Page 1

Air-Conditioners

gepr

fte

Sicherheit

OUTDOOR UNIT

PUHY-P-YSMF-B

FOR INSTALLER

FÜR INSTALLATEURE

gepr

üfte

Sicherheit

POUR L’INSTALLATEUR

VOOR DE INSTALLATEUR

PER L’INSTALLATORE

INSTALLATION MANUAL

For safe and correct use, please read this installation manual thoroughly before installing the air-conditioner unit.

∗ Remote controller (PAR-F25MA) is available as an optional remote controller.

INSTALLATIONSHANDBUCH

Zum sicheren und ordnungsgemäßen Gebrauch der Klimageräte das Installationshandbuch gründlich durchlesen.

∗ Fernbedienung (PAR-F25MA) ist als Zubehör wahlweise erhältlich.

ENGLISH

DEUTSCH

FRANÇAIS

MANUEL D’INSTALLATION

Veuillez lire le manuel d’installation en entier avant d’installer ce climatiseur pour éviter tout accident et vous assurer d’une utilisation

correcte.

∗ La télécommande (PAR-F25MA) est disponible en option.

INSTALLATIEHANDLEIDING

Voor een veilig en juist gebruik moet u deze installatiehandleiding grondig doorlezen voordat u de airconditioner installeert.

∗ De afstandsbedieningseenheid (PAR-F25MA) is verkrijgbaar als een optioneel toe te voegen afstandsbediening.

MANUALE DI INSTALLAZIONE

Per un uso sicuro e corretto, leggere attentamente questo manuale di installazione prima di installare il condizionatore d’aria.

∗ Il comando a distanza (modello PAR-F25MA) disponibile in opzione.

NEDERLANDS

ITALIANO

Page 2

Contents

1. Safety precautions ...................................................................... 3

1.1. Before installation and electric work ............................... 3

1.2. Precautions for devices that use R407C refrigerant....... 3

1.3. Before getting installed ................................................... 4

1.4. Before getting installed (moved) - electrical work ........... 4

1.5. Before starting the test run ............................................. 4

2. Combination with indoor units..................................................... 5

3. Confirmation of parts attached ................................................... 5

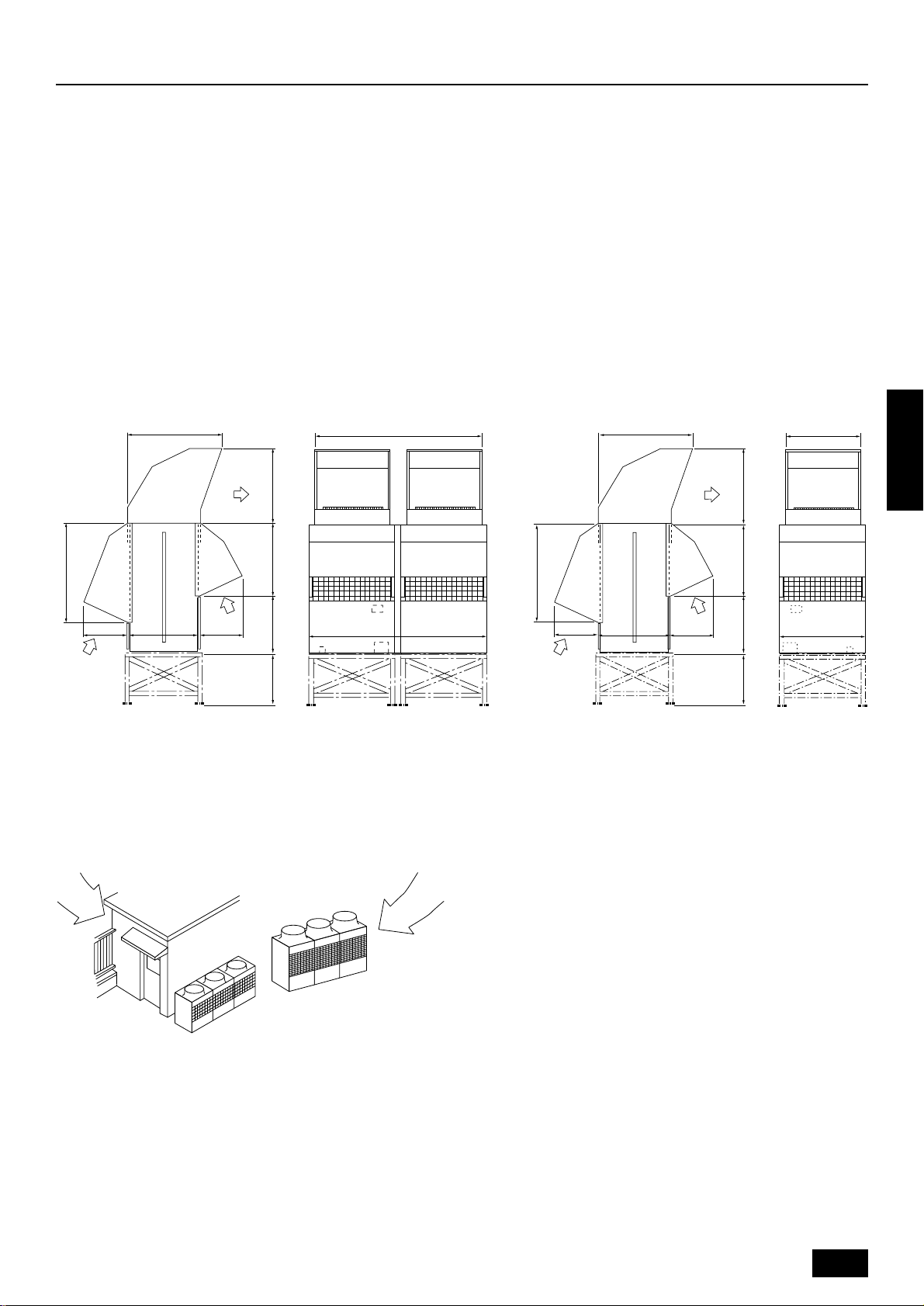

4. Outdoor unit configuration .......................................................... 6

5. Selection of installation site ........................................................ 6

6. Space required around unit ........................................................ 7

6.1. Individual installation ...................................................... 7

6.2. Collective installation and continuous installation........... 8

7. Lifting method and weight of product.......................................... 8

8. Installation of unit........................................................................ 9

8.1. Location of anchor bolt ................................................... 9

8.2. Installation ...................................................................... 9

8.3. Connecting direction for refrigerant piping.................... 10

ENGLISH

8.4. Noise level .................................................................... 10

9. Caution for snow and seasonal wind ........................................ 11

9.1. Snow and seasonal wind.............................................. 11

9.2. Countermeasure to seasonal wind ............................... 11

10. Refrigerant piping installation.................................................. 12

10.1. Areas of caution .......................................................... 12

10.2. Refrigerant piping system ........................................... 14

10.3. Precautions concerning piping connection

and valve operation..................................................... 16

10.4. Oil balance pipe connection method ........................... 19

10.5. Distributor (gas) connection method ........................... 20

10.6. How to install branch pipe ........................................... 21

10.7. Airtight test and evacuation, refrigerant charging........ 22

10.8. Thermal insulation of refrigerant piping....................... 25

11. Electrical work ......................................................................... 27

11.1. Caution........................................................................ 27

11.2. Control box and connecting position of wiring............. 28

11.3. Wiring transmission cables ......................................... 30

11.4. Wiring of main power supply and

equipment capacity ..................................................... 37

12. Test run .................................................................................... 38

12.1. Checking before getting test run ................................. 38

12.2. Test run method .......................................................... 38

12.3. How to cope with test run abnormality ........................ 39

12.4. Coping with remote controller abnormality.................. 42

12.5. The following phenomena do not represent

abnormality (emergency) ............................................ 43

2

Page 3

1. Safety precautions

1.1. Before installation and electric work

s Before installing the unit, make sure you read all the

“Safety precautions”.

s The “Safety precautions” pro vide very important points

regarding safety. Make sure you follow them.

s This equipment may not be applicable to EN61000-3-

2: 1995 and EN61000-3-3: 1995.

s This equipment may cause the adverse effect on the

same supply system.

s Please report to or take consent by the supply author-

ity before connection to the system.

Symbols used in the text

Warning:

Describes precautions that should be observed to prevent danger

of injury or death to the user.

Caution:

Describes precautions that should be observed to prevent damage

to the unit.

Symbols used in the illustrations

: Indicates an action that must be avoided.

: Indicates that important instructions must be followed.

: Indicates a part which must be grounded.

: Indicates that caution should be taken with rotating parts. (This

symbol is displayed on the main unit label.) <Color: Yellow>

: Indicates that the main switch must be turned off before servicing.

(This symbol is displayed on the main unit label.) <Color: Blue>

: Beware of electric shock (This symbol is displayed on the main

unit label.) <Color: Yellow>

: Beware of hot surface (This symbol is display ed on the main unit

label.) <Color: Yellow>

: Please pay attention to electric shock fully because this is

ELV

not Safety Extra Low-Voltage (SELV) circuit.

And at servicing, please shut down the power supply for both

of Indoor Unit and Outdoor Unit.

Warning:

Carefully read the labels affixed to the main unit.

Warning:

• Ask the dealer or an authorized technician to install the air conditioner.

- Improper installation by the user ma y result in water leakage, elec-

tric shock, or fire.

• Install the air unit at a place that can withstand its weight.

- Inadequate strength may cause the unit to fall down, resulting in

injuries.

• Use the specified cables for wiring. Make the connections securely so that the outside force of the cable is not applied to the

terminals.

- Inadequate connection and fastening may gener ate heat and cause

a fire.

• Prepare for typhoons and other strong winds and earthquakes

and install the unit at the specified place.

- Improper installation may cause the unit to topple and result in in-

jury.

• Always use an air cleaner, humidifier, electric heater, and other

accessories specified by Mitsubishi Electric.

- Ask an authorized technician to install the accessories. Improper

installation by the user may result in water leakage, electric shock,

or fire.

• Never repair the unit. If the air conditioner must be repaired,

consult the dealer.

- If the unit is repaired improperly, water leakage, electric shock, or

fire may result.

• Do not touch the heat exchanger fins.

- Improper handling may result in injury.

• If refrigerant gas leaks during installation work, ventilate the

room.

- If the refrigerant gas comes into contact with a flame, poisonous

gases will be released.

• Install the air conditioner according to this Installation Manual.

- If the unit is installed improperly, water leakage, electric shock, or

fire may result.

• Have all electric work done by a licensed electrician according

to “Electric Facility Engineering Standard” and “Interior Wire

Regulations”and the instructions given in this manual and always use a special circuit.

- If the power source capacity is inadequate or electric work is per-

formed improperly, electric shock and fire may result.

• Securely install the outdoor unit terminal cover (panel).

- If the terminal cover (panel) is not installed properly, dust or water

may enter the outdoor unit and fire or electric shock may result.

• When installing and moving the air conditioner to another site,

do not charge the it with a refrigerant different from the refrigerant (R407C) specified on the unit.

- If a different refrigerant or air is mixed with the original refrigerant,

the refrigerant cycle may malfunction and the unit may be damaged.

• If the air conditioner is installed in a small room, measures must

be taken to prevent the refrigerant concentration from exceeding the safety limit even if the refrigerant should leak.

- Consult the dealer regarding the appropriate measures to prevent

the safety limit from being exceeded. Should the refrigerant leak

and cause the safety limit to be exceeded, hazards due to lack of

oxygen in the room could result.

• When moving and reinstalling the air conditioner, consult the

dealer or an authorized technician.

- If the air conditioner is installed improperly, water leakage, electric

shock, or fire may result.

• After completing installation work, make sure that refrigerant

gas is not leaking.

- If the refrigerant gas leaks and is exposed to a fan heater, stove,

oven, or other heat source, it may generate noxious gases.

• Do not reconstruct or change the settings of the protection devices.

- If the pressure switch, thermal switch, or other protection de vice is

shorted and operated forcibly, or parts other than those specified

by Mitsubishi Electric are used, fire or explosion may result.

• To dispose of this product, consult your dealer.

• The installer and system specialist shall secure safety against

leakage according to local regulation or standards.

- Following standards may be applicable if local regulation are not

available.

• Pay a special attention to the place, such as a basement, etc.

where refrigeration gas can stay, since refrigeration is heavier

than the air.

1.2. Precautions for devices that use

R407C refrigerant

Caution:

• Do not use the existing refrigerant piping.

- The old refrigerant and refrigerator oil in the existing piping con-

tains a large amount of chlorine which may cause the refrigerator

oil of the new unit to deteriorate.

• Use refrigerant piping made of C1220 (CU-DHP) phosphorus

deoxidized copper as specified in the JIS H3300 “Copper and

copper alloy seamless pipes and tubes”. In addition, be sure

that the inner and outer surfaces of the pipes are clean and free

ENGLISH

3

Page 4

of hazardous sulphur, oxides, dust/dirt, shaving particles, oils,

moisture, or any other contaminant.

