Page 1

Air-Conditioners

geprgeprüftefte

SicherheitSicherheit

OUTDOOR UNIT

PUHY-P-YMF-B

FOR INSTALLER

FÜR INSTALLATEURE

POUR L’INSTALLATEUR

VOOR DE INSTALLATEUR

PER L’INSTALLAT ORE

INSTALLATION MANU AL

For safe and correct use, please read this installation manual thoroughly before installing the air-conditioner unit.

∗ Remote controller (PAR-F25MA) is available as an optional remote controller.

INSTALLATIONSHANDBUCH

Zum sicheren und ordnungsgemäßen Gebrauch der Klimageräte das Installationshandbuch gründlich durchlesen.

∗ Fernbedienung (PAR-F25MA) ist als Zubehör wahlweise erhältlich.

ENGLISH

DEUTSCH

FRANÇAIS

MANUEL D’INSTALLATION

Veuillez lire le manuel d’installation en entier avant d’installer ce climatiseur pour éviter tout accident et vous assurer d’une utilisation

correcte.

∗ La télécommande (PAR-F25MA) est disponible en option.

INSTALLATIEHANDLEIDING

Voor een veilig en juist gebruik moet u deze installatiehandleiding grondig doorlezen voordat u de airconditioner installeert.

∗ De afstandsbedieningseenheid (PAR-F25MA) is verkrijgbaar als een optioneel toe te voegen afstandsbediening.

MANUALE DI INSTALLAZIONE

Per un uso sicuro e corretto, leggere attentamente questo manuale di installazione prima di installare il condizionatore d’aria.

∗ Il comando a distanza (modello PAR-F25MA) disponibile in opzione.

NEDERLANDS

ITALIANO

Page 2

Contents

1. Safety precautions ...................................................................... 3

1.1. Before installation and electric work ............................... 3

1.2. Precautions for devices that use R407C refrigerant.......3

1.3. Before getting installed ................................................... 4

1.4. Before getting installed (moved) - electrical work ........... 4

1.5. Before starting the test run ............................................. 4

2. Combination with indoor units..................................................... 5

3. Confirmation of parts attached ................................................... 5

4. Combination with outdoor units ................................................... 6

5. Selection of installation site ........................................................ 6

6. Space required around unit ........................................................ 6

6.1. Individual installation ...................................................... 6

6.2. Collective installation and continuous installation........... 7

7. Lifting method and weight of product.......................................... 8

8. Installation of unit........................................................................ 8

8.1. Location of anchor bolt ................................................... 8

8.2. Installation ...................................................................... 9

8.3. Connecting direction for refrigerant piping.................... 10

ENGLISH

8.4. Noise level .................................................................... 10

9. Caution for snow and seasonal wind ........................................ 11

9.1. Snow and seasonal wind.............................................. 11

9.2. Countermeasure to seasonal wind ............................... 11

10. Refrigerant piping installation.................................................. 11

10.1. Areas of caution .......................................................... 12

10.2. Refrigerant piping system ........................................... 13

10.3. Caution for piping connection/valve operation ............ 15

10.4. How to install branch pipe ........................................... 16

10.5. Airtight test and evacuation, refrigerant charging........ 18

10.6. Thermal insulation of refrigerant piping....................... 21

11. Electrical work ......................................................................... 23

11.1. Caution........................................................................ 23

11.2. Control box and connecting position of wiring............. 24

11.3. Wiring transmission cables ......................................... 25

11.4. Wiring of main power supply and equipment

capacity ....................................................................... 31

12. Test run.................................................................................... 32

12.1. Checking before getting test run ................................. 32

12.2. Test run method .......................................................... 32

12.3. How to cope with test run abnormality ........................ 33

12.4. Coping with remote controller abnormality.................. 35

12.5. The following phenomena do not represent

abnormality (emergency) ............................................ 36

2

Page 3

1. Safety precautions

1.1. Before installation and electric work

s Before installing the unit, make sure you read all the

“Safety precautions”.

s The “Safety precautions” provide very important

points regarding safety. Make sure you follow them.

s This equipment may not be applicable to EN61000-3-

2: 1995 and EN61000-3-3: 1995.

s This equipment may cause the adverse effect on the

same supply system.

s Please report to or take consent by the supply author-

ity before connection to the system.

Symbols used in the text

Warning:

Describes precautions that should be observed to prevent danger

of injury or death to the user.

Caution:

Describes precautions that should be observed to prevent damage

to the unit.

Symbols used in the illustrations

: Indicates an action that must be avoided.

: Indicates that important instructions must be followed.

: Indicates a part which must be grounded.

: Indicates that caution should be taken with rotating parts. (This

symbol is displayed on the main unit label.) <Color: Yellow>

: Indicates that the main switch must be turned off before servicing.

(This symbol is displayed on the main unit label.) <Color: Blue>

: Beware of electric shock. (This symbol is displayed on the main

unit label.) <Color: Yellow>

: Beware of hot surface. (This symbol is displayed on the main unit

label.) <Color: Yellow>

: Please pay attention to electric shock fully because this is

ELV

not Safety Extra Low-Voltage (SELV) circuit.

And at servicing, please shut down the power supply for both

of Indoor Unit and Outdoor Unit.

Warning:

Carefully read the labels affixed to the main unit.

Warning:

• Ask the dealer or an authorized technician to install the air conditioner.

- Improper installation by the user ma y result in water leakage, elec-

tric shock, or fire.

• Install the air unit at a place that can withstand its weight.

- Inadequate strength may cause the unit to fall down, resulting in

injuries.

• Use the specified cables for wiring. Make the connections securely so that the outside force of the cable is not applied to the

terminals.

- Inadequate connection and fastening may gener ate heat and cause

a fire.

• Prepare for typhoons and other strong winds and earthquakes

and install the unit at the specified place.

- Improper installation may cause the unit to topple and result in in-

jury.

• Always use an air cleaner, humidifier, electric heater, and other

accessories specified by Mitsubishi Electric.

- Ask an authorized technician to install the accessories. Improper

installation by the user may result in water leakage, electric shock,

or fire.

• Never repair the unit. If the air conditioner must be repaired,

consult the dealer.

- If the unit is repaired improperly, water leakage, electric shock, or

fire may result.

• Do not touch the heat exchanger fins.

- Improper handling may result in injury.

• If refrigerant gas leaks during installation work, ventilate the

room.

- If the refrigerant gas comes into contact with a flame, poisonous

gases will be released.

• Install the air conditioner according to this Installation Manual.

- If the unit is installed improperly, water leakage, electric shock, or

fire may result.

• Have all electric work done by a licensed electrician according

to “Electric Facility Engineering Standard” and “Interior Wire

Regulations”and the instructions given in this manual and always use a special circuit.

- If the power source capacity is inadequate or electric work is per-

formed improperly, electric shock and fire may result.

• Securely install the outdoor unit terminal cover (panel).

- If the terminal cover (panel) is not installed properly, dust or water

may enter the outdoor unit and fire or electric shock may result.

• When installing and moving the air conditioner to another site,

do not charge the it with a refrigerant different from the refrigerant (R407C) specified on the unit.

- If a different refrigerant or air is mixed with the original refrigerant,

the refrigerant cycle may malfunction and the unit may be damaged.

• If the air conditioner is installed in a small room, measures must

be taken to prevent the refrigerant concentration from exceeding the safety limit even if the refrigerant should leak.

- Consult the dealer regarding the appropriate measures to prevent

the safety limit from being exceeded. Should the refrigerant leak

and cause the safety limit to be exceeded, hazards due to lack of

oxygen in the room could result.

• When moving and reinstalling the air conditioner, consult the

dealer or an authorized technician.

- If the air conditioner is installed improperly, water leakage, electric

shock, or fire may result.

• After completing installation work, make sure that refrigerant

gas is not leaking.

- If the refrigerant gas leaks and is exposed to a fan heater, stove,

oven, or other heat source, it may generate noxious gases.

• Do not reconstruct or change the settings of the protection devices.

- If the pressure switch, thermal switch, or other protection de vice is

shorted and operated forcibly, or parts other than those specified

by Mitsubishi Electric are used, fire or explosion may result.

• To dispose of this product, consult your dealer.

• The installer and system specialist shall secure safety against

leakage according to local regulation or standards.

- Following standards may be applicable if local regulation are not

available.

• Pay a special attention to the place, such as a basement, etc.

where refrigeration gas can stay, since refrigeration is heavier

than the air.

1.2. Precautions for devices that use

R407C refrigerant

Caution:

• Do not use the existing refrigerant piping.

- The old refrigerant and refrigerator oil in the existing piping con-

tains a large amount of chlorine which may cause the refrigerator

oil of the new unit to deteriorate.

• Use refrigerant piping made of C1220 (CU-DHP) phosphorus

deoxidized copper as specified in the JIS H3300 “Copper and

copper alloy seamless pipes and tubes”. In addition, be sure

that the inner and outer surfaces of the pipes are clean and free

ENGLISH

3

Page 4

of hazardous sulphur, oxides, dust/dirt, shaving particles, oils,

moisture, or any other contaminant.

- Contaminants on the inside of the refrigerant piping may cause the

refrigerant residual oil to deteriorate.

• Store the piping to be used during installation indoors and keep

both ends of the piping sealed until just before brazing. (Store

elbows and other joints in a plastic bag.)

- If dust, dirt, or water enters the refrigerant cycle, deterioration of

the oil and compressor trouble may result.

• Use ester oil, ether oil or alkylbenzene (small amount) as the

refrigerator oil to coat flares and flange connections.

- The refrigerator oil will degrade if it is mixed with a large amount of

mineral oil.

• Use liquid refrigerant to fill the system.

- If gas refrigerant is used to seal the system, the composition of the

refrigerant in the cylinder will change and performance may drop.

• Do not use a refrigerant other than R407C.

- If another refrigerant (R22, etc.) is used, the chlorine in the refriger-

ant may cause the refrigerator oil to deteriorate.

• Use a vacuum pump with a reverse flow check valve.

- The vacuum pump oil may flow back into the refrigerant cycle and

cause the refrigerator oil to deteriorate.

• Do not use the following tools that are used with conventional

refrigerants.

(Gauge manifold, charge hose, gas leak detector, reverse flow

check valve, refrigerant charge base, vacuum gauge, refrigerant recovery equipment)

- If the conventional refrigerant and refrigerator oil are mixed in the

ENGLISH

R407C, the refrigerant may deteriorated.

- If water is mixed in the R407C, the refrigerator oil may deteriorate.

- Since R407C does not contain any chlorine, gas leak detectors for

conventional refrigerants will not react to it.

• Do not use a charging cylinder.

- Using a charging cylinder may cause the refrigerant to deteriorate.

• Be especially careful when managing the tools.

- If dust, dirt, or water gets in the refrigerant cycle, the refrigerant

may deteriorate.

1.3. Before getting installed

Caution:

• Do not install the unit where combustible gas may leak.

- If the gas leaks and accumulates around the unit, an explosion

may result.

• Do not use the air conditioner where food, pets, plants, precision instruments, or artwork are kept.

- The quality of the food, etc. may deteriorate.

• Do not use the air conditioner in special environments.

- Oil, steam, sulfuric smoke, etc. can significantly reduce the per-

formance of the air conditioner or damage its parts.

• When installing the unit in a hospital, communication station,

or similar place, provide sufficient protection against noise.

- The inverter equipment, private power generator, high-frequency

medical equipment, or radio communication equipment may cause

the air conditioner to operate erroneously , or f ail to operate. On the

other hand, the air conditioner may affect such equipment by creating noise that disturbs medical treatment or image broadcasting.

• Do not install the unit on a structure that may cause leakage.

- When the room humidity exceeds 80% or when the drain pipe is

clogged, condensation may drip from the indoor unit. Perform collective drainage work together with the outdoor unit, as required.

1.4. Before getting installed (moved) -

electrical work

Caution:

• Ground the unit.

- Do not connect the ground wire to gas or water pipes, lightning

rods, or telephone ground lines. Improper grounding may result in

electric shock.

• The reverse phase of L lines (L

cord : 4103), but the reverse phase of L lines and N line can be

not be detected.

- The some electric parts should be damaged when power is sup-

plied under the miss wiring.

• Install the power cable so that tension is not applied to the cable.

- Tension may cause the cable to break and generate heat and cause

a fire.

• Install an leak circuit breaker, as required.

- If an leak circuit breaker is not installed, electric shock may result.

• Use power line cables of sufficient current carrying capacity

and rating.

- Cables that are too small may leak, generate heat, and cause a

fire.

• Use only a circuit breaker and fuse of the specified capacity.

- A fuse or circuit breaker of a larger capacity or a steel or copper

wire may result in a general unit failure or fire.

• Do not wash the air conditioner units.

- Washing them may cause an electric shock.

• Be careful that the installation base is not damaged by long use.

- If the damage is left uncorrected, the unit may fall and cause per-

sonal injury or property damage.

• Install the drain piping according to this Installation Manual to

ensure proper drainage. Wrap thermal insulation around the

pipes to prevent condensation.

- Improper drain piping may cause water leakage and damage to

furniture and other possessions.

• Be very careful about product transportation.

- Only one person should not carry the product if it weighs more than

20 kg.

- Some products use PP bands for packaging. Do not use any PP

bands for a means of transportation. It is dangerous.

- Do not touch the heat exchanger fins. Doing so may cut your fin-

gers.

- When transporting the outdoor unit, suspend it at the specified po-

sitions on the unit base. Also support the outdoor unit at four points

so that it cannot slip sideways.

• Safely dispose of the packing materials.

- Packing materials, such as nails and other metal or wooden parts,

may cause stabs or other injuries.

- Tear apart and throw a way plastic packaging bags so that children

will not play with them. If children pla y with a plastic bag which was

not torn apart, they face the risk of suffocation.

1, L2, L3) can be detected (Error

1.5. Before starting the test run

Caution:

• Turn on the power at least 12 hours before starting operation.

- Starting operation immediately after turning on the main power

switch can result in severe damage to internal parts. Keep the pow er

switch turned on during the operational season.

• Do not touch the switches with wet fingers.

- Touching a switch with wet fingers can cause electric shock.

• Do not touch the refrigerant pipes during and immediately after

operation.

- During and immediately after operation, the refrigerant pipes are

may be hot and may be cold, depending on the condition of the

refrigerant flowing through the refrigerant piping, compressor, and

other refrigerant cycle parts. Your hands may suffer burns or frostbite if you touch the refrigerant pipes.

• Do not operate the air conditioner with the panels and guards

removed.

- Rotating, hot, or high-voltage parts can cause injuries.

• Do not turn off the power immediately after stopping operation.

- Alwa ys wait at least five minutes before turning off the power. Oth-

erwise, water leakage and trouble may occur.

4

Page 5

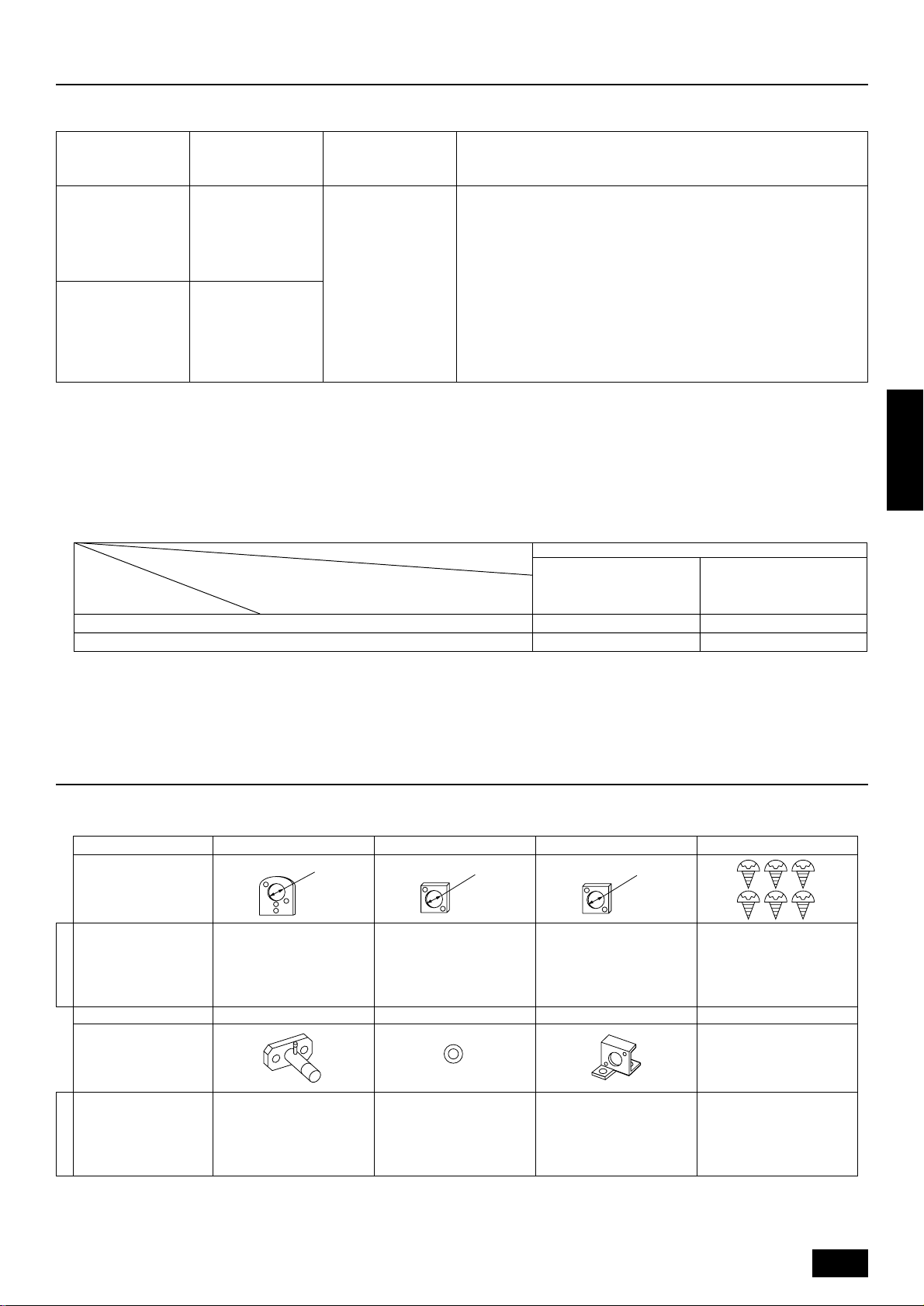

2. Combination with indoor units

The indoor units connectable to this unit are shown below.

Outdoor unit model

name

Note:

1. The total capacity of connected indoor unit models represents the total sum of the figures expressed in the indoor model name.

2. Combinations in which the total capacity of the connected indoor units exceeds the capacity of the outdoor unit will reduce the capacity

of each indoor unit below the rated capacity during simultaneous operation. Therefore, if circumstances allows, combine indoor units

within the capacity of the outdoor unit.

3. A transmission booster (RP) is required when the number of connected indoor unit models in a cooling system exceeds the number of

models specified in the chart below.

* The maximum number of units that can be controlled is determined by the indoor unit model, the type of remote controller and their

capabilities.

(*1)

Capability of the

connected indoor units

*1 If even one unit that is higher than 200 exists in the cooling system, the maximum capacity will be “200 or higher”.

Total capacity of

connected indoor unit

models

200 to 520PUHY-P400

250 to 650PUHY-P500

Number of connected indoor units that can be

connected without a RP.

200 or lower

200 or higher

Quantity of connectable

indoor unit

PMFY-P25 · 32 · 40 · 63 VBM

PLFY- P32· 40 · 50 · 63 · 80 · 100 · 125 VKM

PLFY- P25· 32 · 40 · 50 · 63 · 80 · 100 · 125 VLMD

PEFY-P25 · 32 VML

2 to 20

Remote controller type

The number of indoor units and the total number of remote controllers is displayed within the parenthesis ( ).

PEFY-P40 · 50 · 63 · 71 · 80 · 100 · 125 · 140 · 200 · 250 VMH

PCFY-P40· 63 · 100 · 125 VGM

PKFY-P25 VAM

PKFY-P32 · 40 · 50 VGM

PFFY- P25 · 32 · 40 · 50 · 63 VLEM

PFFY- P25 · 32 · 40 · 50 · 63 VLRM

PDFY-P25· 32 · 40 · 50 · 63 · 71 · 80 · 100 · 125 VM

Model name of connectable indoor unit

Remote controller PAR-F 25MA

Prior to Ver. E After Ver. F

16 (32) 20 (40)

16 (32) 16 (32)

ENGLISH

3. Confirmation of parts attached

This outdoor unit is attached with the parts below. Please check the quantity for each item.

