Page 1

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

TECHNICAL & SERVICE MANUAL

R410A

Outdoor unit

[model names]

[Service Ref.]

No.OC317

PUHZ-RP8YHA

PUHZ-RP10YHA

PUHZ-RP8YHA

PUHZ-RP10YHA

CONTENTS

1. SAFETY PRECAUTION·······································2

2.

COMBINATION OF INDOOR AND OUTDOOR UNITS

3. FEATURES···························································7

4. SPECIFICATIONS ················································8

5. DATA ····································································9

6. OUTLINES AND DIMENSIONS·························11

7. WIRING DIAGRAM············································12

8. WIRING SPECIFICATIONS ·······························13

9. SPECIFICATIONS FOR ELECTRICAL WORK ····14

10.

REFRIGERANT SYSTEM DIAGRAM

11. CAPACITY CURVES ··········································18

12.APPLICABLE EXTENSION PIPE FOR EACH MODEL ···19

13. TROUBLESHOOTING········································25

14. DISASSEMBLY PROCEDURE ··························71

15. PARTS LIST ·······················································79

Model name

indication

16. OPTIONAL PARTS ······························BackCover

····6

···················17

PUHZ-RP8YHA

PUHZ-RP10YHA

Page 2

1 SAFETY PRECAUTION

Use new refrigerant pipes.

Make sure that the inside and outside of refrigerant piping is clean and it has no contamination

such as sulfur hazardous for use, oxides, dirt,

shaving particles, etc.

In addition, use pipes with specified thickness.

Store the piping to be used during installation

indoors and keep both ends of the piping sealed

until just before brazing. (Leave elbow joints, etc.

in their packaging.)

Use ester oil, ether oil or alkylbenzene oil (small

amount) as the refrigerant oil applied to flares

and flange connections.

In case of using the existing pipes for R22, be careful with

the followings.

· Change flare nut to the one provided with this product.

Use a newly flared pipe.

· Avoid using thin pipes.

Charge refrigerant from liquid phase of gas

cylinder.

If the refrigerant is charged from gas phase, composition

change may occur in refrigerant and the efficiency will be

lowered.

Do not use refrigerant other than R410A.

If other refrigerant (R22 etc.) is used, chlorine in refrigerant can cause deterioration of refrigerant oil etc.

Use a vacuum pump with a reverse flow check

valve.

Vacuum pump oil may flow back into refrigerant cycle and

that can cause deterioration of refrigerant oil etc.

Use the following tools specifically designed for

use with R410A refrigerant.

The following tools are necessary to use R410A refrigerant.

Keep the tools with care.

If dirt, dust or moisture enter into refrigerant cycle, that can

cause deterioration of refrigerant oil or malfunction of compressor.

Do not use a charging cylinder.

If a charging cylinder is used, the composition of refrigerant will change and the efficiency will be lowered.

Flare tool

Electronic refrigerant

charging scale

Vacuum pump adaptor

Size adjustment gauge

Gauge manifold

Torque wrench

Gas leak detector

Charge hose

Tools for R410A

Contamination inside refrigerant piping can cause deterioration of refrigerant oil etc.

If dirt, dust or moisture enter into refrigerant cycle, that can

cause deterioration of refrigerant oil or malfunction of compressor.

If large amount of mineral oil enter, that can cause deterioration of refrigerant oil etc.

Ventilate the room if refrigerant leaks during

operation. If refrigerant comes into contact with

a flame, poisonous gases will be released.

1-1. CAUTIONS RELATED TO NEW REFRIGERANT

Cautions for units utilizing refrigerant R410A

2

Page 3

[1] Cautions for service

(1) Perform service after collecting the refrigerant left in unit completely.

(2) Do not release refrigerant in the air.

(3) After completing service, charge the cycle with specified amount of refrigerant.

(4) When performing service, install a filter drier simultaneously.

Be sure to use a filter drier for new refrigerant.

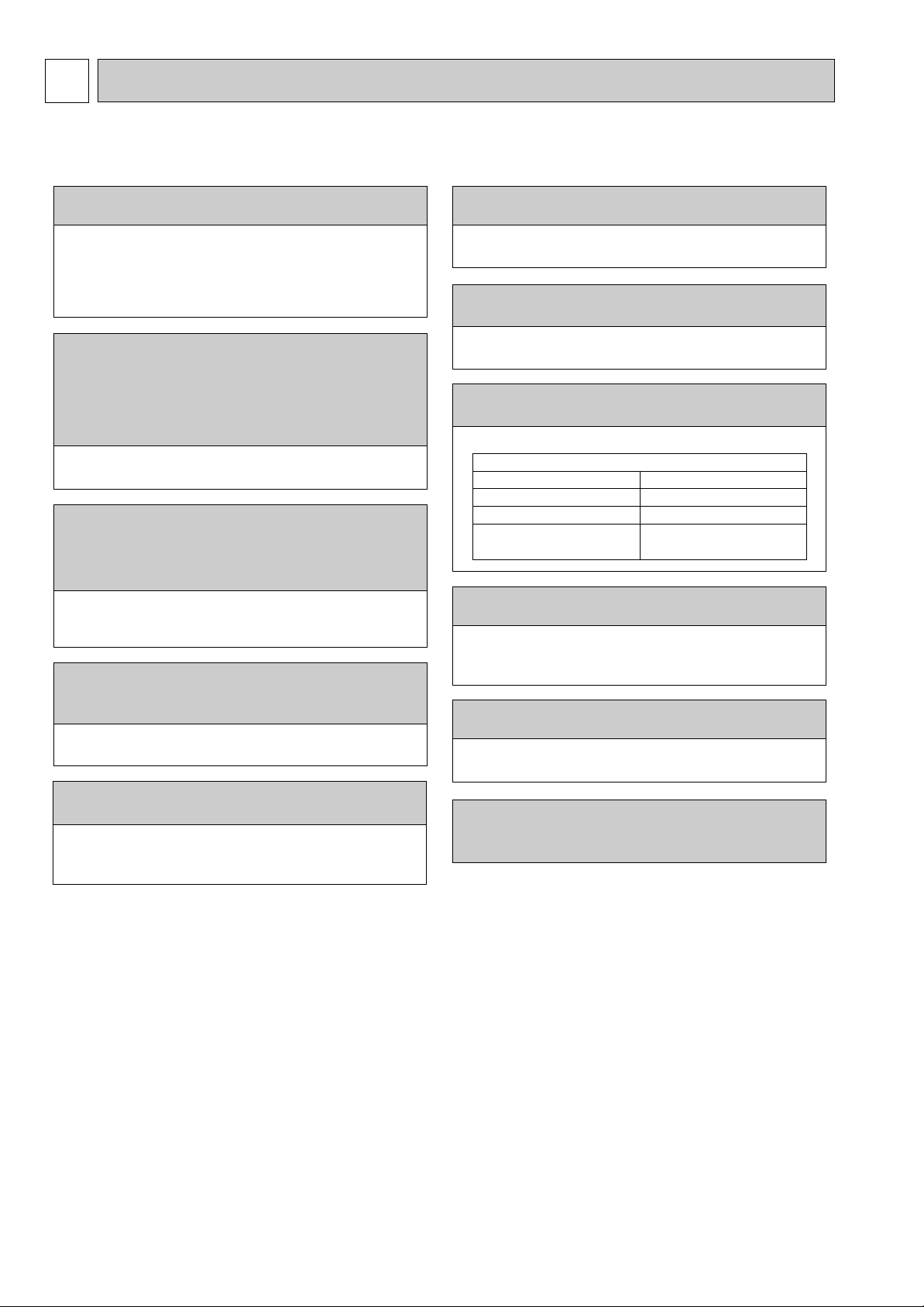

[2] Additional refrigerant charge

When charging directly from cylinder

· Check that cylinder for R410A on the market is syphon type.

· Charging should be performed with the cylinder of syphon stood vertically. (Refrigerant is charged from liquid phase.)

Unit

Gravimeter

[3] Service tools

Use the below service tools as exclusive tools for R410A refrigerant.

No. Specifications

1 Gauge manifold ·Only for R410A

·Use the existing fitting

·Use high-tension side pressure of 5.3MPa·G or over.

2 Charge hose ·Only for R410A

·Use pressure performance of 5.09MPa·G or over.

3 Electronic scale

4 Gas leak detector ·Use the detector for R134a, R407C or R410A.

5 Adaptor for reverse flow check ·Attach on vacuum pump.

6 Refrigerant charge base

7 Refrigerant cylinder ·Only for R410A Top of cylinder (Pink)

8 Refrigerant recovery equipment

specifications

Cylinder with syphon

. (UNF1/2)

3

Page 4

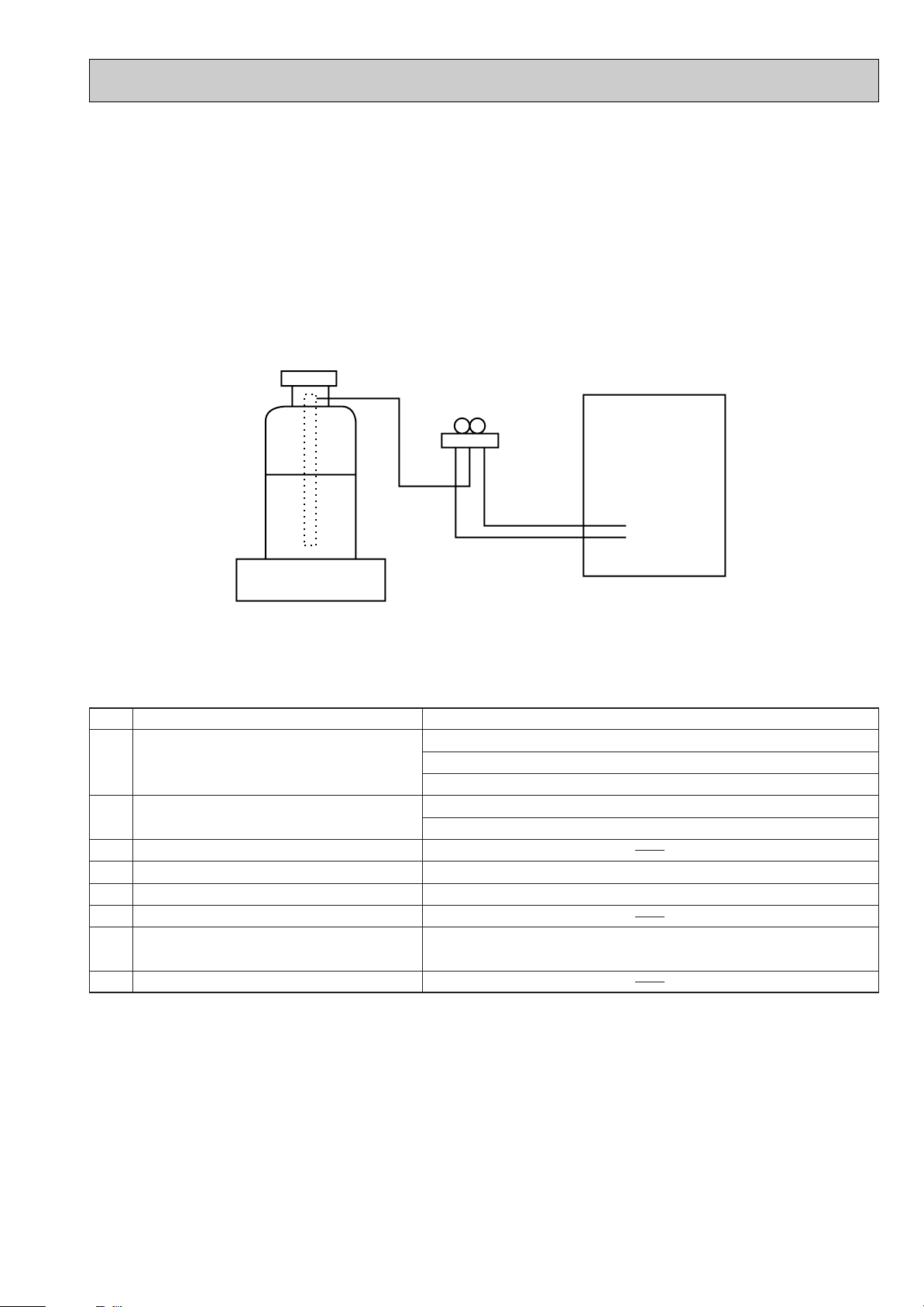

1-2. CHANGED POINT

Measure the existing pipe thickness and check

for damage.

The existing pipe thickness meets specifications and the pipes are not damaged.

The existing pipe thickness does not meet

specifications or the pipes are damaged.

Check if the existing air conditioner can operate.

The existing air conditioner can operate. The existing air conditioner cannot operate.

After operating the cooling system for about

30 minutes, do a pump down work.

Use a refrigerant collecting device to collect the refrigerant.

Check the oil condition when collecting the refrigerant.

Oil is clean. (Clear to brownish color)

Oil is dirty. (Black color)

When the compressor bearings are

glazed, rotation scratches are present,

or the compressor breaks down, iron

particles or oil deterioration will blacken

the oil.

Disconnect the existing air conditioner from

the pipes.

The existing piping can be reused.

After flaring the pipes again, connect the

new air conditioner.

The existing pipes cannot be reused.

Use new pipes.

Perform the following inspections: air

tightness test, vacuum dryness (additional

refrigerant charge), gas leakage check

Replacement operation

Test operation

Replacement operation is the operation by which impurities remaining in

the existing piping (chlorinated compounds) are captured by the activated

carbon filter (replacement filter) in the outdoor unit.

• This model will automatically begin the replacement operation after it has been

installed when it enters the initialization phase for normal heating or cooling. However , the unit will not automatically perf orm the replacement operation if it is moved

to a new location where it will be used with existing R22 refrigerant piping. Under

such conditions, always use the SW8-2 operations to perform the replacement

operation before beginning the test operation.

• Precautions when reusing existing R22 refrigerant pipes

(1) Flowchart

Connecting a new air conditioner to existing R22 refrigerant pipes

1 Flare the pipe for the use with R410A refrigerant.

Use the flare nut attached to indoor and outdoor unit of the new air conditioner only.

2 When reusing existing R22 refrigerant pipes of which gas pipe is [28.58mm and, in addition, when the outdoor unit is

installed to lower position than the indoor unit, be sure to change the setting of the DIP SW8-1 on the controller circuit

board of the outdoor unit to ON.

✽ This is to increase the speed of refrigerant passing in the gas pipe so that refrigerant oil can smoothly flow in the system.

• Use a different-diameter joint or brazing for the connection.

3 When reusing standard-size existing R22 refrigerant pipes.

The pipes can be reused with pipe length restriction described on 12-1.

4

Page 5

(2) Cautions for refrigerant piping work

1/4”

3/8”

1/2”

5/8”

3/4”

7/8”

1”

1”-1/8”

6.35

9.52

12.70

15.88

19.05

22.20

25.40

28.58

0.8

0.8

0.8

1.0

—

—

—

—

0.8

0.8

0.8

1.0

1.0

1.0

1.0

1.0

Nominal

dimensions

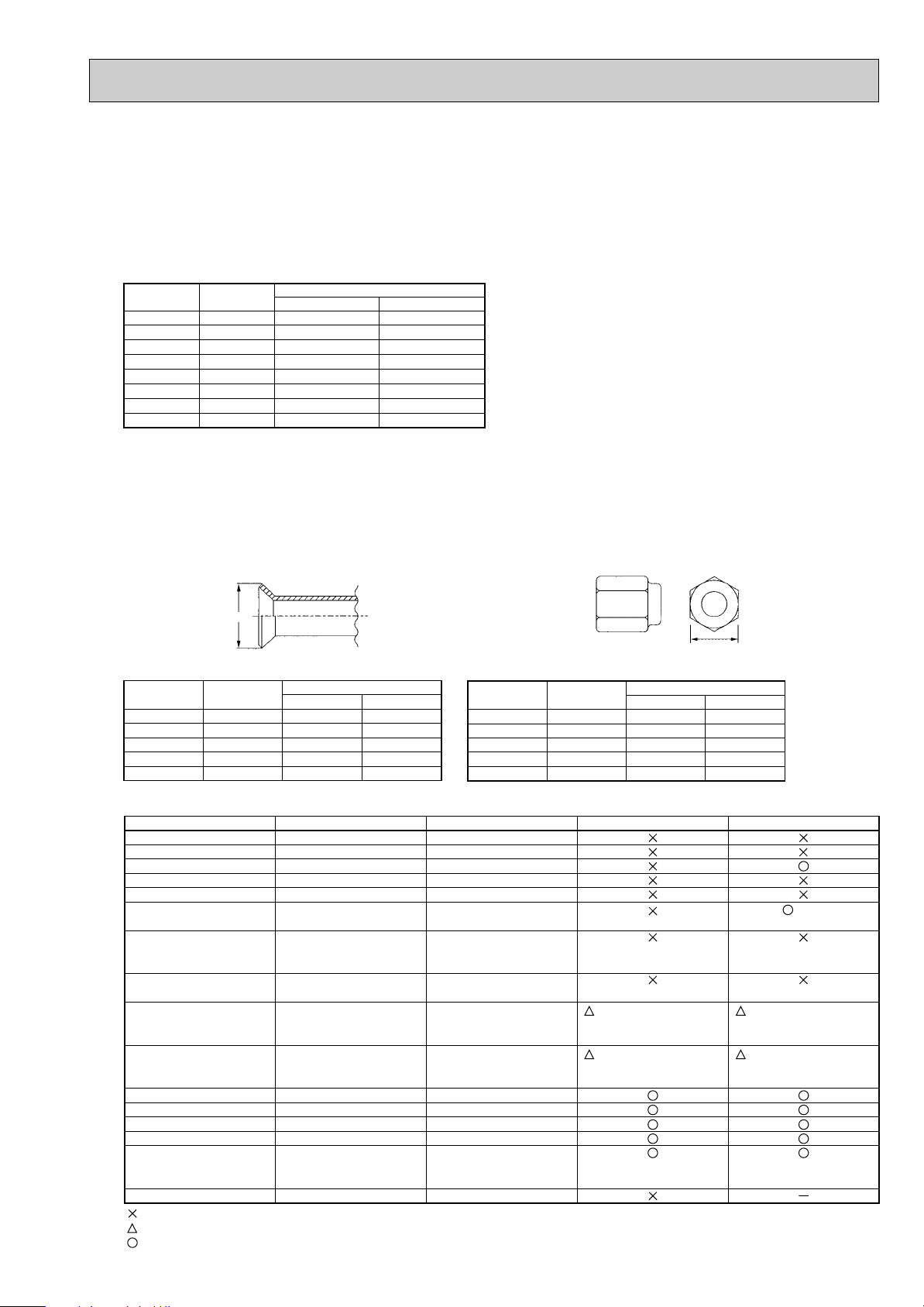

Diagram below: Piping diameter and thickness

Outside

diameter

(mm)

Thickness

(mm)

R410A R22

1/4”

3/8”

1/2”

5/8”

3/4”

6.35

9.52

12.70

15.88

19.05

9.1

13.2

16.6

19.7

—

9.0

13.0

16.2

19.4

23.3

Nominal

dimensions

Flare cutting dimensions

Outside

diameter

Dimension A

( )

+0

-0.4

(mm)

R410A R22

1/4”

3/8”

1/2”

5/8”

3/4”

6.35

9.52

12.70

15.88

19.05

17.0

22.0

26.0

29.0

—

17.0

22.0

24.0

27.0

36.0

Nominal

dimensions

Flare nut dimensions

Outside

diameter

Dimension B

(mm)

R410A

w

w36.0mm for

indoor unit

of RP4, 5

and 6

R22

Gauge manifold

Charge hose

Gas leak detector

Refrigerant recovery equipment

Refrigerant cylinder

Applied oil

Safety charger

Charge valve

Vacuum pump

Flare tool

Bender

Pipe cutter

Welder and nitrogen gas cylinder

Refrigerant charging scale

Vacuum gauge or thermistor vacuum gauge and

vacuum valve

Charging cylinder

Air purge and refrigerant charge

Operation check and the two above

Gas leak check

Collection of refrigerant

Refrigerant charge

Apply to flared section

Prevent compressor malfunction

when charging refrigerant by

spraying liquid refrigerant

Prevent gas from blowing out

when detaching charge hose

Vacuum drying and air

purge

Flaring work of piping

Bend the pipes

Cut the pipes

Weld the pipes

Charge refrigerant

Check the degree of vacuum. (Vacuum

valve prevents back flow of oil and refrigerant to thermistor vacuum gauge)

Charge refrigerant

Tool exclusive for R410A

Tool exclusive for R410A

Tool for HFC refrigerant

Tool exclusive for R410A

Tool exclusive for R410A

Ester oil and alkylbenzene

oil (minimum amount)

Tool exclusive for R410A

Tool exclusive for R410A

Tools for other refrigerants can

be used if equipped with adopter for reverse flow check

Tools for other refrigerants

can be used by adjusting

flaring dimension

Tools for other refrigerants can be used

Tools for other refrigerants can be used

Tools for other refrigerants can be used

Tools for other refrigerants can be used

Tools for other refrigerants

can be used

Tool exclusive for R410A

Tools and materials Use R410A tools Can R22 tools be used?

