Page 1

Air-Conditioners

PUHZ-RP•HA4

PUHZ-RP•KA

INSTALLATION MANUAL

For safe and correct use, read this manual and the indoor unit installation manual thoroughly before installing

the air-conditioner unit.

INSTALLATIONSHANDBUCH

Aus Sicherheitsgründen und zur richtigen Verwendung vor der Installation die vorliegende Bedienungsanleitung

und die Installationsanleitung der Innenanlage gründlich durchlesen die Klimaanlage.

MANUEL D’INSTALLATION

Avant d’installer le climatiseur, lire attentivement ce manuel, ainsi que le manuel d’installation de l’appareil

intérieur pour une utilisation sûre et correcte.

INSTALLATIEHANDLEIDING

Lees deze handleiding en de installatiehandleiding van het binnenapparaat zorgvuldig door voordat u met het

installeren van de airconditioner begint.

MANUAL DE INSTALACIÓN

Para un uso correcto y seguro, lea detalladamente este manual y el manual de instalación de la unidad interior

antes de instalar la unidad de aire acondicionado.

MANUALE DI INSTALLAZIONE

Per un uso sicuro e corretto, leggere attentamente il presente manuale ed il manuale d’installazione dell’unità

interna prima di installare il condizionatore d’aria.

MANUAL DE INSTALAÇÃO

Para uma utilização segura e correcta, leia atentamente este manual e o manual de instalação da unidade

interior antes de instalar o aparelho de ar condicionado.

INSTALLATIONSMANUAL

Læs af sikkerhedshensyn denne manual samt manualen til installation af indendørsenheden grundigt, før du

installerer klimaanlægget.

INSTALLATIONSMANUAL

Läs bruksanvisningen och inomhusenhetens installationshandbok noga innan luftkonditioneringen installeras

så att den används på ett säkert och korrekt sätt.

FOR INSTALLER

FÜR INSTALLATEURE

POUR L’INSTALLATEUR

VOOR DE INSTALLATEUR

PARA EL INSTALADOR

PER L’INSTALLATORE

PARA O INSTALADOR

TIL INSTALLATØREN

FÖR INSTALLATÖREN

English

Deutsch

Français

Nederlands

Español

Italiano

Eλληνικά

Português

Dansk

Svenska

Emniyetli ve doğru kullanım için, klima cihazını monte etmeden önce bu kılavuzu ve iç ünite montaj kılavuzunu

tamamıyla okuyun.

Türkçe

Page 2

Contents

1. Safety precautions.................................................. 2

2. Installation location................................................. 3

3. Installing the outdoor unit............................................ 5

4. Installing the refrigerant piping........................................ 5

5. Drainage piping work................................................ 9

Note: This symbol mark is for EU countries only.

This symbol mark is according to the directive 2002/96/EC Article 10 Information for users and Annex IV.

Your MITSUBISHI ELECTRIC product is designed and manufactured with high quality materials and components which can be recycled and reused.

This symbol means that electrical and electronic equipment, at their end-of-life, should be disposed of separately from your household waste.

Please, dispose of this equipment at your local community waste collection/recycling centre.

In the European Union there are separate collection systems for used electrical and electronic product.

Please, help us to conserve the environment we live in!

Caution:

• Do not vent R410A into the Atmosphere:

• R410A is a Fluorinated Greenhouse gas, covered by the Kyoto Protocol, with a Global Warming Potential (GWP)=1975.

6. Electrical work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

7. Test run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8. Initial settings for refrigerant leakage detection function . . . . . . . . . . . . . . . . . . 12

9. Special Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

10. System control (Fig. 10-1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1. Safety precautions

►

Before installing the unit, make sure you read all the “Safety precautions”.

► Please report to or take consent by the supply authority before connec-

tion to the system.

► Equipment complying with IEC/EN 61000-3-12

(PUHZ-RP100/125/140VKA)

► PUHZ-RP200/250Y

“This equipment complies with IEC 61000-3-12 provided that the short-

circuit power S

between the user’s supply and the public system. It is the responsibility

of the installer or user of the equipment to ensure, by consulation with

the distribution network operator if necessary, that the equipment is

connected only to a supply with a short-circuit power S

equal to S

S

sc (*1)

sc is greater than or equal to Ssc (*1) at the interface point

sc greater than or

sc (*1)”

Model Ssc (MVA)

PUHZ-RP200Y 1.35

PUHZ-RP250Y 1.49

Warning:

Describes precautions that must be observed to prevent danger of injury or

death to the user.

Caution:

Describes precautions that must be observed to prevent damage to the unit.

After installation work has been completed, explain the “Safety Precautions,” use,

and maintenance of the unit to the customer according to the information in the

Operation Manual and perform the test run to ensure normal operation. Both the

Installation Manual and Operation Manual must be given to the user for keeping.

These manuals must be passed on to subsequent users.

: Indicates a part which must be grounded.

Warning:

Carefully read the labels affi xed to the main unit.

Warning:

• The unit must not be installed by the user. Ask a dealer or an authorized

technician to install the unit. If the unit is installed incorrectly, water leakage, electric shock, or fi re may result.

• For installation work, follow the instructions in the Installation Manual and

use tools and pipe components specifi cally made for use with R410A re-

frigerant. The R410A refrigerant in the HFC system is pressurized 1.6 times

the pressure of usual refrigerants. If pipe components not designed for

R410A refrigerant are used and the unit is not installed correctly, the pipes

may burst and cause damage or injuries. In addition, water leakage, electric shock, or fi re may result.

• The unit must be installed according to the instructions in order to minimize the risk of damage from earthquakes, typhoons, or strong winds. An

incorrectly installed unit may fall down and cause damage or injuries.

• The unit must be securely installed on a structure that can sustain its

weight. If the unit is mounted on an unstable structure, it may fall down

and cause damage or injuries.

• If the air conditioner is installed in a small room, measures must be taken

to prevent the refrigerant concentration in the room from exceeding the

safety limit in the event of refrigerant leakage. Consult a dealer regarding

the appropriate measures to prevent the allowable concentration from being exceeded. Should the refrigerant leak and cause the concentration limit

to be exceeded, hazards due to lack of oxygen in the room may result.

• Ventilate the room if refrigerant leaks during operation. If refrigerant comes

into contact with a fl ame, poisonous gases will be released.

• All electric work must be performed by a qualifi ed technician according to

local regulations and the instructions given in this manual. The units must

be powered by dedicated power lines and the correct voltage and circuit

breakers must be used. Power lines with insuffi cient capacity or incorrect

electrical work may result in electric shock or fi re.

1.1. Before installation

Caution:

• Do not use the unit in an unusual environment. If the air conditioner is

installed in areas exposed to steam, volatile oil (including machine oil), or

sulfuric gas, areas exposed to high salt content such as the seaside, or

areas where the unit will be covered by snow, the performance can be signifi cantly reduced and the internal parts can be damaged.

• Do not install the unit where combustible gases may leak, be produced,

fl ow, or accumulate. If combustible gas accumulates around the unit, fi re

or explosion may result.

• Use C1220 copper phosphorus, for copper and copper alloy seamless

pipes, to connect the refrigerant pipes. If the pipes are not connected correctly, the unit will not be properly grounded and electric shock may result.

• Use only specifi ed cables for wiring. The connections must be made se-

curely without tension on the terminals. If the cables are connected or

installed incorrectly, overheating or fi re may result.

• The terminal block cover panel of the outdoor unit must be fi rmly attached.

If the cover panel is mounted incorrectly and dust and moisture enter the

unit, electric shock or fi re may result.

• When installing or moving the air conditioner, use only the specifi ed refrig-

erant (R410A) to charge the refrigerant lines. Do not mix it with any other

refrigerant and do not allow air to remain in the lines. Air enclosed in the

lines can cause pressure peaks resulting in a rupture and other hazards.

• Use only accessories authorized by Mitsubishi Electric and ask a dealer

or an authorized technician to install them. If accessories are incorrectly

installed, water leakage, electric shock, or fi re may result.

• Do not alter the unit. Consult a dealer for repairs. If alterations or repairs

are not performed correctly, water leakage, electric shock, or fi re may re-

sult.

• The user should never attempt to repair the unit or transfer it to another

location. If the unit is installed incorrectly, water leakage, electric shock,

or fi re may result. If the air conditioner must be repaired or moved, ask a

dealer or an authorized technician.

• After installation has been completed, check for refrigerant leaks. If refrigerant leaks into the room and comes into contact with the fl ame of a heater

or portable cooking range, poisonous gases will be released.

• The outdoor unit produces condensation during the heating operation.

Make sure to provide drainage around the outdoor unit if such condensation is likely to cause damage.

• When installing the unit in a hospital or communications office, be prepared for noise and electronic interference. Inverters, home appliances,

high-frequency medical equipment, and radio communications equipment

can cause the air conditioner to malfunction or breakdown. The air conditioner may also affect medical equipment, disturbing medical care, and

communications equipment, harming the screen display quality.

2

Page 3

1. Safety precautions

1.2. Before installation (relocation)

Caution:

• Be extremely careful when transporting or installing the units. Two or

more persons are needed to handle the unit, as it weighs 20 kg or more.

Do not grasp the packaging bands. Wear protective gloves to remove the

unit from the packaging and to move it, as you can injure your hands on

the fi ns or the edge of other parts.

• Be sure to safely dispose of the packaging materials. Packaging materials,

such as nails and other metal or wooden parts may cause stabs or other

injuries.

1.3. Before electric work

Caution:

• Be sure to install circuit breakers. If not installed, electric shock may result.

• For the power lines, use standard cables of suffi cient capacity. Otherwise,

a short circuit, overheating, or fi re may result.

• When installing the power lines, do not apply tension to the cables. If the

connections are loosened, the cables can snap or break and overheating

or fi re may result.

1.4. Before starting the test run

Caution:

• Turn on the main power switch more than 12 hours before starting operation. Starting operation just after turning on the power switch can severely

damage the internal parts. Keep the main power switch turned on during

the operation season.

• Before starting operation, check that all panels, guards and other protective parts are correctly installed. Rotating, hot, or high voltage parts can

cause injuries.

• Do not touch any switch with wet hands. Electric shock may result.

• The base and attachments of the outdoor unit must be periodically

checked for looseness, cracks or other damage. If such defects are left uncorrected, the unit may fall down and cause damage or injuries.

• Do not clean the air conditioner unit with water. Electric shock may result.

• Tighten all fl are nuts to specifi cation using a torque wrench. If tightened

too much, the fl are nut can break after an extended period and refrigerant

can leak out.

• Be sure to ground the unit. Do not connect the ground wire to gas or water

pipes, lightning rods, or telephone grounding lines. If the unit is not properly grounded, electric shock may result.

• Use circuit breakers (ground fault interrupter, isolating switch (+B fuse),

and molded case circuit breaker) with the specifi ed capacity. If the circuit

breaker capacity is larger than the specifi ed capacity, breakdown or fi re

may result.

• Do not touch the refrigerant pipes with bare hands during operation. The

refrigerant pipes are hot or cold depending on the condition of the fl owing

refrigerant. If you touch the pipes, burns or frostbite may result.

• After stopping operation, be sure to wait at least fi ve minutes before turn-

ing off the main power switch. Otherwise, water leakage or breakdown may

result.

1.5. Using R410A refrigerant air conditioners

Caution:

• Use C1220 copper phosphorus, for copper and copper alloy seamless

pipes, to connect the refrigerant pipes. Make sure the insides of the pipes

are clean and do not contain any harmful contaminants such as sulfuric

compounds, oxidants, debris, or dust. Use pipes with the specifi ed thick-

ness. (Refer to 4.1.) Note the following if reusing existing pipes that carried

R22 refrigerant.

- Replace the existing fl are nuts and fl are the fl ared sections again.

- Do not use thin pipes. (Refer to 4.1.)

• Store the pipes to be used during installation indoors and keep both ends

of the pipes sealed until just before brazing. (Leave elbow joints, etc. in

their packaging.) If dust, debris, or moisture enters the refrigerant lines, oil

deterioration or compressor breakdown may result.

