Mitsubishi PUHZ-W85VHA(R1)(-BS), PUHZ-HW112YHA(-BS), PUHZ-HW140VHA(-BS), PUHZ-HW140YHA(-BS) Service Manual

AIR TO WATER HEAT PUMP

SERVICE MANUAL

R410A

[Model name]

PUHZ-W50VHA

PUHZ-W50VHA-BS

PUHZ-W85VHA

PUHZ-W85VHA-BS

PUHZ-HW112YHA

PUHZ-HW112YHA-BS

PUHZ-HW112YHA2

PUHZ-HW112YHA2-BS

PUHZ-HW140VHA

PUHZ-HW140VHA-BS

PUHZ-HW140YHA

PUHZ-HW140YHA-BS

PUHZ-HW140VHA2

PUHZ-HW140VHA2-BS

PUHZ-HW140YHA2

PUHZ-HW140YHA2-BS

[Service Ref.]

PUHZ-W50VHA

PUHZ-W50VHA-BS

PUHZ-W85VHA

PUHZ-W85VHAR1

PUHZ-W85VHA-BS

PUHZ-W85VHAR1-BS

PUHZ-HW112YHA

PUHZ-HW112YHA-BS

PUHZ-HW112YHA2

PUHZ-HW112YHA2-BS

PUHZ-HW140VHA

PUHZ-HW140VHA-BS

PUHZ-HW140YHA

PUHZ-HW140YHA-BS

PUHZ-HW140VHA2

PUHZ-HW140VHA2-BS

PUHZ-HW140YHA2

PUHZ-HW140YHA2-BS

November 2009

No. OCH439

REVISED EDITION-C

Revision:

• PUHZ-HW112Y/140V(Y)HA2(-BS)

are added in REVISED EDITION-C.

• Some descriptions have been modified.

• Please void OCH439 REVISED

EDITION-B.

Note:

• This manual describes only

service data of outdoor unit.

• RoHS compliant products have

<G> mark on the spec name plate.

PUHZ-W85VHA(R1)

PUHZ-W85VHA(R1)-BS

CONTENTS

1. TECHNICAL CHANGES

2. SAFETY PRECAUTION

3. SPECIFICATIONS

4. DATA

5. OUTLINES AND DIMENSIONS

6. WIRING DIAGRAM

7. WIRING SPECIFICATIONS

8. REFRIGERANT SYSTEM DIAGRAM

9. TROUBLESHOOTING

10. DISASSEMBLY PROCEDURE

............................................................................

..........................................

...........................................

......................................................

..........................

..................................................

..................................

............................................

...........................

PARTS CATALOG (OCB439)

....................

2

2

5

13

16

19

26

27

29

66

1

TECHNICAL CHANGES

PUHZ-HW112YHA(-BS) PUHZ-HW112YHA2(-BS)

PUHZ-HW140VHA(-BS) PUHZ-HW140VHA2(-BS)

PUHZ-HW140YHA(-BS) PUHZ-HW140YHA2(-BS)

1. Heat exchanger has been changed.

2. Compressor has been changed. (only HW140)

HW140V : ANB33FJGMT → ANB42FJGMT

HW140Y : ANB33FJFMT → ANB42FJFMT

3. Refrigerant charge has been changed. (only HW140)

4.0 kg → 4.3 kg

4. Plate heat exchanger has been changed.

ACH50 → ACH70

5. Muffler has been deleted.

6. Outdoor controller board (C.B.) has been changed. (S/W version up)

7. Outdoor power board (P.B.) has been changed.

8. Liner expansion valve (for LEV-A,B) have been changed.

9. Charge plug (high pressure side) has been changed. (Straight type → Bend type)

PUHZ-W85VHA PUHZ-W85VHAR1

PUHZ-W85VHA-BS PUHZ-W85VHAR1-BS

1. Comp. surface thermistor (TH33) has been added.

2. Discharge thermistor (TH4) has been changed.

3. Controller circuit board (C.B.) has been changed. (S/W version up)

2

SAFETY PRECAUTION

2-1. ALWAYS OBSERVE FOR SAFETY

Before obtaining access to terminal, all supply circuits must be disconnected.

Preparation before the repair service.

• Prepare the proper tools.

• Prepare the proper protectors.

• Provide adequate ventilation.

• After stopping the operation of the air conditioner, turn off the power-supply beaker.

• Discharge the condenser before the work involving the electric parts.

Precautions during the repair service.

• Do not perform the work involving the electric parts with wet hands.

• Do not pour water into the electric parts.

• Do not touch the refrigerant.

• Do not touch the hot or cold areas in the refrigerating cycle.

• When the repair or the inspection of the circuit needs to be done without turning off the power,

exercise great caution not to touch the live parts.

2

2-2. CAUTIONS RELATED TO NEW REFRIGERANT

Cautions for units utilizing refrigerant R410A

Do not use refrigerant other than R410A.

If other refrigerant (R22 etc.) is used, chlorine in refrigerant can cause deterioration of refrigerant oil etc.

Use a vacuum pump with a reverse flow check valve.

Vacuum pump oil may flow back into refrigerant cycle and that can cause deterioration of refrigerant oil etc.

Use the following tools specifically designed for use with R410A refrigerant.

The following tools are necessary to use R410A refrigerant.

Tools for R410A

Gauge manifold

Charge hose

Gas leak detector

Handle tools with care.

If dirt, dust or moisture enters into refrigerant cycle, that can cause deterioration of refrigerant oil or malfunction of compressor.

Vacuum pump adaptor

Electronic refrigerant charging scale

Torque wrench

Do not use a charging cylinder.

If a charging cylinder is used, the composition of refrigerant will change and the efficiency will be lowered.

Ventilate the room if refrigerant leaks during operation. If refrigerant comes into contact with

a flame, poisonous gases will be released.

Charge refrigerant from liquid phase of gas cylinder.

If the refrigerant is charged from gas phase, composition change may occur in refrigerant and the efficiency will be lowered.

[1] Cautions for service

(1) Perform service after recovering the refrigerant left in unit completely.

(2) Do not release refrigerant in the air.

(3) After completing service, charge the cycle with specified amount of refrigerant.

[2] Additional refrigerant charge

When charging directly from cylinder

· Check that cylinder for R410A on the market is syphon type.

· Charging should be performed with the cylinder of syphon stood vertically. (Refrigerant is charged from liquid phase.)

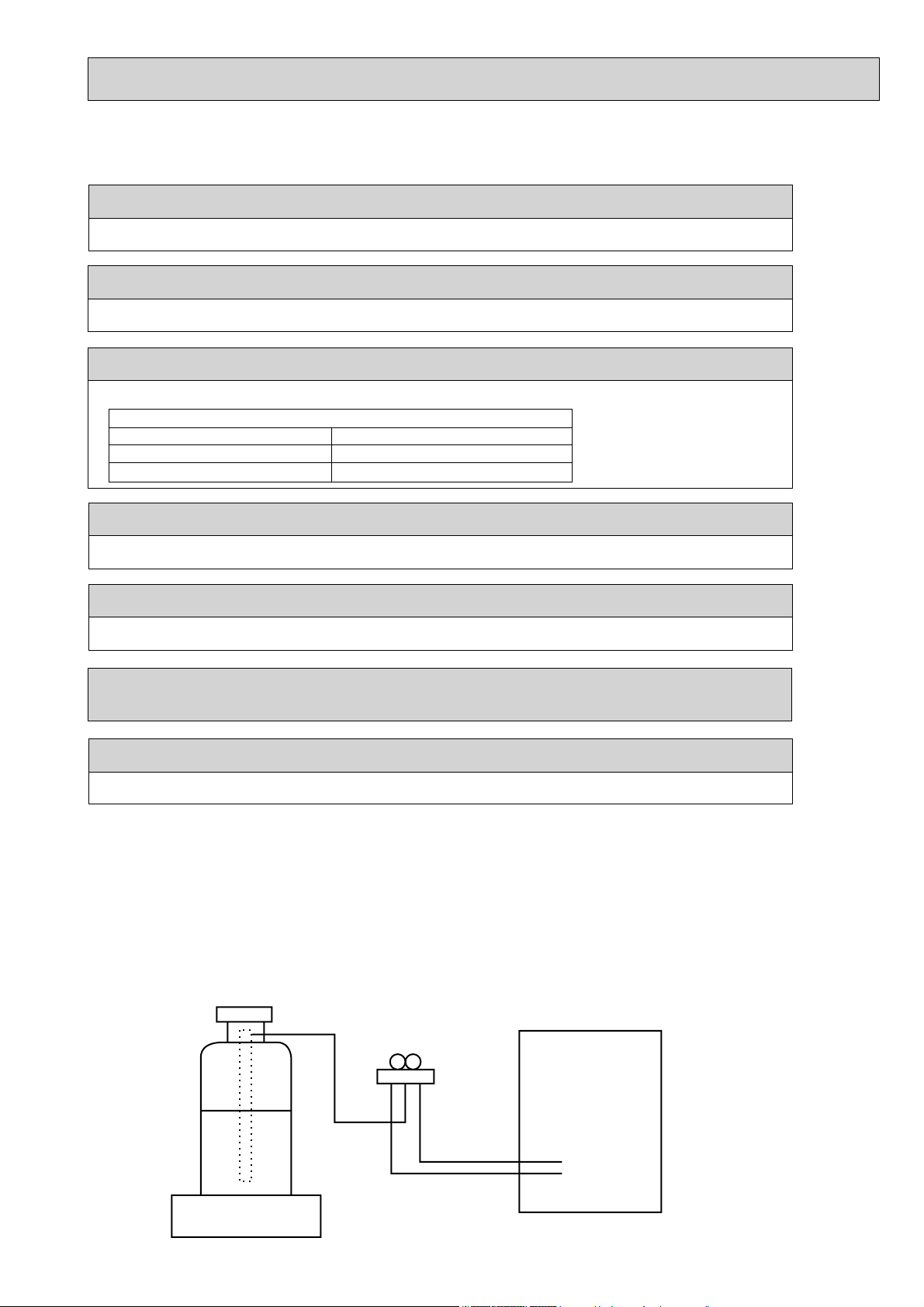

Gravimeter

Unit

3

[3] Service tools

Use the below service tools as exclusive tools for R410A refrigerant.

No.

Tool name

Specifications

· Only for R410A

Gauge manifold

1

· Use the existing fitting

specifications

. (UNF1/2)

· Use high-tension side pressure of 5.3 MPa·G or over.

Charge hose

2

Electronic scale

3

Gas leak detector · Use the detector for R134a, R407C or R410A.

4

Adaptor for reverse flow check · Attach on vacuum pump.

5

Refrigerant charge base

6

Refrigerant cylinder

7

Refrigerant recovery equipment

8

· Only for R410A

· Use pressure performance of 5.09 MPa·G or over.

—

—

· Only for R410A · Top of cylinder (Pink)

· Cylinder with syphon

—

2-3. CAUTIONS FOR REFRIGERANT PIPING WORK

Tools for R410A (The following table shows whether conventional tools can be used or not.)

Tools and materials Use R410A tools Can R22 tools be used?

Gauge manifold

Charge hose

Gas leak detector

Refrigerant recovery equipment

Refrigerant cylinder

Safety charger

Charge valve

Vacuum pump

Bender

Pipe cutter

Welder and nitrogen gas cylinder

Refrigerant charging scale

Vacuum gauge or thermistor vacuum gauge and

vacuum valve

Charging cylinder

: Prepare a new tool. (Use the new tool as the tool exclusive for R410A.)

: Tools for other refrigerants can be used under certain conditions.

: Tools for other refrigerants can be used.

Air purge, refrigerant charge

and operation check

Gas leak check

Refrigerant recovery

Refrigerant charge

Prevent compressor malfunction

when charging refrigerant by

spraying liquid refrigerant

Prevent gas from blowing out

when detaching charge hose

Vacuum drying and air

purge

Bend the pipes

Cut the pipes

Weld the pipes

Charge refrigerant

Check the degree of vacuum. (Vacuum

valve prevents back flow of oil and refrigerant to thermistor vacuum gauge)

Refrigerant charge

Tool exclusive for R410A

Tool exclusive for R410A

Tool for HFC refrigerant

Tool exclusive for R410A

Tool exclusive for R410A

Tool exclusive for R410A

Tool exclusive for R410A

Tools for other refrigerants can

be used if equipped with adapter for reverse flow check

Tools for other refrigerants can be used

Tools for other refrigerants can be used

Tools for other refrigerants can be used

Tools for other refrigerants can be used

Tools for other refrigerants

can be used

Tool exclusive for R410A

(Usable if equipped

with adapter for rever se flow)

Can R407C tools be used?

(Usable if equipped

with adapter for rever se flow)

2-4. PRECAUTIONS FOR SALT PROOF TYPE "-BS" MODEL

Although "-BS" model has been designed to be resistant to salt damage, observe the following precautions to maintain the

performance of the unit.

1. Avoid installing the unit in a location where it will be exposed directly to seawater or sea breeze.

2. If the cover panel may become covered with salt, be sure to install the unit in a location where the salt will be washed away by

rainwater. (If a sunshade is installed, rainwater may not clean the panel.)

3. To ensure that water does not collect in the base of the outdoor unit, make sure that the base is level, not at angle. Water

collecting in the base of the outdoor unit could cause rust.

4. If the unit is installed in a coastal area, clean the unit with water regularly to remove any salt build-up.

5. If the unit is damaged during installation or maintenance, be sure to repair it.

6. Be sure to check the condition of the unit regularly.

7. Be sure to install the unit in a location with good drainage.

4

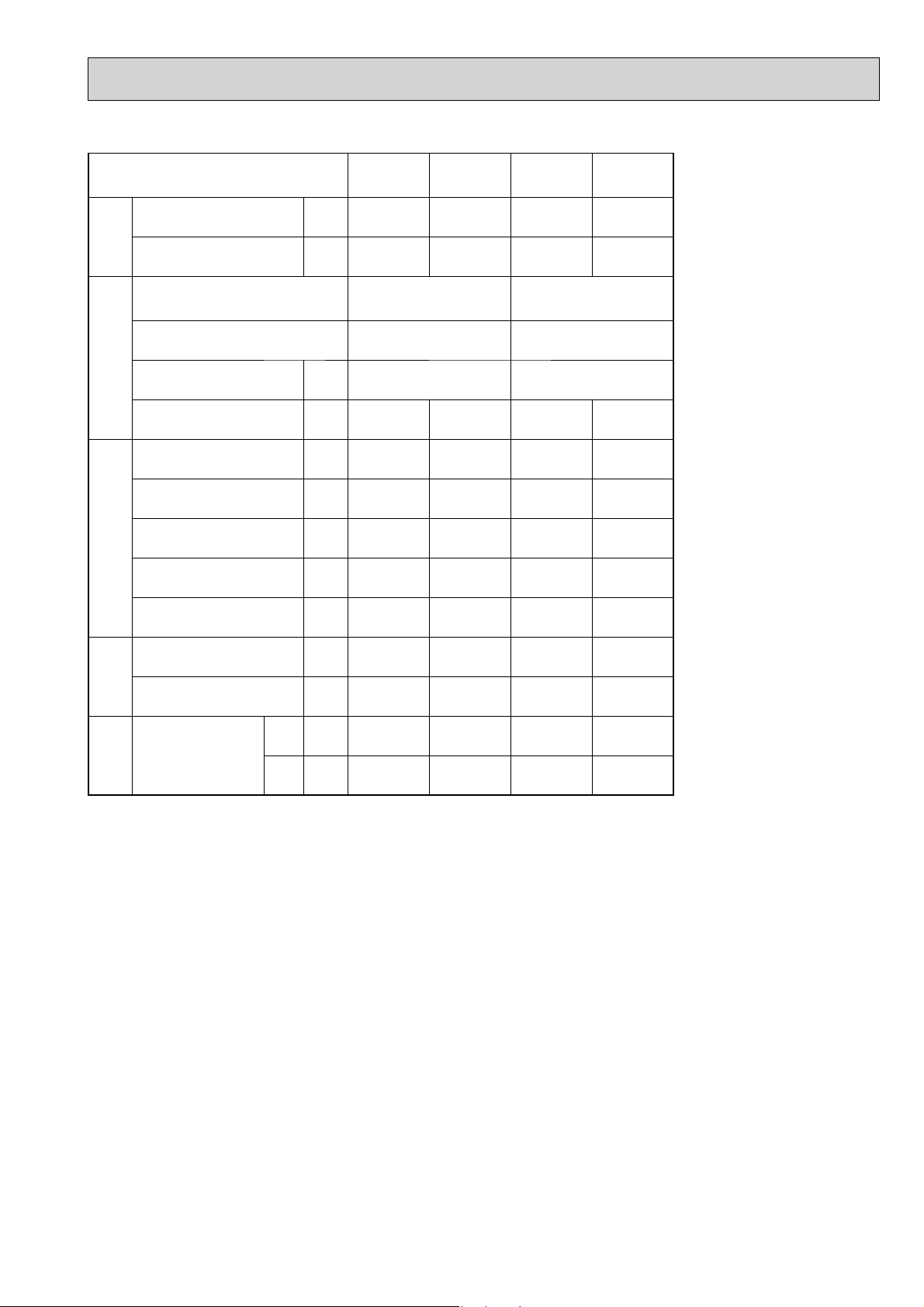

3

SPECIFICATIONS

3-1. SPECIFICATIONS

PUHZ-W50VHA(-BS)

)ycneuqerF,egatloV,esahP(ylppusrewoP

Nominal water flow rate (Heating mode) L/min

Heating

icapaC °C

(A7/W35)

Heating

capaC

Wkyti

(A2/W35)

Pressure difference (water circuit) 䇭 )teltuo/t

Heating pump input (based on EN14511) kW

Cooling

(COP) Water temperature (inlet/outlet) +12/+7°C

(A35/W7)

EER

Power input kW

Cooling

(COP) Outside air temperature (Wet-bulb) + 24°C

(A35/W18)

EER

Pressure difference (water circuit) 䇭kPa

Cooling pump input (based on EN14511) kW

Note: "COP" and "Power input" in the above table are values that contains the "pump input (based on EN 14511) ".