(Usable if equipped

with adopter for rever se flow)

(Usable by adjusting

flaring dimension)

Can R407C tools be used?

Ester oil:

Alkylbenzene oil: minimum amount

(Usable if equipped

with adopter for rever se flow)

(Usable by adjusting

flaring dimension)

: Prepare a new tool. (Use the new tool as the tool exclusive for R410A.)

: Tools for other refrigerants can be used under certain conditions.

: Tools for other refrigerants can be used.

New refrigerant R410A is adopted for replacement inverter series. Although the refrigerant piping work for R410Ais same

as for R22, exclusive tools are necessary so as not to mix with different kind of refrigerant. Furthermore as the working

pressure of R410A is 1.6 time higher than that of R22, their sizes of flared sections and flare nuts are different.

1Thickness of pipes

Because the working pressure of R410A is higher compared to R22, be sure to use refrigerant piping with thickness

shown below. (Never use pipes of 0.7mm or below.)

2Dimensions of flare cutting and flare nut

The component molecules in HFC refrigerant are smaller compared to conventional refrigerants. In addition to that,

R410A is a refrigerant, which has higher risk of leakage because of its working pressure higher than that of other refrigerants. Therefore, to enhance airtightness and intensity, flare cutting dimension of copper pipe for R410A have been specified separately from the dimensions for other refrigerants as shown below. The dimension B of flare nut for R410A also

have partly been changed to increase intensity as shown below. Set copper pipe correctly referring to copper pipe flaring

dimensions for R410A below. For 1/2” and 5/8”, the dimension B changes.

Use torque wrench corresponding to each dimension.

Dimension A

3Tools for R410A (The following table shows whether conventional tools can be used or not.)

5

Dimension B

Page 6

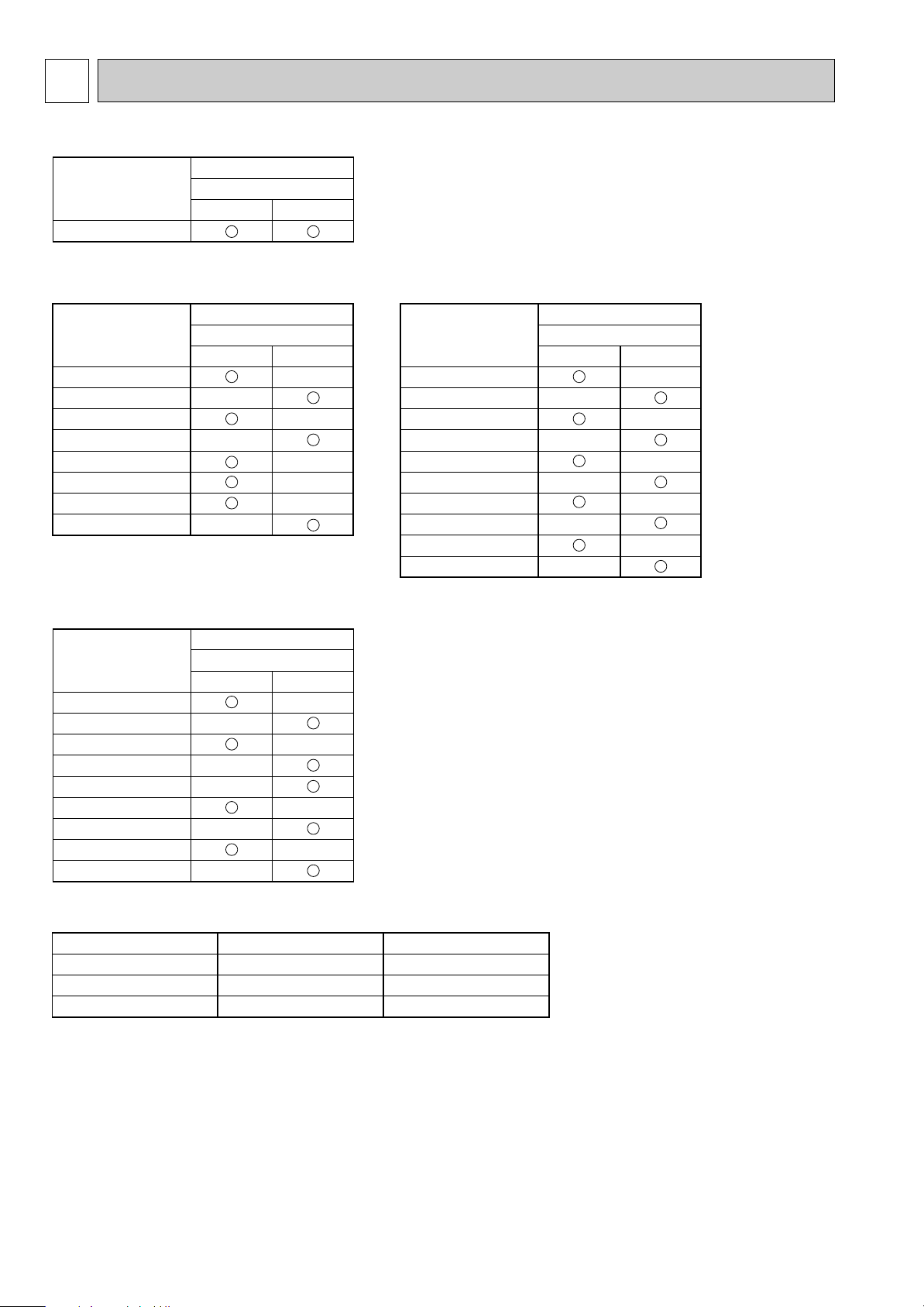

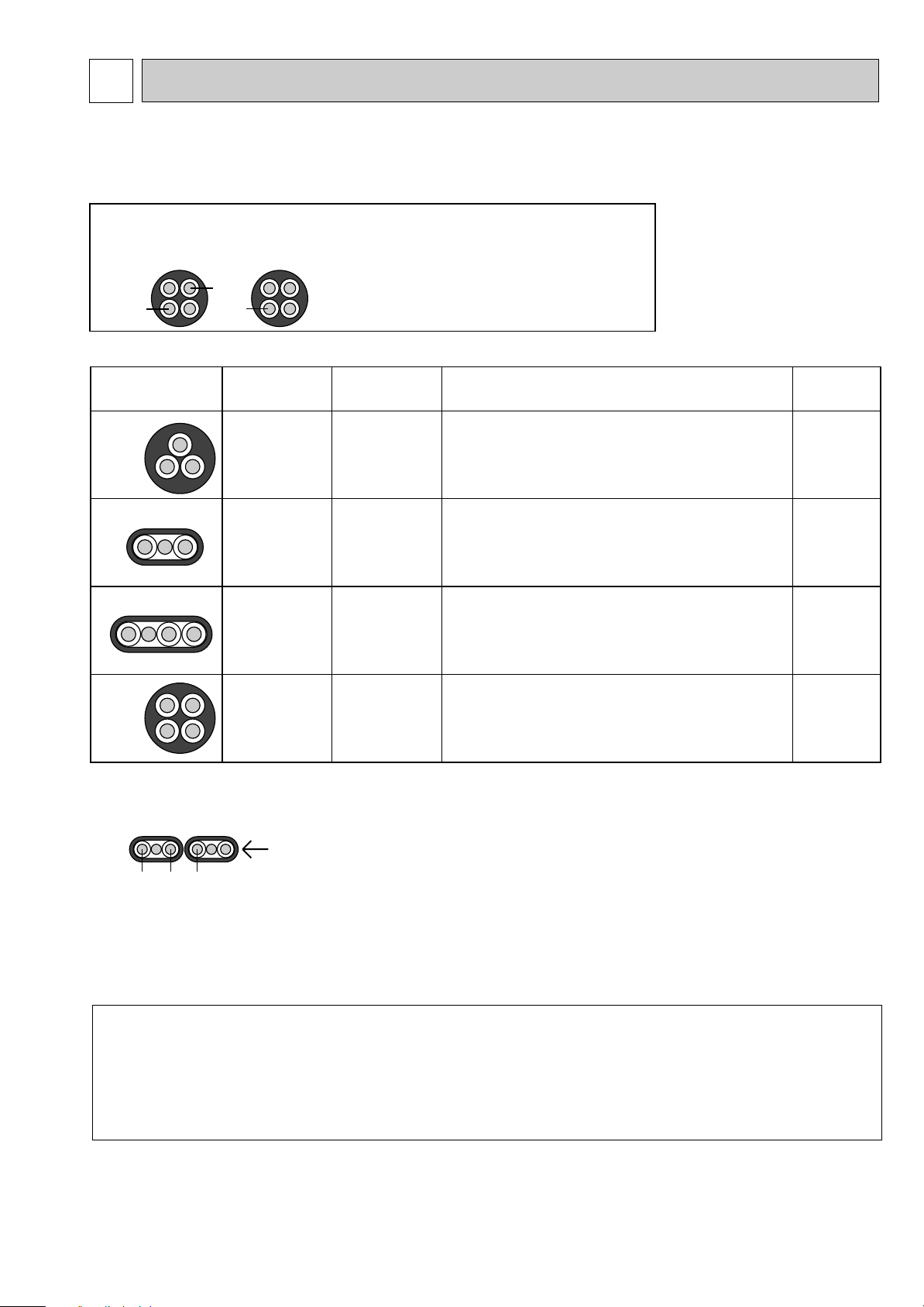

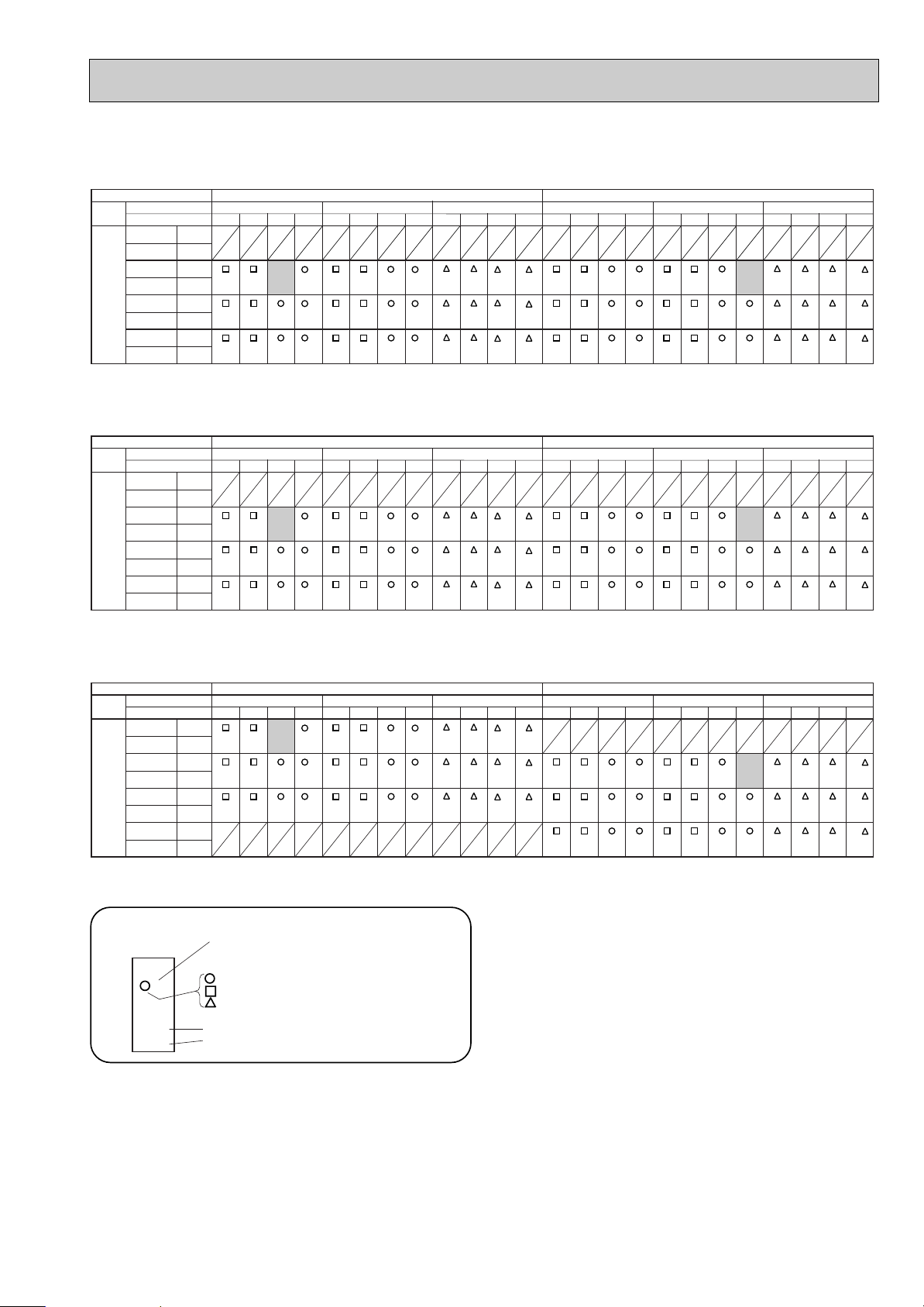

2 COMBINATION OF INDOOR AND OUTDOOR UNITS

2-1. 1:1 SYSTEM

Outdoor unit

Indoor unit

PEH-RP·MYA

2-2. SYNCHRONIZED TWIN, TRIPLE AND QUADRUPLE SYSTEM

(1) Synchronized twin (50:50) (2) Synchronized triple (33:33:33)

Indoor unit

PLA-RP4AA ✕ 2

PLA-RP5AA ✕ 2

PEAD-RP4EA ✕ 2

PEAD-RP5EA ✕ 2

PEAD-RP4GA ✕ 2

PKA-RP4FAL ✕ 2

PCA-RP4GA ✕ 2

PCA-RP5GA ✕ 2

PUHZ-RP·YHA

810

Outdoor unit

PUHZ-RP·YHA

810

Indoor unit

PLA-RP2.5AA ✕ 3

PLA-RP3AA ✕ 3

PEAD-RP2.5EA ✕ 3

PEAD-RP3EA ✕ 3

PEAD-RP2.5GA ✕ 3

PEAD-RP3GA ✕ 3

PKA-RP2.5FAL ✕ 3

PKA-RP3FAL ✕ 3

PCA-RP2.5GA ✕ 3

PCA-RP3GA ✕ 3

Outdoor unit

PUHZ-RP·YHA

810

(3) Synchronized quadruple (25:25:25:25)

Outdoor unit

Indoor unit

PLA-RP2AA ✕ 4

PLA-RP2.5AA ✕ 4

PEAD-RP2EA ✕ 4

PEAD-RP2.5EA ✕ 4

PEAD-RP2.5GA ✕ 4

PKA-RP2GAL ✕ 4

PKA-RP2.5FAL ✕ 4

PCA-RP2GA ✕ 4

PCA-RP2.5GA ✕ 4

PUHZ-RP·YHA

810

2-3. MULTI DISTRIBUTION PIPE (OPTION)

Ratio of distributing Part No.

Synchronized twin 50:50 MSDD-50WR-E

Synchronized triple 33:33:33 MSDT-111R-E

Synchronized quadruple 25:25:25:25 MSDF-1111R-E

6

Page 7

3 FEATURES

PUHZ-RP8YHA

PUHZ-RP10YHA

CHARGELESS SYSTEM

PRE-CHARGED REFRIGERANT IS SUPPLIED FOR PIPING LENGTH AT SHIPMENT.

(Max.30m)

The refrigerant circuit with LEV(Linear Expansion Valve) and accumulator always control the optimal refrigerant

level regardless of the length (30m max. and 5m min.) of piping. The additional refrigerant charging work during

installation often causes problems. Heretofore it is completely eliminated. This unique system improves the quality

and reliability of the work done.It also helps to speed up the installation time.

7

Page 8

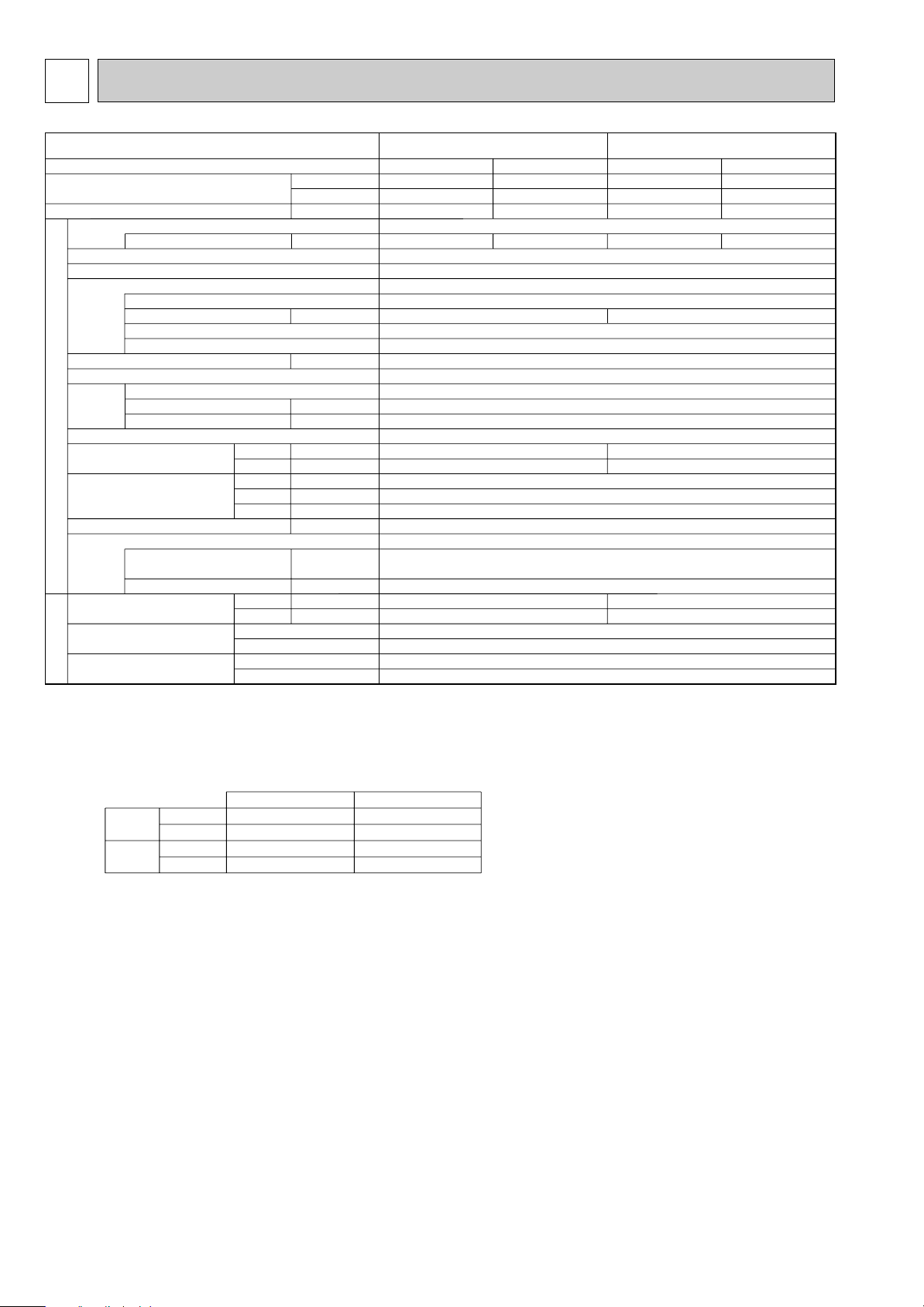

4 SPECIFICATIONS

Service Ref.

