL POWER SUPPLY>

CN40

CONNECTOR <FOR STORING JUMPER CONNECTOR>

CN41

CONNECTOR <COMPRESSOR DRIVE SIGNAL OUTPUT>

CN51

CONNECTOR <INVERTER SIGNAL 5V>

CN4

CONNECTOR <POWER SUPPLY 30V,12V,5V>

CN3

CONNECTOR <POWER SYNC SIGNAL,PROTECTION>

CN2

CONNECTOR <CONTROLLER DRIVE CONTROL>

CN1

CONNECTOR <POWER SUPPLY>

CNA

CONNECTOR <CURRENT DETECTION>

ACCT

NAMENAME

SW2

SW1

CONNECTOR <AUTO CHANGE OVER SIGNAL>

CN3D

REACTOR

THERMAL SWITCH <COMPRESSOR>

TH2

TH5

TH6

63HS

52C

21S4

TH1

SV1

SLEV

MF1,MF2

LD1

X71

CNS1

CNS2

ZNR

FUSE2

TB7

TB3

TB1

MC

DCL

NF

FUSE1

49C

CONNECTOR <MULTI SYSTEM>

CONNECTOR <CENTRALIZED CONTROL>

FUSE (2A)

DIGITAL INDICATION LED

<OPERATION INSPECTION INDICATION>

FAN MOTOR <INNER THERMOSTAT>

EXPANSION VALVE

HIGH PRESSURE SENSOR

<DISCHARGE PRESSURE DETECTION>

MAGNETIC CONTACTOR

4-WAY VALVE

RELAY <MAGNETIC CONTACTOR>

VARISTOR

FUSE (6.3A)

