Mitsubishi PUMY-P125YMA, PUMY-125YMA Installation Manual [ru]

Air-Conditioners For Building Application

OUTDOOR UNIT

PUMY-P125YMA

PUMY-125YMA

GB

D

F

INSTALLATION MANUAL

For safe and correct use, please read this installation manual thoroughly before installing the air-conditioner unit.

INSTALLATIONSHANDBUCH

Zum sicheren und ordnungsgemäßen Gebrauch der Klimageräte das Installationshandbuch gründlich durchlesen.

MANUEL D’INSTALLATION

Veuillez lire le manuel d’installation en entier avant d’installer ce climatiseur pour éviter tout accident et vous assurer d’une utilisation correcte.

MANUAL DE INSTALACIÓN

Para un uso seguro y correcto, lea detalladamente este manual de instalación antes de montar la unidad de aire acondicionado.

MANUALE DI INSTALLAZIONE

Per un uso sicuro e corretto, leggere attentamente questo manuale di installazione prima di installare il condizionatore d’aria.

INSTALLATIEHANDLEIDING

Voor een veilig en juist gebruik moet u deze installatiehandleiding grondig doorlezen voordat u de airconditioner installeert.

MANUAL DE INSTALAÇÃO

Para segurança e utilização correctas, leia atentamente este manual de instalação antes de instalar a unidade de ar condicionado.

E°XEIPI¢IO O¢H°IøN E°KATA™TA™H™

°И· ·ЫК¿ПВИ· О·И ЫˆЫЩ‹ ¯Ъ‹ЫЛ, ·Ъ·О·ПВ›ЫЩВ ‰И·‚¿ЫВЩВ ЪФЫВ¯ЩИО¿ ·˘Щfi ЩФ ВБ¯ВИЪ›‰ИФ ВБО·Щ¿ЫЩ·ЫЛ˜ ЪИУ ·Ъ¯›ЫВЩВ ЩЛУ

ВБО·Щ¿ЫЩ·ЫЛ ЩЛ˜ МФУ¿‰·˜ ОПИМ·ЩИЫМФ‡.

E

I

NL

P

GR

RU

TR

РУКОВОДСТВО ПО УСТАНОВКЕ

Для осторожного и правильного использования прибора необходимо тщательно ознакомиться с данным руководством по

установке до выполнения установки кондиционера.

MONTAJ ELK‹TABI

Emniyetli ve do¤ru biçimde nas›l kullan›laca¤›n› ö¤renmek için lütfen klima cihaz›n› monte etmeden önce bu elkitab›n› dikkatle okuyunuz.

4

;

;

