Mitsubishi PUMY-71VM, PUMY-71VM1, PUMY-71VM2, PUMY-125VM, PUMY-125VM1 Service Manual

...

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

TECHNICAL & SERVICE MANUAL

Outdoor unit

[Model names] [Service Ref.]

PUMY-71VM PUMY-71VM

1999

No.OC183

REVISED EDITION-B

PUMY-71VM

1

PUMY-71VM2

PUMY-125VM PUMY-125VM

PUMY-125VM

1

PUMY-125VM2

PUMY-125YM PUMY-125YM

PUMY-125YM

PUMY-125YMA PUMY-125YMA

CONTENTS

1. TECHNICAL CHANGE ·····································2

2. OVERVIEW OF UNITS······································3

3. SPECIFICATIONS·············································6

4. DATA ·······························································12

5. OUTLINES AND DIMENSIONS······················32

6. WIRING DIAGRAM·········································34

7.

NECESSARY CONDITIONS FOR SYSTEM CONSTRUCTION

8. TROUBLESHOOTING ····································54

9. ELECTRICAL WIRING····································89

10. REFRIGERANT PIPING TASKS ·····················93

11. DISASSEMBLY················································98

12. PARTS LIST ··················································103

1

···42

Revision:

• PUMY-71VM2, PUMY-125VM2, PUMY-125YM1,

PUMY-125YMA are added in Revised Edition-B.

• Please destroy OC183 Revised Edition-A.

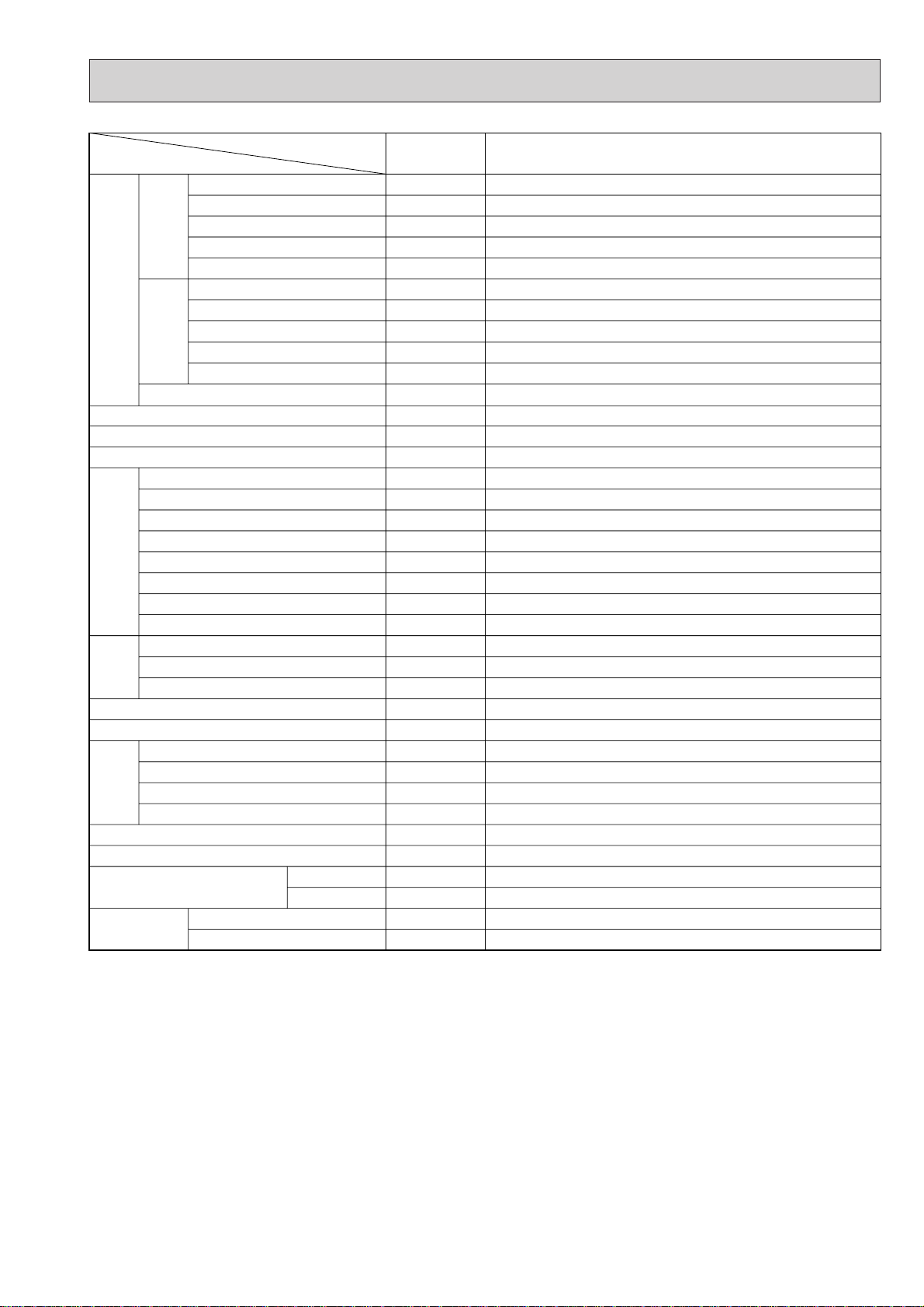

1 TECHNICAL CHANGE

CHANGE POINTS

CONTENTS

OF

CHANGE

Outdoor unit Service Ref.

Base outdoor unit Service Ref.

PUMY-

71VM

2

71VM1

125VM2

125VM1

125YM1

125YM

FAN MOTOR CAPACITOR

FAN MOTOR

COMPRESSOR

HIGH PRESSURE SENSOR

SEPARATOR ASSY

MULTI CONTROLLER BOARD

3.5+ 3.0+

PA6V40-UB PU6V60-GB

PA6V40-UA PU6V60-GA

PA6V60-UC PU6V60-GB

PA6V60-UB PU6V60-GA

PA6V60-UE PU6V60-GD

PA6V60-UD PU6V60-GC

CHV253FAA EHV33FAG

EHV46FAA EHV46FAG

EHV46FAD EHV46FAK

Maker change

Substrate connection

wiring is attached.

Change in accordance with high pressure sensor.

Change in accordance with high pressure sensor.

Substrate connection

wiring is not provided.

( ) ( )

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

Change of the service parts. Refer to the parts list for the details.

ww

Only PUMY-125YMA is new model.

2

2 OVERVIEW OF UNITS

20

25

32

40

50

63

71

80

100

125

-

32VKM

40VKM

50VKM

63VKM

80VAM

100VAM

125VAM

20VLMD

25VLMD

32VLMD

40VLMD

50VLMD

63VLMD

-

80VLMD

100VLMD

125VLMD

20VML / VMM

25VML / VMM

32VML / VMM

40VMH / VMM

50VMH / VMM

63VMH / VMM

71VMH / VMM

80VMH / VMM

100VMH / VMM

125VMH / VMM

20VM

25VM

32VM

40VM

50VM

63VM

71VM

80VM

100VM

125VM

20VAM

25VAM

32VGM

40VGM

50VGM

63VFM

-

-

100VFM

-

20VLEM

25VLEM

32VLEM

40VLEM

50VLEM

63VLEM

-

-

-

-

20VLRM

25VLRM

32VLRM

40VLRM

50VLRM

63VLRM

-

-

-

-

-

-

-

40VGM

-

63VGM

-

100VGM

125VGM

PLFY-P PLFY-P PEFY-P PDFY-P PKFY-P PCFY-P PFFY-P PFFY-P

Capacity

Model

Cassette Ceiling

4-way flow 2-way flow

20VBM

25VBM

32VBM

40VBM

-

-

-

-

-

-

PMFY-P

1-way flow

Ceiling

Concealed

Ceiling mounted

built-in

Ceiling

Suspended

Wall Mounted

Floor standing

Exposed Concealed

Remote

controller

Name

Model number

Functions

M-NET remote controller

PAR-F27MEA-E

• A handy remote controller for use in conjunction

with the Melans centralized management system.

• Addresses must be set.

• Addresses setting is not necessary.

•

Only the indoor unit for MA remote controller

(the end of model name is -A) can be used.

MA remote controller

PAR-20MAA-E

2-1. UNIT CONSTRUCTION

Outdoor unit

Indoor unit

that can be

connected

Outdoor unit

Indoor unit

that can be

connected

Capacity

Number of units

Total systemwide capacity

Capacity

Number of units

Total systemwide capacity

3HP

PUMY-71VM

2~4units

50~130% of outdoor unit capacity

3HP

PUMY-71VM

PUMY-71VM2

Type 20~Type 80

1~4units

50~130% of outdoor unit capacity

Type 20~Type 125

1

5HP

PUMY-125VM,PUMY-125YM

2~5units

5HP

PUMY-125VM1, PUMY-125YM

PUMY-125VM2, PUMY-125YM1

PUMY-125YMA

Type 20~Type 125

1~8units

CMY-Y62-C-E CMY-Y64-C CMY-Y68

Branching pipe

components

Branch header

(2 branches)

Branch header

(4 branches)

Branch header

(8 branches)

Decorative panel

3

CMY-S65

Multi distribution

Piping on outdoor

unit

(5 branches)

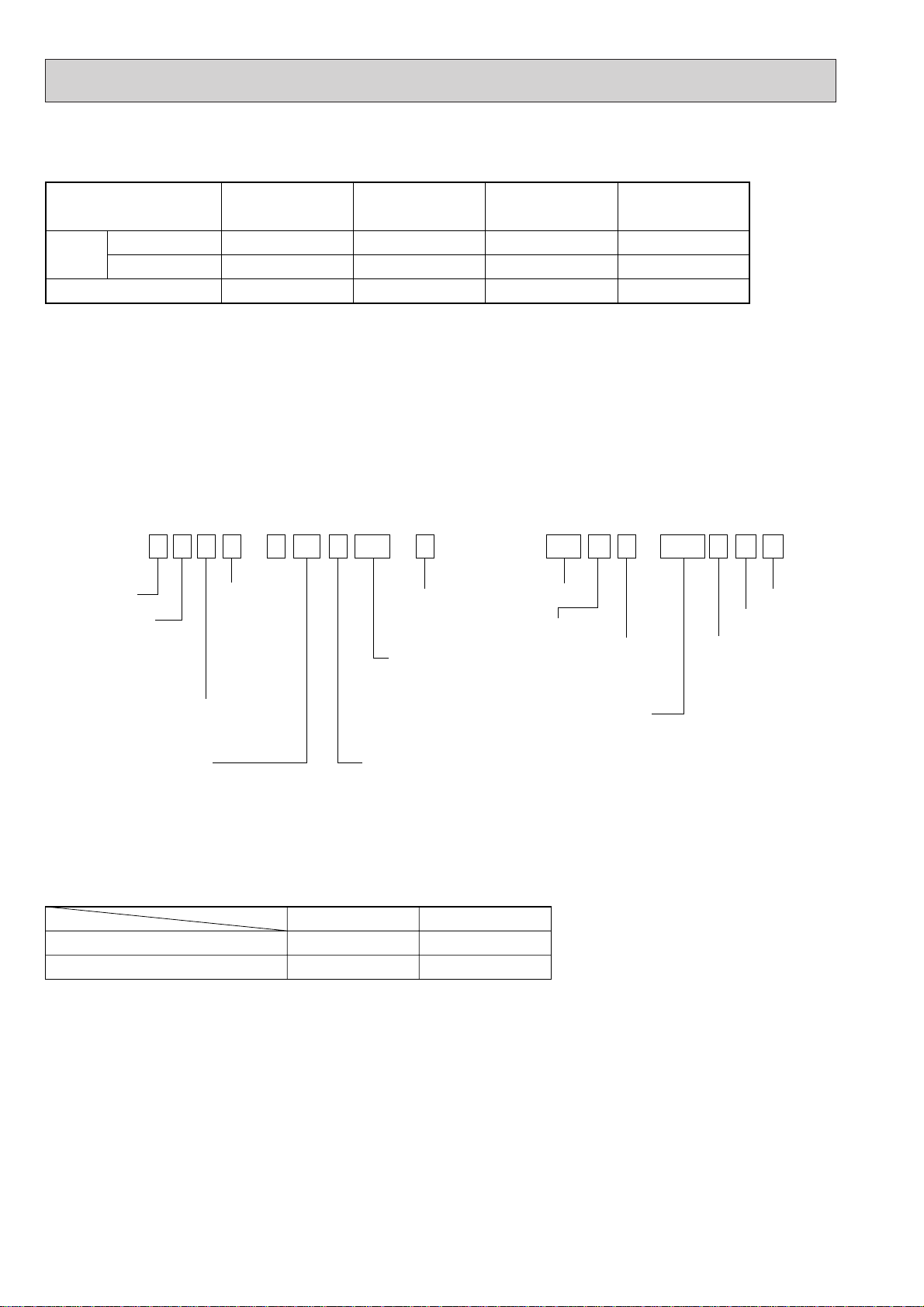

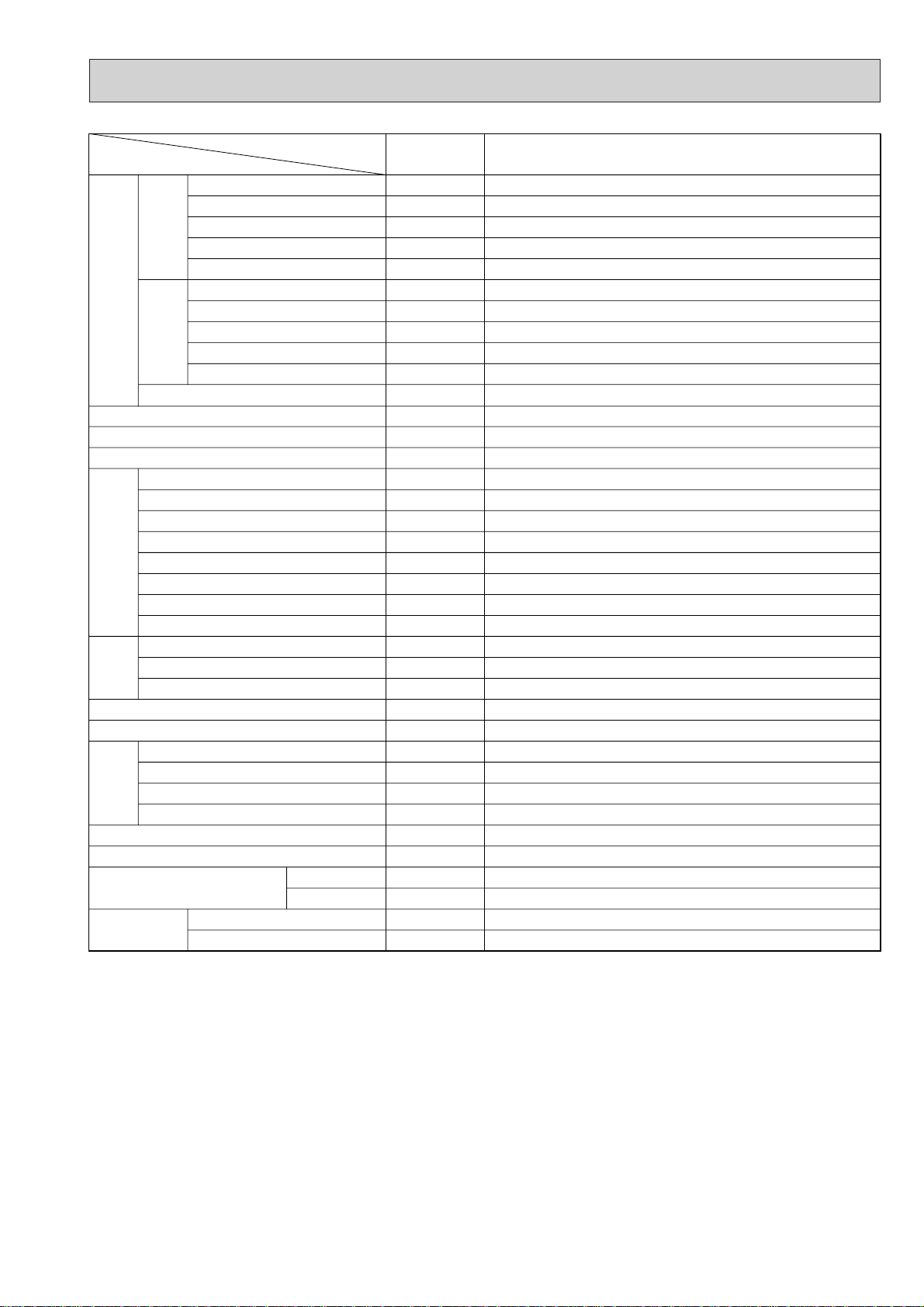

2-2. UNIT SPECIFICATIONS

P L F Y - P 80 V AM - A PU M Y - 125 Y M A

PAC type

AM

KM

M

KM

LMD

Frequency

conversion

controller

NEW frequency converter

one-to-many air conditioners

(flexible design type)

Indicates equivalent

to Cooling capacity

Indicates equivalent

to Cooling capacity

Power supply

V: Single phase

220/230/240V 50Hz

220V 60Hz

Power supply

V: Single phase

220/230/240V 50Hz

220V 60Hz

Y: 3-phase

380/400/415V 50Hz

380V 60Hz

L: Ceiling cassette

K: Wall-mounted type

E: Hidden skylight type

C: Ceiling suspended type

M: Ceiling cassette type

}

M-NET

control

M-NET control

MA control

Sub-number

Frequency

conversion

controller

Outdoor unit

MULTI-S

• Model 125 (5hp)..........For 5 rooms (VM)

...........For 8 rooms VM

1 YM

VM

2 YM1

YMA

( )

Service Ref.

w1

PUMY-71VM

PUMY-71VM

1

PUMY-71VM2 w2

w1

PUMY-125VM

PUMY-125VM

1

PUMY-125YM

w2

PUMY-125VM2

PUMY-125YM1

PUMY-125YMA

Capacity

Cooling (kW)

Heating (kW)

8.3

9.3

2.6

8.0

9.0

2.6

14.5

16.3

3.5

14.0

16.0

3.5Motor for compressor (kW)

Cooling

W.B. 15~24°C

D.B. -5~46°C

Heating

D.B. 15~27°C

W.B. -15~15.5°C

Indoor-side intake air temperature

Outdoor-side intake air temperature

(1) Outdoor Unit

Cooling / Heating capacity indicates the maximum value at operation under the following condition.