Function

Capacity

Total input

Power supply (phase, cycle, voltage)

External finish

Refrigerant control

Compressor

Crankcase heater

Heat exchanger

Fan Fan(drive) o No.

Defrost method

OUTDOOR UNIT

Noise level

Dimensions

Weight

Refrigerant

Pipe size O.D.

Connection method

Between the indoor &

outdoor unit

REFRIGERANT PIPING

Running current

Model

Motor output

Starter type

Protection devices

Fan motor output

Airflow

Charge

Oil (Model)

/min(CFM

K

Cooling

Heating

W

D

H

Liquid

Gas

Indoor side

Outdoor side

Height difference

Piping length

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

mm(in.)

mm(in.)

Btu/h

kW

kW

A

kW

W

kW

dB

dB

L

Cooling

64,800

19.0(10.0~22.4)

)

6.76

10.0

Heating

76,400

22.4(10.0~25.0)

6.98

3-ph, 50Hz, 380-400-415V (4wires)

10.4

Munsell 3Y 7.8/1.1

Linear Expansion Valve

Hermetic

ANV47FFBMT

4.5

Line start

HP switch, LP switch, Discharge thermo

Plate fin coil

Propeller fan o 1

0.635

150(5,300)

Reverse cycle

55

56

900(35-7/16)

750(29-17/32)

1,798(70-25/32)

198(436)

R410A

10.5(23.1)

2.30(MEL56)

9.52(3/8)

25.4(1)

Flared

Flared & Brazing

Max. 40m

Max. 80m

Cooling

75,000

22.0(12.5~28.0)

—

7.83

11.5

PUHZ-RP10YHAPUHZ-RP8YHA

Heating

92,100

27.0(15.7~31.5)

8.41

12.4

5.5

58

58

12.7(1/2)

28.58(1-1/8)

Notes1.Rating Conditions (ISO T1)

Cooling :Indoor : D.B. 27˚C(80˚F), W.B. 19˚C(66˚F) Outdoor : D.B. 35˚C(95˚F), W.B. 24˚C(75˚F)

Heating :Indoor : D.B. 20˚C(68˚F) Outdoor : D.B. 7˚C(45˚F), W.B. 6˚C(43˚F)

Refrigerant piping length (one way) : 5m (16ft)

2. Guaranteed operating range

Indoor

Cooling

Heating

3. Guaranteed voltage

342~457V, 50Hz

4. Above data based on indicated voltage

5. Refer to the service manual of indoor unit for the indoor unit's specifications.

6. The total input is of twin combination of 4-way cassette.

Upper limit

Lower limit

Upper limit

Lower limit

Indoor Unit 1 phase 230V 50Hz

Outdoor Unit 3 phase 400V 50Hz

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C

D.B. 28˚C

D.B. 17˚C

Outdoor

D.B. 46˚C

D.B. -5˚C

D.B. 21˚C, W.B. 15˚C

D.B. -20˚C, W.B. -20˚C

8

Page 9

5 DATA

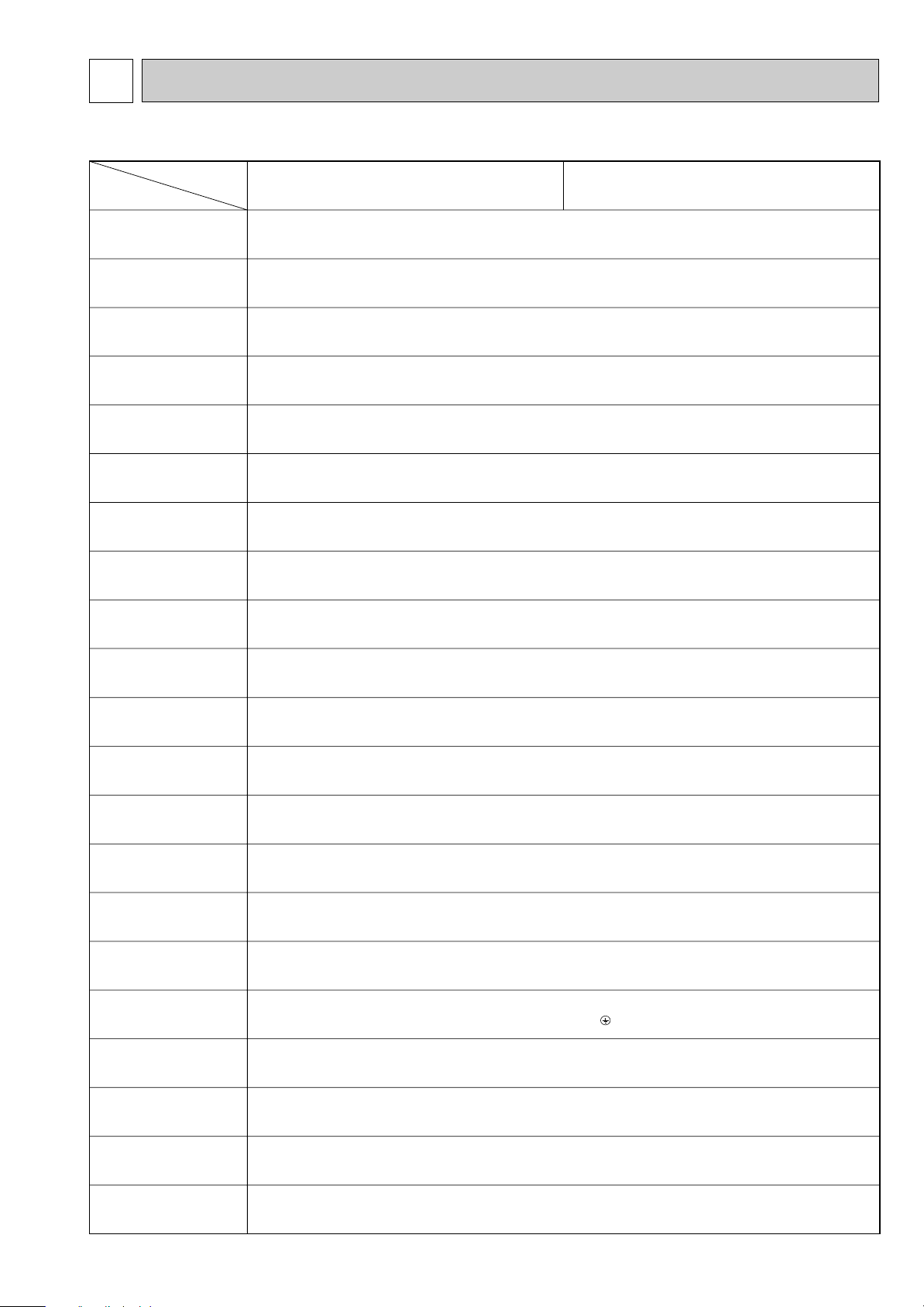

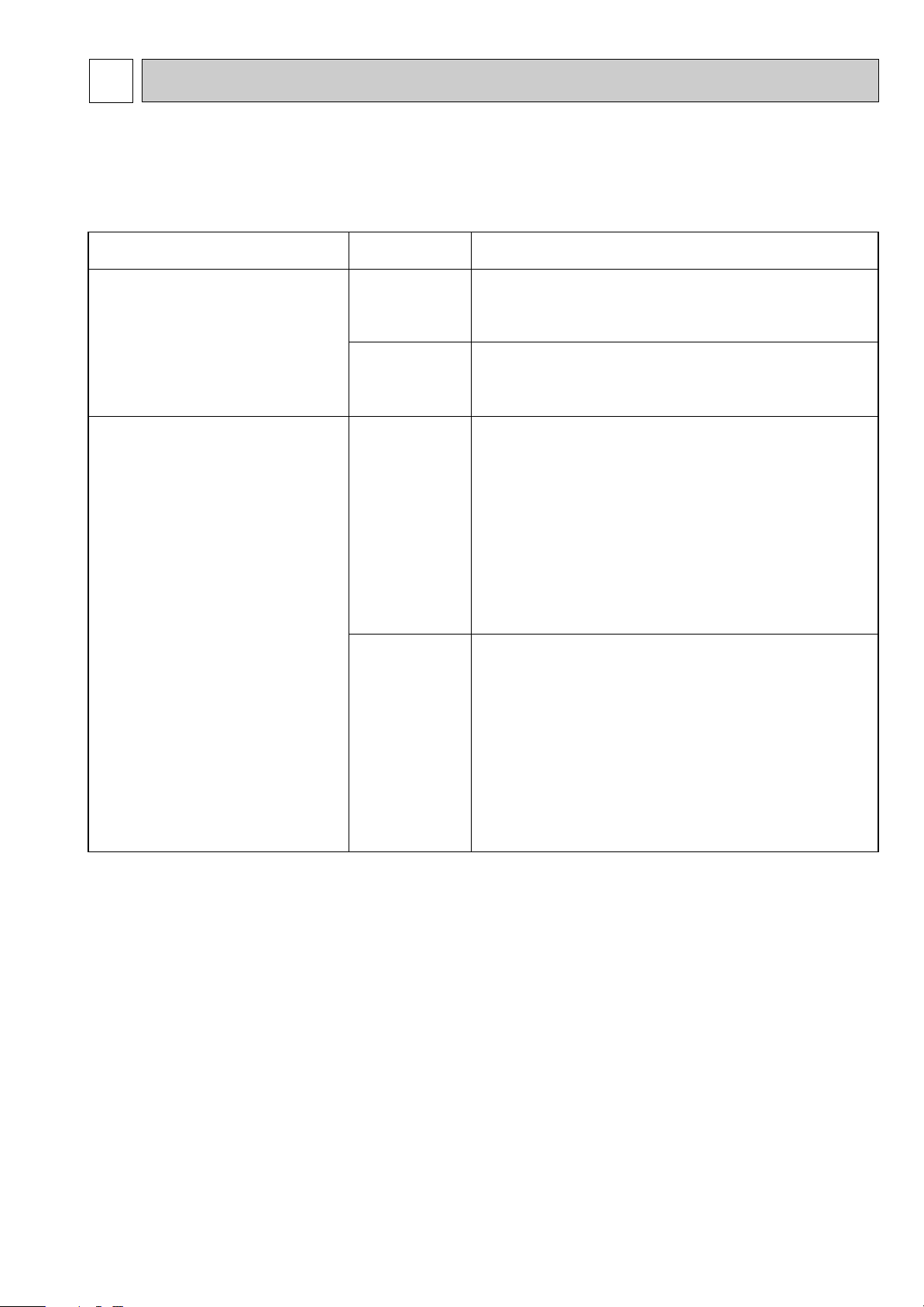

5-1. ELECTRICAL PARTS SPECIFICATIONS

Outdoor unit

Parts name

FUSE

(FUSE1,2)

FUSE

(FUSE3,4)

Solenoid Valve

(Four-way Valve)

Solenoid Valve Coil

(Four-way Valve)

21S4

Linear Expansion

Valve

(LEV-A)

Linear Expansion

Valve Coil

(LEV-A)

Solenoid Valve

<Bypass Valve>

Solenoid Valve Coil

<Bypass Valve>

(SV)

Reactor

(DCL)

High Pressure

Switch

(63H)

Low Pressure

Switch

(63L)

Fan Motor

(MF)

Thermistor

(Outdoor Pipe)

(TH3, TH32 )

Thermistor

(Discharge)

(TH4)

Thermistor

(Outdoor2-PhasePipe)

(TH6)

Thermistor

(Outdoor)

(TH7)

Terminal Block

(Power Supply)

(TB1)

Terminal Block

(Indoor / Outdoor)

(TB2)

Main Smoothing Capacitor

(CB1, CB2)

Rush Current

Protect Resister

(RS)

PUHZ-RP8YHA

250V 15A

250V 6.3A

VT60100

LB64

(DM50G461)

HAM-BD32

(0~480 Pulse)

DC12V

VF20100

LD2

2.7mH 25A

OFF 3.60+0.2MPa

ON 2.80i0.15MPa

OFF -0.03i0.03MPa

ON 0.05i0.04MPa

6P 635W o1

PA6Y635-T

0:/15t, 10:/9.6t, 20:/6.3t, 25:/5.4t, 30:/4.3t, 40:/3.0t

20:/250t, 30:/160t, 40:/104t, 50:/70t, 60:/48t, 70:/34t, 80:/24t, 90:/15t, 100:/13t

0:/15t, 10:/9.6t, 20:/6.3t, 25:/5.4t, 30:/4.3t, 40:/3.0t

0:/15t, 10:/9.6t, 20:/6.3t, 25:/5.4t, 30:/4.3t, 40:/3.0t

5P

(L1, L2, L3, N, )

3P

(S1, S2, S3)

2200= 400V

16" 30W

PUHZ-RP10YHA

Motor Compressor

(MC)

ANV47FFBMT

9

Page 10

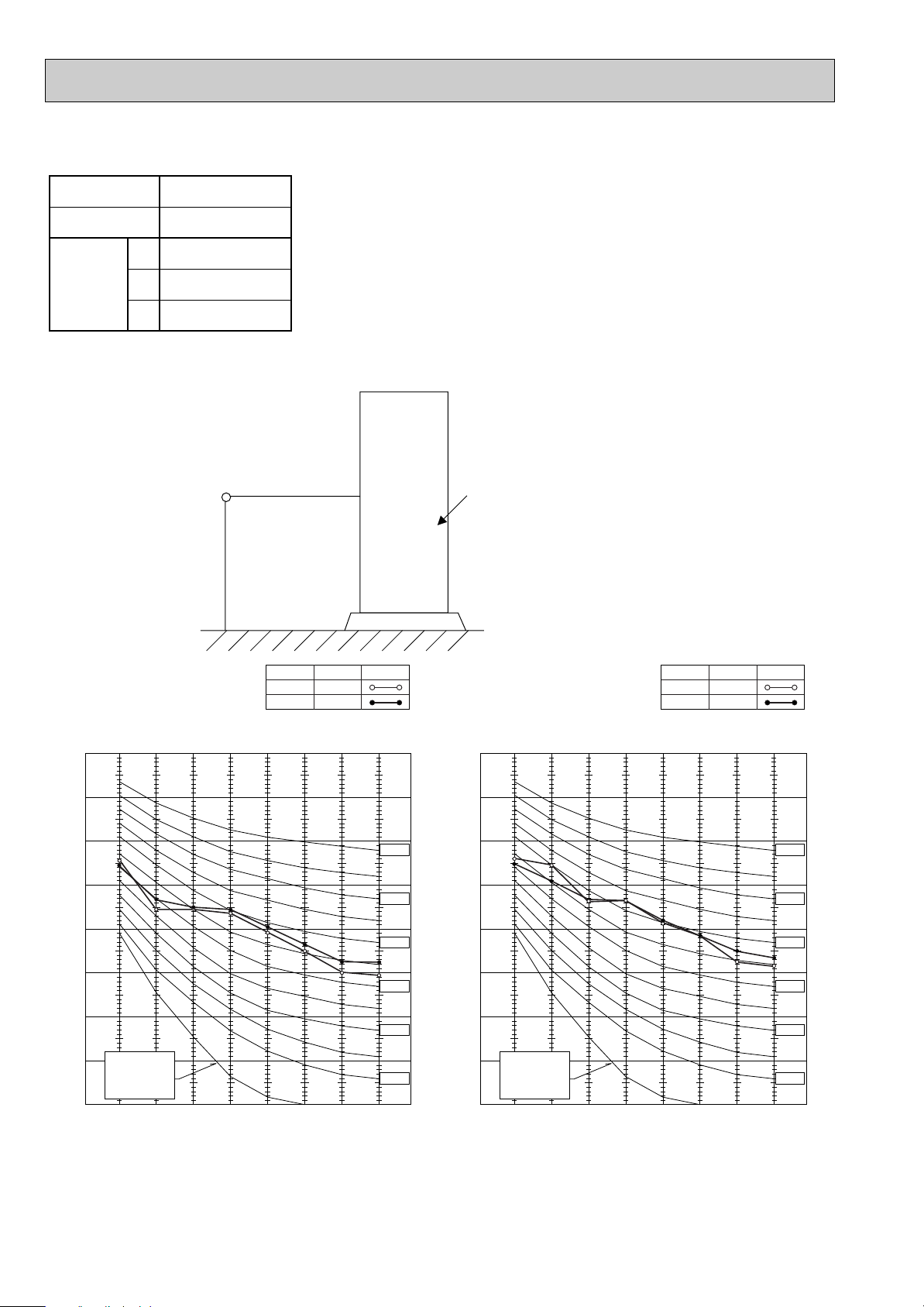

5-2. COMPRESSOR TECHNICAL DATA

U-V

U-W

W-V

Unit

Compressor model

Winding

Resistance

( " )

ANV47FFBMT

(at 20°C)

0.72

0.72

0.72

PUHZ-RP8, 10YHA

1m

1m

MICROPHONE

UNIT

GROUND

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

BAND CENTER FREQUENCIES, Hz

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

PUHZ-RP8YHA

COOLING

MODE

HEATING

55.0

SPL(dB)

56.0

LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

BAND CENTER FREQUENCIES, Hz

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

PUHZ-RP10YHA

COOLING

MODE

HEATING

58.0

SPL(dB)

