Mitsubishi electric PUHY-RP300YJM-A User Manual [ru]

Air-Conditioners For Building Application

OUTDOOR UNIT

PUHY-RP-YJM-A (-BS)

For use with R410A

INSTALLATION MANUAL

For safe and correct use, please read this installation manual thoroughly before installing the air-conditioner unit.

INSTALLATIONSHANDBUCH

Zum sicheren und ordnungsgemäßen Gebrauch der Klimageräte das Installationshandbuch gründlich durchlesen.

MANUEL D’INSTALLATION

Veuillez lire le manuel d’installation en entier avant d’installer ce climatiseur pour éviter tout accident et vous assurer d’une utilisation correcte.

MANUAL DE INSTALACIÓN

Para un uso seguro y correcto, lea detalladamente este manual de instalación antes de montar la unidad de aire acondicionado.

MANUALE DI INSTALLAZIONE

Per un uso sicuro e corretto, leggere attentamente questo manuale di installazione prima di installare il condizionatore d’aria.

INSTALLATIEHANDLEIDING

Voor een veilig en juist gebruik moet u deze installatiehandleiding grondig doorlezen voordat u de airconditioner installeert.

MANUAL DE INSTALAÇÃO

Para segurança e utilização correctas, leia atentamente este manual de instalação antes de instalar a unidade de ar condicionado.

EΓXEIPI∆IO O∆HΓIΩN EΓKATAΣTAΣHΣ

°И· ·ЫК¿ПВИ· О·И ЫˆЫЩ‹ ¯Ъ‹ЫЛ, ·Ъ·О·ПВ›ЫЩВ ‰И·‚¿ЫВЩВ ЪФЫВ¯ЩИО¿ ·˘Щfi ЩФ ВБ¯ВИЪ›‰ИФ ВБО·Щ¿ЫЩ·ЫЛ˜ ЪИУ ·Ъ¯›ЫВЩВ ЩЛУ

ВБО·Щ¿ЫЩ·ЫЛ ЩЛ˜ МФУ¿‰·˜ ОПИМ·ЩИЫМФ‡.

РУКОВОДСТВО ПО УСТАНОВКЕ

Для осторожного и правильного использования прибора необходимо тщательно ознакомиться с данным руководством по

установке до выполнения установки кондиционера.

MONTAJ ELKMONTAJ ELK

MONTAJ ELK

MONTAJ ELKMONTAJ ELK

Emniyetli ve doqru biçimde naswl kullanwlacaqwnw öqrenmek için lütfen klima cihazwnw monte etmeden önce bu elkitabwnw dikkatle okuyunuz.

WW

TABITABI

W

TABI

WW

TABITABI

GB

D

FEINLPGRRUTRCZSVHGPOSL

INSTALLATIONSHANDBOK

Läs den här installationshandboken noga innan luftkonditioneringsenheten installeras, för säker och korrekt användning.

РЪКОВОДСТВО ЗА МОНТАЖ

За безопасна и правилна употреба, моля, прочетете внимателно това ръководство преди монтажа на климатизатора.

