SERVICE

&

PARTS

MANUAL

1

Series PL] Ceiling Cassettes

~0d-l~

PL18FK2/PU18EK, PU1 8EK-I

PL24FK2/PU24EK, PU24EK-I

PL30FK2/PU30EK, PU30EK-I

PL36FK2/PU36EK,PU36EK-i

PL42FK21PU42EK2, PU42EK2-I

-1

Ceiling Cassettes

PLL12FK/PUL12EKJPUL1 2EK-I

PLLl8FK/PUL18EK, PULl 8EK-I

PLL24FK/PUL24EK, PUL24EK-I

Ceiling Suspended

I

Series PC

L

1

Ceiling Suspended

WKI

Wall

Mounted

PKI 8EK/PU18EK,PUI 8EK-I

PK24EK/PU24EK,PU24EK-l

PK30EK/PU30EK, PU30EK-I

Wall

Mounted

PKLI 2EK/PUL12EK, PULl 2EK-I

PKLI 8EK/PUL18EK, PULl 8EK-I

PKL24EK/PUL24EK, PUL24EK-I

@

The

Slim Line.

fof

PU18EK

I

and

PUL18EK-I

CONTENTS

REFRIGERANT SYSTEM DIAGRAM

..........................................

47

DWlRlNG DIAGRAM

..............................................................

48

QPERATION FLOW-CHART

.................................................

...

57

MICROPROCESSOR

CONTROL

...............................................

60

TROUBLE SHOOTING

..........................................................

72

SYSTEM CONTROL

.............................................................

81

MTIMER OPERATION WITH OPTIONAL PARTS

..............................

86

m4-WAY AIR FLOW SYSTEM (PL/PLL

series)

................................

88

/@

DISASSEMBLY PROCEDURE

..................................................

95

OPTIONAL PARTS

..............................................................

109

STANDARD PARTS

............................................................

110

CHANGE

POINTS

1. Outdoor controller board changed to the same type as that of heat pump unit.

2. With the change of outdoor controller board, transformer changed.

3.

Contactor changed from VC-2OF to S-U12. (for PU18EK-1 and PUL18EK-1)

4.

Model name of "PLL" has changed to "PL", specifications are identical.

5.

Model name of "PCL" has changed to "PC", specifications are identical.

6.

Model name of "PKL" has changed to "PK", specifications are identical.

FEATURES

1

Series

pLI

Ceiling Cassettes

Indoor unit

PL18FK2

Remote controller Outdoor unit

PU 1 BEK, PU18EK-1

(MODEL) (COOLING CAPACITY) (SEER)

PL18FK2

18,400

Btu/h

10.2

PL24FK2

23,600

Btu/h

10.0

PL30FK2

31,000

Btu/h

10.4

PL36FK2

36,100

Btu/h

10.0

P L42 F K2

42,500

Btu/h

10.0

1.

SPACE-SAVING CENTRALLY LOCATED CEILING RECESSED INSTALLATION

2.

4-WAY AIR FLOW SYSTEM

This series allows you to select from

2,3,

and 4 way air flow directions according to your requirement. As a result, you get

superb flexibility in choosing a configuration that gives you maximum cooling efficiency in a neat and unobstructive installation.

3.

REDI-CHARGED REFRIGERANT SYSTEM

When refrigerant tubing is

1OOft

or less, it is unnecessary to charge additional refrigerant.

This can contribute to enhance

installation guality and reduce installation time.

4.

STABLE COOLING EVEN AT OUTDOOR TEMPERATURES AS LOW AS

0°F

MAKES YEAR-

ROUND AIR-CONDITIONING POSSIBLE

The microprocessor automatically adjusts fan speed in accordance with outdoor temperature to maintain the coolant at an

even condensing temperature. The result is smooth, efficient cooling even when temperatures outdoors drop as low as

0°F.

This makes the unit ideal for a wide range of specialized cooli

computers and areas subject to strong sunlight. Optional wind baf

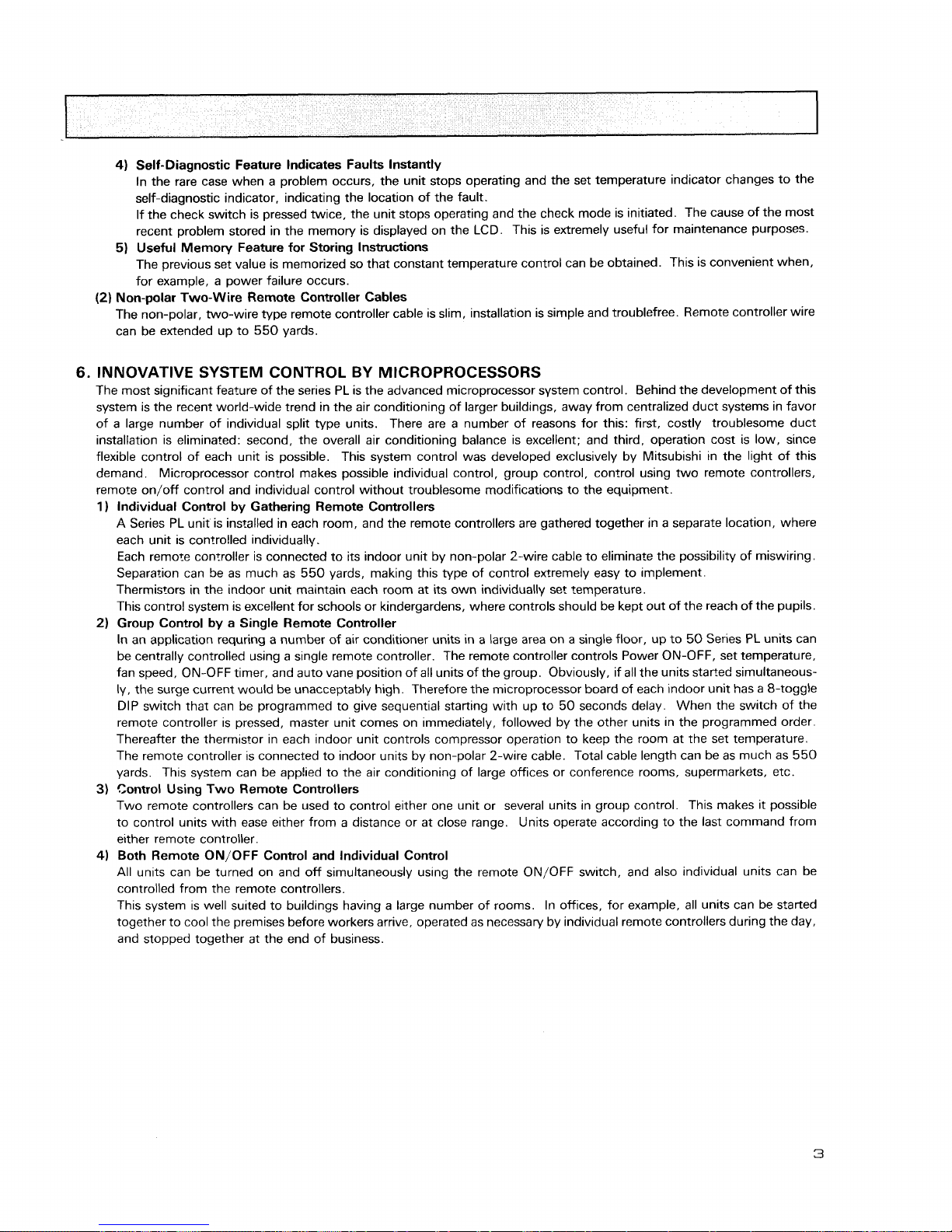

5.

ADVANCED

MICROPROCESSOR

CONTROL

(1)

Easy to use Microprocessor

1) Ultra-Thin Remote Controller

The streamlined, square controller is designed to

blend with any kind of interior and the adopt~on of

a sophisticated microprocessor allows you to

easily carry out a wide range of operations.

2)

Attractive Liquid Crystal Display (LCD)

Unit operation mode, set temperature, room

temperature, timer setting, fan speed, and air

flow direction are displayed of the remote controller by the easily understood visual Liquid Crystal

Display (LCD).

3) Convenient 24-Hour ON-OFF Timer

The timer allows Mr. SLIM to be switched on or

off automatically at the time you set. Once the

timer is set, the remaining time is shown by the

LCD.

8

needs, such as rooms with many office machines

or

must be installed.

POWER-

(ON/OFF)

MODE

SELECT

FAN

COOLiDRY

SET

TEMPERATURE

WARMER

TIMER MODE HOURS

1

LOW HIGH

/

I

FAN

SPEED LOW!HIGH

1

AIR

UPIDOWN

STOP

1

TEST

WN

I

r--

CHECK

TEST

RUN

4) Self-Diagnostic Feature Indicates Faults Instantly

In the rare case when a problem occurs, the unit stops operating and the set temperature indicator changes to the

self-diagnostic indicator, indicating the location of the fault.

If the check switch is pressed twice, the unit stops operating and the check mode is initiated. The cause of the most

recent problem stored in the memory is displayed on the LCD. This is extremely useful for maintenance purposes.

5)

Useful Memory Feature for Storing Instructions

The previous set value is memorized so that constant temperature control can be obtained. This is convenient when,

for example, a power failure occurs.

(2)

Non-polar Two-Wire Remote Controller Cables

The non-polar, two-wire type remote controller cable is slim, installation is simple and troublefree. Remote controller wire

can be extended up to

550

yards.

6.

INNOVATIVE SYSTEM CONTROL BY MICROPROCESSORS

The most significant feature of the series PL is the advanced microprocessor system control. Behind the development of this

system is the recent world-wide trend in the air conditioning of larger buildings, away from centralized duct systems in favor

of a large number of individual split type units.

There are a number of reasons for this: first, costly troublesome duct

installation is eliminated: second, the overall air conditioning balance is excellent; and third, operation cost is low, since

flexible control of each unit is possible. This system control was developed exclusively by Mitsubishi in the light of this

demand. Microprocessor control makes possible individual control, group control, control using two remote controllers,

remote

on/off control and individual control without troublesome modifications to the equipment.

1)

Individual Control by Gathering Remote Controllers

A

Series PL unit is installed in each room, and the remote controllers are gathered together in a separate location, where

each unit is controlled individually.

Each remote controller is connected to its indoor unit by non-polar 2-wire cable to eliminate the possibility of miswiring.

Separation can be as much as

550

yards, making this type of control extremely easy to implement.

Thermistors in the indoor unit maintain each room at its own individually set temperature.

This control system is excellent for schools or kindergardens, where controls should be kept out of the reach of the pupils.

2)

Group Control by a Single Remote Controller

In an application requring a number of air conditioner units in a large area on a single floor, up to

50

Series PL units can

be centrally controlled using a single remote controller. The remote controller controls Power ON-OFF, set temperature,

fan speed, ON-OFF timer, and auto vane position of all units of the group. Obviously, if all the units started simultaneous-

ly, the surge current would be unacceptably high. Therefore the microprocessor board of each indoor unit has a 8-toggle

DIP switch that can be programmed to give sequential starting with up to

50

seconds delay. When the switch of the

remote controller is pressed, master unit comes on immediately, followed by the other units in the programmed order.

Thereafter the thermistor in each indoor unit controls compressor operation to keep the room at the set temperature.

The remote controller is connected to indoor units by non-polar 2-wire cable. Total cable length can be as much as

550

yards. This system can be applied to the air conditioning of large offices or conference rooms, supermarkets, etc.

3)

Control Using Two Remote Controllers

Two remote controllers can be used to control either one unit or several units in group control. This makes it possible

to control units with ease either from a distance or at close range. Units operate according to the last command from

either remote controller.

4) Both Remote

ON/OFF

Control and Individual Control

All units can be turned on and off simultaneously using the remote ON/OFF switch, and also individual units can be

controlled from the remote controllers.

This system is well suited to buildings having a large number of rooms. In offices, for example, all units can be started

together to cool the premises before workers arrive, operated as necessary by individual remote controllers during the day,

and stopped together at the end of business.

a

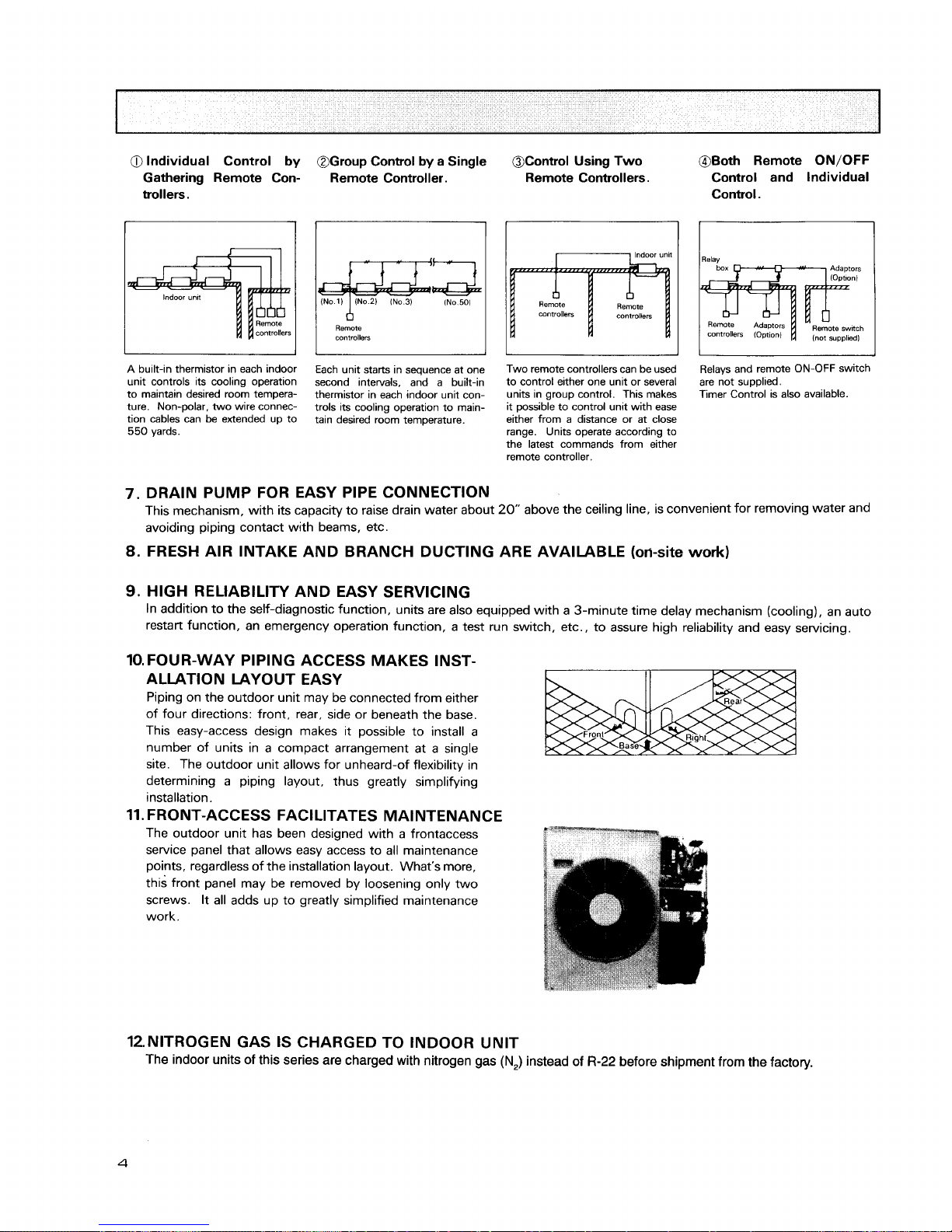

Individual Control

by

Gathering Remote Controllers.

@Group Control

by

a Single

Remote Controller.

I

(No

1)

1

(No

2)

IN0

3)

INo.50)

I

Remote

controllers

OControl Using Two

Remote Controllers.

I

11

Indoor

unlt

A

built-in thermistor in each indoor

unit controls its cooling operation

to maintain desired room temperature. Non-polar, two wire connection cables can be extended up to

550

yards.

Each unit starts in sequence at one

second intervals, and a built-in

thermistor in each indoor unit controls its cooling operation to maintain desired room temperature.

Two remote controllers can be used

to control either one unit or several

units in group control. This makes

it possible to control unit with ease

either from a distance or at close

range. Units operate according to

the latest commands from either

remote controller.

@Both Remote

ON/OFF

Control and Individual

Control.

I

Relays and remote ON-OFF switch

are not supplied.

Timer Control is also available.

7.

DRAIN PUMP FOR EASY PIPE CONNECTION

This mechanism, with its capacity to raise drain water about

20"

above the ceiling line, is convenient for removing water and

avoiding piping contact with beams, etc.

8.

FRESH AIR INTAKE AND BRANCH DUCTING ARE AVAILABLE

(oti-site

work)

9.

HIGH RELIABILITY AND EASY SERVICING

In addition to the self-diagnostic function, units are also equipped with a 3-minute time delay mechanism (cooling), an auto

restart function, an emergency operation function, a test run switch, etc., to assure high reliability and easy servicing.

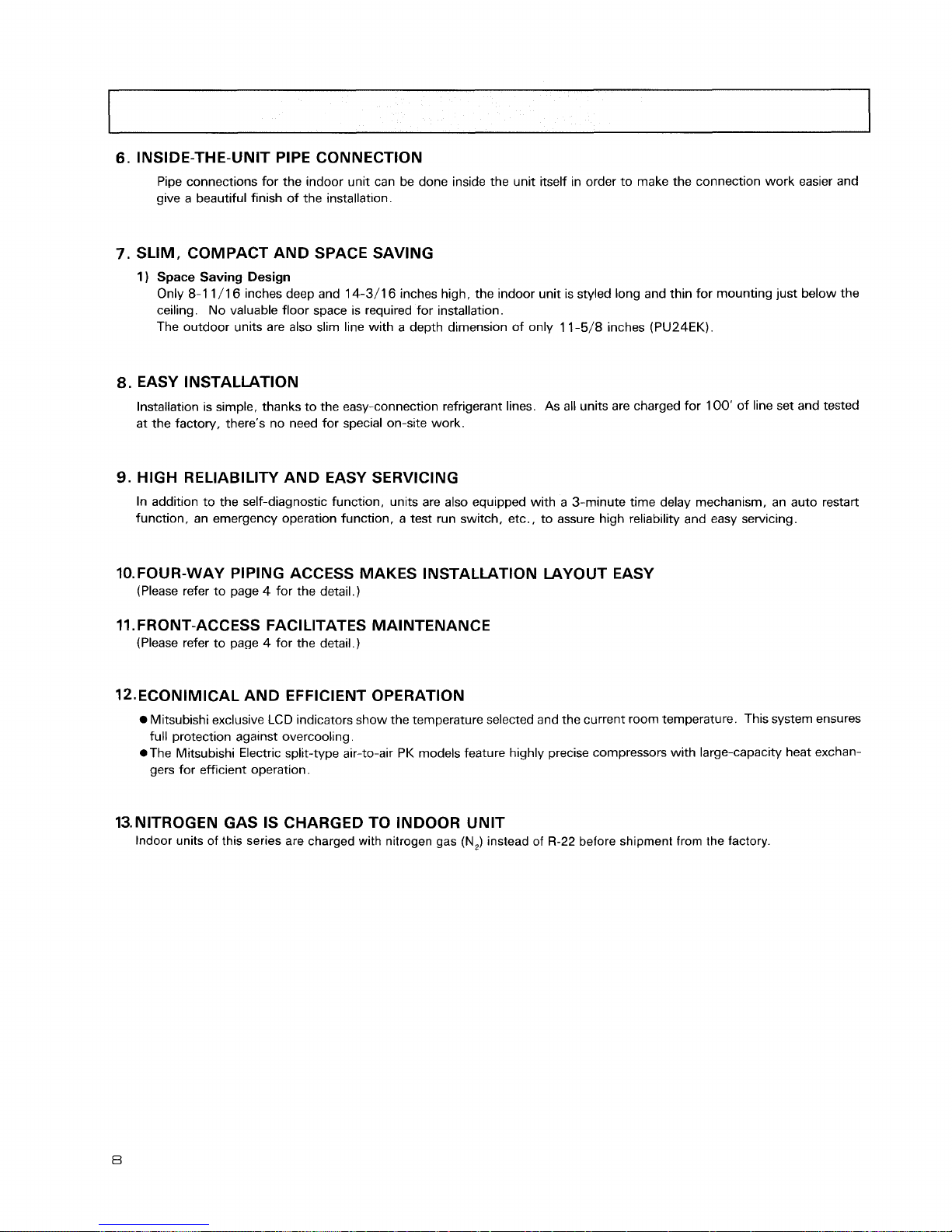

10.