- Contaminants on the inside of the refrigerant piping may cause the

refrigerant residual oil to deteriorate.

• Store the piping to be used during installation indoors and keep

both ends of the piping sealed until just before brazing. (Store

elbows and other joints in a plastic bag.)

- If dust, dirt, or water enters the refrigerant cycle, deterioration of

the oil and compressor trouble may result.

• Use ester oil, ether oil or alkylbenzene (small amount) as the

refrigerator oil to coat flares and flange connections.

- The refrigerator oil will degrade if it is mixed with a large amount of

mineral oil.

• Use liquid refrigerant to fill the system.

- If gas refrigerant is used to seal the system, the composition of the

refrigerant in the cylinder will change and performance may drop.

• Do not use a refrigerant other than R407C.

- If another refrigerant (R22, etc.) is used, the chlorine in the refriger-

ant may cause the refrigerator oil to deteriorate.

• Use a vacuum pump with a reverse flow check valve.

- The vacuum pump oil may flow back into the refrigerant cycle and

cause the refrigerator oil to deteriorate.

• Do not use the following tools that are used with conventional

refrigerants.

(Gauge manifold, charge hose, gas leak detector, reverse flow

check valve, refrigerant charge base, vacuum gauge, refrigerant recovery equipment)

- If the conventional refrigerant and refrigerator oil are mixed in the

ENGLISH

R407C, the refrigerant may deteriorated.

- If water is mixed in the R407C, the refrigerator oil may deteriorate.

- Since R407C does not contain any chlorine, gas leak detectors for

conventional refrigerants will not react to it.

• Do not use a charging cylinder.

- Using a charging cylinder may cause the refrigerant to deteriorate.

• Be especially careful when managing the tools.

- If dust, dirt, or water gets in the refrigerant cycle, the refrigerant

may deteriorate.

1.3. Before getting installed

• Install the power cable so that tension is not applied to the cable.

- Tension may cause the cable to break and generate heat and cause

a fire.

• Install an leak circuit breaker, as required.

- If an leak circuit breaker is not installed, electric shock may result.

• Use power line cables of sufficient current carrying capacity

and rating.

- Cables that are too small may leak, generate heat, and cause a

fire.

• Use only a circuit breaker and fuse of the specified capacity.

- A fuse or circuit breaker of a larger capacity or a steel or copper

wire may result in a general unit failure or fire.

• Do not wash the air conditioner units.

- Washing them may cause an electric shock.

• Be careful that the installation base is not damaged by long use.

- If the damage is left uncorrected, the unit may fall and cause per-

sonal injury or property damage.

• Install the drain piping according to this Installation Manual to

ensure proper drainage. Wrap thermal insulation around the

pipes to prevent condensation.

- Improper drain piping may cause water leakage and damage to

furniture and other possessions.

• Be very careful about product transportation.

- Only one person should not carry the product if it weighs more than

20 kg.

- Some products use PP bands for packaging. Do not use any PP

bands for a means of transportation. It is dangerous.

- Do not touch the heat exchanger fins. Doing so may cut your fin-

gers.

- When transporting the outdoor unit, suspend it at the specified po-

sitions on the unit base. Also support the outdoor unit at four points

so that it cannot slip sideways.

• Safely dispose of the packing materials.

- Packing materials, such as nails and other metal or wooden parts,

may cause stabs or other injuries.

- Tear apart and throw away plastic pac kaging bags so that children

will not play with them. If children pla y with a plastic bag which was

not torn apart, they face the risk of suffocation.

Caution:

• Do not install the unit where combustible gas may leak.

- If the gas leaks and accumulates around the unit, an explosion

may result.

• Do not use the air conditioner where food, pets, plants, precision instruments, or artwork are kept.

- The quality of the food, etc. may deteriorate.

• Do not use the air conditioner in special environments.

- Oil, steam, sulfuric smoke, etc. can significantly reduce the per-

formance of the air conditioner or damage its parts.

• When installing the unit in a hospital, communication station,

or similar place, provide sufficient protection against noise.

- The inverter equipment, private power generator, high-frequency

medical equipment, or radio communication equipment may cause

the air conditioner to operate erroneously , or f ail to operate. On the

other hand, the air conditioner may affect such equipment by creating noise that disturbs medical treatment or image broadcasting.

• Do not install the unit on a structure that may cause leakage.

- When the room humidity exceeds 80% or when the drain pipe is

clogged, condensation may drip from the indoor unit. Perform collective drainage work together with the outdoor unit, as required.

1.4. Before getting installed (moved) -

electrical work

Caution:

• Ground the unit.

- Do not connect the ground wire to gas or water pipes, lightning

rods, or telephone ground lines. Improper grounding may result in

electric shock.

• The reverse phase of L lines (L1, L2, L3) can be detected (Error

cord : 4103), but the reverse phase of L lines and N line can be

not be detected.

- The some electric parts should be damaged when power is sup-

plied under the miss wiring.

1.5. Before starting the test run

Caution:

• Turn on the power at least 12 hours before starting operation.

- Starting operation immediately after turning on the main power

switch can result in severe damage to internal parts. Keep the pow er

switch turned on during the operational season.

• Do not touch the switches with wet fingers.

- Touching a switch with wet fingers can cause electric shock.

• Do not touch the refrigerant pipes during and immediately after

operation.

- During and immediately after operation, the refrigerant pipes are

may be hot and may be cold, depending on the condition of the

refrigerant flowing through the refrigerant piping, compressor, and

other refrigerant cycle parts. Your hands may suffer burns or frostbite if you touch the refrigerant pipes.

• Do not operate the air conditioner with the panels and guards

removed.

- Rotating, hot, or high-voltage parts can cause injuries.

• Do not turn off the power immediately after stopping operation.

- Alwa ys wait at least five minutes before turning off the power. Oth-

erwise, water leakage and trouble may occur.

4

Page 5

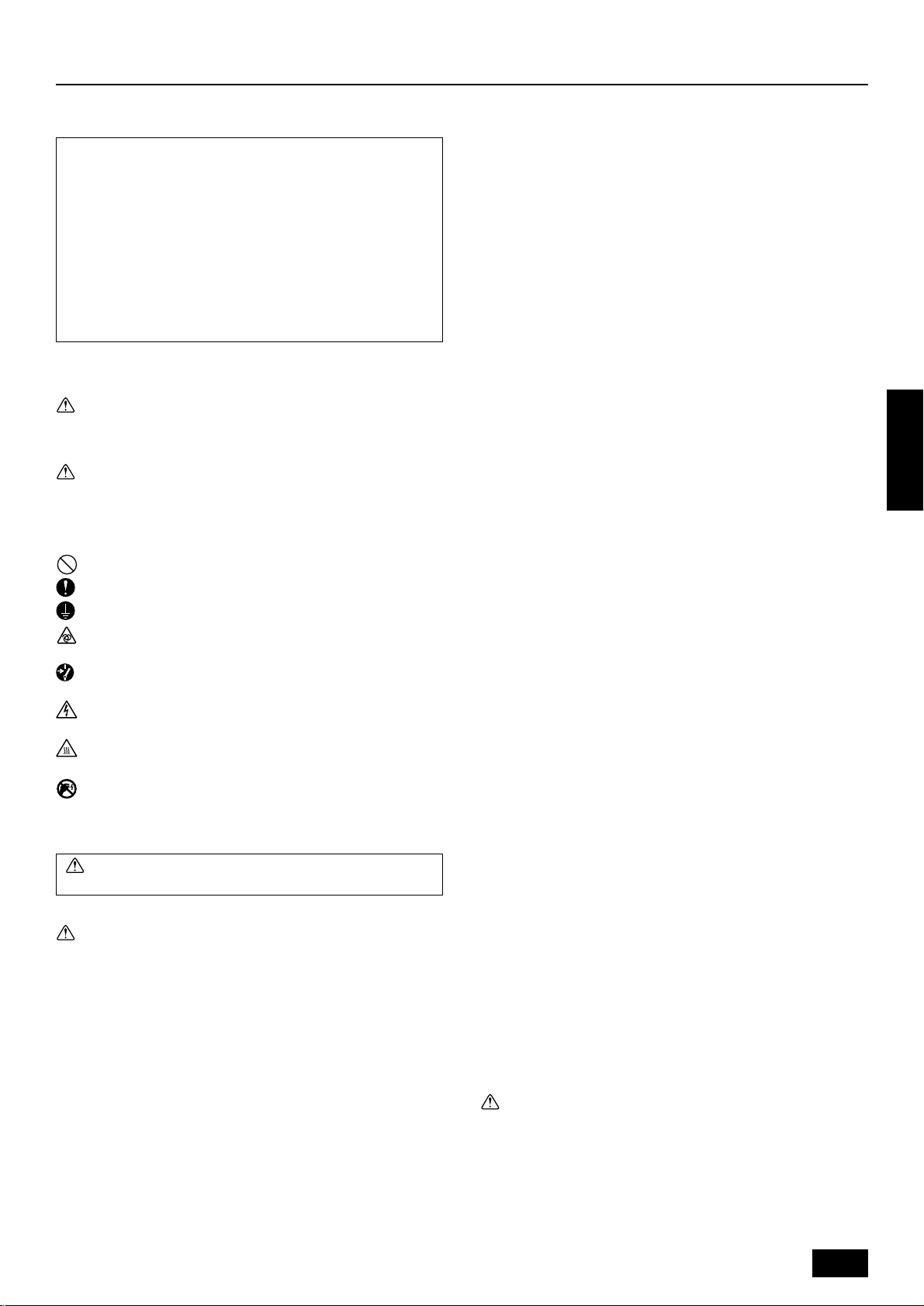

2. Combination with indoor units

The indoor units connectable to this unit are shown below.

Outdoor unit model

name

Note:

1. The total capacity of connected indoor unit models represents the total sum of the figures expressed in the indoor model name.

2. Combinations in which the total capacity of the connected indoor units exceeds the capacity of the outdoor unit will reduce the capacity

of each indoor unit below the rated capacity during simultaneous operation. Therefore, if circumstances allows, combine indoor units

within the capacity of the outdoor unit.

3. A transmission booster (RP) is required when the number of connected indoor unit models in a cooling system exceeds the number of

models specified in the chart below.

* The maximum number of units that can be controlled is determined by the indoor unit model, the type of remote controller and their

capabilities.

(*1)

Capability of the

connected indoor units

*1 If even one unit that is higher than 200 exists in the cooling system, the maximum capacity will be “200 or higher”.

Total capacity of

connected indoor unit

models

300 to 780PUHY-P600

325 to 845PUHY-P650

350 to 910PUHY-P700

375 to 975PUHY-P750

Number of connected indoor units that can be

connected without a RP.

200 or lower

200 or higher

Quantity of connectable

indoor unit

PMFY-P25 · 32 · 40 · 63 VBM

PLFY- P32 · 40 · 50 · 63 · 80 · 100 · 125 VKM

PLFY- P20 · 25 · 32 · 40 · 50 · 63 · 80 · 100 · 125 VLMD

PEFY-P20· 25 · 32 VML

PEFY-P40· 50 · 63 · 71 · 80 · 100 · 125 · 140 · 200 · 250 VMH

3 to 32

Remote controller type

The number of indoor units and the total number of remote controllers is displayed within the parenthesis ( ).

