Mitsubishi Electric PUHZ-SHW230YKA2 Service Manual

SERVICE MANUAL

CONTENTS

TECHNICAL CHANGES

......................................

2

1. SAFETY PRECAUTION

...................................

3

2. SPECIFICATIONS

............................................

5

3. DATA

...............................................................

7

4. OUTLINES AND DIMENSIONS

.......................

9

5. WIRING DIAGRAM

........................................

10

6. WIRING SPECIFICATIONS

...........................

12

7. REFRIGERANT SYSTEM DIAGRAM

...........

14

8. TROUBLESHOOTING

...................................

15

9. DISASSEMBLY PROCEDURE

......................

57

Note:

• This manual describes

service data of the outdoor

unit only.

R410A

PARTS CATALOG (OCB594)

[Model Name]

PUHZ-SHW230YKA2

[Service Ref.]

PUHZ-SHW230YKA2

PUHZ-SHW230YKA2R1

PUHZ-SHW230YKA2R2

SPLIT-TYPE, AIR CONDITIONER

No. OCH594

REVISED EDITION-B

December 2018

OCH594 REVISED EDITION-A

is void.

Revision:

• Added

PUHZ-SHW230YKA2R2

in REVISED EDITION-B.

• Some descriptions have

been modified.

2

OCH594B

TECHNICAL CHANGES

Service ref. have been changed as follows.

PUHZ-SHW230YKA2

PUHZ-SHW230YKA2R1

• A compliance with ErP directive Lot6 has been authorized.

PUHZ-SHW230YKA2R1 PUHZ-SHW230YKA2R2

• Power board, controller board and noise filter board have been changed.

• Quantity of refrigerant has been changed.

• Unit weight has been changed.

3

OCH594B

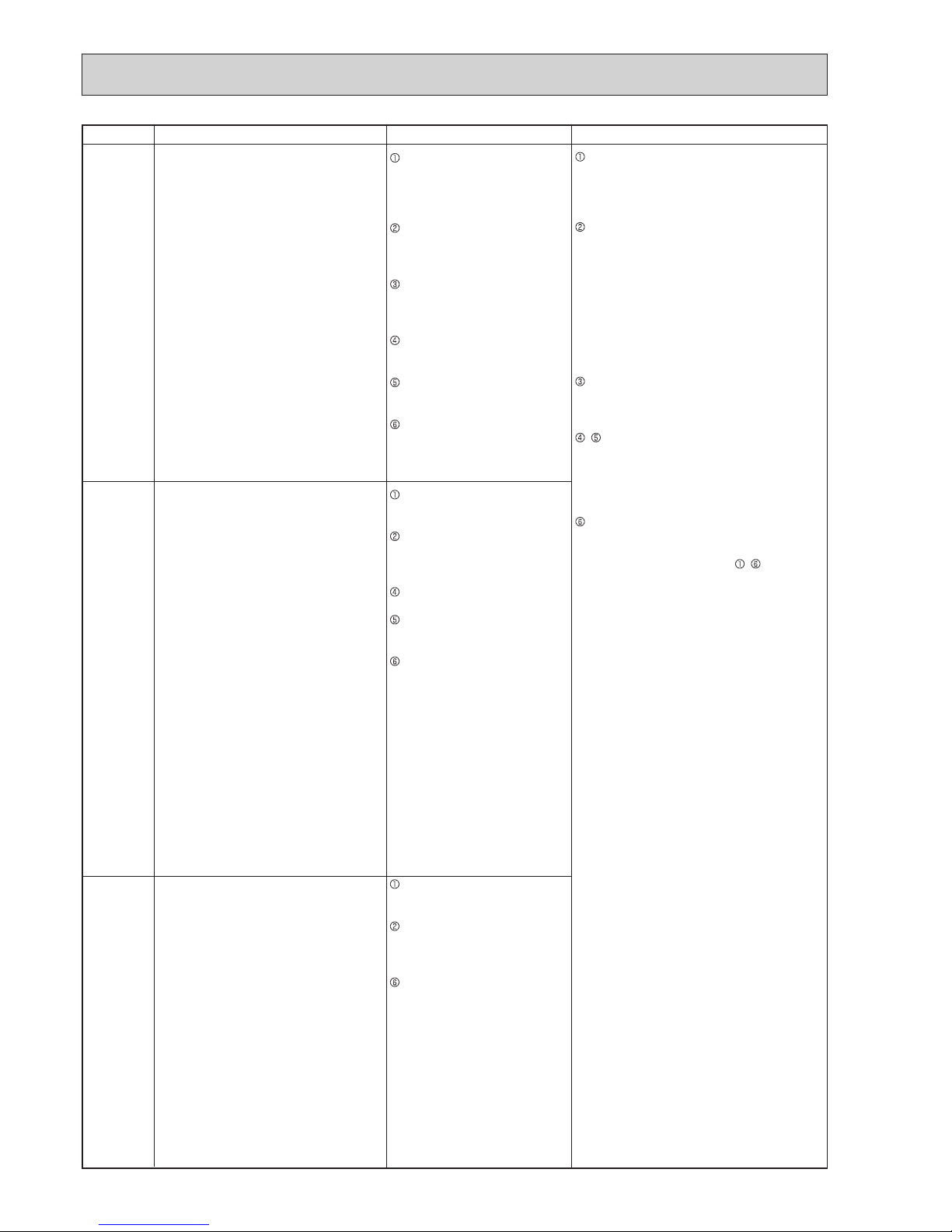

SAFETY PRECAUTION

1

Cautions for units utilizing refrigerant R410A

1-2. CAUTIONS RELATED TO NEW REFRIGERANT

1-1. ALWAYS OBSERVE FOR SAFETY

Before obtaining access to terminal, all supply circuits must be disconnected.

Use a vacuum pump with a reverse flow check

valve.

Vacuum pump oil may flow back into refrigerant cycle and

that can cause deterioration of refrigerant oil, etc.

Use the following tools specifically designed for

use with R410A refrigerant.

The following tools are necessary to use R410A refrigerant.

Handle tools with care.

If dirt, dust or moisture enters into refrigerant cycle, that can

cause deterioration of refrigerant oil or malfunction of compressor.

Do not use a charging cylinder.

If a charging cylinder is used, the composition of refrigerant will change and the efficiency will be lowered.

Electronic refrigerant

charging scale

Vacuum pump adaptor

Gauge manifold

Torque wrench

Gas leak detector

Charge hose

Tools for R410A

Charge refrigerant from liquid phase of gas cylinder.

If the refrigerant is charged from gas phase, composition

change may occur in refrigerant and the efficiency will be

lowered.

Ventilate the room if refrigerant leaks during

operation. If refrigerant comes into contact with

a flame, poisonous gases will be released.

Do not use refrigerant other than R410A.

If other refrigerant (R22, etc.) is used, chlorine in refrigerant can cause deterioration of refrigerant oil, etc.

Use the specified refrigerant only.

Never use any refrigerant other than that specified.

Doing so may cause a burst, an explosion, or fire when the

unit is being used, serviced, or disposed of.

Correct refrigerant is specified in the manuals and on the

spec labels provided with our products.

We will not be held responsible for mechanical failure,

system malfunction, unit breakdown or accidents caused

by failure to follow the instructions.

Preparation before the repair service.

• Prepare the proper tools.

• Prepare the proper protectors.

• Provide adequate ventilation.

• After stopping the operation of the air conditioner, turn off the power-supply breaker.

• Discharge the condenser before the work involving the electric parts.

Precautions during the repair service.

• Do not perform the work involving the electric parts with wet hands.

• Do not pour water into the electric parts.

• Do not touch the refrigerant.

• Do not touch the hot or cold areas in the refrigerating cycle.

• When the repair or the inspection of the circuit needs to be done without turning off the power,

exercise great caution not to touch the live parts.

[1] Cautions for service

(1) Perform service after recovering the refrigerant left in unit completely.

(2) Do not release refrigerant in the air.

(3) After completing service, charge the cycle with specified amount of refrigerant.

4

OCH594B

[2] Additional refrigerant charge

When charging directly from cylinder

· Check that cylinder for R410A on the market is a syphon type.

· Charging should be performed with the cylinder of syphon stood vertically. (Refrigerant is charged from liquid phase.)

Electronic weighing scale

Unit

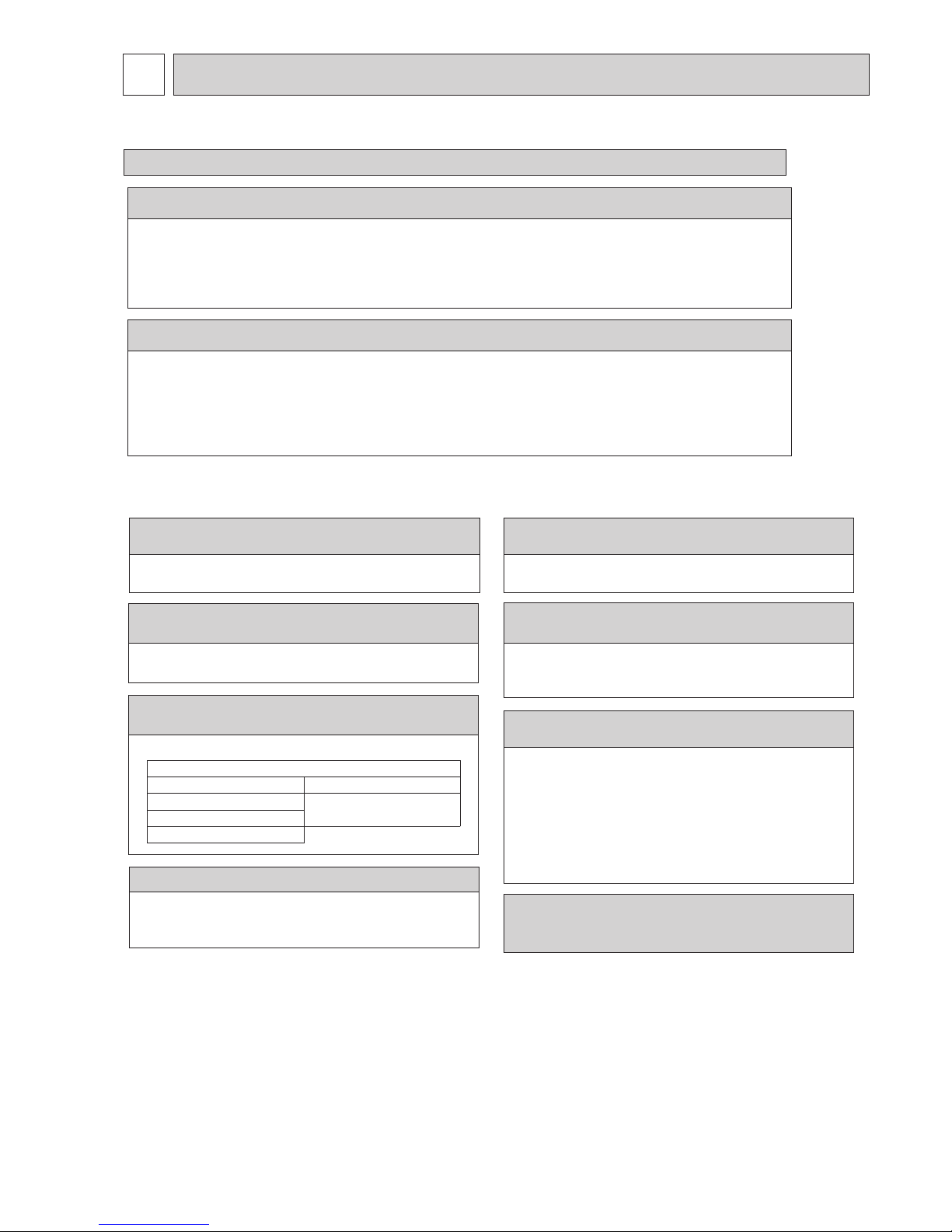

[3] Service tools

Use the below service tools as exclusive tools for R410A refrigerant.

No. Tool name Specifications

1

Gauge manifold · Only for R410A

· Use the existing fitting

specifications

. (UNF1/2)

· Use high-tension side pressure of 5.3 MPa·G or over.

2

Charge hose · Only for R410A

· Use pressure performance of 5.09 MPa·G or over.

3

Electronic weighing scale

—

4

Gas leak detector · Use the detector for R134a, R407C or R410A.

5

Adaptor for reverse flow check · Attach on vacuum pump.

6

Refrigerant charge base

—

7

Refrigerant cylinder · Only for R410A Top of cylinder (Pink)

Cylinder with syphon

8

Refrigerant recovery equipment

—

1-3. CAUTIONS FOR REFRIGERANT PIPING WORK

Tools for R410A (The following table shows whether conventional tools can be used or not.)

Tools and materials Use R410A tools

Can R22 tools be used?

Can R407C tools be used?

Gauge manifold Air purge, refrigerant charge

and operation check

Tool exclusive for R410A × ×

Charge hose Tool exclusive for R410A × ×

Gas leak detector Gas leak check Tool for HFC refrigerant × ○

Refrigerant recovery equipment

Refrigerant recovery Tool exclusive for R410A × ×

Refrigerant cylinder Refrigerant charge Tool exclusive for R410A × ×

Safety charger

Prevent compressor malfunction

when charging refrigerant by

spraying liquid refrigerant

Tool exclusive for R410A

× ×

Charge valve Prevent gas from blowing out

when detaching charge hose

Tool exclusive for R410A

× ×

Vacuum pump Vacuum drying and air purge Tools for other refrigerants

can be used if equipped with

adapter for reverse ow check

Δ(Usable if equipped

with adapter for

reverse flow)

Δ(Usable if equipped

with adapter for

reverse flow)

Bender Bend the pipes

Tools for other refrigerants can be used

○ ○

Pipe cutter Cut the pipes

Tools for other refrigerants can be used

○ ○

Welder and nitrogen gas

cylinder

Weld the pipes

Tools for other refrigerants can be used

○ ○

Refrigerant charging scale Charge refrigerant

Tools for other refrigerants can be used

○ ○

Vacuum gauge or thermistor

vacuum gauge and vacuum

valve

Check the degree of vacuum.

