Mitsubishi PUMY-P100YHM, PUMY-P140YHMA, PUMY-P100YHMA-BS, PUMY-P125YHMA-BS, PUMY-P140YHMA-BS Service Manual

...

TECHNICAL & SERVICE MANUAL

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

CONTENTS

1. TECHNICAL CHANGES

...................................

2

2. SAFETY PRECAUTION

....................................

2

3. OVERVIEW OF UNITS

......................................

5

4. SPECIFICATIONS

.............................................

7

5. DATA

.................................................................

8

6. OUTLINES AND DIMENSIONS

......................

18

7. WIRING DIAGRAM

.........................................

20

8.

NECESSARY CONDITIONS FOR SYSTEM CONSTRUCTION

.....

22

9. TROUBLESHOOTING

....................................

32

10. ELECTRICAL WIRING

....................................

74

11. REFRIGERANT PIPING TASKS

.....................

77

12. DISASSEMBLY PROCEDURE

.......................

81

13. PARTS LIST

.....................................................

87

14. RoHS PARTS LIST

..........................................

90

15. OPTIONAL PARTS

..........................................

93

OUTDOOR UNIT

No. OC355

REVISED EDITION-D

[Service Ref.]

PUMY-P100YHM

PUMY-P100YHM1

PUMY-P100YHMA

PUMY-P125YHM

PUMY-P125YHM1

PUMY-P125YHMA

PUMY-P140YHM

PUMY-P140YHM1

PUMY-P140YHMA

PUMY-P100YHMA-BS

PUMY-P125YHMA-BS

PUMY-P140YHMA-BS

HFC

utilized

R410A

June 2008

NOTE :

· This service manual describes technical data of outdoor unit.

As for indoor units, refer to its service manual.

· RoHS compliant products have <G> mark on spec name plate.

· For servicing of RoHS compliant products, refer to RoHS PARTS LIST.

[Model name]

<Outdoor unit>

PUMY-P100YHM

PUMY-P100YHMA

PUMY-P125YHM

PUMY-P125YHMA

PUMY-P140YHM

PUMY-P140YHMA

PUMY-P100YHMA-BS

PUMY-P125YHMA-BS

PUMY-P140YHMA-BS

• Please void OC355

REVISED EDITION-C.

Model name

indication

Revision:

• PUMY-P100/125/140YHMA-BS

are added in

REVISED EDITION-D.

• Some descriptions have

been modified.

2

2 SAFETY PRECAUTION

Cautions for units utilizing refrigerant R410A

2-1. CAUTIONS RELATED TO NEW REFRIGERANT

Use new refrigerant pipes.

Make sure that the inside and outside of refrigerant piping is clean and it has no contamination

such as sulfur hazardous for use, oxides, dirt,

shaving particles, etc.

In addition, use pipes with specified thickness.

Store the piping to be used during installation

indoors and keep both ends of the piping sealed

until just before brazing. (Leave elbow joints, etc.

in their packaging.)

Use ester oil, ether oil or alkylbenzene oil (small

amount) as the refrigerant oil applied to flares

and flange connections.

Avoid using thin pipes.

Charge refrigerant from liquid phase of gas

cylinder.

If the refrigerant is charged from gas phase, composition

change may occur in refrigerant and the efficiency will be

lowered.

Do not use refrigerant other than R410A.

If other refrigerant (R22 etc.) is used, chlorine in refrigerant can cause deterioration of refrigerant oil etc.

Use a vacuum pump with a reverse flow check

valve.

Vacuum pump oil may flow back into refrigerant cycle and

that can cause deterioration of refrigerant oil etc.

Use the following tools specifically designed for

use with R410A refrigerant.

The following tools are necessary to use R410A refrigerant.

Keep the tools with care.

If dirt, dust or moisture enters into refrigerant cycle, that can

cause deterioration of refrigerant oil or malfunction of compressor.

Do not use a charging cylinder.

If a charging cylinder is used, the composition of refrigerant will change and the efficiency will be lowered.

Flare tool

Electronic refrigerant

charging scale

Vacuum pump adaptor

Size adjustment gauge

Gauge manifold

Torque wrench

Gas leak detector

Charge hose

Tools for R410A

Contamination inside refrigerant piping can cause deterioration of refrigerant oil etc.

If dirt, dust or moisture enters into refrigerant cycle, that can

cause deterioration of refrigerant oil or malfunction of compressor.

If large amount of mineral oil enters, that can cause deterioration of refrigerant oil etc.

Ventilate the room if refrigerant leaks during

operation. If refrigerant comes into contact with

a flame, poisonous gases will be released.

PUMY-P100YHM1 PUMY-P100YHMA

PUMY-P125YHM

1 PUMY-P125YHMA

PUMY-P140YHM1 PUMY-P140YHMA

• Compressor and oil have been changed.

ANB33FDEMT ANB33FDKMT

Ester oil Ether oil

• Electrical parts below have been changed.

1Controller board (MULTI.B.) 2Noise filter (N.F.)

• PEFY-P15 can be connected.

1 TECHNICAL CHANGES

PUMY-P100YHM PUMY-P100YHM1

PUMY-P125YHM PUMY-P125YHM1

PUMY-P140YHM PUMY-P140YHM1

• The parts below have been changed.

14-way valve and coil (21S4) 2Fan motor (MF1,MF2)

3Noise filter circuit board (N.F.) 4Multi controller circuit board (MULTI.B.)

3

Gravimeter

Unit

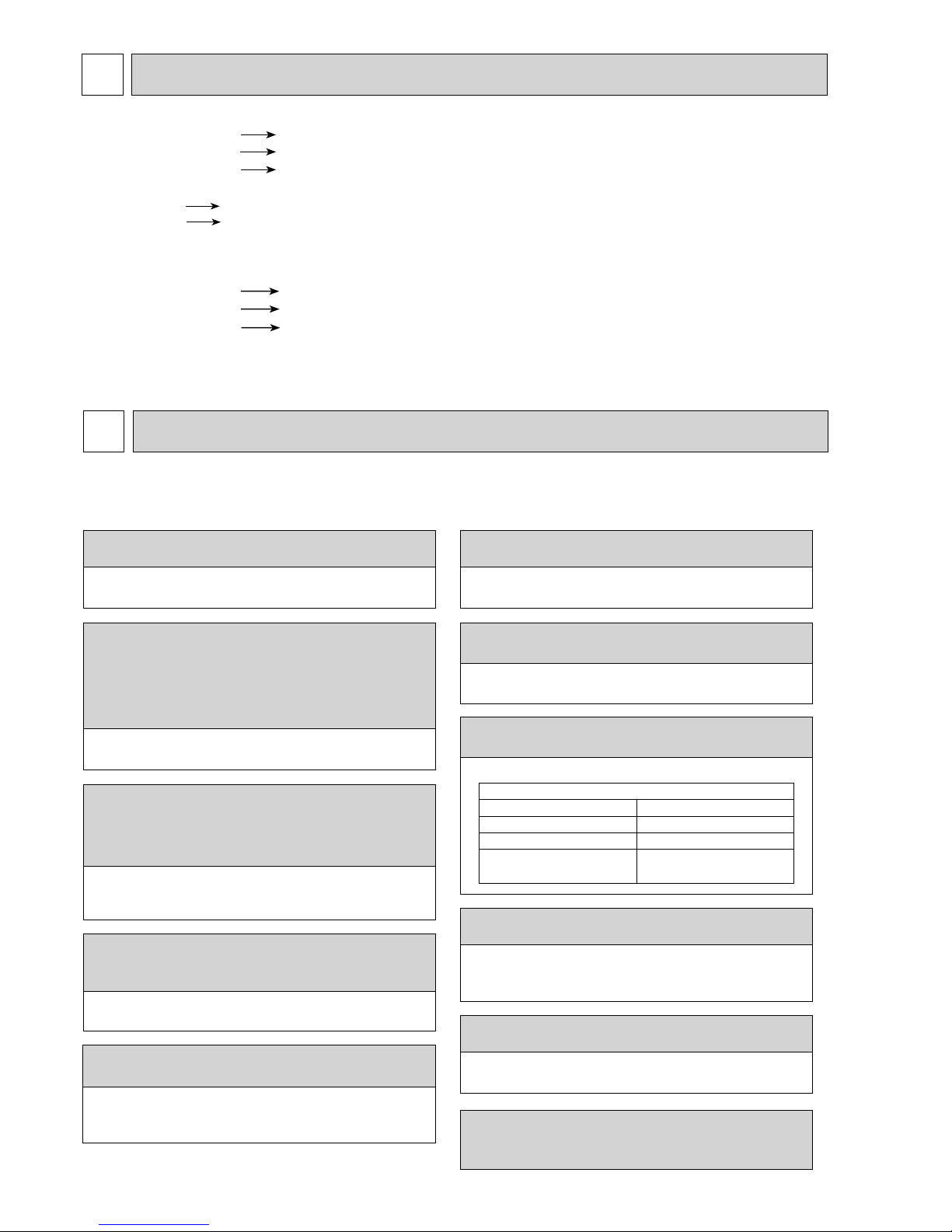

[3] Service tools

Use the below service tools as exclusive tools for R410A refrigerant.

No. Tool name Specifications

1 Gauge manifold ·Only for R410A

·Use the existing fitting

specifications

. (UNF1/2)

·Use high-tension side pressure of 5.3MPa·G or over.

2 Charge hose ·Only for R410A

·Use pressure performance of 5.09MPa·G or over.

3 Electronic scale

4 Gas leak detector ·Use the detector for R134a, R407C or R410A.

5 Adaptor for reverse flow check ·Attach on vacuum pump.

6 Refrigerant charge base

7 Refrigerant cylinder ·Only for R410A ·Top of cylinder (Pink)

·Cylinder with syphon

8 Refrigerant recovery equipment

[1] Cautions for service

(1) Perform service after recovering the refrigerant left in unit completely.

(2) Do not release refrigerant in the air.

(3) After completing service, charge the cycle with specified amount of refrigerant.

(4) When performing service, install a filter drier simultaneously.

Be sure to use a filter drier for new refrigerant.

[2] Additional refrigerant charge

When charging directly from cylinder

· Check that cylinder for R410A on the market is syphon type.

· Charging should be performed with the cylinder of syphon stood vertically. (Refrigerant is charged from liquid phase.)

Although "-BS" model has been designed to be resistant to salt damage, observe the following precautions to maintain the

performance of the unit.

1. Avoid installing the uint in a location where it will be exposed directly to seawater or sea breeze.

2. If the cover panel may become covered with salt, be sure to install the unit in a location where the salt will be washed away by

rainwater. (If a sunshade is installed, rainwater may not clean the panel.)

3. To ensure that water does not collect in the base of the outdoor unit, make sure that the base is level, not at angle. Water

collecting in the base of the outdoor unit could cause rust.

4. If the unit is installed in a coastal area, clean the unit with water regularly to remove any salt build-up.

5. If the unit is damaged during installation or maintenance, be sure to repair it.

6. Be sure to check the condition of the unit regularly.

7. Be sure to install the unit in a location with good drainage.

2-2. PRECAUTIONS FOR SALT PROOF TYPE "-BS" MODEL

4

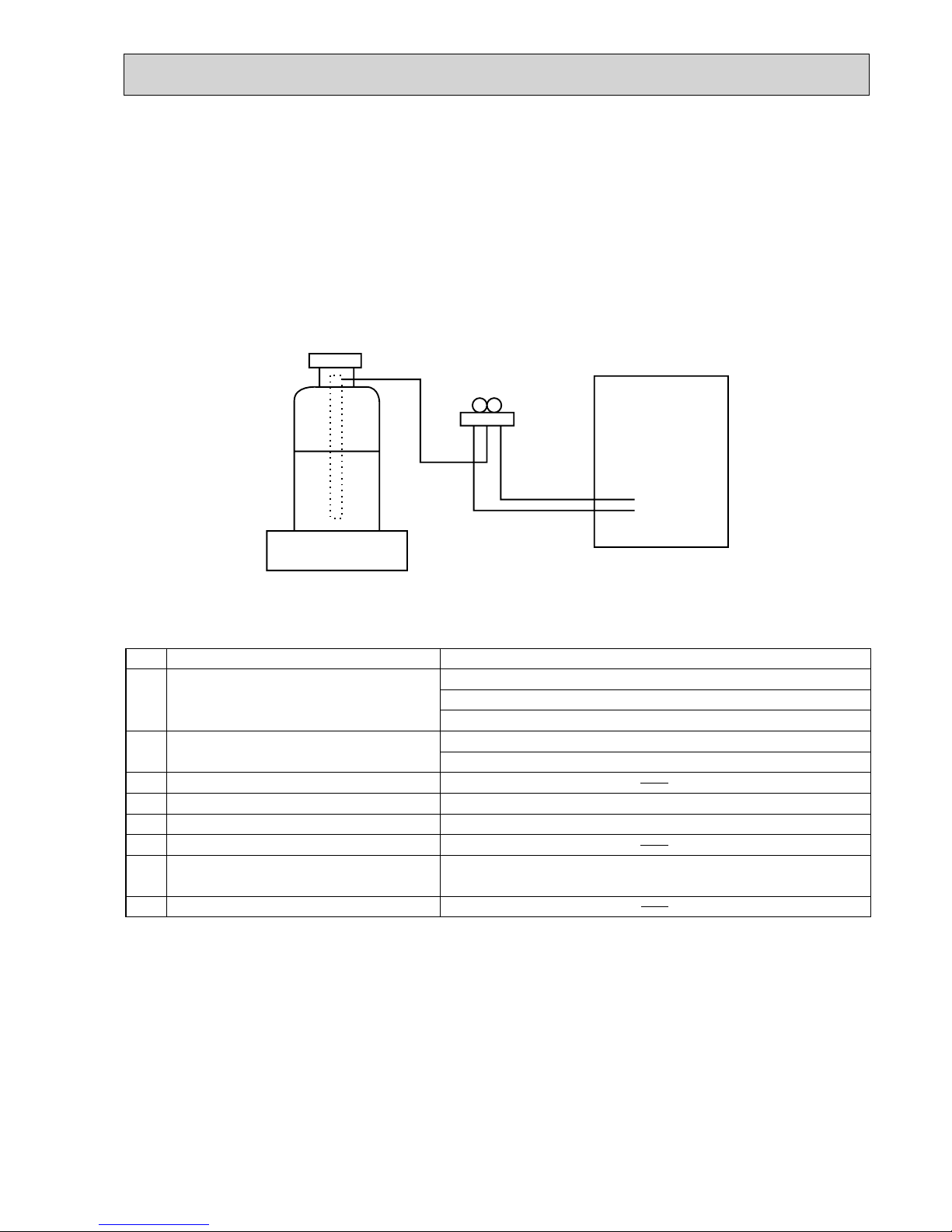

Cautions for refrigerant piping work

New refrigerant R410A is adopted for replacement inverter series. Although the refrigerant piping work for R410A is same

as for R22, exclusive tools are necessary so as not to mix with different kind of refrigerant. Furthermore as the working

pressure of R410A is 1.6 time higher than that of R22, their sizes of flared sections and flare nuts are different.

1Thickness of pipes

Because the working pressure of R410A is higher compared to R22, be sure to use refrigerant piping with thickness

shown below. (Never use pipes of 0.7mm or below.)

2Dimensions of flare cutting and flare nut

The component molecules in HFC refrigerant are smaller compared to conventional refrigerants. In addition to that,

R410A is a refrigerant, which has higher risk of leakage because its working pressure is higher than that of other refriger ants. Therefore, to enhance airtightness and intensity, flare cutting dimension of copper pipe for R410A have been speci fied separately from the dimensions for other refrigerants as shown below. The dimension B of flare nut for R410A also

have partly been changed to increase intensity as shown below. Set copper pipe correctly referring to copper pipe flaring

dimensions for R410A below. For 1/2 and 5/8 inch, the dimension B changes.

Use torque wrench corresponding to each dimension.

3Tools for R410A (The following table shows whether conventional tools can be used or not.)

1/4

3/8

1/2

5/8

3/4

6.35

9.52

12.70

15.88

19.05

0.8

0.8

0.8

1.0

—

0.8

0.8

0.8

1.0

1.0

Nominal

dimensions(inch)

Diagram below: Piping diameter and thickness

Outside

diameter

(mm)

Thickness

(mm)

R410A R22

1/4

3/8

1/2

5/8

3/4

6.35

9.52

12.70

15.88

19.05

9.1

13.2

16.6

19.7

—

9.0

13.0

16.2

19.4

23.3

Nominal

dimensions(inch)

Flare cutting dimensions

Outside

diameter

Dimension A

( )

+0

-0.4

(mm)

R410A R22

1/4

3/8

1/2

5/8

3/4

6.35

9.52

12.70

15.88

19.05

17.0

22.0

26.0

29.0

—

17.0

22.0

24.0

27.0

36.0

Nominal

dimensions(inch)

Flare nut dimensions

Outside

diameter

Dimension B

(mm)

R410A R22

Gauge manifold

Charge hose

Gas leak detector

Refrigerant recovery equipment

Refrigerant cylinder

Applied oil

Safety charger

Charge valve

Vacuum pump

Flare tool

Bender

Pipe cutter

Welder and nitrogen gas cylinder

Refrigerant charging scale

Vacuum gauge or thermistor vacuum gauge and

vacuum valve

Charging cylinder

Air purge, refrigerant charge

and operation check

Gas leak check

Refrigerant recovery

Refrigerant charge

Apply to flared section

Prevent compressor malfunction

when charging refrigerant by

spraying liquid refrigerant

Prevent gas from blowing out

when detaching charge hose

Vacuum drying and air

purge

Flaring work of piping

Bend the pipes

Cut the pipes

Weld the pipes

Refrigerant charge

Check the degree of vacuum. (Vacuum

valve prevents back flow of oil and refrigerant to thermistor vacuum gauge)

Refrigerant charge

Tool exclusive for R410A

Tool exclusive for R410A

Tool for HFC refrigerant

Tool exclusive for R410A

Tool exclusive for R410A

Ester oil, ether oil and

alkylbenzene oil (minimum amount)

Tool exclusive for R410A

Tool exclusive for R410A

Tools for other refrigerants can

be used if equipped with adopter for reverse flow check

Tools for other refrigerants

can be used by adjusting

flaring dimension

Tools for other refrigerants can be used

Tools for other refrigerants can be used

Tools for other refrigerants can be used

Tools for other refrigerants can be used

Tools for other refrigerants

can be used

Tool exclusive for R410A

Tools and materials Use R410A tools Can R22 tools be used?

(Usable if equipped

with adopter for rever se flow)

(Usable by adjusting

flaring dimension)

Can R407C tools be used?

Ester oil, ether oil:

Alkylbenzene oil: minimum amount

(Usable if equipped

with adopter for rever se flow)

(Usable by adjusting

flaring dimension)

: Prepare a new tool. (Use the new tool as the tool exclusive for R410A.)

: Tools for other refrigerants can be used under certain conditions.

: Tools for other refrigerants can be used.