Name 1 Conduit mounting plate 2 Conduit mounting plate 3 Conduit mounting plate 4 Tapping screw M4 × 10

PUHY-P400

PUHY-P500

Model name

PUHY-P400

PUHY-P500

Model name

ø62

Shape

1116

Name 5 Connecting pipe 6 Packing 7 Wire mounting plate

Shape

inside ø29, outside ø39

111

ø53

ø46

*5 Connecting pipe is fixed with the unit.

5

Page 6

C

C

D

A

A

B

Hh

B

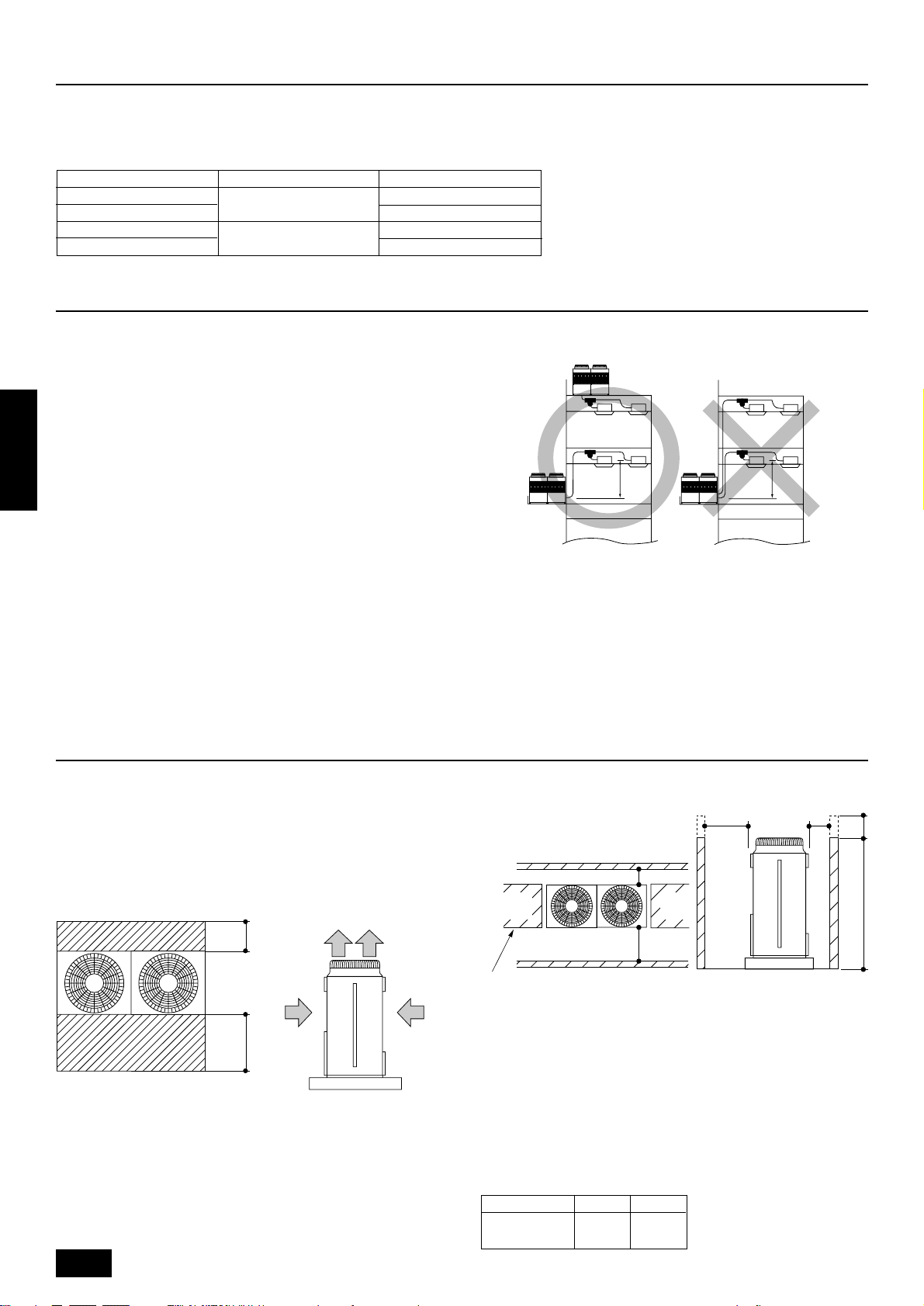

4. Combination with outdoor units

A Super Y (PUHY-P600/650/700/750YSMF-B) is produced when a Constant Capacity Unit (PUHN-P200/250YMF-B) is combined with this unit (PUHYP400/500YMF-B).

Refer to the installation manual that comes with the Constant Capacity Unit when this unit is used as a Super Y.

Super Y

PUHY-P600YSMF-B

PUHY-P650YSMF-B

PUHY-P700YSMF-B

PUHY-P750YSMF-B

Variable capacity unit

PUHY-P400YMF-B

PUHY-P500YMF-B

Constant capacity unit

PUHN-P200YMF-B

PUHN-P250YMF-B

PUHN-P200YMF-B

PUHN-P250YMF-B

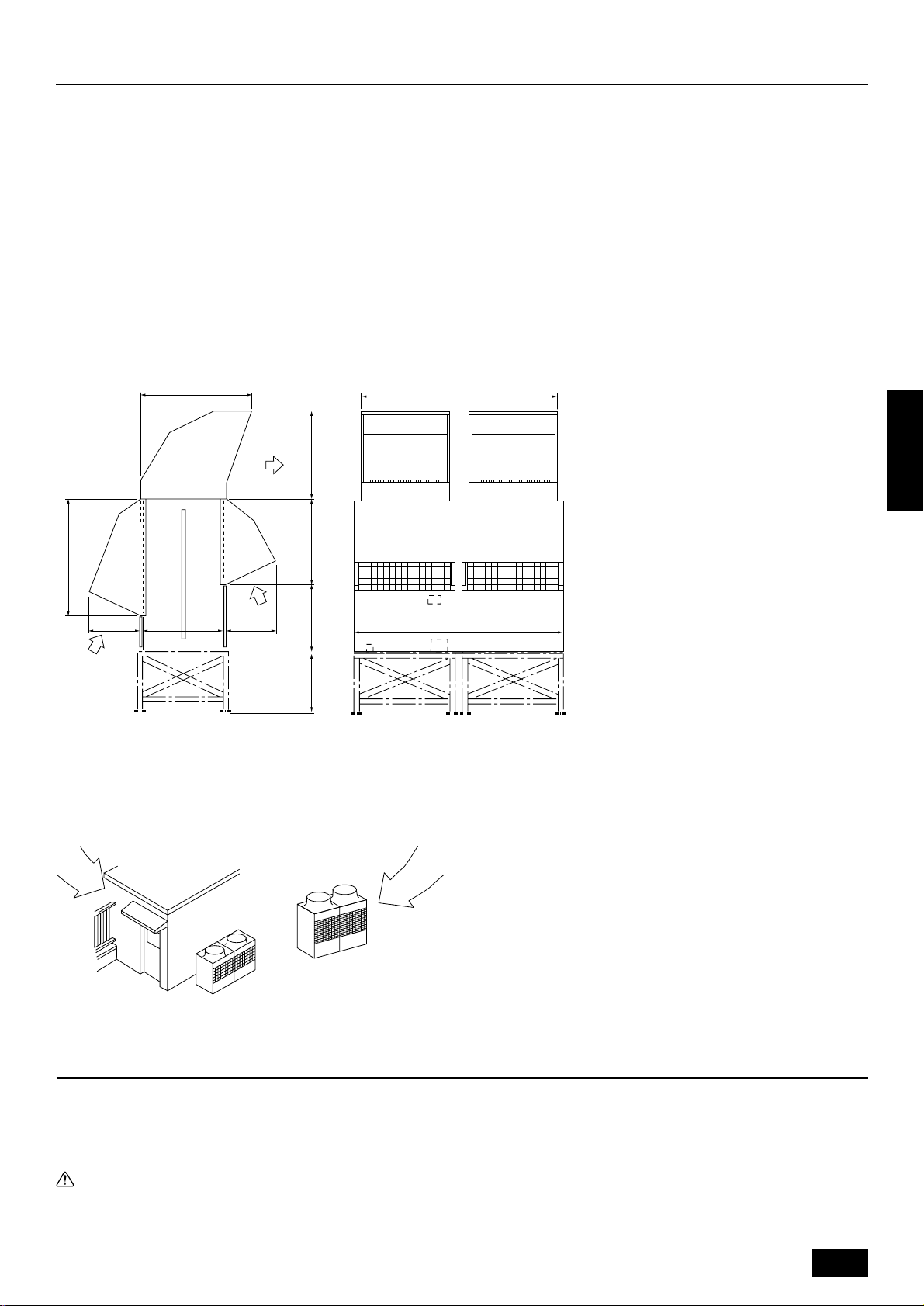

5. Selection of installation site

Select space for installing outdoor unit, which will meet the following

conditions:

• no direct thermal radiation from other heat sources

• no possibility of annoying neighbors by noise from unit

• no exposition to strong wind

• with strength which bears weight of unit

• note that drain flows out of unit when heating

• with space for air passage and service work shown below

Because of the possibility of fire, do not install unit to the space where

ENGLISH

generation, inflow, stagnation, and leak of combustible gas is expected.

• Avoid unit installation in a place where acidic solution and spra y (sulfur)

are often used.

• When having cooling operation at an outside air temperature of below 10°C, in order to obtain steady operation of unit, select an installation site not exposed directly to rain and snow, or install air outlet

and inlet ducts. (Refer to Page 11.) Install the outdoor unit at the

same position on the same floor, or above, the indoor unit. (See the

figure at the right.)

• Do not use unit in any special environment where oil, steam and

sulfuric gas exist.

6. Space required around unit

Installation restriction on outdoor unit when cooling operation is performed

when the outdoor air temperature is 10°C or lower

A

(Same floor as indoor unit, or floor above)

A 4 m or less

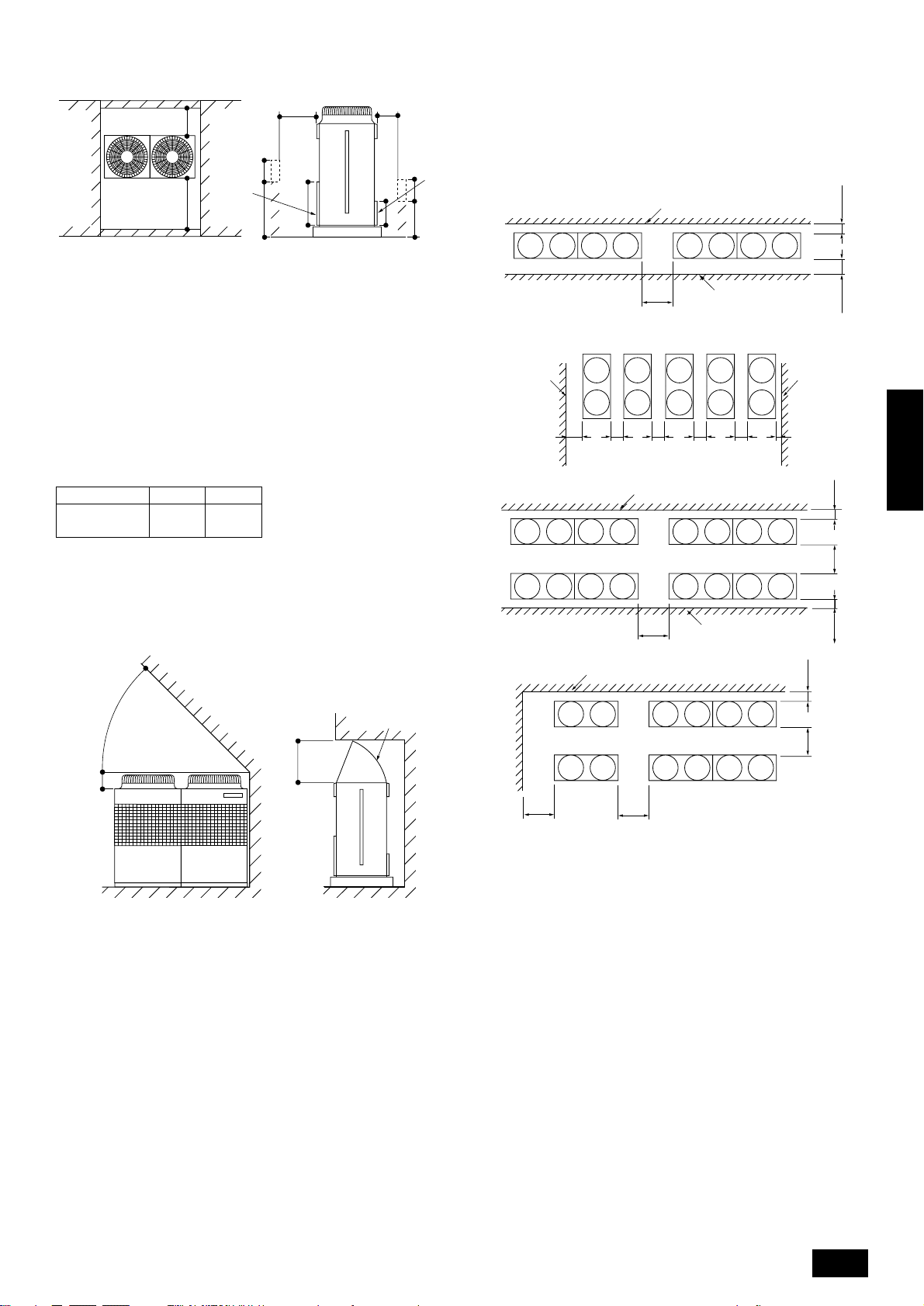

6.1. Individual installation

Basic space required

A space of at least 250 mm is necessary at the back for inlet air. Taking

servicing, etc. from the rear into account, a space of about 450 mm

should be provided, the same as at the front.

D

A

FE

B

C

<Top view> <Side view>

A 250 mm or more

B 450 mm or more

C Front (outside of machine room)

D Top discharge (open in principle)

E Front inlet (open in principle)

F Rear inlet (open in principle)

6

When inlet air enters from right and left sides of unit

<Side view>

A L1 or more

B L

2 or more

C Front

D No restrictions on wall height (left and right)

Note:

• Wall heights (H) of the front and the back sides shall be within

overall height of unit.

• When the total height is exceeded, add the “h” dimension of the

figure above to L1 and L2 in the table above.

Model L1 L2

PUHY-P400

PUHY-P500

450 250

Page 7

When unit is surrounded by walls

B

A

D

A

C

650

Hh

B

325

E

h

H

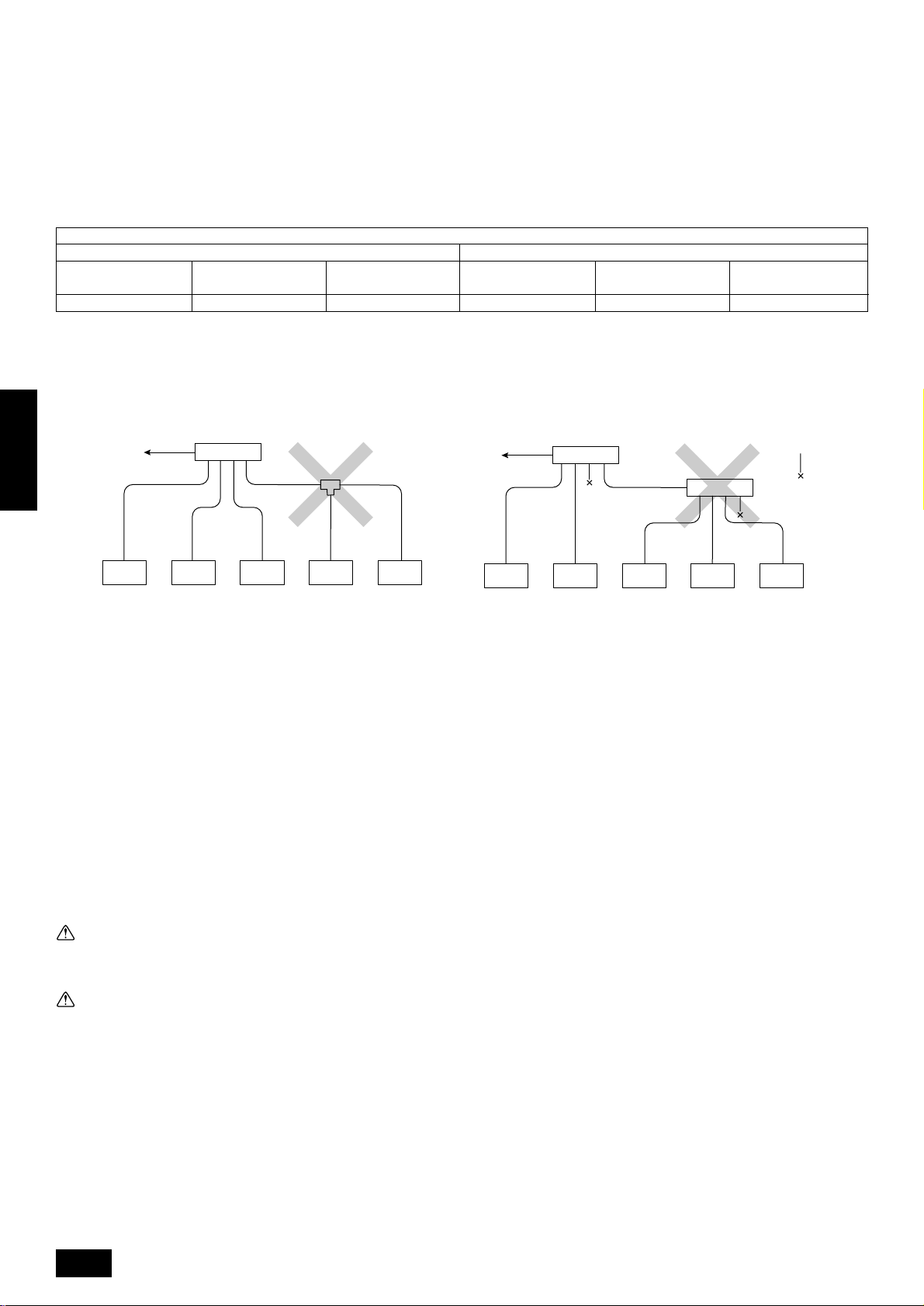

6.2. Collective installation and continuous installation

Space required for collective installation and continuous installation:

When installing several units, leave the space between each block as

shown below considering passage for air and people.

B

*E

C

<Side view>

A L

1 or more

2 or more

B L

C Front

D Front panel

E Rear panel

Note:

• Wall heights (H) of the front and the back sides shall be within

height of front panel and rear panel.

• If the panel height is exceeded, add the “h” dimension of the

figure above to L1 and L2 in the table above.

Model L1 L2

PUHY-P400

PUHY-P500

Example: When h is 100

The L1 dimension becomes 450+100=550 mm.

When there is an obstruction above the unit

450 250

AA

CC

D

B

*F

A

B

CCCCC

*FF F F F*E

B

A

ENGLISH

A

B

B

D

B

E

E

GCC

E

A

A

B

A 45° or more

B 300 mm or more

C Front

D 1000 mm or more

E Air outlet guide (Procured at the site)

F Rear

E

D

CF

When there is little space

up to an obstruction

A

C

DD

A

A (Must be open)

B Wall height (H)

C Front

D 1000 mm or more

E 250 mm or more

F 450 mm or more

G 900 mm or more

Note:

• Open in the two directions.

• In case wall height (H) exceeds overall height of unit, add “h”

dimension (h=wall height <H> – overall height of unit) to * marked

dimension.

• If there is a wall at both the front and the rear of the unit, install

up to three units consecutively in the side direction and provide

a space of 1000 mm or more as inlet space/passage space for

each three units.