58.0

LINE

5-3. NOISE CRITERION CURVES

10

Page 11

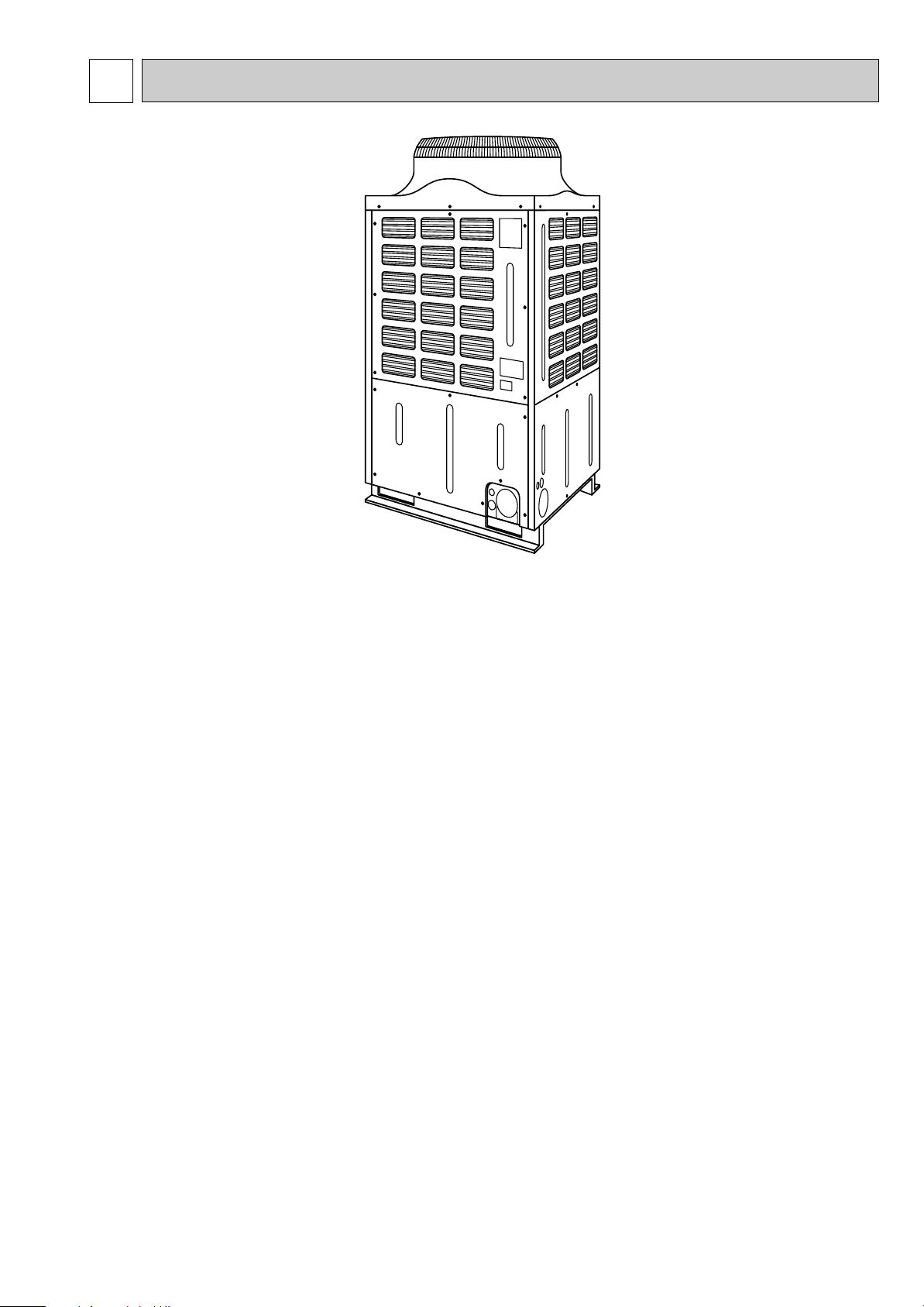

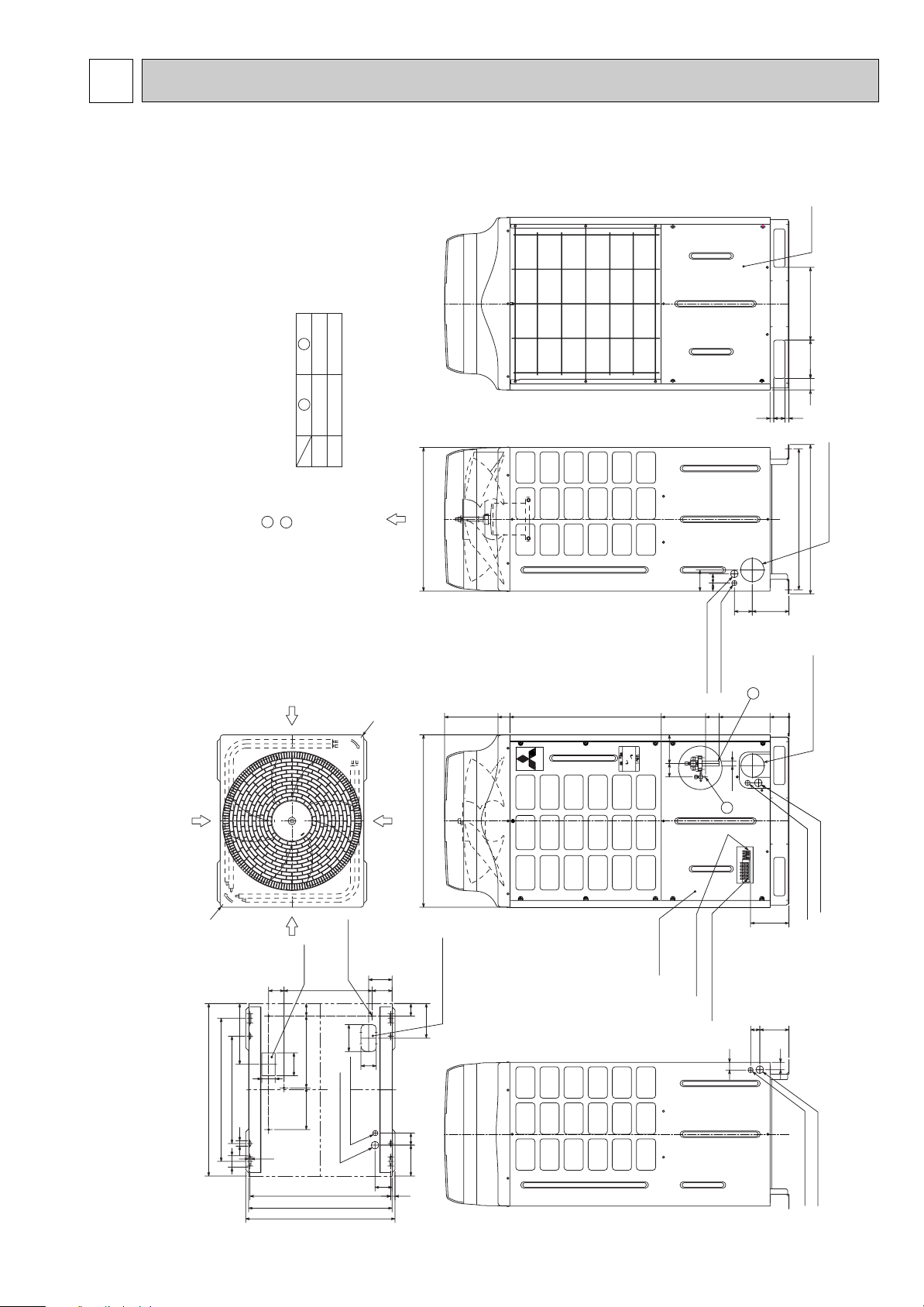

6 OUTLINES AND DIMENSIONS

0

0

[

7

O.D

[

28.58

2

O.D

[

25.4

[

25.4

2

Refrigerant GAS PIPE connection (BRAZING)

[

12.7 (1/2F)

[

9.52 (3/8F)

1

10YHA

8YHA

Refrigerant LIQUID PIPE connection (FLARE)

1

AIR INTAKE

AIR FLOW

218

375

65

460

Drain Hole(4-[10)

Drain Hole

80

Piping Hole (Knock-OUT)

Indoor/Outdoor Wiring

Power supply Wiring (Earth wiring)

Wiring Hole([ 40 Knock-OUT)

Wiring Hole([ 27 Knock-OUT)

200

94

42 48

(Rear Side)

Service panel

Wiring Hole([ 27 Knock-OUT)

Wiring Hole([ 40 Knock-OUT)

110

Piping Hole([ 122 Knock-OUT)

2

70

150

1

Piping Hole([ 122 Knock-OUT)

Wiring Hole([ 40 Knock-OUT)

200

4350364

(780)

(22)

12

28

60

180

65

140

70

120

317

80

123

105

63

161

90

R

15

R

15

900

700~796

560

750

736

900 750

1798

1519

1457

667

0

98

48

152

40

38

191

195821

380

60

780

736

Wiring Hole([ 27 Knock-OUT)

(Front Side)

Service panel

G

L

FOUNDATION BOLTS PITCH & DRAIN HOLES

Front side

Wiring Hole([40 Knock-OUT)

Wiring Hole([27 Knock-OUT)

MITSUBISHI

ELECTRIC

PUHZ-RP8YHA

PUHZ-RP10YHA

Unit : mm

11

Page 12

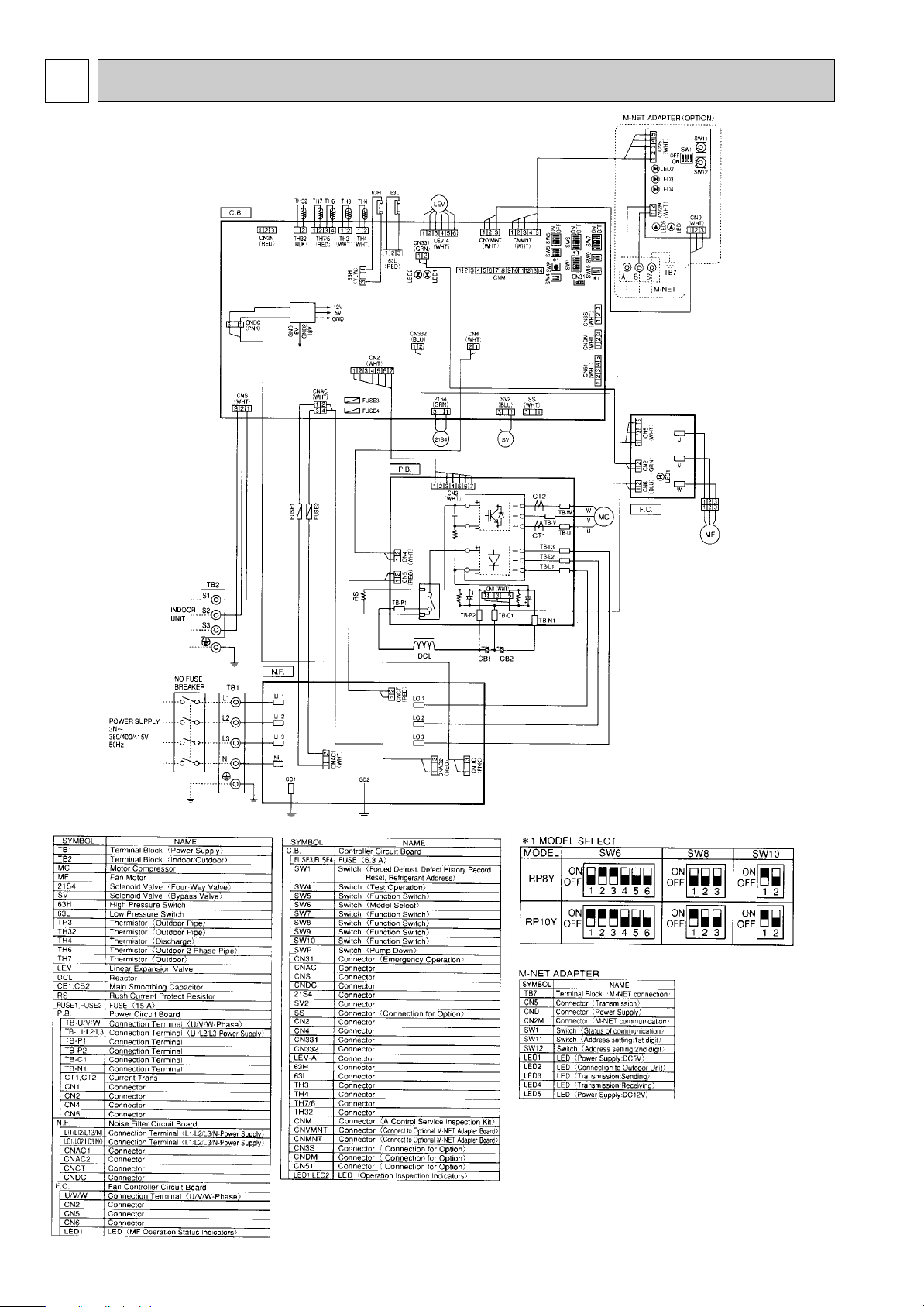

7 WIRING DIAGRAM

PUHZ-RP8YHA

PUHZ-RP10YHA

12

Page 13

8 WIRING SPECIFICATIONS

WIRING SPECIFICATIONS FOR 220V-240V 50Hz

(INDOOR - OUTDOOR CONNECTING CABLE)

The cable shall not be lighter than design 245 IEC or 227 IEC.

When cable length is 30m or more.

Use one cable for S1 and S2 and another for S3 as shown in the picture.

wire size :

cable length 50m : 4mm

cable length 80m : 6mm

2

2

S1

S2

S3

The cable length may vary depending on the condition of installation, humidity or materials, etc.

Cross section

of cable

Wire size

2

)

(mm

Number

of wires

Polarity L(m) ✽5

Round

2.5

3

Clockwise : S1-S2-S3

Flat

2.5

3

Not applicable

(Because center wire has no cover finish)

applicable

Flat

1.5

4

From left to right : S1-Open-S2-S3

Round

2.5

4

Clockwise : S1-S2-S3-Open

Connect S1 and S3 to the opposite angle

(30)

✽1

Not

✽2

(18)

✽3

30

✽4

✽1 : In case that cable with stripe of yellow and green is available.

✽2 : In the flat cables are connected as this picture, they can be used up to 30m.

(3C Flat cable ✕ 2)

S1 S2 S3

✽3 : In case of regular polarity connection (S1-S2-S3), wire size is 1.5mm2.

✽4 : In case of regular polarity connection (S1-S2-S3).

✽5 : Mentioned cable length is just a reference value.

It may be different depending on the condition of installation, humidity or materials, etc.

Be sure to connect the indoor-outdoor connecting cables directly to the units (no intermediate

connections).

Intermediate connections can lead to communication errors if water enters the cables and causes

insufficient insulation to ground or a poor electrical contact at the intermediate connection point.

(If an intermediate connection is necessary, be sure to take measures to prevent water from entering

the cables.)

13

Page 14

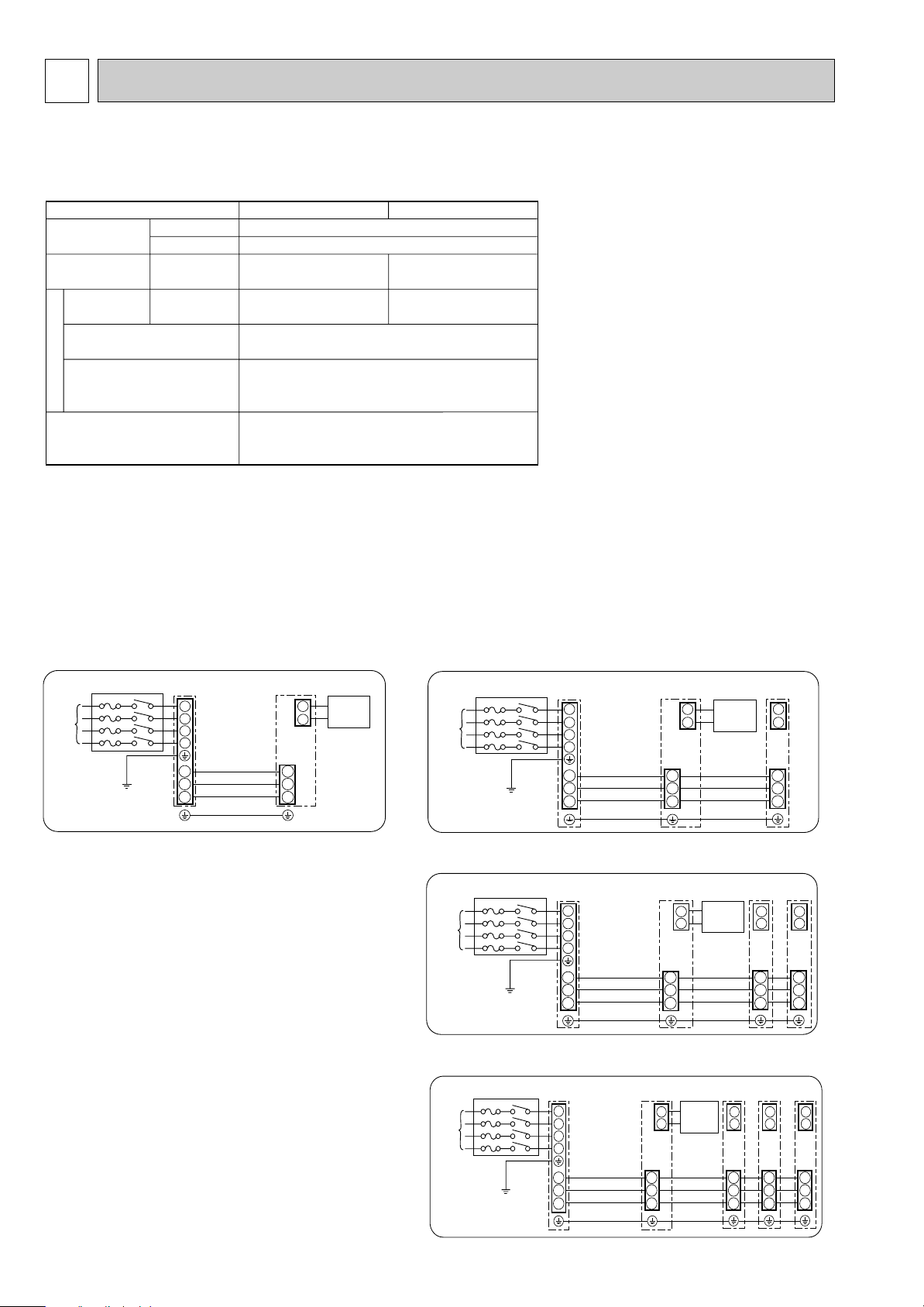

9

Outdoor unit

Power supply

Phase

Frequency & Voltage

Outdoor unit (A)

Wire No.

32

4

32

4

Models (Outdoor unit)

3N~(3ph 4wires)

50Hz, 380-400-415V

Outdoor unit

Power supply

Input capacity

Main switch/Breaker

Indoor unit/Outdoor unit connecting

Wire No. o size (e)

Remote controller-indoor unit connecting

Wire No. o size (e)

Control circuit rating

Wiring

Cable 2C o 0.69

This wire is accessory of remote controller

(Wire length: 10m, Non-polar)

Indoor unit-Outdoor unit: S1-S2 AC220V-230V-240V

S2-S3 DC24V

Remote controller-Indoor unit: DC14V

RP8 RP10

Cable length 50 m : 3 o 4 (Polar)

Cable length 80 m : 3 o 6 (Polar)

1

2

S1

S2

S3

S1

S2

S3

Indoor/outdoor

unit connection

cable

Indoor

unit

Unit

power

supply

Outdoor

unit

Remote

controller

L1

L2

L3

N

Grounding

L1

L2

L3

N

1

2

1

2

S1

Indoor

unit

S2

S3

S1

S2

S3

S1

S2

S3

Unit

power

supply

Indoor/outdoor

unit connection

cable

Indoor

unit

Outdoor

unit

Remote

controller

Grounding

1

2

1

2

1

2

S1

S2

S3

S1

S2

S3

S1

S2

S3

S1

S2

S3

Indoor/outdoor

connection cable

Indoor

unit

Unit

power

supply

Indoor

unit

Indoor

unit

Outdoor

unit

Remote

controller

L1

L2

L3

N

Grounding

1

2

1

2

S1

S2

S3

S1

S2

S3

S1

S2

S3

1

2

S1

S2

S3

1

2

S1

S2

S3

Indoor/outdoor

connection cable

Indoor

unit

Unit

power

supply

Indoor

unit

Indoor

unit

Outdoor

unit

Remote

controller

L1

L2

L3

N

Grounding

Indoor

unit

SPECIFICATIONS FOR ELECTRICAL WORK

9-1. FIELD ELECTRICAL WIRING (POWER WIRING SPECIFICATIONS)

PUHZ-RP•YHA

Check items

1. Wiring size must comply with the applicable local and national code.

2. Be careful about choosing the installation location for the earth leakage breaker and how it is installed as the initial electric

current may cause it to malfunction.