SWHRBGRO

6

15

*

15

*

450

*

300

*

<A>

A

30

450

*

300

*

C

BB

C

A

100

450

*

100

*

BB

C

C

A

15

*

C

AAA

450 450

900

300

*

300

*

BB

C

C

A

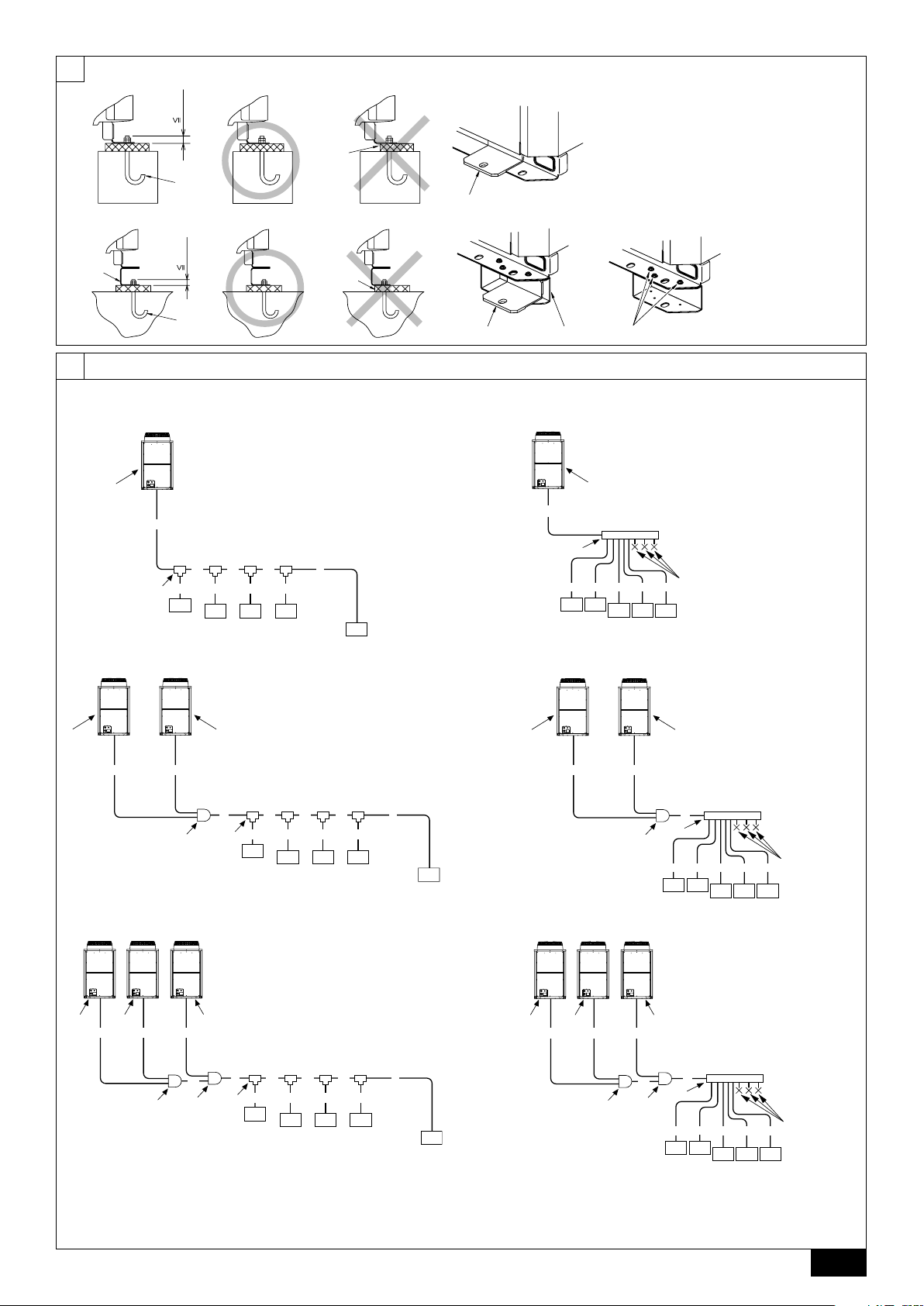

[Fig. 6.0.1]

(1)

[Fig. 6.0.2]

<A> : Top view

<B> : Side view

<C> : When there is little space up to an obstruction

A : Front

B : Unit height

C : Back

D : Air outlet guide (Procured at the site)

(2)

(3)

(4)

240

45°

100

*

*

B

A

450 450

B

A

100*

450

A

50

50

*

*

<A>

*

A

CC

450

h

H

B

A

h

H

500

<B>

1000

C

*

D

50

7

[Fig. 7.0.1]

RP200 ~ RP350

8m

40°

2

8m

A

<C>

C

(mm)

1000

B

A

*

B

900 300

A : Front

B : Must be open

C :Wall height (H)

(mm)

[Fig. 8.1.1]

8

<A> Without detachable leg

<B> With detachable leg

30mm

A

A : M10 anchor bolt procured at the site.

B :Corner is not seated.

C : Fixing bracket for hole-in anchor bolt (3 locations to fix

with screws).

D : Detachable leg

B

C

[Fig. 8.1.2]