CG

7

Page 8

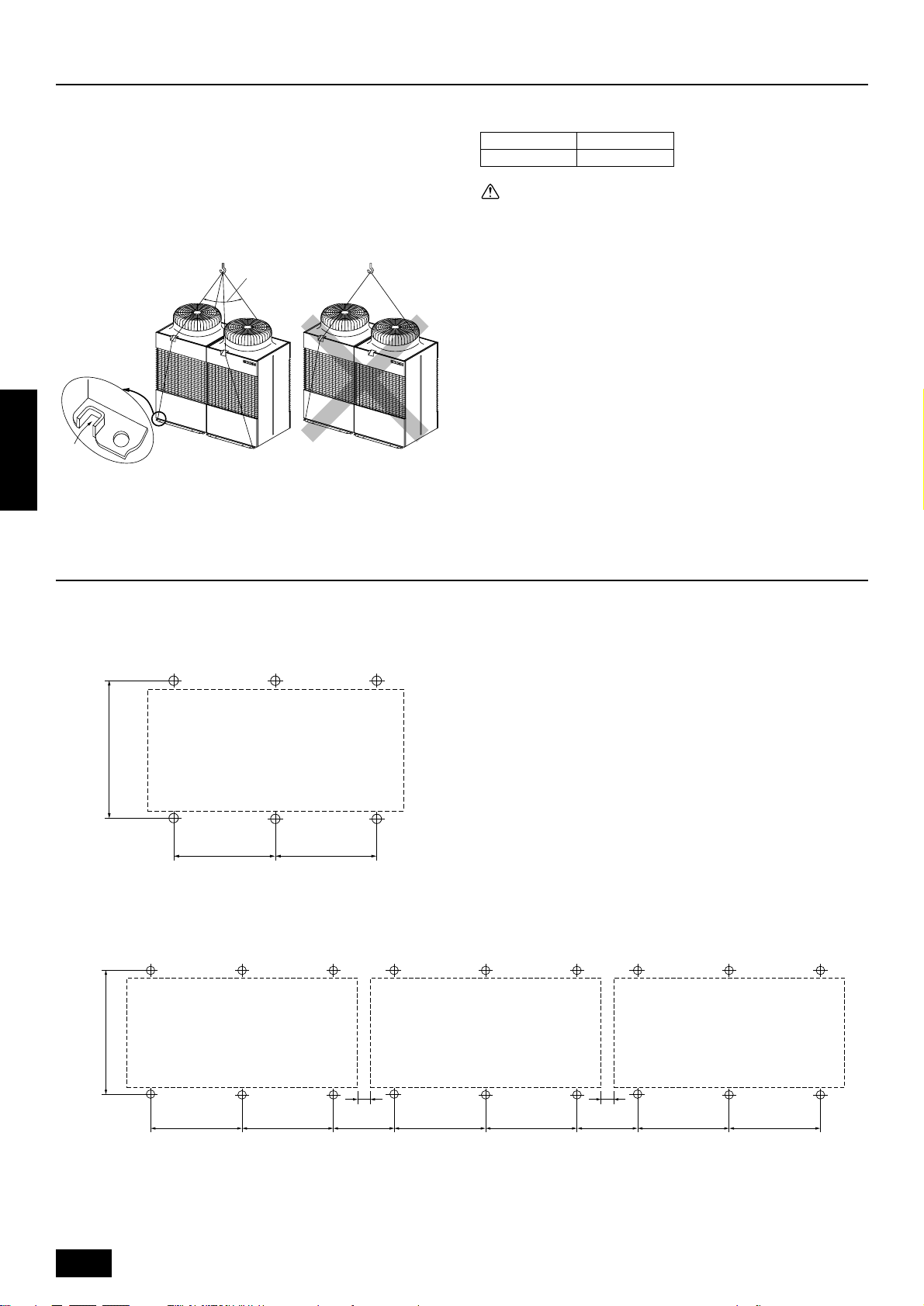

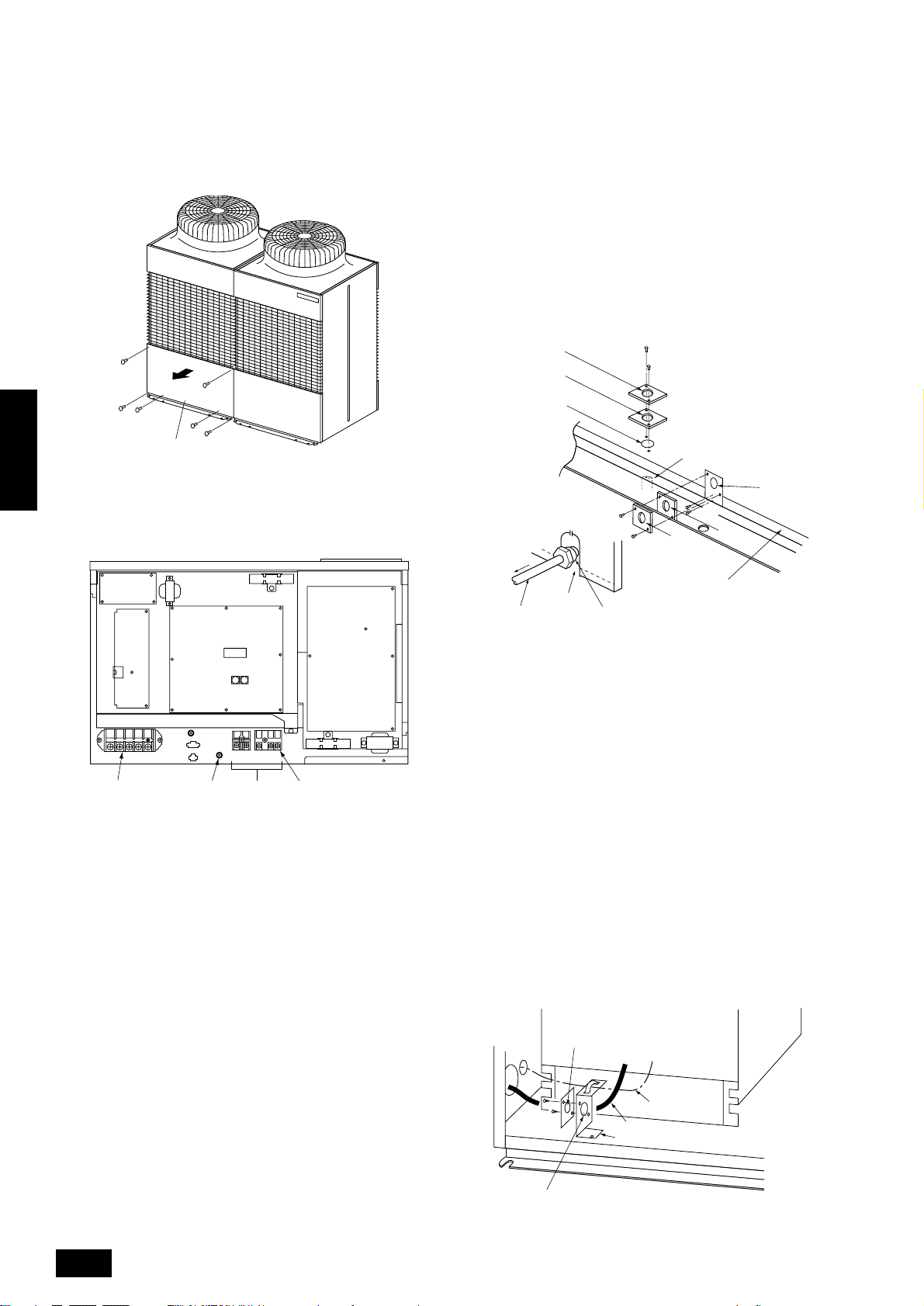

7. Lifting method and weight of product

• When carrying the unit suspended, pass the ropes under the unit

and use the two suspension points each at the front and rear.

• Always lift the unit with ropes attached at four points so that impact is

not applied to the unit.

• Attach the ropes to the unit at an angle of 40° or less.

• Use two ropes at least 8 m long.

A

B

Dangerous!

ENGLISH

A 40° or less

B Rope suspension part

Weight of product:

PUHY-P400 PUHY-P500

455 kg 475 kg

Caution:

Be very careful to carry product.

- Do not have only one person to carry product if it is more than 20 kg.

- PP bands are used to pack some products. Do not use them as a

mean for transportation because they are dangerous.

- Do not touch heat exchanger fins with y our bare hands. Otherwise you

may get a cut in your hands.

- Tear plastic packaging bag and scrap it so that children cannot play

with it. Otherwise plastic pac kaging bag may suffocate children to death.

- When carrying in outdoor unit, be sure to support it at four points. Carrying in and lifting with 3-point support may make outdoor unit unstable, resulting in a fall of it.

8. Installation of unit

8.1. Location of anchor bolt

• Individual installation

880±5

780±2

• Example of collective installation

780±2

A

880±5

A (Service side)

8

780±2

780±2 440 440780±2 780±2 780±2 780±2

10 10

For collective installation, provide a 10 mm gap between units.

Page 9

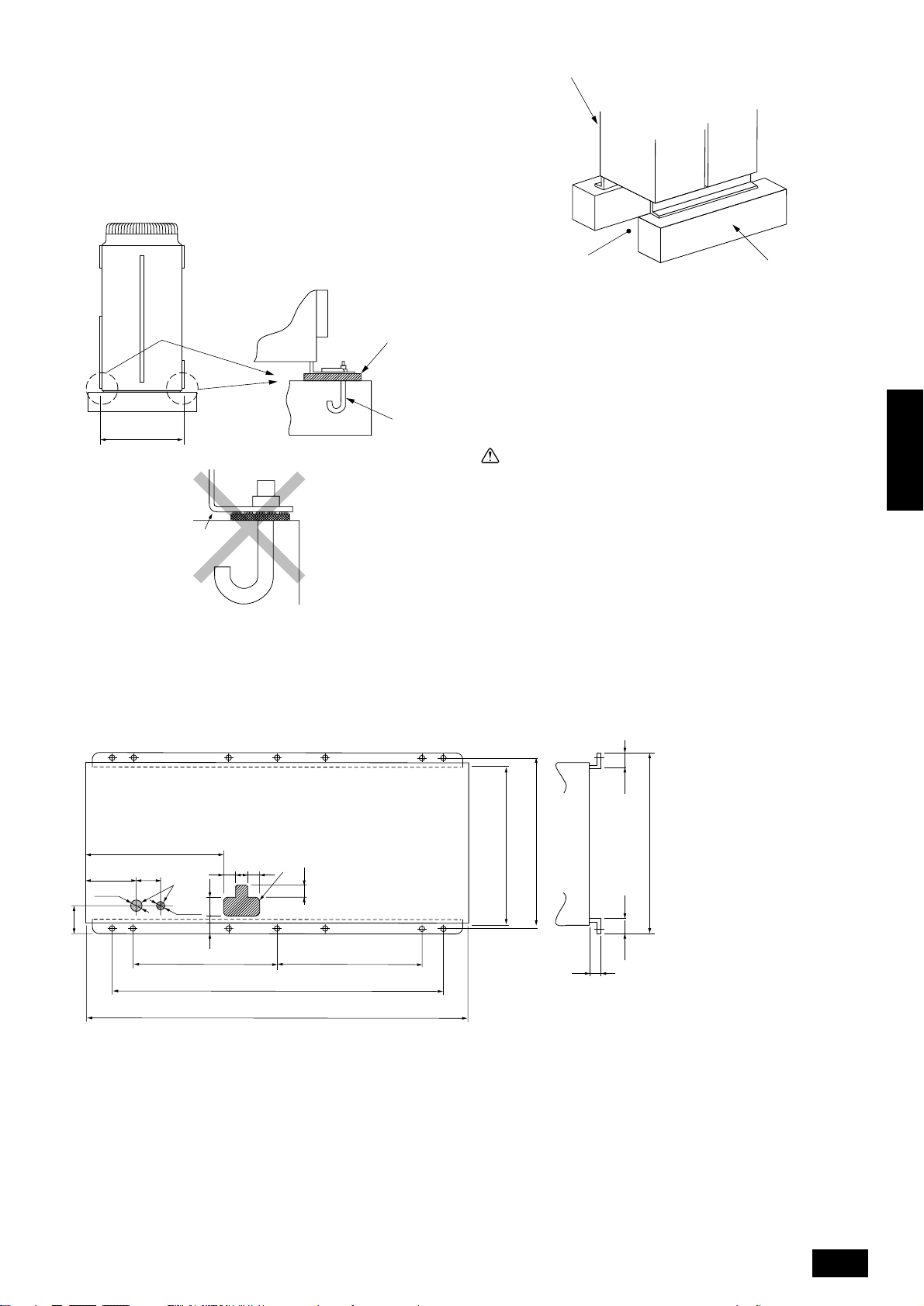

8.2. Installation

• Fix unit tightly with bolts as shown below so that unit will not fall down

due to earthquake or gust.

• Use concrete or angle for foundation of unit.

• Vibration may be transmitted to the installation section and noise

and vibration may be generated from the floor and walls, depending

on the installation conditions. Therefore, provide ample

vibrationproofing (cushion pads, cushion frame, etc.).

D

A

880±5

B

C

Down piping and down wiring precautions

When down piping and down wiring are performed, be sure that foundation and base work does not block the base through holes. When down

piping is performed, make the foundation at least 100 mm high so that

the piping can pass under the bottom of the unit.

E

A Be sure that the corners are firmly seated. If the corners are not firmly

seated, the installation feet may be bent.

B M10 anchor bolt procured at the site

C Corner is not seated.

D Unit

(Provide ample vibrationproofing between the unit and the foundation by

using cushion pads, cushion frame, etc.)

E Piping and wiring space (Bottom piping, bottom wiring)

F Concrete foundation

F

Warning:

• Be sure to install unit in a place strong enough to withstand its

weight.

Any lack of strength may cause unit to fall down, resulting in a

personal injury.

• Have installation work in order to protect against a str ong wind

and earthquake.

Any installation deficiency may cause unit to fall down, resulting in a personal injury.

When building the foundation, give full attention to the floor strength,

drain water disposal <during operation, drain water flows out of the unit>,

and piping and wiring routes.

ENGLISH

694

230

150

Ø62

111

A Bottom piping through hole

B (bolt hole)

C (bolt hole for old models)

D (unit width)

E (unit depth)

F Bottom wiring through hole

F

Ø27

780

80 82 78

90

73

B

1760

1990

5656

840 E

A

80

780

B

C

D

880 B

15

910

9

Page 10

8.3. Connecting direction for refrigerant

piping

Two connecting directions are available f or refriger ant piping of the outdoor unit, bottom piping and front piping, as shown below:

8.4. Noise level

(50/60Hz)

PUHY-P400 PUHY-P500

60/61 dB(A)

1m

A

B

A Knock-out hole

B Bottom piping

C Front piping

Note:

In the case of bottom piping, build a 100 mm or higher foundation

so that piping will go through the bottom of the unit.

ENGLISH

C

A

1m

B

A Front

B Measuring point

Measuring location: a room free from echoes and reverberations

10

Page 11

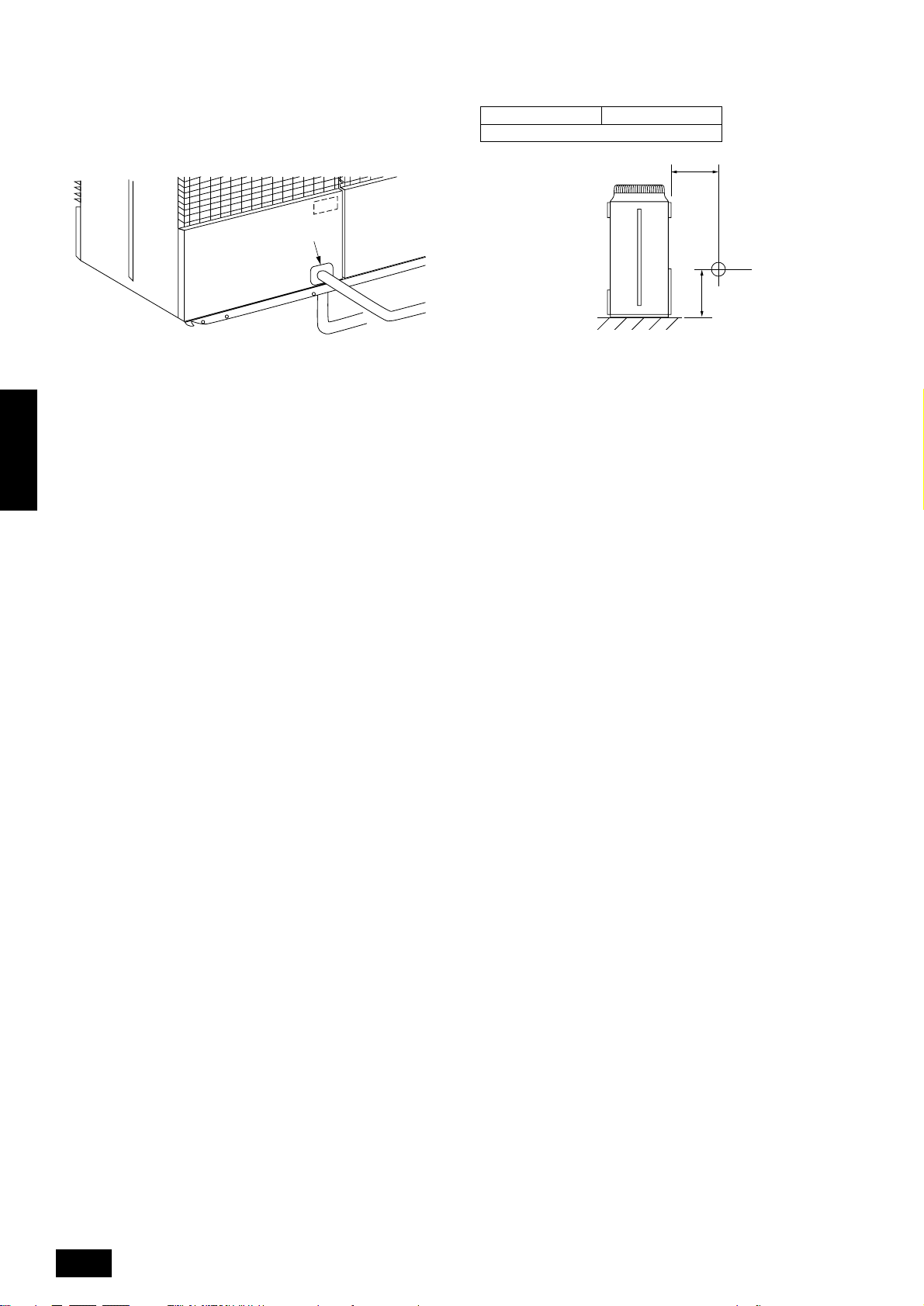

9. Caution for snow and seasonal wind

In cold and/or snowy areas, sufficient countermeasures to wind and snow

damages should be taken for operating unit in normal and good condition in winter time. Ev en in the other areas, full consider ation is required

for installation of unit in order to prevent abnormal operations caused by

seasonal wind or snow. When rain and snow directly fall on unit in

the case of air-conditioning operations in 10 or less degrees centigrade outdoor air, mount inlet and outlet ducts on unit for assuring

stable operations.

9.1. Snow and seasonal wind

■ Prevention of wind and snow damages in cold or snowy areas:

Refer to the figure of snow hood shown below:

• Snow hood

1093

A

Note:

1. Height of frame base for snow damage prevention (H) shall be

twice as high as expected snowfall. Width of frame base shall

not exceed that of the unit. The frame base shall be made of

angle steel, etc., and designed so that sno w and wind slip through

the structure. (If frame base is too wide, snow will be accumulated on it.)

2. Install unit so that seasonal wind will not directly lash against

openings of inlet and outlet ducts.

3. Build frame base at customer referring to this figure.

Material : Galvanized steel plate 1.2T

Painting : Overall painting with polyester powder

Color : Munsell 5Y8/1 (same as that of unit)

4. When the unit is used in a cold region and the heating operation

is continuously performed for a long time when the outside air

temperature is below freezing, install a heater to the unit base

or take other appropriate measures to prevent water from freezing on the base.

1888

ENGLISH

1145

B

500(840)500

(670) 821 903

(1990)

B

H

A Outlet

B Inlet

9.2. Countermeasure to seasonal wind

Referring to the figure shown below, take appropriate measures which

will suit the actual situation of the place for installation.

AA

A Seasonal wind

10. Refrigerant piping installation

Connecting the piping is a terminal-branch type in which refrigerant piping from the outdoor unit is branched at the terminal and connected to each of

the indoor units.