• Use ester oil, ether oil, alkylbenzene oil (small amount) as the refrigeration

oil applied to the fl ared sections. If mineral oil is mixed in the refrigeration

oil, oil deterioration may result.

Fig. 1-1

• Do not use refrigerant other than R410A refrigerant. If another refrigerant is

used, the chlorine will cause the oil to deteriorate.

• Use the following tools specifi cally designed for use with R410A refrigerant.

The following tools are necessary to use R410A refrigerant. Contact your

nearest dealer for any questions.

Gauge manifold Flare tool

Charge hose Size adjustment gauge

Gas leak detector Vacuum pump adapter

Torque wrench Electronic refrigerant charging scale

• Be sure to use the correct tools. If dust, debris, or moisture enters the re-

frigerant lines, refrigeration oil deterioration may result.

• Do not use a charging cylinder. If a charging cylinder is used, the compo-

sition of the refrigerant will change and the effi ciency will be lowered.

Tools (for R410A)

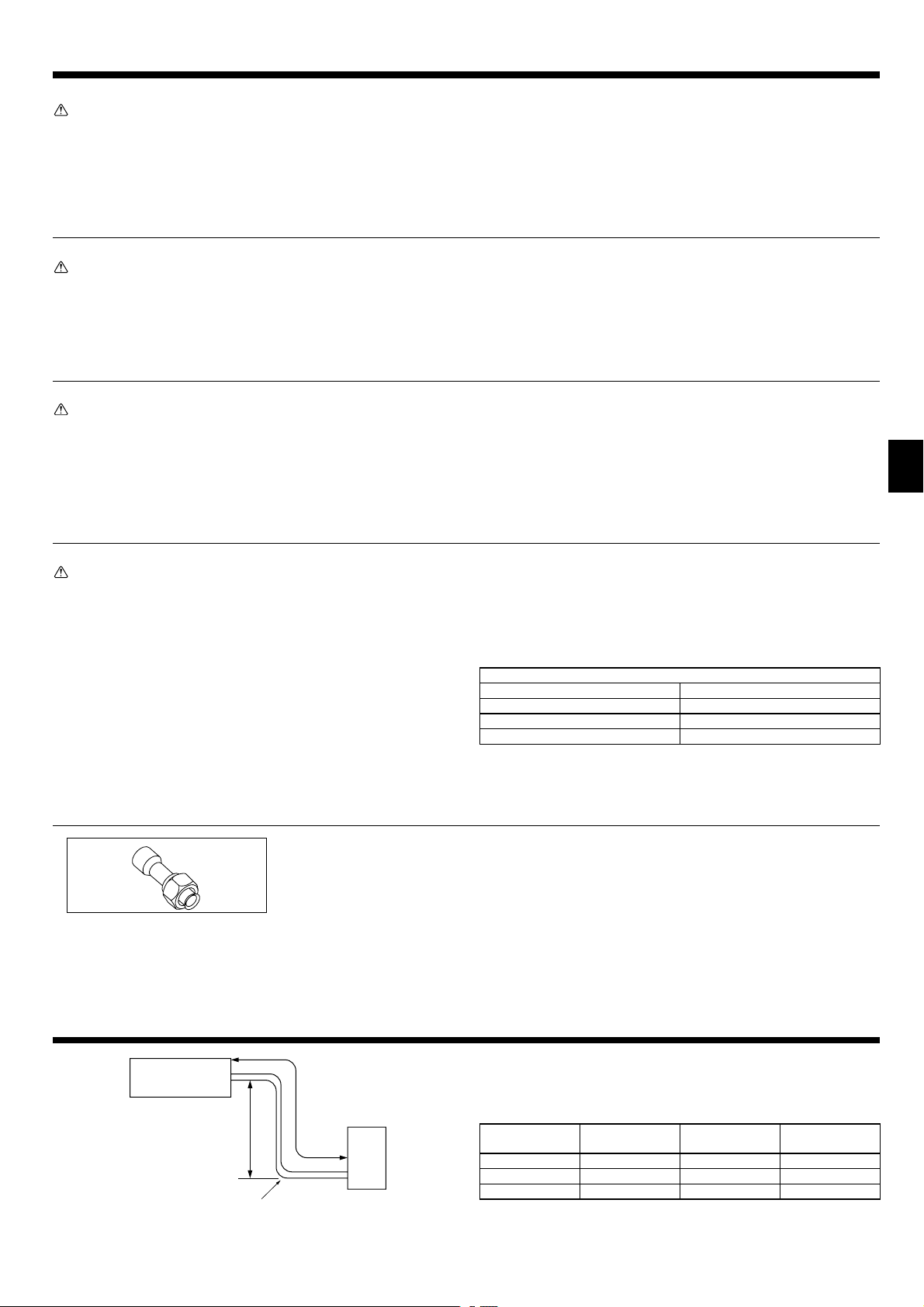

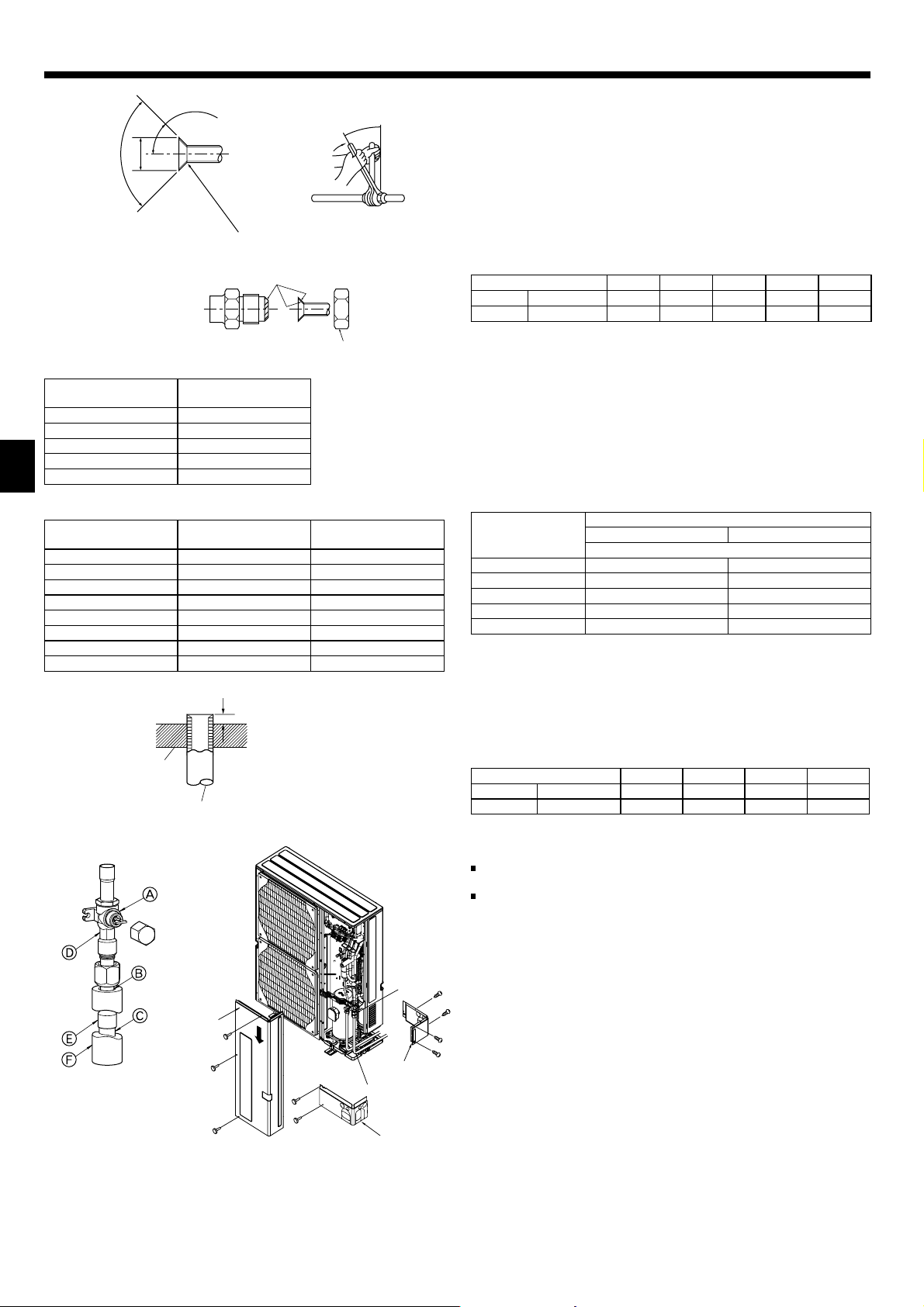

1.6. Accessories of outdoor unit (Fig. 1-1) (RP200/250)

The parts show in the left are the accessories of this unit, which are affi xed to the

inside of the service panel.

1 Joint pipe

.........

×1

2. Installation location

D

B

Fig. 2-1

A

E

2.1. Refrigerant pipe (Fig. 2-1)

► Check that the difference between the heights of the indoor and outdoor

units, the length of refrigerant pipe, and the number of bends in the pipe

are within the limits shown below.

Models

RP35, 50, 60, 71 Max. 50 m Max. 30 m Max. 15

RP100, 125, 140 Max. 75 m Max. 30 m Max. 15

RP200, 250 Max. 120 m Max. 30 m Max. 15

A Pipe length

(one way)

B Height

difference

C

Number of bends

(one way)

C

• Height difference limitations are binding regardless of which unit, indoor or out-

door, is positioned higher.

