Page 1

Models PUHY-P700, P750, P800YSGM-A

Service Handbook

AIR CONDITIONERS CITY MULTI

Page 2

Contents

1 Read Before Servicing ................................................................ 6

[1] Items to Be Checked .............................................................. 6

[2] Necessary Tools and Materials .............................................. 7

[3] Piping Materials ...................................................................... 8

[4] Storage of Piping Material ...................................................... 10

[5] Piping Machining .................................................................... 11

[6] Brazing.................................................................................... 12

[7]

Airtightness Test

...................................................................... 13

[8] Vacuuming .............................................................................. 13

[9] Vacuum Drying........................................................................ 14

[10] Changing Refrigerant.............................................................. 15

[11] Remedies to be taken in case of a refrigerant leak................ 15

[12]

Characteristics of the Conventional and the New Refrigerants

.. 16

[13] Notes on Refrigerating Machine Oil........................................ 17

2 Restrictions .................................................................................. 18

[1] Electrical Work & M-NET control ............................................ 18

[2] Types of Switch Setting and Address Setting ........................ 19

[3] Examples of system connection ............................................ 21

[4] Restrictions on Refrigerant Piping Length.............................. 35

3 Components of the Outdoor Unit ................................................ 36

[1] Appearance of the Components and Refrigerant Circuit........ 36

[2] Control Box ............................................................................ 41

[3] Circuit Board .......................................................................... 44

4 Remote Controller ........................................................................ 49

[1]

Functions and Specifications of MA and ME Remote Controllers

.... 49

[2] Group Setting and Interlocking Settings that are Made on

the ME Remote Controller .................................................... 50

[3]

Interlocking Setting that is Made on the MA Remote Controller

...... 53

[4] Switching to the built-in Thermo on the remote controller ...... 54

5 Electrical Wiring Diagram ............................................................ 55

[1] Compressor unit .................................................................... 55

[2] Heat exchanger unit................................................................ 56

[3]

Power Dispatching Extension Unit for the Transmission Lines

.. 57

6 Refrigerant Circuit ........................................................................ 58

[1] Refrigerant Circuit Diagram .................................................... 58

[2] Functions of Principal Parts.................................................... 59

7 Control.......................................................................................... 62

[1] Dip Switch Functions and Their Factory Settings .................. 62

[2] Controlling the Outdoor Unit .................................................. 68

[3] Operation Flow Chart ............................................................ 75

8 Test Run ...................................................................................... 80

[1] Check Items before Test Run.................................................. 80

[2] Test Run Method .................................................................... 80

[3] Operating Characteristics and Refrigerant Amount................ 81

[4] Adjustment and Judgment of Refrigerant Amount ................ 81

[5] Refrigerant Volume Adjustment Mode Operation .................. 83

[6] Symptoms that do not Signify Problems ................................ 85

[7]

Standard Operation Data (Reference Data)

.............................. 86

9 Troubleshooting............................................................................ 88

[1] Check Code List .................................................................... 88

[2] Responding to Error Display on the Remote Controller ........ 91

[3] Investigation of Transmission Wave Shape/Noise .................. 124

[4] Troubleshooting of Principal Parts .......................................... 127

[5] Refrigerant Leak .................................................................... 143

[6] Compressor Replacement Instructions .................................. 145

[7] Collecting the Cooling Liquid from the Accumulator .............. 146

0 LED display .................................................................................. 147

[1] LED Monitor Display .............................................................. 147

Page 3

Safety Precautions

Symbols used in the text

Warning:

Failure to follow all instructions may result in serious personal injury or death.

Caution:

Failure to follow all instructions may result in personal injury or damage to the unit.

Symbols used in the illustrations

: Indicates an action that must be avoided.

: Indicates that important instructions must be followed.

: Indicates a part which must be grounded.

: Beware of electric shock (This symbol is displayed on the main unit label.) <Color : Yellow>

Warning : Carefully read the labels affixed to the main unit.

Before installing the unit, be sure to carefully read all of the following safety precautions.

These precautions provide important information regarding safety. Be sure to follow them to ensure safety.

After reading this handbook, hand it over to those who will be using the unit.

The user of the unit should keep this manual at hand and make it available to those who will be performing

repairs or relocating the unit.

Also, make it available to the new user when the user changes hands.

Be sure to carefully follow each step in this

handbook when installing the unit.

• Improper installation may result in water leak,

electric shock, smoke or fire.

Securely attach the terminal cover (panel) on the

unit.

• If installed improperly, dust and/or water may enter

the unit and present a risk of electric shock, smoke,

or fire.

Only use Refrigerant R410A as indicated on the

unit when installing or relocating the unit.

• The use of any other refrigerant or an introduction of

air into the unit circuit may cause the unit to run an

abnormal cycle and cause the unit to burst.

Do not make any changes or modifications to the

unit. In case of problems, consult the dealer.

• If repairs are not made properly, the unit may leak

water and present a risk of electric shock, or it may

produce smoke or cause fire.

Have all electrical work performed by a licensed

electrician according to the local regulations and

the instructions given in this manual. Secure a

circuit designated exclusively to the unit.

• Improper installation or a lack of circuit capacity may

cause the unit to malfunction or present a risk of

electric shock, smoke, and fire.

Have the unit professionally installed.

• Improper installation by an unqualified person may

result in water leak, electric shock, or fire.

Only use specified cables for wiring. Securely

connect each cable, and make sure that the cables

are not straining the terminals.

• Cables not connected securely and properly may

generate heat and cause fire.

Place the unit on a stable, level surface that

withstands the weight of the unit to prevent the

unit from tipping over or falling causing injury as a

result.

Take necessary safety measures against typhoons

and earthquakes to prevent the unit from falling

over.

- 1 -

Page 4

When relocating the air conditioner, consult the

dealer or a specialist.

• Improper installation may result in water leak,

electric shock, or fire.

• Consult the dealer for necessary measures to take.

After completing the service work, check for a

refrigerant gas leak.

• If leaked gas refrigerant is exposed to a heart

source such as fan heater, stove, and electric grill,

noxious gases may form.

In the event of a refrigerant gas leak, provide

adequate ventilation to the room.

• If leaked refrigerant gas is exposed to a heat source,

noxious gases may form.

With All-Fresh type air conditioners, outdoor air

may be directly blown into the room upon thermo

off. Take this into consideration when installing the

unit.

• Direct exposure to outdoor air may present a health

hazard, and it may also cause food items to

deteriorate.

When installing the unit in a small room, safeguard

against hypoxia that results from leaked refrigerant

reaching the threshold level.

Do not touch the fins on the heat exchanger with

bare hands: they are sharp and dangerous.

Precautions for Handling Units for Use with R410A

Caution

Warning : Carefully read the labels affixed to the main unit.

Do not try to defeat the safety features of the

devices, and do not change the settings.

• Defeating the safety features on the unit such as the

pressure switch and temperature switch or using

parts other than those specified by Mitsubishi

Electric may result in fire or explosion.

Use refrigerant pipes made of C1220 phosphorus

deoxidized copper categorized under H3000

(Copper and Copper Alloy Seamless Pipes and

Tubes), a standard set by JIS. Keep the inner and

outer surfaces of the pipes clean and free of

contaminants such as sulfur, oxides, dust/dirt,

shaving particles, oils, and moisture.

• Contaminants inside the refrigerant piping will cause

the refrigerant oil to deteriorate.

Do not use the following tools that have been used

with the conventional refrigerants.Prepare tools

that are for exclusive use with R410A.

(Gauge manifold, charging hose, gas leak detector,

reverse-flow check valve, refrigerant charge base,

vacuum gauge, and refrigerant recovery

equipment.)

• If refrigerant and /or refrigerant oil left on these tools

are mixed in with R410A, or if water is mixed with

R410A, it will cause the refrigerant to deteriorate.

• Since R410A does not contain chlorine, gas-leak

detectors for conventional refrigerators will not work.

Only use specified parts.

• Have the unit professionally installed.

Improper installation may cause water leak, electric

shock, smoke, or fire.

Use a vacuum pump with a reverse-flow-check

valve.

• If other types of valves are used, the vacuum pump

oil will flow back into the refrigerant cycle and cause

the refrigerator oil to deteriorate.

Do not use the existing refrigerant piping

• The old refrigerant and refrigerator oil in the existing

piping contain a large amount of chlorine, which will

cause the refrigerator oil in the new unit to

deteriorate.

• R410A is a high-pressure refrigerant, and the use of

the existing piping may result in bursting.

- 2 -

Page 5

Before Installing the Unit

Warning

Caution

Store the piping to be used during installation

indoors, and keep both ends of the piping sealed

until immediately before brazing. (Keep elbows and

other joints wrapped in plastic.)

• If dust, dirt, or water enters the refrigerant cycle, it

may cause the oil in the unit to deteriorate or may

cause the compressor to malfunction.

Use a small amount of ester oil, ether oil, or

alkylbenzene to coat flares and flange connections.

• A large amount of mineral oil will cause the

refrigerating machine oil to deteriorate.

Do not use a charging cylinder.

• The use of charging cylinder will change the

composition of the refrigerant and lead to power

loss.

Exercise special care when handling the tools.

• An introduction of foreign objects such as dust, dirt,

or water into the refrigerant cycle will cause the

refrigerating machine oil to deteriorate.

Only use R410A refrigerant.

• The use of refrigerants containing chlorine (i.e. R22)

will cause the refrigerant to deteriorate.

Use liquid refrigerant to charge the system.

• Charging the unit with gas refrigerant will cause the

refrigerant in the cylinder to change its composition

and will lead to a drop in performance.

Do not install the unit in a place where there is a

possibility of flammable gas leak.

• Leaked gas accumulated around the unit may start a

fire.

Do not use the unit to preserve food, animals,

plants, artifacts, or for other special purposes.

• The unit is not designed to provide adequate

conditions to preserve the quality of these items.

When installing the unit in a hospital, take

necessary measures against noise.

• High-frequency medical equipment may interfere

with the normal operation of the air conditioning unit

or the air conditioning unit may interfere with the

normal operation of the medical equipment.

Do not use the unit in an unusual environment.

• The use of the unit in the presence of a large

amount of oil, steam, acid, alkaline solvents, or

special types of sprays may lead to a remarkable

drop in performance and/or malfunction and

presents a risk of electric shock, smoke, or fire.

• The presence of organic solvents, corroded gas

(such as ammonia, sulfur compounds, and acid)

may cause gas or water leak.

Do not place the unit on or over things that may

not get wet.

• When humidity level exceeds 80% or when the

drainage system is clogged, indoor units may drip

water.

• Installation of a centralized drainage system for the

outdoor unit may also need to be considered to

prevent water drips from the outdoor units.

- 3 -

Page 6

Before Installing (Relocating) the Unit or Performing Electric Work

Caution

Do not spray water on the air conditioners or

immerse the air conditioners in water.

• Water on the unit presents a risk of electric shock.

Install a breaker for current leakage at the power

source to avoid the risk of electric shock.

• Without a breaker for current leakage, there is a risk

of electric shock, smoke, or fire.

Use wires that are specified in the installation

manual.

• The use of other types of wires presents a risk of

electrical current leak, electric shock, smoke, or fire.

Periodically check the platform on which the unit is

placed for damage to prevent the unit from falling.

• If the unit is left on a damaged platform, it may

topple over, causing injury.

Ground the unit.

• Do not connect the grounding on the unit to gas

pipes, water pipes, lightning rods, or the grounding

terminals of telephones. Improper grounding

presents a risk of electric shock, smoke, fire, or the

noise caused by improper grounding may cause the

unit to malfunction.

Use breakers and fuses (electrical current breaker,

remote switch <switch + Type-B fuse>, molded

case circuit breaker) with a proper current

capacity.

• The use of large-capacity fuses, steel wire, or

copper wire may damage the unit or cause smoke or

fire.

When installing draining pipes, follow the

instructions in the manual, and make sure that they

properly drain water so as to avoid dew

condensation.

• If not installed properly, they may cause water leaks

and damage the furnishings.

Make sure the wires are not subject to tension.

• If the wires are too taut, they may break or generate

heat and/or smoke and cause fire.

Exercise caution when transporting products.

• Do not try to move equipments over 20kg (approx.

44 lbs.) alone.

• Do not use the PP bands used on some packages

for transportation.

• Wear protective gloves to avoid injury caused by

touching the fins on the heat exchanger with bare

hands.

• When using a suspension bolt to transport the heatsource unit, use a four-point suspension. A threepoint suspension does not provide adequate stability

and presents a risk of accidents.

Properly dispose of the packing materials.

• Things such as nails and wood pieces may be

included in the package. Dispose of them properly to

prevent injury.

• Plastic bags present a choking hazard to children.

Tear up the plastic bags before disposing of them to

prevent accidents.

- 4 -

Page 7

Before the Test Run

Caution

Turn on the unit at least 12 hours before the test

run.

• Keep the unit on throughout the season.

Turning the unit off during the season may cause

problems.

Do not turn off the power immediately after

stopping the unit.

• Allow for at least five minutes before turning off the

unit; otherwise, the unit may leak water or

experience other problems.

Do not operate the unit without panels and safety

guards in their proper places.

• They are there to keep the users from injury from

accidentally touching rotating, high-temperature, or

high-voltage parts.

Do not touch the refrigerant pipes with bare hands

during and immediately after operation.

• Depending on the state of the refrigerant in the

system, certain parts of the unit such as the pipes

and compressor may become very cold or hot and

may subject the person to frost bites or burning.

Do not operate switches with wet hands to avoid

electric shock.

Do not operate the unit without air filters.

• Dust particles in the air may clog the system and

cause malfunction.

- 5 -

Page 8

- 6 -

¡¡

Read Before Servicing

[1] Items to Be Checked

1. Verify the type of refrigerant used by the unit to be serviced.

Refrigerant Type : R410A

2. Check the symptom exhibited by the unit to be serviced.

Look in this service handbook for symptoms relating to the refrigerant cycle.

3. Be sure to carefully read the Safety Precautions at the beginning of this document.

4. Prepare necessary tools: Prepare tools exclusive for use with each refrigerant type.

Refer to P7 for more information.

5. If the refrigerant circuit is opened (to repair a gas leak etc.), the dryer needs to be replaced.

Only use the dryer designed specifically for Citi Multi YGM-A. The use of other dryers may result in malfunctions.

✻ Replace the dryer after completing all the repairs on the refrigerant circuit.

(If left exposed to air, the dryer will absorb moisture. Replace the dryer as quickly as possible after removing

the old one.)

✻ When all of the following conditions are met, the replacement of drier is not necessary.

(1) Do not leave the refrigerant circuit longer than 2 hours.

(2) Cover the opening end with a cap or tape to keep moisture from entering.

(3) Also cover the opening end of the new part with a cap or tape

(4) Do not perform the task in the rain.

(5) Evacuate the refrigerant circuit as specified.

6. Verification of the connecting pipes: Verify the type of refrigerant used for the unit to be

moved or replaced.

• Use pipes made of phosphorus deoxidized copper. Keep the inner and outer surfaces of the pipes clean and

free of contaminants such as sulfur, oxides, dust/dirt, shaving particles, oils, and moisture.

• Contaminants inside the refrigerant piping will cause the refrigerant oil to deteriorate.

7. If there is a gas leak or if the remaining refrigerant is exposed to an open flame, a noxious gas

hydrofluoric acid may form. Keep workplace well ventilated.

CAUTION

1. Install new pipes immediately after removing old ones to keep moisture out of the refrigerant circuit.

2. Chloride in some types of refrigerants such as R22 will cause the refrigerating machine oil to

deteriorate.