3. Power supply cords and indoor unit / Outdoor unit connecting cords shall not be lighter than polychloroprene sheathed flex-

ible cord. (design 254 IEC 57)

1:1 system Synchronized twin, triple and quadruple system

Electrical wiring

• Synchronized twin

• Synchronized triple

• Synchronized quadruple

14

Page 15

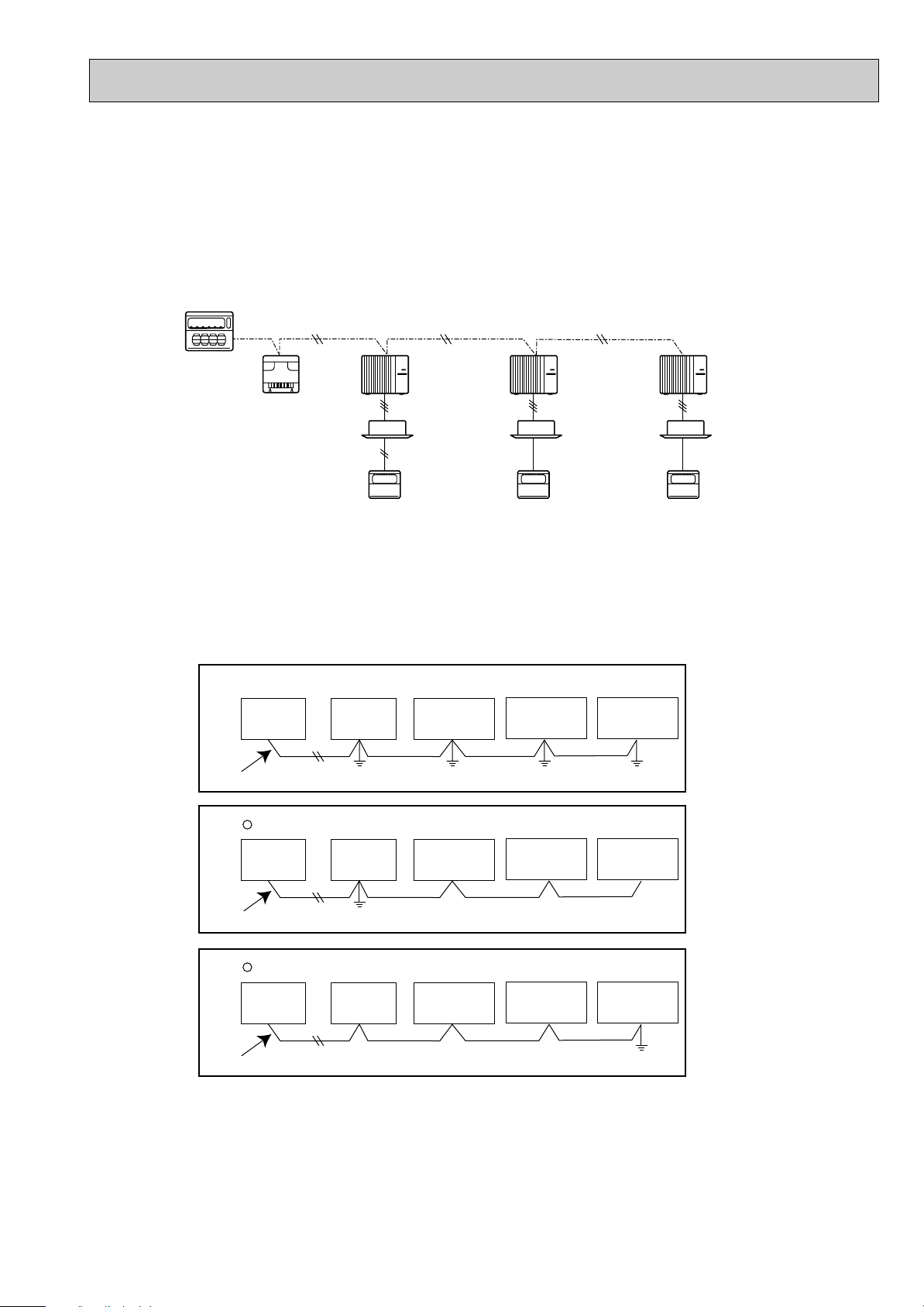

9-2. M-NET WIRING METHOD

Group

remote

controller

Refrigerant

address 00

M-NET

address 01

A-control

remote

controller

A-control

remote

controller

A-control

remote

controller

Refrigerant

address 00

M-NET

address 02

Refrigerant

address 00

M-NET

address 03

Power

supply

unit for

transmission

wire

Central

remote

controller

M-NET transmission wire

✕ Bad example (Multi spot grounding of shield wire)

Good example 1 (Single spot grounding of shield wire)

Power

supply

appliance

M-NET type

outdoor unit

Central

remote

controller

Power

supply

appliance

M-NET type

outdoor unit

M-NET type

outdoor unit

M-NET type

outdoor unit

M-NET transmission wire

M-NET type

outdoor unit

M-NET type

outdoor unit

Central

remote

controller

Power

supply

appliance

M-NET type

outdoor unit

M-NET transmission wire

M-NET type

outdoor unit

M-NET type

outdoor unit

Good example 2 (Single spot grounding of shield wire)

(Points to notice)

(1) Outside the unit, transmission wires should stay away from electric wires in order to prevent electromagnetic noise from

making an influence on the signal communication. Place them at intervals of more than 5cm. Do not put them in the same

conduit tube.

(2) Terminal block (TB7) for transmission wires should never be connected to 220~240V power supply. If it is connected,

electronic parts on M-NET p.c. board may be burn out.

(3) Use 2-core x 1.25mm2shield wire (CVVS, CPEVS) for the transmission wire. Transmission signals may not be sent or

received normally if different types of transmission wires are put together in the same multi-conductor cable. Never do this

because this may cause a malfunction.

It would be ok if M-NET wire (non-polar, 2-cores) is arranged in addition to the wiring for A-control.

(4) Ground only one of any appliances through M-NET transmission wire (shield wire). Communication error may occur due to

the influence of electromagnetic noise.

If there are more than two grounding spots on the shield wire, noise may enter into the shield wire because the ground

wire and shield wire form one circuit and the electric potential difference occurs due to the impedance difference among

grounding spots. In case of single spot grounding, noise does not enter into the shield wire because the ground wire and

shield wire do not form one circuit.

To avoid communication errors caused by noise, make sure to observe the single spot grounding method described in the

installation manual.

“Ed” error will appear on the LED display of outdoor unit.

“0403” error will appear on the central-control remote controller.

15

Page 16

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

12

~

50

M-NET Address No.

<Setting example>

Switng

setting

SW11

ones

digit

SW12

tens

digit

OFF

ON

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

0

Refrigrant

address

OFF

ON

8

OFF

ON

1

OFF

ON

9

OFF

ON

10

OFF

ON

11

OFF

ON

12

OFF

ON

13

OFF

ON

14

OFF

ON

15

OFF

ON

2

OFF

ON

3

OFF

ON

4

OFF

ON

5

OFF

ON

6

OFF

ON

7

System

controller

A-control

remote

controller

Group A Group B Group C

A-control

remote

controller

TB5

A-control

remote

controller

Refrigerant

address 00

M-NET

address 01

Refrigerant

address 00

M-NET

address 02

Refrigerant

address 01

M-NET

address 03

Refrigerant

address 00

M-NET

address 04

Power

supply

unit for

transmission

wire

A-control

remote

controller

A-control

remote

controller

TB5

Group A Group B

Refrigerant

address 00

M-NET

address 01

Refrigerant

address 01

M-NET

address 02

Refrigerant

address 00

M-NET

address 04

Refrigerant

address 01

M-NET

address 03

Refrigerant

address 02

M-NET

address 05

System

controller

Power

supply

unit for

transmission

wire

● M-NET wiring

(1) Use 2-core x 1.25mm

2

shield wire for electric wires.

(Excluding the case connecting to system controller.)

(2) Connect the wire to the M-NET terminal block.Connect one core of the

transmission wire (non-polar) to Aterminal and the other to B. Peel the

shield wire, twist the shield part to a string and connect it to S terminal.

(3) In the system which several outdoor units are being connected, the terminal

(A, B, S) on M-NET terminal block should be individually wired to the other

M-NET

terminal

block

ABS

Transmission

wire

Ground

wire

Shield

part

outdoor unit’s terminal, i.e. Ato A, B to B and S to S.In this case, choose one of those outdoor units and drive a screw

to fix an ground wire on the plate as shown on the right figure.

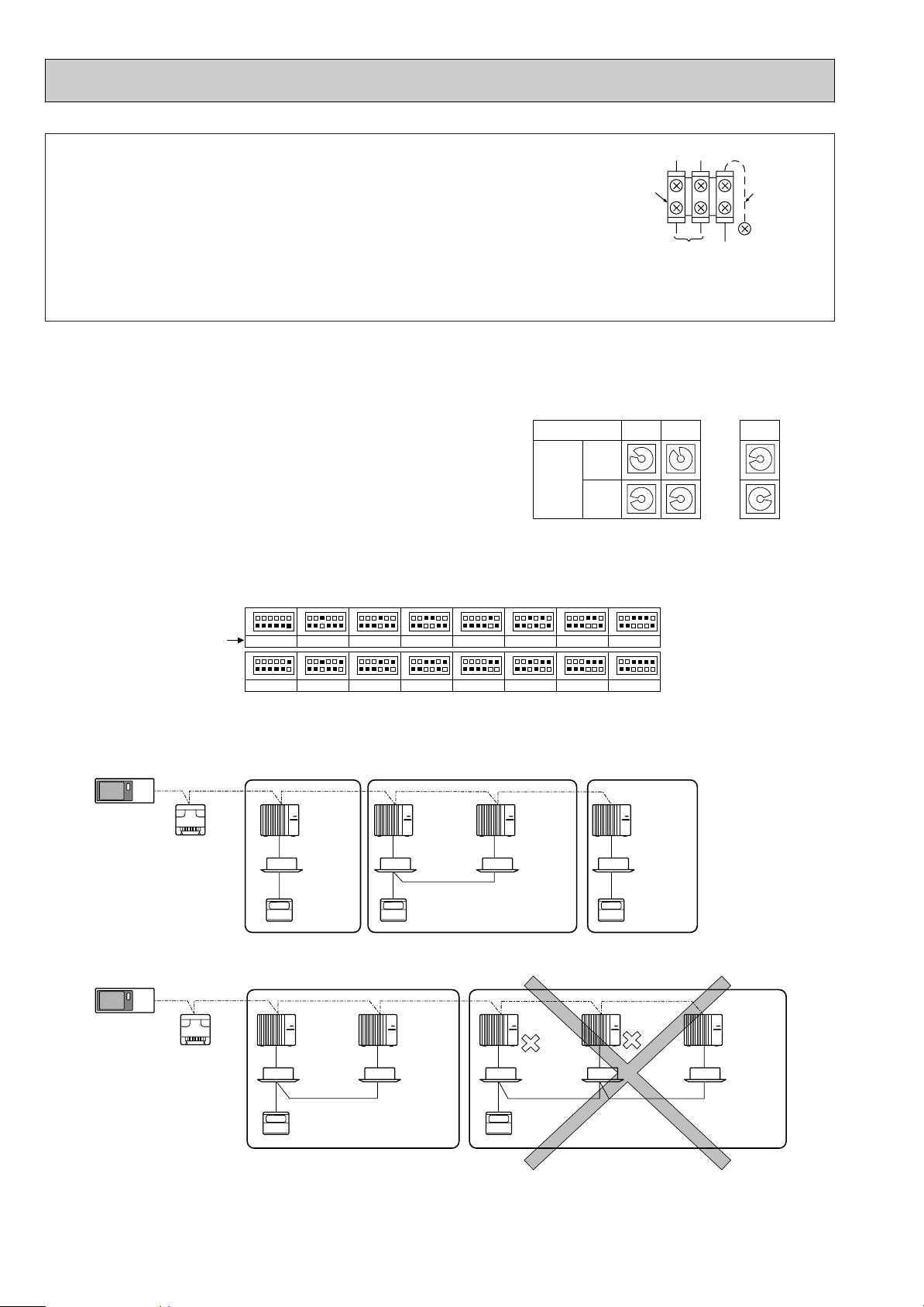

9-2-1. M-NET address setting

In A-control models, M-NET address and refrigerant address should be set only for the outdoor unit. Similar to Free Combo

system, there is no need to set the address of outdoor unit and remote controller. To construct a central control system, the

setting of M-NET address should be conducted only upon the outdoor unit. The setting range should be 1 to 50 (the same as

that of the indoor unit in Free Combo system), and the address number should be consecutively set in a same group.

Address number can be set by using rotary switches

(SW11 for ones digit and SW12 for tens digit), which

is located on the M-NET p.c. board of outdoor unit.

(Factory setting: all addresses are set to “0”.)

9-2-2. Refrigerant address setting

In case of multiple grouping system (multiple refrigerant circuits in one group), indoor units should be connected by remote

controller wiring (TB5) and the refrigerant address needs to be set. Leave the refrigerant addresses to “00” if the group setting is not conducted. Set the refrigerant address by using DIP SW1-3 to -6 on the outdoor controller circuit board. [Factory

setting: all switches are OFF. (All refrigerant addresses are “00”.)]

9-2-3. Regulations in address settings

In case of multiple grouping system, M-NET and refrigerant address settings should be done as explained in the above

section. Set the lowest number in the group for the outdoor unit whose refrigerant address is “00” as its M-NET address.

w Refrigerant addresses can be overlapped if they are in the different group.

w In group B, M-NET address of the outdoor unit whose refrigerant address is “00” is not set to the minimum in the group. As

“3” is right for this situation, the setting is wrong. Taking group A as a good sample, set the minimum M-NET address in

the group for the outdoor unit whose refrigerant address is “00”.

16

Page 17

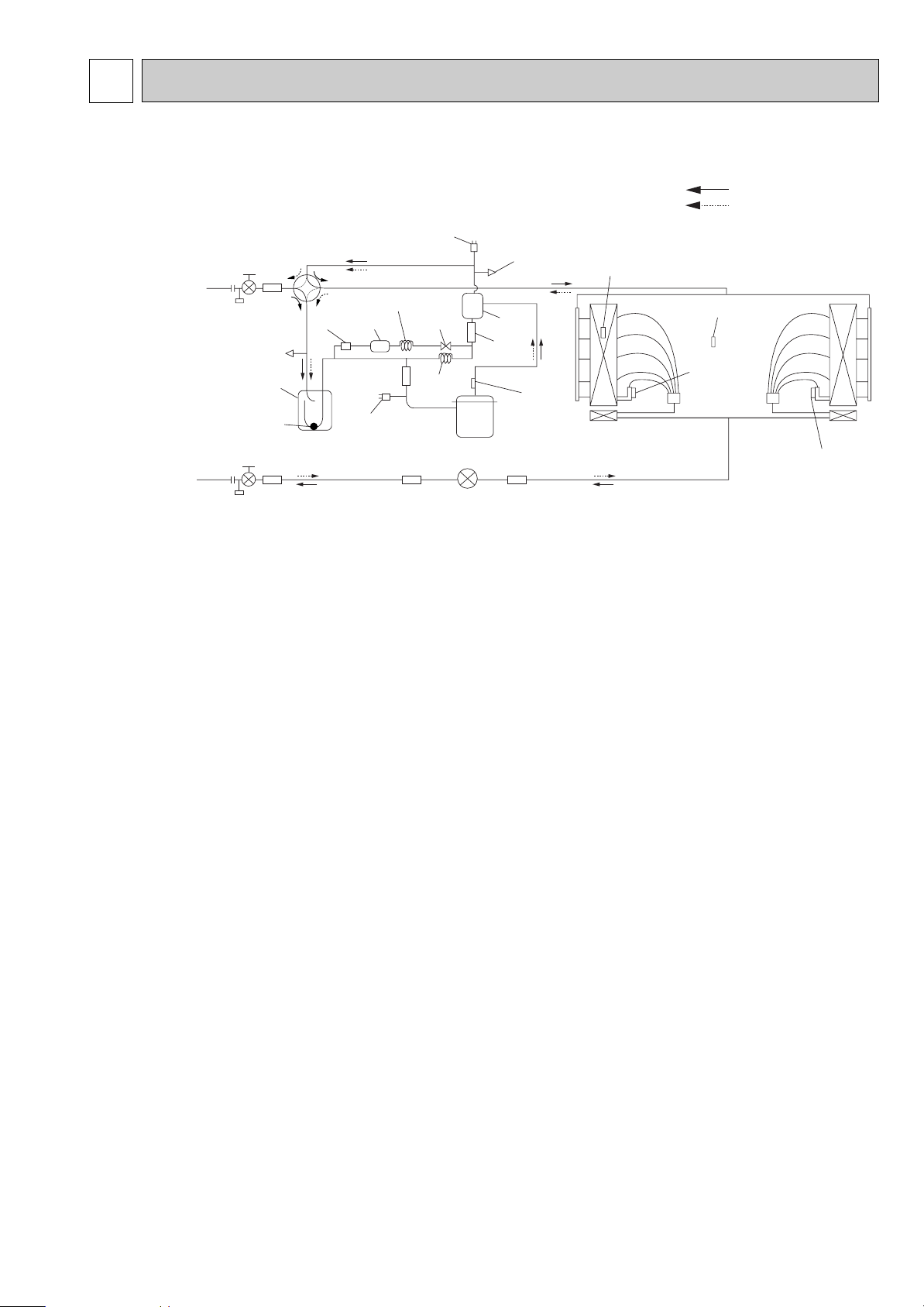

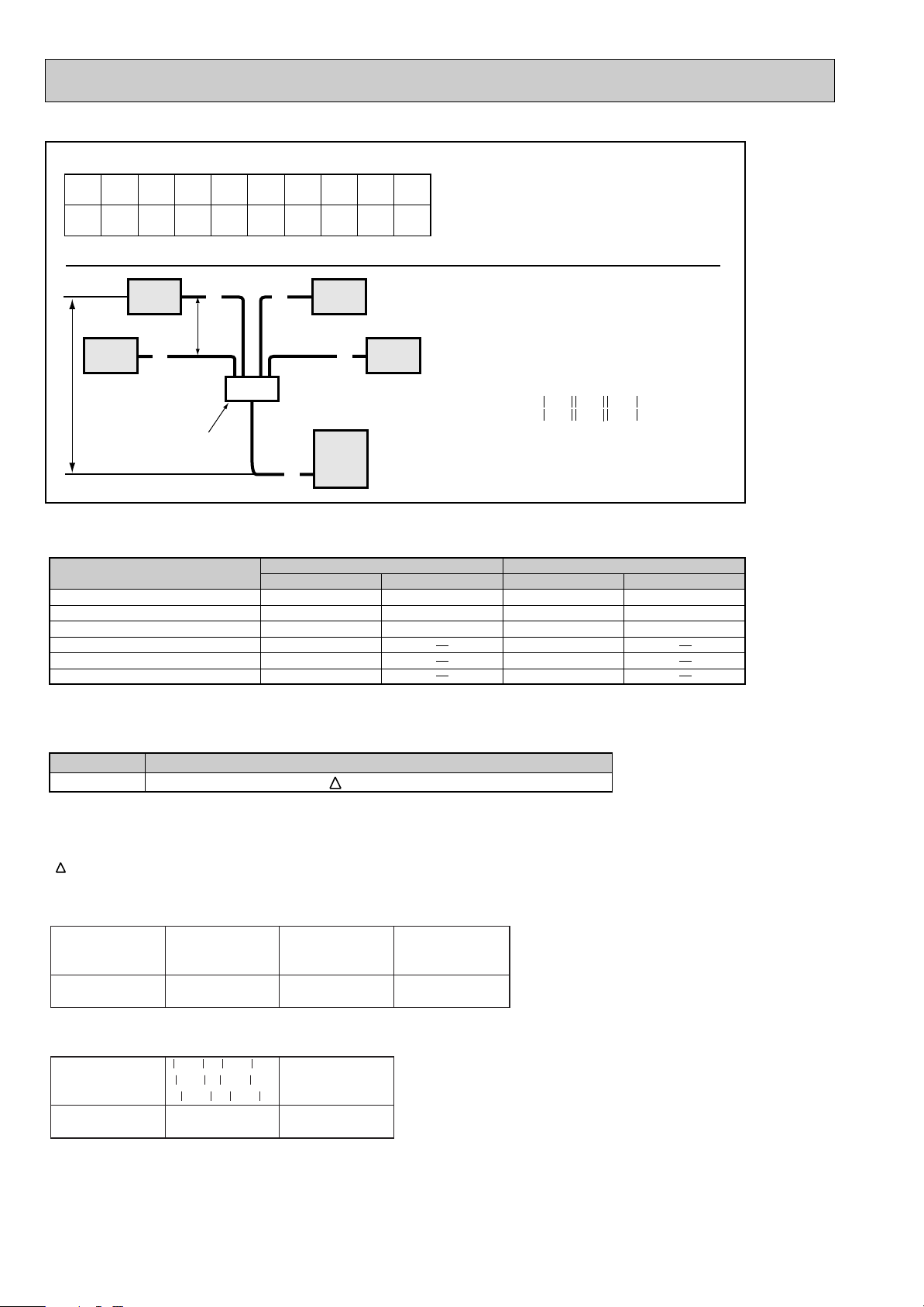

10 REFRIGERANT SYSTEM DIAGRAM

Strainer

#50

Strainer

#50

Strainer

#100

Strainer

#100

Strainer

#100

Strainer

#100

Oil

separator

Strainer

#100

Stop valve

(with service port)