FOUR-WAY PIPING ACCESS MAKES INST-

ALLATION LAYOUT EASY

Piping on the outdoor unit may be connected from either

of four directions: front, rear, side or beneath the base.

This easy-access design makes it possible to install a

number of units in a compact arrangement at a single

site. The outdoor unit allows for unheard-of flexibility in

determining a piping layout, thus greatly simplifying

installation.

11.

FRONT-ACCESS FACILITATES MAINTENANCE

The outdoor unit has been designed with a frontaccess

service panel that allows easy access to all maintenance

points, regardless of the installation layout. What's more,

this front panel may be removed by loosening only two

screws. It all adds up to greatly simplified maintenance

work.

12.NITROGEN GAS IS CHARGED TO INDOOR UNIT

The indoor units of this series are charged with nitrogen gas

(N,)

instead of

R-22

before shipment from the factory.

Ceiling

Suspended

r-~

--

.

-

>--

Microprocessor

Indoor Unit

Remote controller

PU24EK.

PU24EK-I

Outdoor Unit

(Cooling Capacity>

(

24,000 Btu/h

31,000 Btu/h

36,500 Btu/h

42,500 Btu/h

1

.

ADVANCED MICROPROCESSOR CONTROL

(Please refer to page 2 -3 for the detail.)

(1)

Easy to use Microprocessor remote controller

1

)

Ultra-Thin Remote Controller

2) Attractive Liquid Crystal Display (LCD)

3) Convenient 24-Hour ON-OFF Timer

4) Self-Diagnistic Feature Indicates Faults Instantly

5)

Useful Memory Feature for Storing Instructions

(2) Non-polar Two-Wire Remote Controller Cables

2.

INNOVATIVE SYSTEM CONTROL BY MICROPROCESSORS

(Please refer to page 3 for the detail.)

1) Group Control by a Single Remote Controller

2) Control Using Two Remote ~ontrollkrs

3) Both Remote ON/OFF Control and lndividual Control

4) Individual Control by Gathering Remote Controllers

3.

REDI-CHARGED REFRIGERANT SYSTEM

When refrigerant tubing is 100ft or less, it is unnecessary to charge additional refrigerant.

This can contribute to enhance

installation quality and reduce installation time.

4.

MAXIMUM COMFORT AIR CONDITIONING

(1) Indoor Unit Changeable Air Outlet

PC-EK

series have changeable air outlet.

Downward air flow can be obtained at an

angle up to 30". Upward air flow at angle of

10" is able to stretch cool air in a room. This

function enables comfortable air distribution.

(2)

Swing Flow Louvers

The Swing Flow Louvers automatically change

the air flow direction for desirable air distribution.

(3)

Fresh-Air Intake

The PC-EK series also has fresh air intake, providing more comfortable, healthful

air conditioning through better ventilation. The rear panel has a knock-out for

the intake of fresh air.

STABLE COOLING EVEN AT OUTDOOR TEMPERATURES AS LOW

AS

0°F

MAKES YEAR-ROUND AIR-CONDITIONING POSSIBLE

(Please refer to page 2 for the detail.)

DRAIN PUMP FOR EASY PIPE CONNECTION (Option)

This mechanism, with its capacity to raise drainwater 20" above the ceiling line, is convenient for removing water and

avoiding piping contact with beams, etc.

Note

:

This can not be mounted in the unit.

SLIM, COMPACT AND SPACE SAVING

(1

)

Space Saving Design

Because the PC-EK series indoor units are des~gned to be suspended from the ceiling, valuable floor space and wall

surfaces are not used. The unit is only 7-1 1/16" high and 50-7/16" wide

(PC24EK).

The outdoor units are also slim line, with a depth dimension of only

1

1

-5/8" (PU24EK).

(2)

Flush-To-The-Wall Installation

Since the units in the PC-EK series are installed flush against the back wall, connection pipes are hidden. This gives the

room a touch of sleek sophistication.

8.

EASY INSTALLATION

Installation is simple, thanks to the easy-connection refrigerant lines. As all outdoor units are charged for 100' of line set

and tested at the factory, there's no need for special on-site work.

The indoor unit is easy to mount and requires only a minimum of wiring, saving your time, labor, and money.

9.

HIGH

RELIABILITY AND EASY SERVICING

In addition to the self-diagnostic function, units are also equipped with a 3-minute tie delay mechanism, an auto restart

function, an emergency operation function, a test run switch, etc., to assure high reliability and easy servicing.

10.FOUR-WAY PIPING ACCESS MAKES INSTALLATION LAYOUT EASY

(Please refer to page 4 for the detail.)

11. FRONT-ACCESS FACILITATES MAINTENANCE

(Please refer to page 4 for the detail.)

12.ECONOMICAL AND EFFICIENT OPERATION

Mitsubishi exclusive LCD indicators show the temperature selected and the current room temperature.

This system

ensures full protection against overcooling.

@The Mitsubishi Electric split-type air-to-air PC models feature highly precise compressors with large-capacity heat exchan-

gers for efficient operation.

13.NlTROGEN GAS IS CHARGED TO INDOOR UNIT

Indoor units of this series are charged with nitrogen gas

(N,)

instead of

R-22

before shipment from the factory.

BK]

Wall

Mounted

PK24EK

Indoor unit

*umua*arsnr

-

M~croprocessor

remote controller

PU24EK. PU24EK-1

Outdoor unlt

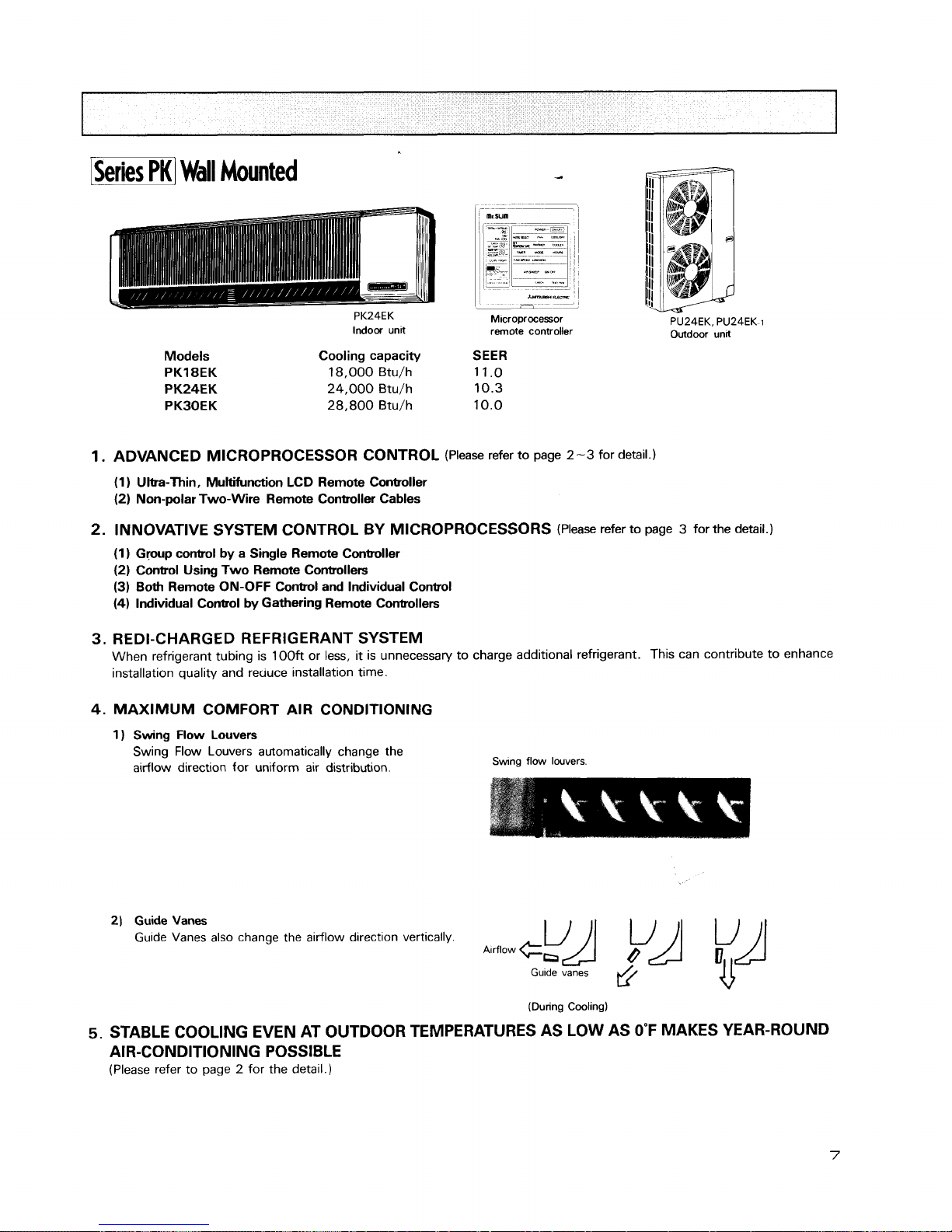

Models

PK18EK

PK24EK

PKBOEK

Cooling capacity SEER

18,000 Btu/h 11.0

24,000 Btu/h 10.3

28,800

Btu/h 10.0

1.

ADVANCED MICROPROCESSOR CONTROL

(Please refer to page

2-3

for detail.)

(1 ) Ultra-Thin, Multifunction LCD Remote Controller

(2) Non-polar Two-Wire Remote Controller Cables

2.

INNOVATIVE SYSTEM CONTROL BY MICROPROCESSORS

(Please refer to page 3 for the detail.)

(1) Gpup control by a Single Remote Controller

(2) Control Using Two Remote Controllers

(3)

Both Remote ON-OFF Control and Individual Conbol

(4)

Individual Control by Gathering Remote Controllers

3.

REDI-CHARGED REFRIGERANT SYSTEM

When refrigerant tubing is 100ft or less,

it

is unnecessary to charge additional refrigerant. This can contribute to enhance

installation quality and reuuce installation time.

4.

MAXIMUM COMFORT AIR CONDITIONING

1 ) Swing Flow Louvers

Swing Flow Louvers automatically change the

airflow direction for uniform air distribution.

Swng

flow louvers

2)

Guide

Vanes

Guide Vanes also change the airflow direction vertically.

(During Cooling)

5.

STABLE COOLING EVEN AT OUTDOOR TEMPERATURES AS LOW AS

0°F

MAKES YEAR-ROUND

AIR-CONDITIONING POSSIBLE

(Please refer to page 2 for the detail.)

6.

INSIDE-THE-UNIT PIPE CONNECTION

Pipe connections for the indoor unit can be done inside the unit itself in order to make the connection work easier and

give a beautiful finish of the installation.

7.

SLIM, COMPACT AND SPACE SAVING

1

)

Space

Saving Design

Only

8-1

1/16 inches deep and 14-3/16 inches high, the indoor unit is styled long and thin for mounting just below the

ceiling. No valuable floor space is required for installation.

The outdoor units are also slim line with a depth dimension of only 11-5/8 inches (PU24EK).

8.

EASY INSTALLATION

Installation is simple, thanks to the easy-connection refrigerant lines. As all units are charged for 100' of line set and tested

at the factory, there's no need for special on-site work.

9.

HIGH RELIABILITY AND EASY SERVICING

In addition to the self-diagnostic function, units are also equipped with a 3-minute time delay mechanism, an auto restart

function, an emergency operation function, a test run switch, etc., to assure high reliability and easy servicing.

10.FOUR-WAY PIPING ACCESS MAKES INSTALLATION LAYOUT EASY

(Please refer to page 4 for the detail.)

11. FRONT-ACCESS FACl LITATES MAINTENANCE

(Please refer to page 4 for the detail.)

12.ECONIMICAL AND EFFICIENT OPERATION

Mitsubishi exclusive

LCD

indicators show the temperature selected and the current room temperature. This system ensures

full protection against overcooling.

*The Mitsubishi Electric split-type air-to-air PK models feature highly precise compressors with large-capacity heat exchan-

gers for efficient operation.

13.NITROGEN GAS IS CHARGED TO INDOOR UNIT

Indoor units of this series are charged with nitrogen gas

(N,)

instead of

R-22

before shipment from the factory.

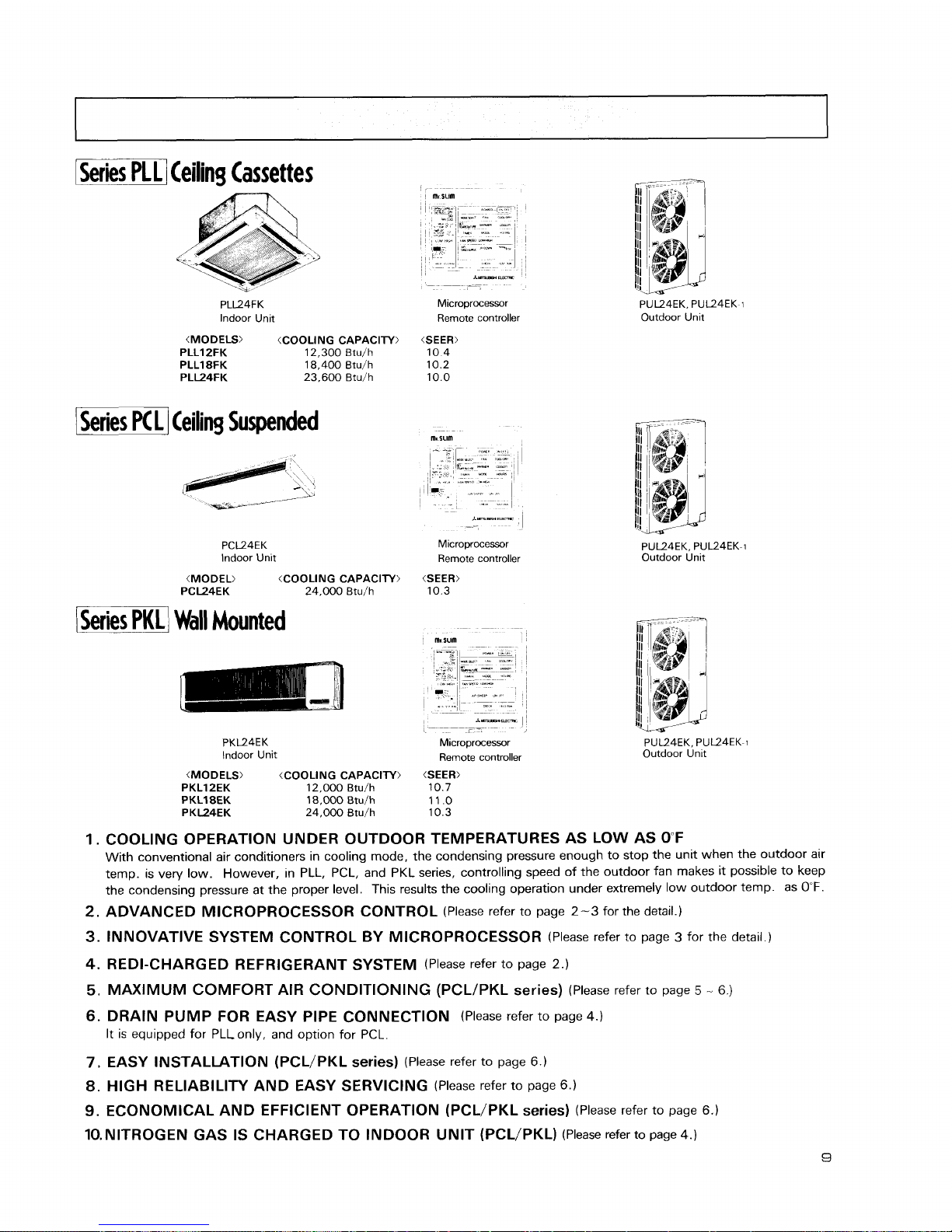

Series

Ceiling Cassettes

PLL24FK

lndoor Unit

(MODELS) (COOLING CAPACITY)

PLLIZFK 12,300 Btu/h

PLL18FK 18,400 Btu/h

PLL24FK 23,600 Btu/h

I

Series

PC

L

1

Ceiling Suspended

PCL24EK

lndoor Unit

(MODEL) (COOLING CAPACITY)

PCL24EK 24,000 Btu/h

1

Series

PKL

1

Wall

Mounted

*"?s,s3.-

-

--

-

-

M~croprocessor

Remote controller

(SEER)

10 4

10 2

10 0

Microprocessor

Remote controller

PK124EK

lndoor Unit

*--

I

I

-

,

Microprocessor

Remote controller

(MODELS) (COOLING CAPACITY)

(SEER:

PKLlZEK 12,000 Btu/h 10.7

PKL18EK 18,000 Btulh 11 .O

PKL24EK 24,000 Btu/h 10.3

PUL24EK. PUL24EK-1

Outdoor Unit

PU124EK. PUL24EK-1

Outdoor Unit

PUL24EK. PUL24EK-1

Outdoor Unlt

COOLING OPERATION UNDER OUTDOOR TEMPERATURES AS LOW AS OF

With conventional air conditioners in cooling mode, the condensing pressure enough to stop the unit when the outdoor air

temp. is very low. However, in PLL, PCL, and PKL series, controlling speed of the outdoor fan makes it possible to keep

the condensing pressure at the proper level. This results the cooling operation under extremely low outdoor temp. as

0°F.

ADVANCED MICROPROCESSOR CONTROL

(Please refer to page

2-3

for the detail.)

INNOVATIVE SYSTEM CONTROL BY MICROPROCESSOR

(Please refer to page 3 for the detail.)

REDI-CHARGED REFRIGERANT SYSTEM

(Please refer to page

2.)

MAXIMUM COMFORT AIR CONDITIONING

(PCLIPKL

series)

(Please refer to page

5

-

6.)

DRAIN PUMP FOR EASY PIPE CONNECTION

(Please refer to page

4.)

It is equipped for PLLonly, and option for PCL.

EASY INSTALLATION (PCL/PKL series)

(Please refer to page 6.)

HIGH RELIABILITY AND EASY SERVICING

(Please refer to page 6.)

ECONOMICAL AND EFFICIENT OPERATION (PCL/PKL series)

(Please refer to page

6.)

10.NlTROGEN GAS IS CHARGED TO INDOOR UNIT (PCL/PKL)

(Please refer to page

4.)