Page 9

- 7 -

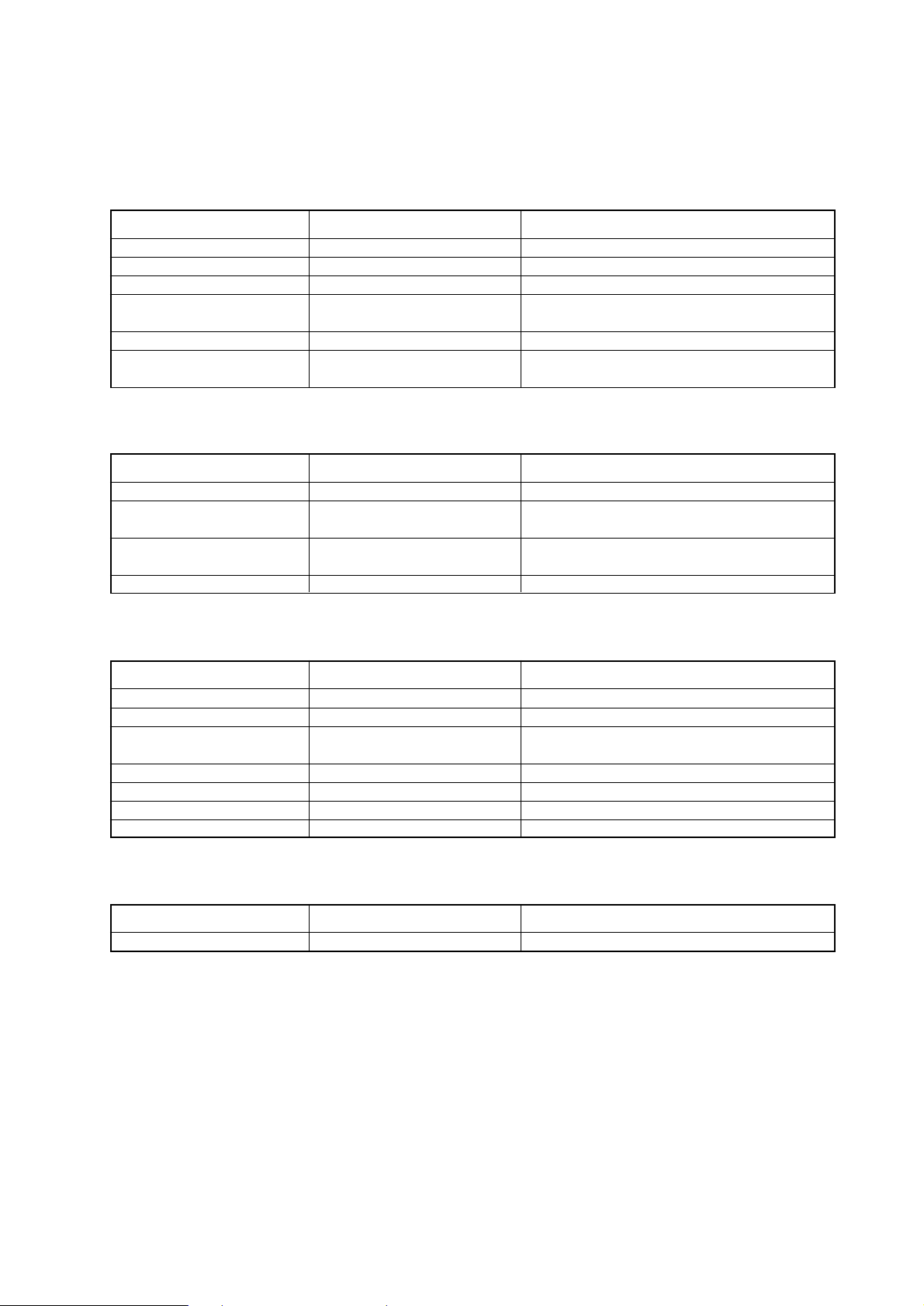

[2] Necessary Tools and Materials

Prepare the following tools and materials necessary for installing and servicing the unit.

[Necessary tools for use with R410A (Adaptability of tools that are for use with R22 and R407C)]

1. To be used exclusively with R410A (not to be used if used with R22 or R407C)

Tools/Materials NotesUse

Gauge Manifold

Charging Hose

Refrigerant Recovery Equipment

Refrigerant Cylinder

Refrigerant Cylinder Charging Port

Flare Nut

Evacuating, refrigerant charging

Evacuating, refrigerant charging

Refrigerant recovery

Refrigerant charging

Refrigerant charging

Connecting the unit to piping

5.09MPa on the High-pressure side.

Hose diameter larger than the conventional ones.

Write down the refrigerant type.

Pink in color at the top of the cylinder.

Hose diameter larger than the conventional ones.

Use Type-2 Flare nuts.

(That are in compliance with JIS B 8607).

2. Tools and materials that may be used with R410A with some restrictions

Tools/Materials NotesUse

Gas leak detector

Vacuum Pump

Flare Tool

Refrigerant Recovery Equipment

Detection of gas leaks

Vacuum drying

Flare machining of piping

Recovery of refrigerant

The ones for HFC type refrigerant may be used.

May be used if a reverse flow check adaptor is

attached.

Changes have been made in the flare machining

dimension. Refer to the next page.

May be used if designed for use with R410A.

3. Tools and materials that are used with R22 or R407C that can also be used with R410A

Tools/Materials NotesUse

Vacuum Pump with a Check valve

Bender

Torque Wrench

Pipe Cutter

Welder and Nitrogen Cylinder

Refrigerant Charging Meter

Vacuum Gauze

Vacuum drying

Bending pipes

Tightening flare nuts

Cutting pipes

Welding pipes

Refrigerant charging

Checking vacuum degree

Only ø 12.70 (1/2”) and ø 15.88 (5/8”) have a

larger flare machining dimension.

4. Tools and materials that must not be used with R410A

Tools/Materials NotesUse

Charging Cylinder Refrigerant Charging Must not be used with R410A-type units.

Tools for R410A must be handled with special care; keep moisture and dust from entering the

cycle.

Page 10

Type-O pipes Soft copper pipes (annealed copper pipes)

They can be bent easily with hands.

Type-1/2H pipes Hard copper pipes (straight pipes)

Stronger than type-O pipes of the same radial thickness.

- 8 -

[3] Piping Materials

NOOK

New Piping Existing Piping

Do not use the existing piping!

<Types of copper pipe>

• The distinction between type-O and type-1/2H pipes is made based on the strength of the pipes themselves.

• Type-O pipes are soft and can easily be bent with hands.

• Type-1/2H pipes are considerably stronger than type-O pipes of the same radial thickness.

Use pipes made of phosphorus deoxidized copper.

Since the operation pressure of the units that use R410A is higher than that of the units for use with R22, use

pipes with at least the radial thickness specified in the chart below.

(Pipes with a radial thickness of 0.7 mm or less may not be used.)

Maximum Operation Pressure Applicable Refrigerants

3.45 MPa

4.30 MPa

R22, R407C etc.

R410A

<Types of Copper Pipes (Reference)>

✻ Use pipes that meet the local standards.

Type-O pipes

Type-1/2H or

H pipes

Size(mm) Size(inch) Radial Thickness(mm) Type

ø 6.35

ø 9.52

ø 12.7

ø 15.88

ø 19.05

ø 22.2

ø 25.4

ø 28.58

ø 31.75

ø 34.93

1/4”

3/8”

1/2”

5/8”

3/4”

7/8”

1”

1 1/8”

1 1/4”

1 3/8”

0.8t

0.8t

0.8t

1.0t

1.0t

1.0t

1.0t

1.0t

1.1t

1.2t

<Piping Materials/Radial Thickness>

✻ Although it was possible to use type-O for pipes with a size of up to ø19.05 (3/4”) with conventional refriger-

ants, use type-1/2H pipes for units that use R410A. (Type-O pipes may be used if the pipe size is

ø19.05 and

the radial thickness is 1.2t.)

✻ The table shows the standards in Japan. Using this table as a reference, choose pipes that meet the local

standards.

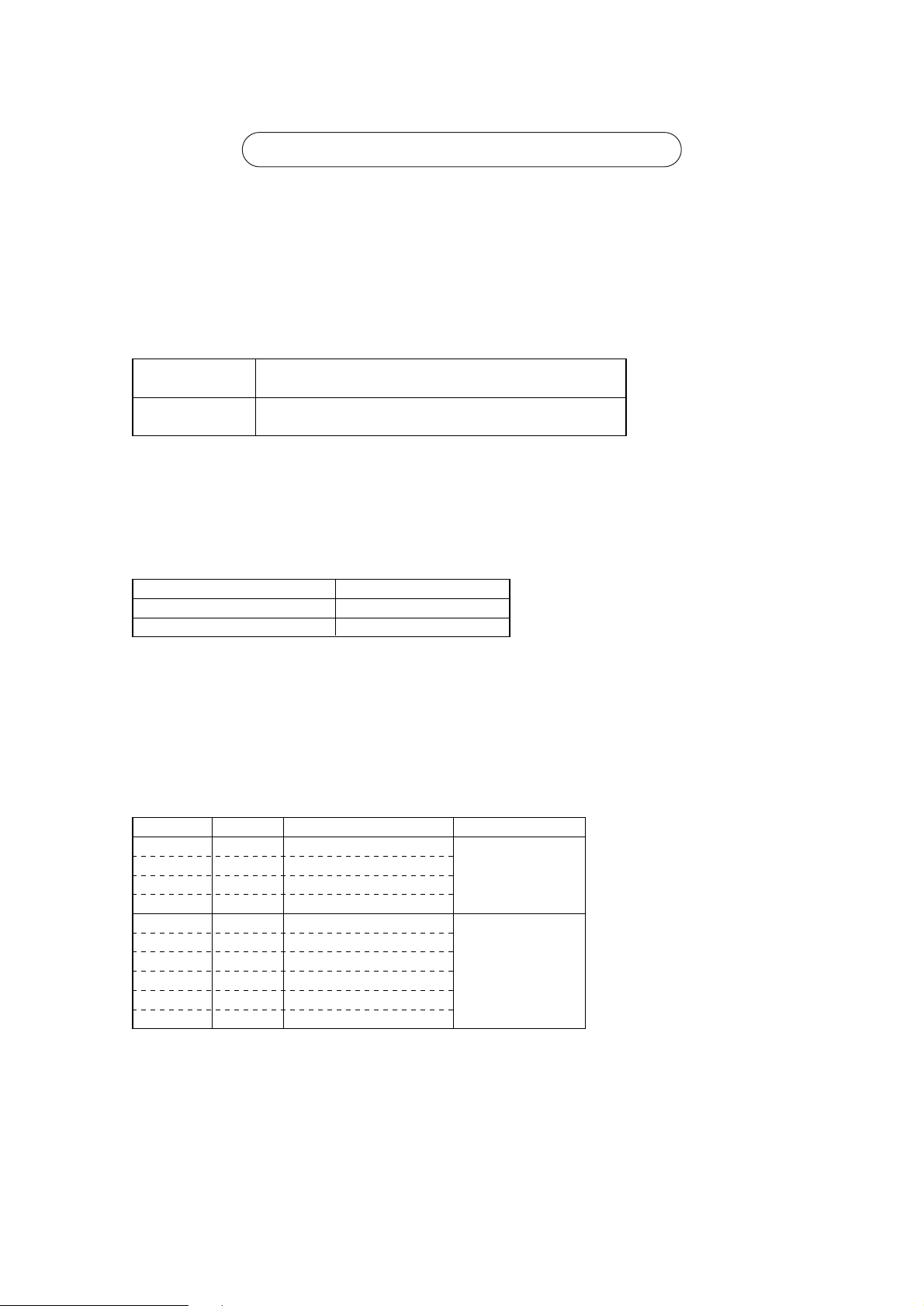

Page 11

- 9 -

“Radial thickness” and “Refrigerant Types” are indicated on the insulation material on the piping materials for the

new refrigerant.

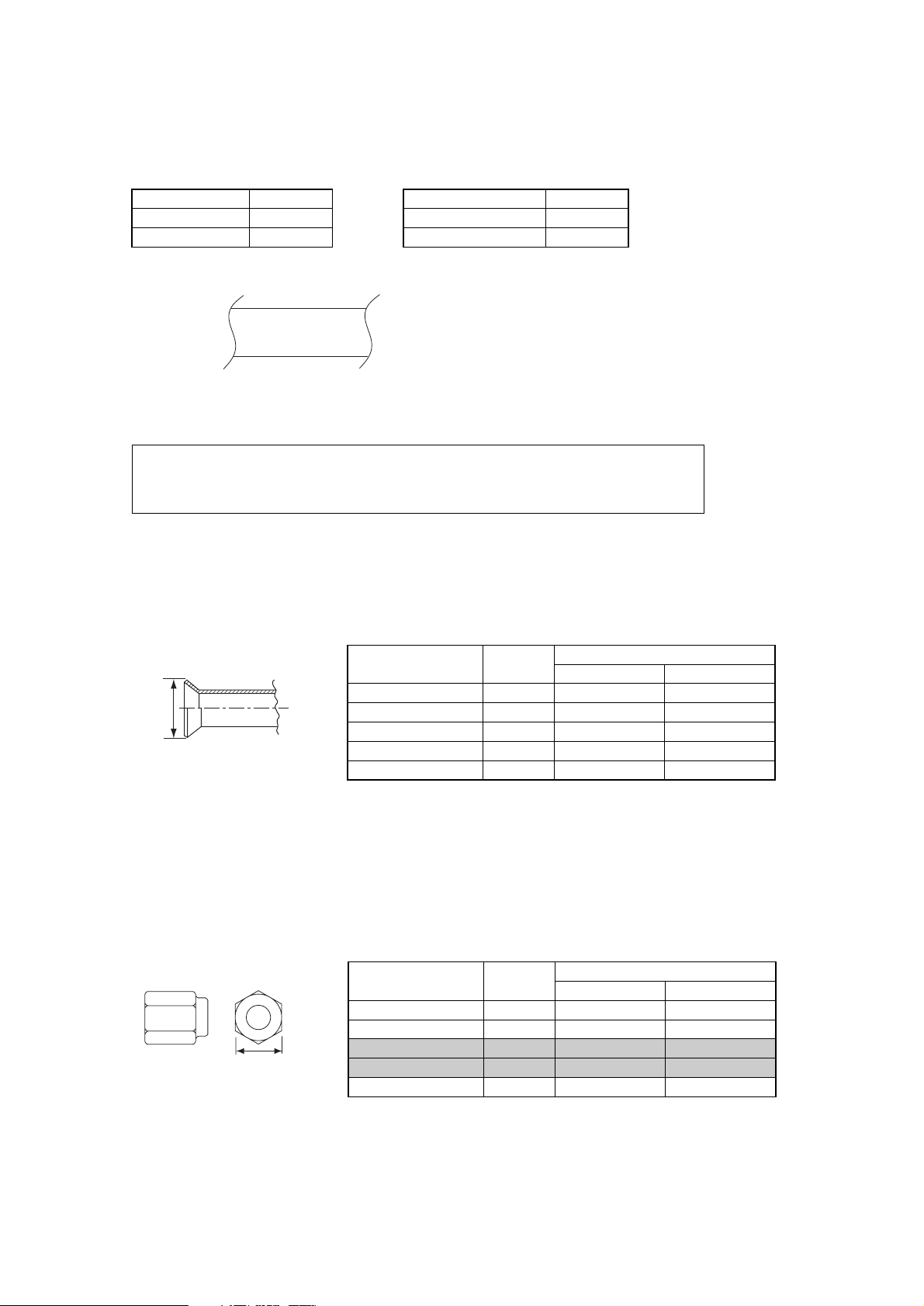

Indication of the radial thickness (mm) Indication of the refrigerant type

Radial thickness Symbols

0.8

1.0

08

10

Refrigerant type Symbol

Type1 R22, R407C

Type2 R410A

1

2

<Example of the symbols indicated on the insulation material>

The type of piping materials can also be found on the package.

<Example of a label found on the package>

~08-2~

Appears every 1 m

2 : common to type 1 and type 2

Refrigerant Type : R22,R407C,R410A

Bore diameter and radial thickness of the copper piping : 9.52✕0.8, 15.88✕1.0

<Indication of the radial thickness and refrigerant type on the piping materials>

The flare machining dimensions for units that use R410A is larger than those for units that use R22 in order to

increase air tightness.

If a clutch type flare tool is used to machine flares on units that use R410A, make the protruding part of the

pipe between 1.0 and 1.5mm. Copper pipe gauge for adjusting the length of pipe protrusion is useful.

Flare Machining Dimension(mm)

External dimension

of pipes

Size

Dimension A

R410A

ø 6.35

ø 9.52

ø 12.7

ø 15.88

ø 19.05

1/4”

3/8”

1/2”

5/8”

3/4”

9.1

13.2

16.6

19.7

24.0

R22

9.0

13.0

16.2

19.4

23.3

Dimension A

<Flare Machining (type-O and OL only)>

Type-2 flare nuts instead of type-1 s are used to increase the strength. The size of some of the flare nuts have

also been changed.

Flare nut dimension(mm)

External dimension

of pipes

Size

Dimension B

R410A(Type2)

ø 6.35

ø 9.52

ø 12.7

ø 15.88

ø 19.05

1/4”

3/8”

1/2”

5/8”

3/4”

17.0

22.0

26.0

29.0

36.0

R22(Type1)

17.0

22.0

24.0

27.0

36.0

Dimension B

<Flare Nut>

✻ The table shows the standards in Japan. Using this table as a reference, choose pipes that meet the local

standards.