COMPRESSOR <INNER THERMOSTAT>

NOISE FILTER

THERMISTOR

THERMISTOR

<PIPE TEMP. DETECTION • JUDGING DEFROST>

CB1,CB2

DMSMOOTHING CAPACITOR DIODE MODULE

NAME

SYMBOL SYMBOL SYMBOL SYMBOL

21

8

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

051

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

056

001

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

010

101

1

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

002

102 104 154

1111

11

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

009

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

008

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

003

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

007

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

006

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

004

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

005

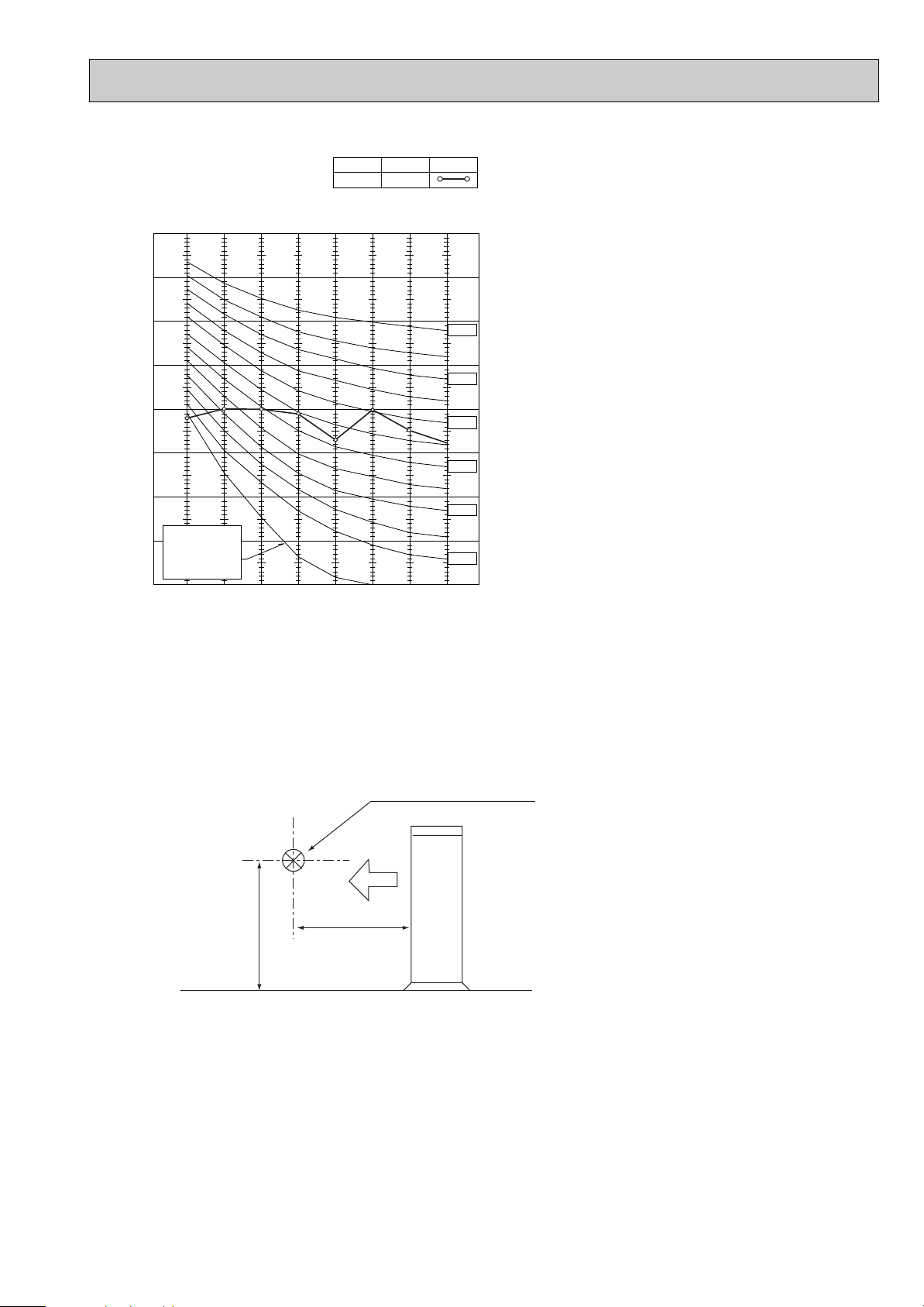