D

9

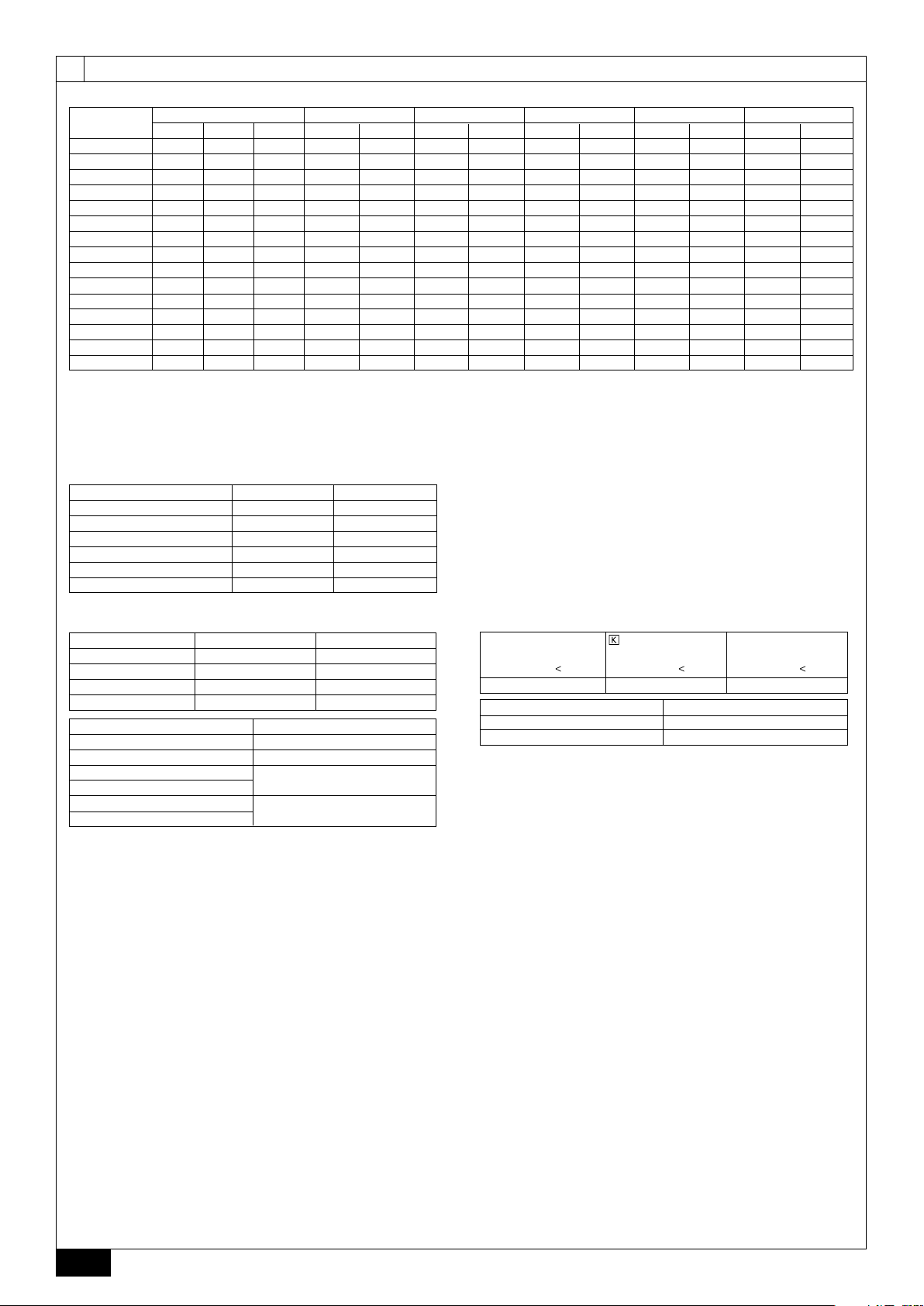

[Fig. 9.2.1]

[RP200 ~ RP350]

A

[RP400 ~ RP650]

unit 1

30mm

A

A

B C D

a b c d

B

C

CC

unit 2

B

C D

A

A : Screws

9.2

A

A

B

e

b

a

C

C

C

unit 1

c d e

C

unit 2

D

CC

C

A

[RP700 ~ RP900]

A

A1

A

A2A1

A

B C D

a b c d

E

unit 3

unit 2unit 1

A2

E

B

C

CC

AA

A3

A

A4

E

B C D

a b c d

B

C

CCC

e

C

C

e

C

A

A1

A

1

unit 3

unit 2unit 1

A

A2

E

A : Outdoor unit

B : First branch

C : Indoor unit

D : Cap

E : Outdoor twinning kit

A

A

2

A

B

E

b

a

C

AA

A3

A4

E

C

c d e

C

A

B

b

a

c d e

C

D

CC

C

D

CC

C

3

9

A (mm)

Å Outdoor model

RP200

RP250

RP300

RP350

RP400

RP450

RP500

RP550

RP600

RP650

RP700

RP750

RP800

RP850

RP900

*1 The pipe sizes listed in columns A1 to A3 in this table correspond to the

sizes for the models listed in the unit 1, 2, and 3 columns. When the order

of the models for unit 1, 2, and 3 change, make sure to use the appropriate

pipe size.

*2 ø25.4 for R22

B, C, D (mm)