Model name

Cooling

Cooling

(A7/W35)

(A35/W7)

(A7/W35)

(A35/W7)

A

Running current Heating

Power factor Heating

Atnerruc.xaM

feR

Compressor

Model

Motor output kW

Start type

Protection devices

Oil (Model) L

WretaehesacknarC

Heat exchanger Air

Water

Fan Fan(drive)×No.

Fan motor output

Air flow

kW

3

/min

m

(CFM)

Defrost method

Noise level

Heating dB (SPL)

Cooling dB

Dimensions Width mm (in.)

Depth mm (in.)

Height mm (in.)

Refrigerant

Quantity kg (lbs)

Guaranteed operating Heating

range (Outdoor) Cooling

Outlet water temp. Heating

(Max in heating, Min in cooling)

Nominal return water

Cooling

Heating

temperature range Cooling

egnaretarwolfretaW

°C

°C

°C

°C

°C

°C

nim/L

1: , 230V, 50Hz

14.3

(Min.1.50䌾) 5.00

4.10

1.22

(Min.1.50䌾) 5.00

3.13

1.60

12

0.01

12.9

4.50

2.94

1.53

4.50

4.13

1.09

10

0.01

PUHZ-W50VHA(-BS)

5.4

6.8

97

97

13.0

16

Galvanized plate

Munsell 3Y 7.8/1.1

Linear expansion valve

Hermetic twin rotary

SNB130FGCM

0.9

Inverter

HP switch

Discharge thermo

Comp. Surface thermo

0.35 (FV50S)

-

Plate fin coil

Plate heat exchanger

Propeller fan × 1

0.086

50

(1,760)

Reverse cycle

46

45

*2

*2

950 (37-3/8)

*3

330 +30

(13+1-3/16)

740 (29-3/16)

)sbl(gkthgieW

64 (141)

R410A

1.7 (3.7)

-15 ~ +35

*4

~ +46

-5

+60

+5

~

+9 +59

~

+8 +28

6.5 14.3

~

Heating(A7/W35)

Heating(A2/W35)

Cooling(A35/W7)

Cooling(A35/W18)

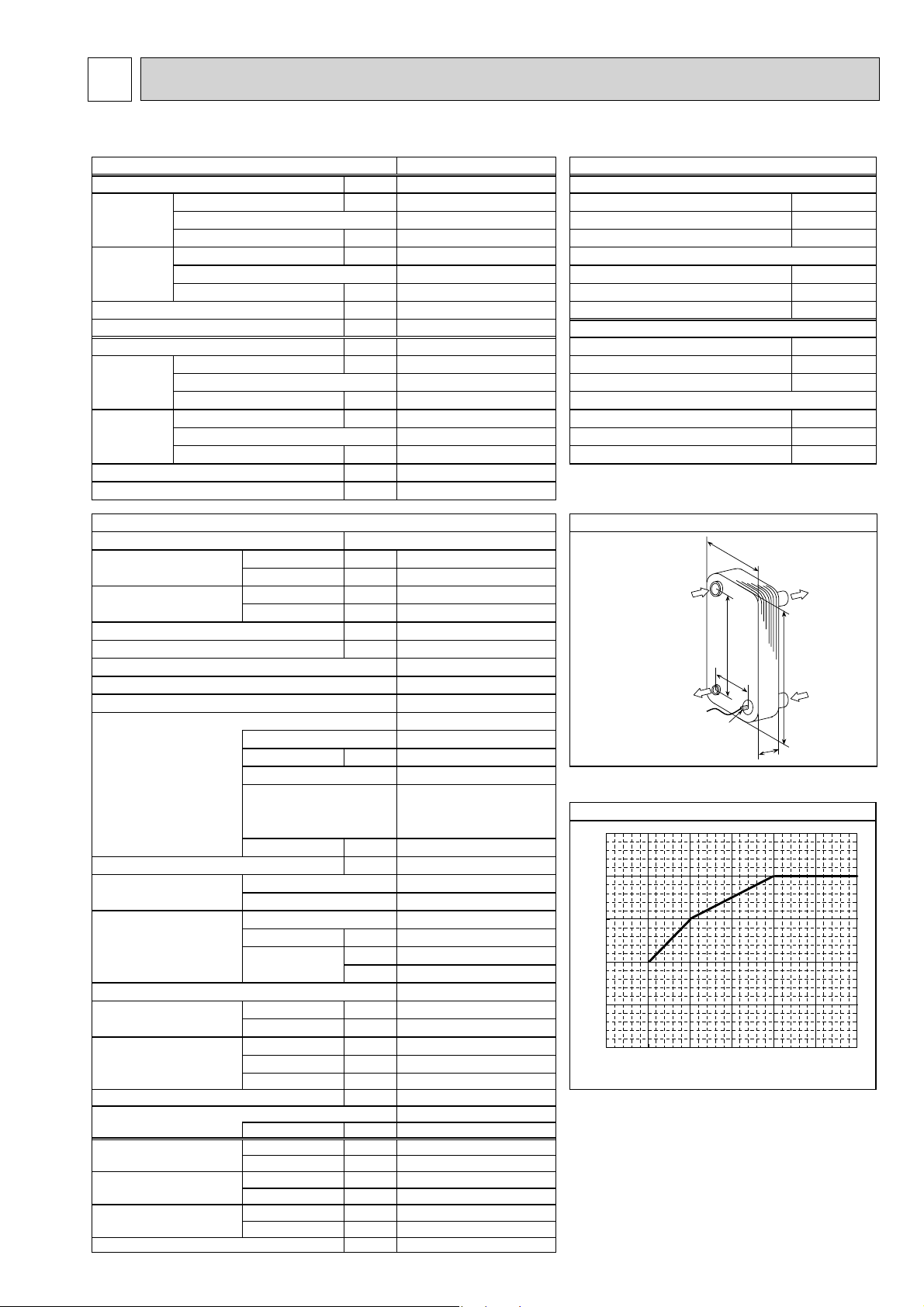

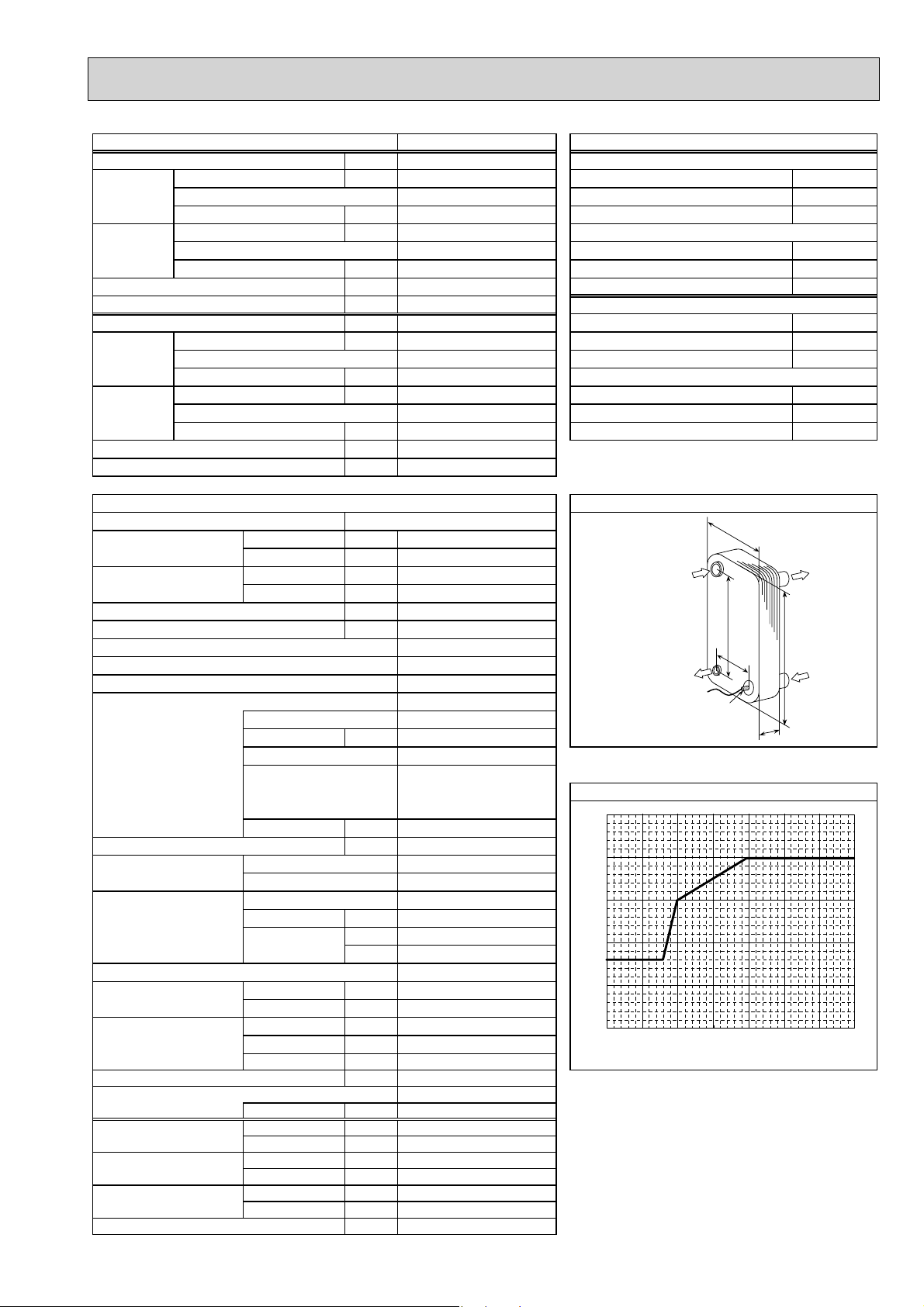

regnahcxetaehetalPsnoitacificepstinuroodtuO

ALFA LAVAL

03-03HCAA

Ref. IN

mm4.04:A%

(Heating)

mm2.862:B%

mm39:WAezisrekaerB

mm523:HgnisacretuO

mm45:DhsiniflanretxE

Ref. O UT

(Heating)

setalp03lortnoctnaregir

Maximum outlet water temperature

65

]

°C

60

55

50

*1

45

Maximum outlet water temptemperature [

40

-20 -15 -10 -5 0 5 10

*1 Hot gas with four-way valve

*2 at distance of 1m from outdoor unit

*3 grill

*4 With the optional air outlet guide, the operation at

-15°C outdoor temperature is possible.

*5 For details of the min. return water temperature at

each water flow rate, refer to the chapter 3-2.

*5

Ambient tem perature [°C]

noitidnocgnitarepolanimoN

7+)blub-yrD(erutarepmetriaedistuOWkyt

6+)blub-teW(erutarepmetriaedistuOPOC °C

53+/03+)teltuo/telni(erutarepmetretaWWktupnirewoP °C

2+)blub-yrD(erutarepmetriaedistuOPOC °C

1+)blub-teW(erutarepmetriaedistuOWktupnirewoP °C

elni(erutarepmetretaWaPk 䋭/+35°C

53+)blub-yrD(erutarepmetriaedistuOnim/L)edomgnilooC(etarwolfretawlanimoN °C

42+)blub-teW(erutarepmetriaedistuOWkyticapaC °C

53+)blub-yrD(erutarepmetriaedistuOWkyticapaC °C

1+/32+)teltuo/telni(erutarepmetretaWWktupnirewoP °C

8

W

Water OUT

B

H

Water IN

D

Thermistor

TH

2

A

5

PUHZ-W85VHA(-BS) PUHZ-W85VHAR1(-BS)

1㱢, 230V, 50Hz

Nominal water flow rate (Heating mode) L/min

Heating

icapaC 㷄

(Min.2.70 䌾) 9.00

(A7/W35)

(Min.2.60 䌾) 8.50

Heating

capaC

Wkyti

(A2/W35)

Pressure difference (water circuit) 䇭 )teltuo/t

Heating pump input (based on EN14511) kW

Cooling

(COP) Water temperature (inlet/outlet) +12/+7㷄

(A35/W7)

EER

Power input kW

Cooling

(COP) Outside air temperature (Wet-bulb) + 24㷄

(A35/W18)

EER

Pressure difference (water circuit) 䇭kPa

Cooling pump input (based on EN14511) kW

Note: "COP" and "Power input" in the above table are values that contains the "pump input (based on EN 14511) ".

Model name

Running current Heating

Cooling

Power factor Heating

Cooling

(A7/W35) 04-03HCAA

(A35/W7) A

(A7/W35) mm4.04:A%

(A35/W7) mm2.862:B%

PUHZ-W85VHA(-BS)/PUHZ-W85VHAR1(-BS)

Atnerruc.xaM

feR

Linear expansion valve

Compressor

Model

Motor output kW

Start type

Protection devices

Oil (Model) L

WretaehesacknarC

Heat exchanger Air

Water

Plate heat exchanger

Fan Fan(drive)×No.

Fan motor output

Air flow

kW

3

/min

m

(CFM)

Defrost method

Noise level Heating dB

(SPL)

Cooling dB

Dimensions Width mm (in.)

Depth mm (in.)

330 +30

Height mm (in.)

)sbl(gkthgieW

Refrigerant

Quantity kg (lbs)

Guaranteed operating Heating

range (Outdoor) Cooling

Outlet water temp. Heating

(Max in heating, Min in cooling)

Nominal return water

Cooling

Heating

temperature range Cooling

㷄

㷄

㷄

㷄

㷄

㷄

nim/LegnaretarwolfretaW

25.8

3.85

2.34

2.95

2.88

20

0.03

21.5

7.50

2.39

3.14

7.50

3.87

1.94

15

0.02

10.3

13.7

98

98

23.0

25

Galvanized plate

Munsell 3Y 7.8/1.1

Hermetic twin rotary

TNB220FLHM1

1.3

Inverter

HP switch

Discharge thermo

0.67 (FV50S)

-

Plate fin coil

Propeller fan × 1

0.060

55

(1,940)

Reverse cycle

48

48

*1

*2

*2

950 (37-3/8)

*3

(13+1-3/16)

943 (37-1/8)

77 (170)

R410A

2.4 (5.3)

-20 䌾 +35

*4

䌾 +46

-5

+60

+5

+9 䌾 +59

+8 䌾 +28

10.0 䌾 25.8

*5

Heating(A7/W35)

Heating(A2/W35)

Cooling(A35/W7)

Cooling(A35/W18)

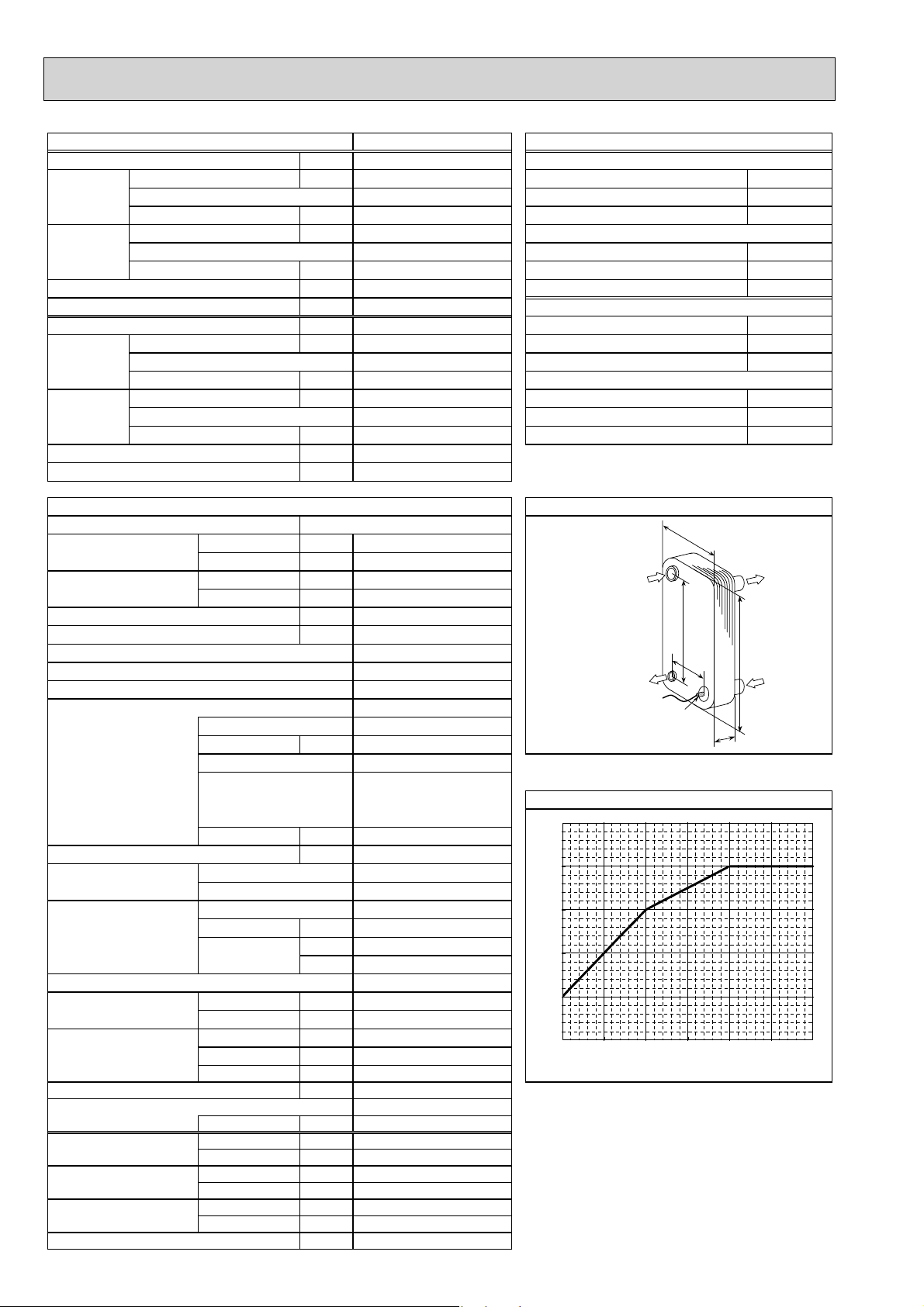

regnahcxetaehetalPsnoitacificepstinuroodtuO

ALFA LAVAL

Ref. IN

(Heating)

mm39:WAezisrekaerB

mm523:HgnisacretuO

mm96:DhsiniflanretxE

Ref. OUT

(Heating)

setalp04lortnoctnaregir

Maximum outlet water temperature

65

]

㷄

60

55

50

45

Maximum outlet watertemptemperature [

40

-20 -15 -10 -5 0 5 10

*1 Hot gas with four-way valve

*2 at distance of 1m from outdoor unit

*3 grill

*4 With the optional air outlet guide, the operation at

-15㷄 outdoor temperature is possible.