(Vacuum valve prevents back

ow of oil and refrigerant to

thermistor vacuum gauge)

Tools for other refrigerants can be used

○ ○

Charging cylinder Refrigerant charge Tool exclusive for R410A × -

×

: Prepare a new tool. (Use the new tool as the tool exclusive for R410A.)

Δ: Tools for other refrigerants can be used under certain conditions.

○

: Tools for other refrigerants can be used.

5

OCH594B

SPECIFICATIONS

2

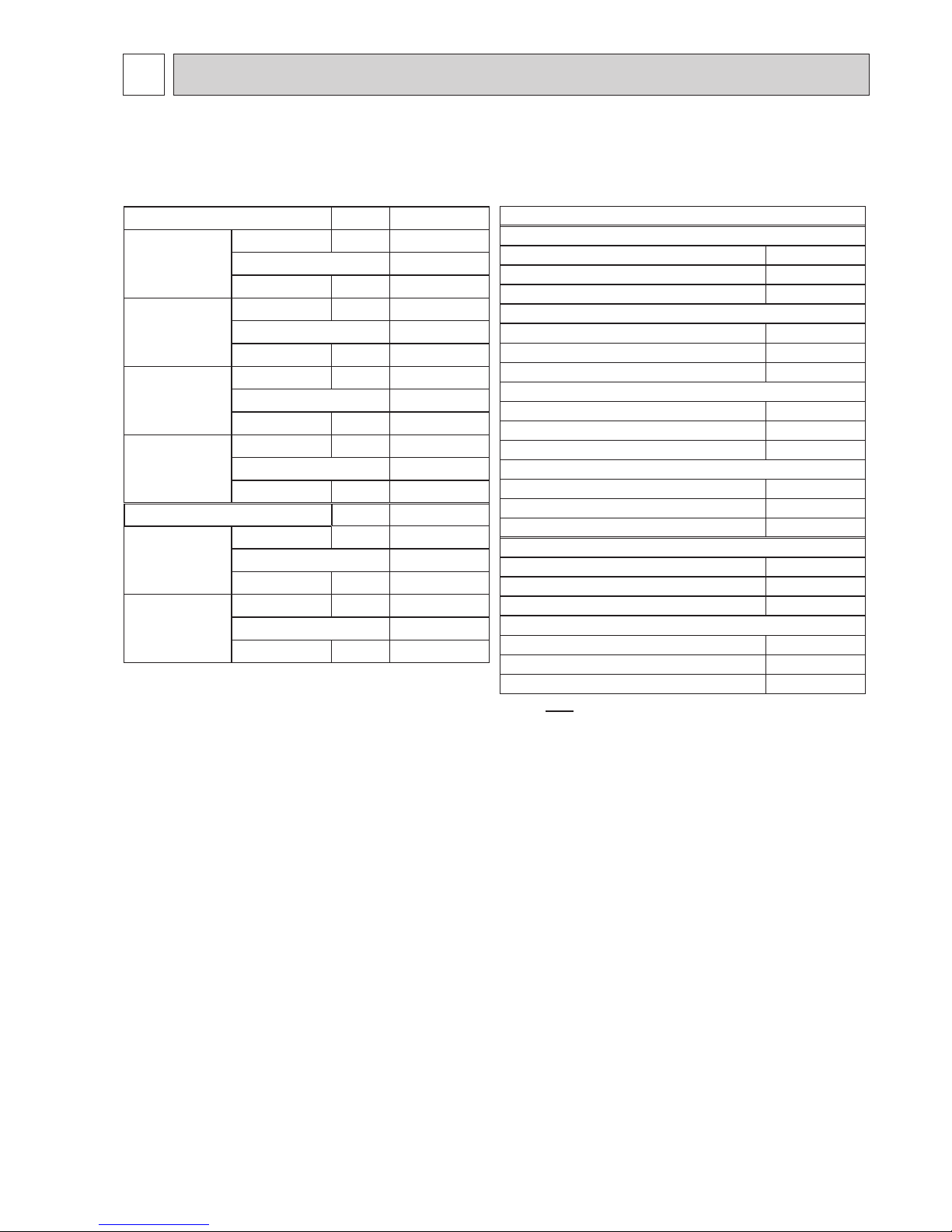

2-1. SPECIFICATION

2-1-1. PUHZ-SHW230YKA2

<Reference data> Plate heat exchanger (MWA2-38PA) *2 pcs [connected in parallel]

Nominal water ow L/min 65.9

Heating

(A7/W35)

Capacity kW 23.0

COP 3.65

Power input kW 6.31

Heating

(A7/W45)

Capacity kW 23.0

COP 3.02

Power input kW 7.62

Heating

(A2/W35)

Capacity kW 23.0

COP 2.37

Power input kW 9.71

Heating

(A2/W45)

Capacity kW 22.9

COP 2.02

Power input kW 11.32

Nominal water ow L/min 57.3

Cooling

(A35/W7)

Capacity kW 20.00

EER 2.22

Power input kW 9.01

Cooling

(A35/W18)

Capacity kW 20.00

EER 3.55

Power input kW 5.63

Rating conditions

Nominal operating condition

Heating (A2/W35)

Outside air temperature (Dry-bulb) + 2°C

Outside air temperature (Wet-bulb) + 1°C

Water temperature (inlet/outlet) + 30°C/+ 35°C

Heating (A2/W45)

Outside air temperature (Dry-bulb) + 2°C

Outside air temperature (Wet-bulb) + 1°C

Water temperature (inlet/outlet) + 40°C/+ 35°C

Heating (A7/W35)

Outside air temperature (Dry-bulb) + 7°C

Outside air temperature (Wet-bulb) + 6°C

Water temperature (inlet/outlet) + 30°C/+ 35°C

Heating (A7/W45)

Outside air temperature (Dry-bulb) + 7°C

Outside air temperature (Wet-bulb) + 6°C

Water temperature (inlet/outlet) + 40°C/+ 45°C

Cooling (A35/W7)

Outside air temperature (Dry-bulb) + 35 °C

Outside air temperature (Wet-bulb) + 24 °C

Water temperature (inlet/outlet) + 12 °C/+ 7 °C

Cooling (A35/W18)

Outside air temperature (Dry-bulb) + 35°C

Outside air temperature (Wet-bulb) + 24°C

Water temperature (inlet/outlet) + 23°C/+ 18°C

Note: "COP" and "Power input" in the above table are the values that do NOT contain the "pump input (based on EN 14511)".

6

OCH594B

2-1-2. Outdoor unit

Maximum outlet water temperature

*1 Hot gas with 4-way valve

*2 At distance of 1 m from outdoor unit

*3 grill

*4 With the optional air outlet guide, the operation at

−15℃ outdoor temperature is possible.

40

45

50

55

60

65

−25 −20 −15 −10 −5 0 5 10

Ambient temperature [°C]

Maximum outlet water temperature [

°C

]

*5 A weighted sound power level in accordance

with ISO9614-1 for EN14511 testing is

*6 Lower limit of use is −5

℃ for EN14511 testing purpose.

75 dBA.

noitidnoc gnitarepo lanimoN

Heating(A7/W35)

7 +)blub-yrD( erutarepmet ria edistuO ℃

6 +)blub-teW( erutarepmet ria edistuO ℃

53+/03+)teltuo/telni( erutarepmet retaW ℃

Cooling(A35/W7)

53+)blub-yrD( erutarepmet ria edistuO ℃

42 +)blub-teW( erutarepmet ria edistuO ℃

7+/21+)teltuo/telni( erutarepmet retaW ℃

Service Ref. PUHZ-SHW230YKA2

PUHZ-SHW230YKA2R1

PUHZ-SHW230YKA2R2

Running current Heating(A7/W35) A 9.6

Cooling(A35/W7) A 9.6

Power factor Heating(A7/W35) % 95

Cooling(A35/W7) % 95

Power supply (phase, voltage, cycle) 3 phase, 400 V, 50 Hz

Max. current A 26.0 20

Breaker size A 32 25

Outer casing Galvanized plate

External nish Munsell 3Y 7.8/1.1

Refrigerant control Liner expansion valve

Compressor Hermetic scroll

Model ANB66FJNMT

Motor output kW 4.7

Start type Inverter

Protection devices HP switch

LP switch

Discharge thermo

Overcurrent detection

Comp. surface thermo

Oil (Model) L 1.7 (FV50S)

Crankcase heater W —

Heat exchanger Air Plate n coil

Water Plate heat exchanger

Fan Fan (drive) × No. Propeller fan × 2

Fan motor output kW 0.150 × 2

Airow m³/min 140

(CFM) (4,940)

Defrost method Reverse cycle *

1

Noise level (SPL) Heating dB 59 *2 *

5

Cooling dB 58 *

2

Noise level (PWL) Heating dB 75

Dimensions Width mm (in) 1050 (41-5/16)

Depth mm (in) 330 + 30(*

3

) (13+1-3/16)

Height mm (in) 1338 (52-11/16)

Weight kg (lbs) 149 (328) 143 (315)

Refrigerant R410A

Quantity kg (lbs) 7.7 (17.0) 7.1 (15.7)

Guaranteed operating range

(Outdoor)

Heating °C

−25(*

6)

to +21

DHW °C −25 to +35

Cooling °C

−5(*

4)

to +46

Outlet water temp.

(Max. in heating, Min. in cooling)

Heating °C +60

Cooling °C +5

Nominal return water

temperature range

Heating °C +10 to +59

Cooling °C +8 to +28

Water ow rate range L/min 28.7 to 65.9

7

OCH594B

DATA

3

1.5m

1m

MICROPHONE

UNIT

GROUND

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

BAND CENTER FREQUENCIES, Hz

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

PUHZ-SHW230YKA2

COOLING

MODE

HEATING

58

SPL(dB)