The method of connection consists of flare connections at the indoor units, flange connections for the piping of the outdoor unit and flare connections

for the liquid piping. Note that the branched sections are brazed.

Warning:

Always use extreme care to prevent the refrigerant gas (R22) from leaking while using fire or flame. If the refrigerant gas comes in contact

with the flame from any source, suc h as a gas sto ve, it breaks down and generates a poisonous gas which can cause gas poisoning. Never

weld in an unventilated room. Always conduct an inspection for gas leakage after installation of the refrigerant piping has been completed.

11

Page 12

10.1. Areas of caution

1 Use the following materials for refrigeration piping.

• Material: Seamless phosphorous deoxidized copper pipe, C1220T-OL or C1220T-O (Note: C1220T-OL is preferred.)

13

• Size: Refer to Pages

2 Commercially available piping often contains dust and other materials. Always blow it clean with a dry inert gas.

3 Use care to prevent dust, water or other contaminants from entering the piping during installation.

4 Reduce the number of bending portions as much as possible, and make bending radius as big as possible.

5 Always use the branch piping set shown below, which are sold separately.

Total of units down-

stream less than 160

CMY-Y102S-F CMY-Y102L-F CMY-Y202-F CMY-Y104-E CMY-Y107-E CMY-Y1010-E

6 If the diameters of the branch piping of the designated refrigerant piping differs, use a pipe cutter to cut the connecting section and then use an

adapter for connecting different diameters to connect the piping.

7 Always observe the restrictions on the refrigerant piping (such as rated length, the difference between high/low pressures, and piping diameter).

Failure to do so can result in equipment failure or a decline in heating/cooling performance.

8 A second branch cannot be made after a header branch. (These are shown by ×.)

to 14.

Branch pipe set name

Line branching Header branching

Total of units down-

stream 161 to 330

Total of units down-

stream more than 331

4 branching 7 branching 10 branching

A

ENGLISH

A To Outdoor Unit

B Capped Piping

9 Always use good-quality materials for brazing.

0 The City Multi Series Y will stop due an abnormality due to excessive or insufficient coolant. At such a time , alwa ys properly charge the unit. When

servicing, always check the notes concerning pipe length and amount of additional refrigerant at both locations, the refrigerant volume calculation

table on the back of the service panel and the additional refrigerant section on the labels for the combined number of indoor units. (Refer to Pages

13

to 14.)

A Use liquid refrigerant to fill the system.

B Never use refrigerant to perform an air purge. Always evacuate using a vacuum pump.

C Always insulate the piping properly. Insufficient insulation will result in a decline in heating/cooling performance, water drops from condensation

and other such problems. (Refer to Pages 21 to

D When connecting the refrigerant piping, make sure the ball valve of the outdoor unit is completely closed (the factory setting) and do not operate it

until the refrigerant piping for the outdoor and indoor units has been connected, a refrigerant leakage test has been performed and the evacuation

process has been completed.

E Always use a non-oxidizing brazing material for brazing the parts. If a non-oxidizing brazing material is not used, it could cause clogging or damage

to the compressor unit. (Details of the piping connections and valve operation can be found on Pages 15 to 16.)

F Never perform outdoor unit piping connection work when it is raining.

22

.)

A

B

Warning:

When installing and moving the air conditioner to another site, do not charge the it with a refrigerant different from the refrigerant (R407C)

specified on the unit.

- If a different refrigerant or air is mixed with the original refrigerant, the refrigerant cycle may malfunction and the unit may be damaged.

Caution:

• Use refrigerant piping made of C1220T-OL phosphorus deoxidized copper. In addition, be sure that the inner and outer surfaces of the

pipes are clean and free of hazardous sulphur, oxides, dust/dirt, shaving particles, oils, moisture, or any other contaminant.

- Contaminants on the inside of the refrigerant piping may cause the refrigerant residual oil to deteriorate.

• Use liquid refrigerant for sealing.

- Sealing with gas refrigerant will change the composition of the refrigerant in the cylinder and reduce the unit’s performance.

• Never use existing refrigerant piping.

- The large amount of chlorine in conventional refrigerant and refrigerator oil in the existing piping will cause the new refrigerant to deteriorate.

• Store the piping to be used during installation indoors and keep both ends of the piping sealed until just before brazing.

- If dust, dirt, or water gets into the refrigerant cycle, the oil will deteriorate and the compressor may fail.

• Do not use a charging cylinder.

- Using a charging cylinder may cause the refrigerant to deteriorate.

12

Page 13

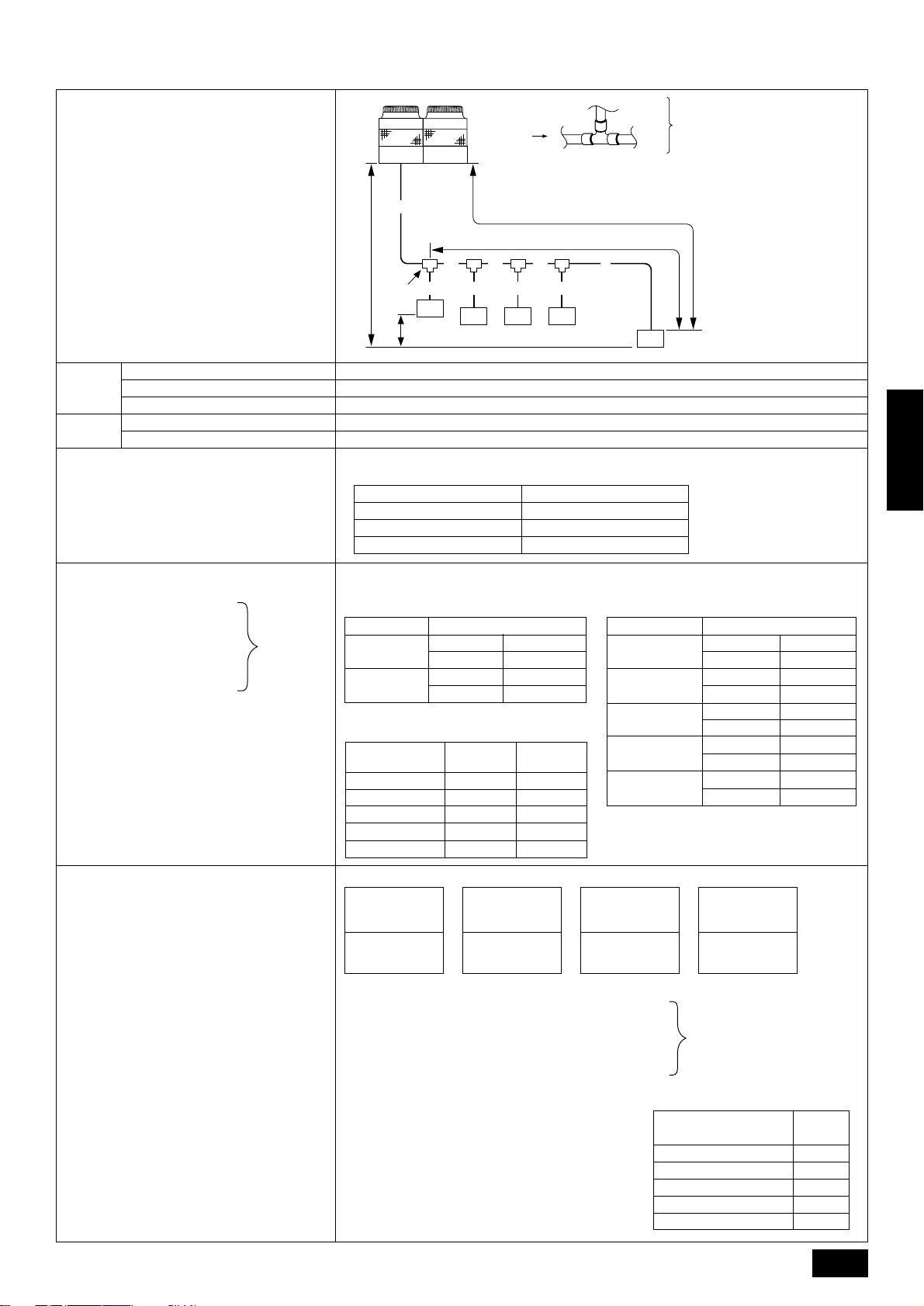

10.2. Refrigerant piping system

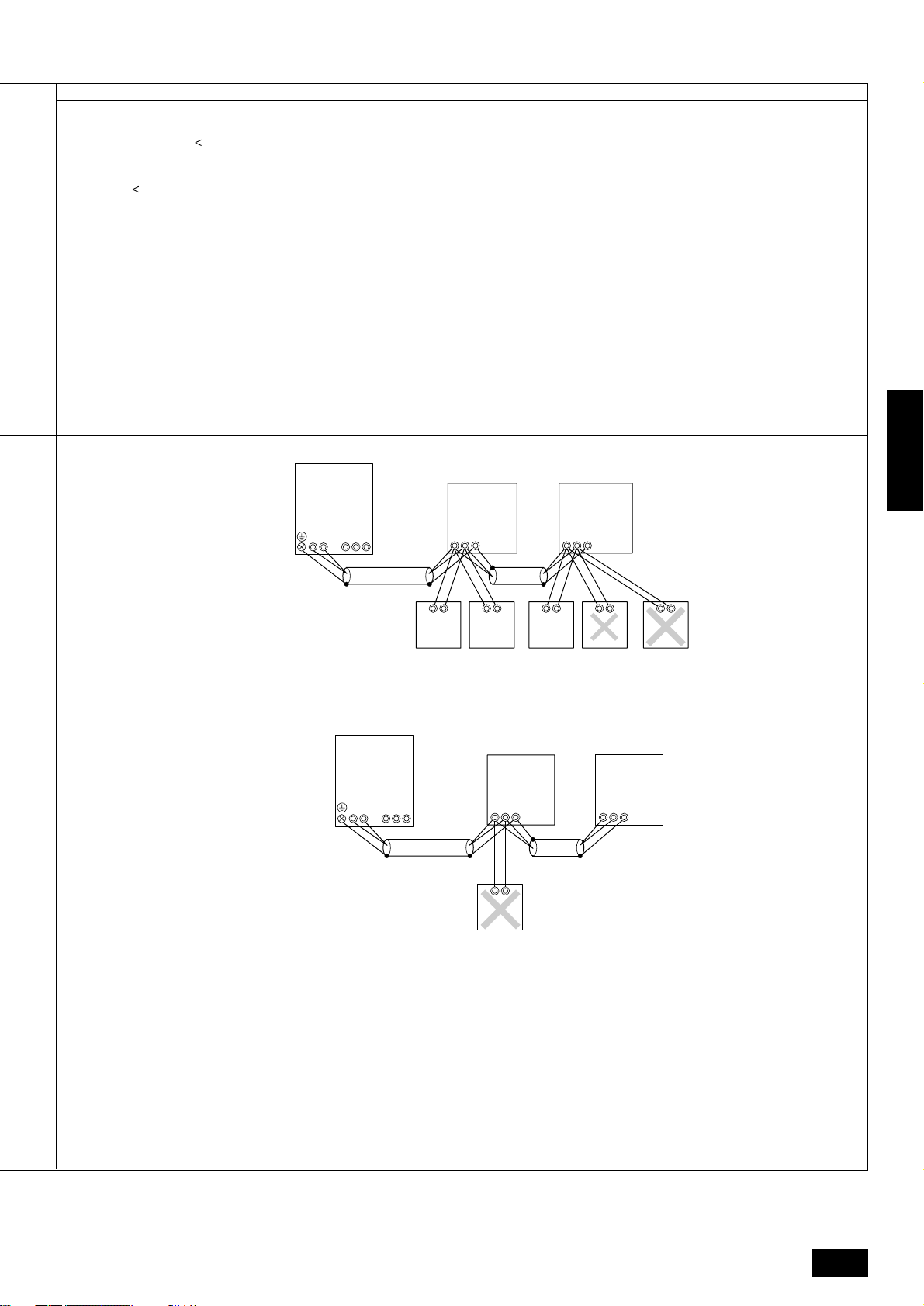

Line-Branch Method

Connection Examples

(Connecting to Five Indoor Units)

Permissible

Length

Permissible High/

Low Difference

Total Piping Length

Farthest Piping Length (L)

Farthest Piping Length After First Branch (r)

High/Low Difference in Indoor/Outdoor Section (H)

High/Low Difference in Indoor/Indoor Section (h)

■ Selecting the Refrigerant Branch Kit

Use the table to the right to make the selection

based on the model total of indoor units downstream from the branch section.

■ Select Each Section of Refrigerant Piping

(1) Section From Outdoor Unit

to First Branch (A)

(2) Sections From Branch to

Indoor Unit (a,b,c,d,e)

(3) Section From Branch to

Each

Section of

Piping

Branch (B, C, D)

Select the size from the table to the right.

C

D

5

A

A

A

H

B

h

B C D

a b c d

C

C2C3C

1

L

R

e

4

Note:

The model total for down-

stream units shown in the

table below is the model

total when viewed from

Point A in the drawing

above.

A Outdoor Unit

B First Branch

The first branch on the

outdoor unit must be

the CMY-Y202-F.

C Indoor unit

D To downstream units

A+B+C+D+a+b+c+d+e is 220 m or less

A+B+C+D+e is 100 m or less

B+C+D+e is 30 m or less

50 m or less (If the outdoor unit is lower, 40 m or less)

15 m or less

Select the branch kit, sold separately , from the tab le below. (Each kit contains a refrigerant and

gas piping set.)

Downstream Unit Model Total Branch Kit Model

160 or less CMY-Y102S-F

161 to 330 CMY-Y102L-F

331 or more CMY-Y202-F

(1) Refr igerant Piping Diameter In Section

From Outdoor Unit to First Branch (Outdoor Unit Piping Diameter)

Model Piping Diameter (mm)

PUHY-P400

PUHY-P500

Liquid Line ø15.88

Gas Line ø31.75

Liquid Line ø15.88

Gas Line ø38.1

(3) Refr igerant Piping Diameter In Section

From Branch to Branch

Downstream Unit

Model Total

80 or less

81 to 160

161 to 330

331 to 480

481 or more

Liquid Line

(mm)

ø9.52

ø12.7

ø12.7

ø15.88

ø15.88

Gas Line

(mm)

ø15.88

ø19.05

ø25.4

ø31.75

ø38.1

(2) Refr igerant Piping Diameter In Section

From Branch to Indoor Unit (Indoor Unit

Piping Diameter)

Model number Piping dia. (mm)

25 · 32 · 40

50 · 63 · 71 · 80

100 · 125 · 140

200

250

Liquid Line ø6.35

Gas Line ø12.7

Liquid Line ø9.52

Gas Line ø15.88

Liquid Line ø9.52

Gas Line ø19.05

Liquid Line ø12.7

Gas Line ø25.4

Liquid Line ø12.7

Gas Line ø28.58

ENGLISH

■ Additional Refrigerant Charge

At the time of shipping, the outdoor unit PUHY -P400

is charged with 16 kg of refrigerant and the PUHYP500 is charged with 22 kg. As this charge does not

include the amount needed for extended piping, additional charging for each refrigerant line will be required on site. In order that future servicing may be

properly provided, always keep a record of the size

and length of each refrigerant line and the amount of

additional charge by writing it in the space provided

on the outdoor unit.

■ Calculation of Additional Refrigerant Charge

• Calculate the amount of additional charge based

on the length of the piping extension and the size

of the refrigerant line.

• Use the table to the right as guide to calculating

the amount of additional charging and charge the

system according.

• If the calculation results of the calculation result

in a fraction of less than 0.1 kg, round up to the

next 0.1 kg. F or example , if the result of the calculation was 16.76 kg, round the result up to 16.8

kg.

<Additional Charge>

Liquid pipe size

Total length of

ø15.88 × 0.25

(m) × 0.25 (kg/m)

Liquid pipe size

Total length of

ø12.7 × 0.12

++++ α

(m) × 0.12 (kg/m)

Liquid pipe size

Total length of

ø9.52 × 0.06

(m) × 0.06 (kg/m)

<Example>

Indoor 1 : 125 A : ø15.88 40 m a : ø9.52 10 m

2 : 100 B : ø12.7 10 m b : ø9.52 10 m

3:50 C:ø12.7 5 m c : ø9.52 10 m

4:32 D:ø9.52 5 m d : ø6.35 5 m

5:32 e:ø6.35 10 m

The total length of each liquid line is as follows:

ø15.88 : A = 40 m

ø12.7 : B + C = 10 + 5 = 15 m

ø9.52 : D + a + b + c = 5 + 10 + 10 + 10 = 35 m

ø6.35 : d + e = 5 + 10 = 15 m

Therefore,

<Calculation example>

Additional

refrigerant charge = 40 × 0.25 + 15 × 0.12 + 35 × 0.06

+ 15 × 0.024 + 2.5 = 16.8 kg

Liquid pipe size

Total length of

ø6.35 × 0.024

(m) × 0.024 (kg/m)

At the conditions

below:

Value of α

Total capacity of

connecting indoor units

to Model 80 1.0 kg

Models 81 to 160 1.5 kg

Models 161 to 330 2.0 kg

Models 331 to 480 2.5 kg

Models 481 or more 3.0 kg

α

13

Page 14

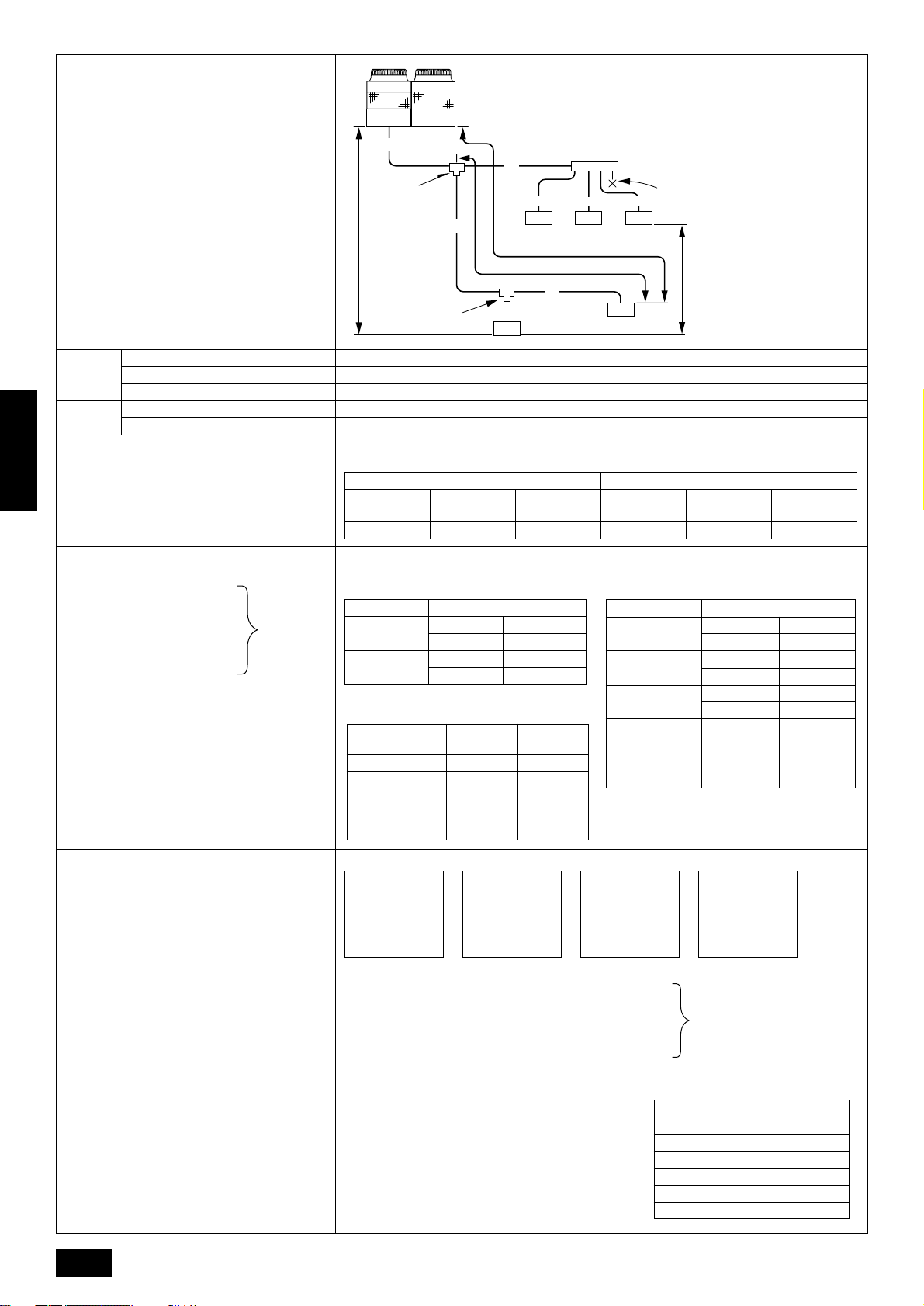

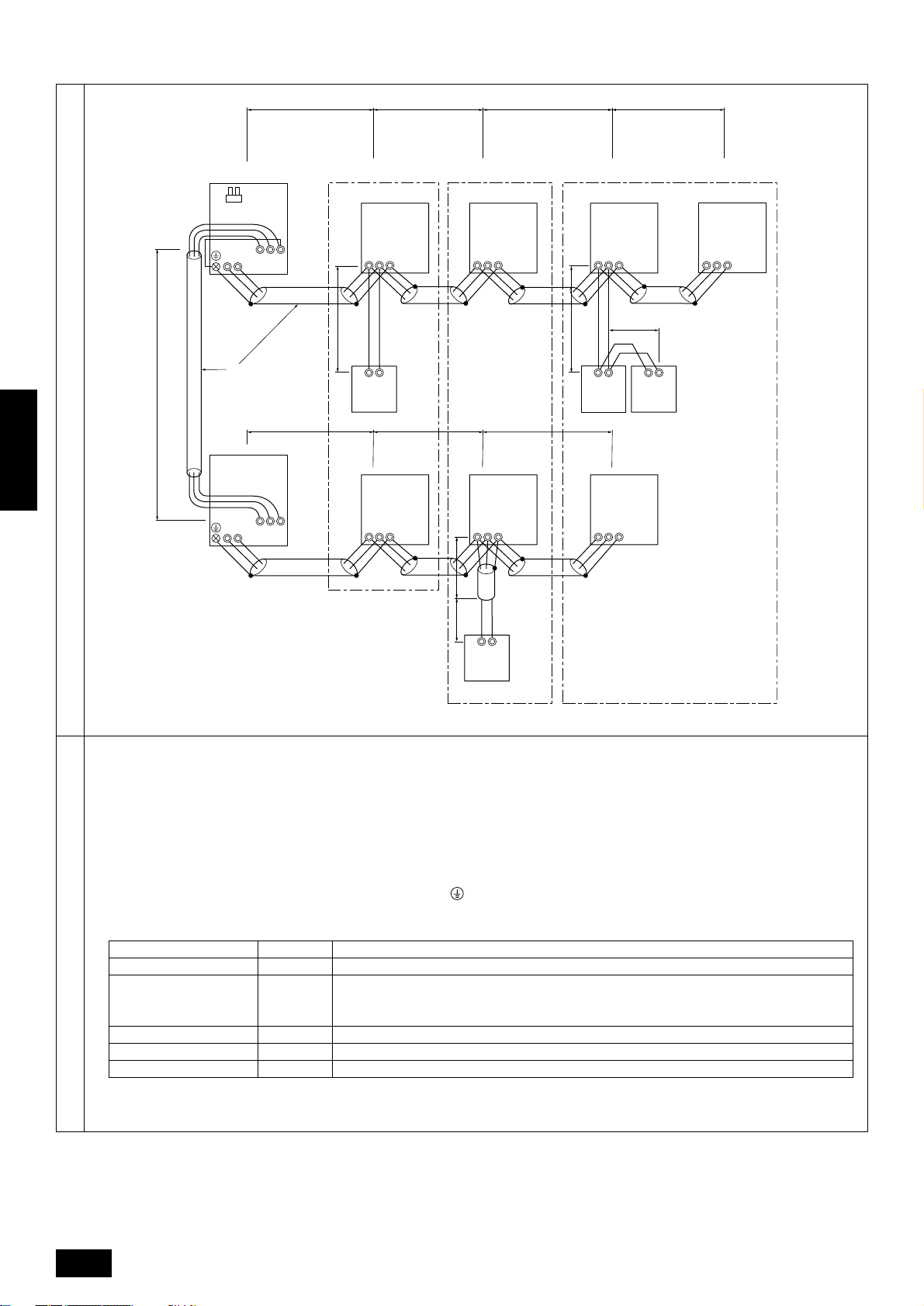

Multiple Line/Header

Connection Example

(When Connecting Five Indoor Units)

Permissible

Length

Permissible High/

Low Difference

Total Piping Length

Farthest Piping Length (L)

Farthest Piping Length After First Branch (r)

High/Low Difference in Indoor/Outdoor Section (H)

High/Low Difference in Indoor/Indoor Section (h)

■ Selecting the Refrigerant Branch Kit

Use the table to the right to make the selection

based on the model total of indoor units down-

ENGLISH

stream from the branch section or on the number

of indoor units to be connected on the header

branch.

■ Select Each Section of Refrigerant Piping

(1) Section From Outdoor Unit

to First Branch (A)

(2) Sections From Branch to

Indoor Unit (a,b,c,d,e)

(3) Section From Branch to

Branch (B, C)

Select the size from the table to the right.

Each

Section of

Piping

Note:

A

A

C

B

H

B

C

1

c

34

D

L

R

b

a

D

D

E

F

d

e

5

D

2

D

• Branch piping cannot be used

again after the header branch.

• The model total for downstream units shown in the table below is the model total

when viewed from Point A in

the drawing above.

A Outdoor Unit

B First Branch (Branch Joint)

The first branch must be the

CMY-Y202-F when the outdoor unit and header branch

h

are to be used.

C Branch Joint

D Indoor Unit

E Branch Header

F Cap

A+B+C+a+b+c+d+e is 220 m or less

A+B+b is 100 m or less

B+b is 30 m or less

50 m or less (If the outdoor unit is lower, 40 m or less)

15 m or less

Select the branch kit, sold separately , from the tab le below. (Each kit contains a refrigerant and

gas piping set.)

Line branching Header branching

Total of units downstream

less than 160

Total of units downstream

161 to 330

Total of units downstream

more than 331

4 branching

header

7 branching

header

10 branching

header

CMY-Y102S-F CMY-Y102L-F CMY-Y202-F CMY-Y104-E CMY-Y107-E CMY-Y1010-E

(1) Refr igerant Piping Diameter In Section

From Outdoor Unit to First Branch (Outdoor Unit Piping Diameter)

Model Piping Diameter (mm)

PUHY-P400

PUHY-P500

Liquid Line ø15.88

Gas Line ø31.75

Liquid Line ø15.88

Gas Line ø38.1

(3) Refr igerant Piping Diameter In Section

From Branch to Branch

Downstream Unit

Model Total

80 or less

81 to 160

161 to 330

331 to 480

481 or more

Liquid Line

(mm)

ø9.52

ø12.7

ø12.7

ø15.88

ø15.88

Gas Line

(mm)

ø15.88

ø19.05

ø25.4

ø31.75

ø38.1

(2) Refrigerant Piping Diameter In Section

From Branch to Indoor Unit (Indoor Unit

Piping Diameter)

Model number Piping dia. (mm)

25 · 32 · 40

50 · 63 · 71 · 80

100 · 125 · 140

200

250

Liquid Line ø6.35

Gas Line ø12.7

Liquid Line ø9.52

Gas Line ø15.88

Liquid Line ø9.52

Gas Line ø19.05

Liquid Line ø12.7

Gas Line ø25.4

Liquid Line ø12.7

Gas Line ø28.58

■ Additional Refrigerant Charge

At the time of shipping, the outdoor unit PUHYP400 is charged with 16 kg of refrigerant and the

PUHY -P500 is charged with 22 kg. As this charge

does not include the amount needed for extended

piping, additional charging for each refrigerant

line will be required on site. In order that future

servicing may be properly provided, always keep

a record of the size and length of each refrigerant line and the amount of additional charge by

writing it in the space provided on the outdoor

unit.

■ Calculation of Additional Refrigerant Charge

• Calculate the amount of additional charge

based on the length of the piping extension

and the size of the refrigerant line.

• Use the table to the right as guide to calculating the amount of additional charging and

charge the system according.

• If the calculation results of the calculation result in a fraction of less than 0.1 kg, round up

to the next 0.1 kg. For example, if the result

of the calculation was 14.32 kg, round the

result up to 14.4 kg.

14

<Additional Charge>

Liquid pipe size

Total length of

ø15.88 × 0.25

(m) × 0.25 (kg/m)

Liquid pipe size

Total length of

ø12.7 × 0.12

++++ α

(m) × 0.12 (kg/m)

Liquid pipe size

Total length of

ø9.52 × 0.06

(m) × 0.06 (kg/m)

<Example>

Indoor 1 : 125 A : ø15.88 30 m a : ø9.52 10 m

2 : 100 B : ø12.7 10 m b : ø9.52 20 m

3:40 C:ø12.7 15 m c : ø6.35 10 m

4:32 d:ø6.35 10 m

5:32 e:ø6.35 10 m

The total length of each liquid line is as follows:

ø15.88 : A = 30 m

ø12.7 : B + C = 10 + 15 = 25 m

ø9.52 : a + b = 10 + 20 = 30 m

ø6.35 : c + d + e = 10 + 10 + 10 = 30 m

Therefore,

<Calculation example>

Additional

refrigerant charge = 30 × 0.25 + 15 × 0.12 + 30 × 0.06

+ 30 × 0.024 + 2.5 = 14.4 kg

Liquid pipe size

Total length of

ø6.35 × 0.024

(m) × 0.024 (kg/m)

At the conditions

below:

Value of α

Total capacity of

connecting indoor units

to Model 80 1.0 kg

Models 81 to 160 1.5 kg

Models 161 to 330 2.0 kg

Models 331 to 480 2.5 kg

Models 481 or more 3.0 kg

α

Page 15

10.3. Caution for piping connection/valve

operation

• Conduct piping connection and valve operation accurately b y follo w-

ing the figure below.

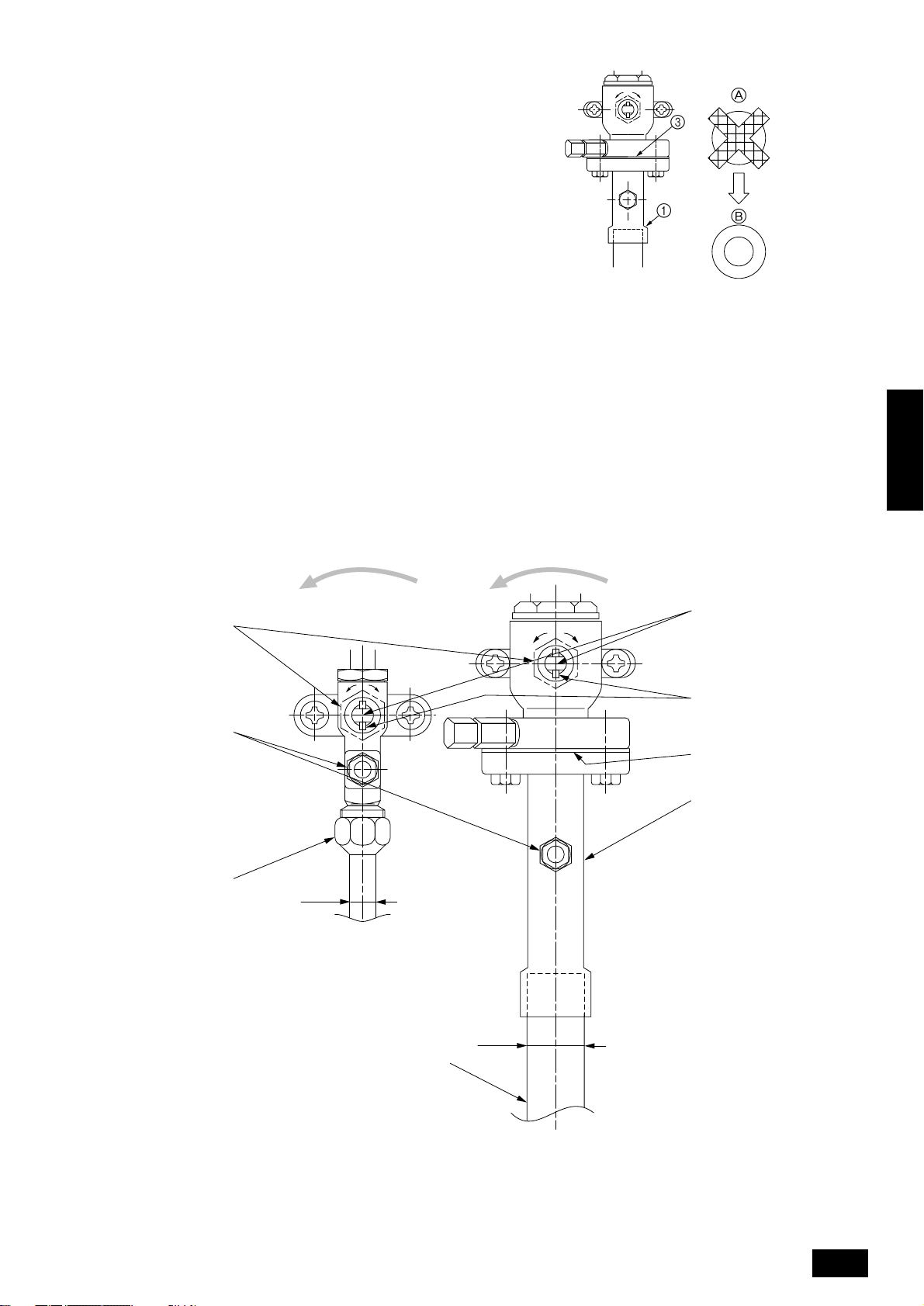

• The gas side connecting pipe is being assembled for shipment.

(See the figure at the right.)

1 For brazing to the connecting pipe with flange, remove the con-

necting pipe with flange from the ball valve, and braze it at the

outside of the unit.

2 During the time when removing the connecting pipe with flange,

remove the seal attached on the back side of this sheet and paste

it onto the flange surface of the ball valve to prevent the entry of

dust into the valve.

3 The refrigerant circuit is closed with a round, close-packed pack-

ing at the shipment to prevent gas leak between flanges. As no

operation can be done under this state, be sure replace the packing with the hollow packing attached at the piping connection.

4 At the mounting of the hollow packing, wipe off dust attached on

the flange sheet surface and the packing. Coat refrigerating machine oil onto both surfaces of the packing.

A

3

1

A Replace the close-packed packing

B Hollow packing

• After evacuation and refrigerant charge, ensure that the handle is

fully open. If operating with the v alve closed, abnormal pressure will

be imparted to the high- or low-pressure side of the refrigerant circuit, giving damage to the compressor, four-w ay valve, etc.

• Determine the amount of additional refrigerant charge by using the

formula, and charge refrigerant additionally through the service port

after completing piping connection work.

• After completing work, tighten the service port and cap securely not

to generate gas leak.

B

ENGLISH

F

G

H

[Ball valve (liquid side)] [Ball valve (gas side)]

EE

O

S

O

S

I

A

B

C

D

J

K

(This figure shows the valve in the fully open state.)

15

Page 16

A Valve stem

[Fully closed at the factory , when connecting the piping, when evacuating,

and when charging additional refrigerant. Open fully after the operations

above are completed.]

B Stopper pin [Prevents the valve stem from turning 90° or more.]

C Packing (Accessory)

D Connecting pipe (Accessory)

[Use packing and securely install this pipe to the valve flange so that gas

leakage will not occur. (Tightening torque: 43 N·m (430 kg-cm)) Coat both

surfaces of the packing with refrigerator oil.]

E Open (Operate slowly)

F Cap, copper packing

[Remove the cap and operate the valv e stem. Alwa ys reinstall the cap after

operation is completed. (Valve stem cap tightening torque: 25 N·m (250

kg-cm) or more)]

G Service port

[Use this port to evacuate the refrigerant piping and add an additional charge

at the site.

Open and close the port using a double-ended wrench.

Always reinstall the cap after operation is completed. (Service port cap

tightening torque: 14 N·m (140 kg-cm) or more)]

H Flare nut

[Tightening torque: 80 N·m (800 kg-cm)

Loosen and tighten this nut using a double-ended wrench.

Coat the flare contact surface with refrigerator oil.]

I ø15.88

J ø31.75 (PUHY-P400)

ø38.1 (PUHY-P500)

K Field piping

ENGLISH

[Braze to the connecting pipe. (When brazing, use unoxidized brazing.)]

Appropriate tightening torque by torque wrench

Copper pipe external dia. (mm) Tightening torque (N·m) / (kg-cm)

ø6.35 14 to 18 / 140 to 180

ø9.52 35 to 42 / 350 to 420

ø12.7 50 to 57.5 / 500 to 575

ø15.88 75 to 80 / 750 to 800

ø19.05 100 to 140 / 1000 to 1400

Tightening angle standard

Caution:

• Always remove the connecting pipe from the ball valve and braze

it outside the unit.

- Brazing the connecting pipe while it is installed will heat the ball

valve and cause trouble or gas leakage. The piping, etc. inside the

unit may also be burned.

• Use ester oil, ether oil or alkylbenzene (small amount) as the

refrigerator oil to coat flares and flange connections.

- The refrigerator oil will degrade if it is mixed with a large amount of

mineral oil.

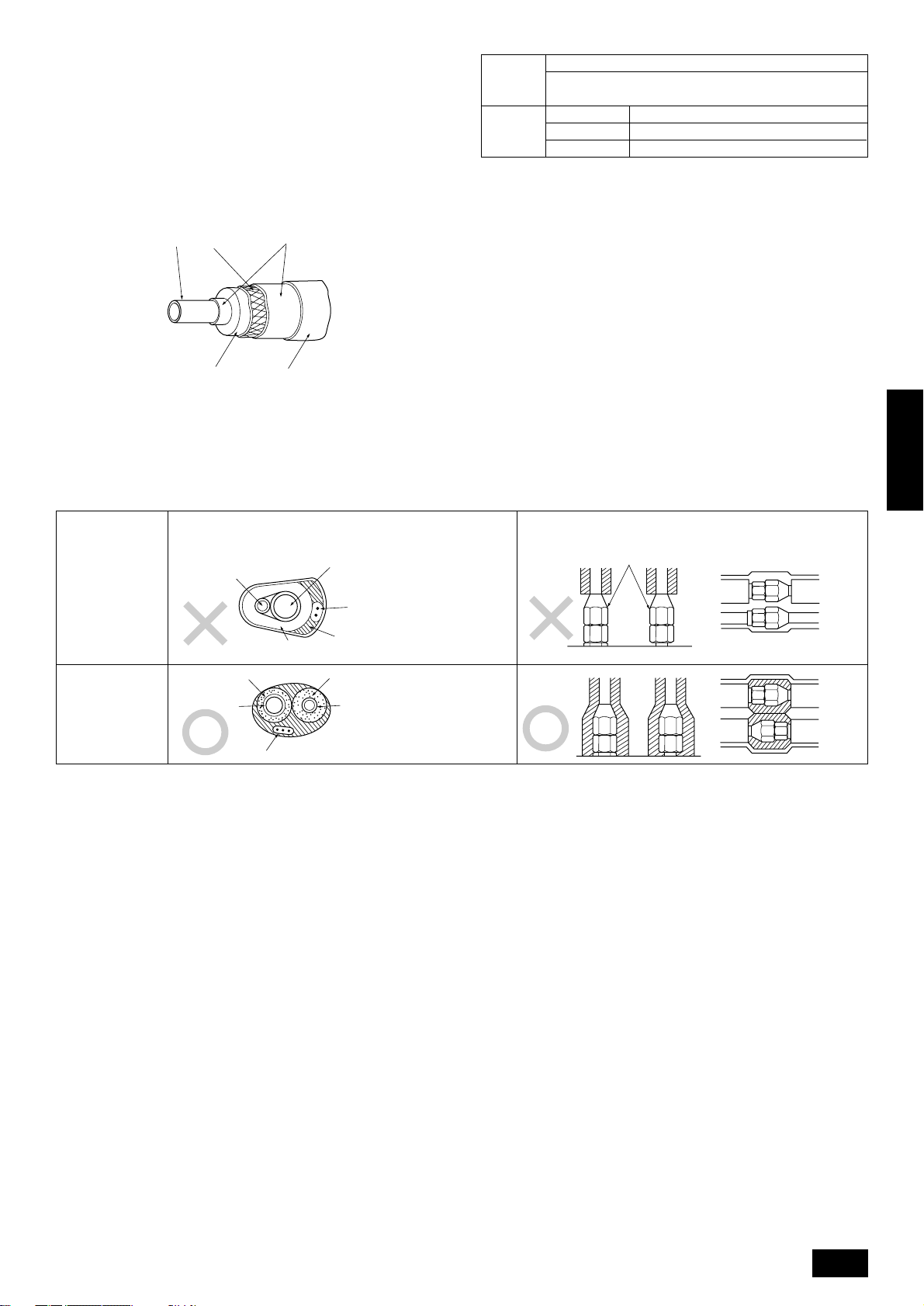

10.4. How to install branch pipe

For detail, please observe the instruction manual attached to the optional refrigerant branch kit.