*5 For details of the min. return water temperature at

each water flow rate, refer to the chapter 3-2.

Ambient temperature [㷄]

noitidnocgnitarepolanimoN)ycneuqerF,egatloV,esahP(ylppusrewoP

7+)blub-yrD(erutarepmetriaedistuOWkyt

6+)blub-teW(erutarepmetriaedistuOPOC 㷄

53+/03+)teltuo/telni(erutarepmetretaWWktupnirewoP 㷄

2+)blub-yrD(erutarepmetriaedistuOPOC 㷄

1+)blub-teW(erutarepmetriaedistuOWktupnirewoP 㷄

elni(erutarepmetretaWaPk 䋭/+35㷄

53+)blub-yrD(erutarepmetriaedistuOnim/L)edomgnilooC(etarwolfretawlanimoN

㷄

42+)blub-teW(erutarepmetriaedistuOWkyticapaC 㷄

53+)blub-yrD(erutarepmetriaedistuOWkyticapaC 㷄

81+/32+)teltuo/telni(erutarepmetretaWWktupnirewoP 㷄

W

Water OUT

B

H

Water IN

D

Thermistor

(TH32)

A

6

PUHZ-HW112YHA(-BS)

3㱢, 400V, 50Hz

Nominal water flow rate (Heating mode) L/min

Heating

icapaC 㷄

(Min. 3.40 䌾) 11.20

(A7/W35)

Heating

capaC

(Min. 3.40 䌾) 11.20

Wkyti

(A2/W35)

Pressure difference (water circuit) 䇭 )teltuo/t

Heating pump input (based on EN14511) kW

Cooling

(COP) Water temperature (inlet/outlet) +12/+7㷄

(A35/W7)

EER

Power input kW

Cooling

(COP) Outside air temperature (Wet-bulb) + 24㷄

(A35/W18)

EER

Pressure difference (water circuit) 䇭kPa

Cooling pump input (based on EN14511) kW

Note: "COP" and "Power input" in the above table are values that contains the "pump input (based on EN 14511) ".

Model name

Running current Heating

Cooling

Power factor Heating

Cooling

(A7/W35) 05-05HCAA

(A35/W7) A

(A7/W35) mm05:A%

(A35/W7) mm664:B%

PUHZ-HW112YHA(-BS)

Atnerruc.xaM

feR

Linear expansion valve

Compressor

Model

Motor output kW

Start type

Protection devices

Oil (Model) L

WretaehesacknarC

Heat exchanger Air

Water

Plate heat exchanger

Fan Fan(drive)×No.

Fan motor output

Air flow

kW

3

/min

m

(CFM)

Defrost method

Noise level Heating dB

(SPL)

Cooling dB

Dimensions Width mm (in.)

Depth mm (in.)

330 +30

Height mm (in.)

)sbl(gkthgieW

Refrigerant

Quantity kg (lbs)

Guaranteed operating Heating

range (Outdoor) Cooling

Outlet water temp. Heating

(Max in heating, Min in cooling)

Cooling

Nominal return water Heating

temperature range Cooling

㷄

㷄

㷄

㷄

㷄

㷄

nim/LegnaretarwolfretaW

32.1

4.24

2.64

3.01

3.72

6

0.01

28.7

10.00

2.72

3.68

10.00

4.07

2.46

5

0.01

4.0

5.6

95

95

13.0

16

Galvanized plate

Munsell 3Y 7.8/1.1

Hermetic scroll

ANB33FJFMT

2.5

Inverter

HP switch

LP switch

Discharge thermo

0.9 (FV50S)

-

Plate fin coil

Propeller fan × 2

0.074 x 2

100

(3,530)

Reverse cycle

53

53

*1

*2

*2

1020 (40-3/16)

*3

(13+1-3/16)

1350 (53-1/8)

148 (326)

R410A

4.0 (8.8)

-25 䌾 +35

*4

䌾 +46

-5

+60

+5

+11 䌾 +59

+8 䌾 +28

14.4 䌾 32.1

*5

Heating(A7/W35)

Heating(A2/W35)

Cooling(A35/W7)

Cooling(A35/W18)

regnahcxetaehetalPsnoitacificepstinuroodtuO

ALFA LAVAL

Ref. IN

(Heating)

mm211:WAezisrekaerB

mm625:HgnisacretuO

mm031:DhsiniflanretxE

Ref. OUT

(Heating)

setalp05lortnoctnaregir

Maximum outlet water temperature

65

]

㷄

60

55

50

45

Maximum outlet water temptemperature [

40

-25 -20 -15 -10 -5 0 5 10

*1 Hot gas with four-way valve

*2 at distance of 1m from outdoor unit

*3 grill

*4 With the optional air outlet guide, the operation at

-15㷄 outdoor temperature is possible.

*5 For details of the min. return water temperature at

each water flow rate, refer to the chapter 3-2.

Ambient temperature [㷄]

noitidnocgnitarepolanimoN)ycneuqerF,egatloV,esahP(ylppusrewoP

7+)blub-yrD(erutarepmetriaedistuOWkyt

6+)blub-teW(erutarepmetriaedistuOPOC 㷄

53+/03+)teltuo/telni(erutarepmetretaWWktupnirewoP 㷄

2+)blub-yrD(erutarepmetriaedistuOPOC 㷄

1+)blub-teW(erutarepmetriaedistuOWktupnirewoP 㷄

elni(erutarepmetretaWaPk 䋭/+35㷄

㷄

53+)blub-yrD(erutarepmetriaedistuOnim/L)edomgnilooC(etarwolfretawlanimoN

42+)blub-teW(erutarepmetriaedistuOWkyticapaC 㷄

53+)blub-yrD(erutarepmetriaedistuOWkyticapaC 㷄

81+/32+)teltuo/telni(erutarepmetretaWWktupnirewoP 㷄

W

Water OUT

B

H

Water IN

D

Thermistor

TH

2

A

7

PUHZ-HW140VHA(-BS) PUHZ-HW140YHA(-BS)

1/3㱢, 230/400V, 50Hz

Nominal water flow rate (Heating mode) L/min

Heating

icapaC 㷄

(Min. 4.20 䌾 ) 14.00

(A7/W35)

Heating

capaC

(Min. 4.20 䌾 ) 14.00

Wkyti

(A2/W35)

Pressure difference (water circuit) 䇭 )teltuo/t

Heating pump input (based on EN14511) kW

Cooling

EER

(A35/W7)

(COP)

Power input kW

Cooling

(COP)

(A35/W18)

EER

Pressure difference (water circuit) 䇭kPa

Cooling pump input (based on EN14511) kW

Note: "COP" and "Power input" in the above table are values that contains the "pump input (based on EN 14511) ".

Model name

PUHZ-HW140VHA(-BS) /

PUHZ-HW140YHA(-BS)

Running current Heating

Power factor Heating

Refrigerant control

Cooling

Cooling

(A7/W35)

(A35/W7)

(A7/W35)

(A35/W7)

A

%

Linear expansion valve

Compressor

Model

ANB33FJGMT/ANB33FJFMT

Motor output kW

Start type

Oil (Model) L

WretaehesacknarC

Heat exchanger Air

Water

Plate heat exchanger

.oN×)evird(naFnaF

Fan motor output

Air flow

kW

3

m

/min

(CFM)

Defrost method

Noise level Heating dB

(SPL)

Cooling dB

Dimensions Width mm (in.)

Depth mm (in.)

330 +30

Height mm (in.)

134 (296) / 148 (326)

)sbl(gkthgieW

Refrigerant

Quantity kg (lbs)

Guaranteed operating Heating

range (Outdoor) Cooling

Outlet water temp. Heating

(Max in heating, Min in cooling)

Nominal return water

Cooling

Heating

temperature range Cooling

㷄

㷄

㷄

㷄

㷄

㷄

nim/LegnaretarwolfretaW

40.1

4.19

3.34

2.69

5.21

9

0.02

35.8

12.50

2.59

4.82

12.50

4.01

3.12

7

0.02

14.9 / 5.1

21.5 / 7.3

97 / 95

97 / 95

35.0 / 13.0

40 / 16

Galvanized plate

Munsell 3Y 7.8/1.1

Hermetic scroll

2.5

Inverter

HP switch

LP switch

Discharge thermo

0.9 (FV50S)

-

Plate fin coil

Propeller fan × 2

0.074 x 2

100

(3,530)

Reverse cycle

1020 (40-3/16)

*2

53

*2

53

*3

(13+1-3/16)

1350 (53-1/8)

R410A

4.0 (8.8)

-25 䌾 +35

*4

䌾 +46

-5

+60

+5

+10 䌾 +59

+8 䌾 +28

17.9 䌾 40.1

*5

Heating(A7/W35)

Heating(A2/W35)

Cooling(A35/W7)

Water temperature (inlet/outlet) +12/+7㷄

Cooling(A35/W18)

Outside air temperature (Wet-bulb) + 24㷄

regnahcxetaehetalPsnoitacificepstinuroodtuO

ALFA LAVAL

ACH50-50

mm05:AA

Ref. IN

(Heating)

mm664:B%

mm211:WAtnerruc.xaM

mm625:HAezisrekaerB

mm031:DgnisacretuO

Ref. OUT

(Heating)

setalp05hsiniflanretxE

eltuomumixaMsecivednoitcetorP

65

]

㷄

60

55

50

*1

45

Maximum outlet water temptemperature [

40

-25 -20 -15 -10 -5 0 5 10

*1 Hot gas with four-way valve

*2 at distance of 1m from outdoor unit

*3 grill

*4 With the optional air outlet guide, the operation at

-15㷄 outdoor temperature is possible.

*5 For details of the min. return water temperature at

each water flow rate, refer to the chapter 3-2.

Ambient temperature [㷄]

noitidnocgnitarepolanimoN)ycneuqerF,egatloV,esahP(ylppusrewoP

7+)blub-yrD(erutarepmetriaedistuOWkyt

6+)blub-teW(erutarepmetriaedistuOPOC 㷄

53+/03+)teltuo/telni(erutarepmetretaWWktupnirewoP 㷄

2+)blub-yrD(erutarepmetriaedistuOPOC 㷄

1+)blub-teW(erutarepmetriaedistuOWktupnirewoP 㷄

elni(erutarepmetretaWaPk 䋭/+35㷄

㷄

53+)blub-yrD(erutarepmetriaedistuOnim/L)edomgnilooC(etarwolfretawlanimoN

42+)blub-teW(erutarepmetriaedistuOWkyticapaC 㷄

53+)blub-yrD(erutarepmetriaedistuOWkyticapaC 㷄

81+/32+)teltuo/telni(erutarepmetretaWWktupnirewoP 㷄

W

Water OUT

B

H

Water IN

D

Thermistor

TH

2

A

erutarepmetretawt

8

PUHZ-HW112YHA2(-BS)

(TH32)

3 㱢, 400V, 50Hz

Nominal water flow rate (Heating mode) L/min

Heating

icapaC 㷄

(Min. 3.40 䌾 ) 11.20

(A7/W35)

Heating

capaC

(Min. 3.40 䌾 ) 11.20

Wkyti

(A2/W35)

Pressure difference (water circuit) 䇭 )teltuo/t

Heating pump input (based on EN14511) kW

Cooling

EER

(A35/W7)

(COP) Water temperature (inlet/outlet) +12/+7㷄

Power input kW

Cooling

(COP) Outside air temperature (Wet-bulb) + 24㷄

(A35/W18)

EER

Pressure difference (water circuit) 䇭kPa

Cooling pump input (based on EN14511) kW

Note: "COP" and "Power input" in the above table are values that contains the "pump input (based on EN 14511) ".

Model name

Running current Heating

Cooling

Power factor Heating

Cooling

Refrigerant control

(A7/W35) A

(A35/W7) mm05:AA

(A7/W35) mm664:B%

(A35/W7) %

PUHZ-HW112YHA2(-BS)

Linear expansion valve

Compressor

Model

Motor output kW

Start type

Oil (Model) L

WretaehesacknarC

Heat exchanger Air

Water

.oN×)evird(naFnaF

Fan motor output

Air flow

kW

3

/min

m

(CFM)

Defrost method

Noise level Heating dB

(SPL)

Cooling dB

Dimensions Width mm (in.)

Depth mm (in.)

330 +30

Height mm (in.)

)sbl(gkthgieW

Refrigerant

Quantity kg (lbs)

Guaranteed operating Heating

range (Outdoor) Cooling

Outlet water temp. Heating

(Max in heating, Min in cooling)

Nominal return water

Cooling

Heating

temperature range Cooling

㷄

㷄

㷄

㷄

㷄

㷄

nim/LegnaretarwolfretaW

32.1

4.42

2.53

3.11

3.60

6

0.01

28.7

10.00

2.78

3.60

10.00

4.10

2.44

5

0.01

4.0

5.6

95

95

13.0

16

Galvanized plate

Munsell 3Y 7.8/1.1

Hermetic scroll

ANB33FJFMT

2.5

Inverter

HP switch

LP switch

Discharge thermo

0.9 (FV50S)

-

Plate fin coil

Plate heat exchanger

Propeller fan × 2

0.074 x 2

100

(3,530)

Reverse cycle

53

53

*1

*2

*2

1020 (40-3/16)

*3

(13+1-3/16)

1350 (53-1/8)

148 (326)

R410A

4.0 (8.8)

-25 䌾 +35

*4

䌾 +46

-5

+60

+5

+11 䌾 +59

+8 䌾 +28

14.4 䌾 32.1

*5

Heating(A7/W35)

Heating(A2/W35)

Cooling(A35/W7)

Cooling(A35/W18)

regnahcxetaehetalPsnoitacificepstinuroodtuO

ALFA LAVAL

ACH70-52

Ref. IN

(Heating)

mm211:WAtnerruc.xaM

mm625:HAezisrekaerB

mm031:DgnisacretuO

Ref. OUT

(Heating)

setalp25hsiniflanretxE

tuomumixaMsecivednoitcetorP

65

]

㷄

60

55

50

45

Maximum outlet water temptemperature [

40

-25-20-15-10 -5 0 5 10

*1 Hot gas with four-way valve

*2 at distance of 1m from outdoor unit

*3 grill

*4 With the optional air outlet guide, the operation at -15 °C

outdoor temperature is possible.

*5 For details of the min. return water temperature at

each water flow rate, refer to the chapter 3-2.

Ambient temperature [㷄]

noitidnocgnitarepolanimoN)ycneuqerF,egatloV,esahP(ylppusrewoP

7+)blub-yrD(erutarepmetriaedistuOWkyt

6+)blub-teW(erutarepmetriaedistuOPOC 㷄

53+/03+)teltuo/telni(erutarepmetretaWWktupnirewoP 㷄

2+)blub-yrD(erutarepmetriaedistuOPOC 㷄

1+)blub-teW(erutarepmetriaedistuOWktupnirewoP 㷄

elni(erutarepmetretaWaPk 䋭/+35㷄

53+)blub-yrD(erutarepmetriaedistuOnim/L)edomgnilooC(etarwolfretawlanimoN

㷄

42+)blub-teW(erutarepmetriaedistuOWkyticapaC 㷄

53+)blub-yrD(erutarepmetriaedistuOWkyticapaC 㷄

81+/32+)teltuo/telni(erutarepmetretaWWktupnirewoP 㷄

W

Water OUT

B

A

Thermistor

H

Water IN

D

erutarepmetretawtel

9

PUHZ-HW140VHA2(-BS) PUHZ-HW140YHA2(-BS)

(TH32)

1/3㱢, 230/400V, 50Hz

Nominal water flow rate (Heating mode) L/min

Heating

icapaC 㷄

(Min. 4.20 䌾 ) 14.00

(A7/W35)

Heating

capaC

(Min. 4.20 䌾 ) 14.00

Wkyti

(A2/W35)

Pressure difference (water circuit) 䇭 )teltuo/t

Heating pump input (based on EN14511) kW

Cooling

EER

(A35/W7)

(COP) Water temperature (inlet/outlet) +12/+7㷄

Power input kW

Cooling

EER

(A35/W18)

(COP) Outside air temperature (Wet-bulb) + 24㷄

Pressure difference (water circuit) 䇭kPa

Cooling pump input (based on EN14511) kW

Note: "COP" and "Power input" in the above table are values that contains the "pump input (based on EN 14511) ".