Stop valve

(with service port)

Charge plug

(Low pressure)

Accumulator

Oil-back hole

Strainer#40

Linear expansion valve

Low pressure switch 63L

Compressor

Capillary tube1

Capillary tube2

Replace

filter

High pressure switch 63H

Bypass valve

Charge plug

(High pressure)

Thermistor TH4

(Discharge)

Thermistor TH6

(Outdoor 2-phase pipe)

Thermistor TH7

(Outdoor)

Thermistor TH3

(Outdoor pipe)

Thermistor TH32

(Outdoor pipe)

Heat exchanger

4-way valve

Refrigerant GAS pipe

connection

(RP8:1, RP10:1-1/8)

Refrigerant LIQUID pipe

connection

(RP8:3/8F, RP10:1/2F)

Refrigerant flow in cooling

Refrigerant flow in heating

PUHZ-RP8YHA

PUHZ-RP10YHA

17

Page 18

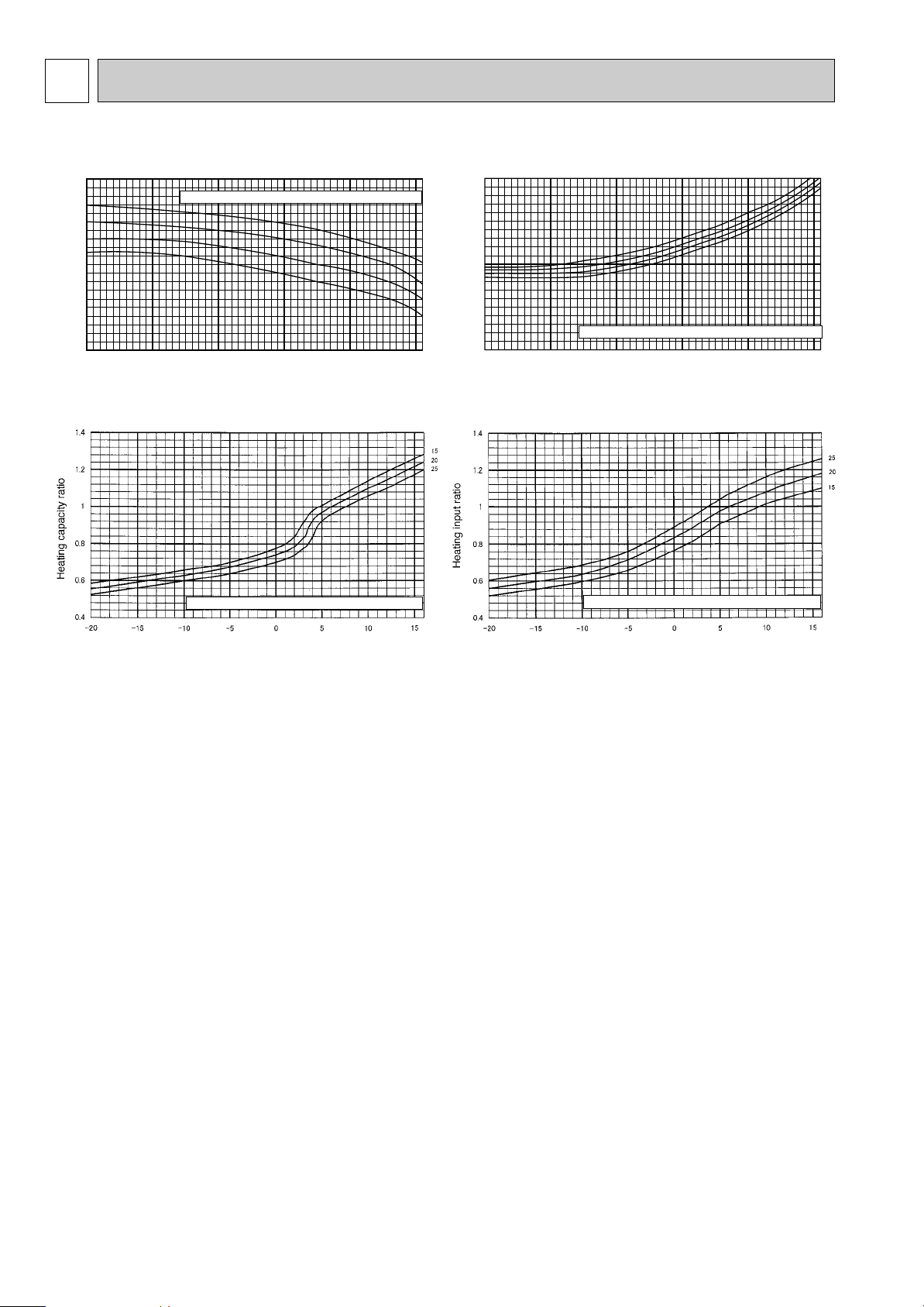

11 CAPACITY CURVES

Cooling capacity

1.4

Indoor intake air wet-bulb temperature <W.B. :>

1.2

1

0.8

Cooling capacity ratio

0.6

-5 0 5 10 15 20 25 30 35 40 46

1.2

1.0

0.8

22

20

18

0.6

Cooling input ratio

16

0.4

Cooling input

-5 0 5 10 15 20 25 30 35 40 46

Outdoor intake air dry-bulb temperature <D.B. :>

Heating capacity Heating input

Indoor intake air dry-bulb temperature <D.B. :>

Indoor intake air wet-bulb temperature <W.B. :>

Outdoor intake air dry-bulb temperature <D.B. :>

Indoor intake air dry-bulb temperature <D.B. :>

22

20

18

16

Outdoor intake air wet-bulb temperature <W.B. :> Outdoor intake air wet-bulb temperature <W.B. :>

Note : These diagrams show the case where the operation frequency of a compressor is fixed.

18

Page 19

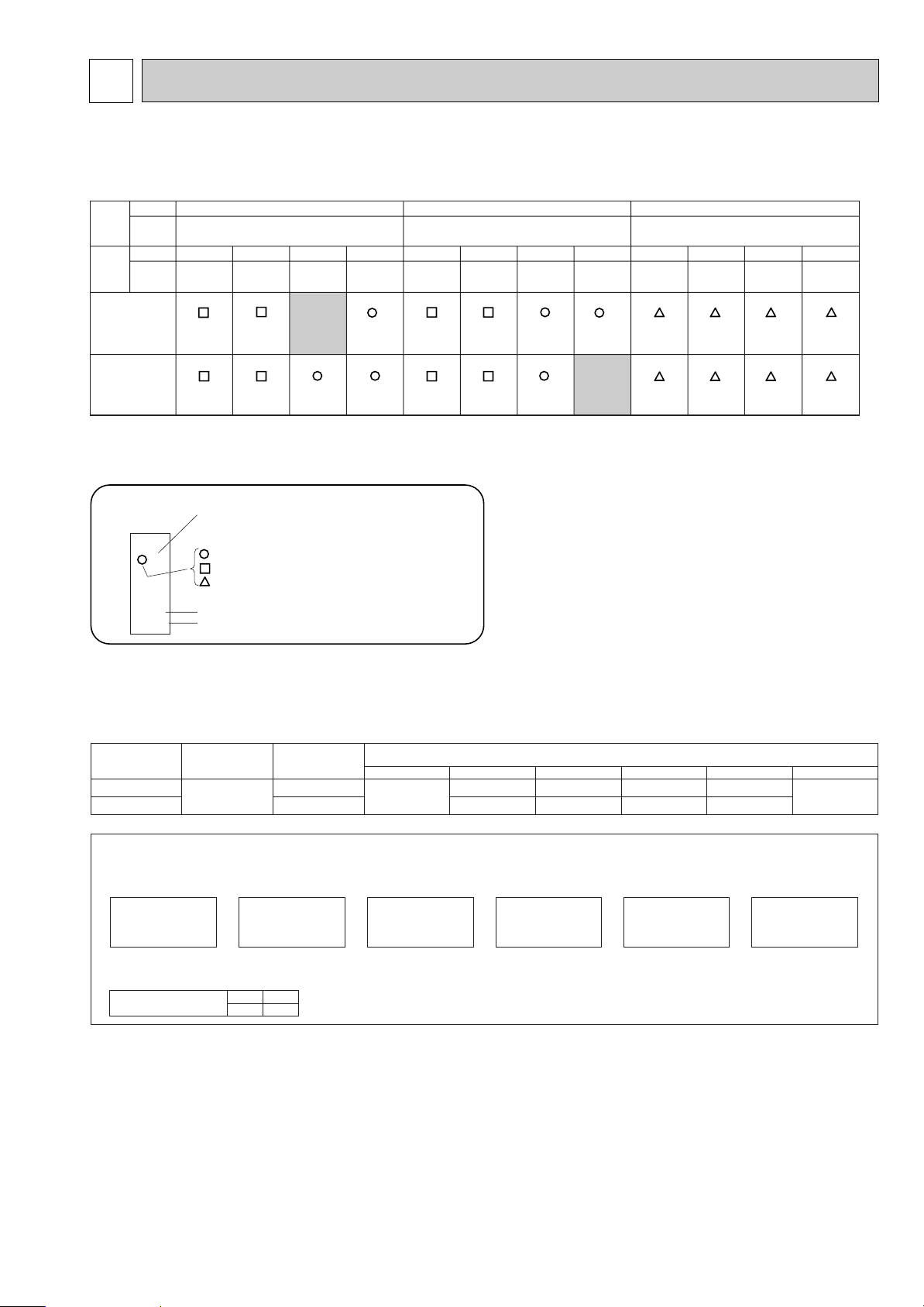

12 APPLICABLE EXTENSION PIPE FOR EACH MODEL

70m

[30m]

SW

SW : When the outdoor unit is located lower than

the indoor unit, set DIP SW8-1 on the outdoor

unit controller board to ON.

RP8

RP10

Liquid

pipe

(mm)

OD

Thick-

ness

OD

Thick-

ness

gas

pipe

(mm)

[

19.05

t1.0

20m

[20m]

20m

[20m]

[

22.2

t1.0

50m

[30m]

50m

[30m]

[

25.4

t1.0

Normal piping

70mw1

[30m]

70m

[30m]

[

28.58

t1.0

SW

70m

[30m]

70m

[30m]

[

19.05

t1.0

20m

[20m]

20m

[20m]

[

22.2

t1.0

50m

[30m]

50m

[30m]

[

25.4

t1.0

70m

[30m]

70m

[30m]

[

28.58

t1.0

SW

70m

[30m]

Normal piping

70mw1

[30m]

[

28.58

t1.0

SW

50m

[20m]

50m

[20m]

[

31.75

t1.0

w

2

SW

50m

[20m]

w

2

50m

[20m]

[

25.4

t1.0

50m

[20m]

50m

[20m]

[

22.2

t1.0

50m

[20m]

50m

[20m]

Note : The maximum pipe length is 80m in case of new piping.

w1 Be sure to use hard (tempered) one for pipe over [22.2.(Do not use soft (annealed) one.)

w2 When using [31.75 pipe, the outdoor temperature range (dry-bulb temperature) for heating operation is -11 to +21:.

<Table 1> Maximum pipe length (RP8·RP10)

<

Marks in the table above

>

[

9.52

t0.8

[

12.7

t0.8

[

15.88

t1.0

The maximum pipe length

Charge-less pipe length

: It can be used.

: Cooling capacity is lowered.➝ Refer to <Table6>

: Additional refrigerant charge is required when

the pipe length exceeds 20m.➝ Refer to <Table7>

Amount of additional refrigerant charge (kg)

30 m and less 31-40 m and less 41-50 m and less 51-60 m and less 61-70 m and less 71-80 m and less

0.9 kg 1.8 kg 2.7 kg 3.6 kg

1.2 kg 2.4 kg 3.6 kg 4.8 kg

Outdoor unit

permitted

pipe length

RP8

RP10

80m or less

At time of shipping

(kg)

10.5

10.5

No additional

charge necessary

The additional charge

amount is obtained by

the following formula.

Main piping:

Liquid line size

[9.52 overall length [m]

o

0.09

[kg/m]

Branch piping: Liquid

line size

[9.52 overall length [m]

o 0.06 [kg/m]

Branch piping: Liquid

line size

[6.35 overall length [m]

o 0.02 [kg/m]

3.6 (kg)

Amount of additional

charge [kg]

Main piping:

Liquid line size

[12.7 over all length [m]

o 0.12 [kg/m]

–=

Additional charge amount

for 70 m

RP8 3.6 kg

RP10 4.8 kg

+

+

+

Calculate the additional charge amount based on the following procedure.

If the calculation results in an amount that is smaller than the "Additional charge amount for 70m," perform the additional charge using the amount shown

in "Additional charge amount for 70m."

12-1. 1:1 SYSTEM

(1) Pipe length

(2) Adjusting the amount of refrigerant

Check additional refrigerant charging amount referring to table 7 when the liquid pipe diameter is larger than

the standard size, and table 2 when the pipe of the standard diameter is used.

<Table 2>

19

Page 20

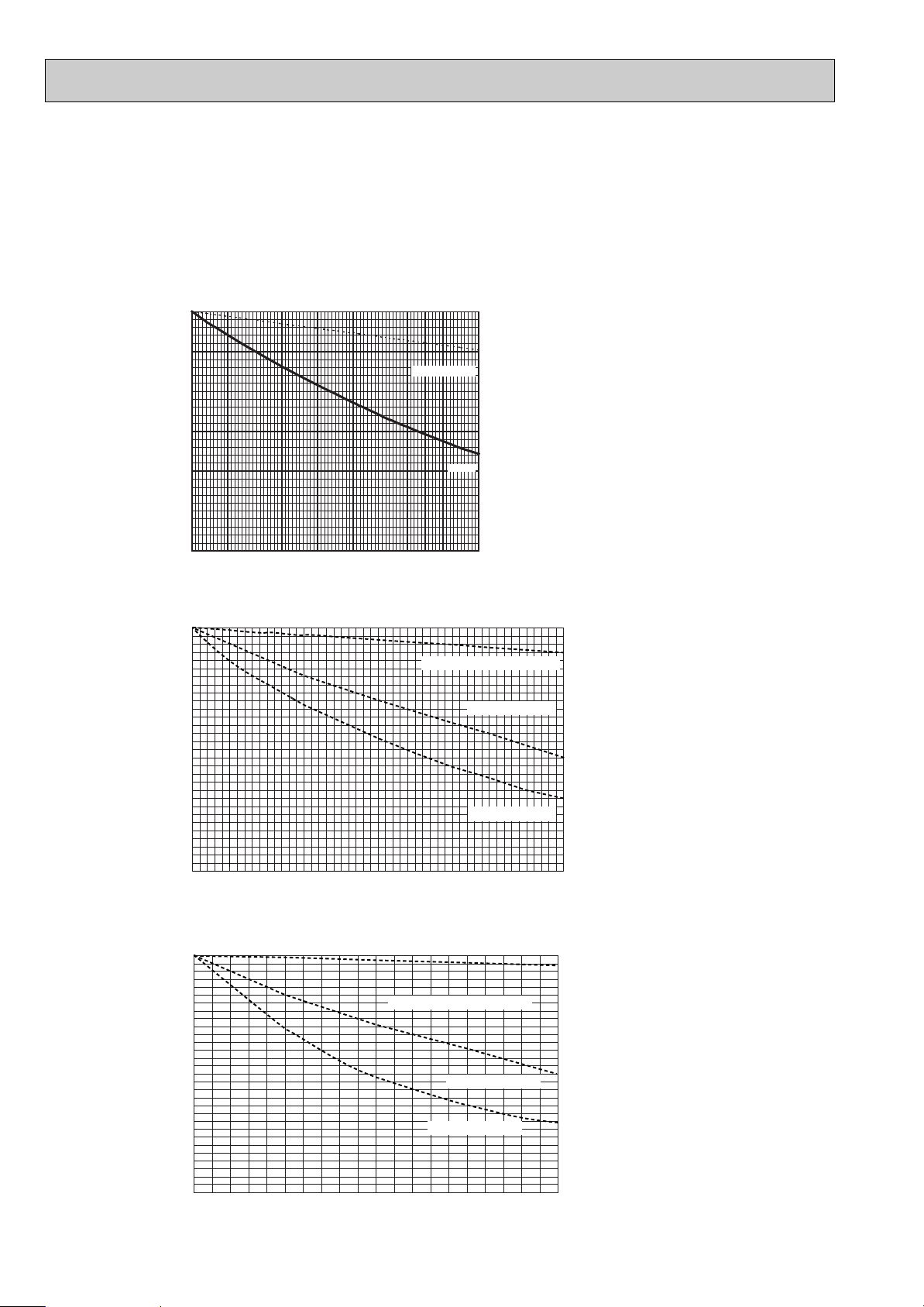

(3) Capacity correction

70

75

80

85

90

95

100

5 10152025303540455055606570758085

Corrected pipe length (m)

Capacity ratio [%]

RP8·10

Heating RP8·10

70

75

80

85

90

95

100

510152025303540455055

Corrected pipe length [m]

Capacity ratio [%]

Heating RP8([22.2), RP10([25.4)

Cooling RP8([22.2)

Cooling RP10([25.4)

70

75

80

85

90

95

100

510152025

Corrected pipe length [m]

Cpacity ratio [%]

Cooling RP10([22.2)

Cooling RP8([19.05)

Heating RP8([19.05), RP10([22.2)

Cooling and heating capacity is lowered according to the piping length. Capacity can be obtained by referring

to the following capacity curves.

When the diameter of the gas pipe is smaller than the standard size, cooling capacity is lowered comparing to

the operation using the standard diameter pipe.

The lowered capacity can be obtained by referring to the capacity curves for gas pipe which is one or two size

smaller than standard size.