1

Operating range

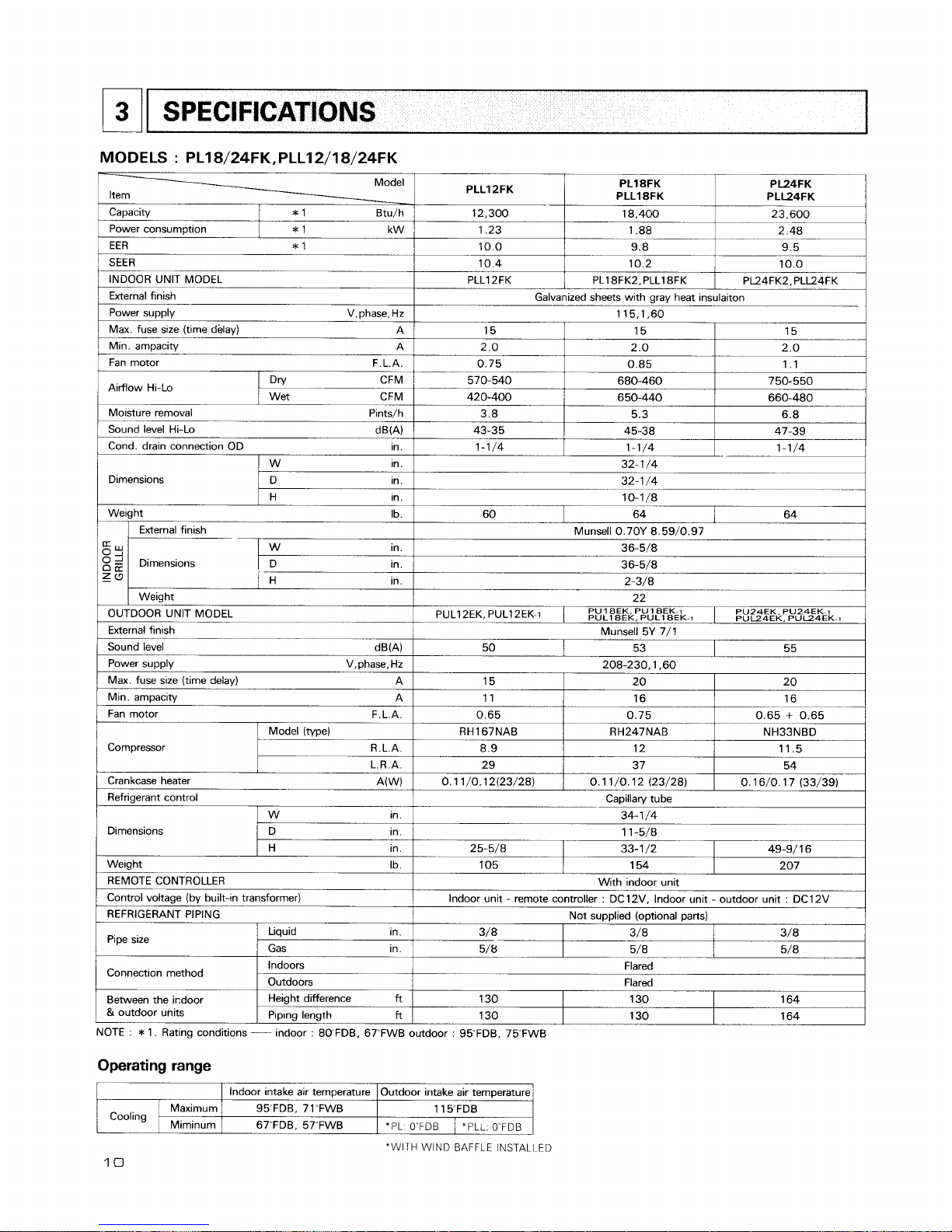

SPECIFICATIONS

MODELS : PL18/24FK,PLLl2/18/24FK

Model

Item

PLLIPFK

12,300

1.23

10.0

10.4

PLLl 2FK

Capacity

*

1 Btu/h

Cooling

PL18FK

PLL18FK

18.400

1.88

9.8

10.2

PL18FK2, PLL18FK

"WITH WIND BAFFLE INSTALLED

10

lndoor intake air temperature

95"FDB, 71~FWB

67~FDB. 57'FWB

Maximum

Miminum

PL24FK

PLL24FK

23,600

2.48

9.5

10.0

PL24FK2, PLL24FK

Power consumption

Galvanized sheets with gray heat insulaiton

115,1,60

*

1 kW

15

2.0

0.75

I

570-540

420-400

3.8

43-35

1-1/4

Outdoor intake air temperature

1 15"FDB

*PL 0"FDB

15

2.0

0.85

680-460

650-440

5.3

45-38

1-1/4

EER

*

1

SEER

INDOOR UNIT MODEL

External finish

Power supply V,phase,Hz

Max. fuse size (time delay) A

Min. ampacity A

Fan motor F.L.A.

Airflow Hi-Lo

I

Dn/

CFM

Wet CFM

Moisture removal Pints/h

Sound level Hi-Lo dm)

Cond. drain connection OD ~n.

"PLL. 0"FDB

15

2.0

1.1

750-550

660-480

6.8

47-39

1-1/4

Dimensions

32-1/4

32-1

/4

10-1/8

W ~n.

D ~n.

H in.

60

64

Weight Ib.

64

g

Y

O

2

0

a

Z

a

Munsell 0.70Y 8.59/0.97

36-51'8

36-5/8

2-3/8

22

PUL12EK. PUL12EK-1

1

PUL~~EK,

PU

18~~.

PU

PULI~EK-1

1

~EK-I

External finish

PU24EK. PU24EK~t

PUU4EK. PUU4EK-1

Dimensions

OUTDOOR UNIT MODEL

External finish

Sound level dB(A)

Power supply V,phase,Hz

Max. fuse size (time delay) A

Min. ampacity A

Fan motor F.L.A.

W

in.

D in.

H in.

Munsell 5Y 7/1

Compressor

Weight

50

Model (type)

R.L.A.

L.R.A.

53

Crankcase heater A(W)

Refrigerant control

55

208-230.1.60

Dimensions

15

11

0.65

RH167NAB

8.9

29

0.11/0.12(23/28)

W ~n.

D in.

H in.

20

16

0.75

RH247NAB

12

37

0.1 1 /O. 12 (23/28)

Weight Ib.

REMOTE CONTROLLER

Control voltage (by built-in transformer)

REFRIGERANT PIPING

20

16

0.65

+

0.65

NH33NBD

11.5

54

0.16/0.17 (33/39)

Capillan/ tube

34-1 /4

1 1 -5/8

Pipe size

Connection method

Between the indoor

&

outdoor units

25-5/8

Liquid in.

Gas in.

Indoors

Outdoors

Height difference

ft

Piping length

ft

NOTE

:

*

1. Rating conditions

----

indoor : 80FDB. 67~FWB

33-1 /2 49-9/ 1 6

105

154 207

With indoor unit

Indoor unit

-

remote controller : DC12V. Indoor unit - outdoor unit : DC12V

Not supplied (optional parts)

3/8 3/8 3/8

5/8- 5/8 5/8

Flared

Flared

130 130 164

130

outdoor

:

95"FDB. 75"FWB

130 164

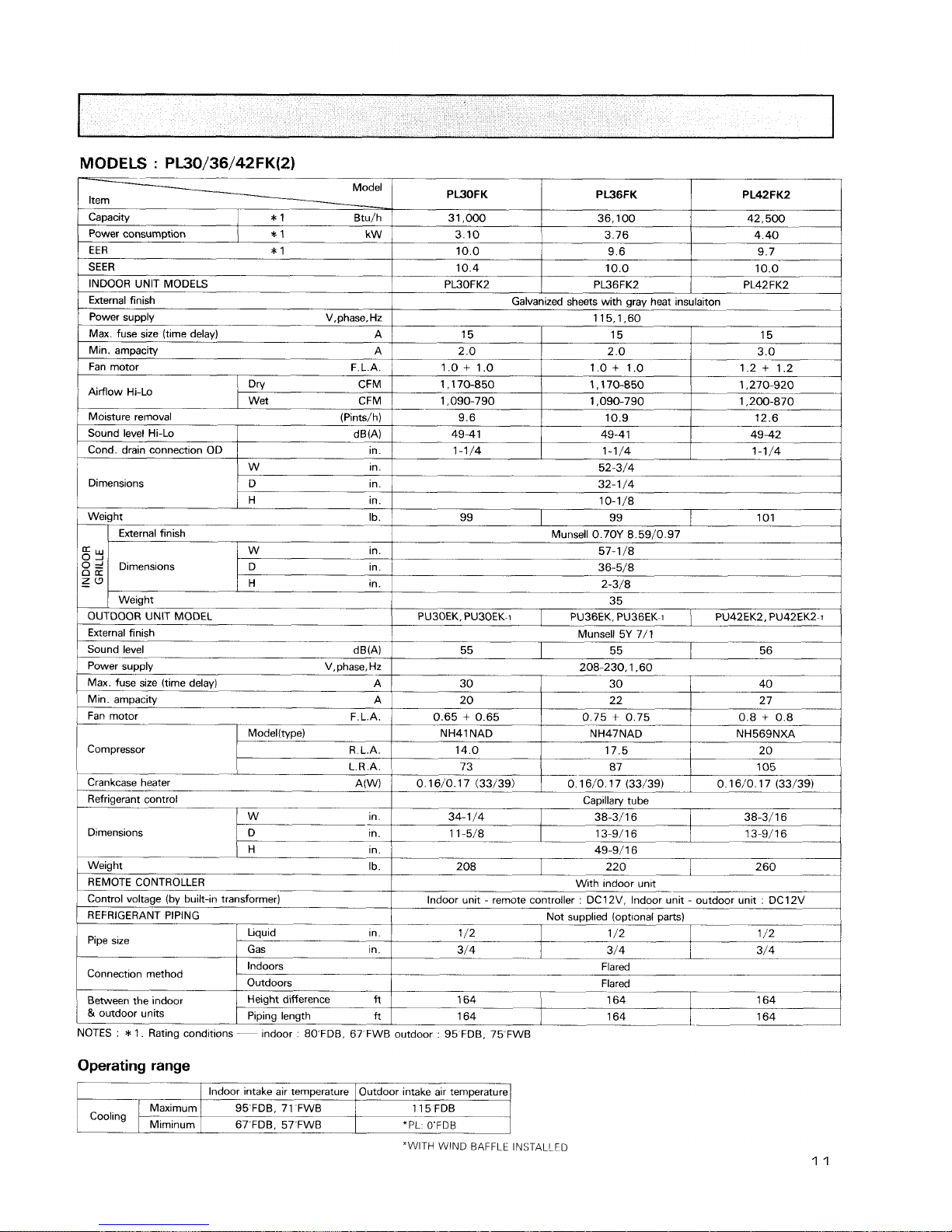

MODELS

:

PL30/36/42FK(2)

Model

Item

-

PWOFK

31,000

3.10

10.0

10.4

PL30FK2

Capacity

Moisture removal (Pints/h)

Fan motor F.L.A.

1

0.65 + 0.65

*

1 Btu/h

9.6

49-41

1-11'4

Sound level Hi-Lo

Cond. drain connection OD

Dimensions

compressor

PW6FK

36,100

3.76

9.6

10.0

PL36FK2

dw)

in.

W

~n.

D in.

H in.

0.75

+

0.75

Pipe slze

Operating range

PL42FK2

42,500

4.40

9.7

10.0

PL42FK2

Power consumption

Galvanized sheets with gray heat insulaiton

115,1,60

10.9

49-4 1

1-1/4

0.8

+

0.8

ModeKtype)

R.L.A.

L.R.A.

Connection method

Between the indoor

&

outdoor units

*

1 kW

15

2.0

1 .O

+

1 .O

1 ,170-850

1,090-790

12.6

49-42

1-1/4

52-3/4

32- 1

/4

10-1/8

Weight Ib.

Liquid in.

I

1 /2

"WITH

WIND BAFFLE INSTALLED

99

Sr

0

='

0

a

zu

-

NH41 NAD

14.0

73

Crankcase heater A(W)

Refrigerant control

NOTES

:

*

1. Rating conditions

--

indoor : 8OFDB. 67 FWB outdoor : 95 FDB, 75 FWB

Indoors

Outdoors

Height difference

fl

Piping length

ft

15

2.0

1.0+ 1.0

1,170-850

1,090-790

EER

*

1

SEER

INDOOR UNIT MODELS

External finish

Power supply V,phase, Hz

Max. fuse size (time delay)

A

Min. ampacity A

Fan motor F.L.A.

0.16/0. 17 (33/39)

Dimensions

1 /2

Cooling

15

3.0

1.2

+

1.2

1,270-920

1,200-870

Aidow Hi-Lo

99

OUTDOOR UNIT MODEL

External finish

Sound level dB(A)

Power supply V, phase, Hz

Max. fuse size (time delay)

A

Min.

ampacity A

External finish

NH47NAD

17.5

87

W in.

D ~n.

1 /2

Gas ~n.

-

Flared

Flared

lndoor intake air temperature

95 FDB, 71 FWB

67'FDB. 57"FWB

Maximum

Miminurn

Dnl CFM

Wet CFM

101

Dimensions

Munsell 0.70Y 8.59/0.97

57-1 /8

36-5/8

2-3/8

35

NH569NXA

20

105

0.16/0. 17 (33/39)

H in.

Weight Ib.

REMOTE CONTROLLER

Control voltage (by built-in transformer)

REFRIGERANT PIPING

164

Outdoor intake air temperature

115 FDB

*PL: O'FDB

W in.

D in.

H in.

PU30EK. PU30EK-1

0.16/0.17 (33/39)

Capillary tube

34-1/4

1

38-3/16

1

38-3/16

11-5/8

1

13-9/16

/

13-9/16

49-9/16

3/4

Weight

PU36EK. PU36EK-1

1

PU42EK2, PU42EK2-i

208

164

3/4

164

164

Munsell 5Y 7/1

With mdoor unit

-

Indoor unit - remote controller : DC12V, Indoor unit - outdoor unit : DC12V

Not supplied (optional parts)

220

3/4

164

---

164

55

260

55 56

208-230.1.60

30

I

30

1

40

20 22 2 7

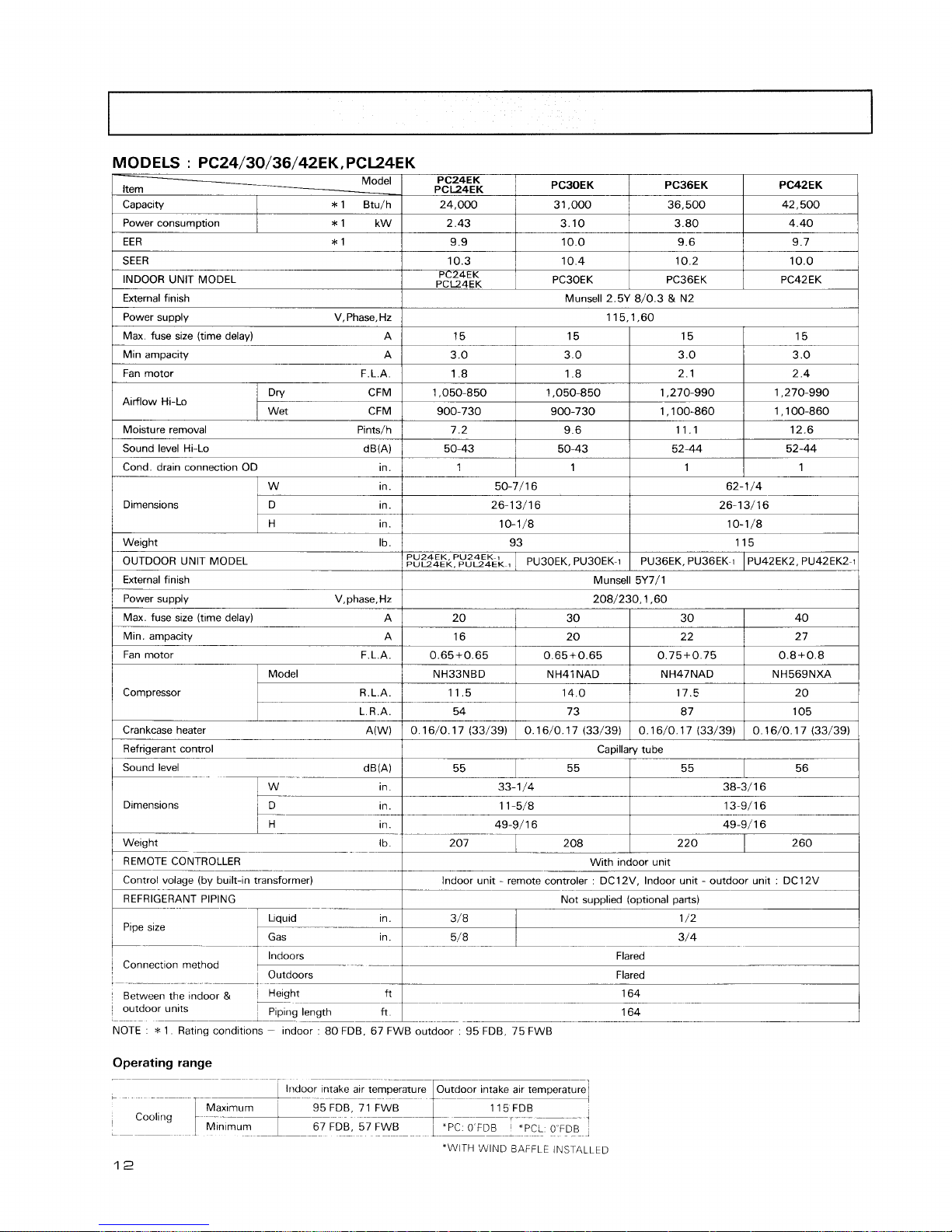

MODELS : PC24/30/36/42EK, PCL24EK

1

Power consurn~tion

1

*1 kWI 2.43

1

3.10

1

3.80

I

4.40

I

1

EER

*

1

1

9.9

I

10.0

1

9.6

1

9.7

I

-

Model

Item

-

Capacity

PC42EK

42,500

PC24EK

PCL24EK

24,000

*

1 Btu/h

SEER

INDOOR

UNlT MODEL

External finish

1

Max fuse size (time delay) A

/

15

1

15

I

15

1

15

I

Power supply V,Phase, Hz

PC30EK

31.000

10.3

PC24EK

PCL24EK

115,1,60

1

Fan motor F.L.A.

I

1.8

1

1.8

I

2.1

I

2.4

1

PC36EK

36,500

Min ampacity A

Munsell 2.5Y 8/0.3

&

N2

10.4

PC30EK

1

Sound level Hi-Lo dB(A)/ 50-43

1

50-43

1

52-44

1

52-44

1

3.0

Airflow Hi-Lo

1

Cond. drain connection OD in.

1

1

1

1

1

1

I

1

1

10.2

PC36EK

10.0

PC42EK

3.0

Dry CFM

Wet CFM

/

Weight Ib.

/

93

I

115

1

Pints/h

3.0

1,050-850

900-730

1

w

in.

/

power supply V,phase,Hz

/

208/230,1,60

I

3.0

7.2

50-7/16

26-1 3/16

10-11'8

Dlrnensions

OUTDOOR UNlT MODEL

External finish

/

Max. fuse size

(time

delavl

1,050-850

900-730

62-1

/4

26-13/16

10-1/8

D in.

H in.

I

Min. ampacity

9.6

I

1,270-990

1,100-860

PU24EK. PU24EK-7

~"124~~.