59

LINE

PUHZ-SHW230YKA2R1

PUHZ-SHW230YKA2R2

3-3. NOISE CRITERION CURVES

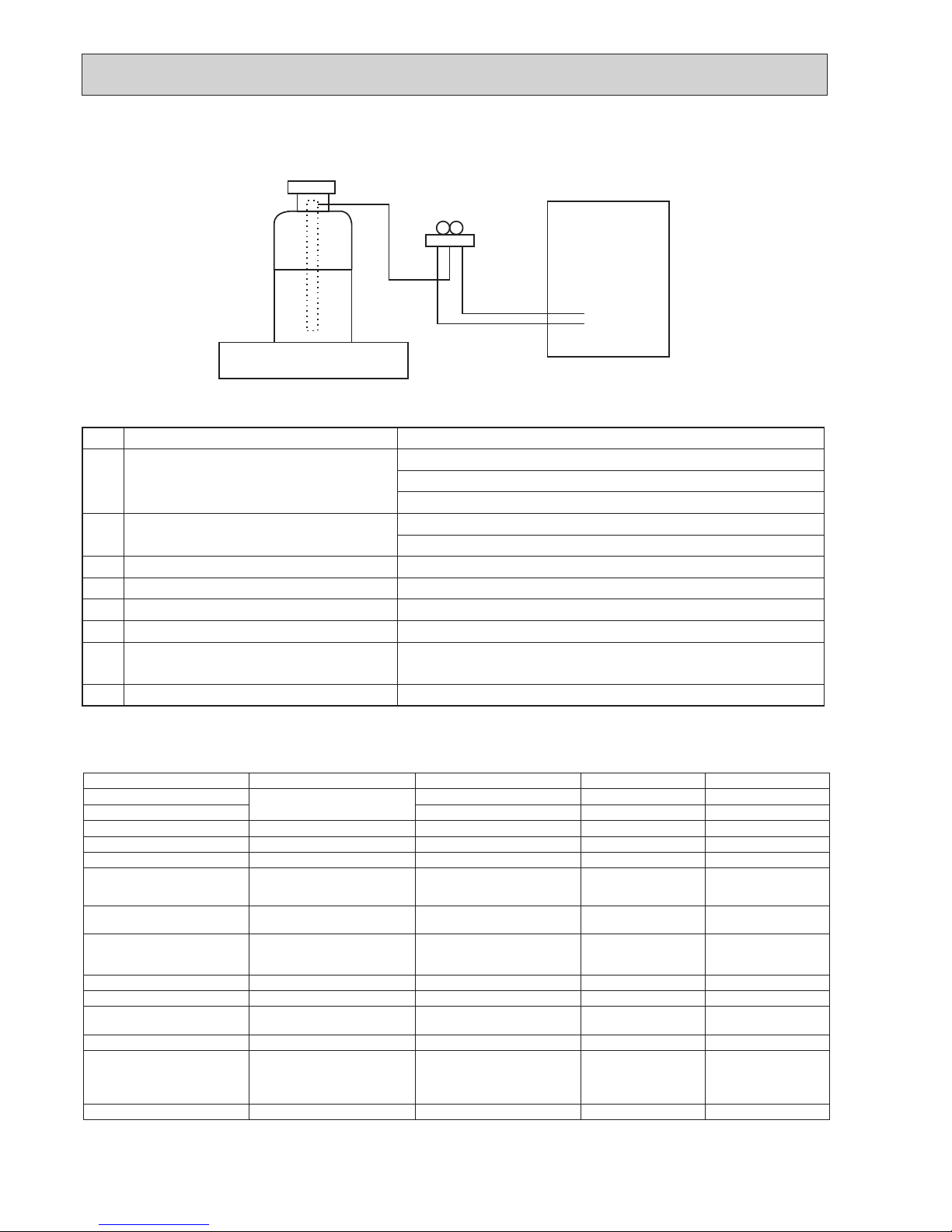

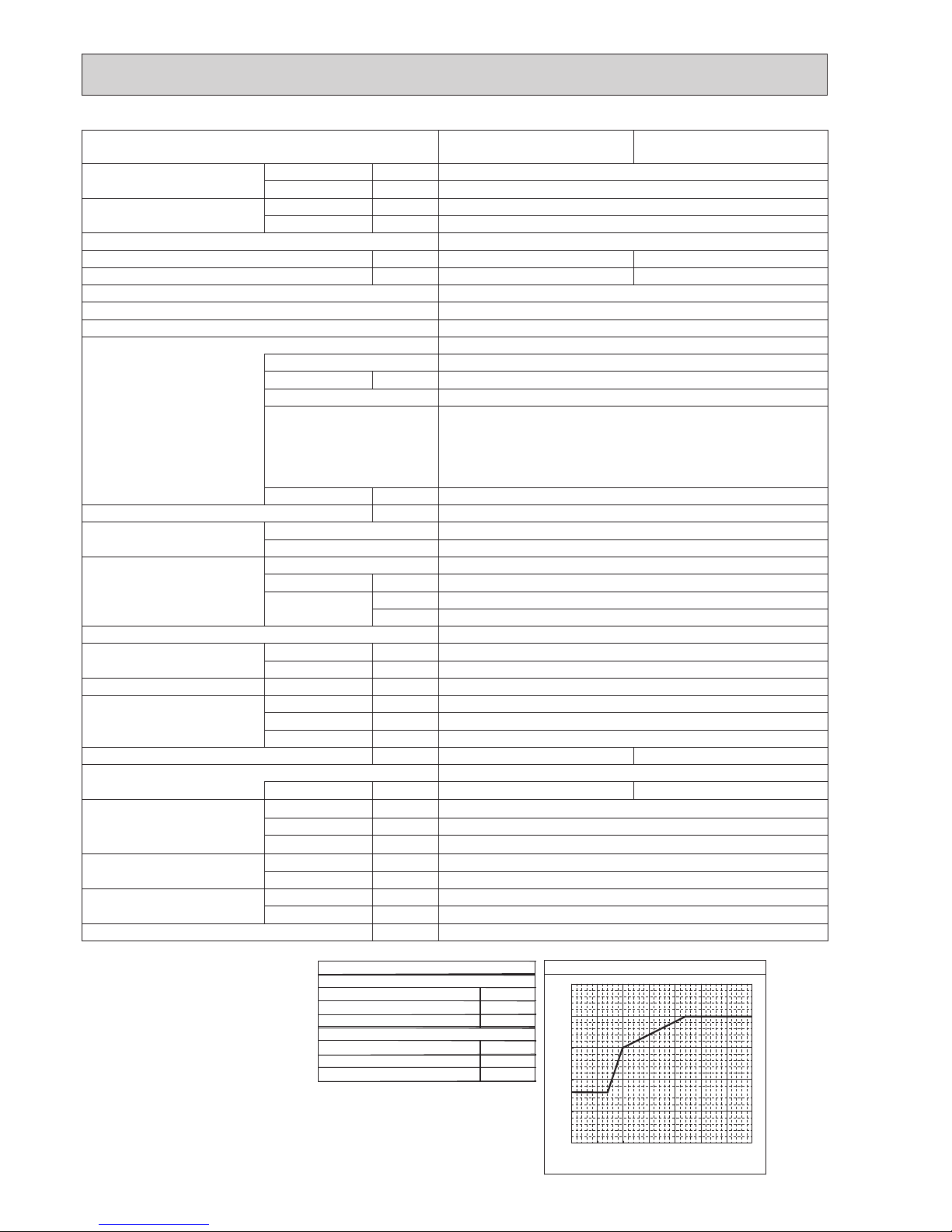

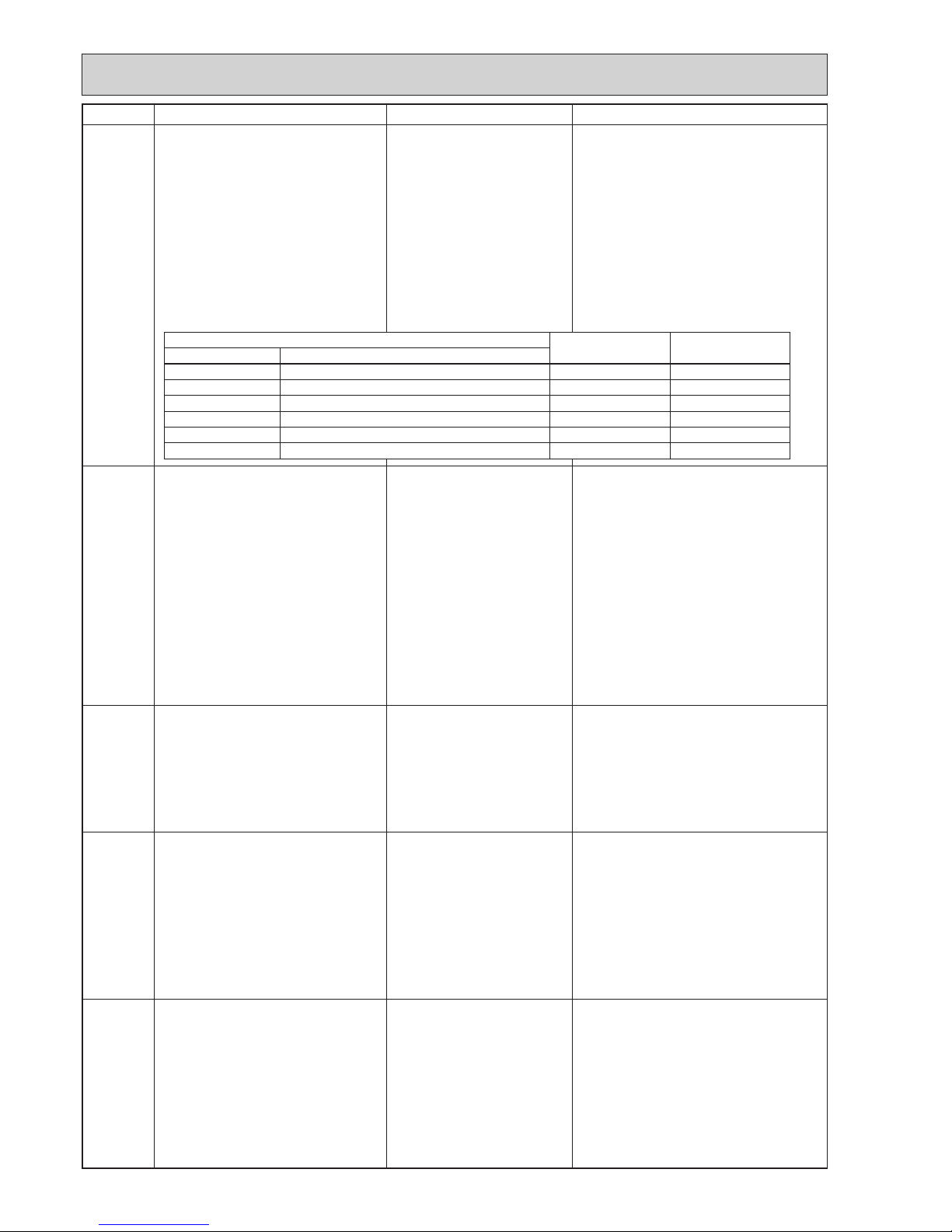

3-1. Additional refrigerant charge (R410A)

Service Ref.

Initial

charge

(kg)

Operation

method

Liquid

pipe

size

Total piping length (one way)

Amount of additional refrigerant charge (kg)

2 - 10 m

11 - 20 m 21 - 30 m 31 - 40 m 41–50 m 51–60 m 61–70 m 71–80 m

PUHZ-SHW230YKA2

PUHZ-SHW230YKA2R1

7.7

ATW/ATA/

AHU

- - - - 1.2 2.4 3.6 4.8 5.2

PUHZ-SHW230YKA2R2*17.1

ATW

ø12.7 - - - 1.4 2.8 4.2 5.6 7.0

ø9.52 - - - - 0.8 1.7 2.6 3.5

ATA/AHU

ø12.7 - - 1.4 2.8 4.2 5.6 7.0 8.4

ø9.52 - - - 0.8 1.7 2.6 3.5 4.4

*1 Set the SW8-2 on controller board ON when the piping length is 10 m or less. (for models from PUHZ-SHW230YKA2R2)

3-2. Recharge refrigerant amount (R410A)

Service Ref.

Operation

method

Liquid

pipe

size

Total piping length (one way)

Amount of recharge refrigerant (kg)

2 - 10 m

11 - 20 m 21 - 30 m 31 - 40 m 41–50 m 51–60 m 61–70 m 71–80 m

PUHZ-SHW230YKA2

PUHZ-SHW230YKA2R1

ATW/ATA/

AHU

ø12.7 5.5 6.6 7.7 8.9 10.1 11.3 12.5 12.9

ø9.52 5.4 6.3 6.7 8.3 9.4 10.4 11.5 11.8

PUHZ-

SHW230YKA2R2

*1

ATW

ø12.7 5.9 6.5 7.1 8.5 9.9 11.3 12.7 14.1

ø9.52 5.7 6.1 6.5 7.1 7.9 8.8 9.7 10.6

ATA/AHU

ø12.7 6.5 7.1 8.5 9.9 11.3 12.7 14.1 15.5

ø9.52 6.1 6.5 7.1 7.9 8.8 9.7 10.6 11.5

*1 Set the SW8-2 on controller board ON when the piping length is 10 m or less. (for models from PUHZ-SHW230YKA2R2)

8

OCH594B

3-5. CAPACITY CORRECTION (Refrigerant piping length)

Cooling and heating capacity is lowered according to the piping length. Capacity can be obtained by referring to the following

capacity curves.

Corrected pipe length (m) = actual pipe length (m) + number of bends × 0.3 (m)

Cooling

Heating

HRP200

HRP200

5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80

70

75

80

85

90

95

100

Corrected pipe length [m]

Capacity ratio [%]

SHW230

SHW230

3-4. Standard operation data Reference data (connect to Plate HEX)

(MWA2-38PA) o 2 pcs [connected in parallel]

Mode

Cooling

(A35/W7)

Heating

(A7/W35)

Total

Capacity W 20,000 23,000

Input kW 9.01 6.31

Electrical circuit

Outdoor unit PUHZ-SHW230YKA2

Phase, Hz 3, 50

Voltage V 400

Current A 13.7 9.6

Refrigerant circuit

Discharge pressure MPa 3.0 2.0

Suction pressure MPa 0.7 0.6

Discharge temperature ºC 79 73

Condensing temperature

ºC 49 35

Suction temperature ºC 8 8

Evaporating temperature

ºC 6 2

Evaporator inlet temperature

ºC 7 ——

Evaporator outlet temperature

ºC 6 ——

Condenser inlet temperature

ºC —— 65

Condenser outlet temperature

ºC —— 34

Water

conditions

Flow volume L/min 57.3 65.9

Outlet water temperature

ºC 7 35

Outdoor

conditions

Intake air

temperature

D.B. ºC 35 7

W.B. ºC 24 6

Piping length : Main 2.5 m, Branch 2.5 m/2.5 m

The unit of pressure has been changed to MPa based on international SI system.

The conversion factor is: 1 (MPa) = 10.2 (kgf/cm²)