PCFY-P40 · 63 · 100 · 125 VGM

PKFY-P20 · 25 VAM

PKFY-P32· 40 · 50 VGM

PFFY- P20 · 25 · 32 · 40 · 50 · 63 VLEM

PFFY- P20 · 25 · 32 · 40 · 50 · 63 VLRM

PDFY-P20 · 25 · 32 · 40 · 50 · 63 · 71 · 80 · 100 · 125 VM

Model name of connectable indoor unit

Remote controller PAR-F 25MA

Prior to Ver. E After Ver. F

16 (32) 20 (40)

16 (32) 16 (32)

ENGLISH

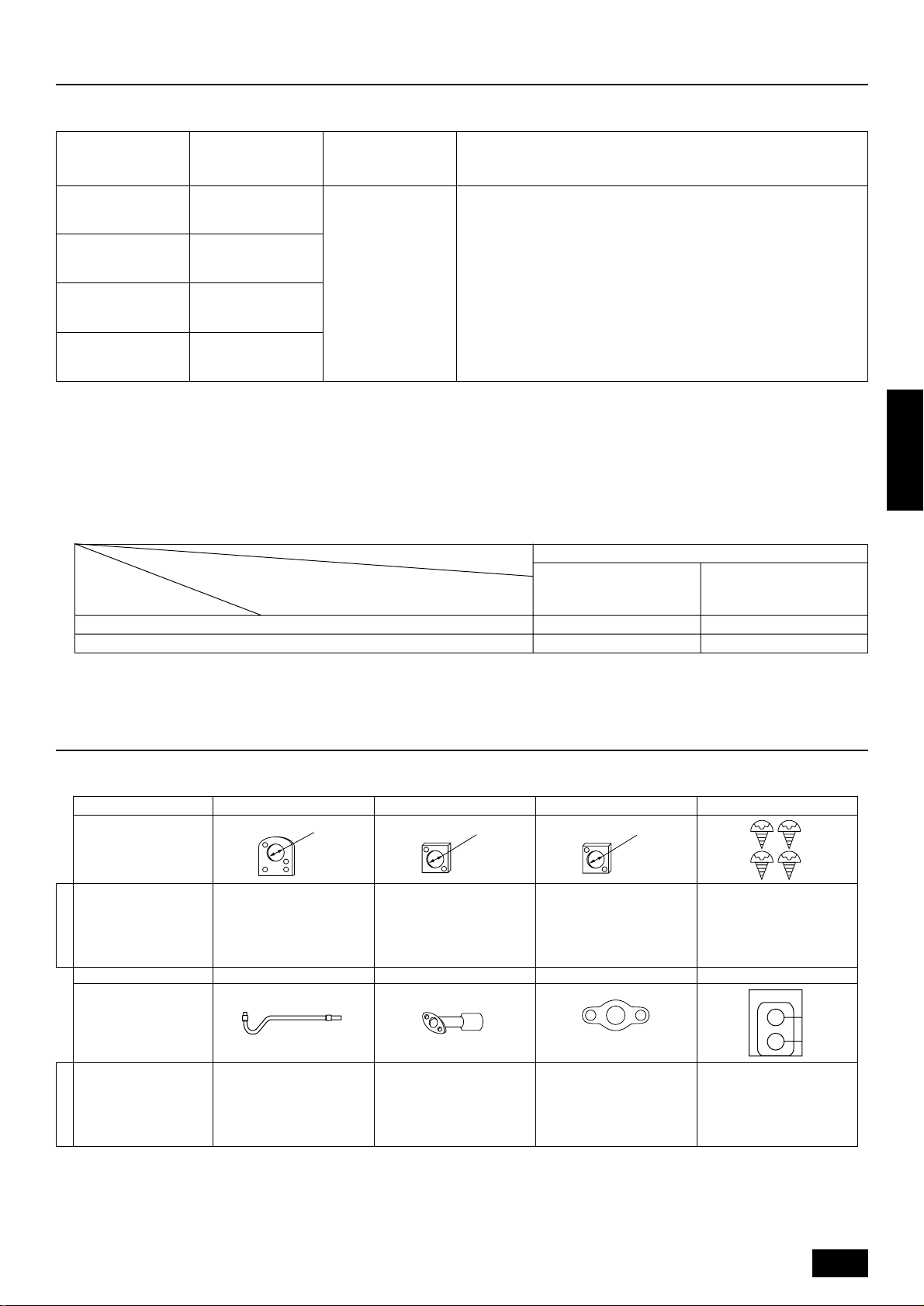

3. Confirmation of parts attached

This outdoor unit is attached with the parts below. Please check the quantity for each item.

Name 1 Conduit mounting plate 2 Conduit mounting plate 3 Conduit mounting plate 4 Tapping screw M4 × 12

Shape

PUHN-P200YMF-B

PUHN-P250YMF-B

Model name

Name 5 Oil balance pipe 6 Connecting pipe 7 Packing 8 Seal

Shape

PUHN-P200YMF-B

PUHN-P250YMF-B

Model name

ø40

1114

1112

ø33

ø27

insideø23 outsideø35

insideø23 outsideø35

*6 Connecting pipe is fixed with the unit.

5

Page 6

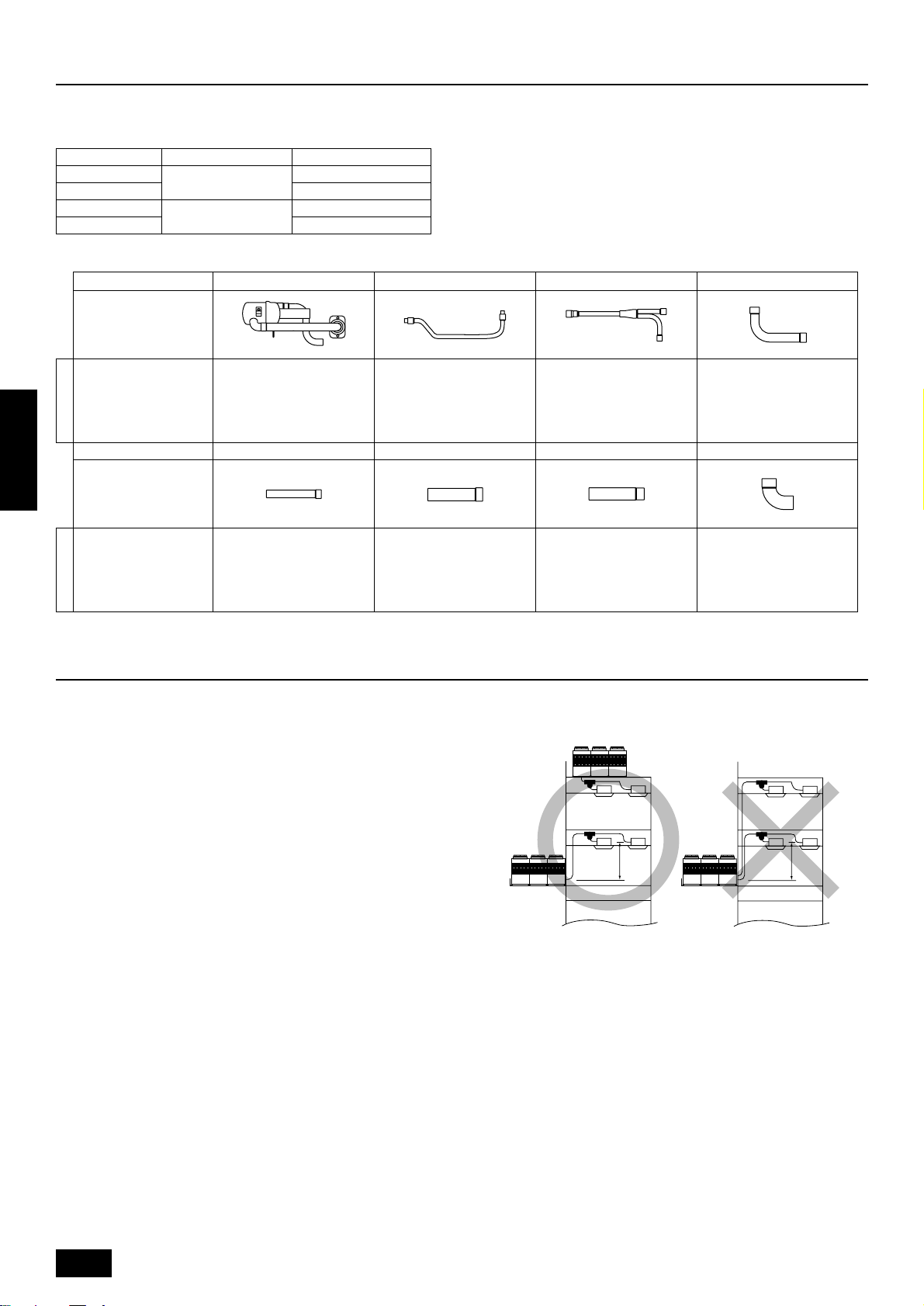

4. Outdoor unit configuration

The unit (PUHY-P600/650/700/750YSMF-B) consists of a combination of variable capacity units (PUHY-P400/500YMF-B) and constant capacity units

(PUHN-P200/250YMF-B). A CMC-30A (optional) is required when using a combination of these units.

Super Y Variable capacity unit Constant capacity unit

PUHY-P600YSMF-B

PUHY-P650YSMF-B

PUHY-P700YSMF-B

PUHY-P750YSMF-B

CMC-30A (optional)

Name 1 Distributer (gas) 2 Oil balance pipe 2 3 Distributer (liquid) 4 Connecting pipe

Shape

CMC-30A 1 1 1 1

Model name

Name 5 Connecting pipe 6 Connecting pipe 7 Connecting pipe 8 Elbow

PUHY-P400YMF-B

PUHY-P500YMF-B

PUHN-P200YMF-B

PUHN-P250YMF-B

PUHN-P200YMF-B

PUHN-P250YMF-B

ENGLISH

Model name

Shape

CMC-30A 1 1 1 2

5. Selection of installation site

Select space for installing outdoor unit, which will meet the following

conditions:

• no direct thermal radiation from other heat sources

• no possibility of annoying neighbors by noise from unit

• no exposition to strong wind

• with strength which bears weight of unit

• note that drain flows out of unit when heating

• with space for air passage and service work shown below

Because of the possibility of fire, do not install unit to the space where

generation, inflow, stagnation, and leak of combustible gas is expected.

• Avoid unit installation in a place where acidic solution and spra y (sulfur)

are often used.

• When having cooling operation at an outside air temperature of below 10°C, in order to obtain steady operation of unit, select an installation site not exposed directly to rain and snow, or install air outlet

and inlet ducts. (Refer to Page 11.) Install the outdoor unit at the

same position on the same floor, or above, the indoor unit. (See the

figure at the right.)

• Do not use unit in any special environment where oil, steam and

sulfuric gas exist.

Installation restriction on outdoor unit when cooling operation is performed

when the outdoor air temperature is 10°C or lower.

A

(Same floor as indoor unit, or floor above)

A 4 m or less

6

Page 7

6. Space required around unit

C

B

A

B

650

325

A

C

H

h

Hh

E

D

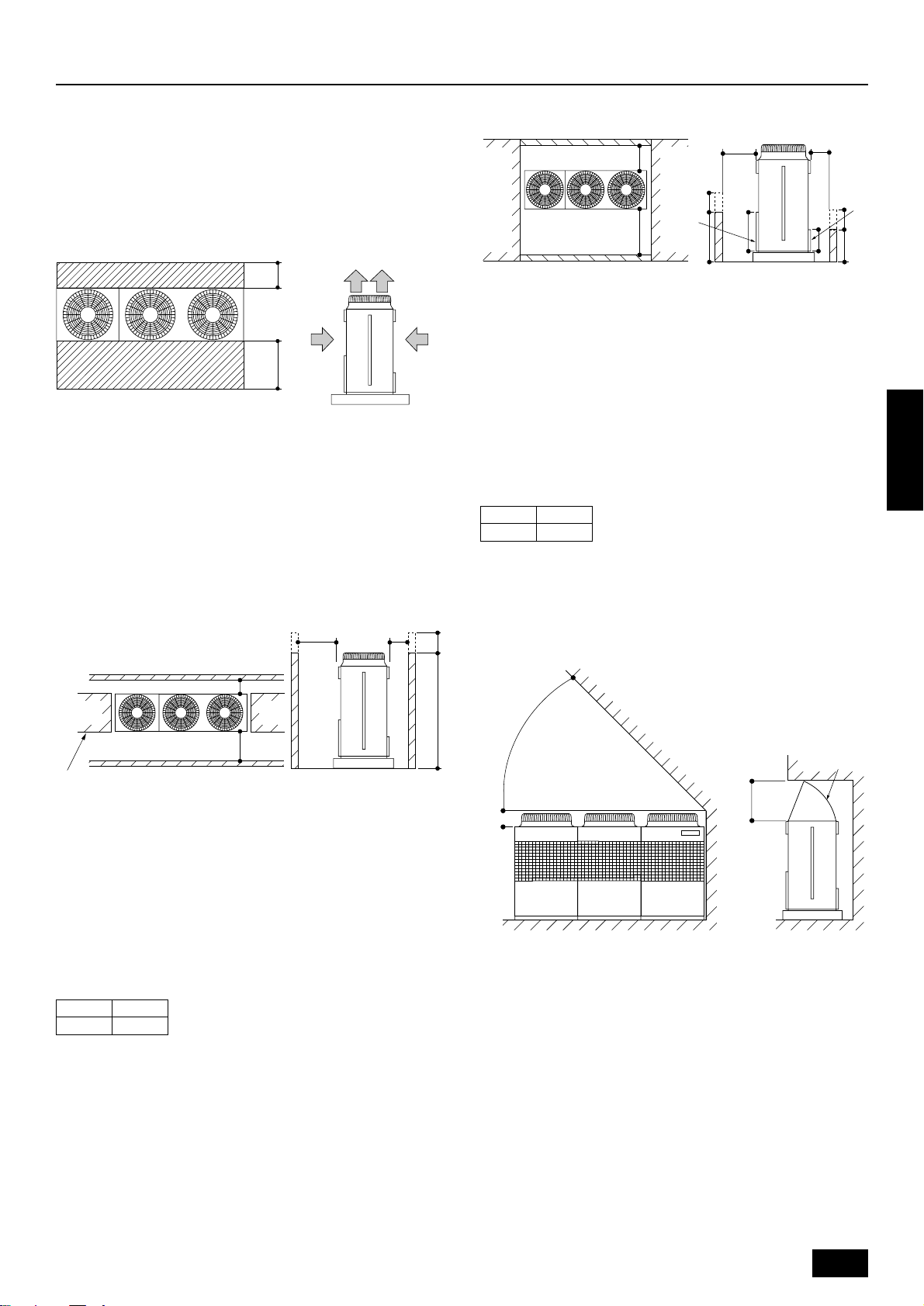

6.1. Individual installation

Basic space required

A space of at least 250 mm is necessary at the back for inlet air. Taking

servicing, etc. from the rear into account, a space of about 450 mm

should be provided, the same as at the front.