Î Total capacity of indoor units

81 ~ 160

161 ~ 330

331 ~ 480

481 ~ 630

631 ~

Unit combination A A1 *1 A2 *1 A3 *1 A4

unit1

RP200

RP200

RP250

RP250

RP300

RP300

RP200

RP250

RP250

RP250

RP300

~ 80

unit2

-

-

-

RP200

RP250

RP250

RP300

RP300

RP350

RP250

RP250

RP250

RP300

RP300

-

-

-

-

ı Liquid pipe

unit3

-

-

-

-

-

-

-

-

-

RP250

RP250

RP300

RP300

RP300

ø9.52

ø12.7

ø12.7

ø15.88

ø15.88

ø19.05

ı Liquid pipe

ø12.7

ø12.7

ø12.7

ø15.88

ø15.88

ø15.88

ø15.88

ø15.88

ø19.05

ø19.05

ø19.05

ø19.05

ø19.05

ø19.05

ø19.05

Ç Gas pipe

ø25.4 or ø28.58

ø31.75 or ø34.93

ø38.1 or ø34.93

Ç Gas pipe

ø28.58*2

ø28.58

ø28.58

ø34.93

ø34.93

ø34.93

ø34.93

ø34.93

ø34.93

ø41.28

ø41.28

ø41.28

ø41.28

ø41.28

ø41.28

ø15.88

ø19.05

ø41.28

9.2

ı Liquid pipe

-

-

-

ø9.52

ø9.52

ø9.52

ø9.52

ø12.7

ø12.7

ø9.52

ø9.52

ø9.52

ø9.52

ø12.7

Ç Gas pipe

-

-

-

ø19.05

ø19.05

ø22.2

ø22.2

ø22.2

ø22.2

ø19.05

ø22.2

ø22.2

ø22.2

ø22.2

ı Liquid pipe

-

-

-

ø9.52

ø9.52

ø9.52

ø12.7

ø12.7

ø12.7

ø9.52

ø9.52

ø9.52

ø12.7

ø12.7

Ç Gas pipe

-

-

-

-

ø19.05

ø22.2

ø22.2

ø22.2

ø22.2

ø28.58

ø22.2

ø22.2

ø22.2

ø22.2

ø22.2

ı Liquid pipe

-

-

-

-

-

-

-

-

-

ø9.52

ø9.52

ø12.7

ø12.7

ø12.7

Ç Gas pipe

-

-

-

-

-

-

-

-

-

ø22.2

ø22.2

ø22.2

ø22.2

ø22.2

ı Liquid pipe

-

-

-

-

-

-

-

-

-

ø19.05

ø19.05

ø19.05

ø19.05

ø19.05

Ç Gas pipe

-

-

-

-

-

-

-

-

-

ø34.93

ø34.93

ø34.93

ø34.93

ø34.93

a, b, c, d, e (mm)

‰ Model number

15,20,25,32,40

50,63,71,80

100,125,140

200,250

Ï Downstream unit model total

Ó The 1st branch of P450 ~ P650

The 1st branch of P700, P750, P800

È

~ 200

201 ~ 400

401 ~ 650

651 ~

ı Liquid pipe

ø6.35

ø9.52

ø9.52

ø12.7

Ç Gas pipe

ø12.7

ø15.88

ø19.05

ø28.58

Ì Joint

CMY-Y102S-G2

CMY-Y102L-G2

CMY-Y202-G2

CMY-Y302-G2

Ô 4-Branching header

(Downstream unit

model total

CMY-Y104-G

200)

=

Å Outdoor model

P400 ~ P650

P700 ~ P900

8-Branching header

(Downstream unit

model total

CMY-Y108-G

=

400)

˜

10-Branching header

Ò

(Downstream unit

model total

CMY-Y1010-G

Outdoor twinning kit

CMY-RP100VBK

CMY-RP200VBK

=

650)

4

9

F

G

[Fig. 9.2.2]

9.2

A

B

<A> Make sure the pipes from the twinning pipe to the outdoor unit are

sloped downwards (towards the twinning pipes).

<C> Slope of twinning pipes

F

C

C

F

±15°

F

2m

D

E

<B> When the piping on the outdoor unit side (from the twinning pipe)

exceeds 2 m, ensure a trap (gas pipe only) within 2 m.

C

F

C

<D> Pipe connection example

H

I

J

H

A : Downward slope

B : Upward slope

C : Indoor unit

D :Trap (gas pipe only)

E : Within 2 m

F :Twinning pipe

G :

Slope of the

H : Pipes on site

I :Twinning kit

J : Straight run of pipe that is 500 mm or more

twinning

pipe is at an angle within ±15° to the gro

und

5

10

[Fig. 10.2.1] [Fig. 10.2.3]

B

<B>

10.2

<A>

C

E

[Fig. 10.2.2]

<A> Front pipe routing

98

<C>

32

<C>

D

A

<A> Refrigerant service valve

(liquid side/brazed type)

<B> Refrigerant service valve

(gas side/brazed type)

A : Shaft

B : Service port

C : Cap

D : Pinched connecting pipe severing portion

E : Pinched connecting pipe brazing portion

1

<C>

4567

A

B

<C>

AB

A : Example of closure materials (field supply)

B : Fill the gap at the site

<B> Bottom pipe routing

4567

23

<C>

A

B

<C>

No.

C Shape

No.

C Shape

PUHY-RP200YJM-A

PUHY-RP250YJM-A

PUHY-RP300YJM-A

PUHY-RP350YJM-A

<A> Front pipe routing <B> Bottom pipe routing

<C> Included with outdoor unit

A Gas pipe (field supply required) B Liquid pipe (field supply required)

C Shape

1357 9

IDø25.4

ODø25.4

<gas side> <gas side> <gas side> <liquid side>

2468

ODø12.7

IDø9.52

<liquid side>

12345678 9

11 1 1 1

11 11 1

11 11 1

11 11 1

ODø15.88

IDø12.7

<liquid side>

ODø19.05

IDø25.4

<gas side> <gas side>

ODø22.2

IDø25.4

ODø28.58

IDø25.4

ODø34.93

IDø25.4

IDø9.52

ODø9.52

<liquid side>

IDø12.7

ODø12.7

6

10.3

F

D

C

A

B

D

E

[Fig. 10.3.1]

A

C

[Fig. 10.3.3]

A : Nitrogen gas

B

B

C

LOW

D

B In case of the R410A cylinder having no syphon pipe.