Model name

PUHZ-HW140VHA2(-BS) /

PUHZ-HW140YHA2(-BS)

Running current Heating

Power factor Heating

Refrigerant control

Cooling

Cooling

(A7/W35) A

(A35/W7) mm05:AA

(A7/W35) mm664:B%

(A35/W7) %

Linear expansion valve

Compressor

Model

ANB42FJGMT/ANB42FJFMT

Motor output kW

Start type

Oil (Model) L

WretaehesacknarC

Heat exchanger Air

Water

.oN×)evird(naFnaF

Fan motor output

Air flow

kW

3

/min

m

(CFM)

Defrost method

Noise level Heating dB

(SPL)

Cooling dB

Dimensions Width mm (in.)

Depth mm (in.)

330 +30

Height mm (in.)

)sbl(gkthgieW

Refrigerant

Quantity kg (lbs)

Guaranteed operating Heating

range (Outdoor) Cooling

Outlet water temp. Heating

(Max in heating, Min in cooling)

Nominal return water

Cooling

Heating

temperature range Cooling

㷄

㷄

㷄

㷄

㷄

㷄

nim/LegnaretarwolfretaW

40.1

4.25

3.29

3.11

4.50

9

0.02

35.8

12.50

2.50

5.00

12.50

3.60

3.47

7

0.02

14.4/5.0

22.2/7.6

97/95

97/95

35.0/13.0

40/16

Galvanized plate

Munsell 3Y 7.8/1.1

Hermetic scroll

3.0

Inverter

HP switch

LP switch

Discharge thermo

0.9 (FV50S)

-

Plate fin coil

Plate heat exchanger

Propeller fan × 2

0.074 x 2

100

(3,530)

Reverse cycle

53

53

1020 (40-3/16)

*3

*1

*2

*2

(13+1-3/16)

1350 (53-1/8)

134 (296)/148 (326)

R410A

4.3 (9.5)

-25 䌾 +35

*4

-5

䌾 +46

+60

+5

+10 䌾 +59

+8 䌾 +28

17.9 䌾 40.1

*5

Heating(A7/W35)

Heating(A2/W35)

Cooling(A35/W7)

Cooling(A35/W18)

regnahcxetaehetalPsnoitacificepstinuroodtuO

ALFA LAVAL

ACH70-52

Ref. IN

(Heating)

mm211:WAtnerruc.xaM

mm625:HAezisrekaerB

mm031:DgnisacretuO

Ref. OUT

(Heating)

setalp25hsiniflanretxE

eltuomumixaMsecivednoitcetorP

65

]

㷄

60

55

50

45

Maximum outlet water temptemperature [

40

-25 -20 -15 -10 -5 0 5 10

*1 Hot gas with four-way valve

*2 at distance of 1m from outdoor unit

*3 grill

*4 With the optional air outlet guide, the operation at -15 °C

outdoor temperature is possible.

*5 For details of the min. return water temperature at

each water flow rate, refer to the chapter 3-2.

Ambient temperature [㷄]

noitidnocgnitarepolanimoN)ycneuqerF,egatloV,esahP(ylppusrewoP

7+)blub-yrD(erutarepmetriaedistuOWkyt

6+)blub-teW(erutarepmetriaedistuOPOC 㷄

53+/03+)teltuo/telni(erutarepmetretaWWktupnirewoP 㷄

2+)blub-yrD(erutarepmetriaedistuOPOC 㷄

1+)blub-teW(erutarepmetriaedistuOWktupnirewoP 㷄

elni(erutarepmetretaWaPk 䋭/+35㷄

53+)blub-yrD(erutarepmetriaedistuOnim/L)edomgnilooC(etarwolfretawlanimoN

㷄

42+)blub-teW(erutarepmetriaedistuOWkyticapaC 㷄

53+)blub-yrD(erutarepmetriaedistuOWkyticapaC 㷄

81+/32+)teltuo/telni(erutarepmetretaWWktupnirewoP 㷄

W

Water OUT

B

A

Thermistor

H

Water IN

D

erutarepmetretawt

10

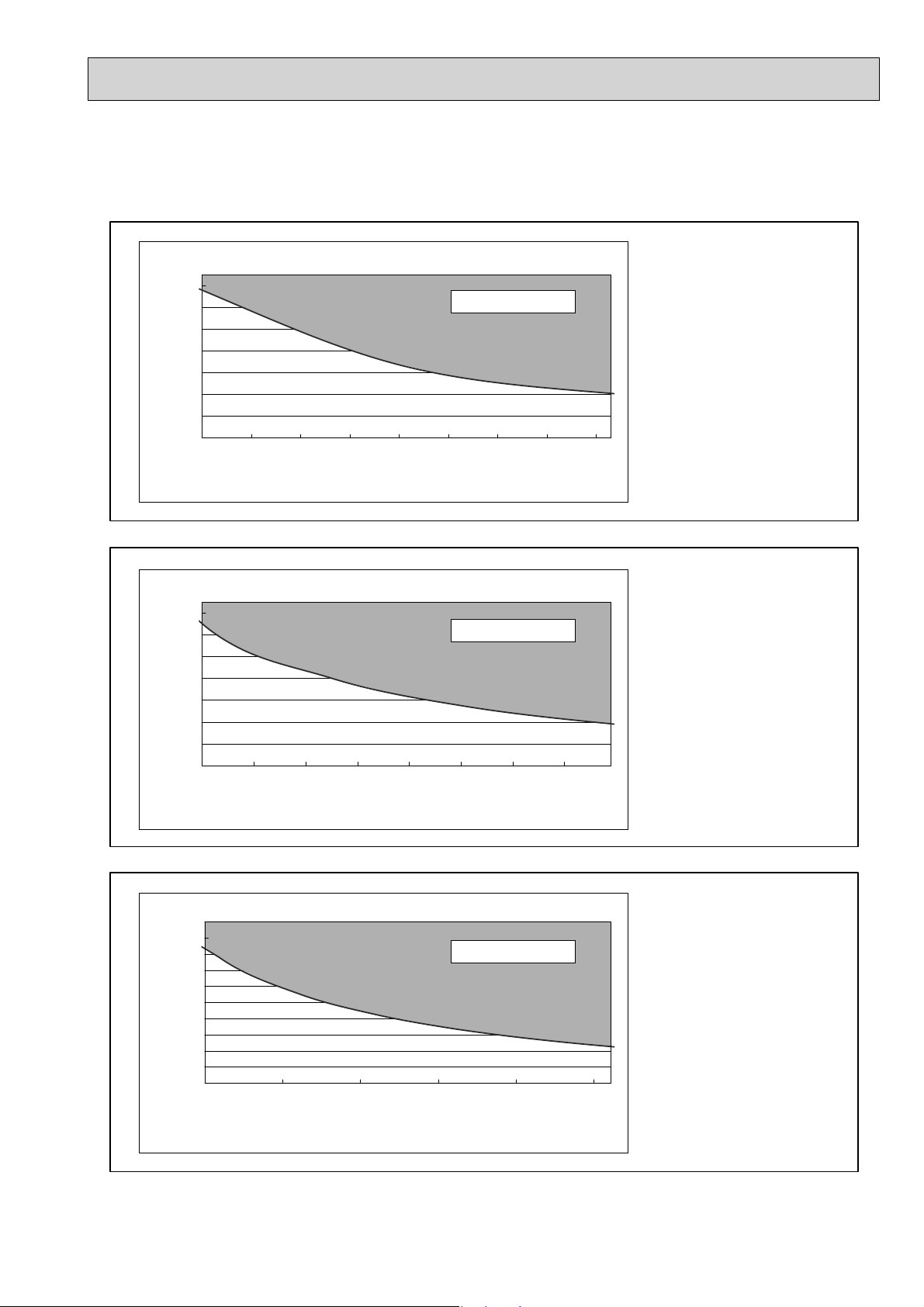

3-2. AVAILABLE RANGE (WATER FLOW RATE, RETURN WATER TEMP.)

Note: If using the unit out of the available range, the parts of unit might be damaged.

<Heating>

<Applicable Models>

19.0

17.0

15.0

13.0

11.0

9.0

Return water temp []

7.0

5.0

6.0 7.0 8.0 9.0 10.0

19.0

17.0

15.0

13.0

11.0

9.0

Return water temp []

7.0

5.0

10.0

12.0 14.0 16.0 18.0 20.0 22.0 24.0

Available range

11.0

Water flow rate [L/min]

Table 1

Available range

Water flow rate [L/min]

Table 2

12.0 13.0 14.0

•PUHZ-W50VHA(-BS)

<Applicable Models>

•PUHZ-W85VHA(-BS)

•PUHZ-W85VHAR1(-BS)

25.0

23.0

21.0

19.0

17.0

15.0

13.0

11.0

9.0

Return water temp []

7.0

5.0

14.0 19.0 24.0 29.0 34.0 39.0

Water flow rate [L/min]

Table 3

Available range

11

<Applicable Models>

•PUHZ-HW112YHA(-BS)

•PUHZ-HW140VHA(-BS)

•PUHZ-HW140YHA(-BS)

•PUHZ-HW112YHA2(-BS)

•PUHZ-HW140VHA2(-BS)

•PUHZ-HW140YHA2(-BS)

<Cooling>

Return water temp []

19.0

17.0

15.0

13.0

11.0

9.0

7.0

5.0

7.06.0 8.0 9.0 10.0

Water flow rate [L/min]

Table 4

Available range

11.0

12.0 13.0 14.0

<Applicable Models>

•PUHZ-W50VHA(-BS)

15.0

14.0

13.0

12.0

11.0

10.0

9.0

8.0

7.0

Return water temp []

6.0

5.0

12.010.0 14.0 16.0 18.0

17.0

15.0

13.0

11.0

9.0

Return water temp []

7.0

5.0

14.0 19.0 24.0

Available range

20.0

Water flow rate [L/min]

Table 5

Available range

29.0

Water flow rate [L/min]

Table 6

<Applicable Models>

•PUHZ-W85VHA(-BS)

•PUHZ-W85VHAR1(-BS)

22.0 24.0

<Applicable Models>

•PUHZ-HW112YHA(-BS)

•PUHZ-HW140VHA(-BS)

•PUHZ-HW140YHA(-BS)

•PUHZ-HW112YHA2(-BS)

•PUHZ-HW140VHA2(-BS)

•PUHZ-HW140YHA2(-BS)

34.0 39.0

12

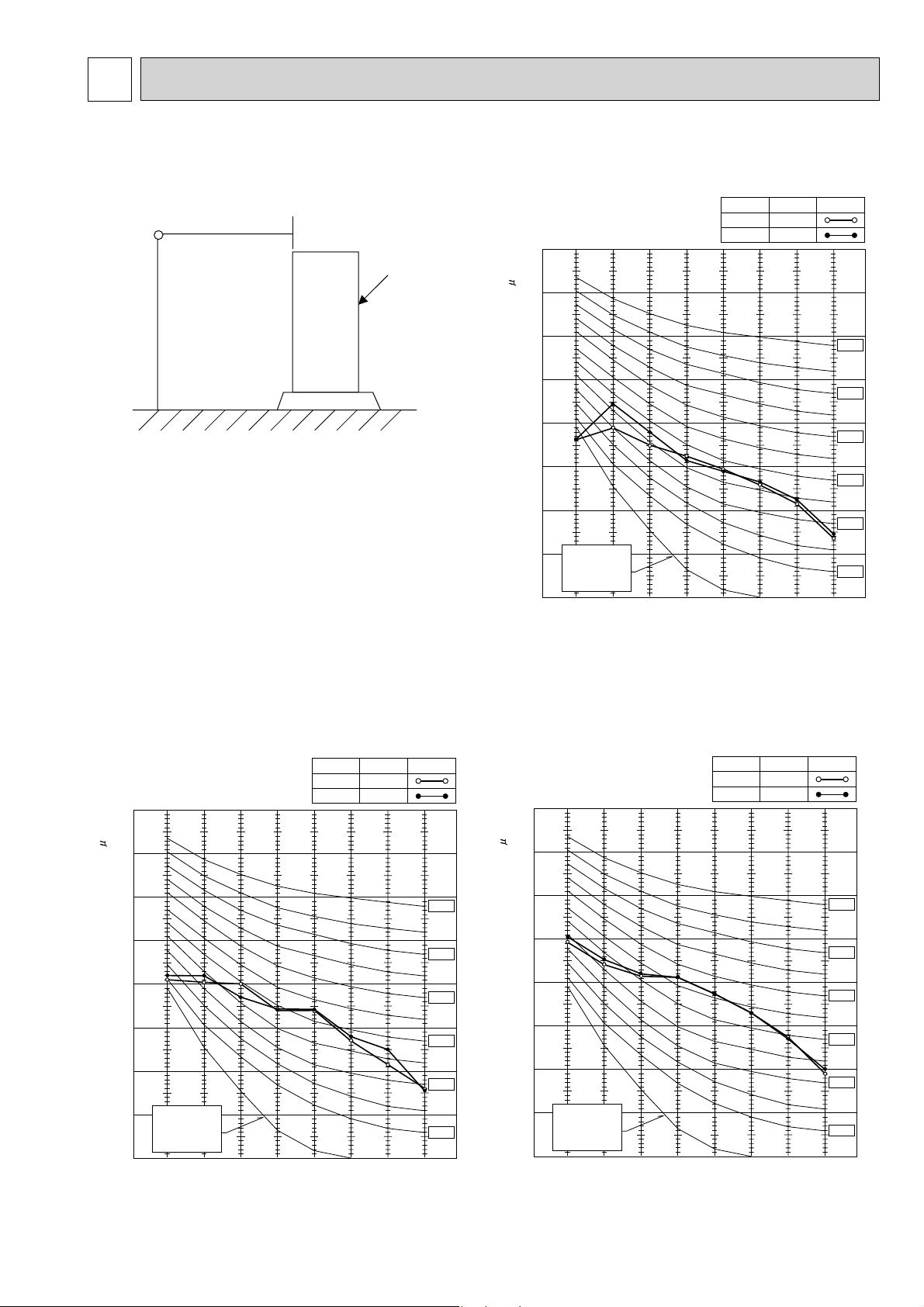

4

DATA

4-1. NOISE CRITERION CURVES

MICROPHONE

1m

UNIT

PUHZ-W50VHA(-BS)

90

80

MODE

COOLING

HEATING

SPL(dB)

45

46

LINE

1.5m

PUHZ-W85VHA(-BS)

PUHZ-W85VHAR1(-BS)

90

MODE

COOLING

HEATING

SPL(dB)

48

48

GROUND

LINE

70

60

50

40

30

APPROXIMATE

20

THRESHOLD OF

HEARING FOR

CONTINUOUS

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 bar)

NOISE

10

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

PUHZ-HW112YHA(-BS)

PUHZ-HW140VHA(-BS)

PUHZ-HW140YHA(-BS)

PUHZ-HW112YHA2(-BS)

PUHZ-HW140VHA2(-BS)

PUHZ-HW140YHA2(-BS)

90

COOLING

HEATING

MODE

SPL(dB)

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

LINE

53

53

80

70

60

50

40

30

APPROXIMATE

20

THRESHOLD OF

HEARING FOR

CONTINUOUS

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 bar)

NOISE

10

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

13

80

70

60

50

40

30

APPROXIMATE

20

THRESHOLD OF

HEARING FOR

CONTINUOUS

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 bar)

NOISE

10

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

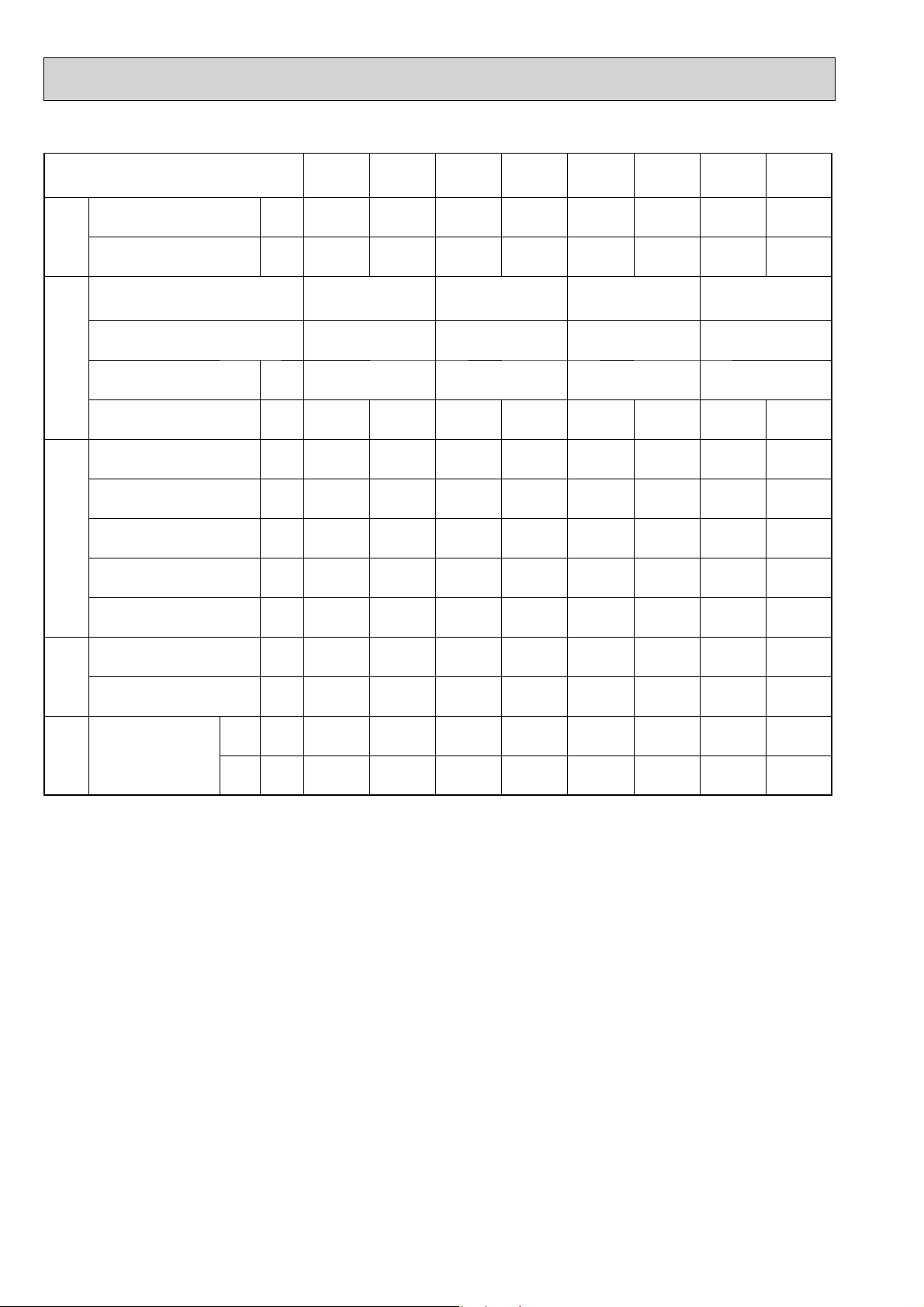

4-2. STANDARD OPERATION DATA

Mode

Capacity W 4,500 5,000 7,500 9,000 10,000 11,200 12,500 14,000

Total

Input kW 1.52 1.21 3.12 2.31 3.67 2.63 4.80 3.32

Cooling

(A35/W7)