Page 12

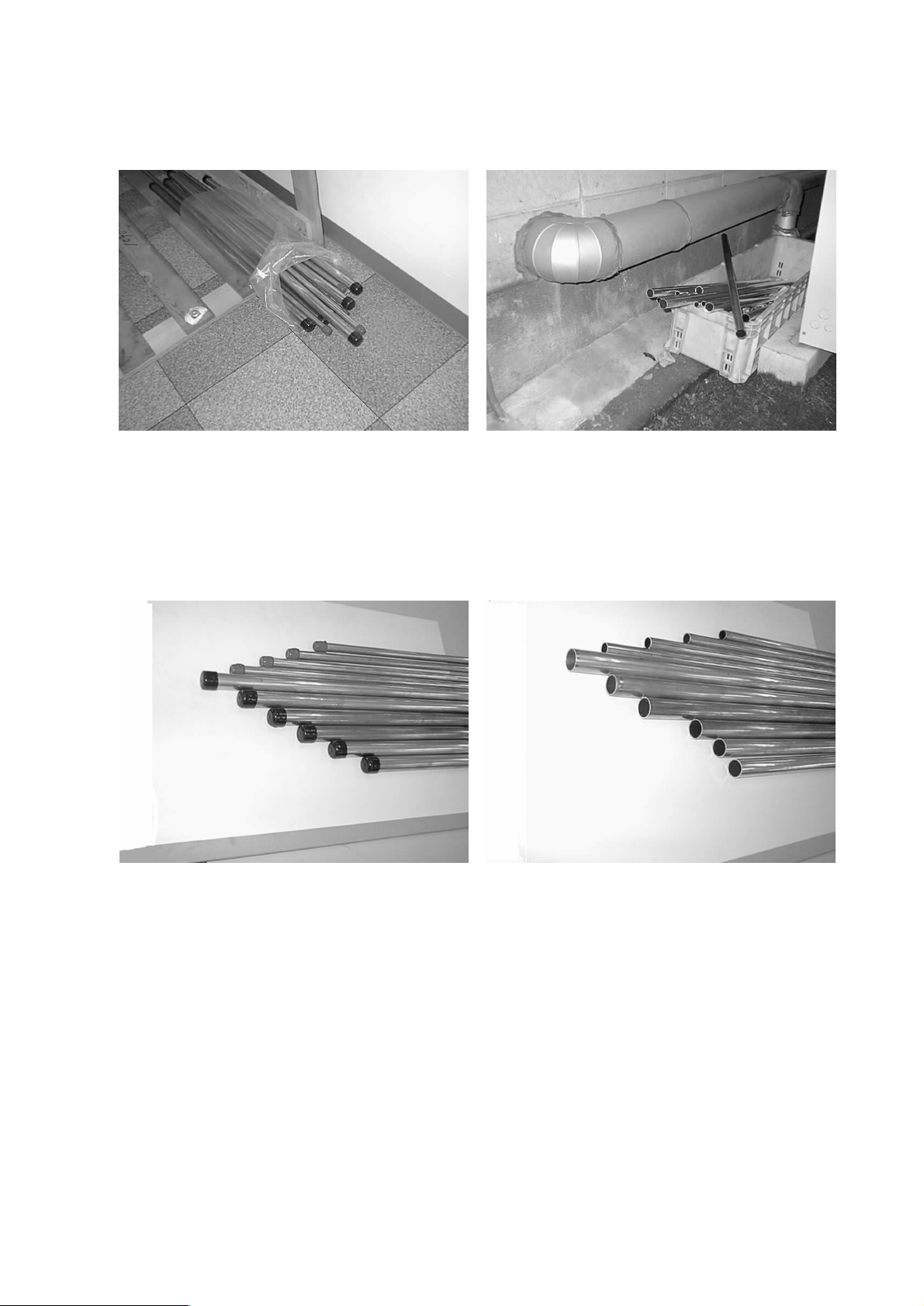

Store the pipes to be used indoors. (Warehouse at site or owner’s warehouse)

Storing them outdoors may cause dirt, waste, or water to infiltrate.

Both ends of the pipes should be sealed until immediately before brazing.

Wrap elbows and T’s in plastic bags for storage.

✻

The new refrigerator oil is 10 times more hygroscopic than the conventional refrigerator oil (such as Suniso). Water

infiltration in the refrigerant circuit may deteriorate the oil or cause a compressor failure. Piping materials must be

stored with more care than with the conventional refrigerant pipes.

OK

OK

NO

NO

- 10 -

[4] Storage of Piping Material

1. Storage location

2. Pipe sealing before storage

Page 13

Use ester oil, ether oil or alkylbenzene (small amount) as the refrigerator oil to coat flares and flange connections.

Reason :

1. The refrigerator oil used for the equipment is highly hygroscopic and may introduce water inside.

Notes :

• Introducing a great quantity of mineral oil into the refrigerant circuit may also cause a compressor failure.

• Do not use oils other than ester oil, ether oil or alkylbenzene.

- 11 -

[5] Piping Machining

Page 14

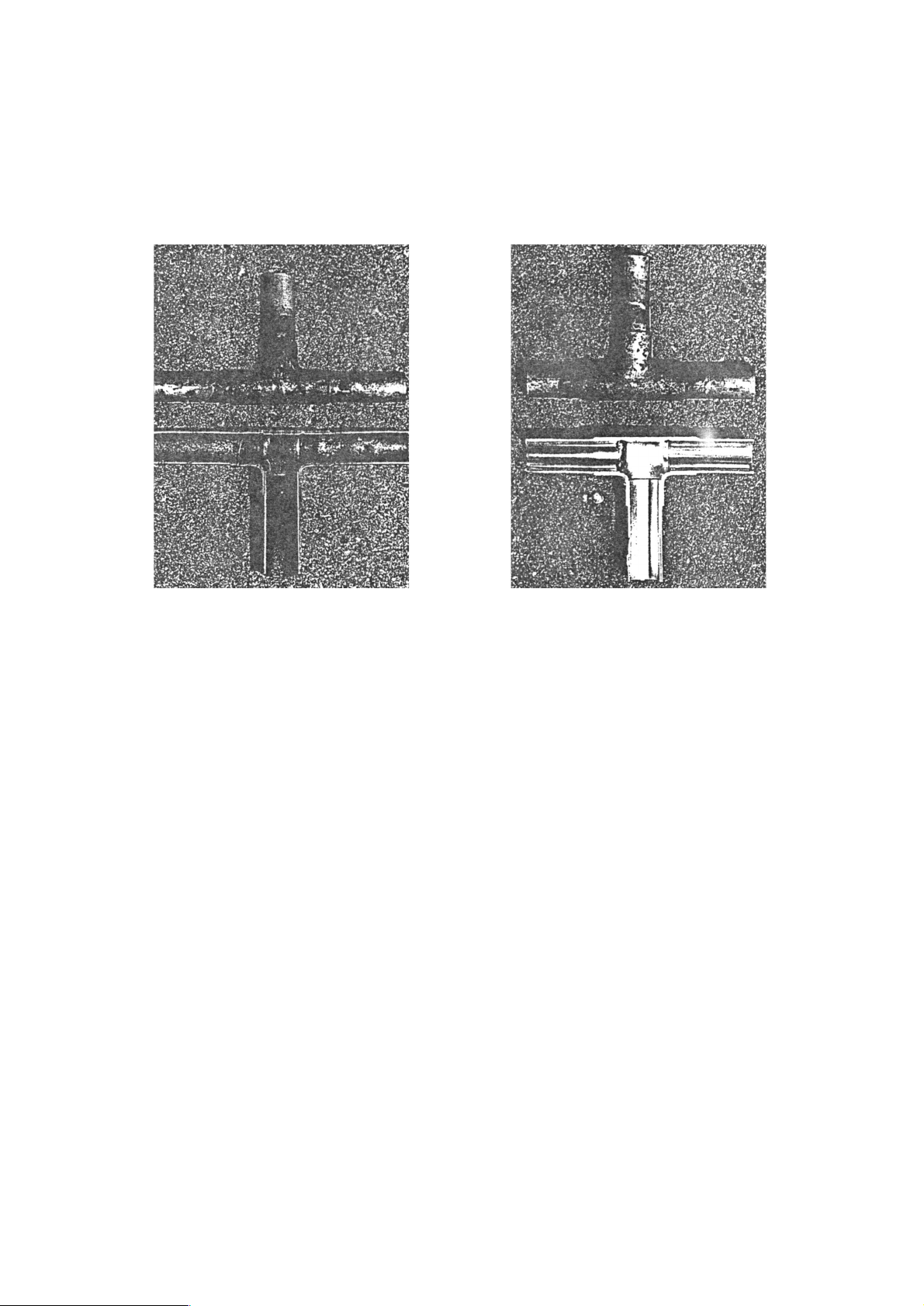

No changes from the conventional method, but special care is required so that foreign matter (ie. oxide scale, water, dirt,

etc.) does not enter the refrigerant circuit.

Example : Inner state of brazed section

When non-oxide brazing was not used When non-oxide brazing was used

Items to be strictly observed :

1. Do not conduct refrigerant piping work outdoors on a rainy day.

2. Apply non-oxide brazing.

3. Use a brazing material (BCuP-3) which requires no flux when brazing between copper pipes or between a copper pipe

and copper coupling.

4. If installed refrigerant pipes are not immediately connected to the equipment, then braze and seal both ends of them.

Reasons :

1. The new refrigerant oil is 10 times more hygroscopic than the conventional oil. The probability of a machine failure if

water infiltrates is higher than with conventional refrigerant oil.

2. A flux generally contains chlorine. A residual flux in the refrigerant circuit may generate sludge.

Note :

• Commercially available antioxidants may have adverse effects on the equipment due to its residue, etc. When

applying non-oxide brazing, use nitrogen.

- 12 -

[6] Brazing

Page 15

No changes from the conventional method. Note that a refrigerant leakage detector for R22 or R407C cannot detect

R410A leakage.

Halide torch R22 or R407C leakage detector

Items to be strictly observed :

1. Pressurize the equipment with nitrogen up to the design pressure and then judge the equipment’s airtightness, taking

temperature variations into account.

2. When investigating leakage locations using a refrigerant, be sure to use R410A.

3. Ensure that R410A is in a liquid state when charging.

Reasons :

1. Use of oxygen as the pressurized gas may cause an explosion.

2. Charging with R410A gas will lead the composition of the remaining refrigerant in the cylinder to change and this

refrigerant can then not be used.

Note :

• A leakage detector for R410A is sold commercially and it should be purchased.

1. Vacuum pump with check valve

A vacuum pump with a check valve is required to prevent the vacuum pump oil from flowing back into the refrigerant

circuit when the vacuum pump power is turned off (power failure).

It is also possible to attach a check valve to the actual vacuum pump afterwards.

2. Standard degree of vacuum for the vacuum pump

Use a pump which reaches 65Pa or below after 5 minutes of operation.

In addition, be sure to use a vacuum pump that has been properly maintained and oiled using the specified oil. If the

vacuum pump is not properly maintained, the degree of vacuum may be too low.

3. Required accuracy of the vacuum gauge

Use a vacuum gauge that can measure up to 650Pa. Do not use a general gauge manifold since it cannot measure a

vacuum of 650Pa.

4. Evacuating time

• Evacuate the equipment for 1 hour after 650Pa has been reached.

• After envacuating, leave the equipment for 1 hour and make sure the that vacuum is not lost.

5. Operating procedure when the vacuum pump is stopped

In order to prevent a backflow of the vacuum pump oil, open the relief valve on the vacuum pump side or loosen the

charge hose to drawn in air before stopping operation.

The same operating procedure should be used when using a vacuum pump with a check valve.

NO

NO

- 13 -

[7] Airtightness Test

[8] Vacuuming

Page 16

Recommended vacuum gauge : ROBINAIR 14010 Thermistor Vacuum Gauge

1. Vacuum pump with reverse-flow check valve (Photo 1)

To prevent vacuum pump oil from flowing back into the refrigerant circuit upon turning off the vacuum pump’s power

source, use a vacuum pump equipped with a reverse flow check valve.

A check valve may also be added to the vacuum pump currently in use.

2. Standard of vacuum degree (Photos 1 and 2)

Use a vacuum pump that shows a vacuum degree of 65Pa or less after 5 minutes of operation. Use a pump well-

maintained with an appropriate lubricant.

3. Required precision of vacuum gauge

Use a vacuum gauge that registers a vacuum degree of 650Pa and measures at intervals of 130Pa. (A recommended

vacuum gauge is shown in Photo 2.)

Do not use a vacuum gauge that does not register a vacuum degree of 650Pa.

4. Evacuation time

• After the vacuum gauge has registered the vacuum degree of 650Pa, evacuate for 1 hour. (A thorough vacuum drying

removes moisture in the pipes.)

• Verify that the vacuum degree has not risen by more than 130Pa 1 hour after evacuation. A rise by less than 130Pa is

acceptable.

• If it has exceeded by more than 130Pa, conduct vacuuming following the instructions in the “6. Special vacuum drying”

section.

5. Procedures for stopping vacuum pump

To prevent the reverse flow of vacuum pump oil, open the relief valve on the vacuum pump side, or draw in air by

loosening the charge hose, and then stop the operation.

The same procedures should be followed when stopping a vacuum pump with a reverse-flow check valve.

6. Special vacuum drying

• When 650Pa or lower degree of vacuum cannot be attained after 3 hours of evacuation, it is likely that water has

penetrated the system or that there is a leak. When water infiltration is suspected, vacuum with nitrogen gas.

After breaking the vacuum, pressurize the system with nitrogen gas to a degree of 0.05MPa, and conduct an evacuation

again. Repeat it until 650Pa or lower degree of vacuum is attained or the vacuum pressure rise will be lost.

• Only use nitrogen gas for vacuum breaking. (Use of oxygen may cause an explosion.)