■ Joint

A

A To Outdoor Unit

B To Branch Piping or Indoor Unit

• Apart from the CMY -Y202-F gas side, there are no restrictions on the

posture for attaching joints.

• Ensure that the branch pipes for the CMY-Y202-F gas side are attached horizontally or facing upwards. (See the diagram below.)

Horizontal Facing upwards

(Facing downwards is not possible)

B

Pipe diameter (mm) Tightening angle (°)

ø6.35, ø9.52 60 to 90

ø12.7, ø15.88 30 to 60

ø19.05 20 to 35

Note:

If a torque wrench is not available, use the following method as a

standard.

When you tighten the flare nut with a wrench, y ou will reach a point

where the tightening torque will abrupt increase. Turn the flare nut

beyond this point by the angle shown in the table above.

Within ± 15˚

Within ± 15˚

Within ± 15˚

• There is no limitation on the joint mounting configuration.

• If the diameter of the refrigerant piping selected by the procedures

described on pages 13 to 14 is different from the size of the joint,

match the sizes using a deformed joint. The deformed joint is included with the kit.

16

Page 17

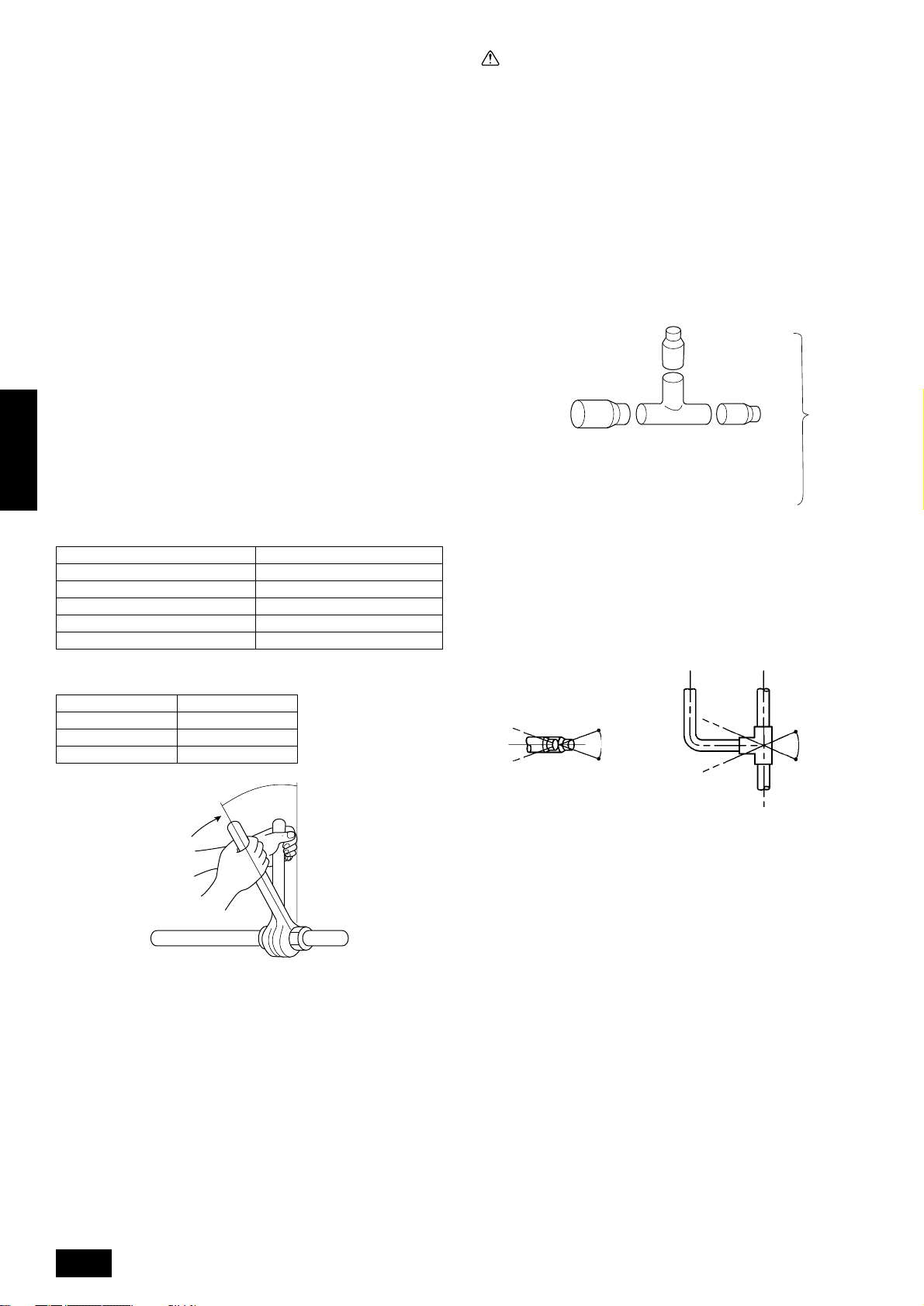

■ Header

C

D

A

B

A To outdoor unit

B To indoor unit

• No restriction is applied to the mounting posture of the header.

• If the diameter of the refrigerant piping selected using the proce-

dures described on pages 14 and the size of the joint is different,

match the sizes using a deformed joint. The deformed joint is included with the kit.

C Pipe cutter

D or

E Deformed joint

• When the number of pipes to be connected is smaller than the number

of header branches, install a cap to the unconnected branches. The

cap is included with the kit.

E

ENGLISH

17

Page 18

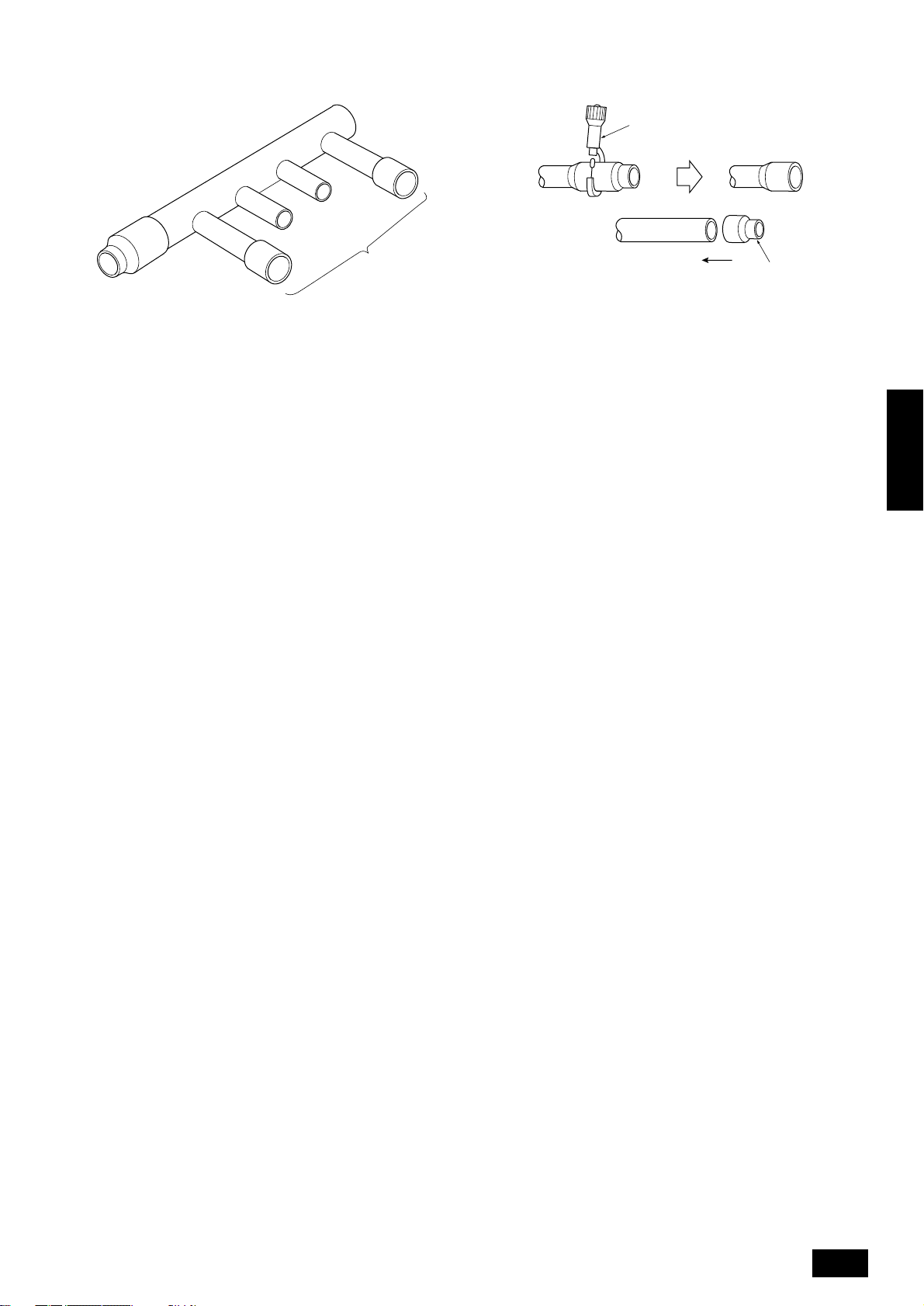

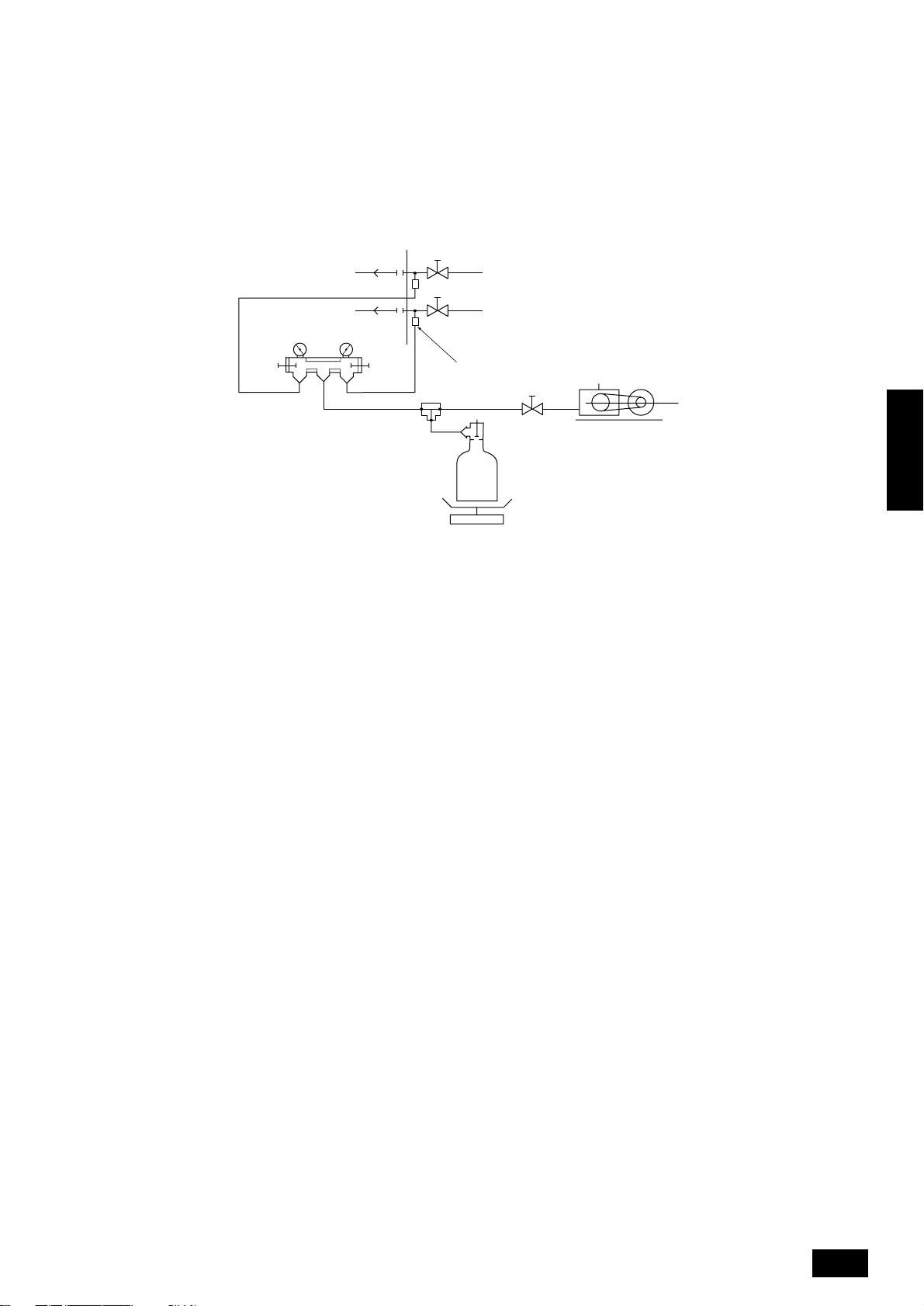

10.5. Airtight test and evacuation, refrigerant charging

1 Airtight test

Perform with the stop valv e of the outdoor unit closed, and pressurize the connection piping and the indoor unit from the service port provided on the

stop valve of the outdoor unit. (Always pressurize from both the liquid pipe and the gas pipe service ports.)

A Nitrogen gas

B To indoor unit

C System analyzer

D Lo Knob

E Hi Knob

F Ball valve

G Liquid pipe

H Gas pipe

I Outdoor unit

J Service port

The method of conducting the airtight test is basically the same as for older models. Howe ver, since the restrictions have a large affect on deterioration

of the refrigerator oil, always observe them. Also, with nonazeotropic refrigerant (R407C, etc.), gas leakage causes the composition to change and

affects performance. Therefore, since the entire amount must be replaced if gas leakage occurs, perform the airtightness test cautiously.

Airtight test procedure

1.Nitrogen gas pressurization

(1) After pressurizing to the design pressure (2.98 MPa) using nitrogen gas, let stand

ENGLISH

for about one day. If the pressure does not drop, airtightness is good.

However, if the pressure drops, since the leaking point is unknown, the following

bubble test may also be performed.

(2) After the pressurization described above, spra y the flare connection parts, brazed

parts, flanges, and other parts that may leak with a bubbling agent (Kyuboflex,

etc.) and visually check for bubbles.

(3) After the airtight test, wipe off the bubbling agent.

2.Pressurization using refrigerant gas and nitrogen gas

(1) After sealing with liquid R407C from a cylinder and pressurizing to a gas pressure

of approximately 0.2 MPa, pressurize to the design pressure (2.98 MPa) using

nitrogen gas.

However , do not pressurize at one time . Stop during pressurization and check that

the pressure does not drop.

(2) Check f or gas leaks by checking the flare connection parts, braz ed parts, flanges,

and other parts which may leak using an R407C compatible electric leak detector.

(3) This test may be used together the with bubble type gas leak test.

A

C

D

B

LO HI

C

LO

HI

E

• If a flammable gas or air (oxygen) is used as the pressurization gas, it may catch fire or explode.

• Do not use a refrigerant other than that indicated on the

unit.

• Sealing with gas from a cylinder will cause the composition of the refrigerant in the cylinder to change.

• Use a pressure gauge, charge box, and other parts especially for R407C.

• An electric leak detector for R22 cannot detect leaks.

• Do not use a haloid torch. (Leaks cannot be detected.)

F

G

H

I

J

Restriction

Caution:

Do not use a refrigerant other than R407C.

- If a refrigerant (R22, etc,) other than R407C is used, the chlorine in the refrigerant will cause the refrigerator oil to deteriorate.

18

Page 19

2 Evacuation

As shown in the figure below, evacuate with the stop valve of the outdoor unit closed and evacuate both the connection piping and the indoor unit

from the service port provided on the stop valve of the outdoor unit using a vacuum pump. (Alwa ys e v acuate from the service port of both the liquid

pipe and the gas pipe.) After the vacuum reaches 650 Pa, continue evacuation for at least one hour or more. Then, stop the vacuum pump and let

stand for one day and check if they vacuum does not rise. (If the v acuum rises, since water may be mixed in, pressurize up to 0.05 MPa using dry

nitrogen gas and evacuate again.)

Evacuate from the service port of the ball valve with a vacuum pump.

Finally, seal with liquid refrigerant from the liquid pipe. Moreover, during operation, adjust the refrigerant amount from the gas pipe so that the

refrigerant is always an appropriate amount.

* Never perform air purging using refrigerant.

D

E

F

A

LO HI

LO HI

A System analyzer

B Lo Knob

C Hi Knob

D Ball valve

E Liquid pipe

F Gas pipe

G Service port

H Three-way joint

I Valve

J Valve

K R407C cylinder

B

C

H

G

K

I

J

M

L

L Scale

Use a graviometer. (One that can measure down to 0.1 kg.)

M Vacuum pump

Use a vacuum pump with a reverse flow check valve.

(Recommended vacuum gauge: ROBINAIR 14830A Thermistor Vacuum

Gauge)

Also use a vacuum gauge that reaches 65 Pa or greater after oper ating for

five minutes.