D

A

B

C

<Top view> <Side view>

A 250 mm or more

B 450 mm or more

C Front (outside of machine room)

D Top discharge (open in principle)

E Front inlet (open in principle)

F Rear inlet (open in principle)

When inlet air enters from right and left sides of unit

When unit is surrounded by walls

<Side view>

A L

1 or more

B L

FE

2 or more

C Front

D Front panel

E Rear panel

Note:

• Wall heights (H) of the front and the back sides shall be within

height of front panel and rear panel.

• If the panel height is exceeded, add the “h” dimension of the

figure above to L

L

1 L2

1 and L2 in the table above.

ENGLISH

450 250

Example: When h is 100

The L1 dimension becomes 450+100 = 550 mm.

A

B

B

C

C

A

D

<Side view>

A L1 or more

B L

2 or more

C Front

D No restrictions on wall height (left and right)

Note:

• Wall heights (H) of the front and the back sides shall be within

overall height of unit.

• When the total height is exceeded, add the “h” dimension of the

figure above to L1 and L2 in the table above.

L1 L2

450 250

When there is an obstruction above the unit

Hh

A

E

D

B

CF

When there is little space

up to an obstruction

A 45° or more

B 300 mm or more

C Front

D 1000 mm or more

E Air outlet guide (procured at the site)

F Rear

7

Page 8

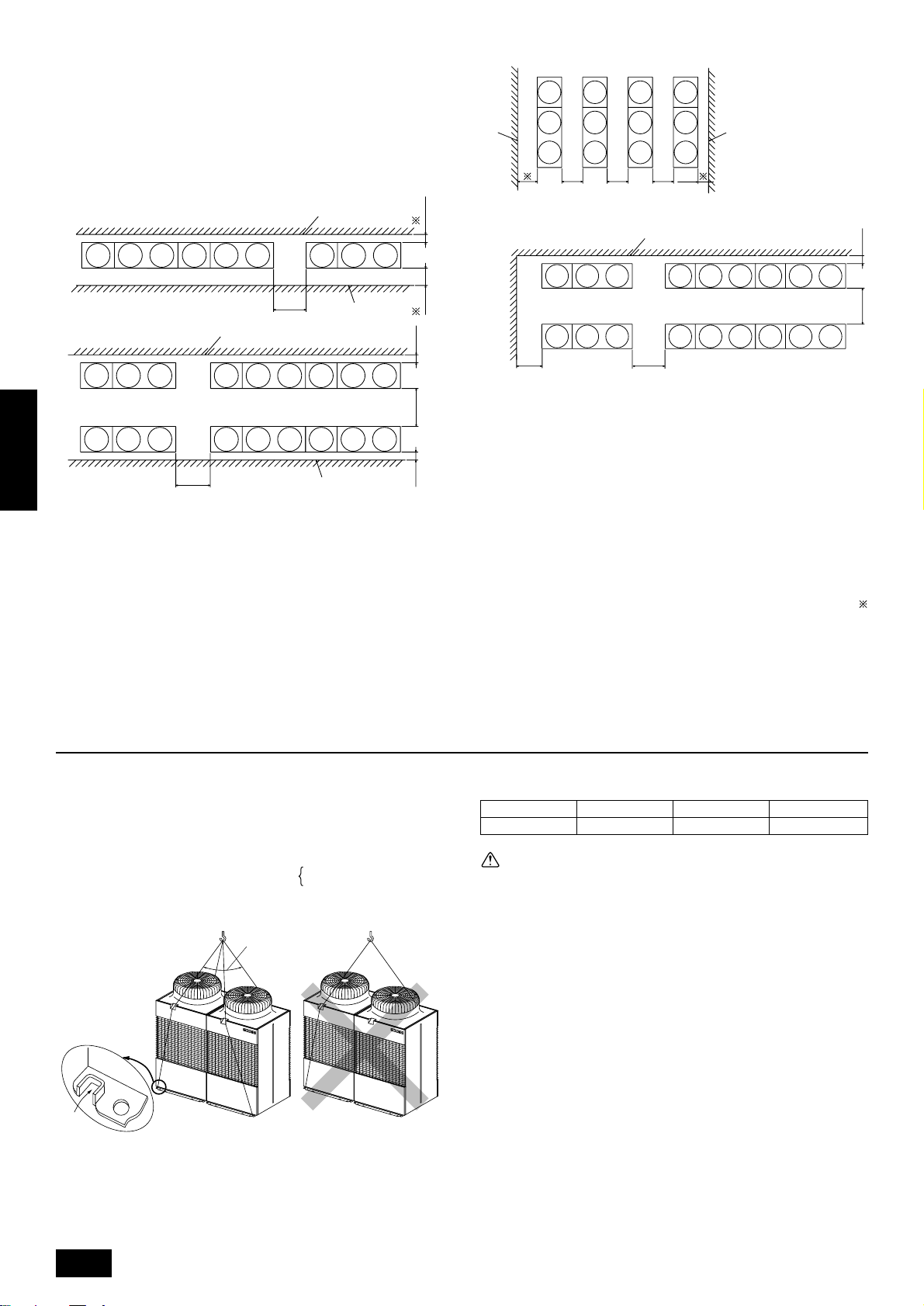

6.2. Collective installation and continu-

D D

B

B

B

A

A

A

CCCC

FEFFF

G

C

C

E

ous installation

Space required for collective installation and continuous installation:

When installing several units, leave the space between each block as

shown below considering passage for air and people.

B

A

A

ENGLISH

D

B

D

A

CC

B

FE

EE

CC

B

G

A

A (Must be open)

B Wall height (H)

C Front

D 1000 mm or more

E 250 mm or more

F 450 mm or more

G 900 mm or more

Note:

• Open in the two directions

• In case wall height (H) exceeds overall height of unit, add “h”

dimension (h=wall height <H> – overall height of unit) to

marked dimension.

• If there is a wall at both the front and the rear of the unit, install

up to three units consecutively in the side direction and provide

a space of 1000 mm or more as inlet space/passage space for

each three units.

7. Lifting method and weight of product

• When carrying the unit suspended, pass the ropes under the unit

and use the two suspension points each at the front and rear.

• Always lift the unit with ropes attached at four points so that impact is

not applied to the unit.

• Attach the ropes to the unit at an angle of 40° or less.

• Use two ropes at least A m long.

B

A 40° or less

B Rope suspension part

A

7 ··· PUHN-P200/250YMF-B

A =

8 ··· PUHY-P400/500YMF-B

Dangerous!

Weight of product:

PUHY-P400 PUHY-P500 PUHN-P200 PUHN-P250

455 kg 475 kg 240 kg 255 kg

Caution:

Be very careful to carry product.

- Do not have only one person to carry product if it is more than 20 kg.

- PP bands are used to pack some products. Do not use them as a

mean for transportation because they are dangerous.

- Do not touch heat exchanger fins with y our bare hands. Otherwise you

may get a cut in your hands.

- Tear plastic packaging bag and scrap it so that children cannot play

with it. Otherwise plastic pac kaging bag may suffocate children to death.

- When carrying in outdoor unit, be sure to support it at four points. Carrying in and lifting with 3-point support may make outdoor unit unstable, resulting in a fall of it.

8

Page 9

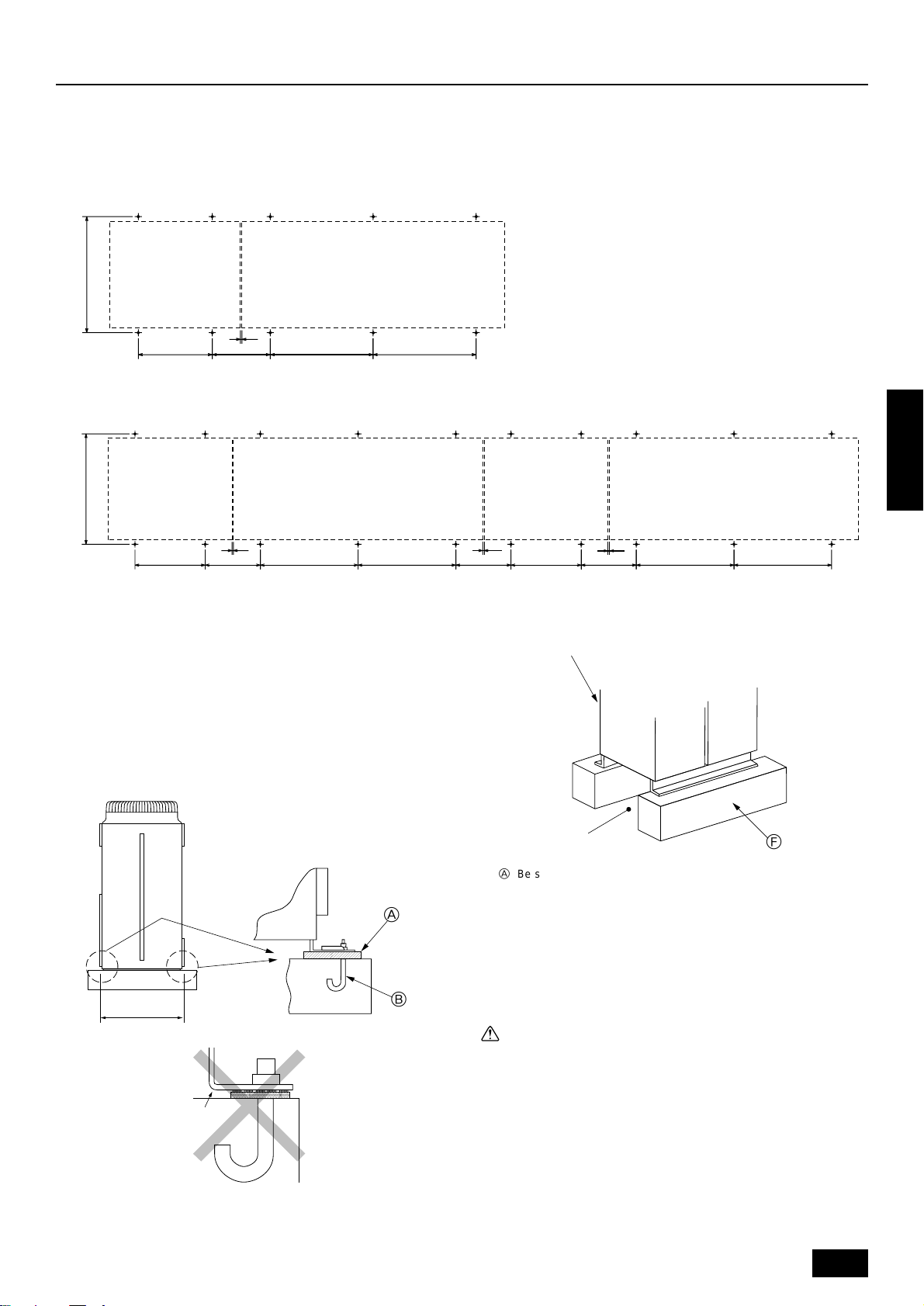

8. Installation of unit

8.1. Location of anchor bolt

Mount the constant capacity unit on the left and variable capacity unit on the right of the same frame (as seen from the front of the unit). Allow

10 mm of clearance between the units.

• Individual installation (Unit: mm)

Constant capacity unit

Constant capacity unit Variable capacity unit

880±5

10

Service side

Service side

• Example of collective installation

Constant capacity unit

Constant capacity unit Variable capacity unit

880±5

10

Variable capacity unit

780±2780±2440560±2

Variable capacity unit

780±2780±2440560±2

8.2. Installation

• Fix unit tightly with bolts as shown below so that unit will not fall down

due to earthquake or gust.

• Use concrete or angle for foundation of unit.

• Vibration may be transmitted to the installation section and noise

and vibration may be generated from the floor and walls, depending

on the installation conditions. Therefore, provide ample

vibrationproofing (cushion pads, cushion frame, etc.).

Constant capacity unit

Constant capacity unit Variable capacity unit

440 780±2780±2440560±2

Service side

Service side

For collective installation, provide a 10 mm gap between units.

1010

Variable capacity unit

D

ENGLISH

880±5

C

A

B

E

A Be sure that the cor ners are firmly seated. If the corners are not firmly

seated, the installation feet may be bent.

B M10 anchor bolt procured at the site.

C Corner is not seated.

D Unit

(Provide ample vibrationproofing between the unit and the foundation by

using cushion pads, cushion frame, etc.)