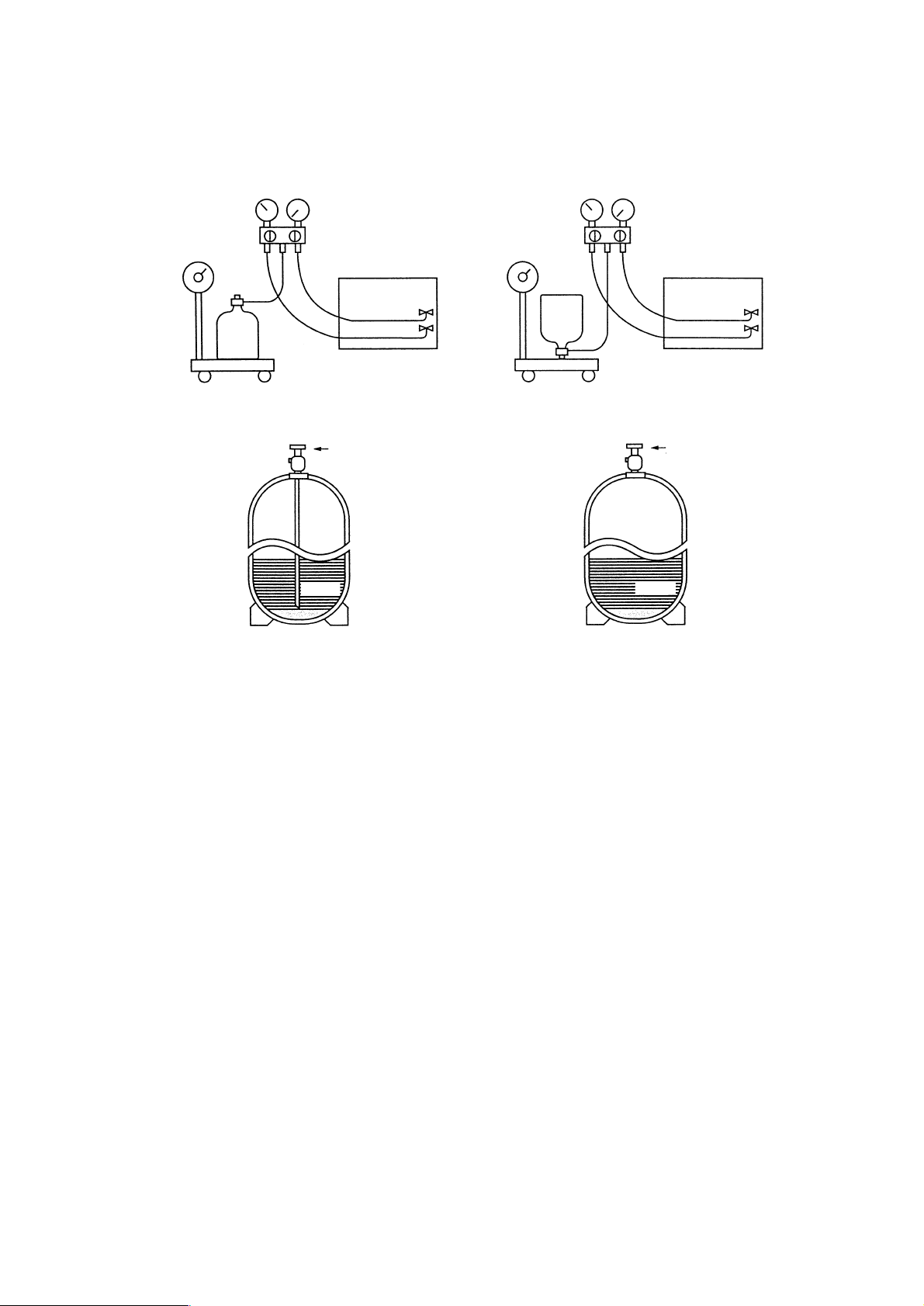

Photo 1 15010H Photo 2 14010

- 14 -

[9] Vacuum Drying

Page 17

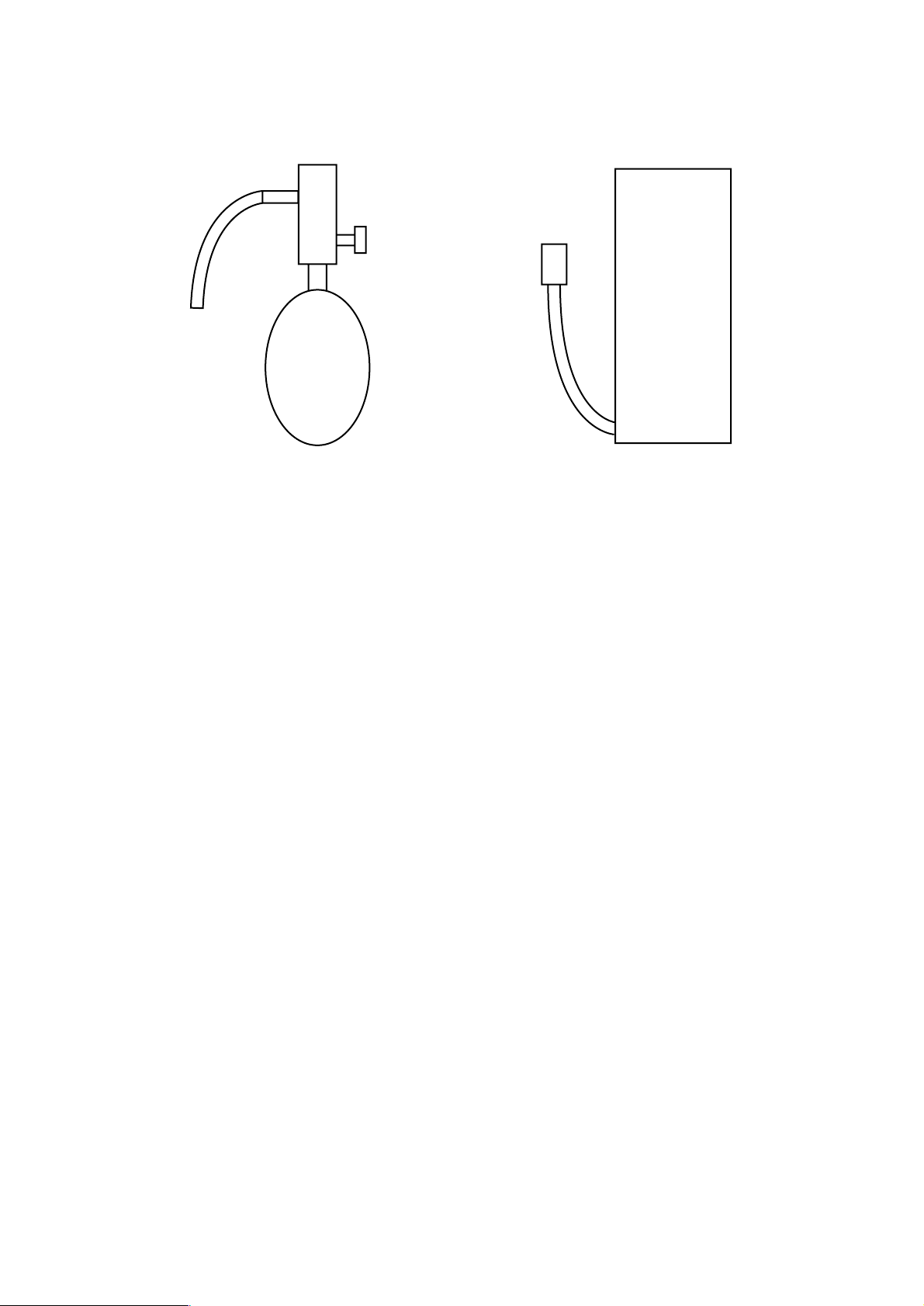

R410A must be in a liquid state when charging.

For a cylinder with a syphon attached For a cylinder without a syphon attached

Cylinder color identification R407C-Gray Charged with liquid refrigerant

R410A-Pink

Reasons :

1.

Note :

• In the case of a cylinder with a syphon, liquid R410A is charged without turning the cylinder up side down. Check the

type of cylinder before charging.

Cylin-

der

Cylin-

der

Valve

Val ve

Liquid

Liquid

R410A is a pseudo-azeotropic refrigerant (boiling point R32 = -52˚C, R125 = -49˚C) and can roughly be handled

in the same way as R22; however, be sure to fill the refrigerant from the liquid side, for doing so from the gas

side will somewhat change the composition of the refrigerant in the cylinder.

When refrigerant leaks, additional refrigerant may be charged. (Add the refrigerant from the liquid side.)

✻Refer to 9-[5].

- 15 -

[10] Changing Refrigerant

[11] Remedies to be taken in case of a refrigerant leak

Page 18

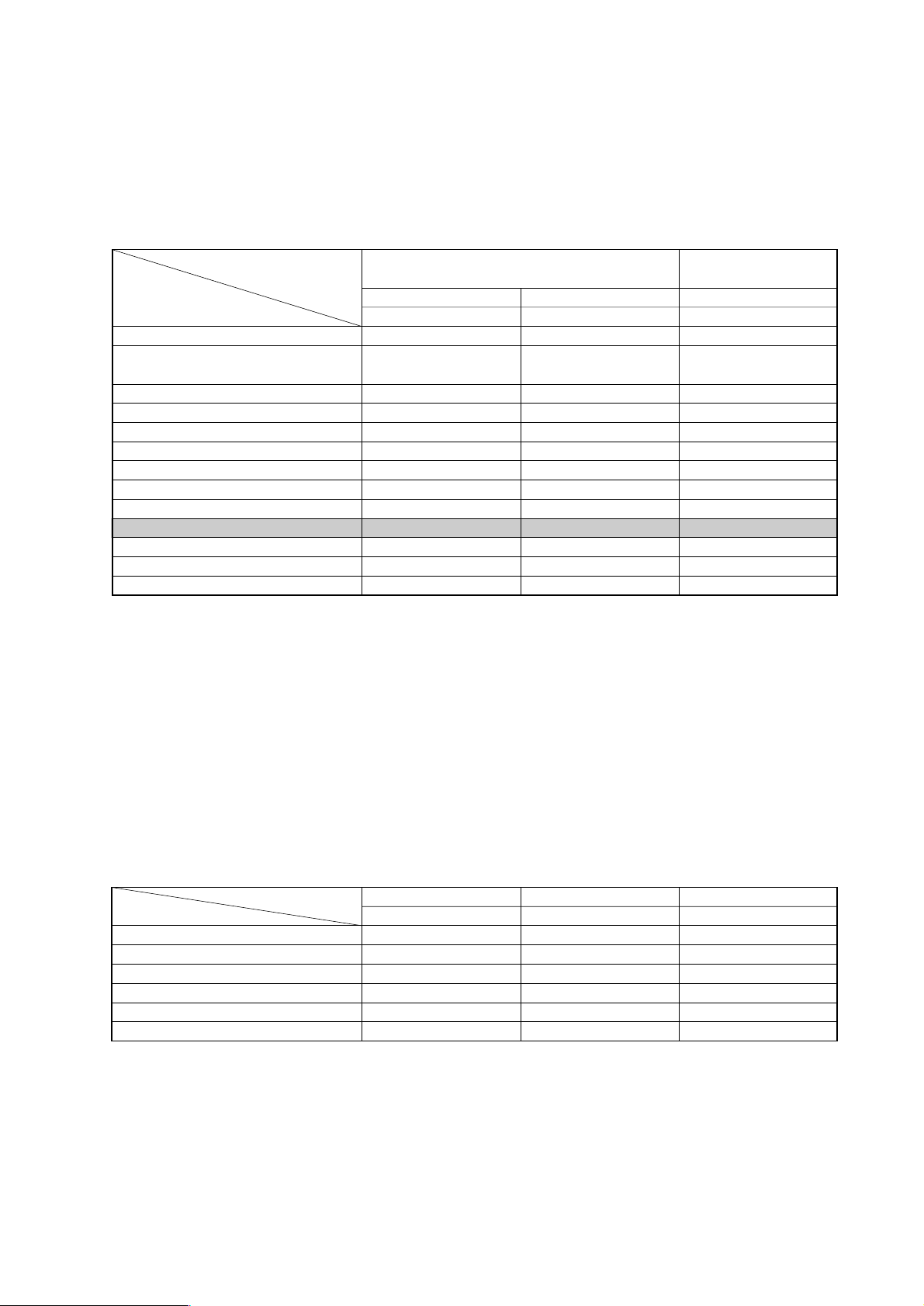

Composition (wt%)

Type of refrigerant

Chloride

Safety Class

Molecular Weight

Boiling Point

Steam Pressure (25

˚C,MPa)(gauge)

Saturated Steam Density (25

˚C,kg/m3)

Flammability

Ozone Depletion Coefficient (ODP)✻1

Global Warming Coefficient (GWP)✻2

Refrigerant charging method

Addition of refrigerant in case of a leak

R410A

R32/R125

(50/50)

Simulated azeotropic

refrigerant

Not contained

A1/A1

72.6

-51.4

1.557

64.0

Non-flammable

0

1730

Liquid charging

Possible

R407C

R32/R125/R134a

(23/25/52)

Non-azeotropic

refrigerant

Not contained

A1/A1

86.2

-43.6

0.9177

42.5

Non-flammable

0

1530

Liquid charging

Possible

New Refrigerant

(HFC system)

Conventional Refrigerant

(HCFC system)

R22

R22

(100)

Single refrigerant

Contained

A1

86.5

-40.8

0.94

44.4

Non-flammable

0.055

1700

Gas charging

Possible

✻1: When CFC11 is used as a reference ✻2: When CO

2 is used as a reference

- 16 -

[12] Characteristics of the Conventional and the New Refrigerants

1. Chemical property

As with R22, the new refrigerant (R410A) is low in toxicity and a chemically stable non-flammable refrigerant.

However, because the specific gravity of steam is greater than that of air, leaked refrigerant in a closed room will

accumulate at the bottom of the room and may cause hypoxia. Also, leaked refrigerant exposed directly to an

open flame will generate noxious gasses. Use the unit in a well-ventilated room.

R410A

MPa

0.30

0.70

1.34

2.31

3.73

4.17

-20

0

20

40

60

65

R407C

MPa

0.18

0.47

0.94

1.44

2.44

2.75

R22

MPa

0.14

0.40

0.81

1.44

2.33

2.60

Pressure (gauge)

Temperature (

˚C)

3. Pressure Characteristics

The pressure in the units that use R410A is 1.6 times as great as that in the units that use R22.

2. Refrigerant Composition

Because R410A is a simulated azeotropic refrigerant, it can be handled in almost the same manner as a single

refrigerant such as R22. However, if the refrigerant is removed in the vapor phase, the composition of the refriger

ant in the cylinder will somewhat change.

Remove the refrigerant in the liquid phase. Additional refrigerant may be added in case of a refrigerant leak.

Page 19

- 17 -

Refrigerant Refrigerating machine oil

R22

R407C

R410A

Mineral oil

Ester oil

Ester oil

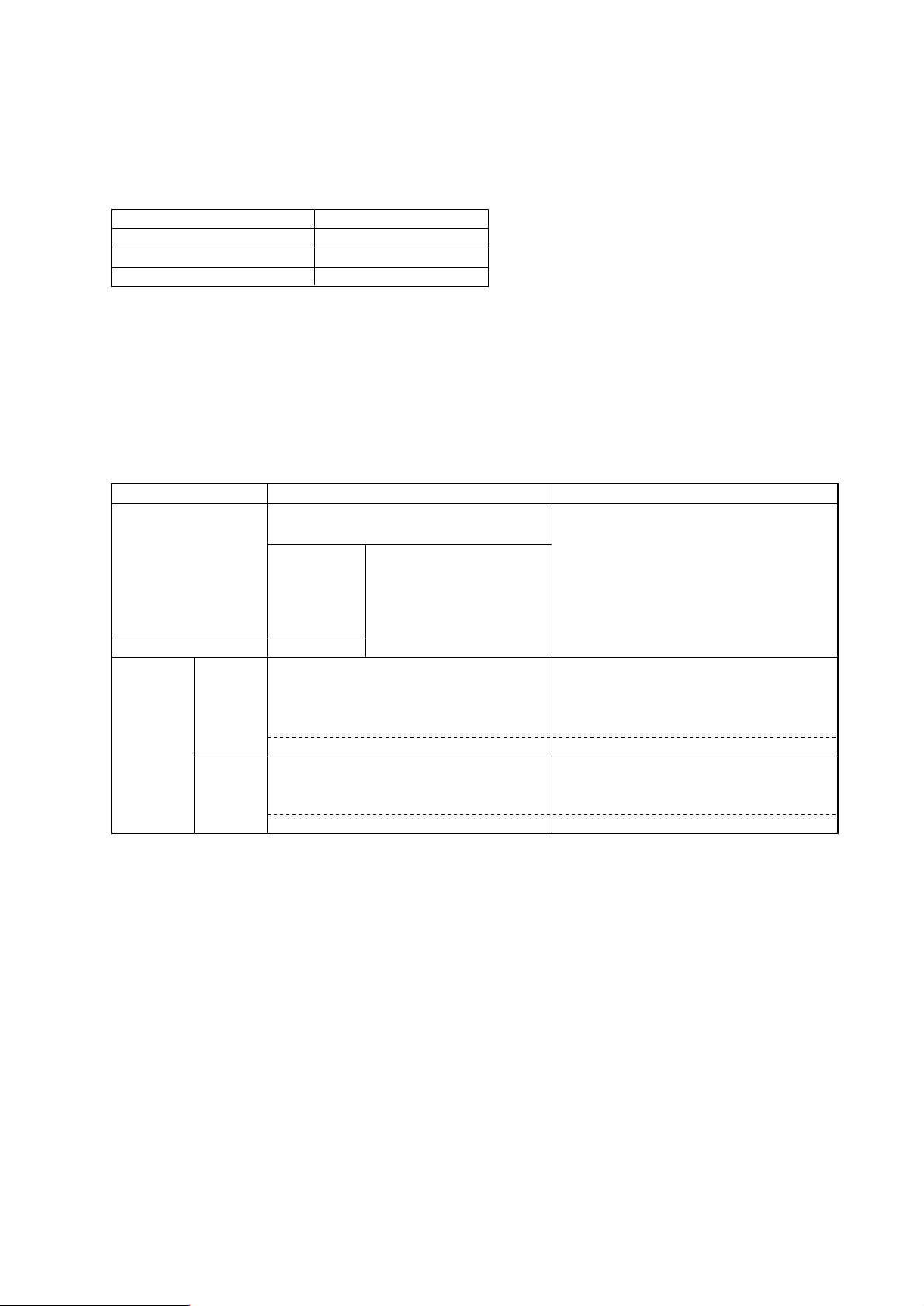

[13] Notes on Refrigerating Machine Oil

1. Refrigerating Machine Oil in the HFC Refrigerant System

HFC type refrigerants use a refrigerating machine oil different from that used in the R22 refrigerant system.

Please note that the ester oil sealed in the unit is not the same as commercially available ester oil.

Cause Symptom

Clogged expansion valve and capillary

Poor cooling performance

Compressor overheat

Poor motor insulation

Motor burning

Coppering of the orbiting part

Locking

Burning in the orbiting part

Expansion valve/capillary

Poor cooling performance

Drier clogging

Compressor overheat

Burning in the orbiting part

Expansion valve and capillary clogging

Poor cooling performance

Compressor overheat

Burning in the orbiting part

Effects on the refrigeration cycle

Sludge formation

Generation of acid

Oxidization

Oil degradation

Water infiltration

Air infiltration

Infiltration

of

contaminants

Dust, dirt

Mineral oil

etc.

Expansion valve and capillary freeze

Hydrolysis

Oxidization

Adhesion to expansion valve and capillary

Infiltration of contaminants into the compressor

Sludge formation and adhesion

Oil degradation

2. Effects of the ✻Contaminants in the System

Refrigerating machine oil used in the HFC system must be handled more carefully than conventional mineral oils.

The table below shows the effects of air, moisture, and contaminants in the refrigerating machine oil on the refrigeration cycle.

✻ “ Contaminants ” is defined as moisture, air, process oil, dust/dirt, the wrong types of refrigerant and refrigerat-

ing machine oil.

<The Effects of Air, Moisture, and Contaminants in the Refrigerating Machine Oil on the Refrigeration Cycle.>

Page 20

OK NO

➀ Follow ordinance of your governmental organization for technical standard related to electrical equipment, wiring

regulations, and guidance of each electric power company.

➁ Wiring for control (hereinafter referred to as transmission line) shall be (5cm or more) apart from power source wiring so

that it is not influenced by electric noise from power source wiring. (Do not insert transmission line and power source wire

in the same conduit.)