D Indoor unit

E Outdoor unit

3

Page 4

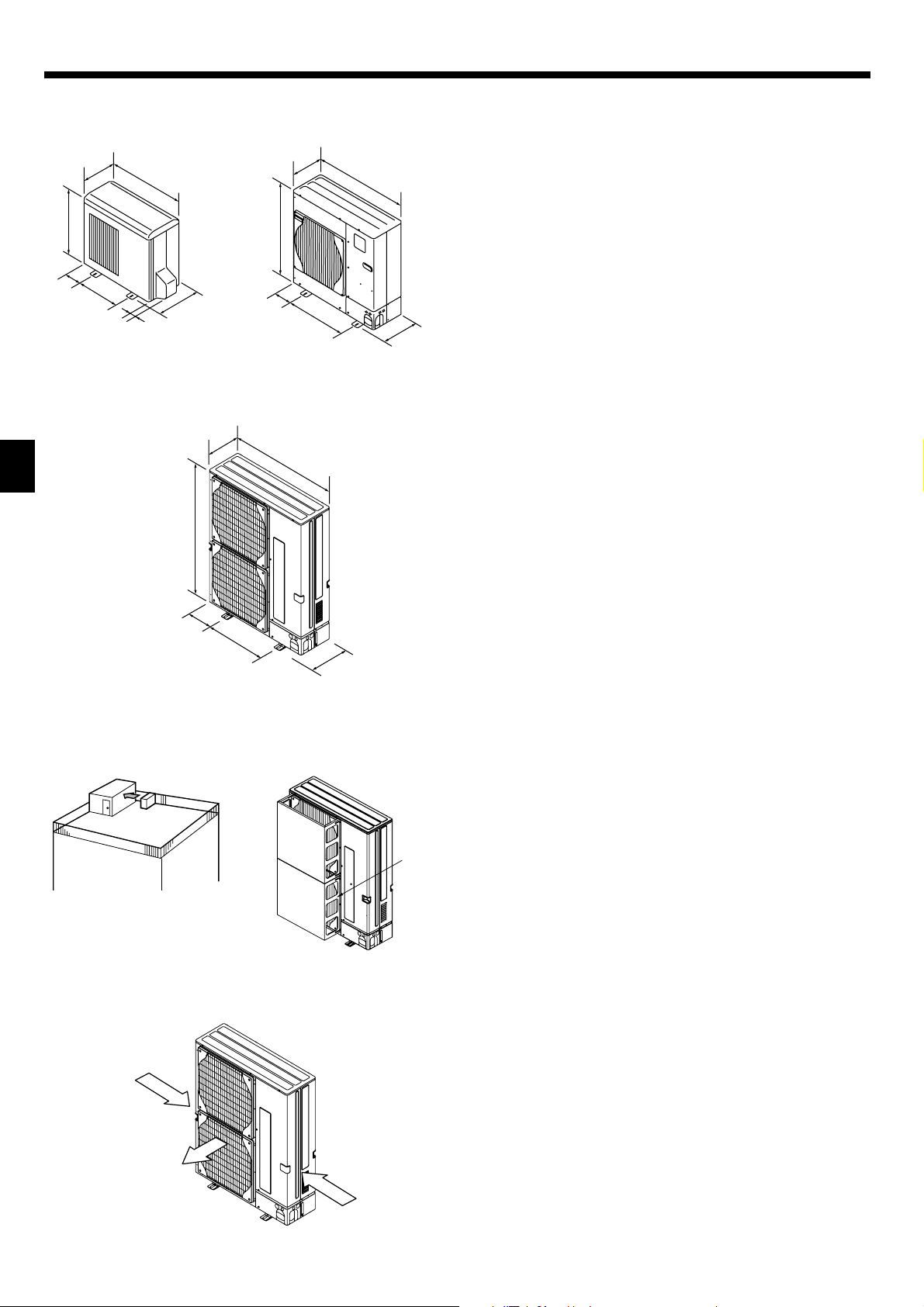

2. Installation location

■

RP35, 50

300+23

600

150

500

■

RP100, 125, 140, 200, 250

800

69

Fig. 2-3

330

225

3

1338

30+25

600

Fig. 2-2

■

RP60, 71

330+30

943

175

1050

600

70

3

Fig. 2-4

2.2. Choosing the outdoor unit installation location

• Avoid locations exposed to direct sunlight or other sources of heat.

• Select a location from which noise emitted by the unit will not inconvenience

neighbors.

• Select a location permitting easy wiring and pipe access to the power source

950

370

and indoor unit.

• Avoid locations where combustible gases may leak, be produced, fl ow, or accu-

mulate.

• Note that water may drain from the unit during operation.

• Select a level location that can bear the weight and vibration of the unit.

• Avoid locations where the unit can be covered by snow. In areas where heavy

snow fall is anticipated, special precautions such as raising the installation location or installing a hood on the air intake must be taken to prevent the snow from

blocking the air intake or blowing directly against it. This can reduce the airfl ow

and a malfunction may result.

• Avoid locations exposed to oil, steam, or sulfuric gas.

• Use the transportation handles of the outdoor unit to transport the unit. If the unit

is carried from the bottom, hands or fi ngers may be pinched.

2.3. Outline dimensions (Outdoor unit) (Fig. 2-2)

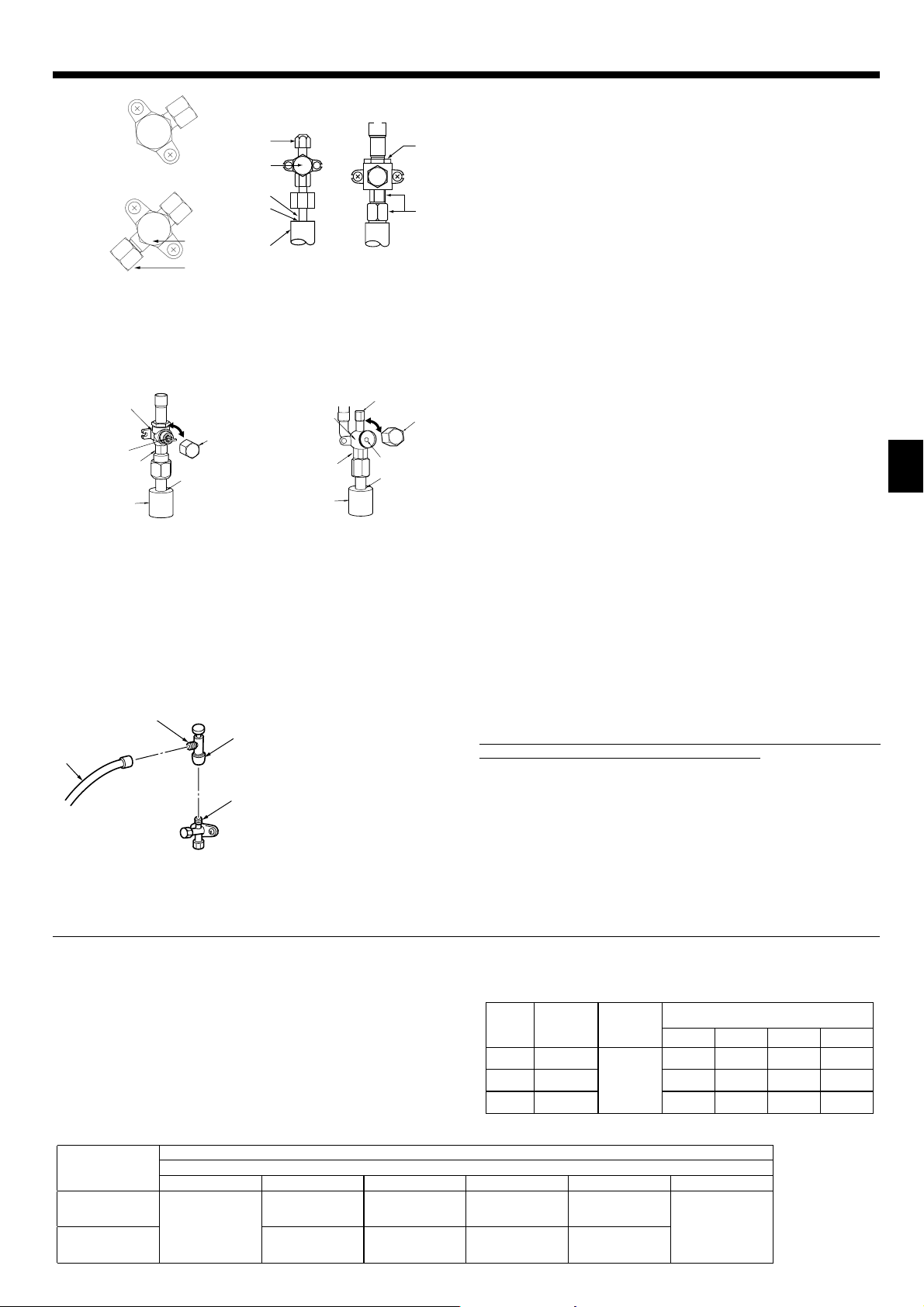

2.4. Ventilation and service space

2.4.1. Windy location installation

When installing the outdoor unit on a rooftop or other location unprotected from

the wind, situate the air outlet of the unit so that it is not directly exposed to strong

winds. Strong wind entering the air outlet may impede the normal airflow and a

malfunction may result.

The following shows three examples of precautions against strong winds.

1 Face the air outlet towards the nearest available wall about 50 cm away from the

wall. (Fig. 2-3)

2 Install an optional air guide if the unit is installed in a location where strong winds

from a typhoon, etc. may directly enter the air outlet. (Fig. 2-4)

A Air outlet guide

3 Position the unit so that the air outlet blows perpendicularly to the seasonal wind

direction, if possible. (Fig. 2-5)

B Wind direction

2.4.2. When installing a single outdoor unit (Refer to the last page)

Minimum dimensions are as follows, except for Max., meaning Maximum dimensions, indicated.

The fi gures in parentheses are for RP100-250 models.

Refer to the fi gures for each case.

1

Obstacles at rear only (Fig. 2-6)

2

Obstacles at rear and above only (Fig. 2-7)

3

Obstacles at rear and sides only (Fig. 2-8)

* 350 for RP35, 50.

4

Obstacles at front only (Fig. 2-9)

* When using an optional air outlet guide, the clearance for RP100-250 models is 500 mm or

more.

5

Obstacles at front and rear only (Fig. 2-10)

* When using an optional air outlet guide, the clearance for RP100-250 models is 500 mm or

A

B

more.

6

Obstacles at rear, sides, and above only (Fig. 2-11)

* 350 for RP35, 50.

• Do not install the optional air outlet guides for upward airfl ow.

2.4.3. When installing multiple outdoor units (Refer to the last page)

Leave 350 mm for RP35, 50 and 10 mm for RP60-250 space or more between the

units.

The fi gures in parentheses are for RP100-250 models.

1

Obstacles at rear only (Fig. 2-12)

2

Obstacles at rear and above only (Fig. 2-13)

• No more than 3 units must be installed side by side. In addition, leave space as shown.

• Do not install the optional air outlet guides for upward airfl ow.

3

Obstacles at front only (Fig. 2-14)

* When using an optional air outlet guide, the clearance for RP100-250 models is 1000 mm

or more.

4

Obstacles at front and rear only (Fig. 2-15)

* When using an optional air outlet guide, the clearance for RP100-250 models is 1000 mm

or more.

5

Single parallel unit arrangement (Fig. 2-16)

* When using an optional air outlet guide installed for upward airfl ow, the clearance is

500 (1000) mm or more.

6

Multiple parallel unit arrangement (Fig. 2-17)

* When using an optional air outlet guide installed for upward airfl ow, the clearance is

1000 (1500) mm or more.

7

Stacked unit arrangement (Fig. 2-18)

• The units can be stacked up to two units high.

• No more than 2 stacked units must be installed side by side. In addition, leave space as

shown.

Fig. 2-5

4

Page 5

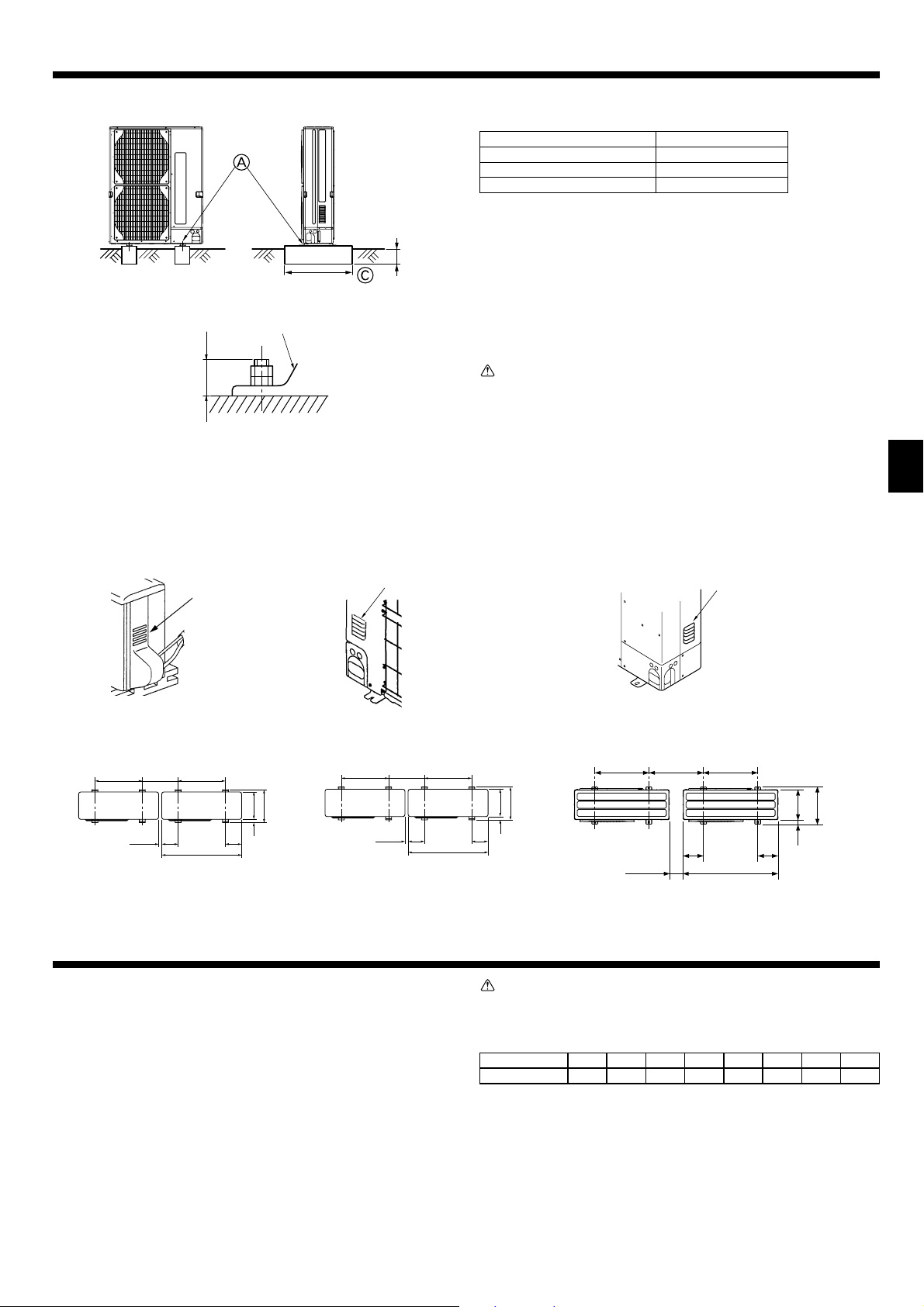

3. Installing the outdoor unit

Max. 18 for RP35, 50

Max. 30 for RP60-250

M10 (3/8") bolt

Base

As long as possible.