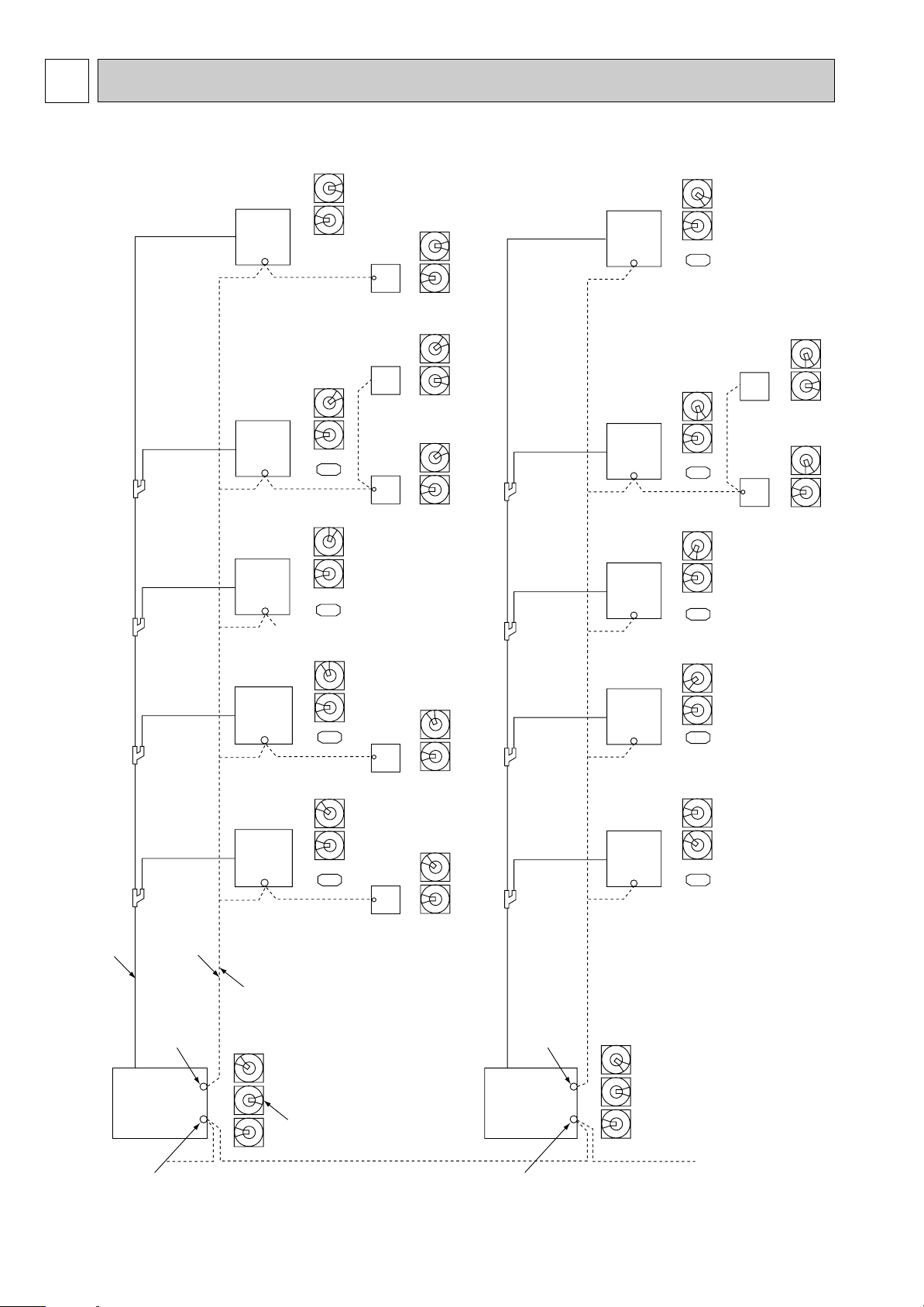

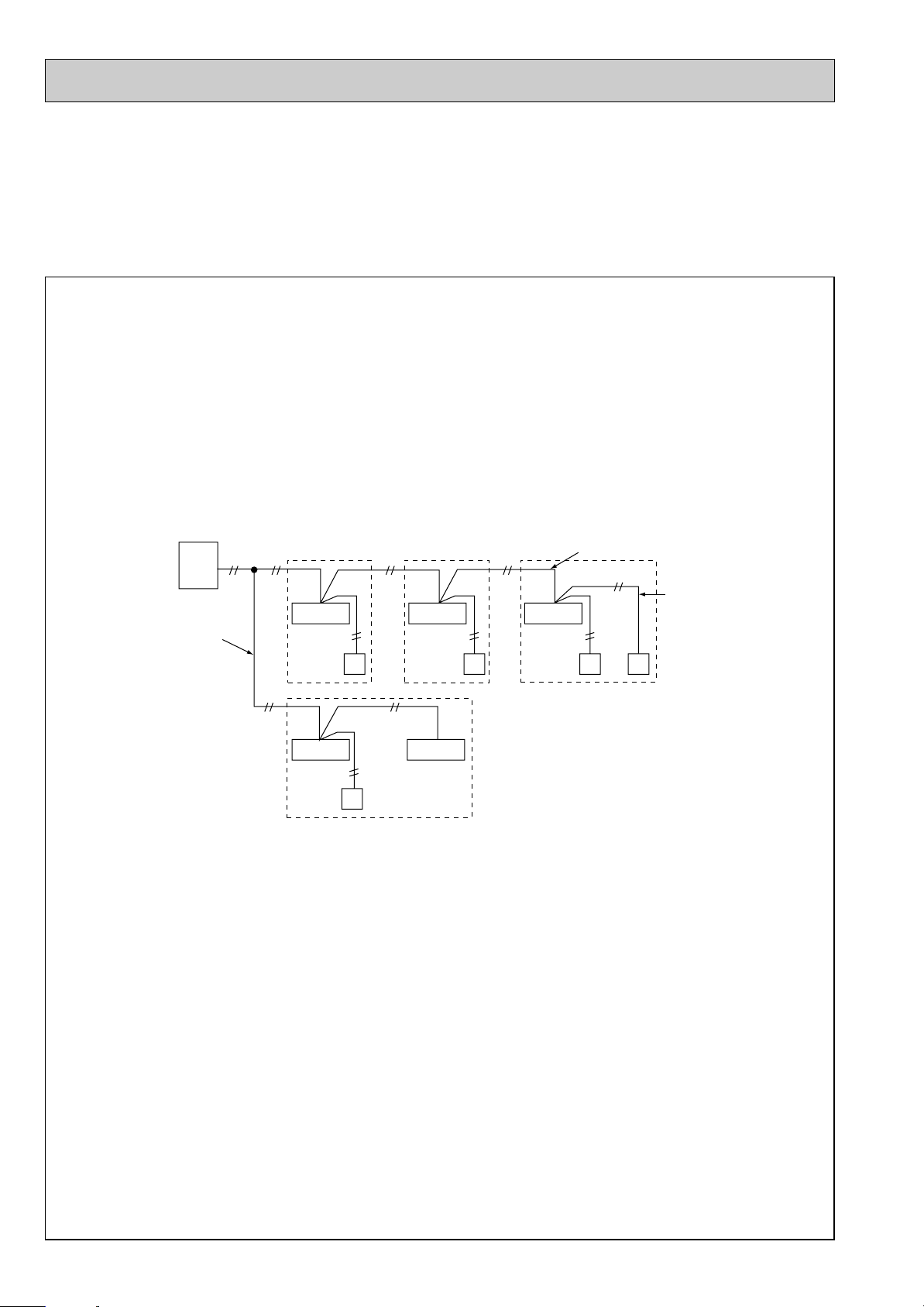

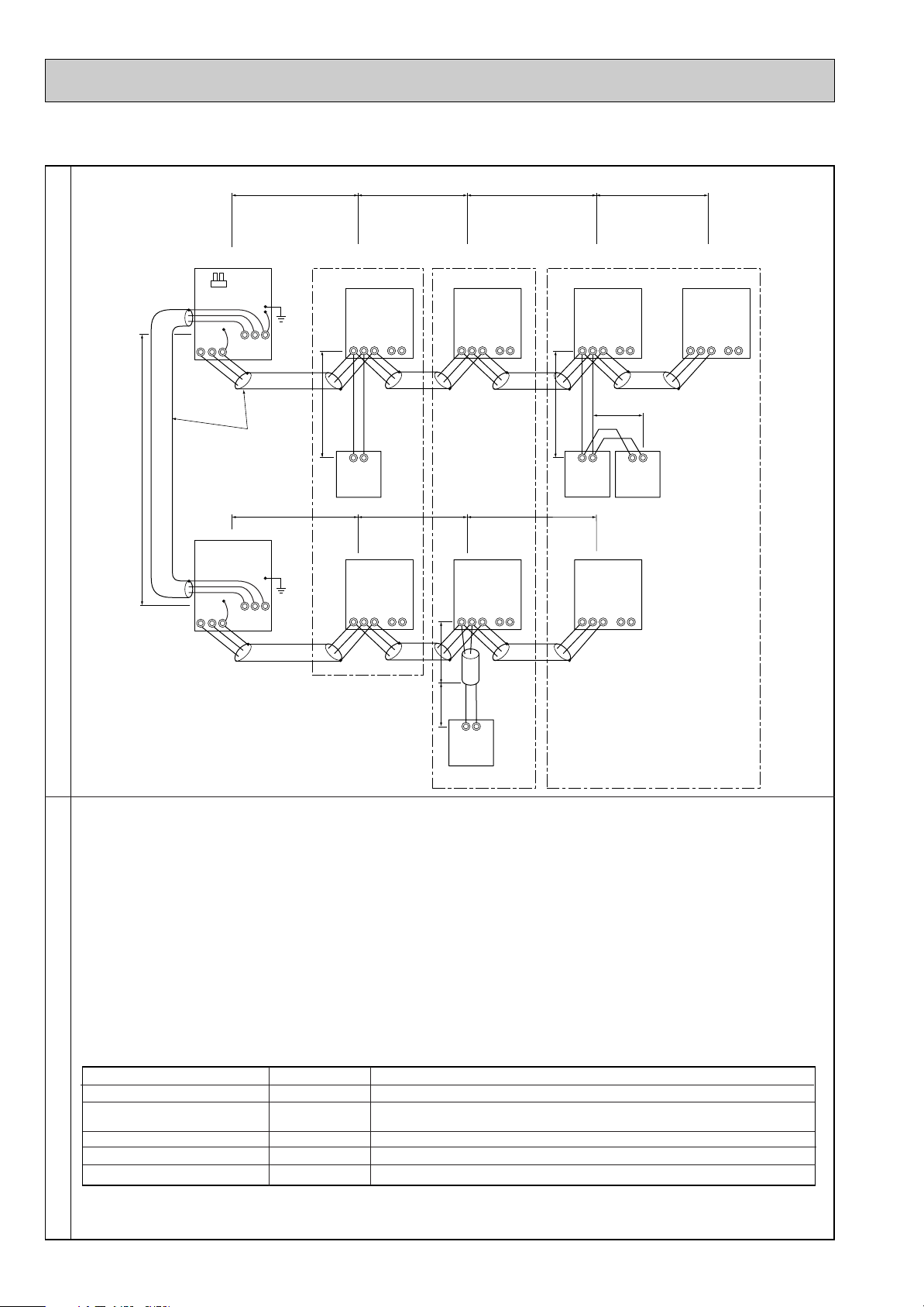

1 A transmission wire must be

connected to each refrigerant

system (outdoor and indoor).

2 Set addresses:

Outdoor unit ..............051-100

Indoor unit .................001-050

Remote controller .....101-200

3 PUMY-P125VMA has no SW 3(3rd digit).

The address automatically become

"100" if it is set as "01~50".