Dimension A

Dimension B

5

3

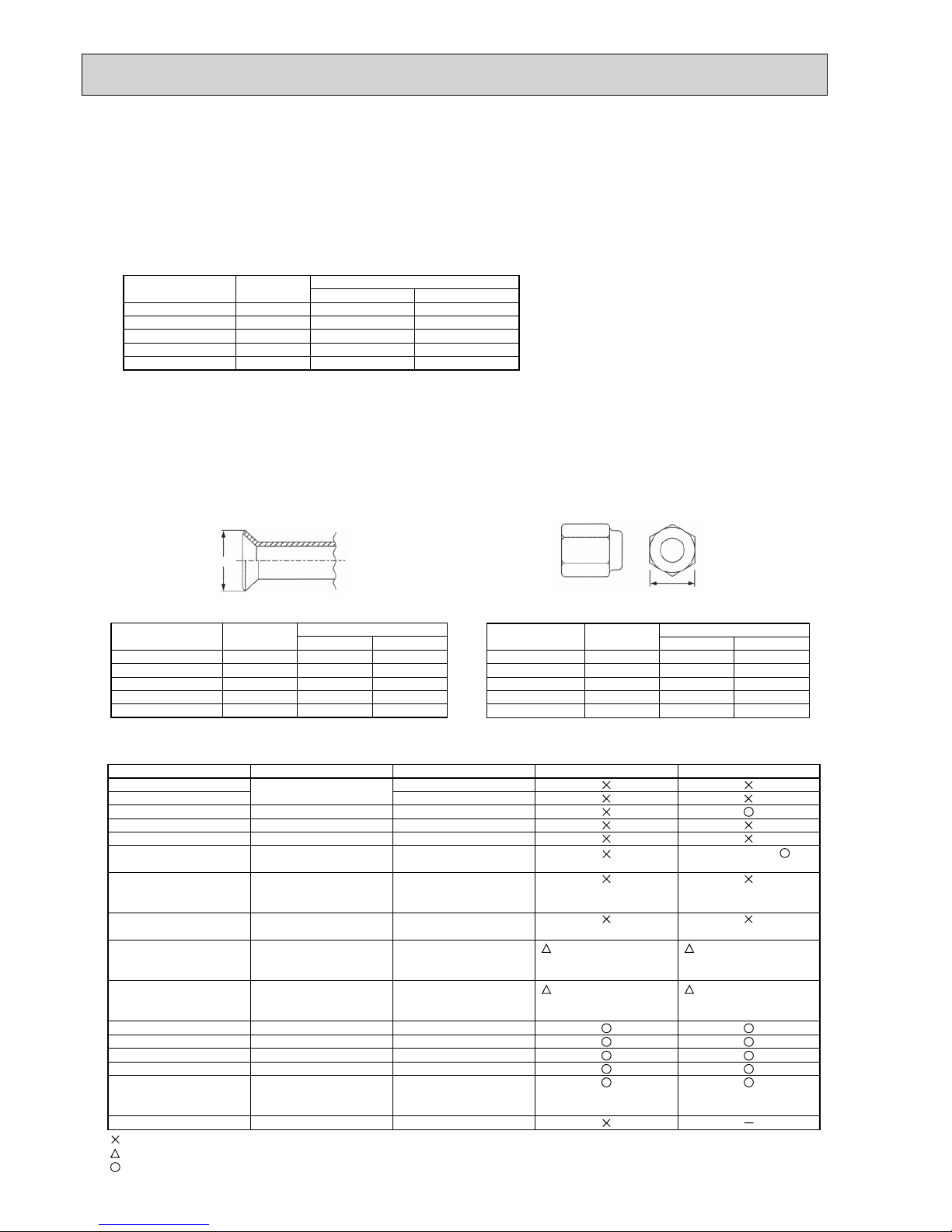

OVERVIEW OF UNITS

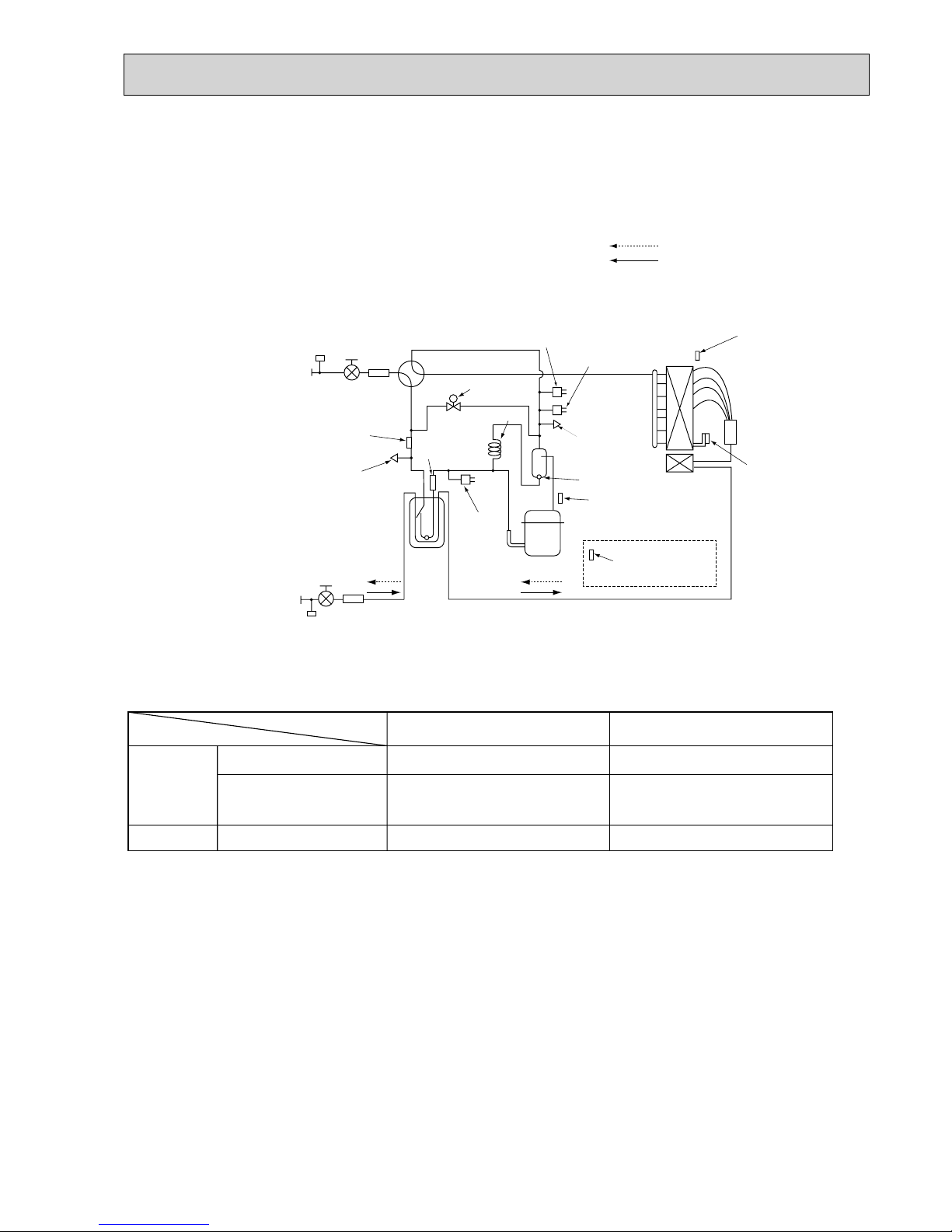

3-1. UNIT CONSTRUCTION

15

20

25

32

40

50

63

71

80

100

125

140

–

20VCM-E

25VCM-E

32VCM-E/32VBM-E

40VCM-E/40VBM-E

50VBM-E

63VBM-E

–

80VBM-E

100VBM-E

125VBM-E

–

–

20VLMD-E

25VLMD-E

32VLMD-E

40VLMD-E

50VLMD-E

63VLMD-E

–

80VLMD-E

100VLMD-E

125VLMD-E

–

15VMS/(L)-E

20VML-E / VMM-E

25VML-E / VMM-E

32VML-E / VMM-E

40VMH-E / VMM-E

50VMH-E / VMM-E

63VMH-E / VMM-E

71VMH-E / VMM-E

80VMH-E / VMM-E

100VMH-E / VMM-E

125VMH-E / VMM-E

140VMM-E

–

20VM-E

25VM-E

32VM-E

40VM-E

50VM-E

63VM-E

71VM-E

80VM-E

100VM-E

125VM-E

–

–

20VBM-E

25VBM-E

32VGM-E

40VGM-E

50VGM-E

–

–

–

–

–

–

–

20VLEM-E

25VLEM-E

32VLEM-E

40VLEM-E

50VLEM-E

63VLEM-E

–

–

–

–

–

–

20VLRM-E

25VLRM-E

32VLRM-E

40VLRM-E

50VLRM-E

63VLRM-E

–

–

–

–

–

–

–

–

–

40VGM-E

–

63VGM-E

–

–

100VGM-E

125VGM-E

–

PLFY-P PLFY-P PEFY-P PDFY-P PKFY-P PCFY-P PFFY-P PFFY-P

–

–

–

–

–

–

–

–

80VMH-E-F

–

–

140VMH-E-F

PEFY-P

Capacity

Model

Cassette Ceiling

4-way flow 2-way flow

–

20VBM-E

25VBM-E

32VBM-E

40VBM-E

–

–

–

–

–

–

–

PMFY-P

1-way flow

Ceiling

Concealed

Ceiling

mounted

built-in

Ceiling

Suspended

Ceiling

Concealed

(Fresh Air)

*1

Wall

Mounted

Floor standing

Exposed Concealed

Remote

controller

Name

Model number

Functions

M-NET remote controller

PAR-F27MEA-E

• A handy remote controller for use in conjunction

with the Melans centralized management system.

• Addresses must be set.

• Addresses setting is not necessary.

MA remote controller

PAR-21MAA

Outdoor unit

Capacity

Type 15(YHMA) / 20(YHM(1))~Type 125

1~ 6 unit

50% ~130% of outdoor unit capacity

*2

Type 15(YHMA) / 20(YHM

(1))~Type 140

1~ 8 unit

Indoor

unit that

can be

connected

Number of units

Total system wide capacity

4HP 5HP 6HP

PUMY-P100YHM

PUMY-P100YHM1

PUMY-P100YHMA (-BS)

PUMY-P125YHM

PUMY-P125YHM1

PUMY-P125YHMA (-BS)

PUMY-P140YHM

PUMY-P140YHM1

PUMY-P140YHMA (-BS)

Branching pipe

components

Branch header

(2 branches)

Branch header

(4 branches)

Branch header

(8 branches)

CMY-Y62-G-E CMY-Y64-G-E CMY-Y68-G-E

*1. PUMY-P·YHM1/YHMA can connect Fresh Air type indoor unit. (PUMY-P·YHM can NOT connect.)

It is possible only by 1: 1 system.

(1 indoor unit of Fresh Air type is connected with 1 outdoor unit.)

Operating temperature range(outdoor temperature) for fresh air type indoor units differ from other indoor units.

Refer to 3-2(3).

*2. When the indoor unit of Fresh Air type is connected with the outdoor unit, the maximum connectable total indoor unit

capacity is 110% (100% in case of heating below -5:[23˚F]).

Decorative panel

6

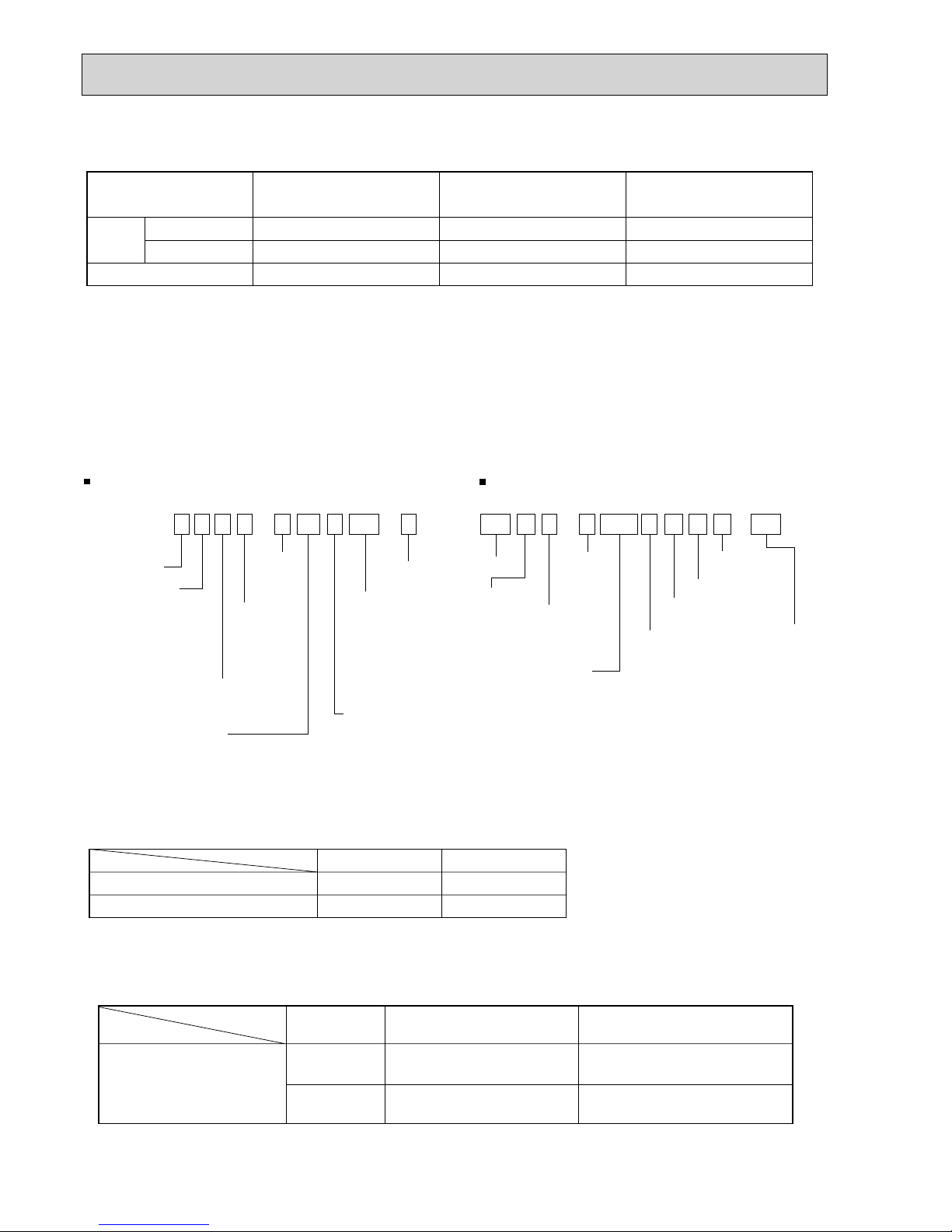

3-2. UNIT SPECIFICATIONS

(2) Method for identifying MULTI-S model

(1) Outdoor Unit

Indoor unit < When using Model 80 >

Outdoor unit <When using model 125 >

P L F Y - P 80 V AM - E PU M Y - P 125 Y H M A - BS

PAC type

AM

BM

CM

KM

M

KM

LMD

Frequency

conversion

controller

Refrigerant

R407C/R22

R410A

commonness

Refrigerant

R410A

NEW frequency converter

one-to-many air conditioners

(flexible design type)

Indicates equivalent

to Cooling capacity

Indicates equivalent

to Cooling capacity

Power supply

V: Single phase

220-230-240V 50Hz

220V 60Hz

Power supply

Y: 3-phase

380-400-415V 50Hz

L : Ceiling cassette

K : Wall-mounted type

E : Hidden skylight type

C : Ceiling suspended type

M : Ceiling cassette type

F : Floor standing type

}

M-NET

control

Outdoor unit

model type

Sub-number

M-NET control

Sub-number

Frequency

conversion

controller

Outdoor unit

MULTI-S

(k cal / h)

(k cal / h)

Salt proof type

Service Ref.

PUMY-P100YHM

PUMY-P100YHM

1

PUMY-P100YHMA(-BS)

Capacity

Cooling (kW)

Heating (kW)

11.2

12.5

1.9

PUMY-P125YHM

PUMY-P125YHM1

PUMY-P125YHMA (-BS)

14.0

16.0

2.4

PUMY-P140YHM

PUMY-P140YHM1

PUMY-P140YHMA (-BS)

16.0

18.0

2.9Motor for compressor (kW)

Cooling / Heating capacity indicates the maximum value at operation under the following condition.

w. Cooling Indoor : D.B. 27°C / W.B. 19.0°C

Outdoor : D.B. 35°C

Heating Indoor : D.B. 20°C

Outdoor : D.B. 7°C / W.B. 6°C

(3) Operating temperature range

Notes D.B. : Dry Bulb Temperature

W.B. : Wet Bulb Temperature

w1. 10~46°C DB : In case of connecting PKFY-P20/P25 type indoor unit.

Cooling

W

.B. 15~24C

D.B. -5~46C

+1

Heating

D.B. 15~27C

W.B. -15~15C

Indoor-side intake air temperature

Outdoor-side intake air temperature

■ In case of connecting fresh air type indoor unit (Only PUMY-P·YHM1/YHMA can connect Fresh air type indoor unit.)

air type indoor

Capacity of Fresh

Cooling

Heating

Indoor-side and Outdoor-side

P80

D.B.21~43

+

2

W.B.15.5~35

D.B.-10~20

+

3

intake air temperature

P140

D.B.21~43

+

2

W.B.15.5~35

D.B.-5~20

+

3

+

2.Thermo-off (FAN-mode) automatically starts if the outdoor temp. is lower than 21D.B..

+

3.Thermo-off (FAN-mode) automatically starts if the outdoor temp. is higher than 20D.B..

7

4

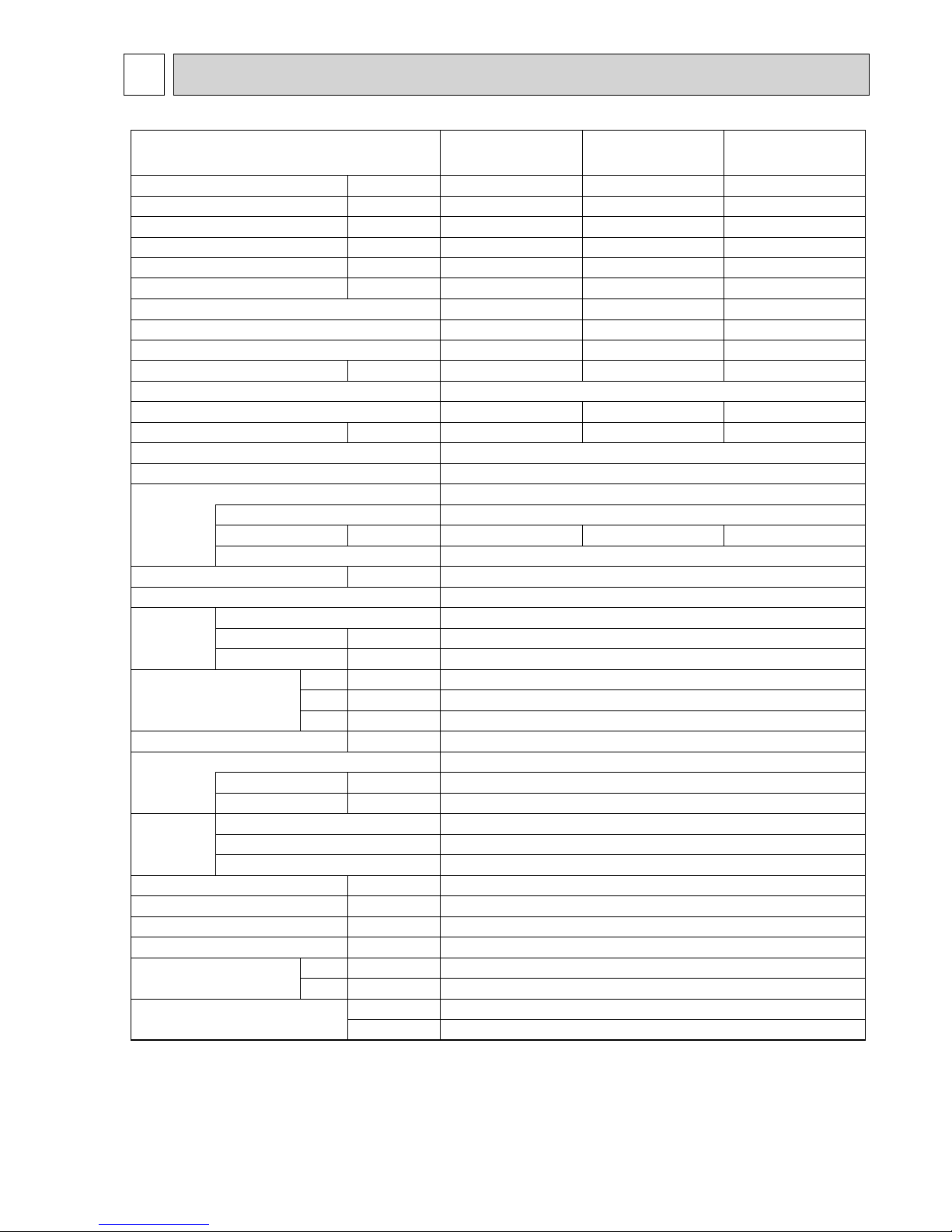

SPECIFICATIONS

PUMY-P100YHM

(1)

PUMY-P100YHMA

PUMY-P100YHMA-BS

PUMY-P125YHM

(1)

PUMY-P125YHMA

PUMY-P125YHMA-BS

PUMY-P140YHM

(1)

PUMY-P140YHMA

PUMY-P140YHMA-BS

Cooling Capacity

Service Ref.

kW 11.2 14.0 15.5

Heating Capacity kW 12.5 16.0 18.0

Input(Cool

)

kW 3.3 4.27 5.32

Input Current (Cool

)

A 5.28/5.02/4.84 6.83/6.49/6.26 8.51/8.09/7.80

Input(Heat

)

kW 3.63 4.29 5.32

Input Current (Heat

)

A 5.81/5.52/5.32 6.87/6.52/6.29 8.51/8.09/7.80

EER(Cool

)

3.39 3.28 2.91

COP (Heat

)

3.44 3.73 3.38

Connectable indoor units (Max.

)

688

Max. Connectable Capacity kW 14.5(130%

)

18.2(130%

)

20.2(130%

)

Power Supply 3 phase ,50Hz,380/400/415V

Breaker Size 16A 16A 16A

Sound level (Cool/Heat

)

dB 49 / 51 50 / 52 51 / 53

External finish Munsell 3Y 7.8/1.1

Refrigerant control Linear Expansion Valve

Compressor Hermetic

YHM

(1)

:ANB33FDEMT, YHMA:ANB33FDKMT

Model

Motor output kW 1.9 2.4 2.9

Starting method Inverter

Crankcase heater W —

Heat exchanger Plate fin coil (Anti corrosion fin treatment

)

Fan Fan(drive

) %

No. Propeller fan % 2

Fa motor output kW 0.060 + 0.060

Airflow m

3

/min(CFM

)

100(3,530

)

Dimensions(HxWxD

)

Wmm

(

in.

)

950(37-3/8

)

Dmm

(

in.

)

330+30(13+1-3/16

)

Hmm

(

in.

)

1,350(53-1/8

)

Weight kg(lbs

)

140(309

)

Refrigerant R410A

Charge kg(lbs

)

8.5(18.7

)

Protection High pressure protection HP switch

devices Compressor protection Discharge thermo,Over current detection

Fan motor protection Overheating/Voltage protection

Oil(Model

)

2.3(YHM

(1)

: MEL56, YHMA:FV50S

)

Total Piping length (Max.

)

m

L

120

Farthest m 80

Max. Height difference m 30

Chargeless length m 50

Piping diameter

Gas :mm(in.) 15.88(5/8

)

Liquid :mm(in.) 9.52(3/8

)

Guranteed operation range

(

cool

)

-5~ 46 DB

(

heat

)

-15~ 15 WB

+3

+3

+3

+3

+3

+3

+1

+2

Rating conditions (JIS B 8616)

Cooling Indoor : D.B. 27: / W.B. 19:

Outdoor : D.B. 35: / W.B. 20:

Heating Indoor : D.B. 20:

Outdoor : D.B. 7: / W.B. 6:

Note.w1. 20m : In case of installing outdoor unit lower than

indoor unit.

w2. 10~46:DB : In case of connecting PKFY-P20/P25 type

indoor unit.

w3. Electrical data is for only outdoor unit.