w1. Cooling Indoor : D.B. 27°C / W.B. 19.5°C

Outdoor : D.B. 35°C

Heating Indoor : D.B. 21°C

Outdoor : D.B. 9°C / W.B. 6°C

(2) Method for identifying MULTI-S model

■ Indoor unit < When using Model 80 >

w2. Cooling Indoor : D.B. 27°C / W.B. 19.0°C

Outdoor : D.B. 35°C

Heating Indoor : D.B. 20°C

Outdoor : D.B. 7°C / W.B. 6°C

■ Outdoor unit <When using model 125 >

(3) Operating temperature range

Notes D.B. : Dry Bulb Temperature

W.B. : Wet Bulb Temperature

4

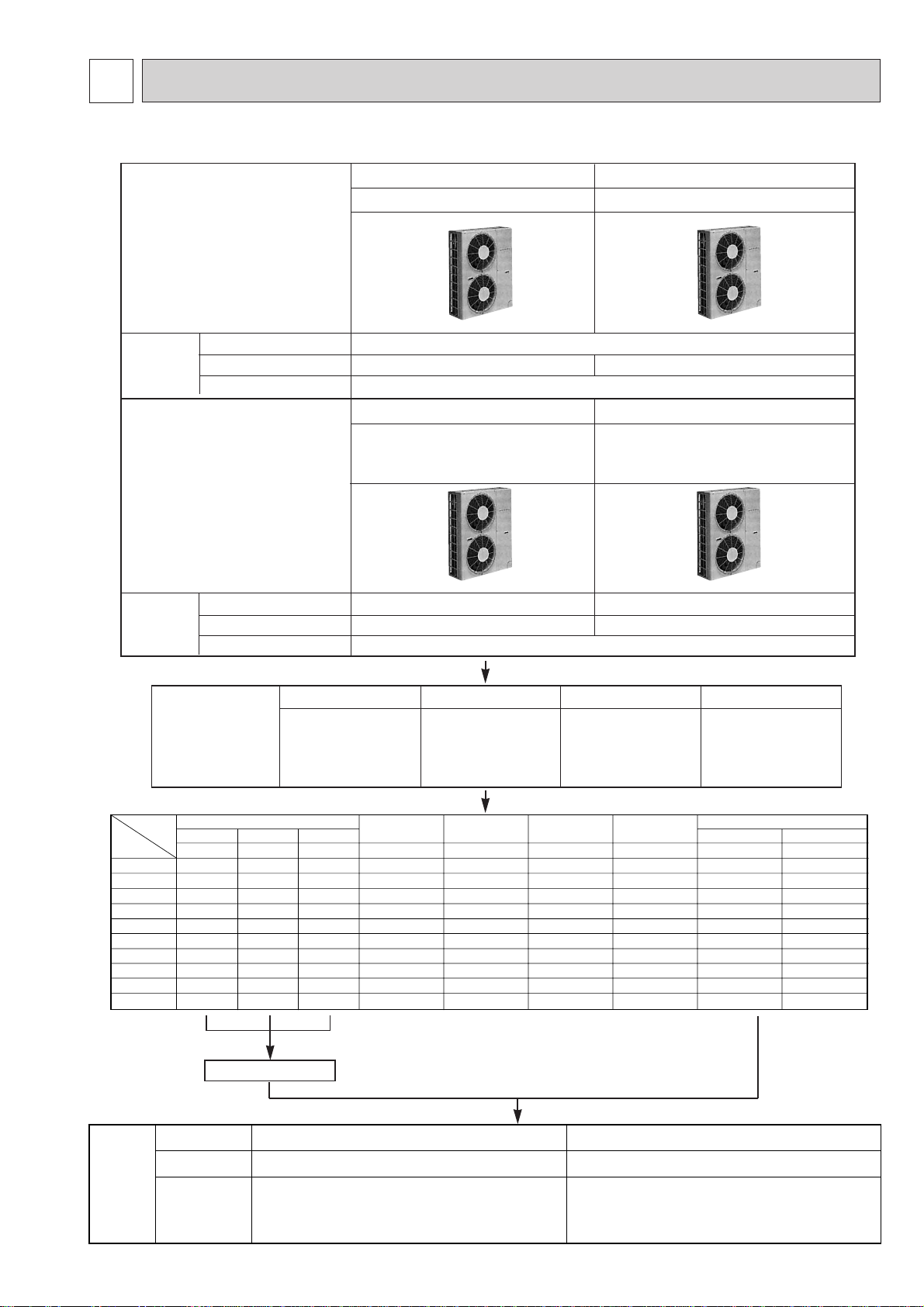

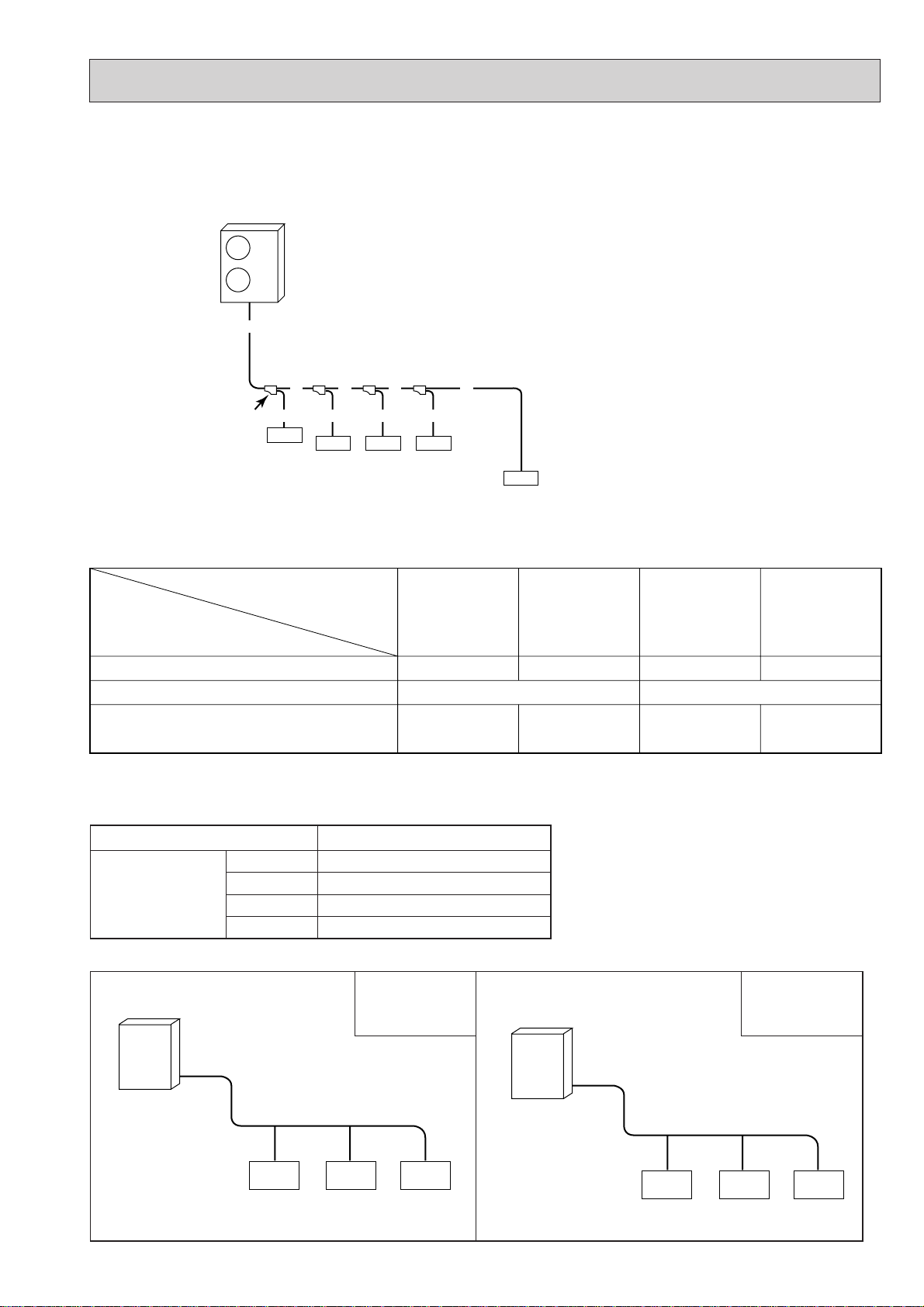

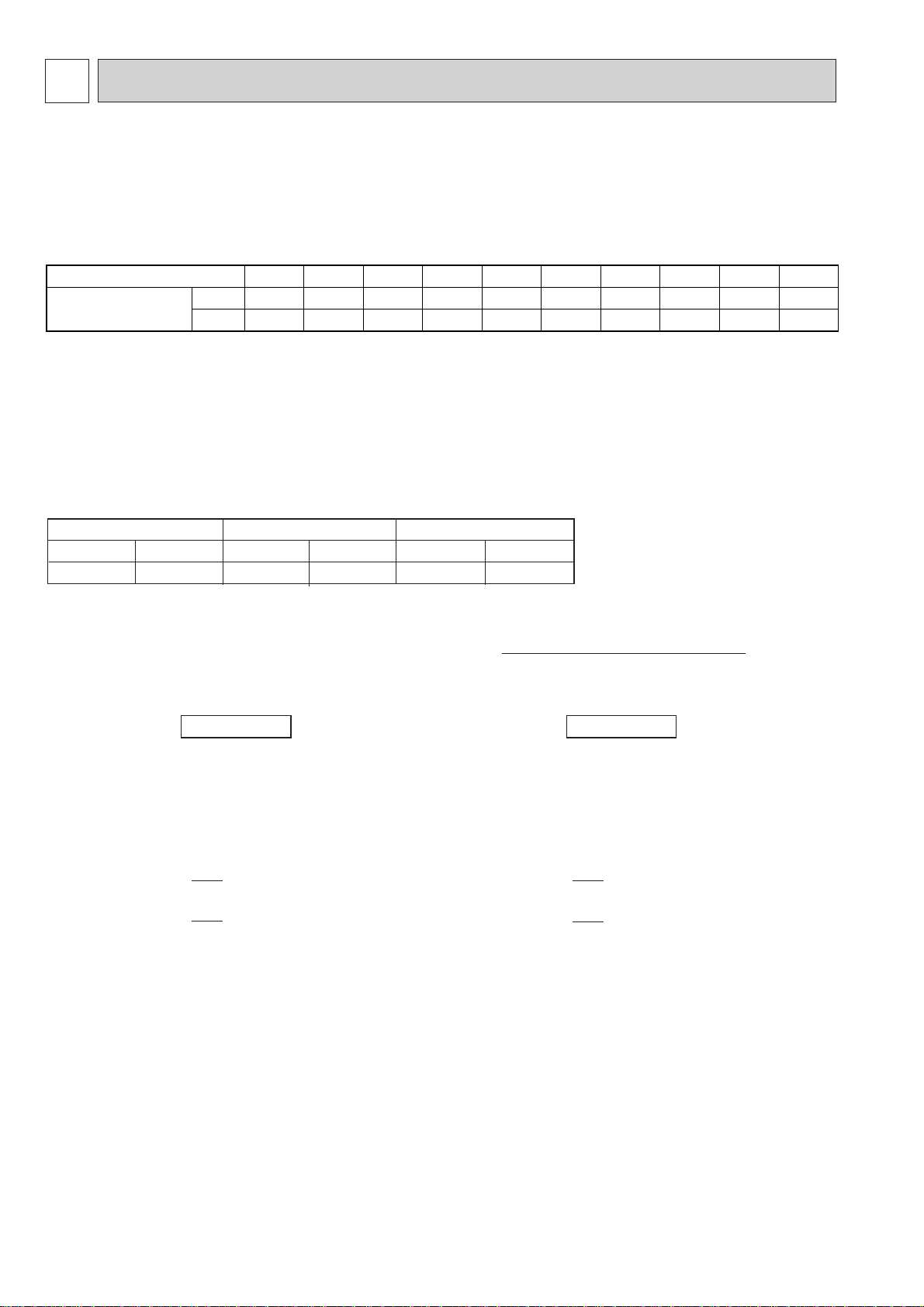

2-3. SYSTEM LAYOUT

A

B

a

indoor

1

C

b

indoor

2

D

c

indoor

3

e

d

indoor

4

indoor

5

First branch

(branching connector)

Outdoor unit

71

25 25 40

125

80 40 40

Outdoor unit

Indoor unit

Type 20 ~ Type 80 Type 20 ~ Type 125

PUMY-71VM

PUMY-71VM

1

PUMY-71VM2

PUMY-125VM

PUMY-125VM

1

PUMY-125VM2

PUMY-125YM

PUMY-125YM

1

PUMY-125YMA

1~8 units

63~163

2~4 units

35~92

2~5 units

63~163

1~4 units

35~92

Indoor unit that can connected

Available capacity of indoor unit

Total capacity of units that can be included system

(50-130% of outdoor unit capacity)

2-3-1. System layout

One outdoor unit using branching connectors can be connected to a maximum of five or eight indoor units.

■ Examples of a branching method

2-3-2. Notes on the connection of indoor and outdoor units

Note: When the total capacity of indoor units exceeds the capacity of the outdoor unit (more than 100%), the rated power of

each indoor unit will be less when they are running simultaneously.

2-3-3. Capacity for outdoor unit

(1) Branching pipe

Model

CMY-Y62C-E

Branching connector

(2) Examples of System Construction (All models)

PIping method

Indoor units

CMY-Y64-C

CMY-Y68

CMY-S65

Outdoor unit

NUMBER OF BRANCHING POINTS

2

4

8

5

Total capacity of

indoor units.

PIping method

90

5

Indoor units

Outdoor unit

Total capacity of

indoor units.

160

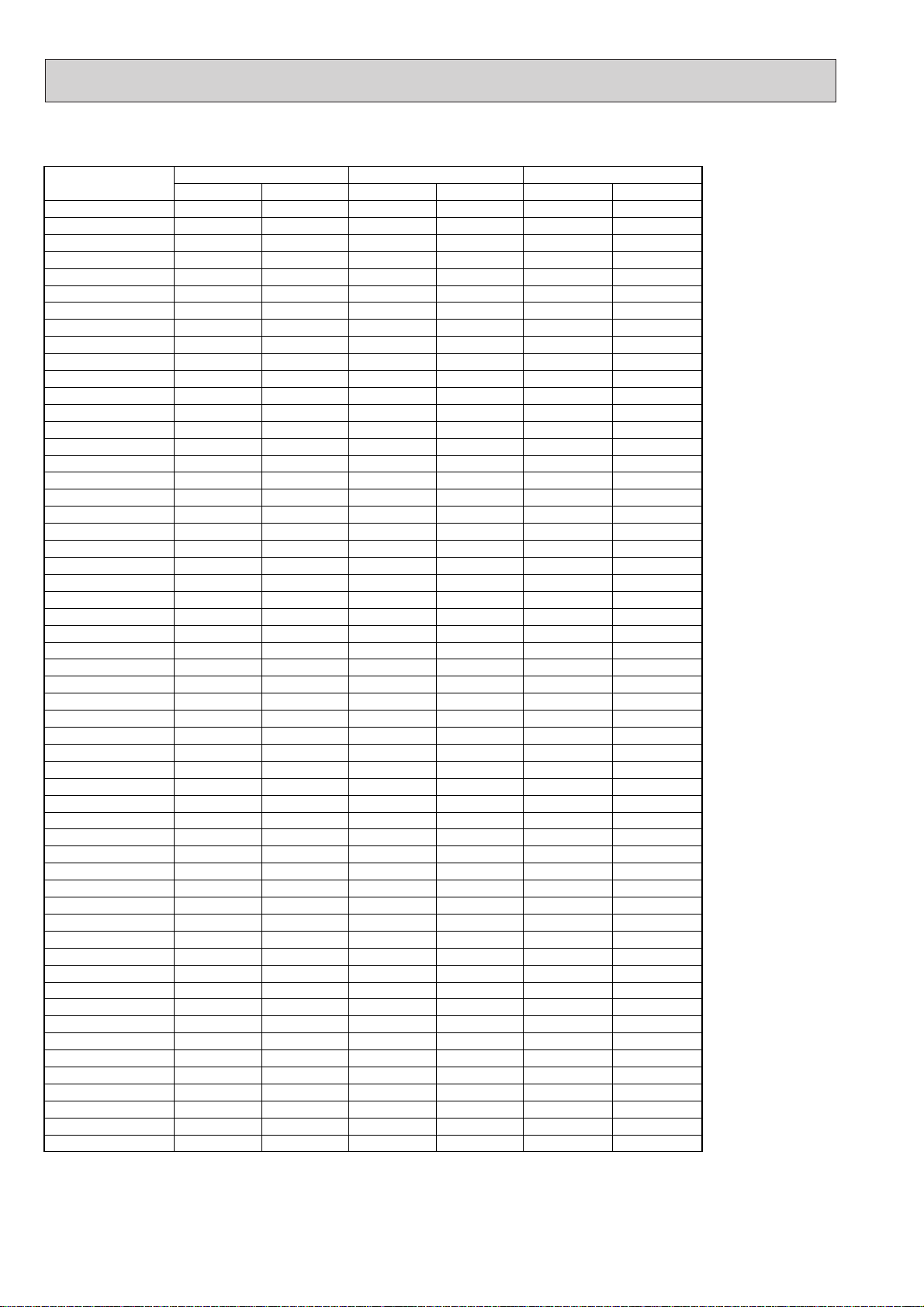

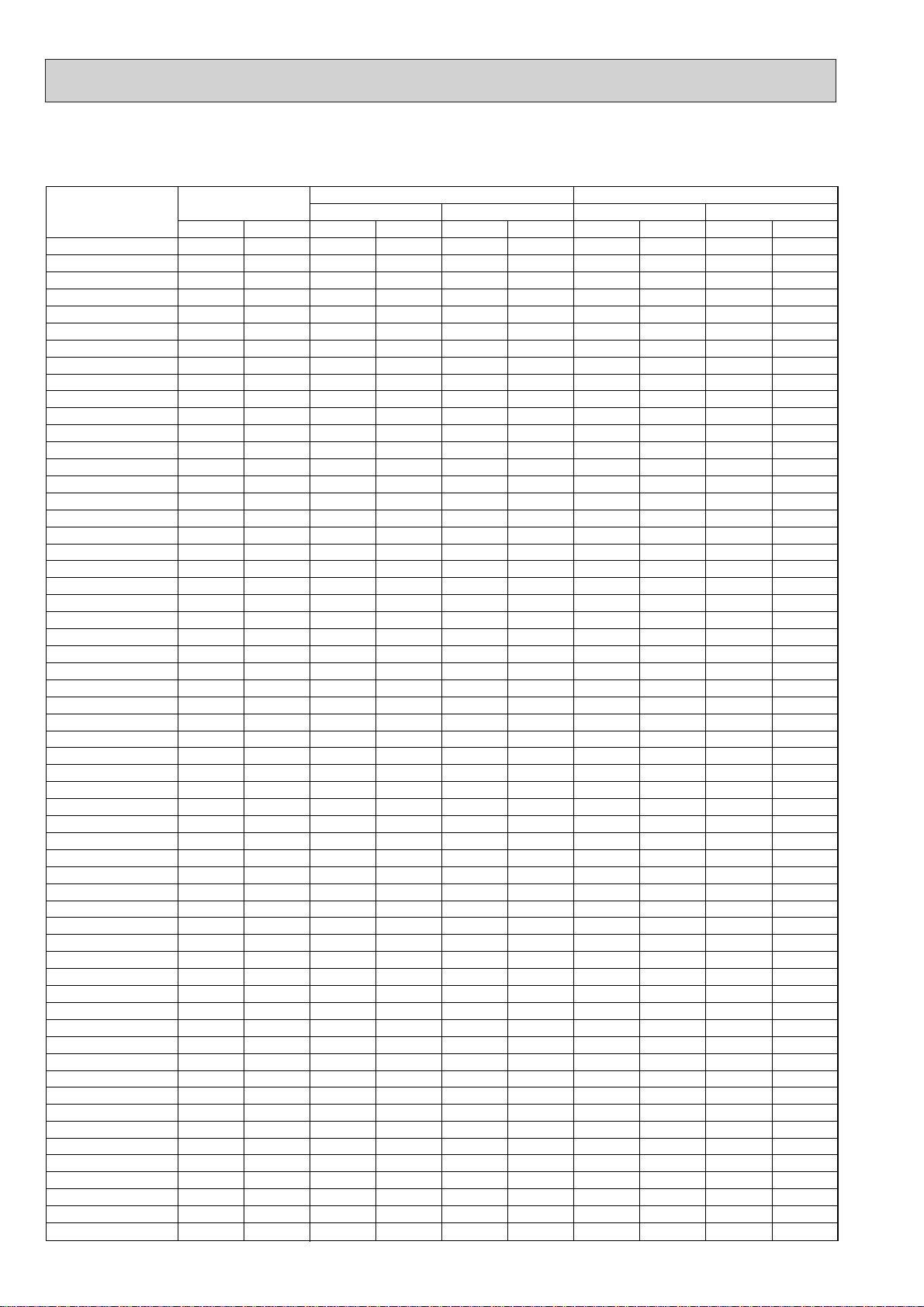

3 SPECIFICATIONS

Item

Rated Cooling capacity

Rated power consumption

Operating current

Operating power factor

Starting current

Rated Heating capacity

Rated power consumption

Operating current

Operating power factor

Standard performance

External finish (Munsell colour-coded markings)

Dimensions H o W o D (Note 1)

Heat exchanger type

Compressor

Fan

Defrost method

Pressure gauge

Protection

Noise level

Weight

Refrigerant pipe size

Refrigerant

Note 1: External dimensions in parentheses indicate the dimensions of protruding parts.