E Piping and wiring space (bottom piping, bottom wiring)

F Concrete foundation

F

Warning:

• Be sure to install unit in a place strong enough to withstand its

weight.

Any lack of strength may cause unit to fall down, resulting in a

personal injury.

• Have installation work in order to protect against a str ong wind

and earthquake.

Any installation deficiency may cause unit to fall down, resulting in a personal injury.

When building the foundation, give full attention to the floor strength,

drain water disposal <during operation, drain water flows out of the unit>,

and piping and wiring routes.

9

Page 10

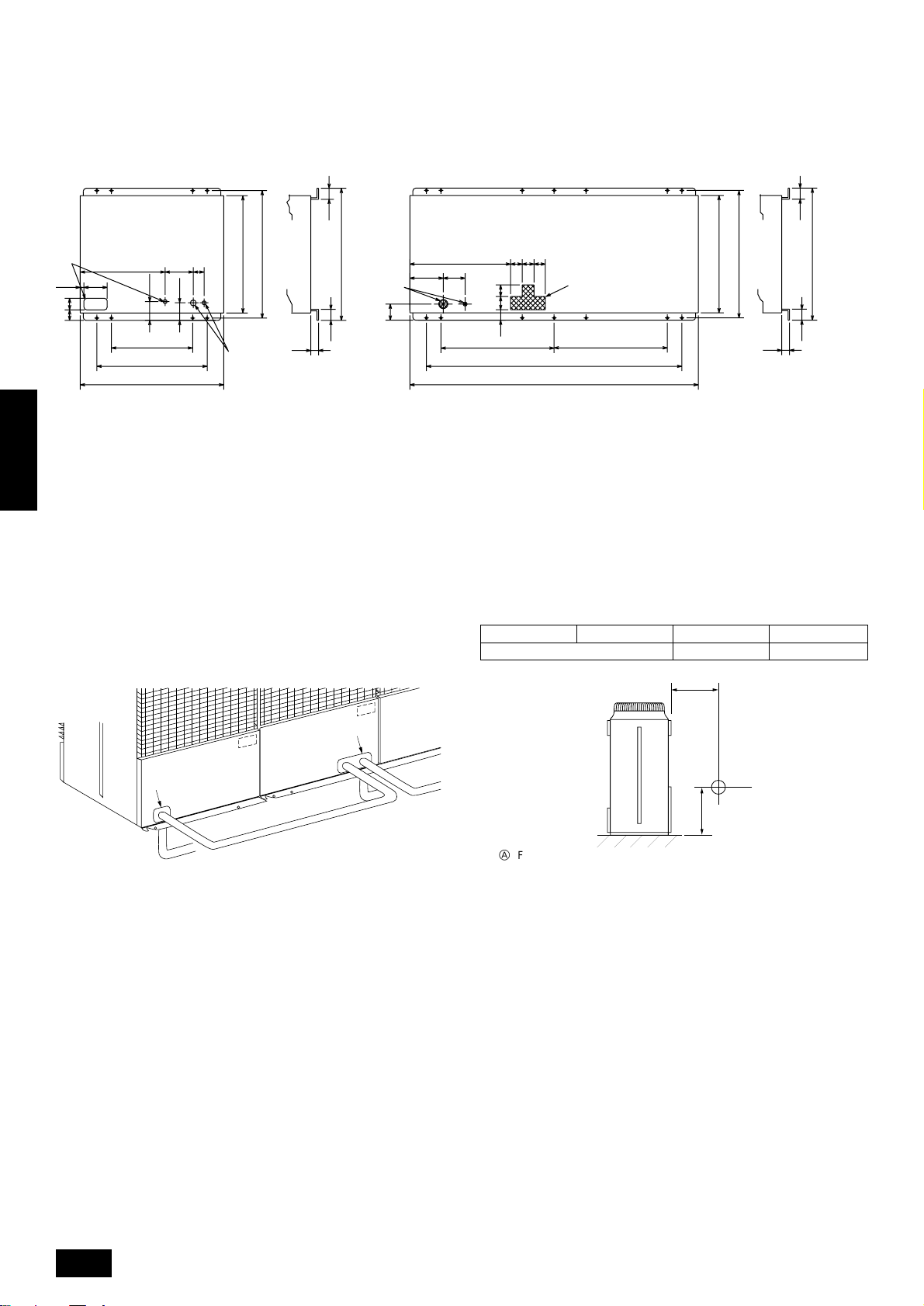

Down piping and down wiring precautions

When down piping and down wiring are performed, be sure that foundation and base work does not block the base through holes. When down

piping is performed, make the foundation at least 150 mm high so that

the piping can pass under the bottom of the unit.

<PUHN-P200/250YMF-B>

55

A

25

8073

ENGLISH

584

160

A Bottom piping through hole

B (bolt hole)

C (bolt hole for old models)

D (unit width)

E (unit depth)

F Bottom wiring through hole

G (bolt hole for packing)

560

760

990

130

B

G

D

194

121

B

75

840E880

F

910

55

15

8.3. Connecting direction for refrigerant

piping

Two connecting directions are available f or refriger ant piping of the outdoor unit, bottom piping and front piping, as shown below:

<PUHY-P400/500YMF-B>

694

150230

F

111

8.4. Noise level

56

788280

B

840E880

910

A

73 90 80

780

B

1760

1990

G

D

780

B

PUHY-P400 PUHY-P500 PUHN-P200 PUHN-P250

60/61 dB (A-weighted)

56 dB (A-weighted) 57 dB (A-weighted)

56

15

(50/60Hz)

A

A

B

A Knock-out hole

B Bottom piping

C Front piping

D Connect piping (to constant capacity unit)

B

D

C

Note:

In the case of bottom piping, build a 100 mm or higher foundation

so that piping will go through the bottom of the unit.

1m

A

1m

B

A Front

B Measuring point

Measuring location: a room free from echoes and reverberations

10

Page 11

9. Caution for snow and seasonal wind

In cold and/or snowy areas, sufficient countermeasures to wind and snow

damages should be taken for operating unit in normal and good condition in winter time. Ev en in the other areas, full consider ation is required

for installation of unit in order to prevent abnormal operations caused by

seasonal wind or snow. When rain and snow directly fall on unit in

the case of air-conditioning operations in 10 or less degrees centigrade outdoor air, mount inlet and outlet ducts on unit for assuring

stable operations.

9.1. Snow and seasonal wind

■ Prevention of wind and snow damages in cold or snowy areas:

Refer to the figure of snow hood shown below:

• Snow hood

<PUHY-P400/500YMF-B>

1093

A

1888

Note:

1. Height of frame base for snow damage prevention (H) shall be

twice as high as expected snowfall. Width of frame base shall

not exceed that of the unit. The frame base shall be made of

angle steel, etc., and designed so that sno w and wind slip through

the structure. (If frame base is too wide, snow will be accumulated on it.)

2. Install unit so that seasonal wind will not directly lash against

openings of inlet and outlet ducts.

3. Build frame base at customer referring to this figure.

Material : Galvanized steel plate 1.2T

Painting : Overall painting with polyester powder

Color : Munsell 5Y8/1 (same as that of unit)

4. When the unit is used in a cold region and the heating operation

is continuously performed for a long time when the outside air

temperature is below freezing, install a heater to the unit base

or take other appropriate measures to prevent water from freezing on the base.

<PUHN-P200/250YMF-B>

1093

888

A

ENGLISH

1145

B

A Outlet

B Inlet

B

500(840)500

(670) 821 903

H

(1990)

1145

B

B

500(840)500

(670) 821 903

H

9.2. Countermeasure to seasonal wind

Referring to the figure shown below, take appropriate measures which

will suit the actual situation of the place for installation.

AA

(990)

A Seasonal wind

11

Page 12

10. Refrigerant piping installation

Connecting the piping is a terminal-branch type in which refrigerant piping from the outdoor unit is branched at the terminal and connected to each of

the indoor units.

The method of connection consists of flare connections at the indoor units, flange connections for the piping of the outdoor unit and flare connections

for the liquid, oil balance piping. Note that the branched sections are brazed.

Warning:

Always use extreme care to prevent the refrigerant gas (R407C) from leaking while using fire or flame. If the refrigerant gas comes in contact

with the flame from any source, such as a gas sto ve, it breaks do wn and generates a poisonous gas which can cause gas poisoning. Ne ver

weld in an unventilated room. Al wa ys conduct an inspection f or gas leakage after installation of the refrigerant piping has been completed.

10.1. Areas of caution

1 Use the following materials for refrigeration piping.

• Material: Seamless phosphorous deoxidized copper pipe, C1220T-OL or C1220T-O (Note: C1220T-OL is preferred).

• Size: Refer to pages 14 to 15.

2 Commercially available piping often contains dust and other materials. Always blow it clean with a dry inert gas.

3 Use care to prevent dust, water or other contaminants from entering the piping during installation.

4 Reduce the number of bending portions as much as possible, and make bending radius as big as possible.

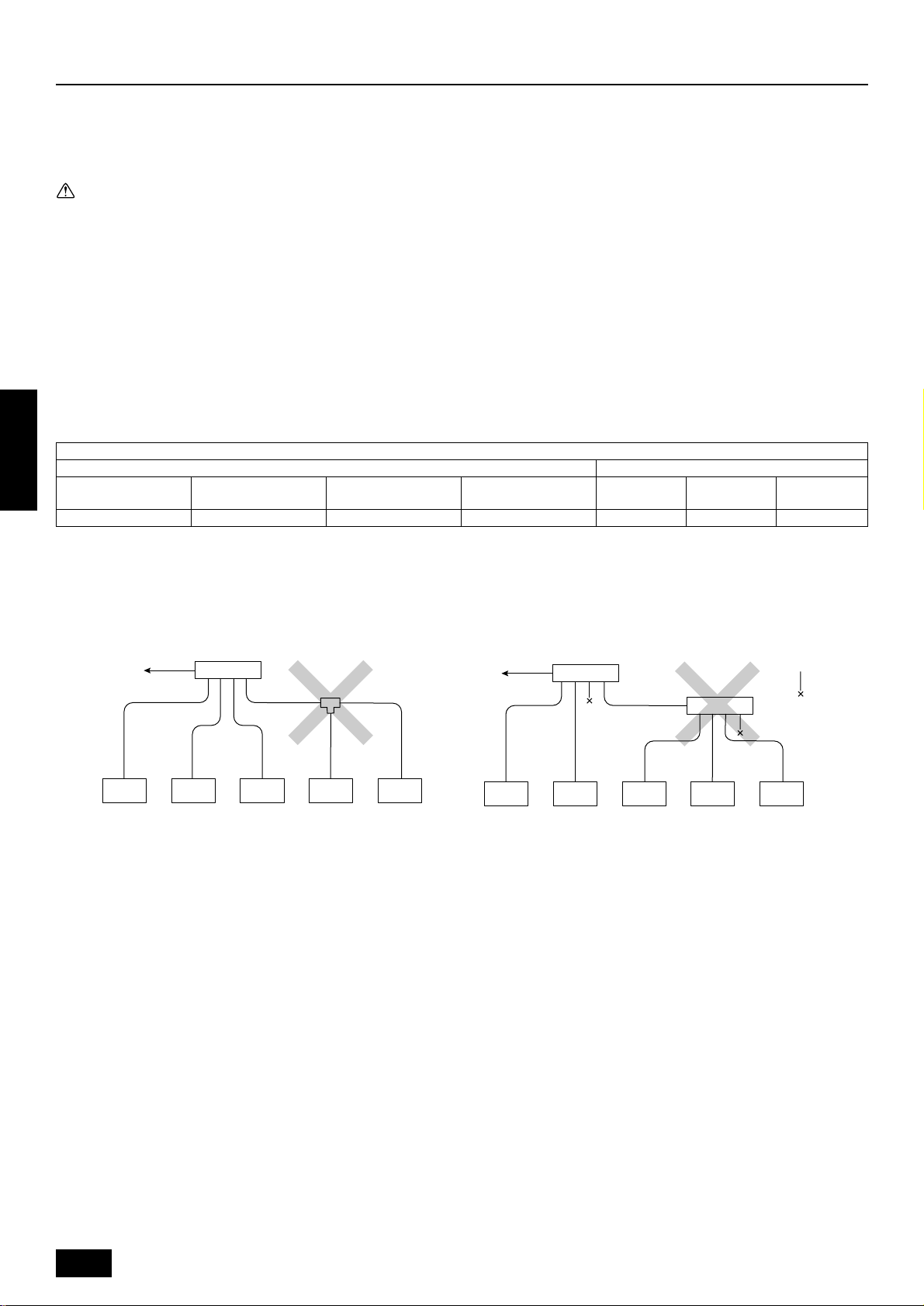

5 Always use the branch piping set shown below , which are sold separ ately. This unit requires a CMC-30A (optional).

Branch pipe set name

Line branching Header branching

Total of units down-

ENGLISH

stream less than 160

CMY-Y102S-F CMY-Y102L-F CMY-Y202-F CMY-Y302-F CMY-Y104-E CMY-Y107-E CMY-Y1010-E

Total of units down-

stream 161 to 330

Total of units downstream

more than 331 to 630

Total of units down-

stream more than 631

4 branching 7 branching 10 branching

6 If the diameters of the branch piping of the designated refrigerant piping differs, use a pipe cutter to cut the connecting section and then use an

adapter for connecting different diameters to connect the piping.