Remote

controller

Remote

controller

Remote

controller

Remote

controller

105

Remote

controller

157

Remote

controller

107

Remote

controller

For centralized

management

For remote

controller

Address SW Address SW Address SW Address SW Address SW

Piping

Outdoor unit

Outdoor unit

Indoor unit Indoor unit Indoor unit Indoor unit Indoor unit

Indoor unitIndoor unitIndoor unitIndoor unitIndoor unit

Address SW Address SW Address SW Address SW Address SW

Address SWAddress SWAddress SWAddress SWAddress SW

Address SWAddress SW

For centralized

management

For remote

controller

Transmission wire

2

1

NECESSARY CONDITIONS FOR SYSTEM CONSTRUCTION

8-1. TRANSMISSION SYSTEM SETUP

22

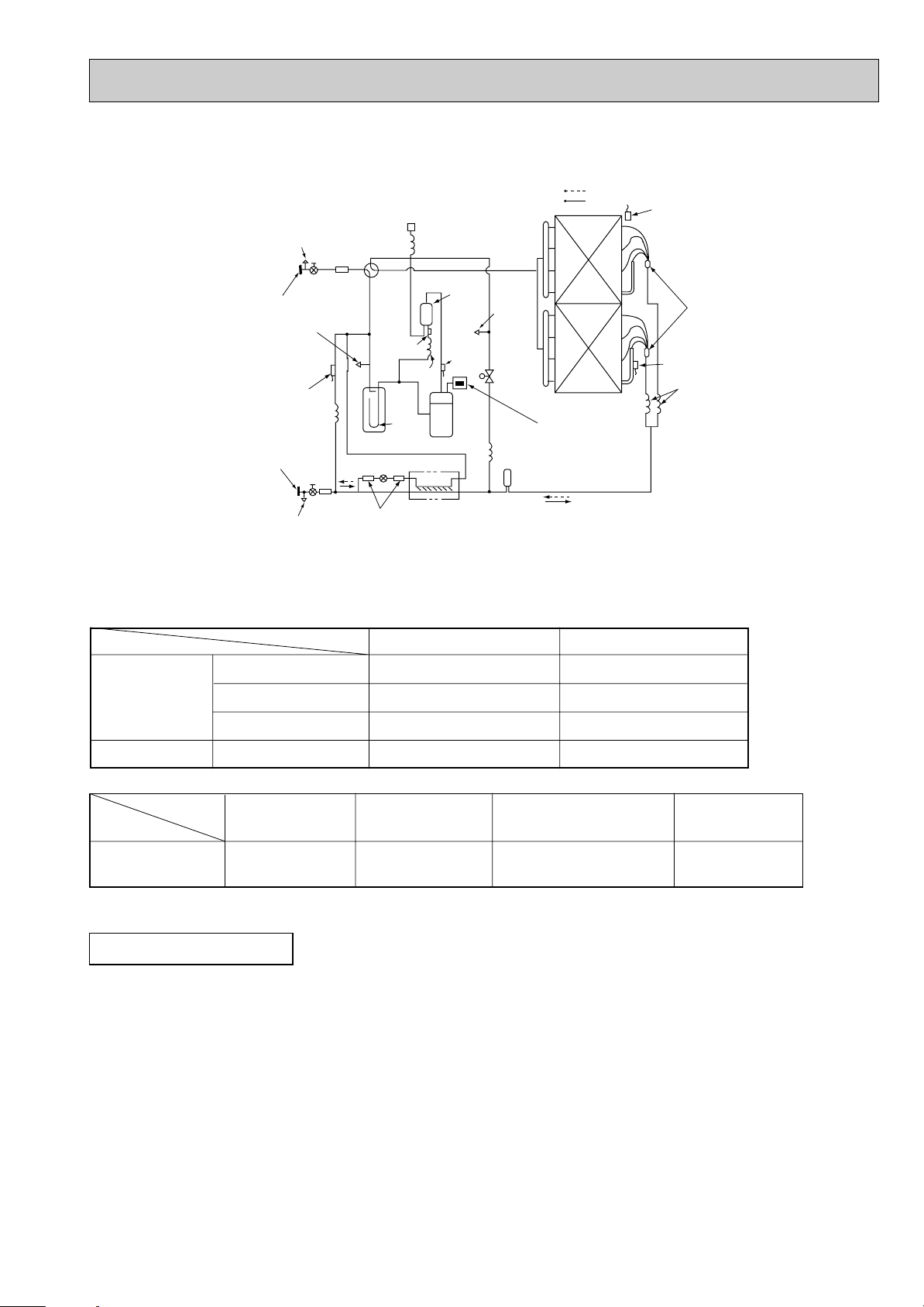

8-2. REFRIGERANT SYSTEM DIAGRAM

Flare

Flare

Strainer

#100

Strainer

#100

Strainer

(#100)

Strainer

Strainer

#100

(Refrigerant flow)

Cooling

Heating

#50

Strainer

Compressor

(MC)

Expansion valve (LEV(A), SLEV)

Accumulator

Overcooling heat exchanger

Outdoor heat exchanger

Service port

Service port

Thermistor TH2

(Saturation temperature

of suction pressure)

Capillary

tube 2

Capillary

tube 4

Dryer

Capillary

tube 3

Oil

separator

Check valve

(low pressure)

Thermistor THHS

(Radiator panel

temperature sensor)

W Only PUMY-P125VMA

Thermistor THHS-A

Thermistor THHS-B

Thermistor TH6

(outdoor air

temperature sensor)

4-way

valve

High-pressure sensor

discharge pressure sensor

(63HS)

Capillary

tube 1

Check valve

(High pressure)

Electromagnetic valve

(SV1)

Thermistor TH5

(piping temperature

monitoring and

determination)

Thermistor

TH1 (discharge

temperature

sensor)

Outdoor unit

PUMY-P125VMA

PUMY-P125YMA

PUMY-P125YMA

1

Refrigerant Piping Specifications (dimensions of flared connector)

Capacity

Indoor unit

Outdoor unit

Item

20 , 25 , 32 , 40

50 , 63 , 71, 80

100 , 125

125

Capillary tube 1

(for return of oil from

oil separator)

Capillary tube 2

(for Evaporating

temperature detection)

Liquid piping Gas piping

{6.35 <1/4”>

{9.52 <3/8”>

{9.52 <3/8”>

{9.52 <3/8”>

Capillary tube 3

(for maintaining equilibrium

between upper and lower coils)

{12.7 <1/2”>

{15.88 <5/8”>

{19.05 <3/4”>

{19.05 <3/4”>

Capillary tube 4

(for SV1)

PUMY-P125VMA

PUMY-P125YMA

PUMY-P125YMA

Concerning the Compressor

This system has a scroll compressor. This compressor uses a low pressure shell that typically has a temperature in the

range 30-80°C.