8

5

DATA

5-1. COOLING AND HEATING CAPACITY AND CHARACTERISTICS

5-1-1. Method for obtaining system cooling and heating capacity:

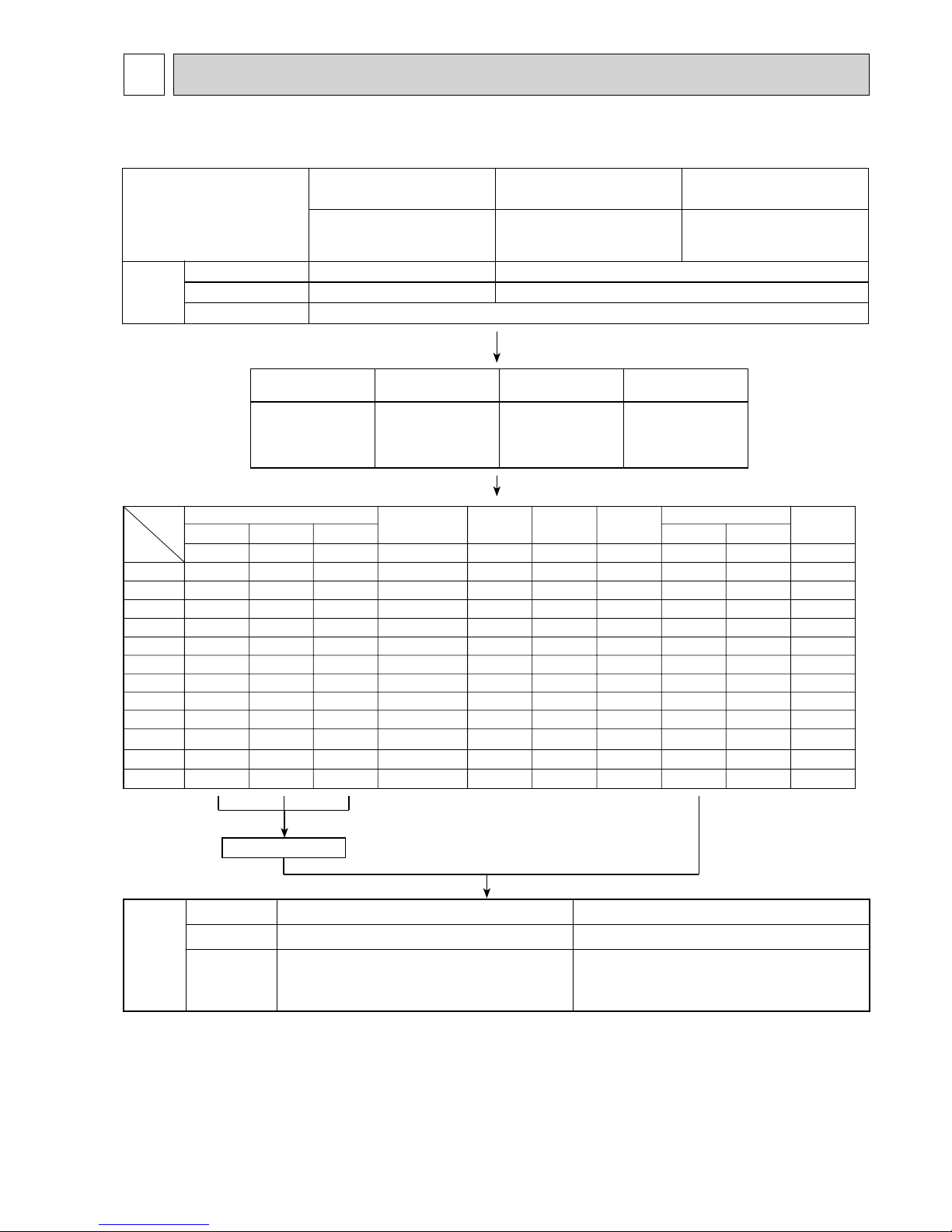

To obtain the system cooling and heating capacity and the electrical characteristics of the outdoor unit, first add up the rati ngs

of all the indoor units connected to the outdoor unit (see table below), and then use this total to find the standard capacity with

the help of the tables on 5-2.STANDARD CAPACITY DIAGRAM.

(1) Capacity of indoor unit

5-1-2. Method for obtaining the heating and cooling capacity of an indoor unit:

(1) The capacity of each indoor unit (kW) = the capacity A (or B)

o

(2) Sample calculation (using the system described above in 5-1-1. (2) ):

model capacity

total model capacity of all indoor units

During cooling: During heating:

• The total model capacity of the indoor unit is:

2.8 o 2 + 5.6 o 2=16.8kW

Therefore, the capacity of PKFY-P25VAM-E and

PLFY-P50VLMD-E will be calculated as follows by

using the formula in 5-1-2. (1):

Model 25=14.6 o = 2.43kW

Model 50=14.6 o = 4.87kW

• The total model capacity of indoor unit is:

3.2 o 2 + 6.3 o 2=19.0

Therefore, the capacity of PKFY-P25VAM-E and PLFYP50VLMD-E will be calculated as follows by using the

formula in 5-1-2. (1):

Model 25=16.33 o = 2.75kW

Model 50=16.33 o = 5.41kW

2.8

16.8

5.6

16.8

6.3

19.0

3.2

19.0

(2) Sample calculation

1System assembled from indoor and outdoor unit (in this example the total capacity of the indoor units is greater than that of

the outdoor unit)

• Outdoor unit PUMY-P125YHM PUMY-P125YHM

1

• Indoor unit PKFY-P25VAM-E o 2 , PLFY-P50VLMD-E o 2

2According to the conditions in 1, the total capacity of the indoor unit will be: 28 o 2 + 56 o 2 = 168

3The following figures are obtained from the 168 total capacity row of the standard capacity diagram (5-2.):

Model 20

Model Number for indoor unit

Model Capacity

22

Model 15

17

Model 2528Model 3236Model 4045Model 5056Model 6371Model 7180Model 8090Model 100

112

Model 125

140

Model 140

160

Cooling

A 14.60

Heating

6.01

Cooling

6.59

Heating

3.95

Cooling

4.34

Heating

B 16.33

Capacity (kW)

Outdoor unit power consumption (kW)

Outdoor unit current (A)/400V

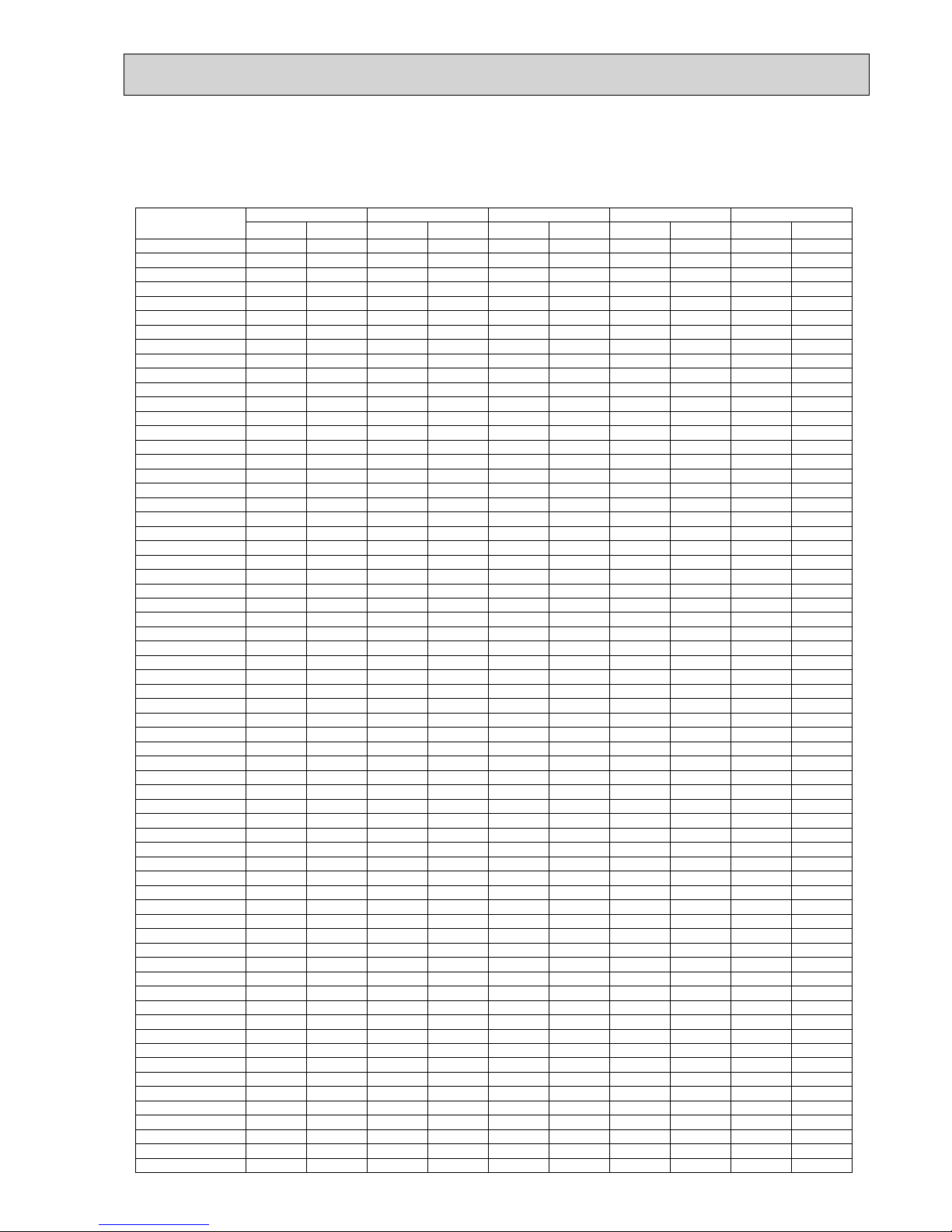

9

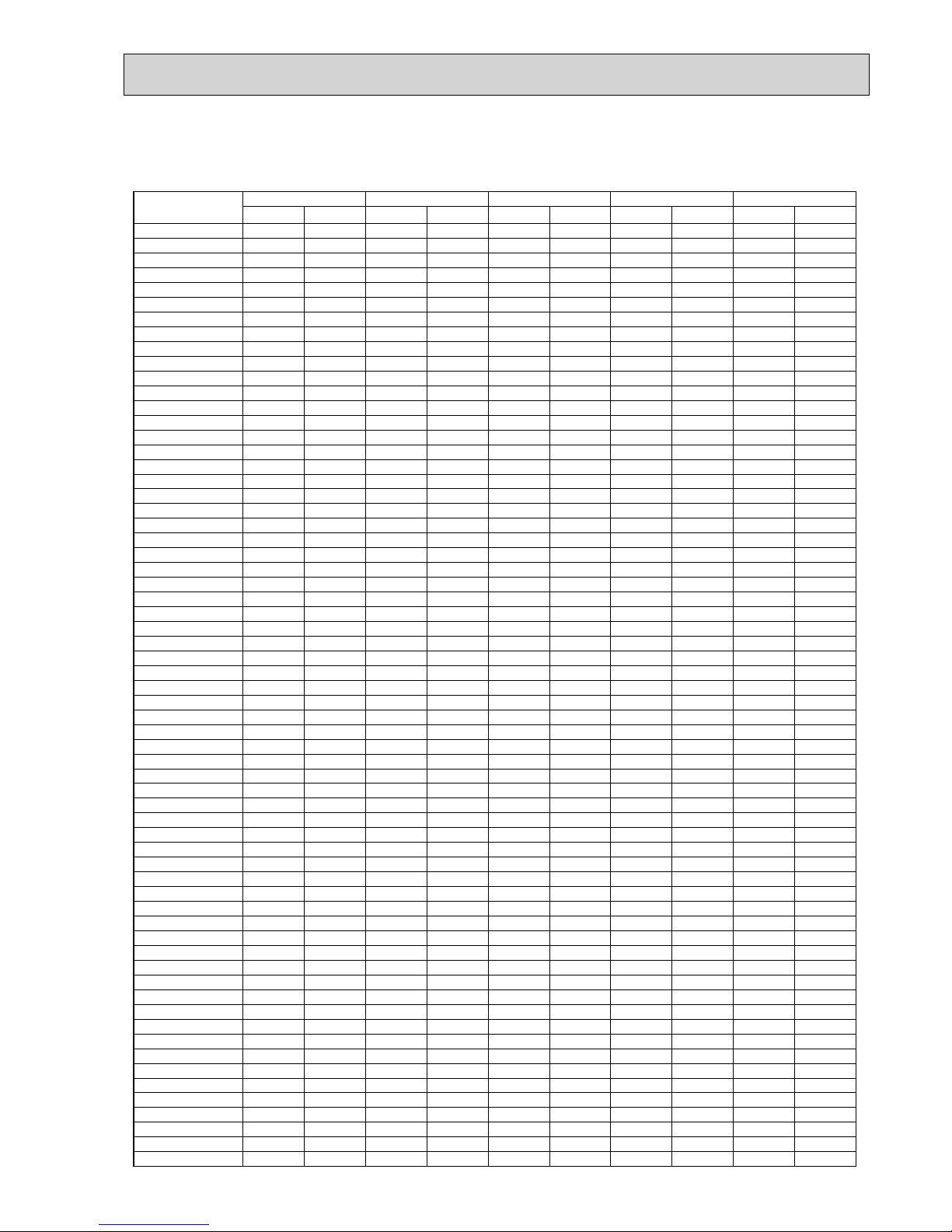

Total capacity of

Capacity(kW)

Power Consumption(kW)

Current(A)/380V Current(A)/400V Current(A)/415V

indoor units

*

Cooling Heating Cooling Heating Cooling Heating Cooling Heating Cooling Heating

56 5.60 6.30 1.57 1.87 2.52 3.00 2.39 2.85 2.31 2.75

57 5.70 6.41 1.59 1.90 2.55 3.05 2.42 2.89 2.34 2.79

58 5.80 6.53 1.62 1.92 2.60 3.08 2.47 2.93 2.38 2.82

59 5.90 6.64 1.64 1.95 2.63 3.13 2.50 2.97 2.41 2.86

60 6.00 6.75 1.66 1.98 2.66 3.17 2.53 3.02 2.44 2.91

61 6.10 6.87 1.69 2.00 2.71 3.21 2.58 3.05 2.48 2.94

62 6.20 6.98 1.71 2.03 2.74 3.26 2.61 3.09 2.51 2.98

63 6.30 7.09 1.74 2.06 2.79 3.30 2.65 3.14 2.56 3.02

64 6.40 7.20 1.76 2.08 2.82 3.34 2.68 3.17 2.59 3.05

65 6.50 7.32 1.78 2.11 2.85 3.38 2.71 3.21 2.61 3.10

66 6.60 7.43 1.81 2.14 2.90 3.43 2.76 3.26 2.66 3.14

67 6.70 7.54 1.83 2.17 2.93 3.48 2.79 3.31 2.69 3.19

68 6.80 7.66 1.86 2.20 2.98 3.53 2.83 3.35 2.73 3.23

69 6.90 7.77 1.89 2.22 3.03 3.56 2.88 3.38 2.78 3.26

70 7.00 7.88 1.91 2.25 3.06 3.61 2.91 3.43 2.81 3.30

71 7.10 8.00 1.94 2.28 3.11 3.66 2.96 3.47 2.85 3.35

72 7.20 8.11 1.97 2.31 3.16 3.70 3.00 3.52 2.89 3.39

73 7.30 8.22 1.99 2.34 3.19 3.75 3.03 3.56 2.92 3.44

74 7.40 8.33 2.02 2.37 3.24 3.80 3.08 3.61 2.97 3.48

75 7.50 8.44 2.05 2.40 3.28 3.85 3.12 3.66 3.01 3.52

76 7.60 8.56 2.08 2.43 3.33 3.90 3.17 3.70 3.05 3.57

77 7.70 8.67 2.11 2.46 3.38 3.94 3.21 3.75 3.10 3.61

78 7.80 8.78 2.13 2.49 3.41 3.99 3.24 3.79 3.13 3.66

79 7.90 8.89 2.16 2.52 3.46 4.04 3.29 3.84 3.17 3.70

80 8.00 9.00 2.19 2.55 3.51 4.09 3.34 3.88 3.22 3.74

81 8.10 9.10 2.22 2.58 3.56 4.14 3.38 3.93 3.26 3.79

82 8.20 9.20 2.25 2.61 3.60 4.18 3.43 3.97 3.30 3.83

83 8.30 9.30 2.28 2.64 3.65 4.23 3.47 4.02 3.35 3.88

84 8.40 9.40 2.31 2.67 3.70 4.28 3.52 4.07 3.39 3.92

85 8.50 9.50 2.35 2.70 3.76 4.33 3.58 4.11 3.45 3.96

86 8.60 9.60 2.38 2.74 3.81 4.39 3.62 4.17 3.49 4.02

87 8.70 9.70 2.41 2.77 3.86 4.44 3.67 4.22 3.54 4.07

88 8.80 9.80 2.44 2.80 3.91 4.49 3.72 4.26 3.58 4.11

89 8.90 9.90 2.47 2.83 3.96 4.54 3.76 4.31 3.63 4.15

90 9.00 10.00 2.51 2.86 4.02 4.58 3.82 4.35 3.68 4.20

91 9.10 10.10 2.54 2.90 4.07 4.65 3.87 4.42 3.73 4.26

92 9.20 10.22 2.57 2.93 4.12 4.70 3.91 4.46 3.77 4.30

93 9.30 10.33 2.60 2.96 4.16 4.74 3.96 4.51 3.82 4.34

94 9.40 10.45 2.64 3.00 4.23 4.81 4.02 4.57 3.88 4.40

95 9.50 10.56 2.67 3.03 4.28 4.86 4.07 4.61 3.92 4.45

96 9.60 10.67 2.71 3.06 4.34 4.90 4.13 4.66 3.98 4.49

97 9.70 10.79 2.74 3.10 4.39 4.97 4.17 4.72 4.02 4.55

98 9.80 10.90 2.78 3.13 4.45 5.02 4.23 4.77 4.08 4.59

99 9.90 11.02 2.81 3.17 4.50 5.08 4.28 4.83 4.12 4.65

100 10.00 11.13 2.85 3.20 4.56 5.13 4.34 4.87 4.18 4.70

101 10.10 11.24 2.88 3.24 4.61 5.19 4.39 4.93 4.23 4.75

102 10.20 11.36 2.92 3.27 4.67 5.24 4.45 4.98 4.29 4.80

103 10.30 11.47 2.96 3.31 4.74 5.30 4.51 5.04 4.34 4.86

104 10.40 11.59 2.99 3.34 4.79 5.35 4.55 5.08 4.39 4.90

105 10.50 11.70 3.03 3.38 4.85 5.42 4.61 5.15 4.45 4.96

106 10.60 11.81 3.07 3.41 4.91 5.46 4.67 5.19 4.51 5.00

107 10.70 11.93 3.11 3.45 4.98 5.53 4.74 5.25 4.56 5.06

108 10.80 12.04 3.14 3.48 5.03 5.58 4.78 5.30 4.61 5.11

109 10.90 12.16 3.18 3.52 5.09 5.64 4.84 5.36 4.67 5.17

110 11.00 12.27 3.22 3.56 5.15 5.70 4.90 5.42 4.73 5.22

111 11.10 12.38 3.26 3.59 5.22 5.75 4.96 5.47 4.78 5.27

112 11.20 12.50 3.30 3.63 5.28 5.81 5.02 5.52 4.84 5.32

113 11.22 12.51 3.31 3.62 5.30 5.80 5.04 5.51 4.86 5.31

114 11.24 12.53 3.31 3.61 5.30 5.78 5.04 5.50 4.86 5.30

115 11.26 12.54 3.32 3.60 5.31 5.77 5.05 5.48 4.87 5.28

116 11.28 12.55 3.32 3.59 5.31 5.75 5.05 5.47 4.87 5.27

117 11.30 12.56 3.32 3.58 5.31 5.74 5.05 5.45 4.87 5.25

118 11.32 12.57 3.33 3.56 5.33 5.70 5.07 5.42 4.89 5.22

119 11.34 12.58 3.33 3.55 5.33 5.69 5.07 5.40 4.89 5.21

120 11.36 12.60 3.34 3.54 5.35 5.67 5.08 5.39 4.90 5.19

5-2. STANDARD CAPACITY DIAGRAM

5-2-1.PUMY-P100YHM PUMY-P100YHM1 PUMY-P100YHMA (-BS)

*Before calculating the sum of total capacity of indoor units, please convert the value into the kW model capacity

following the formula on 5-1-1.

10

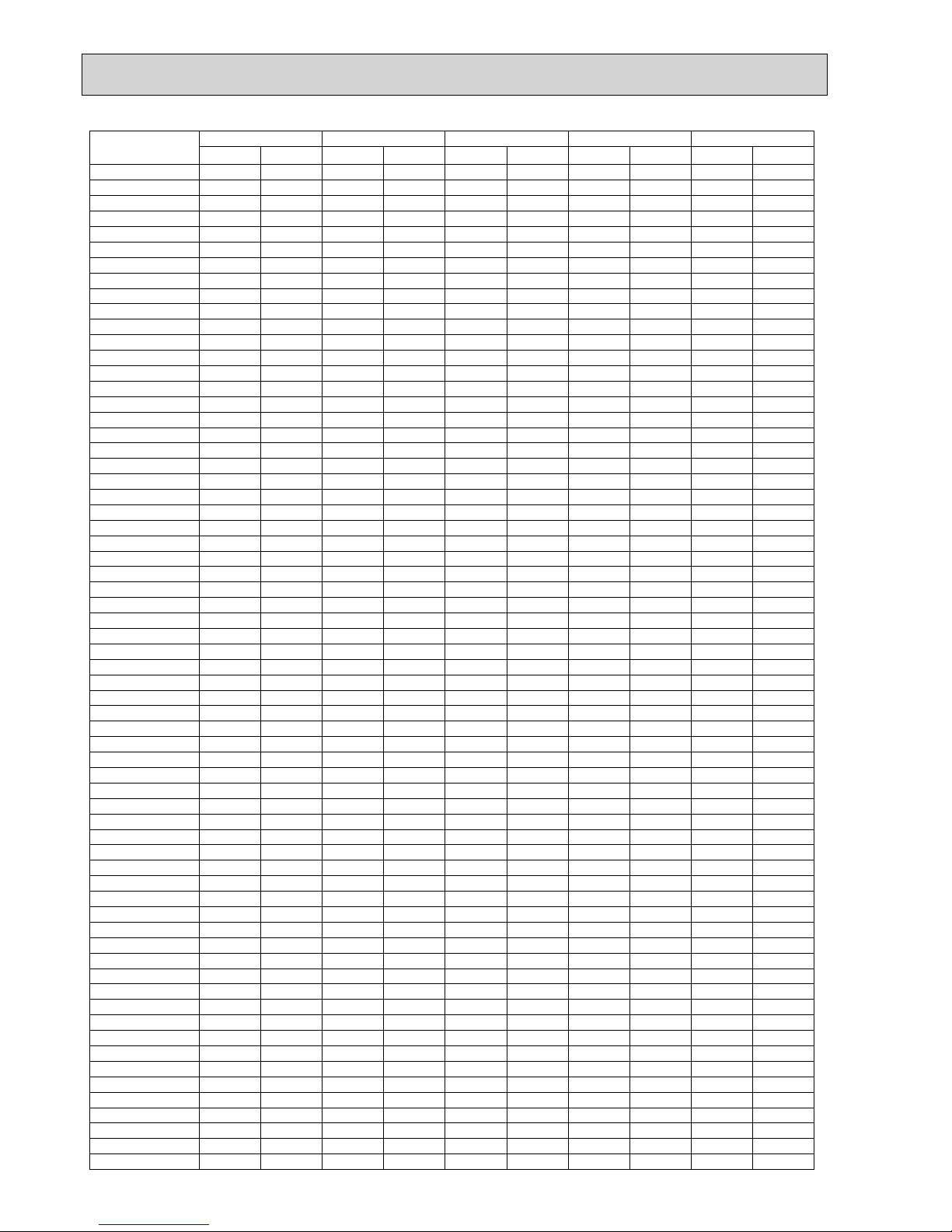

Total capacity of Capacity(kW)