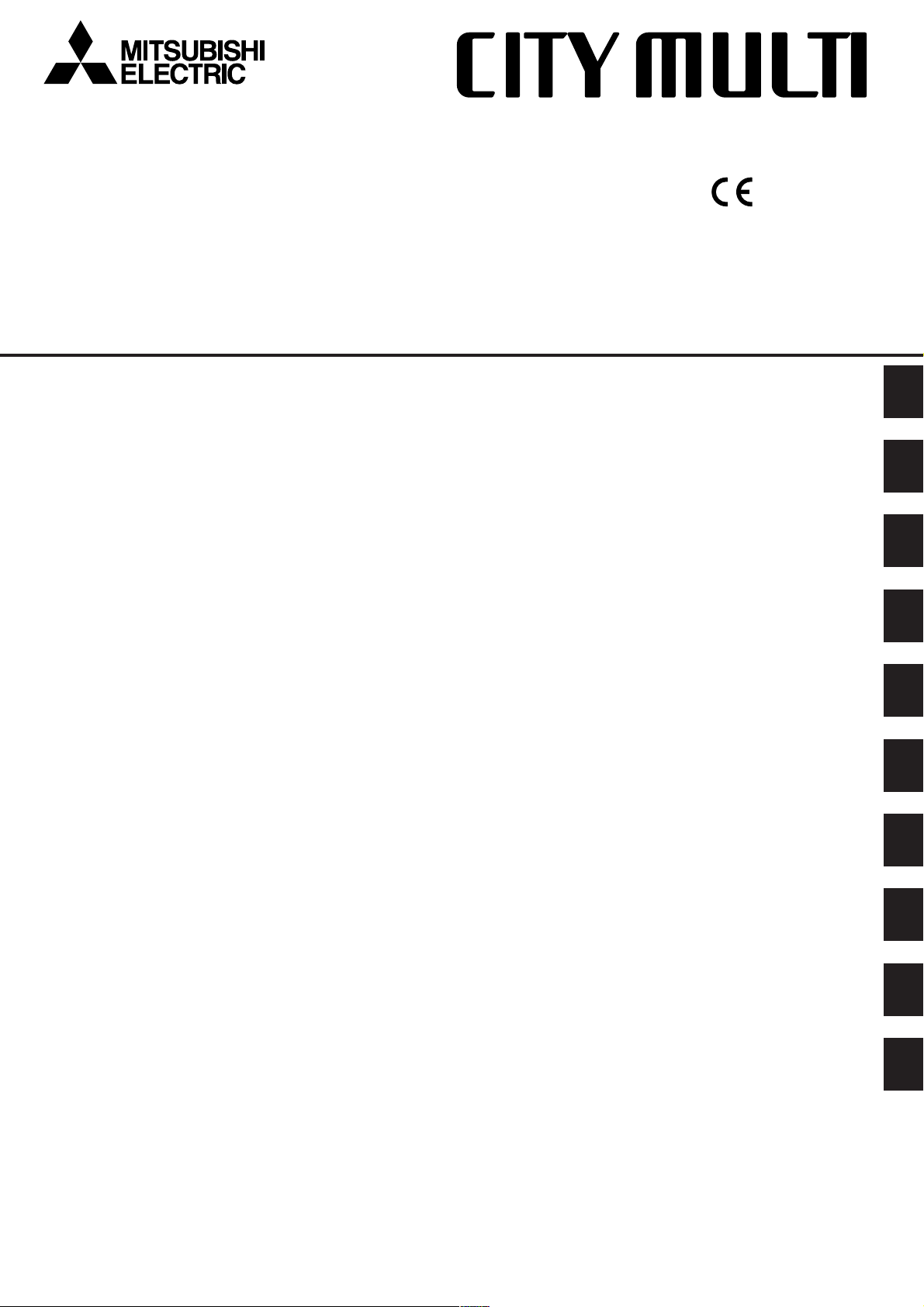

[Fig. 4.0.1]

(1)

Min. 10

<A>

Min.

500

Min.

500

(mm)

Service space

<A>

Max.

Max.

3800

150

(2)

(3)

(4)

Min.

500

Min. 10

;;;

<B>

<B>

<A>

Min. 150

Min. 10

Min. 300

Min.

150

(6)

(7)

Min. 300

1

Min. 10

2

<B>

<A>

Up to 10 units

Keep the top side open

in. 500

M

Min.

Min. 300

1000

(mm)

3

Min. 300

5

(5)

[Fig. 5.0.1]

;;;

<A>

Air outlet guideObstruction

A

Min. 150

Min.

500

Min. 500

Min. 1500

(mm)

45

Min. 3800

Min. 1500

1

2

(mm)