9

OCH594B

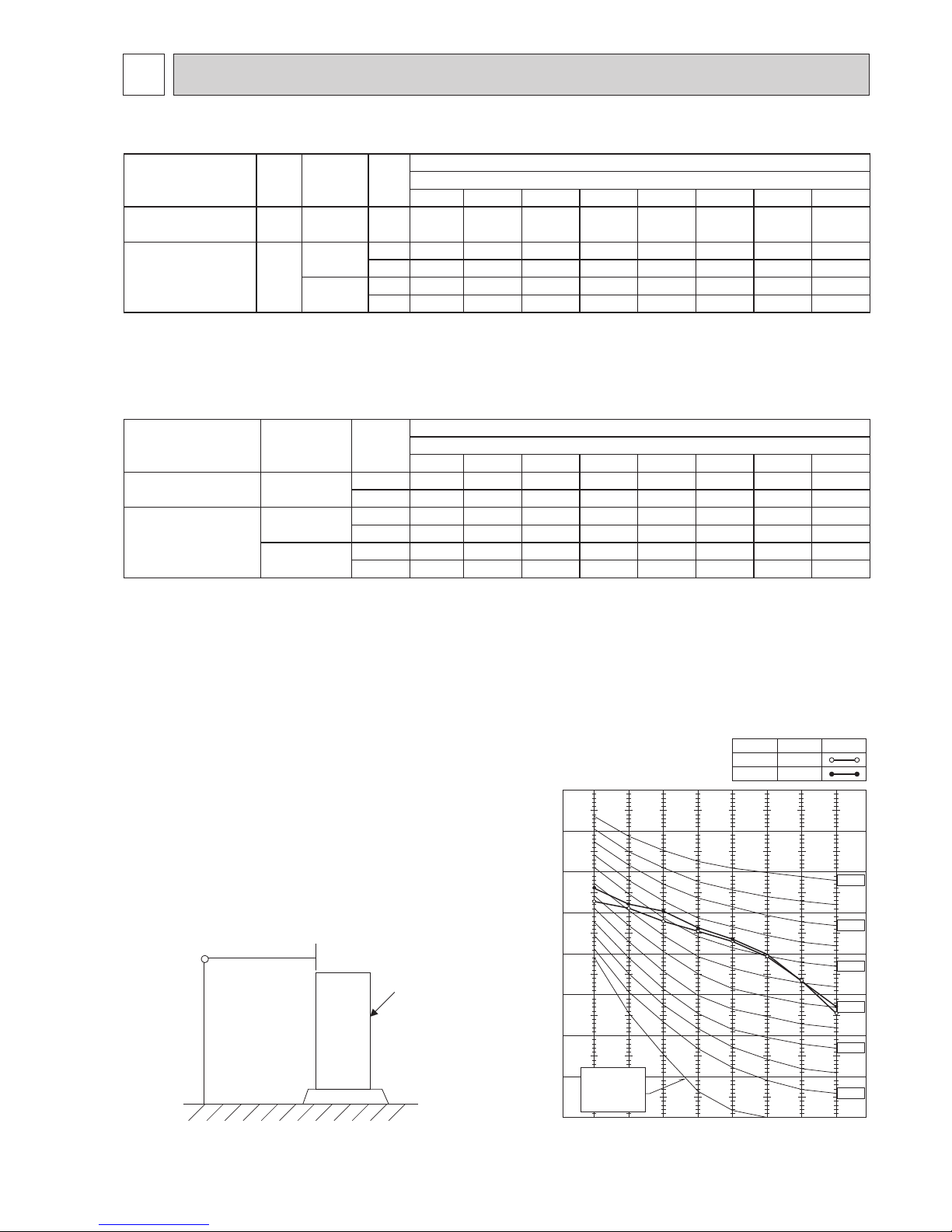

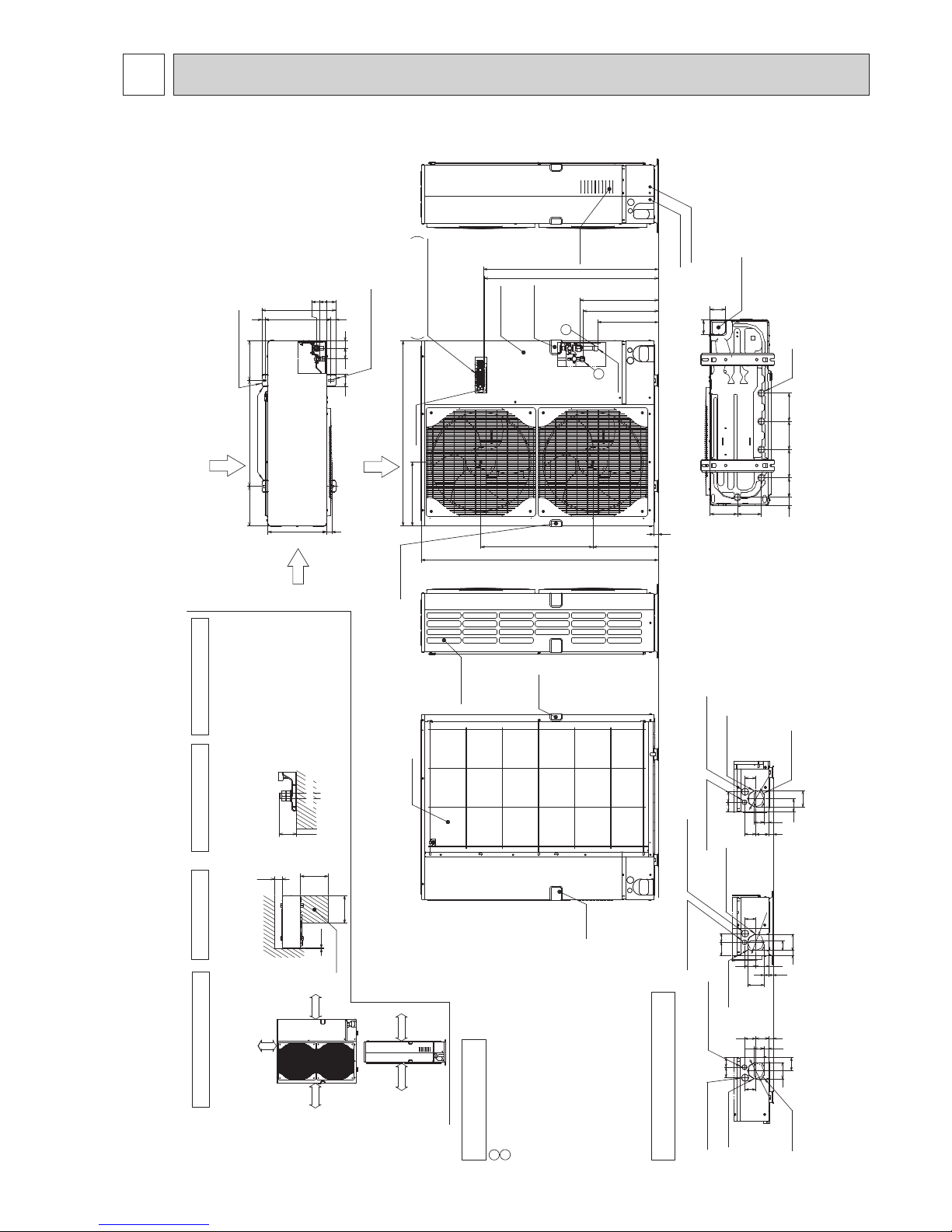

OUTLINES AND DIMENSIONS

4

Unit: mm

PUHZ-SHW230YKA2

PUHZ-SHW230YKA2R1

PUHZ-SHW230YKA2R2

FOUNDATION

30

Service space

150

500

500

10

The diagram below shows a

basic example.

Explanation of particular details are

given in the installation manuals etc.

Dimensions of space needed

for service access are

shown in the below diagram.

<Foundation bolt height>

Please secure the unit firmly

with 4 foundation (M10) bolts.

(Bolts and washers must be

purchased locally.)

1 FREE SPACE (Around the unit)

2 SERVICE SPACE

3 FOUNDATION BOLTS

4 PIPING-WIRING DIRECTIONS

Piping and wiring connections

can be made from 4 directions:

FRONT,Right,Rear and Below.

Less than

Over

Over

Over

Over

Over 10mm

Over 10mm

FREE

Over 150mm

Over 1000mm

···Refrigerant GAS pipe connection (attached JOINT)ø25.4(Brazing locally)

···Refrigerant LIQUID pipe connection (FLARE) ø 12.7(1/2F)

*1···Indication of STOP VALVE connection location.

*2···(FLARE)ø 19.05(3/4F)

1

2

Example of Notes

Piping Knockout Hole Details

Power supply wiring hole

(ø27Knockout)

Front piping hole

(Knockout)

Front trunking hole

(Knockout)

Power supply wiring hole

(ø40Knockout)

60 55

6373

55

27

26

75

92

60

ø92

Power supply wiring hole

(ø27Knockout)

Right piping hole

(Knockout)

Right trunking hole

(Knockout)

Power supply wiring hole

(ø40Knockout)

75 50

26

27

63

73

29 92

55

92

60

ø92

Power supply wiring hole

(ø27Knockout)

Rear piping hole

(Knockout)

Rear trunking hole

(Knockout)

Power supply wiring hole

(ø40Knockout)

75

6055

6373

26

55

27

60

92

ø92

Drain hole

(5-ø33)

Bottom piping hole

(Knockout)

81

45

154136

110 160 160 160

86

1050

Rear Air Intake

Air Discharge

Side Air Intake

Installation Feet

2-U Shaped notched holes

(Foundation Bolt M10)

2-12×36 Oval holes

(Foundation Bolt M10)

28

370

60

30

225

225

330

600

417

19

70

42

405356

0

Handle for

moving

Rear Air Intake

Side Air Intake

Handle for

moving

632

369

26

1338

Handle for moving

Handle for moving

Earth terminal

362

Brazing

Service panel

Terminal connection

Left···Power supply wiring

Right···Indoor/Outdoor wiring

*1,*2 : 442

982

986

*1 450

342

Air intake

2

1

Front piping cover

Rear piping cover

10

OCH594B

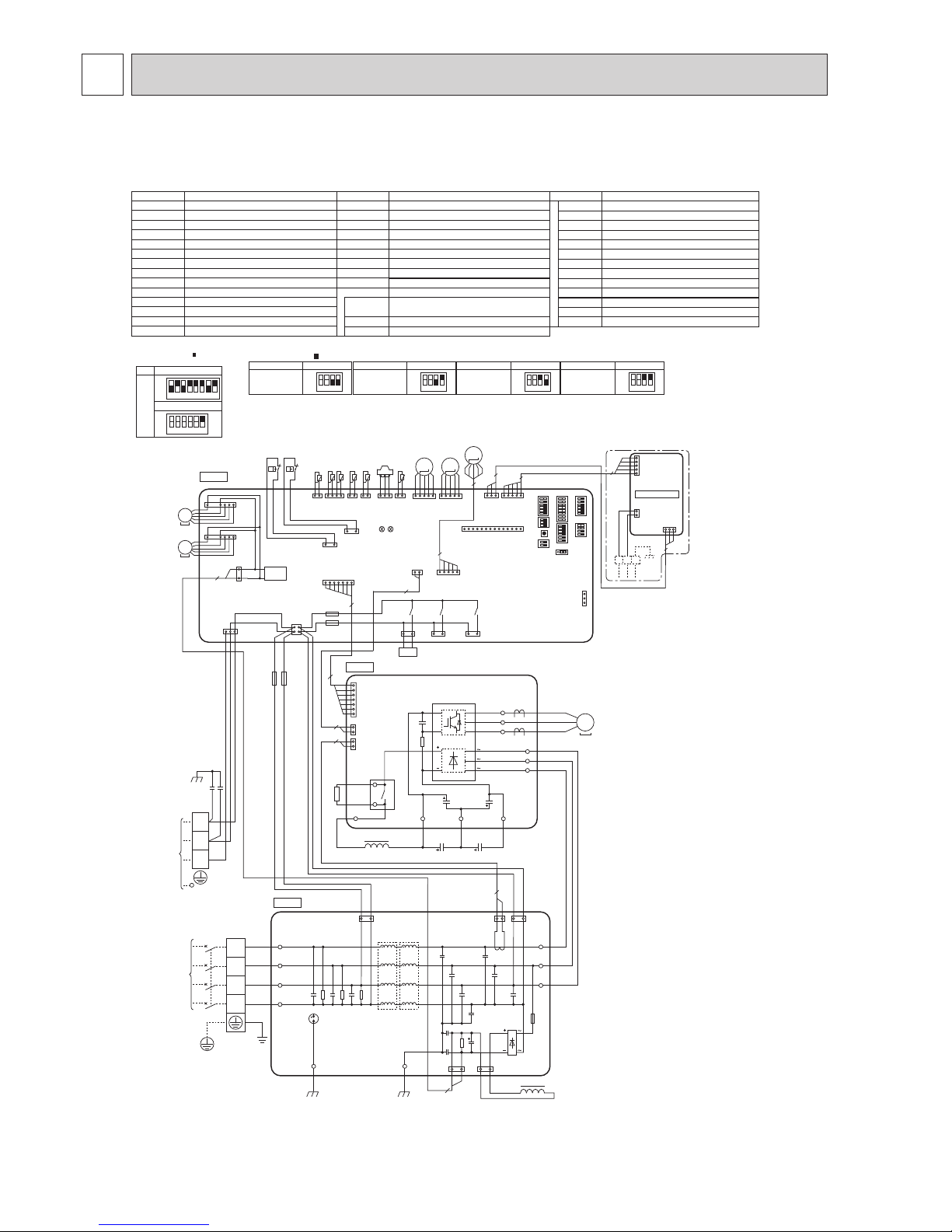

5 WIRING DIAGRAM

PUHZ-SHW230YKA2 PUHZ-SHW230YKA2R1

FUSE1, FUSE2

TB1

MC

MF1,MF2

21S4

63H

TH3

TH4

TH6

TH7

LEV-A, LEV-B, LEV-C

DCL

Terminal Block<Power Supply>

TB2 Terminal Block<Indoor/Outdoor>

Motor for Compressor

Fan Motor

Solenoid Valve (4-Way Valve)

High Pressure Switch

63L Low Pressure Switch

63HS High Pressure Sensor

Thermistor<Suction>

TH32

Fuse

<T15AL250V

>

Linear Expansion Valve

Reactor

ACL4

Reactor

P. B.

Power Circuit Board

RS

Rush Current Protect Resistor

CB1, CB2

Main Smoothing Capacitor

Noise Filter Circuit Board

N. F.

Controller Circuit Board

C. B.

SYMBOL NAME SYMBOL NAME SYMBOL NAME

Switch<Manual Defrost, Defect History Record

Reset, Refrigerant Address>

Switch<Test Operation>

Switch<Function Switch, Model Select>

SW1

SW4

SW5

SW9

Switch<Pump Down>

SWP

Connector<Emergency Operation>

CN31

F3, F4

CNMNT

CNVMNT

CNDM

Fuse<T6.3AL250V

>

CNM

SV3/SS

Connector<Connection for Option>

Connector<Connection for Option>

SV1/CH

Connector<Connection for Option>

Connector<Connection for Option>

Connector<Connection for Option>

Connector<Connection for Option>

Capacitor

CY1, CY2

TH34

Thermistor<Liquid>

Thermistor<Discharge>

Thermistor<2-Phase Pipe>

Thermistor<Ambient>

Thermistor<Comp. Surface>

Switch<Function Switch>

Switch<Function Switch>

Switch<Model Select>

SW6

SW8

Switch<Function Switch>

SW7

CN2

(WH)

7

7

1

P. B.

2

2

1

2

2

1

CN4

(WH)

CN5

(RD)

WH

FUSE1

FUSE2

WH

RD

RD

MS

3

~

POWER

SUPPLY

3N

~

400V 50Hz

TO

INDOOR

UNIT

TB1

L3

L2

L1

N

31

2

2

13

CNDC

(PK)

CNL

(BU)

311 2

CNCT

(RD)

CNAC2

(RD)

31

CNAC1

(WH)

BK

BK

LO1

LO2

LO3

LI1

LI2

LI3

NI

RD

WH

BU

BK

GNYE

GD2GD1

RD

WH

BK

N. F.

TB2

DCL

ACL4

S3

S2

S1

OG

YE

CY2

CY1

BN

RD

RD

RS

RD

WH

WH

WH

BK

BK

BK

X52A

BK

BK

TB-P2

TB-P1

TB-C1 TB-N1

CB1 CB2

W

V

MC

U

TB-L1

TB-L2

TB-L3

SC-U

SC-V

SC-W

RD

TH6TH7 TH4TH3

21S4

t˚ t˚ t˚ t˚

LEV-A

CNS

(WH)

CNAC

(WH)

CNDC

(PK)

F3

F4

21S4

(GN)

CN2

(WH)

CN4

(WH)

TH7/6

(RD)

TH3

(

WH

)

TH4

(WH)

TRANS

CNM

(WH)

LED1

LED2

X52

SV1

/CH

(GY)

X54

63H

(YE)

2

7

1 4 1 2 2 1

1 3

1 14

1 2

1 7

3

1

13

1 2

3 4

31 31

LEV-A

(WH)

51

SV3

/SS

(WH)

X51

31

MF1

CNF1

(WH)

1

7

63L

63H

63L

(RD)

1 3

31

TH34

t˚

2 1

TH34

(RD)

63HS

(WH)

63HS

LEV-B

(RD)

M

LEV-B

51

M

MF2

CNF2

(WH)

1

7

2

CNDM

(WH)

1

3

SW7

SW6SW1

SW9

CN31

SW5

SW8SW4

SWP

C. B.

TH32

(BK)

TH32

t˚

1 2

*1*

1

*

3

CNVMNT

(WH)

CNMNT

(WH)

31 1 5

5

LEV-C

(BU)

5

1

LEV-C

5

M

MS

3~

MS

3~

3

5

CN5

(WH)

3 1

TB7

2

1

CND

(WH)

CN2M

(WH)

M-NET

A B S

When M-NET Adapter is connected

5

3

5

1

M-NET ADAPTER

MODEL

SW6

SW5-6

*

2

1 2 3 4 5 6 7 8

*

2

SW5 -1 to 5 : Function Switch.