7 Always observe the restrictions on the refrigerant piping (such as rated length, the difference between high/low pressures, and piping diameter).

Failure to do so can result in equipment failure or a decline in heating/cooling performance.

8 A second branch cannot be made after a header branch. (These are shown by ×.)

A

A

B

A To outdoor unit

B Capped piping

9 Always use good-quality materials for brazing.

0 The City Multi Series Super Y will stop due an abnormality due to excessive or insufficient coolant. At such a time, alw a ys properly charge the unit.

When servicing, always check the notes concerning pipe length and amount of additional refrigerant at both locations, the refrigerant volume

calculation table on the back of the service panel and the additional refrigerant section on the labels for the combined number of indoor units (Refer

to pages 14 to 15).

A Use liquid refrigerant to fill the system.

B Never use refrigerant to perform an air purge. Always evacuate using a vacuum pump.

C Always insulate the piping properly. Insufficient insulation will result in a decline in heating/cooling perf ormance, water drops from condensation and

other such problems (Refer to pages 25 to

D When connecting the refrigerant piping, make sure the ball valve of the outdoor unit is completely closed (the factory setting) and do not operate it

until the refrigerant piping for the outdoor and indoor units has been connected, a refrigerant leakage test has been performed and the evacuation

process has been completed.

E Always use a non-oxidizing brazing material for brazing the parts. If a non-oxidizing br azing material is not used, it could cause clogging or damage

to the compressor unit. (Details of the piping connections and valve operation can be found on pages 16 to 20.)

F Never perform outdoor unit piping connection work when it is raining.

26

).

12

Page 13

Warning:

When installing and moving the air conditioner to another site, do not charge the it with a refrigerant different from the refrigerant (R407C)

specified on the unit.

- If a different refrigerant or air is mixed with the original refrigerant, the refrigerant cycle may malfunction and the unit may be damaged.

Caution:

• Use refrigerant piping made of C1220T-OL phosphorus deoxidized copper. In addition, be sure that the inner and outer surfaces of the

pipes are clean and free of hazardous sulphur, oxides, dust/dirt, shaving particles, oils, moisture, or any other contaminant.

- Contaminants on the inside of the refrigerant piping may cause the refrigerant residual oil to deteriorate.

• Use liquid refrigerant for sealing.

- Sealing with gas refrigerant will change the composition of the refrigerant in the cylinder and reduce the unit’s performance.

• Never use existing refrigerant piping.

- The large amount of chlorine in conventional refrigerant and refrigerator oil in the existing piping will cause the new refrigerant to deteriorate.

• Store the piping to be used during installation indoors and keep both ends of the piping sealed until just before brazing.

- If dust, dirt, or water gets into the refrigerant cycle, the oil will deteriorate and the compressor may fail.

• Do not use a charging cylinder.

- Using a charging cylinder may cause the refrigerant to deteriorate.

ENGLISH

13

Page 14

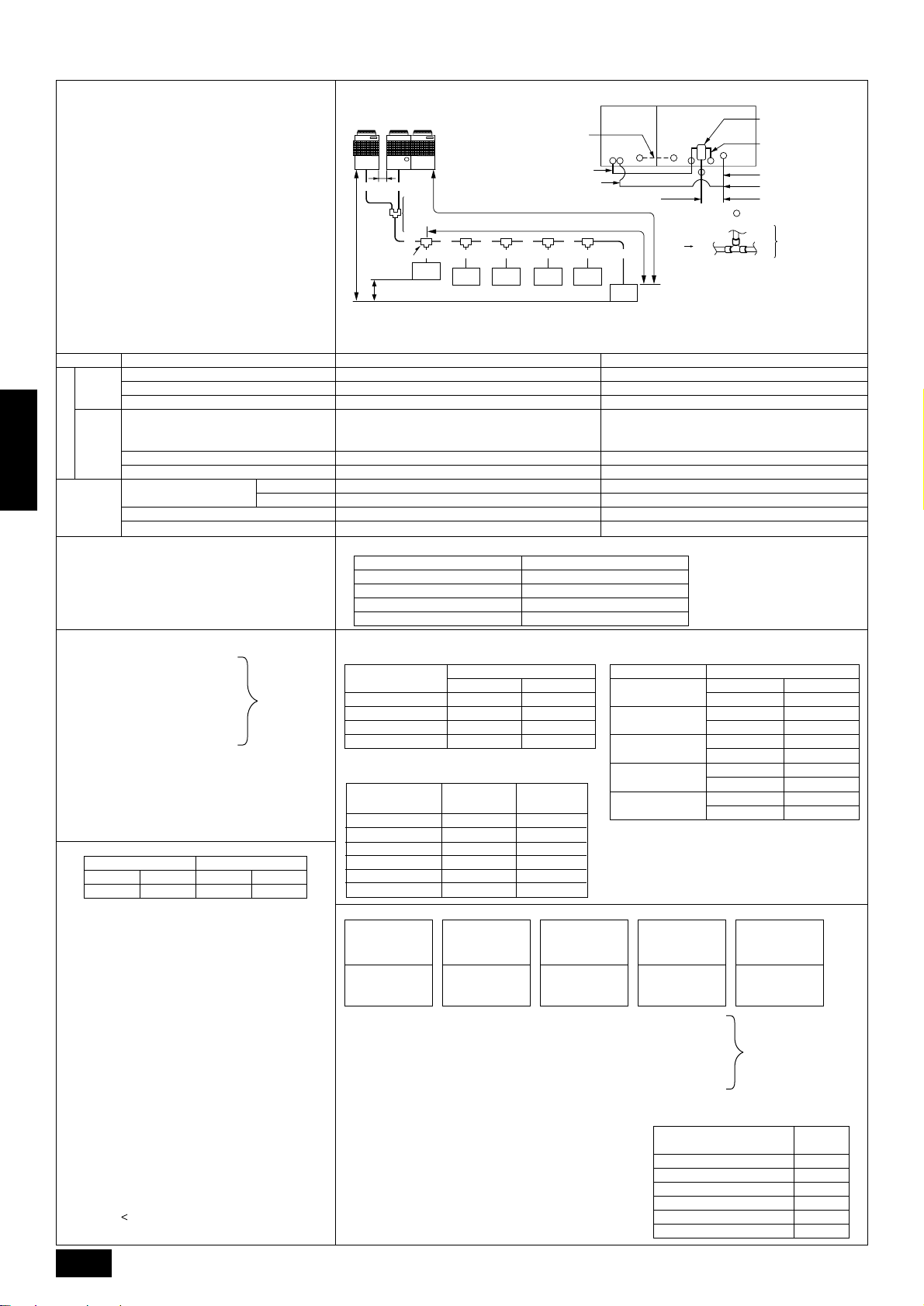

10.2. Refrigerant piping system

A

To down stream units

Liquid line (main) CGas line (main) C

Liquid line B

Gas line B

Gas line A

Distributer (gas) (optional)

Distributer (liguid) (optional)

Liquid line A

Oil balance pipe (optional) I

(for distribution within the unit)

Constant

capacity unit

Variable

capacity unit

:indicates piping connection points

Line-branch method

Connection examples

(connecting to six indoor units)

Indoor

side

Outdoor

side

Permissible length

ENGLISH

Permissible high/

Low difference

■ Selecting the refrigerant branch kit

Use the table to the right to make the selection based

on the model total of indoor units downstream from the

branch section.

■ Select each section of refrigerant piping

(1) Section from outdoor unit to first

branch (C)

(2) Sections from branch to indoor

unit (a, b, c, d, e, f)

(3) Section from branch to branch

(D, E, F, G)

Select the size from the table to the right.

Variable capacity unit Constant capacity unit

■

Additional refrigerant charge

The outdoor unit is charged with refrigerant at the time of shipping according to the chart above. As this charge does not

include the amount needed for extended piping, additional charging for each refrigerant line will be required on site. In order that

future servicing may be properly provided, always keep a record

of the size and length of each refrigerant line and the amount of

additional charge by writing it in the space provided on the outdoor unit.

■

Calculation of additional refrigerant charge

•

Calculate the amount of additional charge based on the length

of the piping extension and the size of the refrigerant line.

•

Use the table to the right as guide to calculating the amount

of additional charging and charge the system according.

•

If the calculation results in a fraction of less than 0.1 kg, round

up to the next 0.1 kg. For example, if the result of the calculation was 23.28 kg, round the result up to 23.3 kg.

•

If the total amount of refrigerant including the amount of refrigerant sealed in the outdoor unit when shipped from the

factor plus additional refrigerant for extension piping e xceeds

73 kg, use 73 kg as the total amount of refrigerant.

Amount of refrigerant when shipped from factory + added

refrigerant

14

Total piping length

Item

Farthest piping length (L)

Farthest piping length after first branch (r)

Oil balance pipe

Distributer (liquid)/Variable capacity unit, Constant capacity unit

Distributer (gas)/Constant capacity unit

Indoor/Outdoor

Outdoor upper

Outdoor lower

Indoor/Indoor

Variable capacity unit/Constant capacity unit

Each section

of piping

(kg)

400 500 200 250

16 22 6.5 8.5

73 kg.

=

Constant

Constant

Constant

capacity unit

capacity unit

H

Note 1: Because it is built into the variable capacity unit, B is used to carry liquid only. Set the constant capacity unit and

Variable

Variable

capacity unit

capacity unit

A B

G

Note 1

Note 1

Distributer

Distributer

(liquid)

(liquid)

Distributer

Distributer

(gas)

(gas)

CG

First branch

First branch

h

acde

oor

Ind

Indoor

unit

unit

1

variable capacity unit in accordance with the G dimension given in the figure above (G = 0.01 m).

Oil balance pipe (optional) I

(for distribution within the unit)

Gas line A

Liquid line A

L

R

D

EF

b

Indoor

Indoor

unit

unit

3

Indoor

Indoor

unit

unit

Indoor

Indoor

unit

unit

245

capacity unit

Gas line (main) C

Indoor

Indoor

unit

unit

Indoor

Indoor

unit

unit

f

6

Variable

capacity unit

Distributer (gas) (optional)

Gas line B

Liquid line B

Distributer (liguid) (optional)

Liquid line (main) C

:indicates piping connection points

To down stream units

Note:

• The model total for downstream units shown

in the table below is the model total when

viewed from Point A in the drawing abo ve.

• With the exception of PUHY -P600YSMF-B,

the first branch is always CMY-Y302-F.

Piping components Tolerance

A+B+C+D+E+F+G+a+b+c+d+e+f 220 m or less

A (B)+C+D+E+F+G+f 100 m or less (Max. equivalent length 125 m)

D+E+F+G+f 40 m or less

The included oil balance pipe must be used. If any other piping is used, the length

I

of the oil balance pipe must be no more than 3 m (max. equivalent length 4 m),

and height from the bottom of the unit must be no more than 0.1 m.

A, B (Liquid line) 4 m or less (Max. equivalent length 5 m)

A (Gas line) 4 m or less (Max. equivalent length 5 m)

H 50 m or less

H 40 m or less

h 15 m or less

–

Must be installed on same frame, and there must be no high/low difference.

Select the branch kit, sold separately , from the tab le below . (Each kit contains a refrigerant and gas piping set.)