Air outlet

guide

3

Strong wind

90°

2

6

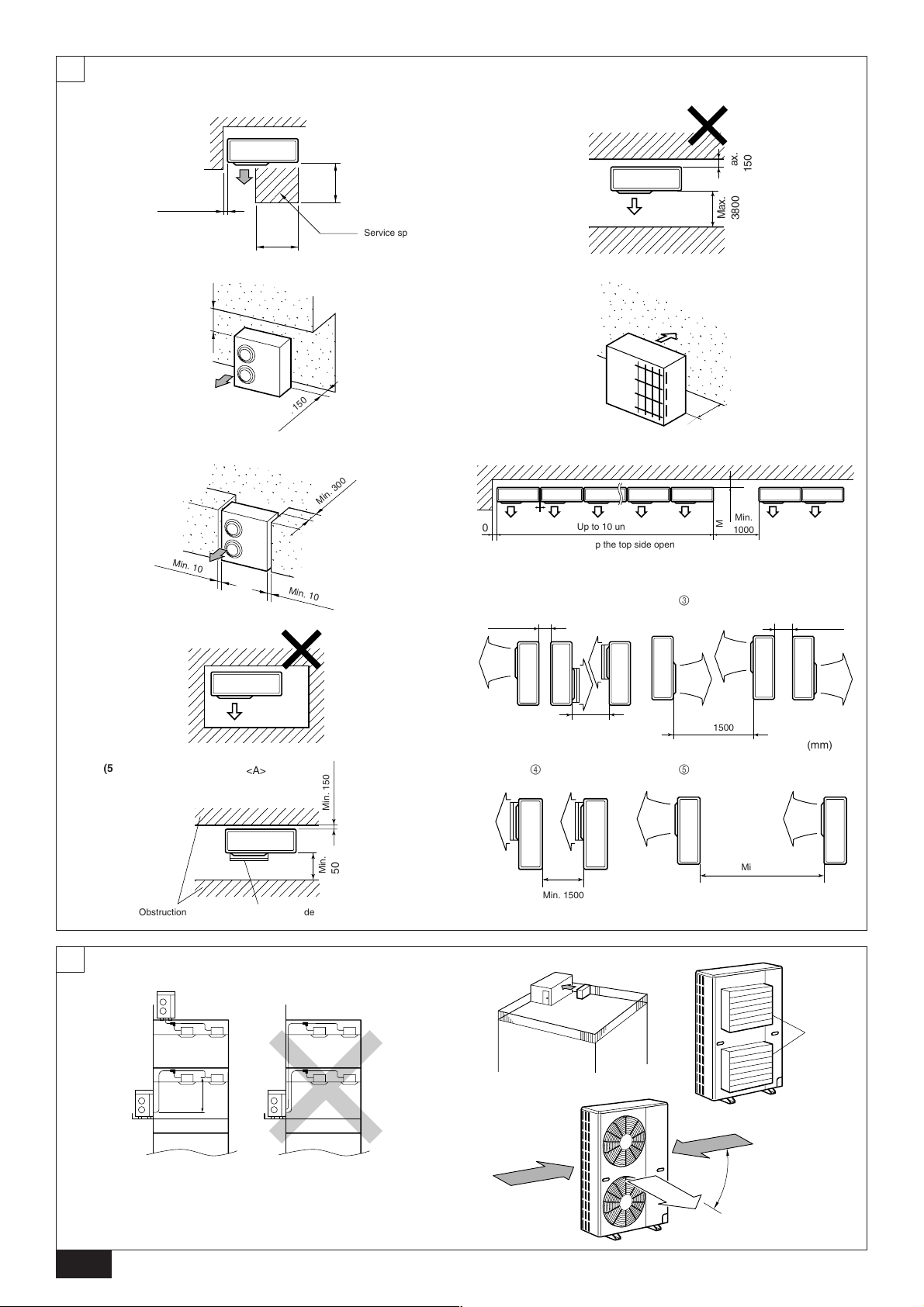

6.1

[Fig. 6.1.1]

Make the

embedding

deep

M10 bolt (Fasten with bolt)

Max. 25 mm

Length of foundation bolts

A M10 bolt

Installation base

Make wide

[Fig. 6.1.2]

600 Min. 430

Min. 10

600

385

(mm)

Drainage hole

(3-ø33)

[Fig. 6.2.1]

210 600 210

Air outlet

U-shaped cut-out (×2)

Rear air inlet

(Foundation bolts: M10)

Slot (2-12 × 36)

(Foundation bolts:

M10)

Viewed from bottom

6.2

Front piping

(knockout)

Lower piping

Rear piping

Piping cover

Right piping

(knockout)