OFF

1 2 3 4 5 6

OFF

ON

230Y

ON

*

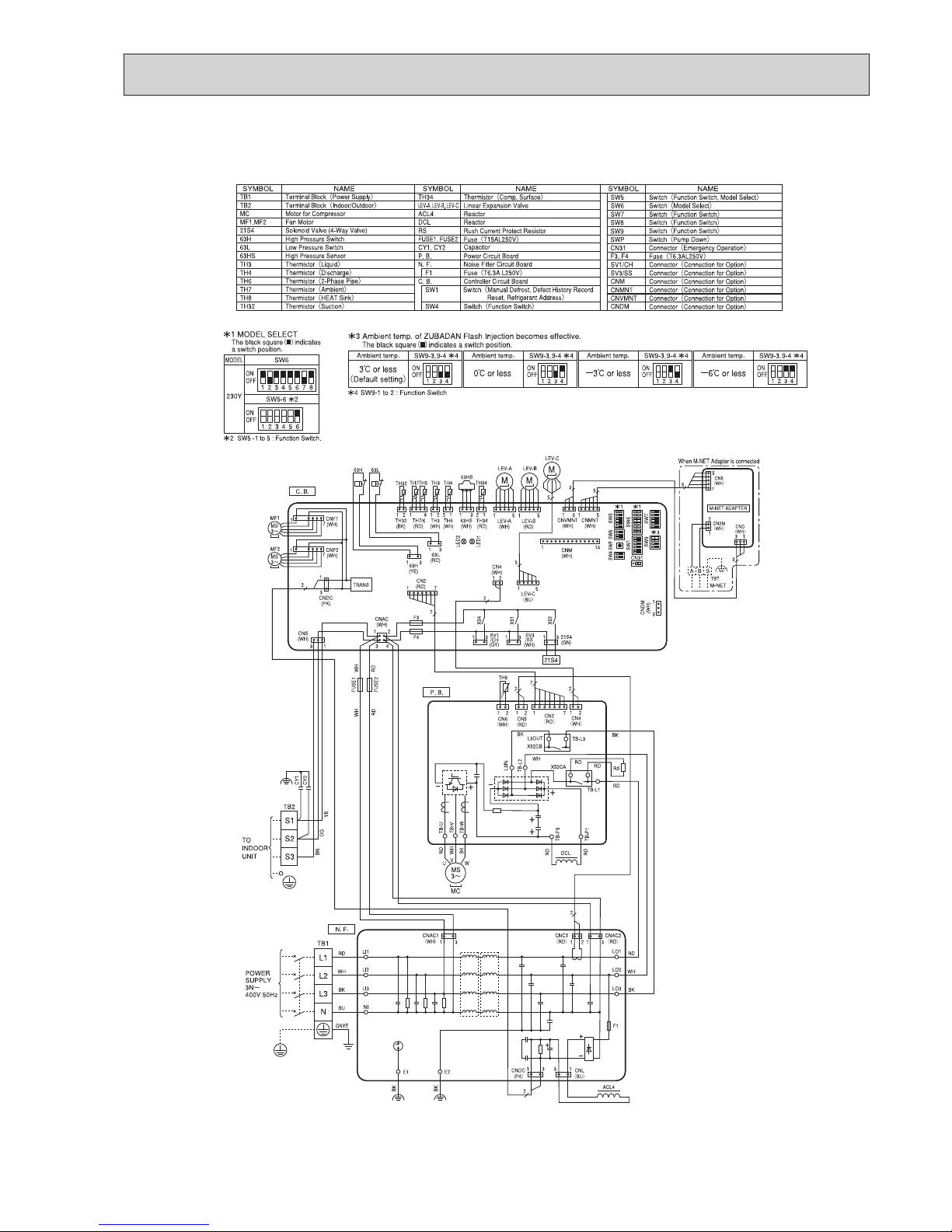

1 MODEL SELECT

The black square ( ) indicates

a switch position.

1 2 3 4

OFF

ON

1 2 3 4

OFF

ON

SW9-3, 9-4 *4

Ambient temp.

3ºC or less

(Default setting

)

*

4 SW9-1 to 2 : Function Switch

0ºC or less

SW9-3, 9-4 *4

Ambient temp.

−3ºC or less

−6ºC or less

1 2 3 4

OFF

ON

1 2 3 4

OFF

ON

SW9-3, 9-4 *4

Ambient temp.

SW9-3, 9-4 *4

Ambient temp.

*

3 Ambient temp. of ZUBADAN Flash Injection becomes effective.

The black square ( ) indicates a switch position.

11

OCH594B

PUHZ-SHW230YKA2R2

12

OCH594B

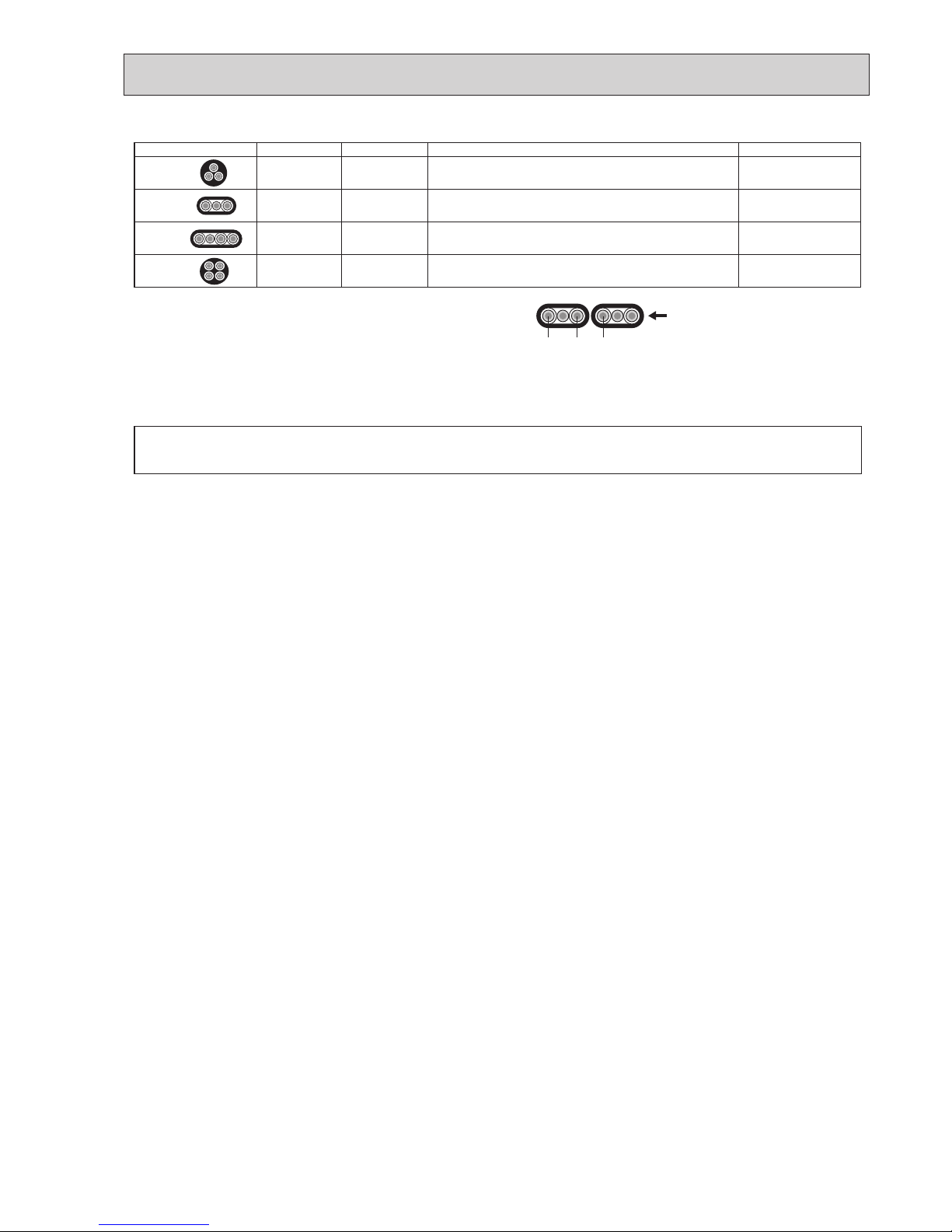

WIRING SPECIFICATIONS6

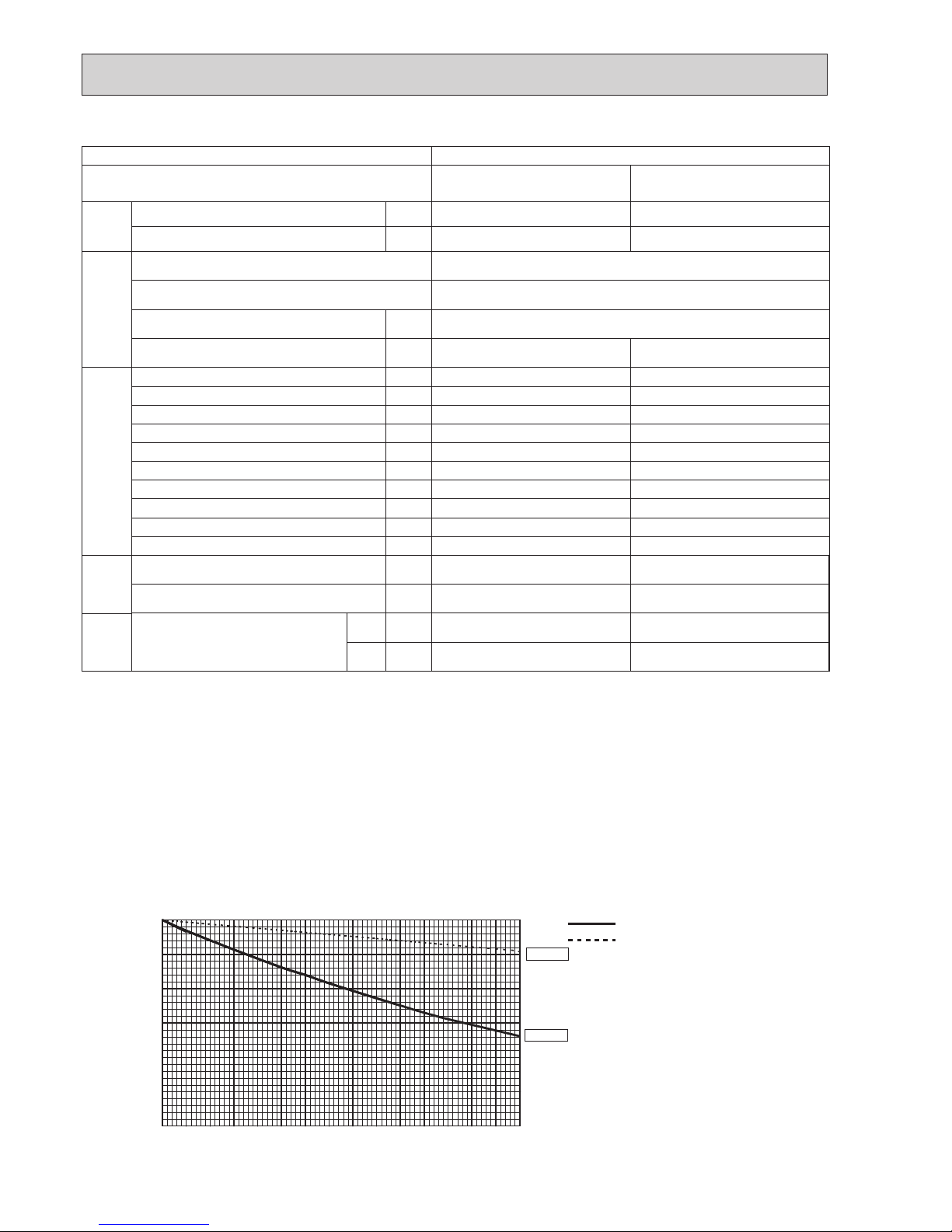

FIELD ELECTRICAL WIRING (power wiring specifications)

S1

Power supply

3 poles isolator

A-Control

Indoor Unit

A-Control

Outdoor Unit

Isolator

S2

S3

S1

S2

S3

Outdoor unit model SHW230Y

Outdoor unit power supply

3N~ (3 ph 4-wires),

50 Hz, 400 V

Outdoor unit input capacity Main switch (Breaker) *1

YKA2/YKA2R1: 32 A

YKA2R2: 25A

Wiring

Wire No. ×

size (mm

2

)

Outdoor unit power supply 5 × Min. 4

Indoor unit-Outdoor unit *2

Cable length 50 m: 3×4 (Polar)/

Cable length 80 m: 3×6 (Polar)

Indoor unit-Outdoor unit earth *2 1 × Min. 2.5

Remote controller-Indoor unit *3 2 × 0.3 (Non-polar)

Circuit rating

Outdoor unit L-N (single)

Outdoor unit L1-N, L2-N, L3-N (3 phase)

*4 230 V AC

Indoor unit-Outdoor unit S1-S2 *4 230 V AC

Indoor unit-Outdoor unit S2-S3 *4 24 V DC

Remote controller-Indoor unit *4 12 V DC

*1. A breaker with at least 3.0 mm contact separation in each poles shall be provided. Use earth leakage breaker (NV).