HI

E

G

H

I

J

B :To indoor unit

C : System analyzer

D : Low knob

E : Hi knob

F :Valve

G : Liquid pipe

H : Gas pipe

I : Outdoor unit

J : Service port

[Fig. 10.3.2]

10.4

M

A : System analyzer

B : Low knob

C : Hi knob

D :Valve

E : Liquid pipe

F : Gas pipe

G : Service port

H : Three-way joint

I :Valve

J :Valve

K : R410A cylinder

L : Scale

M :Vacuum pump

N :To indoor unit

O : Outdoor unit

EN

N

A

LOW

B

HI

C

H

F

O

G

I

K

J

L

A

A : Syphon pipe

[Fig. 10.4.1]

A : Steel wire B : Piping

C : Asphaltic oily mastic or asphalt

D : Heat insulation material A

E : Outer covering B

[Fig. 10.4.4]

<A> Inner wall (concealed)

A B

<E> Roof pipe shaft

G

C

<F> Penetrating portion on fire

limit and boundary wall

I

D

B

H

F

<B> Outer wall

D

A

1m1m

A B

A

B

[Fig. 10.4.3][Fig. 10.4.2]

C

D

E

E

B

E

A

D

A : Liquid pipe B : Gas pipe

C : Electric wire D : Finishing tape

E : Insulator

<C> Outer wall (exposed)

E

B

I

<D> Floor (waterproofing)

D

F

G

B

A : Sleeve B : Heat insulating material

C : Lagging D : Caulking material

J

E : Band F:Waterproofing layer

G : Sleeve with edge H: Lagging material

I : Mortar or other incombustible caulking

J : Incombustible heat insulation material

7

B

B

11

[Fig. 11.2.1]

Control box

[Fig. 11.2.2]

A

Power supply terminal block

(TB1)

L1 L2 L3 N

Terminal block for indoor –

outdoor transmission line

(TB3)

C

11.2

Terminal block for

centralized control

(TB7)

A : Power source

B :Transmission line

C : Earth screw

A : Cable strap

B : Power source line

C :Transmission line

A

[Fig. 11.3.1]

<A> Change the jumper connec-

tor from CN41 to CN40 *1

<B> SW2-1:ON *2

( ) Address

<C> Keep the jumper connector

on CN41

<B> SW2-1:ON *2

C

11.3

L

1

OC

CN40

(51)

TB3

M1M2

M1M2

S

TB7

2

L

D

L

OC

CN40

(52)

TB3

M1M2

M1M2

S

TB7

6

L

System

controller

ABS

A BC

IC

(01)

TB5

M1 M2 S

1

r

AB AB AB

(101)

RC

3

IC

(02)

TB5

M1 M2 S

IC

(04)

TB5

M1 M2 S

L

4

IC

(03)

TB5

M1 M2 S

5

L

4

r

A

B

(103)

RC

IC

(05)

TB5

M1 M2 S

2

r

(105)

RC

TB5

M1 M2 S

3

(155)

E

IC

(07)

r

M1 M2 S

RC

IC

(06)

TB5

*1: When the power supply unit is not connected to the transmission line for centralized control, disconnect the male power supply

connector (CN41) from ONE outdoor unit in the system and connect it to CN40.

*2: If a system controller is used, set SW2-1 on all of the outdoor units to ON.

8

[Fig. 11.3.2]

L

1

<A> Change the jumper connec-

tor from CN41 to CN40 *1

<B> SW2-1:ON *2

<C> Keep the jumper connector

on CN41

<B> SW2-1:ON *2

A : Group 1

B : Group 3

C : Group 5

D : Shielded wire

E : Sub remote

controller

( ) Address

[Fig. 11.3.3]

To another

refrigerant system

OC

CN40

(51)

TB3

M1 M2

M1M2

S

TB7

2

L

D

L

A BC

IC

(01)

TB15

TB5

M1 M2 1 2S

2

c

3

MA

IC

(04)

TB5

M1 M2 S

1

c

L

4

IC

(05)

c

2

TB15

TB5

12

M1 M2 S

2

c

ABABAB

MAMAMA

E

TB5

M1 M2 S

1

c

c

4

(06)

IC

TB15

12

3

c

OC

(02)

TB5

M1 M2 S

L

2

IC

TB15

12

CN40

(52)

TB3

M1 M2

M1M2

S

TB7

6

L

System

controller

A

B

S

L

1

TB5

M1 M2 S

(03)

IC

IC

(07)

TB5

M1 M2 S

TB15

12

L

L

5

6

L

TB 15

3

12

AB

1

c

OS2

(53)