Power Consumption(kW)

Current(A)/380V Current(A)/400V Current(A)/415V

indoor units

*

Cooling Heating Cooling Heating Cooling Heating Cooling Heating Cooling Heating

121 11.38 12.61 3.34 3.53 5.35 5.66 5.08 5.37 4.90 5.18

122 11.40 12.62 3.34 3.52 5.35 5.64 5.08 5.36 4.90 5.17

123 11.42 12.63 3.35 3.51 5.36 5.62 5.10 5.34 4.92 5.15

124 11.44 12.64 3.35 3.50 5.36 5.61 5.10 5.33 4.92 5.14

125 11.47 12.66 3.36 3.48 5.38 5.58 5.12 5.30 4.93 5.11

126 11.49 12.67 3.36 3.47 5.38 5.56 5.12 5.28 4.93 5.09

127 11.51 12.68 3.36 3.46 5.38 5.54 5.12 5.27 4.93 5.08

128 11.53 12.69 3.37 3.45 5.39 5.53 5.13 5.25 4.95 5.06

129 11.55 12.70 3.37 3.44 5.39 5.51 5.13 5.24 4.95 5.05

130 11.57 12.71 3.38 3.43 5.41 5.50 5.15 5.22 4.96 5.03

131 11.59 12.73 3.38 3.41 5.41 5.46 5.15 5.19 4.96 5.00

132 11.61 12.74 3.38 3.40 5.41 5.45 5.15 5.18 4.96 4.99

133 11.63 12.75 3.39 3.39 5.43 5.43 5.16 5.16 4.97 4.97

134 11.65 12.76 3.39 3.38 5.43 5.42 5.16 5.15 4.97 4.96

135 11.67 12.77 3.40 3.37 5.44 5.40 5.18 5.13 4.99 4.95

136 11.69 12.78 3.40 3.36 5.44 5.38 5.18 5.12 4.99 4.93

137 11.71 12.80 3.40 3.34 5.44 5.35 5.18 5.08 4.99 4.90

138 11.73 12.81 3.41 3.33 5.46 5.34 5.19 5.07 5.00 4.89

139 11.75 12.82 3.41 3.32 5.46 5.32 5.19 5.05 5.00 4.87

140 11.77 12.83 3.42 3.31 5.47 5.30 5.21 5.04 5.02 4.86

141 11.79 12.84 3.42 3.30 5.47 5.29 5.21 5.02 5.02 4.84

142 11.82 12.86 3.42 3.29 5.47 5.27 5.21 5.01 5.02 4.83

143 11.84 12.87 3.43 3.27 5.49 5.24 5.22 4.98 5.03 4.80

144 11.86 12.88 3.43 3.26 5.49 5.22 5.22 4.96 5.03 4.78

145 11.88 12.89 3.44 3.25 5.51 5.21 5.24 4.95 5.05 4.77

11

Total capacity of

Capacity(kW)

Power Consumption(kW)

Current(A)/380V Current(A)/400V Current(A)/415V

indoor units

*

Cooling Heating Cooling Heating Cooling Heating Cooling Heating Cooling Heating

70 7.00 7.88 1.80 2.04 2.88 3.27 2.74 3.10 2.64 3.00

71 7.10 8.00 1.83 2.06 2.93 3.30 2.79 3.13 2.69 3.02

72 7.20 8.11 1.85 2.09 2.96 3.35 2.82 3.18 2.72 3.07

73 7.30 8.22 1.88 2.11 3.01 3.38 2.86 3.21 2.76 3.10

74 7.40 8.33 1.91 2.14 3.06 3.43 2.91 3.26 2.81 3.14

75 7.50 8.44 1.93 2.17 3.09 3.48 2.94 3.30 2.83 3.19

76 7.60 8.56 1.96 2.19 3.14 3.51 2.98 3.33 2.88 3.22

77 7.70 8.67 1.99 2.22 3.19 3.56 3.03 3.38 2.92 3.26

78 7.80 8.78 2.01 2.25 3.22 3.61 3.06 3.42 2.95 3.30

79 7.90 8.89 2.04 2.28 3.27 3.66 3.10 3.47 3.00 3.35

80 8.00 9.00 2.07 2.30 3.32 3.69 3.15 3.50 3.04 3.38

81 8.10 9.10 2.10 2.33 3.36 3.74 3.20 3.55 3.08 3.42

82 8.20 9.20 2.12 2.36 3.40 3.78 3.23 3.59 3.11 3.46

83 8.30 9.30 2.15 2.39 3.44 3.83 3.27 3.64 3.16 3.51

84 8.40 9.40 2.18 2.42 3.49 3.88 3.32 3.68 3.20 3.55

85 8.50 9.50 2.21 2.44 3.54 3.91 3.36 3.71 3.24 3.58

86 8.60 9.60 2.24 2.47 3.59 3.96 3.41 3.76 3.29 3.63

87 8.70 9.70 2.27 2.50 3.64 4.01 3.45 3.80 3.33 3.67

88 8.80 9.80 2.30 2.53 3.68 4.06 3.50 3.85 3.38 3.71

89 8.90 9.90 2.33 2.56 3.73 4.10 3.55 3.89 3.42 3.76

90 9.00 10.00 2.36 2.59 3.78 4.15 3.59 3.94 3.46 3.80

91 9.10 10.10 2.39 2.62 3.83 4.20 3.64 3.99 3.51 3.85

92 9.20 10.22 2.42 2.65 3.88 4.25 3.68 4.03 3.55 3.89

93 9.30 10.33 2.45 2.68 3.92 4.30 3.73 4.08 3.60 3.93

94 9.40 10.45 2.49 2.71 3.99 4.34 3.79 4.12 3.66 3.98

95 9.50 10.56 2.52 2.74 4.04 4.39 3.83 4.17 3.70 4.02

96 9.60 10.67 2.55 2.77 4.08 4.44 3.88 4.21 3.74 4.07

97 9.70 10.79 2.58 2.80 4.13 4.49 3.92 4.26 3.79 4.11

98 9.80 10.90 2.62 2.83 4.20 4.54 3.99 4.30 3.85 4.15

99 9.90 11.02 2.65 2.86 4.24 4.58 4.03 4.35 3.89 4.20

100 10.00 11.13 2.68 2.89 4.29 4.63 4.08 4.40 3.93 4.24

101 10.10 11.24 2.72 2.92 4.36 4.68 4.14 4.44 3.99 4.29

102 10.20 11.36 2.75 2.96 4.40 4.74 4.18 4.50 4.04 4.34

103 10.30 11.47 2.79 2.99 4.47 4.79 4.24 4.55 4.10 4.39

104 10.40 11.59 2.82 3.02 4.52 4.84 4.29 4.59 4.14 4.43

105 10.50 11.70 2.86 3.05 4.58 4.89 4.35 4.64 4.20 4.48

106 10.60 11.81 2.89 3.08 4.63 4.94 4.40 4.68 4.24 4.52

107 10.70 11.93 2.93 3.12 4.69 5.00 4.46 4.75 4.30 4.58

108 10.80 12.04 2.96 3.15 4.74 5.05 4.50 4.79 4.34 4.62

109 10.90 12.16 3.00 3.18 4.80 5.10 4.56 4.84 4.40 4.67

110 11.00 12.27 3.04 3.21 4.87 5.14 4.62 4.88 4.46 4.71

111 11.10 12.38 3.07 3.25 4.91 5.21 4.67 4.94 4.51 4.77

112 11.20 12.50 3.11 3.28 4.98 5.26 4.73 4.99 4.56 4.81

113 11.30 12.63 3.15 3.31 5.04 5.30 4.79 5.03 4.62 4.86

114 11.40 12.75 3.19 3.35 5.11 5.37 4.85 5.09 4.68 4.92

115 11.50 12.88 3.22 3.38 5.15 5.42 4.90 5.14 4.73 4.96

116 11.60 13.00 3.26 3.42 5.22 5.48 4.96 5.20 4.78 5.02

117 11.70 13.13 3.30 3.45 5.28 5.53 5.02 5.25 4.84 5.06

118 11.80 13.25 3.34 3.49 5.35 5.59 5.08 5.31 4.90 5.12

119 11.90 13.38 3.38 3.52 5.41 5.64 5.14 5.35 4.96 5.17

120 12.00 13.50 3.42 3.55 5.47 5.69 5.20 5.40 5.02 5.21

121 12.10 13.63 3.46 3.59 5.54 5.75 5.26 5.46 5.08 5.27

122 12.20 13.75 3.50 3.62 5.60 5.80 5.32 5.51 5.14 5.31

123 12.30 13.88 3.54 3.66 5.67 5.86 5.38 5.57 5.19 5.37

124 12.40 14.00 3.58 3.70 5.73 5.93 5.44 5.63 5.25 5.43

125 12.50 14.13 3.62 3.73 5.79 5.98 5.51 5.67 5.31 5.47

126 12.60 14.25 3.66 3.77 5.86 6.04 5.57 5.73 5.37 5.53

127 12.70 14.38 3.70 3.80 5.92 6.09 5.63 5.78 5.43 5.58

128 12.80 14.50 3.74 3.84 5.99 6.15 5.69 5.84 5.49 5.63

129 12.90 14.63 3.79 3.88 6.07 6.22 5.76 5.90 5.56 5.69

130 13.00 14.75 3.83 3.91 6.13 6.26 5.82 5.95 5.62 5.74

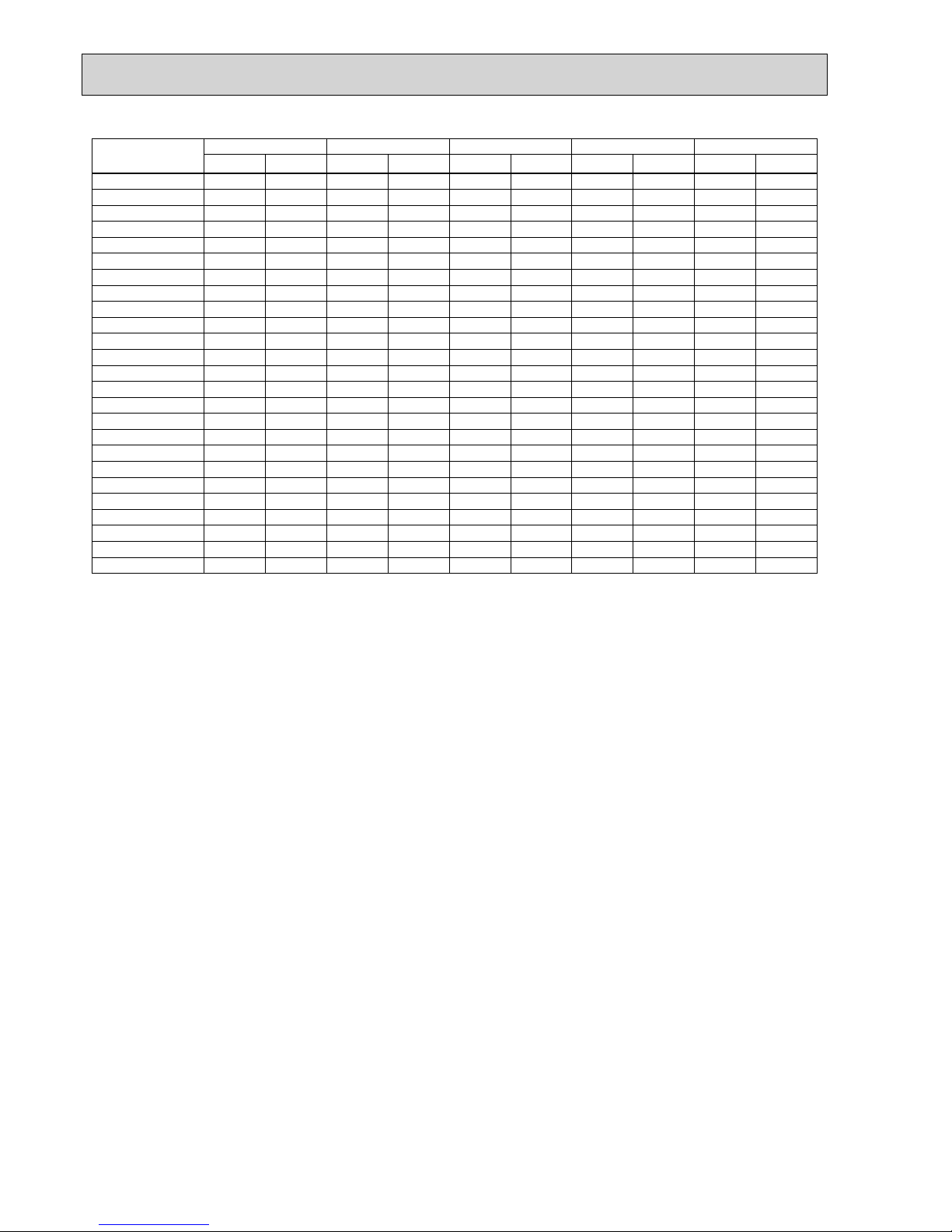

5-2-2.PUMY-P125YHM PUMY-P125YHM1 PUMY-P125YHMA (-BS)

*Before calculating the sum of total capacity of indoor units, please convert the value into the kW model capacity

following the formula on 5-1-1.

12

Total capacity of

Capacity(kW)

Power Consumption(kW)

Current(A)/380V Current(A)/400V Current(A)/415V

indoor units

*

Cooling Heating Cooling Heating Cooling Heating Cooling Heating Cooling Heating

131 13.10 14.88 3.87 3.95 6.19 6.33 5.88 6.01 5.68 5.80

132 13.20 15.00 3.91 3.99 6.26 6.39 5.95 6.07 5.74 5.85

133 13.30 15.13 3.96 4.02 6.34 6.44 6.02 6.11 5.81 5.90

134 13.40 15.25 4.00 4.06 6.40 6.51 6.08 6.17 5.87 5.96

135 13.50 15.38 4.04 4.10 6.47 6.57 6.14 6.23 5.93 6.02

136 13.60 15.50 4.09 4.14 6.55 6.63 6.22 6.30 6.00 6.07

137 13.70 15.63 4.13 4.17 6.61 6.68 6.28 6.34 6.06 6.12

138 13.80 15.75 4.18 4.21 6.69 6.75 6.36 6.40 6.13 6.18

139 13.90 15.88 4.22 4.25 6.75 6.81 6.42 6.46 6.19 6.24

140 14.00 16.00 4.27 4.29 6.83 6.87 6.49 6.52 6.26 6.29

141 14.02 16.01 4.28 4.28 6.84 6.86 6.50 6.51 6.27 6.28

142 14.04 16.02 4.28 4.27 6.85 6.84 6.50 6.49 6.28 6.26

143 14.06 16.03 4.28 4.26 6.85 6.82 6.51 6.47 6.28 6.24

144 14.08 16.04 4.28 4.24 6.85 6.80 6.51 6.45 6.28 6.23

145 14.10 16.06 4.28 4.23 6.86 6.78 6.51 6.43 6.29 6.21

146 14.12 16.07 4.29 4.22 6.86 6.76 6.52 6.42 6.29 6.19

147 14.15 16.08 4.29 4.21 6.86 6.74 6.52 6.40 6.29 6.17

148 14.17 16.09 4.29 4.19 6.87 6.72 6.52 6.38 6.29 6.15

149 14.19 16.10 4.29 4.18 6.87 6.70 6.53 6.36 6.30 6.14

150 14.21 16.12 4.30 4.17 6.87 6.68 6.53 6.34 6.30 6.12

151 14.23 16.13 4.30 4.16 6.88 6.66 6.53 6.32 6.30 6.10

152 14.25 16.14 4.30 4.15 6.88 6.64 6.54 6.31 6.31 6.08

153 14.27 16.15 4.30 4.13 6.88 6.62 6.54 6.29 6.31 6.07

154 14.30 16.16 4.30 4.12 6.89 6.61 6.54 6.27 6.31 6.05

155 14.32 16.17 4.31 4.11 6.89 6.59 6.55 6.25 6.32 6.03

156 14.34 16.19 4.31 4.10 6.90 6.57 6.55 6.23 6.32 6.01

157 14.36 16.20 4.31 4.09 6.90 6.55 6.55 6.21 6.32 6.00

158 14.38 16.21 4.31 4.07 6.90 6.53 6.56 6.20 6.33 5.98

159 14.40 16.22 4.32 4.06 6.91 6.51 6.56 6.18 6.33 5.96

160 14.42 16.23 4.32 4.05 6.91 6.49 6.56 6.16 6.33 5.94

161 14.45 16.25 4.32 4.04 6.91 6.47 6.57 6.14 6.34 5.92

162 14.47 16.26 4.32 4.03 6.92 6.45 6.57 6.12 6.34 5.91

163 14.49 16.27 4.32 4.01 6.92 6.43 6.57 6.10 6.34 5.89

164 14.51 16.28 4.33 4.00 6.92 6.41 6.58 6.09 6.35 5.87

165 14.53 16.29 4.33 3.99 6.93 6.39 6.58 6.07 6.35 5.85

166 14.55 16.31 4.33 3.98 6.93 6.37 6.58 6.05 6.35 5.84

167 14.57 16.32 4.33 3.97 6.93 6.35 6.59 6.03 6.36 5.82

168 14.60 16.33 4.34 3.95 6.94 6.33 6.59 6.01 6.36 5.80

169 14.62 16.34 4.34 3.94 6.94 6.32 6.59 5.99 6.36 5.78

170 14.64 16.35 4.34 3.93 6.95 6.30 6.60 5.98 6.37 5.77

171 14.66 16.36 4.34 3.92 6.95 6.28 6.60 5.96 6.37 5.75

172 14.68 16.38 4.34 3.91 6.95 6.26 6.61 5.94 6.37 5.73

173 14.70 16.39 4.35 3.89 6.96 6.24 6.61 5.92 6.38 5.71

174 14.72 16.40 4.35 3.88 6.96 6.22 6.61 5.90 6.38 5.69

175 14.75 16.41 4.35 3.87 6.96 6.20 6.62 5.88 6.38 5.68

176 14.77 16.42 4.35 3.86 6.97 6.18 6.62 5.87 6.39 5.66

177 14.79 16.44 4.36 3.84 6.97 6.16 6.62 5.85 6.39 5.64

178 14.81 16.45 4.36 3.83 6.97 6.14 6.63 5.83 6.39 5.62

179 14.83 16.46 4.36 3.82 6.98 6.12 6.63 5.81 6.40 5.61

180 14.85 16.47 4.36 3.81 6.98 6.10 6.63 5.79 6.40 5.59

181 14.87 16.48 4.36 3.80 6.98 6.08 6.64 5.77 6.40 5.57

182 14.89 16.50 4.37 3.78 6.99 6.06 6.64 5.76 6.41 5.55

13

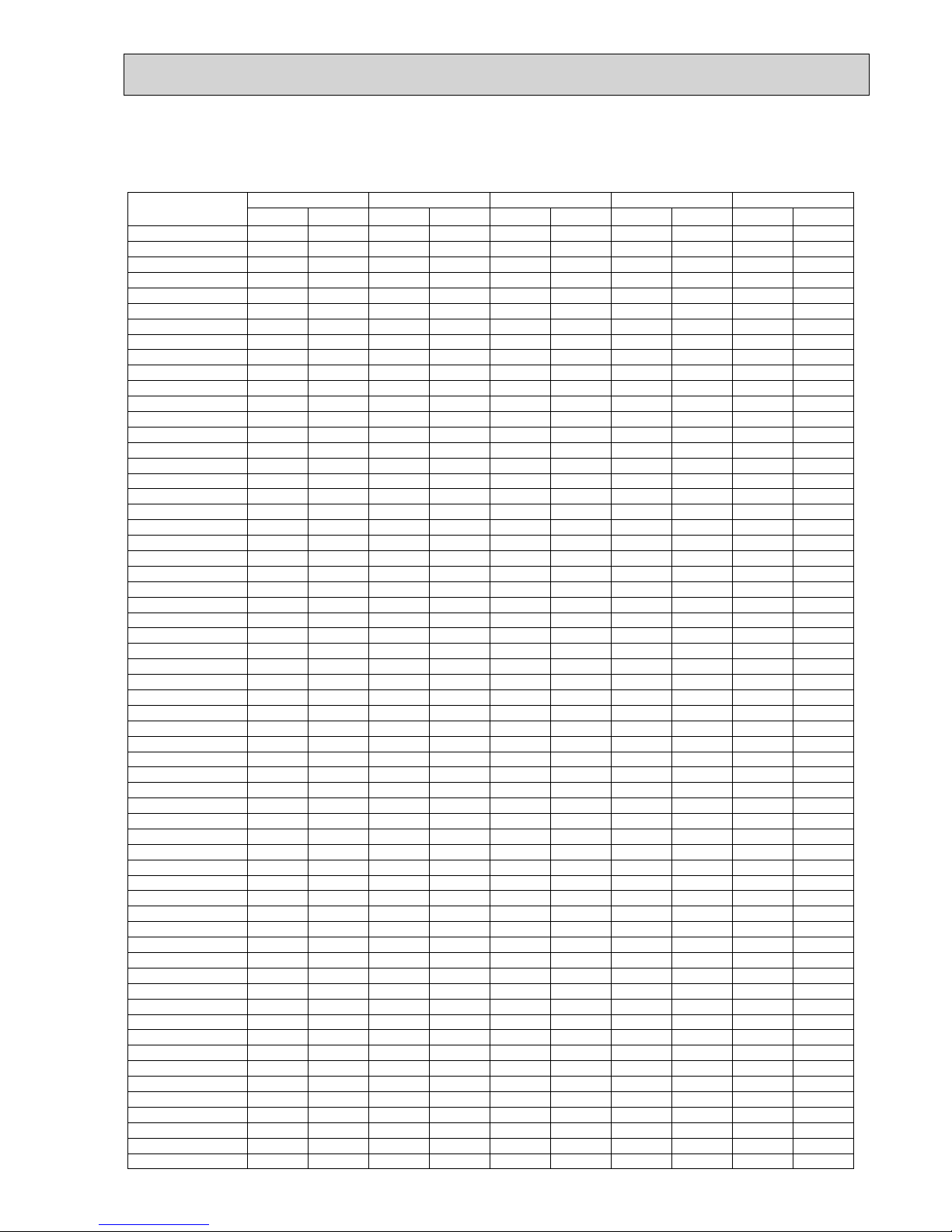

Total capacity of

Capacity(kW)

Power Consumption(kW)