Vent

Set deep in the ground

(mm)

• Be sure to install the unit in a sturdy, level surface to prevent rattling noises

during peration. (Fig. 3-1)

<Foundation specifi cations>

Foundation bolt M10 (3/8")

Thickness of concrete 120 mm

Length of bolt 70 mm

Weight-bearing capacity 320 kg

• Make sure that the length of the foundation bolt is within 30 mm of the bottom

surface of the base.

• Secure the base of the unit fi rmly with four-M10 foundation bolts in sturdy loca-

tions.

Installing the outdoor unit

• Do not block the vent. If the vent is blocked, operation will be hindered and

breakdown may result.

• In addition to the unit base, use the installation holes on the back of the unit to

attach wires, etc., if necessary to install the unit. Use self-tapping screws (ø5 ×

15 mm or less) and install on site.

Warning:

• The unit must be securely installed on a structure that can sustain its

weight. If the unit is mounted on an unstable structure, it may fall down

and cause damage or injuries.

• The unit must be installed according to the instructions in order to minimize the risk of damage from earthquakes, typhoons, or strong winds. An

incorrectly installed unit may fall down and cause damage or injuries.

■

RP35, 50

■

RP35, 50

500

Min. 350

Min. 650

150

500

800

150

300

15

330

■

RP60, 71

■

RP60, 71

600 600Min. 360

175 175

Min. 10

950

Fig. 3-1

4. Installing the refrigerant piping

4.1. Precautions for devices that use R410A refrigerant

• Refer to 1.5. for precautions not included below on using air conditioners

with R410A refrigerant.

• Use ester oil, ether oil, alkylbenzene oil (small amount) as the refrigeration oil

applied to the fl ared sections.

• Use C1220 copper phosphorus, for copper and copper alloy seamless pipes,

to connect the refrigerant pipes. Use refrigerant pipes with the thicknesses

specified in the table to the below. Make sure the insides of the pipes are

clean and do not contain any harmful contaminants such as sulfuric compounds, oxidants, debris, or dust.

Always apply no-oxidation brazing when brazing the pipes, otherwise, the

compressor will be damaged.

■

RP100-250

■

RP100-250

600 600

Min. 460

330

370

25

225 225

1050Min. 10

Warning:

When installing or moving the air conditioner, use only the specifi ed refriger-

ant (R410A) to charge the refrigerant lines. Do not mix it with any other refrigerant and do not allow air to remain in the lines. Air enclosed in the lines can

cause pressure peaks resulting in a rupture and other hazards.

Pipe size (mm)

Thickness (mm) 0.8 0.8 0.8 1.0 1.0 1.0 1.0 1.0

• Do not use pipes thinner than those specifi ed above.

• Use 1/2 H or H pipes if the diameter is 22.2 mm or larger.

• For RP250, use 1/2 H or H pipes if the diameter is 19.05 mm or larger.

[6.35 [9.52 [12.7 [15.88 [19.05 [22.2 [25.4 [28.58

33025

370

5

Page 6

4. Installing the refrigerant piping

A B

o

0.5

90op

A Flare cutting dimensions

B Flare nut tightening torque

A (Fig. 4-1)

Copper pipe O.D.

(mm)

ø6.35 8.7 - 9.1

ø9.52 12.8 - 13.2

ø12.7 16.2 - 16.6

ø15.88 19.3 - 19.7

ø19.05 23.6 - 24.0

B (Fig. 4-1)

Copper pipe O.D.

(mm)

ø6.35 17 14 - 18

ø6.35 22 34 - 42

ø9.52 22 34 - 42

ø12.7 26 49 - 61

ø12.7 29 68 - 82

ø15.88 29 68 - 82

ø15.88 36 100 - 120

ø19.05 36 100 - 120

øA

45op 2o

A

R0.4~R0.8

C

Fig. 4-1

Flare dimensions

øA dimensions (mm)

Flare nut O.D.

(mm)

A

B

A Die

B Copper pipe

Fig. 4-2

D

Tightening torque

(N·m)

4.2. Connecting pipes (Fig. 4-1)

• When commercially available copper pipes are used, wrap liquid and gas pipes

with commercially available insulation materials (heat-resistant to 100 °C or

more, thickness of 12 mm or more).

• The indoor parts of the drain pipe should be wrapped with polyethylene foam

insulation materials (specifi c gravity of 0.03, thickness of 9 mm or more).

• Apply thin layer of refrigerant oil to pipe and joint seating surface before tightening fl are nut.

• Use two wrenches to tighten piping connections.

• Use leak detector or soapy water to check for gas leaks after connections are

completed.

• Apply refrigerating machine oil over the entire fl are seat surface.

• Use the fl are nuts for the following pipe size.

Gas side Pipe size (mm)

Liquid side Pipe size (mm)

• When bending the pipes, be careful not to break them. Bend radii of 100 mm to

150 mm are suffi cient.

• Make sure the pipes do not contact the compressor. Abnormal noise or vibration

may result.

1 Pipes must be connected starting from the indoor unit.

Flare nuts must be tightened with a torque wrench.

2 Flare the liquid pipes and gas pipes and apply a thin layer of refrigeration oil (Ap-

plied on site).

• When usual pipe sealing is used, refer to Table 1 for fl aring of R410A refrigerant

pipes.

The size adjustment gauge can be used to confi rm A measurements.

Table 1 (Fig. 4-2)

Copper pipe O.D.

ø6.35 (1/4") 0 - 0.5 1.0 - 1.5

ø9.52 (3/8") 0 - 0.5 1.0 - 1.5

ø12.7 (1/2") 0 - 0.5 1.0 - 1.5

ø15.88 (5/8") 0 - 0.5 1.0 - 1.5

ø19.05 (3/4") 0 - 0.5 1.0 - 1.5

3 Use the following procedure for connecting the gas-side piping. (Fig.4-3)

1 Braze the E Joint pipe provided to the outdoor unit using locally procured braz-

ing materials and C Local piping without oxygen.

2 Connect the E Joint pipe to the gas-side Stop valve.

Use 2 wrenches to tighten the fl are nut.

* If order is reversed, refrigerant leak occurs because of the part damaging by

brazinig fi re.

• For PEA-RP200, 250, 400, 500GA

The method of pipe connection is brazing connection.

Gas side Pipe size (mm)

Liquid side Pipe size (mm)

(mm)

A

RP35, 50 RP60, 71

[12.7 [15.88 [15.88 [25.4 [25.4

[6.35 [9.52 [9.52 [9.52 [12.7

Flare tool for R410A Flare tool for R22·R407C

PEA-200 PEA-250 PEA-400 PEA-500

[25.4 [25.4 [25.4 [25.4

[9.52 [12.7 [9.52 [12.7

B

D

RP100-140

A (mm)

Clutch type

C

RP200 RP250

AStop valve

BSeal section

CLocal piping

DDouble spanner section

EJoint pipe

FPipe cover

Fig. 4-3

6

AFront piping cover

BPiping cover

CStop valve

DService panel

EBend radius : 100mm -150mm

Fig. 4-4

4.3. Refrigerant piping (Fig. 4-4)

For RP35, 50

Remove the service panel D (1 screw).

For RP60-250

Remove the service panel D (3 screws) and the front piping cover A (2 screws)

and rear piping cover B (2 screws:RP60, 71) (4 screws:RP100-250).

1 Perform refrigerant piping connections for the indoor/outdoor unit when the out-

door unit’s stop valve is completely closed.

2 Vacuum-purge air from the indoor unit and the connection piping.

3 After connecting the refrigerant pipes, check the connected pipes and the indoor

unit for gas leaks. (Refer to 4.4 Refrigerant pipe airtight testing method)

4 A high-performance vacuum pump is used at the stop valve service port to main-

tain a vacuum for an adequate time (at least one hour after reaching –101 kPa

(5 Torr)) in order to vacuum dry the inside of the pipes. Always check the degree

of vacuum at the gauge manifold. If there is any moisture left in the pipe, the degree of vacuum is sometimes not reached with short-time vacuum application.

After vacuum drying, completely open the stop valves (both liquid and gas) for

the outdoor unit. This completely links the indoor and outdoor refrigerant circuits.

•

If the vacuum drying is inadequate, air and water vapor remain in the refrigerant circuits and can cause abnormal rise of high pressure, abnormal drop of

low pressure, deterioration of the refrigerating machine oil due to moisture, etc.

• If the stop valves are left closed and the unit is operated, the compressor and

control valves will be damaged.

• Use a leak detector or soapy water to check for gas leaks at the pipe connec-

tion sections of the outdoor unit.

• Do not use the refrigerant from the unit to purge air from the refrigerant lines.

• After the valve work is completed, tighten the valve caps to the correct torque:

20 to 25 N·m (200 to 250 kgf·cm).

Failure to replace and tighten the caps may result in refrigerant leakage. In

addition, do not damage the insides of the valve caps as they act as a seal to

prevent refrigerant leakage.

5 Use sealant to seal the ends of the thermal insulation around the pipe connec-

tion sections to prevent water from entering the thermal insulation.

Page 7

4. Installing the refrigerant piping

A

B

D

C

A Stop valve <Liquid side>

B Stop valve <Gas side>

C Service port

D Open/Close section

Fig. 4-5

(1) (2)

Fig. 4-6 Fig. 4-7

A Valve

B Unit side

C Handle

D Cap

E Local pipe side

F Pipe cover

G Service port

H Wrench hole

I Double spanner section

(Do not apply a spanner other than to this section.

Doing so would cause coolant leaks.)

J Seal section

(Seal the end of the heat insulation material at

the pipe connection section with whatever seal

material you have on hand so that water does not

infi ltrate the heat insulation material.)

A

C

D

E

F

G

E Local pipe

F Sealed, same way for gas side

G Pipe cover

H Do not use a wrench here.

Refrigerant leakage may result.

I Use two wrenches here.

B

H

I

4.4. Refrigerant pipe airtight testing method (Fig.4-5)

(1)

Connect the testing tools.

• Make sure the stop valves

• Add pressure to the refrigerant lines through the service port C of the liquid

stop valve A.

(2)

Do not add pressure to the specifi ed pressure all at once; add pressure little by

little.

1 Pressurize to 0.5 MPa (5 kgf/cm

pressure does not decrease.

2 Pressurize to 1.5 MPa (15 kgf/cm

pressure does not decrease.

3 Pressurize to 4.15 MPa (41.5 kgf/cm

perature and refrigerant pressure.