Note 2: Rating conditions (JIS B 8615)

Heating Cooling

Starting current

Rated power supply

Model

Type o quantity

Starting method

Motor output

Capacity control

Daily cooling capacity

Heater <crankcase>

Refrigerating oil (Model)

Type o quantity

Airflow

Motor output

High pressure protection

Compressor protection

Blower protection

devices

Frequency converter circuit

Type o charge amount

Control method

Cooling : Indoor : D.B. 27: W.B. 19.5:

: Outdoor : D.B. 35: W.B. 24:

Heating : Indoor : D.B. 21:

: Outdoor : D.B. 7: W.B. 6:

Service Ref

Gas

Liquid

kcal/h

kW

A

%

A

kcal/h

kW

A

%

A

mm

kW

%

Legal tons

W

L

k/min

W

dB

kg

[ mm

[ mm

kg

7,100

3.50

17.5-16.7-16.0

91

15.0

8,000

3.65

18.2-17.4-16.7

91

15.0

Single phase 220-230-240V 50Hz

Molten-galvanized steel plate (with polyester coating), ivory white <5Y 8/1>

1280 o 900 o 320 (+30) 1280 o 1020 o 350 (+30)

CHV253FAA

Fully enclosed type o 1

Frequency converter start

2.6

Cooling 27-100% Heating 24-100%

1.1 (110Hz)

25-28-30

1.07 (MS56)

Propeller (direct) o 2

95

40 o 2

High pressure pressure sensor (3.0MPa)

Overheating, excessive current protection

52

93

15.88

9.52

R22 o 5

PUMY-125VM PUMY-71VM Unit

12,500

6.57

34.9-33.5-32.2

85

22.0

14,000

6.10

32.6-31.2-29.9

85

22.0

Crossover fin

EHV46FAA

3.5

Cooling 27-100% Heating 25-100%

1.9 (104Hz)

38-41-45

1.4 (MS32)

90

60 o 2

Reverse cycle

—

Thermal switch

Thermal switch

54

130

19.05

9.52

R22 o 8.5

Expansion valve

6

Item

Service Ref

Rated Cooling capacity

Rated power consumption

Operating current

Operating power factor

Starting current

Rated Heating capacity

Rated power consumption

Operating current

Operating power factor

Standard performance

Heating Cooling

Starting current

Rated power supply

External finish (Munsell colour-coded markings)

Dimensions H o W o D (Note 1)

Unit

kcal/h

kW

A

%

A

kcal/h

kW

A

%

A

mm

7,100

3.50 / 3.63

17.5-16.7-16.0 / 18.1

91

15.0

8,000

3.65 / 3.53

18.2-17.4-16.7 / 17.6

91

15.0

Single phase 220-230-240V 50Hz / 220V 60Hz

Molten-galvanized steel plate (with polyester coating), ivory white <5Y 8/1>

1280 o 900 o 320 (+30) 1280 o 1020 o 350 (+30)

Heat exchanger type

Model

Type o quantity

Starting method

Motor output

Capacity control

Compressor

Daily cooling capacity

Heater <crankcase>

Refrigerating oil (Model)

Type o quantity

Airflow

Fan

Motor output

kW

%

Legal tons

W

L

k/min

W

Cooling 27-100% Heating 24-100%

CHV253FAA

Fully enclosed type o 1

Frequency converter start

2.6

1.1 (110Hz)

—

1.07 (MS56)

Propeller (direct) o 2

95

40 o 2

Defrost method

Pressure gauge

High pressure protection

High pressure pressure sensor (3.0MPa)

Compressor protection

Blower protection

Protection

devices

Frequency converter circuit

Noise level

Weight

Refrigerant pipe size

Refrigerant

Type o charge amount

Control method

Gas

Liquid

dB

kg

[ mm

[ mm

kg

Overheating, excessive current protection

52

93

15.88

9.52

R22 o 5

Note 1: External dimensions in parentheses indicate the dimensions of protruding parts.

Note 2: Rating conditions (JIS B 8615)

Cooling: Indoor : D.B. 27: W.B. 19.5:

: Outdoor : D.B. 35: W.B. 24:

Heating : Indoor : D.B. 21:

: Outdoor : D.B. 7: W.B. 6:

Crossover fin

Cooling 27-100% Heating 25-100%

Reverse cycle

—

Thermal switch

Thermal switch

Expansion valve

PUMY-125VM

1 PUMY-71VM1

12,500

6.57 / 6.43

34.9-33.5-32.2 / 33.6

85 / 87

22.0

14,000

6.10 / 6.03

32.6-31.2-29.9 / 31.5

85 / 87

22.0

EHV46FAA

3.5

1.9 (104Hz)

—

1.4 (MS32)

90

60 o 2

54

130

19.05

9.52

R22 o 8.5

7

Item

Service Ref

Rated Cooling capacity

Rated power consumption

Operating current

Operating power factor

Starting current

Rated Heating capacity

Rated power consumption

Operating current

Operating power factor

Standard performance

Heating Cooling

Starting current

Rated power supply

External finish (Munsell colour-coded markings)

Dimensions H o W o D (Note 1)

Heat exchanger type

Model

Type o quantity

Starting method

Motor output

Capacity control

Daily cooling capacity

Compressor

Heater <crankcase>

Refrigerating oil (Model)

Type o quantity

Airflow

Fan

Motor output

Defrost method

Pressure gauge

High pressure protection

Compressor protection

Blower protection

Protection

devices

Frequency converter circuit

Noise level

Weight

Refrigerant pipe size

Refrigerant

Type o charge amount

Control method

Gas

Liquid

Unit

kW

kW

A

%

A

kW

kW

A

%

A

mm

kW

%

Legal tons

W

L

k/min

W

dB

kg

[ mm

[ mm

kg

2 PUMY-71VM2

8.0

3.50 / 3.63

17.5-16.7-16.0 / 18.1

91

15.0

9.0

3.65 / 3.53

18.2-17.4-16.7 / 17.6

91

15.0

PUMY-125VM

14.0

6.57 / 6.43

34.9-33.5-32.2 / 33.6

85 / 87

22.0

16.0

6.10 / 6.03

32.6-31.2-29.9 / 31.5

85 / 87

22.0

Single phase 220-230-240V 50Hz / 220V 60Hz

Molten-galvanized steel plate (with polyester coating), ivory white <5Y 8/1>

1280 o 900 o 320 (+30) 1280 o 1020 o 350 (+30)

Crossover fin

EHV33FAG

EHV46FAG

Fully enclosed type o 1

Frequency converter start

2.6

Cooling 36-100% Heating 32-100%

1.1 (83Hz)

—

1.4 (MS32)

Cooling 27-100% Heating 25-100%

3.5

1.9 (104Hz)

—

1.4 (MS32)

Propeller (direct) o 2

95

40 o 2

90

60 o 2

Reverse cycle

—

High pressure pressure sensor (3.0MPa)

Thermal switch

Thermal switch

Overheating, excessive current protection

52

102

15.88

9.52

R22 o 5

54

130

19.05

9.52

R22 o 8.5

Expansion valve

Note 1: External dimensions in parentheses indicate the dimensions of protruding parts.

Note 2: Rating conditions (JIS B 8616)

Cooling: Indoor : D.B. 27: W.B. 19.0:

: Outdoor : D.B. 35: W.B. 24:

Heating : Indoor : D.B. 20:

: Outdoor : D.B. 7: W.B. 6:

8

Item

Rated Cooling capacity

Rated power consumption

Operating current

Operating power factor

Starting current

Rated Heating capacity

Rated power consumption

Operating current

Operating power factor

Standard performance

External finish (Munsell colour-coded markings)

Dimensions H o W o D (Note 1)

Heat exchanger type

Compressor

Fan

Defrost method

Pressure gauge

Protection

Noise level

Weight

Refrigerant pipe size

Refrigerant

Note 1: External dimensions in parentheses indicate the dimensions of protruding parts.

Note 2: Rating conditions (JIS B 8615)

Cooling : Indoor : D.B. 27: W.B. 19.5:

Heating Cooling

Starting current

Rated power supply

Model

Type o quantity

Starting method

Motor output

Capacity control

Daily cooling capacity

Heater <crankcase>

Refrigerating oil (Model)

Type o quantity

Airflow

Motor output

High pressure protection

Compressor protection

Blower protection

devices

Frequency converter circuit

Type o charge amount

Control method

: Outdoor : D.B. 35: W.B. 24:

Heating : Indoor : D.B. 21:

: Outdoor : D.B. 7: W.B. 6:

Service Ref

Gas

Liquid

Unit

kcal/h

kW

A

%

A

kcal/h

kW

A

%

A

mm

kW

%

Legal tons

W

L

k/min

W

dB

kg

[ mm

[ mm

kg

3 phase 380-400-415V 50Hz

Molten-galvanized steel plate (with polyester coating), ivory white <5Y 8/1>

1280 o 1020 o 350 (+30)

Fully enclosed type o 1

Frequency converter start

Cooling 27-100% Heating 25-100%

Propeller (direct) o 2

High pressure pressure sensor (3.0MPa)

Overheating, excessive current protection

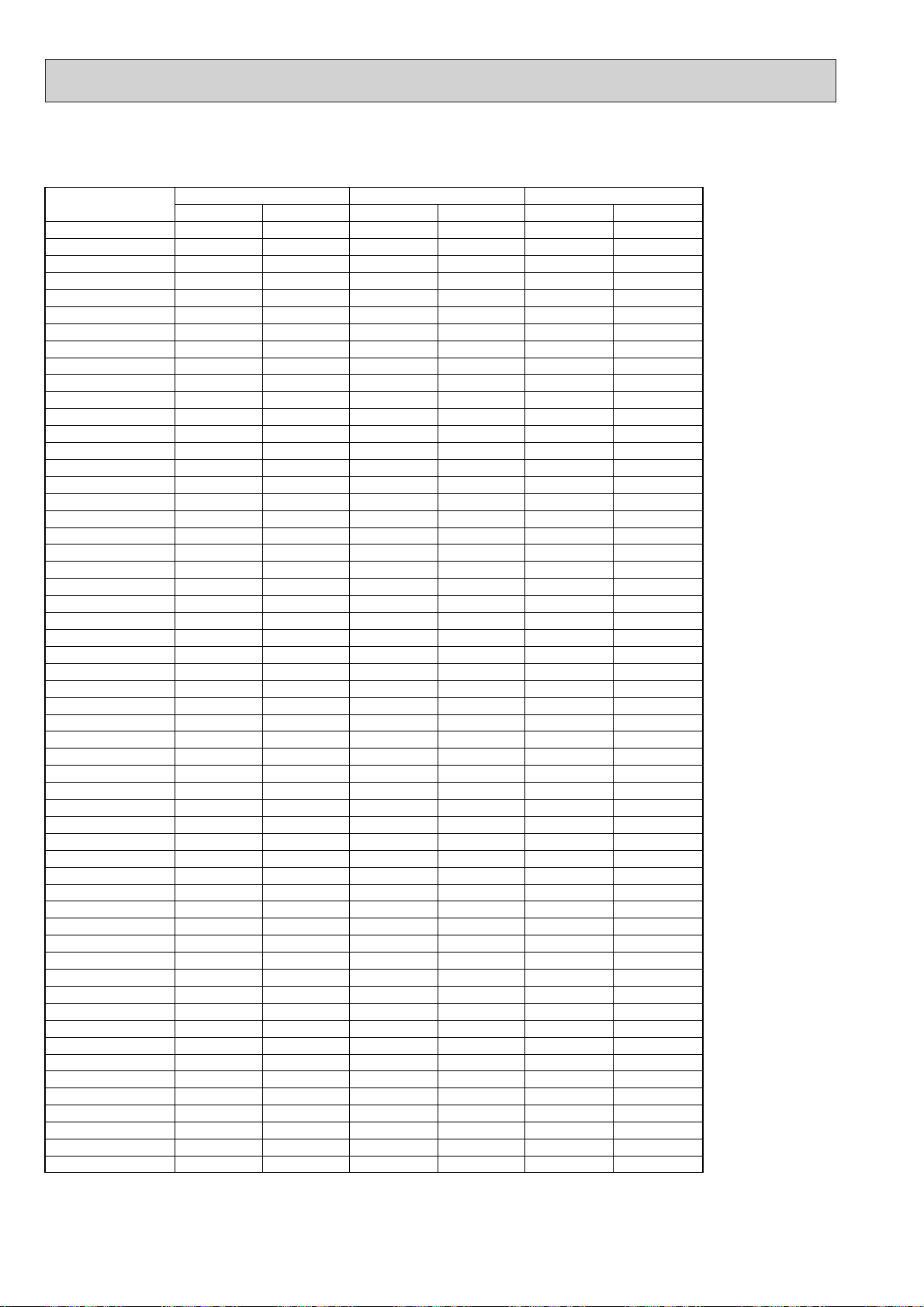

PUMY-125YM

12,500

5.95

9.6-9.1-8.8

94

8.0

14,000

5.58

9.0-8.6-8.3

94

8.0

Crossover fin

EHV46FAD

3.5

1.9 (104Hz)

—

1.4 (MS32)

90

60 o 2

Reverse cycle

—

Thermal switch

Thermal switch

54

127

19.05

9.52

R22 o 8.5

Expansion valve

9

Item

Rated Cooling capacity

Rated power consumption

Operating current

Operating power factor

Starting current

Rated Heating capacity

Rated power consumption

Operating current

Operating power factor

Standard performance

External finish (Munsell colour-coded markings)

Dimensions H o W o D (Note 1)

Heat exchanger type

Compressor

Fan

Defrost method

Pressure gauge

Protection

Noise level

Weight

Refrigerant pipe size

Refrigerant

Note 1: External dimensions in parentheses indicate the dimensions of protruding parts.

Note 2: Rating conditions (JIS B 8616)

Cooling : Indoor : D.B. 27: W.B. 19.0:

Heating Cooling

Starting current

Rated power supply

Model

Type o quantity

Starting method

Motor output

Capacity control

Daily cooling capacity

Heater <crankcase>

Refrigerating oil (Model)

Type o quantity

Airflow

Motor output

High pressure protection

Compressor protection

Blower protection

devices

Frequency converter circuit

Type o charge amount

Control method

: Outdoor : D.B. 35: W.B. 24:

Heating : Indoor : D.B. 20:

: Outdoor : D.B. 7: W.B. 6:

Service Ref

Gas

Liquid

Unit

kW

kW

A

%

A

kW

kW

A

%

A

mm

kW

%

Legal tons

W

L

k/min

W

dB

kg

[ mm

[ mm

kg

3 phase 380-400-415V 50Hz / 380V 60Hz

Molten-galvanized steel plate (with polyester coating), ivory white <5Y 8/1>

1280 o 1020 o 350 (+30)

Fully enclosed type o 1

Frequency converter start

Cooling 27-100% Heating 25-100%

Propeller (direct) o 2

High pressure pressure sensor (3.0MPa)

Overheating, excessive current protection

PUMY-125YM1

14.0

5.95

9.6-9.1-8.8 / 9.6

94

8.0

16.0

5.58

9.0-8.6-8.3 / 9.0

94

8.0

Crossover fin

EHV46FAK

3.5

1.9 (104Hz)

—

1.4 (MS32)

90

60 o 2

Reverse cycle

—

Thermal switch

Thermal switch

54

127

19.05

9.52

R22 o 8.5

Expansion valve

10

Item

Rated Cooling capacity

Rated power consumption

Operating current

Operating power factor

Starting current

Rated Heating capacity

Rated power consumption

Operating current

Operating power factor

Standard performance

External finish (Munsell colour-coded markings)

Dimensions H o W o D (Note 1)

Heat exchanger type

Compressor

Fan

Defrost method

Pressure gauge

Protection

Noise level

Weight

Refrigerant pipe size

Refrigerant

Note 1: External dimensions in parentheses indicate the dimensions of protruding parts.

Note 2: Rating conditions (JIS B 8616)

Cooling : Indoor : D.B. 27: W.B. 19.0:

Heating Cooling

Starting current

Rated power supply

Model

Type o quantity

Starting method

Motor output

Capacity control

Daily cooling capacity

Heater <crankcase>

Refrigerating oil (Model)

Type o quantity

Airflow

Motor output

High pressure protection

Compressor protection

Blower protection

devices

Frequency converter circuit

Type o charge amount

Control method

: Outdoor : D.B. 35: W.B. 24:

Heating : Indoor : D.B. 20:

: Outdoor : D.B. 7: W.B. 6:

Service Ref

Gas

Liquid

Unit

kW

kW

A

%

A

kW

kW

A

%

A

mm

kW

%

Legal tons

W

L

k/min

W

dB

kg

[ mm

[ mm

kg

3 phase 380-400-415V 50Hz

Molten-galvanized steel plate (with polyester coating), ivory white <5Y 8/1>

1280 o 1020 o 350 (+30)

Fully enclosed type o 1

Frequency converter start

Cooling 27-100% Heating 25-100%

Propeller (direct) o 2

High pressure pressure sensor (3.0MPa)

Overheating, excessive current protection

PUMY-125YMA

14.0

5.95

9.6-9.1-8.8

94

8.0

16.0

5.58

9.0-8.6-8.3

94

8.0

Crossover fin

EHV46FAK

3.5

1.9 (104Hz)

—

1.4 (MS32)