PU~~EK-,

1

Refrigerant control

1

Capillary tube

I

1,270-990

1,100-860

11.1

Sound level

12.6

Munsell 5Y7/1

PU30EK. PU30EK-1

Fan motor F.L.A.

0.65+0.65

NH33NBD

11.5

54

0.16/0. 17 (33/39)

Compressor

1

Welght

--

-

-

lbi

207

1

208

1

220

1

260j

--

With

Indoor unlt

--

lndoor unlt - remote controler DC12V. Indoor unlt - outdoor unit

DC12V

PU36EK. PU36EK-1

Model

R.L.A.

L.R.A.

dB(A)

in.

in.

1

REFRIGERANT PIPING

1

Not supplied (optional parts)

1

PU42EK2, PU42EK2-1

0.65+0.65

NH41 NAD

14.0

73

0.16/0. 17 (33/39)

Crankcase heater A(W)

Llquid

1

P~pe size

55

1

55

-.

33-1 /4

1 1 -5/8

0.75+0.75

NH47NAD

17.5

87

0.16/0. 17 (33/39)

38-3/ 1 6

13-9/16

in. 49-9/16

I

/

Connection

method

1

Indoors

--

.

I

Outdoors

0.8+0.8

NH569NXA

20

105

0.16/0. 17 (33/39)

49-9/16

~n.

Flared

3/8

Flared

Between the

mdoor

&

Pght-

9-

.

-

-

-

164

--

outdoor

units

'

Plplng length

ft

--

.

-

--

164

NOTE

*

1 Rat~ng condltlons - Indoor 80 FDB. 67 FWB outdoor 95 FDB 75 FWB

~n.

Operating range

5/8

--

-

--

--

-

-

--

-

-

-

1

Indoor ~ntake a~r temperature Outdoor lntake a~r temperature

7

95 FDB 71 FWB

Cooling

1

;'':;+--

115FDB

T

L---

1

67 FDB, 57 FW8

'PCL

OFDB

:

-

I--

*WITH

'SIIIND BAFFLE INSTALLED

12

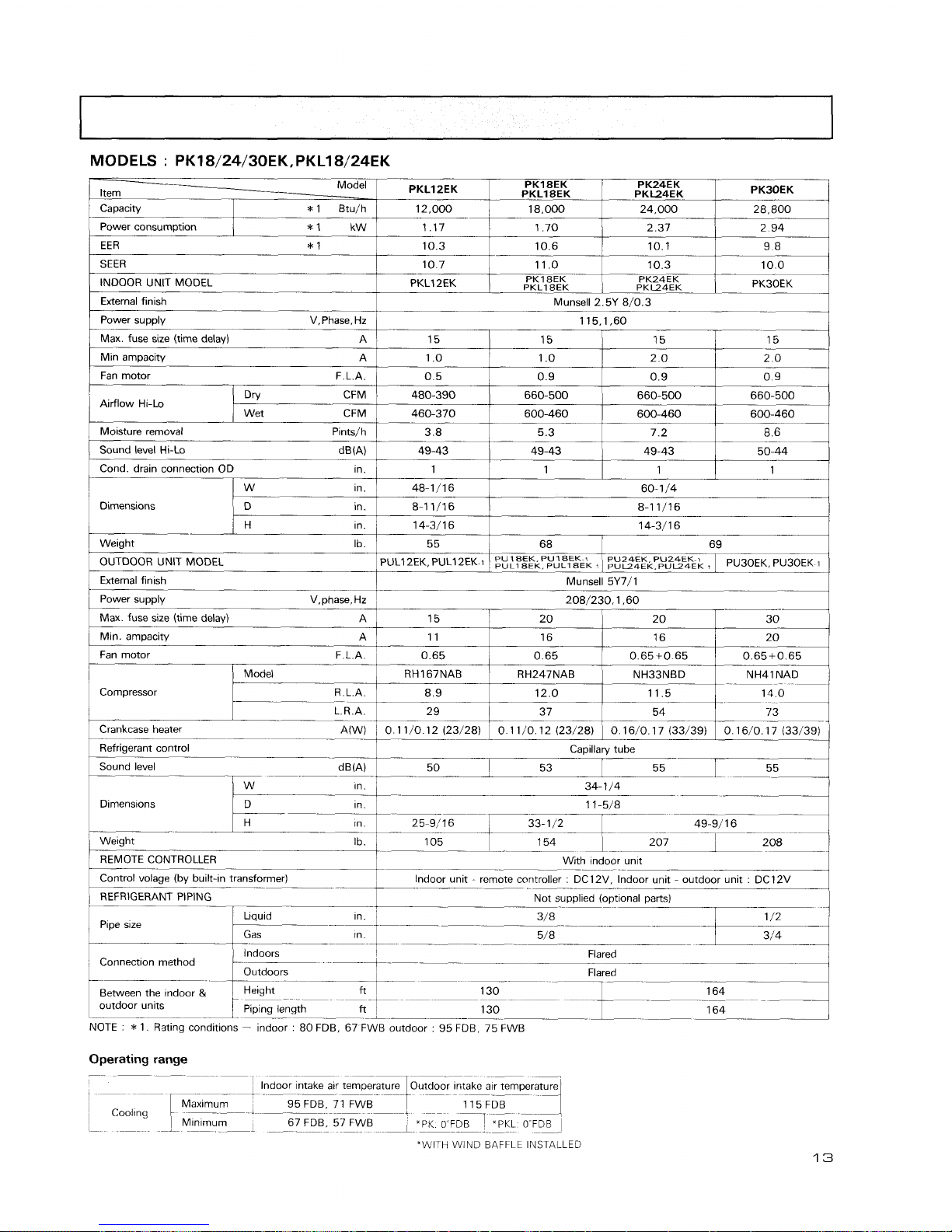

MODELS : PK18/24/30EKrPKL18/24EK

-

/

power supply V,Phase.Hz

/

115,1,60

I

PKLIZEK

Item

-

Power consumption

10.7

INDOOR UNIT MODEL PKL12EK

I

I

I

OUTDOOR UNIT MODEL

I

PULl2EK. PULl2EK

1

I

~~:~~~li.p~,"~&~

$1

P~~~&P,"~~Pu~oEK

1

PK18EK

PKLl8EK

External finish

MM

1.70

10.6

11 .O

PKl SEK

PKLZK

External finlsh

Munsell 5Y7/1

Power supplv V,phase,Hz

,

208/230.1.60

Capacity

Max. fuse size (time delay)

A

Min ampacity A

Fan motor F.L.A.

I

1

T

-

(

Max. fuse size (time delay) A

1

15 20 20 30

1

PK24EK

PKL24EK

2.37

10.1

10.3

PK24EK

PKL24EK

15

1 .O

0.5

480-390

460-370

3.8

49-43

1

48-1/16

8-1 1/16

14-311 6

55

Airflow Hi-Lo

PK30EK

*

1 Btu/h

/

12,000

2.94

9.8

10.0

PK3OEK

Dn! CFM

Wet CFM

I

/

Model

1

RH167NAB

1

RH247NAB

1

NH33NBD

1

NH41NAD

1

15

1 .O

0.9

660-500

600-460

5.3

49-43

1

Min.

arnpacity A

Fan motor

-

F.L.A.

Compressor 8 9 12 0 11 5

--

29 37 54 73

18,000

Moisture removal Pintsjh

Sound level Hi-Lo d Em)

Cond. drain connection OD ~n.

Crankcase heater

0 1 1

/0 12 (23128)

1

0 16/0 1 7 (33139) 1 0 16/0 17 (33139)

Capillary

tube

Sound level

-

--

--

53 55

I

34- 1 /4

---

Dlrnens~ons

--

1 1 -5/8

--

--

15

2.0

ppp

0.9

660-500

600-460

7.2

49-43

1

Dimensions

11

0.65

1

1n.1 25-9/16

1

33-112

1

49-91 1 6

I

24,000

15

2.0

0.9

660-500

600-460

8.6

50-44

1

W

in.

D in.

60-1

/4

8-1 1/16

14-3/16

Weight

-

.

REMOTE CONTROLLER

28.800

in.

Ib.

68

16

0.65

Control volage (by

built-ln transformer)

--

1

l"door unit - remote controller : DClIV, Indoor unit - outdoor unit : DCl2V

.

-

.

REFRIGERANT PIPING

Not su~olied lo~t~onal ~arts)

69

Pipe sue

16

0.65+0 65

/

Llquid in.

1

0.65+0.65

4

1

Gas ~n.

1

Connection

method

Indoors

--

Outdoors

Flared

Flared

Between the mdoor

&

I

Height

ft

1

outdoor unlts

1

Plplnq length

-7.7

-

NOTE

:

*

1. Rating conditions - indoor : 80 FDB, 67 FWB outdoor : 95 FDB, 75 FWB

Operating range

I

1

-

--

F

Max~mum 95 FDB, 71 FWB

--

--

,

-

--

115FDB

1

Cooling

i

-

Mlnlmurn 67 FDB, 57 FWB

I

-

--

-2

--

_-I

_

-

*PK

o

FDB

T

"PKL

OFDB

1

-I

-

_-

-

"WITH WIND BAFFLE INSTALLED

MODELS

:

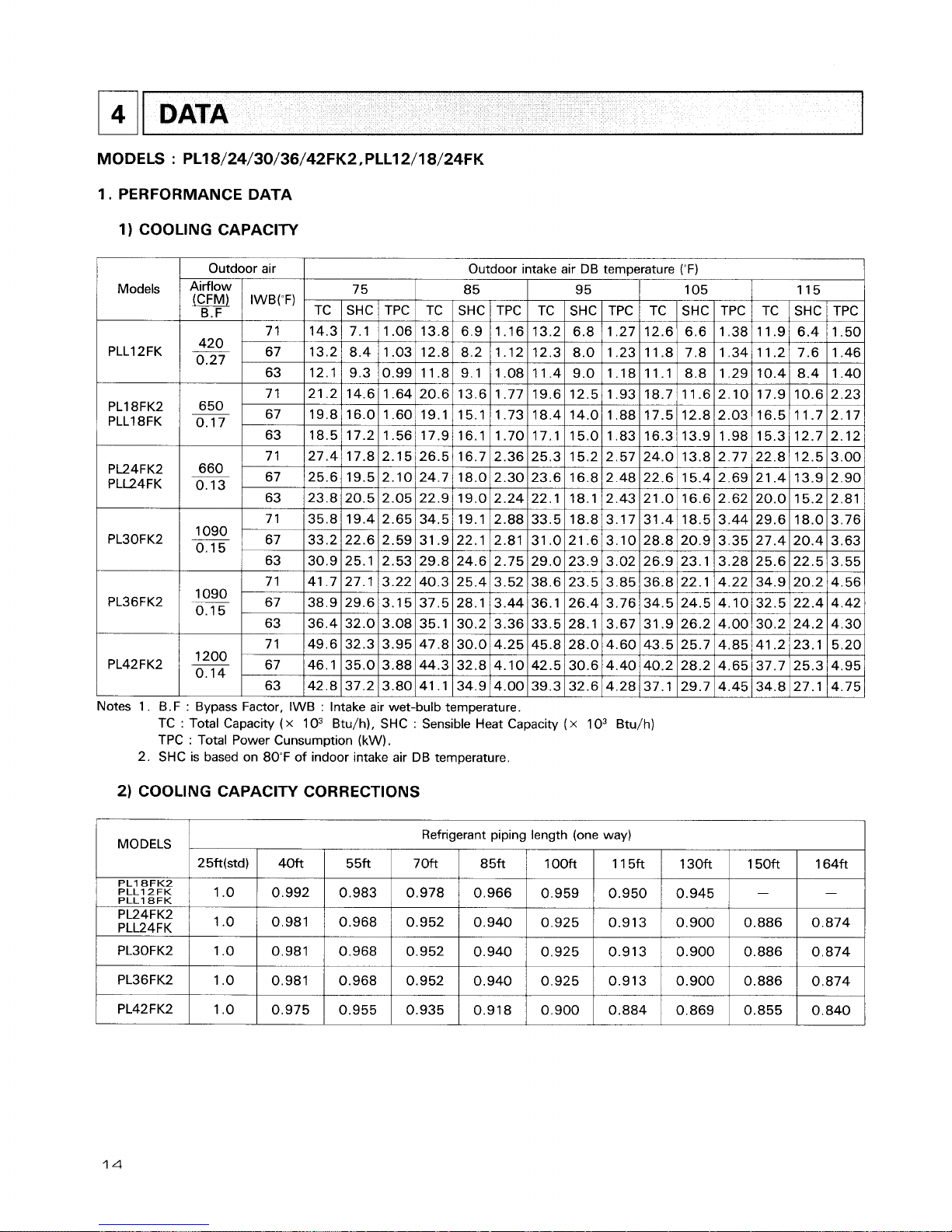

PL18/24/30/36/42FK2,PLL12/18/24FK

1.

PERFORMANCE DATA

1)

COOLING CAPACITY

1

Models

PLLI 2FK

DATA

PL18FK2

PLLI 8FK

-

Outdoor air

I

Outdoor mtake air DB temperature (OF)

1

75 8 5 95 105 115

TC

I

SHC / TPC I TC

SHC

/

TPC I TC I SHC I TPC / TC 1 SHC 1 TPC 1 TC 1 SHC I TPC

Notes 1. B.F

:

Bypass Factor, IWB : Intake air wet-bulb temperature.

TC

:

Total Capacity ( x

1 O3 Btu/h), SHC : Sensible Heat Capacity

(

x

1 O3 Btu/h)

TPC

:

Total Power Cunsumption (kW).

2. SHC is based on 80°F of indoor intake air DB temperature.

2)

COOLING CAPACITY CORRECTIONS

MODELS

PL18FK2

PLL12FK

PLL18FK

PL24FK2

PLL24FK

Refrigerant piping length (one way)

25ft(std)

1 .o

,0

40ft

0.992

0.981

5 5ft

0.983

0.968

7 Oft

0.978

0.952

8 5ft

0.966

0.940

1OOft

0.959

0.925

11 5ft

0.950

0.913

130ft

0.945

0.900

150ft

-

0.886

164ft

-

0.874

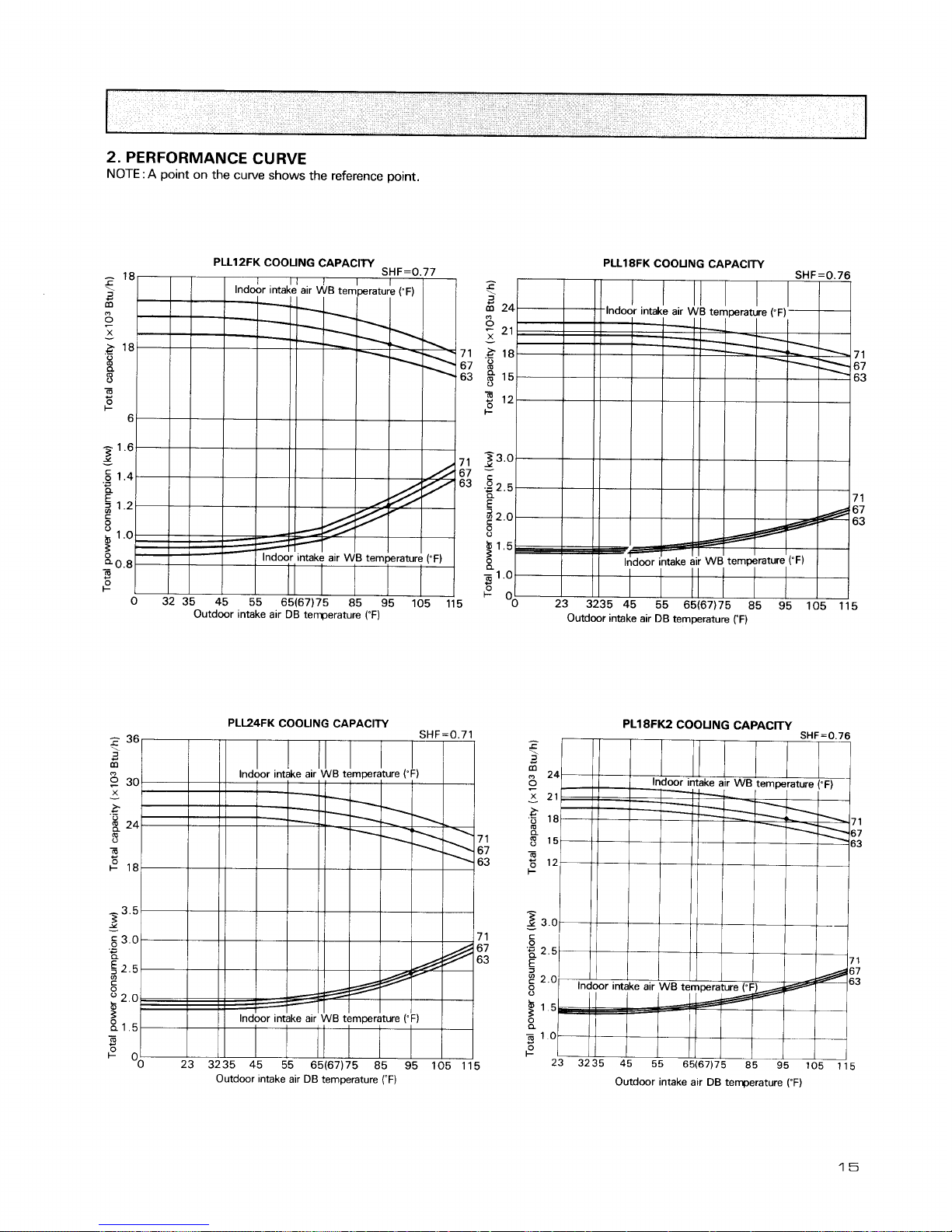

2.

PERFORMANCE CURVE

NOTE

:

A

point on the curve shows the reference point.