➂ Be sure to provide designated grounding work to outdoor unit.

➃ Give some allowance to wiring for electrical part box of indoor and outdoor units, because the box is sometimes removed

at the time of service work.

➄ Never connect 380~415V(220~240V )power source to terminal block of transmission line.If connected,electrical parts

will be burnt out

➅ Use 2-core shield cable for transmission line. If transmission lines of different systems are wired with the same multiple-

core cable, the resultant poor transmitting and receiving will cause erroneous operations.

Outdoor

unit

Indoor unit

Remote

controller

2-core cable

2-core cable

Outdoor

unit

Remote

controller

Indoor unit

Multiple-

core cable

Type of cable

Cable diameter

Remarks

Sheathed 2-core cable (unshielded)

CVV

0.3

~ 1.25mm

2

(0.75 ~ 1.25mm2) ✻1

More than 1.25mm

2

Shielding wire (2-core)

CVVS or CPEVS

When 10m is exceeded, use cables with

the same specification as transmission cables.

0.3 ~ 1.25mm

2

(0.75 ~ 1.25mm2) ✻1

Max length : 200m

Transmission cables M-NET Remote controller cables MA Remote controller cables

CVVS : PVC insulated PVC jacketed shielded control cable

CPEVS : PE insulated PVC jacketed shielded communication cable

CVV : PV insulated PVC sheathed control cable

—

✻

1 Connected with simple remote controller.

- 18 -

™™

Restrictions

[1] Electrical Work & M-NET control

1. Attention

2. Types of control cable

Page 21

00

00

101

Main

00

201

201

201

202

000

247

Address (1) setting varies depending on the system configuration. See “[3] Examples of system connection”

section for details.

Unit or controller Symbol

Address

Setting method

setting range

Indoor unit Main/sub units IC

Lossnay LC

M-NET

remote

controller

Main remote controller RC

Sub remote controller RC

MA remote controller MA

Outdoor unit OC

System

controller

Group remote controller GR, SC

System remote controller SR, SC

ON/OFF remote controller AN, SC

ST, SCSchedule timer (for M-NET)

Centralized controller TR, SC

(Note 5)

LM adapter SC

0, 01~50

(Note 1)

101~150

151~200

(Note 2)

0, 51~100

(Note 1, 3, 4)

52~100

(Note 3, 4)

201~250

201~250

201~250

201~250

0, 201~250

201~250

Notes:

Factory

setting

Type and method of switch setting

Switch setting vary depending on the system configuration. Make sure to read “[3] Examples of system connection”

before conducting electrical work. Turn off the power before setting the switch. Operating the switch while the unit is

being powered will not change the setting, and the unit will not properly function.

1. Address setting is not required for a single refrigerant system (with a few exception).

2. When setting M-NET remote controller address to “200,” make it “00.”

3. When setting the outdoor unit and outdoor auxiliary unit address to “100,” make it “50.”

4. When an address in a system overlapped with the outdoor unit or BC controller (Main) address of other refrigerant system,

choose an another address within theset range that is not in use (with a few exceptions).

5. When controlling the K-control units;

(1) A K-transmission converter (Model name: PAC-SC25KA) is required. To set the address for the K-transmission converter,

set it to thelowest address of the K-control unit to be controlled + 200.

(2) Set the address of the system controller (G-50A) to “0.” The K-control unit can only be controlled by the system controller

with theaddress “0.”

(3) To control both K-control unit and M-NET model unit, make the address of the K-control unit larger than that of the indoor

unit of M-NET model.

Group-register on the system controller so that the group No. and the lowest address of the K-controlled indoor units

belonging to thegroup will be identical.

Use the address that equals the sum of the smallest indoor

unit address in the same refrigerant system and 50.

Use the address that equals the sum of the smallest

address of the indoor unit out of all the indoor units

that are connected to the BC controller and 50.

When a sub BC controller is connected, the automatic

start up function will not be available.

Auxiliary

units

Hex. unit

BC controller (Sub)

OS

BC

BS

Use the address that equals the sum of the address of the

outdoor unit in the same refrigerant system and 1.

BC controller (Main)

Choose any number within the range of addresses shown left.

However when using with the upper SC setting, or wishing to

control the k-control units, set to “0.”

Assign the smallest address to the indoor unit to

become the main unit within the same group, and

then use sequential numbers to assign an address

to all the indoor units in the group. (Note 5)

If applicable, set the sub BC controllers in an R2

system in the following order:

(1)

Indoor unit to be connected to the main BC controller

(2)

Indoor unit to be connected to No.1 sub BC controller

(3)

Indoor unit to be connected to No.2 sub BC controller

Set the address so that (1) < (2) < (3)

Assign any unused address after setting all indoor units.

Set to the lowest address of the indoor main unit

within the same group + 150.

Set to the lowest No. of the group to be controlled + “200.”

Set to the lowest No. of the group desired tobe controlled + “200.”

Choose any number within the range of addresses shown left.

Choose any number within the range of ad-dresses shown left.

Choose any number within the range of addresses shown left.

Set to the lowest address of the indoor main unit

within the same group + 100.

No address setting required. (When operating with 2 remote controllers,

the main/sub selector switch must be set.

- 19 -

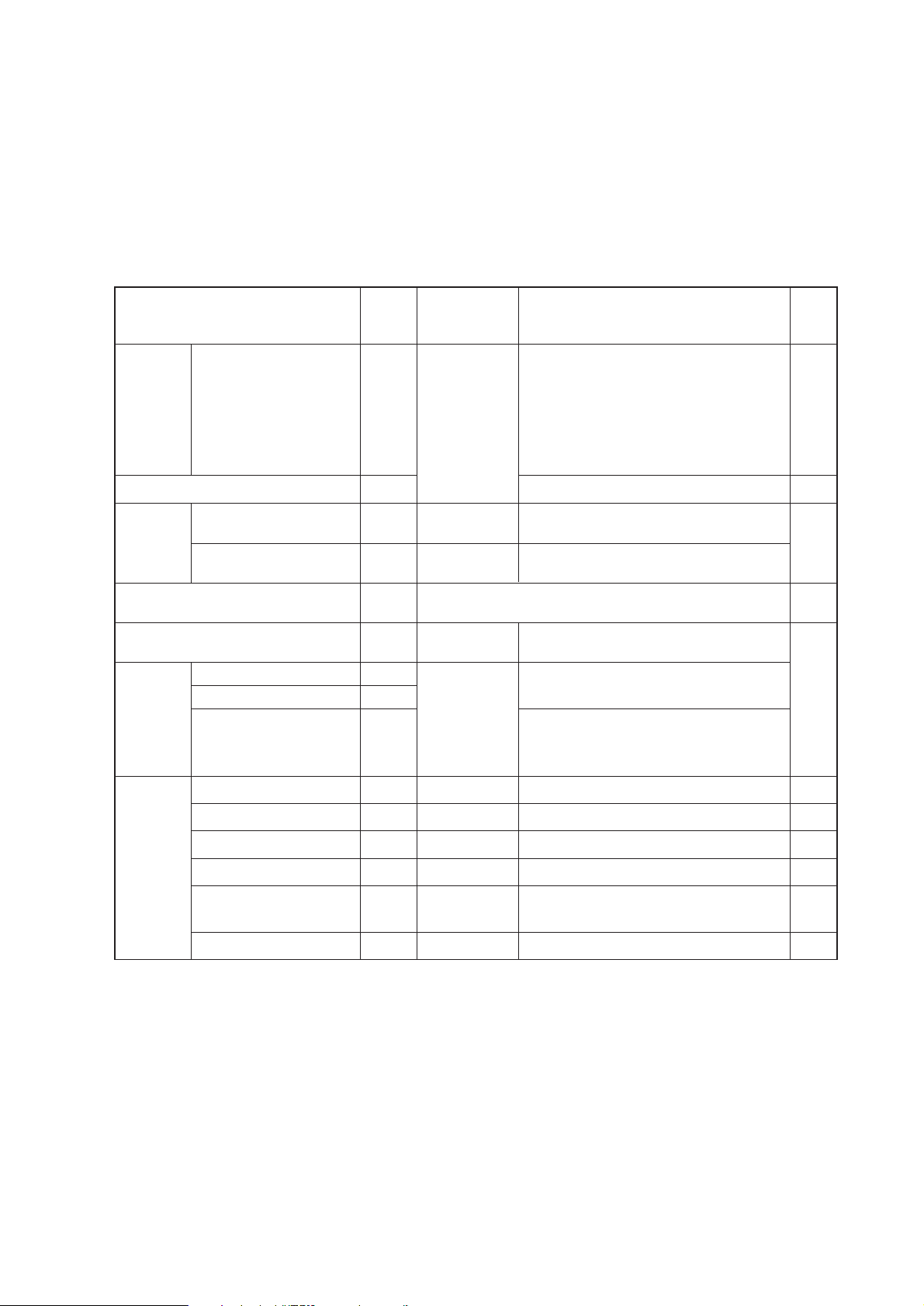

[2] Types of Switch Setting and Address Setting

1. Switch setting

2. Address setting

Page 22

- 20 -

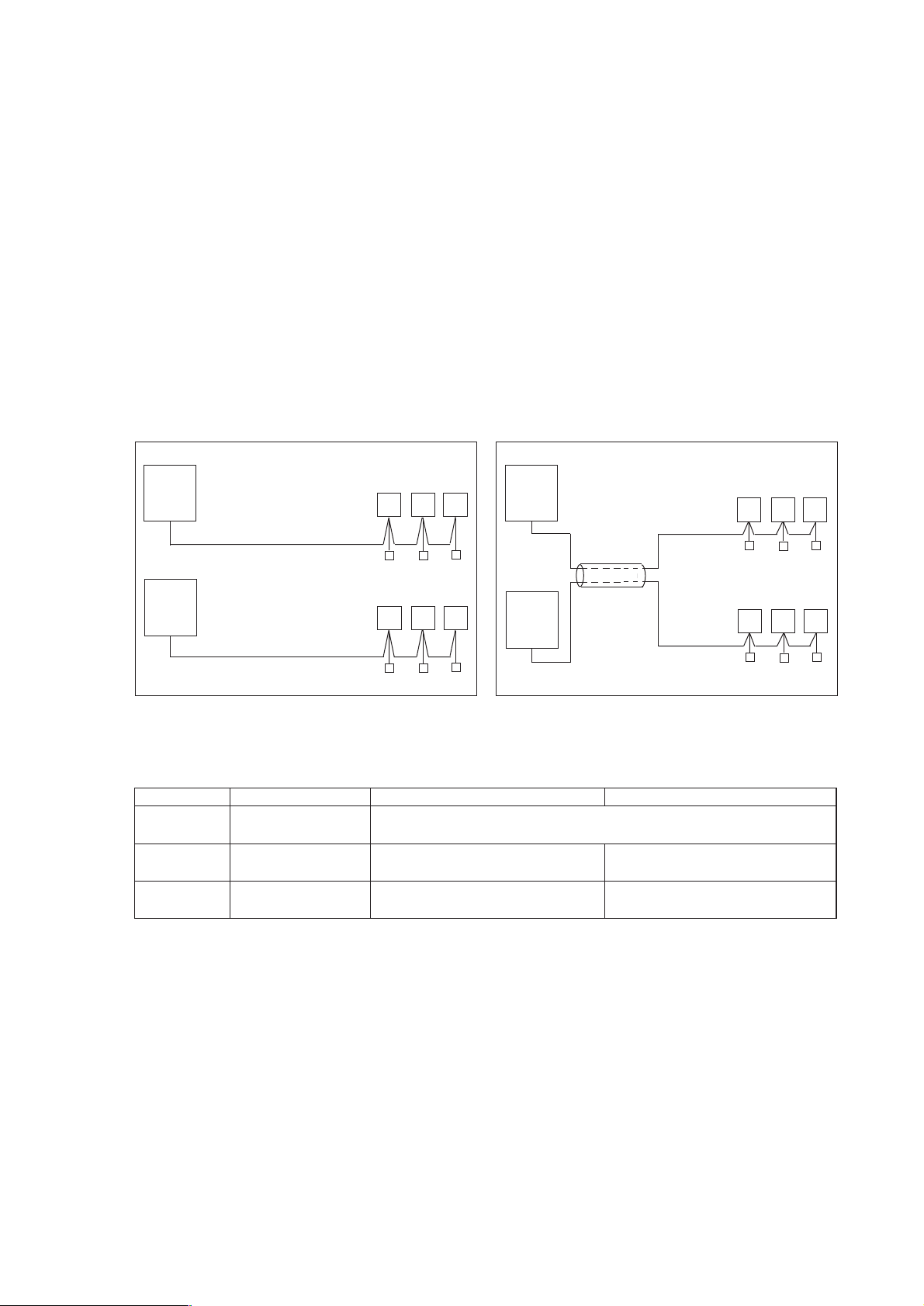

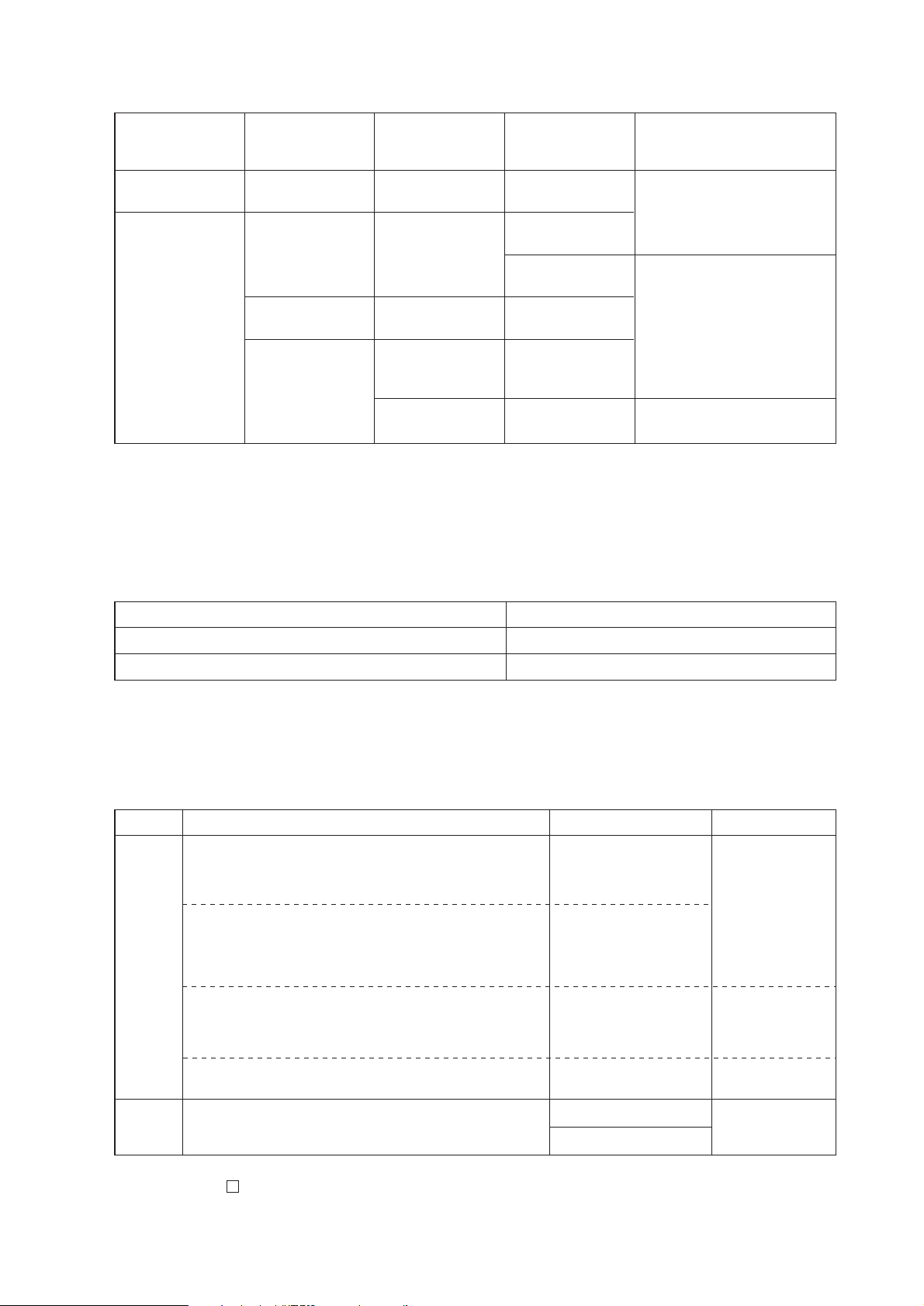

System

Configuration

Single refrigerant

system

___

_

Multiple refrigerant

system

Connection with

the system

controller

Power supply unit

for the

transmission lines

Unnecessary

Unnecessary (Note2)

(Supplied from the

outdoor unit)

Applicable

Grouping operation

of different

refrigerant systems

n/a

applicable

applicable // n/a

applicable // n/a

applicable // n/a

The setting of the power supply

selecting connector

Use CN41 as is (Factory setting)

Replace the CN41 with CN40 on

only one of the outdoor units.