(3)

If the specifi ed pressure holds for about one day and does not decrease, the

pipes have passed the test and there are no leaks.

• If the surrounding temperature changes by 1 °C, the pressure will change by

about 0.01 MPa (0.1 kgf/cm

(4)

If the pressure decreases in steps (2) or (3), there is a gas leak. Look for the

source of the gas leak.

are closed and do not open them.

A B

2

G), wait five minutes, and make sure the

2

G), wait fi ve minutes, and make sure the

2

G) and measure the surrounding tem-

2

G). Make the necessary corrections.

4.5. Stop valve opening method

The stop valve opening method varies according to the outdoor unit model. Use the

appropriate method to open the stop valves.

(1)

Gas side of RP100-250 (Fig. 4-6)

1 Remove the cap, pull the handle toward you and rotate 1/4 turn in a counter-

clockwise direction to open.

2 Make sure that the stop valve is open comletely, push in the handle and rotate

the cap back to its original position.

(2)

Liquid side of RP100-250 and Gas/Liquid side of RP35-71 (Fig. 4-7)

1 Remove the cap and turn the valve rod counterclockwise as far as it will go with

the use of a 4 mm hexagonal wrench. Stop turning when it hits the stopper.

(ø9.52: Approximately 10 revolutions)

2 Make sure that the stop valve is open completely, push in the handle and rotate

the cap back to its original position.

Refrigerant pipes are protectively wrapped for RP60-250

• The pipes can be protectively wrapped up to a diameter of ø90 before or after

connecting the pipes. Cut out the knockout in the pipe cover following the groove

and wrap the pipes.

Pipe inlet gap for RP60-250

• Use putty or sealant to seal the pipe inlet around the pipes so that no gaps re-

main. (If the gaps are not closed, noise may be emitted or water and dust will

enter the unit and breakdown may result.)

B

A

C

* The fi gure to the left is an example only.

The stop valve shape, service port position,

etc., may vary according to the model.

* Turn section A only.

(Do not further tighten sections A and B

D

together.)

C Charge hose

D Service port

Precautions when using the charge valve (Fig.4-8)

Do not tighten the service port too much when installing it, otherwise, the valve core

could be deformed and become loose, causing a gas leak.

After positioning section B in the desired direction, turn section A only and tighten it.

Do not further tighten sections A and B together after tightening section A.

Fig. 4-8

4.6. Addition of refrigerant

• Additional charging is not necessary if the pipe length does not exceed 30 m.

• If the pipe length exceeds 30m, charge the unit with additional R410A refrigerant

according to the permitted pipe lengths in the chart below.

* When the unit is stopped, charge the unit with the additional refrigerant

through the liquid stop valve after the pipe extensions and indoor unit have

been vacuumized.

When the unit is operating, add refrigerant to the gas check valve using a

safety charger. Do not add liquid refrigerant directly to the check valve.

* After charging the unit with refrigerant, note the added refrigerant amount on

the service label (attached to the unit).

Refer to the “1.5. Using R410A refrigerant air conditioners” for more informa-

tion.

Outdoor unit

RP200

RP250 1.2 kg 2.4 kg 3.6 kg 4.8 kg

30 m andless 31-40 m andless 41-50 m and less 51-60 m and less 61-70 m andless 71-120 m and less

No additional

charge necessary

0.9 kg 1.8 kg 2.7 kg 3.6 kg

Amount of additionalrefrigerant charge (kg)

• Be careful when installing multiple units. Connecting to an incorrect indoor unit

can lead to abnormally high pressure and have a serious effect on operation

performance.

Model

RP35, 50

RP60, 71

RP100-140

A+B+C+D

Permitted

pipe

length

-50 m

-50 m 0.6 kg 1.2 kg — —

-75 m 0.6 kg 1.2 kg 1.8 kg 2.4 kg

Permitted

vertical

difference

-30 m

Additional refrigerant charging amount

31 - 40 m 41 - 50 m 51 - 60 m 61 - 75 m

0.2 kg 0.4 kg — —

Calculate the

amount of additional

refrigerant charge

using formula pro

vided next page

-

7

Page 8

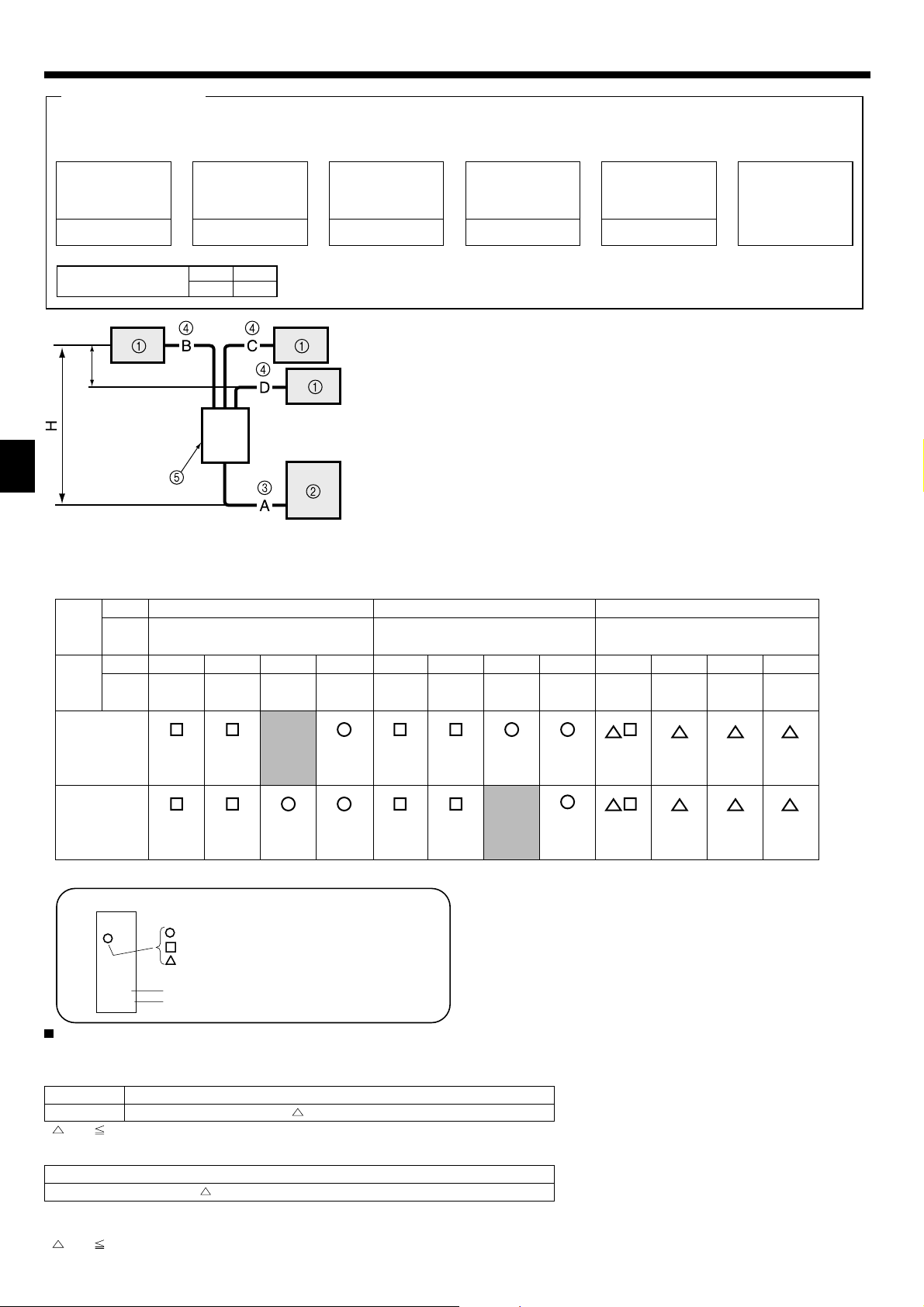

4. Installing the refrigerant piping

When length exceeds 70 m

When the total length of the piping exceeds 70 m, calculate the amount of additional charge based on the following requirements.

Note: If the calculation produces a negative number (i.e. a “minus” charge), of if calculation results in an amount that is less than the “Additional charage amount for 70 m”,

perform the additional charge using the amount shown in “Additional charge amount for 70 m”.

Main piping:

Amount of additional

charge

(kg)

Additional charge amount

for 70 meters

Max. 1m

Liquid line size

ø12.7 overall length ×

=

0.11

(m) × 0.11 (kg/m)

RP200 3.6 kg

RP250 4.8 kg

Fig. 4-9

Maximum pipe length (RP200·RP250)

Liquid

pipe

(mm)

Gas

pipe

(mm)

O.D.

Thick-

ness

O.D.

Thick-

ness

:19.05

t1.0

:22.2

t1.0

:9.52

t0.8

:25.4

t1.0

Main piping:

Liquid line size

ø9.52 overall length ×

+++–

0.09 (Gas line: ø25.4)

(m) × 0.09 (kg/m)

Indoor unit

Outdoor unit

Main piping

Branch piping

Multi distribution

pipe (option)

:28.58

t1.0

:19.05

t1.0

Branch piping:

Liquid line size

ø9.52 overall length ×

0.06 (Gas line: ø15.88)

(m) × 0.06 (kg/m)

Outdoor unit : RP250 A: ø12.7 ... 65 m

Indoor unit 1 : RP71 B: ø9.52 ... 5 m

Indoor unit 2 : RP71 C: ø9.52 ... 5 m

Indoor unit 3 : RP71 D: ø9.52 ... 5 m

Main piping ø12.7 is A = 65 m

Branch piping ø9.52 is B + C + D = 15 m

Therefore, the amount of additional charge is: 65 × 0.12 + 15 × 0.06 - 3.6 = 5.1(kg)

(Fractions are rounded up)

:12.7

t0.8

:22.2

t1.0

:25.4

t1.0

:28.58

t1.0

Branch piping:

Liquid line size

ø6.35 overall length ×

0.02

(m) × 0.02 (kg/m)

:15.88

t1.0

:22.2

t1.0

:25.4

t1.0

:28.58

t1.0

3.6 (kg)

:31.75

t1.1

Standard size

RP200

20m

[20m]

50m

[30m]

120m

[30m]

120m

[30m]

20m

[20m]

50m

[30m]

Standard size

RP250

20m

[20m]

50m

[30m]

120m

[30m]

120m

[30m]

20m

[20m]

50m

[30m]

Note : Be sure to use hard (tempered) one for pipe over :22.2.

<Marks in the table above>

: It can be used.

: Cooling capacity is lowered.

: Additional refrigerant charge is required when

the pipe length exceeds 20m.

120m

[30m]

The maximum pipe length

Charge-less pipe length

RP200, 250

Additional refrigerant amount when the liquid pipe of the larger diameter is used.

1:1 system

Liquid pipe When the pipe length exceeds 20 m

[15.88

w (g) 0 : Additional charge is not necessary.

*

Additional refrigerant amount w (g) =180 × Pipe length (m) - 3000

Simultaneous twin/triple/quadruple system

When the pipe length (main piping and branch piping) exceeds 20 m

Additional refrigerant amount w (g) =(180 × L1)+(120

×

L2) +(90

×

L3)+(30

×

L4) - 3000

L1 : [15.88 liquid pipe length (m) L2 : [12.7 liquid pipe length (m)

L3 : [9.52 liquid pipe length (m) L4 : [6.35 liquid pipe length (m)

w (g) 0 : Additional charge is not necessary.

*

120m

[30m]

120m

[30m]

120m

[30m]

120m

[30m]

50m

[20m]

50m

[20m]

50m

[20m]

50m

[20m]

50m

[20m]

50m

[20m]

50m

[20m]

50m

[20m]

8

Page 9

4. Installing the refrigerant piping

4.7. Precautions when reusing existing R22 refrigerant pipes

• Refer to the fl owchart below to determine if the existing pipes can be used and if it is necessary to use a fi lter dryer.