M1M2 S

TB7

TB3

M1M2

M1M2 S

( ) Address

[Fig. 11.4.1]

A : Switch (Breakers for

wiring and current

leakage)

B : Breakers for current

leakage

C : Outdoor unit

D : Pull box

E : Indoor unit

TB7

TB3

M1M2

OS1

(52)

M1M2 S

TB7

TB3

M1M2

3N~380–415V

L1, L2, L

3,

N

~220–240V

L, N

OC

(51)

TB5

M1M2 S

BA

BA

IC

IC

TB5

M1M2 S

4

L

1

r

RC

TB2

AB

RP

S

TB3

ABS

7

L

1

r

TB5

M1M2 S

ABAB

IC

RC

TB5

M1M2 S

IC

11.4

C

Ground

PE

PE

E

E

PE

D

E E

PE PE

9

Contents

1. Safety precautions .................................................................................... 10

1.1. Before installation and electric work ........................................ 10

1.2. Precautions for devices that use R410A refrigerant ................. 11

1.3. Before installation ..................................................................... 11

1.4. Before installation (relocation) - electrical work ........................ 11

1.5. Before starting the test run ....................................................... 11

2. About the product ...................................................................................... 11

3. Combination of outdoor units .................................................................... 12

4. Specifications ............................................................................................ 12

5. Confirmation of parts attached .................................................................. 13

6. Space required around unit ...................................................................... 13

7. Lifting method ........................................................................................... 13

8. Installation of unit ...................................................................................... 14

8.1. Installation ............................................................................... 14

9. Refrigerant piping installation ................................................................... 14

9.1. Caution .................................................................................... 14

9.2. Refrigerant piping system ........................................................ 15

GB

1. Safety precautions

1.1. Before installation and electric work

s Before installing the unit, make sure you read all the “Safety

DFEINLPGRRUTRCZSVSLHGPO

precautions”.

s The “Safety precautions” provide very important points re-

garding safety. Make sure you follow them.

Symbols used in the text

Warning:

Describes precautions that should be observed to prevent danger of injury

or death to the user.

Caution:

Describes precautions that should be observed to prevent damage to the

unit.

Symbols used in the illustrations

: Indicates an action that must be avoided.

: Indicates that important instructions must be followed.

: Indicates a part which must be grounded.

: Beware of electric shock. (This symbol is displayed on the main unit label.)

<Color: yellow>

Warning:

Carefully read the labels affixed to the main unit.

HIGH VOLTAGE WARNING:

• Control box houses high-voltage parts.

• When opening or closing the front panel of the control box, do not let it

come into contact with any of the internal components.

• Before inspecting the inside of the control box, turn off the power, keep

the unit off for at least 10 minutes, and confirm that the voltage between

FT-P and FT-N on INV Board has dropped to DC20V or less.

(It takes about 10 minutes to discharge electricity after the power supply

is turned off.)

Warning:

• Ask the dealer or an authorized technician to install the air conditioner.

- Improper installation by the user may result in water leakage, electric shock,

or fire.

• This appliance is not intended for use by persons (including children)

with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning use of the appliance by a person responsible for

their safety.

• Install the unit at a place that can withstand its weight.

- Failure to do so may cause the unit to fall down, resulting in injuries and

damage to the unit.

• Use the specified cables for wiring. Make the connections securely so

that the outside force of the cable is not applied to the terminals.

- Inadequate connection and fastening may generate heat and cause a fire.

• Prepare for strong winds and earthquakes and install the unit at the specified place.

- Improper installation may cause the unit to topple and result in injury and

damage to the unit.

10. Additional refrigerant charge ..................................................................... 15

10.1. Calculation of additional refrigerant charge ............................. 15

10.2. Precautions concerning piping connection and

valve operation ........................................................................ 16

10.3. Airtight test, evacuation, and refrigerant charging ................... 17

10.4. Thermal insulation of refrigerant piping ................................... 17

11. Wiring (For details, refer to the installation manual of

each unit and controller.) .......................................................................... 18

11.1. Caution .................................................................................... 18

11.2. Control box and connecting position of wiring ......................... 18

11.3. Wiring transmission cables...................................................... 18

11.4. Wiring of main power supply and equipment capacity ............ 20

12. Test run ..................................................................................................... 21

12.1. The following phenomena do not represent faults. ................. 21

13. Information on rating plate ........................................................................ 21

Always use filters and other accessories specified by Mitsubishi Electric.

•

- Ask an authorized technician to install the accessories. Improper installation

by the user may result in water leakage, electric shock, or fire.

• Never repair the unit. If the air conditioner must be repaired, consult the

dealer.

- If the unit is repaired improperly, water leakage, electric shock, or fire may

result.

• If the supply cord is damaged, it must be replaced by the manufacturer,

its service agent or similarly qualified persons in order to avoid a hazard.

• Do not touch the heat exchanger fins.