Downstream unit model total Branch kit model

160 or less CMY-Y102S-F

161 to 330 CMY-Y102L-F

331 to 630 CMY-Y202-F

631 or more CMY-Y302-F

(1) Refrigerant piping diameter in section from outdoor

unit to first branch (outdoor unit piping diameter)

Model

PUHY-P600YSMF-B

PUHY-P650YSMF-B

PUHY-P700YSMF-B

PUHY-P750YSMF-B

Piping diameter (mm)

Liquid line Gas line

ø19.05 ø38.1

ø19.05 ø44.45

ø19.05 ø44.45

ø19.05 ø44.45

(3) Refrigerant piping diameter in section from

branch to branch

Downstream unit

model total

80 or less

81 to 160

161 to 330

331 to 480

481 to 630

631 or more

Liquid line

(mm)

ø9.52

ø12.7

ø12.7

ø15.88

ø15.88

ø19.05

Gas line

(mm)

ø15.88

ø19.05

ø25.4

ø31.75

ø38.1

ø44.45

(2) Refrigerant piping diameter in section from branch

to indoor unit (indoor unit piping diameter)

Model number Piping diameter (mm)

20 · 25 · 32 · 40

50 · 63 · 71 · 80

100 · 125 · 140

200

250

Liquid line ø6.35

Gas line ø12.7

Liquid line ø9.52

Gas line ø15.88

Liquid line ø9.52

Gas line ø19.05

Liquid line ø12.7

Gas line ø25.4

Liquid line ø12.7

Gas line ø28.58

<Additional charge>

Liquid pipe size

total length of

ø19.05 × 0.29

(m) × 0.29 (kg/m)

<Example> Indoor 1 : 125 A : ø12.7 3 m a :ø9.52 15 m

Liquid pipe size

total length of

ø15.88 × 0.25

+++++ α

(m) × 0.25 (kg/m)

2 : 125 B : ø15.88 1 m b :ø9.52 15 m

Liquid pipe size

total length of

ø12.7 × 0.12

(m) × 0.12 (kg/m)

3 : 125 C : ø19.05 40 m c :ø9.52 10 m

4 : 125 D : ø15.88 10 m d :ø9.52 5 m

5 : 100 E : ø15.88 5 m e :ø9.52 5 m

Liquid pipe size

total length of

ø9.52 × 0.06

(m) × 0.06 (kg/m)

Liquid pipe size

total length of

ø6.35 × 0.024

(m) × 0.024 (kg/m)

At the conditions

below:

6:40 F:ø12.7 5 m f : ø6.35 5 m

The total length of each liquid line is as follows

ø19.05 : C = 40 m

ø15.88 : B + D + E = 1 + 10 + 5 = 16 m

ø12.7 : A + F + G = 3 + 5 + 5 = 13 m

ø9.52 : a + b + c + d + e = 50 m

ø6.35 : f = 5 m

Therefore,

<Calculation example>

Additional

refrigerant charge = 40 × 0.29 +16 × 0.25 + 13 × 0.12 +

50 × 0.06 + 5 × 0.024 + 3.0 = 23.3 kg

G:ø12.7 5 m

Value of α

Total capacity of

connecting indoor units

to Model 80 1.0 kg

Models 81 to 160 1.5 kg

Models 161 to 330 2.0 kg

Models 331 to 480 2.5 kg

Models 481 to 630 3.0 kg

Models 631 or more 4.0 kg

α

Page 15

Multiple line/header

Connection examples

(connecting to six indoor units)

Item

Total piping length

Indoor

Farthest piping length (L)

side

Farthest piping length after first branch (r)

Outdoor

Permissible length

Permissible high/

Low difference

Oil balance pipe

side

Distributer (liquid)/Variable capacity unit, Constant capacity unit

Distributer (gas)/Constant capacity unit

Indoor/Outdoor

Outdoor upper

Outdoor lower

Indoor/Indoor

Variable capacity unit/Constant capacity unit

■ Selecting the refrigerant branch kit

Use the table to the right to make the selection based

on the model total of indoor units downstream from the

branch section or on the number of indoor units to be

connected on the header branch.

■ Select each section of refrigerant piping

(1) Section from outdoor unit to first

branch (C)

(2) Sections from branch to indoor

unit (a, b, c, d, e, f)

Each section

of piping

(3) Section from branch to branch

(D, E, F)

Select the size from the table to the right.

(kg)

Variable capacity unit Constant capacity unit

400 500 200 250

16 22 6.5 8.5

■

Additional refrigerant charge

The outdoor unit is charged with refrigerant at the time of shipping according to the chart above. As this charge does not

include the amount needed for extended piping, additional charging for each refrigerant line will be required on site. In order that

future servicing may be properly provided, always keep a record

of the size and length of each refrigerant line and the amount of

additional charge by writing it in the space provided on the outdoor unit.

■

Calculation of additional refrigerant charge

•

Calculate the amount of additional charge based on the length

of the piping extension and the size of the refrigerant line.

•

Use the table to the right as guide to calculating the amount

of additional charging and charge the system according.

•

If the calculation results in a fraction of less than 0.1 kg, round

up to the next 0.1 kg. For example, if the result of the calculation was 20.03 kg, round the result up to 20.1 kg.

•

If the total amount of refrigerant including the amount of refrigerant sealed in the outdoor unit when shipped from the

factor plus additional refrigerant for e xtension piping exceeds

73 kg, use 73 kg as the total amount of refrigerant.

Amount of refrigerant when shipped from factory + added

refrigerant

73 kg.

=

Constant

Constant

capacity unit

capacity unit

Oil balance pipe (optional) I

Oil balance pipe (optional) I

(for distribution within the unit)

Constant

Constant

capacity unit

capacity unit

H

Note 1: Because it is built into the variable capacity unit, B is used to carry liquid only. Set the constant capacity unit and

Variable

Variable

capacity unit

capacity unit

Note 1

Note 1

BA

G

Distributer

Distributer

(liquid)

(liquid)

Distributer

Distributer

(gas)

(gas)

C F

First branch

First branch

(branch joint)

(branch joint)

D

Branch joint

Branch joint

variable capacity unit in accordance with the G dimension given in the figure above (G = 0.01 m).

Indoor

In door

(for distribution within the unit)

L

R

E

Indoor

Indoor

In door

In door

b

a

unit

unit

unit

unit

12

unit

unit

3

Gas line A

Liquid line A

c

Gas line A

Liquid line A

d

In door

Indoor

unit

unit

4

Gas line (main) C

Branch header

Branch header

e

In door

In door

Indoor

Indoor

unit

unit

5

Variable

Variable

capacity unit

capacity unit

:indicates piping connection points

:indicates piping connection points

A

Note:

• The model total for downstream units

shown in the table below is the model

Cap

f

Cap

total when viewed from Point A in the

drawing above.

With the exception of PUHY-P600YSMF-

•

unit

unit

h

6

B, the first branch is always CMY-Y302-F.

Distributer (gas) (optional)

Distributer (gas) (optional)

Gas line B

Gas line B

Liquid line B

Liquid line B

Distributer (liguid) (optional)

Distributer (liguid) (optional)

Liquid line (main) C

Liquid line (main) CGas line (main) C

To down stream units

To down stream units

Piping components Tolerance

A+B+C+D+E+F+a+b+c+d+e+f 220 m or less

A (B)+C+D+E+c 100 m or less (Max. equivalent length 125 m)

D+E+c 40 m or less

The included oil balance pipe must be used. If any other piping is used, the length

I

of the oil balance pipe must be no more than 3 m (max. equivalent length 4 m),

and height from the bottom of the unit must be no more than 0.1 m.

A, B (Liquid line) 4 m or less (Max. equivalent length 5 m)

A (Gas line) 4 m or less (Max. equivalent length 5 m)

H 50 m or less

H 40 m or less

h 15 m or less

–

Must be installed on same frame, and there must be no high/low difference.

Select the branch kit, sold separately , from the tab le below . (Each kit contains a refrigerant and gas piping set.)

Line branching Header branching

Total of units downstream

less than 160

Total of units downstream

161 to 330

Total of units downstream

331 to 630

Total of units downstream

more than 631

CMY-Y102S-C CMY-Y102L-C CMY-Y202-C CMY-Y302-C

(1) Refrigerant piping diameter in section from out-

door unit to first branch (outdoor unit piping diameter)

Model

PUHY-P600YSMF-B

PUHY-P650YSMF-B

PUHY-P700YSMF-B

PUHY-P750YSMF-B

Piping diameter (mm)

Liquid line Gas line

ø19.05 ø38.1

ø19.05 ø44.45

ø19.05 ø44.45

ø19.05 ø44.45

(2) Refrigerant piping diameter in section from

branch to indoor unit (indoor unit piping diameter)

Model number Piping diameter (mm)

20 · 25 · 32 · 40

50 · 63 · 71 · 80

100 · 125 · 140

(3) Refrigerant piping diameter in section from branch

to branch

Downstream unit model total

Liquid line (mm) Gas line (mm)

80 or less ø9.52 ø15.88

4 branching

header

7 branching

header

CMY-Y104 CMY-Y107 CMY-Y1010

Liquid line ø6.35

Gas line ø12.7

Liquid line ø9.52

Gas line ø15.88

Liquid line ø9.52

Gas line ø19.05

200

250

Liquid line ø12.7

Gas line ø25.4

Liquid line ø12.7

Gas line ø28.58

10 branching

header

81 to 160 ø12.7 ø19.05

161 to 330 ø12.7 ø25.4

331 to 480 ø15.88 ø31.75

481 to 630 ø15.88 ø38.1

631 or more ø19.05 ø44.45

<Additional charge>

Liquid pipe size

total length of

ø19.05 × 0.29

(m) × 0.29 (kg/m)

Liquid pipe size

total length of

ø15.88 × 0.25

+++++ α

(m) × 0.25 (kg/m)

Liquid pipe size

total length of

ø12.7 × 0.12

(m) × 0.12 (kg/m)

Liquid pipe size

total length of

ø9.52 × 0.06

(m) × 0.06 (kg/m)

Liquid pipe size

total length of

ø6.35 × 0.024

(m) × 0.024 (kg/m)

<Example> Indoor 1 : 125 A : ø12.7 3 m a :ø9.52 10 m

2 : 125 B : ø15.88 1 m b :ø9.52 5 m

3 : 125 C : ø19.05 30 m c :ø9.52 5 m

4 : 125 D : ø15.88 10 m d :ø9.52 10 m

At the conditions

below:

5 : 100 E : ø12.7 5 m e :ø9.52 15 m

6:40 F:ø12.7 15 m f :ø6.35 5 m

The total length of each liquid line is as follows

ø19.05 : C = 30 m

ø15.88 : B + D = 1 + 10 = 11 m

ø12.7 : A + E + F = 3 + 5 + 15 = 23 m

ø9.52 : a + b + c + d + e = 10 + 5 + 5 + 10 + 15 = 45 m

ø6.35 : f = 5 m

Therefore,

<Calculation example>

Additional

refrigerant charge = 30 × 0.29 +11 × 0.25 + 23 × 0.12 +

45 × 0.06 + 5 × 0.024 + 3.0 = 20.1 kg

Value of α

Total capacity of

connecting indoor units

to Model 80 1.0 kg

Models 81 to 160 1.5 kg

Models 161 to 330 2.0 kg

Models 331 to 480 2.5 kg

Models 481 or more 3.0 kg

α

ENGLISH

15

Page 16

10.3. Precautions concerning piping connection and valve operation

<For variable capacity unit>

• Connect piping and operate valves e xactly as described in the figure below.

• After performing the following distributor (gas) connection, remove the con-

necting pipe included with the gas ball valve of the variable capacity unit, and

mount the distributor (gas) (optional).

1 When brazing the distributor (gas), braze it outside of the unit before mount-

<When shipped from

the manufacturer>

3

A

^

<After installation>

O

ing on the variable capacity unit.

2 During the time when removing the connecting pipe with flange, remove

the seal attached on the back side of this sheet and paste it onto the flange

surface of the ball valve to prevent the entry of dust into the valve.

3 The refrigerant circuit is closed with a round, close-packed packing at the

shipment to prevent gas leak between flanges. As no operation can be

1

1

B

done under this state, be sure replace the packing with the hollow packing

attached at the piping connection.

4 At the mounting of the hollow packing, wipe off dust attached on the flange

sheet surface and the packing. Coat refrigerating machine oil onto both

1

surfaces of the packing.

• After evacuation and refrigerant charge, ensure that the handle is fully open. If operating with the valve closed, abnormal pressure will be imparted

to the high- or low-pressure side of the refrigerant circuit, or a shortage of oil in the compressor may occur due to lack of oil flow between units, giving

damage to the compressor, four-way valve, etc.

For evacuating, be sure to provide an oil balance pipe between the variable capacity and constant capacity units.

•

• Determine the amount of additional refrigerant charge by using the formula, and charge refrigerant additionally through the service por t after

completing piping connection work.

• After completing work,

ENGLISH

shut the service port and cap tightly so that gas leaking does not occur.

• Connect ball valve piping in the order of (oil balance) → (liquid side) → (gas side).

Ball valve

Ball valve

Ball valve

(liquid side)

(liquid side)

E

Ball valve

(gas side)

(gas side)

E

A

S

3

F

G

H

Ball valve

Ball valve

(oil balance side)

(oil balance side)

E

S

O

ø15.88

To distributor

To distributor

(liquid)

(liquid)

ø12.7

To constant capacity unit

To constant capacity unit

O

S

O

ø28.6

I

(Figure shows valve fully open.)

(Figure shows valve fully open.)

J

S

B

C

D

Warning:

Braze the distributor (gas) outside the unit, before mounting distributor (gas)* to ball valve of the variable capacity unit.

- If brazed while mounted, the ball valve is heated and could result in cracking or gas leaks. The wiring inside the unit could also be burned.

16

Page 17

<For constant capacity unit>

Replace the solid packing.

Hollow packing

S

O

1

3

• Connect piping and operate valves e xactly as described in the figure below.

• Gas side connecting piping is already assembled when the equipment is shipped. (See figure

Replace the solid packing.

on right.)

1 When brazing to connecting pipe with flange, remove the connecting pipe with flange from

the ball valve, and braze at the outside of the unit.

2 During the time when removing the connecting pipe with flange, remove the seal attached

on the back side of this sheet and paste it onto the flange surface of the ball valv e to prev ent

the entry of dust into the valve.