90

60 o 2

Reverse cycle

—

Thermal switch

Thermal switch

54

127

19.05

9.52

R22 o 8.5

Expansion valve

11

4 DATA

Model 20

Model Number for indoor unit

Model Capacity

Kcal/h

kW w

20

22

Model 25

25

28

Model 32

32

36

Model 40

40

45

Model 50

50

56

Model 63

63

71

Model 71

71

80

Model 80

80

90

Model 100

100

112

Model 125

125

140

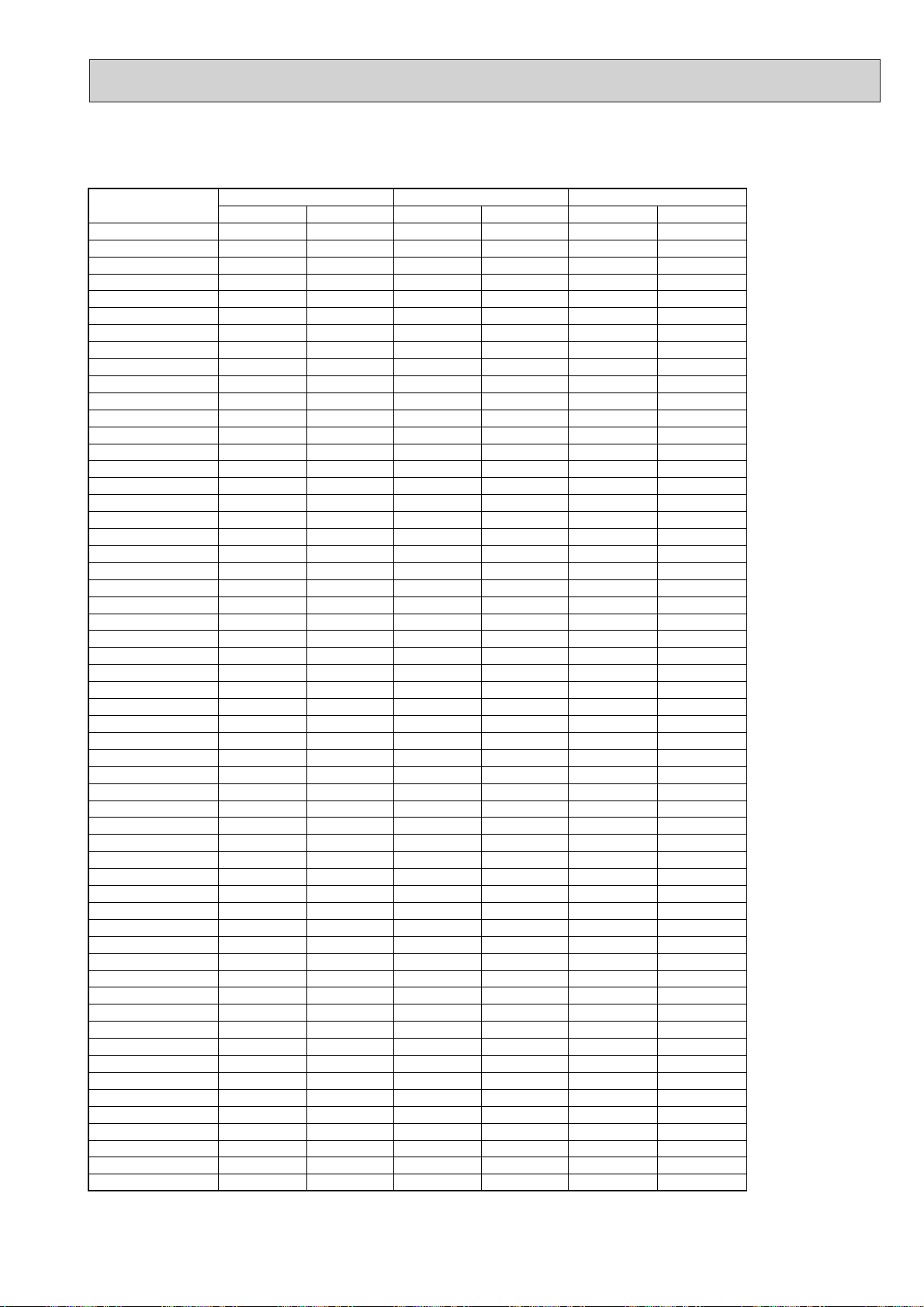

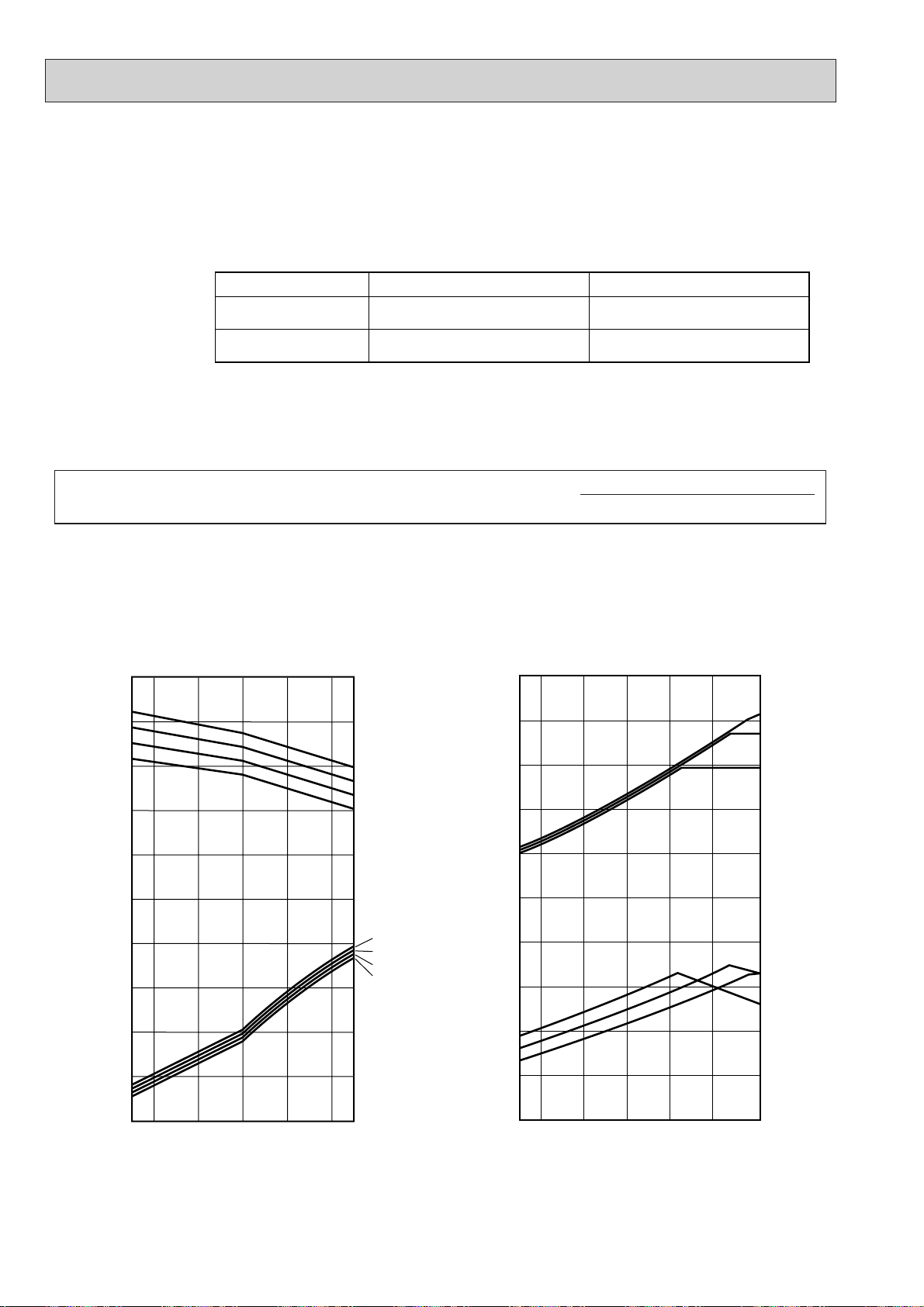

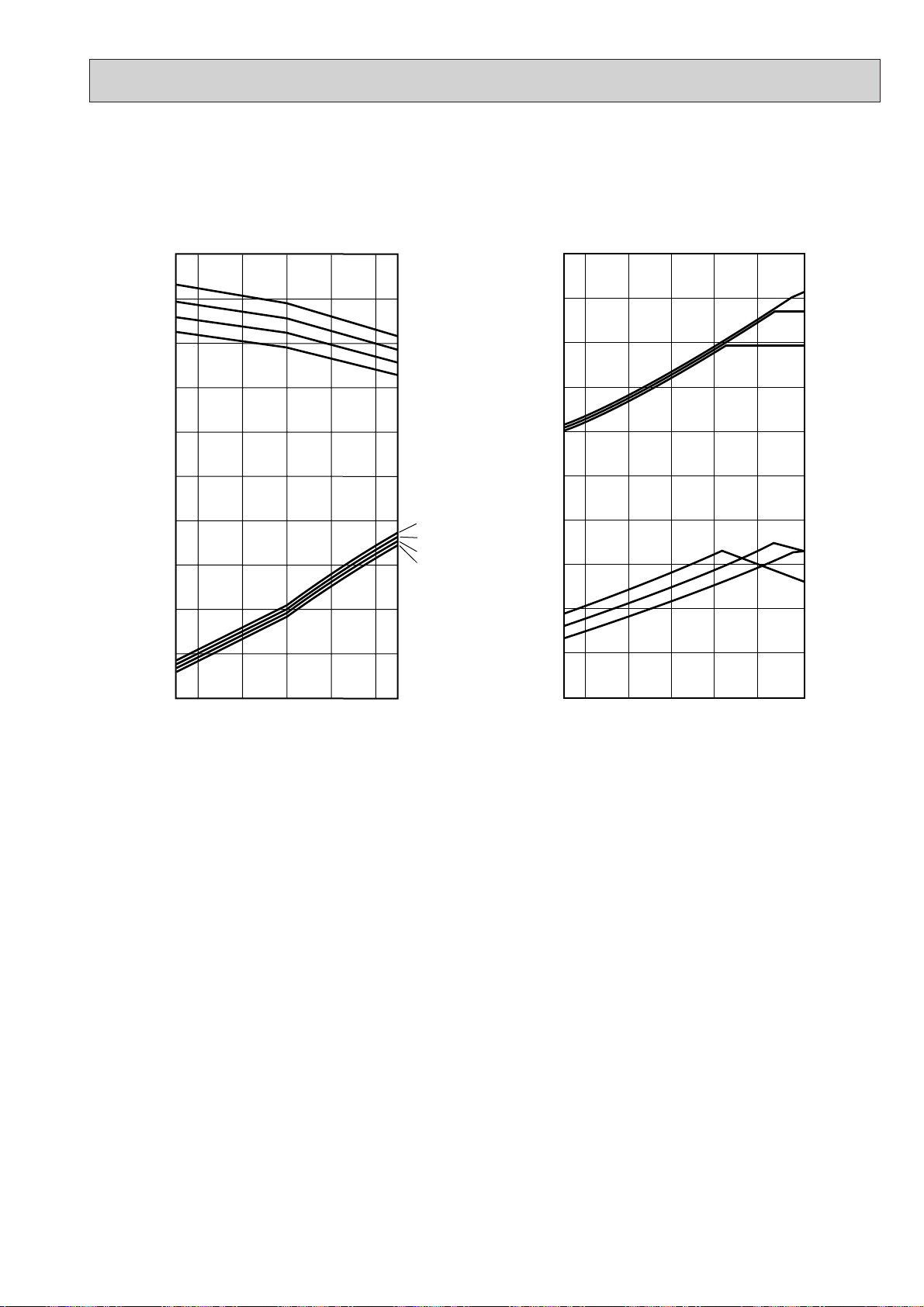

4-1. COOLING AND HEATING CAPACITY AND CHARACTERISTICS

4-1-1. Method for obtaining system cooling and heating capacity:

To obtain the system cooling and heating capacity and the electrical characteristics of the outdoor unit, first add up the ratings

of all the indoor units connected to the outdoor unit (see table below), and then use this total to find the standard capacity with

the help of the tables on p.13~27.

(1) Capacity of indoor unit

w : Model of indoor unit “–A”

(2) Sample calculation

1System assembled from indoor and outdoor unit (in this example the total capacity of the indoor units is greater than that of

the outdoor unit)

• Outdoor unit PUMY-125YM

• Indoor unit PKFY-P25VAM o 2 , PLFY-P50VLMD o 2

2According to the conditions in 1, the total capacity of the indoor unit will be: 25 o 2 + 50 o 2 = 150

3The following figures are obtained from the 150 total capacity row of the standard capacity table (p.23):

Capacity (kcal/h)

Cooling

13,026

AB

Heating

14,288

Outdoor unit power consumption (kW)

Cooling

6.15

Heating

5.98

Outdoor unit current (A)

Cooling

9.4

Heating

9.2

4-1-2. Method for obtaining the heating and cooling capacity of an indoor unit:

(1) The capacity of each indoor unit (kcal/h) = the capacity A(or B) o

(2) Sample calculation (using the system described above in 4-1-1. (2) ):

During cooling: During heating:

• The total model capacity of the indoor unit is:

25 o 2 + 50 o 2=150kcal/h

Therefore, the capacity of PKFY-P25VAM and

PLFY-P50VLMD will be calculated as follows by

using the formula in 4-1-2. (1):

Model 25=13,026 o = 2,171kcal/h

Model 50=13,026 o = 4,342kcal/h

25

150

50

150

• The total model capacity of indoor unit is:

28 o 2 + 56 o 2=168kcal/h

Therefore, the capacity of PKFY-P25VAM and PLFYP50VLMD will be calculated as follows by using the formula in 4-1-2. (1):