- Improper handling may result in injury.

• If refrigerant gas leaks during installation work, ventilate the room.

- If the refrigerant gas comes into contact with a flame, poisonous gases will

be released.

• Install the air conditioner according to this Installation Manual.

- If the unit is installed improperly, water leakage, electric shock, or fire may

result.

Have all electric work done by a licensed electrician according to “Electric

•

Facility Engineering Standard” and “Interior Wire Regulations” and the

instructions given in this manual and always use a dedicated power supply.

- If the power source capacity is inadequate or electric work is performed im-

properly, electric shock and fire may result.

• Securely install the outdoor unit terminal cover (panel).

- If the terminal cover (panel) is not installed properly, dust or water may enter

the outdoor unit and fire or electric shock may result.

• When installing and moving the air conditioner to another site, do not

charge it with a refrigerant different from the refrigerant specified on the

unit.

- If a different refrigerant or air is mixed with the original refrigerant, the refrig-

erant cycle may malfunction and the unit may be damaged.

• If the air conditioner is installed in a small room, measures must be taken

to prevent the refrigerant concentration from exceeding the safety limit if

the refrigerant should leak.

- Consult the dealer regarding the appropriate measures to prevent the safety

limit from being exceeded. Should the refrigerant leak and cause the safety

limit to be exceeded, hazards due to lack of oxygen in the room could result.

• When moving and reinstalling the air conditioner, consult the dealer or

an authorized technician.

- If the air conditioner is installed improperly, water leakage, electric shock, or

fire may result.

• After completing installation work, make sure that refrigerant gas is not

leaking.

- If the refrigerant gas leaks and is exposed to a fan heater, stove, oven, or

other heat source, it may generate noxious gases.

• Do not reconstruct or change the settings of the protection devices.

- If the pressure switch, thermal switch, or other protection device is shorted

or operated forcibly, or parts other than those specified by Mitsubishi Electric

are used, fire or explosion may result.

•To dispose of this product, consult your dealer.

• The installer and system specialist shall secure safety against leakage

according to local regulation or standards.

- The size of the wire and capacities of the switch for the main power supply

are applicable if local regulations are not available.

• Pay special attention to the place of installation, such as a basement,

etc. where refrigeration gas can accumulate, since refrigeration is heavier

than the air.

• For outdoor units that allow fresh air intake to the indoor unit, the

installation site must be carefully chosen because outdoor air can directly

blow into the room when the thermostat is turned off.

- Direct exposure to outdoor air may have harmful effects on people or food.

• Children should be supervised to ensure that they do not play with the

appliance.

10

1.2. Precautions for devices that use R410A

refrigerant

Caution:

• Do not use existing refrigerant piping.

- The old refrigerant and refrigerator oil in the existing piping contains a large

amount of chlorine which may cause the refrigerator oil of the new unit to

deteriorate.

- R410A is a high-pressure refrigerant and can cause the existing piping to

burst.

• Use refrigerant piping made of phosphorus deoxidized copper and copper alloy seamless pipes and tubes. In addition, be sure that the inner

and outer surfaces of the pipes are clean and free of hazardous sulphur,

oxides, dust/dirt, shaving particles, oils, moisture, or any other contaminant.

- Contaminants on the inside of the refrigerant piping may cause the refriger-

ant residual oil to deteriorate.

• Store the piping to be used during installation indoors and keep both

ends of the piping sealed until just before brazing. (Store elbows and

other joints in a plastic bag.)

- If dust, dirt, or water enters the refrigerant cycle, deterioration of the oil and

compressor failure may result.

• Apply a small amount of ester oil, ether oil, or alkyl benzene to flares. (for

indoor unit)

- Infiltration of a large amount of mineral oil may cause the refrigerator oil to

deteriorate.

• Use liquid refrigerant to fill the system.

- If gas refrigerant is used to fill the system, the composition of the refrigerant

in the cylinder will change and performance may drop.

• Do not use a refrigerant other than R410A.

- If another refrigerant (R22, etc.) is mixed with R410A, the chlorine in the

refrigerant may cause the refrigerator oil to deteriorate.

• Use a vacuum pump with a reverse flow check valve.

- The vacuum pump oil may flow back into the refrigerant cycle and cause the

refrigerator oil to deteriorate.

• Do not use the following tools that are used with conventional refrigerants.

(Gauge manifold, charge hose, gas leak detector, reverse flow check valve,

refrigerant charge base, refrigerant recovery equipment)

- If the conventional refrigerant and refrigerator oil are mixed in the R410A,

the refrigerant may deteriorated.

- If water is mixed in the R410A, the refrigerator oil may deteriorate.

- Since R410A does not contain any chlorine, gas leak detectors for conven-

tional refrigerants will not react to it.

• Do not use a charging cylinder.

- Using a charging cylinder may cause the refrigerant to deteriorate.

• Be especially careful when managing the tools.