PLL18FK COOUNG CAPACITY

Outdoor intake air

DB

temperature

('F)

PL18FK2

COOUNG

CAPACITY

Outdwr intake air

Dl3

temperature

rF)

Outdoor intake air

DB

terrperature

(OF)

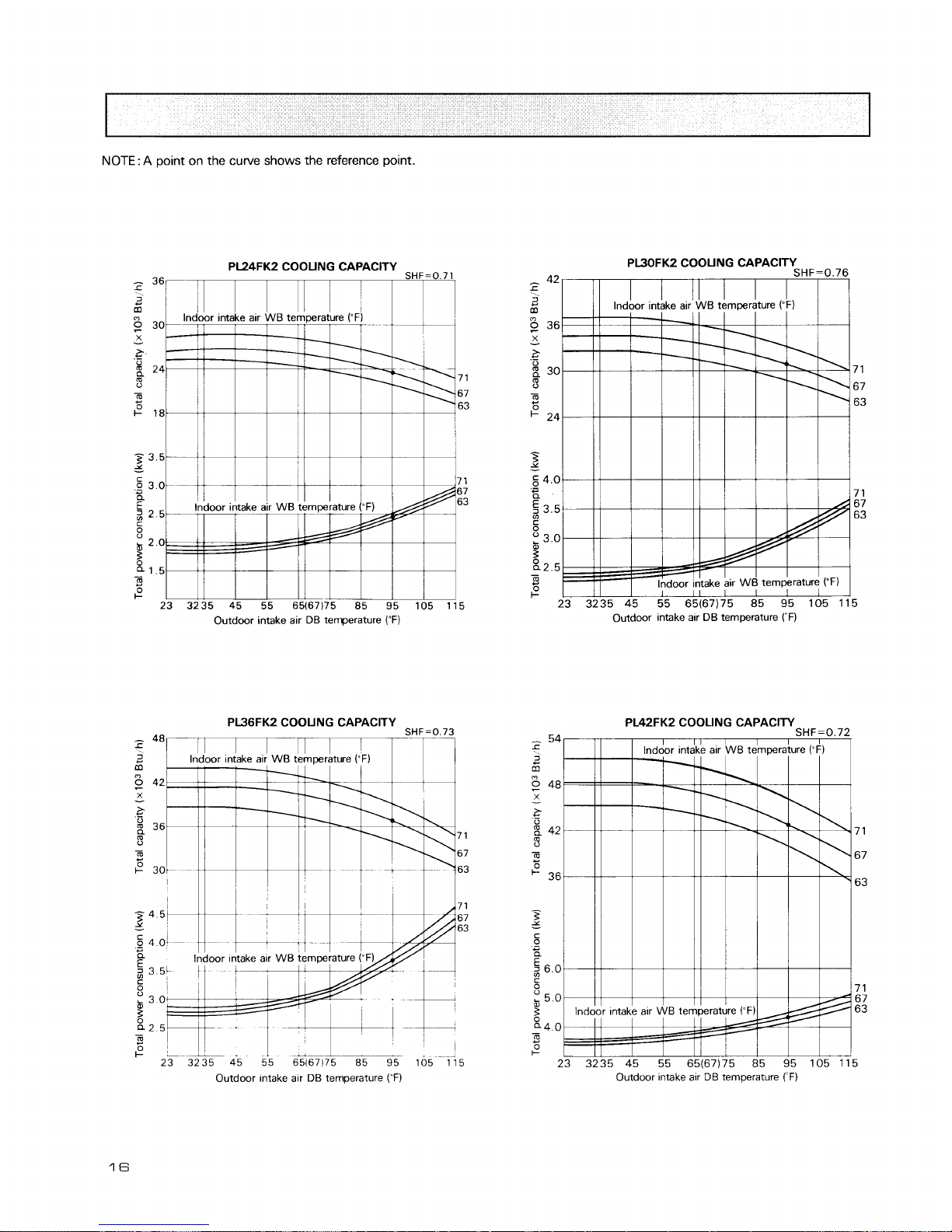

NOTE

:

A

point on the curve shows the reference point.

Outdoor intake air DB temperature

(OF)

Outdoor intake alr

DB

temperature

("F)

?

lndoor

, ,

&take air WB temperature

(;FW

Outdoor ~ntake air DB temperature

(-F)

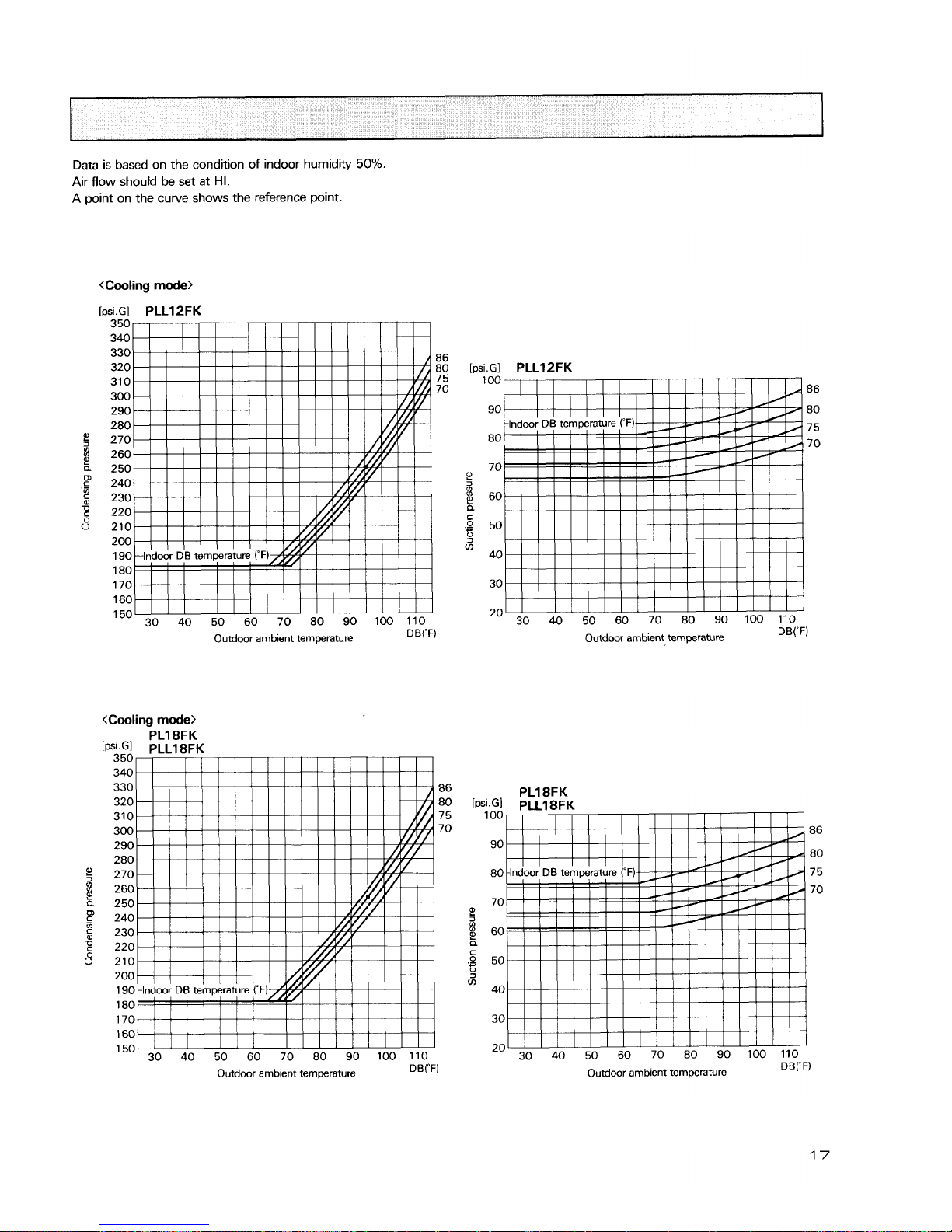

Data is based on the condition of indoor humidity

50%.

Air flow should be set at

HI.

A point on the curve shows the reference point.

<Cooling

mode>

[psiGI

PLLl 2FK

350

340

330

86

320 80

310 7 5

300

70

290

280

270

260

250

240

230

220

210

200

190

180

170

1

60

150 30 40 50 60 70 80 90 100 110

Outdoor ambient temperature

DB("F)

.

--

-~~

350

340

330 86

320 80

310 7 5

300 70

290

280

270

260

250

240

230

220

210

200

190

180

170

1

60

150

30 40 50 60 70 80 90 100 110

Outdoor ambient temperature

DB("F)

[psi.GI

PLLl2FK

100

86

90 80

7 5

80

70

70

e!

$

60

a

c

.g

50

0

V)

40

30

20

30 40 50 60 70 80 90 100 110

Outdoor ambient temperature DB("F)

PL18FK

[t~si.G]

PLL18FK

100

86

90

80

80 7 5

70

70

e!

$

60

a

.:

50

3

V)

40

30

20

30 40 50 60 70 80 90 100 110

Outdoor ambient temperature DB("F)

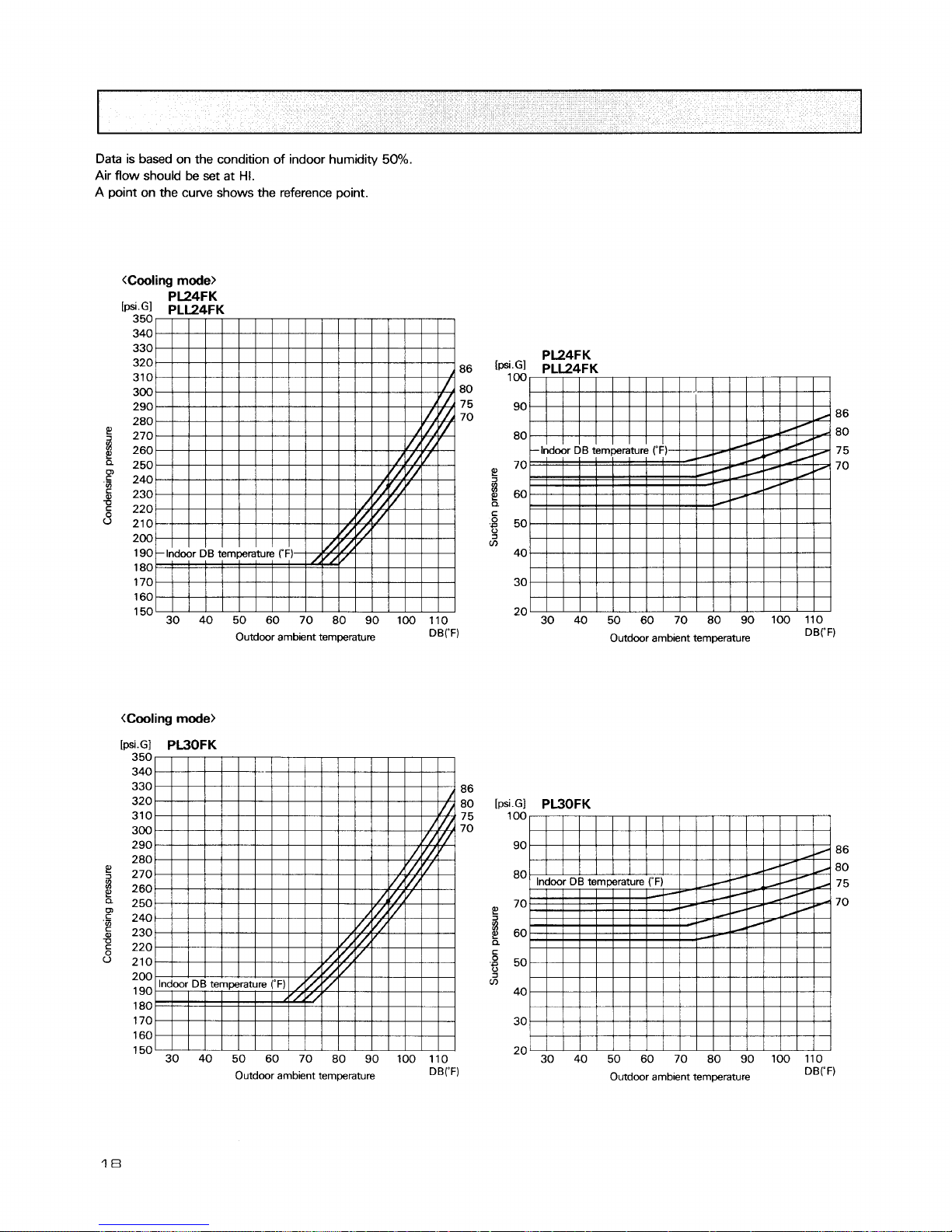

Data is based on the condition of indoor humidity

50%.

Air flow should be set at

HI.

A point on the curve shows the reference point.

35U

340

330

320

310

86

300 80

290 7 5

280

70

270

260

250

240

230

220

210

200

190

180

170

160

150 30 40 50 60 70 80 90 100 110

Outdoor ambient temperature

DB("F)

.

--

-

350

340

330 86

320 80

310 75

300 70

290

280

270

260

250

240

230

220

210

200

190

180

170

160

150

30 40 50 60 70 80 90 100 110

Outdoor ambient temperature

DB("F)

PL24FK

86

80

7 5

70

30 40 50 60 70 80 90 100 110

Outdoor ambient temperature

DB("F)

Outdoor amb~ent temperature

DBrF)

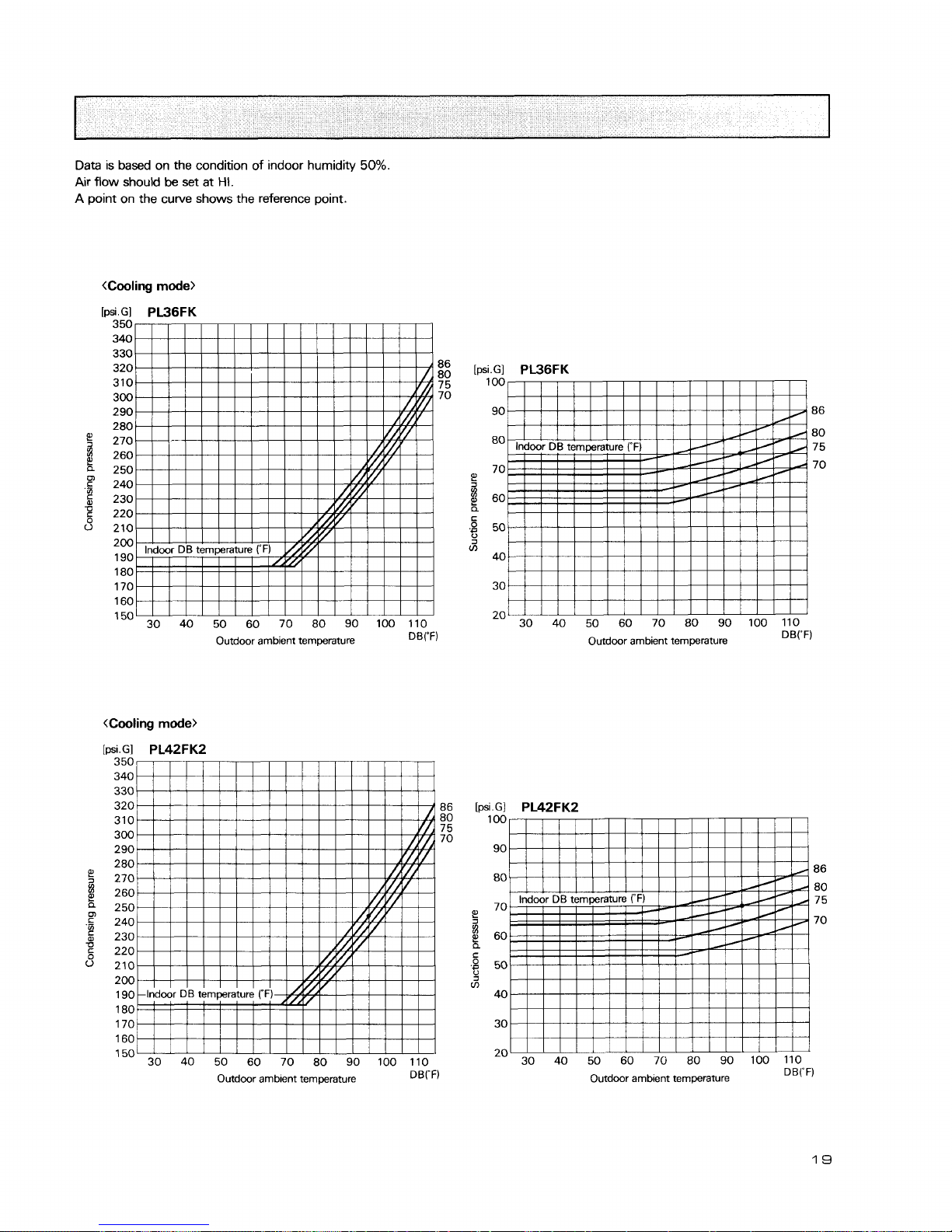

Data is based on the condition of indoor humidity

50%.

Air

flow should

be

set at

HI.

A

point on the curve shows the reference point.

[psi.Gl

PL36FK

350

340

330

320 86

310

80

7 5

300 70

290

280

270

260

250

m

c

240

'Si

230

g

220

0

210

200

190

180

170

160

150 30 40 50 60 70 80 90 100 110

Outdoor ambient temperature

DB("F)

Outdoor ambient temperature

DBrF)

[psi.GI

PL36FK

100

90 86

80

80

7 5

70

70

E'

g

60

a

C

.$

50

J

m

40

30

20

30 40 50 60 70 80 90 100 110

Outdoor ambient temperature

DB("F)

30 40 50 60 70 80 90 100 110

Outdoor ambient temperature

DB("F)