Model 25=14,288 o = 2,381kcal/h

Model 50=14,288 o = 4,762kcal/h

total model capacity of all indoor units

model capacity

28

168

56

168

12

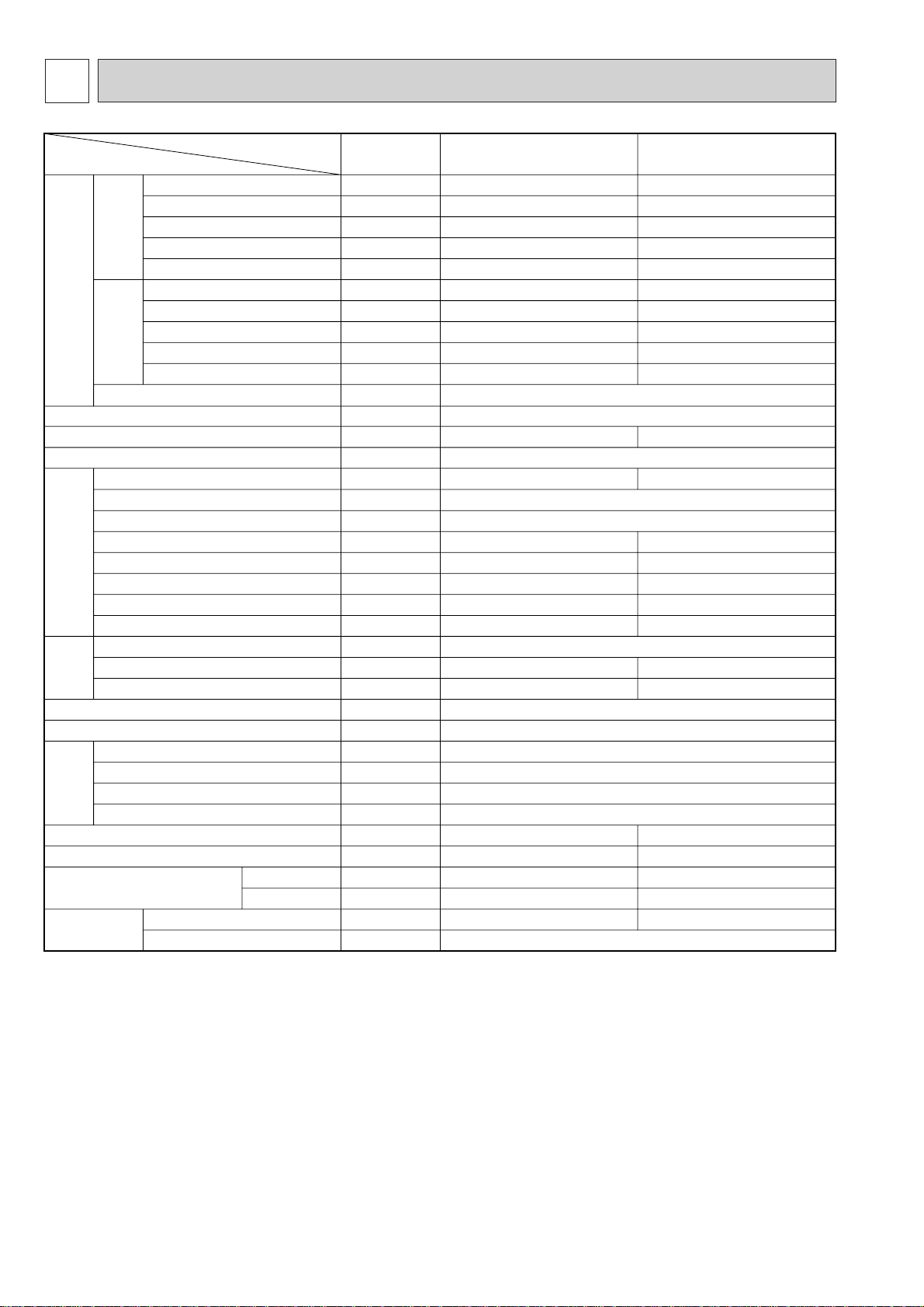

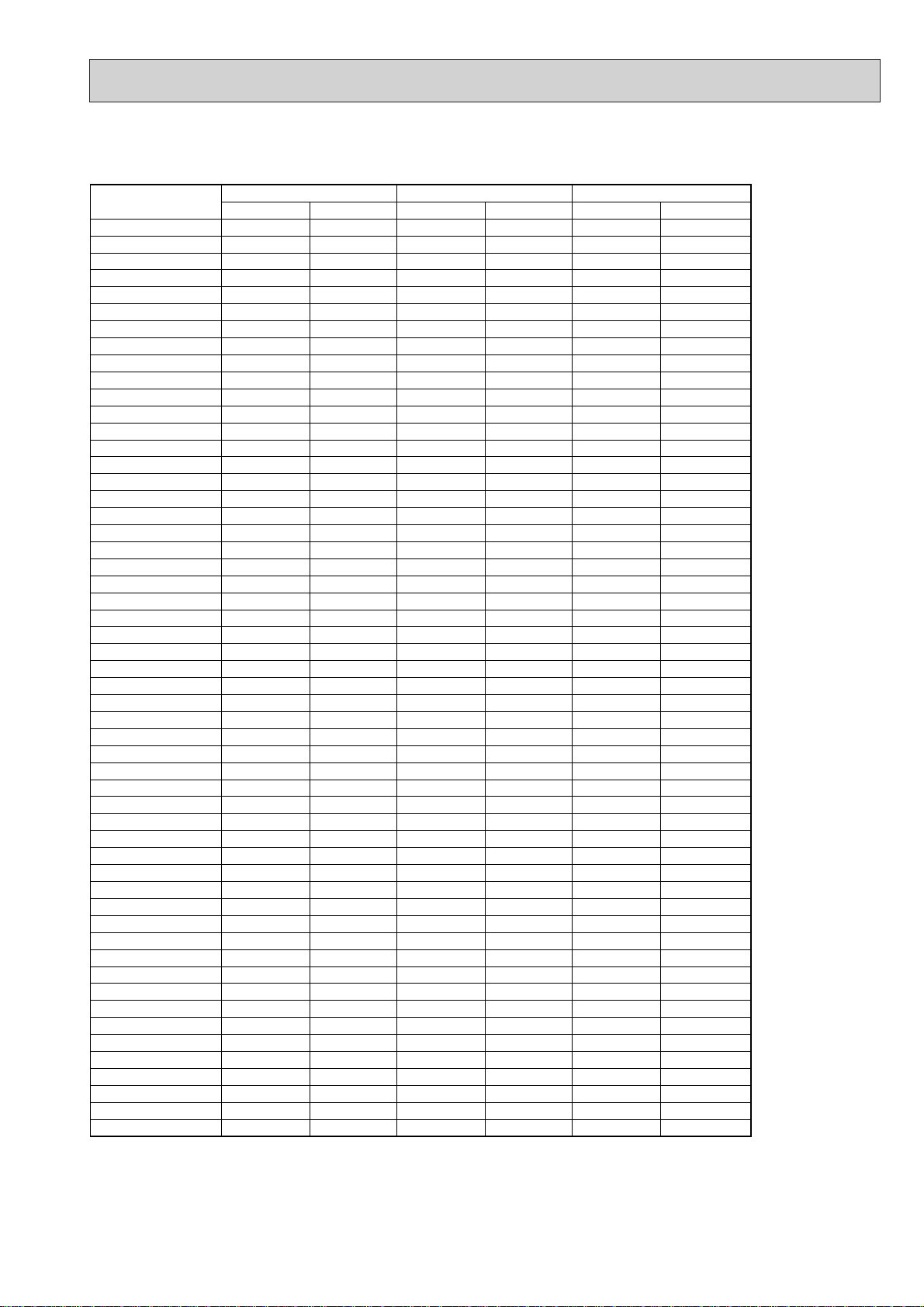

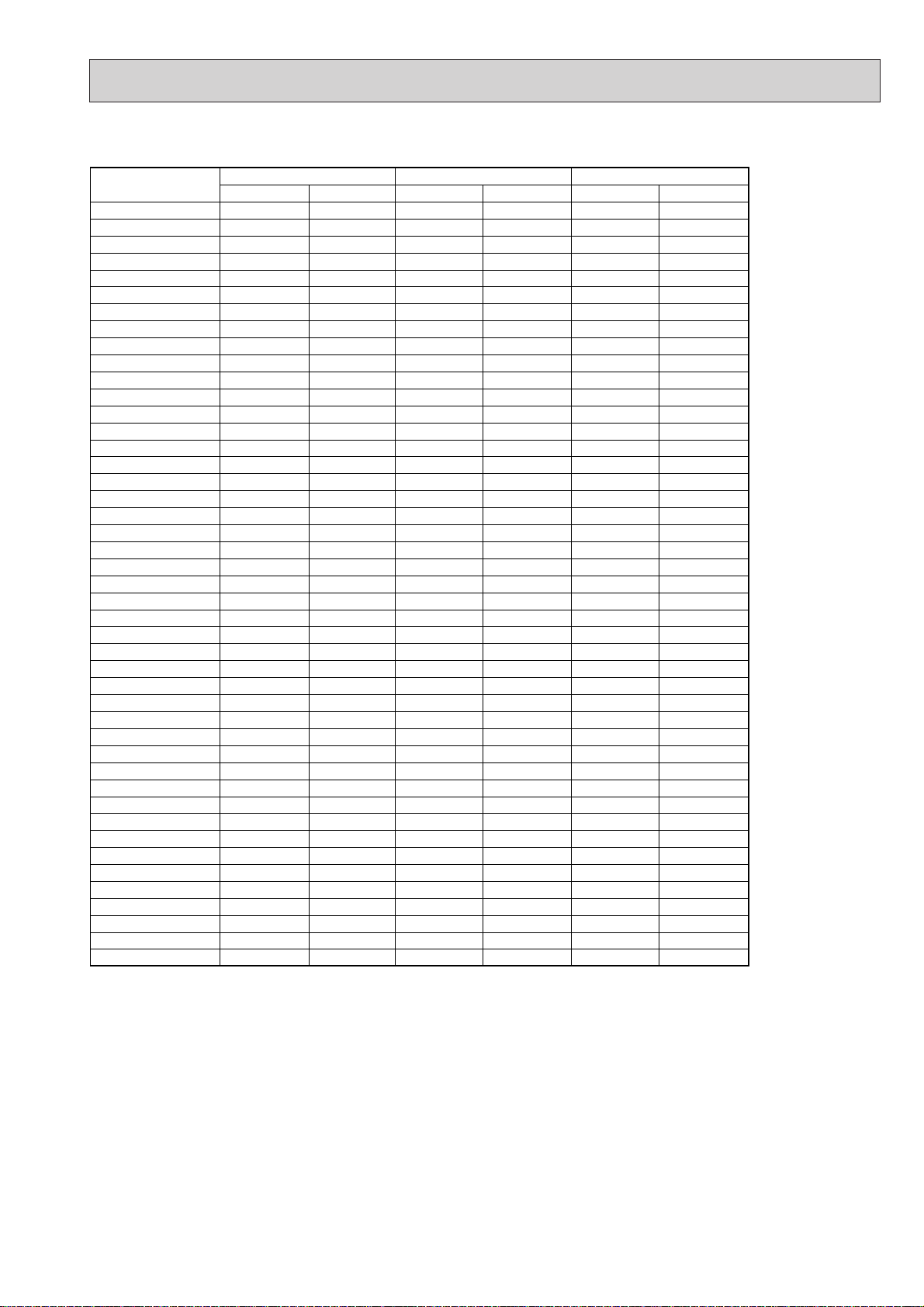

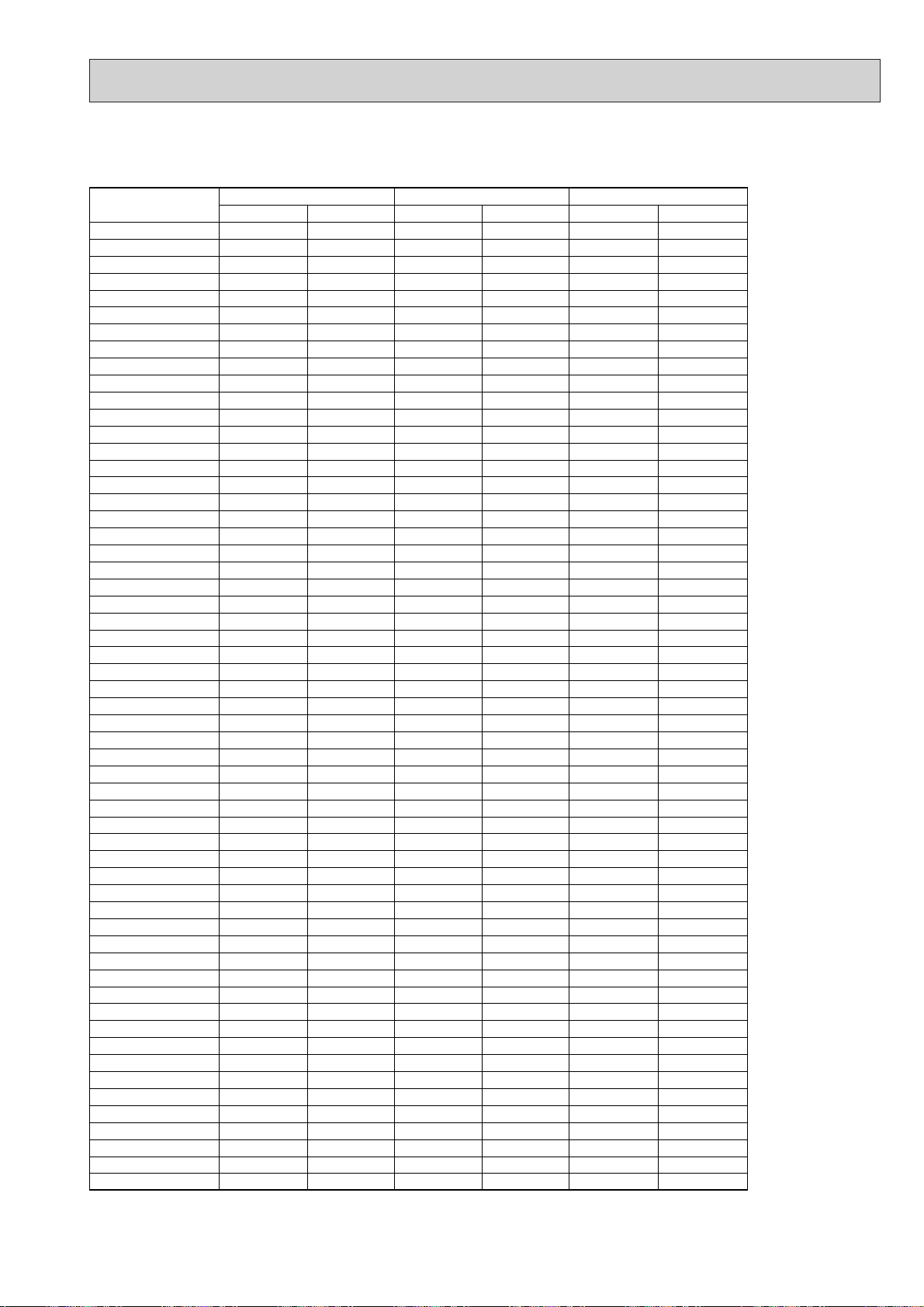

4-2. STANDARD CAPACITY DIAGRAM

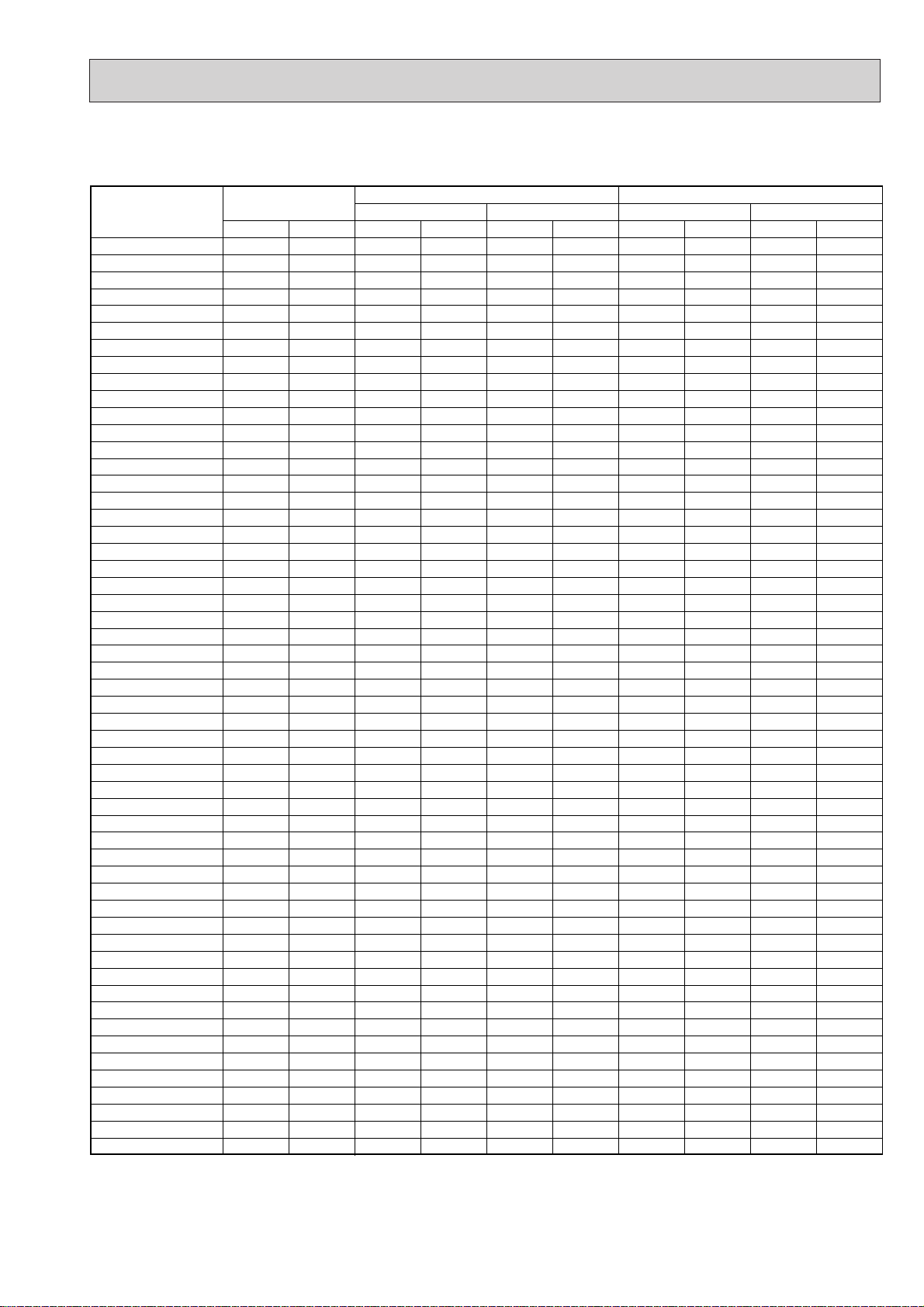

• PUMY-71VM, PUMY-71VM1 STANDARD CAPACITY DIAGRAM

Total capacity of

indoor units(kcal/h)

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

Capacity (kcal/h) Power consumption (kW) Current (A)

Cooling Heating

4000

4100

4200

4300

4400

4500

4600

4700

4800

4900

5000

5100

5200

5300

5400

5500

5600

5700

5800

5900

6000

6100

6200

6300

6400

6500

6600

6700

6800

6900

7000

7100

7122

7144

7166

7189

7211

7223

7255

7277

7299

7322

7344

7366

7388

7410

7432

7455

7477

7499

7542

7543

7566

7588

4500

4610

4720

4830

4940

5050

5160

5270

5380

5490

5600

5715

5831

5946

6062

6177

6292

6408

6523

6638

6754

6869

6985

7100

7213

7325

7438

7550

7663

7775

7888

8000

8012

8024

8036

8049

8061

8073

8085

8097

8109

8121

8133

8146

8158

8170

8182

8194

8206

8218

8231

8243

8255

8267

Cooling Heating

2.02

2.07

2.12

2.17

2.22

2.27

2.31

2.36

2.41

2.46

2.51

2.55

2.59

5.64

2.69

2.74

2.79

2.83

2.88

2.93

2.98

3.02

3.07

3.11

3.16

3.21

3.26

3.31

3.36

3.40

3.45

3.50

3.50

3.51

3.51

3.52

3.52

3.53

3.53

3.54

3.54

3.55

3.55

3.56

3.56

3.57

3.57

3.58

3.58

3.59

3.60

3.60

3.61

3.61

2.41

2.45

2.49

2.53

2.58

2.63

2.67

2.71

2.75

2.79

2.83

2.87

2.92

2.96

3.00

3.04

3.08

3.12

3.16

3.20

3.24

3.28

3.31

3.35

3.39

3.42

3.46

3.49

3.54

3.58

3.61

3.65

3.64

3.63

3.61

3.60

3.58

3.57

3.55

3.54

3.52

3.51

3.48

3.47

3.45

3.44

3.42

3.41

3.39

3.38

3.36

3.35

3.33

3.32

220V, 50Hz

Cooling Heating

10.1

10.4

10.6

10.8

11.1

11.3

11.6

11.8

12.0

12.3

12.5

12.7

13.0

13.2

13.4

13.7

13.9

14.2

14.4

14.6

14.9

15.1

15.3

15.6

15.8

16.0

16.3

16.5

16.8

17.0

17.2

17.5

18.7

18.8

18.8

18.8

18.8

18.9

18.9

18.9

18.9

19.0

19.0

19.0

19.0

19.1

19.1

19.1

19.1

19.2

19.2

19.2

19.3

19.3

12.0

12.2

12.4

12.7

12.9

13.1

13.3

13.5

13.7

13.9

14.2

14.4

14.6

14.8

15.0

15.2

15.4

15.6

15.8

16.0

16.2

16.4

16.5

16.7

16.9

17.1

17.3

17.5

17.7

17.9

18.0

18.2

19.5

19.4

19.3

19.2

19.1

19.1

19.0

18.9

18.8

18.7

18.6

18.6

18.5

18.4

18.3

18.2

18.1

18.1

18.0

17.9

17.8

17.7

13

• PUMY-71VM1 STANDARD CAPACITY DIAGRAM

10.8

11.0

11.2

11.5

11.7

11.9

12.1

12.3

12.5

12.7

12.9

13.1

13.3

13.5

13.7

13.9

14.1

14.3

14.5

14.7

14.9

15.1

15.2

15.4

15.6

15.8

16.0

16.1

16.3

16.5

16.7

16.8

17.0

17.2

17.3

17.5

17.6

17.6

17.6

17.5

17.4

17.4

17.3

17.2

17.1

17.1

17.0

16.9

16.9

16.8

16.7

16.6

16.6

16.5

16.4

16.4

16.3

16.2

16.2

Total capacity of

indoor units(kcal/h)

Capacity (kcal/h) Power consumption (kW) Current (A)

Cooling Heating

Cooling Heating

Cooling Heating

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

3500

3600

3700

3800

3900

4000

4100

4200

4300

4400

4500

4600

4700

4800

4900

5000

5100

5200

5300

5400

5500

5600

5700

5800

5900

6000

6100

6200

6300

6400

6500

6600

6700

6800

6900

7000

7100

7122

7144

7166

7189

7211

7233

7255

7277

7299

7322

7344

7366

7388

7410

7432

7455

7477

7499

7521

7543

7566

7588

3906

4025

4144

4263

4381

4500

4610

4720

4830

4940

5050

5160

5270

5380

5490

5600

5715

5831

5946

6062

6177

6292

6408

6523

6638

6754

6869

6985

7100

7213

7325

7438

7550

7663

7775

7778

8000

8012

8024

8036

8049

8061

8073

8085

8097

8109

8121

8133

8146

8158

8170

8182

8194

8206

8218

8231

8243

8255

8267

1.86

1.91

1.96

2.01

2.06

2.10

2.15

2.20

2.25

2.30

2.35

2.40

2.45

2.50

2.55

2.60

2.64

2.69

2.74

2.79

2.84

2.89

2.94

2.99

3.04

3.09

3.13

3.18

3.23

3.28

3.33

3.38

3.43

3.48

3.53

3.58

3.63

3.63

3.64

3.64

3.65

3.65

3.66

3.66

3.67

3.67

3.68

3.68

3.69

3.69

3.70

3.70

3.71

3.71

3.72

3.73

3.73

3.74

3.74

2.11

2.15

2.19

2.24

2.28

2.33

2.37

2.41

2.45

2.50

2.54

2.58

2.62

2.66

2.70

2.74

2.78

2.82

2.86

2.90

2.94

2.98

3.02

3.06

3.09

3.13

3.17

3.20

3.24

3.28

3.31

3.35

3.38

3.42

3.46

3.49

3.53

3.52

3.51

3.49

3.48

3.46

3.45

3.43

3.42

3.40

3.39

3.37

3.36

3.34

3.33

3.31

3.30

3.28

3.27

3.25

3.24

3.22

3.21

9.6

9.8

10.1

10.3

10.6

10.8

11.0

11.3

11.5

11.8

12.0

12.2

12.5

12.7

13.0

13.2

13.4

13.7

13.9

14.2

14.4

14.6

14.9

15.1

15.3

15.6

15.8

16.0

16.3

16.5

16.7

17.0

17.2

17.4

17.7

17.9

18.1

18.2

18.2

18.2

18.2

18.3

18.3

18.3

18.3

18.4

18.4

18.4

18.4

18.5

18.5

18.5

18.5

18.6

18.6

18.6

18.6

18.7

18.7

220V, 60Hz

14

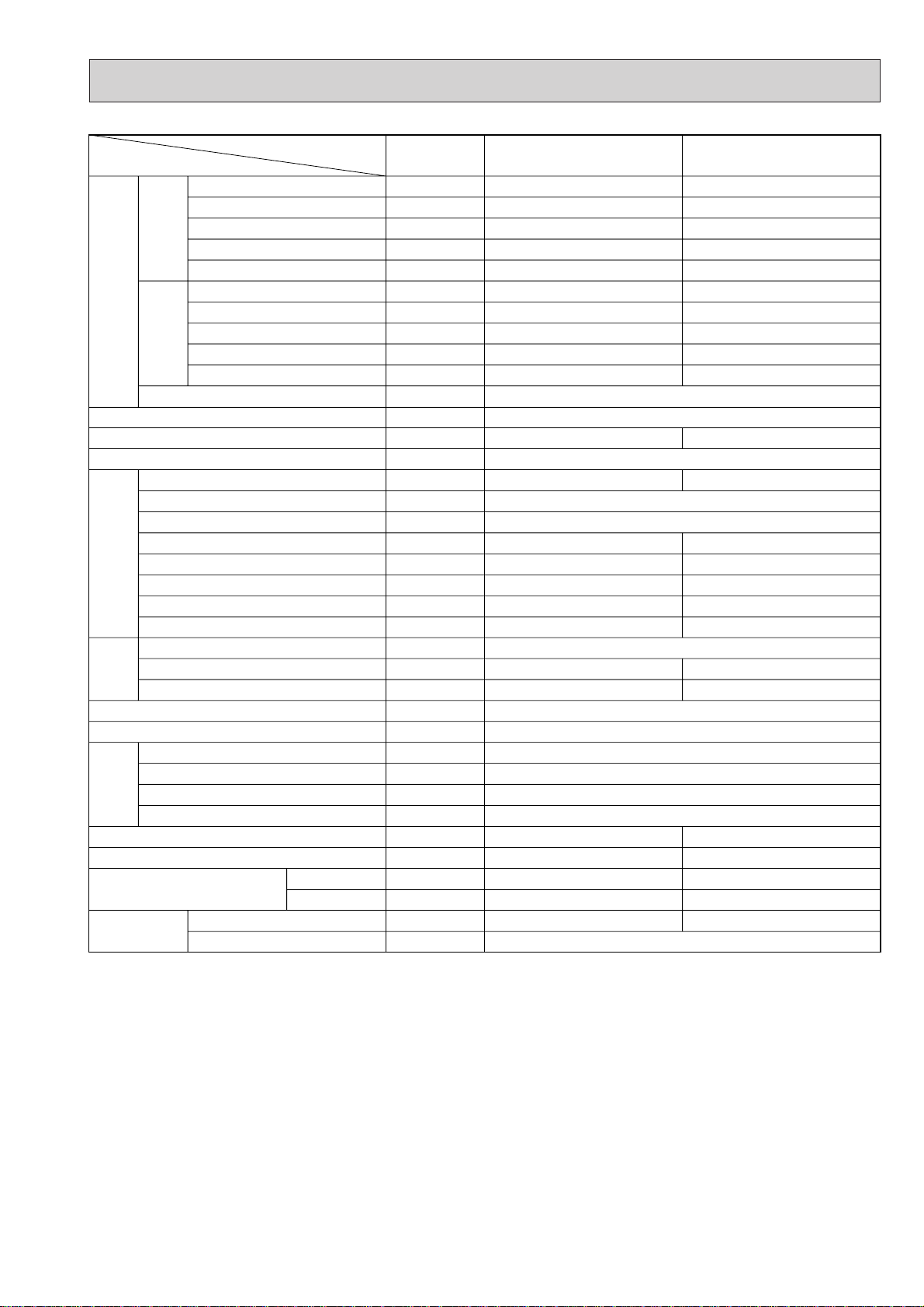

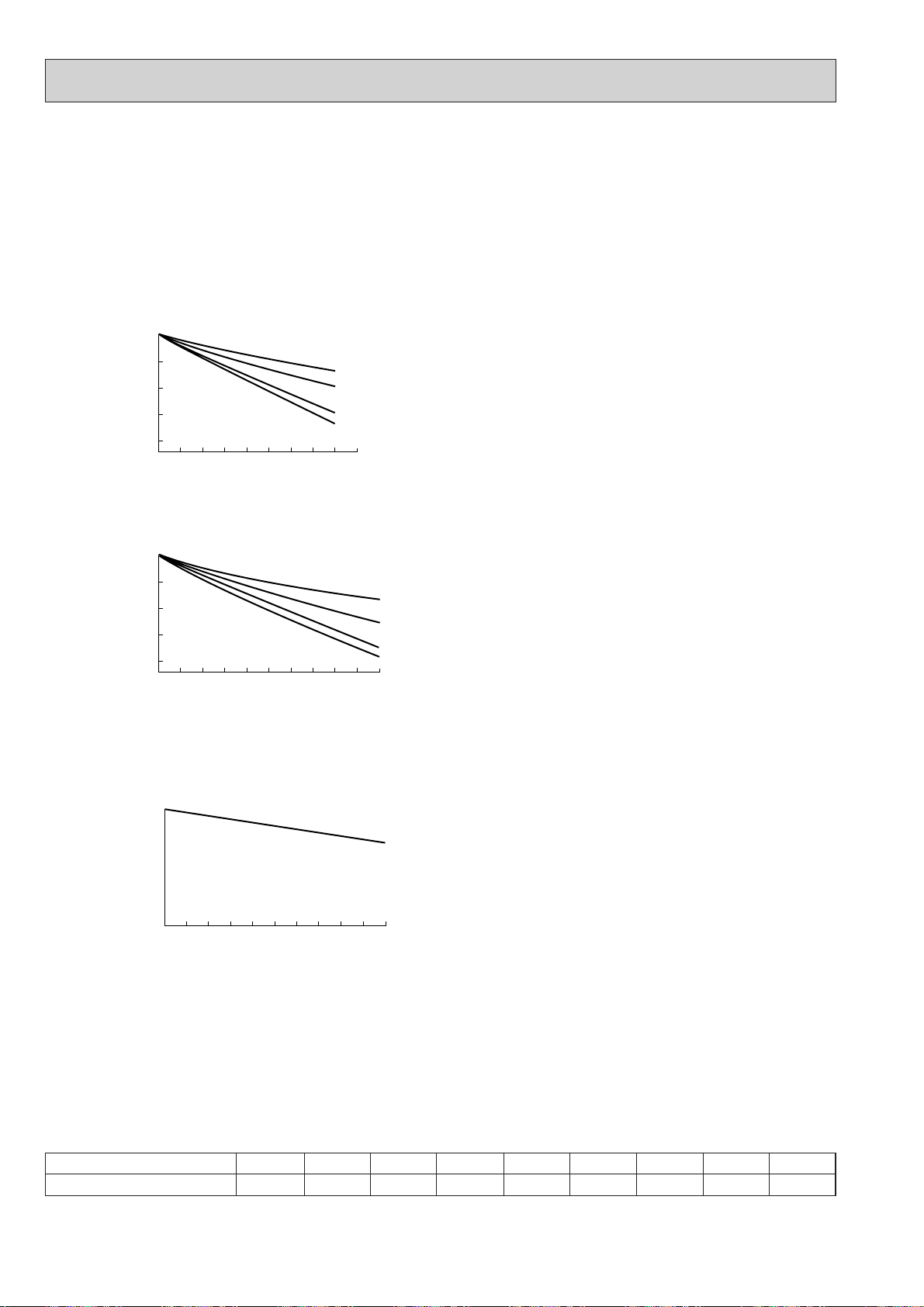

• PUMY-71VM2 STANDARD CAPACITY DIAGRAM

w Before calculating the sum of total capacity of indoor units, please convert

the valve into the kW model capacity following the table on page 12.