- If dust, dirt, or water gets into the refrigerant cycle, the refrigerant may dete-

riorate.

1.3. Before installation

Caution:

• Do not install the unit where combustible gas may leak.

- If the gas leaks and accumulates around the unit, an explosion may result.

• Do not use the air conditioner where food, pets, plants, precision instruments, or artwork are kept.

- The quality of the food, etc. may deteriorate.

• Do not use the air conditioner in special environments.

- Oil, steam, sulfuric smoke, etc. can significantly reduce the performance of

the air conditioner or damage its parts.

• When installing the unit in a hospital, communication station, or similar

place, provide sufficient protection against noise.

-Inverter equipment, private power generator, high-frequency medical equip-

ment, or radio communication equipment may cause the air conditioner to

operate erroneously, or fail to operate. On the other hand, the air conditioner

may affect such equipment by creating noise that disturbs medical treatment

or image broadcasting.

• Do not install the unit on a structure that may cause leakage.

- When the room humidity exceeds 80% or when the drain pipe is clogged,

condensation may drip from the indoor unit. Perform collective drainage work

together with the outdoor unit, as required.

1.4. Before installation (relocation) - electrical work

Caution:

• Ground the unit.

- Do not connect the ground wire to gas or water pipes, lightning rods, or

telephone ground lines. Improper grounding may result in electric shock.

• Never connect in reverse phases.

Never connect the Power Line L1, L2, and L3 to Terminal N.

- If the unit is miss wired, when power is supplied, some electrical parts will be

damaged.

• Install the power cable so that tension is not applied to the cable.

-Tension may cause the cable to break and generate heat and cause a fire.

• Install a leak circuit breaker, as required.

- If a leak circuit breaker is not installed, electric shock may result.

• Use power line cables of sufficient current carrying capacity and rating.

- Cables that are too small may leak, generate heat, and cause a fire.

• Use only a circuit breaker and fuse of the specified capacity.

-A fuse or circuit breaker of a larger capacity, or the use of a substitute simple

steel or copper wire may result in a general unit failure or fire.

• Do not wash the air conditioner units.

-Washing them may cause an electric shock.

• Be careful that the installation base is not damaged by long use.

- If the damage is left uncorrected, the unit may fall and cause personal injury

or property damage.

• Install the drain piping according to this Installation Manual to ensure

proper drainage. Wrap thermal insulation around the pipes to prevent

condensation.

- Improper drain piping may cause water leakage causing damage to furniture

and other possessions.

• Be very careful about transporting the product.

- One person should not carry the product. Its weight is in excess of 20kg.

- Some products use PP bands for packaging. Do not use any PP bands as a

means of transportation. It is dangerous.

- Do not touch the heat exchanger fins. Doing so may cut your fingers.

- When transporting the outdoor unit, support it at the specified positions on

the unit base. Also support the outdoor unit at four points so that it cannot

slip sideways.

• Safely dispose of the packing materials.

- Packing materials, such as nails and other metal or wooden parts, may cause

stabs or other injuries.

-Tear apart and throw away plastic packaging bags so that children will not

play with them. If children play with a plastic bag which has not been torn

apart, they face the risk of suffocation.

1.5. Before starting the test run

Caution:

•Turn on the power at least 12 hours before starting operation.

- Starting operation immediately after turning on the main power switch can

result in irreversible damage to internal parts. Keep the power switch turned

on during the operational season. Make sure of the phase order of power

supply and voltage between each phase.

• Do not touch the switches with wet fingers.

-Touching a switch with wet fingers can result in an electric shock.

• Do not touch the refrigerant pipes during and immediately after operation.

- During and immediately after operation, the refrigerant pipes may be hot or

cold, depending on the condition of the refrigerant flowing through the refrigerant piping, compressor, and other refrigerant cycle parts. Your hands may

suffer burns or frostbite if you touch the refrigerant pipes.

• Do not operate the air conditioner with the panels and guards removed.

- Rotating, hot, or high-voltage parts can cause injuries.

• Do not turn off the power immediately after stopping operation.

- Always wait at least 5 minutes before turning off the power. Otherwise,

drainage water leakage or mechanical failure of sensitive parts may occur.

• Do not touch the surface of the compressor during servicing.

- If unit is connected to a supply and not running, the crank case heater lo-

cated at the base of the compressor may still be operating.

GB

DFEINLPGRRUTRCZSVSLHGPO

2. About the product

• This unit uses R410A-type refrigerant.

• Piping for systems using R410A may be different from that for systems using

conventional refrigerant because the design pressure in systems using R410A

is higher. Refer to the Data Book for more information.

• Some of the tools and equipment used for installation with systems that use

other types of refrigerant cannot be used with the systems using R410A. Refer

to the Data Book for more information.

Caution:

• Do not vent R410A into the atmosphere.

• R410A is a Fluorinated Greenhouse gas, covered by the Kyoto Protocol

with a Global Warming Potential (GWP) = 1975.

11

Loading...

Loading...