ENGLISH

19

Page 20

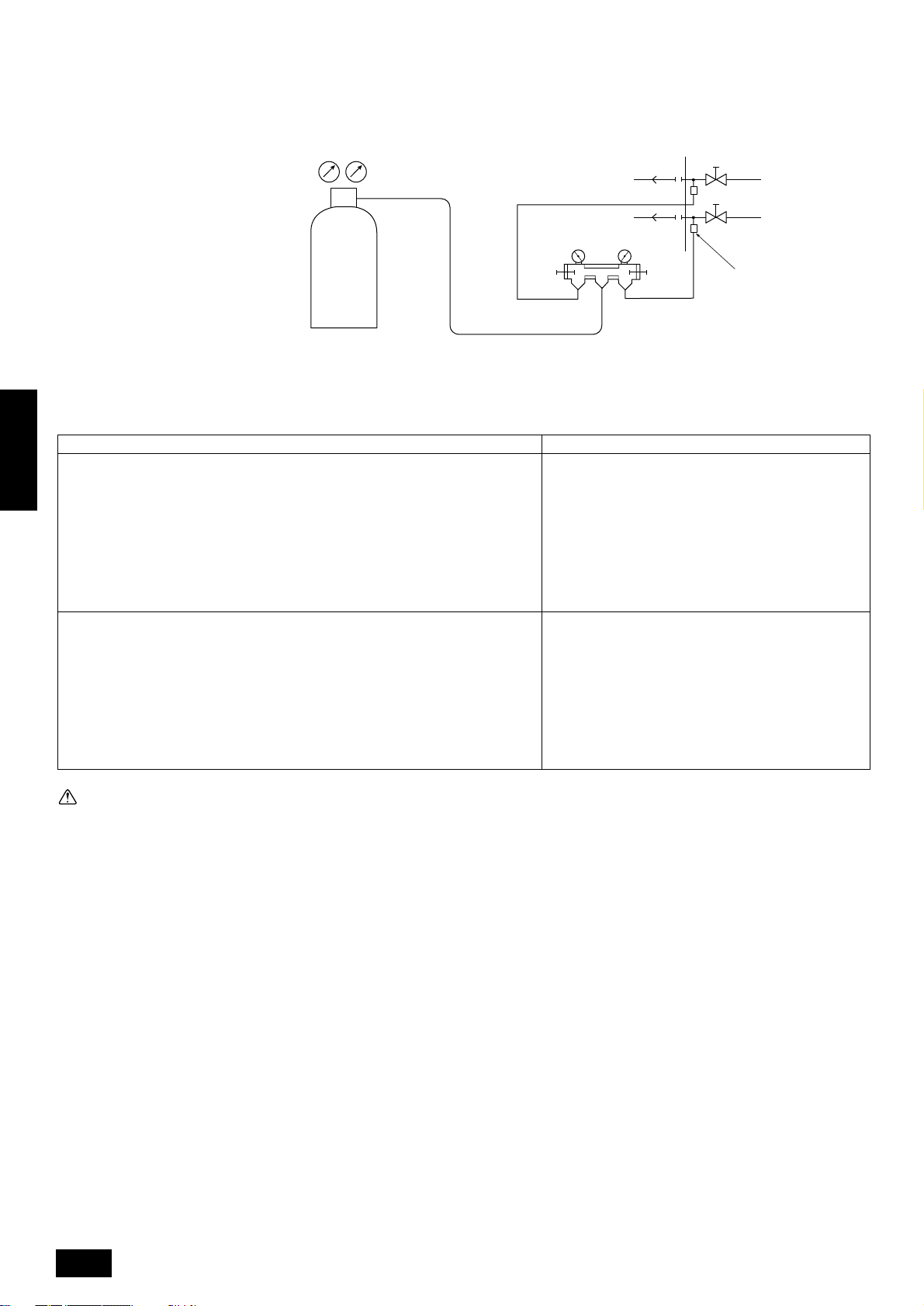

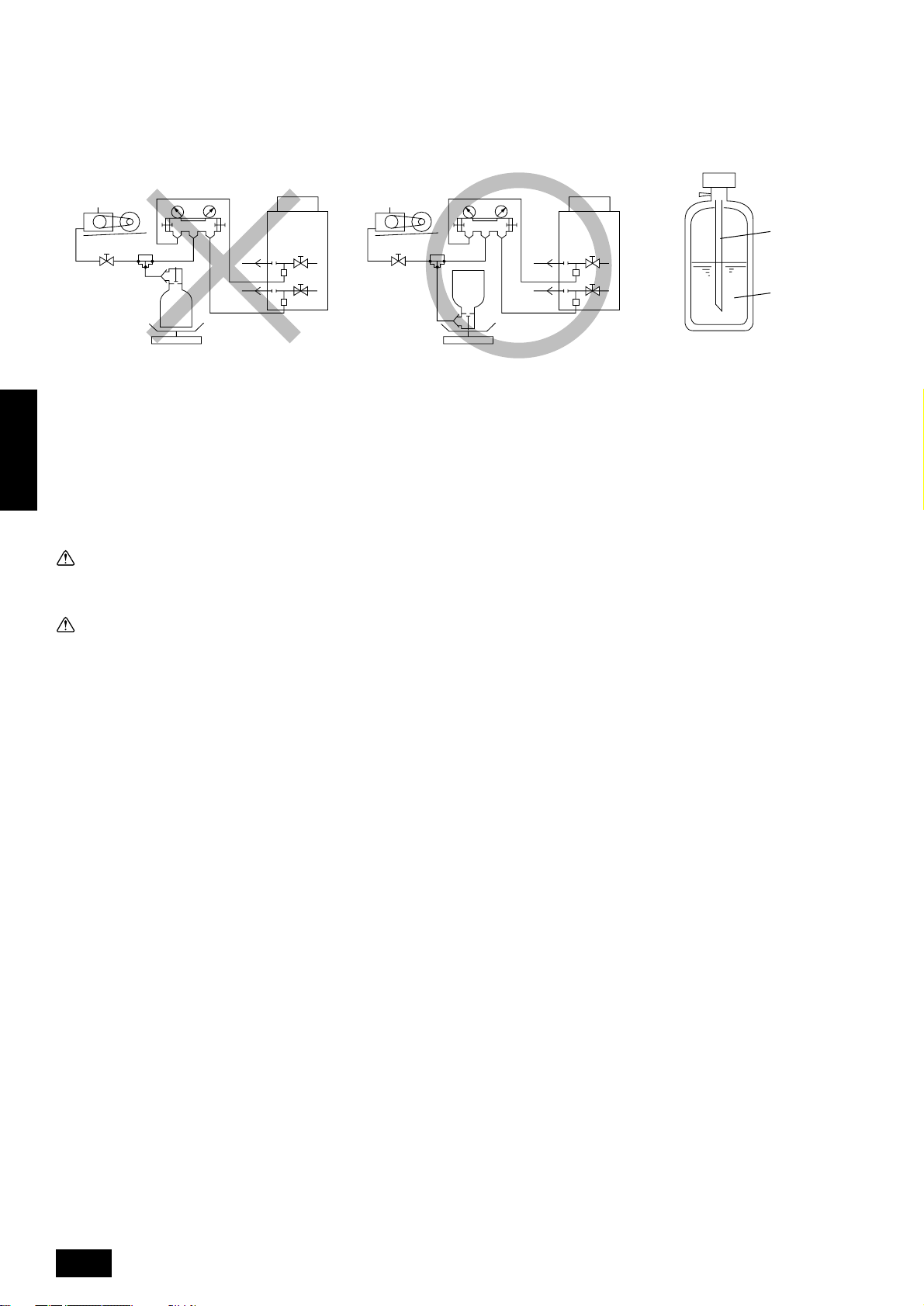

3 Refrigerant Charging

Since the refrigerant used with the unit is nonazerotropic, it must be charged in the liquid state. Consequently , when charging the unit with refrigerant

from a cylinder, if the cylinder does not hav e a syphon pipe, charge the liquid refrigerant by turning the cylinder upside-down as shown below. If the

cylinder has a syphon valve like that shown in the figure at the right, the liquid refrigerant can be charged with the cylinder standing upright.

Therefore, give careful attention to the cylinder specifications. If the unit should be charged with gas refrigerant, replace all the refrigerant with new

refrigerant. Do not use the refrigerant remaining in the cylinder.

B

A

C

A

[When cylinder does not have a syphon pipe] [When cylinder has a syphon pipe

A R407C cylinder

B Syphon pipe

C Liquid refrigerant

Note:

ENGLISH

Always add an appropriate amount of refrigerant. (For the refrigerant additional charge, see pages 13 to 14.) Also always seal the system

with liquid refrigerant. Too much or too little refrigerant will cause trouble.

Use a gauge manifold, charging hose, and other parts for the refrigerant indicated on the unit.

Note that it is not possible to determine if a correct amount is being used with the accumulator level (AL).

(Refrigerant can be charged with the

cylinder standing upright.)]

Warning:

When installing or moving the unit, do not charge it with refrigerant other than the refrigerant (R407C) specified on the unit.

- Mixing of different refrigerant, air, etc. may cause the refrigerant cycle to malfunction and result in severe damage.

Caution:

• Use a vacuum pump with a reverse flow check valve.

- If the vacuum pump does not hav e a re v erse flo w chec k valv e , the v acuum pump oil ma y flow bac k into the refrigerant cycle and cause deterioration of the refrigerator oil and other trouble.

• Do not use a charging cylinder.

- Using a charging cylinder may cause the refrigerant to deteriorate.

• Do not use the tools shown below used with conventional refrigerant.

(Gauge manifold, charge hose, gas leak detector, check valve, refrigerant charge base, vacuum gauge, refrigerant recovery equipment)

- Mixing of conventional refrigerant and refrigerator oil may cause the refrigerator oil to deteriorate.

- Mixing of water will cause the refrigerator oil to deteriorate.

- R407C refrigerant does not contain any chlorine. Therefore, gas leak detectors for conventional refrigerants will not react to it.

• Manage the tools more carefully than normal.

- If dust, dirt, or water gets in the refrigerant cycle, the refrigerator oil will deteriorate.

20

Page 21

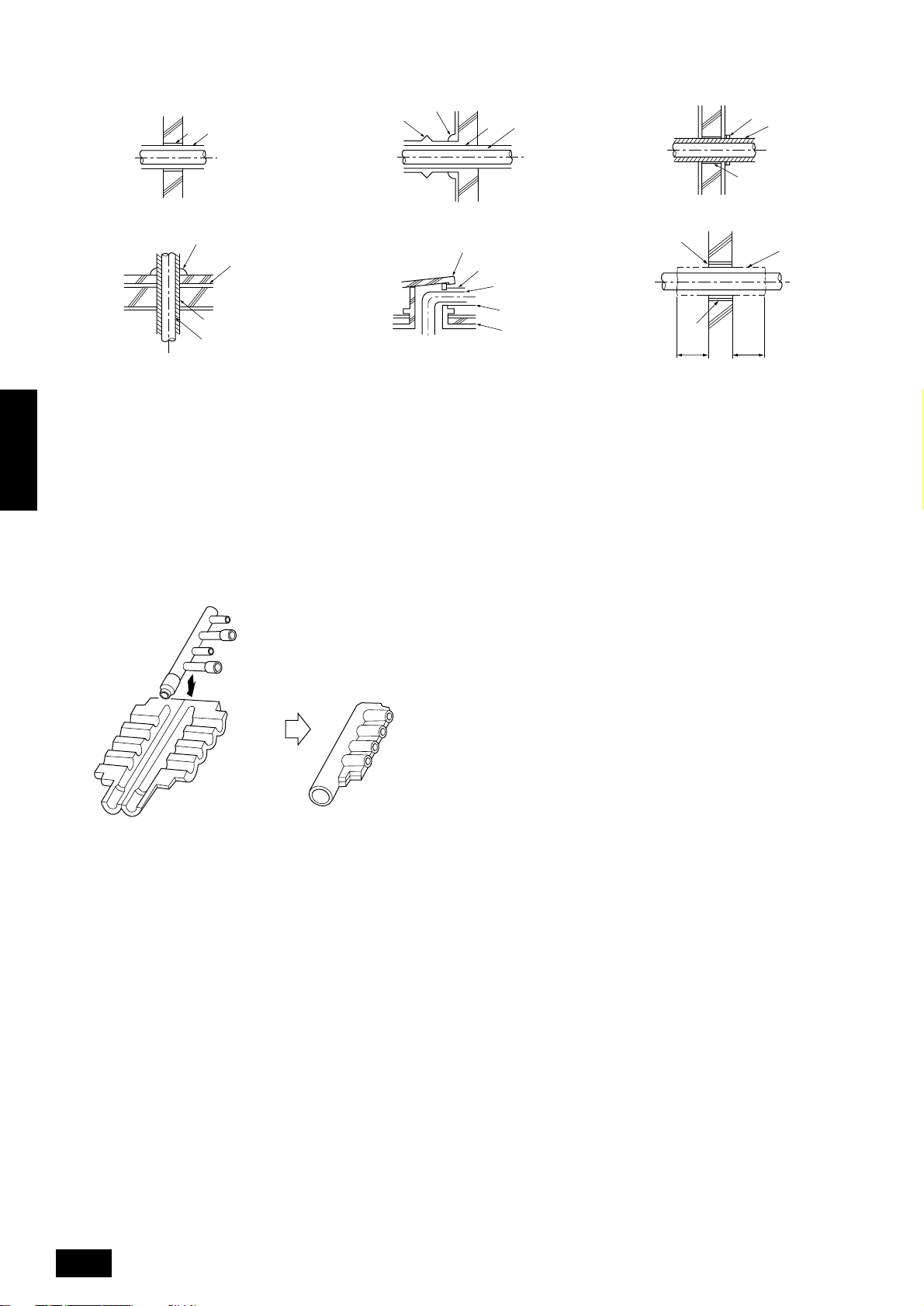

10.6. Thermal insulation of refrigerant

piping

Be sure to give insulation work to refrigerant piping by covering liquid

pipe and gas pipe separately with enough thickness heat-resistant

polyethylene, so that no gap is observed in the joint between indoor unit

and insulating material, and insulating materials themselves. When insulation work is insufficient, there is a possibility of condensation drip,

etc. Pay special attention to insulation work to ceiling plenum.

B

A

C

Heat

insulation

material A

Outer

covering B

Note:

When using polyethylene cover as covering material, asphalt roofing shall not be required.

Glass fiber + Steel wire

Adhesive + Heat - resistant polyethylene foam +

Adhesive tape

Indoor Vinyl tape

Floor exposed

Outdoor

Water-proof hemp cloth + Bronze asphalt

Water-proof hemp cloth + Zinc plate + Oily paint

D

A Steel wire

B Piping

C Asphaltic oily mastic or asphalt

D Heat insulation material A

E Outer covering B

• Do not insulate gas or low pressure pipe and liquid or high

pressure pipe together.

Bad example

A

E

B

C

D

E

A

Good example

E

E

B

D

Note:

No heat insulation must be provided for electric wires.

A Liquid pipe

B Gas pipe

C Electric wire

D Finishing tape

E Insulating material

A Liquid pipe

B Gas pipe

D Finishing tape

E Insulating material

ENGLISH

• Be sure to fully insulate connecting portion.

A

A These parts are not insulated.

21

Page 22

Penetrations

E

I

B

A Sleeve

B Heat insulating material

C Lagging

D Caulking material

E Band

F Waterproofing layer

G Sleeve with edge

ENGLISH

Inner wall (concealed) Outer wall Outer wall (exposed)

D

A B

C

Floor (fireproofing) Roof pipe shaft Penetrating portion on fire limit and boundary wall

D

F

G

A B

D

I

J

B

H

G

B

F

H Lagging material

I Mortar or other incombustible caulking

J Incombustible heat insulation material

When filling a gap with mortar, cover the penetration part with steel plate

so that the insulation material will not be caved in. For this part, use

incombustible materials for both insulation and cov ering. (Vinyl co vering

should not be used.)

A

1m1m

Branch piping section

Insulate the header using

the insulation

material attached to the

branch pipe kit

as shown in the figure.

22

Page 23

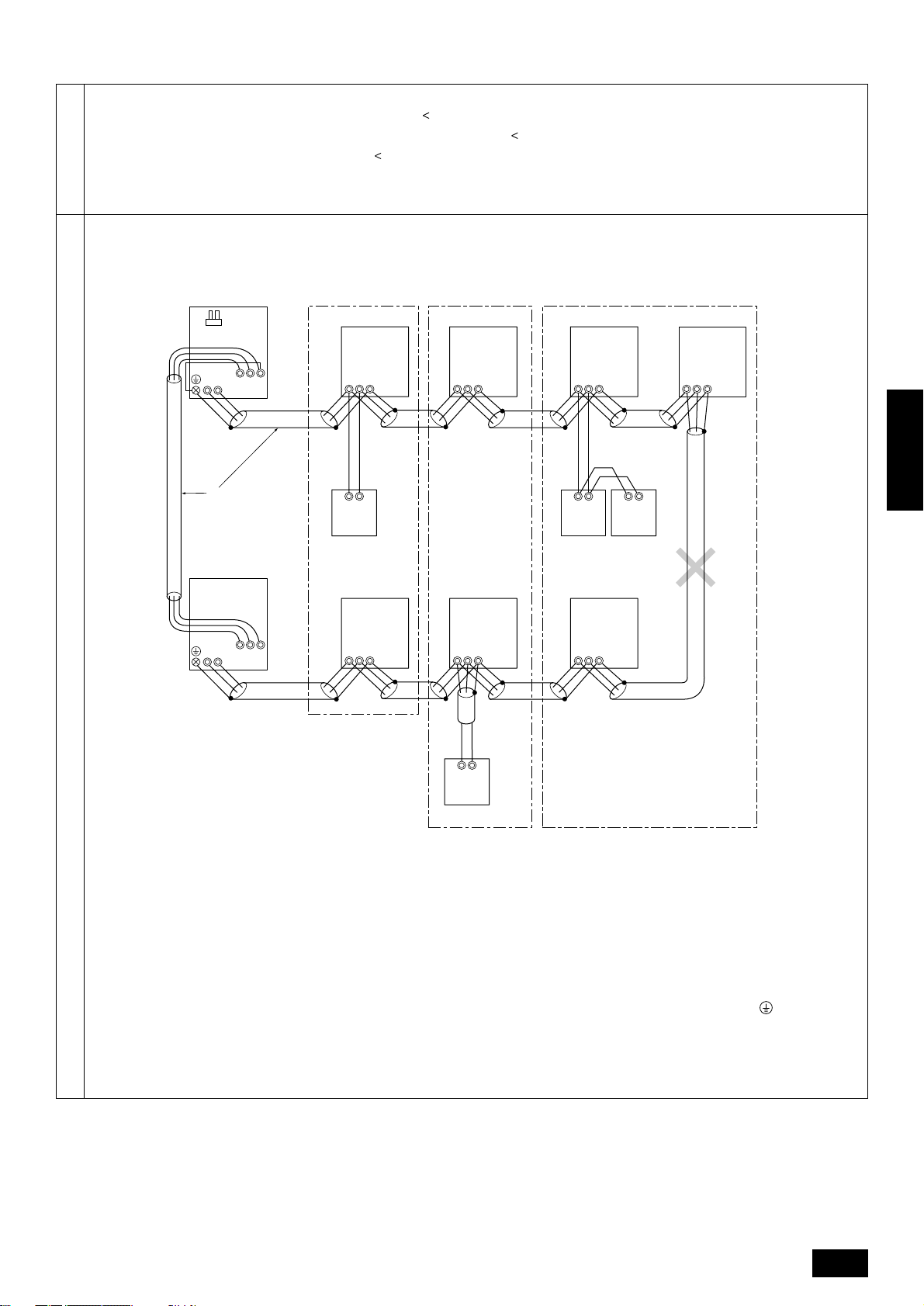

11. Electrical work

11.1. Caution

1 Follow ordinance of your governmental organization for technical standard related to electrical equipment, wiring regulations and guidance of each

electric power company.

Warning:

Be sure to have authorized electric engineers do electric work using special circuits in accordance with regulations and this installation

manual. If power supply circuit has a lack of capacity or electric work deficiency, if may cause an electric shock or fire.

2 Install the outdoor unit transmission line away from the power source wiring so that it is not affected by electric noise from the power source . (Do not

run it through the same conduit.)

3 Be sure to provide designated grounding work to outdoor unit.

Caution:

Be sure to put outdoor unit to earth. Do not connect earth line to any gas pipe, water pipe, lightning rod or telephone earth line. If earth is

incomplete, it may cause an electric shock.

4 Give some allowance to wiring for electrical part box of indoor and outdoor units, because the box is sometimes removed at the time of service work.