• If the diameter of the existing pipes is different from the specifi ed diameter, refer to technological data materials to confi rm if the pipes can be used.

Measure the existing pipe thickness and

check for damage.

The existing pipe thickness meets specifi ca-

tions and the pipes are not damaged.

▼

Check if the existing air conditioner can operate.

▼

After operating the cooling system for about 30

minutes, do a pump down work.

▼

Disconnect the existing air conditioner from the

pipes.

▼

Attach the new air conditioner

▼

Perform the airtight test, vacuum air purging,

additional refrigerant charging (if necessary),

and gas leak check.

The existing pipe thickness does not meet

specifi cations or the pipes are damaged.

* If the existing air conditioner cannot operate, use

a refrigerant recovery device to collect the refrigerant.

* In case existing pipes were used for gas or oil

heat pump systems, be sure to clean the pipes

for RP100-250 models.

Use new pipes for RP35-71 models.

Test run

* Refer to 7.2.

<Limits of refrigerant piping installation>

RP71 : A+B+C 50 m

RP100-140 : A+B+C(+D) 75 m

RP200, 250 : A+B+C(+D)(+E) 120 m

* “D” is for triple“.

* “E” is for four (quadruple).

▼ ▼

The existing pipes cannot be reused.

Use new pipes.

4.8. For twin/triple/quadruple combination (Fig. 4-10)

• When this unit is used as a FREE COMPO MULTI unit, install the refrigerant

piping with the restrictions indicated in the drawing on the left. In addition, if the

restrictions are going to be exceeded, or if there are going to be combinations of

indoor and outdoor units, refer to installation instructions for the indoor unit for

Indoor unit

Outdoor unit

Multi distribution pipe (option)

Height difference (Indoor unit-

Outdoor unit) Max. 30 m

Height difference (Indoor unit-

Indoor unit) Max. 1 m

A: Main piping

B, C, D, E: Branch piping

details about the installation.

Outdoor unit

RP71

RP100-140

RP200

RP250

Outdoor unit

RP71 - 250

Permissible total

piping length

A+B+C+D+E

50 m and less

75 m and less

120 m and less

|

B-C|or|B-D|or

|

B-E|or|C-D|or

|

C-E|or|D-E

8 m and less

Fig. 4-10

A+B or A+C

or

A+D or A+E

—

—

100 m and less

|

Charge-less

piping length

A+B+C+D+E

30 m and less

30 m and less

30 m and less

No. of bends

Within 15

5. Drainage piping work

Outdoor unit drainage pipe connection

When drain piping is necessary, use the drain socket or the drain pan (option).

RP35, 50 RP60, 71 RP100-250

Drain socket PAC-SG61DS-E

Drain pan PAC-SG63DP-E PAC-SG64DP-E PAC-SH97DP-E

9

Page 10

6. Electrical work

6.1. Outdoor unit (Fig. 6-1, Fig. 6-2)

1 Remove the service panel.

2 Wire the cables referring to the Fig. 6-1 and the Fig. 6-2.

* Except PEA-RP200, 250, 400, 500GA

L

N

D

For Heater

* With Heater

model only

S1

S2

S3

A

B

S3

S2S1LN

C

D

For Power For Power

For Heater For Heater For Heater

D D D D

E

C

Fig. 6-1

* In case of PEA-200, 250

PUHZ-200, 250

A Indoor unit

B Outdoor unit

C Remote controller

D Main switch (Breaker)

E Earth

EE

PEA-200, 250

E

■

■

RP35, 50

RP35, 50

■

RP60-250

RP60-140V

LN

S1 S2 S3

AAAB

RP100-250Y

L1 L2 L3 N

S1 S2 S3

Fig. 6-2

F Termial block

G Indoor/Outdoor connection terminal block (S1, S2, S3)

H Service panel

I Clamp

* Clamp the cables so that they do not contact the center of the service panel or the gas valve.

J Earth terminal

Note :

If the protective sheet for the electrical box is removed during servicing, be sure to

reinstall it.

Caution:

Be sure to install N-Line. Without N-Line, it could cause damage to unit.

* In case of PEA-400, 500

(No.1 Outdoor)

PUHZ-200, 250 PEA-400, 500

(No.2 Outdoor)

PUHZ-200, 250

* In case of PEA-200, 250 * In case of PEA-400, 500

! $

)2-4BT()1-4BT(

!" #$

Power supply

Earth leakage breaker

Circuit breaker or local switch

LCD remote controller

Outdoor unit

Indoor unit

Power cable wiring

Indoor/outdoor connection wiring

Grounding

Main remote controller

Subordinate remote controller

Standard (Refrigerant address = 00)

Refrigerant address = 01

! Refrigerant address = 02

" Refrigerant address = 03

# Refrigerant address = 14

$ Refrigerant address = 15

10

Fig. 6-3

Page 11

6. Electrical work

6.2. Field electrical wiring

Outdoor unit model RP35, 50V RP60, 70V RP100,125V

Outdoor unit power supply

Outdoor unit input capacity Main switch (Breaker) *1 16 A 25 A 32 A 40 A 16 A 32 A

*1. A breaker with at least 3.0 mm contact separation in each poles shall be provided. Use earth leakage breaker (NV).

*2. (RP35-140)

Max. 45 m

If 2.5 mm

If 2.5 mm

(RP200, 250)

Max. 80 m Total Max. including all indoor/indoor connection is 80 m.

*3. The 10 m wire is attached in the remote controller accessory.

*4. The fi gures are NOT always against the ground.

S3 terminal has DC 24 V against S2 terminal. However between S3 and S1, these terminals are NOT electrically insulataed by the transformer or other device.

Outdoor unit power supply 3 × Min. 1.5 3 × Min. 2.5 3 × Min. 4 3 × Min. 6 5 × Min. 1.5 5 × Min. 4

)

2

Indoor unit-Outdoor unit *2 3 × 1.5 (Polar) 3 × 1.5 (Polar) 3 × 1.5 (Polar) 3 × 1.5 (Polar) 3 × 1.5 (Polar)

Wiring

Indoor unit-Outdoor unit earth *2 1 × Min. 1.5 1 × Min. 1.5 1 × Min. 1.5 1 × Min. 1.5 1 × Min. 1.5 1 × Min. 2.5

Wire No. ×

size (mm

Remote controller-Indoor unit *3 2 × 0.3 (Non-polar) 2 × 0.3 (Non-polar) 2 × 0.3 (Non-polar) 2 × 0.3 (Non-polar) 2 × 0.3 (Non-polar) 2 × 0.3 (Non-polar)

Outdoor unit L-N (single)

Outdoor unit L1-N, L2-N, L3-N (3 phase)

Indoor unit-Outdoor unit S1-S2 *4 AC 230 V AC 230 V AC 230 V AC 230 V AC 230 V AC 230 V

Indoor unit-Outdoor unit S2-S3 *4 DC 24 V DC 24 V DC 24 V DC 24 V DC 24 V DC 24 V

Circuit rating

Remote controller-Indoor unit *4 DC 12 V DC 12 V DC 12 V DC 12 V DC 12 V DC 12 V

2

used, Max. 50 m

2

used and S3 separated, Max. 80 m

• Use one cable for S1 and S2 and another for S3 as shown in the picture.

• Max. 50 m Total Max. for PEA. Wiring size 3 × 1.5 (Polar).

~/N (single), 50 Hz,

230 V

*4 AC 230 V AC 230 V AC 230 V AC 230 V AC 230 V AC 230 V

~/N (single), 50 Hz,

230 V

~/N (single), 50 Hz,

230 V

Notes: 1. Wiring size must comply with the applicable local and national code.

2.

Power supply cords and Indoor/Outdoor unit connecting cords shall not be lighter than polychloroprene sheathed fl exible cord. (Design 60245 IEC 57

3. Use an earth wire which is longer than the other cords so that it will not become disconnected when tension is applied.

RP140V RP100, 125, 140Y RP200, 250

~/N (single), 50 Hz,

230 V

3N~ (3 ph 4-wires),

50 Hz, 400 V

3N~ (3 ph 4-wires),

Cable length 50m:3×4(Polar)/

Cable length 80m:3×6(Polar)

50 Hz, 400 V

)

Power supply

A-Control

Outdoor Unit

Isolator

S1

S2

S3

3 poles isolator

S1

S2

S3

A-Control

Indoor Unit

Warning:

· In case of A-control wiring, there is high voltage potential on the S3 terminal caused by electrical circuit design that has no electrical insulation between

power line and communication signal line. Therefore, please turn off the main power supply when servicing. And do not touch the S1, S2, S3 terminals when

the power is energized. If isolator should be used between indoor unit and outdoor unit, please use 3-pole type.

INDOOR-OUTDOOR CONNECTING CABLE (RP200,250)

Cross section of cable Wire size (mm2) Number of wires Polarity L (m)*6

Round

Flat

Flat

Round

2.5 3

2.5 3

1.5 4

2.5 4

Clockwise : S1-S2-S3

*Pay attention to stripe of yellow and green

Not applicable

(Because center wire has no cover finish)

From left to right : S1-Open-S2-S3

Clockwise : S1-S2-S3-Open

*Connect S1 nad S3 to the opposite angle

(30)

*2

Not applicable

*5

(18)

*3

(30)

*4

*1 :Power supply cords of appliances shall not be lighter than design 60245 IEC or

227 IEC.

*2 :In case that cable with stripe of yellow and green is available.

*3 :In case of regular polarity connection (S1-S2-S3), wire size is 1.5 mm

2

.

*4 :In case of regular polarity connection (S1-S2-S3).

*5 :In the flat cables are connected as this picture, they can be used up to 30 m.

S1

S2

S3

*6 :Mentioned cable length is just a reference value.

It may be different depending on the condition of installation, humidity or

materials, etc.

(3C Flat cable × 2)

Be sure to connect the indoor-outdoor connecting cables directly to the units (no intermediate connections).

Intermediate connections can lead to communication error if water enters the cables and causes insufficient insulation to ground or a poor electrical contact at the intermediate connection point.

11

Page 12

7. Test run

7.1. Before test run

► After completing installation and the wiring and piping of the indoor and

outdoor units, check for refrigerant leakage, looseness in the power supply or control wiring, wrong polarity, and no disconnection of one phase in

the supply.

► Use a 500-volt megohmmeter to check that the resistance between the

power supply terminals and ground is at least 1.0M".

► Do not carry out this test on the control wiring (low voltage circuit) termi-

nals.

Warning:

Do not use the air conditioner if the insulation resistance is less than 1.0M".

Insulation resistance

After installation or after the power source to the unit has been cut for an extended

period, the insulation resistance will drop below 1 M" due to refrigerant accumulating in the compressor. This is not a malfunction. Perform the following procedures.

1. Remove the wires from the compressor and measure the insulation resistance of

the compressor.

2. If the insulation resistance is below 1 M", the compressor is faulty or the resistance dropped due the accumulation of refrigerant in the compressor.

3. After connecting the wires to the compressor, the compressor will start to warm

up after power is supplied. After supplying power for the times indicated below,

measure the insulation resistance again.

7.2. Test run

7.2.1. Using SW4 in outdoor unit

SW4-1 ON

SW4-2 OFF

SW4-1 ON

SW4-2 ON

* After performing the test run, set SW4-1 to OFF.

• After power is supplied, a small clicking noise may be heard from the inside of

the outdoor unit. The electronic expansion valve is opening and closing. The unit

is not faulty.

Cooling operation

Heating operation

• The insulation resistance drops due to accumulation of refrigerant in the compressor. The resistance will rise above 1 M" after the compressor is warmed

up for four hours.

(The time necessary to warm up the compressor varies according to atmo-

spheric conditions and refrigerant accumulation.)

• To operate the compressor with refrigerant accumulated in the compressor,

the compressor must be warmed up at least 12 hours to prevent breakdown.

4. If the insulation resistance rises above 1 M", the compressor is not faulty.

Caution:

• The compressor will not operate unless the power supply phase connec-

tion is correct.