Heating

(A7/W35)

Cooling

(A35/W7)

Heating

(A7/W35)

Cooling

(A35/W7)

Heating

(A7/W35)

Cooling

(A35/W7)

Heating

(A7/W35)

Outdoor unit PUHZ-W50VHA PUHZ-W85VHA PUHZ-HW112YHA

Phase, Hz 1, 50 1, 50 3, 50 1 / 3, 50

Voltage V 230 230 400 230 / 400

Electrical circuit

Current A 6.8 5.4 13.7 10.3 5.6 4.0 21.5 / 7.314.9 / 5.1

Discharge pressure MPa 2.51 2.13 2.81 2.21 2.63 2.07 2.81 2.11

Suction pressure MPa 0.83 0.68 0.73 0.64 0.78 0.69 0.78 0.66

Discharge temperature ºC 69 68 80 65 78 64 84 67

Condensing temperature

Refrigerant circuit

Suction temperature ºC 6 6 3 -1 9 5 11 3

Flow volume L/min 12.9 14.3 20.4 25.8 28.7 32.1 35.8 40.1

Water

Outlet water temperature

conditions

Intake air

temperature

Outdoor

conditions

The unit of pressure has been changed to MPa based on international SI system.

The conversion factor is: 1 (MPa) = 10.2 (kgf/cm2)

W.B. ºC 24 6 24 6 24 6 24 6

ºC 43 37 46 38 46 36 47 37

ºC735735735735

D.B. ºC 35 7 35 7 35 7 35 7

PUHZ-HW140VHA/

PUHZ-HW140YHA

14

Mode

Capacity W 10,000 11,200 12,500 14,000

Total

Input kW 3.60 2.53 5.00 3.29

Cooling

(A35/W7)

Heating

(A7/W35)

Cooling

(A35/W7)

Heating

(A7/W35)

Outdoor unit PUHZ-HW112YHA2

Phase, Hz 3, 50 1 / 3, 50

Voltage V 400 230 / 400

Electrical circuit

Current A 5.6 4.0 22.2 / 7.6 14.4 / 5.0

Discharge pressure MPa 2.63 2.07 2.81 2.11

Suction pressure MPa 0.78 0.69 0.78 0.66

Discharge temperature ºC 78 64 84 67

Condensing temperature

Refrigerant circuit

Suction temperature ºC 9 5 11 3

Flow volume L/min 28.7 32.1 35.8 40.1

Water

Outlet water temperature

conditions

Intake air

temperature

Outdoor

conditions

The unit of pressure has been changed to MPa based on international SI system.

The conversion factor is: 1 (MPa) = 10.2 (kgf/cm2)

W.B. ºC 24 6 24 6

ºC 46 36 47 37

ºC735735

D.B. ºC 35 7 35 7

PUHZ-HW140VHA2/

PUHZ-HW140YHA2

15

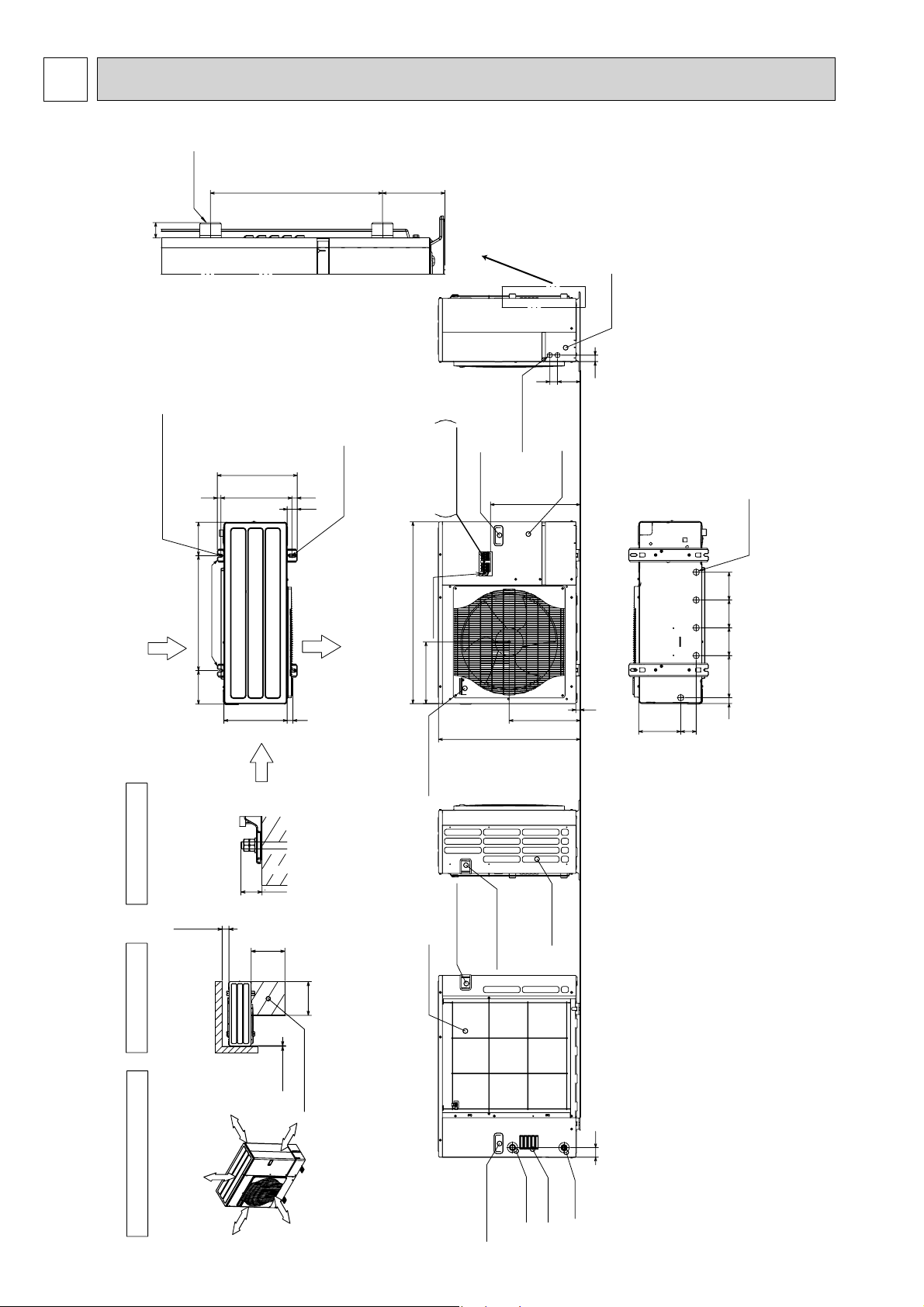

5

OUTLINES AND DIMENSIONS

PUHZ-W50VHA(-BS)

Unit: mm

ISO 228/1-G1 B

24

19

2-U Shaped notched holes

(Foundation Bolt M10)

Rear Air Intake

Installation Feet

417

37028

53

2-12 x 36 oval holes

(Foundation Bolt M10)

Air Discharge

85 269

950

Earth terminal

Detail

Handle for moving

Terminal Connections

Left•••• Power supply wiring

Right•• Controller wiring

27Knock Out)

:

Power supply

wiring hole

(2-

40

469

see Detail

34

119

Service panel

Front cover

Drain hole

(5-:33)

175 175600

Please secure the unit firmly

with 4 foundation (M10) bolts.

(Bolts and washers must be

purchased locally.)

Over300

2 SERVICE SPACE 3 FOUNDATION BOLTS

Dimensions of space needed

for service access are

shown in the below diagram.

33030

Side Air Intake

FOUNDATION

<Foundation bolt height>

30

Less than

500

Over

Over10

500

Over

Service space

322

Handle for moving

Handle for moving

Rear Air Intake

740

Handle for moving

371

Side Air Intake

220 145145145

23

219

30

81

Over 300mm

FREE

1 FREE SPACE (Around the unit)

The diagram below shows a

basic example.

Explanation of particular details are

given in the installation manuals etc.

Over 10mm

Over 10mm

Over 500mm

16

Water OUT

Handle for moving

Air Intake

50

Water IN

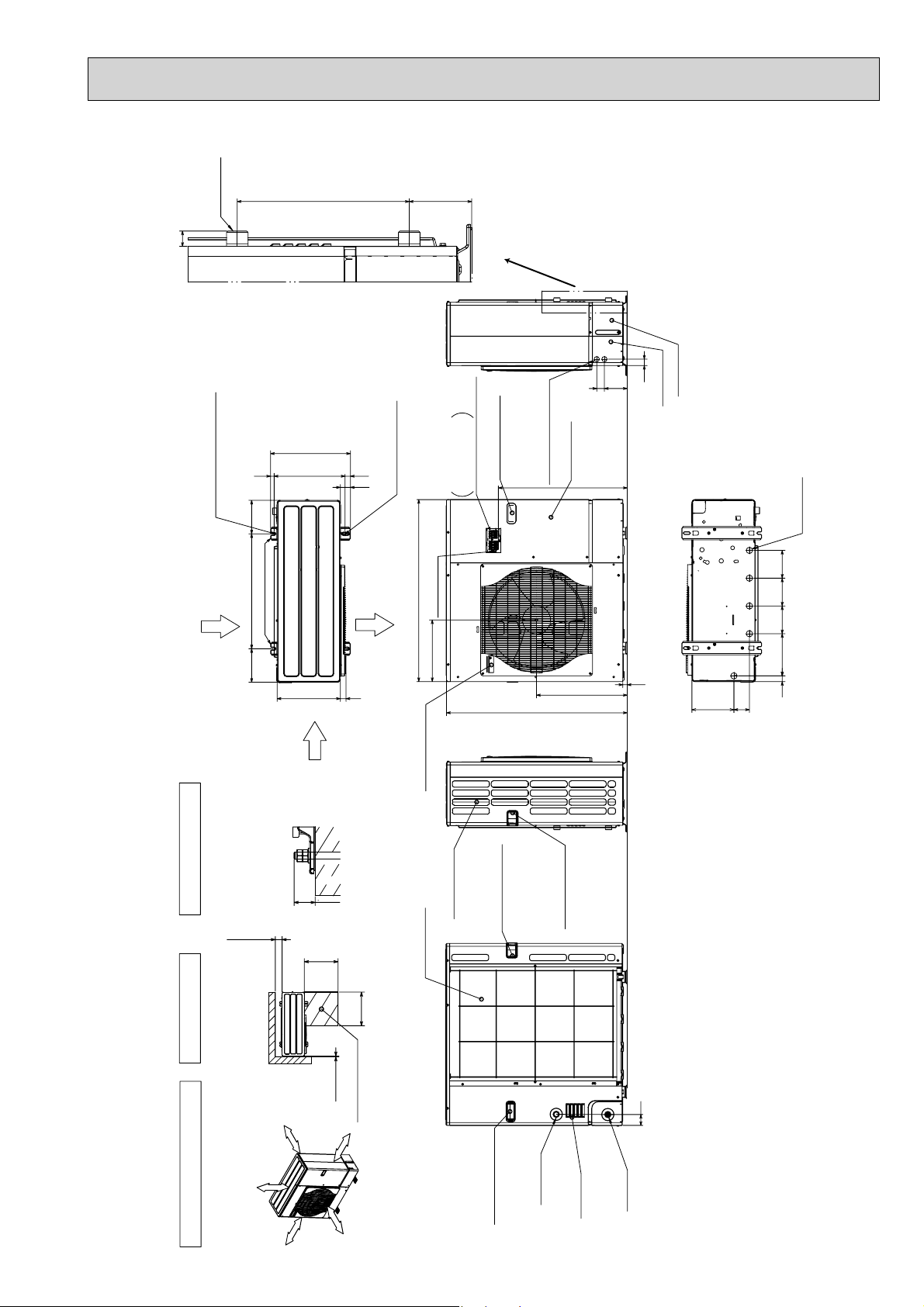

PUHZ-W85VHA(-BS) PUHZ-W85VHAR1(-BS)

Unit: mm

ISO 228/1-G1 B

24

2-U Shaped notched holes

(Foundation Bolt M10)

Rear Air Intake

19

Installation Feet

417

37028

53

2-12 x 36 oval holes

(Foundation Bolt M10)

Air Discharge

950

Earth terminal

98 269

Detail

Handle for moving

Terminal Connections

Left...Power supply wiring

Right...Controller wiring

Power supply wiring hole

(2-:27 knockout)

Service panel

673

See Detail

34

40119

Rear cover

Front cover

Drain hole

(5-:33)

175 175600

Please secure the unit firmly

with 4 foundation (M10) bolts.

(Bolts and washers must be

purchased locally.)

Over300

2 SERVICE SPACE 3 FOUNDATION BOLTS

Dimensions of space needed

for service access are

shown in the below diagram.

FREE

33030

Side Air Intake

FOUNDATION

<Foundation bolt height>

30

500

Less than

Over

500

Over

Over10

Service space

r 300mm

Ove

Ove

r 10mm

322

Handle for moving

Side Air Intake

Rear Air Intake

943

Handle for moving

473

Handle for moving

220 145145145

23

219

57

30

81

1 FREE SPACE (Around the unit)

The diagram below shows a

basic example.

Explanation of particular details are

given in the installation manuals etc.

Over 10mm

Over 500mm

17

Water OUT

Handle for moving

Air Intake

Water IN

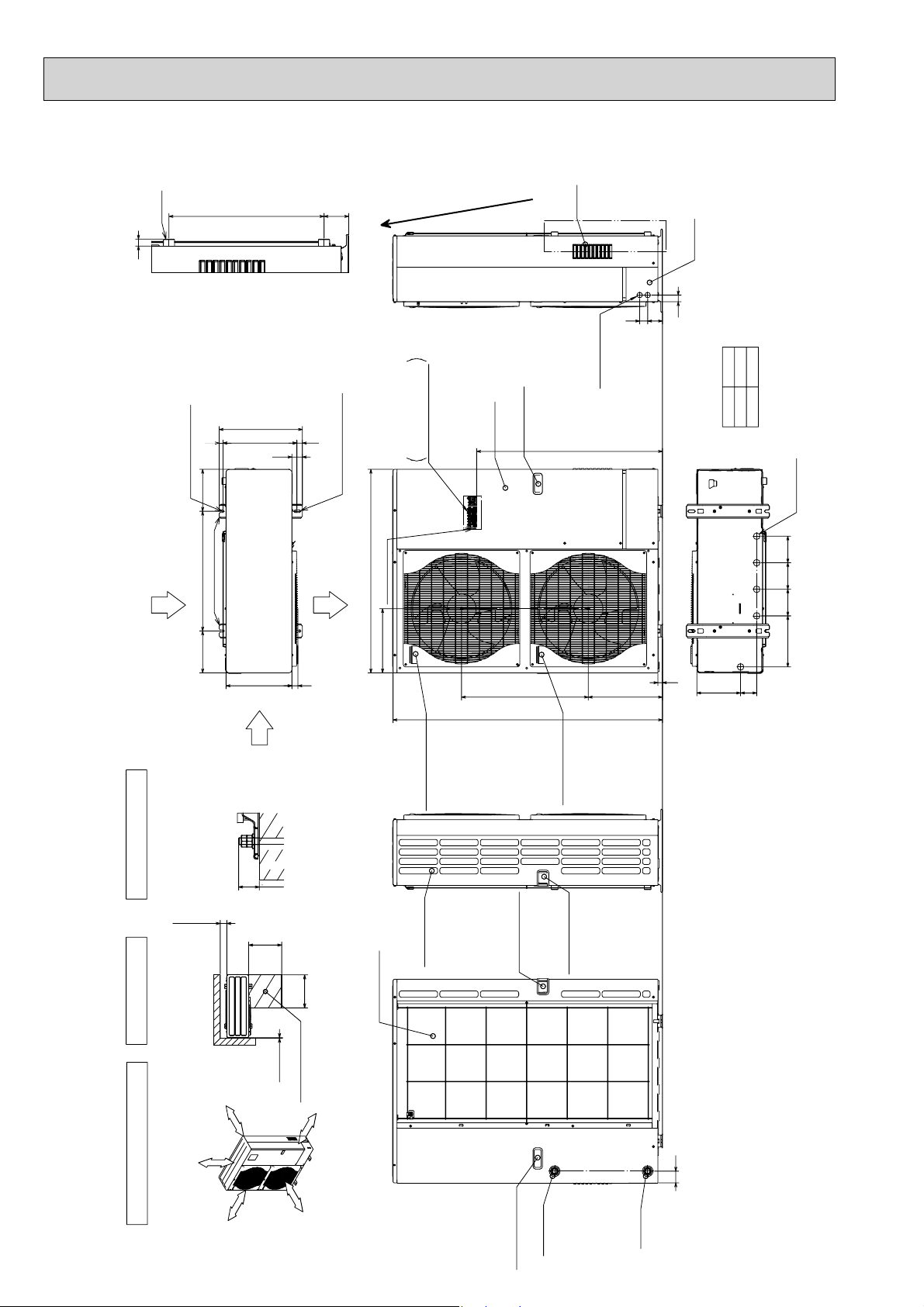

PUHZ-HW112YHA(-BS) PUHZ-HW140VHA(-BS) PUHZ-HW140YHA(-BS)

PUHZ-HW112YHA2(-BS) PUHZ-HW140VHA2(-BS) PUHZ-HW140YHA2(-BS)

see Detail

Air Intake

Front cover

34

74 40

24

ISO 228-1

G1 B

46674

Detail

Unit: mm

2-U Shaped notched holes

(Foundation Bolt M10)

Rear Air Intake

19

210

600

Installation Feet

210

Side Air Intake

417

370

330

53

28

2-12×36 oval holes

(Foundation Bolt M10)

Air Discharge

30

1020

Earth terminal

322

Terminal connections

Left••••• Power supply wiring

Right••• Controller wiring

Handle for moving

Handle for moving

Service panel

635

1350

Handle for moving

27Knock Out)

:

Power supply

wiring hole

(2-

A

371

A

931

1079

VHA

YHA

33)

:

Drain hole

(5-

256 133 133 133

23

81 219

Please secure the unit firmly

with 4 foundation (M10) bolts.