In addition, compressor wiring should be in the direction of rotation to the right. Wire colors are red (U), white(V),

black (W), yellow and yellow (thermal switch).

{2.5 O {0.6 O L500

1

23

({4 O {3.0 O L200) O 2{2.5 O {0.6 O L500

{4 O {2.4 O L360

8-3. SYSTEM CONTROL

For indoor-outdoor

transmission wire

Remote

control wire

indoor-outdoor trnasmission cable

2 remote controllers

Group operation (maximum

16 indoor units)

Outdoor

unit

Indoor unit

Indoor unit Indoor unit

NR

NR

Remote controller

network

Indoor unit Indoor unit

NR NR NR

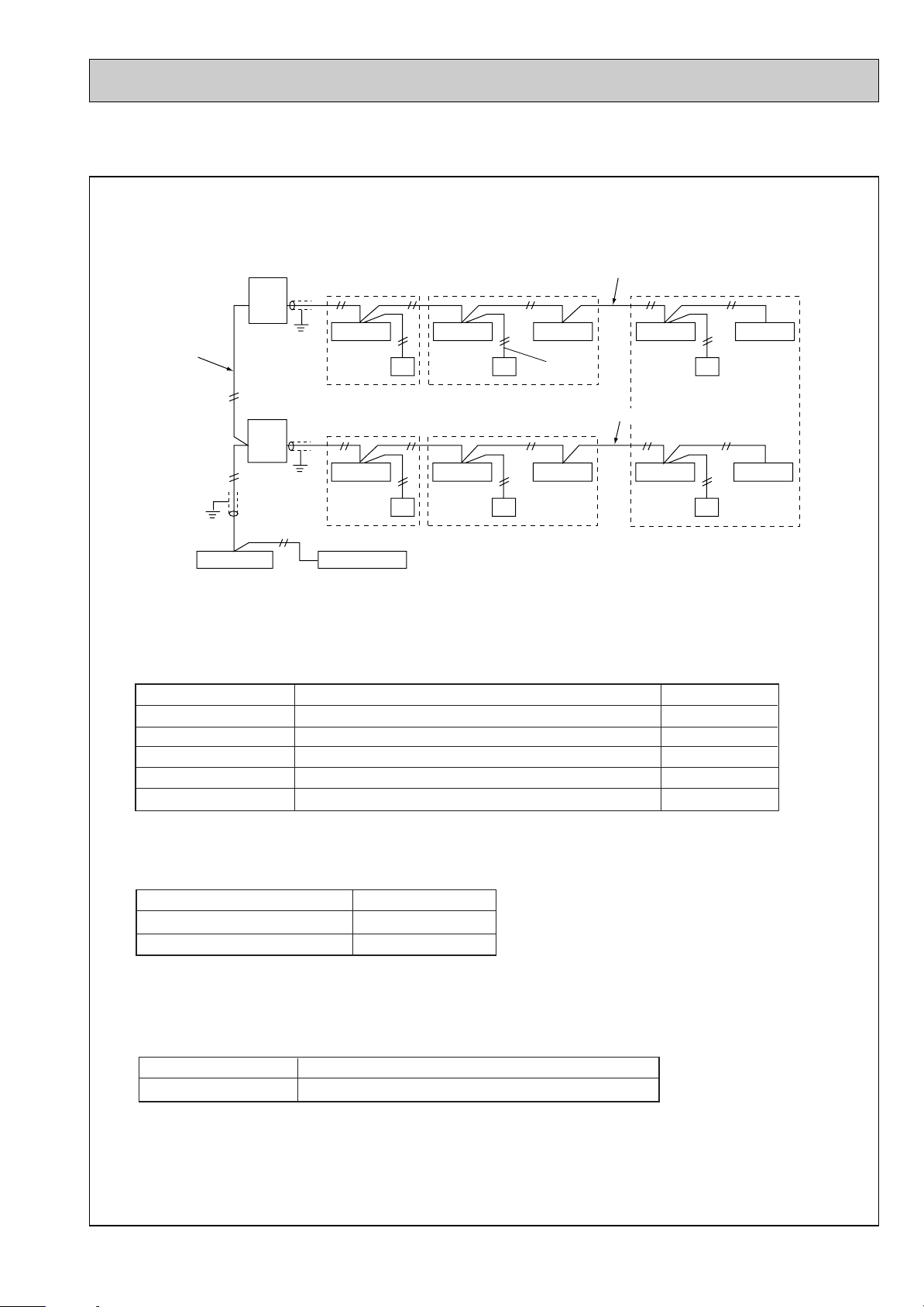

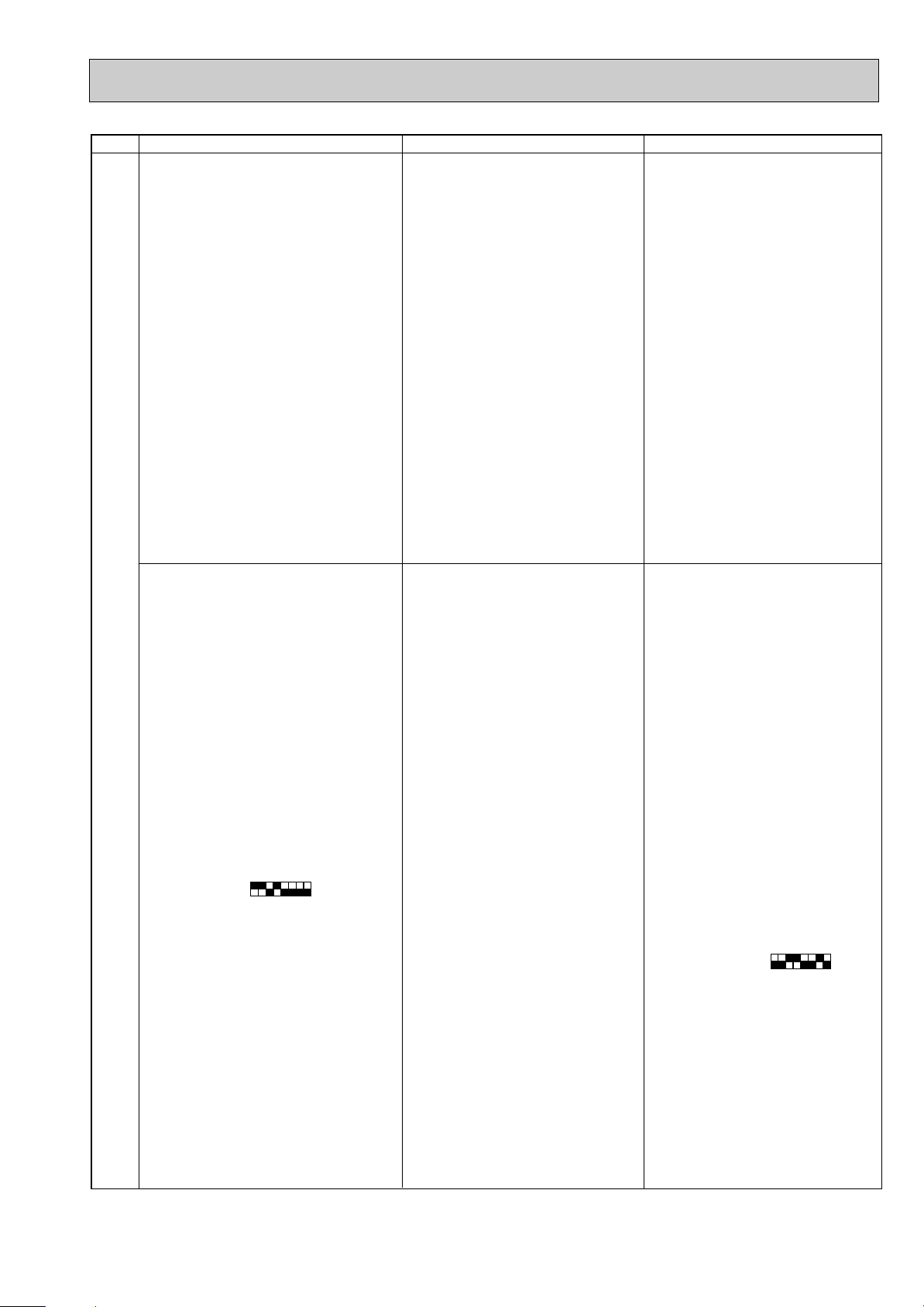

8-3-1. Operating a Single Refrigerant System

When operating either alone or as part of a group, a M-NET remote controller (NR) may be used to control a single

refrigerant system that does not overlap with any other system.

<Example of system arrangement>

Using a M-NET remote controller (NR)

✽ Address setting must be performed.

✽ The NR wire and indoor and outdoor transmission wires must be a non-polar two wire cable.

✽ One NR may be connected to a maximum of 16 indoor unit.

✽ Two NR units may be used to perform control tasks (the second one pressed will have priority if two are pressed

simultaneously).

✽ For the system utilizing R-Converter units (PAC-SF29LB), the following systems are not available. Group operation

system, centralized controller, group remote controller, etc. (See the installation manual of R-Converter units.)

✽ If the user plans to install multiple refrigerant

systems and a centralized controller in the

future, it is strongly suggested that a NR be

used.