Extraction direction

for service panel

Service panel

Bending radius

R 100 - 150 mm

Piping cover

Stop valve

Piping cover

Racking

3

7

7.2

8

8.2

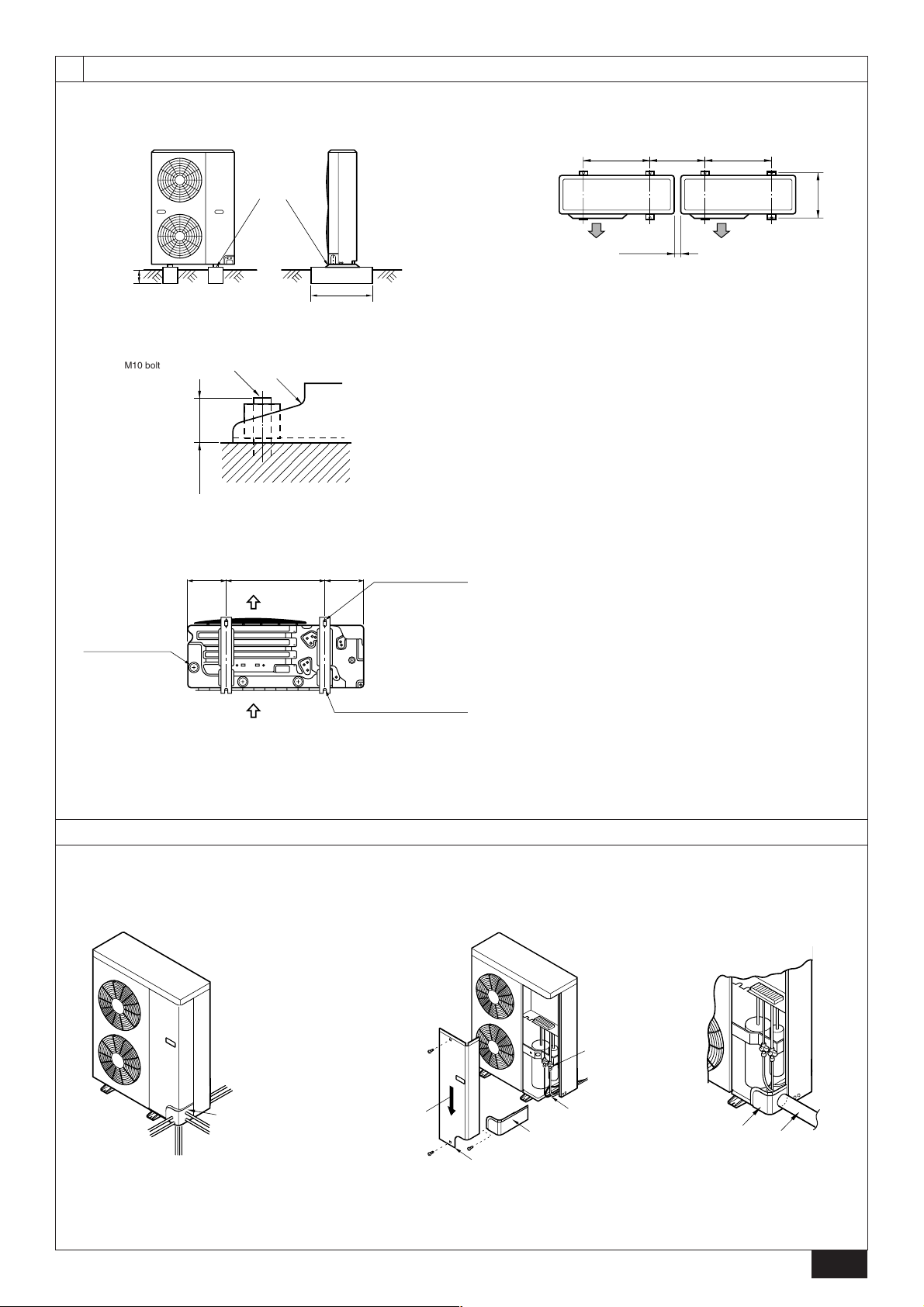

[Fig. 7.2.1]

A+B+C+D+a+b+c+d+e = 100m

L = A+B+C+D+e = 70m

R= B+C+D+e = 30m

H = 30m (Outdoor lower H = 20m)

A

H

ahb c d

B

C

h = 12m

B C

D

CCC

L

r

e

C

A+a+b+c+d+e+f = 100m

L = A+e = 70m, R= f = 30m

H = 30m (Outdoor lower H = 20m)

A

H

h

A (mm)

PUMY-(P)125 ø9.52 ø19.05

B, C, D (mm)

Ç Total capacity of indoor units Å Liquid pipe ı Gas pipe

a, b, c, d, e, f (mm)

Î Model number Å Liquid pipe ı Gas pipe

20,25,32,40 ø6.35 ø12.7

h = 12m

B

b

a

c d

CC

L

r

D

e f

CCC

A : Outdoor Unit

B : First Branch

C : Indoor unit

D : Cap

C

Å Liquid pipe ı Gas pipe

~ 80 ø9.52 ø15.88

81 ~ ø9.52 ø19.05

50,63,80 ø9.52 ø15.88

100,125 ø9.52 ø19.05

[Fig. 8.2.1]

F

G

H

[Fig. 8.2.2]

<A> Stop valve (gas pipe)

<B> Stop valve (liquid pipe)

EE

To open

(turn

slowly)

EE

SO

(This figure shows the handle when it is fully open.)