• Turn on the power at least 12 hours before starting operation.

- Starting operation immediately after turning on the main power switch can result

in severe damage to internal parts. Keep the power switch turned on during the

operational season.

► The followings must be checked as well.

• The outdoor unit is not faulty. LED1 and LED2 on the control board of the out-

door unit fl ash when the outdoor unit is faulty.

• Both the gas and liquid stop valves are completely open.

• A protective sheet covers the surface of the DIP switch panel on the control

board of the outdoor unit. Remove the protective sheet to operate the DIP

switches easily.

• A few seconds after the compressor starts, a clanging noise may be heard from

the inside of the outdoor unit. The noise is coming from the check valve due to

the small difference in pressure in the pipes. The unit is not faulty.

The test run operation mode cannot be changed by DIP switch SW4-2 during

the test run. (To change the test run operation mode during the test run, stop

the test run by DIP switch SW4-1. After changing the test run operation mode,

resume the test run by switch SW4-1.)

7.2.2. Using remote controller

Refer to the indoor unit installation manual.

Note : Occasionally, vapor that is made by the defrost operation may seem

as if smoke come up from the outdoor unit.

8.Initial settings for refrigerant leakage detection function

Remote control button positions

Outdoor unit information

C B

Indoor unit information

Activate/cancel maintenance mode

A

D

Compressor information

Operation mode

Fig. 8-1

A

D

Refrigerant

leakage detection

(initial teaching)

GAS LEAK

TEST START

[Display ]

[Display ] Waiting for stabilization

Fig. 8-3

Confirm

Refrigerant leakage

detection judgment

GAS LEAK

JUDGE

Fig. 8-2

Stabilized

After 45 minutes

This air conditioner (outdoor unit) can detect refrigerant leakage which may happen

during a long period of use. In order to enable the leakage detection, the following

settings are required to let the unit memorize the initial conditions (initial learning).

* Except RP200, 250.

Caution:

Make sure to perform the “7. Test run” and confi rm the unit works without

any problems, before starting the following settings.

► How to select the “Refrigerant Leakage Detection” mode

Detection is possible regardless the unit’s operation (ON or OFF).

1 Press button for more than three seconds to switch to the maintenance

TEST

mode.

[Display ]

A

► How to start the initial learning

2 Press button and select the [GAS LEAK TEST START] (Fig. 8-2)

CLOCK

* The initial learning for the leakage detection is always done once after the new

installation or the data reset.

Press

FILTER

How to finish the initial learning

Once the unit’s operation is stabilized, the initial learning is completed.

Press

TEST

The initial learning can also be cancelled by pressing

* Refer to the T echnical Manual f or the refrigerant leakage detection judgment method.

MAINTENANCE

( ) button to confirm. (Fig. 8-3)

button for more than three seconds to cancel the initial learning.

button.

ON/OFF

12

Page 13

9. Special Functions

A

X

SW1

A Circuit diagram example (low noise mode)

B On-site arrangement

C External input adapter (PAC-SC36NA)

X: Relay

X

A

X

Y

SW2

SW3

A Circuit diagram example (Demand function)

B On-site arrangement

X, Y: Relay

X

Y

C D

Orange

Brown

Red

D Outdoor unit control board

E Max. 10 m

F Power supply for relay

C

Orange

Brown

Red

C External input adapter (PAC-SC36NA)

D Outdoor unit control board

E Max. 10 m

F Power supply for relay

CNDM

D

CNDM

1

3

1

3

Fig. 9-1

Fig. 9-2

9.3. Refrigerant collecting (pump down)

Perform the following procedures to collect the refrigerant when moving the indoor

unit or the outdoor unit.

1 Supply power (circuit breaker).

* When power is supplied, make sure that “CENTRALLY CONTROLLED” is not

displayed on the remote controller. If “CENTRALLY CONTROLLED” is displayed, the refrigerant collecting (pump down) cannot be completed normally.

2 After the gas stop valve is closed, set the SWP switch on the control board of the

outdoor unit to ON. The compressor (outdoor unit) and ventilators (indoor and

outdoor units) start operating and refrigerant collecting operation begins. LED1

and LED2 on the control board of the outdoor unit are lit.

* Only set the SWP switch (push-button type) to ON if the unit is stopped. How-

ever, even if the unit is stopped and the SWP switch is set to ON less than

three minutes after the compressor stops, the refrigerant collecting operation

cannot be performed. Wait until compressor has been stopped for three minutes and then set the SWP switch to ON again.

9.1. Low noise mode (on-site modifi cation) (Fig. 9-1)

By performing the following modifi cation, operation noise of the outdoor unit can be

reduced by about 3-4 dB.

The low noise mode will be activated when a commercially available timer or the

contact input of an ON/OFF switch is added to the CNDM connector (option) on the

control board of the outdoor unit.

• The ability varies according to the outdoor temperature and conditions, etc.

1 Complete the circuit as shown when using the external input adapter

(PAC-SC36NA). (Option)

2 SW7-1 (Outdoor unit control board): OFF

3 SW1 ON: Low noise mode

SW1 OFF: Normal operation

9.2. Demand function (on-site modifi cation) (Fig. 9-2)

By performing the following modifi cation, energy consumption can be reduced to 0

–100% of the normal consumption.

The demand function will be activated when a commercially available timer or the

contact input of an ON/OFF switch is added to the CNDM connector (option) on the

control board of the outdoor unit.

1 Complete the circuit as shown when using the external input adapter

(PAC-SC36NA). (Option)

2 By setting SW7-1 on the control board of the outdoor unit, the energy consump-

tion (compared to the normal consumption) can be limited as shown below.

SW7-1 SW2 SW3 Energy consumption

Demand

function

ON

3 Because the unit automatically stops in about two to three minutes after the

refrigerant collecting operation (LED1 and LED2 are lit), be sure to quickly close

the gas stop valve. When LED1 and LED2 are lit and the outdoor unit is stopped,

open the liquid stop valve completely, and then repeat step 2 after three minutes have passed.

* If the refrigerant collecting operation has been completed normally (LED1 and

LED2 are lit), the unit will remain stopped until the power supply is turned off.

4 Turn off the power supply (circuit breaker).

* Note that when the length of the extension piping is long, it may not be pos-

sible to perform a pump-down operation. When performing the pump-down

operation, make sure that the low pressure is lowered to near 0 MPa (gauge).

OFF OFF 100%

ON OFF 75%

ON ON 50%

OFF ON 0% (Stop)

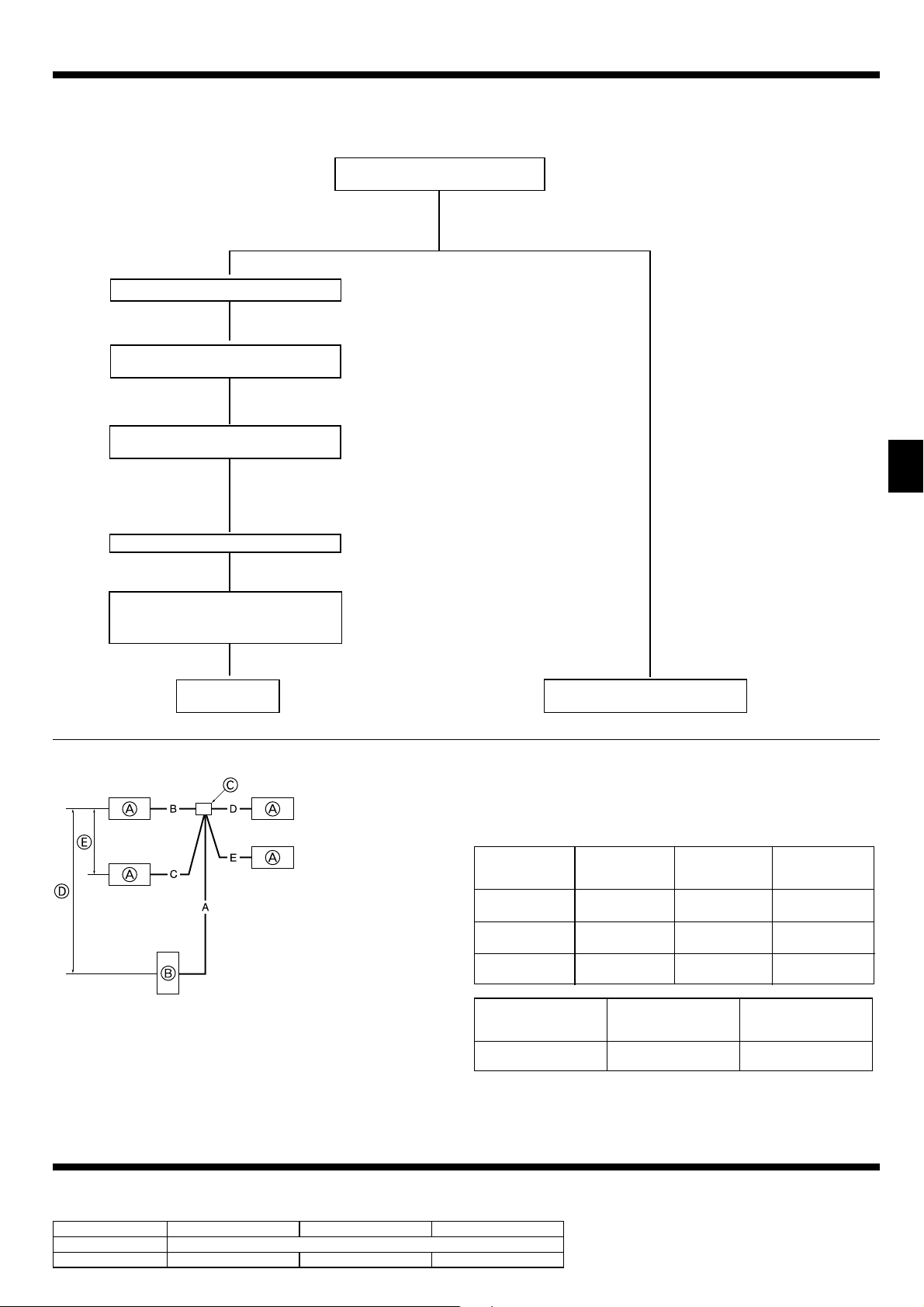

10. System control (Fig. 10-1)

E SW 1 - 3 ~ 6

F SW 1 - 3 ~ 6

G SW 1 - 3 ~ 6

TB1

TB4

TB5

ON

OFF

3 4 5 6

ON

OFF

3 4 5 6

ON

OFF

3 4 5 6

TB1 TB1

TB4

B B B B B

2

TB5

1

2

1

DC

A Outdoor unit

B Indoor unit

C Master remote controller

D Subordinate remote controller

E Standard 1:1 (Refrigerant address = 00)

F Simultaneous twin (Refrigerant address = 01)

G Simultaneous triple (Refrigerant address = 02)

A GFAA E

TB4 TB4

TB5

Fig. 10-1

TB4 TB4

* Set the refrigerant address using the DIP switch of the outdoor unit.

1 Wiring from the Remote Control

This wire is connected to TB5 (terminal board for remote controller) of the indoor

unit (non-polar).

2 When a Different Refrigerant System Grouping is Used.

Up to 16 refrigerant systems can be controlled as one group using the slim MA remote controller.

Note:

In single refrigerant system (twin/triple), there is no need of wiring 2.

SW1

Function table

B

<SW1>

ON

OFF

123456

SW1

function

settings

Function

1 Compulsory

defrosting

2 Error history

clear

3

Refrigerant

4

system ad-

5

dress setting

Operation according to switch setting

ON OFF

Start Normal

Clear Normal

Settings for outdoor unit addresses

0 to 15

6

13

Page 14

Содержание

1. Меры предосторожности.....................................................................134

2. Место установки ..................................................................................135

3. Установка наружного прибора ............................................................137

4. Прокладка труб хладагента ................................................................137

5. Дренажные трубы ................................................................................141

Осторожно:

• Не выпускайте R410A в атмосферу:

• R410A является фторированным парниковым газом, использование которого ограничивается Киотским протоколом; потенциал глобального потепления

(GWP) данного газа равен 1975.