19

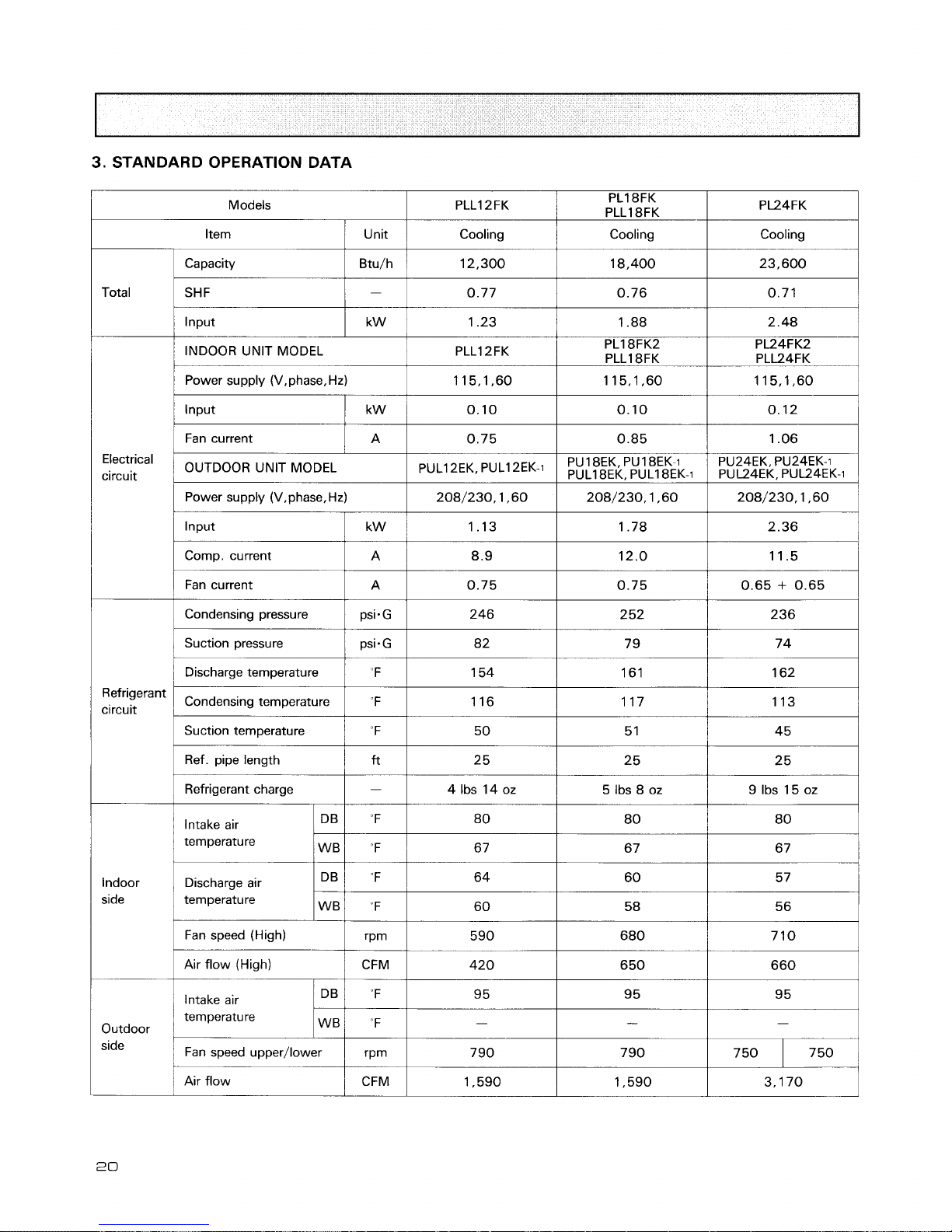

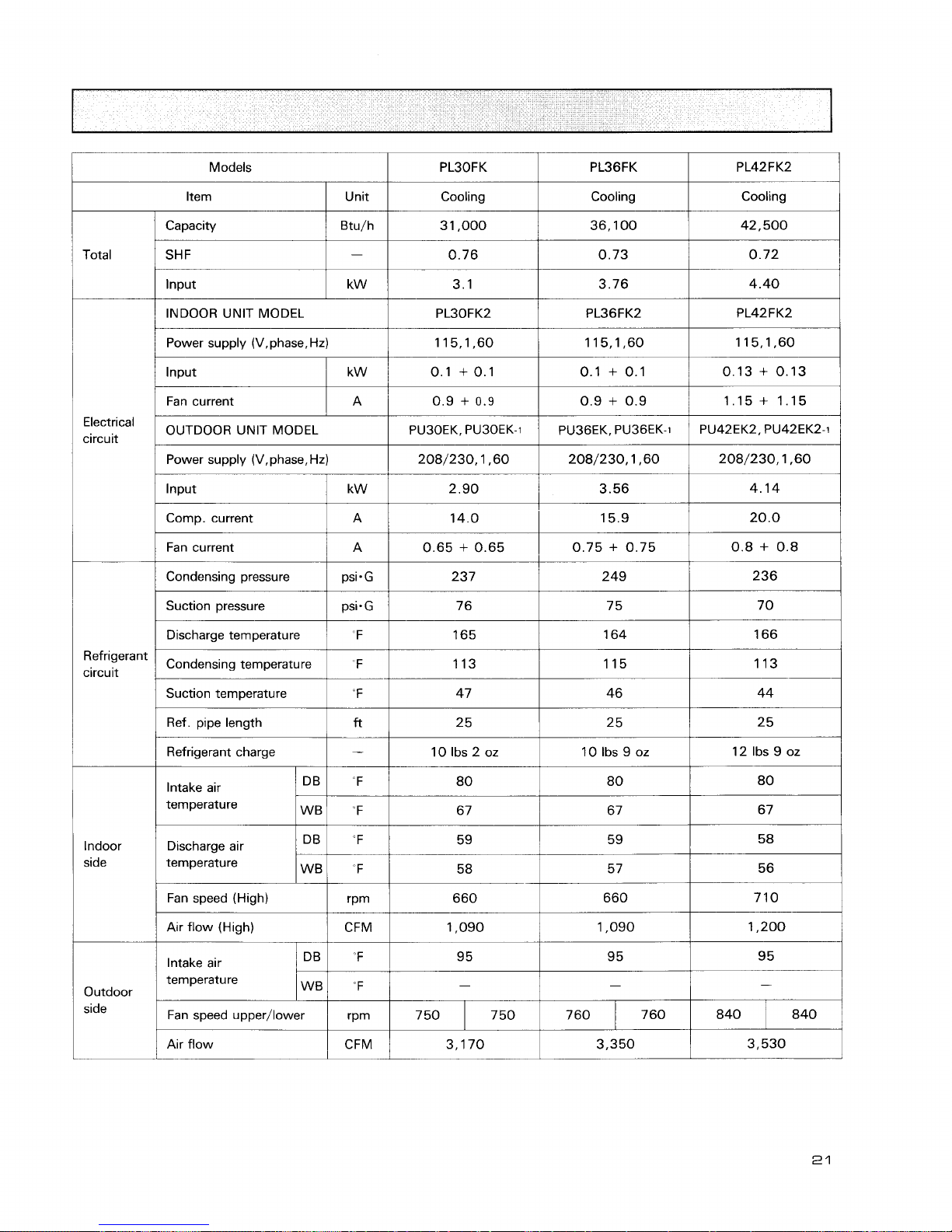

3.

STANDARD OPERATION DATA

1

Unit

1

Cooling

Cooling

Cooling

1

Capacity

1

Btu/h

1

12,300

I

18,400

I

23,600

1

Total

1

SHF

1-1

0.77

I

0.76

I

0.71

I

1

lnput

I

kw

/

1.23

1

1.88

I

2.48

1

/

Power supply (V,phase,Hz)

1

115,1,60

1

115,1,60

1

115,1,60

1

I

INDOOR UNIT MODEL

I

Fan current

Electrical

circuit

PLLI 2FK

I

Power supply (V,phase, Hz)

1

208/230,1 ,60

1

208/230,1 ,60 208/230,1,60

/

PL18FK2

PLLI 8FK

I

OUTDOOR UNIT MODEL

PL24FK2

PLL24FK

I

Condensing pressure psisG

I

PUL1

2EKr

PUL1

2EK-1

Comp. current

Fan current

1

Suction pressure

1

Discharge temperature "F

I

1

A

A

PU24EK, PU24EK-i

PUY4EK, PUU4EK.i

1

Suction temperature

1

"F

I

50

1

5 1

1

45

1

8.9

0.75

Refrigerant

circuit

Ref. pipe length

f?

25

Refrigerant charge

-

4 Ibs 14 oz

5 Ibs 8 oz

12.0

0.75

Condensing temperature

Intake air

temperature

11.5

0.65

+

0.65

Indoor Discharge air

side temperature

"

F

Fan speed (High)

Air flow (High)

1

Intake air

1 16

temperature

Outdoor

1

I

Fan speed upper/lower

1

rprn

I

1 17

1

Air flow

1 13

Models

kern

I

unit

I

Cooling

1

Cooling

I

Cooling

1

Capacity

/

Btu/h

I

3 1,000

1

36,100

1

42,500

I

Total

SHF

lnput

INDOOR UNIT MODEL

I

PL30FK2

1

Power supply (V,phase. Hz)

lnput

Fan current

Electrical

circuit

OUTDOOR

UNlT MODEL

camp.

current

I

A

I

14.0

i

15.9

I

20.0

I

Refrigerant

circuit

Power supply

(V,phase,Hz)

208/230,1,60

2.90

Input

Suction pressure

kW

Fan current

Condensing pressure

Dischargetemperature

1

I

208/230,1,60

3.56

Condensing temperature F

I

208/230,1,60

4.14

A

psi.

G

Suction temperature

Ref. pipe length

0.65 + 0.65

237

Refrigerant charge

0.75 + 0.75

249

Discharge air

temperature

0.8 + 0.8

236

Indoor

side

Intake air

temperature

Fan speed (High)

"F

"F

DB

WB

temperature

IWBI

"F

I

-

I

-

I

-

I

80

67

Outdoor

side

Air flow (High)

80

67

CFM

'F

Intake air

80

67

DB

I

Fan speed upper/lower

Air flow

1,090

95

rPm

CFM

1,090

95

1,200

9 5

7 50 750

760

3,170

840 7 60 840

3,350

3,530

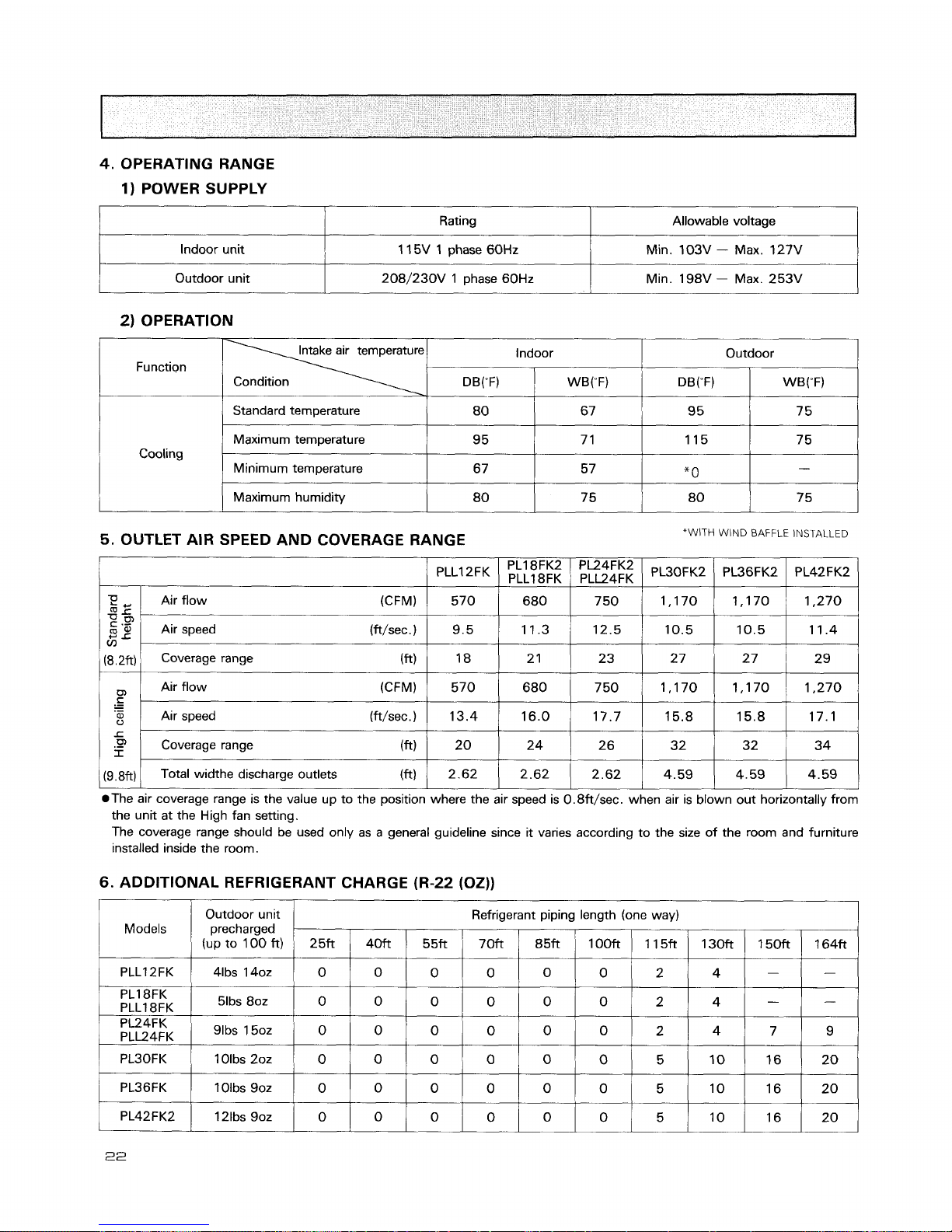

4.

OPERATING RANGE

1) POWER SUPPLY

1

Rating

Allowable voltage

2) OPERATION

Indoor unit

Outdoor unit

I

Standard temperature

1 15V 1 phase 60Hz

208/230V 1 phase 60Hz

Intake air temperature

Function

Condition

Min. 103V

-

Max. 127V

Min. 198V - Max. 253V

1

Maximum humidity

Indoor

DB(W

1

WB("F)

Cooling

5.

OUTLET AIR SPEED AND COVERAGE RANGE

*WITH

WIND

BAFFLE

INSTALLED

Outdoor

Maximum temperature

Minimum temperature

DB("F)

PLLI 2FK

@The air coverage range is the value up to the position where the air speed is 0.8ft/sec. when air is blown out horizontally from

the unit at the High fan setting.

The coverage range should be used only as a general guideline since it varies according to the size of the room and furniture

installed inside the room.

WB("F)

9 5

67

T!

dr'

c

.G'

V)

(8.2ft)

C

.-

-

.-

L

.P

I

(9.8ft)

6.

ADDITIONAL REFRIGERANT CHARGE (R-22 (OZ))

I

I

1

I

I I

I

7 1

57

PLl8FK2

PLLl

8FK

Air flow (CFM)

Air speed (ft/sec.)

Coverage range (ft)

Air flow (CFM)

Air speed (ft/sec.)

Coverage range

(

ft

Total widthe discharge outlets (ft)

PL36FK2

Models

PLLI 2FK

1 15

*

0

PL42FK2

PL24FK2

PLL24FK

570

9.5

18

570

13.4

20

2.62

PL18FK

PLLI 8FK

PL24FK

PLL24FK

7 5

-

PL30FK2

Outdoor unit

precharged

(up to 100 ft)

41bs 1402

PL30FK

PL36FK

680

11.3

2

1

680

16.0

24

2.62

51bs 80z

'Ibs

50z

Refrigerant piping length (one way)

1 Olbs 202

1 Olbs 902

7 50

12.5

23

7 50

17.7

2 6

2.62

2513

0

0

0

0

0

1,170

10.5

27

1,170

15.8

32

4.59

4Mt

0

0

0

0

0

1,170

10.5

2 7

1,170

15.8

32

4.59

55ft

0

0

0

1,270

11.4

2

9

1,270

17.1

34

4.59

0

0

70ft

0

0

0

0

0

85ft

0

0

0

0

0

100ft

0

0

0

0

0

2

2

115ft

2

5

5

150ft

-

130ft

4

I

4

4

164ft

-

10

10

-

7

-

9

16

16

20

2 0

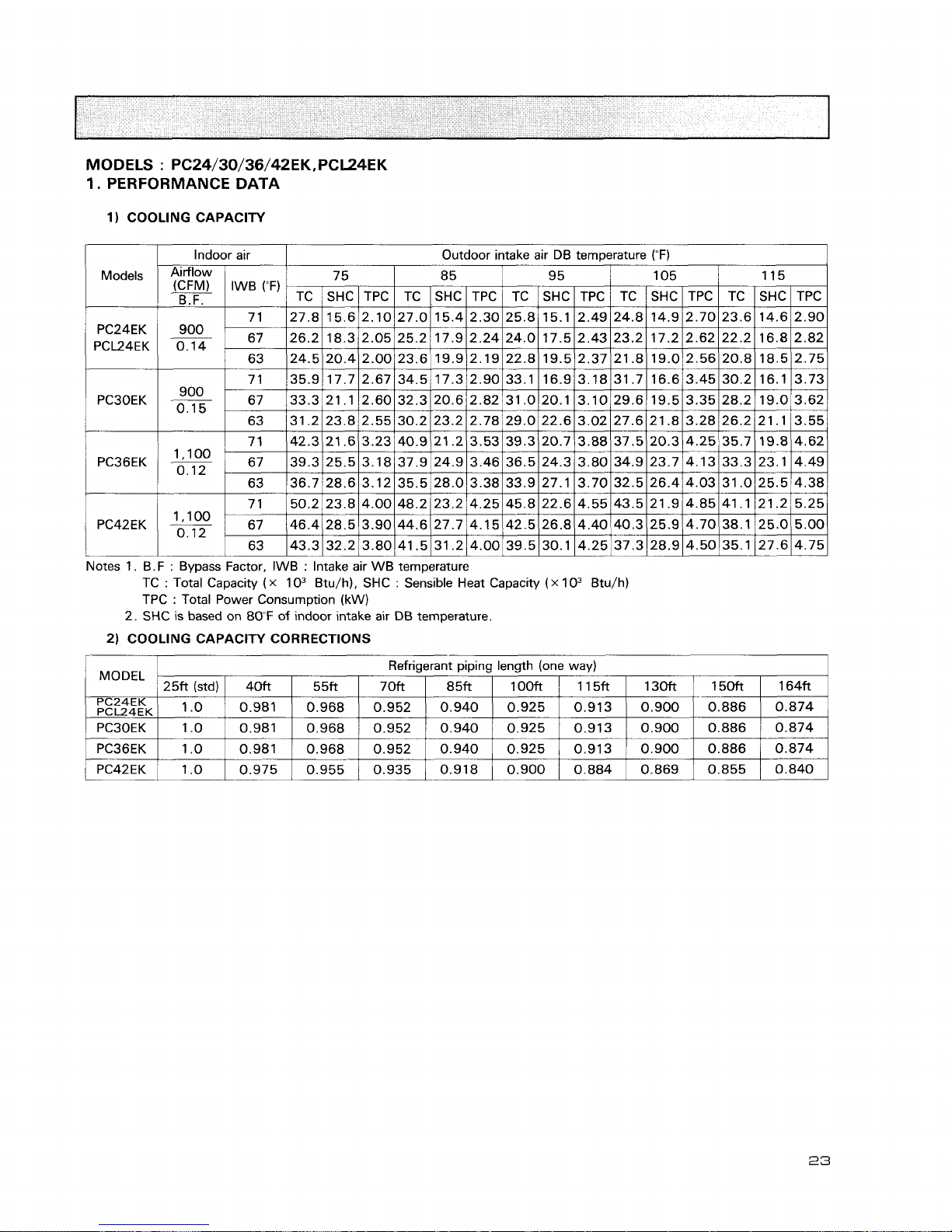

M 0 D

E

LS : PC24/30/36/42 E

K,

PCK4E

K

1.

PERFORMANCE DATA

1)

COOLING CAPACITY

2)

COOLING CAPACITY CORRECTIONS

PC42EK

Notes 1.

6.F : Bypass Factor, IWB : Intake air WB temperature

TC

:

Total Capacity

(x

lo3

Btu/h), SHC : Sensible Heat Capacity

(x

lo3

Btu/h)

TPC

:

Total Power Consumption

(kW)

2. SHC is based on 80°F of indoor intake air

DB

temperature.

A

loo

0.12

1

MODEL

Refrigerant piping length (one way)

25ft(std)I 40ft

I

55ft

I

70ft

I

85ft

I

10013

I

115ft

I

130ft

/

150ft

I

164ft

67

63

46.4

43.3

28.5

32.2

3.90

3.80

44.6

41.5

27.7

31.2

4.15

4.00

42.5

39.5

26.8

30.1

4.40

4.25

40.3

37.3

25.9

28.9

4.70

4.50

38.1

35.1

25.0

27.6

5.00

4.75

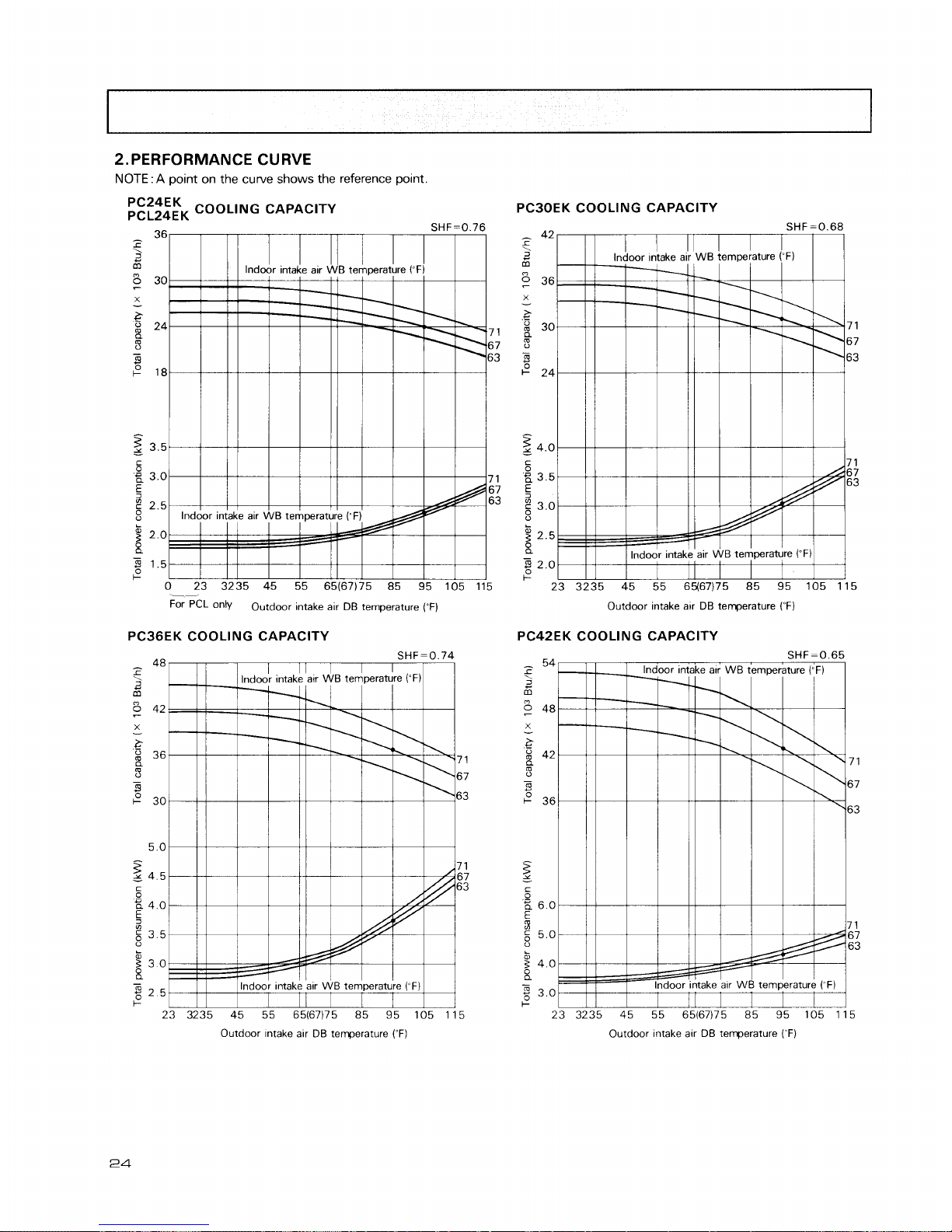

2.