24

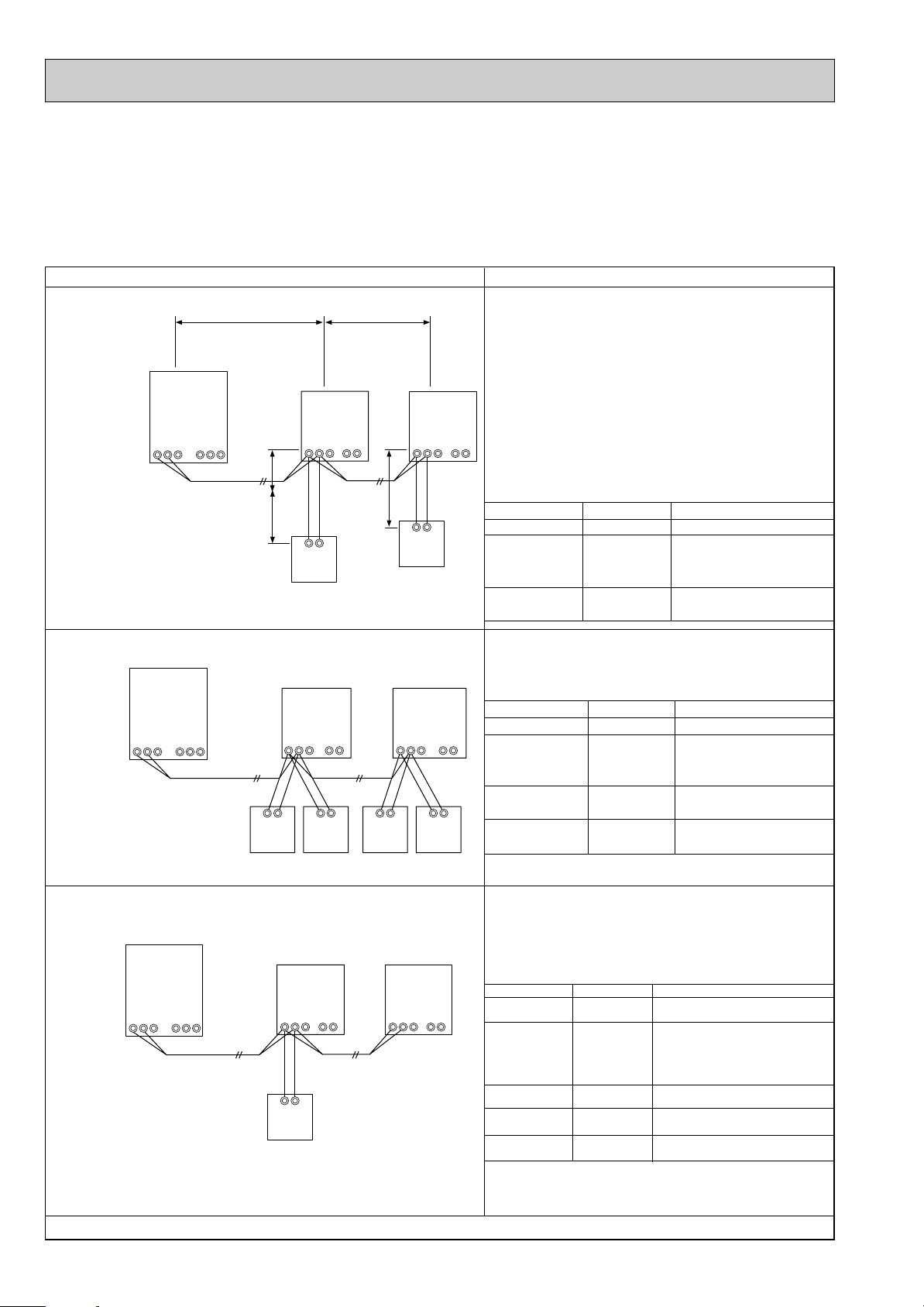

8-3-2. System Controller (SC) to Perform Centralized Control

Transmission

wire for centralized control

<Room A>

For transmission

wire

PAC-SC33KUA

PAC-SC34KUA

<Room B>

<Room D> <Room E>

<Room C>

Outdoor

unit

Indoor unit

A

Indoor unit Indoor unit Indoor unit

Remote controller network

Remote control

wire

Indoor • outdoor transmission wire (Shielded wire)

SC: Centralized controller, linked system control board, group remote controller, etc.

A : M-NET or MA remote controller

(Coexistence of M-NET remote controller and MA remote controller is not admitted in the same system.)

Indoor unit

Indoor unitIndoor unitIndoor unitIndoor unitIndoor unit

Power supply installation

System controller

Outdoor

unit

Indoor • outdoor transmission wire (Shielded wire)

A

A

A

AA

<Example of System Arrangement>

The following diagram shows the use of system controller (SC) to control a system that includes the multiple outdoor unit.