Corrected pipe length (m) = actual pipe length (m) + number of bends o 0.3 (m)

1. Capacity curves 1 <Standard size>

2. Capacity curves 2 <When the gas pipe's diameter is one-size-smaller than the standard

3. Capacity curves 3 <When the gas pipe's diameter is two-size-smaller than the standard

20

Page 21

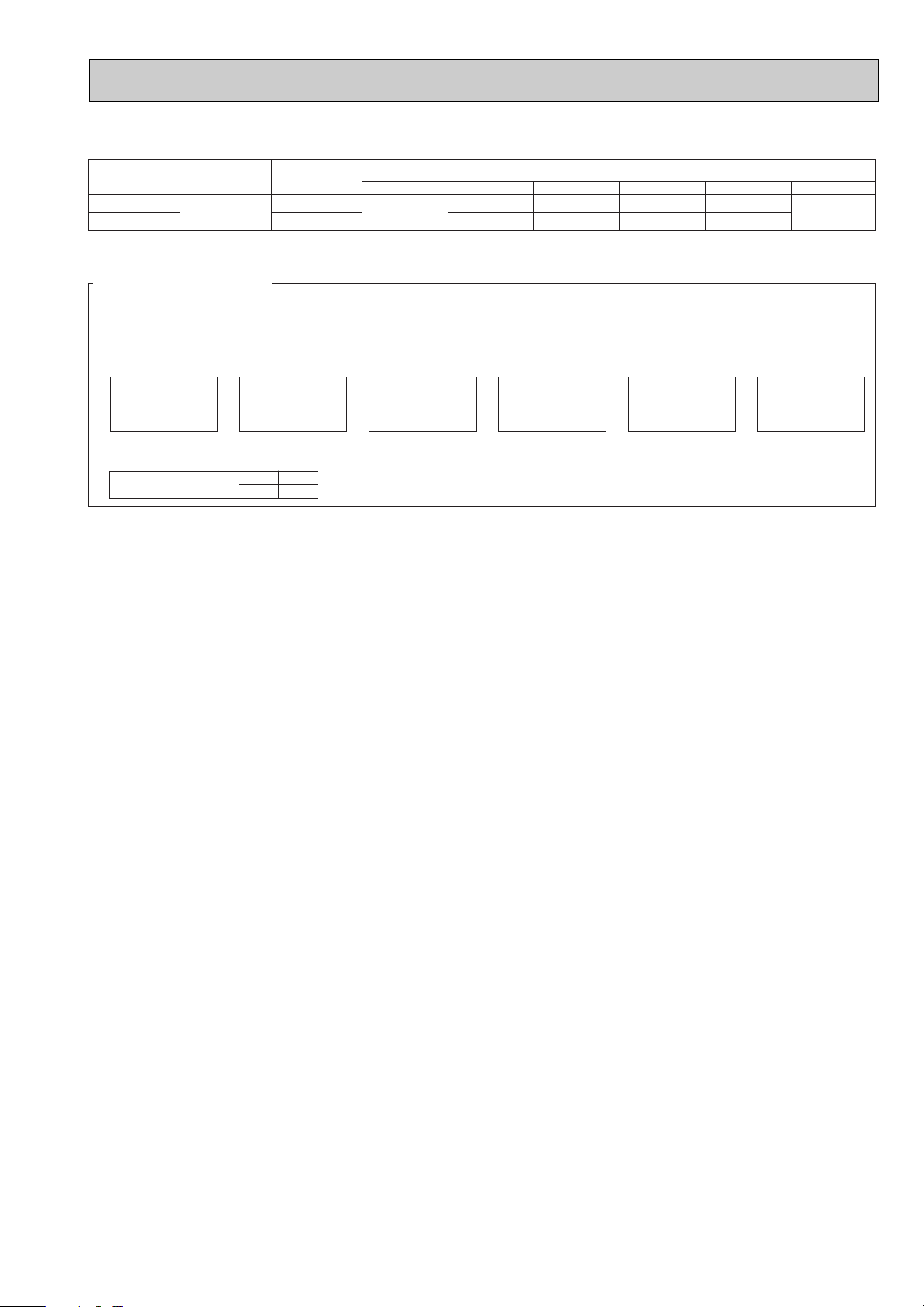

12-2. SYNCHRONIZED TWIN, TRIPLE AND QUADRUPLE SYSTEM

(1) Synchronized twin

Maximum pipe length (Main pipe[A]+Branch pipe diameter [ B and C ])

Main pipe

(mm)[A]

Branch

pipe

[mm]

[B, C]

w1 The maximum pipe length is 80m in case of new pipping.

w2 When using [31.75 pipe, the outdoor temperature range (dry-bulb temperature) for heating operation is -11 to +21:.

Liquid pipe

Gas pipe

Liquid pipe

Gas pipe

Liquid pipe

Gas pipe

Liquid pipe

Gas pipe

Liquid pipe

Gas pipe

[6.35

[12.7

[9.52

[15.88

[9.52

[19.05

[12.7

[19.05

(2) Synchronized triple

Maximum pipe length (Main pipe [A] + Branch pipe [ B, C and D ])

Main pipe

(mm)[A]

Branch

pipe

[mm]

[B, C, D]

w1 The maximum pipe length is 80m in case of new pipping.

w2 When using [31.75 pipe, the outdoor temperature range (dry-bulb temperature) for heating operation is -11 to +21:.

Liquid pipe

Gas pipe

Liquid pipe

Gas pipe

Liquid pipe

Gas pipe

Liquid pipe

Gas pipe

Liquid pipe

Gas pipe

[6.35

[12.7

[9.52

[15.88

[9.52

[19.05

[12.7

[19.05

[9.52

[19.05 [22.2 [25.4 [28.58 [19.05 [22.2 [25.4 [28.58 [22.2 [25.4 [28.58 [31.75 [19.05 [22.2 [25.4 [28.58 [19.05 [22.2 [25.4 [28.58 [22.2 [25.4 [28.58 [31.75

Normal

sw

piping

[9.52

70mw1

[30m]

70m

[30m]

70m

[30m]

Normal

piping

70mw1

[30m]

70m

[30m]

70m

[30m]

70m

[30m]

70m

[30m]

70m

[30m]

70m

[30m]

70m

[30m]

70m

[30m]

sw

sw

sw

sw

sw

50m

20m

[30m]

[20m]

20m

50m

[20m]

[30m]

20m

50m

[20m]

[30m]

[19.05 [22.2 [25.4 [28.58 [19.05 [22.2 [25.4 [28.58 [22.2 [25.4 [28.58 [31.75 [19.05 [22.2 [25.4 [28.58 [19.05 [22.2 [25.4 [28.58 [22.2 [25.4 [28.58 [31.75

20m

50m

[20m]

[30m]

20m

50m

[20m]

[30m]

20m

50m

[20m]

[30m]

[12.7 [15.88 [9.52 [12.7 [15.88

sw

20m

[20m]

20m

[20m]

20m

[20m]

20m

[20m]

20m

[20m]

20m

[20m]

50m

[30m]

50m

[30m]

50m

[30m]

50m

[30m]

50m

[30m]

50m

[30m]

70m

70m

[30m]

70m

[30m]

70m

[30m]

[12.7 [15.88 [9.52 [12.7 [15.88

70m

[30m]

70m

[30m]

70m

[30m]

[30m]

70m

[30m]

70m

[30m]

70m

[30m]

70m

[30m]

70m

[30m]

50m

50m

[20m]

[20m]

sw

50m

50m

[20m]

[20m]

sw

50m

50m

[20m]

[20m]

sw

50m

50m

[20m]

[20m]

sw

50m

50m

[20m]

[20m]

sw

50m

50m

[20m]

[20m]

50m

[20m]

50m

[20m]

50m

[20m]

50m

[20m]

50m

[20m]

50m

[20m]

sw

sw

w2

50m

20m

[20m]

w2

sw

50m

[20m]

w2

sw

50m

[20m]

sw

w2

50m

[20m]

w2

sw

50m

[20m]

w2

sw

50m

[20m]

50m

[20m]

[30m]

sw

20m

50m

[20m]

[30m]

sw

20m

50m

[20m]

[30m]

sw

20m

50m

[20m]

[30m]

sw

20m

50m

[20m]

[30m]

sw

20m

50m

[20m]

[30m]

70m

[30m]

70m

[30m]

70m

[30m]

70m

[30m]

70m

[30m]

70m

[30m]

70m

[30m]

70m

[30m]

70m

[30m]

70m

[30m]

70m

[30m]

70m

[30m]

20m

[20m]

20m

[20m]

20m

[20m]

20m

[20m]

20m

[20m]

20m

[20m]

RP10 twin (RP5✕2)RP8 twin (RP4✕2)

Normal

70m

[30m]

70m

[30m]

70m

[30m]

70m

[30m]

70m

[30m]

70m

[30m]

piping

70mw1

[30m]

70m

[30m]

70m

[30m]

Normal

piping

70mw1

[30m]

70m

[30m]

70m

[30m]

50m

[20m]

50m

[20m]

50m

[20m]

50m

[20m]

50m

[20m]

50m

[20m]

50m

[20m]

50m

[20m]

50m

[20m]

50m

[20m]

50m

[20m]

50m

[20m]

50m

[30m]

50m

[30m]

50m

[30m]

RP10 triple (RP3✕3)RP8 triple (RP2.5✕3)

50m

[30m]

50m

[30m]

50m

[30m]

50m

[20m]

50m

[20m]

50m

[20m]

50m

[20m]

50m

[20m]

50m

[20m]

w2

50m

[20m]

w2

50m

[20m]

w2

50m

[20m]

w2

50m

[20m]

w2

50m

[20m]

w2

50m

[20m]

(3) Synchronized quadruple

Maximum pipe length (Main pipe[A]+Branch pipe [ B, C, D and E ])

Main pipe

(mm)[A]

Branch

pipe

[mm]

[B, C, D, E]

w1 The maximum pipe length is 80m in case of new pipping.

w2 When using [31.75 pipe, the outdoor temperature range (dry-bulb temperature) for heating operation is -11 to +21:.

<

Liquid pipe

Gas pipe

Liquid pipe

Gas pipe

Liquid pipe

Gas pipe

Liquid pipe

Gas pipe

Liquid pipe

Gas pipe

Marks in the table above

[19.05 [22.2 [25.4 [28.58 [19.05 [22.2 [25.4 [28.58 [22.2 [25.4 [28.58 [31.75 [19.05 [22.2 [25.4 [28.58 [19.05 [22.2 [25.4 [28.58 [22.2 [25.4 [28.58 [31.75

[6.35

20m

[12.7

[20m]

[9.52

20m

[15.88

[20m]

[9.52

20m

[20m]

[19.05

[12.7

[19.05

>

SW : When the outdoor unit is located lower than

SW

70m

[30m]

: It can be used.

: Cooling capacity is lowered.➝ Refer to <Table6>

: Additional refrigerant charge is required when

the pipe length exceeds 20m.➝ Refer to <Table7>

The maximum pipe length

Charge-less pipe length

[9.52

Normal

sw

piping

70mw1

[30m]

70m

[30m]

70m

[30m]

70m

[30m]

70m

[30m]

70m

[30m]

sw

sw

50m

[30m]

50m

[30m]

50m

[30m]

the indoor unit, set DIP SW8-1 on the outdoor

unit controller board to ON.

[12.7 [15.88 [9.52 [12.7 [15.88

20m

[20m]

20m

[20m]

20m

[20m]

50m

[30m]

50m

[30m]

50m

[30m]

70m

[30m]

70m

[30m]

70m

[30m]

70m

[30m]

70m

[30m]

70m

[30m]

sw

sw

sw

50m

50m

[20m]

[20m]

sw

50m

50m

[20m]

[20m]

sw

50m

50m

[20m]

[20m]

50m

[20m]

50m

[20m]

50m

[20m]

w2

50m

[20m]

sw

w2

sw

20m

50m

[20m]

[20m]

sw

w2

sw

50m

20m

[20m]

[20m]

20m

[20m]

50m

[30m]

50m

[30m]

50m

[30m]

70m

[30m]

70m

[30m]

70m

[30m]

70m

[30m]

70m

[30m]

70m

[30m]

RP10 quadruple (RP2.5✕4)RP8 quadruple (RP2✕4)

20m

[20m]

20m

[20m]

20m

[20m]

50m

[30m]

50m

[30m]

50m

[30m]

70m

[30m]

70m

[30m]

70m

[30m]

Normal

piping

70mw1

[30m]

70m

[30m]

70m

[30m]

50m

[20m]

50m

[20m]

50m

[20m]

50m

[20m]

50m

[20m]

50m

[20m]

50m

[20m]

50m

[20m]

50m

[20m]

w2

50m

[20m]

w2

50m

[20m]

w2

50m

[20m]

21

Page 22

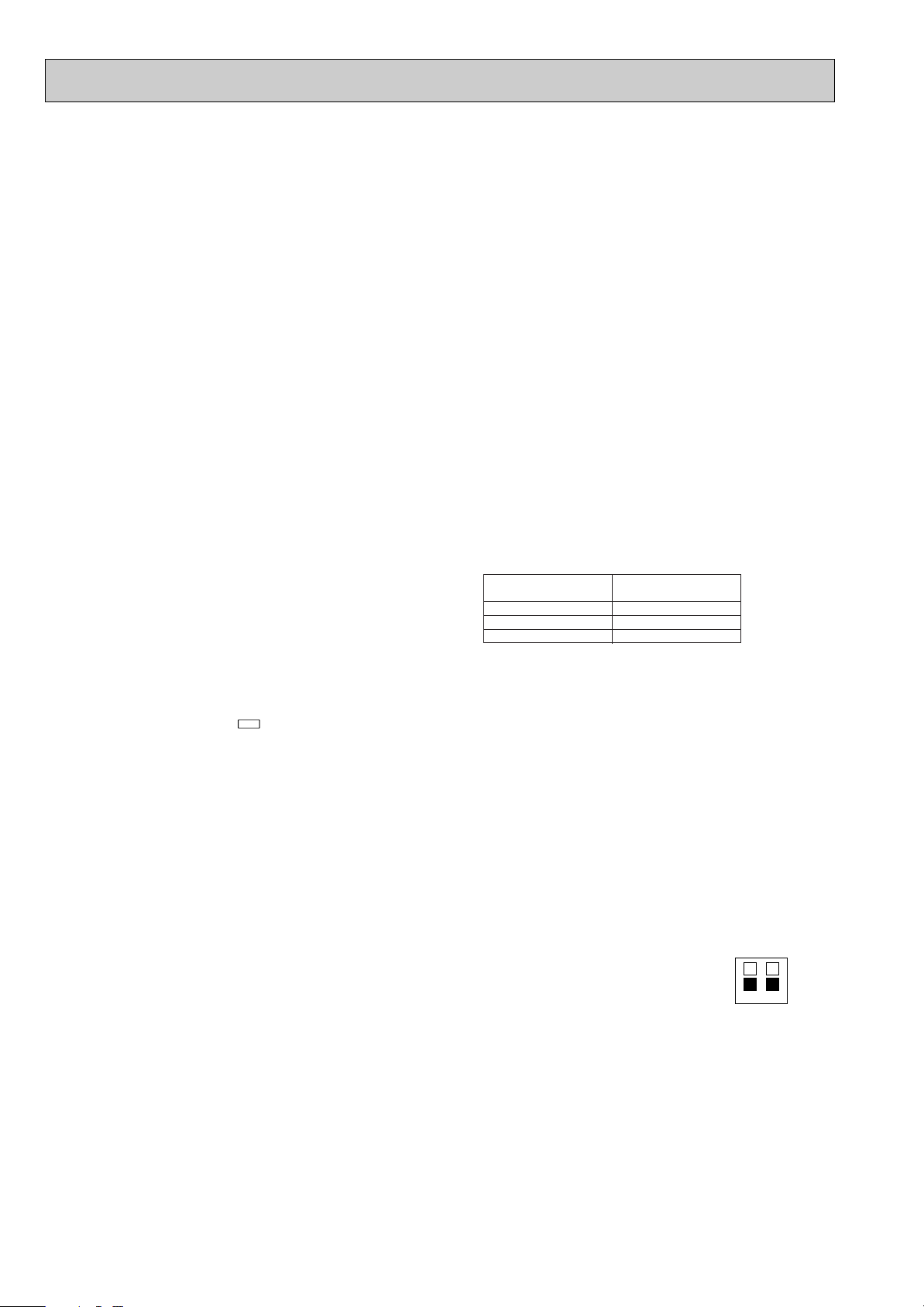

Pipe diameter and thickness

OD

[6.35

(mm)

Thickness

(mm)

Be sure to use hard (tempered) one for pipe over [22.2.(Do not use soft (annealed) one.)

[9.52 [12.7 [

0.8

0.8 0.8 1.0 1.0 1.0 1.0 1.0

15.88[19.05

[22.2 [25.4 [

28.58

[

31.75

1.1

1

1

44

B C

2

4

D

1

4

E

1

1 Indoor unit

2

Outdoor unit

3

Main piping

4

Branch piping

5

Multi disttibution

pipe (option)

1

5

3

2

A

<Table 6> Lowered cooling capacity by the smaller gas pipe diameter

Pipe length

5m and less

6~10m

11~20m

21~30m

31~40m

41~50m

gas pipe [22.2 gas pipe [19.05

100%

100~96%

96~91%

91~86%

86~83%

83~80%

100%

100~91%

91~81%

Height difference (Indoor unit-

1

Outdoor unit) Max. 40 m

Height difference (Indoor unit-

2

Indoor unit) Max. 1 m

Distance between indoor and indoor units

3

pipe length.

B—C B—D B—E

C—D C—E D—E

Number of pipe bends

4

Within 15

points8 points between main pipe A and

each branch pipe (B, C, D, E).

RP10 Cooling capacity ratioRP8 Cooling capacity ratio

gas pipe [25.4 gas pipe [22.2

100%

100~98%

98~94%

94~91%

91~88%

88~86%

100%

100~95%

95~88%

<Table 7> Additional refrigerant amount when the liquid pipe of the larger diameter is used.

(Single /Simultaneous Twin / Simultaneous Triple / Simultaneous Quadruple)

When the extension pipe length (main piping + branch piping) exceeds 20mCapacity

RP8, RP10

L1 : [15.88 liquid pipe (m) L2 : [12.7 liquid pipe (m)

L3 : [9.52 liquid pipe (m) L4 : [6.35 liquid pipe (m)

If the calculation produces a negative number (i.e. a "minus" charge), additional charging is not necessary.

( W [ 0)

Additional refrigerant amount W(g)=(180oL1)+(120oL2) (90oL3)+(30oL4)-3000

<Table 8>

Permissible total A+B or A+C Charge-less

Outdoor unit piping length or piping length

A+B+C+D+E A+D or A+E A+B+C+D+E

RP8

PR10

80 m and less 80 m and less 30 m and less

<Table 9>

Outdoor unit

RP8

RP10

B-C or B-D or

B-E or C-D or

C-E or D-E

8 m and less Within 15

Number of

pipe bends

22

Page 23

<Table 10>

Outdoor unit

RP8

RP10

permitted

pipe length

80m or less

At time of shipping

(kg)

10.5

10.5

30 m and less 31-40 m and less 41-50 m and less 51-60 m and less 61-70 m and less 71-80 m and less

No additional

charge necessary

0.9 kg 1.8 kg 2.7 kg 3.6 kg

1.2 kg 2.4 kg 3.6 kg 4.8 kg

Amount of additional refrigerant charge (kg)

A+B+C+D

The additional charge

amount is obtained by

the following formula.

When length exceeds 70 m

When the total length of the piping exceeds 70 m, calculate the amount of additional charge based on the following requirements.

Note: If the calculation produces a negative number (i.e. a “minus” charge), of if calculation results in an amount that is less than the

“Additional charge amount for 70 m,”perform the additional charge using the amount shown in “Additional charge amount for 70 m.”