Make sure that the current leakage breaker is one compatible with higher harmonics.

Always use a current leakage breaker that is compatible with higher harmonics as this unit is equipped with an inverter.

The use of an inadequate breaker can cause the incorrect operation of inverter.

*2. Maximum 80 m. Total maximum including all indoor/indoor connection is 80 m.

• Use one cable for S1 and S2 and another for S3 as shown in the picture.

*3. The 10 m wire is attached in the remote controller accessory.

*4. The gures are NOT always against the ground.

S3 terminal has 24 V DC against S2 terminal. However between S3 and S1, these terminals are NOT electrically insulated by the transformer or other device.

Notes: 1. Wiring size must comply with the applicable local and national code.

2.

Power supply cords and Indoor/Outdoor unit connecting cords shall not be lighter than polychloroprene sheathed exible cord.

(Design 60245 IEC 57

)

3. Use an earth wire which is longer than the other cords so that it will not become disconnected when tension is applied.

Caution: Be sure to install N-line. Without N-line, it could cause damage to the unit.

S3

S3

S2

S1

S2S1

N

L1 L2 L3

C

A Indoor unit

B Outdoor unit

C Remote controller

D Main switch (Breaker)

E Earth

A

B

D

D

A

A

A

B

C

E

E

E

For Power

For Power

E

Warning:

· In case of A-control wiring, there is high voltage potential on the S3 terminal caused by electrical circuit design that has no electrical insulation

between power line and communication signal line. Therefore, please turn off the main power supply when servicing. And do not touch the S1, S2, S3

terminals when the power is energized. If isolator should be used between indoor unit and outdoor unit, please use 3-pole type.

· Turn on the main power when the ambient temperature is −20°C or higher.

· In below −20°C condition, it needs at least 12 hrs standby to operate in order to warm the electrical parts.

Note: When multiple indoor units (hydroboxes) are connected to the outdoor unit, wire the PCB of either one of the indoor unit and the outdoor unit

(S1,S2,S3).

It is impossible to connect the PCBs of multiple indoor units to the outdoor unit.

Twin or triple system construction of the hydrobox is not

allowed.

When the hydrobox is constructed as a slave, remote

controller must be connected by crossover wiring.

13

OCH594B

INDOOR-OUTDOOR CONNECTING CABLE

Cross section of cable Wire size (mm2) Number of wires Polarity L (m)*

5

Round

2.5 3

Clockwise : S1-S2-S3

(Pay attention to stripe of yellow and green.)

(30)*

1

Flat

2.5 3

Not applicable

(Since center wire has no cover finish.)

Not applicable*

4

Flat

1.5 4

From left to right: S1-Open-S2-S3

(18)*

2

Round

2.5 4

Clockwise : S1-S2-S3-Open

(Connect S1 and S3 to the opposite angle.)

(30)*

3

Note: Power supply cords of appliances shall not be lighter than design 60245 IEC or

227 IEC.

*

1

In case that cable with stripe of yellow and green is available.

*

2

In case of regular polarity connection (S1-S2-S3), wire size is 1.5 mm

2

.

*3 In case of regular polarity connection (S1-S2-S3).

*

4

In the flat cables are connected as this picture, they can be used up to 30 m.

*

5

Mentioned cable length is just a reference value.

It may be different depending on the condition of installation, humidity or

materials, etc.

(3C Flat cable × 2)

Be sure to connect the indoor-outdoor connecting cables directly to the units (no intermediate connections).

Intermediate connections can lead to communication error if water enters the cables and causes insufficient insulation to ground or a poor electrical contact at

the intermediate connection point.

S1

S3S2

14

OCH594B

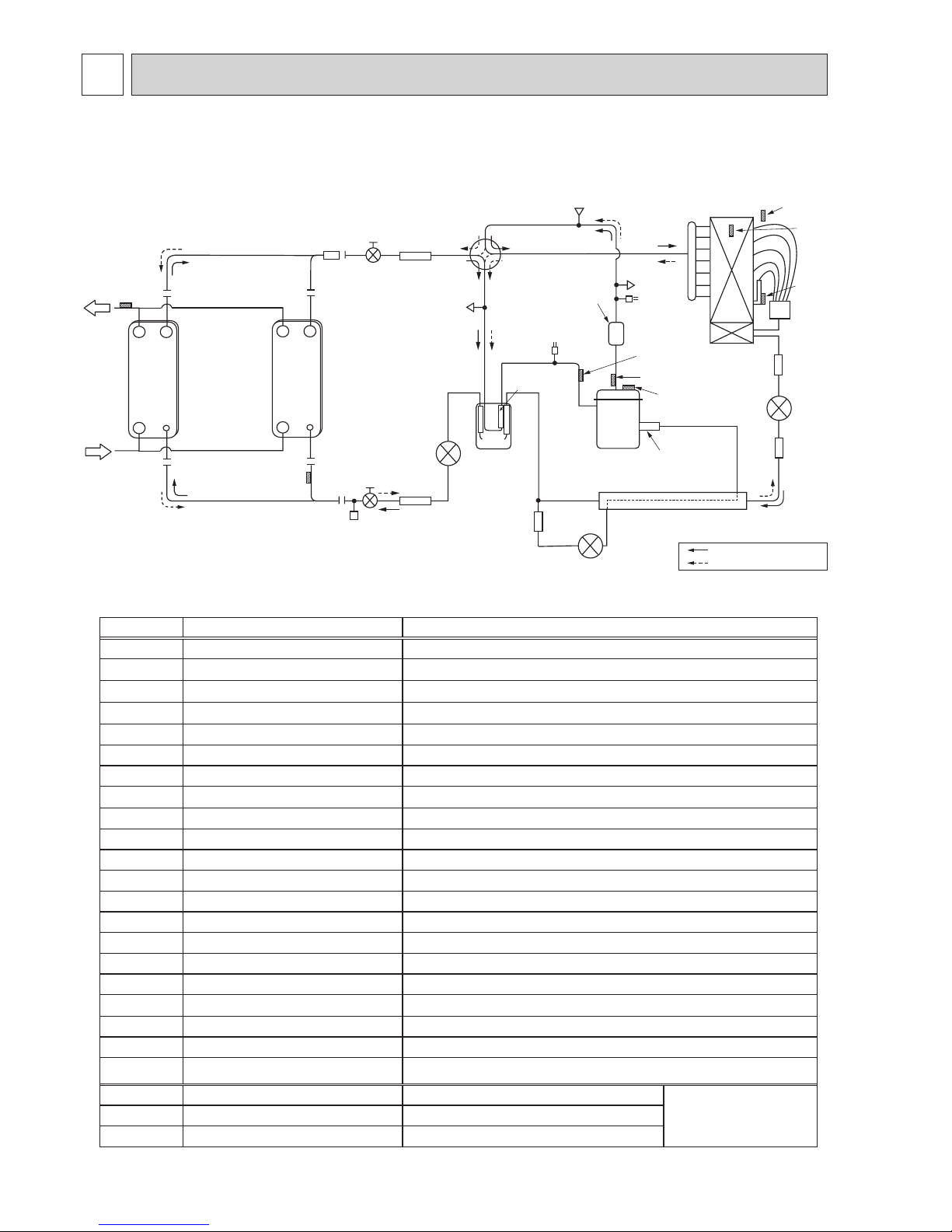

REFRIGERANT SYSTEM DIAGRAM7

Distributor

TH7

HEX

Refrigerant

GAS pipe

connection

(1 inch)

Refrigerant

LIQUID pipe

connection

(1/2 inch)

Stop valve

(with service port)

Strainer

#100

Power

receiver

LEV-B

Strainer

#100

Strainer

#100

TH6

TH3

Charge plug

(Low pressure)

Charge plug

(High pressure)

HIC

TH4

TH34

COMP

INJ. port

Strainer

#50

REV/V

Strainer

#100

Strainer

#100

Muffler

P-sensor

Ball valve

TH32

L/P SW

H/P SW

Refrigerant flow in cooling

Refrigerant flow in heating

TH2

TH1

Plate HEX

Strainer

#100

Strainer

#100

Plate HEX

Water IN

Water OUT

Joint pipe

(Brazing)

LEV-C

LEV-A

PUHZ-SHW230YKA2 PUHZ-SHW230YKA2R1 PUHZ-SHW230YKA2R2

<Reference> System example: Plate HEX (MWA2 * 2 pcs) + FTC (TH1/2)

Symbol Part name Detail

COMP Compressor DC inverter scroll compressor (Mitsubishi Electric Corporation)

INJ. port Compressor Injection port

Muffler Discharge mufer

HEX Heat exchanger

H/P SW High pressure switch (63H) For protection (OFF: 4.15MPa)

L/P SW Low pressure switch (63L) For protection (OFF: -0.03MPa)

REV/V Reversing (4-way) valve (21S4) Change the refrigerant circuit (Heating / Cooling) and for Defrosting

CHECK/V Check valve

P-Sensor Pressure sensor (63HS) For calculation of the condensing temperature from high pressure

LEV-A Linear expansion valve -A Heating:Secondary LEV Cooling:Primary LEV

LEV-B Linear expansion valve -B Heating:Primary LEV Cooling:Secondary LEV

LEV-C Linear expansion valve -C For HIC (heating only)

TH32 Suction temperature thermistor For LEV control

TH3 Liquid temperature thermistor Heating:Evaporating temperature Cooling:Sub cool liquid temperature

TH4 Discharge temperature thermistor For LEV control and for compressor protection

TH6

2-phase pipe temperature thermistor

Outdoor 2-phase pipe temperature

TH7 Ambient temperature thermistor For fan control and for compressor frequency control

TH8 Heat sink temperature

TH34 Comp. surface temperature thermistor For protection

Power Receiver

Power Receiver For accumulation of refrigerant

HIC Heat interchange circuit For high heating capacity

Plate HEX Plate Heat Exchanger MWA2-38PA (MITSUBISHI)

<Reference>

System example

TH1

Outlet water temperature thermistor For ow temp. controller

TH2

Liquid pipe temperature thermistor For ow temp. controller

15

OCH594B

TROUBLESHOOTING8

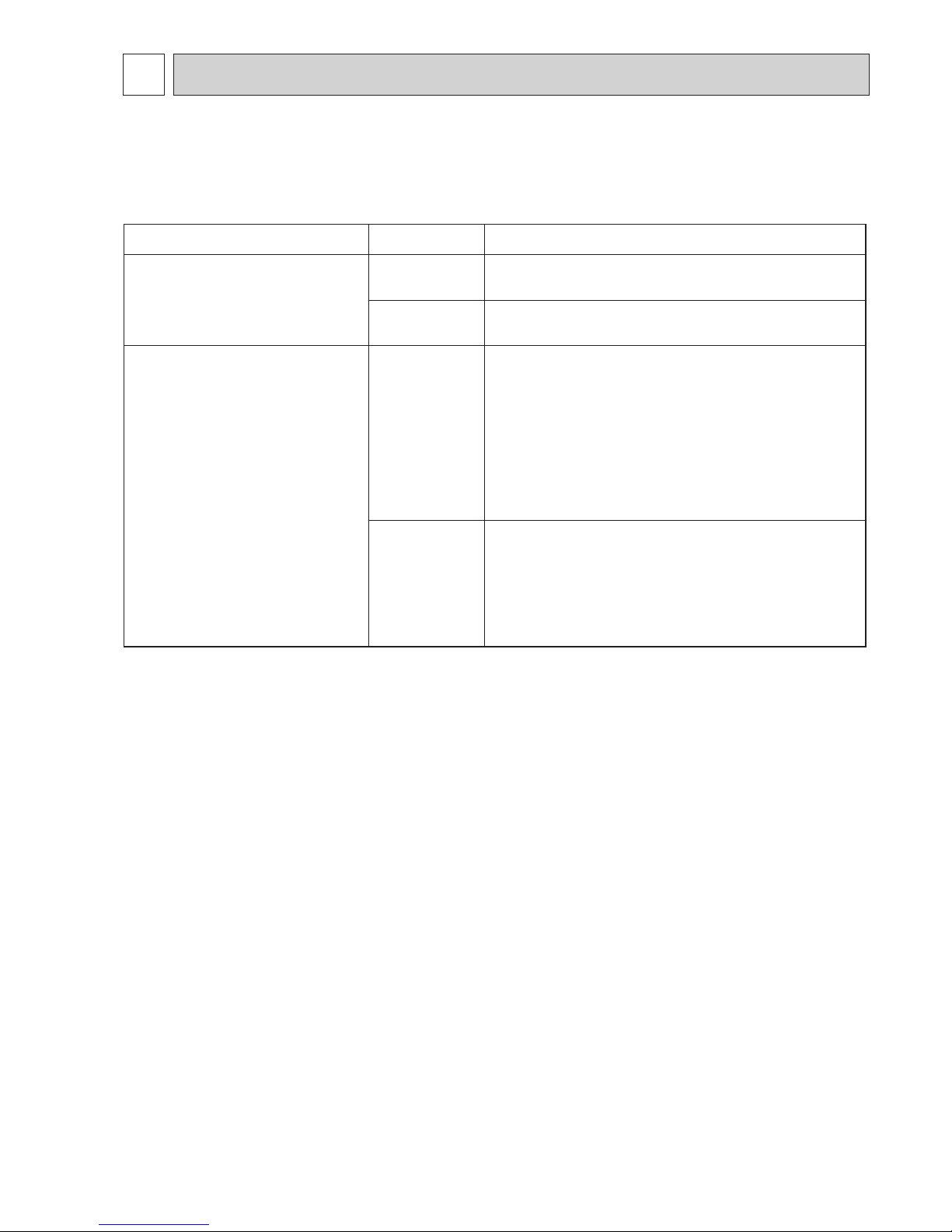

<Check code displayed by self-diagnosis and actions to be taken for service (summary)>

Present and past check codes are logged, and they can be displayed on the control board of outdoor unit. Actions to be taken

for service, which depends on whether or not the trouble is reoccurring in the field, are summarized in the table below. Check

the contents below before investigating details.