Current(A)/380V Current(A)/400V Current(A)/415V

indoor units

*

Cooling Heating Cooling Heating Cooling Heating Cooling Heating Cooling Heating

80 8.00 9.00 2.34 2.73 3.75 4.37 3.56 4.16 3.44 4.01

81 8.10 9.10 2.37 2.76 3.80 4.42 3.61 4.20 3.48 4.05

82 8.20 9.20 2.40 2.79 3.84 4.47 3.66 4.25 3.52 4.10

83 8.30 9.30 2.43 2.82 3.89 4.52 3.70 4.29 3.57 4.14

84 8.40 9.40 2.46 2.86 3.94 4.58 3.75 4.35 3.61 4.20

85 8.50 9.50 2.49 2.89 3.99 4.63 3.79 4.40 3.66 4.24

86 8.60 9.60 2.53 2.92 4.05 4.67 3.85 4.45 3.71 4.29

87 8.70 9.70 2.56 2.95 4.10 4.72 3.90 4.49 3.76 4.33

88 8.80 9.80 2.59 2.98 4.15 4.77 3.94 4.54 3.80 4.37

89 8.90 9.90 2.62 3.01 4.20 4.82 3.99 4.58 3.85 4.42

90 9.00 10.00 2.66 3.04 4.26 4.87 4.05 4.63 3.90 4.46

91 9.10 10.11 2.69 3.08 4.31 4.93 4.10 4.69 3.95 4.52

92 9.20 10.23 2.72 3.11 4.36 4.98 4.14 4.74 3.99 4.56

93 9.30 10.34 2.76 3.14 4.42 5.03 4.20 4.78 4.05 4.61

94 9.40 10.46 2.79 3.17 4.47 5.07 4.25 4.83 4.10 4.65

95 9.50 10.57 2.83 3.21 4.53 5.14 4.31 4.89 4.15 4.71

96 9.60 10.68 2.86 3.24 4.58 5.19 4.35 4.93 4.20 4.75

97 9.70 10.80 2.89 3.27 4.63 5.23 4.40 4.98 4.24 4.80

98 9.80 10.91 2.93 3.30 4.69 5.28 4.46 5.02 4.30 4.84

99 9.90 11.03 2.97 3.34 4.75 5.35 4.52 5.08 4.36 4.90

100 10.00 11.14 3.00 3.37 4.80 5.39 4.57 5.13 4.40 4.95

101 10.10 11.25 3.04 3.40 4.87 5.44 4.63 5.18 4.46 4.99

102 10.20 11.37 3.07 3.43 4.91 5.49 4.67 5.22 4.51 5.03

103 10.30 11.48 3.11 3.47 4.98 5.55 4.74 5.28 4.56 5.09

104 10.40 11.60 3.14 3.50 5.03 5.60 4.78 5.33 4.61 5.14

105 10.50 11.71 3.18 3.53 5.09 5.65 4.84 5.37 4.67 5.18

106 10.60 11.82 3.22 3.57 5.15 5.71 4.90 5.43 4.73 5.24

107 10.70 11.94 3.26 3.60 5.22 5.76 4.96 5.48 4.78 5.28

108 10.80 12.05 3.29 3.63 5.27 5.81 5.01 5.53 4.83 5.33

109 10.90 12.17 3.33 3.67 5.33 5.87 5.07 5.59 4.89 5.39

110 11.00 12.28 3.37 3.70 5.39 5.92 5.13 5.63 4.95 5.43

111 11.10 12.39 3.41 3.74 5.46 5.99 5.19 5.69 5.00 5.49

112 11.20 12.51 3.45 3.77 5.52 6.03 5.25 5.74 5.06 5.53

113 11.30 12.63 3.48 3.80 5.57 6.08 5.30 5.78 5.11 5.58

114 11.40 12.75 3.52 3.84 5.63 6.15 5.36 5.85 5.17 5.63

115 11.50 12.88 3.56 3.87 5.70 6.19 5.42 5.89 5.22 5.68

116 11.60 13.00 3.60 3.91 5.76 6.26 5.48 5.95 5.28 5.74

117 11.70 13.13 3.64 3.94 5.83 6.31 5.54 6.00 5.34 5.78

118 11.80 13.25 3.68 3.98 5.89 6.37 5.60 6.06 5.40 5.84

119 11.90 13.38 3.72 4.01 5.95 6.42 5.66 6.10 5.46 5.88

120 12.00 13.50 3.76 4.05 6.02 6.48 5.72 6.16 5.52 5.94

121 12.10 13.63 3.80 4.08 6.08 6.53 5.78 6.21 5.58 5.99

122 12.20 13.75 3.84 4.12 6.15 6.59 5.85 6.27 5.63 6.04

123 12.30 13.88 3.88 4.15 6.21 6.64 5.91 6.32 5.69 6.09

124 12.40 14.00 3.92 4.19 6.27 6.71 5.97 6.38 5.75 6.15

125 12.50 14.13 3.97 4.22 6.35 6.75 6.04 6.42 5.82 6.19

126 12.60 14.25 4.01 4.26 6.42 6.82 6.10 6.48 5.88 6.25

127 12.70 14.38 4.05 4.29 6.48 6.87 6.16 6.53 5.94 6.29

128 12.80 14.50 4.09 4.33 6.55 6.93 6.23 6.59 6.00 6.35

129 12.90 14.63 4.13 4.36 6.61 6.98 6.29 6.64 6.06 6.40

130 13.00 14.75 4.18 4.40 6.69 7.04 6.36 6.70 6.13 6.46

131 13.10 14.88 4.22 4.44 6.75 7.11 6.42 6.76 6.19 6.51

132 13.20 15.00 4.26 4.47 6.82 7.15 6.48 6.80 6.25 6.56

133 13.30 15.13 4.31 4.51 6.90 7.22 6.56 6.86 6.32 6.62

134 13.40 15.25 4.35 4.54 6.96 7.27 6.62 6.91 6.38 6.66

135 13.50 15.38 4.39 4.58 7.03 7.33 6.68 6.97 6.44 6.72

136 13.60 15.50 4.44 4.62 7.11 7.39 6.76 7.03 6.51 6.78

137 13.70 15.63 4.48 4.65 7.17 7.44 6.82 7.08 6.57 6.82

138 13.80 15.75 4.53 4.69 7.25 7.51 6.89 7.14 6.65 6.88

139 13.90 15.88 4.57 4.73 7.31 7.57 6.96 7.20 6.70 6.94

140 14.00 16.00 4.62 4.76 7.39 7.62 7.03 7.24 6.78 6.98

141 14.10 16.13 4.66 4.80 7.46 7.68 7.09 7.31 6.84 7.04

142 14.20 16.26 4.71 4.84 7.54 7.75 7.17 7.37 6.91 7.10

143 14.30 16.40 4.76 4.87 7.62 7.79 7.24 7.41 6.98 7.14

5-2-3.PUMY-P140YHM PUMY-P140YHM1 PUMY-P140YHMA (-BS)

*Before calculating the sum of total capacity of indoor units, please convert the value into the kW model capacity

following the formula on 5-1-1.

14

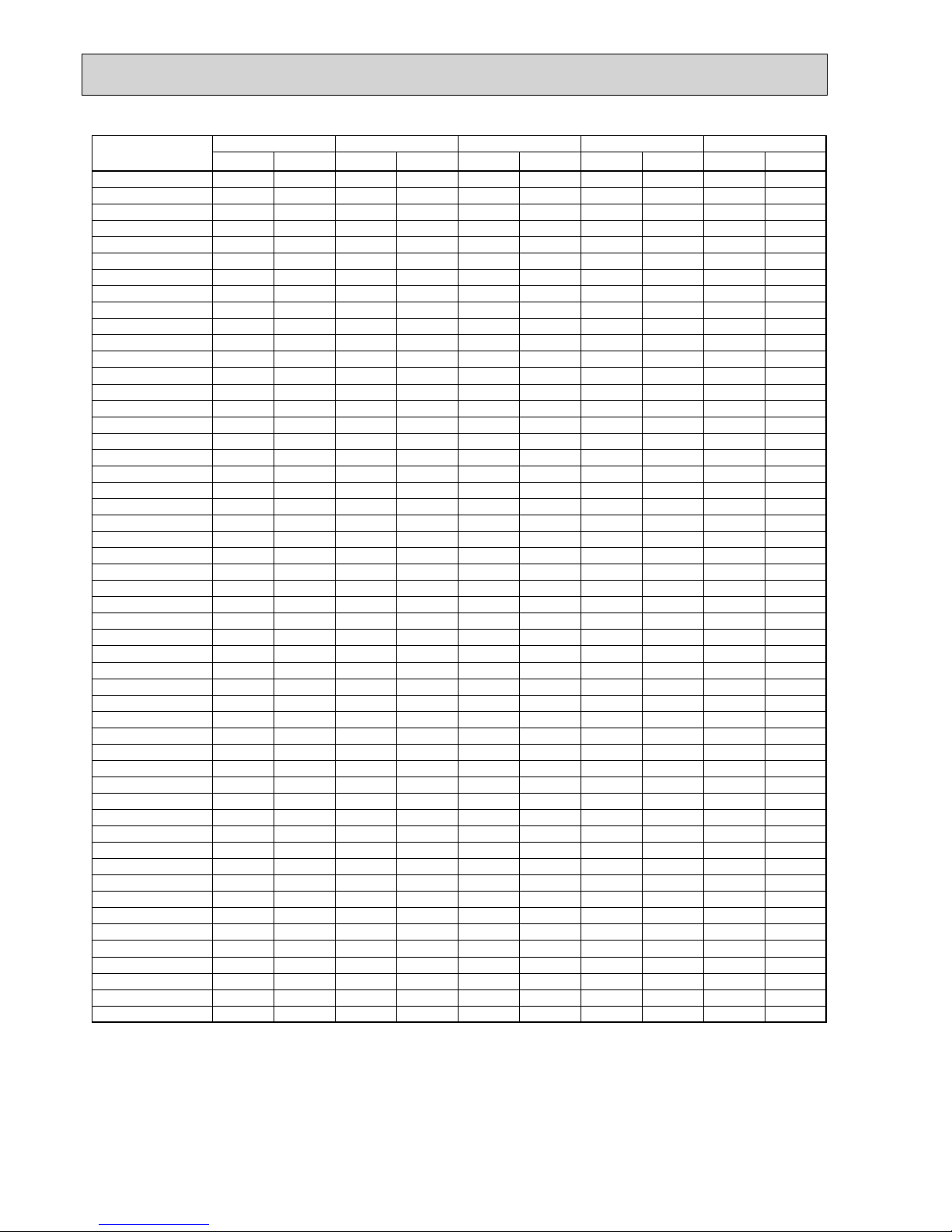

Total capacity of

Capacity(kW)

Power Consumption(kW)

Current(A)/380V Current(A)/400V Current(A)/415V

indoor units

*

Cooling Heating Cooling Heating Cooling Heating Cooling Heating Cooling Heating

144 14.40 16.53 4.80 4.91 7.68 7.86 7.31 7.47 7.04 7.20

145 14.50 16.66 4.85 4.95 7.76 7.92 7.38 7.53 7.11 7.26

146 14.60 16.80 4.89 4.99 7.83 7.99 7.44 7.59 7.17 7.32

147 14.70 16.93 4.94 5.02 7.91 8.03 7.52 7.64 7.25 7.36

148 14.80 17.06 4.99 5.06 7.99 8.10 7.59 7.70 7.32 7.42

149 14.90 17.20 5.04 5.10 8.07 8.16 7.67 7.76 7.39 7.48

150 15.00 17.33 5.08 5.14 8.13 8.23 7.73 7.82 7.45 7.54

151 15.10 17.46 5.13 5.17 8.21 8.27 7.81 7.87 7.53 7.58

152 15.20 17.60 5.18 5.21 8.29 8.34 7.88 7.93 7.60 7.64

153 15.30 17.73 5.23 5.25 8.37 8.40 7.96 7.99 7.67 7.70

154 15.40 17.86 5.28 5.29 8.45 8.47 8.04 8.05 7.75 7.76

155 15.50 18.00 5.32 5.32 8.51 8.51 8.09 8.09 7.80 7.80

156 15.51 18.01 5.32 5.31 8.52 8.49 8.10 8.08 7.81 7.79

157 15.52 18.02 5.32 5.29 8.52 8.47 8.10 8.06 7.81 7.77

158 15.54 18.04 5.33 5.28 8.52 8.45 8.11 8.04 7.81 7.74

159 15.55 18.05 5.33 5.27 8.53 8.43 8.11 8.01 7.82 7.72

160 15.57 18.06 5.33 5.25 8.53 8.40 8.12 7.99 7.82 7.70

161 15.58 18.07 5.34 5.24 8.54 8.38 8.12 7.97 7.83 7.68

162 15.60 18.09 5.34 5.22 8.54 8.36 8.12 7.95 7.83 7.66

163 15.61 18.10 5.34 5.21 8.55 8.34 8.13 7.93 7.83 7.64

164 15.62 18.11 5.34 5.20 8.55 8.32 8.13 7.91 7.84 7.62

165 15.64 18.12 5.35 5.18 8.56 8.29 8.14 7.89 7.84 7.60

166 15.65 18.14 5.35 5.17 8.56 8.27 8.14 7.87 7.85 7.58

167 15.67 18.15 5.35 5.16 8.56 8.25 8.14 7.85 7.85 7.56

168 15.68 18.16 5.35 5.14 8.57 8.23 8.15 7.83 7.85 7.54

169 15.70 18.17 5.36 5.13 8.57 8.21 8.15 7.80 7.86 7.52

170 15.71 18.19 5.36 5.11 8.58 8.18 8.16 7.78 7.86 7.50

171 15.73 18.20 5.36 5.10 8.58 8.16 8.16 7.76 7.87 7.48

172 15.74 18.21 5.37 5.09 8.59 8.14 8.17 7.74 7.87 7.46

173 15.76 18.22 5.37 5.07 8.59 8.12 8.17 7.72 7.87 7.44

174 15.77 18.24 5.37 5.06 8.59 8.10 8.17 7.70 7.88 7.42

175 15.79 18.25 5.37 5.05 8.60 8.07 8.18 7.68 7.88 7.40

176 15.80 18.26 5.38 5.03 8.60 8.05 8.18 7.66 7.89 7.38

177 15.81 18.27 5.38 5.02 8.61 8.03 8.19 7.64 7.89 7.36

178 15.83 18.29 5.38 5.00 8.61 8.01 8.19 7.62 7.89 7.34

179 15.84 18.30 5.38 4.99 8.62 7.99 8.19 7.59 7.90 7.32

180 15.86 18.31 5.39 4.98 8.62 7.96 8.20 7.57 7.90 7.30

181 15.87 18.32 5.39 4.96 8.63 7.94 8.20 7.55 7.91 7.28

182 15.89 18.34 5.39 4.95 8.63 7.92 8.21 7.53 7.91 7.26

183 15.90 18.35 5.40 4.94 8.63 7.90 8.21 7.51 7.91 7.24

184 15.92 18.36 5.40 4.92 8.64 7.88 8.22 7.49 7.92 7.22

185 15.93 18.37 5.40 4.91 8.64 7.85 8.22 7.47 7.92 7.20

186 15.95 18.39 5.40 4.89 8.65 7.83 8.22 7.45 7.93 7.18

187 15.96 18.40 5.41 4.88 8.65 7.81 8.23 7.43 7.93 7.16

188 15.97 18.41 5.41 4.87 8.66 7.79 8.23 7.41 7.93 7.14

189 15.99 18.42 5.41 4.85 8.66 7.77 8.24 7.39 7.94 7.12

190 16.00 18.44 5.41 4.84 8.66 7.74 8.24 7.36 7.94 7.10

191 16.02 18.45 5.42 4.82 8.67 7.72 8.24 7.34 7.95 7.08

192 16.03 18.46 5.42 4.81 8.67 7.70 8.25 7.32 7.95 7.06

193 16.05 18.47 5.42 4.80 8.68 7.68 8.25 7.30 7.95 7.04

194 16.06 18.49 5.43 4.78 8.68 7.66 8.26 7.28 7.96 7.02

195 16.08 18.50 5.43 4.77 8.69 7.63 8.26 7.26 7.96 7.00

196 16.09 18.51 5.43 4.76 8.69 7.61 8.27 7.24 7.97 6.98

197 16.11 18.52 5.43 4.74 8.70 7.59 8.27 7.22 7.97 6.96

198 16.12 18.54 5.44 4.73 8.70 7.57 8.27 7.20 7.97 6.94

199 16.14 18.55 5.44 4.71 8.70 7.54 8.28 7.18 7.98 6.92

200 16.15 18.56 5.44 4.70 8.71 7.52 8.28 7.15 7.98 6.90

201 16.16 18.57 5.44 4.69 8.71 7.50 8.29 7.13 7.99 6.88

202 16.18 18.59 5.45 4.67 8.72 7.48 8.29 7.11 7.99 6.86

203 16.19 18.60 5.45 4.66 8.72 7.46 8.29 7.09 7.99 6.84

204 16.21 18.61 5.45 4.65 8.73 7.43 8.30 7.07 8.00 6.82

205 16.22 18.62 5.46 4.63 8.73 7.41 8.30 7.05 8.00 6.79

206 16.24 18.64 5.46 4.62 8.73 7.39 8.31 7.03 8.01 6.77

207 16.25 18.65 5.46 4.60 8.74 7.37 8.31 7.01 8.01 6.75

208 16.27 18.66 5.46 4.59 8.74 7.35 8.31 6.99 8.01 6.73

15

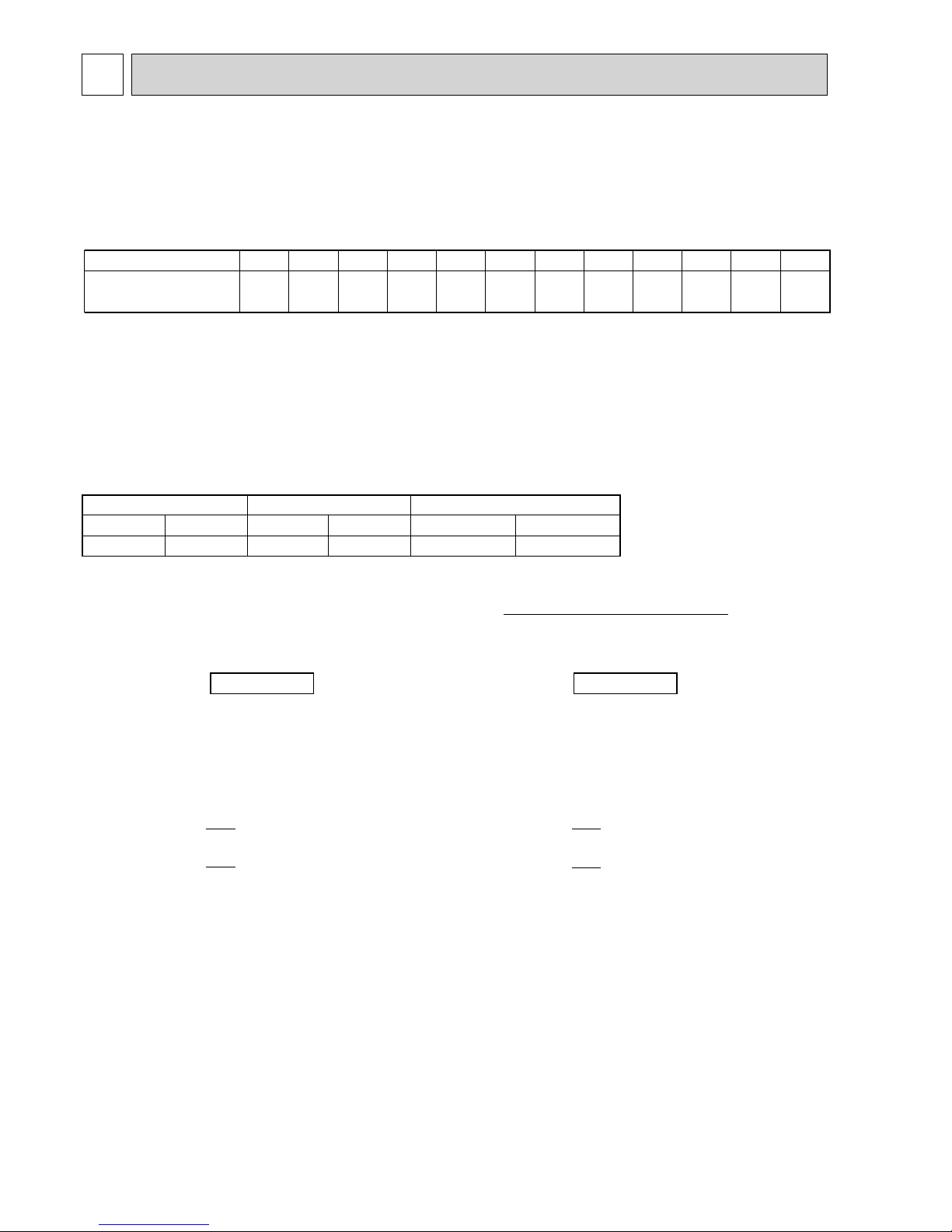

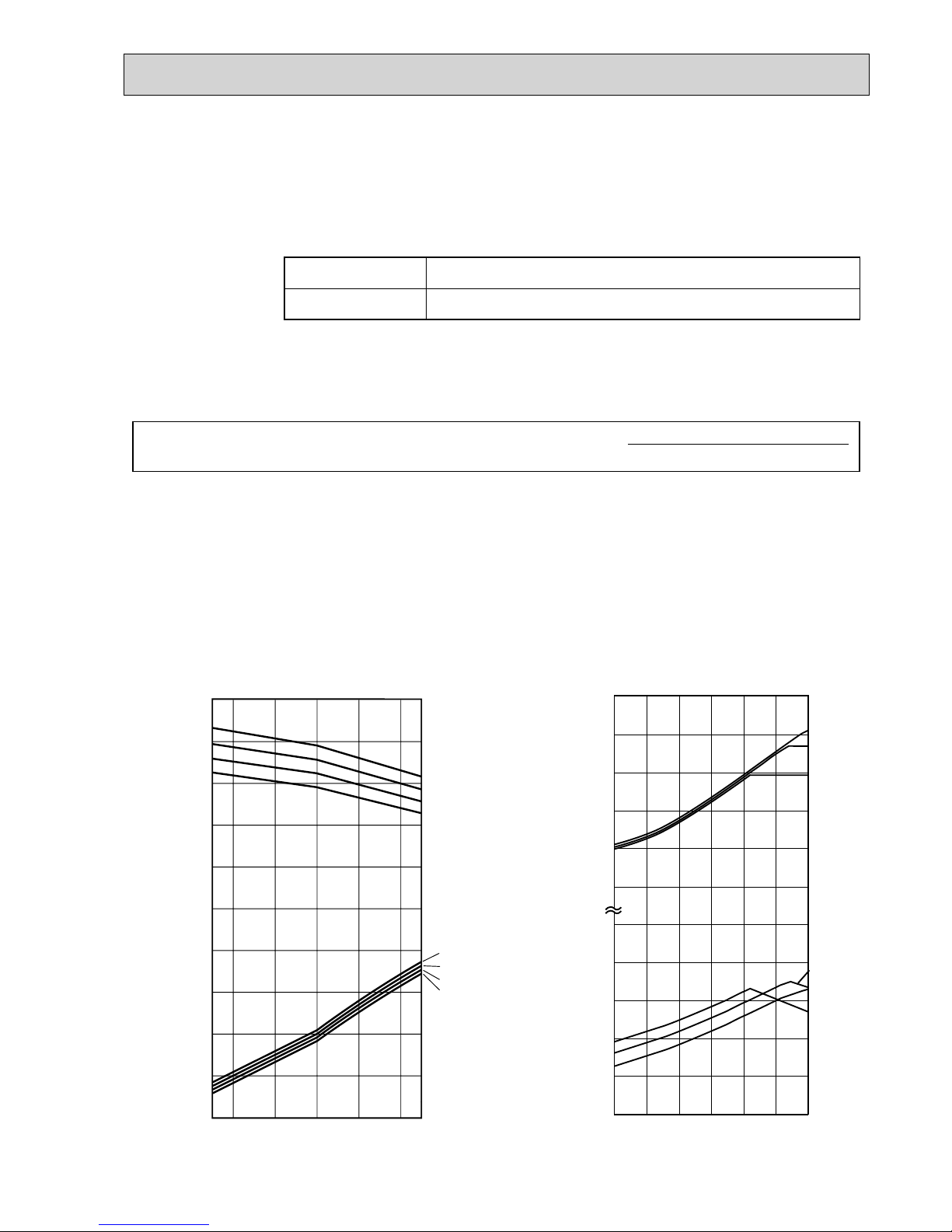

5-3. CORRECTING COOLING AND HEATING CAPACITY

5-3-1. Correcting Changes in Air Conditions

(1)The performance curve charts (Figure 1, 2) show the change ratio of capacity and input (power consumption) according to the

indoor and outdoor temperature condition when defining the rated capacity (total capacity) and rated input under the standard

condition in standard piping length (5m) as “1.0”.