✻

Connect the S terminal of the TB7

(terminal block on the outdoor

unit) on the outdoor unit whose

CN41 was replaced with CN40 to

the earth terminal of the electric

box.

Use CN41 as is (Factory setting)

n/a

Connected with the

indoor units

Connected with the

centralized system

Notes:

1. Will limit the total connectable units in the refrigerant system.

2. The need for a power supply unit for the transmission lines depends on the system configuration. Refer to “ DATA BOOK ” for

more details.

Setting the power supply selecting connector for the outdoor unit (Factory setting: CN41 is connected.)(2)

System configuration Setting of the centralized controller switch (SW 2-1)

Connection system with the system controller n/a Leave it to OFF. (Factory setting)

Connection system with the system controller applicable (Note 1) ON

Note:

1. When connecting only the LM adapter, leave SW2-1 to OFF.

Note:

1.

Refer to section “ 7 [2] 12. Demand control ” for detailed information on demand control settings.

Setting the centralized control switch on the outdoor unit (factory setting: SW2-1 OFF )(3)

Category

Output

Input

Usage

Cooling operation is disabled (thermo OFF) by the external

input to the outdoor units.

✻ Can be used as an on-demand control for each refrigerant

system.

Quiet operation of outdoor units is run with an external input to

the outdoor units.

(Night mode can be run under the following conditions: Outdoor

air temperature below 30

˚C when running a cooling operation

and above 3˚C when running a heating operation.)

Forces the outdoor units to run a fan operation by receiving the

snow signal from the snow sensor.

The operation mode can be switched between cooling and

heating with an external input to the outdoor units.

Outdoor units’ signal output

✻ Can be used as a device that displays the operation status

✻ Can run an interlocking control operation with external devices

Function

Demand (level)

Night mode or Demand

(Level) ✻

Note1

Snow sensor

Signal input (level)

You can switch the operation mode between cooling and

heating by input from the outside to the outdoor unit.

Auto-changeover

Compressor in operation

Abnormal operation status

CN3S

CN3N

CN3D

CN51

Terminal to be used

Various types of control using the connectors on the outdoor unit for input-output signal

(various types of connections with optional parts)

(4)

Page 23

IC

TB5 TB

15

12

00

IC

TB5 TB

15

12

00

A1 B2

MA

A1 B2

MARC

TB5

00

IC

TB5

12

TB

15

IC

TB5 TB

15

12

0000

IC

TB5 TB

15

12

00

A1 B2

MA

A1 B2

MA

A1 B2

MA

MA

m1

L11

m2

L3 L4

L12 L13

m3

m5

m4

NO

NO

L2

A1 B2

A1 B2

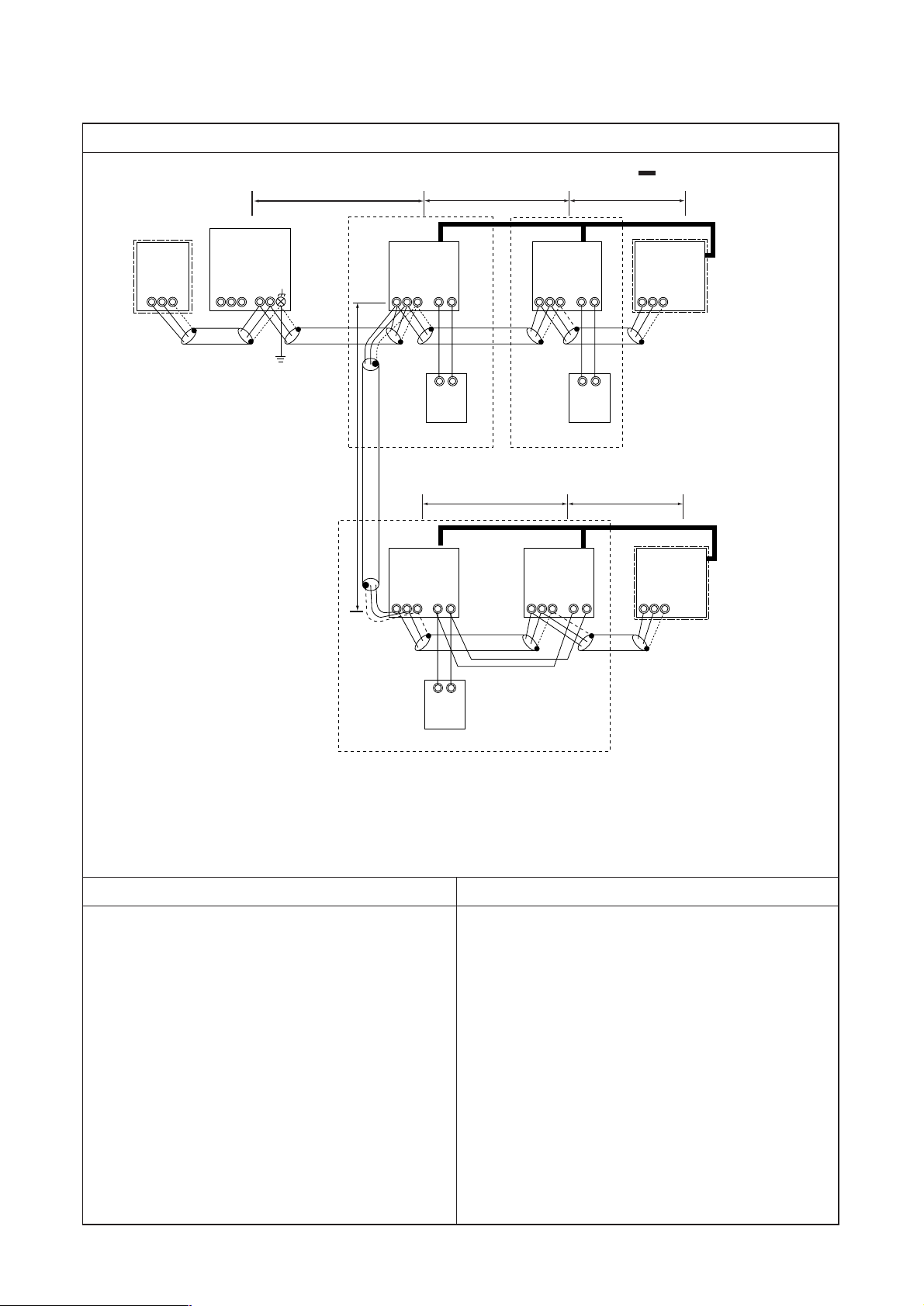

a. Indoor/outdoor transmission line

Farthest length (1.25mm2 or more)

L2 + L3 + L4 200m

L2 + L11 + L12 + L13 200m

b. Centralized control transmission line

No connection is required.

c. MA remote controller wiring

Total length (0.3 ~ 1.25mm2)

m1 200m

m2 + m3 200m

m4 + m5 200m

Note 1. For the connection to the terminal block of compact

remote controller, employ wire with a diameter of 0.75

~ 1.25mm

2

Control wiring example

Group

Prohibited items Allowable length

1. M-NET and MA remote controllers can not be connected to-

gether to the indoor unit within the same group.

2. MA remote controller of 3 units or more can not be connected

to the indoor unit within the same group.

3. When the total number of indoor units exceeds 26 units In-

cluding that above Type 200, a transmission booster is re-

quired.

4. In the case when start/stop input (CN32, CN51, CN41) is used

by indoor group operation, the “Automatic address set-up”

can not be employed. Please refer to 1. (2) “ Manual address

set-up.”

5. For the connection of LOSSNAY with more than 2 units in a

single refrigerant system, refer to the following “Connection

of 2 LOSSNAY units in refrigerant system.”

Interlocking with ventilation

– Example to use shielded wire –

Group

Group

Group

LC

≤

≤

≤

≤

≤

S

M1M2

S

M1M2

S

M1M2

S

M1M2

S

M1M2

S

M1M2

OC

TB3

TB7

00

OS

TB3

S

(00)

S

M1M2 M1M2M1M2

- 21 -

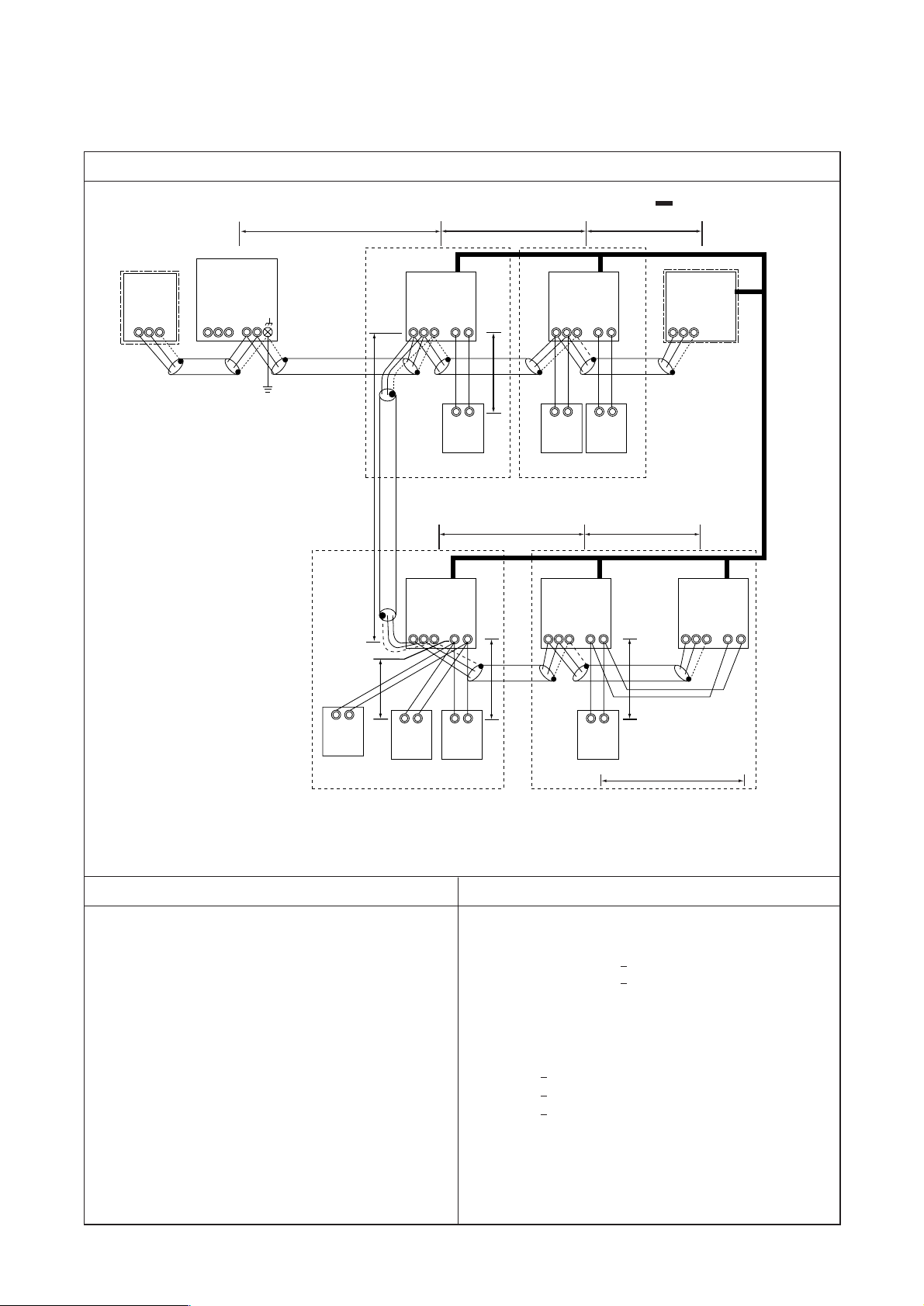

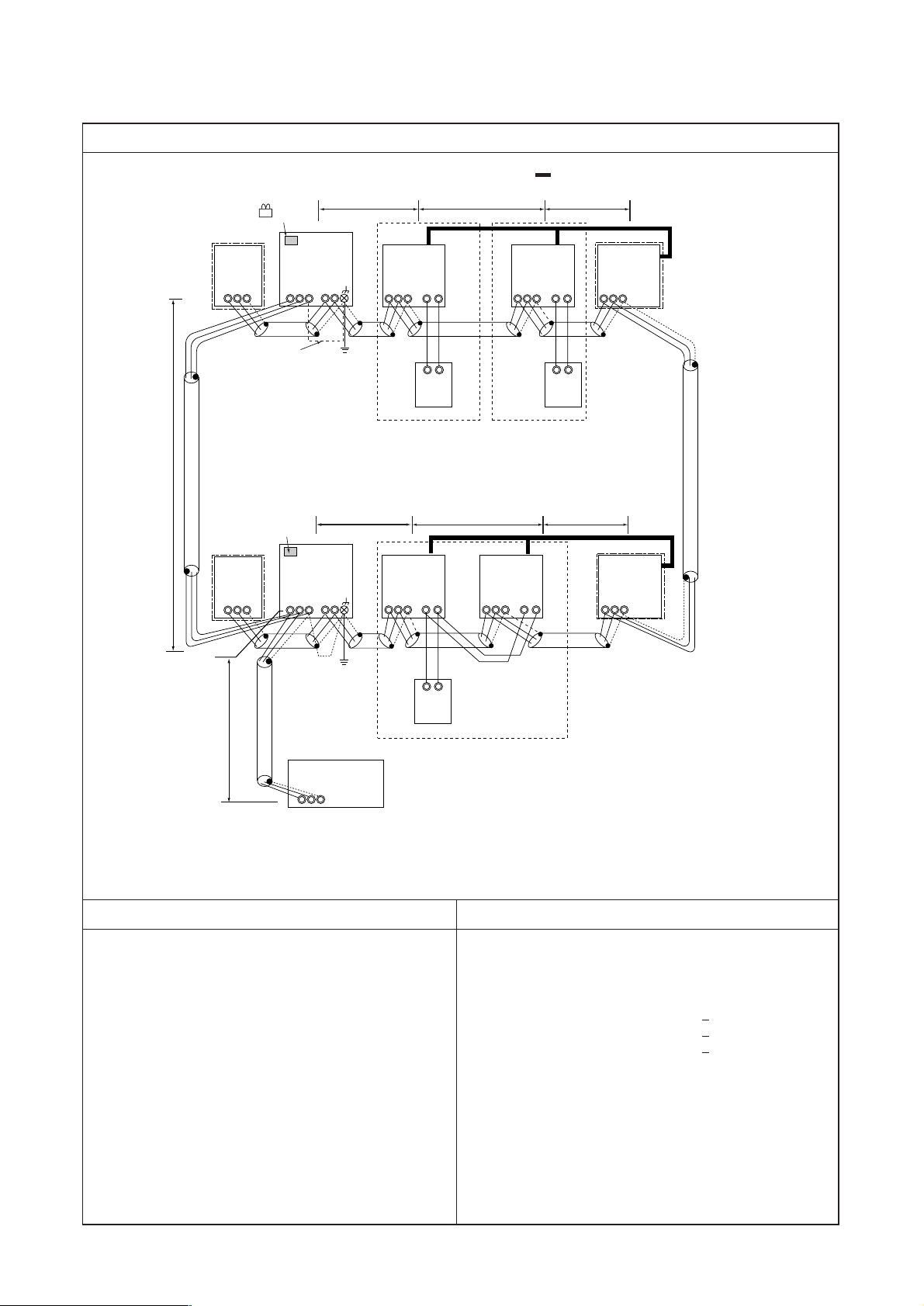

[3] Examples of system connection

1. System using MA remote controller

(1) In the case of single refrigerant system (Automatic address set-up)

Page 24

Wiring method • Address setting method

a. Indoor/outdoor transmission line

Apply jumper wiring connection between M1, M2 terminals of the indoor/outdoor transmission line terminal block

(TB3) on the outdoor unit (OC) and that of indoor/outdoor transmission line terminal block (TB5) on each indoor

unit (IC). (with non-polarity two wires)

❉ When the transmission line is long or noise sources are located near the unit, recommend to use shielded wire.

Connection of shielded wire:

For the earth of shielded wire, apply jumper wiring connection between the earth screw of OC and the S-terminal of

IC terminal block (TB5).

b. Centralized control transmission line

Connection is not required.

c. MA remote controller wiring

Connect the 1, 2 terminals of MA remote controller wiring terminal block (TB15) on IC to the terminal block of MA

remote controller (MA). (with non-polarity two wires)

❉ MA remote controller can be connected to A-type indoor unit or later.

For 2-remote controller operation:

To employ 2-remote controller operation, connect 1, 2 terminals of the terminal block (TB15) on IC to the terminal

block of two MA remote controllers.

❉ Set the main/sub selector switch of one MA remote controller to the sub remote controller. (For the setting method,

see the installation manual of MA remote controller.)