3 The refrigerant circuit is closed with a round, close-packed packing at the shipment to pre-

vent gas leak between flanges. As no operation can be done under this state, be sure re-

Hollow packing

place the packing with the hollow packing attached at the piping connection.

4 At the mounting of the hollow packing, wipe off dust attached on the flange sheet surface

and the packing. Coat refrigerating machine oil onto both surfaces of the packing.

• After evacuation and refrigerant charge, ensure that the handle is fully open. If operating with the valve closed, abnormal pressure will be imparted

to the high- or low-pressure side of the refrigerant circuit, or a shortage of oil in the compressor may occur due to lack of oil flow between units, giving

damage to the compressor, four-w ay valve, etc.

•

For evacuating, be sure to provide an oil balance pipe between the variable capacity and constant capacity units.

• Determine the amount of additional refrigerant charge by using the formula, and charge refrigerant additionally through the service por t after

completing piping connection work.

• After completing work, shut the service port and cap tightly so that gas leaking does not occur.

C

D’

Ball valve

Ball valve

(Gas side)

(gas side)

E

O

Ball valve

Ball valve

(Liquid side)

(liquid side)

E

Ball valve

Ball valve

(Oil balance side)

(oil balance side)

E

The unit is set vertically between

The unit is set vertically between

the compressor and control box.

the compressor and control box.

ENGLISH

A

Fastening plate

S

S

O

MP35K

O

Fastening plate

S

F

ø28.6

G

ø12.7

To distributor

T o distributor

(liquid)

(liquid)

B

H’

To variable capacity unit

To variable capacity unit

ø12.7

To distributor (gas) inside

To distributor (gas) inside

variable capacity unit

variable capacity unit

(Figure shows valve fully open.)

(Figure shows valve fully open.)

Warning:

Be sure to remove the connecting pipe from the ball valve, and braze it outside the unit.

- If brazed while mounted, the ball valve is heated and could result in cracking or gas leaks. The wiring inside the unit could also be burned.

17

Page 18

A Valve stem

[Fully closed at the factory , when connecting the piping, when evacuating,

and when charging additional refrigerant. Open fully after the operations

above are completed.]

B Stopper pin [Prevents the valve stem from turning 90° or more.]

C Packing (accessory)

D Distributer (gas) (option)

[Mount packing (accessory) securely to the valve flange so that gas does

not leak. (screw tightening torque is 43 N·m (430 kg·cm).) Apply a coat of

refrigerating machine oil to both surfaces of the packing.]

D’ Connecting pipe (accessory)

[Use packing and securely install this pipe to the valve flange so that gas

leakage will not occur. (tightening torque: 25 N·m (250 kg·cm)) Coat both

surfaces of the packing with refrigerator oil.]

E Open (operate slowly)

F Cap, copper packing

[Remove the cap and operate the valv e stem. Alwa ys reinstall the cap after

operation is completed. (valve stem cap tightening torque: 25 N·m (250

kg·cm) or more)]

G Service port

[Use this port to evacuate the refrigerant piping and add an additional charge

at the site.

Open and close the port using a double-ended wrench.

Always reinstall the cap after operation is completed. (service port cap

tightening torque: 14 N·m (140 kg·cm) or more)]

H Flare nut

[Tightening torque: 80 N·m (800 kg·cm) ··· liquid, 55 N·m (550 kg·cm) ··· oil

blance

ENGLISH

Loosen and tighten this nut using a double-ended wrench.

Coat the flare contact surface with refrigerator oil.]

H’ Flare nut

[Tightening torque: 55 N·m (550 kg·cm)

Use a double spanner to open and close. Apply a coat of refrigerating

machine oil to the flare bonding surface.]

I ø38.1 (PUHY-P600YSMF-B)

ø44.5 (PUHY-P650/700/750YSMF-B)

J Field piping

[Braze to the connecting pipe. (when brazing, use unoxidized brazing.)]

Appropriate tightening torque by torque wrench

Copper pipe external dia. (mm) Tightening torque (N·m) / (kg·cm)

ø6.35 14 to 18 / 140 to 180

ø9.52 35 to 42 / 350 to 420

ø12.7 50 to 57.5 / 500 to 575

ø15.88 75 to 80 / 750 to 800

ø19.05 100 to 140 / 1000 to 1400

Tightening angle standard

Pipe diameter (mm) Tightening angle (°)

ø6.35, ø9.52 60 to 90

ø12.7, ø15.88 30 to 60

ø19.05 20 to 35

Note:

If a torque wrench is not available, use the following method as a

standard.

When you tighten the flare nut with a wrench, you will reach a point

where the tightening torque will abrupt increase. Turn the flare nut

beyond this point by the angle shown in the table above.

Caution:

• Always remove the connecting pipe from the ball valve and braze

it outside the unit.

- Brazing the connecting pipe while it is installed will heat the ball

valve and cause trouble or gas leakage. The piping, etc. inside the

unit may also be burned.

• Use ester oil, ether oil or alkylbenzene (small amount) as the

refrigerator oil to coat flares and flange connections.

- The refrigerator oil will degrade if it is mixed with a large amount of

mineral oil.

18

Page 19

10.4. Oil balance pipe connection method

• Oil balance piping can be took out from the front, bottom or side of the unit (left side for the variable capacity unit, right side for the constant capacity

unit).

• Connect piping and operate valves exactly as described below (for details, see item 10.3.).

1 After connecting oil balance pipe, be sure to evacuate using the service port of the variable capacity unit side valve.

2 After evacuating, be sure to fully open each valve stem. If you operate with the valve closed, a shortage of oil in the compressor may occur due

to lack of oil flow between units, which could result in damage to the compressor.

3 After completing work, shut the cap of the service port and handle section tightly so that gas leaking does not occur.

Warning:

Failure to connect the oil balance pipe will result in the compressor being damaged.

• Provide 10 mm of clearance between the variable capacity and constant capacity units. Position the v ariable capacity unit so that its front is f acing

on the right side and the constant capacity unit so that its front is facing on the left. Connect the oil balance pipe f or the optional CMC-30A according

to the following procedure.

1 Open the knock-out holes of the left side panel for the variable capacity unit, and the right side panel for the constant capacity unit.

2 After installing the units, flare-connect the piping included with the unit (ø12.7).

3 Block the clearance between units with the 2 seals included with the constant capacity unit.

10 mm (clearance between units)

10 mm (clearance between units)

Right side panel

(Constant capacity unit)

(Constant capacity unit)

Right side panel

Left side panel

Left side panel

(Variable capacity unit)

(Variable capacity unit)

ENGLISH

Control box

Compressor

Compressor

Ball valve (oil balance)

Ball valve (oil balance)

ø12.7 (flare)

ø12.7 (flare)

Oil balance pipe 1 (optional)

Oil balance pipe 1 (optional)

Seal material (2 pieces, included)

Seal material (2 pieces, included)

Through holes for oil balance pipe

Through holes for oil balance pipe

and transmission cables

and transmission cables

• If the oil balance piping for the constant capacity unit from the front of the unit is took out, bend the piping as shown in the figure below . (When doing

so, be careful not to the piping doesn’t touch the compressor or other parts.)

Front panel

Front panel

Knock-out holes for

Knock-out holes for

taking out oil balance pipe

taking out oil balance pipe

from front surface

from front surface

Control box

Compressor

Compressor

Oil balance pipe

Oil balance pipe

(field supply)

(field supply)

Control boxControl box

Control box

Control box

Oil balance pipe 2

Oil balance pipe 2

(optional)

(optional)

Flare connection (2 places)

Flare connection (2 places)

Tightening torque is 55 N·m (550 kg·cm)

Tightening torque is 55 N·m (550 kg·cm).

Open and close using a double

Open and close using a double

spanner. Apply a coat of refrigerating

spanner. Apply a coat of refrigerating

machine oil on both sides of the flare

machine oil on both sides of the flare

contact surface.

contact surface.

Ball valve (oil balance)

Ball valve (oil balance)

ø12.7 (flare)

ø12.7 (flare)

Ball valve (oil balance)

Ball valve (oil balance)

ø12.7 (flare)

ø12.7 (flare)

(Constant capacity unit)

(Constant capacity unit)

Oil balance pipe (Bend piping at the site.)

Oil balance pipe (Bend piping at the site.)

19

Page 20

10.5. Distributor (gas) connection

method

■ Taking out piping from the front direction

(1) Remove the copper cap and rubber packing attached to the pip-

ing and flange of the distributor (gas) (optional).

(2) Assemble outside the unit with the elbow (8) in the specified

shape and braze (see Fig. 1).

For the 600 type, braze the connecting pipe (7) also.

Brazing

Brazing

8Elbow

8

Elbow

7

Connecting pipe

8

Elbow

8Elbow

(3) Braze the connecting pipe (4) and piping assembled in step (2)

to the distributor (gas) so that the connecting pipe is attached as

shown in Fig. 2. For assembly procedure, see Fig. 3. When brazing piping, cool the brazed portion of the distributor side piping

with a dampened waste cloth to prevent heating by brazing.

Flange

Flange

ENGLISH

7Connecting pipe

Fig. 1

■ Taking out piping in the downward direction

(1) Remove the copper cap and rubber packing attached to the pip-

ing and flange of the distributor (gas) (optional).

(2) Assemble outside the unit with the elbow (8), connecting pipe

(7 for 600 type), or connecting pipe (6 for types other than 600)

in the specified shape and braze (see Fig. 4).

Brazing

Brazing

Brazing

Brazing

(3) Braze the connecting pipe (5) and connecting piping assembled

in step (2) to the distributor (gas) outside the unit. For assembly

procedure, see Fig. 5. When brazing piping, cool the braz ed portion of the distributor side piping with a dampened waste cloth to

prevent heating by brazing.

8Elbow

8Elbow

For 600

For 600

For other than 600

For other than 600

Fig. 4

7Connecting pipe

:

: 7Connecting pipe

:

: 6Connecting pipe

6Connecting pipe

4Connecting

Connecting

4

pipe

pipe

Elbow assembly

Elbow assembly

4Connecting pipe

4

Connecting pipe

Flange

Flange

Fig. 2

Distributor (gas)

Distributor (gas)

Fastening plate

Fastening plate

Fastening plate

Fastening plate

Distributor (gas)

Distributor (gas)

5Connecting pile

5

Connecting pile

Flange

Flange

Fastening plate

Fastening plate

Distributor (gas)

Distributor (gas)

Fig. 5

The rest of the procedure is the same as for “Running piping from front

direction.”

Caution:

When brazing, cool with a waste cloth dampened with water so that

the flange and ends of the distributor side piping don’t get heated.

- Part could be damaged if not cooled sufficiently.

Fig. 3

(4) Connect the ø12.7 oil balance pipe to the ball valve of the vari-

able capacity unit (oil balance) and constant capacity unit.

(5) Connect the ø15.88 piping branched by the distributor (liquid) to

the ball valve of the variable capacity unit (liquid side).

(6) Insert the distributor (gas) into the variable capacity unit and con-

nect to the flange of the ball valve (gas side). (Use a socket wrench

and socket wrench extension.) When doing so, be sure to mount

the included packing between the ball valve (gas side) and flange

of the distributor.

(7) Fasten the plate of the distributor (gas) to the frame of the unit

with screws.

(8) Connect and braze the ø44.45 (ø38.1 for 600 type) gas piping

(main pipe) and ø28.58 gas pipe that connects the constant capacity unit with the distributor (gas).

20

Page 21

10.6. How to install branch pipe

For detail, please observe the instruction manual attached to the optional refrigerant branch kit.

■ Joint

C

D

A

A To outdoor unit

B To branch piping or indoor unit

• Apart from the CMY -Y202-F and CMY-Y302-F gas side, there are no

restrictions on the posture for attaching joints.

• Ensure that the branch pipes for the CMY-Y202-F and CMY -Y302-F

gas side are attached horizontally or facing upwards (see the diagram below).

Horizontal Facing upwards

(Facing downwards is not possible)

Within ± 15°

• There is no limitation on the joint mounting configuration.

• If the diameter of the refrigerant piping selected by the procedures

described on pages 14 to 15 is different from the size of the joint,

match the sizes using a deformed joint. The deformed joint is included with the kit.

B

Within ± 15°

Within ± 15°

C Pipe cutter

D or

E Deformed joint

• When the number of pipes to be connected is smaller than the number

of header branches, install a cap to the unconnected branches. The

cap is included with the kit.

■ Distributer (liquid)

Field piping

Field piping

Variable

Variable

capacity unit

capacity unit

• Mount the distributor (liquid, optional CMC-30A) so that it is within

±15° in relation to the horizontal plane (see figure above).

Constant

Constant

capacity unit

capacity unit

E

±15°

ENGLISH

■ Header

A

B

A To outdoor unit

B To indoor unit

• No restriction is applied to the mounting posture of the header.

• If the diameter of the refrigerant piping selected using the proce-