PERFORMANCE CURVE

NOTE

: A point on the curve shows the reference point.

FE;;EFK

COOLING CAPACITY

36

SHF=0.76

-

r

\

6

5

30

X

-

g

24

7 1

-

67

8

63

+

18

z

3.5

-

5

P,

3.0 7 1

5

67

g

2.5

63

0

g

2.0

X

-

3

1.5

+

0 23 3235 45 55 65(67)75 85 95 105 115

--,

For

PCL

only

Outdoor intake air DB temperature

(-F)

PC36EK COOLING CAPACITY

Outdoor intake alr DB temperature

(OF)

PC42EK COOLING CAPACITY

?

atr

WB

tempe

1

\

3ke alr

WB

tern

n

i7)75 85

'

SHF=(

rature

("

F

\,

.

1

.

/

/

43

95 105

Outdoor Intake alr DB temperature

(OF)

Outdoor Intake alr

DB

temperature

(~F)

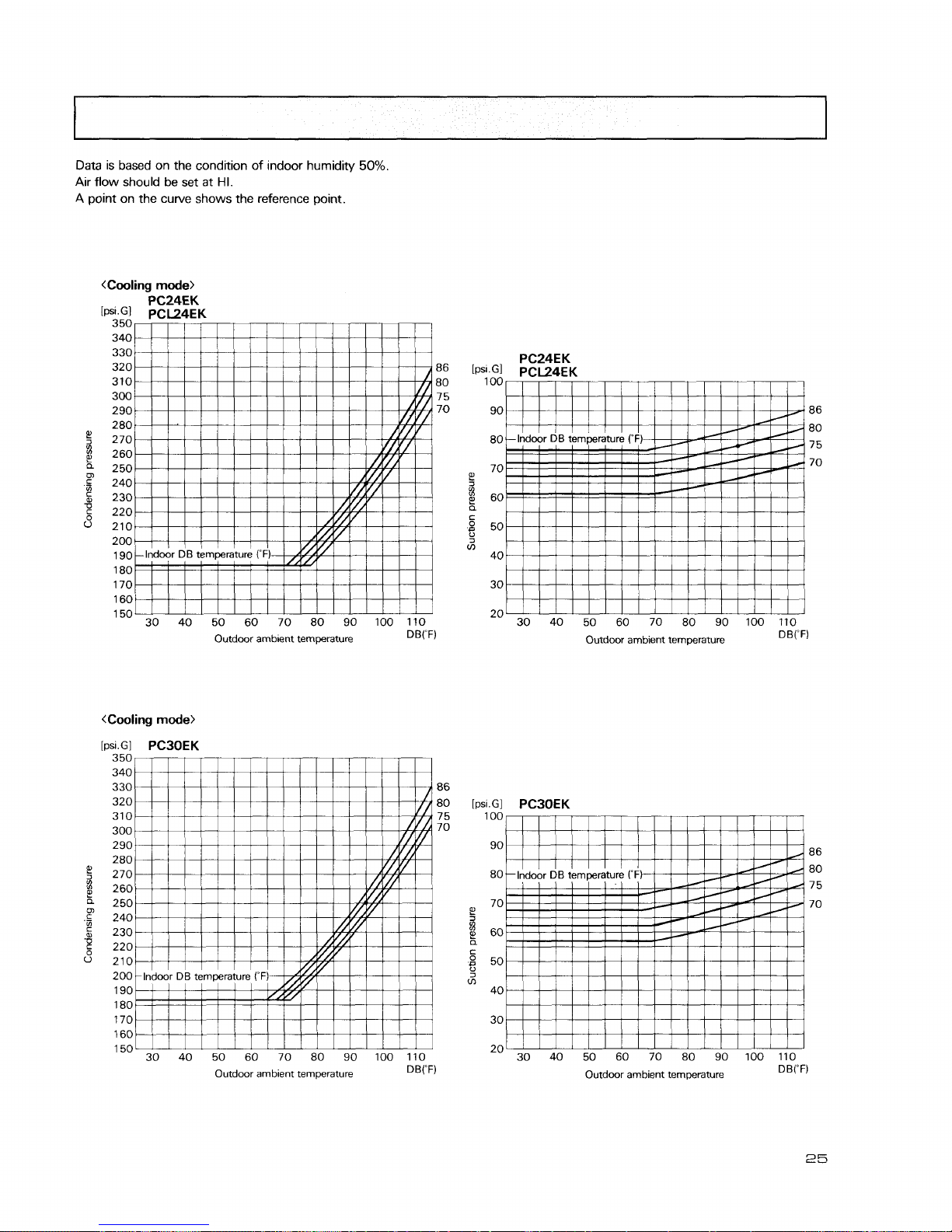

Data is based on the condition of indoor humidity

50%

Air flow should be set at HI.

A

point on the curve shows the reference point.

<Cooling

mode>

PC24EK

[PS~.GI

pCL24EK

350

340

330

320 86

310 80

300 75

290

70

280

5

270

8

260

a

250

0,

240

5

230

u

5

220

0

210

200

190

180

170

160

150 30 40 50 60 70 80 90 100 110

Outdoor amb~ent temperature

DBrF)

Outdoor ambient temperature

DB("F)

[psi.Gl

PC30EK

350

340

330 86

320 80

310 7 5

300 70

290

280

$

270

8

260

a

250

0,

.

240

230

g

220

0

210

200

190

180

Outdoor ambient temperature

DBrF)

170

160

-

150-

30 40 50 60 70 80 90 100 110

Outdoor ambient temperature

DB('F)

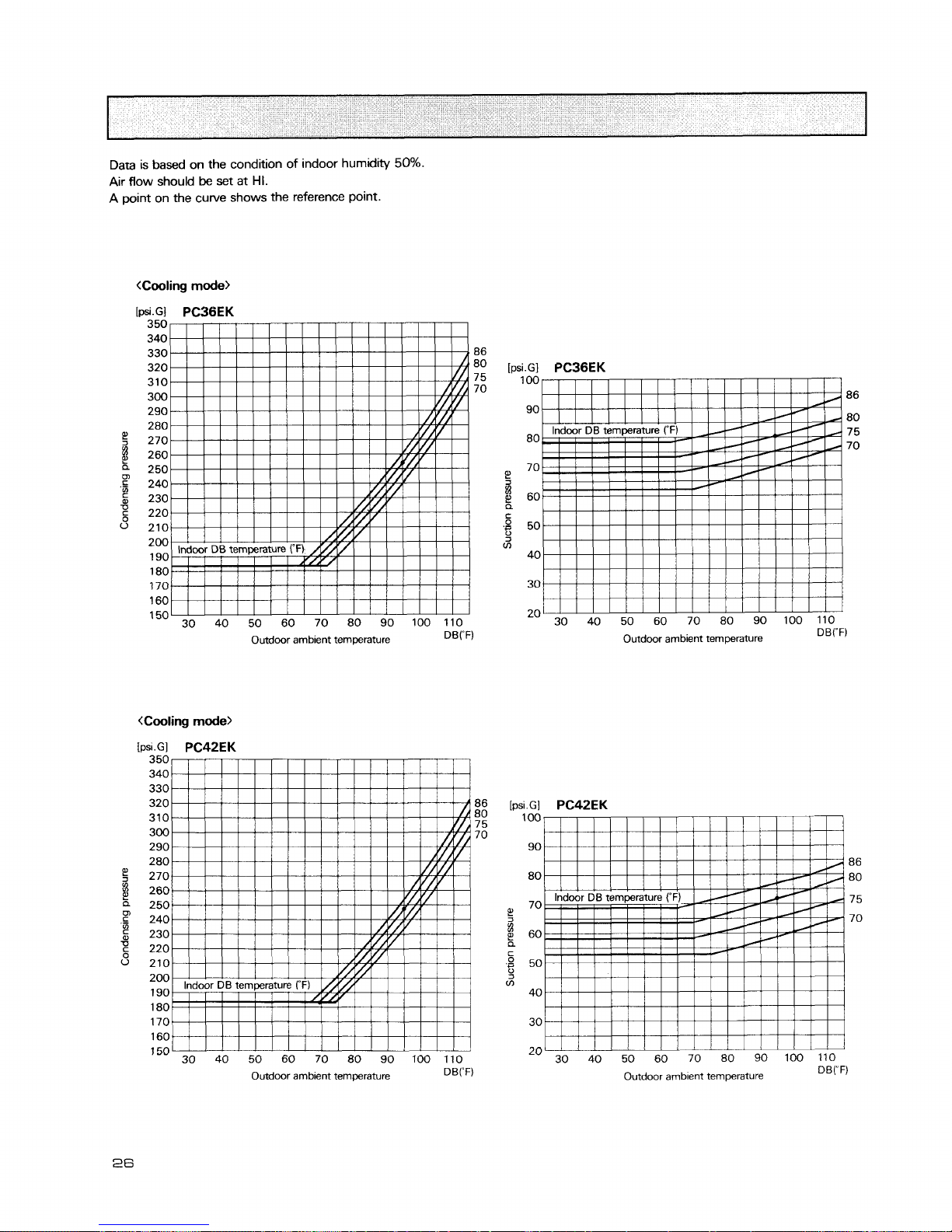

Data

is based on the condition of indoor humidity 50%.

Air flow should

be

set at

HI.

A

point on the curve shows the reference point.

<Cooling

mode>

[psi.Gl

PCBBEK

350

340

330 86

320

80

310

7 5

300

70

290

280

270

260

250

240

230

220

210

200

190

180

170

1 60

1

50

30 40 50 60 70 80 90 100 110

Outdoor ambient temperature

DB('F)

Outdoor ambient temperature

DB('F)

350

340

330

320

86

[psi.Gl

PC42EK

310

Em

100

7

5

300 70

290 90

280 86

270 80 80

260

250 70

7 5

240

2

70

230

8

60

220

a

C

210

.B

50

200

3

m

190 40

180

170 30

160

1

50

30 40 50 60 70 80 90 100110

20

30 40 50 60 70 80 90 100 110

Outdoor ambient temperature

D8('F)

Outdoor ambient temperature

DB('F)

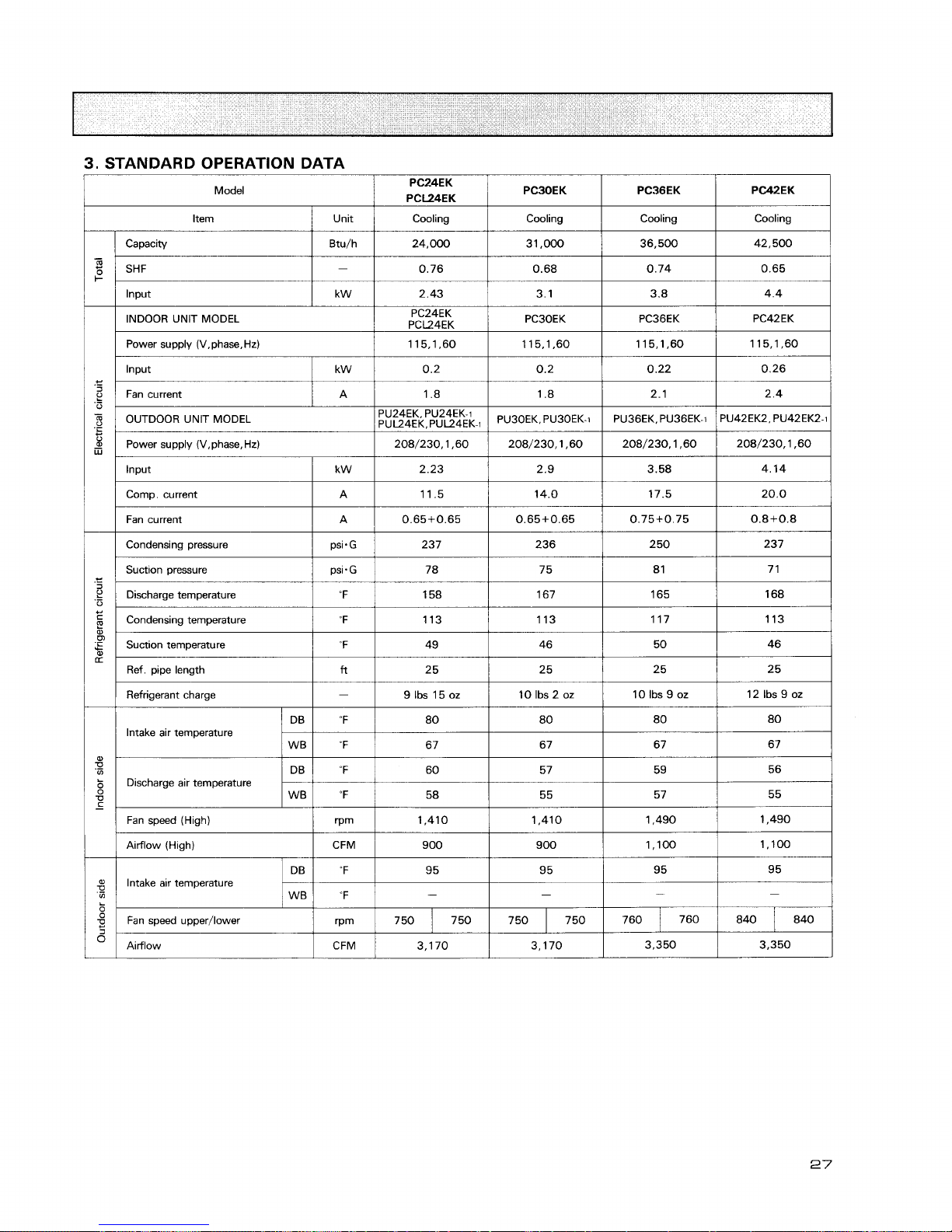

3.

STANDARD OPERATION DATA

Model

Item

/

Unit

1

Cooling

I

Cooling

I

Cooling

I

Cooling

I

lnput

Capacity

SHF

Power supply (V.phase.Hd

/

115.1.60

1

115.1.60

1

115,1,60

1

115,1*60

1

Btu/h

-

I I

1

I

I

Input

I

kw

1

0.2

I

0.2

1

0.22

1

0.26

1

INDOOR UNlT MODEL

Fan current

/

A

/

1.8

I

1.8

1

2.1

I

2.4

1

24,000

0.76

PC24EK

PCL24EK

Power supply (V,phase,Hz)

1

208/230,1,60

1

208/230,1,60

1

208/230,1,60

1

208/230,1,60

1

31.000

0.68

I I I

I

I

Input

/

kW

1

2.23

1

2.9

1

3.58

1

4.14

1

PC3OEK

Comp. current

I

A

1

11.5

/

14.0

1

17.5

1

20.0

/

36,500

0.74

PU42EK2, PU42EK2-1

OUTDOOR UNlT MODEL

Fan current

I

A

1

0.65+0.65

1

0.65+0.65

/

0.75+0.75

1

0.8+0.8

1

42,500

0.65

PC36EK

Condensing pressure

1

psi.G

1

237

I

236

1

250

I

237

1

PC42EK

PU24EK. PU24EK-1

PU~~EK,PU~~~K-~

Condensing temperature 113

/

113

1

117

1

113

/

PU30EK. PU30EK-1

Suction pressure

Discharge temperature

Suction temperature

1

"F

I

49

1

46

I

50

I

46

I

PU36EK, PU36EK-I

Ref. pipe length

/ftl

2 5

1

25

1

25

1

25

I

psi.G

'F

Refrigerant charge

I

-

1

9Ibs15oz

/

10Ibs2oz

1

10Ibs9oz

/

12Ibs9oz

I

Intake air temperature

78

158

Fan speed (High)

/

rpm

1

1,410

1

1,410

1

1,490

1

1,490

1

75

167

Discharge air temperature

Airflow (High)

I

CFM

/

900

I

900

1

1,100

1

1,100

1

8 1

165

I

I

I

I

I

Airflow

~CFM/

3,170

1

3,170

1

3.350

1

3.350

/

7 1

168

WB

Intake air temperature

DB

W8

"F

Fan speed upper/lower

57

OF

"F

55

58

rPm

55

95

-

95

-

750

7 50

95

-

7 50

95

-

7 50

760

840

760

840

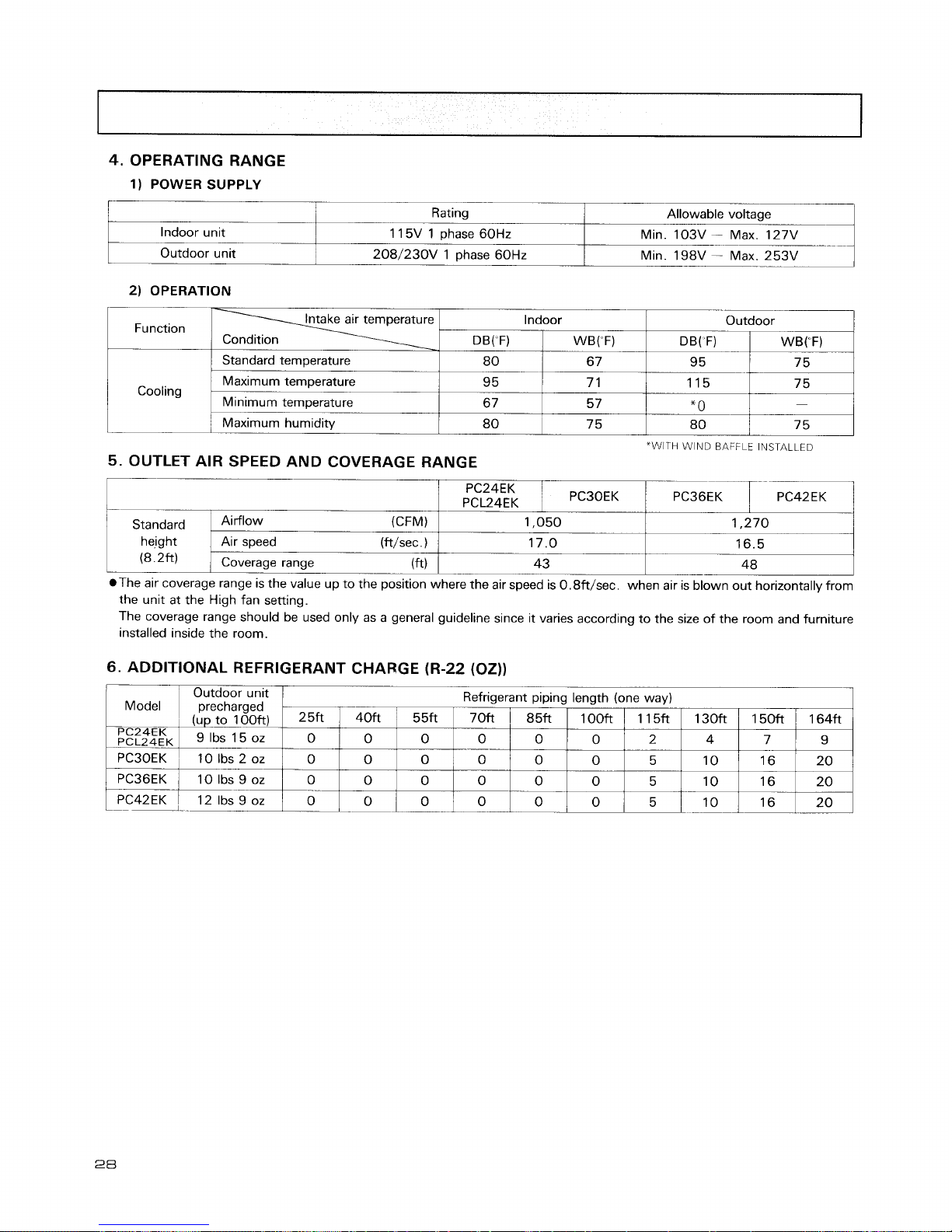

4.