6. Электрические работы ........................................................................142

7. Выполнение испытания.......................................................................144

8.

Первый обучающий прогон функции обнаружения утечки хладагента

9. Специальные функции ........................................................................145

10. Управление системой (Fig. 10-1) ........................................................145

...144

1. Меры предосторожности

► До установки прибора убедитесь, что Вы прочли все “Меры предо-

сторожности”.

► Пожалуйста, проконсультируйтесь с органами электроснабжения до

подключения системы.

►

Оборудование соответствует IEC/EN 61000-3-12 (PUHZ-RP100/125/140VKA)

► PUHZ-RP250/250Y

“Данное оборудование соответствует требованиям IEC 61000-3-12

при условии, что мощность короткого замыкания S

или равняется S

теля с системой энергоснабжения. Лицо, устанавливающее или использующее оборудование, обязано убедиться, что оборудование

подключено к источнику питания, мощность короткого замыкания

которого превышает или равна Ssc (*1), а в случае необходимос-

S

sc

ти проконсультироваться с оператором распределительных сетей.”

Ssc (*1)

Модель S

PUHZ-RP200 1,35

PUHZ-RP250 1,49

(*1) в точке контакта источника питания пользова-

sc

(MVA)

sc

превышает

sc

Предупреждение:

Описывает меры предосторожности, необходимые для предотвращения

получения травмы или гибели пользователя.

Осторожно:

Описывает меры предосторожности, необходимые для предотвращения

повреждения прибора.

После окончания установочных работ проинструктируйте пользователя относительно правил эксплуатации и обслуживания аппарата, а также ознакомьте с

разделом “Мера предосторожности” в соответствии с информацией, приведенной в Руководстве по использованию

аппарата для того, чтобы убедиться, что он работает нормально. Обязательно

передайте пользователю на хранение экземпляры Руководства по установке

и Руководства по эксплуатации. Эти Руководства должны быть переданы и

последующим пользователям данного прибора.

: Указывает, что данная часть должна быть заземлена.

Предупреждение:

Внимательно прочтите текст на этикетках главного прибора.

аппарата, и выполните тестовый прогон

Предупреждение:

• Прибор не должен устанавливаться пользователем. Для выполнения уста-

новки прибора обратитесь к дилеру или сертифицированному техническому

специалисту. Неправильная установка аппарата может повлечь за собой

протечку воды, удар электрическим током или возникновение пожара.

• При установочных работах следуйте инструкциям в Руководстве по установке. Используйте инструменты и детали трубопроводов, специально предна

значенные для использования с хладагентом марки R410A. Хладагент R410A

в HFC-системе находится под давлением в 1,6 раза большим, чем давление,

создаваемое при использовании обычных хладагентов. Если компоненты

трубопроводов не предназначены для использования с хладагентом R410A,

и аппарат установлен неправильно, трубы могут лопнуть и причинить повреждение или нанести травму. Кроме того, это может привести

поражению электрическим током или возникновению пожара.

• Прибор должен быть установлен согласно инструкциям, чтобы свести к

минимуму риск повреждения от землетрясений, тайфунов или сильных

порывов ветра. Неправильно установленный прибор может упасть и

причинить повреждение или нанести травму.

• Прибор должен быть установлен на конструкции, способной выдержать

его вес.

упасть и причинить повреждение или нанести травму.

• Если кондиционер установлен в небольшом помещении, необходимо

принять меры для предотвращения концентрации хладагента свыше

безопасных пределов в случае утечки хладагента. Проконсультируйтесь у дилера относительно соответствующих мер, предотвращающих

превышение допустимой концентрации. В случае утечки хладагента и

превышении

помещении может произойти несчастный случай.

• Если во время работы прибора произошла утечка хладагента, проветрите помещение. При контакте хладагента с пламенем образуются ядовитые газы.

• Все электроработы должны выполняться квалифицированным техническим

специалистом в соответствии с местными правилами и инструкциями, приведенными в данном

ально выделенным линиям электропитания с соответствующим напряжением

через автоматические выключатели. Использование линий электропитания

недостаточной мощности или неправильно проведенных линий может привести

к поражению электрическим током или возникновению пожара.

Прибор, установленный на неустойчивой конструкции, может

допустимой его концентрации из-за нехватки кислорода в

Руководстве. Приборы должны быть подключены к специ-

к утечке воды,

• Для соединения медных или медносплавных бесшовных труб, предназначенных для хладагента, используйте медный фосфор C1220. Если

трубы соединены неправильно, прибор не будет должным образом

заземлен, что может привести к поражению электрическим током.

• Используйте только указанные кабели для электропроводки. Соединения

должны быть выполнены надежно, без натяжения около клемм. Если

-

кабели подключены или укреплены неправильно, это может привести к

перегреву или возникновению пожара.

• Крышка наружного прибора должна

бору. Если крышка установлена неправильно, в прибор могут попасть

пыль и влага, что может привести к поражению электрическим током или

возникновению пожара.

• При монтаже или перемещении кондиционера используйте только указанный

хладагент (R410A) для заполнения трубопроводов хладагента. Не смешивайте

его ни с каким другим хладагентом и не

роводах. Наличие воздуха в трубопроводах может вызывать скачки давления,

в результате которых может произойти разрыв или другие повреждения.

• Используйте только те дополнительные принадлежности, на которые

имеется разрешение от Mitsubishi Electric; для их установки обратитесь к

дилеру или уполномоченному техническому специалисту. Неправильная

установка дополнительных принадлежностей может привести к

воды, поражению электрическим током или возникновению пожара.

• Не изменяйте конструкцию прибора. При необходимости ремонта обратитесь к дилеру. Если изменения или ремонт выполнены неправильно,

это может привести к протечке воды, удару электрическим током или

возникновению пожара.

• Пользователю не следует пытаться ремонтировать прибор или перемещать его на другое место

привести к утечке воды, удару электрическим током или возникновению

пожара. Если необходимо отремонтировать или переместить кондиционер,

обратитесь к дилеру или уполномоченному техническому специалисту.

• По окончании установки убедитесь в отсутствии утечки хладагента. Если хладагент проникнет в помещение и произойдет контакт его с пламенем

или переносного пищевого нагревателя, образуются ядовитых газов.

. Если прибор установлен неправильно, это может

быть надежно присоединена к при-

допускайте наличия воздуха в трубоп-

протечке

обогревателя

1.1. Перед установкой

Осторожно:

• Не используйте прибор в нестандартной окружающей среде. Установка

кондиционера в местах, подверженных воздействию пара, летучих масел

(включая машинное масло) или сернистых испарений, местах с повышенной

концентрацией соли (таких, как берег моря), или местах, где прибор будет

засыпан снегом, может привести к значительному снижению эффективности

работы прибора или повреждению его

• Не устанавливайте прибор в местах, где возможна утечка, возникновение,

приток или накопление горючих газов. Если горючий газ будет накапливаться вокруг прибора, это может привести к возникновению пожара или

взрыву.

внутренних частей.

134

• При использовании режима обогрева на наружном приборе образуется конденсат. Удостоверьтесь, что обеспечен хороший дренаж в районе наружного

прибора, если этот конденсат может принести какой-либо вред.

• При монтаже прибора в больнице или центре

шумовое и электронное воздействие. Работа таких устройств, как инверторы, бытовые приборы, высокочастотное медицинское оборудование и

оборудование радиосвязи может вызвать сбои в работе кондиционера или

его поломку. Кондиционер также может повлиять на работу медицинского

оборудования и медицинское обслуживание, работу коммуникационного

оборудования, вызывая искажение изображения на дисплее.

связи примите во внимание

Page 15

1. Меры предосторожности

1.2. Перед установкой (перемещением)

Осторожно:

• Соблюдайте особую осторожность при транспортировке или установке

приборов. Прибор должны переносить два или более человека, поскольку

он весит не менее 20 кг. Не поднимайте прибор за упаковочные ленты. При

извлечении прибора из упаковки или при его перемещении используйте

защитные перчатки, во избежание травмирования рук о пластины или о

другие выступающие

• Утилизируйте упаковочные материалы надлежащим образом. Упаковочные

материалы, такие, как гвозди и другие металлические или деревянные части,

могут поранить или причинить другие травмы.

1.3. Перед электрическими работами

Осторожно:

• Обязательно установите автоматические выключатели. В противном

случае возможно поражение электрическим током.

• Используйте для электропроводки стандартные кабели, рассчитанные

на соответствующую мощность. В противном случае может произойти

короткое замыкание, перегрев или пожар.

• При монтаже кабелей питания не прикладывайте растягивающих усилий.

Если соединения ненадежны, кабель может отсоединиться или порвать-

может привести к перегреву или возникновению пожара.

ся, что

1.4. Перед тестовым прогоном

Осторожно:

• Включайте главный выключатель питания не позднее, чем за 12 часов до

начала эксплуатации. Запуск прибора сразу после включения выключателя

питания может серьезно повредить внутренние части. Держите главный

выключатель питания включенным в течение всего времени работы.

• Перед началом эксплуатации проверьте, что все пульты, щитки и другие

защитные части правильно установлены. Вращающиеся

находящиеся под напряжением части могут нанести травмы.

• Не прикасайтесь ни к каким выключателям влажными руками. Это может

части.

, нагретые или

• Необходимо периодически производить проверку основного блока наружного

прибора и установленных на нем компонентов на разболтанность, наличие

трещин или других повреждений. Если такие дефекты оставить неисправленными, прибор может упасть и причинить повреждение или нанести травму.

• Не мойте кондиционер водой. Это может привести к поражению электрическим током.

• Затягивайте все

ключ с регулируемым усилием. Слишком сильно затянутый хомут муфты по прошествии некоторого времени может сломаться, что вызовет утечку хладагента.

• Обязательно заземлите прибор. Не присоединяйте провод заземления

к газовым или водопроводным трубам, громоотводам или телефонным

линиям заземления. Отсутствие надлежащего заземления может привести

к поражению электрическим током.

• Используйте автоматические выключатели (прерыватель утечки тока на землю, разъединитель (плавкий предохранитель +B) и предохранитель корпуса)

с указанным предельным током. Если предельный ток автоматического вы

ключателя больше, чем необходимо, может произойти поломка или пожар.

привести к поражению электрическим током.

• Не прикасайтесь к трубам с хладагентом голыми руками во время работы прибора. Трубы с хладагентом при работе прибора нагреваются или

охлаждаются в зависимости от состояния циркулирующего хладагента.

Прикосновение к трубам может привести к ожогу или обморожению.

• После остановки прибора обязательно подождите по крайней мере

минут перед выключением главного выключателя питания. В противном

случае возможна протечка воды или поломка прибора.

хомуты на муфтах в соответствии со спецификациями, используя

пять

-

1.5.

Использование кондиционеров с хладагентом R410A

Осторожно:

• Для соединения медных или медносплавных бесшовных труб, предназначенных для хладагента, используйте медный фосфор C1220. Удостоверьтесь, что

изнутри трубы чисты и не содержат никаких вредных загрязнителей, таких как

соединения серы, окислители, мелкий мусор или пыль. Используйте трубы

указанной толщины. (См. 4.1.) При использовании имеющихся труб, которые

применялись для хладагента R22, обратите внимание

- Замените хомуты на муфтах и перезатяните соединенные секции.

- Не используйте тонкие трубы. (См. 4.1.)

• Храните трубы, предназначенные для установки в закрытом помещении,

запечатанными, а также оставьте запечатанными их концы; распаковывайте их непосредственно перед пайкой. (Оставьте коленчатые трубы и т.д. в

упаковке.) Если пыль, мелкий мусор или

хладагента, может произойти порча масла или поломка компрессора.

• Используйте в качестве масла охлаждения для покрытия соединительных муфт масло сложного или простого эфира или алкинбензол (в