To open

(turn

slowly)

SO

A : Valve stem

B : Stopper pin

E : Open (Operate slowly)

F : Cap, copper packing

G : Service port

H : Flare nut

A

B

H

‰ Branch Kit Model

CMY-Y62-C-E

Ï 4-Branching Header Ì 8-Branching Header

CMY-Y64-C CMY-Y68

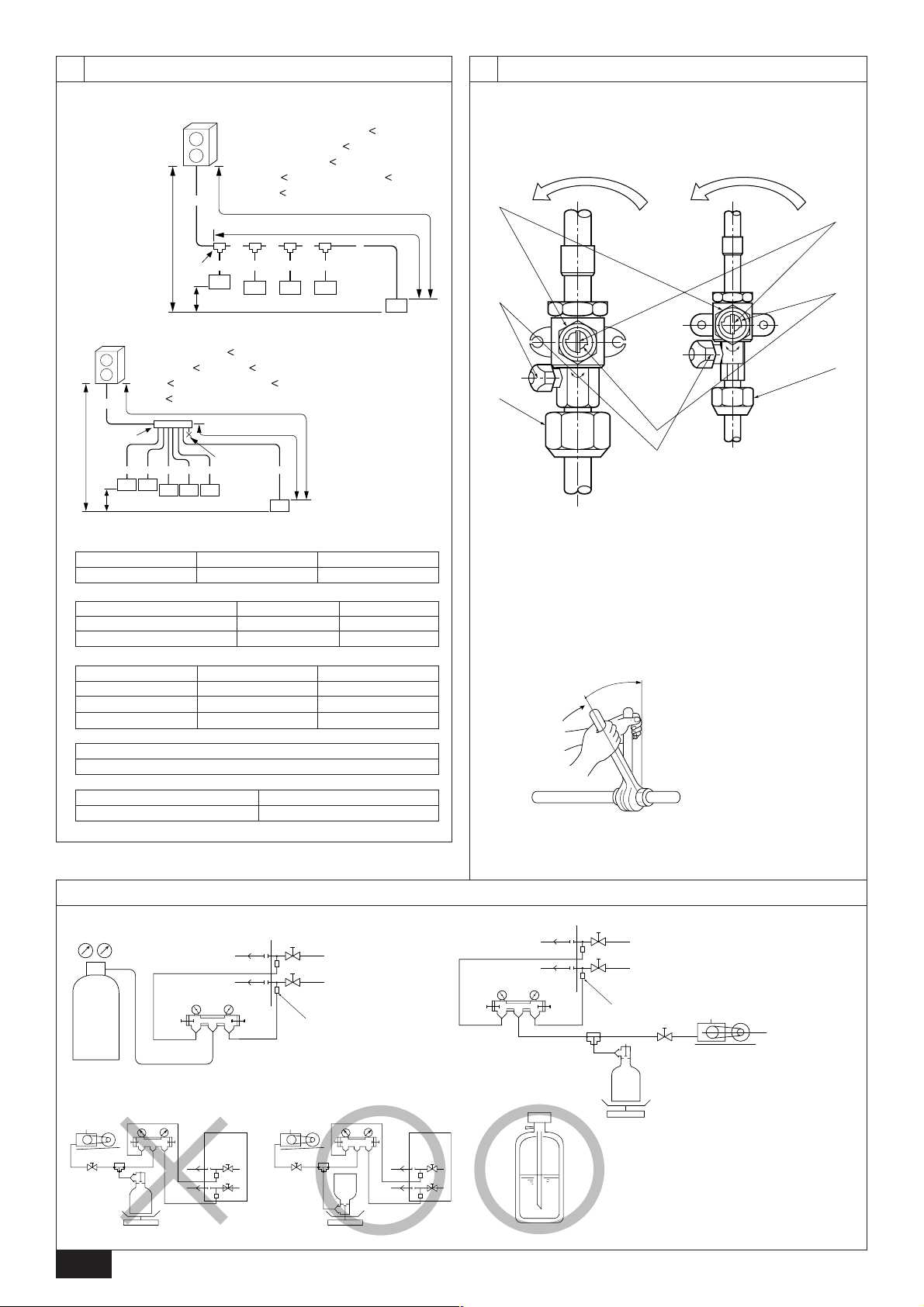

[Fig. 8.3.1]