OPERATING RANGE

1)

POWER SUPPLY

Indoor unlt

Outdoor unit

2)

OPERATION

The coverage range should be used only as a general guideline since it varies according to the size of the room and furniture

installed inside the room.

Rating

1 15V 1 phase 60Hz

208/230V 1 phase 60Hz

Function

Cooling

Standard

hejght

(8.2ft)

6.

ADDITIONAL REFRIGERANT CHARGE (R-22 (02))

Allowable voltage

Mm. 10%

-

Max 127V

Mm. 198V

ax.

253V

"WITH WIND

BAFFLE

INSTALLED

5.

OUTLET AIR SPEED AND COVERAGE RANGE

The air coverage range is the value up to the position where the air speed is 0.8ft/sec. when air is blown out horizontally from

the unit at the High fan setting.

(CFM)

Air speed (ft/sec

.

)

Coverage range

(

ft

Indoor

Outdoor unlt

Refrigerant plplng length (one way)

Model precharged

Outdoor

1,050

17.0

43

WB("F)

6 7

7 1

5 7

75

DB( F)

-

95

DB("F)

1,270

16.5

-

48

25ft

PC24EK

PCL24EK

Ibs

OZ

PC30EK 10 Ibs 2 oz

WB("F)

-

75

Standard temperature

Maximum temperature

Minimum temperature

Maximum humidity

40ft

0

0

0

0

PC36EK

PC42EK

1

80

9 5

6

7

80

115

*

0

--

80

55ft

0

0

0

0

10 Ibs

9

oz

-

12 Ibs 9 oz

75

-

7 5

0

--

L--

-1

70ft

0

0

0

0

0

85ft

0

0

0

0

1OOft

0

0

0

0

1 l5ft

2

5

5

5

130ft

4

10

10

--

10

150ft

7

16

16

--

16

164ft

9

20

20

2 0

MODELS : PKI 8/24/30EK, PKLI 2/18/24EK

1. PERFORMANCE DATA

1

)

COOLING CAPACITY

Models

r--

PKI 8EK

PKLI 8EK

Indoor air

I

Outdoor intake air DB tem~erature ("F)

1

Airflow

7 5 8 5 95 105

(CFM) IWB

(OF)

1 I5

R

F

TC I SHC/

TPC

TC

SHC / TPC

TC I SHC/

TPC

TC 1 SHC

TPC

TC

SHC / TPC

Notes

1.

B.F : Bypass Factor, IWB : Intake air wet-bulb temperature.

TC

:

Total Capacity

(

X

1

O3

Btu/h), SHC : Sensible Heat Capacity

(

x

I

O3

Btu/h)

TPC

:

Total Power Consumption (kW)

2.

SHC is based on

80°F

of

indoor intake air

DB

temperature.

2)

COOLING CAPACITY CORRECTIONS

MODEL

PKL12EK

PKl8EK

.

PKL18EK

PK24EK

pK,,,EK

PK30EK

-

--

Refrigerant piping length (one way)

25ft

(std)

1.0

.0

1

.O

1.0

40ft

0.992

0.992

0.981

0.981

5 5ft

0.983

0.983

-

0.968

0.968

7

Oft

0.978

0.978

0.952

0.952

8 5ft

0.966

0.966

0.940

0.940

1OOf3

0.959

0.959

0.925

0.925

.-

115ft

0.950

0.950

0.913

0.913

130ft

0.945

0.945

0.900

--

0.900

150ft

-

-

0.886

-

0.886

164ft

-

-

-

0.874

0.874

2.

PERFORMANCE CURVE

NOTE

:

A

point on the curve shows the reference point.

PKL12EK COOLING CAPACITY

take air WB temp

PKL

only

Outdoor intake air DB tewerature (OF)

;:::&

COOLING CAPACITY

nperature

&&

/

85

For

PKL

only

Outdoor intake air DB temperature ('F)

COOLING CAPACITY

v

For

PKL

only

Outdoor intake air DB temperature (OF)

PK30EK COOLING CAPACITY

SHF=0.63

Indoor intake air WB ternmrature ("F)

Data is based on the condition of indoor humidity

50%.

Air flow should be set at HI.

A point on the curve shows the reference point.

350

340

330 86

320

80

310

7 5

300

70

290

280

270

260

250

240

230

220

210

200

190

180

170

1 60

150

30 40 50 60 70 80 90 100 110

Outdoor ambient temperature

DB("F)

Outdoor ambient temperature

DBrF)

Outdoor ambient temperature

DB("F)

PK18EK

[psi.G]

PKLI 8EK

100

86

90 80

7 5

80

70

P

70

60

g

50

'5

m

40

30

20

30 40 50 60 70 80 90 100 110

Outdoor ambient temperature

DB("F)

Data is based on the condition of indoor humidity

50%.

Air flow should

be

set at

HI.

A point on the curve shows the reference point.

350

340

330

320

310

86

300

80

290

7 5

280

70

270

260

250

240

230

220

210

200

190

180

170

160

150

30 40 50 60 70 80 90 100 110

Outdoor ambient temperature

DB('F)

350

340

330 86

320 80

310

75

70

300

290

280

270

260

2

50

240

230

220

210

200

190

180

170

160

l5O3O 40 50 60 70 80 90 100110

Outdoor ambient temperature

DB(-F)

PK24EK

.GI

PKL24EK

00

90

86

80

80

7

5

70

70

60

50

40

30

20

30 40 50 60 70 80 90 100 110

Outdoor ambient temperature

DBYF)

bi.GI

PKBOEK

100

90

86

80

80

7 5

70

70

1

60

a

C

,g

50

3

40

30

20

30 40 50 60 70 80 90 100 110

Outdoor ambient temperature

DBrF)

3.

STANDARD OPERATION DATA

Model

kern

I

Unit

/

Cooling

I

Cooling

I

Cooling

I

Cooling

I

Capacity

/

~tu/h

1

12,000

1

18,000

1

24.000

1

28.800

1

Input

1

kW

I

1.17

/

1.70

/

2.37

1

2.94

1

I I

I

I

I

Power supply (V,phase, Hz)

/

208/230,1,60

1

208/230,1,60

1

208/230,1,60

1

208/230,1,60

1

INDOOR UNIT MODEL

Rwer supply (V,phase,Hz)

Condensing pressure Ipsi-GI 243

1

245

/

233

/

235

1

PKL12EK

115,1,60

0.06

Input

Input

Comp. current

Fan current

Suction pressure

I

psi.G

I

80

I

81

I

71

I

70

1

k W

Discharge temp.

1

"F

1

155

1

165

1

158

I

166

I

PKl8EK

PKL18EK

115.1.60

0.10

kW

A

A

Refrigerant charge

(

-

/

4Ibs14oz

/

5Ibs8oz

1

9Ibs15oz

/

10Ibs2oz

1

PK24EK

PKL24EK

115,1,60

0.10

1.11

8.9

0.65

Condensing temp.

Suction temp.

Ref. pipe length

PK3OEK

115,1,60

0.10

1.60

12.0

0.75

"F

"F

ft

Intake air temperature

Discharge air temperature

2.27

11.5

0.65+0.65

115

49

2 5

DB

WB

2.84

14.0

0.65+0.65

DB

WB

Airflow (High)

116

49

2 5

~F

-F

Fan speed (High)

CFM

'F

~F

rpm

CFM

Intake air temperature

'F

"F

DB

WB

112

43

25

80

67

rpm

460

95

-

720

1,590

Fan speed

upper/lower

Airflow

113

43

2

5

6 1

59

80

67

1,350

600

95

-

790

1,590

6 1

58

80

67

1,390

80

67

58

55

600

95

-

53

5 1

1,410

750

600

95

-

1,440

750 750

3,170

750

3,170

4.

OPERATING RANGE

1)

POWER SUPPLY

1 1

Rating

1

Allowable voltage

1

2)

OPERATION

Indoor unit

1 15V 1

phase

60Hz

--

208/230V

I

phase

60Hz

Function

-

"WITH WIND

BAFFLE

INSTALLED

5.

OUTLET AIR SPEED AND COVERAGE RANGE

Min.

103V

-

Max.

127V

Min.

198V

-

Max.

253V

Intake air temperature

\

1-4

DB(F)

1

Outdoor

Condition

Cooling

PKLI 2EK

The air coverage range is the value up to the position where the air speed is 0.8ft/sec. when air is blown out horizontally from

the unit at the High fan setting.

The coverage range should be used only as a general guideline since it varies according to the size of the room and furniture

installed inside the room.

Standard temperature

Maximum temperature

Standard

height

(8.2ft)

6.

ADDITIONAL REFRIGERANT CHARGE (R-22 (OZ))

67

-

Minimum temperature

-

PKI 8EK

PKLI 8EK

6 7

(CFM)

Air speed (ft/sec

.

)

Coverage range

(fd

95

Maximum humiditv

PK24EK

PKL24EK

7 5

7

1

5 7

v

75

80

PK30EK

480

13.8

3 1

75

660

14.1

3 6

1 15 75

*

0

-

5.1 Indoor unit PL18/24FK2, PLL12/18/24FK

Unit

:

inch

1

Note

1 For dralnage plplng use

PVC

plpe 1 Inch O.D.

2

For

suspension

bolts

use W3/8 or M 10 screws. (Actual arrangement)

3. F~gure 35-1 /16

*

35-1 /16celCng holes are standard but the cehg holes for 33.718

33-7/8 can also

be

~nstalled In th~s

case,

the ~nstallatlon and servlce are

a little more dicult.

OUTLINES AND DIMENSIONS

Fresh a" mtake

Electrical

box

Draw

-

-

W~nng arrangement openmg 1311 6,

1

35.1 /1 6 celhng hole 13/16

:I

-

i

-+-

?I

2-91'1 6 3-15/1612-9/16

Branch duct hole

ill

6:

1

- - -- - -

--

(knock out hole)

'

\

I1

'

I

25-7/8 lntake hole

;;I

-,I

*

I;

Cehg slde,

--

k

/

\Secure holes 61 /8

Deta~l draw~ng of fresh alr Intake

Bar rlng holes

Auto vane

i:

??

a

j

-I

\

Air

~ntake

Air

outlet

Bar rlng hole

Indoor

unit

P

L30136142

F

K2

Note

1 For dramage plplng use PVC plpe 1 Inch

0

D

2 For suspenwon bolts use W3/8 or MI0 screws (Actual arrangement)

3

F~gure 35-1/16* 55-1/2 cehg holes are standard but the cehg holesfor 33-7/8

*

54-5/16 can also

be

~nstalled In thls case, the ~nstallat~on and sewce are

shghtly more d~fficuk

YY;,

Refngerant p~pe

flared connectlon 1 /2F

Refngerant pipe flared

connection

3/4F/2-3/16

\

lnspectlon hole

(dram water Ilh-up

Unit

:

inch

n

Fresh alr Intake

Wlnng arrangement

openlng

Electrical

box

13/16

-

-7

-+

55-1/2 Cehg hole

1311 6

-

l

m'

Deta~l draw~ng of fresh alr Intake

-.

-

L

Celllng wde

Knock out hole for

51

\$I

-I

2'

N

Secure holes $1/8

I.

46-5/16

Fmh

alr Intake hole

Bar nng holes

I

43-5/16 Pur outlet

1

2-15/16

57-1/16

Pur oudet

fresh alr make

\

4-@1/8

Bar nng hde

NOTES.

1

Allow dimensions for protruded archrtectural members on celllng

2 For dramage piping use VP20 (OD1') PVC pipes.

3. For anchor bob use W3/8 screws.

UPPER PIPING

ARRANGEMENT POSITION

TOP VlEW

4

da

wan

h&kf

--

I

&45

13

16

twrrpnsm

bdl

mch

wnh

mountjng

ohre

on

(-1

1

]

'

5

6

l6

51

5

8(--nt&

VCh

w*h

mnW

Weon

oud!?

16r

RIGHT SlDE VlEW

KNOCK OUT HOLE

1

10

!il)rammgel

'

l6

POSITION FOR REAR PIPING HOLE POSITION FOR

Ebctrral

mx

REAR PIPING

BOlTOM VIEW

I

1

ODrainage pipe

connection

(1

inch

dm.

I.

D

.)

@Knock out hole for rear dramage piping arrangement

ORefngerant-p~pe

Rared

connection 5/8F(PC24EK,PCCZ4EK), 3/4F(PC30EK)

@Refwerant-pipe

%red

connection 3/8F(PC24EK,PCCZ4EK), 1/2F(PC30EK)

@Knock out hole for rear refngerant-piping arrangement

@Knock out hole for upper refngerant-piping arrangement

@)Knock out hole for right piping

(refrigerant,

drainage and wiring)

@Knock

out

hole for wiring arrangement

@Wall hole for piping arrangement

@Ceiling hole for p~ping arrangement

@Terminal

bed

for power line

@Terminal bed for indoor and outdoor units connewn

@Terminal

bed

for Remote controller

@Knock out hole for

fresh

air intake

SERVICE SPACE REQUIRED

AROUND INDOOR UNIT

For workability and safety of suspension work, leave as much

space as possible between one de of the unit and wall.

Space required for bottom and nght hand sde for piping and

wiring

maintenance

are shown above.

SUSPENSION BOLT INSIDE MOUNTING

I..

SUSPENSION BOLT OUTSIDE MOUNTING

Indoor unit

PC36/42EK

UNIT:

inch

Indoor unit

PKLl2EK

U

Uppet

surface

9.718 or more

Q

11-13/16or more

8

48-1/16

Front vtew

'

J

Rtght surface

Unit

:

inch

-

Lower surface

@

a

%.

@

@

@

@

@

0

@

@

Alr Intake grdk

Swtng louver

Inset

Knockout hole for rear wlrlng

(maon clrcutt)

Knockwt hole for rear wtrlng

(control c~rcult)

Wood screw holes

Bolt holes

Wall

ftnmg

6

hok for maln untts

Bolt 13/16 (max

)

Refrigerant

plpe flared connectlon

03

8

05

8

Dramage connectlon 01

-

Indoor

unit

PKl8/24/3OEK, PKLl8/24EK

Unit:

inch

Lower surface

u

9-718

or more

Upper surface

11-13/16

or more

I

Rlght surface

Front vlew

%

Mark

2

&

g

5

&

7

hole for rear wmg

-

(mar clrcutt)

Knockout hole for rear wlrmg

(control clrcultl

Wood screw holes

Name

Knock out hole for rear plplng

(refr~gerant dralnage)

--

MI~ of

9 718

servlce space

Knockout hole for upper plplng

(refrlgerant and wlnng)

Mln of

1

1

13/ 16

servtce space

Alr outlet

Air

Intake gr~lle

Swmg louver

4th holes

Wall fmng

10

6

hole for mam unlfs

1

Refrigerant-plpe

flared connectlon

--

Dramage connectlon

dl

I$

Bolt

13/16

Imax

I

5.2

Remote controller

(PL/PLL

series)

-CWIRULYCONIRJLED-

POWER-

[ON/OFF)

I

LOW

HIGH

/

I

FAN

SPEED LOWIHIGH

I

/

CHECK TEST

EW

I I

CHEW

TEST

RUN

1

Unit : inch

Rear side wiring arrangement opening

Remote controller

(PC/PCL/PK/PKL

series)

CHECK

lJ17

'F

SET

TEMP

1-10

I

LOW HIGH

/

I

CHECK

TEST

RUN

I

POWER-

[E)

I

MODESENT FAN COOLIDRY

I

WARMER

COOLER

I

I

TIMER MODE HOURS

I

FAN SPEED LOWIHIGH

I

AIR SWEEP ONIOFF

I

I

CHECK

TEST

RUN

Unit : inch

=I

A

Rear

sde wiring arrangement opening

r?

Outdoor

unit

PU18EK. PUL18EK. PU18EK-1, PUL18EK-1

Unit : inch

.\\\

I

Outdoor

unit

PU24130EK. PUL24EK. PU24130EK-I, PUL24EK-1

I

Unit

:

inch

Outdoor

unit

PU36EK, PU42EK2, PU36EK-I, PU42EK2-1

Unit

:

inch

11

lare red

connectron

'

1

Refrigerant plpe

piiGGiz

REFRIGERANT SYSTEM DIAGRAM

Accumulator

Compressor

Stra~ner

Cap~llary tube-

ii

l~

Flared connection

I

I

'

I

\

Refr~gerant plpe

Ball valve

%Capillary tube size (OD

x

ID x Length)

(Option)

(w~th

service

For PLL12FK. PKL12FK (40.126x q50.071 ~31.5)

@/a''

port)

For PL(L)18FK, PK(L)18EK (40.126~ 40.063~ 31.5) x2

sets

(with heat ~nsulator)

For PL(L)24FK, PC(L)24EK, PK(L)24EK (40. 126 x 40.063 x 17.3) x2 sets

-

Flow of refrigerant

Refrigerant pipe

pizzx

Outdoor

thermistor

(with heat insulator)

Flared connection

Flared connection

(Option)

(with service

For

PL30FK. PC30EK. PK3OEK (40.157~ 40.079~29.1) x2 sets

.$I

/2,'

port)

For PL36FK, PC36EK (40.157 x 40.079 x 17.7)

X

2 sets

(with heat insulator)

For

PL42FK2, PC42EK (40.1 57x 40.079~ 7.1)x2 sets

-

Flow of refrigerant

NOTE

:

The symbol 4 indicates the diameter.