• Standard conditions:

• Use the rated capacity and rated input given in “5-2.”.

• The input is the single value on the side of the outdoor unit; the input on the sides of each indoor unit must be

added to obtain the total input.

(2)The capacity of each indoor unit may be obtained by multiplying the total capacity obtained in (1) by the ratio between the

individual capacity at the rated time and the total capacity at the rated time.

individual capacity at the rated time

Individual capacity under stated conditions = total capacity under the stated conditions o

total capacity at the rated time

Rated cooling capacity

Rated heating capacity

Indoor D.B. 27˚C / W.B. 19˚C

Outdoor D.B. 35˚C

Indoor D.B. 20˚C

Outdoor D.B. 7˚C / W.B. 6˚C

0.4

-5 0 10 20 30 40 46

0.6

0.8

1.0

1.2

1.4

0.6

0.8

1.0

1.2

1.4

22

20

18

16

22

20

18

16

Cooling performance curve

0.6

0.4

0.8

1.0

1.2

1.4

0.4

0.6

0.8

1.0

1.2

1.4

-10-15 -5 0 5 10 15

20

25

15

20

25

15

Heating performance curve

Cooling

Capacity

(ratio)

Cooling

Power

consumption

(ratio)

Heating

Power

consumption

(ratio)

Heating

Capacity

(ratio)

INDOOR

<D.B. :>

INDOOR

<W.B. :>

INDOOR

<W.B. :>

INDOOR

<D.B. :>

Outdoor <D.B. :>

Outdoor <W.B. :>

Figure 2.

PUMY-P100YHM PUMY-P100YHM1 PUMY-P100YHMA(-BS)

PUMY-P125YHM PUMY-P125YHM

1 PUMY-P125YHMA(-BS)

PUMY-P140YHM PUMY-P140YHM

1 PUMY-P140YHMA(-BS)

(3)Capacity correction factor curve

Figure 1.

PUMY-P100YHM PUMY-P100YHM1 PUMY-P100YHMA(-BS)

PUMY-P125YHM PUMY-P125YHM

1 PUMY-P125YHMA(-BS)

PUMY-P140YHM PUMY-P140YHM

1 PUMY-P140YHMA(-BS)

16

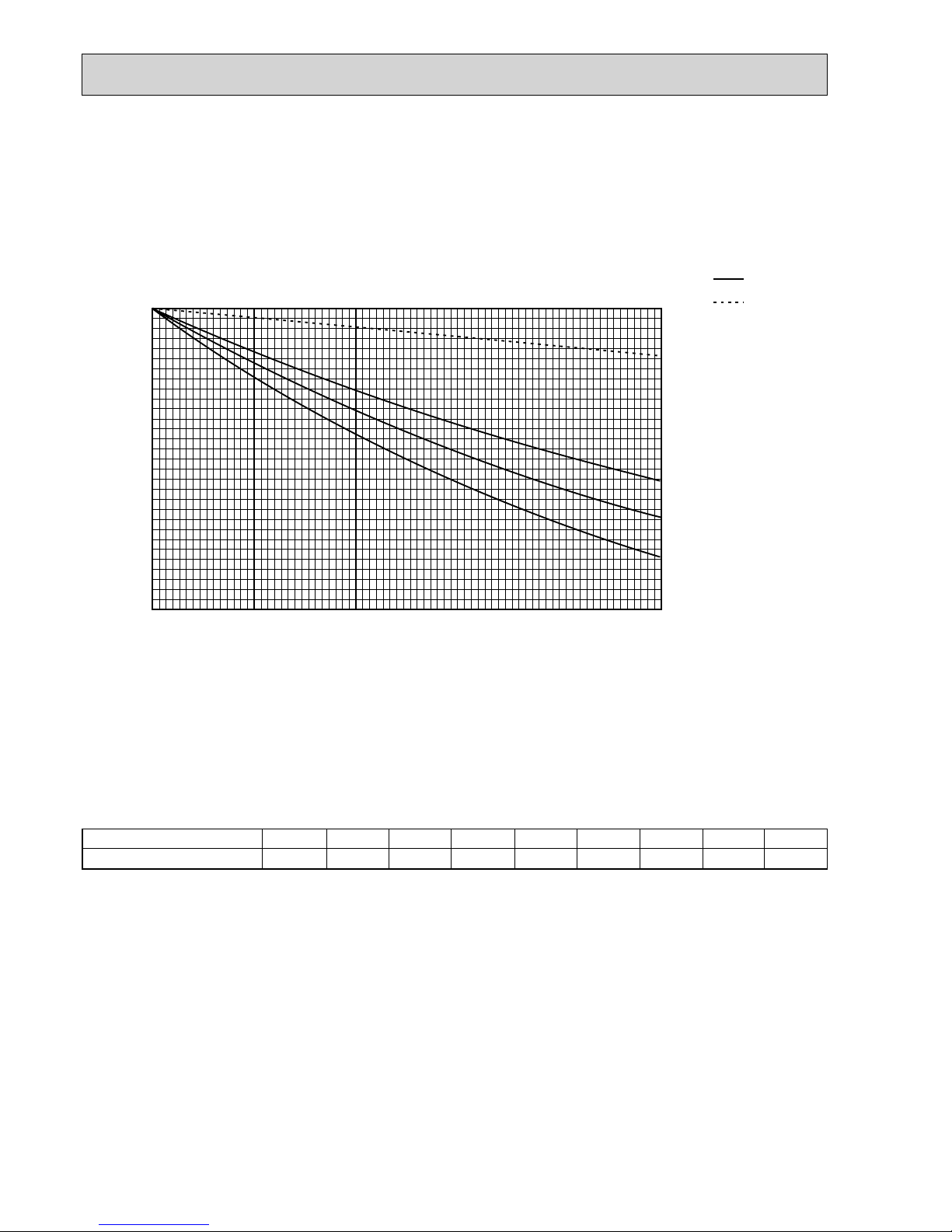

5-3-2. Correcting Capacity for Changes in the Length of Refrigerant Piping

(1) During cooling, obtain the ratio (and the equivalent piping length) of the outdoor units rated capacity and the total in-use

indoor capacity, and find the capacity ratio corresponding to the standard piping length from Figure 3. Then multiply by

the cooling capacity from Figure 1 to obtain the actual capacity.

(2) During heating, find the equivalent piping length, and find the capacity ratio corresponding to standard piping length from

Figure 3. Then multiply by the heating capacity from Figure 2 to obtain the actual capacity.

(2) Method for Obtaining the Equivalent Piping Length

Equivalent length for type P100·125·140 = (length of piping to farthest indoor unit) + (0.3 o number of bends in the piping) (m)

Length of piping to farthest indoor unit: type P100~P140.....80m

5-3-3. Correction of Heating Capacity for Frost and Defrosting

If heating capacity has been reduced due to frost formation or defrosting, multiply the capacity by the appropriate correction

factor from the following table to obtain the actual heating capacity.

Correction factor diagram

6

1.0

-10

0.95

-8

0.95

-6

0.95

-4

0.9

-2

0.89

0

0.88

2

0.89

4

0.98

Outdoor Intake temperature (W.B.°C)

Correction factor

(1) Capacity CORRECTION CURVE (Figure.3)

Cooling

Heating

100

95

90

85

80

75

70

5 101520253035404550556065707580

Cooling P100 model

Heating P100, 125, 140

models

Cooling P125 model

Cooling P140 model

Capacity ratio [%]

Corrected pipe length

[m]

17

1.5m

1m

MICROPHONE

UNIT

GROUND

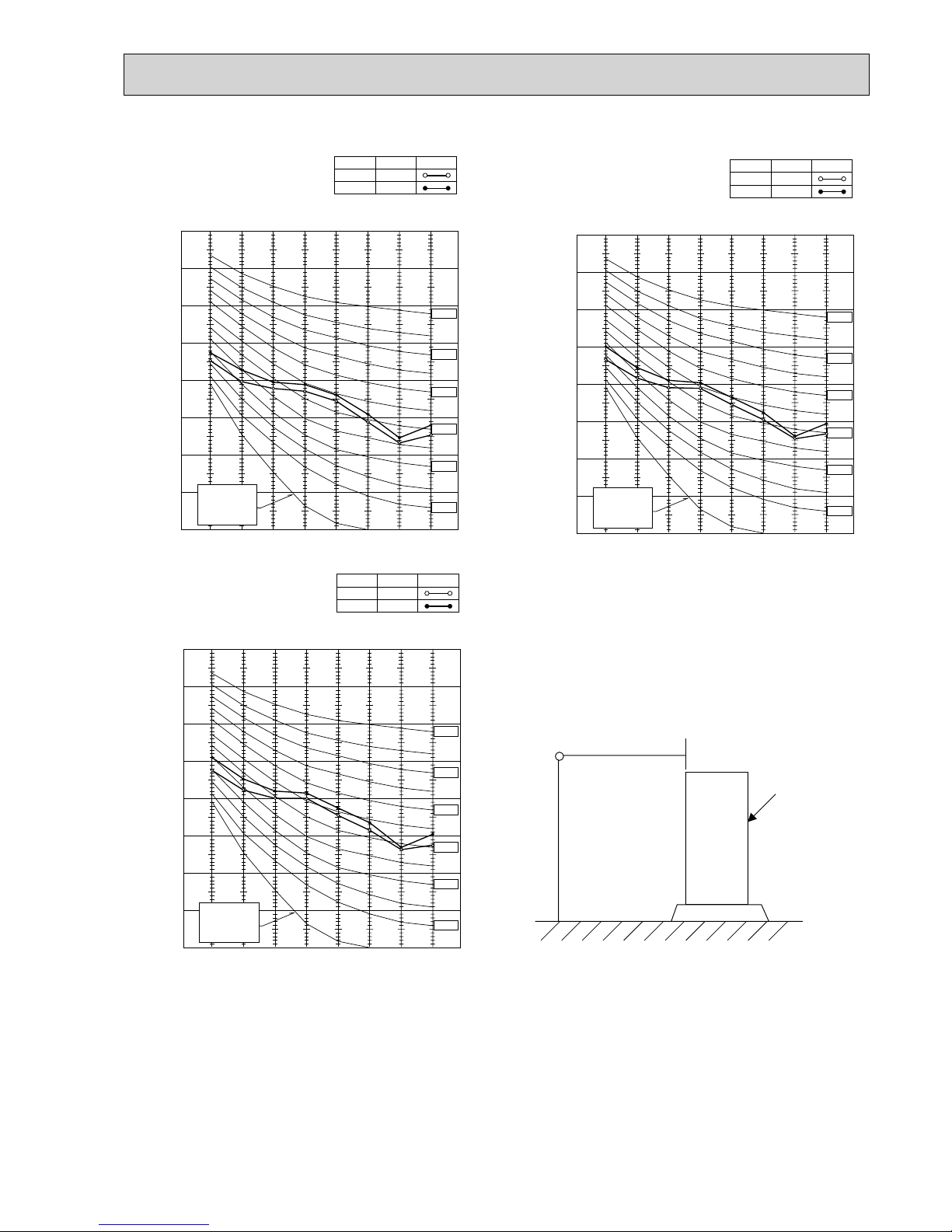

5-4.NOISE CRITERION CURVES

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 μbar)

BAND CENTER FREQUENCIES, Hz

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

PUMY-P100YHM

PUMY-P100YHM

1

PUMY-P100YHMA(-BS)

COOLING

MODE

HEATING

49

SPL(dB)

51

LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 μbar)

BAND CENTER FREQUENCIES, Hz

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

PUMY-P125YHM

PUMY-P125YHM1

PUMY-P125YHMA(-BS)

COOLING

MODE

HEATING

50

SPL(dB)

52

LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 μbar)

BAND CENTER FREQUENCIES, Hz

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

PUMY-P140YHM

PUMY-P140YHM

1

PUMY-P140YHMA(-BS)

COOLING

MODE

HEATING

51

SPL(dB)

53

LINE

18

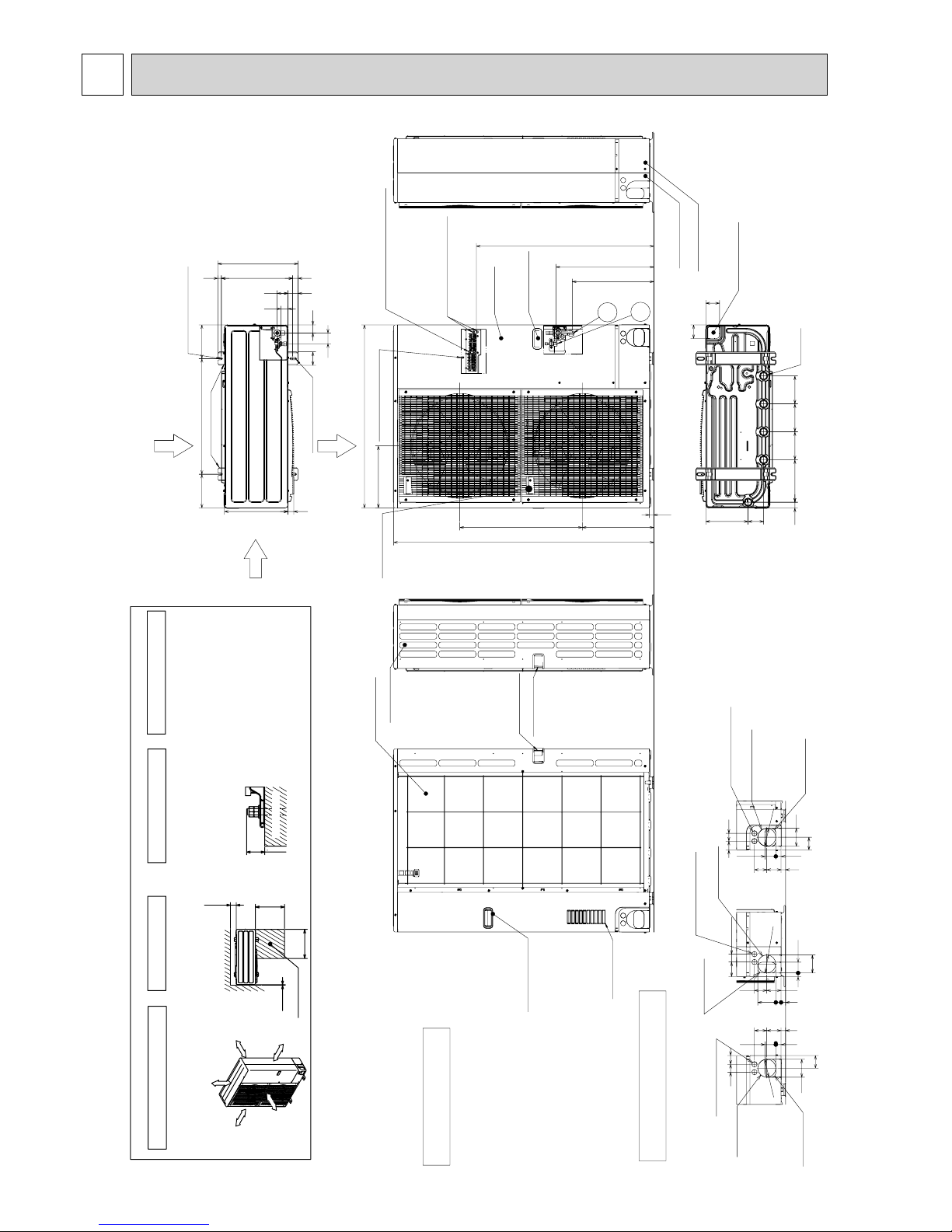

6

OUTLINES AND DIMENSIONS

Handle for moving

Side Air Intake

Front piping cover

Rear piping cover

Air intake

Rear Air Intake

Handle for moving

Handle for moving

Service panel

Handle for moving

Air Discharge

Rear Air Intake

Side Air Intake

14514522030 145

81 219

71

71

Bottom piping hole

(Knockout)

Drain hole

5-:33

600175 175

28 370

70

56

42

56

37

19

53

417

330

Installation Feet

2-12%36 Oval holes

(Foundation Bolt M10)

2-U Shaped notched holes

(Foundation Bolt M10)

30

920

322

635

371

950

23

1350

+1 423

+1 507

Handle for moving

1

2

( )

Left····· For the power supply

Center·····For the transmission line

Right····· For concentration control

Terminal connection

Ground for the transmission line

Ground for concentration control

Ground for the power supply

Over

Over

Over

Over

Less than

Piping and wiring connections

can be made from 4 directions:

front, right, rear and below.

4 PIPING-WIRING DIRECTIONS

3 FOUNDATION BOLTS2 SERVICE SPACE

1 FREE SPACE (Around the unit)

Please secure the unit firmly

with 4 foundation (M10) bolts.

(Bolts and washers must be

purchased locally.)

<Foundation bolt height>

Dimensions of space needed

for service access are

shown in the below diagram.

The diagram below shows a

basic example.

Explantion of particular details is

given in the installation manuals etc.

FREE

Over 10mm

Over 10mm

Over 150mm

Over 1000mm

30

FOUNDATION

10

500

500

150

Service space

Piping Knockout Hole Details

Example of Notes

···

Refrigerant GAS pipe connction (FLARE):15.88 (5/8 inch)

···

Refrigerant LIQUID pipe connection (FLARE): 9.52 (3/8 inch)

+1

···

Indication of STOP VALVE connection location.

637323

5527

92

65

4045

Power supply wiring hole

(2-:27Knockout)

Rear trunking hole

(Knockout)

Rear piping hole

(Knockout)

:92

922723

6373

4075

92

5519

Power supply wiring hole

(2-:27Knockout)

Right trunking hole

(Knockout)

Right piping hole

(Knockout)

:92

637323

5527

40 45

65

92

Power supply wiring hole

(2-:27Knockout)

Front trunking hole

(Knockout)

Front piping hole

(Knockout)

:92

PUMY-P100YHM PUMY-P100YHM1

PUMY-P125YHM PUMY-P125YHM1

PUMY-P140YHM PUMY-P140YHM1

Unit : mm

19

45 40

65

92

27 55

23 73 63

Rear piping hole

(Knockout)

Rear trunking hole

(Knockout)

Power supply wiring hole

(2-:27Knockout)

19 55

92

75 40

73 63

23 27

92

Right piping hole

(Knockout)

Right trunking hole

(Knockout)

Power supply wiring hole

(2-:27Knockout)

n92

92

65

4540

27 55

23 73 63

Front piping hole

(Knockout)

Front trunking hole

(Knockout)

Power supply wiring hole

(2-:27Knockout)

n92

14514522030 145

81 219

71

71

Bottom piping hole

(Knockout)

Drain hole

(5-:33)

600175 175

28 370

70

56

42

56

37

19

53

417

330

Installation Feet

2-12%36 Oval holes

(Foundation Bolt M10)

2-U Shaped notched holes

(Foundation Bolt M10)

30

1088

322

635371

950

23

1350

+1 423

+1 507

Handle for moving

1

2

Ground for the power supply

("GR"marking position)

Ground for the transmission line

Ground for concentration control

Terminal block

Left·········For the power supply

Center····For the transmission line

Right·······For concentration control

( )

Less than

Over

Over

Over

Over

Handle for moving

Side Air Intake

Front piping cover

Rear piping cover

Air intake

Rear Air Intake

Handle for moving

Handle for moving

Service panel

Handle for moving

The diagram below shows a

basic example.

Explantion of particular details is

given in the installation manuals etc.

Dimensions of space needed

for service access are

shown in the below diagram.

<Foundation bolt height>

Please secure the unit

firmly with 4 foundation (M10)

bolts.(Bolts and washers must

be purchased locally.)

Air Discharge

Rear Air Intake

Side Air Intake

Refrigerant GAS pipe connction(FLARE):15.88(5/8 inch)

Refrigerant LIQUID pipe connection(FLARE): 9.52(3/8 inch)

+1·····Indication of STOP VALVE connection location.

Example of Notes

Piping Knockout Hole Details

1 FREE SPACE (Around the unit)

2 SERVICE SPACE 3 FOUNDATION BOLTS

4 PIPING-WIRING DIRECTIONS

Piping and wiring connections

can be made from 4 directions:

front, right, rear and below.