For indoor group operation:

For the group operation of IC, connect 1, 2 terminals of the terminal block (TB15) on all ICs within the same group,

and connect 1, 2 terminals of the terminal block (TB15) on another IC to the terminals of MA remote controller.

(with non-polarity two wires)

❉ To operate the indoor units with different function in the same group, refer to 1. (2).

d. LOSSNAY connection

Apply jumper wiring to connect M1, M2 terminals of the terminal block (TB5) on IC to the indoor/outdoor

transmission terminal block (TB5) on LOSSNAY (LC). (with non-polarity two wires)

❉ Linked and registered automatically with all indoor units within a refrigerant system.

❉ Please refer to the 1. (2) “Manual address set-up,” when interlocking partial indoor units with Lossnay, using

Lossnay alone without interlocking, interlocking indoor units and Lossnay for over 16 units within a refrigerant

system, or connecting LOSSNAY for over 2 units in a refrigerant system.

e. Switch setting

Address setting is not required.

Order

Unit or controller

Address

Setting method Caution

Factory

setting range

setting

Main unit IC

Not required – 00

1 Indoor unit

Sub unit IC

2 LOSSNAY LC Not required –

3

MA remote

Main uni

Hex. unit

t MA Not required –

Main

controller

Sub unit

Comp. unit

MA Sub unit

4 Outdoor unit OC

Not required –

5 Sub unit OS

• Refer to 1. (2) to operate indoor units

with different function in the same

group.

Set with main/sub

selector switch.

00

00

- 22 -

Page 25

L2

IC

TB5 TB

15

12

01

IC

TB5 TB

15

12

02

A1 B2

MA

A1 B2

MA

TB5

05

IC

TB5

12

TB

15

IC

TB5 TB

15

12

0403

TB5

06

A1 B2

MA

L11

L3 L4

L12 L13

a. Indoor/outdoor transmission line

The same as 1. (1)

b. Centralized control transmission line

No connection is required.

c. MA remote controller wiring

The same as 1. (1)

Control wiring example

Group

Prohibited items Allowable length

1. M-NET and MA remote controllers can not be connected to-

gether to the indoor unit within the same group.

2. MA remote controller of 3 units or more can not be connected

to the indoor unit within the same group.

3. When the total number of indoor units exceeds 26 units in-

cluding that above Type 200, a transmission booster is re-

quired.

Interlocking with ventilation

– Example to use shielded wire –

Group

Group

LC

LC

S

M1M2

S

M1M2

S

M1M2

S

M1M2

S

M1M2

S

M1M2

S

M1M2

OC

TB3

TB7

51

OS

(52)

TB3

S

M1M2 M1M2

- 23 -

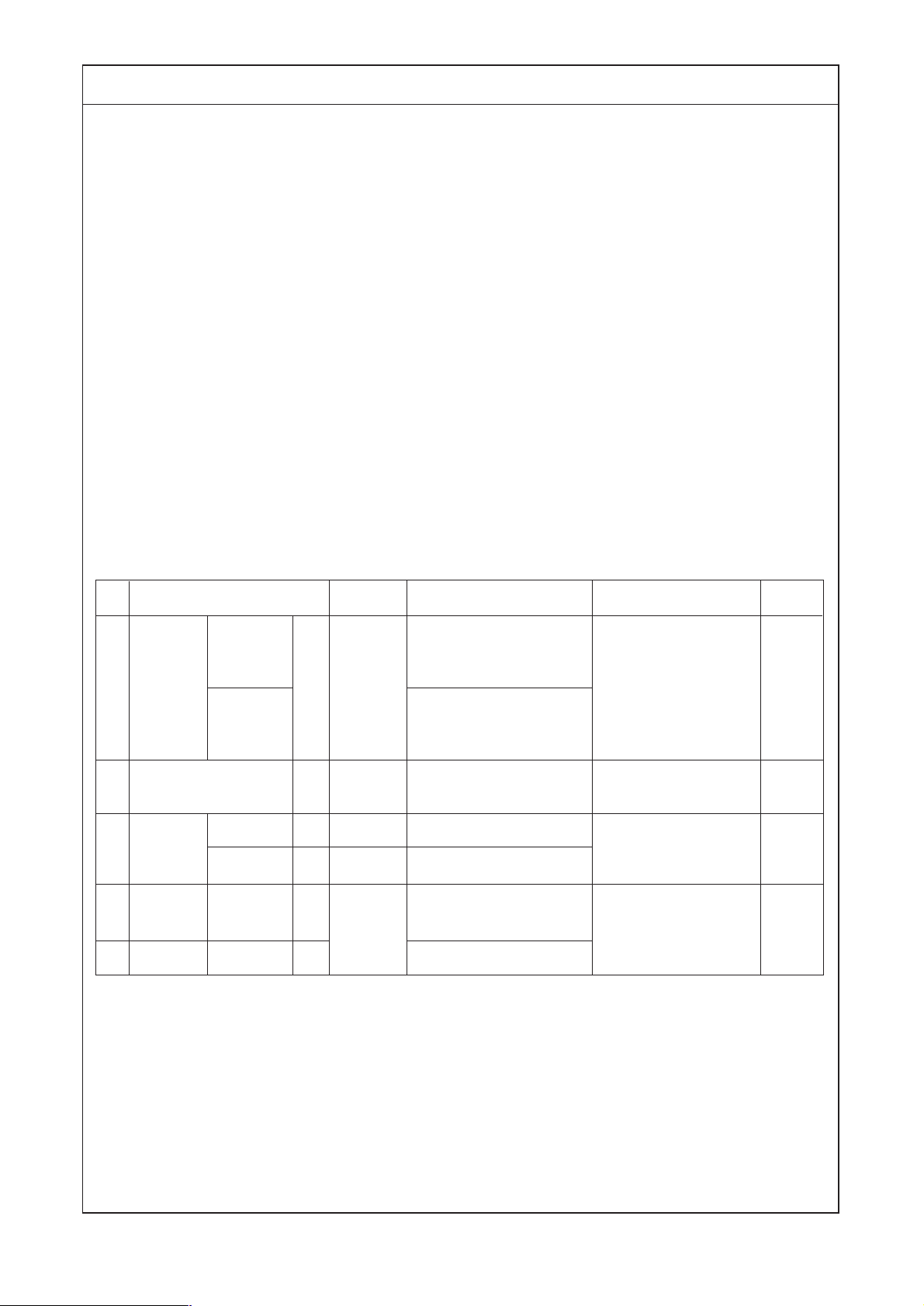

1. System using MA remote controller

(2) In the case of single refrigerant system connecting 2 or more LOSSNAY units (Manual address set-up)

Page 26

- 24 -

1 Indoor unit

2 LOSSNAY

3

MA remote

controller

4 Outdoor unit

Main unit

Sub unit

Main uni

t

Sub uni

Comp. unit

Hex. unit

t

IC

LC

MA

MA

OC

01 ~ 50

01 ~ 50

Not required

Not required

51 ~ 100

Wiring method • Address setting method

a. Indoor/outdoor transmission line

The same as 1. (1)

Connection of shielded wire:

The same as 1. (1)

b. Centralized control transmission line

No connection is required.

c. MA remote controller wiring

The same as 1. (1)

For 2-remote controller operation:

The same as 1. (1)

For indoor group operation:

The same as 1. (1)

d. LOSSNAY connection

Apply jumper wiring to connect M1, M2 terminals of the terminal block (TB5) on the indoor unit (IC) to the terminal

block (TB5) on Lossnay (LC). (with non-polarity two wires)

❉ The interlocking registration of the indoor unit and Lossnay from the remote controller is required. (For the regis-

tration method, see the installation manual of remote controllers.)

e. Switch setting

Address setting is required as listed below.

Order

Unit or controller

Address

Setting method Caution

Factory

setting range

setting

• Set the lowest address within

a same group to the indoor unit

desired to be the main unit.

Set to the main unit address

within a same group in serial order.

[Main unit +1, +2, +3, .... ]

Set any address after setting al

Set with main/sub selector

switch.

5 Sub unit OS Oundoor unit address + 1

l

indoor units.

–

00

00

Main

00

• When operating indoor

units with different function

within a same group, assign the indoor unit with the

most plenty of function to

the main unit.

• Set the address not to be

overlapped with the indoor

unit address.

• When setting address to

“100,” make it “50.”

The lowest address of indoor

unit within refrigerant system

+ 50

Page 27

- 25 -

IC

TB5 TB

15

12

01

IC

TB5 TB

15

12

03

A1 B2

MA

A1 B2

MA

TB5

06

IC

TB5

12

TB

15

IC

TB5 TB

15

12 12

0402

IC

TB5 TB15

05

A1 B2

MA

L3 L4

L23L22 L24

NO

NO

L2

m2

m3

a. Indoor/outdoor transmission line

Farthest length (1.25mm

2

or more)

L2 + L3 + L4 200m

L22 + L23 + L24 200m

b. Centralized control transmission line

Farthest length via outdoor unit (1.25mm

2

or more)

L2 + L3 + L4 + L31 + L22 + L23 + L24 500m

c. MA remote controller wiring

The same as 1. (1)

Control wiring example

Group

Prohibited items Allowable length

1. M-NET and MA remote controllers can not be connected together to the indoor unit within the same group.

2. MA remote controller of 3 units or more can not be connected

to the indoor unit within the same group.

3. Do not connect together the terminal blocks (TB5) of the indoor unit connected to different outdoor units.

4. Replacement of the power supply selecting connector (CN41)

on the outdoor unit should be done only on one outdoor unit.

5. Grounding of S-terminal of the centralized control terminal

block (TB7) on outdoor unit should be done only on one outdoor unit.

6. When the total number of indoor units exceeds 26 units including that above Type 200, a transmission booster is required.

Interlocking with ventilation

– Example to use shielded wire –

Group

Group

LC

≤

≤

≤

S

M1M2

S

M1M2

S

M1M2

S

M1M2

S

M1M2

S

M1M2

CN41→CN40

Replace

OC

TB3

TB7

51

OC

TB3

TB7

52

S

(54)

OS

S

(53)

L31

OS

TB3

Leave CN41

as it is.

TB3

Connect

S

M1M2 M1M2M1 M2

M1M2

S

M1M2 M1M2

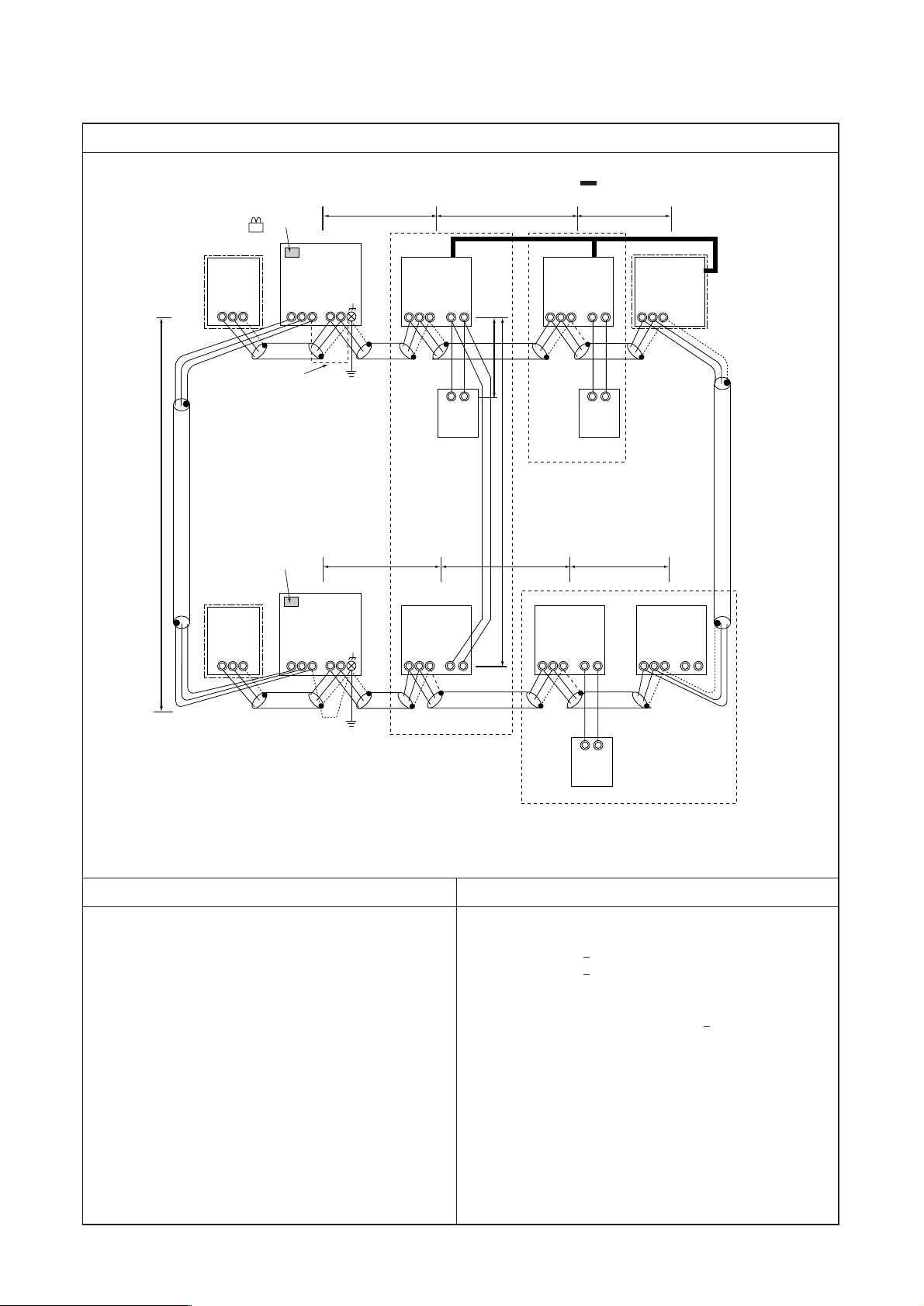

1. System using MA remote controller

(3) In the case of different refrigerant grouping operation

Page 28

- 26 -

Wiring method • Address setting method

a. Indoor/outdoor transmission line

Apply jumper wiring connection between M1, M2 terminals of the indoor/outdoor transmission line terminal block

(TB3) on the outdoor unit (OC) and that of indoor/outdoor transmission line terminal block (TB5) on each indoor

unit (IC). (with non-polarity two wires)

❉ Make sure to use shielded wire.

Connecting of shielded wire:

The same as 1. (1)

b. Centralized control transmission line

Apply jumper wiring between M1, M2 terminals of centralized control transmission line terminal blocks (TB7) on

each OC. For one OC only, replace the power selecting connector (CN41) with (CN40).

❉ Make sure to use shielded wire.

Connecting of shielded wire:

Apply jumper wiring to connect the shielded earth to S-terminal of the terminal block (TB7) on each OC. Connect

Sterminal of the terminal block (TB7) on the one OC with (CN40) replaced to the earth screw ( ) of the electrical

parts box.

c. MA remote controller wiring

The same as 1. (1)

For 2-remote controller operation:

The same as 1. (1)

For indoor unit group operation:

The same as 1. (2)

d. LOSSNAY connection

The same as 1. (2)

e. Switch setting

Address setting is required as follows.

1 Indoor unit

2 LOSSNAY

3

MA remote

controller

4 Outdoor unit

Main unit

Sub unit

Main unit

Sub unit

IC

LC

MA

MA

OC

01 ~ 50

01 ~ 50

Not required

Sub unit

51 ~ 100

• Set the address not to be

overlapped with the indoor

unit address.

• When setting address to

“100,” make it “50.”

Order

Unit or controller

Address

Setting method Caution

Factory

setting range

setting

• Set the lowest address within

a same group to the indoor unit

desired to be the main unit.

Set to the main unit address

within a same group in serial order.

[Main unit +1, +2, +3, .... ]

Set any address after setting all

indoor units.

–

Set by the main/sub selector

switch.

The lowest address of indoor

unit within refrigerant system

+ 50

00

00

Main

Hex. unit

Comp. unit

5 Sub unit OS Oundoor unit address + 1

00

Page 29

- 27 -

IC

TB5 TB

15

12

01

IC

TB5 TB

15

12

02

A1 B2

MA

A1 B2

MA

TB5

05

IC

TB5

12

TB

15

IC

TB5 TB

15

12

0403

TB5

06

A1 B2

MA

L3 L4

L23 L24

NO

L2

L22

NO

a. Indoor/outdoor transmission line

The same as 1. (3)

b. Centralized control transmission line

Farthest length via outdoor unit (1.25mm2 or more)

L32 + L31 + L2 + L3 + L4 500m

L32 + L22 + L23 + L24 500m

L2 + L3 + L4 + L31 + L22 + L23 + L24 500m

c. MA remote controller wiring

The same as 1. (1)

Control wiring example

Group

Prohibited items Allowable length

1. M-NET and MA remote controllers can not be connected together to the indoor unit within the same group.

2. MA remote controller of 3 units or more can not be connected

to the indoor unit within the same group.