Amount of additional

charge

Additional charge amount

for 70 m

Main piping:

Liquid line size

[12.7 overall length

0.12

RP8 3.6 kg

RP10 4.8 kg

Main piping:

Liquid line size

+++

[9.52 overall length

0.09 (Gas line:[28.58)

Branch piping: Liquid

line size

[9.52 overall length

0.06 (Gas line: [15.88)

Branch piping: Liquid

line size

[6.35 overall length

0.02 (Gas line: [15.88)

–=

3.6 (kg)

1. Perform refrigerant piping connections for the indoor / outdoor unit while the outdoor unit's stopvalve is completely

closed (factory setting), and then vacuumize the refrigerant lines through the service port of the outdoor unit.

2. Open the stop valves of the outdoor unit completely.

This will completely connects the refrigerant lines of the indoor and outdoor units.

Handling of the stop valve is shown on the outdoor unit.

Note :

· Apply refrigerating machine oil over the flare seat surface. Do not apply to the threaded portion.

(It will cause the flare nut to loosen.)

· Use two wrenches to tighten piping connection.

· Use leak detector or soapy water to check for gas leaks after connections are completed.

· For the insulation of the connection at the indoor side, make sure to use the attached insulation materials and

thoroughly follow the instruction shown in the manual.

· Always use a non-oxidizing brazing material when brazing the pipes.

Adjusting the amount of refrigerant

Check additional refrigerant charging amount referring to the procedure 2 below when the liquid pipe diameter of the main

piping Ais larger than the standard size.

1 When the standard diameter pipe is used for the main piping A, calculate the additional refrigerant amount by

referring to <Table 2> as well as the 1:1 system.

2 When the liquid pipe diameter of the main piping A is one size larger than the standard size:

· When the extension pipe length (main piping + branch piping) does not exceeds 20m, adjustment of the

refrigerant is not necessary (charge-less).

· When the extension pipe length (main piping + branch piping) exceeds 20m, charge the amount of refrigerant

that is obtained by the formula shown in <Table 7>.

If the calculation produces a negative number (i.e. a "minus" charge), additional charging is not necessary.

Note: Apply 0 to L1 to L3 corresponding to the piping that are not used.

Correcting the capacity value

When calculating the lowered capacity by the extension pipe length, use the longest length between the indoor and the outdoor

units.

23

Page 24

Refrigerant collecting (pump down)

OFF

12

ON

<SW4>

AB

CD

A Stop C operation

B Cooling D Heating

Perform the following procedures to collect the refrigerant when moving the indoor

unit or the outdoor unit.

1 Before collecting the refrigerant, first make sure that the all of the SW5 DIP switches

for function changes on the control board of the outdoor unit are set to OFF. If all of the

SW5 switches are not set to OFF, record the settings and then set all of the switches

to OFF. Start collecting the refrigerant. After moving the unit to a new location and

completing the test run, set the SW5 switches to the previously recorded settings.

2

Supply power (circuit breaker).

* When power is supplied, make sure that “CENTRALLY CONTROLLED” is not

displayed on the remote controller. If “CENTRALLY CONTROLLED” is displayed, the refrigerant collecting (pump down) cannot be completed normally.

3

After the liquid stop valve is closed, set the SWP switch on the control board of the

outdoor unit to ON. The compressor (outdoor unit) and ventilators (indoor and

outdoor units) start operating and refrigerant collecting operation begins. LED1

and LED2 on the control board of the outdoor unit are lit.

* Set the SWP switch (push-button type) to ON in order to perform refrigerant

collecting operation only when the unit is stopped.

However, refrigerant collecting operation cannot be performed until compressor stops even if the unit is stopped.

Wait three minutes until compressor is completely stopped and set the SWP

switch to ON again.

4 As the unit automatically stops after two or three minutes of refrigerant

collecting operation (LED1 if not lit and LED2 is lit), be sure to quickly

close the gas stop valve.

If the unit stops while both LED1 and LED2 are lit, open the liquid valve

completely, wait three minutes, then repeat the step 3.

* If the refrigerant collecting operation has been completed normally

(LED1 and LED2 are lit), the unit will remain stopped until the power

supply is turned off.

5 Turn off the power supply (circuit breaker).

* Note that when the length of the extension piping is long, it may not be

possible to perform a pump-down operation.When performing the pumpdown operation, make sure that the low pressure is lowered to near

0 MPa (gauge).

Unit replacement operation

· This model will automatically begin the replacement operation after it has been

installed when it enters the initialization phase for normal heating or cooling. Ho wever , the unit will not automatically perf orm the replacement operation if it is moved

to a new location where it will be used with existing R22 refrigerant piping. Under

such conditions, always use the SW8-2 operations to perform the replacement

operation before beginning the test operation.

Some models can perform the replacement operation only by SW8-2 operation.

Refer to the outdoor unit's Installation Manual for detail.

Replacement operation procedures (When moving the unit and connecting it

to existing R22 piping.)

1 Supply power.

2

Set DIP switch SW8-2 on the control board of the outdoor unit to ON to start

replacement operation.

* The replacement operation is performed using the cooling system. Cool air will

flow from the indoor unit during the replacement operation.

* During the replacement operation,

and LED1 and LED2 on the control board of the outdoor unit flash together.

The duration of the replacement operation is determined by the length of the pip-

3

ing. Alwa ys perform the replacement operation f or longer than the stipulated time.

* Always perform one of the following operations at the completion of the re-

placement operation. The replacement operation will end and the unit will automatically stop.

TEST RUN

is displayed on the remote controller

(1)Set SW8-2 from ON to OFF. (When ending a replacement operation of less

than 2 hours.)

· Each time SW8-2 is set from OFF to ON, the replacement operation can be

started. Always perf orm the replacement operation for longer than the stipulated time.

Required replacement operation times

Piping Length

0 to 20 meters 30 minutes or more

21 to 30 meters 45 minutes or more

31 to 70 meters 60 minutes or more

(2)The replacement operation will automatically stop after 2 hours. (It will end with

SW8-2 still in the ON position.)

· When the replacement operation has ended automatically after 2 hours of

operation, there is no need to set SW8-2 from ON to OFF; normal air conditioning operations can bestarted with the SW8-2 being set to ON.However, to repeat the replacement operation, SW8-2 will have to be returned

to OFF and then set to ON.

* If the indoor temperature is below 15:, the compressor will operate

intermittently but the unit is not faulty.

Replacement

Operation Time

Start and finish of test run

• Operation from the indoor unit

Execute the test run using the installation manual for the indoor unit.

• Operation from the outdoor unit

By using the DIP switch SW4 on the control board of the outdoor unit, test run can be started and finished, and its operation

mode (cooling/heating) can be set up.

1Set the operation mode (cooling/heating) using SW4-2.

2Turn on SW4-1 to start test run with the operation mode set by SW4-2.

3Turn off SW4-1 to finish the test run.

• There may be a faint knocking sound around the machine room after power is supplied, but this is

no problem with product because the linear expansion pipe is just moving to adjust opening pulse.

• There may be a knocking sound around the machine room for several seconds after compressor

starts operating, but this is no problem with product because the check valve, itself, generates the

sound because pressure difference is small in the refrigerant circuit.

Note:

The operation mode cannot be changed by SW4-2 during test run. (To change test run mode, stop the unit by SW4-1,

change the operation mode and restart the test run by SW4-1.)

24

Page 25

13 TROUBLESHOOTING

Unit conditions at service

Error code

Actions to be taken for service (summary)

The inferior phenomenon is

reoccurring.

Displayed

Not displayed

Judge what is wrong and take a corrective action according

to “13-4. SELF-DIAGNOSIS ACTION TABLE”.

Conduct trouble shooting and ascertain the cause of the

inferior phenomenon according to “13-5. TROUBLESHOOTING BY INFERIOR PHENOMENA”.

The inferior phenomenon is

not reoccurring.

Logged

Not logged

1Consider the temporary defects such as the work of

protection devices in the refrigerant circuit including

compressor, poor connection of wiring, noise and etc.

Re-check the symptom, and check the installation

environment, refrigerant amount, weather when the

inferior phenomenon occurred, matters related to wiring

and etc.

2Reset error code logs and restart the unit after finishing

service.

3There is no abnormality concerning of parts such as

electrical component, controller board, remote controller

and etc.

1Re-check the abnormal symptom.

2Conduct trouble shooting and ascertain the cause of the

inferior phenomenon according to “13-5.

TROUBLE SHOOTING BY INFERIOR PHENOMENA”.

3Continue to operate unit for the time being if the cause

is not ascertained.

4There is no abnormality concerning of parts such as

electrical component, controller circuit board,

remote controller and etc.

13-1. TROUBLESHOOTING

<Error code display by self-diagnosis and actions to be taken for service (summary)>

Present and past error codes are logged and displayed on the wired remote controller and control board of outdoor unit.

Actions to be taken for service, which depends on whether or not the inferior phenomenon is reoccurring at service, are summarized in the table below. Check the contents below before investigating details.

25

Page 26

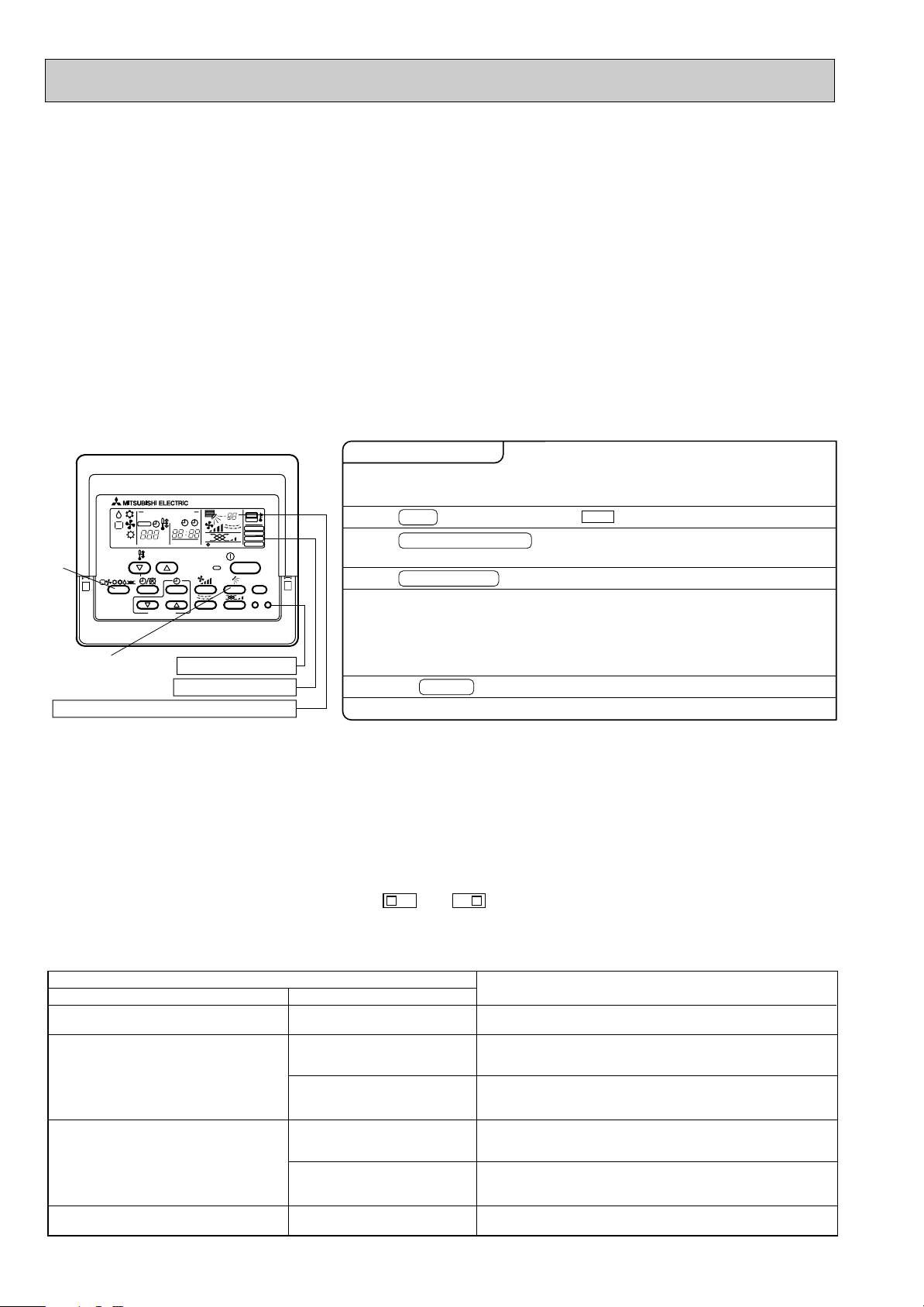

13-2. CHECK POINT UNDER TEST RUN

PAR-20MAA

ON/OFF

CENTRALLY CONTROLLED

ERROR CODE

CLOCK

ON OFF

˚C

CHECK

CHECK MODE

FILTER

TEST RUN

FUNCTION

˚C

1Hr.

NOT AVAILABLE

STAND BY

DEFROST

FILTER

CHECK TEST

TEMP.

TIMER SET

TEST RUN button

TEST RUN display

LIQUID PIPE TEMPERATURE display

(MA remote controller)

(1) Before test run

• After installation of indoor and outdoor units, piping work and electric wiring work, re-check that there is no refrigerant leak-

age, loosened connections and incorrect polarity.

• Measure impedance between the ground and the power supply terminal block(L, N) on the outdoor unit by 500V Merger and

check that it is 1.0M" or over.

wDon’t use 500V Merger to indoor/outdoor connecting wire terminal block(S1, S2, S3) and remote controller terminal block

(1, 2). This may cause malfunction.

• Make sure that test run switch (SW4) is set to OFF before turning on power supply.

• Make sure that all of the SW5 switches for function changes on the control board of the outdoor unit are set to OFF. If all of

the SW5 switches are not set to OFF, record the settings and then set all of the switches to OFF. And perform emergency

operation. After finishing emergency operation, set the SW5 switches to the recorded settings.

• Turn on power supply twelve hours before test run in order to protect compressor.

• For specific models which requires higher ceiling settings or auto-recovery feature from power failure, make proper changes

of settings referring to the description of “Selection of Functions through Remote Controller”.

Make sure to read operation manual before test run. (Especially items to secure safety.)

13-2-1. Test run by remote controller

A

B

Operating procedures

1. Turn on the main power supply.

2. Press TEST button twice.

3. Press OPERATION SWITCH

button.

4. Press AIR DIRECTION

5. Check the outdoor unit fan for

correct running.

6. Press the ON/OFF button to reset the test run in progress.

7. Turn off the main power supply.

B button.

While the room temperature display on the remote

controller is “H0”, the remote controller is disabled.

Wait until “H0” disappears before using remote controller.

“H0” appears for about 2 minutes after power supply is

turned on. w1

The TEST appears on the screen.

Cooling mode:

A

Heating mode: Check if warm air blows. (It takes a little

while until warm air blows.)

Check for correct motion of auto-vanes.

The outdoor unit features automatic capacity control to

provide optimum fan speeds. Therefore, the fan keeps

running at a low speed to meet the current outside air

condition unless it exceeds its available maximum power.

Then, in actuality, the fan may stop or run in the reverse

direction depending on the outside air, but this does not

mean malfunction.

Check if cool air blows and water is drained.

• In case of test run, the OFF timer will be activated, and the test run will automatically stop after two hours.

• The room temperature display section shows the pipe temperature of indoor units during the test run.

• Check that all the indoor units are running properly in case of simultaneous twin and triple operation. Malfunctions may not

be displayed regardless of incorrect wiring.

w1 After turning on the power supply, the system will go into startup mode, “H0” will blink on the display section of the room

temperature, and lamp(red) of the remote controller will flash.

As to INDOOR BOARD LED, LED1 and LED2 will be lit up in case the address is 0, or turned off in case the address is not

0. LED3 will blink.

As to OUTDOOR BOARD LED, LED1(green) and LED2(red) will light up. (After the startup mode of the system finishes,

LED2(red) will be turned off.)

In case OUTDOOR BOARD LED is digital display, — and — will be displayed alternately every second.

• If one of the above operations doesn’t function correctly, the causes written below should be considered. Find causes from

the symptoms.

The below symptoms are under test run mode. “startup” in the table means the display status of w1 written above.

Symptoms in test run mode

Remote Controller Display

Remote controller displays “H0”, and

cannot be operated.

After power is turned on, “H0” is displayed

for 3 minutes, then error code is

displayed.

No display appears even when remote

controller operation switch is turned on.

(Operation lamp does not light up.)

Display appears but soon disappears

even when remote controller is operated.

OUTDOOR BOARD LED Display

< > indicates digital display.

After “startup” is displayed, only

green lights up. <00>

After “startup” is displayed,

green(once) and red(once) blink

alternately. <F1>

After “startup” is displayed,

green(once) and red(twice) blink

alternately. <F3, F4, F9>

After “startup” is displayed,

green(twice) and red(once) blink

alternately. <EA. Eb>

After “startup” is displayed, only

green lights up. <00>

After “startup” is displayed, only

green lights up. <00>

• After power is turned on, “H0” is displayed for 2 minutes during

system startup. (Normal)

• Incorrect connection of outdoor terminal block (L, N and S1,

S2, S3.)

• Outdoor unit’s safeguard installation connector is open.

• Incorrect wiring between the indoor and outdoor unit (Polarity

is wrong for S1, S2, S3.)

• Remote controller transmission wire short.

• There is no outdoor unit of address 0.

(Address is other than 0.)

• Remote controller transmission wire burnout.

• After canceling function selection, operation is not possible for

about 30 seconds. (Normal)

Cause

26

Page 27

wPress the remote controller’s CHECK button twice to perform self-diagnosis. See the table below for the

LCD

Contents of inferior phenomena

P1

P2

P4

P5

P6

P8

P9

Abnormality of room temperature thermistor

Abnormality of pipe temperature thermistor/Liquid

Abnormality of drain sensor

Drain overflow protection is working.

Freezing/overheating protection is working.

Abnormality of pipe temperature

Abnormality of pipe temperature thermistor/Cond./Eva

LCD

Contents of inferior phenomena

U1~UP

F3~F9

E0~E5

E6~EF

----

FFFF

Malfunction outdoor unit

Malfunction

outdoor unit

Remote controller transmitting error

Indoor/outdoor unit communication error

No error history

No applied unit

LED1

(microcomputer power supply)

LED2

(remote controller)

LED3

(indoor/outdoor communication)

Lits when power is supplied.

Remote controller

The indoor unit should be connected to the outdoor unit with address “0” setting.

Flash when indoor and outdoor unit are communicating.

ON

SW4

12

A Stop

B Cooling

C Operation

D Heating

A

CD

B

(Factory setting)

contents of LCD display.

See the table below for details of the LED display (LED 1, 2, 3) on the indoor controller circuit board.

13-2-2. Test run by outdoor unit SW4

The setting of test run (ON/OFF) and its operation mode (cooling/heating) can be set by SW4 on the controller circuit board of

outdoor unit. Check that SW5-1 is set to OFF before performing test run. If SW5-1 is set to ON, turn it OFF and then perform

test run. After finishing test run, set SW5-1 back to ON.

1Set operation mode(cooling or heating) by SW4-2.

2Start test run by setting SW4-1 to ON ( ) with the indicated operation mode of SW4-2.

3Finish test run by setting SW4-1 to OFF ( ).

• Operation mode cannot be changed by SW4-2 during test run.

Stop test run to change operation mode by SW4-1, and restart test run by SW4-1 after

the mode is changed.

• Test run automatically stops 2 hours later by 2-hour OFF timer function.

• Test run can be performed by the remote controller.

• The remote controller display of test run by outdoor unit is the same as that of test run by

remote controller.

27

Page 28

13-3. MALFUNCTION-DIAGNOSIS METHOD BY REMOTE CONTROLLER

Mode number

Setting number

Refrigerant address

Unit number

PAR-20MAA

ON/OFF

CENTRALLY CONTROLLED

ERROR CODE

CLOCK

ON OFF