Total capacity of

w

indoor units(kW)

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

Capacity (kW)

Cooling Heating

4.00

4.10

4.20

4.30

4.40

4.50

4.60

4.70

4.80

4.90

5.00

5.10

5.20

5.30

5.40

5.50

5.60

5.70

5.80

5.90

6.00

6.10

6.20

6.30

6.40

6.50

6.60

6.70

6.80

6.90

7.00

7.10

7.20

7.30

7.40

7.50

7.60

7.70

7.80

7.90

8.00

8.02

8.05

8.07

8.09

8.12

8.14

8.16

8.19

8.21

8.23

8.25

8.28

8.30

8.32

8.35

8.37

8.39

8.41

8.44

8.46

8.48

8.51

8.53

8.55

4.44

4.56

4.67

4.78

4.89

5.00

5.12

5.24

5.35

5.47

5.59

5.71

5.83

5.94

6.06

6.18

6.30

6.41

6.53

6.64

6.75

6.87

6.98

7.10

7.20

7.32

7.43

7.54

7.66

7.77

7.88

8.00

8.11

8.22

8.33

8.44

8.56

8.67

8.78

8.89

9.00

9.01

9.03

9.04

9.05

9.06

9.08

9.09

9.10

9.11

9.13

9.14

9.15

9.16

9.18

9.19

9.20

9.21

9.23

9.24

9.25

9.26

9.28

9.29

9.30

Power consumption (kW)

Cooling Heating

1.83

1.87

1.91

1.95

1.99

2.03

2.08

2.12

2.15

2.21

2.25

2.29

2.33

2.37

2.41

2.45

2.50

2.54

2.57

2.62

2.66

2.70

2.75

2.78

2.82

2.87

2.91

2.95

2.99

3.03

3.08

3.13

3.17

3.20

3.25

3.29

3.33

3.38

3.41

3.45

3.50

3.50

3.50

3.51

3.51

3.52

3.52

3.53

3.53

3.54

3.54

3.55

3.55

3.56

3.56

3.57

3.57

3.58

3.58

3.59

3.59

3.59

3.59

3.60

3.60

220V, 50Hz 220V, 60Hz

2.05

2.09

2.13

2.16

2.20

2.24

2.27

2.30

2.35

2.39

2.42

2.27

2.50

2.53

2.57

2.62

2.66

2.68

2.73

2.77

2.81

2.86

2.90

2.93

2.98

3.02

3.05

3.10

3.14

3.18

3.23

3.27

3.31

3.35

3.39

3.43

3.48

3.53

3.56

3.61

6.65

6.65

3.63

3.62

3.60

3.58

3.57

3.55

3.54

3.53

3.52

3.51

3.49

3.48

3.46

3.44

3.41

3.40

3.39

3.38

3.37

3.36

3.33

3.33

3.31

Current (A)

Cooling Heating

9.1

9.3

9.5

9.8

10.0

10.2

10.4

10.6

10.8

11.0

11.2

11.4

11.6

11.8

12.0

12.2

12.5

12.7

12.8

13.1

13.3

13.5

13.7

13.9

14.1

14.3

14.6

14.8

15.0

15.2

15.4

15.6

15.8

16.0

16.2

16.4

16.6

16.9

17.0

17.2

17.5

17.5

17.5

17.5

17.5

17.6

17.6

17.6

17.6

17.7

17.7

17.7

17.7

17.8

17.8

17.8

17.8

17.9

17.9

17.9

17.9

17.9

17.9

18.0

18.0

Power consumption (kW)

Cooling Heating

10.3

10.5

10.6

10.8

11.0

11.2

11.4

11.5

11.7

11.9

12.1

12.3

12.5

12.6

12.8

13.1

13.3

13.4

13.6

13.8

14.0

14.3

14.5

14.7

14.9

15.1

15.2

15.5

15.7

15.9

16.1

16.3

16.5

16.8

16.9

17.1

17.4

17.6

17.8

18.0

18.2

18.2

18.1

18.1

18.0

17.9

17.8

17.8

17.7

17.6

17.6

17.5

17.4

17.4

17.3

17.2

17.0

17.0

16.9

16.9

16.8

16.8

16.7

16.6

16.5

1.90

1.94

1.98

2.02

2.07

2.11

2.16

2.20

2.23

2.29

2.33

2.37

2.41

2.45

2.50

2.54

2.59

2.63

2.66

2.72

2.76

2.80

2.85

2.89

2.93

2.98

3.02

3.06

3.11

3.15

3.19

3.24

3.28

3.32

3.37

3.41

3.45

3.50

3.54

3.58

3.63

3.63

3.63

3.64

3.64

3.65

3.65

3.66

3.66

3.67

3.67

3.68

3.68

3.69

3.69

3.70

3.70

3.71

3.71

3.72

3.72

3.72

3.72

3.73

3.73

1.99

2.02

2.06

2.09

2.13

2.16

2.20

2.23

2.27

2.31

2.34

2.20

2.42

2.45

2.49

2.53

2.57

2.60

2.64

2.68

2.72

2.76

2.80

2.84

2.88

2.92

2.95

2.99

3.04

3.08

3.12

3.16

3.20

3.24

3.28

3.32

3.36

3.41

3.45

3.49

3.53

3.53

3.51

3.50

3.48

3.47

3.46

3.44

3.43

3.41

3.40

3.39

3.37

3.36

3.35

3.33

3.30

3.29

3.28

3.27

3.26

3.25

3.23

3.22

3.20

220V, 50Hz/60Hz

Current (A)