8-1. TROUBLESHOOTING

Unit conditions at service Check code Actions to be taken for service (summary)

The trouble is reoccurring.

Displayed

Judge the problem and take a corrective action according to

“8-3. SELF-DIAGNOSIS ACTION TABLE”.

Not displayed

Conduct troubleshooting and ascertain the cause of the

trouble.

The trouble is not reoccurring.

Logged

1

Consider the temporary defects such as the work of

protection devices in the refrigerant circuit including

compressor, poor connection of wiring, noise, etc. Recheck the symptom, and check the installation environment,

refrigerant amount, weather when the trouble occurred,

matters related to wiring, etc.

2

Reset check code logs and restart the unit after nishing

service.

3

There is no abnormality in electrical component, controller

board, etc.

Not logged

1

Re-check the abnormal symptom.

2

Conduct troubleshooting and ascertain the cause of the

trouble.

3

Continue to operate unit for the time being if the cause is

not ascertained.

4

There is no abnormality concerning of parts such as

electrical component, controller board, etc.

16

OCH594B

8-2. CHECKPOINT UNDER TEST RUN

Before test run

• After installation of outdoor unit, piping work and electric wiring work, re-check that there is no water leakage, loosened con-

nections and incorrect polarity.

• Measure impedance between the ground and the power supply terminal block (L, N) on the outdoor unit by 500 V Megger

and check that it is 1.0 M

or over.

• Turn on power supply 12 hours before test run in order to protect compressor.

• Make sure to read operation manual before test run. (Especially items to secure safety.)

Warning:

Do not use the system if the insulation resistance is less than 1.0 MΩ.

Caution:

Do not carry out this test on the control wiring (low voltage circuit) terminals.

Self-check

1

Turn on the power.

2

Press [CHECK] button twice.

3

Press [CHECK] button twice to nish self-check.

A

CHECK button B IC : Interface or FTC unit OC : Outdoor unit C Check code

Check code Symptom

P1 Flow water (TH1) sensor error

P2 Refrigerant liquid Pipe (TH2) sensor error

P6 Freezing/Overheating protection operation

P9 Actual tank temp. (TH5)/ (THW5 for FTC2B) sensor error

Fb FTC unit control system error (memory error, etc.)

E0–E5 Signal transmission failure between remote controller and FTC.

E6–EF Signal transmission failure between outdoor unit and FTC.

– – – – No trouble generated in the past.

FFFF No corresponding unit

U*, F* Outdoor unit failure. Refer to the outdoor unit wiring diagram.

For description of each LED (LED1–5) provided on the FTC, refer to the following table.

LED 1 (Power for microprocessor) Indicates whether control power is supplied. Make sure that this LED is always lit.

LED 2 (Power for remote controller) Indicates whether power is supplied to the remote controller. This LED lights only in

the case of the FTC unit which is connected to the outdoor unit refrigerant address “0“.

LED 3 (Communication between FTC

and outdoor unit)

Indicates state of communication between the FTC and outdoor unit. Make sure that

this LED is always blinking.

LED 4 —

LED 5 —

ON/OFF

TEMP.

ERROR CODE

B

A

C

17

OCH594B

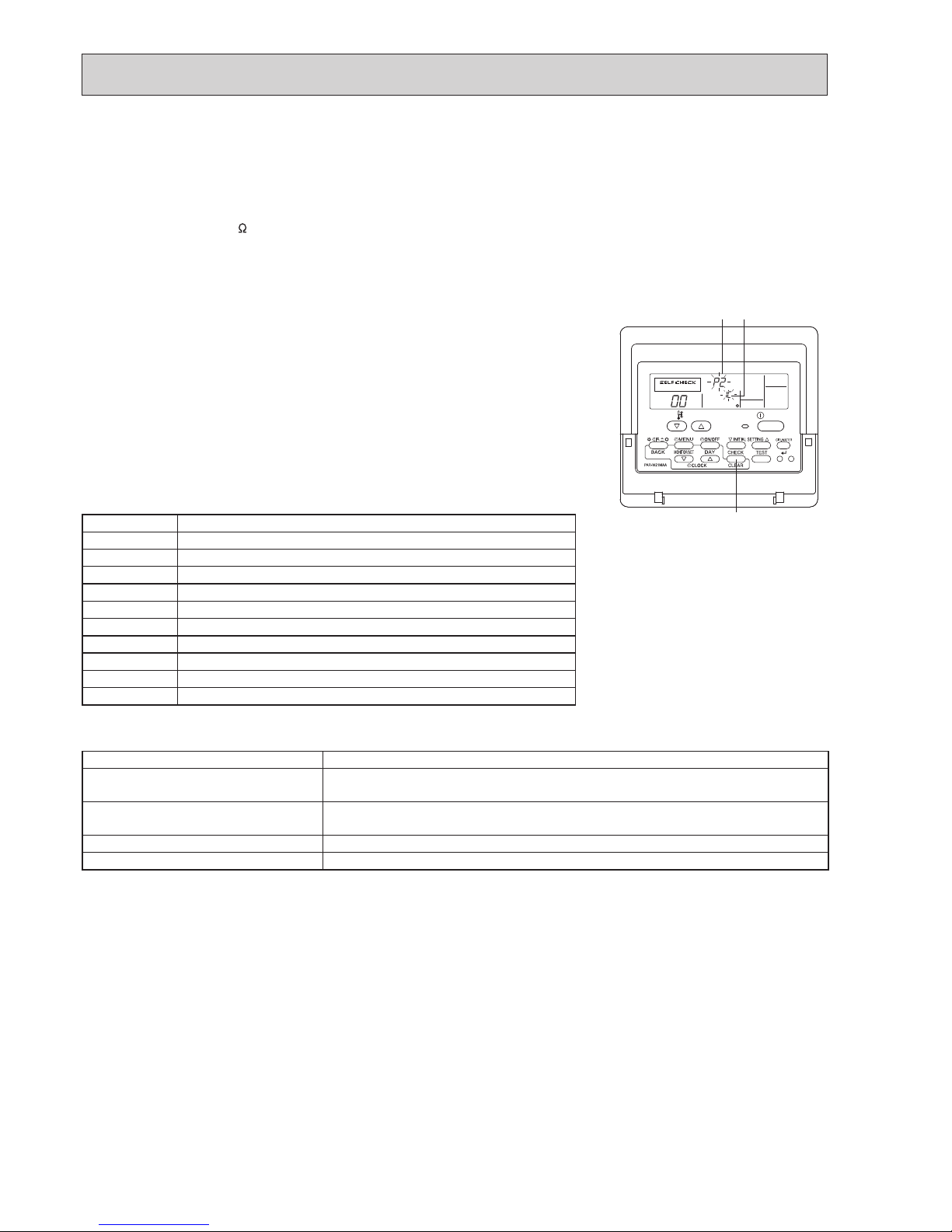

8-3. SELF-DIAGNOSIS ACTION TABLE

<Abnormalities detected when the power is turned on>

Check Code

Abnormal point and detection method

Case

Judgment and action

None —

1 No voltage is supplied to termi-

nal block (TB1) of outdoor unit.

a) Power supply breaker is

turned off.

b) Contact failure or disconnec-

tion of power supply terminal

c) Open phase (L or N phase)

2 Electric power is not charged to

power supply terminal of outdoor power circuit board.

a) Contact failure of power

supply terminal

b) Open phase on the outdoor

power circuit board

3 Electric power is not supplied

to outdoor controller circuit

board.

a) Disconnection of connector

(CNDC)

4 Disconnection of reactor (DCL)

5 Disconnection of outdoor noise

filter circuit board or parts failure in outdoor noise filter circuit

board

6

Defective outdoor power circuit board

7

Open of rush current resistor (RS)

(Only for YKA2R2 type)

8 Defective outdoor controller cir-

cuit board

1 Check following items.

a) Power supply breaker

b) Connection of power supply terminal block

(TB1)

c) Connection of power supply terminal block

(TB1)

2 Check following items.

a) Connection of power supply terminal block

(TB1)

b) Connection of terminal on outdoor

power circuit board

3 Check connection of the connector (CNDC)

on the outdoor controller circuit board.

Check connection of the connector CNDC on

the outdoor noise filter. Refer to "8-7. TEST

POINT DIAGRAM".

4 Check connection of reactor. (DCL)

5 a) Check connection of outdoor noise filter

circuit board.

b) Replace outdoor noise filter circuit board.

Refer to "8-7. TEST POINT DIAGRAM".

6 Replace outdoor power circuit board.

7 Replace rush current protect resistor (RS).

Power circuit board might be short-circuit.

Check the power circuit board.

(Refer to "8-7. TEST POINT DIAGRAM".)

(Only for YKA2R2 type)

8 Replace controller board (When items above

are checked but the units cannot be repaired).

F5

63H connector open

Abnormal if 63H connector circuit is open

for 3 minutes continuously after power supply.

63H: High pressure switch

1 Disconnection or contact failure

of 63H connector on outdoor

controller circuit board

2 Disconnection or contact failure

of 63H

3 63H is working due to defective

parts.

4 Defective outdoor controller cir-

cuit board

1 Check connection of 63H connector on out-

door controller circuit board.

Refer to "8-7. TEST POINT DIAGRAM".

2 Check the 63H side of connecting wire.

3 Check continuity by tester.

Replace the parts if the parts are defective.

4 Replace outdoor controller circuit board.

F3

63L connector open

Abnormal if 63L connector circuit is open

for 3 minutes continuously after power supply.

63L: Low pressure switch

1 Disconnection or contact failure

of 63L connector on outdoor

controller circuit board

2 Disconnection or contact failure

of 63L

3 63L is working due to refriger-

ant leakage or defective parts.

4 Defective outdoor controller cir-

cuit board

1 Check connection of 63L connector on

outdoor controller circuit board.

Refer to "8-7. TEST POINT DIAGRAM".

2 Check the 63L side of connecting wire.

3 Check refrigerant pressure.

Charge additional refrigerant.

Check continuity by tester.

Replace the parts if the parts are defective.

4 Replace outdoor controller circuit board.

F9

2 connector open

Abnormal if both 63H and 63L connector

circuits are open for three minutes continuously after power supply.

63H: High pressure switch

63L: Low pressure switch

1 Disconnection or contact failure

of connector (63H,63L) on outdoor controller circuit board.

2 Disconnection or contact failure

of 63H, 63L

3 63H and 63L are working due

to defective parts.

4 Defective outdoor controller

board.

1 Check connection of connector (63H,63L) on

outdoor controller circuit board.

Refer to "8-7. TEST POINT DIAGRAM".

2 Check the 63H and 63L side of connecting

wire.

3 Check continuity by tester.

Replace the parts if the parts are defective.

4 Replace outdoor controller circuit board.

18

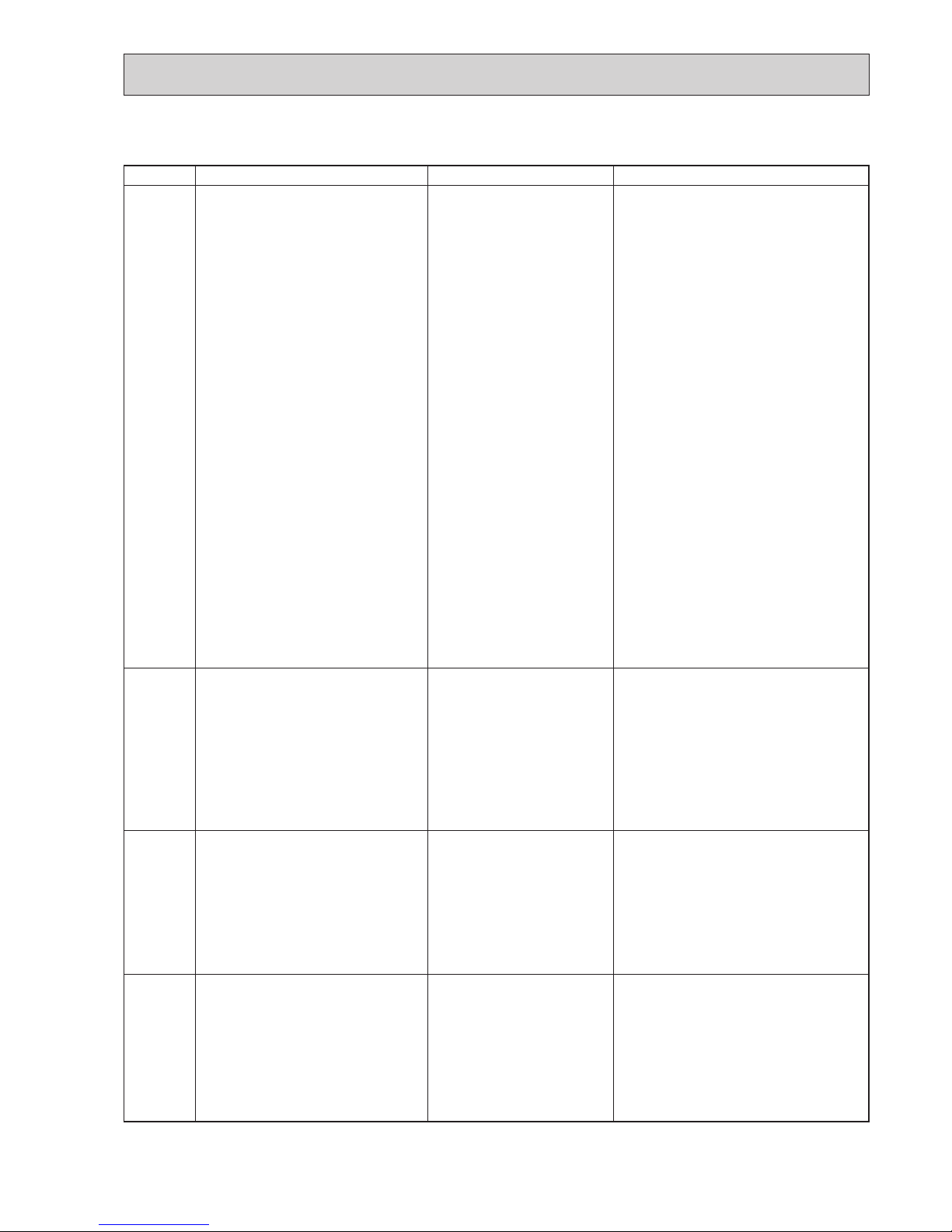

OCH594B

Abnormal point and detection method

Judgment and action

Case

Eb

Miswiring of Interface unit/Flow temp.

controller-outdoor unit connecting wire

(reverse wiring or disconnection)

Outdoor controller circuit board can automatically set the unit number of Interface

unit/Flow temp. controller.