(Bolts and washers must be

2 SERVICE SPACE 3 FOUNDATION BOLTS

Dimensions of space needed

for service access are

shown in the below diagram.

1 FREE SPACE (Around the unit)

The diagram below shows a

basic example.

Explanation of particular details are

<Foundation bolt height>

purchased locally.)

Over300

Over 300mm

FREE

given in the installation manuals etc.

Over 10mm

FOUNDATION

30

Less than

500

Over

Over

Over10

Service space

Over 10mm

500

Over 500mm

Rear Air Intake

Side Air Intake

18

Handle for moving

Handle for moving

Handle for moving

Water OUT

59

Water IN

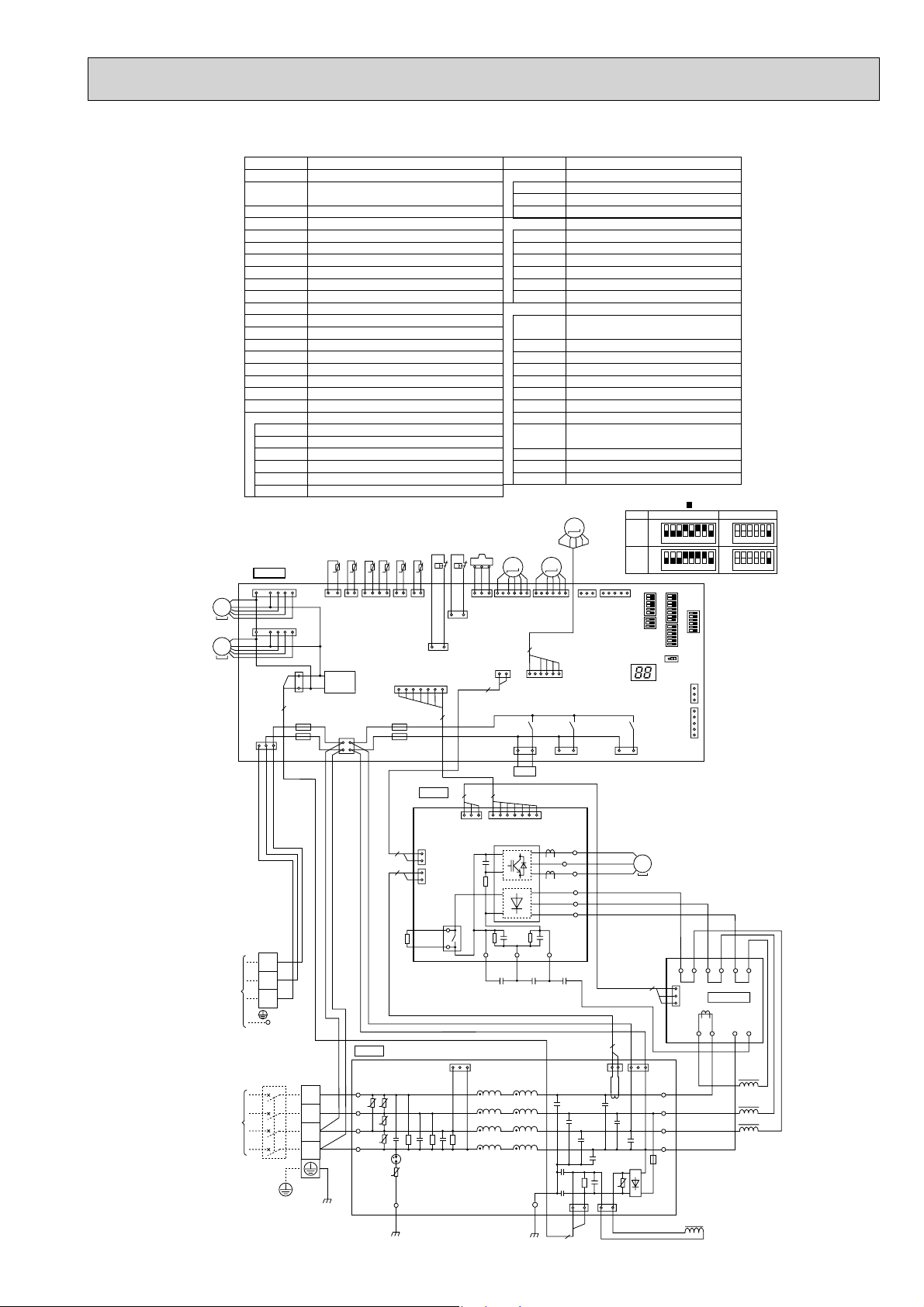

6 WIRING DIAGRAM

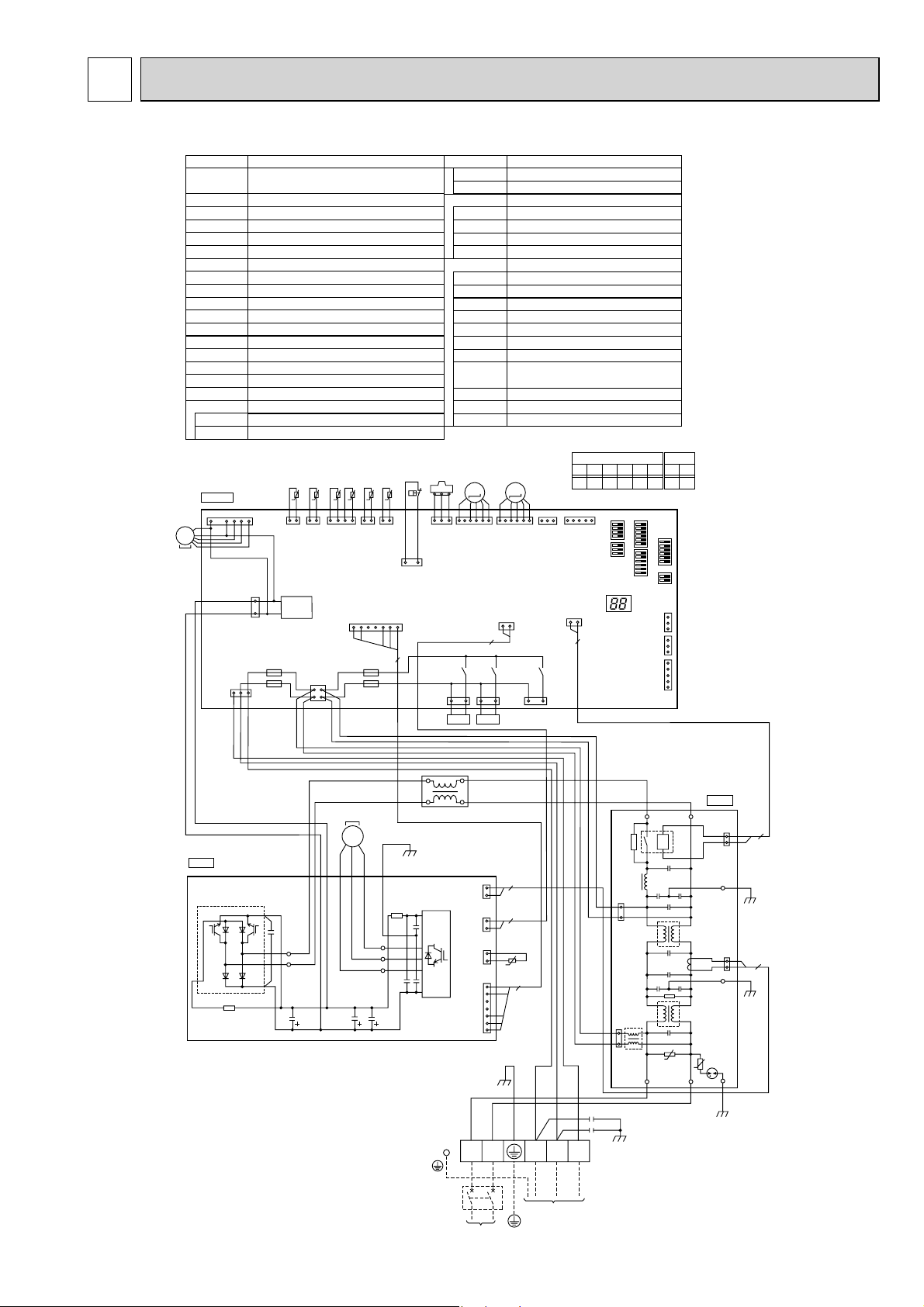

PUHZ-W50VHA(-BS)

SYMBOL NAME SYMBOL NAME

TB1

MC

MF1

21S4

SV Solenoid Valve<Bypass Valve>

63H

63HS

TH3

TH4

TH6

TH7

TH8

TH32 Thermistor<Inlet water>

TH33 Thermistor<Comp Surface>

LEV-A, LEV-B

ACL

CY1,CY2 Capacitor

P. B.

R/S

U/V/W

MF1

MS

3~

Terminal Block

Flow temp. controller>

Motor for Compressor

Fan Motor

Solenoid Valve<Four-Way Valve>

High Pressure Switch

High Pressure Sensor

Thermistor<Liquid>

Thermistor<Discharge>

Thermistor<Plate HEX Iiquid>

Thermistor<Ambient>

Thermistor<Heatsink>

Electronic Expansion Valve

Reactor

Power Circuit Board

Connection Terminal<L/N-Phase>

Connection Terminal<U/V/W-Phase>

TH32

7

3

1

CNDC

(PNK)

1

CNF1

(WHT)

F2

F1

TH33

t°

12

TH33

(YLW)

TRANS

C. B.

1

CNS

(WHT

)

3

<Power Supply,Interface unit /

TH6 TH3 TH4

TH7

t° t° t° t°

t°

12

TH7/6

TH32

(BLK)

CNAC

(WHT)

1

3

TH3

(RED)

(WHT)

CN2

(WHT)

17

F3

2

F4

4

TH4

(WHT)

Main Smoothing CapacitorCB1-3

Power ModulePFC/IPM

N.F.

LI,LO

NI,NO

EI,E2,E3

52C

C.B.

SW1

SW2

SW5

SW6

SW8

SW10

SV1

CNDM

LED3

F1~ F4

X52,X54, X55

63HS

63H

2

1

63H

(YLW)

5

3

21S4

(GRN)

11121

63HS

(WHT

LEV-A

34

LEV-A

(WHT)

)

21S4 SV

Noise Filter Circuit Board

Connection Terminal<L-Phase>

Connection Terminal<N-Phase>

Connection Terminal<Ground>

52C Relay

Controller Circuit Board

Switch<Function Switch>

Switch<Function Switch>

Switch<Function Switch>

Switch<Model Select>

Switch<Function Switch>

Switch<Model Select>

Connector<Connection for Option>

Connector

<Connection

for Option (Contact Input)>

LED<Operation/Inspection Indicators>

Fuse<T6.3AL250V>

Relay

*1 MODEL SELECT

LEV-B

M

M

61

LEV-B

CNVMNT

(RED)

CN4

(WHT)

12

2

X52

X55

SV2

1313

(BLU)

12345 6

00110 0

1=ON, 0=OFF

1

1613

CNMNT

(WHT)

(WHT)

CN52C

(RED)

12

2

X54

SV1

13

(GRY)

SW6

SW10

12

01

*1

5

SW5

SW6

SW8

SW2

SW1

*1

SW10

LED3

1

(WHT)

CN3S

3

1

3

(WHT)

CNDM

1

CN51

(WHT)

5

P. B .

PFC

MS

3

W

V

BLK

TABR

RED

WHT

TABS

CB1 CB2 CB3

~

WHT

MC

U

RED

TABV

TAB W

TABU

RED

WHT

ACL

IPM

RED

WHT

1

CN5

(RED)

2

1

CN4

(WHT)

2

1

CN3

(WHT)

2

1

CN2

(WHT)

7

BLU

RED

N

L

POWER SUPPLY

~ / N 230V 50Hz

2

2

TH8

t°

5

YLW

GRN/YLW

S2 S3

S1

Interface unit /

Flow temp. controller

ORN

BRN

CY1

TB1

CY2

RED

1

3

(RED)

CNAC2

1

3

(WHT)

CNAC1

WHT

N. F.

NO

LO

52C

U

LI

U

NI

1

2

CN52C

E3

CN5

1

2

E2

BLK

EI

(BLK)

BLK

(RED)

BLK

2

2

19

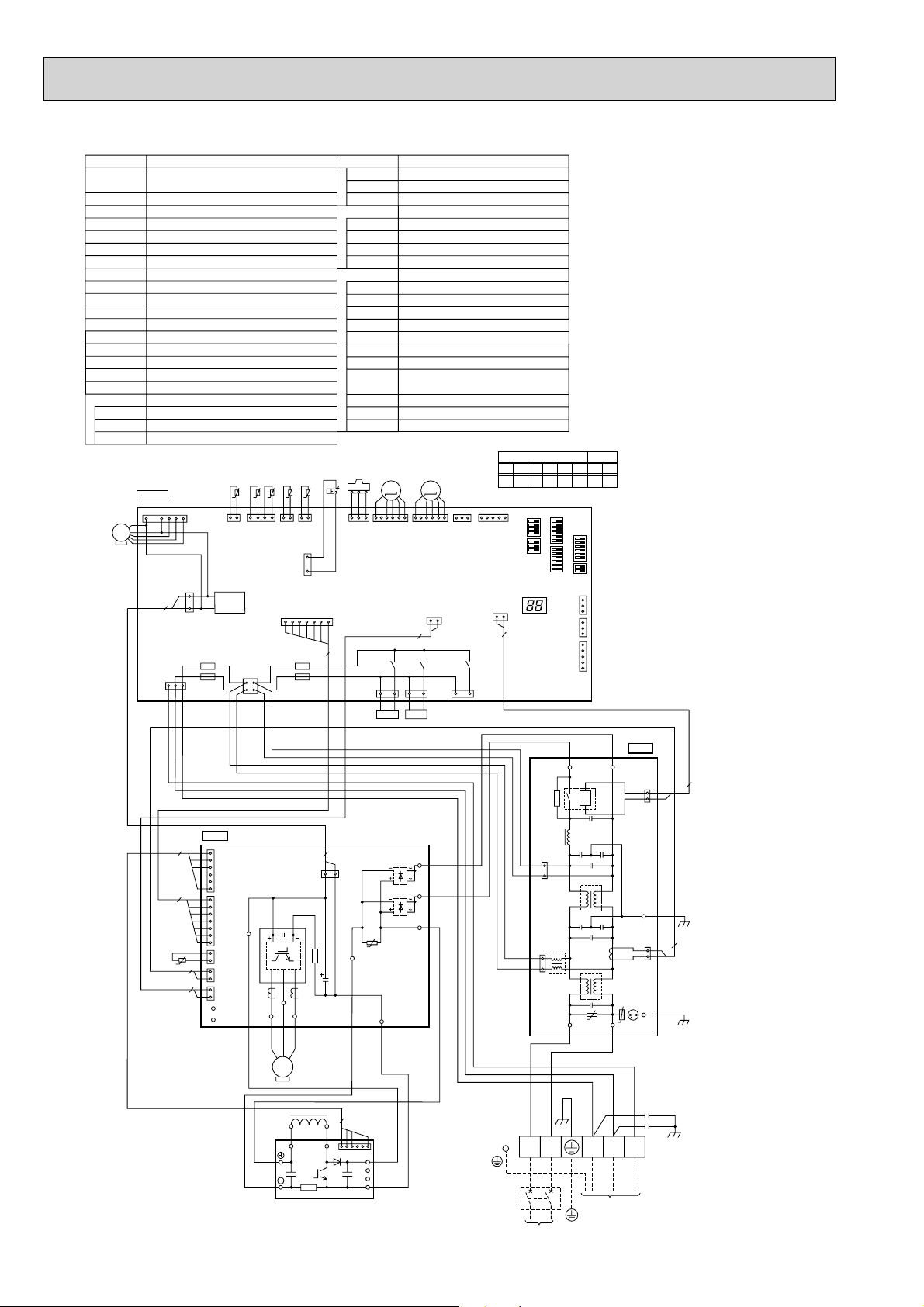

PUHZ-W85VHA(-BS)

SYMBOL NAME SYMBOL NAME

TB1

MC

MF1

21S4

SV Solenoid Valve <Bypass Valve>

63H

63HS

TH3

TH4

TH6

TH7

TH8

TH32 Thermistor <Inlet water>

LEV-A, LEV-B

DCL

ACTM Active Filter Module

CY1,CY2 Capacitor

P. B.

TABU/V/W

TABS/T

TABP1/P2

Terminal Block <Power Supply,Interface unit /

Flow temp. controller>

Motor for Compressor

Fan Motor

Solenoid Valve <Four-Way Valve>

High Pressure Switch

High Pressure Sensor

Thermistor <Liquid>

Thermistor <Discharge>

Thermistor <Plate HEX Liquid>

Thermistor <Ambient>

Thermistor <Heatsink>

Electronic Expansion Valve

Reactor

Power Circuit Board

Connection Terminal <U/V/W-Phase>

Connection Terminal <L/N-Phase>

Connection Terminal <DC Voltage>

C. B.

1

7

CNS

CNF1

(WHT)

3

2

1

CNDC

(PNK)

F2

F1

)

1

3

MF1

MS

3~

(WHT

TH32

12

TH32

(BLK)

TRANS

TH7

t° t° t° t°

t°

TH7/6

(RED)

CNAC

(WHT)

1

3

TH6 TH3 TH4

TH3

(WHT)

(WHT)

1

3

63H

(YLW)

CN2

(WHT)

17

F3

2

F4

4

TH4

2

63H

7

TABN1/N2

N.F.