3. Do not connect together the terminal blocks (TB5) of the indoor unit connected to different outdoor units.

6. When the total number of indoor units exceeds 26 units Including that above Type 200, a transmission booster is required.

Interlocking with ventilation

– Example to use shielded wire –

Group

Group

LC

LC

Notes:

1. Leave SW2-1 as “OFF” when connecting LM adapter only.

2. LM adapter requires the power source of 1-phase AC 230V

Note 1

.

≤

≤

≤

4. Replacement of the power supply selecting connector (CN41)

on the outdoor unit should be done only on one outdoor unit.

5. Grounding work is required for S-terminal of the centralized

control transmission block (TB7) on one outdoor unit onl

CN41→CN40 Replace

SW2-1 OFF→ON

y.

S

M1M2

S

M1M2

S

M1M2

S

M1M2

S

M1M2

S

M1M2

OC

TB3

TB7

51

OS

S

(52)

OC

TB3

TB7

53

(54)

System controller

S

L31

L32

Note 2

TB3

TB3

OS

S

M1M2 M1M2

S

S

M1M2 M1M2

M1M2

M1M2

M1M2

Connect

Note 1

Leave CN41 as it is.

SW2-1 OFF→ON

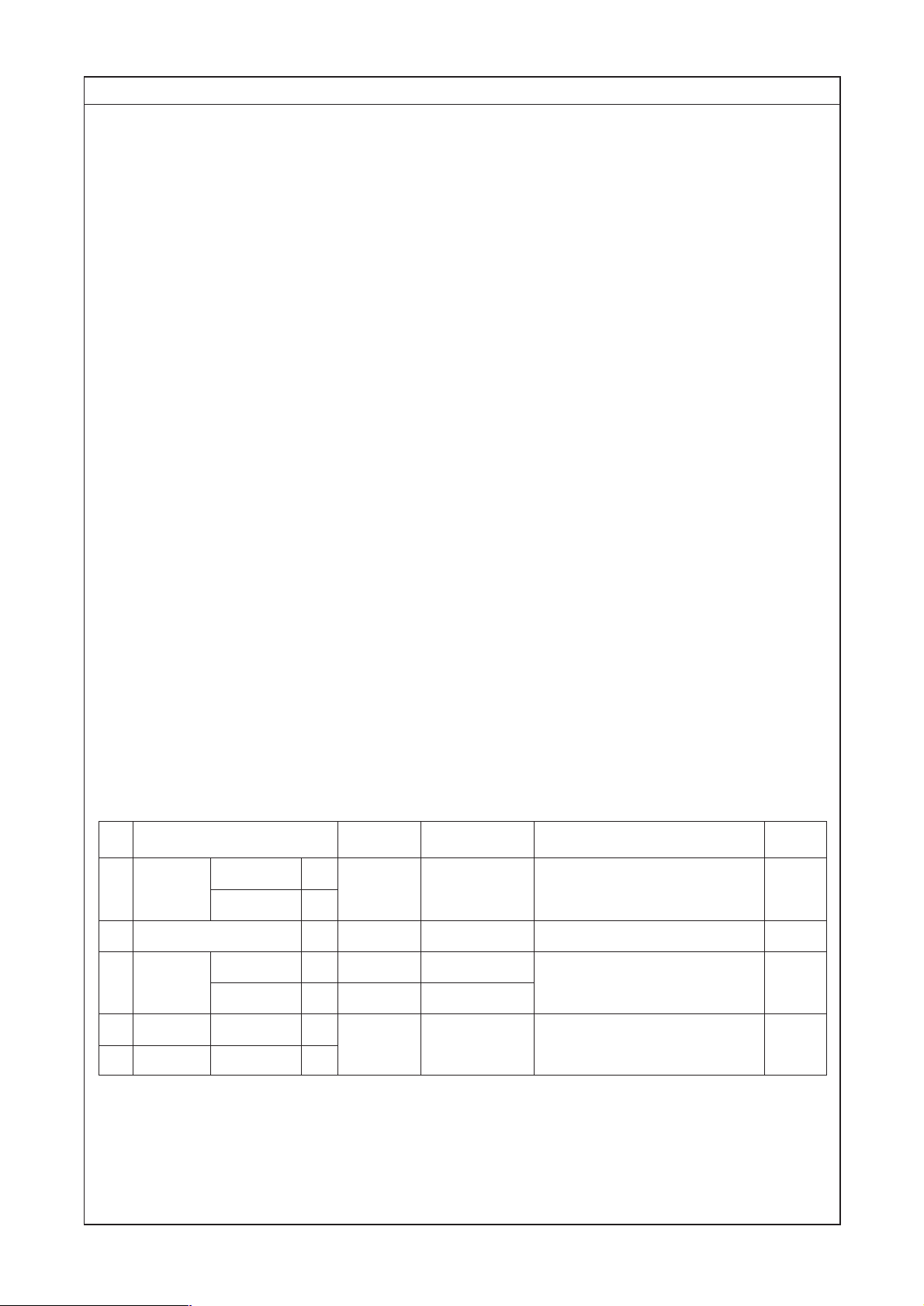

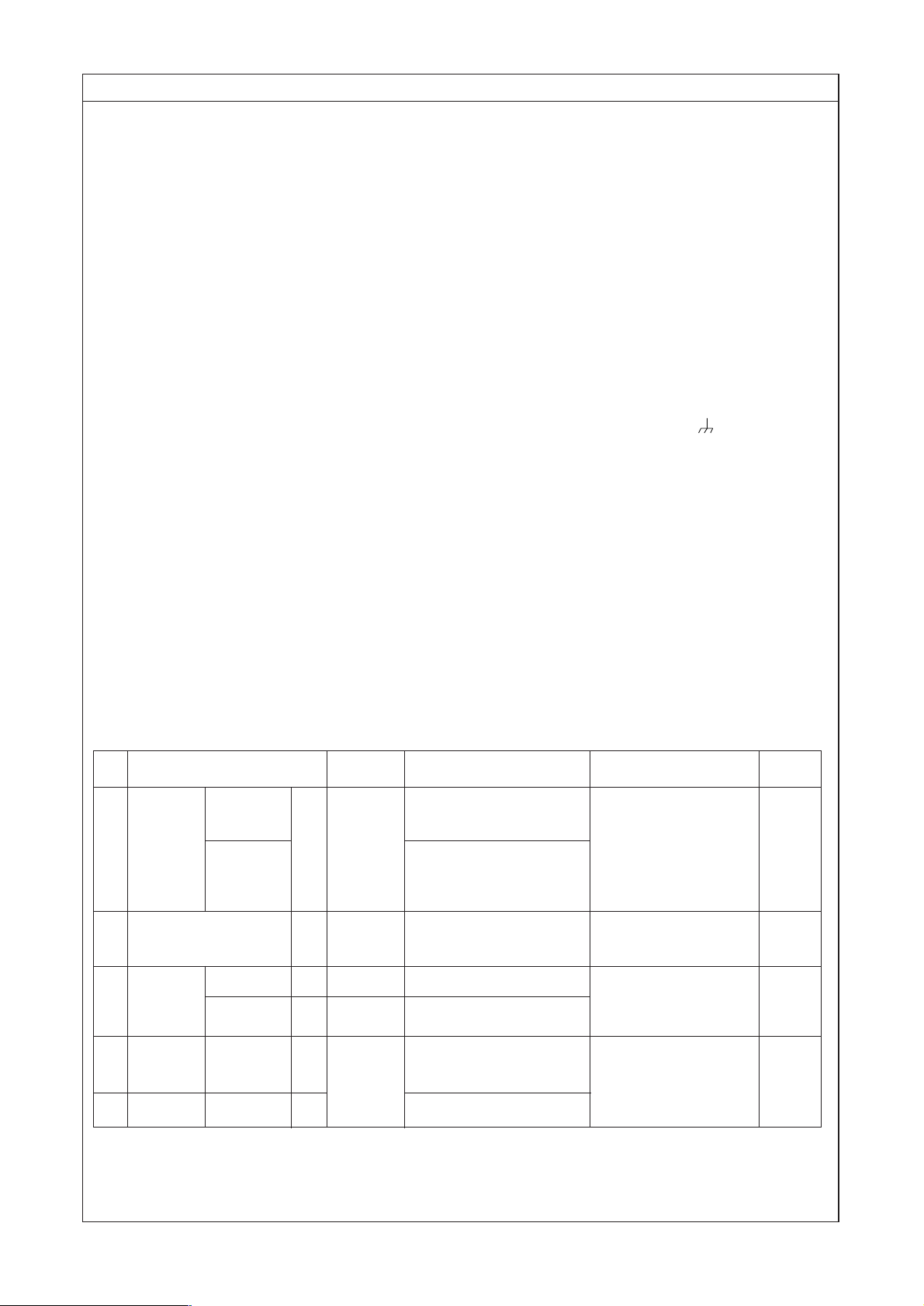

1. System using MA remote controller

(4) In the case of connecting system controller to centralized control transmission line

Page 30

- 28 -

Wiring method • Address setting method

a. Indoor/outdoor transmission line

The same as 1. (3)

Connection of shielded wire:

The same as 1. (1)

c. MA remote controller wiring

The same as 1. (1)

For 2-remote controller operation:

The same as 1. (1)

For indoor group operation:

The same as 1. (1)

d. LOSSNAY connection

Apply jumper wiring to connect M1, M2 terminals of the terminal block (TB5) on (IC) to the terminal block (TB5)

on the indoor/outdoor transmission line terminal block (TB5) on Lossnay (LC). (with non-polarity two wires)

❉ The interlocking registration of the indoor unit and LOSSNAY from the system controller is required. (For the

registration method, see the installation manual of the system remote controllers.)

When connecting ON/OFF remote controller and LM adaptor only, the interlocking registration from the remote

controller is required.

e. Switch setting

Address setting is required as listed below.

1 Indoor unit

2 LOSSNAY

3

MA remote

controller

4 Outdoor unit

Main unit

Sub unit

Main unit

Sub unit

IC

LC

MA

MA

OC

01 ~ 50

01 ~ 50

Not required

Sub unit

• Set the address not to be

overlapped with the indoor

unit address.

• Conduct initial setting by the

system controller with the

same setting detail of indoor

unit applied in MA remote

controller wiring.

• When setting address to

“100,” make it “50.”

Order

Unit or controller

Address

Setting method Caution

Factory

setting range

setting

• Set the lowest address within

a same group to the indoor unit

desired to be the main unit.

Set to the main unit address

within a same group in serial order.

[Main unit +1, +2, +3, .... ]

Set any address after setting all

indoor units.

–

Set by the main/sub selector

switch.

The lowest address of indoor

unit within refrigerant system

+ 50

00

00

Main

b. Centralized control transmission line

Apply jumper wiring between M1, M2 terminals of centralized control transmission line terminal blocks (TB7) on

each OC. On one OC only, replace the power selecting connector (CN41) with (CN40). Set the centralized control

switch (SW2-1) on the main board of all outdoor units to “ON.”

❉ Make sure to use shielded wire.

Connection of shielded wire:

Apply jumper wiring to connect the shielded earth to S-terminal of the terminal block (TB7) on each OC. Connect S-

terminal of the terminal block (TB7) on one OC with (CN40) connected to the earth screw ( ) of the electrical

parts box.

51 ~ 100

Hex. unit

Comp. unit

5 Sub unit OS Oundoor unit address + 1

00

Page 31

- 29 -

IC

TB5 TB

15

12

01

IC

TB5 TB

15

12

02

A1 B2

MA

A1 B2

MA

TB5

05

IC

TB5

12

TB

15

IC

TB5 TB

15

12

0403

TB5

06

A1 B2

MA

L3 L4

L23 L24

L2

L22

NO

a. Indoor/outdoor transmission line

Farthest length (1.25mm2 or more)

L2 + L3 + L4 200m

L22 + L23 + L24 200m

L25 200m

b. Centralized control transmission line

Farthest length via outdoor unit (1.25mm2 or more)

L25 + L31 + L2 + L3 + L4 500m

L2 + L3 + L4 + L31 + L22 + L23 + L24 500m

c. MA remote controller wiring

The same as 1. (1)

Control wiring example

Group

Prohibited items Allowable length

1. M-NET and MA remote controllers can not be connected together to the indoor unit within the same group.

2. MA remote controller of 3 units or more can not be connected

to the indoor unit within the same group.

3. Do not connect together the terminal blocks (TB5) of the indoor unit connected to different outdoor units.

4. Replacement of the power supply selecting connector (CN41)

on the outdoor unit should be done only on one outdoor unit.

5. Grounding work is required for S-terminal of the centralized

control transmission block (TB7) on one outdoor unit only.

6. The system controller connectable to the indoor/outdoor transmission line counts for 3 sets maximum. While G-50 counts

for only 1 set

7. When the total number of indoor units exceeds 26 sets, th e

system controller may not be connected to the indoor/outdoor transmission line.

8. When the total number indoor units exceed 18 sets and they

includes Type 200 or above, the system controller may not

be connected to the indoor/outdoor transmission line.

Interlocking with ventilation

– Example to use shielded wire –

Group

Group

LC

LC

Note 1. LM adaptor may not be connected to indoor/outdoor transmission line.

≤

≤

≤

≤

≤

NO

CN41→CN40 Replace

SW2-1 OFF→ON

Leave CN41 as it is.

SW2-1 OFF→ON

S

M1M2

S

M1M2

S

M1M2

S

M1M2

S

M1M2

S

M1M2

OC

TB3

TB7

51

OS

(52)

OC

TB3

TB7

53

(54)

L31

Connect

System controller

Note 1

L25

TB3

OS

TB3

S

M1M2

S

M1M2 M1M2

S

M1M2

S

M1M2 M1M2

S

M1M2

1. System using MA remote controller

(5) In the case of connecting system controller to indoor/outdoor transmission line (excluding LM adaptor)

Page 32

- 30 -

Wiring method • Address setting method

a. Indoor/outdoor transmission line

Apply jumper wiring connection between M1, M2 terminals of the indoor/outdoor transmission line terminal block

(TB3) on the outdoor unit (OC) and that of indoor/outdoor transmission line terminal block (TB5) on each indoor

unit (IC). (with non-polarity two wires)

❉ Make sure to use shielded wire.

Connection of shielded wire:

For the grounding of shielded wire, apply jumper wiring between the grounding screw of OC, S-terminal of the

terminal block (TB3), and S-terminal of the system controller.

b. Centralized control transmission line

Apply jumper wiring between M1, M2 terminals of centralized control transmission line terminal blocks (TB7) on

each OC. On one OC only, replace the power selecting connector (CN41) with (CN40). Set the centralized control

switch (SW2-1) on the main board of all outdoor units to “ON.”

❉ Make sure to use shielded wire.

Connection of shielded wire:

Apply jumper wiring to connect the shielded earth to S-terminal of the terminal block (TB7) on each OC. Connect S-

terminal of the terminal block (TB7) on one OC with (CN40) connected to the earth screw ( ) of the electrical

parts box.

c. MA remote controller wiring

The same as 1. (1)

For 2-remote controller operation:

The same as 1. (1)

For indoor unit group operation:

The same as 1. (2)

d. LOSSNAY connection

Apply jumper wiring to connect A, B terminals of the terminal block (TB5) on (IC) to the terminal block (TB5) on the

indoor/outdoor transmission line terminal block (TB5) on Lossnay (LC). (with non-polarity two wires)

❉ The interlocking registration of the indoor unit and Lossnay is required from the system controller. (For the

registration method, see the instruction manual of system controller.)

To connect ON/OFF remote controller only, interlocking registration from the remote controller is required.

e. Switch setting

Address setting is required as follows.

1 Indoor unit

2 LOSSNAY

3

MA remote

controller

4 Outdoor unit

Main unit

Sub unit

Main unit

Sub unit

IC

OC

LC

MA

MA

01 ~ 50

01 ~ 50

Not required

Sub unit

• Set the address not to be

overlapped with the indoor

unit address.

• Conduct initial setting by the

system controller with the

same setting detail of indoor

unit applied in MA remote

controller wiring.

• When setting address to

“100,” make it “50.”

Order

Unit or controller

Address

Setting method Caution

Factory

setting range

setting

• Set the lowest address within

a same group to the indoor unit

desired to be the main unit.

Set to the main unit address

within a same group in serial order. [Main unit +1, +2, +3,]

Set any address after setting all

indoor units.

–

Set by the main/sub selector

switch

.

The lowest address of indoor

unit within refrigerant system

+ 50

00

00

Main

51 ~ 100

Hex. unit

Comp. unit

5 Sub unit OS Oundoor unit address + 1

00

Page 33

- 31 -

IC

TB5 TB

15

12

01

101

103

102

IC

TB5 TB

15

12

02

A1 B2

RC

A1 B2

RC

TB5

05

IC

TB5

12

TB

15

IC

TB5 TB

15

12

0403

TB5

06

A1 B2

RC

L3 L4