Cooling Heating

9.5

9.7

9.9

10.1

10.3

10.5

10.8

11.0

11.2

11.4

11.6

11.8

12.1

12.3

12.5

12.7

12.9

13.2

13.3

13.6

13.8

14.0

14.3

14.4

14.6

14.9

15.1

15.3

15.5

15.7

15.9

16.2

16.4

16.6

16.8

17.0

17.2

17.5

17.7

17.9

18.1

18.1

18.1

18.2

18.2

18.2

18.2

18.3

18.3

18.3

18.3

18.4

18.4

18.4

18.4

18.5

18.5

18.6

18.6

18.6

18.6

18.6

18.6

18.7

18.7

9.9

10.1

10.3

10.4

10.6

10.8

11.0

11.1

11.4

11.5

11.7

11.9

12.1

12.2

12.4

12.6

12.8

13.0

13.2

13.4

13.6

13.8

14.0

14.2

14.4

14.6

14.7

15.0

15.2

15.4

15.6

15.8

16.0

16.2

16.4

16.6

16.8

17.0

17.2

17.4

17.6

17.6

17.5

17.5

17.4

17.3

17.3

17.2

17.1

17.0

17.0

16.9

16.8

16.8

16.7

16.6

16.5

16.4

16.4

16.3

16.3

16.2

16.1

16.1

16.0

15

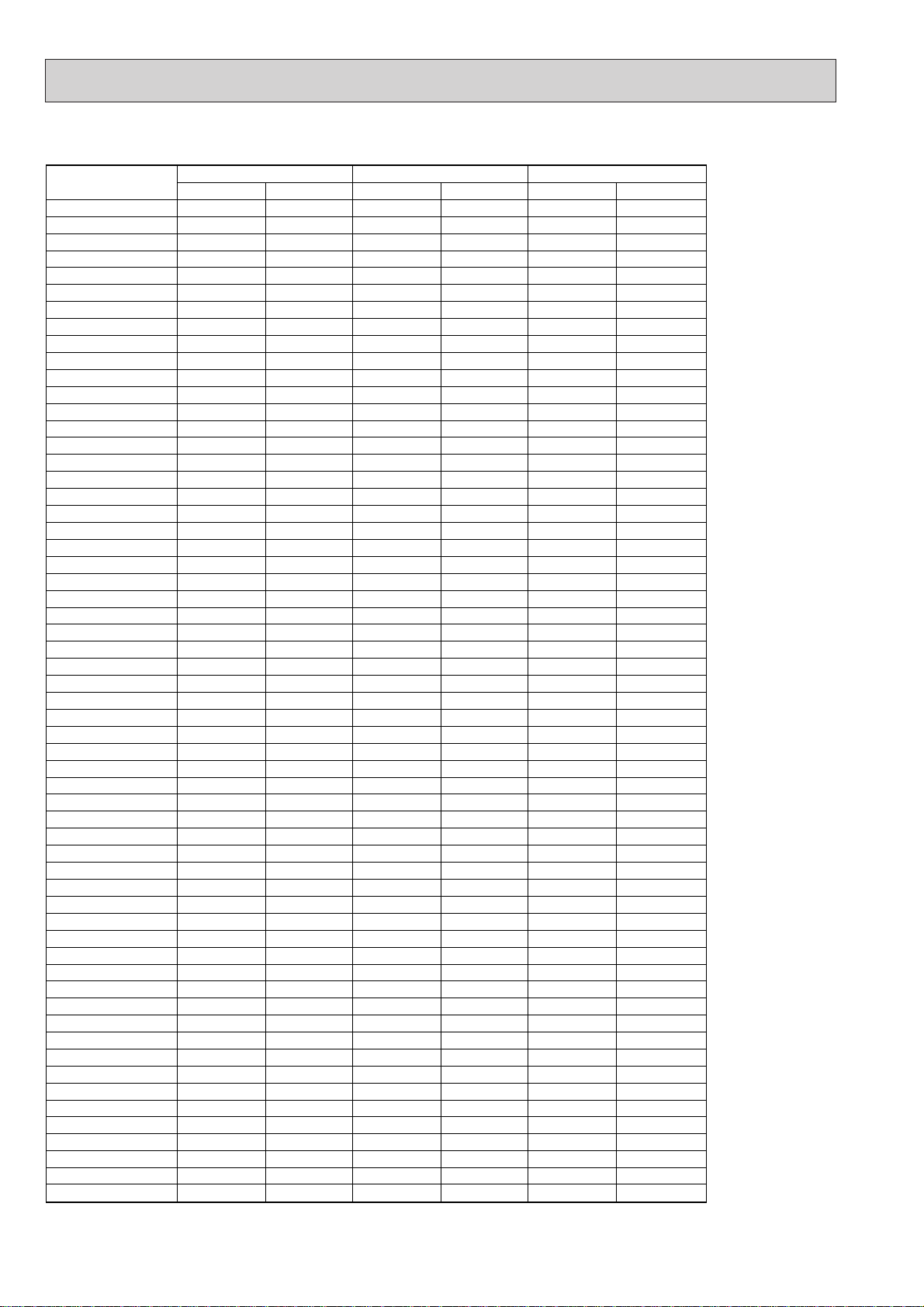

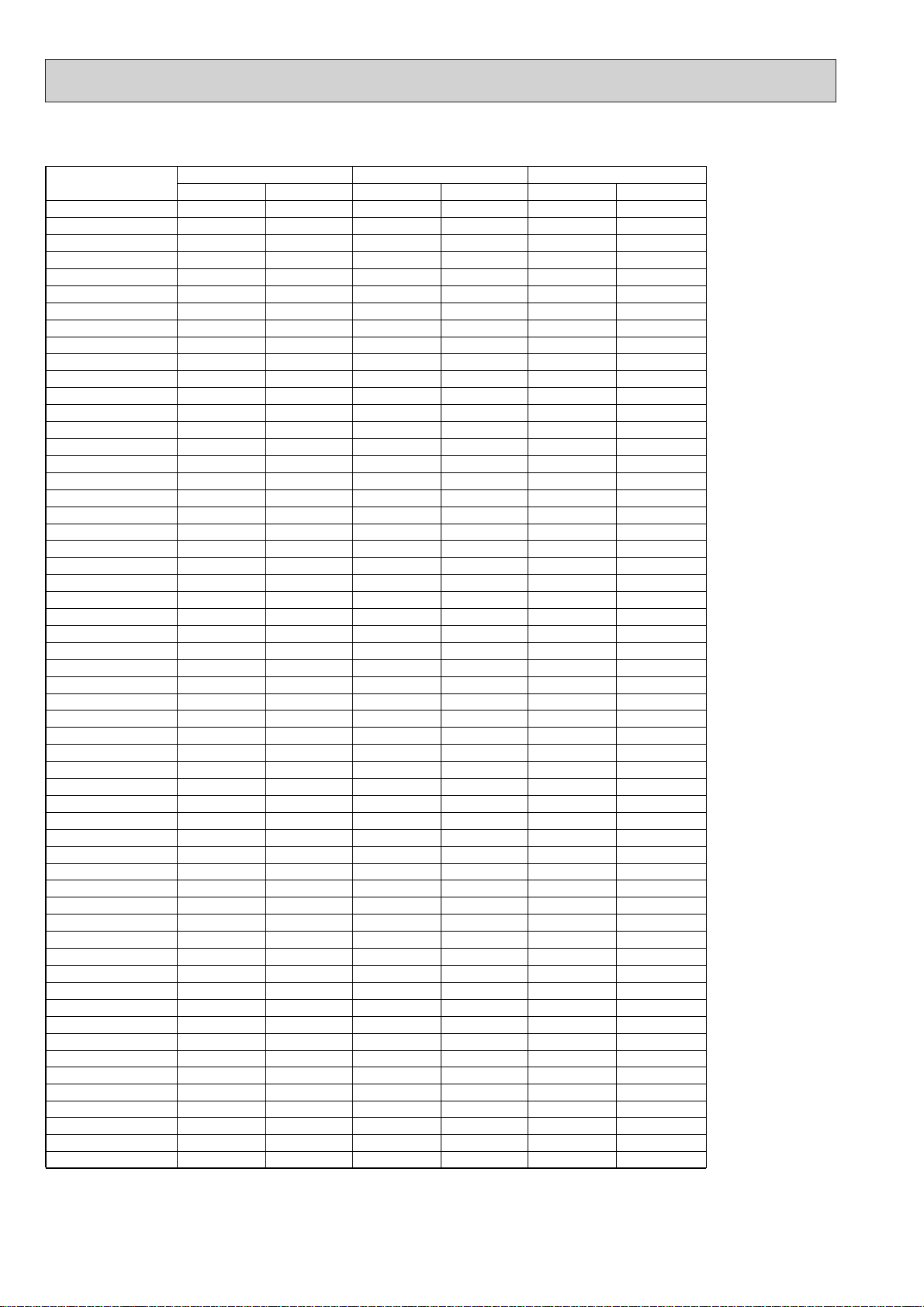

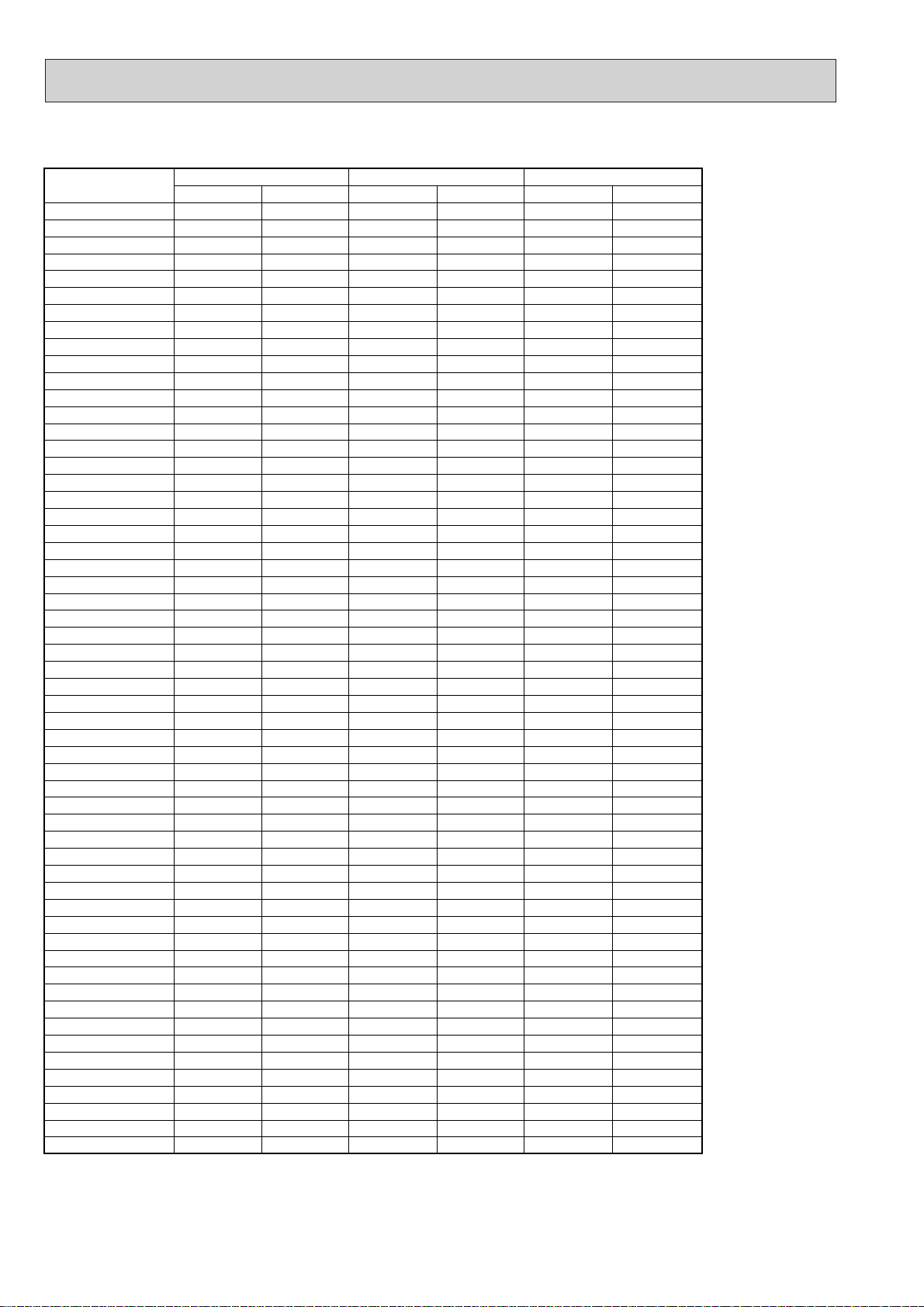

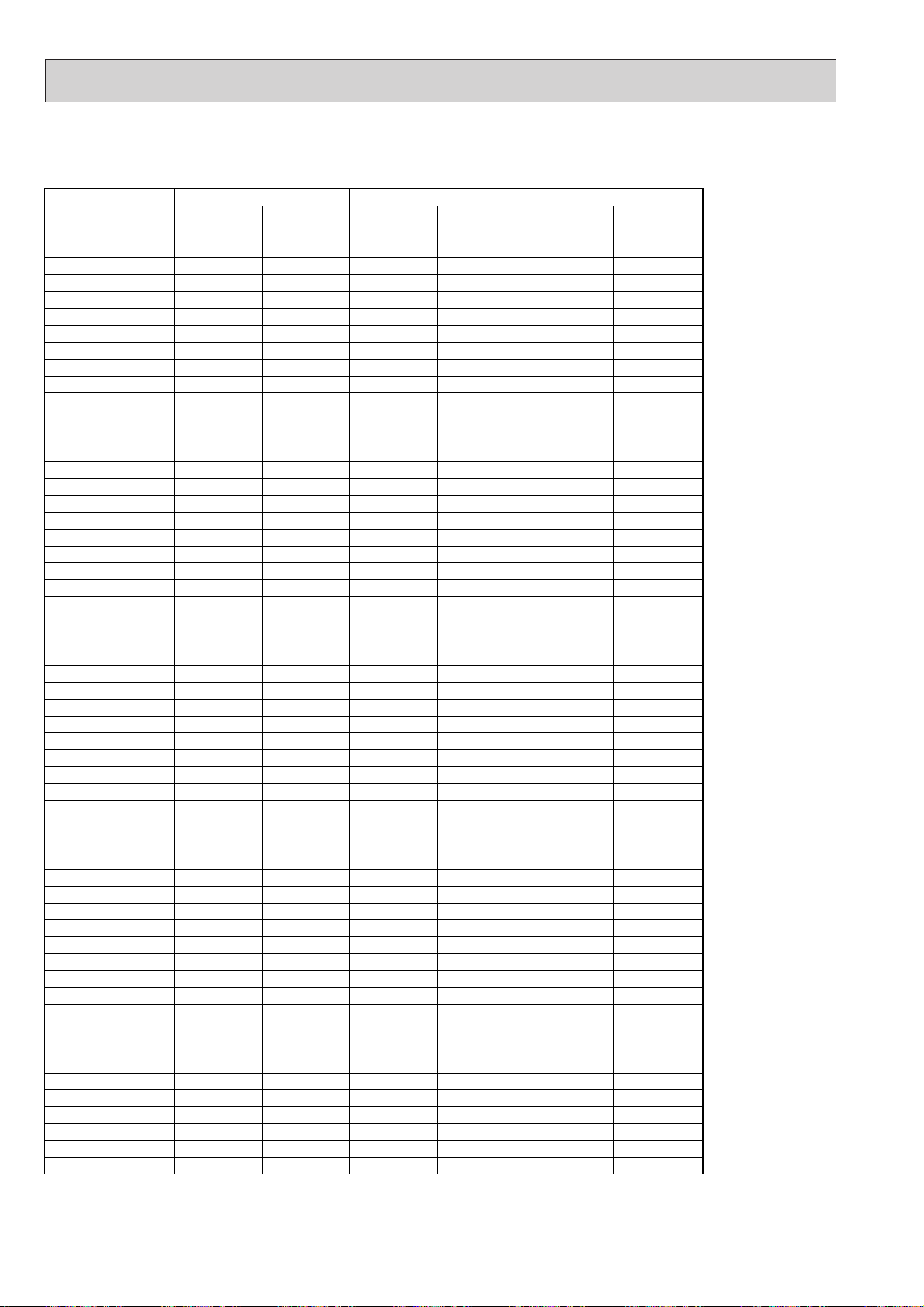

• PUMY-125VM, PUMY-125VM1 STANDARD CAPACITY DIAGRAM

Total capacity of

indoor units(kcal/h)

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

Capacity (kcal/h)

Cooling

6300

6400

6500

6600

6700

6800

6900

7000

7100

7200

7300

7400

7500

7600

7700

7800

7900

8000

8100

8200

8300

8400

8500

8600

8700

8800

8900

9000

9100

9200

9300

9400

9500

9600

9700

9800

9900

10000

10100

10200

10300

10400

10500

10600

10700

10800

10900

11000

11100

11200

11300

11400

11500

11600

11700

11800

Heating

7100

7213

7325

7438

7550

7663

7776

7888

8000

8111

8222

8333

8445

8556

8667

8778

8889

9000

9110

9220

9330

9440

9550

9660

9770

9880

9990

10100

10210

10320

10430

10540

10650

10760

10870

10980

11090

11200

11312

11424

11536

11648

11760

11872

11984

12096

12208

12320

12432

12544

12656

12768

12880

12992

13104

13216

Power consumption (kW) Current (A)

Cooling

2.74

2.78

2.83

2.87

2.92

2.96

3.01

3.06

3.11

3.16

3.21

3.25

3.30

3.35

3.40

3.45

3.51

3.57

3.62

3.67

3.73

3.78

3.84

3.89

3.95

4.01

4.07

4.13

4.19

4.25

4.31

4.37

4.43

4.50

4.56

4.62

4.68

4.75

4.81

4.88

4.95

5.02

5.08

5.15

5.22

5.29

5.35

5.43

5.50

5.57

5.64

5.72

5.79

5.86

5.94

6.02

Heating

2.88

2.92

2.97

3.01

3.07

3.11

3.15

3.20

3.24

3.29

3.33

3.38

3.43

3.47

3.52

3.57

3.61

3.66

3.71

3.76

3.80

3.85

3.90

3.96

4.01

4.06

4.11

4.16

4.21

4.26

4.31

4.36

4.41

4.46

4.51

4.57

4.62

4.67

4.72

4.78

4.84

4.89

4.95

5.00

5.05

5.11

5.16

5.22

5.27

5.33

5.38

5.44

5.50

5.55

5.61

5.68

Cooling

14.6

14.9

15.1

15.4

15.6

15.8

16.1

16.3

16.6

16.9

17.2

17.4

17.6

17.9

18.2

18.5

18.8

19.1

19.3

19.6

19.9

20.2

20.5

20.8

21.1

21.4

21.7

22.1

22.4

22.7

23.1

23.4

23.7

24.0

24.4

24.7

25.0

25.4

25.7

26.1

26.4

26.8

27.2

27.5

27.9

28.3

28.6

29.0

29.4

29.8

30.2

30.6

31.0

31.4

31.7

32.2

220V, 50Hz

Heating

15.4

15.6

15.9

16.1

16.4

16.6

16.8

17.1

17.3

17.6

17.8

18.1

18.3

18.6

18.8

19.1

19.3

19.6

19.9

20.1

20.3

20.6

20.9

21.2

21.4

21.7

22.0

22.2

22.5

22.8

23.0

23.3

23.6

23.9

24.1

24.5

24.7

25.0

25.3

25.6

25.9

26.1

26.5

26.7

27.0

27.3

27.6

27.9

28.2

28.5

28.8

29.1

29.4

29.7

30.0

30.3

16

• PUMY-125VM, PUMY-125VM1 STANDARD CAPACITY DIAGRAM

Total capacity of

indoor units(kcal/h)

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

163

Capacity (kcal/h) Power consumption (kW) Current (A)

Cooling Heating

11900

12000

12100

12200

12300

12400

12500

12521

12542

12563

12584

12605

12626

12647

12668

12689

12710

12731

12753

12774

12795

12816

12837

12859

12879

12900

12921

12942

12963

12984

13005

13026

13047

13068

13089

13110

13131

13153

13174

13195

13216

13237

13258

13279

13300

13328

13440

13552

13664

13776

13888

14000

14012

14023

14035

14046

14058

14069

14081

14092

14104

14115

14127

14138

14150

14161

14173

14184

14196

14207

14219

14230

14242

14253

14265

14276

14288

14299

14311

14322

14334

14345

14357

14368

14380

14391

14403

14414

14426

14437

Cooling Heating

6.09

6.17

6.24

6.32

6.40

6.48

6.57

6.57

6.57

6.57

6.58

6.58

6.58

6.58

6.58

6.59

6.59

6.59

6.59

6.60

6.60

6.60

6.60

6.60

6.60

6.61

6.61

6.61

6.61

6.62

6.62

6.62

6.62

6.62

6.63

6.63

6.63

6.63

6.64

6.64

6.64

6.64

6.64

6.65

6.65

5.73

5.79

5.85

5.91

5.97

6.02

6.10

6.08

6.06

6.04

6.03

6.01

5.99

5.97

5.95

5.93

5.91

5.89

5.88

5.86

5.84

5.82

5.80

5.78

5.76

5.74

5.73

5.71

5.69

5.67

5.64

5.62

5.60

5.58

5.57

5.55

5.53

5.51

5.49

5.47

5.45

5.43

5.42

5.40

5.38

220V, 50Hz

Cooling Heating

32.6

33.0

33.4

33.8

34.2

34.6

34.9

34.9

34.9

34.9

35.2

35.2

35.2

35.2

35.2

35.2

35.2

35.2

35.2

35.3

35.3

35.3

35.3

35.3

35.3

35.4

35.4

35.4

35.4

35.4

35.4

35.4

35.4

35.4

35.5

35.5

35.5

35.5

35.5

35.5

35.5

35.5

35.5

35.6

35.6

30.6

30.9

31.3

31.6

31.9

32.2

32.6

32.5

32.4

32.3

32.2

32.1

32.0

31.9

31.8

31.7

31.6

31.5

31.4

31.3

31.2

31.1

31.0

30.9

30.8

30.7

30.6

30.5

30.4

30.3

30.2

30.1

30.0

29.9

29.8

29.7

29.6

29.5

29.4

29.3

29.2

29.0

29.0

28.9

28.8

17

• PUMY-125VM1 STANDARD CAPACITY DIAGRAM

15.1

15.3

15.5

15.8

16.0

16.2

16.4

16.7

16.9

17.1

17.4

17.6

17.9

18.1

18.3

18.6

18.8

19.1

19.3

19.6

19.8

20.1

20.3

20.6

20.8

21.1

21.3

21.6

21.9

22.1

22.4

22.6

22.9

23.2

23.4

23.7

24.0

24.2

24.5

24.8

25.1

25.3

25.6

25.9

26.2

26.5

26.7

27.0

27.3

27.6

27.9

28.2

28.5

28.7

29.0

29.3

29.6

Total capacity of

indoor units(kcal/h)

Capacity (kcal/h) Power consumption (kW) Current (A)

Cooling Heating

Cooling Heating

Cooling Heating

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

2.68

2.72

2.77

2.81

2.86

2.90

2.95

2.99

3.04

3.09

3.14

3.18

3.23

3.28

3.33

3.38

3.44

3.49

3.54

3.59

3.65

3.70

3.76

3.81

3.87

3.92

3.98

4.04

4.10

4.16

4.22

4.28

4.34

4.40

4.46

4.52

4.58

4.65

4.71

4.78

4.84

4.91

4.97

5.04

5.11

5.18

5.24

5.31

5.38

5.45

5.52

5.60

5.67

5.74

5.81

5.89

5.96

2.85

2.89

2.94

2.98

3.03

3.07

3.11

3.16

3.20

3.25

3.29

3.34

3.39

3.43

3.48

3.53

3.57

3.62

3.67

3.72

3.76

3.81

3.86

3.91

3.96

4.01

4.06

4.11

4.16

4.21

4.26

4.31

4.36

4.41

4.46

4.52

4.57

4.62

4.67

4.73

4.78

7.83

4.89

4.94

4.99

5.05

5.10

5.16

5.21

5.27

5.32

5.38

5.44

5.49

5.55

5.61

5.66

14.2

14.4

14.6

14.9

15.1

15.3

15.6

15.8

16.1

16.3

16.5

16.8

17.1

17.3

17.6

17.8

18.1

18.4

18.7

18.9

19.2

19.5

19.8

20.1

20.4

20.7

20.9

21.2

21.5

21.9

22.2

22.5

22.8

23.1

23.4

23.7

24.1

24.4

24.7

25.1

25.4

25.7

26.1

26.4

26.8

27.1

27.5

27.8

28.2

28.5

28.9

29.3

29.6

30.0

30.4

30.8

31.2

6300

6400

6500

6600

6700

6800

6900

7000

7100

7200

7300

7400

7500

7600

7700

7800

7900

8000

8100

8200

8300

8400

8500

8600

8700

8800

8900

9000

9100

9200

9300

9400

9500

9600

9700

9800

9900

10000

10100

10200

10300

10400

10500

10600

10700

10800

10900

11000

11100

11200

11300

11400

11500

11600

11700

11800

11900

7100

7213

7325

7438

7550

7663

7775

7888

8000

8111

8222

8333

8445

8556

8667

8778

8889

9000

9110

9220

9330

9440

9550

9660

9770

9880

9990

10100

10210

10320

10430

10540

10650

10760

10870

10980

11090

11200

11312

11424

11536

11648

11760

11872

11984

12096

12208

12320

12432

12544

12656

12768

12880

12992

13104

13216

13328

220V, 60Hz

18

• PUMY-125VM1 STANDARD CAPACITY DIAGRAM

Total capacity of

indoor units(kcal/h)

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

163

Capacity (kcal/h) Power consumption (kW) Current (A)