LI,LO

NI,NO

EI,E2

52C

C.B.

SW1

SW2

SW5

SW6

SW8

SW10

SV1

CNDM

LED3

F1~ F4

X52,X54, X55

63HS

34

11121

63HS

(WHT

)

21S4

(GRN)

Connection Terminal <DC Voltage>

Diode bridgeDS2, DS3

Power ModuleIPM

Noise Filter Circuit Board

Connection Terminal <L-Phase>

Connection Terminal <N-Phase>

Connection Terminal <Ground>

52C Relay

Controller Circuit Board

Switch <Function Switch>

Switch <Function Switch>

Switch <Function Switch>

Switch <Model Select>

Switch <Function Switch>

Switch <Model Select>

Connector <Connection for Option>

Connector

<Connection

for Option(Contact Input)>

LED <Operation/ Inspection Indicators>

Fuse <T6.3AL250V>

Relay

*

LEV-A

LEV-B

M

LEV-A

(WHT)

X52

21S4 SV

LEV-B

(RED)

2

M

CN4

(WHT)

12

X55

SV2

1313

(BLU)

61

CNVMNT

(WHT)

1=ON, 0=OFF

1

1613

CNMNT

(WHT)

CN52C

(RED)

12

2

X54

SV1

13

(GRY)

1 MODEL SELECT

SW 6

12345 6

00101 0

1

*

5

SW5

SW6

SW8

SW2

SW1

SW10

*1

1

CN3S

(WHT)

CNDM

(WHT)

CN51

(WHT)

3

1

3

1

5

LED3

SW10

12

00

7

TH8

t°

N. F.

BLU

WHT

NO

LO

52C

P. B .

4

1

CNAF

(WHT)

6

1

CN2

IPM

(WHT)

7

TAB P2

RED

1

CN3

(WHT)

2

2

1

CN5

(RED)

2

2

1

CN4

(WHT)

2

TAB N

TAB P

TAB U

RED

U

RED

BLK

V

MS

3

DCL

TAB V

WHT

~

BLK

W

WHT

CNDC

(PNK)

MC

L1

TAB W

2

1

L2

ACTM

3

4

WHT

16

TAB T

WHT

TAB S

TABP1

BLU

WHT

RED

DS3

DS2

U

TAB N1

BLK

TAB N2

RED

P

N1

N2

WHT

Io

3

1

(RED)

CNAC2

3

1

(WHT)

CNAC1

BLU

RED

N

L

POWER SUPPLY

~ / N 230V 50Hz

U

LI

RED

YLW

GRN/YLW

S1

Interface unit /

Flow temp. controller

NI

U

BLU

ORN

S2 S3

BRN

1

2

CN52C

E2

1

2

CN5

EI

2

(BLK)

BLK

2

(RED)

BLK

CY1

CY2

TB1

20

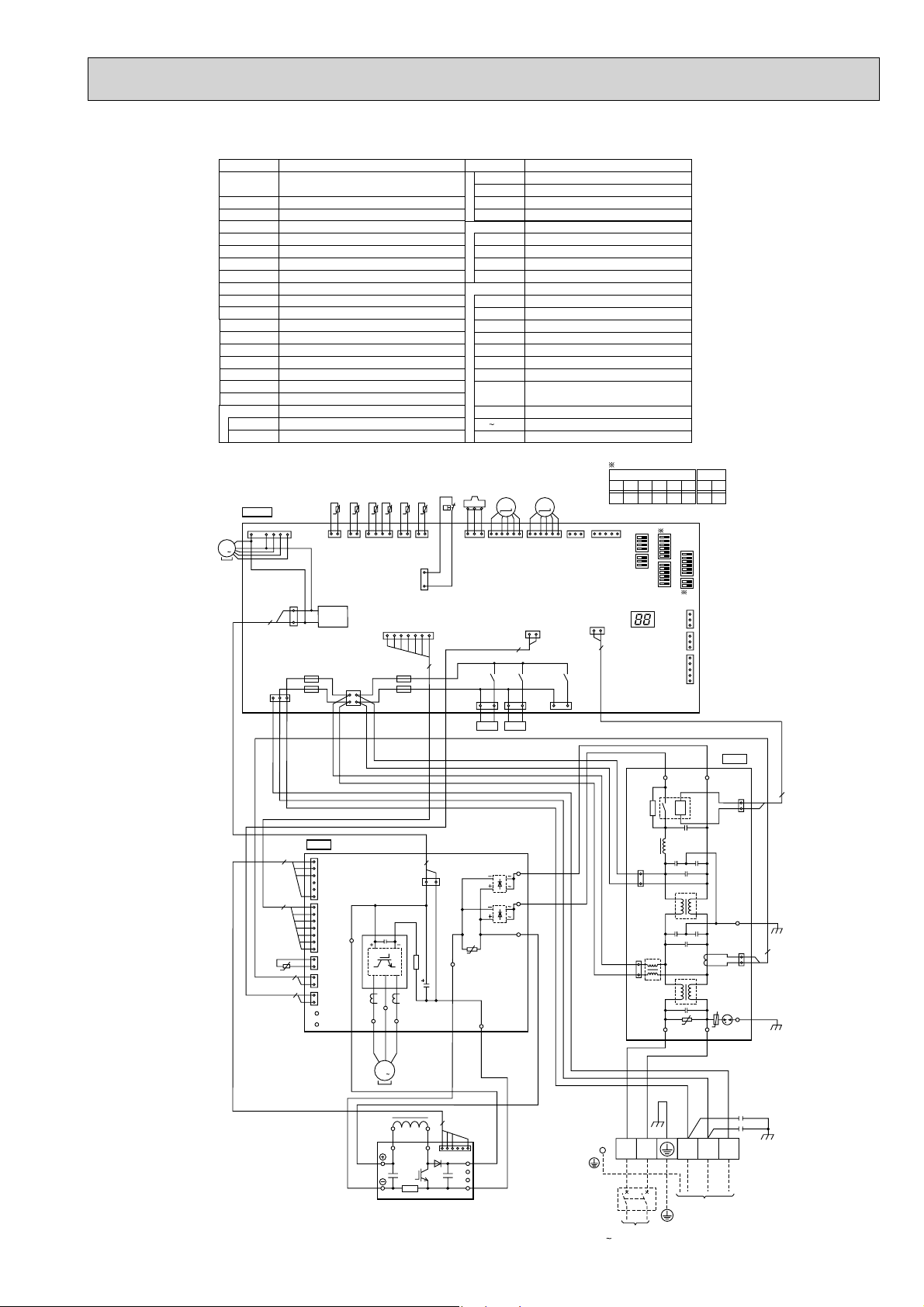

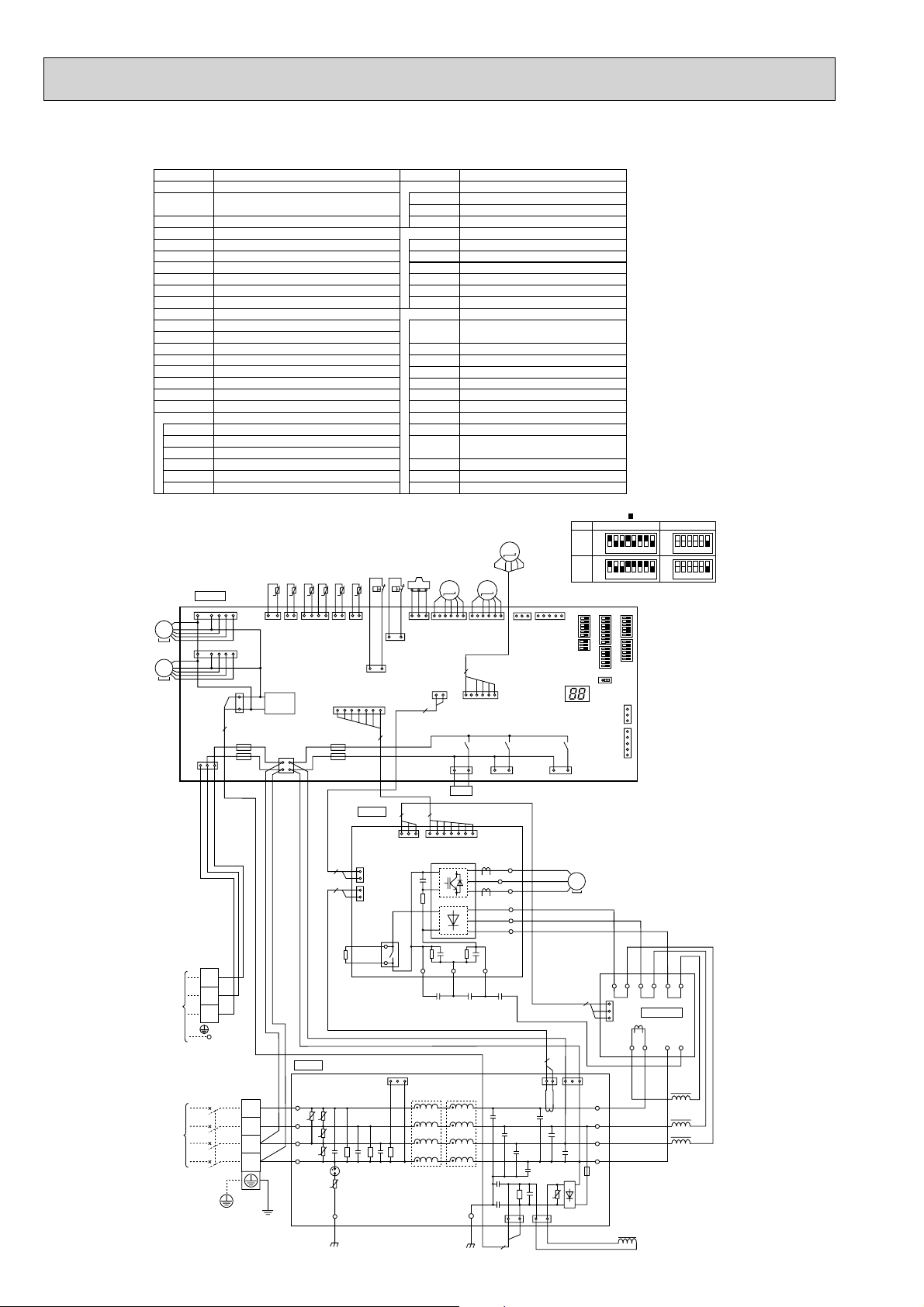

PUHZ-W85VHAR1(-BS)

SYMBOL NAME SYMBOL NAME

TB1

MC

MF1

21S4

SV Solenoid Valve <Bypass Valve>

63H

63HS

TH3

TH4

TH6

TH7

TH8

TH32 Thermistor <Inlet water>

TH33 Thermistor <Comp Surface>

LEV-A, LEV-B

DCL

ACTM

CY1,CY2

P. B.

TABU/V/W

TABS/T

C. B.

1

MF1

MS

3

2

CNS

(WHT)

3

Terminal Block <

Flow temp. controller>

Motor for Compressor

Fan Motor

Power Supply,Interface unit /

Solenoid Valve <Four-Way Valve>

High Pressure Switch

High Pressure Sensor

Thermistor <Liquid>

Thermistor <Discharge>

Thermistor <Plate HEX Iiquid>

Thermistor <Ambient>

Thermistor <Heat sink>

Electronic Expansion Valve

Reactor

Active Filter Module

Capacitor

Power Circuit Board

Connection Terminal

Connection Terminal <L/N-Phase>

7

CNF1

(WHT)

3

1

CNDC

(PNK)

F2

F1

1

TH33

t°

12

TH33

(YLW)

TRANS

TH32

12

TH32

(BLK)

CNAC

(WHT)

1

3

t°

2

4

<

U/V/W-Phase>

TH6 TH3 TH4

TH7

t° t° t° t°

TH7/6

TH3

(RED)

(WHT)

CN2

(WHT)

17

F3

F4

TH4

(WHT)

1

3

63H

(YLW)

7

TABP1/P2

TABN1/N2

DS2, DS3

IPM

N.F.

LI,LO

NI,NO

EI,E2

52C

C.B.

SW1

SW2

SW5

SW6

SW8

SW10

SV1

CNDM

LED3

F1 F4

X52,X54, X55

63HS

63H

34

11121

2

63HS

(WHT)

21S4

(GRN)

21S4 SV

Connection Terminal

Connection Terminal <DC Voltage>

Diode bridge

Power Module

Noise Filter Circuit Board

Connection Terminal

Connection Terminal <N-Phase>

Connection Terminal

52C Relay

Controller Circuit Board

<

Function Switch>

Switch

Switch

<

Function Switch>

Switch

<

Function Switch>

Switch <Model Select>

<

Function Switch>

Switch

<

Model Select>

Switch

Connector

Connector

<

Connection

LED <Operation/Inspection Indicators>

<

T6.3AL250V>

Fuse

Relay

LEV-A

LEV-B

M

M

CN4

(WHT)

12

X55

SV2

1313

(BLU)

LEV-B

(RED)

61

CNVMNT

LEV-A

(WHT)

X52

2

<

DC Voltage>

<

L-Phase>

<

Ground>

<

Connection for Option>

for Option(Contact Input)

1 MODEL SELECT

12345 6

00101 0

1=ON, 0=OFF

5

1

1613

(WHT)

CN52C

X54

SV1

13

(GRY)

CNMNT

(RED)

12

2

(WHT)

SW5

SW8

LED3

SW6

SW6

SW1

CNDM

1

CN3S

(WHT)

(WHT)

CN51

(WHT)

>

SW2

SW10

1

1

3

1

3

1

5

SW10

12

01

N. F.

BLU

WHT

NO

LO

52C

P. B .

4

1

CNAF

(WHT)

6

7

1

CN2

IPM

(WHT)

7

1

CN3

(WHT)

2

1

CN5

(RED)

2

1

CN4

(WHT)

2

TABN

TABP

TABP2

RED

TAB U

RED

U

RED

BLK

TH8

t°

2

2

V

DCL

MS

3

TAB V

WHT

BLK

W

WHT

CNDC

MC

L1

(PNK)

TAB W

2

1

L2

ACTM

3

4

WHT

16

TABT

WHT

TABS

TABP1

BLU

WHT

RED

DS3

DS2

U

TAB N1

BLK

TAB N2

RED

P

N1

N2

WHT

Io

3

1

(RED)

CNAC2

3

1

(WHT)

CNAC1

BLU

RED

N

L

POWER SUPPLY

/ N 230V 50Hz

U

LI

RED

YLW

GRN/YLW

S1

Interface unit /

Flow temp. controller

NI

U

BLU

ORN

S2 S3

BRN

1

2

E2

1

2

EI

(BLK)

CN52C

CN5

(RED)