30

FOUNDATION

150

500

500

10

Service space

Over 10

Over 10

FREE

Over 150Over 1000

:

92

PUMY-P100YHMA(-BS)

PUMY-P125YHMA(-BS)

PUMY-P140YHMA(-BS)

Unit : mm

20

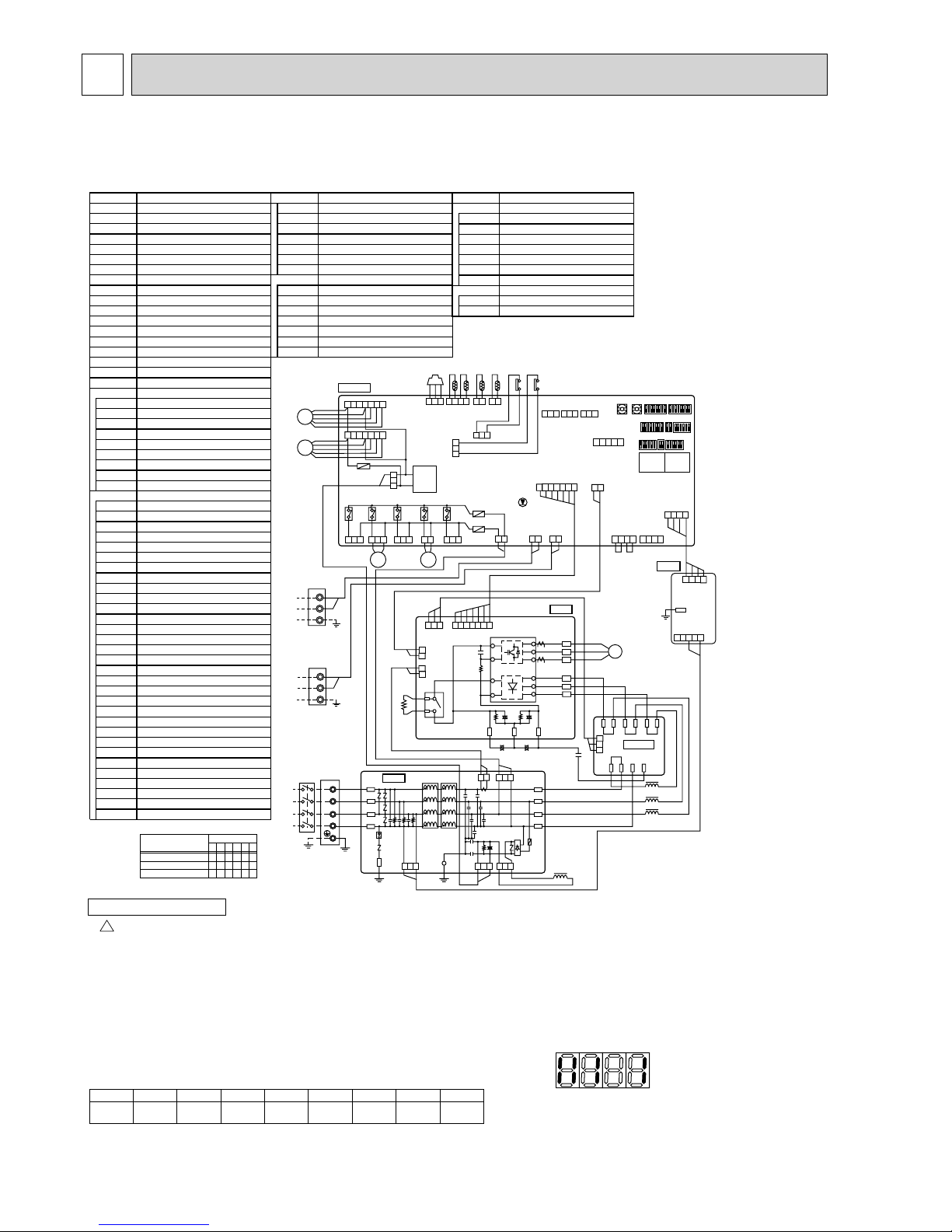

8

WIRING DIAGRAM

12345678

[Example]

When the compressor and

SV1 are turned on during cooling

operation.

Bit

Indication

1

Compressor

operated

2

52C321S44SV15(SV2)6—

7

—

8

Always lit

During normal operation

The LED indicates the drive state of the controller in the outdoor unit.

When fault requiring inspection has occurred,

the LED alternately indicates the inspection code and the location of the unit in which the fault has occurred.

NOTES:

1. Refer to the wiring diagrams of the indoor units for details on wiring of each indoor unit.

Self-diagnosis function

The indoor and outdoor units can be diagnosed automatically using the self-diagnosis switch

(SW1), LED1 and LED2 (LED indication) found on the multi-controller of the outdoor unit.

LED indication : Set all contacts of SW1 to OFF.

Cautions when Servicing

!

WARNING: When the main supply is turned off, the voltage [540 V] in the main capacitor will drop to 20 V in approx. 5 minutes (input voltage: 380 V).

When servicing, make sure that LED1 and LED2 on the outdoor circuit board goes out, and then wait for at least 5 minute.

Components other than the outdoor board may be faulty: Check and take corrective action, referring to the service manual.

Do not replace the outdoor board without checking.

1

MF1

4 5 6 7

CN2

(WHT)

CN4

(WHT)

CN51

(WHT)

1

MF2

4567

52C

(BLK)

3

X505

1

21S4

(GRN)

3 1

SV2

(BLU)

3 1

SV1

(WHT)

SS

(WHT)

21

2

1

21 21

3

1

21S4

SV1

76543 2 1

54321

21

LED3

SW6

SW2SW8SW1

SW7SW3SW4

+1

SW5

SWU2 SWU1

TRANS

LED2

88

LED1

88

12 1

2 1 234

CN3D

(WHT)

123

12

3

CN3S

(RED)

1 23

CN3N

(BLU)

123

3 1

31

CNAC

(RED)

CNS1

(RED)

CNS2

(YLW)

31

TH7TH6 TH3 TH463HS 63H63L

F1

F500

F2

X504

X503

X502

X501

CN102

(WHT)

CN41

(WHT)

CN40

(WHT)

4 321

4 3 2 14321

M-P.B.

P.B .

31

CN2

(WHT)

CN1

(WHT)

TP1

1234

M1

M2

S

TB3

TO INDOOR UNIT

CONNECTING WIRES

DC 30V(Non-polar)

FOR CENTRALIZED

CONTROL

DC 30V(Non-polar)

M1

M2

S

TB7

TB-W

TB-V

TB-U

TB-L3

TB-L2

TB-L1

(BLK)

(WHT)

(RED)

(BLK)

(BLK)

(BLU)

(WHT)

(WHT)

(RED)

(RED)

(BLK)

(BLU)

(WHT)

(RED)

L1

NO FUSE

BREAKER

POWER SUPPLY

3N~

AC380/400/415V 50Hz

L2

L3

N

MC

-

+

-

+

3 1 1 3 3 1

1 31 2

ACL4

+

+

+

CN2

(WHT)

CN7

(WHT)

CN4

(WHT)

CN7

(WHT)

CN5

(RED)

7 654321321

2 121

++

3 12

ACL1

ACL2

ACL3

CONV.B.

MULTI. B.

N.F.

TB1

CNF1

(WHT)

TH7/6

(RED)

TH3

(WHT)

TH4

(WHT)

63HS

(WHT)

63H

(YLW)

63L

(RED)

CNDC

(PNK)

CNF2

(WHT)

TB-P2

TB-C1

TB-N1

L1-IN

L1-A1

L3-OU

L3-A2

L2-OU

L1-OU

L2-A2

L1-A2

CK-OU

N-IN

CB1

CN5

(RED)

CNAC2

(RED)

CB2

CK

RS

LO1

LO2

LO3

NO

LI1

LI2

LI3

NI

GD1

GD2

CNAC1

(WHT)

CNDC

(PNK)

CNL

(BLU)

(BRN)

(BRN)

(ORN)

(ORN)

+1 MODEL SELECT 1:ON 0:OFF

MODELS

PUMY-P100YHM

PUMY-P125YHM

PUMY-P140YHM

110010

123456

SW4

110001

110011

SYMBOL NAME SYMBOL NAME SYMBOL NAME

TB1 Terminal Block <Power Supply>

TB3 Terminal Block <Transmission>

TB7

Terminal Block <Centralized Control>

MC Motor for Compressor

MF1,MF2 Fan Motor

21S4 Solenoid Valve<Four way valve>

SV1 Solenoid Valve<Bypass valve>

TH3

Thermistor<Outdoor Pipe Temperature>

TH4

Thermistor<Discharge Temperature>

TH6

Thermistor<Low Pressure Saturated Temperature>

TH7

Thermistor<Outdoor Temperature>

63HS

High Pressure Sensor<Discharge Pressure>

63H High Pressure Switch

63L Low Pressure Switch

CB1,CB2 Main Smoothing Capacitor

CK Capacitor

RS Rush Current Protect Resistor

P.B Power Circuit Board

Connection Terminal<U/V/W -Phase>

ACL1~ACL4

TB-U/V/W

MULTI.B.

CONV.B.

Multi Controller Board

Fuse<6.3A>

F1,F2

Fuse<3A>

F500

Switch<Display Selection>

SW1

Switch<Function Selection>

SW2

Switch<Test Run>

SW3

Switch<Model Selection>

SW4

Switch<Function Selection>

SW5

Switch<Function Selection>

SW6

Switch<Function Selection>

SW7

Switch<Function Selection>

SW8

Switch<Unit Address Selection, 1st digit>

SWU1

Switch<Unit Address Selection, 2nd digit>

SWU2

Transformer

TRANS

Digital Indicator<Operation Inspection Display>

LED1,2

LED<Power Supply to Main Microcomputer>

LED3

Connector<Multi System>

CNS1

Connector<Centralized Cotrol>

CNS2

Connector<To Noise Filter Circuit Board>

CNAC

Connector<To Noise Filter Circuit>

CNDC

Connector<To Power Circuit Board>

CN2

Connector<To Power Circuit Board>

CN4

Connector<Centralized Cotrol Power Supply>

CN40

Connector<For shorting Jumper Connector>

CN41

Connector<Thermistor>

TH3

Connector<Thermistor>

TH4

Connector<Thermistor>

TH7/6

Connector<High Pressure Sensor>

63HS

Connector<High Pressure Switch>

63H

Connector<Low Pressure Switch>

63L

Connector<Fan Motor>

CNF1,CNF2

Connector<Four-way Valve>

21S4

Connector<Bypass Valve>

SV1

Connector<For Option>

SS

Connector<For Option>

CN3D

Connector<For Option>

CN3S

Connector<For Option>

CN3N

Connector<For Option>

Connection Terminal<L1-Power Supply>

CN51

Relay

X501~505

Converter Circuit Board

L1-A1,L1-IN

N.F.

Connection Terminal<L1/L2/L3/N-Power Supply>

Noise Filter Circuit Board

LI1/LI2/LI3/NI

M-P.B.

Connector<To Noise Filter Circuit Board>

Transmission Power Board

CN1

Connector<To Multi Controller Board>

CN2

Connector<To Transmission Power Board>

CNAC1

Connector<To Multi Controller Board>

CNAC2

Connector<To Power Circuit Board>

CNCT

Connector<To Reactor>

CNL

Fuse<6.3A>

FUSE

Connection Terminal<L1/L2/L3/N-Power Supply>

LO1/LO2/LO3/NO

Connection Terminal<L1-Power Supply>

L1-A2,L1-OU

Connection Terminal<L2-Power Supply>

L2-A2,L2-OU

Connection Terminal<L3-Power Supply>

L3-A2,L3-OU

Connection Terminal

N-IN

Connection Terminal

CK-OU

Connector<To Power Circuit Board>

CN7

Connection Terminal<L1/L2/L3-Power Supply>

TB-L1/L2/L3

Connection Terminal

TB-P2

Connection Terminal

TB-C1

Connection Terminal

TB-N1

Connection <To Multi Controller Board>

CN2

Connection <To Multi Controller Board>

CN4

Connection <To Noise Filter Circuit Board>

CN5

Connection <To Multi Controller Board>

CNDC

Reactor

PUMY-P100YHM PUMY-P100YHM1

PUMY-P125YHM PUMY-P125YHM1

PUMY-P140YHM PUMY-P140YHM1

21

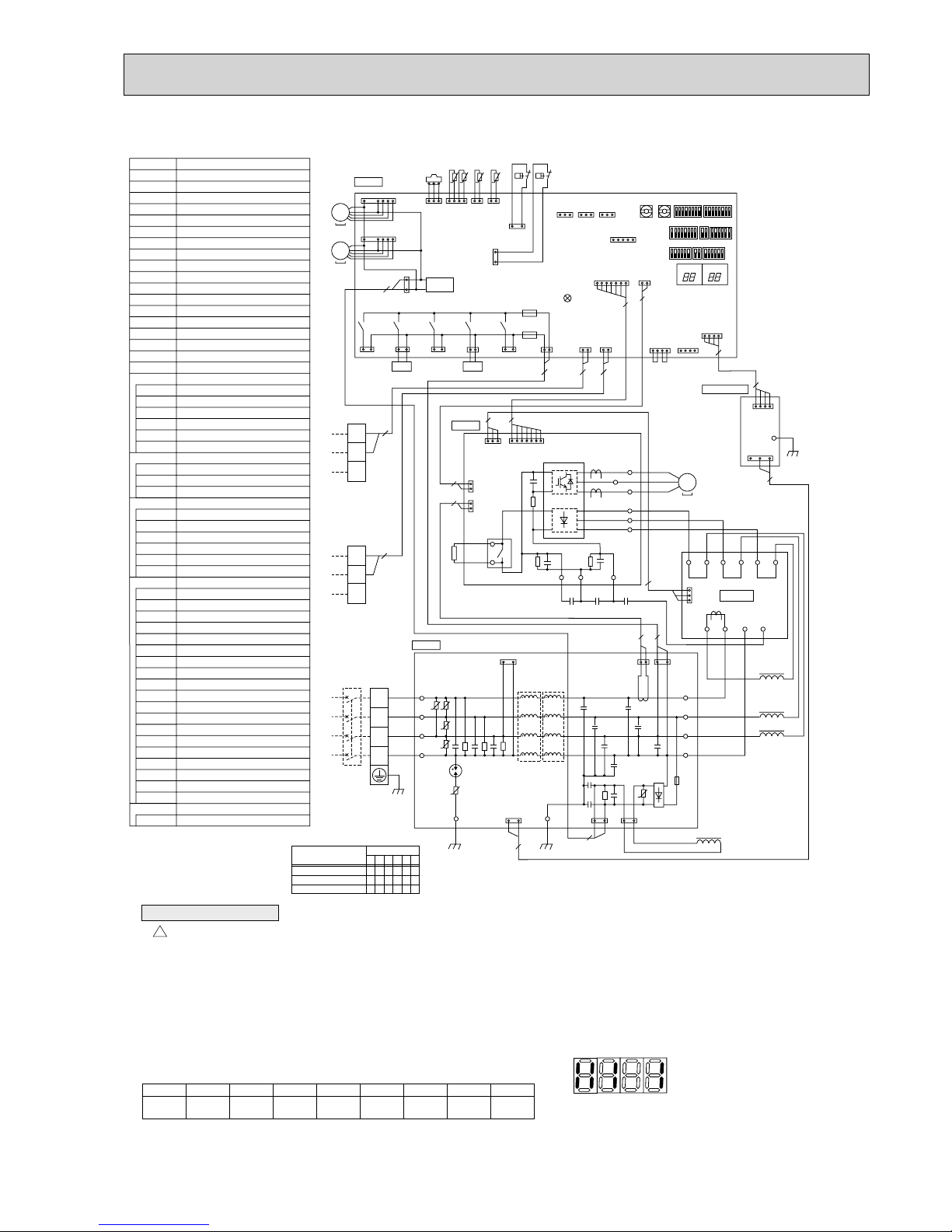

12345678

[Example]

When the compressor and

SV1 are turned on during cooling

operation.

Bit

Indication

1

Compressor

operated

2

52C321S44SV15(SV2)6—

7

—

8

Always lit

• During normal operation

The LED indicates the drive state of the controller in the outdoor unit.

• When fault requiring inspection has occurred,

the LED alternately indicates the inspection code and the location of the unit in which the fault has occurred.

NOTES:

1.Refer to the wiring diagrams of the indoor units for details on wiring of each indoor unit.

Self-diagnosis function

The indoor and outdoor units can be diagnosed automatically using the self-diagnosis switch

(SW1), LED1 and LED2 (LED indication) found on the multi-controller of the outdoor unit.

LED indication : Set all contacts of SW1 to OFF.

SYMBOL NAME

TB1

Terminal Block <Power Supply>

TB3

Terminal Block <Comunication Line>

TB7

Terminal Block <Centralized Control Line>

MC Motor For Compressor

MF1,MF2 Fan Motor

21S4 Solenoid Valve<Four-Way Valve>

SV1 Solenoid Valve<Bypass Valve>

TH3

Thermistor<Outdoor Pipe>

TH4 Thermistor<Discharge>

TH6 Thermistor<Low Pressure Saturated>

TH7 Thermistor<Outdoor>

63HS

63H High Pressure Switch

High Pressure Sensor

63L Low Pressure Switch

CB1,CB2 Main Smoothing Capacitor

CK Capacitor

RS Rush Current Protect Resistor

P.B. Power Circuit Board

C.B. Controller Circuit Board

Connection Terminal<U/V/W -Phase>

ACL1~ACL4

TB-U/V/W

CONV.B.

Fuse<T6.3AL250V>

F1,F2

Switch<Display Selection>

SW1

Switch<Function Selection>

SW2

Switch<Test Run>

SW3

Switch<Model Selection>

SW4

Switch<Function Selection>

SW5

Switch<Function Selection>

SW6

Switch<Function Selection>

SW7

Switch<Function Selection>

SW8

Switch<Unit Address Selection, 1st digit>

SWU1

Switch<Unit Address Selection, 2nd digit>

SWU2

LED<Operation Inspection Display>

LED1,LED2

LED<Power Supply to Main Microcomputer>

LED3

Connector<Connection For Option>

SS

Connector<Connection For Option>

CN3D

Connector<Connection For Option>

CN3S

Connector<Connection For Option>

CN3N

Connector<Connection For Option>

Connection Terminal<L1-Power Supply>

CN51

Relay

X52A

Relay

X501~X505

Connection Terminal<Ground>

Connection Terminal<Ground>

GD1,GD3

TP1

Converter Circuit Board

L1-A1/IN

N.F.

Connection Terminal<L1/L2/L3-Power Supply>

Noise Filter Circuit Board

LI1/LI2/LI3/NI

M-NET P.B.

M-NET Power Circuit Board

Connection Terminal<L1/L2/L3-Power Supply>

LO1/LO2/LO3/NO

Connection Terminal<L1-Power Supply>

L1-A2/OU

Connection Terminal<L2-Power Supply>

L2-A2/OU

Connection Terminal<L3-Power Supply>

L3-A2/OU

Connection Terminal

N-IN

Connection Terminal

CK-OU

Connection Terminal<L1/L2/L3-Power Supply>

TB-L1/L2/L3

Connection Terminal

TB-P2

Connection Terminal

TB-C1

Connection Terminal

TB-N1

Reactor

Cautions when Servicing

!

• WARNING: When the main supply is turned off, the voltage [570 V] in the main capacitor will drop to 20 V in approx. 5

minutes (input voltage: 400 V). When servicing, make sure that LED1 and LED2 on the outdoor circuit board goes out, and

then wait for at least 5 minute.

• Components other than the outdoor board may be faulty: Check and take corrective action, referring to the service manual.

Do not replace the outdoor board without checking.

+1 MODEL SELECT 1:ON 0:OFF

MODELS

PUMY-P100YHMA

PUMY-P125YHMA

PUMY-P140YHMA

123456

110010

110001

110011

SW4

CN51

(WHT)

SW6

SW2SW8SW1

SW7SW3SW4

+

1

SW5

SWU2SWU1

TRANS

LED1

CN2

(WHT)

CN4

(WHT)

LED3

CN3D

(WHT)

CN3S

(RED)

CN3N

(BLU)

CN2

(WHT)

CN1

(WHT)

TP1

BLK

M1

M2

S

TB3

TO INDOOR UNIT

CONNECTING WIRES

DC 30V(Non-polar)

FOR CENTRALIZED

CONTROL

DC 30V(Non-polar)

TB-W

TB-V

TB-U

TB-L3

TB-L2

TB-L1

BLK

BLK

WHT

W

V

U

WHT

RED

RED

BLK

BLK

BLK

WHT

WHT

RED

RED

RED

RED

ACL4

CN2

(WHT)

CN7

(WHT)

CN4

(WHT)

CN5

(RED)

RED

RED

X52A

CNDC

(PNK)

TB-P2

TB-C1

TB-N1

CB1

CNCT

(RED)

CNAC2

(RED)

CNAC1

(WHT)

CNAC1

(WHT)

CB2

CK

RS

GD3GD1

BLK

WHT

WHT

CNDC

(PNK)

CNL

(BLU)

t t t t

MF1

MS

3~

141

1

1

7

3

131313

113

3

13

1

3

3

3

13 13

1

3

2

1

3

1

3

13

3

2

2112

1

2

2

1

2

1

2

22

1

2

22

12 12

1

2

2

TH7 TH6 TH3 TH4

63HS

63H

63L

CNF1

(WHT)

MF2

MS

3~

1

7

1

7

7

1

5

CNF2

(WHT)

TH7/6

(RED)

TH3

(WHT)

TH4

(WHT)

63HS

(WHT)

63H

(YLW)

63L

(RED)

C. B.

LED2

P. B.

N. F.

M-NET P.B.

52C

(BLK)

1

3

1

3

1

3

X505

21S4

(GRN)

SV1

(WHT)

SV2

(BLU)

SS

(WHT)

21S4

SV1

CNAC

(RED)

CNS1

(RED)

CNS2

(YLW)

F1

F2

X504

X503

X502

X501

CN102

(WHT)

4

1

CN40

(WHT)

4

1

4

4

1

5

1

CN41

(WHT)

4

1

1

7

7

-

+

+

+

-

+

1

2

2

-

+

++

+

MC

MS

3~

4

2

M1

M2

S

TB7

2

2

BLK

BLU

WHT

RED

BLK

BLU

BLU

WHT

RED

LI1

POWER

SUPPLY

3N~

400V

50Hz

LI2

U

U

U

U

U

U

LI3

NI

TB1

L1

L2

L3

N

BLK

2

ACL1

ACL2

ACL3

LO1

LO2

LO3

NO

CN7

(WHT)

Conv.B.