F

B

C

A

C

LO

D

HI

E

J

[Fig. 8.3.3]

A : Nitrogen gas

B : To indoor unit

G

C : System analyzer

D : Lo Knob

H

E : Hi Knob

I

F : Stop valve

G : Liquid pipe

H : Gas pipe

I : Outdoor unit

J : Service port

8.3

[Fig. 8.3.2]

B

A

LO HI

D

E

F

C

G

H

I

J

M

K

L

A : System analyzer

B : Lo Knob

C : Hi Knob

D : Ball valve

E : Liquid pipe

F : Gas pipe

G : Service port

H : Three-way joint

I : Valve

J : Valve

K : Cylinder

L : Scale

M : Vacuum pump

4

8.4

C

A

B

D

E

D D

C

A

D D

A

B

3 N~380 - 415 V

~/N 220 - 240 V

B

A

D

C

E

A

B

C

E

D

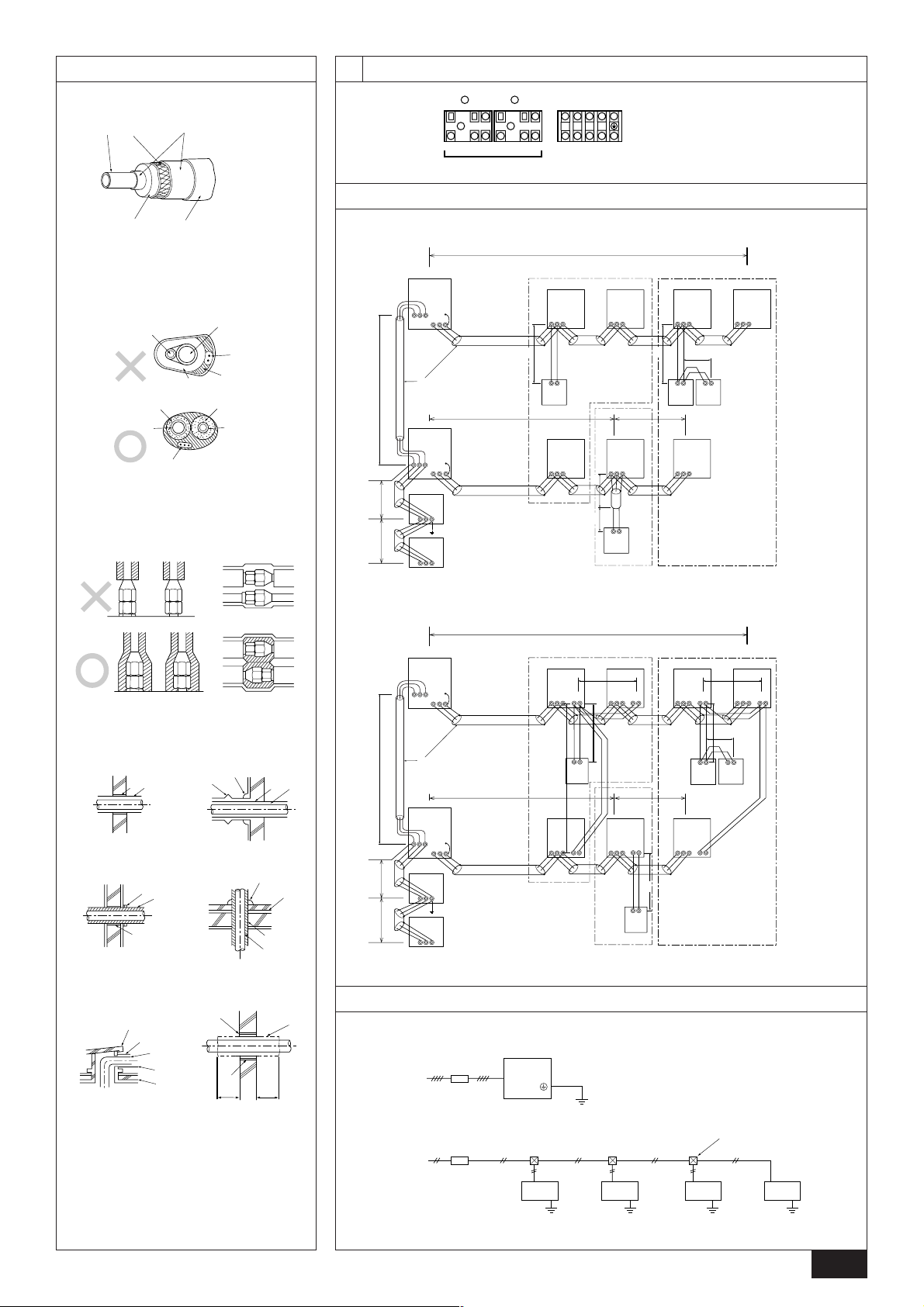

M1M2S

M1 M2 S

TB7

TB3

IC

(51)

M1 M2 S

TB5

RC

(01)

IC

M1 M2 S

TB5

(03)

IC

M1 M2 S

TB5

(02)

IC

M1 M2 S

TB5

(04)

IC

M1 M2 S

TB5

(05)

IC

M1 M2 S

TB5

(07)

IC

M1 M2 S

TB5

(06)

L

2

L

1

(101)

RC

(105)

RC

(104)

RC

(155)

OC

M1 M2 S

TB7

(53)

OC

r

3

M1M2S

Power Supply

Unit

M1M2S

MJ103

L

3

L

6

L

7

L

4

L

5

r

2

r

4

r

1

AB AB AB

AB

M1M2 S

TB3

A

B

C

E

D

M1 M2 S

TB7

IC

(51)

M1 M2 1 2S

TB5 TB15

12

TB15

12

TB15

12

TB15

12

TB15

12

TB15

12

TB15

MA

(01)

IC

M1 M2 S

TB5

(03)

IC

M1 M2 S

TB5

(02)

IC

M1 M2 S

TB5

(04)

IC

M1 M2 S

TB5

(05)

IC

M1 M2 S

TB5

(07)

IC

M1 M2 S

TB5

(06)

L

2

L