Cooling Heating

12000

12100

12200

12300

12400

12500

12521

12542

12563

12584

12605

12626

12647

12668

12689

12710

12731

12753

12774

12795

12816

12837

12858

12879

12900

12921

12942

12963

12984

13005

13026

13047

13068

13089

13110

13131

13153

13174

13195

13216

13237

13258

13279

13300

13440

13552

13664

13776

13888

14000

14012

14023

14035

14046

14058

14069

14081

14092

14104

14115

14127

14138

14150

14161

14173

14184

14196

14207

14219

14230

14242

14253

14265

14276

14288

14299

14311

14322

14334

14345

14357

14368

14380

14391

14403

14414

14426

14437

Cooling Heating

6.04

6.11

6.19

6.26

6.34

6.43

6.43

6.43

6.43

6.44

6.44

6.44

6.44

6.44

6.45

6.45

6.45

6.45

6.46

6.46

6.46

6.46

6.46

6.47

6.47

6.47

6.47

6.47

6.48

6.48

6.48

6.48

6.48

6.49

6.49

6.49

6.49

6.50

6.50

6.50

6.50

6.50

6.51

6.51

5.72

5.78

5.84

5.90

5.95

6.03

6.01

5.99

5.97

5.96

5.94

5.92

5.90

5.88

5.86

5.84

5.82

5.81

5.79

5.77

5.75

5.73

5.71

5.69

5.67

5.66

5.64

5.62

5.60

5.58

5.56

5.54

5.52

5.51

5.49

5.47

5.45

5.43

5.41

5.39

5.37

5.36

5.34

5.32

220V, 60Hz

Cooling Heating

31.5

31.9

32.3

32.7

33.1

33.6

33.6

33.6

33.6

33.6

33.6

33.6

33.6

33.6

33.6

33.6

33.7

33.7

33.7

33.7

33.7

33.7

33.7

33.7

33.7

33.8

33.8

33.8

33.8

33.8

33.8

33.8

33.8

33.8

33.9

33.9

33.9

33.9

33.9

33.9

33.9

33.9

33.9

33.9

29.9

30.2

30.5

30.8

31.1

31.5

31.4

31.3

31.2

31.1

31.0

30.9

30.8

30.7

30.6

30.5

30.5

30.4

30.3

30.2

30.1

30.0

29.9

29.8

29.7

29.6

29.5

29.4

29.3

29.2

29.1

29.0

28.9

28.8

28.7

28.6

28.5

28.4

28.3

28.2

28.1

28.0

27.9

27.9

19

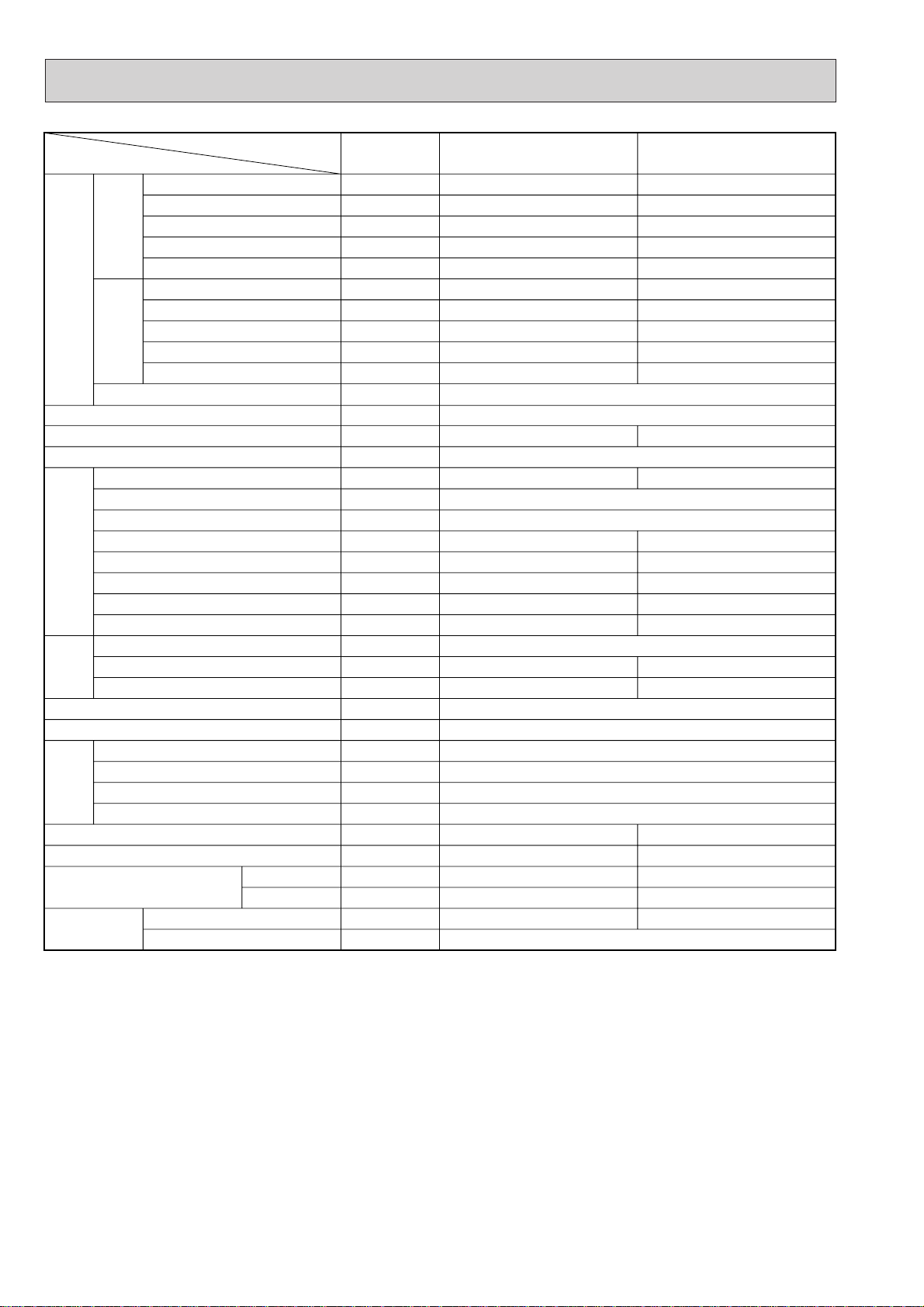

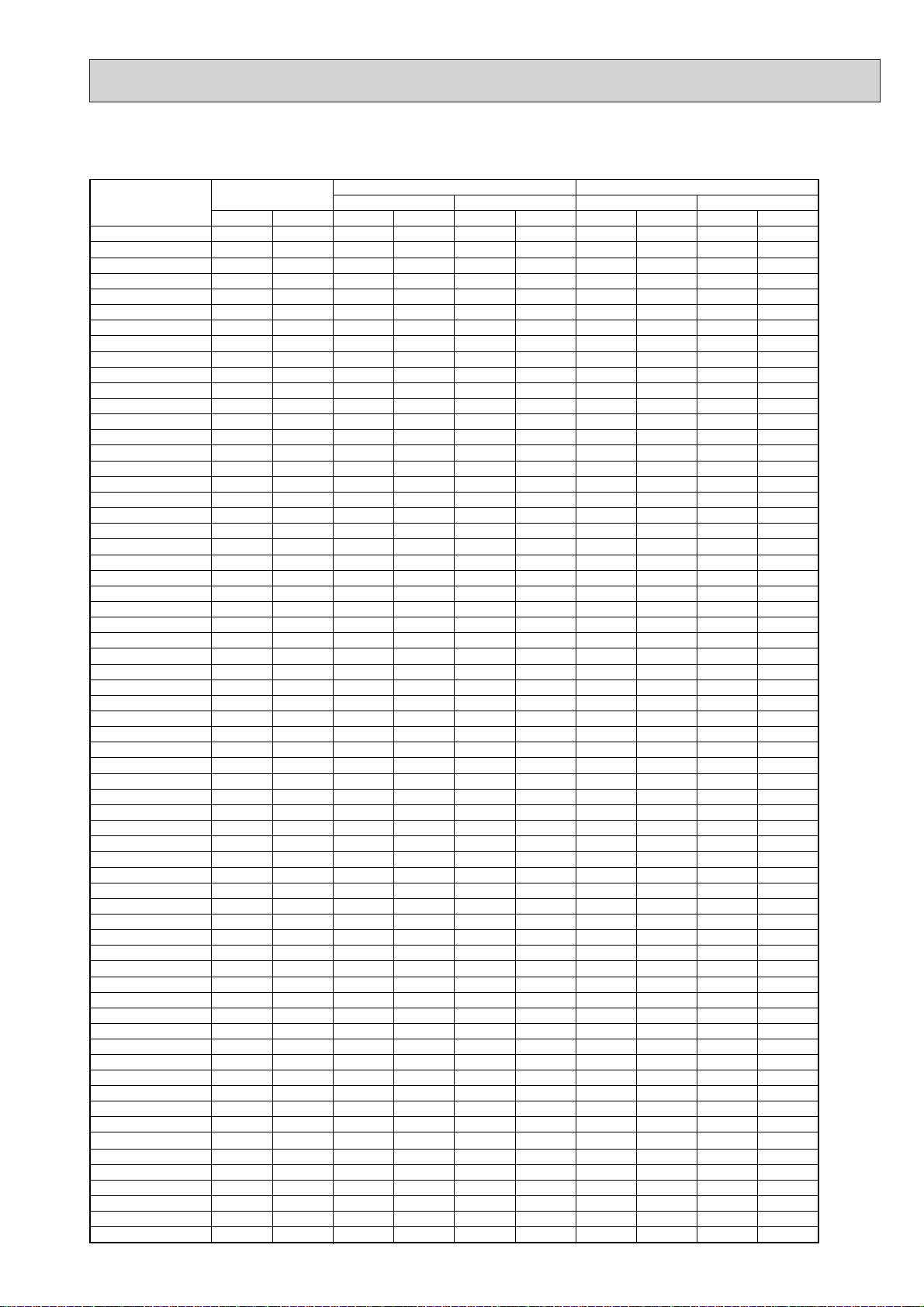

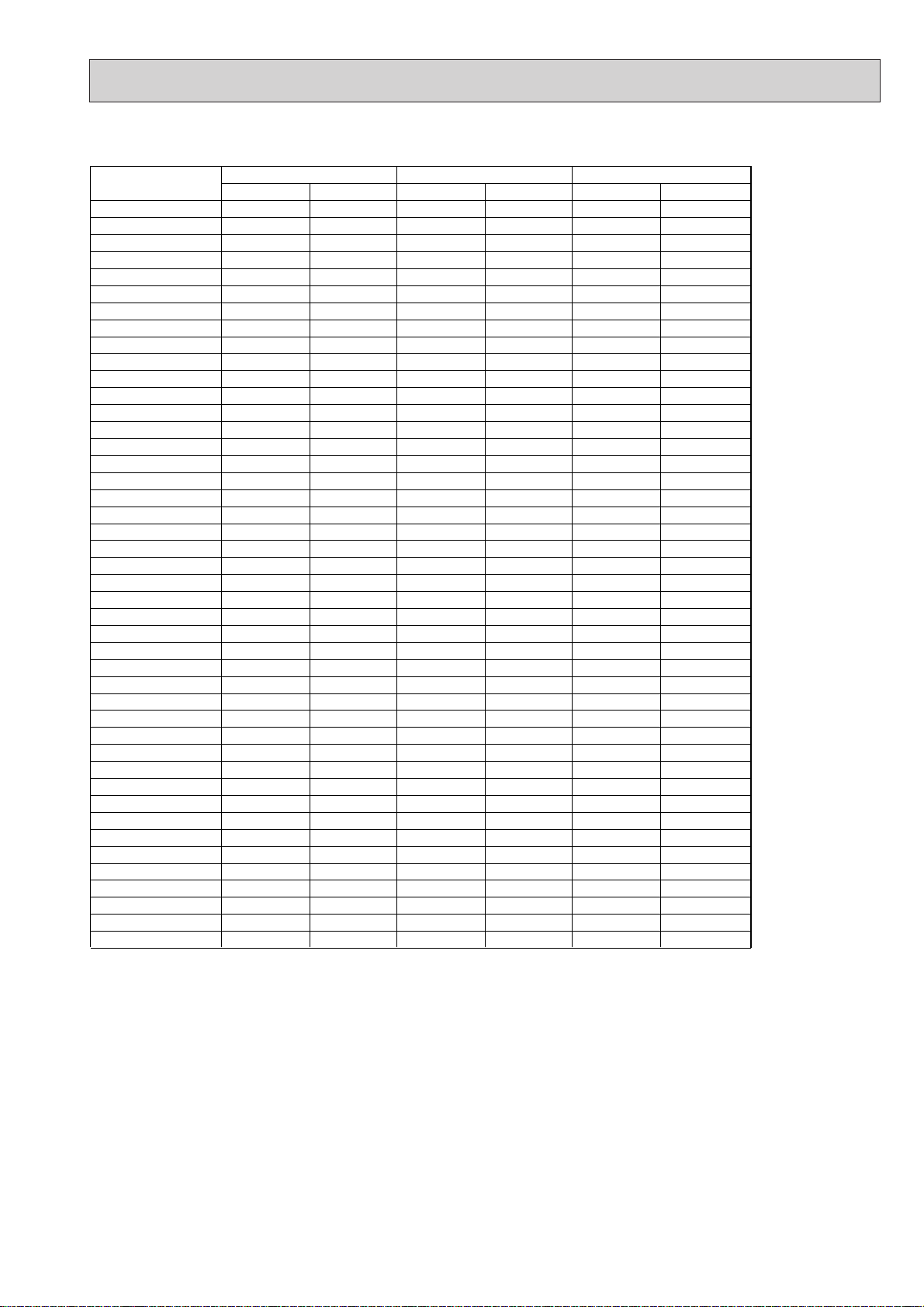

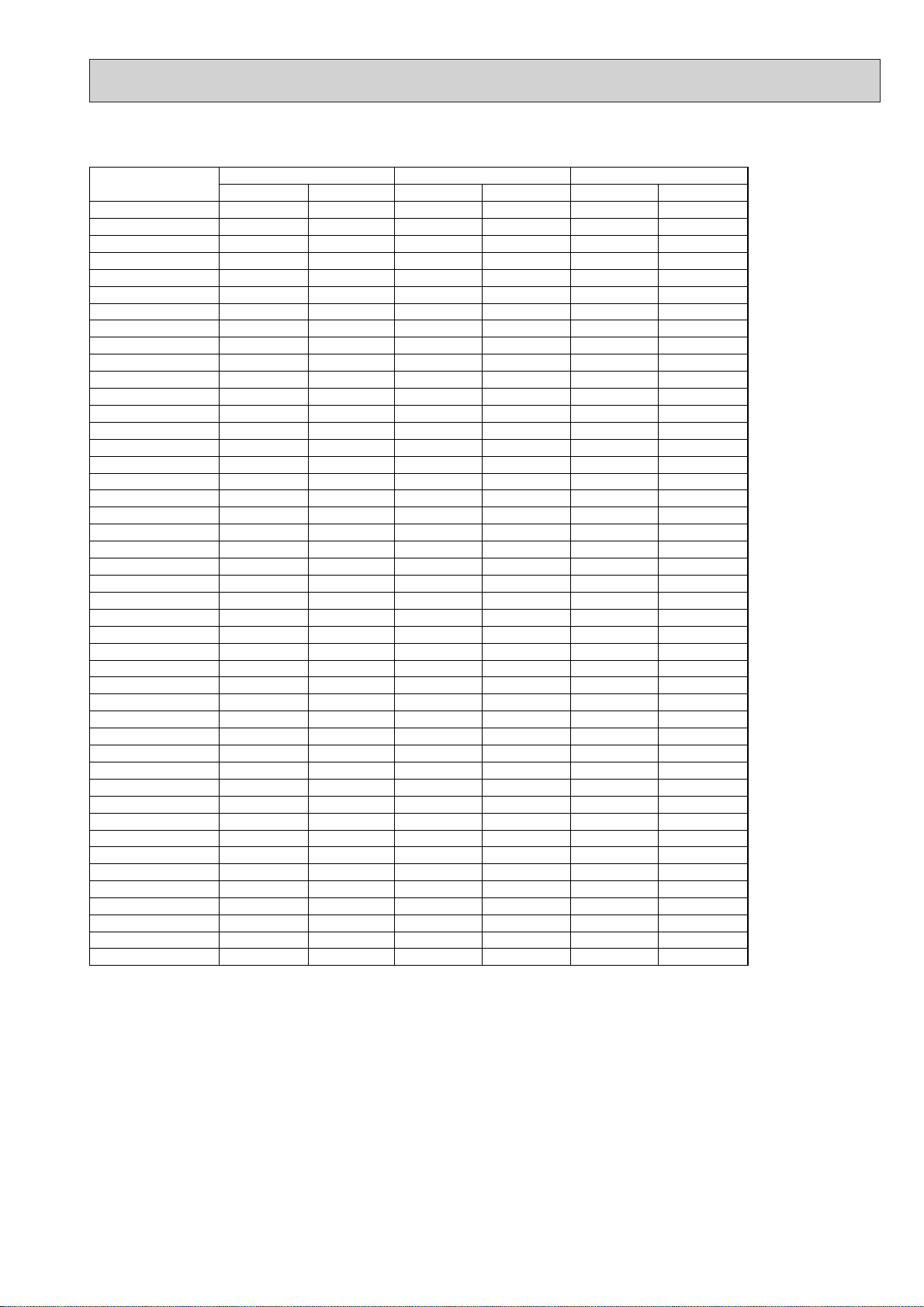

• PUMY-125VM2 STANDARD CAPACITY DIAGRAM

w Before calculating the sum of total capacity of indoor units, please convert

the valve into the kW model capacity following the table on page 12.

Total capacity of

w

indoor units(kW)

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

Capacity (kW)

Cooling Heating

7.00

7.10

7.20

7.30

7.40

7.50

7.60

7.70

7.80

7.90

8.00

8.10

8.20

8.30

8.40

8.50

8.60

8.70

8.80

8.90

9.00

9.10

9.20

9.30

9.40

9.50

9.60

9.70

9.80

9.90

10.00

10.10

10.20

10.30

10.40

10.50

10.60

10.70

10.80

10.90

11.00

11.10

11.20

11.30

11.40

11.50

11.60

11.70

11.80

11.90

12.00

12.10

12.20

12.30

12.40

12.50

12.60

12.70

12.08

7.88

8.00

8.11

8.22

8.33

8.44

8.56

8.67

8.78

8.89

9.00

9.10

9.20

9.30

9.40

9.50

9.60

9.70

9.80

9.90

10.00

10.10

10.22

10.33

10.45

10.56

10.67

10.79

10.90

11.02

11.13

11.24

11.36

11.47

11.59

11.70

11.81

11.93

12.04

12.16

12.27

12.38

12.50

12.63

12.75

12.88

13.00

13.13

13.25

13.38

13.50

13.63

13.75

13.88

14.00

14.13

14.25

14.38

14.50

Power consumption (kW) Power consumption (kW)

Cooling

2.73

2.76

2.80

2.84

2.88

2.92

2.96

3.00

3.05

3.09

3.12

3.17

3.21

3.26

3.30

3.35

3.39

3.45

3.49

3.53

3.58

3.63

3.68

3.72

3.78

3.82

3.88

3.92

3.98

4.03

4.07

4.13

4.18

4.24

4.28

4.34

4.39

4.45

4.51

4.56

4.62

4.68

4.74

4.79

4.85

4.90

4.97

5.02

5.09

5.15

5.21

5.27

5.33

5.39

5.45

5.52

5.58

5.64

5.71

220V, 50Hz 220V, 60Hz

Current (A)

Heating

2.88

2.91

2.95

2.98

3.03

3.06

3.10

3.14

3.18

3.21

3.26

3.30

3.33

3.38

3.42

3.45

3.50

3.54

3.57

3.62

3.66

3.71

3.75

3.79

3.84

3.88

3.92

3.96

4.01

4.06

4.10

4.14

4.19

4.23

4.27

4.32

4.36

4.42

4.46

4.50

4.55

4.60

4.65

4.70

4.74

4.79

4.84

4.89

4.94

4.98

5.04

5.08

5.14

5.18

5.24

5.29

5.33

5.39

5.44

Cooling Heating

14.6

14.8

15.0

15.2

15.4

15.6

15.8

16.1

16.3

16.5

16.7

16.9

17.2

17.4

17.7

17.9

18.1

18.4

18.7

18.9

19.1

19.4

19.7

19.9

20.2

20.4

20.7

21.0

21.3

21.6

21.8

22.1

22.4

22.7

22.9

23.2

23.5

23.8

24.1

24.4

24.7

25.0

25.3

25.6

25.9

26.2

26.6

26.9

27.2

27.5

27.9

28.2

28.5

28.8

29.2

29.5

29.8

30.2

30.5

15.4

15.6

15.8

16.0

16.2

16.4

16.6

16.8

17.0

17.2

17.4

17.7

17.8

18.1

18.3

18.5

18.7

18.9

19.1

19.4

19.6

19.8

20.1

20.3

20.5

20.8

21.0

21.2

21.5

21.7

21.9

22.2

22.4

22.6

22.9

23.1

23.3

23.6

23.9

24.1

24.3

24.6

24.8

25.1

25.4

25.6

25.9

26.1

26.4

26.7

26.9

27.2

27.5

27.7

28.0

28.3

28.5

28.8

29.1

Cooling Heating

2.67

2.70

2.74

2.78

2.82

2.85

2.90

2.94

2.98

3.03

3.06

3.10

3.14

3.19

3.23

3.27

3.32

3.37

3.41

3.46

3.50

3.56

3.60

3.64

3.70

3.74

3.79

3.84

3.89

3.94

3.99

4.04

4.10

4.15

4.19

4.25

4.30

4.36

4.41

4.46

4.52

4.58

4.64

4.69

4.74

4.80

4.86

4.92

4.98

5.04

5.10

5.15

5.22

5.27

5.34

5.40

5.46

5.52

5.59

2.84

2.87

2.92

2.95

2.99

3.03

3.07

3.10

3.14

3.18

3.22

3.26

3.30

3.34

3.38

3.41

3.46

3.50

3.53

3.58

3.62

3.66

3.71

3.75

3.79

3.84

3.88

3.91

3.97

4.01

4.05

4.10

4.14

4.18

4.23

4.27

4.31

4.37

4.41

4.45

4.50

4.55

4.59

4.65

4.69

4.73

4.79

4.83

4.88

4.93

4.98

5.03

5.08

5.12

5.18

5.23

5.27

5.33

5.38

220V, 50Hz/60Hz

Current (A)

Cooling Heating

13.9

14.1

14.3

14.5

14.7

14.9

15.1

15.4

15.6

15.8

16.0

16.2

16.4

16.7

16.9

17.1

17.3

17.6

17.8

18.1

18.3

18.6

18.8

19.0

19.3

19.5

19.8

20.0

20.3

20.6

20.8

21.1

21.4

21.7

21.9

22.2

22.5

22.8

23.0

23.3

23.6

23.9

24.2

24.5

24.8

25.1

25.4

25.7

26.0

26.3

26.6

26.9

27.3

27.6

27.9

28.2

28.5

28.9

29.2

14.8

15.0

15.2

15.4

15.6

15.8

16.0

16.2

16.4

16.6

16.8

17.1

17.2

17.4

17.7

17.8

18.1

18.3

18.5

18.7

18.9

19.1

19.4

19.6

19.8

20.0

20.3

20.4

20.7

20.9

21.2

21.4

21.6

21.9

22.1

22.3

22.5

22.8

23.0

23.3

23.5

23.8

24.0

24.3

24.5

24.7

25.0

25.2

25.5

25.7

26.0

26.3

26.5

26.8

27.0

27.3

27.6

27.8

28.1

20

• PUMY-125VM2 STANDARD CAPACITY DIAGRAM

w Before calculating the sum of total capacity of indoor units, please convert

the valve into the kW model capacity following the table on page 12.

Total capacity of

w

indoor units(kW)

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

177

178

179

180

181

182

Capacity (kW)

Cooling Heating

12.90

13.00

13.10

13.20

13.30

13.40

13.50

13.60

13.70

13.80

13.90

14.00

14.02

14.04

14.06

14.08

14.10

14.12

14.15

14.17

14.19

14.21

14.23

14.25

14.27

14.30

14.32

14.34

14.36

14.38

14.40

14.42

14.45

14.47

14.49

14.51

14.53

14.55

14.57

14.60

14.62

14.64

14.66

14.68

14.70

14.72

14.75

14.77

14.79

14.81

14.83

14.85

14.87

14.89

14.63

14.75

14.88

15.00

15.13

15.25

15.38

15.50

15.63

15.75

15.88

16.00

16.01

16.02

16.03

16.04

16.06

16.07

16.08

16.09

16.10

16.12

16.13

16.14

16.15

16.16

16.17

16.19

16.20

16.21

16.22

16.23

16.25

16.26

16.27

16.28

16.29

16.31

16.32

16.33

16.34

16.35

16.36

16.38

16.39

16.40

16.41

16.42

16.44

16.45

16.46

16.47

16.48

16.50

Power consumption (kW) Power consumption (kW)

Cooling

5.77

5.84

5.91

5.97

6.04

6.11

6.17

6.24

6.30

6.37

6.45

6.57

6.58

6.58

6.58

6.59

6.59

6.59

6.60

6.60

6.60

6.61

6.61

6.61

6.61

6.63

6.63

6.63

6.64

6.64

6.64

6.65

6.65

6.65

6.66

6.66

6.66

6.66

6.67

6.67

6.67

6.68

6.68

6.68

6.69

6.69

6.69

6.70

6.70

6.70

6.70

6.71

6.71

6.71

220V, 50Hz 220V, 60Hz

Current (A)

Heating

5.50

5.54

5.60

5.65

6.71

6.76

5.82

5.86

5.91

5.97

6.02

6.10

6.09

6.07

6.05

6.03

6.01

6.00

5.98

5.97

5.95

5.94

5.91

5.89

5.88

5.86

5.85

5.83

5.82

5.79

5.77

5.76

5.74

5.73

5.71

5.70

5.67

5.65

5.64

5.62

5.61

5.59

5.58

5.55

5.53

5.52

5.50

5.49

5.47

5.46

5.43

5.41

5.40

5.38

Cooling Heating

30.9

31.2

31.6

31.9

32.3

32.7

33.0

33.4

33.7

34.1

34.5

34.9

35.2

35.2

35.2

35.3

35.3

35.3

35.3

35.3

35.3

35.4

35.4

35.4

35.4

35.4

35.4

35.4

35.5

35.5

35.5

35.5

35.5

35.5

35.6

35.6

35.6

35.6

35.7

35.7

35.7

35.7

35.7

35.7

35.8

35.8

35.8

35.8

35.8

35.8

35.8

35.9

35.9

35.9

29.4

29.6

29.9

30.2

30.5

30.8

31.1

31.2

31.6

31.9

32.2

32.6

32.6

32.4

32.3

32.3

32.2

32.1

32.0

31.9

31.8

31.7

31.6

31.5

31.5

31.3

31.3

31.2

31.1

31.0

30.9

30.8

30.7

30.6

30.5

30.5

30.3

30.2

30.2

30.0

30.0

29.9

29.8

29.7

29.6

29.5

29.4

29.3

29.2

29.2

29.1

28.9

28.9

28.8

Cooling Heating

5.65

5.72

5.78

5.85

5.91

5.98

6.04

6.11

6.17

6.24

6.31

6.43

6.44

6.44

6.44

6.45

6.45

6.45

6.46

6.46

6.46

6.47

6.47

6.47

6.47

6.48

6.48

6.48

6.49

6.49

6.49

6.51

6.51

6.51

6.52

6.52

6.52

6.52

6.53

6.53

6.53

6.54

6.54

6.54

6.55

6.55

6.55

6.56

6.56

6.56

6.56

6.57

6.57

6.57

5.44

5.48

5.53

5.59

5.64

5.70

5.75

5.79

5.85

5.90

5.95

6.03

6.02

6.00

5.98

5.97

5.94

5.93

5.91

5.90

5.88

5.87

5.85

5.82

5.81

5.79

5.78

5.76

5.75

5.73

5.71

5.70

5.67

5.66

5.64

5.63

5.61

5.59

5.58

5.55

5.54

5.52

5.51

5.49

5.47

5.46

5.44

5.42

5.40

5.39

5.37

5.35

3.34

5.32

220V, 50Hz/60Hz

Current (A)

Cooling Heating