L1-IN

L1-A1

L3-OU

L3-A2

L2-OU

L1-OU

L2-A2

L1-A2

CK-OU

N-IN

2

RED

YLW

YLW

GRN/YLW

RED

PUMY-P100YHMA(-BS) PUMY-P125YHMA(-BS) PUMY-P140YHMA(-BS)

22

8

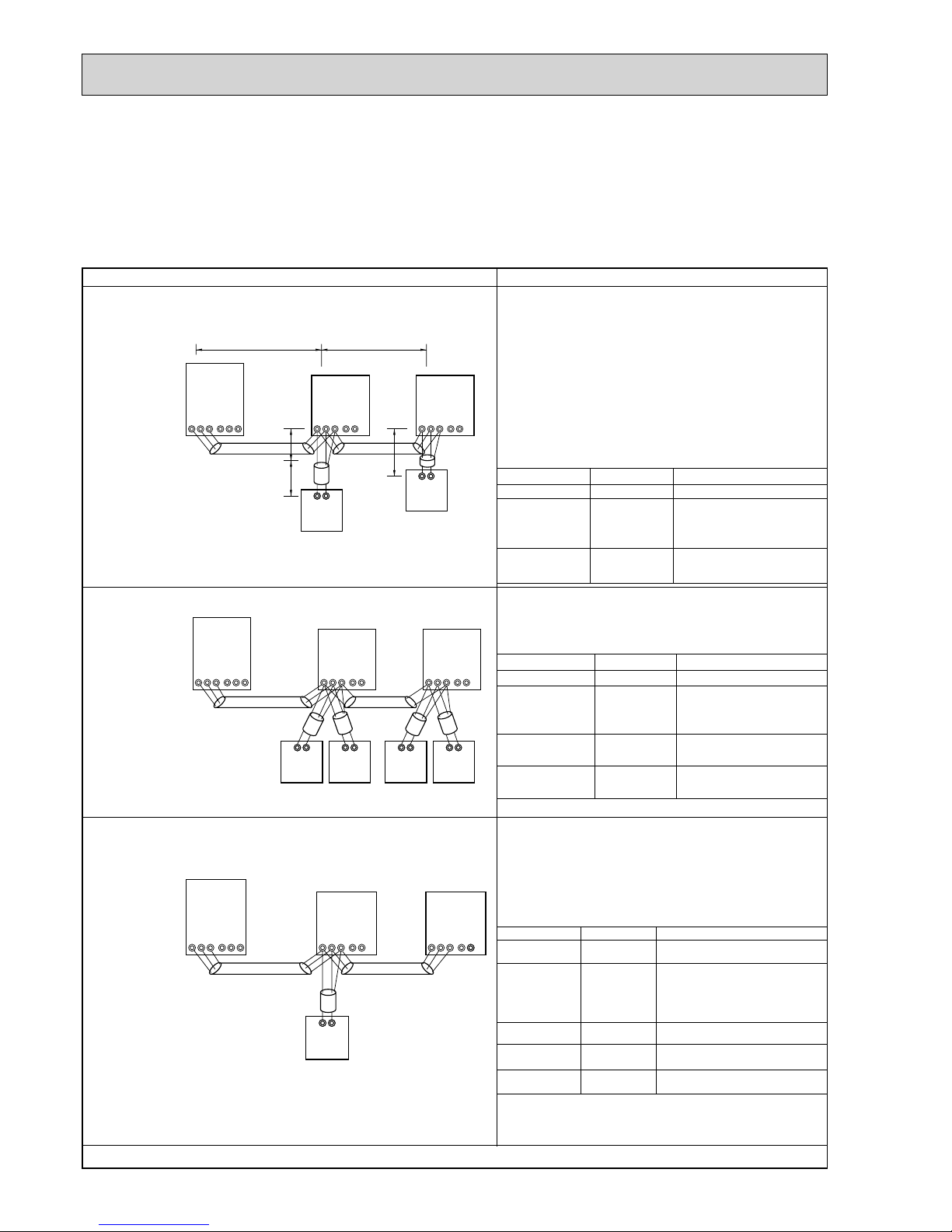

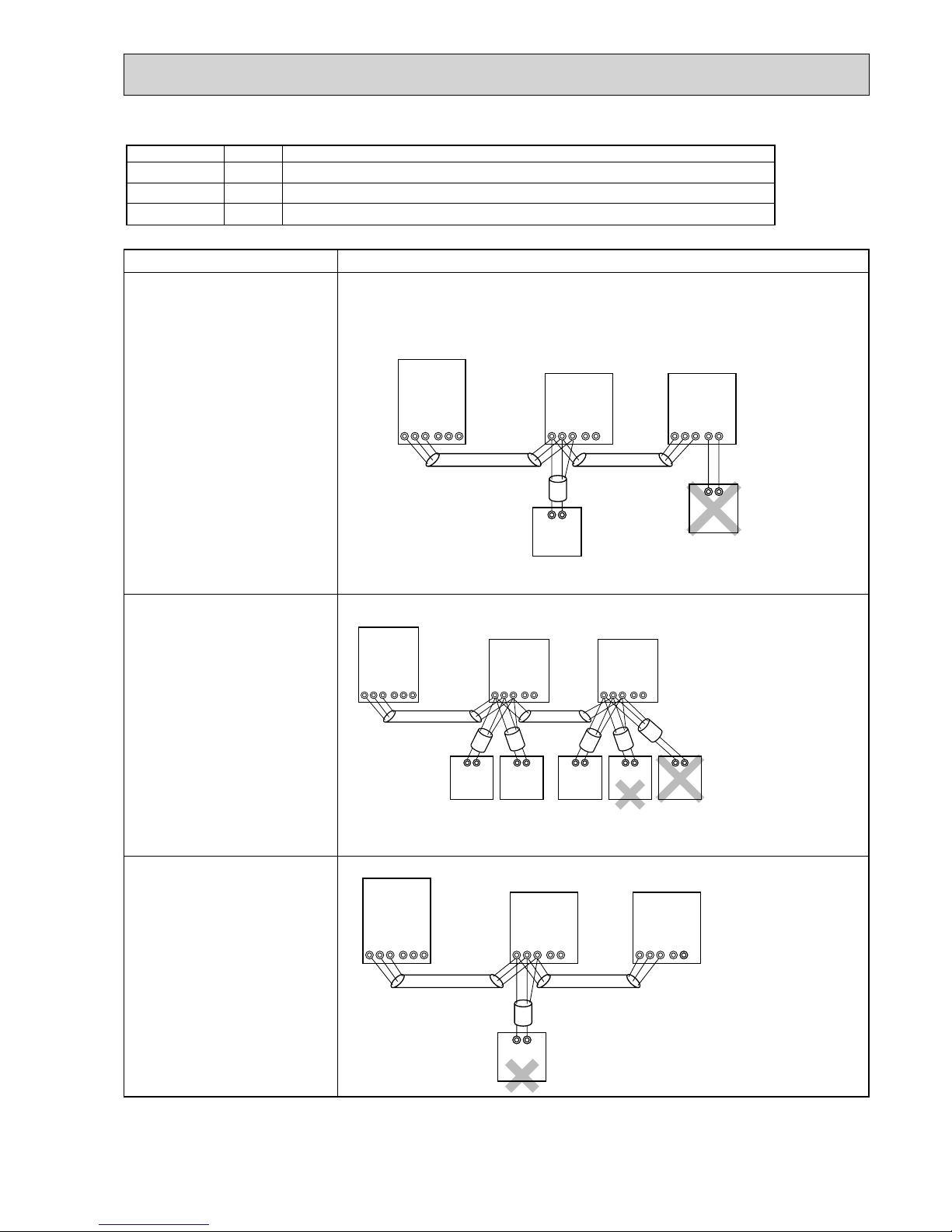

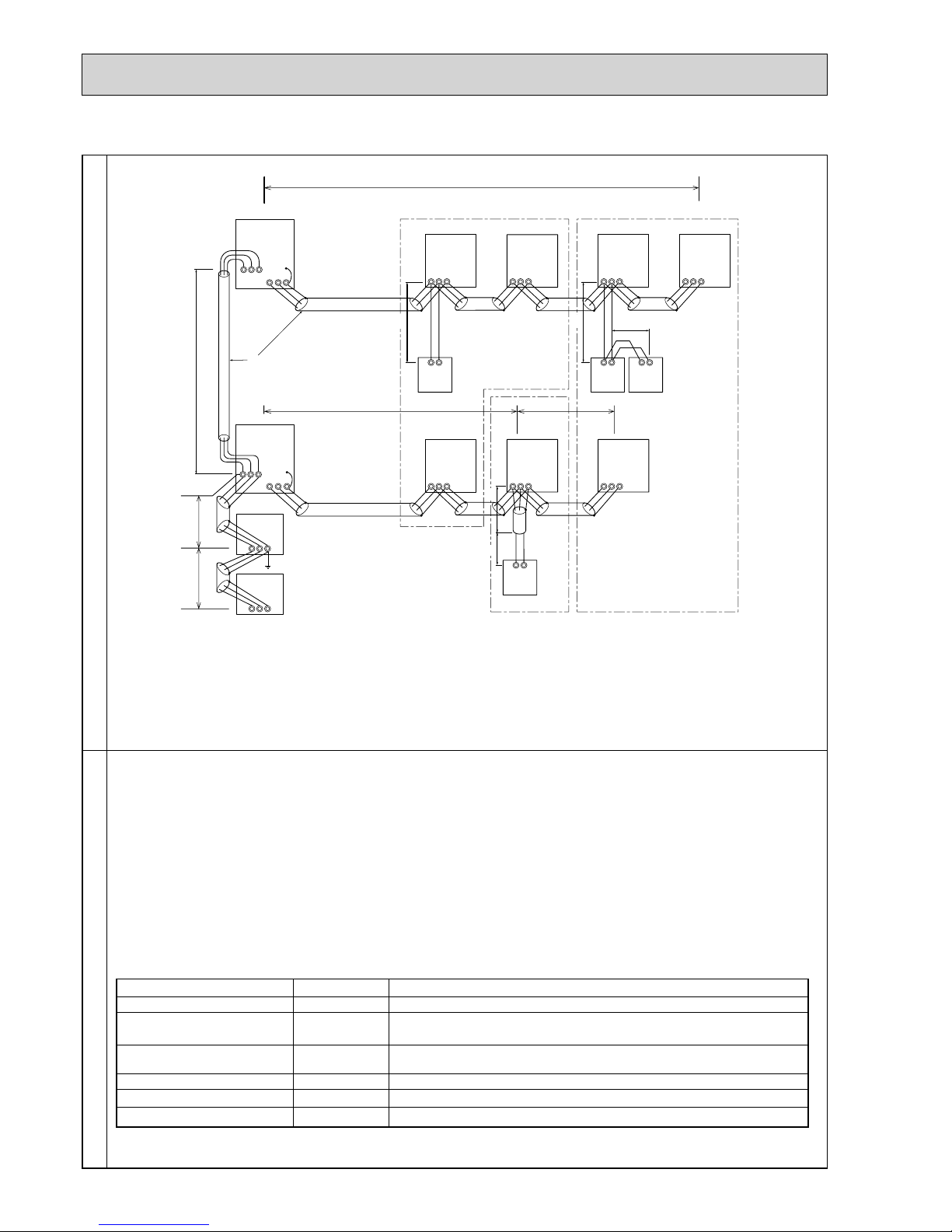

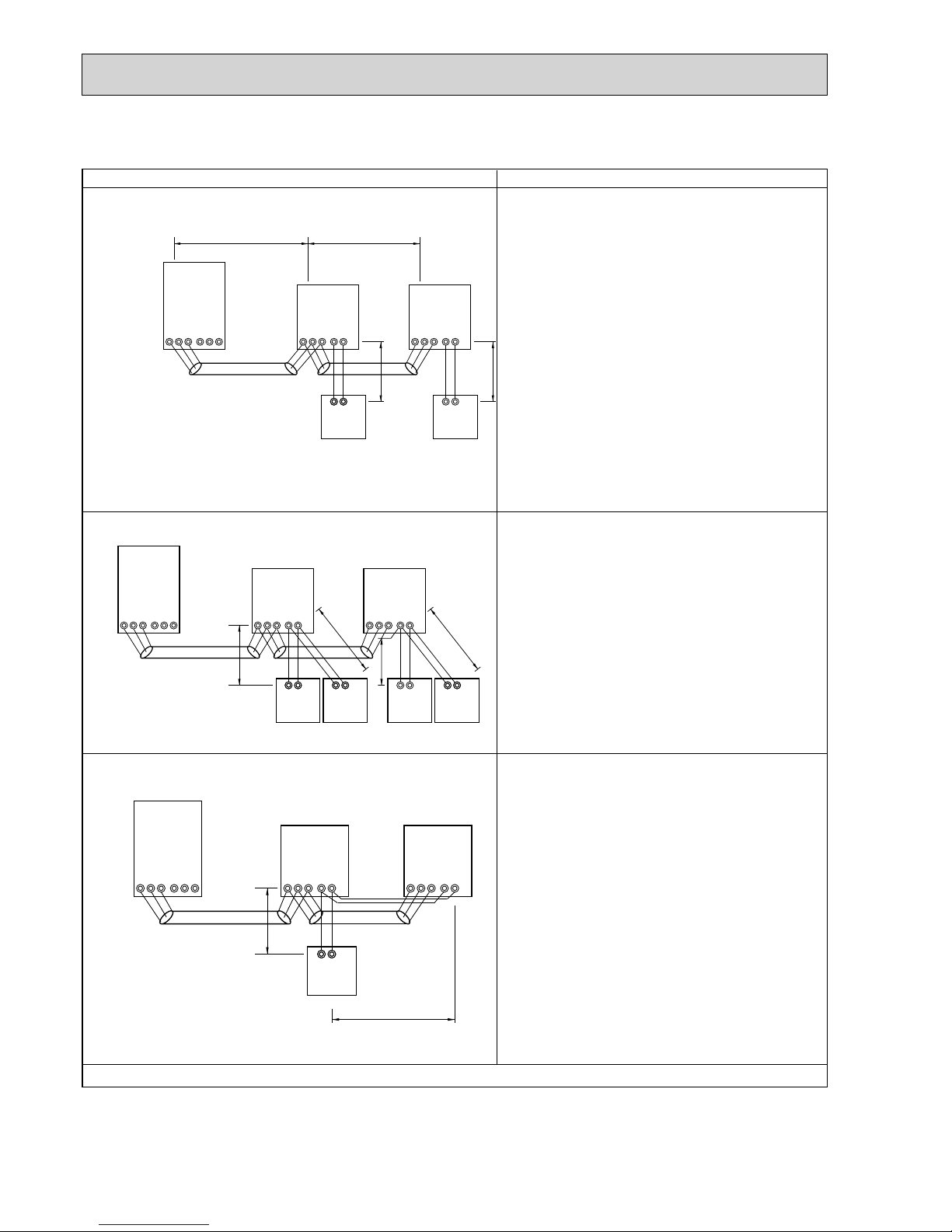

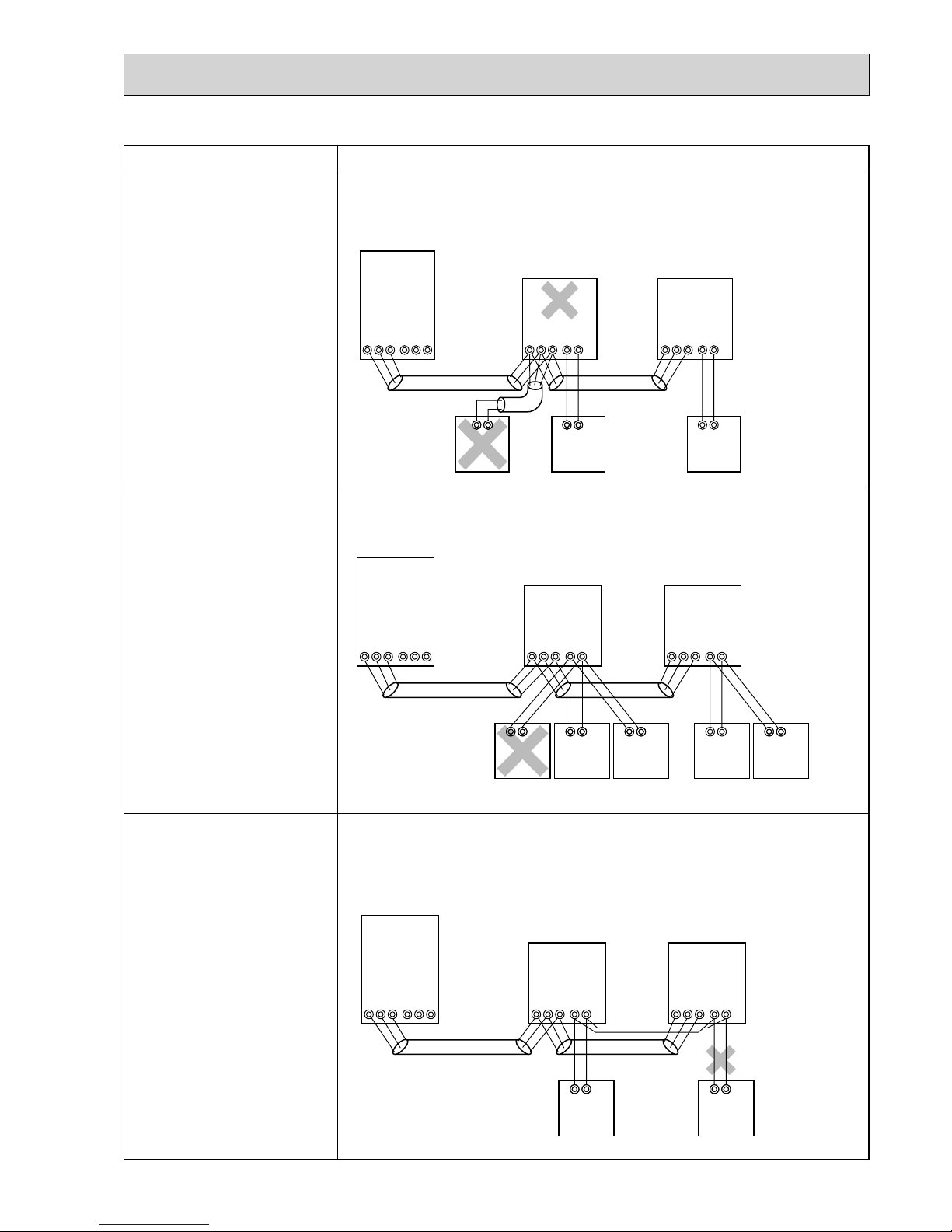

NECESSARY CONDITIONS FOR SYSTEM CONSTRUCTION

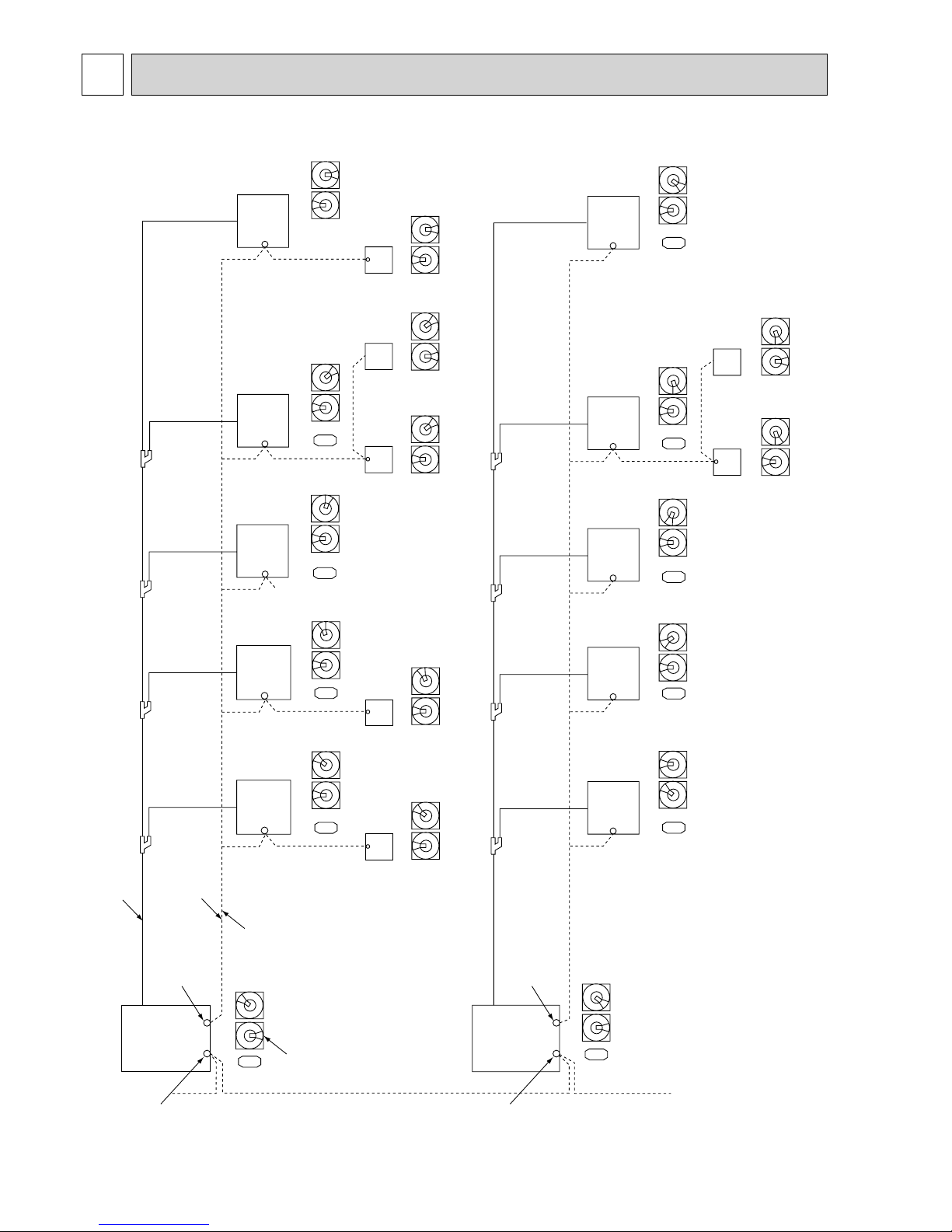

8-1. TRANSMISSION SYSTEM SETUP

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

051

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

056

001

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

010

101

1

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

002

102 104 154

1111

11

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

009

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

008

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

003

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6