1

MAMAMA

OC

M1 M2 S

TB7

(53)

OC

c

1

c

4

c

3

S

Power Supply

Unit

S

MJ103

L

3

L

6

L

7

L

4

c

3

ABABAB

M1M2

M1M2

c

1

c

1

c

2

c

2

AB

M1M2S

TB3

M1M2S

TB3

9

9.2

[Fig. 8.4.1]

A : Steel wire B: Piping

C : Asphaltic oily mastic or asphalt

D : Heat insulation material A

E : Outer covering B

[Fig. 8.4.2]

E

B

E

A

D

A : Liquid pipe B : Gas pipe

C : Electric wire D : Finishing tape

E : Insulater

[Fig. 8.4.3]

[Fig. 9.2.1]

[Fig. 9.3.1]

M1SM2

TB3 TB7

M1SM2 L1

B

L2 L3

A

9.3

N

A : Power source

B : Transmission line

[Fig. 8.4.4]

<A> Inner wall (concealed)

A B

<C> Outer wall (exposed)

E

B

<B> Outer wall

D

C

<D> Floor (fireproofing)

I

<E> Roof pipe shaft

A : Sleeve B : Heat insulating material

C : Lagging D : Caulking material

E : Band F: Waterproofing laye

G : Sleeve with edge H : Lagging material

I : Mortar or other incombustible caulking

J : Incombustible heat insulation material

G

<F> Penetrating portion on fire

limit and boundary wall

I

D

B

H

F

A

[Fig. 9.3.2]

A B

A : Group 1

B : Group 3

D

F

G

C : Group 5

D : Shielded Wire

E : Sub Remote

Controller

( ): Address

B

[Fig. 9.4.1]

1m1m

J

9.4

A : Switch (Breakers for Wiring and Current Leakage)

B : Outdoor Unit C : Pull Box

D : Indoor Unit

5

Loading...

Loading...