CY1

CY2

TB1

2

BLK

2

BLK

21

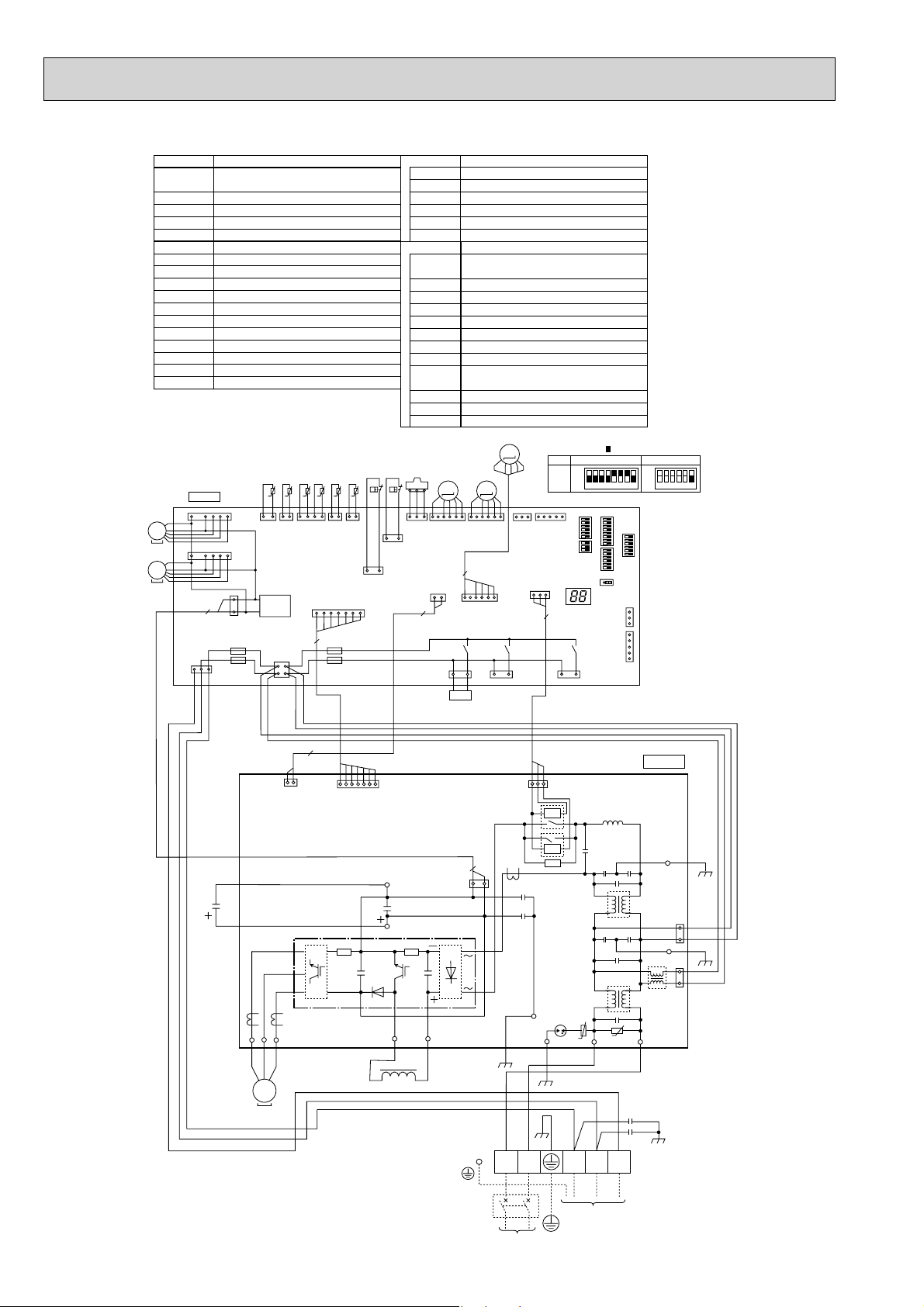

PUHZ-HW140VHA(-BS)

SYMBOL NAME

TB1

MC

MF1,MF2

21S4

63H

63L Low Pressure Switch

63HS

TH3

TH4

TH6 Thermistor<Plate HEX Liquid>

TH7

TH32 Thermistor<Return Water>

TH33 Thermistor<Suction>

LEV-A, LEV-B, LEV-C

DCL

CB Main Smoothing Capacitor

CY1,CY2 Capacitor

MF1

MS

3~

MF2

MS

3~

Terminal Block

Flow Temp. controller-Outdoor>

Motor for Compressor

Fan Motor

Solenoid Valve<Four-Way Valve>

High Pressure Switch

High Pressure Sensor

Thermistor<Liquid>

Thermistor<Discharge>

Thermistor<Ambient>

Electronic Expansion Valve

Reactor

C. B.

1

1

CNS

(WHT

CNF1

(WHT)

7

CNF2

(WHT)

7

3

2

1

CNDC

(PNK)

F2

)

F1

1

3

<Power Supply, Interface unit /

TH6TH3 TH4

TH32

TH33

TH7

t° t° t° t°

t°

t°

4

1121

12

13

TH33

(YLW)

TRANS

CNAC

(WHT)

1

3

TH32

(BLK)

2

4

2

TH7/6

TH3

(RED)

TH4

(WHT)

(WHT)

CN2

(WHT)

17

7

F3

F4

63H

1

(YLW)

63H

63L

1

63L

(RED)

3

P. B.

U/V/W

LI

NI

DCL1,DCL2

IGBT

EI,E2,E3,E4

C.B.

SW1

SW2

SW5

SW6

SW8

CN31

SS

SV1

CNDM

LED3

F1,F2,F3,F4

X51,X52, X54

63HS

3

1

3

63HS

(WHT

)

CN4

(WHT)

12

2

21S4

(GRN)

Power Circuit Board

Connection Terminal<U/V/W-Phase>

Connection Terminal<L-Phase>

Connection Terminal<N-Phase>

Connection Terminal<Reactor>

Power Module

Connection Terminal<Ground>

Controller Circuit Board

Switch<Manual Defrost, Defect History

Record Reset, Function Switch>

Switch<Function Switch>

Switch<Function Switch,Model Select>

Switch<Model Select>

Switch<Function Switch>

Connector<Emergency Operation>

Connector<Connection for Option>

Connector<Connection for Option>

Connector

<Connection

for Option(Contact Input)>

LED<Operation/Inspection Indicators>

Fuse<T6.3AL250V>

Relay

LEV-C

LEV-BLEV-A

M

M

M

*

The black square ( )

MODEL

*

1

1613

5

LEV-B

(RED)

LEV-C

(BLU)

X52

61

61

CNVMNT

(WHT)

X54

SV1

1313

(GRY)

CN52C

(RED)

1

CNMNT

(WHT)

3

3

LEV-A

(WHT)

21S4

1 MODEL SELECT

140V

2. SW5 -1 to 5 : Function Switch

5

LED3

SW6

ON

OFF

12345678

2

SW5SW8

CN31

X51

SS

13

(WHT)

indicates a switch position.

ON

OFF

*1*

SW6SW1

SW2

1

(WHT)

3

CNDM

1

CN51

(WHT)

5

SW5-6*2

123456

2

P. B.

RED

1

BLU

BLK

E4

EI

CN52C

(RED)

3

52C

52C

BLK

E3

(RED)

CNAC2

1

3

BLK

E2

1

RED

3

WHT

(WHT)

CNAC1

U

BRN

CY1

CY2

LINI

U

YLW

GRN/YLW

ORN

TB1

2

1

CN4

(WHT)

WHT

CB

RED

W

U

V

BLK

RED

WHT

V

W

U

MS

3~

7

1

CN2

(WHT)

2

DCL2

DCL

DCL1

CNDC

(PNK)

IGBT

3

1

BLK

N2

P2

MC

L N S1 S2 S3

POWER SUPPLY

~/N 230V 50Hz

22

Interface unit /

Flow Temp. controller

PUHZ-HW112YHA(-BS) PUHZ-HW140YHA(-BS)

SYMBOL NAME SYMBOL NAME

TB1 Terminal Block

TB2

MC

MF1,MF2

21S4

63H

63L Low Pressure Switch

63HS

TH3

TH4

TH6

TH7

TH32 Thermistor<Inlet Water>

TH33 Thermistor<Suction>

LEV-A, LEV-B, LEV-C

ACL1/2/3/4

RS

CB1,CB2

CK

P. B.

TB-U/V/W

TB-L1/L2/L3

TB-P2

TB-C1

TB-N1

X52A

C. B.

1

MF1

MS

3~

MF2

1

MS

3~

CNS

(WHT

)

3

Terminal Block

controller-Outdoor>

Motor for Compressor

Fan Motor

Solenoid Valve<Four-Way Valve>

High Pressure Switch

High Pressure Sensor

Thermistor<Liquid>

Thermistor<Discharge>

Thermistor<Plate HEX Liquid>

Thermistor<Ambient>

Electronic Expansion Valve

Reactor

Rush Current Protect Resistor

Main Smoothing Capacitor

Capacitor

Power Circuit Board

Connection Terminal<U/V/W-Phase>

Connection Terminal<L1/L2/L3-Power Supply>

Connection Terminal

Connection Terminal

Connection Terminal

52C Relay

TH33

CNF1

(WHT)

7

13

TH33

(YLW)

CNF2

(WHT)

7

3

TRANS

1

CNDC

2

(PNK)

F2

F1

1

<Power Supply>

<Interface unit /Flow Temp.

TH7

TH6 TH3 TH4

TH32

t° t° t° t°

t°

t°

4

12

112

TH7/6

TH32

(RED)

(WHT)

(BLK)

CNAC

(WHT)

2

1

3

4

63H

63L

12

TH4

(WHT)

CN2

(WHT)

1

(YLW)

P.B .

63H

1

63L

(RED)

3

7

TH3

17

F3

F4

63HS

3

1

3

63HS

(WHT

)

CN4

(WHT)

12

2

21S4

(GRN)

37

N.F.

LI1/LI2/LI3/NI

LO1/LO2/LO3/NO

GD1,GD3

CONV.B.

L1-A1/IN

L1-A2/OU

L2-A2/OU

L3-A2/OU

N-IN

CK-OU

C.B.

SW1

SW2

SW5

SW6

SW8

CN31

SS

SV1

CNDM

LED3

F1,F2,F3,F4

X51,X52, X54

LEV-B

LEV-A

M

LEV-A

LEV-B

(WHT)

(RED)

5

LEV-C

(BLU)

X52

21S4

Noise Filter Circuit Board

Connection Terminal<L1/L2/L3/N-Power Supply>

Connection Terminal<L1/L2/L3/N-Power Supply>

Connection Terminal<Ground>

Converter Circuit Board

Connection Terminal<L1-Power Supply>

Connection Terminal<L1-Power Supply>

Connection Terminal<L2-Power Supply>

Connection Terminal<L3-Power Supply>

Connection Terminal<N-Power Supply>

Connection Terminal

Controller Circuit Board

Switch<Manual Defrost, Defect History

Record Reset, Function Switch>

Switch<Function Switch>

Switch<Function Switch,Model Select>

Switch<Model Select>

Switch<Function Switch>

Connector<Emergency Operation>

Connector<Connection for Option>

Connector<Connection for Option>

Connector

<Connection

LED<Operation/Inspection Indicators>

Fuse<T6.3AL250V>

Relay

LEV-C

M

M

1613

61

CNVMNT

61

1313

for Option (Contact Input)>

*1 MODEL SELECT

The black square ( )

MODEL

112Y

140Y

*2. SW5 -1 to 5 : Function Switch

5

1

CNMNT

(WHT)

(WHT)

X54

SV1

(GRY)

LED3

13

(WHT)

SW5SW8

X51

SS

ON

OFF

ON

OFF

SW6

12345678

12345678

*1*2

SW6SW1

CN31

CNDM

CN51

indicates a switch position.

SW5-6 *2

ON

OFF

123456

ON

OFF

123456

SW2

1

(WHT)

3

1

(WHT)

5

Interface

unit /

Flow temp.

controller

POWER

SUPPLY

3N~

400V 50Hz

TB2

31

CN7

2

1

2

1

RED

RED

CNAC1

(WHT)

CN4

(WHT)

CN5

(RED)

X52A

(WHT)

TB-P2

RED

1

3

2

2

RS

BRN

TB1

ORN

L1

L2

L3

N

YLW

N.F.

LI1

RED

LI2

WHT

BLK

BLU

GRN/YLW

UU

LI3

U

NI

U

U

GD1

BLK

S1

S2

S3

71

CN2

(WHT)

+

-

+

-

+

+

TB-N1

TB-C1

WHT

GD3

BLK

BLK

CNDC

(PNK)

++

CB1 CB2 CK

TB-W

TB-V

TB-L3

TB-L2

TB-L1

2

TB-U

BLK

W

MC

WHT

MS

V

3~

U

RED

BLK

WHT

RED

BLK

BLK

WHT

WHT

RED

RED

L2-A2

L2-OU

L1-IN

BLU

L1-OU

N-IN

ACL1

ACL2

ACL3

L1-A2

CK-OU

BLK

L3-A2

L3-OU

3

3

CONV.B.

CN7

1

(WHT)

CNAC2

(RED)

LO1

LO2

LO3

NO

RED

WHT

BLK

BLU

ACL4

L1-A1

RED

RED

2

CNCT

(RED)

+

1

3

3

BRN

3

1

1

2

+

U

--

1

CNL

(BLU)

WHT

23

PUHZ-HW112YHA2(-BS) PUHZ-HW140YHA2(-BS)

SYMBOL NAME SYMBOL NAME

TB1 Terminal Block

TB2

MC

MF1,MF2

21S4

63H

63L Low Pressure Switch

63HS

TH3

TH4

TH6

TH7

TH32 Thermistor<Inlet Water

TH33 Thermistor<Suction

LEV-A, LEV-B, LEV-C

ACL1/2/3/4

RS

CB1,CB2

CK

P. B.

TB-U/V/W

TB-L1/L2/L3

TB-P2

TB-C1

TB-N1

X52A

MF1

MS

3~

MF2

MS

3~

Terminal Block

controller-Outdoor>

Motor for Compressor

Fan Motor

Solenoid Valve

High Pressure Switch

High Pressure Sensor

Thermistor <Liquid

Thermistor<Discharge

Thermistor<Plate HEX Liquid

Thermistor<Ambient

Electronic Expansion Valve

Reactor

Rush Current Protect Resistor

Main Smoothing Capacitor

Capacitor

Power Circuit Board

Connection Terminal <U/V/W-Phase

Connection Terminal<L1/L2/L3-Power Supply

Connection Terminal

Connection Terminal

Connection Terminal

52C Relay

C. B.

1

1

3

1

CNDC

2

(PNK

CNS

(WHT

)

1

3

7

7

<

Power Supply>

<

Interface unit /Flow Temp.

<

TH32

TH33

t°

CNF1

(WHT

)

12

13

TH32

TH33

(

(

YLW)

CNF2

(WHT

)

TRANS

)

F2

CNAC

(WHT

1

F1

3

Four-Way Valve

>

>

>

>

>

TH7

TH6 TH3 TH4

t° t° t° t°

t°

4

112

TH7/6

TH3

(

RED)

(

WHT

BLK)

17

F3

)

2

F4

4

>

>

TH4

)(WHT)

CN2

(WHT

>

12

1

63H

(

)

P.B .

63H

YLW)

7

N.F.

LI1/LI2/LI3/NI

LO1/LO2/LO3/NO

GD1,GD3

CONV.B.

L1-A1/IN

L1-A2/OU

L2-A2/OU

L3-A2/OU

N-IN

CK-OU

C.B.

SW1

SW2

SW5

SW6

SW7

SW8

CN31

SS

SV1

>

CNDM

LED3

F1,F2,F3,F4

X51,X52, X54

63L

63HS

1

1

3

63HS

(WHT

63L

(

RED)

3

37

Noise Filter Circuit Board

Connection Terminal<L1/L2/L3/N-Power Supply

Connection Terminal<L1/L2/L3/N-Power Supply

Connection Terminal <Ground

Converter Circuit Board

Connection Terminal<L1-Power Supply

Connection Terminal<L1-Power Supply

Connection Terminal<L2-Power Supply

Connection Terminal<L3-Power Supply

Connection Terminal<N-Power Supply

Connection Terminal

Controller Circuit Board

Switch <Manual Defrost, Defect History

Record Reset, Function Switch

Switch <Function Switch

Switch <Function Switch,Model Select

Switch <Model Select

Switch <Function Switch

Switch <Function Switch

Connector <Emergency Operation

Connector <Connection for Option

Connector <Connection for Option

Connector

<Connection

LED <Operation/Inspection Indicators

Fuse <T6.3AL250V

Relay

LEV-A

M

3

LEV-A

(WHT

)

)

5

CN4

(WHT

)

12

2

21S4

(GRN

)

21S4

LEV-B

LEV-B

(RED

LEV-C

(BLU

X52

LEV-C

M

M

61

CNVMNT

)

(WHT)

61

)

1313

for Option(Contact Input)>

1613

X54

SV1

(GRY

1

)

>

CNMNT

(WHT)

>

>

>

>

The black square ( )

5

LED3

13

>

>

>

>

>

>

>

>

>

>

>

>

>

>

+1 MODEL SELECT

MODEL

112Y

140Y

+2. SW5 -1 to 5 : Function Switch

SW5SW8

X51

SS

(WHT

)

ON

OFF

12345678

ON

OFF

12345678

+1+2

SW6SW1

CN31

)

(WHT

CNDM

CN51

SW6

SW7SW2

1

3

1

)

(WHT

5

indicates a switch position.

ON

OFF

ON

OFF

SW5-6 +2

123456

123456

Interface

unit /

Flow temp.

controller

POWER

SUPPLY

3N~

400V 50Hz

TB2

31

CN7

(

WHT

CN4

WHT

CN5

RED

X52A

)

)

)

RED

1

3

2

2

(

1

2

2

(

1

RED

RS

RED

CNAC1

(

WHT)

UU

U

U

U

GD1

BLK

ORN

BRN

TB1

YLW

N.F.

LI1

RED

L1

L2

L3

LI2

WHT

LI3

BLK

NI

BLU

N

GRN/YLW

S1

S2

S3

71

CN2

(

WHT

)

+

--

+

--

+

+

TB-P2

TB-C1

WHT

++

CB1 CB2 CK

GD3

BLK

TB-V

TB-L3

TB-L2

TB-L1

TB-N1

BLK

CNDC

(

PNK)

TB-W

TB-U

2

BLK

W

MC

WHT

MS

V

3~

U

RED

BLK

WHT

RED

BLK

BLK

L3-OU

3

3

CN7

1

CNAC2

(

RED

LO1

LO2

LO3

NO

)

L1-A1

RED

RED

WHT

BLK

BLU

ACL4

2

CNCT