Abnormal if the Interface unit/Flow temp.

controller number cannot be set within 4

minutes after power on because of miswiring (reverse wiring or disconnection) of

Interface unit/Flow temp. controller-outdoor

unit connecting wire.

EC

Startup time over

The unit cannot finish start up process

within 4 minutes after power on.

Contact failure of Interface unit

/Flow temp. controller-outdoor

unit connecting wire

Diameter or length of Interface

unit/Flow temp. controlleroutdoor unit connecting wire is

out of specified capacity.

Noise has entered into power supply or Interface unit/Flow temp.

controller-outdoor unit connecting

wire.

Contact failure or miswiring of

Interface unit/Flow temp. control

-

ler-outdoor unit connecting wire

Diameter or length of Interface

unit/Flow temp. controller-outdoor unit connecting wire is out

of specified capacity.

Defective transmitting receiving circuit

of outdoor controller circuit board

Defective transmitting receiving

circuit of Interface/Flow temp.

controller board

Noise has entered into power supply

or Interface unit/Flow temp. control

-

ler-outdoor unit connecting wire.

Miswiring of Interface unit/Flow temp.

controller-outdoor unit connecting wire

1. Outdoor controller circuit board can

automatically check the number of connected Interface unit/Flow temp. controller. Abnormal if the number cannot be

checked automatically due to miswiring

of Interface unit/Flow temp. controlleroutdoor unit connecting wire, etc. after

power is turned on for 4 minutes.

2. Abnormal if outdoor controller circuit

board recognizes excessive number of

Interface unit/Flow temp. controller.

Check disconnection or looseness or polarity

of Interface unit/Flow temp. controller-outdoor

unit connecting wire of Interface unit/Flow

temp. controller and outdoor units.

Check diameter and length of Interface unit/

Flow temp. controller-outdoor unit connecting

wire.

Total wiring length: 80 m

(Including wiring connecting each Interface

unit/Flow temp. controller unit and between

Interface unit/Flow temp. controller and out-

door unit)

Also check if the connection order of flat

cable is S1, S2, S3.

Check the number of Interface unit/Flow

temp. controller that is connected to 1 out-

door unit. (If EA is detected.)

– Turn the power off once, and on again to

check.

Replace outdoor controller circuit board

or Interface/Flow temp. controller board if

abnormality occurs again.

Check transmission path, and remove the

cause.

Note: The descriptions above,

– , are for EA,

Eb and EC.

Contact failure or miswiring of

Interface unit/Flow temp. controlleroutdoor unit connecting wire

Diameter or length of Interface

unit/Flow temp. controller-outdoor unit connecting wire is out

of specified capacity.

Excessive number of Interface

unit/Flow temp. controller is

connected to 1 outdoor unit.

(2 units or more)

Defective transmitting receiv-

ing circuit of outdoor controller

circuit board

Defective transmitting receiving

circuit of Interface/Flow temp.

controller board

Noise has entered into power

supply or Interface/Flow temp.

controller-outdoor unit connecting wire.

EA

Check Code

19

OCH594B

Abnormal point and detection method Judgment and action

U1

High pressure (High pressure switch

63H operated)

Abnormal if high pressure switch 63H operated(*) during compressor operation.

*4.15 MPa

63H: High pressure switch

1 Short cycle of indoor unit

2 Clogged filter of indoor unit

3 Decreased airflow caused by

dirt of indoor fan

4 Dirt of indoor heat exchanger

5 Locked indoor fan motor

6 Malfunction of indoor fan motor

7 Defective operation of stop

valve (Not full open)

8 Clogged or broken pipe

9 Locked outdoor fan motor

0 Malfunction of outdoor fan

motor

1 Short cycle of outdoor unit

2 Dirt of outdoor heat exchanger

3 Decreased airflow caused by

defective inspection of outside

temperature thermistor

(It detects lower temperature

than actual temperature.)

4 Disconnection or contact failure

of connector (63H) on outdoor

controller board

5 Disconnection or contact failure

of 63H connection

6 Defective outdoor controller

board

7 Defective action of linear

expansion valve

8 Malfunction of fan driving circuit

1–6 Check indoor unit and repair defectives.

7 Check if stop valve is fully open.

8 Check piping and repair defect.

9–2 Check outdoor unit and repair defect.

3 Check the detected temperature of outside

temperature thermistor on LED display.

(SW2 on A-Control Service Tool : Refer

to "8-8. FUNCTION OF SWITCHES,

CONNECTORS AND JUMPERS".)

4–6 Turn the power off and check F5 is dis-

played when the power is turned again.

When F5 is displayed, refer to “Judgment

and action” for F5.

7 Check linear expansion valve.

Refer to "8-6. HOW TO CHECK THE

COMPONENTS".

8 Replace outdoor controller board.

Case

U2

<Abnormalities detected while unit is operating>

U3

Open/short circuit of discharge

temperature thermistor (TH4)/Comp.

surface temperature thermistor (TH34)

Abnormal if open (3: or less) or short

(217: or more) is detected during

compressor operation.

(Detection is inoperative for 10 minutes

of compressor starting process and for 10

minutes after and during defrosting.)

1 Disconnection or contact

failure of connector (TH4/

TH34) on the outdoor

controller circuit board

2 Defective thermistor

3

Defective outdoor controller circuit board

1 Check connection of connector (TH4/TH34)

on the outdoor controller circuit board.

Check breaking of the lead wire for

thermistor (TH4/TH34). Refer to "8-7. TEST

POINT DIAGRAM".

2 Check resistance value of thermistor (TH4/

TH34) or temperature by microprocessor.

(Thermistor/TH4, TH34: Refer to "8-4.

TROUBLESHOOTING".)

(SW2 on A-Control

Service Tool: Refer to "8-8. FUNCTION OF

SWITCHES, CONNECTORS AND JUMPERS".)

3 Replace outdoor controller board.

High discharge temperature

(1) Abnormal if discharge temperature ther-

mistor (TH4) exceeds 125: or 110:

continuously for 5 minutes.

Abnormal if discharge temperature ther-

mistor (TH4) exceeds 110: or more

continuously for 30 seconds after 90

seconds have passed since the defrosting operation started.

(2) Abnormal if discharge superheat

(Cooling: TH4−T

63HS /

Heating: TH4−T63HS)

exceeds 70: continuously for 10 min-

utes.

High comp. surface temperature

Abnormal if comp. surface temperature

(TH34) exceeds 125:.

In the case of high comp. surface

temperature error, compressor does

not restart unless the thermistor (TH34)

becomes less than 95:.

1 Overheated compressor opera-

tion caused by shortage of

refrigerant

2 Defective operation of stop

valve

3 Defective thermistor

4 Defective outdoor controller

board

5 Defective action of linear

expansion valve

6 Clogging with foreign objects in

refrigerant circuit

Note: Clogging occurs in the

parts which become below

freezing point when water

enters in refrigerant circuit.

7 In the case of the unit does not

restart:

Detection temp. of thermistor

(TH34) ] 95:

1 Check intake superheat.

Check leakage of refrigerant.

Charge additional refrigerant.

2 Check if stop valve is fully open.

34 Turn the power off and check if U3 is dis-

played when the power is turned on again.

When U3 is displayed, refer to “Judgment

and action” for U3.

5 Check linear expansion valve.

Refer to "8-6. HOW TO CHECK THE

COMPONENTS".

6 After recovering refrigerant, remove water

from entire refrigerant circuit under vacuum

more than 1 hour.

Check Code

20

OCH594B

Abnormal point and detection method

Case

Judgment and action

U5

Temperature of heat sink

Abnormal if heat sink thermistor (TH8)

detects 95:

1 The outdoor fan motor is

locked.

2 Failure of outdoor fan motor

3 Airflow path is clogged.

4 Rise of ambient temperature

5 Defective thermistor

6 Defective input circuit of

outdoor power circuit board

7

Failure of outdoor fan drive circuit

12 Check outdoor fan.

3 Check airflow path for cooling.

4 Check if there is something which causes

temperature rise around outdoor unit.

(Upper limit of ambient temperature is 46:.)

Turn off power, and on again to check if U5 is

displayed within 30 minutes.

If U4 is displayed instead of U5, follow the

action to be taken for U4.

5 Check the thermistor (TH8) temperature by

microprocessor.

(SW2 on A-Control Service

Tool: Refer to

"8-7. TEST POINT DIAGRAM".

)

6 Replace outdoor power circuit board.

7 Replace outdoor controller circuit board.

U4

Open/short of outdoor unit thermistors

(TH3, TH32, TH6, TH7 and TH8)

Abnormal if open or short is detected

during compressor operation.

Open detection of thermistors TH3, TH32

and TH6 is inoperative for 10 seconds to

10 minutes after compressor starting and

10 minutes after and during defrosting.

Notes: 1. Check which unit has abnormality in

its thermistor by switching the mode of

SW2. (PAC-SK52ST) (Refer to "8-7.

TEST POINT DIAGRAM".)

2.

Heat sink thermistor (TH8) is in the

power module. (YKA2/YKA2R1)

1

Check connection of connector (TH3, TH32,

TH7/6) on the outdoor controller circuit board.

Check connection of connector (CN3) on the

outdoor power circuit board. Check break

ing of the lead wire for thermistor (TH3, TH32,

TH6,TH7,TH8).

Refer to "8-7. TEST POINT DIAGRAM".

2

Check resistance value of thermistor (TH3, TH32,

TH6,TH7,TH8) or check temperature by micro

processor. (Thermistor/TH3,TH6,TH7,TH32,TH8:

Refer to "8-5. HOW TO CHECK THE PARTS".)

(SW2 on A-Control Service Tool: Refer to "8-8.

FUNCTION OF SWITCHES, CONNECTORS

AND JUMPERS".)

3 Replace outdoor controller circuit board.

1 Disconnection or contact failure

of connectors

Outdoor controller circuit board

:

TH3, TH32, TH7/6

Outdoor power circuit board

:

CN3

2 Defective thermistor

3 Defective outdoor controller

circuit board

( )

U6

Power module

Check abnormality by driving power module

in case overcurrent is detected.

(UF or UP error condition)

1 Outdoor stop valve is closed.

2 Decrease of power supply voltage

3 Looseness, disconnection or

reverse of compressor wiring

connection

4 Defective compressor

5 Defective outdoor power circuit board

1 Open stop valve.

2 Check facility of power supply.

3 Correct the wiring (U

•V•

W phase) to

compressor. Refer to "8-7. TEST POINT

DIAGRAM" (Outdoor power circuit board).

4 Check compressor referring to "8-5. HOW TO

CHECK THE PARTS".

5 Replace outdoor power circuit board.

U7

Too low superheat due to low discharge

temperature

Abnormal if discharge superheat is

continuously detected less than or equal

to −15: for 3 minutes even though linear

expansion valve has minimum open pulse

after compressor starts operating for 10

minutes.

1 Disconnection or loose

connection of discharge

temperature thermistor (TH4)

2 Defective holder of discharge

temperature thermistor

3 Disconnection or loose connection

of linear expansion valve’s coil

4 Disconnection or loose

connection of linear expansion

valve’s connector

5 Defective linear expansion valve

12 Check the installation conditions of

discharge temperature thermistor (TH4).

3 Check the coil of linear expansion valve.

Refer to "8-6. HOW TO CHECK THE COMPONENTS".

4

Check the connection or contact of LEV-A

and LEV-B on outdoor controller circuit board.

5 Check linear expansion valve.

Refer to "8-6. HOW TO CHECK THE COMPONENTS".

Thermistors

Open detection Short detection

Symbol Name

TH3 Thermistor <Liquid> −40°C or below 90°C or above

TH32 Thermistor <Suction> −40°C or below 90°C or above

TH6 Thermistor <2-phase pipe> −40°C or below 90°C or above

TH7 Thermistor <Ambient> −40°C or below 90°C or above

TH8 (YKA2/YKA2R1) Internal thermistor −35°C or below 170°C or above

TH8 (YKA2R2) Thermistor <Heat sink> −34°C or below 102°C or above

U8

Outdoor fan motor

Abnormal if rotational frequency of the fan

motor is not detected during DC fan motor

operation.

Fan motor rotational frequency is abnormal

if;

• 100 rpm or below detected continuously

for 15 seconds at 20: or more outside

air temperature.

• 50 rpm or below or 1500 rpm or more

detected continuously for 1 minute.

1 Failure in the operation of the

DC fan motor

2 Failure in the outdoor circuit

controller board

1 Check or replace the DC fan motor.

2 Check the voltage of the outdoor circuit

controller board during operation.

3 Replace the outdoor circuit controller board.

(When the failure is still indicated even after

performing the action 1 above.)

Check Code

Loading...

Loading...