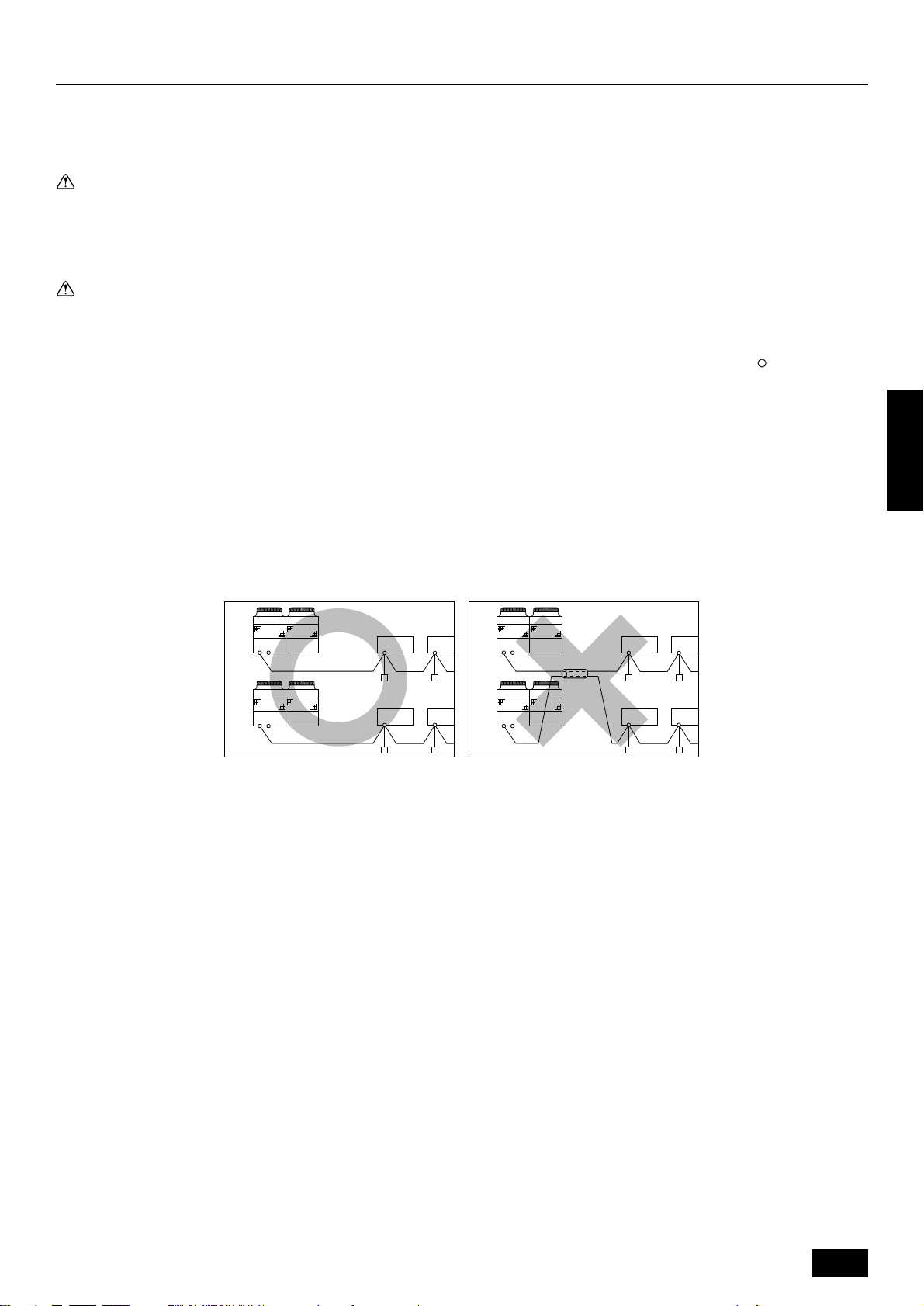

5 Never connect the main power source to terminal block of transmission line. If connected, electrical parts will be burnt out ( mark in the figure

below).

6 Use 2-core shield cable for transmission line. If transmission lines of different systems are wired with the same multiplecore cable , the resultant poor

transmitting and receiving will cause erroneous operations (× mark in the figure below).

7 Only the transmission line specified should be connected to the terminal block for outdoor unit transmission.

(Transmission line to be connected with indoor unit : Terminal block TB3 for transmission line, Other : Terminal block TB7 for centralized control)

Erroneous connection does not allow the system to operate.

8 In case to connect with the upper class controller or to conduct group operation in different refrigerant systems, the control line for transmission is

required between the outdoor units each other.

Connect this control line between the terminal blocks for centralized control. (2-wire line with no polarity)

When conducting group operation in different refrigerant systems without connecting to the upper class controller, replace the insertion of the short

circuit connector from CN41 of one outdoor unit to CN40.

9 Group is set by operating the remote controller.

ENGLISH

A

C

TB3

TB7

B

D

TB3

TB7

TB3: Transmission line terminal board, TB7: Central control line terminal board

A Outdoor unit

B 2-core cable

C Indoor unit

D Remote controller

E Multi-core cable

B

TB3

TB3

TB7

TB7

A

C

E

D

23

Page 24

11.2. Control box and connecting posi-

To prevent external tensile force from applying to the wiring connection

section of power source terminal block, use buffer bushing like PG

connection or the like.

knockout hole

T

e

n

s

i

l

e

f

o

r

c

e

A

D

A

F

G

E

B

C

B

tion of wiring

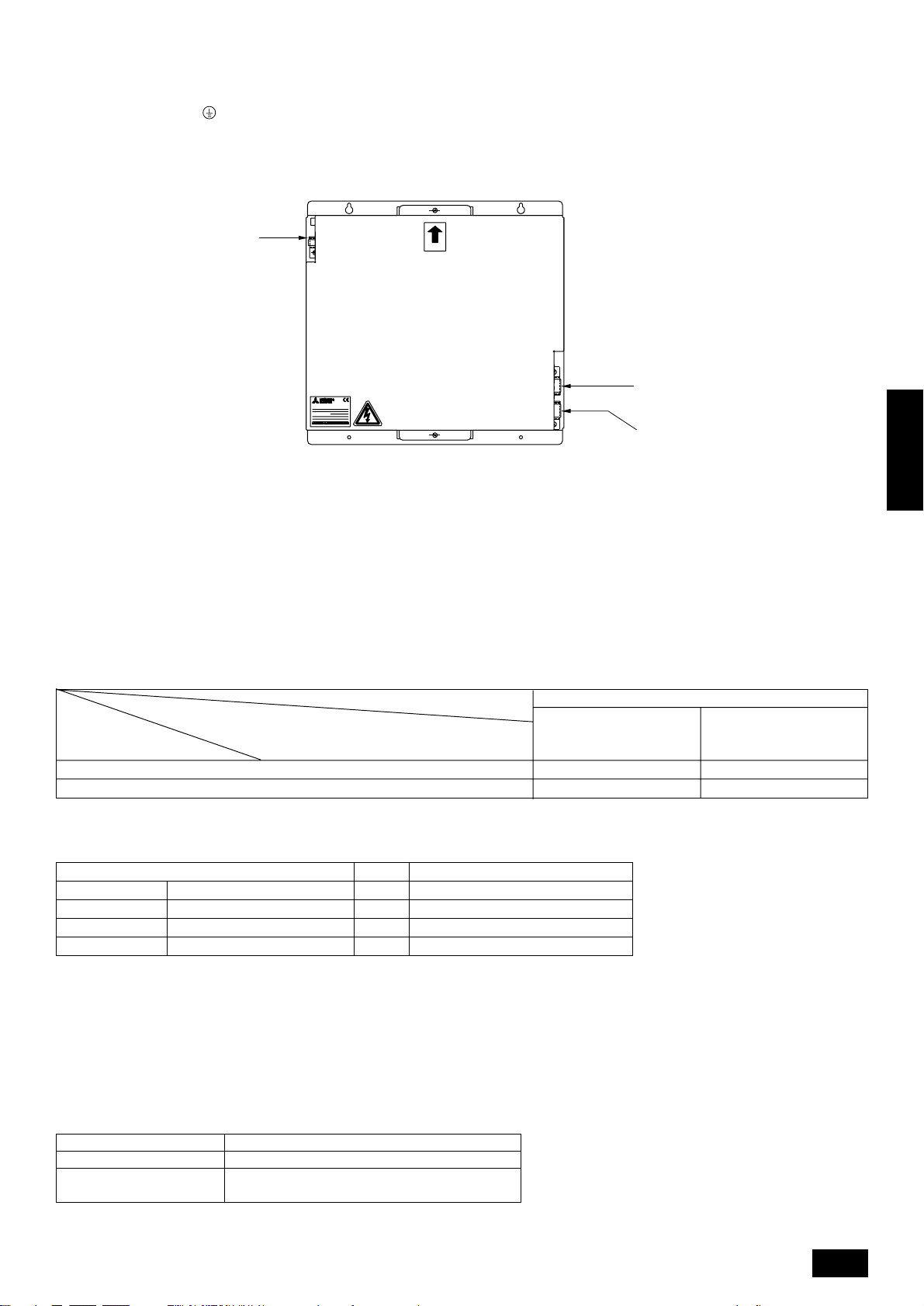

1 Outdoor unit

1. Remove the total of six screws at the top and bottom, and remove

the service panel by pulling it forward. (See the figure below.)

A

A Service panel

ENGLISH

2. Remove the two screws on the left and right-hand of the base of the

control box and pull the overall co ver do wnwards to detach it. (A diagram with the control box cover removed is shown below.)

3. Connect indoor and outdoor units through the terminal block for transmission lines (TB3). Outdoor units and connections to central control

systems go through the terminal block for centralized control (TB7).

When making an indoor/outdoor connection with shielded wiring, connect the shield ground to the shield screw. When making a central

control system connection with shielded wiring, use the terminal block

for centralized control (TB7).

When the CN41 power supply connector of an outdoor unit has been

replaced with a CN40, the shield terminal (S) for centralized control

(TB7) should also be connected to the shield screw.

2 How to use the conduit mounting plate

(1) Conduit mounting plates (ø46, ø53, ø62) are being provided.

Select conduit mounting plate based on the outside diameter of conduit to be used and mount it as shown in the figure.

(2) Fix power source wiring to control box by using buffer bushing for

tensile force (PG connection or the like).

J

B

F

LD1

CD A

E

L1 L2 L3

N

TB1

GHI

A INV board

B MAIN board

C Ten position

D One position

E Address switch

F FANCON board

G Power source

H Shield screw

I Transmission line

J RELAY board

K Shield terminal (S)

M1 M2M1 M2 S

TB7TB3

K

Tensile force

knockout hole

A ø46 mounting hole

B ø53 mounting hole

C ø62 knockout hole

D For the connection of conduit at bottom

E ø62 mounting hole

F For the connection of conduit at front

G The front of outdoor unit

To prevent external tensile force from applying to the wiring connection

section of power source terminal block, use buffer bushing like PG

connection or the like.

3 How to use the wire mounting plate

(1) When the power source and transmission lines are wired through

the knock-out hole of the left wiring, it is necessary to attach the

mounting plate onto the base of the front of the control box with two

screws.

In this case, please use the top clamp to fasten the transmission line

and the lower installation hole to fasten the power supply line.

If it does not match with the outer diameter of the power line conduit,

mount the power line conduit mounting plate (ø46) as shown in the fig-

ure below.

Also, please fasten it so that no tension is brought to bear on the power

line, as shown above.

Control Box

Control Box

ø46 mounting hole

Ø46 mounting hole

Transmission

Transmission

wire

wire

Source wire

Source wire

Wire mounting plate

Wire mounting plate

Front side

Ø53 mounting hole

24

ø53 mounting hole

Front side

Page 25

4 Transmission booster (optional)

Transmission cables

terminal block 2 (TB3)

Transmission cables

terminal block 1 (TB2)

Power terminal

block (TB1)

and Earth

(For details, see item 11.3. “Wiring transmission cables”)

Connect 220/230/240 VAC to L/N of power terminal block (TB1).

Connect the ground to the terminal of power terminal block (TB1).

Connect the outdoor unit side transmission cables to A/B of transmission cables terminal block 1 (TB2).

Connect the outdoor unit side shield to S of transmission cables terminal block 1 (TB2).

Connect additional indoor unit side transmission cables to A/B of transmission cables terminal block 2 (TB3).

Connect additional indoor unit side shield to S of transmission cables terminal block 2 (TB3).

Power terminal

Power terminal

block (TB1)

block (TB1)

and Earth

and Earth

TRANSMISSION BOOSTER

MODEL

PAC-SF46EPA

POWER RATING

WEIGHT

MADE IN JAPAN

220-240V:0.7A ~/N

50

3.4kg

UP

Transmission cables

Transmission cables

terminal block 2 (TB3)

terminal block 2 (TB3)

Transmission cables

Transmission cables

terminal block 1 (TB2)

terminal block 1 (TB2)

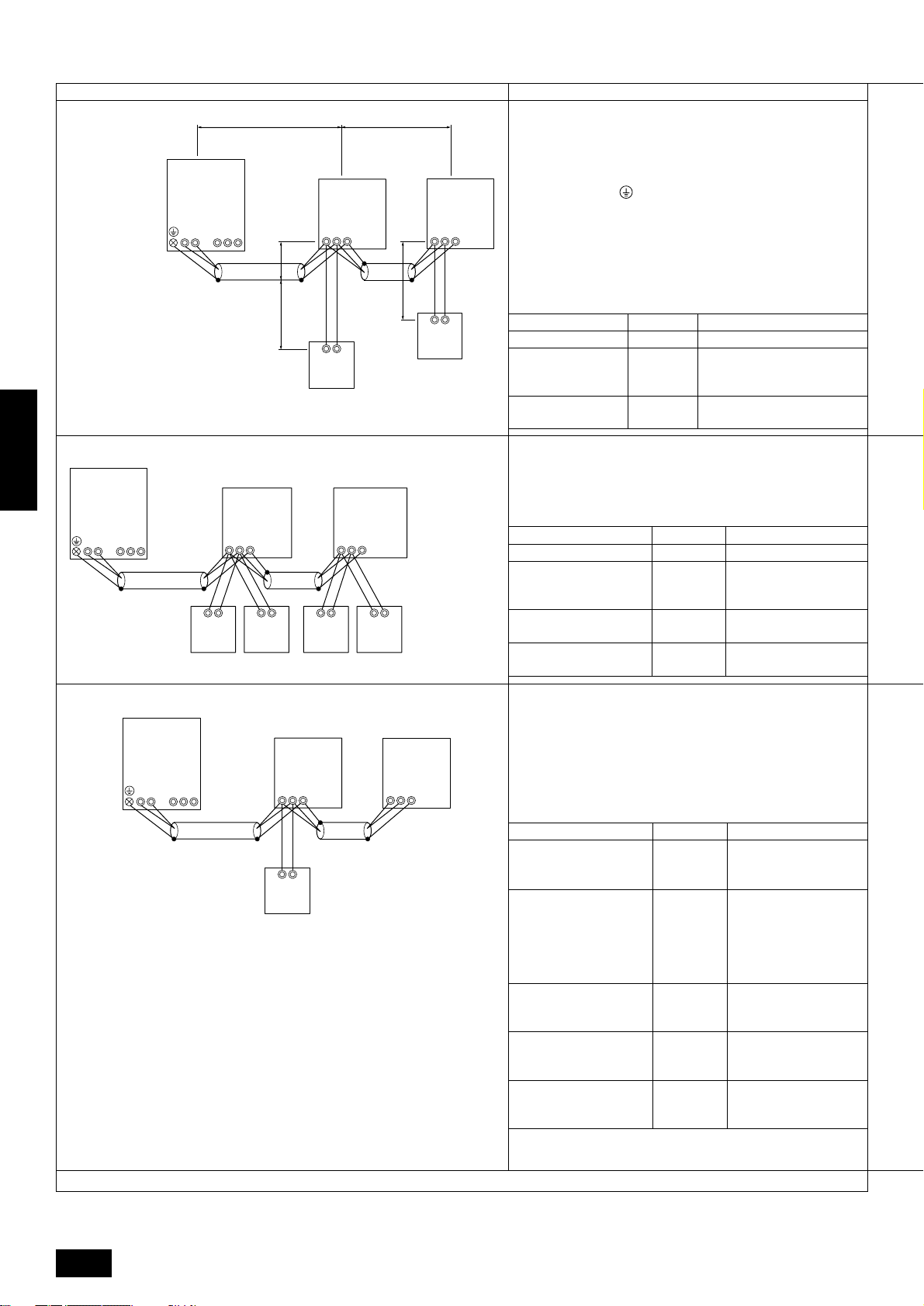

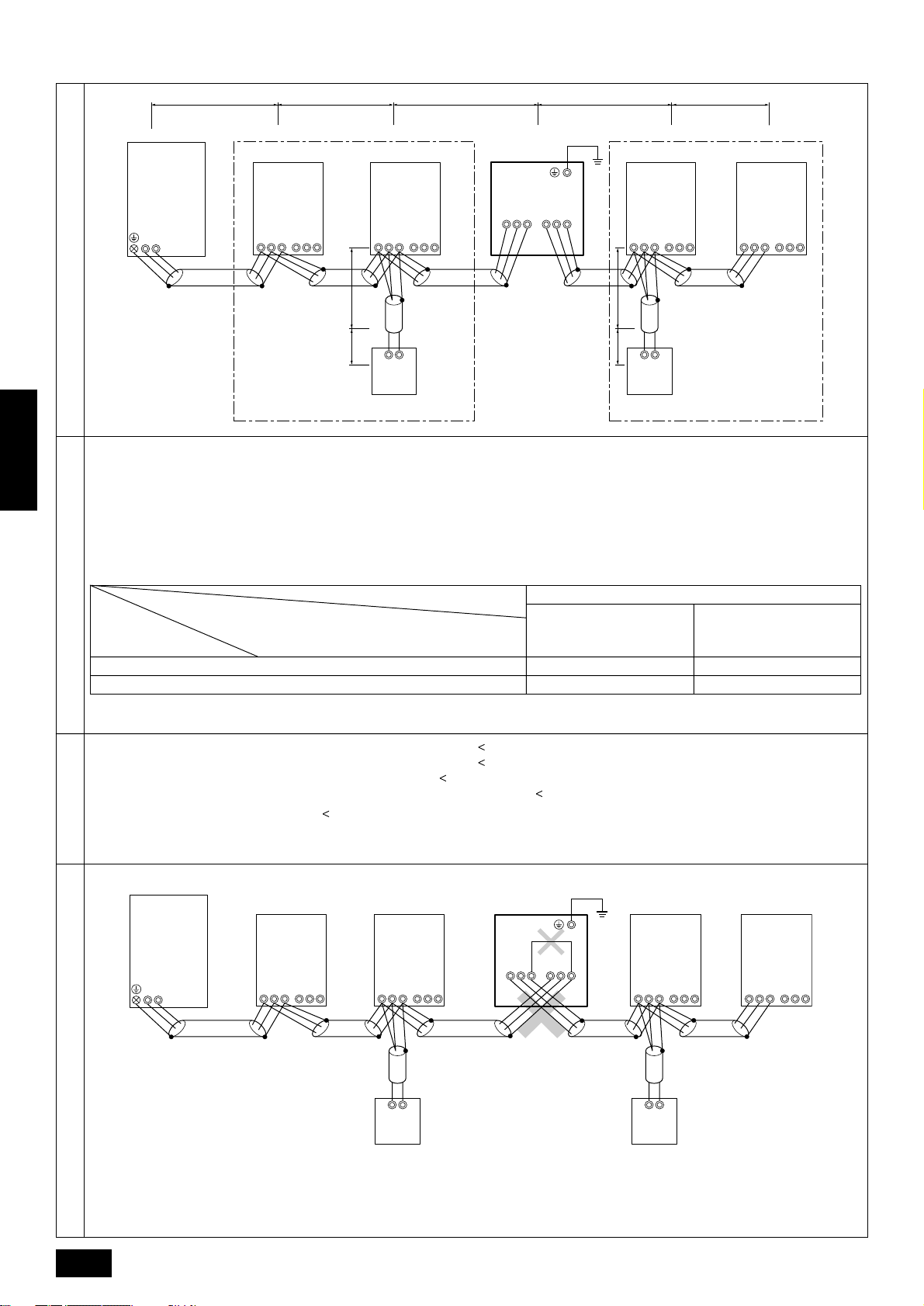

11.3. Wiring transmission cables

Wiring method, address setting method and permissible wiring length differ according to and whether or not you are using transmission booster. Chec k

permissible wiring length before wiring.

A may be required depending on the number of indoor units.

Item 4 “Wiring examples” gives typical wiring examples (A – C).

A. System using remote controller (1 outdoor unit)

B. System using remote controller (system operated as a group among multiple refrigerant systems)

C. System using power supply extension unit for transmission booster (combination of systems a – b)

1 Connecting a transmission booster

A transmission booster (RP) is required when the number of connected indoor unit models in a cooling system exceeds the number of models specified

in the chart below.

* The maximum number of units that can be controlled is determined by the indoor unit model, the type of remote controller and their capabilities.

(*1)

Capability of the

connected indoor units

*1 If even one unit that is higher than 200 exists in the cooling system, the maximum capacity will be “200 or higher”.

2 Name, code and possible unit connections

Outdoor unit

Indoor unit

Remote controller

Other

*1 A transmission booster (RP) may be required depending on the number of connected indoor unit controllers.

3 Types of control cables

(1) Wiring transmission cables

• Types of transmission cables

Shielding wire CVVS or CPEVS

• Cable diameter

More than 1.25 mm

• Maximum wiring length within 200 m

(2) Remote control cables

Kind of remote control cable 2-core cable (unshielded)

Cable diameter 0.5 to 0.75 mm

Remarks

4 Wiring examples

Typical wiring examples are shown on pages 26 to 30 (Wiring examples A – C).

Remote controller type

Number of connected indoor units that can be

connected without a RP.

200 or lower

200 or higher

The number of indoor units and the total number of remote controllers is displayed within the parenthesis ( ).

Name Code Possible unit connections

Outdoor unit controller

Indoor unit controller

Remote controller (*1)

Transmission booster unit

2

2

OC

IC

2 to 32 units per 1 OC (*1)

RC